Patents

Literature

1121results about How to "Consistent thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

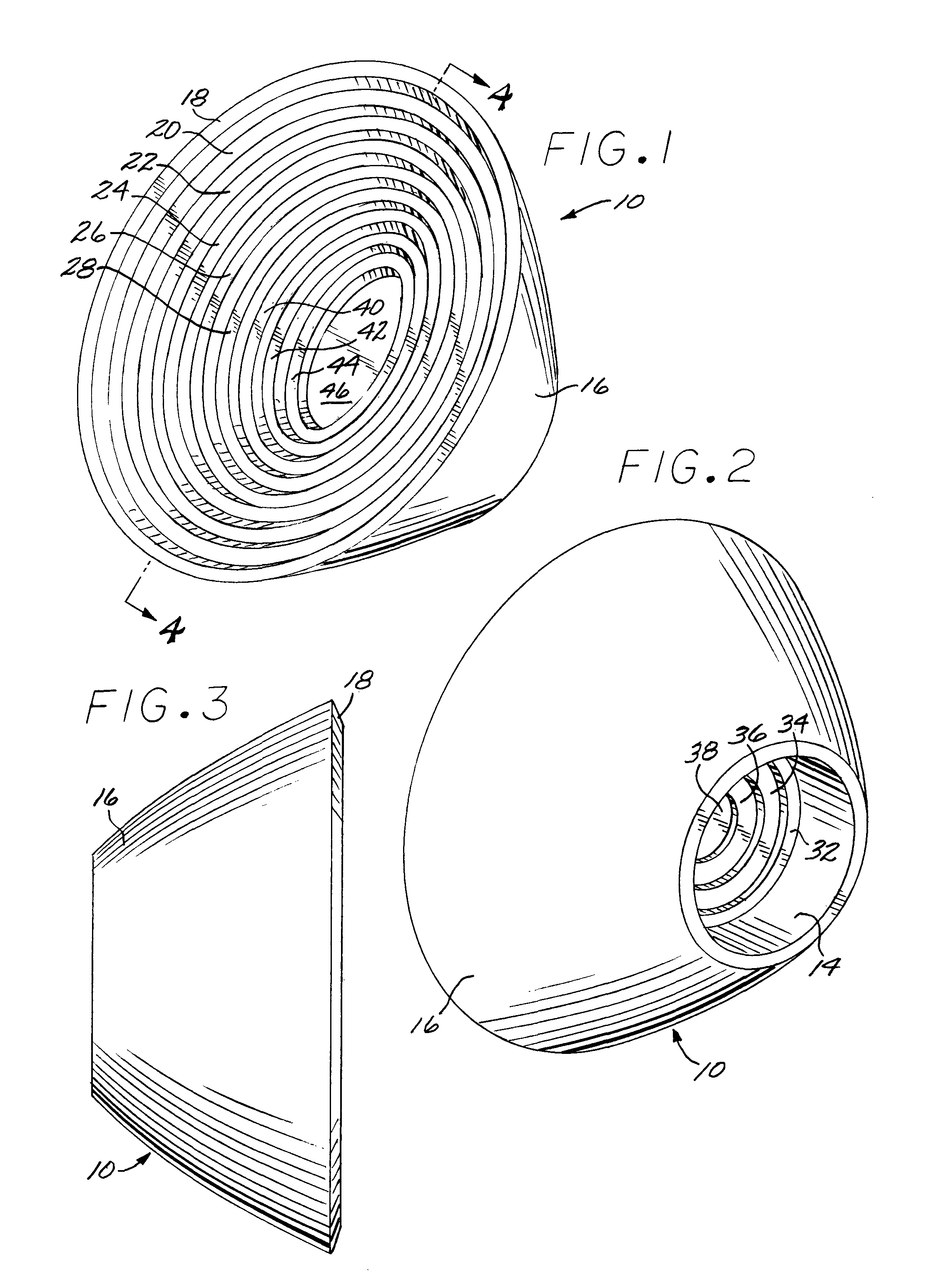

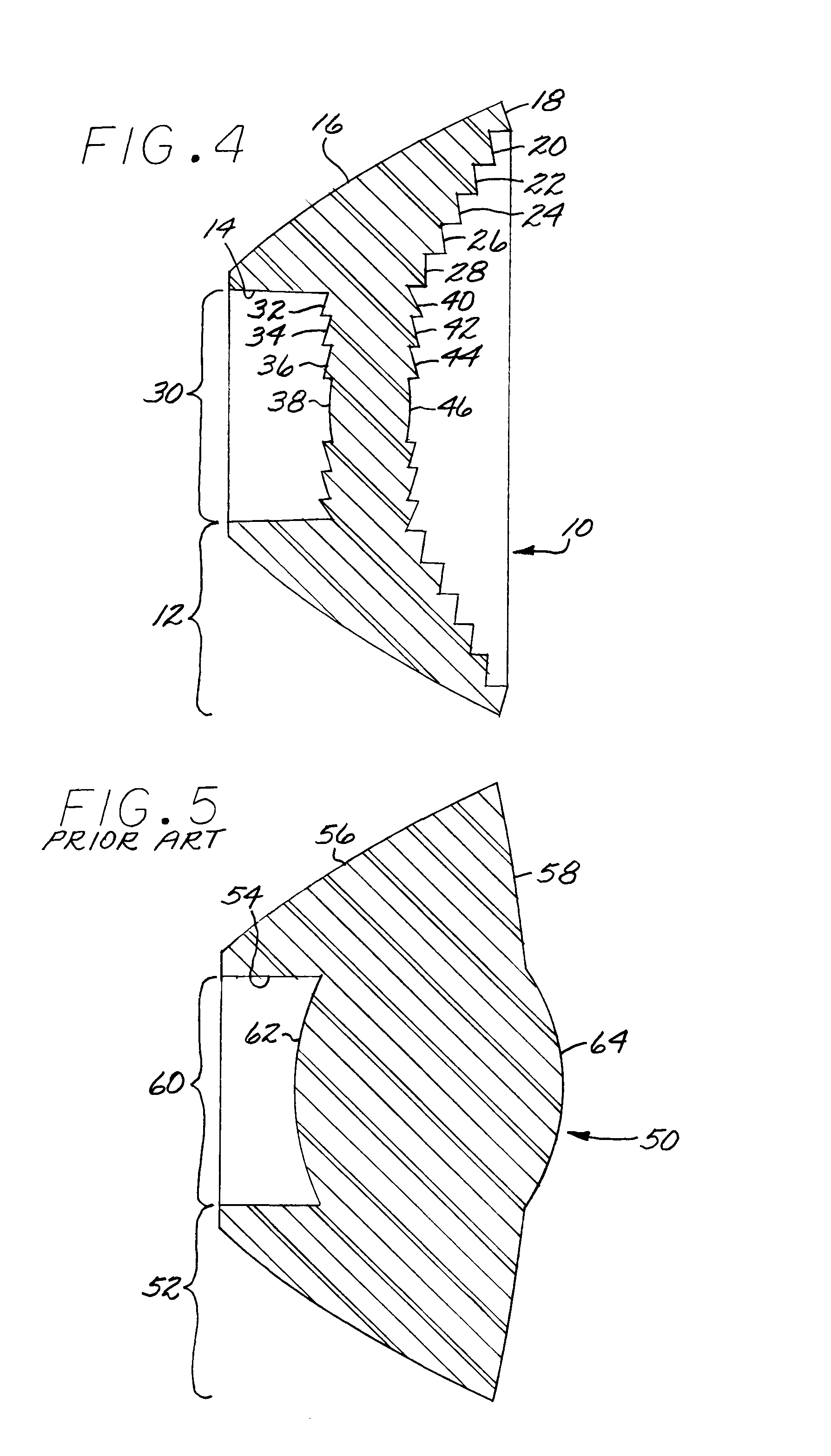

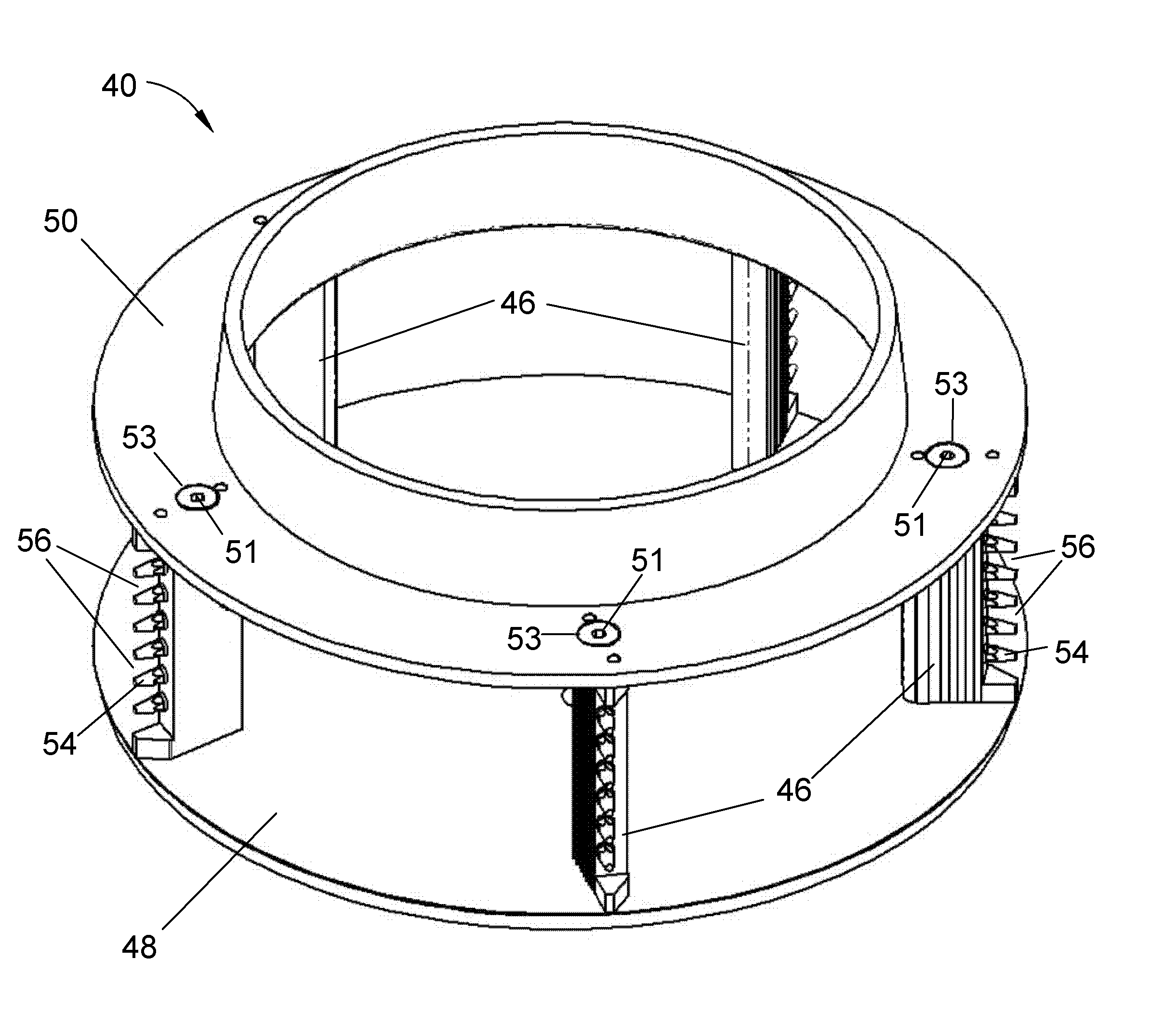

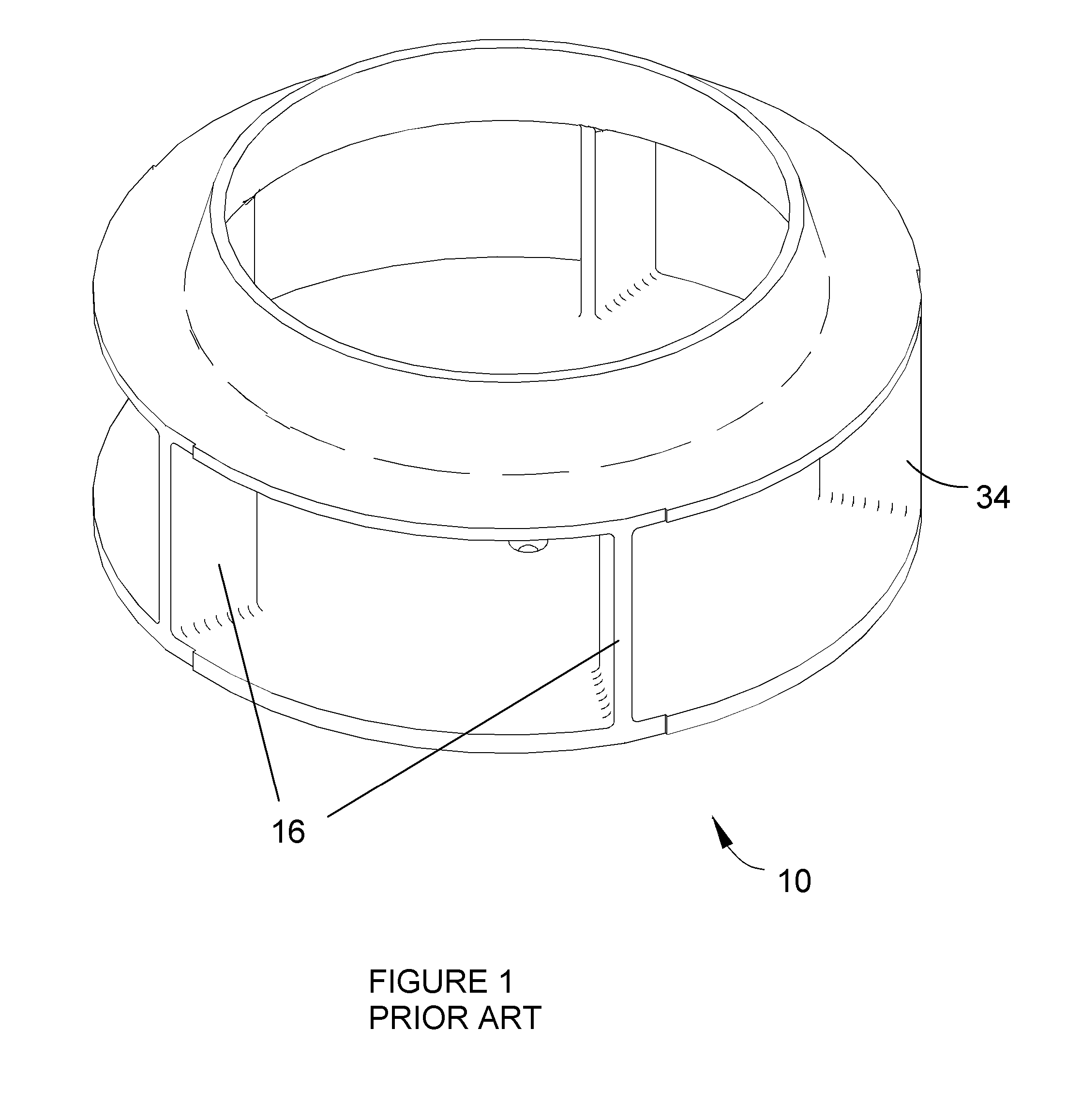

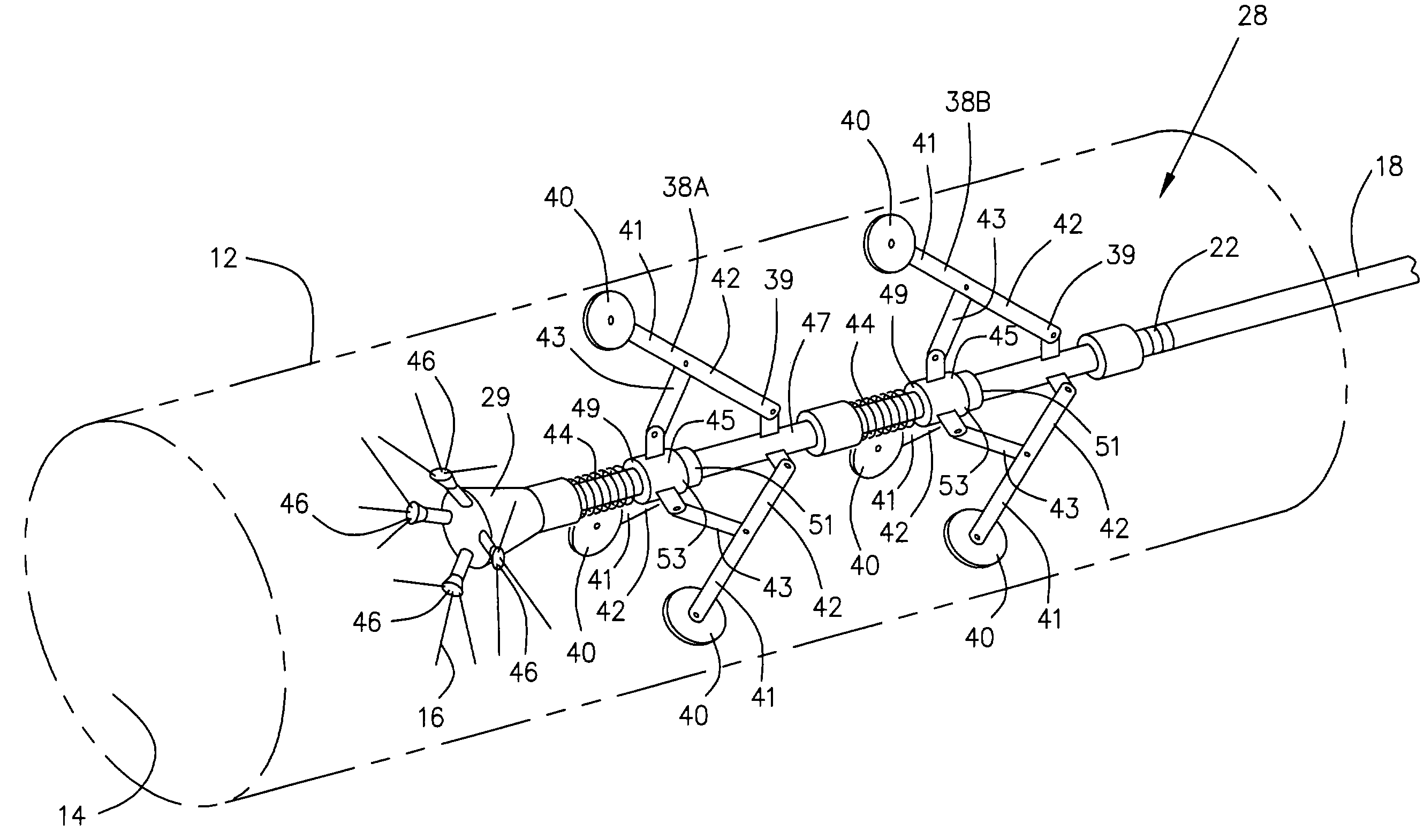

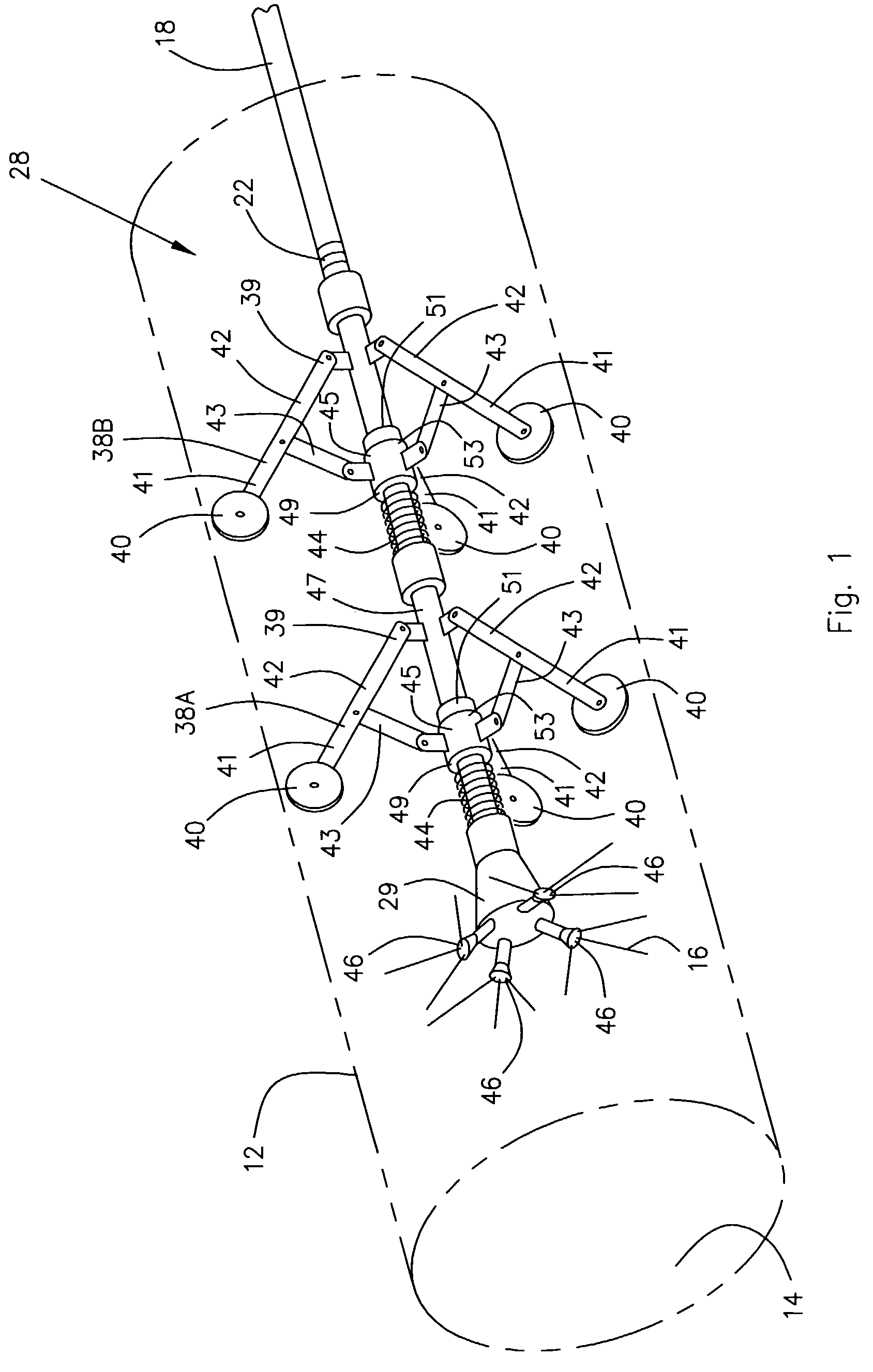

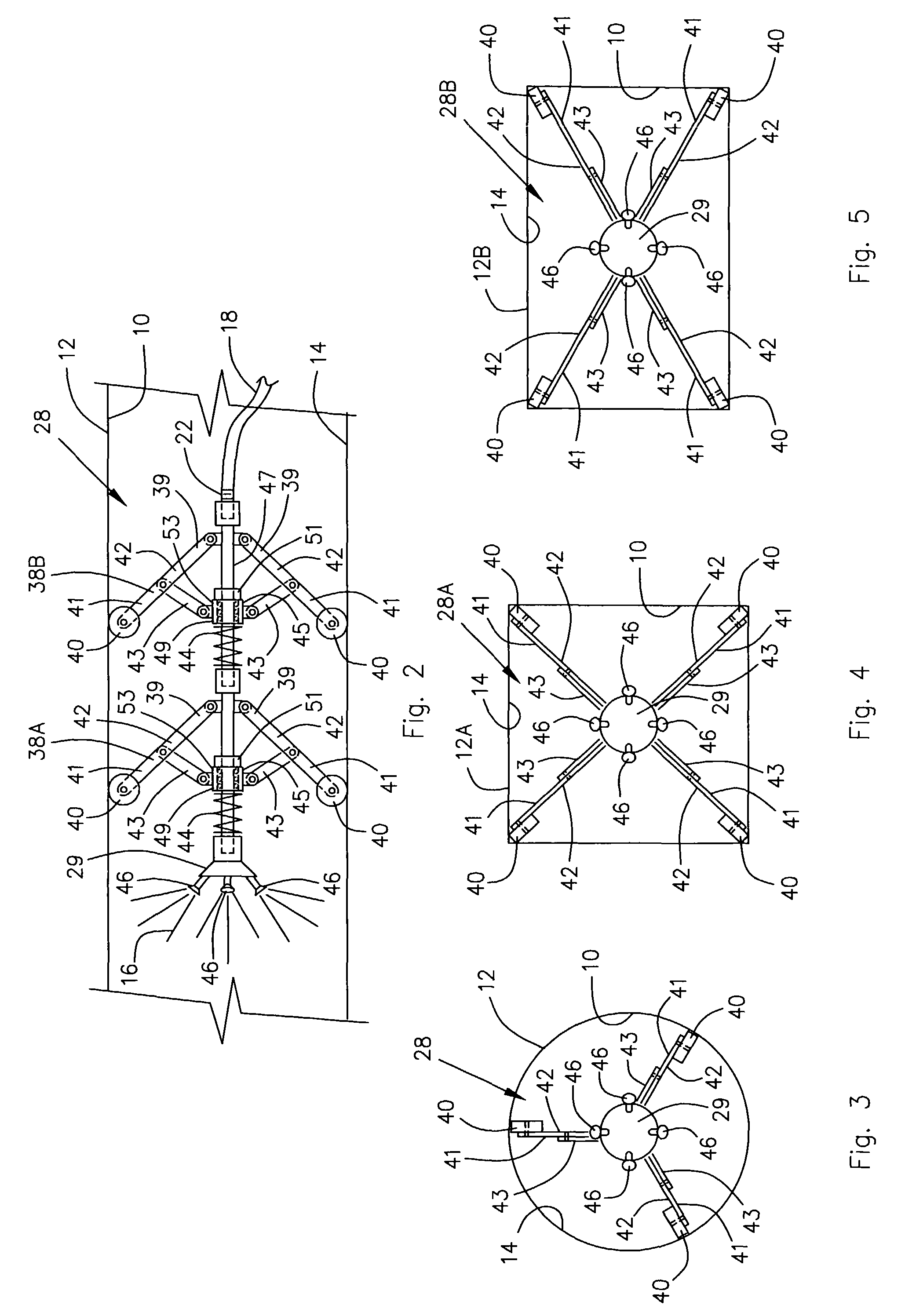

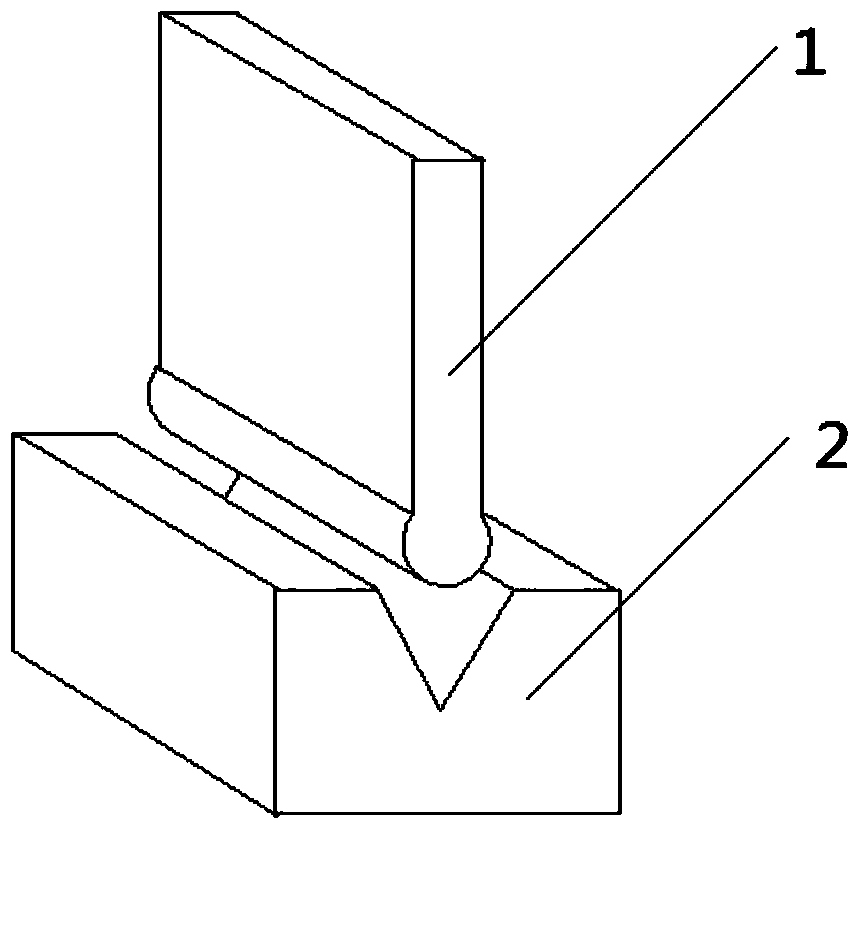

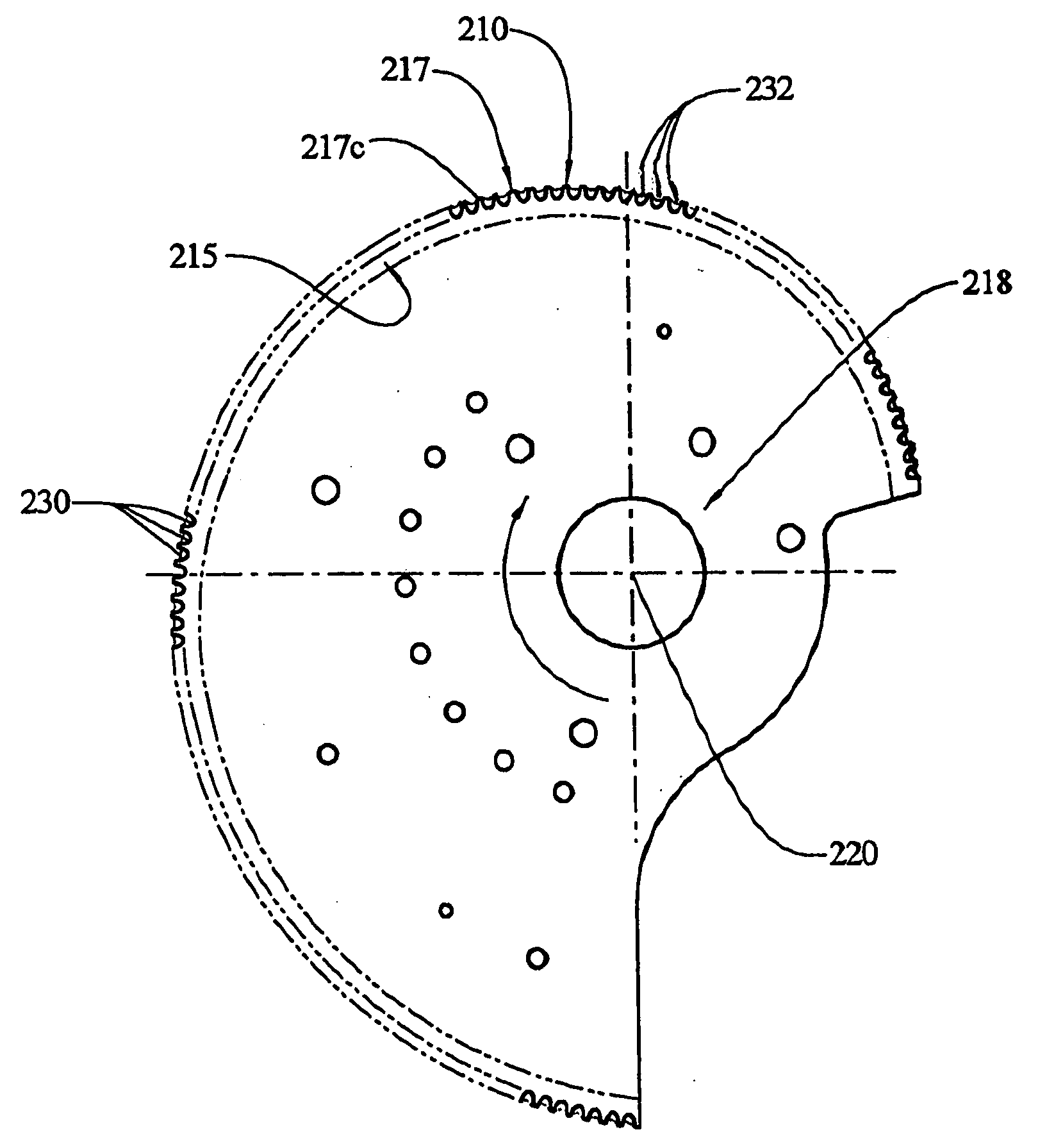

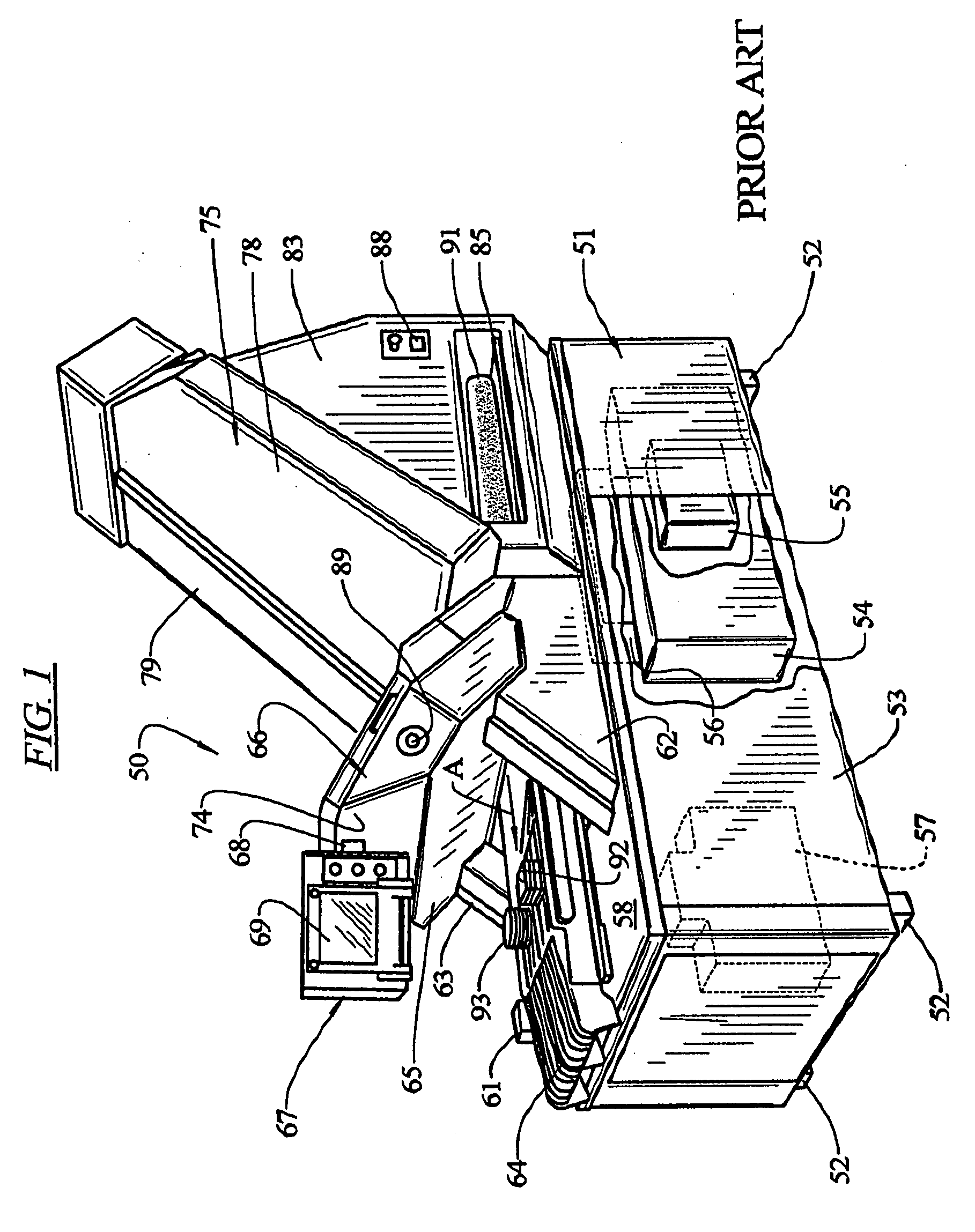

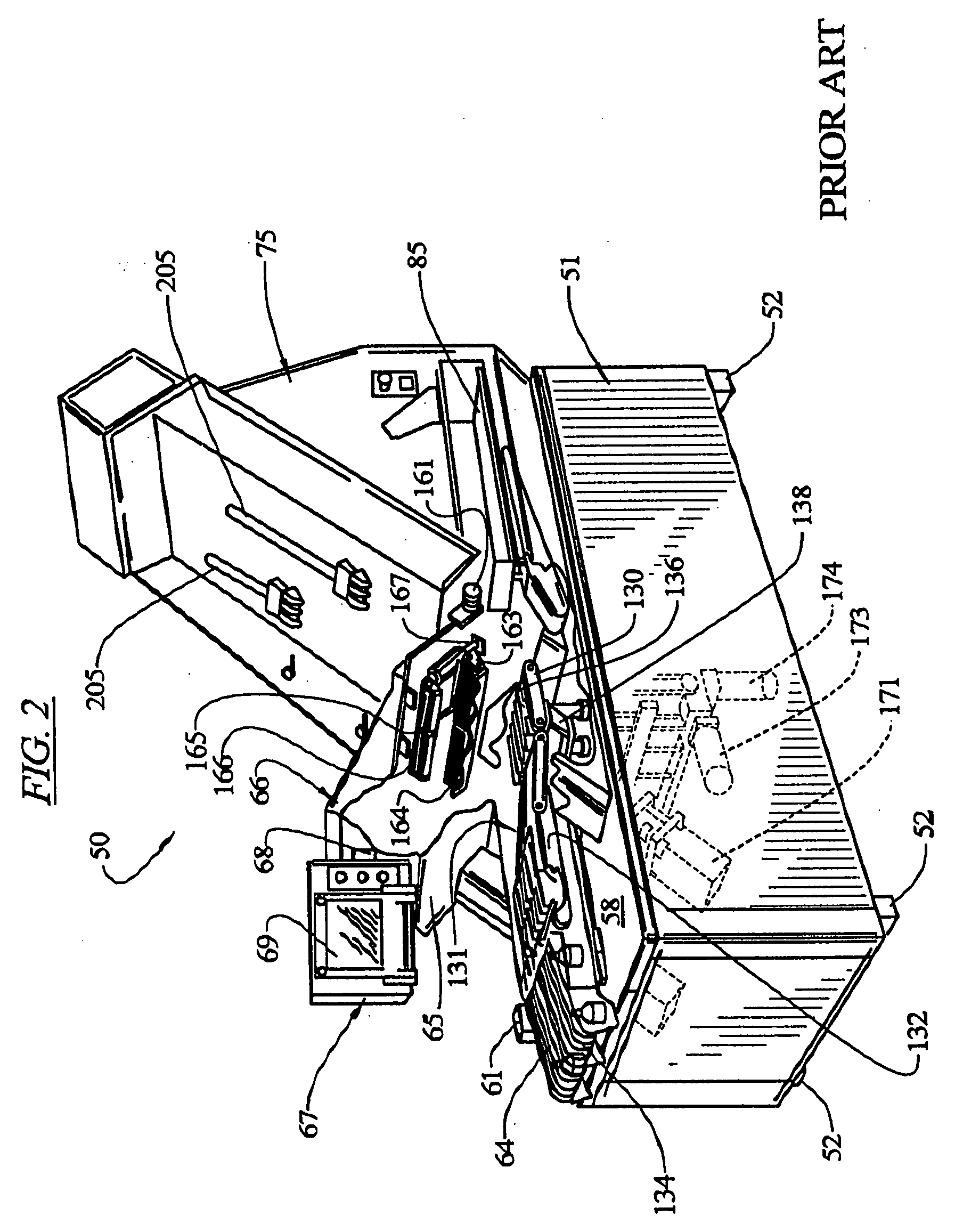

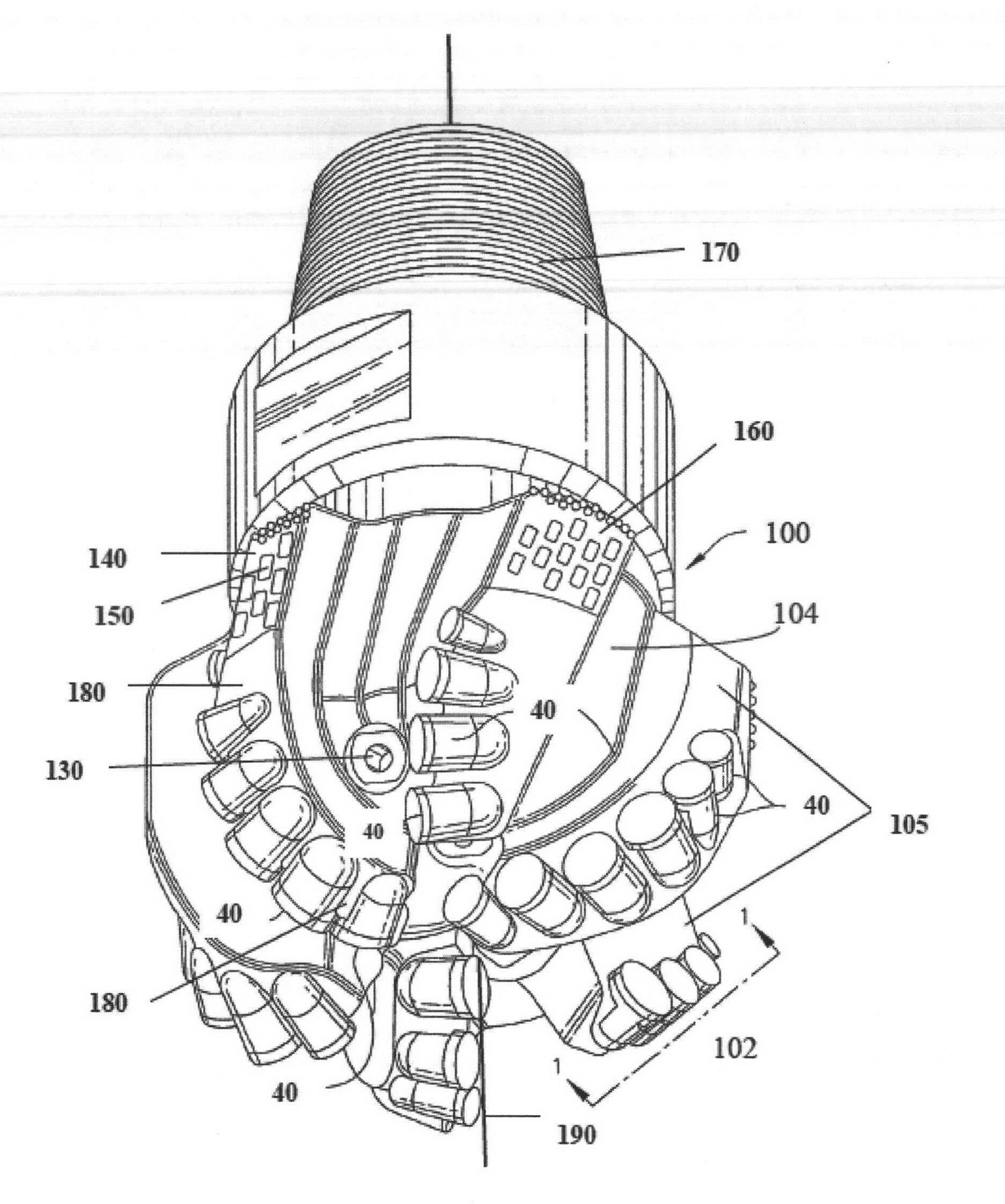

Apparatus for cutting food product

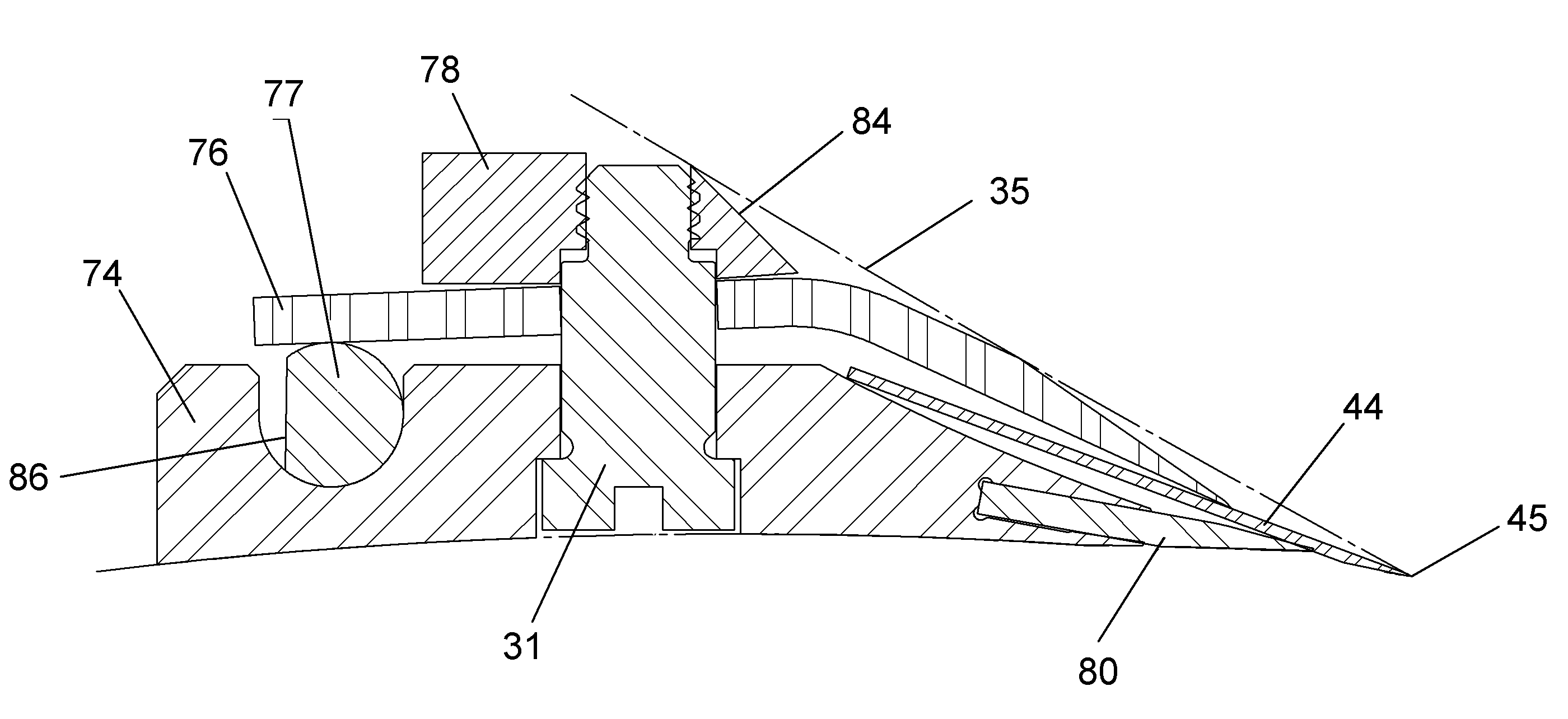

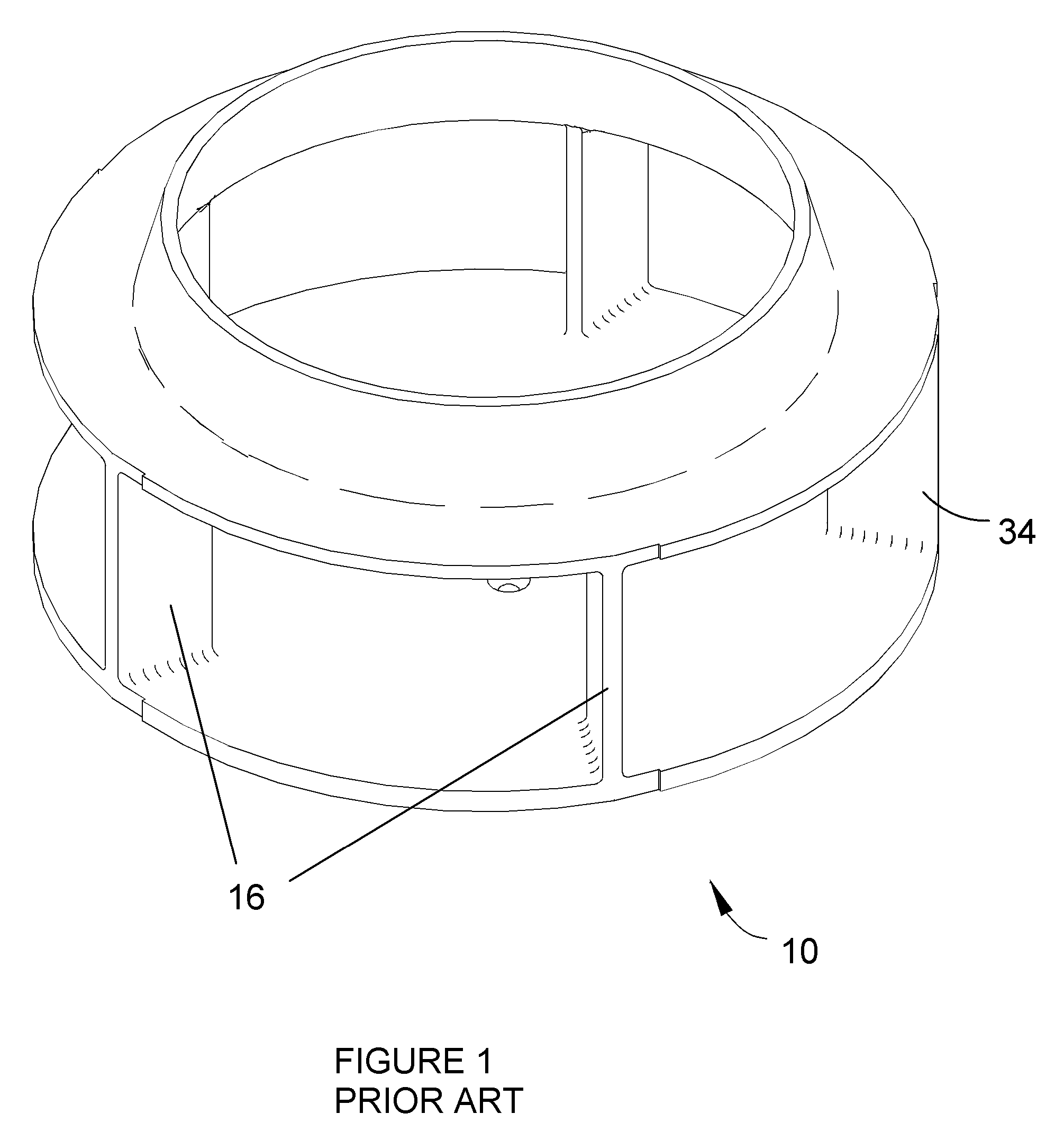

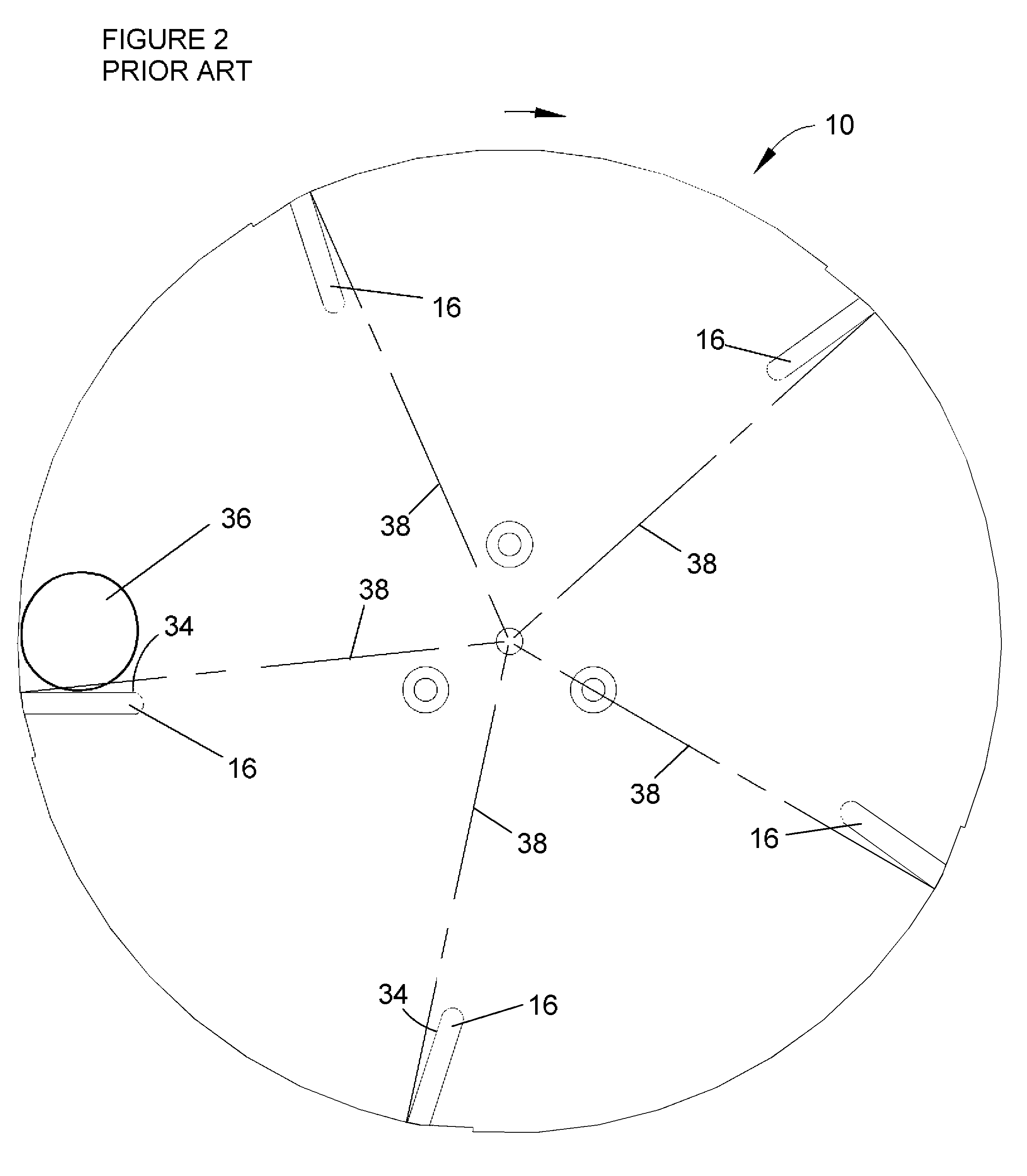

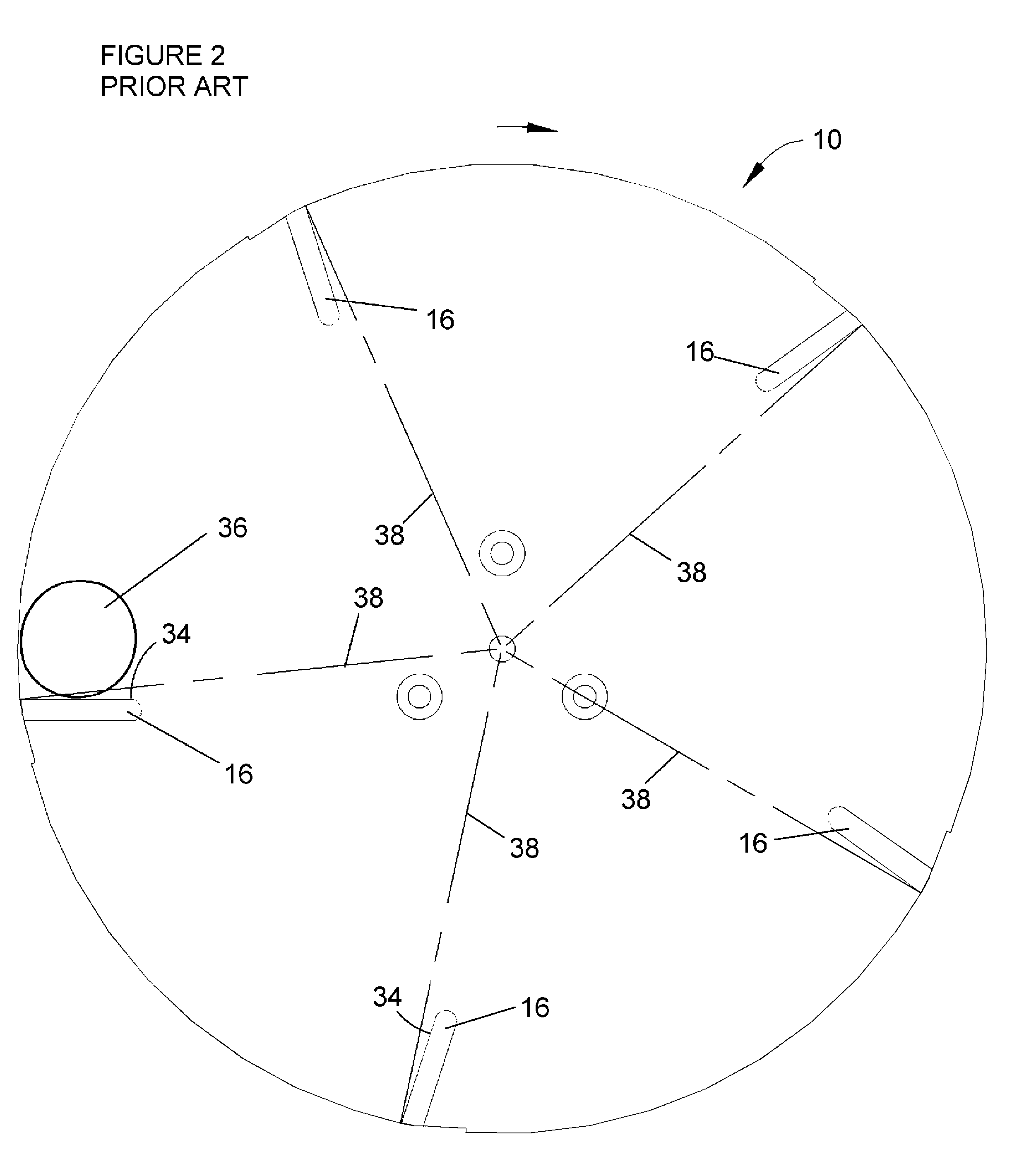

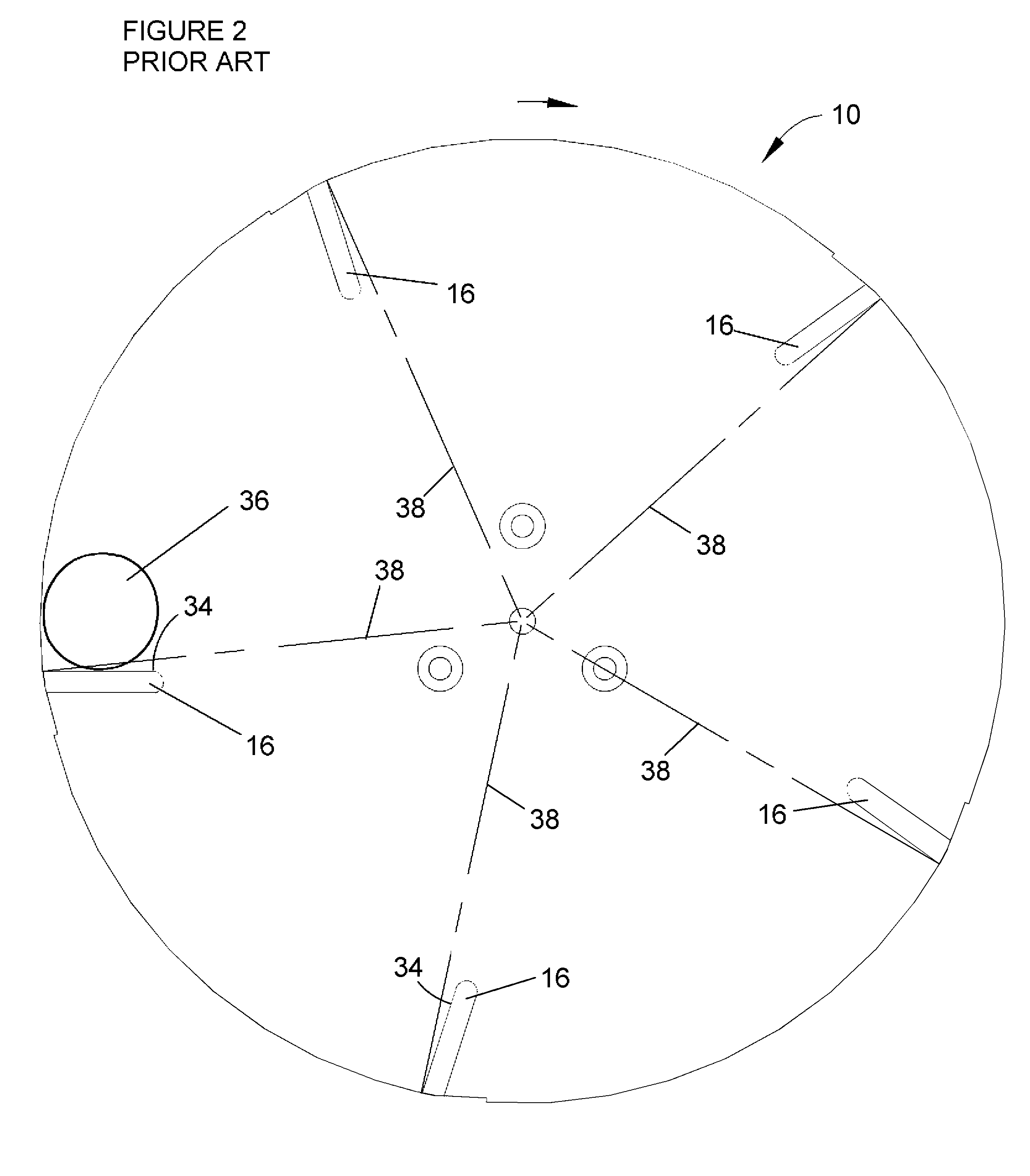

A cutting apparatus having an annular-shaped cutting head and an impeller assembly coaxially mounted for rotation within the cutting head to deliver food products radially outward toward the cutting head. The cutting head has at least one knife extending radially inward toward the impeller assembly. The knife has a cutting edge at a radially innermost extremity and a radially outer face that defines a trajectory plane for slices removed from the products by the cutting edge. The knife is clamped to the cutting head with a clamping feature that provides clearance for slices when traveling the trajectory plane of the knife.

Owner:URSCHEL LAB +1

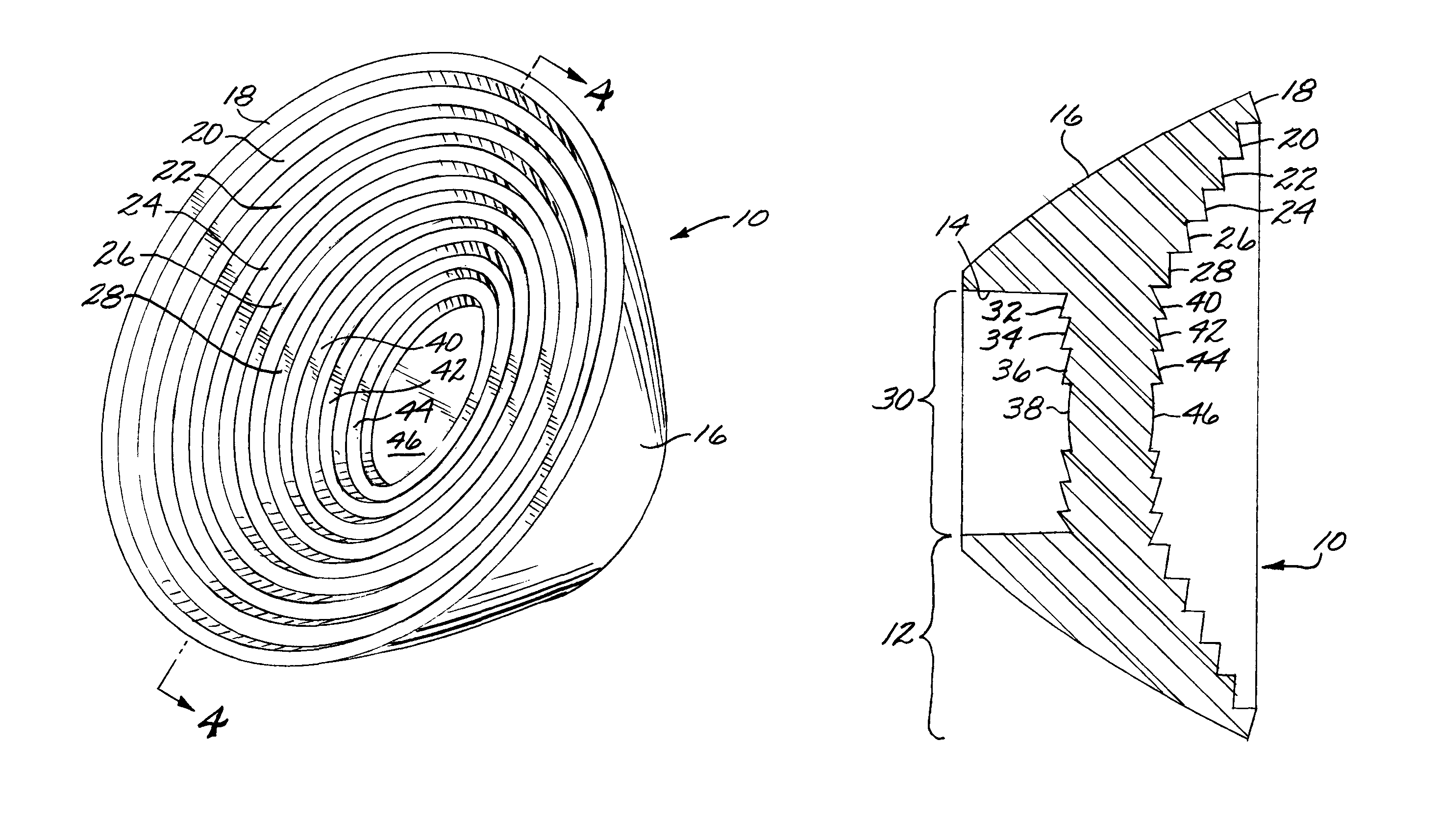

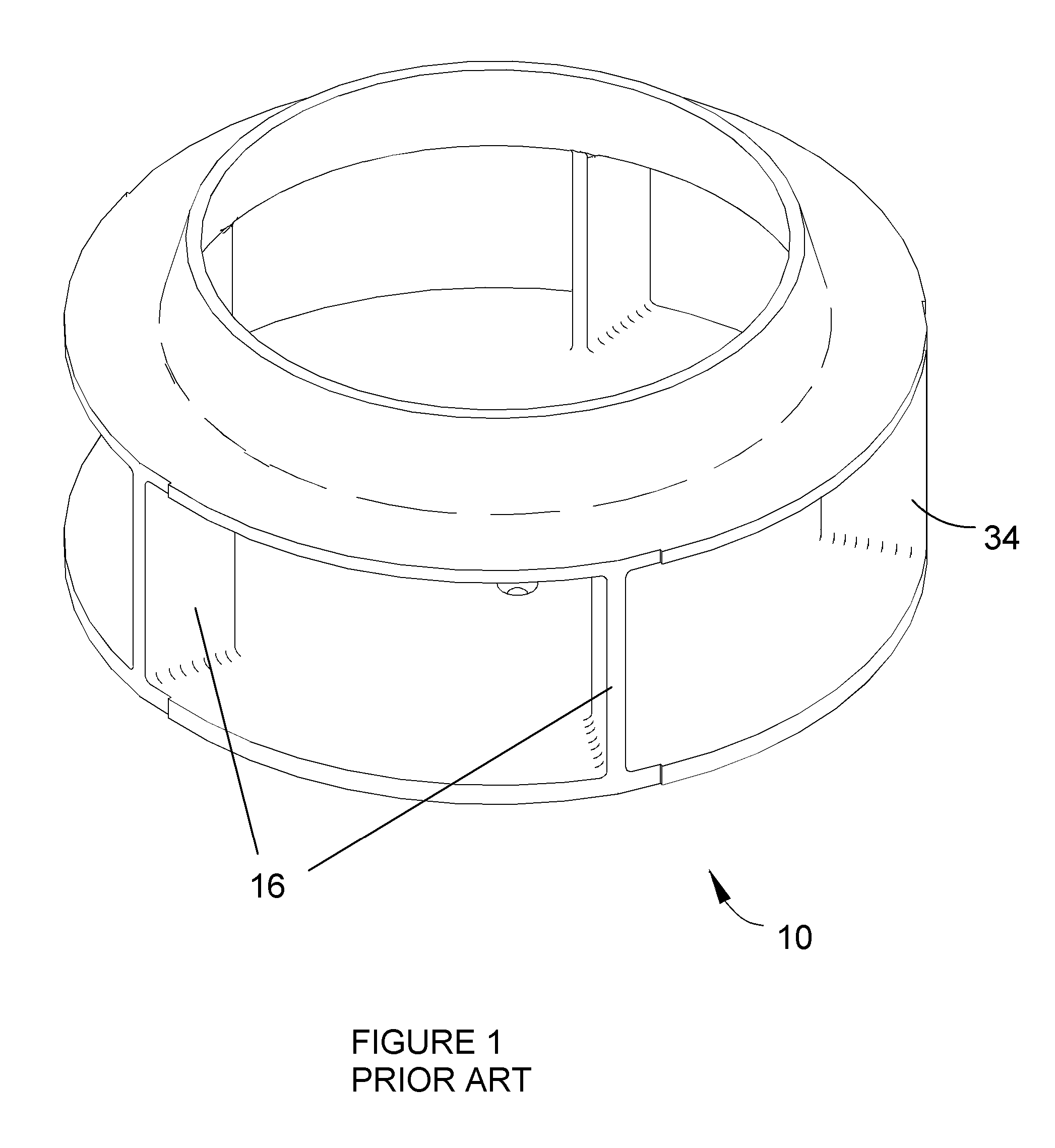

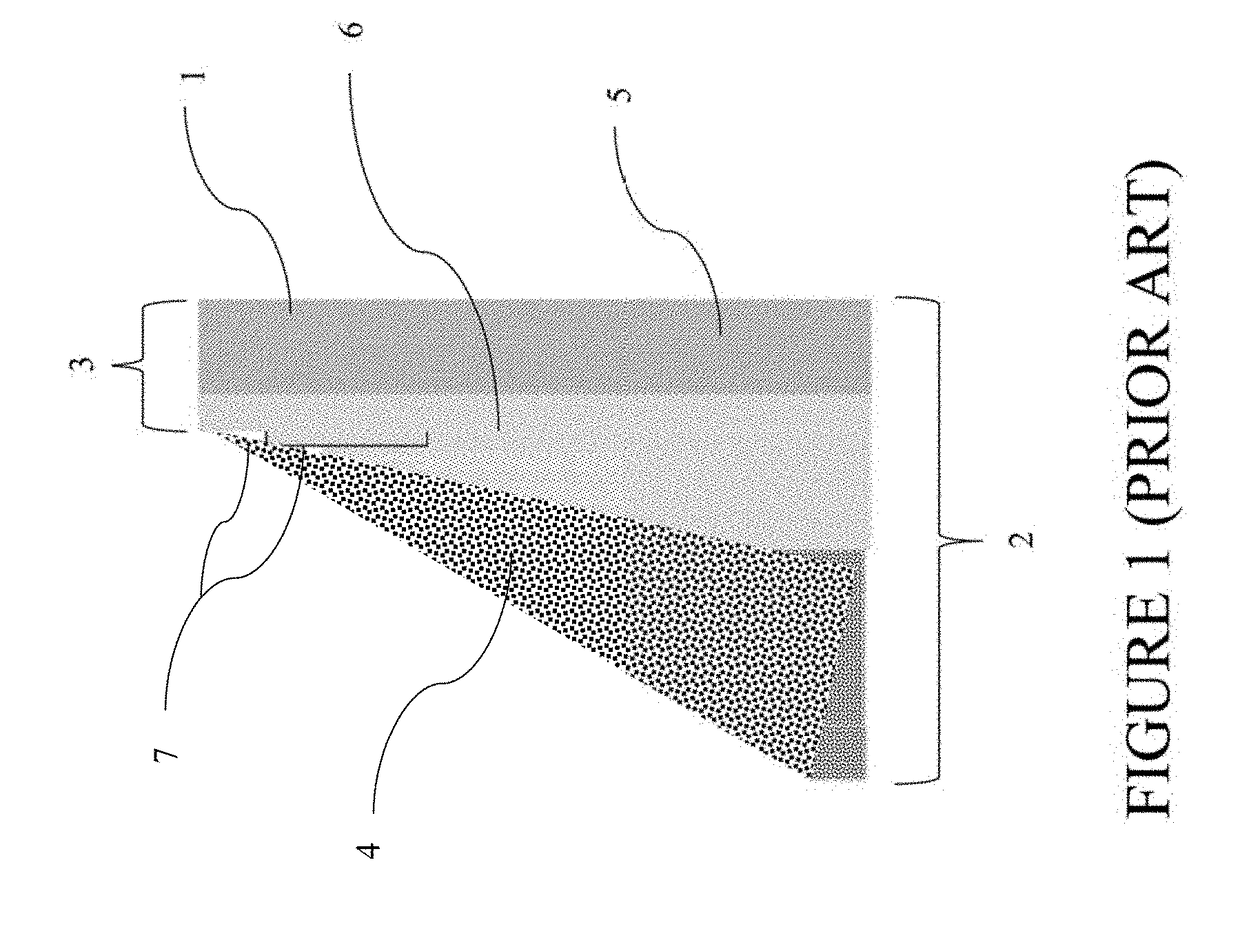

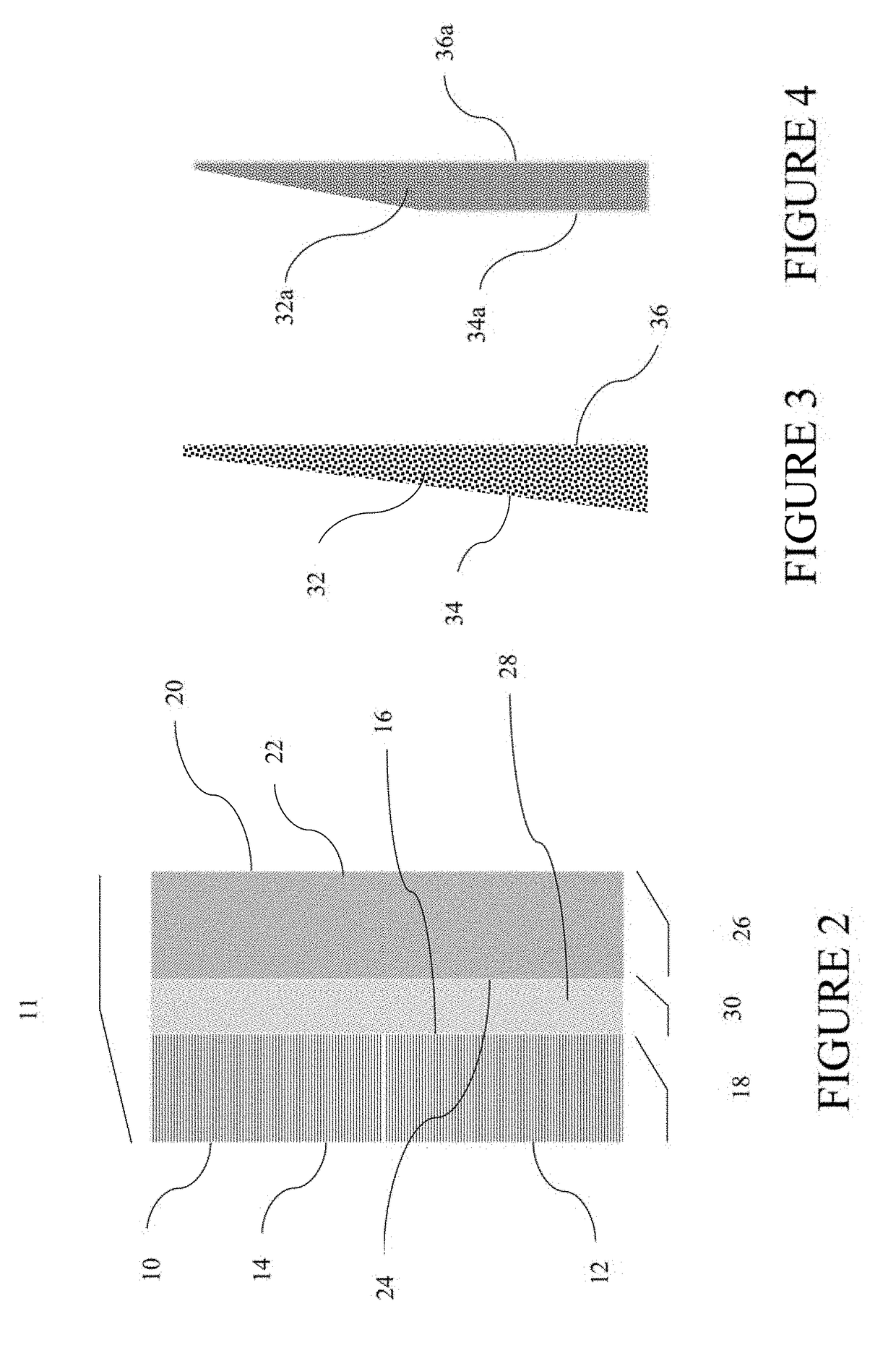

Thin stepped tulip lens

InactiveUS8068288B1Thin structureImprove yieldPoint-like light sourceSemiconductor devices for light sourcesTotal internal reflectionOptical axis

A secondary illumination optic, principally directed toward managing light from light emitting diode illumination sources having a primary optical element, is provided comprising a lens combination arranged along the optical axis, a central convex lens portion being centrally positioned on the optical axis, and a surrounding total internal reflection lens portion, with the central optic having a first and incident surface and a second and exiting surface, both comprising refractive faceted optical lens elements, and the total internal reflection optic lens portion having a cylinder shaped aspheric first and incident surface, a second and internal total reflection surface, and a third and exiting surface comprising refractive faceted optic lens elements, wherein, being constructed of resin having optical characteristic, the central and total internal reflection lens portions are molded as an integrated assembly from an optical resin providing a stepped tulip type lens, thinner and higher yielding than prior art lenses.

Owner:TRIFORMIX

Apparatus for cutting food product

ActiveUS20070240550A1Minimize compressionConsistent thicknessMetal working apparatusImpellerBiomedical engineering

A cutting apparatus having an annular-shaped cutting head and an impeller assembly coaxially mounted for rotation within the cutting head to deliver food products radially outward toward the cutting head. The cutting head has at least one knife extending radially inward toward the impeller assembly. The knife has a cutting edge at a radially innermost extremity and a radially outer face that defines a trajectory plane for slices removed from the products by the cutting edge. The knife is clamped to the cutting head with a clamping feature that provides clearance for slices when traveling the trajectory plane of the knife.

Owner:URSCHEL LAB +1

Apparatus for cutting food product

ActiveUS7658133B2Minimize compressionGood precisionGrain treatmentsMetal working apparatusImpellerBiomedical engineering

Owner:FRITO LAY NORTH AMERICA INC +1

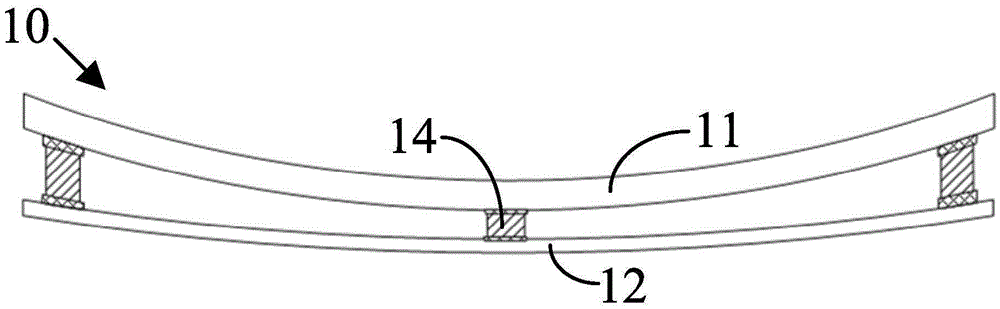

Glass steel radar cover single element and forming method thereof

InactiveCN101630774AAdjust and control thicknessFlat surfaceRadiating element housingsRadarSingle element

The invention relates to a glass steel radar cover single element and a forming method thereof. The radar cover single element is a spherical body, the periphery of which is provided with a sewing structure, wherein the spherical body is formed by assembling the inner skin and the outer skin of the glass steel with a foam core layer and the foam core layer is formed by solidifying injected polyurenthane foam glue material. The forming method comprises the following steps of: presetting a fundamental mould, and copying the female mould and the male mould of the glass steel with the same curvature based on the fundamental mould; respectively manufacturing the inner skin and the outer skin of the radar cover single element on the inner surfaces of the female mould and the male mould of the glass steel; and merging the moulds, and forming an inner cavity between the inner skin and the outer skin. The invention is characterized in that the inner skin is provided with a plurality of through holes which enter into the inner cavity; and the inner cavity is filled with polyurenthane foam glue material from the outside to the inside by the through holes and is solidified to be a foam core layer. The method has simple operation, effectively reduces the use waste of polyurenthane foam, has low cost, guarantees the consilient thickness of the inner skin and the outer skin, and can assemble the radar cover with good safety, reliability and wave permeability.

Owner:北京玻钢院复合材料有限公司

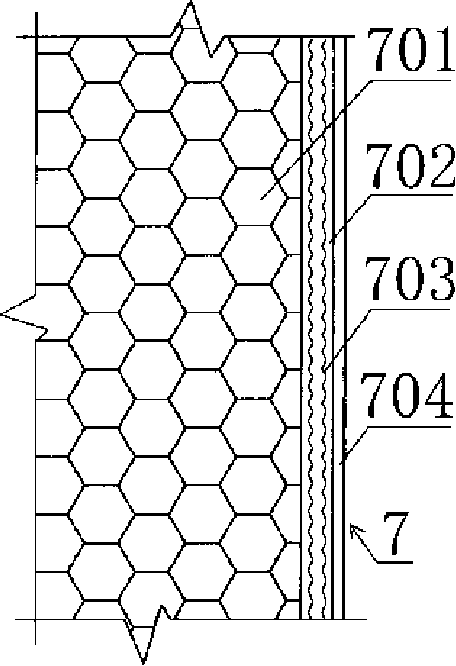

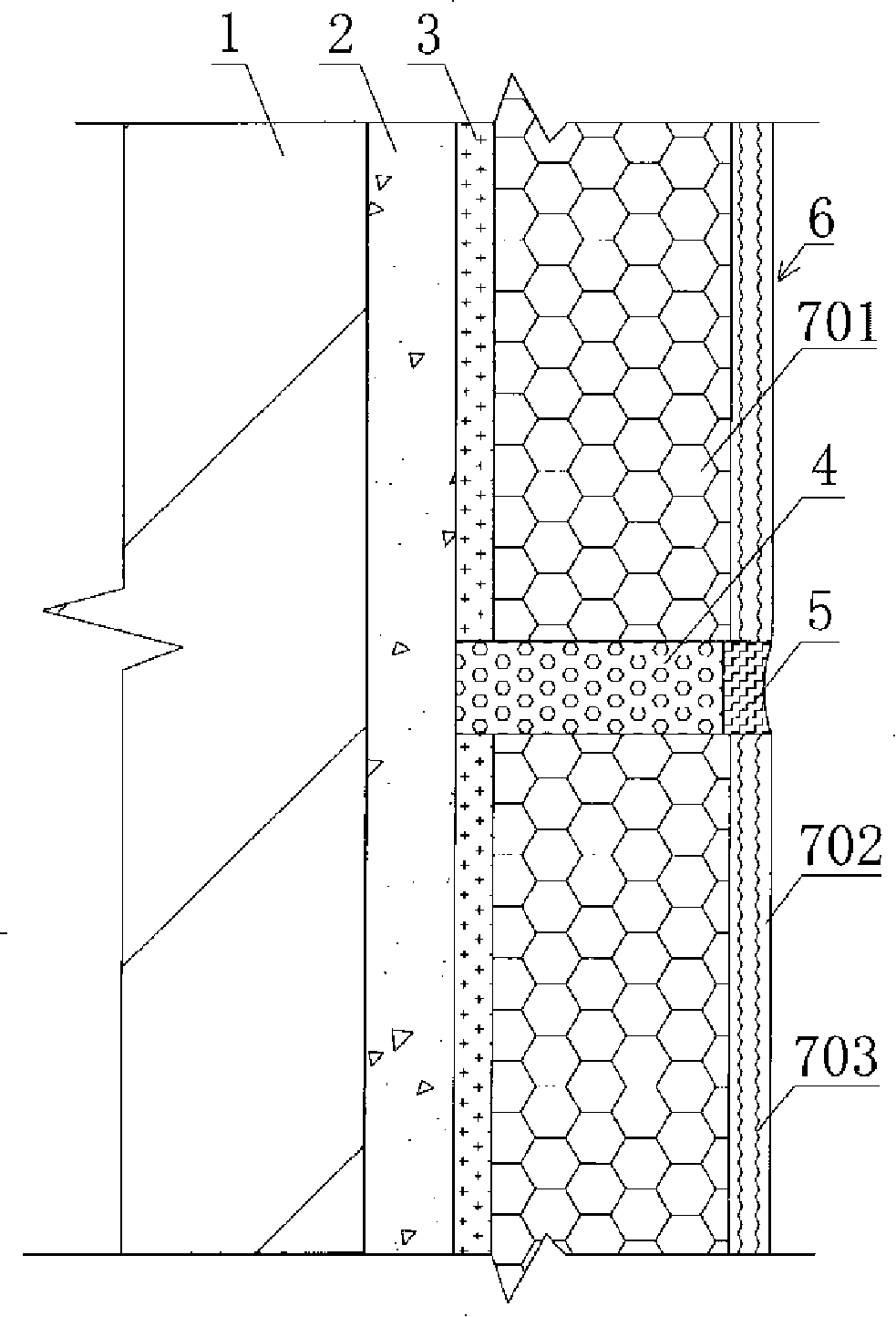

Direct-compress EPS inorganic clad plate and exterior outer-insulating system and construction method thereof

InactiveCN101158213AAvoid field workRapid productionCovering/liningsSolid waste managementComposite plateWeather proofing

The invention discloses an external insulation system and a construction method of a straight compressing EPS inorganic composite plate. The external wall firstly pre-produces the straight compressing EPS inorganic composite plate or a straight compressing EPS inorganic composite decorative board in a factory and compresses an inorganic composite enhancement layer onto a single-side of an expanded EPS plate by using a mechanical method; the outer surfaces of a base course wall of a building all adopt the EPS inorganic composite plate which adheres to a leveling blanket through bonding sands; the slab joint is pointed by jointing material and the outside of the jointing material is sealed again by weather proofing sealant; and a finish is arranged at the lateral of the system. The invention is characterized by the anti-crack, the good durability, the reliability and safety, the low cost and the fast construction.

Owner:余景春

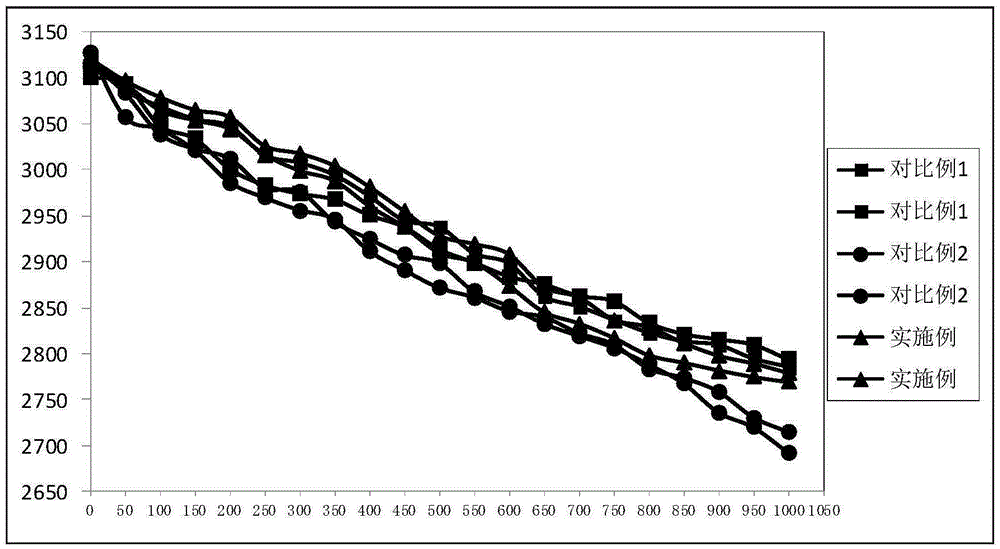

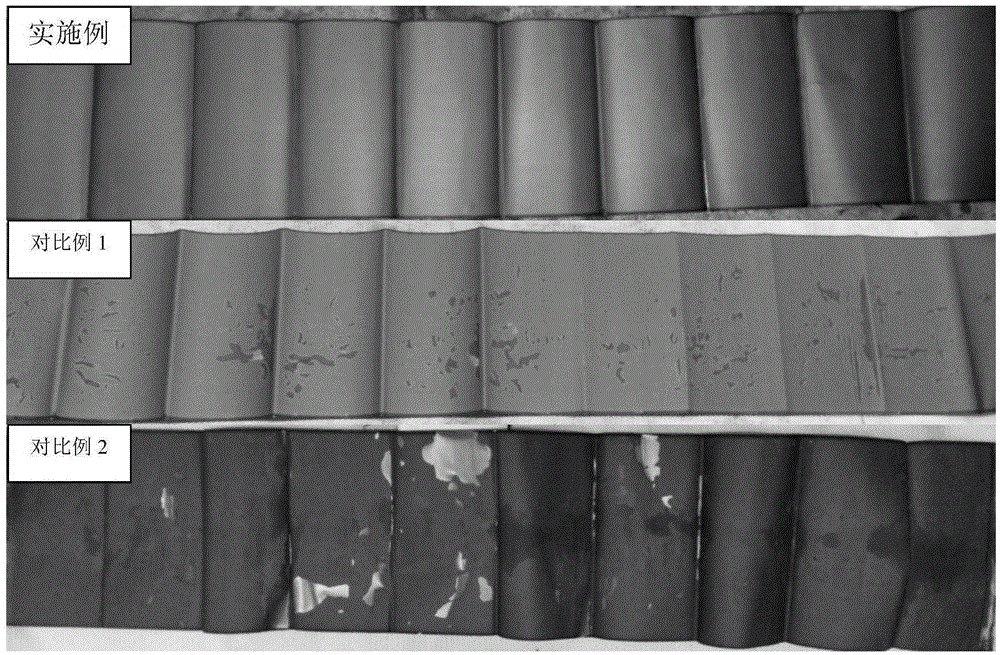

Formation method of lithium ion battery

ActiveCN105406129AConsistent thicknessReduce scrapFinal product manufactureSecondary cells charging/dischargingVacuum pumpingPower flow

A formation method of a lithium ion battery comprises the following steps of placing an aged battery in a formation device for formation in a high-temperature pressurized environment, charging by using 0.1-0.5CmA current during charging until to a cut-off voltage of 3.7V, and then charging by using 0.5-2.0CmA current until to a cut-off voltage of 4.0V; increasing the temperature and keeping the pressure unchanged, and carrying out heat preservation and pressure maintaining on the battery; reducing the temperature and the pressure, and cooling the battery; and carrying out vacuum pumping and secondary sealing on the battery subjected to cooling finish, and completing formation. According to the formation method, a battery core is placed in a high temperature and certain pressure condition for large-current charging formation, the processing time is shortened, and the production efficiency is improved; moreover, the contact of an operator to the lithium battery core is reduced, and the cost problems caused by poor appearance, damage and the like are reduced; and the consistencies on the thickness, the capacity and pole piece interface states of the battery are higher, and the cycle ability is improved.

Owner:ZHUHAI COSMX BATTERY CO LTD

Active packaging film based on essential oil/beta-cyclodextrin inclusion compound and preparation method for active packaging film

InactiveCN102585412AConsistent thicknessDelicate feelFlexible coversWrappersAntibacterial actionBroad spectrum

The invention relates to a novel active packaging film. The active packaging film is characterized in that a film-forming base material is polyvinyl alcohol; a film-forming assistant contains ethylene glycol and lauryl sodium sulfate. The novel active packaging film contains broad-spectrum long-acting antibacterial beta-cyclodextrin inclusion compound particles. The inclusion compound particles account for 4-24 percent of the weight of the active antibacterial film. The particles are 1-100 nanometers in particle size; through the slow release of essential oil in the inclusion compound and the migration in the film, an antibacterial action is performed on surfaces of foods finally. The active packaging film provided by the invention is a colorless transparent film which is light in spice smell, consistent in thickness, fine and smooth in hand feeling and better in mechanical property, is not obvious in bubbles, is complete, bright and clean, and is capable of meeting the mechanical requirement of food packaging. The transparency is good, so that content held in the active packaging film can be clearly seen when the active packaging film is used for packaging the foods.

Owner:邓靖 +1

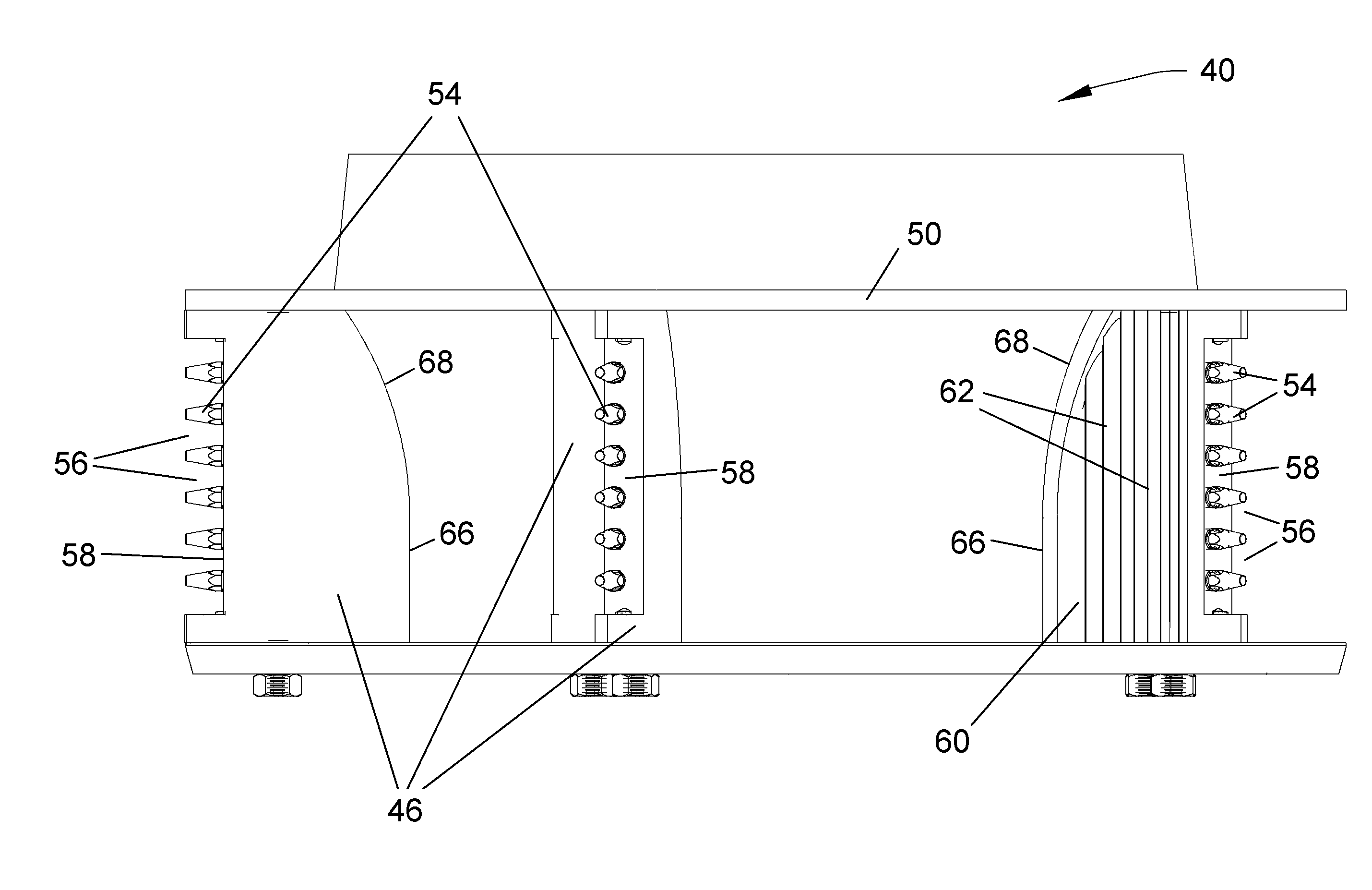

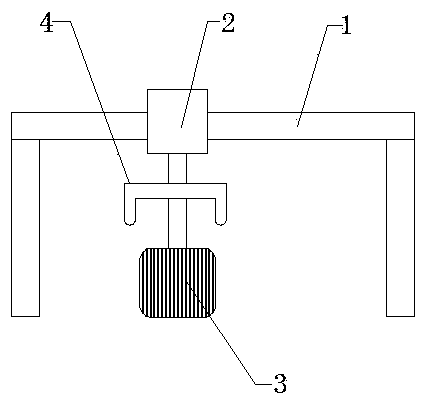

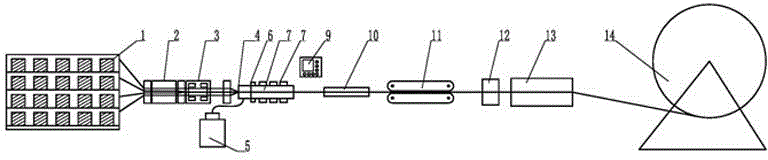

Method for applying liner to air duct

ActiveUS7112350B1Improve complianceConsistent thicknessLighting and heating apparatusPipe elementsEngineeringTruck

A system for sealing an air duct by coating the interior of the duct with a material similar to the coating used for spray-on truck bed liners. A spray device applies the liner material to the interior surface of the ducts and the spray device is held in the center of the duct by retractable sets of wheels. The spray device is removably attached to a supply hose that provides liner material to the spray device from a storage tank via a supply pump. The supply hose is first fed through the duct, the spray head is attached to the supply hose and the liner material is sprayed onto the duct as the spray head is retracted through the duct. The system can be either computer or manually controlled and can optionally employ an electrostatic unit to put opposite electrical charges on the duct and the liner material.

Owner:DUCT SEAL TECH

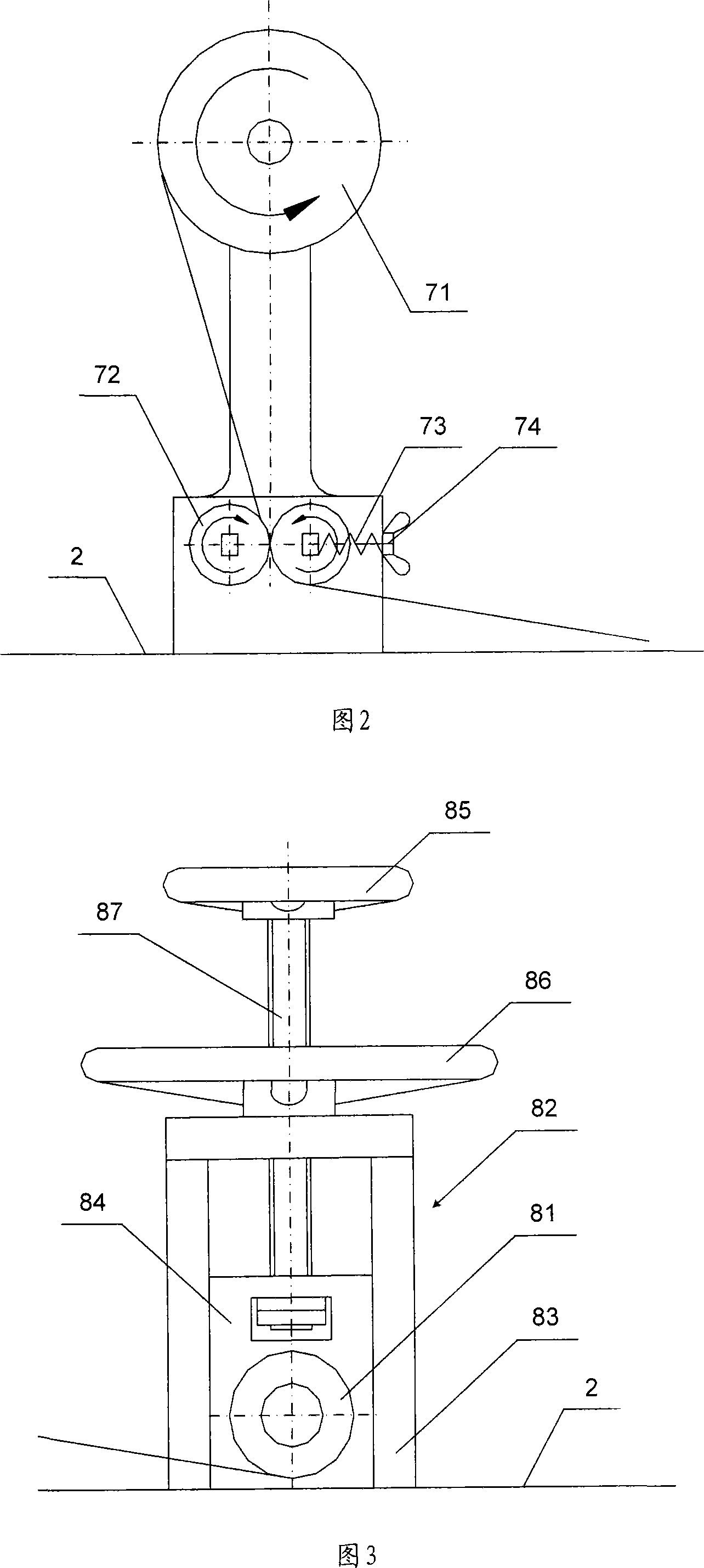

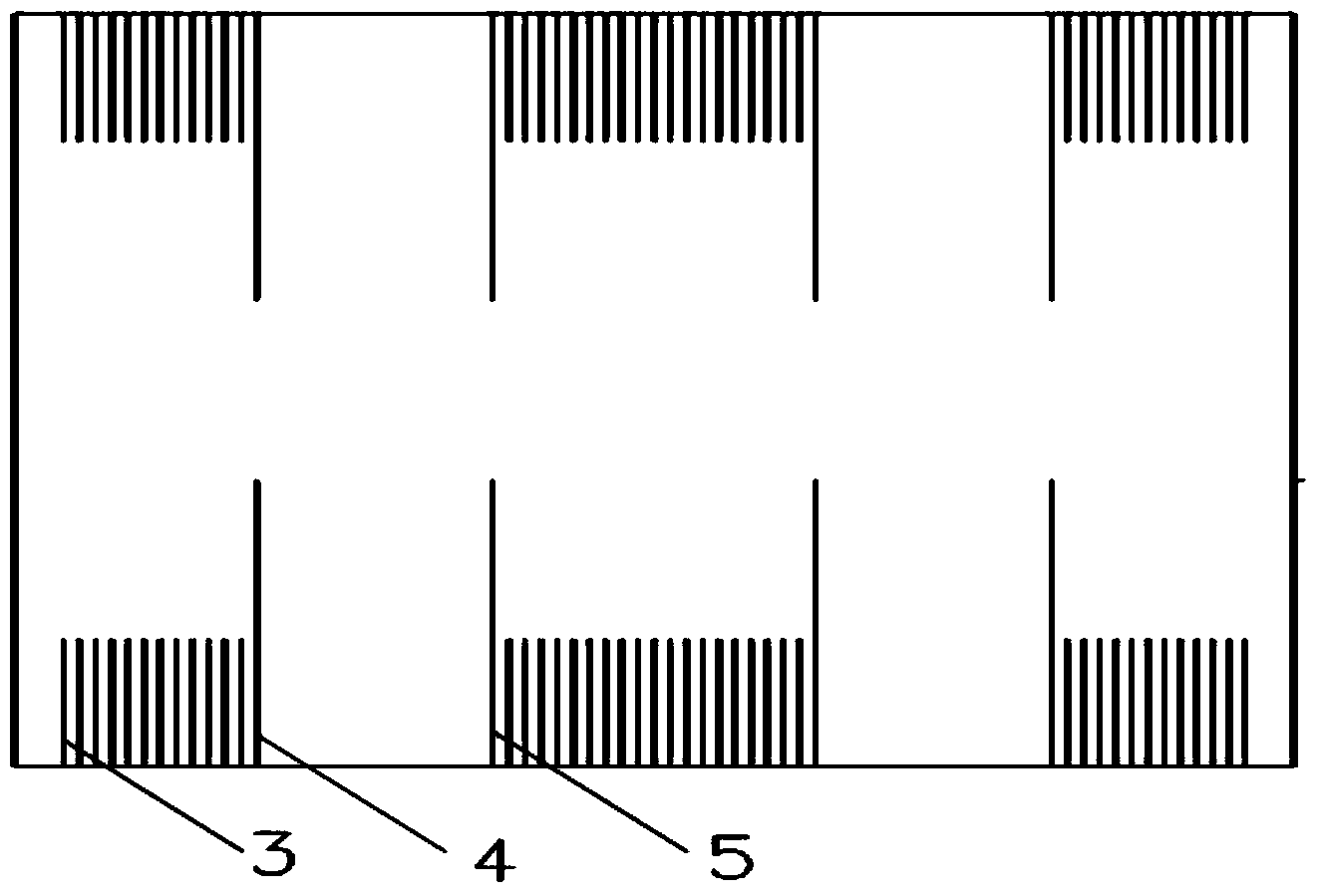

Nano-plate plane glue distributing device and method

InactiveCN101085563AConsistent thicknessImprove efficiencyLamination plant layoutLamination ancillary operationsFiberglass meshGlass fiber

The invention relates to the nanometer plate surface glue equipment and the cloth glue that comprises the working platform, cloth hopper distributing nanometer fluid on the compound extractor, vibrating device connected with the cloth hopper, cloth applying device setting the glass fiber net on the nanometer glue band, and the scraping device and compression device. The compound extraction band moving horizontally on the working platform and forming nanometer band, setting glass fiber net cloth with tension on the nanometer band, compressing the glass fiber net cloth and the nanometer band into nanometer compound band, compressing the compound band tightly. It is heat and sound insulation, radiation resistant, and improved in product feature and reduced in production cost.

Owner:KEDA INDUSTRIAL GROUP CO LTD

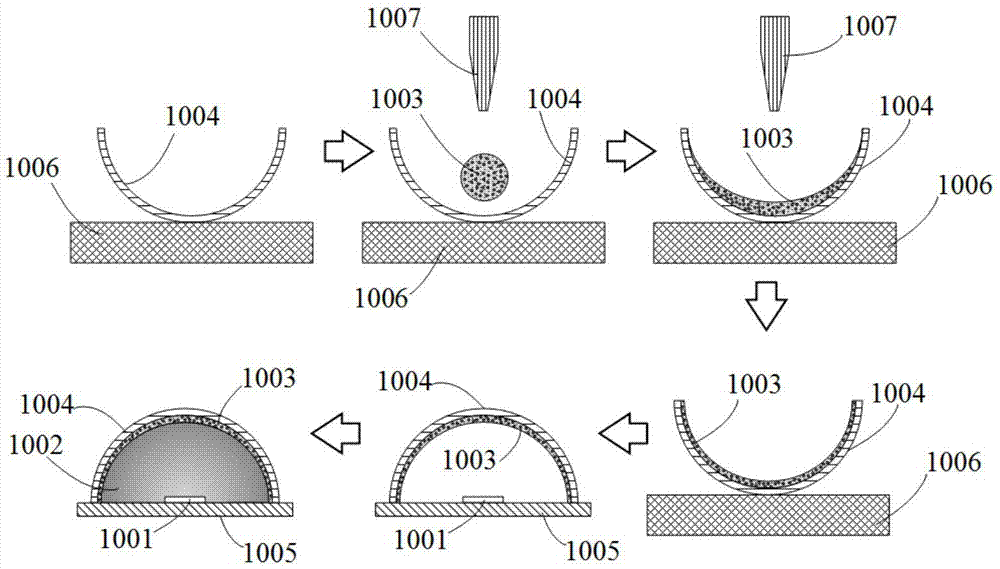

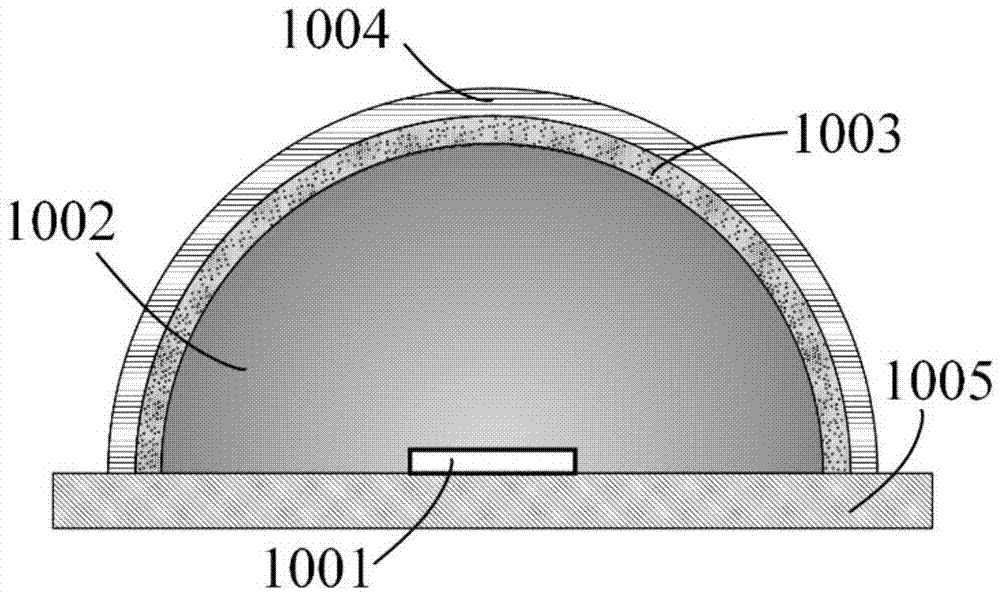

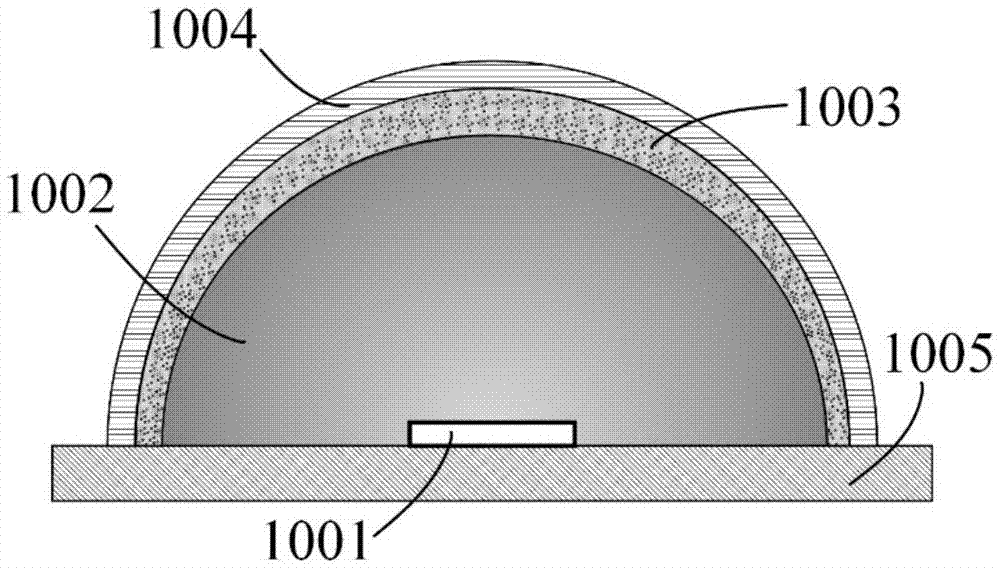

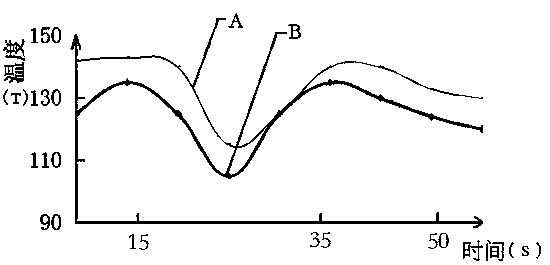

White light LED and preparation method thereof

InactiveCN105449078AImprove Optical ConsistencyAvoid wastingSemiconductor devicesQuantum dotRejection rate

The invention discloses a white light LED. The white light LED comprises a substrate, an LED chip and a transmitting shell, wherein the bottom of the LED chip is fixed on the surface of the substrate; the upper part of the LED chip is sleeved by the transmitting shell; a quantum dot thin film is adhered to the inner surface of the transmitting shell; and encapsulation glue is filled between the transmitting shell and the substrate. The invention furthermore discloses a preparation method of the white light LED. According to the white light LED and the preparation method, the operation method is simple, the cost is low, and the thickness, morphology and ingredients of the quantum dot thin film can be flexibly controlled, so that the optical consistency and space color uniformity of the white light quantum dot LED are improved; and the quantum dot thin film is prepared on a batch produced curved surface die, but not directly dispensed on the LED chip, so that the rejection rate of the quantum dot LED products is effectively decreased and the preparation method is suitable for the large-scale production of white light quantum dot LEDs.

Owner:HUAZHONG UNIV OF SCI & TECH

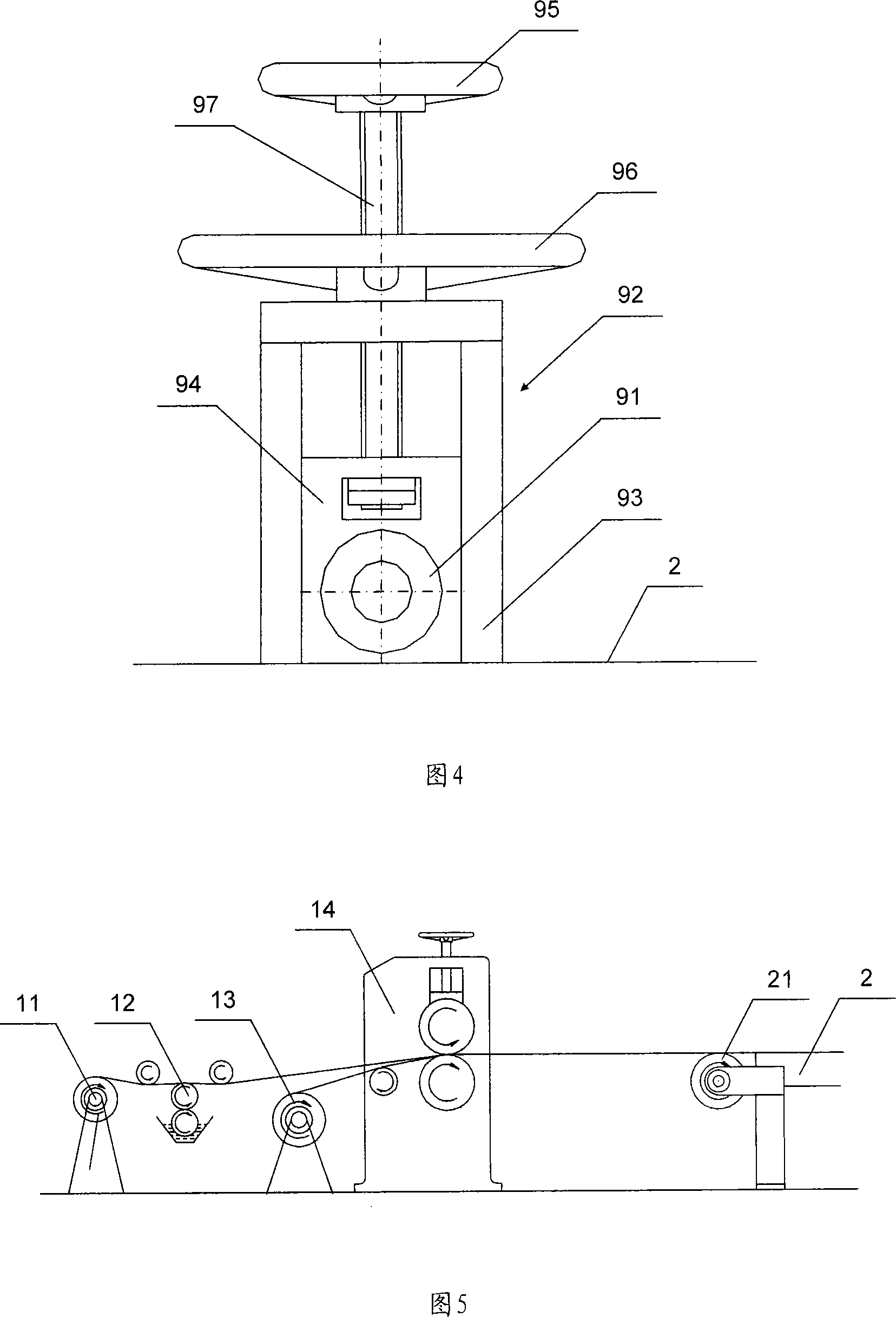

Manufacturing method of impregnated bond paper for low formaldehyde furniture

ActiveCN105369687AIncrease crosslink densityPromote chemical reactionSpecial paperPaper/cardboardPulp and paper industryWetting

The invention discloses a manufacturing method of impregnated bond paper for low formaldehyde furniture. The method comprises the steps of raw paper selection and treatment, uncoiling, pre-wetting, impregnation, first time drying, gluing, preparation of coating glue, second time drying, deviation adjustment traction and cutting. The manufacturing method has the advantages that the quality of the impregnated bond paper prepared with the method is high, the content of formaldehyde is further reduced, the uniformity of impregnation and gluing of the impregnated bond paper is guaranteed in the manufacturing process, the flexibility of a glue layer and the sealing performance of the surface of the glue layer are guaranteed, and accordingly, the problems that the content of formaldehyde is high and the quality is not high in impregnated bond paper are fundamentally solved.

Owner:成都建丰新材料股份有限公司

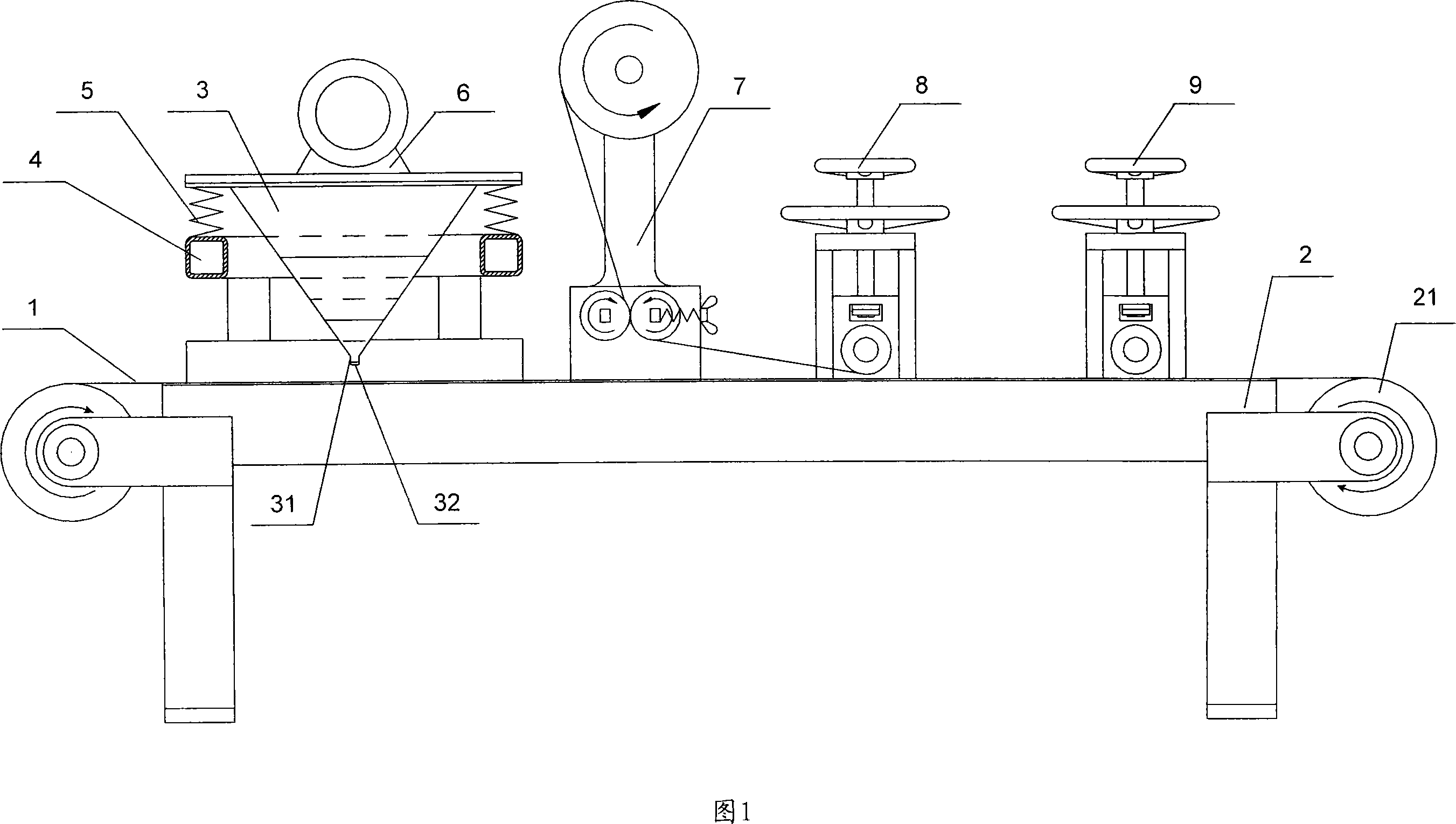

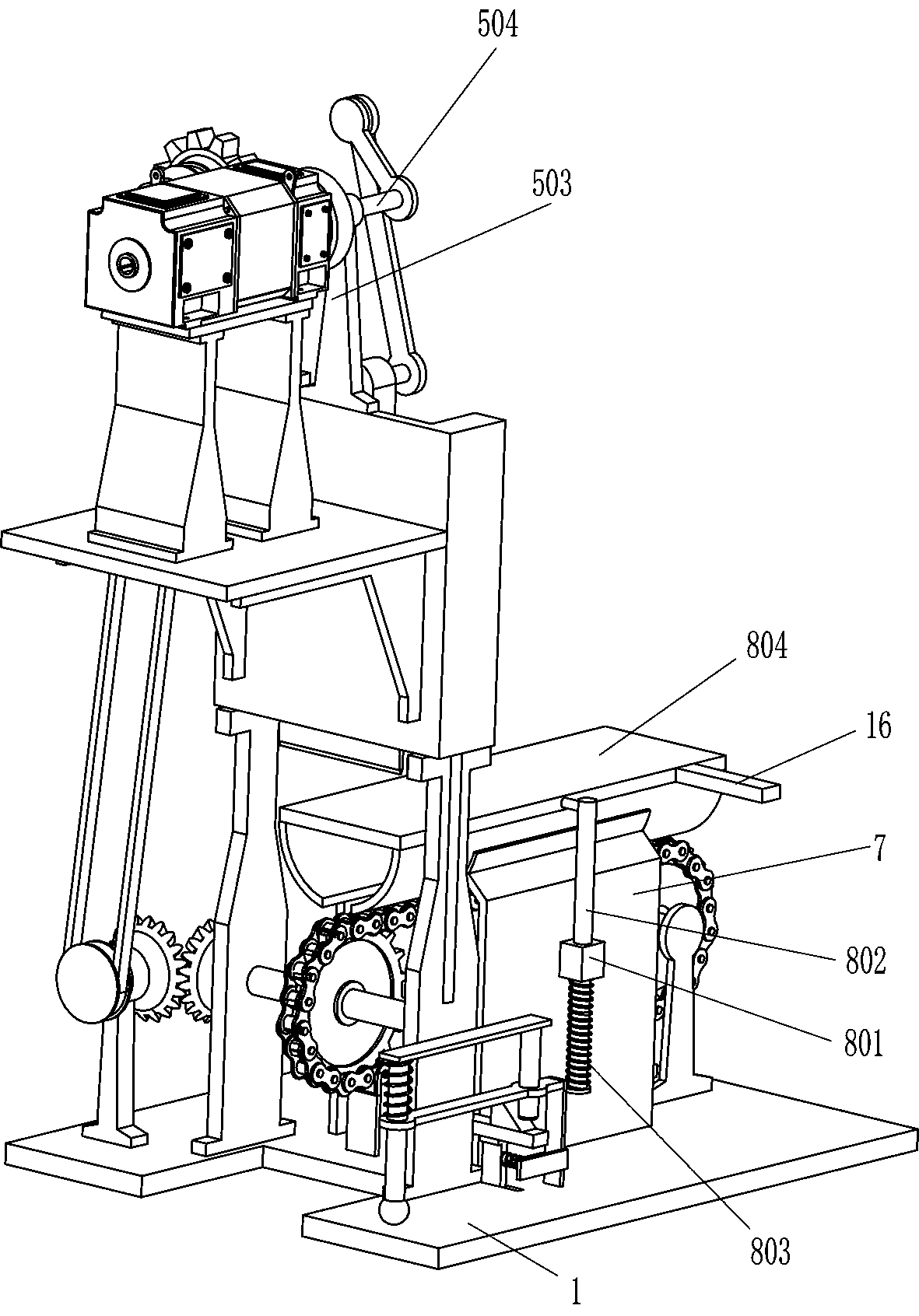

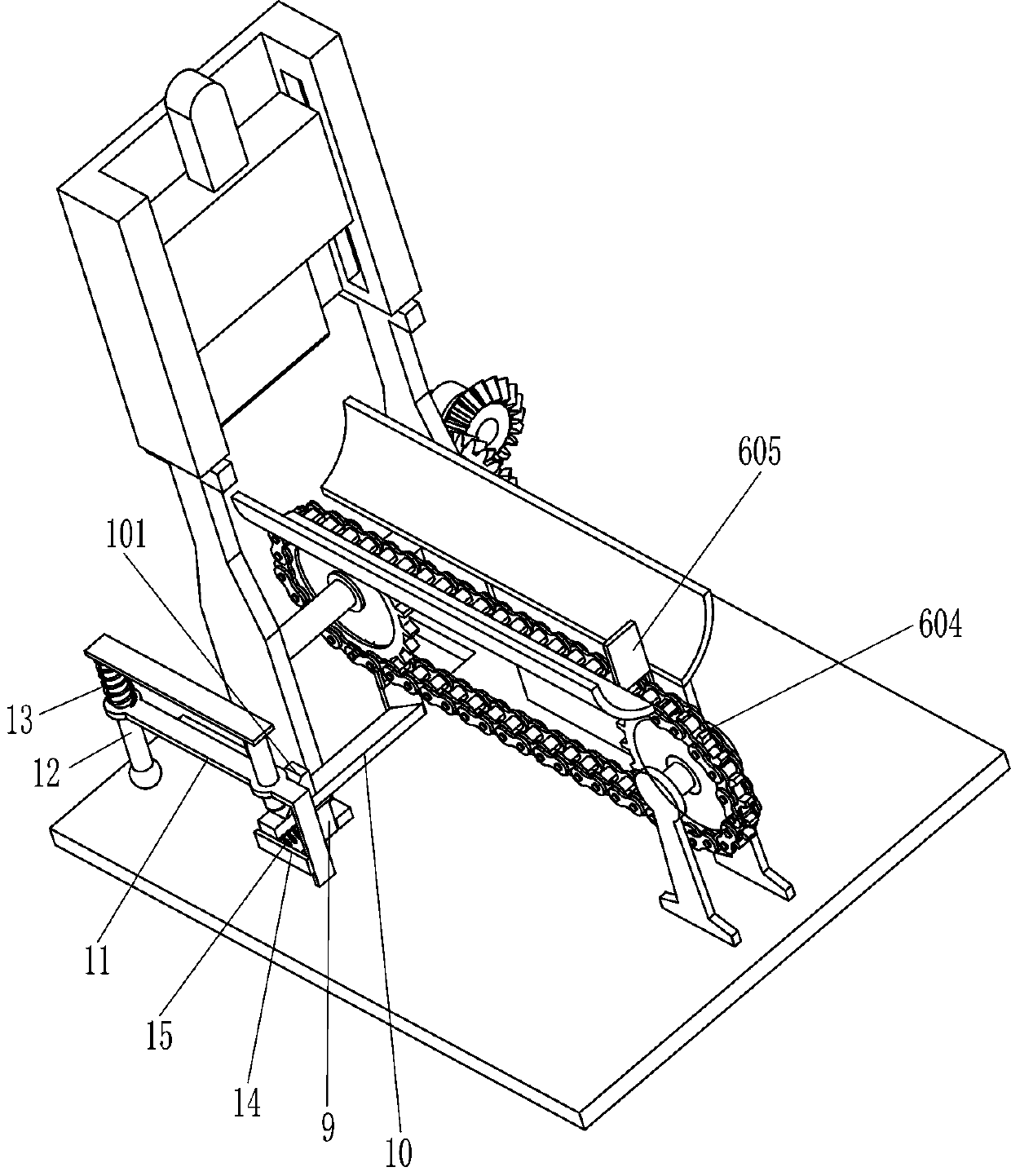

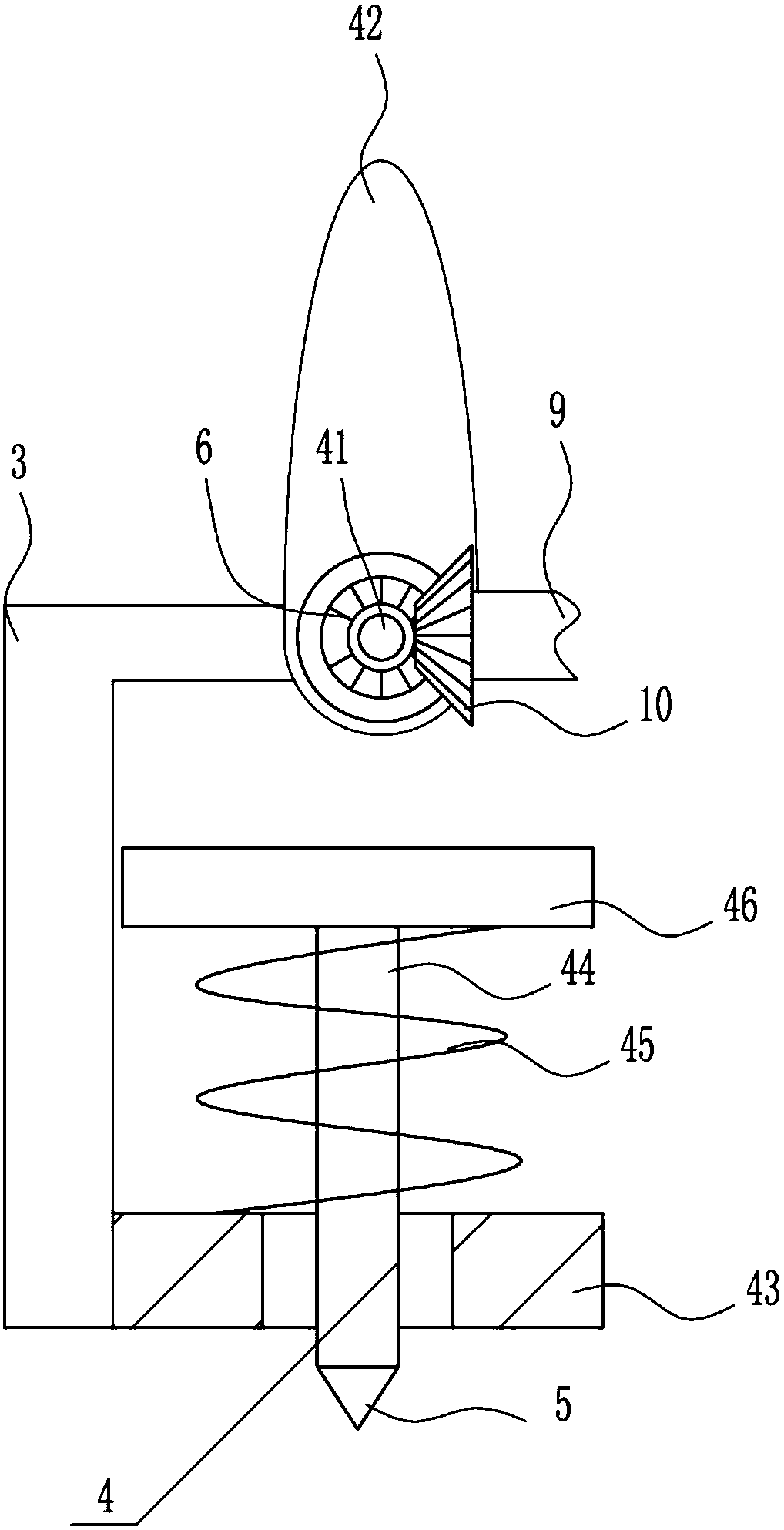

Radish equivalent slicing machine

ActiveCN111496862AAvoid sorenessImprove work efficiencyMetal working apparatusEngineeringMechanical engineering

The invention relates to a slicing machine, in particular to a radish equivalent slicing machine. The technical problem is how to design a radish equivalent slicing machine which can conduct slicing instead of manual work, is not likely to cause hand aches, is high in work efficiency, capable of making thickness of radish sheets obtained through slicing consistent and does not influence use. The radish equivalent slicing machine comprises a bottom plate and an installation plate. Supporting plates are symmetrically and fixedly connected to one side of the bottom plate. A guide rail is fixedlyconnected between the sides, away from the bottom plate, of the two supporting plates. The installation plate is installed on one side outside the guide rail. Radish can be sliced through a slicing sheet by pulling a pressing plate upwards to an appropriate position, placing the radish between arc-shaped plates on the front side and the rear side, releasing the pressing plate to press the radish and starting a servo motor, complete slicing is conducted by intermittently pushing the radish to move through a material push plate, people do not need to manually conduct slicing, hand aches are avoided, the work efficiency is high, and the thickness of slices is consistent.

Owner:邳州市鑫盛创业投资有限公司

Active packaging film for chilled meat and preparation method of the active packaging film

ActiveCN102604292AConsistent thicknessDelicate feelFlexible coversMeat/fish preservationChemistryPolylactic acid

The invention relates to an active packaging film for chilled meat and a preparation method of the active packaging film. The active packaging film employs polyvinyl acetate (PVA) and polylactic acid (PLA) as film-forming materials and sustained-release microcapsules as an active antimicrobial agent. The natural antimicrobial agent is slowly released from the microcapsules, migrates in the film and finally reaches the surface of the chilled meat to achieve antimicrobial and fresh-keeping effects. Meanwhile, as PVA has a good gas barrier property, good chilled meat packaging atmosphere conditions can be kept. PLA has a good water vapor barrier property, and can effectively reduce the moisture loss of the chilled meat during storage. The active packaging film for the chilled meat provided by the invention is a colorless transparent film with a smooth and uniform surface without visible air bubbles, and mechanical properties of the film can meet the mechanical requirements of chilled meat packaging.

Owner:HUNAN NEW WELLFUL CO LTD +1

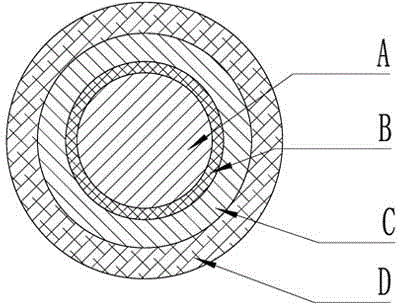

Multilayer compound eccentric-wear-preventing continuous sucker rod and manufacturing device and method thereof

ActiveCN104060944AAccelerated corrosionImprove partial wear resistanceDrilling rodsLayered productsEpoxyManufacturing technology

The invention relates to a multilayer compound eccentric-wear-preventing continuous sucker rod and a manufacturing device and a manufacturing method thereof. The sucker rod is characterized in that one section or several sections of the external surface of a fiber reinforced resin matrix composite rod body are respectively covered with a thermosetting wear layer; each thermosetting wear layer is made from one of polyurethane, a fluorocarbon coating, modified epoxide resin, vinylester resin, unsaturated polyester and phenolic resin; by adopting a manufacturing technology of multilayer composite winding and pultrusion or weaving and pultrusion, an internal layer of longitudinal fibers, an intertwining layer or a weaving layer and an external layer of longitudinal fibers are formed from interior to exterior in sequence; the manufactured rod body has a continuous length of 0-5000m. The sucker rod has the beneficial effects that the radial strength and the axial compressive strength are enhanced; the corrosion resistance and the eccentric wear resistance of the thermosetting wear layers are improved by 30%; the maximum temperature tolerance of the thermosetting wear layers is up to 190 DEG C; meanwhile, the bonding between an sucker rod body and each thermosetting wear layer is greater in length and quite high in strength, so that the slippage and the layering of an eccentric-wear-preventing layer from the surface of the sucker rod in the normal operation of an oil well are avoided.

Owner:SHENGLI OIL FIELD XINDA PIPE IND TECH DEV CO LTD

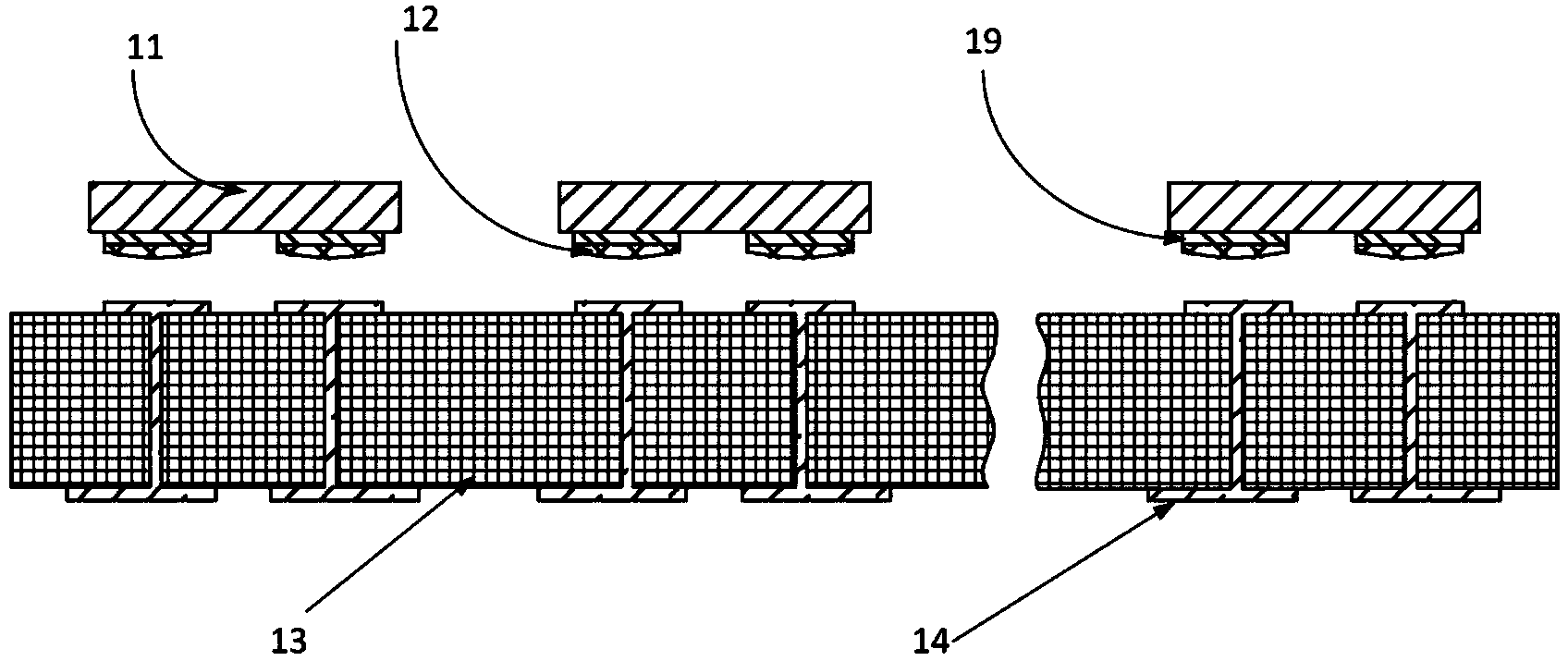

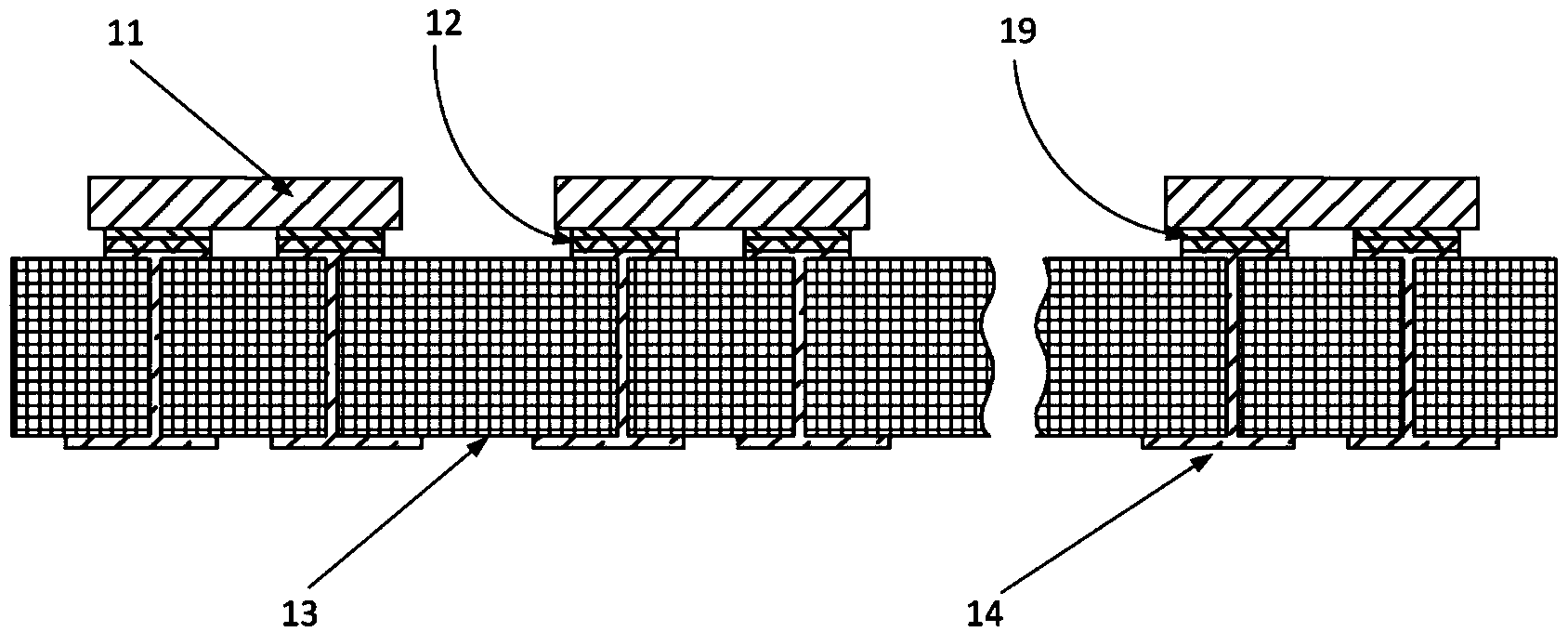

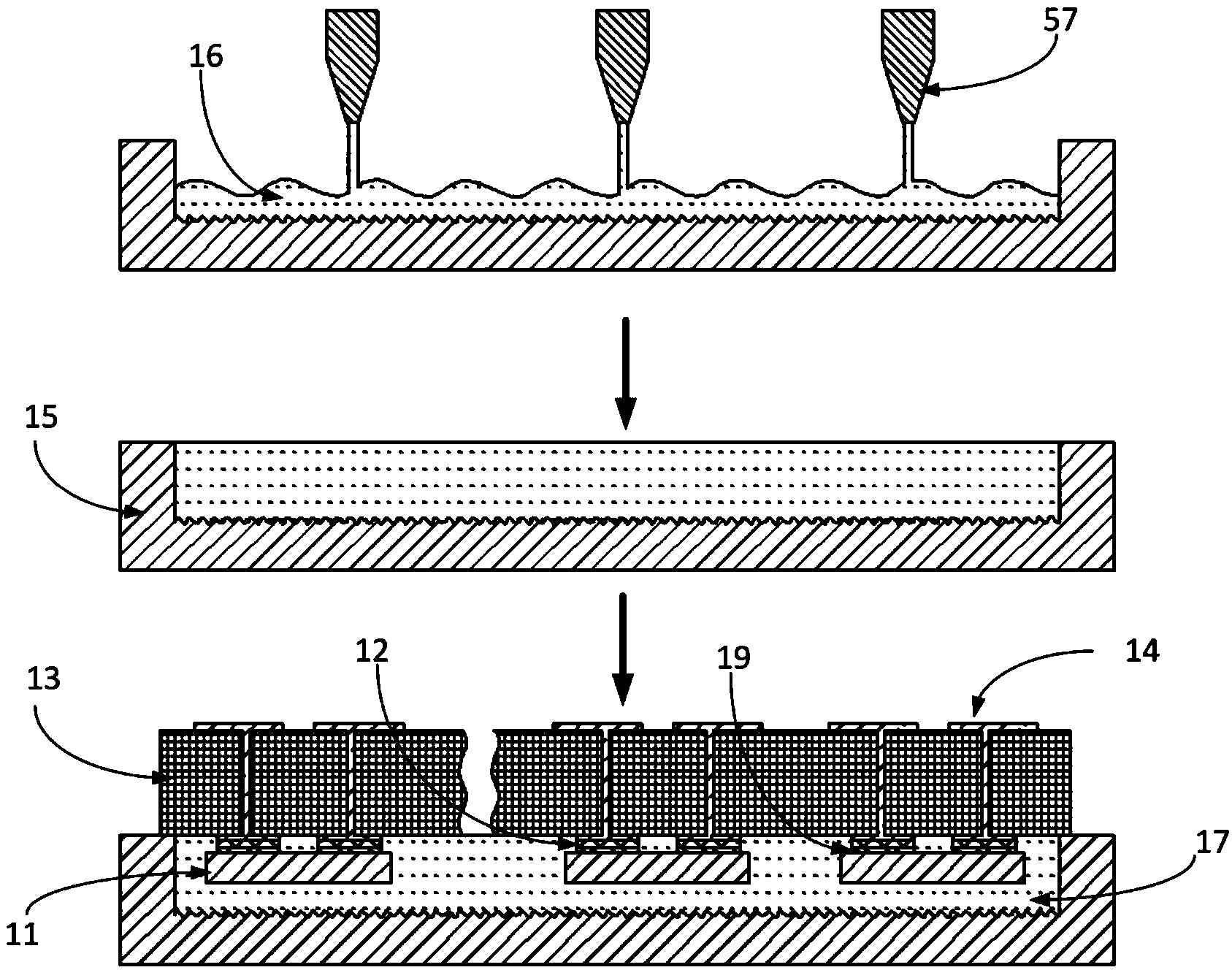

Wafer level packaging method for LED (Light-Emitting Diode) chip level white light source

InactiveCN104393154AImprove packaging efficiencyImprove color temperature consistencySemiconductor devicesEngineeringSilica gel

The invention discloses a wafer level packaging method for an LED chip level white light source. A packaging method of inverted LEDs comprises the following steps: firstly transferring the chips onto a wafer substrate plate (film), then carrying out fluorescent powder coating on a wafer sheet with a method that film vacuum press is obtained through a die, and finally carrying out cutting on the wafer sheet to obtain single LED direct white light source chips with chip levels. A packaging method of positive LEDs comprises the following steps: firstly completing solid crystal and gold thread bonding technology on a wafer substrate upper sheet for LED chips, then forming a silica gel protective lens with a spot-coating method for each LED chip, then coating uniform fluorescent powder layers on the silica gel protective lenses with a film vacuum pressing method, and finally carrying out cutting on the wafer sheet to obtain single LED direct white light source chips with chip levels. The LED packaging efficiency is greatly improved, an LED white light chip with good space color uniformity and overall color temperature consistency is obtained, and the development and innovation of LED packaging technology are greatly promoted.

Owner:WUHAN UNIV

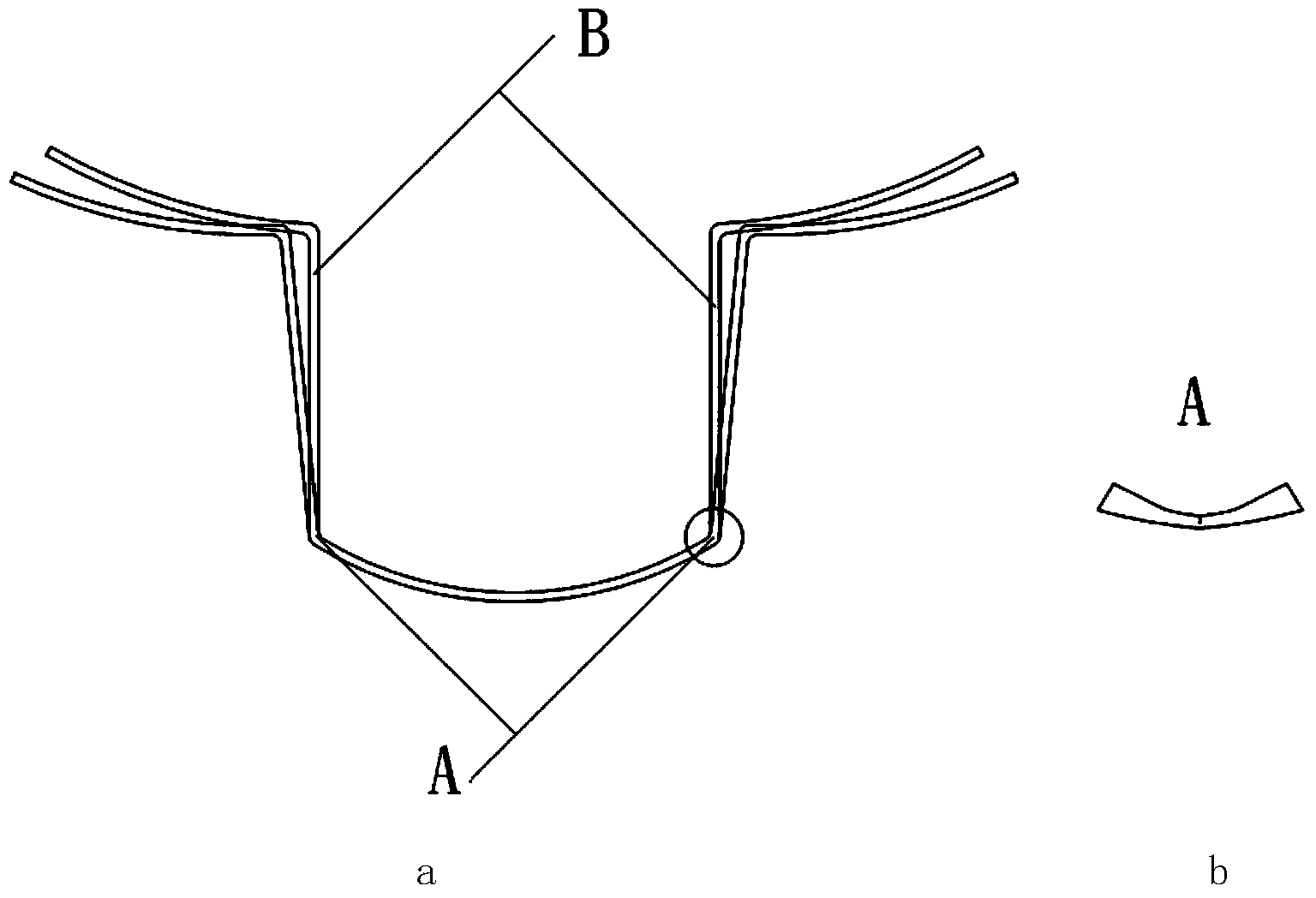

Incremental bending and forming method of hat-shaped member

InactiveCN103480704AHigh quality and precisionHigh forming precisionShaping toolsPunchingEngineering

Disclosed is an incremental bending and forming method of a hat-shaped member. Complex hat-shaped member with multi-arcs is formed through a simple mold matching with a plant bending machine. The method includes unfolding each arc of the complex hat-shaped member with the multi-arcs into a plane to determine the size of the plane blank; establishing a three-dimensional model according to the size of the plane blank, and dividing areas by adopting arcs as standards; performing numerical simulation on the forming process complex hat-shaped member with the multi-arcs, incremental bending arcs on two sides, then bending a central arcs, and finally bending boundaries of the areas; determining feeding amount of the plate blanks and downward punching amount of each step during the bending process according to the simulation result. By the aid of the method, the thickness of each part of a formed hat-shaped member is consistent basically, and surface quality and forming accuracy of the formed member can be guaranteed well; the process of controlling deformation is simple, and the method has the advantages of low cost and short period.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

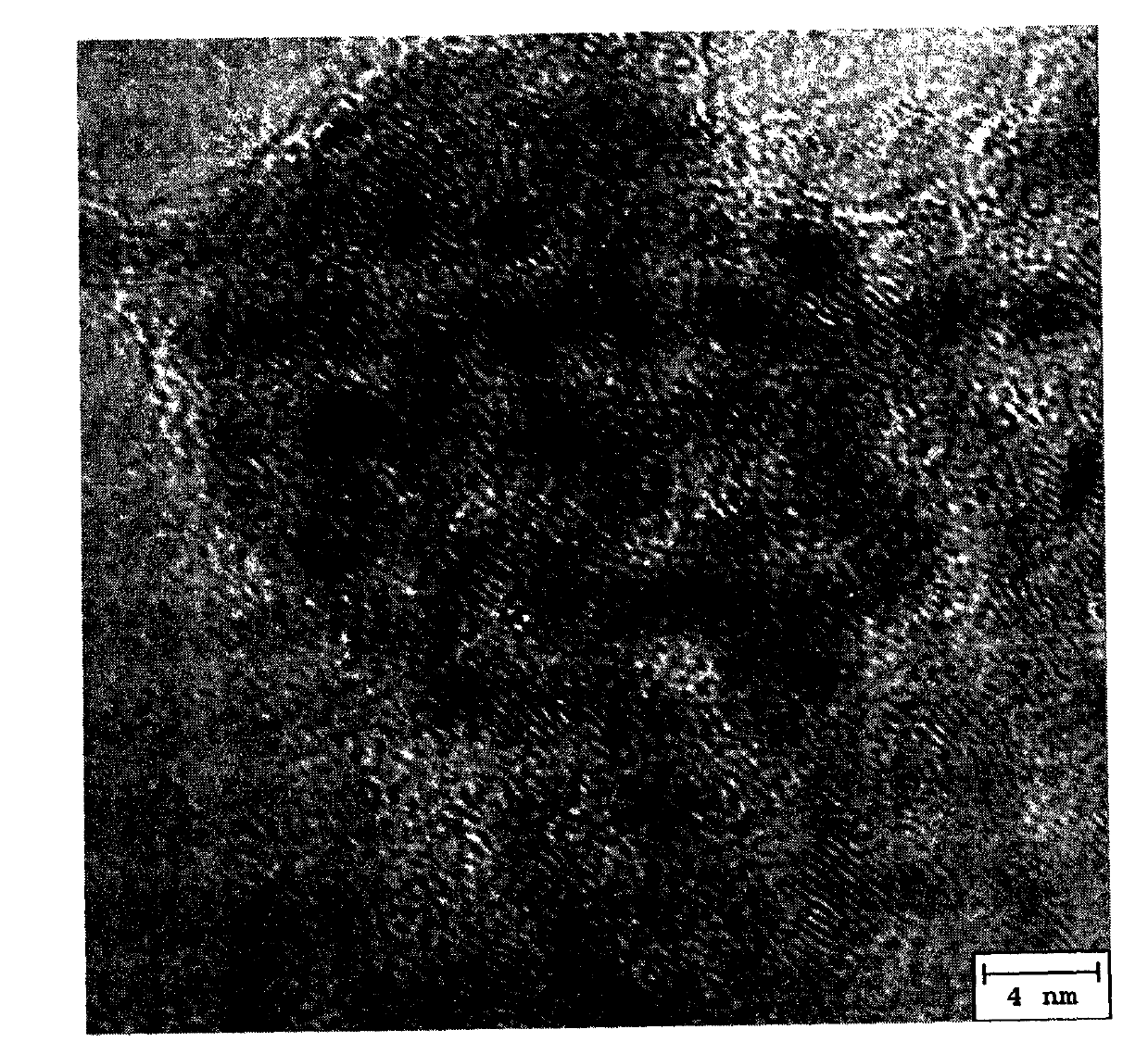

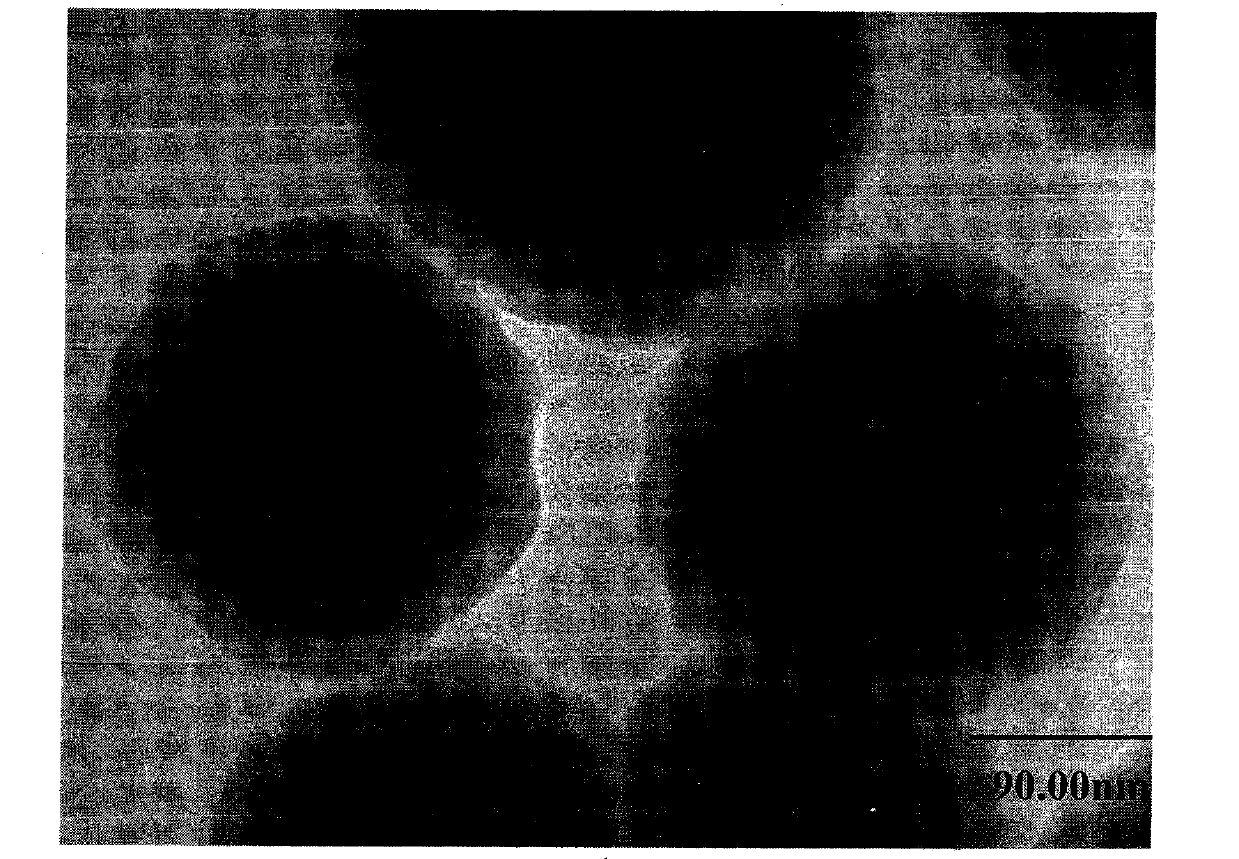

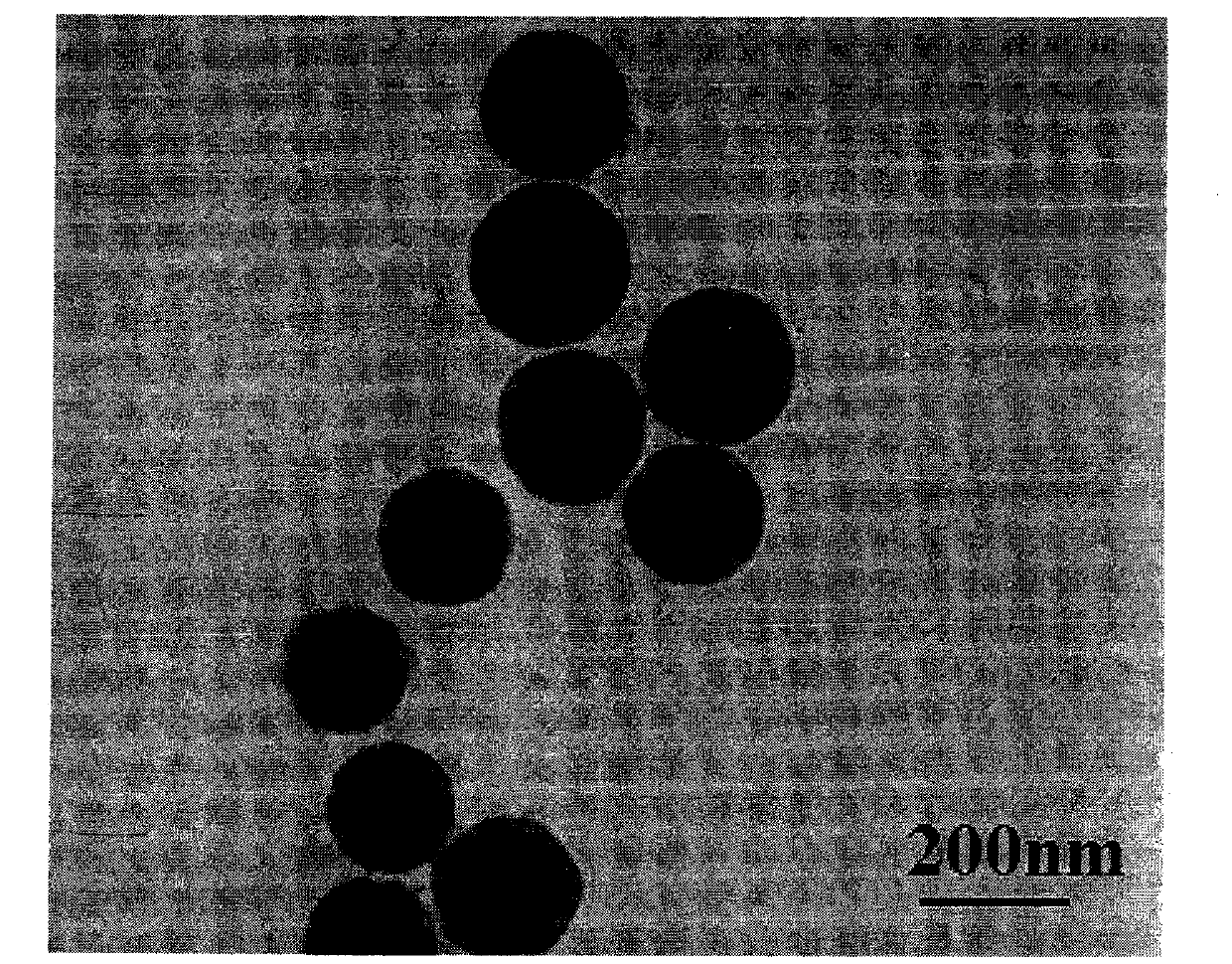

Preparation method of magnetic fluorescent composite nanospheres

InactiveCN103372407AEasy to manufactureSimple processMaterial nanotechnologyInorganic non-active ingredientsSolubilitySodium acetate

The invention provides a preparation method of magnetic fluorescent composite nanospheres. The preparation method comprises the steps of (1) preparing CdSe quantum dots by taking Na2SO3, selenium powder, cadmium acetate, N-acetylcysteine and deionized water as raw materials; (2) with FeCl3.6H2O sodium acetate anhydrous and ethylene glycol as raw materials, reacting in an autoclave to obtain Fe3O4 nanoparticles; (3) preparing a Fe3O4@SiO2 product by taking the Fe3O4 nanoparticles, tetraethoxysilane, absolute ethyl alcohol, deionized water and ammonium hydroxide as raw materials; and (4) conducting amino modification on the surface of the Fe3O4@SiO2 by utilizing a silane coupling agent KH-550, then loading CdSe onto the surface of the SiO2 through reaction, so as to obtain the final product magnetic fluorescent composite nanospheres. The preparation method has the characteristics that the prepared CdSe quantum dots have excellent water solubility and excellent fluorescent property and are about 3-4nm in diameter; the Fe3O4 nanoparticles are even in particle size and have good dispersity; the Fe3O4@SiO2 nanoparticles have an obvious core-shell structure, shell layers are evenly coated and are consistent in thickness; the magnetic fluorescent composite nanospheres has strong magnetism and excellent fluorescence property and can be used for site-specific drug transportation in a biological body and the fluorescence imaging of the biological body.

Owner:BEIJING UNIV OF CHEM TECH

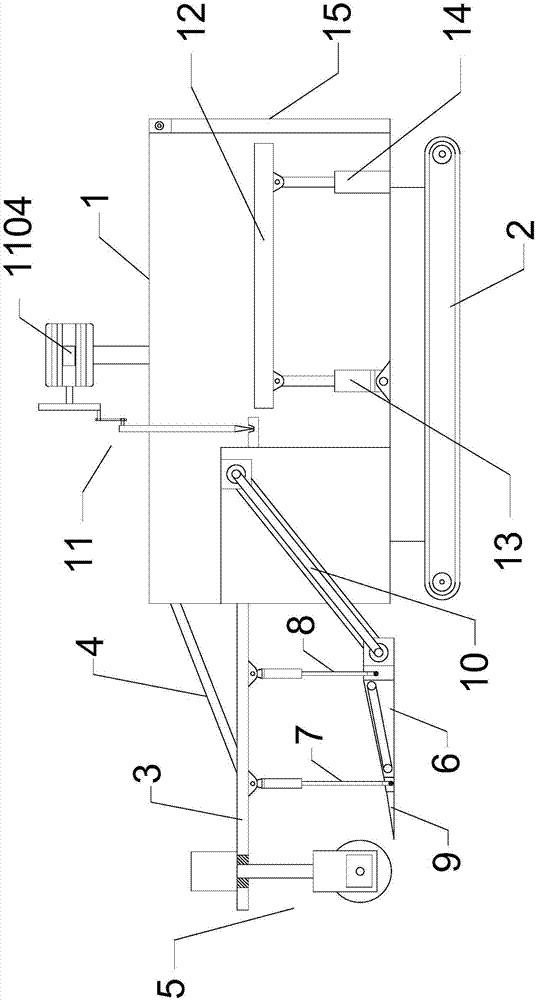

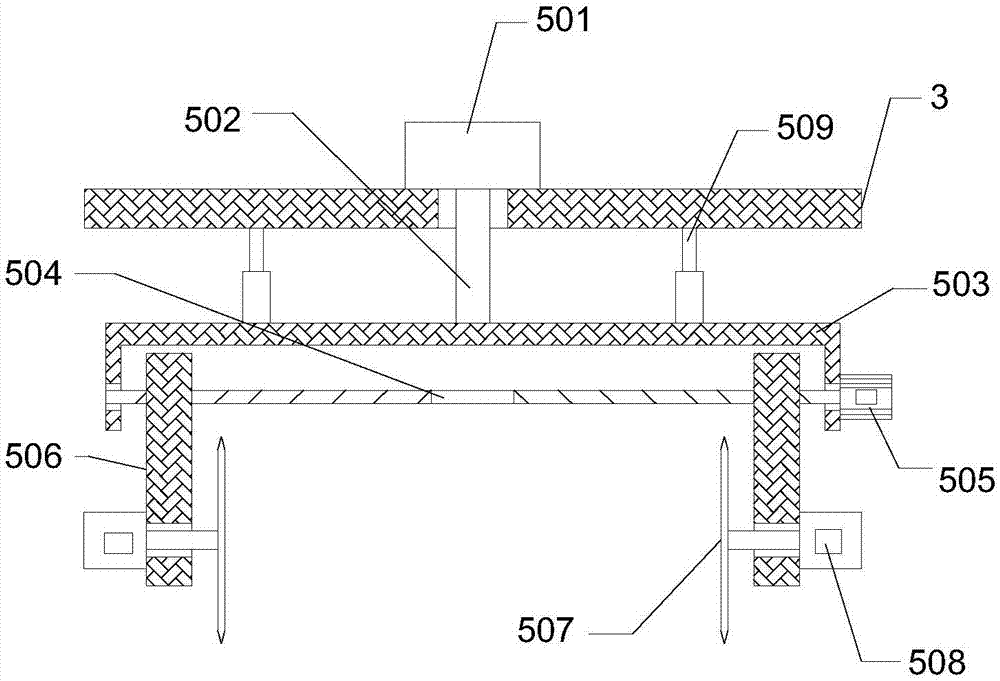

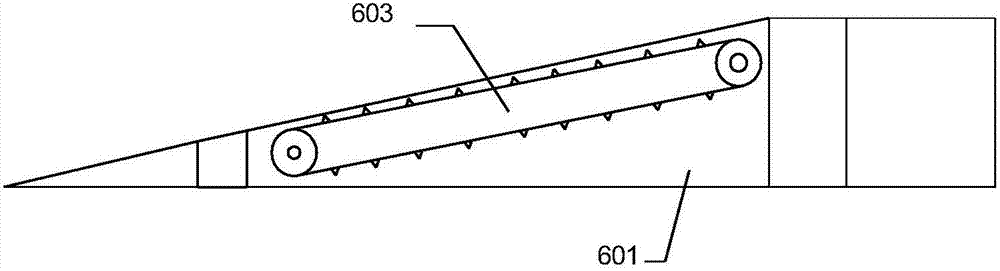

Adjustable turf harvester

InactiveCN107347274AImprove harvesting efficiencyImprove cutting accuracyHops/wine cultivationTurf growingEngineeringSoil horizon

The invention discloses an adjustable turf harvester, which comprises a car body; the left side wall of the car body is fixedly connected with a beam plate; the left side of the beam plate is provided with a turf cutting device; the right side of the turf cutting device is provided There is a shovel device. The present invention is equipped with a turf cutting device and a turf shoveling device with an adjustable width, which can cut the turf into a specified width according to the needs and efficiently shovel and collect it, greatly improving the harvesting efficiency and cutting accuracy of the turf, and ensuring the turf block The thickness of the soil layer is consistent; the invention is equipped with a turf cutting device, which can cut out a specified area of turf according to the needs, so as to realize accurate harvesting; the invention is equipped with a rotatable lifting plate, which is convenient for unloading the turf, and is convenient for shipment and subsequent laying.

Owner:ZHENGZHOU BINGTONG LIZHI ELECTRONICS TECH CO LTD

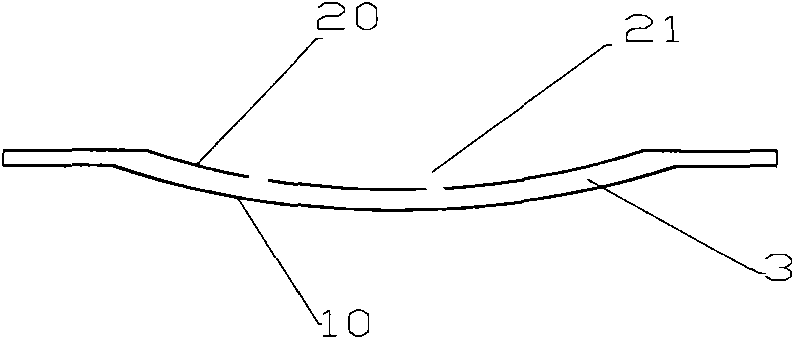

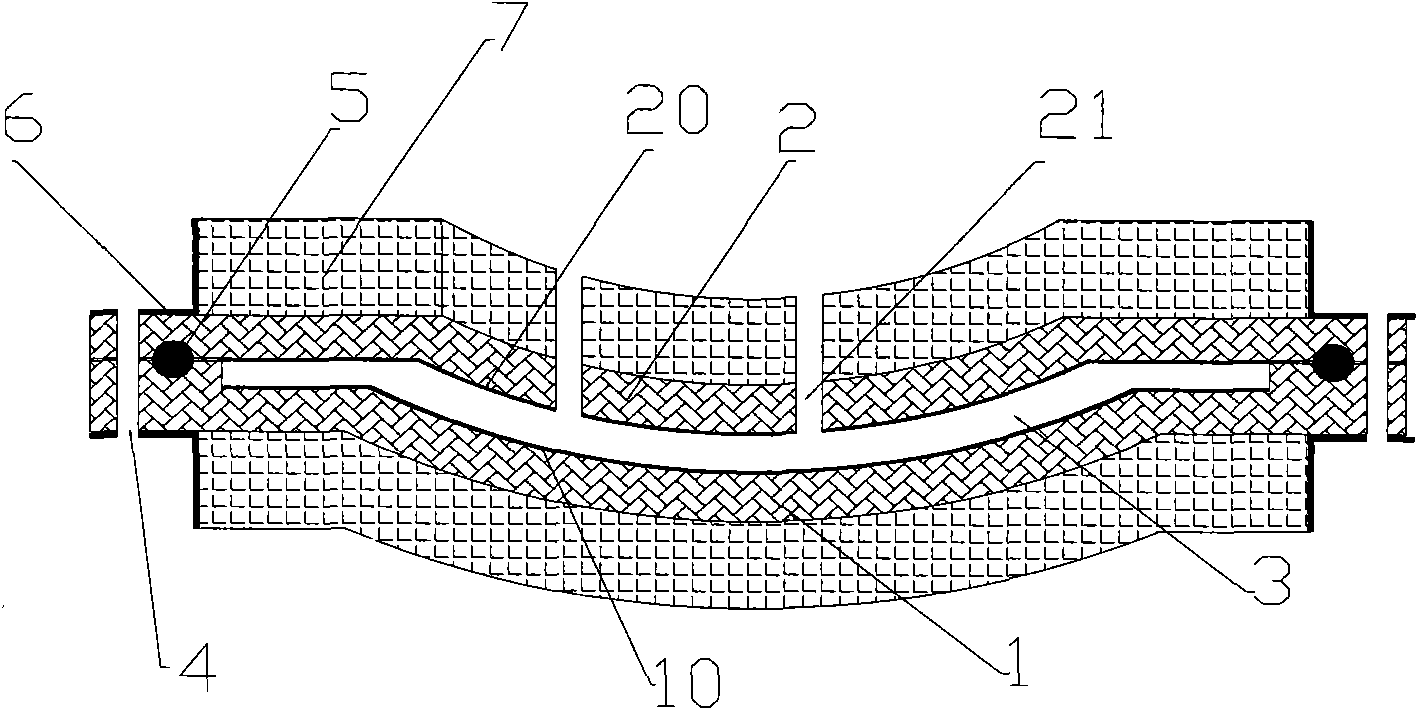

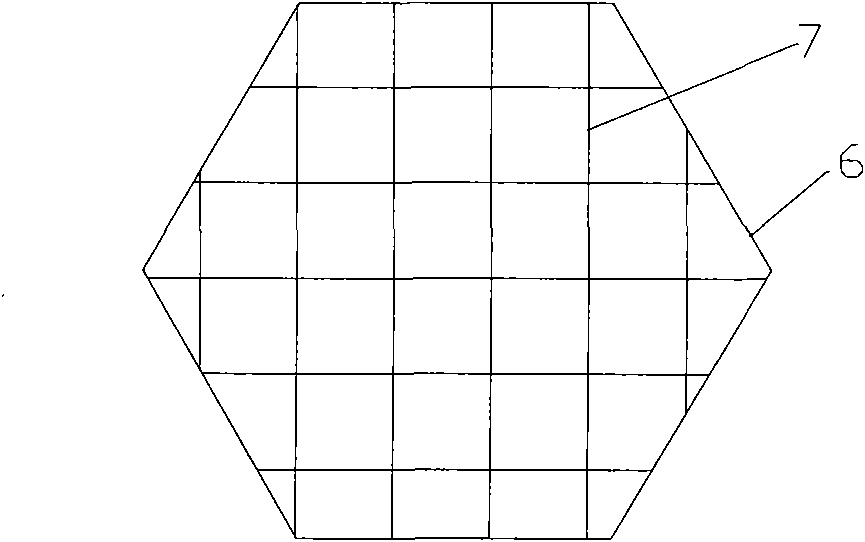

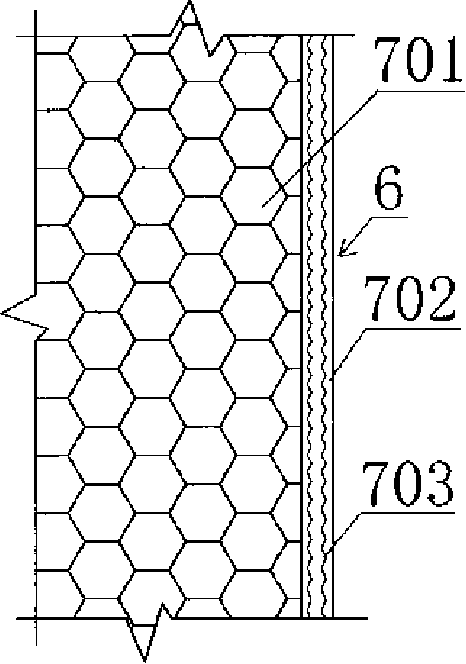

Wedge-shaped multilayer interlayer and glass laminate

InactiveUS20180117883A1Great ease of manufactureReduce wasteSynthetic resin layered productsLaminationEngineeringWedge shape

Owner:KURARAY EURO GMBH

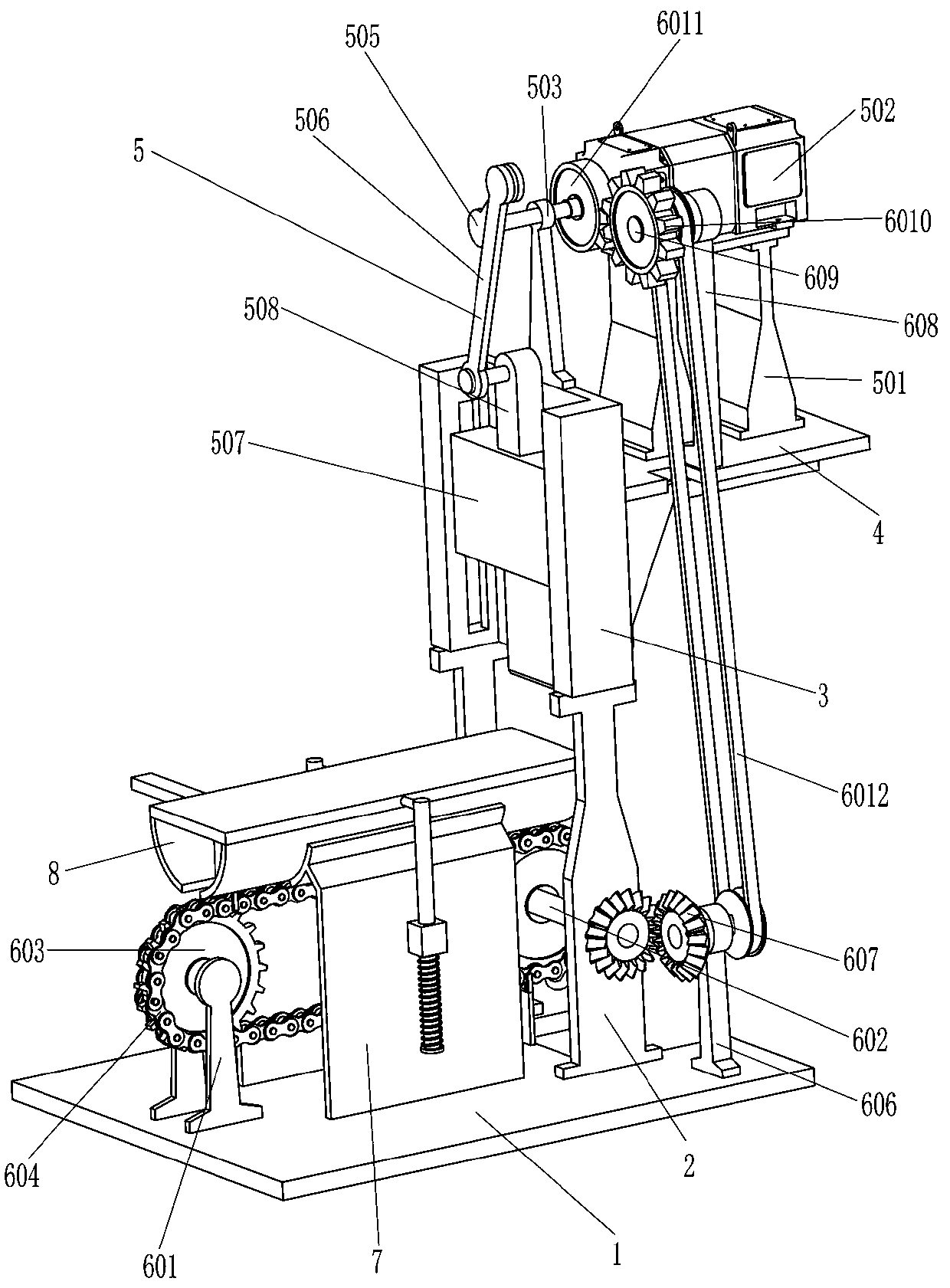

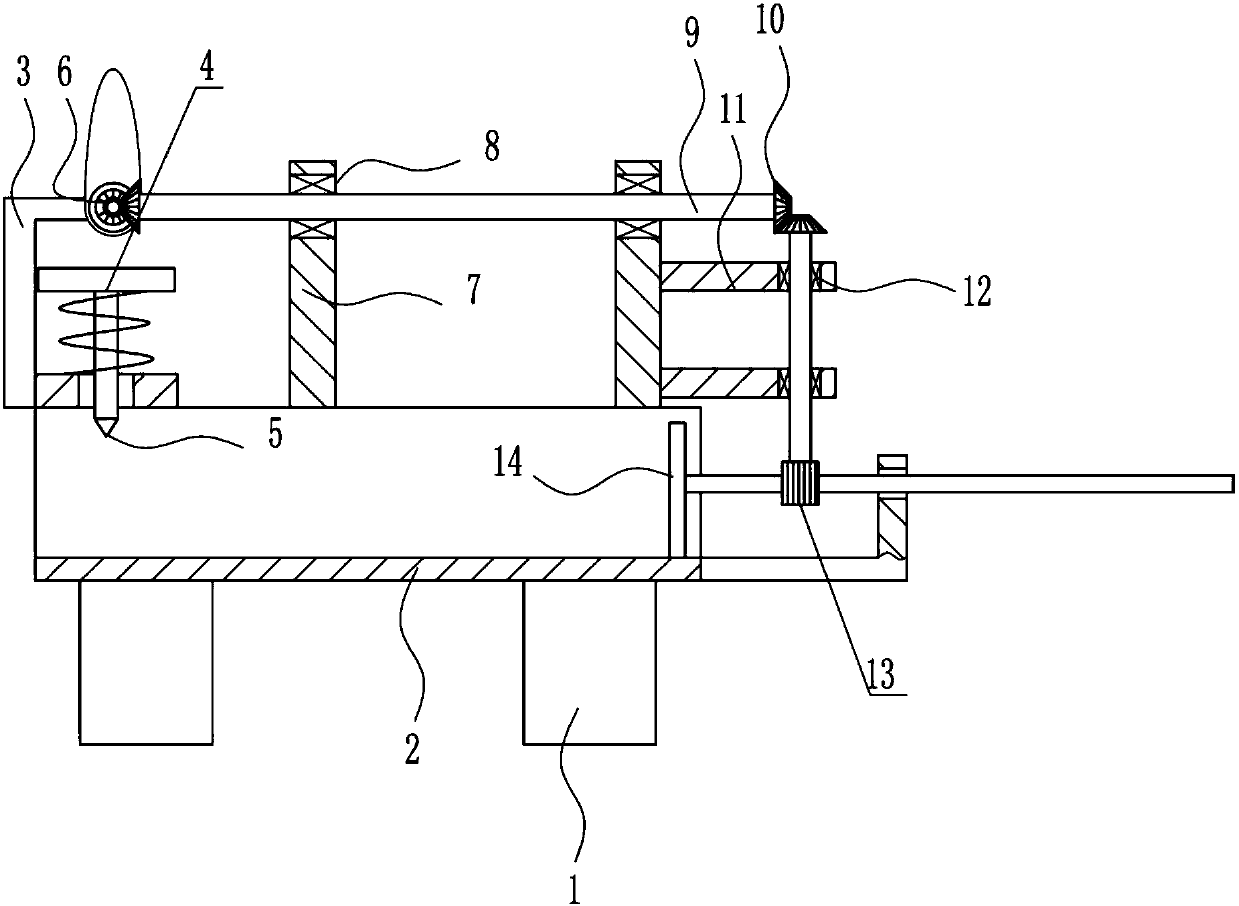

Radish slicing device

InactiveCN107775682AAffect sliceConsistent thicknessMetal working apparatusEngineeringMechanical engineering

The invention relates to a slicing device, in particular to a radish slicing device. The technical problem to be solved by the present invention is to provide a radish slicing device with fast slicing speed, uniform thickness of cut radish slices, no manual slicing, and no hand injury by blades. In order to solve the above-mentioned technical problems, the present invention provides such a radish slicing device, which includes a leg, a U-shaped frame, a 7-shaped plate, a lifting device, a blade, a first bevel gear, a vertical plate, a first bearing seat, a first Rotating shaft, second bevel gear, horizontal plate, etc.; symmetrical mounting legs on the left and right sides of the outer bottom of the u-shaped frame, a push plate is arranged in the u-shaped frame, the push plate is vertically arranged, and the push plate slides with the u-shaped frame Cooperate. Through the cleaning device, the present invention can not only remove the radish slices sticking to the blade, but also clean the blade, so that the slicing speed is fast, the thickness of the cut radish slices is uniform, no manual slicing is required, and the radish slices will not be damaged by the blade. The effect of cutting hands.

Owner:卢勇军

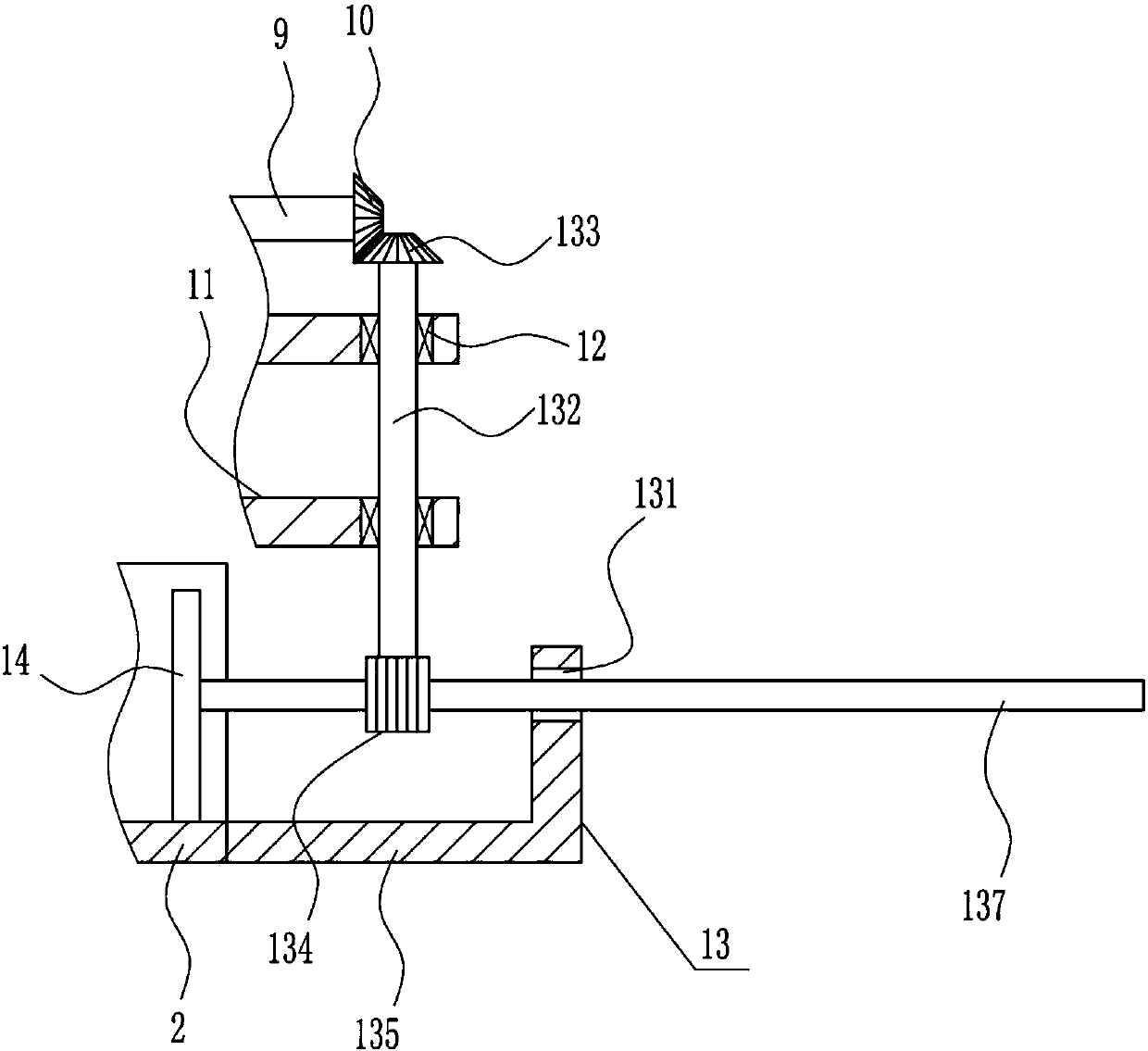

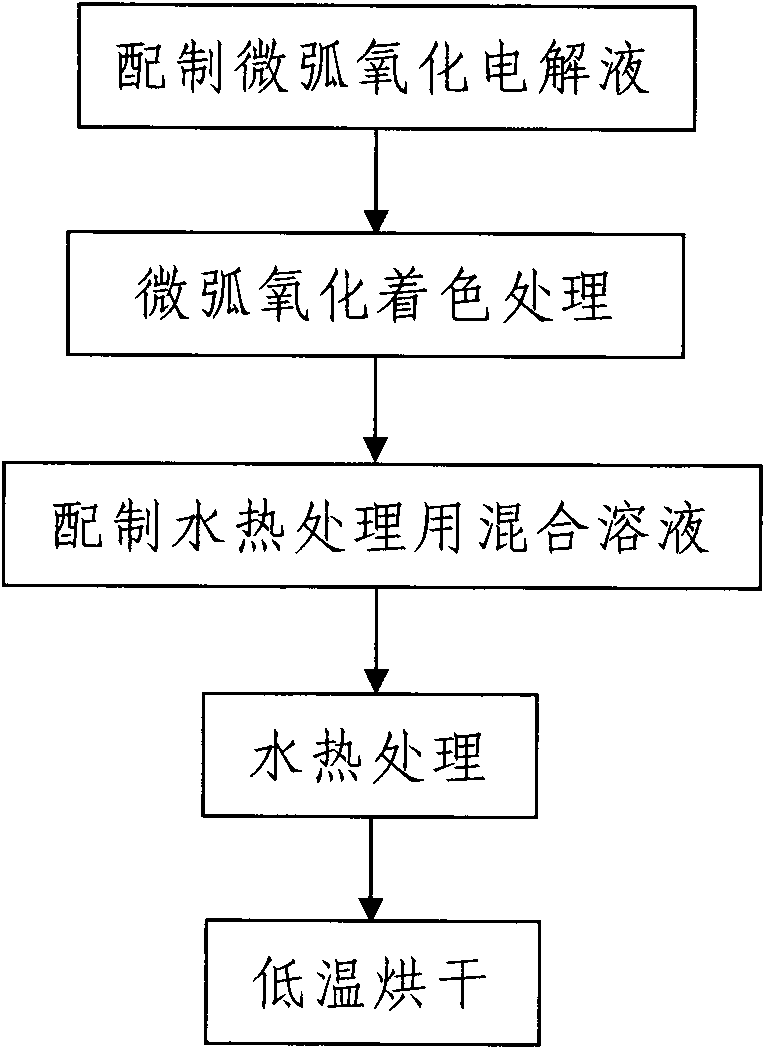

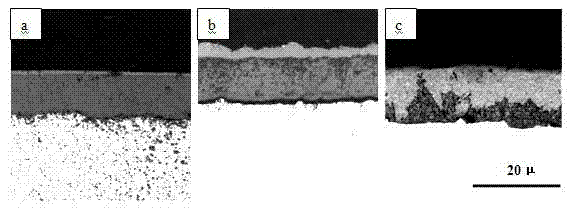

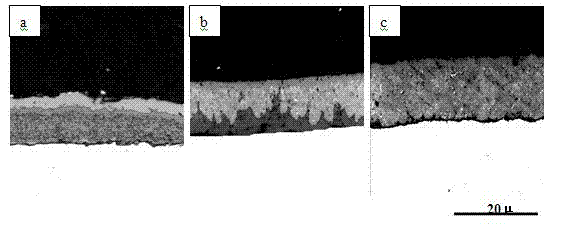

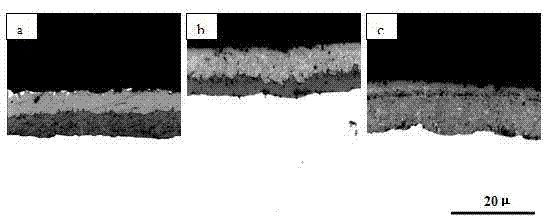

Preparation method of titanium and titanium alloy surface black protective film for surgical implantation

ActiveCN101660190AThe preparation process steps are simpleEasy to operateSurface reaction electrolytic coatingProsthesisTectorial membranePlasma electrolytic oxidation

The invention discloses a preparation method of a titanium and titanium alloy surface black protective film for surgical implantation, comprising the following steps: step 1: carrying out micro-arc oxidation coloring processing on titanium and titanium alloy surface to be processed, in the process, firstly, preparing a micro-arc oxidation electrolysing solution, and then carrying out the micro-arcoxidation coloring processing; and step 2: carrying out subsequent processing on the micro-arc oxidation film, wherein the subsequent processing comprises the following steps: firstly, preparing a mixed solution for hydro-thermal processing, completely dipping the titanium and titanium alloy after micro-arc oxidation shading processing in the mixed solution, carrying out the hydro-thermal processing on the surface by adopting a hydro-thermal method, drying the titanium and titanium alloy under the condition of low temperature when the hydro-thermal processing is completed, and generating a layer of pure black micro-arc oxidation film with uniform and plump surface on the titanium and titanium alloy surface. The invention has simple and convenient operation, economy, high production efficiency, and high bonding strength between a generated ceramic film, i.e. the micro-arc oxidation film and a substrate, and the invention can effectively overcome various defects and deficiencies which exist in the prior coating processing techniques.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

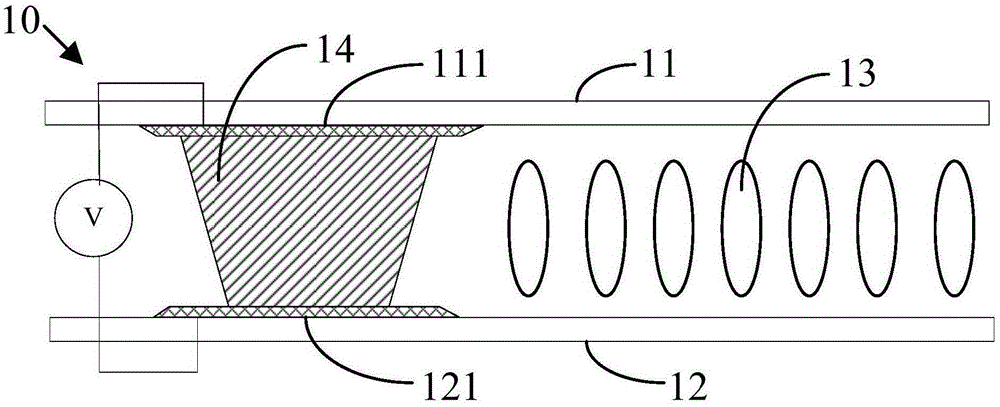

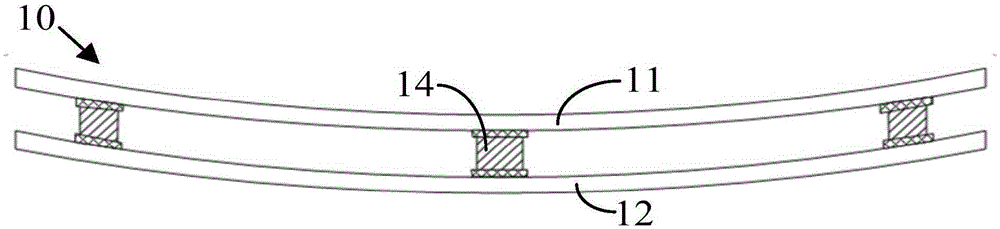

Curved-surface liquid crystal display panel and liquid crystal display panel

InactiveCN105278175AConsistent thicknessSolve technical problems arising from adverse phenomenaNon-linear opticsElectricityLiquid-crystal display

The invention provides a curved-surface liquid crystal display panel, which comprises an array substrate, a color-film substrate, a liquid crystal layer and a liner. The height of the liner can be adjusted according to the bending degree of the curved-surface liquid crystal display panel. The invention also provides a liquid crystal display panel. According to the technical scheme of the curved-surface liquid crystal display panel and the liquid crystal display panel, the electricity-induced elastic liner is arranged in the liquid crystal layer, and then the thickness of the liquid crystal layer is controlled through adjusting the height of the electricity-induced elastic liner. Therefore, the thickness of the liquid crystal layer is ensured to be uniform.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Serrated blade for slicing machine

InactiveUS20080000337A1Increase speedConsistent thicknessMetal sawing devicesBand sawsEngineeringKnife blades

Owner:DICKOVER WILLIAM +1

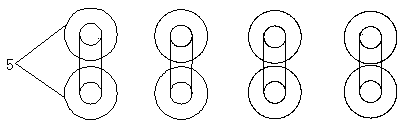

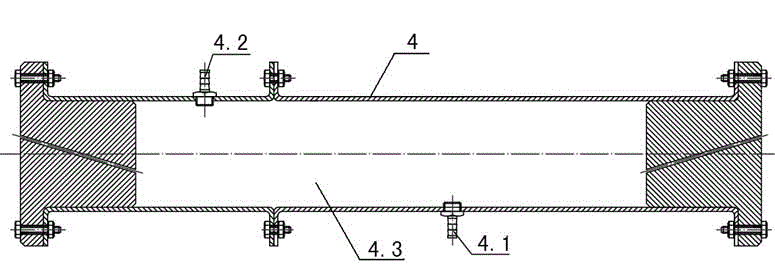

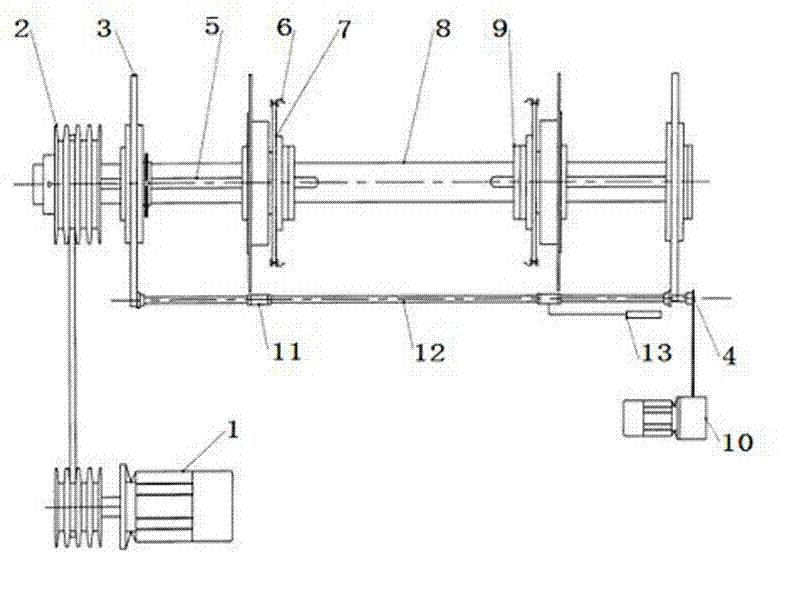

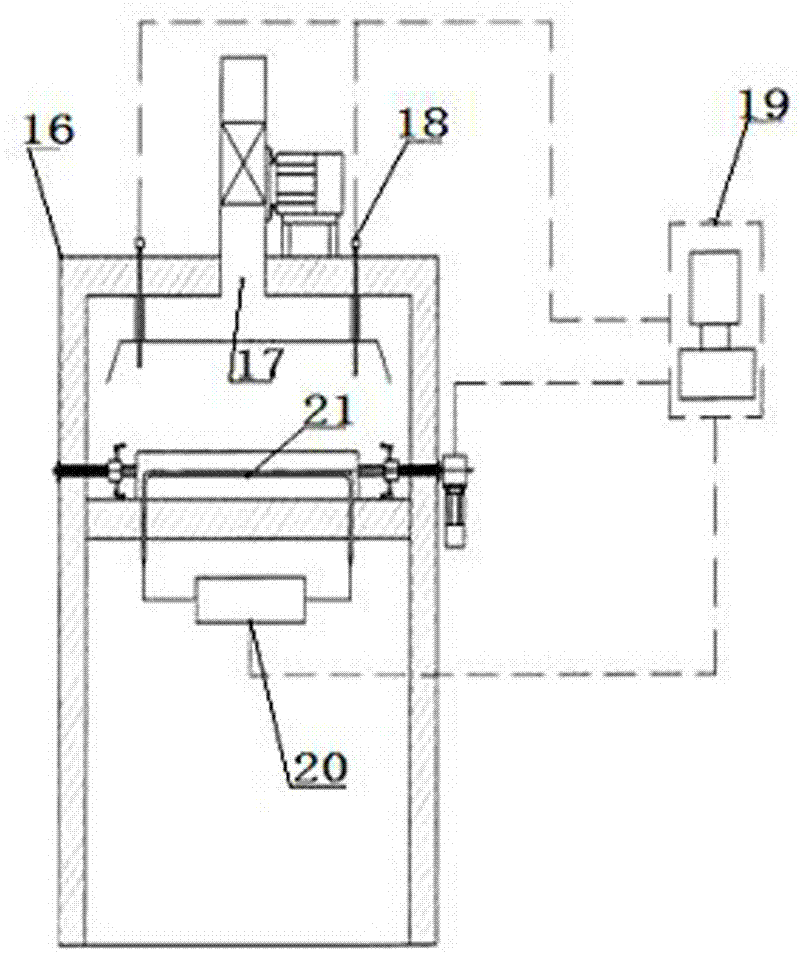

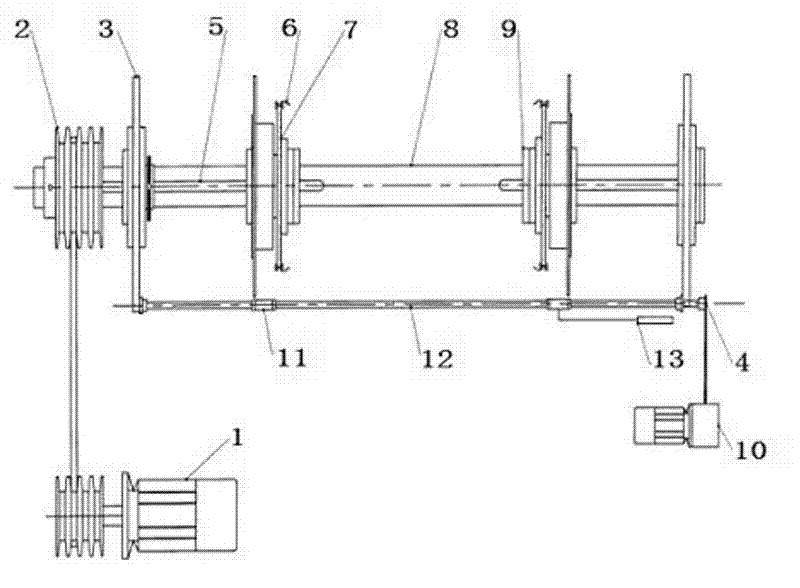

Bidirectional drawing machine for polymide films

The invention provides a bidirectional drawing machine for polymide films; the bidirectional drawing machine comprises a needle plate type chain mechanism, a drawing machine box body, a vertical chain and transmission mechanism, an automatic expanding mechanism, an automatic closed loop heating system and an inner circulating air bellows, wherein the vertical chain and transmission mechanism comprises a main driving motor, a belt pulley, a main shaft, a guide key and a chain wheel; the automatic expanding mechanism comprises a speed reducing motor, a small chain wheel, a breadth adjusting screw rod, a nut and a sliding seat; the electric heating system comprises an embedded type electric heater, a temperature sensor, a temperature controller and an upper computer; by adopting the bidirectional drawing machine, the films are uniformly stressed during stretching and have consistent thickness and high quality, the space of a heating area is reduced, the heating power is minimized, the electric energy is saved, and the exhaust emission is reduced; and therefore, the bidirectional drawing machine is more environmental-friendly.

Owner:万达集团股份有限公司

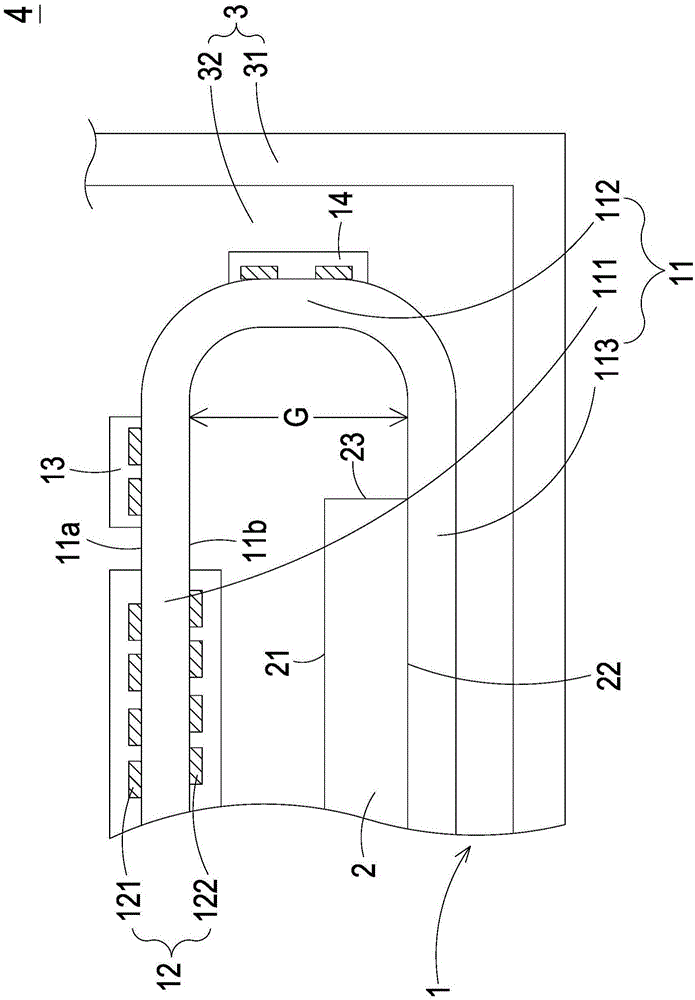

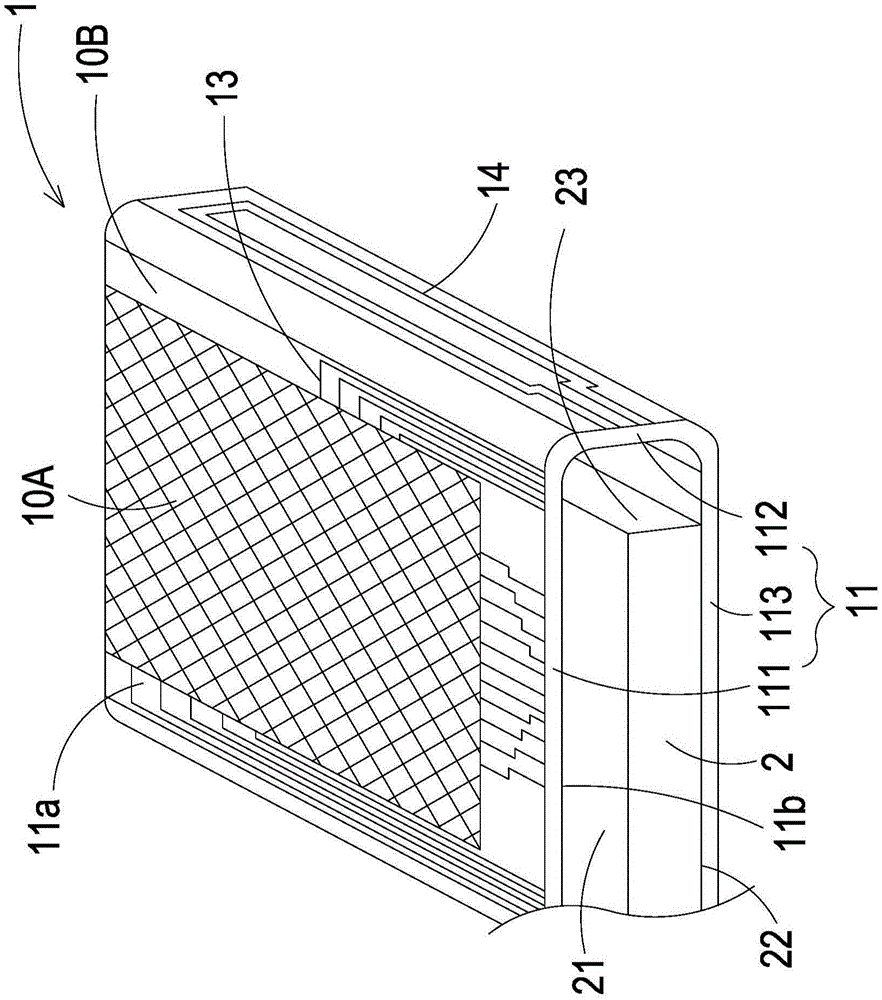

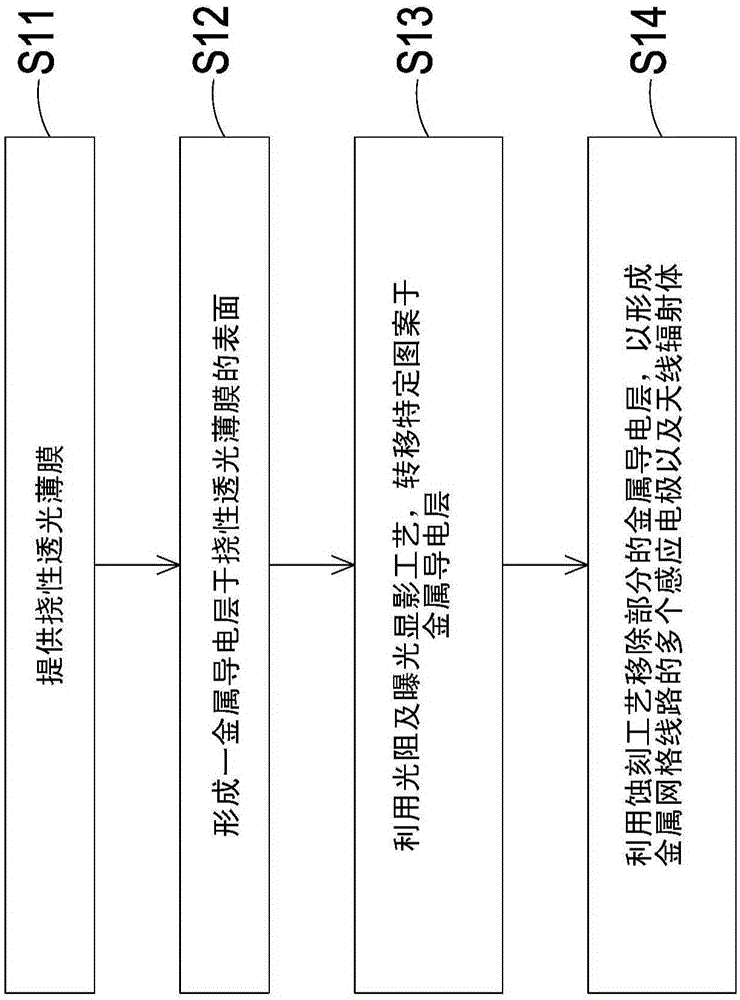

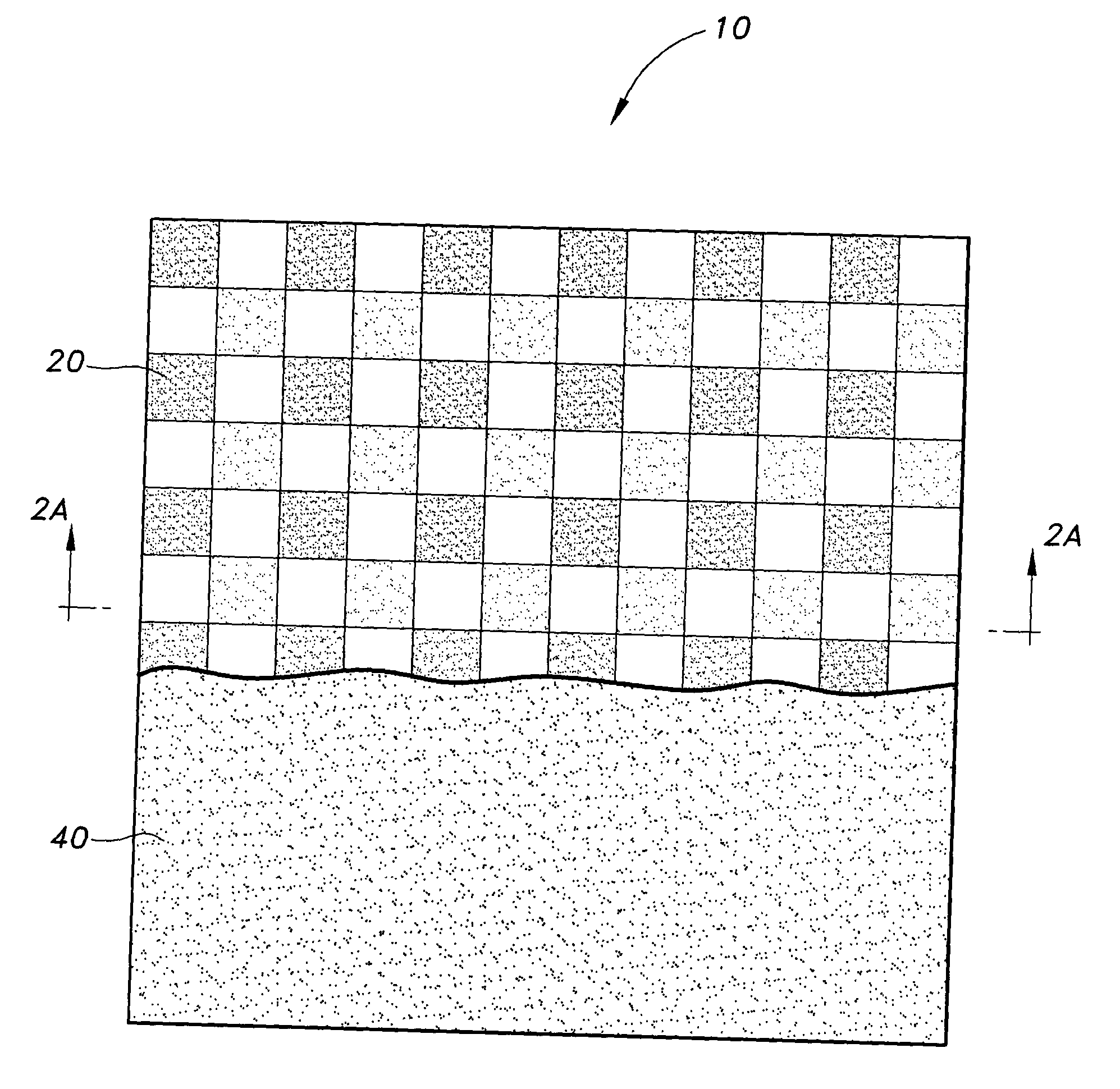

Touch panel with antenna and touch display device

PendingCN106547382ADoes not affect sizeConsistent thicknessInput/output processes for data processingDisplay deviceComputer science

The invention relates to a touch panel with an antenna and a touch display device. The touch display device comprises the touch panel and a display module; the touch panel comprises a flexible transparent film with a first section and a bending part; a metal mesh line, which is arranged on at least one surface of the flexible transparent film and arranged in the first section, and is structured as a visible touch area; a plurality of metal wires, which are arranged on at least one surface of the flexible transparent film and arranged at the periphery of the visible touch area, and electrically connected with the metal mesh line; and an antenna radiator, which is arranged on at least one surface of the flexible transparent film, and located at the bending part, wherein the antenna radiator, the metal mesh line and at least one of the plurality of metal wires are located at the same surface and molded on the surface once. The display module includes a side, and the antenna radiator is opposite to the side of the display module. The antenna radiator is formed by using a same process step of forming an induction electrode of the visible touch area and metal wires in a peripheral line area, so that the overall thickness is consistent.

Owner:J TOUCH CORPORATION

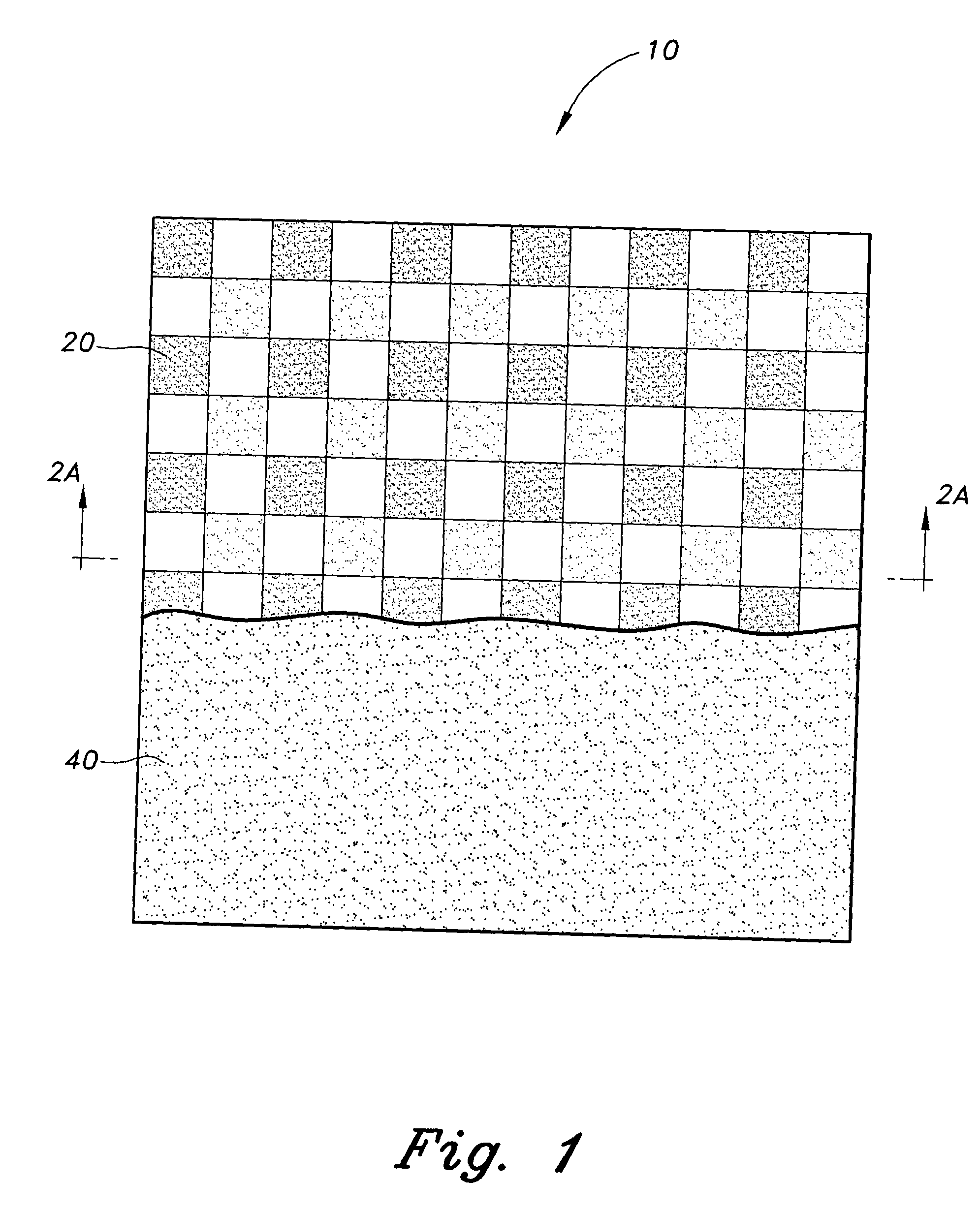

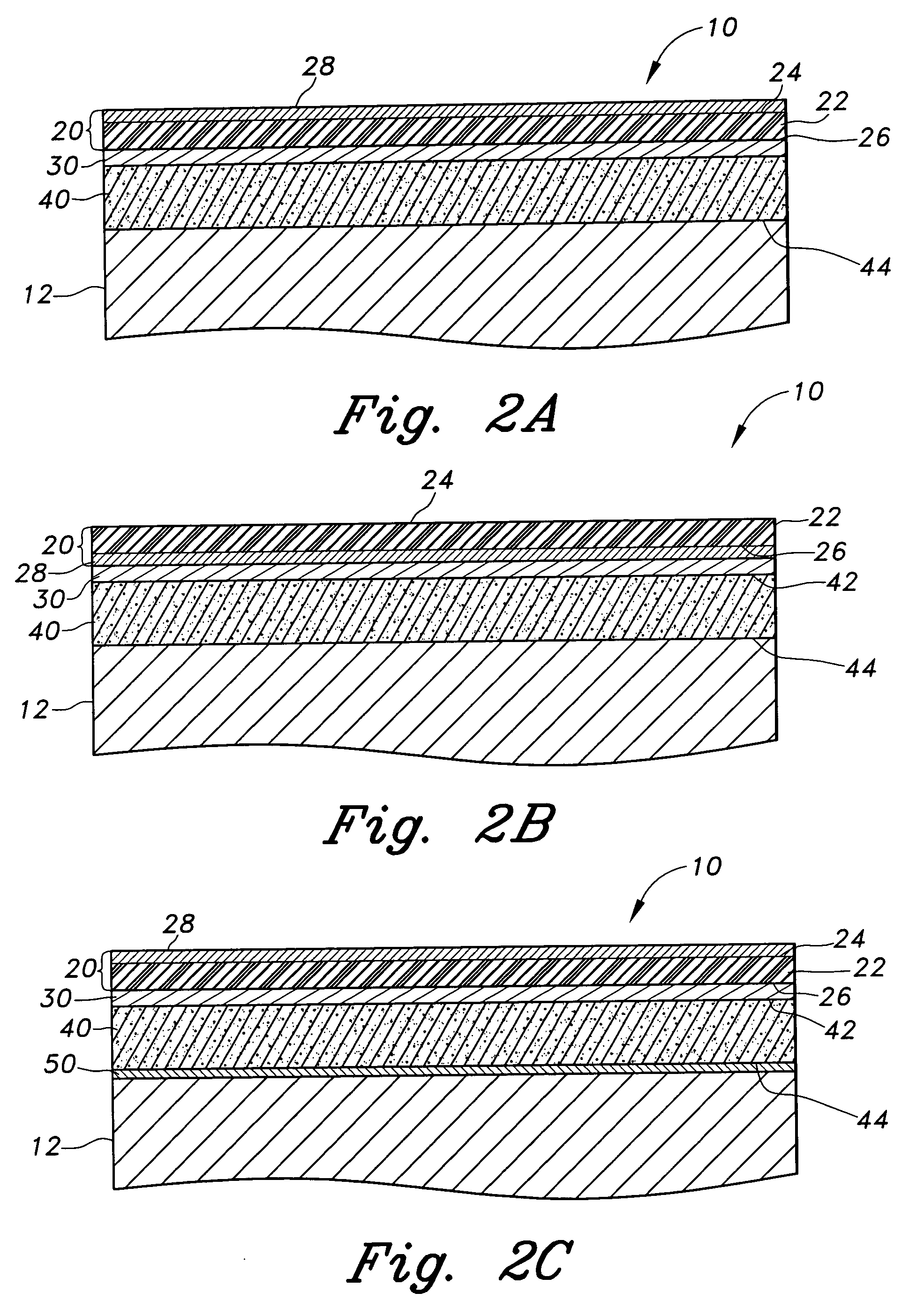

Shelf liner

InactiveUS20050037190A1Enhances fused bonding of layerConsistent thicknessLamination ancillary operationsSynthetic resin layered productsPolyvinyl chlorideEngineering

The shelf liner is a multi-layered thermoplastic composite sheet of consistent thickness, with a non-slip bottom side and a decorative top side. A decorative top sheet is fused to a top surface of a substrate layer. The substrate layer comprises a nonwoven fabric or material that is coated on both sides, and can be fully impregnated, with a foamed plasticized polyvinyl chloride. The foamed plasticized polyvinyl chloride coating on the bottom side of the substrate layer gives the shelf liner a non-slip characteristic. An interlayer of polyvinyl chloride plastisol is disposed between the top sheet and the substrate to enhance the fused bonding of the layers. A bottom surface of the substrate layer may be fully or partly covered with a bottom coating to modify the non-slip nature of the shelf liner.

Owner:MARKETING & SALES MANAGEMENT CORP

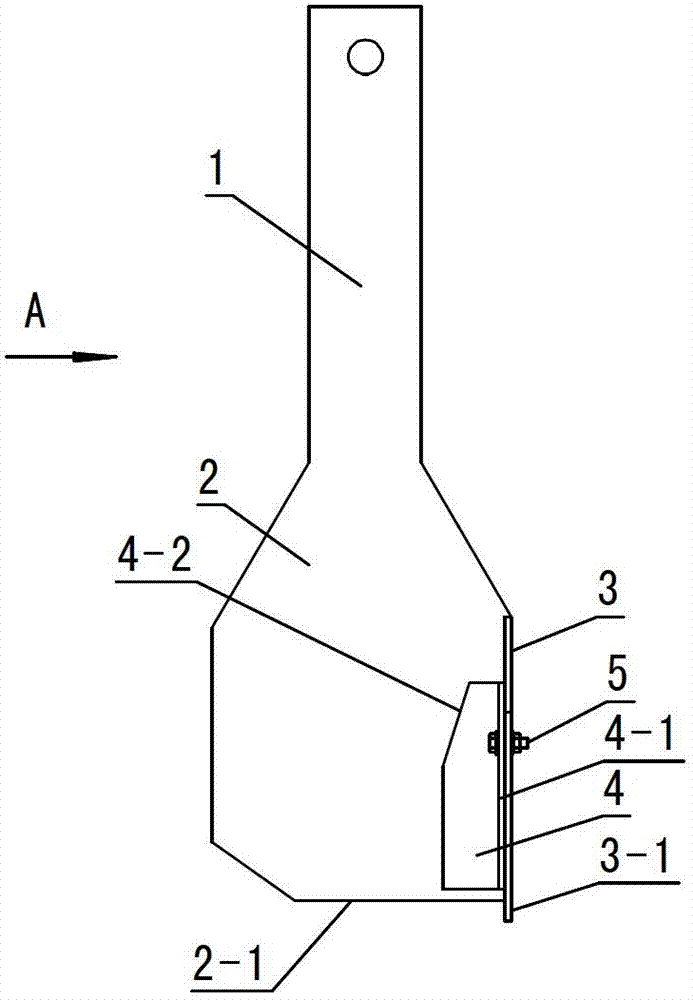

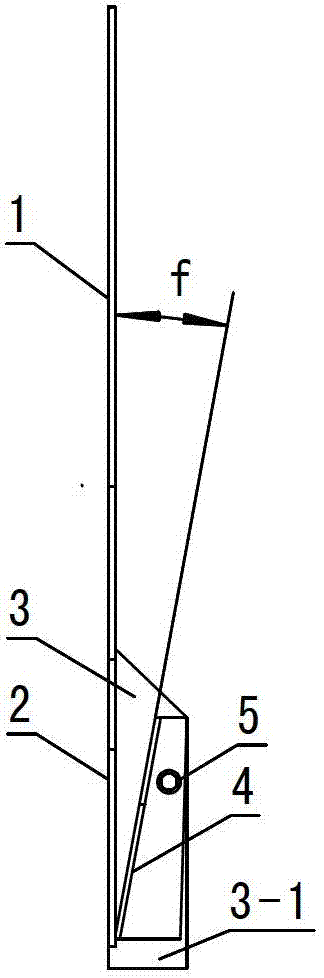

Special tool for coating face gluing layer on stretching net of surface mount technology (SMT) laser template

ActiveCN102773193AConsistent thicknessUniform thicknessLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention relates to a special tool for coating a face gluing layer on a stretching net of a surface mount technology (SMT) laser template. The special tool is characterized in that a main body is formed by a handle and a scraper plate connected with the bottom end of the handle. The width of the bottom end of the scraper plate is equal to the width of the face gluing layer, a baffle is arranged on one side of the scraper plate and is provided with a protruding portion protruding relative to the bottom end of the scraper plate, a glue liquid backflow plate is arranged on one side of the baffle corresponding to the scraper plate, and the width of the glue liquid backflow plate is 1 / 4-1 / 3 of that of the bottom end of the scraper plate. The bottom end of the glue liquid backflow plate is connected with the bottom end of the scraper plate, and an included angle of 15-30 degrees is formed between the glue liquid backflow plate and the plate face of the scraper plate. The baffle and the protruding portion of the special tool enable the scraper plate to be located at the position of the gauze face gluing layer, and the width of the bottom end of the scraper plate is the width of the face gluing layer, so that the width of the face gluing layer formed by the tool is consistent. The glue liquid backflow plate enables glue liquid gathering at the bottom end of the scraper plate to flow to the upper portion of the scraper plate along the surface and then flow back to a glue feeding area to enable the thickness of the face gluing layer to be consistent. The special tool has the advantages of removing working procedures of manual bonding of beautiful line adhesive tapes and remarkably improving production efficiency.

Owner:天津光韵达光电科技有限公司

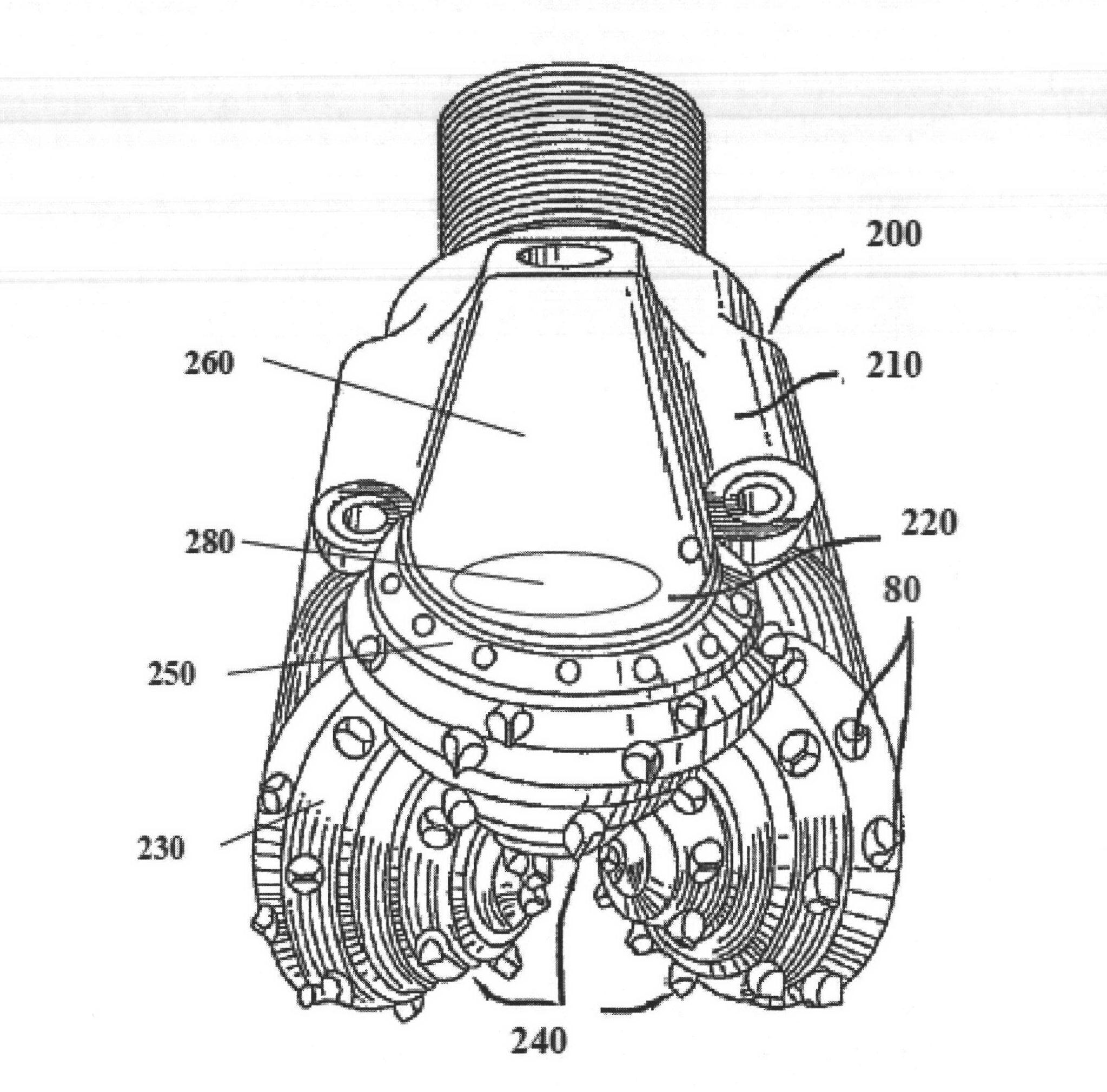

Wear-resistant material used in drilling application

The invention relates to a hard-face metal composition with strong wear resistance and fracture resistance, in particular to a wear-resistant material used in drilling application. The wear-resistant material contains tungsten carbide and a nickel matrix binder, wherein the content of the tungsten carbide in the hard-face metal composition exceeds 50% by weight, and at least 60% by volume of tungsten carbide particles are spherical; and the binder consists of (in weight percent) at least 80% of nickel, 4.5-11% of fusing agent, 3-7% of copper and 1-5% of Cr or Mo or mixture of the Cr and the Mo, wherein the fusing agent is selected from boron, silicon and phosphorus.

Owner:SEED TECH CORP LTD

A kind of production method of pickling-reducing steel

InactiveCN102266868AImprove surface quality and labor productivityReduce generationRoll mill control devicesMetal rolling arrangementsMicrostructureReaction curve

The invention relates to a production method for pickling steel with reduced acid and belongs to the technical field of metal rolling. The technical scheme is that: a FeO eutectoid reaction curve in a scale microstructure in the hot rolling process of target steel is formed; a rolling process is controlled, optimized and adjusted according to the FeO eutectoid reaction curve in the scale microstructure in the hot rolling process of the target steel; and the scale microstructure is changed, the generation of Fe2O3 which is difficult to pickle is reduced, the pickling speed is improved in the pickling process, and acid consumption of each ton of steel is reduced to pickle steel with acid. The invention has the advantages that: the scale is well controlled in the hot rolling process, and thesurface quality of a hot rolled strip coil and labor productivity are greatly improved; and the scale microstructure is changed, the generation of Fe2O3 which is difficult to pickle is reduced, the pickling speed is improved by 10 percent in the subsequent pickling process, and the acid consumption of each ton of steel is reduced by 7.5 percent. The pressure of excessive waste acid emission on the environment is greatly lightened, and the method has the advantages of energy conservation, emission reduction and great social benefit.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com