Synthetic method for trifunctional and high-cohesive-energy flame-retardant polyol used for woodworking adhesive

A technology of flame retardant polyol and trifunctionality, which is applied in the field of synthesis of flame retardant polyol for wood glue, can solve the problems of no flame retardant performance and weak initial adhesion, and achieve the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

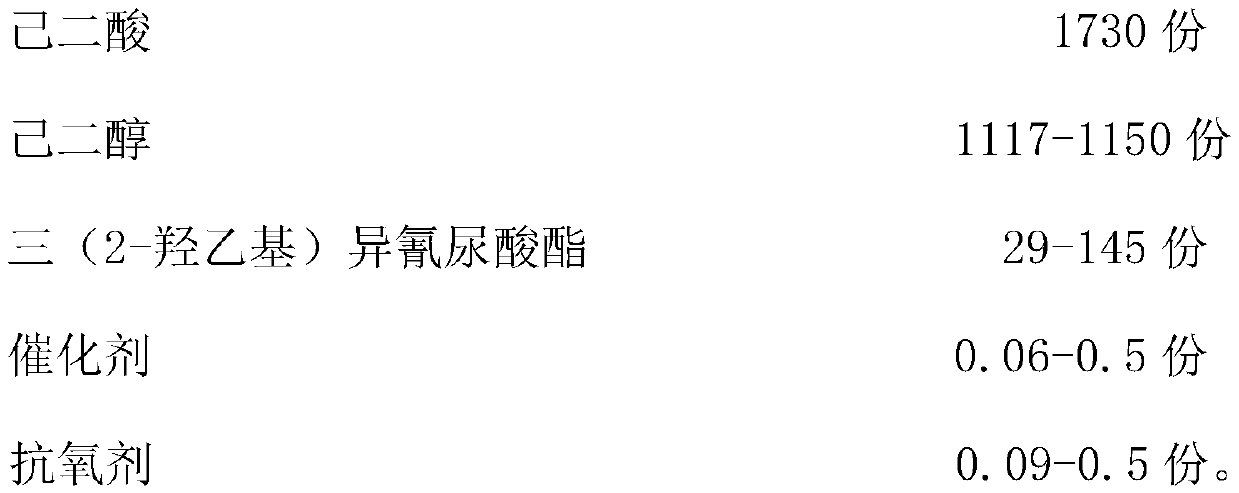

Method used

Image

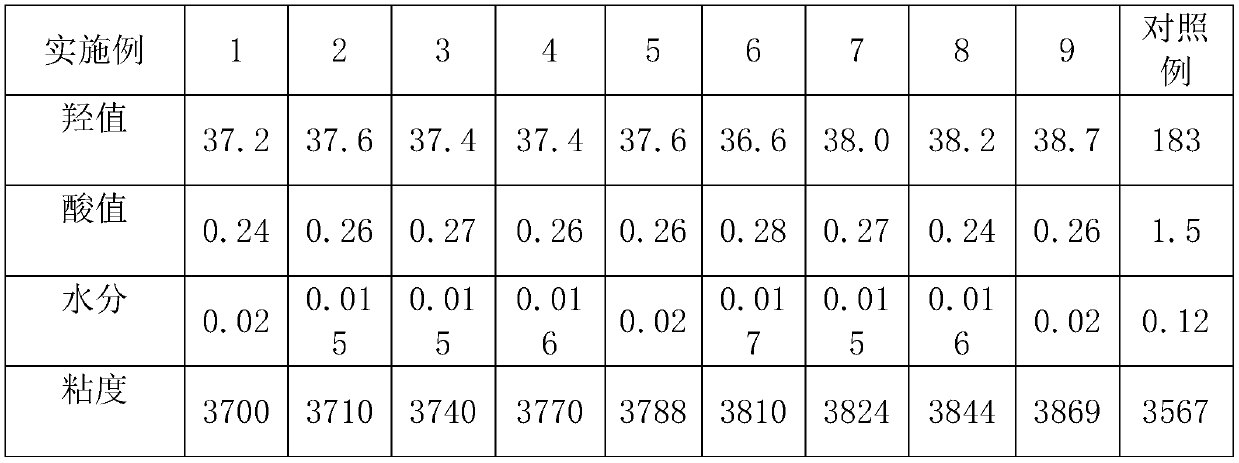

Examples

Embodiment 1

[0023] Step 1: accurately weigh the adipic acid of 1730g, the hexanediol of 1150g, the three (2-hydroxyethyl) isocyanurate of 29g, the catalyst of 0.06g, the antioxidant of 0.09g, nitrogen protection, in React at a temperature of 140°C for 1 hour;

[0024] Step 2: heat up to 150°C, react for 1 hour, heat up to 167°C again, react for 1 hour, heat up again to 184°C, react for 1 hour, heat up again to 201°C, react for 1 hour, heat up again to 218°C, react for 2 hours;

[0025] Step 3: Turn on the vacuum pump connected to the reaction device, slowly increase the vacuum degree to < -0.096MPa within 2 hours, take samples regularly until the acid value of the sample is ≤2mgKOH / g, and the hydroxyl value of the sample is between 35 and 40mgKOH / g , the temperature was lowered to 180°C, the vacuum was broken with nitrogen, the temperature was lowered to 160°C, and the obtained product was discharged and packaged.

Embodiment 2

[0027] Step 1: accurately weigh the adipic acid of 1730g, the hexanediol of 1145g, the three (2-hydroxyethyl) isocyanurate of 43.5g, the catalyst of 0.12g, the antioxidant of 0.14g, nitrogen protection, React at a temperature of 140°C for 1h;

[0028] Step 2: heat up to 150°C, react for 1 hour, heat up to 167°C again, react for 1 hour, heat up again to 184°C, react for 1 hour, heat up again to 201°C, react for 1 hour, heat up again to 218°C, react for 2 hours;

[0029] Step 3: Turn on the vacuum pump connected to the reaction device, slowly increase the vacuum degree to < -0.096MPa within 2 hours, take samples regularly until the acid value of the sample is ≤2mgKOH / g, and the hydroxyl value of the sample is between 35 and 40mgKOH / g , the temperature was lowered to 180°C, the vacuum was broken with nitrogen, the temperature was lowered to 160°C, and the obtained product was discharged and packaged.

Embodiment 3

[0031] Step 1: accurately weigh the adipic acid of 1730g, the hexanediol of 1142g, the three (2-hydroxyethyl) isocyanurate of 58g, the catalyst of 0.18g, the antioxidant of 0.19g, nitrogen protection, in React at a temperature of 140°C for 1 hour;

[0032] Step 2: heat up to 150°C, react for 1 hour, heat up to 167°C again, react for 1 hour, heat up again to 184°C, react for 1 hour, heat up again to 201°C, react for 1 hour, heat up again to 218°C, react for 2 hours;

[0033] Step 3: Turn on the vacuum pump connected to the reaction device, slowly increase the vacuum degree to < -0.096MPa within 2 hours, take samples regularly until the acid value of the sample is ≤2mgKOH / g, and the hydroxyl value of the sample is between 35 and 40mgKOH / g , the temperature was lowered to 180°C, the vacuum was broken with nitrogen, the temperature was lowered to 160°C, and the obtained product was discharged and packaged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com