Patents

Literature

176results about How to "Improve cohesive energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

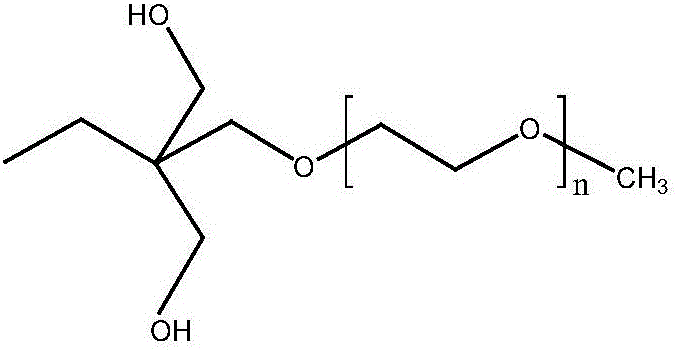

Epoxy resin modified water-based polyurethane emulsion and preparation method thereof

InactiveCN101717488AHigh molecular weightImprove cohesive energyPolyurea/polyurethane coatingsPolyesterWater based

The invention relates to an epoxy resin modified water-based polyurethane emulsion and a preparation method thereof. The emulsion comprises the following components in percentage by weight: 20 to 40 percent of isophorone diisocyanate, 20 to 40 percent of polyester, 5 to 10 percent of hydrophilic chain extender, 2 to 10 percent of chain extender, 1 to 3 percent of crosslinker, 3 to 10 percent of neutralizing agent, 2 to 10 percent of epoxy resin and 10 to 20 percent of acetone. The preparation method comprises the steps of feed preparation, polyester dehydration, the synthesis and neutralization of prepolymer, and chain extension and emulsification. Compared with the prior art, the epoxy resin modified water-based polyurethane emulsion has the advantages of high hardness of film, good water resistance and solvent resistance and the like, and is widely applied in the field of packaging coatings.

Owner:SHANGHAI WEIKAI CHEM

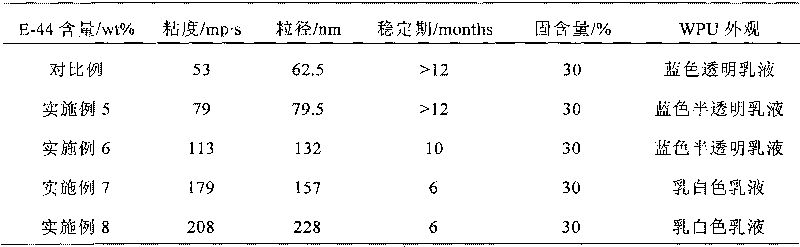

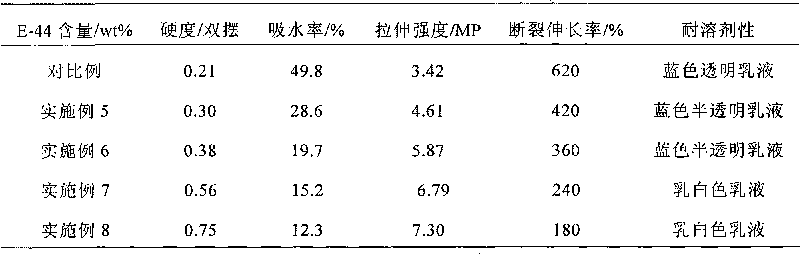

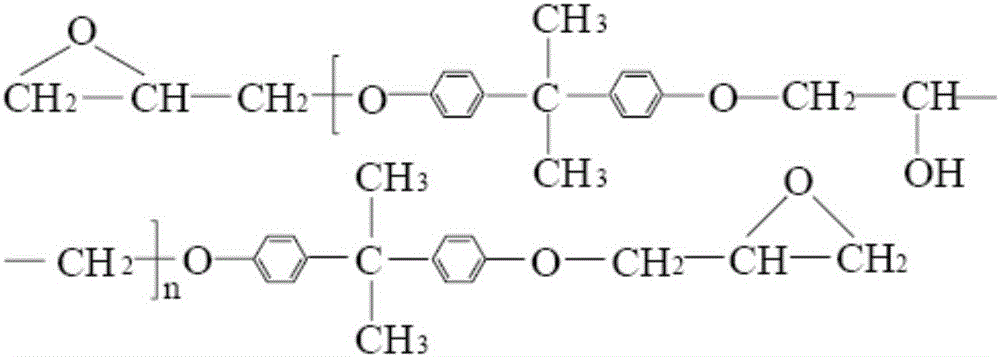

Epoxy modified anionic/nonionic waterborne polyurethane resin and preparation method thereof

ActiveCN106496485AImprove cohesive energyImprove water resistancePolyurea/polyurethane coatingsLeather surface finishingEpoxyPolyol

The invention relates to the technical field of preparation of modified waterborne polyurethane, in particular to epoxy modified anionic / nonionic waterborne polyurethane resin and a preparation method thereof. The preparation method comprises the steps: mixing a macromolecular polyol and a nonionic hydrophilic chain extender, heating to 70-80 DEG C, adding diisocyanate and a catalyst, and holding the temperature and stirring for reaction for 1 to 3 h to obtain a prepolymer; adding an anionic hydrophilic chain extender and a macromolecular polyol, stirring for reaction at 60 to 70 DEG C for 1 to 3 h to obtain a hydrophilic chain extender prepolymer; adding epoxy resin solution, stirring for reaction at 60 to 70 DEG C for 2 to 4 h to obtain epoxy modified prepolymer; cooling, and adding a salt agent to form a salt by neutralizing; adding water for emulsifying; adding polyamine for reaction for 10 to 60 min to obtain the epoxy modified anionic / nonionic waterborne polyurethane resin which has excellent resistance to hydrolysis and resistance to low temperature, high film strength, and excellent mechanical properties, and can be used as a leather finishing agent.

Owner:GUANGZHOU HUMAN CHEM

Preparation method of waterborne resin and water-based paint composite

ActiveCN102020759AImprove water resistanceImprove wear resistancePolyurea/polyurethane coatingsWater basedPolyester

The invention discloses a preparation method of waterborne resin and a water-based paint composite. The waterborne resin prepared with the preparation method of the invention contains various functional groups, such as a polyester group, a polypropylene resin group, an organic siloxane group, a polyurethane group and the like, and is acrylic ester graft modified polyester-type polyurethane water dispersion containing siloxane structure, and the siloxane structure can be hydrolyzed to form inorganic-organic crosslinking structure so as to improve the water resistance and the abrasive resistance of waterborne resin. The acrylic acid functional group structure improves the gloss and the weather fastness of a paint film; meanwhile, the polyester-type polyurethane structure ensures high hardness of the paint film because of larger cohesive energy. The water-based paint composite takes the waterborne resin as the main material for forming films, does not contain toxic and harmful substances of toluene and dimethylbenzene, has excellent gloss, good abrasive resistance, and excellent waterproof property and anti-ageing property and is an environmentally-friendly water-based paint with excellent comprehensive performance.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

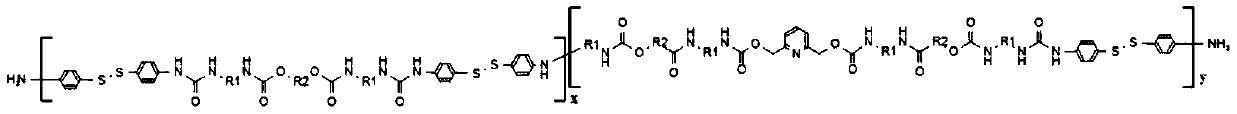

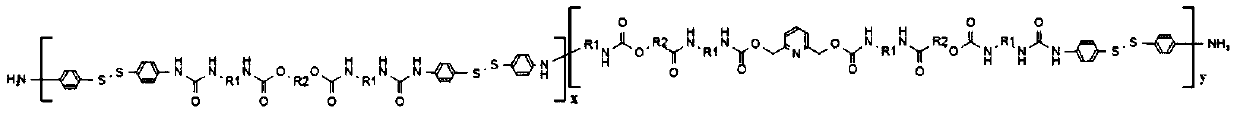

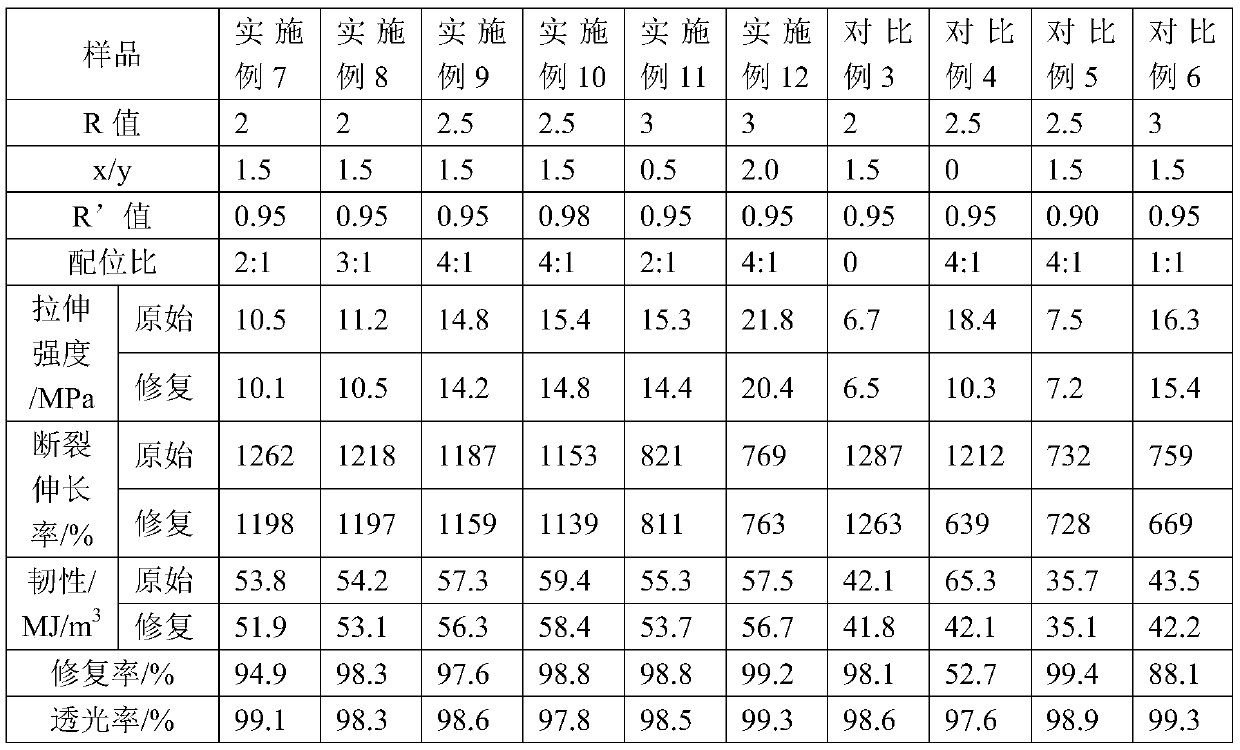

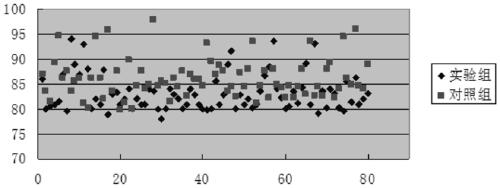

Transparent high strength and high toughness room temperature self-repairing thermoplastic polyurethane urea elastomer and preparation method

The invention discloses a transparent high strength and high toughness room temperature self-repairing thermoplastic polyurethane urea elastomer and a preparation method. The elastomer is synthesizedby: conducting chain extension twice on a prepolymer generated from diisocyanate and polyether diol with 2, 6-pyridine dimethanol and 4, 4'-diaminodiphenyl disulfide respectively. The pyridine ring onthe main chain can coordinate with polyvalent metal ions to form coordinate bonds between macromolecular chains, thus inducing self-repairing capability and also limiting molecular chain slip so as to improve the tensile strength and toughness. The aromatic disulfide on the main chain has low activation energy, and can produce reversible exchange reaction under room temperature condition to realize efficient self-repairing ability. By controlling the R value and the relative ratio of the two chain extenders, the tensile strength of the polyurethane urea elastomer can reach 8MPa or above, thetoughness can reach 45MJ / m<3> or above, the 6h self-repairing efficiency at 25DEG C can reach 90% or above, and the light transmittance can reach 95% or above. The transparent high strength and high toughness room temperature self-repairing thermoplastic polyurethane urea elastomer provided by the invention has excellent mechanical properties, self-repairing capability and light transmittance, canmeet the use requirements of flexible intelligent electronic equipment, and has great application potential.

Owner:ZHENGZHOU UNIV

Method for preparing melt spun chlorine-resistance high resilient polyurethane fiber

InactiveCN102011211AIncrease elasticityGuaranteed physical propertiesFilament/thread formingArtificial filament heat treatmentFiberCross-link

The invention discloses a method for preparing melt spun chlorine-resistance high resilient polyurethane fiber, comprising the following steps: 1) a thermoplastic polyurethane slice is prepared by a one-step method; 2) the slice is uniformly mixed with chlorine-resistance cross-linking agent; 3) melt extrusion is carried out; 4) spinning moulding is carried out; and 5) post curing is carried out. By utilizing the invention, the requirement on higher chlorine resistance and resilience in special fields is met, combination of the chlorine-resistance cross-linking agent and polyurethane fiber is good, and the physical performance of fiber can be effectively maintained when being used in a chlorine-containing environment; and besides, diamine is adopted as chain extension agent, the hard section of the formed polyurethane urea has higher cohesive energy, three-dimensional hydrogen bonds can be formed, and the microphase separation degree is improved, thus improving the resilience of fiber.

Owner:奥斯汀新材料(张家港)有限公司

Two-component PU (polyurethane) coating and preparation method thereof

InactiveCN104893558AIncrease the degree of cross-linkingLow water absorptionPolyurea/polyurethane coatingsPrepolymerInteraction forces

The invention discloses a two-component PU (polyurethane) coating. Firstly, castor oil is used for cross-linking prepolymers: a multifunctional group structure in the castor oil can cross-link the polymers to a certain extent, the cross-linking degree of the polymers is increased, so that the interaction force among molecular chains is increased, motion of the molecular chains is hindered, water molecules can hardly enter the molecular chains to enable the polymers to swell, and the water absorption of a film is reduced; meanwhile, the castor oil is a triglyceride of fatty acid, the film has the good hydrophobicity due to long nonpolar fatty acid chains in molecules of the castor oil, and the water absorption is further reduced; besides, ester groups in the castor oil have higher cohesive energy, so that the tensile strength of the film can be enhanced; ethyl cellulose has better heat resistance and thermoplasticity, has good compatibility with PU and can improve the comprehensive performance of the prepolymers; then blending modification is performed on the PU prepolymers and polysilsesquioxane.

Owner:HEFEI JIKE NEW MATERIALS

Waterproof high-hardness waterborne polyurethane coating

InactiveCN104312411AImprove thermal stabilityHigh hardnessAnti-corrosive paintsPolyurea/polyurethane coatingsSilanesCarbon nanotube

The invention discloses a waterproof high-hardness waterborne polyurethane coating which is characterized by comprising the following components in parts by weight: 65-80 parts of modified waterborne polyurethane, 20-35 parts of waterborne polyaniline, 3-6 parts of polyisocyanate, 5-20 parts of nano-silica, 3-9 parts of isopropanol, 5-10 parts of ethylene glycol propyl ether, 0.5-1.6 parts of dipentaerythritol, 15-20 parts of polydimethylsiloxane, 3-8 parts of gamma-isocyanate propyl triethoxy silane, 3-8 parts of polytetrafluoroethylene, 0.5-3 parts of modified carbon nanotubes, 5-20 parts of precipitated barium sulphate, 2-6 parts of amino resin, 3-8 parts of zinc powder and 30-60 parts of water. The waterproof high-hardness waterborne polyurethane coating is good in water resistance, high in harness and long in service life.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

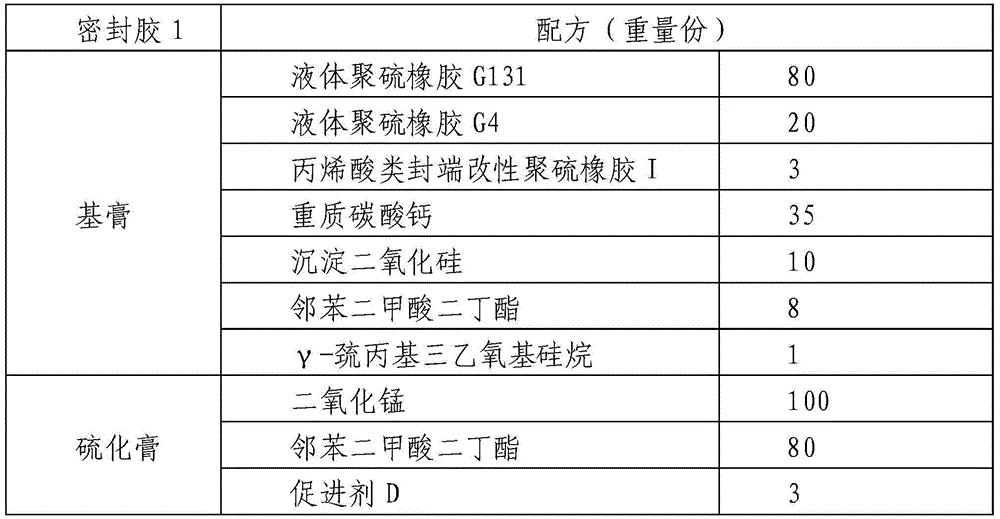

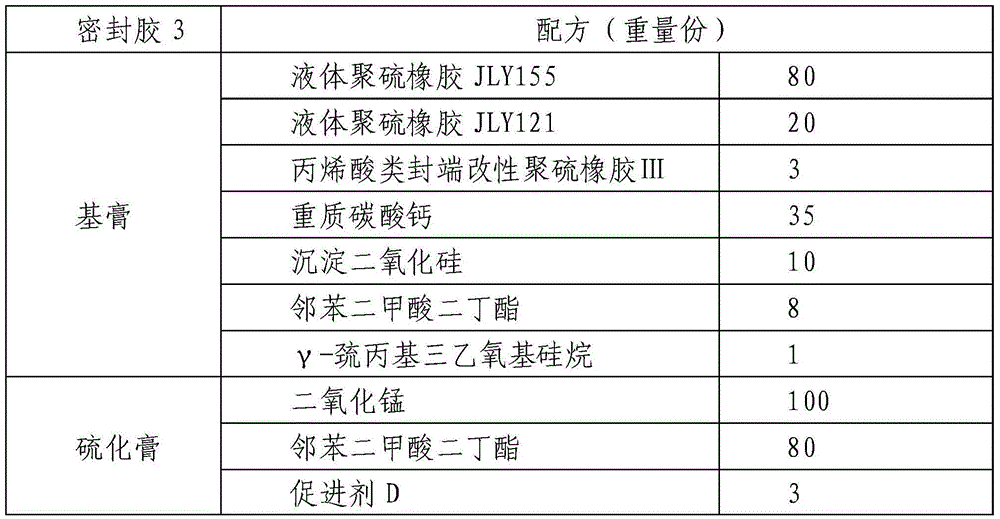

High peeling strength polysulfide sealant and sealing method

ActiveCN103555264AGood adhesionAdhesion does not increaseNon-macromolecular adhesive additivesOther chemical processesPolysulfide rubberPolymer science

The invention belongs to the technical field of polymer sealants, and relates to a high peeling strength polysulfide sealant and a method for sealing by using the sealant. The sealant is composed of a component A-based paste and a component B sulfur paste, wherein the component A is composed of a filler, a plasticizer, a crylic acid-terminated modified polysulfide rubber, a coupling agent and a liquid polysulfide rubber; and the component B is composed of manganese dioxide, dibutyl phthalate and an accelerator D. The invention provides the high peeling strength polysulfide sealant and a sealing method thereof. The adhesive property of the sealant is increased without increasing the viscosity of the sealant.

Owner:BAIMTEC MATERIAL CO LTD

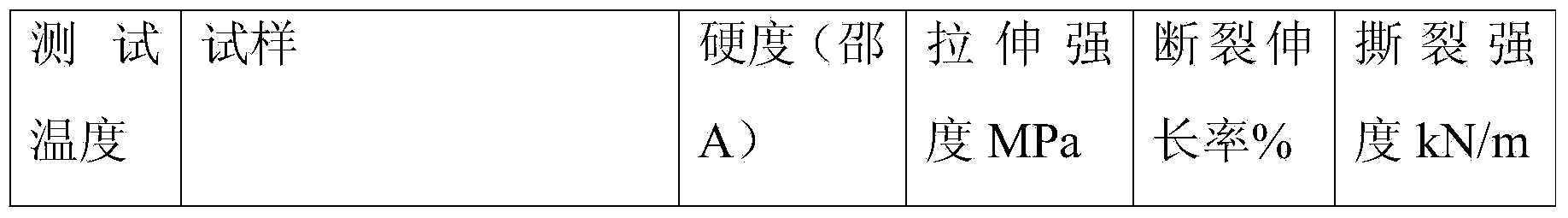

Preparation method of heat-resistant polyester plastic polyurethane elastomer

The invention discloses a preparation method of a heat-resistant polyester plastic polyurethane elastomer, which comprises the following steps: 1) adding polyester polyol and a catalyst into a reaction kettle, and dehydrating under the conditions of heating and vacuum to obtain a component A; respectively heating 1,5-naphthyldiisocyanate and a chain extender, evenly mixing with the component A, and carrying out extrusion reaction with a double screw extruder to obtain a polyester polyurethane elastomer; and 2) blending an epoxy resin with the polyester polyurethane elastomer obtained in the step 1) to obtain a blend, and drying the blend at 80-150 DEG C under the pressure of -0.08 to -0.1 MPa for 4-24 hours to obtain the heat-resistant polyester thermoplastic polyurethane elastomer. The heat-resistant polyester thermoplastic polyurethane elastomer prepared by the method is mainly used in the field of application of TPU (thermoplastic polyurethane) at higher temperature.

Owner:苏州奥斯汀新材料科技有限公司

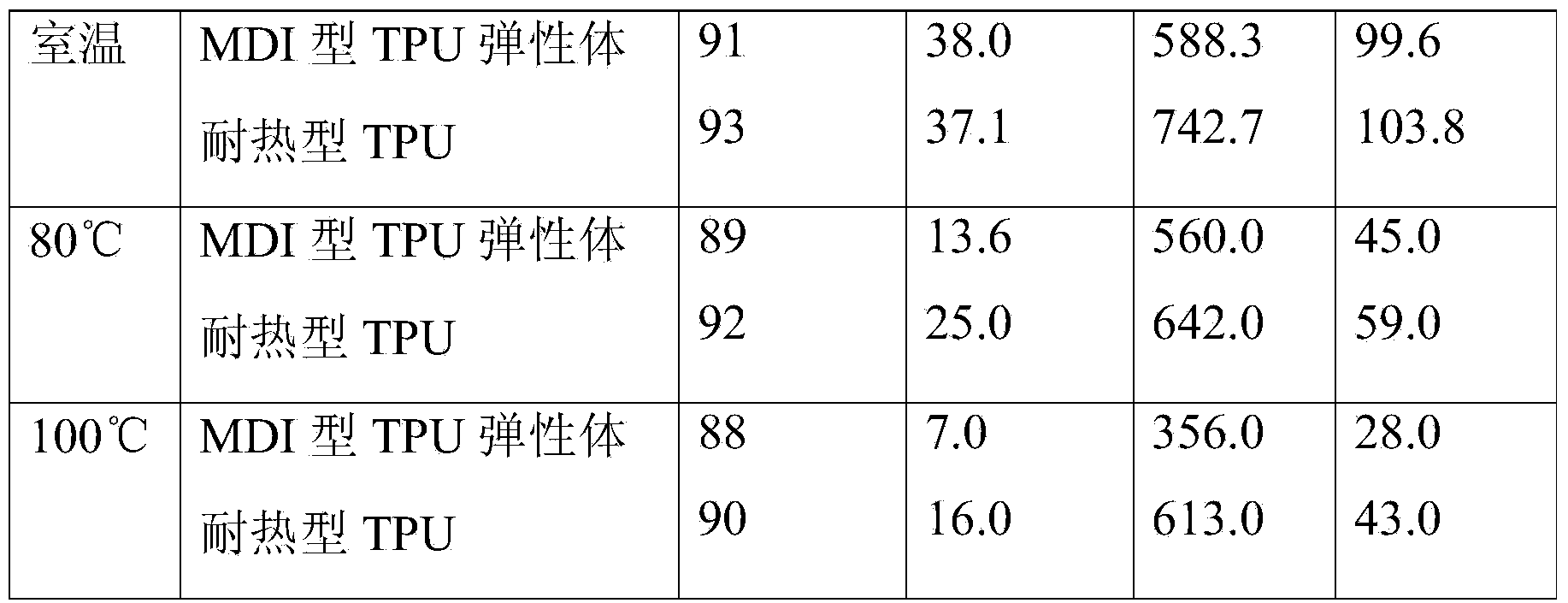

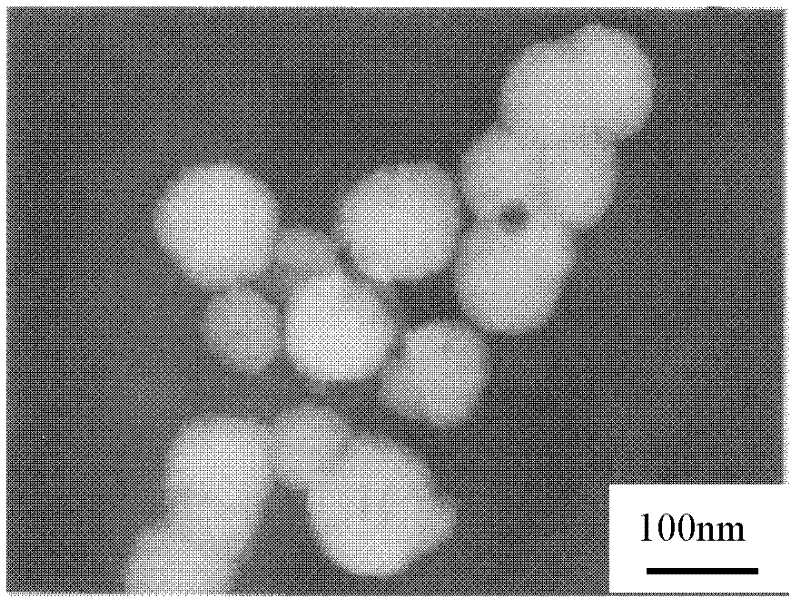

Preparation method of nuclear shell water-based polyurethane-acrylate composite emulsion adhesive for polyolefin film composition

ActiveCN102492383AImprove cohesive strengthStrong adhesionEster polymer adhesivesHydrocarbon polymer adhesivesWater basedPolyolefin

The invention discloses a preparation method of a core-shell water-based polyurethane-acrylate composite emulsion adhesive for polyolefin film lamination. The preparation method comprises: preparation of a vinyl-terminated net-shaped polyurethane emulsion, preparation of a core layer polyurethane-acrylate interpenetrating network polymer and preparation of the core-shell polyurethane-acrylate composite emulsion adhesive. By using the method, the defects that the existing water-based laminating glue product is low in adhering strength, poor in water tolerance and low in drying speed are solved. The adhesive prepared by using the method has the advantages of high peeling strength, good water tolerance, high drying speed and low VOC (volatile organic compound) content and the like.

Owner:HEFEI UNIV OF TECH

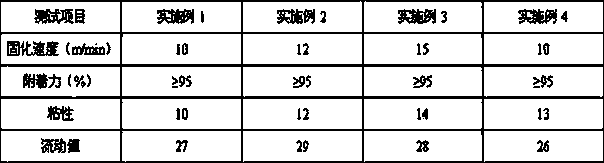

Environment-friendly waterless offset ink

The invention discloses environment-friendly waterless offset ink which comprises the following raw materials in parts by weight: 40-50 parts of polymerized rosin resin, 5-15 parts of an adhesive, 10-25 parts of refined linseed oil, 6-15 parts of a photoinitiator, 10-15 parts of phthalocyanine blue, 0.5-5 parts of an antiwear agent, 1-3 parts of a neutralizing agent and 0.1-2 parts of an addition agent, wherein the photoinitiator is one or a mixture of several of a cracking type initiator 907, BP (benzophenone) and triaryl iodonium salt, is one of important components of a photocuring adhesive, and plays a decisive role in the curing speed. The obtained ink is good in resin rheological property; a connecting material is higher in cohesive energy; the obtained ink is good in flowing property; the curing speed is not less than 10 m / min; and the ink is good in printing quality, clean and pollution-free.

Owner:苏州凹凸彩印厂

Adhesive for light-reflecting particles and preparation method thereof

ActiveCN101698788AFeel goodSoft touchPolyureas/polyurethane adhesivesFunctional monomerPolymer science

The invention discloses adhesive for light-reflecting particles and a preparation method thereof, which belongs to the technical field of adhesive preparation. The adhesive comprises a component A and a component B which are mixed in a weight ratio of 100:5-9, wherein the component A comprises the following raw materials in percentage by mass: 30 to 55 percent of acrylate soft monomer, 0.2 to 5 percent of functional monomer containing carboxyl or hydroxyl groups, 0.5 to 10 percent of crosslinking monomer containing hydroxyl groups, 40 to 60 percent of non-alcohol solvent, 0.2 to 5 percent of oil-soluble initiator and 0.05 to 0.2 percent of thiol chain transfer agent; and the component B adopts low-molecular polymer with the content of NCO between 10 and 14 percent. The crosslinking monomer containing hydroxyl groups in the component A of the adhesive undergoes crosslinking reaction with NCO in the component B to increase the cohesive energy and polarity of an adhesive system, thereby increasing the adhesive bonding action of the system on base materials and inorganic light-reflecting particles.

Owner:NANTONG GAOMENG NEW MATERIAL

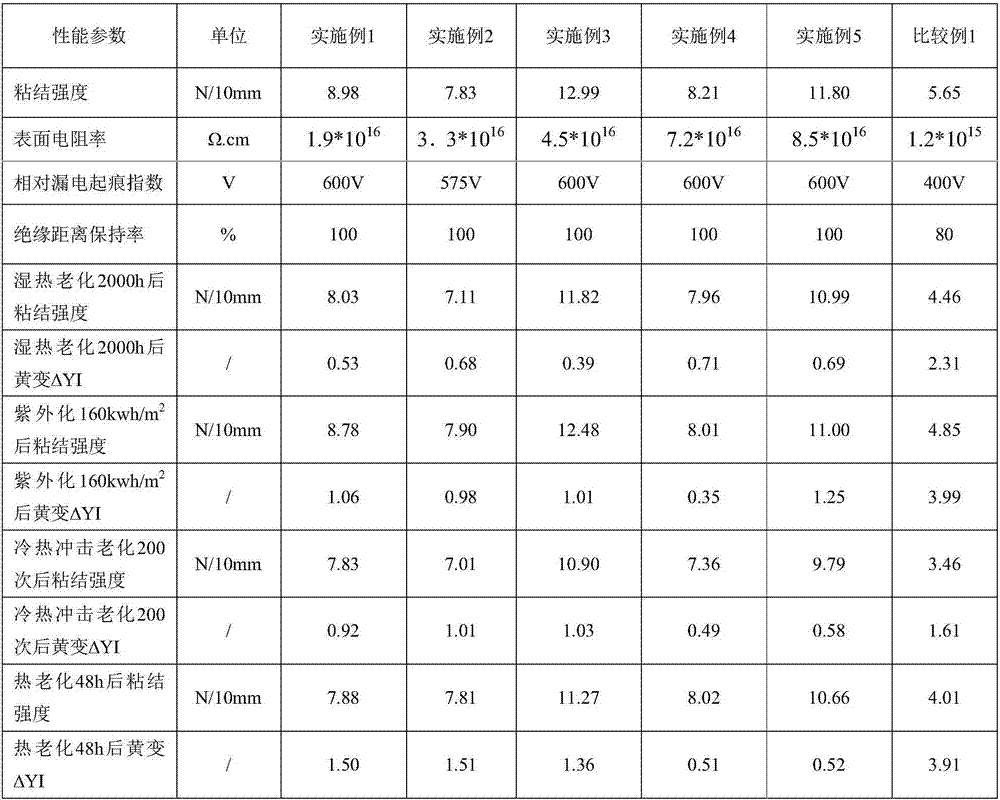

Insulation adhesive material for compound photovoltaic backsheet and application

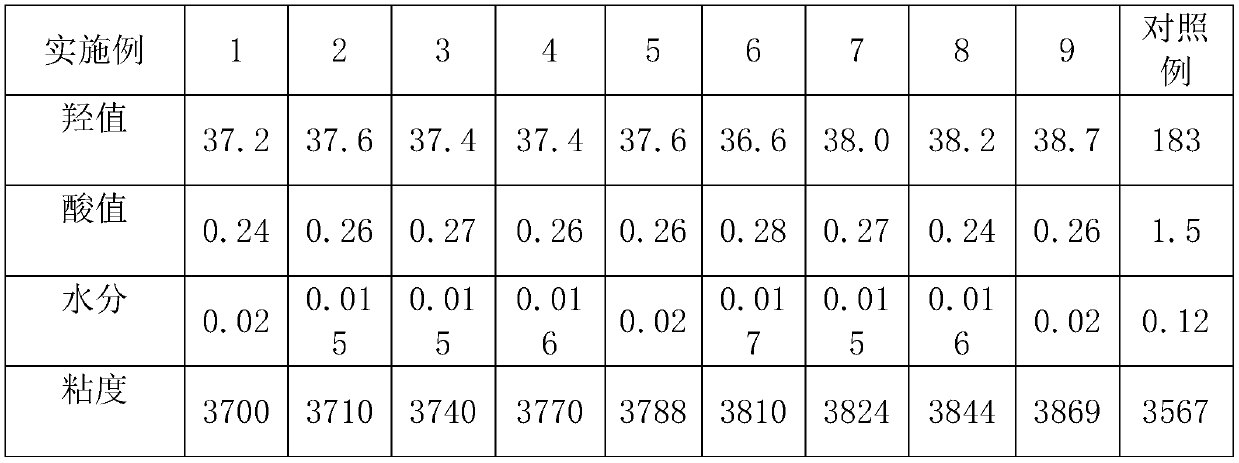

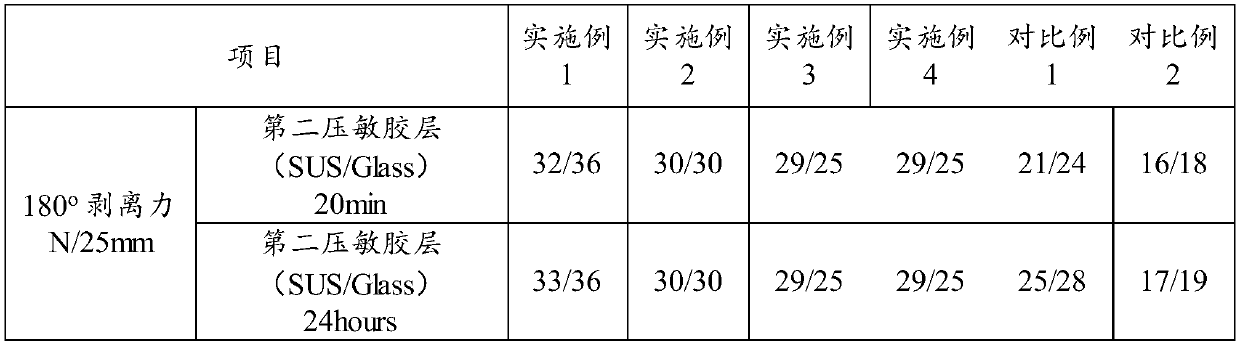

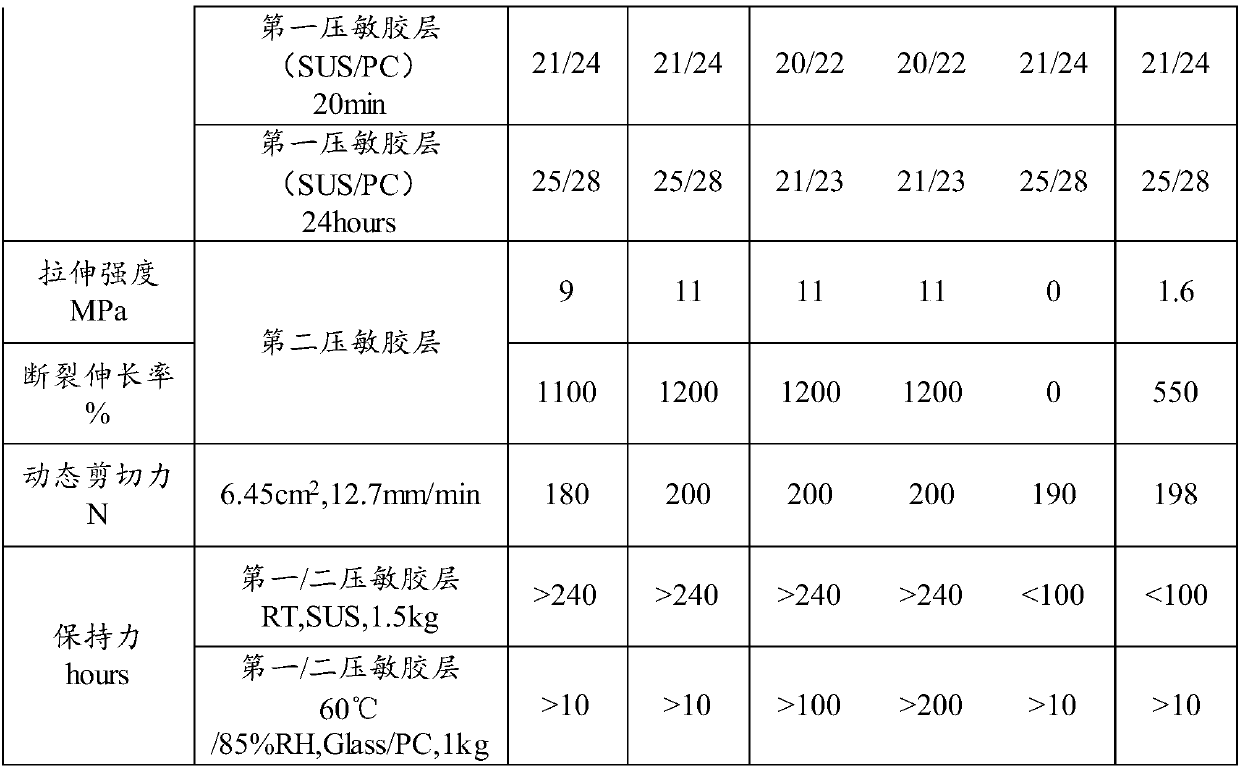

ActiveCN107353859AImprove insulation performanceImprove cohesive energyPolyureas/polyurethane adhesivesEpoxy resin adhesivesHeat resistanceAcid value

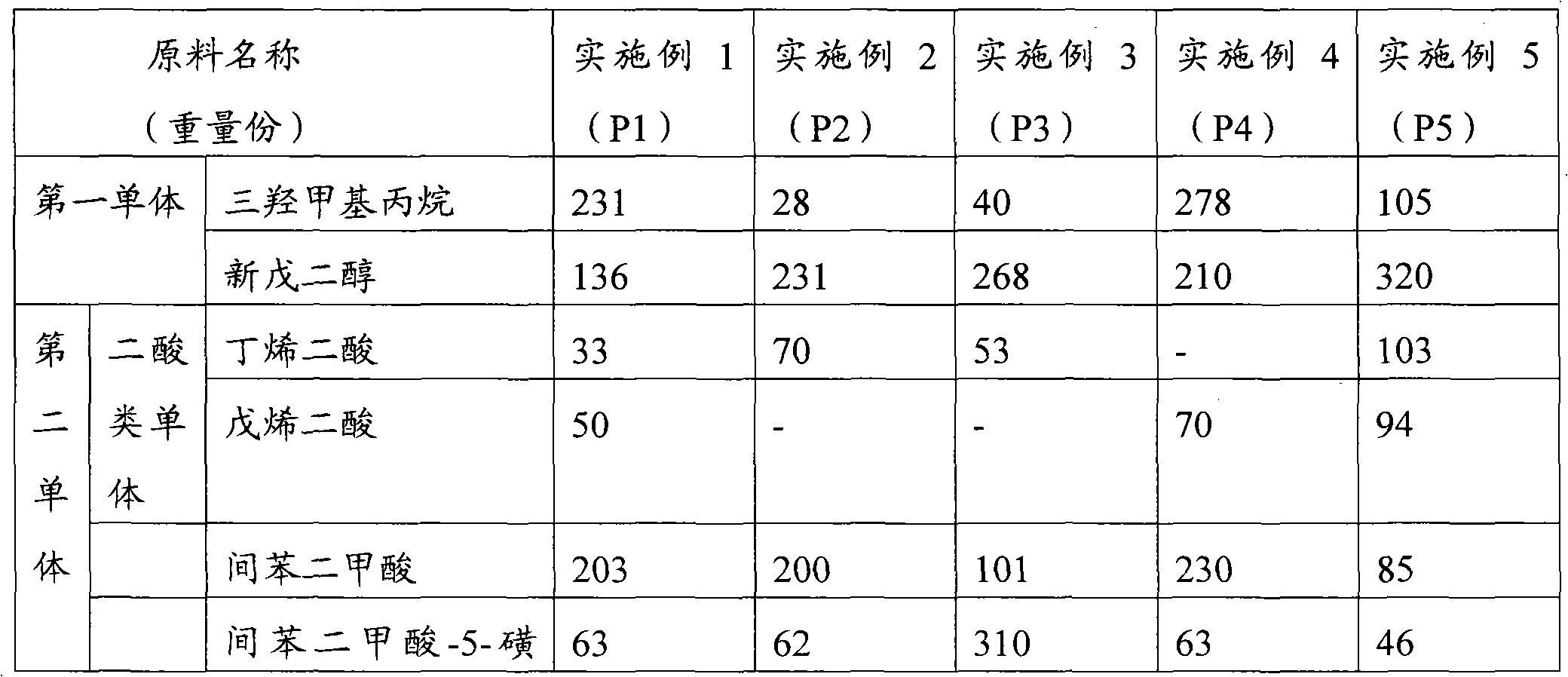

The invention discloses an insulation adhesive material for a compound photovoltaic backsheet and application. The insulation adhesive material is composed of a component A and a component B. The component A contains matrix resin, assistant resin and an assistant, wherein the matrix resin is hydroxyl polyester resin, which has a hydroxyl value of 5-30mgKOH / g, an acid value of 0.2-5mgKOH / g, a number-average molecular weight of 5000-50000, a glass transition temperature ranging from -40DEG C to 30DEG C, and is prepared by esterification polycondensation reaction of small molecular polyprotic acid and polyol under inert gas protection. The component B is a crosslinked component. During use, the component A and the component B are mixed in different proportions according to requirements. The insulation adhesive material provided by the invention not only has long-term and stable bonding performance, but also has excellent performance in heat resistance, insulation and weatherability, and can be used for preparation of high weather resistant compound photovoltaic backsheets. Also, the raw materials are easily available, the process is controllable, and the operation is simple.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

Dispersing type anti-agglomeration polyurethane coating and preparation method thereof

InactiveCN104893552AEasy reunionGood dispersionPolyurea/polyurethane coatingsPolymer scienceHeat resistance

The invention discloses a dispersing type anti-agglomeration polyurethane coating. Firstly, a castor oil crosslinking prepolymer is adopted, wherein a multifunctional group structure of castor oil can endow a polymer with certain crosslinking, accordingly, the crosslinking degree of the polymer is improved, the interaction force of molecular chains is increased, movement of the molecular chains is blocked, water molecules cannot easily enter the molecular chains to swell the polymer, and the water absorption of the coating is reduced; meanwhile, the castor oil is triglycerin of fatty acid, nonpolar fatty acid chains of medium-long chains in molecules of the castor oil enable the coating to have excellent hydrophobicity, and the water absorption is further reduced; besides, ester in the castor oil has higher cohesive energy and can improve the tensile strength of the coating; ethyl cellulose has better heat resistance and thermoplasticity and has good compatibility with polyurethane, and the comprehensive performance of the prepolymer can be improved; the polyurethane prepolymer and polysilsesquioxane are subjected to blending modification.

Owner:HEFEI JIKE NEW MATERIALS

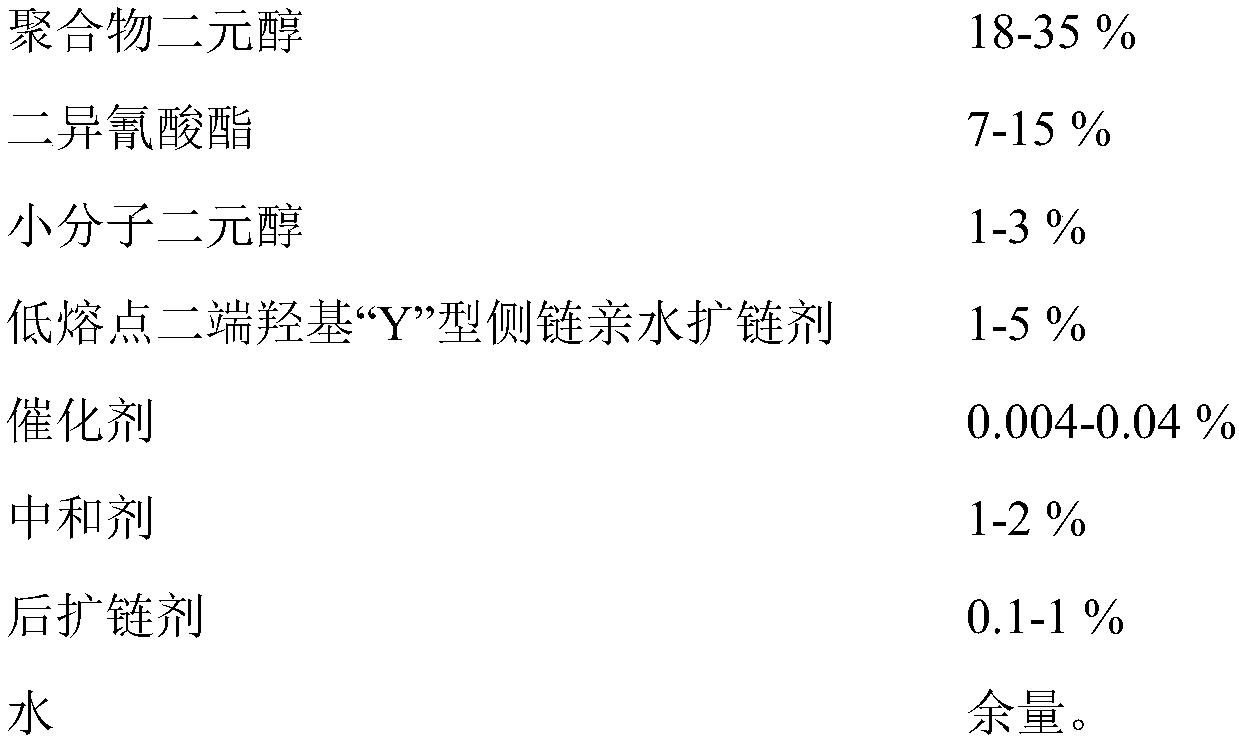

Extrusion-molding method solvent-free waterborne polyurethane dispersion as well as preparation method and application thereof

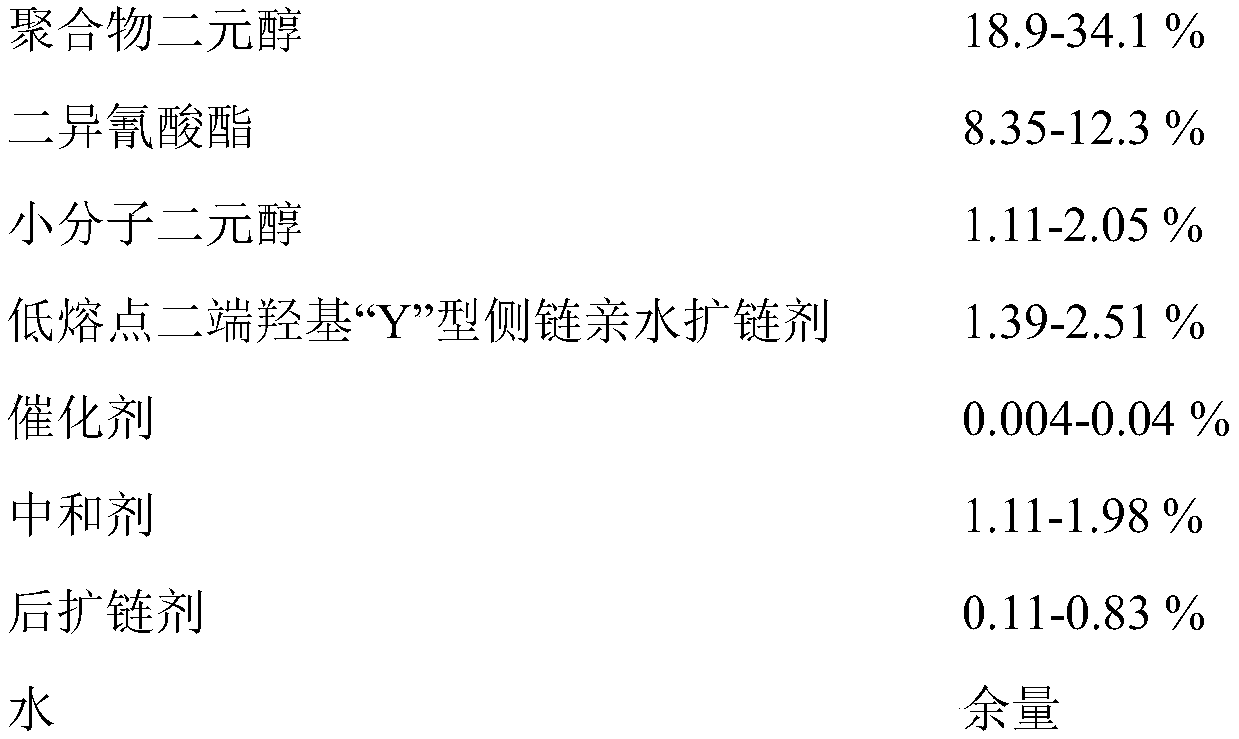

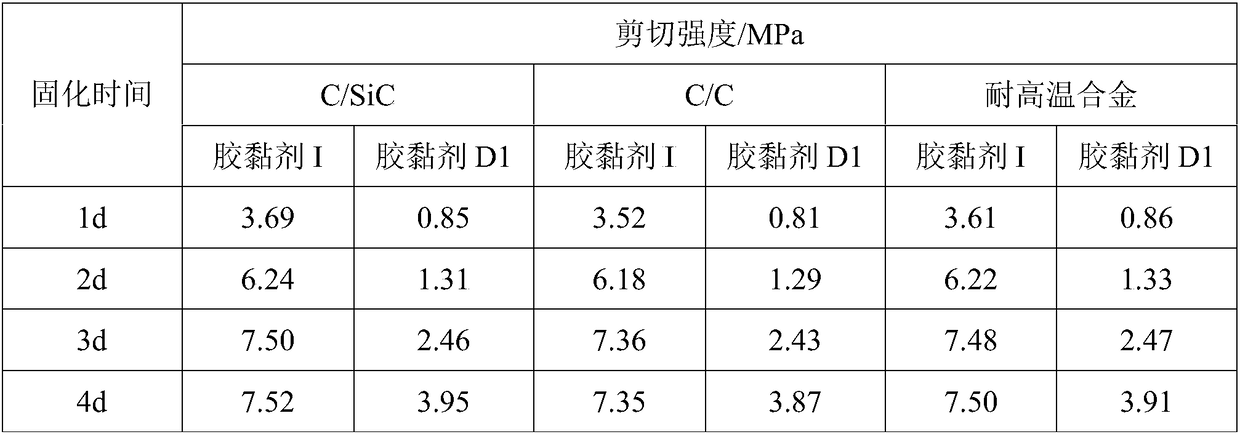

The invention provides an extrusion-molding method solvent-free waterborne polyurethane dispersion as well as a preparation method and application thereof. The preparation method comprises the following steps: (1) preheating polymeric diol, diisocyanate, micromolecular diol, a low-melting-point dihydroxy-terminated Y type side chain hydrophilic chain extender and a catalyst respectively, then inputting the materials into a mixer to disperse and mix the materials, and inputting the mixture into a twin-screw reactor to perform a reaction in order to obtain polyurethane melt; (2) injecting the polyurethane melt into a shear pump, injecting water containing a neutralizing agent into the shear pump, and performing shearing and dispersion at a high temperature of 120 to 200 DEG C under the pressure of 0.2 to 1.5Mpa; (3) cooling and decompressing, adding a chain extender, and reacting while stirring to obtain the solvent-free waterborne polyurethane dispersion. The method provided by the invention is environmentally friendly; by adopting the method, the cohesive energy of a product is increased greatly, the production process is efficient, and the performance of the waterborne polyurethane can be improved greatly.

Owner:SHANGHAI HUAFON NEW MATERIAL R&D TECH CO LTD

Emulsion for seal adhesive at normal temperature and preparation method thereof

InactiveCN101591514AImprove adhesionLower initial tackOther chemical processesEster polymer adhesivesPolymer scienceEmulsion

The invention discloses an emulsion for seal adhesive at a normal temperature and a preparation method and an application thereof. The emulsion is composed of styrene or methyl methacrylate, butyl acrylate, methyl acrylate, adhesive force acceleration monomer, tackifying resin (specific gravity in the gross mass of all monomers of the system), emulsifier, initiator, pH value modifier, tert-butyl hydroperoxide, deionized water and buffer. Firstly, the tackifying resin is fully dissolved in the monomer, and the monomer dissolved with the tackifying resin is pre-emulsified; other components are preformed with dripping preparation by continuous dripping technology to obtain emulsion. The emulsion can be respectively prepared into two systems of styrene-acrylic emulsion and pure acrylic acid emulsion, and the synthetic emulsion has higher base material adhering property and low initial adhesive, and not only can ensure glue solution compounded by the emulsion has high stripping strength, but also can be stored at different environment temperatures without conglutination, so that the invention greatly satisfies each property index of a cold sealing adhesive system.

Owner:BEIJING COMENS YANSHAN TECH +1

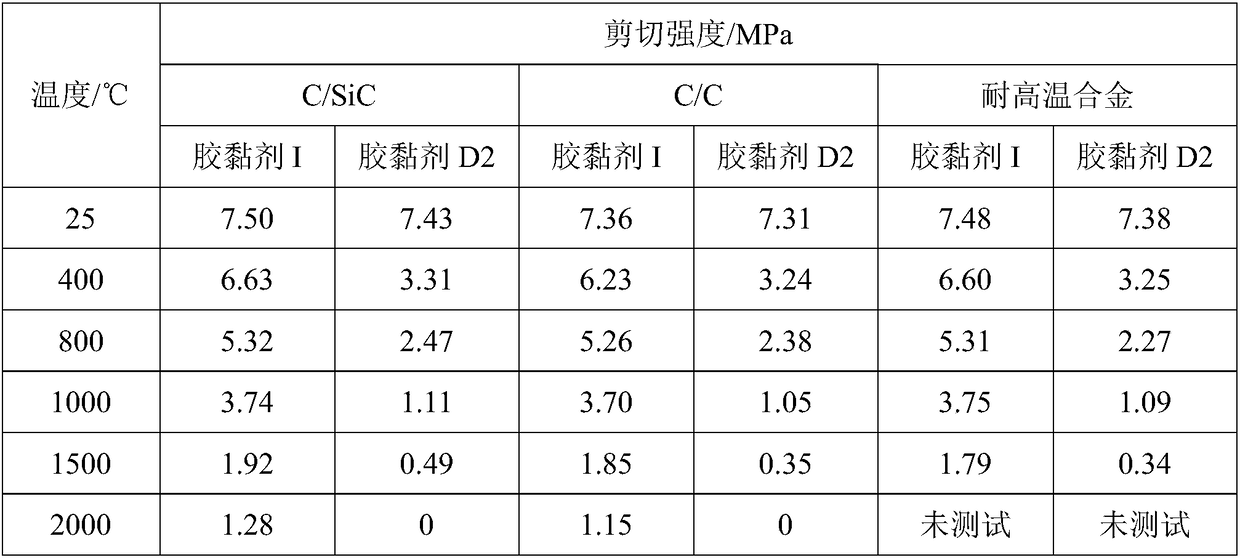

Normal-temperature curing organic and inorganic compound high-temperature-resistant adhesive and preparation method thereof

ActiveCN108148532AHigh bonding strengthGuaranteed bonding strengthNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesPhosphateEnd-group

The invention belongs to the technical field of adhesives, and particularly relates to a normal-temperature curing organic and inorganic compound high-temperature-resistant adhesive and a preparationmethod thereof. The normal-temperature curing organic and inorganic compound high-temperature-resistant adhesive comprises, by weight, 50-100 parts of modified aluminum dihydrogen phosphate, 20-50 parts of phenolic resin with activity end groups, 5-30 parts of silane coupling agents, 38-80 parts of curing cross-linking agents, 2-5 parts of curing accelerators, 15-30 parts of high-temperature-resistant filling agents and 50-100 parts of fillers. The normal-temperature curing organic and inorganic compound high-temperature-resistant adhesive shows excellent adhesive performance of an organic matter at the temperature of 400 DEG C or less and shows heat resistance of an inorganic matter at high temperature of 400 DEG C or more, normal-temperature curing can be achieved, raw materials used inthe preparation method of the adhesive are low in cost, the method is simple in process and easy to operate, the prepared adhesive has high curing environmental adaptability and is low in operation requirement and convenient to use, components of the adhesive are uniformly mixed, and the adhesive can be normally coated.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

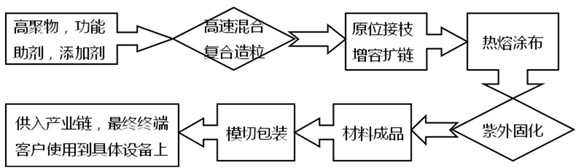

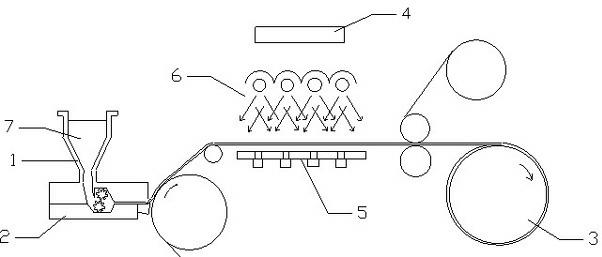

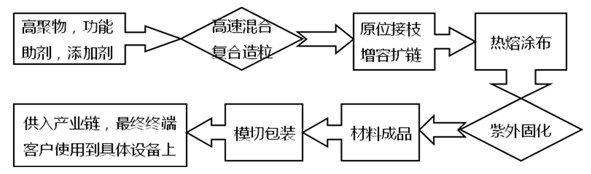

Acrylate hot melt adhesive composition and preparation method of hot melt adhesive by UV (ultraviolet) crosslinking

ActiveCN102660205AGood bonding performanceImprove heat resistanceFilm/foil adhesivesEster polymer adhesivesAntioxidantGrafting

The invention belongs to the technical field of a hot melt adhesive, and particularly relates to an acrylate hot melt adhesive composition and a preparation method of a hot melt adhesive by UV (ultraviolet) crosslinking. The composition of the acrylate hot melt adhesives comprises the following components based on weight content ratio: 9-90% of acrylate copolymer, 9-90% of copolyester and 0.1-1% of antioxidant. The preparation method of the hot melt adhesive by UV crosslinking comprises the following specific steps of: polymerizing at least one of acrylate monomer bodies; and adding the composition into a double-screw extruder to carry out high-speed mixing, in-situ grafting, compatibilization and chain extension, coating a base material by means of hot melting at the temperature of 130-160 DEG C, carrying out ultraviolet light crosslinking, and packing in a rolling way. The preparation method has the benefit effects that part of hot melt adhesive is crosslinked by means of UV crosslinking, so that the cohesive strength of the hot melt adhesive can be improved, and the glue-overflowing performance can be resistant, and the joint strength can be improved. Meanwhile, the hot melt adhesive provided by the invention is further added with copolyester with equivalent quantity besides the main body resin, and the higher wettability, cohesive strength and heat resistance, and good weather fastness can be obtained due to the introduction of the copolyester.

Owner:中新联科环境科技(安徽)有限公司

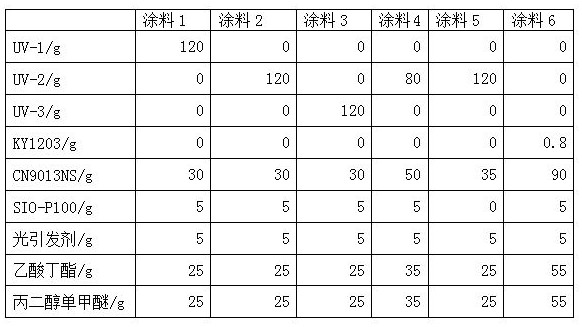

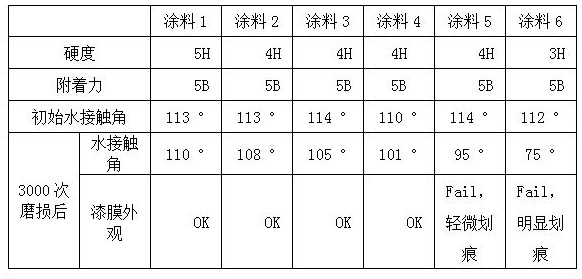

High-wear-resistance UV resin with anti-fingerprint function and preparation method thereof

ActiveCN112574390AGood anti-fingerprint and abrasion resistanceImprove wear resistanceAntifouling/underwater paintsPaints with biocidesPolyesterPolymer science

The invention relates to high-wear-resistance UV resin with an anti-fingerprint function and a preparation method of the high-wear-resistance UV resin. Raw materials of the resin comprise the following components: an isocyanate mixture, perfluoropolyether alcohol containing a hydroxyl group at one end, a mixture of single-end-carbon hydroxyl polysiloxane and double-end-carbon hydroxyl polysiloxane, linear polyester glycol free of fluorine and silicon, hydroxyl acrylate containing a polyurethane structure and a polyurethane reaction catalyst. According to the invention, perfluoropolyether and an organic silicon chain segment are introduced into a molecular chain of an UV resin polymer at the same time through reaction among the components, and the friction coefficient and the surface energyof the surface of the resin are reduced by utilizing the synergistic effect of fluorine-silicon molecules, so the prepared UV resin has good fingerprint resistance and wear resistance; and meanwhile,the hydrogen bond content of the molecular chain is increased by introducing carbamate with relatively high content into the molecular chain of the UV resin polymer, so the cohesive energy of the molecular chain is further improved, and the wear resistance of the UV resin is further improved.

Owner:太仓中化环保化工有限公司

Preparation method of disposable paper cup

InactiveCN108797224AGood compatibilityImprove hydrophobicityBio-packagingBox making operationsWater resistantPaper cup

The invention discloses a preparation method of a disposable paper cup. The preparation method comprises the following steps that S1, bagasse, polylactic acid, tackifying resin, isobornyl acrylate, ethyl maltol and water are mixed and the stirred, and impurities are removed with a double-layer filter net to obtain a filter liquor; S2, after the filter liquor is placed, extrusion and drainage are carried out, a supernatant liquid is drained away to obtain a fine processing raw material; the fine processing raw material is added on a die, and hot pressing is carried out to obtain a paper cup blank mold; S3, a lamination machine is used for spraying single-face polyethylene film on the front face of the paper cup blank mold, corona treatment is carried out on the reverse face of the paper cupblank mold, then a printing machine is used for printing required patterns, the paper cup blank mold is cut into fan-shaped pieces and folded into a circular paper cup body, a fiber cotton layer is arranged on the portion, where the hand holds a cup body, of the thumb and index finger, and the disposable paper cup is obtained. The prepared cup paper has excellent water resistant performance.

Owner:安庆市恒原纸塑有限公司

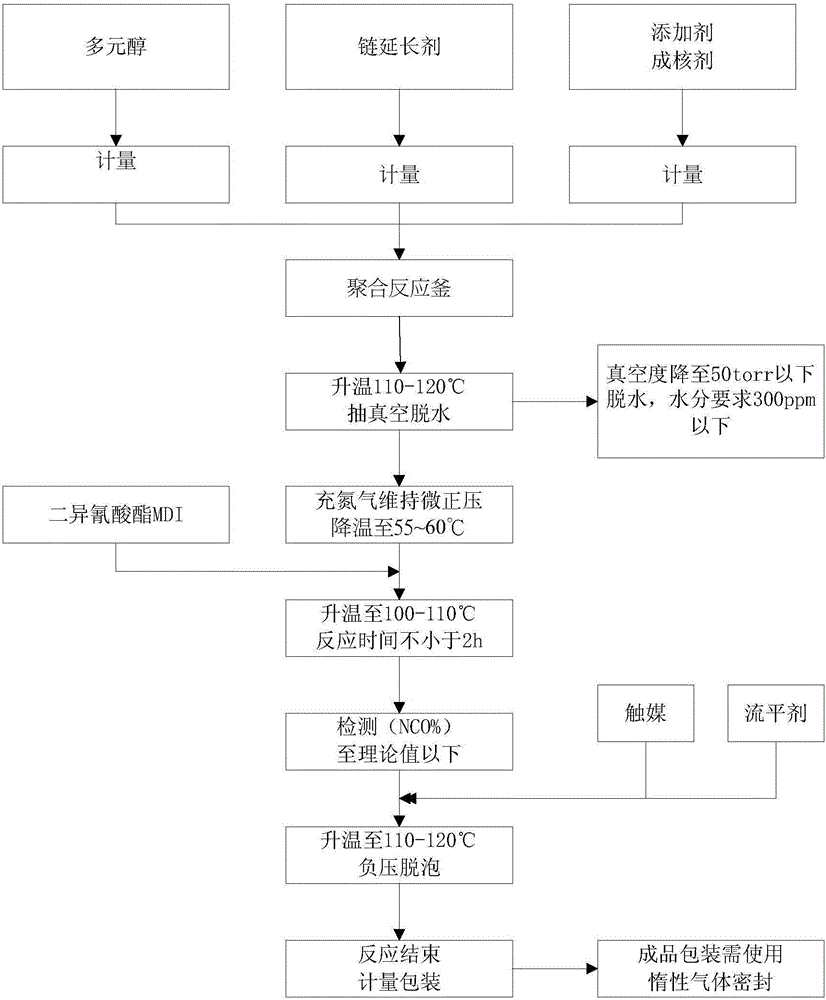

Preparation method and application of moisture reaction type polyurethane hot-melt adhesive for composite floor

The invention disclose a preparation method and application of moisture reaction type polyurethane hot-melt adhesive for a composite floor and belongs to the technical field of macromolecule material preparation .According to the method, polyester polyol, diisocyanate and chain extender are adopted as basic raw materials, auxiliary agents such as accelerant, a flatting agent and a nucleating agent are combined, and a high temperature polymerization reaction is conducted, so that the moisture reaction type polyurethane hot-melt adhesive (PUR) is obtained .A product prepared through the method is the one-component moisture reaction type polyurethane hot-melt adhesive, no cross-linking agent is used for hardening, and instead, an NCO functional group with the resin molecular chain tail end reactive is adopted for reacting with moisture to achieve cross-linking .The solid content of the product is 100%, no solvent is contained, no solvent is used in the technological process, a baking channel does not need to be arranged, cost is lowered, and no safety or environmental protection problem exists .In addition, the polyurethane adhesive product produced through the method is high in cohesive energy, good in initial adhesion and excellent in heat resistance, weather resistance, hydrolysis resistance and aging resistance after being cured and can be widely applied to processing of building decorative materials.

Owner:高鼎精细化工(昆山)有限公司

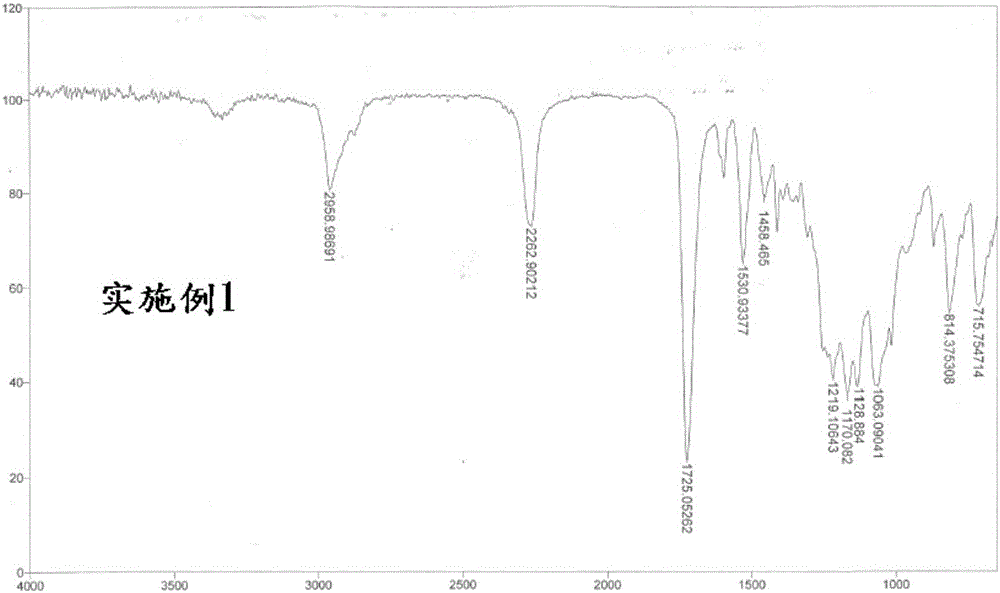

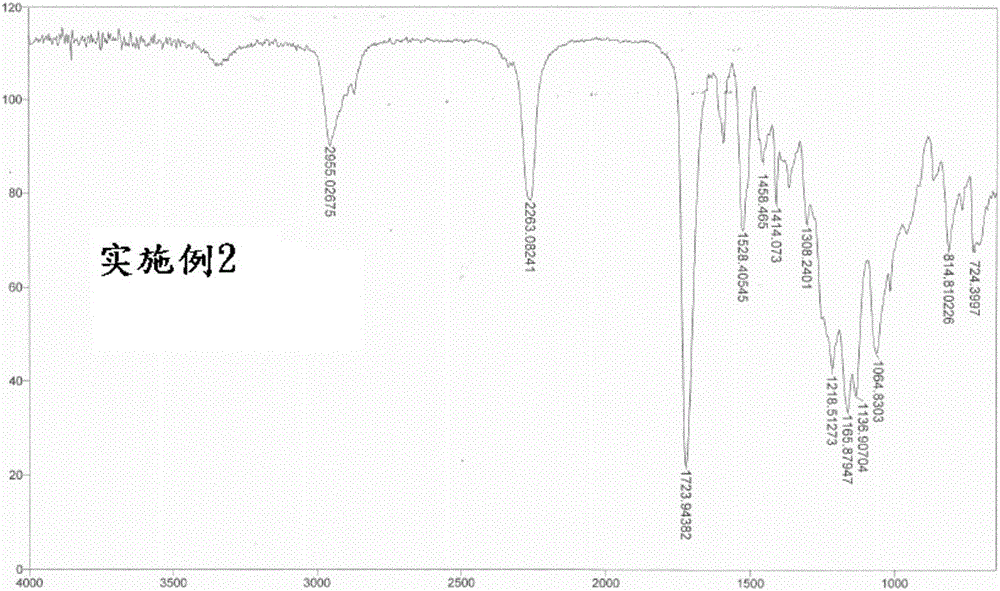

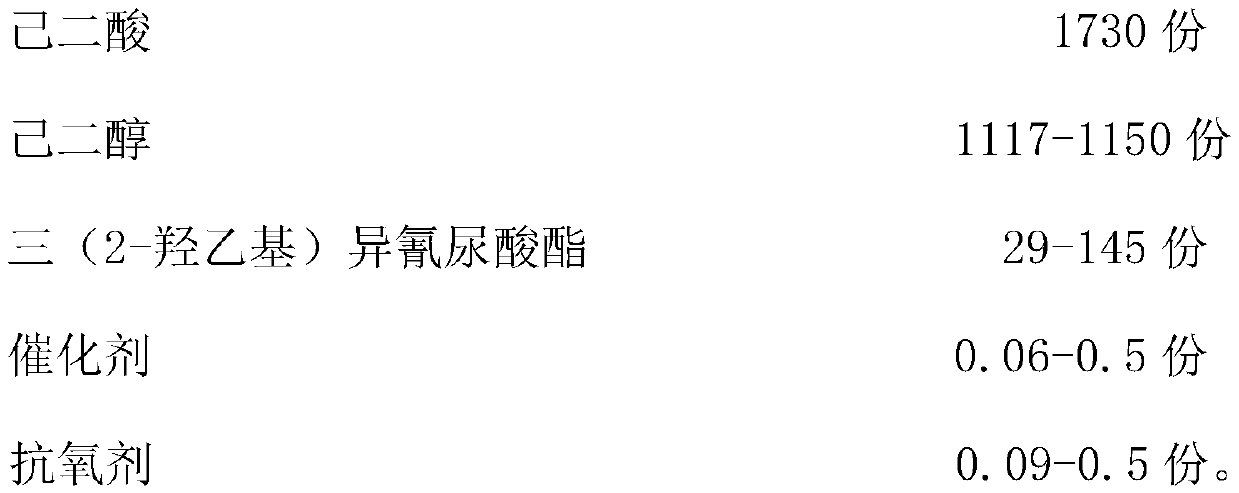

Synthetic method for trifunctional and high-cohesive-energy flame-retardant polyol used for woodworking adhesive

ActiveCN110372851AGood mechanical propertiesImprove cohesive energyPolyureas/polyurethane adhesivesPolyurethane adhesiveAntioxidant

The invention provides a synthetic method for trifunctional and high-cohesive-energy flame-retardant polyol used for a woodworking adhesive. The synthetic method comprises the following steps: step 1,accurately weighing adipic acid, hexanediol, tris(2-hydroxyethyl)isocyanurate, a catalyst and an antioxidant, and carrying out a reaction at 140 DEG C for 1 h under the protection of nitrogen; step 2, carrying out heating to 150 DEG C, carrying out a reaction for 1 h, carrying out heating again to 167 DEG C, carrying out a reaction for 1 h, then carrying out heating again to 184 DEG C, carrying out a reaction for 1 h, carrying out heating again to 201 DEG C, carrying out a reaction for 1 h, carrying out heating again to 218 DEG C, and carrying out a reaction for 2 h; and step 3, opening a vacuum pump connected with a reaction device, raising a vacuum degree to less than minus 0.096 MPa in 2 h, periodically carrying out sampling for detection until an acid value and a hydroxyl value of a sample meet standards, then carrying out cooling to 180 DEG C, breaking vacuum with nitrogen, carrying out cooling to 160 DEG C, and carrying out discharging and packaging so as to obtain a product. According to the invention, through introduction of the tris(2-hydroxyethyl)isocyanurate, the cohesive energy, crystallinity and wettability of a polyurethane adhesive are improved; and when the trifunctional and high-cohesive-energy flame-retardant polyol is applied to the woodworking adhesive, the initial adhesion of the polyurethane adhesive can be well improved.

Owner:CHONGQING HANTUO TECH CO LTD

Foam double-sided adhesive tape and production method thereof

ActiveCN110878190AImprove the bonding force between layersNo layer separationNon-macromolecular adhesive additivesMacromolecular adhesive additivesElastomerPolymer science

The invention relates to a foam double-sided adhesive tape, which comprises: a release material, a first pressure-sensitive adhesive layer compounded on the release material, a foam layer compounded on the first pressure-sensitive adhesive layer, and a second pressure-sensitive adhesive layer compounded on the foam layer, wherein at least one of the first pressure-sensitive adhesive layer and thesecond pressure-sensitive adhesive layer is a removable pressure-sensitive adhesive layer, and the removable pressure-sensitive adhesive layer is prepared from the following raw materials in parts byweight: 40-60 parts of a thermoplastic elastomer, 40-60 parts of a tackifying resin, 10-20 parts of a reinforcing agent, 10-25 parts of a softener, 0.2-5 parts of an antioxidant, and 0.1-5 parts of afiller. The foam double-sided adhesive tape provided by the invention adopts a specific structure, realizes good interaction, has excellent bonding performance, excellent environment testing resistance, excellent shading performance, excellent buffer performance and excellent shearing resistance, has the tensile and removable easy-to-rework characteristic, and is particularly suitable for assembling a large-size liquid crystal display module.

Owner:安徽屹珹新材料科技有限公司

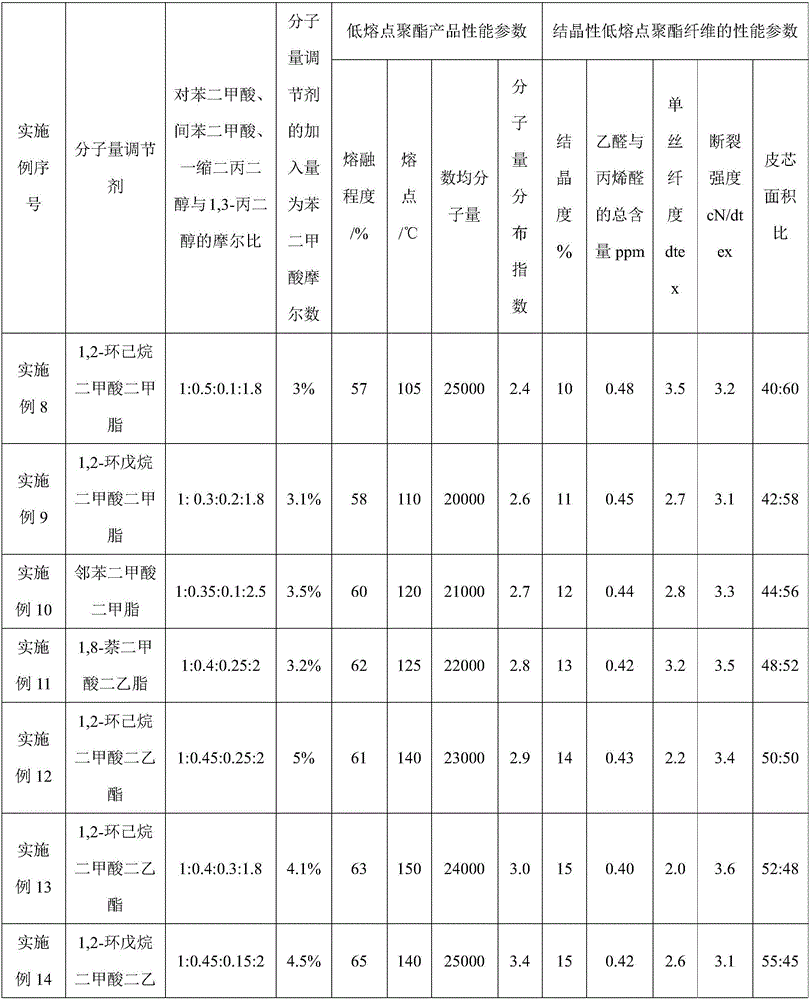

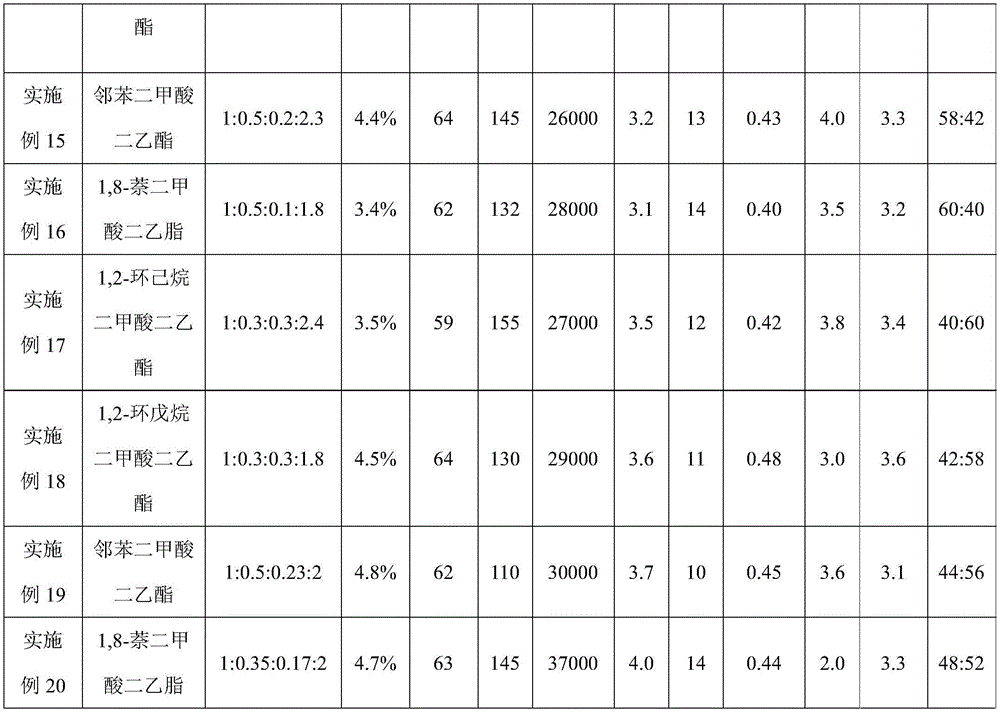

Crystallinity low-melting point polyester fiber and preparation method thereof

ActiveCN106811829AImprove cohesive energyFast curingConjugated synthetic polymer artificial filamentsStretch-spinning methodsFiberPolymer science

The invention relates to a crystallinity low-melting point polyester fiber and a preparation method thereof; the crystallinity low-melting point polyester fiber is a belt core structure, wherein a belt layer is a low-melting-point polyester, and a core layer is PET; the low-melting point polyester fiber consists of terephthalic acid chain section, isophthalic acid chain section, 1, 3-propylene glycol chain section, dipropylene glycol chain section and molecular weight modifier, wherein the molecular weight modifier corresponding to the molecular weight modifier chain section is 1, 8-naphthalic acid, phthalic acid, 1, 2-cyclopentane dioctyl phthalate, 1, 2-cyclohexane dioctyl phthalate or corresponding dimethyl ester or diethyl ester. The preparation method includes low-melting-point polyester polymerization and belt core composite spinning, wherein post spinning adopts drafting-water washing technique, and drafting adopts oil bath drafting added with sodium sulfite; through rolling, cutting and drying, the crystallinity low-melting point polyester fiber is acquired. The crystallinity low-melting point polyester fiber prepared by the invention is low in melting point, and low in total content of acetaldehyde and acrolein.

Owner:扬州富威尔复合材料有限公司

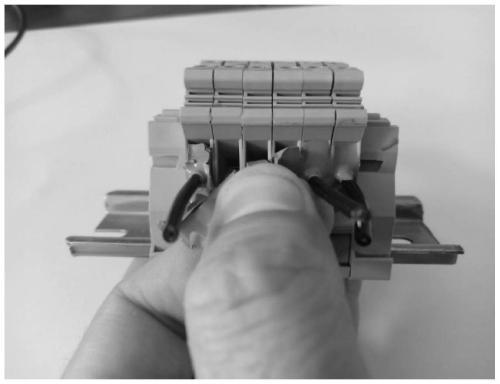

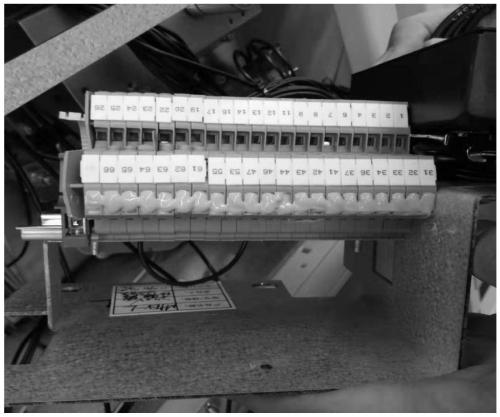

Peelable anti-condensation material as well as preparation method and application thereof

The invention relates to a peelable anti-condensation material which comprises the following raw materials in parts by weight: 30-65 parts of vinyl silicon oil, 6-15 parts of containing hydrogen silicone oil, 1-5 parts of a vinyl silicon resin, 1-5 parts of a hydrogen-containing silicon resin, 4-10 parts of fluorine-containing silane, 3-8 parts of an organic silicon modified fluorinated acrylate copolymer, 8-20 parts of a reinforcing filler, 10-30 parts of a flame-retardant filler, 1-3 parts of a catalyst and 0.5-2 parts of an inhibitor. The invention further provides a preparation method andapplication of the peelable anti-condensation material. The anti-condensation material for electric equipment is capable of preventing condensation, peelable, good in adherence, good in insulation andflame retardancy and excellent in mechanical property, and is an anti-condensation material with excellent comprehensive properties, the humidity inside the electric equipment can be reduced when theelectric equipment is coated by the material, corrosion can be reduced, and safe and stable operation of the electric equipment can be ensured.

Owner:中电保力(北京)科技有限公司

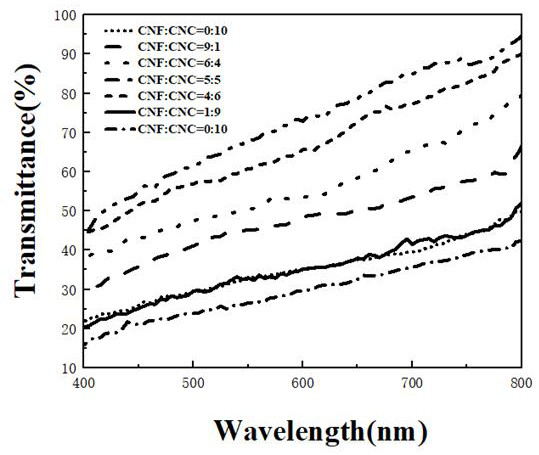

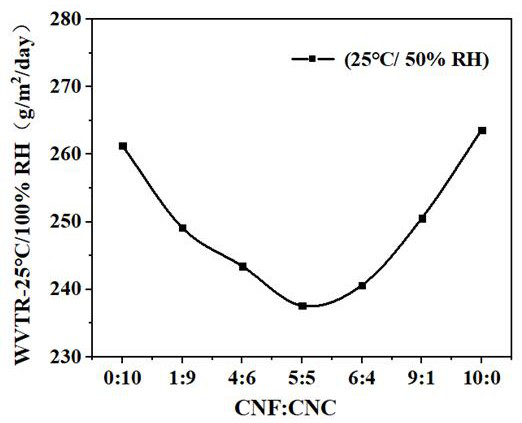

Preparation method of high-transparency and high-barrier cellulose paper

InactiveCN113152150AEasy to operateEnvironmentally friendly operationSpecial paperPaper/cardboardThin membraneEconomic benefits

The invention relates to the technical field of cellulose paper preparation, in particular to a preparation method of high-transparency and high-barrier cellulose paper. The method comprises the following steps: preparing cellulose nanocrystals (CNC) and cellulose nanofibrils (CNF) into a CNC / CNF mixed solution according to a certain proportion; then uniformly dispersing by ultrasonic waves, and carrying out suction filtration for 1.5-6 hours through a sand core funnel; and finally, drying in a drying oven at the temperature of 15-50 DEG C for 1-8 hours, and stripping the cellulose paper from a filter membrane. The raw materials are wide in source, the preparation process is simple, the production cost can be effectively saved, and the economic benefit is improved; and the raw materials are green, environment-friendly and biodegradable, and have a very good environmental effect. More importantly, the cellulose paper prepared by the method not only has better barrier property, but also has higher transparency, and has wide application prospects in the fields of biological composite films, packaging materials and the like.

Owner:阿尔诺维根斯(衢州)特种纸有限公司

Frosting coating and preparation method thereof

InactiveCN104893530ATight textureUniform and fine grainPolyurea/polyurethane coatingsCross-linkPolymer science

The invention discloses a frosting coating. Firstly, a castor oil is used for cross-linking a prepolymer: the multifunctional-group structure in the castor oil can cross-link a polymer to a certain extent, the cross-linking degree of the polymer is increased, the interaction force among molecular chains is increased, molecular chain movement is resisted, water molecules cannot enter the molecular chains to swell the polymer, and the water absorption of an adhesive film is decreased; meanwhile, the castor oil is a triglyceride of fatty acid, due to long nonpolar fatty acid chains in molecules, the adhesive film has good hydrophobicity, and the water absorption is further reduced; meanwhile, ester groups in the castor oil have higher cohesive energy and can improve the tensile strength of the adhesive film; ethyl cellulose has better heat resistance and thermal plasticity, has good compatibility with polyurethane and can improve the comprehensive property of the prepolymer; then the polyurethane prepolymer is mixed with polysilsesquioxane for modification.

Owner:HEFEI JIKE NEW MATERIALS

In-situ compatibilization polymerization enhanced thermosetting phenolic foam insulation board and preparation method thereof

The invention discloses an in-situ compatibilization polymerization enhanced thermosetting phenolic foam insulation board and a preparation method thereof, wherein the in-situ compatibilization polymerization enhanced thermosetting phenolic foam insulation board comprises the following materials in parts by weight: 50-60 parts of resol, 20-30 parts of hydroxymethyl polyamide resin, 20-35 parts of a modified filler, 5-10 parts of a curing agent, 3-7 parts of an emulgator, 8-15 parts of a foaming agent, 0.5-1 part of a heat stabilizer, and 0.5-1 part of an ultraviolet light absorber; the resol is a component of foamex, the hydroxymethyl polyamide resin is a chain extender and a toughening component, and the modified filler is an in-situ compatibilization polymerization enhancing component. The resol, the hydroxymethyl polyamide resin, the modified filler, the curing agent, the emulgator, the foaming agent, the heat stabilizer and the ultraviolet light absorber prepared in advance are added into a reaction kettle, stirred evenly, and applied onto a non-woven fabric; on a continuous board production line, the temperature is kept at 70-75 DEG C, and crosslinking and foaming are performed within 20 minutes to obtain the in-situ compatibilization polymerization enhanced thermosetting phenolic foam insulation board. The in-situ compatibilization polymerization enhanced thermosetting phenolic foam insulation board is low in residue rate, high in compression strength and tensile strength, and good in heat resistance and ageing resistance.

Owner:NANTONG DEMING PLASTIC NEW MATERIALS

Polymer coating and preparation method thereof

InactiveCN104893529AHigh hardnessGood surface effectPolyurea/polyurethane coatingsPrepolymerInteraction forces

The invention discloses a polymer coating. Firstly, a castor oil crosslinking prepolymer is adopted, wherein a multifunctional group structure of castor oil can endow a polymer with certain crosslinking, accordingly, the crosslinking degree of the polymer is improved, the interaction force of molecular chains is increased, movement of the molecular chains is blocked, water molecules cannot easily enter the molecular chains to swell the polymer, and the water absorption of the coating is reduced; meanwhile, the castor oil is triglycerin of fatty acid, nonpolar fatty acid chains of medium-long chains in molecules of the castor oil enable the coating to have excellent hydrophobicity, and the water absorption is further reduced; besides, ester in the castor oil has higher cohesive energy and can improve the tensile strength of the coating; ethyl cellulose has better heat resistance and thermoplasticity and has good compatibility with polyurethane, and the comprehensive performance of the prepolymer can be improved; the polyurethane prepolymer and polysilsesquioxane are subjected to blending modification.

Owner:HEFEI JIKE NEW MATERIALS

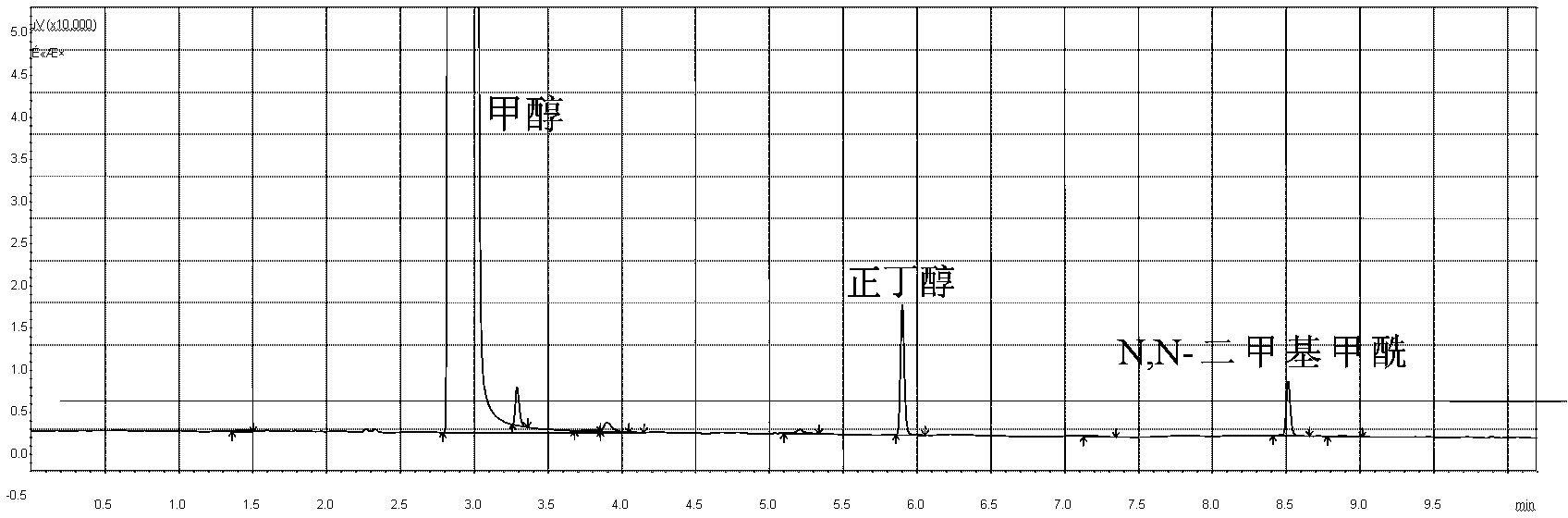

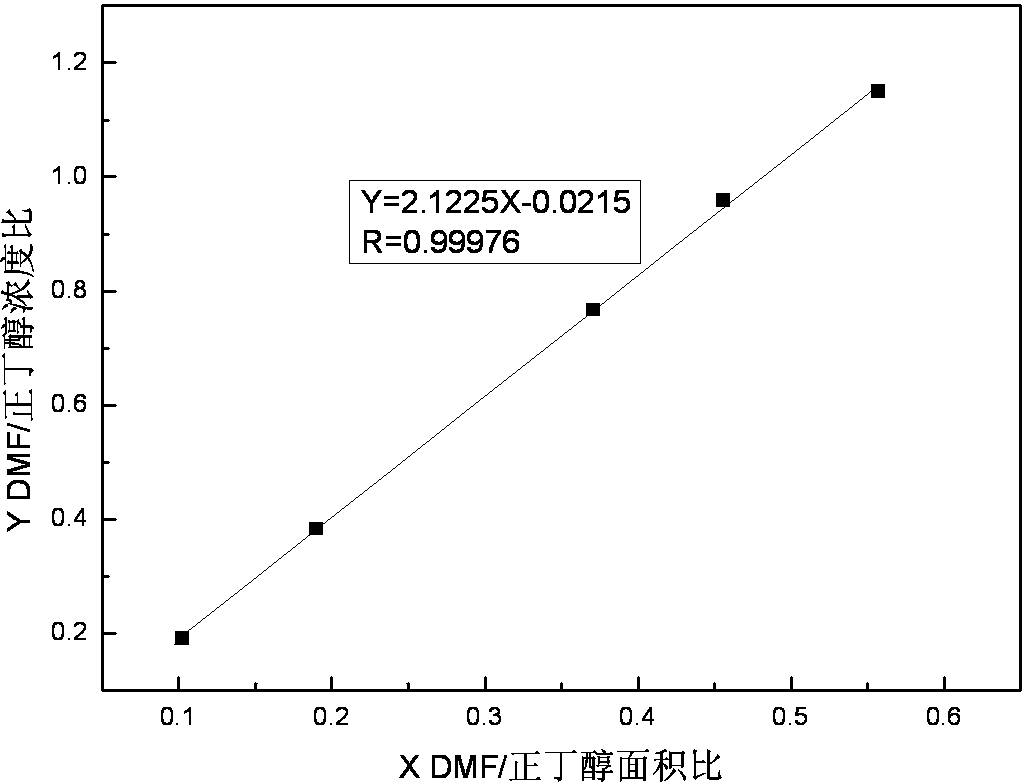

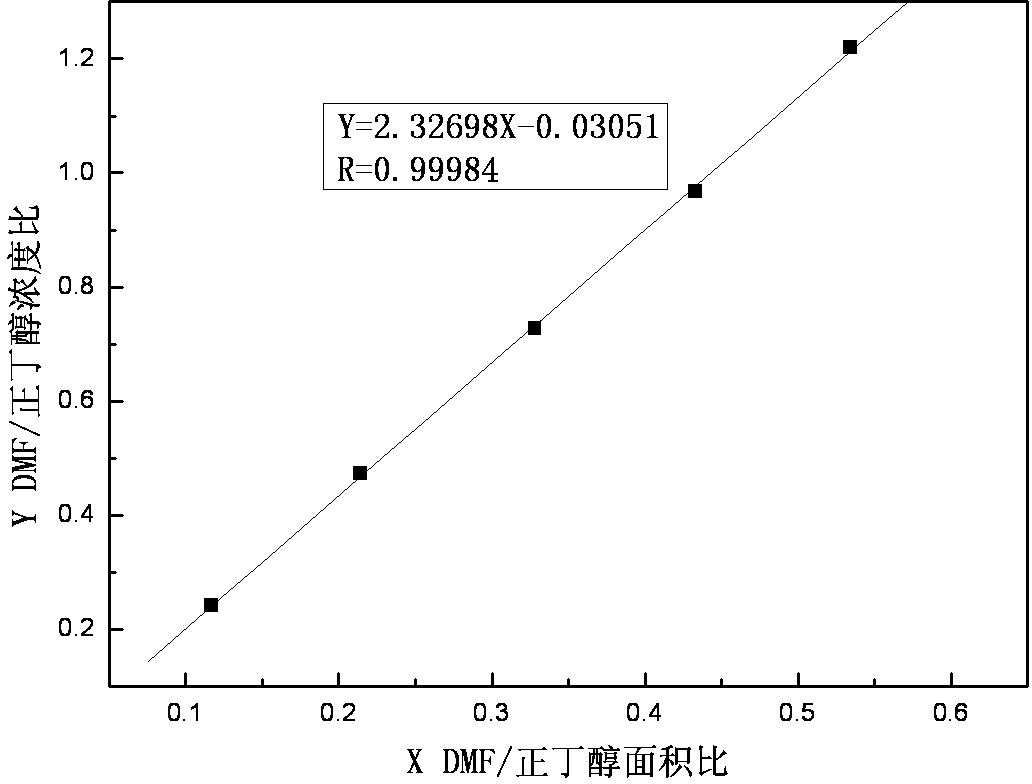

Gas chromatography detection method for trace N,N-dimethyl formamide in synthesized leather

InactiveCN103969389AEasy to separateEasy extractionComponent separationGas liquid chromatographicUltrasound assisted

The invention belongs to the product quality detection range, and mainly relates to a quick detection method for N,N-dimethyl formamide with trace content in polyurethane synthesized leather. The residual trace N,N-dimethyl formamide in the polyurethane synthesized leather is extracted through ultrasonic auxiliary enhanced methyl alcohol extraction; a gas chromatography analysis method is adopted to execute qualification, and an internal standard method is adopted to execute quantification, so that the content of the N,N-dimethyl formamide in an extracting solution is measured; the accuracy of the method is checked through a standard adding method. The method disclosed by the invention can be used for detecting micro or trace N,N-dimethyl formamide residues in a synthesized leather product. Compared with the conventional method, the method disclosed by the invention is low in cost and high in accuracy.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com