Patents

Literature

83959results about How to "Improve processing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

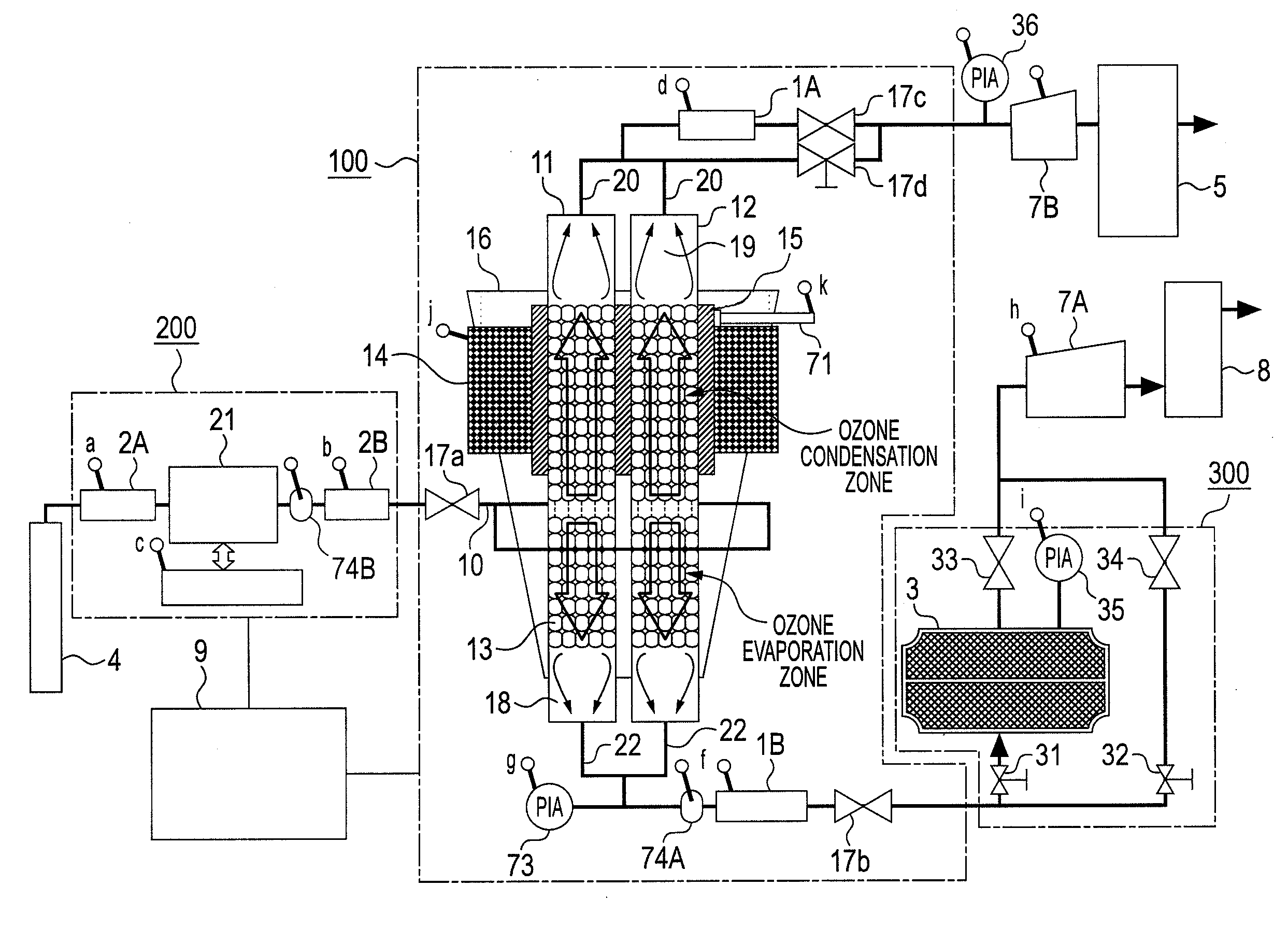

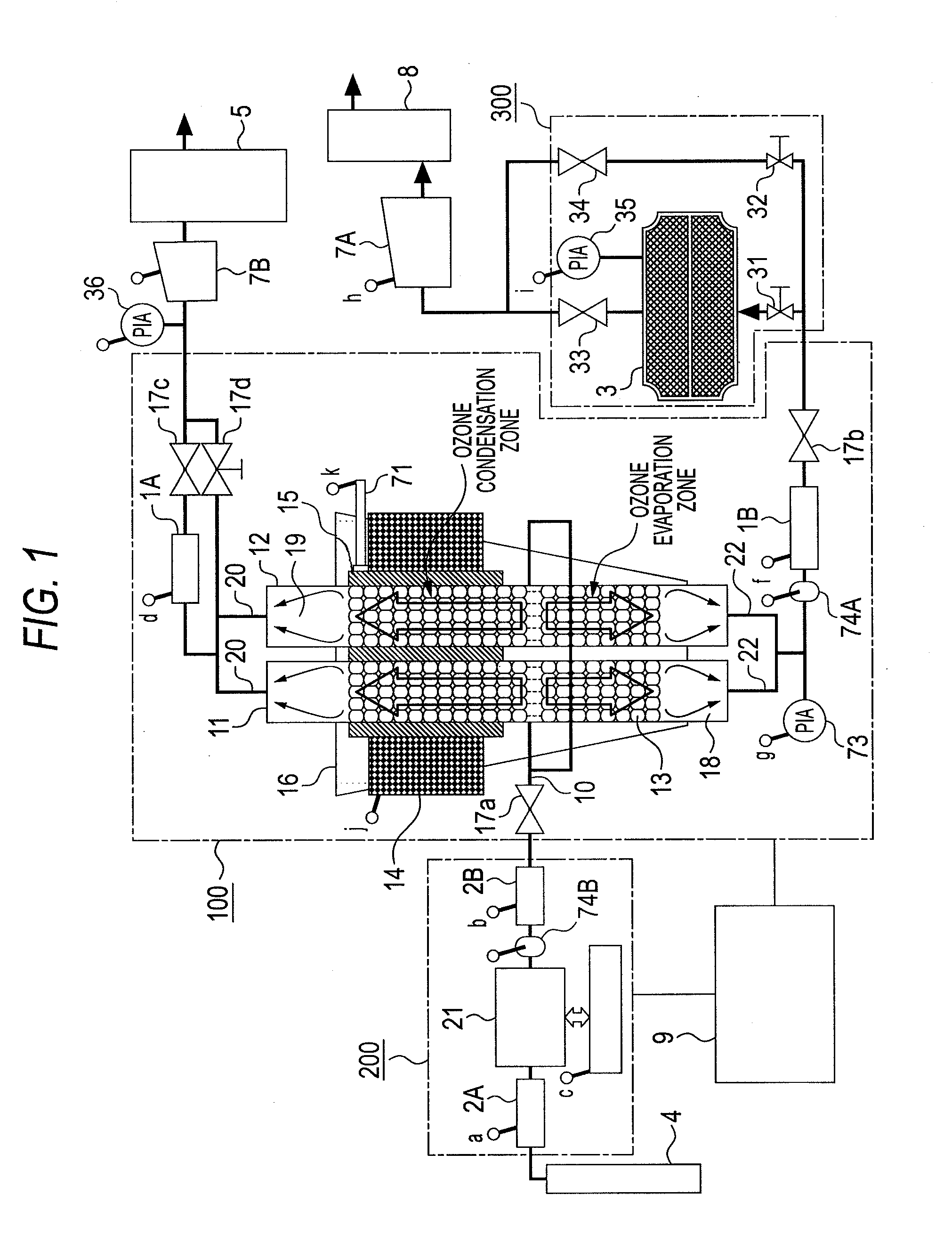

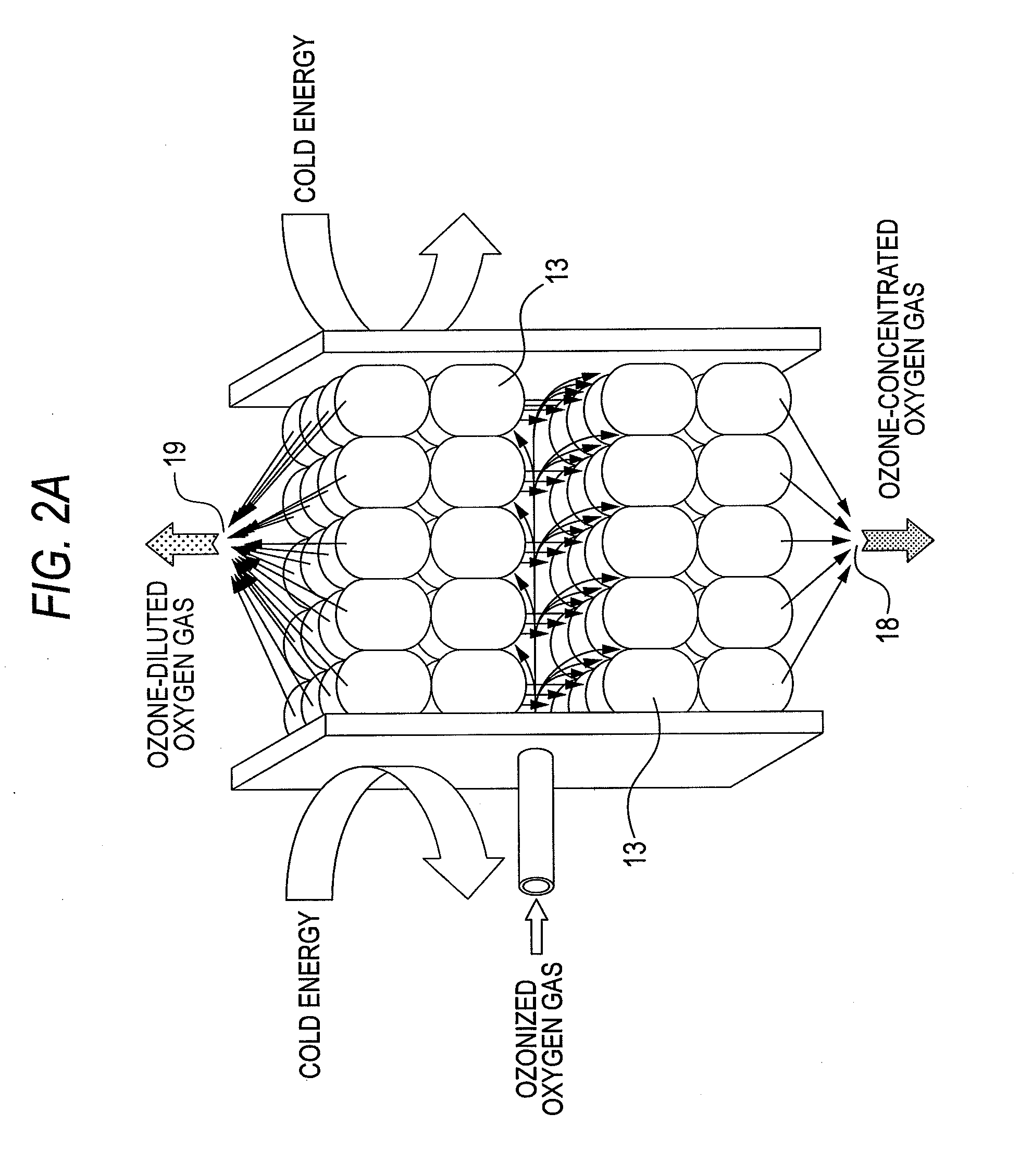

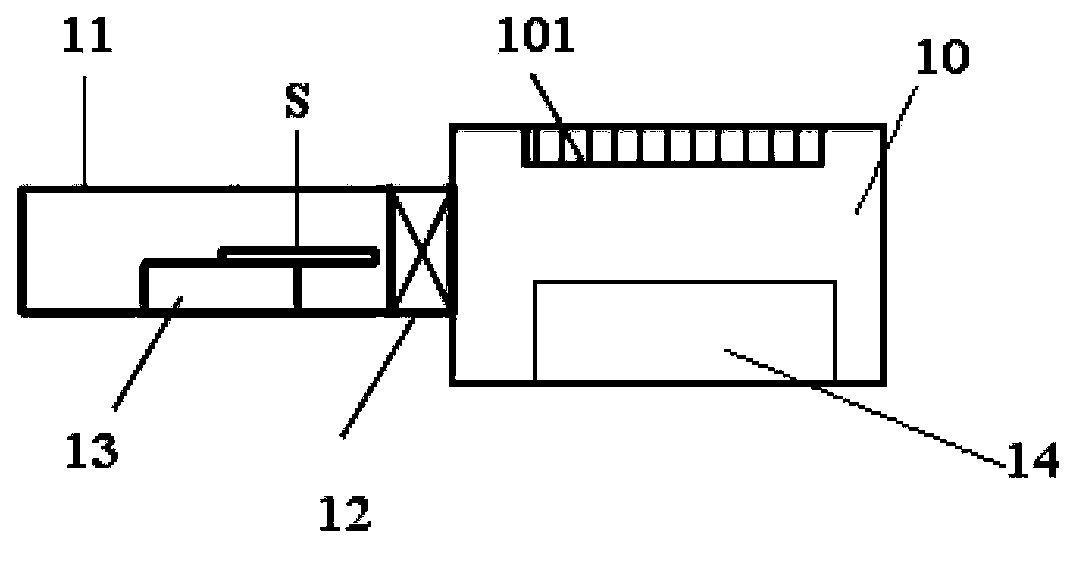

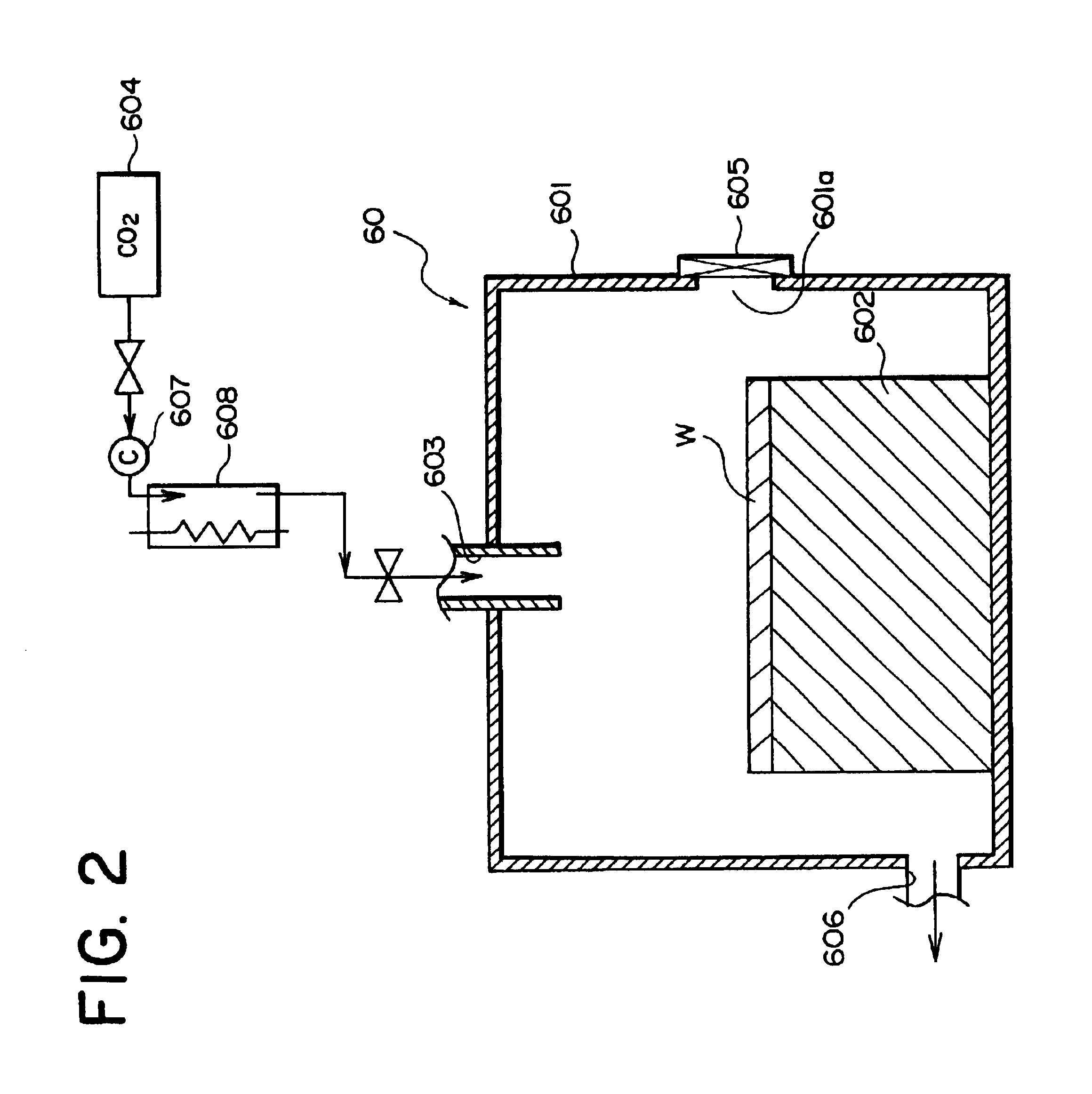

Apparatus for concentrating and diluting specific gas and method for concentrating and diluting specific gas

ActiveUS20100162752A1Improve processing efficiencySmall sizeSolidificationGas treatmentSpherical shapedVaporization

One ozone concentrating chamber is provided therein with a part of a cooling temperature range where ozone can be selectively condensed or an oxygen gas can be selectively removed by transmission from an ozonized oxygen gas, and a part of a temperature range where condensed ozone can be vaporized, and condensed ozone is vaporized by moving condensed ozone with flow of a fluid or by gravitation to the part where condensed ozone can be vaporized, whereby the ozonized oxygen gas can be increased in concentration. Such a constitution is provided that a particle material 13 for condensation and vaporization filled in the ozone concentrating chambers 11 and 12 has a spherical shape of a special shape with multifaceted planes on side surfaces, or an oxygen transmission membrane 130 capable of selectively transmitting an oxygen gas in an ozone gas is provided.

Owner:TOSHIBA MITSUBISHI-ELECTRIC IND SYST CORP

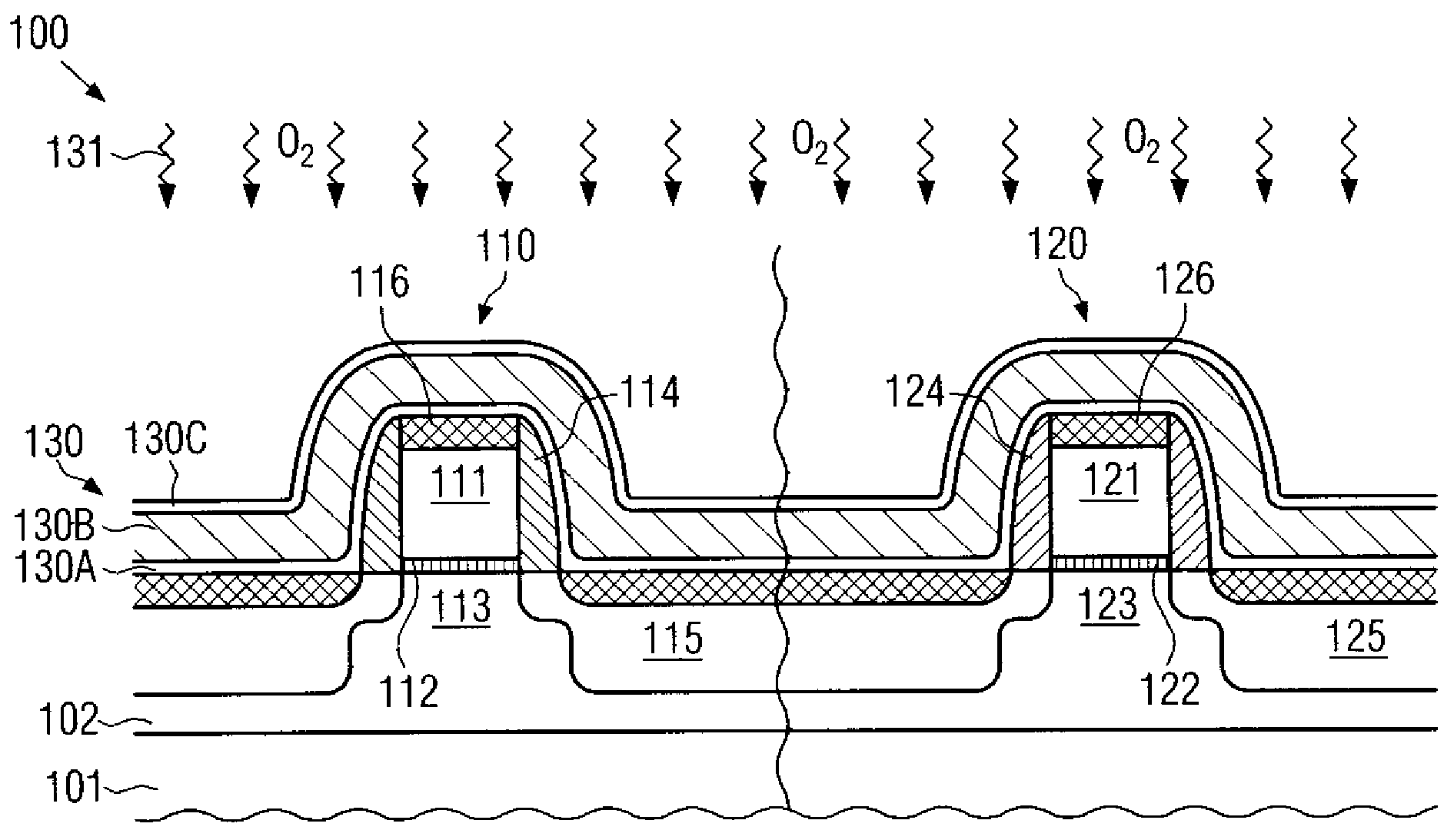

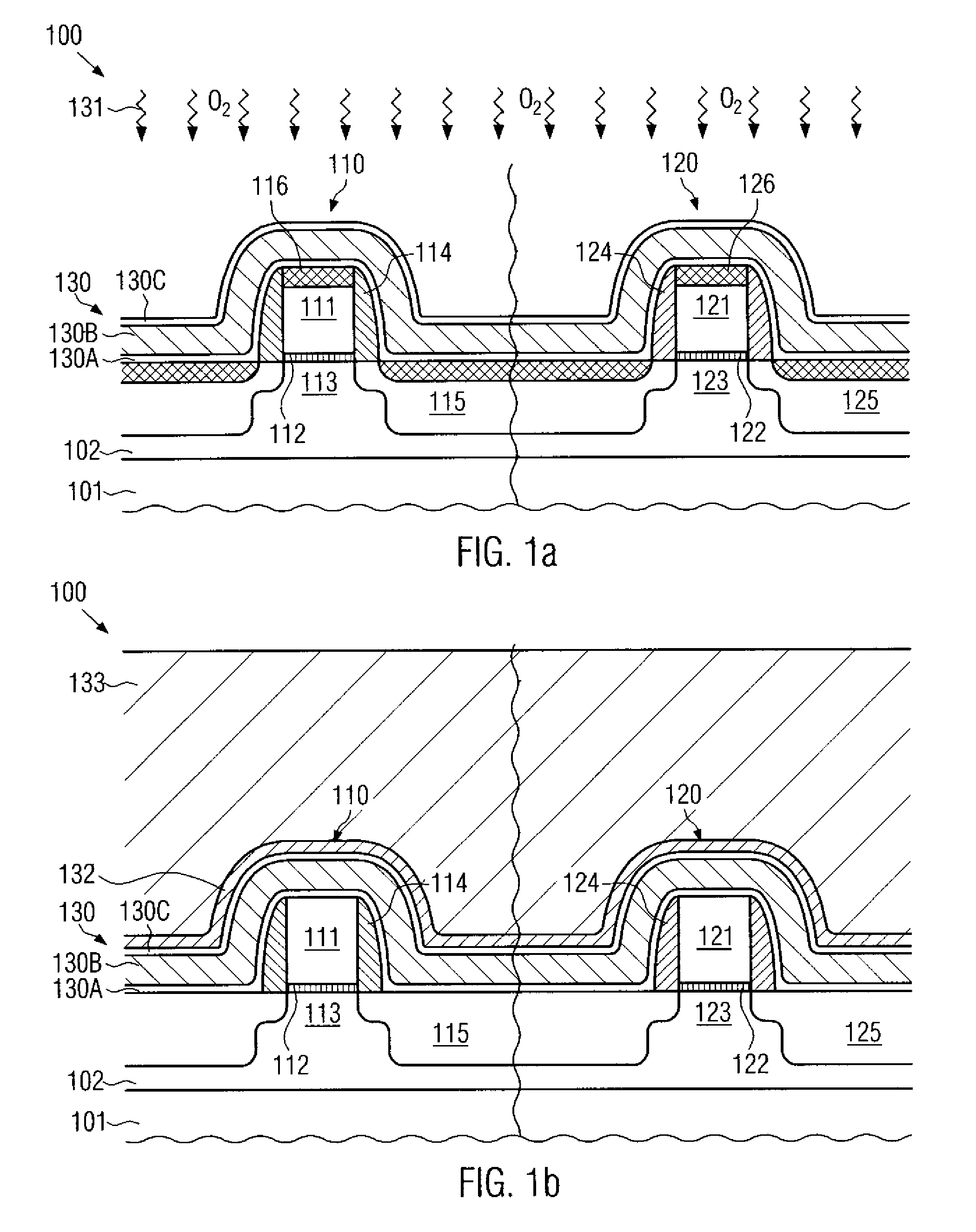

Method for reducing resist poisoning during patterning of silicon nitride layers in a semiconductor device

ActiveUS7550396B2Improve performanceReduce diffuseSemiconductor/solid-state device manufacturingSemiconductor devicesResistNitrogen

By performing a plasma treatment for efficiently sealing the surface of a stressed dielectric layer containing silicon nitride, an enhanced performance during the patterning of contact openings may be achieved, since nitrogen-induced resist poisoning may be significantly reduced during the selective patterning of stressed layers of different types of intrinsic stress.

Owner:TAIWAN SEMICON MFG CO LTD

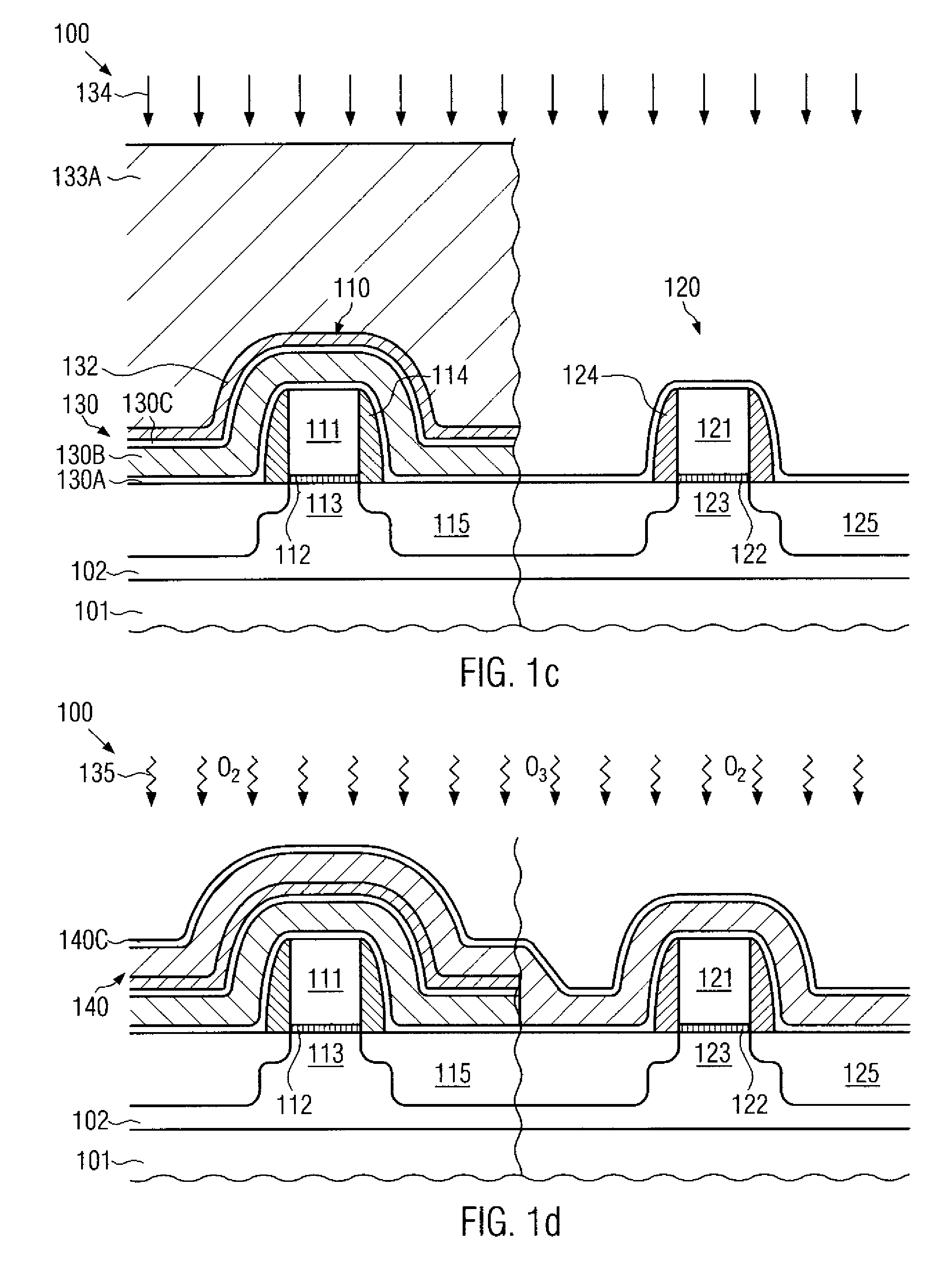

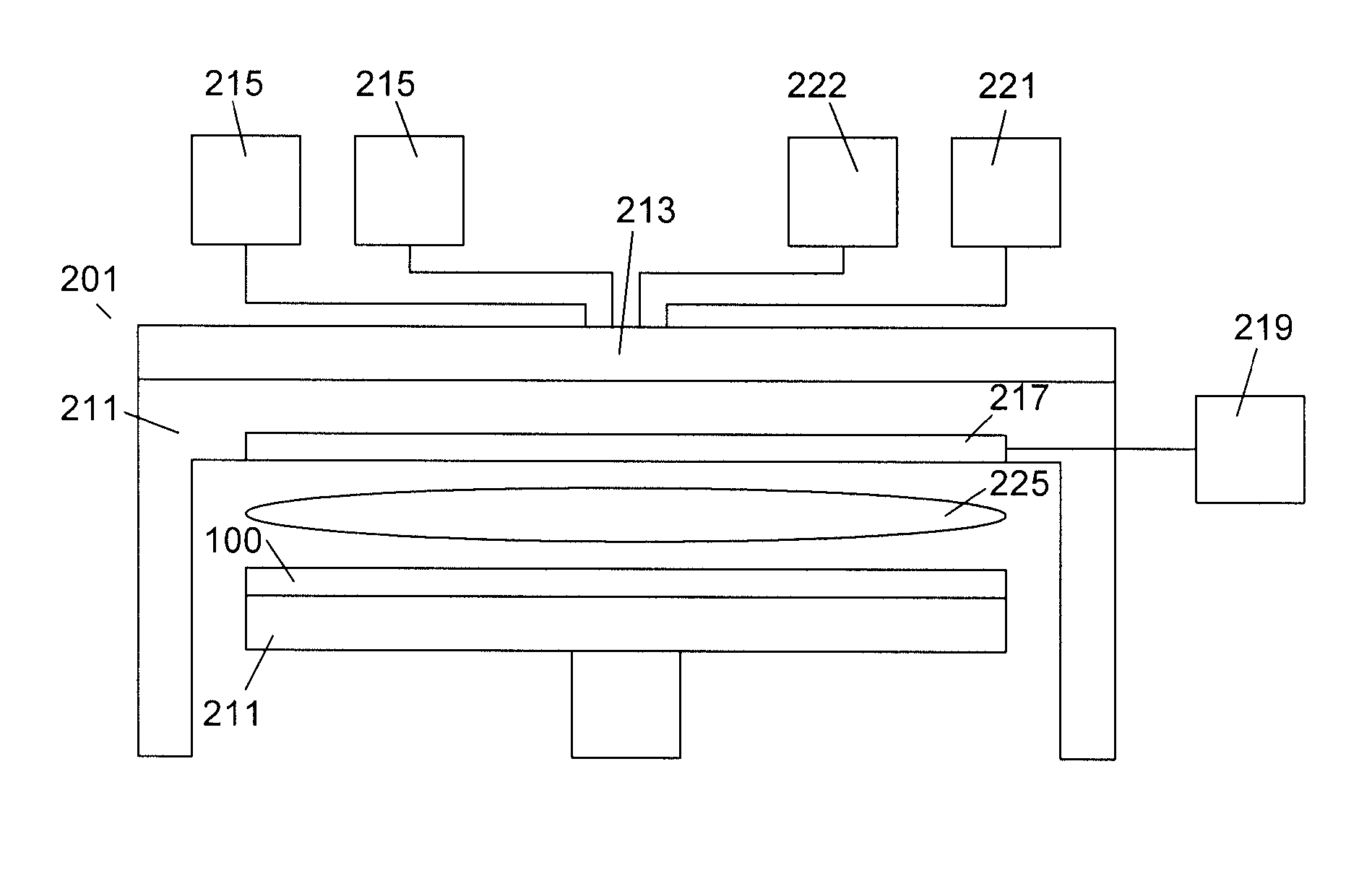

PECVD oxide-nitride and oxide-silicon stacks for 3D memory application

ActiveUS8076250B1Improve bonding interfaceAvoid layeringSemiconductor/solid-state device detailsSolid-state devicesMaterials science3d memory

A layer stack of different materials is deposited on a substrate in a single plasma enhanced chemical vapor deposition processing chamber while maintaining a vacuum. A substrate is placed in the processing chamber and a first processing gas is used to form a first layer of a first material on the substrate. A plasma purge and gas purge are performed before a second processing gas is used to form a second layer of a second material on the substrate. The plasma purge and gas purge are repeated and the additional layers of first and second materials are deposited on the layer stack.

Owner:APPLIED MATERIALS INC

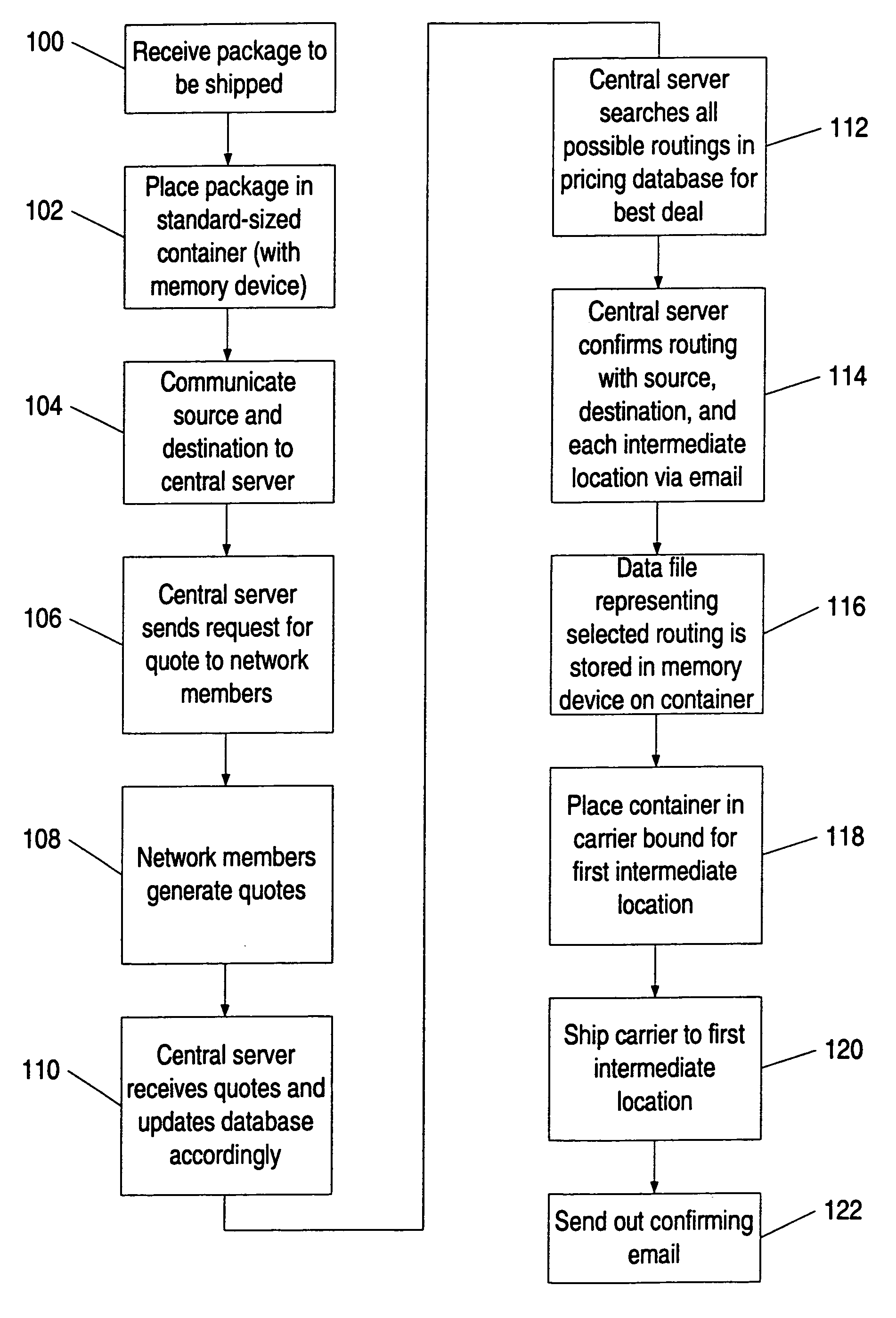

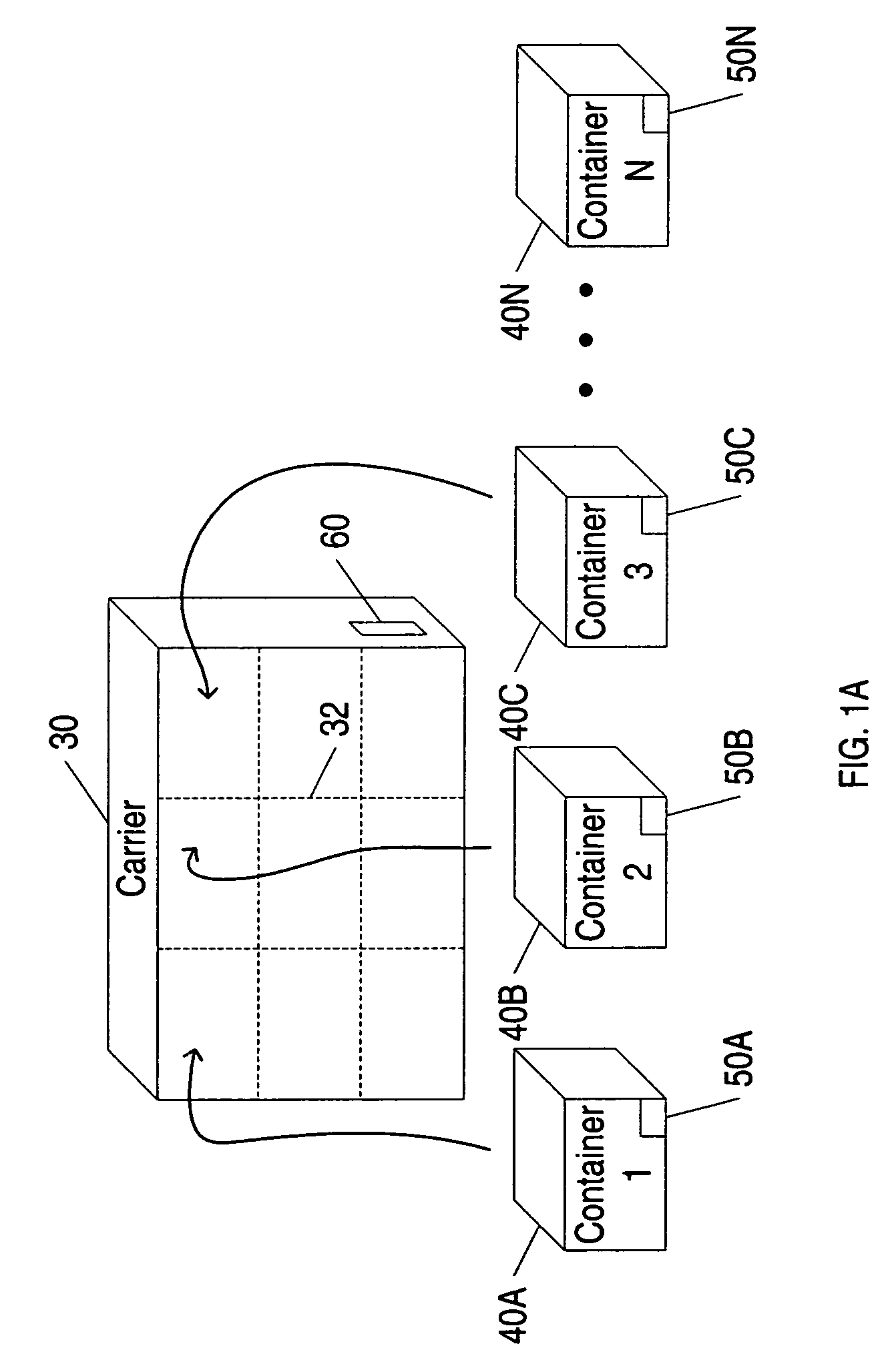

System and method for tracking and routing shipped items

InactiveUS7035856B1Simplify the shipping processSimple processContainer decorationsLevel indicationsData fileFile storage

A method and system for shipping items. A server is configured to send out requests for quotes to a number of regional shipping companies using a network. The server receives responses from the network and selects a route based on the responses. The route may include shipping the item to one or more intermediate destinations before the item arrives at the final destination. The server may create a data file reflecting the selected route. The items are packed in one or more containers, wherein each container has a memory device. At least part of the data file is then stored into the memory device. The memory device may be accessed as needed during shipping to determine where the item is going and when the item needs to arrive. Additional information may also be stored in the memory device, and the device may be updated at intermediate destinations. Each container may take a different routing, and the server may actively search for better routings as the item proceeds along the selected route. The containers may be configured to be placed within carriers that hold multiple containers, and the carriers may also be configured with memory devices.

Owner:NIHON DOT COM

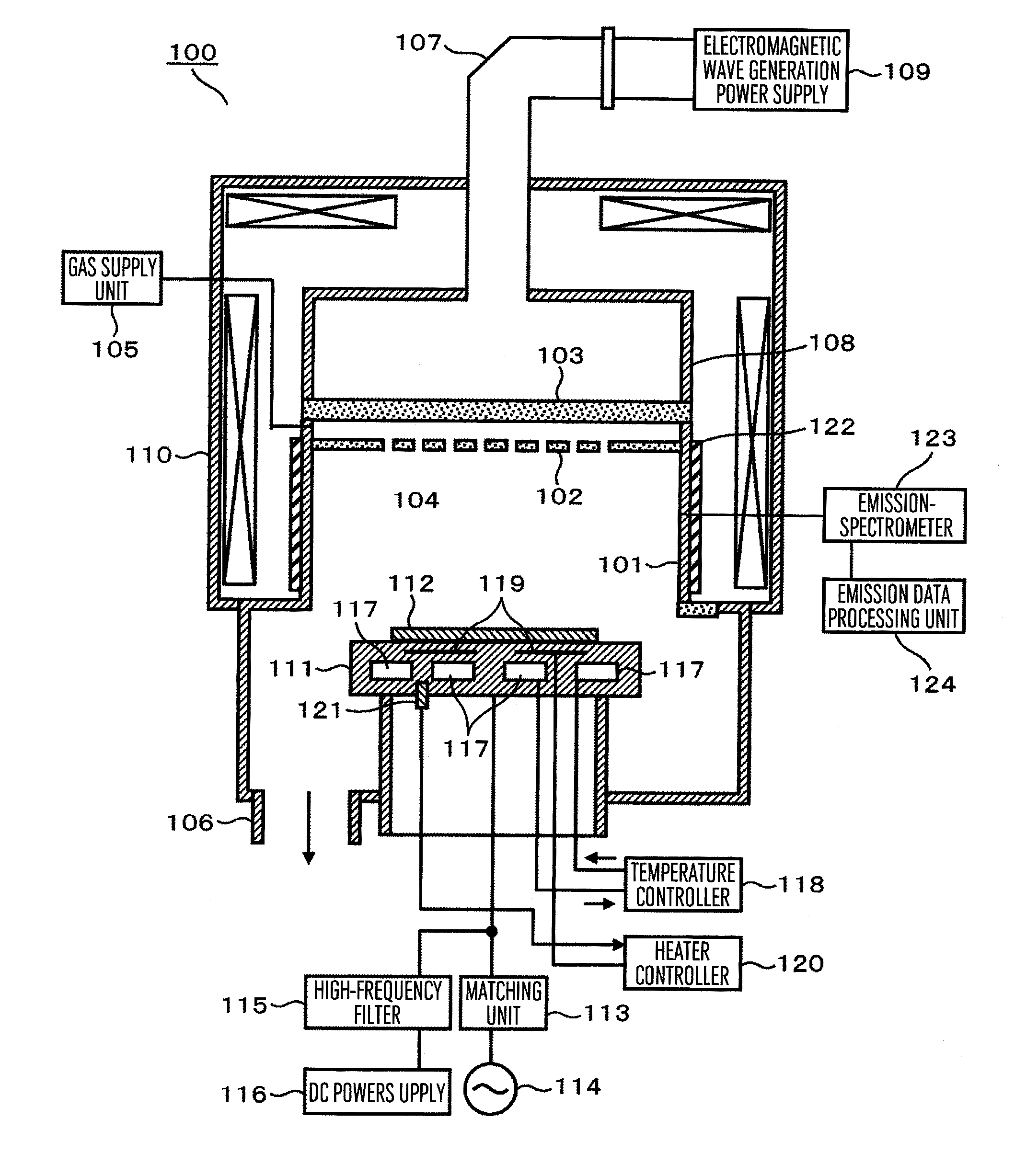

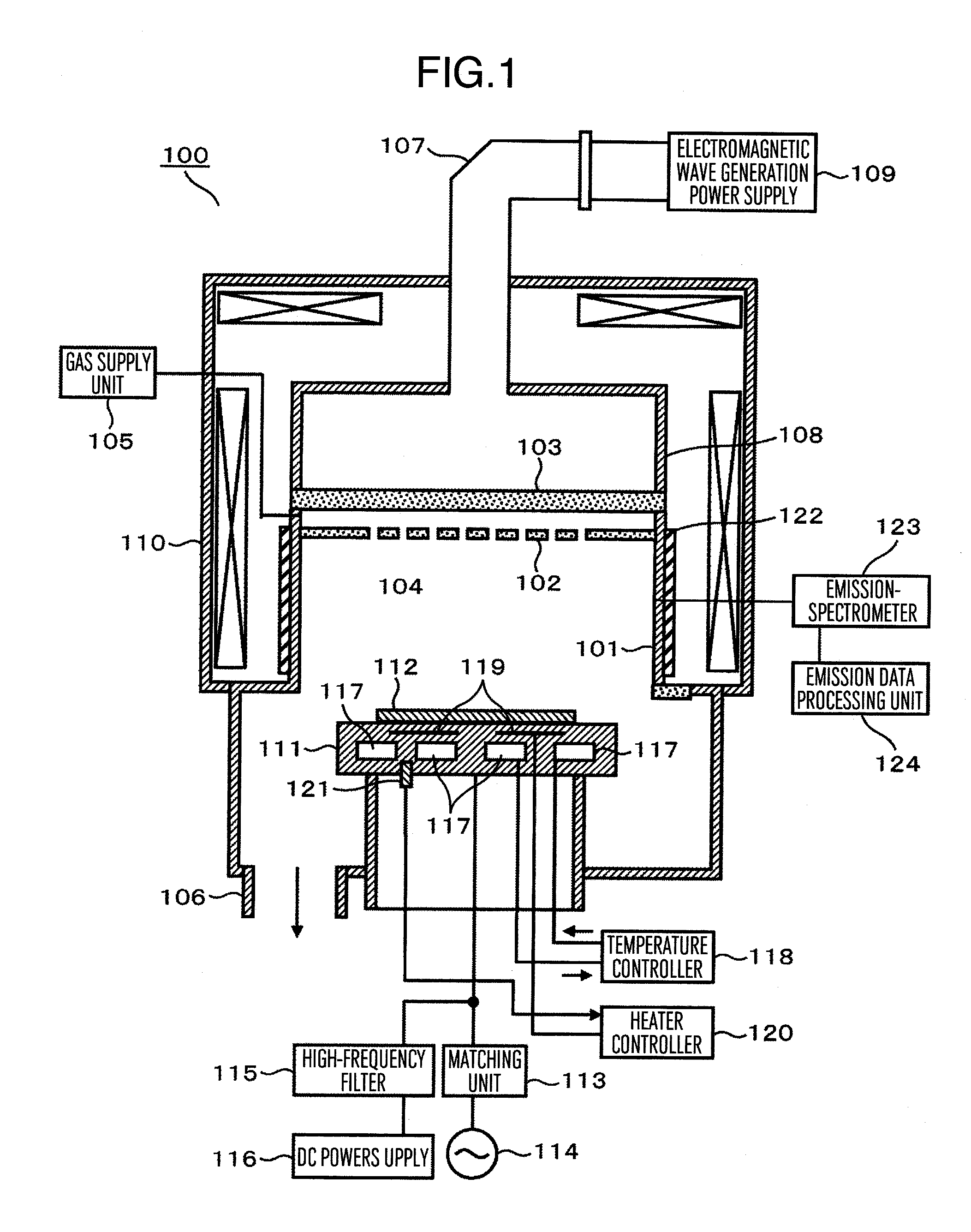

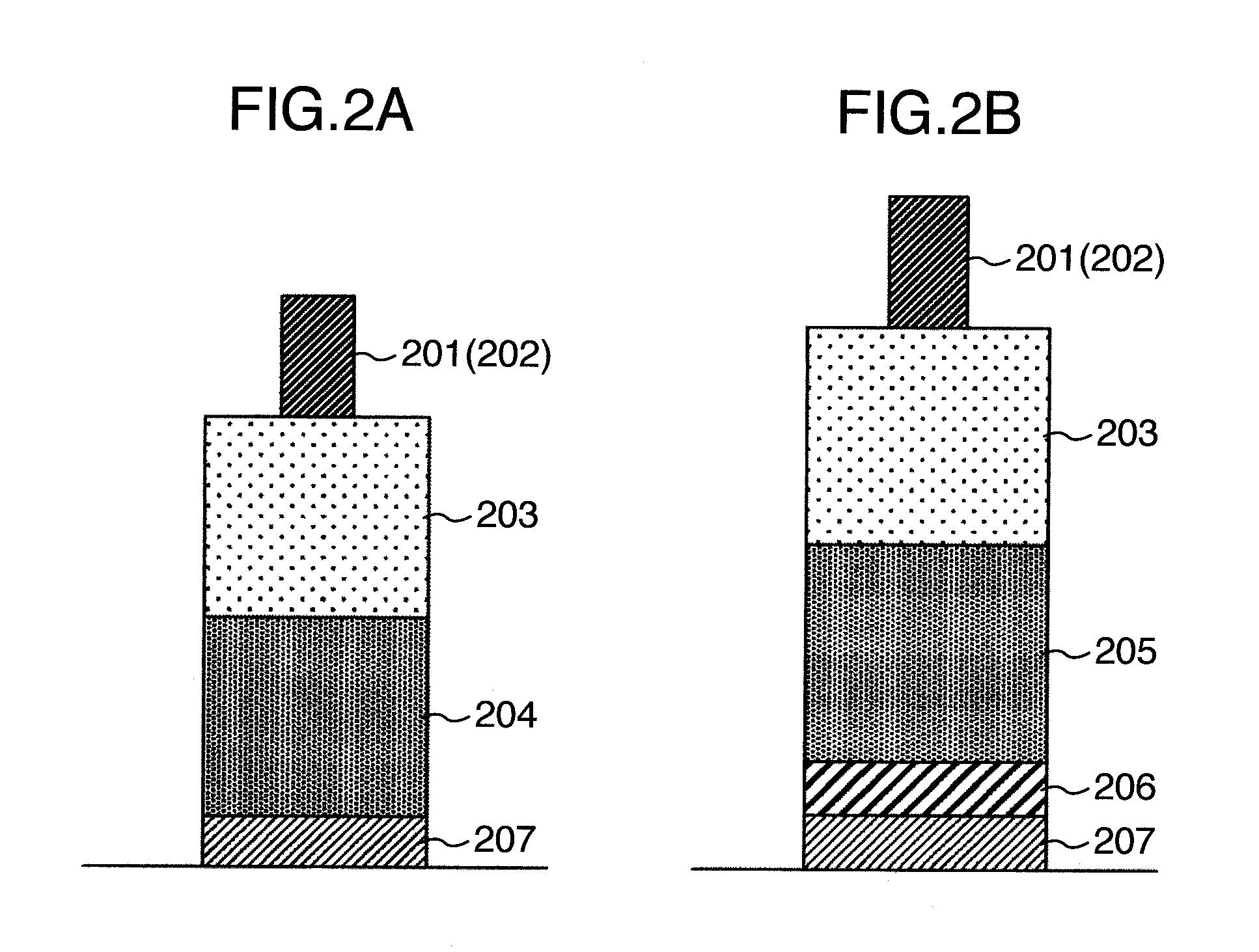

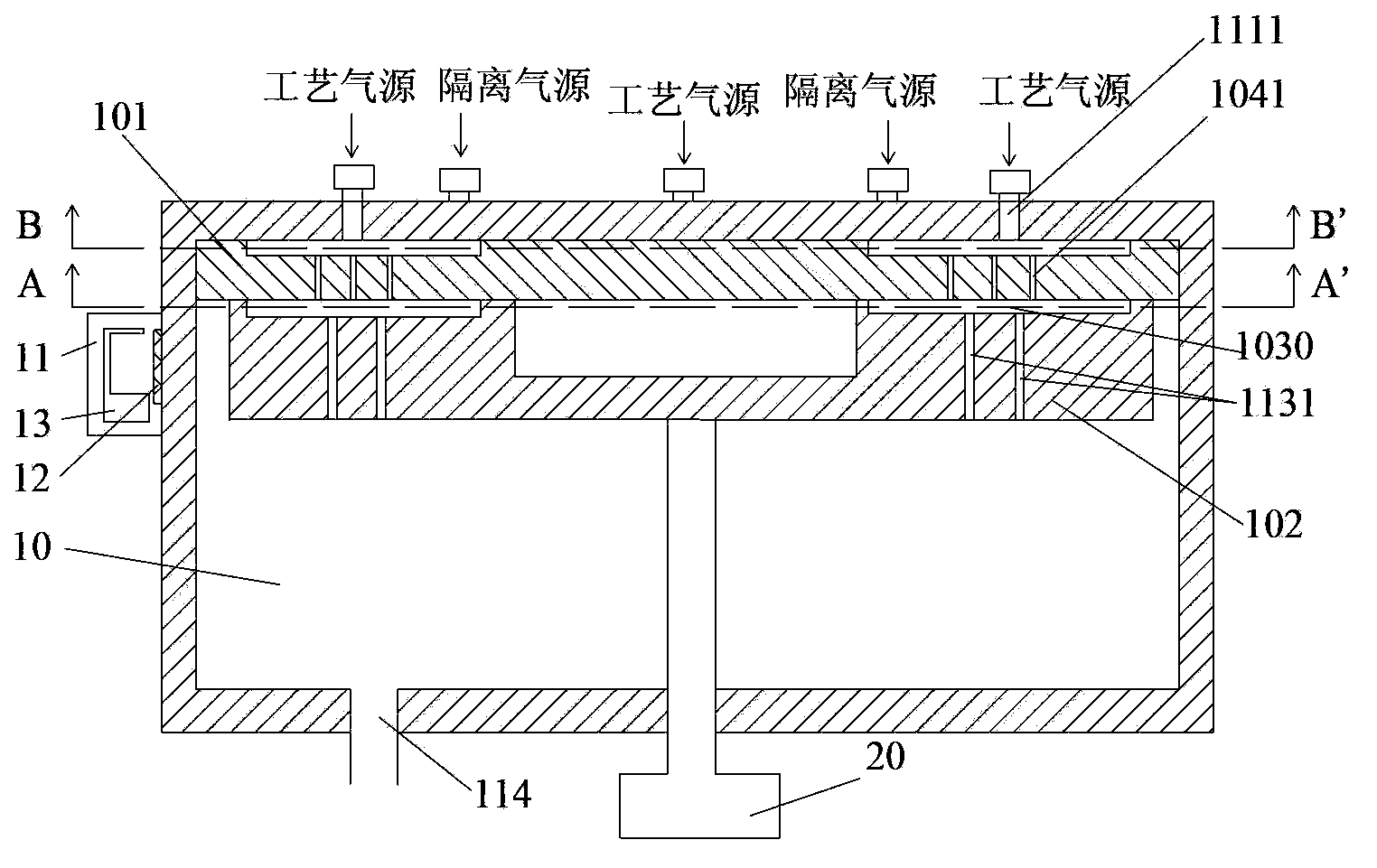

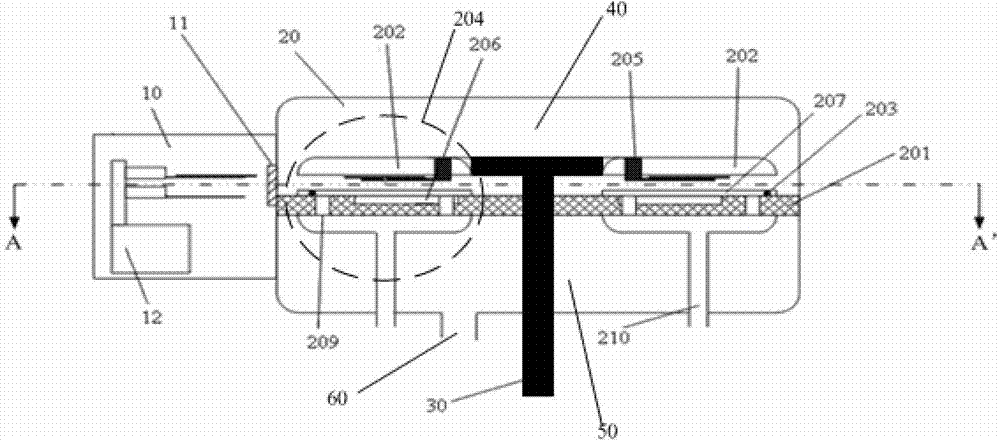

Plasma processing apparatus and plasma processing method

ActiveUS20110226734A1Reduce changeImprove efficiencyElectric discharge tubesDecorative surface effectsResistFilm structure

In a plasma processing apparatus comprising a processing chamber arranged in a vacuum chamber, a sample stage arranged under the processing chamber and having its top surface on which a wafer to be processed is mounted, a vacuum decompression unit for evacuating the interior of the processing chamber to reduce the pressure therein, and introduction holes arranged above said sample stage to admit process gas into the processing chamber, the wafer having its top surface mounted with a film structure and the film structure being etched by using plasma formed by using the process gas, the film structure is constituted by having a resist film or a mask film, a poly-silicon film and an insulation film laminated in this order from top to bottom on a substrate and before the wafer is mounted on the sample stage and the poly-silicon film underlying the mask film is etched, plasma is formed inside the processing chamber to cover the surface of members inside the processing chamber with a coating film containing a component of Si.

Owner:HITACHI HIGH-TECH CORP

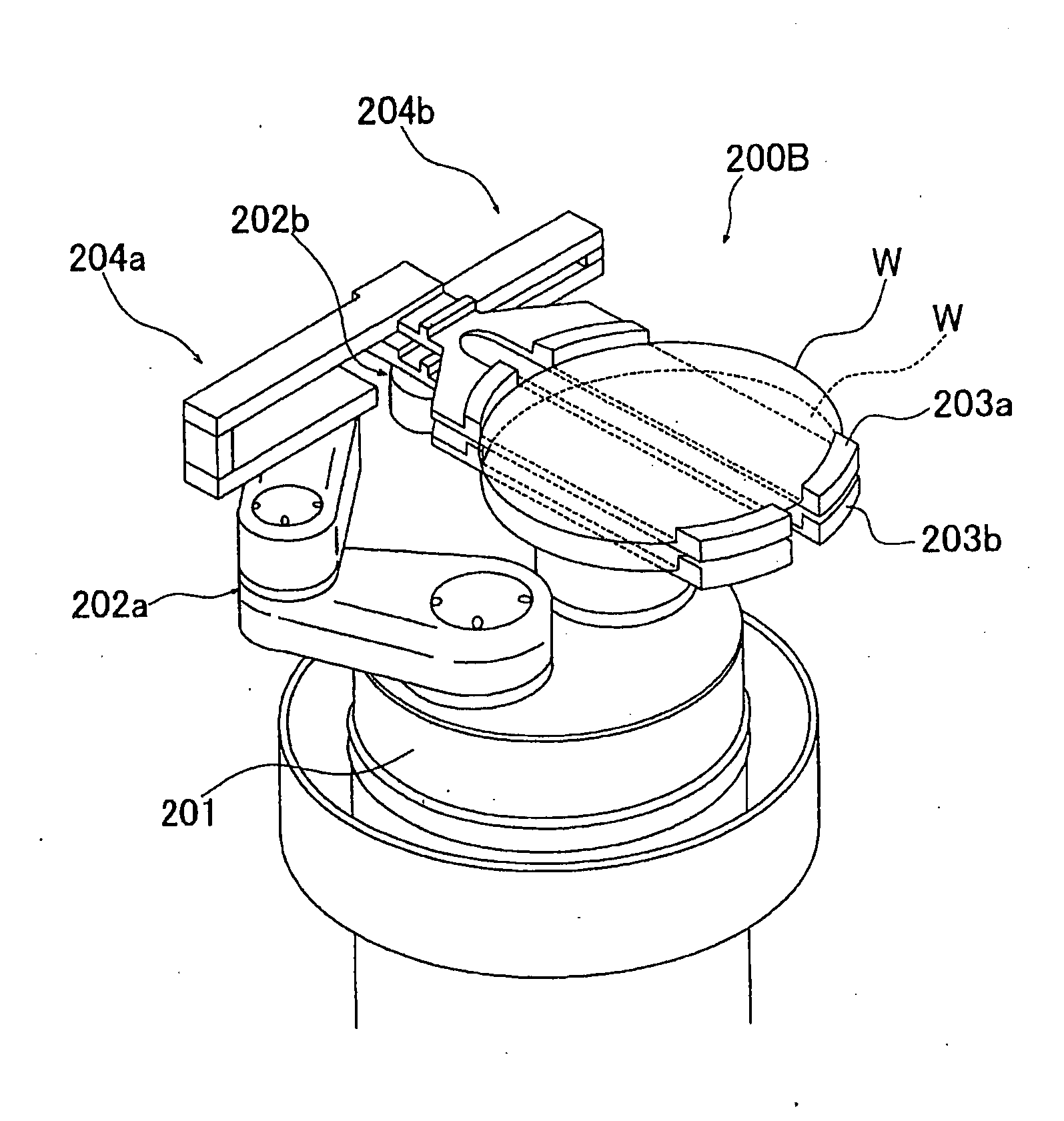

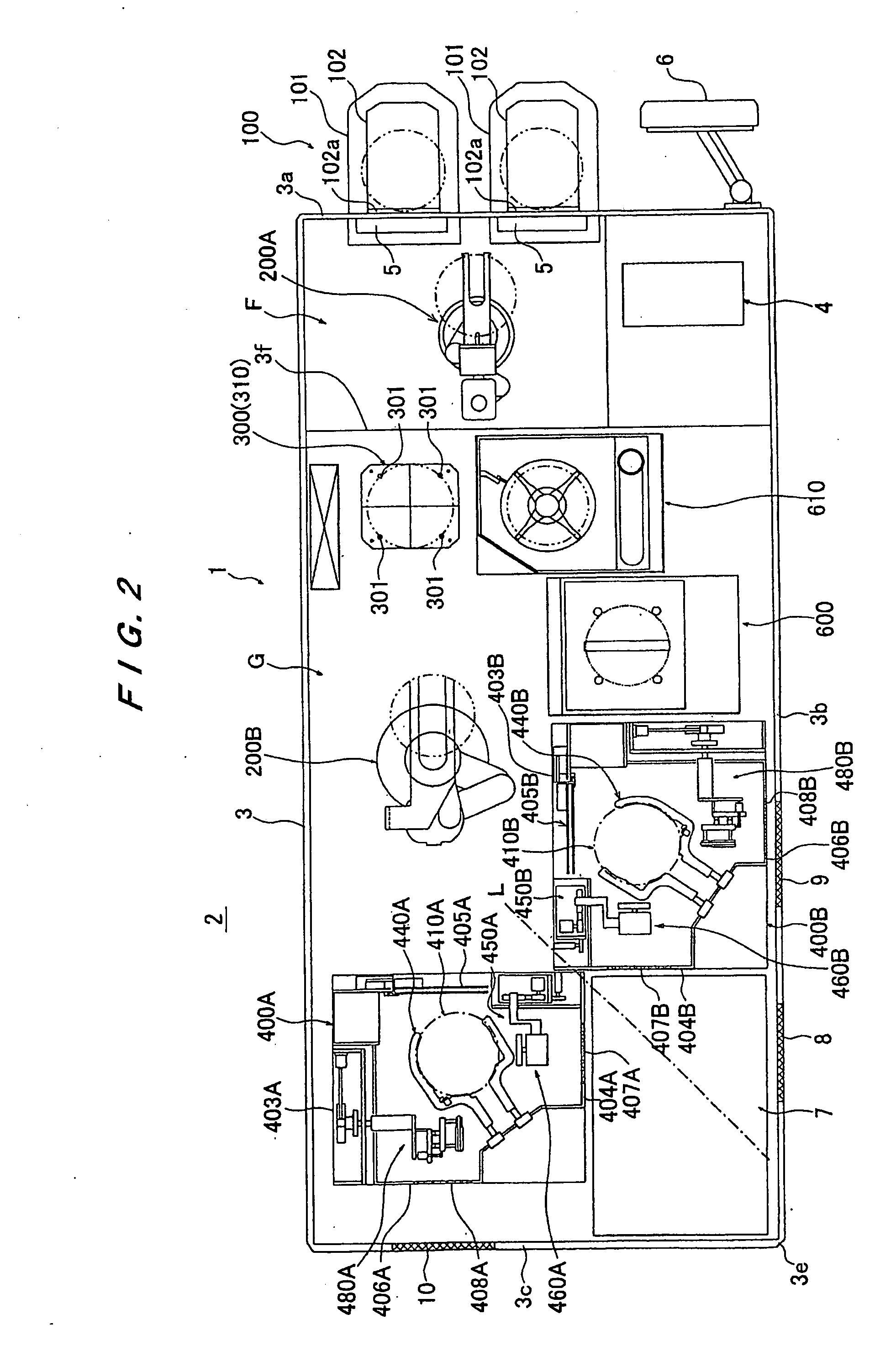

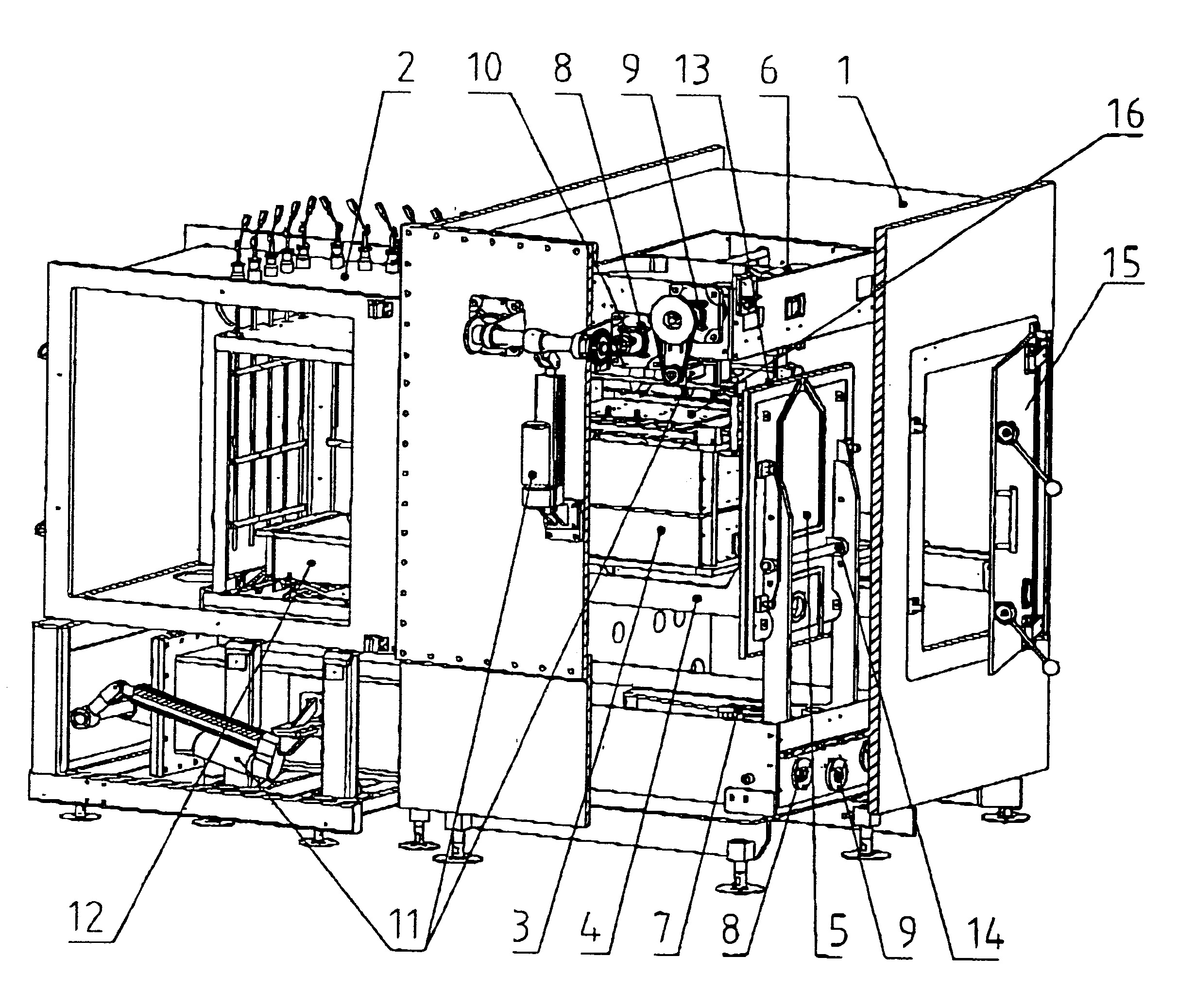

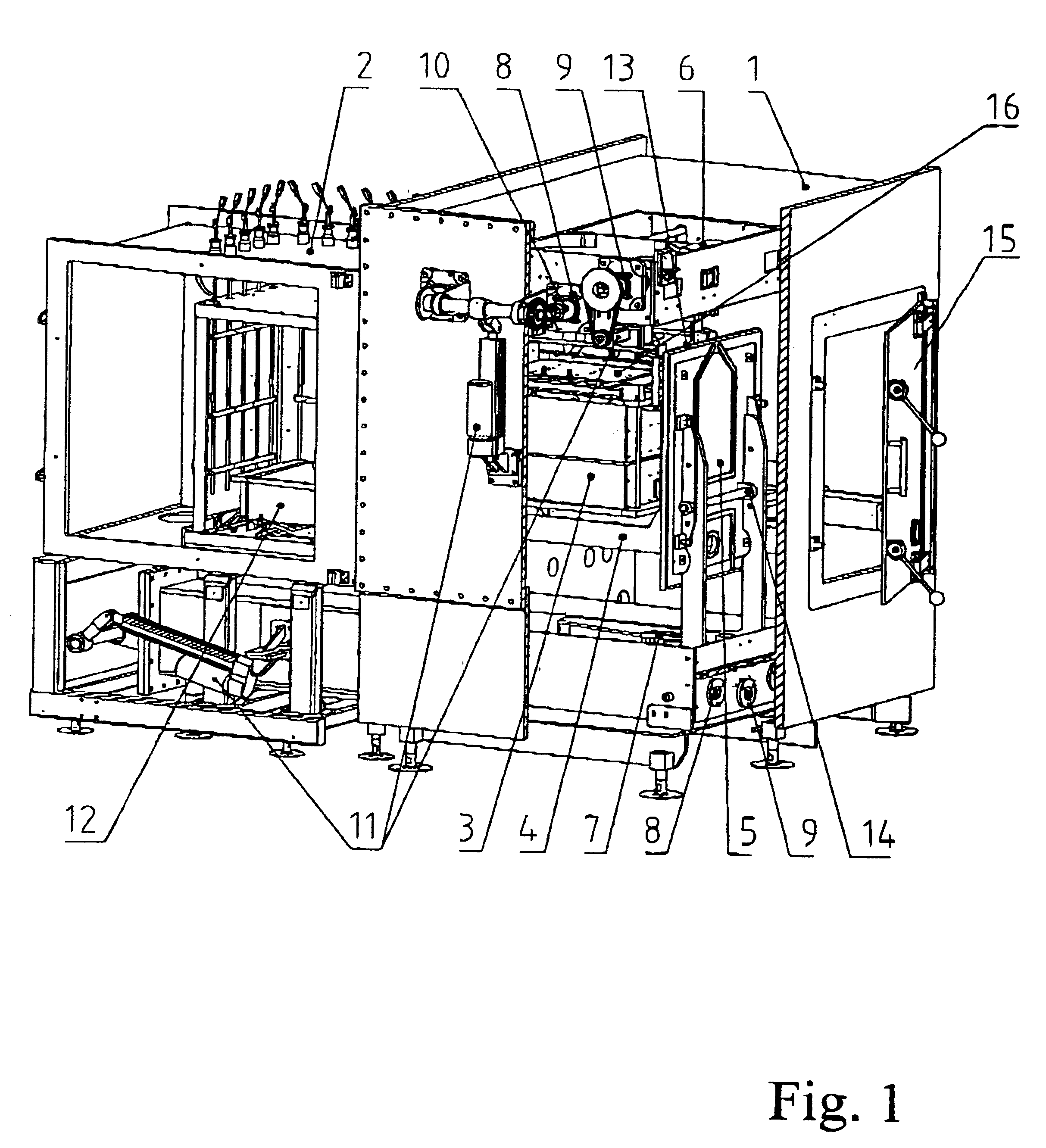

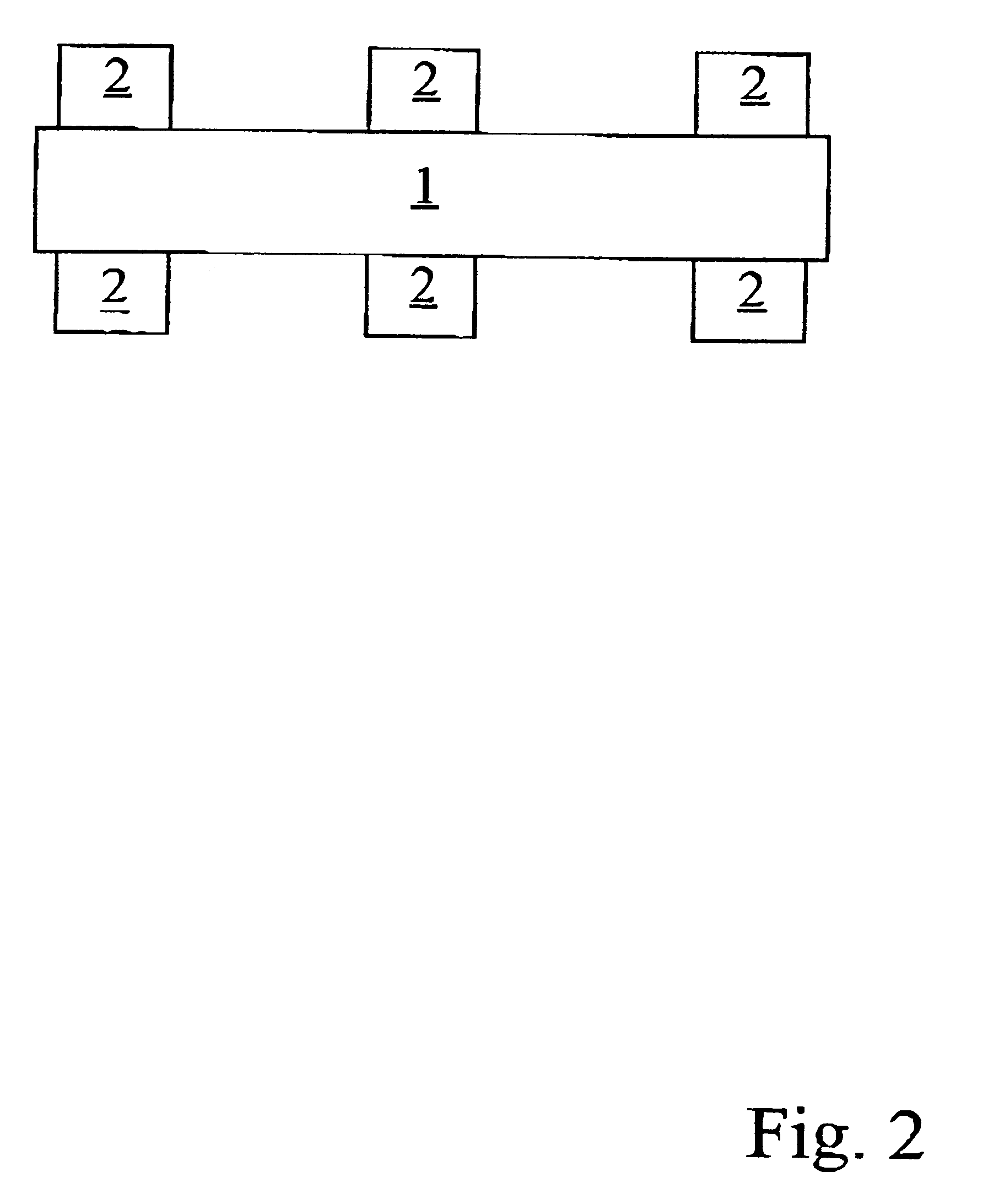

Substrate processing apparatus

InactiveUS20090017733A1Improve processing efficiencyEfficiently conductedEdge grinding machinesPolishing machinesEngineering

A substrate processing apparatus (1) has a first polishing unit (400A) and a second polishing unit (400B) for polishing a peripheral portion of a substrate. Each of the two polishing units (400A, 400B) includes a bevel polishing device (450A, 450B) for polishing a peripheral portion of a substrate and a notch polishing device (480A, 480B) for polishing a notch of a substrate. The substrate processing apparatus (1) has a maintenance space (7) formed between the two polishing units (400A, 400B). The bevel polishing devices (450A, 450B) in the two polishing units (400A, 400B) face the maintenance space (7) so as to be accessible from the maintenance space (7).

Owner:EBARA CORP

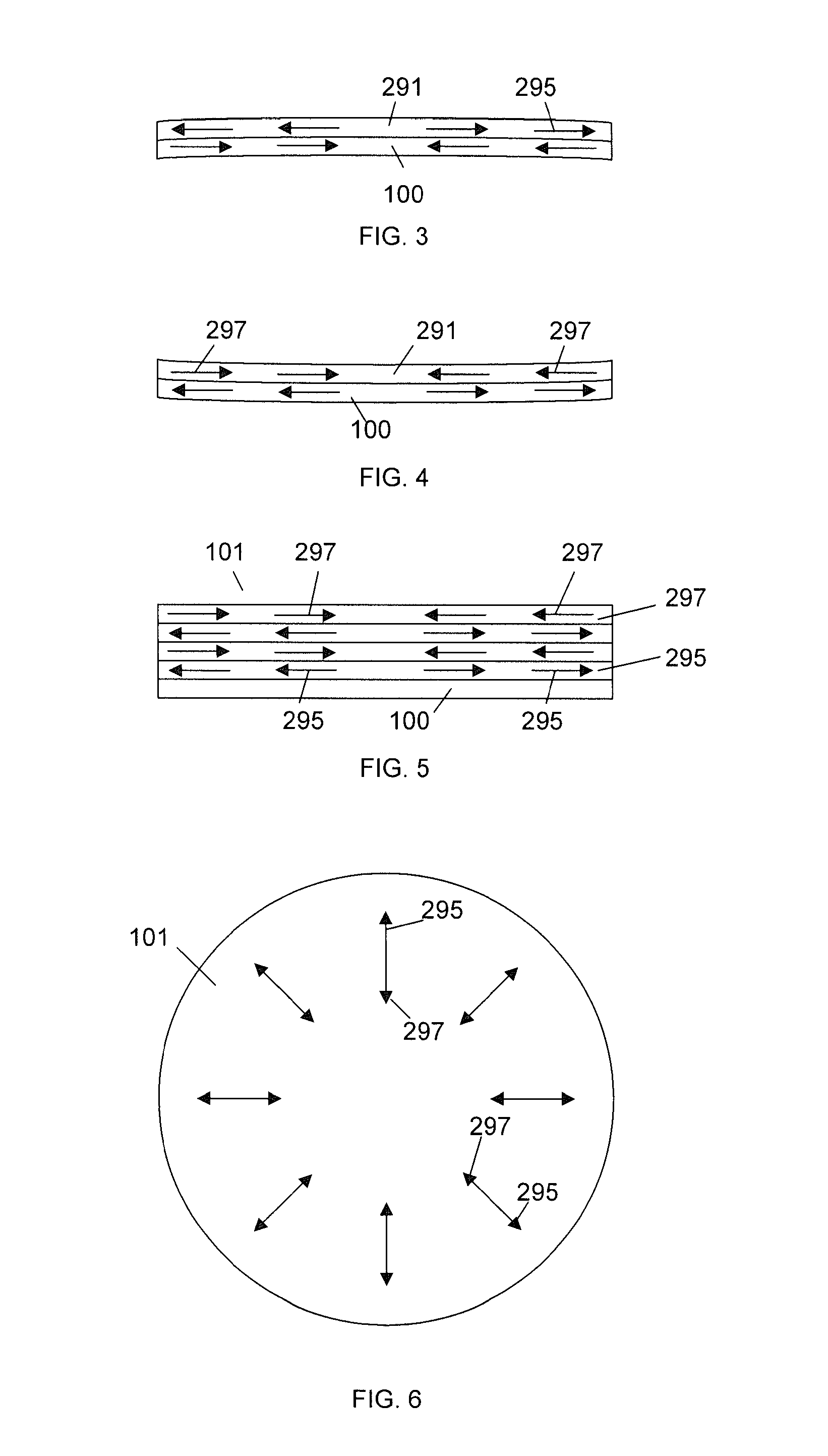

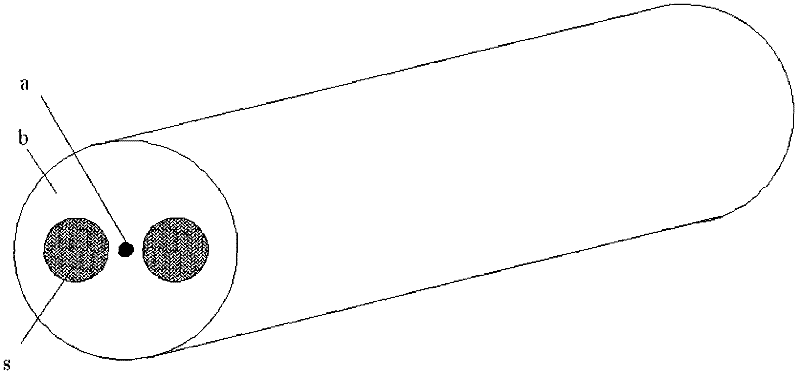

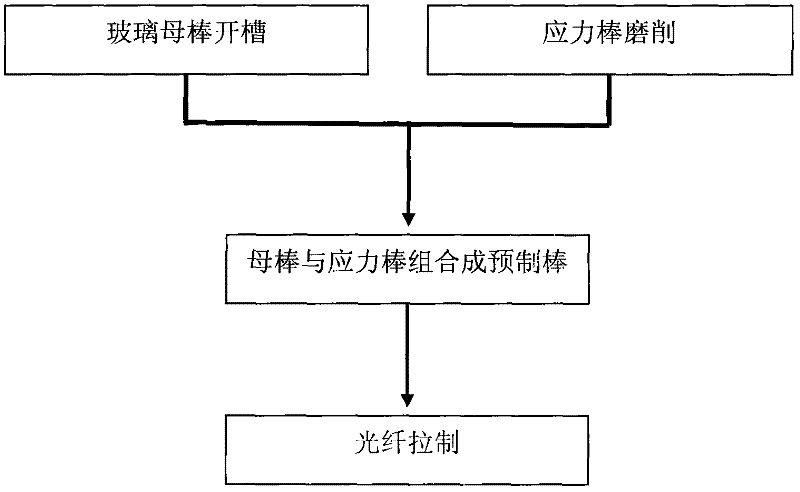

Manufacture method for polarization maintaining fiber and polarization maintaining fiber

InactiveCN102351415AImprove the finishImprove processing efficiencyGlass making apparatusOptical fibre with polarisationSurface finishPolarization-maintaining optical fiber

The invention provides a manufacture method for polarization maintaining fiber and a polarization maintaining fiber, and relates to optical waveguide fibers in the field of fiber-optical communication and fiber optical sensors. The method comprises the following steps that: (1) two oppositely arranged open slots with a same shape are inwardly provided at a side surface of a glass mother rod, stress rods are machined to obtain a shape matching the open slots, and the centers of the cross sections of the two open slots and the center of circle in the cross section of the glass mother rod are in a same line; (2) the stress rods are respectively inserted into each open slot on the glass mother rod, and the assembled glass mother rod and stress rods are put in a cannula to form a preformed rod of the polarization maintaining fiber; (3) the preformed rod of the polarization maintaining fiber is drew to form the polarization maintaining fiber. According to the invention, the glass mother rod is provided with the open slots, and the stress rods are embedded in the open slots, thereby obtaining high process repeatability; inner surfaces of the open slots have high fineness, and the open slots have good symmetry, thereby improving processing efficiency; therefore, the optical performance and reliability of the polarization maintaining fiber are substantially improved.

Owner:RUIGUANG TELECOMM TECH CO LTD

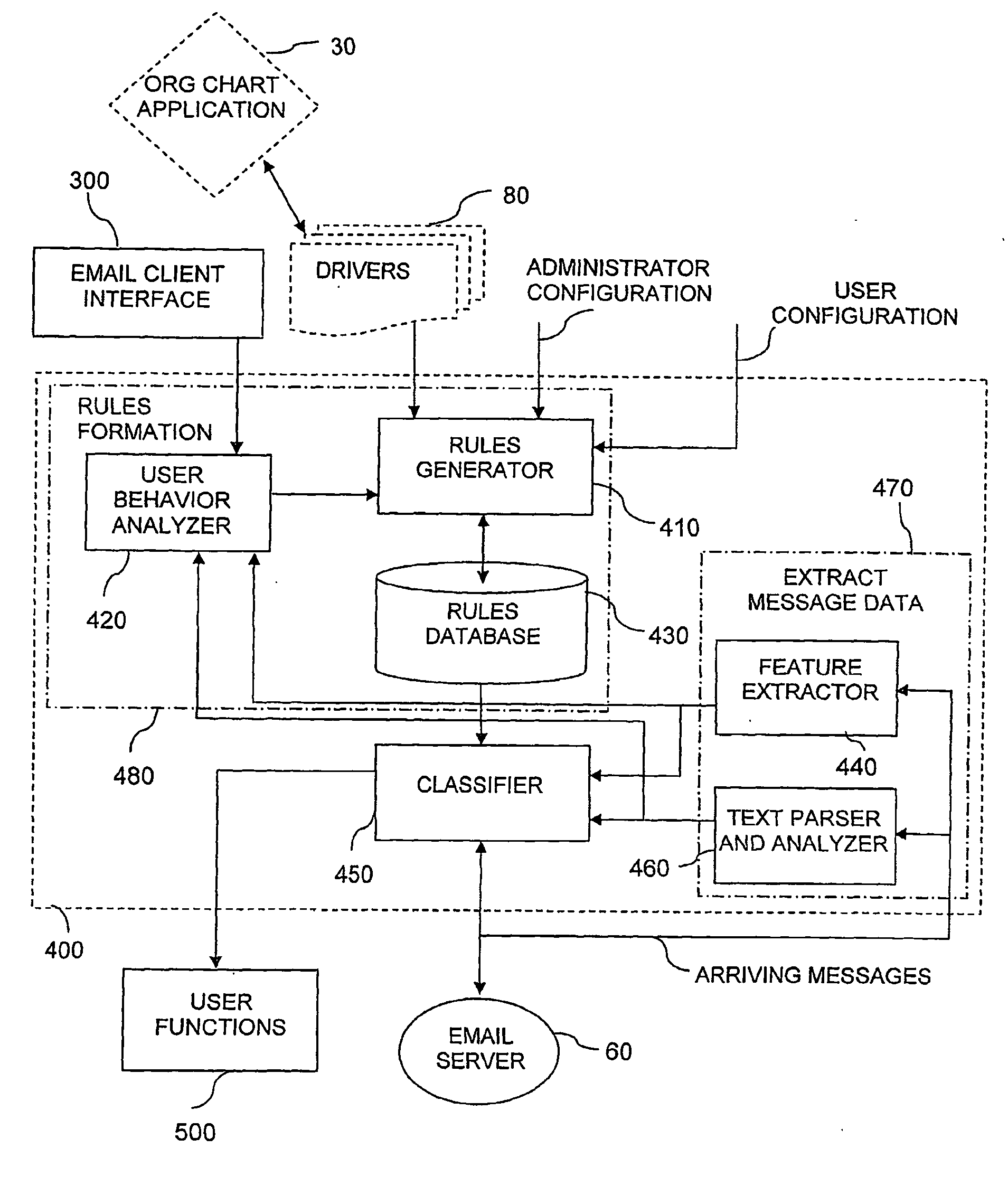

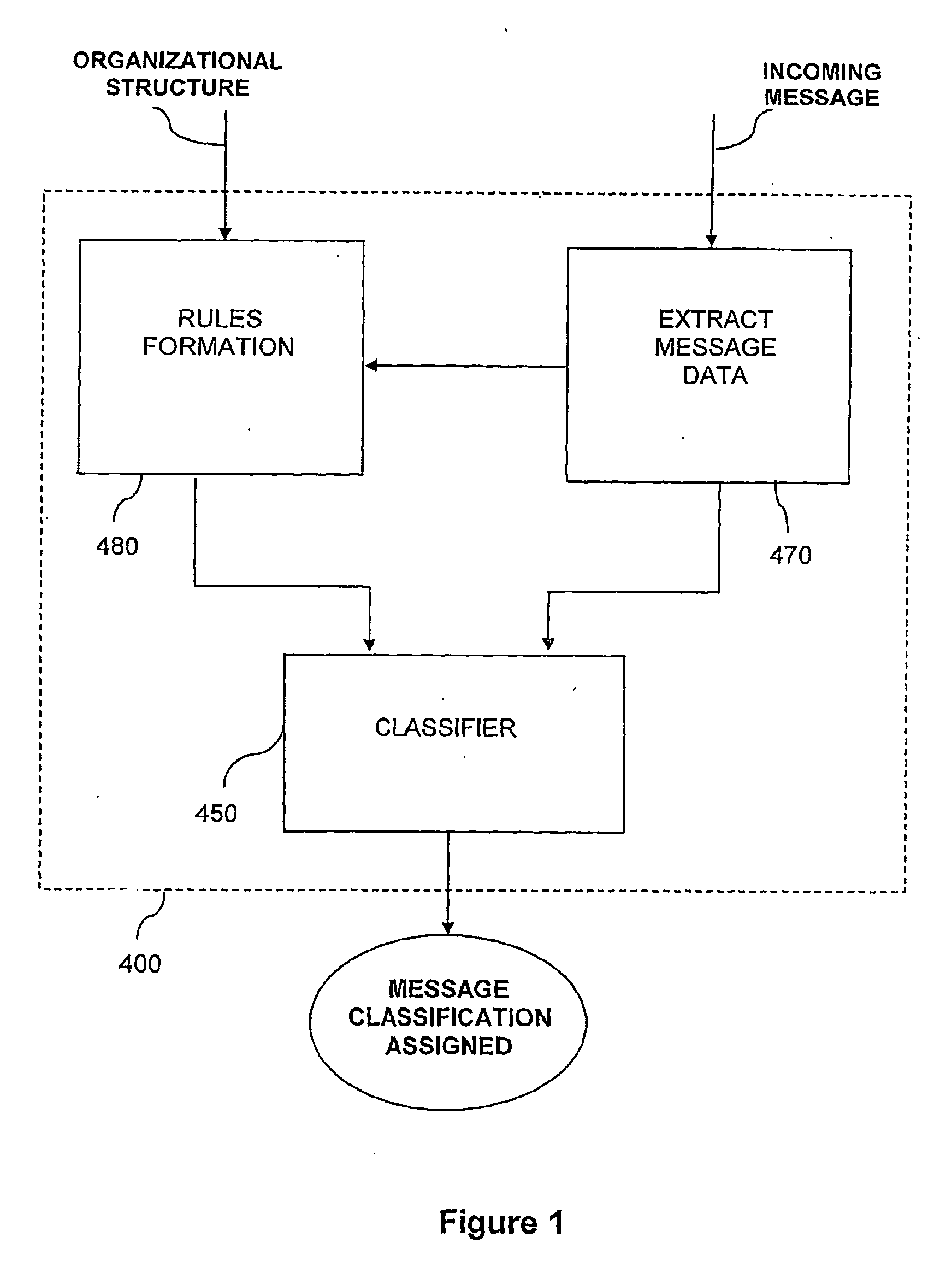

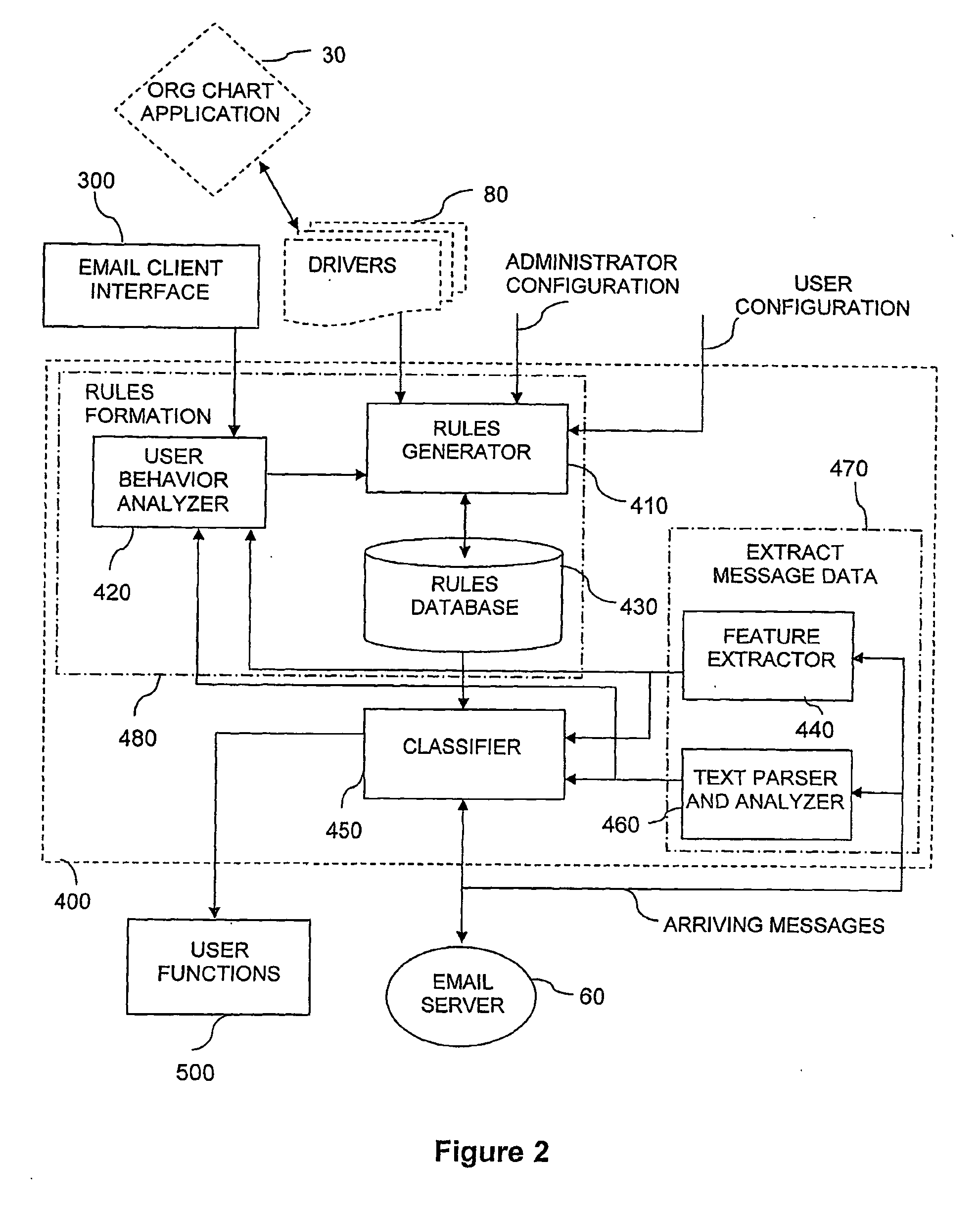

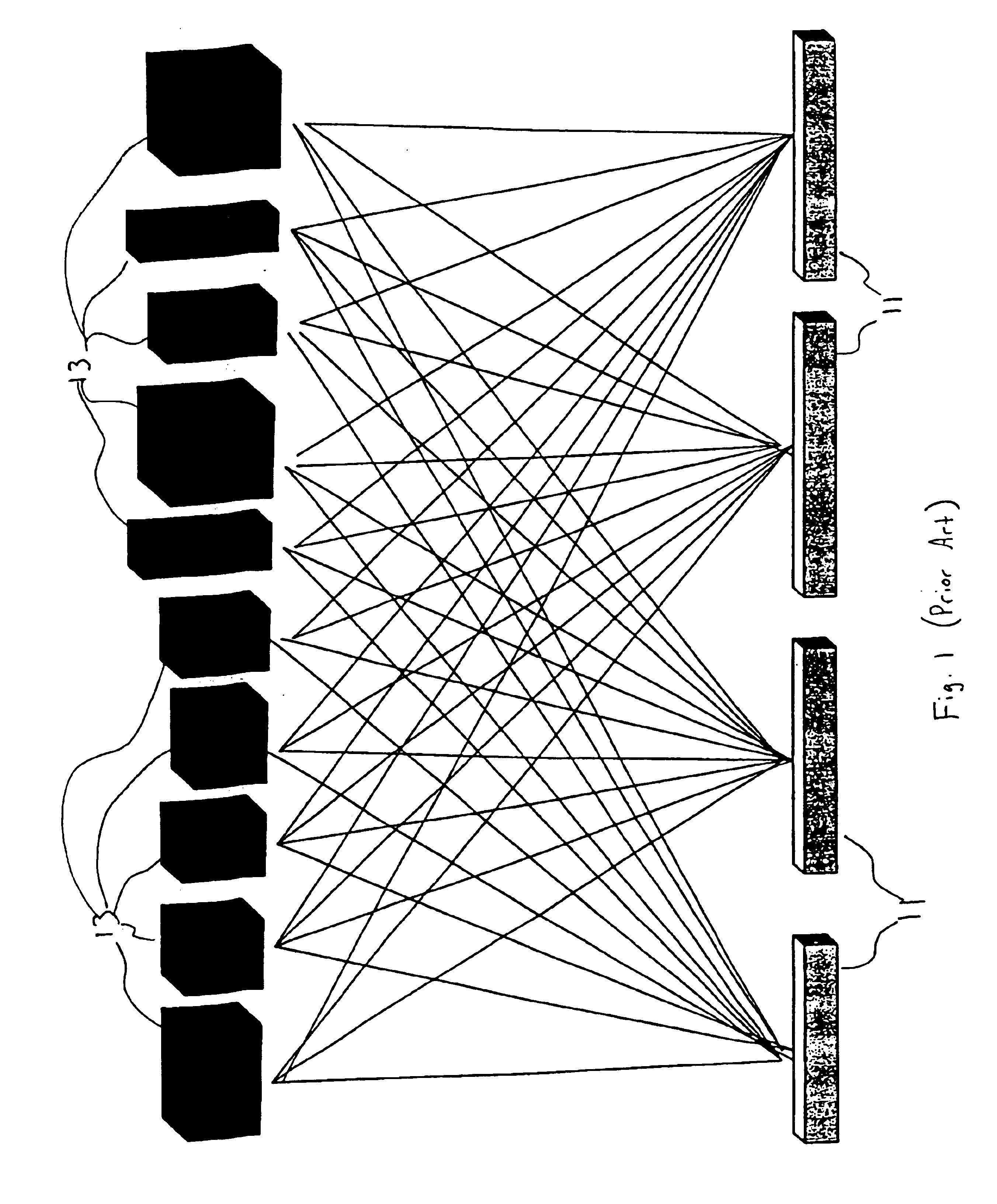

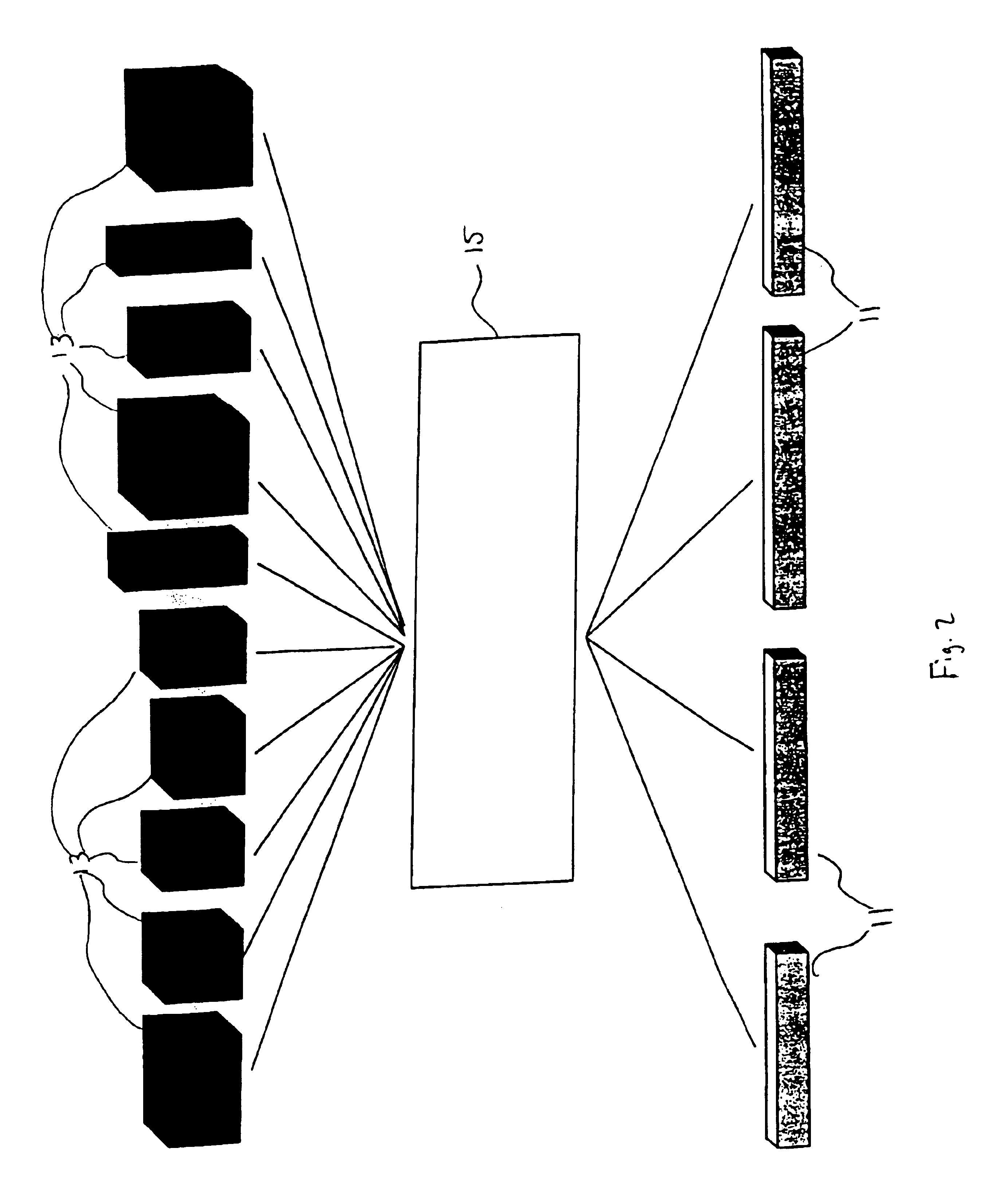

Method and devices for prioritizing electronic messages

InactiveUS20050204001A1Improve processing efficiencyRaise the importanceMultiple digital computer combinationsData switching networksArtificial intelligenceComputer science

Importance classes are assigned to electronic messages, by identifying the sender and recipient of an electronic message, determining a relative organizational distance between the sender and the recipient, and assigning the electronic message an importance class, according to the relative organizational distance between the sender and the recipient. The importance setting is further weighted by content criteria and a plurality of rules formed by a machine learning algorithm.

Owner:STEIN TZVI +3

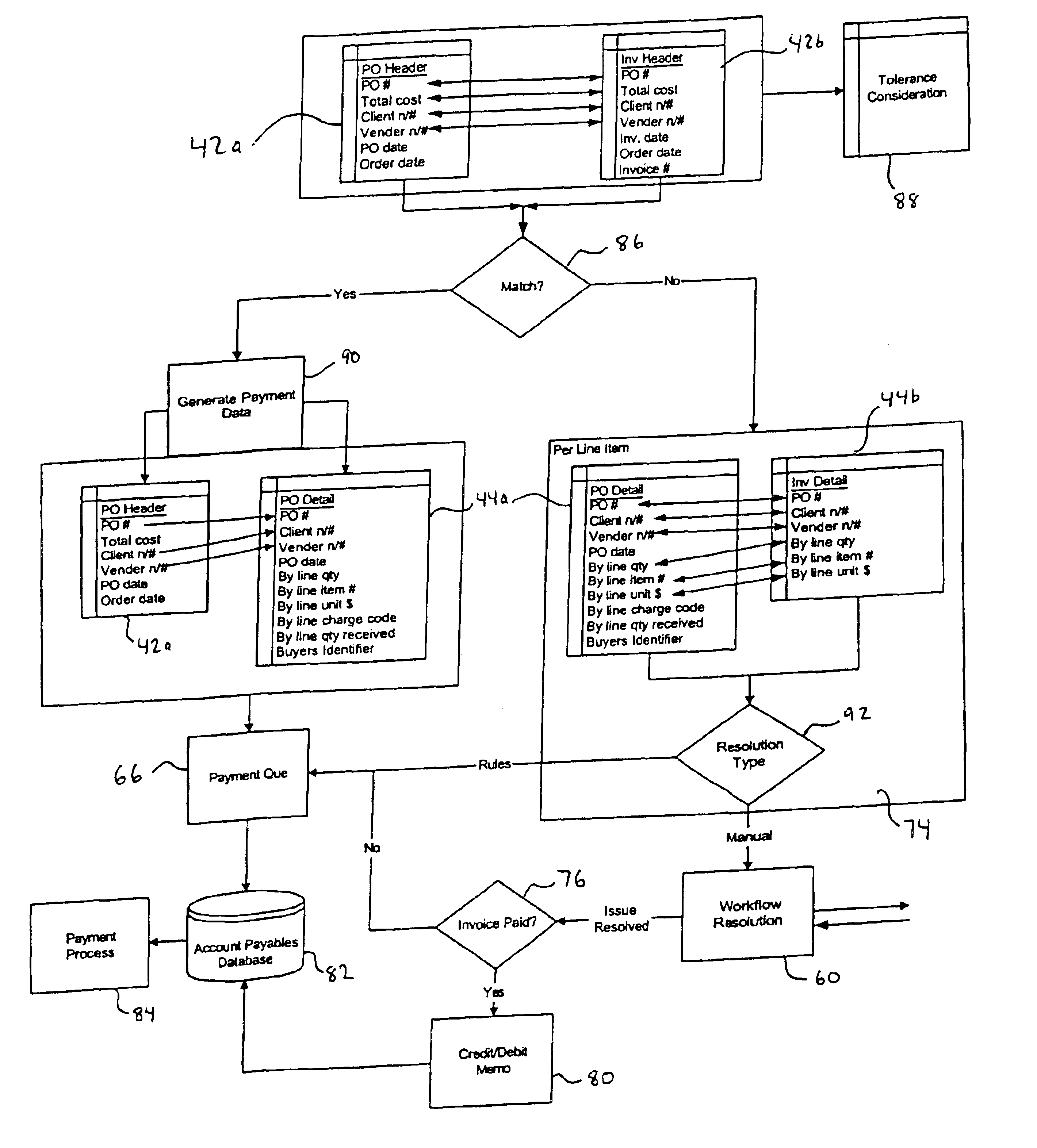

Method and system for processing transactions

InactiveUS6882983B2Minimize resource requirementFurther efficiencyComplete banking machinesFinancePaymentInvoice

The present invention discloses a system and method for processing business transactions between trading partners using a central interactive platform. The processing may include comparing purchase order data and invoice data to identify matching information and non-matching information. If the information matches, the invoices are processed for payment. If the information does not match, the discrepancies are identified to the buying company or the selling company for resolution.

Owner:ORACLE INT CORP

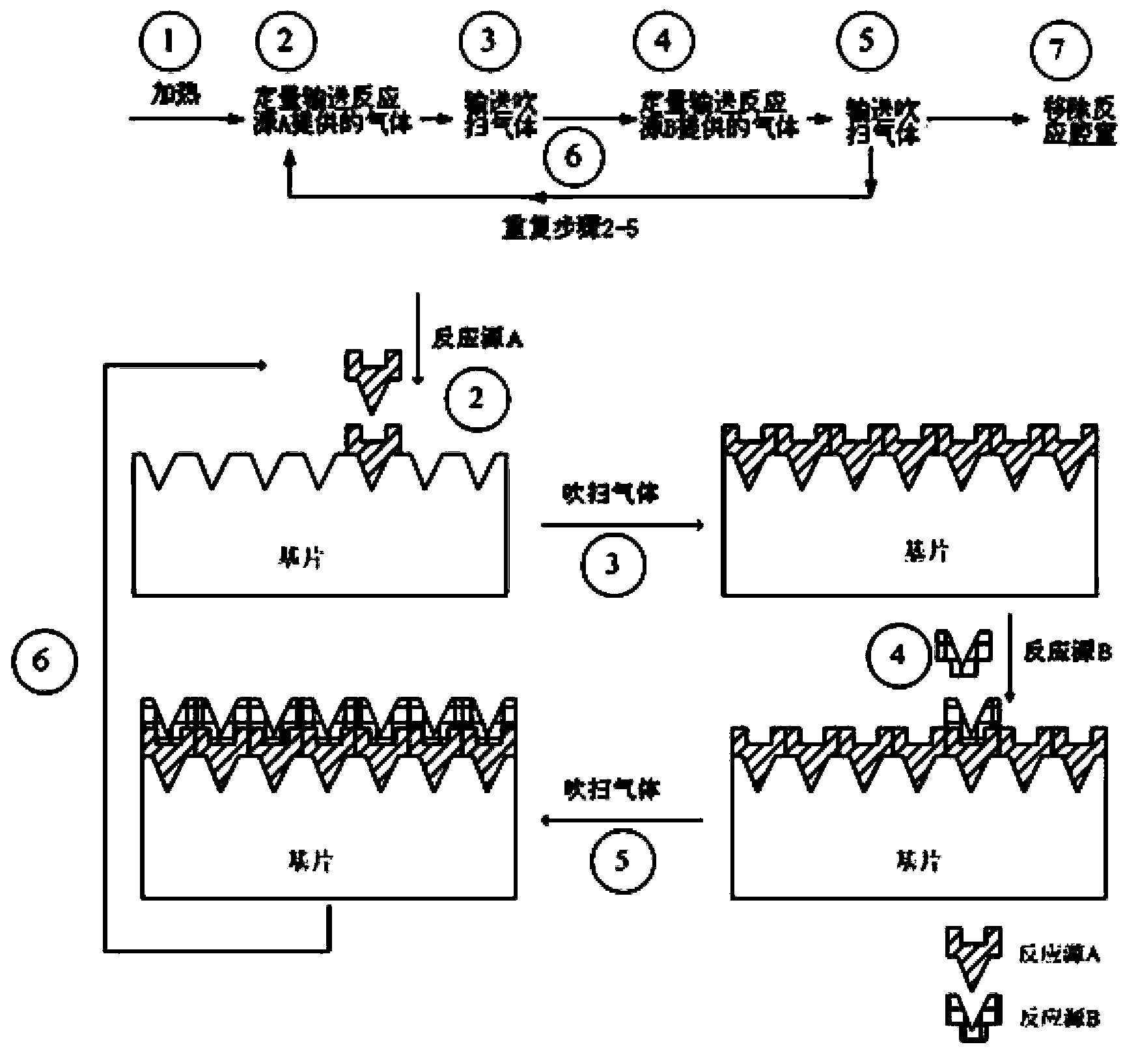

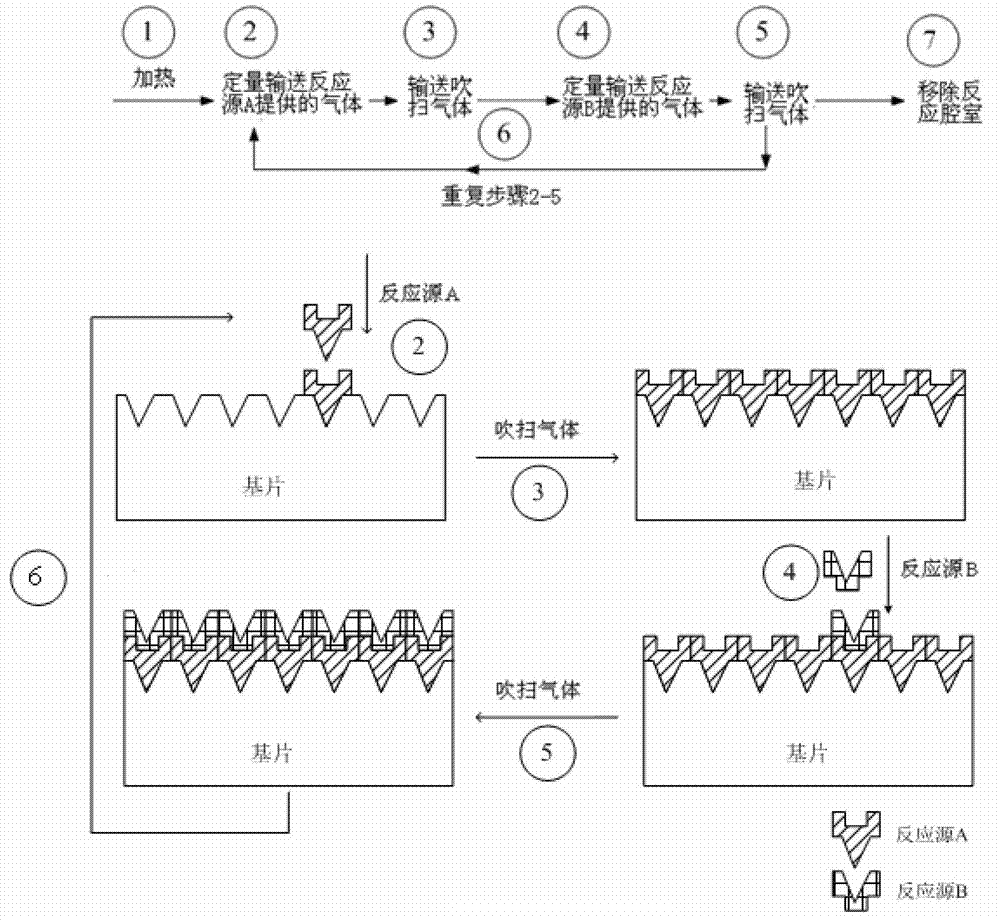

Atomic layer deposition equipment

ActiveCN104342637AImprove processing efficiencyIncrease production capacityChemical vapor deposition coatingEngineeringAtomic layer deposition

Provided atomic layer deposition equipment comprises a reaction chamber and a gas source; the reaction chamber is inside provided with a gas distribution plate arranged at the top, a base disc and a rotary driving mechanism; the upper surface of the base disc and the lower surface of the gas distribution plate are mutually superposed; multiple sub-spaces uniformly distributed along the circumferential direction of the reaction chamber at intervals are formed between the upper surface of the base disc and the lower surface of the gas distribution plate, the multiple sub-spaces are successively arranged according to the operation sequence, and each sub-space is corresponding to one operation in a process of performing once technology on a base chip; and the rotary driving mechanism is used to drive the base disc to rotate relatively to the gas distribution plate so as to enable the base disc to drive all base chips thereon to be successively placed into the multiple sub-spaces for technological processing according to the operation sequence. The provided atomic deposition equipment is capable of processing multiple base chips at the same time by using different operations, thereby improving the technological efficiency and further improving the production power.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

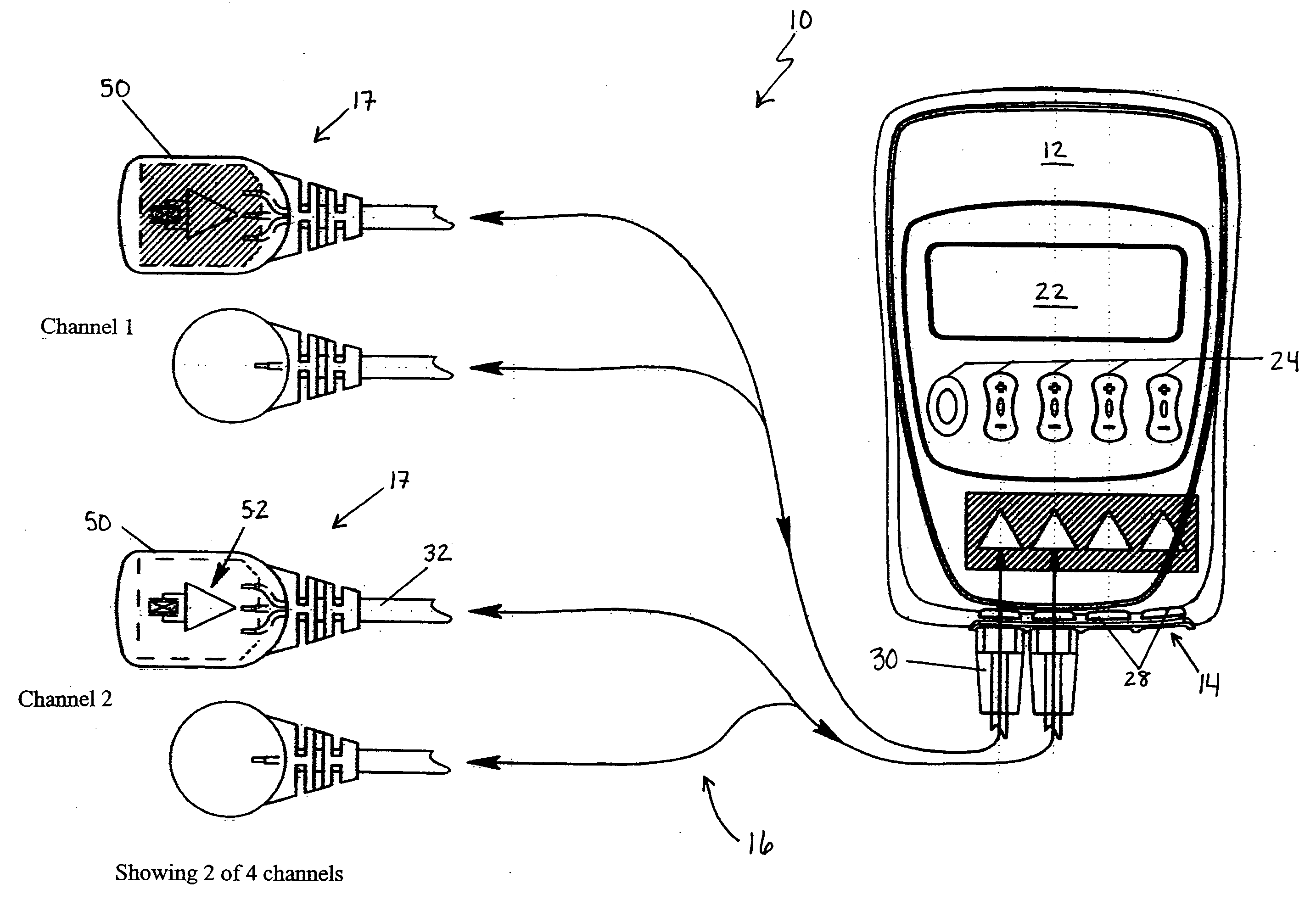

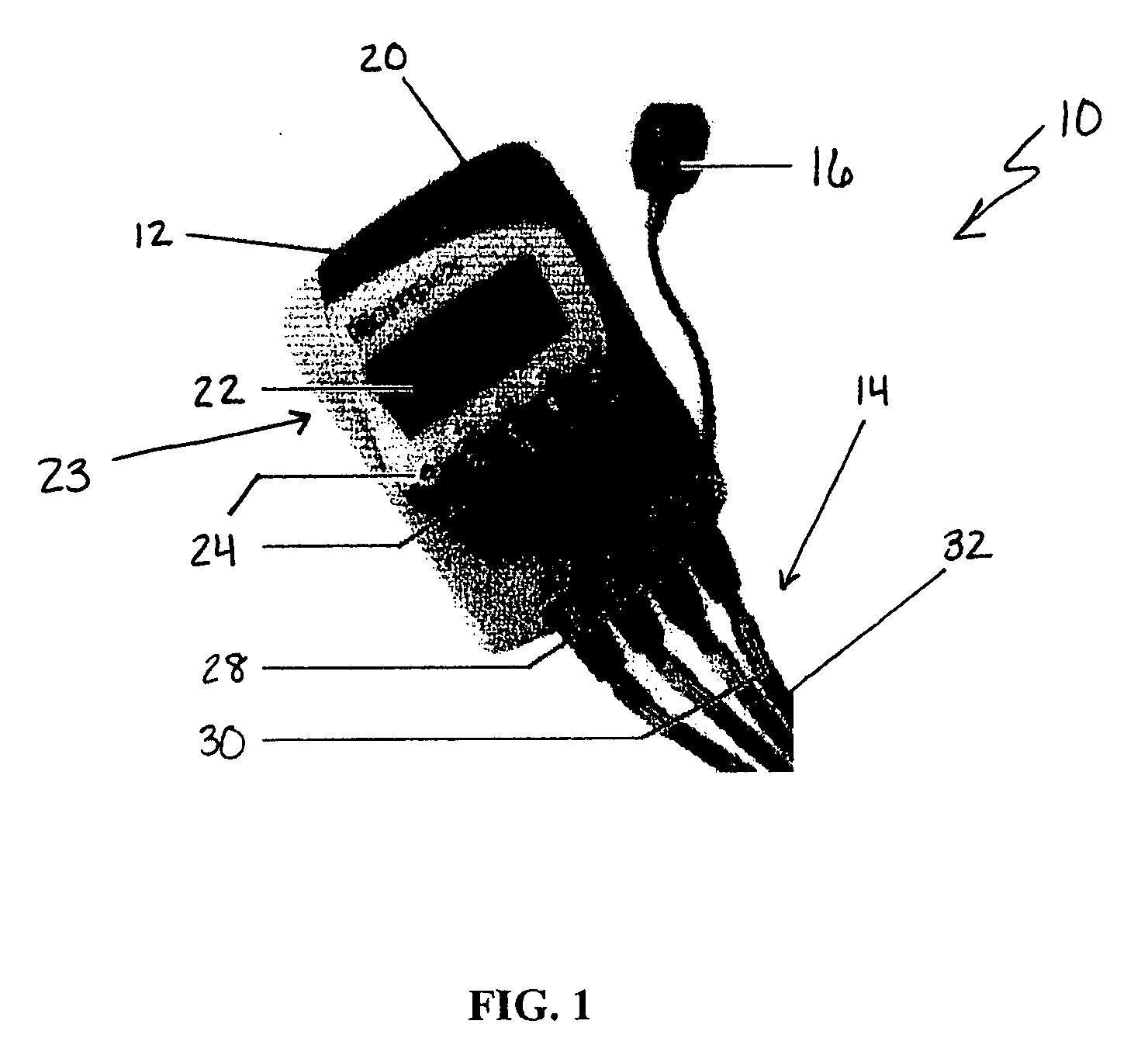

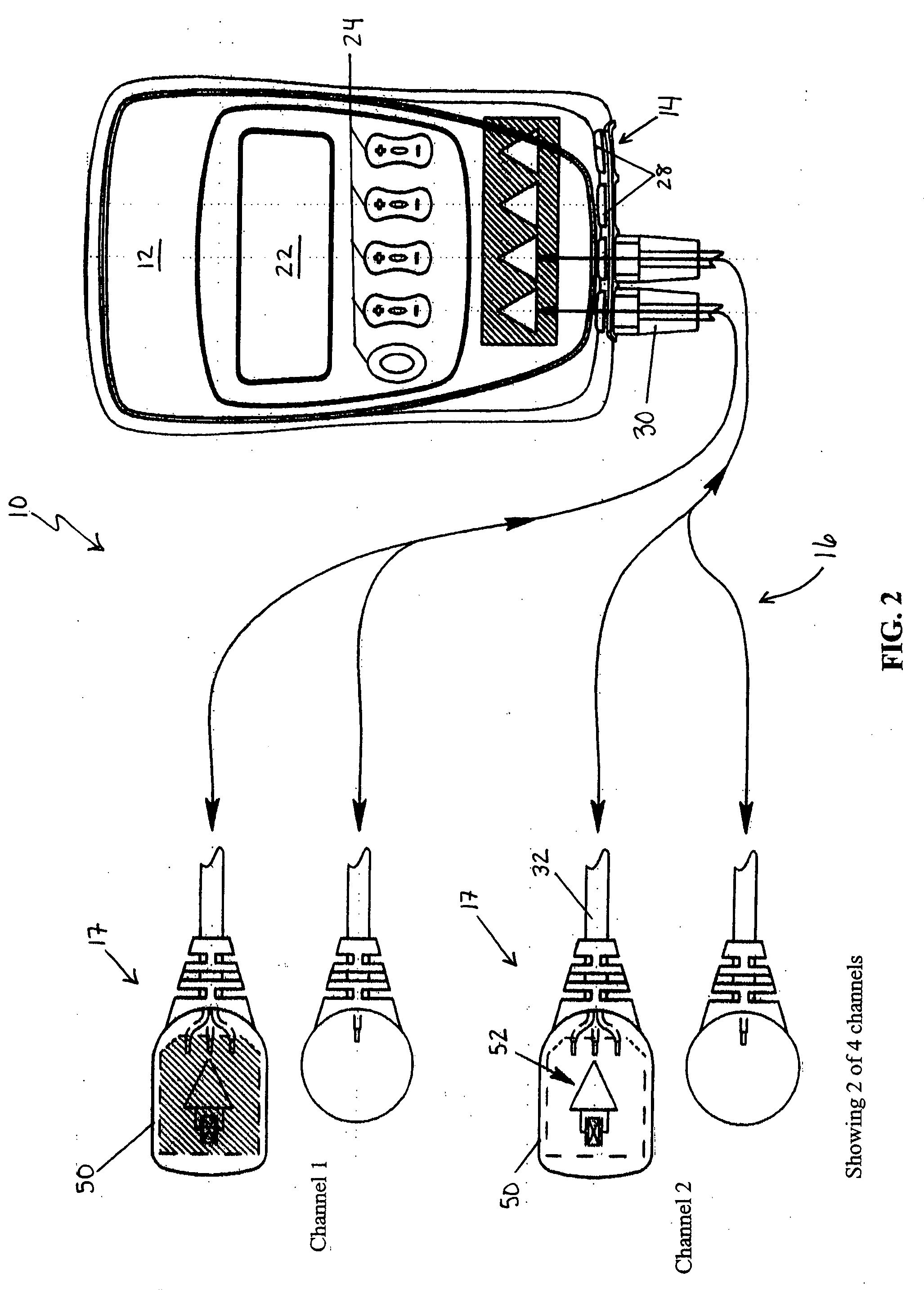

Automated adaptive muscle stimulation method and apparatus

ActiveUS20050283204A1Easy to integrateEnhancing user comfortElectrotherapyDiagnostic recording/measuringElectricityPhysical medicine and rehabilitation

An automated adaptive muscle stimulation system and method are disclosed. The stimulation system includes at least one electrode assembly adapted to deliver a muscle stimulation signal to the tissue of a user, a sensor system adapted to detect a muscle response, and an electrical stimulation device operably coupled to the at least on electrode assembly and the sensor system, the electrical stimulation device including a control system operable to automatically diagnose at least one characteristic of a muscle from the detected muscle response and adjust at least one parameter of the muscle stimulation signal in response thereto to deliver an adjusted muscle stimulation signal. A dual mode muscle stimulation system adapted to accept first and second data sets and provide first and second levels of treatment data is also disclosed.

Owner:DJO GLOBAL SWITZERLAND SARL

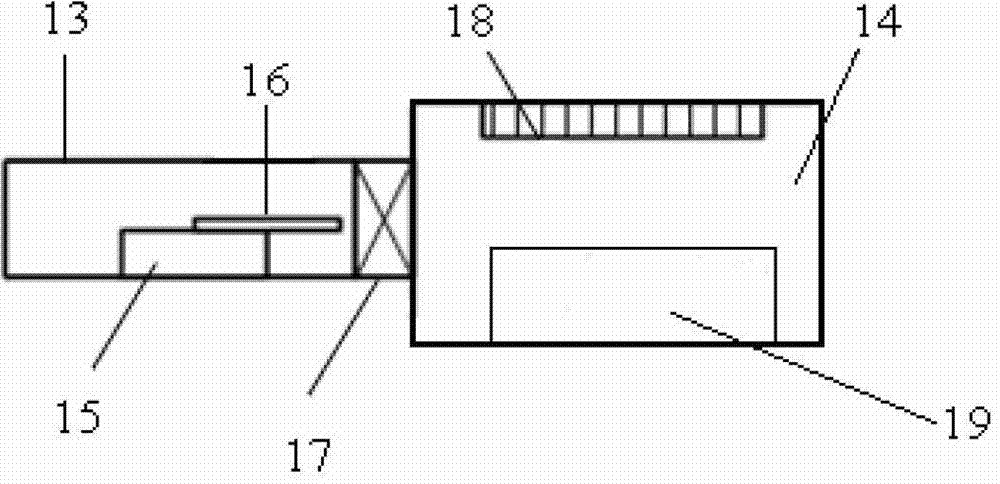

Atomic layer deposition equipment

ActiveCN104233226AImprove processing efficiencyIncrease production capacityChemical vapor deposition coatingSingle processProcess efficiency

The invention provides atomic layer deposition equipment. The atomic layer deposition equipment comprises a reaction chamber which comprises a plurality of sub chambers and a drive unit, wherein a plurality of process positions are arranged on the same horizontal plane in the reaction chamber, the plurality of process positions are arranged at intervals along the peripheral direction of the reaction chamber, and are uniformly arranged in sequence according to the sequence of processes, the quantity and positions of the sub chambers are in one-to-one correspondence with those of the process positions, and each sub chamber is used for completing one process of single processes for a substrate in each sub chamber; the drive unit is used for enabling each substrate to complete the corresponding process in the sub chamber placed on the position of each process according to the sequence of the process. The automatic layer deposition equipment provided by the invention can be used for processing a plurality of substrates at the same time by a single process, so that the process efficiency is improved, and thus, the yield is increased.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

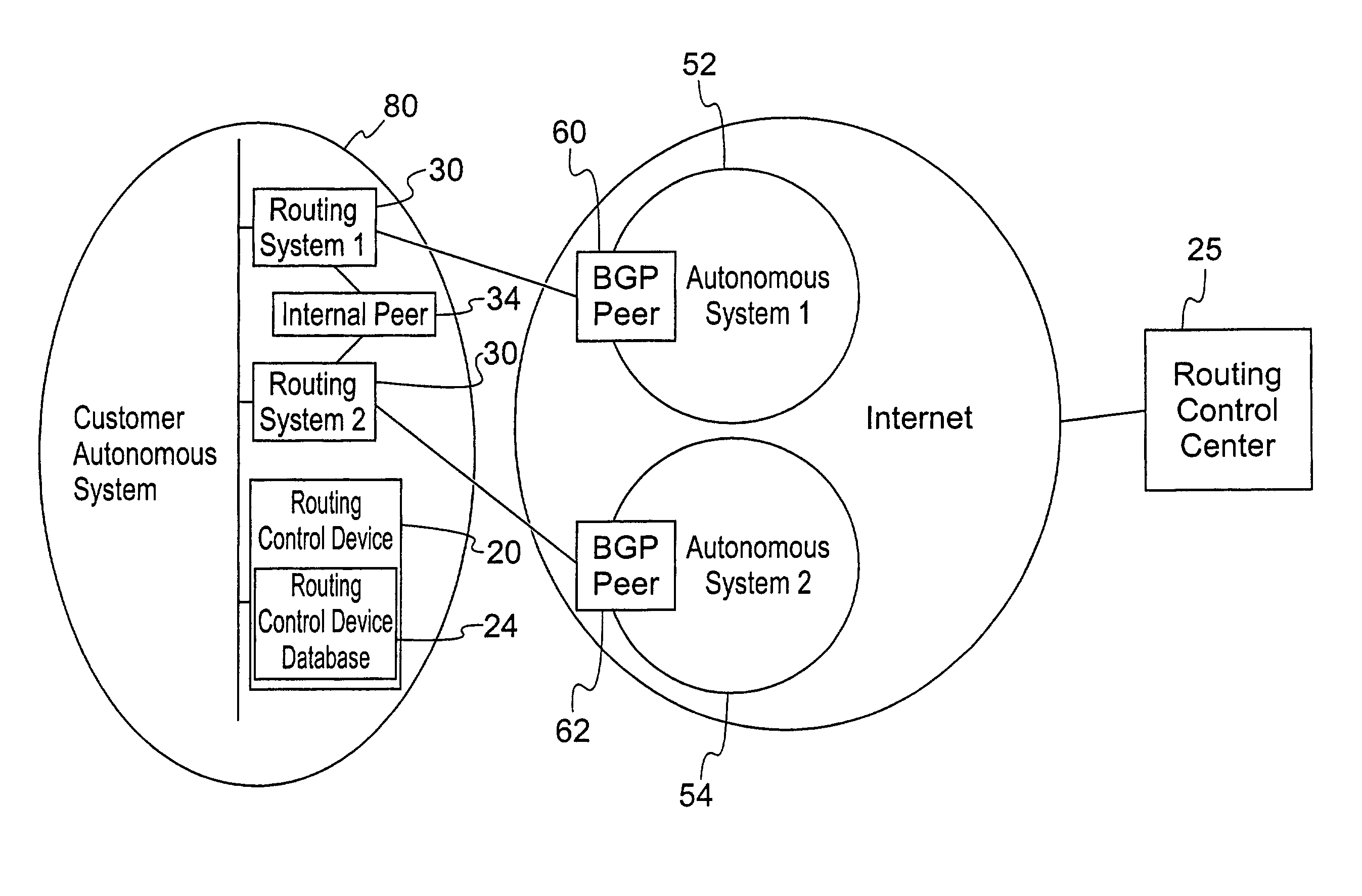

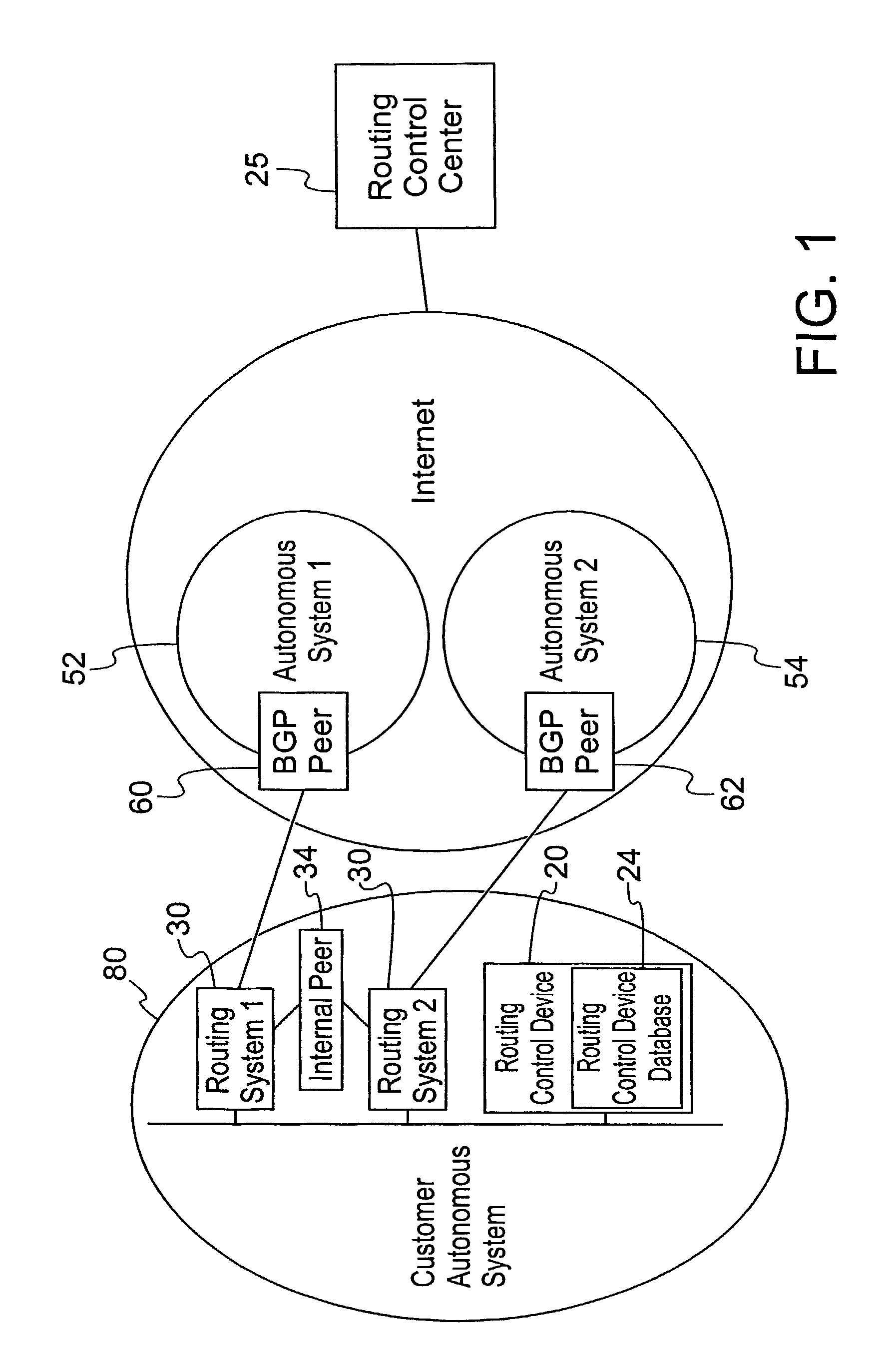

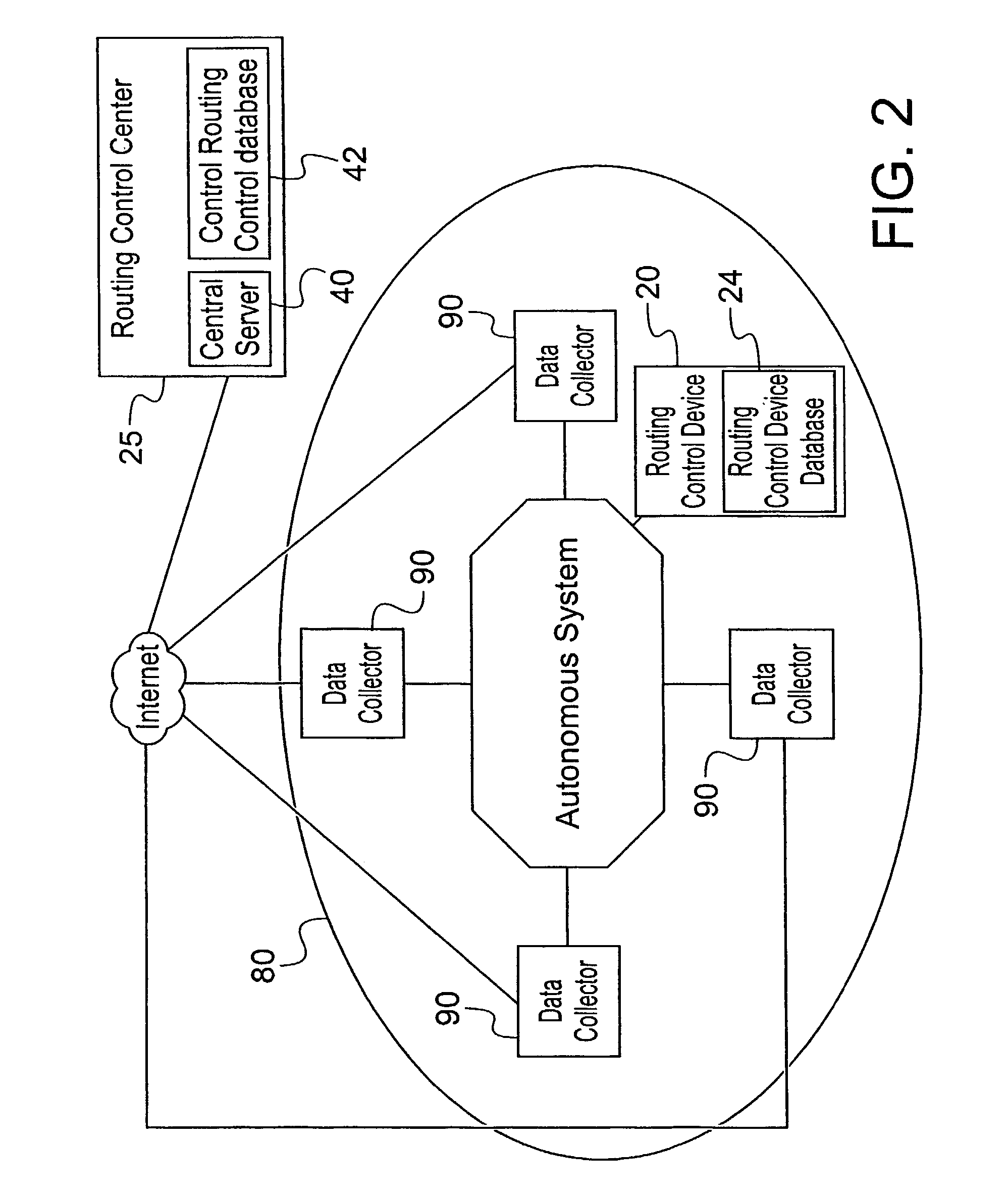

Methods, apparatuses and systems facilitating determination of network path metrics

InactiveUS7260645B2Easy to configureEasy to deployMultiple digital computer combinationsData switching networksThe InternetTime of day

Methods, apparatuses and systems relating to the control and application of policies for routing data over a computer network, such as the Internet. Some implementations of the invention facilitate the configuration, deployment and / or maintenance of network routing policies. Some implementations of the invention are particularly useful for controlling the routing of data among autonomous systems or organizations. Certain implementations allow for dynamic modification of routing policy based on such factors as current Internet performance, load sharing, user-defined parameters, and time of day. In one embodiment, the present invention provides methods, apparatuses and systems implementing enhanced network path testing methodologies that enhance the efficiency of processes associated with testing of a network path, while reducing the perceived intrusiveness of test packets associated with such metrics tests.

Owner:SUNTRUST BANK AS SUCCESSOR AGENT +1

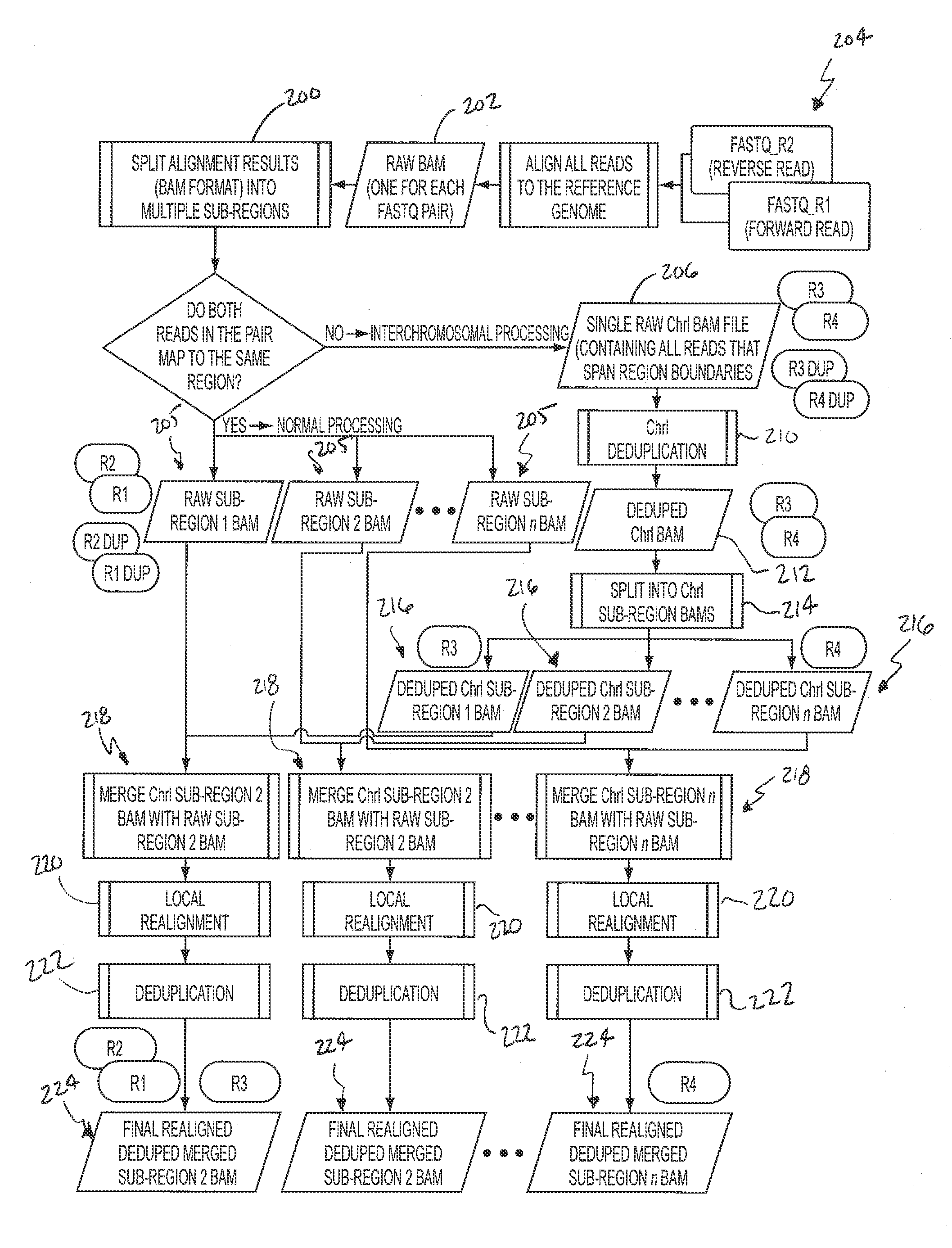

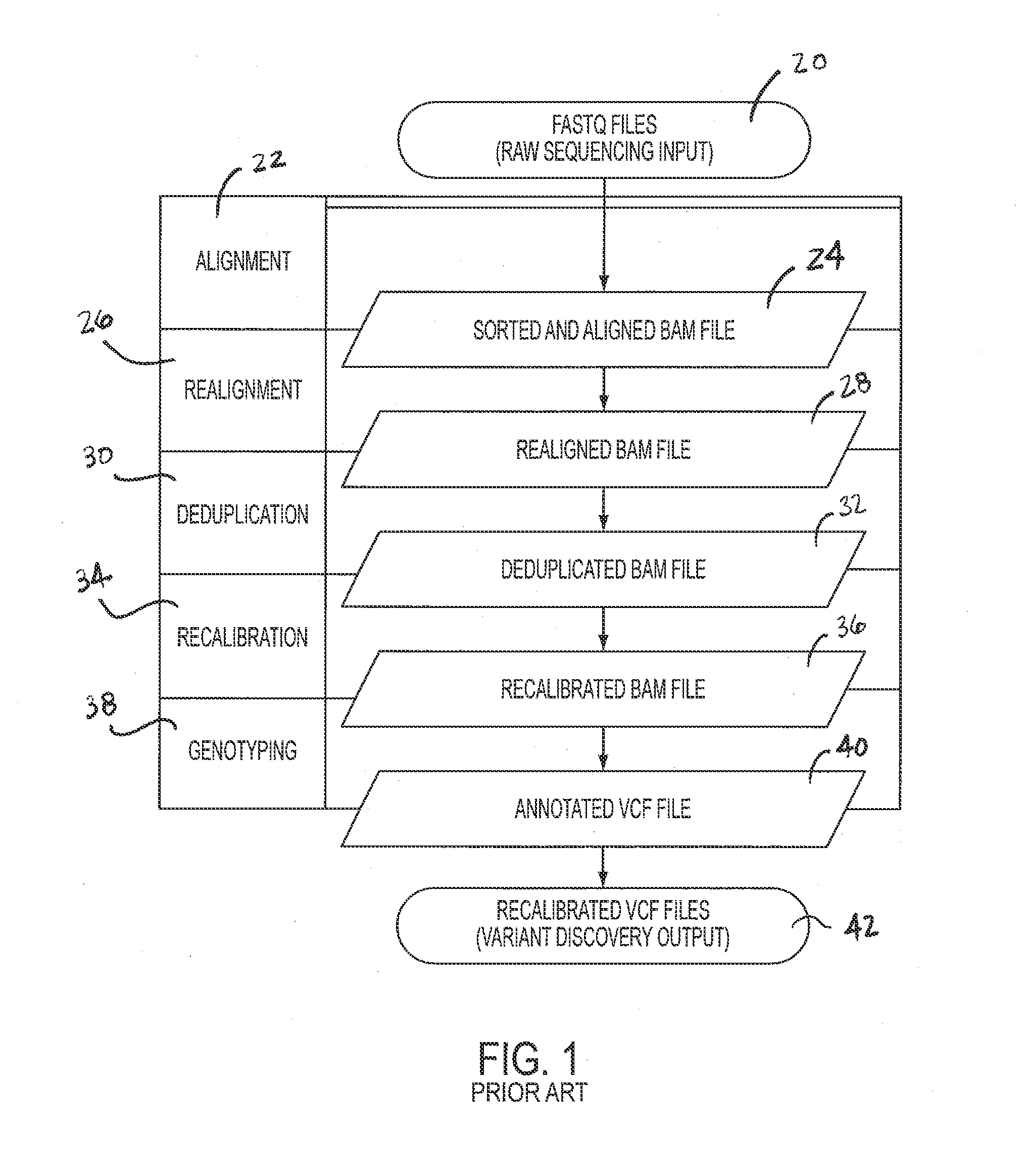

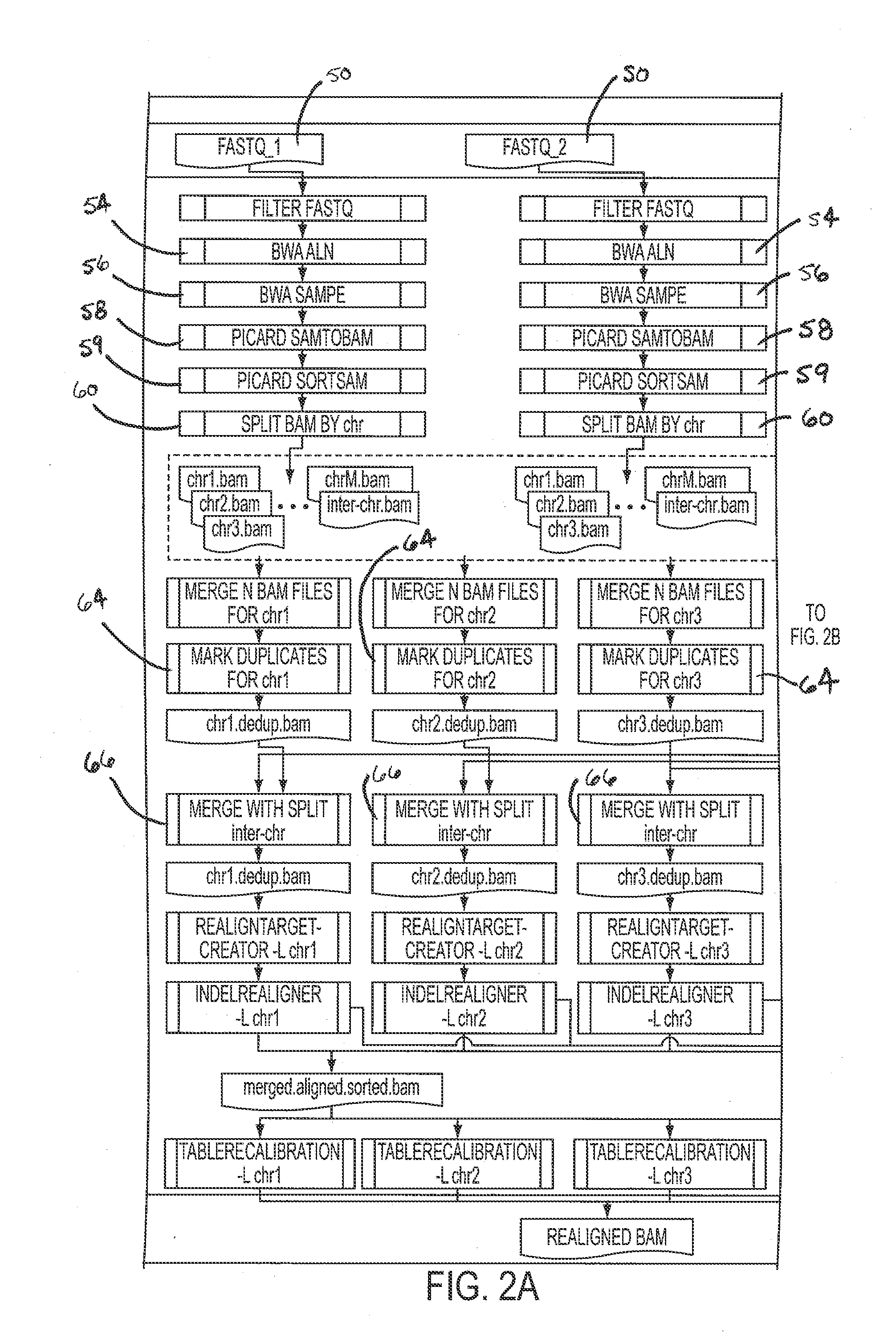

Comprehensive Analysis Pipeline for Discovery of Human Genetic Variation

ActiveUS20130311106A1Shorten analysis timeQuick identificationMicrobiological testing/measurementProteomicsData setProcessing core

Systems and methods for analyzing genetic sequence data involve: (a) obtaining, by a computer system, genetic sequencing data pertaining to a subject; (b) splitting the genetic sequencing data into a plurality of segments; (c) processing the genetic sequencing data such that intra-segment reads, read pairs with both mates mapped to the same data set, are saved to a respective plurality of individual binary alignment map (BAM) files corresponding to that respective segment; (d) processing the genetic sequencing data such that inter-segment reads, read pairs with both mates mapped to different segments, are saved into at least a second BAM file; and (e) processing at least the first plurality of BAM files along parallel processing paths. The plurality of segments may correspond to any given number of genomic subregions and may be selected based upon the number of processing cores used in the parallel processing.

Owner:RES INST AT NATIONWIDE CHILDRENS HOSPITAL

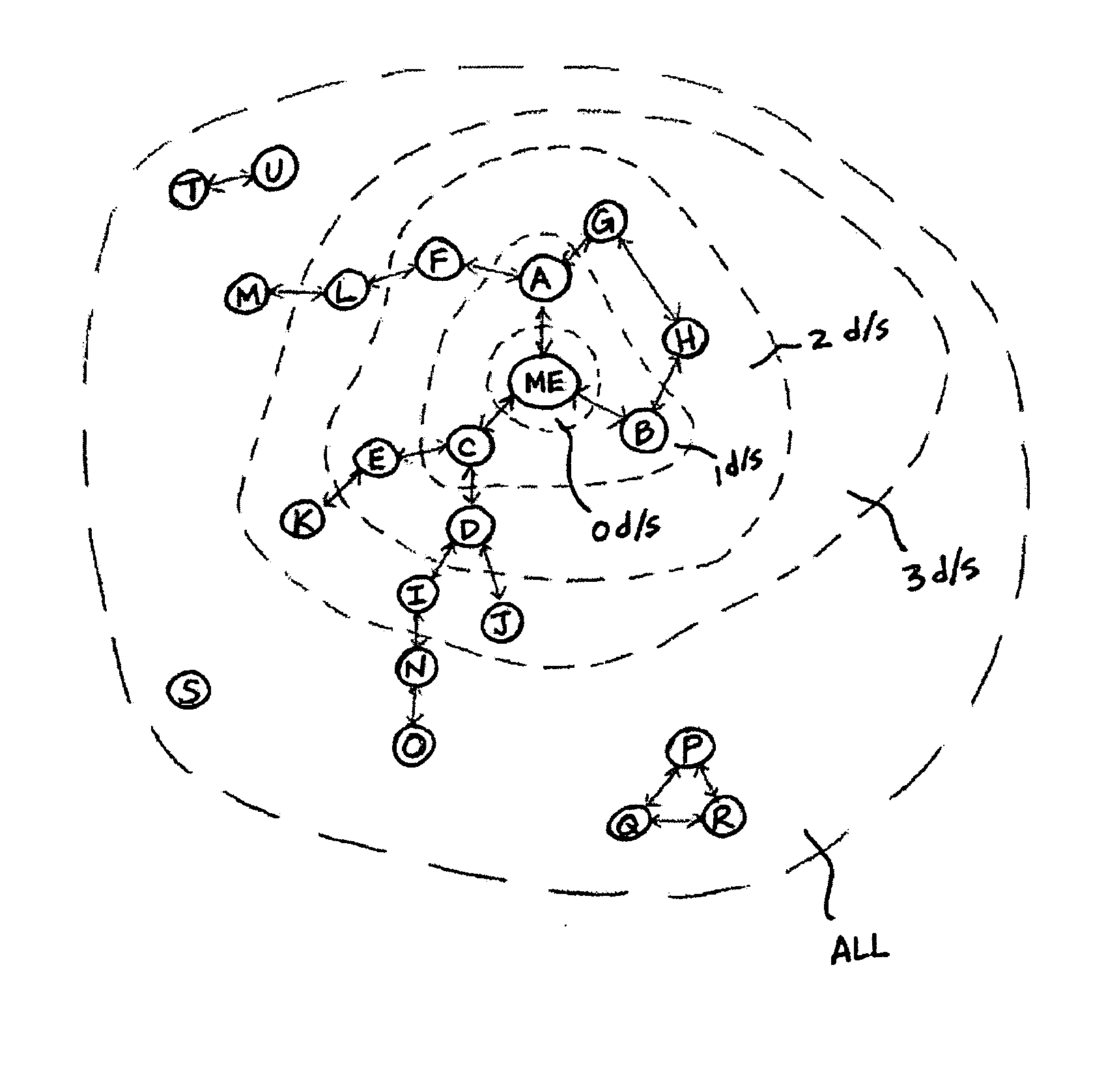

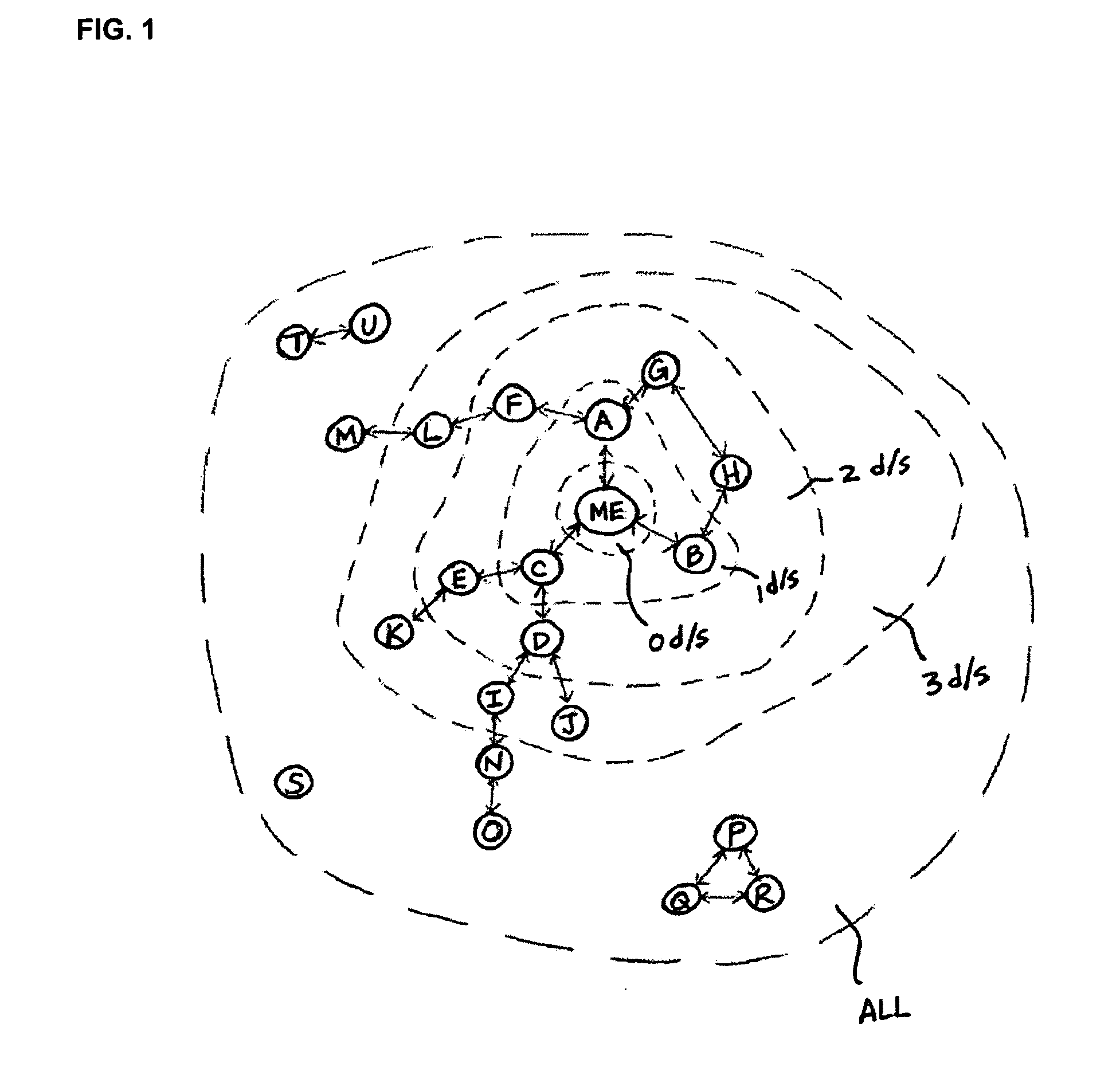

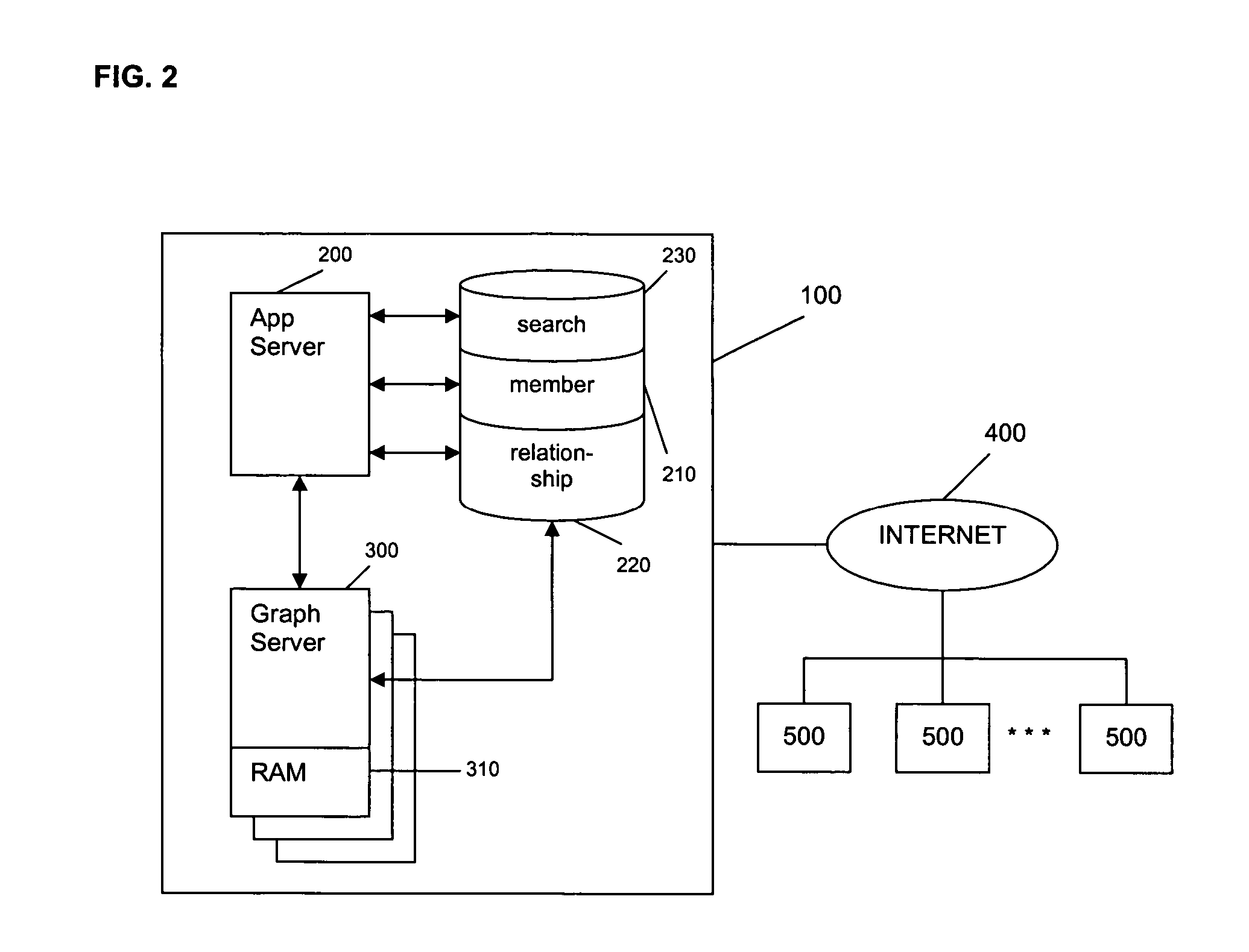

System and method for managing an online social network

ActiveUS20050267940A1Improve processing speedReduce in quantityComputer security arrangementsMultiple digital computer combinationsSocial webDatabase

An online social network is managed using one server for database management tasks and another server, preferably in a distributed configuration, for CPU-intensive computational tasks, such as finding a shortest path between two members or a degree of separation between two members. The additional server has a memory device containing relationship information between members of the online social network and carries out the CPU-intensive computational tasks using this memory device. With this configuration, the number of database lookups is decreased and processing speed is thereby increased.

Owner:META PLATFORMS INC

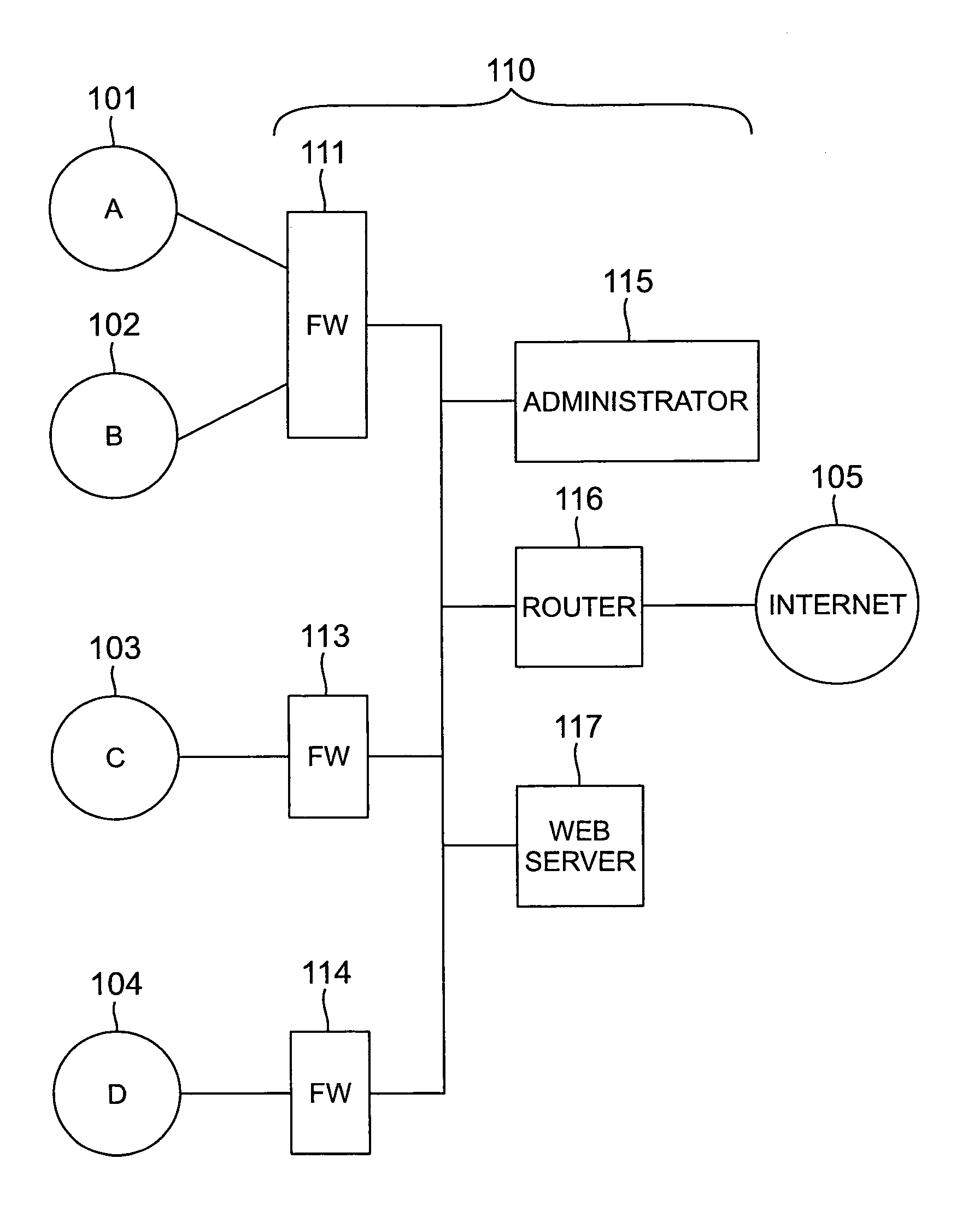

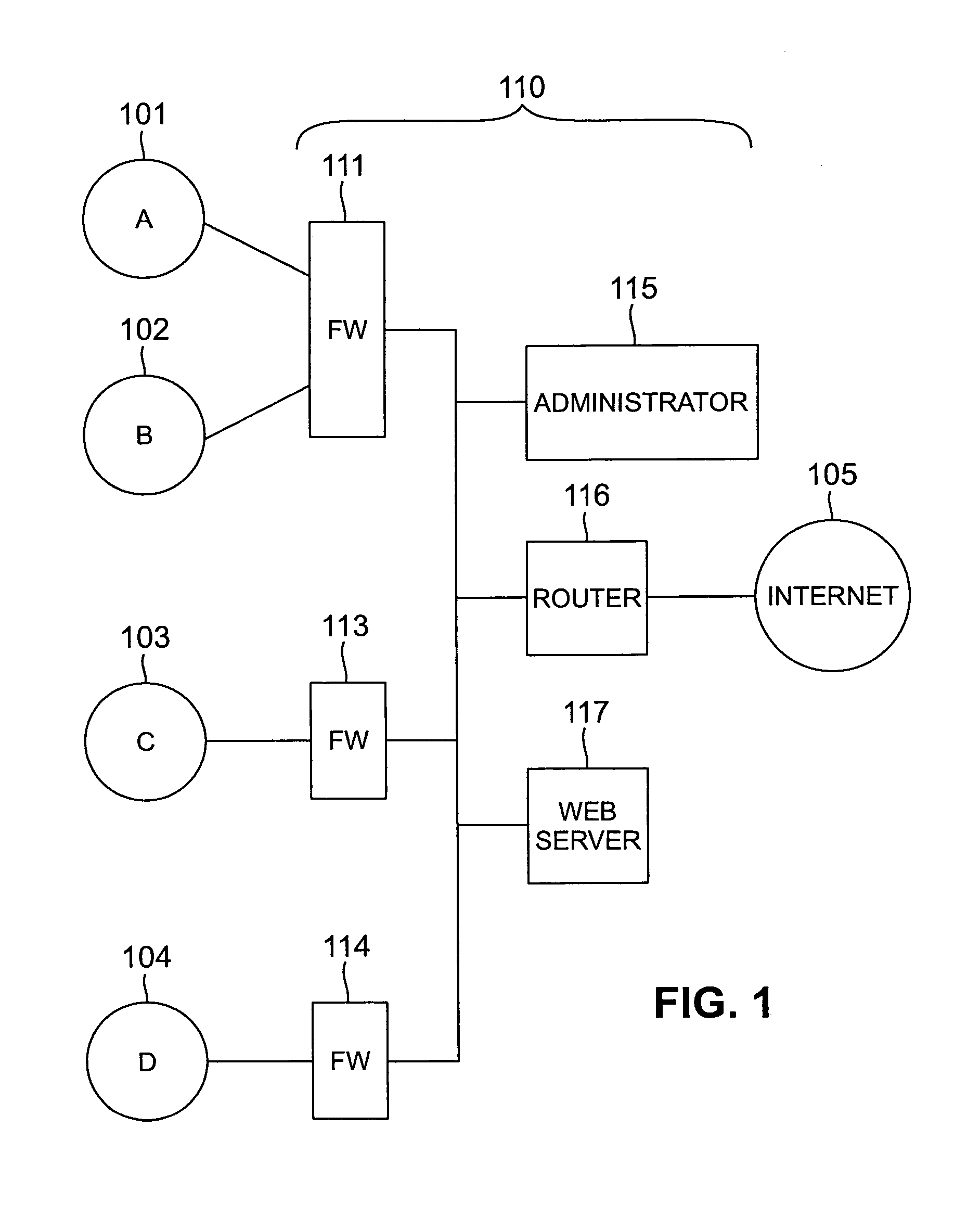

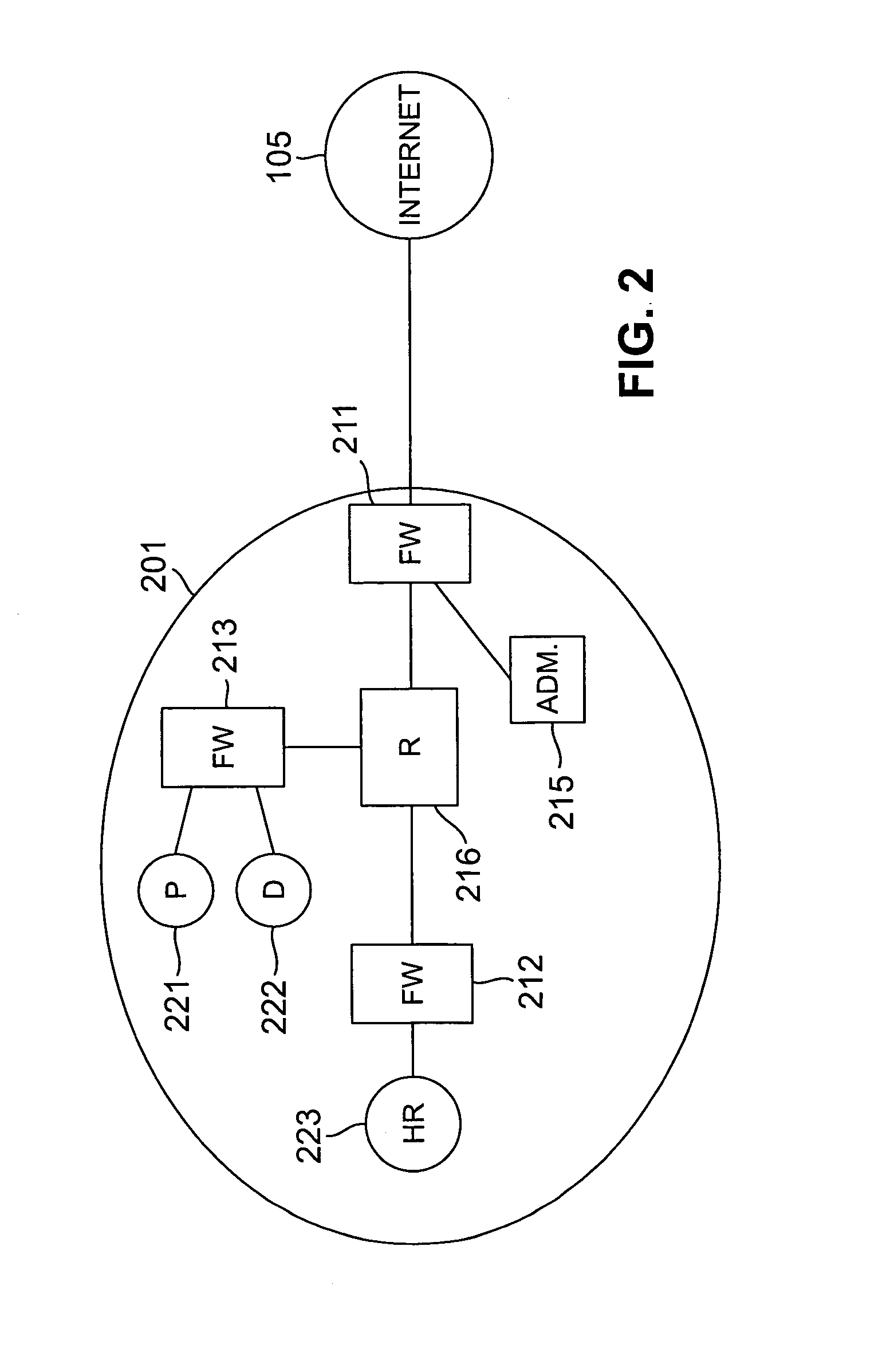

Methods and apparatus for a computer network firewall with multiple domain support

InactiveUS7143438B1Improve processing efficiencyIncrease access rule flexibilityUser identity/authority verificationHardware monitoringData packEngineering

The invention provides improved computer network firewalls which include one or more features for increased processing efficiency. A firewall in accordance with the invention can support multiple security policies, multiple users or both, by applying any one of several distinct sets of access rules. The firewall can also be configured to utilize “stateful” packet filtering which involves caching rule processing results for one or more packets, and then utilizing the cached results to bypass rule processing for subsequent similar packets. To facilitate passage to a user, by a firewall, of a separate later transmission which is properly in response to an original transmission, a dependency mask can be set based on session data items such as source host address, destination host address, and type of service. The mask can be used to query a cache of active sessions being processed by the firewall, such that a rule can be selected based on the number of sessions that satisfy the query. Dynamic rules may be used in addition to pre-loaded access rules in order to simplify rule processing. To unburden the firewall of application proxies, the firewall can be enabled to redirect a network session to a separate server for processing.

Owner:LUCENT TECH INC

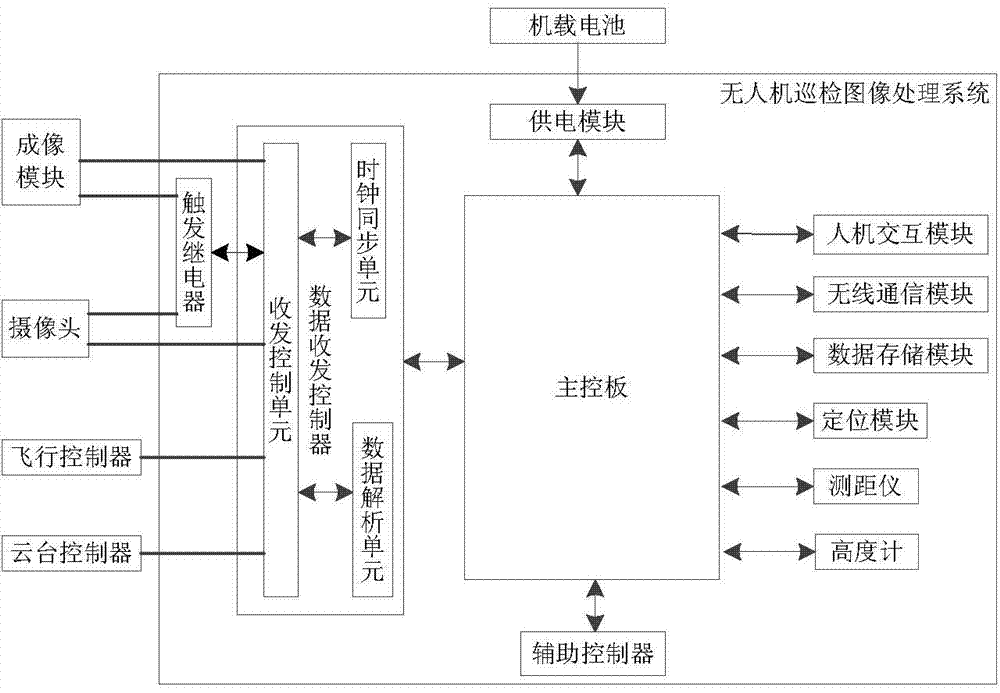

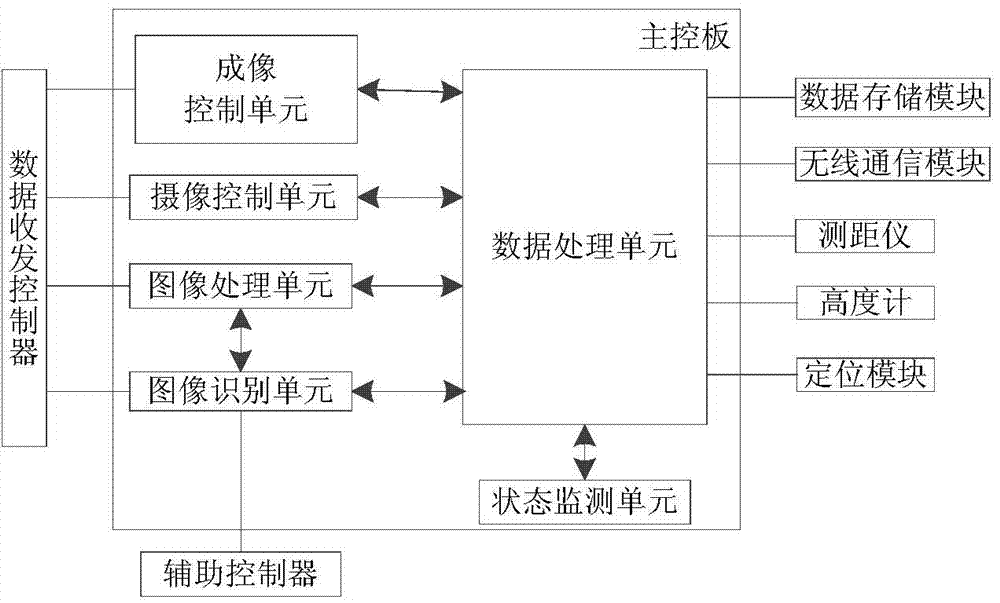

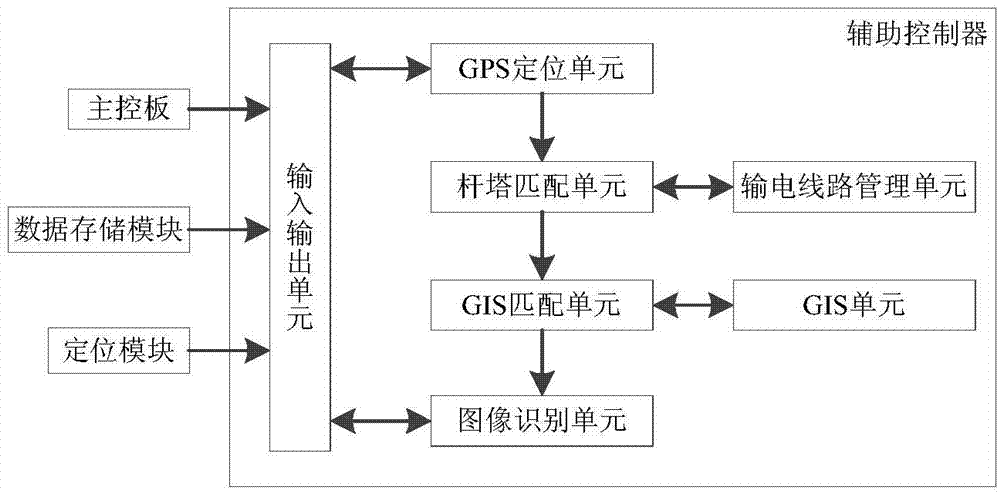

System and method for processing unmanned aerial vehicle polling image

ActiveCN103941746AEasy to handleRapid positioningPosition/course control in three dimensionsInformatizationImaging processing

The invention discloses a system and method for processing an unmanned aerial vehicle polling image. The system comprises an unmanned aerial vehicle polling image processing system body which comprises a human-computer interaction module. After the human-computer interaction module obtains a user instruction, a main control panel analyzes the user instruction and transmits the analyzed instruction to a data receiving and transmitting controller, the data receiving and transmitting controller sends a parameter configuration instruction to corresponding peripheral equipment according to the instruction and transmits an instruction execution result back to the main control panel, and the main control panel processes the execution result of the parameter configuration instruction and then sends processed information to the human-computer interaction module so that the information can be displayed to a user. The main control panel is respectively communicated with a secondary controller, a power supply module, a wireless communication module, a data storage module, a locating module, a distance measuring meter and a height gauge. The system and the method improve the automation degree and the informationization degree of polling image processing, improve the efficiency of searching for and processing the polling result, and lower the cost of processing the polling result.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

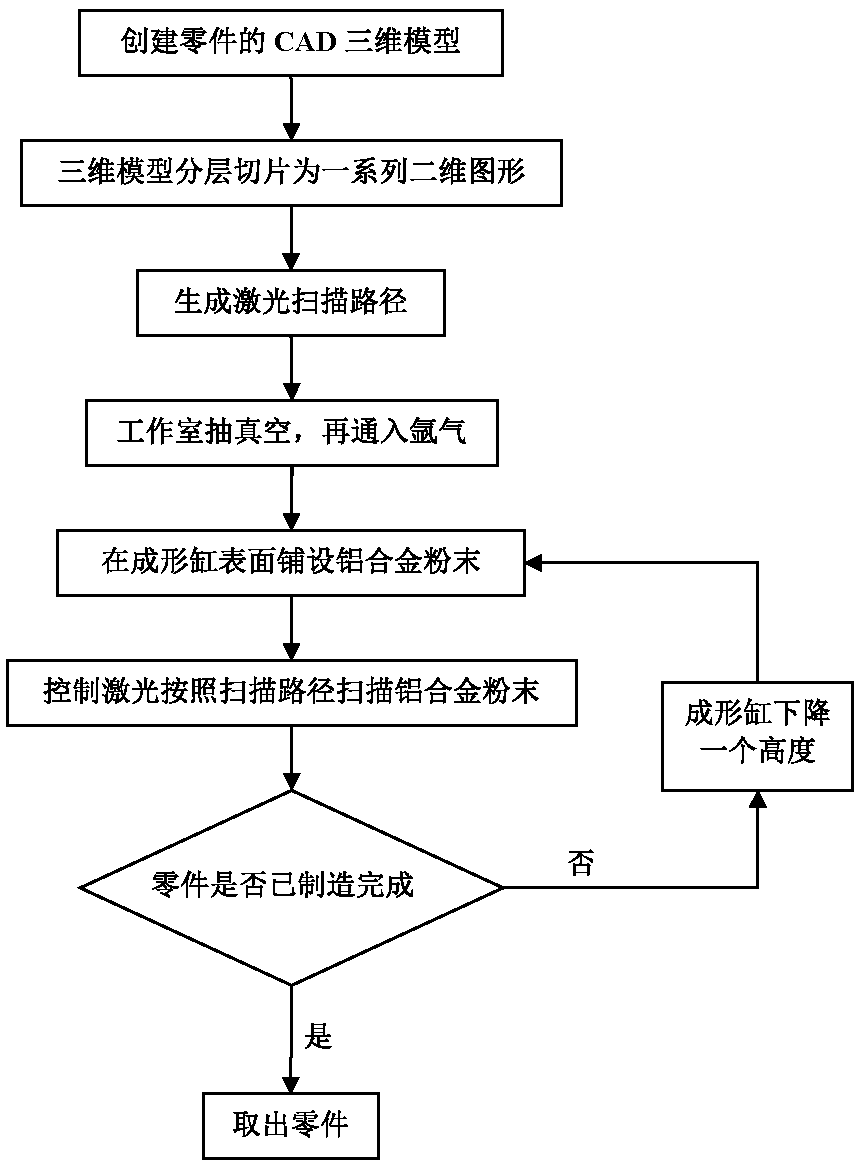

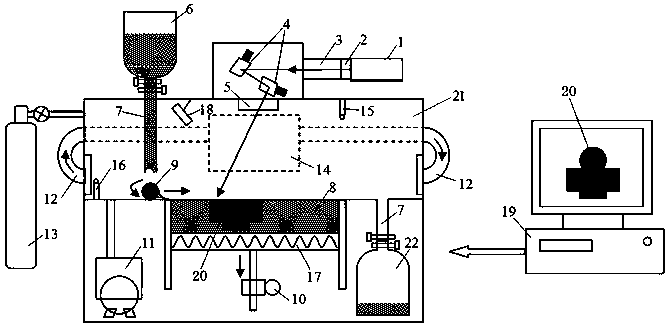

3D printing manufacturing device and method of metal parts

ActiveCN103341625AImprove processing efficiencyHigh material utilizationIncreasing energy efficiencyManufacturing efficiencyHeating system

The invention discloses a 3D printing manufacturing device and method of metal parts. The 3D printing manufacturing device and method aim to efficiently manufacture the metal parts. The 3D printing manufacturing device of the metal parts comprises a laser system, a powder laying system, an atmosphere protecting system, a heating system and a computer control system. The 3D printing manufacturing device further comprises a closed work cavity, a forming cylinder is arranged inside the work cavity, and the laser system is arranged above the forming cylinder; the powder laying system is arranged on the upper side of the work cavity; one side of the work cavity is provided with the atmosphere protecting system, and the bottom of the forming cylinder is provided with the heating system; the lower side of the forming cylinder is provided with a driving device; one side of the work cavity is provided with a vacuum pump; the computer control system comprises a computer which is connected with a control card of the driving device and a control card of the laser system through data wires. According to the 3D printing manufacturing device and method, the metal parts of any structures can be directly manufactured, digital manufacturing from 3D digital models to part entities is achieved, and processing and manufacturing efficiency and the material using ratio of aluminium alloy parts of complex structures can be greatly improved.

Owner:航天科工(长沙)新材料研究院有限公司

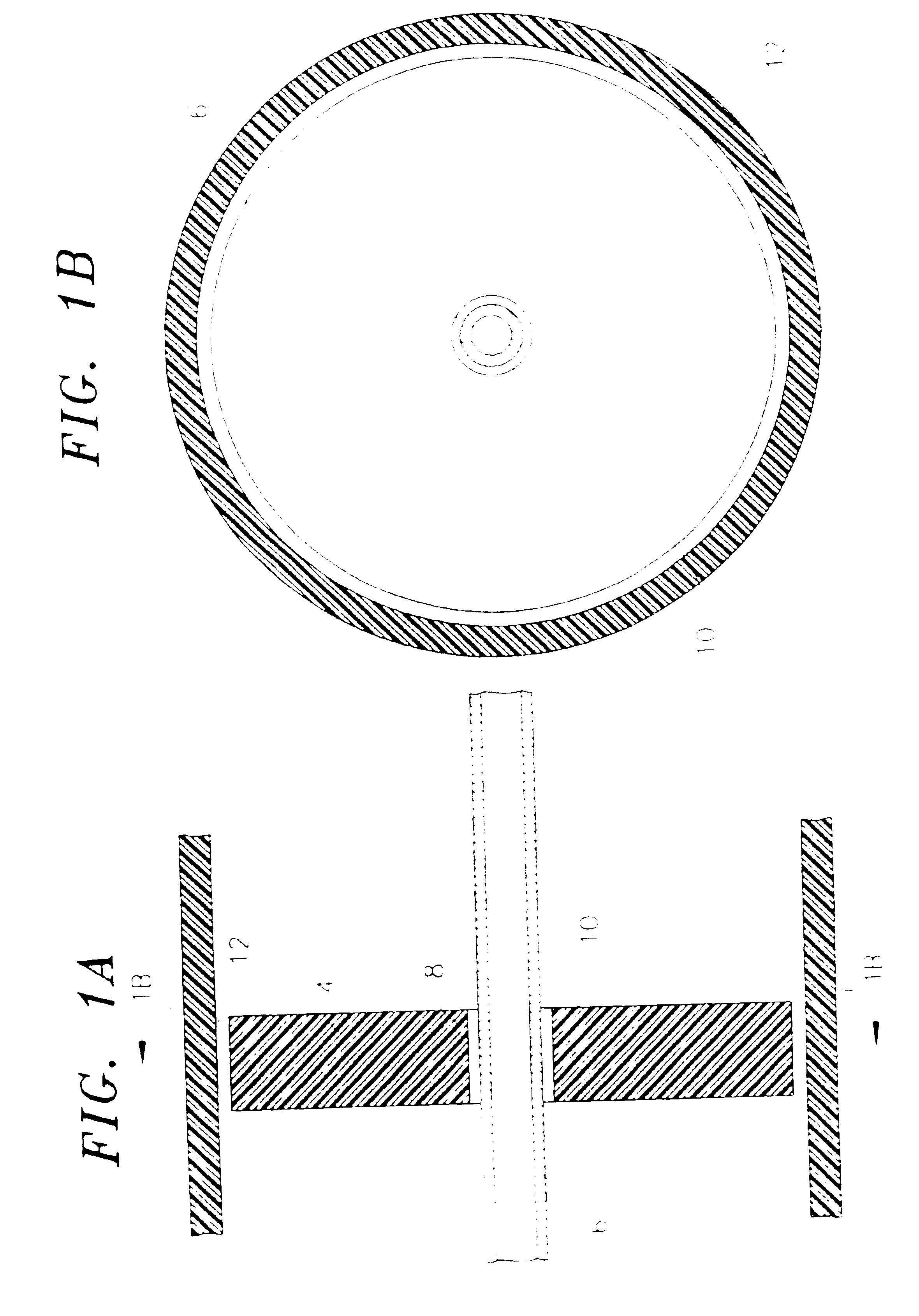

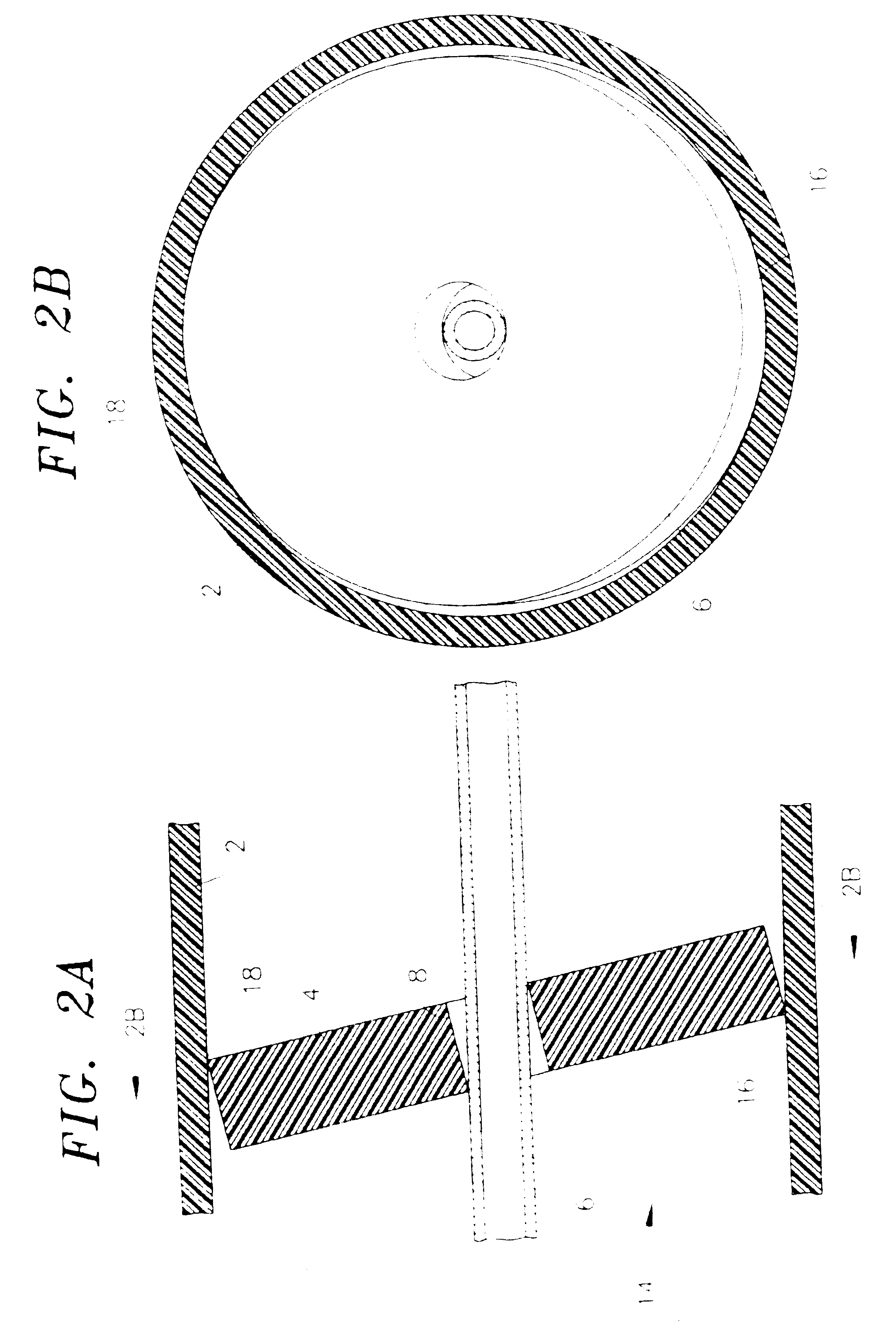

Apparatus for growing thin films

InactiveUS6447607B2Uniform thicknessAvoid possibilityAfter-treatment apparatusPolycrystalline material growthEngineeringVapor phase

The invention relates to an apparatus for growing thin films onto the surface of a substrate by exposing the substrate to alternately repeated surface reactions of vapor-phase reactants. The apparatus comprises at least one process chamber having a tightly sealable structure, at least one reaction chamber having a structure suitable for adapting into the interior of said process chamber and comprising a reaction space of which at least a portion is movable, infeed means connectable to said reaction space for feeding said reactants into said reaction space, and outfeed means connectable to said reaction space for discharging excess reactants and reaction gases from said reaction space, and at least one substrate adapted into said reaction space. At least one loading chamber is arranged to cooperate with said process chamber so as to permit said reaction space or a portion thereof to be moved into said process chamber and away from said process chamber and, further, the operating pressure of the loading chamber is arranged to be controllable independently from said pressure chamber.

Owner:ASM INTERNATIONAL

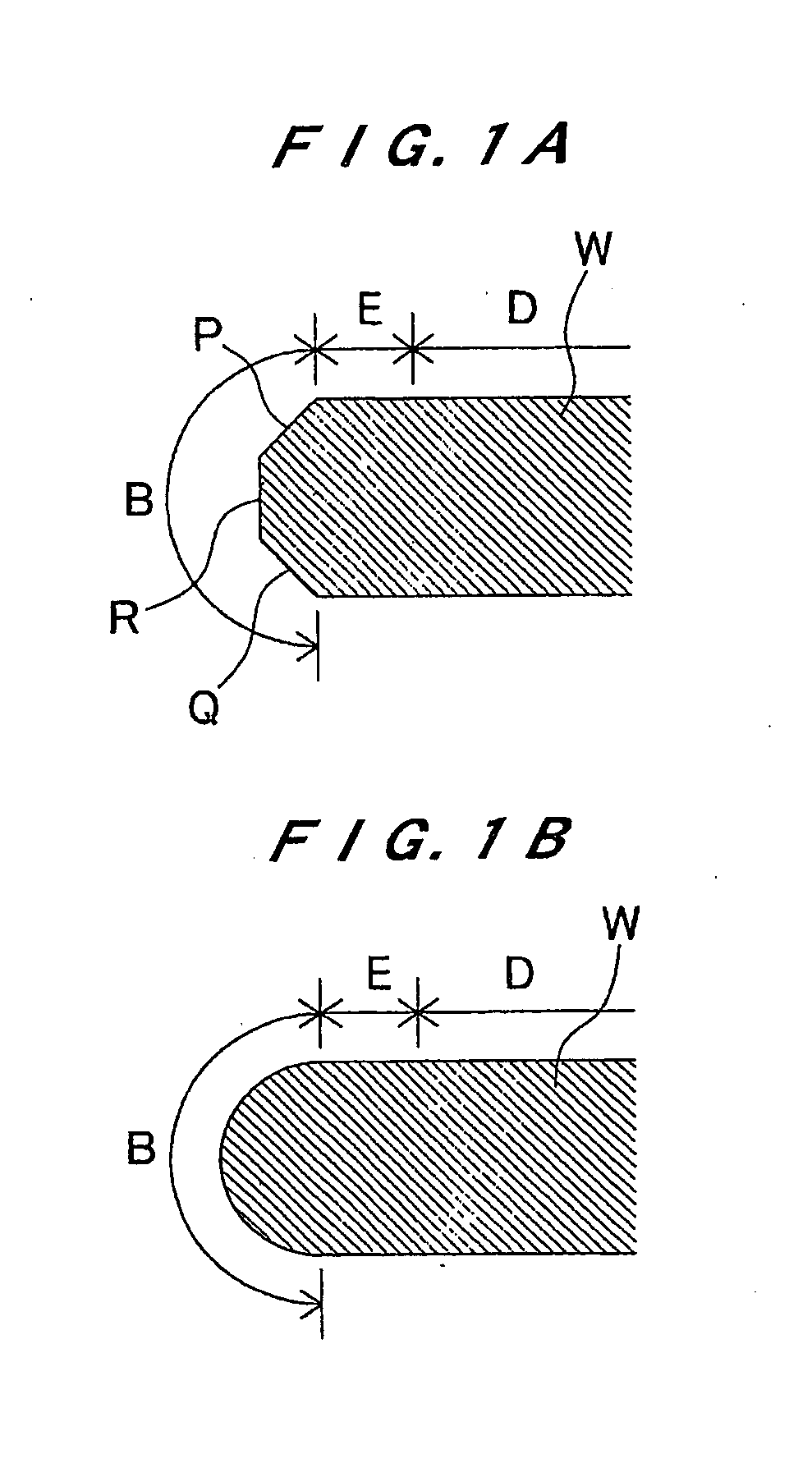

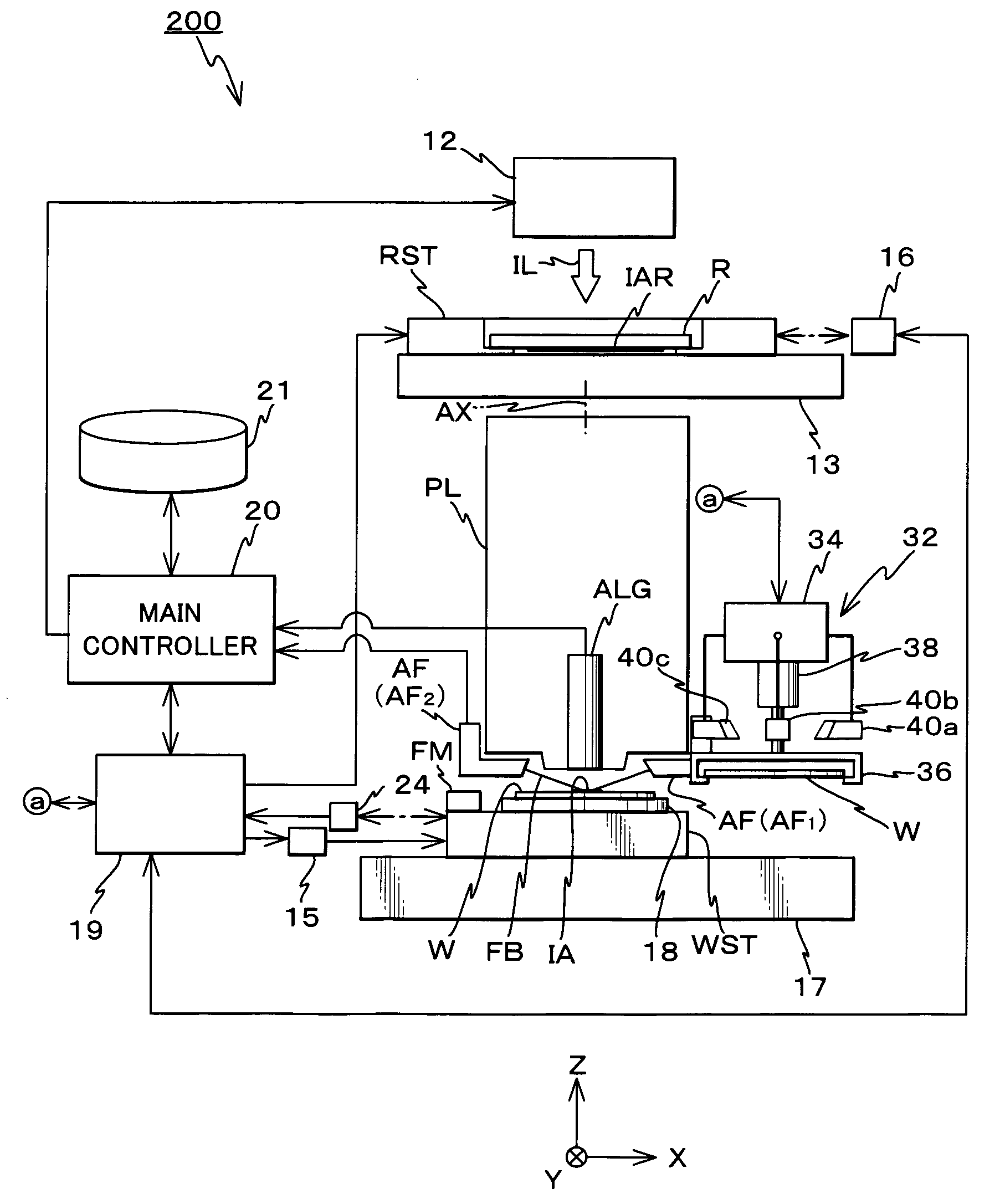

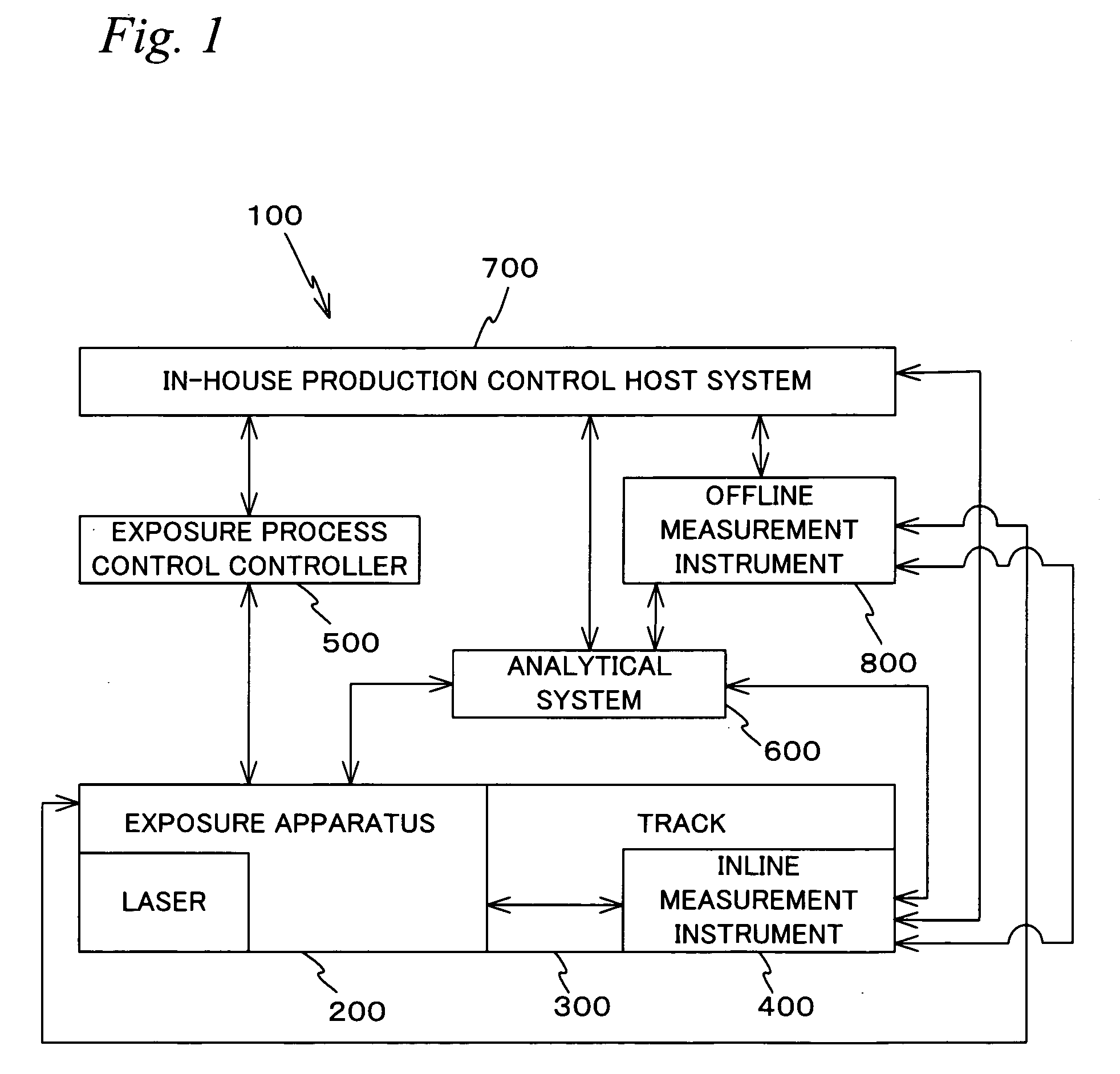

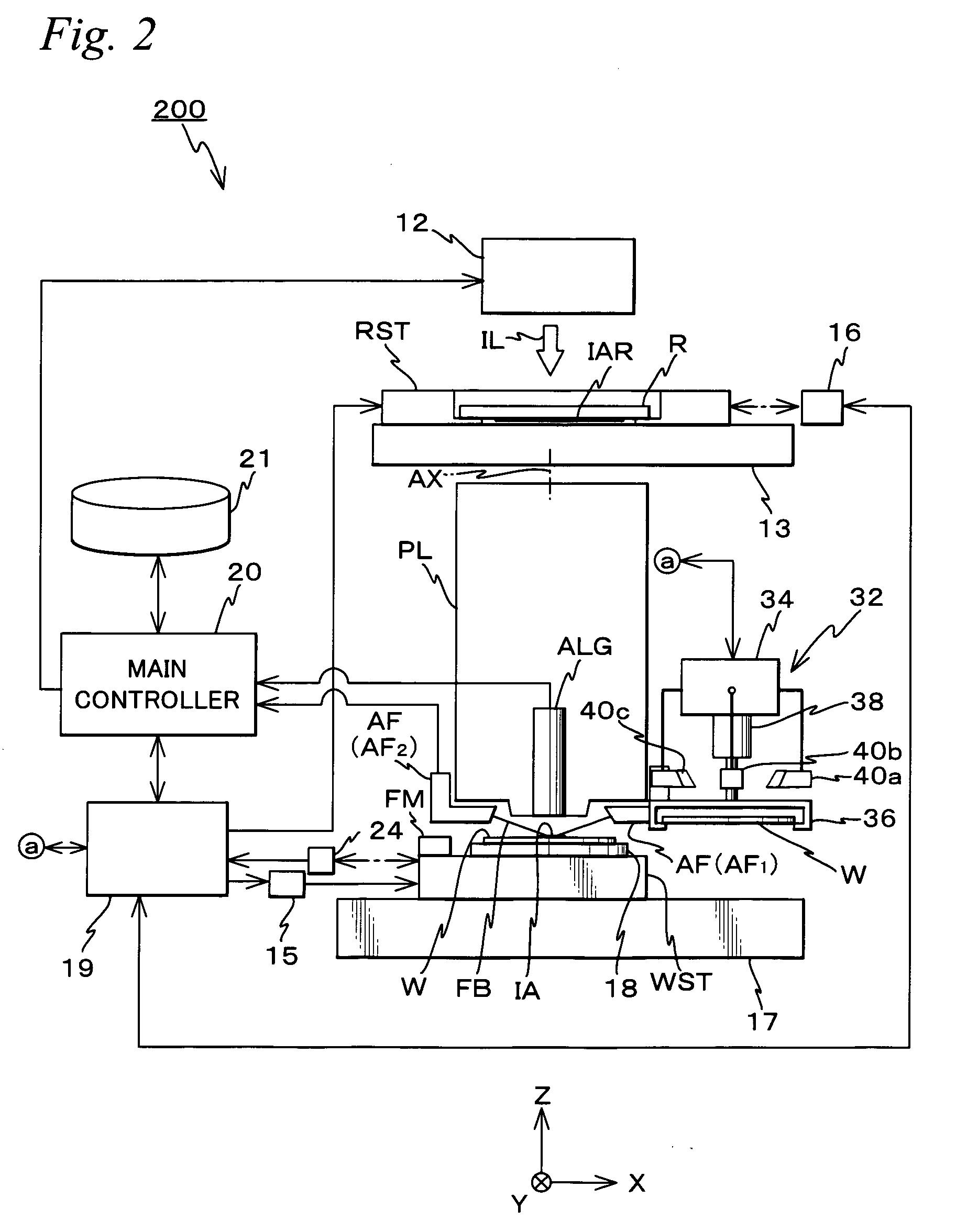

Positioning method, processing system, measurement method of substrate loading repeatability, position measurement method, exposure method, substrate processing apparatus, measurement method, and measurement apparatus

InactiveUS20080013089A1Improve accuracyImprove throughputPhotomechanical apparatusSemiconductor/solid-state device manufacturingMeasurement deviceMeasuring instrument

An edge of a surface to be measured of wafer and each of search alignment marks on the wafer are detected by an inline measurement instrument or the like that operates independently of an exposure apparatus, and position coordinates of the search marks in an X′Y′ coordinate system, which is a two-dimensional coordinate system substantially parallel to the surface to be measured and is set by a position of a notch of the wafer, are measured. Then, in pre-alignment performed when loading the wafer into the exposure apparatus, the edge of the wafer is detected, and from the detection results, position information of the object in the X′Y′ coordinate system is measured. Further, a relative position in the X′Y′ coordinate system of the wafer to be loaded into the exposure apparatus based on measurement results of the pre-alignment with respect to a measurement field of an alignment system that measures positions of the search marks on the wafer is adjusted based on measurement results of the inline measurement instrument or the like.

Owner:NIKON CORP

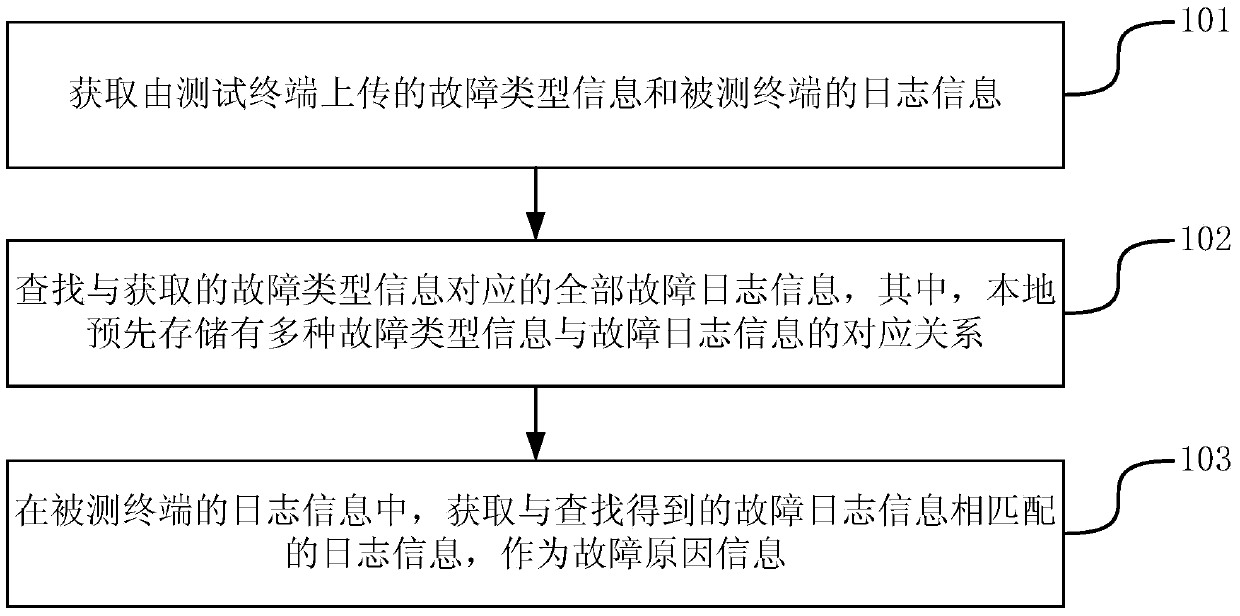

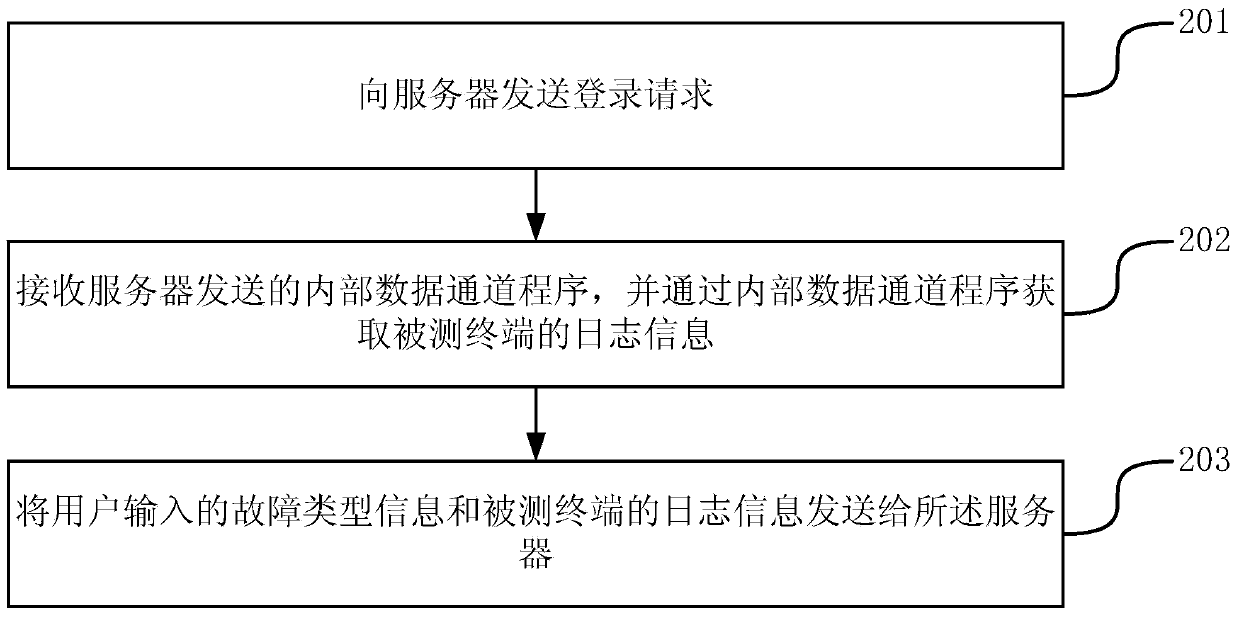

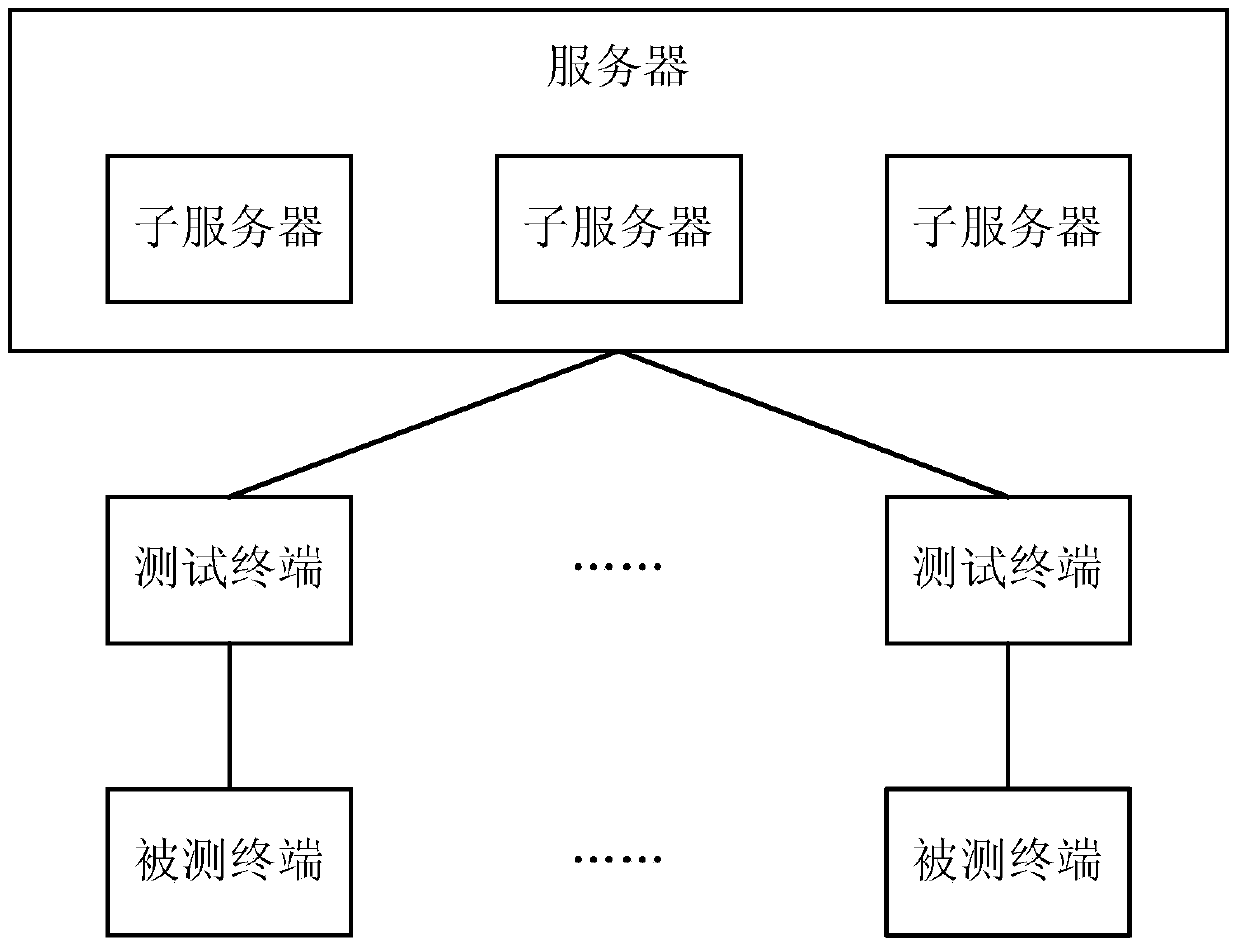

Method, device and system for obtaining fault reason information

ActiveCN103701926AImprove processing efficiencyReduce time consumptionHardware monitoringTransmissionResonanceComputer terminal

The invention relates to a method, a device and a system for obtaining fault reason information and belongs to the technical field of computers. The method comprises the steps of obtaining fault type information uploaded by a test terminal and log information of a tested terminal; searching all fault long information corresponding to the fault type information, wherein multiple corresponding relations between the fault type information and the fault log information are locally previously stored; in the log information of the tested terminal, obtaining the log information matched with the fault log information, obtained by searching, as the fault resonance information. By adopting the method, the device and the system for obtaining the fault reason information, the processing efficiency for determining the fault reason information is improved.

Owner:XIAOMI INC

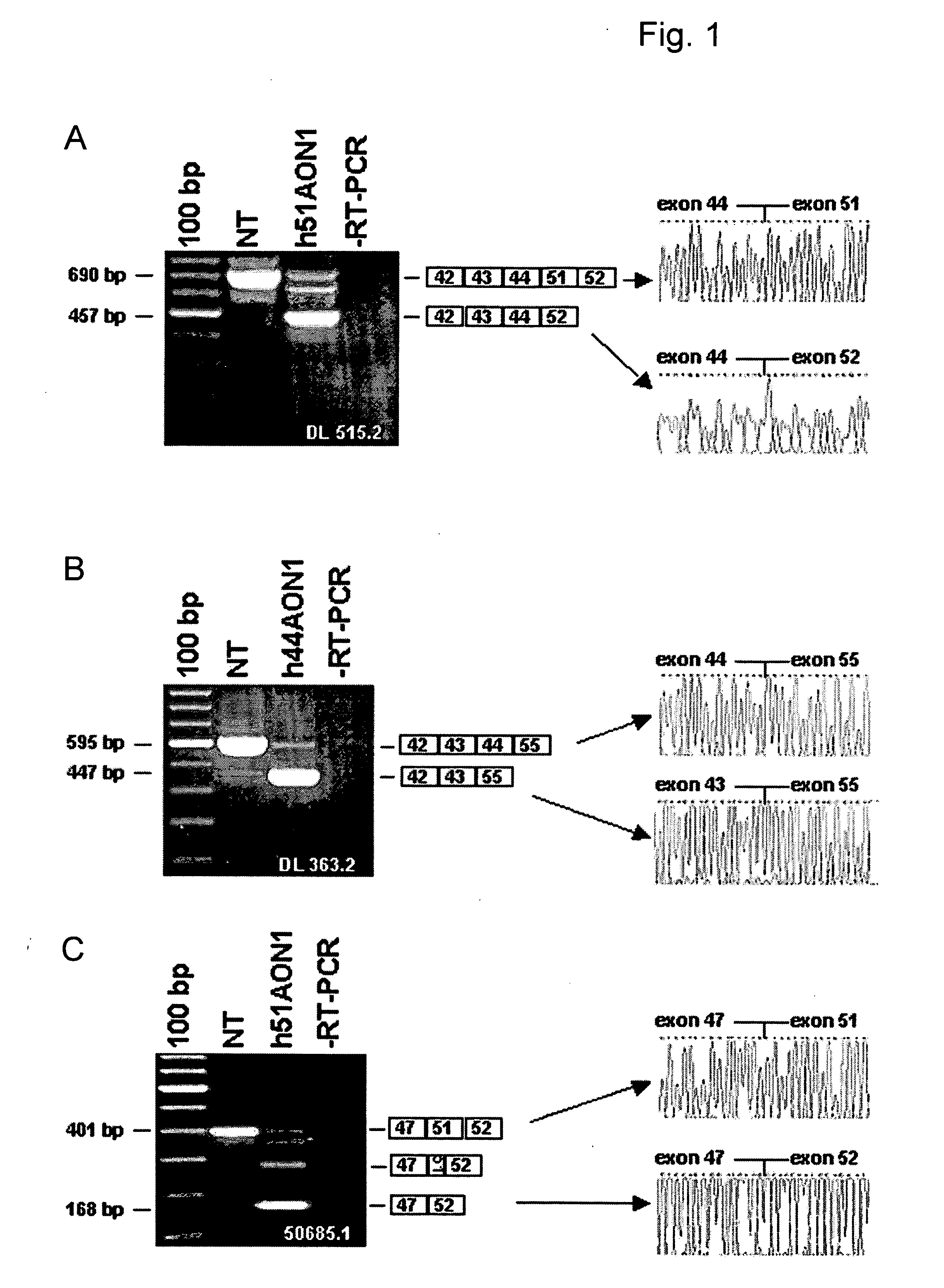

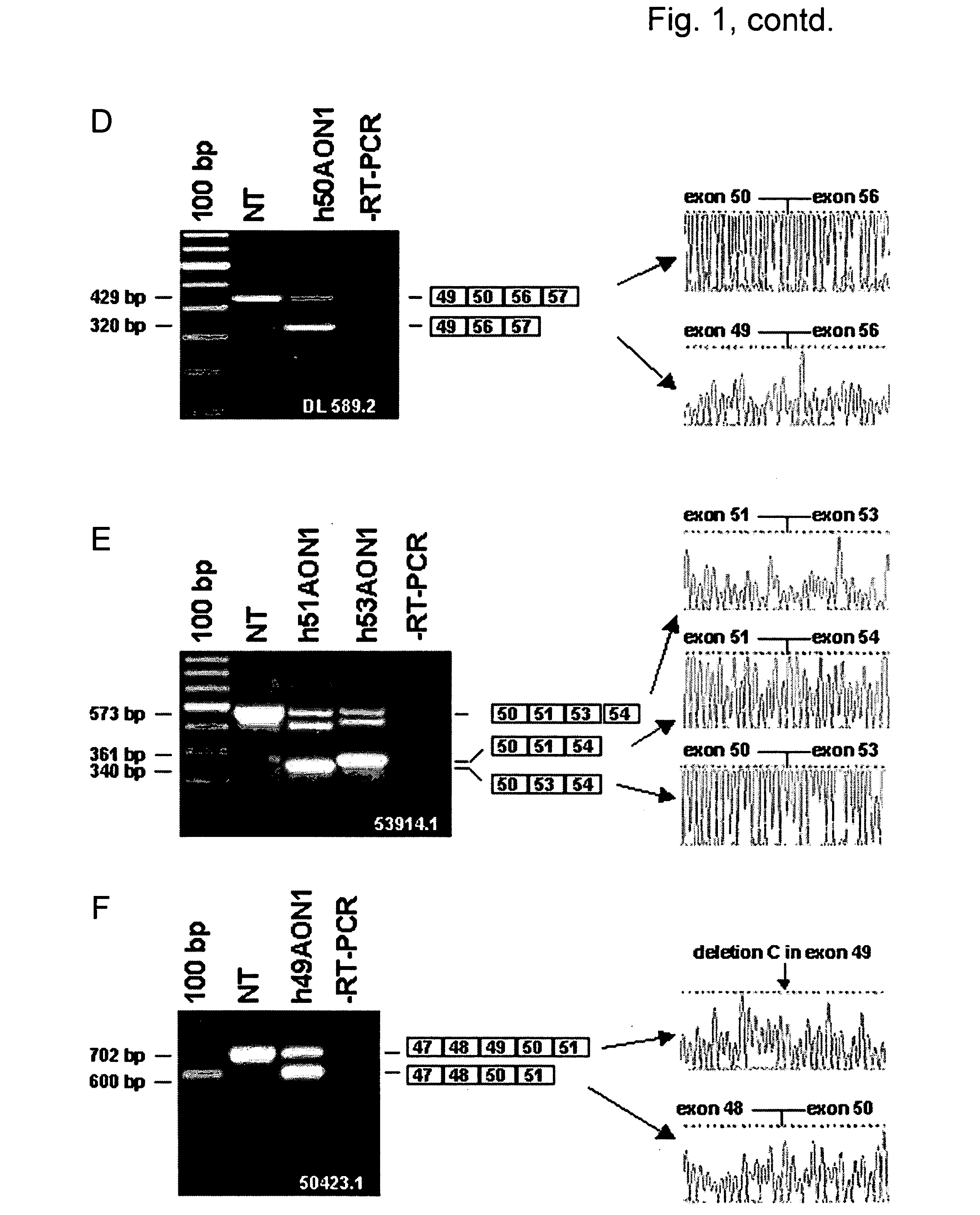

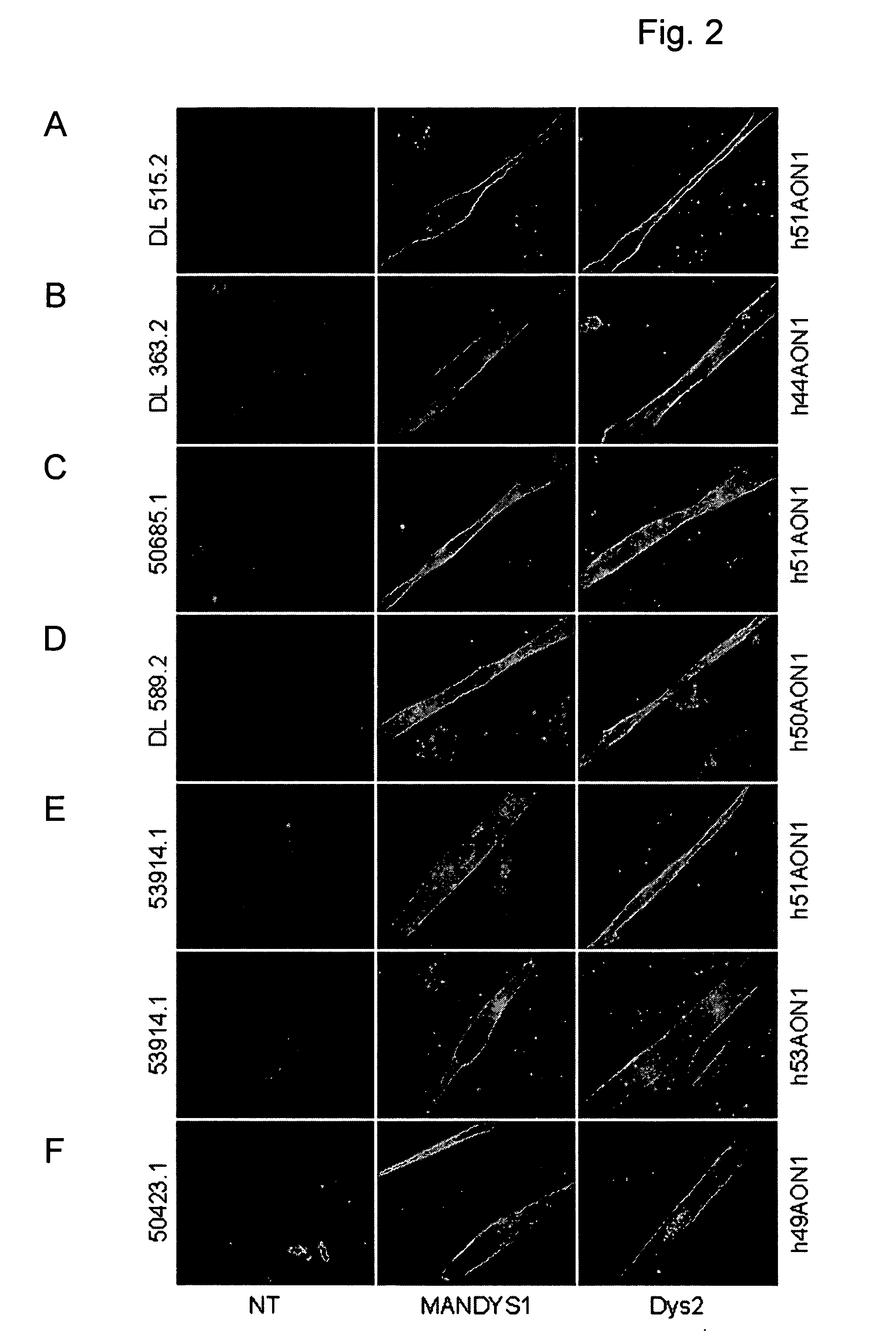

Modulation of exon recognition in pre-mRNA by interfering with the secondary RNA structure

InactiveUS20060099616A1Improves invasion efficiencyImprove efficiencySplicing alterationSugar derivativesPrecursor mRNAOligonucleotide

The invention provides a method for generating an oligonucleotide with which an exon may be skipped in a pre-mRNA and thus excluded from a produced mRNA thereof. Further provided are methods for altering the secondary structure of an mRNA to interfere with splicing processes and uses of the oligonucleotides and methods in the treatment of disease. Further provided are pharmaceutical compositions and methods and means for inducing skipping of several exons in a pre-mRNA.

Owner:ACADEMISCH ZIEKENHUIS BIJ DE UNIV VAN AMSTERDAM ACADEMISCH MEDISCH CENT

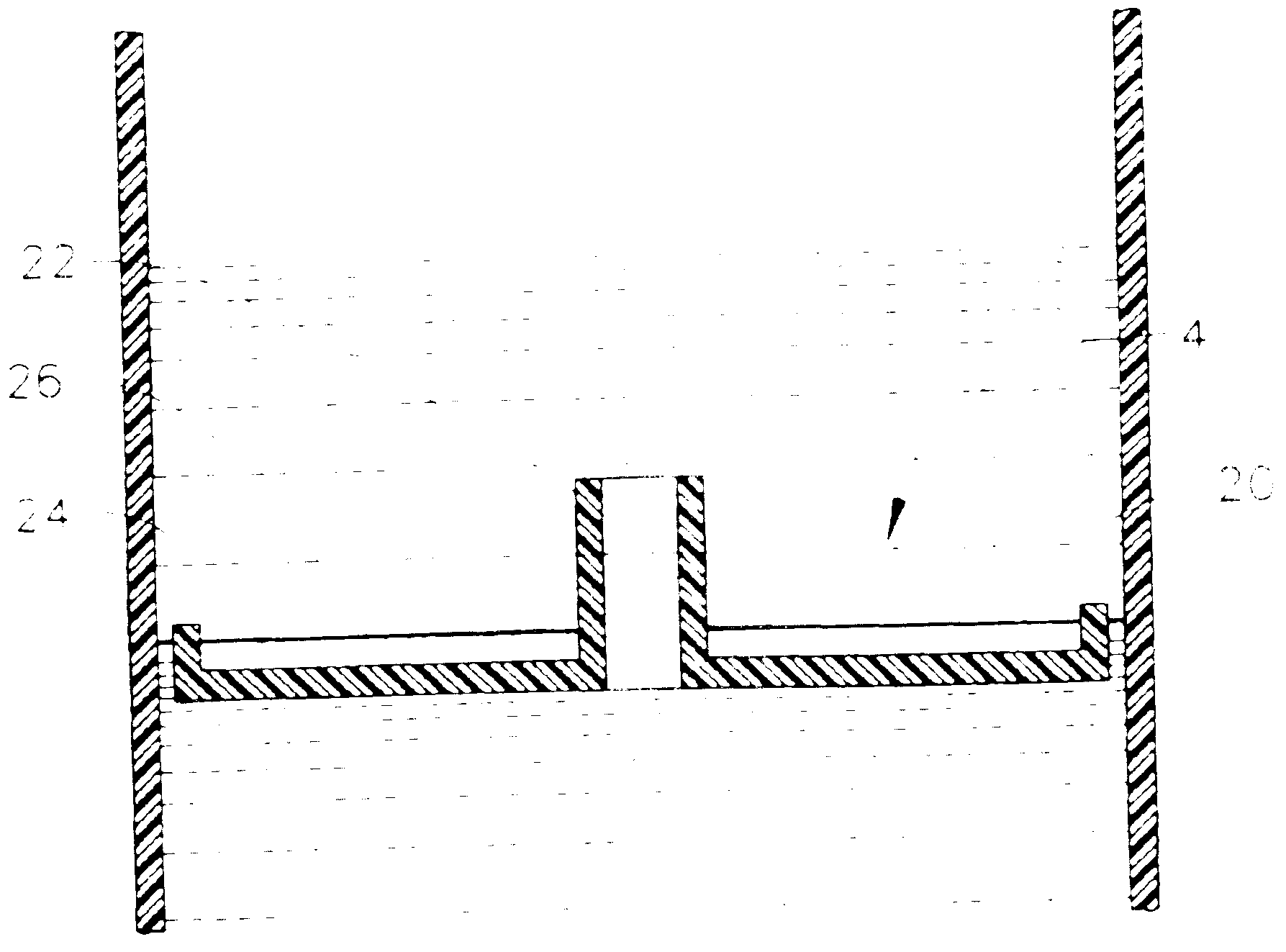

Blood component separator disk

InactiveUS7077273B2Improve processing efficiencyControl flowOther blood circulation devicesDispersed particle separationBlood component separatorRed blood cell

A separator disk (4) for use in centrifugal separation of components is designed to automatically position itself during separation at the interface between the supernatant and the remaining components. Preferably the interface is between plasma and red blood cells.

Owner:HARVEST TECH

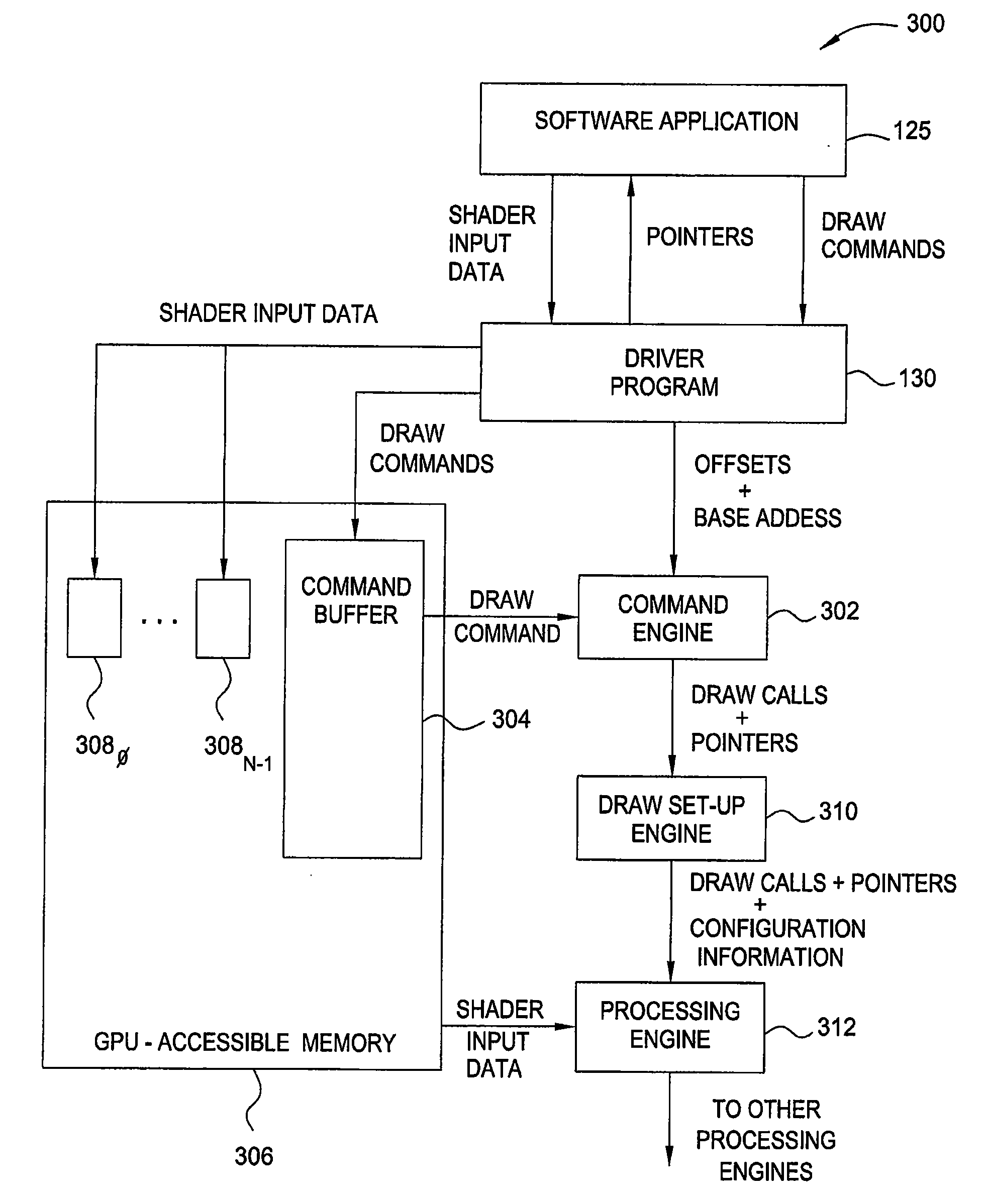

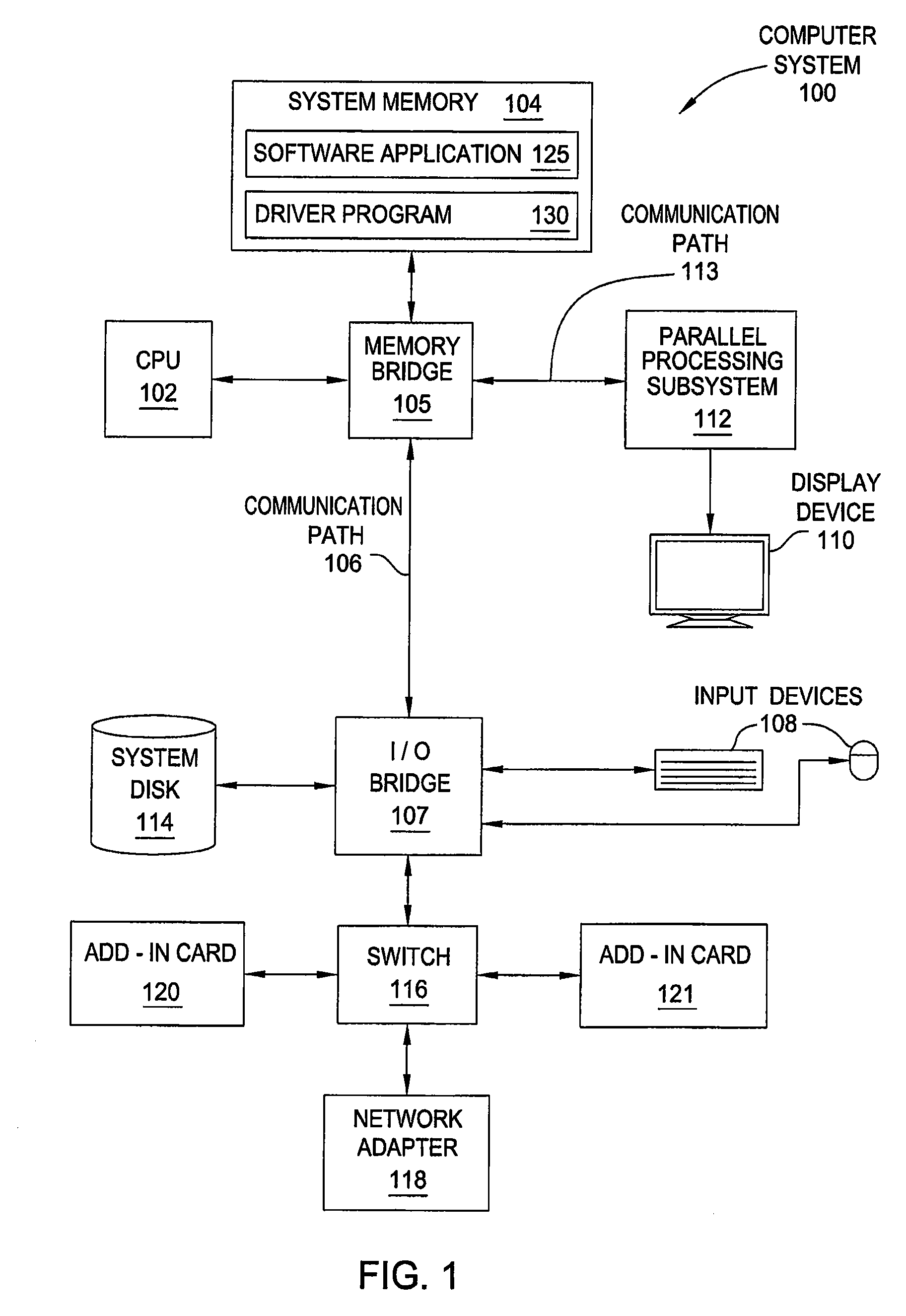

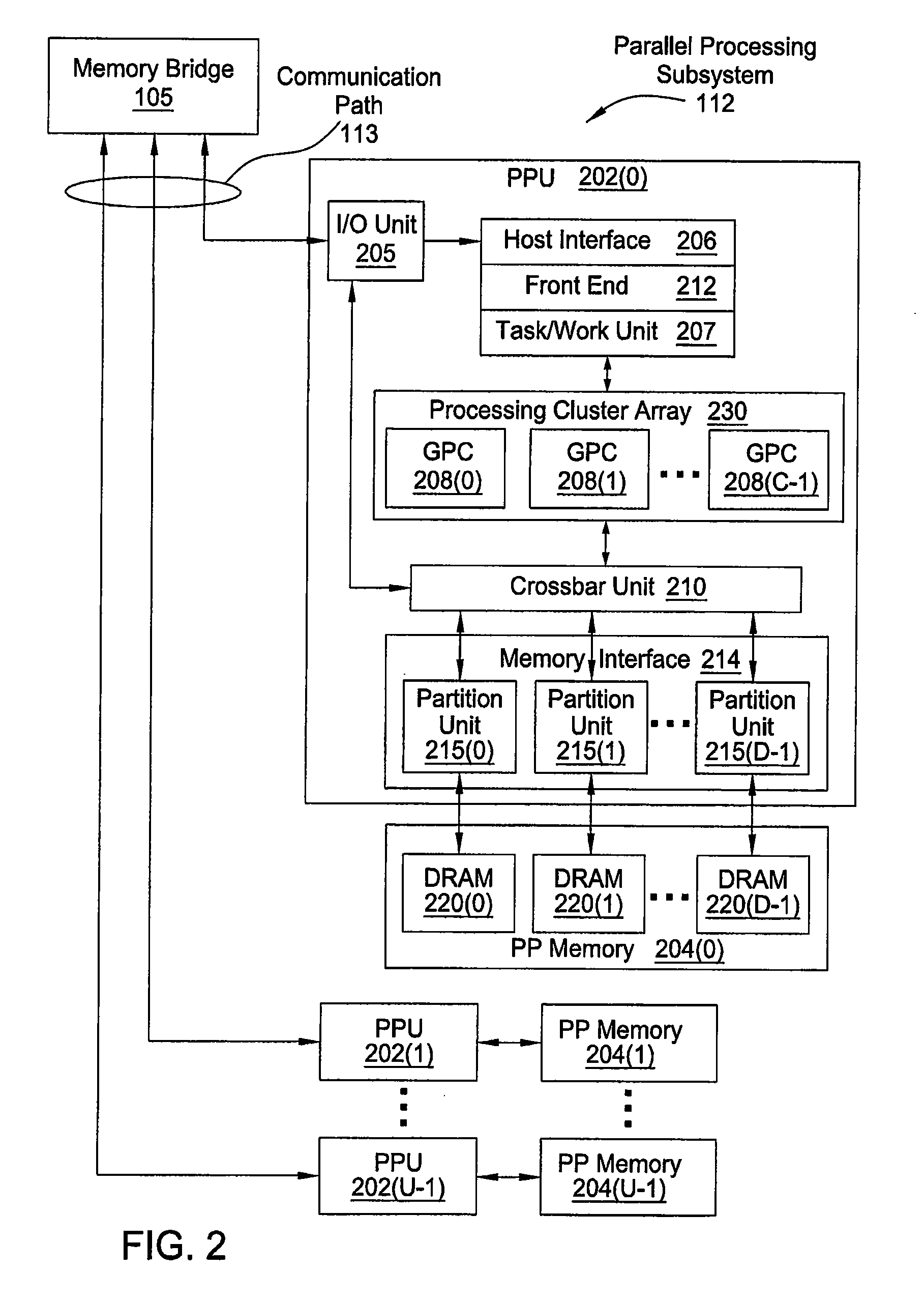

Techniques for setting up and executing draw calls

ActiveUS20140168242A1Improve processing efficiencyImage memory managementProgram controlComputational scienceApplication software

One embodiment sets forth a method for processing draw calls that includes setting up a plurality of shader input buffers in memory, receiving shader input data related to a graphics scene from a software application, storing the shader input data in the plurality of shader input buffers, computing a pointer to each shader input buffer included in the plurality of shader input buffers, and passing the pointers to the plurality of shader input buffers to the software application. By implementing the disclosed techniques, a shader program advantageously can access the shader input data associated with a graphics scene and stored in various shader input buffers without having to go through the central processing unit to have the shader input buffers binded to the shader program.

Owner:NVIDIA CORP

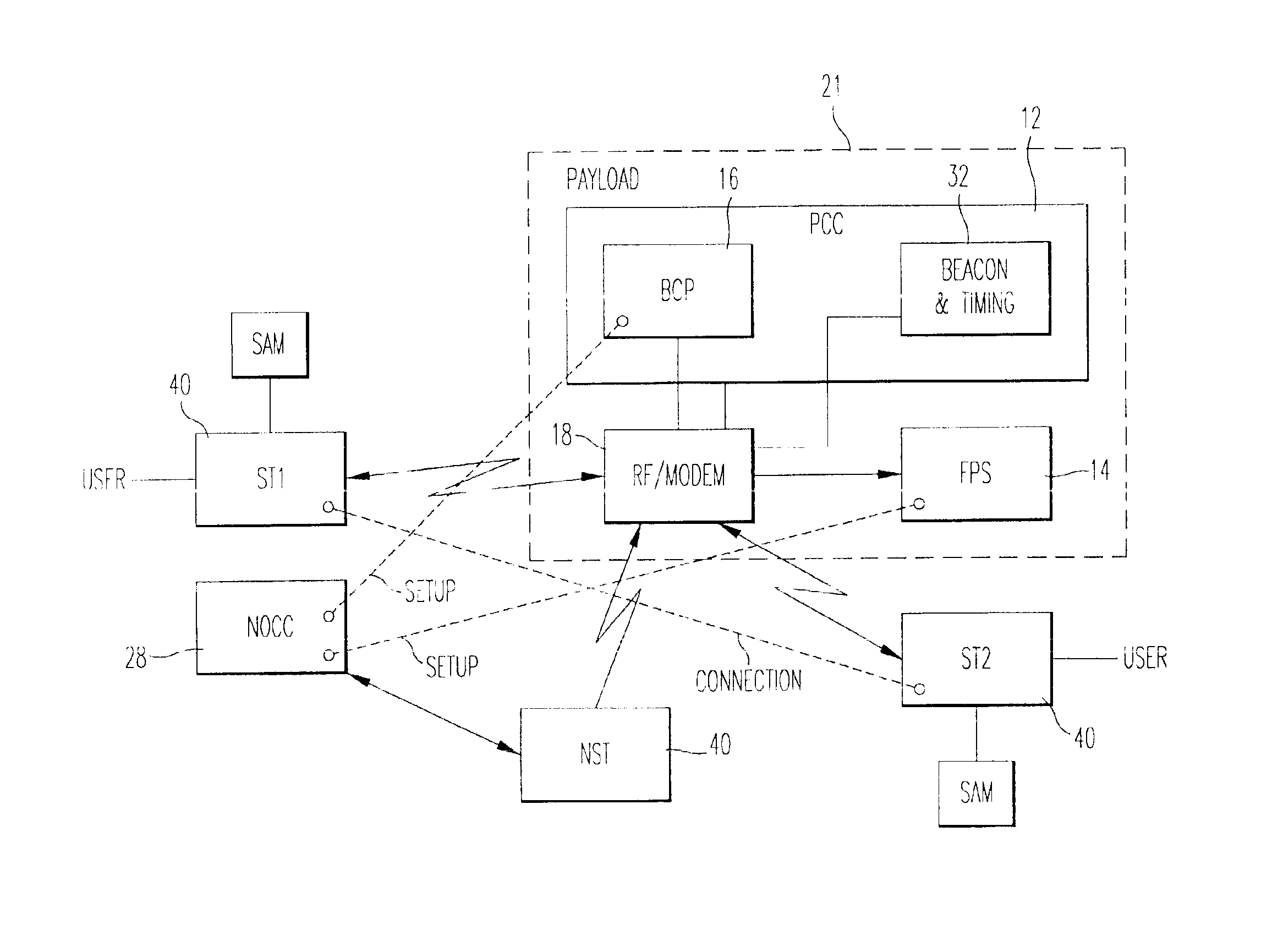

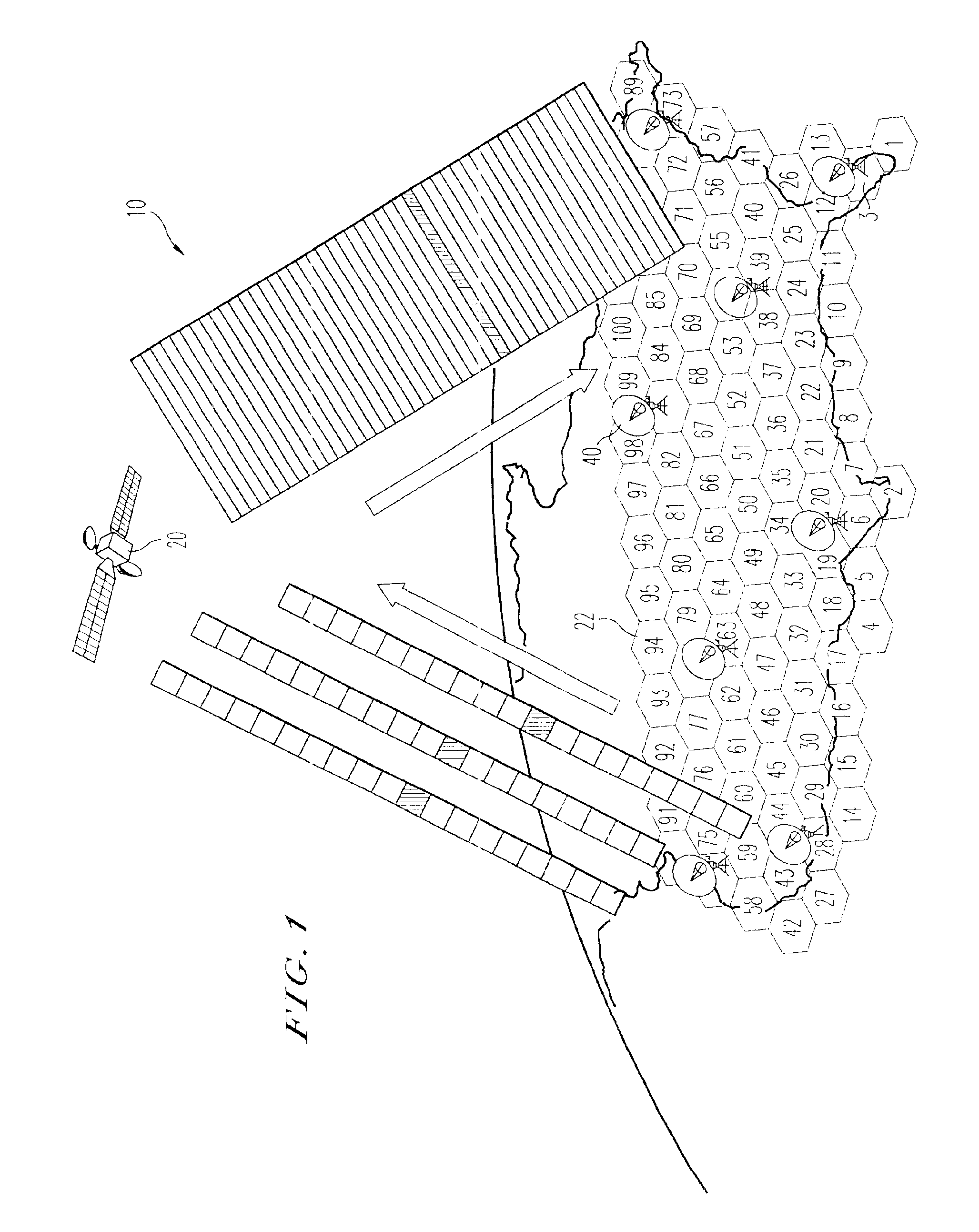

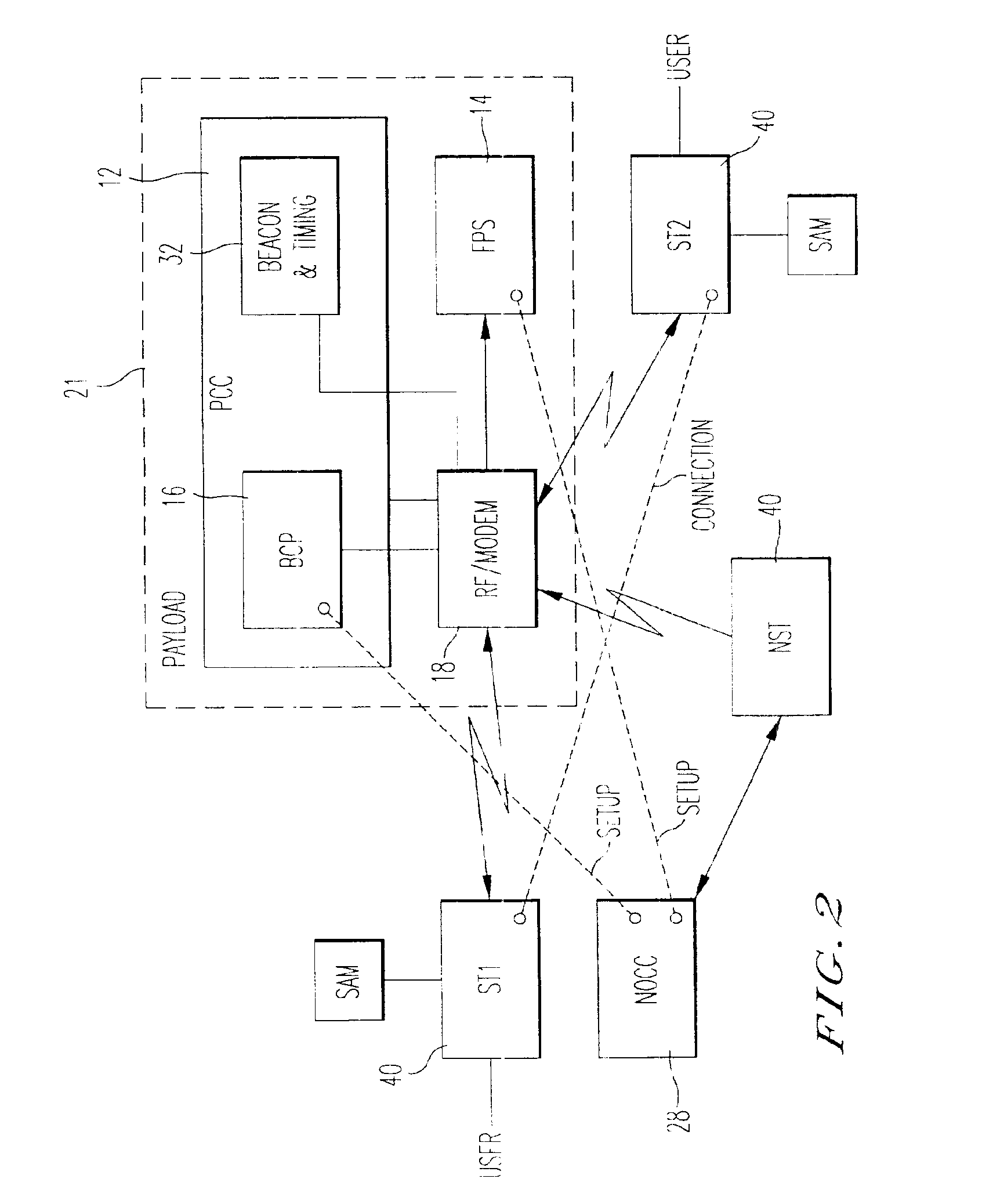

System for providing satellite bandwidth on demand employing uplink frame formatting for smoothing and mitigating jitter and dynamically changing numbers of contention and data channels

InactiveUS6842437B1Limit jitterReduce fragmentationTime-division multiplexRadio transmissionSatelliteOn demand

A method of transmitting time division multiplexed data from a satellite terminal to a satellite wherein the satellite terminal receives a command indicating to transmit data during a frame comprising a plurality of timeslots in accordance with a timeslot reordering scheme. The timeslot reordering scheme is selected to spread data from respective satellite terminals to different timeslots throughout the frames. A processor monitors the use of channels by the satellite terminals, stores bandwidth requests using queues, allocates channels in accordance with bandwidth requests and a bandwidth allocation algorithm, and transmits the channel allocations in a frame. Timeslots not allocated to any of the satellite terminals are contention channels. The number of contention channels changes dynamically, depending on demand for the plurality of channels by the satellite terminals. Queues are provided for each channel for storing high and low priority rate requests and high and low priority volume requests. The bandwidth allocation algorithm determines the preemption of the queues, and allocation priorities.

Owner:HUGHES NETWORK SYST

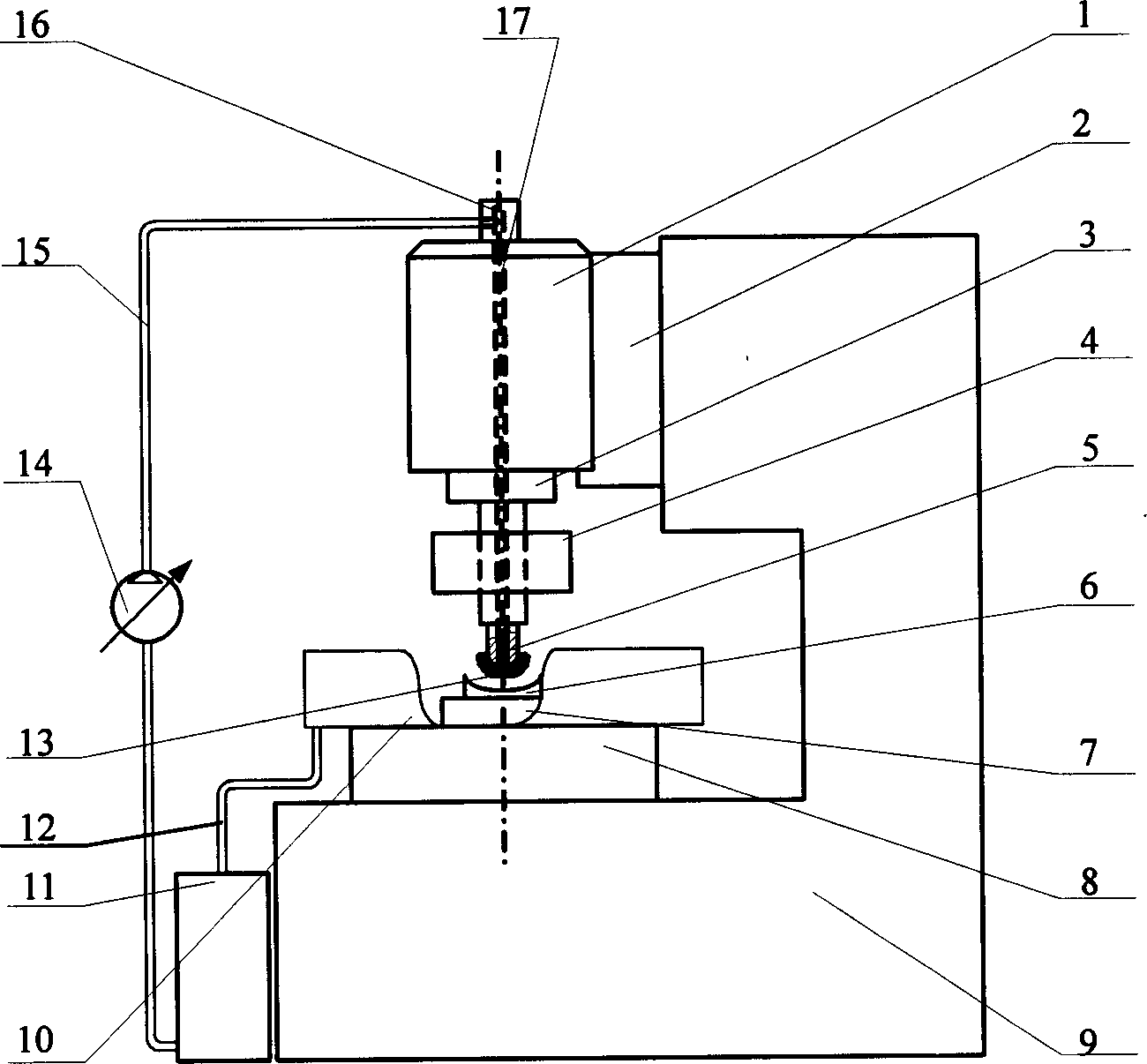

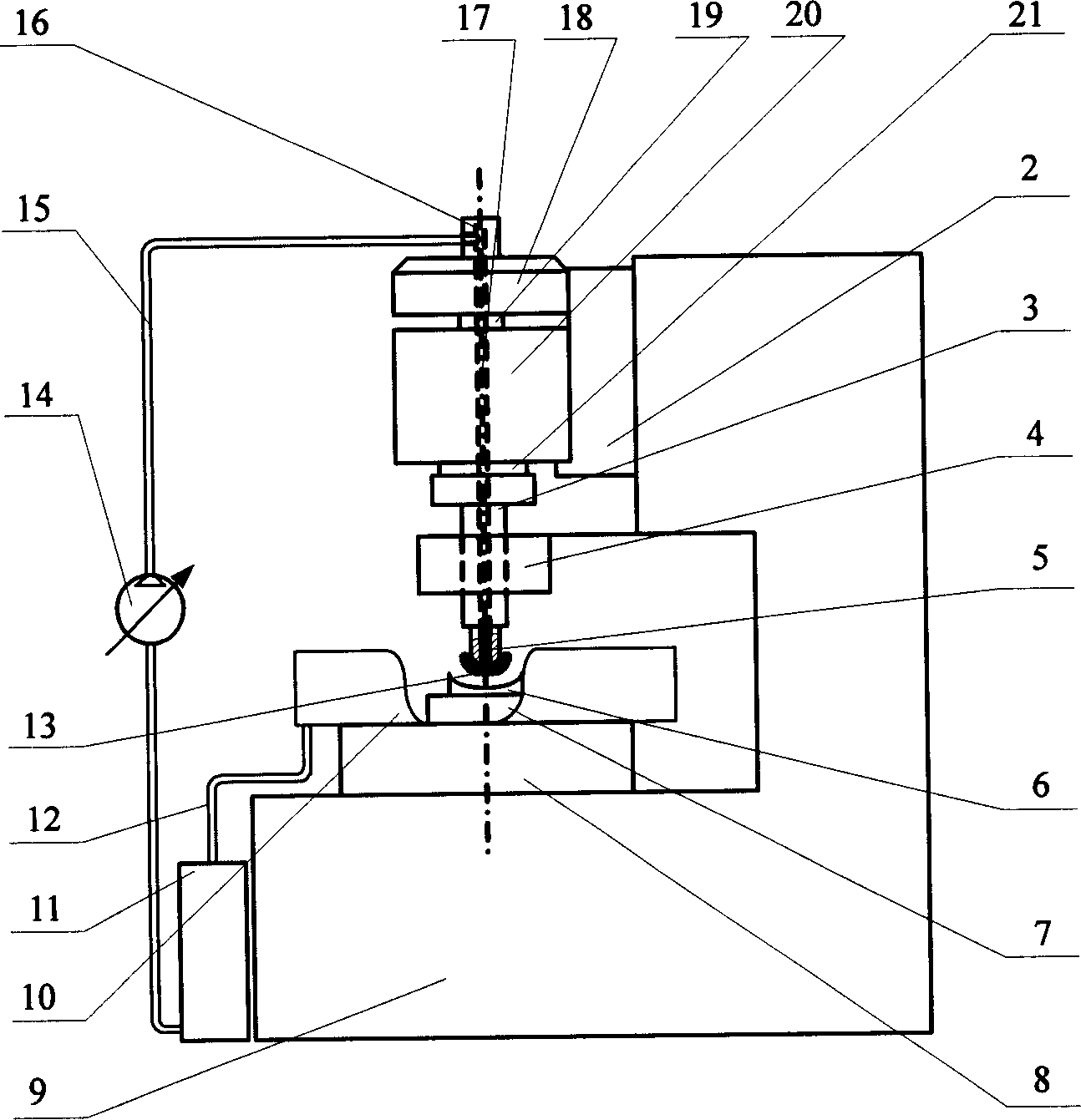

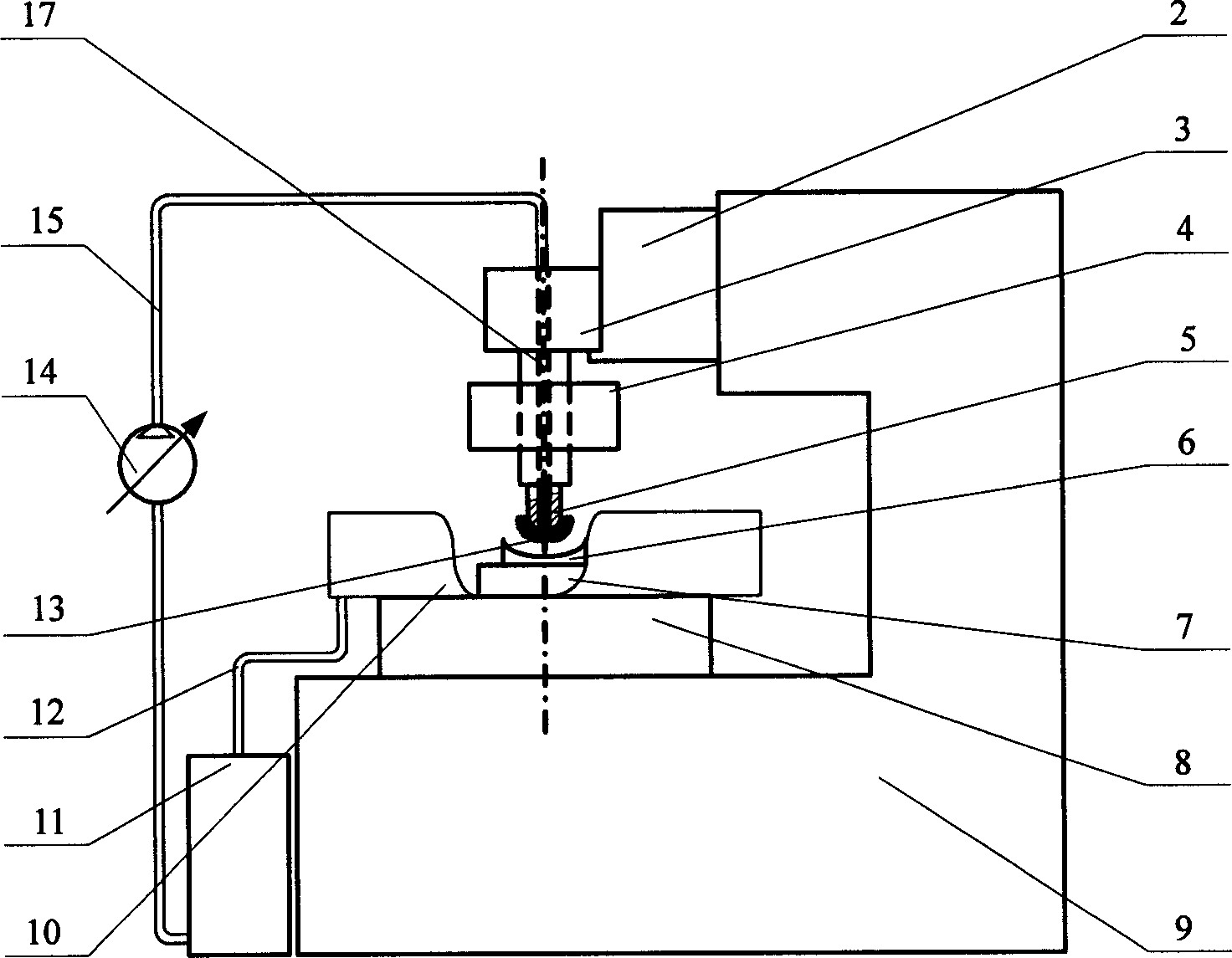

Ultrasonic magnetic rheological composite polishing method and polisher thereof

InactiveCN1613605AAchieve recyclingStable Polishing PropertiesOptical surface grinding machinesUltrasonic vibrationEngineering

An ultrasonic-magnetorheologic polishing method features that the mixture of abrasive material and magnetorheologic liquid is filled in a small-diameter rotary hollow polishing head and a magnetic field is applied to it to make the magnetorheologic liquid become flexible polishing liquid on the polishing head while the ultrasonic vibration is applied to it for higher polishing effect. Its apparatus is composed of polishing head, ultrasonic generator, and electromagnet.

Owner:HARBIN INST OF TECH

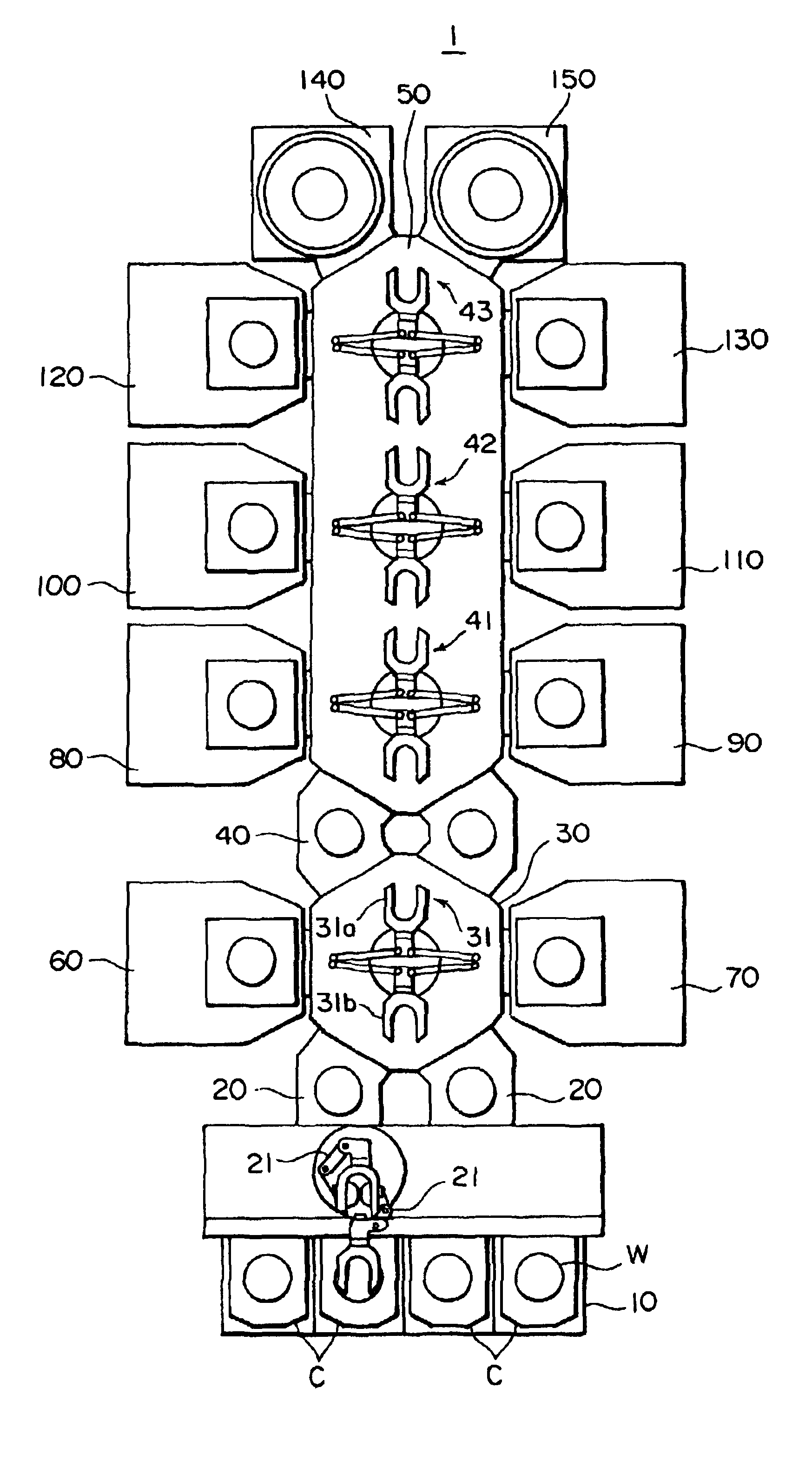

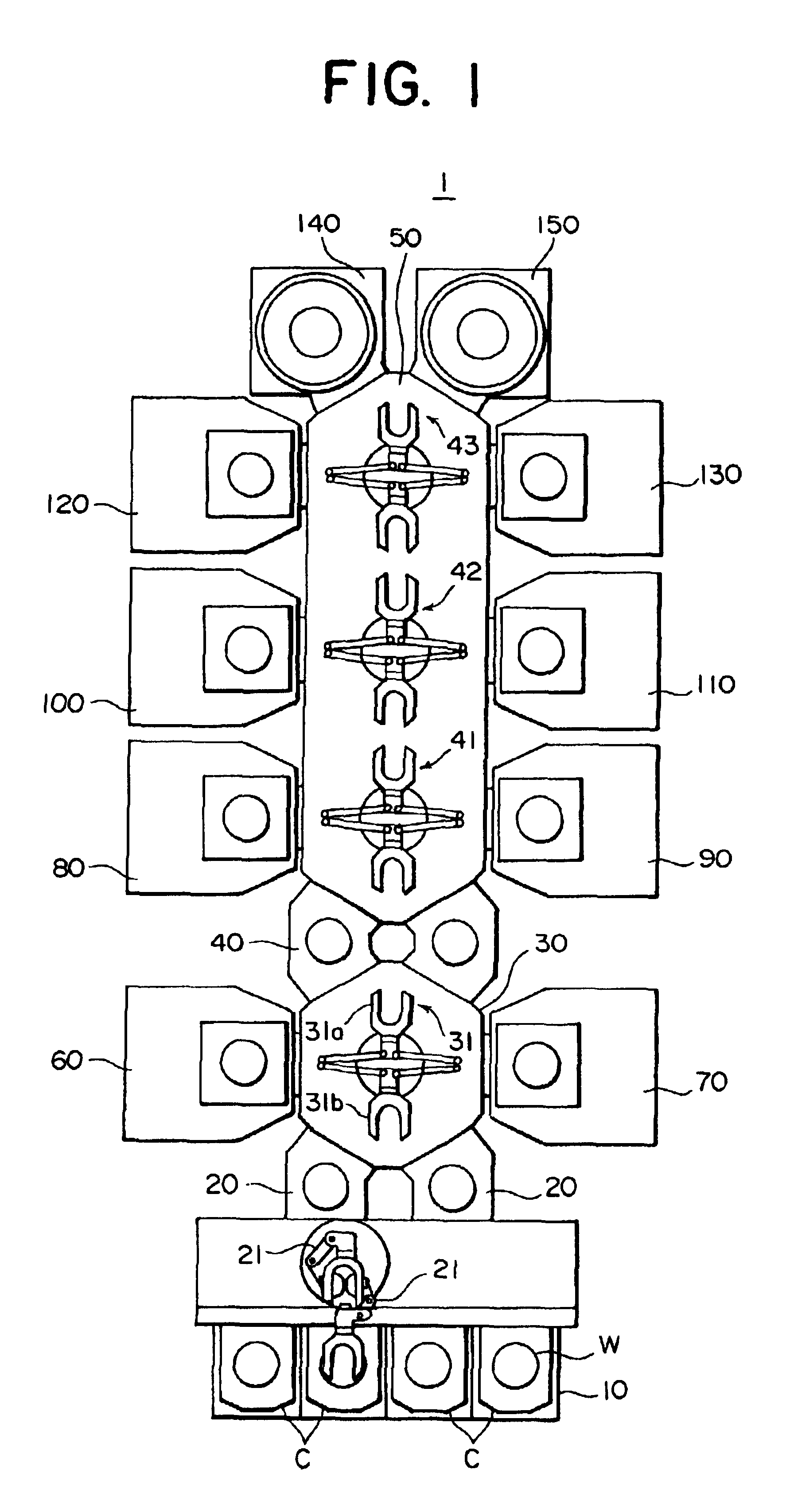

Processing apparatus, transferring apparatus and transferring method

InactiveUS6852194B2Improve processing effectivenessQuality improvementCellsVacuum evaporation coatingEngineeringTransfer mechanism

Processing apparatus is disclosed, that comprises substrate container holding table that can hold substrate container that contains plurality of target substrates, first transferring chamber, disposed adjacent to the substrate container holding table, that maintains the interior at first pressure, first processing unit group, disposed around the first transferring chamber, that processes target substrate at the first pressure, first transferring mechanism, disposed in the first transferring chamber, that transfers target substrate, second transferring chamber, disposed adjacent to the first transferring chamber, that maintains the interior at second pressure, second processing unit group, disposed around the second transferring chamber, that processes target substrate at the second pressure, and second transferring mechanism, disposed in the second transferring chamber, wherein the first transferring mechanism and / or the second transferring mechanism has at least two transferring arms.

Owner:TOKYO ELECTRON LTD

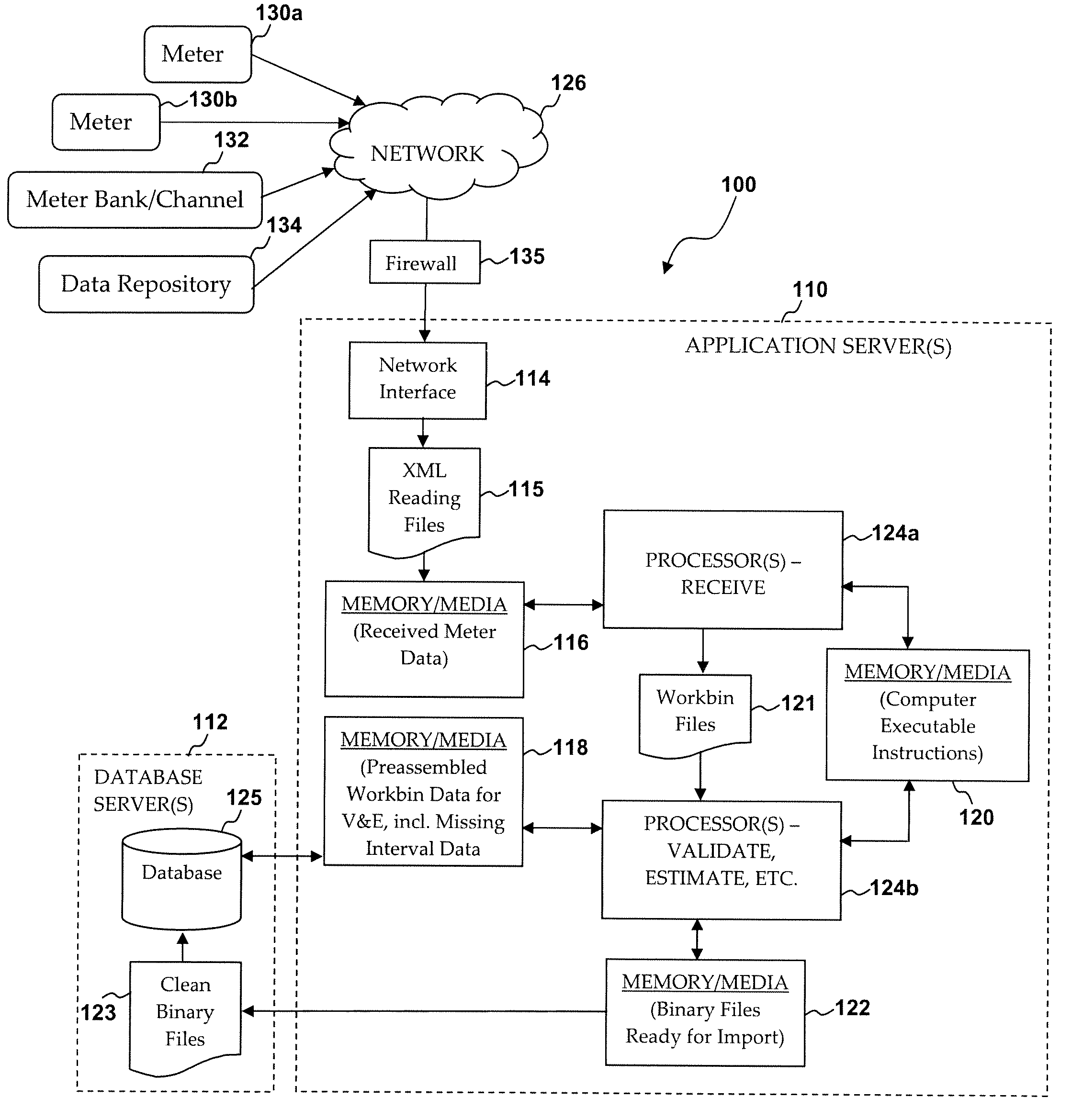

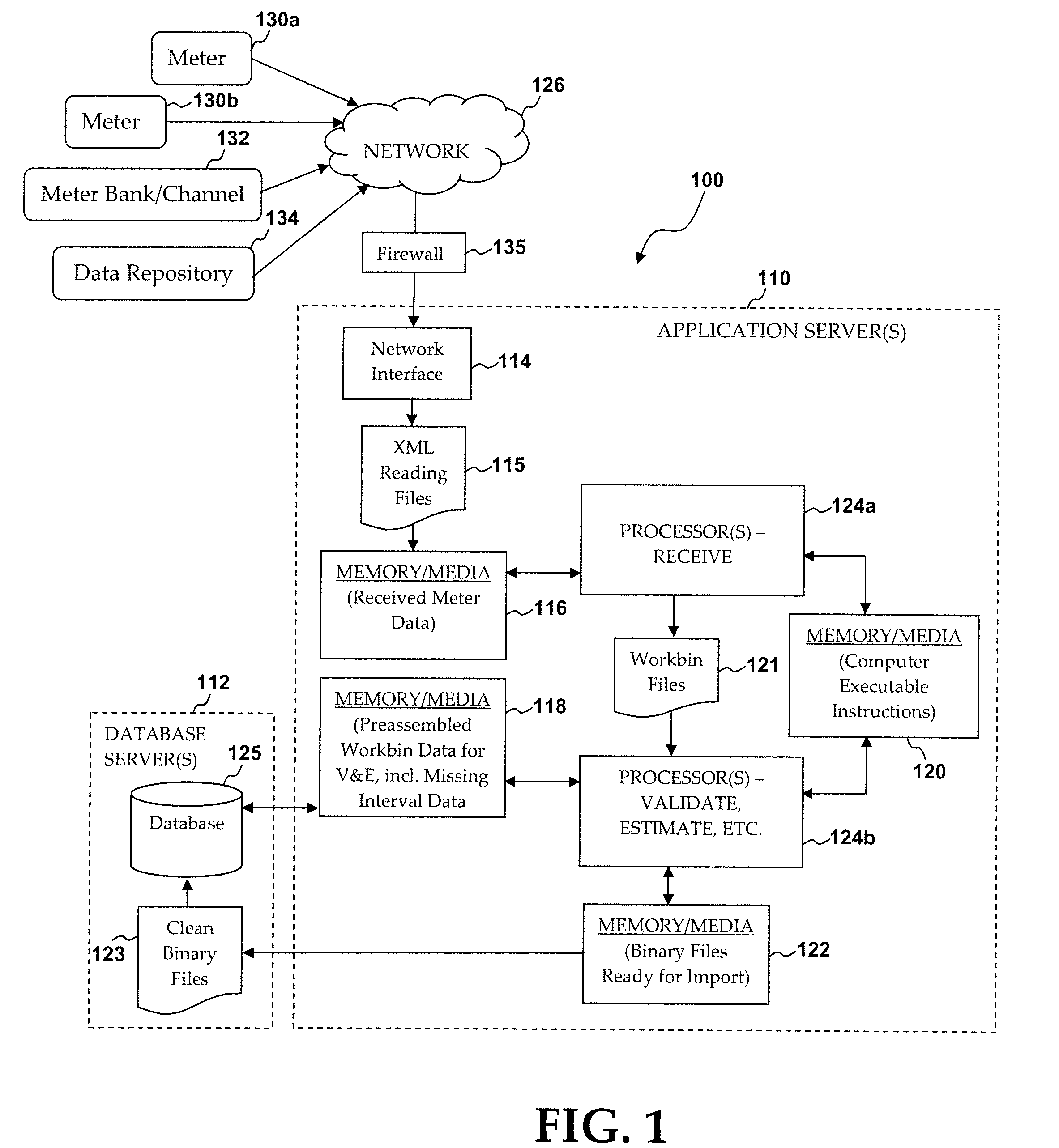

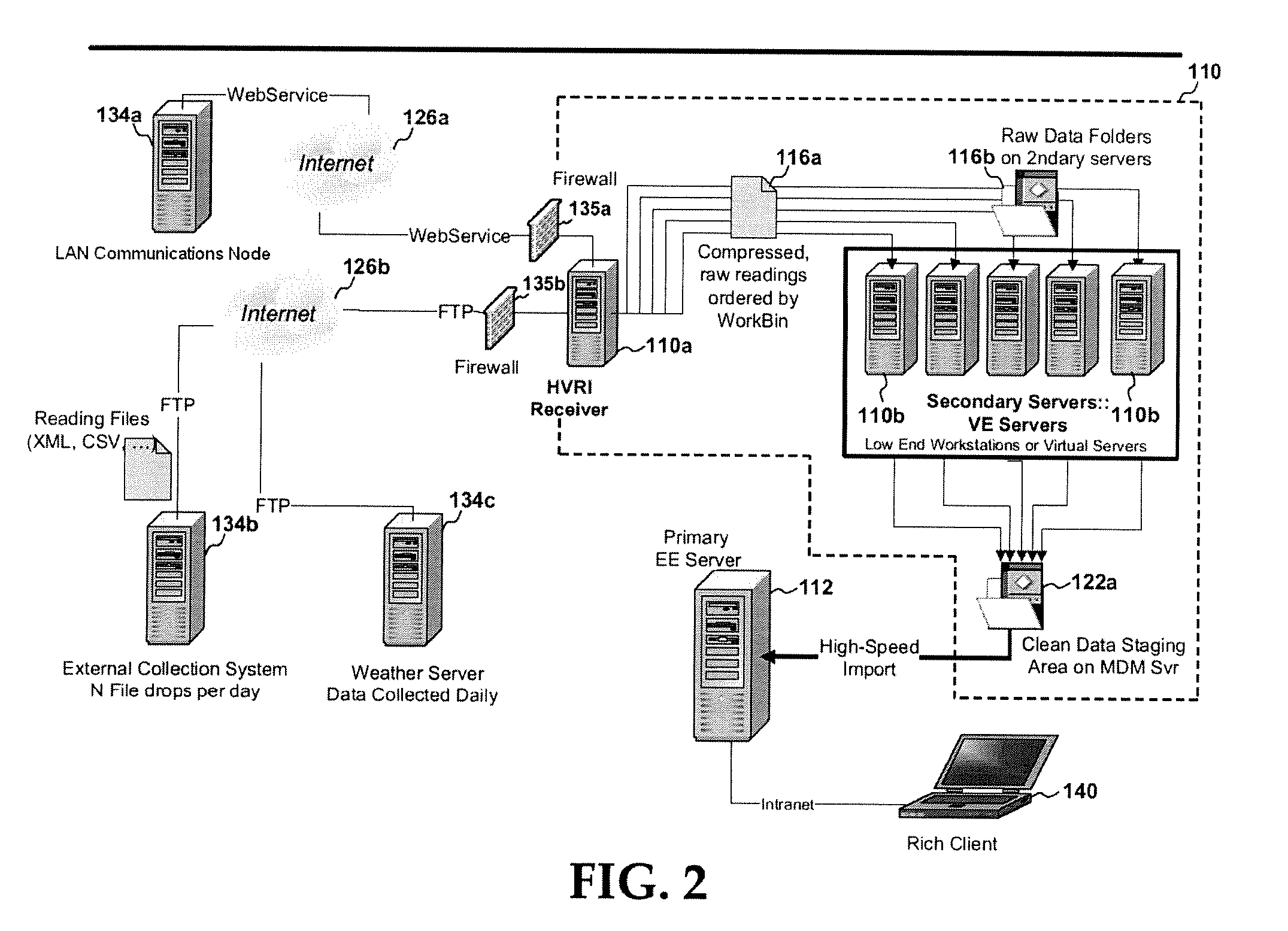

System and method of high volume import, validation and estimation of meter data

ActiveUS20100117856A1Efficient collectionReduce the amount of solutionElectric signal transmission systemsTariff metering apparatusApplication serverMeter data management system

A meter data management system includes one or more application servers configured to receive, validate and estimate received meter data. The one or more application servers may include various memory / media elements for storing raw and transformed meter data as well as software in the form of computer-executable instructions, which are executed by a processor to implement a variety of functions, including establishing a mapping between the plurality of external devices and a plurality of preconfigured processing workbins (e.g., collections of meter channels in the same time zones), transforming the received meter data into a plurality of data files identified by timing parameter and workbin, validating data provided in each data file, estimating missing or invalid data, and automatically writing validated (and optionally estimated) data as import files to a database server. Such clean data files are then imported to one or more dedicated databases installed on the database server.

Owner:ITRON

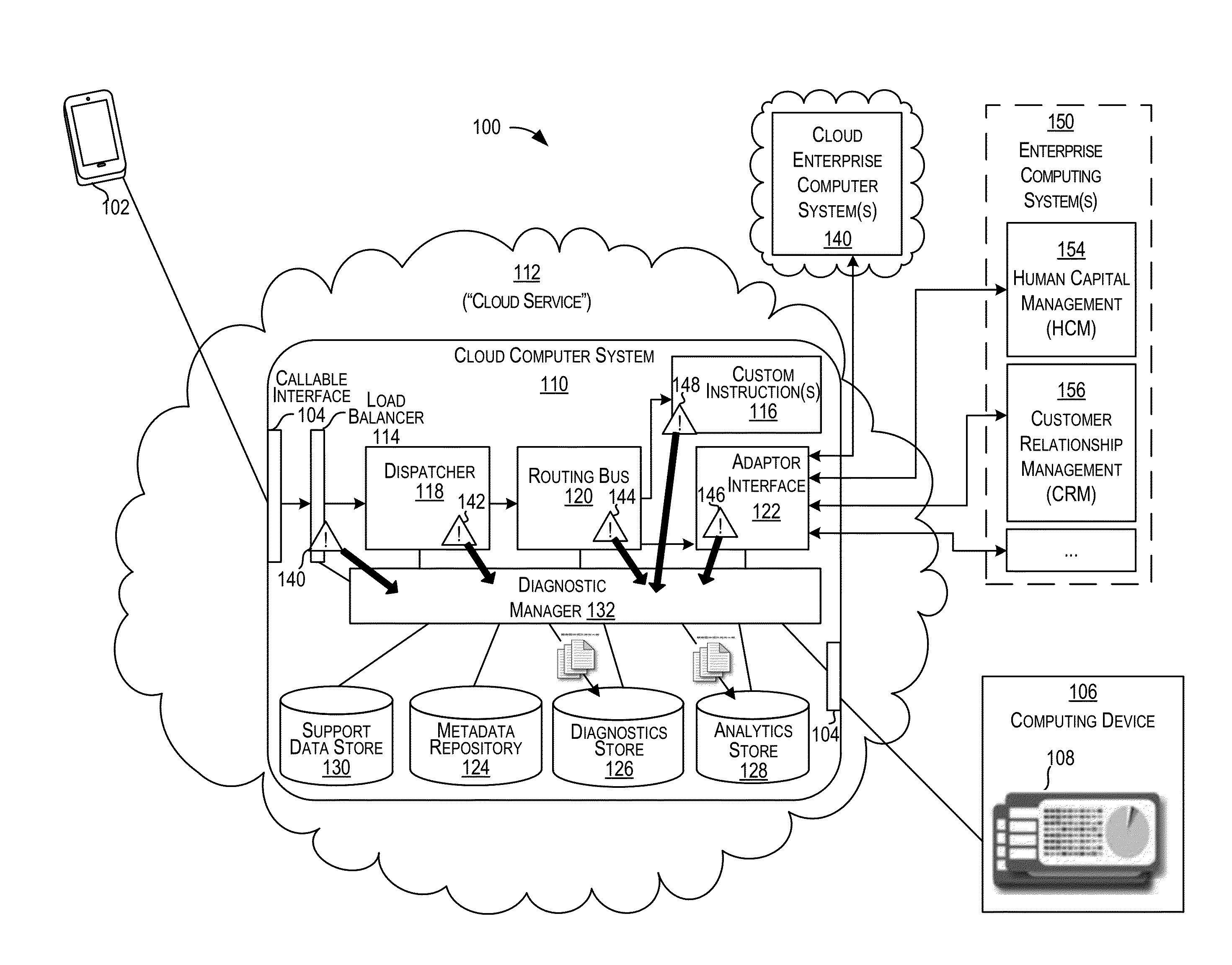

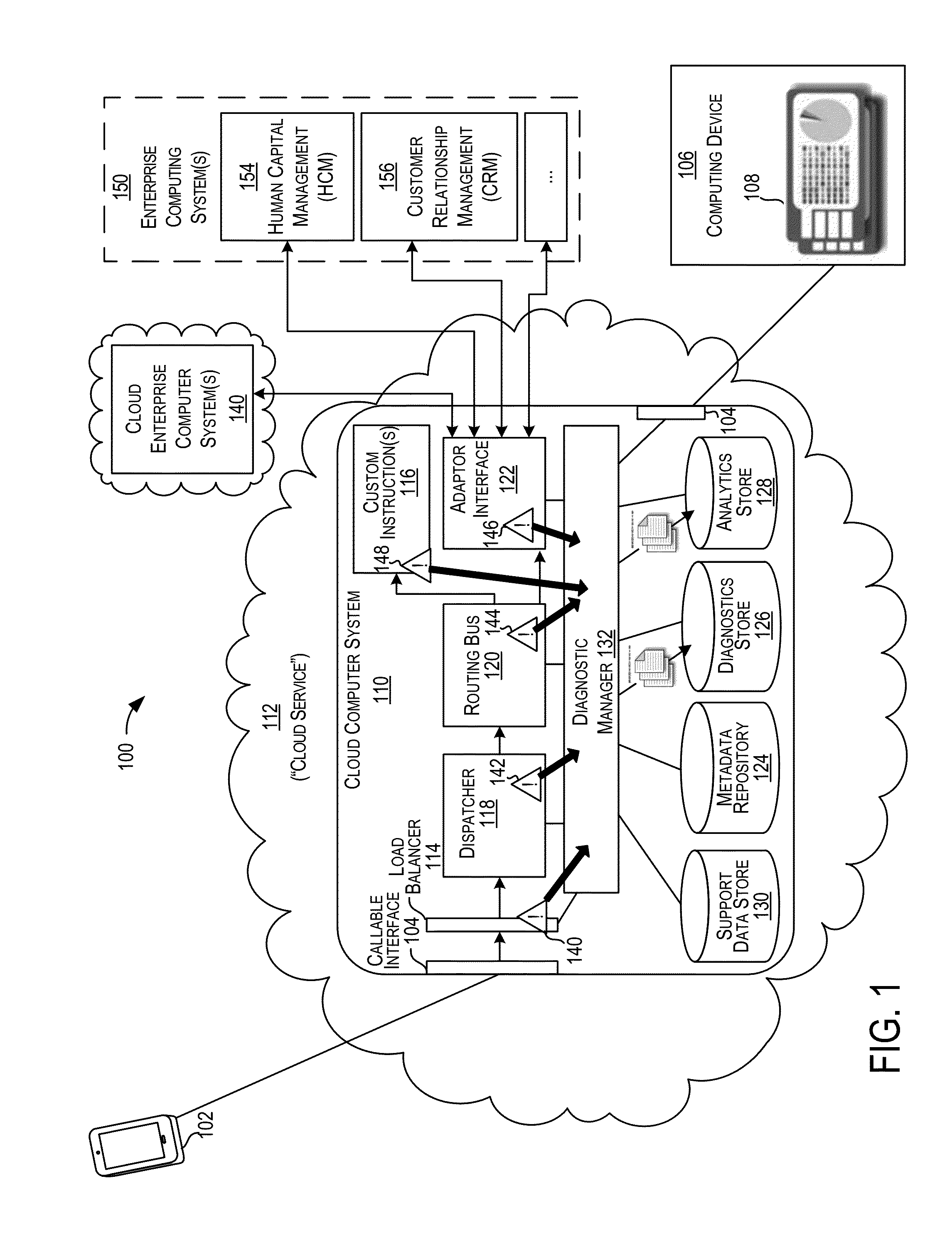

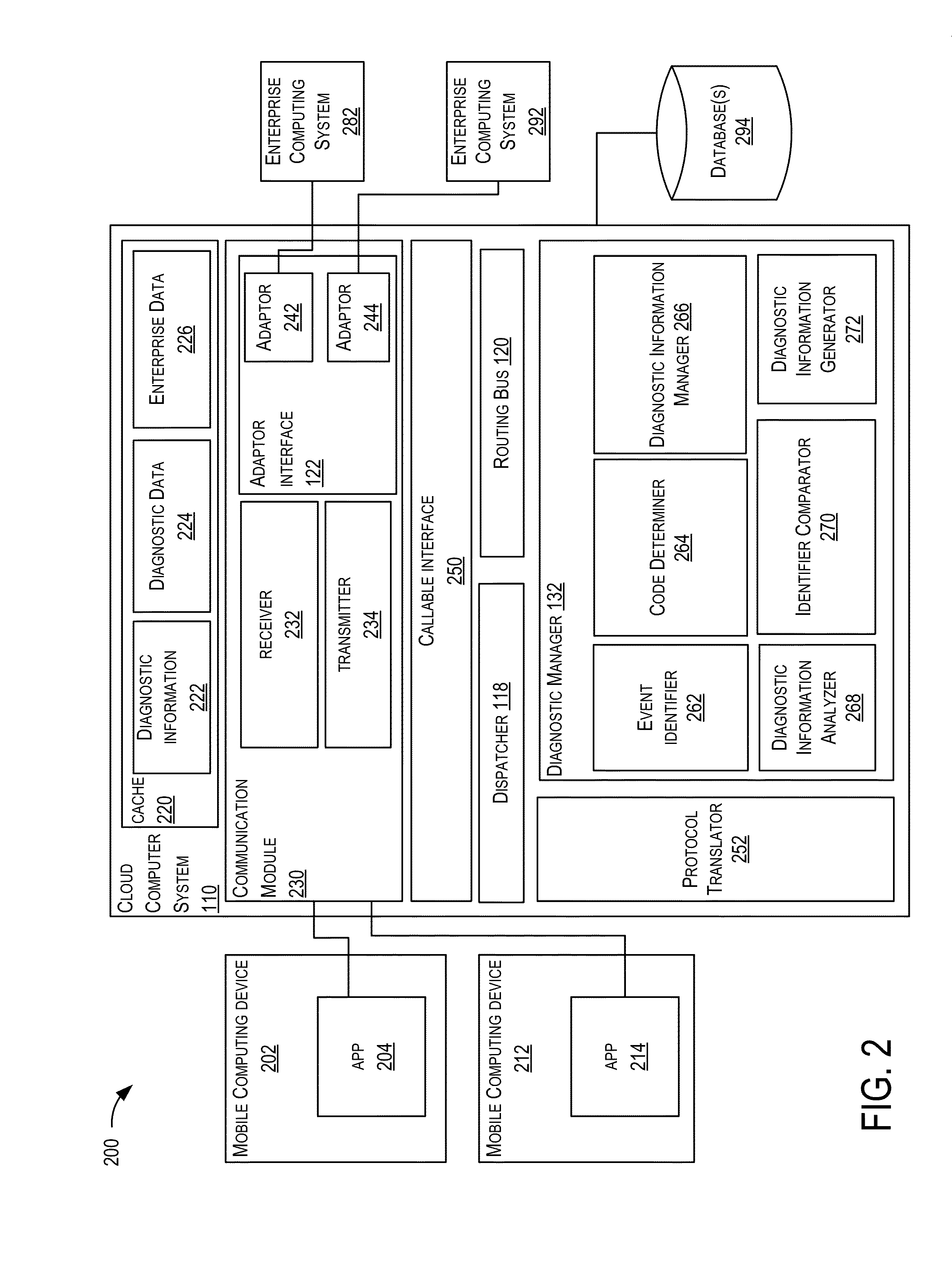

Techniques for generating diagnostic identifiers to trace events and identifying related diagnostic information

ActiveUS20150227405A1Improve processing efficiencyUsed to determineNon-redundant fault processingDiagnostic dataDiagnostic information

Techniques are described for determining diagnostic information (e.g., a diagnostic identifier) for one or more events related to operations performed in a cloud computer system. A diagnostic identifier may be generated based on diagnostic data corresponding to one or more attributes about an event. A computing operation may be performed to generate a code (e.g., a hash code) for each attribute in the diagnostic data. The generated code(s) may be combined to form a diagnostic identifier to identify the diagnostic data. A comparison may be performed by comparing each code in one diagnostic identifier to a code in another diagnostic identifier corresponding to an attribute for which the codes were generated. A measure of a match between the two identifiers may be determined using a result of the comparison. The measure of the match may enable tracing and analysis of one or more events occurring in the cloud computer system.

Owner:ORACLE INT CORP

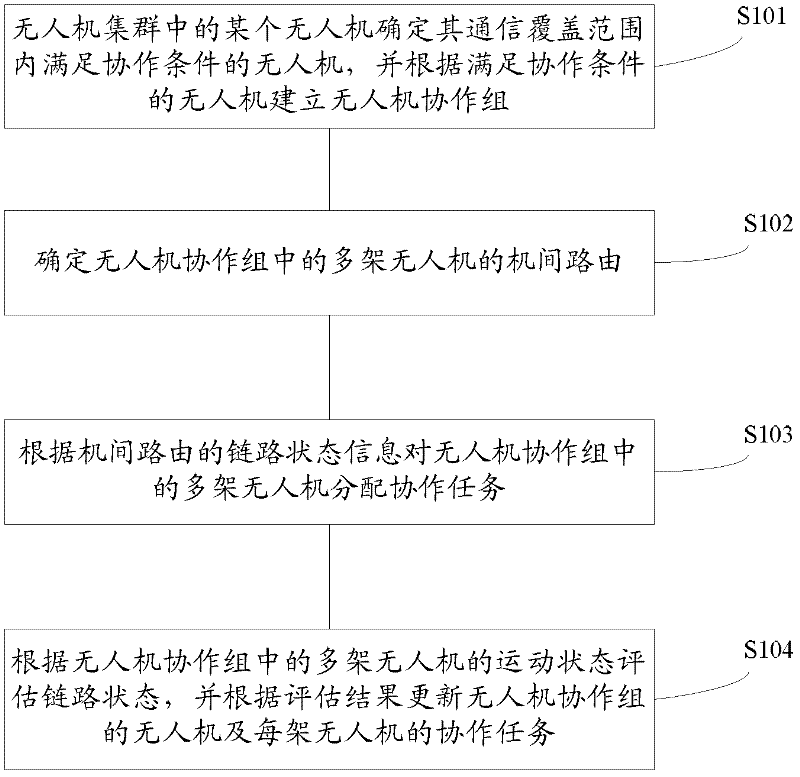

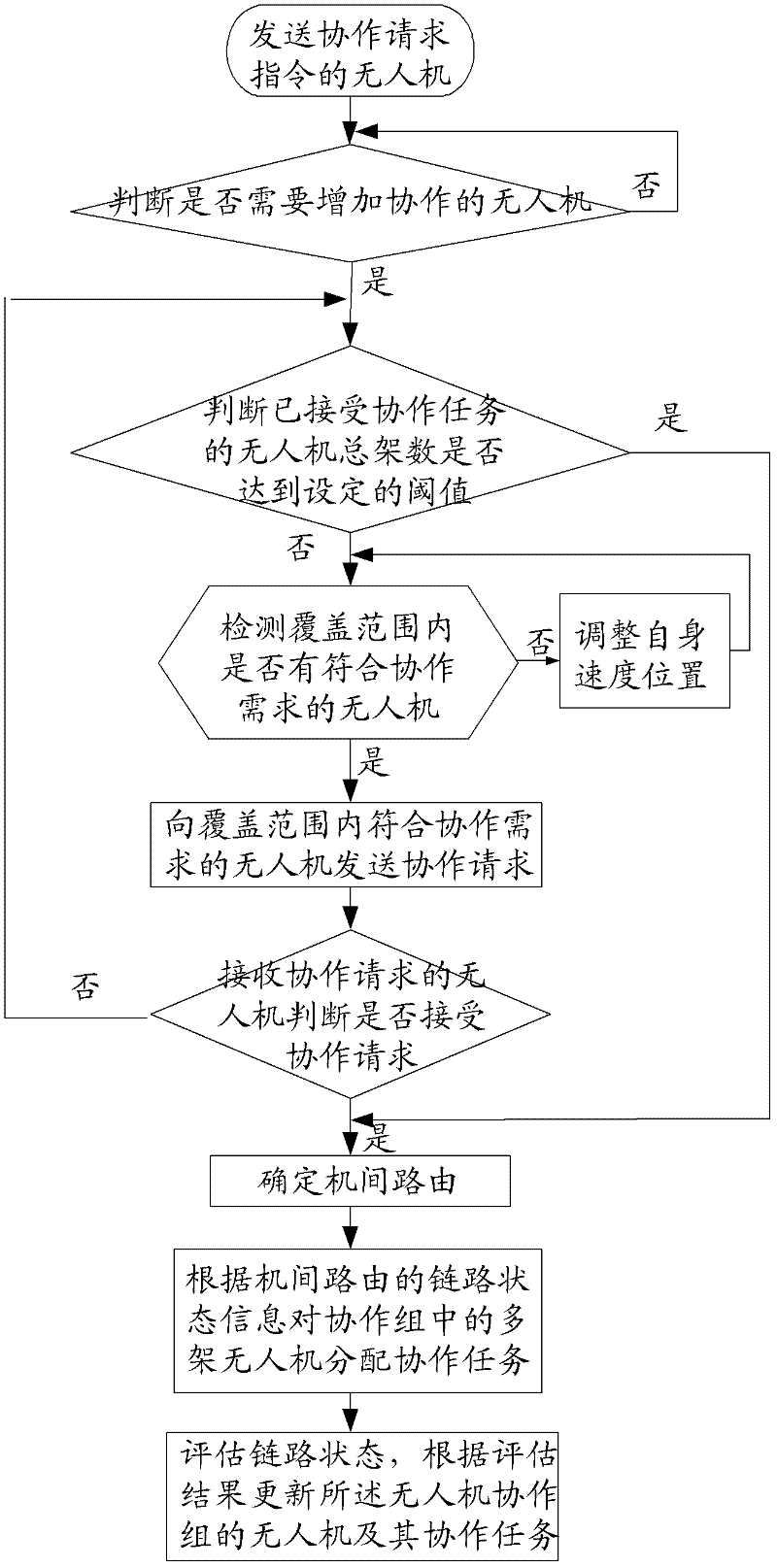

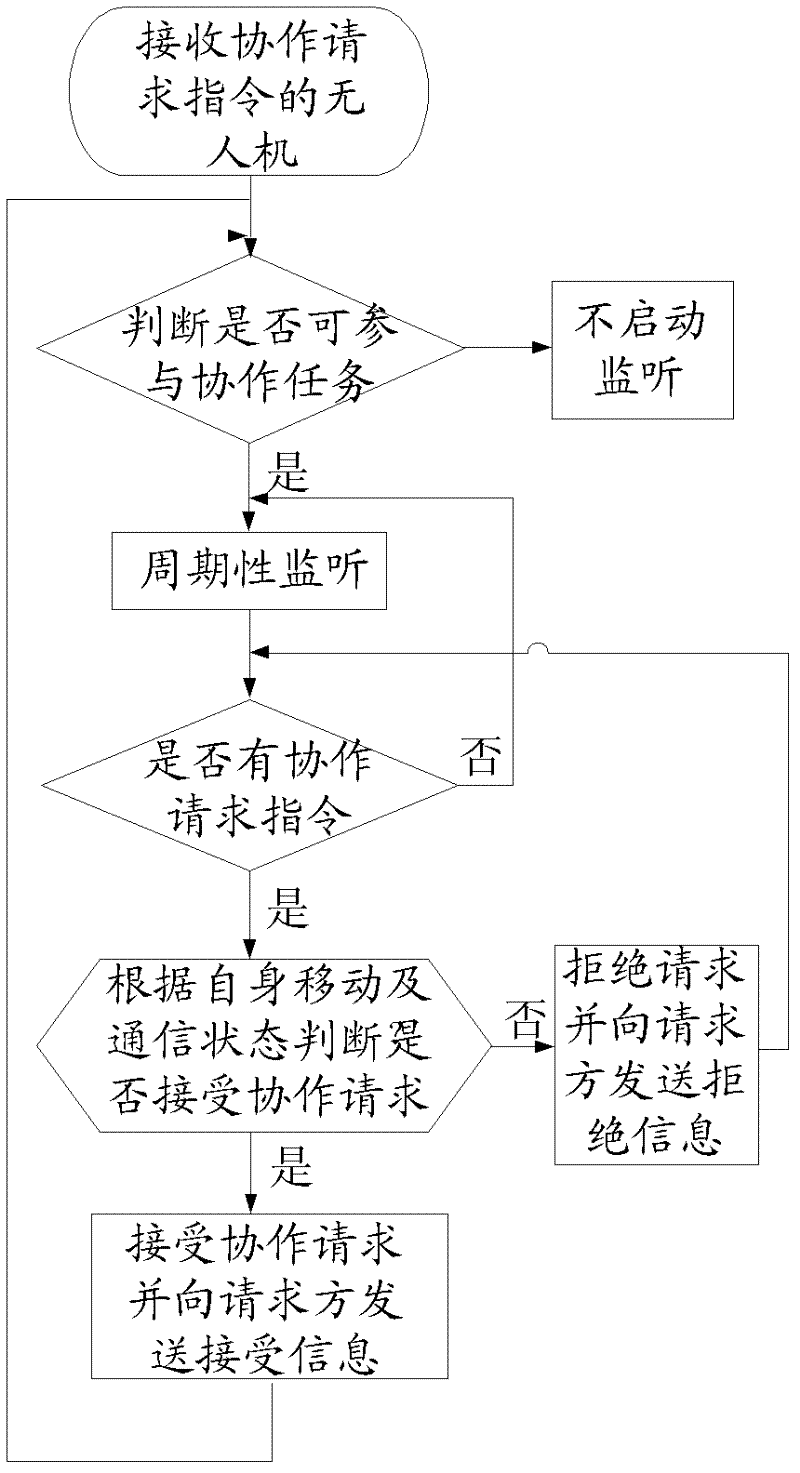

Collaborative interaction method for unmanned plane cluster and visual navigation system of unmanned plane

ActiveCN102393747AReal-time planningReduce latencyInstruments for comonautical navigationPosition/course control in three dimensionsEvaluation resultCommunication quality

The invention discloses a collaborative interaction method for an unmanned plane cluster and a visual navigation system of an unmanned plane. The collaborative interaction method for the unmanned plane cluster comprises the following steps of: determining unmanned planes satisfying a collaborative condition in a communication coverage area of a certain unmanned plane by the unmanned plane in the unmanned plane cluster, and establishing an unmanned plane collaboration group according to the unmanned planes satisfying the collaborative condition; determining inter-plane routes of multiple unmanned planes in the unmanned plane collaboration group; allocating collaborative tasks to multiple unmanned planes in the unmanned plane collaboration group according to link state information of the inter-plane routes; and evaluating the link state according to the motion state of multiple unmanned planes in the unmanned plane collaboration group, and updating unmanned planes in the unmanned plane collaboration group and the collaborative task of each unmanned plane according to an evaluation result. The collaborative interaction method for the unmanned plane cluster is good in real-time, strong in reliability and high in communication quality, and can better adapt to an unmanned plane cluster communication environment during visual navigation.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com