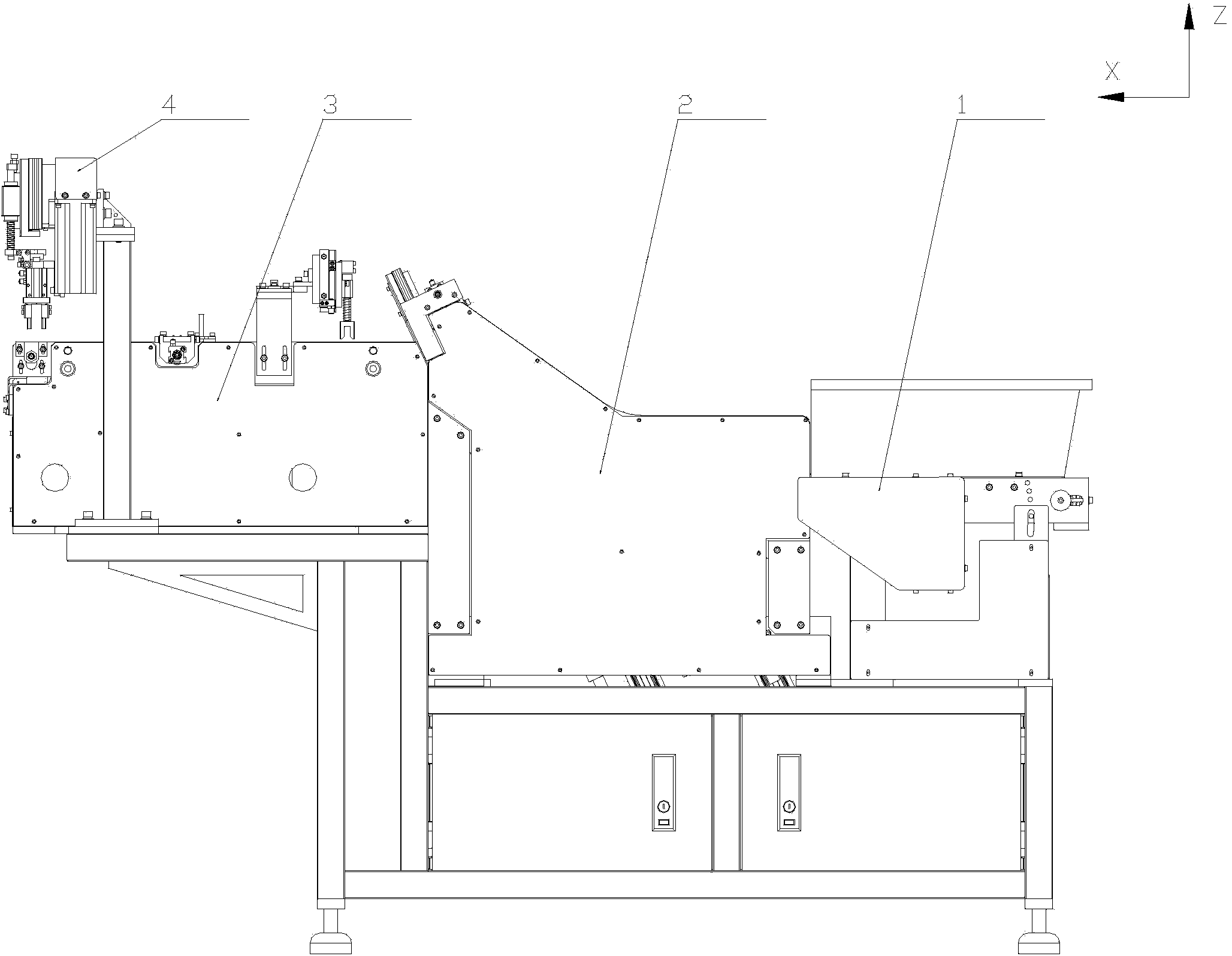

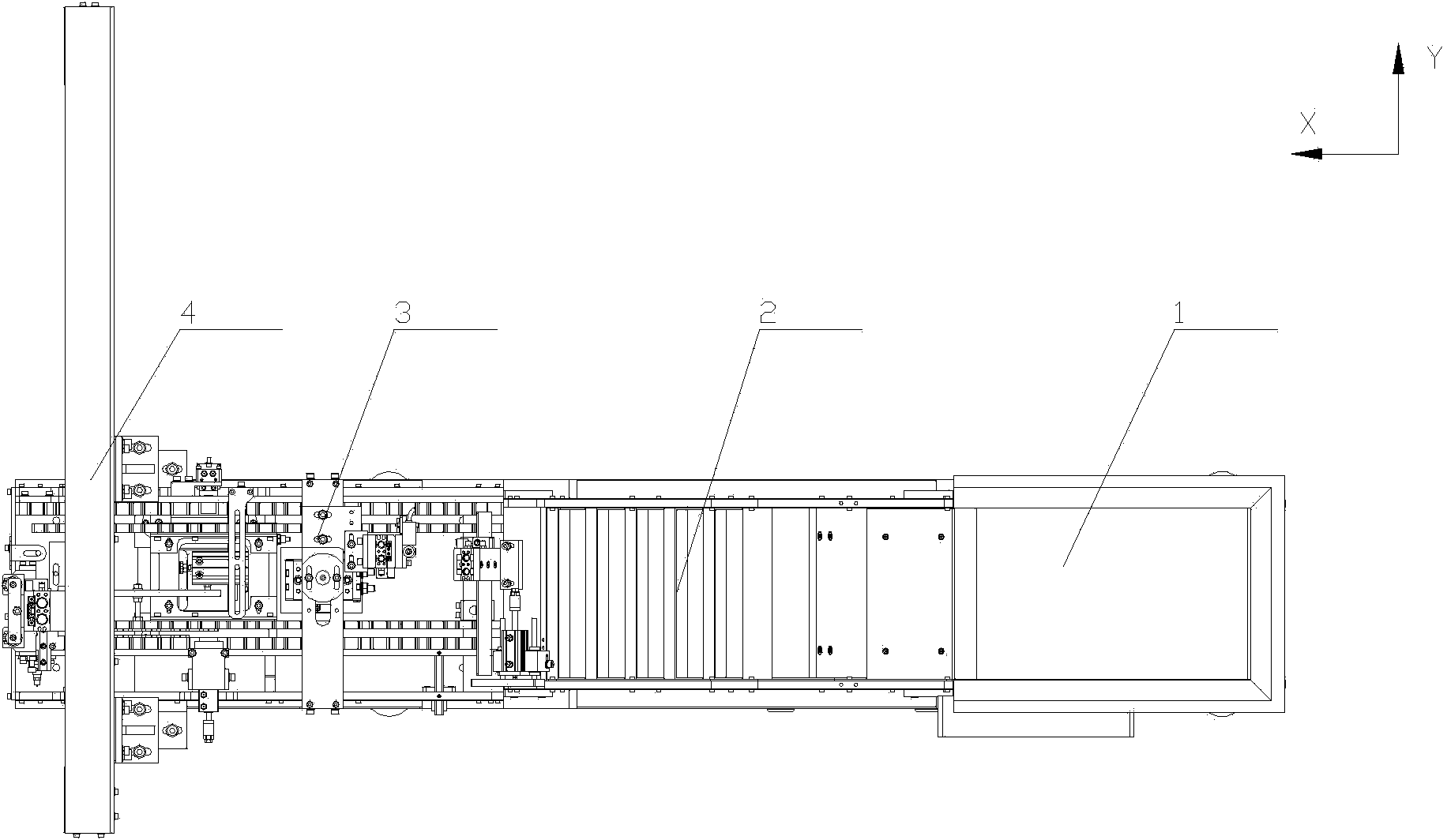

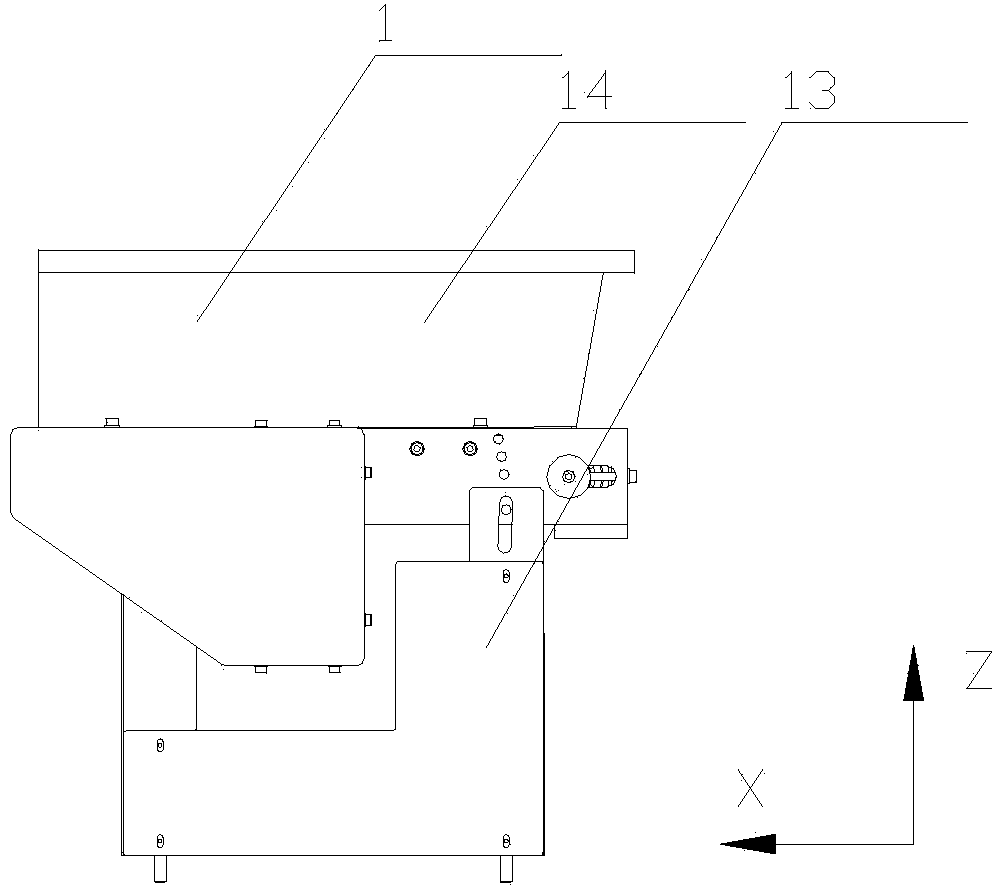

Feeding system of toothbrush bristle planting machine

A feeding system and tufting machine technology, applied in the field of toothbrush manufacturing, can solve the problems of lower yield and processing effect, waste of raw materials, and inability to implant bristles, and achieve high processing efficiency, stable overall structure, and stable transportation mode.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0105] The walking drive device 323 in the walking system 32 includes a vertical drive device 3231 (which can be a linear drive device in the form of an air cylinder, a hydraulic cylinder, etc.) arranged along the Z direction and a horizontal drive device 3232 (which can be an air cylinder) arranged along the X direction. , Hydraulic cylinder and other linear drive devices), the vertical drive device 3231 is connected to the bottom of the frame 31, the horizontal drive device 3232 is connected to the top of the vertical drive device 3231 and a pair of the movable Between the bottoms of the plates 322, the vertical driving device 3231 drives a pair of the movable plates 322 to move in the Z direction, and the horizontal driving device 3232 drives a pair of the movable plates 322 to move in the X direction, so that A pair of movable plates 322 are driven by the vertical driving device 3231 and the horizontal driving device 3232 to move upward, forward, downward, and backward; in t...

Embodiment 2

[0109] The walking drive device 323 in the walking system 32 includes a drive wheel 3233, a rotating shaft 3234, a support frame and a wheel drive device (which can be a rotary drive device in the form of a servo motor, a timing motor, etc.). The support frame is arranged along the Z direction, And fixedly connected in the frame, the rotating shaft is arranged along the Y direction, and both ends of the rotating shaft 3234 are fixedly connected to the support frame, the driving wheel 3233 is sleeved on the rotating shaft 3234 and is coaxial with the rotating shaft 3234 The driving wheel 3233 is located between the pair of movable plates 322, and the pair of movable plates 322 are respectively hinged on the edges of the two ends of the driving wheel 3233; the wheel driving device is connected to the frame 31, and Connected with the driving wheel 3233, the driving wheel 3233 is driven to rotate around the shaft 3234 through the wheel driving device, and drives a pair of the movabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com