Patents

Literature

1246results about How to "Guaranteed position" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

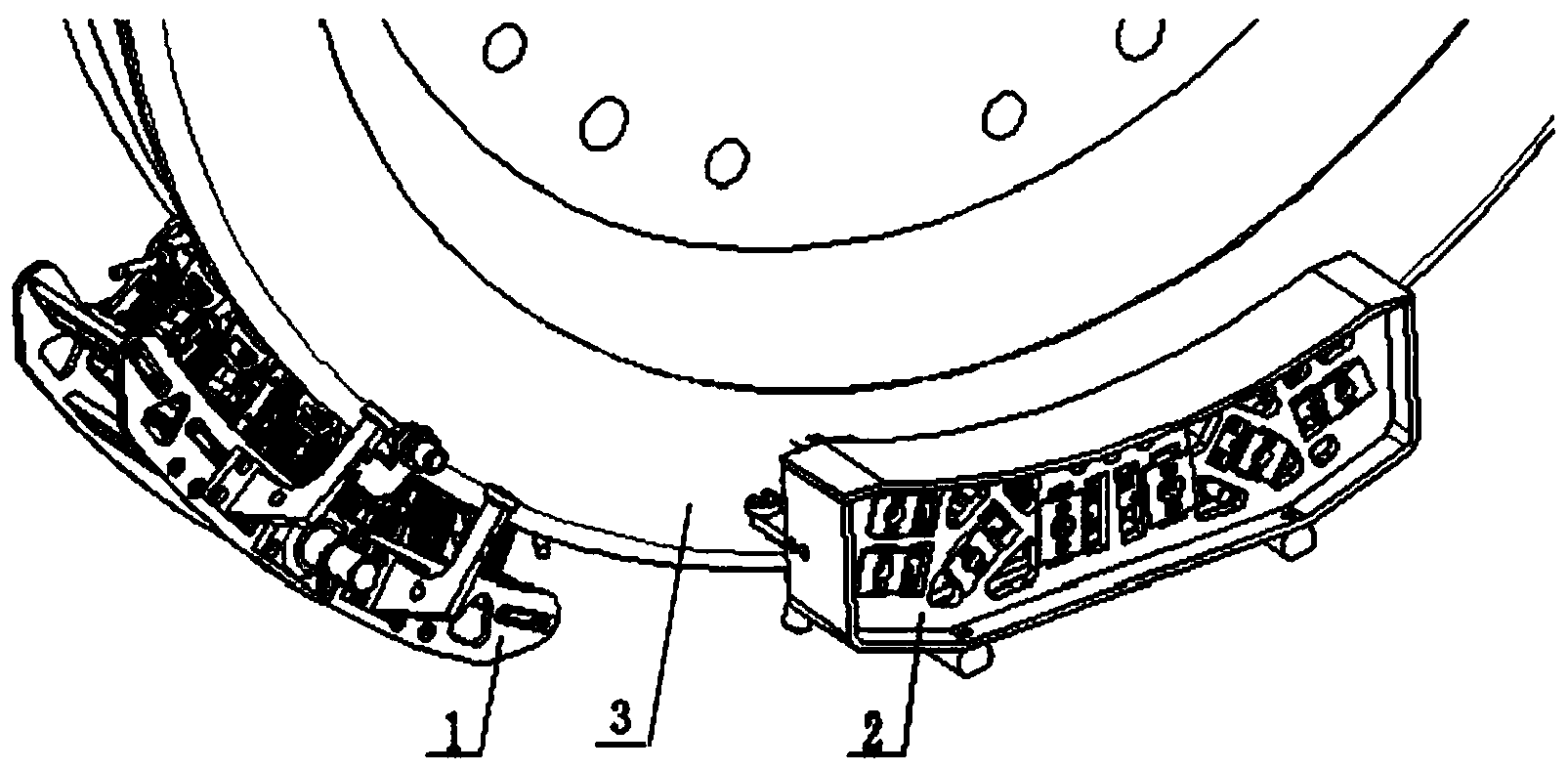

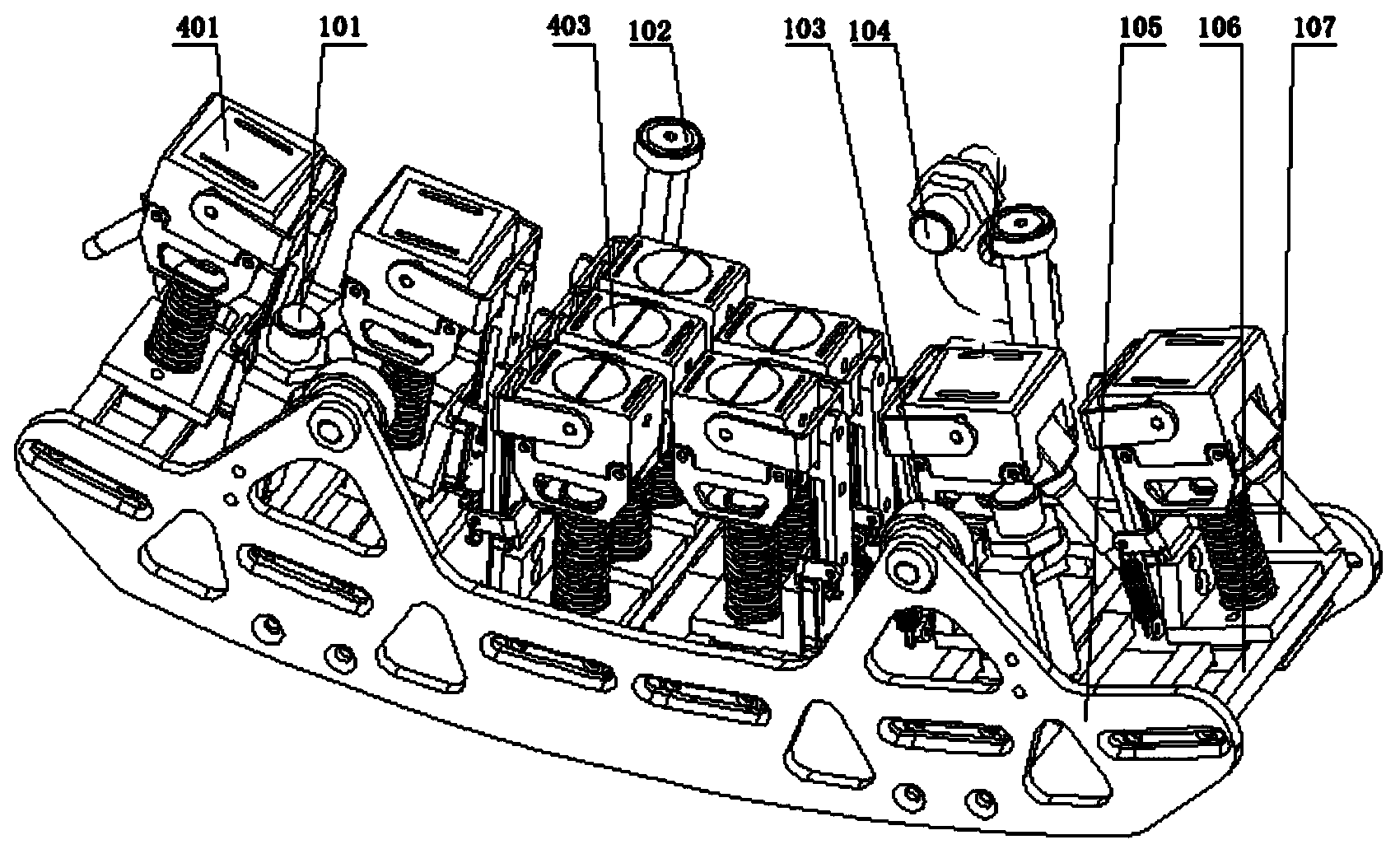

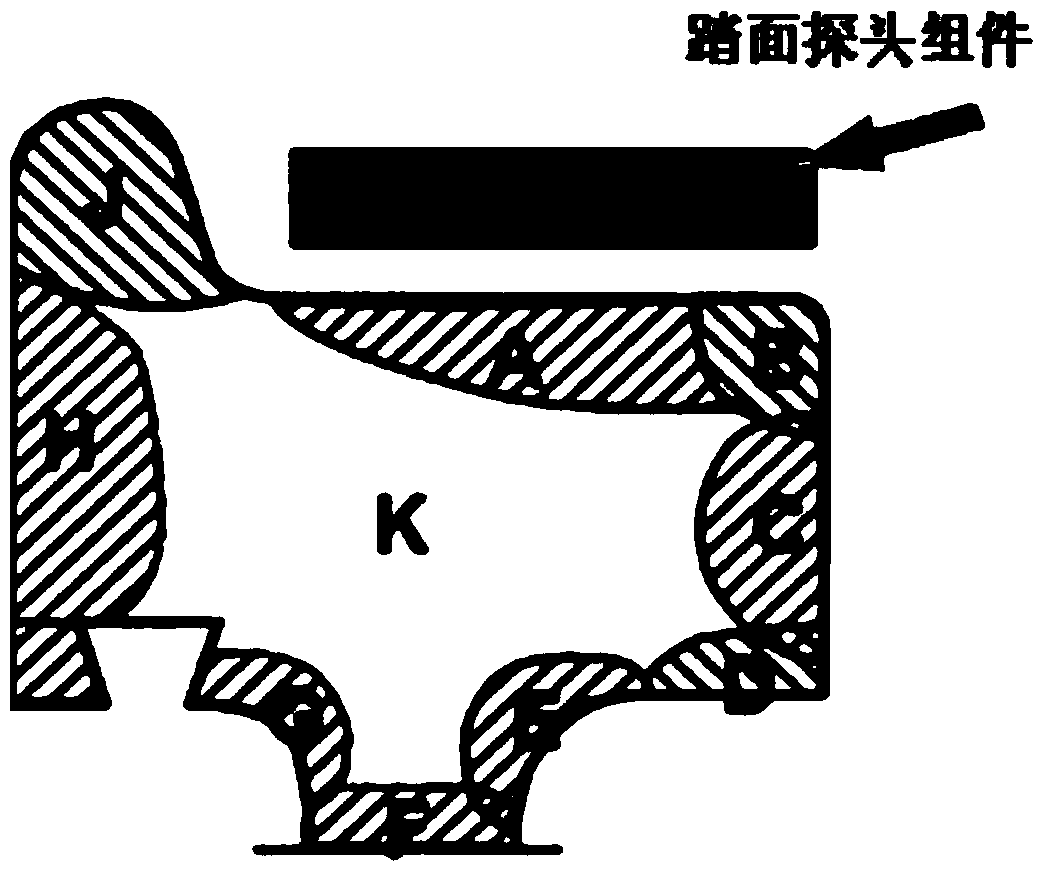

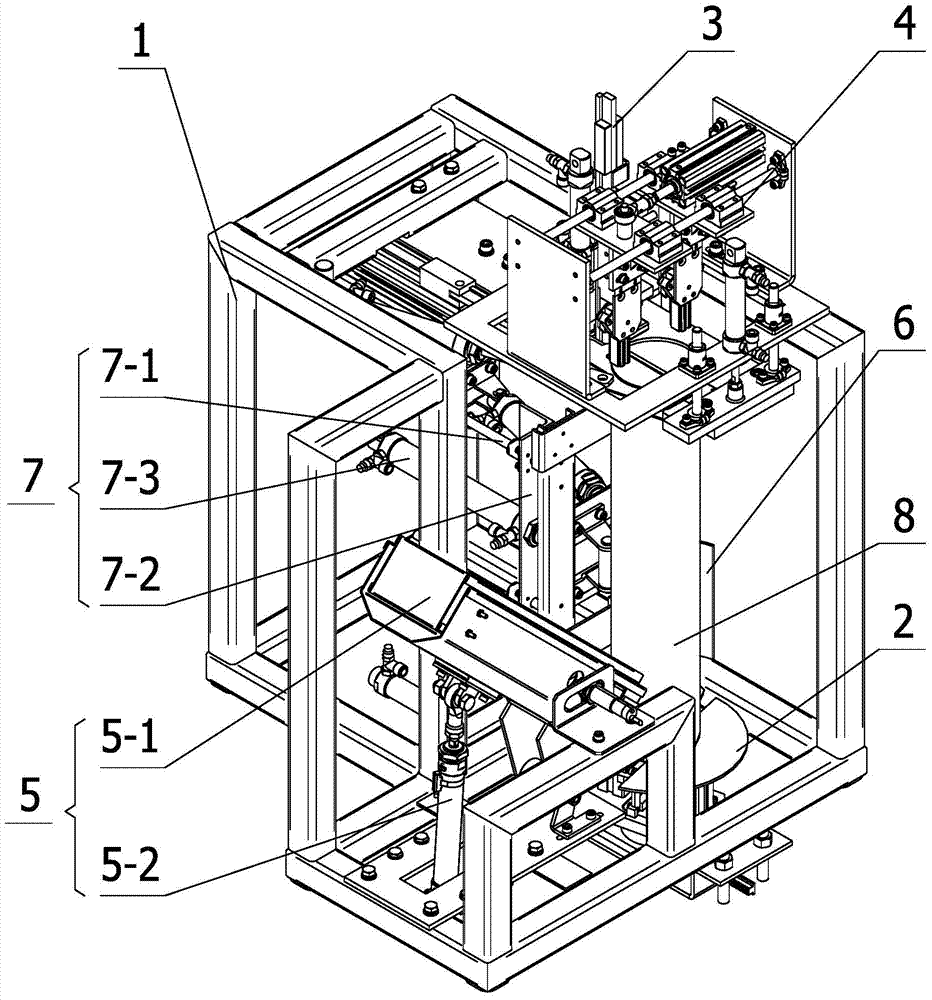

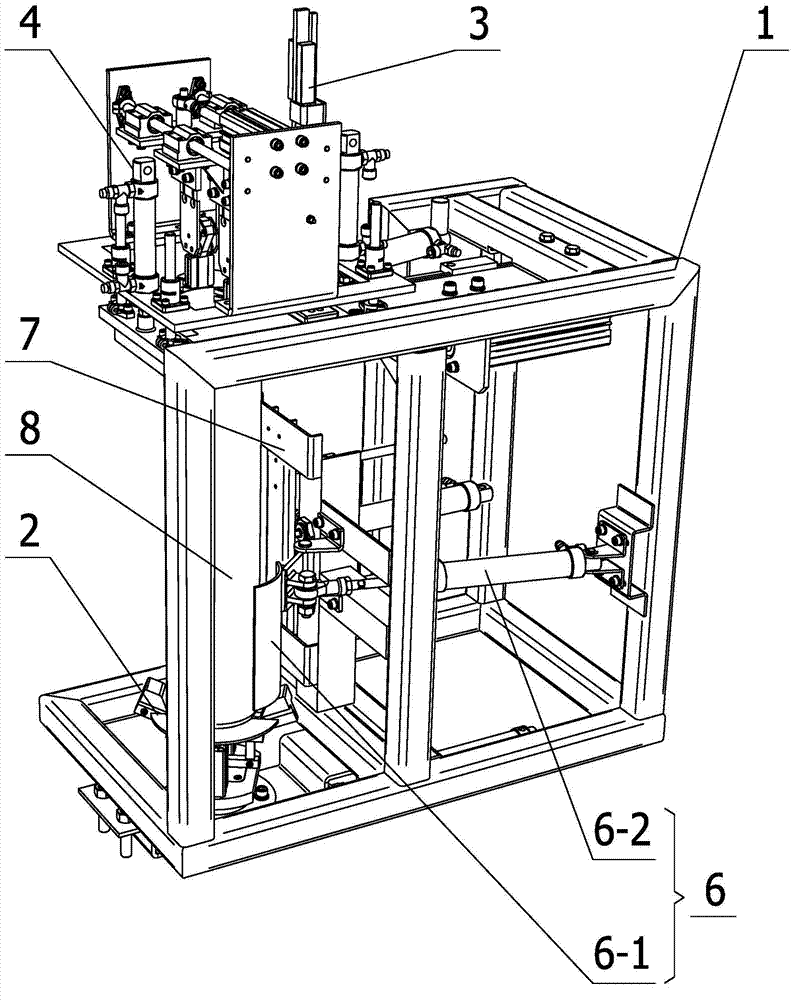

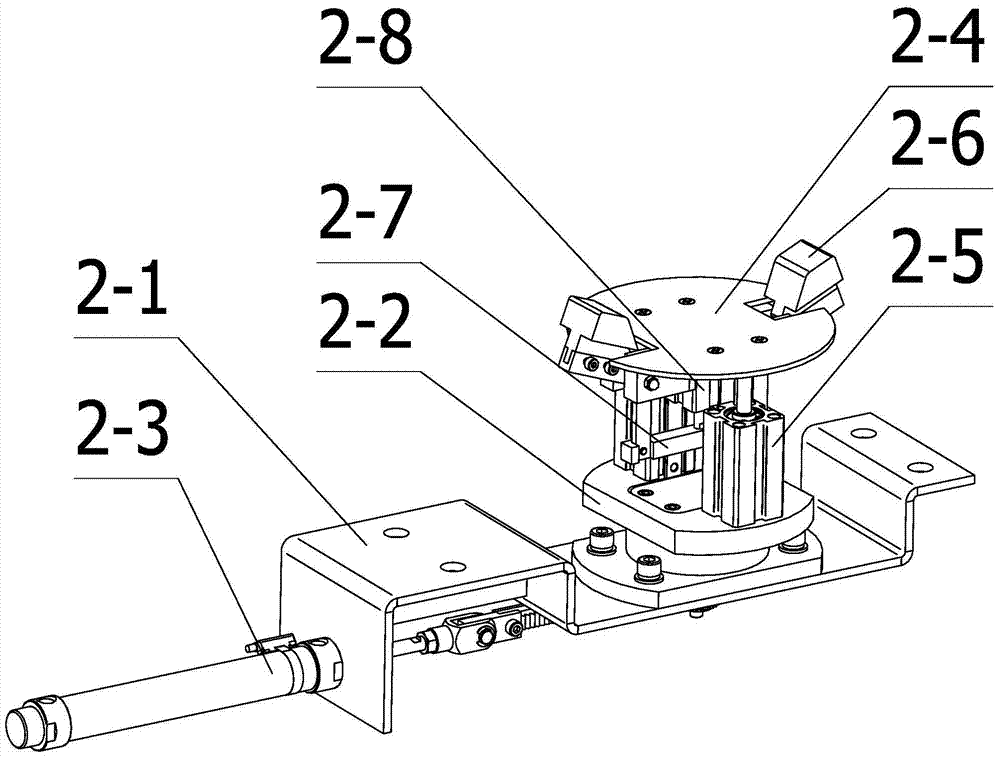

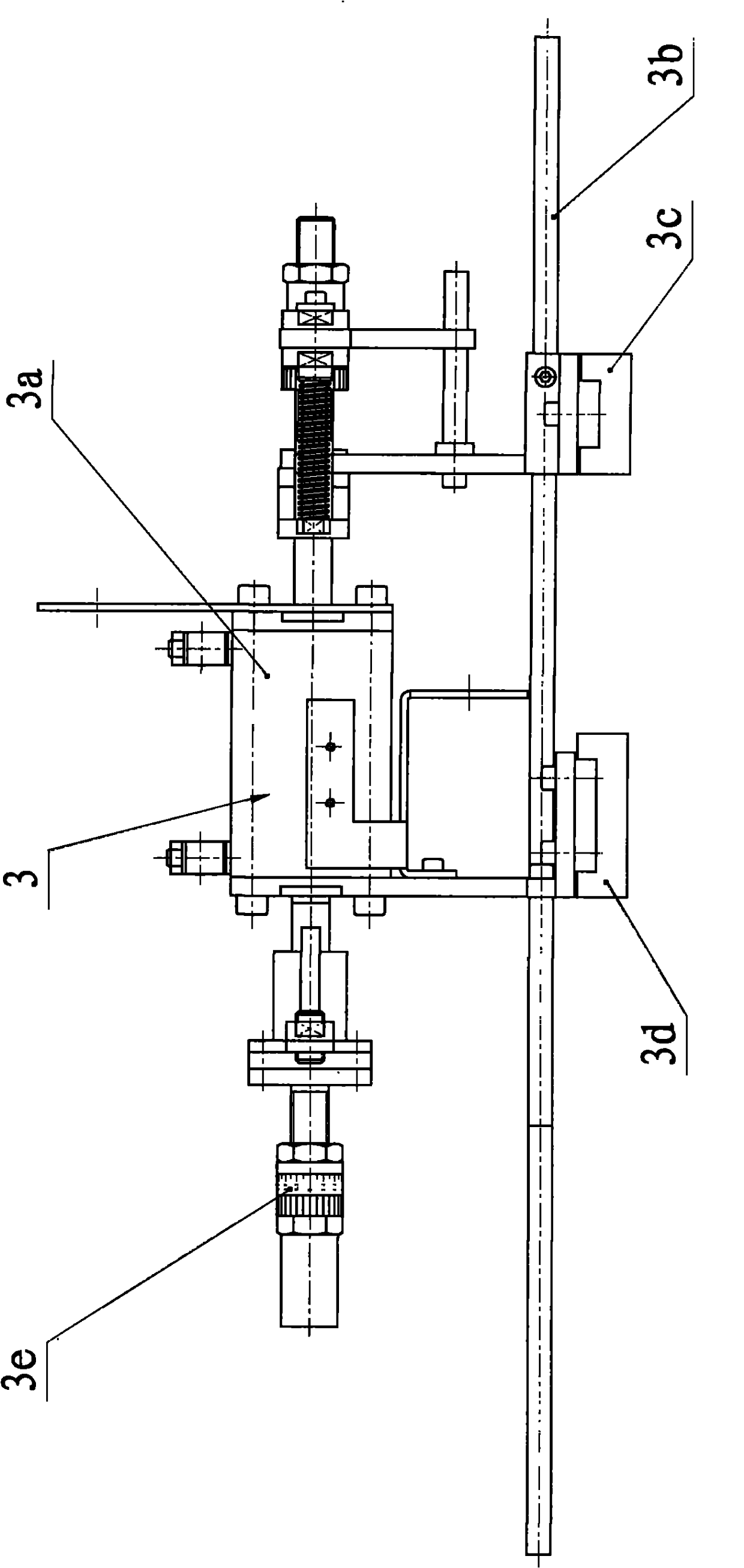

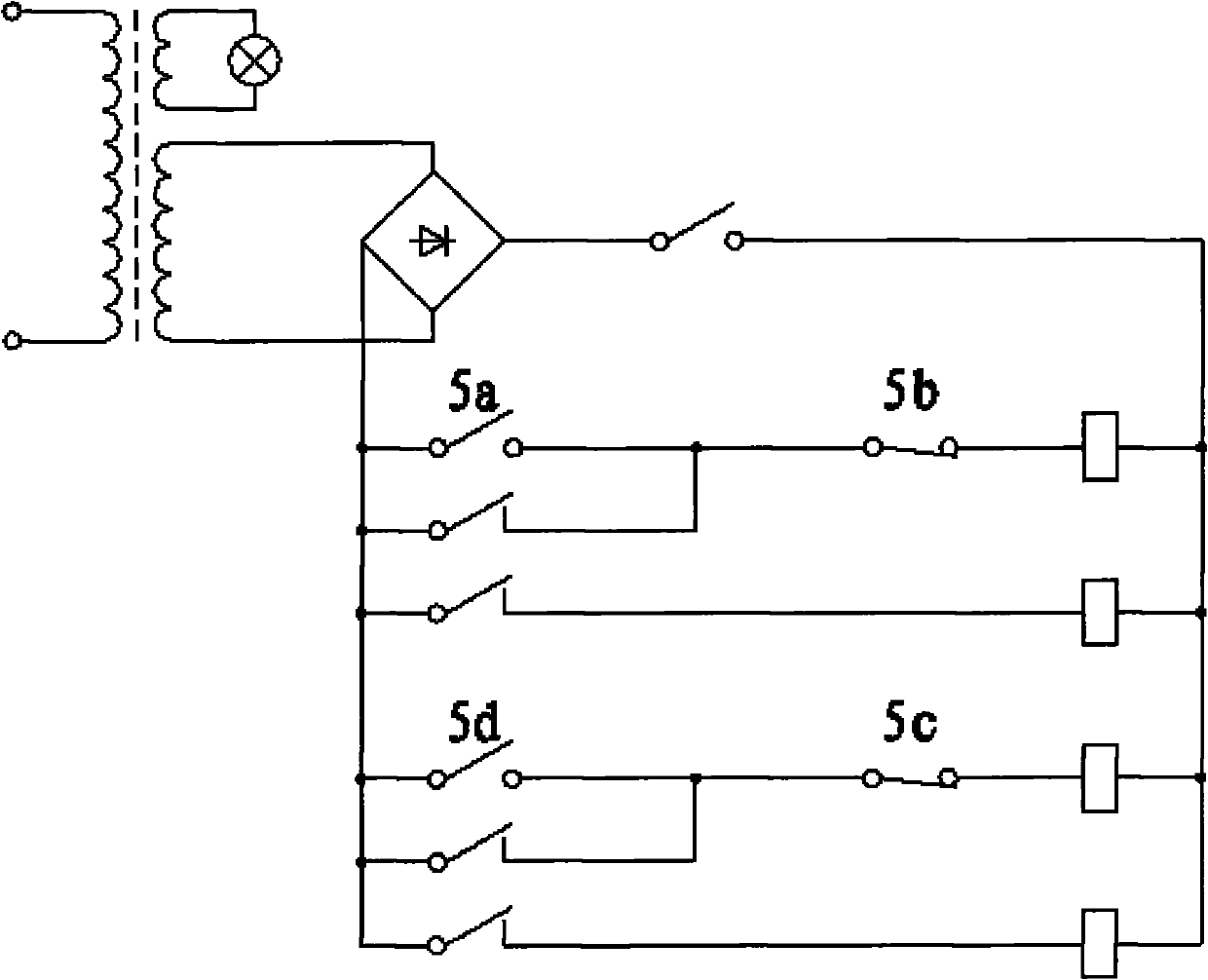

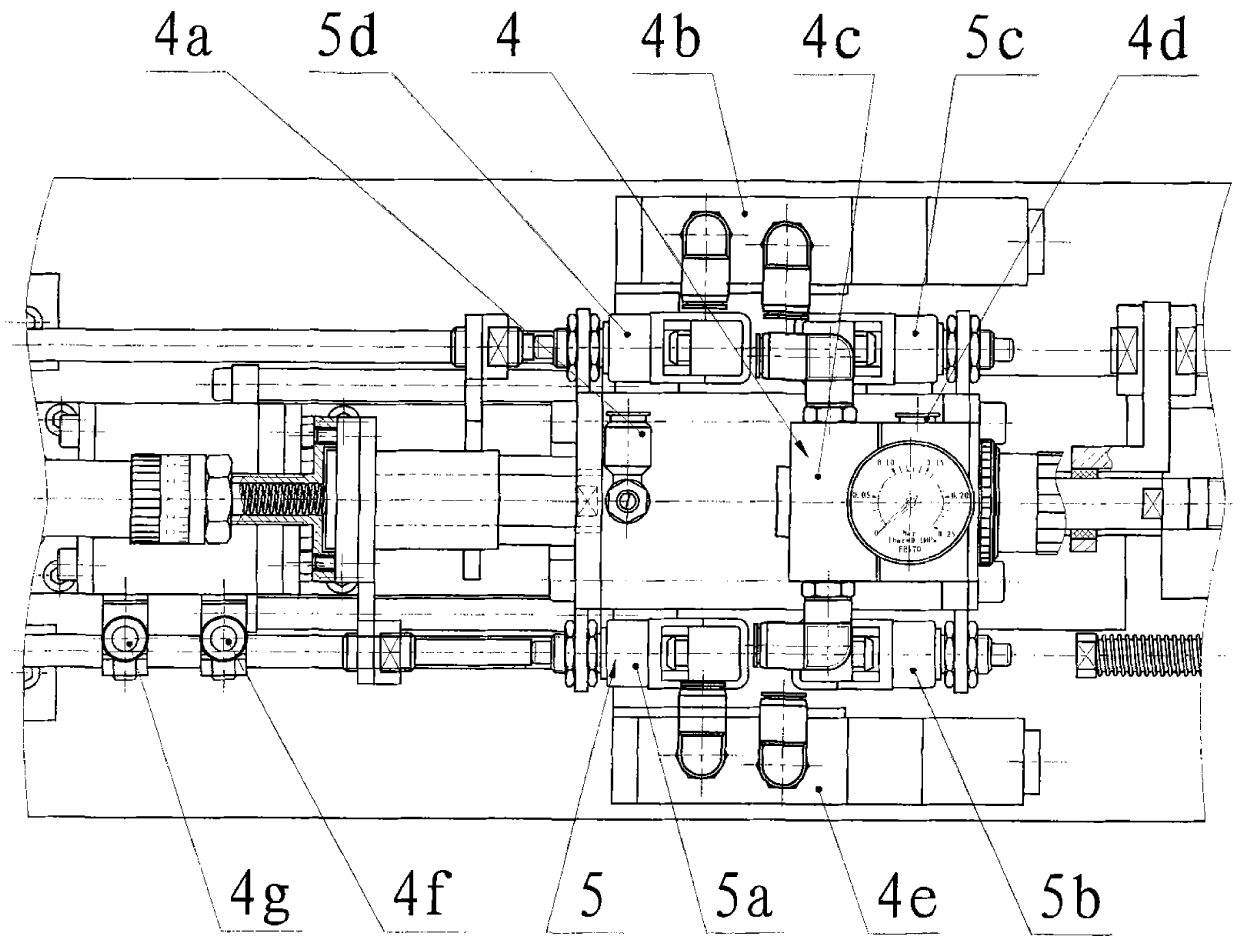

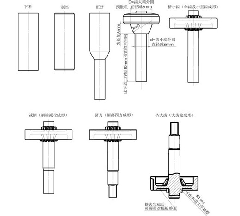

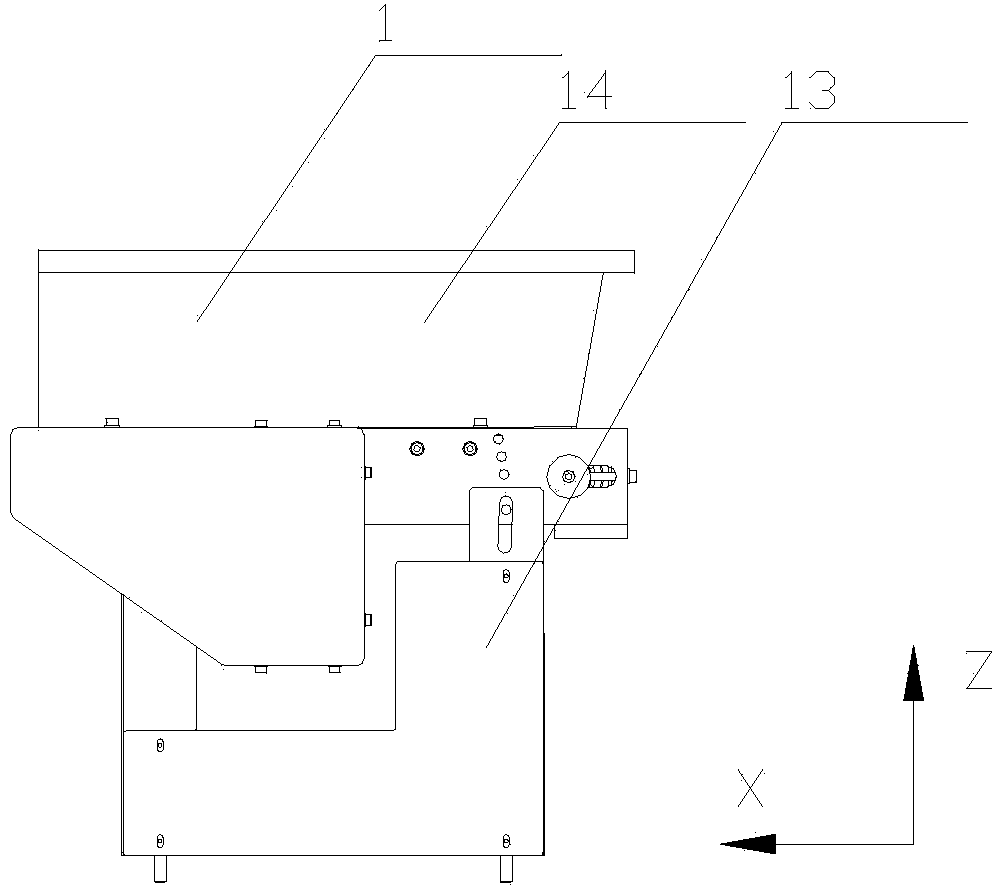

Track vehicle rim and tread flaw detection probe assembly system

ActiveCN103472138AEasy to useProtect the safety of useMaterial analysis using sonic/ultrasonic/infrasonic wavesEngineeringManipulator

The invention discloses a track vehicle rim and tread flaw detection probe assembly system. The track vehicle rim and tread flaw detection probe assembly system comprises a tread flaw detection probe assembly and a rim flaw detection probe assembly. The tread flaw detection probe assembly leans on the tread of a wheel through a mechanical arm; the rim flaw detection probe assembly leans on the rim surface of the wheel through the mechanical arm; the tread flaw detection probe assembly can automatically detect wheel tread and rim defects from the tread in an online mode and is high in detection efficiency, accurate in detection result, simple in structure and convenient to use and operate; the rim flaw detection probe assembly can automatically detect wheel rim surface and tread detects from the inner lateral side of the rim in on online-mode and is high in detection efficiency, accurate in detection result, simple in structure and convenient to use and operate.

Owner:BEIJING SHEENLINE GRP CO LTD

Manufacturing method for superlow shrinkage type PET industrial yarn

ActiveCN102797056AGuaranteed positionControl and reduce dwell timeArtificial thread manufacturing machinesMelt spinning methodsFiberYarn

The invention relates to a manufacturing method for superlow shrinkage type PET industrial yarn, which is characterized in that the superlow shrinkage type PET industrial yarn is manufactured through selecting and controlling cooling conditions, and the technological process is as follows: hyperviscous melting to polyester raw materials, metering, spanning, cooling, oil supplying, stretching, hot shaping, and reeled forming. For lowing the irregularity and shrinkage percentage of fiber, a slow cooling device is arranged in the production of industrial yarn, a precooling device adopted is a hollow stepped ring-shaped belt comprising an upper part and a lower part, through holes with the diameters of 5 to 7 mm are uniformly distributed in the upper part of the ring-shaped belt, through holes with the diameters of 3 to 4 mm are uniformly distributed in the lower part, and the hole arrangement densities are the same. The natural target of the PET industrial yarn is as follows: the fracture strength is equal or greater than 7.0 cN / dtex, the breaking elongation is 20.0 plus or minus 1.5 percent, and the dry heat shrinkage percentage under the test conditions of 170 DEGC, 0.05cN / dtex reaches 1.9 plus or minus 0.25 percent.

Owner:JIANGSU HENGLI CHEM FIBER

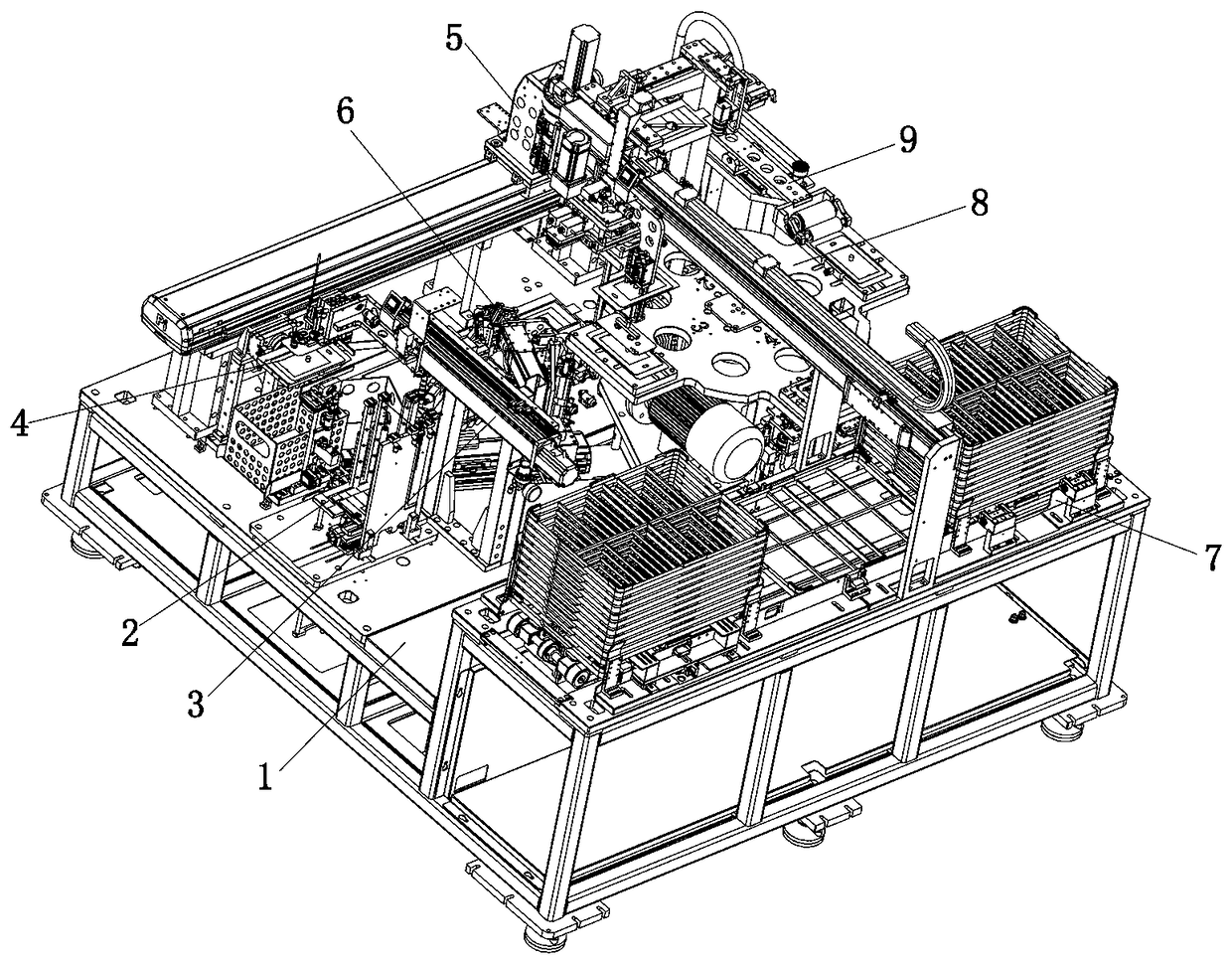

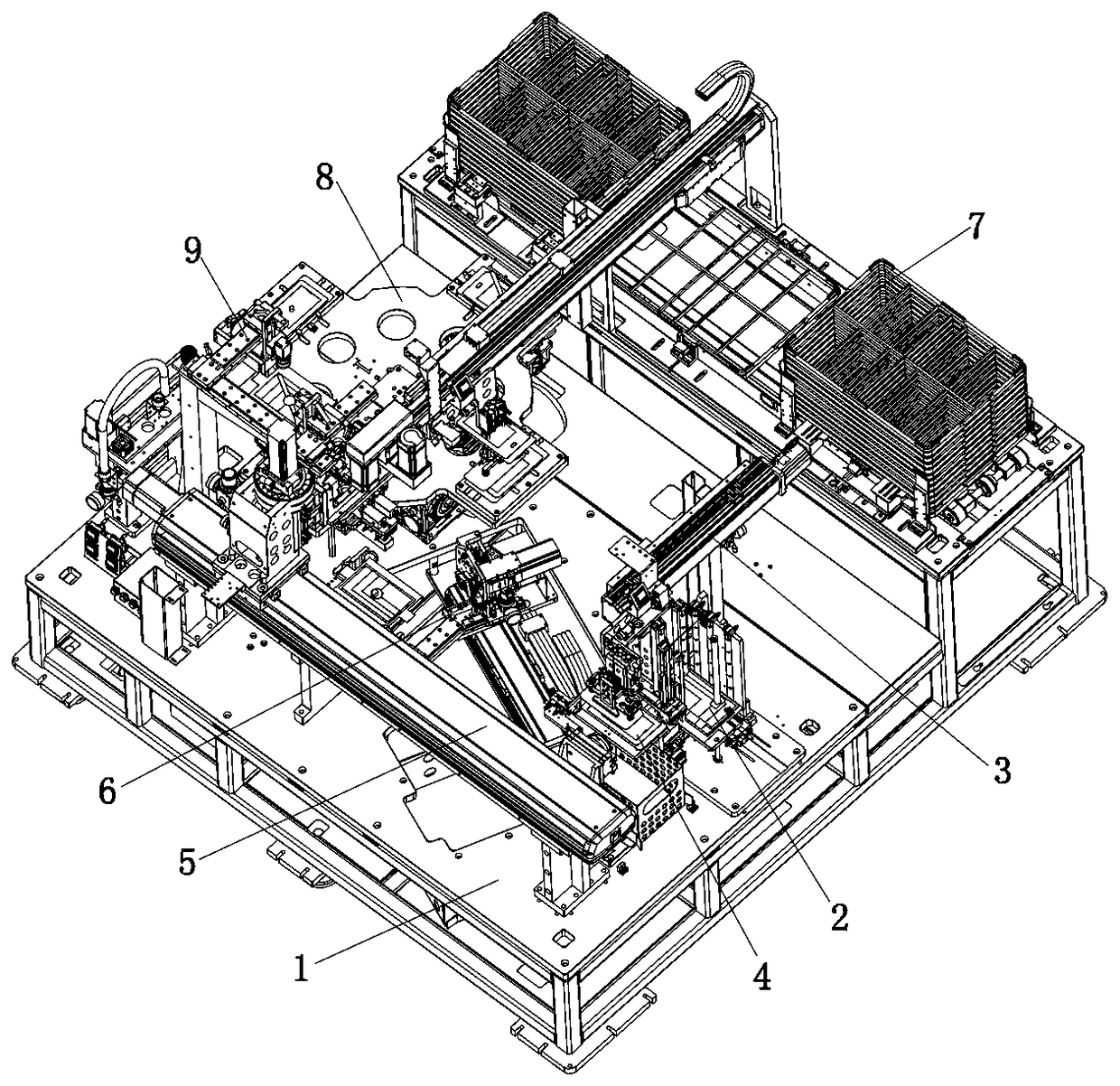

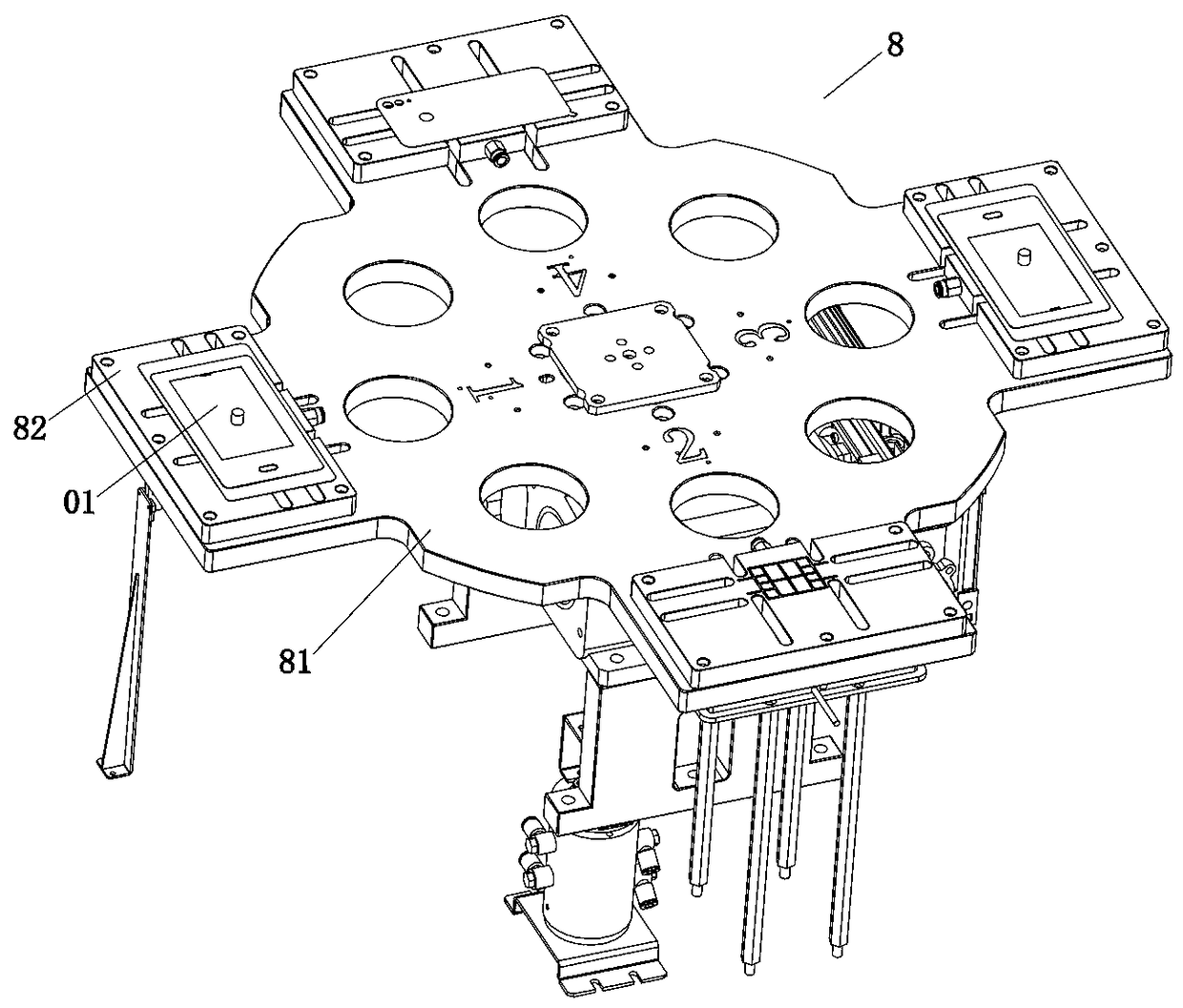

Full-automatic film detecting and pasting production line and film pasting process thereof

ActiveCN109318474AReduce bendingGuaranteed accuracyFinal product manufactureProduction lineGlass sheet

The invention discloses a full-automatic film detecting and pasting production line and a film pasting process thereof. The production line comprises a film feeding assembly, a film taking and detecting mechanical arm, a film transfer table, a correcting and mounting mechanical arm, a film tearing assembly, a glass loading assembly and a turntable; the film pasting process comprises the followingprocess steps of transferring a material frame, picking up the glass sheets and laminating the empty material frames, removing dust of the glass and photographing, film feeding, double-piece detectingand correcting, film recovering and primary correction, film taking and film tearing, membrane position correcting and film pasting. According to the film detecting and pasting production line and afilm pasting process, automatic centralized feeding of the diaphragm and the glass sheet is realized, the production line has a film suction quantity detection function and an automatic film tearing function on the surface of the film, the situation of sticking the double films is effectively avoided, the accuracy of the position of the film pieces in the film tearing process is guaranteed, the bending situation of the film sheet during film tearing is reduced, a sticking head which integrates the functions of film collecting sheet correction and pasting and mounting is adopted, in the film pasting process, the film is in contact rolling with the edge of the glass sheet, so that the situation of film sticking bubbles and crease marks can be effectively reduced, and the film sticking quality can be improved.

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

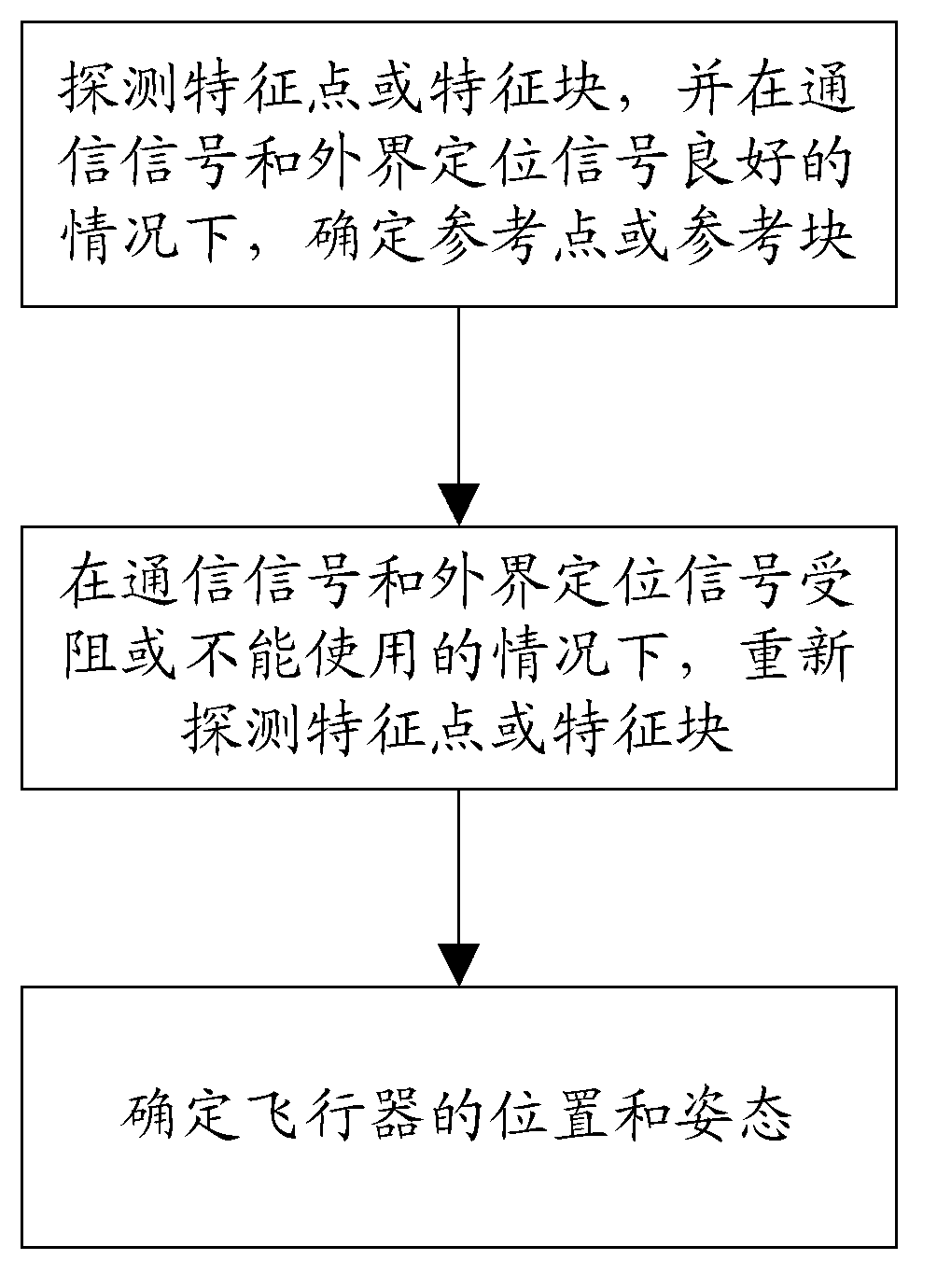

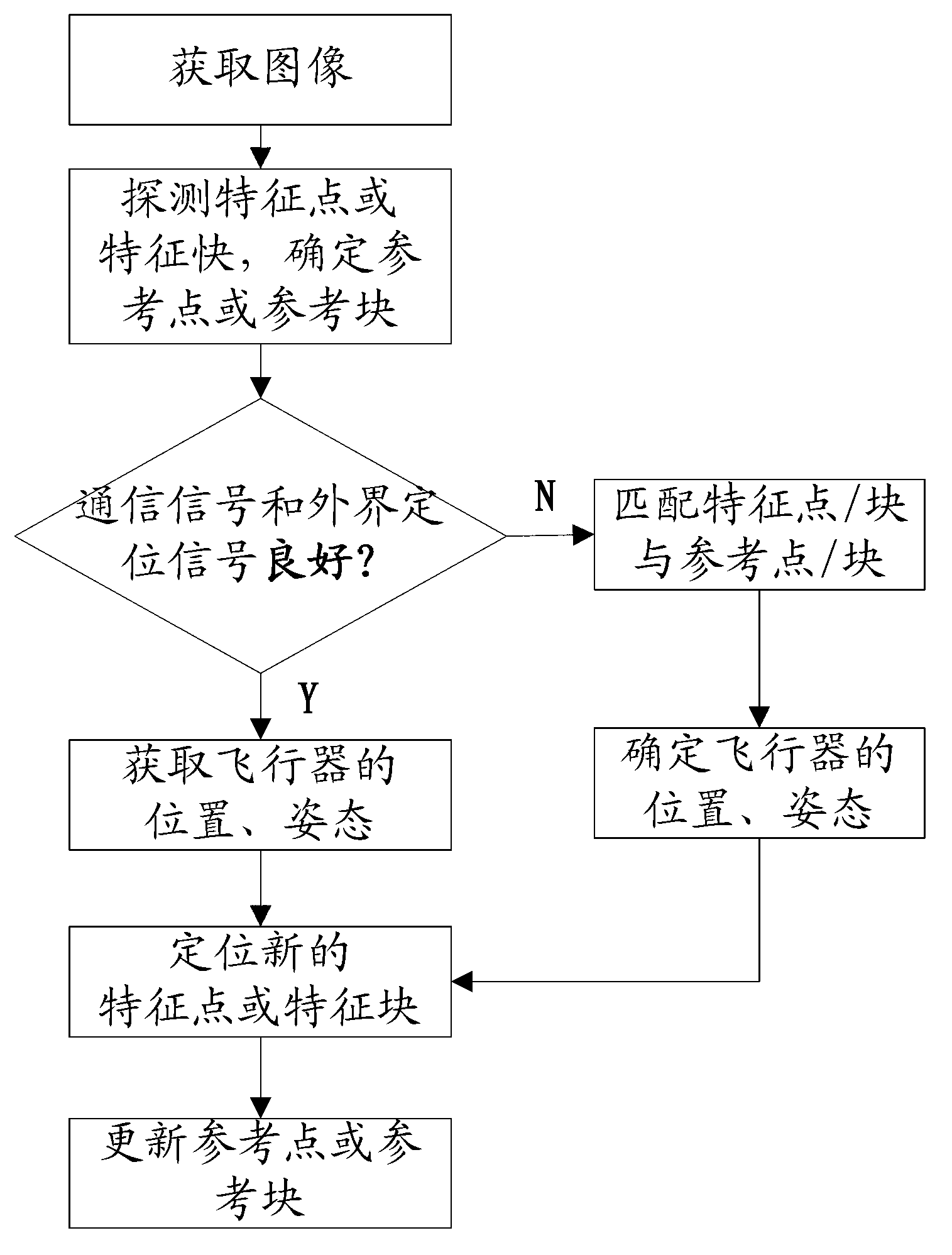

Visual-sense-based aircraft position and attitude determination method under mark-free environment

ActiveCN103175524AAccurate locationAccurate attitude determinationNavigation instrumentsVision basedControl theory

The invention discloses a visual-sense-based aircraft position and attitude determination method under a mark-free environment. The method comprises the following steps of: detecting characteristic points or characteristic blocks, and confirming the characteristic points or the characteristic blocks under the condition that a communication signal and an external positioning signal are good; detecting the characteristic points or the characteristic blocks again under the condition that the communication signal and the external positioning signal are blocked or can not be used; and matching the characteristic points or the characteristic blocks detected in the step above with the characteristic points or the characteristic blocks to confirm the position and the attitude of an aircraft. According to the method, under the condition that the communication and positioning signals are blocked, and geographic information of a fly region lacks, the position and the attitude of the aircraft can be exactly determined by an imaging system carried by the aircraft, and the guarantee can be provided for the safe fly of the aircraft. Furthermore, the precision can be further improved by using the method in combination with a sensor such as a gyro, a distance measurement machine and an inertia measurement unit, and the autonomous navigation of the aircraft can be carried out in combination with the method.

Owner:TSINGHUA UNIV

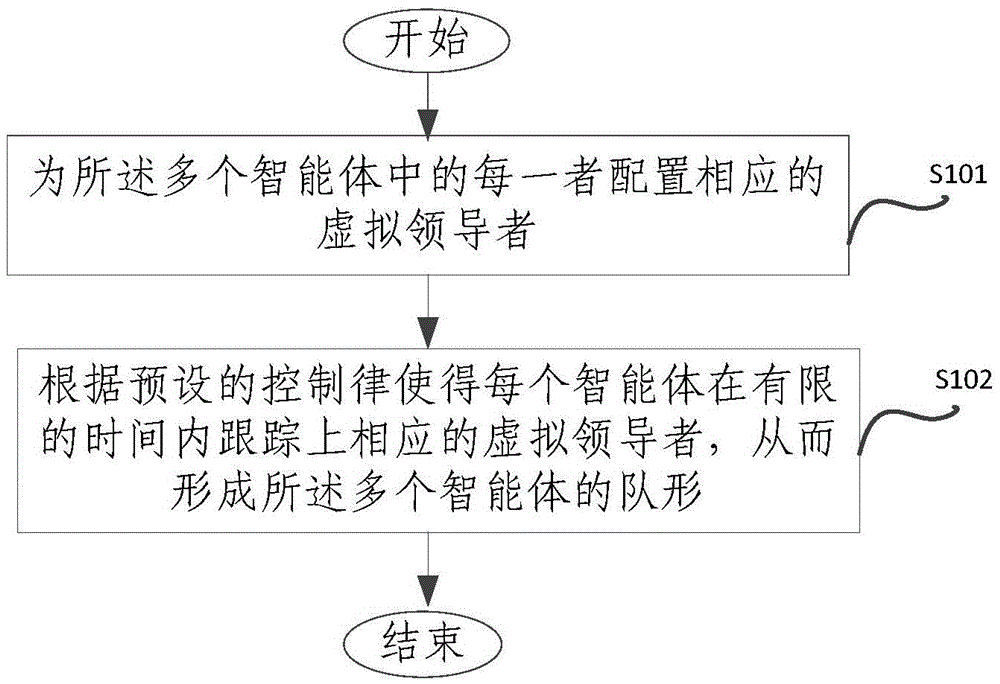

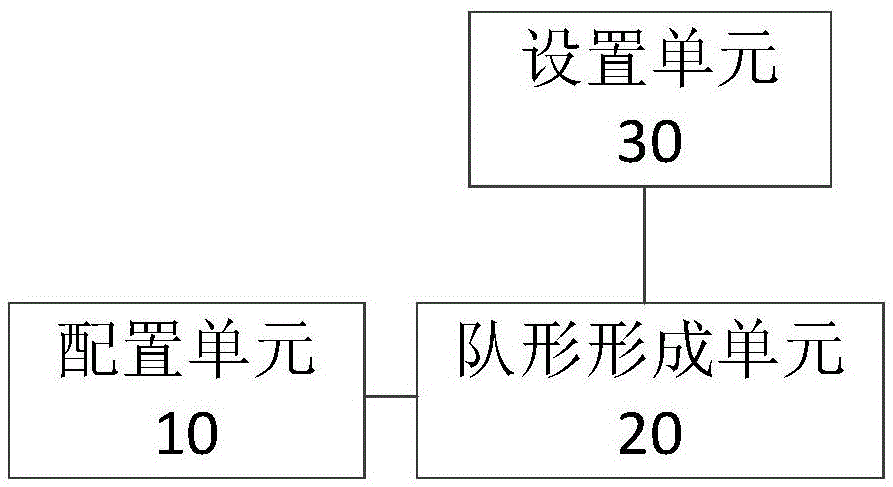

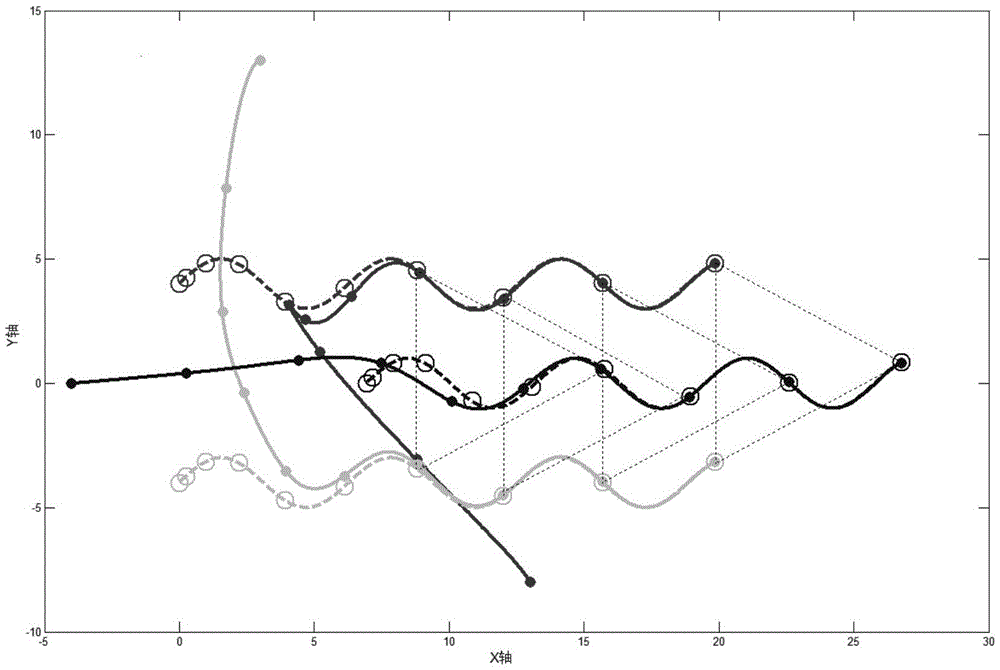

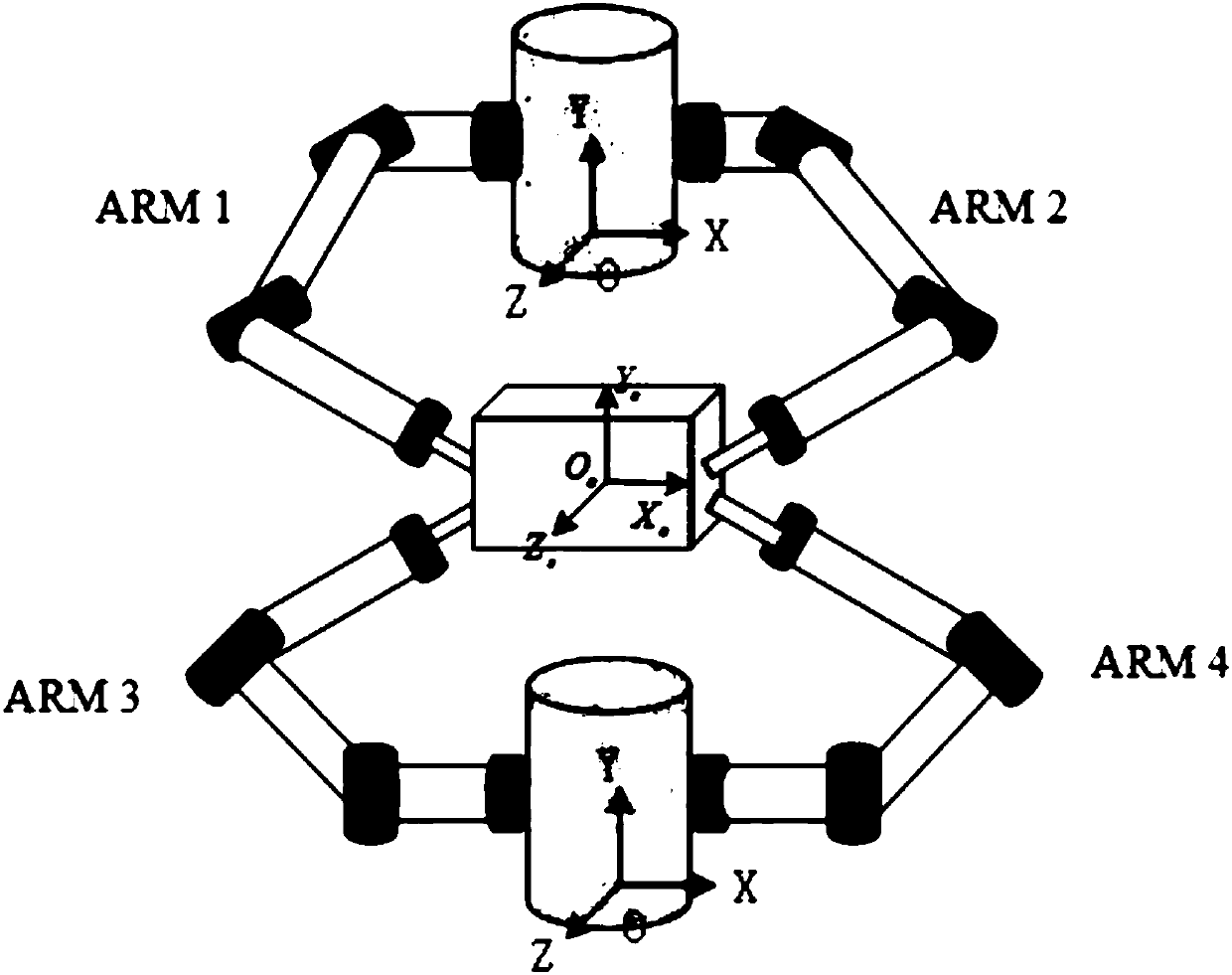

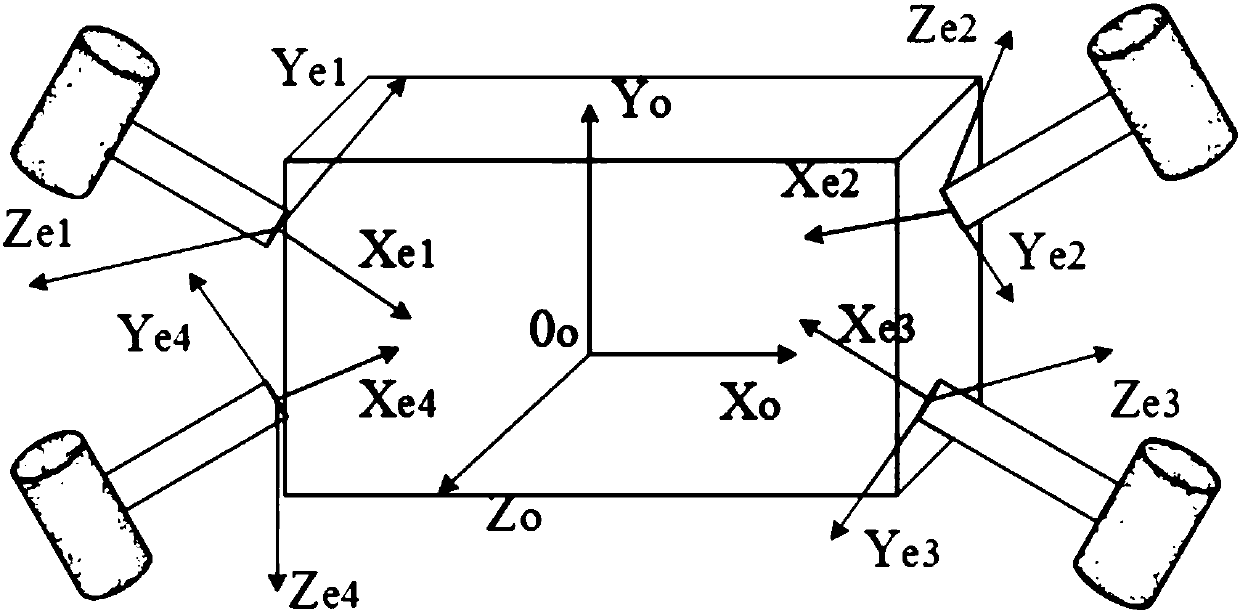

Method and device for formation aiming at multiple intelligent agents

InactiveCN105467981AGuaranteed positionAvoid formation disorderVehicle position/course/altitude controlPosition/direction controlControl engineeringIntelligent agent

The invention discloses a method and device for formation aiming at multiple intelligent agents, wherein the method comprises the steps that a corresponding virtual leader is configured for each of the multiple intelligent agents; and each intelligent agent is made to track the corresponding virtual leader in limited time according to preset control rules, so that a formation pattern of the multiple intelligent agents can be formed. The method disclosed by the invention configures the corresponding virtual leader for each intelligent agent, makes a speed and a position of each intelligent agent consistent with a speed and a position of the corresponding virtual leader in the limited time according to the preset control rules and tracks the corresponding virtual leader so as to form the formation pattern of the multiple intelligent agents, so that a certain relative position among the multiple intelligent agents can be ensured, and formation pattern disordering caused by tracking errors which are accumulated by multiple times of formation pattern conversion can be avoided.

Owner:CENT SOUTH UNIV

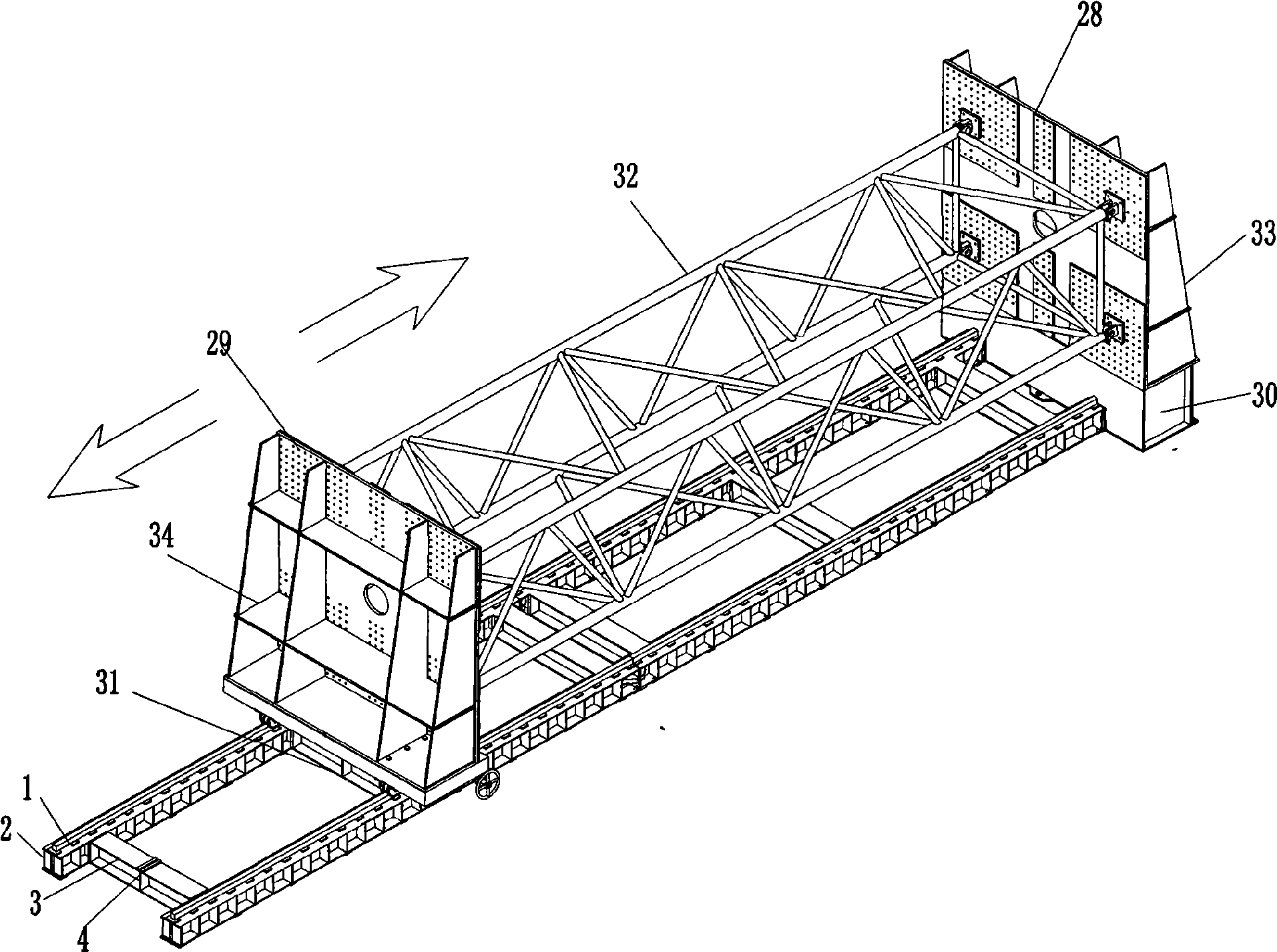

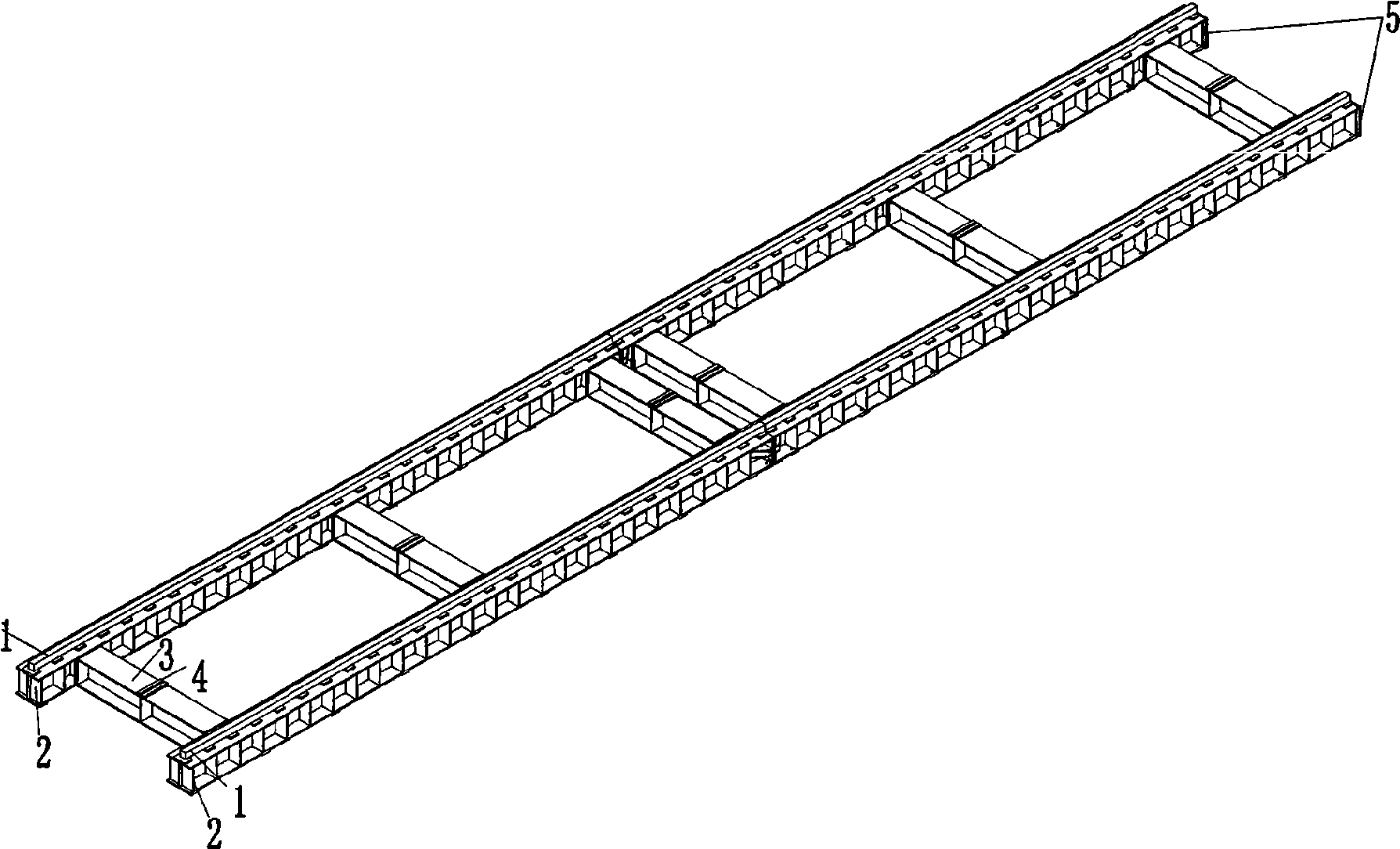

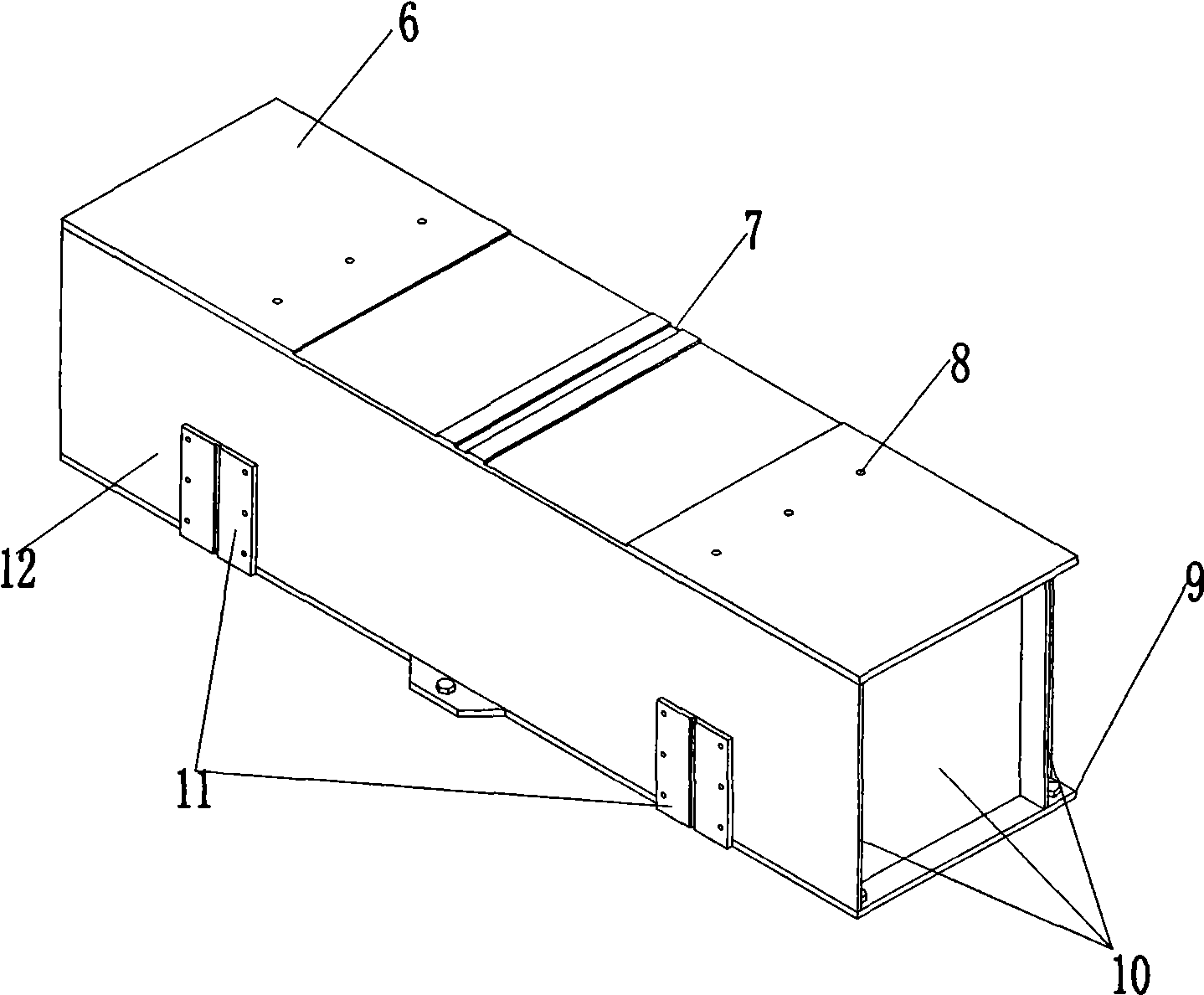

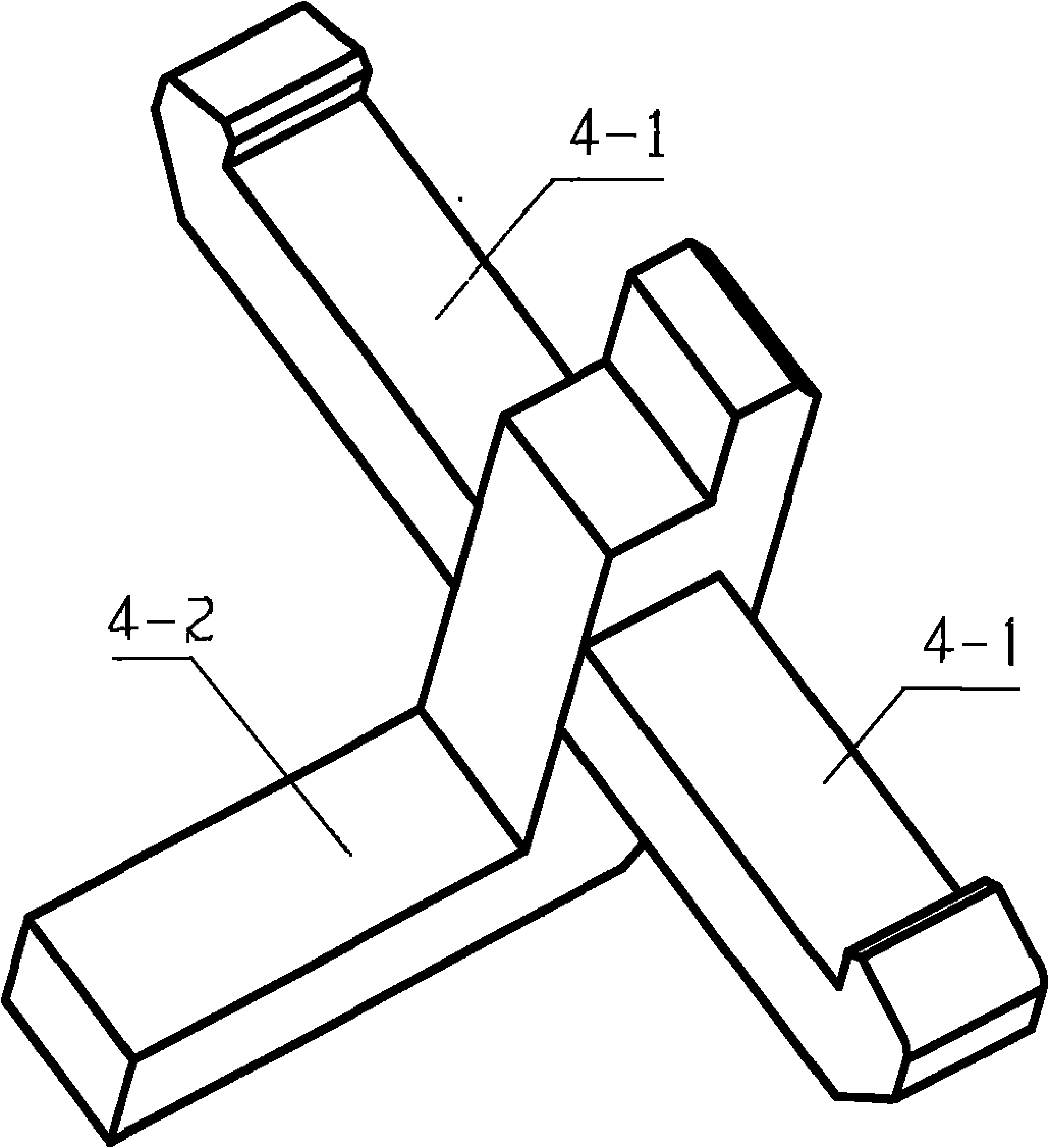

Fixture for assembling and welding universal crane arm standard knot

ActiveCN101502924AGuaranteed exact relative positionGuaranteed positionWelding/cutting auxillary devicesAuxillary welding devicesMobile endWelding

The invention discloses a universal crane boom standard knot assembly welding fixture. The universal crane boom standard knot assembly welding fixture can improve the assembly quality, reduce deflection oversize, improve the work efficiency, realize high-efficient interchange and achieve the welding and assembling of boom standard knots of different length, size, and section type on a fixture. The structure thereof comprises a track device; a movable end and a fixed end are installed on the track device; the fixed end comprises a first end plate and a base; the first end plate is arranged on the base; the base is installed on the track device; the movable end comprises a handcart and a second end plate; the handcart is placed on the track device for traveling, and the second end plate is installed on the handcart; meanwhile, the first end plate and the second end plate are equipped with a movably mounted connector positioning device.

Owner:SHANDONG FENGHUI EQUIP TECH

Rotary type opening-tying and cramping integrated device

ActiveCN104512575AGood sealing effectAutomateWrapper twisting/gatheringCultivating equipmentsAluminiumCulture mediums

Owner:临沂高新物业管理有限公司

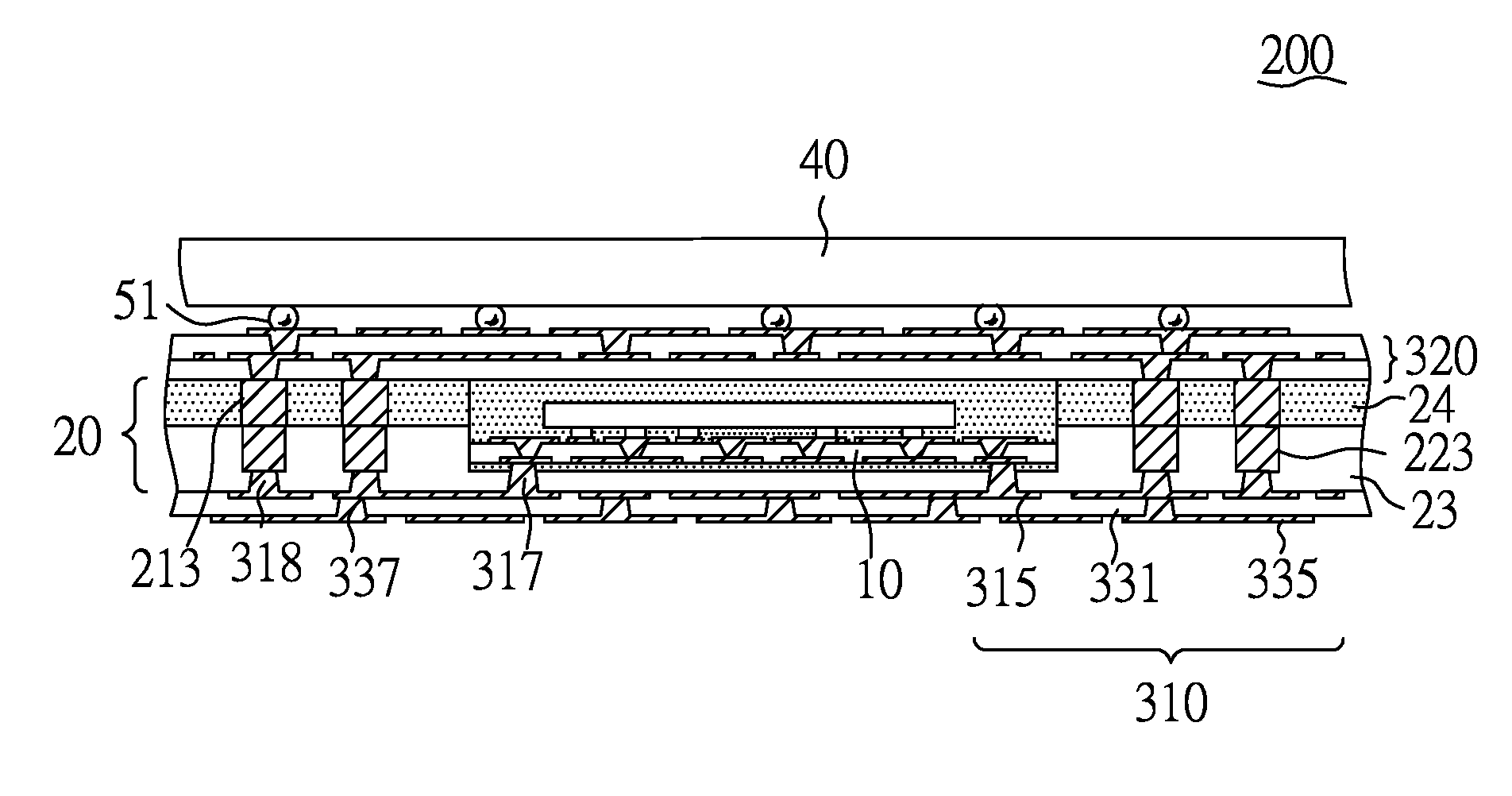

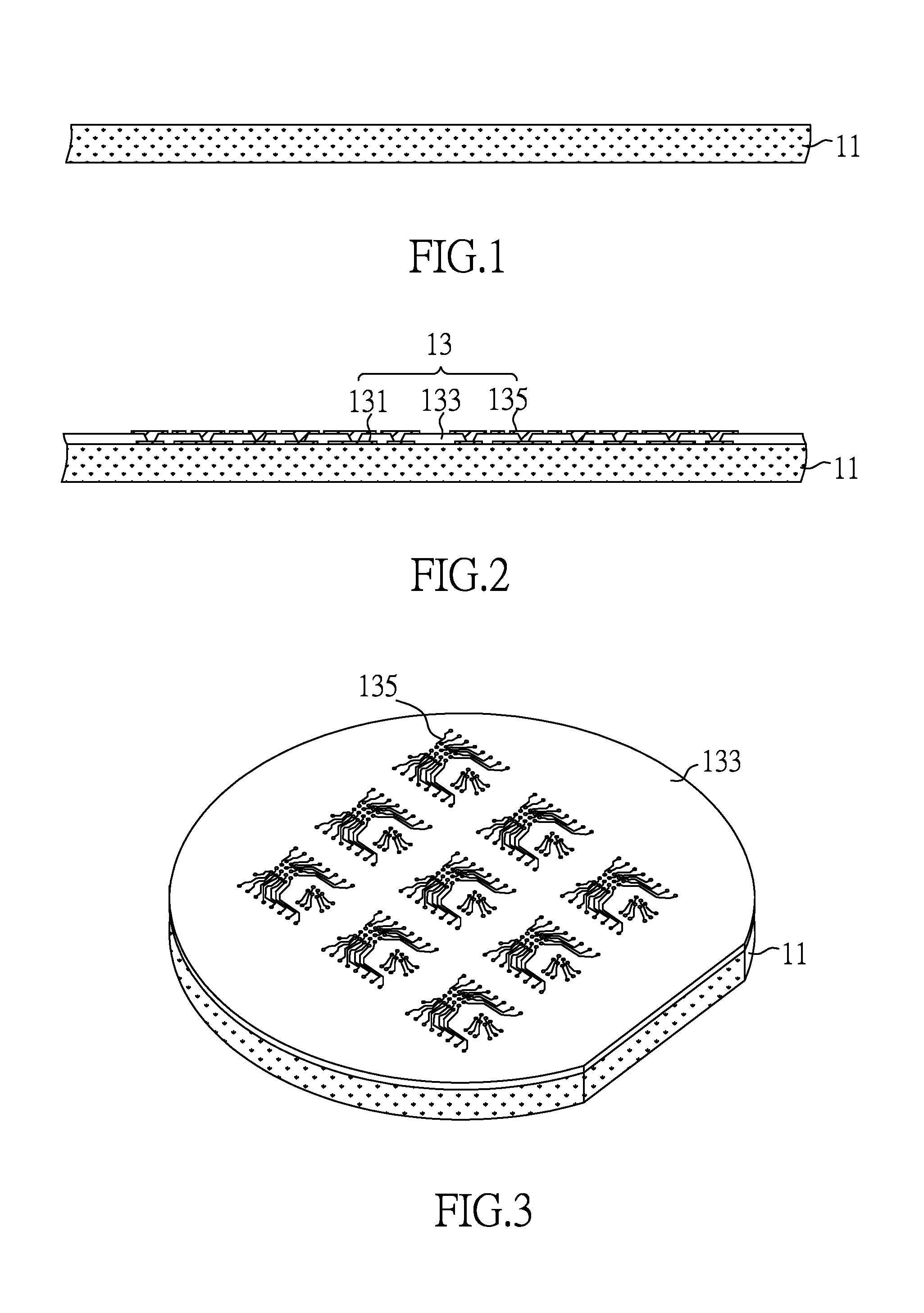

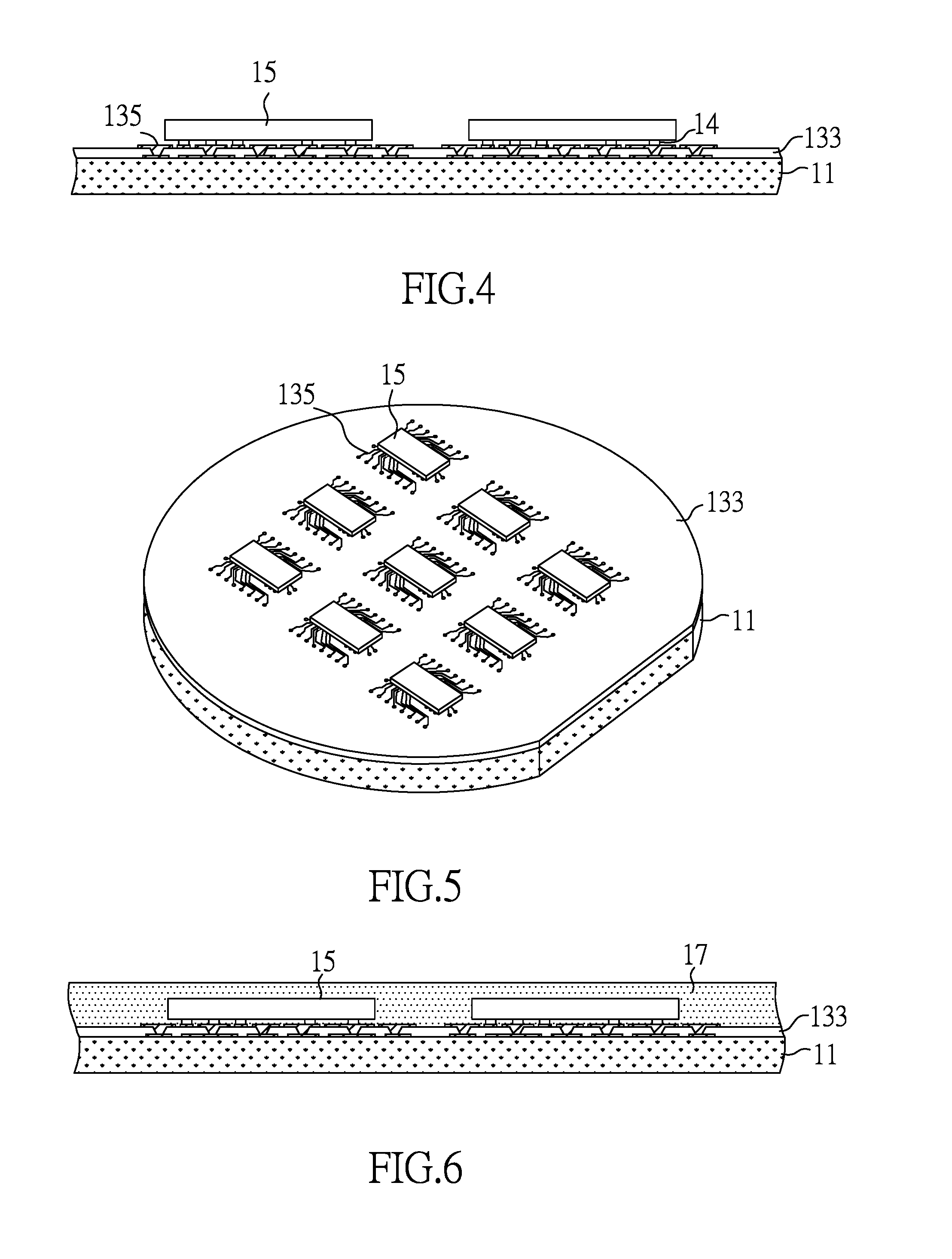

Package-on-package semiconductor assembly having bottom device confined by dielectric recess

InactiveUS20170033083A1Control displacementGuaranteed positionSemiconductor/solid-state device detailsSolid-state devicesDielectricDevice material

A package-on-package semiconductor assembly is characterized by a semiconductor device positioned in a dielectric recess of a core base and surrounded by an array of metal posts. The recess in the core provides lateral displacement control between the device and the metal posts, and the minimal height of the metal posts needed for the vertical connection between two both opposite sides of the core base can be reduced by the amount equal to the depth of the recess. Further, another semiconductor device is disposed over a top surface of the core base and is electrically coupled to the semiconductor device in the dielectric recess through a buildup circuitry under a bottom surface of the core base.

Owner:BRIDGE SEMICON

Pre-gluing machine of bolt

ActiveCN101816996AGuaranteed lengthGuaranteed positionLiquid surface applicatorsCoatingsGas cylinderElectric control

The invention discloses a pre-gluing machine of a bolt. The machine is characterized in comprising a gluing head, a gluing opening turning on-off mechanism, a pushing mechanism, an electric control device system, a glue storing cylinder and an adjusting component, wherein the glue storing cylinder is connected with a glue inlet of the gluing head; the gluing head comprises a baffle ring of an opening of a gluing cavity, a gluing cavity sleeve, a gluing cavity sleeve seat, a pushing rod, a gluing cavity, a gluing opening and a glue storing cavity; an annular gluing opening is formed between the baffle ring of the gluing cavity and the gluing cavity sleeve; the pushing mechanism and the gluing opening turning on-off mechanism respectively comprises a gas cylinder; the gluing opening turning on-off mechanism and the pushing mechanism are driven by the gas cylinders to realize the sequential linkage; the pushing rod gradually and axially pushes a bolt of a work piece; glue liquid is peripherally, axially and continuously injected among screw thread teeth of the bolt of the work piece from the gluing opening along the bolt of the work piece; and the adjusting component can adjust the action position of the pushing rod, the turning on-off position of the gluing opening, the opening width of the gluing opening, and the opening pressure of the gluing opening. The pre-gluing machine can peripherally, axially and fast inject the glue into an elastic die cavity, can evenly and exactly glue, guarantees the gluing length and position, and guarantees the quality.

Owner:FAWER AUTOMOTIVE PARTS

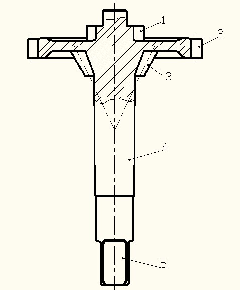

Integral forging near net shaping process for triple gear block, and prepared gear shaft

ActiveCN102189373AGuaranteed coaxialityGuaranteed positionPortable liftingGearing elementsHobbingEngineering

The invention discloses an integral forging near net shaping process for a triple gear block. The process is characterized by comprising the following steps of: blanking and preparing blank; extruding a handle part in a forward direction; pre-upsetting; extruding to obtain a small gear; performing spheroidizing; performing saponification of phosphorus; and extruding to obtain a large gear. The adopted technological scheme has the advantages that: (1) the triple gear block is subjected to integral forging near net shaping; (2) a bevel gear is pre-set, and a material at a tooth space is extruded out, so that the disadvantage of folding caused by pressing a spoke wheel during rear-pass warm forging is avoided; (3) a large straight gear is obtained through cold extrusion, and positioning orientation is adopted, so that the coaxiality and the position of a bevel gear mold and a large straight mold are guaranteed; and by using a lower pressure block, a spoke plate is prevented from being deformed due to gear extrusion, the disadvantages of gear root bending, gear face galling, and damage to a gear mold are eliminated, and in the tooth profile, the undercutting caused by hobbing is avoided.

Owner:JIANGSU CHUANGYI PRECISION FORGING

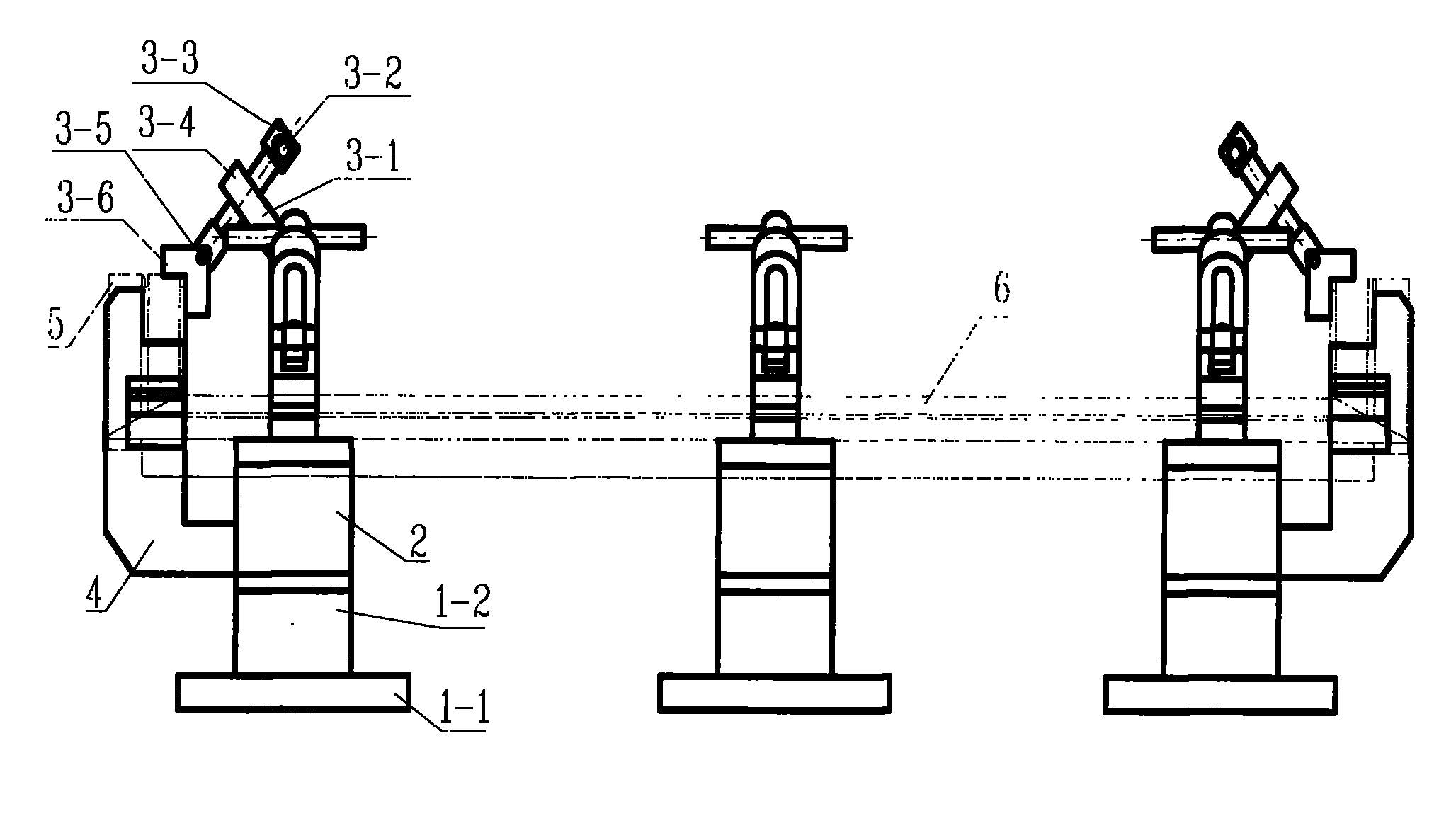

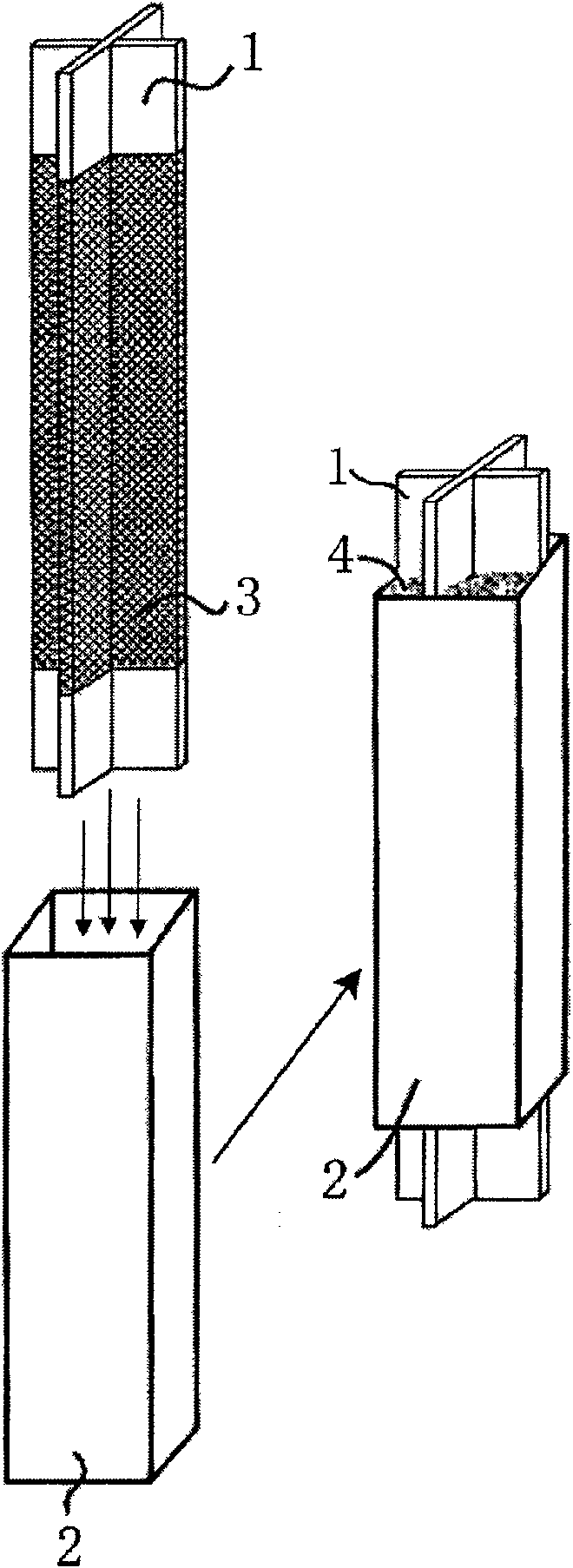

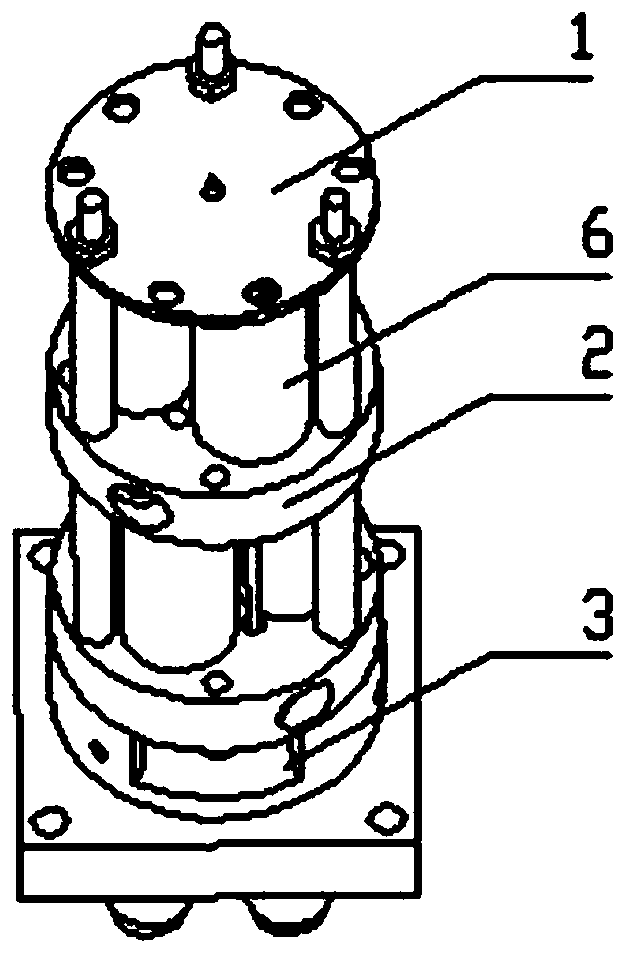

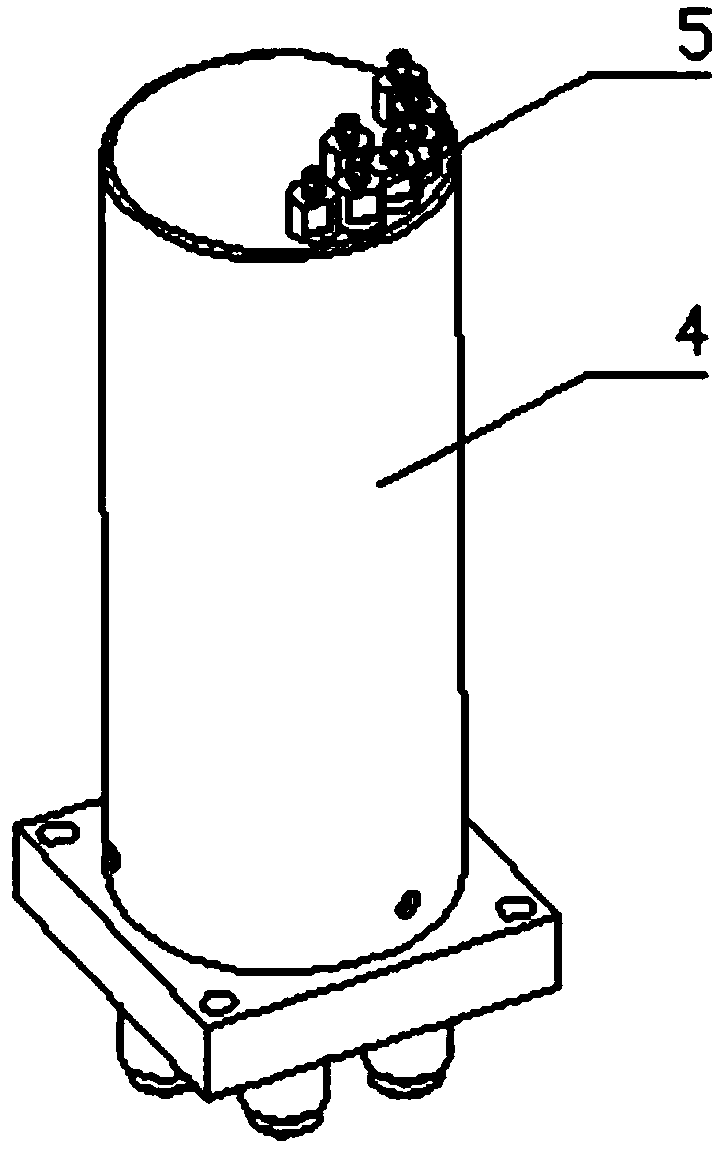

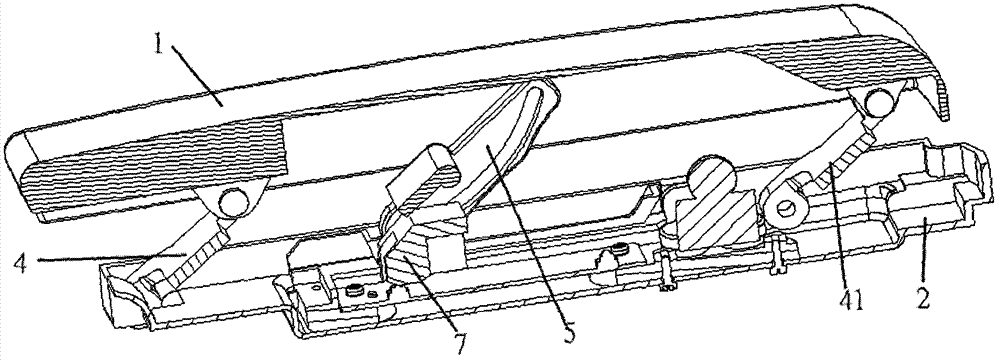

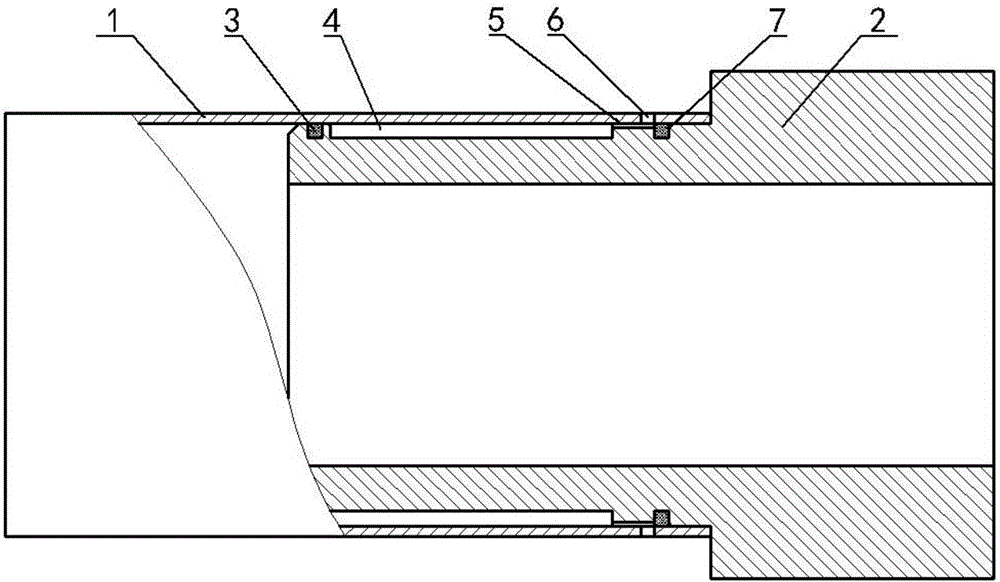

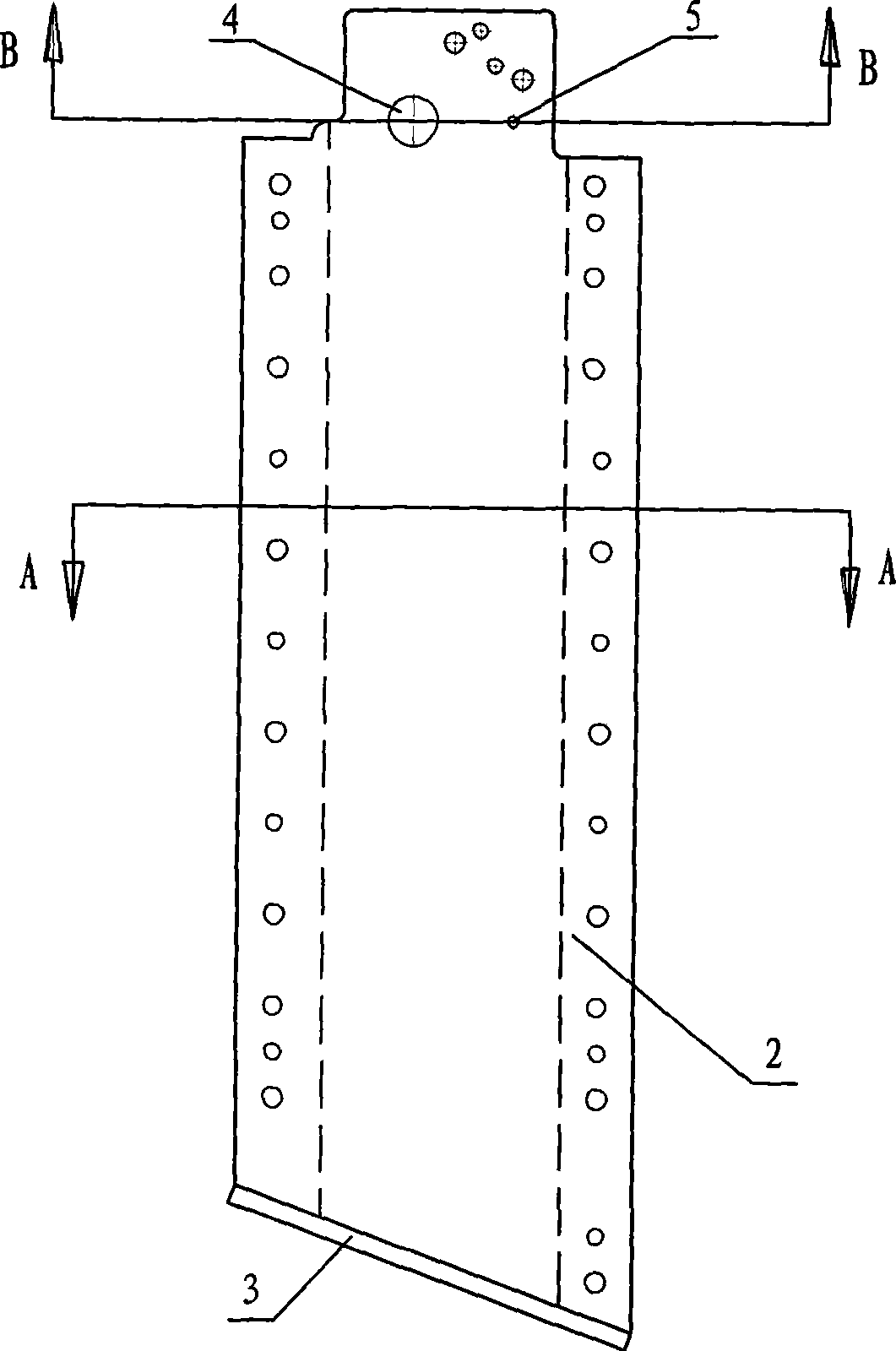

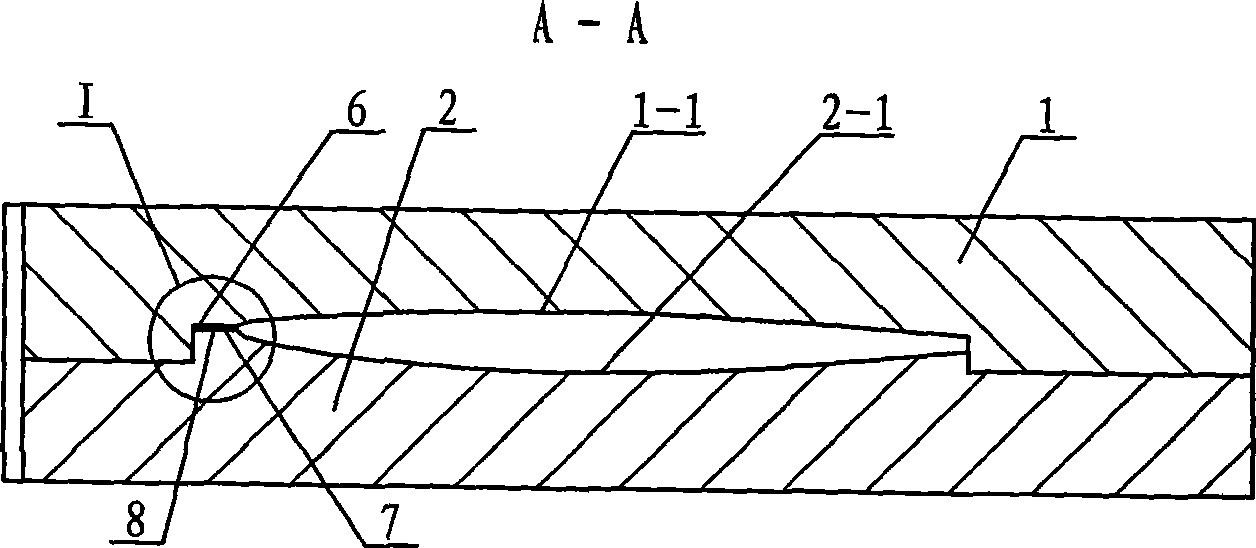

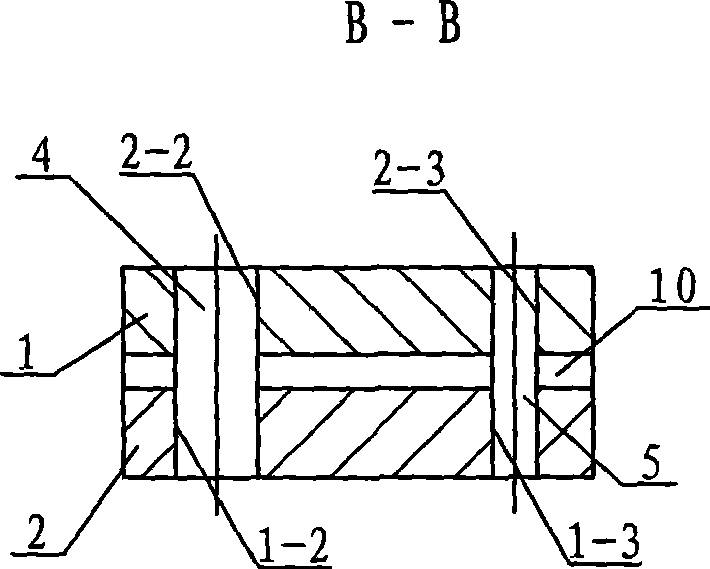

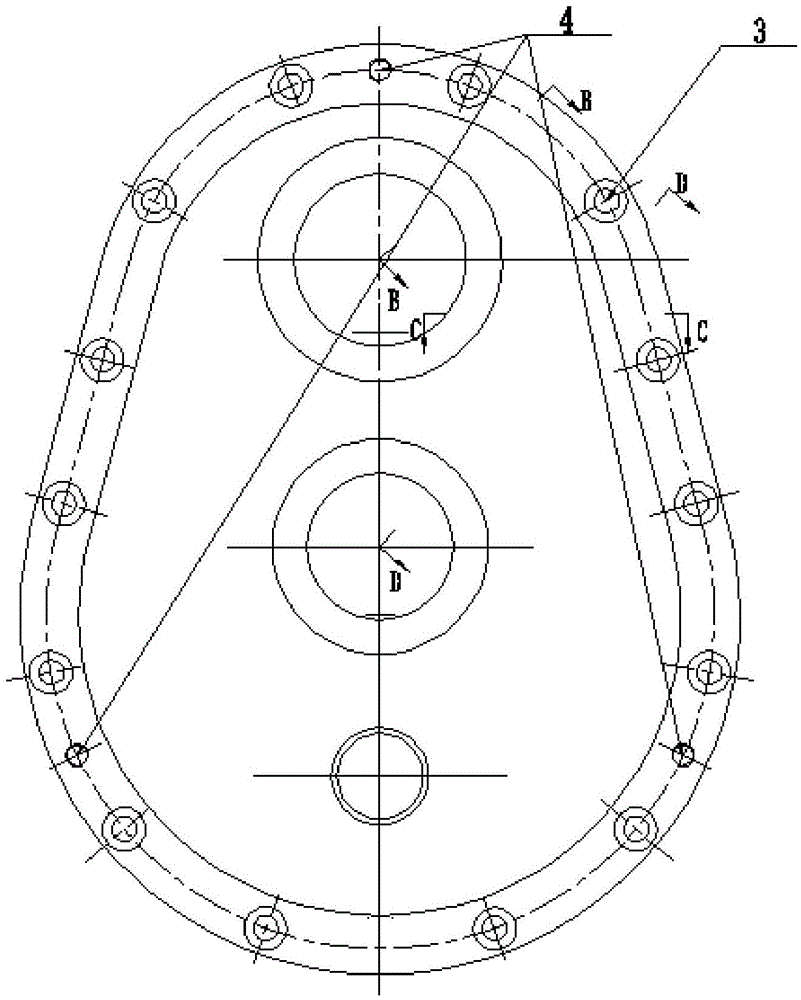

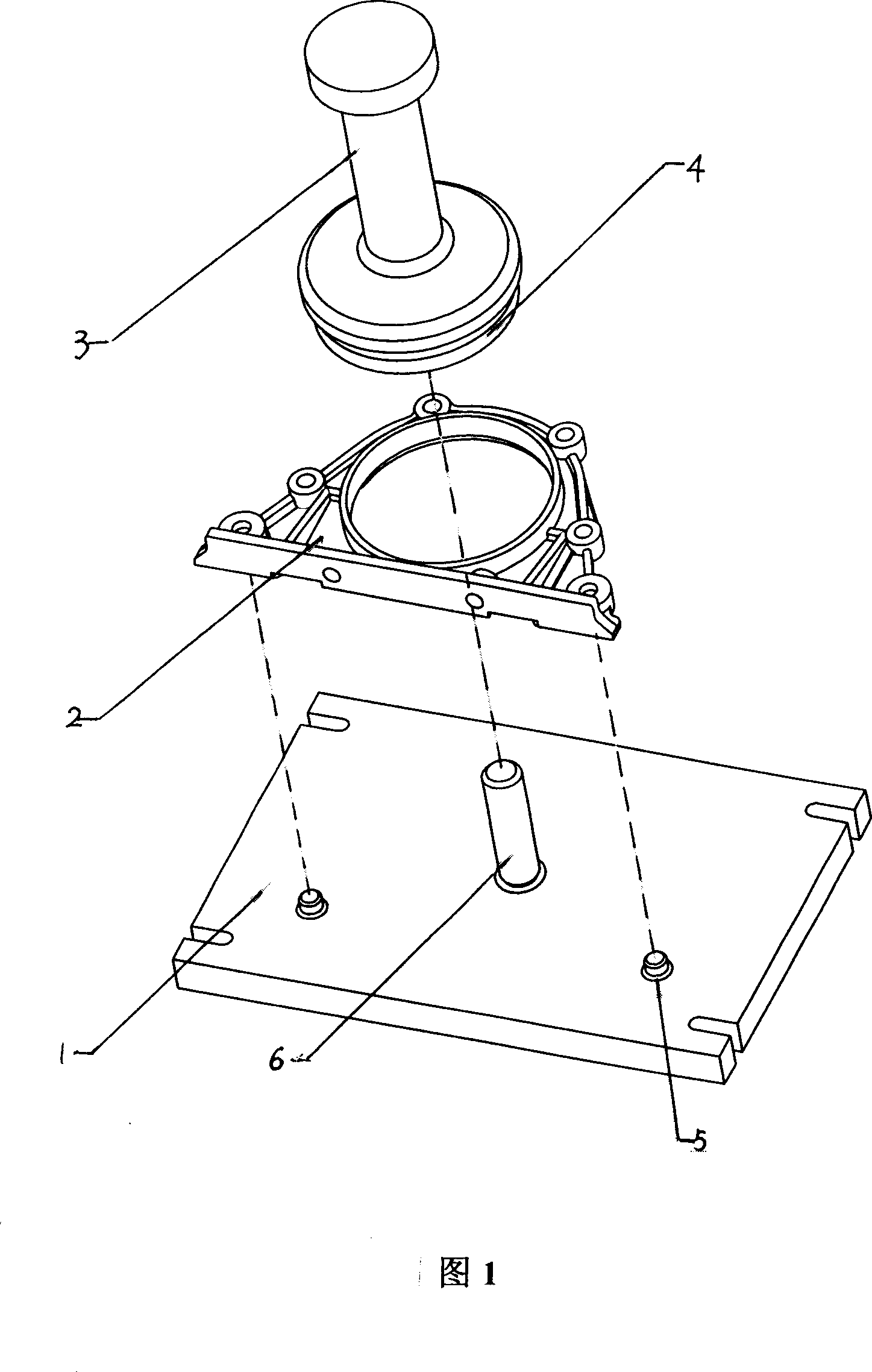

Process apparatus for fixedly welding camber profile frame and positioning method thereof

InactiveCN101804538ASimple structurePrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesModularityEngineering

The invention discloses a process apparatus for fixedly welding a camber profile frame, comprising at least three groups of parallel welding and positioning devices for supporting rectangular frames to be welded. The welding and positioning device comprises a base module (1) movably and fixedly connected with a universal platform, the base module (1) is respectively provided with a port positioning module (2) and a pressing module (3) for positioning the upper end face and the lower end face at two sides of the rectangular frame camber profile (5), the symmetrical central line of the base module (1) is further provided with a frame edge positioning module (4) used for flexibly positioning the two sides of the rectangular frame. By adopting the modularized assembly welding and positioning device with the combined structure, the large rectangular frame with the length of 10 meters and the camber profile are correctly positioned on the module, thereby realizing the replaceable performance of welding and positioning, the universalization of the platform, and the physical dimension seriation, the parameterization and the universalization of the welding and positioning module. The invention can be movably and fixedly connected with the universal platform, thereby greatly reducing the idleness ratio of tools and the space occupation during the idleness time.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

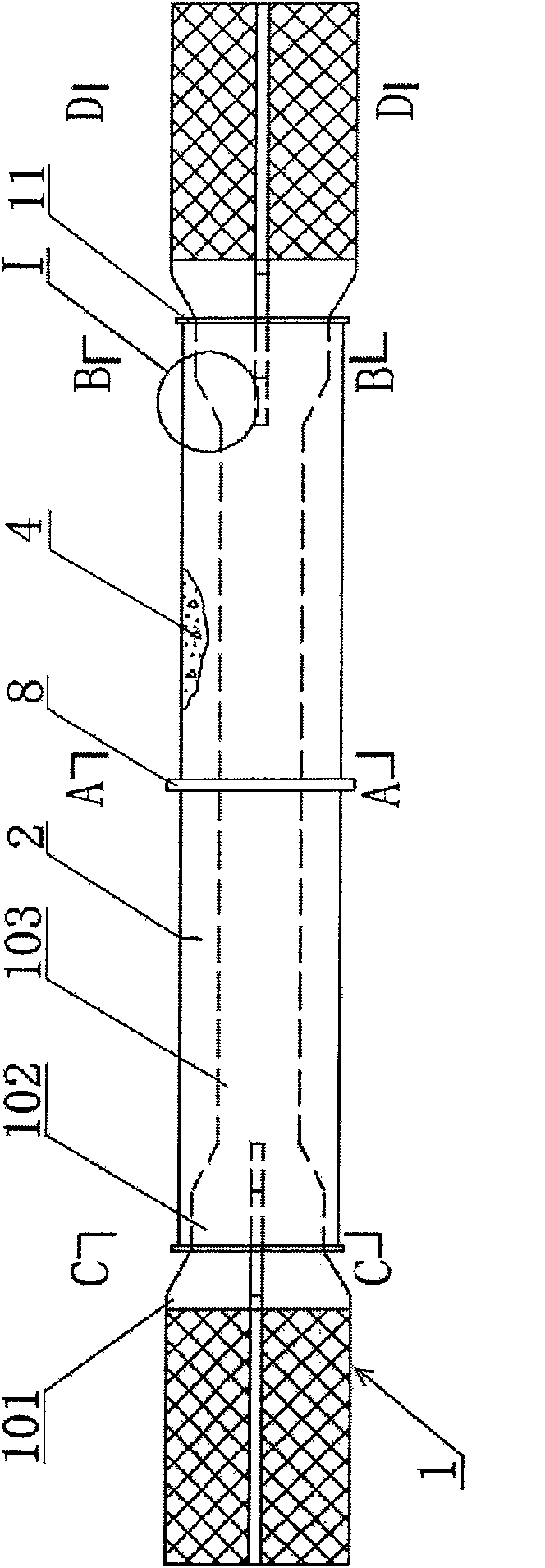

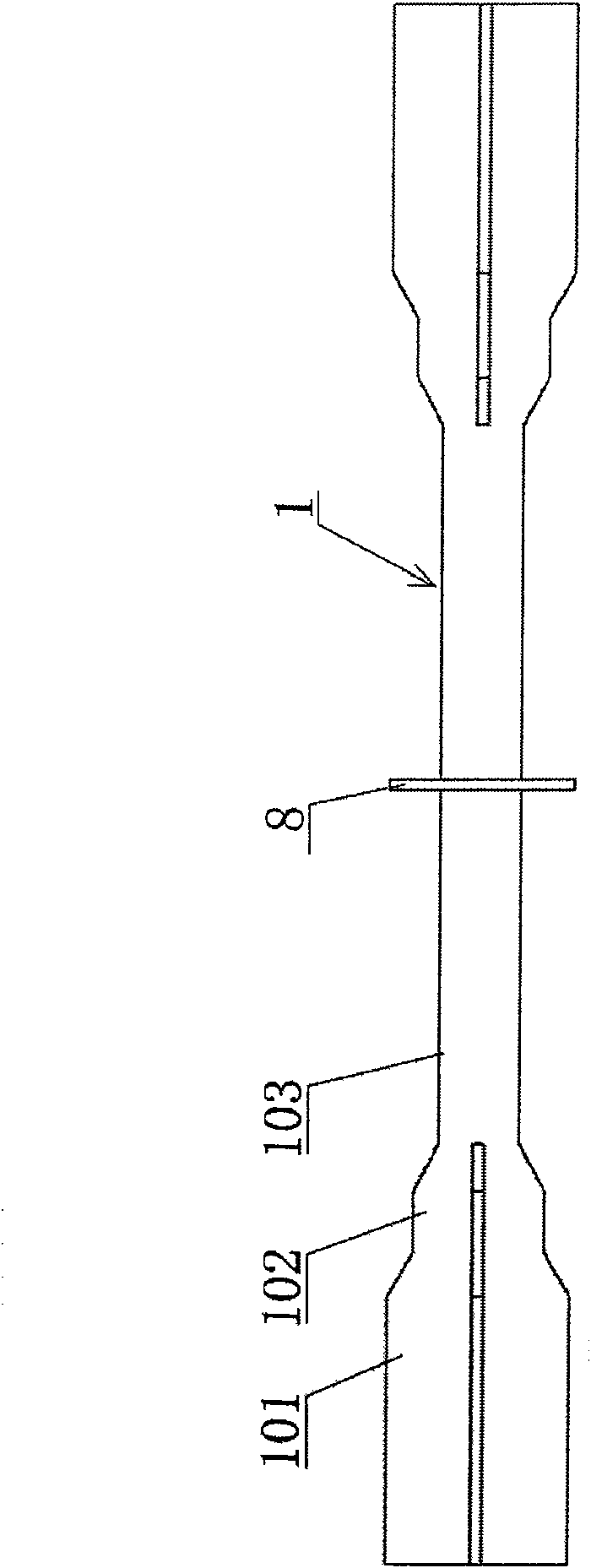

Double-layer bushing straight-line flexuosity restriction support with transverse diaphragm

InactiveCN100560884CSolve the problem of limited lateral expansionEliminates the problem of limited lateral expansionShock proofingCompressible materialCruciform

A linear buckling restrained brace with transverse partition double-layered bushing is provided. The core steel brace comprises a middle segment (buckling segment) as major body with a smaller width, two distal end segments (extension segments), and a transition segment between the buckling segment and the extension segment. The cross section of the buckling segment is shaped like the Chinese character 'Yi'. The cross sections of the transition segment and extension segment are cruciform. A transverse partition is welded in the middle of the buckling segment and provided outside with outer restraining steel bushings at two sides. An inner steel bushing is arranged between the outer restraining steel bushing and the core steel and has a linear cross section with respect to the buckling segment and a cruciform cross section with respect to the transition segment. The space between the inner steel bushing and outer restraining steel bushing is packed with fillers. An anti-adhesion material is coated on the surface of the core steel brace, with a gap between the anti-adhesion material and the inner steel bushing and filled with a compressible material. The invention has the advantages of simple structure, low fabrication cost, suitability for streamline production, and wide application in high-rise buildings, towering buildings, and highway and railway bridges.

Owner:CHINA ACAD OF BUILDING RES +2

Case deep hole processing method and application thereof

InactiveCN110497152AGuaranteed positionPrevent deviationBoring/drilling machinesCyclic processPilot hole

The invention discloses a case deep hole processing method and application thereof in aluminum-magnesium case deep hole processing. The case deep hole processing method comprises the steps of (S1) processing a pilot hole; and (S2) peck drilling and cycling. The peck drilling and cycling step comprises the steps of firstly controlling a long drill bit to enter the pilot hole at low rotary speed; when at a predetermined safety distance away from the working allowance, increasing the rotary speed to the processing rotary speed, then carrying out peck drilling processing, pausing for the predetermined time after drilling for the depth which is 1 to 2 times of the diameter of the drill bit every time in the peck drilling process every time, breaking a produced continuous chip and discharging out of a hole port through the feeding pause of the long drill bit, and retreating the long drill bit to the position at the predetermined drilling depth far away from a drill hole port after peck drilling for the predetermined depth every time so as to remove chips and cool; and repetitively circulating until processing to the target depth. According to the method, in the deep hole peck drilling circulating process, pause and chip breaking is adopted, the position of drill bit retraction is controlled, and the pilot hole is used for guiding and supporting the long drill bit, so that the problems of deflection and unsmoothness in chip removal are effectively avoided, and the processing quality and the stability are ensured.

Owner:CHINA HANGFA SOUTH IND CO LTD

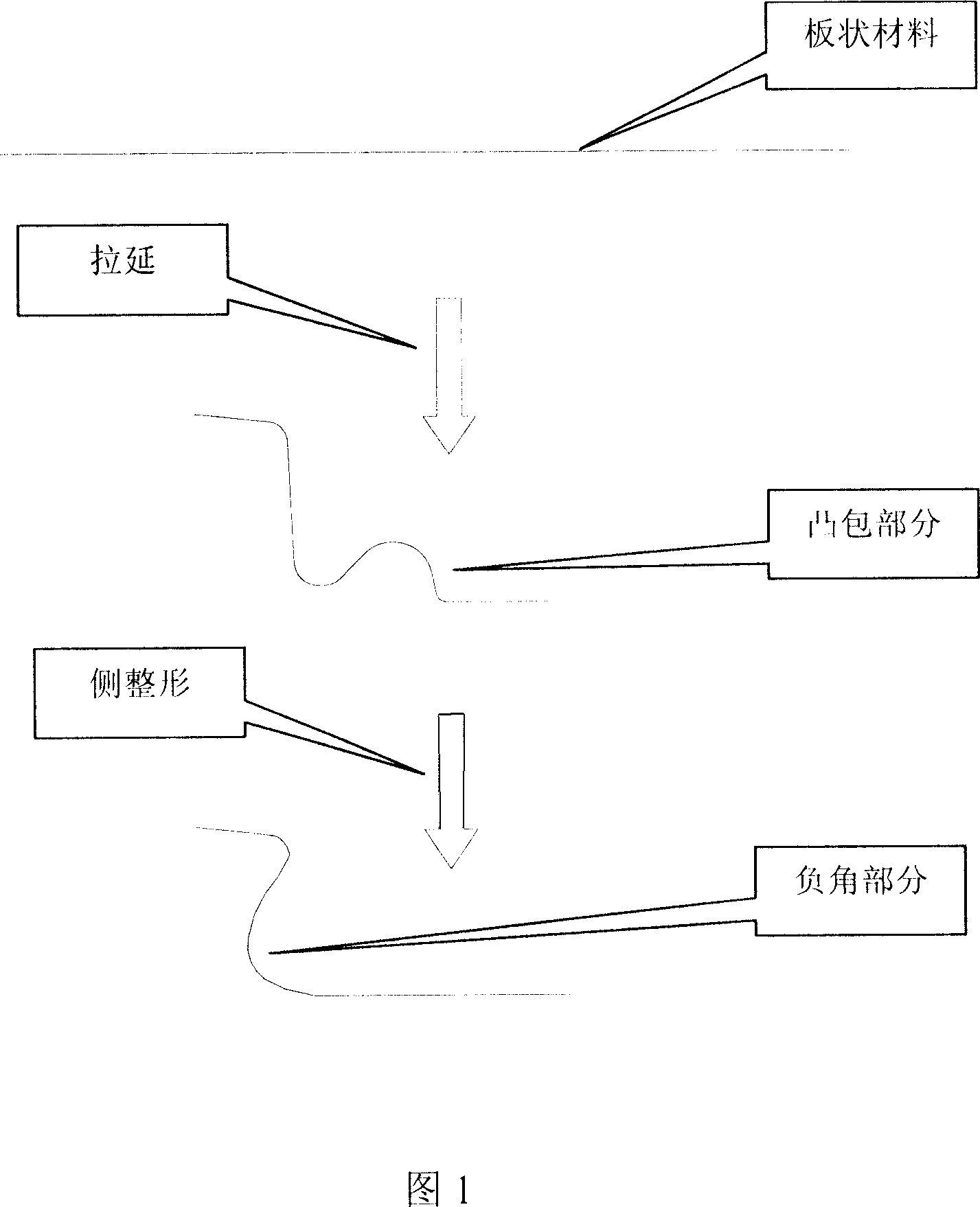

Method for forming platy pieces with negative angle

Owner:BYD CO LTD

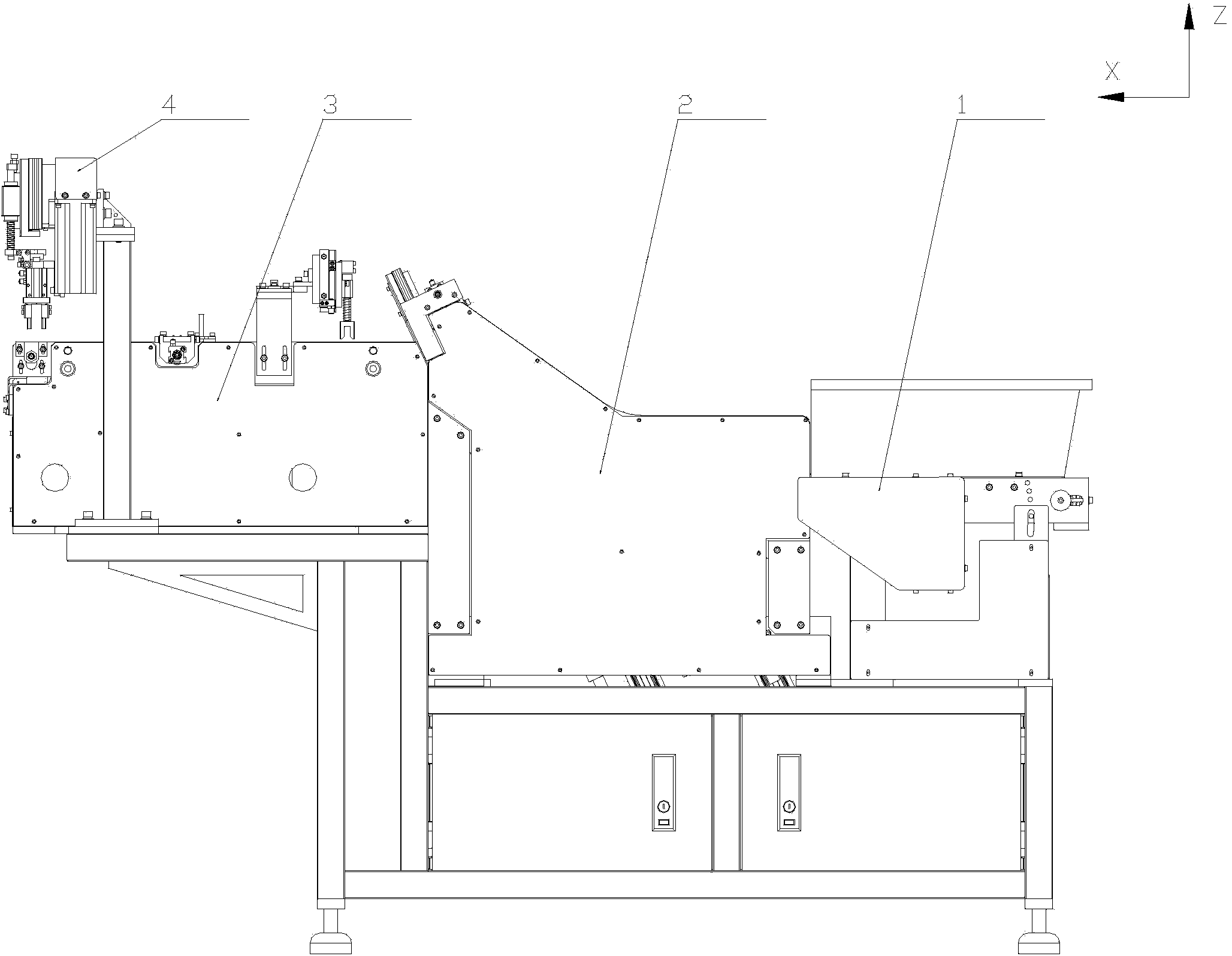

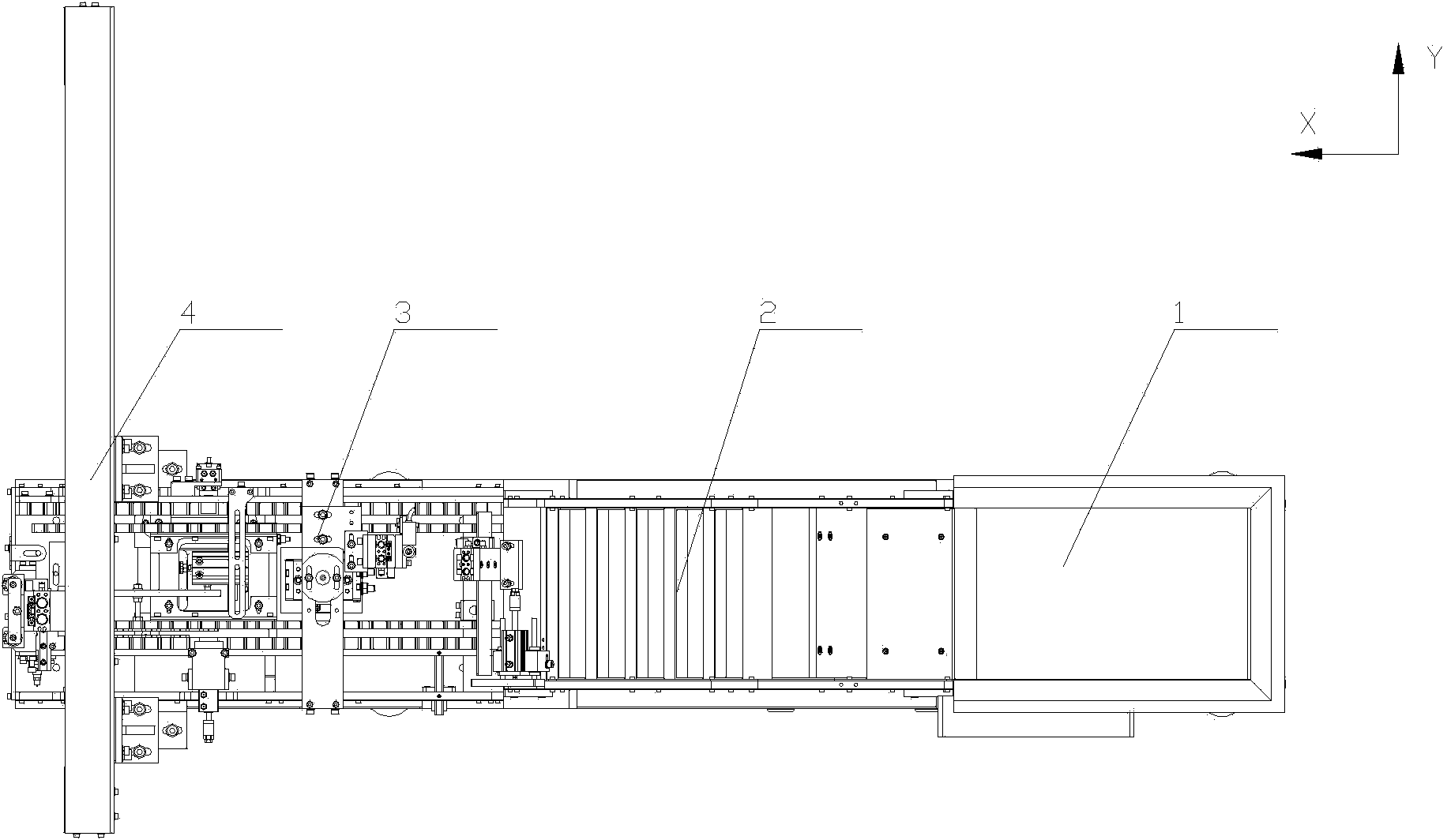

Feeding system of toothbrush bristle planting machine

The invention provides a feeding system of a toothbrush bristle planting machine and relates to the field of toothbrush manufacture. The feeding system comprises a conveyor belt system, a separating and feeding system, a steering and turnover system and a grabbing and transfer system, wherein the conveyor belt system, the separating and feeding system, the steering and turnover system and the grabbing and transfer system are sequentially connected in the X direction. The conveyor belt system comprises a conveyor belt moving in the X direction, a conveyor belt driving device, a conveyor belt rack and a feeding bin arranged in the Z direction. The separating and feeding system comprises a feeding system, a separating system and a pair of side baffles. The side baffles are fixedly connected and are respectively parallel to a ZX plane. The steering and turnover system comprises a rack, a walking system, a steering system and a turnover system. The grabbing and transfer system comprises a support arranged in the Z direction, a beam arranged in the Y direction, a transfer system and a grabbing system. The feeding system further comprises a control system. In conclusion, a single toothbrush can be fed to the toothbrush bristle planting machine by the feeding system, it is effectively guaranteed that the position of a toothbrush handle of the toothbrush, the forward face and backward face of the toothbrush handle and the facing direction of a toothbrush head are uniform, and therefore the purpose that the bristle planting effect and the bristle planting speed of the toothbrush bristle planting machine are effectively guaranteed is achieved.

Owner:JIANGSU ASK TECH

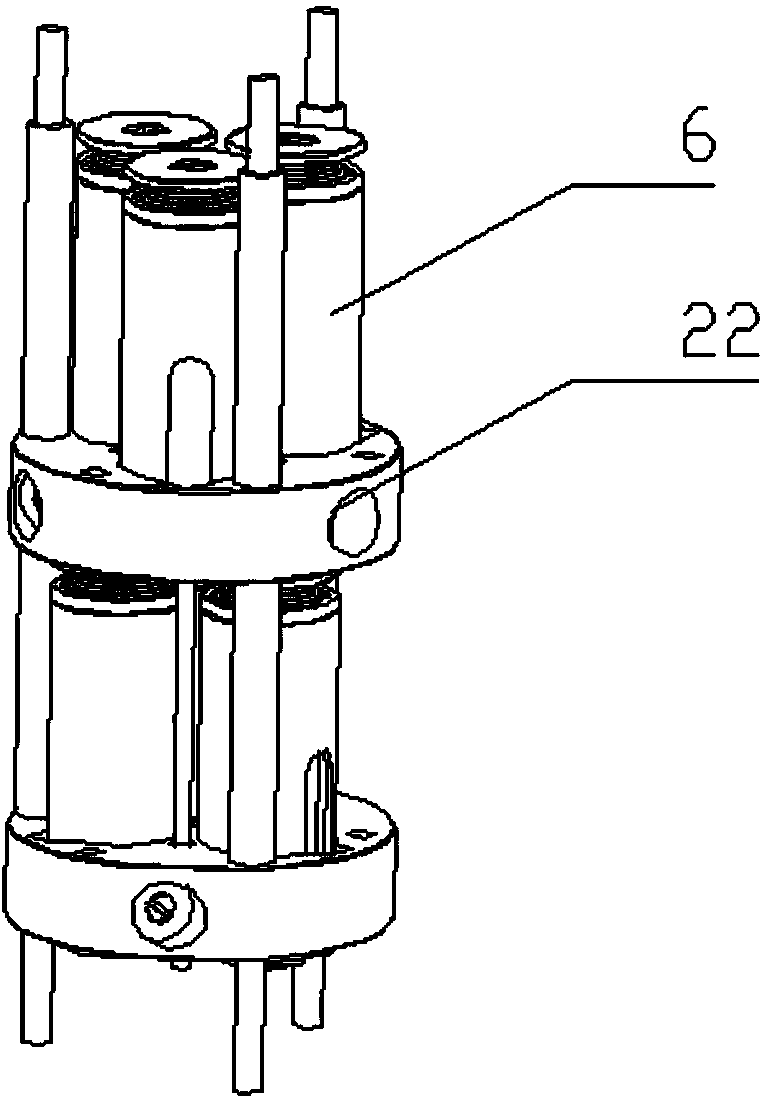

Miniaturized high-frequency single-pole six-throw coaxial mechanical and electrical switch

ActiveCN104183423AReduced axial areaOffset discontinuityElectromagnetic relay detailsMiniaturizationTransmission channel

The invention provides a miniaturized high-frequency single-pole six-throw coaxial mechanical and electrical switch which is composed of a control circuit assembly, an electromagnetic drive assembly, a microwave signal transmission channel assembly and an outer shell part. The control circuit assembly controls the fact whether currents pass through a coil in the electromagnetic drive assembly or not, once the currents pass through the coil, the coil generates a magnetic field, generated electromagnetic force enables a fixed terminal to attract a movable terminal to drive an ejection rod to move, and therefore a transmission reed is pushed to move. Accordingly, a microwave signal input end and a microwave output end are connected or disconnected, connecting of any one of a middle connector or six peripheral connectors is controlled to be achieved. The above scheme is used, the advantages of being small in size and high in efficiency are achieved, and the special requirement for a miniaturized mechanical and electrical switch of a switch matrix in an automatic testing system can be met.

Owner:CHINA ELECTRONIS TECH INSTR CO LTD

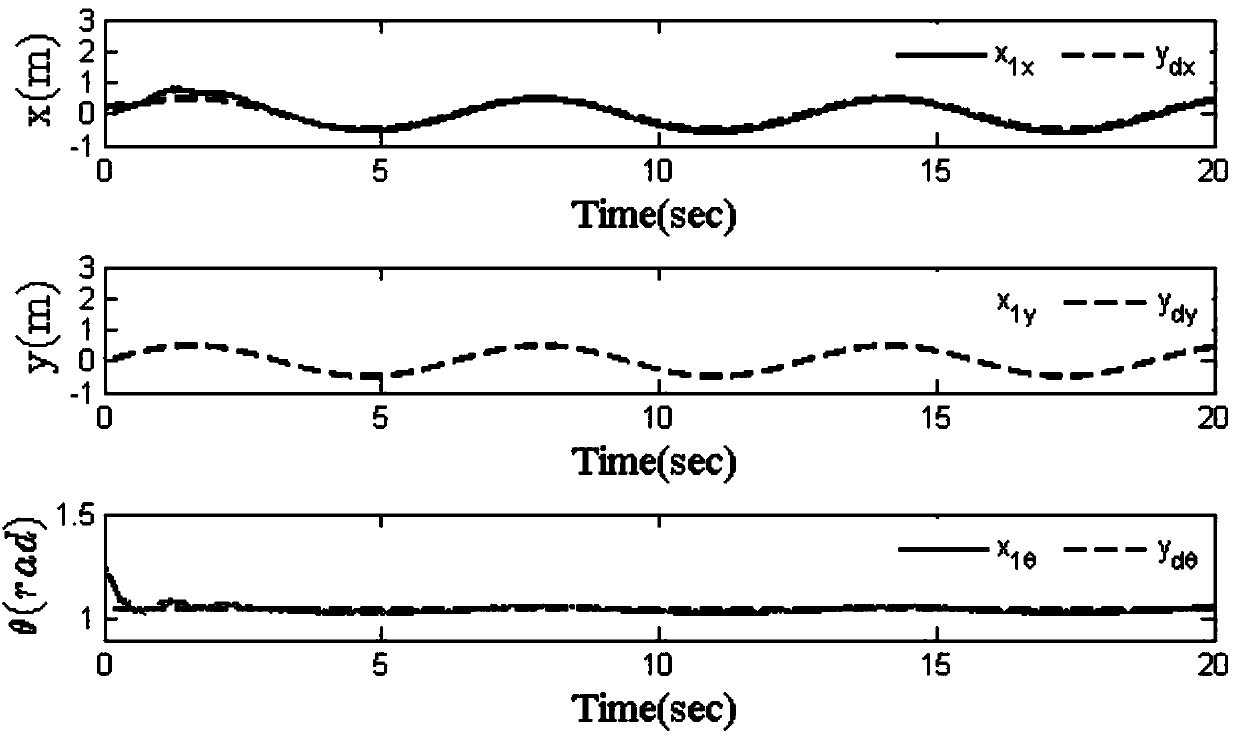

Adaptive control method for multiple humanoid robots in case of immeasurable speed

ActiveCN108388123AGuaranteed uptimeEliminate the effects ofAdaptive controlState observerMathematical model

The invention discloses an adaptive control method for multiple humanoid robots in the case of an immeasurable speed, which comprises the steps of first, building a mathematical model of the multiplehumanoid robots for cooperatively grasping an object; second, designing a state observer; and third, designing a neural network adaptive controller to control the humanoid robots. According to the invention, influences of driving saturation are eliminated through constructing an auxiliary system in allusion to a humanoid robot system with input saturation; the input of the neural network is enabled to be maintained within a bounded compact set range through introducing an obstacle Lyapunov function, and the normal running of the neural network is ensured; and the state observer is introduced to estimate the speed, the controller design is performed in the case that the speed of the object is immeasurable, and an unknown constant matrix W2 is converted into an unknown scalar virtual parameter c, so that only one adaptive parameter needs to be adjusted online, and the computational burden is greatly reduced.

Owner:青岛格莱瑞智能控制技术有限公司

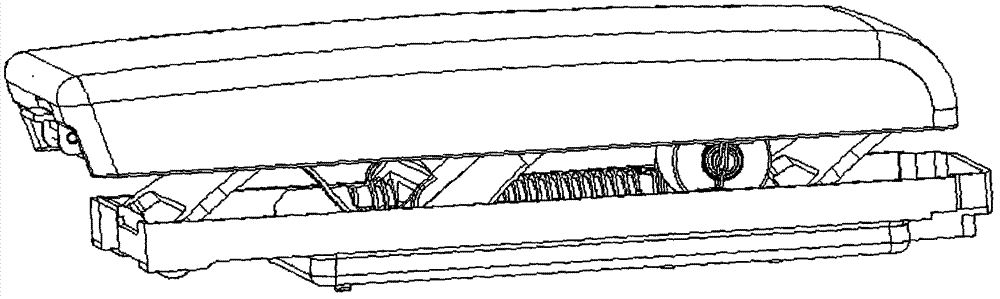

Electric armrest of automobile seat

InactiveCN102774299AHeight adjustableThe effect is positive and obviousArm restsControl lineSelf locking

An electric armrest of an automobile seat comprises a top cover and a bottom cover, wherein the top cover is separated from the bottom cover, a mechanical transmission mechanism is arranged between the top cover and the bottom cover, the top cover is connected with a moving end of the mechanical transmission mechanism, the mechanical transmission mechanism is connected with an output shaft of an electric motor, and a control end of the electric motor is connected with a control circuit. A self-locking structure is arranged inside the mechanical transmission mechanism. The mechanical transmission mechanism comprises a parallel four-rod mechanism and a driving mechanism, the driving mechanism comprises a transmission device and a sliding block, a fixing support and a guide rail are arranged on the bottom cover, and the transmission device is composed of a worm-and-gear structure and a screw nut pair two-stage transmission mechanism. The control circuit is arranged between the top cover and the bottom cover and is connected with a key plate, a control line and a power line. By the aid of the electric armrest, the height of the top cover can be adjusted at random, so that the height of the armrest can be adjusted, the comfort of driving is improved, and the fatigue during long-term driving is avoided.

Owner:YANFENG VISTEON AUTOMOTIVE ELECTRONICS

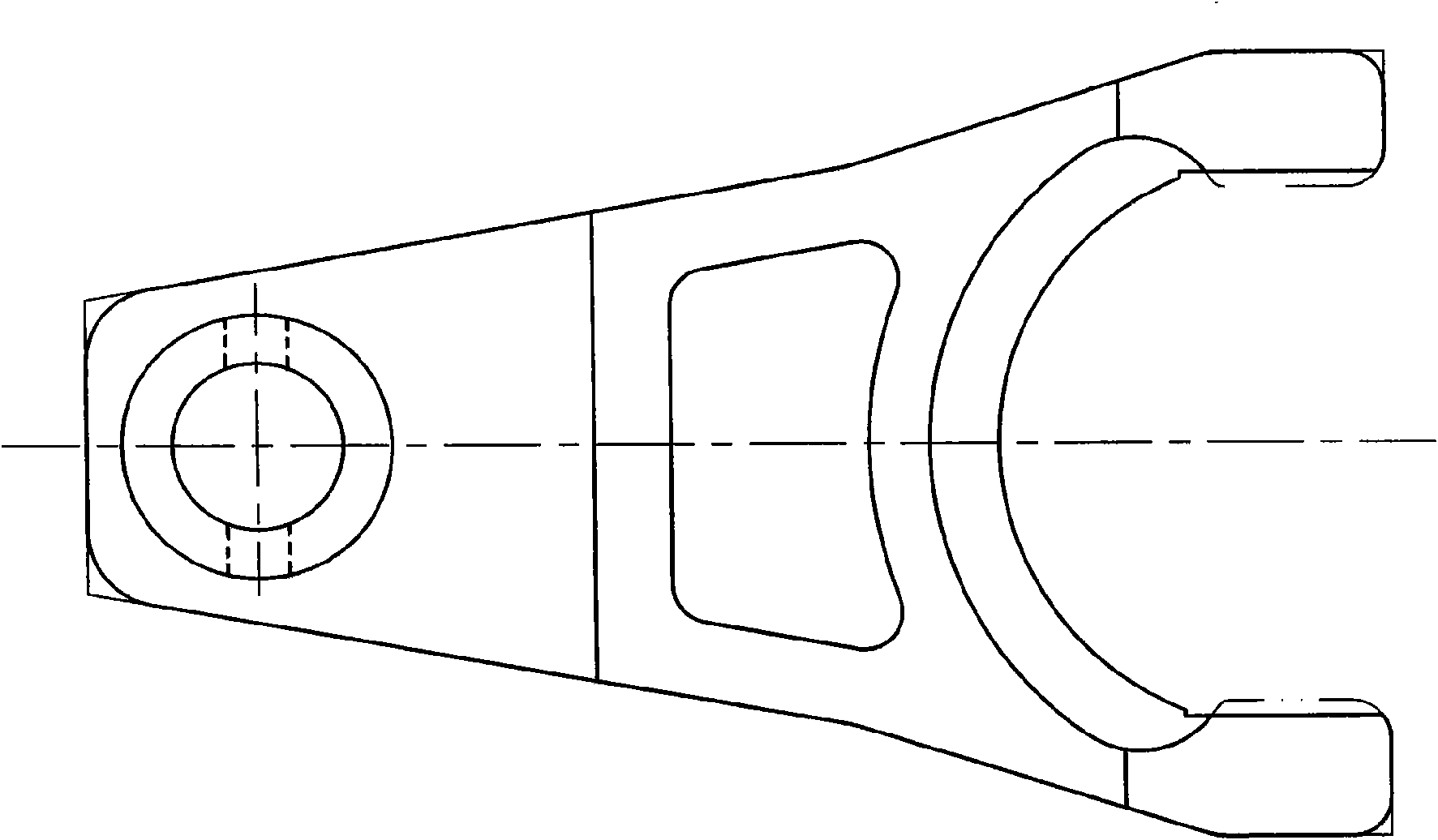

Method for processing shifting fork of automobile parts

InactiveCN101633101AMeet the needs of rapid developmentGuaranteed symmetryGearing controlEngineeringHardness

The invention provides a method for processing a shifting fork of automobile parts, which comprises the following steps: according to the requirements of a drawing, drilling a through hole and lathing the end face and downside surface of a convex plate; boring the through hole; raising a core rod and lathing the end face of the convex plate; milling the planes of two feet; milling openings; drilling, expanding and reaming two phi8<+0.045> holes on the outer circles of the machined hole; performing heat treatment through carbonitriding till the surface hardness reaches 59 to 63 HRC and the effective hardened depth reaches 0.1 to 0.3 millimeter; honing inner holes, wherein the position degree between the inner holes and the two phi8 holes is required to be less than phi0.1; testing with corresponding measuring tools and apparatuses; and deburring, washing, applying oil on, packaging and warehousing the shifting fork. The method fully guarantees the product in terms of symmetry, position degree, work hardness and high quality, greatly prolongs the service life of the product and meets the requirements for the rapid development of the automobile industry.

Owner:JIANGSU HENGYI IND TECH CO LTD

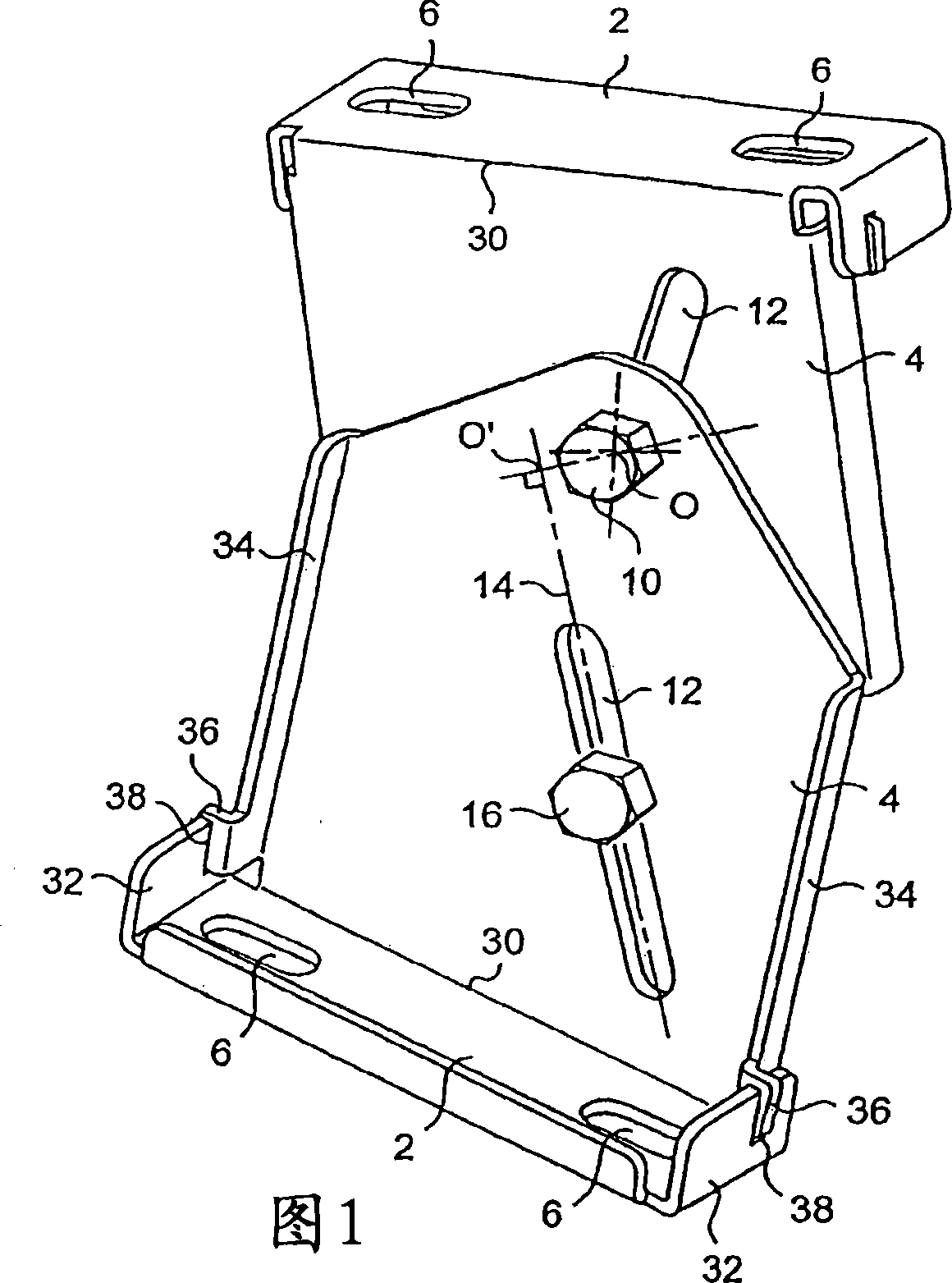

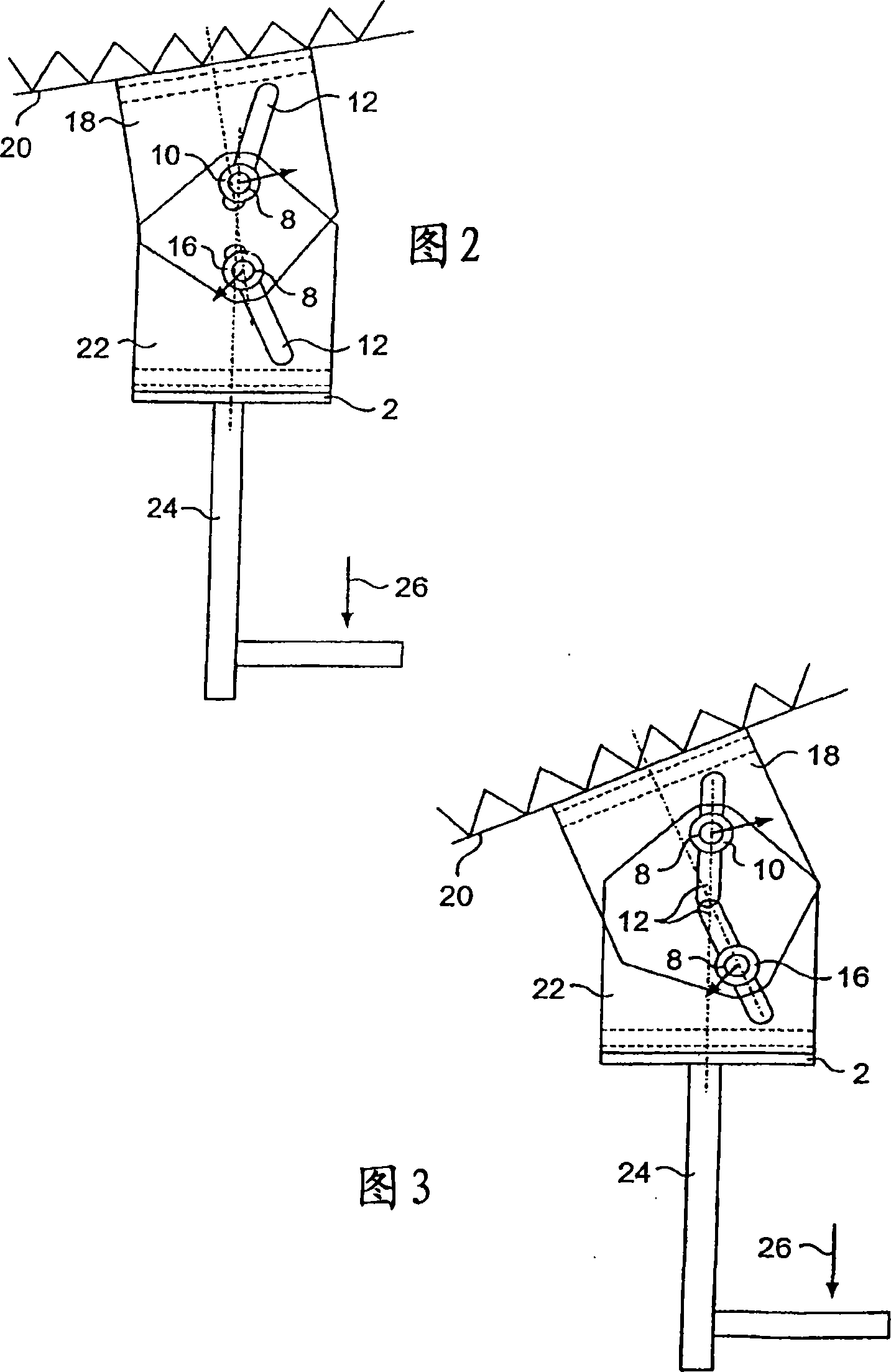

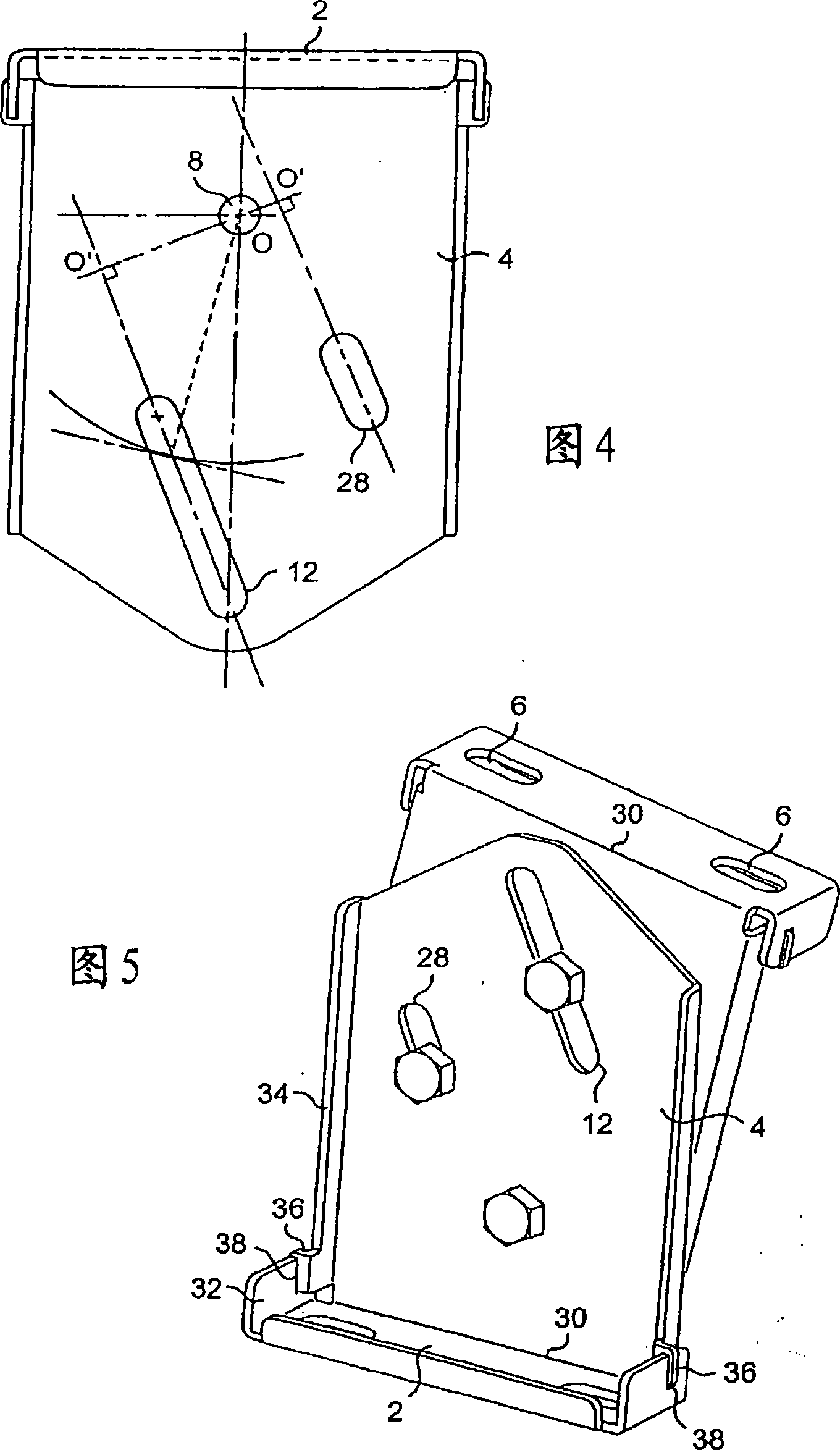

Connecting part and a steerable connecting part arrangement

InactiveCN101189467ALow costGuaranteed positionPipe supportsElectrical apparatusEngineeringMechanical engineering

Owner:I C M GRP

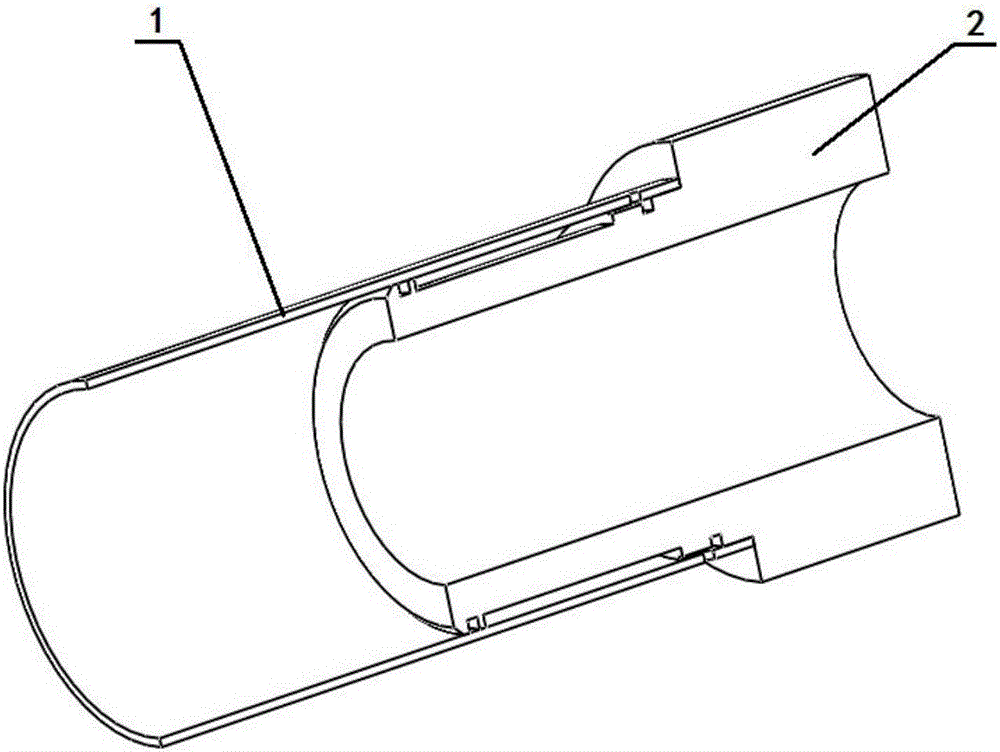

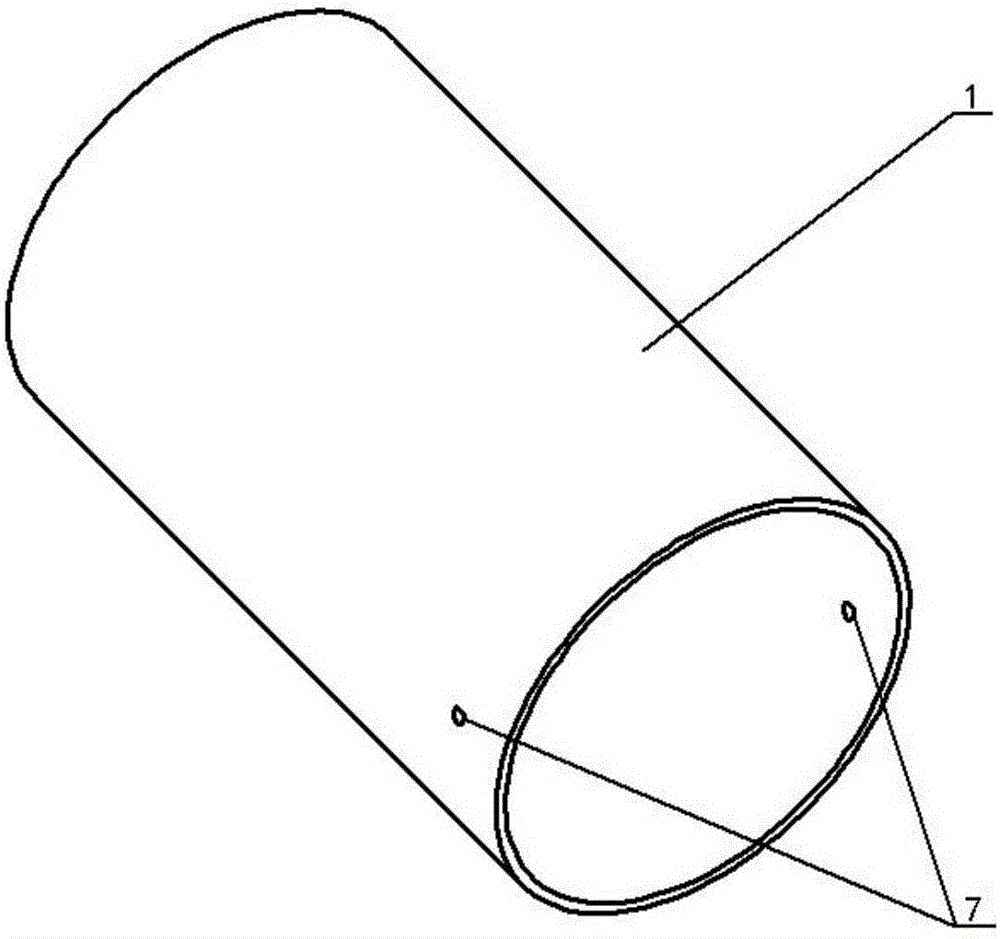

Glue joint connecting structure of composite round pipe

The invention discloses a glue joint connecting structure of a composite round pipe. The glue joint connecting structure is composed of the composite round pipe (1) and a metal part (2) connected with the composite round pipe (1) in a glue joint manner. A plurality of glue pouring ports (6) are formed in the joint of the composite round pipe (1). A groove for installing a first annular sealing ring (3), a glue groove (4), a glue guiding groove (5) and a groove for installing a second annular sealing ring (7) are sequentially machined in the joint of the metal part (2) from left to right. According to the glue joint connecting structure, the glue joint defect of composites can be greatly reduced, the glue joint connecting performance and reliability of the composites are improved, and wide application prospects are achieved.

Owner:WUHAN UNIV OF TECH

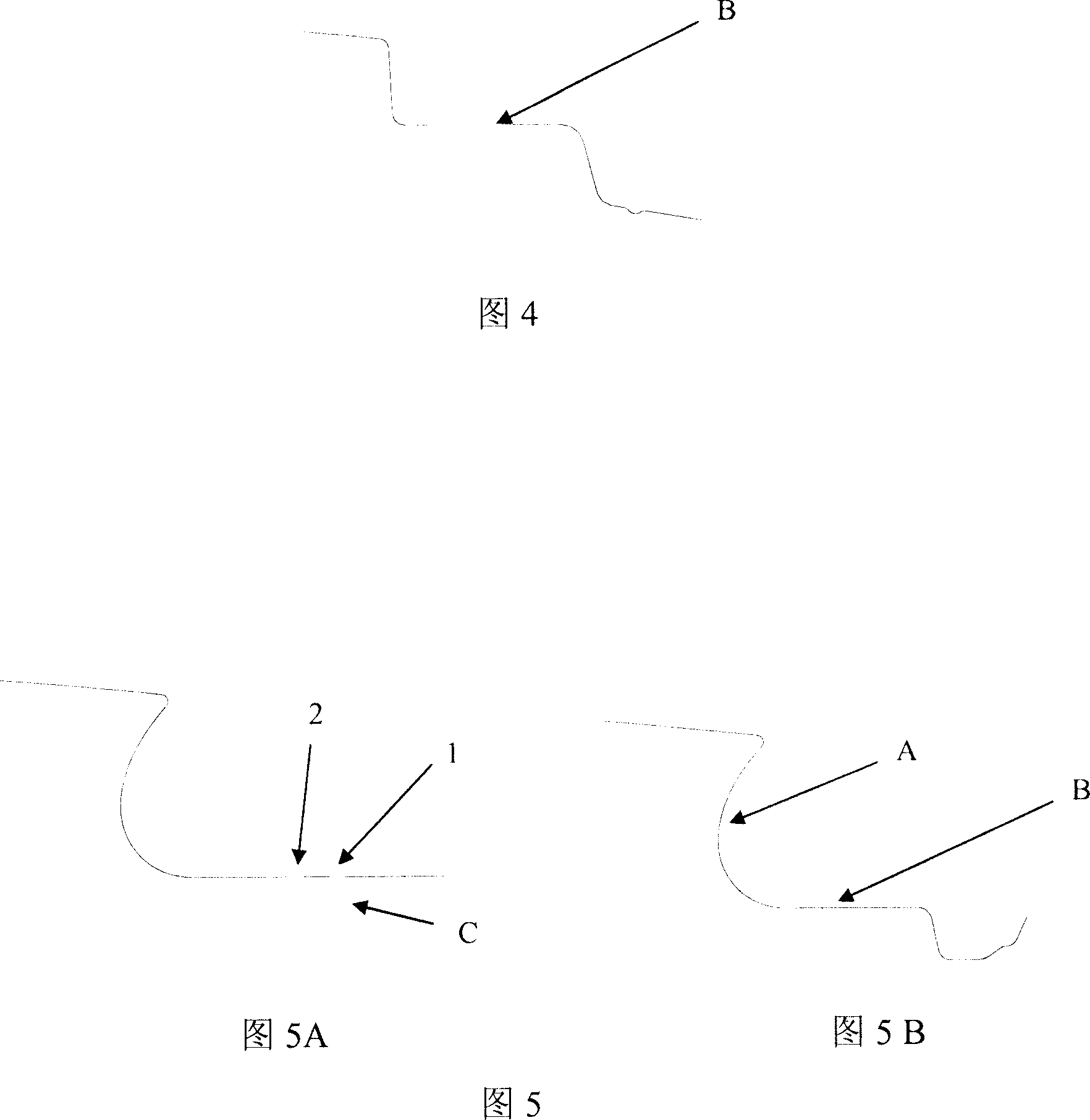

Fibre reinforced resin based composite material fin piece molding mould

InactiveCN101367257AProduct porosity reductionGood surface qualityDomestic articlesPorosityResin-Based Composite

The invention provides a molding die for fiber reinforced resin-based composite vanes. The invention relates to molding die for composite vanes, which aims to solve the problems that the prior composite vane molding die is insufficient in die assembly and too tight to seal die cavities, can not discharge air in a product, can not guarantee the geometrical size of the airfoil surface of a vane and the relative position of a vane handle, and causes that the product is large in porosity or has air holes on surface. A parting surface of an upper die and a lower die is provided with an upper model groove; a parting surface of the lower die and the upper die is provided with a lower model groove; a first positioning pin is arranged in a first positioning pinhole and a third positioning pinhole; a second positioning pin is arranged in a second positioning pinhole and a fourth positioning pinhole; and a gap between the parting surfaces of the upper die and the lower die is configured as a material overflow groove. The material overflow groove can ensure that the upper and lower dies are sufficient in die assembly; die cavities are incompletely sealed; the air in the product can be smoothly discharged; the geometrical size of the airfoil surface of the vane and the relative position of the vane handle are guaranteed; and the product is good in surface quality.

Owner:HARBIN FRP INST

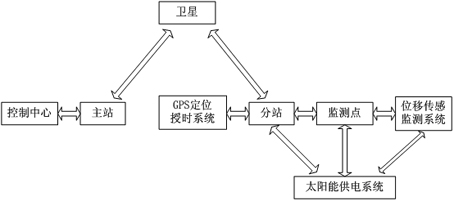

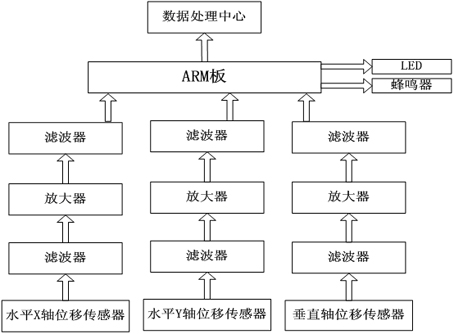

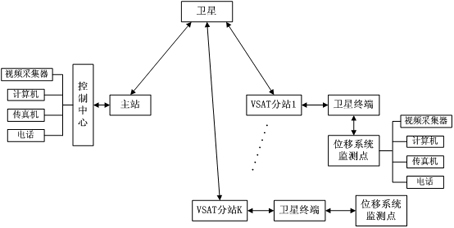

Satellite communication-based earthquake real-time monitoring system

InactiveCN101995582AIncrease the level of automationGuaranteed positionBatteries circuit arrangementsSeismic signal receiversInterference (communication)Three dimensional measurement

The invention discloses a satellite communication-based earthquake real-time monitoring system, which comprises a control center sub-system, a monitoring center sub-system, a displacement sensing sub-system, a solar power supply sub-system, a satellite global positioning system (GPS) high-precision positioning sub-system, a satellite GPS precision time service sub-system and a very small aperture terminal (VSAT) satellite communication sub-system. The three-dimensional measurement of earthquake waves in horizontal and vertical directions is realized by displacement sensor technology; equipment at all monitoring points is supplied with solar power; the three-dimensional navigation and positioning of the monitoring points are realized by using the GPS high-precision positioning technology with high anti-interference; the GPS precision time service system is used, so that the control center and all the monitoring points have the synchronous clock signals with the same frequency and the same phase; and the seamless coverage and networking of the monitoring system across China are realized by using the VSAT satellite communication technology.

Owner:CHENGDU LINHAI ELECTRONICS

High-speed gearbox processing method

ActiveCN104308468AControl coaxialityGuarantee the positioning accuracy of combined processingOffset distanceEngineering

The invention discloses a high-speed gearbox processing method, which is characterized in that when a body is roughly processed, a screw hole for matching a rear cover having roughly processed end faces in a processing body, coaxial bearing holes of the body and the rear cover, and a location pinhole for matching the body and the rear cover are adopted to guarantee the coaxiality of coaxial bearing holes of a gearbox and the position accuracy of the screw hole and the location pinhole; meanwhile after the end faces, various stages of bearing holes and gear pump holes are finely processed in gearbox combination processing, the high-speed bearing hole center of the gearbox and the rotation center of a machine tool are coincided by using a special spindle for equipment, then various inclined holes in the gearbox are drilled, a boring rod offset distance and an angle of the inclined hole shorter than the circle center offsetting the high-speed bearing hole center of the gearbox are calculated at the same time, and the position accuracy of the inclined holes in the gearbox is guaranteed.

Owner:CHONGQING JIANGJIN SHIPBUILDING IND

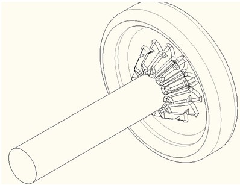

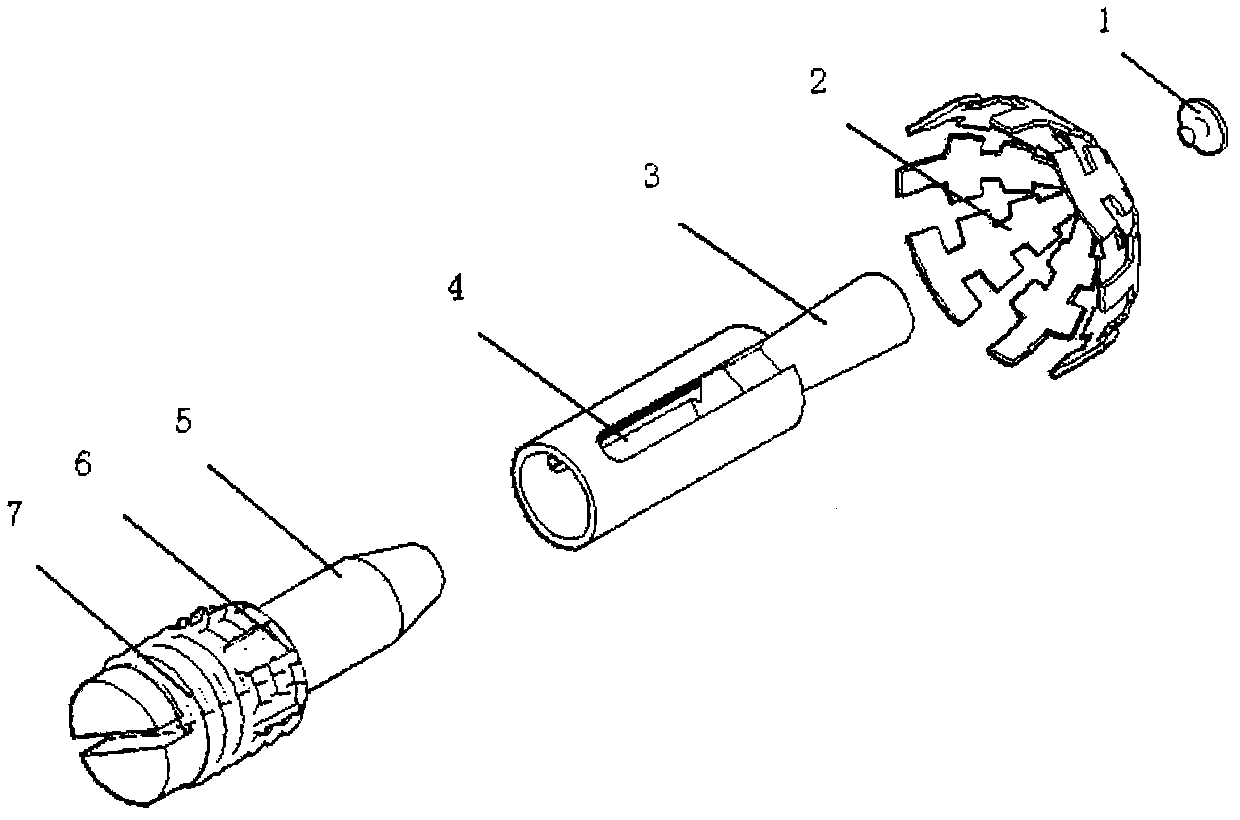

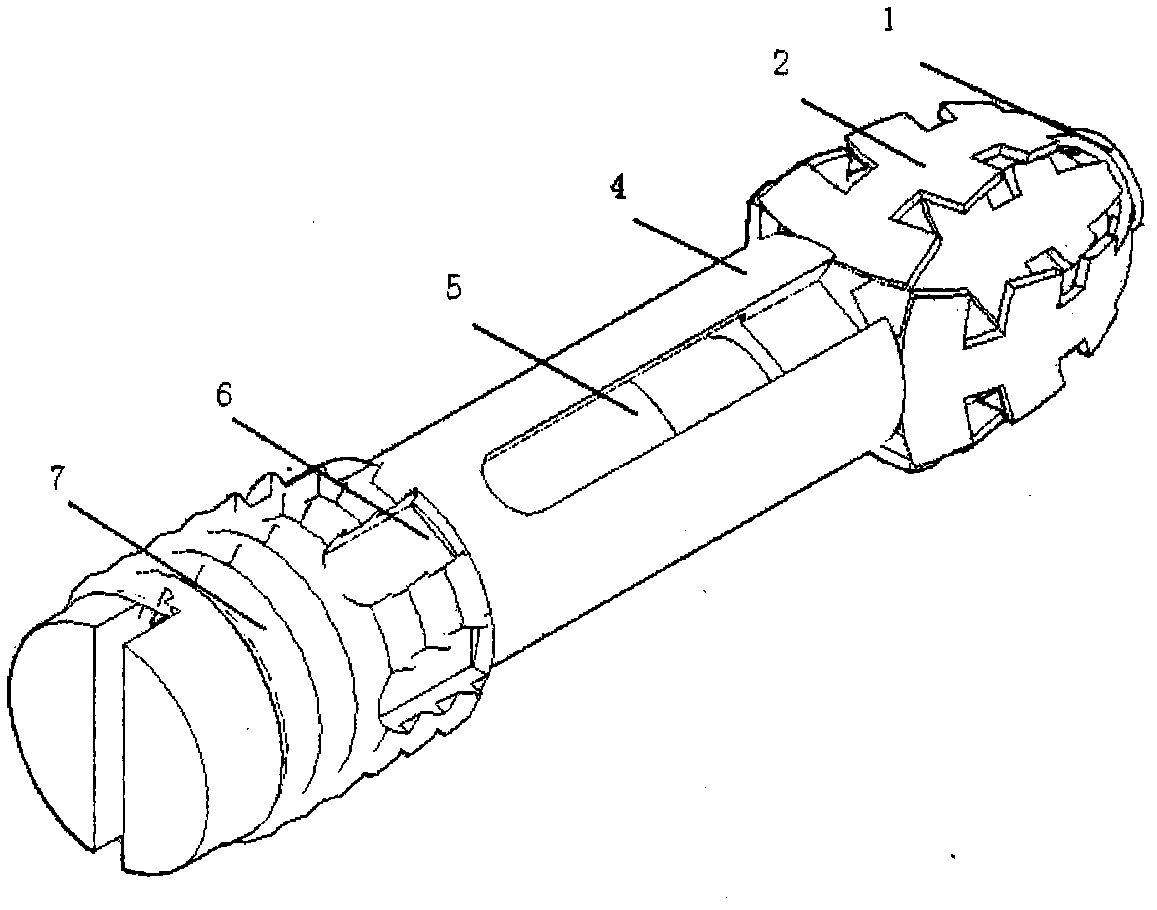

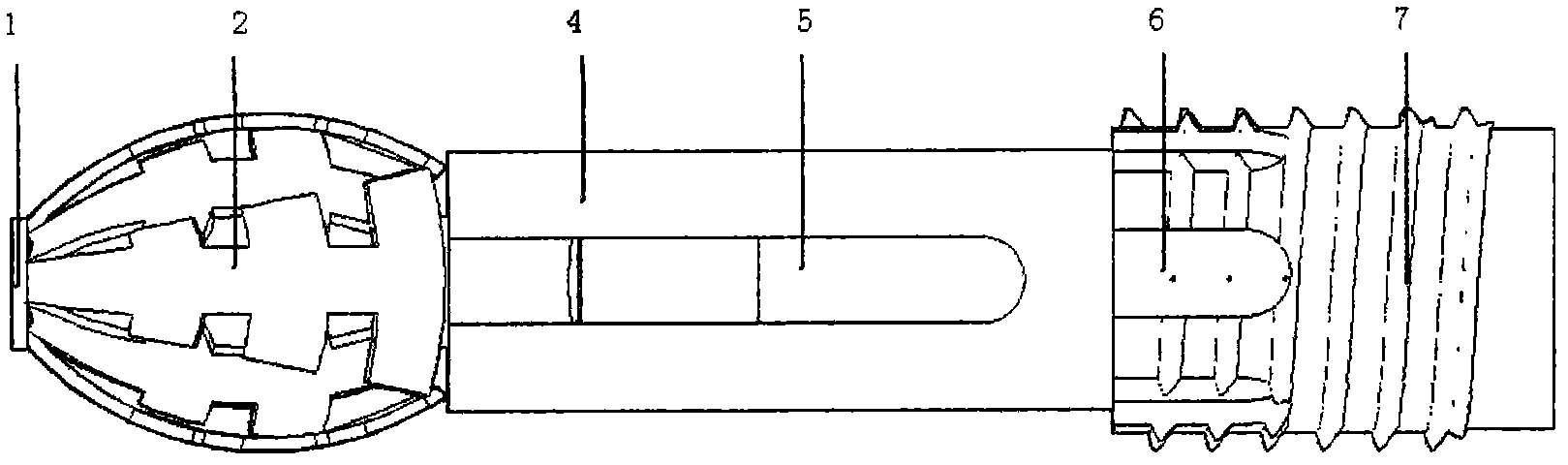

Nickel-titanium shape memory alloy umbrella-titanium mesh femoral head internal supporting device

InactiveCN102824208AGuaranteed positionPromote ingrowthInternal osteosythesisBone tunnelRight femoral head

The invention provides a built-in instrument for preventing from osteonecrosis and collapse of the femoral head, and particularly discloses a built-in device which can be implanted into the femoral head to prevent from osteonecrosis of the femoral head and preventing the femoral head from early collapsing after a core compression. The build-in device mainly comprises a nickel-titanium shape memory alloy umbrella, a TA2 pure titanium supporting device body, and TA2 pure titanium tail fastening screws, wherein the nickel-titanium shape memory alloy umbrella is arranged at one end of the supporting device body, and the other end of the supporting device body is jointly inserted to the tail fastening screw; the nickel-titanium shape memory alloy umbrella comprises eight supporting belts, and is structured as a semispherical umbrella shape; the nickel-titanium shape memory alloy umbrella is controlled through the phase-transition temperature after being expanded; the supporting device body has a titanium mesh structure which can contain bone materials or growth factors; and the tail fastening screw has the function of guiding and self-tapping, which is capable of fixing the supporting device and transmitting the stress. The supporting device has the characteristics that the nickel-titanium shape memory alloy umbrella is arranged; after being implanted into a small-aperture core compression bone tunnel, the nickel-titanium shape memory alloy umbrella can be automatically expanded to increase the supporting area and adapt to the defect of endoskeleton of the femoral head; with adoption of the titanium mesh structure, the bone ingrowth can be increased. By adopting the supporting device, the femoral head can be effectively prevented from osteonecrosis and collapse after the core compression.

Owner:王坤正 +2

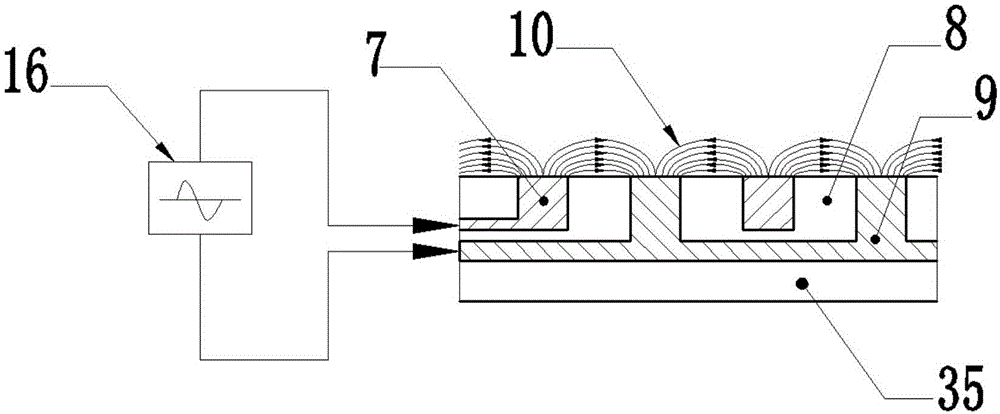

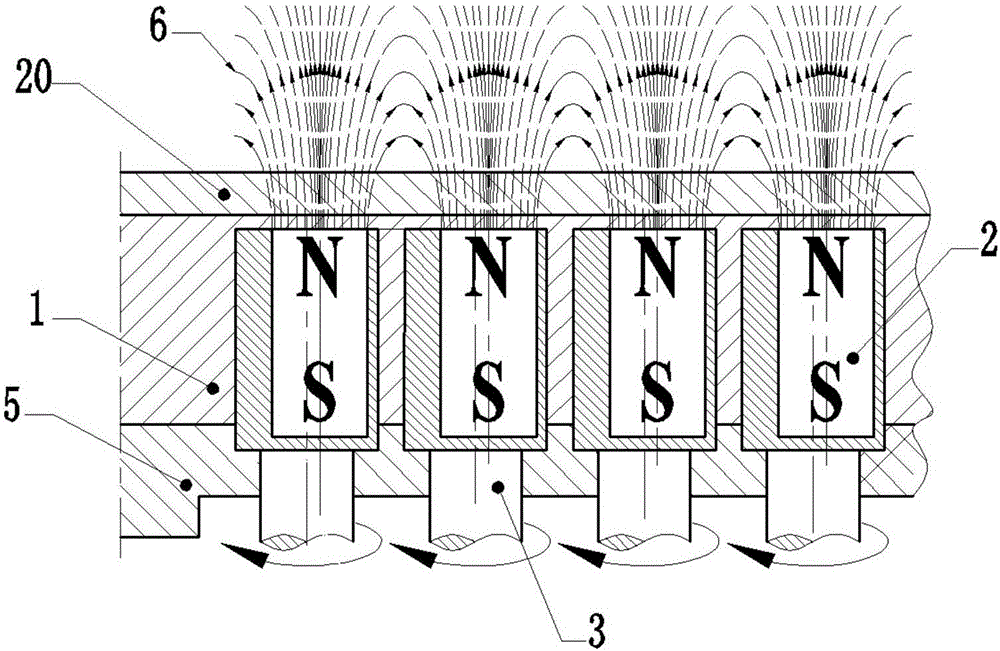

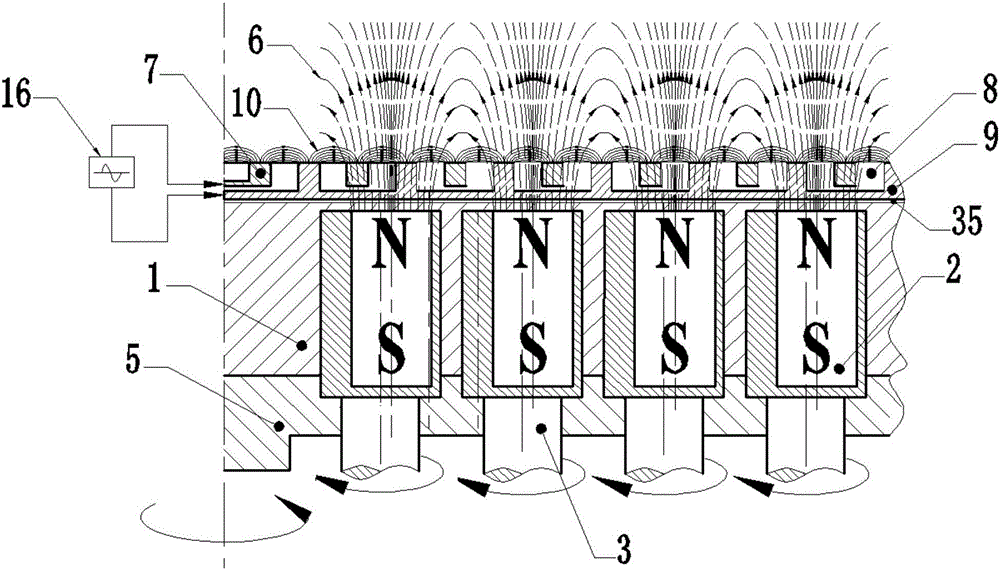

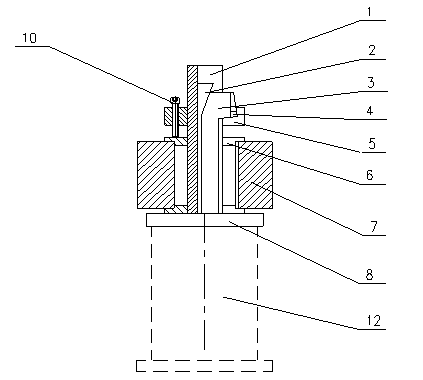

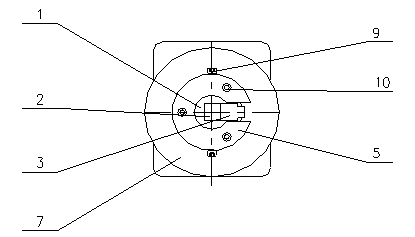

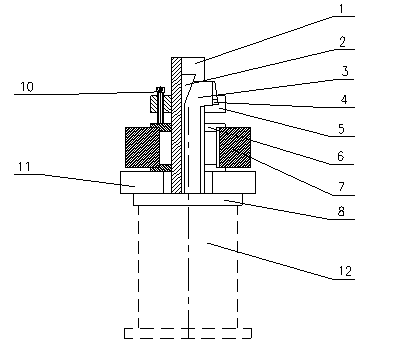

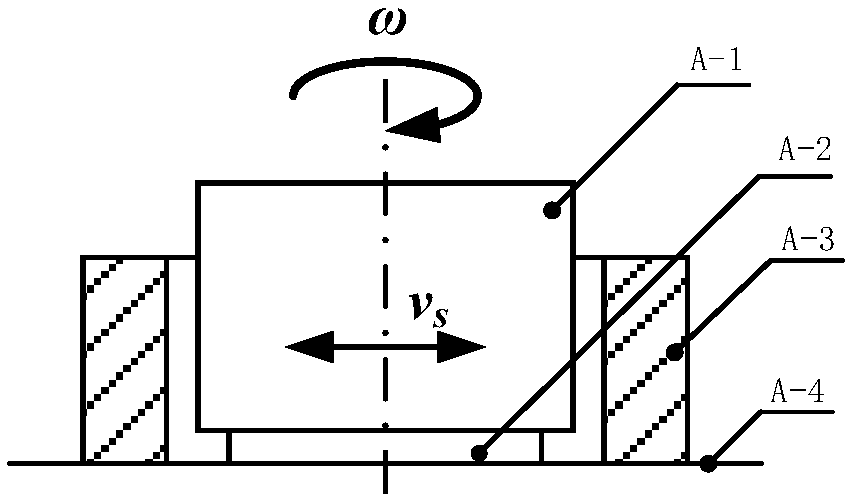

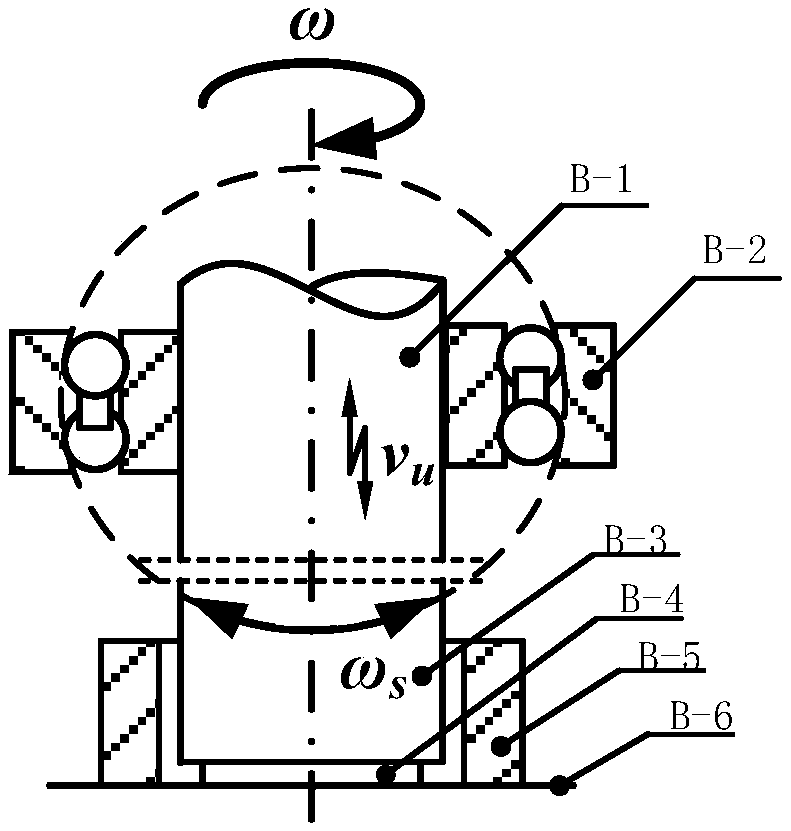

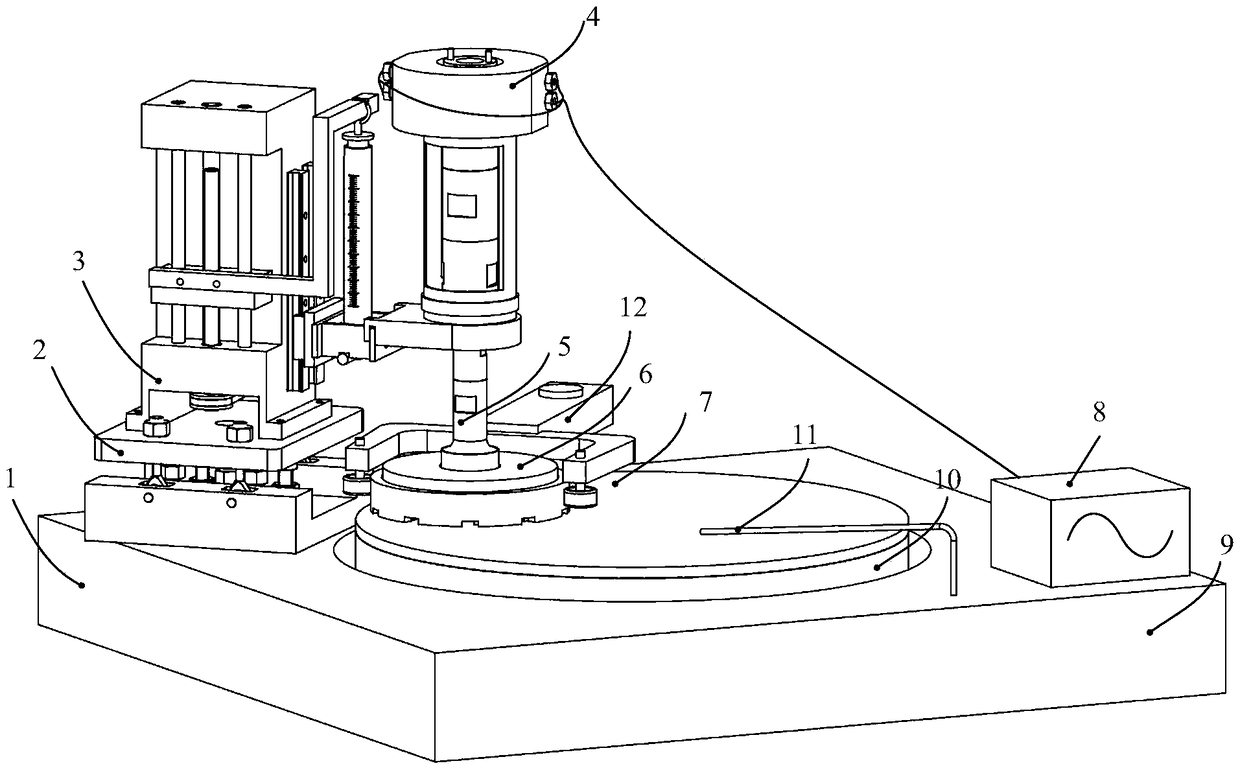

Planarization machining device and single-face and double-face planarization machining system

ActiveCN106312796AQuality improvementImprove efficiencyLapping machinesLapping toolsMagnetic polesEngineering

The invention discloses a planarization machining device and a single-face and double-face planarization machining system. The planarization machining device comprises a plurality of permanent magnets used for forming a multi-point self-rotation array magnetic pole, array positive electrodes, array negative electrodes and electromagnetic rheologic fluid; the end faces of the permanent magnets are arranged in a parallel and level manner in the same direction or in different directions; the permanent magnets are arranged in a magnetic pole installing disk through magnetic pole installing end covers; the permanent magnets are correspondingly arranged at the first end of a rotating shaft; a polishing disk is installed on the magnetic pole installing disk; the second end of the rotating shaft is connected with a magnetic pole synchronous rotating motor used for driving the permanent magnets to rotate synchronously and a transmission system; the array positive electrodes and the array negative electrodes are arranged on the polishing disk; the array positive electrodes, the array negative electrodes and the magnetic pole installing disk are arranged in a mutual insulation manner; the array positive electrodes and the array negative electrodes are connected with a low-frequency high-voltage square wave alternating power source; the electromagnetic rheologic fluid is arranged in the polishing disk and mixed with abrasive materials; and the electromagnetic rheologic fluid forms a polishing pad under the coupling action of a dynamic magnetic field and a low-frequency high-voltage square wave alternating electric field. By means of the device, the planarization machining quality and efficiency of the surface of a workpiece is improved.

Owner:GUANGDONG NANOGRIND TECH CO LTD

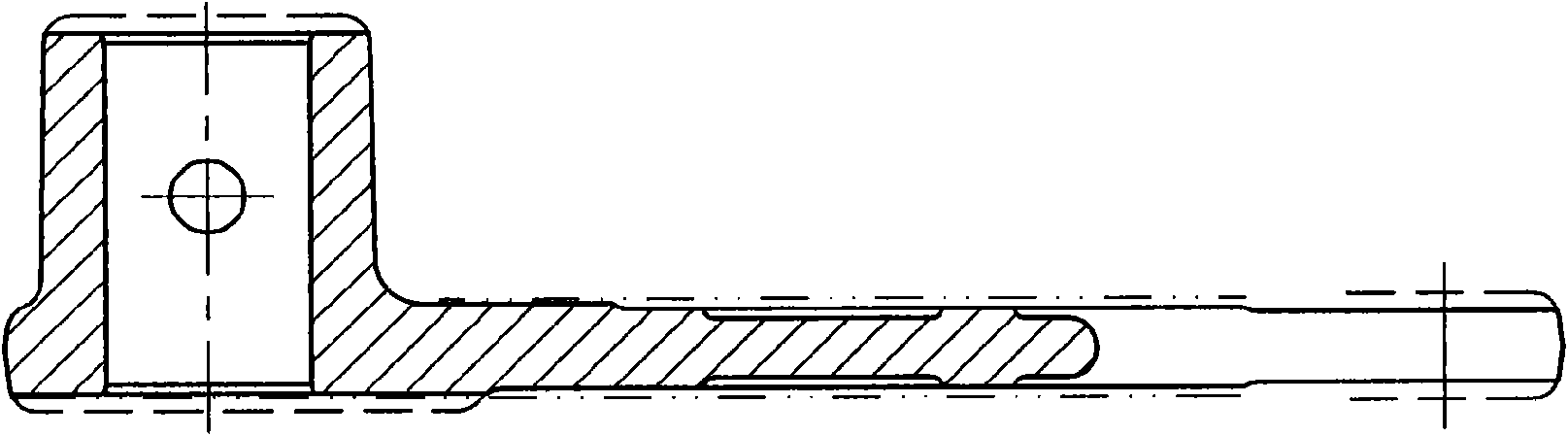

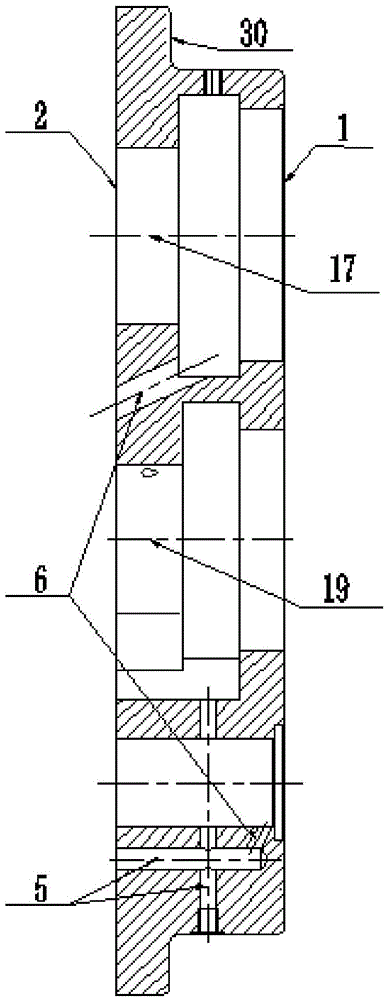

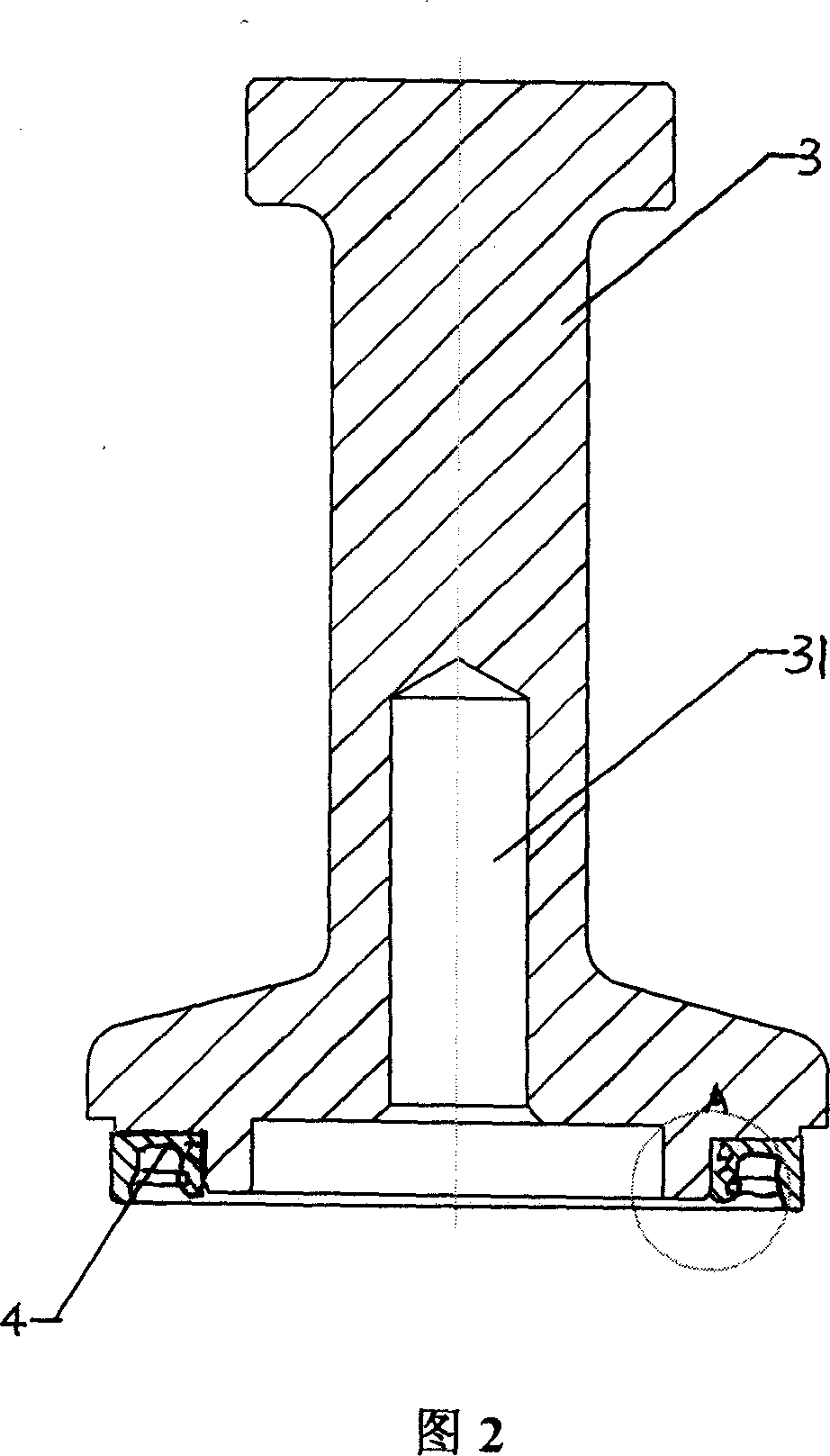

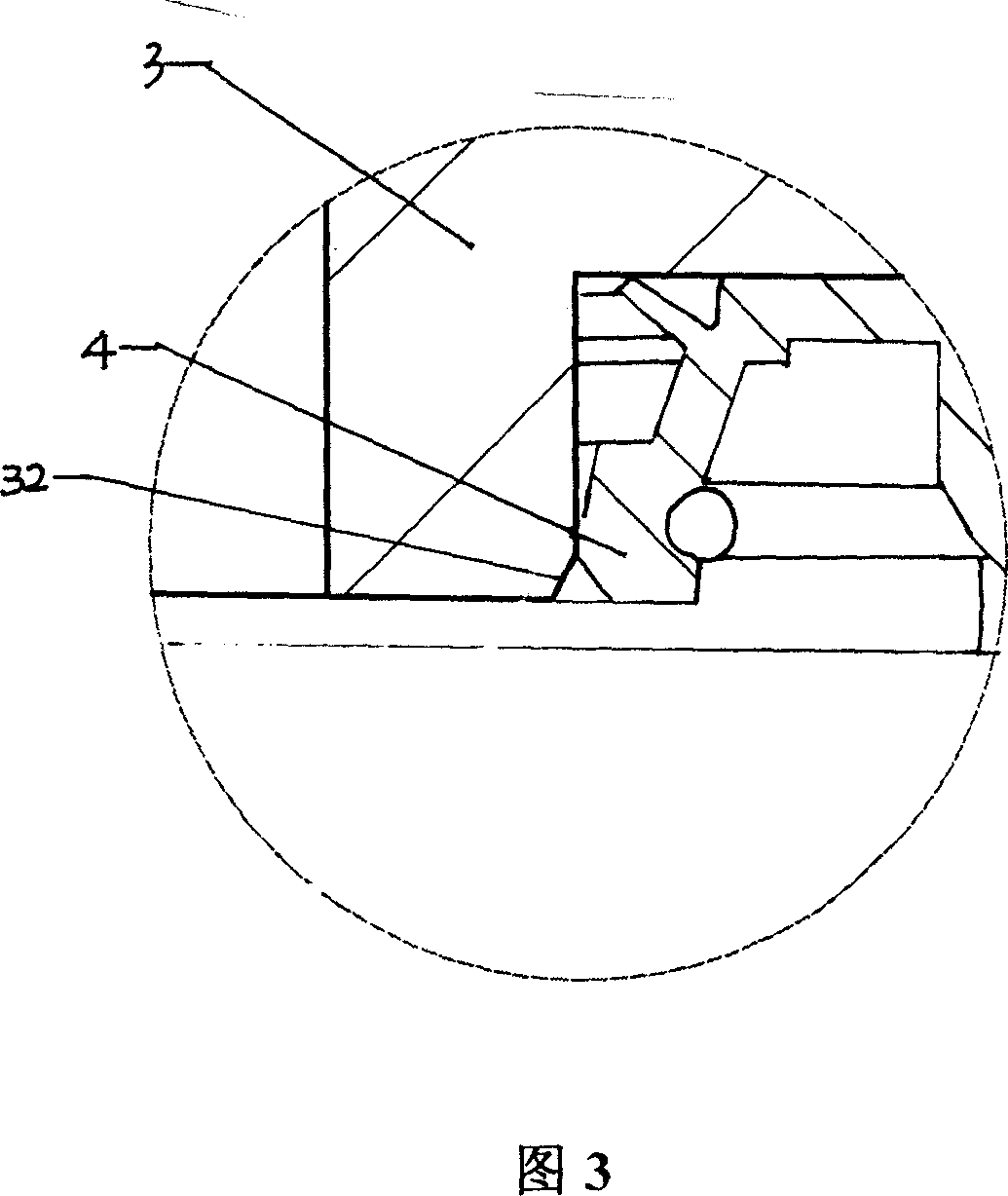

Tool for pressed assembling of rear oil seal of carnkshaft of engine

InactiveCN1947955AGuaranteed assembly accuracyGuaranteed positionMetal-working hand toolsInterference fitEngineering

A press tool for installing the back oil seal for the crankshaft of engine is composed of a supporter, a locating pin inserted in the supporter for locating the back end cover of crankshaft, a guide rod on said supporter, relative to the central position of back end cover and matched with the central hole of press sleeve, and a press sleeve for guiding the back oil seal and transferring pressure to it.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

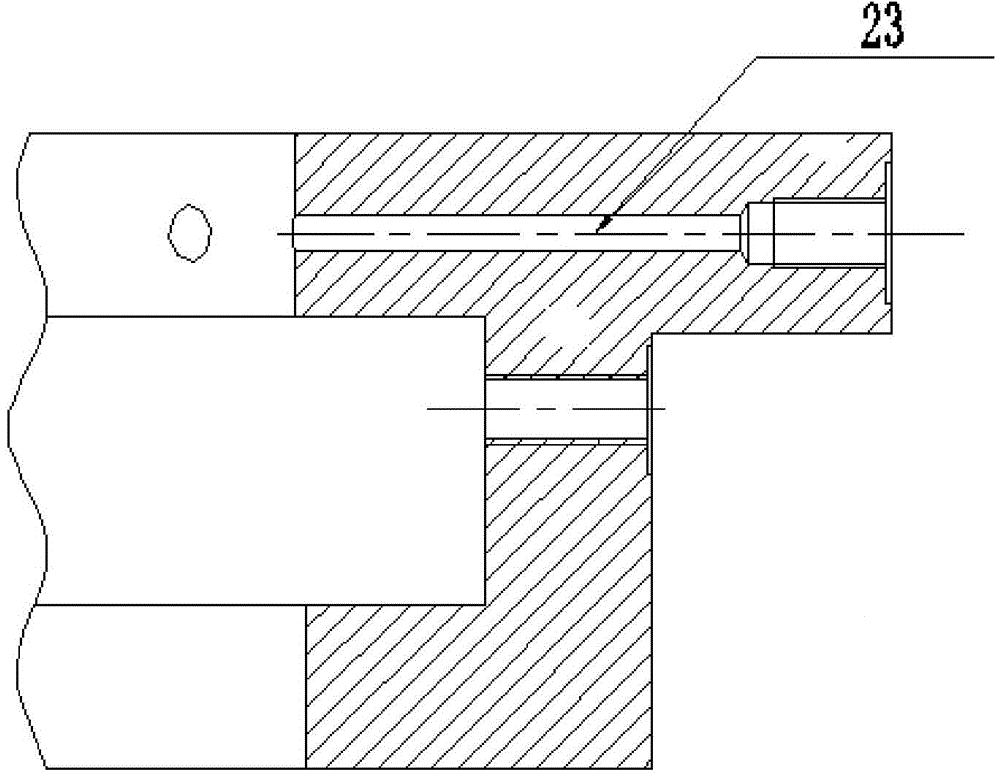

Precision cutting head for inner-hole keyways

ActiveCN102699442AEasy clampingHigh positioning accuracyFeeding apparatusLarge fixed membersEngineeringMetal cutting

The invention relates to metal cutting machinery and particularly relates to a precision cutting head for an inner-hole keyways. The cutting head comprises a cutter guide rail, a feeding rod, a cutter rod, a blade, a clamping block, an embedded lining, a work table, a fixed screw, a pressing screw, a precision dividing disc and a machine seat. The precision cutting head adopts a new processing concept to create a processing method which integrates the cutter with the clamper. The cutter guide rail is provided with a rectangular precision groove. The feeding rod and the cutter rod which can slide upwards and downwards along the rectangular precision groove are installed in the rectangular groove according to the precision sliding fit tolerance. The heads of the feeding rod and the cutter rod are provided with inclined surfaces which are mutually adhered with each other, and the slopes of the inclined surfaces are the same. The feeding rod and the cutter rod are driven by an external power source. A molded blade of which the width is the same as the keyway is installed on the cutter rod. The embedded lining of the cutter guide rail is embedded in the inner hole of the working piece to positioning, and the working piece is fixed by a manner of processing the embedded lining through the pressing bolt. The precision cutting head has the advantages of simple installation and clamping, accurate centering, high processing precision and high processing efficiency, so that the precision cutting head can be applied to the mechanical processing industry, in particular to the precision machinery industry.

Owner:HUBEI MINGCHENG PRECISION MACHINERY

Ultrasonic auxiliary silicon carbide wafer grinding and polishing device

InactiveCN108890408AEconomic precision is not highEasy to implementBall bearingMulti degree of freedom

The invention discloses an ultrasonic auxiliary silicon carbide wafer grinding and polishing device, and aims to solve the problems of severe damage to silicon carbide wafer grinding and polishing surface and low removing rate of materials. The device comprises a machine tool, a multi-degree-of-freedom positioning platform, a load adjusting component, an ultrasonic power component, a clamp component, a keeping ring, a grinding disk or polishing pad and an ultrasonic digital power supply, the multi-degree-of-freedom positioning platform comprises a movable platform and a seat, the load adjusting component comprises a frame and a bearing block, the ultrasonic power component comprises an energy converter and a self-aligning ball bearing, the multi-degree-of-freedom positioning platform is mounted on the machine tool through the frame, the load adjusting component is mounted on the movable platform through the frame, the ultrasonic power component is mounted on the bearing block, the topend of a clamp of the clamp component is fixedly connected with the bottom end of the energy converter, the bottom end of the clamp is mounted in the keeping ring and is rotatably connected with the keeping ring, the keeping ring is placed on the grinding disk or polishing pad, the grinding disk or polishing pad is mounted on the machine tool, and the ultrasonic power component is connected with the ultrasonic digital power supply through a signal line.

Owner:JILIN UNIV

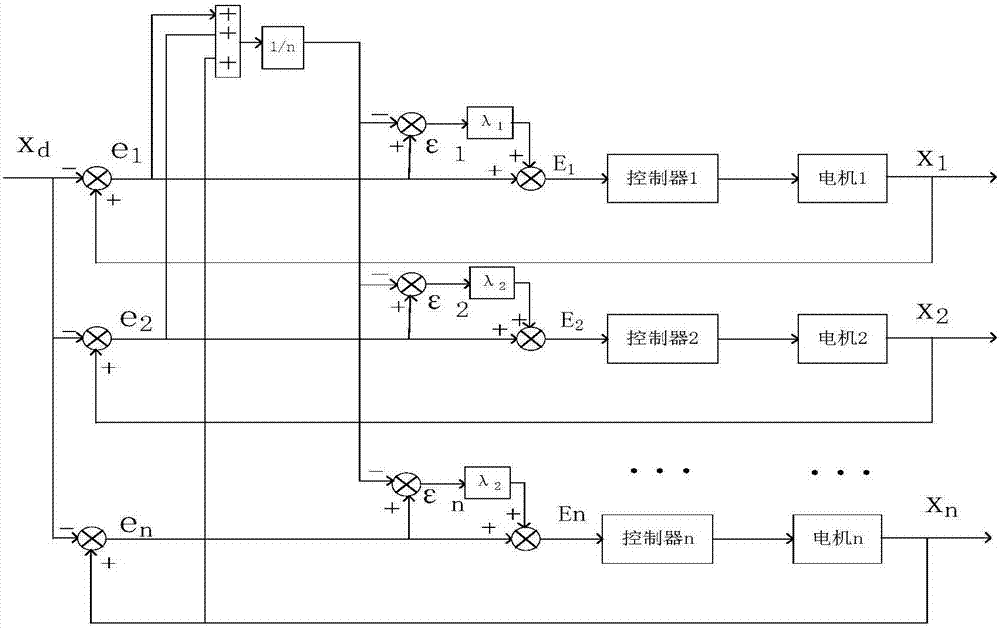

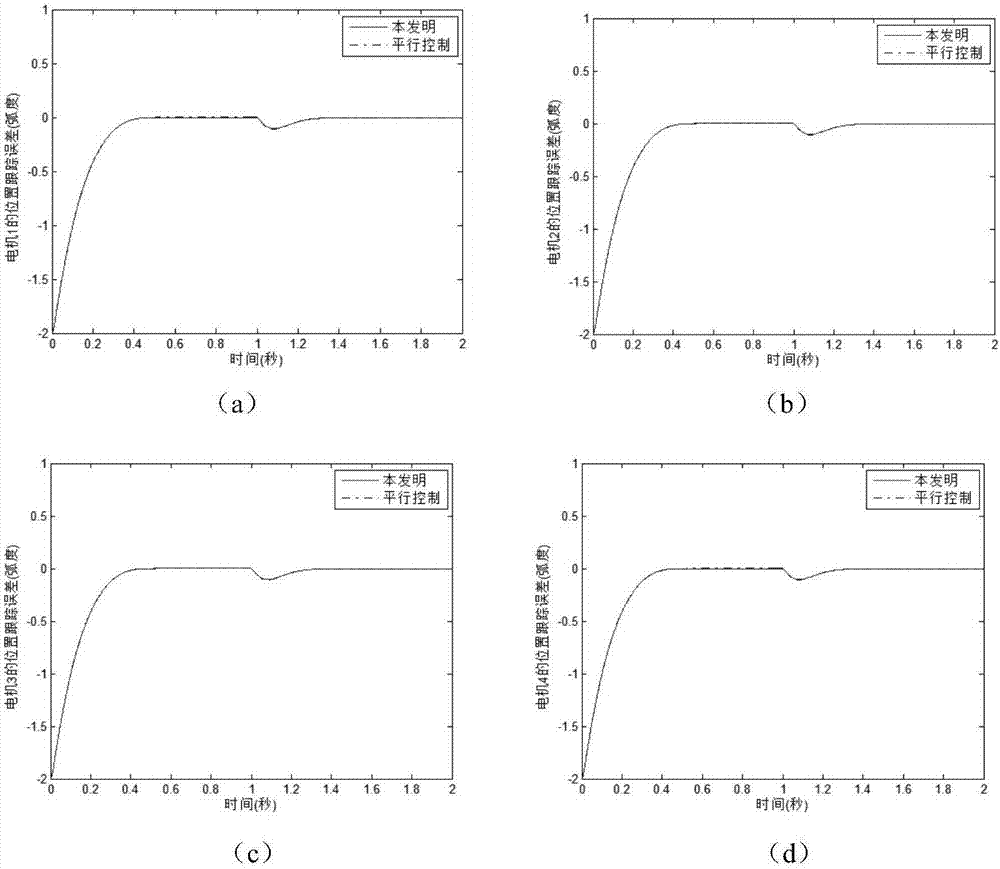

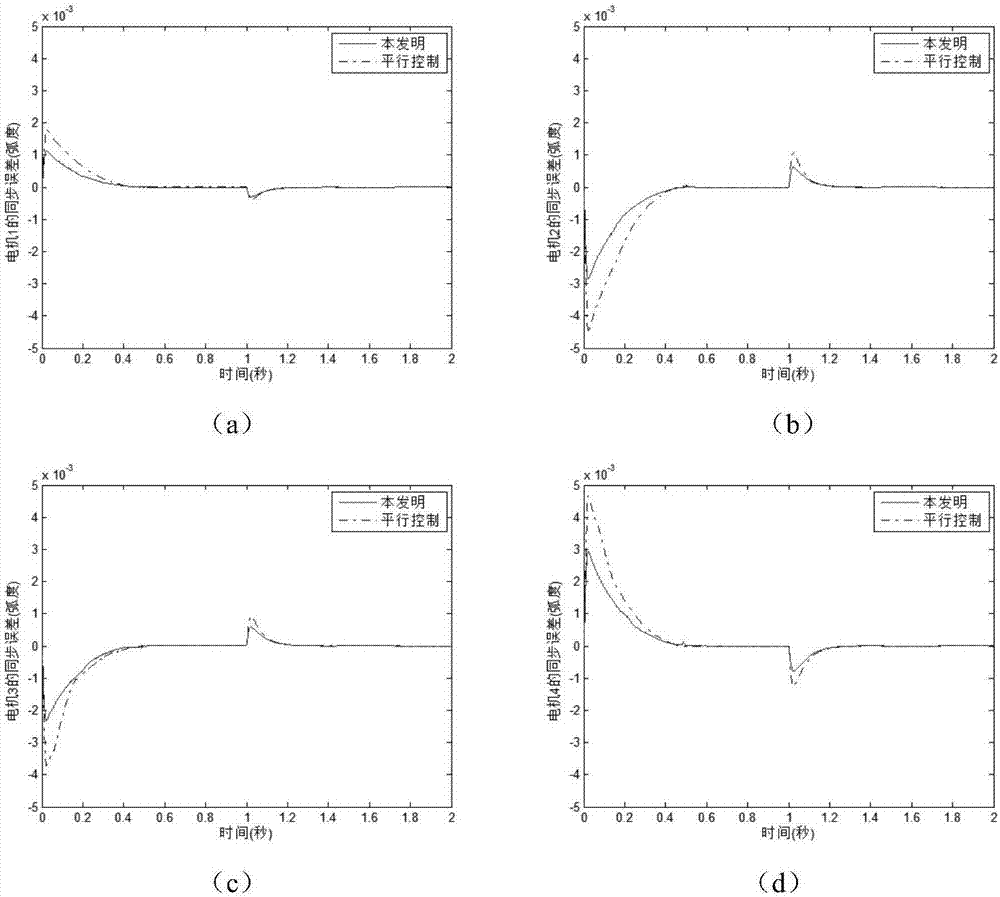

Mean-value coupling error-based sliding-mode synchronous control method of self-adaptive rapid terminal of multi-motor system

ActiveCN107994834AGuaranteed positionGuaranteed synchronicityGeneral control strategiesMultiple dynamo-electric motors speed regulationTerminal sliding modeSelf adaptive

The invention relates to a mean-value coupling error-based limited time position synchronous control method of a multi-motor system. With regard to the multi-motor system considering disturbance influence, a position tracking error and a mean-value coupling error are combined to obtain a composite error, a sliding-mode synchronous control method of a self-adaptive rapid terminal is designed by thecomposite error and by combining the sliding-mode control method and a self-adaptive method of the rapid terminal, the composite error is used for simultaneously ensuring the position tracking performance and the synchronous performance of the system, the terminal sliding-mode control method is used for ensuring rapid and stable convergence of the system, and the self-adaptive method is used forestimating unknown disturbance of the system. The invention provides the control method which can be used for simultaneously ensuring the position tracking performance and the synchronous performanceof the system and effectively compensating the unknown disturbance of the system, and rapid and stable control of the system is achieved.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com