Wave-absorbing ceramic made of silicon carbide composite material and preparation method thereof

A technology of composite materials and silicon carbide, which is applied in the field of radar absorbing ceramics, can solve problems such as difficulty in achieving gradient distribution of dielectric properties, poor toughness of particle-reinforced ceramic materials, and difficulty in preparing large and complex components, so as to achieve good absorption of electromagnetic waves and lighten the product. The effect of weight and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

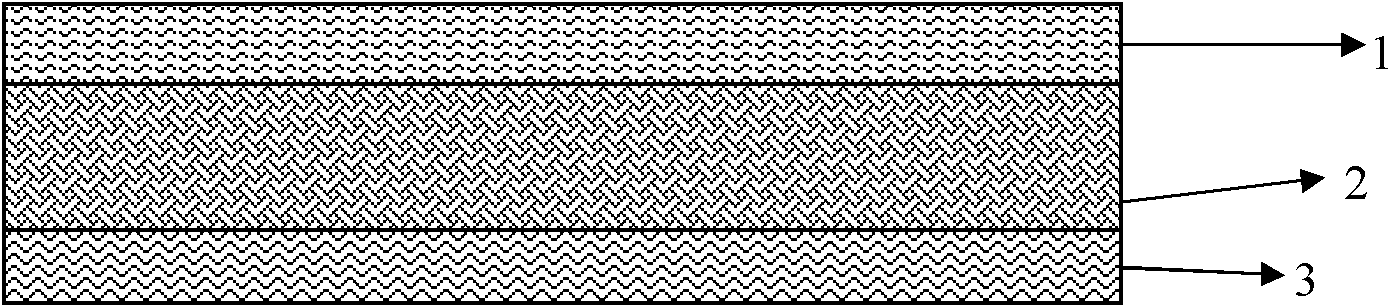

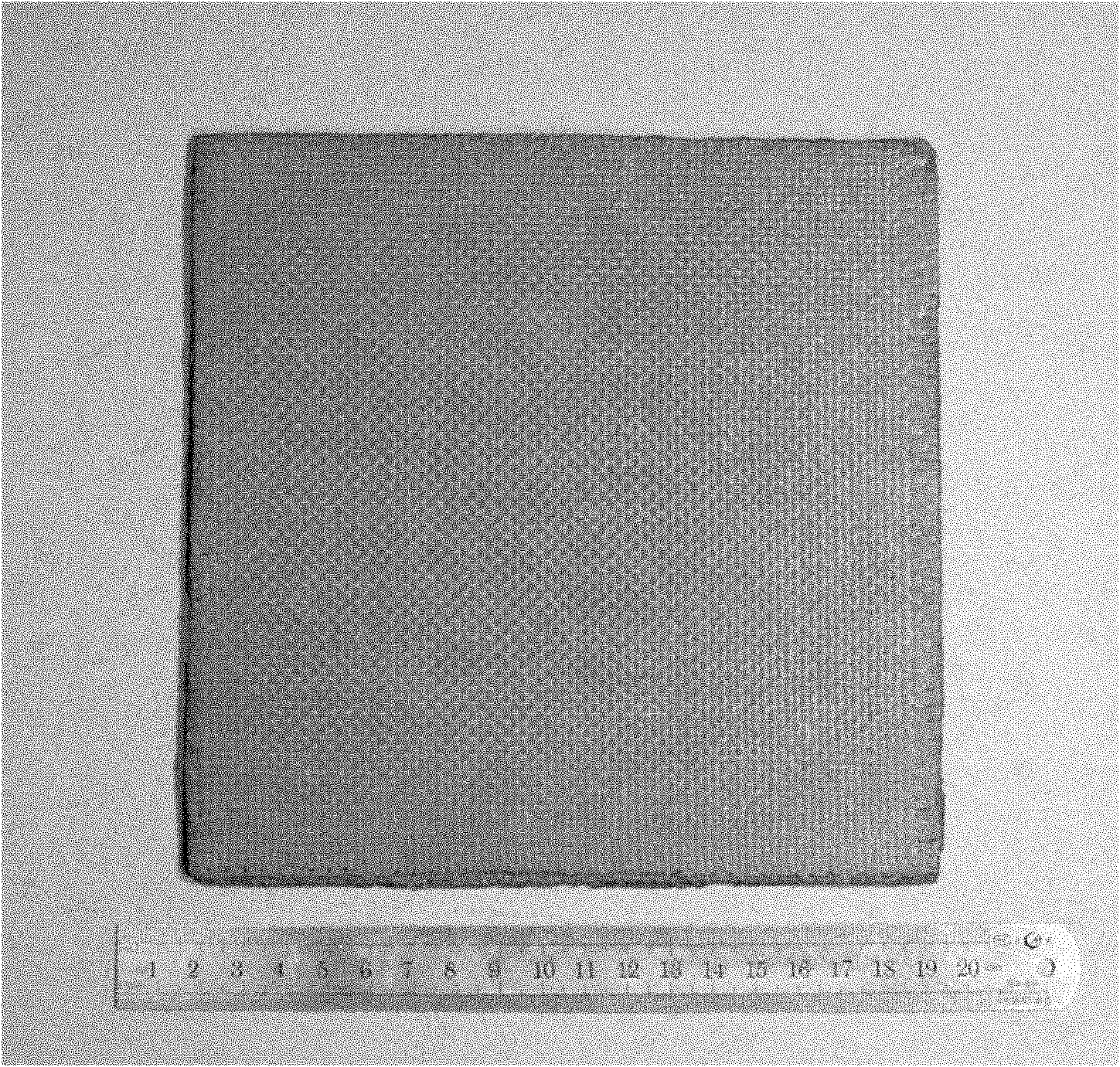

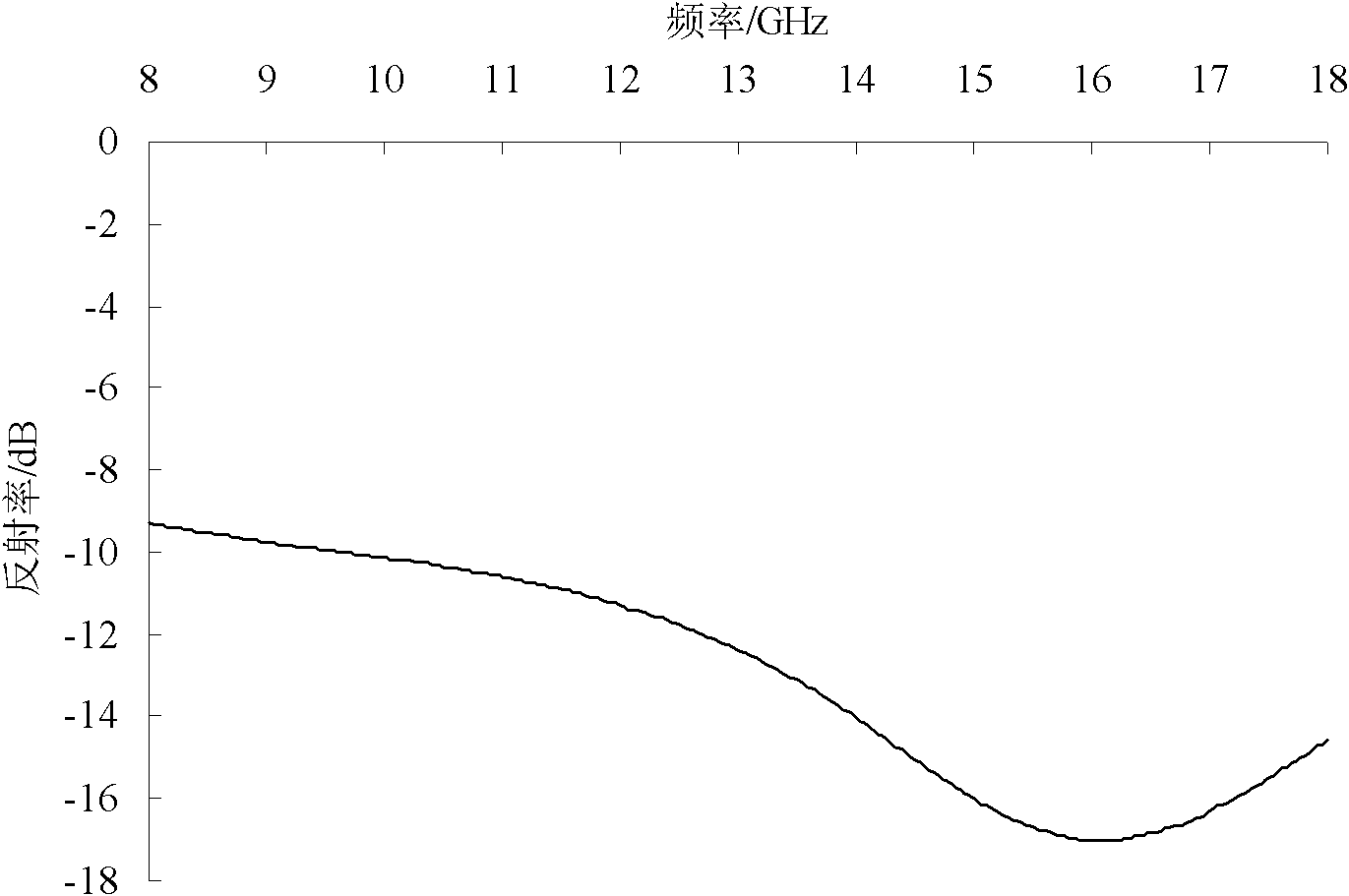

[0025] Embodiment 1: a kind of as figure 1 , figure 2 The wave-absorbing ceramic of the silicon carbide composite material of the present invention shown, the wave-absorbing ceramic is a multifunctional layer superposition structure including a matching layer 1, a loss layer 2 and a reflection layer 3, and each functional layer is made of continuous silicon carbide fiber Reinforced SiC-based composites consist of continuous SiC fibers acting as reinforcements in each functional layer with different electrical resistivities. Among them, the matching layer 1 is located in the outermost layer, the reflective layer 3 is located in the innermost layer, the lossy layer 2 is located in the middle of the matching layer 1 and the reflective layer 3, and the resistivity of the continuous silicon carbide fiber in the matching layer 1 is much greater than that of the inner reflective layer 3 The resistivity of the continuous silicon carbide fiber in the middle lossy layer 2 is greater t...

Embodiment 2

[0039] Embodiment 2: a kind of as figure 1 Another silicon carbide composite wave-absorbing ceramic of the present invention is shown, the wave-absorbing ceramic is a multi-functional layer superposition structure including a matching layer 1, a loss layer 2 and a reflection layer 3, and each functional layer consists of a continuous Silicon carbide fiber-reinforced silicon carbide-based composites consist of continuous silicon carbide fibers that act as reinforcing materials in each functional layer with different resistivities. Among them, the matching layer 1 is located in the outermost layer, the reflective layer 3 is located in the innermost layer, the lossy layer 2 is located in the middle of the matching layer 1 and the reflective layer 3, and the resistivity of the continuous silicon carbide fiber in the matching layer 1 is much greater than that of the inner reflective layer 3 The resistivity of the continuous silicon carbide fiber in the middle lossy layer 2 is great...

Embodiment 3

[0054] Embodiment 3: a kind of as figure 1 The wave-absorbing ceramic of the silicon carbide composite material of the present invention shown, the wave-absorbing ceramic is a multifunctional layer superposition structure including a matching layer 1, a loss layer 2 and a reflection layer 3, and each functional layer is made of continuous silicon carbide fiber Reinforced SiC-based composites consist of continuous SiC fibers acting as reinforcements in each functional layer with different electrical resistivities. Among them, the matching layer 1 is located in the outermost layer, the reflective layer 3 is located in the innermost layer, the lossy layer 2 is located in the middle of the matching layer 1 and the reflective layer 3, and the resistivity of the continuous silicon carbide fiber in the matching layer 1 is much greater than that of the inner reflective layer 3 The resistivity of the continuous silicon carbide fiber in the middle lossy layer 2 is greater than the resis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com