Patents

Literature

887 results about "Dry heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dry heat. a thermal effect produced by adding dry air or reducing the humidity of the environment. Heat that has no moisture. It may take the form of a hot dry pack, hot water bottle, electric light bath, heliotherapy, hot bricks, resistance coil, electric pad or blanket, hot air bath, or therapeutic lamp.

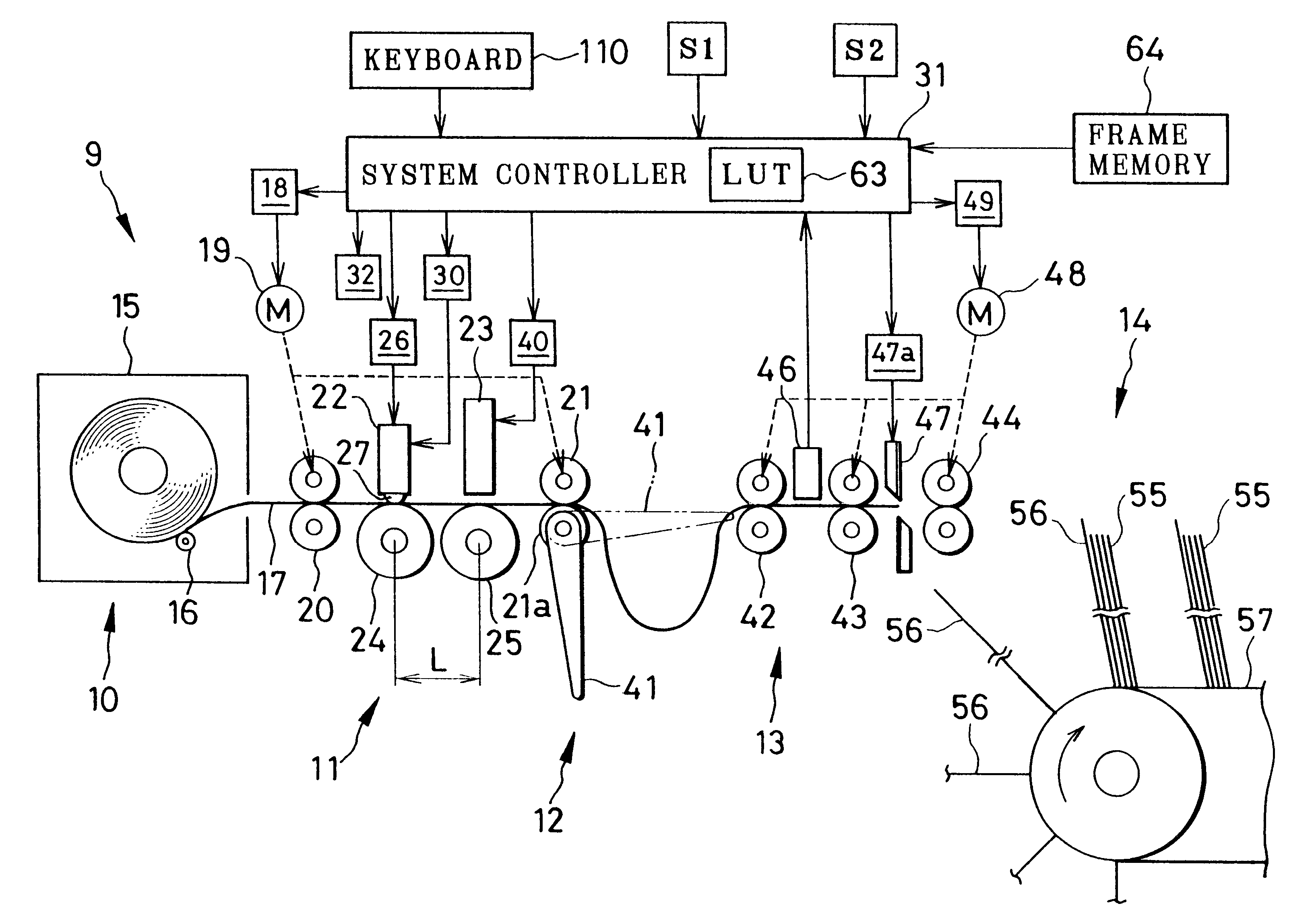

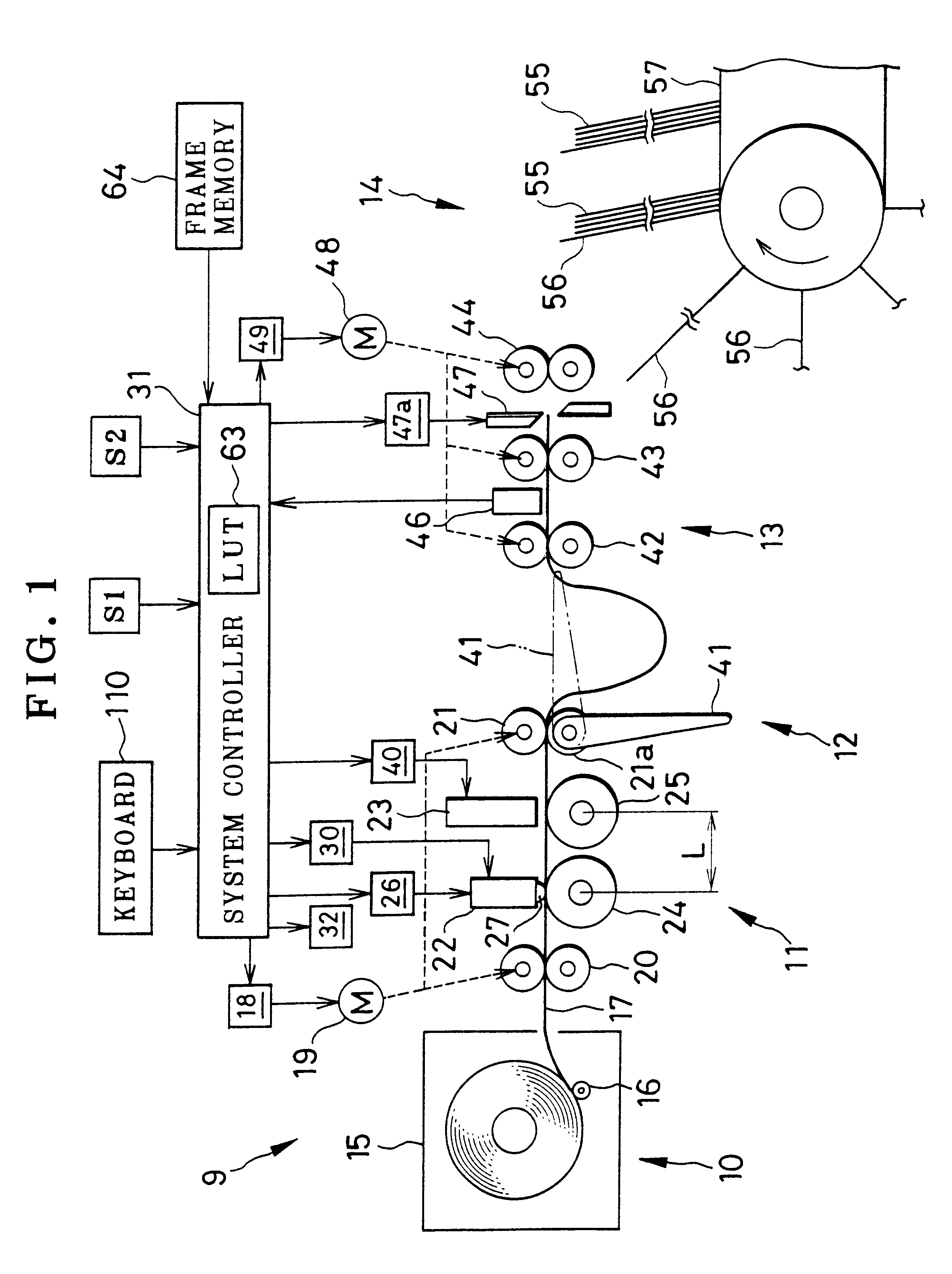

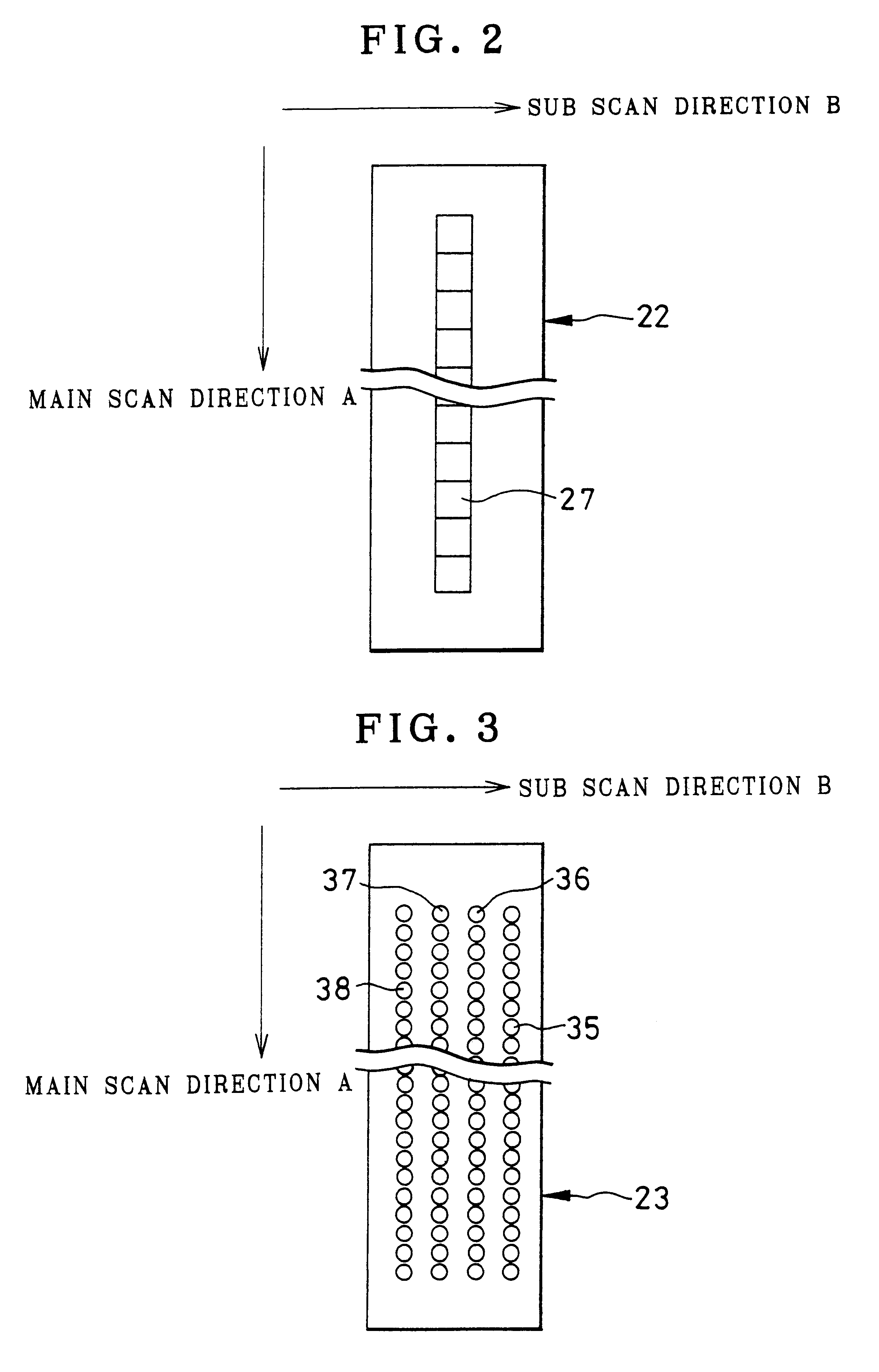

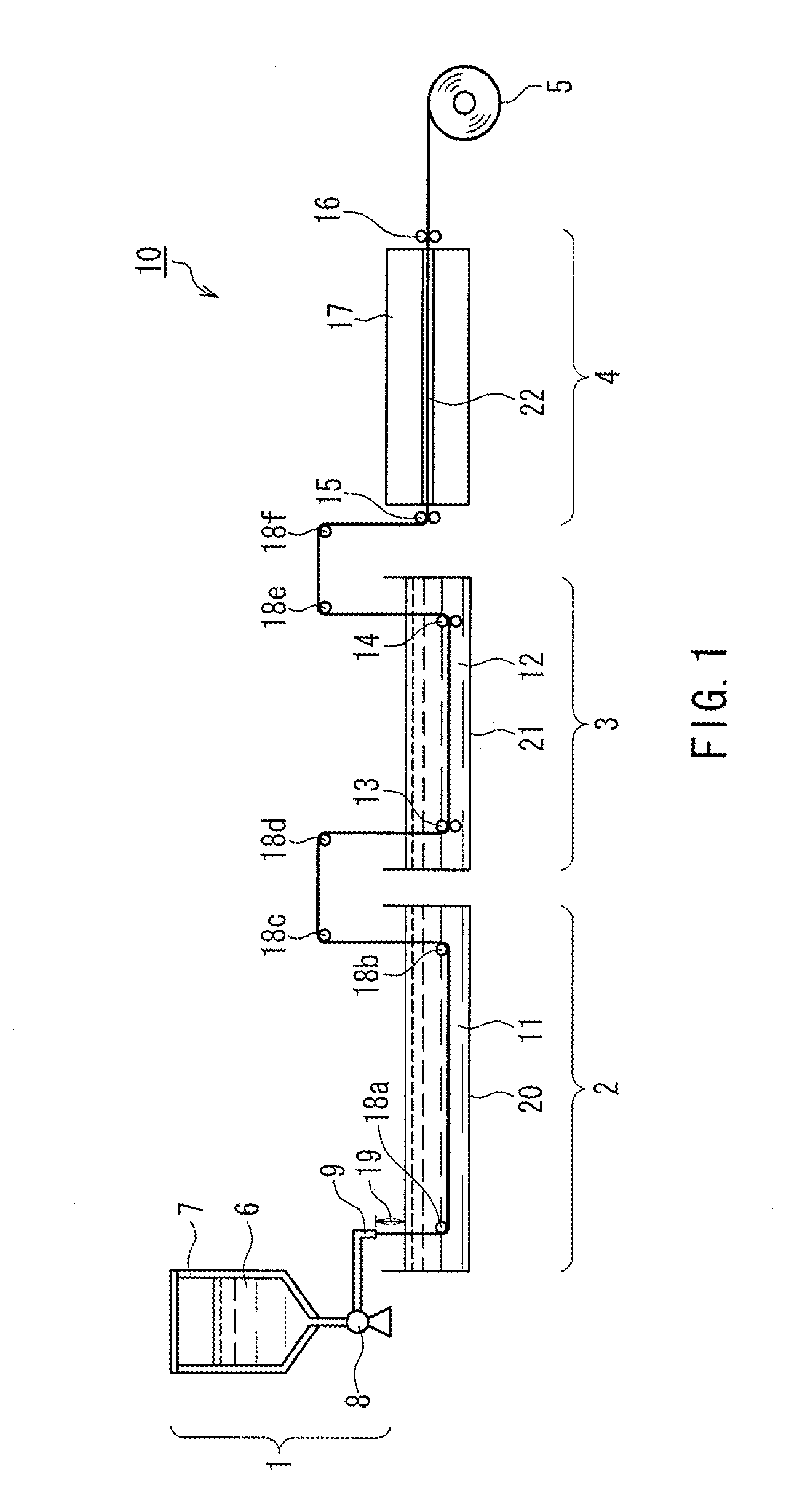

Ink jet printer and ink jet printing method

An ink jet printer comprises at least one ink jet head, in which plural nozzles are arranged in an array in a main scan direction, and eject a droplet of ink to recording material respectively at an ejected amount according to information of an image. Feeder rollers feed the recording material relative to the ink jet head in a sub scan direction, to print the image to the recording material two-dimensionally. A thermal head includes plural heating elements arranged in an array in the main scan direction, for applying heat to the recording material respectively in a heating region. A system controller sets drying heat energy according to the ejected amount, and drives the thermal head to apply the drying heat energy to the heating region, to promote drying of the droplet in the heating region.

Owner:FUJI FILM CO LTD +1

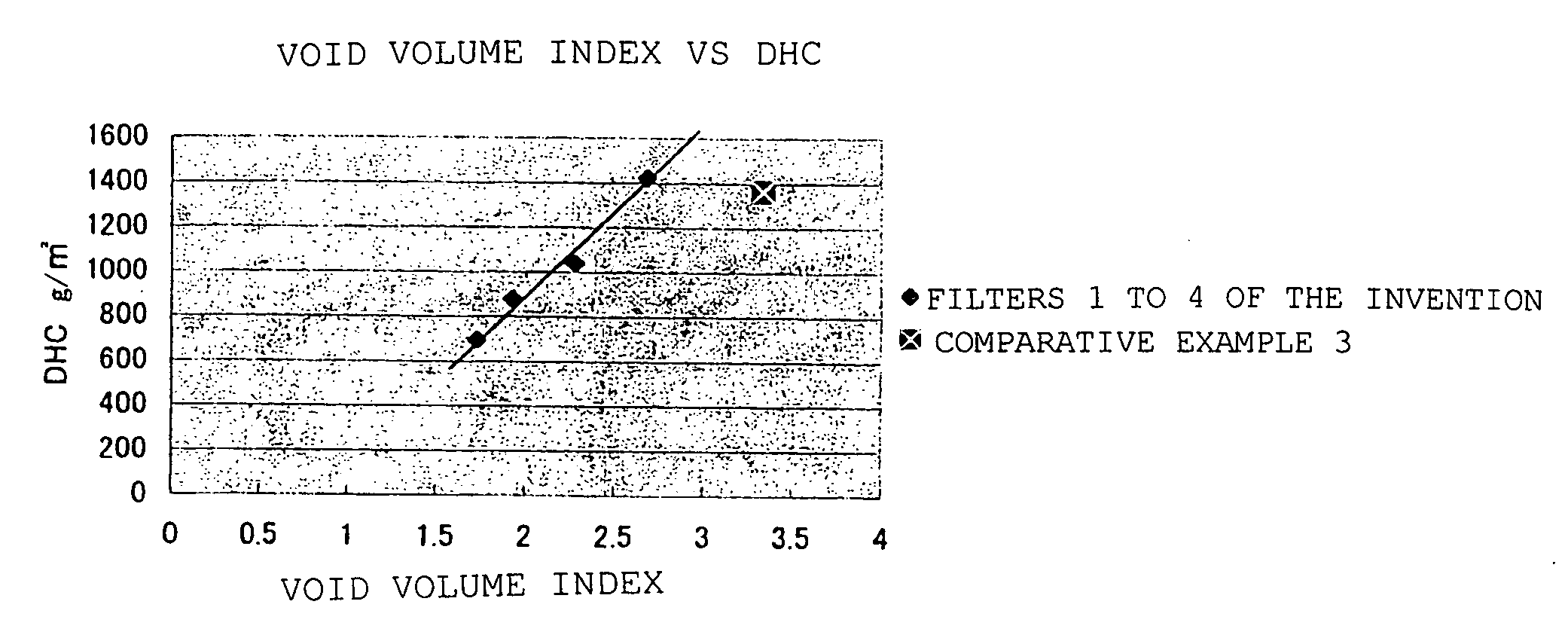

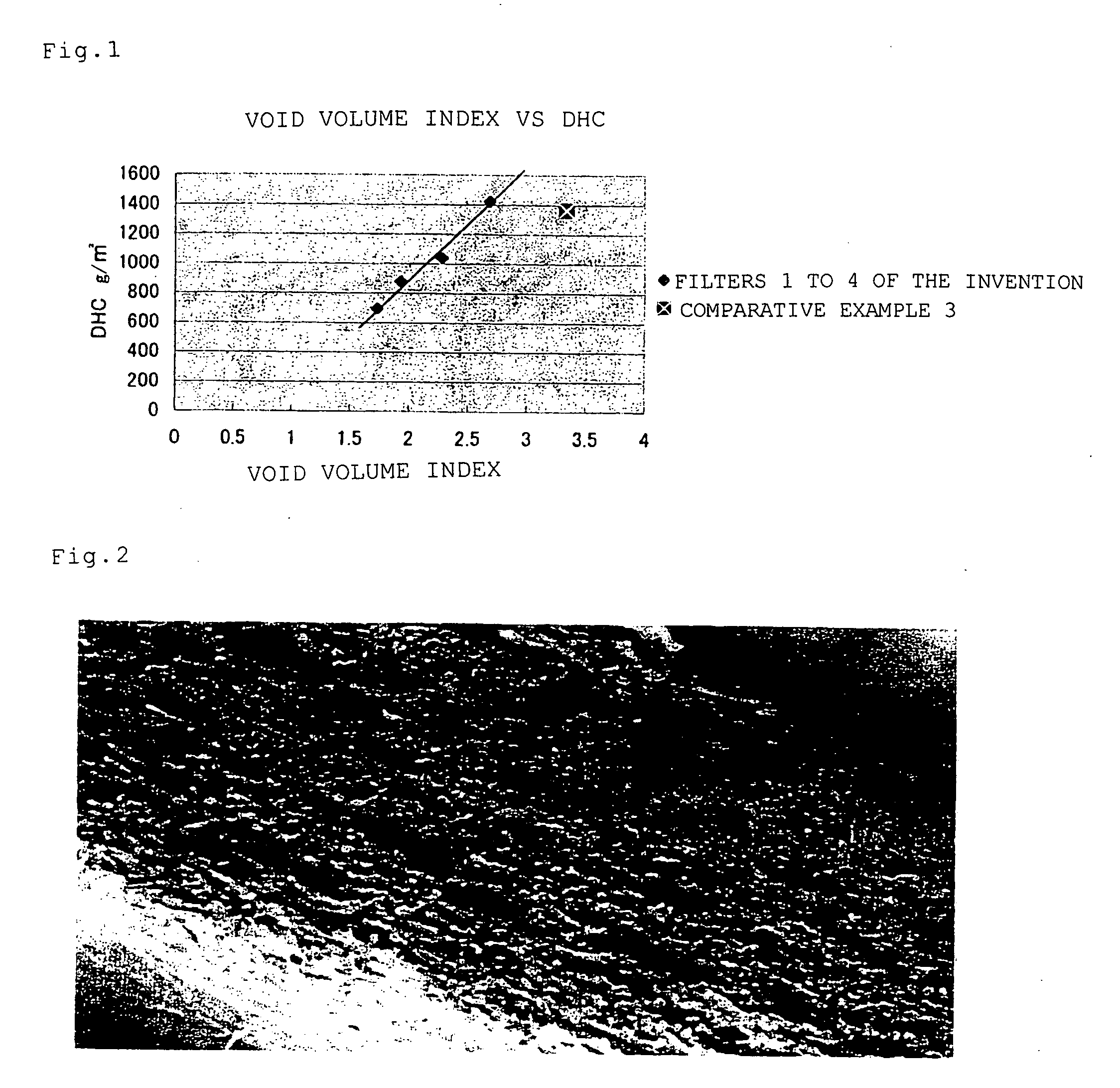

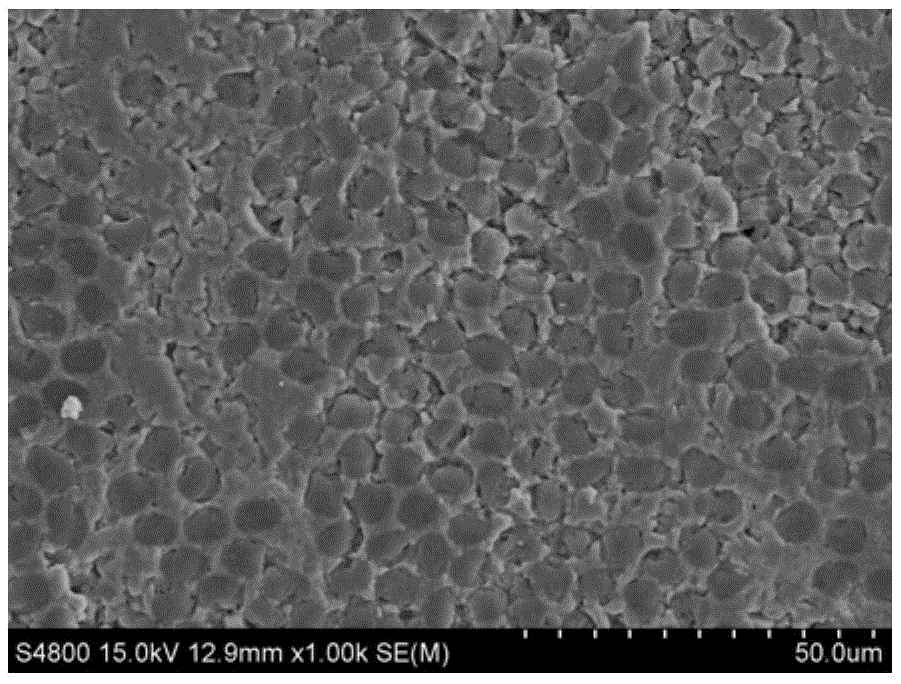

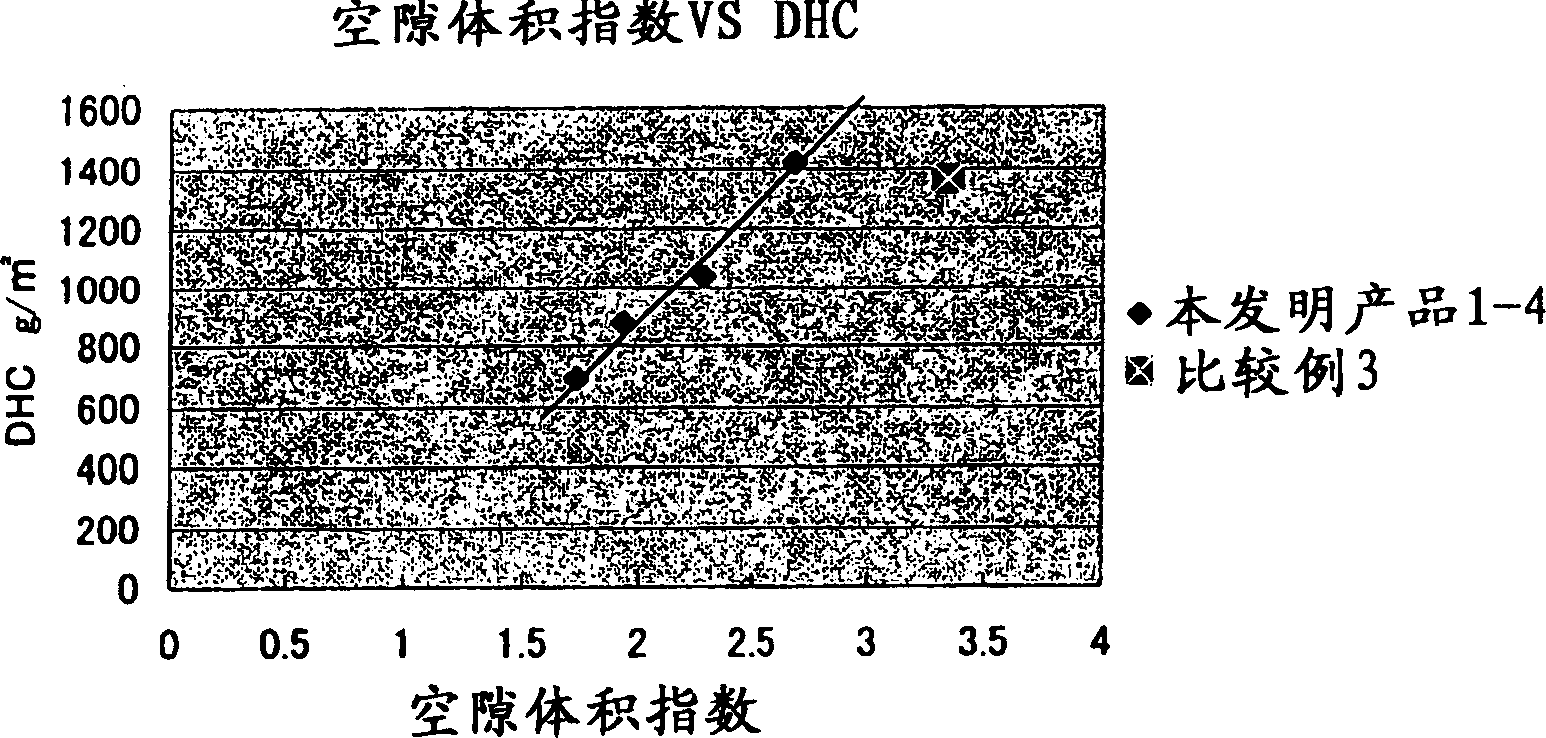

Nonwoven fabric air filter for internal combustion engine

A thin and uniform nonwoven fabric air filter for an internal combustion engine with a pleated form which comprises an air-laid nonwoven fabric obtained by forming a plurality of layers mainly composed of polyester-based binder fibers having a fiber length of 1 to 10 mm by an air-laid nonwoven fabric production process and performing heat adhesion, wherein an upper layer side (fluid inflow side) comprises large fibers, a lower layer side (fluid outflow side) comprises fine fibers, a final fluid outflow side comprises 100% of the polyester-based binder fibers, the basis weight (METSUKE) is from 100 to 350 g / m2, the apparent density is from 0.04 g / cm3 to 0.3 g / cm3, and the dry-heat shrinkage factor after 300 hours at 100° C. is 3% or less. The air filter induces no environmental pollution, is high in dust collection efficiency, and has long life.

Owner:AMBIC +1

Haemostatic composition comprising hyaluronic acid

The present invention relates to a haemostatic composition comprising a biologically absorbable material and hyaluronic acid or a derivative thereof, methods of producing such compositions and the use of these compositions. In particular the method of producing said haemostatic composition comprises treating it with dry heat at a temperature between 110-200° C.

Owner:FERROSAN MEDICAL DEVICES

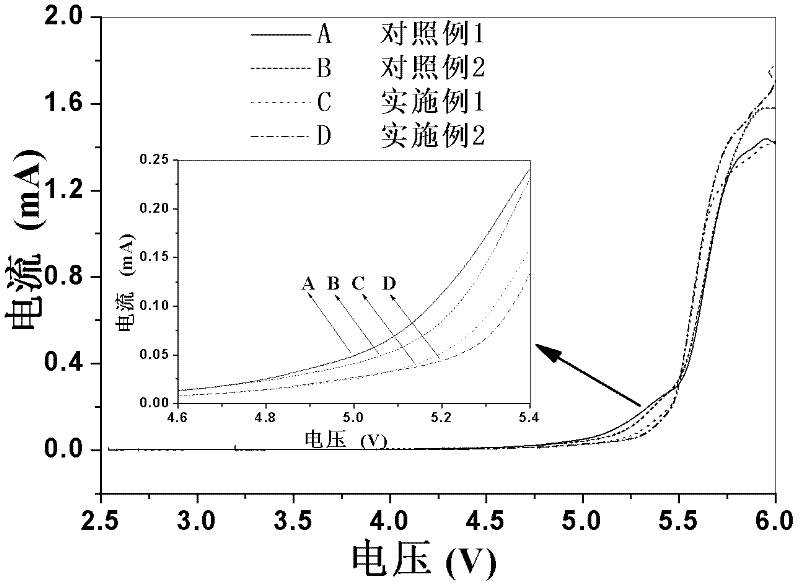

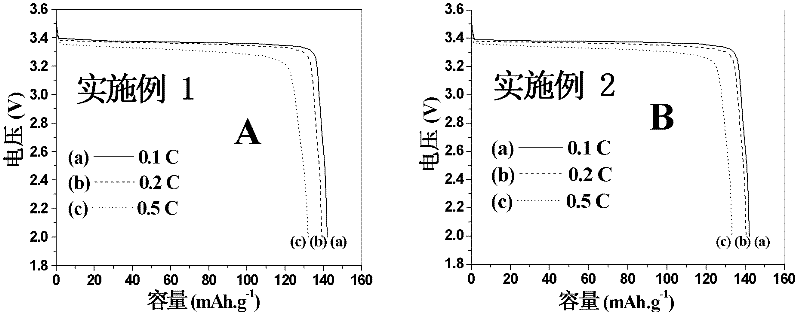

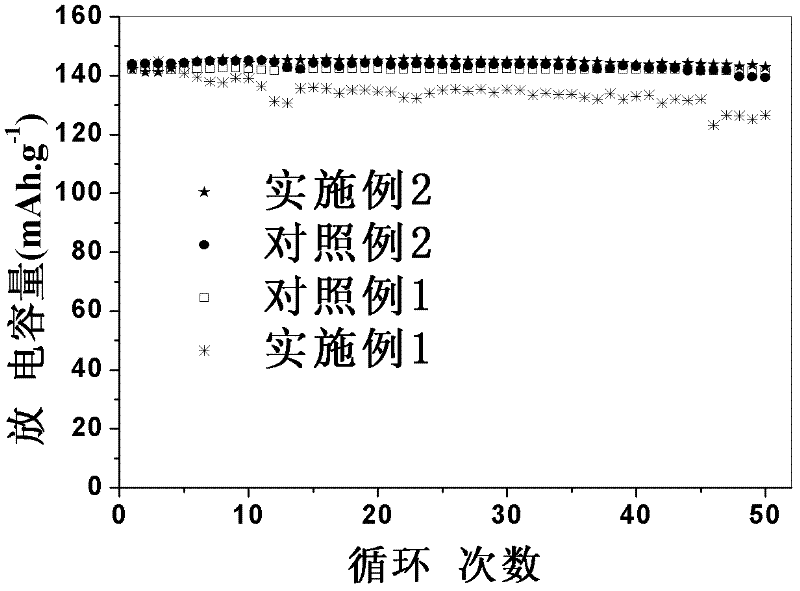

Lithium ion battery ionic liquid based gel polymer electrolyte as well as preparation and applications thereof

InactiveCN102244292AFix security issuesHigh mechanical strengthSecondary cellsPolymer dissolutionPolymer electrolytes

The invention discloses a lithium ion battery ionic liquid based gel polymer electrolyte as well as a preparation method and applications thereof. The method comprises the following steps: dissolving a polymer into an organic solvent; then adding deionized water and an inorganic ceramic material, thus obtaining a gel liquid; soaking an non-activated supporting body in the gel liquid; taking out and airing, thus a heat-resistant contracted lithium ion battery polymer diaphragm doped with the inorganic ceramic materials is obtained; dissolving lithium salt in an ion liquid, and adding a film formation addition agent, thus an ion liquid based electrolyte capable of gelating the polymer diaphragm is obtained; and soaking the dried heat-resistant contracted lithium ion battery polymer diaphragm doped with the inorganic ceramic material in the ion liquid based electrolyte, thus the heat-resistant contracted lithium ion battery ionic liquid based gel polymer electrolyte doped with the inorganic ceramic material is obtained. The preparation method is simple, and the safety performance, mechanical intensity and electromechanical performance of the lithium ion battery ionic liquid based gel polymer electrolyte are improved.

Owner:SOUTH CHINA NORMAL UNIVERSITY

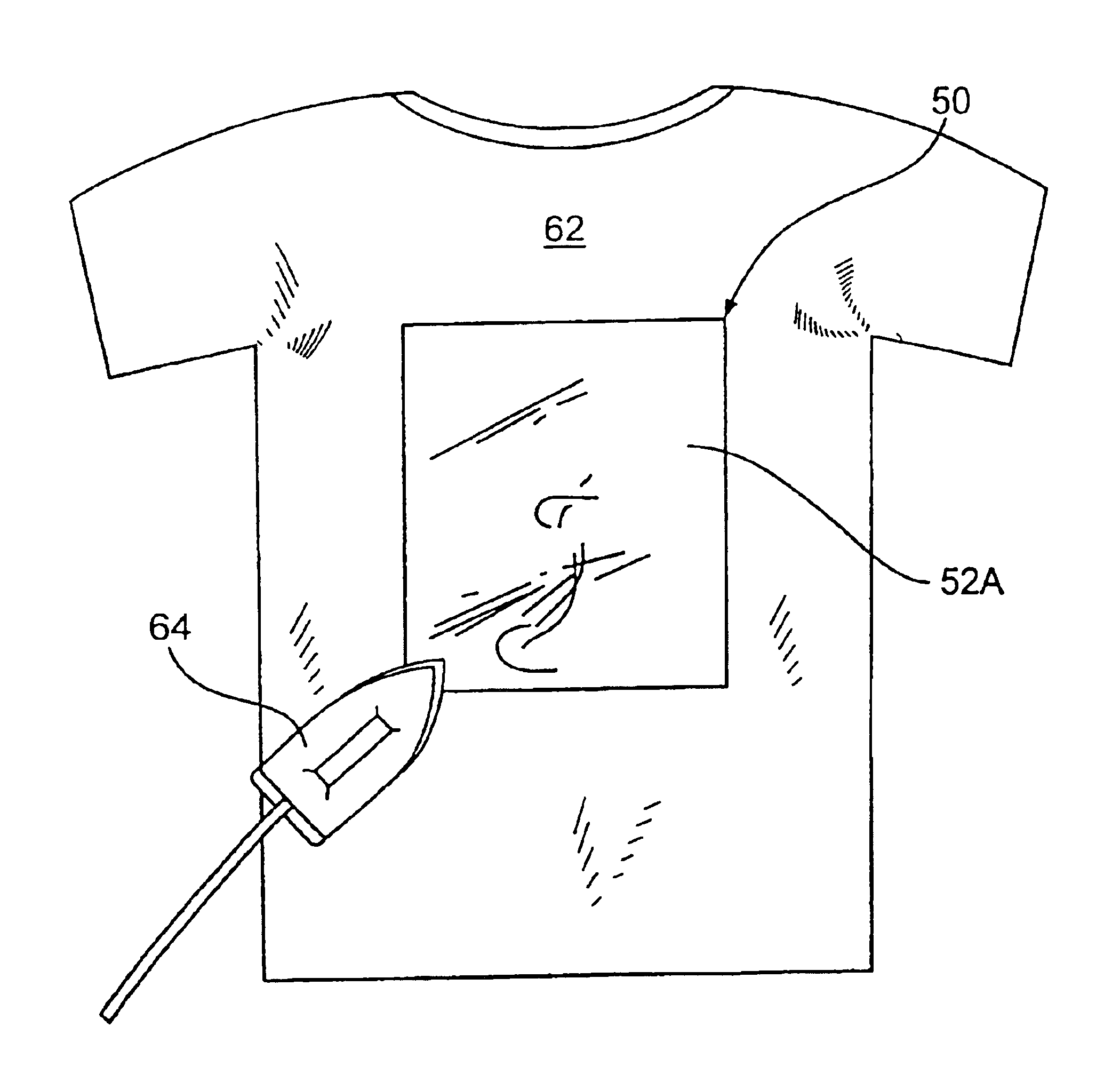

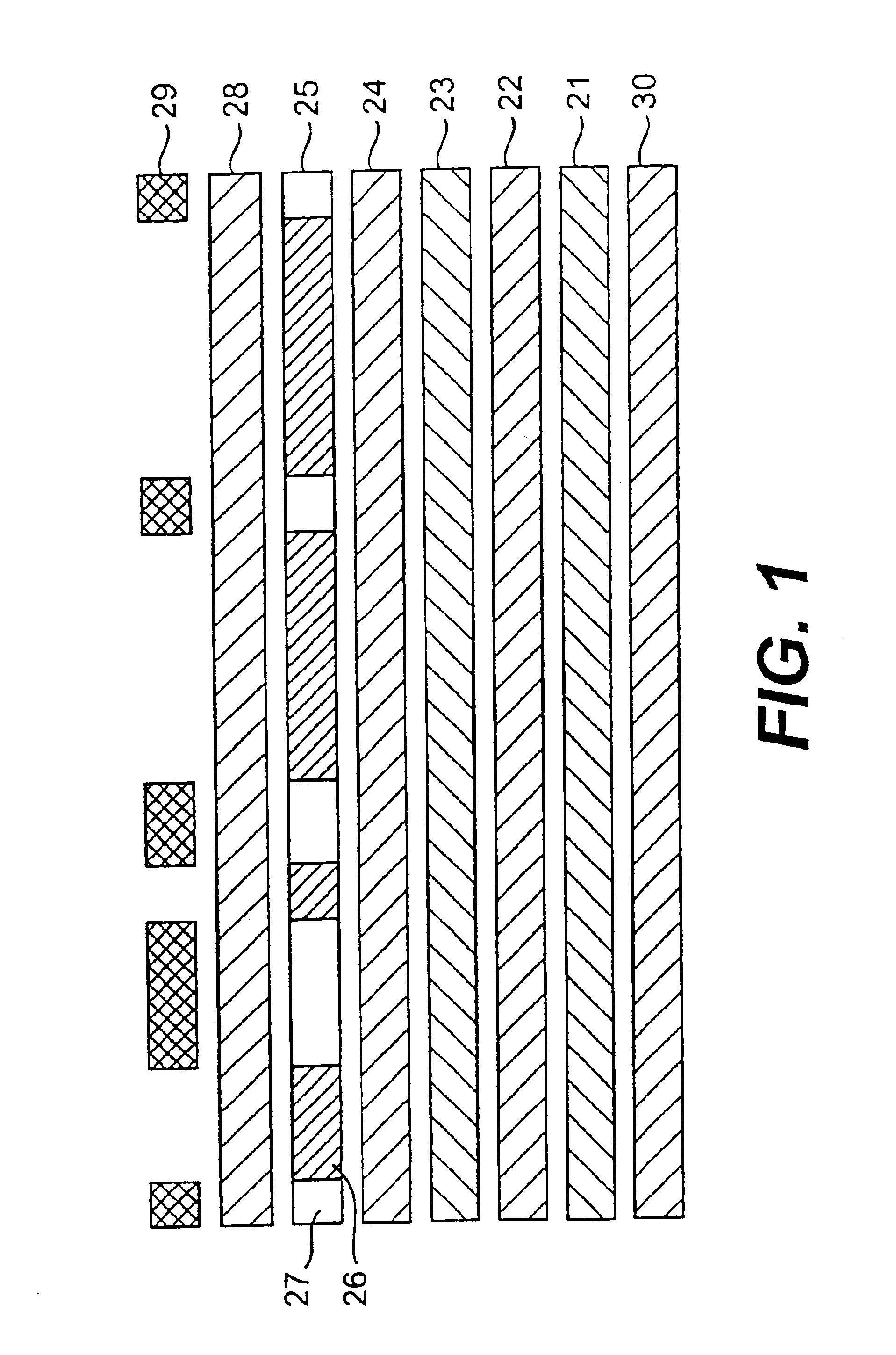

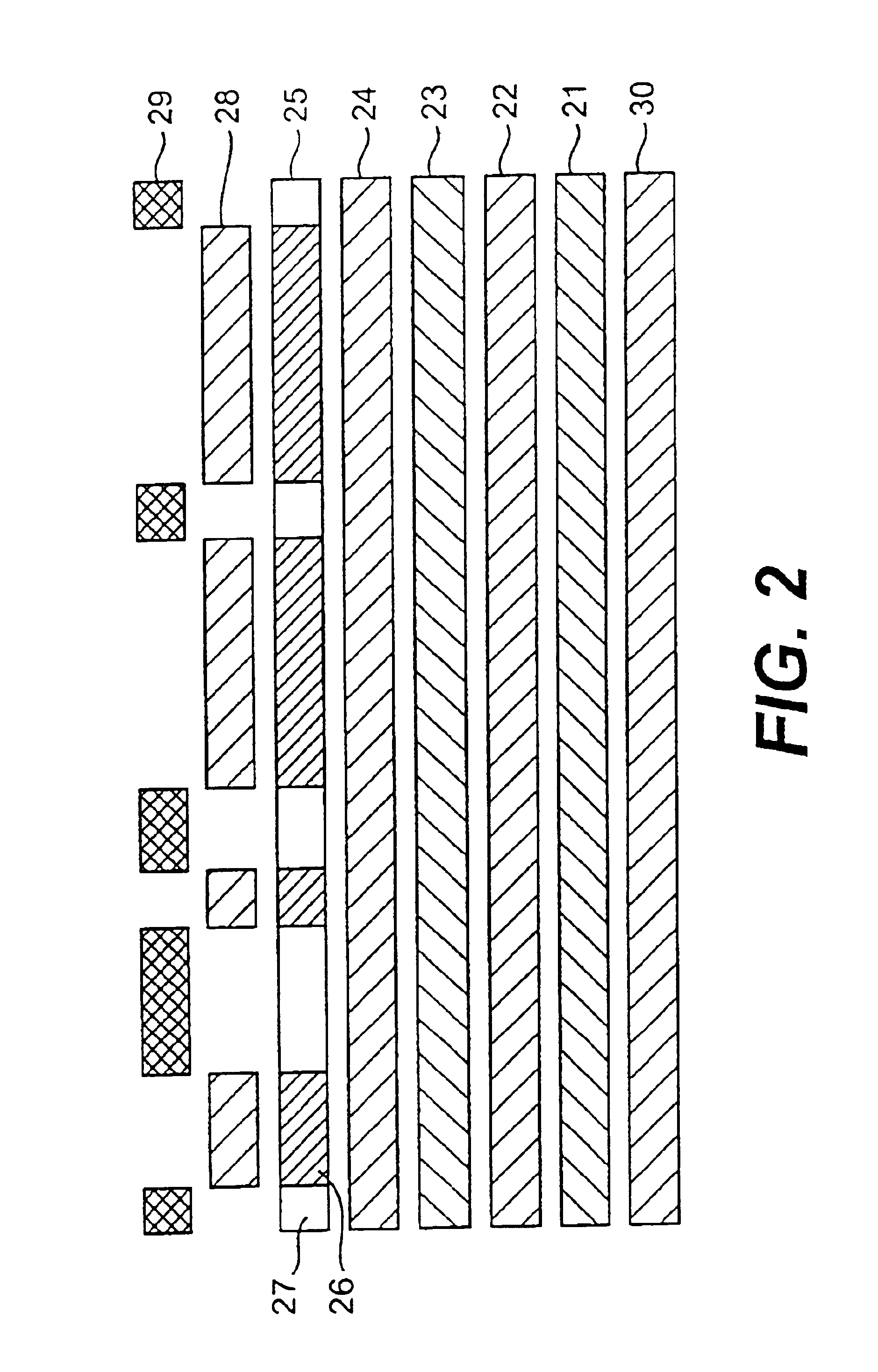

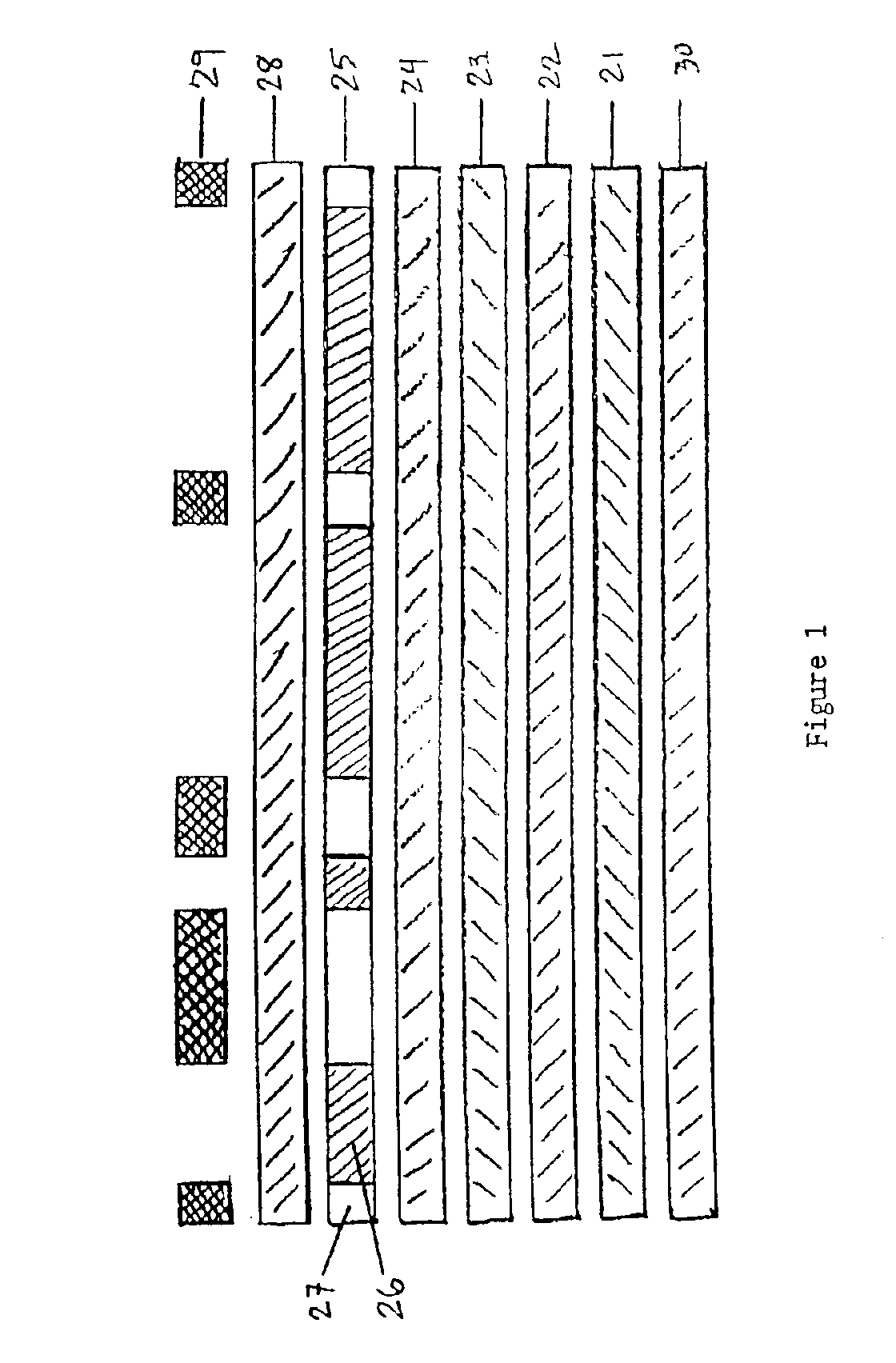

Image transfer sheet with transfer blocking overcoat and heat transfer process using the same

InactiveUS6849312B1Cost efficientReduction of the polymer haloDecorative surface effectsSynthetic resin layered productsImage transferBiochemical engineering

An image transfer sheet, having a support sheet, an optional barrier layer on the support sheet, a heat release layer on the optional barrier layer or on the support sheet, an optional image-receiving layer on the heat release layer, a design layer having image and non-image areas on the optional image-receiving layer on the heat release layer, an optional non-water-dispersible polymer layer on the design layer, and a transfer blocking overcoat layer on the optional polymer layer or the design layer, is used in a dry heat transfer process to transfer an image area to a receptor.

Owner:SCHWENDIMANN JODI

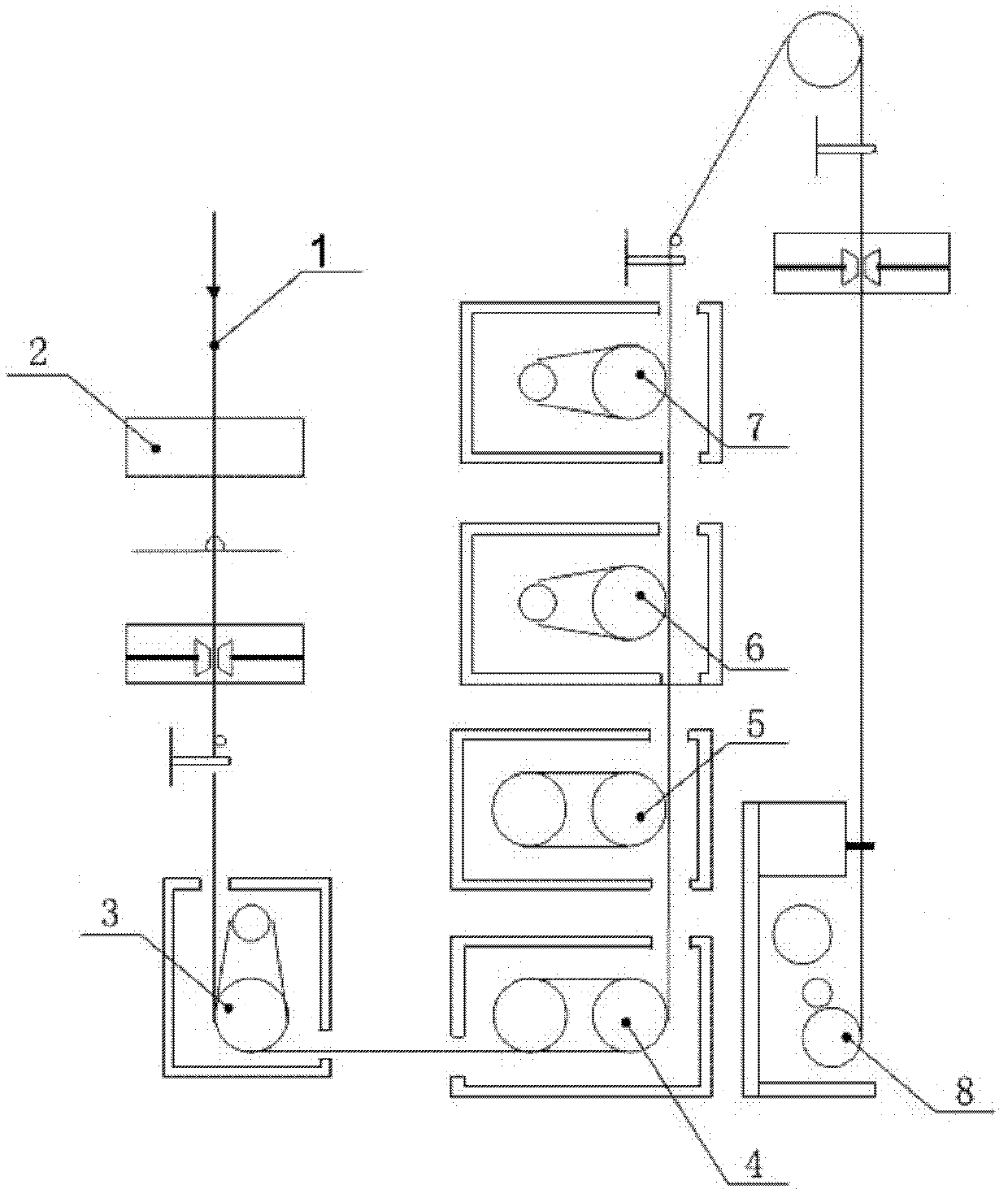

Manufacturing method of high-strength, high-modulus and low-shrinkage polyester industrial yarn

ActiveCN102797054AGuaranteed positionAvoid stretching unevenlyFilament/thread formingMonocomponent polyesters artificial filamentYarnFiber

The invention discloses a manufacturing method of a high-strength, high-modulus and low-shrinkage polyester industrial yarn. The manufacturing method comprises the processes of preparation of a highly viscous melt polyester raw material, metering, spinning, cooling, oil applying, drawing, heat shaping and winding formation; the cooling comprises slow cooling, precooling, cooling in an air free zone and air blast cooling in sequence; the precooling part uses a driven hollow-out successive annular strip. Through the introduction of a precooling device, irregularity caused by tow shaking due to move-down of a curing point of a fiber is reduced, the linear density deviation is controlled within a lower range, and orientation and crystallization of an as-spun fiber are reduced, so that the high-strength, high-modulus and low-shrinkage polyester industrial yarn is obtained; and the high-strength, high-modulus and low-shrinkage polyester industrial yarn has the advantages of high breaking tenacity, high initial modulus, low linear density deviation, low breaking elongation and lower dry-heat shrinkage rate and can be used for preferably satisfying requirements on application.

Owner:JIANGSU HENGLI CHEM FIBER

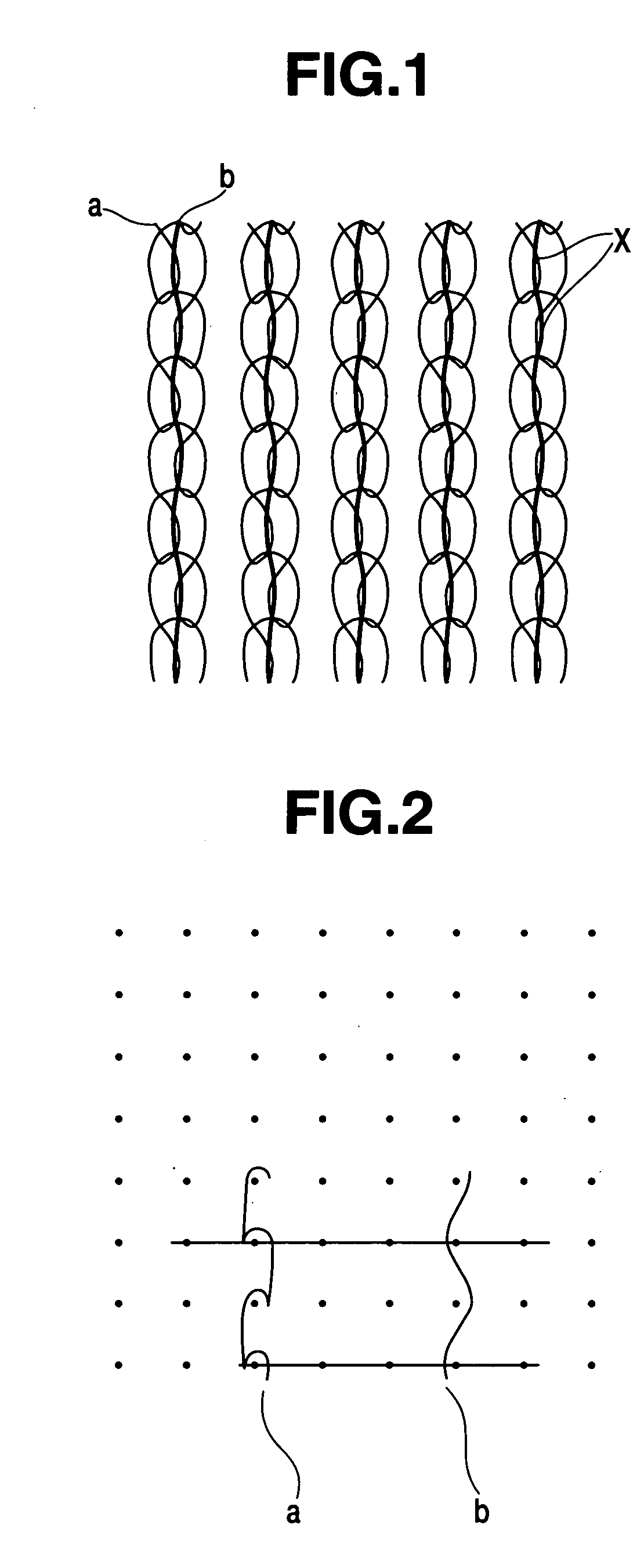

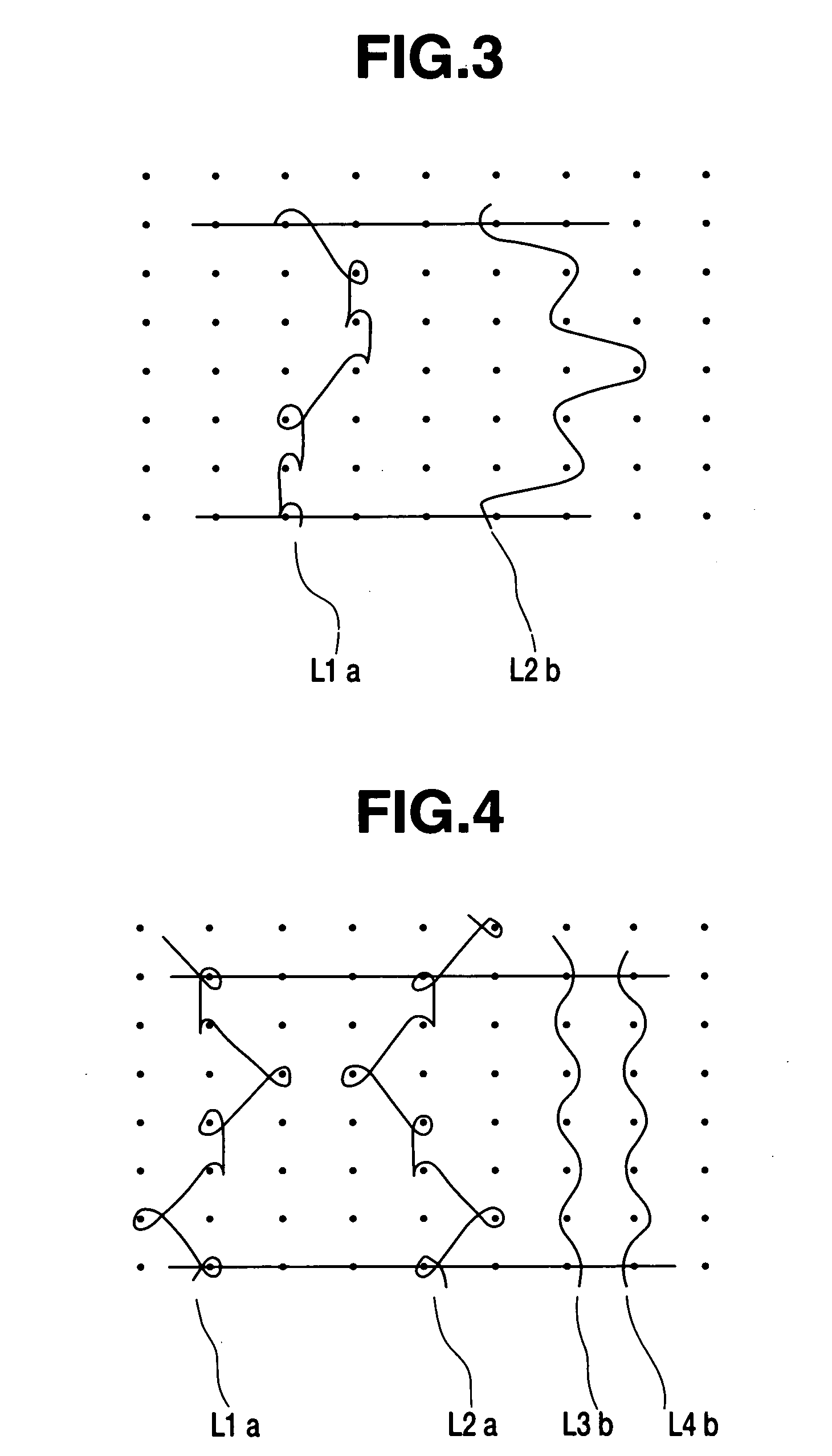

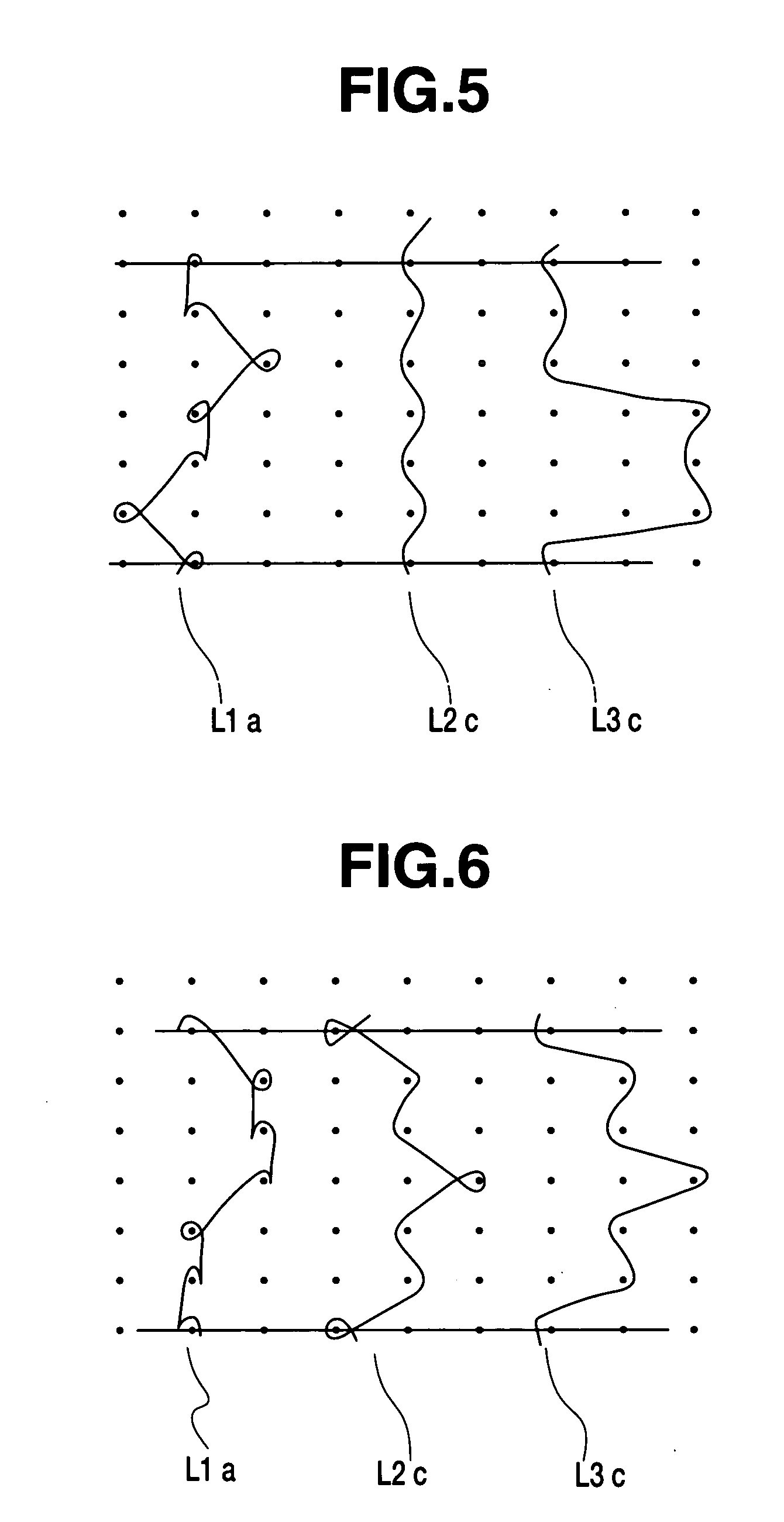

Blended woven or knitted fabrics containing polyerethane elastic fibers and process for the production thereof

A blended woven or knitted fabric which contains both highly fusible polyurethane elastic fibers exhibiting a retention of tenacity of 50% or above after the dry heat treatment at 150° C. for 45 s at 100% elongation and a melting point of 180° C. or below and at least one kind of non-elastic yarns and which is produced by fusing the polyurethane elasotomeric fibers to each other or the polyurethane elastic fibers to the non-elastic yarns at the crossover points by dry- or wet-heat setting; and a process for the production thereof.

Owner:NISSHINBO IND INC

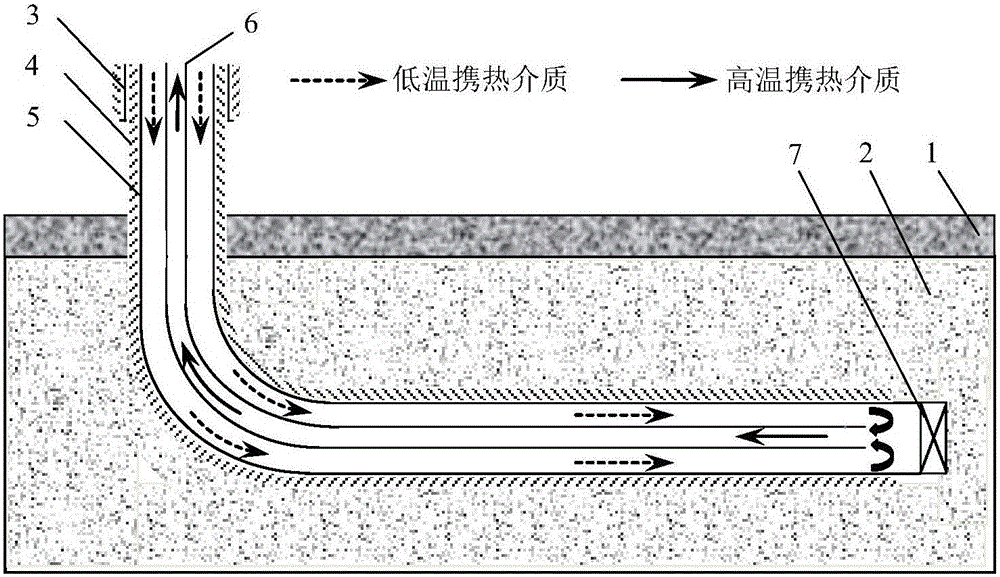

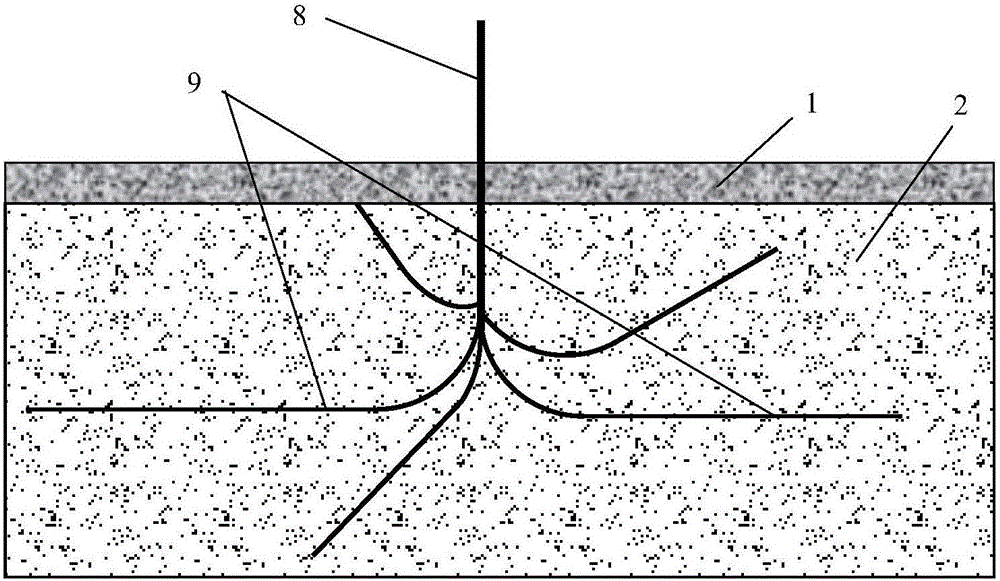

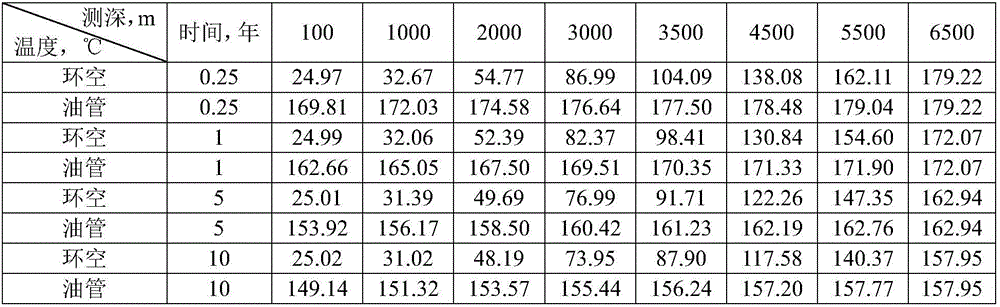

Method for exploiting compact dry heat rock geothermal energy by utilizing long horizontal well self-circulation structure

InactiveCN105909214AIncrease temperatureHigh hardnessOther heat production devicesGeothermal energy generationDry heatHeat losses

The invention relates to a field of geothermal energy development and provides a method for exploiting compact dry heat rock geothermal energy by utilizing a long horizontal well self-circulation structure. According to the invention, a single long horizontal well in a dry heat rock storage layer is utilized, an oil pipe-loop empty circulation structure of the single long horizontal well is adopted under a condition of not cracking the dry heat rock storage layer for performing circulation injection and production of heat carrying medium. During the injection process, a horizontal segment can be utilized fully for heating the heat carrying medium. During a production process, a prestress heat isolation oil tube is used for reducing heat loss of the heat carrying medium by using the prestress heat isolation oil tube. According to the invention, fluid loss caused by cracking can be avoided and the contact area of a well shaft and the storage layer is increased effectively due to the long horizontal segment. During the injection and production process, the temperature difference of the heat carrying medium also causes heat siphonage, so that ground injection and suction pump power is reduced effectively. At the same time, due to the closeness of the long horizontal well self-circulation structure, condition is provided for performance optimization of the heat carrying medium and problems of corrosion and scale formation are avoided and the heat collecting process becomes more reliable and stable.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

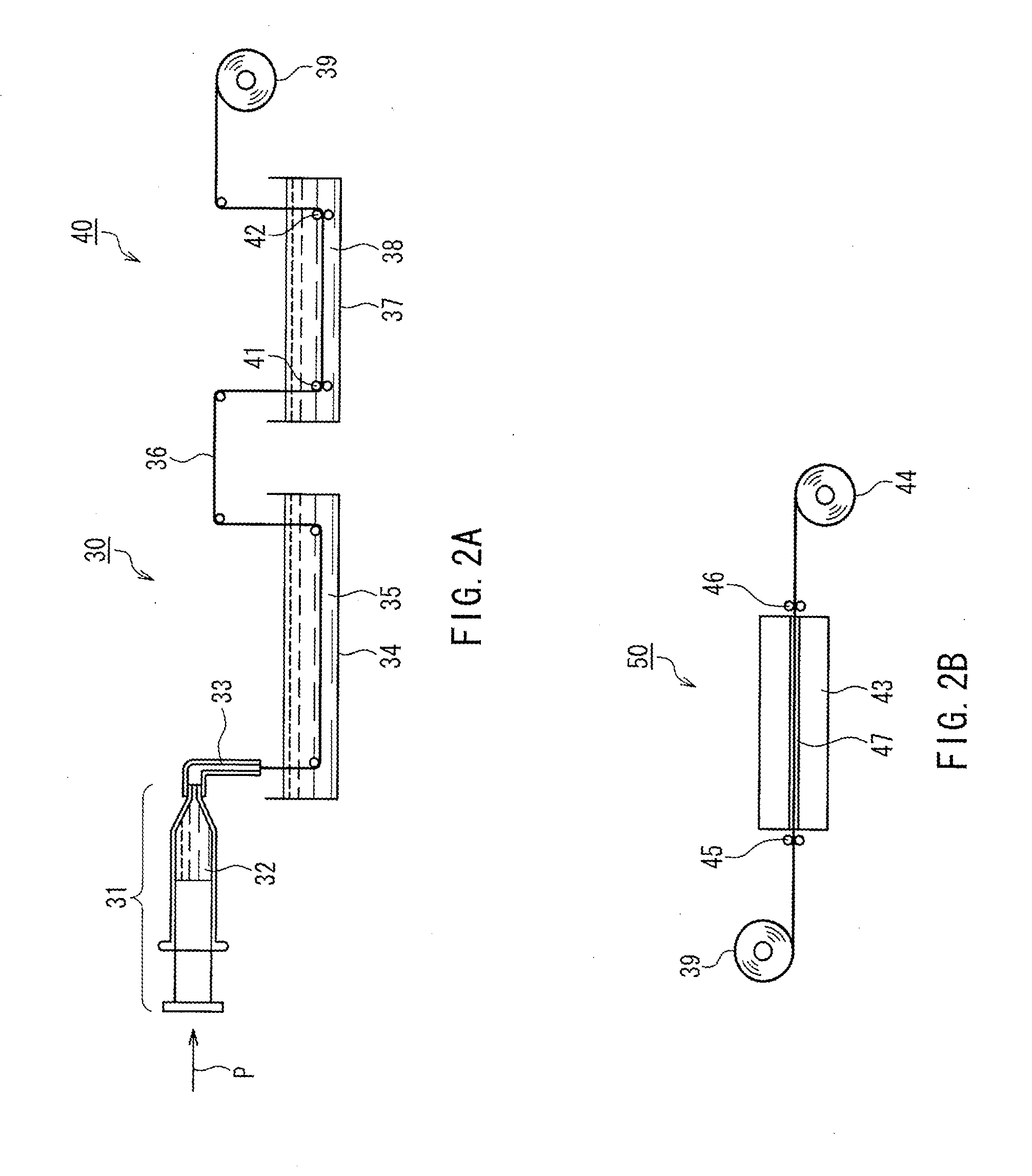

Artificial polypeptide fiber and method for producing the same

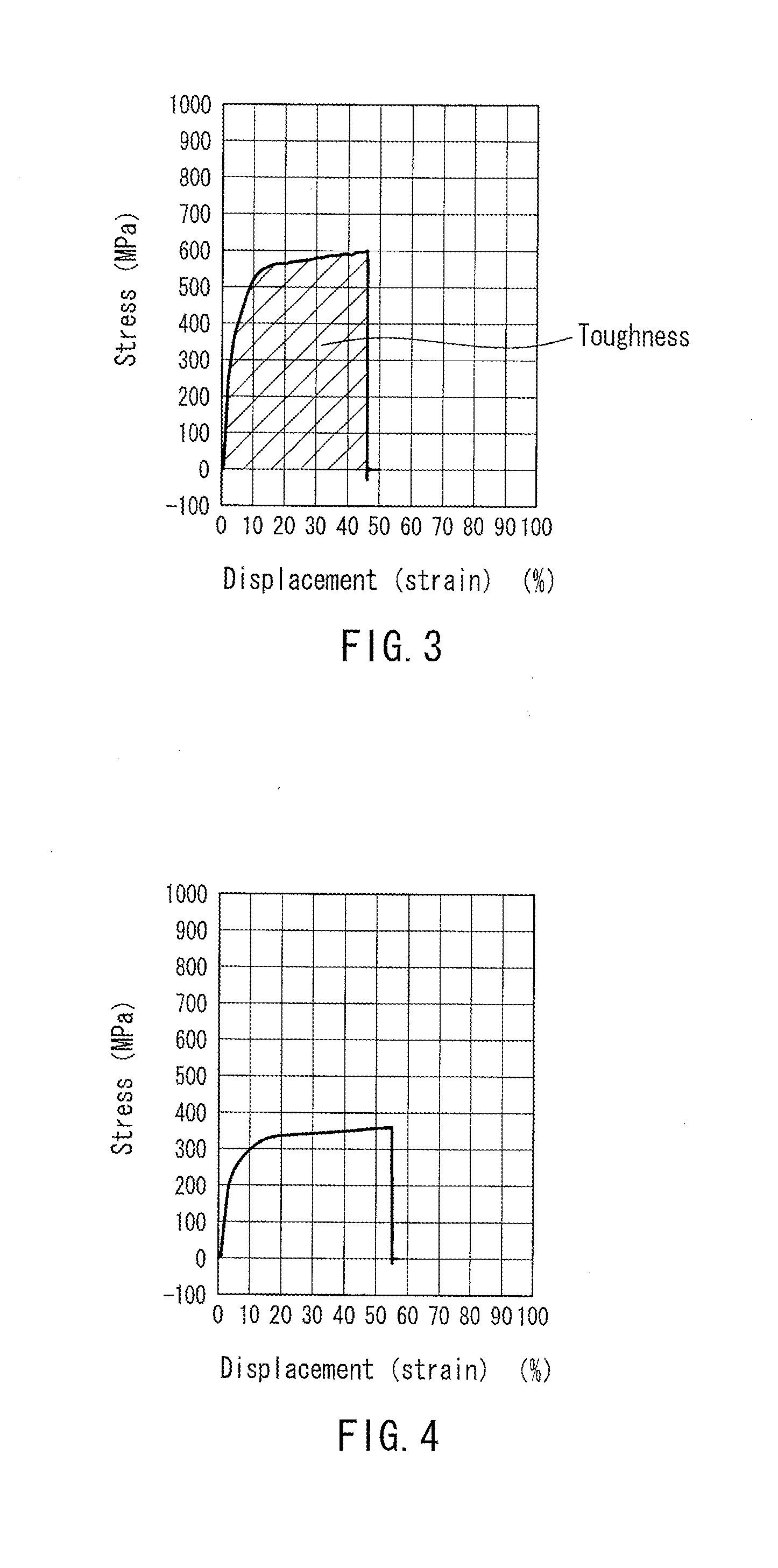

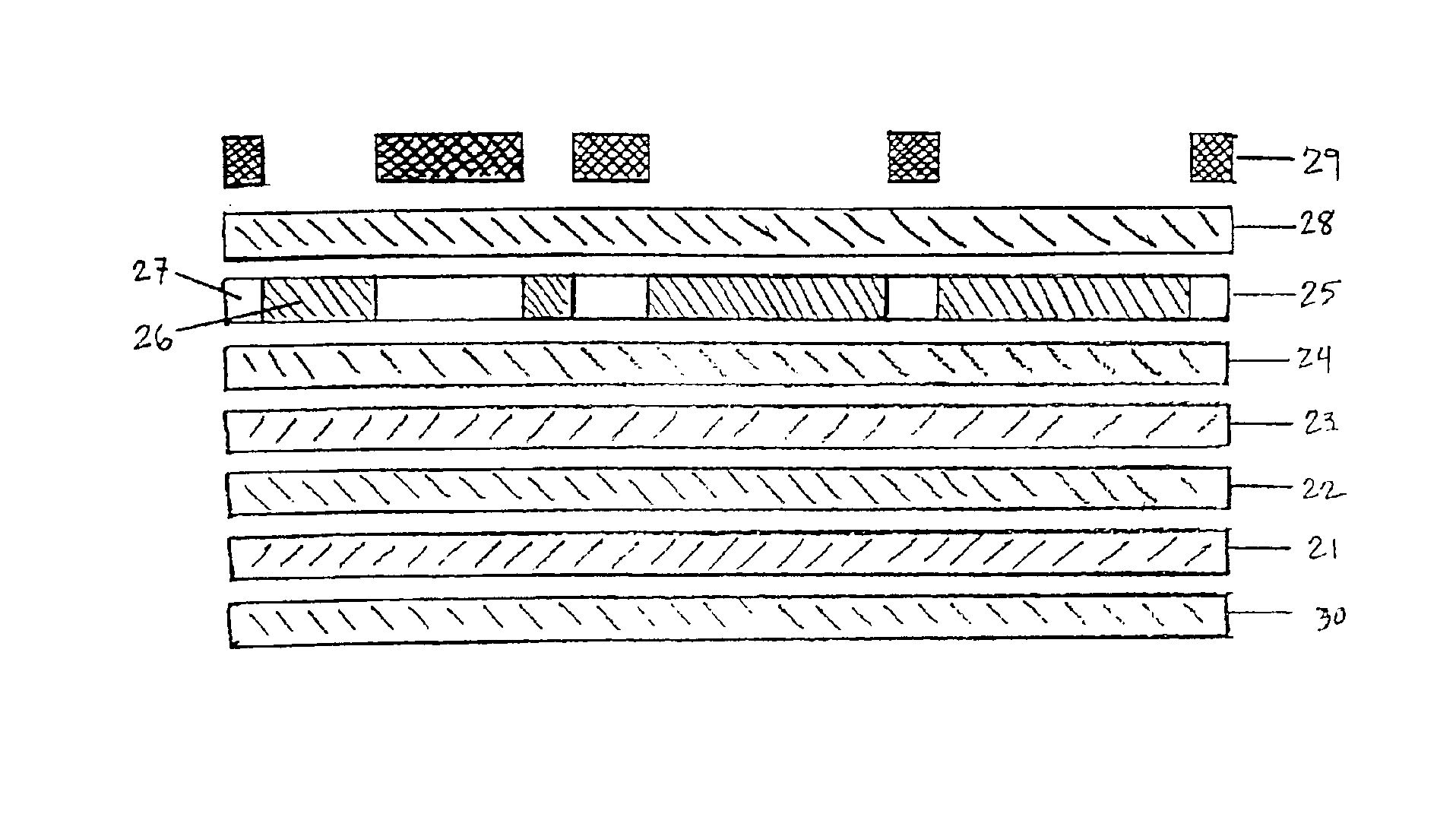

ActiveUS20140058066A1High stressImprove toughnessPeptide/protein ingredientsMonocomponent polypeptides artificial filamentFiberSpider Proteins

An artificial polypeptide fiber of the present invention is an artificial fiber containing a polypeptide as a main component, and has a stress of 350 MPa or more and a toughness of 138 MJ / m3 or more. A method for producing an artificial polypeptide fiber of the present invention is a method for producing the artificial polypeptide fiber obtained by spinning a spinning solution (6) containing a polypeptide derived from natural spider silk proteins and performing drawing of at least two stages. The drawing of at least two stages includes a first-stage drawing (3) in wet heat and a second-stage drawing (4) in dry heat. Thereby, the present invention provides high-toughness artificial polypeptide fibers having favorable stress and rupture elongation, and a method for producing the same.

Owner:SPIBER INC

A method for manufacturing high-strength, high-modulus, low-shrinkage polyester industrial yarn

ActiveCN102797054BReduce disturbanceReduce the temperatureFilament/thread formingMonocomponent polyesters artificial filamentYarnFiber

The invention discloses a manufacturing method of a high-strength, high-modulus and low-shrinkage polyester industrial yarn. The manufacturing method comprises the processes of preparation of a highly viscous melt polyester raw material, metering, spinning, cooling, oil applying, drawing, heat shaping and winding formation; the cooling comprises slow cooling, precooling, cooling in an air free zone and air blast cooling in sequence; the precooling part uses a driven hollow-out successive annular strip. Through the introduction of a precooling device, irregularity caused by tow shaking due to move-down of a curing point of a fiber is reduced, the linear density deviation is controlled within a lower range, and orientation and crystallization of an as-spun fiber are reduced, so that the high-strength, high-modulus and low-shrinkage polyester industrial yarn is obtained; and the high-strength, high-modulus and low-shrinkage polyester industrial yarn has the advantages of high breaking tenacity, high initial modulus, low linear density deviation, low breaking elongation and lower dry-heat shrinkage rate and can be used for preferably satisfying requirements on application.

Owner:JIANGSU HENGLI CHEM FIBER

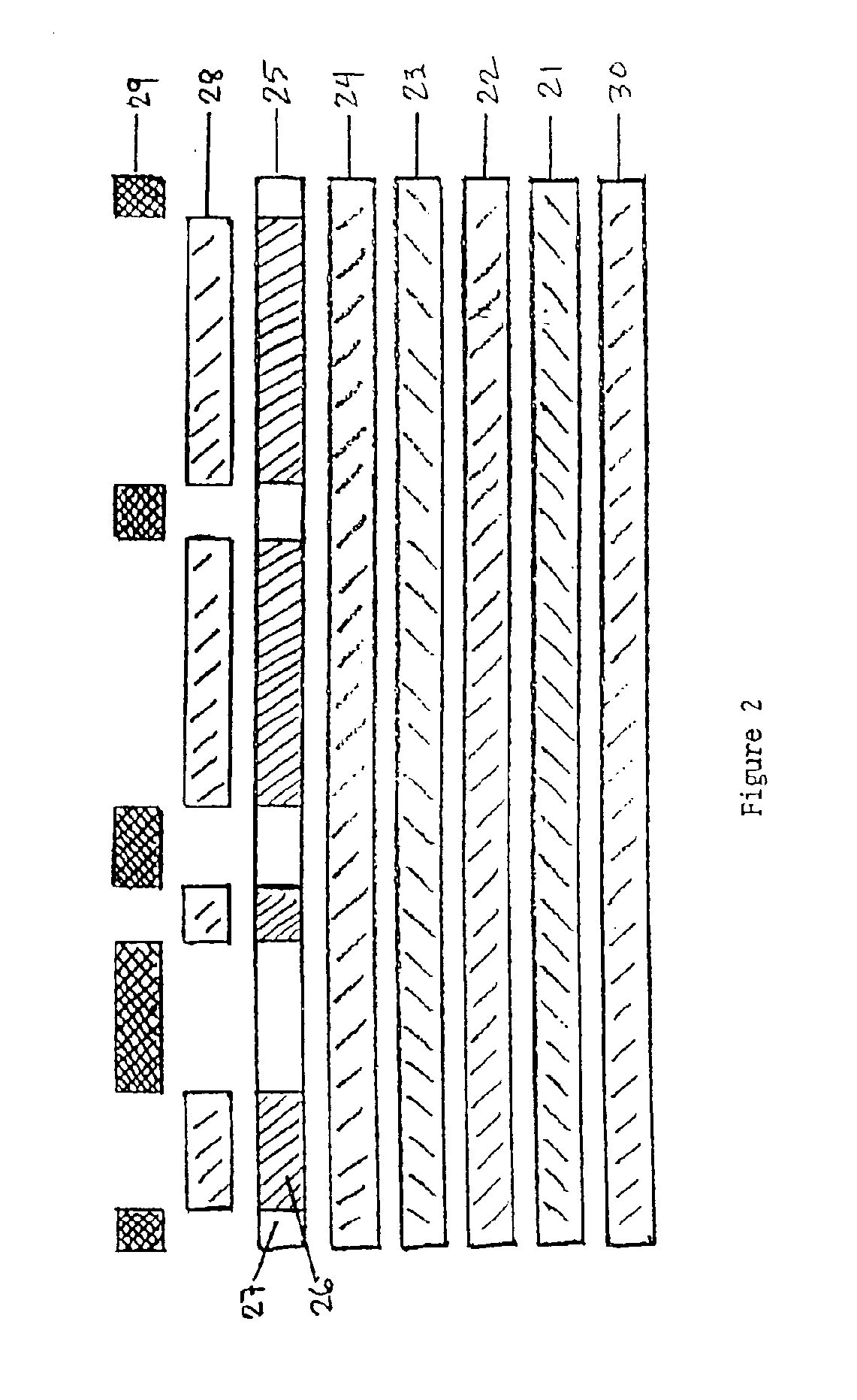

Image transfer material with image receiving layer and heat transfer process using the same

InactiveUS6869910B2Cost efficientDecorative surface effectsAblative recordingWater dispersiblePrecipitated calcium carbonate

An image transfer sheet, having a support sheet, an optional barrier layer on the support sheet, at least one heat release layer on the optional barrier layer or on the support sheet, an image receiving layer on the heat release layer, an optional image layer on the image receiving layer, an optional non-water-dispersible polymer layer on the image layer, and an optional transfer blocking overcoat layer on the optional polymer layer or the image layer, is used in a dry heat transfer process to transfer an image to a receptor element. The image receiving layer of the present invention is a precipitated calcium carbonate (PCC)-containing image receiving layer, a polyvinylpyrrolidone (PVP)-containing image receiving layer, or an image receiving layer containing both PCC and PVP (PCC / PVP).

Owner:SCHWENDIMANN JODI

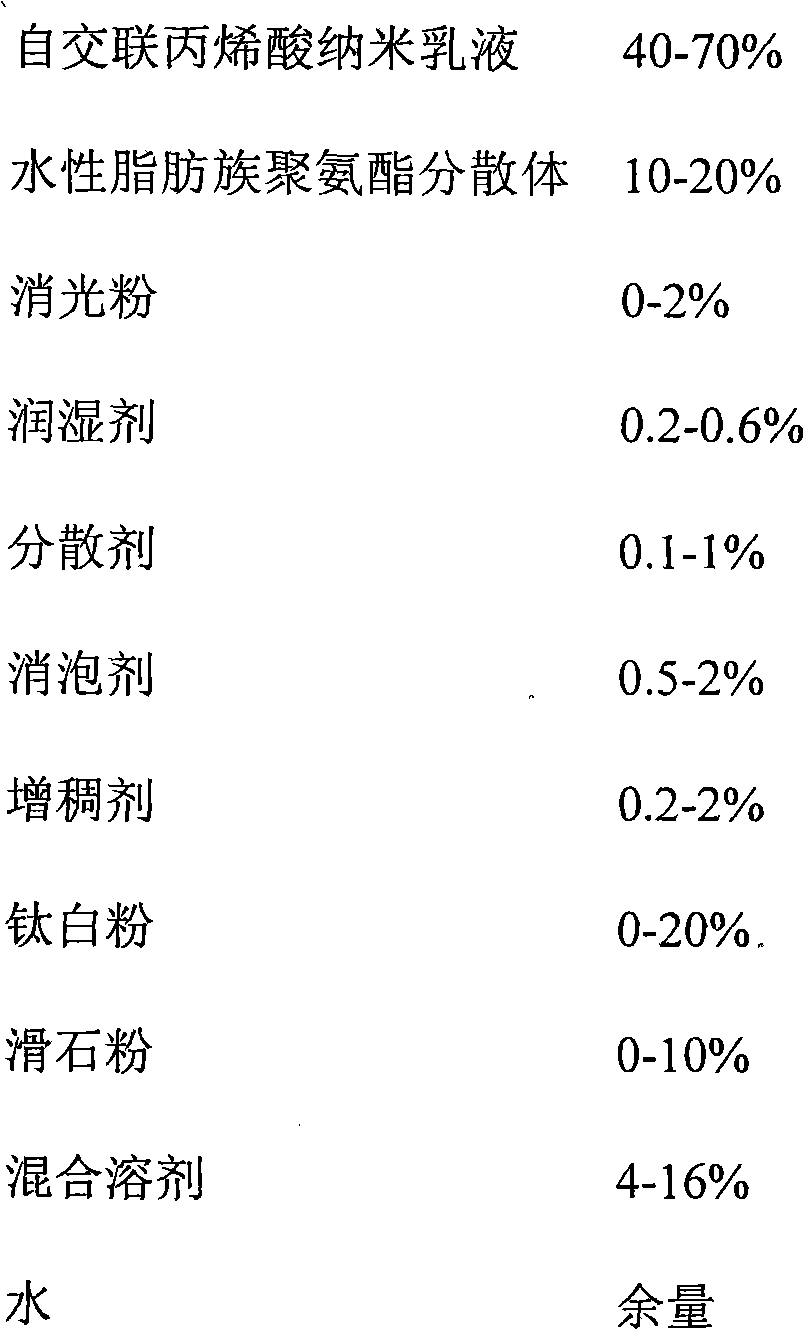

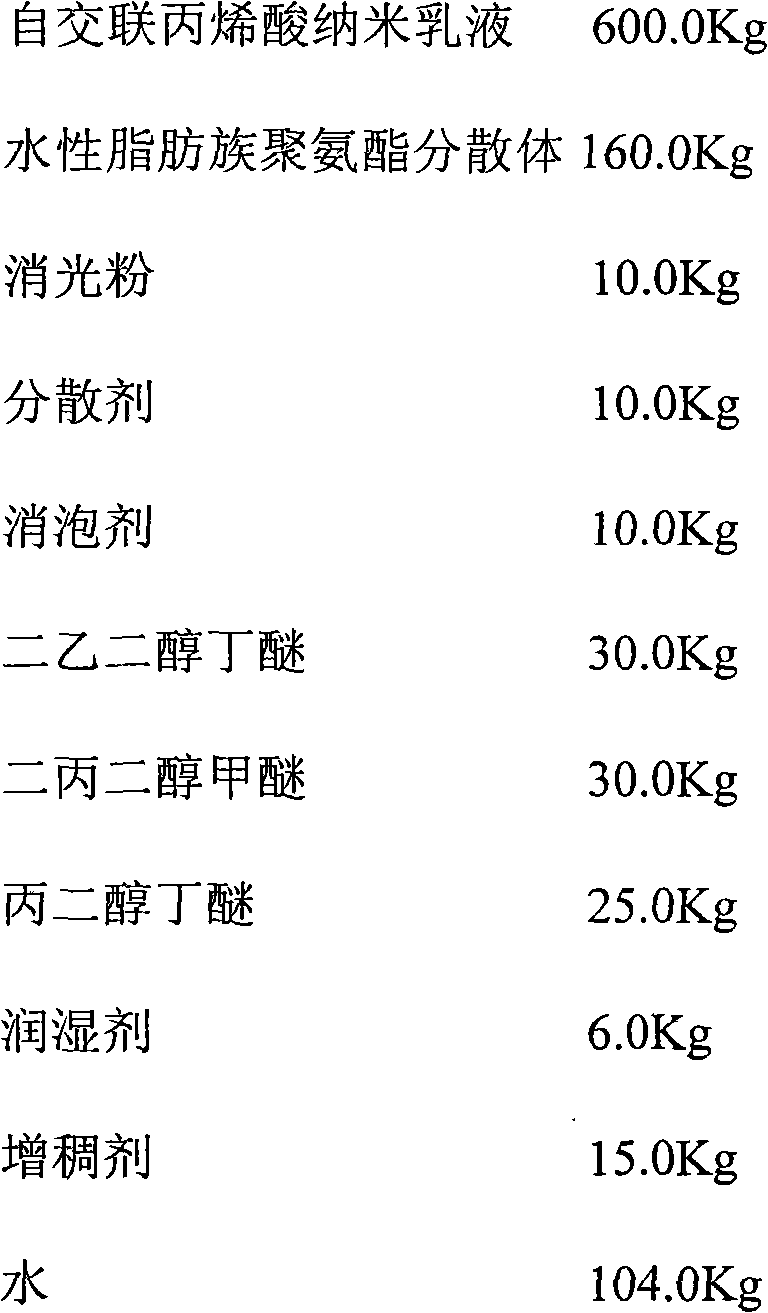

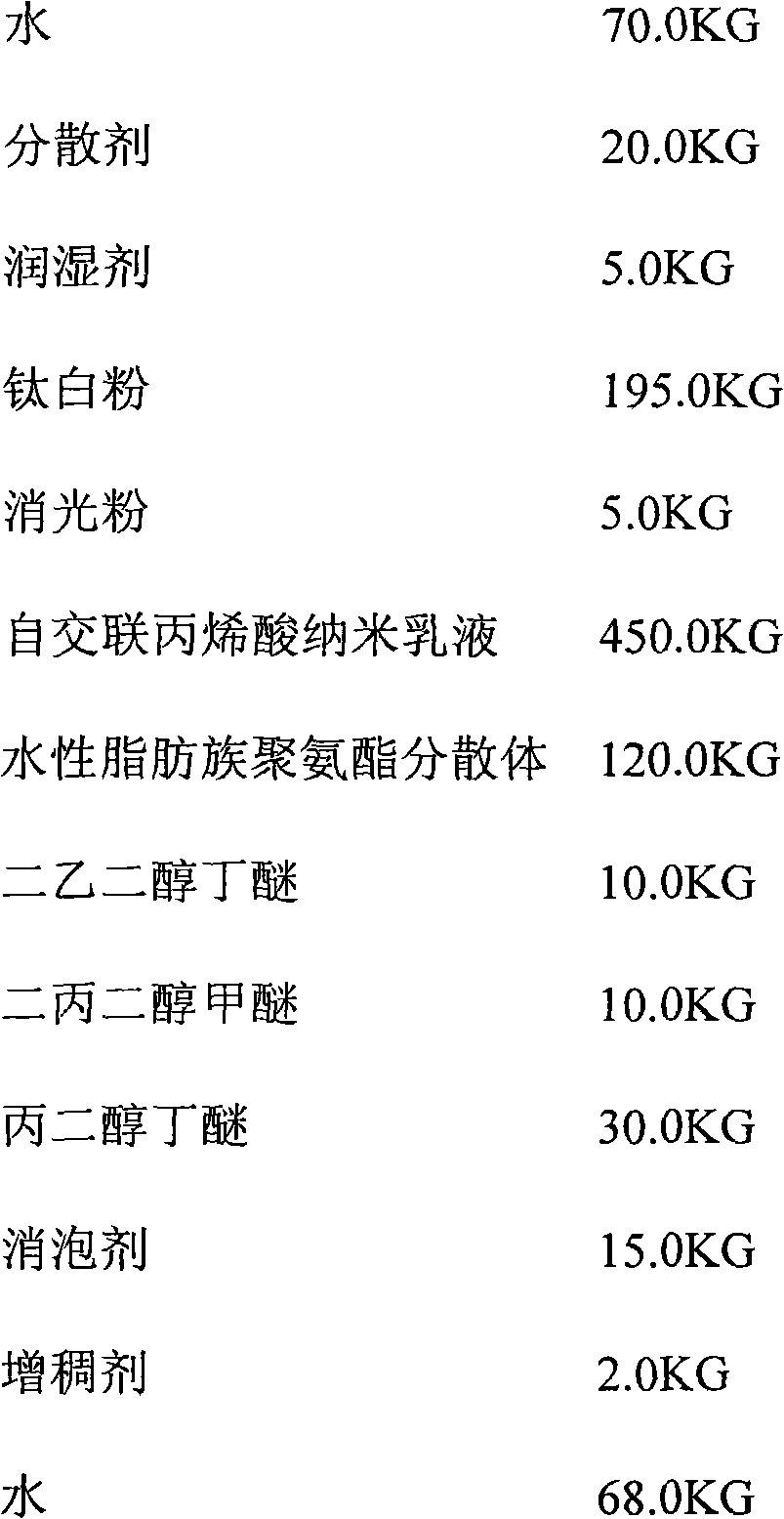

Environmentally-friendly high-performance water-based woodware paint and using method thereof

ActiveCN102051096AGood weather resistanceGood quick dryingPolyurea/polyurethane coatingsDiethylene glycol monobutyl etherWater based

The invention discloses an environmentally-friendly high-performance water-based woodware paint and a using method thereof. The environmentally-friendly high-performance water-based woodware paint comprises 40 to 70 weight percent of self-crosslinking acrylic nano-emulsion and 10 to 20 weight percent of water-based aliphatic polyurethane dispersion. The water-based woodware paint is mainly prepared from the self-crosslinking acrylic emulsion with high triglyceride (Tg) content and weather resistance, so that a paint film has high quick-drying property, chemical resistance and weather resistance, and economy; the self-crosslinking acrylic emulsion is compounded with castor oil modified aliphatic polyurethane dispersion, so that the paint film has high adhesion, hardness, fullness, weather resistance, dry heat resistance and block resistance; and diethylene glycol monobutyl ether is matched with dipropylene glycol methyl ether and propylene glycol monobutyl ether, so that the film forming property of the paint film is ensured, and high drying property is achieved.

Owner:BAUHINIA PAINTS SHANGHAI CO LTD

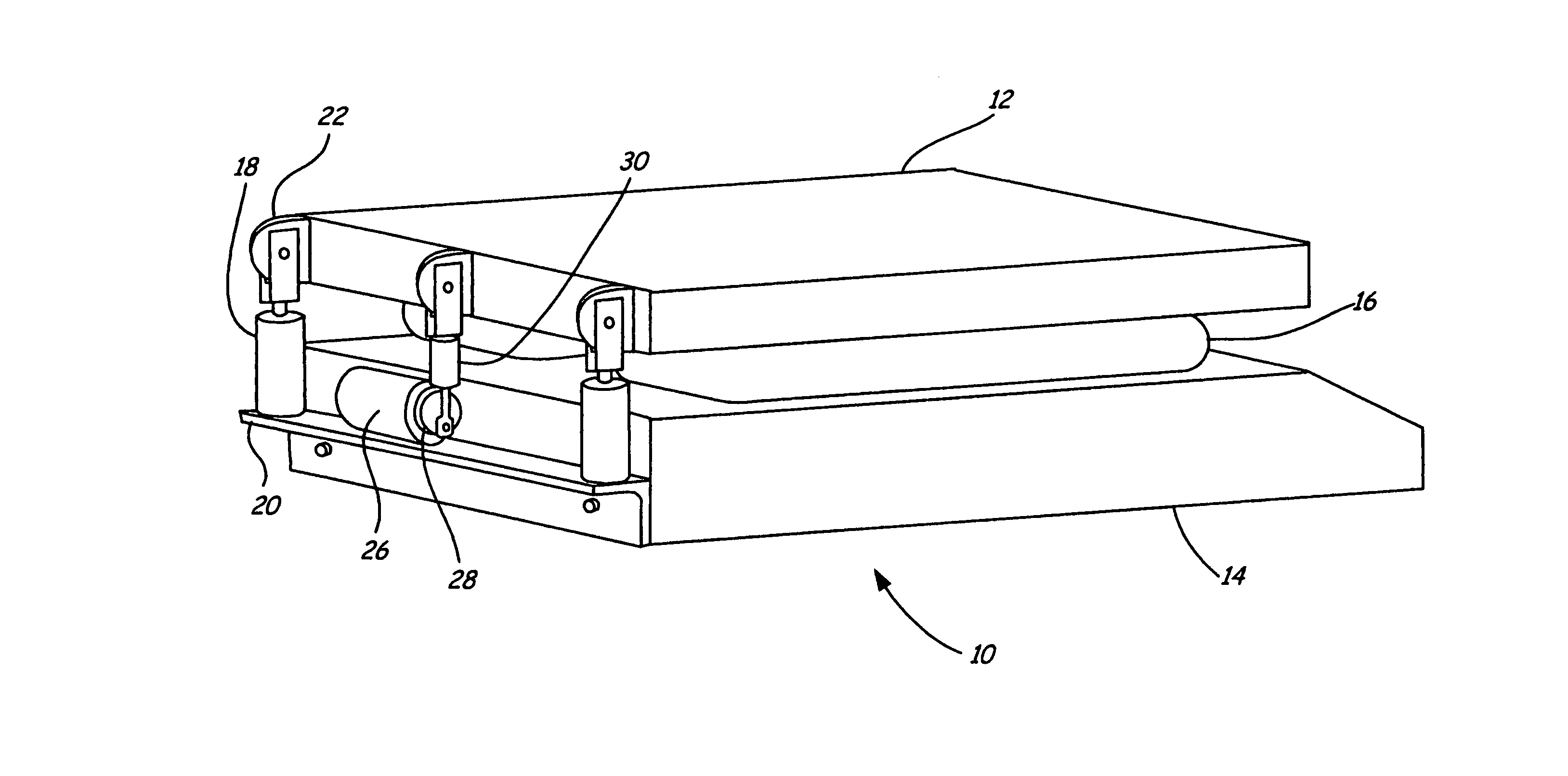

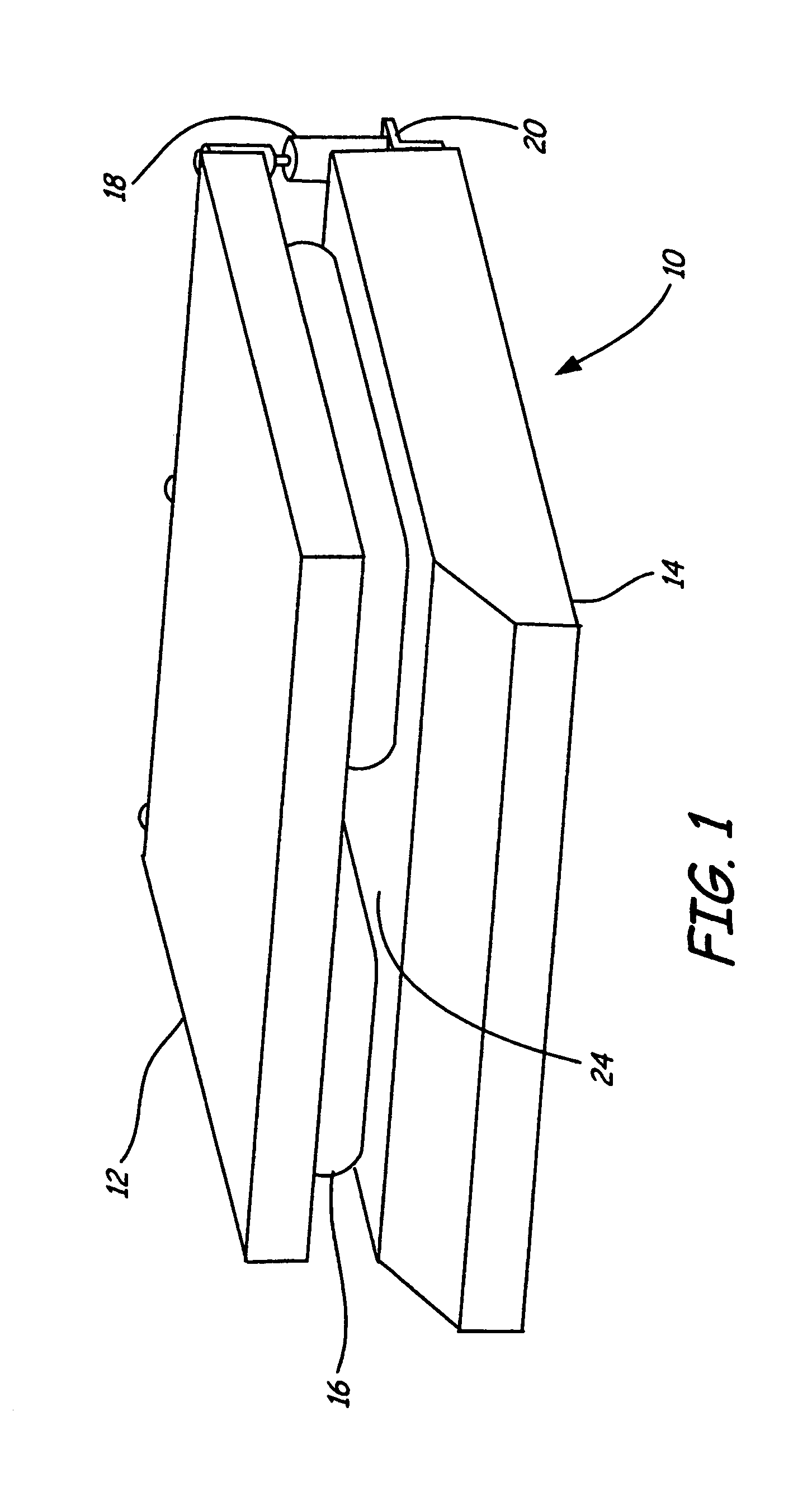

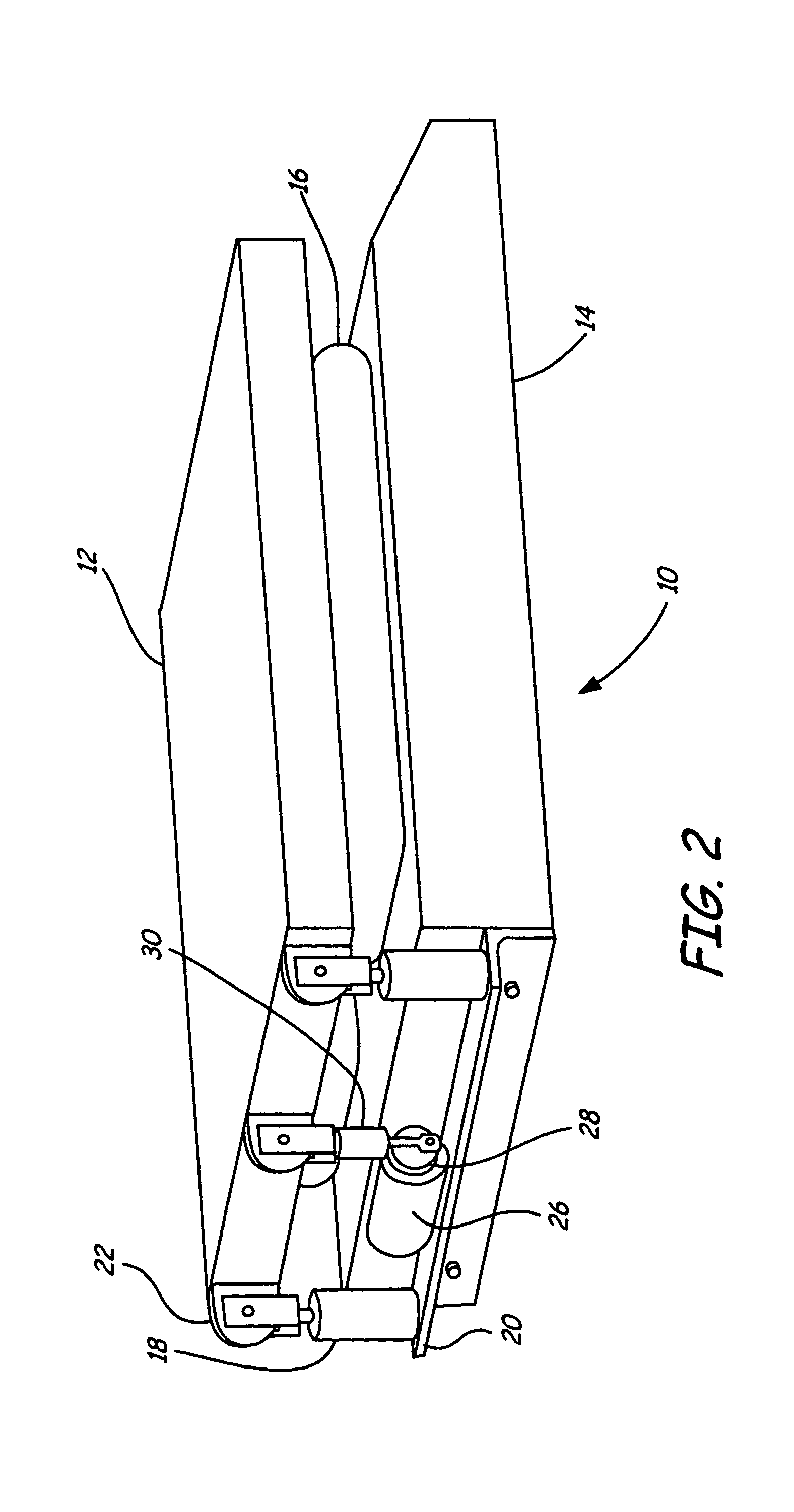

Apparatus for thawing frozen biological fluids utilizing heating plates and oscillatory motion to enhance heat transfer by mixing

ActiveUS7011797B2Less timeEliminate thermal resistanceSurgeryMaterial analysis by optical meansWater bathsElectricity

An improved dry heat method and apparatus for thawing frozen biological fluids utilizing electrically heated plates and oscillatory motion to enhance heat transfer by mixing as the fluid thaws. Bags of frozen fluid to be thawed are lightly squeezed between two heating plates, one of which is gently oscillated to facilitate mixing of the thawing fluid, increasing heat transfer and reducing time required for thawing. Direct contact of the heating plates against the bag surfaces increases heat transfer by eliminating insulative effects of another bag wall and a water boundary layer, compared to water bath units. Flat (or curved to conform to bag) heat pipes are preferred as heating plates compared to plain aluminum sheet. Flat heat pipes have the property of an isothermal heating surface, thus maximizing heat transfer to the coldest areas, preventing hot spots, and simplifying heating plate temperature control.

Owner:BAKKE ALLAN P

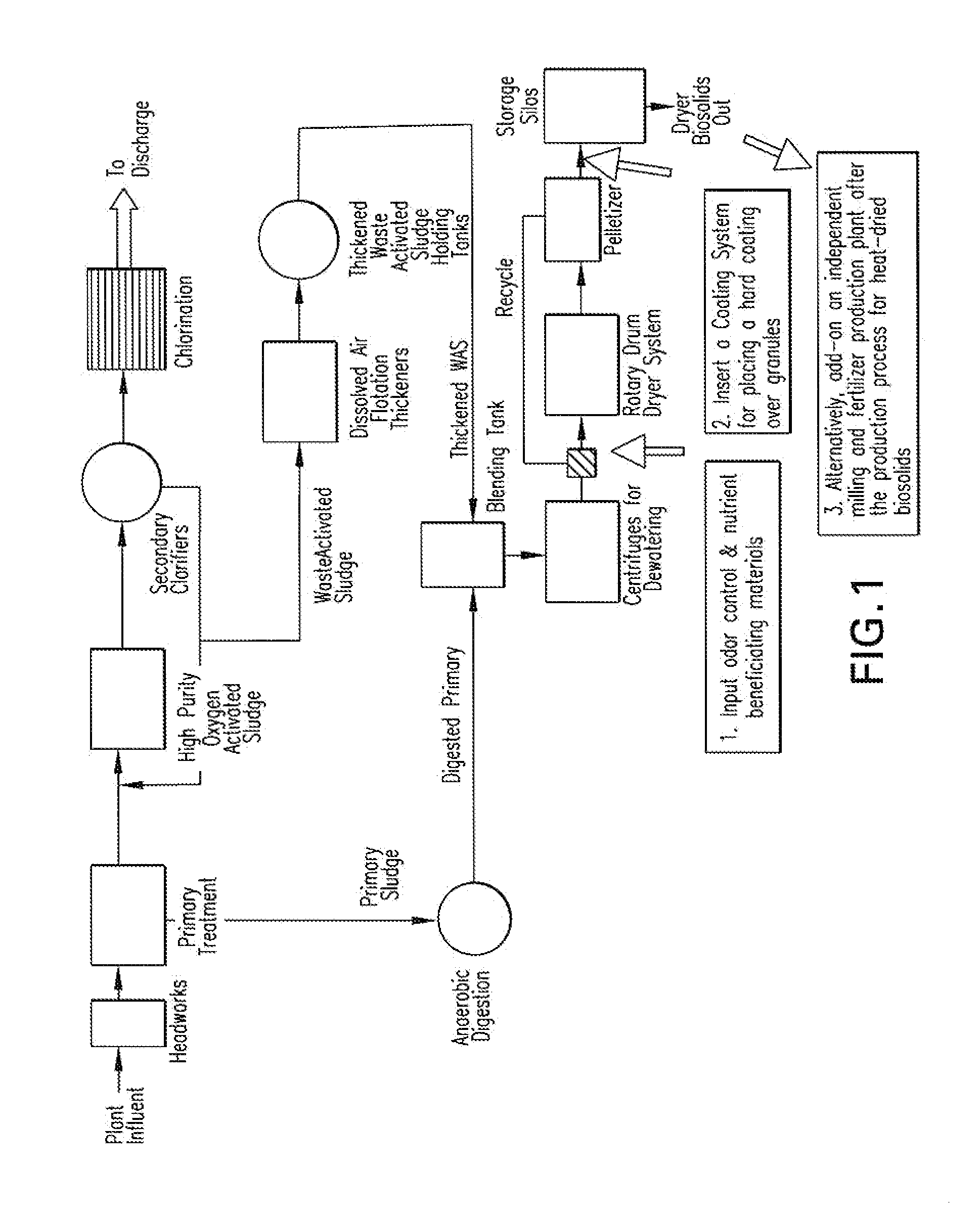

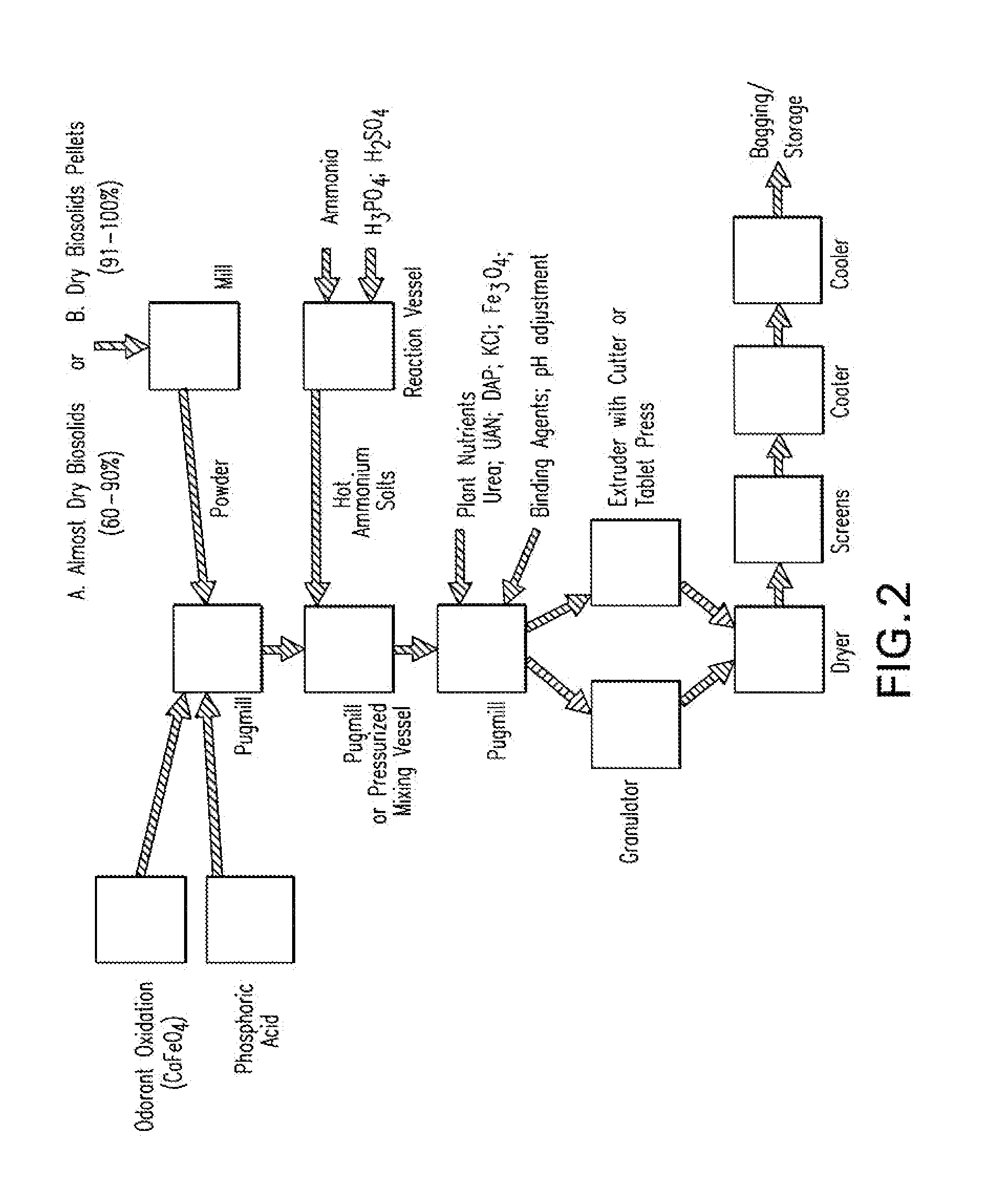

Beneficiated, heat-dried biosolid pellets

ActiveUS20100139346A1Calcareous fertilisersSludge treatment by de-watering/drying/thickeningDry heatSolid particle

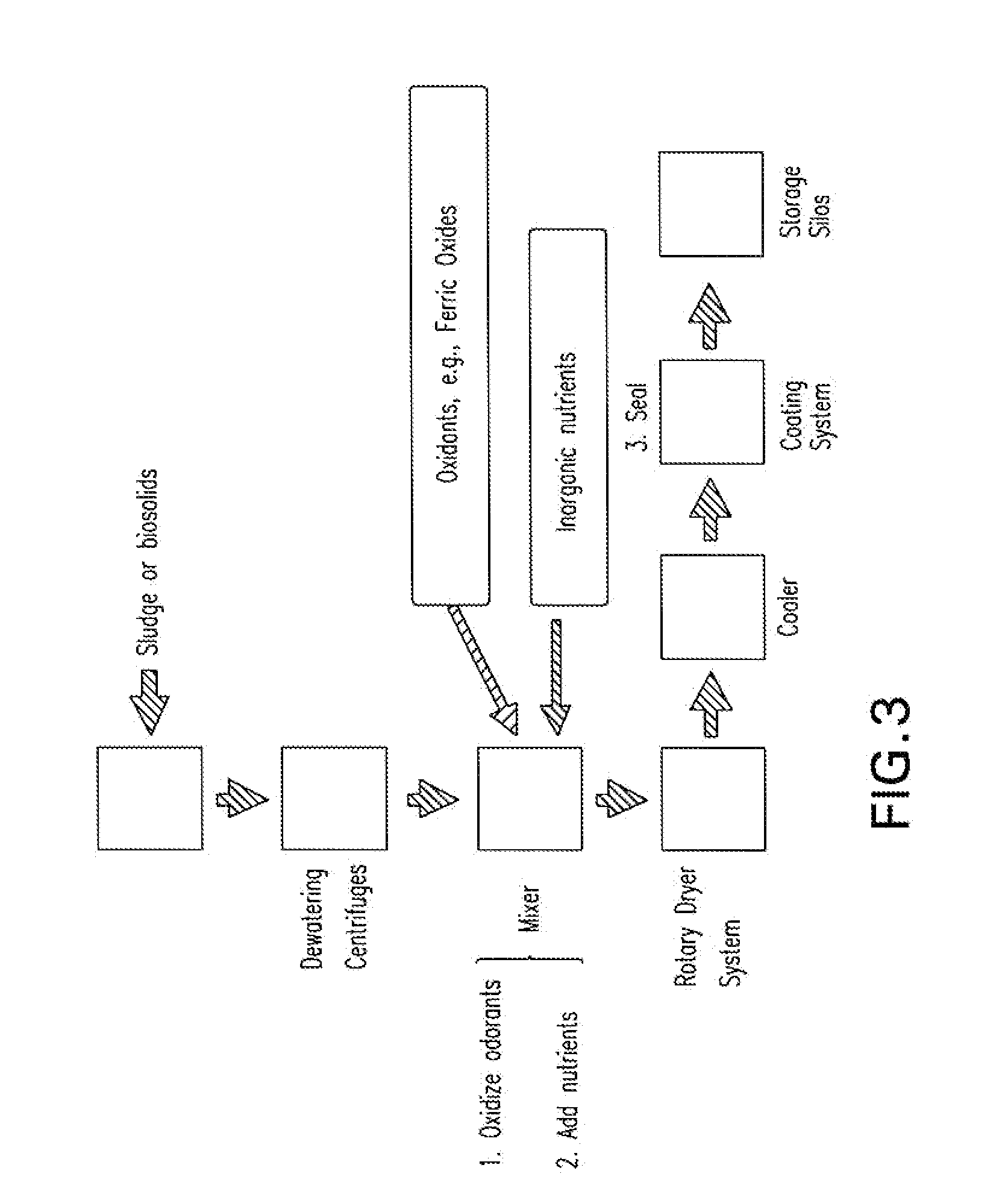

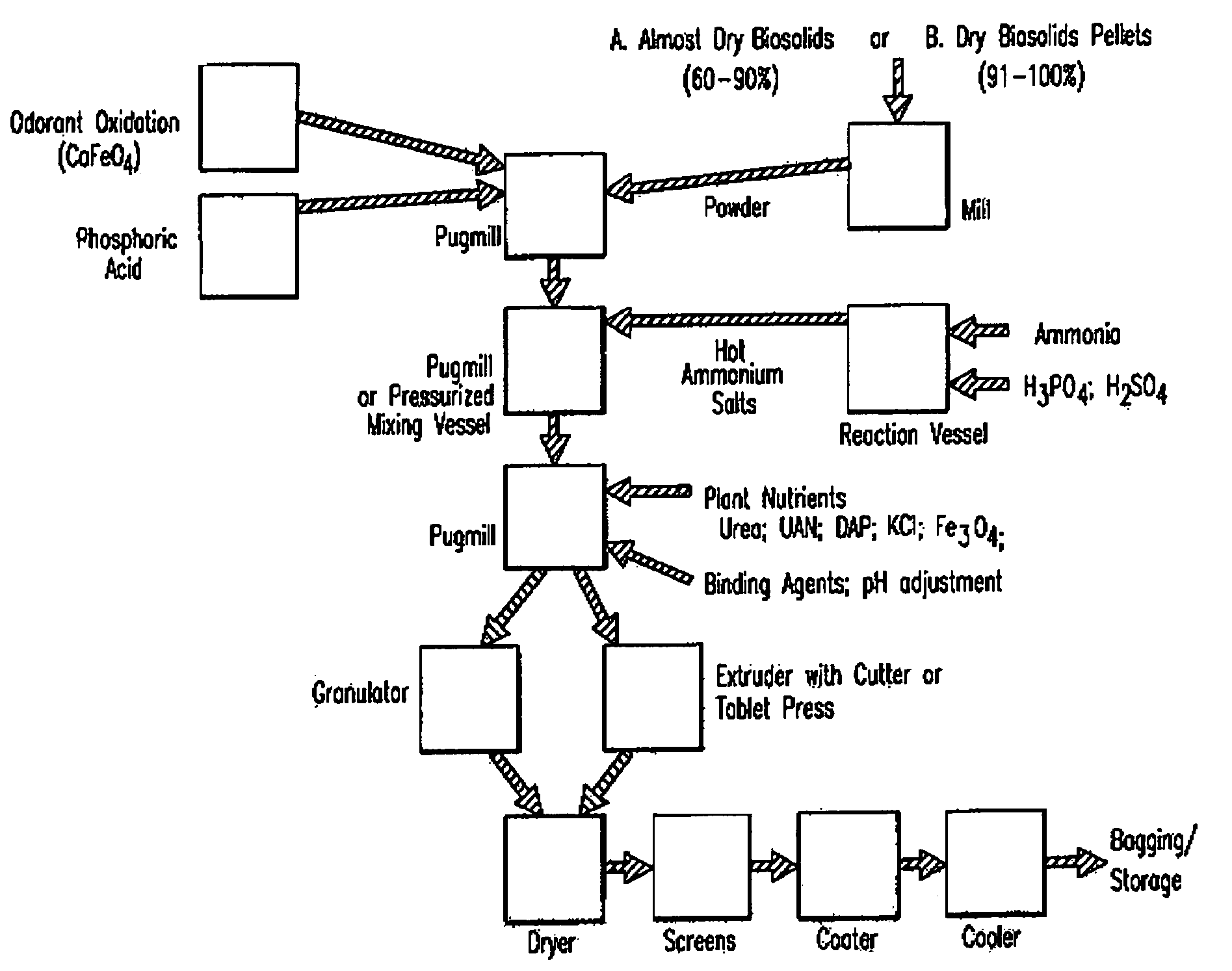

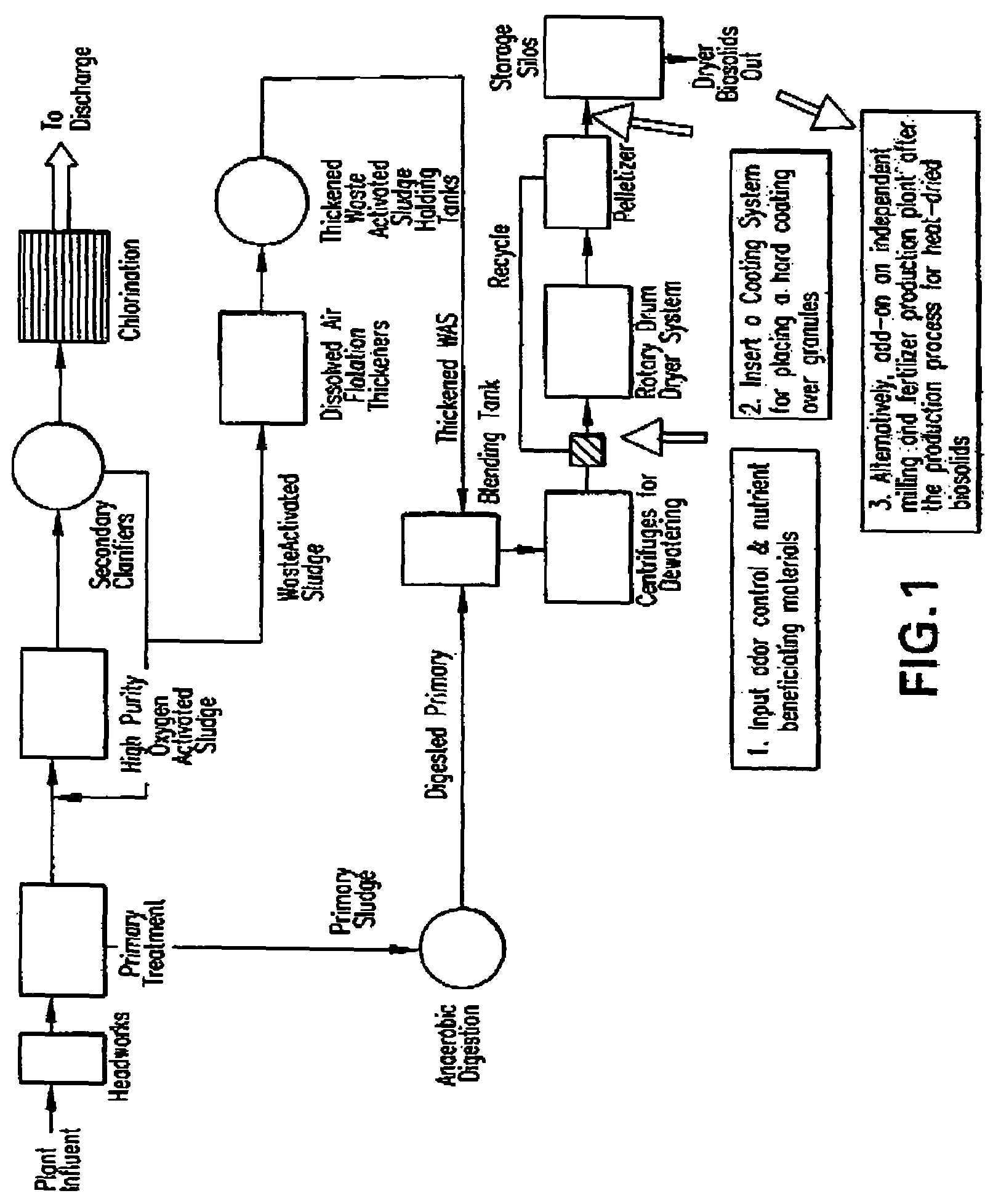

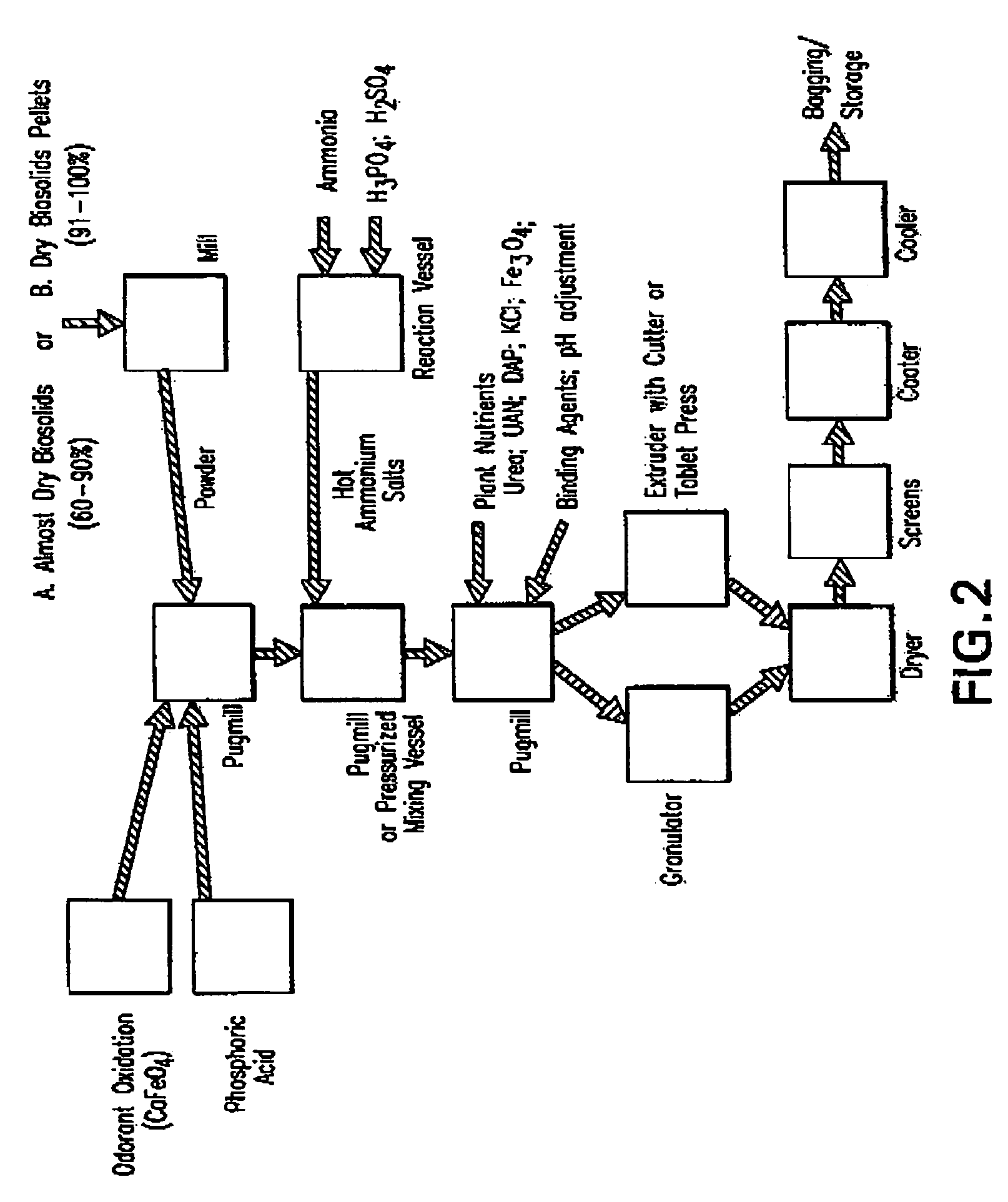

This invention is directed to systems, devices and methods for modifying the process of producing dried biosolids pellets or granules into beneficiated inorganically-augmented bioorganic fertilizer. The present invention describes a method to beneficiate heat-dried biosolids or sludge pellets or granules as presently manufactured by municipalities or companies from a) dewatered municipal wastewater biosolids or sludges within the municipal wastewater treatment plant heat-dried biosolids production facility or from b) finished dry heat dried biosolids pellets or granules in a separate manufacturing facility from the municipal wastewater treatment plant to produce a fertilizer containing sufficient organic and inorganic plant nutrients to be valuable and saleable into the commercial agricultural industry. The present invention describes beneficiation methods to increase the plant nutrient content to a level which permits the finished beneficiated dried biosolids pellet or granule product to compete in the commercial agricultural fertilizer marketplace and also to reduce the odors associated with traditionally-produced heat dried biosolids.

Owner:PROFILE PRODS LLC +1

Processes to beneficiate heat-dried biosolid pellets

This invention is directed to systems, devices and methods for modifying the process of producing dried biosolids pellets or granules into beneficiated inorganically-augmented bioorganic fertilizer. The present invention describes a method to beneficiate heat-dried biosolids or sludge pellets or granules as presently manufactured by municipalities or companies from a) dewatered municipal wastewater biosolids or sludges within the municipal wastewater treatment plant heat-dried biosolids production facility or from b) finished dry heat dried biosolids pellets or granules in a separate manufacturing facility from the municipal wastewater treatment plant to produce a fertilizer containing sufficient organic and inorganic plant nutrients to be valuable and saleable into the commercial agricultural industry. The present invention describes beneficiation methods to increase the plant nutrient content to a level which permits the finished beneficiated dried biosolids pellet or granule product to compete in the commercial agricultural fertilizer marketplace and also to reduce the odors associated with traditionally-produced heat dried biosolids.

Owner:GENERATE LENDING LLC +1

Processing method of high-strength low-shrinkage nylon 6 fine denier filament

InactiveCN102181951ALow dry heat shrinkageArtificial filament heat treatmentStretch-spinning methodsBreaking strengthNitrogen

The invention discloses a processing method of a high-strength low-shrinkage nylon 6 fine denier filament, belonging to the technical field of nylon filament processing. The method comprises the following steps: preparing materials: adding the nylon 6 slices into a bin of nitrogen protective gas to obtain a material to be melted; melting: introducing the material to be melted into a screw extruder for melting to obtain a melt; forming: introducing the melt from the upper part of a spinning box, and ejecting from a spinneret orifice of a spinneret plate to obtain a filament bundle; cooling: introducing the filament bundle into a slow-cooling area for slow cooling, forming through side-blowing air cooling, and further cooling through a channel; oiling and pre-interlacing: oiling the cooling-formed filament bundle through an oil lip or oil wheel, and pre-interlacing; drafting: feeding the filament bundle to be drafted through a feeding roller, drafting through a heat roller, and then performing relax-type setting to obtain the drafting-set filament; and re-interlacing and re-oiling: re-interlacing and re-oiling the drafting-set filament before packaging to obtain the high-strength low-shrinkage nylon 6 fine denier filament. The method can adapt to different purposes of products, and can be applied to the occasions having rigorous requirements on the breaking strength and dry heat shrinkage.

Owner:CHANGSHU POLYESTER

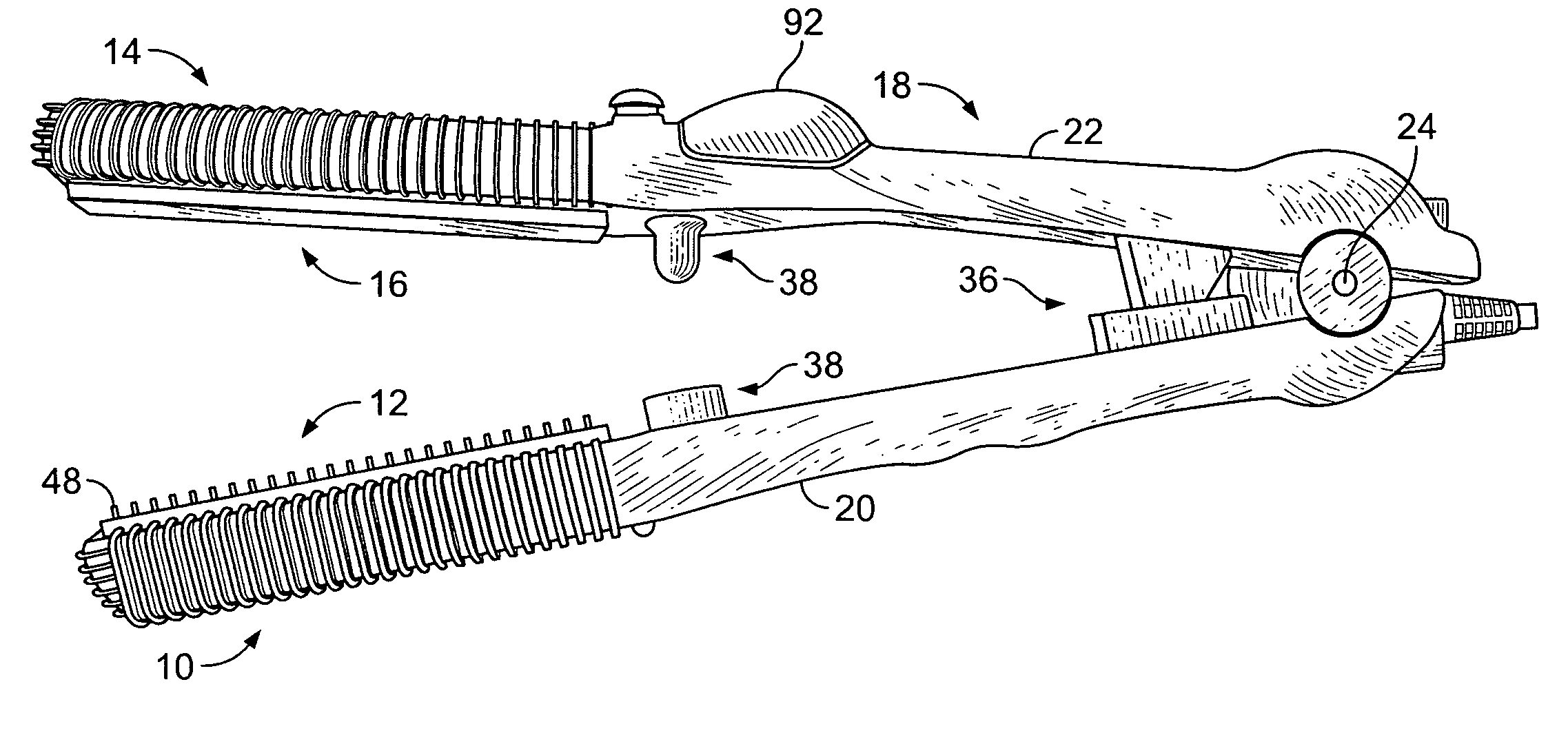

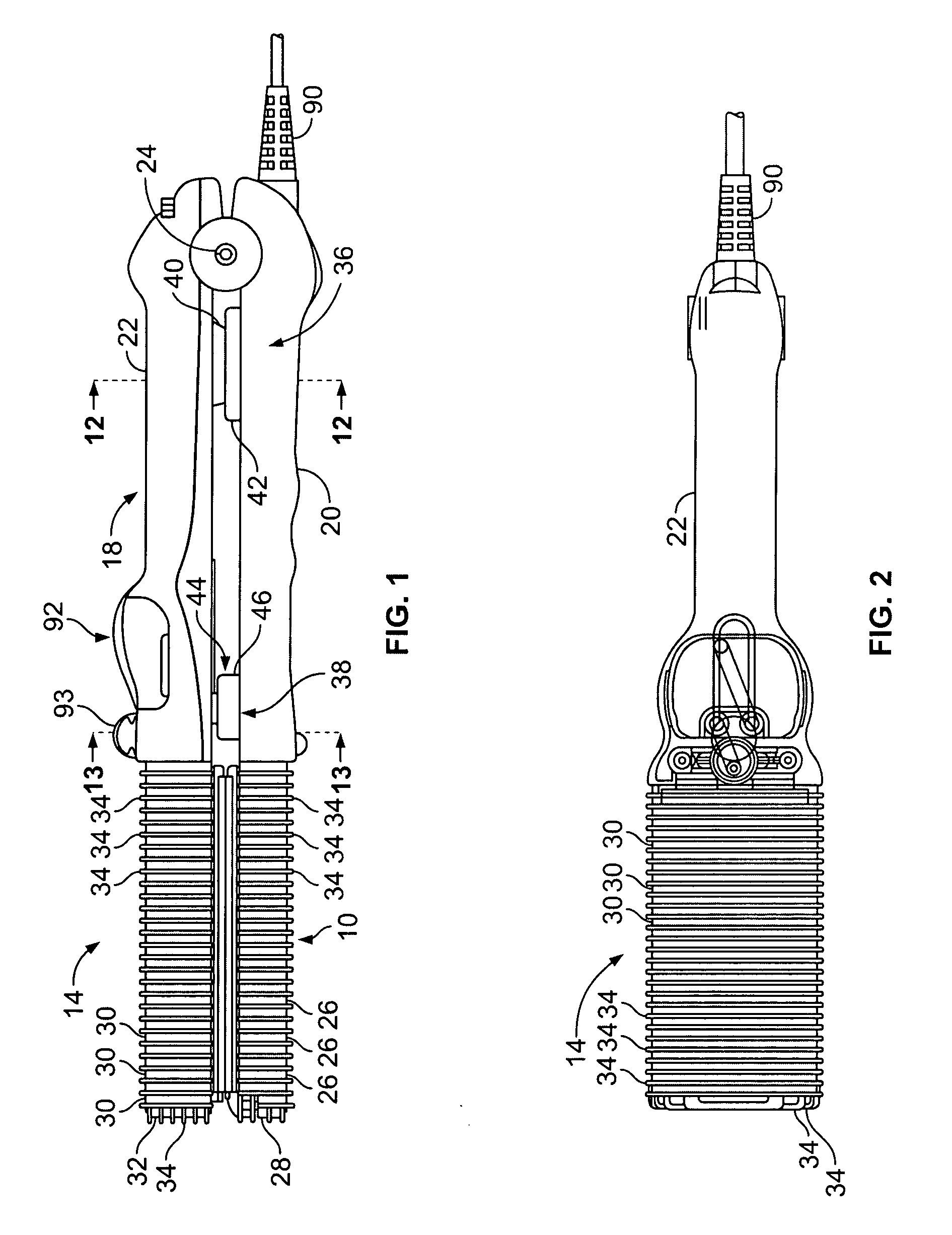

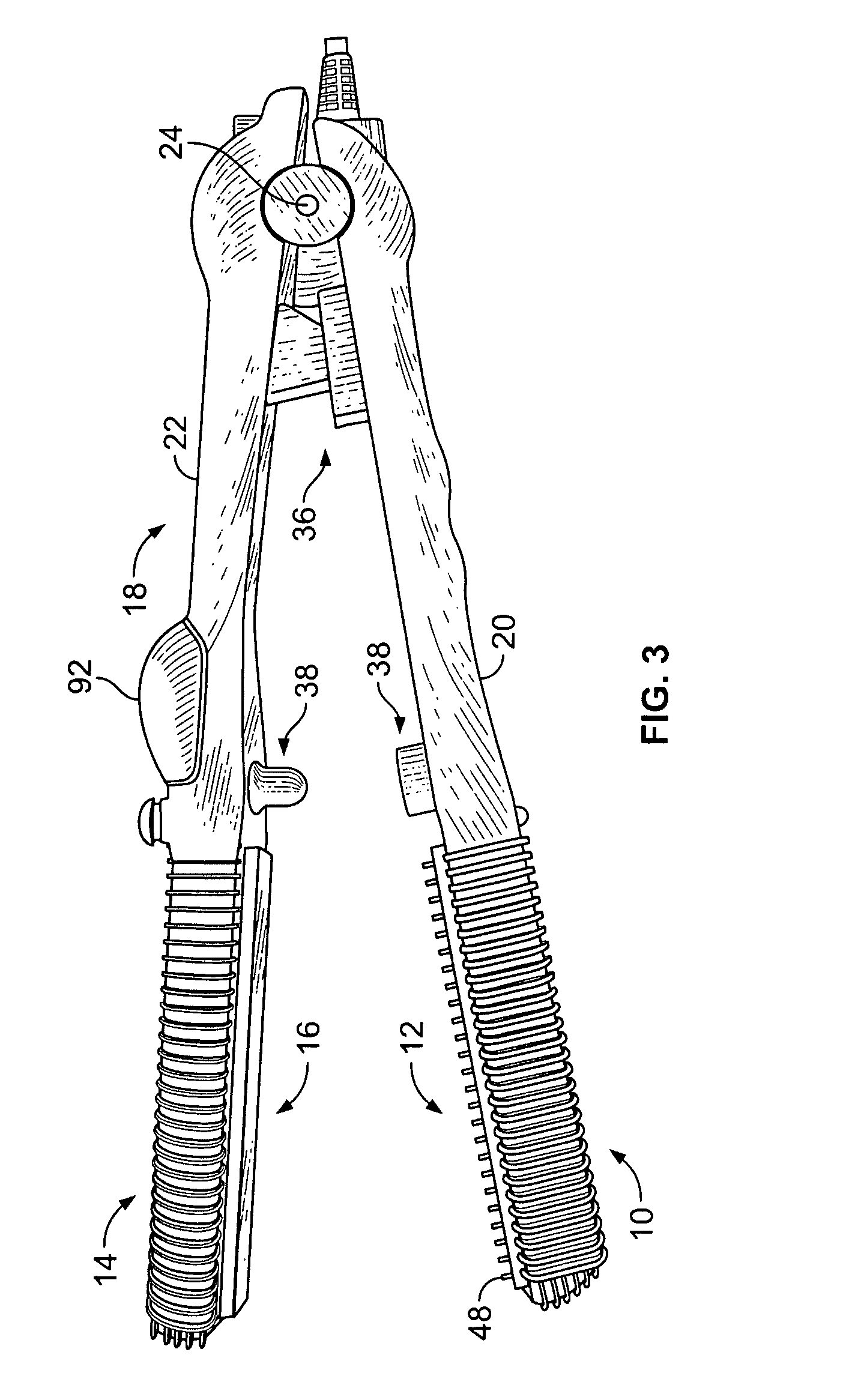

Hair styling device

A hair styling apparatus includes a pair of mating surfaces which engage one another and a handle which guides them into engagement at the manual control of a user. Hair to be styled is placed between the engaged surfaces. A plurality of pins extend from both of the surfaces and engage holes in the other of the surfaces. One or both surfaces may incorporate a source of dry heat. In another aspect of the invention, a source of steam is provided together with a trigger for discharging the steam through holes in at least one of the surfaces as an aid to hair styling.

Owner:HABIBI MASOOD

Pet food product and method of manufacture

InactiveUS20050031673A1High adsorption rateImprove adsorption capacityMeat/fish preservationPharmaceutical delivery mechanismCooking & bakingFood body

A pet food is provided, comprising a sorbent food body and a fluid carrier comprising a functional ingredient absorbed into the body. The body preferably is realtively moist, having a moisture content for example of from 35% to 60% by weight and firm structure that is resilient under initial biting by a pet animal. Protein content is preferably at least 20% by weight. The sorptivity of the body is increased by depleting the body of a first liquid, for example by causing drying by exposure to a source of dry heat, such as in roasting, grilling, frying and baking. Methods of manufacture are disclosed including providing a sorptive food body, causing the body to take up a carrier fluid containing a functional ingredient and packing the body in suitable packaging. The invention further provides delivery means for delivering a functional ingredient to a pet animal, the delivery means comprising a sorbent food body with the functional ingredient absorbed therein. The functional ingredient may be a nutrient or a pharmaceutical.

Owner:SOC DES PROD NESTLE SA

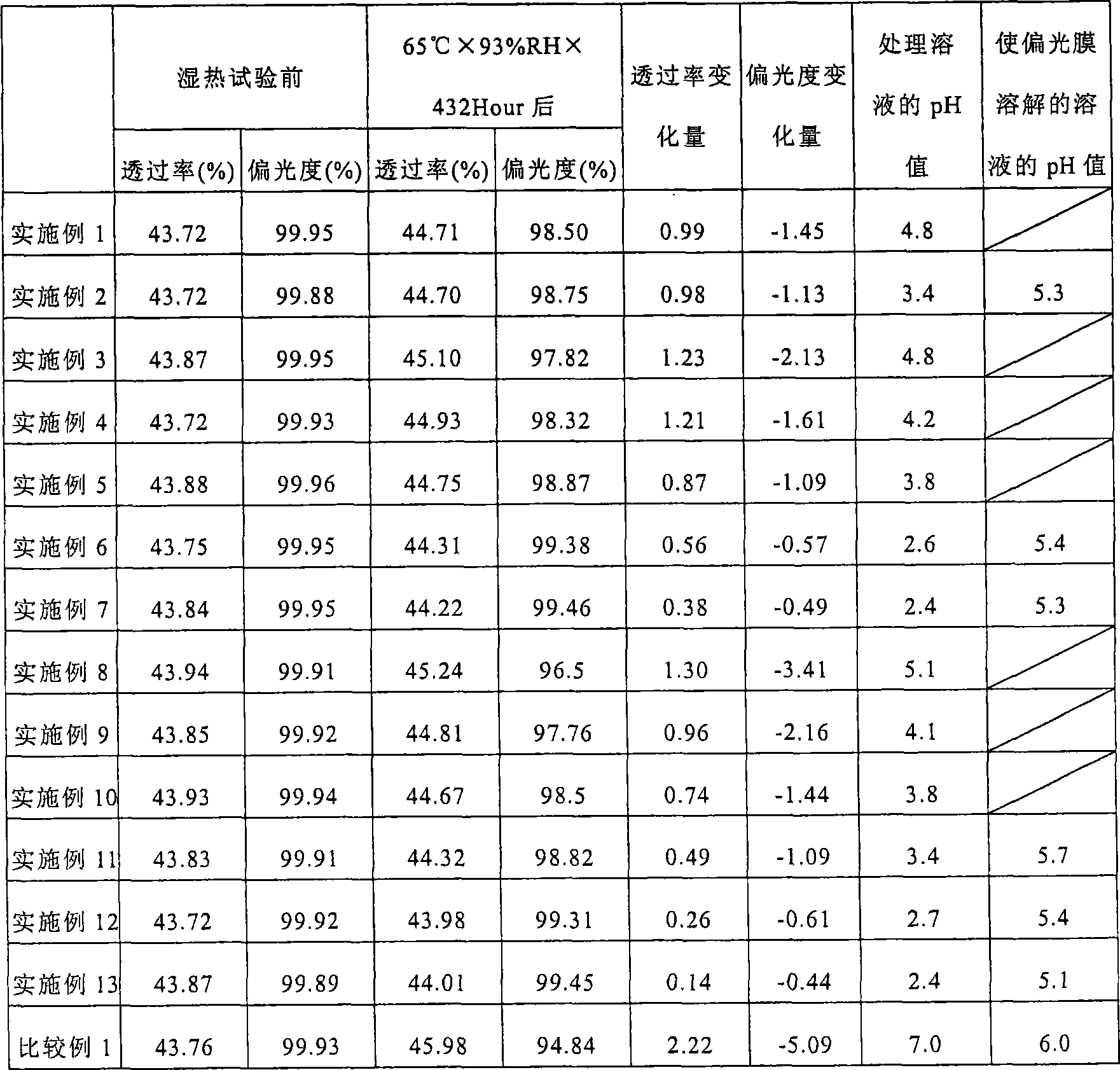

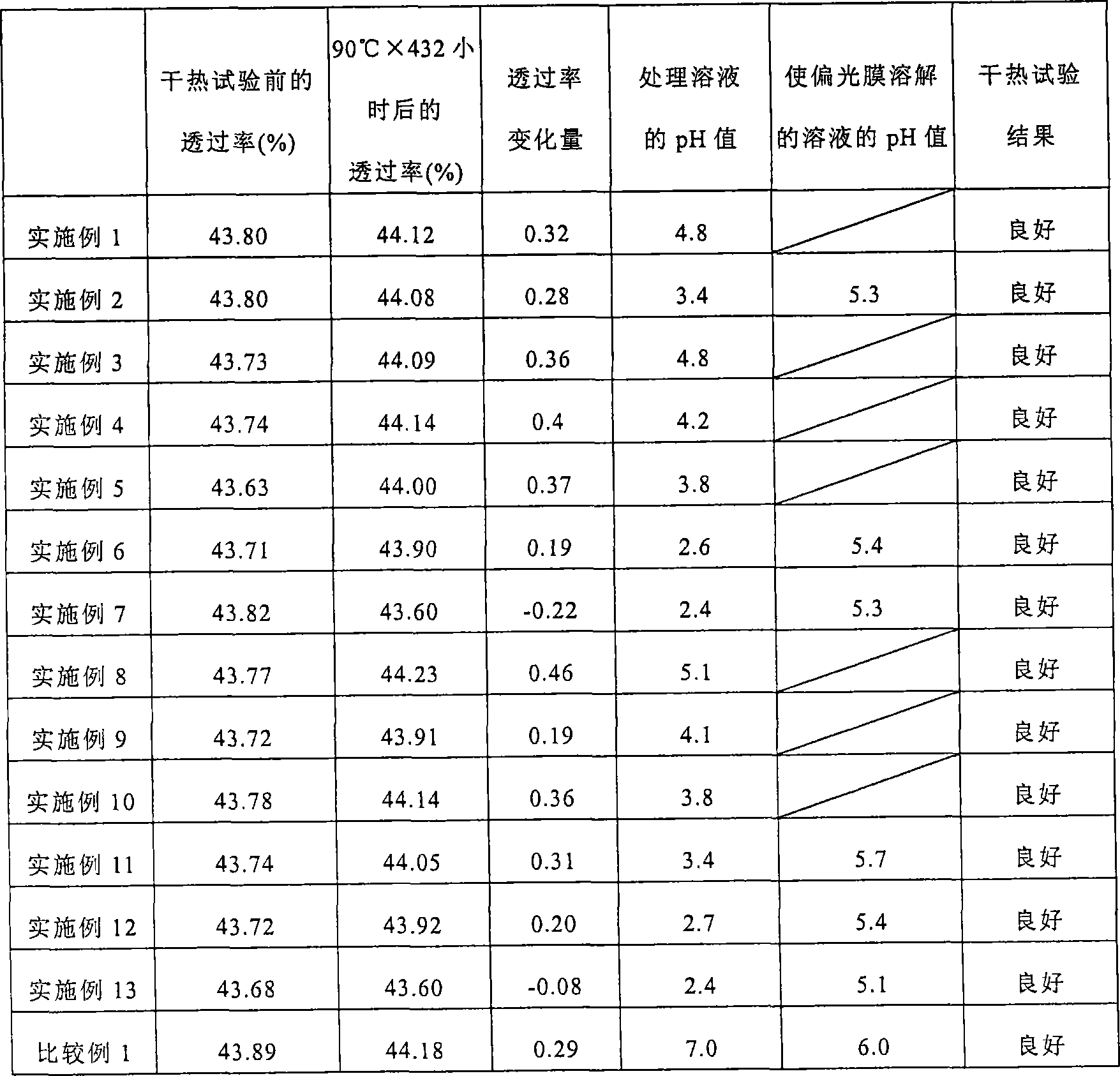

Iodine Polarizing Film, a Method for Producing the Same, and a Polarizing Plate Using the Same

InactiveUS20080192345A1Stably produced industriallyExcellent polarizing filmLiquid crystal compositionsOptical articlesCross-linkOrganic acid

The present invention relates to a polarizing film obtained by stretching a polyvinyl alcohol resin film containing iodine, an iodide a cross-linking agent and / or waterproofing agent and then treating the film with a solution containing 0.0001 to 5.0 wt % of inorganic acid except for boric acid or a salt thereof and / or organic acid and having a pH of preferably 2≦pH≦5, more preferably 2.2≦pH≦5. Said polarizing film is excellent in wet heat durability and shows less decrease in polarization characteristics in wet heat test and said polarizing film obtained in a further preferable embodiment is also excellent in dry heat durability.

Owner:NIPPON KAYAKU CO LTD +1

Pure cotton bleached thermal smelting adhesive lining with extremely low washing shrinkage and production method thereof

ActiveCN101942728AEnvironmental protection is goodEasy to operateDry-cleaning apparatus for textilesBleaching apparatusDry heatHot melt

The invention discloses a pure cotton bleached thermal smelting adhesive lining with extremely low washing shrinkage. The adhesive lining is characterized in that the warp-wise and zonal washing dimensional change rate is larger than or equal to minus 0.5%; the quantity of the formaldehyde released by the interlining is less than or equal to 35mg / kg; and the peeling strength is larger than or equal to 12N; the warp-wise and zonal dry heat dimensional change rate is larger than or equal to minus 0.8%. The production method of the invention comprises the following steps in sequence: overedging,singeing, bleaching, stoving, re-bleaching, liquid ammonia finishing, shrink resistant finishing, powder point coating and compressive shrinkage. The invention has the following advantages: the warp-wise and zonal washing dimensional change rate is large; the peeling strength is high; the environmental-friendly performance is good; and the production method can be easily operated.

Owner:曹平

Three-dimensional fiber prefabricated member reinforced aluminum oxide composite material and preparation method thereof

The invention discloses a three-dimensional fiber prefabricated member reinforced aluminum oxide composite material and a preparation method thereof. The three-dimensional fiber prefabricated member reinforced aluminum oxide composite material comprises a three-dimensional fiber prefabricated member and aluminum oxide, wherein the aluminum oxide uniformly fills pores of the three-dimensional fiber prefabricated member and is physically combined with the three-dimensional fiber prefabricated member, the aluminum oxide is alpha-Al2O3 ceramics, and the porosity of the three-dimensional fiber prefabricated member reinforced aluminum oxide composite material is 9 percent to 16 percent. The preparation method comprises: (1) immersing; (2) drying; (3) carrying out the heat treatment; (4) repeating an immersion-drying-heat treatment process of the step (1) to (3). The three-dimensional fiber prefabricated member reinforced aluminum oxide composite material has the advantages of low porosity, high compactness, high stability and excellent mechanical performance. The preparation method is high in preparation efficiency; and moreover, the compactness and the mechanical performance of the prepared composite material are remarkably improved.

Owner:NAT UNIV OF DEFENSE TECH

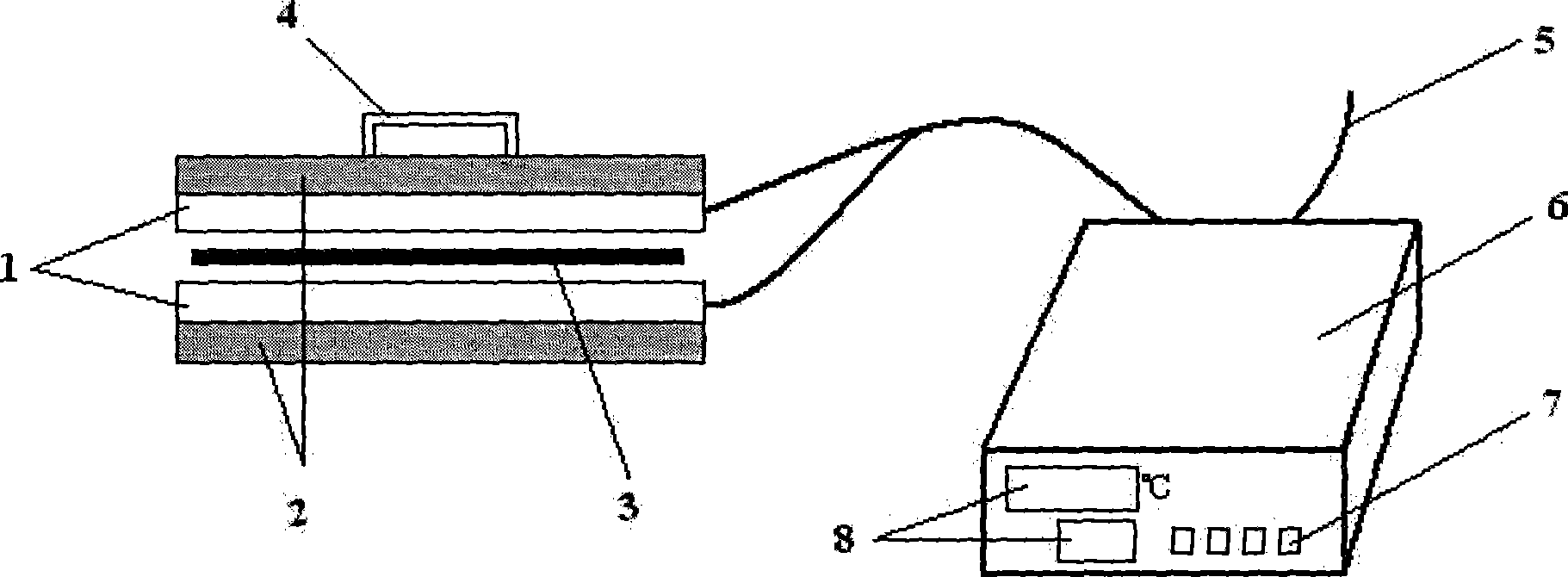

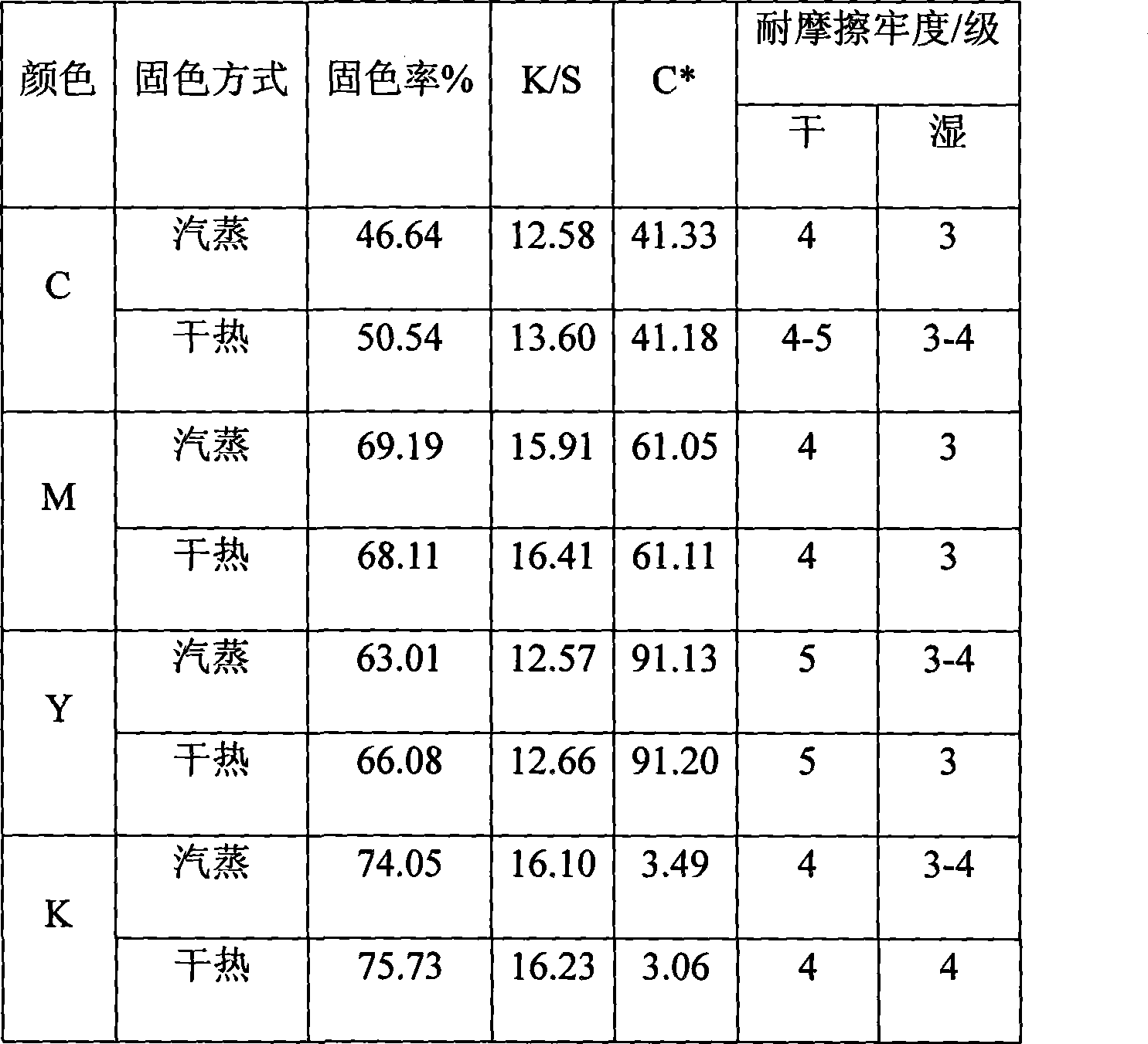

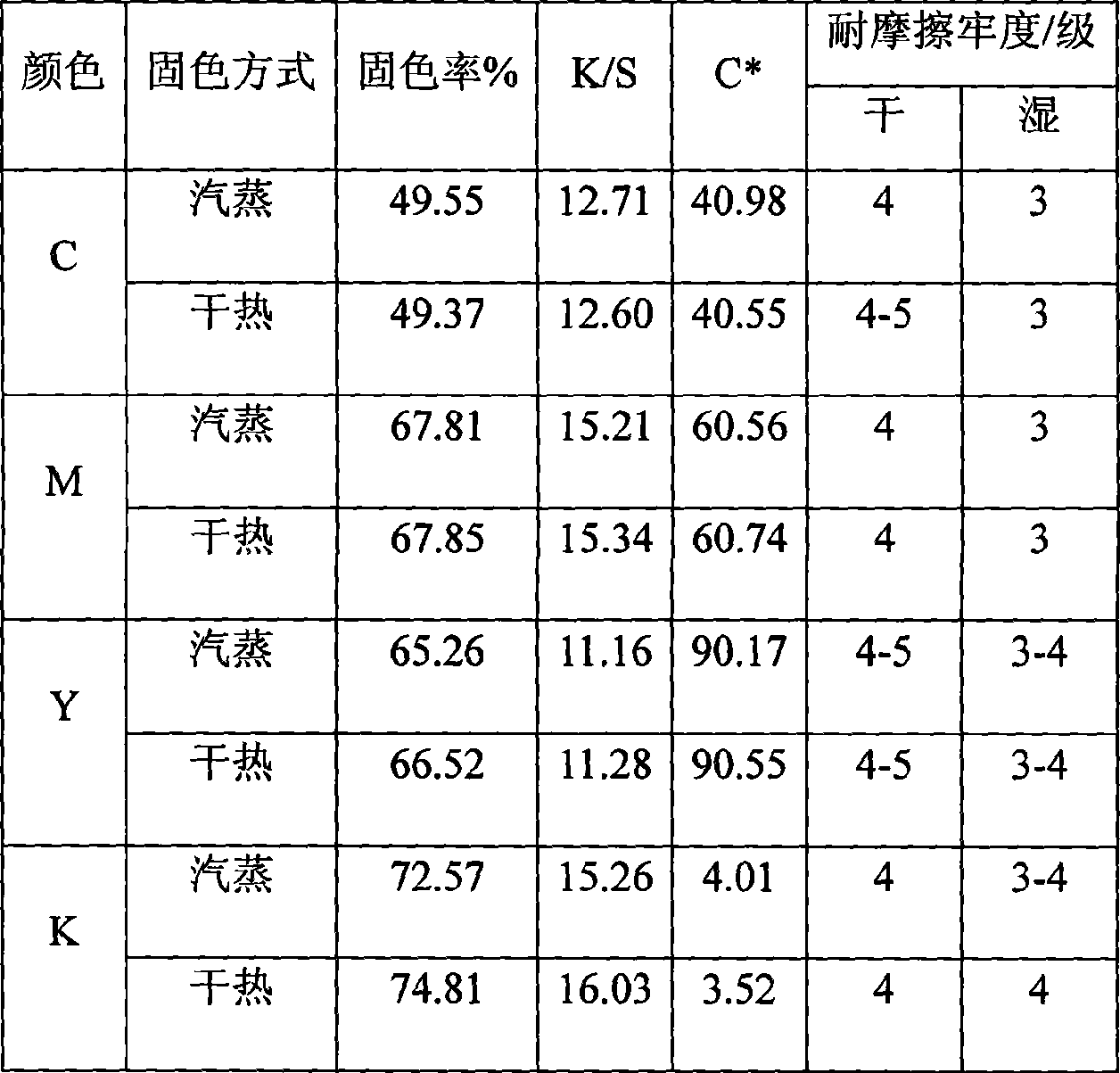

Fixation method and apparatus for inking and printing on cotton with active ink

InactiveCN101381934AHigh color fixing rateImprove color vividnessHeating/cooling textile fabricsDyeing processEngineeringDry heat

The invention relates to a method and a device for fixing cotton fabric reactive ink inkjet printing. The method comprises the following: (1) a step of pretreating fabric, which is to make thickener into stock thickener, dissolve alkaline agent, urea and antifoaming agent in water, add the alkaline agent, the urea and the antifoaming agent to the stock thickener, evenly mix the mixture so as to form a pretreatment solution, pad the fabric with the pretreatment solution and then dry the fabric; (2) a step of performing inkjet printing, which is to adopt reactive dye ink to perform inkjet printing to the pretreated fabric on a digital inkjet printing machine; and (3) a step of after-treating the fabric, which is to adjust humidity of the jet-printed fabric for 4 hours, adopt a contact-type dry-heat fixation device, regulate the temperature of a heating plate to be between 150 and 160 DEG C, set the treatment time to be between 40 and 80 seconds, complete fixation through contact-type dry-heat treatment, wash and dry or air the fabric, so as to obtain a finished product. The invention has the advantages of convenient operation of technological process, strong flexibility and high fixation rate, and solves the problems existing in small-batch steaming fixation.

Owner:DONGHUA UNIV

Iodine-containing polarizing film, process for producing the same, and polarizer comprising the same

InactiveCN101137917AStable manufacturingReduce transmittancePolarising elementsNon-linear opticsOrganic acidIodide

A polarizing film obtained by stretching a polyvinyl alcohol resin film containing iodine, an iodide, and a crosslinking agent and / or water resistance imparter and then treating the film with a solution which contains either an inorganic acid other than boric acid or a salt thereof and / or an organic acid in an amount of 0.0001-5.0 wt.% and which has a pH of desirably 2-5, preferably 2.2-5. The polarizing film is excellent in wet heat durability and is less apt to decrease in polarizing properties in a wet heat durability test. The polarizing film obtained according to the preferred embodiment is excellent also in dry heat durability.

Owner:NIPPON KAYAKU CO LTD +1

Manufacturing method for superlow shrinkage type PET industrial yarn

ActiveCN102797056AGuaranteed positionControl and reduce dwell timeArtificial thread manufacturing machinesMelt spinning methodsFiberYarn

The invention relates to a manufacturing method for superlow shrinkage type PET industrial yarn, which is characterized in that the superlow shrinkage type PET industrial yarn is manufactured through selecting and controlling cooling conditions, and the technological process is as follows: hyperviscous melting to polyester raw materials, metering, spanning, cooling, oil supplying, stretching, hot shaping, and reeled forming. For lowing the irregularity and shrinkage percentage of fiber, a slow cooling device is arranged in the production of industrial yarn, a precooling device adopted is a hollow stepped ring-shaped belt comprising an upper part and a lower part, through holes with the diameters of 5 to 7 mm are uniformly distributed in the upper part of the ring-shaped belt, through holes with the diameters of 3 to 4 mm are uniformly distributed in the lower part, and the hole arrangement densities are the same. The natural target of the PET industrial yarn is as follows: the fracture strength is equal or greater than 7.0 cN / dtex, the breaking elongation is 20.0 plus or minus 1.5 percent, and the dry heat shrinkage percentage under the test conditions of 170 DEGC, 0.05cN / dtex reaches 1.9 plus or minus 0.25 percent.

Owner:JIANGSU HENGLI CHEM FIBER

Nonwoven fabric air filter for internal combustion engine

A nonwoven fabric air filter for internal combustion engine produced by forming multiple layers composed mainly of polyester binder fibers of 1 to 10 mm fiber length according to airlaid nonwoven fabric production process and effecting thermal bonding thereof. In particular, a thin uniform nonwoven fabric air filter for internal combustion engine with pleats configuration, having an upper layer side (fluid inflow side) composed of thick fibers, having a lower layer side (fluid outflow side) composed of thin fibers, and having a last fluid outflow side layer composed 100% of polyester binder fibers, which thin uniform nonwoven fabric air filter is comprised of airlaid nonwoven fabrics whose weight per square meter, apparent density and dry-heat shrinkage factor after 300 hr at 100 1 / 2 C are 100 to 350 g / m<2>, 0.04 to 0.3 g / cm<3> and 3% or less, respectively. This thin uniform nonwoven fabric air filter is free from environmental pollution, realizes high dust collection efficiency and ensures prolonged life.

Owner:AMBIC +1

Industrial functional chinlon 66 fibre and preparation method thereof

ActiveCN103290497ASmall shrinkageHigh strengthNew-spun product collectionMelt spinning methodsYarnDry heat

The invention discloses industrial functional chinlon 66 fibre and a preparation method thereof, and belongs to the technical field of fibre production. The method comprises the following steps: adopting chinlon 66 slices, tackifying through solid-phase polymerization, adopting a one stage process route of spinning, drafting and forming, and producing the industrial functional chinlon 66 FDY (Fully Drawn Yarn) fibre with middle low denier, high strength and low shrink on a spin-draft integrated device with an unique structure, wherein the total denier of a tow is 50 to 300 tex; the single silk fineness dpf is 1 to 5; the strength is larger than or equal to 8.5 g / d; and the dry heat shrinking percentage is less than or equal to 3%.

Owner:LIAONING YINZHU CHEMTEX GROUP

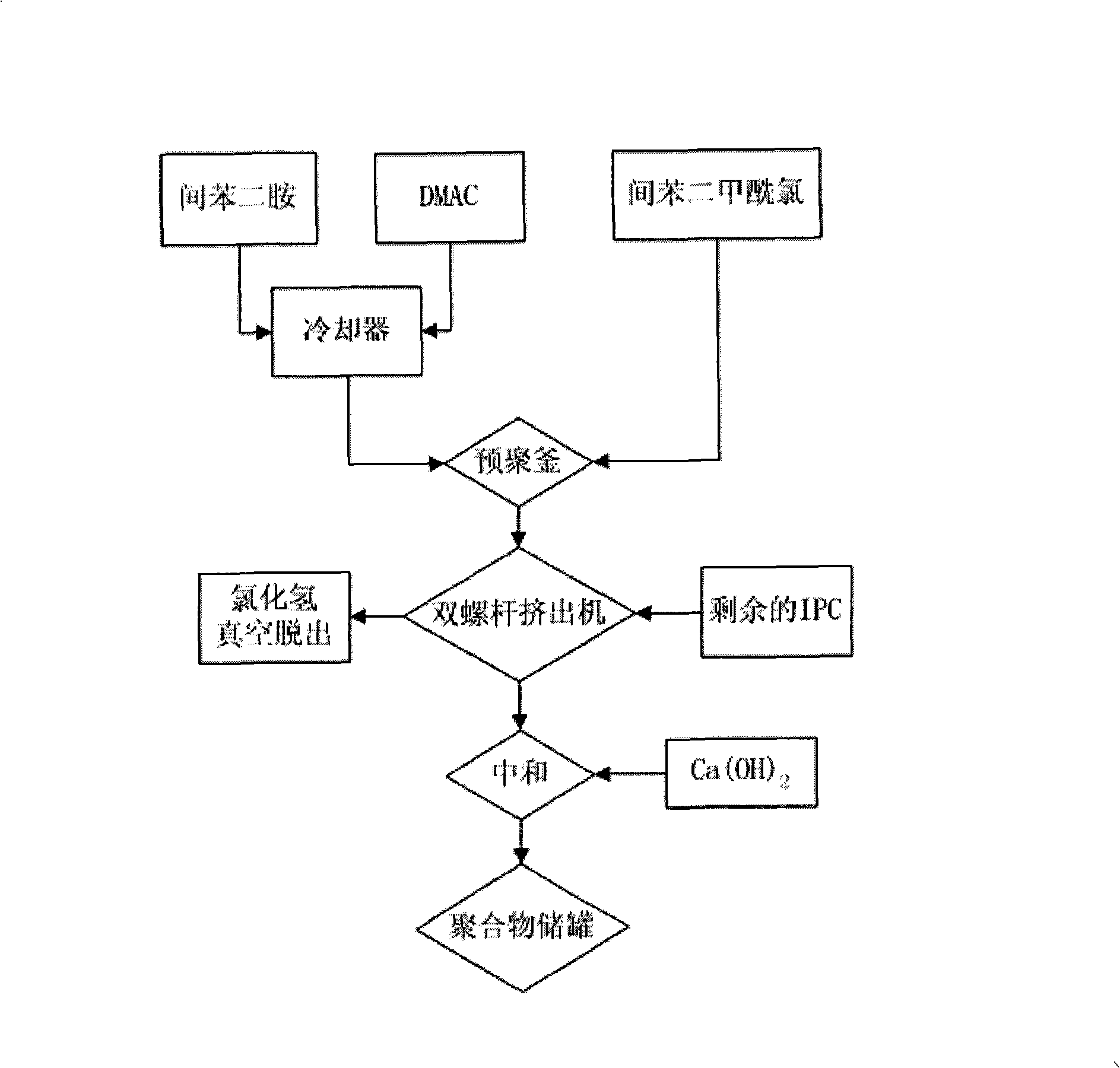

Preparation of low salt-containing aramid fiber 1313spinning solution and process for spinning fibre by wet method

ActiveCN101285214AWell mixedHigh molecular weightWet spinning methodsSpinning solutions preparationPolymer scienceDry heat

The invention relates to a method for spinning aramid fiber 1313 with low salt content by wet spinning. The method comprises the following steps of: prepolymerizing m-phenylenediamine (MPD) and part m-phthaloyl chloride (IPC); adding the preformed polymer and the rest m-phthaloyl chloride into a double-screw extruder to extrude the aramid fiber 1313 containing chlorine hydride; extruding spinning dope into a aqueous coagulation bath after neutralizing the chlorine hydride with calcium hydroxide; crimping and cutting coagulated tows into the required fiber length via hot water drawing, water rinsing, drying, dry-heat drawing and heat setting after being taken out of the coagulation bath to receive a finished fiber. The method is convenient and simple, can improve the molecular weight of products and the evenness of polycondensate, and reduce the salt content of the final spinning solution.

Owner:DONGHUA UNIV +1

Process for preparing vapour pressure air-entrained concrete light heat-insulation fireproof bricks by gold tailings

The invention relates to a firebrick preparation method, in particular to a method of preparing an autoclaved aerated concrete light heat insulating firebrick with gold tailings. The invention takes the gold tailings as the main raw material which is made by a pre-activating treatment, then a certain amount of cement, lime, foam stabilizer of nekal bx or soap pod powder and aluminum power paste are added, and then plaster and self-made compound admixtures are added to prepare into sizing agent. The later preparing procedures are as follows: pour mold for gas-forming and stilling, dry heat pre-curing, cutting and stacking, being steamed in a caldron and being taken out of the caldron, and finally the firebrick is formed. The firebrick is put into the caldron to steam for 5 to 7 hours under constant voltage; the steam pressure is 1.1 to 1.5 MPa, the temperature is from 185 DEG C to 195 DEG C. The firebricks prepared by the method have good effect of heat insulation in stove owing to low coefficient of heat conductivity, thereby being used in the low temperature section of ceramics kiln collapses, tunnels, resistance furnace and being capable of realizing energy saving. The firebricks prepared by the method also have the advantage of being light owing to the volume and density being less than those of the majority of light heat insulating firebricks.

Owner:福建省万旗非金属材料有限公司

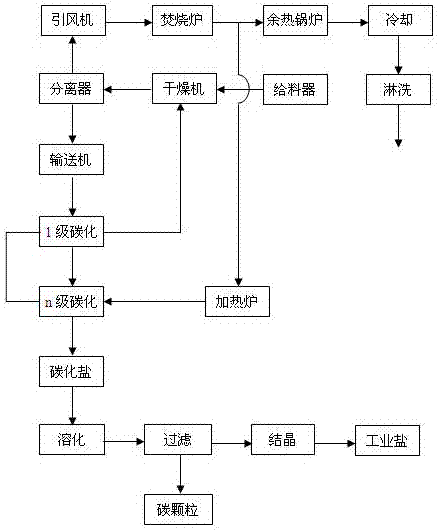

Process and equipment for graded decomposition and carbonization harmless treatment of industrial waste salt

ActiveCN106914474AGood dispersionLarge specific surface areaSolid waste disposalTransportation and packagingEnvironmental resistanceDecomposition

The invention belongs to the field of environmental protection, and particularly relates to a process and equipment for graded decomposition and carbonization harmless treatment of industrial waste salt. According to the process and the equipment disclosed by the invention, aiming at the characteristics that each kind of industrial waste salt contains various organic materials and has different physicochemical properties, a plurality of grades of decomposition and carbonization furnaces are arranged to perform graded heating on the industrial waste salt; the heating process is reasonable; the organic materials are decomposed and carbonized within the respective decomposition and carbonization temperature range; the heat-containing exhaust gas generated by decomposition and carbonization is used as a dry heat source; the exhaust gas generated by drying is introduced into an incinerator for incineration; and the hot gas generated by incineration is recycled. According to the process and equipment disclosed by the invention, continuous industrial production is realized, and during the operation of the system, no melting, agglomeration or bonding of the waste salt occurs, no secondary pollutants are generated, no toxic and harmful gas is exhausted, thermal efficiency is high, energy is saved, environmental protection is achieved, and the investment cost is lower than that of other methods; and the process and equipment have the advantages that the process and equipment are high in practicality, are suitable for the removal and harmless treatment of the organic materials of the industrial waste salt in various fields, and are suitable for popularization in industrial production.

Owner:辽宁东大粉体工程技术有限公司

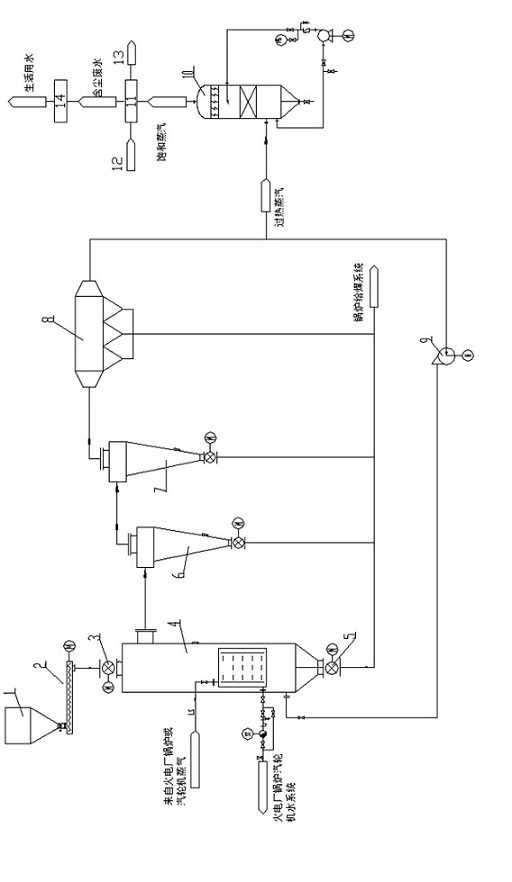

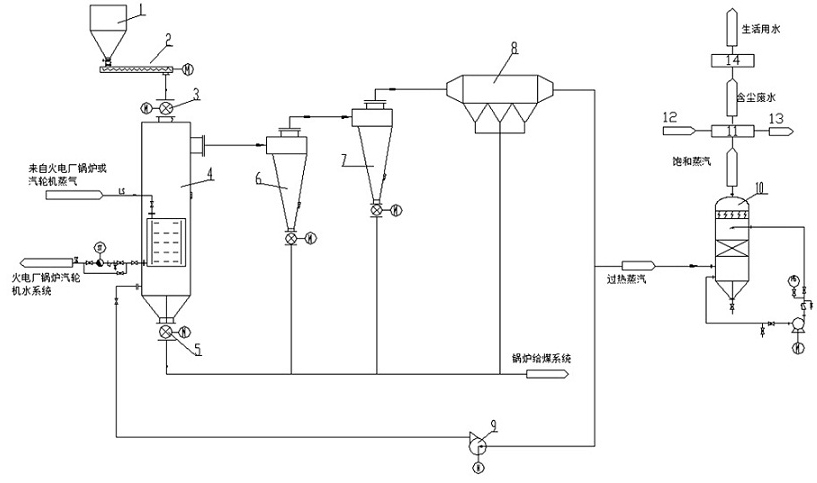

Comprehensive utilization system for drying low-order coal of thermal power plant in steam pumping and indirect heat exchanging way and process thereof

The invention relates to a comprehensive utilization system for drying low-order coal of a thermal power plant in a steam pumping and indirect heat exchanging way and a process thereof. The system comprises an indirect-heat-exchange low-order coal predrying device using a steam pipeline of a boiler or a steam turbine of the thermal power plant as a heat source, wherein tail steam obtained by the drying low-order coal of the device is connected with a secondary steam heat insulating and washing device; the secondary steam heat insulating and washing device is connected with a secondary steam recycling device; and the secondary steam recycling device is connected with a dust-containing waste water purifying and utilizing device. In the invention, the steam pumped by the boiler or the steam turbine is used as the drying heat source, high-moisture low-order coal (brown coal) is dewatered and dried through an indirect-heat-exchange drier, and secondary steam generated by dewatering the low-order coal (brown coal) is butt jointed with a steam-water system of the power plant, thereby the operating condition of the boiler is improved, the CO2 emission and fuel consumption are obviously reduced, the loss of a coal mill and matched systems is reduced, the generating efficiency of the power plant is improved, and the blank of the drying and the comprehensive utilization of the low-order coal (brown coal) of the thermal power plant in China is filled.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com