Patents

Literature

314results about How to "The preparation process steps are simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing complexly shaped biomedical porous titanium molybdenum alloy implant body

InactiveCN102335742ADesign personalizationHigh dimensional accuracyIncreasing energy efficiencyProsthesisNatural boneMetallic materials

The invention provides a method for preparing a complexly shaped biomedical porous titanium molybdenum alloy implant body and belongs to the technical field of biomedical porous metallic material preparation. The method comprises the following steps of: taking a mixture of titanium and molybdenum metallic element powder and organic polymer powder as raw materials, and then preparing the biomedical porous titanium molybdenum alloy implant body by adopting the processes, such as three-dimensional modeling, selective laser-firing rapid forming, thermal de-greasing, vacuum sintering, and the like. The processing steps are simple, the period is short, the use ratio of materials is high, the cost is low, any complexly shaped porous titanium alloy implant body can be conveniently manufactured, and the method has efficiency and economic advantages in individual design and rapid manufacturing of the implant body. A titanium molybdenum alloy material prepared by using the method has the advantages that pore space is uniform, adjustment scopes of porosity, aperture ratio and aperture are wide, elasticity modulus and compression strength are in close proximity to natural bone, and the demand on biomechanical compatibility required by a biomedical material is met.

Owner:UNIV OF SCI & TECH BEIJING

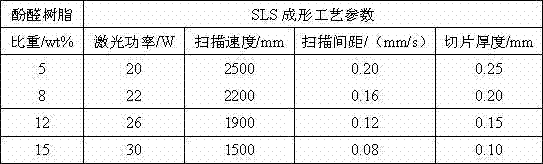

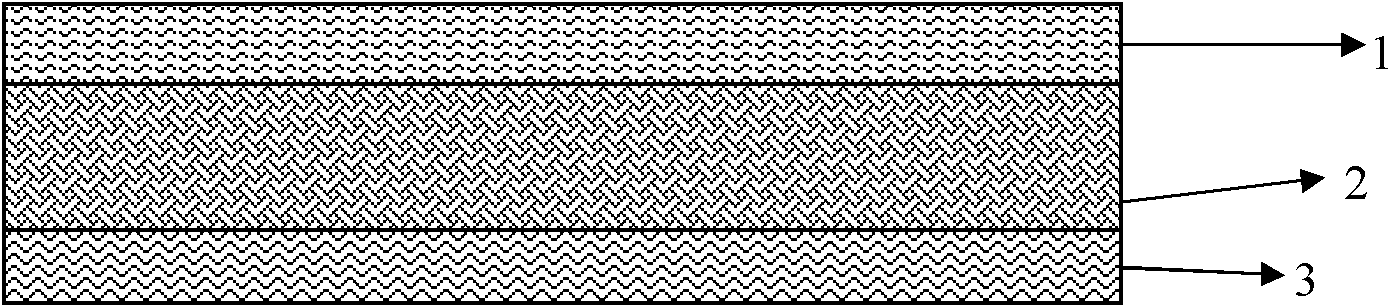

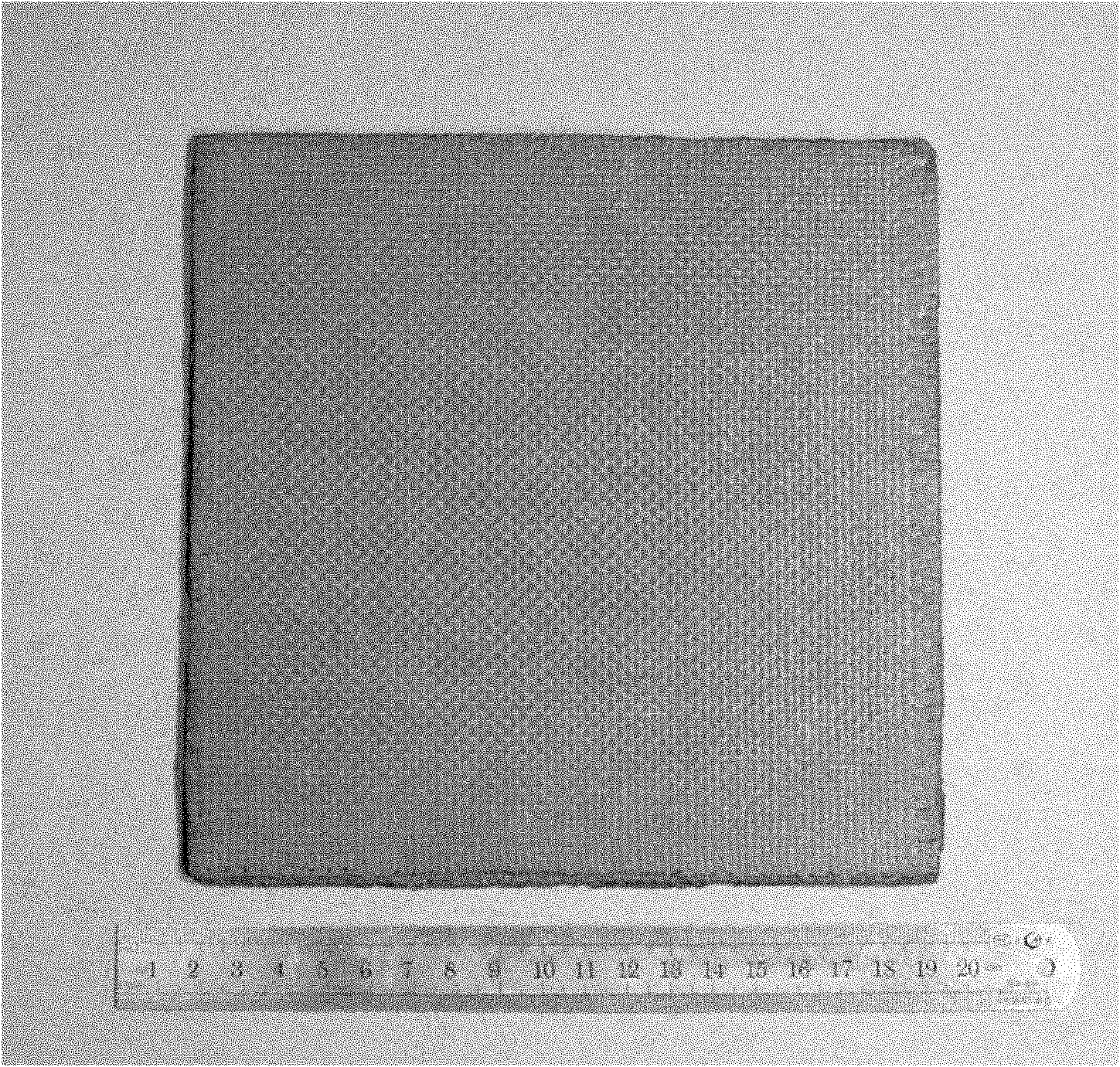

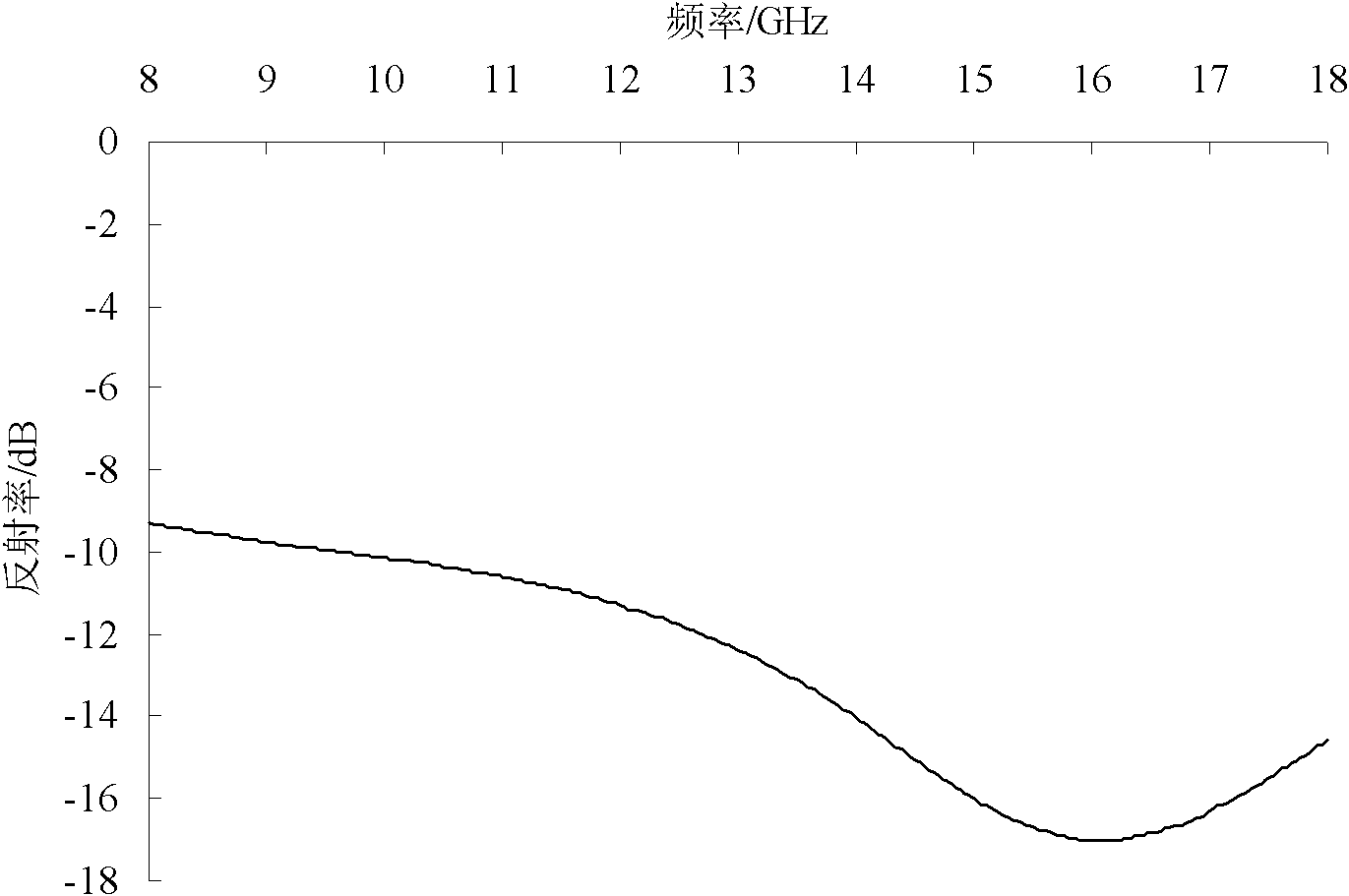

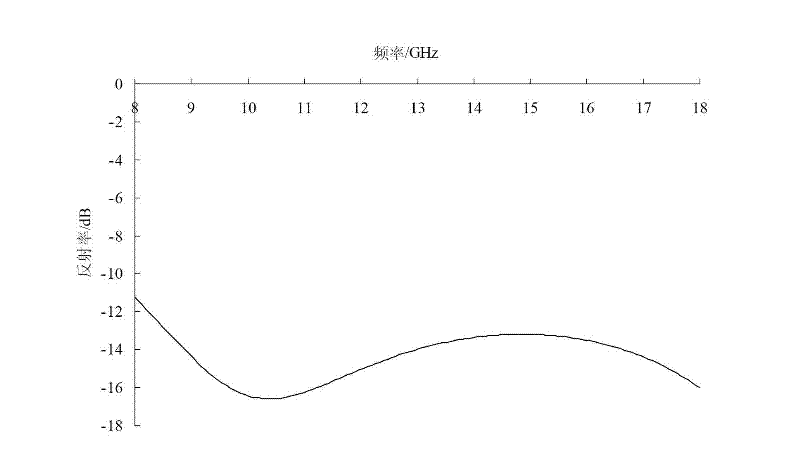

Wave-absorbing ceramic made of silicon carbide composite material and preparation method thereof

The invention discloses a wave-absorbing ceramic made of a silicon carbide composite material and a preparation method thereof. The wave-absorbing ceramic has a multifunctional superimposed structure comprising a matching layer, a consuming layer and a reflecting layer, wherein each functional layer is made of a continuous silicon carbide fiber reinforced silicon carbide-based composite material;and continuous silicon carbide fibers serving as a reinforced material of each functional layer have different resistivity. The preparation method for the wave-absorbing ceramic comprises the following steps of: selecting continuous silicon carbide fiber plain cloth; dipping and cracking the plain cloth of the consuming layer; mixing with polycarbosilane, divinylbenzene, dimethylbenzene and the like to prepare slurry; performing mould pressing, thermal crosslinking and cracking to prepare a wave-absorbing ceramic rough blank; and preparing the wave-absorbing ceramic made of the silicon carbide composite material by adopting a precursor dipping and cracking process. The wave-absorbing ceramic has wide absorption frequency band, high mechanical property and heatproof function.

Owner:NAT UNIV OF DEFENSE TECH

Preparation method of molding sand for gray iron casting

InactiveCN102366811AThe preparation process steps are simpleEasy to operateFoundry mouldsFoundry coresDrying timePollution

The invention discloses a preparation method of molding sand for gray iron casting, comprising the following three steps: preparing raw materials, preparing the molding sand, and mixing the molding sand. The preparation method has the advantages of simple process steps, easy operation, no use of coal dust, clean workshop, little pollution, and low cost and environmental protection by using straw powder, modified starch and other renewable raw materials. The prepared molding sand has small gas content, short drying time, good permeability and high baked tensile strength in casting, and can improve the releasability of the sand mold, further improving the fineness of casts.

Owner:辛培兴

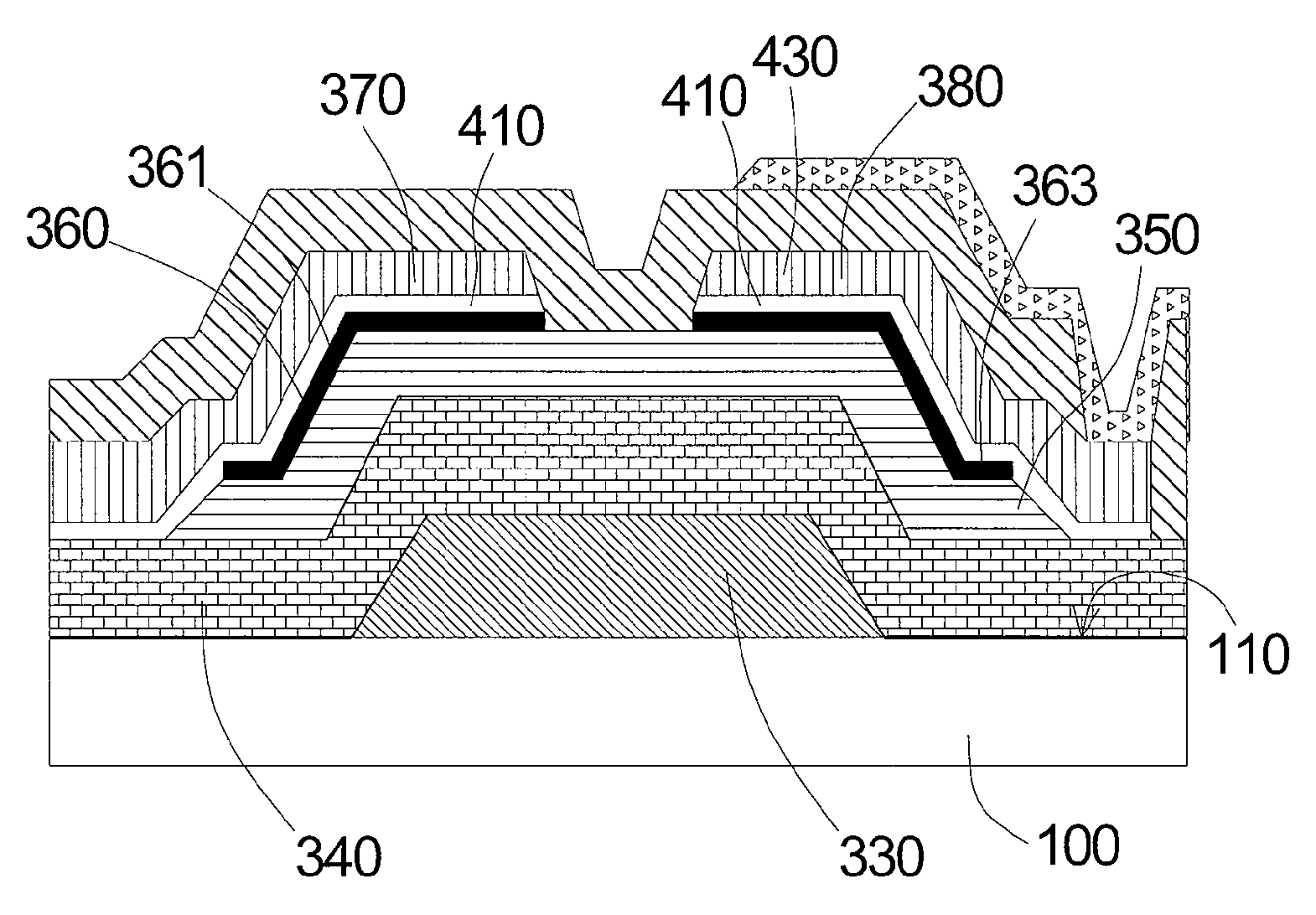

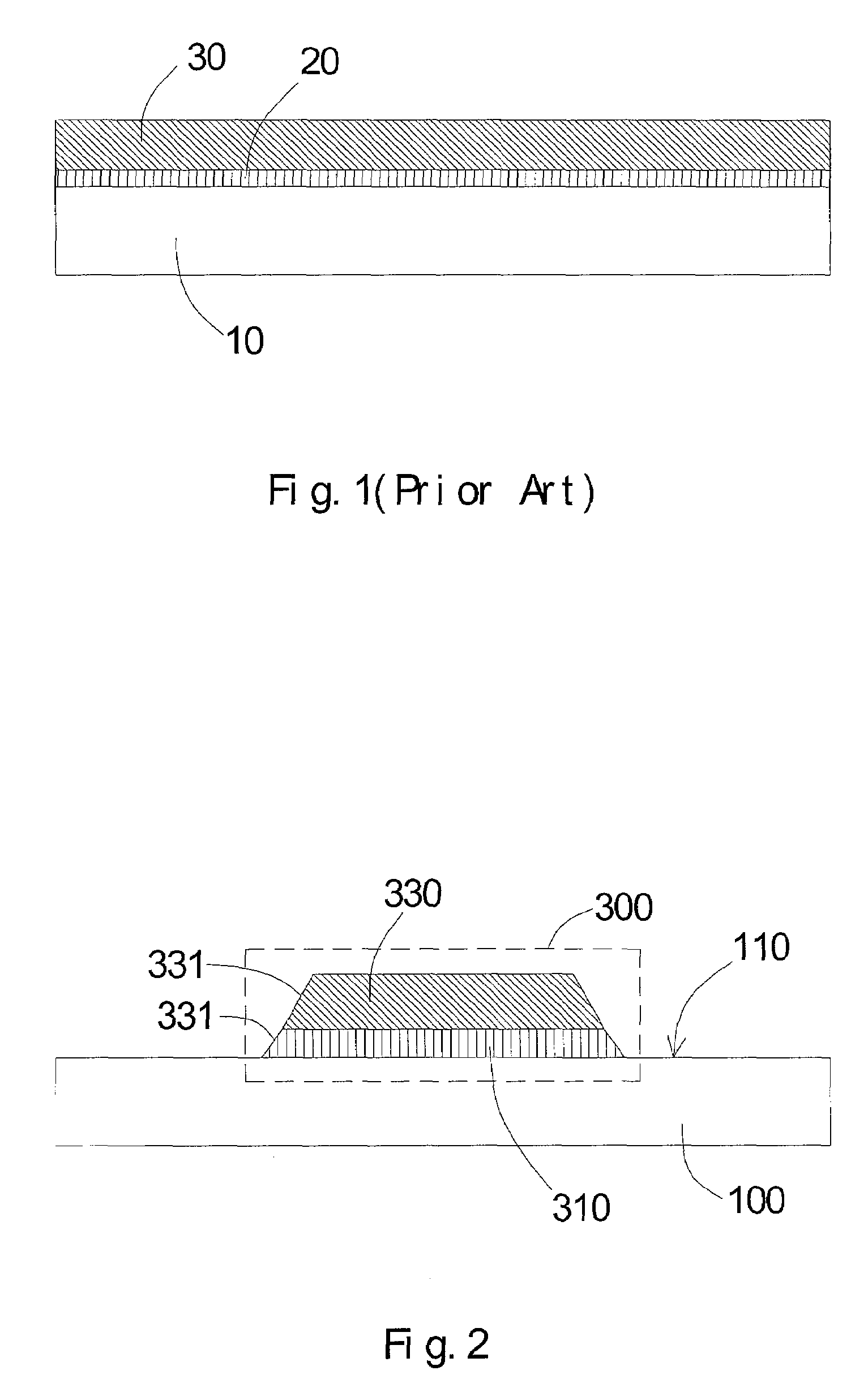

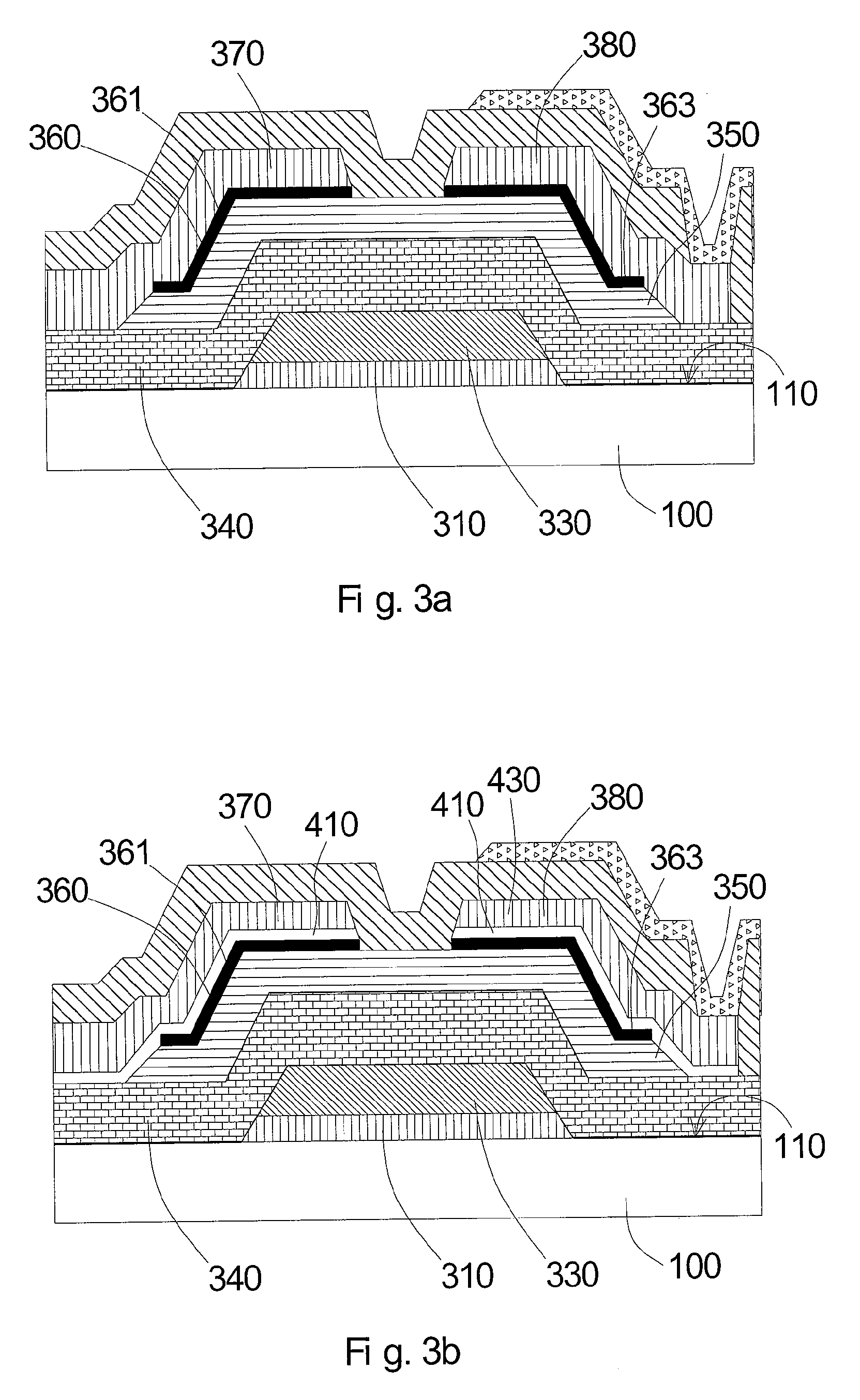

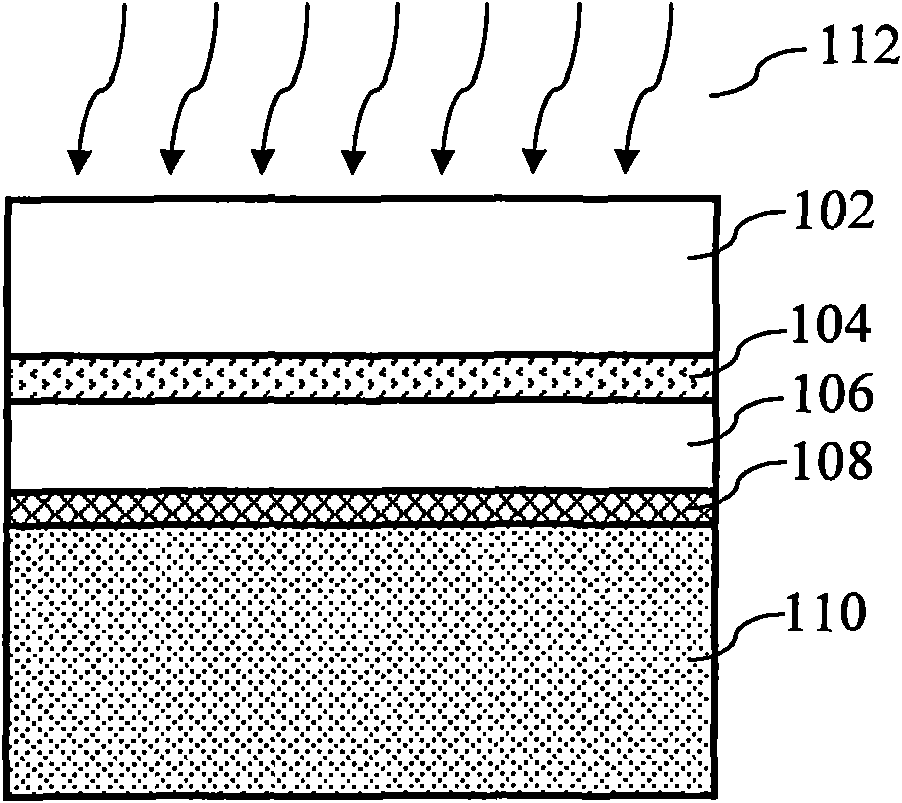

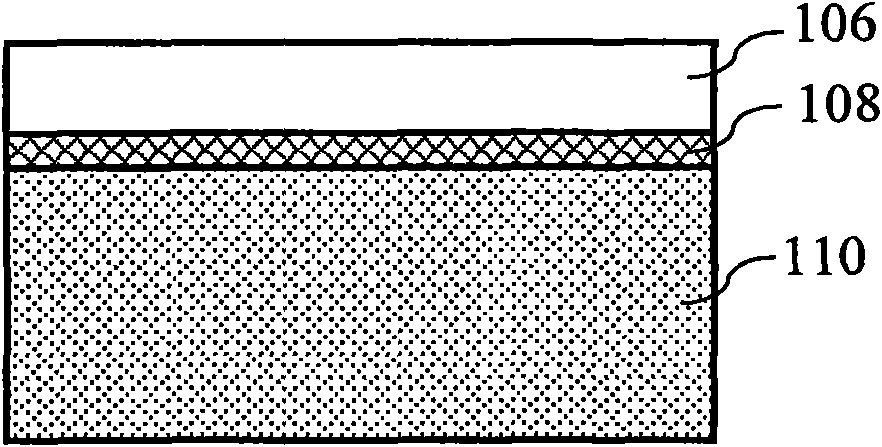

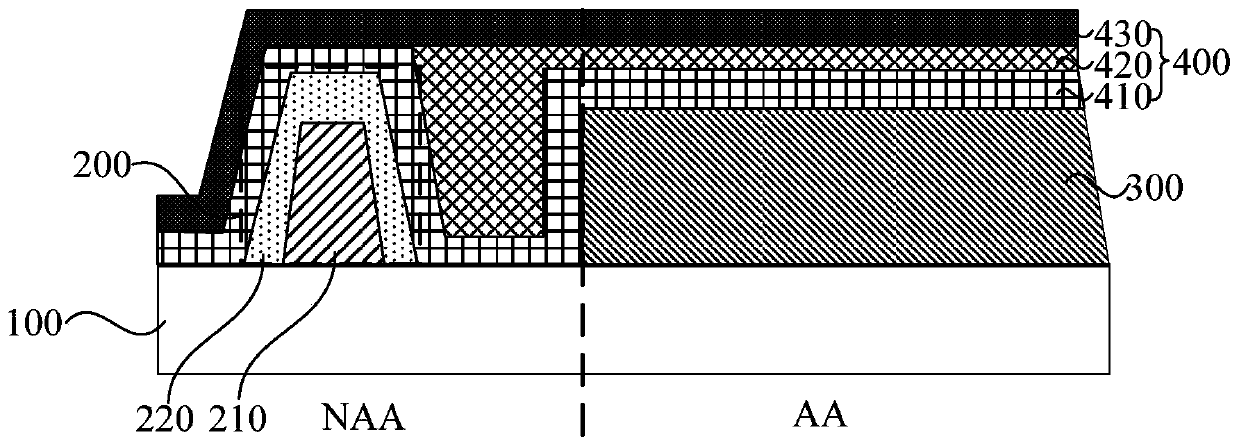

Display Panel Structure and Manufacture Method Thereof

ActiveUS20080009108A1The preparation process steps are simpleImprove adhesionSemiconductor/solid-state device detailsSolid-state devicesInterface layerEngineering

A display panel structure having a circuit element disposed thereon and method of manufacture are provided. The display panel includes a substrate and the circuit element disposed on the substrate. The circuit element has a first interface layer and a first conductive layer. Both the first interface layer and the first conductive layer have copper materials. The material which makes the first interface layer includes a reactant or a compound of the material which makes the first conductive layer. The method for manufacturing includes the following steps: forming a first interface layer on the substrate; forming a first conductive layer on the first interface layer; and etching the first conductive and interface layers to form a pattern. The existence of the first interface reduces the penetration of the first conductive layer on the substrate and improves the adhesive force between the first conductive layer and the substrate.

Owner:AU OPTRONICS CORP

Preparation technology of camomile tea

InactiveCN104621279AKeep bright colorsNatural color revealPre-extraction tea treatmentWork in processCitrus fruit

The invention discloses a preparation technology of camomile tea. The preparation technology comprises the following steps: a manually or mechanically cleaning the surface of picked citrus fruit with clean water; b airing, naturally blowing or heating to 30 DEG C and drying; b uncapping, forming an open hole in the position of the bottom of the citrus fruit, and dividing the citrus fruit into two parts, namely a bottom cover and a fruit shell; d digging out pulp in the fruit shell; e filling tea, fully filling the fruit shell with the tea; f capping, closing the open hole in the bottom cover left while uncapping, pushing into the pulp with proper force to encircle the bottom cover with the edge of the open hole in the fruit shell; g drying, putting the capped semi-finished product into a drying oven, drying and controlling the temperature at 30-50 DEGC; and h packaging, namely packaging into goods and delivering. The camomile tea prepared by the preparation technology is vivid in color, full and mellow in appearance, and free of a visible damage, has the advantages of practicability and ornamental value.

Owner:邱建雄

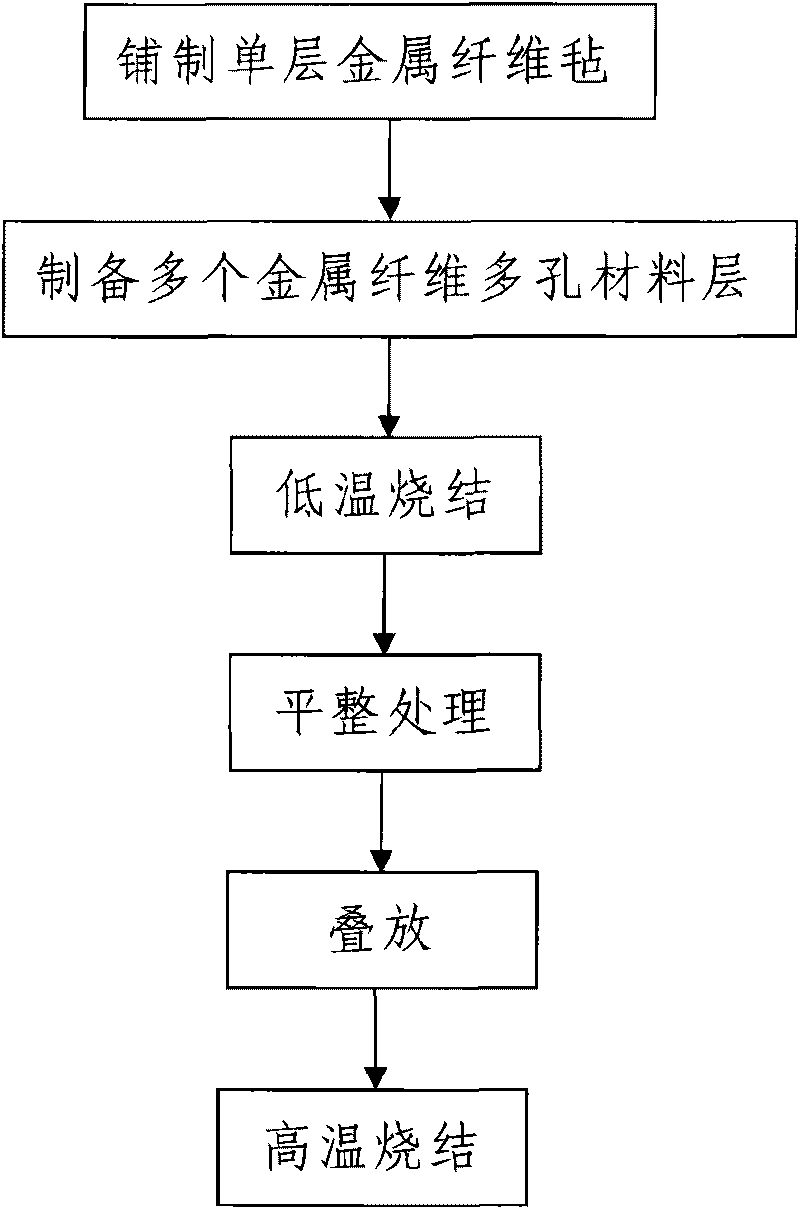

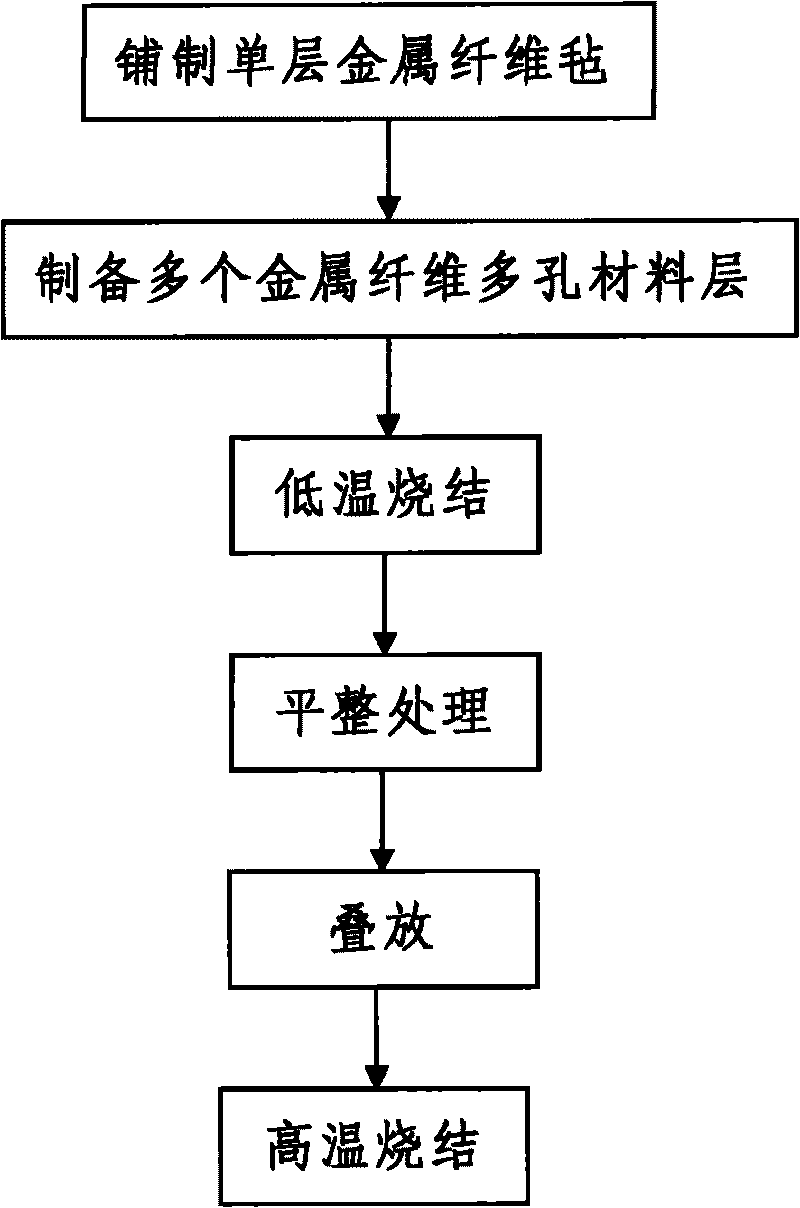

Metallic fiber gradient hole sound absorbing material and method for preparing same

InactiveCN101740022AImprove sound absorptionImprove bindingSound producing devicesPorosityNoise control

The invention discloses a metallic fiber gradient hole sound absorbing material and a method for preparing the same. The metallic fiber gradient hole sound absorbing material is formed by multi-layers of metallic fiber porous material layers which are piled, the multi-layers of metallic fiber porous material layers are sintered into a whole, and the pore sizes or porosities of the multi-layers of metallic fiber porous material layers are in gradient arrangement from top to bottom. The preparation method comprises the following steps of: 1, laying the single-layer metallic fiber felt; 2, preparing a plurality of metallic fiber porous material layers; 3, performing low-temperature sintering of the plurality of metallic fiber porous material layers by using a vacuum sintering furnace respectively; 4, performing flattening treatment; 5, piling; and 6, performing low-temperature sintering of the piled metallic fiber porous material layers by using the vacuum sintering furnace. The preparation process is simple and conveniently realized, the used equipment are all the common equipment, the investment cost is low, the operability is strong, the produced metallic fiber gradient hole sound absorbing material has excellent performance, particularly desirable full frequency sound absorbing performance, so that the metallic fiber gradient hole sound absorbing material can be widely used as the sound absorbing lining in the field of noise control.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

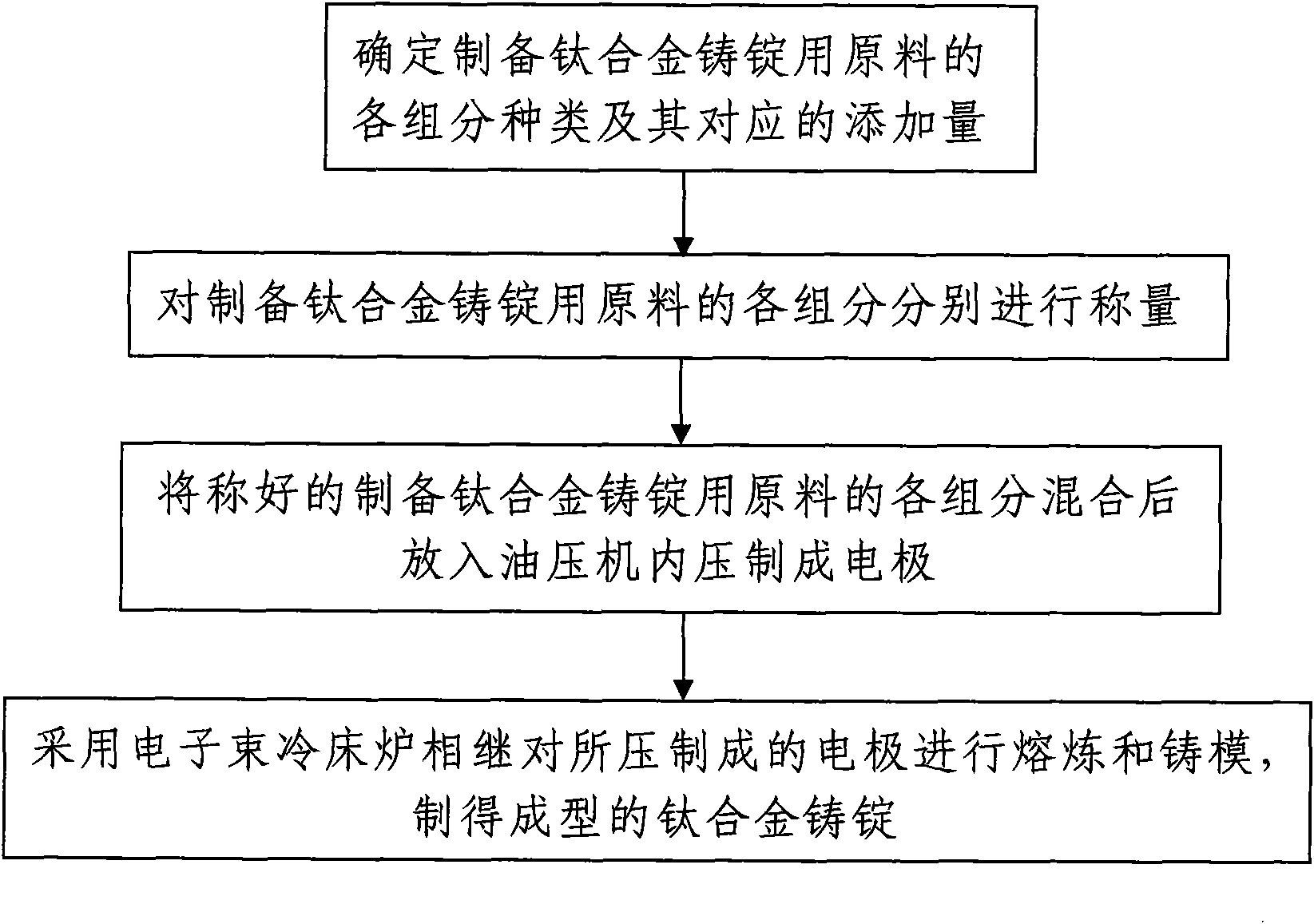

Method for preparing titanium alloy ingots through electron-beam cold bed furnaces by adopting conventional raw materials

The invention discloses a method for preparing titanium alloy ingots through electron-beam cold bed furnaces by adopting conventional raw materials. The method comprises the following steps: firstly, determining the species of every component of raw material for preparing the titanium alloy ingots, as well as corresponding addition amount thereof; secondly, weighing; thirdly, mixing the weighed components of the raw material for preparing the titanium alloy ingots, putting the mixture into an oil press and pressing the mixture to form electrodes; and fourthly, adopting an electron-beam cold bed furnace to melt and mold the pressed electrodes in succession and obtaining the molded titanium alloy ingots. The method has the advantages of simple process, convenient operation, good use effects and the capability of adopting simple-substance aluminum and master alloy of the aluminum and other conventional raw materials to successfully prepare the titanium alloy ingots. In addition, the prepared titanium alloy ingots have excellent performance and can effectively solve the defect and deficiency that the prior process for producing the titanium alloy ingots needs to use a large amount of return material.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Method for separating base plate and semiconductor layer

InactiveCN101866880ASimple manufacturing process stepsLow technical costSemiconductor/solid-state device manufacturingSemiconductor devicesEtchingSemiconductor components

The invention relates to a method for separating a base plate and a semiconductor layer. The method is characterized in that a pattern silicon dioxide layer is formed between a temporary base plate and the semiconductor layer; then, the temporary base plate is separated from the pattern silicon dioxide layer by a secondary wet type etching way. The temporary base plate is removed by using the secondary wet type etching way, thereby avoiding damaging the structure of the semiconductor layer by using a the laser lift off (LLO) method. In addition, by utilizing the secondary wet type etching method, the manufacture process step is simpler, and the technical cost is decreased. On a vertical semiconductor element, the light emitting benefit of the element is increased due to the irregular surface formed by a manufacture process. In addition, by utilizing the wet type etching in the manufacture process, the batch amplification can be increased, and the cost of the manufacture process is decreased.

Owner:ZHANJING TECH SHENZHEN +1

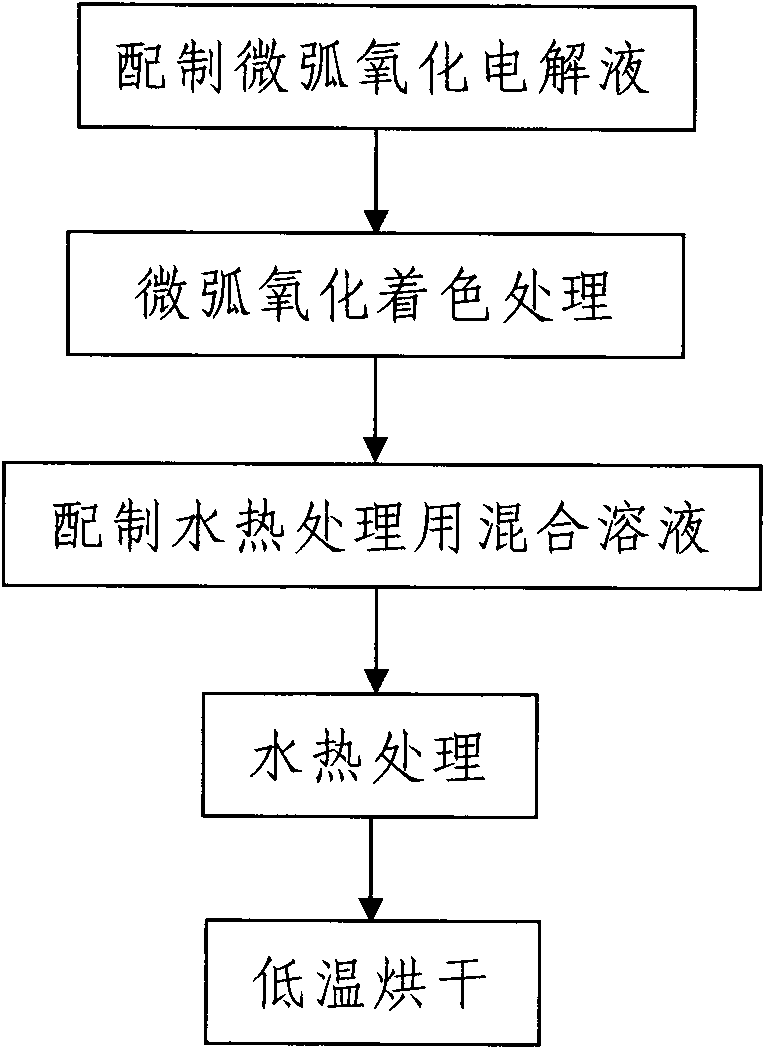

Preparation method of titanium and titanium alloy surface black protective film for surgical implantation

ActiveCN101660190AThe preparation process steps are simpleEasy to operateSurface reaction electrolytic coatingProsthesisTectorial membranePlasma electrolytic oxidation

The invention discloses a preparation method of a titanium and titanium alloy surface black protective film for surgical implantation, comprising the following steps: step 1: carrying out micro-arc oxidation coloring processing on titanium and titanium alloy surface to be processed, in the process, firstly, preparing a micro-arc oxidation electrolysing solution, and then carrying out the micro-arcoxidation coloring processing; and step 2: carrying out subsequent processing on the micro-arc oxidation film, wherein the subsequent processing comprises the following steps: firstly, preparing a mixed solution for hydro-thermal processing, completely dipping the titanium and titanium alloy after micro-arc oxidation shading processing in the mixed solution, carrying out the hydro-thermal processing on the surface by adopting a hydro-thermal method, drying the titanium and titanium alloy under the condition of low temperature when the hydro-thermal processing is completed, and generating a layer of pure black micro-arc oxidation film with uniform and plump surface on the titanium and titanium alloy surface. The invention has simple and convenient operation, economy, high production efficiency, and high bonding strength between a generated ceramic film, i.e. the micro-arc oxidation film and a substrate, and the invention can effectively overcome various defects and deficiencies which exist in the prior coating processing techniques.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

EPT rubber waterproofing paint and process for preparing the same

InactiveCN101113262AImprove waterproof performanceImprove anti-agingReclaimed rubber coatingsAntifouling/underwater paintsVertical planePolymer science

The invention relates to an epdm rubber waterproof coating and a preparation method thereof. The total weight portions of dry raw material component of the waterproof coating are: epdm rubber 5-7, chlorinated polyethylene 10-15, reclaimed rubber 20-25, coumarone resin 2-3, naphthenic oil 5-10, carbon black 5-8, zinc oxide 0.5-0.7, stearic acid 0.1-0.3, sulfur 0.4-0.6, accelerator 0.5-0.9 and antioxidant 1-3. The waterproof coating adopts epdm rubber, reclaimed rubber and chlorinated polyethylene as film forming main bodies and also various modified promoter and fillings, which results in that the waterproof coating not only has excellent waterproof, ageing and cold resistance, but also has the advantages of convenient construction and low cost, and the components and construction thereof meet the requirements of national environmental standards. The invention has simple preparation process steps, is convenient to be widely industrially produced, and the store property and life service of the waterproof coating obtained is greatly prolonged. The waterproof coating can be widely applied to the waterproof construction in building, engineering, vertical plane and various waterproof datum planes.

Owner:北京立高科技股份有限公司

Antibacterial ceramic tile and preparation method thereof

ActiveCN110698227AGood antibacterial effectImprove bindingClaywaresAnti bacterialAntibacterial agent

The invention discloses an antibacterial ceramic tile. The antibacterial ceramic tile comprises an antibacterial glaze layer arranged on the upper surface of a ceramic tile; the antibacterial glaze layer is composed of a basic transparent glaze and a zirconium phosphate loaded composite antibacterial agent; the zirconium phosphate loaded composite antibacterial agent comprises a zirconium phosphate carrier and a composite antibacterial agent; the zirconium phosphate loaded composite antibacterial agent is accumulated at the upper part of the antibacterial glaze layer, and antibacterial effective components of the composite antibacterial agent are antibacterial oxides and antibacterial ions. According to a preparation method, zirconium phosphate is introduced into the antibacterial glaze layer on the surface of the ceramic tile; by utilizing the characteristic of low density of zirconium phosphate, zirconium phosphate is accumulated at the upper part of the glaze layer after being sintered at a high temperature to form a surface with a porous structure, so that the zirconium phosphate is used as a carrier to which the composite antibacterial agent is attached, the binding force of antibacterial materials and the ceramic tile is enhanced, the ceramic tile is endowed with long-acting and excellent antibacterial performance, and meanwhile, the surface appearance decoration effect of the ceramic tile is not influenced. The invention further discloses a preparation process of the antibacterial ceramic tile, and the preparation process is simple in step, high in controllability and beneficial to large-scale industrial production.

Owner:FOSHAN OCEANO CERAMICS

Traditional Chinese medicine composite and premixed feed capable of increasing production performance of livestock and poultry

InactiveCN101700332APromote absorptionReduce negative impactFood processingAnimal feeding stuffSide effectFodder

The invention relates to a traditional Chinese medicine composite capable of increasing production performance of livestock and poultry. The traditional Chinese medicine composite comprises the following components by weight percent: 3-40% of astragalus root, 5-10% of atractylodes macrocephala, 3-20% of radix sileris, 3-20% of golden cypress, 5-10% of atraotydin, 1-5% of agastache, 5-8% of root of hairy asiabell, 5-50% of spina date seed, 3-10% of hawthorn, 5-10% of dried orange peel and 5-10% of areca seed. The preparation process of the traditional Chinese medicine composite has simple steps, effectively reduces the stress response of livestock and poultry and increases the immunity of the organism and has no toxic and side effects and drug residue, the use is convenient, the composite is easy to absorb, and the safety is high, thus the traditional Chinese medicine composite and the premixed feed of the invention is a high effective traditional Chinese medicine composite and premixed feed capable of increasing production performance of livestock and poultry.

Owner:TIANJIN ZHONGAO BIOTECH

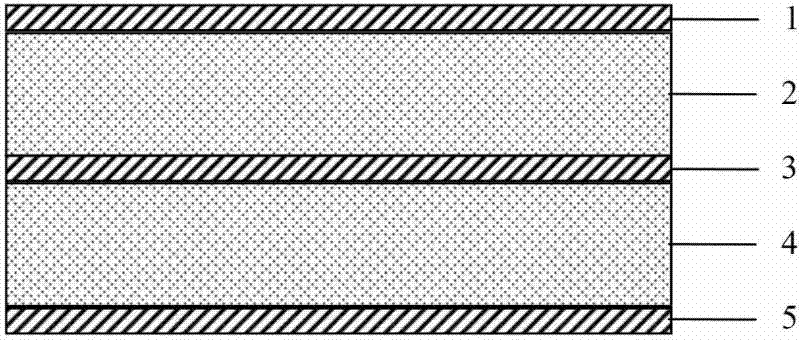

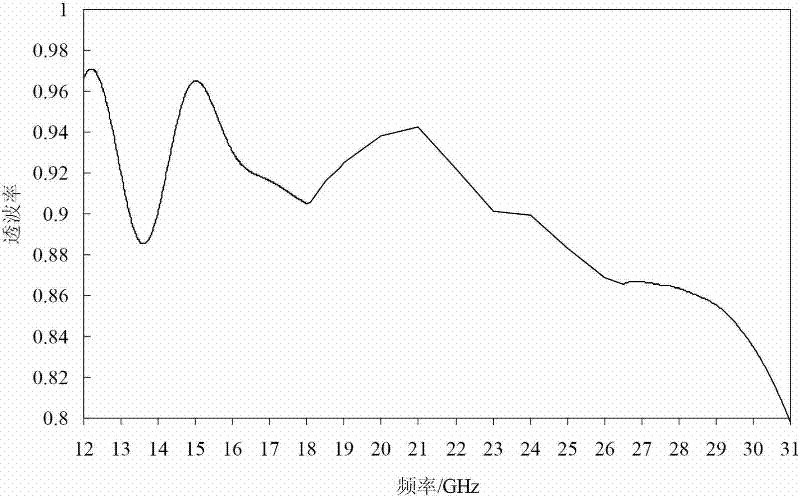

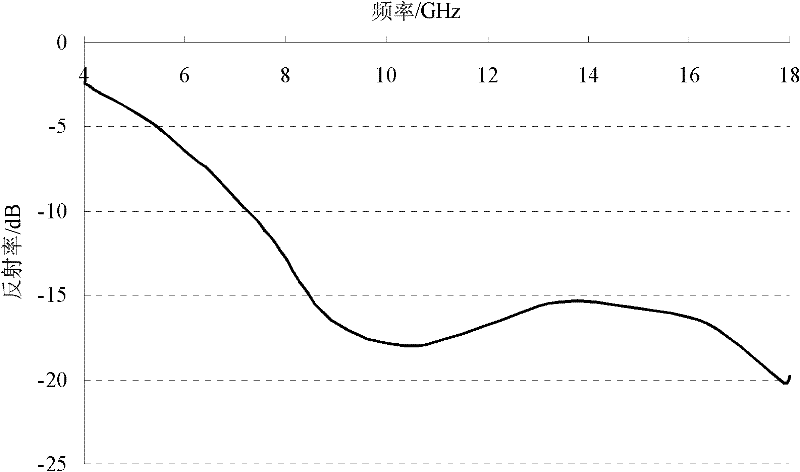

Wave-transmitting material with broadband resin matrix interlayer structure and preparation method of wave-transmitting material

ActiveCN102303441AImprove toughnessHigh strengthSynthetic resin layered productsPolymer scienceResin matrix

The invention discloses a wave-transmitting material with a broadband resin matrix interlayer structure and a preparation method of the wave-transmitting material. The wave-transmitting material comprises an outer skin layer, a first foam sandwich layer, a middle skin layer, a second foam sandwich layer and an inner skin layer which are sequentially overlapped and tightly combined, wherein the outer skin layer, the middle skin layer and the inner skin layer are made of continuous quartz fibre reinforced resin-base composite materials; the first foam sandwich layer and the second foam sandwich layer are made of polyurethane foams, the outer skin layer, the middle skin layer and the inner skin layer have dielectric constants of 3.1-3.2 and loss angle tangent values of 0.009-0.01; and the first foam sandwich layer and the second foam sandwich layer have dielectric constants of 1.10-1.15 and loss angle tangent values of 0.005-0.006. The preparation method comprises the steps of: preparing reinforced materials, and laying the reinforced materials according to the layering order and the thickness of each layer, pre-forming and curing to obtain the wave-transmitting material. The wave-transmitting material has the advantages of simple structure and high cost performance.

Owner:NAT UNIV OF DEFENSE TECH

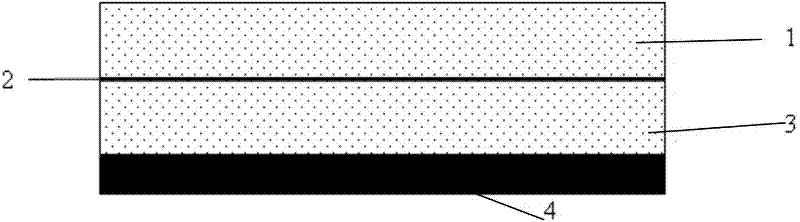

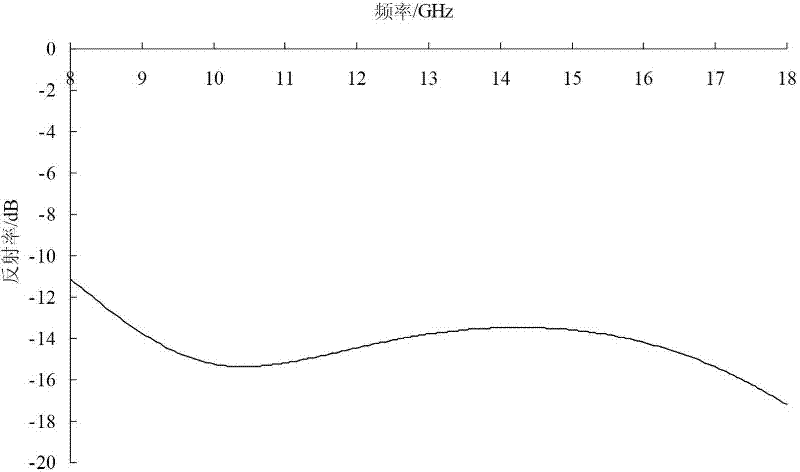

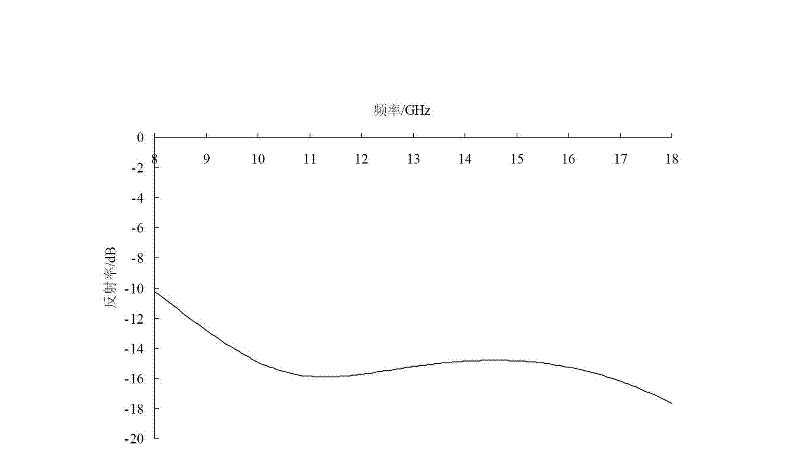

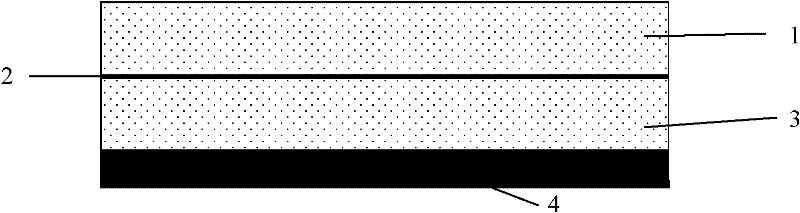

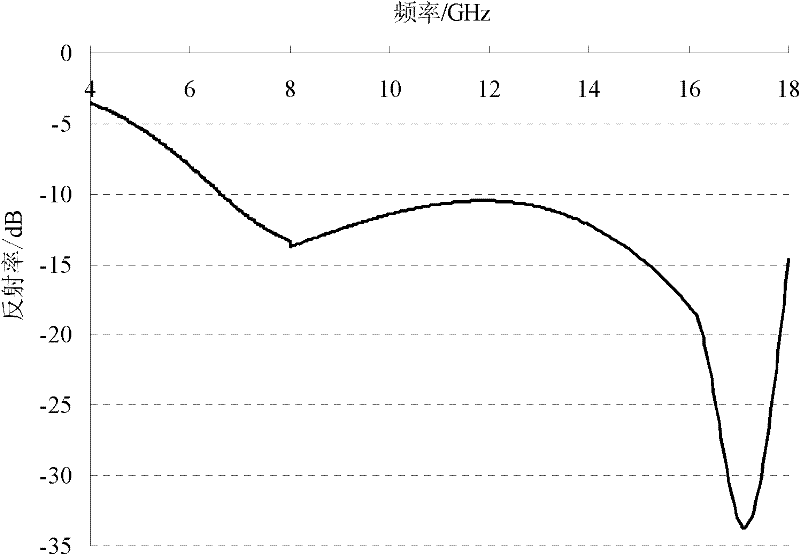

Wave-absorbing material for assorted fibre reinforced resin base sandwich structure and preparation method thereof

ActiveCN102218867AImprove toughnessHigh strengthSynthetic resin layered productsCarbon fibersResin-Based Composite

The invention discloses a wave-absorbing material for an assorted fibre reinforced resin base sandwich structure and a preparation method thereof. The wave-absorbing material has a multi-functional layer laminated structure. The structure comprises a first medium layer, an absorbing layer, a second medium layer and a reflection layer in sequence from the outside to the inside; the first medium layer consists of a basalt fibre reinforced resin base composite material; the absorbing layer consists of a continuous silicon carbide fibre reinforced resin base composite material; the second medium layer consists of a basalt fibre reinforced resin base composite material; and the reflection layer consists of a carbon fibre reinforced resin base composite material. The preparation method for the wave-absorbing material comprises the steps as follows: various fibres satisfying each functional layer are selected firstly; and then the resin is used as a basal body and the wave-absorbing materialis manufactured by adopting a resin base composite material forming technique according to the laminated sequence and thickness of each functional layer. The wave-absorbing material has the advantages of simple structure, good parameter tolerance level, easy forming, excellent wave-absorbing functions, low material cost, etc.

Owner:NAT UNIV OF DEFENSE TECH

Process method for baking angilica keiskei koidzumi

ActiveCN103719305AGuaranteed nutrition and health careReduce lossesPre-extraction tea treatmentVitamin CTwo step

The invention relates to the field of tea preparation and particularly relates to a process method for baking angilica keiskei koidzumi. According to the process method, an angilica keiskei koidzumi baking technical method, comprising the steps of baking at low temperature, adding jasmine flowers and producing fragrance at high temperature, is established, the steps of a preparation process are simple, the loss of chalcone and vitamin C in angilica keiskei koidzumi during preparation is reduced, and the content of chalcone and vitamin C is obviously higher than that of tea products which are prepared by only frying leaves under conventional process conditions, so that the nutritional healthcare effects of angilica keiskei koidzumi are guaranteed; according to the prepared angilica keiskei koidzumi product, baking and frying processes are replaced with low-temperature baking, so that the tea is uniform in heated degree and good in sensory character, and the problem of charring due to excessive baking and frying is effectively solved; due to the two steps of adding jasmine flowers and producing fragrance at high temperature, the fragrance of angilica keiskei koidzumi is guaranteed.

Owner:青岛海隆达生物科技有限公司

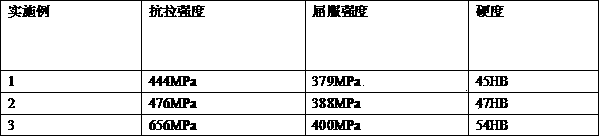

Boron nitride reinforced multi-element heat-resistant magnesium alloy and preparation method thereof

The invention provides a boron nitride reinforced multi-element heat-resistant magnesium alloy which comprises the following components in percentage by weight: 0.5-0.7% of Gd, 3.35-3.6% of Al, 1.7-1.95% of Zn, 4.0-5.0% of Si, 0.9-1.0% of Ca, 1.0-1.1% of Sr, 0.8-1.0% of Nd, 0.1-0.3% of Zr, 1-2% of Sn, 0.15-0.20% of Be, 0.7-1.0% of Mn, 0.1-0.15% of Sb, 0.5-0.8% of Cu, 1-15% of boron nitride nanotube particles and the balance of Mg, wherein the size of the boron nitride nanotube particles is below 100 microns. The invention also provides a preparation method of the alloy. The alloy has good mechanical property.

Owner:宏辉磁电科技(安徽)有限公司

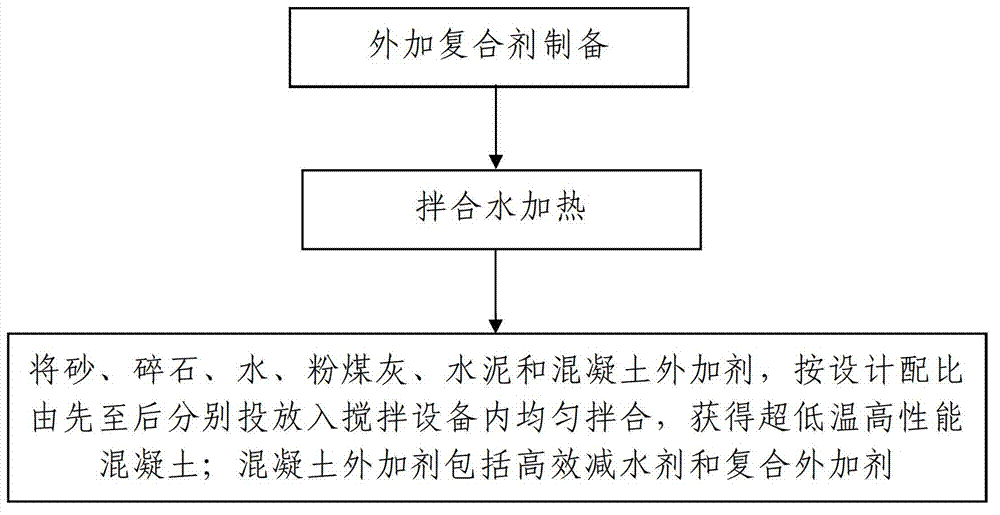

Ultralow-temperature high-performance concrete for railway construction in severe cold regions and preparation technique thereof

ActiveCN102815901AThe preparation process steps are simpleEasy to operateHigh performance concreteCalcium nitrite

The invention discloses an ultralow-temperature high-performance concrete for railway construction in severe cold regions and a preparation technique thereof. The concrete is prepared by evenly mixing cementing material, sand, gravel, high-efficiency water reducing agent, composite antifreezing agent and water, wherein the cementing material is prepared by evenly mixing cement and mineral admixture in a weight ratio of (15-20):(85-80); the water reducing rate of the high-efficiency water reducing agent is not less than 25%; the composite antifreezing agent comprises 30-35 wt% of nitrate, 30-33 wt% of organic compound, 0.5-1 wt% of calcium formate and the balance of water; the nitrate is calcium nitrate or calcium nitrite; and the organic compound is methanol or ethanol. The preparation technique comprises the following steps: 1. preparing the composite antifreezing agent; and 2. evenly mixing to obtain the ultralow-temperature high-performance concrete. The preparation technique disclosed by the invention is simple to operate and has the advantages of simple steps and favorable use effect; and the workability of concrete, and the mechanical properties and endurability after curingcan satisfy the design requirements.

Owner:CHINA RAILWAY 20 BUREAU GRP

High impact resistant mobile phone glass cover-plate and manufacturing technology thereof

InactiveCN106183501AGood printing effectGood curing effectCoatingsGlass tempering apparatusBrightness perceptionMobile phone

The invention relates to the technical field of a mobile phone glass cover-plate, in particular to a high impact resistant mobile phone glass cover-plate and manufacturing technology thereof. The manufacturing technology comprises the following steps of (1) cutting; (2) fine machining; (3) grinding, that is, conducting sanding treatment on the surface of a fine machined plate glass; (4) reinforcing; (5) plane grinding; (6) the first time of cleaning; (7) silk printing, specifically, silk printing comprises the following steps of the first time of mirror-like silver printing, the second time of black printing, the third time of gold printing, the fourth time of gold printing, the fifth time of bluish violet printing, the sixth time of black printing, the seventh time of white printing, and the eighth time of gloss oil printing; and (8) the second time of cleaning, that is, the glass cover-plate is cleaned neatly after being subjected to the silk printing treatment, and then the high impact resistant mobile phone glass cover-plate is obtained. The obtained high impact resistant mobile phone glass cover-plate has the advantages that impact resistance is good; abrasive resistance is high; brightness is good; color stability is high; the effect of environment protection is achieved; and water resistant performance, acid and alkali resistant performance and ageing resistant performance are better.

Owner:DONGGUAN JINGBO PHOTOELECTRIC BIT CO

Hybrid fiber reinforced resin matrix sandwich structural absorbing material and its preparation method

ActiveCN102229267AImprove toughnessHigh strengthSynthetic resin layered productsGlass/slag layered productsGlass fiberCarbide silicon

The invention discloses a hybrid fiber reinforced resin matrix sandwich structural absorbing material and its preparation method. The absorbing material has a multifunctional laminated structure from the outside to the inside comprising a first dielectric layer, an absorbed layer, a second dielectric layer and a reflecting layer, wherein the first dielectric layer and the second dielectric layer are both composed of a glass fiber reinforced resin matrix composite material; the absorbed layer is composed of a continuous silicon carbide fiber reinforced resin matrix composite material; and the reflecting layer is composed of a carbon fiber reinforced resin matrix composite material. The preparation method of the absorbing material comprises the following steps of: firstly, each kind of fiber that satisfies each functional layer is selected; secondly, with the resin as the matrix, according to the laminated order and thickness of each functional layer, the absorbing material provided by the invention is prepared by the resin matrix composite material molding technology. The absorbing material provided by the invention has advantages of simple structure, good parameter tolerance, excellent wave absorbing function and low material cost, and furthermore is easy to mold.

Owner:NAT UNIV OF DEFENSE TECH

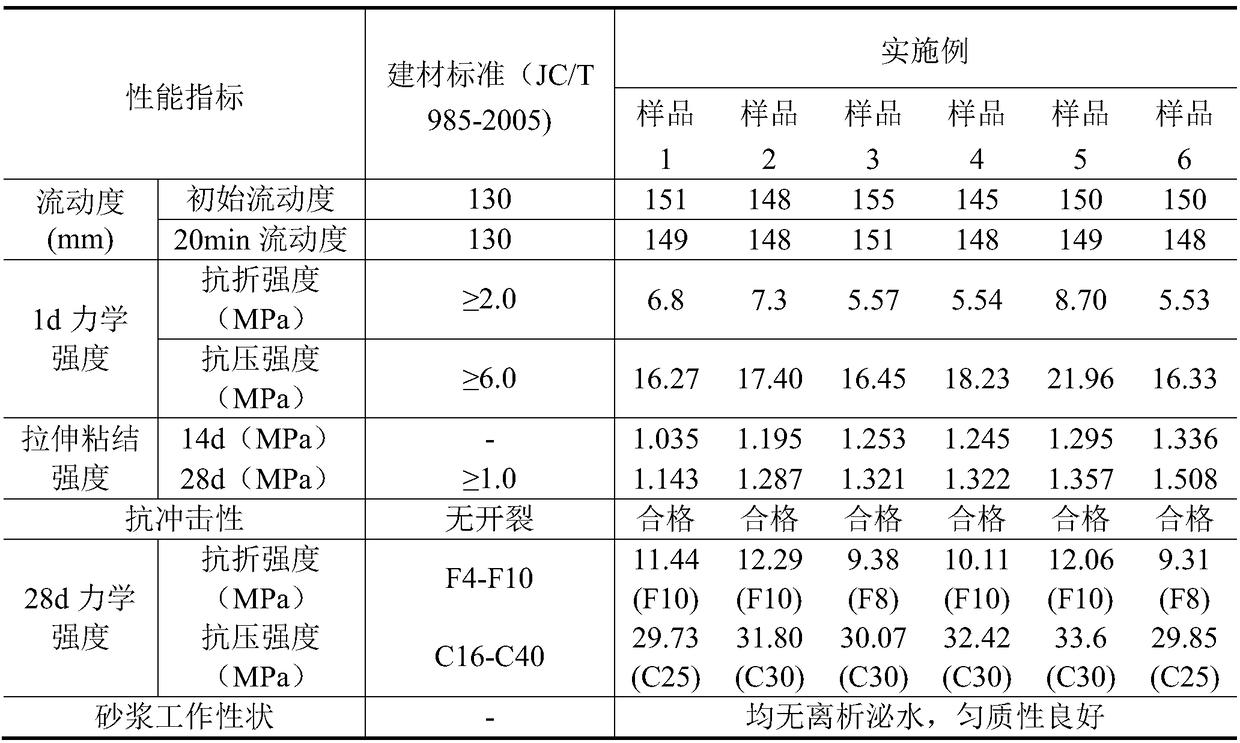

Sulfoaluminate cement-based self-leveling mortar and preparation method thereof

InactiveCN108706937ALow lime-sand ratioImprove the phenomenon of segregation bleedingPortland cementCompressive strength

The invention provides sulfoaluminate cement-based self-leveling mortar and a preparation method thereof. a dry material for preparing the sulfoaluminate cement-based self-leveling mortar is preparedfrom the following raw materials in parts by weight: 10 to 20 parts of ordinary Portland cement, 15 to 25 parts of sulfoaluminate cement, 4 to 8 parts of natural gypsum, 35 to 50 parts of fine aggregate natural river sand, 10 to 25 parts of filler heavy calcium carbonate powder, 0.20 to 0.40 part of water reducing agent, 0.10 to 0.20 part of retarder, 0.05 to 0.02 part of early strength agent, 0.40 to 0.80 part of latex powder and 0.01 to 0.04 part of thickening agent. The sulfoaluminate cement-based self-leveling mortar provided by the invention has good working and mechanical properties suchas low cement-sand ratio, high early strength, high uniformity and high flowability, the cost is low, the preparation technology is simple, and one-day compressive strength is 16.0MPa or above.

Owner:WUHAN UNIV OF TECH

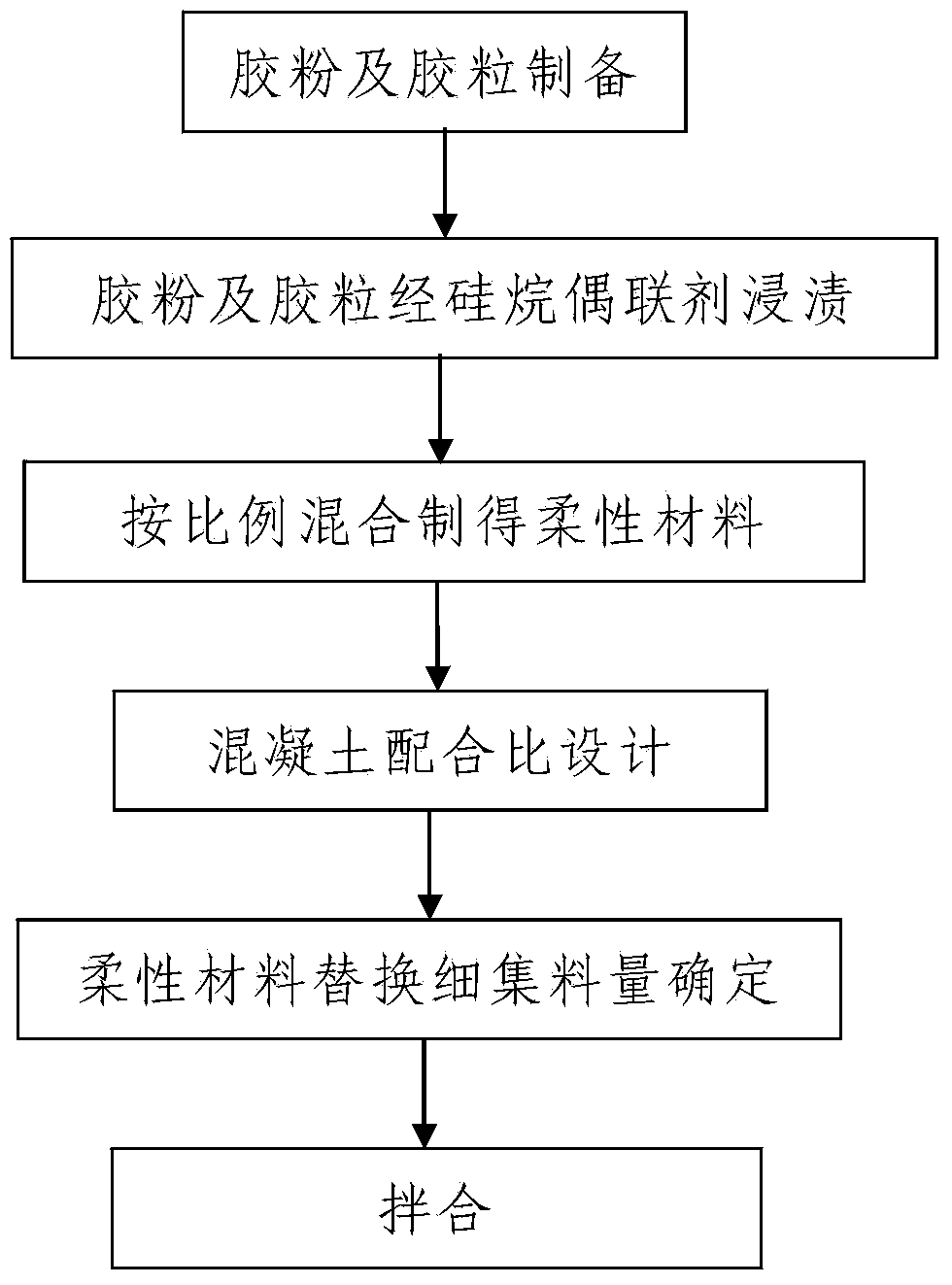

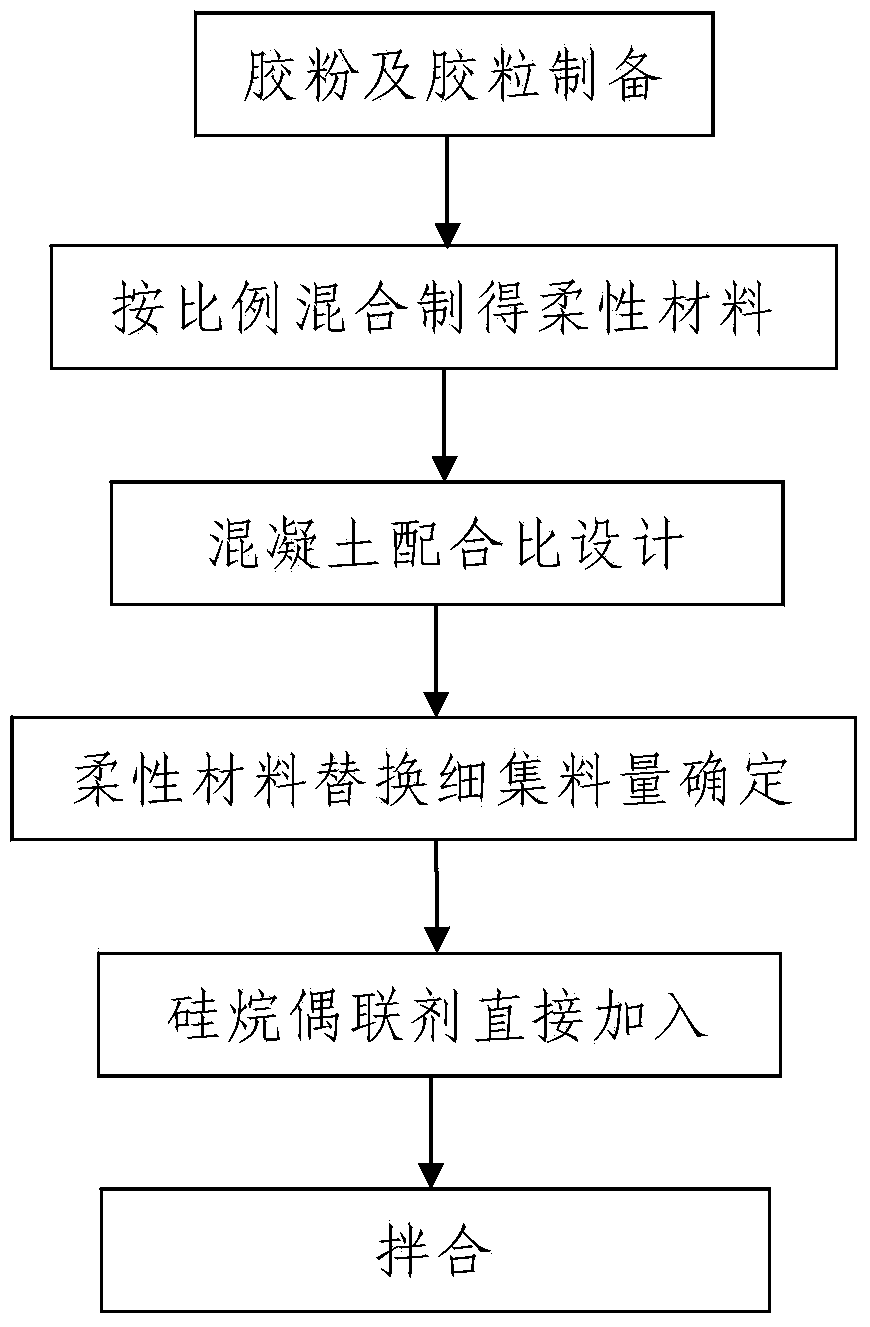

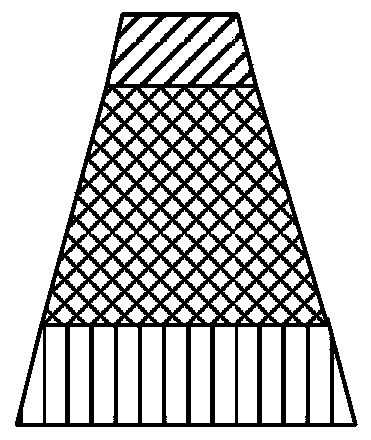

Semi-rigid concrete and preparation process thereof

ActiveCN103641417AThe preparation process steps are simpleEasy to operateSolid waste managementPolymer scienceFly ash

The invention discloses semi-rigid concrete and a preparation process thereof. The semi-rigid concrete is concrete which is prepared through replacing part of fine aggregate of ordinary concrete with a flexible material and then blending, wherein the mass of the replaced fine aggregate is equal to that of the replacing flexible material; the flexible material contains the following ingredients in percentage by mass: 30-40% of rubber powder, 30-40% of rubber grains, 0.5-1.5% of polypropylene fibers, 3-8% of fly ash and 20-28% of mineral admixture; zinc stearate is required to be removed from the surfaces of the rubber grains and the surface of the rubber powder through a strong-base solution. The preparation process comprises the steps: (1) preparing the flexible material and carrying out grading combination in proportion; (2) preparing the semi-rigid concrete. According to the preparation process disclosed by the invention, the steps are simple, the operation is simple and convenient, the invested cost is low, the use effect is good, and the defects in the existing ordinary concrete that the deformation is little, the brittleness is high, the tensile strength is low, and the like can be made up.

Owner:THE FOURTH ENG CO LTD OF CHINA RAILWAYNO 20 BUREAU GRP

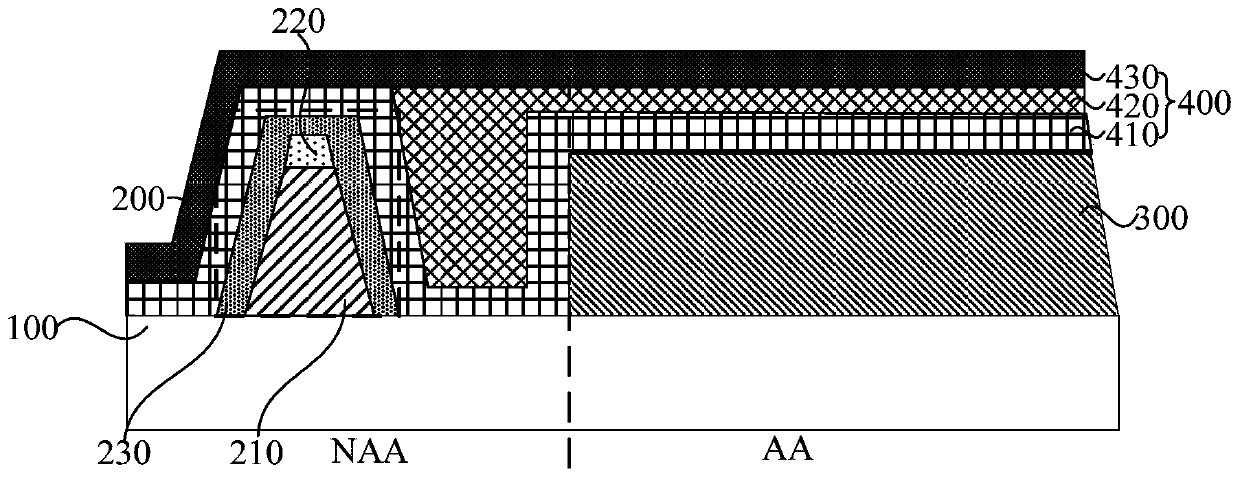

Display panel

ActiveCN109920937AExtended service lifePrevent intrusionSolid-state devicesSemiconductor/solid-state device manufacturingWater vaporEngineering

An embodiment of the invention discloses a display panel. The display panel comprises a substrate, at least one retaining wall, a light-emitting device and a packaging layer, wherein the substrate comprises a display area and a non-display area; the retaining wall is arranged on one side of the substrate, is positioned in the non-display area, and is arranged around the display area; the light-emitting device and the retaining wall are arranged on the same side of the substrate and are located in the display area; the packaging layer covers the retaining wall and the light-emitting device, wherein each retaining wall comprises at least two layers of blocking structures, wherein the blocking structure farthest from the packaging layer is coated by at least one of the other blocking structures, and then the invasion path of water oxygen between blocking structure film layers of the retaining wall is further prolonged, so that water vapor and oxygen are difficult to enter the display areaof the display panel between the barrier structure film layers of the retaining wall, the packaging effect of the display panel is improved, water vapor and oxygen are difficult to corrode the light-emitting device, and the service life of the display panel is prolonged.

Owner:YUNGU GUAN TECH CO LTD

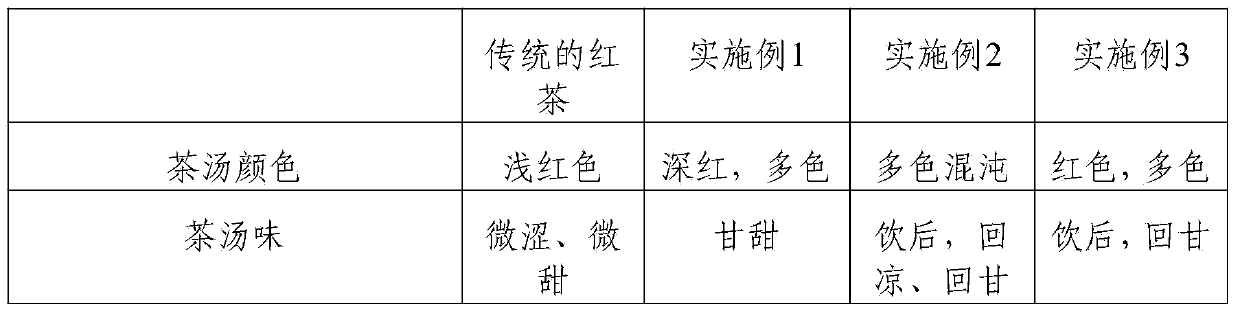

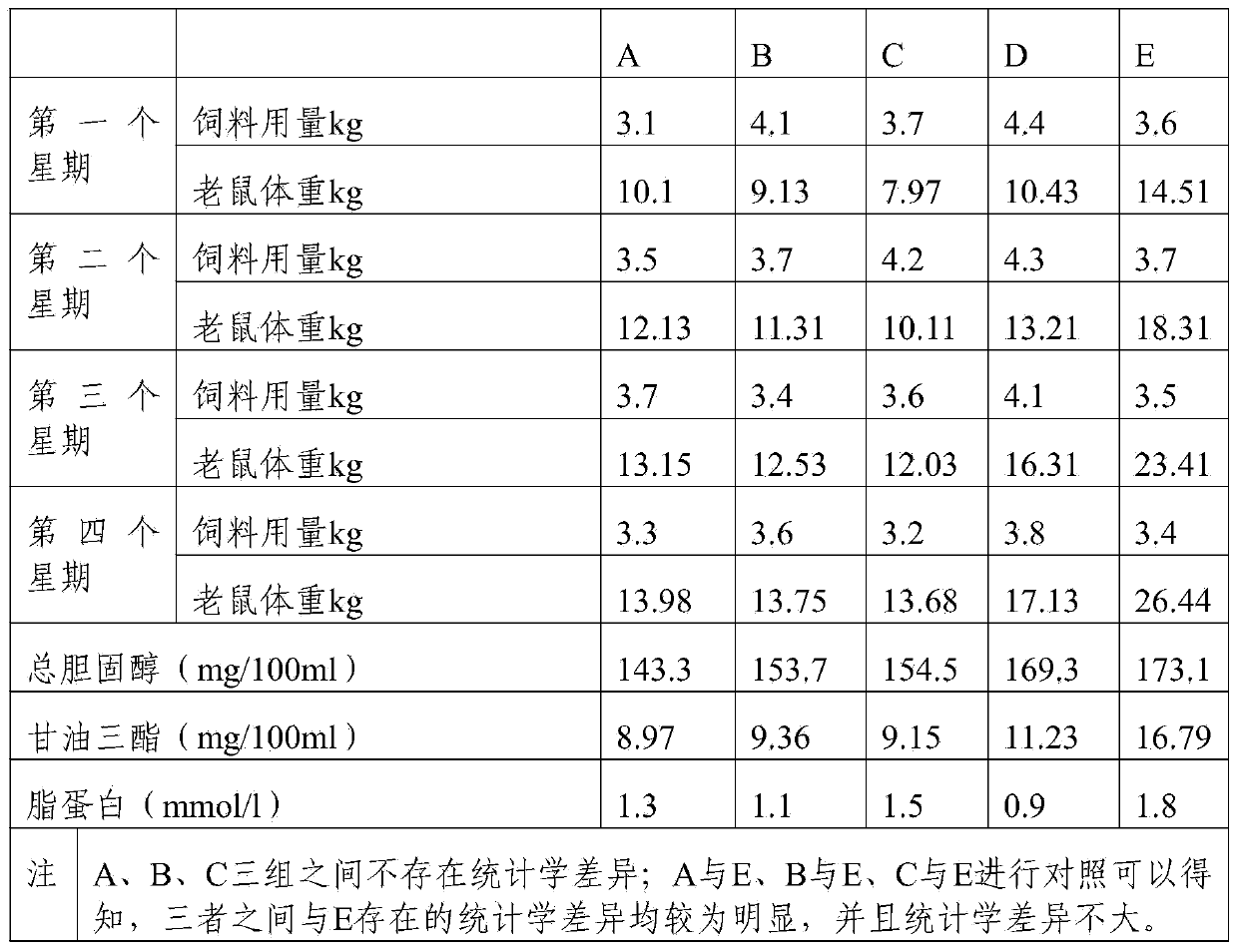

Black tea preparation method capable of improving content of tea polyphenol

ActiveCN104186742ALow costBroaden the range of offeringsPre-extraction tea treatmentHazardous substanceBlack tea

The invention relates to the technical field of black tea preparation, and particularly relates to a black tea preparation method capable of improving the content of tea polyphenol. By the steps of classifying, processing, mixing and twisting the tea leaves, carrying out fixation, twisting again, unbinding, fermenting, reshaping, carrying out fixation, drying, sterilizing and the like, nutritional components in the tea leaves are subjected to great microcosmic change, the nutrition structures in the tea leaves are enriched and relative high nutritional substance leaching rate is achieved; technological parameters are controlled properly, so that the nutrient elements in green tea leaves are controlled effectively, and harmful substances in the tea leaves are discharged out in the preparation process; useful substances, namely tea polyphenol and the like are converted and retained, the content of tea polyphenol and similar substances (condensed polyphenols) in prepared black tea is relatively high, and the health function of tea leaves is enhanced; according to testing, the content of polyphenols in the black tea is improved by 17-19% compared with that in the traditional black tea.

Owner:GUIZHOU FENGGANG XIANRENLING ZINC & SELENIUM ORGANIC TEA IND

Graphite base plate for LED (light emitting diode) high-power illumination module and manufacturing technology of graphite base plate

InactiveCN102692000AReduce weightImprove heat transfer performanceCarbon compoundsPoint-like light sourceInsulation layerManufacturing technology

The invention discloses a graphite base plate for an LED (light emitting diode) high-power illumination module and a manufacturing technology of the graphite base plate. The graphite base plate comprises a high heat-conduction graphite base layer, a heat-conduction insulation layer and a circuit layer. The heat-conduction graphite base layer is formed by the steps of sintering WT70 % of fine graphite powder, WT5 % of copper powder, WT5% of aluminium powder, WT14 % of silane coupling agent, WT6 % of titanate coupling agent under the condition of high temperature of 1000-1200 DEG C to obtain a graphite composite, and manufacturing the graphite composite into a high heat-conduction graphite sheet-shaped base material by graphite coiled material production equipment. The heat-conduction insulation layer is made from a ceramic-filled polymer. The circuit layer is manufactured by a copper foil with thickness being 35-280 Mu m through a PCB (printed circuit board) technology. The main component of the graphite base plate is carbon material which is easy and convenient to obtain, and therefore the graphite base plate is low in cost and has strong resistance to corrosion, acid and alkali, oxidation and aging; and the waste does not pollute environment.

Owner:SHANXI SHANDI XINYUAN TECH

Plant weight reducing enzymes and preparation method thereof

InactiveCN106072519AAchieve balanceGood for weight lossAcidic food ingredientsFood ingredient functionsAmino acid compositionColoring food

The present invention relates to the field of food processing and more particularly relates to plant weight reducing enzymes and a preparation method thereof. The preparation method of the plant weight reducing enzymes comprises the following steps: raw materials are screened, the screened raw materials are crushed, the crushed raw materials are mixed with water, brown sugar, white sugar, apple vinegar and protease are added, the mixture is mixed evenly, and the mixture is subjected to a closed fermentation for 3-6 months; after the fermentation is finished, a solid-liquid separation is conducted to obtain a first fermentation liquid, the first fermentation liquid is purified to obtain a first product, fermentation residues are subjected to a second fermentation to obtain a second fermentation liquid, and the second fermentation liquid is purified to obtain a second product; the first product and the second product are mixed to obtain the plant weight reducing enzymes; and the raw materials are five color food with the efficacies of reducing weight. The provided preparation method of the plant weight reducing enzymes is simple and low in costs. The obtained plant weight reducing enzymes mainly contain substances with special biologically activity and consisting of amino acids, can comprehensively regulate human body to be well, enable the human body to be healthier, at the same time achieve a good effect of weight reducing, and are high in safety.

Owner:北京解脂生物科技有限公司

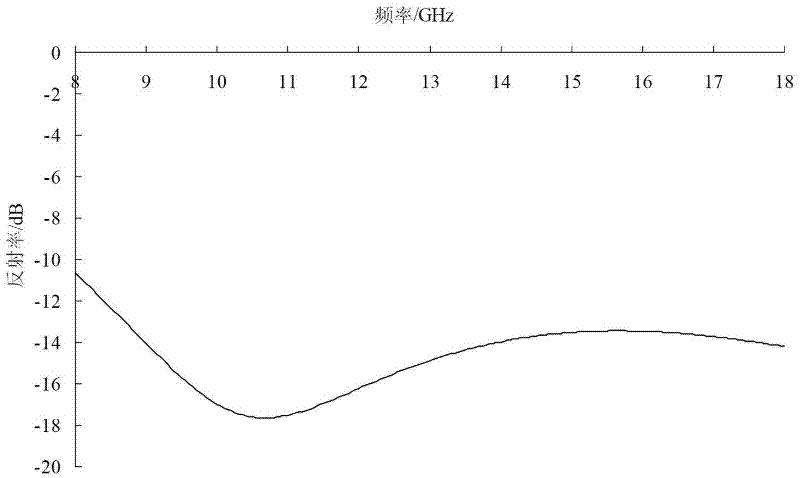

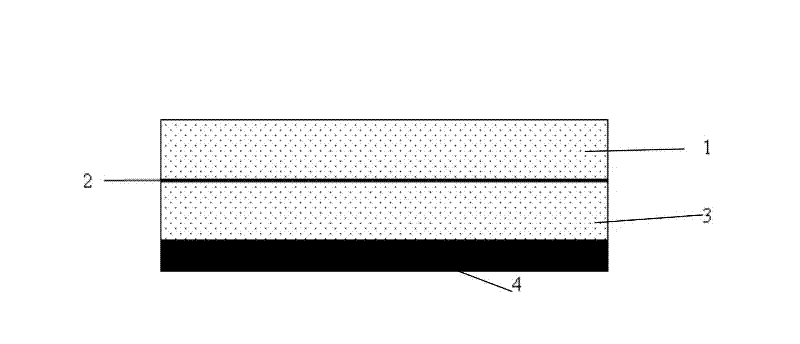

Wave-absorbing material for silicon carbide fibre reinforced resin base sandwich structure and preparation method thereof

ActiveCN102218868AImprove toughnessHigh strengthSynthetic resin layered productsResin-Based CompositeMedia layer

The invention discloses a wave-absorbing material for a silicon carbide fibre reinforced resin base sandwich structure and a preparation method thereof. The wave-absorbing material has a multi-functional layer laminated structure. The structure comprises a first medium layer, an absorbing layer, a second medium layer and a reflection layer; all the functional layers consist of a continuous silicon carbide fibre reinforced resin base composite material; and the continuous silicon carbide fibres serving as the reinforcing materials in each functional layer have different specific resistances. The preparation method for the wave-absorbing material comprises the steps as follows: the continuous silicon carbide fibres are selected firstly and woven into plain cloth; and then the resin is used as a basal body and the wave-absorbing material is manufactured by adopting a resin base composite material forming technique according to the laminated sequence and thickness of each functional layer. The wave-absorbing material has the advantages of simple structure, good parameter tolerance level, easy forming, excellent wave-absorbing functions, etc.

Owner:NAT UNIV OF DEFENSE TECH

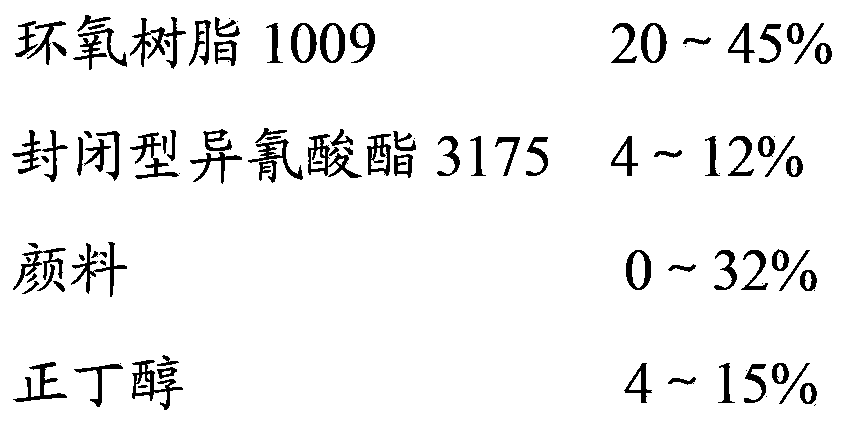

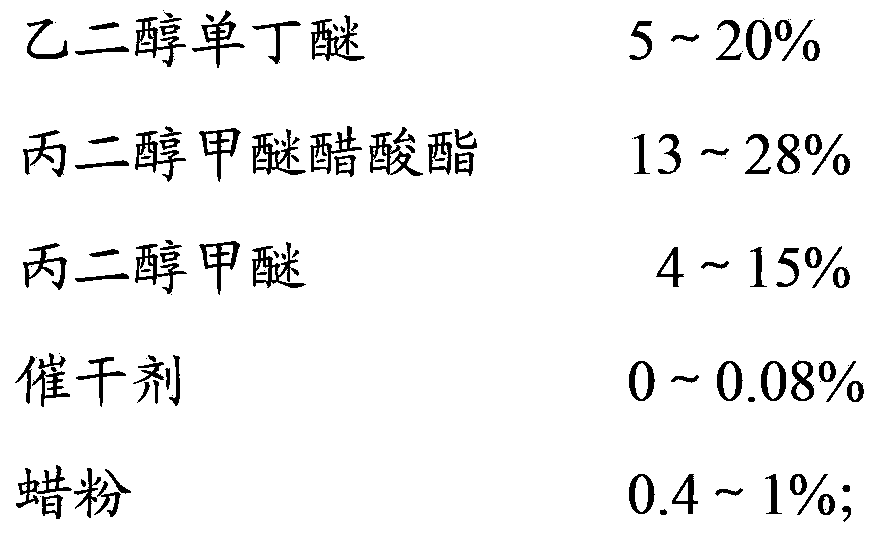

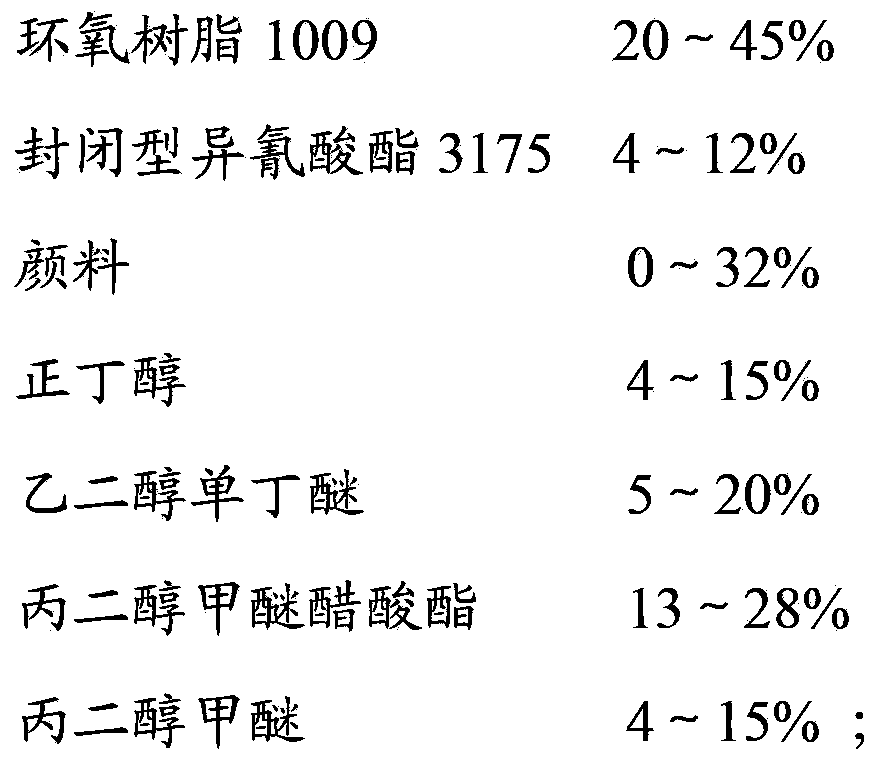

Sulphur-resisting acid-proof food can inner wall paint and preparation method thereof

The invention discloses a sulphur-resisting acid-proof food can inner wall paint and a preparation method thereof. The sulphur-resisting acid-proof food can inner wall paint comprises an organic solvent and an auxiliary and further comprises the following components in percentage by weight: 20 to 45 percent of epoxy resin 1009, 4 to 12 percent of blocked isocyanates 3175 and 0 to 32 percent of pigment. The preparation method of the sulphur-resisting acid-proof food can inner wall paint comprises the following steps; preparing first solution of the epoxy resin 1009; carrying out mixing processing on the first solution of the epoxy resin 1009 and the rest of components. An inner wall coating of a food can is formed by coating, baking and curing the sulphur-resisting acid-proof food can inner wall paint. The coating formed by the sulphur-resisting acid-proof food can inner wall paint has excellent acid resistance, sulphur resistance and salt tolerance; the color of the coating is not changed in the baking process and the coating is not corroded in the using process. Meanwhile, an excellent adhesion force is given to the coating and hardness, flexibility and scratch resistance of the coating are improved.

Owner:CHINA PAINT MFG CO SHENZHEN

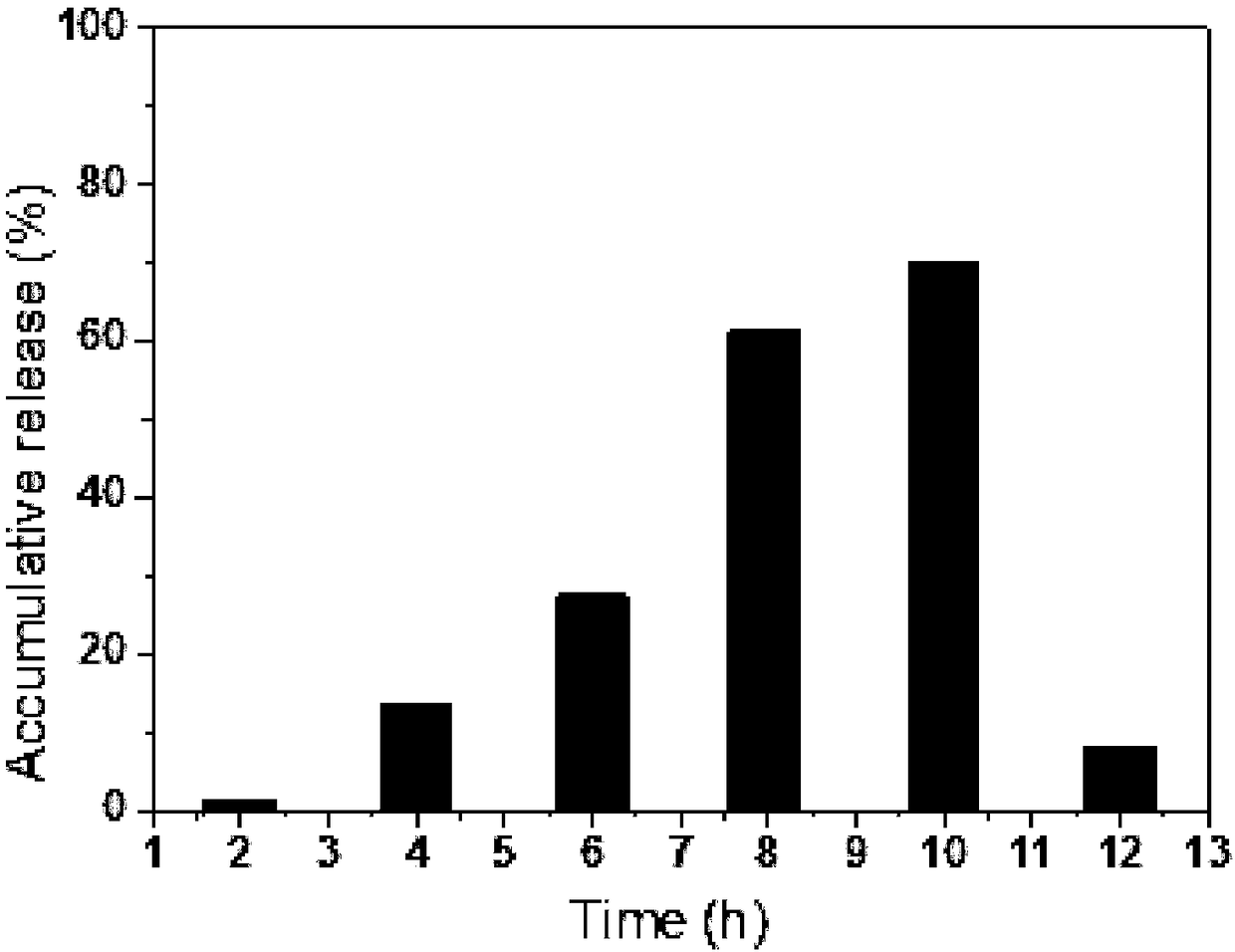

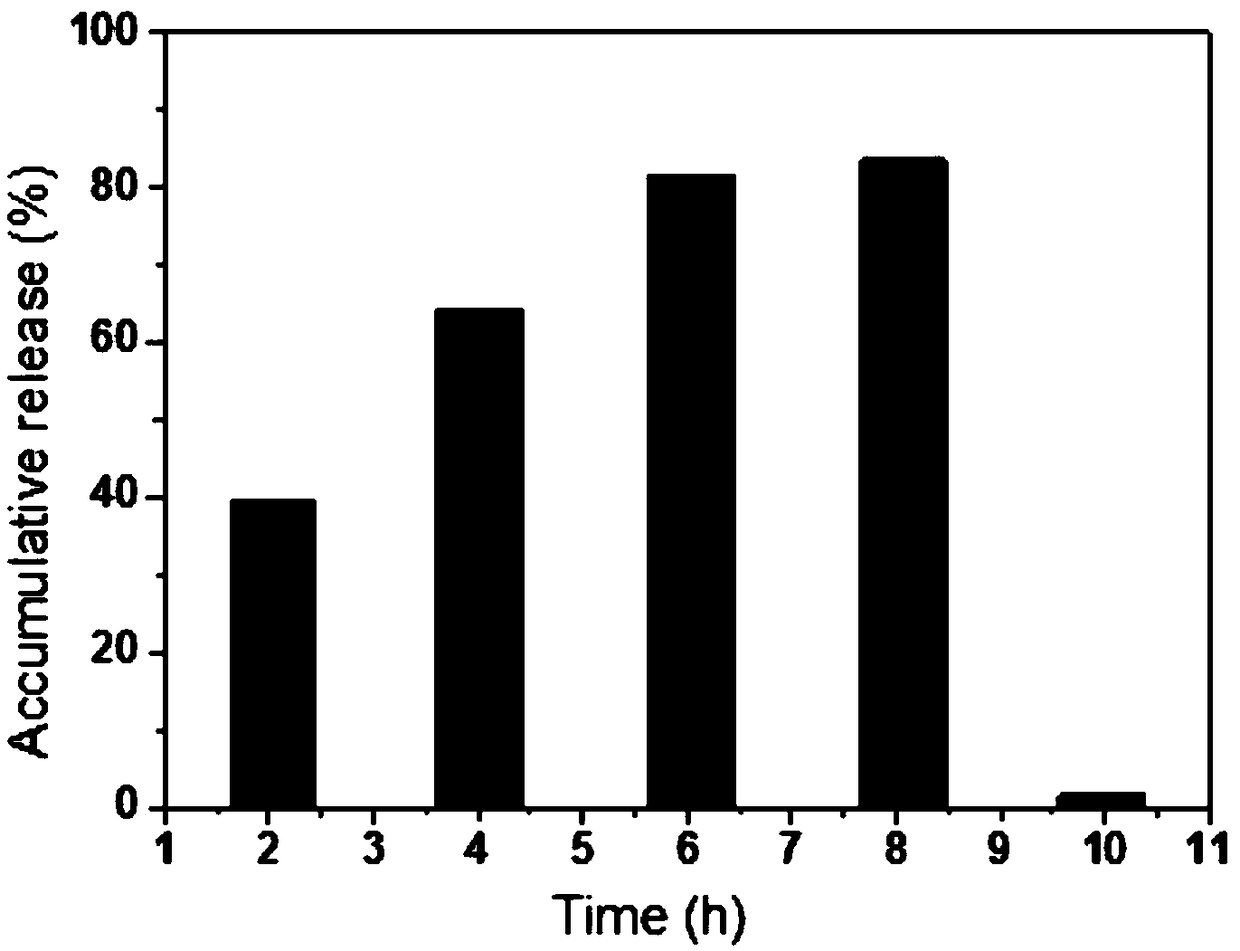

NMN nano microspheres coated with konjac glucomannan as well as preparation process and application thereof

ActiveCN109350611AAvoid decompositionPrevent proliferationOrganic active ingredientsNervous disorderNanometreDecomposition

The invention discloses NMN nano microspheres coated with konjac glucomannan. The NMN nano microspheres comprise NMN nanospheres, wherein the NMN nanospheres re externally coated with konjac glucomannan nanospheres, a particle size of the NMN nanosphere is 500 to 1000 nm, and the particle size of the konjac glucomannan nanosphere is 200 to 1000 nm. The NMN with instable performance is externally coated with the konjac glucomannan (KGM) nanoparticles, and the KGM nanoparticles protect the NMN, so that the instability and easy decomposition of the NMN when in light or after being oxidized can beprevented. The NMN and the KGM are prepared into a coated complex, and the NMN can be slowly released in a given time, so that the NMN can be prevented from being immediately decomposed by the gastric acid. The composite nano microspheres can be used for producing oral preparations and for resisting the cancers. The invention also discloses a preparation process and application of the NMN nano microspheres coated with the konjac glucomannan. The preparation process is simple in procedures and mild in conditions; and the prepared nano microspheres can be widely applied to the production of anticancer drugs, healthcare drugs and pet drugs.

Owner:HOBOOMLIFE BIO TECH SHENZHEN CO LTD +1

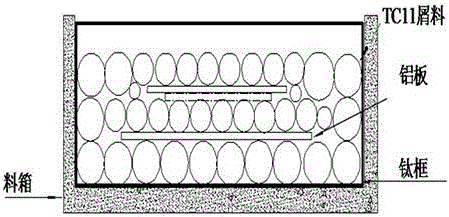

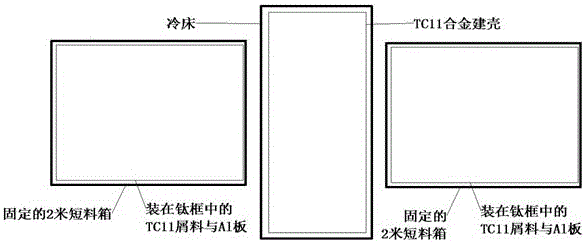

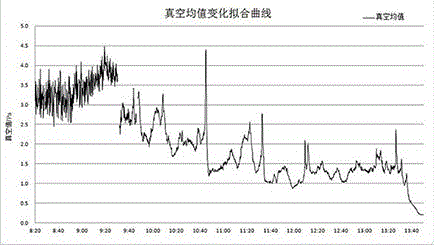

Process of electron beam cold bed furnace for recycling and remelting TC11 scraps

The invention discloses a process of an electron beam cold bed furnace for recycling and remelting TC11 scraps, and belongs to the technical field of titanium alloy preparation. The method comprises the steps that S1, in combination with the size of a material box, a thin titanium plate is selected to be welded into a titanium frame, and weighing is carried out; S2, the weight of the TC11 scraps capable of being contained in the titanium frame is estimated according to the stacking density of the TC11 scraps, the adding amount of an A1 plate is calculated, and cutting is carried out according to requirements; S3, the TC11 scraps and the A1 plate are stacked to be placed in the titanium frame, and materials are dried; and S4, the dried materials are fed into the electron beam cold bed furnace for smelting, and TC11 titanium alloy is obtained through one time of smelting. The reliable, practical and efficient treatment scheme for recycling and remelting the TC11 scraps at low cost is provided, meanwhile, the process is coherent in technological process, convenient and fast to operate and thorough in treatment, and the need of recycling and remelting the TC11 scraps of an electrode incapable of being pressed can be met.

Owner:QINGHAI JUNENG TITANIUM IND CO LTD

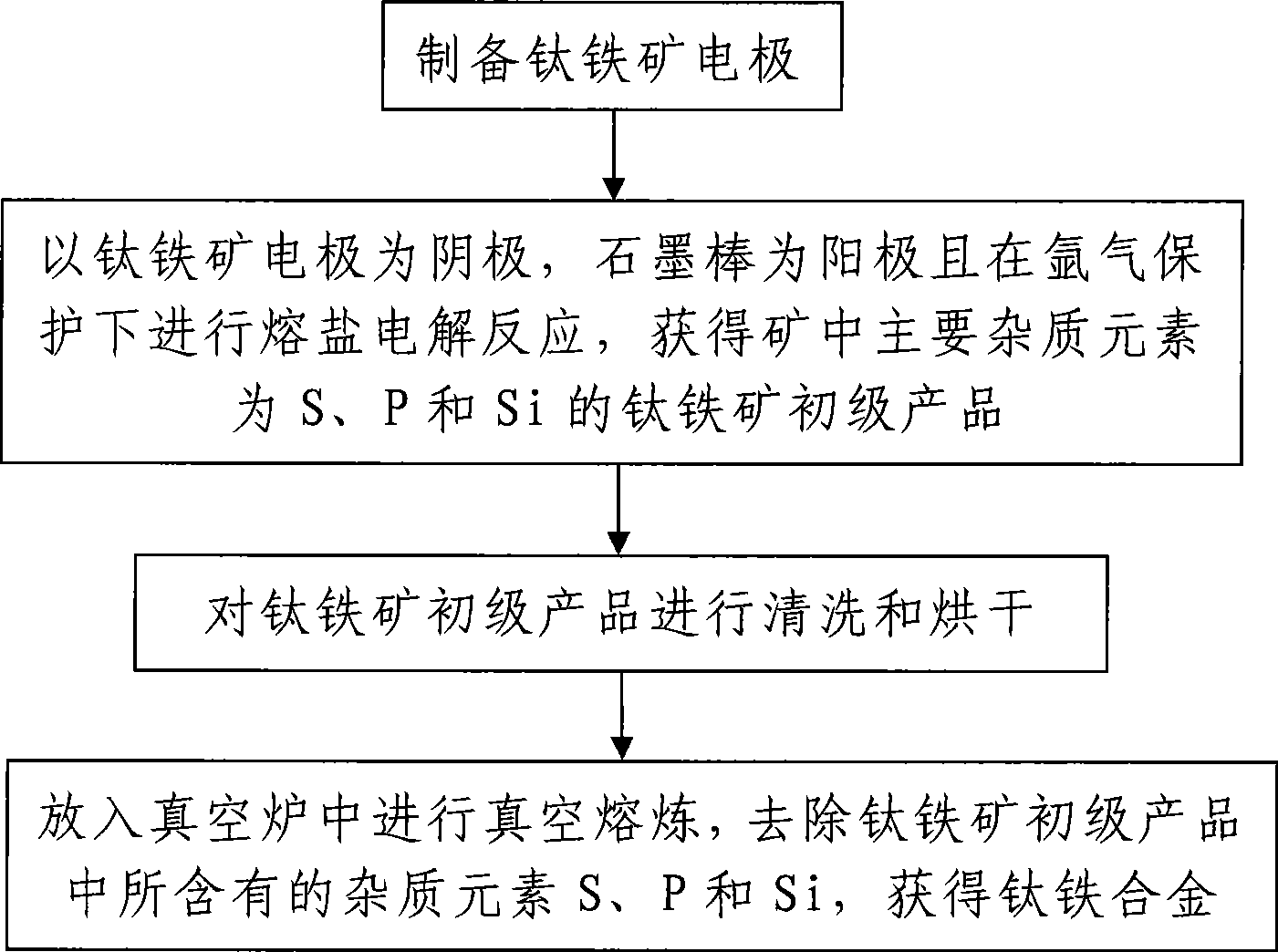

Method for producing titanium iron alloy with titanic iron ore

The invention discloses a method for preparing ferrotitanium with titanic iron ore, comprising the following steps: 1, preparing titanic iron ore electrode by crushing, evenly mixing, press-forming and high-temperature sintering the titanic iron ore raw material in the selected ore, of which the main impurity elements are P, S, Mg, Al, Ca, O and Si; 2, carrying out fused salt electrolysis by taking titanic iron ore electrode as the cathode, and graphite rod as the anode under the protection of argon to obtain the primary titanic iron ore product in which the main impurity elements are S, P and Si; and 3, vacuum melting the washed and dried primary titanic iron ore product in a vacuum furnace to remove the impurity elements of S, P and Si contained in the primary product so as to obtain the ferrotitanium. The method has simple preparing steps and convenient operation and low cost, can greatly reduce the energy consumption and environment pollution in metallurgy process and can effectively avoid waste of mineral resources.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com