Patents

Literature

688results about How to "High material utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

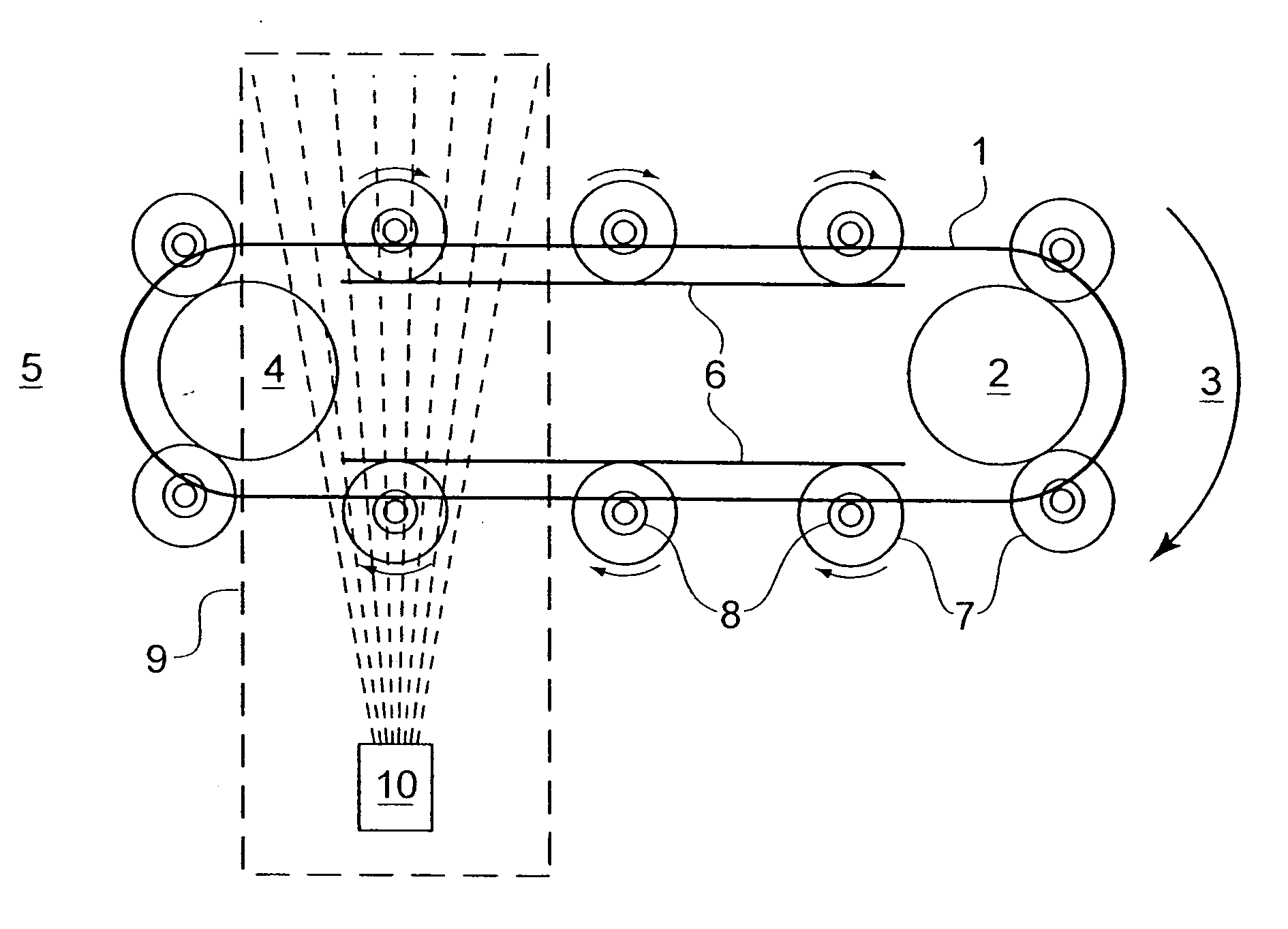

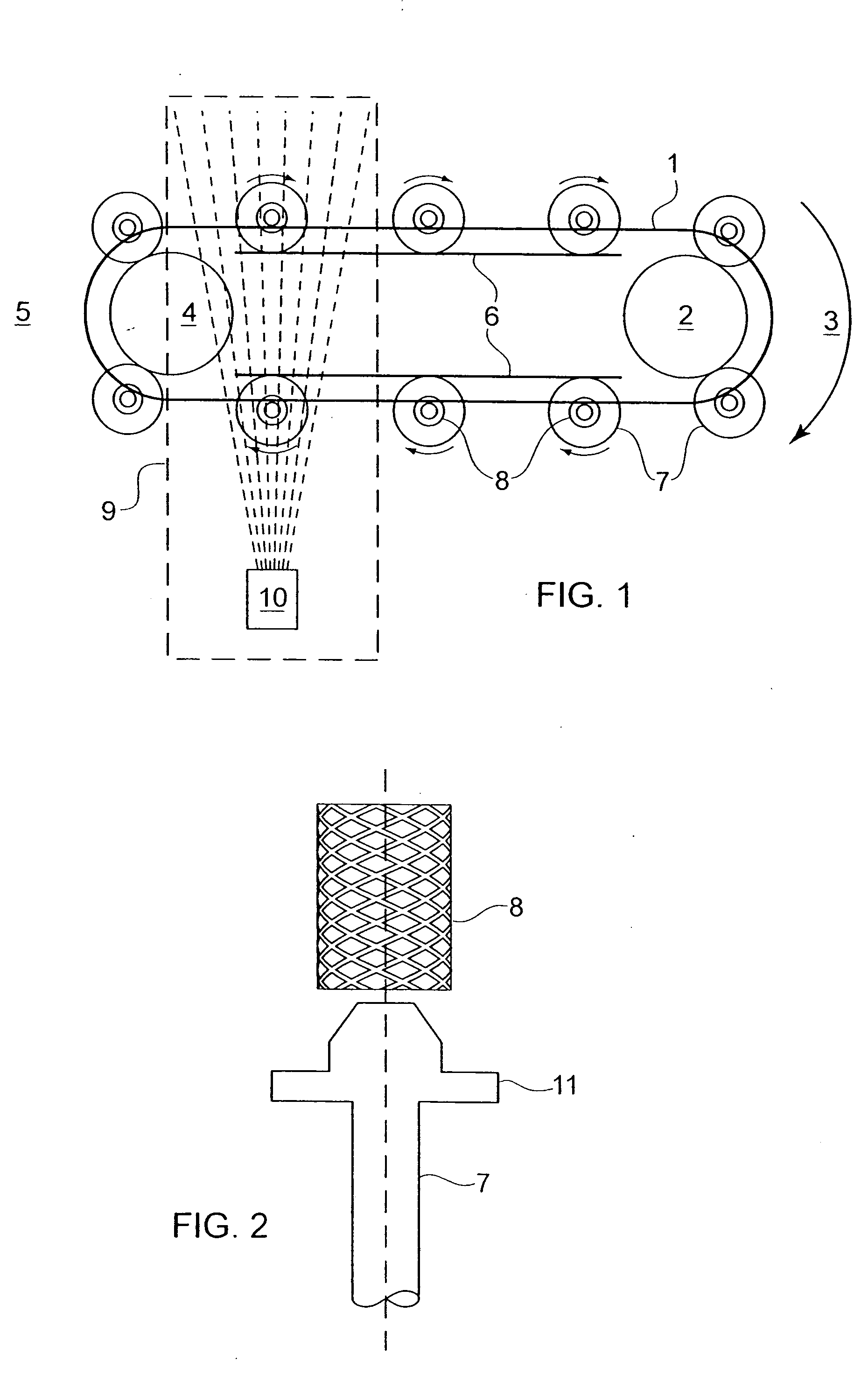

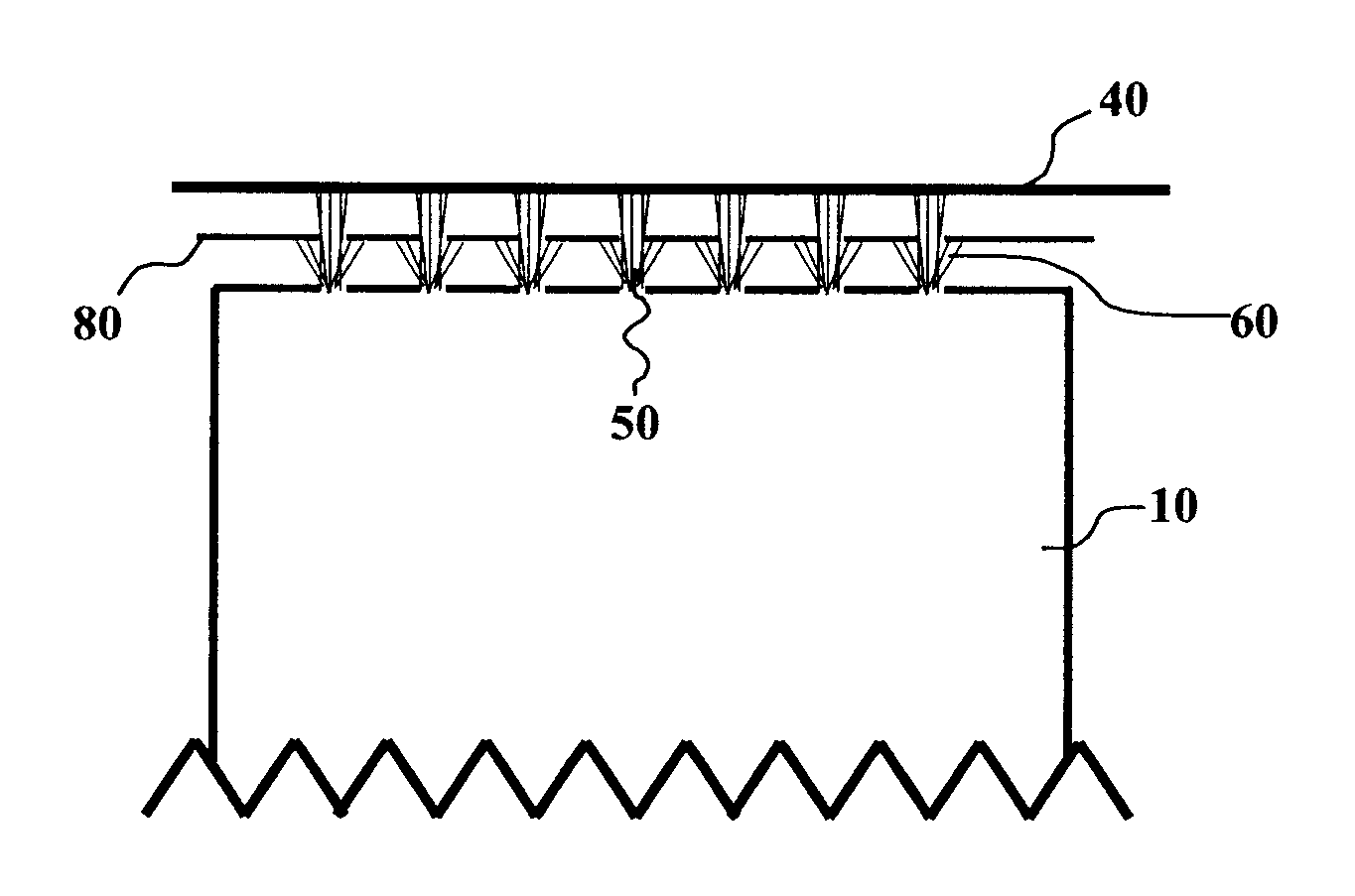

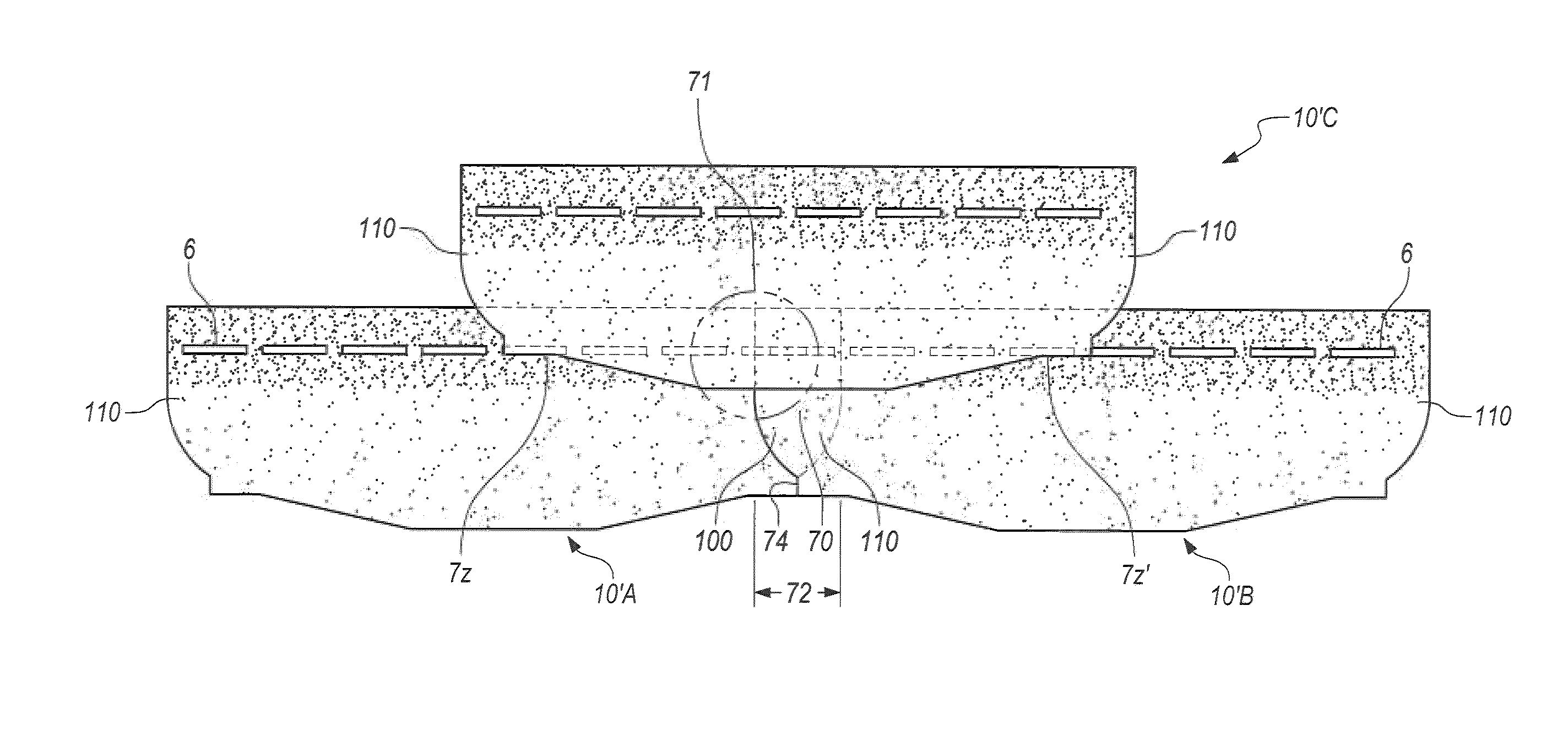

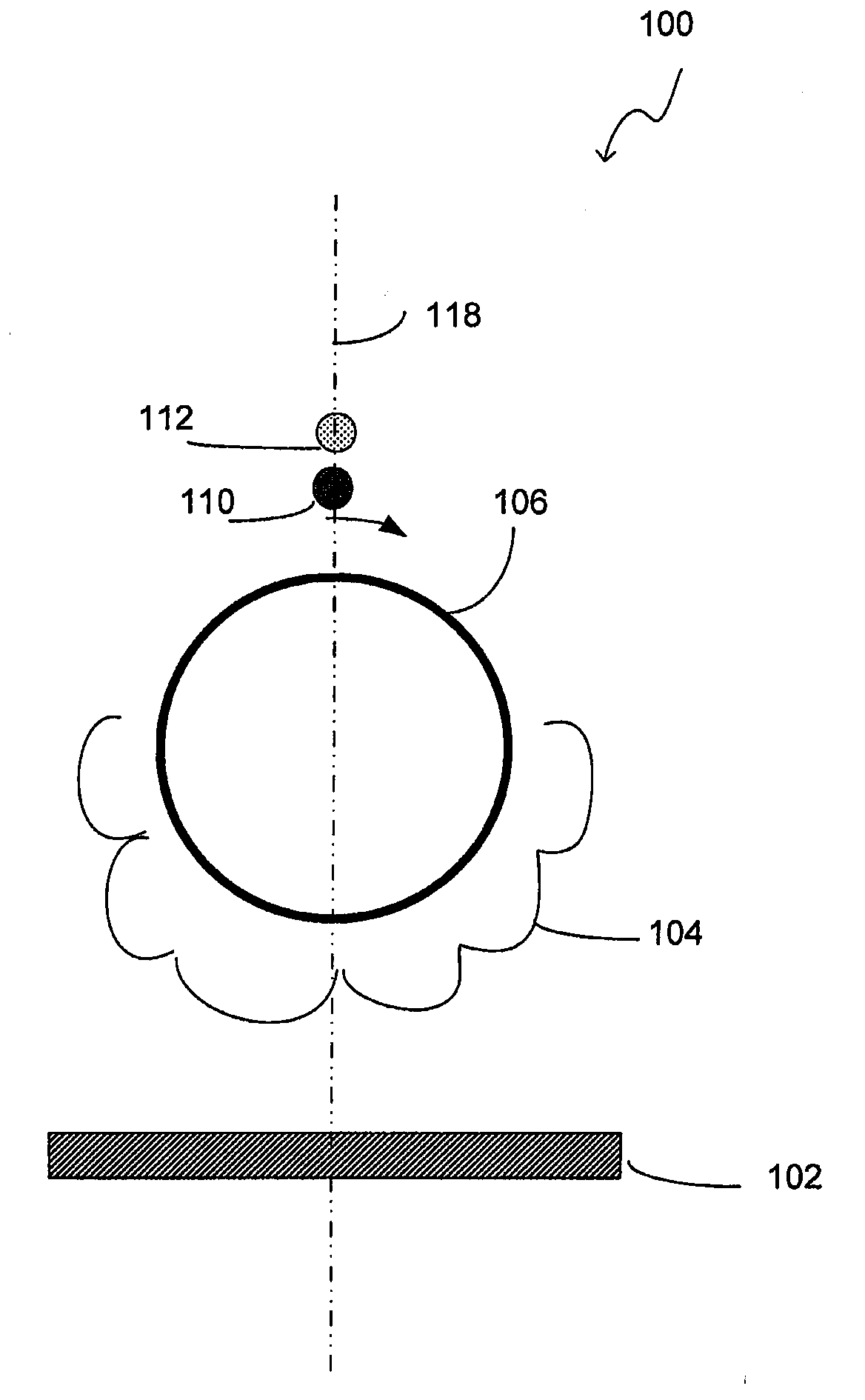

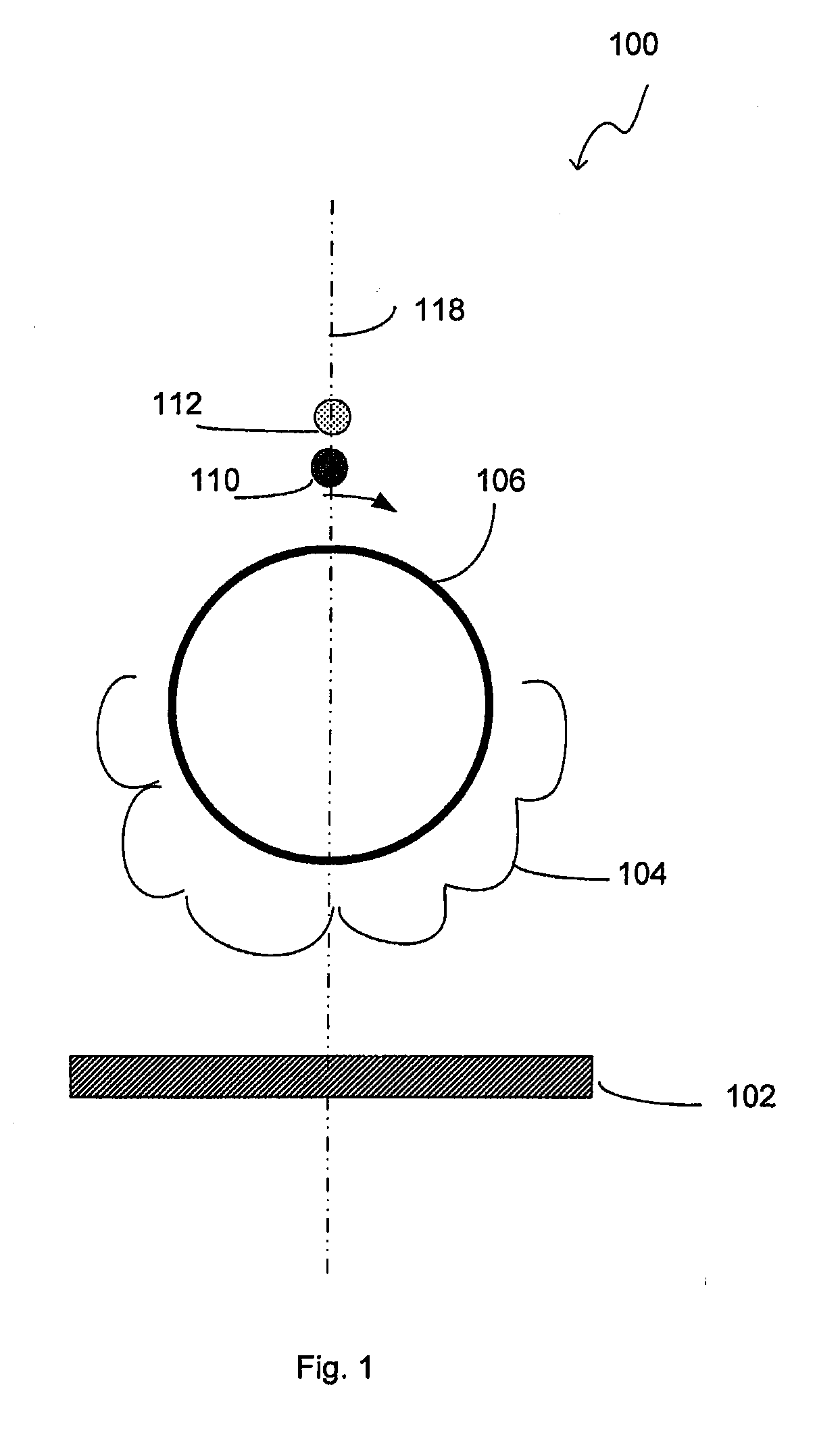

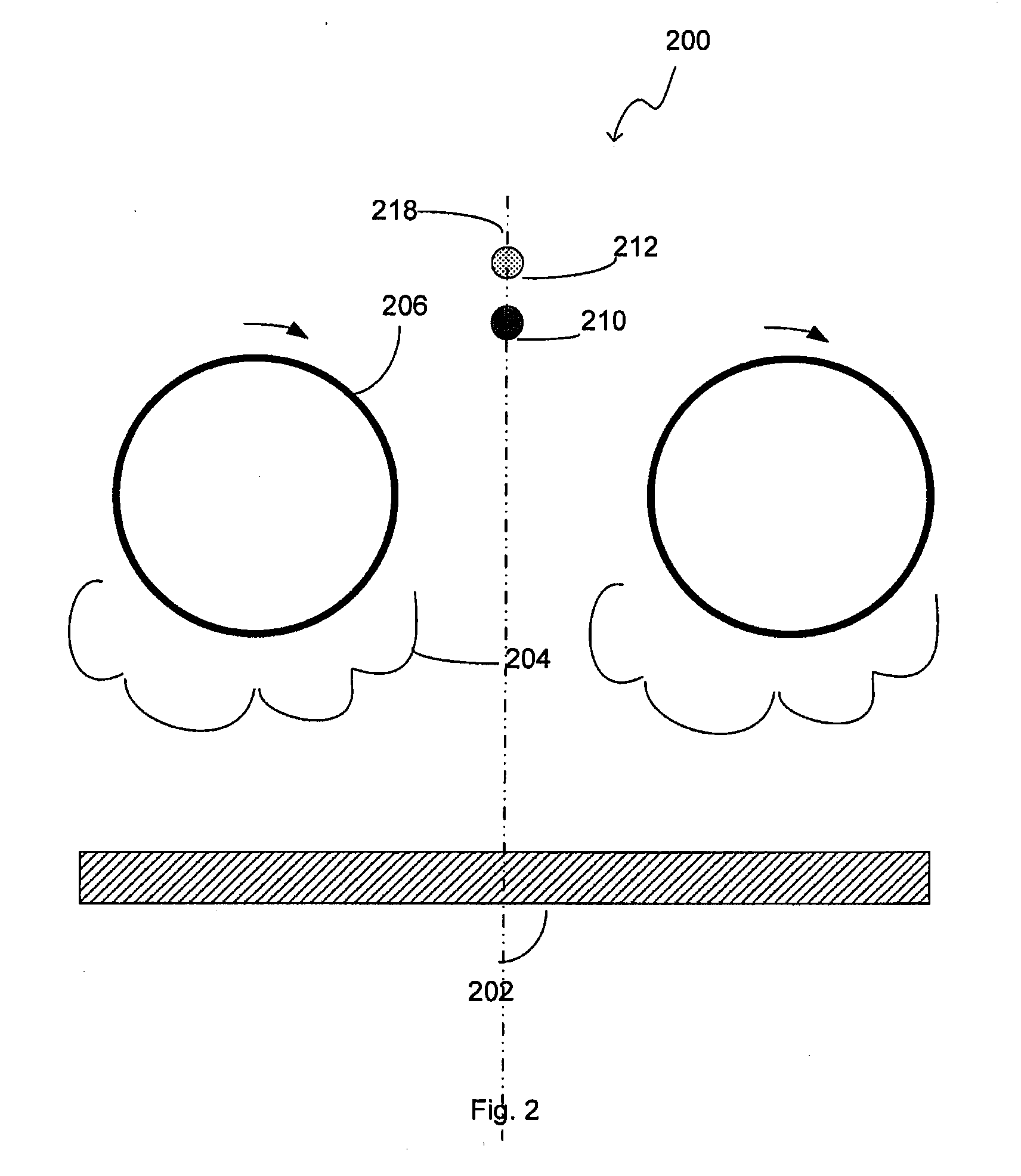

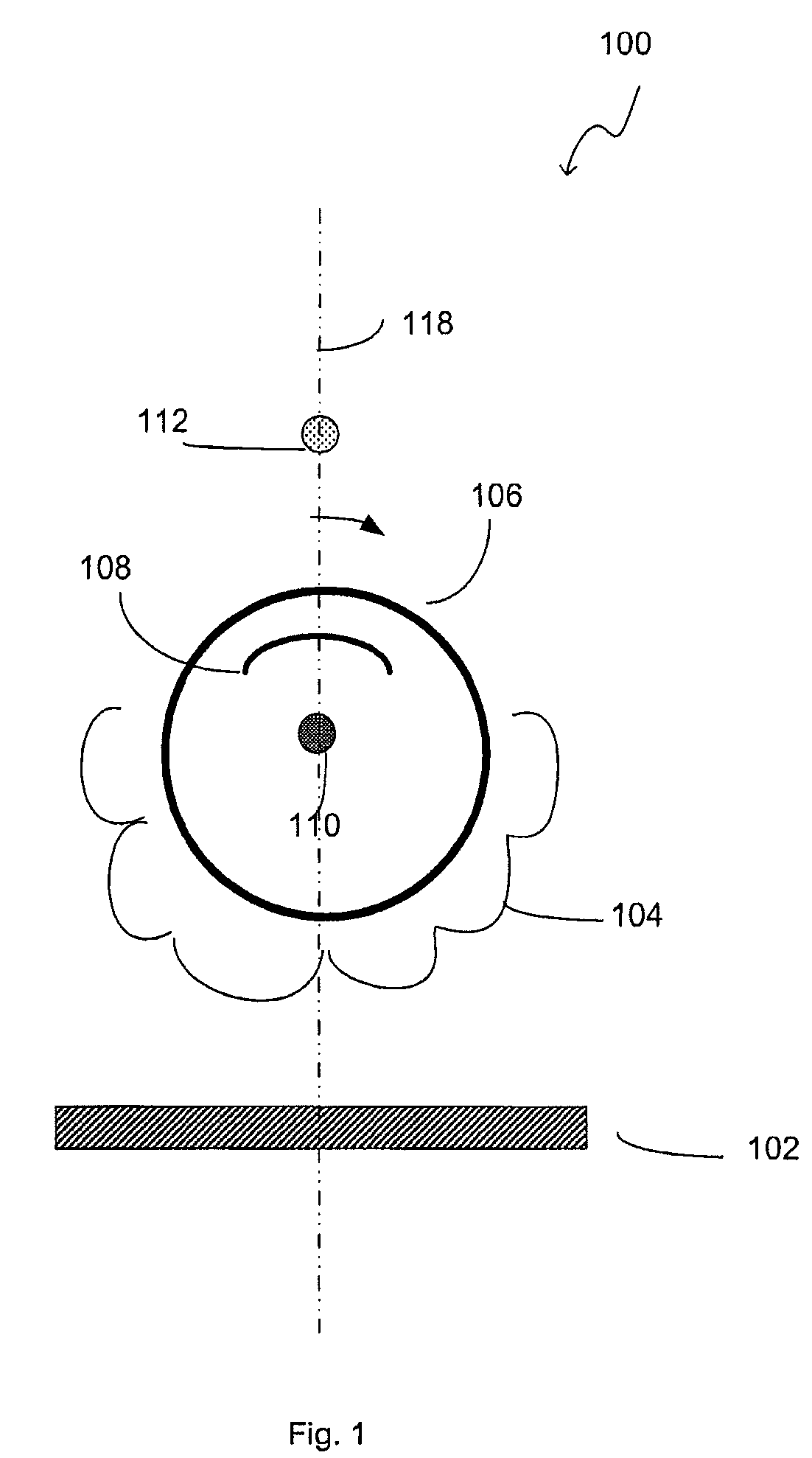

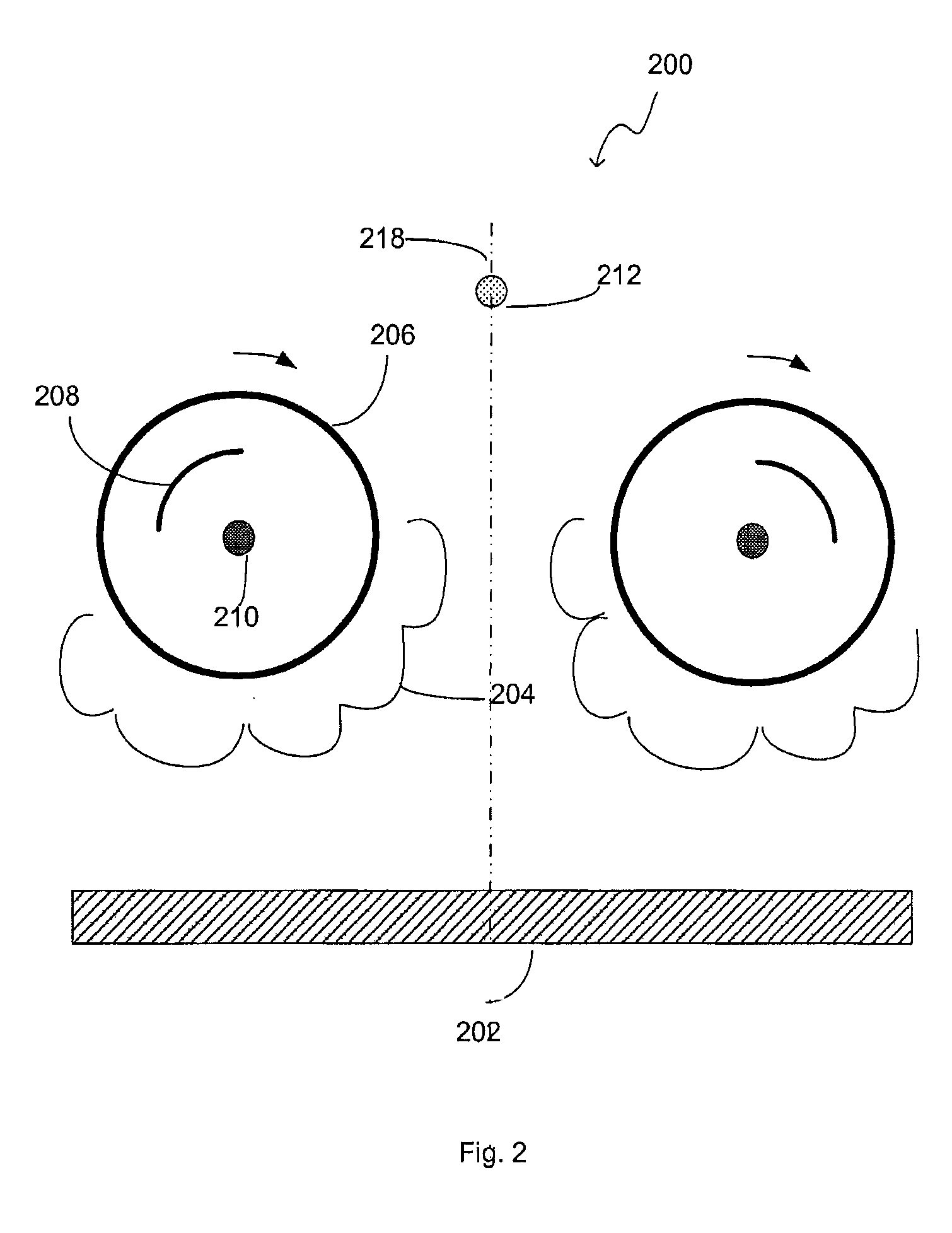

Method for coating multiple stents

ActiveUS20050079274A1Facilitate stent handlingLong exposureSpraying apparatusPretreated surfacesMedicineInsertion stent

An improved method for high-volume production of coated stents with highly uniform stent coatings using a roll coating technique is provided. In a first embodiment, uncoated stents are placed onto rotating stent holders with automated stent handling equipment. The holders are mounted on an endless conveyer belt which advances the stents toward a stent coater. As the stents advance through the coater, the holders rotate, thereby rolling the stents about their longitudinal axes as coating material is sprayed toward them, ensuring the stents are uniformly coated on their exterior and interior surfaces. After the conveyer turns to carry the coated stents back toward the loading area, the rotating stents pass again through the coating spray, downstream of the initial coating location, thereby increasing the efficient utilization of the coating material. The conveyer then advances the coated stents to an unloading area for removal before the holders return to the stent loading area to receive new stents.

Owner:BOSTON SCI SCIMED INC

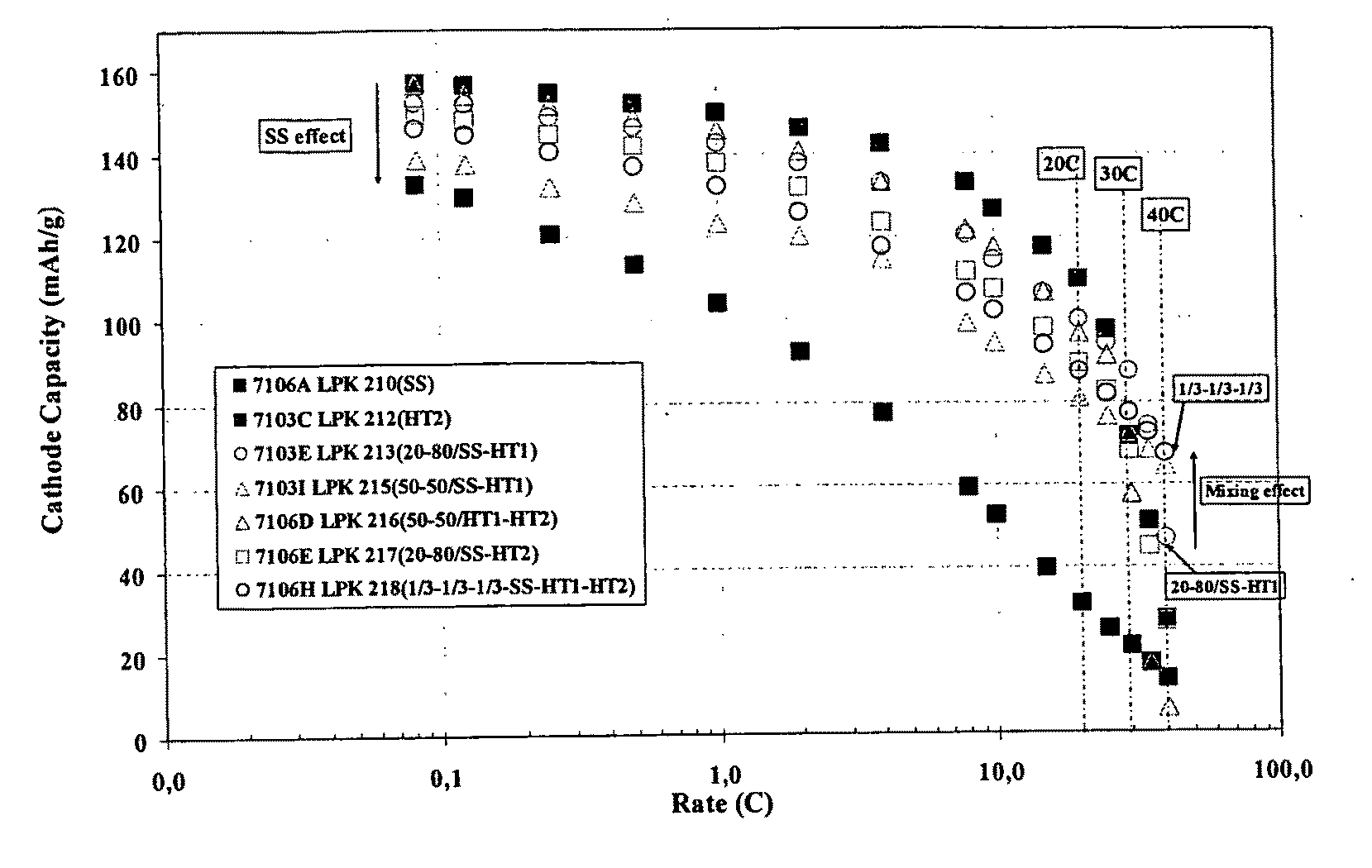

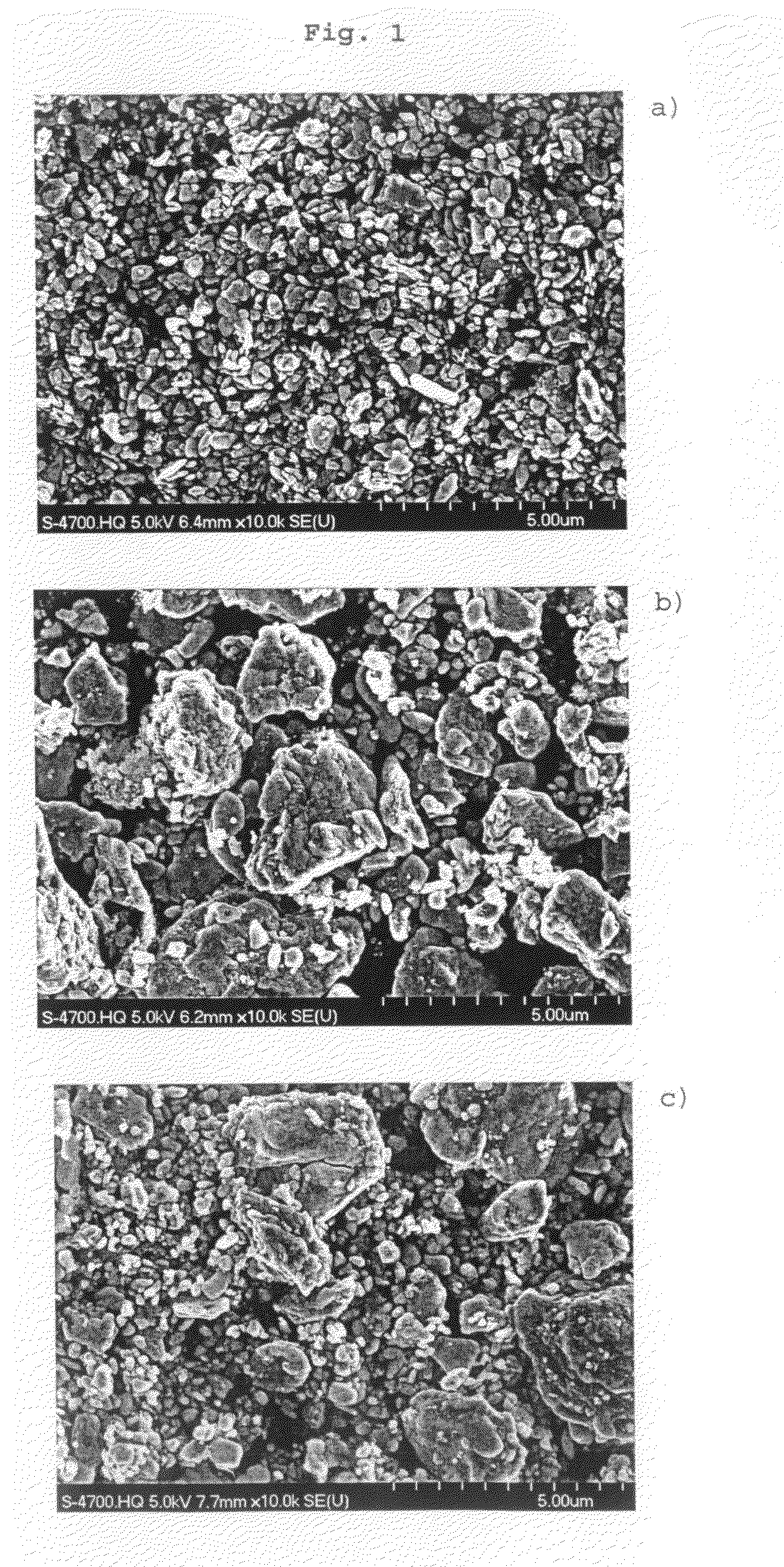

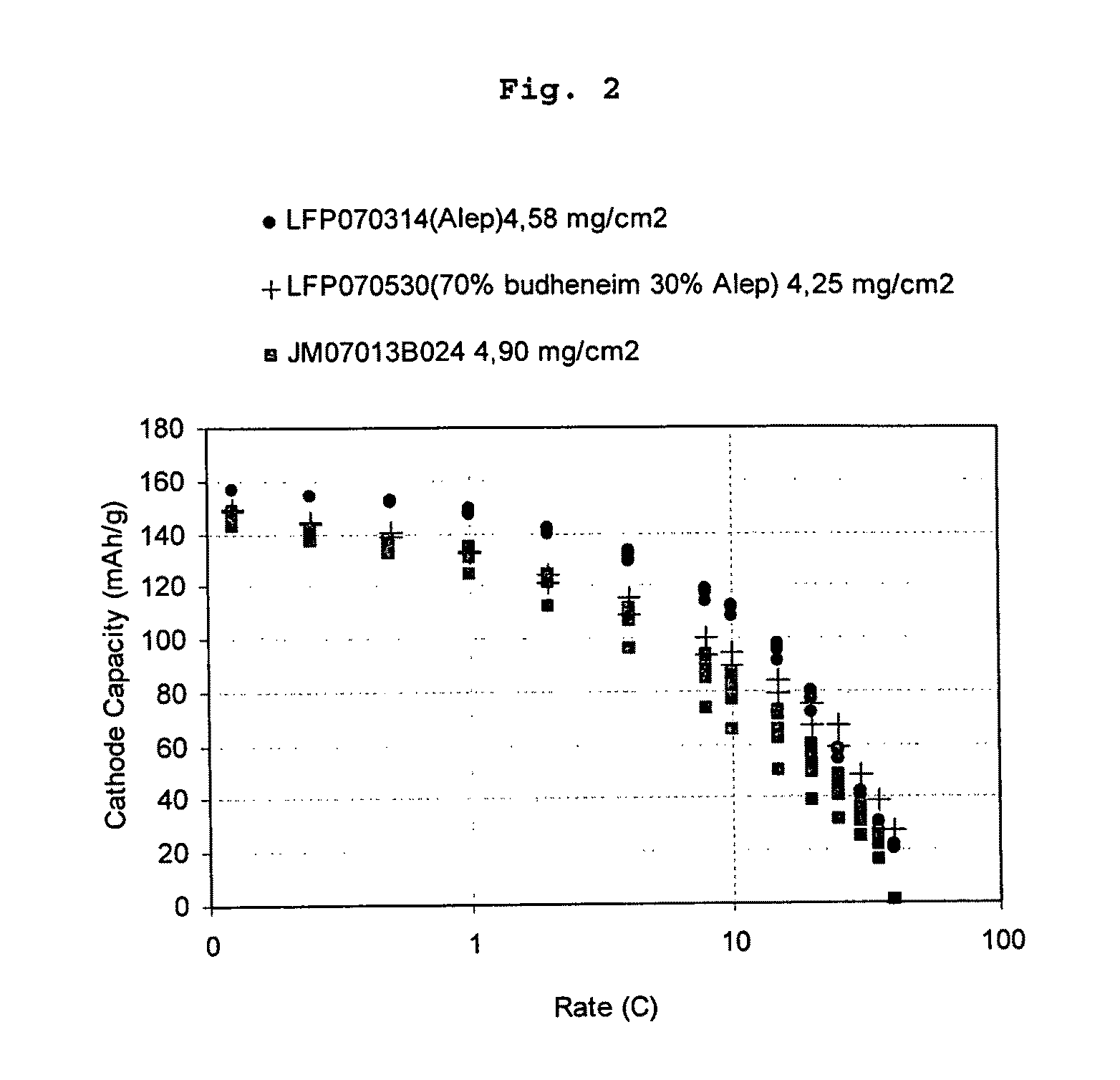

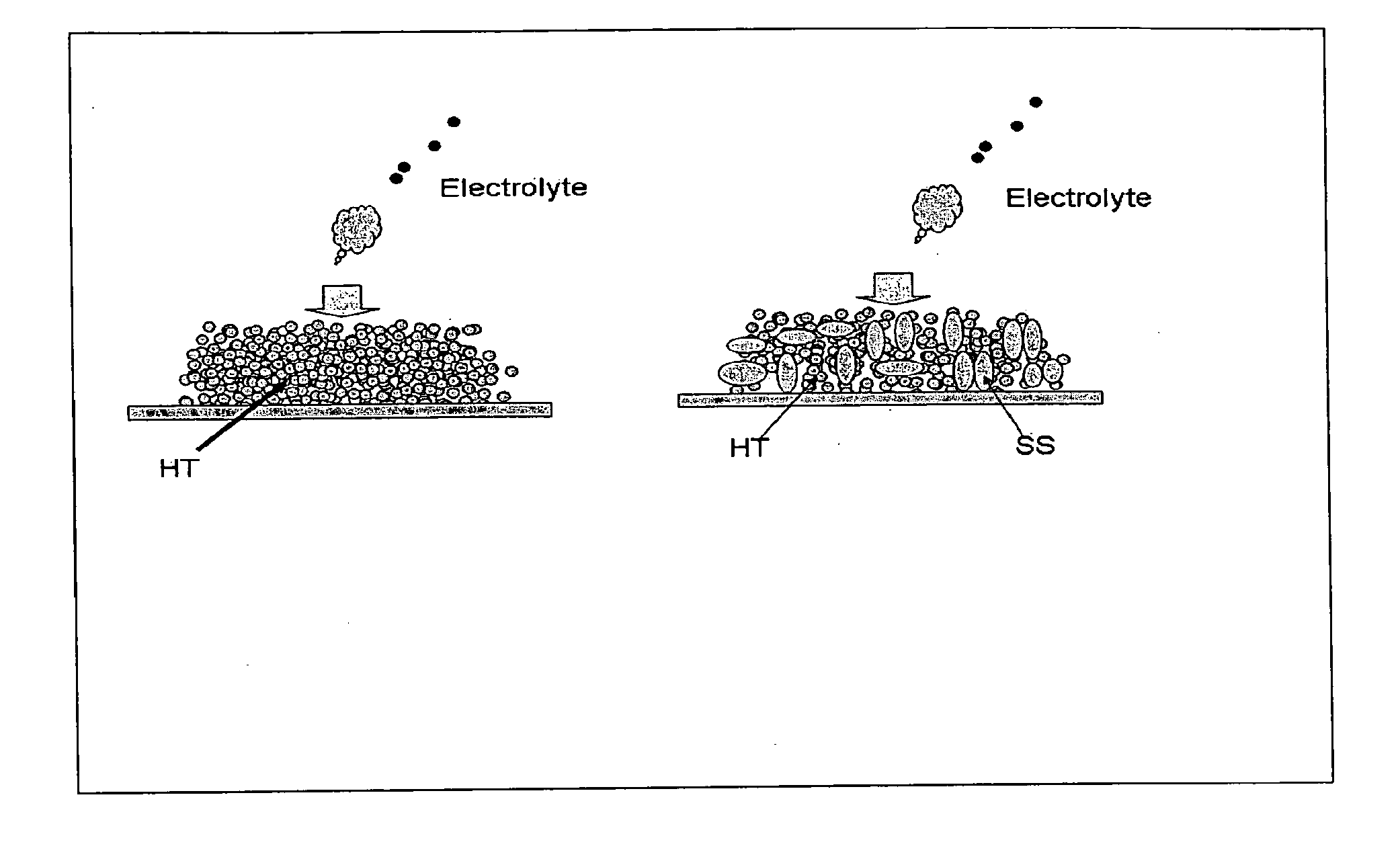

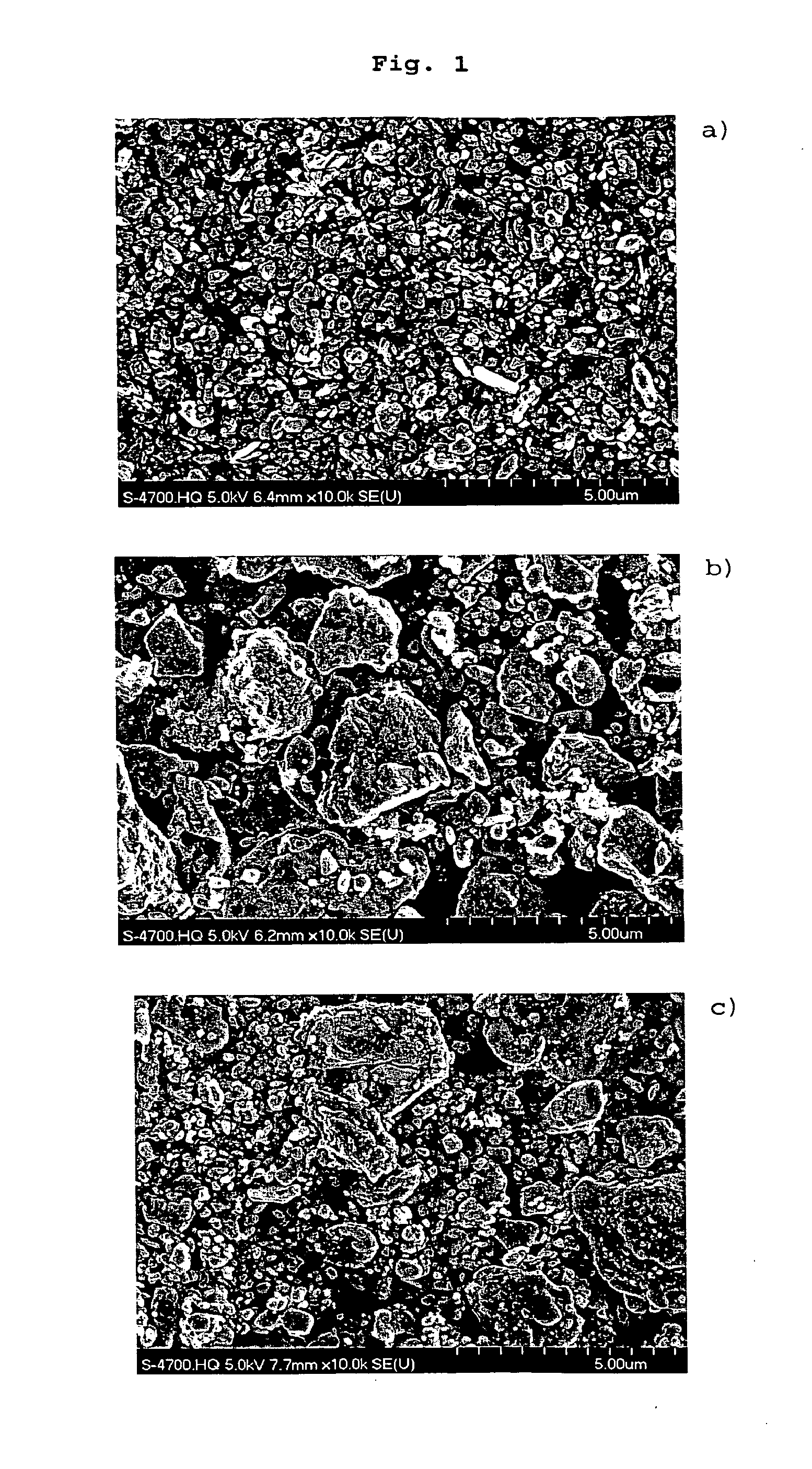

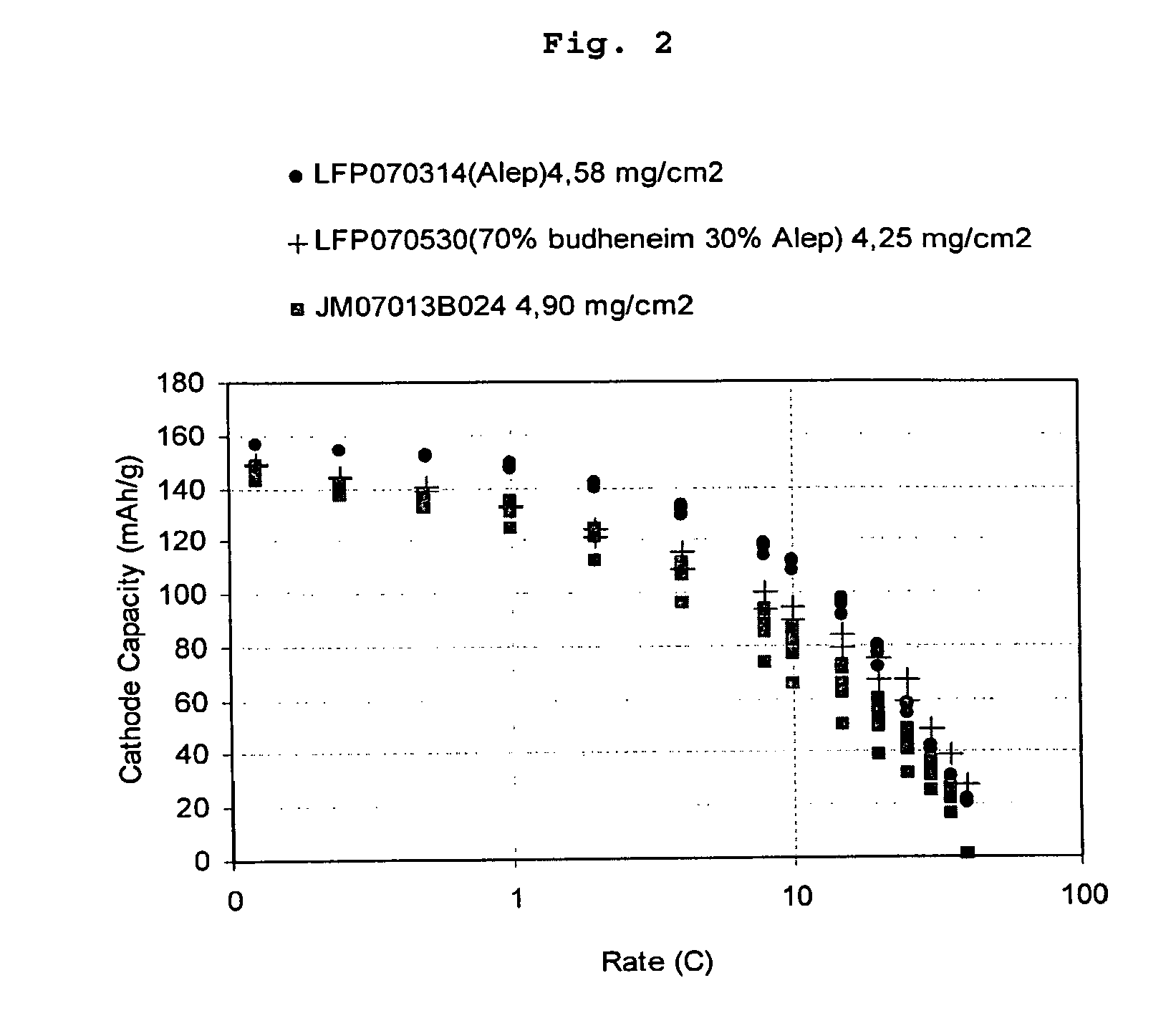

Lithium iron phosphate cathode materials with enhanced energy density and power performance

InactiveUS20090155689A1Powerful performanceHigh discharge ratePhosphatesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesFiberPhosphate

The invention is related to a cathode material comprising particles having a lithium metal phosphate core and a pyrolytic carbon deposit, said particles having a synthetic multimodal particle size distribution comprising at least one fraction of micron size particles and one fraction of submicron size particles, said lithium metal phosphate having formula LiMPO4 wherein M is at least Fe or Mn.Said material is prepared by method comprising the steps of providing starting micron sized particles and starting submicron sized particles of at least one lithium metal phosphate or of precursors of a lithium metal phosphate; mixing by mechanical means said starting particles; making a pyrolytic carbon deposit on the lithium metal phosphate starting particles before or after the mixing step, and on their metal precursor before or after mixing the particles; optionally adding carbon black, graphite powder or fibers to the said lithium metal phosphate particles before the mechanical mixing.

Owner:PHOSTECH LITHIUM

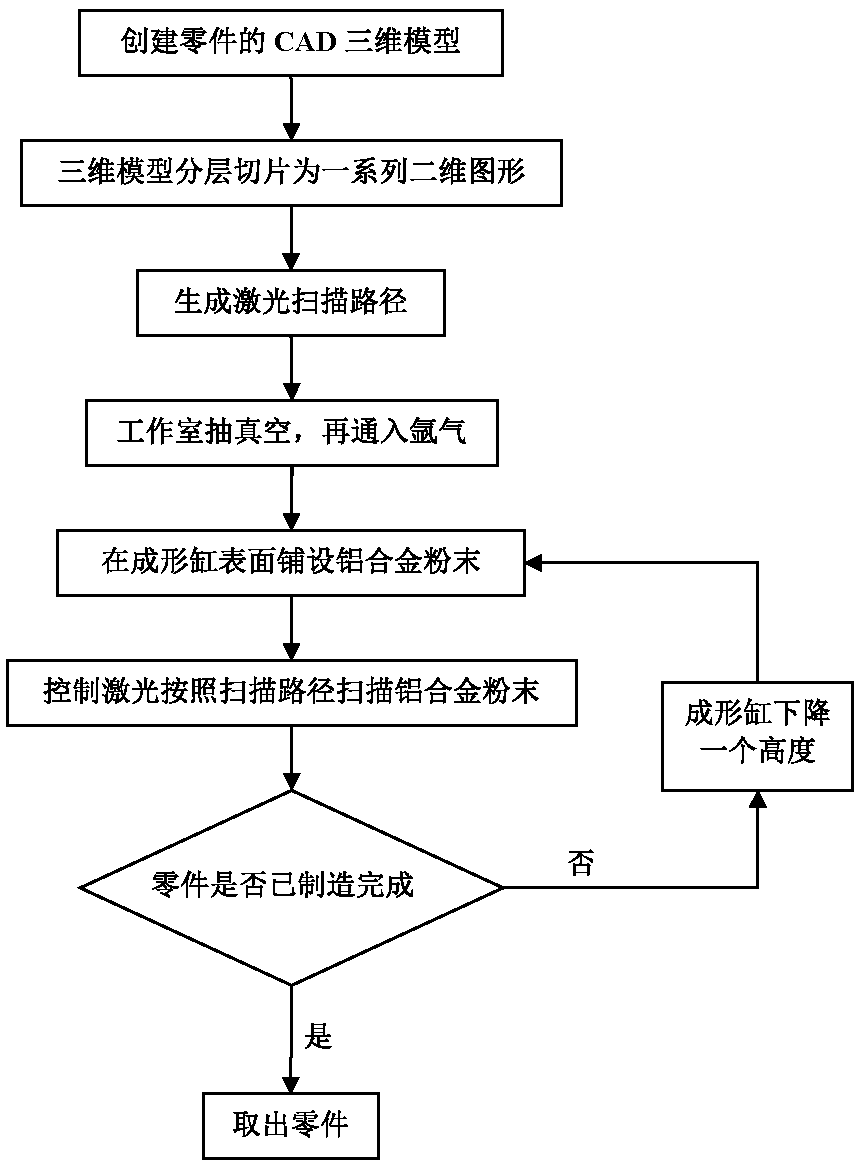

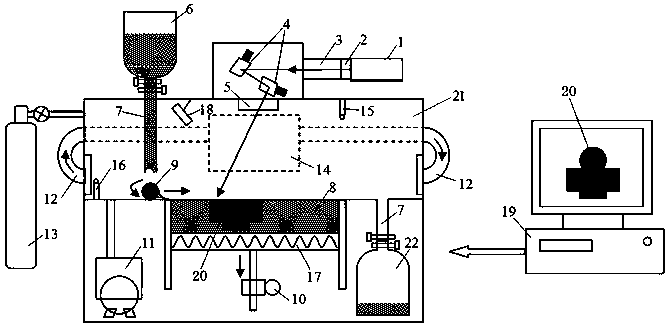

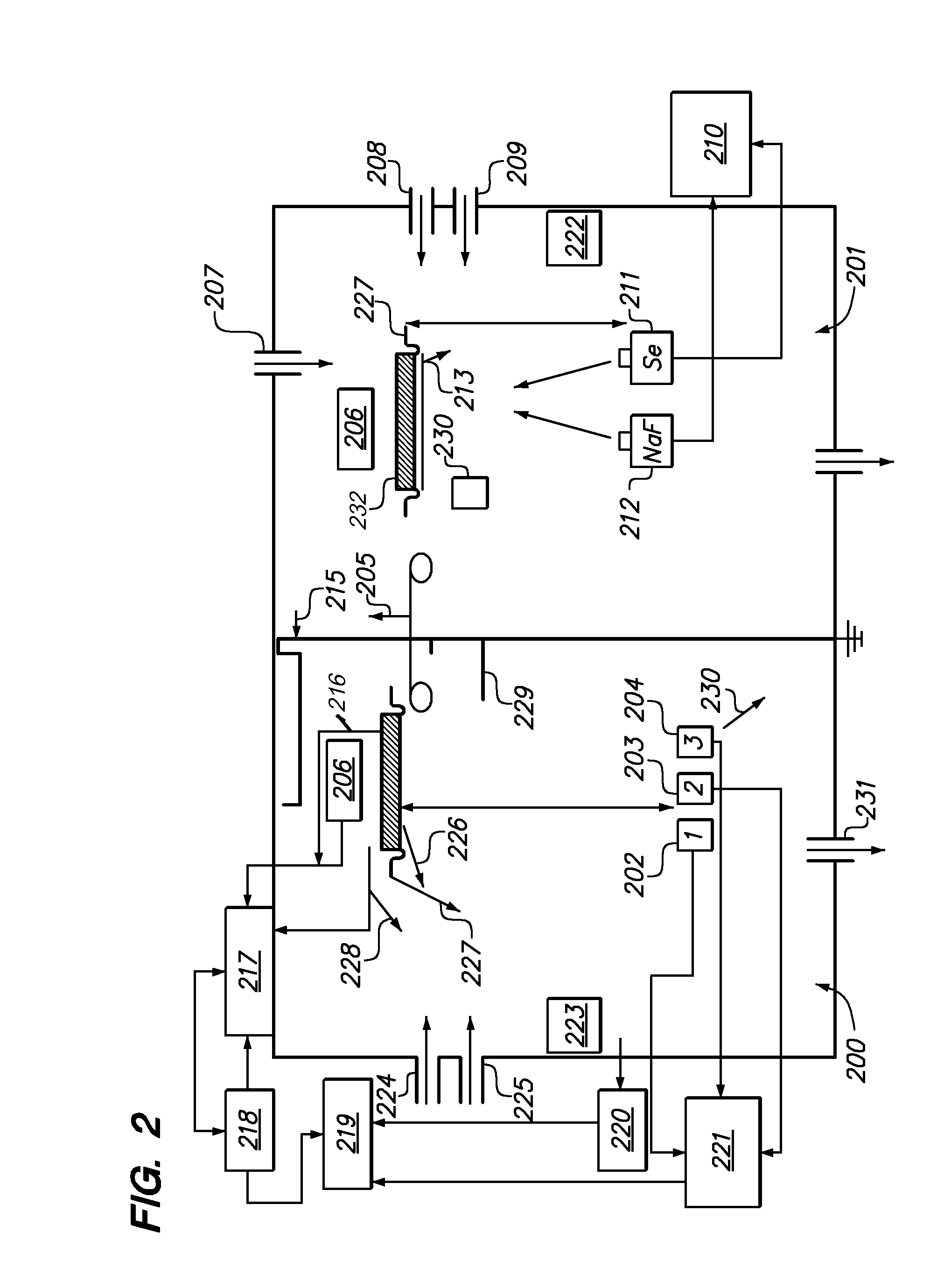

3D printing manufacturing device and method of metal parts

ActiveCN103341625AImprove processing efficiencyHigh material utilizationIncreasing energy efficiencyManufacturing efficiencyHeating system

The invention discloses a 3D printing manufacturing device and method of metal parts. The 3D printing manufacturing device and method aim to efficiently manufacture the metal parts. The 3D printing manufacturing device of the metal parts comprises a laser system, a powder laying system, an atmosphere protecting system, a heating system and a computer control system. The 3D printing manufacturing device further comprises a closed work cavity, a forming cylinder is arranged inside the work cavity, and the laser system is arranged above the forming cylinder; the powder laying system is arranged on the upper side of the work cavity; one side of the work cavity is provided with the atmosphere protecting system, and the bottom of the forming cylinder is provided with the heating system; the lower side of the forming cylinder is provided with a driving device; one side of the work cavity is provided with a vacuum pump; the computer control system comprises a computer which is connected with a control card of the driving device and a control card of the laser system through data wires. According to the 3D printing manufacturing device and method, the metal parts of any structures can be directly manufactured, digital manufacturing from 3D digital models to part entities is achieved, and processing and manufacturing efficiency and the material using ratio of aluminium alloy parts of complex structures can be greatly improved.

Owner:航天科工(长沙)新材料研究院有限公司

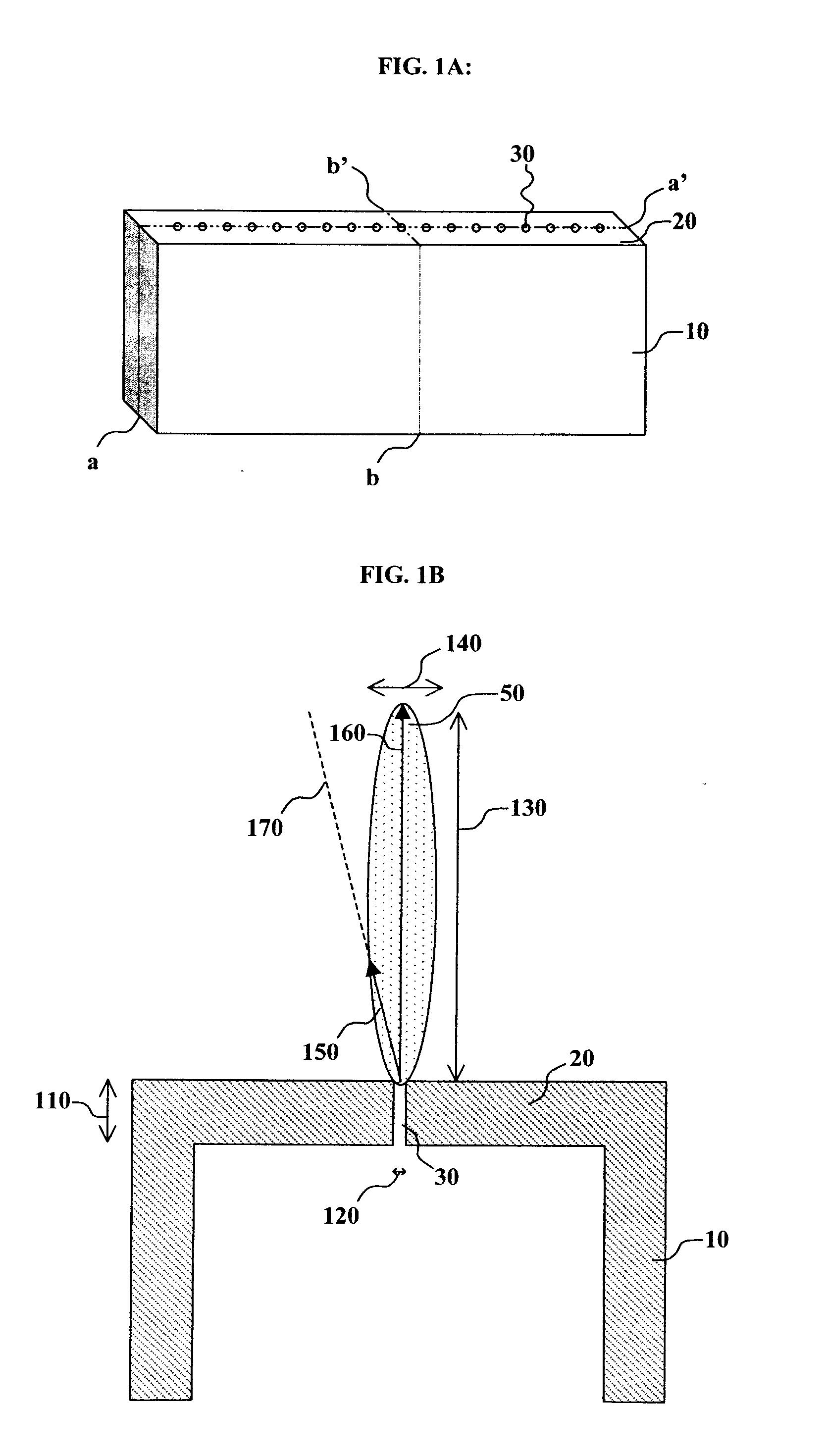

Depositing organic material onto an OLED substrate

InactiveUS20080131587A1Easy to makeHigh material utilizationSolid-state devicesVacuum evaporation coatingLight beamOptoelectronics

A method of depositing organic material onto an OLED substrate, comprising: providing a manifold for receiving vaporized organic material, the manifold including an aperture plate having openings, the aperture plate openings being selected to provide beams of vaporized organic material directed to the substrate, such beams having off-axis components; and providing a mask spaced between the OLED substrate and the manifold, the mask having openings that respectively correspond to the aperture plate openings, the mask openings being selected to skim off at least a portion of the off-axis components of the beams.

Owner:EASTMAN KODAK CO

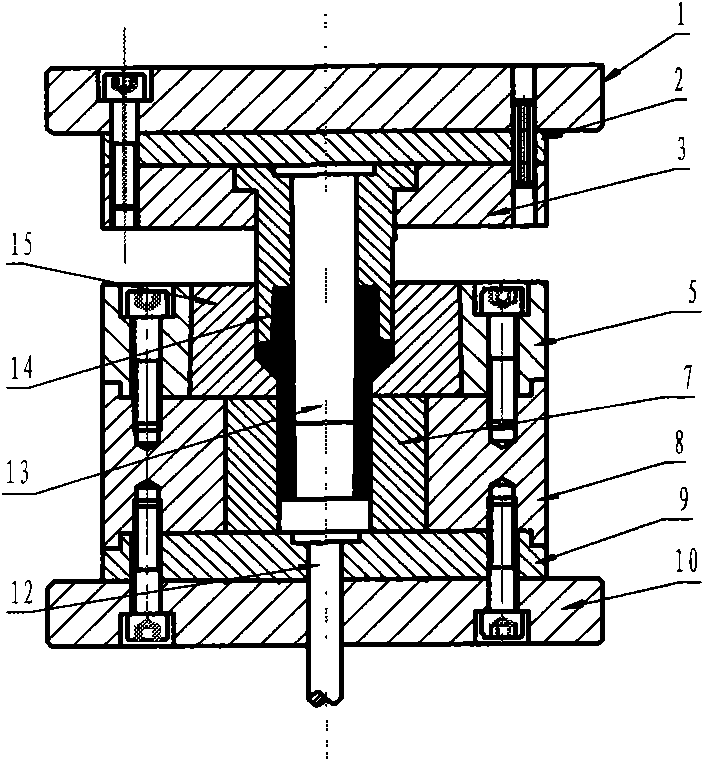

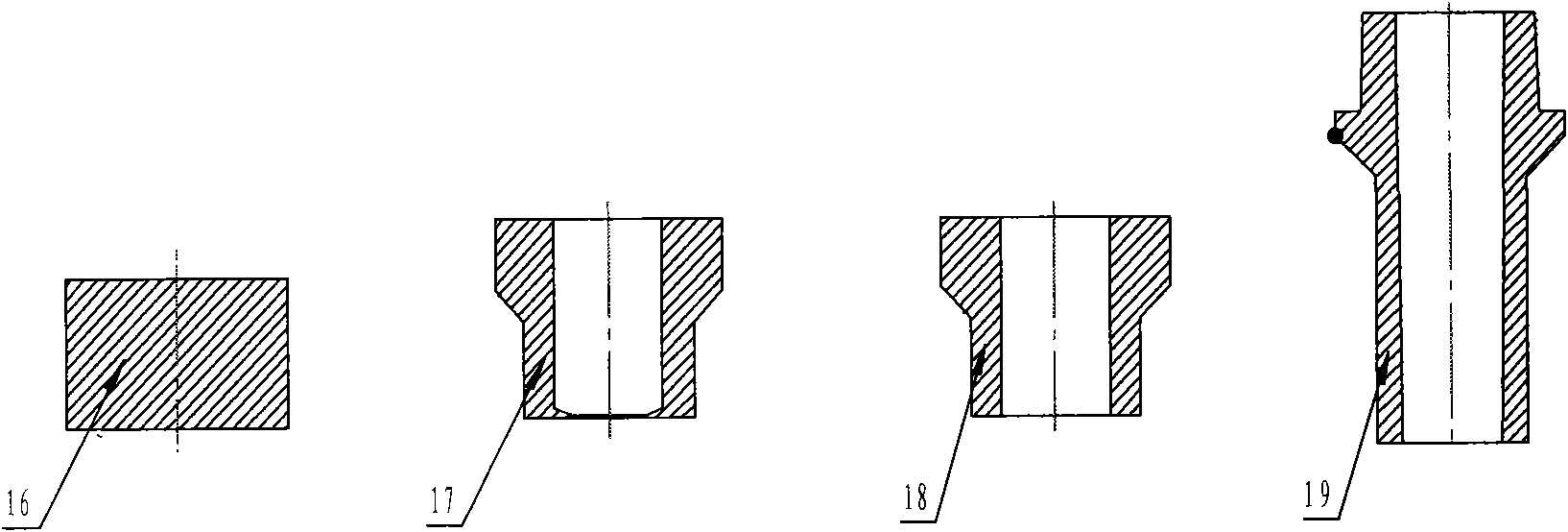

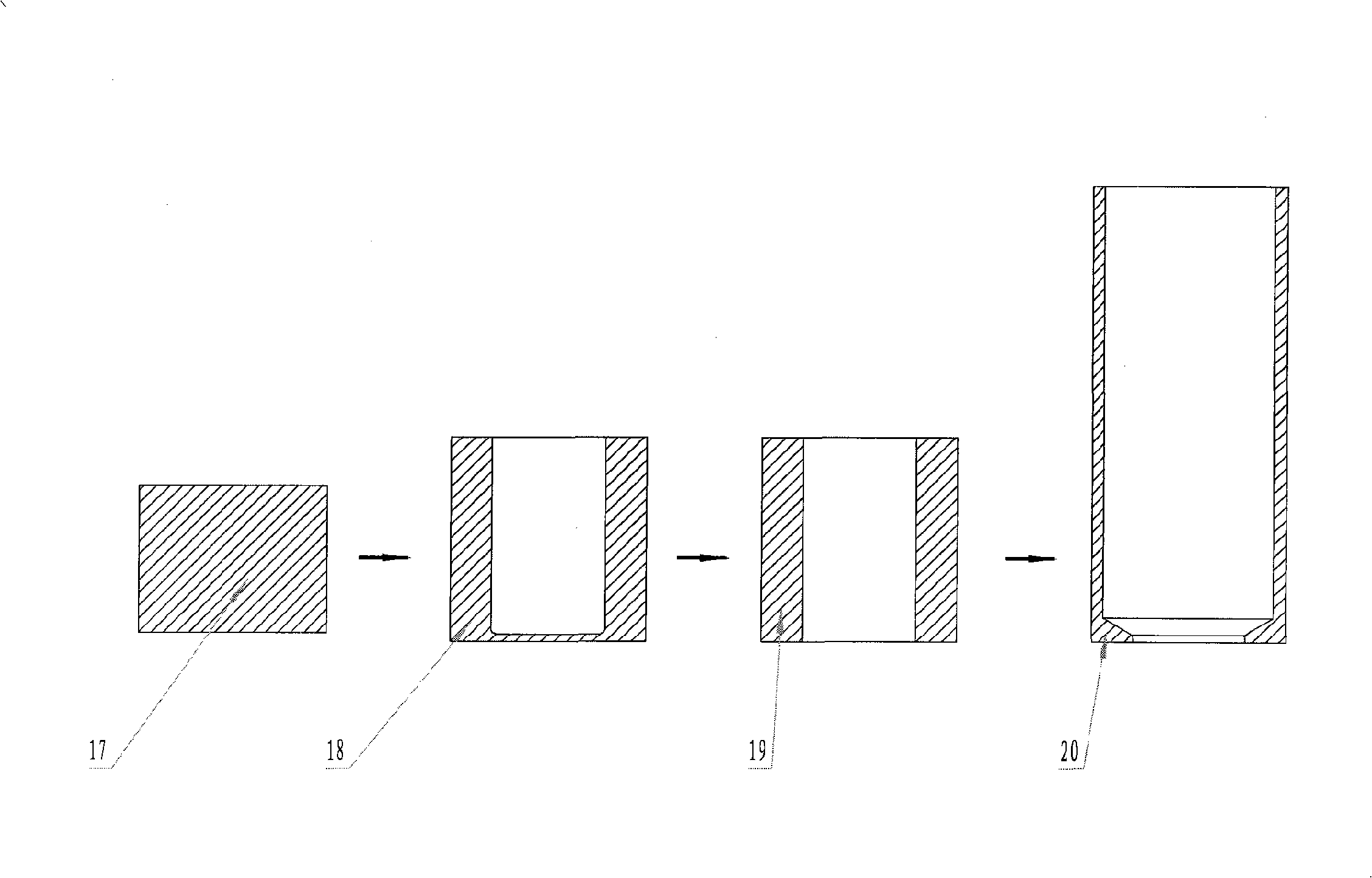

Extrusion forming process of thin-wall long pipe-shaped part blank with flange and mould

InactiveCN101829698AImprove internal qualityHigh dimensional accuracyExtrusion diesMaterials scienceForming processes

The invention belongs to extrusion forming technologies for non-ferrous metal materials and relates to a precise extrusion forming process of a thin-wall long pipe-shaped part blank with a flange. The forming process comprises two steps of primary backward extrusion and secondary forward extrusion, wherein in the step of primary backward extrusion, a primary backward extrusion convex mould (6) is utilized to match with a primary backward extrusion concave mould to together with a piece pusher (11) as an auxiliary for obtaining a primary backward extrusion pipe blank (17) with a web; a secondary forward extrusion convex mould consisting of a forward extrusion convex mould (14) and a mandrel (13) and a secondary forward extrusion concave mould (15) are utilized to carry out the secondary forward extrusion; and the secondary forward extrusion convex mould is placed into a primary backward extrusion pipe blank (18) and moves downwards to extrude the primary backward extrusion pipe blank (18) to obtain a secondary forward extrusion pipe blank (19) so as to finish a secondary forward extrusion process. The internal quality, the size precision and the material utilization rate of the produced thin-wall long pipe-shaped part blank with the flange are greatly improved; and meanwhile, the production efficiency is improved, and the production cost is reduced.

Owner:HENAN UNIV OF SCI & TECH

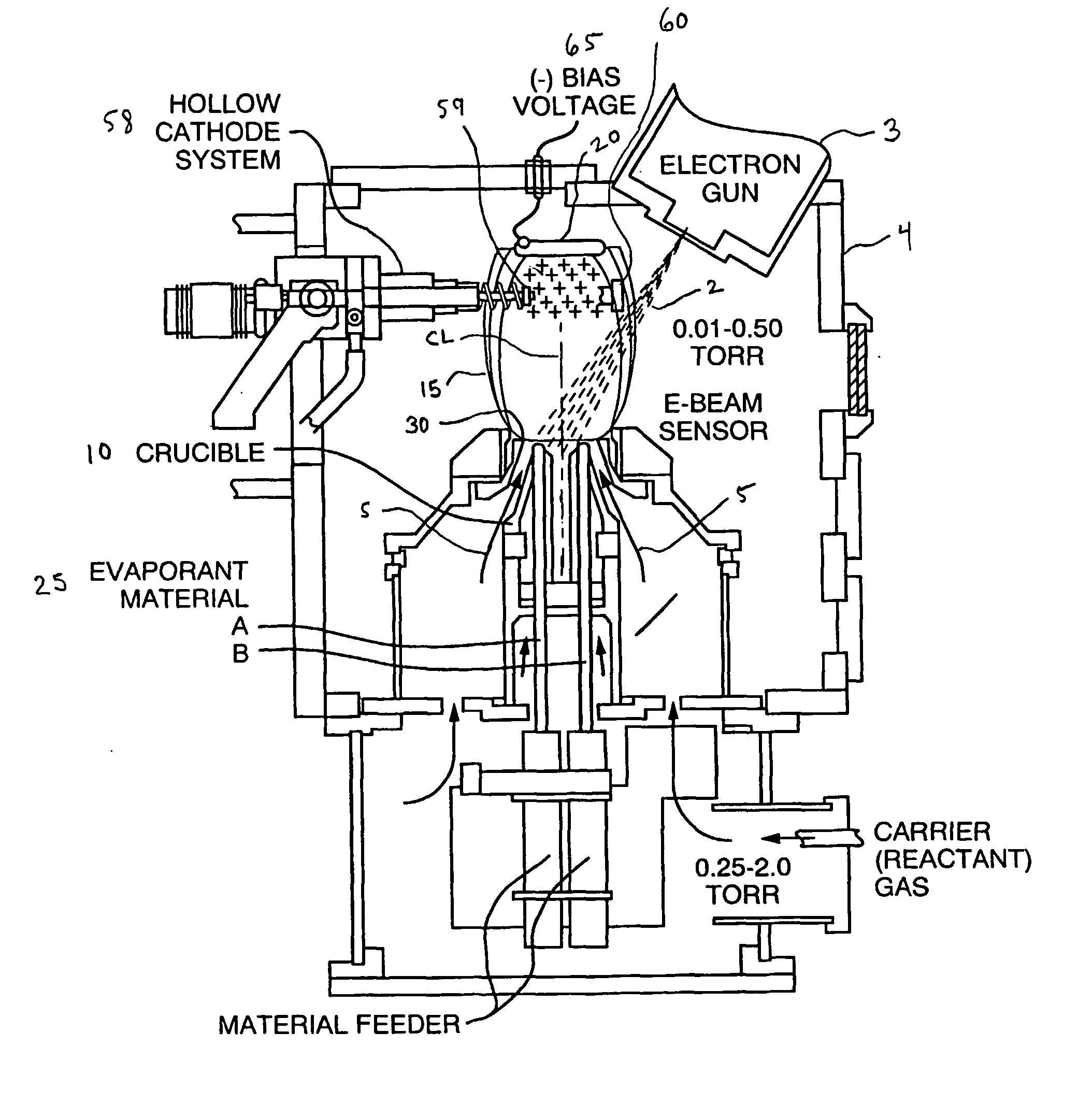

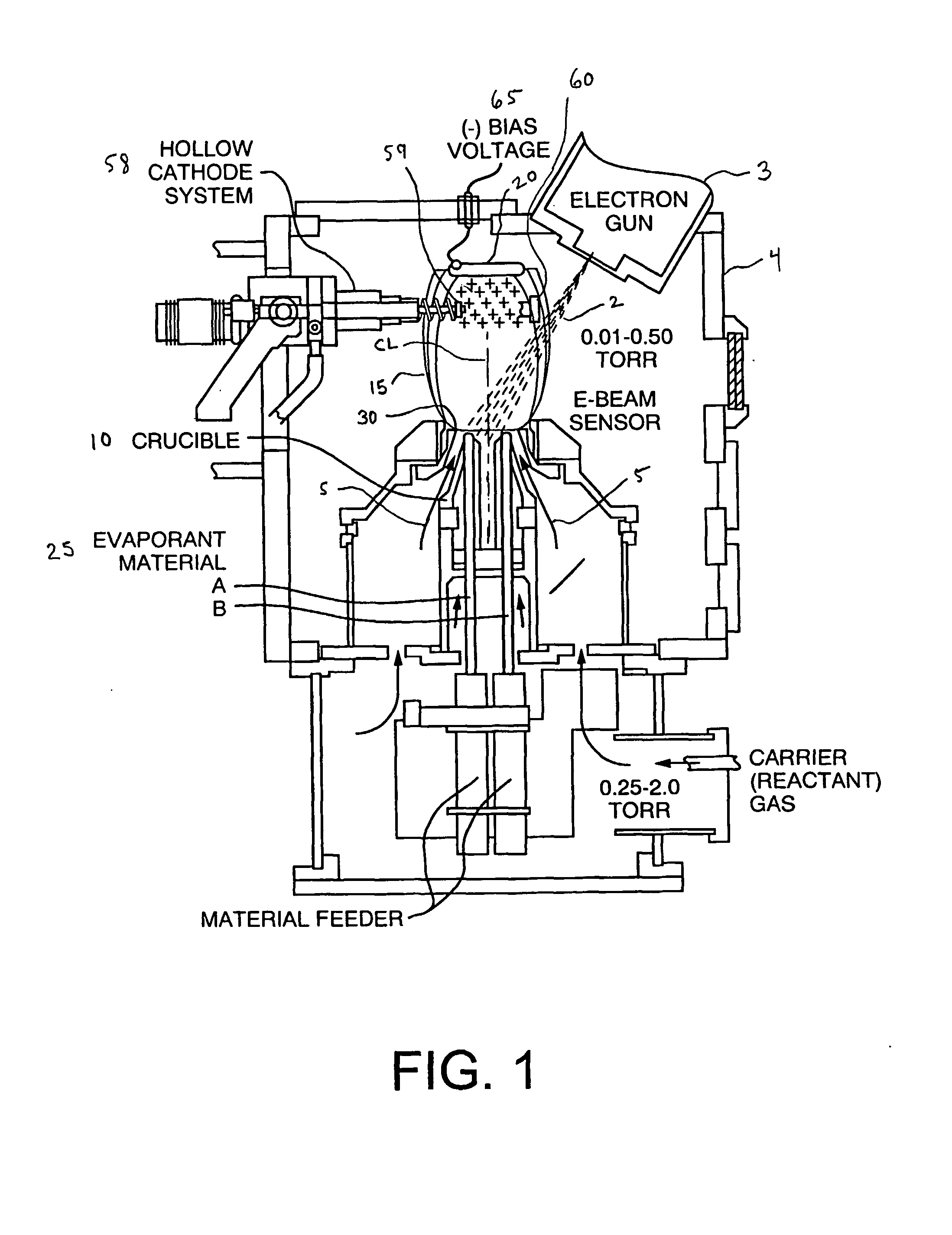

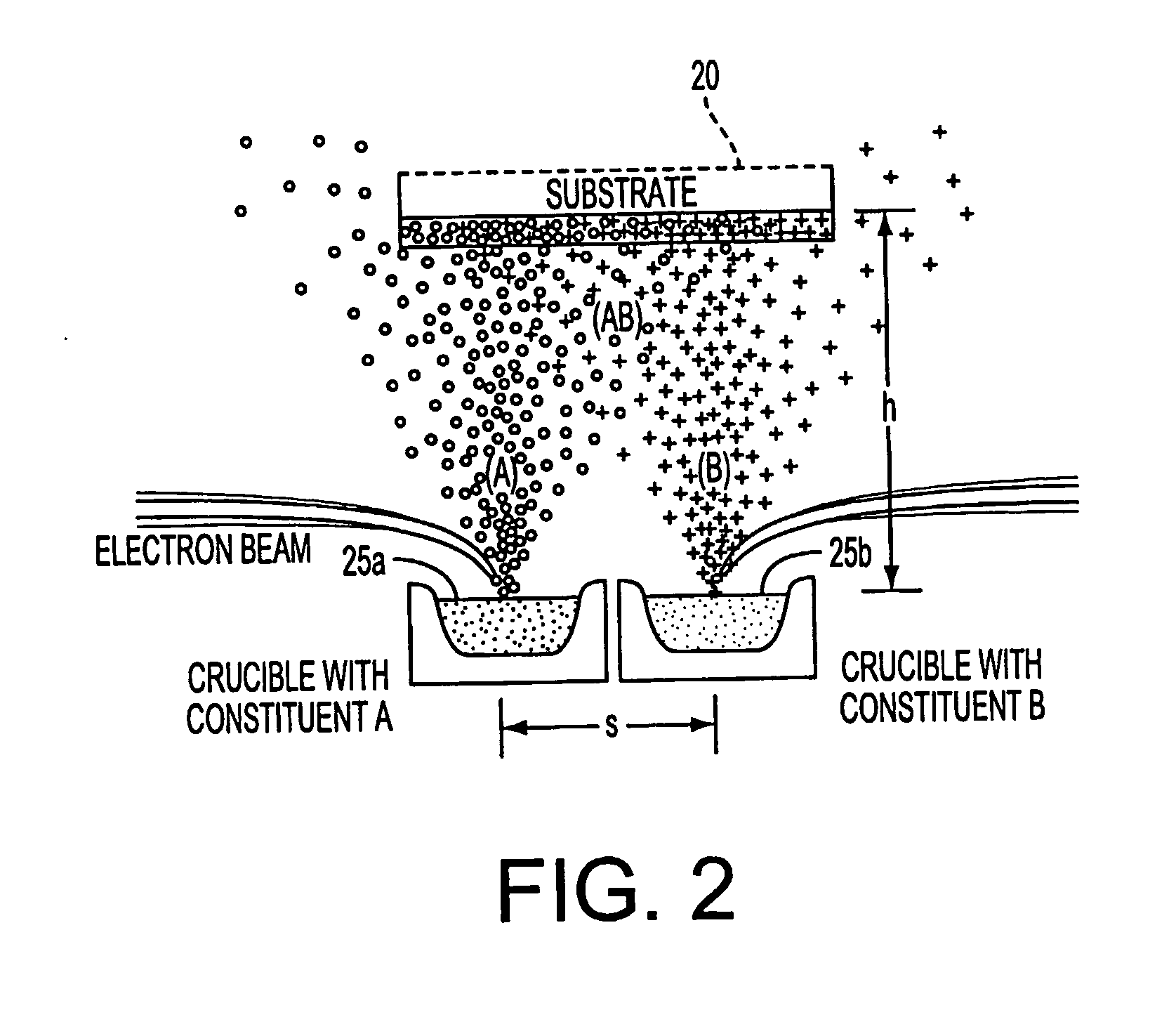

Method and apparatus application of metallic alloy coatings

ActiveUS20050000444A1High material utilizationEfficiently coatSpark gapsElectric discharge heatingBond coatingHigh rate

A directed vapor deposition (DVD) method and system for applying at least one bond coating on at least one substrate for thermal barrier coating systems. To overcome the limitations incurred by conventional methods, the DVD system uses an electron beam directed vapor deposition (DVD) technique to evaporate and deposit compositionally and morphologically controlled bond coats at high rate. The present DVD system uses the combination of an electron beam and a combined inert gas / reactive gas carrier jet of controlled composition to create engineering films. In this system, the vaporized material can be entrained in the carrier gas jet and deposited onto the substrate at a high rate and with high materials utilization efficiency. The velocity and flux of the gas atoms entering the chamber, the nozzle parameters, and the operating chamber pressure can all be significantly varied, facilitating wide processing condition variation and allowing for improved control over the properties of the deposited layer.

Owner:UNIV OF VIRGINIA

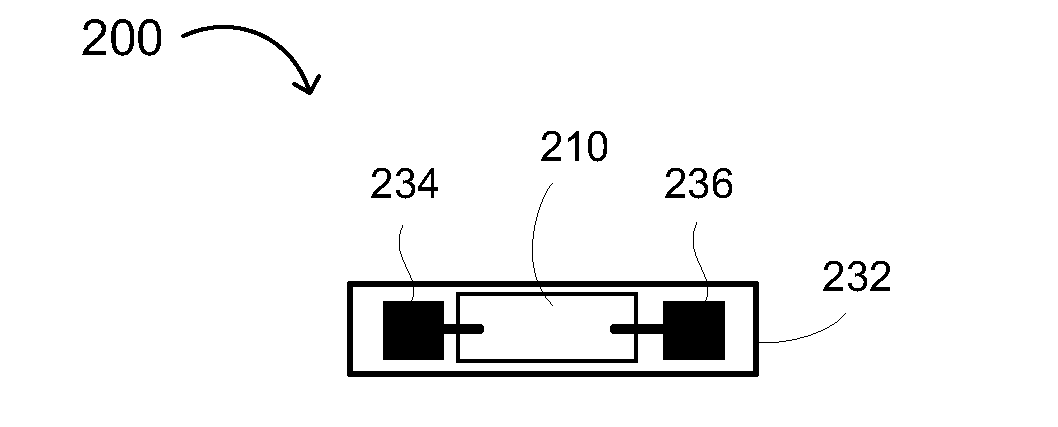

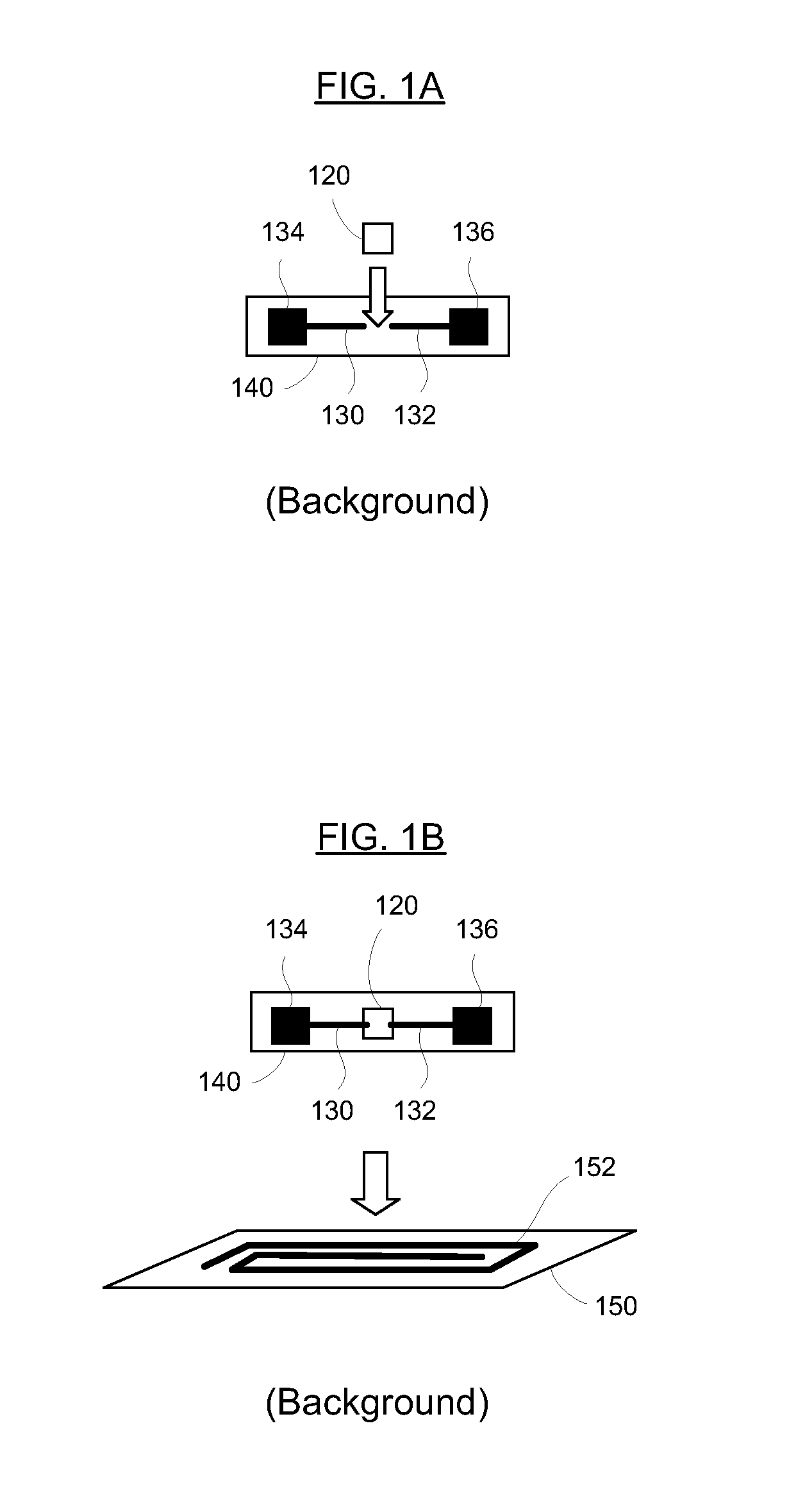

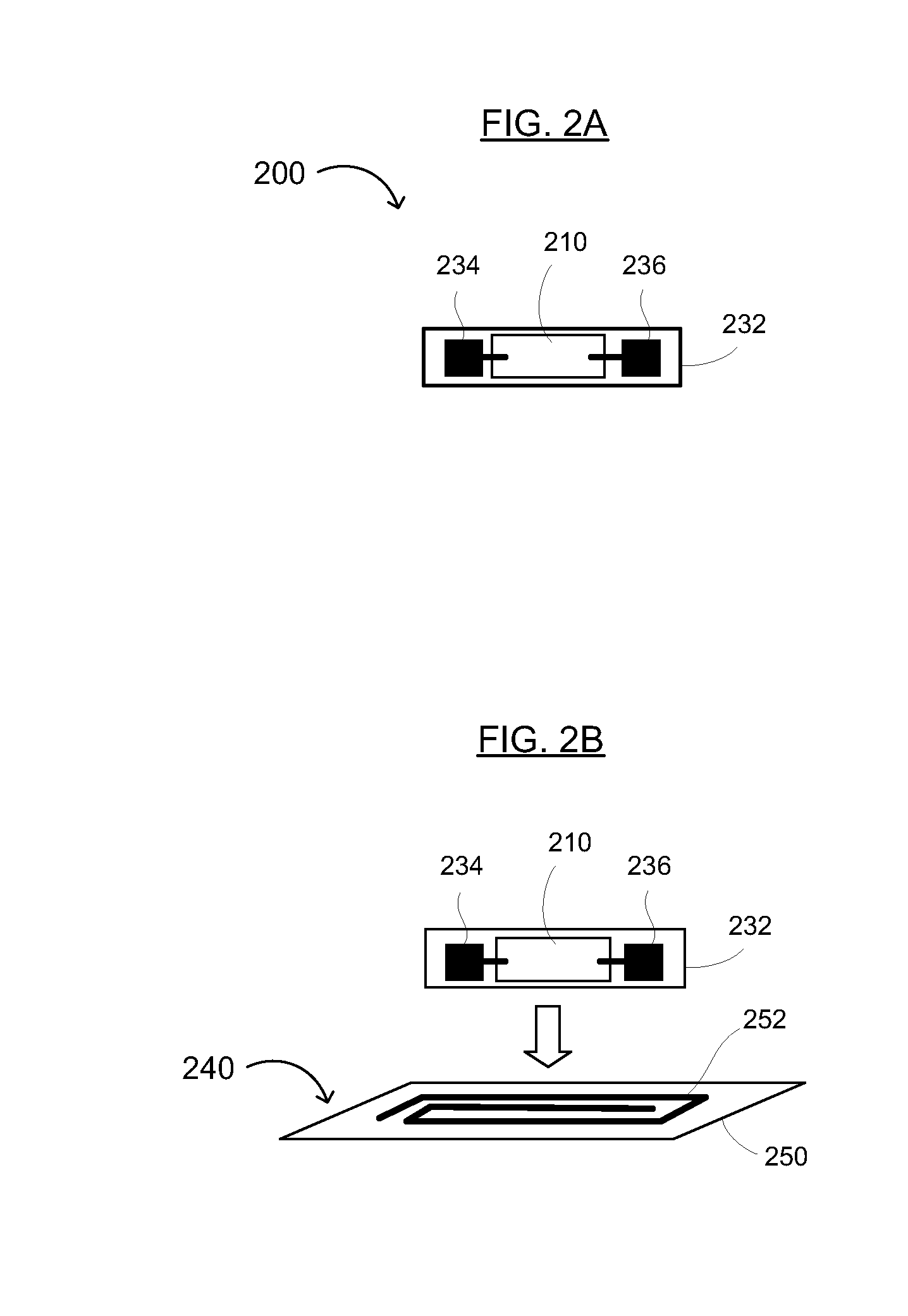

Wireless Devices Including Printed Integrated Circuitry and Methods for Manufacturing and Using the Same

InactiveUS20090095818A1Leverage low capital expenditure and operating costLow costPrinted circuit manufactureSubscribers indirect connectionElectricityElectrical devices

Printed integrated circuitry and attached antenna and / or inductor for sensors, electronic article surveillance (EAS), radio frequency (RF) and / or RF identification (RFID) tags and devices, and methods for its manufacture. The tag generally includes printed integrated circuitry on one carrier and an antenna and / or inductor on another carrier, the integrated circuitry being electrically coupled to the antenna and / or inductor. The method of manufacture generally includes of printing an integrated circuit having a plurality of first pads on a carrier, forming an antenna and / or inductor having a plurality of second pads on a substrate, and attaching at least two of the first pads of the printed integrated circuit to corresponding second pads of the antenna and / or inductor. The present invention advantageously provides a low cost RFID tag capable of operating at MHz frequencies that can be manufactured in a shorter time period than conventional RFID tags that manufacture all active electrical devices on a conventional wafer.

Owner:ENSURGE MICROPOWER ASA

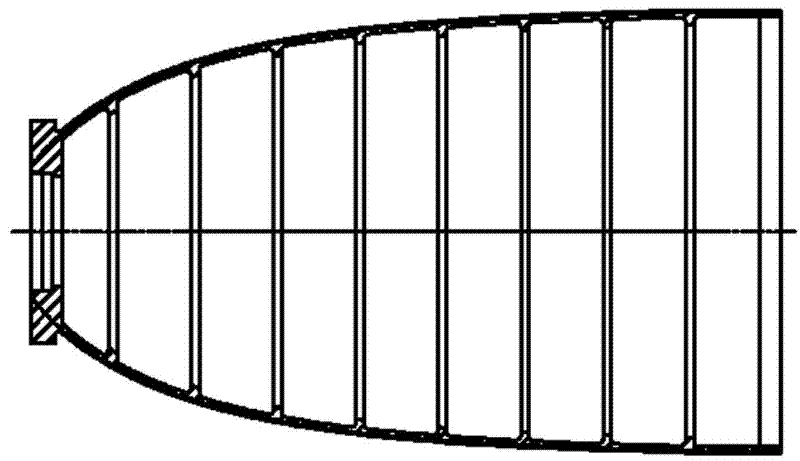

Processing method of thin and long aluminium alloy thin-walled cylinder

ActiveCN102513785AHigh material utilizationShort processing cycleNon-electric welding apparatusWeld seamThin walled cylinder

The invention provides a processing method of a thin and long aluminium alloy thin-walled cylinder and belongs to a mechanical processing method of a slewing structure, and the processing method is used for carrying out friction stir welding on a shell blank so as to process and mold the shell blank into a bent generatrix thin-walled cylinder shell. The method provided by the invention can be used for solving the problems of poor shell generatrix displacement, poor shell roundness, uneven wall thickness, clearance at welding seams, unqualified performance detection and incapability of ensuring use requirements in the existing processing method. The method comprises a part manufacturing step, a matching step, a caustic washing step, a trial assembly step, a positioned welding step, a friction stir welding step, a welding seam polishing step, a stress-relief annealing step, an X-ray detection step, a shape processing step, a ultrasonic flaw detection step and an end face hole processingstep. The method provided by the invention can be used for solving the problems of poor shell roundness, uneven wall thickness, clearances at the welding seams and unqualified performance detection in the existing processing method, improving the shell processing precision and reliably ensuring the product quality.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

Centrifugal high-carbon, high-boron and high-speed steel composite roller shell and fabrication method of combined roller of composite roller shell

ActiveCN102962423AHigh material utilizationExtended service lifeFurnace typesRollsHigh-speed steelHigh carbon

The invention discloses a centrifugal high-carbon, high-boron and high-speed steel composite roller shell and belongs to the technical field of casting. An outer layer of the roller shell is made of a high-carbon, high-boron and high-speed steel material; an inner layer of the roller shell is made of graphitic steel; good metallurgical bonding is achieved by centrifugal casting; an appropriate heat treatment process is adopted for property improvement on the high-carbon, high-boron and high-speed steel composite roller shell; a high-carbon, high-boron and high-speed steel combined roller is fabricated by a hot charging method; the high-carbon, high-boron and high-speed steel composite roller shell can be replaced after being abraded; and the cyclic utilization of a roller shaft is achieved. Compared with a high-speed steel roller by centrifugal casting, the material utilization ratio is increased by more than 30%, and the service life is prolonged by more than 20%.

Owner:JIANGSU GONGCHANG ROLL

Preparation method of heavy-calibre nickel base alloy thin-walled tubular product

The invention relates to a preparation method of a heavy-calibre nickel base alloy thin-walled tubular product, which comprises the steps of: 1, preparing a nickel base alloy tube blank by adopting a thermal backward extrusion process, wherein the extrusion temperature is 1000-1250 DEG C, the worker die preheating temperature is 450-550 DEG C, the extrusion speed is 25mm / s-60mm / s; 2, thinning through cold spinning with strong force, wherein the first pass of thinning rate is 20-75 percent, other passes of thinning rates are 25-30 percent, the deformation during thermal treatment (annealing or solution treatment) is 50-75 percent, the feeding ratio of two passes before a finished product is obtained is 0.5mm / n-0.7mm / n, and feeding ratios of other passes are 0.8mm / n-1.5mm / n; and 3, carrying out thermal treatment (annealing or solution treatment) on a semi-finished product or finished product, scouring and cleaning. The heavy-calibre nickel base alloy thin-walled tubular product processed by adopting the invention has the advantages of high material utilization rate, low cost and high additional value, is suitable for massive production, and has remarkable economic benefit and social benefit.

Owner:有研科技集团有限公司

Lithium Iron Phosphate Cathode Materials With Enhanced Energy Density And Power Performance

The invention is related to a cathode material comprising particles having a lithium metal phosphate core and a pyrolytic carbon deposit, said particles having a synthetic multimodal particle size distribution comprising at least one fraction of micron size particles and one fraction of submicron size particles, said lithium metal phosphate having formula LiMPO4 wherein M is at least Fe or Mn.Said material is prepared by method comprising the steps of providing starting micron sized particles and starting submicron sized particles of at least one lithium metal phosphate or of precursors of a lithium metal phosphate; mixing by mechanical means said starting particles; making a pyrolytic carbon deposit on the lithium metal phosphate starting particles before or after the mixing step, and on their metal precursor before or after mixing the particles; optionally adding carbon black, graphite powder or fibers to the said lithium metal phosphate particles before the mechanical mixing.

Owner:CLARIANT (CANADA) INC

Casting high ferrochrome or casting high chromium steel roll for welding steel pipe

ActiveCN101015836AReduce the amount of processingHigh material utilizationRollsMetal rolling arrangementsSteel tubeFerrochrome

The invention provides a cast high chrome iron or cast high chrome steel roller used to roll weld steel tube and on straight-slim welding steel tube roller, or the like, wherein the cast high chrome iron roller comprises C in 1.8-2.8%, Si <=1.0%, Mn <=1.0%, P<=0.05%, S<=0.05%, Cr in 12-22%, Ni in 0.5-3.0%, Mo in 0. 0%, Ti in 0-0.3%, V in 0-1.0%, Cu in 0-1.0%, RE in 0.01-0.5%, and the left is Fe. The inventive roller has uniform organism, high abrasion resistance and flexibility, while its service life is 2-5 times of general product and material utilization can reach 70% or 80%, with low cost.

Owner:SHANDONG PROVINCE SIFANG TECHN DEV

Aluminum alloy special-shaped member equivalent temperature precision forging technique method

ActiveCN101185954AImprove overall performanceIncreased internal densityForging/hammering/pressing machinesHeat treatment process controlEquivalent temperatureFiber

The invention relates to a constant temperature fine-forging technique process used for the aluminum alloy parts with different shapes. The invention is mainly characterized in that constant temperature blank forging, die pre-forging, corrode-washing, fine forging of dies, heat treatment and re-corrode washing, etc. processes are adopted under a given temperature to enlarge the internal density of the parts and optimize the fiber direction and distribution of the inner construction of the parts, so as to enhance the strength and improve the appearance quality of the parts. The invention can enhance machining efficiency, reduce machining cost and conserve precious materials. The invention can enhance the compound capability of the materials of parts.

Owner:HENAN COSTAR GRP CO LTD

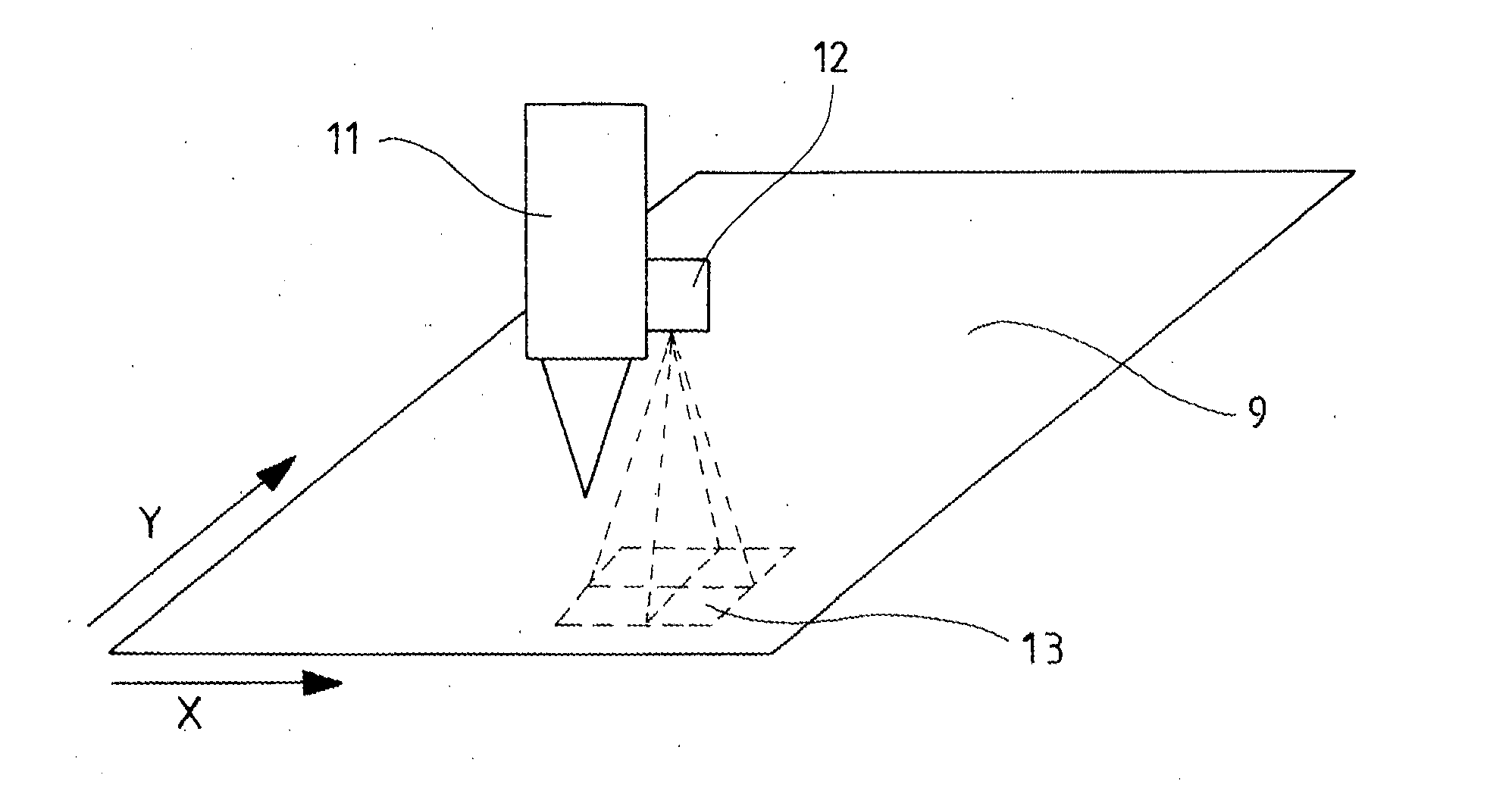

Method for controlling a tool

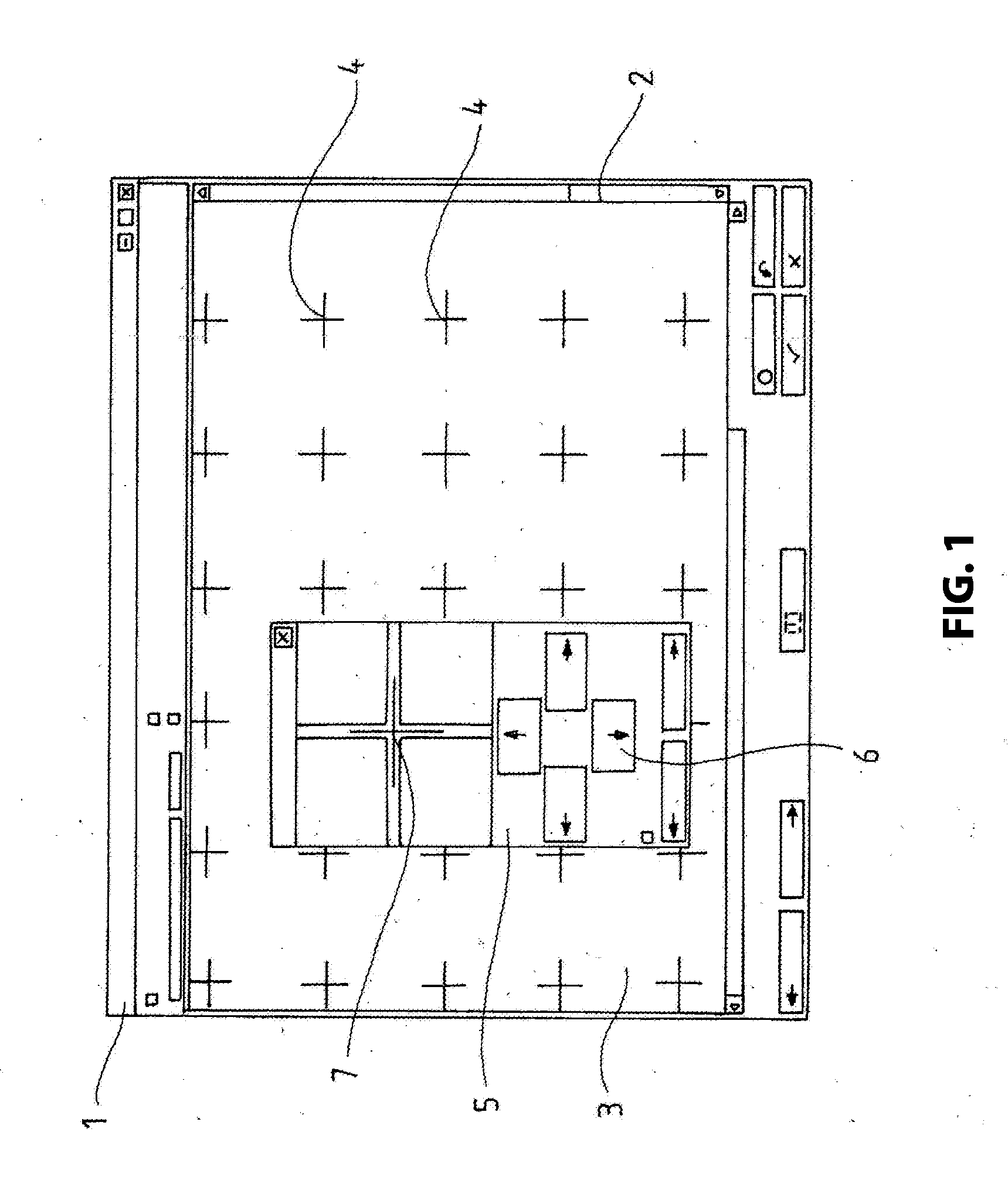

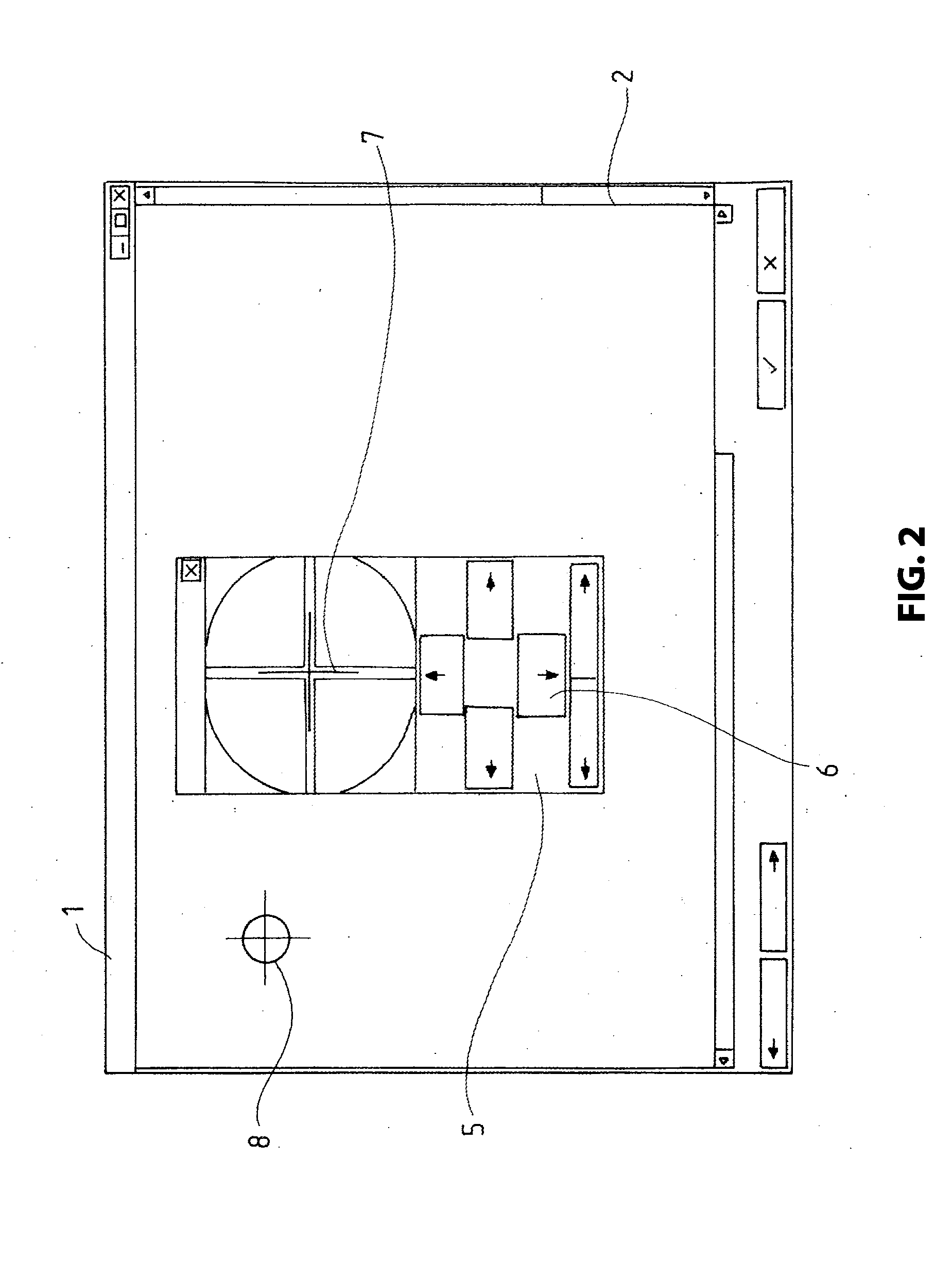

InactiveUS20140160273A1Complex setPrecise positioningProgramme controlCharacter and pattern recognitionCamera imageCentering matrix

A method for controlling a tool, including the steps: providing a reference matrix including reference points and a centering matrix including centering points in a material processing plane; imaging the material processing plane through a camera as a camera image in a size of a camera image field; de-skewing the camera image of the material processing plane by aligning with the reference matrix; scaling a pixel size of the camera image through aligning with the reference matrix; centering the camera image through aligning with the centering points; projecting a processing contour onto the de-skewed and scaled camera image of a workpiece; and aligning the processing contour on the camera image of the work piece and starting the processing, wherein the processing of the work piece is performed though the tool along the processing contour.

Owner:ACSYS LASERTECHN

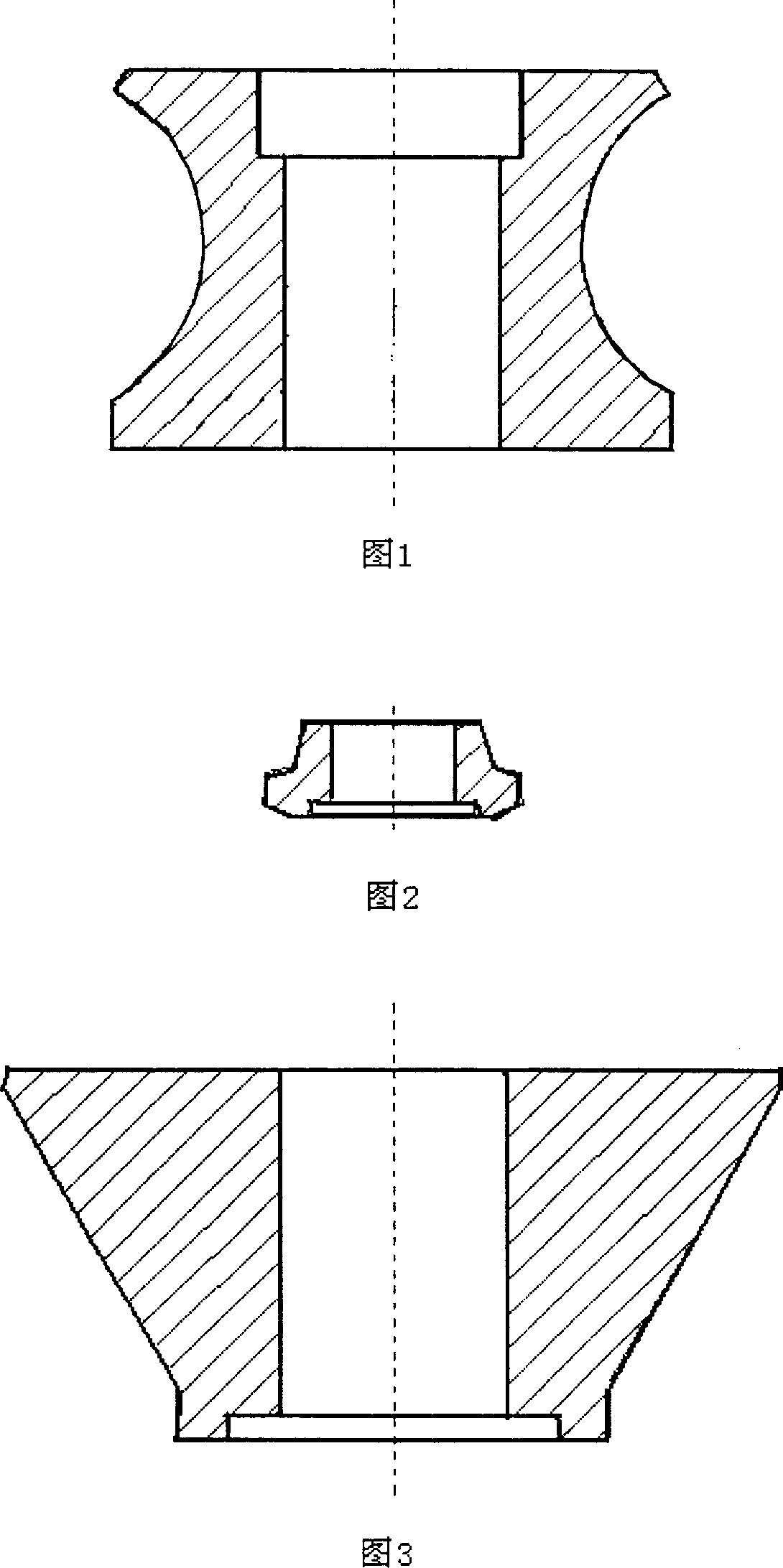

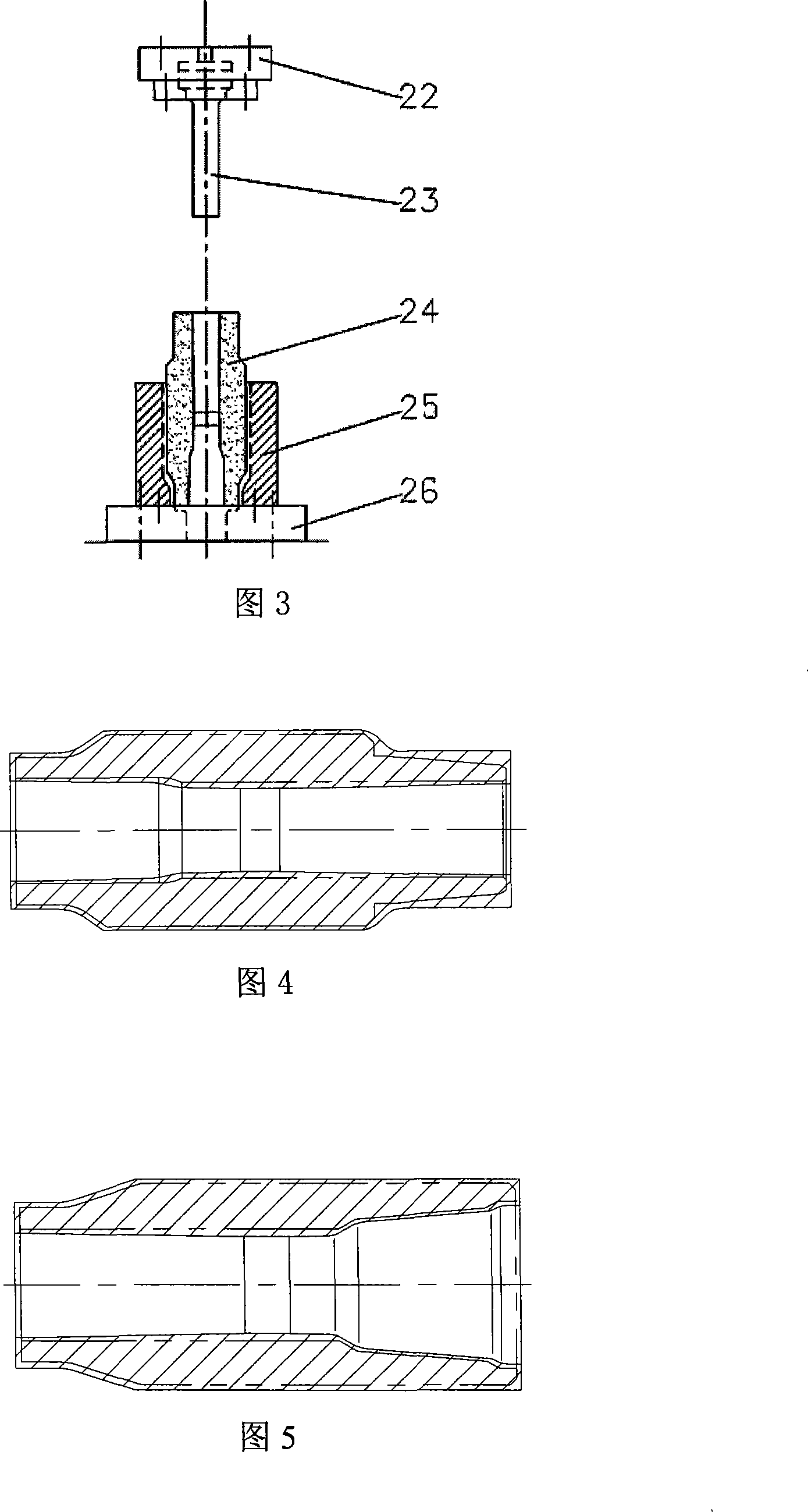

Drill pipe joint precision die forging process

InactiveCN101181730AEasy to moldSmall machining allowanceForging/hammering/pressing machinesMedium frequencyMaterial consumption

The invention discloses a precise die forging technique of a petroleum drill rod connector and is characterized in that: 1) flan material is prepared with a band saw; 2) the flan material is heated quickly at a temperature that is suitable for forging by a medium frequency electric induction furnace; 3) then the flan material is extruded in a close type into a prefabricated flan and a flan makes concave die on a quick flan-making oil hydraulic machine; 4) a molding concave by die level method extrudes and presses the prefabricate flan into a connector die forging piece on the quick flan-making oil hydraulic machine which can implement combination of the upper molding concave die and the lower molding concave die and relative extrusion and pressing from right and left and inner holes of the connector die forging piece is provided with wad; 5) finally a hole punching die punches away the recess inside the inner hole of the forging piece on a special hole punching oil hydraulic machine to obtain the connector forging piece with accurate specifications, excellent structure performance and central through holes. The invention has the advantages of good streamline distribution, material conservation, environmental protection and high production efficiency.

Owner:JIANGYIN LONGCHENG DRILLING & PRODN MACHINERY MFG

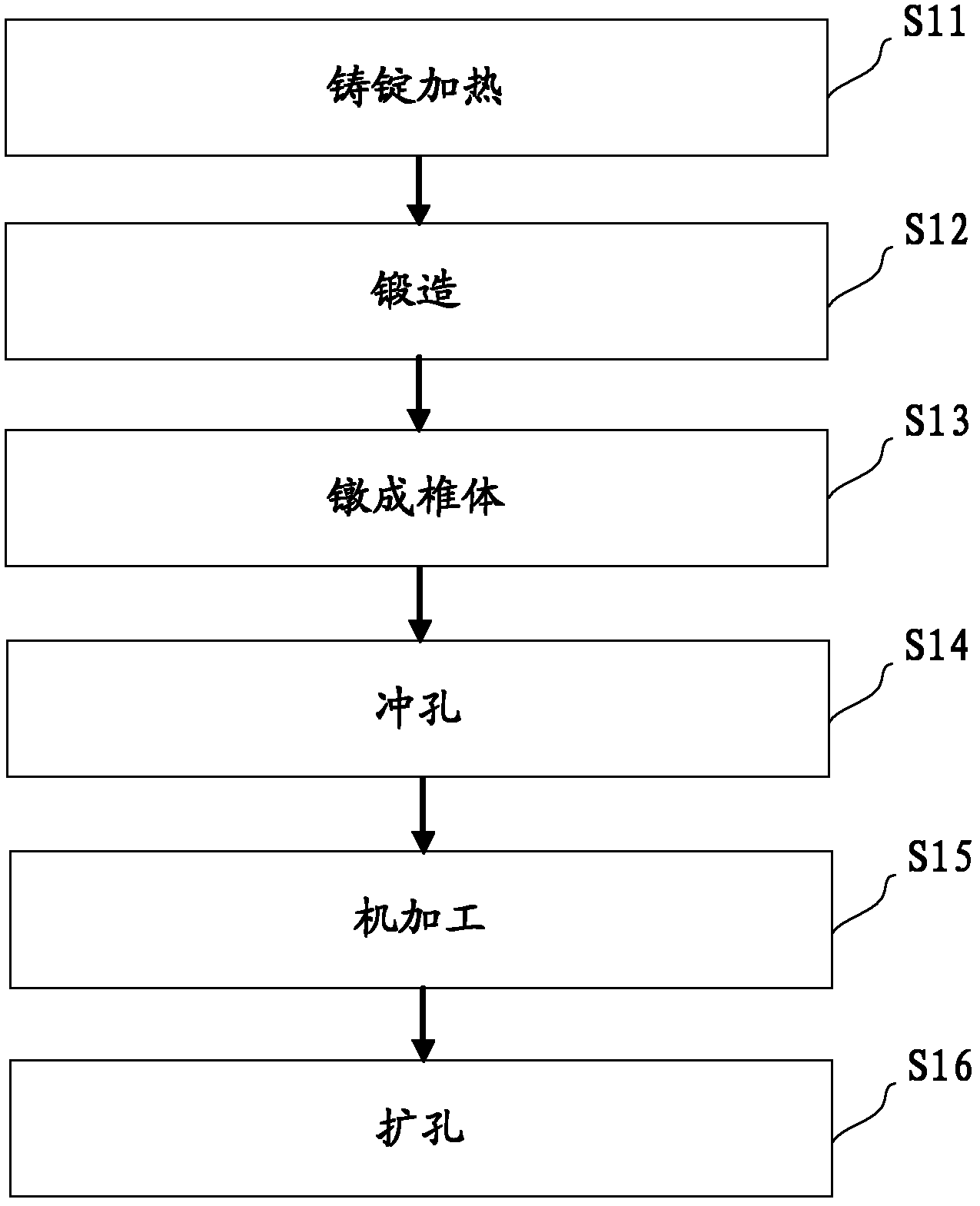

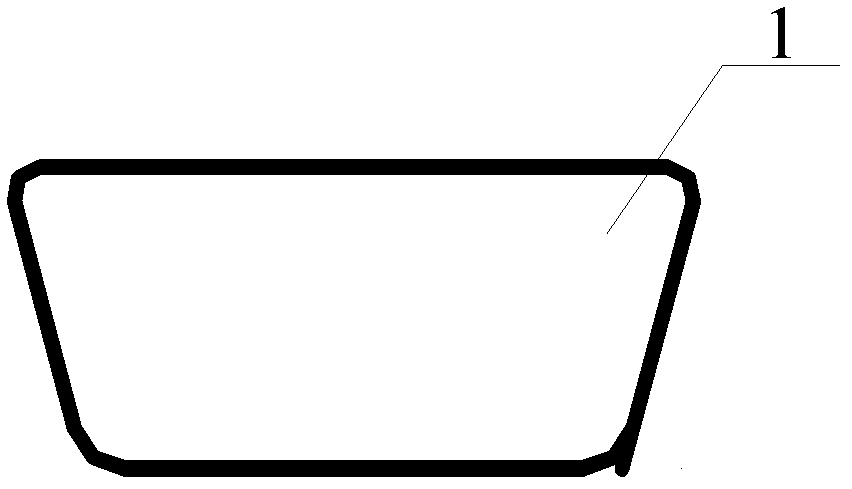

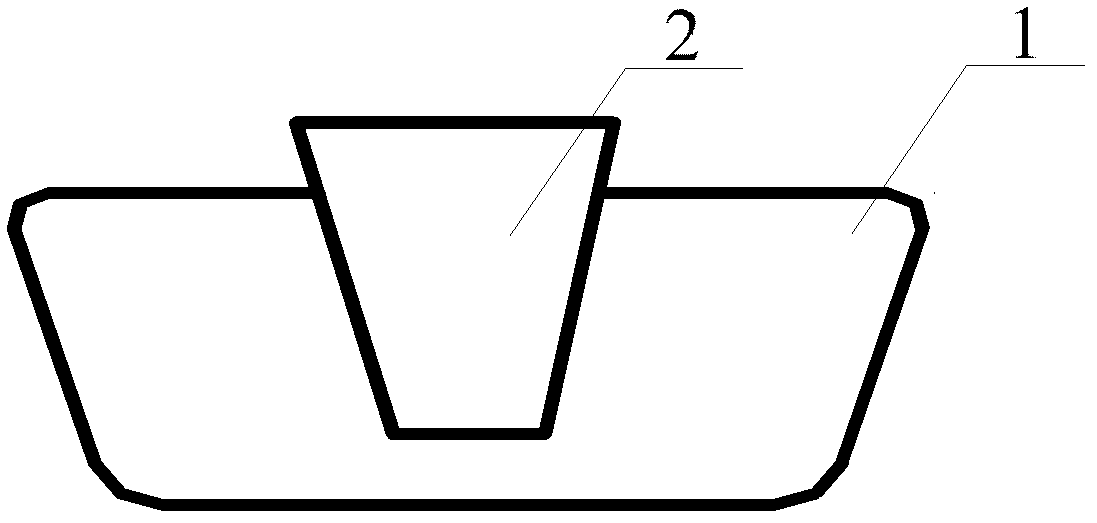

Forging molding method of large-scale aluminum alloy conical ring

The invention discloses a forging molding method of a large-scale aluminum alloy conical ring, and the method comprises the following steps: heating a cast ingot: heating the large-size cast ingot to the appropriate forging temperature; forging: performing compression and stretching on the cast ingot on a hydraulic machine multiple times; upsetting into a cone: utilizing an upper flat anvil and a lower flat anvil to upset the cast ingot repeatedly so as to enable the cast ingot to form the cone; punching: adopting a conical punch to punch a center hole on the cone so as to form the conical ring; machining: performing machining and shaping treatment on the conical ring so as to keep the obliqueness of the inner surface and the obliqueness of the outer surface of the conical ring consistent; and reaming: supporting a core rod through a saddle support, utilizing the core rod to prop against the inner surface of the conical ring and utilizing the upper flat anvil to press the outer surface of the conical ring so as to expand the inner hole of the conical ring. The method provided by the invention has the advantages of low cost, high utilization rate of materials, capability of ensuring that internal tissues of the conical ring can not be damaged and the like.

Owner:SOUTHWEST ALUMINUM GRP

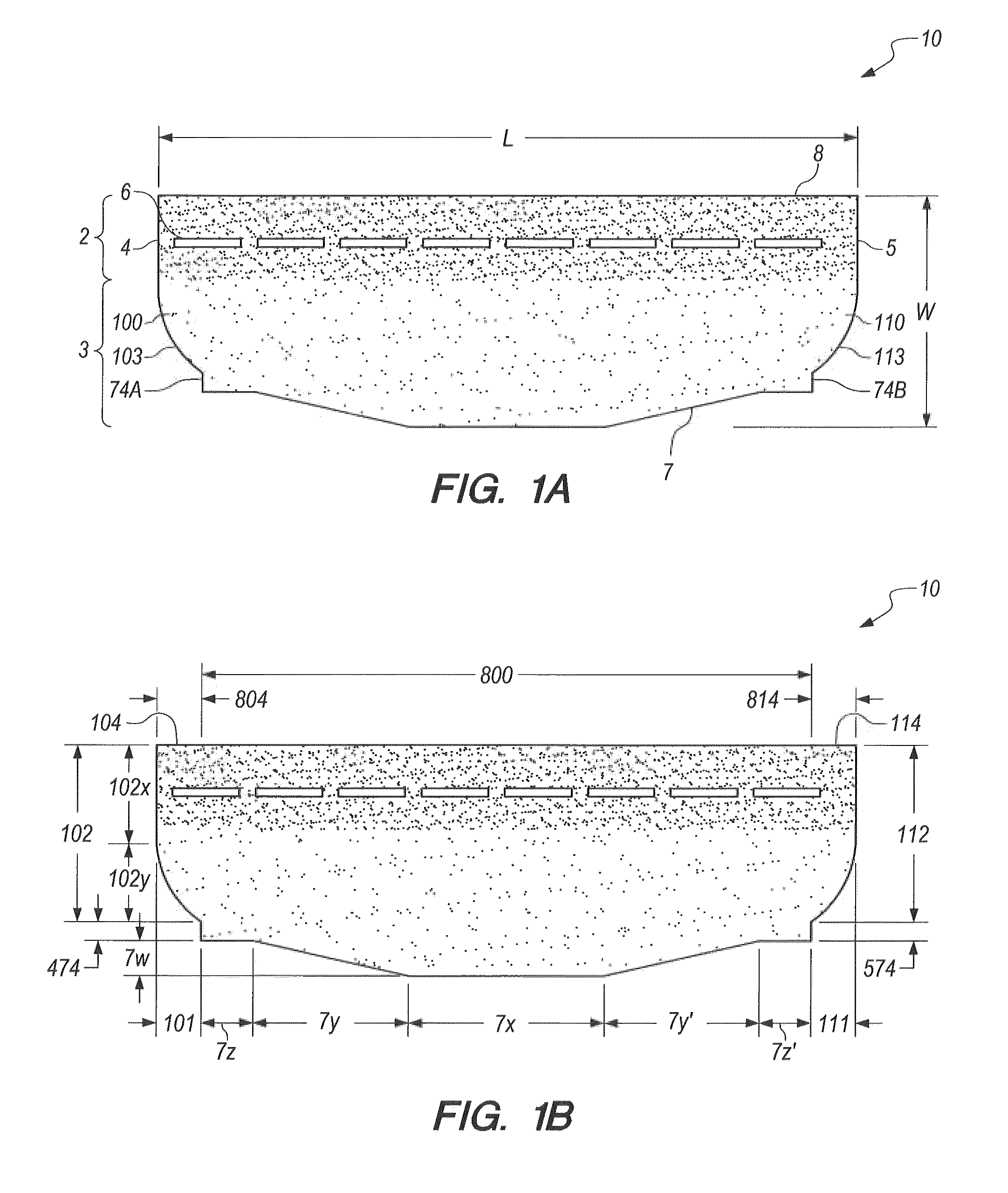

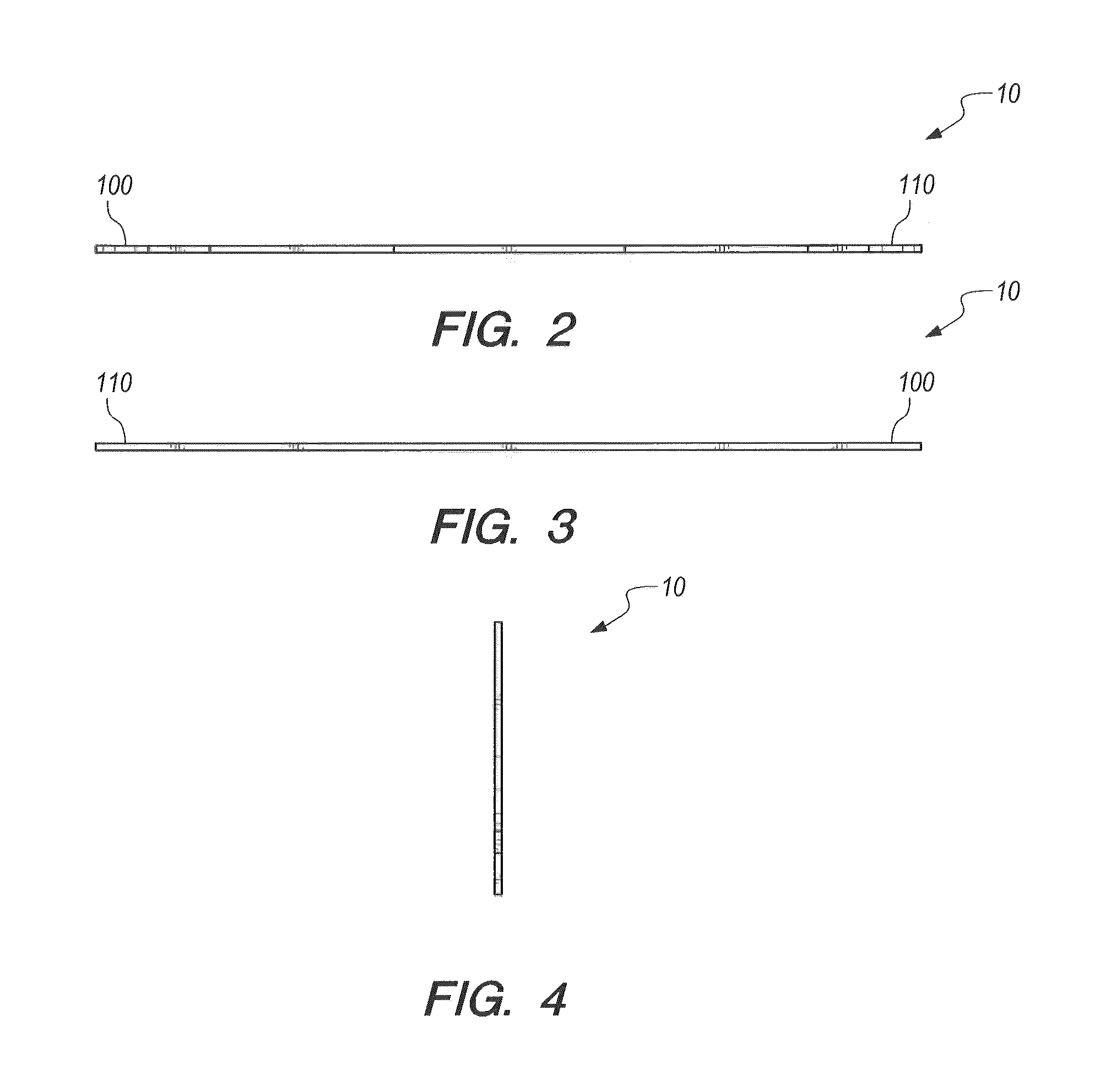

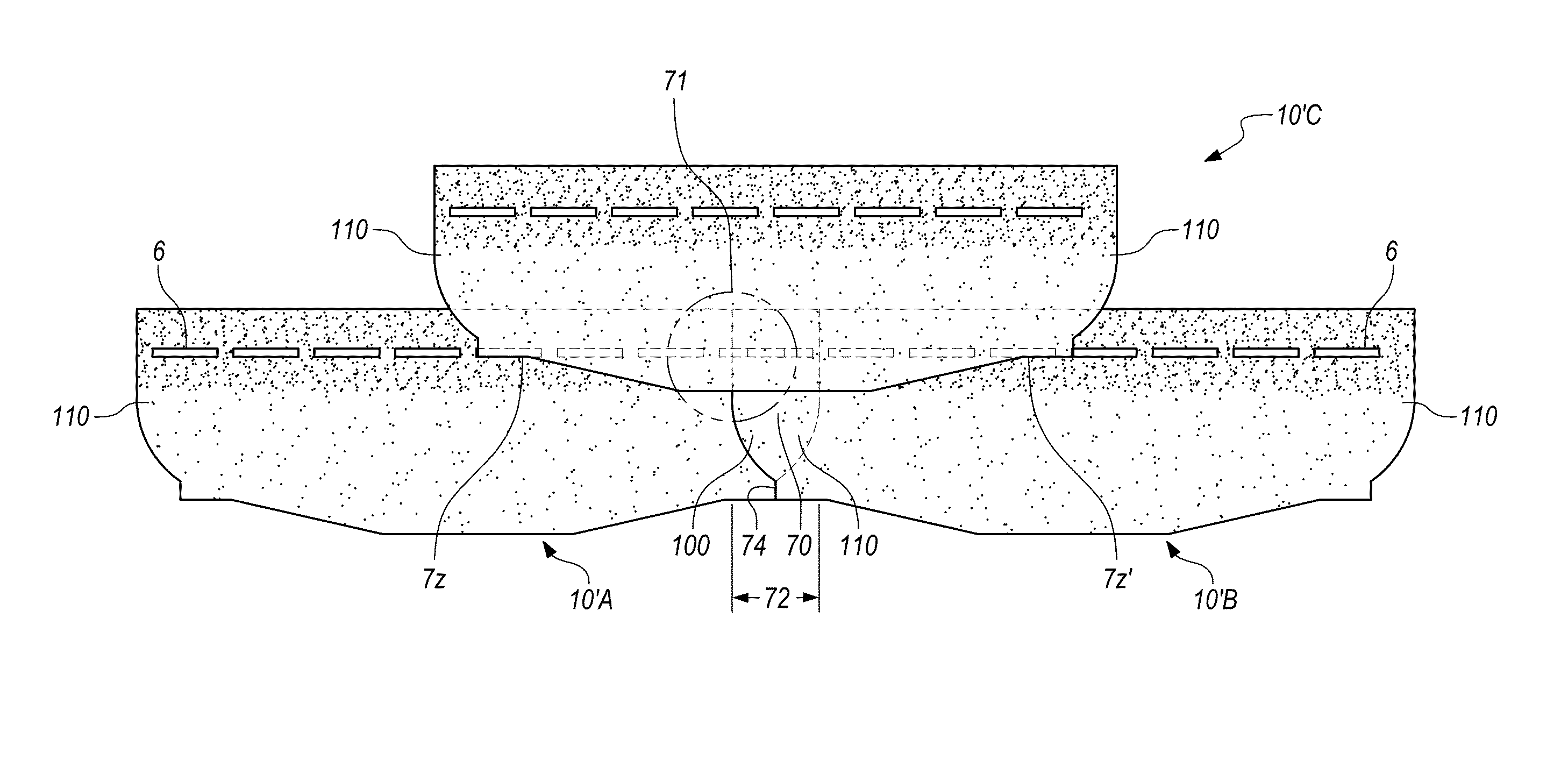

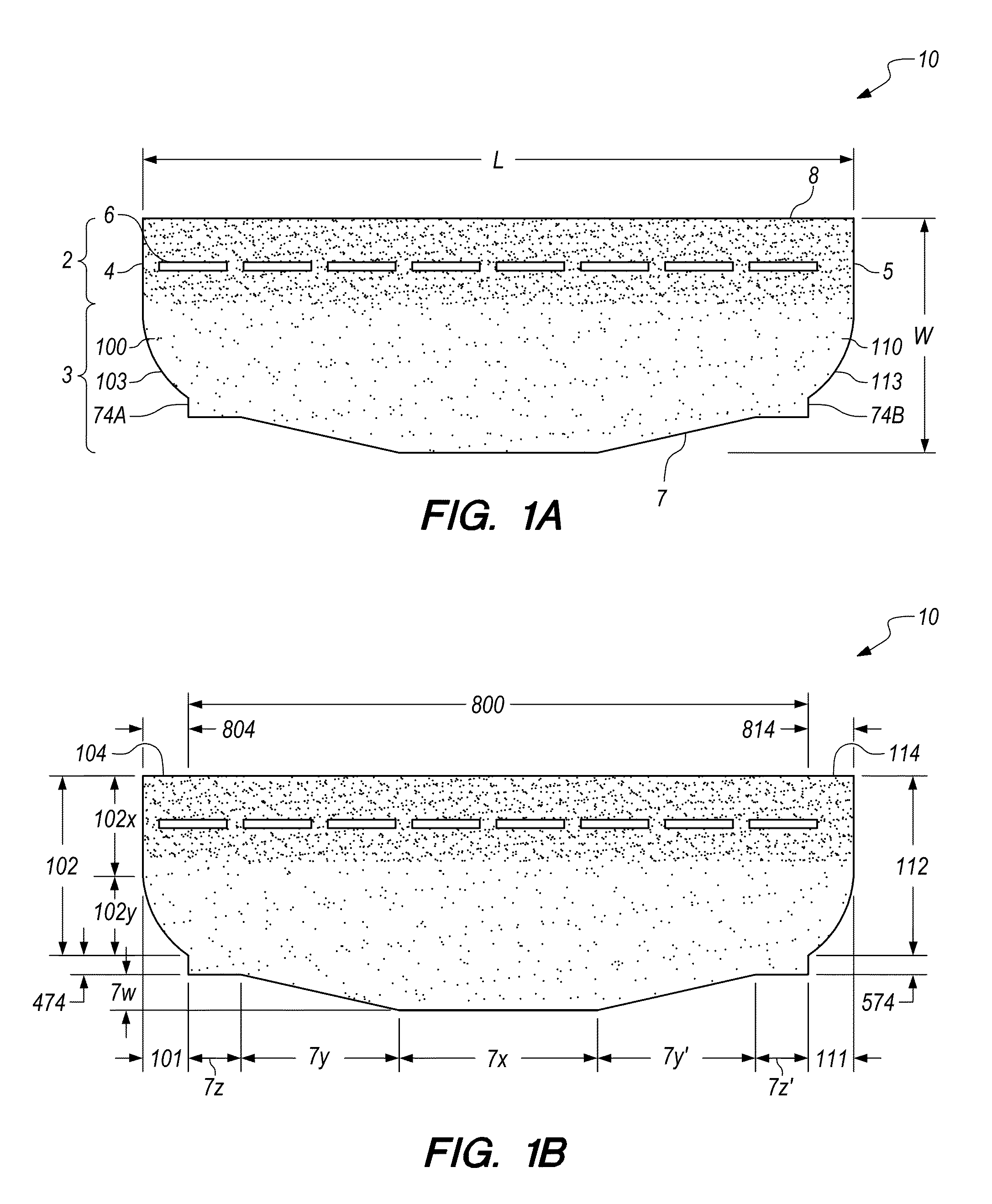

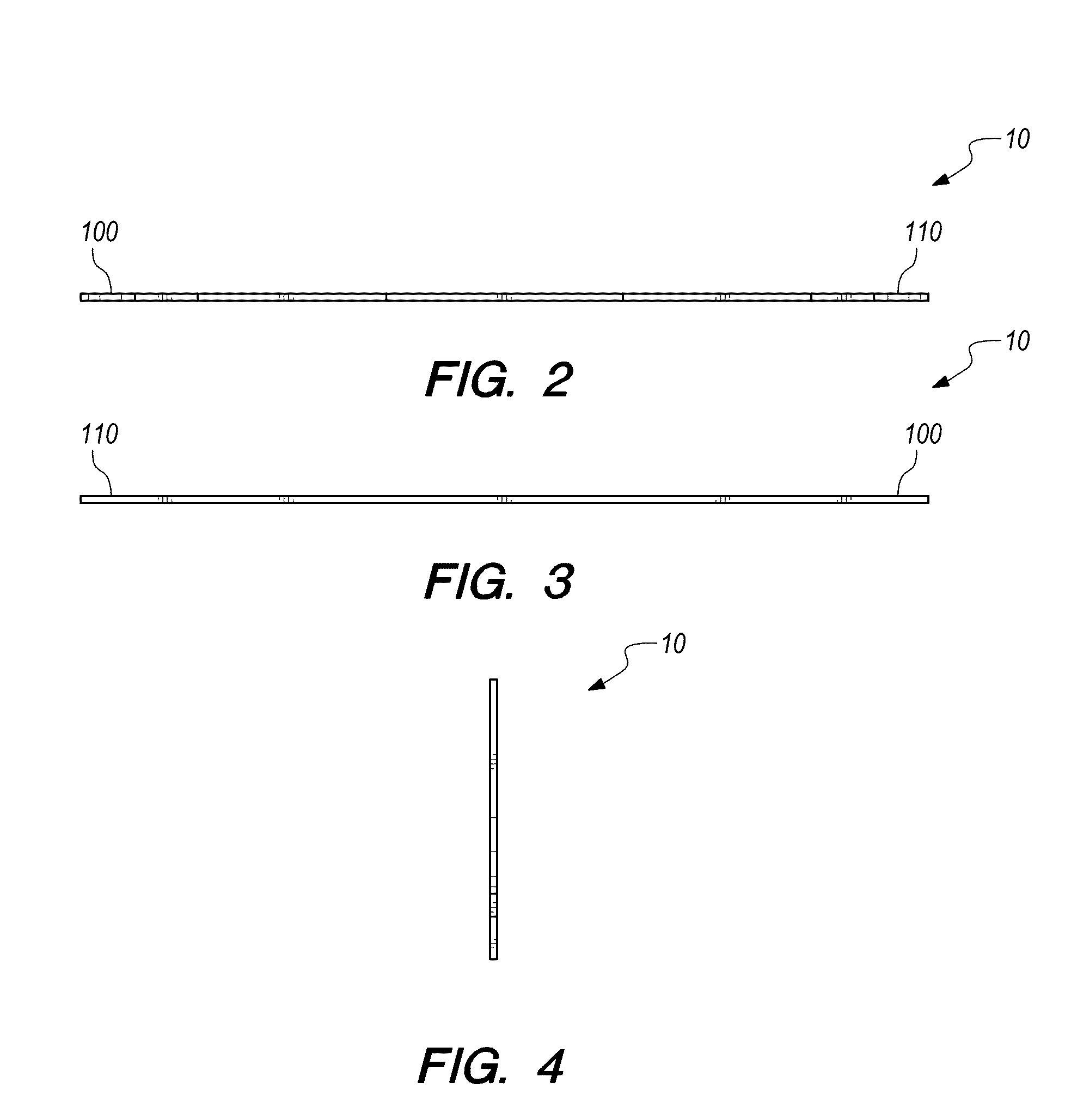

Roofing shingle system and shingles for use therein

ActiveUS9399871B2High material utilizationPromote infiltrationRoof covering using tiles/slatesCovering/liningsLeading edgeTrailing edge

A roofing system and roofing shingles for use therein are disclosed. The roofing system comprises a multiplicity of courses of roofing shingles having a headlap portion, a buttlap portion, a lateral leading edge, and a lateral trailing edge, wherein the headlap portion has a width that is less than a width of the buttlap portion defining a reduced-width headlap, wherein the lateral trailing edge of a shingle in a course partially overlaps and partially abuts the lateral leading edge of an adjacent previously installed shingle to form an interlocking edge between adjacent shingles in the course, and wherein the lateral edge includes a trailing edge projection having a weather edge, a rear edge, and a variable breadth that increases toward the rear edge of the trailing edge projection.

Owner:BMIC LLC

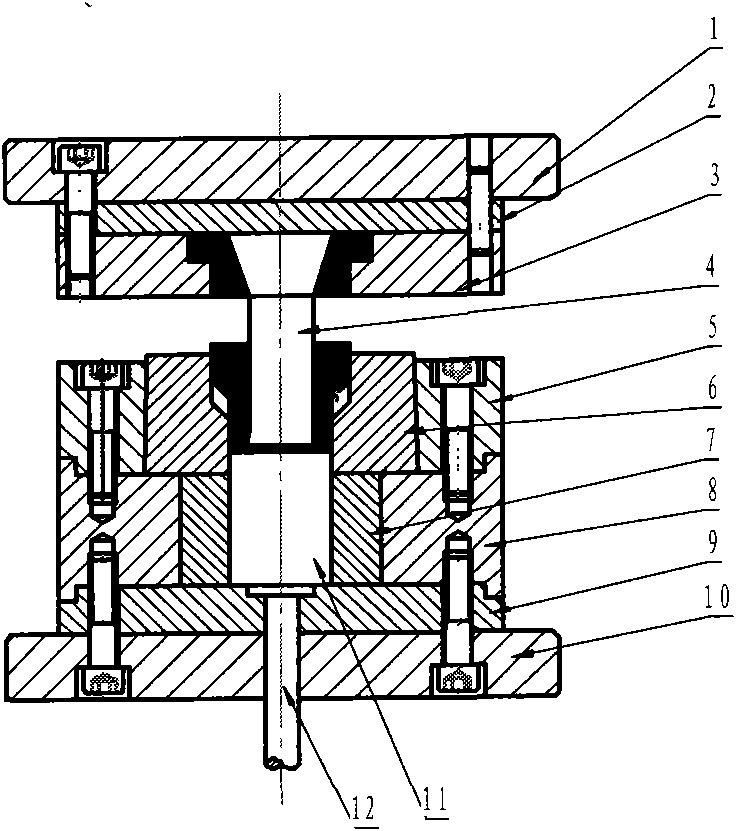

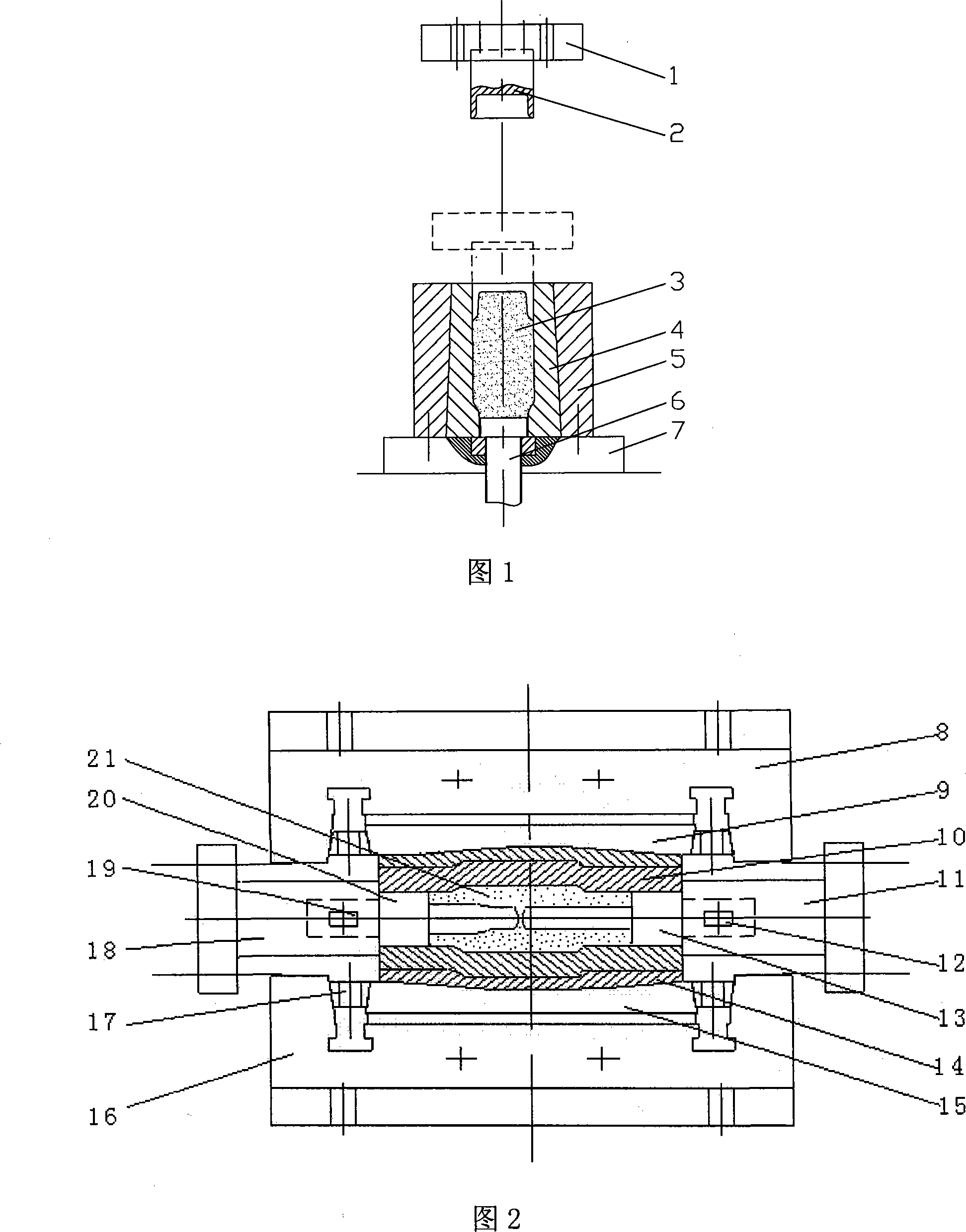

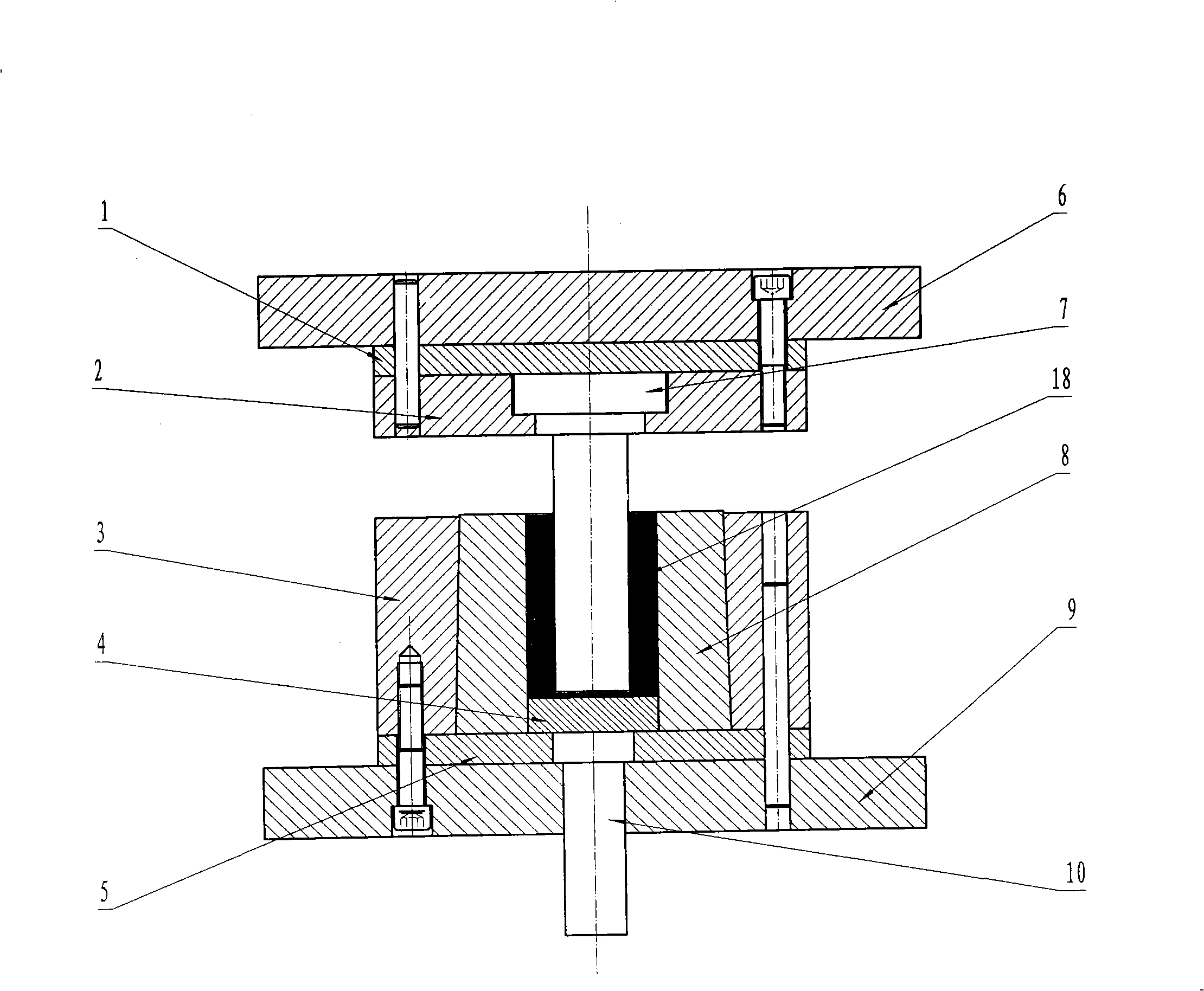

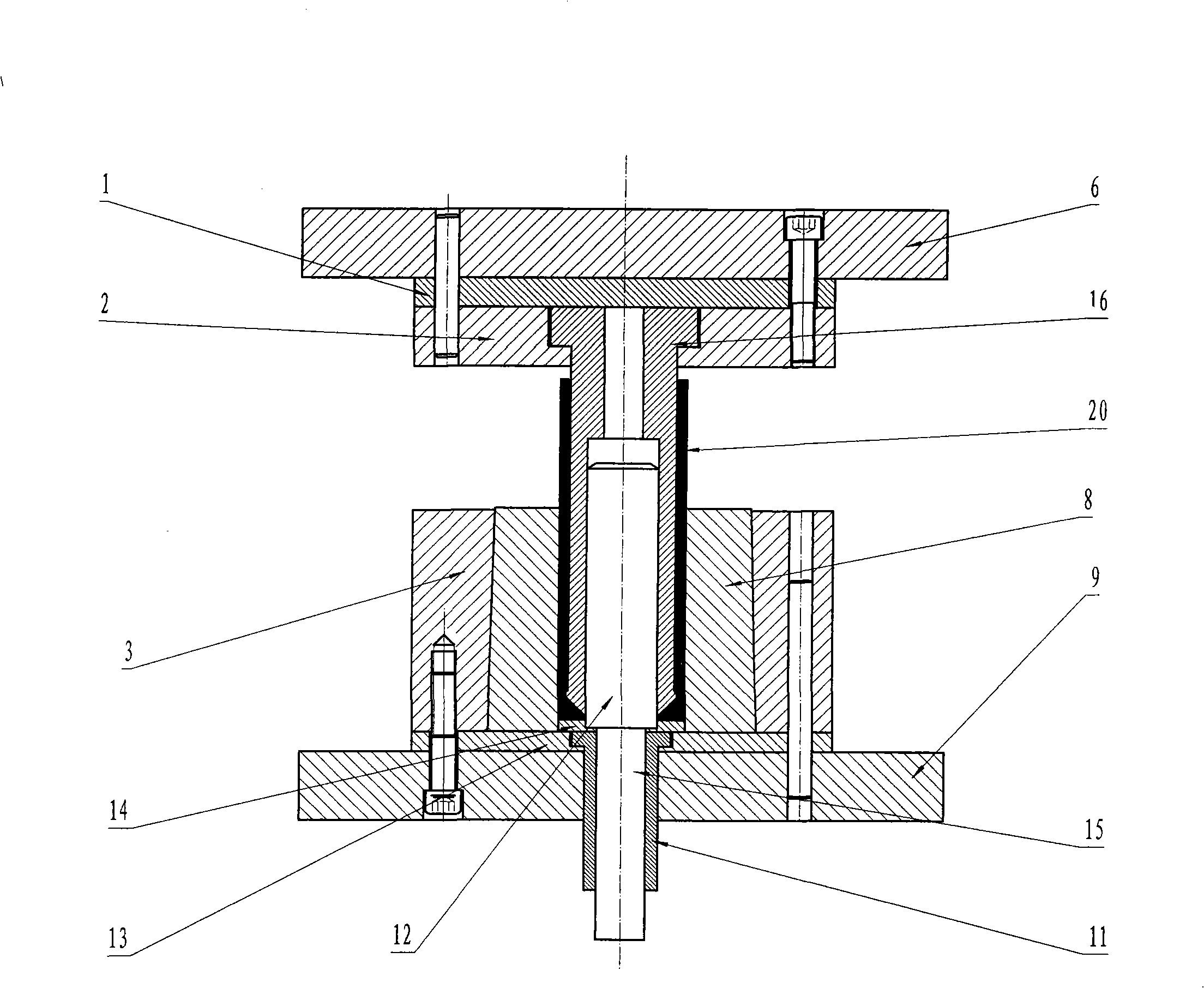

Precise extrusion molding method of thin wall long-pipe shaped parts bland and special mould

InactiveCN101332476AIncreased dimensional accuracy and material utilizationIncrease productivityExtrusion diesThin walledNonferrous metal

The invention belongs to an extrusion forming technique of non-ferrous materials. The precise extrusion forming technique of a thin-wall long-tube part blank comprises two procedures, namely, a primary reverse extrusion and a secondary reverse extrusion; the primary reverse extrusion obtains a primarily extruded tube blank (18) by adopting a primary male die (7) and a primary concave die (8) by virtue of a primary backing-out punch (4), the secondary reverse extrusion is carried out by adopting a secondary fixed male die (16), a secondary movable male die (12), a secondary concave die (6) by virtue of a secondary backing-out punch (14); the secondary movable male die (12) is placed into the primarily extruded tube blank (18), the secondary fixed male die (16) moves downward along the secondary movable male die (12) to extrude the primarily extruded tube blank (18), therefore, the secondary reverse extrusion is completed. The thin-wall long-tube part blank produced by adopting the technique of the invention has the advantages that the internal quality, dimensional accuracy and the utilization ratio of materials are greatly improved, and the production efficiency is improved and the production cost is lowered.

Owner:HENAN UNIV OF SCI & TECH

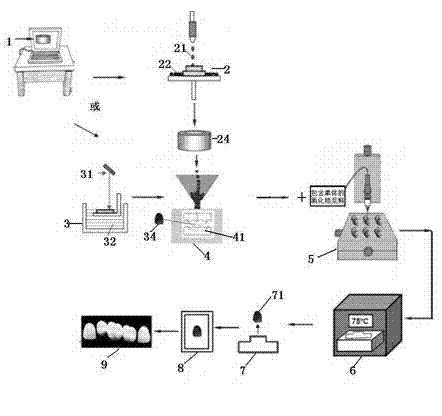

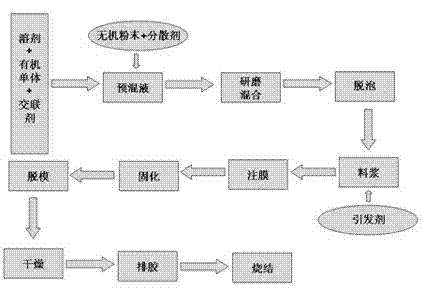

Method for producing zirconia denture through rapid prototype of gel-casting

InactiveCN102755199AHigh material utilizationImprove production efficiencyArtificial teethComputer Aided DesignDentures

The invention discloses a method for producing zirconia denture through rapid prototype of gel-casting. The method comprises the following steps of step one, collecting three-dimensional data of an oral cavity through a computer to generate a three-dimensional computer-aided design (CAD) virtue model of the required denture; step two, producing a male die of the required denture according to the three-dimensional CAD virtue model obtained in the step one; step three, producing a female die by wrapping the male die obtained in the step two; step four, injecting zirconia colloidal slurry into the female die obtained in the step three through a gel-casting process, and performing heating to induce a polymerization reaction to enable the zirconia colloidal slurry to be cured; step five, demoulding and drying the cured zirconia to obtained a blank of the required denture; and step six, sintering the blank to obtain the zirconia denture. The method for producing the zirconia denture through the rapid prototype of the gel-casting has the advantages of being high in material utilization rate, producing efficiency and product density, and good in strength.

Owner:SHANGHAI I DENTAL TECH CO LTD

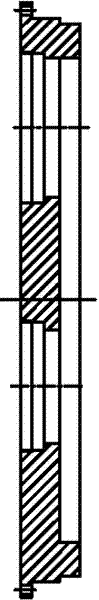

Halbach disc type magnetic coupling

InactiveCN102545538AHigh material utilizationIncrease air gap flux densityPermanent-magnet clutches/brakesMagnetEngineering

The invention provides a Halbach disc type magnetic coupling, which comprises a driving disc fixed by a driving shaft and a driven disc fixed by a load shaft. The driving disc comprises a disc body and a Halbach permanent magnet array, wherein the Halbach permanent magnet array is arranged on the surface of the disc body, and the surface faces the driven disc; and the Halbach permanent magnet array is uniformly distributed around the driving shaft, and is axially magnetized.

Owner:SHANGHAI DIANJI UNIV

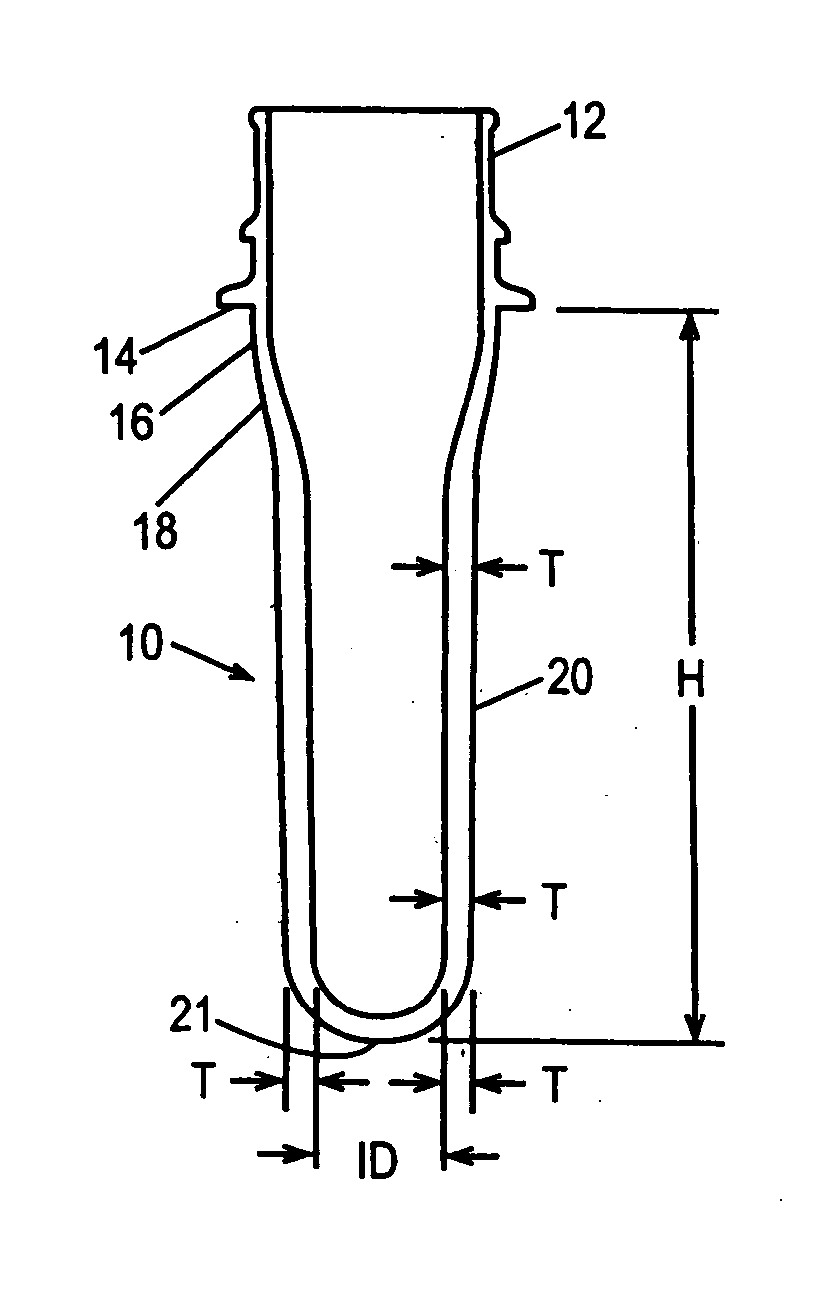

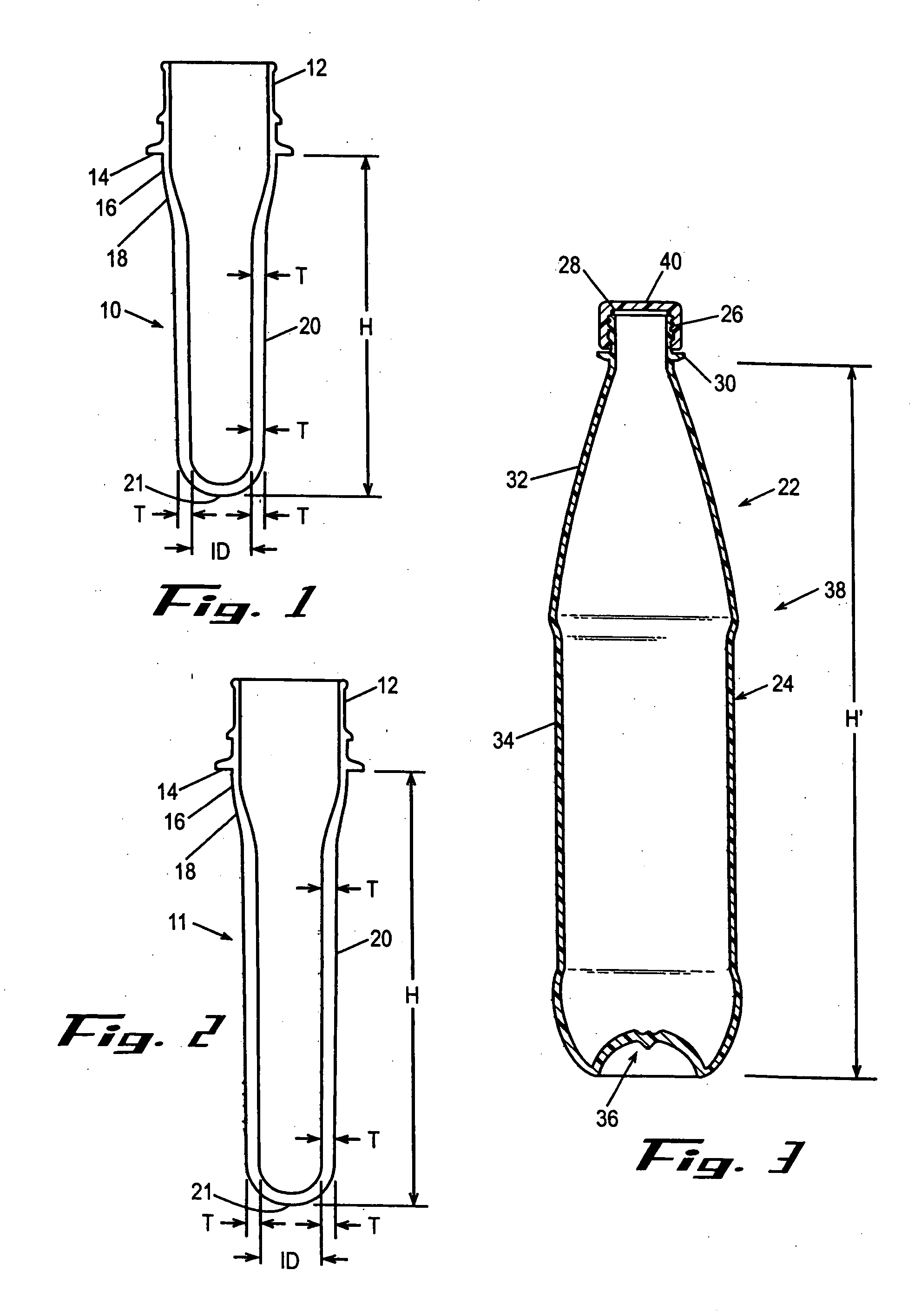

PET copolymer composition with enhanced mechanical properties and stretch ratio, articles made therewith, and methods

InactiveUS20050118371A1Shorten cycle timeImprove mechanical propertiesBottlesSynthetic resin layered productsDiolStretch ratio

A container is made from a preform comprising a PET Copolymer comprising a diol component having repeat units from ethylene glycol and a non-ethylene glycol diol component and a diacid component having repeat units from terephthalic acid and a non-terephthalic acid diacid component. The total amount of non-ethylene glycol diol component and non-terephthalic acid diacid component is present in the poly(ethylene terephthalate) copolymer in an amount from about 0.2 mole percent to less than 2.2 mole percent. The container is useful in packaging beverages and corresponding methods are disclosed.

Owner:THE COCA-COLA CO +1

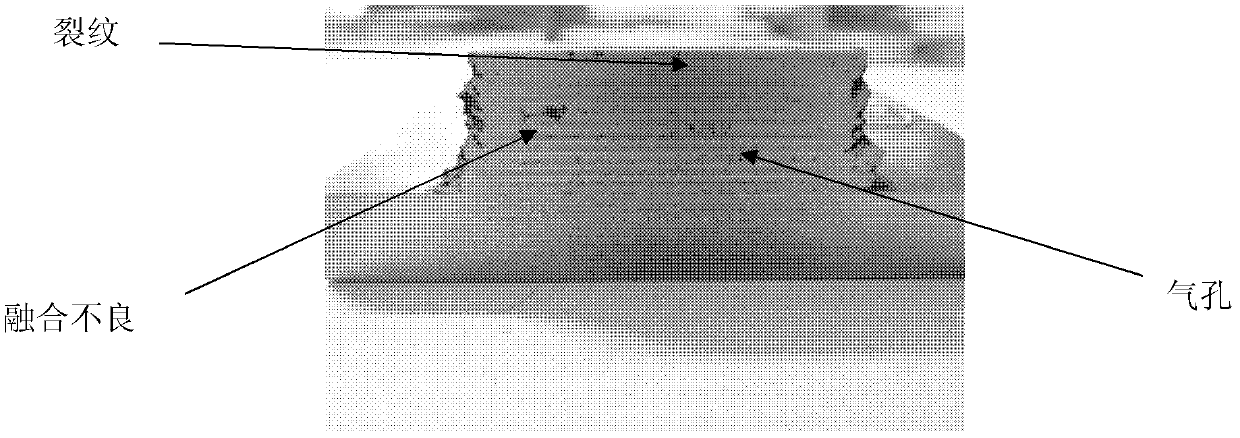

Laser additive manufacturing technology of high-temperature alloy parts

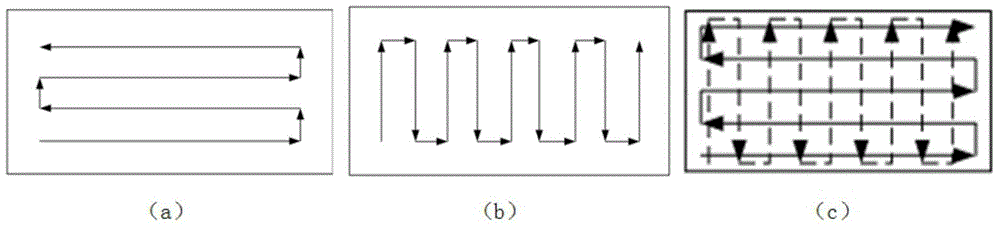

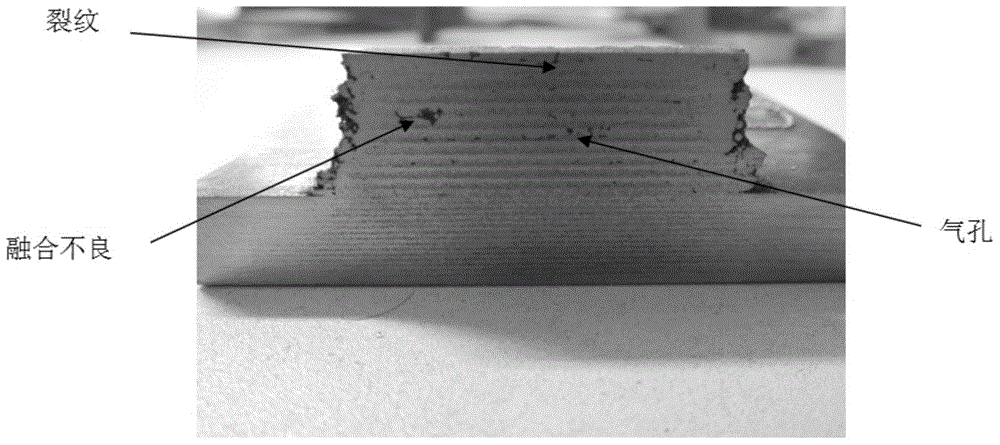

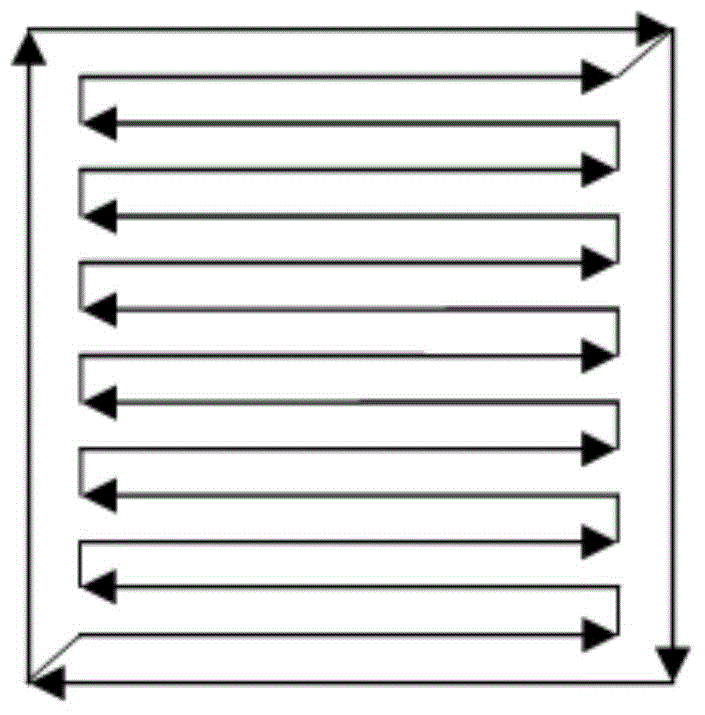

InactiveCN104785778AImplement defect controlControl internal defectsIncreasing energy efficiencyManufacturing technologyLaser scanning

The invention discloses a laser additive manufacturing technology of high-temperature alloy parts, and belongs to the technical field of laser additive manufacturing of metal powder. According to the invention, the technological parameter ranges of different high-temperature alloy materials are determined through basic technological experiments, and then additive manufacturing is carried out by adopting specific laser scanning paths and related internal defect control methods in the manufacturing process. The parts manufactured through the technology have the advantages that the forming efficiency is high, the cost is low, the internal quality is high, the automation degree is high and operation is easy. The high-temperature alloy parts capable of being applied industrially can be directly manufactured by adopting the technology, so that a new approach for manufacturing the high-temperature alloy parts is provided.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

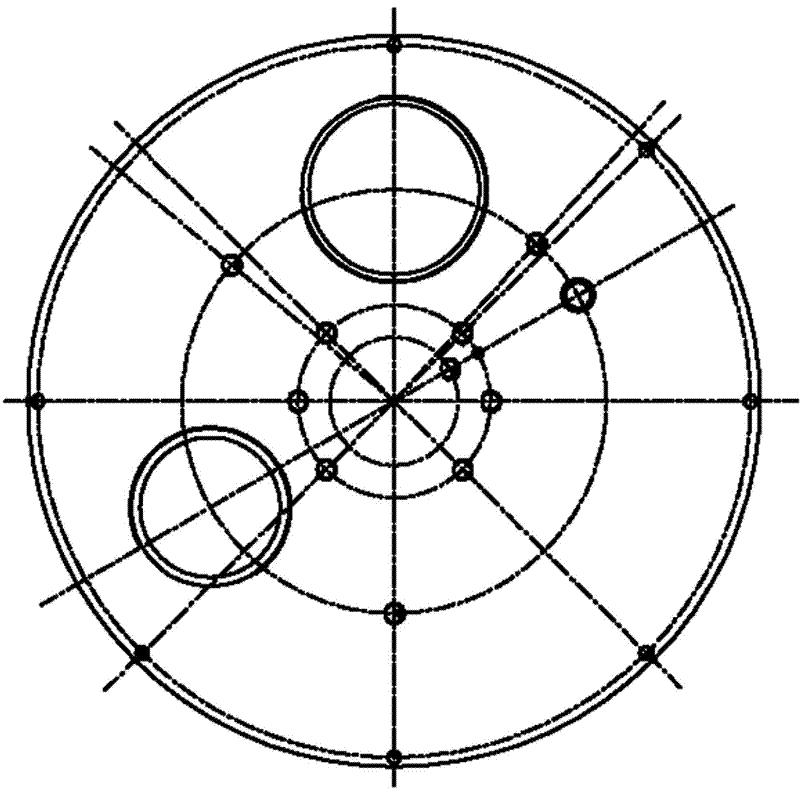

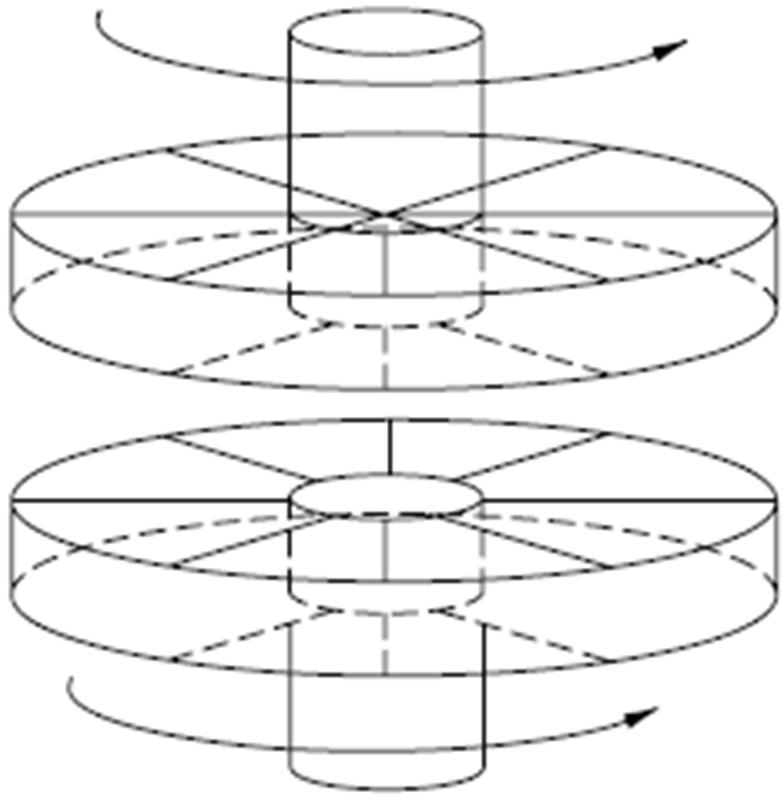

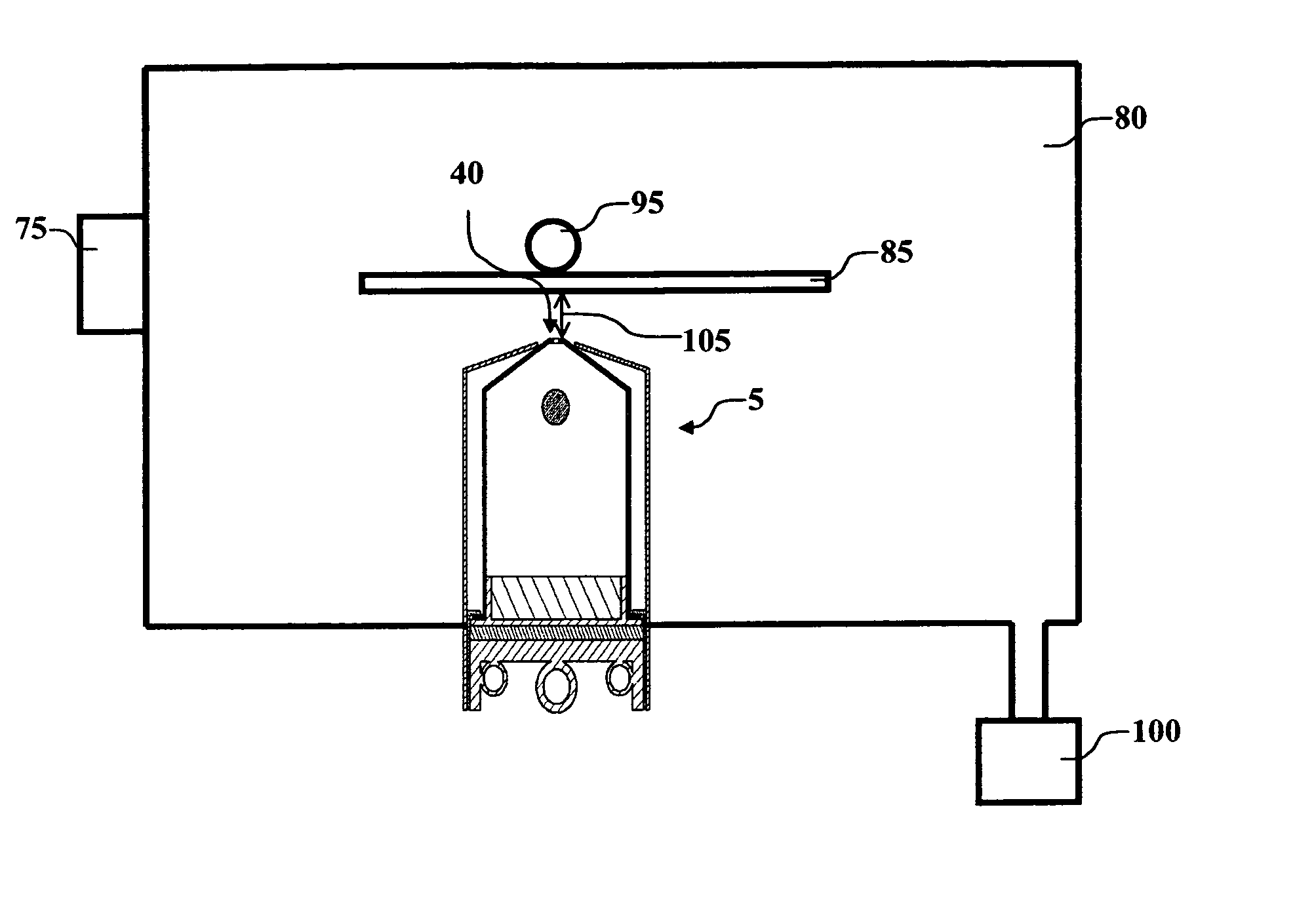

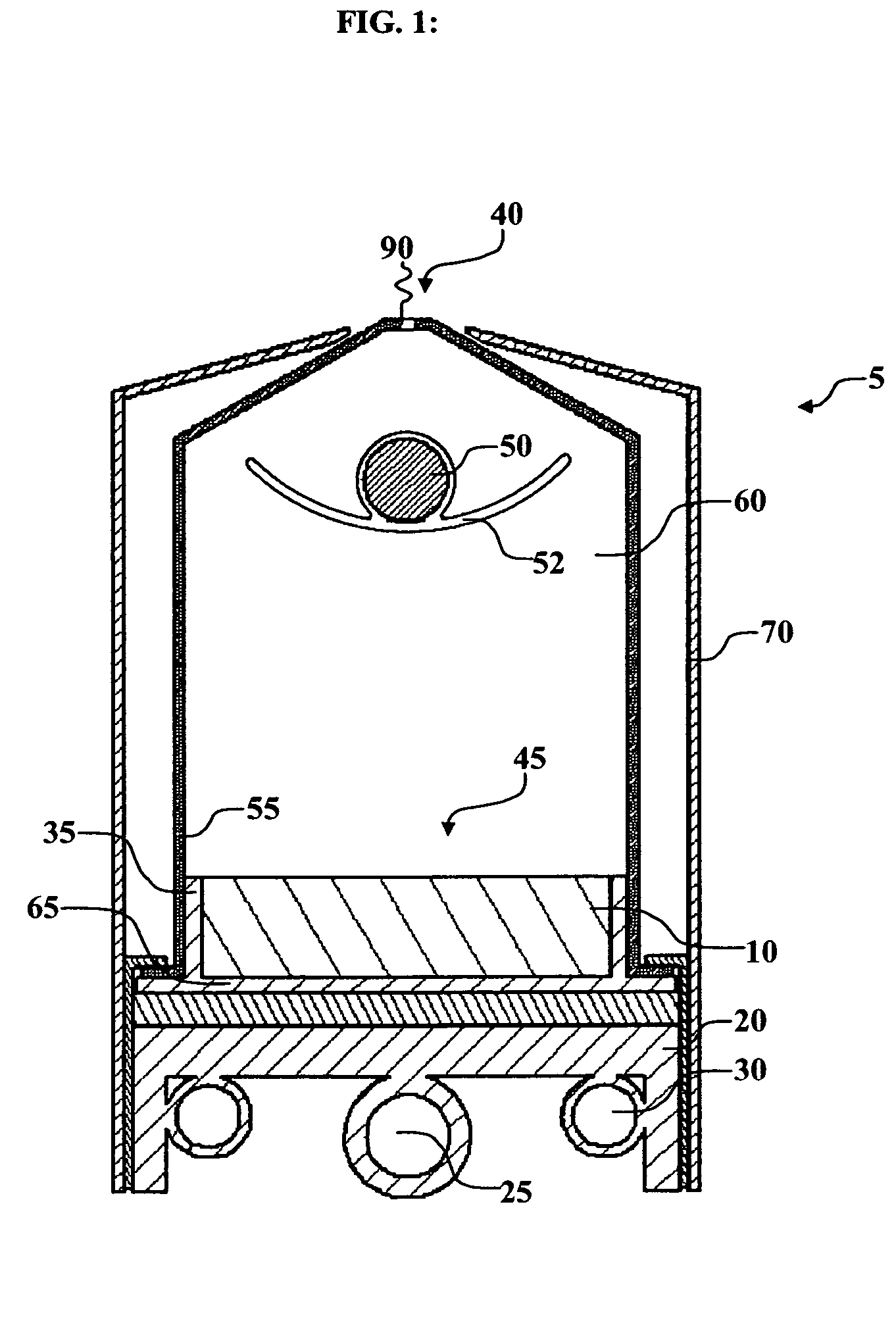

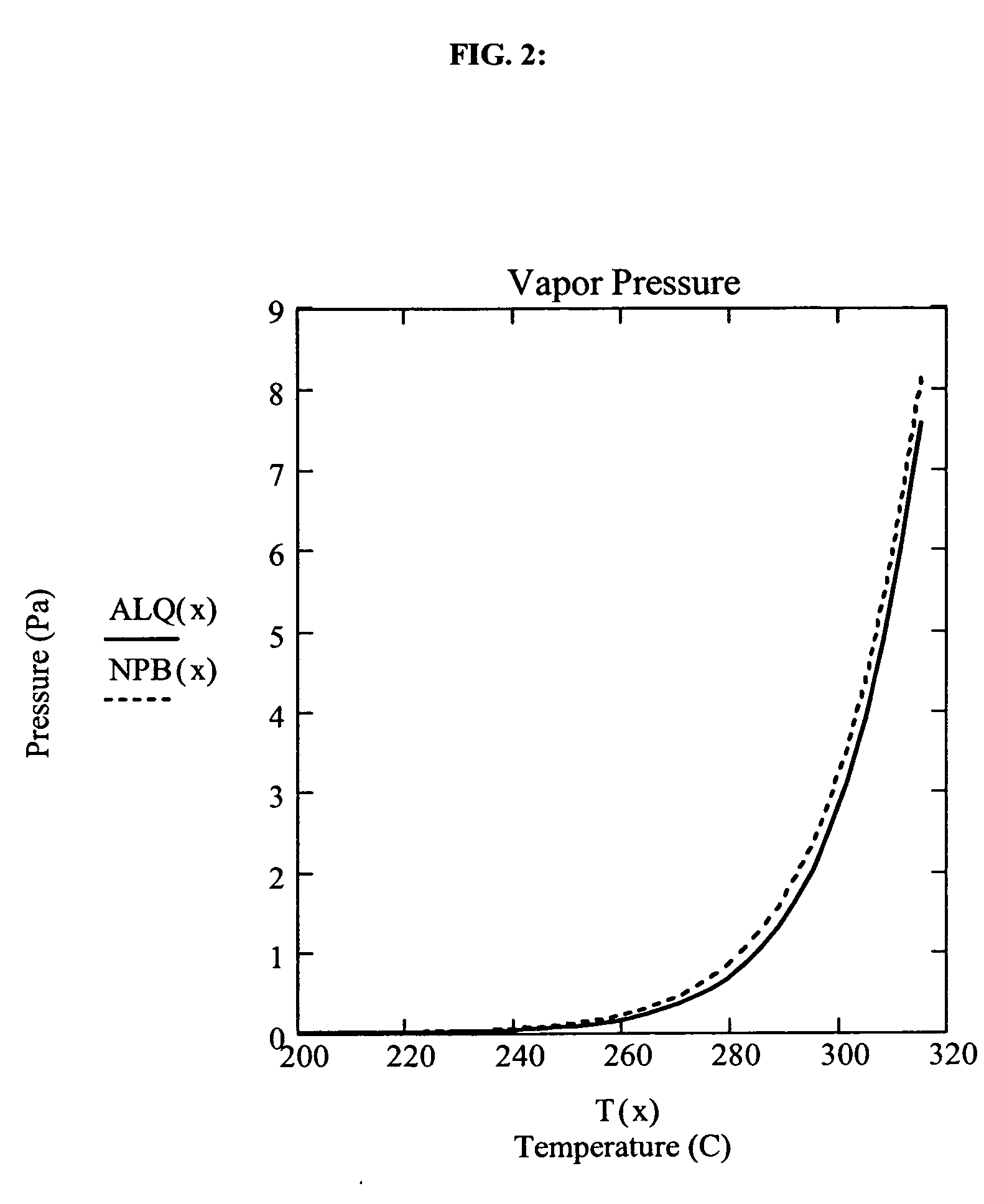

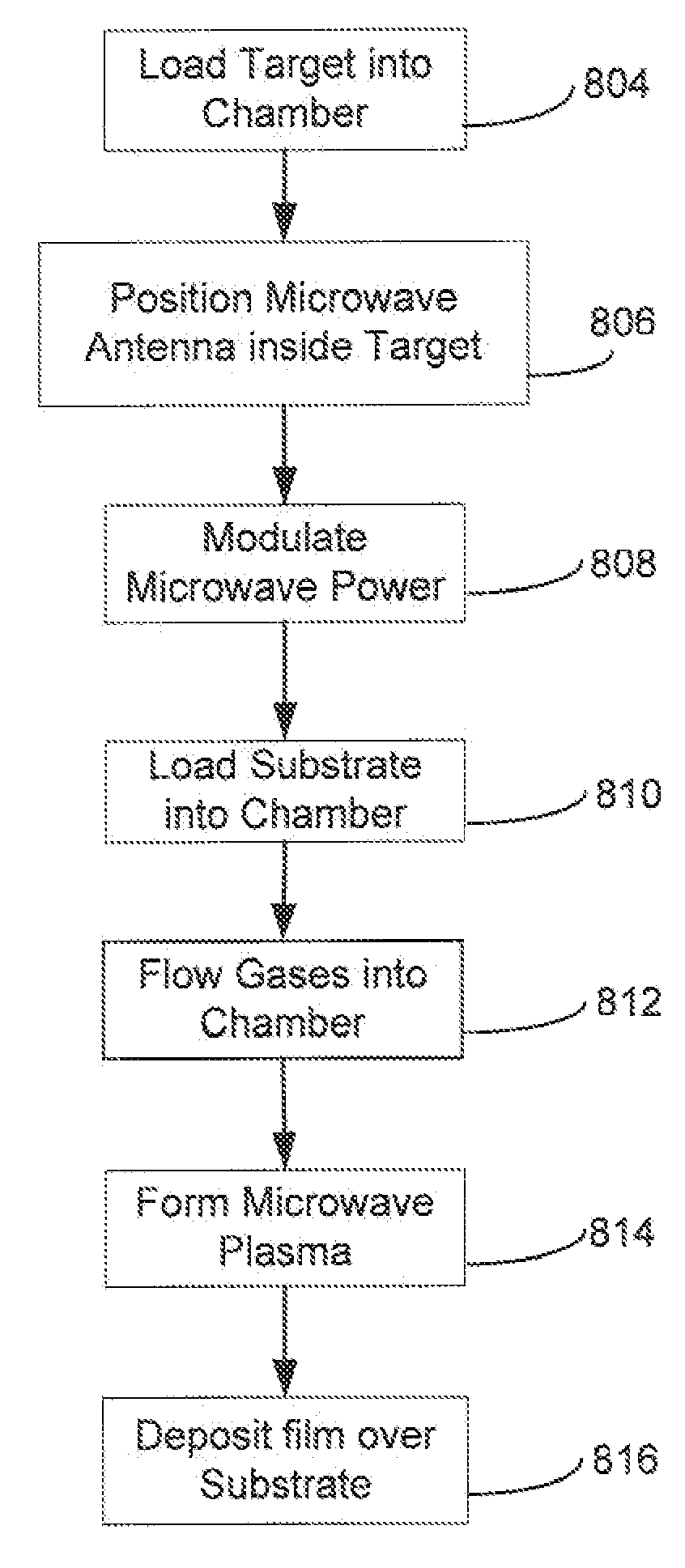

Microwave-assisted rotatable pvd

InactiveUS20090283400A1Increased ionizationImprove utilization efficiencyCellsElectric discharge tubesSputteringPlasma density

Disclosed invention uses a coaxial microwave antenna to enhance ionization in PVD or IPVD. The coaxial microwave antenna increases plasma density homogeneously adjacent to a sputtering cathode or target that is subjected to a power supply. The coaxial microwave source generates electromagnetic waves in a transverse electromagnetic (TEM) mode. The invention also uses a magnetron proximate the sputtering cathode or target to further enhance the sputtering. Furthermore, for high utilization of expensive target materials, a target can rotate to improve the utilization efficiency. The target comprises dielectric materials, metals, or semiconductors. The target also has a cross section being substantially symmetric about a central axis that the target rotates around. The target may have a substantially circular or annular a cross section.

Owner:APPLIED MATERIALS INC

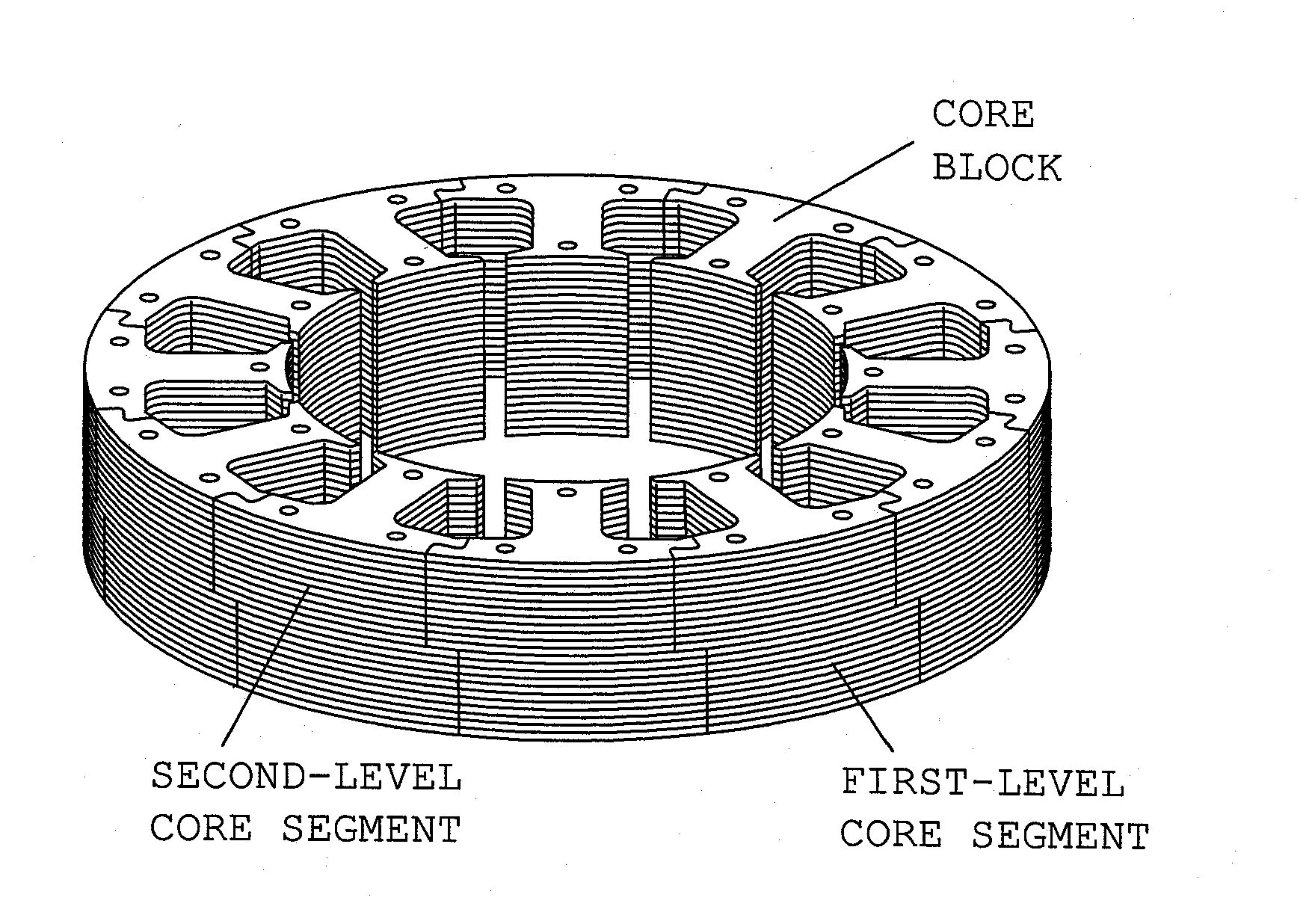

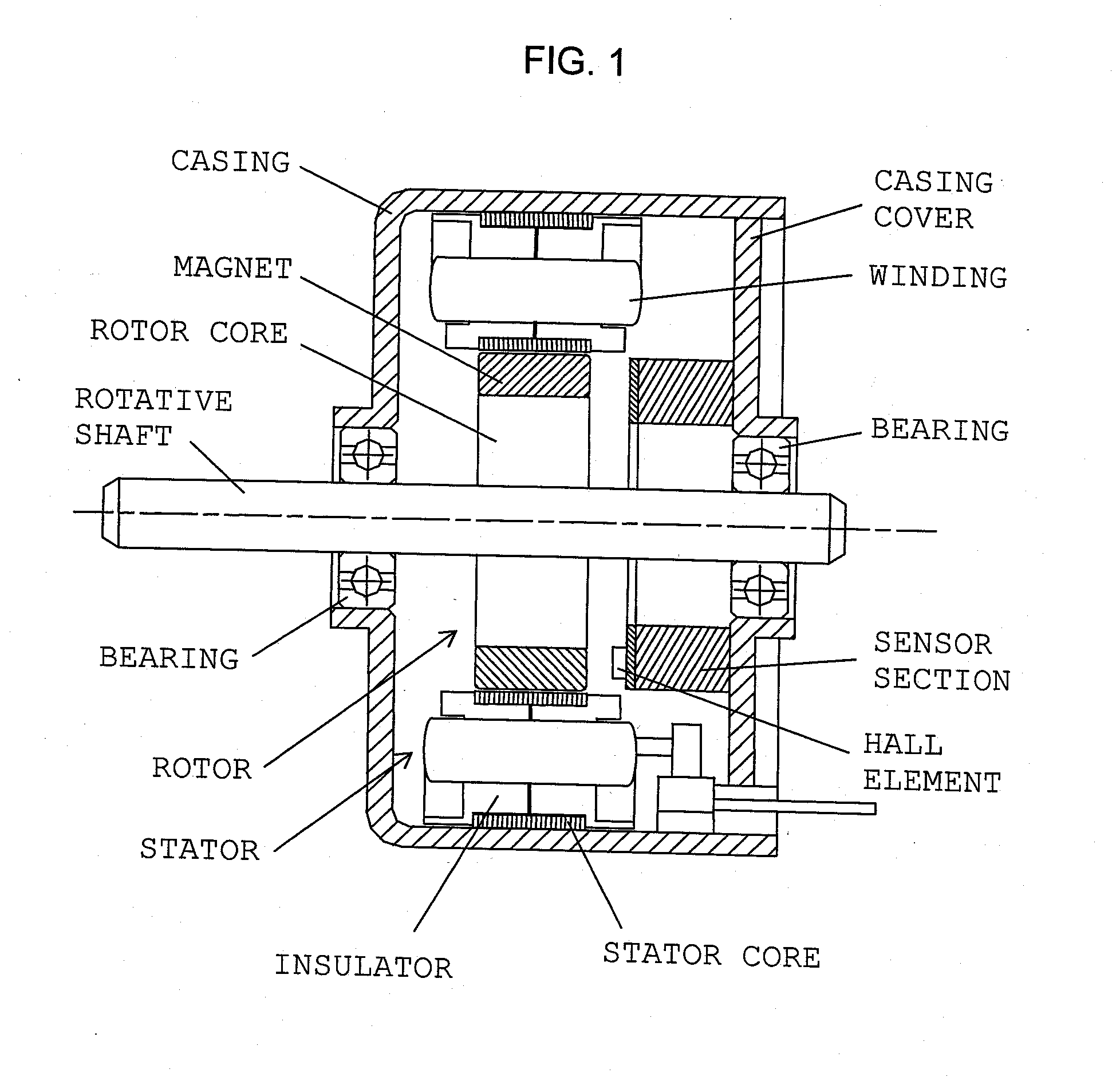

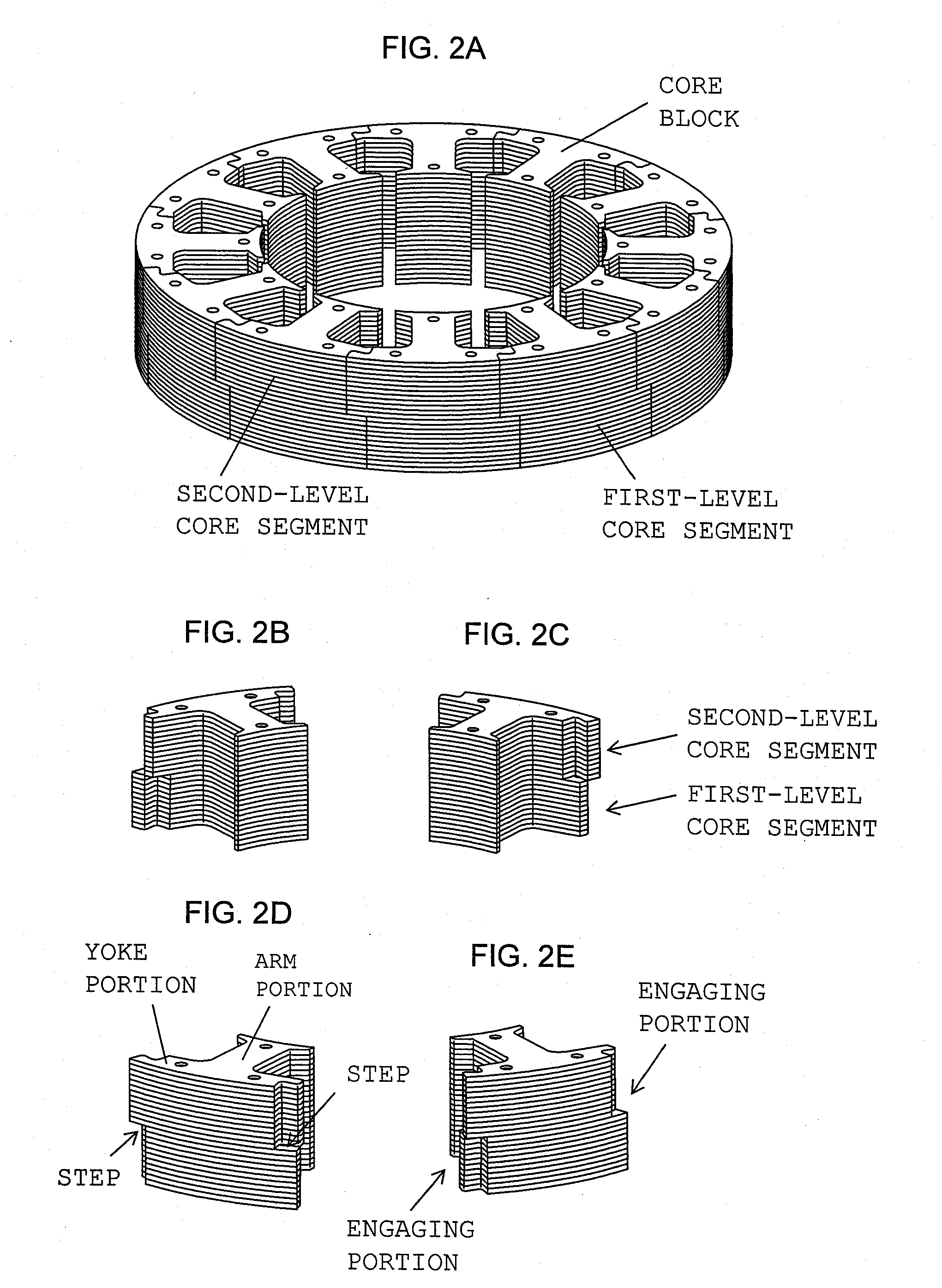

Core block, and magnetic pole core using core blocks for motor

InactiveUS20100231084A1High material utilizationEasy windingMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetic polesMechanical engineering

Owner:MABUCHI MOTOR

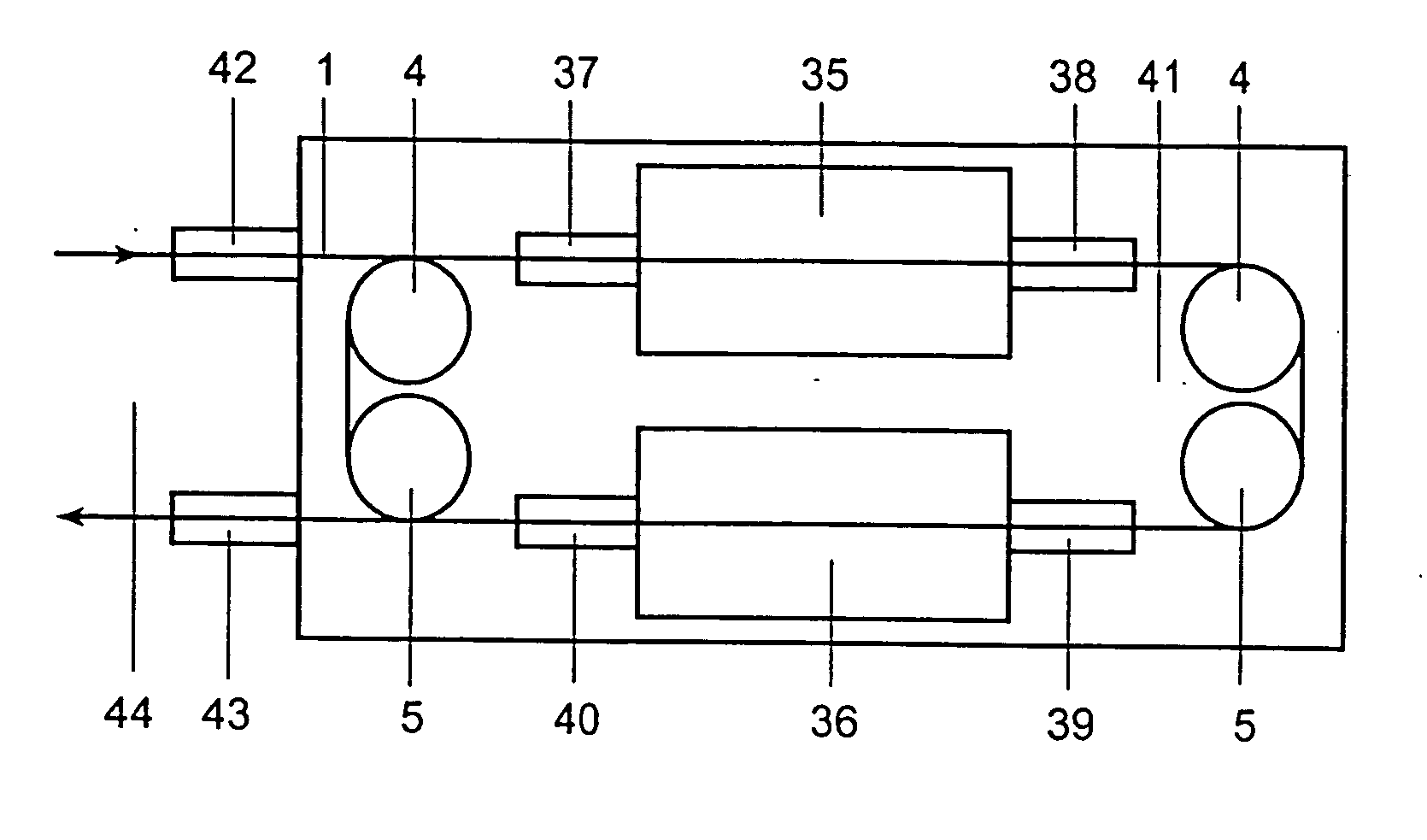

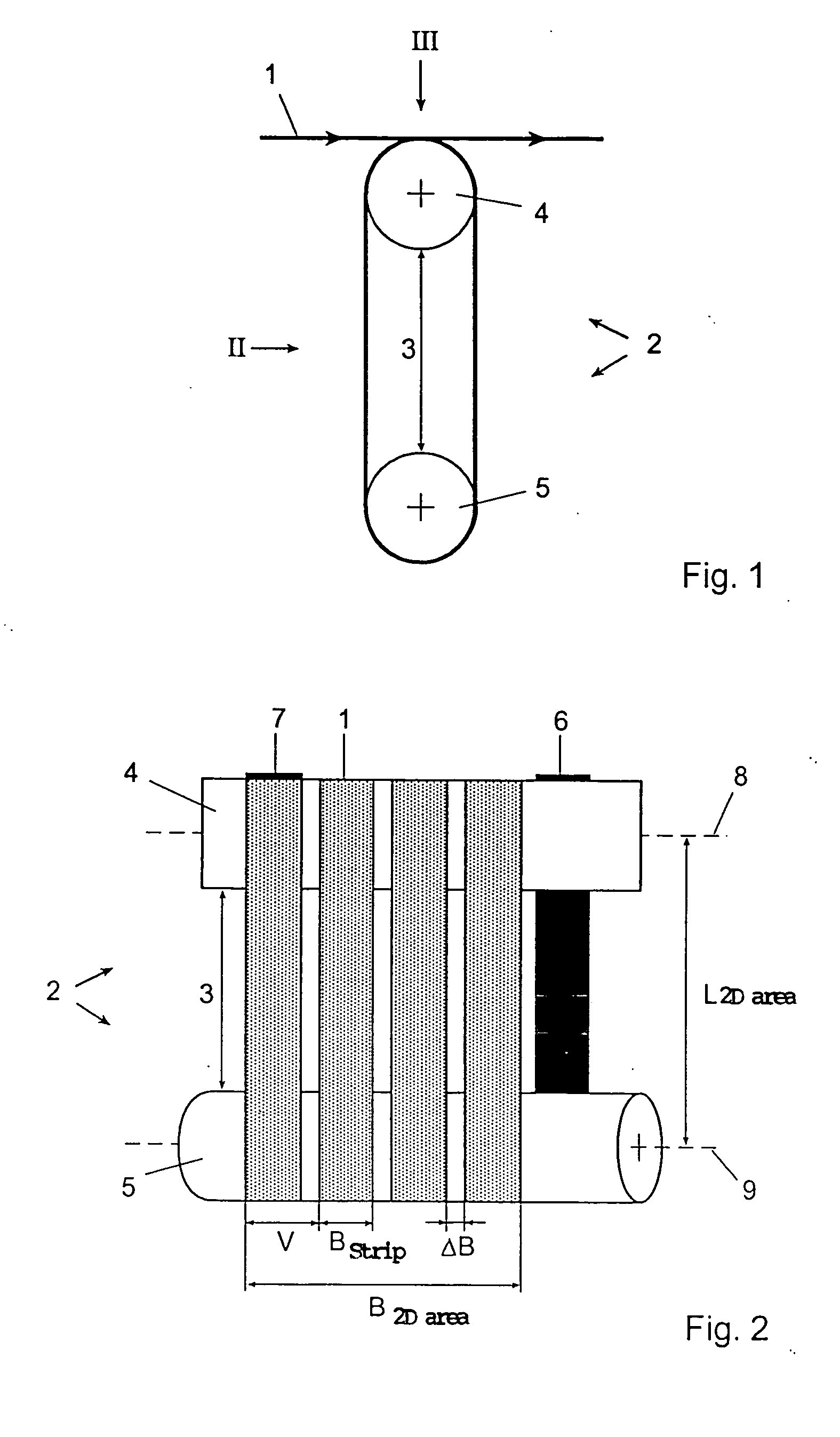

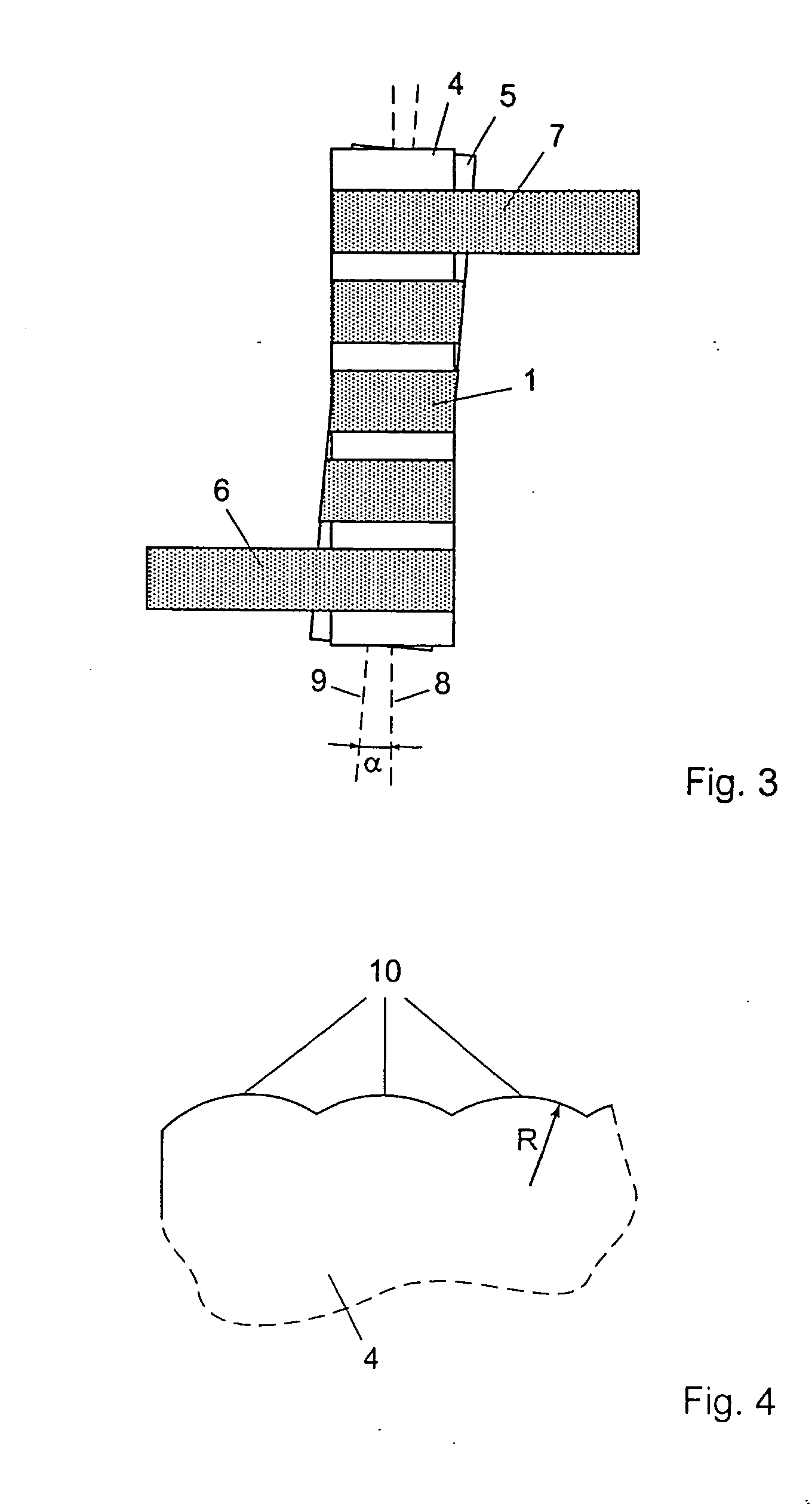

Process and device for coating strips

InactiveUS20070169695A1Easy constructionHigh material utilizationVacuum evaporation coatingSputtering coatingEngineeringMechanical engineering

A process and a device for coating a strip in which the strip is transported along a strip guide inside a coating chamber. At least two guide elements of the strip guide are positioned a certain distance apart, their longitudinal axes being arranged at a slant to each other in such a way that the distance between the guide elements varies along the longitudinal axes. The strip is conducted along the guide elements inside the coating chamber in such a way that at least two sections of the strip are traveling essentially adjacent to each other as they are being coated.

Owner:CIS SOLARTECHN

High thickness uniformity vaporization source

ActiveUS20050208216A1Improving deposit uniformityReduce heat radiationVacuum evaporation coatingSputtering coatingOrganic layerVaporization

A vapor deposition source for use in vacuum chamber for coating an organic layer on a substrate of an OLED device, includes a manifold including side and bottom walls defining a chamber for receiving organic material, and an aperture plate disposed between the side walls, the aperture plate having a plurality of spaced apart apertures for emitting vaporized organic material; the aperture plate including conductive material which in response to an electrical current produces heat; means for heating the organic material to a temperature which causes its vaporization, and heating the side walls of the manifold; and an electrical insulator coupling the aperture plate to the side walls for concentrating heat in the unsupported region of the aperture plate adjacent to the apertures, whereby the distance between the aperture plate and the substrate can be reduced to provide high coating thickness uniformity on the substrate.

Owner:GLOBAL OLED TECH

Microwave rotatable sputtering deposition

InactiveUS20090277778A1Increase plasma densityImprove utilization efficiencyCellsElectric discharge tubesSputteringMicrowave

Disclosed is an invention that uses a coaxial microwave antenna as a primary plasma source in PVD. The coaxial microwave antenna is positioned inside a sputtering target. Instead of using a cathode assist in sputtering, microwaves generated from the coaxial microwave antenna may leak through the sputtering target that comprises a dielectric material to form microwave plasma outside the sputtering target. To further enhance plasma density, a magnetron or a plurality of magnetrons may be added inside the target to help confine secondary electrons. An electric potential may be formed between adjacent magnetrons and may further enhance ionization. To achieve directional control of the generated microwaves, a shield that comprises a dielectric material or dielectric material coated metal may be added proximate the coaxial microwave antenna. Furthermore, for high utilization of expensive target materials, a target can rotate to improve the utilization efficiency.

Owner:APPLIED MATERIALS INC

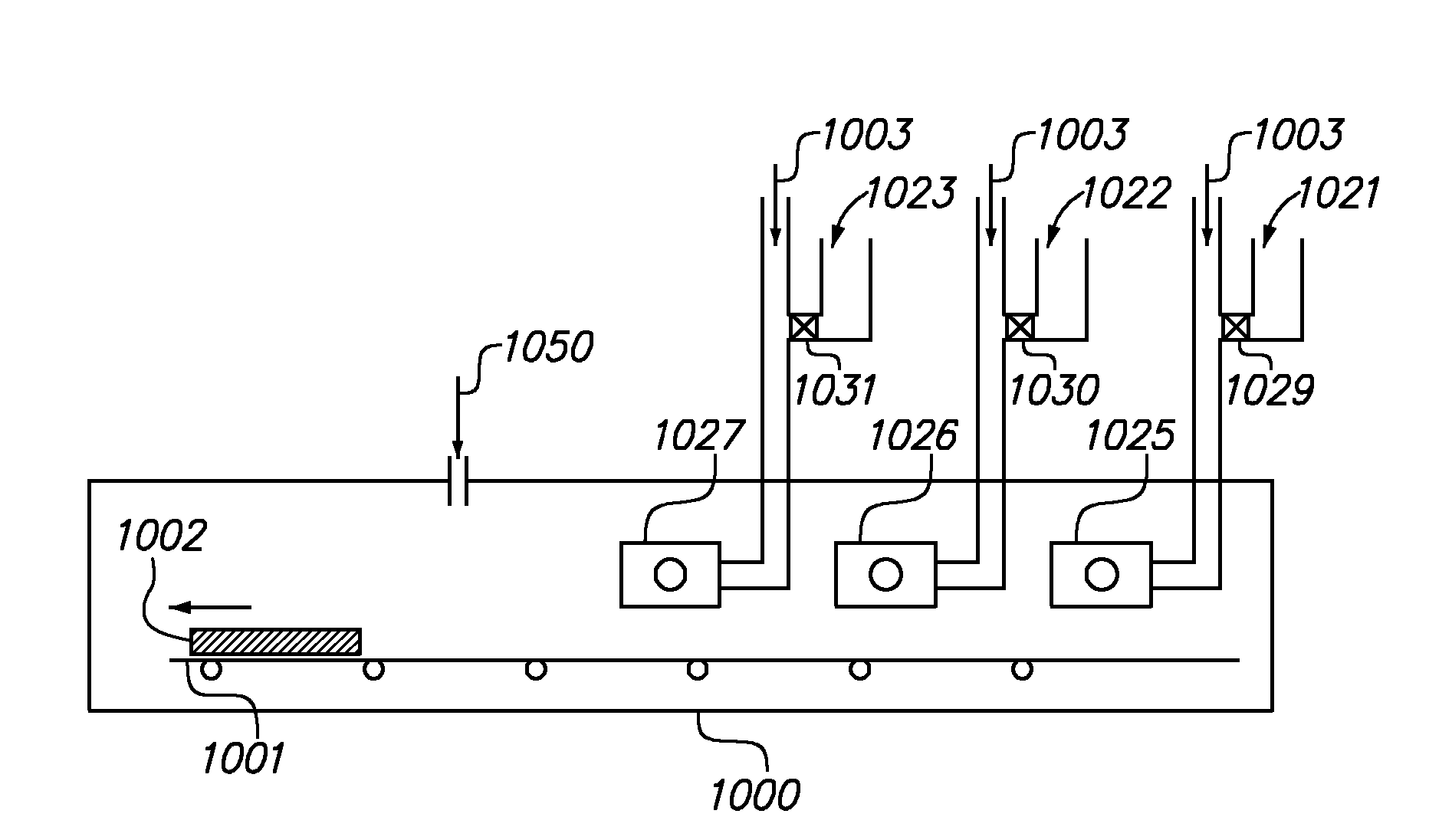

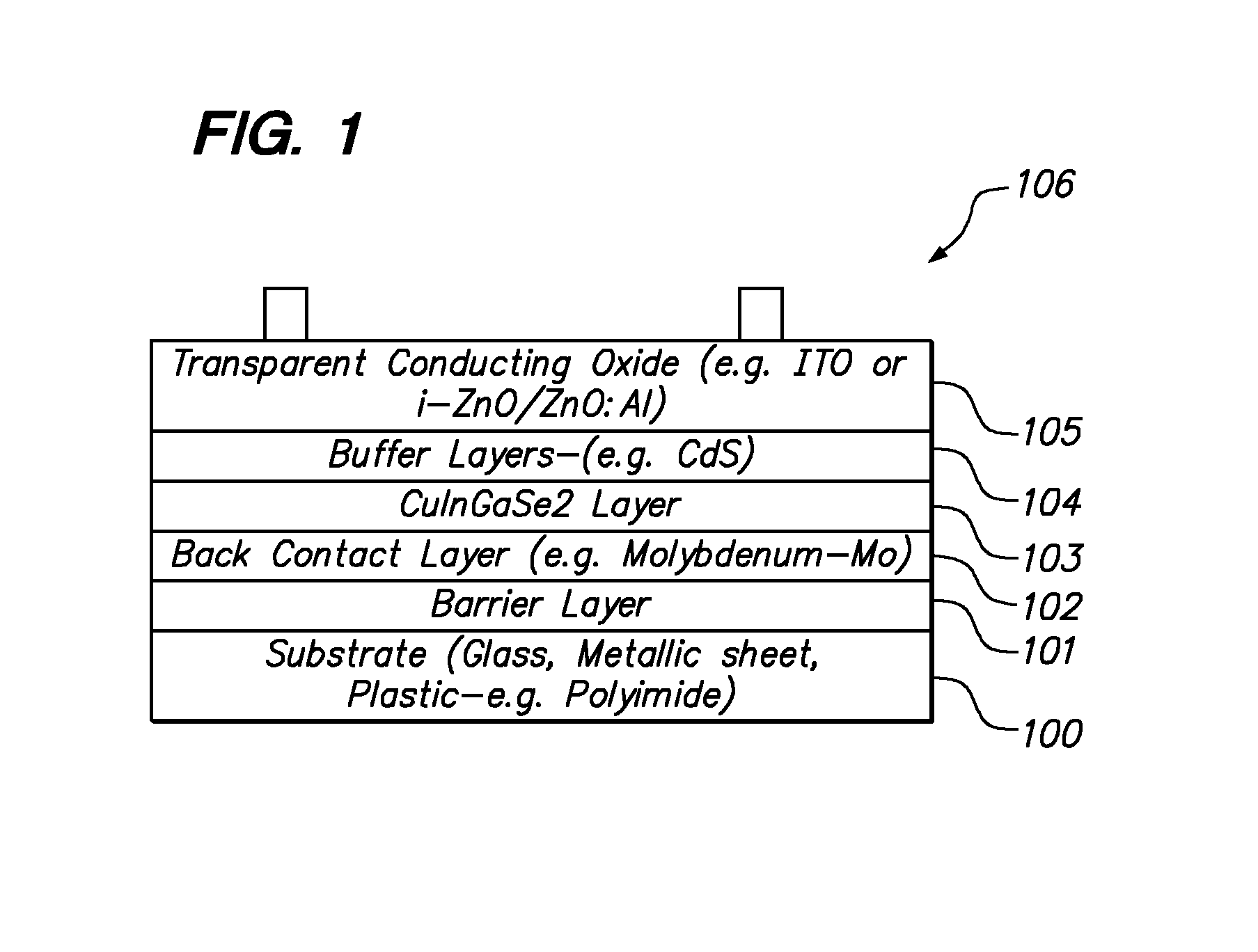

METHOD AND APPARATUS FOR DEPOSITING COPPER-INDIUM-GALLIUM SELENIDE (CuInGaSe2-CIGS) THIN FILMS AND OTHER MATERIALS ON A SUBSTRATE

ActiveUS20140273335A1Low costLow production costLiquid surface applicatorsFinal product manufactureSource materialEngineering

An apparatus for deposition of a plurality of elements onto a solar cell substrate comprising: a housing; a transporting apparatus to transport said substrate in and out of said housing; a first tubing apparatus to deliver powders of a first elements to said housing wherein said first tubing apparatus is comprised of a first feeder tube located outside of said housing and joined to said housing; a first source material tube located outside of said housing and joined to said feeder tube; a valves located inside of said first source material tube sufficient to block access between said first source material tube and said first feeder tube; a first heating tube located inside of said housing and connected to said first feeder tube; a second tubing apparatus to deliver powders of a second elements to said housing wherein said second tubing apparatus is comprised of a second feeder tube located outside of said housing and joined to said housing; a second source material tube located outside of said housing and joined to said second feeder tube; valves located inside of said second source material tube sufficient to block access between said second source material tube and said second feeder tube; a second heating tube located inside of said housing and connected to said second feeder tube; a loading station for loading said substrate onto said transporting apparatus; one or more thermal sources to heat said housing and said first heating tube and said second heating tube.

Owner:SOLACTRON

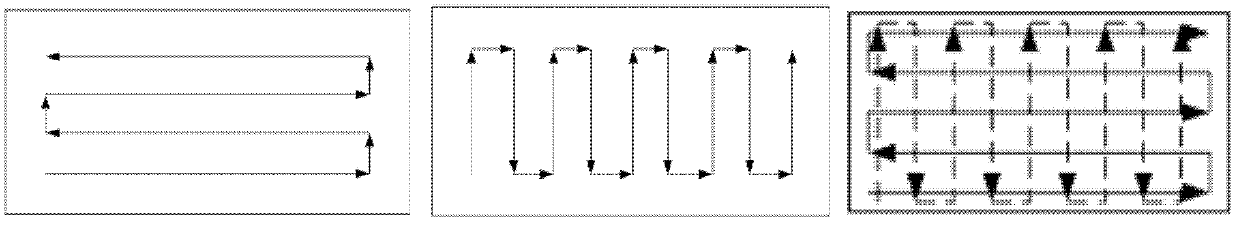

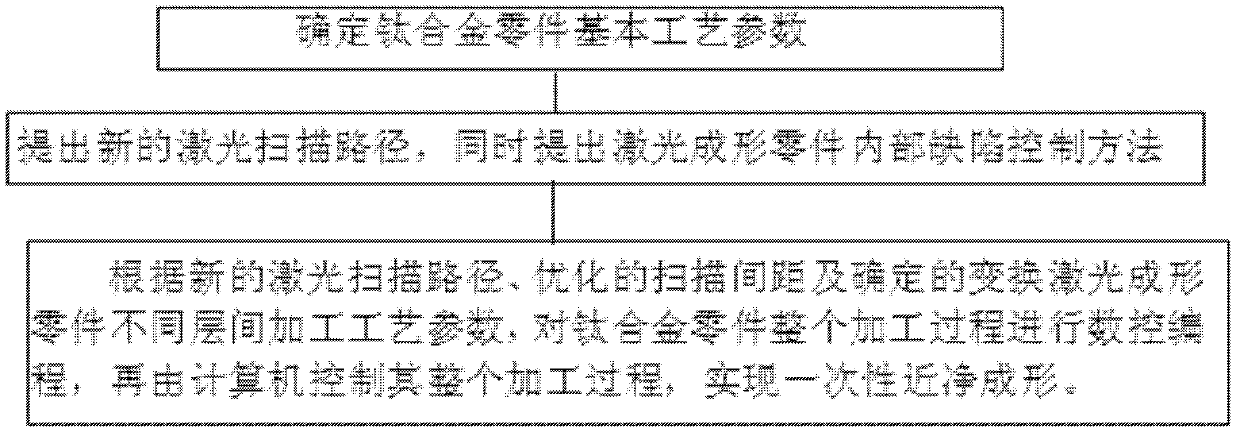

Laser direct forming process for titanium alloy part

ActiveCN103302292AImprove forming efficiencyLow costIncreasing energy efficiencyLaser scanningMetal powder

The invention discloses a laser direct forming process for a titanium alloy part, and relates to a laser rapid forming technology for metal powder. The process mainly comprises the following steps of determining basic process parameters of the titanium alloy part, and disclosing a new laser scanning path and a method for controlling an internal defect of a laser formed part, i.e. firstly determining a process parameter range of spherical TA15 powder by a basic process experiment, and transforming processing process parameters of different layers of the laser formed part to form the titanium alloy part by adopting the laser scanning path and the related internal defect control method, namely by adopting an optimal scanning interval. The part formed by the process has the advantages of high forming efficiency, low cost, high internal quality, high automation degree, easiness in operation and the like. The process can be used for directly forming the titanium alloy part at an industrial application level, and a novel way for the production of a titanium alloy structural part is provided.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Roofing shingle system and shingles for use therein

ActiveUS9399870B2High material utilizationPromote infiltrationRoof covering using tiles/slatesCovering/liningsLeading edgeTrailing edge

A roofing system and roofing shingles for use therein are disclosed. The roofing system comprises a multiplicity of courses of roofing shingles having a headlap portion, a buttlap portion, a lateral leading edge, and a lateral trailing edge, wherein the headlap portion has a width that is less than a width of the buttlap portion defining a reduced-width headlap, wherein the lateral trailing edge of a shingle in a course partially overlaps and partially abuts the lateral leading edge of an adjacent previously installed shingle to form an interlocking edge between adjacent shingles in the course, and wherein the lateral edge includes a trailing edge projection having a weather edge, a rear edge, and a variable breadth that increases toward the rear edge of the trailing edge projection.

Owner:BMIC LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com