Patents

Literature

229results about How to "Improve cross-linking efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for Identifying and Quantifying Organic and Biochemical Substances

InactiveUS20100184062A1Improve cross-linking efficiencyReduce detection limitMicrobiological testing/measurementBiological testingBinding siteAnalyte molecule

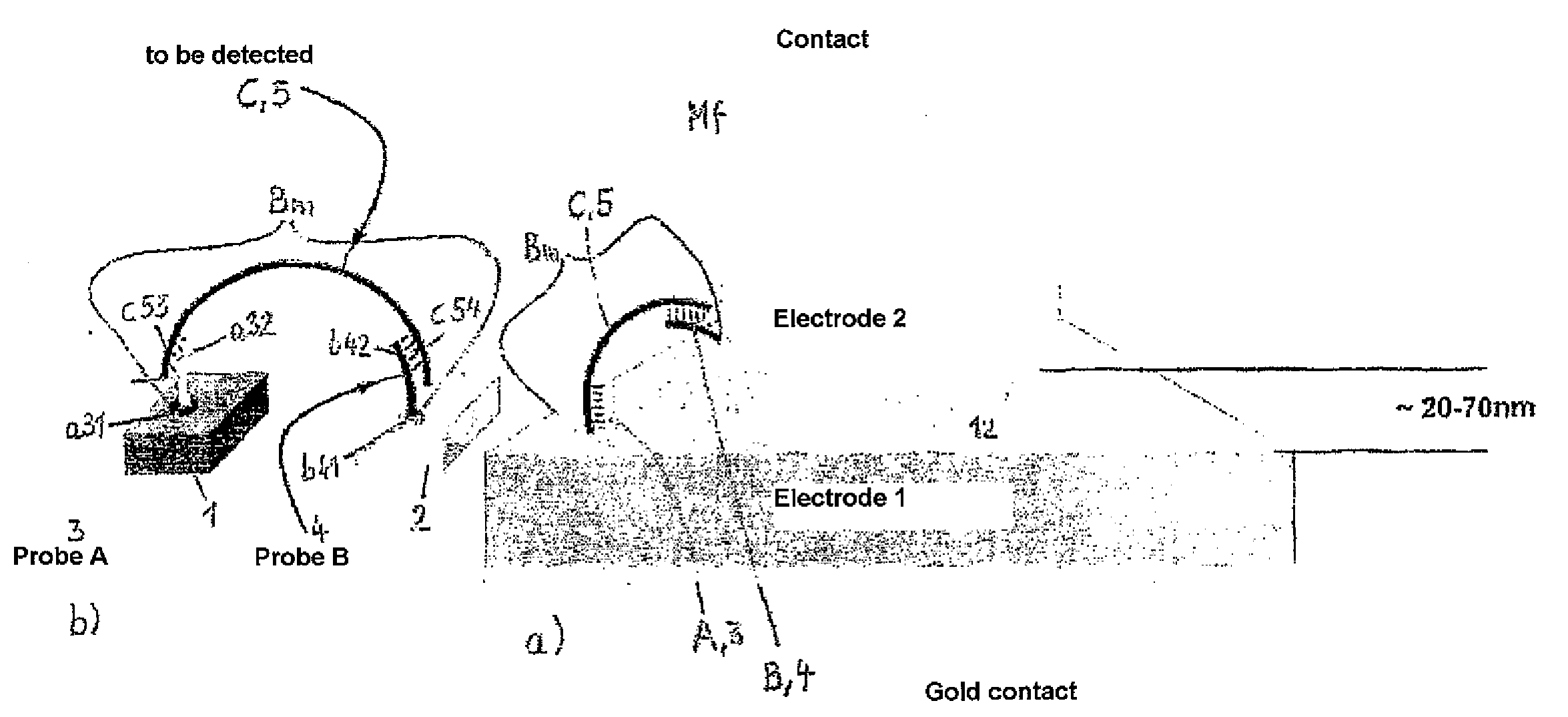

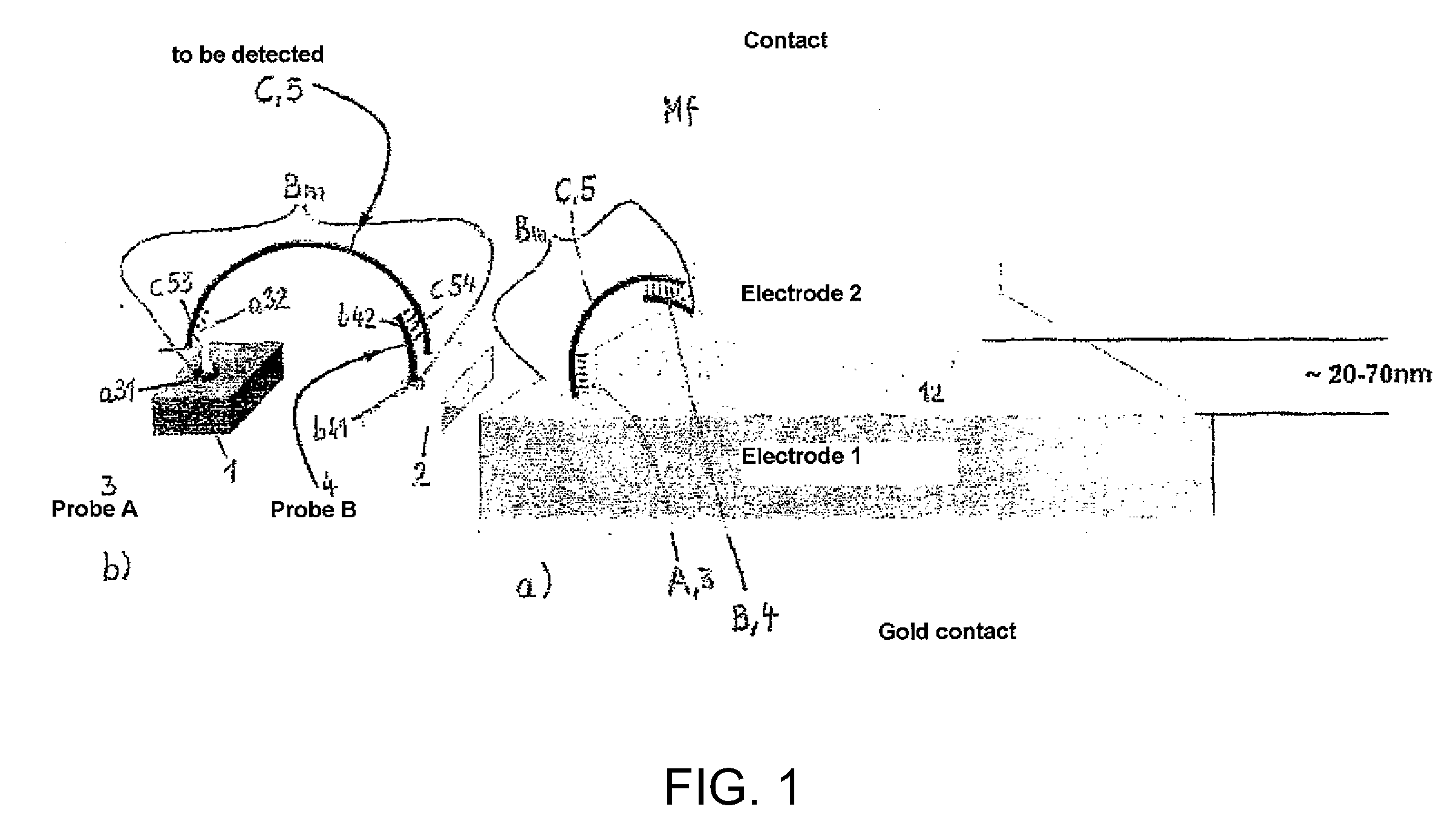

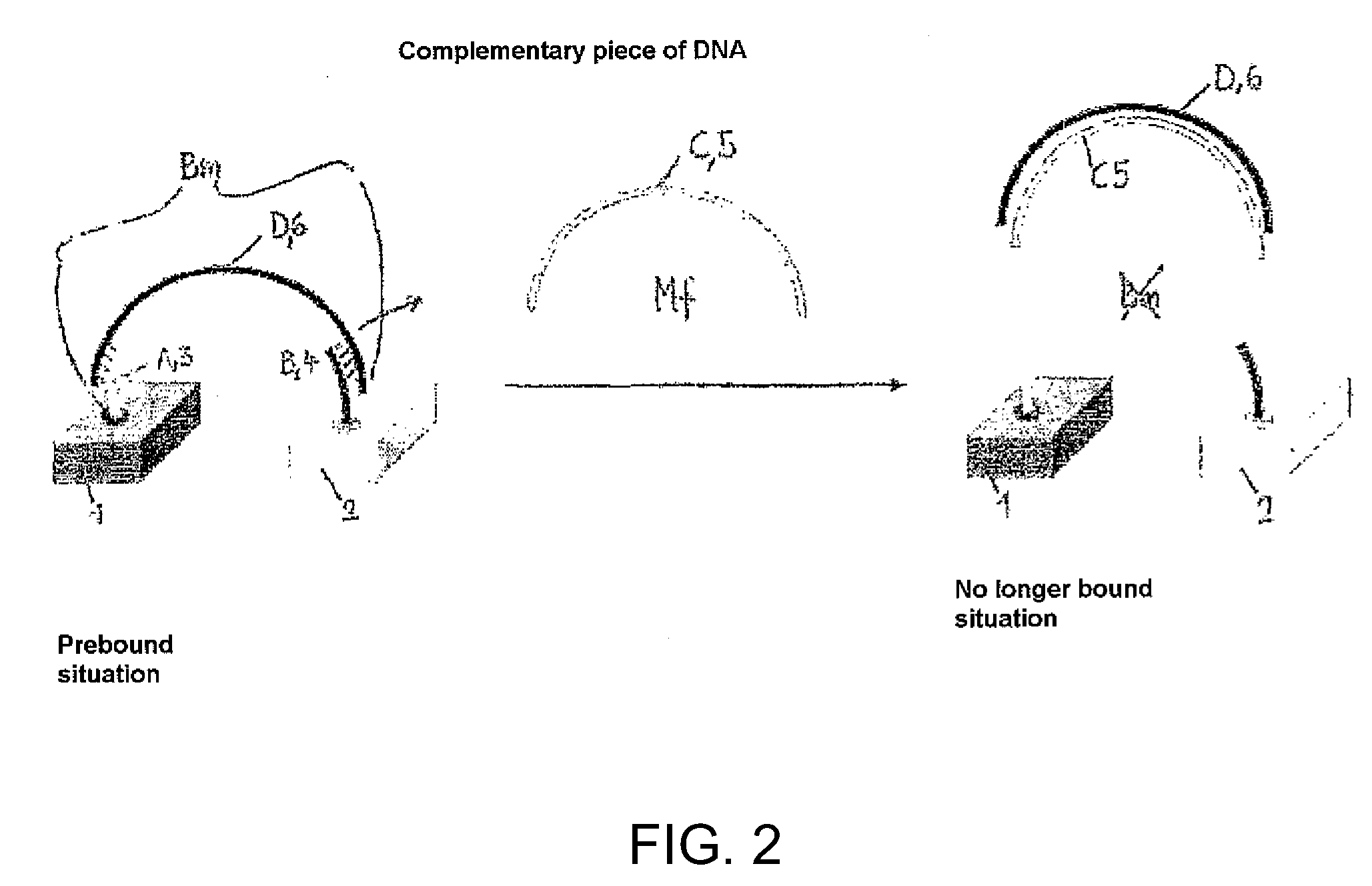

The invention relates to a method for identifying organic or biochemical substances and for determining their concentration in a fluid medium using a nanogap sensor that comprises at least two electrodes. The invention is characterized in that: a nanogap sensor) with electrodes of different materials is used, a respective probe molecule is bonded to each surface of the two electrodes of the sensor and the free remainder of the probe molecules have at least one bondable group with specificity for bonding to a sought substance or to an analyte molecule in the fluid medium. The analyte molecule has at least two binding sites and passes selectively out of the fluid medium in which it is contained, binds to the free ends of the probe molecules, forming a bridge with the probe molecule, and modifies the resulting impedance between the electrodes. The concentration of the substance in the fluid medium can be determined as a result of the modification.

Owner:ROSWELL BIOTECH INC +1

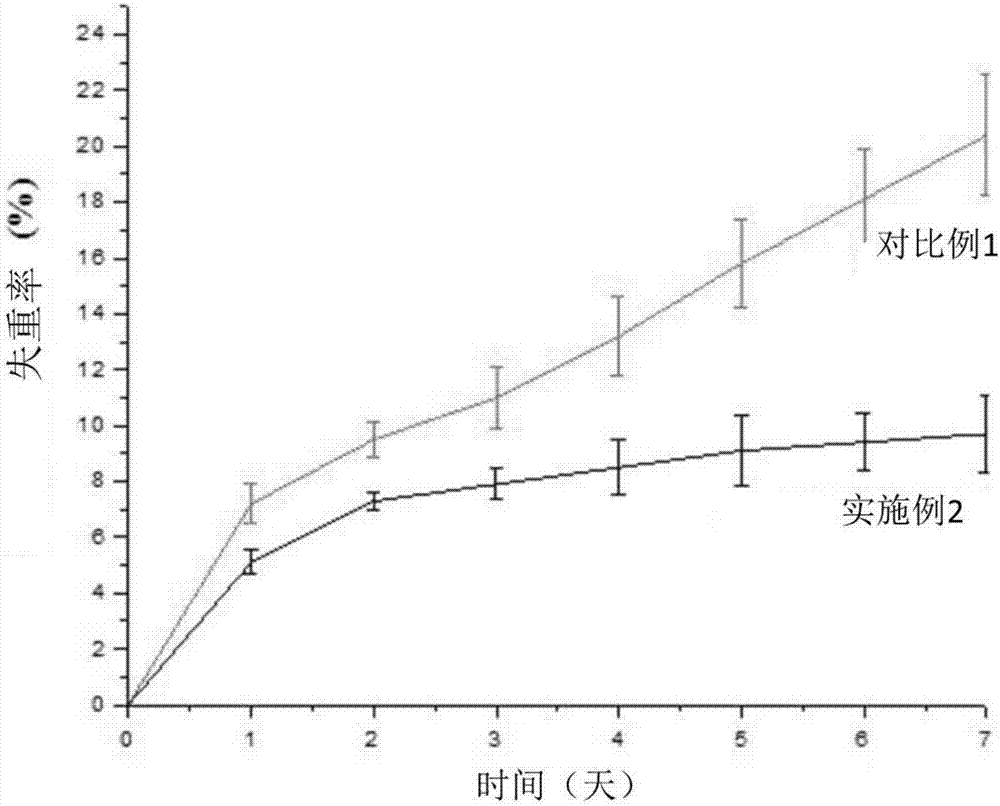

Method for improving creep resistant performance of ultra-high molecular weight polyethylene fiber

ActiveCN102493168AHigh surfaceIncrease internal cross-link pointsPhysical treatmentFibre typesFiberPolymer science

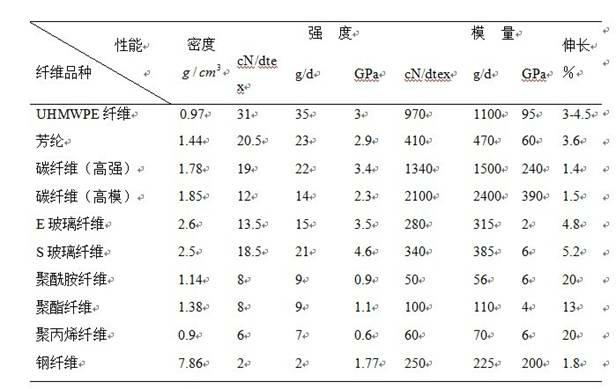

The invention relates to a method for improving the creep resistant performance of an ultra-high molecular weight polyethylene fiber; and the method is characterized by jointly triggering crosslinking by using a photosensitizer and a thermal initiating agent, thereby crosslinking points of the surface and interior of the ultra-high molecular weight polyethylene fiber are increased, the crosslinking efficiency of a cross-linking agent is improved, the relative slippage among molecules of the ultra-high molecular weight polyethylene fiber is effectively impeded and the creep resistant performance of the fiber is increased.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

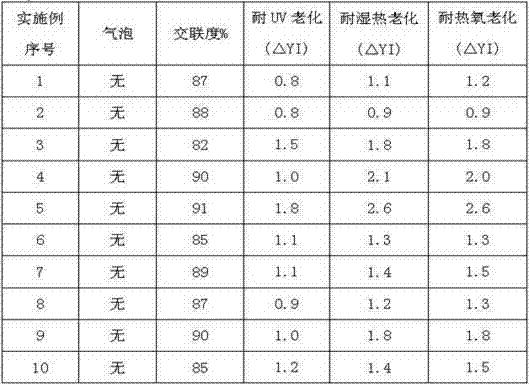

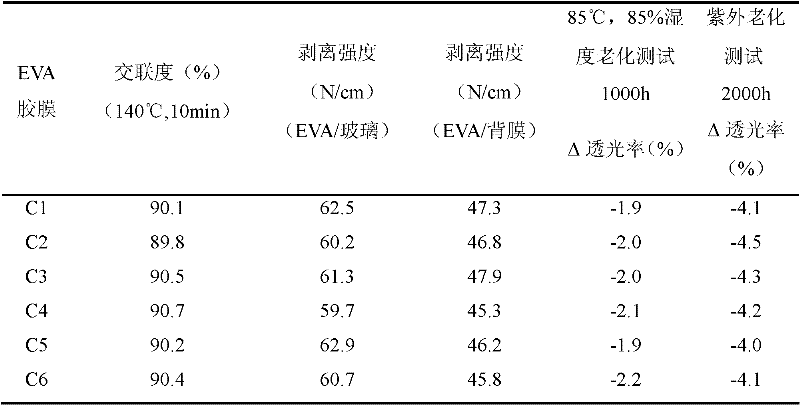

Ethylene-vinyl acetate copolymer packaging thin film

InactiveCN102391568AEnhanced network structureImprove moisture resistancePhotovoltaic energy generationSemiconductor devicesPolymer scienceNetwork structure

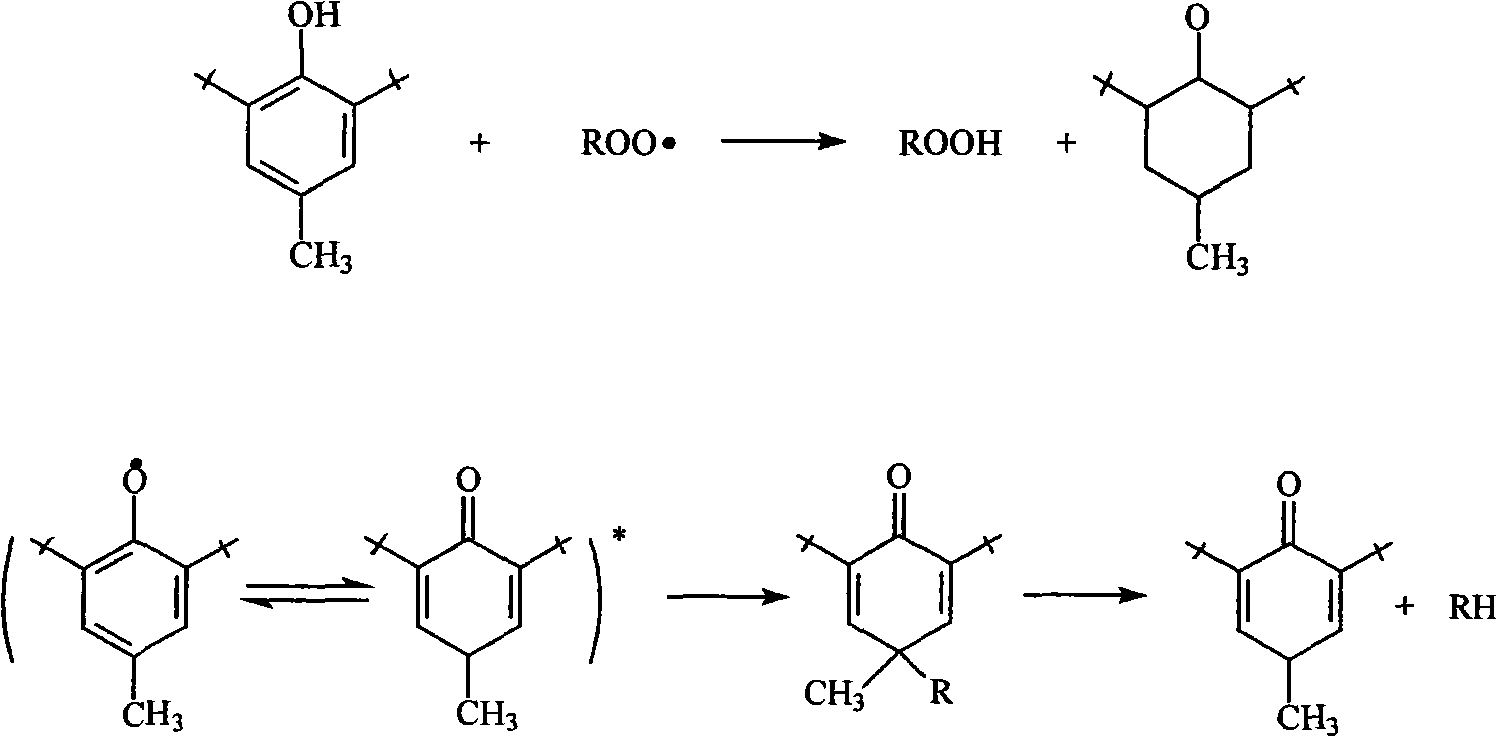

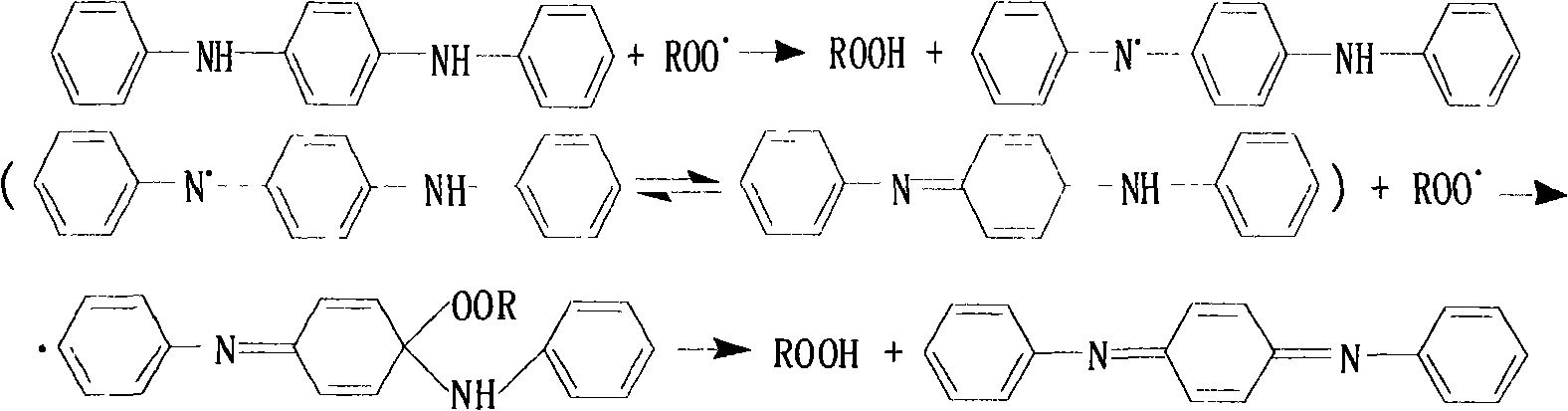

The invention discloses an ethylene-vinyl acetate copolymer packaging thin film, which is used for packaging solar cell components. The thin film is prepared from the following raw materials in part by weight: 100 parts of an ethylene-vinyl acetate copolymer, 0.1 to 2.0 parts of crosslinking agent, 0.1 to 10.0 parts of aid crosslinking agent and a proper amount of aid. The ethylene-vinyl acetate copolymer contains 25 to 33 percent of vinylacetate, and the ratio of the amount of the aid crosslinking agent and the crosslinking agent is 1:10 to 10:1. In the invention, the introduction of the aid improves the network structure of crosslinked resin, improves crosslinking efficiency, greatly reduces the dosage and residue of the crosslinking agent greatly and avoids aging phenomenon caused by residual crosslinking agent, and the prepared thin film has higher dampness and heat resistance, high ultraviolet resistance, high thermal-oxidative aging resistance and the like and has long service life.

Owner:DONGFANG TURBINE CO LTD

Preparation method of high temperature and high pressure resistant rubber sealing material

InactiveCN101824172AImprove mechanical propertiesImprove heat resistanceSealing/packingPolymer scienceVulcanization

The invention belongs to the technical field of rubber sealing material, and relates to a preparation method of a high temperature and high pressure resistant rubber sealing material which can be applied to an oilfield deep oil production engineering process; first, 100 parts of hydrogenated nitrile rubber is weighed by parts in weight, put into a mixing mill to be plasticated; and then 2 to 20 parts of metal oxide, 1 to 5 parts of stearic acid, 5 to 100 parts of acrylate, 10 to 70 parts of carbon black, 1 to 6 parts of aging inhibitor, 5 to 30 parts of plasticizer, 2 to 10 parts of antiscorcher, 2 to 10 parts of vulcanizer and 2 to 10 parts of vulcanization aid are sequentially added into the mixing mill to be mixed uniformly; mixing rubber is vulcanized primarily in a plate vulcanizing press, the vulcanizing temperature is controlled to be 150 to 180DEG C, the vulcanizing time is 20 to 40min, and the vulcanizing pressure is 10 to 20MPa; after being taken out from the plate vulcanizing press, the rubber is secondarily vulcanized at 150 to 180DEG C to obtain vulcanized rubber with excellent performance; and the preparation method of the high temperature and high pressure resistant rubber sealing material has the advantages of simple process, convenient operation and use, low preparation cost, excellent mechanical performance, and in particular better high-temperature mechanical performance.

Owner:QINGDAO UNIV OF SCI & TECH +1

Solar cell packaging EVA adhesive film capable of resisting heat, humidity, ultraviolet light and aging

InactiveCN101626039AIncrease crosslink densityModerate reaction temperatureElectrical equipmentGlass/slag layered productsAntioxidantPhosphate

The invention relates to a solar cell packaging EVA adhesive film capable of resisting heat, humidity, ultraviolet light and aging, which comprises the following materials by weight portions: 100 portions of copolymer of ethylene vinyl acetate, 0.8-1.4 portions of crosslink curing agent, 0.05-0.15 portion of crosslink curing accelerator, 0.2-0.6 portion of tackifier, 0.1-0.5 portion of antioxidant, 0.05-0.25 portion of ultraviolet light stabilizer and 0.1-0.3 portion of ultraviolet light absorbent, wherein the crosslink curing agent is tert butyl peroxy 2-ethyl hexyl carbonate; the crosslink curing accelerator is triallyl isocyanurate; the tackifier is r-glycidyl ether oxy-propylltrimethoxysilane; the antioxidant is one or two selected from the group consisting of bis(2,4-dicumylphenyl)pentaerythritol diphosphite, distearyl pentaerythritol diphosphite, tris(nonyl phenyl)phosphate and tris(2,4-butylphenyl)phosphate; and ultraviolet light absorbent is gas phase silicon dioxide. The solar cell packaging EVA adhesive film can resist high temperature of 85 DEG C, humidity of 85 percent, ultraviolet light and thermal oxidative aging.

Owner:苏州爱康商务咨询服务有限公司

Ultraviolet deep-crosslinked expansion flame-retardant polyolefine cable material, and preparation method of insulating or jacket layer thereof

ActiveCN102161793AImprove deep penetrating abilityImprove efficiencyInsulated cablesInsulated conductorsAntioxidantUltraviolet

The invention relates to an ultraviolet deep-crosslinked expansion phosphorus-nitrogen flame-retardant polyolefine cable material, and a preparation method of an insulating or jacket layer thereof. Polyethylene or graft-modified polyethylene and / or ethylene-vinyl acetate or graft-modified copolymer thereof are used as base materials, surface-modified expansion phosphorus-nitrogen halogen-free flame retardant, cation photoinitiator, free-radical photoinitiator, polyfunctional group crosslinking agent and composite antioxidant are added, and flame-retardant synergist, synergistic smoke suppressor and processing assistant are matched to obtain the ultraviolet deep-crosslinked expansion phosphorus-nitrogen flame-retardant polyolefine cable material. The preparation method comprises the following steps: proportionally and evenly mixing the materials to obtain granules, extruding to obtain an optical crosslinked expansion flame-retardant wire cable insulating layer or jacket layer, and radiating by a specific ultraviolet source for several seconds to obtain the deep-crosslinked insulating layer or jacket layer. The new material and new technology have the advantages of low investment required for crosslinking equipment, simple technique, energy saving, environmental protection, high production efficiency, low cost and good product quality, and can be widely used for manufacturing rail transportation cables, various mechanical wires, indoor assembly wires and the like.

Owner:HEILONGJIANG MINGXIANG TECH

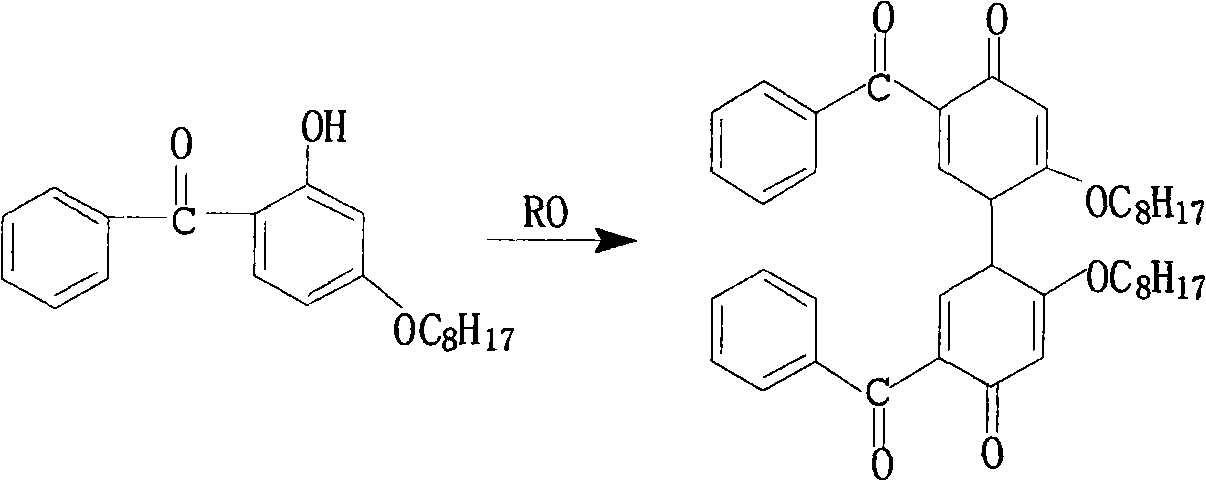

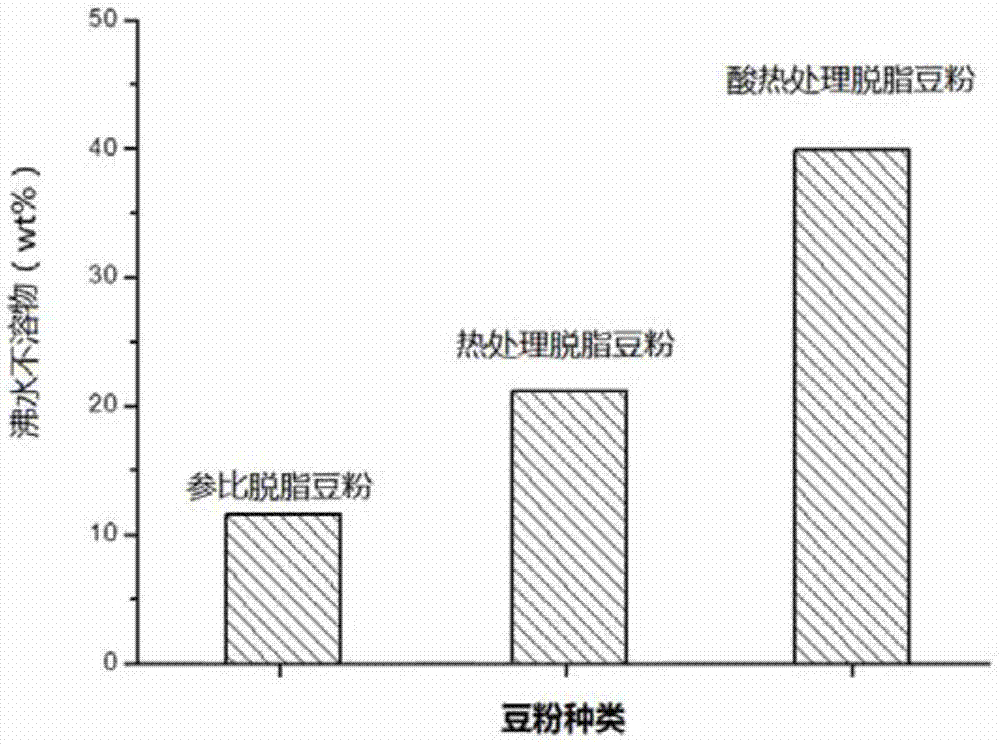

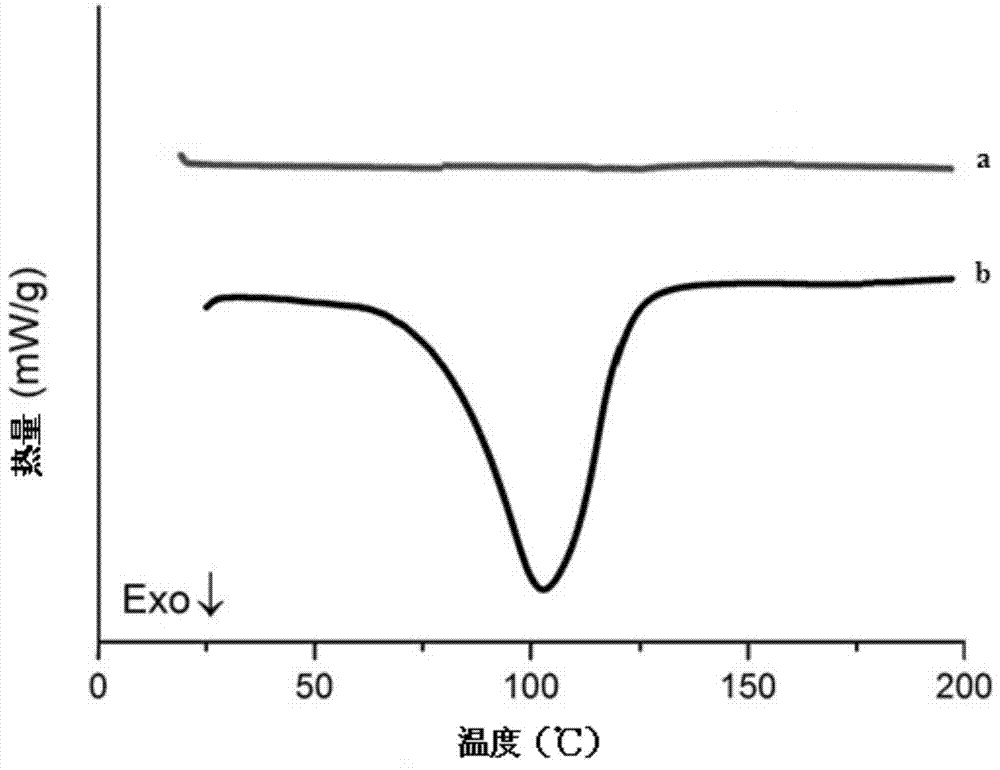

Waterproof-level soy protein adhesive and preparation method thereof

ActiveCN104497965AFacilitate cross-linkingImprove water resistanceProtein adhesivesGlue/gelatin preparationAdhesiveWorking life

The invention provides a waterproof-level soy protein adhesive and a preparation method thereof and relates to an adhesive and a preparation method thereof, in particular to a modified soyabean protein adhesive for waterproof-level plywood. The waterproof-level soy protein adhesive aims at solving the technical problem that an existing adhesive for plywood is not waterproof. The preparation method comprises the steps of beam flour acid heat treatment, beam flour liquidation, polyamide solution synthesis and adhesive modulation. Degreased beam flour or soya bean meal left after soybean oil expelling is used as a main raw material, the water resisting property of the beam flour and the solid content of the soy protein adhesive are improved through acid heat treatment, the cross-linking efficiency, cementing effect and process usability of the soy protein adhesive are improved through liquidation, the water resisting property of the soy protein adhesive is improved through cross-linking of polyamide polyamine resin, and finally the soy protein adhesive high in beam flour content, low in viscosity, long in working life and good in water resisting property and used for the waterproof-level plywood is prepared. The waterproof-level soy protein adhesive and the preparation method belong to the field of adhesive preparation.

Owner:浙江蓝歌新材料科技有限公司

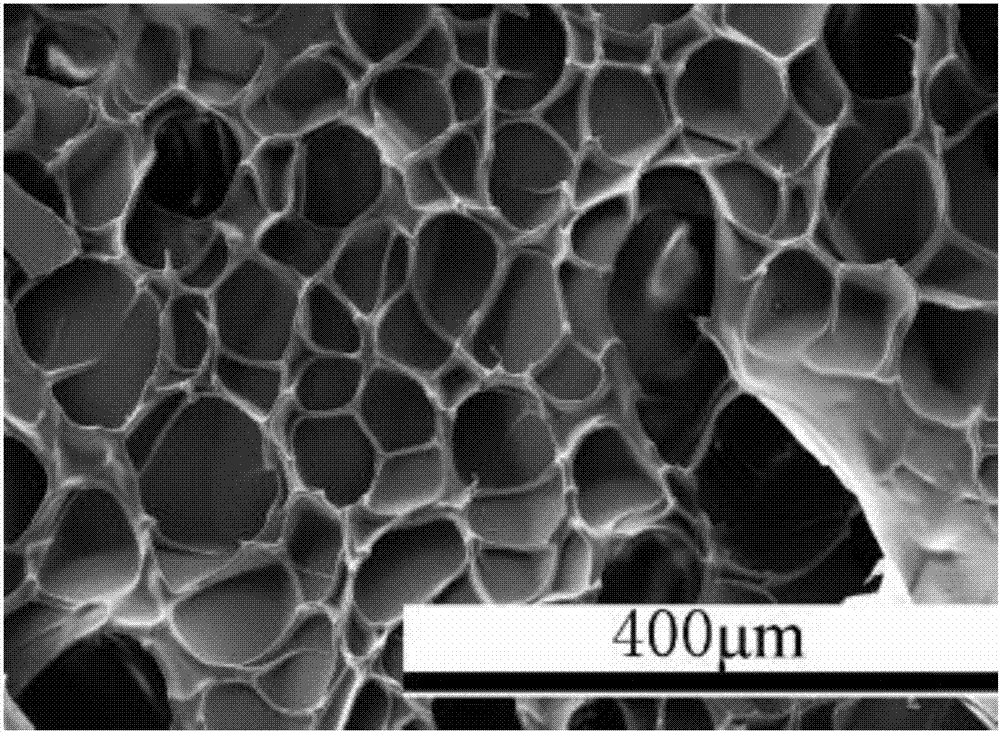

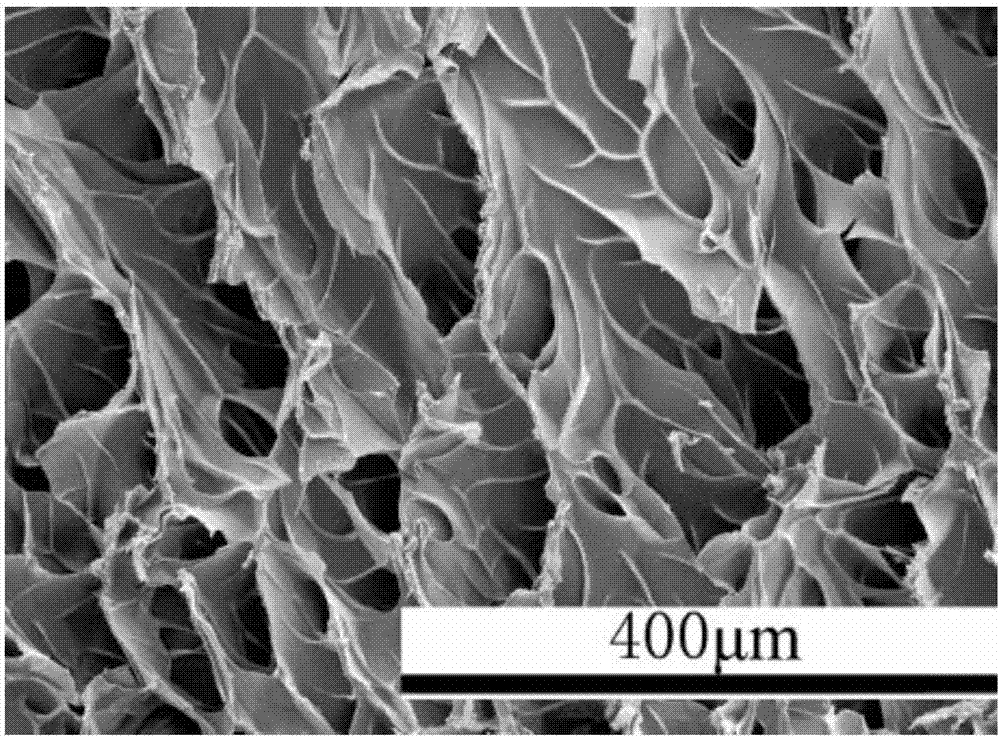

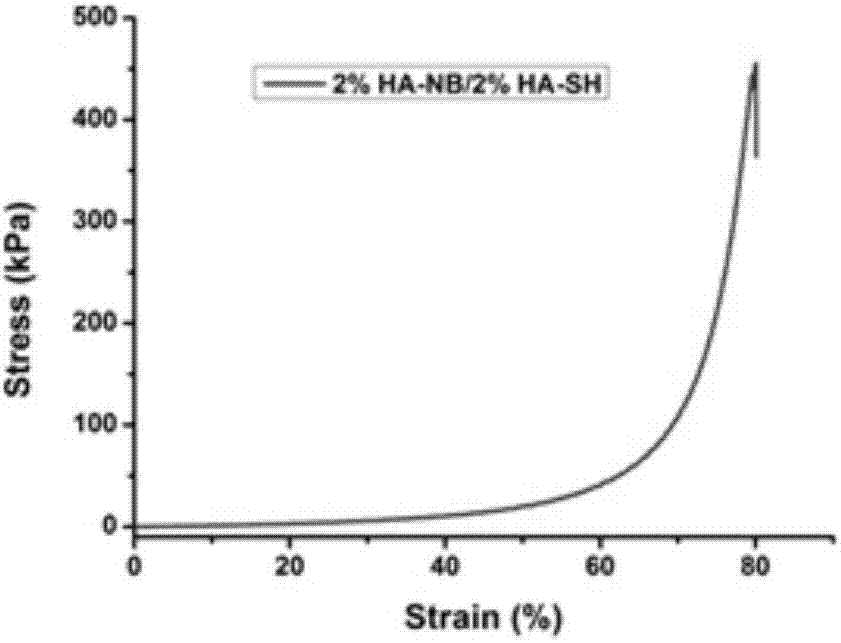

Gelatin hydrogel and preparation method and application thereof

InactiveCN107236135AIncrease satietyIncrease the amount of double bondsAerosol deliverySurgeryCross-linkUltraviolet lights

The invention discloses gelatin hydrogel, which is of a water molecule filled porous three-network structure, wherein the first network is a cross-linked network between the modified gelatin; the second network is a cross-linked network between polyethylene glycol diacrylate; the third network is a cross-linked network between the modified gelatin and the polyethylene glycol diacrylate. The invention also discloses a preparation method of the gelatin hydrogel. By using an ultraviolet light catalytic crosslinking technology, the modified gelatin is cross-linked with the polyethylene glycol diacrylate; the gelatin hydrogel is obtained through preparation. The gelatin hydrogel provided by the invention has the advantages that the elasticity modulus and the degrading performance of the support frame can be regulated and controlled through changing the modification degree of the modified gelatin and the addition quantity of the polyethylene glycol diacrylate; the structure regulation can be better performed according to the requirements of different tissue engineering support frames; the proper space and the intensity can be provided for the growth of the cells; the ordered space structure is formed.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Radiation crosslinking polyvinyl chloride material and its prepn. method

A radiation cross-linked polyvinyl chloride material is prepared from polyvinyl chloride, nitrile rubber, cross-linking agent, plasticizer, stabilizer, lubricant, antioxidizing agent and filler through mixing and radiating by electronic accelerator. Its advantages are high gel content up to 84-95%, and better mechanical performance, and antiwear and refractory nature.

Owner:SHANGHAI CHLOR ALKALI CHEM

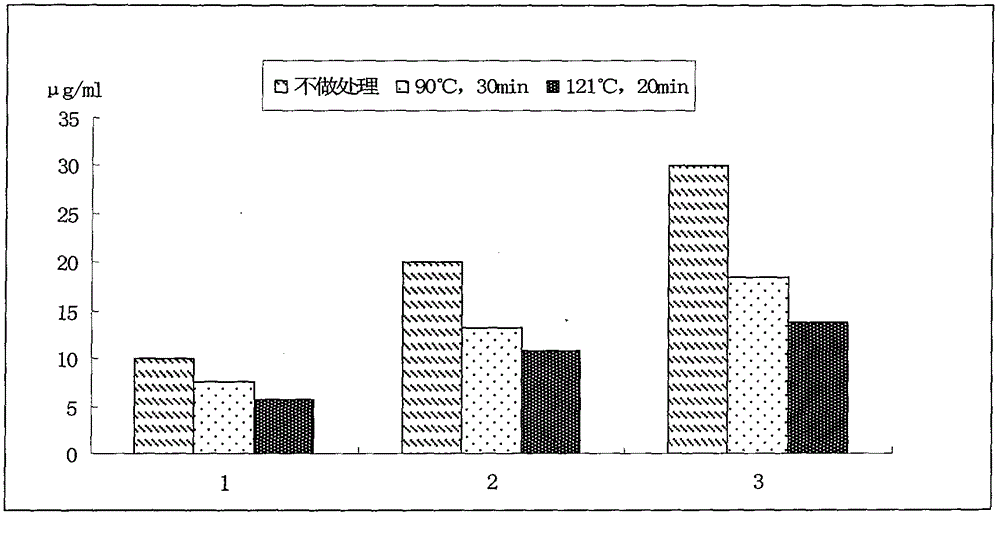

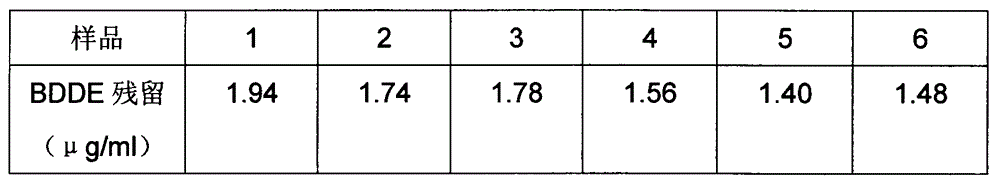

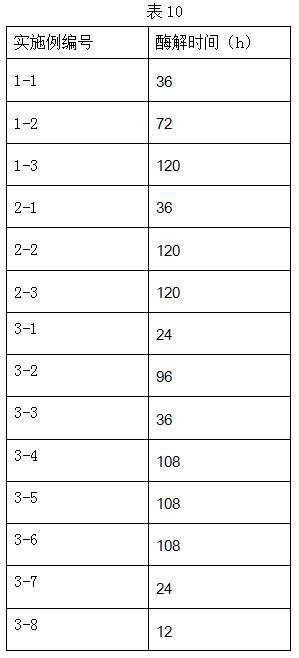

Preparation method of low-temperature secondary cross-linked sodium hyaluronate gel

InactiveCN103146003AImprove cross-linking efficiencyAvoid the disadvantages of yellowingProsthesisHigh concentrationCross linker

The invention relates to a preparation method of 1,4-butanediol diglycidyl ether cross-linked sodium hyaluronate gel. The method comprises the steps of: by taking high-concentration sodium hyaluronate solution as reaction matrix, performing first cross-linking for a longer time under the low-temperature condition by adding less cross-linking agent, then performing secondary deep cross-linking under high-temperature condition, and finally processing and pelleting through short-time dialysis technique, thereby obtaining the sodium hyaluronate gel product. With the method, the cross-linking condition of the high-concentration cross-linking agent under the traditional high-temperature condition can be eliminated, milder secondary depth cross-linking condition is adopted, the reaction efficiency of the less cross-linking agent can be greatly improved, the residual cross-linking agent is more easily removed, and the excellent biocompatibility of the cross-linked sodium hyaluronate gel can be ensured. The method is simple in preparation technique, excellent in controllability and easier to practically produce on large scale.

Owner:SHANGHAI QISHENG BIOLOGICAL PREPARATION CO LTD

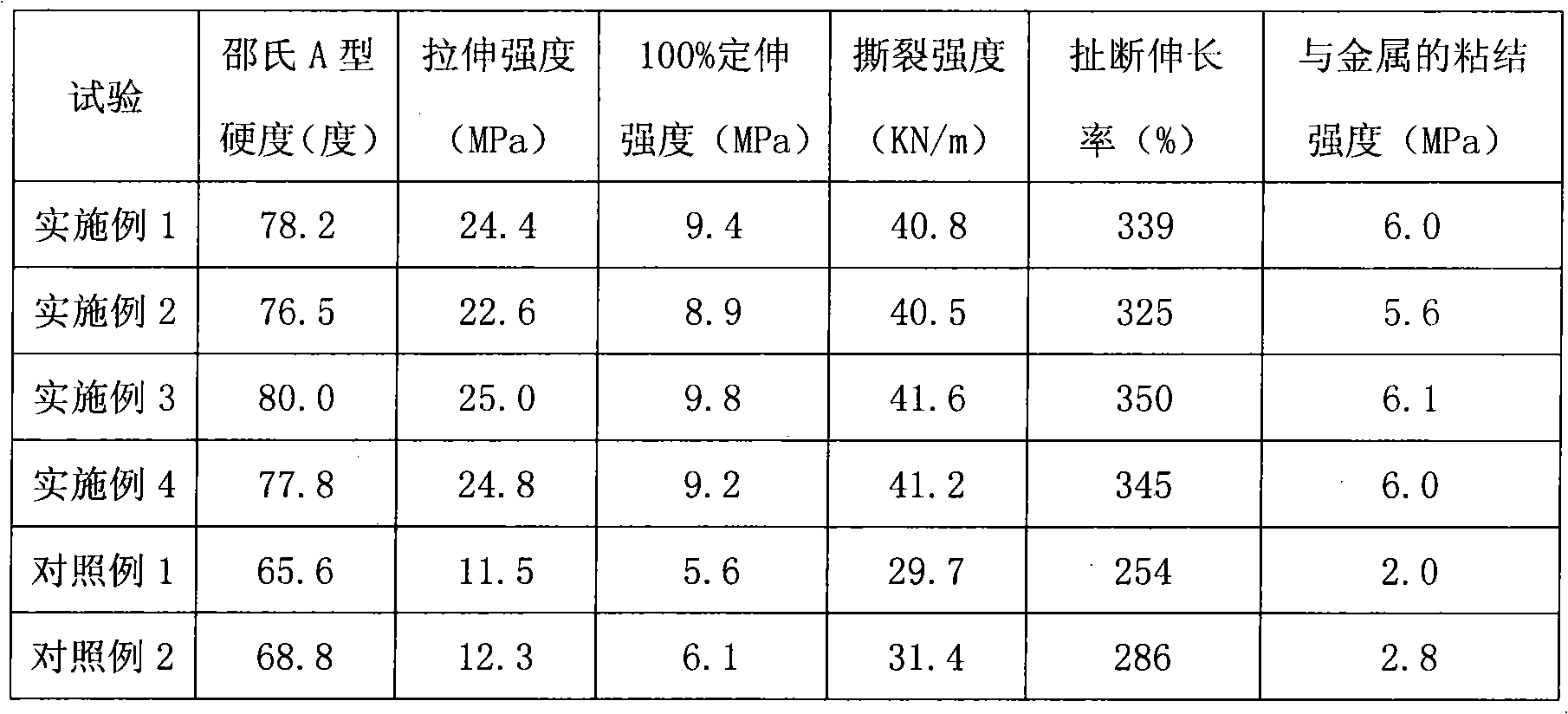

Unsaturated carboxylic acid metal salt modified ethylene-propylene-diene monomer (EPDM) and preparation method thereof

ActiveCN103131088ANo pollution in the processSimple preparation processSuperoxideEthylene-propylene-diene-monomer

The invention discloses unsaturated carboxylic acid metal salt modified ethylene-propylene-diene monomer (EPDM) and a preparation method thereof. Carbon black, metallic compound, stearic acid, accelerant, inert filler, sulphur, superoxide and unsaturated carboxylic acid are added in the EPDM, then mixing treatment and sulfidizing are conducted, and therefore the unsaturated carboxylic acid metal salt modified EPDM is obtained. According to the unsaturated carboxylic acid metal salt modified EPDM and the preparation method thereof, unsaturated carboxylic acid metal salt in in-situ reaction is used for modifying the EPDM, preparation process is simple, modification effect is good, the prepared modified rubber has good physical mechanical performance and especially has good bonding strength with metal, and the application range is wide.

Owner:TIANJIN XINZHONGHE RUBBER IND

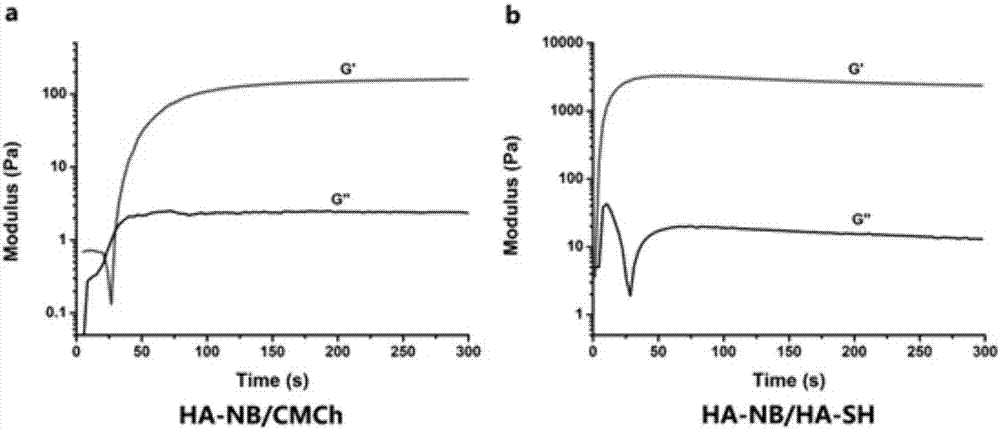

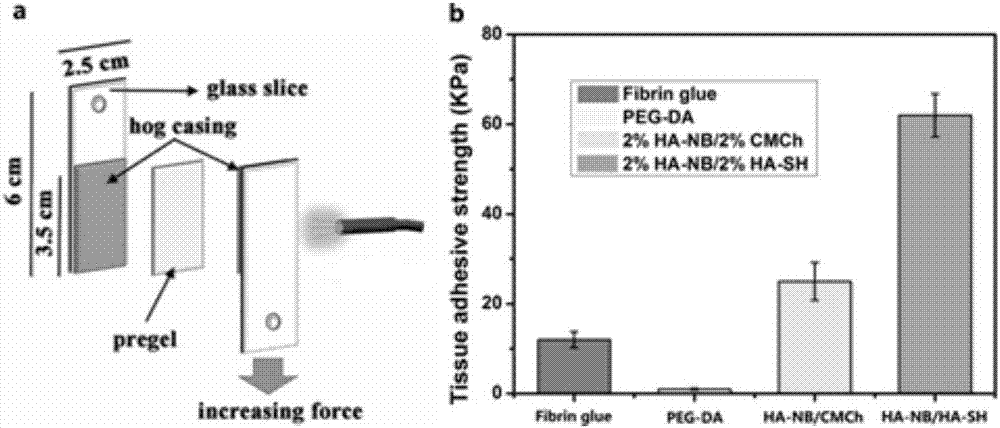

Photoinduced nitroso crosslinked hydrogel material and preparation method and application thereof

ActiveCN107987287ANo free radical toxicityHigh photocrosslinking efficiencyAdditive manufacturing apparatusSurgical adhesivesDrugTissue engineering

The invention relates to a photoinduced nitroso crosslinked hydrogel material and a preparation method and application thereof. The preparation method comprises the following steps of dissolving a macromolecular derivative which is modified by an o-nitrobenzyl photo trigger in a component A into a biocompatible medium, so as to obtain a solution A; uniformly mixing the solution A, or adding a solution B containing a component B, so as to obtain a hydrogel precursor solution; under the condition of using light source to radiate the hydrogel precursor solution, enabling the o-nitrobenzyl photo trigger in the component A to produce nitroso groups through photo-inducing, and enabling the nitroso group to generate dimerization crosslinking by self to form the hydrogel, or generate addition crosslinking with nucleophile or electrophile in the component B to form the hydrogel. The invention also provides a kit for preparing the hydrogel, and application of the hydrogel in tissue engineering,regeneration medicines, 3D (three-dimensional) printing or cell, protein or drug carriers. The photoinduced nitroso crosslinked hydrogel material has the advantages that the hydrogel precursor solution can be sprayed or smeared onto the surface of the tissue, so as to realize the in-situ gelling under the condition of light radiation; the photoinduced nitroso crosslinked hydrogel material is especially suitable for the post-operation wound sealing and the tissue liquid leakage blockage.

Owner:ZHONGSHAN GUANGHE MEDICAL TECH CO LTD

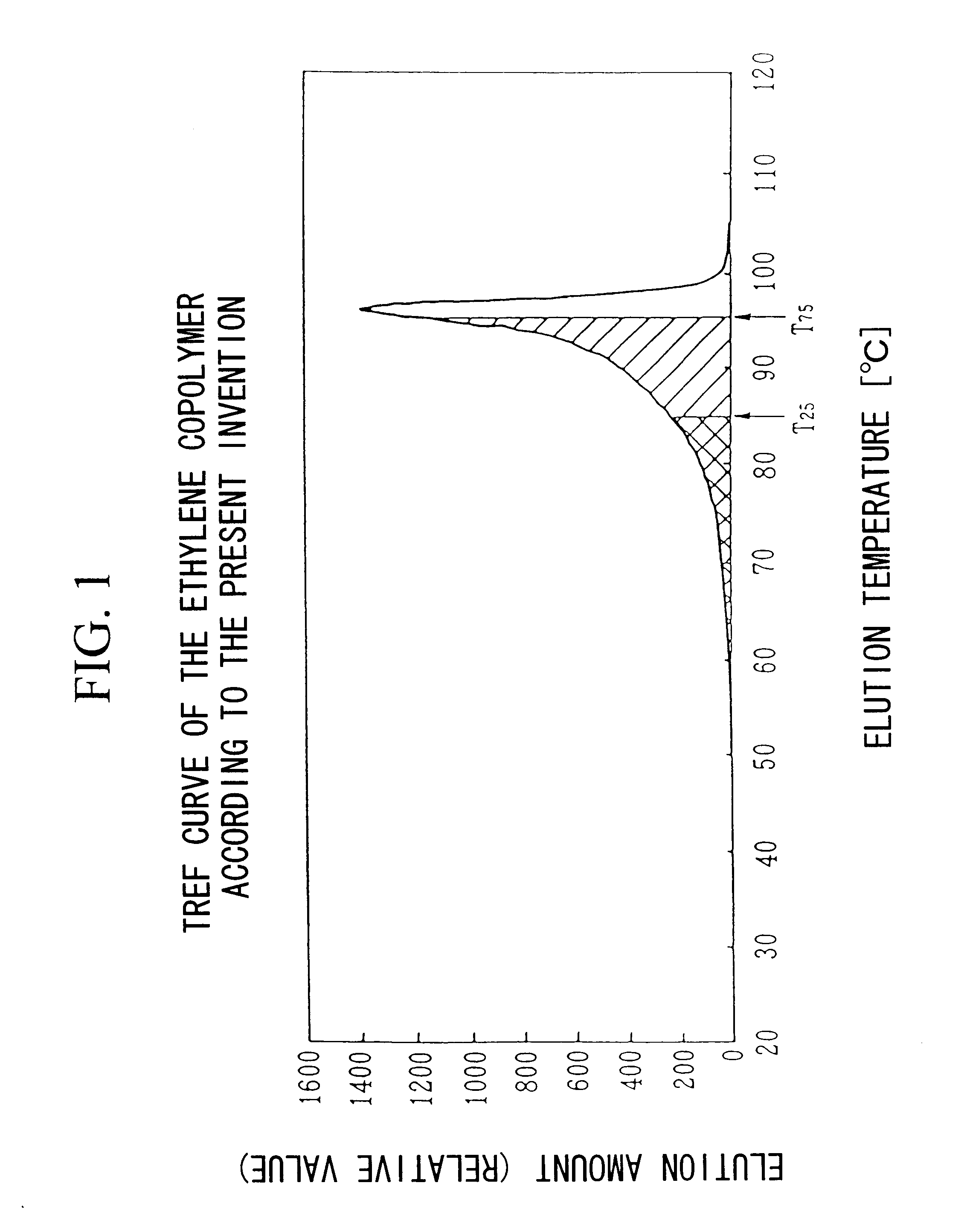

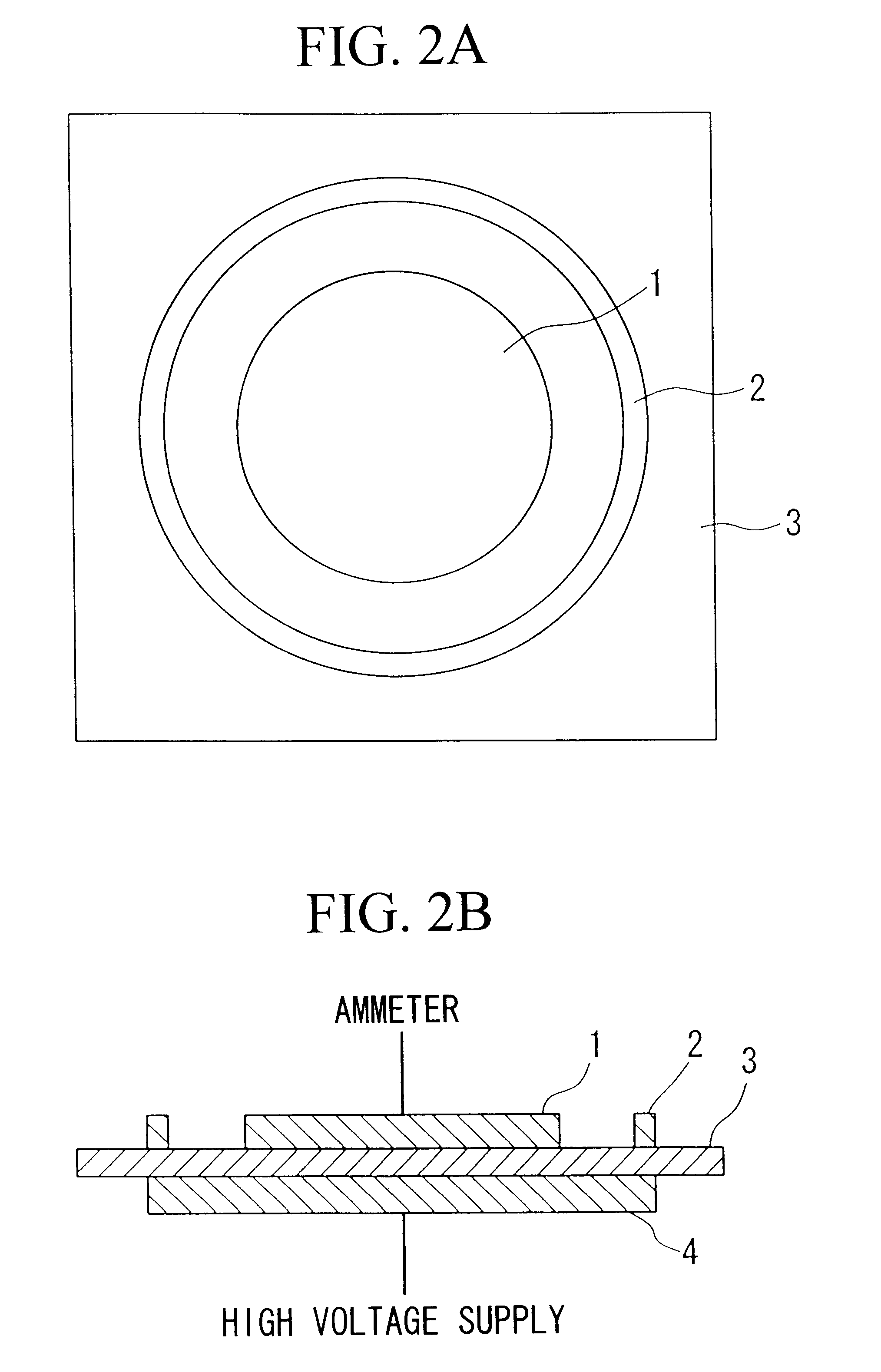

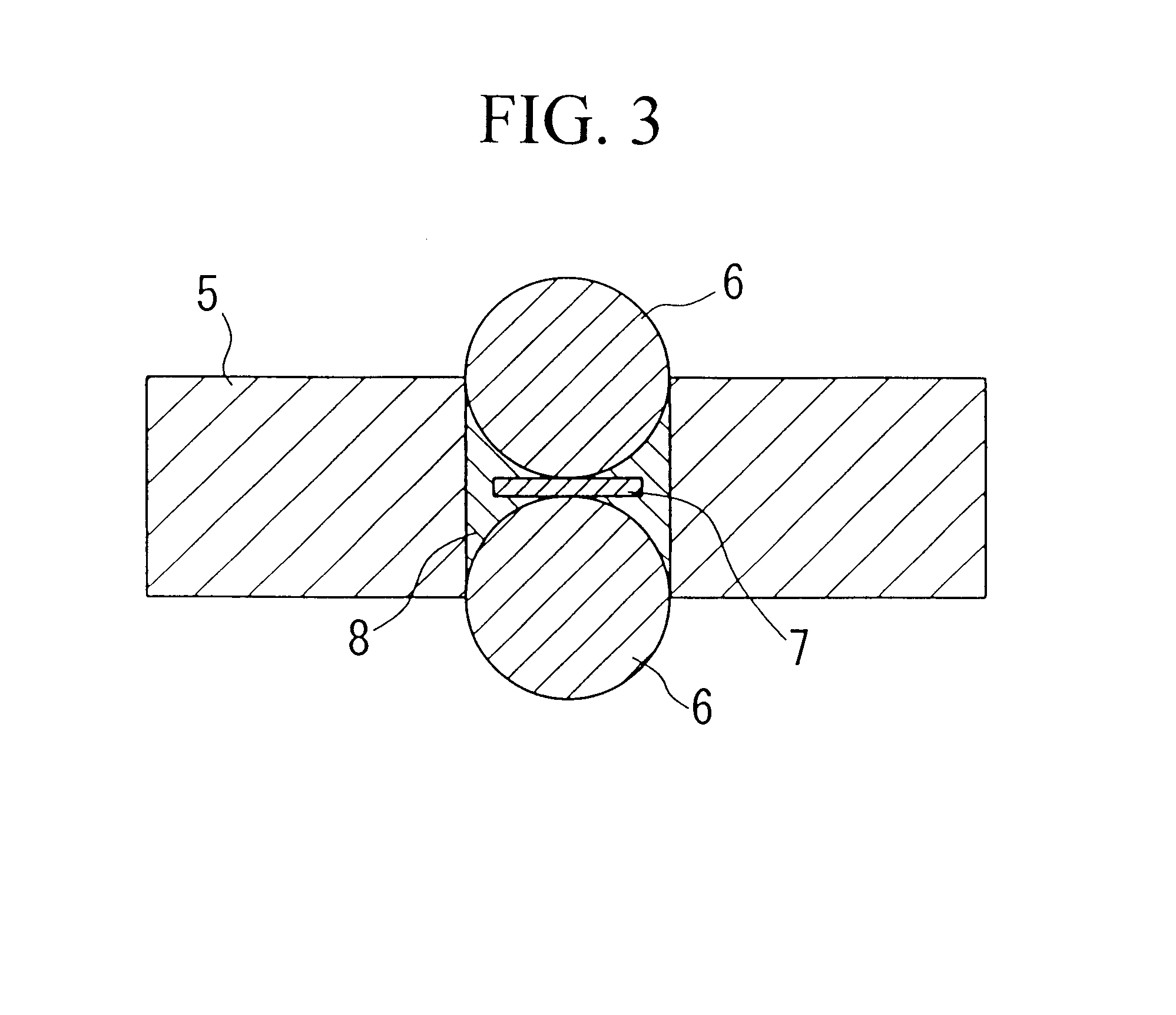

Electrical insulating resin material, electrical insulating material, and electric wire and cable using the same

InactiveUS6479590B1Easy to processSuperior low temperature forming propertyPlastic/resin/waxes insulatorsInsulated cablesPolymer scienceAlkene

The present invention relates to a resin material for an electrical insulating material, an electrical insulating material and electric wire and cable using the same. A resin material for an electrical insulating material according to present invention is characterized in that the resin component thereof comprises an ethylene alpha-olefin copolymer (A) which satisfies specific conditions, such as a density of 0.92~0.96 g / cm3, a melt flow rate (MFR) of 0.01~200 g / 10 minutes, a molecular weight distribution (Mw / Mn) of 1.5~5.0, and possessing only one peak in terms of the number of peaks observed in an elution temperature-eluted amount curve as measured by the temperature raising elution fractionation (TREF) method, etc., wherein said resin component contains a unit derived from at least one type of monomer selected from among a carbonyl or carbonyl derivative group-containing monomer, a hydroxyl group-containing monomer, a nitro group-containing monomer, a nitrile group-containing monomer, an aromatic ring-containing monomer, and a compound or monomer containing two or more ethylenic linkages. This resin material for an electrical insulating material is suitable for use in an electrical insulating material for an electric wire and cable, as it exhibits excellent processability and electrical insulating properties without degradation of the mechanical strength, and even after cross-linking, exhibits superior electrical insulating properties.

Owner:JAPAN POLYOLEFINS CO LTD

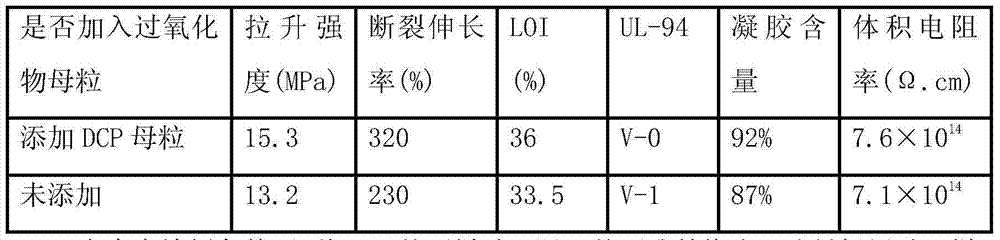

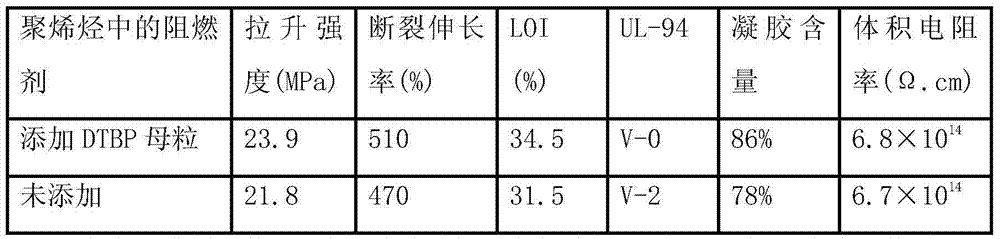

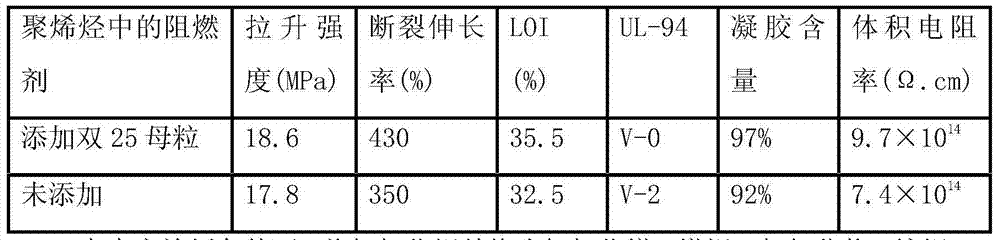

Peroxide pre-crosslinked low smoke zero halogen flame retarding irradiation crosslinking polyolefin composite and preparation method thereof

The invention discloses a peroxide pre-crosslinked low smoke zero halogen flame retarding irradiation crosslinking polyolefin composite and a preparation method thereof. The preparation method comprises steps of adding 0.5-5 parts of antiflaming synergist into 50-70 parts of polyolefin, mixing uniformly, then adding 30-50 parts of fire retardant, 0.5-5 parts of polyfunctional group cross-linking agent and 0.1-1 part of antioxygen, mixing uniformly, then extruding and pelletizing so as to obtain an irradiation crosslinking material, then uniformly mixing 100 parts of irradiation crosslinking material and 1-5 parts of peroxide master batch, extruding and wrapping on the electric lead core of an electric wire, finally, irradiating 60-180KGy dosage with high-power electron beam or cobalt source for crosslinking, wherein the components above are weighed in parts by weight. The low smoke zero halogen flame retarding irradiation crosslinking polyolefin composite prepared through peroxide pre-crosslinking has fast crosslinking speed, high productivity, low energy consumption, and good flame resistance, and also has excellent smoke suppression performance and better mechanical property.

Owner:合肥聚泰安全材料合伙企业(有限合伙)

Ethylene vinyl acetate (EVA) adhesive film for solar cell and preparation method thereof

InactiveCN102433077AImprove cross-linking efficiencyImprove adhesionNon-macromolecular adhesive additivesFilm/foil adhesivesChemistryAdhesion force

The invention relates to an EVA adhesive film for a solar cell and a preparation method thereof. The EVA adhesive film comprises the following components in part by mass: 100 parts of ethylene-vinyl acetate copolymer, 0.1 to 5 parts of peroxide crosslinking curing agent, 0.1 to 5 parts of auxiliary crosslinking agent, 0.01 to 5 parts of composite antioxygen, 0.01 to 5 parts of hindered amine light stabilizer, 0.01 to 5 parts of ultraviolet absorber, 0.01 to 5 parts of silane coupling agent and 0.1 to 5 parts of graft modified EVA adhesive particles. The preparation method comprises: (1) mixing the raw materials, rocking under a heating condition, cooling and obtaining EVA master batch; and (2) subjecting the EVA master batch to melting, heating, casting, cooling drawing and winding, and obtaining the EVA adhesive film. In the invention, the lamination time of the EVA adhesive film is within 10 minutes, the adhesion force is big, the damp and heat resistance and ultraviolet aging resistance are high, and the service life of the EVA adhesive film is more than 25 years. The preparation method disclosed by the invention is easy to operate and has a bright application prospect.

Owner:宁波威克丽特功能塑料有限公司

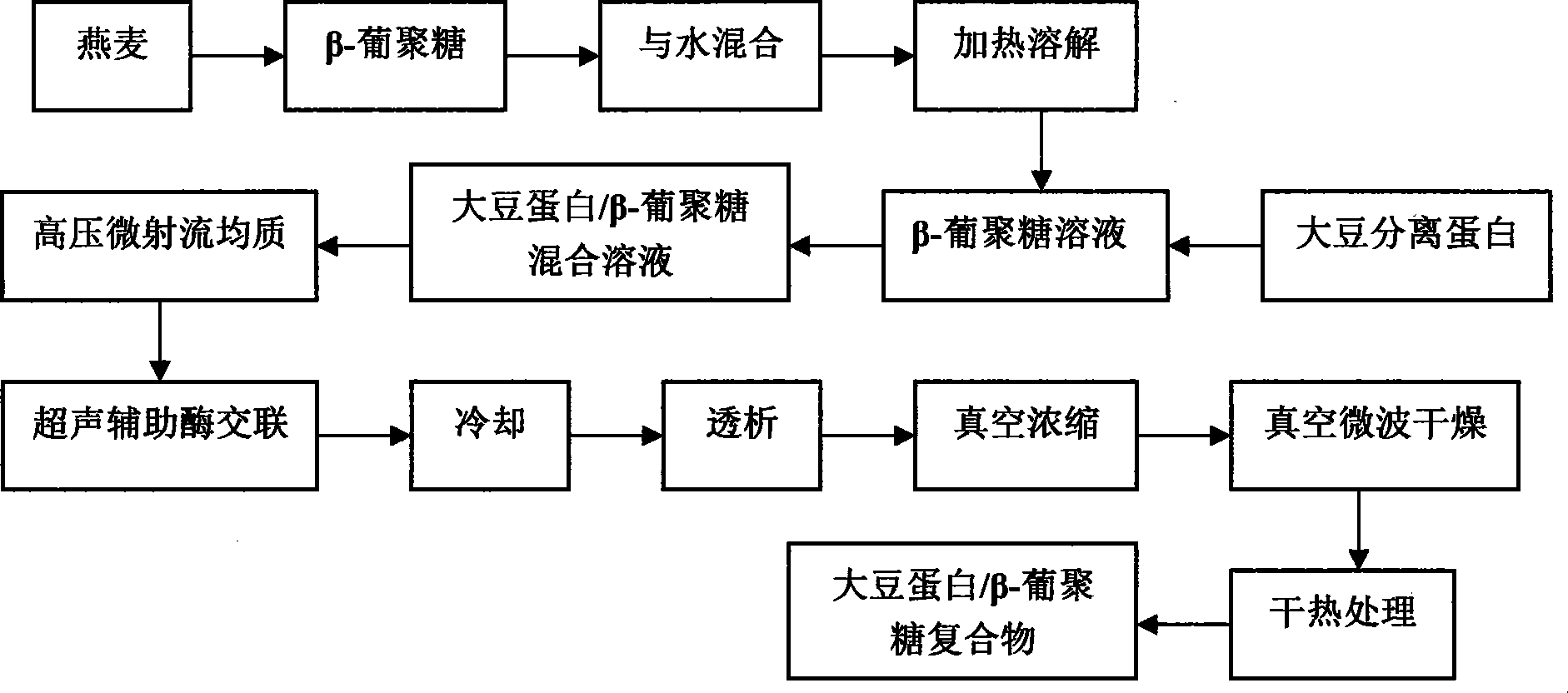

Preparation method of high-gelling-property soybean protein/beta-glucan compound

The invention relates to a preparation method of a high-gelling-property soybean protein / beta-glucan compound, belonging to the technical field of soybean protein processing. The method comprises the following steps: (1) mixing oat beta-glucan with water to form a beta-glucan solution, and adding soybean protein isolate into the solution to obtain a soybean protein / beta-glucan mixed solution; (2) carrying out high-pressure microjet homogenization treatment on the mixed solution, adding transglutaminase into the homogenized mixed solution, and carrying out ultrasonic assisted enzyme crosslinking treatment; and (3) dialyzing the mixed solution subjected to enzyme crosslinking treatment, concentrating, drying to obtain dry powder, and carrying out dry heating treatment on the dry powder to obtain the soybean protein / beta-glucan compound. The method combining the high-pressure microjet homogenization technique and the ultrasonic assisted enzyme crosslinking technique is applicable to preparation of the soybean protein / beta-glucan compound, and the dry heating processing technique is used as a synergic means, thereby improving the gelling property and gelling stability of the soybean protein / beta-glucan compound and widening the application range in food.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

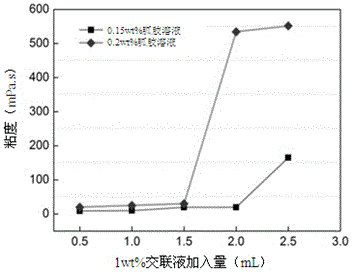

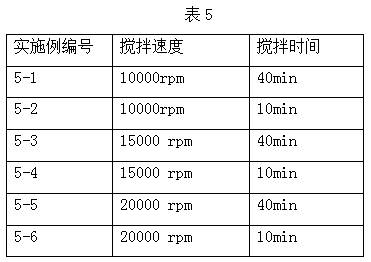

Inner crosslinking type caster oil-based waterborne polyurethane emulsion and preparation method thereof

InactiveCN106188457AImprove cross-linking efficiencySimple processPolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsPolyolEmulsion

The invention relates to inner crosslinking type caster oil-based waterborne polyurethane emulsion and a preparation method thereof. The preparation method of the inner crosslinking type caster oil-based waterborne polyurethane emulsion is characterized by comprising the following steps of (1) adding polymer polyol, castor oil, diisocyanate, a catalyst and a small molecule chain extender into a reactor for reaction, so as to obtain caster oil-based waterborne polyurethane low polymers; (2) adding a hydrophilic chain extender and a polyfunctional-group crosslinking agent into the caster oil-based waterborne polyurethane low polymers, then, performing reaction; adding butanone to regulate the viscosity to be 16.5mPa*S, so as to obtain inner crosslinking type caster oil-based waterborne polyurethane; (3) adding a neutralizer into the inner crosslinking type caster oil-based waterborne polyurethane; after reaction, adding deionized water; performing high-speed shearing emulsification, thus obtaining the inner crosslinking type caster oil-based waterborne polyurethane emulsion after butanone is steamed out. The method has the advantages that the technical process is simple; the crosslinking efficiency is greatly improved; the mechanical property of the product is good.

Owner:WUHAN UNIV OF TECH

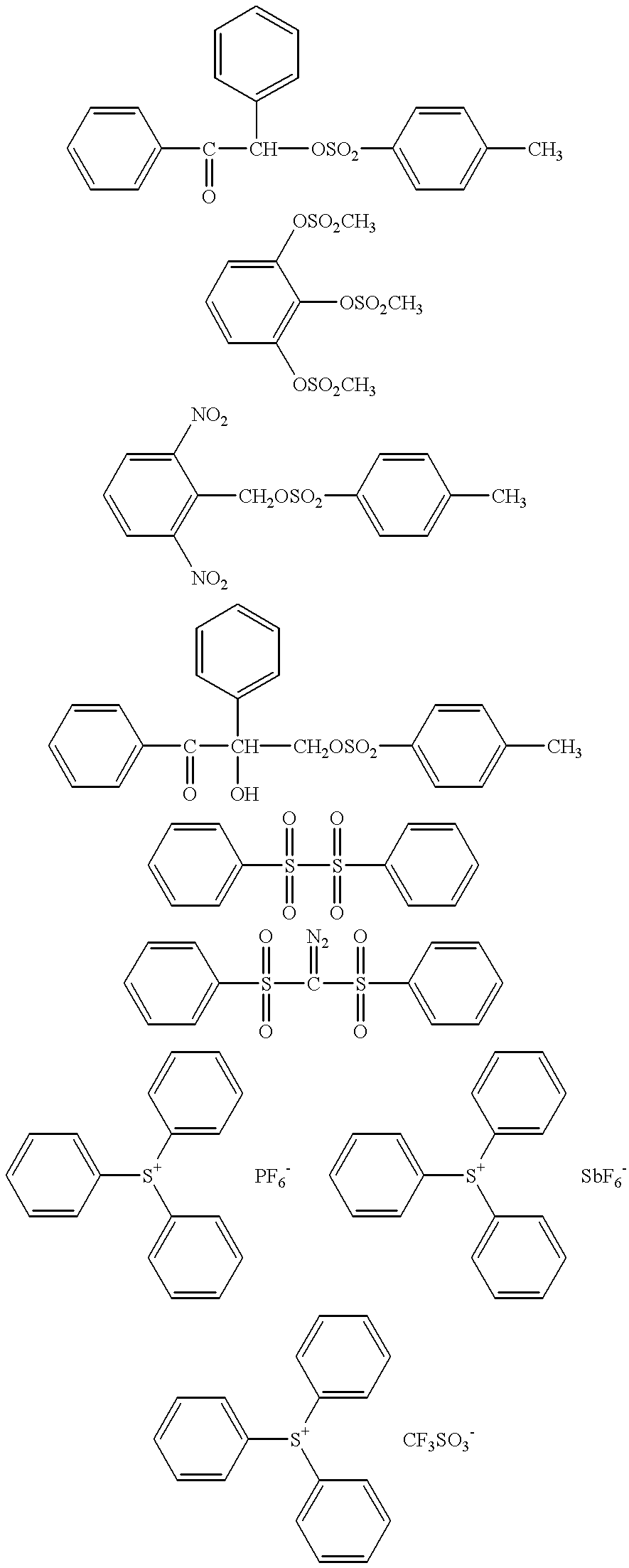

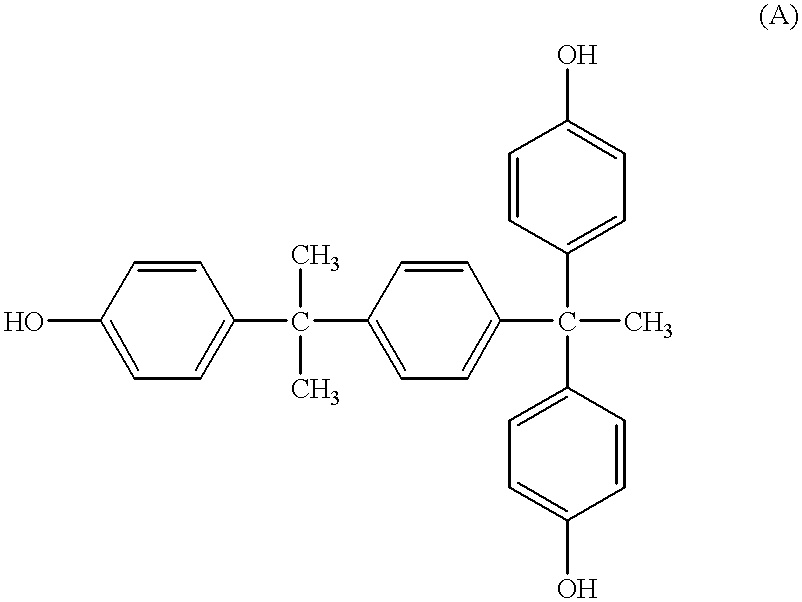

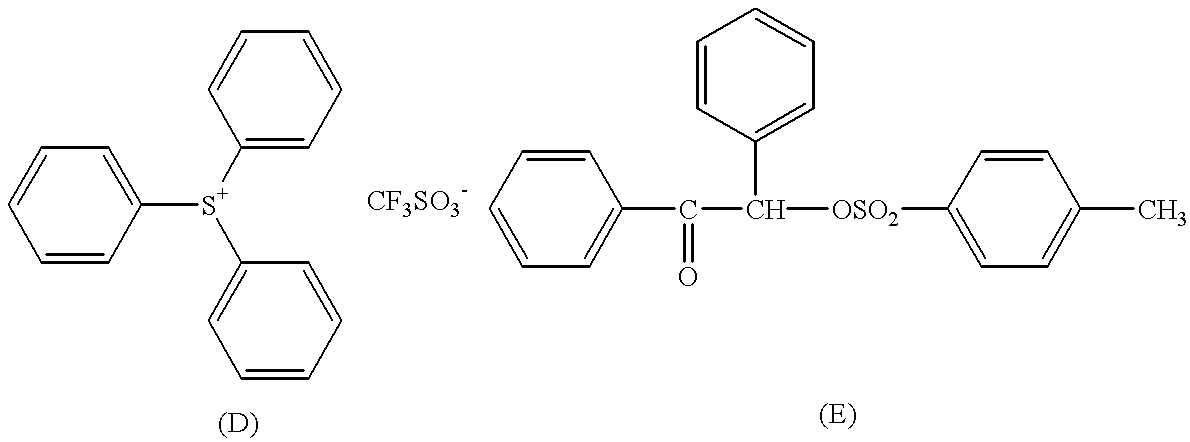

Photosensitive resin composition and process for producing the same

InactiveUS6440632B2Promote absorptionHard surfaceSemiconductor/solid-state device manufacturingDiazo compound compositionsImage resolutionLength wave

A photosensitive resin composition comprises a base resin (e.g., novolak resins, polyvinylphenol-series polymers), a first photoactive ingredient (e.g., diazobenzoquinone derivatives, diazonaphthoquinone derivatives) and a second photoactive ingredient (e.g., mixtures with azide compounds) each having an absorption range at wavelength lambd1 or lambd2, the wavelengths thereof being different from each other. Between the first and second photoactive ingredients, at least one photoactive ingredient is substantially inert at the absorption wavelength of the other. After exposing the photosensitive resin composition to a light to form a pattern, the whole surface of the photosensitive layer is exposed to a light of the other wavelength to make the surface hardly soluble (in the case a positive pattern is formed) or readily soluble (in the case a negative pattern is formed) in a developer, and developed, thereby forming a pattern of high resolution. Utilizing an existing exposure system, there can be obtained photosensitive resin compositions (especially, resists for semiconductor production) having improved sensitivity and resolution.

Owner:KRI INC

Polyolefin cable material and preparation method thereof

InactiveCN106543517AIncrease alkalinityPromote cross-linking reactionPlastic/resin/waxes insulatorsElastomerPolymer science

The invention discloses a polyolefin cable material and a preparation method thereof. The polyolefin cable material is prepared from, by weight, 20-40 parts of ethylene-vinyl acetate copolymer resin, 10-30 parts of polyolefin elastomers, 20-50 parts of ultralow-density polyethylene, 0-15 parts of functional polyolefin resin, 0-180 parts of a flame retardant, 0.5-1.5 parts of a crosslinking sensitizer, 0.5-2 parts of an auxiliary crosslinking agent, 0.1-0.5 part of a chain extender, 0.5-2 parts of an antioxidant and 3-9 parts of a processing aid. The polyolefin cable material is wide in application range, the flame-retardant polyolefin cable material or the non-flame-retardant polyolefin cable material can be prepared, and extrusion moulding is easy; in addition, the polyolefin cable material has the high crosslinking sensitization activity, volatilization is not prone to occur and no smoke is generated during extrusion, health of production personnel can be protected, and the operation environment is improved.

Owner:WUXI JAKE PLASTIC

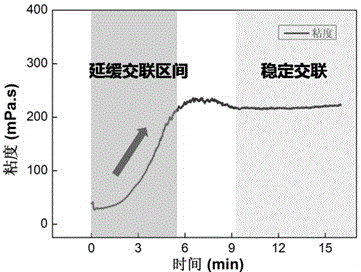

Method for preparing guanidine-gum fracturing-liquid nanometer cross-linking agent

The invention discloses a method for preparing a guanidine-gum fracturing-liquid nanometer cross-linking agent.The method includes the steps that sodium silicate serves as a silicon source to be hydrolyzed, surface modification is carried out with an organic silicon modifier, reactive nanometer silicon dioxide is prepared, and boric acid is loaded on the surface of the reactive nanometer silicon dioxide.According to the method, the raw materials are low in cost, the preparation technology is simple, and the cross-linking time can be controlled by adjusting the content of surface amido and the loading capacity of the boric acid; as cross-linking time is delayed, frictional resistance between fracturing liquid and a conveying pipe in the construction process can be reduced, and effective time is bought for construction while energy consumption is reduced; meanwhile, as the spatial size of the boric acid is increased, the cross-linking efficiency can be improved, the fracturing liquid has the good temperature resistance and the good shearing resistance accordingly, and gum breaking is complete.

Owner:HENAN UNIVERSITY

Preparation method of cross-linked hyaluronic acid filling agent for injection

ActiveCN111840638AEasy to removeLow costPharmaceutical delivery mechanismTissue regenerationMicrosphereOrganic chemistry

The invention discloses a preparation method of a cross-linked hyaluronic acid filling agent for injection. The method comprises the following steps: preparing cross-linked hyaluronic acid microspheres by a low-temperature control reversed-phase emulsification cross-linking technique, uniformly mixing the cross-linked hyaluronic acid microspheres with hyaluronic acid gel, and drying to obtain thefilling agent. The microsphere has the characteristics of simple preparation steps, mild reaction conditions, less cross-linking agent dosage, good cross-linking uniformity, high safety and the like;the obtained filler contains non-crosslinked hyaluronic acid and crosslinked hyaluronic acid microspheres at the same time, can achieve the purposes of quickly filling pits and maintaining a long filling effect at the same time, can be quickly degraded by taking measures during excessive correction or misoperation, reduces the risk of product injection, and is suitable for being applied to the field of soft tissue filling.

Owner:BLOOMAGE BIOTECHNOLOGY CORP LTD

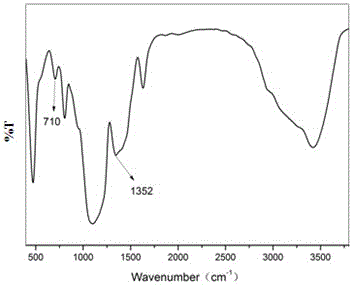

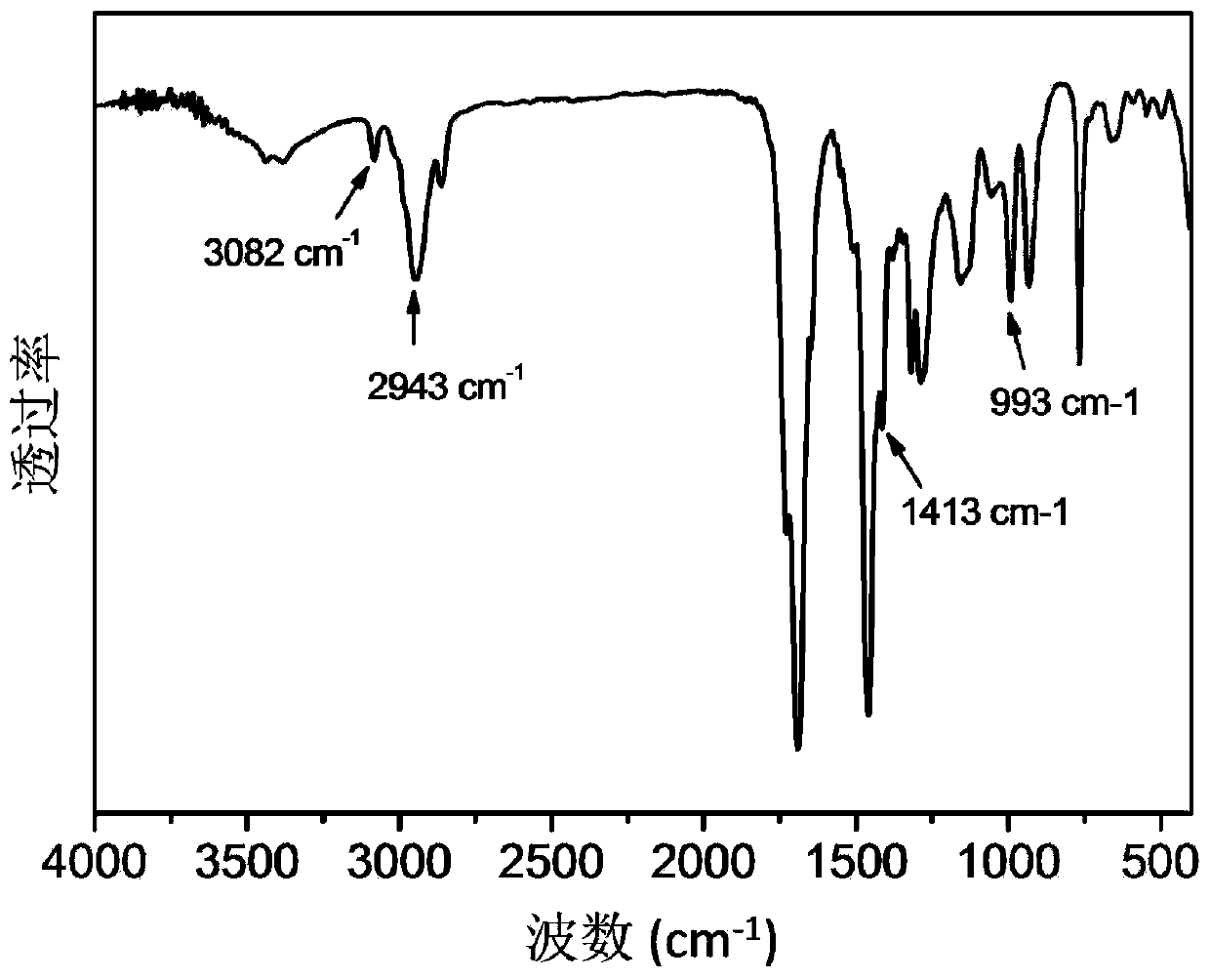

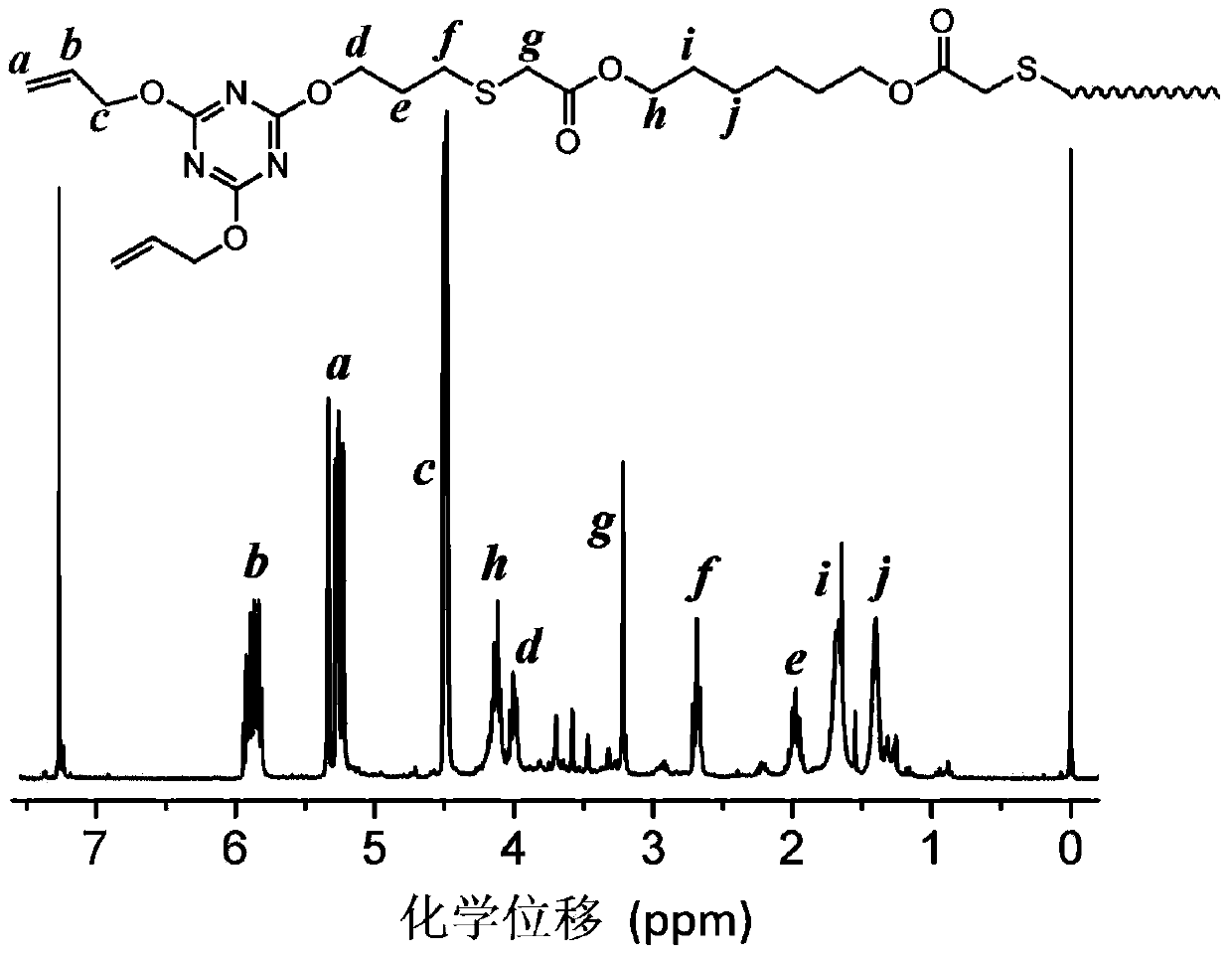

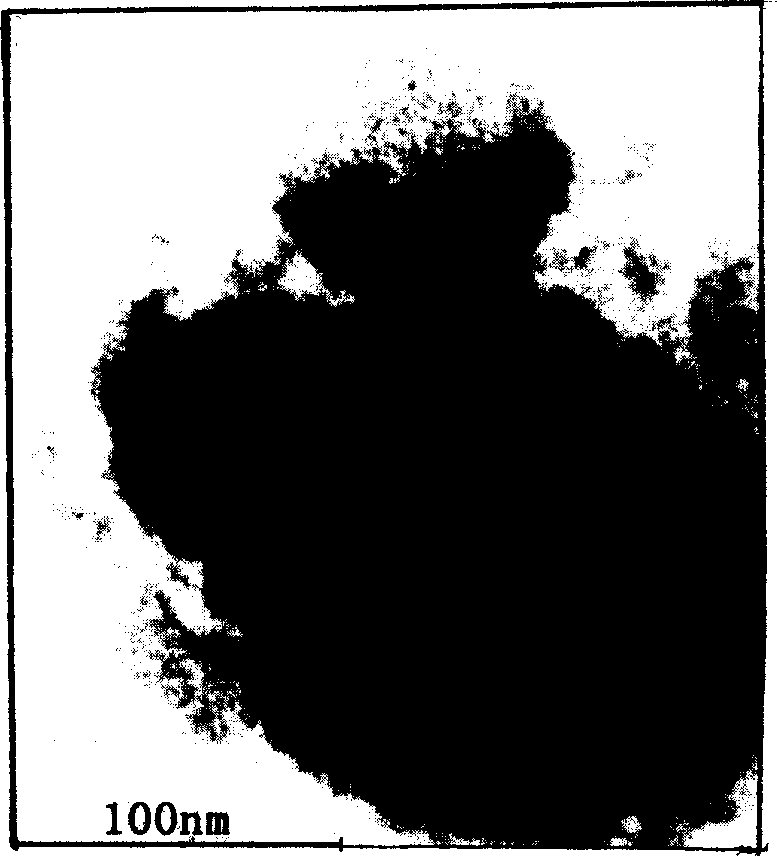

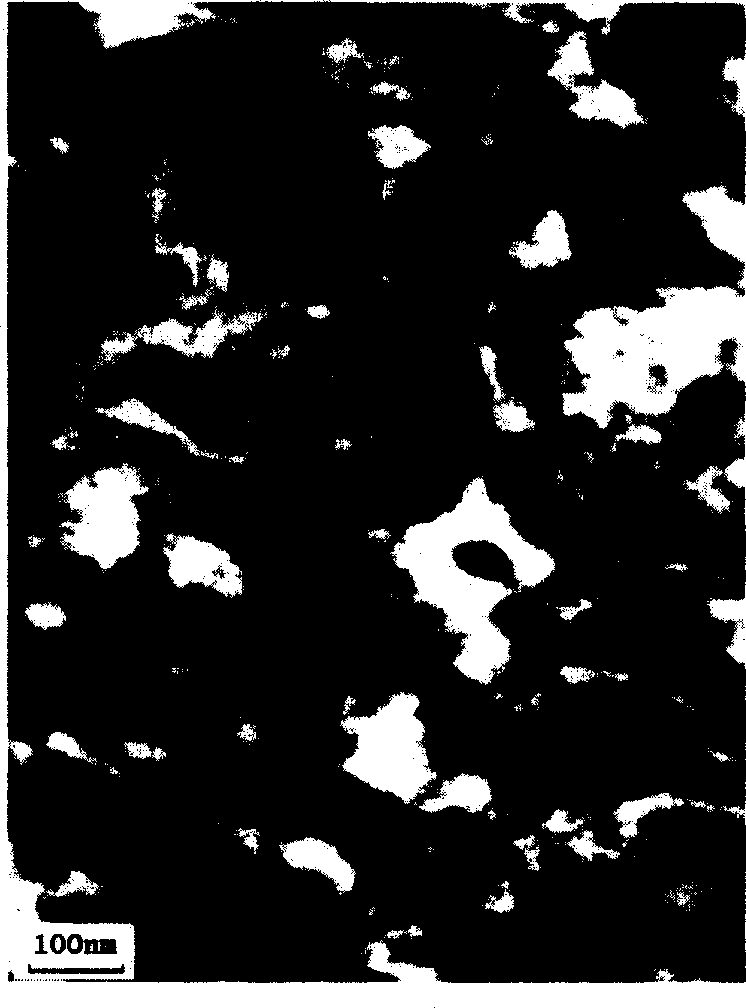

Preparation method of macromolecular crosslinking agent for ultraviolet light crosslinking polyolefin

The invention discloses a preparation method of a macromolecular crosslinking agent for ultraviolet light crosslinking polyolefin. The preparation method comprises the steps of adding a dimercapto compound, an allyl crosslinking agent and an initiator into a solvent for reaction under a nitrogen shielding condition till a characteristic peak of a sulfhydryl group at 2570cm<-1> on an infrared spectrum disappears, removing the solvent after the reaction, and obtaining the macromolecular crosslinking agent in a hyperbranched structure. Compared with a micromolecular crosslinking agent, the molecular weight of the macromolecular crosslinking agent is obviously increased; volatility is reduced significantly at the same operating temperature; and at the same time, due to the uniqueness of the hyperbranched structure, the macromolecular crosslinking agent has many end groups and a good crosslinking effect. The preparation method is mild in reaction condition, high in conversion rate and easy and simple to operate, effectively solves the problems of the volatility and mobility of the micromolecular crosslinking agent in a storage and processing procedure of ultraviolet light crosslinking polyolefin, and has higher crosslinking efficiency and good compatibility with polyolefin.

Owner:UNIV OF SCI & TECH OF CHINA

Microwave radioradiation crosslinked complete biodegradable material and its processing method

The invention relates the microwave radio-frequency radiation cross-linking biodegradation material, comprising starch, cellulose, A, aminocaprolactam or polyatomic alcohol, B, coupling agent, C, nucleation agent, D, undecylenic acid, calcium carbonate, natrii chloridum, and urea. The method comprises the following steps: mixing the raw material, cross linking with microwave radio-frequency device, foaming, forming, and getting the product. The invention solves the problems of no degradation, complex procedure, high cost and hard technology. The product has the advantages of good draftability, suppleness and obstructing property. The invention has the advantages of wide application area, completely degradation and non pollution. The invention also has the advantages of simple technology, easy operation and low cost.

Owner:杨军现

Prepn process of emulsive interpenetrating thermoplastic elastomer

InactiveCN1548462AImprove cross-linking efficiencyMaintain structural stabilityEmulsionThermoplastic polymer

The preparation process of emulsive interpenetrating thermoplastic elastomer includes synthesis of slightly cross-linked rubber elastomer seed emulsion, synthesis of interpenetrating emulsion, agglomeration, drying and mixing pelletizing. The synthesis of rubber elastomer seed emulsion includes two steps. Cross-linking vinyl monomer with certain bifunctional degree and multifunctional degree is mixed into the seed emulsion monomer and the consumption of cross-linking agent is controlled to obtain rubber elastomer seed emulsion with controlled and low cross-linking degree. Into the seed emulsion, thermoplastic vinyl monomer with mixed acrylonitrile is dropped while adding certain amount of emulsifier, and through swelling, initiating polymerization and other courses, the emulsive interpenetrating polymer with proper cross-linking degree is obtained, which is further processed into emulsive interpenetrating thermoplastic elastomer agglomerate.

Owner:BEIJING UNIV OF CHEM TECH

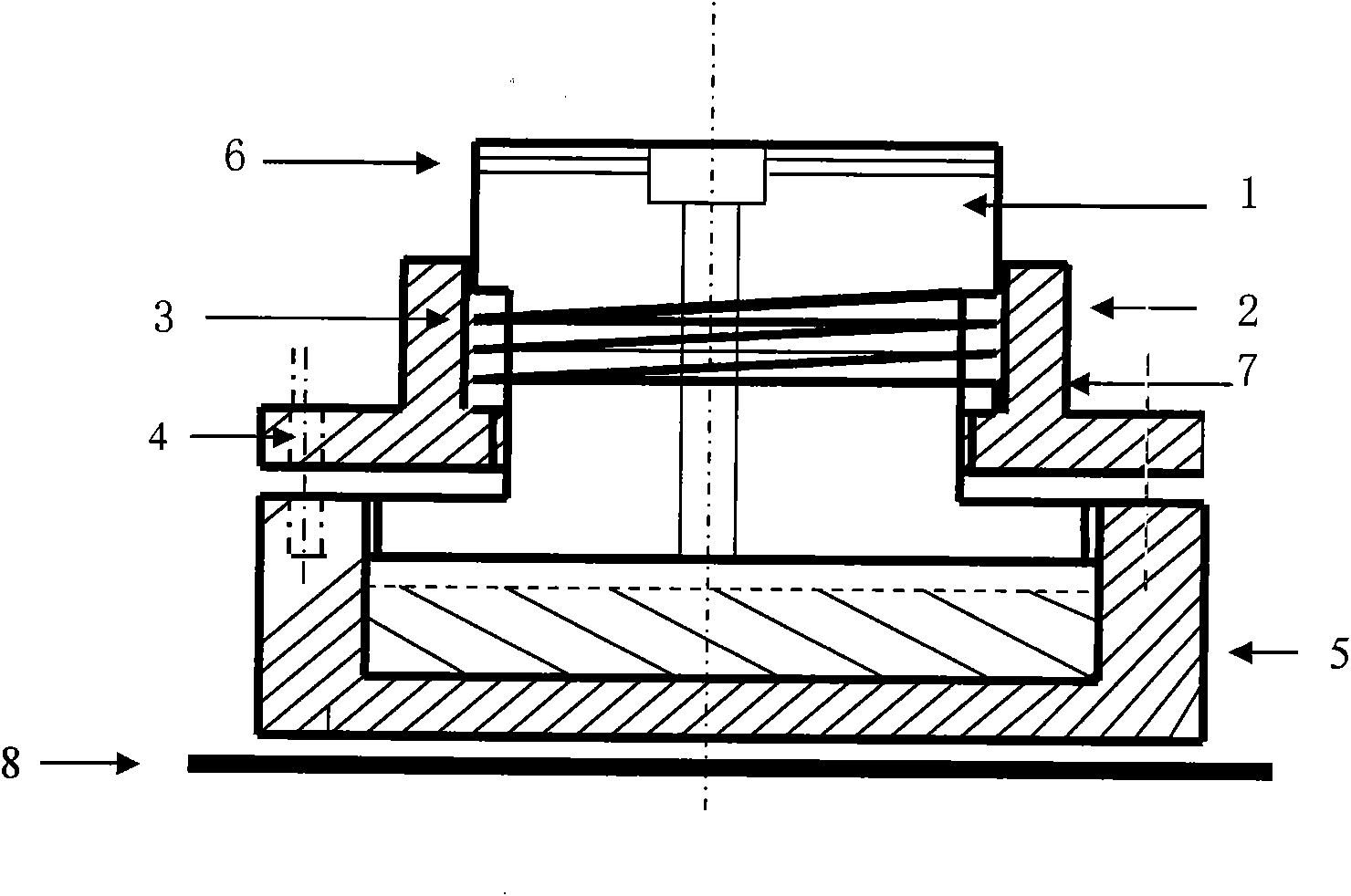

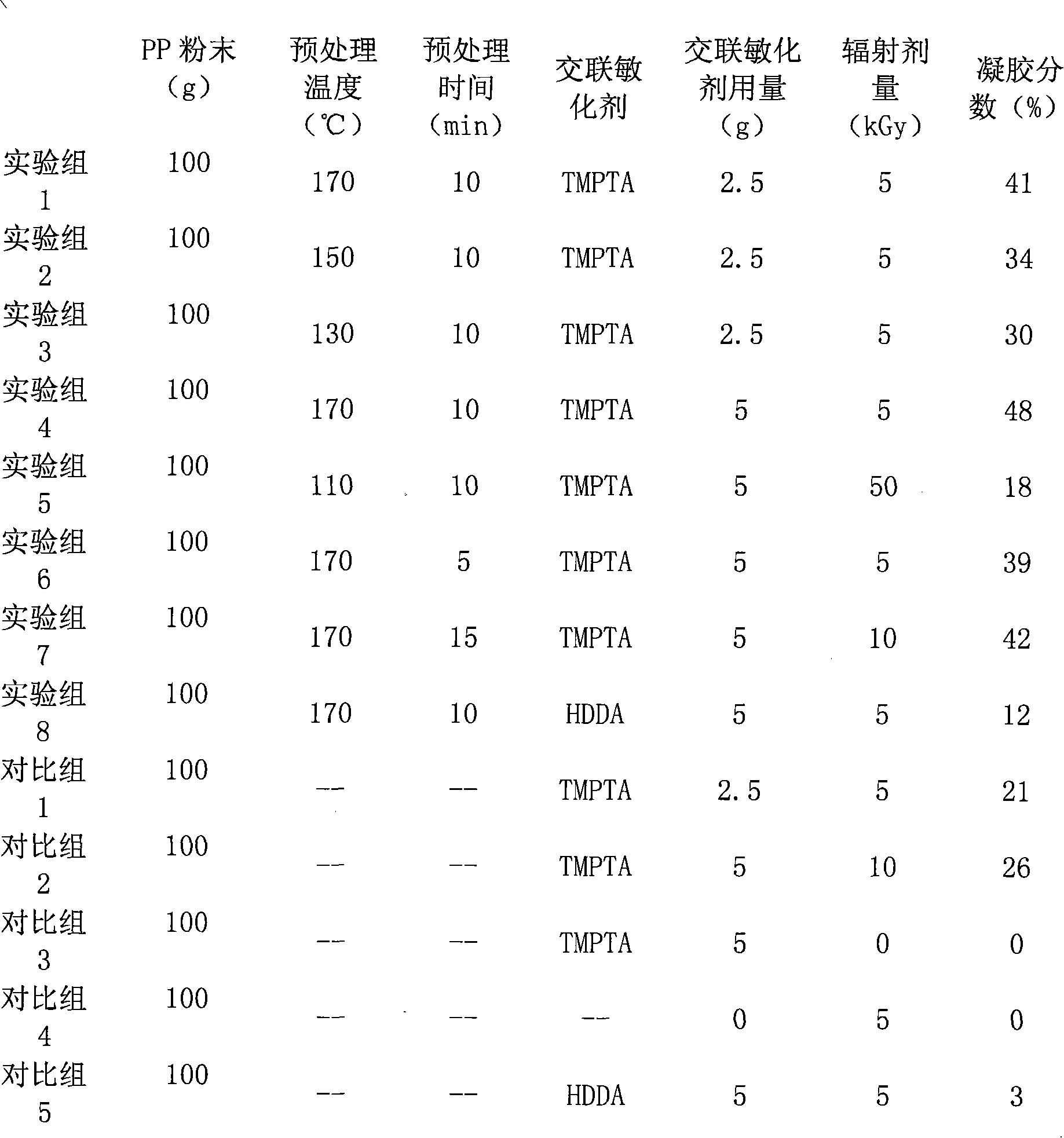

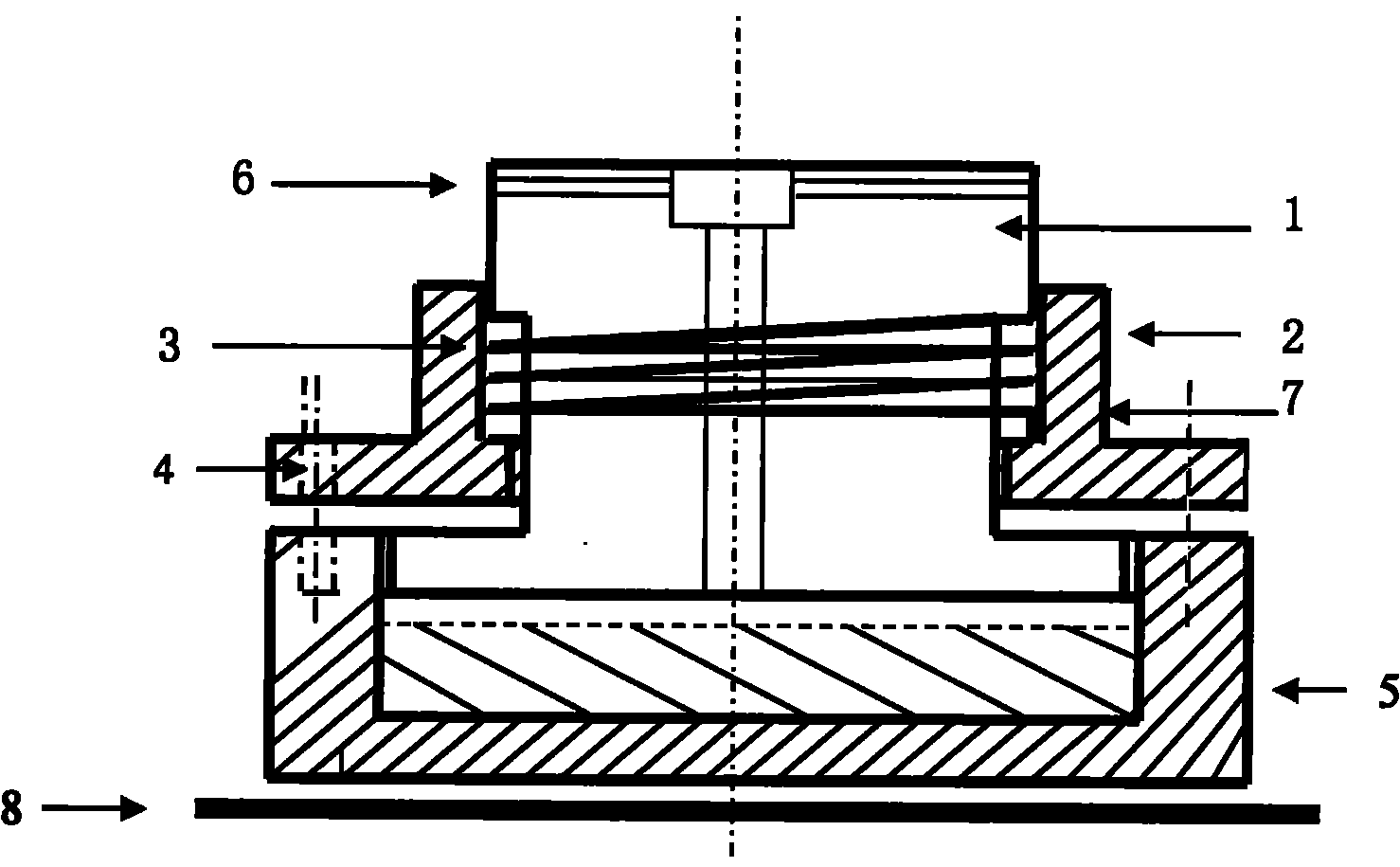

Preparation method of radiation-crosslinked polypropylene

InactiveCN102399390AWell mixedImprove the environmentChemical industryPolymer scienceElectron radiation

The invention discloses a preparation method of radiation-crosslinked polypropylene. According to the invention, polypropylene powder is added to a solution containing a croddlinking auxiliary agent; the mixture is processed through bake-drying, solvent removing and heat treatment; an antioxidant is added to the mixture, and the mixture is milled by using a double-roller mixing mill; the mixture is molded by extrusion or mold-pressing; and the molded polypropylene is irradiated. With the method provided by the invention, polypropylene and the croddlinking auxiliary agent can be sufficiently and uniformly mixed beforehand; the milling time can be shortened; the crosslinking efficiency can be improved; and the heat resistance and the melt strength can both be improved. In the radiation-crosslinking process, no chemical crosslinking agent is used, such that the method is environment-friendly. The crosslinking degree is uniform and controllable. The method is also advantaged in low energyconsumption and high yield. With electron radiation, environmental-aging resisting and temperature resisting performances of the polypropylene foam are substantially improved.

Owner:SICHUAN INST OF ATOMIC ENERGY

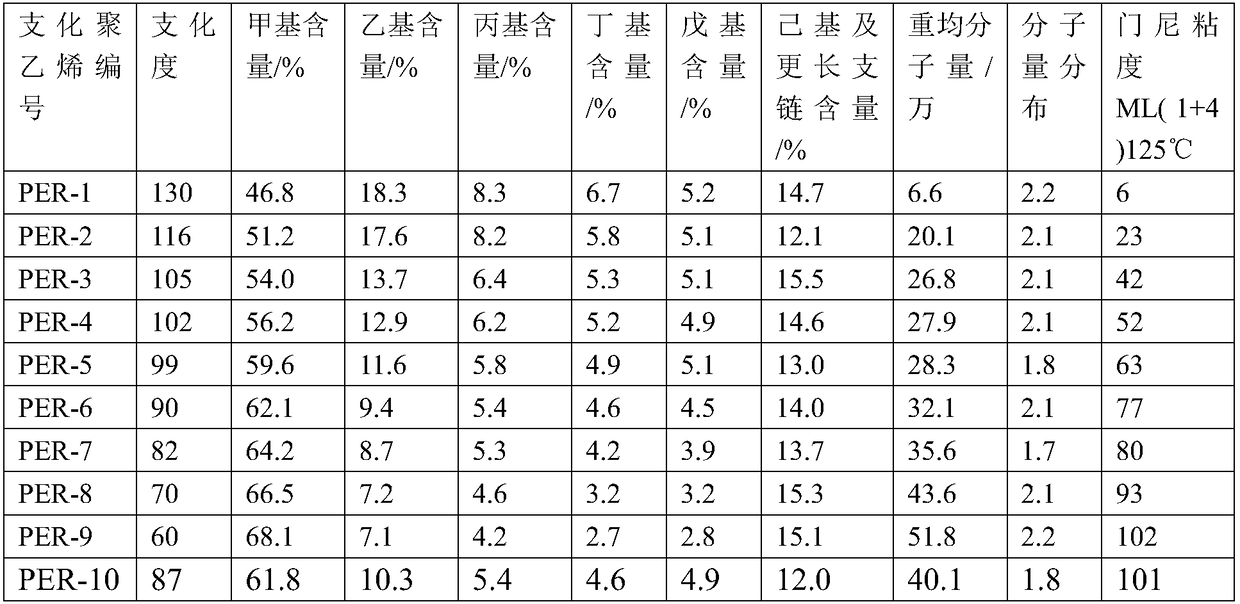

Rubber composition, processing method, application and method for producing flame-retardant products

ActiveCN108299743AReduced mechanical propertiesReduced processing performanceCold airPolymer science

The invention discloses rubber composition, a processing method thereof and an application of the composition to processing of flame-retardant products. The rubber composition is prepared from a rubber matrix and essential components, wherein the rubber matrix contains a parts of branched polyethylene and b parts of EPM rubber and EPDM rubber, a is larger than 0 and smaller than or equal to 100 parts, and b is larger than or equal to 0 and smaller than 100 parts; the essential components comprise 1.5-10 parts of a crosslinking agent and 40-300 parts of a flame retardant. The rubber compositionapplies to production of flame-retardant products such as flame-retardant cables, flame-retardant cold air hoses of automobiles, flame-retardant sealing strips, high-temperature-resistant flame-retardant conveyor belts, flame-retardant waterproof rolls and the like, and the flame-retardant products have good flame retardance and mechanical properties.

Owner:HANGZHOU XINGLU TECH CO LTD +1

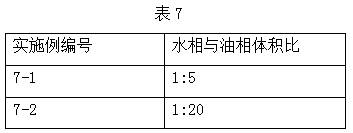

Preparation method of cross-linked hyaluronic acid microspheres

The invention discloses a preparation method of cross-linked hyaluronic acid microspheres. The method comprises the following steps: uniformly mixing and dispersing hyaluronic acid or salt thereof, across-linking agent, alkali and water at low temperature to obtain a water phase; adding the water phase into an oil phase containing an emulsifier, and fully emulsifying to obtain an emulsion; and cross-linking the emulsion at a cross-linking temperature, removing the oil phase after cross-linking, and carrying out post-treatment to obtain the cross-linked hyaluronic acid microspheres. The cross-linked hyaluronic acid microspheres which are uniform in particle and high in mechanical property are prepared by using a small amount of cross-linking agent through a low-temperature control reversed-phase emulsification cross-linking technology, are controllable in particle size, have certain expansibility and can be applied to the fields of drug-loaded microspheres and cosmetic filling.

Owner:BLOOMAGE BIOTECHNOLOGY CORP LTD

High performance aging resistant cable sheath material

ActiveCN103897272AGood heat resistance and flame retardant performanceExcellent ozone resistanceInsulated cablesInsulatorsSilanesLead salt

The invention discloses a high performance aging resistant cable sheath material which comprises the following raw materials in parts by weight: 30-40 parts of chlorinated polyethylene 135B, 15-20 parts of chlorinated polyethylene, 1.5-3 parts of magnesium oxide, 4-6 parts of dioctyl phthalate, 5-8 parts of dioctyl phthalate, 20-30 parts of white carbon black, 0.5-1 part of rare earth stabilizer, 0.3-0.6 part of a lead salt composite stabilizer, 2-5 parts of antimonous oxide, 8-12 parts of zinc borate, 2-4 parts of trichloroethyl phosphate, 8-12 parts of carbon black N770, 15-20 parts of calcium carbonate, 0.7-0.9 part of a surfactant gamma-mercaptopropyl triethoxyl silane, 0.5-1.3 parts of avulcanizing agent dicumyl peroxide and 0.5-1 part of a co-vulcanizing agent triallyl isocyanurate. The high performance aging resistant cable sheath material disclosed by the invention is excellent in heat resistant and flame retardant effect, good in ozone resistance and oil resistance, excellent in physical and mechanical properties and long in service life.

Owner:江苏鑫海腾线缆有限公司

Ultraviolet light cross-linked high flame-retardant low-smoke halogen-free polyolefin cable material and preparation method thereof

PendingCN110746683AImprove mechanical propertiesShorten the production cycleLow smoke zero halogenPolymer science

The invention discloses an ultraviolet light cross-linked high flame-retardant low-smoke halogen-free polyolefin cable material and a preparation method thereof. The ultraviolet light cross-linked high flame-retardant low-smoke halogen-free polyolefin cable material comprises the following raw material components in parts by mass: 100 parts of a base material, 100-130 parts of a low-smoke halogen-free flame retardant, 5-15 parts of a synergistic flame retardant, 1-3 parts of a cationic initiator, 1-3 parts of a free radical initiator, 1-5 parts of an assistant crosslinking agent, 0.5-1.5 partsof a compound antioxidant, and 1-3 parts of a lubricant. The combination of two different photo-initiation mechanisms is utilized, the crosslinking efficiency is significantly improved, and wire andcable products have shorter production cycle, and more stable heat resistance and mechanical properties. At the same time, the low-smoke halogen-free flame retardant and the flame-retardant synergistare used, so that relatively good flame retardancy can be obtained and the mechanical properties of the material can be improved in the case of a relatively small total amount of the flame retardant.The base material with a specific composition and the lubricant with a specific composition are selected, so that the mechanical properties of the cable material are further improved, the processing performance of the material is improved, and the preparation efficiency is improved.

Owner:JIANGSU SHANGSHANG CABLE GRP NEW MATERIAL CO LTD

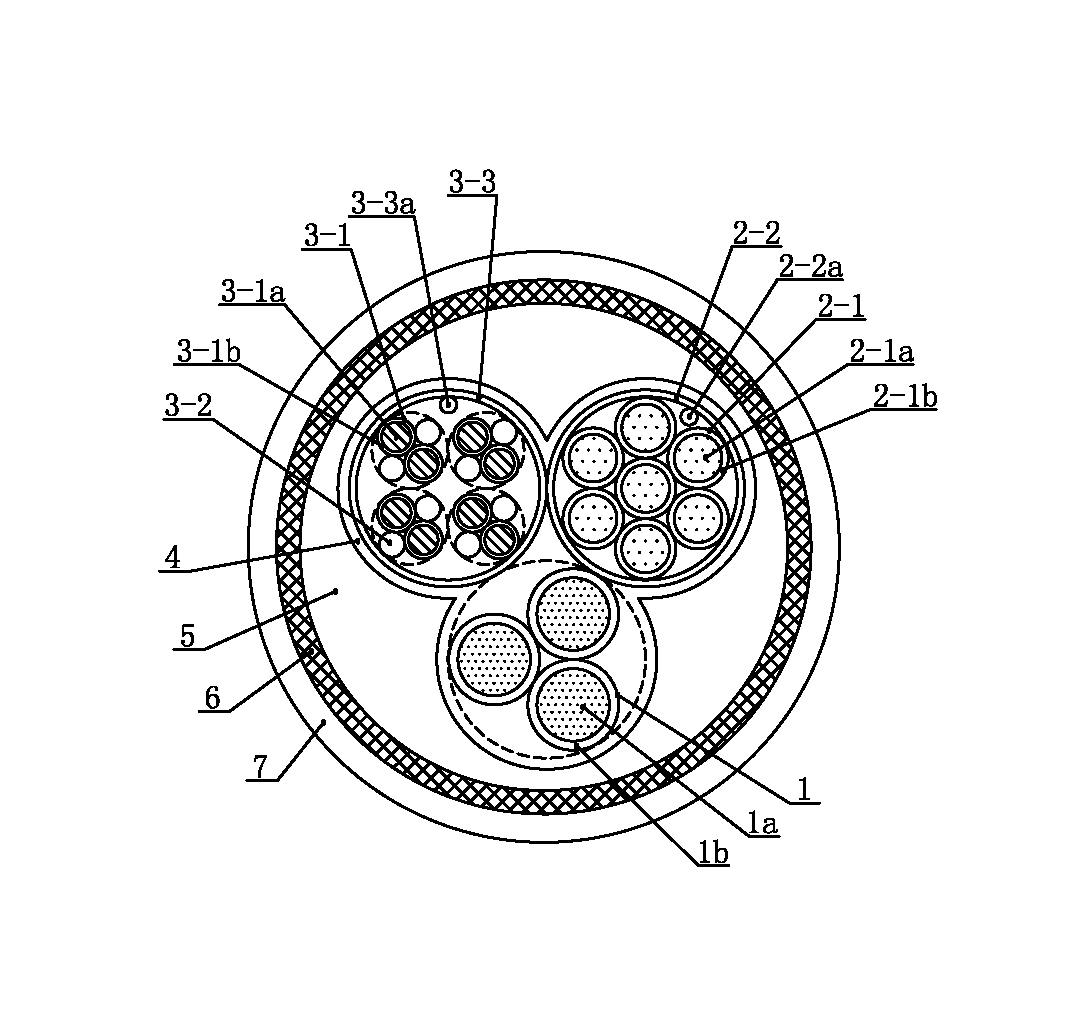

Composite cable for flame-retardant fireproof boat and manufacturing method thereof

ActiveCN103226992AIncrease working temperatureEliminate voidsInsulated cablesInsulated conductorsPower cableEngineering

The invention relates to a composite cable for a flame-retardant fireproof boat and a manufacturing method thereof. A power cable core, a control cable core and an instrument cable core are stranded into a composite cable core; the periphery of the composite cable core is coated with a low-intensity non-woven fabric longitudinally-covered layer; an inner jacket is extruded on the periphery of the low-intensity non-woven fabric longitudinally-covered layer in a wrapping way; the periphery of the inner jacket is coated with an armor braid; and an outer jacket is extruded on the periphery of the armor braid in a wrapping way. The low-intensity non-woven fabric longitudinally-covered layer is completely in fit with each insulated conductor in shape, so that gaps between the low-intensity non-woven fabric longitudinally-covered layer and the insulated cores are eliminated, and flame can be conveniently prevented from being spread inwards; and meanwhile, the inner jacket and the insulated cores are guaranteed not to be adhered, so that the insulated cores are not damaged when the jacket is stripped in the constructing process.

Owner:浙江华威设备制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com