Preparation method of high temperature and high pressure resistant rubber sealing material

A rubber sealing, high temperature resistant technology, used in sealing/isolation, earthmoving, wellbore/well components, etc., it can solve the problem that the rubber cartridge is not sold or used, and achieves excellent enhancement effect and high bond energy. , the effect of improving cross-linking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

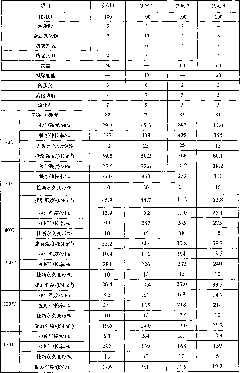

[0009] Embodiment 1-4: wherein the reinforcing material of embodiment 1 is ultrafine particle size carbon black 220; The reinforcing material of embodiment 2 is methacrylate; The reinforcing material of embodiment 3 is ultrafine particle size carbon black 401; Implementation The reinforcing material of Example 4 is ultra-fine particle size carbon black 220 and methacrylate synergy.

[0010] The present embodiment weighs the listed raw materials according to the proportion recorded in Table 1, first hydrogenated nitrile rubber is put into the open mill and masticated, then other materials and auxiliary agents are added into the open mill successively for mixing until well mixed. The mixed rubber is vulcanized for one stage in a flat vulcanizer, the vulcanization temperature is controlled at 150-180°C, the vulcanization time is 20-40 minutes, and the vulcanization pressure is 10-20MPa. After the rubber is taken out from the flat vulcanizer, it is subjected to two-stage vulcaniz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com