Preparation method of high-gelling-property soybean protein/beta-glucan compound

A technology of soybean protein and glucan, applied in food preparation, food science, application, etc., can solve problems such as limited application and poor functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

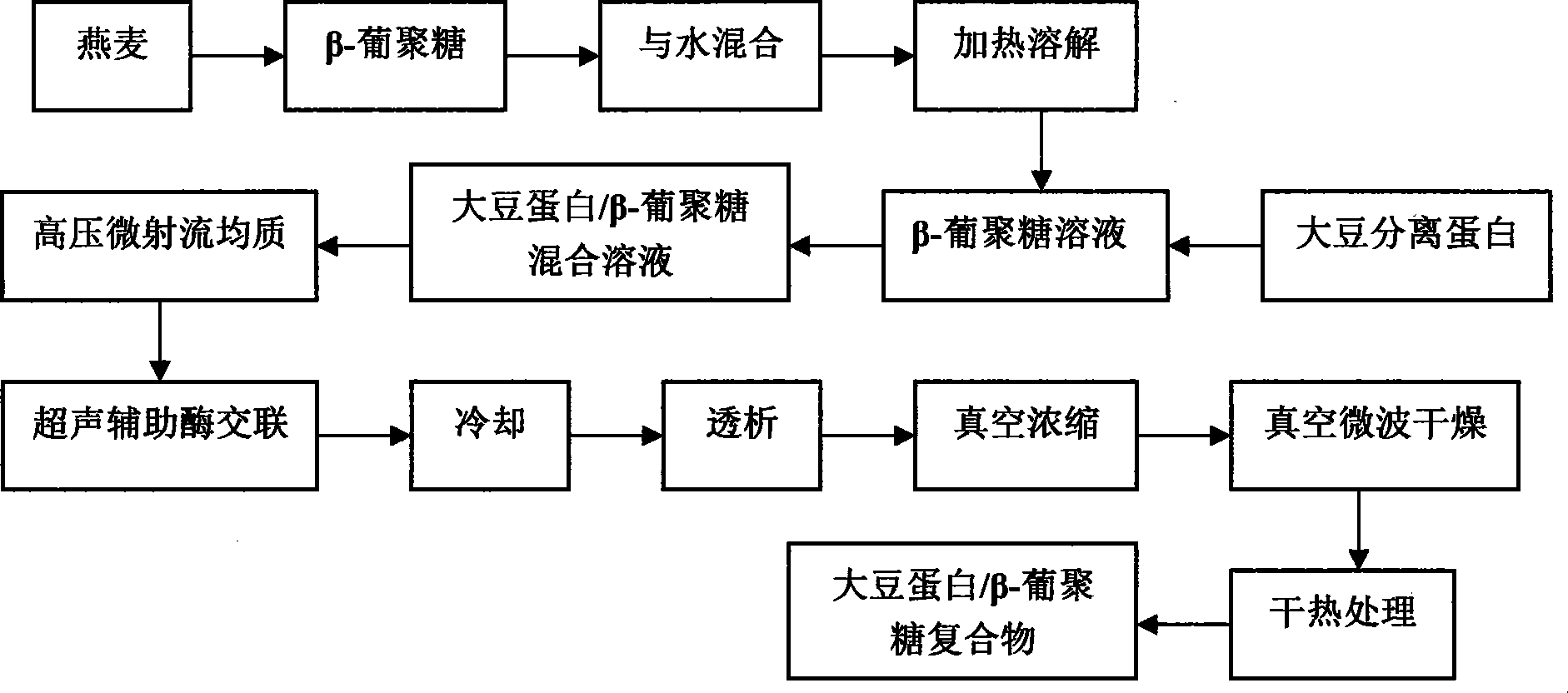

[0016] A method for preparing a high-gelling soybean protein / β-glucan complex, the method comprising the following steps: (1) extracting β-glucan from oats, mixing the β-glucan with water, Heat to 85°C to fully dissolve to form a 1% β-glucan solution. After cooling to room temperature, add a certain amount of soybean protein isolate to the β-glucan solution to make the protein concentration reach 5%. Mix well to obtain soybeans protein / β-glucan mixed solution; (2) subjecting the mixed solution to high-pressure micro-jet homogenization, the pressure of the micro-jet homogenization is 40-120MPa, adding transglutamine to the homogenized mixed solution enzyme, and place it in an ultrasonic processor for ultrasonic-assisted enzyme cross-linking treatment, the ultrasonic power is 100-300W, the amount of enzyme added is 1-5% of the mass of the mixed solution, and the reaction temperature is 30-50°C, The reaction time is 0.5-2.5h, and the reaction pH is 6-8; (3) Cool the mixed solutio...

Embodiment 1

[0021] Extract β-glucan from oats, mix β-glucan with water, heat to 85°C to fully dissolve it to form a 1% β-glucan solution, cool to room temperature and add β-glucan Add a certain amount of soybean protein isolate to the solution to make the protein concentration reach 5%, and mix thoroughly to obtain a soybean protein / β-glucan mixture, and carry out high-pressure micro-jet homogenization on the mixed liquid under the micro-jet homogenization pressure of 100MPa , and then add 2% transglutaminase to the homogenized mixed solution at an ultrasonic power of 250W, a reaction temperature of 40°C, and a reaction pH of 7 for ultrasonic-assisted enzyme cross-linking treatment for 1 hour, and the ultrasonic-assisted enzyme cross-linked The treated mixed solution was cooled to room temperature, and then dialyzed at 4°C for 24 hours. The dialyzed mixed solution was vacuum concentrated and vacuum microwave dried to obtain a dry powder. The dry powder was subjected to dry heat treatment a...

Embodiment 2

[0023] Extract β-glucan from oats, mix β-glucan with water, heat to 85°C to fully dissolve it to form a 1% β-glucan solution, cool to room temperature and add β-glucan Add a certain amount of soybean protein isolate to the solution to make the protein concentration reach 5%, and mix well to obtain a soybean protein / β-glucan mixed solution, and carry out high-pressure micro-jet homogenization treatment on the mixed solution at a micro-jet homogenization pressure of 80MPa , and then add 1.5% transglutaminase to the homogenized mixed solution at an ultrasonic power of 200W, a reaction temperature of 45°C, and a reaction pH of 7.5 for ultrasonic-assisted enzyme cross-linking treatment for 1 h, and the ultrasonic-assisted enzyme cross-linked The treated mixed solution was cooled to room temperature, and then dialyzed at 4°C for 24 hours. The dialyzed mixed solution was vacuum concentrated and vacuum microwave dried to obtain a dry powder. The dry powder was subjected to dry heat tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gel strength | aaaaa | aaaaa |

| gel strength | aaaaa | aaaaa |

| gel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com