Patents

Literature

2709results about How to "Short processing cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Timber wood hot pressing charing intensification method

ActiveCN101214675AUnlimited thicknessGood dimensional stabilityDrying using combination processesWood compressionCarbonizationVolumetric Mass Density

The present invention discloses a hot-pressing carbonization strengthening method of timbers, which includes drying, planing, hot-pressing carbonization, cooling and other steps. The present invention applies a hot press as a timber-carbonizing device, and the timbers under the state of compression are processed by hot-pressing carbonization. The present invention is characterized in that the investment on carbonization devices is less, the carbonization process is simple, the production is safe, the production efficiency is high, the consumption of heat energy is little, and the production cost is low; moreover, the thickness of the carbonized timbers is not limited, the defects of the timbers, such as deformation, cracking, stiker stain, color difference, knot fall-off, etc., do not occur in the process of production, so the quality of products is high; not only is the size stability and noncorrodibility of the carbonized timbers improved, but also the density and mechanical property of the timbers is increased.

Owner:广州豪沃仕家具有限公司

Method for producing instant pleurotus eryngii chips

The invention relates to a method for producing instant pleurotus eryngii chips, and belongs to the technical field of the deep processing of agricultural products. The main pleurotus eryngii chip production process comprises: performing pretreatment such as conventional selection, washing, precise segmenting, blanching, enzyme killing, cooling and the like on pleurotus eryngii, and performing ultrasonic auxiliary dipping, hot-air drying, vacuum frying and dewatering, centrifugal deoiling, seasoning and packaging. In the method, due to the adoption of a new process of combining the ultrasonic auxiliary dipping, the hot-air drying, the vacuum frying and dewatering, the dipping efficiency is improved, the moisture content of pleurotus eryngii pieces is reduced due to hot-air predrying, and the vacuum frying time is shortened greatly; and products of the pleurotus eryngii chips have the characteristics of high puffing rate, low oil content, excellent sensory quality and the like. In the method, the pleurotus eryngii is not processed by conventional freezing, so the production period of the finished products is shortened greatly, the production cost is saved, and a feasible new path is provided for the deep processing of the pleurotus eryngii.

Owner:NANJING AGRICULTURAL UNIVERSITY +1

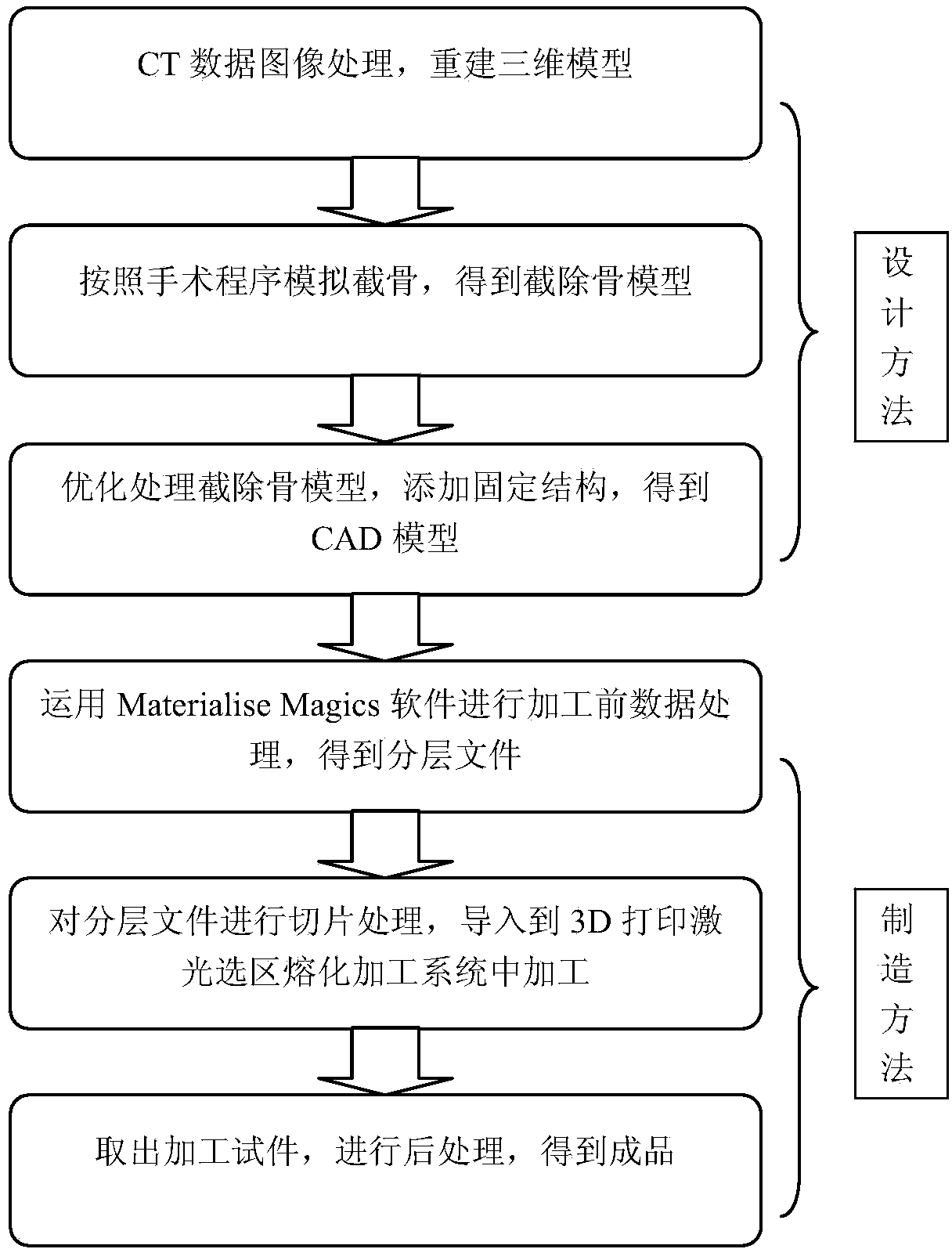

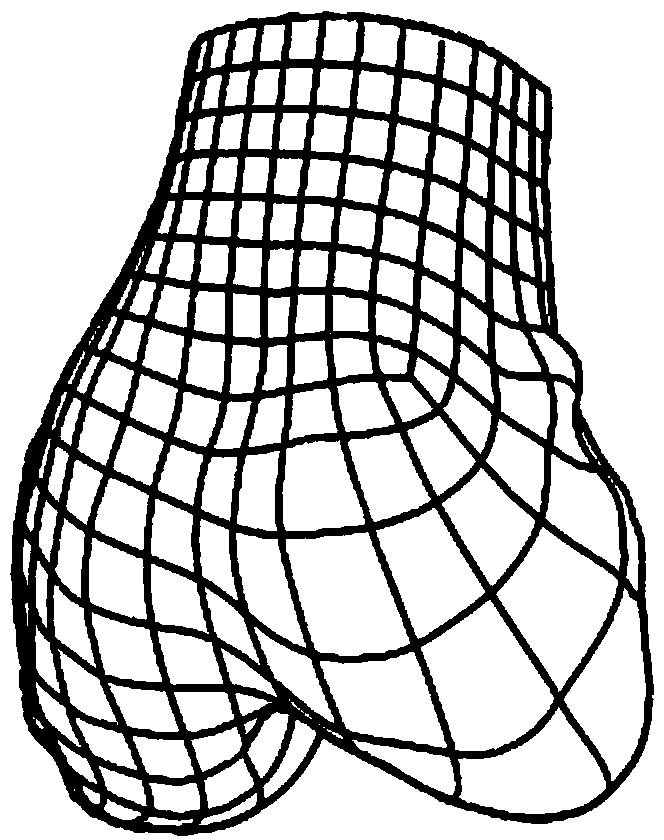

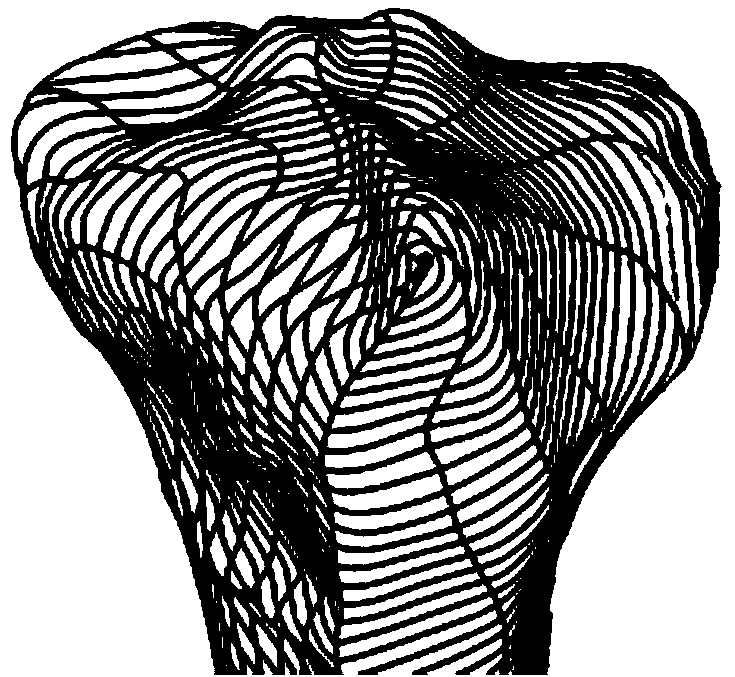

Individualized reversal design and manufacturing method for full knee joint replacing prosthesis

ActiveCN103860293AImprove matchShort processing cycleJoint implantsImage data processingTibiaMedical imaging data

The invention relates to an individualized reversal design and manufacturing method for a full knee joint replacing prosthesis. The method comprises the following steps that 1, three-dimensional digital models of the thighbone and the tibia are built on the basis of the medical image data of the knee joint of a patient; 2, virtual bone cutting software is used for respectively carrying out simulated bone cutting on the three-dimensional digital models of the thighbone and the tibia; 3, the reversal design of CAD (computer-aided design) models of a thighbone replacing prosthesis, a tibia replacing prosthesis and a tibia gasket prosthesis is carried out; 4, the full knee joint replacing prosthesis is manufactured according to the CAD models of each prosthesis through the 3D (three-dimensional) printing technology. The method provided by the invention has the advantages that on the basis of the original bone structure of the patient, the virtual knee joint replacing operation bone cutting form is combined, the structural form of the replacing prosthesis is subjected to reversal design, the structural form consistency of the cut bone and the replacing implanted body structure is realized to the greatest degree, and the optimum matching between the prosthesis and the individual bone form is reached. In addition, the laser selective melting 3D printing technology is used for manufacturing the designed replacing prosthesis, the optimum matching between the prosthesis and the knee joint bone cutting surface is ensured on the basis of the minimum bone cutting quantity, and the effect optimization is reached.

Owner:BEIJING NATON TECH GRP CO LTD +1

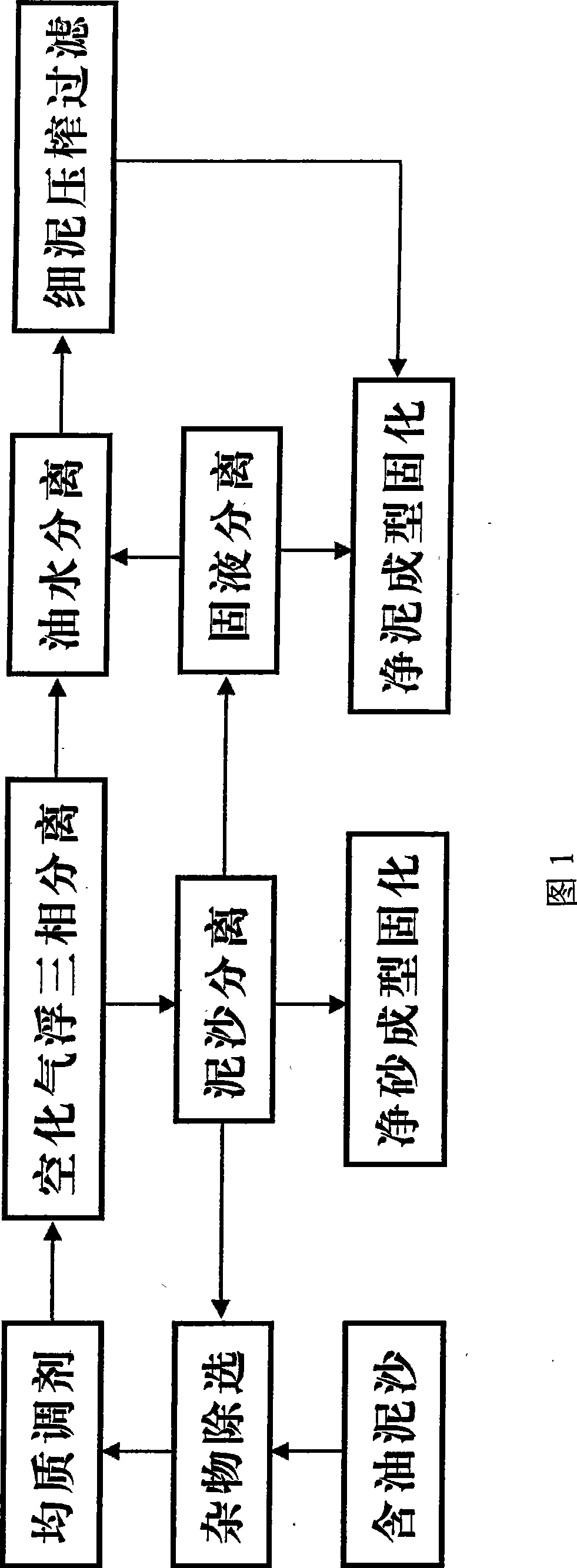

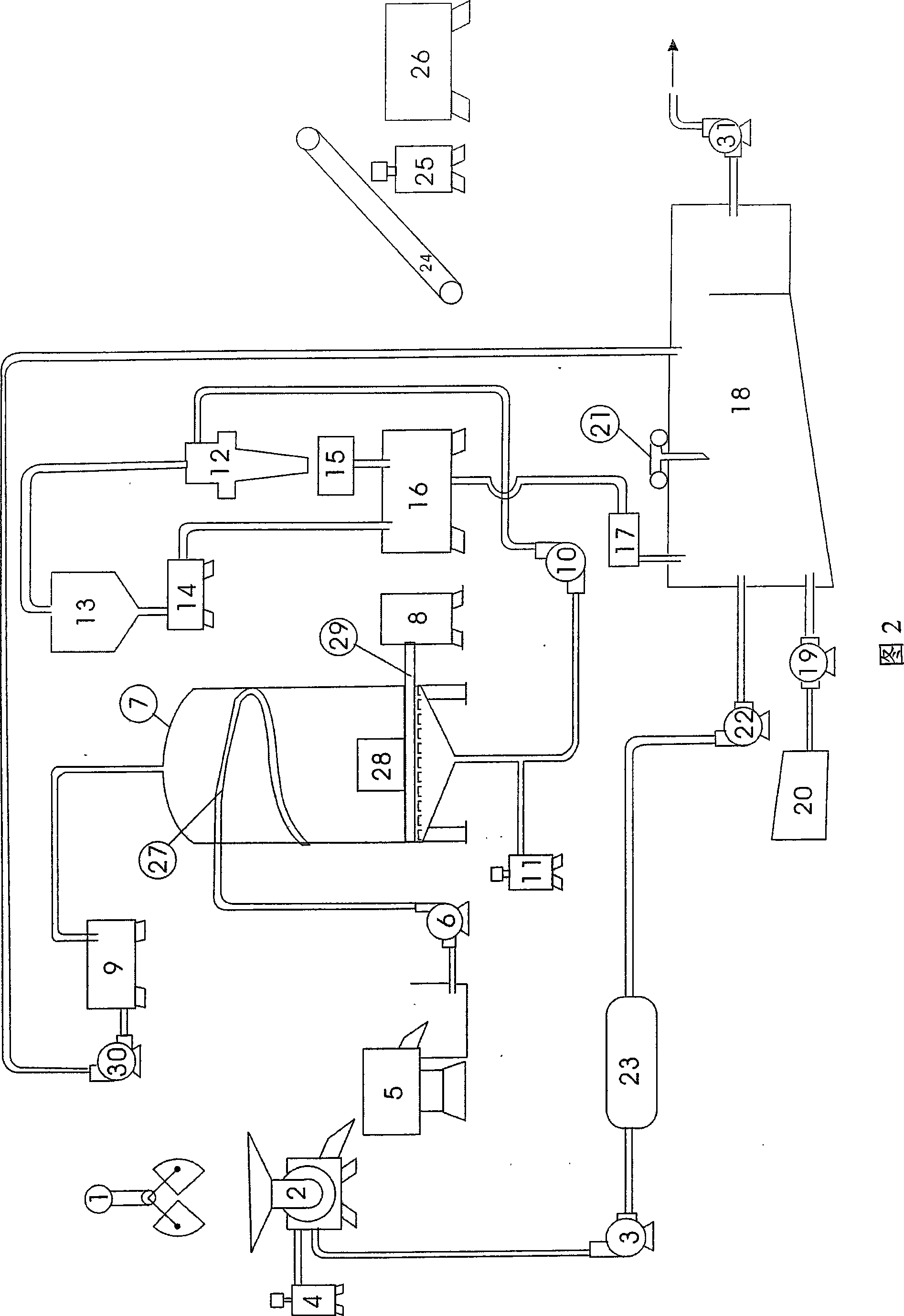

Pollution-free oil-containing mud cleaning treatment method and treatment system thereof

InactiveCN101428247ASolve the problem of secondary pollutionSimple purification processWet separationResource recoverySlurry

The invention relates to a pollution-free oily sediment purification treatment method and a treatment system, and the implementation steps are as follows: adopting a mechanical feeding device for conveying oily sediment to a miscellany removing and sorting device, filtering out and removing the miscellanies therein, perfusing hot water and a reagent into the oily sediment; evenly regulating the oily sediment through mechanical rolling; treating oil, water and sediment in an input tank through a cavitation and air flotation three-phase separator, so as to realize the three-phase separation of the oil, the water and the sediment, and discharging most of the separated oil; separating the sediment through a cyclone separator, and discharging net sand; separating slurry through a centrifuge, discharging net mud; separating fine mud from the water through a pressing filter, discharging net fine mud; separating the oil-water through natural ascending and descending, outputting the oil, and continuously heating water for the cyclic utilization; and curling and molding the discharged net sand and net mud according to routine. The invention realizes the resource recovery of crude oil in oily sediment and reduces the cost for purifying and treating oily sediment effectively, and the purified sediment is made into cured resin used for building materials.

Owner:TIANJIN TAIXING ENG TECH CO LTD

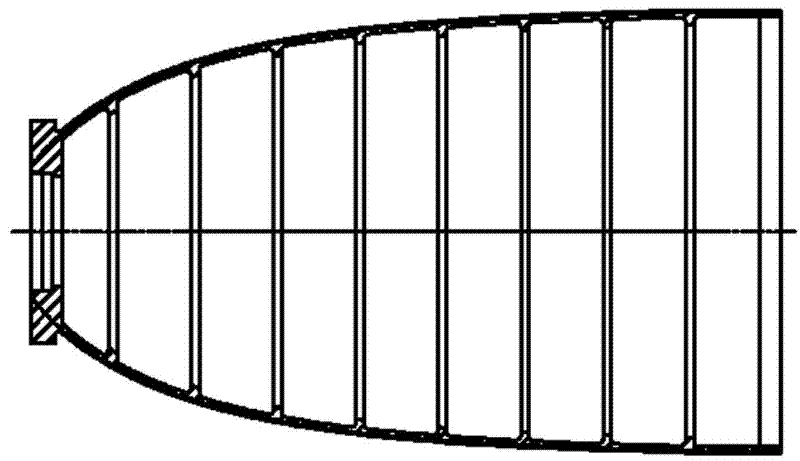

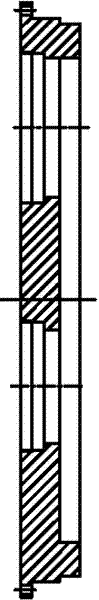

Processing method of thin and long aluminium alloy thin-walled cylinder

ActiveCN102513785AHigh material utilizationShort processing cycleNon-electric welding apparatusWeld seamThin walled cylinder

The invention provides a processing method of a thin and long aluminium alloy thin-walled cylinder and belongs to a mechanical processing method of a slewing structure, and the processing method is used for carrying out friction stir welding on a shell blank so as to process and mold the shell blank into a bent generatrix thin-walled cylinder shell. The method provided by the invention can be used for solving the problems of poor shell generatrix displacement, poor shell roundness, uneven wall thickness, clearance at welding seams, unqualified performance detection and incapability of ensuring use requirements in the existing processing method. The method comprises a part manufacturing step, a matching step, a caustic washing step, a trial assembly step, a positioned welding step, a friction stir welding step, a welding seam polishing step, a stress-relief annealing step, an X-ray detection step, a shape processing step, a ultrasonic flaw detection step and an end face hole processingstep. The method provided by the invention can be used for solving the problems of poor shell roundness, uneven wall thickness, clearances at the welding seams and unqualified performance detection in the existing processing method, improving the shell processing precision and reliably ensuring the product quality.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

Process method for rapidly fermenting chopped hot peppers

InactiveCN101982104AShort fermentation timeReduce churnClimate change adaptationFood preparationAllium sativumWater content

The invention mainly relates to a process method for rapidly fermenting chopped hot peppers, and mainly relates to the field of food processing application. The process method comprises the following steps: washing, soaking and disinfecting the fresh hoppers; draining and removing the water content on the surface of the fresh hoppers; directly chopping by a chopper mixer; adding 2% of salt, 0.5% of calcium chloride, 0.05% of citric acid; inoculating 0.05% of lactobacillus plantarum, and 0.05% of lactobacillus fermentium cultured in high density, wherein, the number of the lactic acid bacteria is 1010cfu / g and the amount of the ester-producing yeast is over 107cfu / m; fermenting for 48h in a sealing mode at the temperature of 37 DEG C; filtering, wherein, the filter pulp can be used as the strain water of the next batch; adjusting the salt concentration of the filtered and fermented hot peppers according to the different tastes to 8%; adding spices, such as white wine, Liuyang brown bean and garlic and the like; encapsulating after evenly stirring; and pasteurizing to obtain the finished product.

Owner:HUNAN AGRICULTURAL UNIV

Ultrasonic process of preparing theasaponin

The present invention is ultrasonic process of preparing theasaponin and belongs to the field of agricultural side product processing technology. The technological scheme is that tea seed cake residue after extracting oil is processed through crushing, mixing with organic solvent, ultrasonic leaching, separating, recovering solvent, ultrafiltering to purify and to obtain theasaponin concentrate, decolorizing and drying to obtain theasaponin product. The present invention has the beneficial effects of physical extraction process caused high theasaponin extracting rate, high product purity and quality, simple technological process with low power consumption and low production cost, less pollution, etc.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

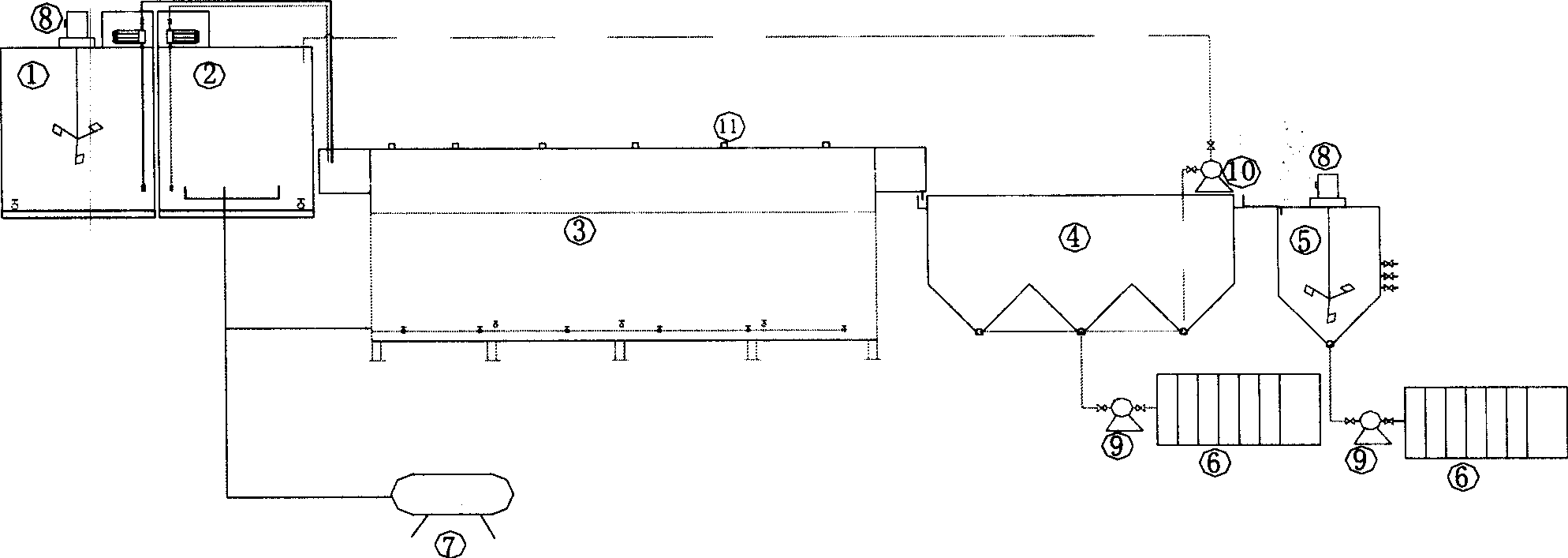

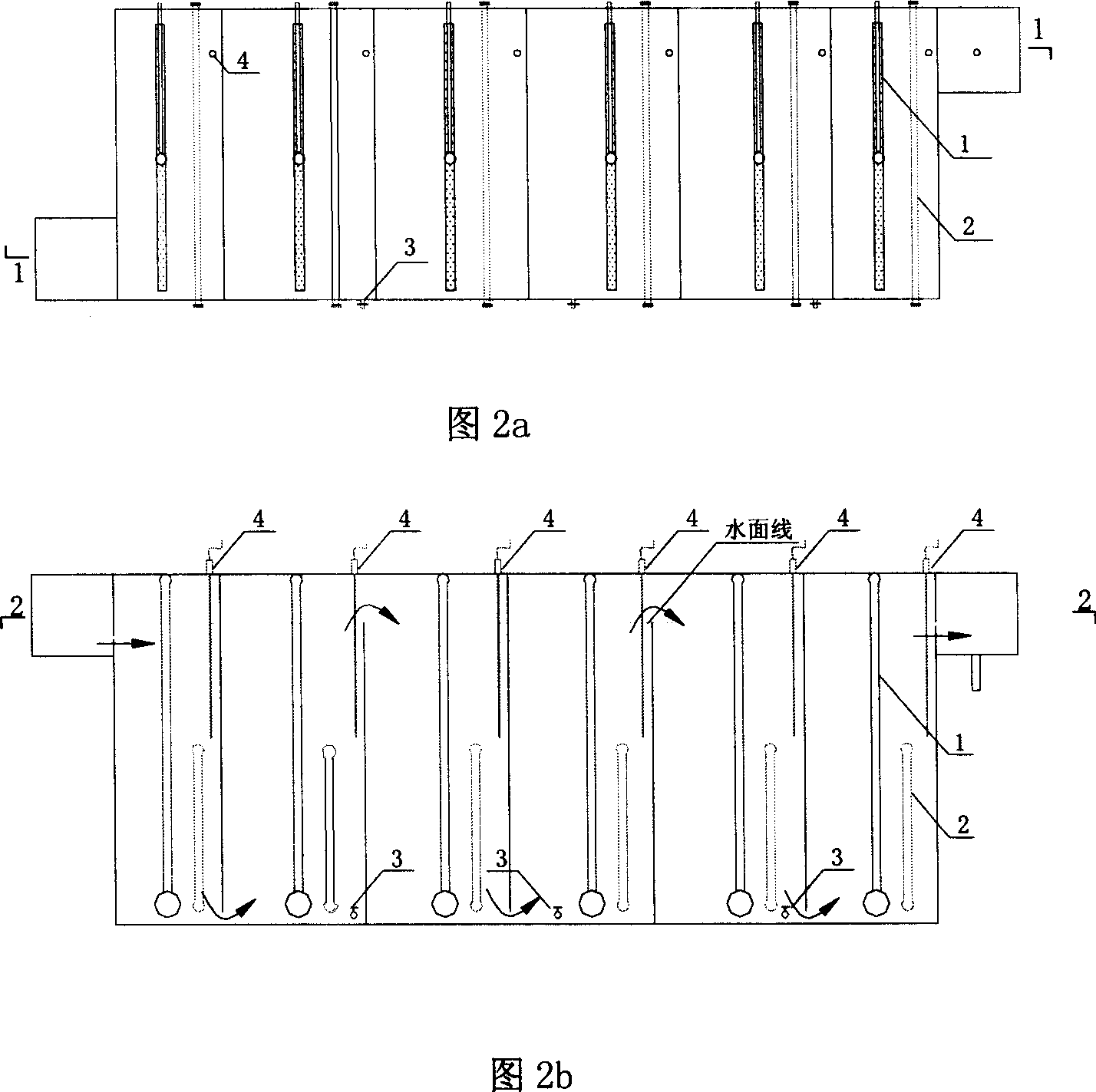

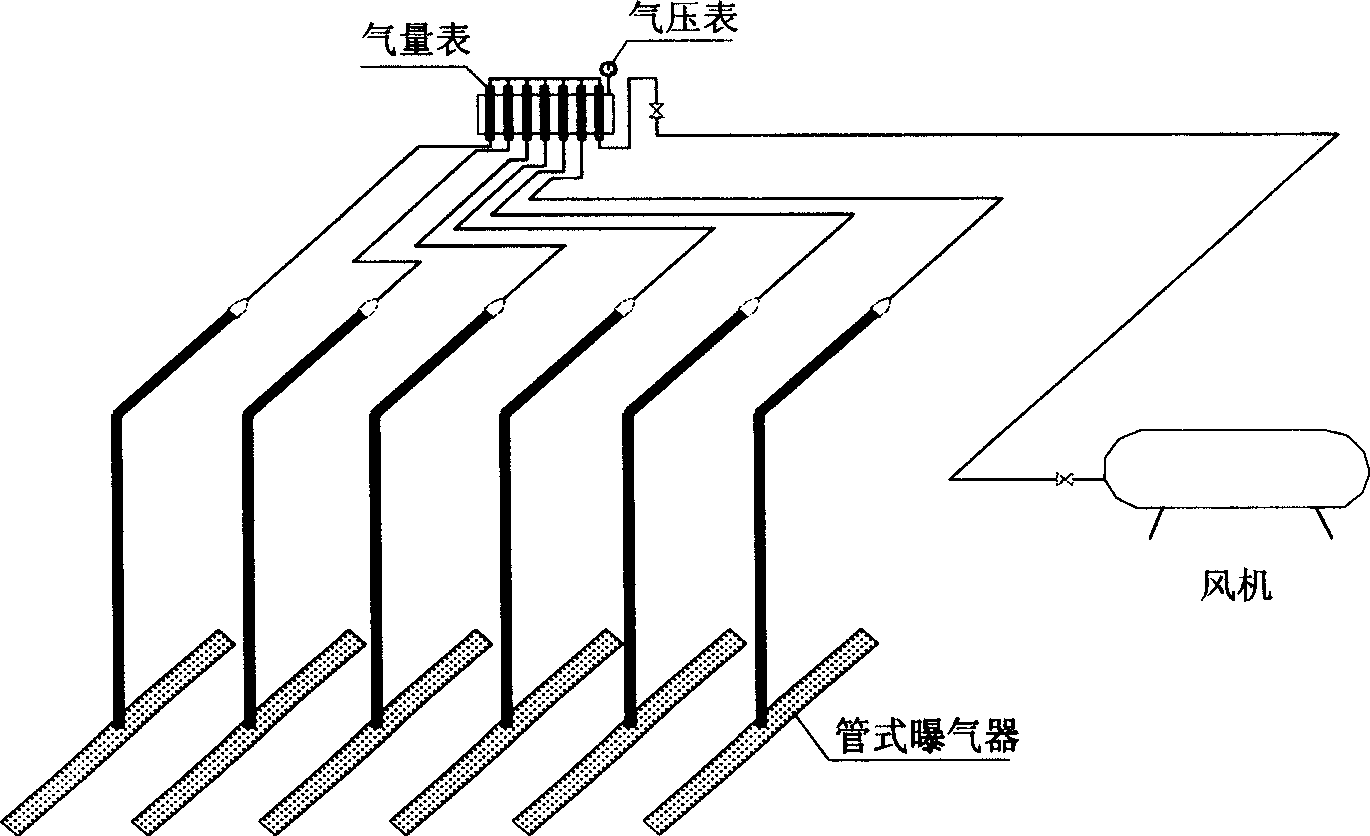

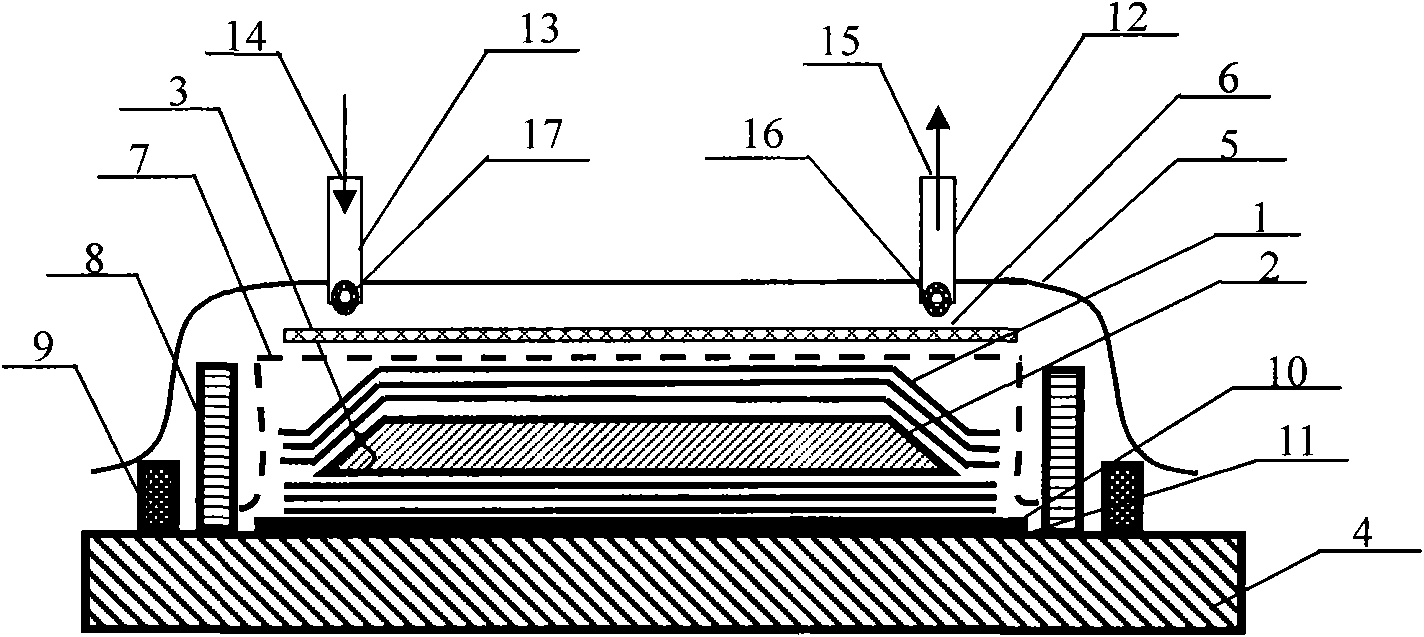

Plug flow type bioleaching process and apparatus for sludge treatment

InactiveCN101503269AStable productionLow investment costSludge treatment by de-watering/drying/thickeningSludge processingFluid phaseSludge

The invention provides a plug-flow type bioleaching treatment process for sludge treatment and equipment thereof. The equipment comprises a sludge regulating reservoir, an activating tank, a plug-flow type bioleaching reactor, an advection type sludge concentrated tank, a heavy metal recovery pond and other facilities, an aeration device, a heating device, a dehydration device, a stirring device and other devices. The process comprises the following steps that: a sludge system is acidified by a composite bacterium consisting of a thiobacillus and an acid resistant heterotrophic bacterium under conditions of aerobism and existence of sulfur powder and other composite nutriments, heavy metal in the sludge is massively dissolved in liquid phase, the sludge is regulated at the same time so as to facilitate sedimentation and dehydration; the sludge stays in the reactor for 2 to 4 days; discharged treated sludge enters the concentrated tank to be subjected to gravity thickening; 20 to 50 percent of concentrated bioleaching sludge flows back to the reactor, and the rest sludge is subjected to chamber filtration and dehydration without adding any flocculating agent until the water ratio is below 60 percent; and the heavy metal in the water is recycled by an alkali precipitation method. The method can remove massive heavy metals of the sludge, has over 99 percent of sludge pathogen kill ratio, and ensures that the treated sludge does not have malodor and is in khaki color, thereby realizing the aims of innoxiousness and minimization of the sludge.

Owner:NANJING AGRICULTURAL UNIVERSITY

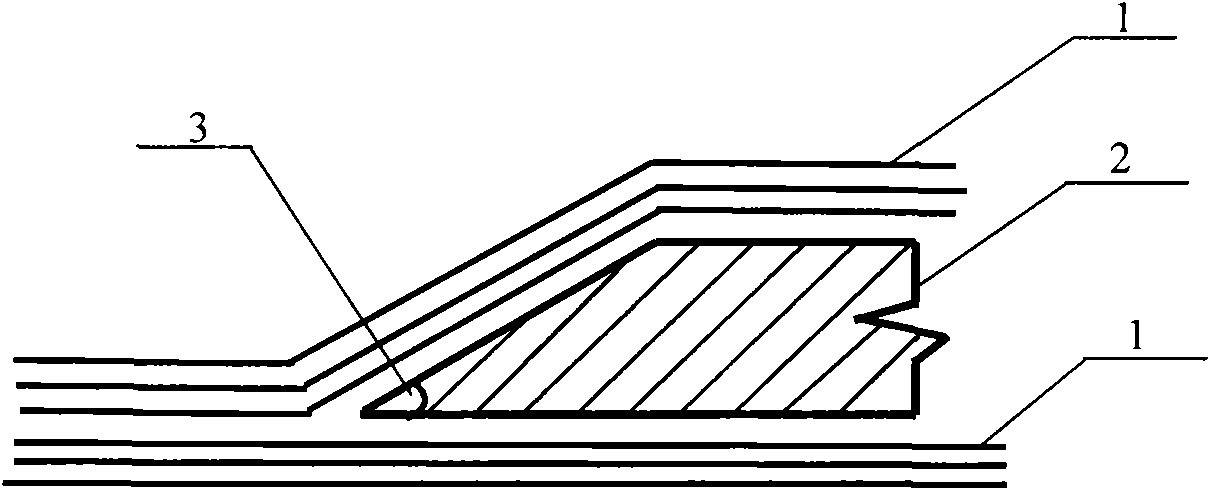

Technology of making automobile engine cover with carbon fiber reinforcement resin-based composite material

The invention discloses a technology of making automobile engine cover with carbon fiber reinforcement resin-based composite material, sequentially comprising: cleaning and preparing dies, coating sealant, gluing seal tape, coating mold lubricant, cutting carbon fabric and foam core material, paving and covering carbon fabric and foam core material, paving and covering auxiliary materials, sealing the vacuum section sealed by seal tape, absorbing and injecting resin, and solidifying, demolding and trimming. The making technology of the invention requires relatively short processing period and low labor cost, and is beneficial to both environmental protection and human health. Compared with conventional metal automobile engine covers, the automobile engine cover made of carbon fiber reinforcement resin-based composite material, with equal rigidity, is light in weight, stable in quality, and satisfactory in surface effects.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

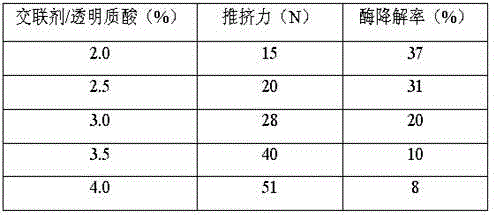

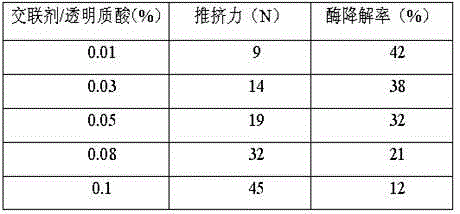

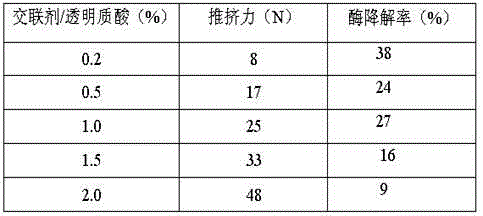

Modified sodium hyaluronate gel for injection

Owner:BLOOMAGE BIOTECHNOLOGY CORP LTD

Method for producing organic fertilizer by processing edible fungi residues

InactiveCN101412642ALess investmentSimple and efficient operationBio-organic fraction processingOrganic fertiliser preparationZymogenDecomposition

The invention relates to a method for treating edible fungus residue to produce an organic fertilizer. The method is realized through a series of steps of pretreating raw materials, preparing an original fungus preparation and a zymogen preparation, treating the fungus residue to produce the organic fertilizer and the like. The method has small investment, simple operation, easy actualization, small energy consumption and low treatment cost, and is easy to commonly accept; the treatment period is far shorter than that of natural decomposition; under the condition of natural climate in a southwestern region, the treatment period is 35 to 40 days in summe and 50 to 55 days in winter; simultaneously, pig manure produced in an intensive hogpen is combined and treated and has a fermentation temperature as high as 60 to 65 DEG C; and the organic fertilizer has thorough deodorization and sterilization as well as good treatment effect and manurial effect.

Owner:SOUTHWEST UNIVERSITY

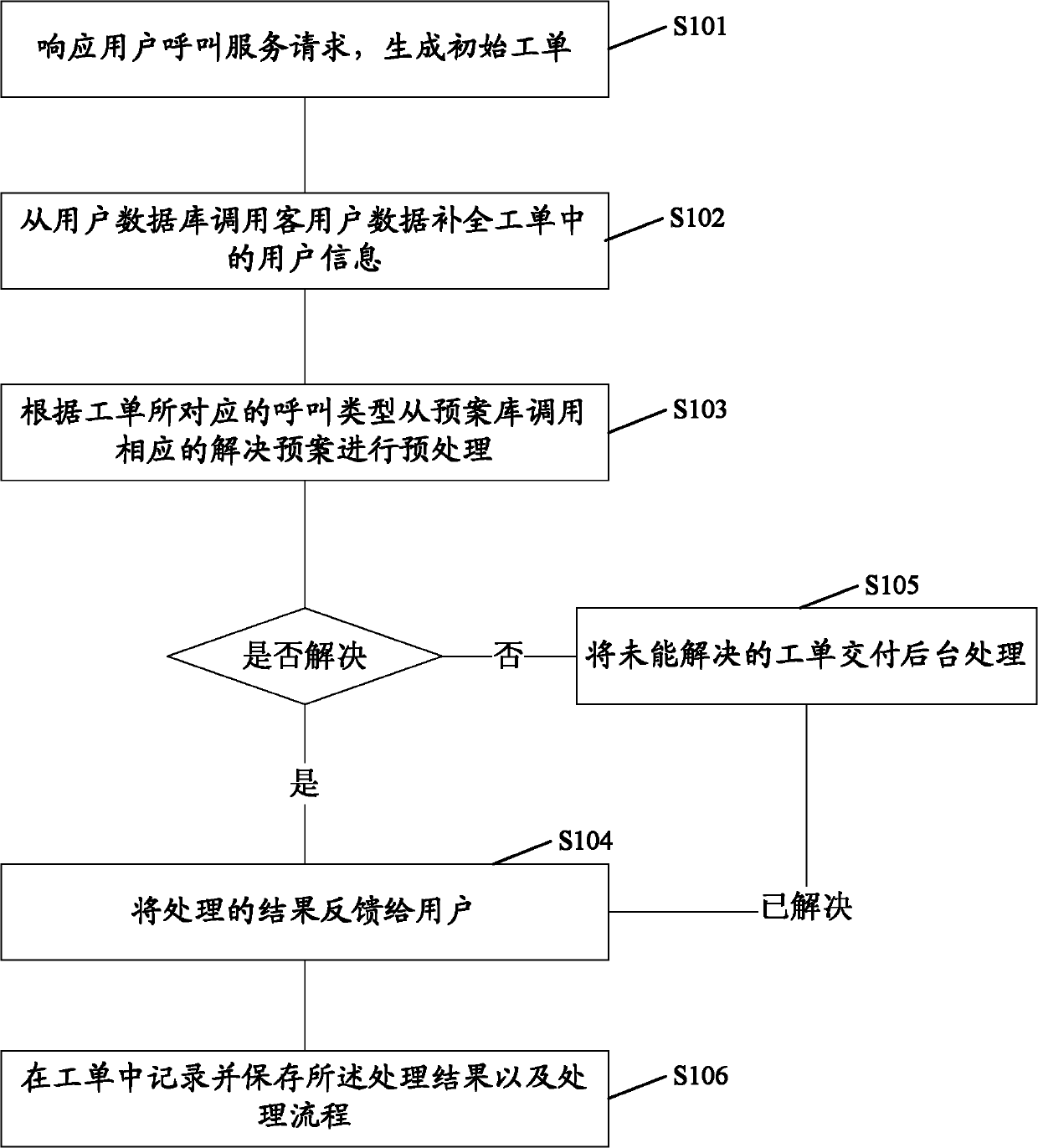

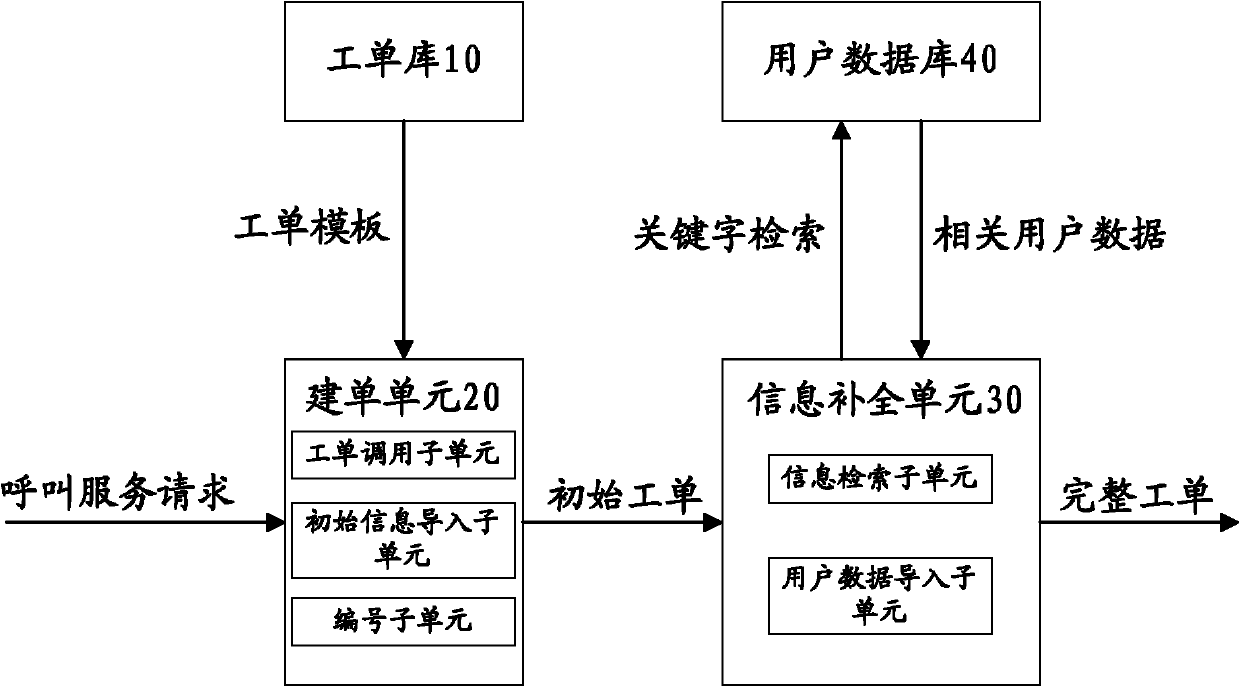

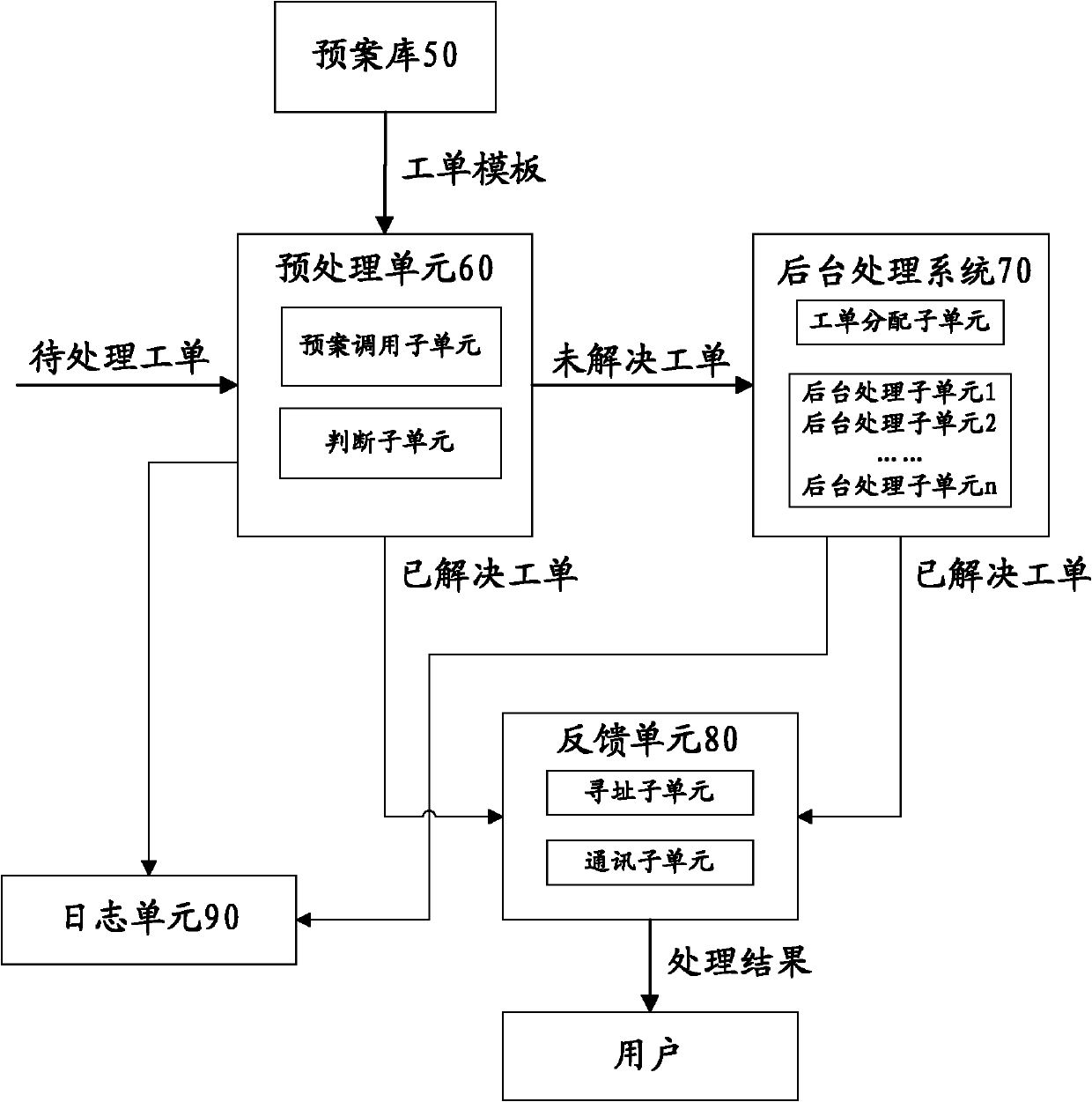

Work order processing method, work order building system and work order processing system

ActiveCN102572134AAvoid demandShort processing cycleSpecial service for subscribersPlan libraryOrder processing

The invention provides a work order processing method, a work order building system and a work order processing system. The work order processing method comprises the following steps of: responding a user calling service request to generate an initial work order; invoking user data from a user database to complement user information in the initial work order; according to a calling service type corresponding to the work order, invoking a corresponding solution plan from a plan library for pre-processing; feeding a pre-processing result to a user; and recording and storing a processing result and a processing flow in the work order. The work order processing method has the following advantages that the work order user information is automatically matched and complemented by building the user database, the solution plan is invoked to directly solve user requirements as much as possible, the processing period of the work order is shortened, and the work order processing method has the characteristics that the flow link and the manual resource are saved.

Owner:SHANGHAI PATEO ELECTRONIC EQUIPMENT MANUFACTURING CO LTD

Method for selective laser sintering for quick and direct production of injection die

InactiveCN1970202AImprove sinterabilityHigh strengthIncreasing energy efficiencyTotal factory controlEpoxySelective laser sintering

A selective laser sintering quick manufacturing of the mold comprises CAD three dimension model design, storing STL files after treatment by the section software, sending the STL data to SLS quick forming machine. Spreading a composite powder of polyamide and copper on the power bed of selective laser sintering machine, with copper powder grain side 200--400, their weight ratio ranging 2:1-7:1, scanning and sintering in the selected zone of the laser harness, laser speckle 10-250 mum, scanning distance 0.04-0.1mm, scanning speed 1000- 3000mm / s, single layer thickness 70-150 mum, repeating till the formation of the complete mold inlaid, coating the surface with epoxide resin or acrylic acid series solidification system, polishing the surface thereafter. It is simple in process, short in processing period, low in cost, suitable for small volume plastic parts pilot run, testing and production.

Owner:HUAZHONG UNIV OF SCI & TECH

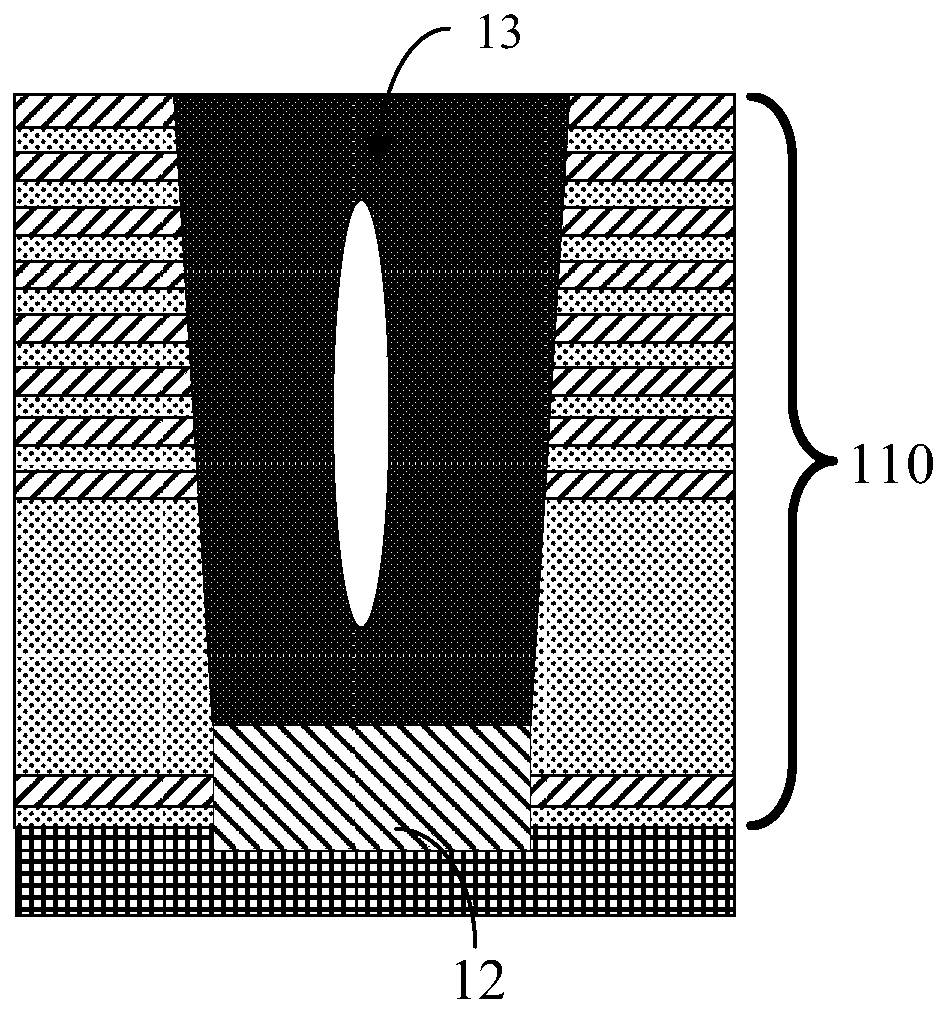

Three-dimensional memory device and preparation method thereof

ActiveCN109712977AAvoid destructionReduce processing costsSolid-state devicesSemiconductor devicesEngineeringPolycrystalline silicon

The invention provides a preparation method of a three-dimensional memory device. The method includes the following steps: sequentially forming an etching stop layer, a first stack, and first channelholes exposing the etching stop layer on a first substrate; forming a first polysilicon plug on a first sacrificial material layer filled in each of the first channel holes, and disposing a carrier wafer thereon; removing the first substrate, and forming a second stack and second channel holes on the other side of the etching stop layer to expose the etching stop layer; removing the etching stop layer between each of the first channel holes and each of the second channel holes, and removing the first sacrificial material layer; covering sidewalls of the first channel holes and the second channel holes with protective layers, and etching parts of the first stack and the second stack exceeding the remaining etching stop layer along radial directions of the channel holes, and removing the protective layers to form a through channel hole; and filling the through channel hole form a single channel. The invention also provides the three-dimensional memory device.

Owner:YANGTZE MEMORY TECH CO LTD

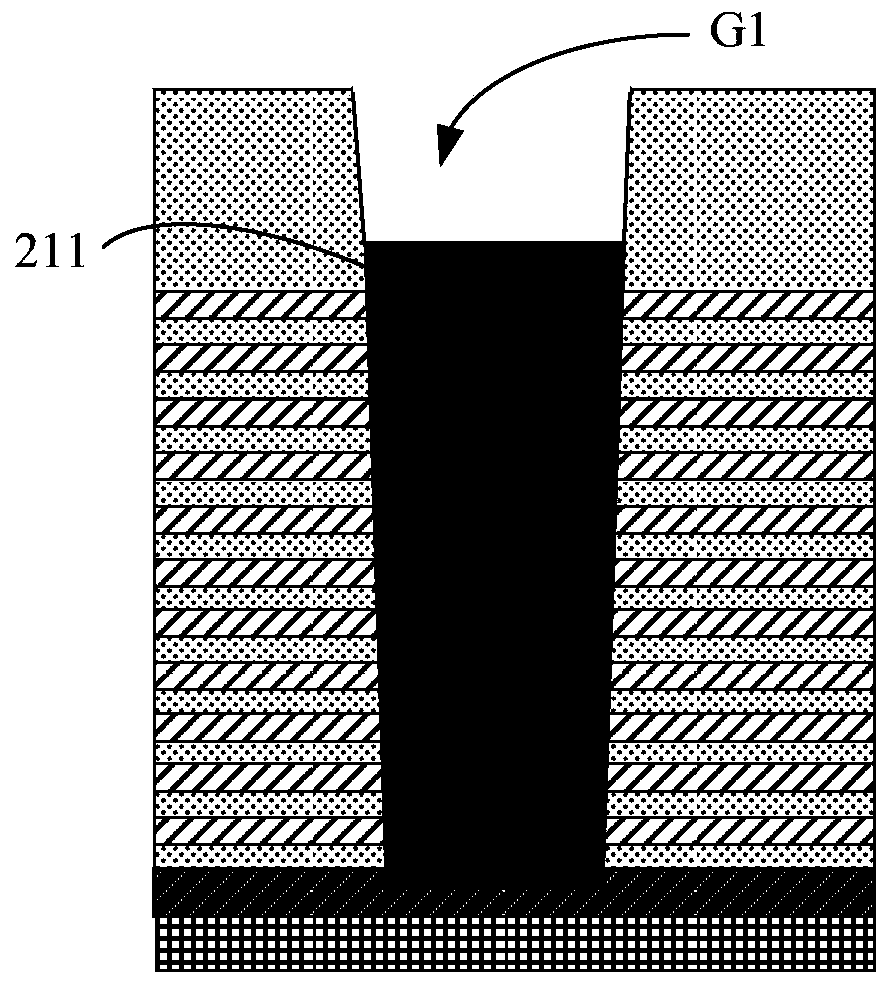

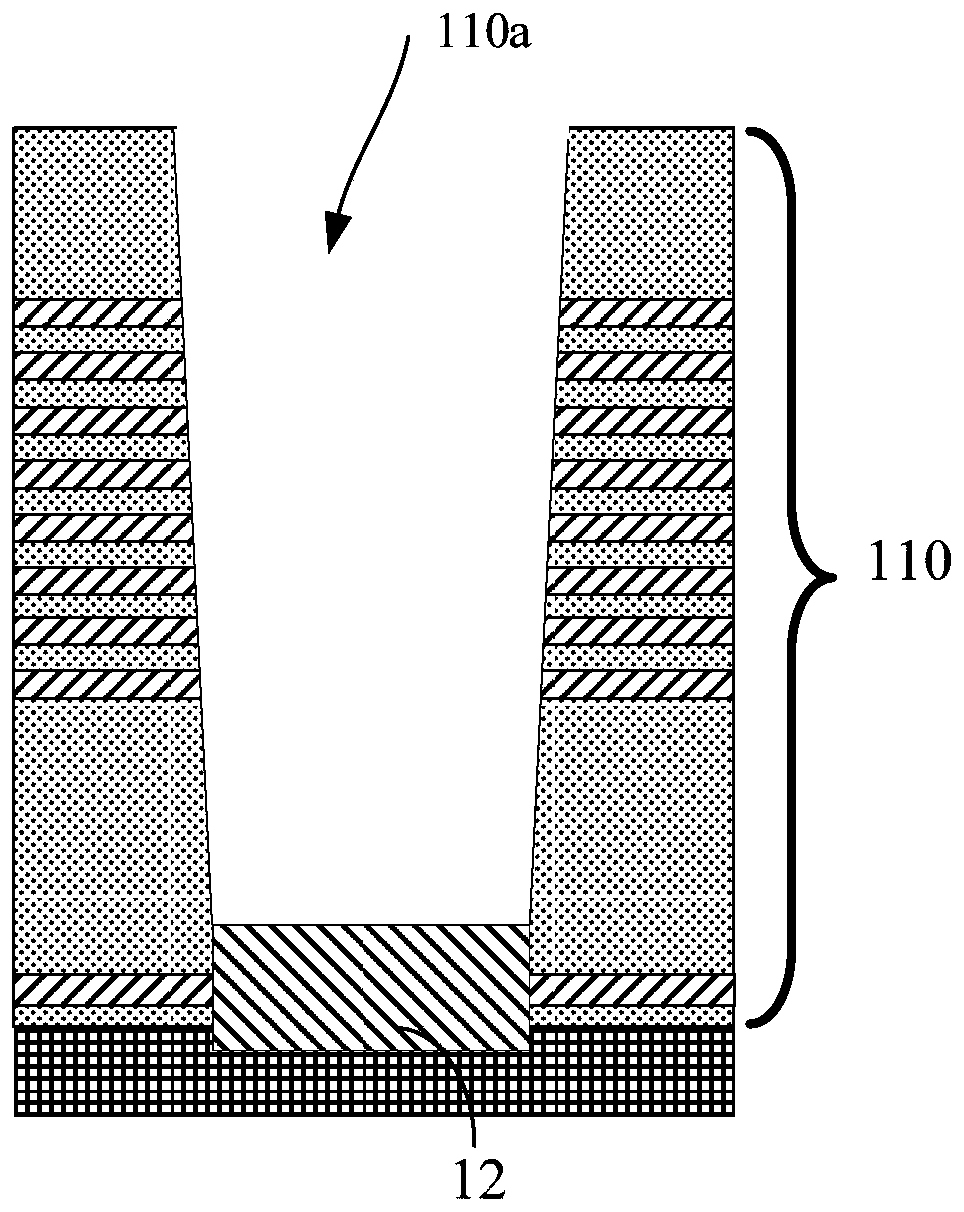

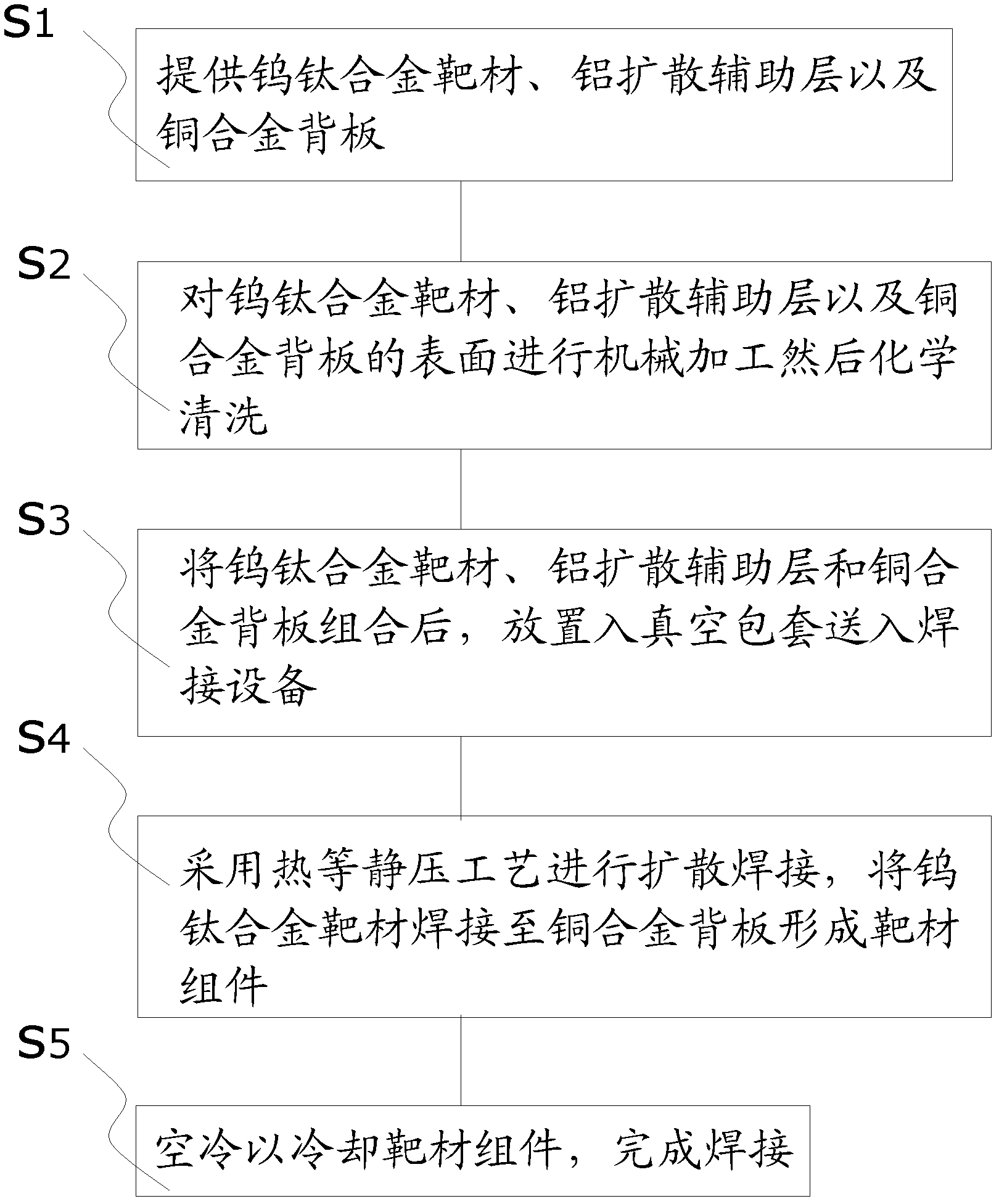

Diffusion welding method for tungsten-titanium alloy target and copper alloy back plate

ActiveCN102554455APrevent oxidationLow costNon-electric welding apparatusThermal deformationTitanium alloy

Disclosed is a diffusion welding method for a tungsten-titanium alloy target and a copper alloy back plate. An aluminum diffusion auxiliary layer is arranged between the tungsten-titanium alloy target and the copper alloy back plate, diffusion welding of the tungsten-titanium alloy target, the aluminum diffusion auxiliary layer and the copper alloy back plate is realized by the aid of high-strength atomic diffusivity between the tungsten-titanium alloy target and the aluminum diffusion auxiliary layer and between the aluminum diffusion auxiliary layer and the copper alloy back plate, and finally, welding quality of the tungsten-titanium alloy target and the copper alloy back plate is improved. Diffusion welding of the tungsten-titanium alloy target and the copper alloy back plate is implemented by a hot isostatic pressing process. As diffusion welding is performed in a vacuum sheath and air is isolated, the contact surface of welded metal can be effectively prevented from being oxidized, the bonding strength of the tungsten-titanium alloy target, the aluminum diffusion auxiliary layer and the copper alloy back plate is enhanced, the target is prevented from being separated from the back plate during sputtering, and sputtering coating is normally performed. A target assembly formed by the diffusion welding method has the advantages of high bonding compactness, high thermal deformation resistance and the like.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

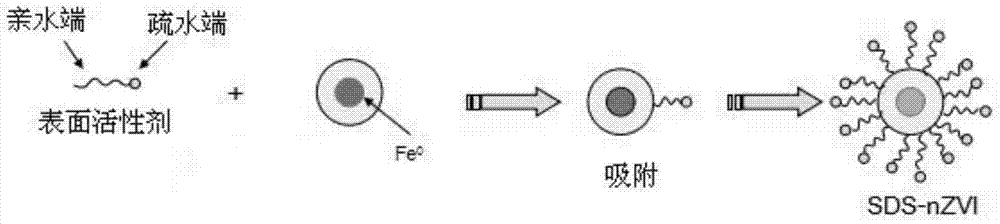

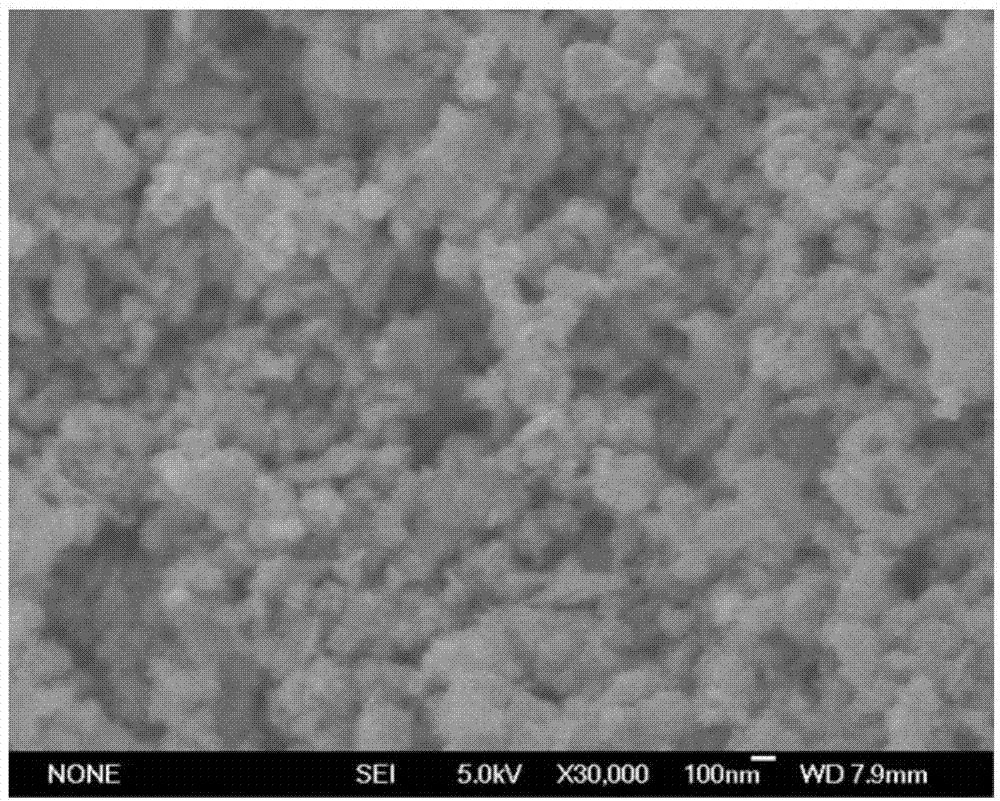

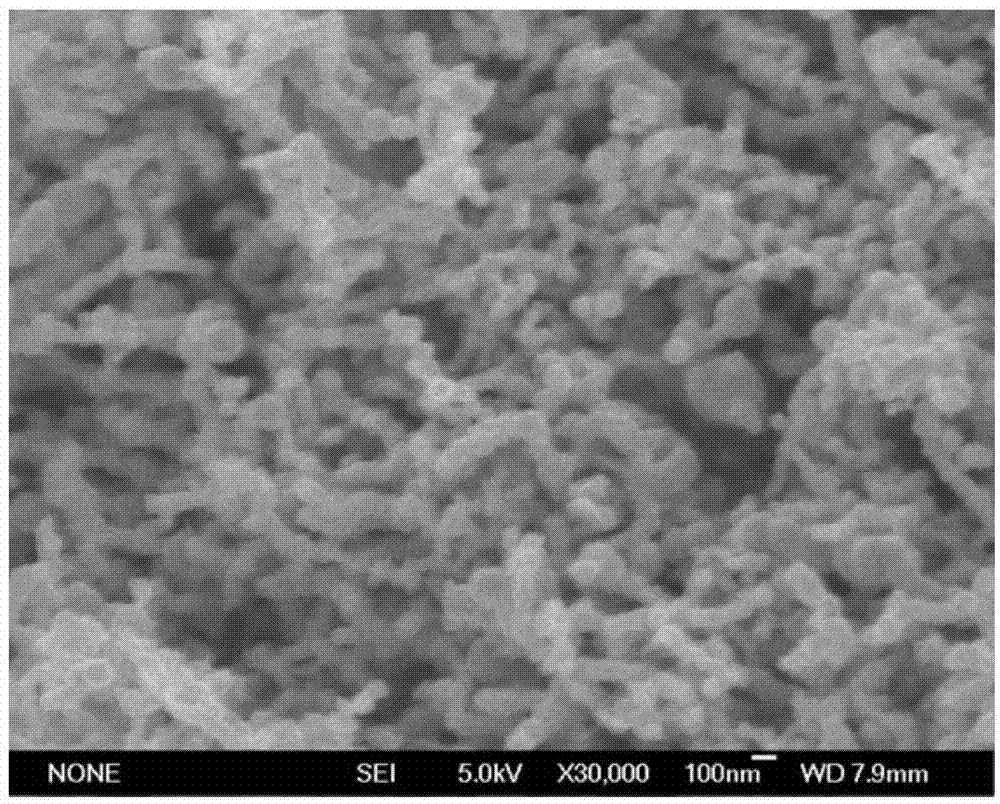

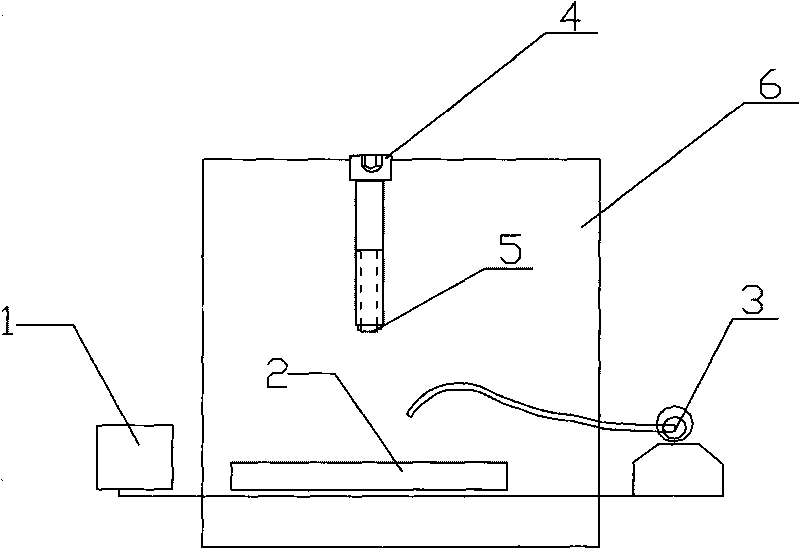

Modified nanoscale zero-valent iron and preparing method thereof

InactiveCN104226987AGood dispersionImprove stabilityMaterial nanotechnologySludge treatmentSodium sulfateNanometre

The invention discloses modified nanoscale zero-valent iron and a preparing method thereof. The modified nanoscale zero-valent iron comprises nanoscale zero-valent iron and lauryl sodium sulfate. The lauryl sodium sulfate is wrapped on the surface of the nanoscale zero-valent iron, and the mass ratio of the lauryl sodium sulfate and the nanoscale zero-valent iron is 0.01-0.07. The preparing method of the modified nanoscale zero-valent iron comprises the following steps that nanoscale zero-valent iron particles are dispersed in a lauryl sodium sulfate solution through ultrasound, and the modified nanoscale zero-valent iron is obtained. According to the modified nanoscale zero-valent iron and the preparing method thereof, the lauryl sodium sulfate is used for modifying the nanoscale zero-valent iron, through a steric-hinerance effect, nano materials are stabilized, and the advantages of being good in dispersing performance, good in stability, high in reactivity and the like are achieved.

Owner:HUNAN UNIV

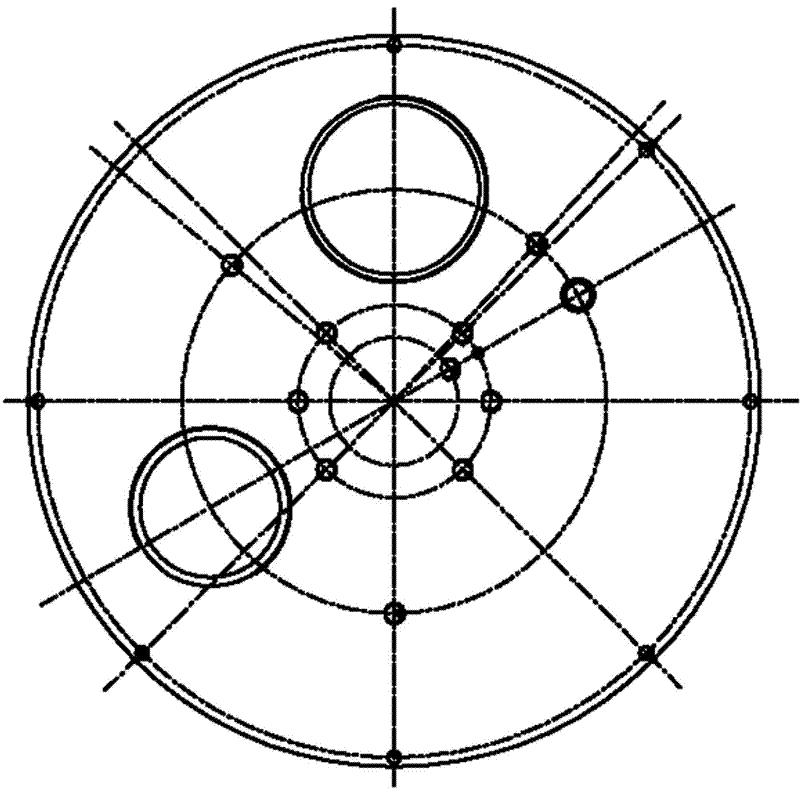

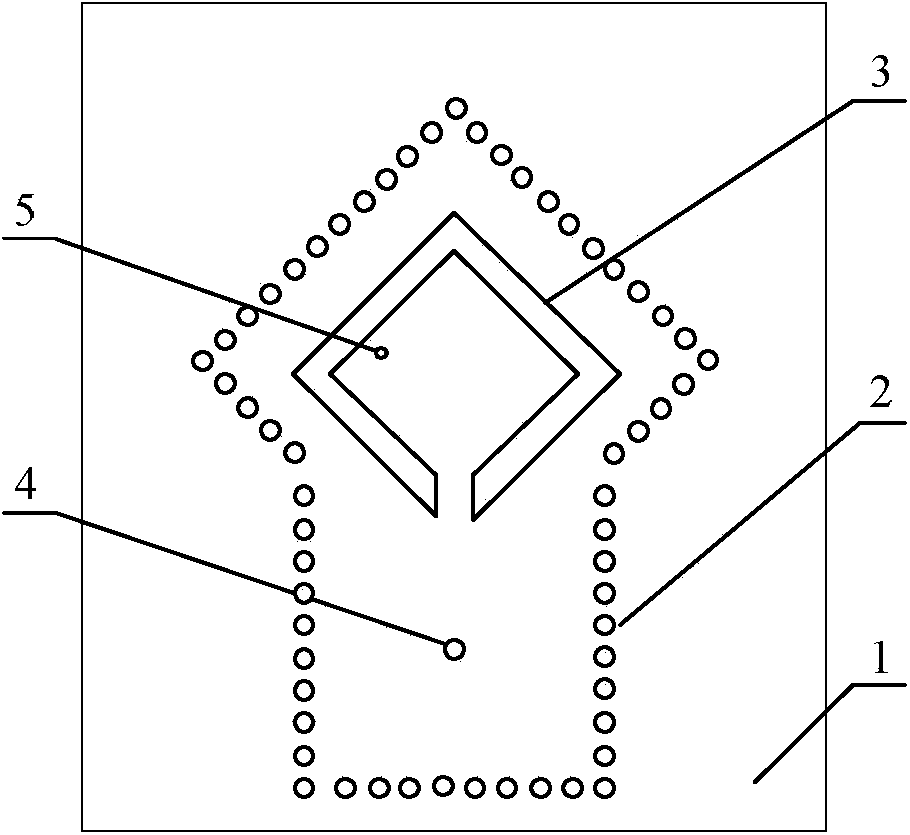

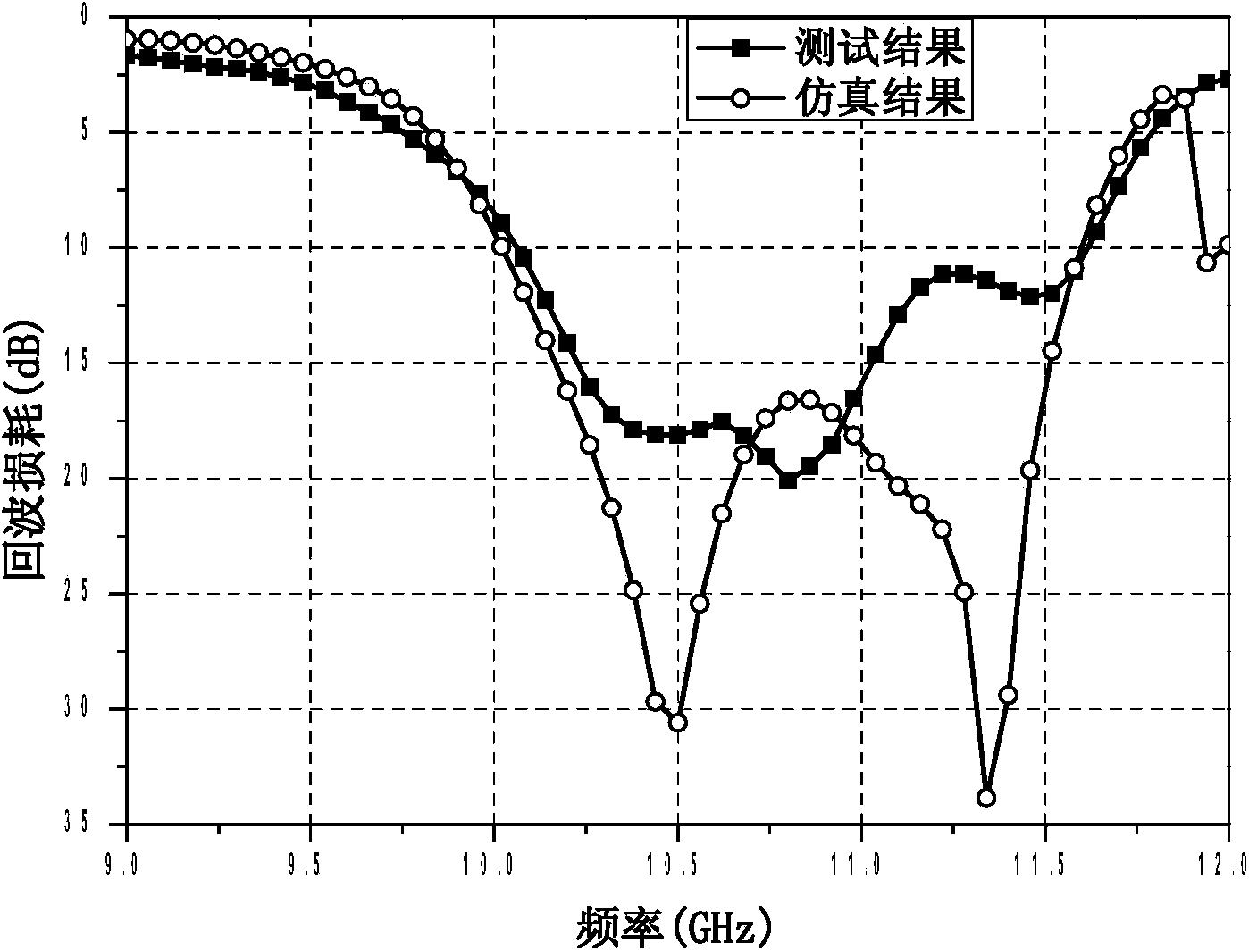

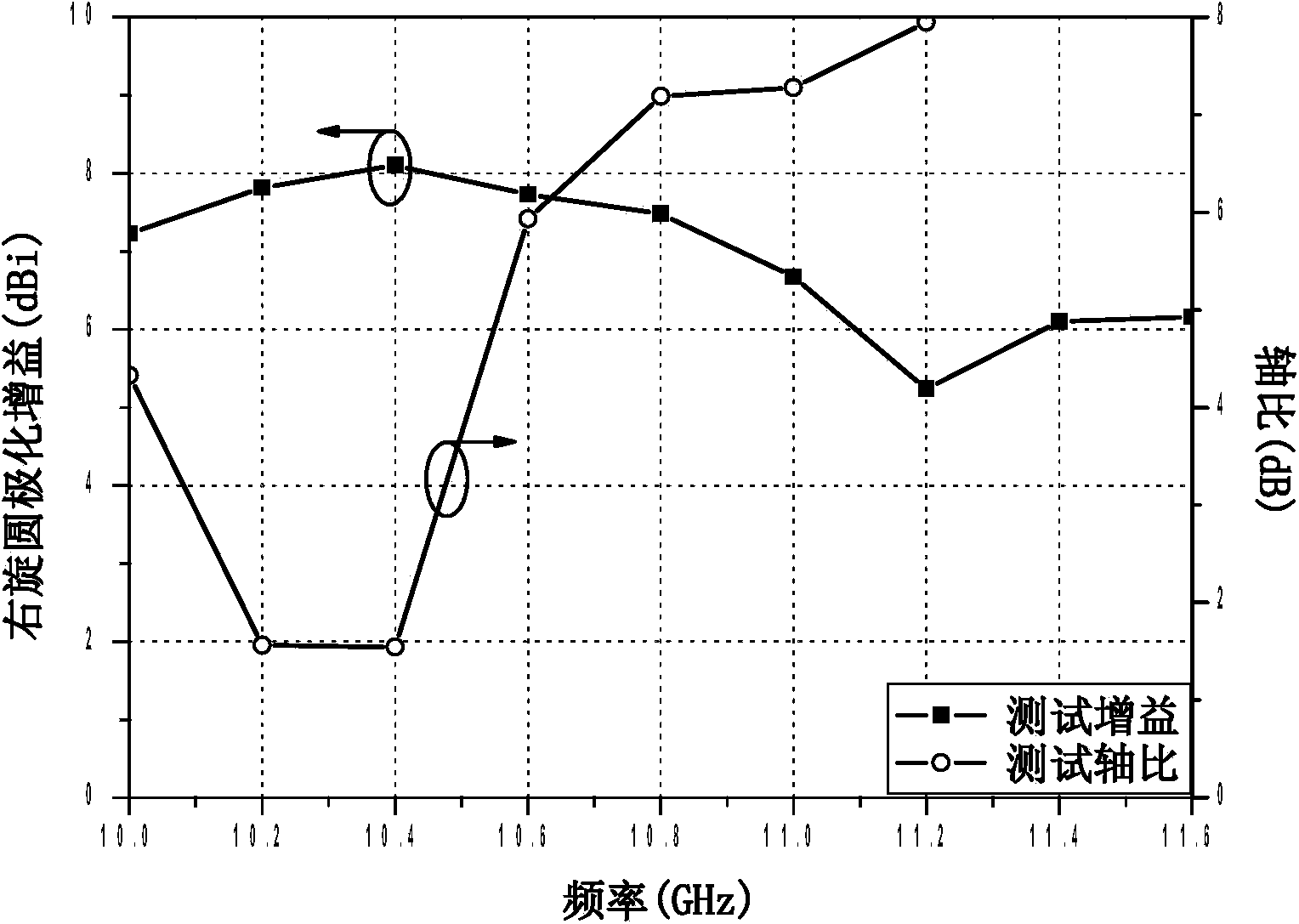

Broadband substrate integrated waveguide circularly polarized antenna array and manufacturing method thereof

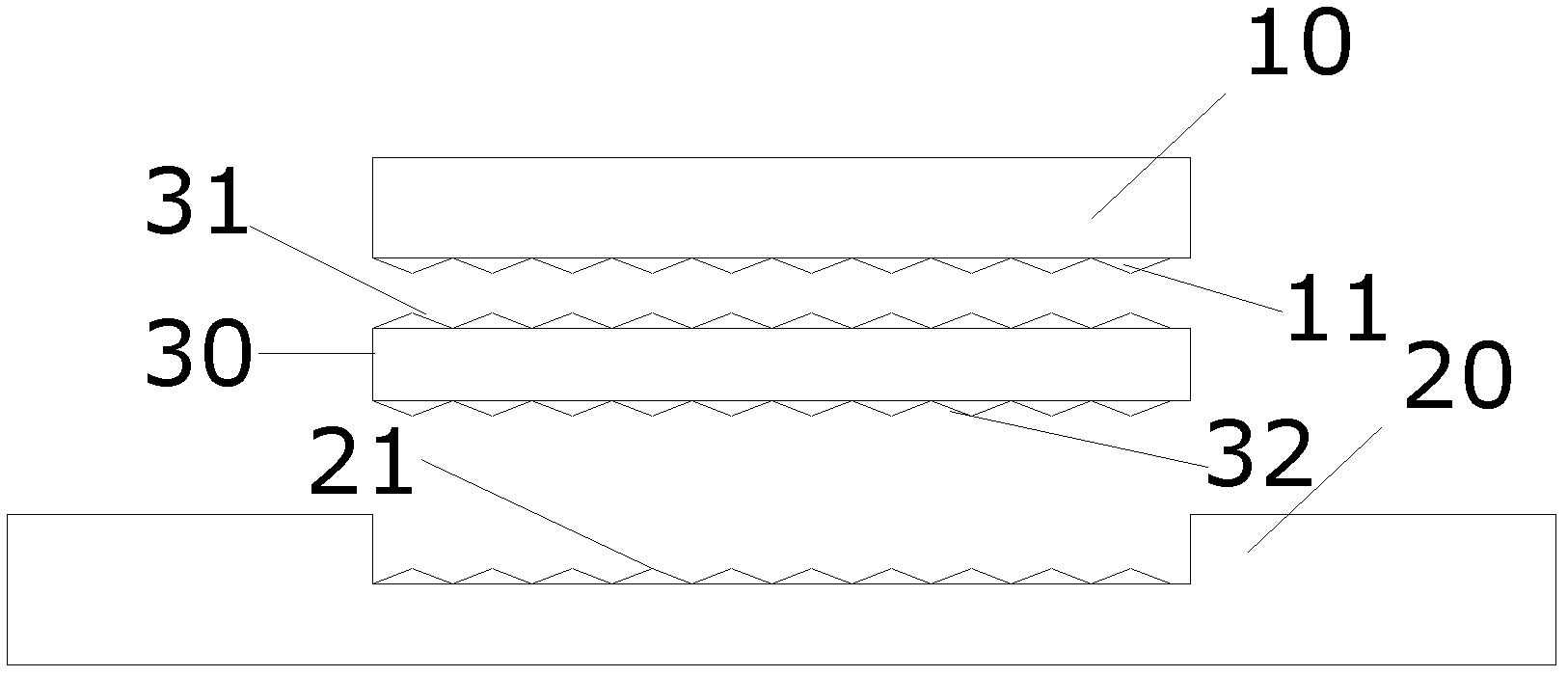

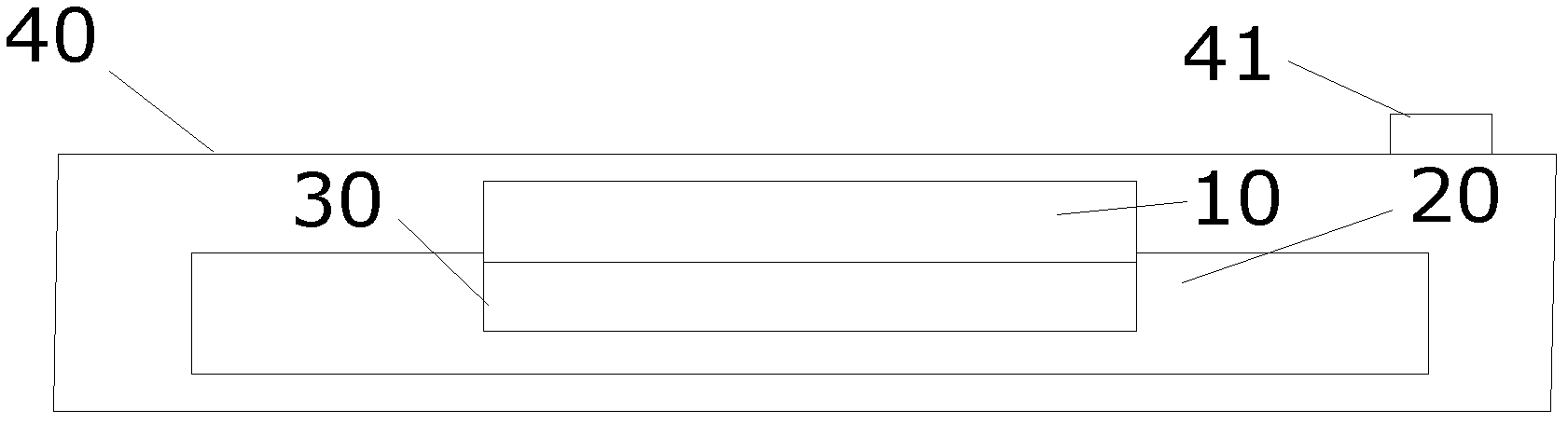

InactiveCN103531918ASimple structureSimple working principleAntenna arraysRadiating elements structural formsCircularly polarized antennaBroadband

The invention discloses a substrate integrated waveguide technology-based high-gain circularly polarized antenna array and a manufacturing method of the antenna array. The broadband substrate integrated waveguide circularly polarized antenna array comprises an upper-layer radiation substrate and a lower-layer feed substrate, wherein the radiation substrate comprises a first antenna unit, a second antenna unit, a third antenna unit and a fourth antenna unit, and the first antenna unit, the second antenna unit, the third antenna unit and the fourth antenna unit are symmetrically arranged by taking the center of a circle as an axis; a radial substrate integrated waveguide power distributor which is divided into four parts is distributed on the feed substrate and is used for feeding the four antenna units. The high-gain circularly polarized antenna array disclosed by the invention has the advantages that the gain is high, the broadband is wide, the radiation characteristic is good, the design is simple, the machining is easy and the cost is low; compared with the current substrate integrated waveguide circularly polarized antenna, the antenna provided by the invention has the advantages that the gain is remarkably improved and the circularly polarized bandwidth is remarkably increased.

Owner:XIDIAN UNIV

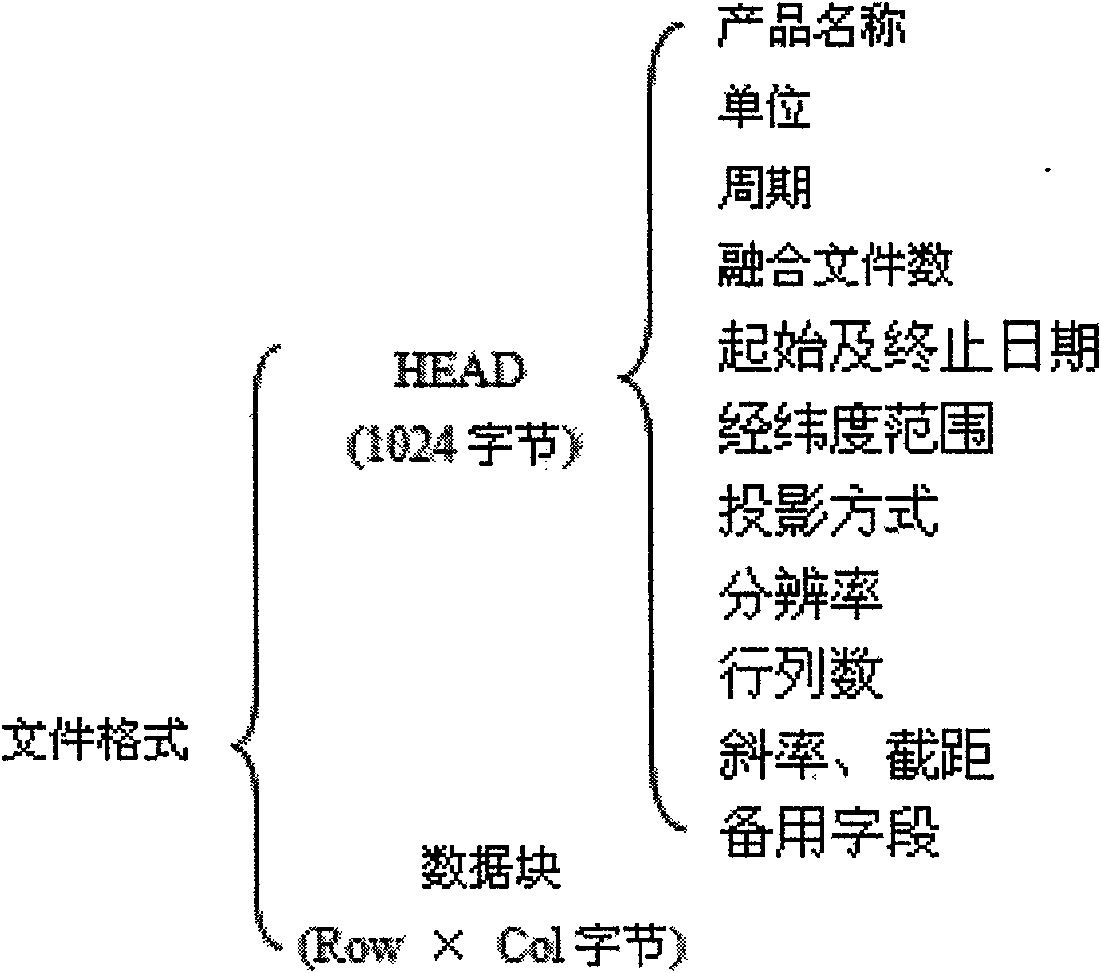

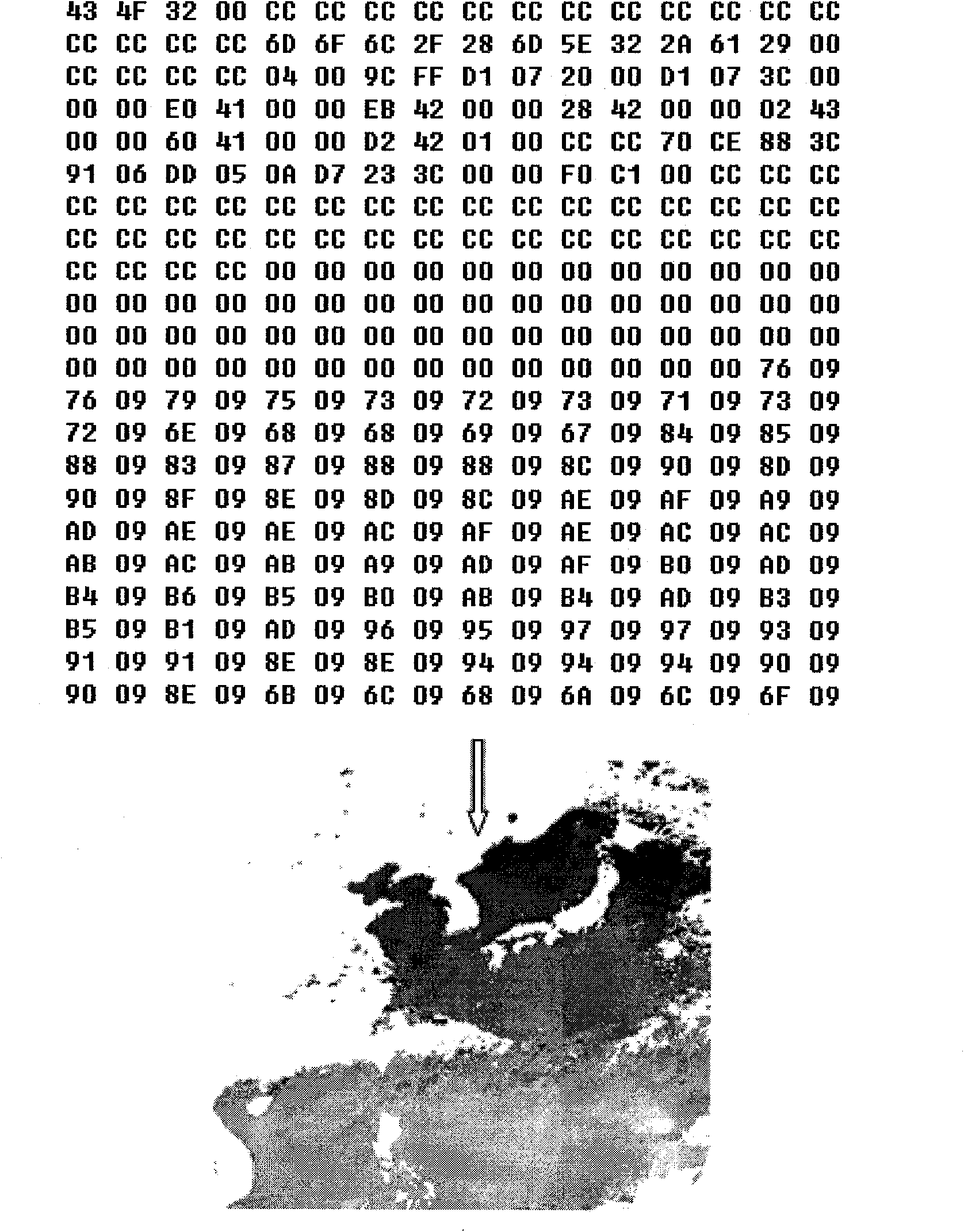

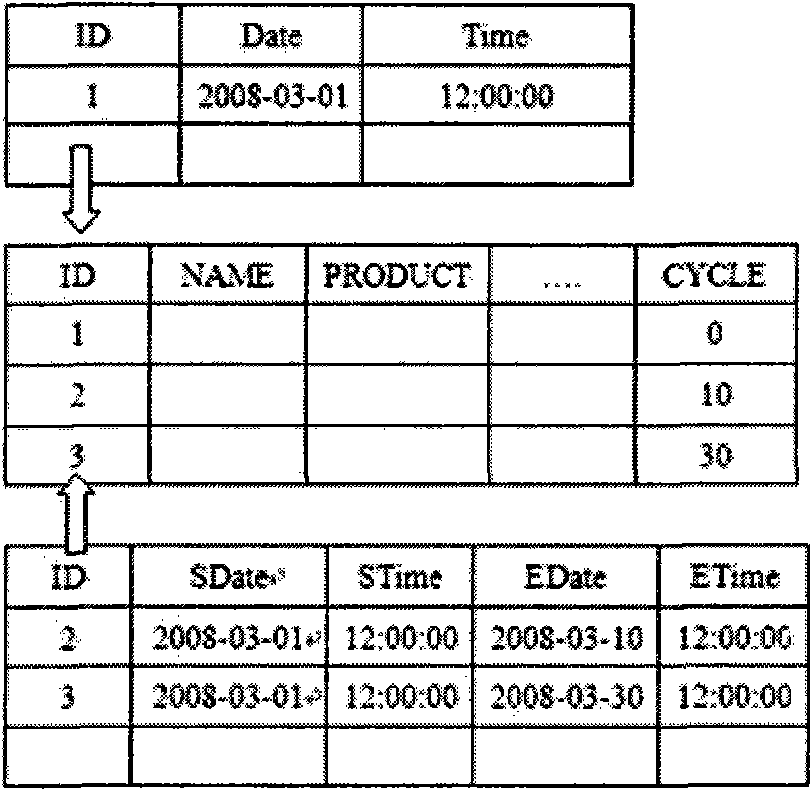

Virtual-reality modeling method of ocean water body

InactiveCN101650837AShorten the data processing cycleImprove timeliness3D-image rendering3D modellingTechnical supportGeographic information system

The invention discloses a virtual-reality modeling method of an ocean water body. The method comprises the following steps: constructing a main body of a model by utilizing remote sensing (RS) data ina convenient and high-efficiency data-processing process and a scientific storage mode based on an OpenGL technology; adopting a contour line of an ocean surface experimental area to construct a three-dimensional modeling method of a three-dimensional ocean water body; presenting ocean surface waves by texture mapping; utilizing the projection of a parallel contour line to construct a cylindricalbody of the water body to present physical quantity change conditions of the RS data, such as the water depth, the water quality, and the like; and representing the ocean water body and undersea topography in a transparent body mode. The new method realizes the modeling of the three-dimensional ocean water body by utilizing the OpenGL technology as a modeling tool under the technical support of the RS and the GIS (Geographic Information System). The real-time modeling of the three-dimensional ocean water body is realized by effectively utilizing the long-term collected RS data through convenient and feasible data processing and the model-drawing method. The invention has extremely wide application prospects in the ocean environmental monitoring field.

Owner:ZHEJIANG UNIV

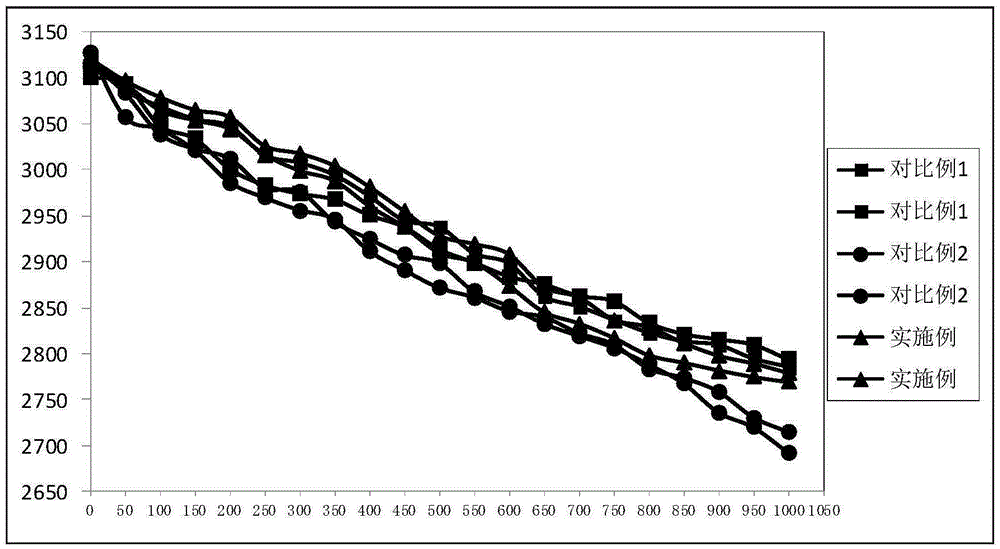

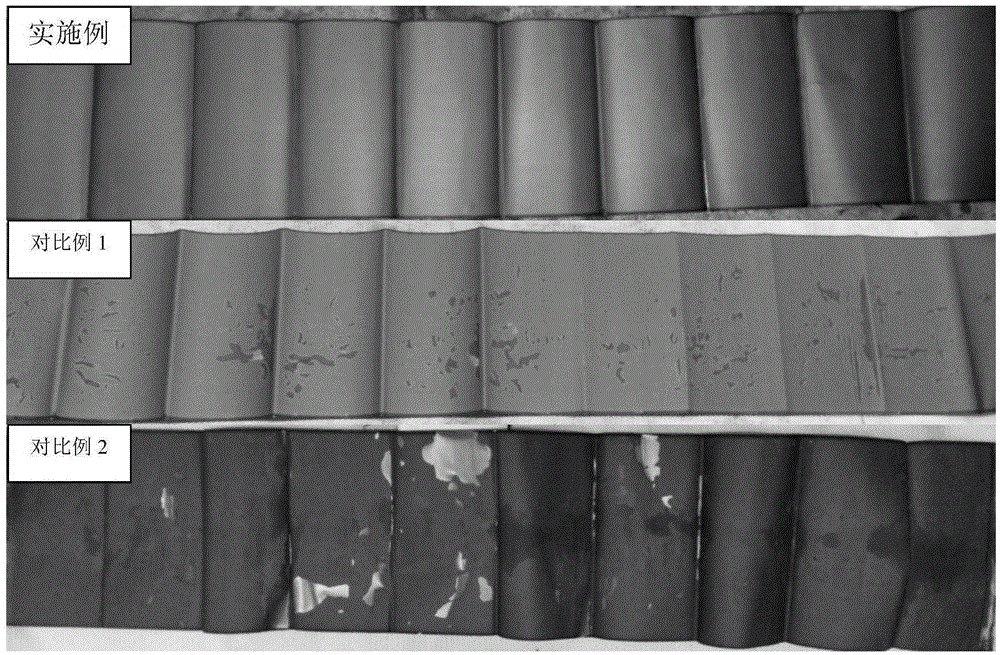

Formation method of lithium ion battery

ActiveCN105406129AConsistent thicknessReduce scrapFinal product manufactureSecondary cells charging/dischargingVacuum pumpingPower flow

A formation method of a lithium ion battery comprises the following steps of placing an aged battery in a formation device for formation in a high-temperature pressurized environment, charging by using 0.1-0.5CmA current during charging until to a cut-off voltage of 3.7V, and then charging by using 0.5-2.0CmA current until to a cut-off voltage of 4.0V; increasing the temperature and keeping the pressure unchanged, and carrying out heat preservation and pressure maintaining on the battery; reducing the temperature and the pressure, and cooling the battery; and carrying out vacuum pumping and secondary sealing on the battery subjected to cooling finish, and completing formation. According to the formation method, a battery core is placed in a high temperature and certain pressure condition for large-current charging formation, the processing time is shortened, and the production efficiency is improved; moreover, the contact of an operator to the lithium battery core is reduced, and the cost problems caused by poor appearance, damage and the like are reduced; and the consistencies on the thickness, the capacity and pole piece interface states of the battery are higher, and the cycle ability is improved.

Owner:ZHUHAI COSMX BATTERY CO LTD

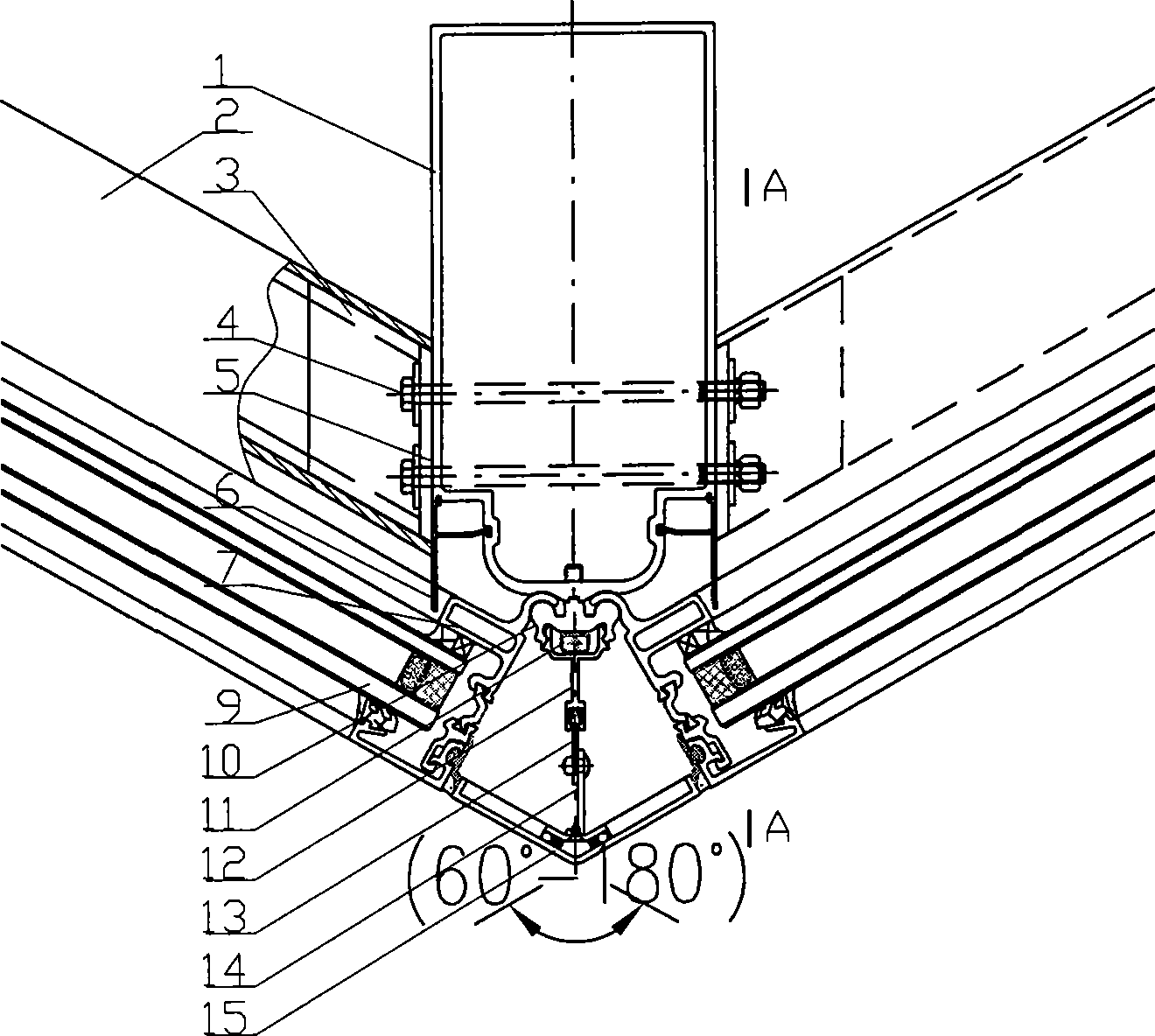

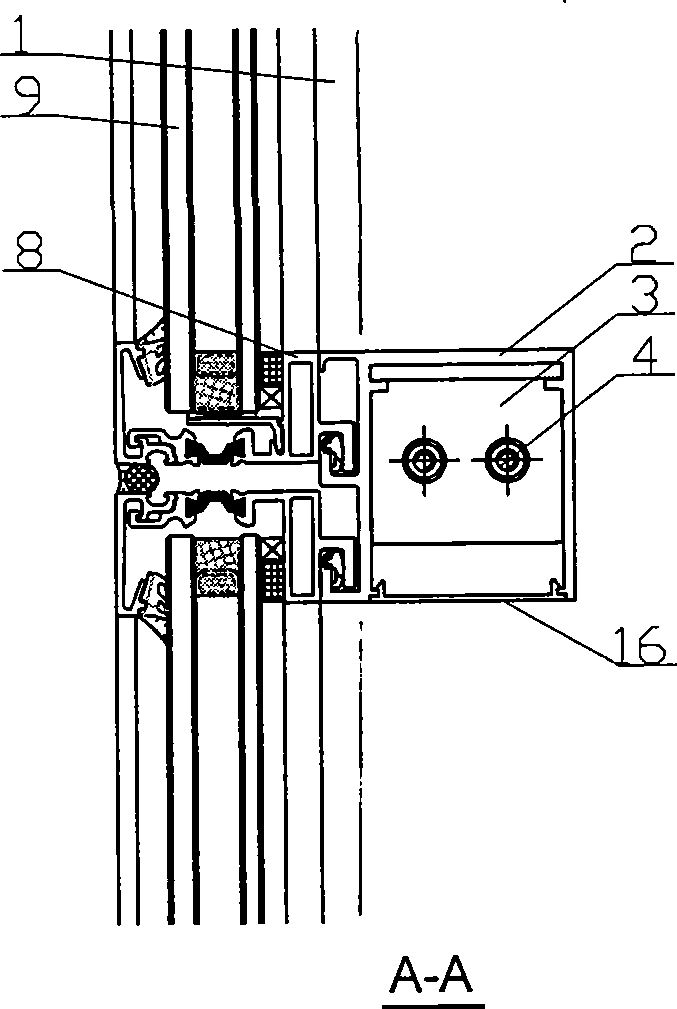

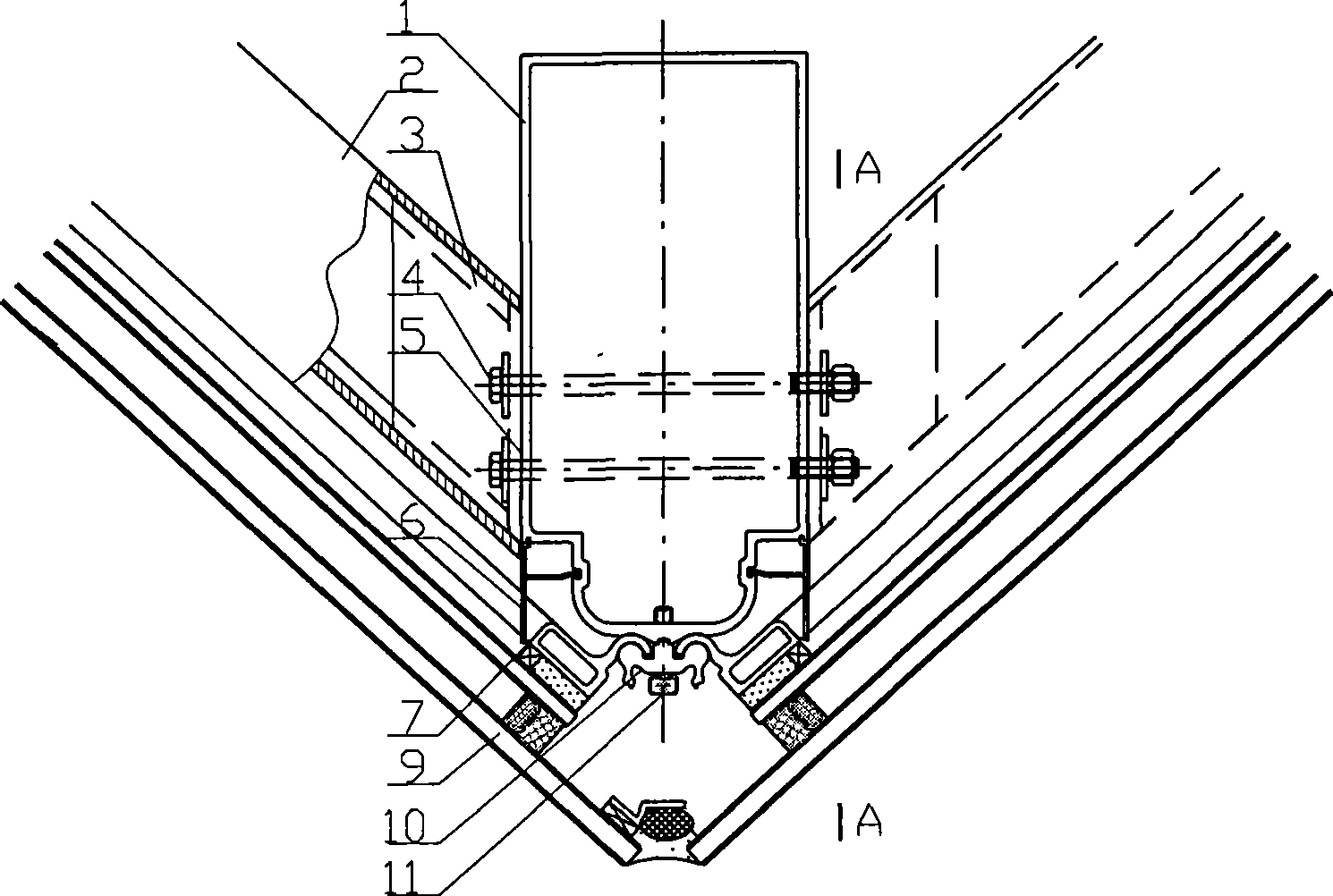

Angle adjustable corner section bar system for curtain wall

ActiveCN101392569AShort processing cycleConvenient construction and installation positioningWallsAdhesiveMaterial system

The invention discloses an adjustable angle corner section material system for a curtain wall, which relates to a multi-corner section material system for a curtain wall, in particular to a corner section material system for a glass curtain wall. The section material system comprises a corner column, a corner cross beam, a connecting corner connector, an insulation spacer, a cross beam cover plate, a corner auxiliary frame, a common auxiliary frame, a curtain wall panel, a corner press piece and a side sealing gland. The corner column is used for installing the curtain wall; the connecting corner connector is arranged on one end part of the corner cross beam; the insulation spacer is arranged on the corner column together with the corner cross beam and the connecting corner connector through connecting bolts; the cross beam cover plate is arranged on the corner cross beam; the corner auxiliary frame and the common auxiliary frame adhere to a processed curtain wall panel through silicone structural adhesive; after the silicone structural adhesive is solidified, the common auxiliary frame on a horizontal edge of the curtain wall panel is hung onto the corner cross beam, and the corner auxiliary frame on a vertical edge of the curtain wall panel is arranged on the corner column through the corner press piece and a connecting screw; and after all parts are in position, the side sealing gland is installed to form the adjustable angle corner section material system.

Owner:GUANGDONG GOLDEN CURTAIN WALL ENGINEERING CO LTD

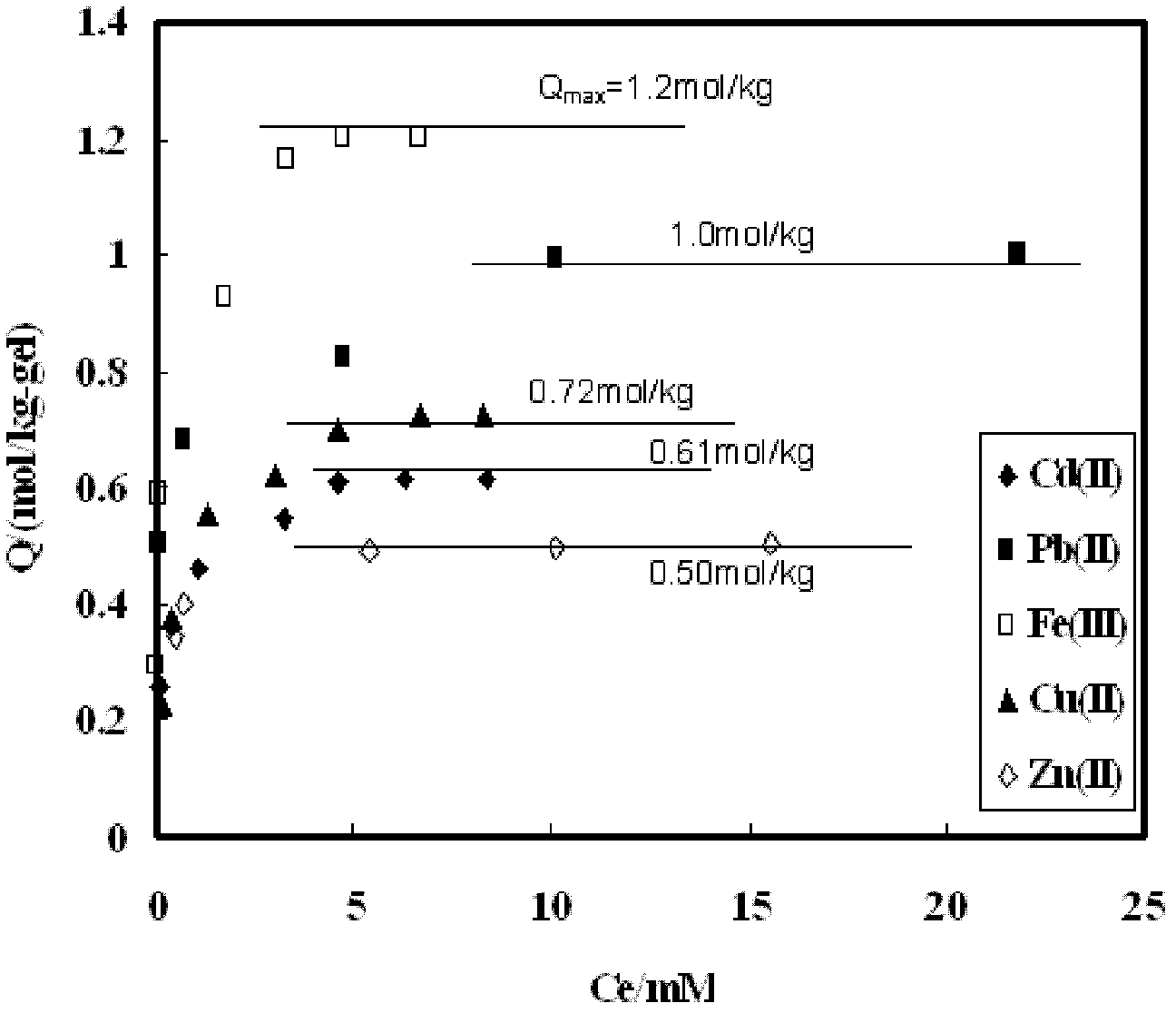

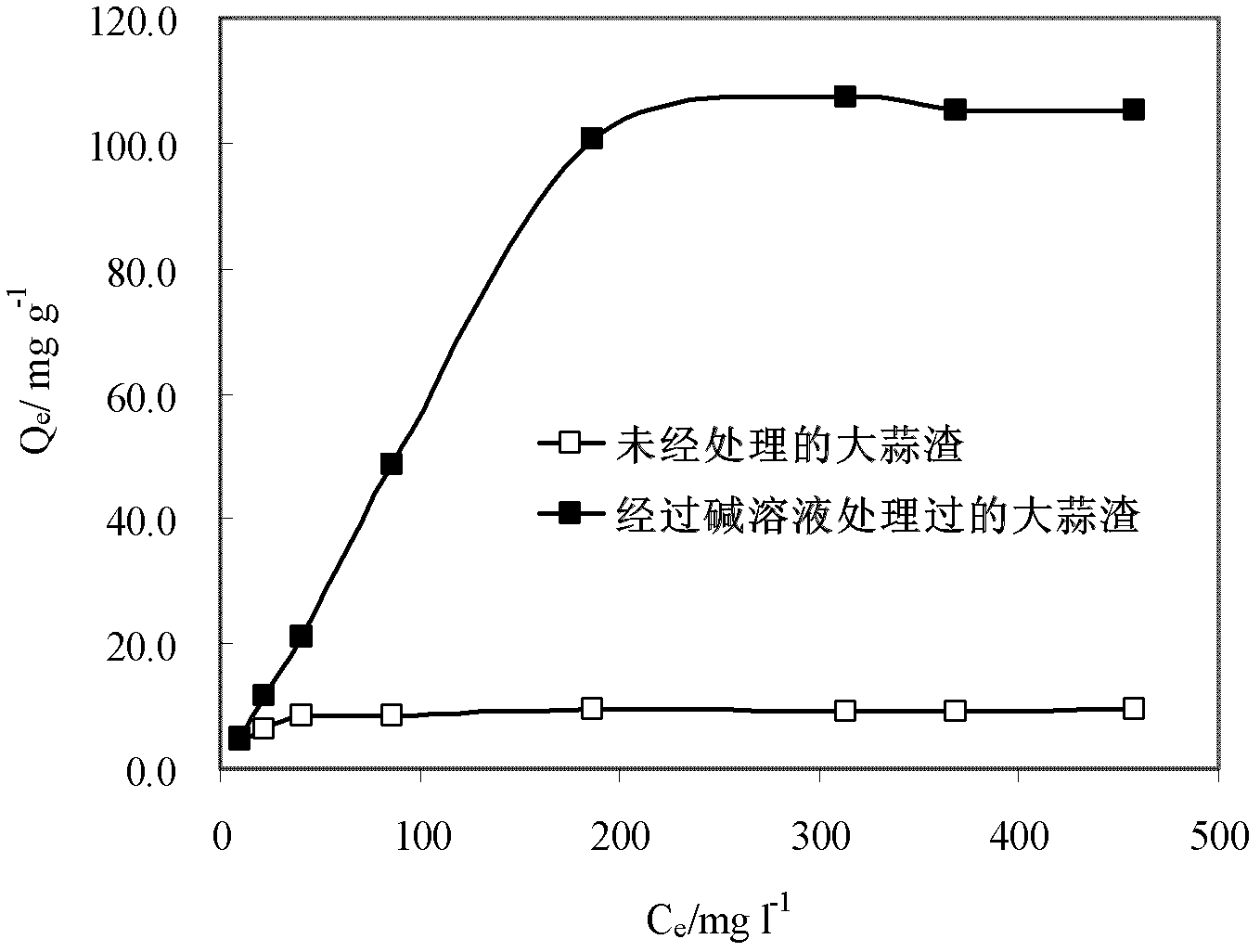

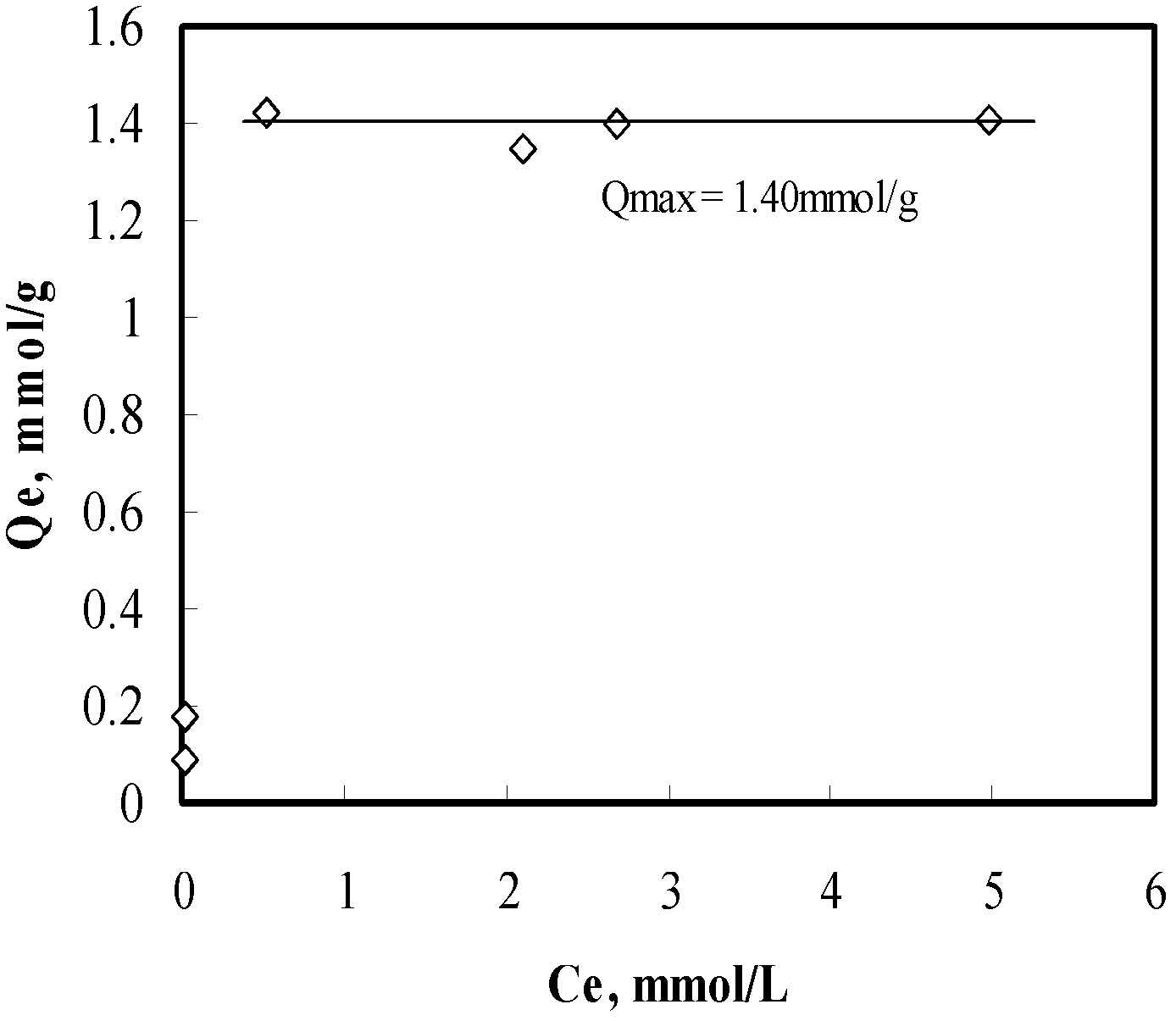

Method for adsorption and removal of heavy metals and dye of waste water by garlic waste

InactiveCN102557181AReasonable designEasy to operateOther chemical processesWater contaminantsSorbentPhysical chemistry

The invention discloses a method for adsorption and removal of heavy metals and dye of waste water by garlic waste. The method provided by the invention comprises the following steps of washing a certain amount of garlic waste by water; mixing the washed garlic waste, one or more alkalis and water by stirring for 12 to 24 hours according to a mass ratio of 1: (0.05 to 0.2): (0.5 to 2) for a reaction, filtering to obtain a solid product, washing the solid product by water until the solid product has a pH value of 7, feeding the washed solid product into a vacuum baking oven, drying at a temperature of 60 to 120 DEG C, carrying out fragmentation and screening, collecting particles below 40 meshes, wherein the particles below 40 meshes are utilized as adsorbents, preparing a heavy metal ion or dye molecule aqueous solution having concentration of 0.1 to 10mmol / L, adding a certain amount of the adsorbents into the heavy metal ion or dye molecule aqueous solution according to a volume ratio of 0.5 to 10g / L, and shaking the mixed solution obtained by the previous step at a room temperature for 0.5 to 24 hours so that the adsorbents can fully adsorb heavy metal ions or dye molecules of the heavy metal ion or dye molecule aqueous solution. The method provided by the invention has a reasonable design and simple processes, realizes obvious effects, greatly reduces a treatment cost, wherein the treatment cost of the method is 10 to 15% of that of the traditional treatment method, greatly shortens a treatment period, does not produce secondary pollution after adsorption treatment, andcan be operated and popularized easily.

Owner:河北强久自行车配件集团有限公司

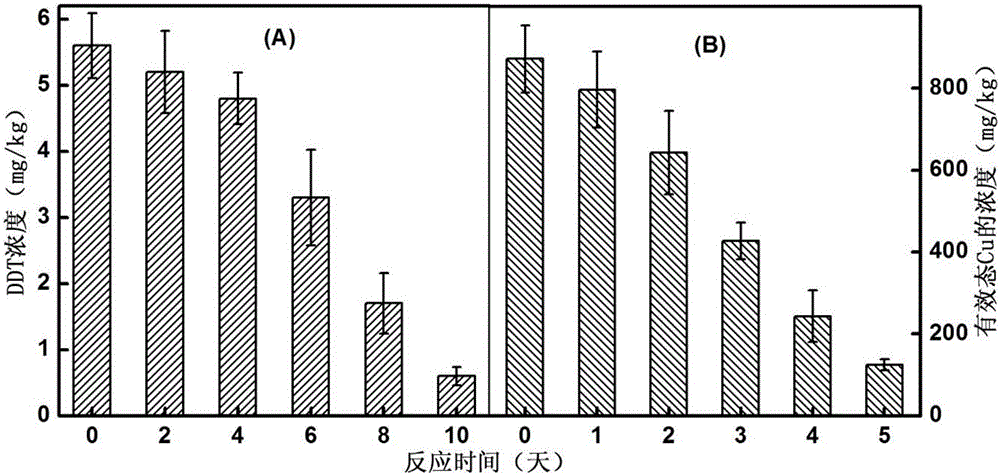

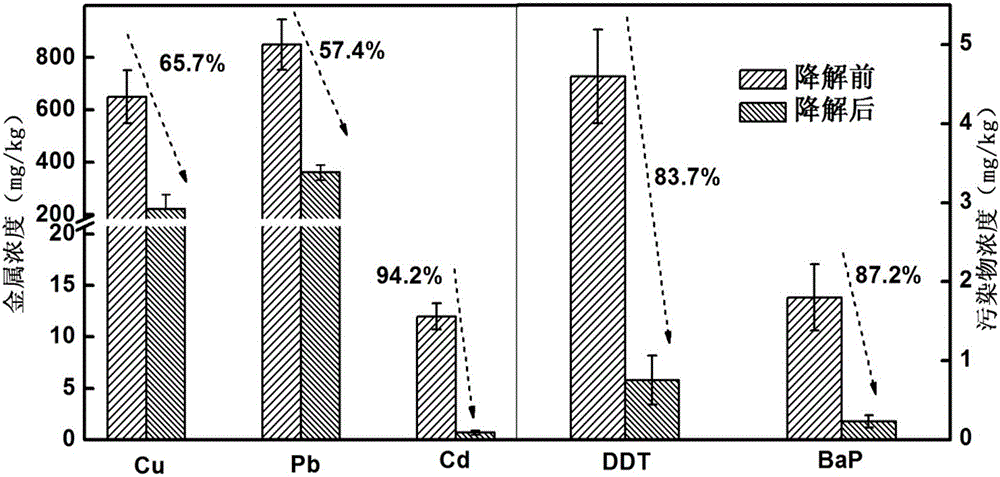

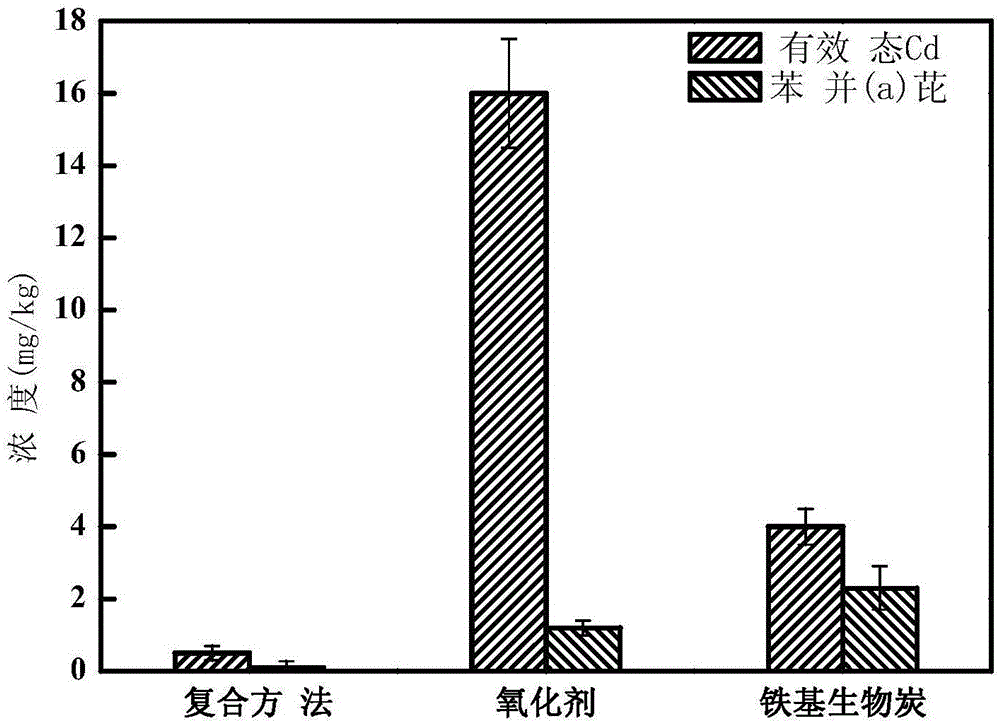

Remediation method of organic contaminant-heavy metal compound contaminated soil

ActiveCN106623380AEfficient repairReduce repair costsContaminated soil reclamationHeavy metal compoundPersulfate

The invention discloses a remediation method of organic contaminant-heavy metal compound contaminated soil. The remediation method comprises the following steps: adding persulfate into organic matter-heavy metal compound contaminated soil, and on the basis of effective oxidative degradation of organic contaminant, further using iron-based biochar for passivating heavy metals after playing an activating effect so as to achieve effective remediation of the organic matter-heavy metal compound contaminated soil. Compared with the method for remedying contaminated soil with single contamination by using the biochar or the persulfate, the remediation method provided by the invention has the advantages as follows: two methods are combined for remedying organic matter-heavy metal compound contamination, the persulfate is used for oxidizing organic matters and can fully mineralize the organic matters; for heavy metal contaminated soil, the persulfate can oxidize the heavy metals, and reduces the pH of the soil to cause an increase in the concentration of effective-state metal; the biochar fixes the heavy metals to the surface through adsorption, so that the bioavailability of the heavy metals is reduced.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

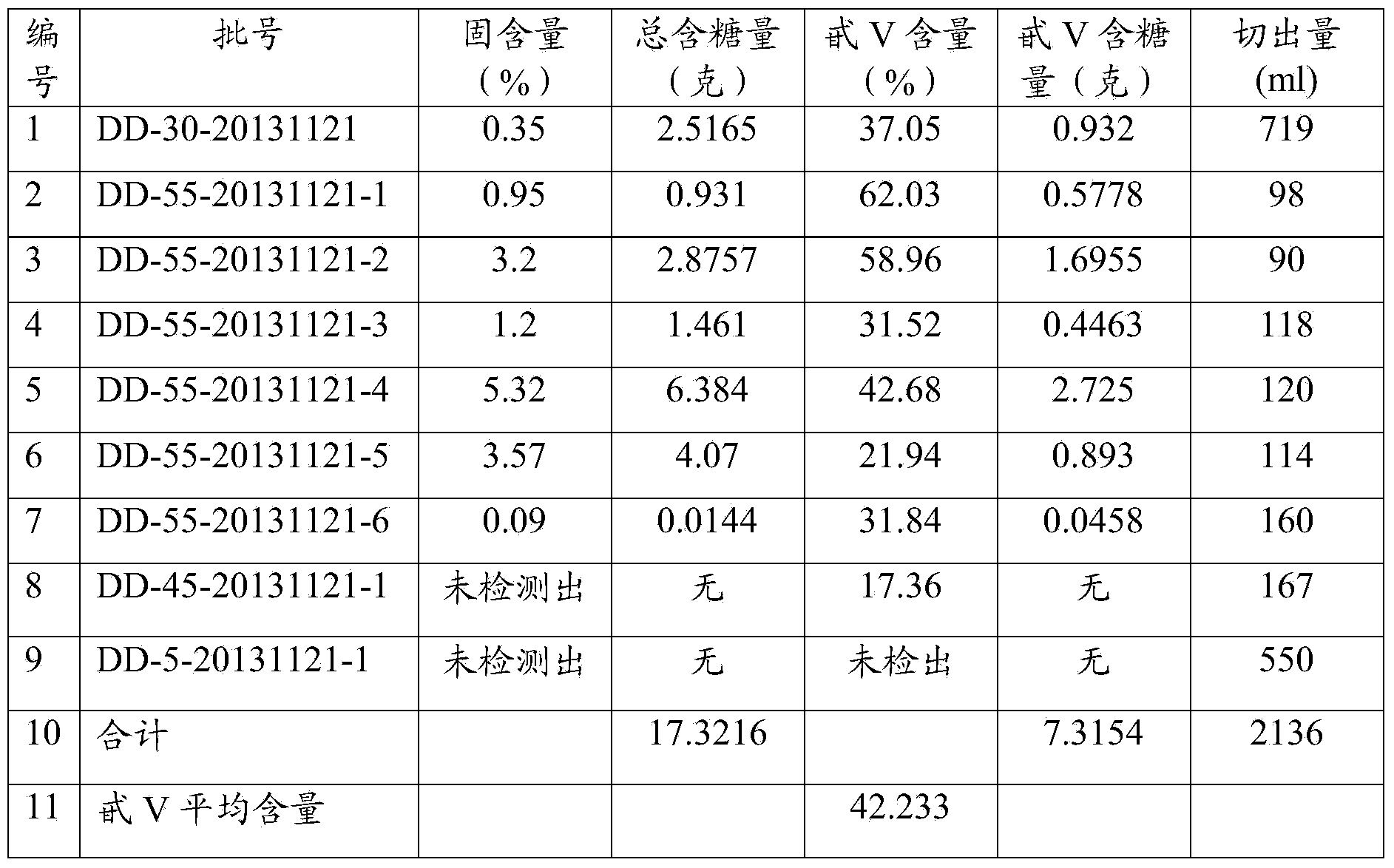

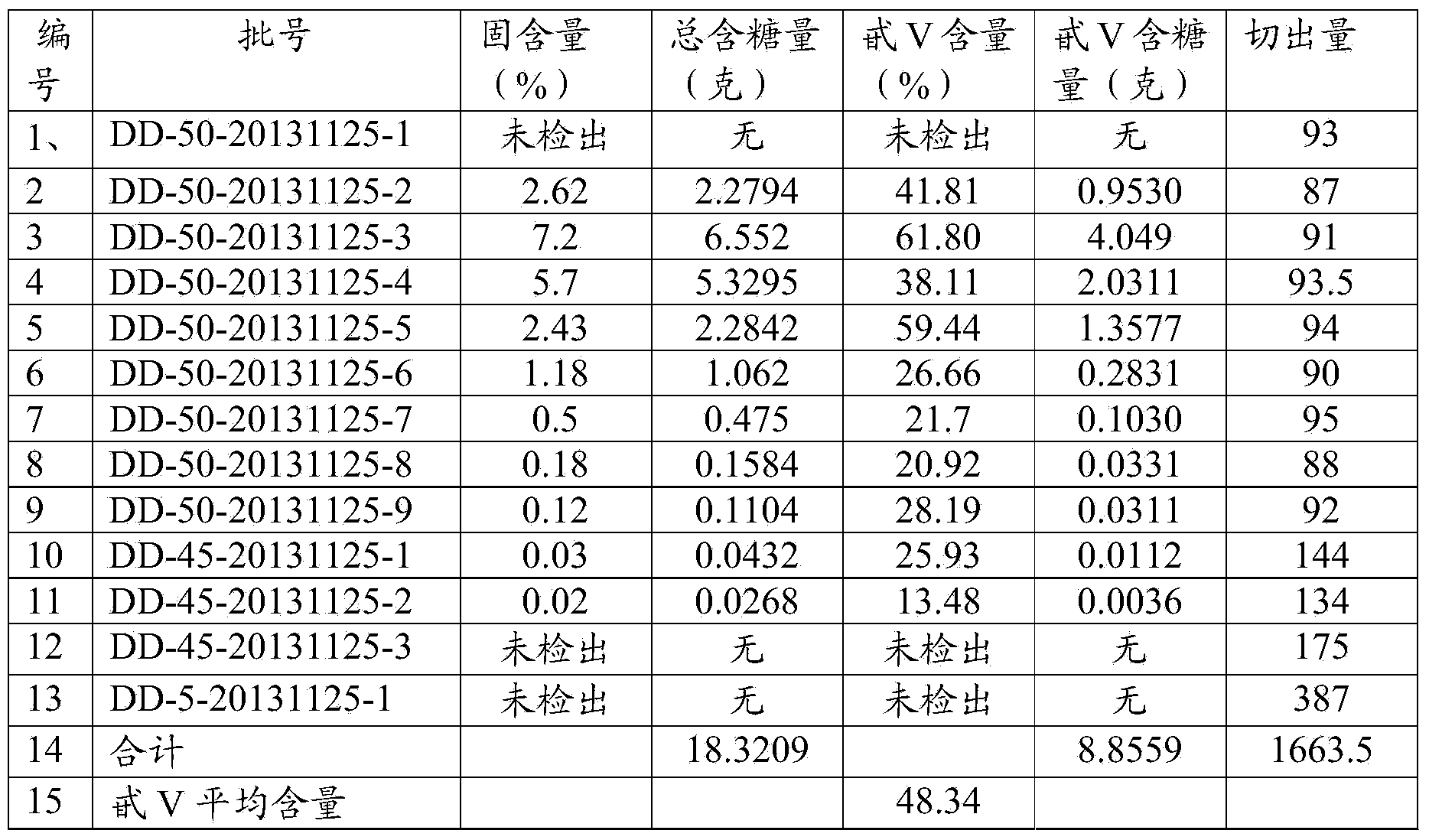

Method for extracting mogroside V

ActiveCN103923152AExtended service lifeTo achieve the effect of segmented enrichmentOrganic active ingredientsGlycoside steroidsFructoseAlcohol

The invention provides a method for extracting mogroside V. According to the method, fresh fructus momordicae serves as a raw material and is washed, smashed and extracted according to the following steps that (1) the fresh fructus momordicae is saccharifed; (2) aqueous extraction and concentration are conducted; (3) sedimentation and centrifugation are conducted; (4) adsorption and separation are conducted through macroporous resin, wherein multiple resin column groups are used for adsorption, resolution liquid is collected in sections, and according to different contents, combination is conducted in batches; (5) ion exchange resin is refined; (6) ethyl alcohol is concentrated and recycled; (7) silica gel is refined; (8) concentration and spray drying are conducted, so that mogroside V extract serving as a final product is obtained. According to the technology of refinement, various types of aglucone of fructose of the fructus momordicae are gathered in a bed layer in sections and the extracted mogroside V is high in purity, good in color and pure in taste.

Owner:QINGDAO RUNDE BIOTECH

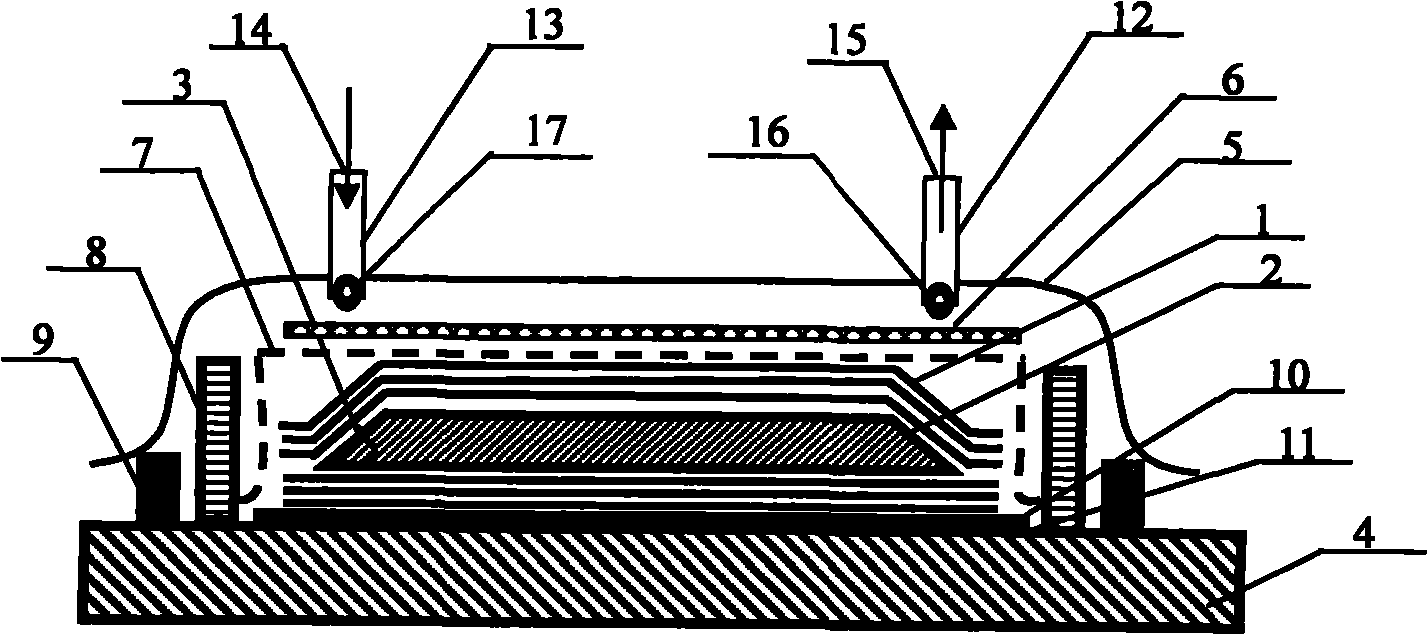

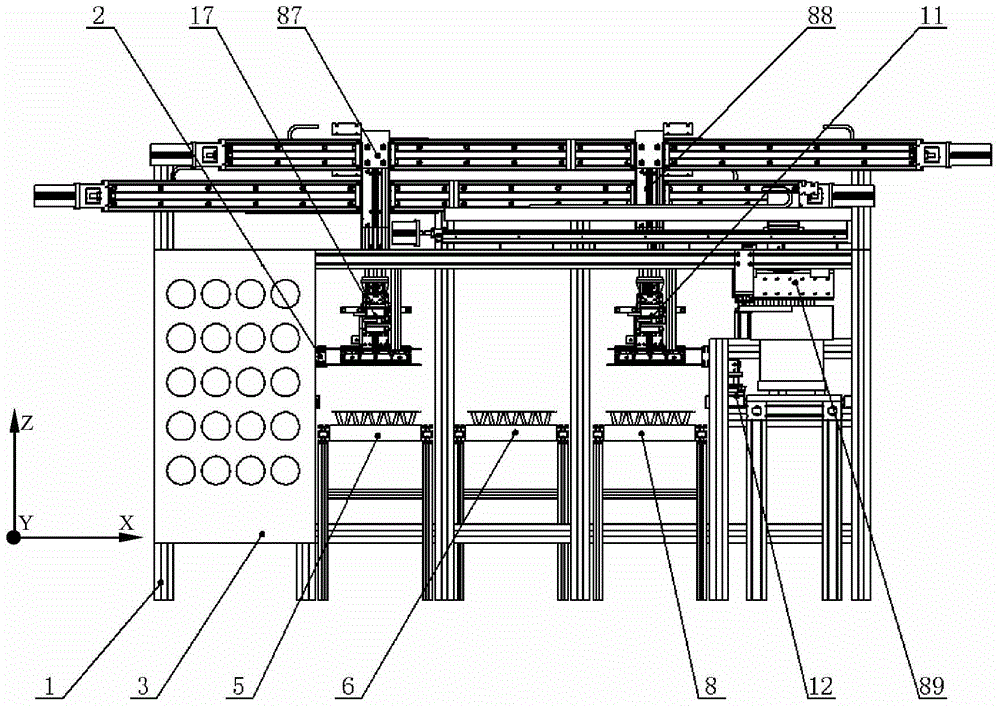

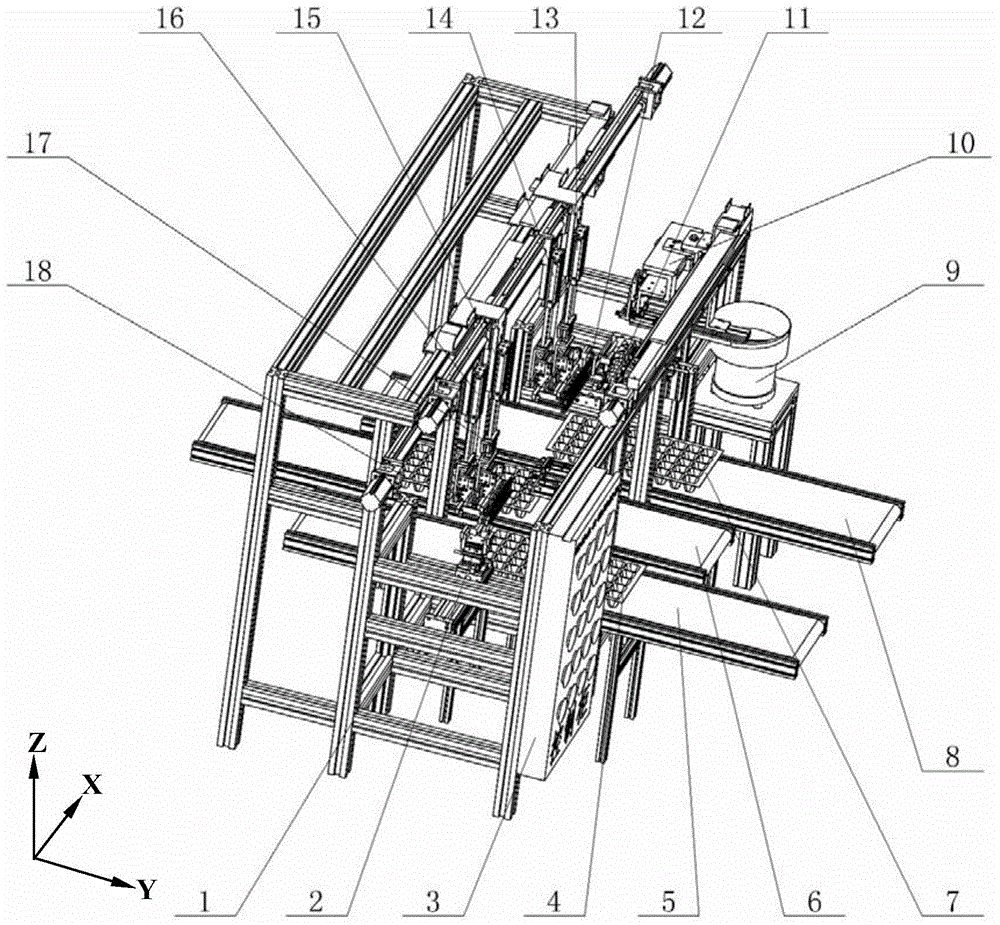

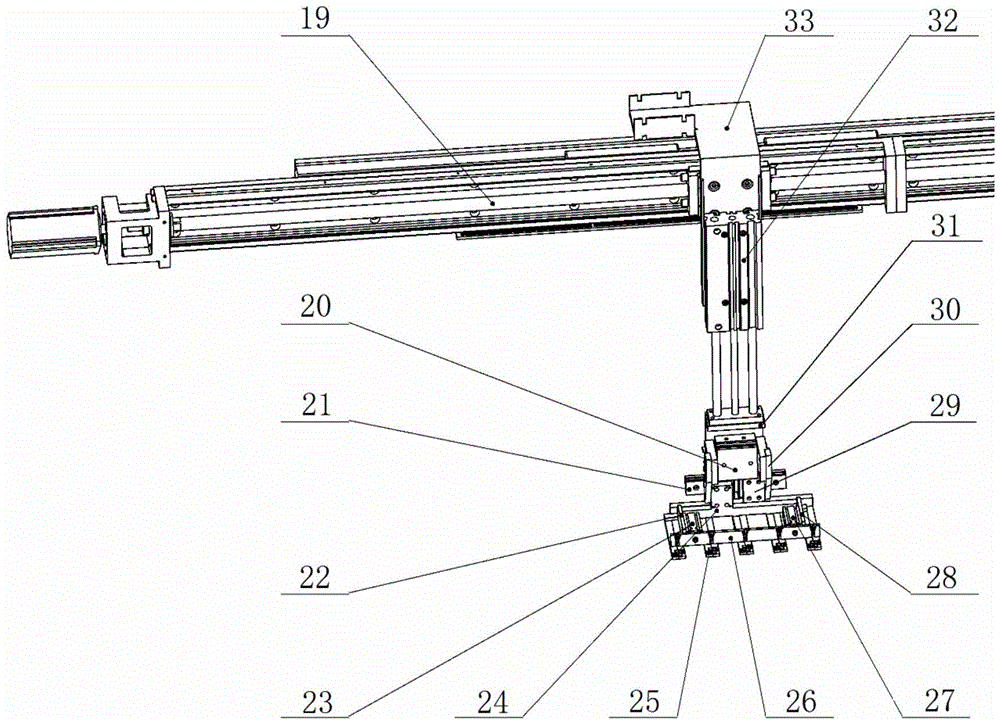

Automatic whole-row grafting device for grafted seedlings

The invention relates to the technical field of agricultural machinery, in particular to an automatic whole-row grafting device for grafted seedlings. The device comprises a rack (1), an electric control cabinet (3), a scion conveying mechanism I (5), a scion conveying mechanism II (8), a grafted seedling conveying mechanism (6), a scion clamping mechanism (87), a rootstock clamping mechanism (88), a scion seedling cutting mechanism (17), a rootstock seedling cutting mechanism (11), a scion seedling gathering mechanism (2), a rootstock seedling gathering mechanism (12) and an automatic whole-row grafting clamp conveying mechanism (89). According to the automatic whole-row grafting device for the grafted seedlings, plug seedling supply, whole-row seedling grabbing, seedling cutting, fixing and grafting of plug rootstock seedlings and plug scion seedlings are realized, and the whole operation process is automatically completed by a machine; the plug seedlings are rapidly grafted, the labor efficiency of grafting operation is improved, and the labor force is saved.

Owner:CHINA AGRI UNIV

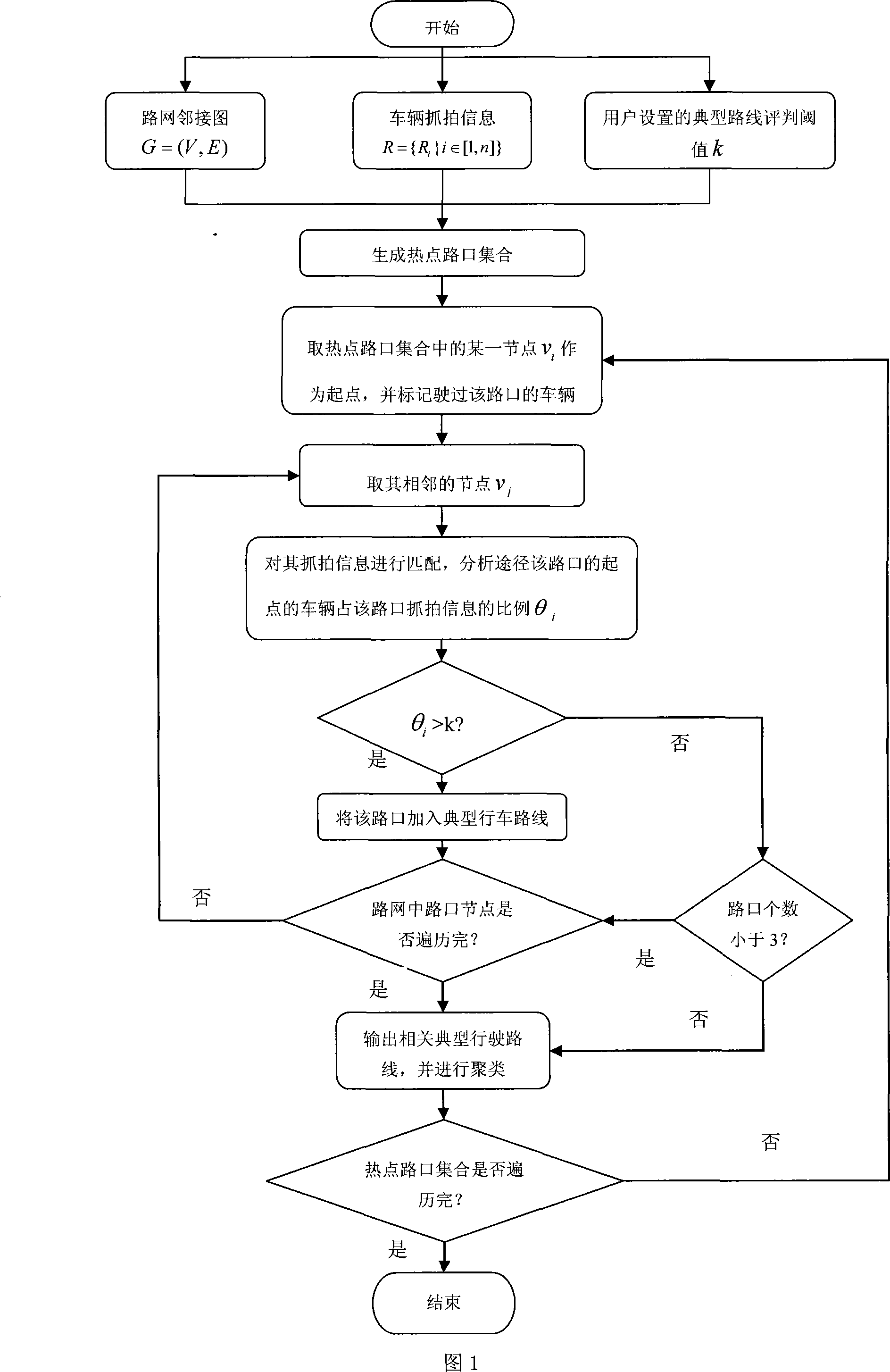

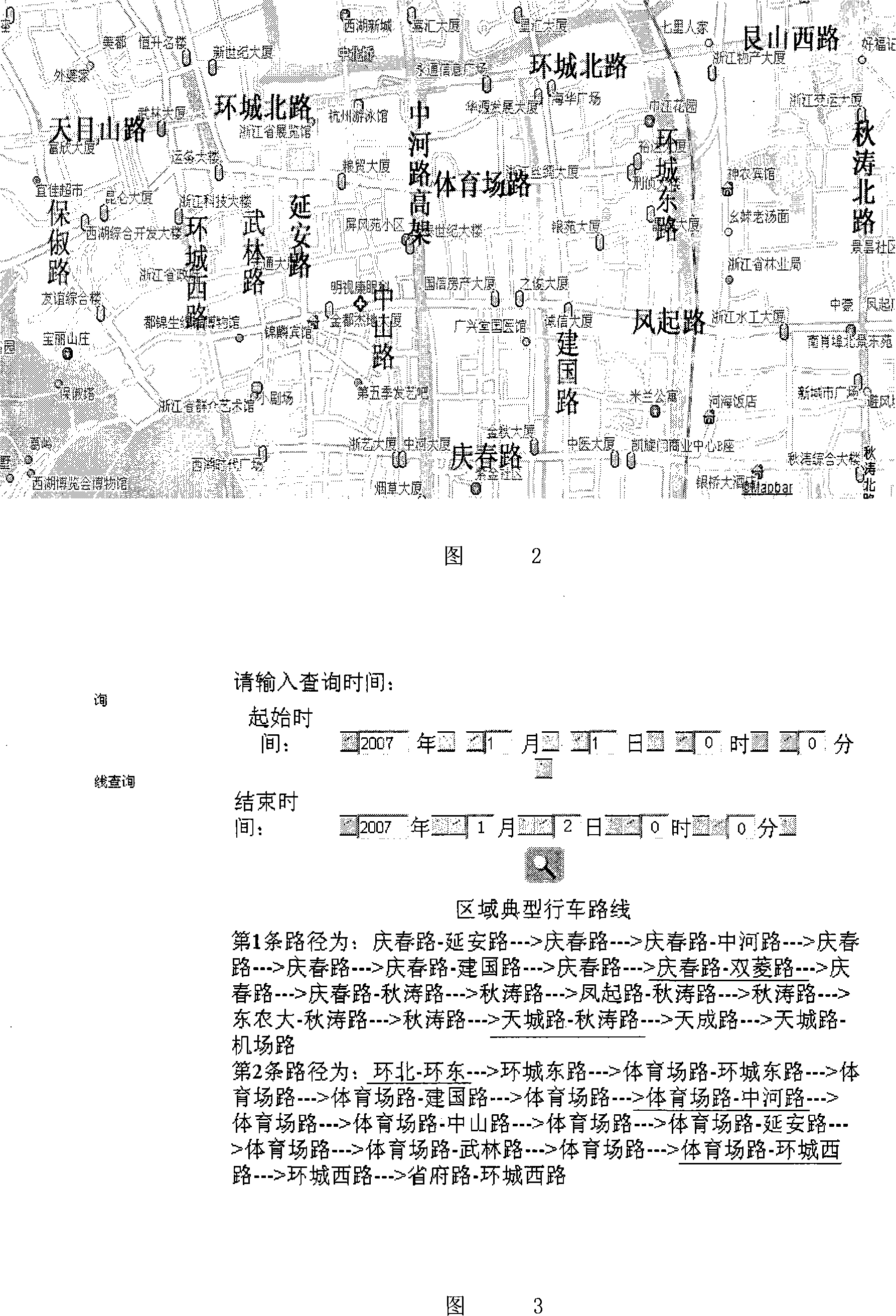

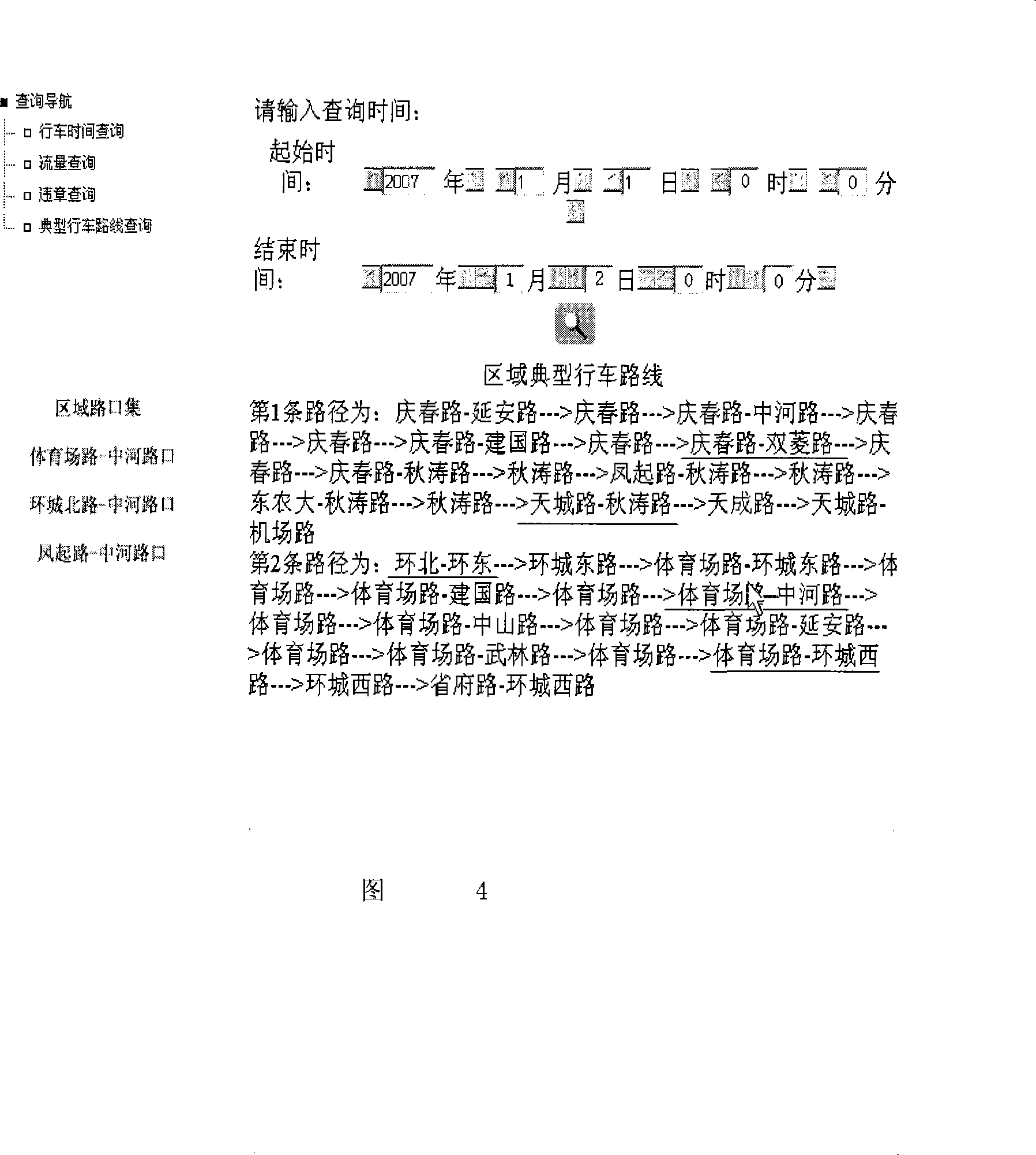

Method for analysis of prototype run route in urban traffic

InactiveCN101226687AImprove effectivenessImprove targetingDetection of traffic movementSpecial data processing applicationsEngineeringAnalysis method

Disclosed is an analytical method for typical running routes in urban traffic, comprising steps as follows: (1) setting a road net topology structure as G = (V, E), vehicle information of every road junction at a corresponding certain time as R = (Ri|ií—(1,n)), judgment threshold of hotspot junction as k and judgment threshold of typical running route as k', (2) generating first sorting typical running routes between hotspots, which comprises obtaining a hotspot road junction aggregate by filtering road junction volume, in regard to vií—V' and Hií—H, generating a running route aggregate W' between the hotspots and obtaining a first sorting typical running route W'' by calculating the occupancy of the route according to the generated route W', (3)initially selecting the clustering of the first sorting running route and the generating of the traffic junction merger routes in every clustering aggregate according to the method to obtain the typical running route aggregate W with different particle sizes. The invention is short in processing period, low in cost and high in efficiency, and can reflect the change of the traffic conditions by calculating the typical running route.

Owner:ZHEJIANG UNIV OF TECH

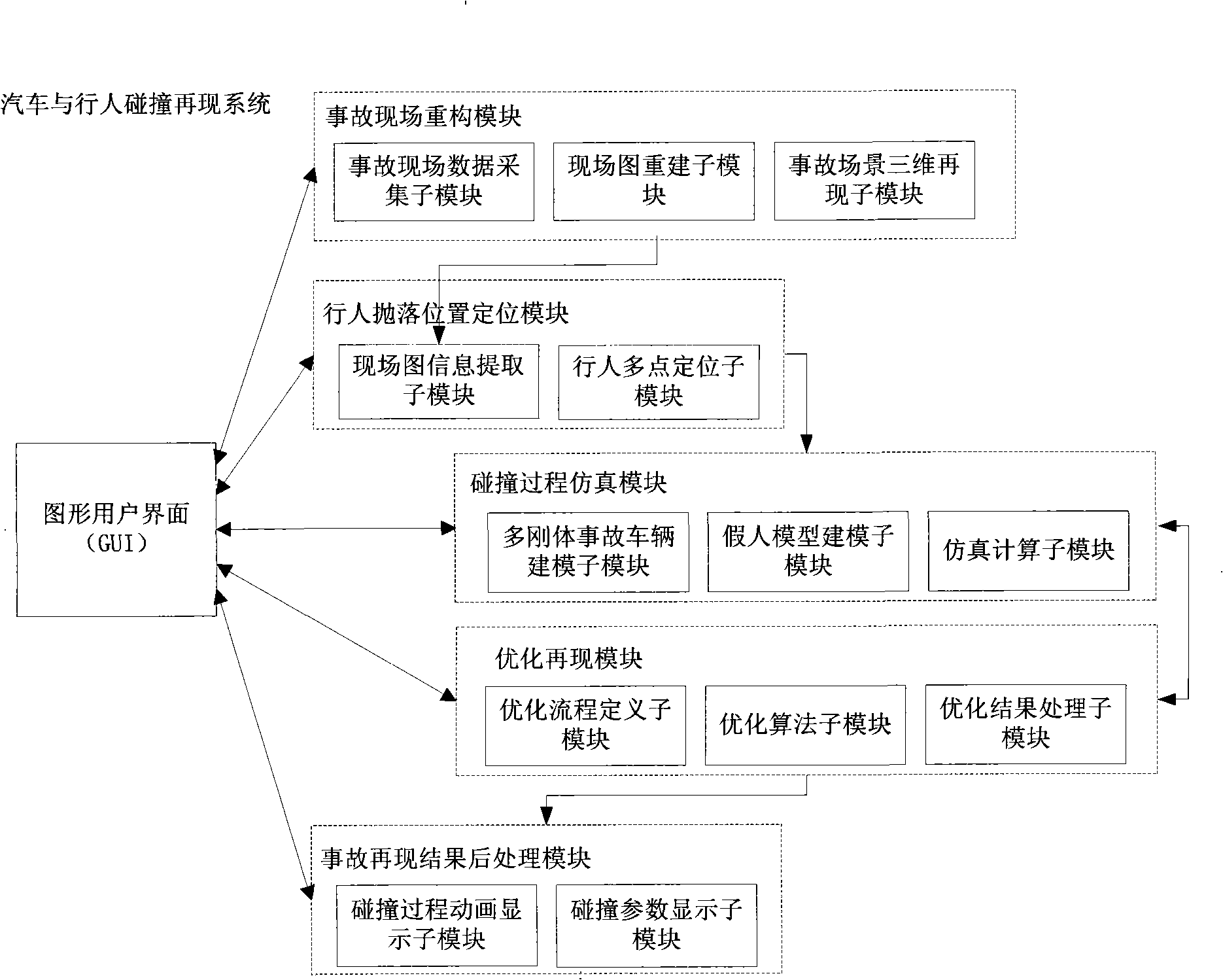

System for reproducing collision accident of vehicle and pedestrian

InactiveCN101281660AEfficient collectionEfficient extractionAnimation3D-image renderingAnimationSimulation

The invention relates to a collision case playback system of the cars and walkers, which adopts a uniform Visualization user interface, realizes the accident treatment global interactive operation, wherein an accident site reconstitution module collects the accident field data and picture, reconstitutes and reverts the site, performs the second collection on the site data according to the requirement; a walker throwing and falling position positioning module provides the precise description for the walker throwing and falling position and the configuration; a collision process emulating module performs the scaling of model matching with the sufferer bodily form characteristics, meanwhile builds the integral accident site three-dimensional model before the accident, and simulates and computes the primary collision result; an optimization recurrence module optimizes the collision simulation, and recurs the collision whole process of the car and walker; an accident recurrence result post-processing module displays the optimized simulation result in the collision process animation and the collision parameters. The invention can realizes the site information collection, fast simulation and modelization, short treating period, high precision and high reliability.

Owner:SHANGHAI JIAO TONG UNIV

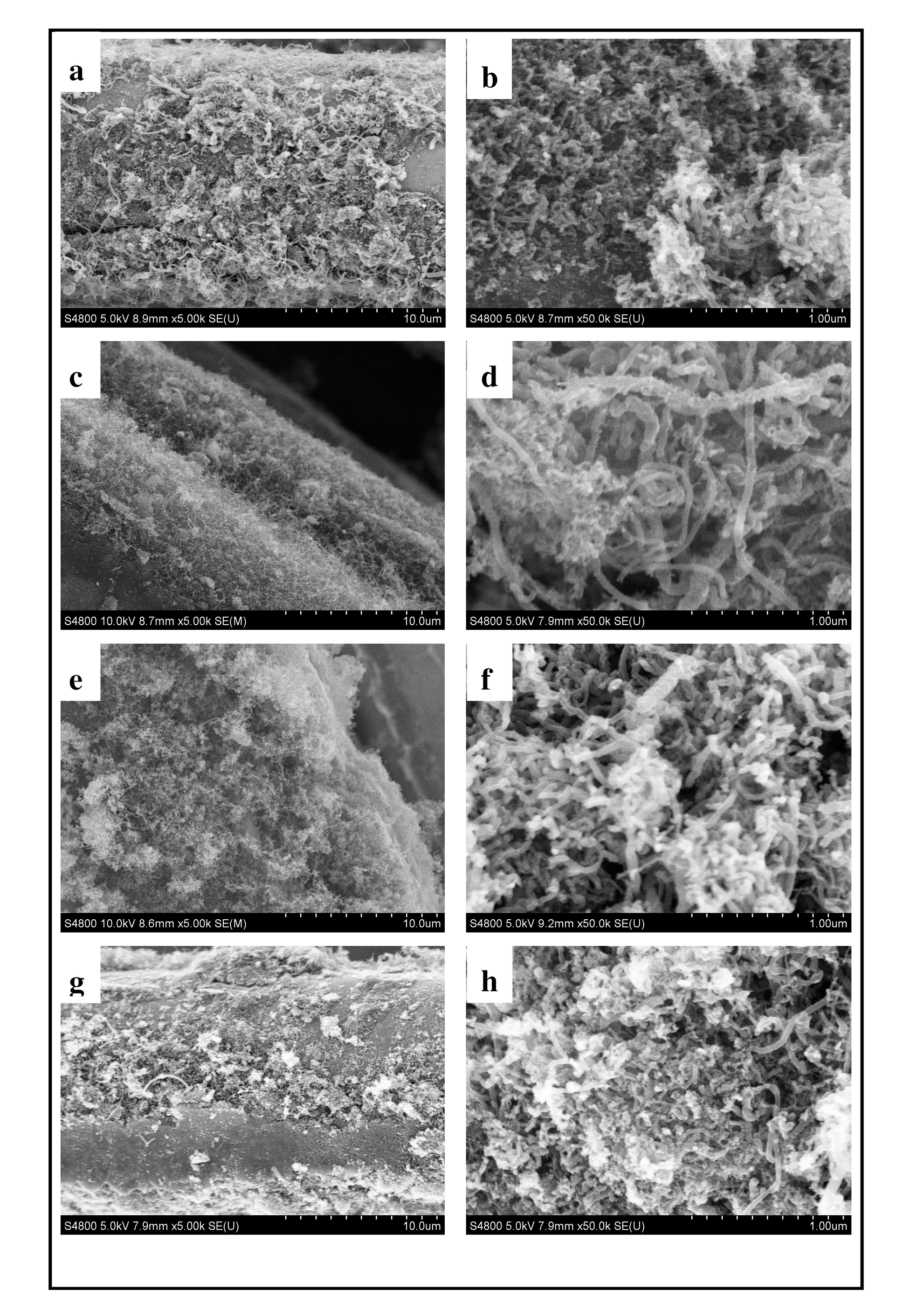

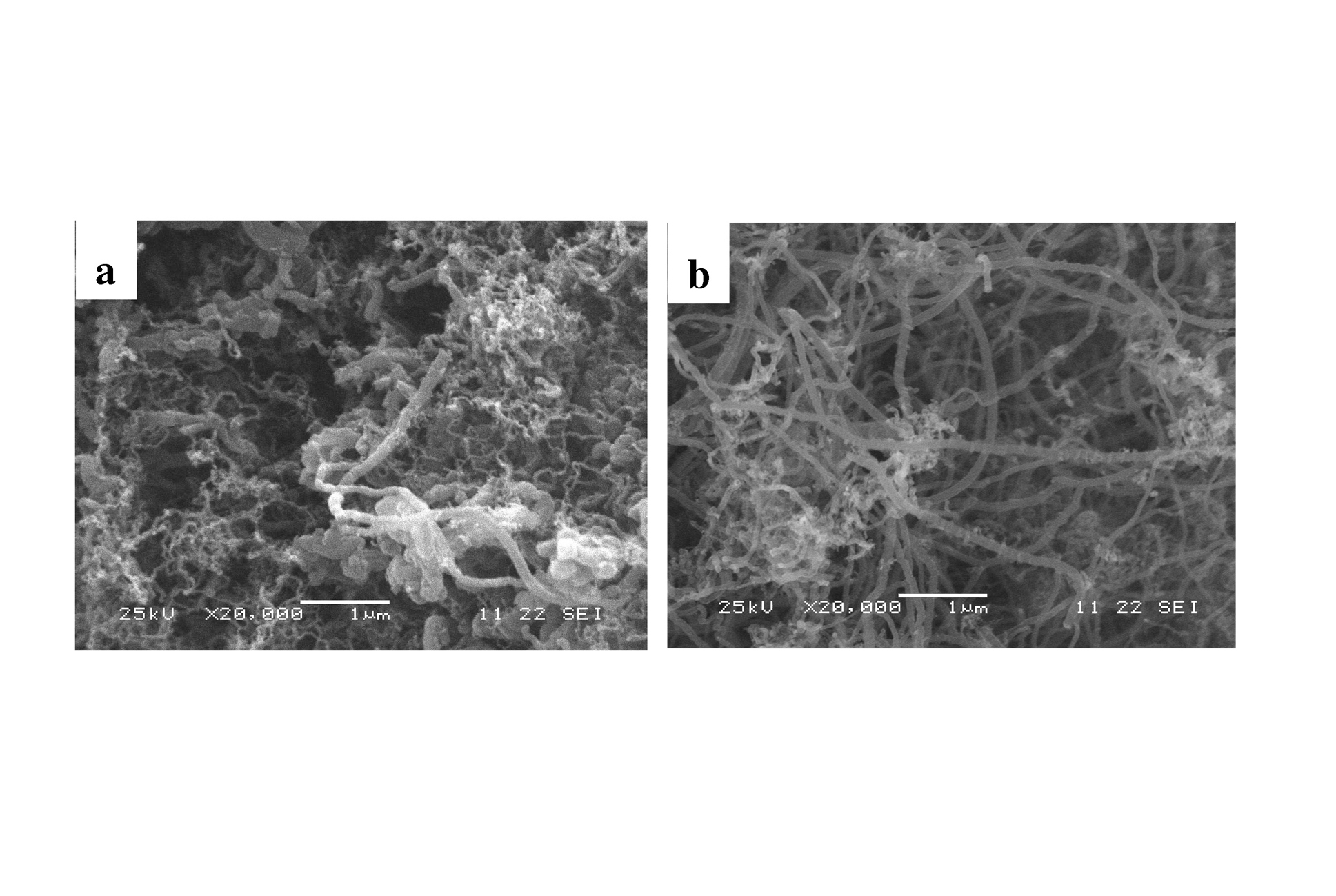

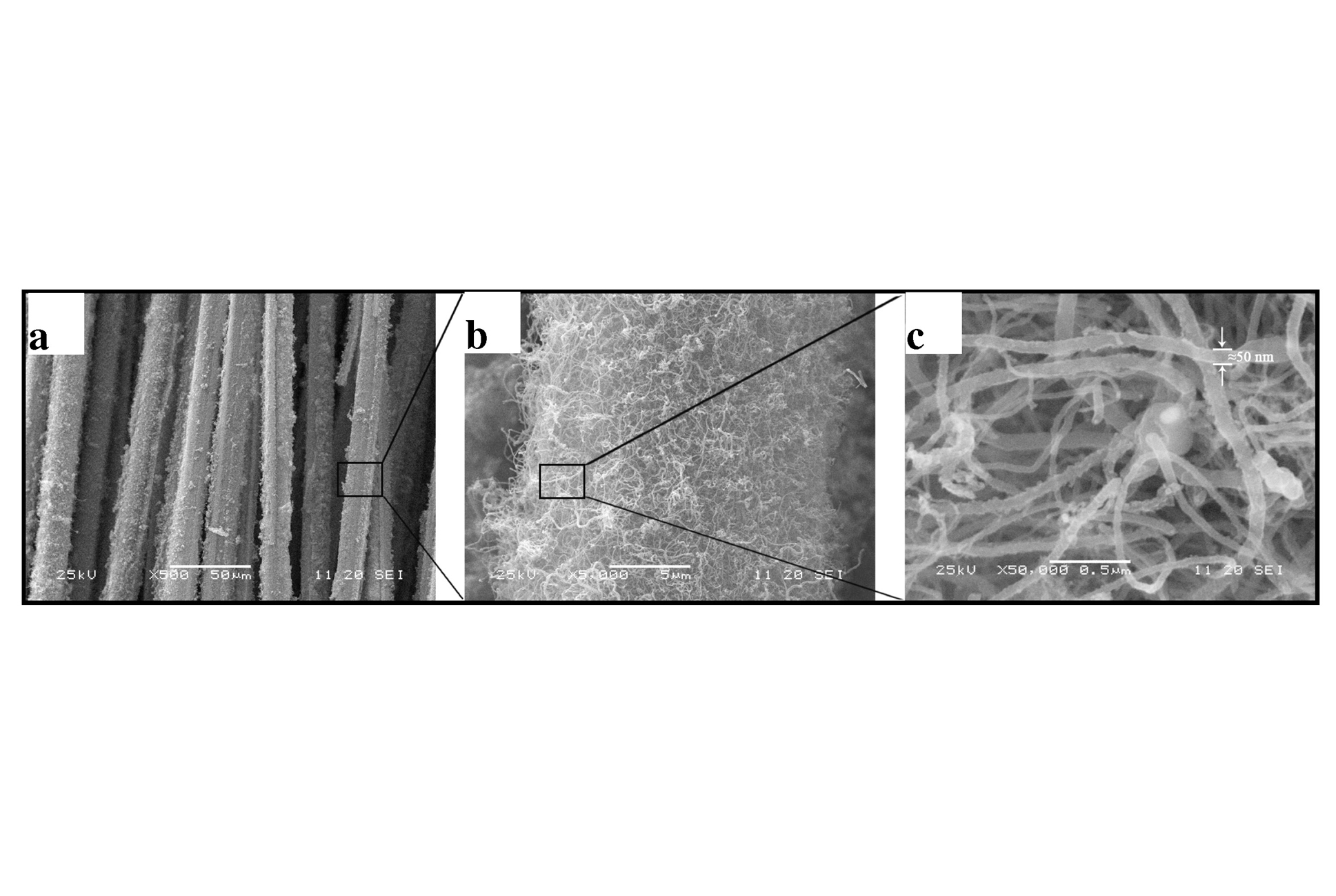

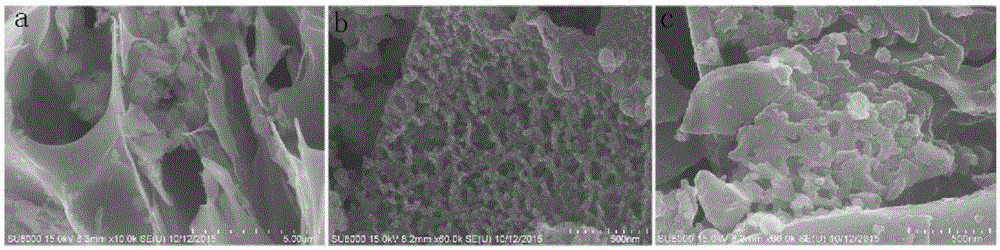

Silicon carbide fiber solid fabric for in-situ growing carbon nano tubes, composite material and preparation method thereof

The invention discloses a silicon carbide fiber solid fabric for in-situ growing carbon nano tubes, which is formed by mainly weaving silicon carbide fibers. In the invention, in-situ grown carbon nano tubes are uniformly distributed on the surfaces of the silicon carbide fibers and mutually wound to form a reticular structure. The preparation method comprises the following steps of: pretreating the silicon carbide fiber solid fabric; loading a Ni-La-Al composite catalyst by adopting a catalyst precursor vacuum impregnation-reduction method; and finally, carrying out chemical gas-phase deposition to ensure that the carbon nano tubes are in-situ grown on the silicon carbide fiber solid fabric. The invention also discloses a carbon nano tube-silicon carbide fiber mixed enhanced composite material which is prepared by using silicon carbide as a substrate and the silicon carbide fiber solid fabric as a reinforcement body by adopting a traditional precursor impregnation-conversion method. The silicon carbide fiber solid fabric has the advantages of uniform carbon nano tube dispersion, higher and controllable carbon nano tube content, good combination with fibers, and the like.

Owner:NAT UNIV OF DEFENSE TECH

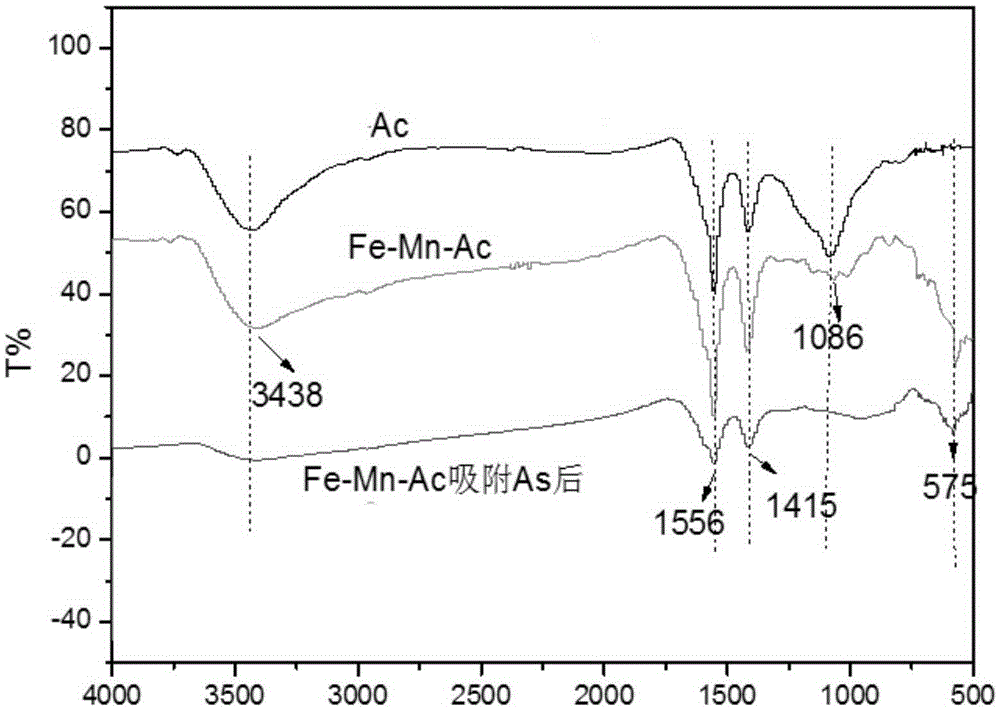

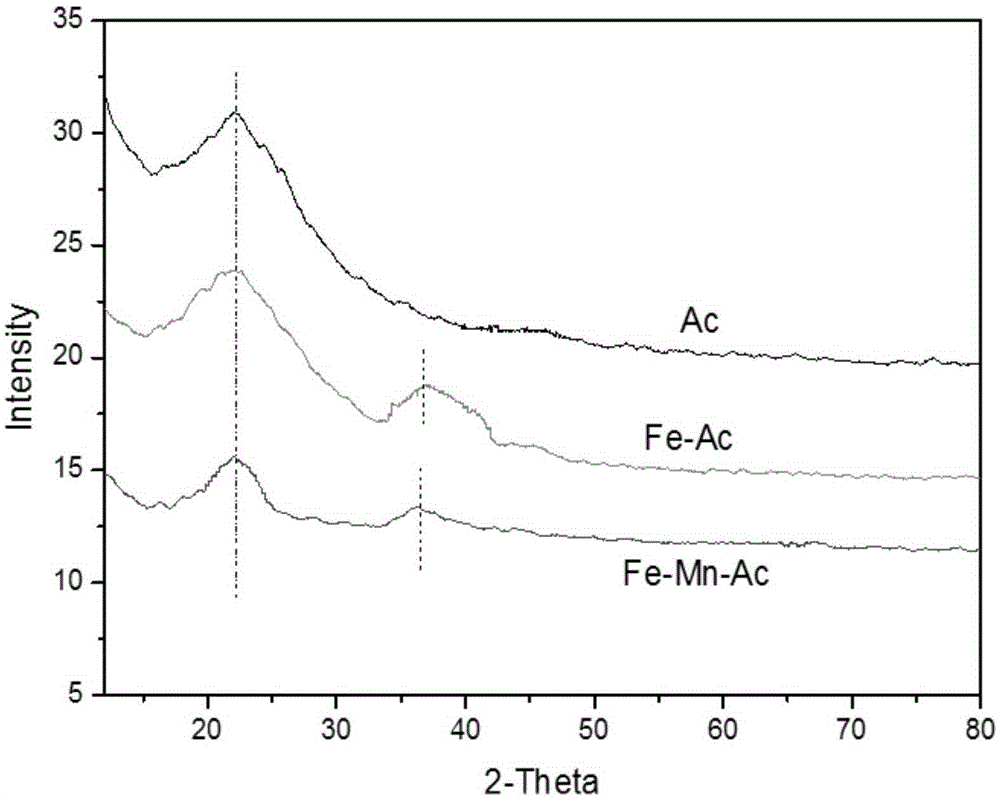

Ferromanganese modified straw active carbon adsorbent for As (III) adsorption, and applications thereof

ActiveCN105289493AHuge productionIncrease profitOther chemical processesWater/sewage treatment by sorptionActivated carbonSorbent

The present invention relates to a ferromanganese modified straw active carbon adsorbent for As (III) adsorption, and applications thereof. The technical scheme comprises: preparing straw into straw active carbon, adding to nitric acid, carrying out an acidification treatment to obtain acidified straw active carbon, adding the acidified straw active carbon to a metal iron salt and HCl mixing solution, carrying out a reaction at a room temperature for 22-24 h, heating to a temperature of 95-105 DEG C, carrying out a reaction for 6-7 h to obtain iron modified active carbon, mixing a metal manganese salt and the iron modified active carbon, carrying out a reaction at a temperature of 75-85 DEG C, adding a KMnO4 and KOH mixing aqueous solution, carrying out a reflux reaction at a temperature of 75-85 DEG C, and washing he product so as to obtain the target product. According to the present invention, with the ferromanganese modified straw active carbon adsorbent, the As (III) can be selectively recovered from the solution containing the As (III) ions and the impurity metal ions; and the ferromanganese modified straw active carbon adsorbent has advantages of low cost, high selectivity, high adsorption capacity, and the like.

Owner:LIAONING UNIVERSITY

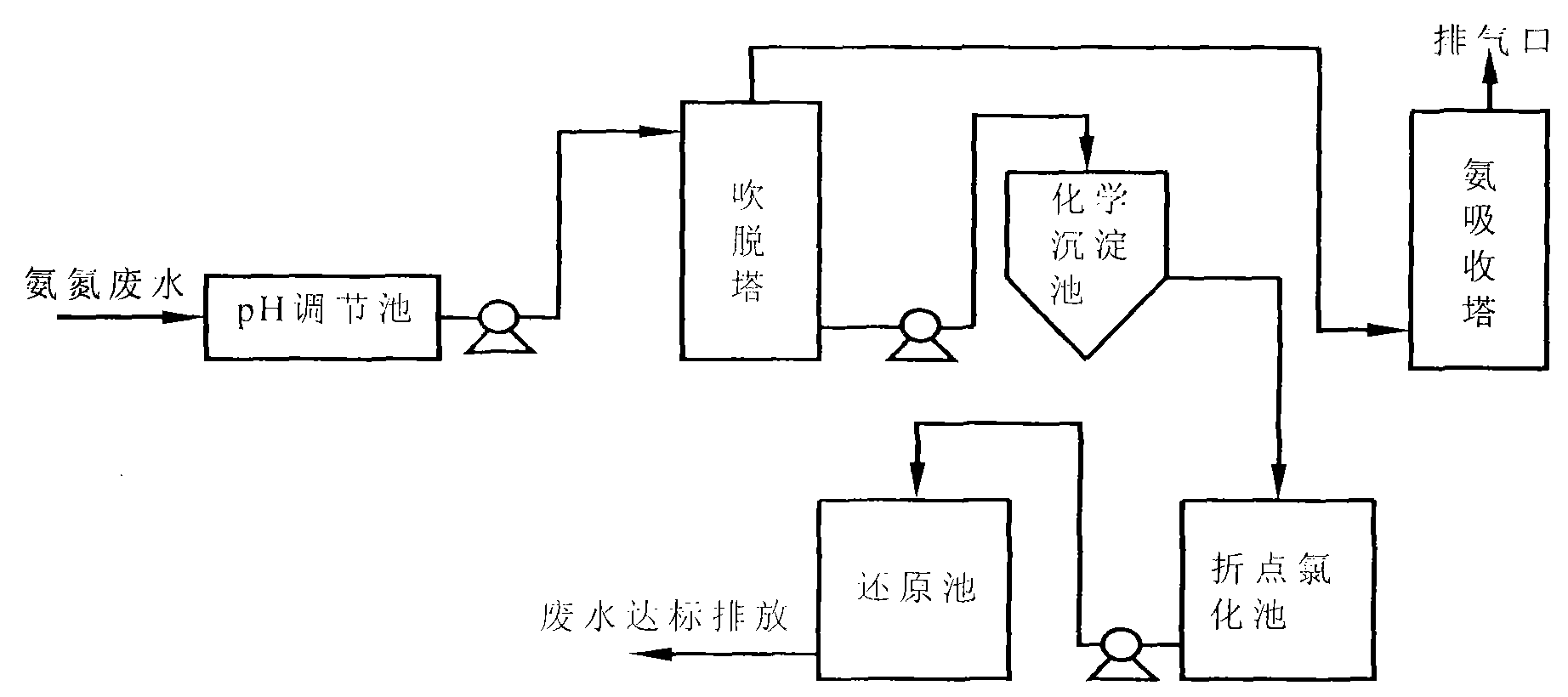

Method for treating highly concentrated ammonian wastewater with poor biodegradability by using a multiple-technique combination

InactiveCN101555077AShort processing cycleEasy to operateMultistage water/sewage treatmentWater/sewage treatment by neutralisationMagnesium saltEmission standard

The invention relates to a method for treating highly concentrated ammonian wastewater with poor biodegradability by using a multiple-technique combination, which belongs to the technical field of wastewater treatment. The method is characterized in that: the ammonian wastewater primarily enters a pH adjusting tank for adjusting the pH value to be 11-12.5 and enters a blow-off tower for blowing off with the gas-liquid ratio being 3000-4500, the blown-off wastewater enters a chemical precipitation tank, magnesium salts and phosphates are added according to the mol ratio of Mg : N : P being 1.4-1.7:1:1 for reacting with the wastewater to generate ammonium magnesium phosphate precipitate for removing ammonian, yielding water enters a break point chlorination tank, chlorine-containing oxide is added according to the weight ratio Cl / N being 9-12:1 of active chlorine and ammonian, the wastewater is transferred to a reducing tank after the reaction, reducing agent is added according to 1-1.1 times of theoretical mol value of the yielding water completely reacting with residual chlorine, and the wastewater can be directly discharged after the reaction. The treatment method has simple operation, high reaction speed and low wastewater treatment cost, and can lead ammonian to be recovered without secondary pollution to environment; and the yielding water can reach primary emission standard.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Preparation method of nanometer iron-based soft magnetic block

InactiveCN101752074ALow costSimple processInductances/transformers/magnets manufactureAutomatic controlLaser scanning

The invention discloses a preparation method of a nanometer iron-based soft magnetic block. Nanometer iron-based soft magnetic powder is served as the main raw material. The shape of a nanometer iron-based soft magnetic block to be prepared is designed by professional 3D graphics software on a computer; then, computer graphics processing software decomposes the designed 3D graphics into a series of processing signals controlling laser scanning speed, output power, sintering paths, feeder feeding amount, feeding position and the like by an automatic control device; the feeder and the laser feed and sinter by layers under the control of the signals until the shape of the nanometer iron-based soft magnetic block to be prepared is sintered. The novel nanometer iron-based soft magnetic block is different from the block produced by nanometer ligatures, forms a unified entity, does not have gaps and has favourable permeability; with respect to the known production process of other nanometer soft magnetic blocks, the preparation method has low requirements of environment and technology and does not need to manufacture the corresponding mould in advance.

Owner:WUHAN FUHAN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com