Patents

Literature

4129 results about "Mullite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mullite or porcelainite is a rare silicate mineral of post-clay genesis. It can form two stoichiometric forms: 3Al₂O₃2SiO₂ or 2Al₂O₃ SiO₂. Unusually, mullite has no charge balancing cations present. As a result, there are three different aluminium sites: two distorted tetrahedral and one octahedral.

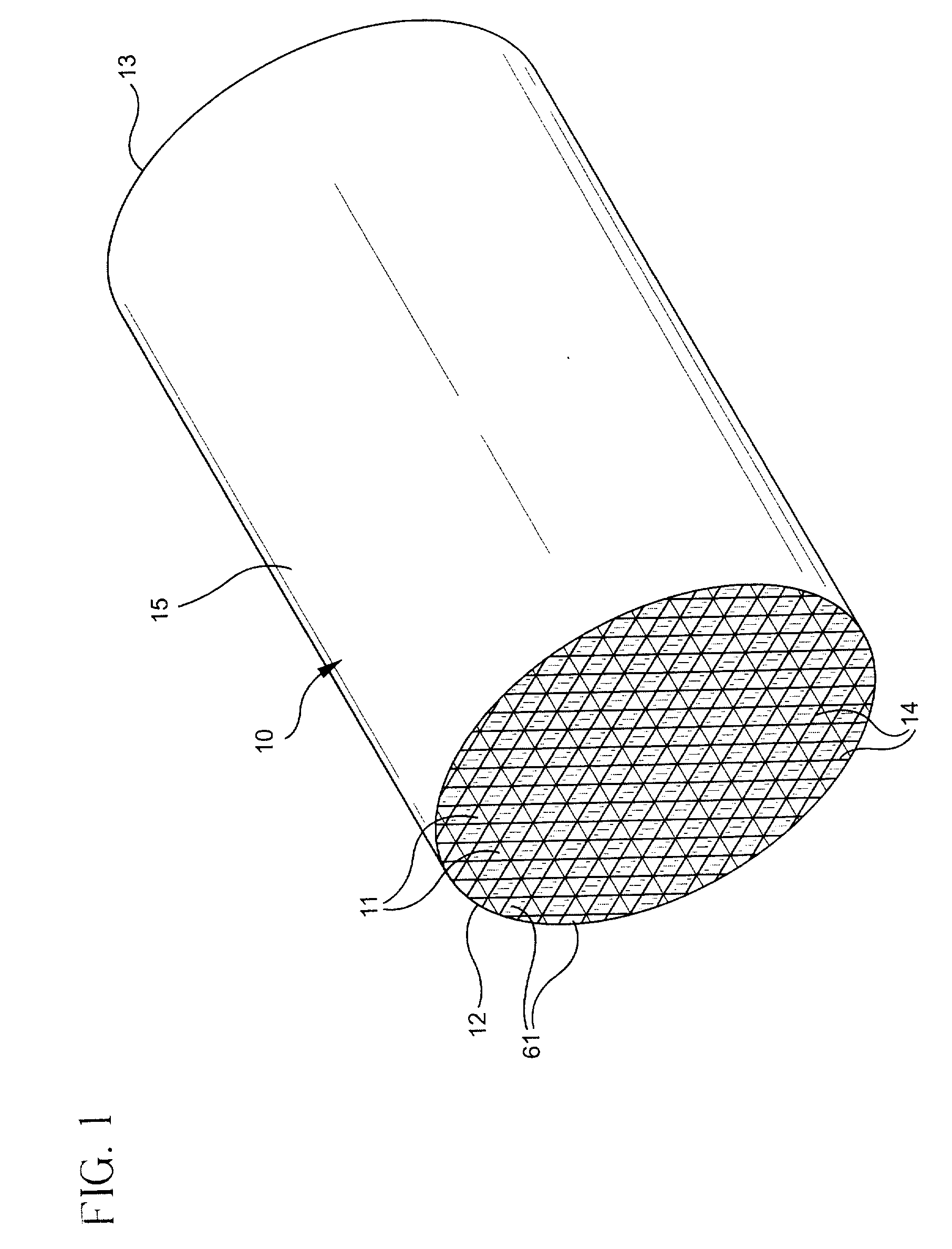

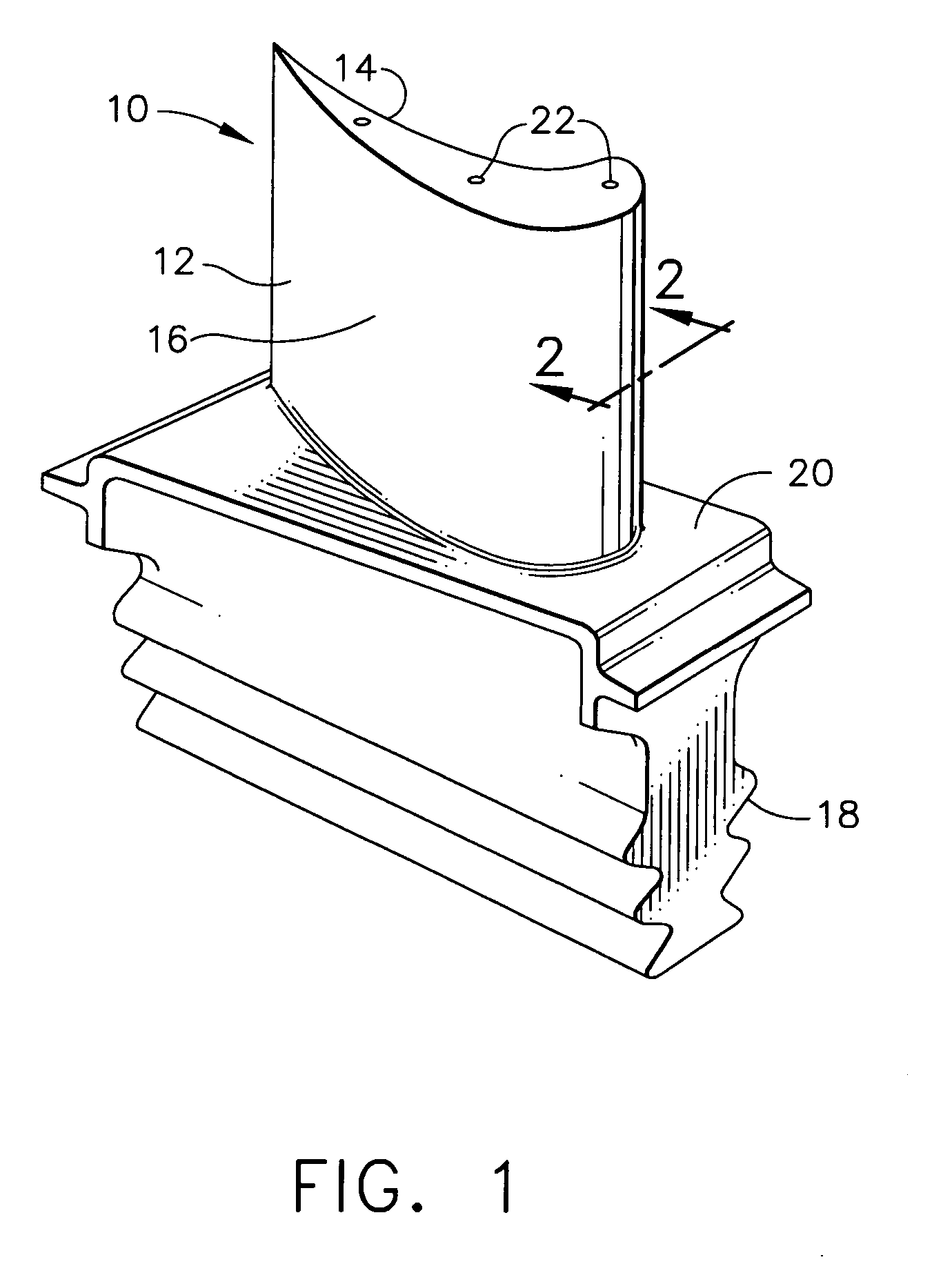

Mullite-aluminum titanate diesel exhaust filter

InactiveUS6849181B2High porosityLarge apertureIron oxides/hydroxidesExhaust apparatusFiltrationMullite

The invention is directed at a mullite-aluminum titanate porous diesel particulate filter constituting a porous ceramic body containing, expressed in terms of weight percent of the total body, of 60-90%, preferably 70-80%, most preferably 70% iron-aluminum titanate solid solution having a stoichiometry of Al2(1−x)Fe2xTiO5, where x is 0-0.1, and 10-40%, preferably 20-30%, most preferably 30% mullite (3Al2O3.2SiO2), and consists essentially, expressed in terms of weigh percent on the oxide basis, of 3 to 15% SiO2, 55 to 65% Al2O3, 22 to 40% TiO2, and 0 to 10% Fe2O3, and being useful for filtration of diesel exhaust. The inventive diesel particulate filter exhibits high interconnected open porosity and large median pore size, in combination with high permeability when fired to a temperature of between 1650° to 1700° C., along with high thermal shock resistance and good filtration capability.

Owner:CORNING INC

Mullite-aluminum titanate diesel exhaust filter

InactiveUS20040020846A1High interconnected porosityReduce back pressureIron oxides/hydroxidesExhaust apparatusFiltrationWhole body

The invention is directed at a mullite-aluminum titanate porous diesel particulate filter constituting a porous ceramic body containing, expressed in terms of weight percent of the total body, of 60-90%, preferably 70-80%, most preferably 70% iron-aluminum titanate solid solution having a stoichiometry of Al2(1-x)Fe2xTiO5, where x is 0-0.1, and 10-40%, preferably 20-30%, most preferably 30% mullite (3Al2O3.2SiO2), and consists essentially, expressed in terms of weigh percent on the oxide basis, of 3 to 15% SiO2, 55 to 65% Al2O3, 22 to 40% TiO2, and 0 to 10% Fe2O3, and being useful for filtration of diesel exhaust. The inventive diesel particulate filter exhibits high interconnected open porosity and large median pore size, in combination with high permeability when fired to a temperature of between 1650° to 1700° C., along with high thermal shock resistance and good filtration capability.

Owner:CORNING INC

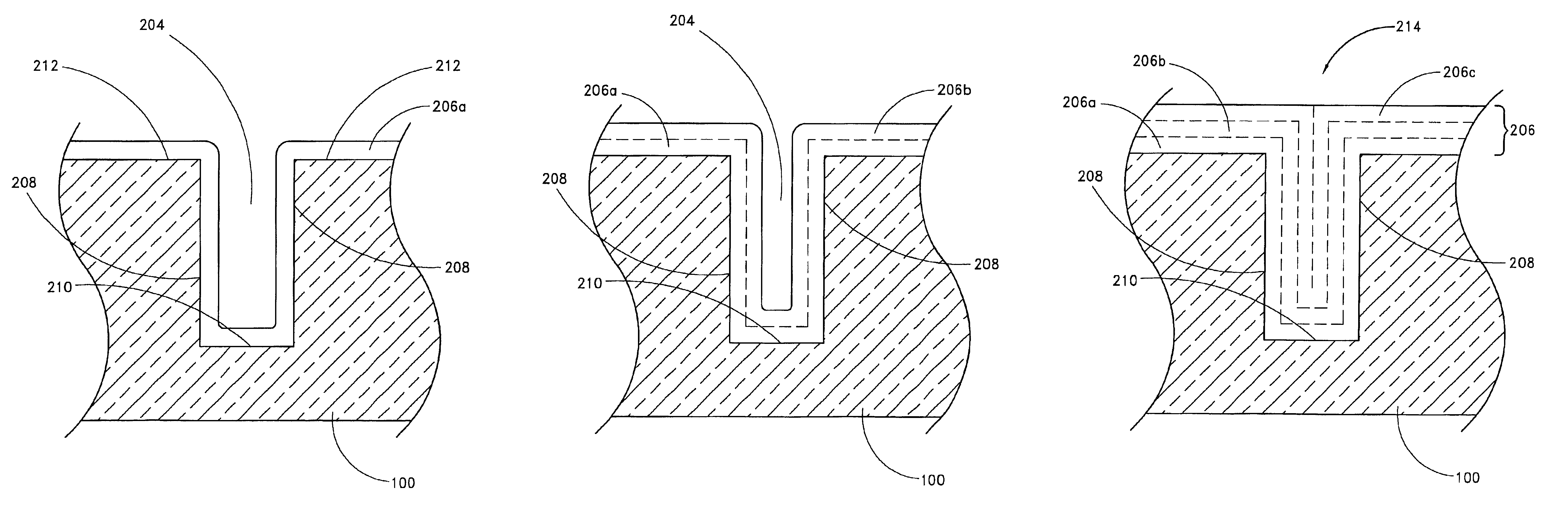

Method of fabricating trench isolation structures for integrated circuits using atomic layer deposition

InactiveUS6861334B2Semiconductor/solid-state device manufacturingSemiconductor devicesMulliteSilicon oxide

A dielectric film is formed by atomic layer deposition to conformally fill a narrow, deep trench for device isolation. The method of the illustrated embodiments includes alternately pulsing vapor-phase reactants in a string of cycles, where each cycle deposits no more than about a monolayer of material, capable of completely filling high aspect ratio trenches. Additionally, the trench-fill material composition can be tailored by processes described herein, particularly to match the coefficient of thermal expansion (CTE) to that of the surrounding substrate within which the trench is formed. Mixed phases of mullite and silica have been found to meet the goals of device isolation and matched CTE. The described process includes mixing atomic layer deposition cycles of aluminum oxide and silicon oxide in ratios selected to achieve the desired composition of the isolation material, namely on the order of 30% alumina and 70% silicon oxide by weight.

Owner:ASM INTERNATIONAL

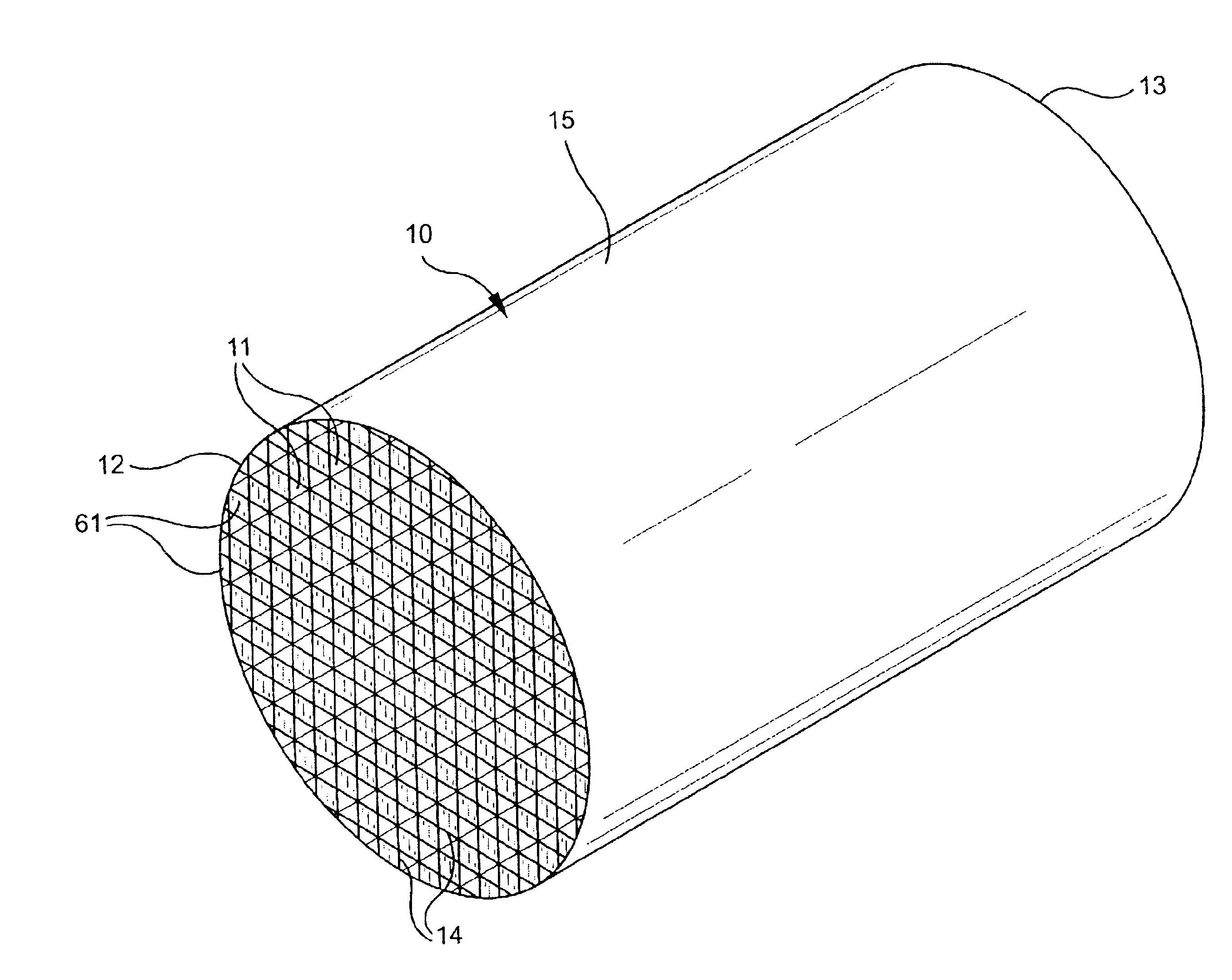

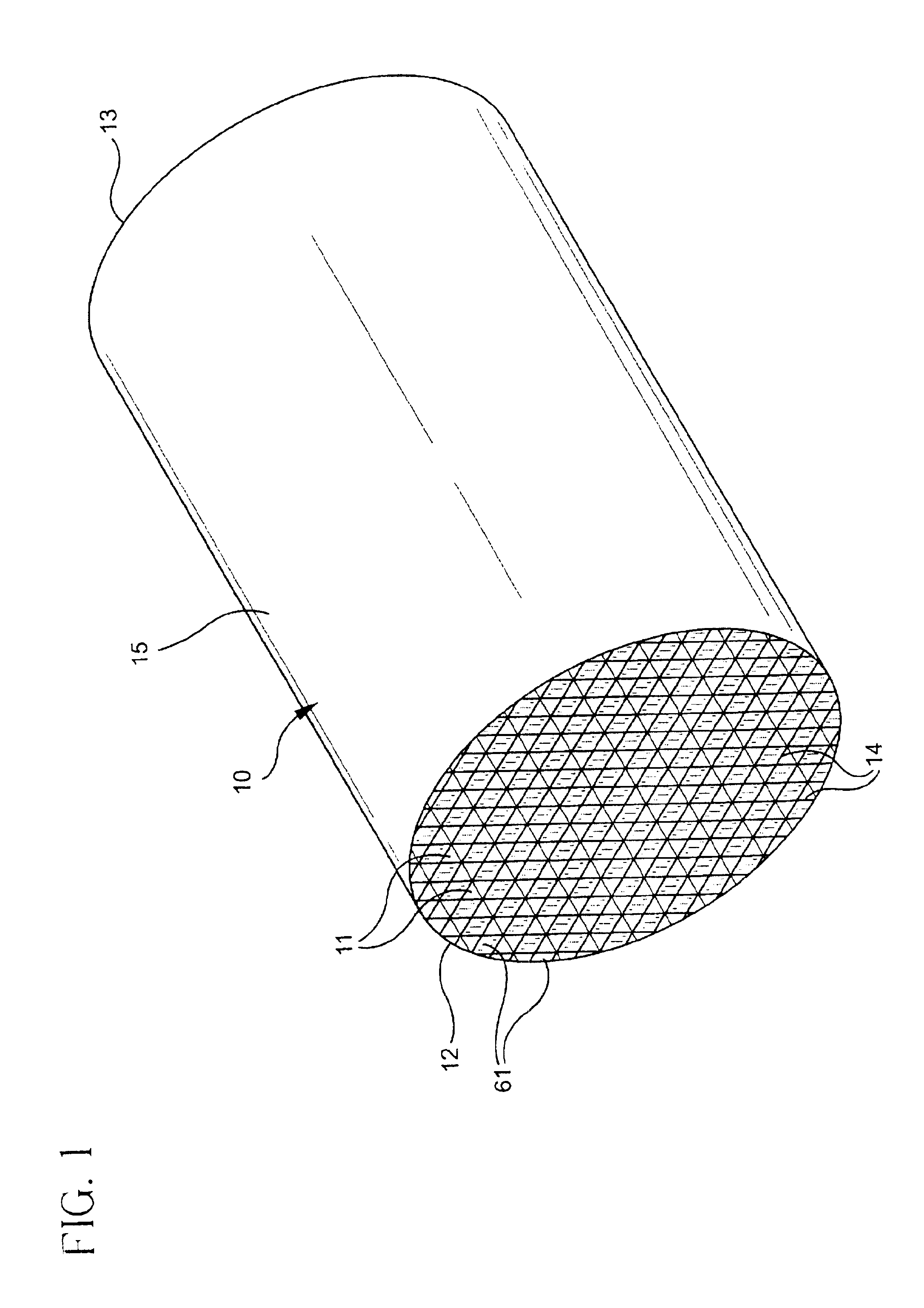

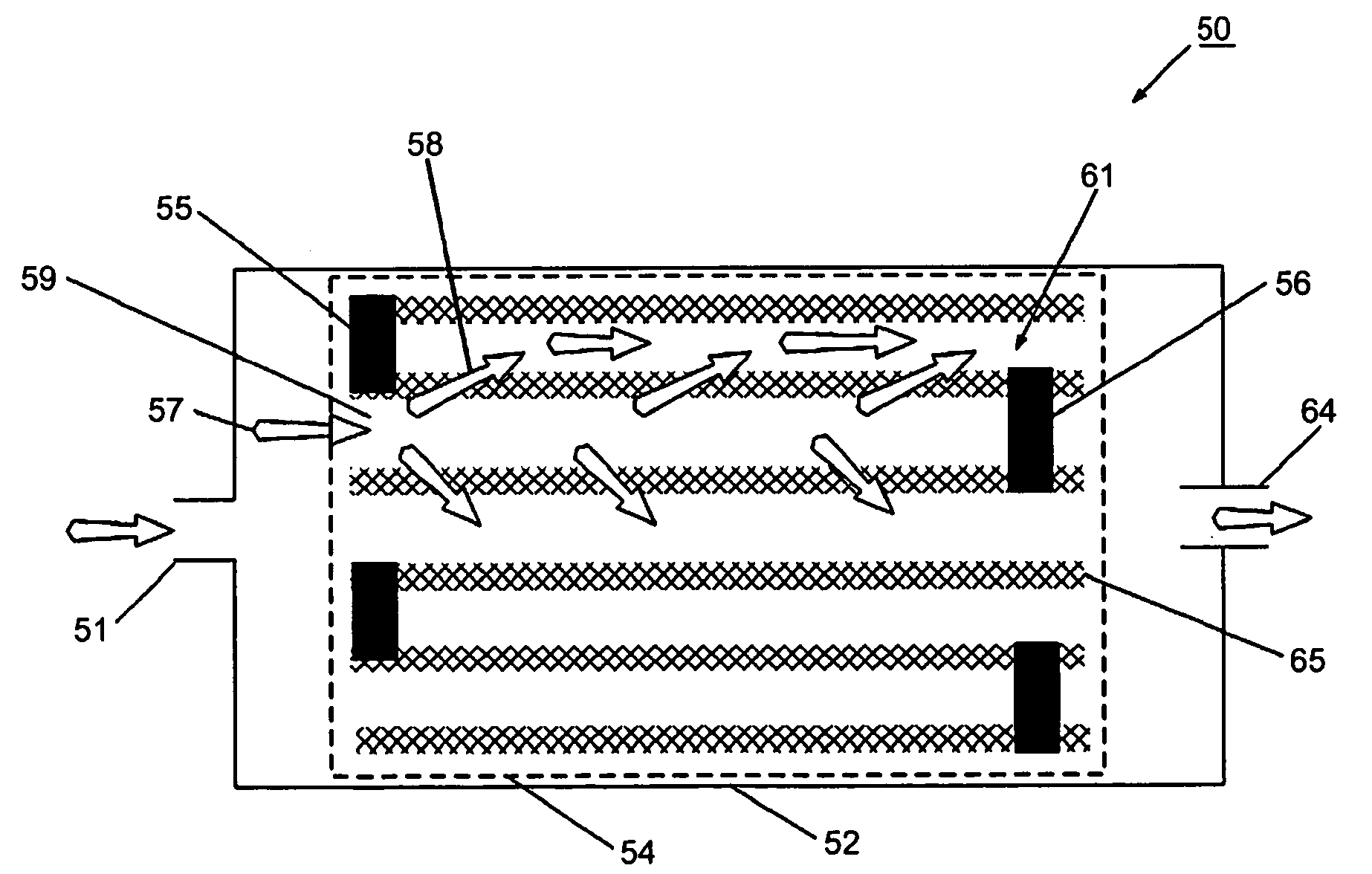

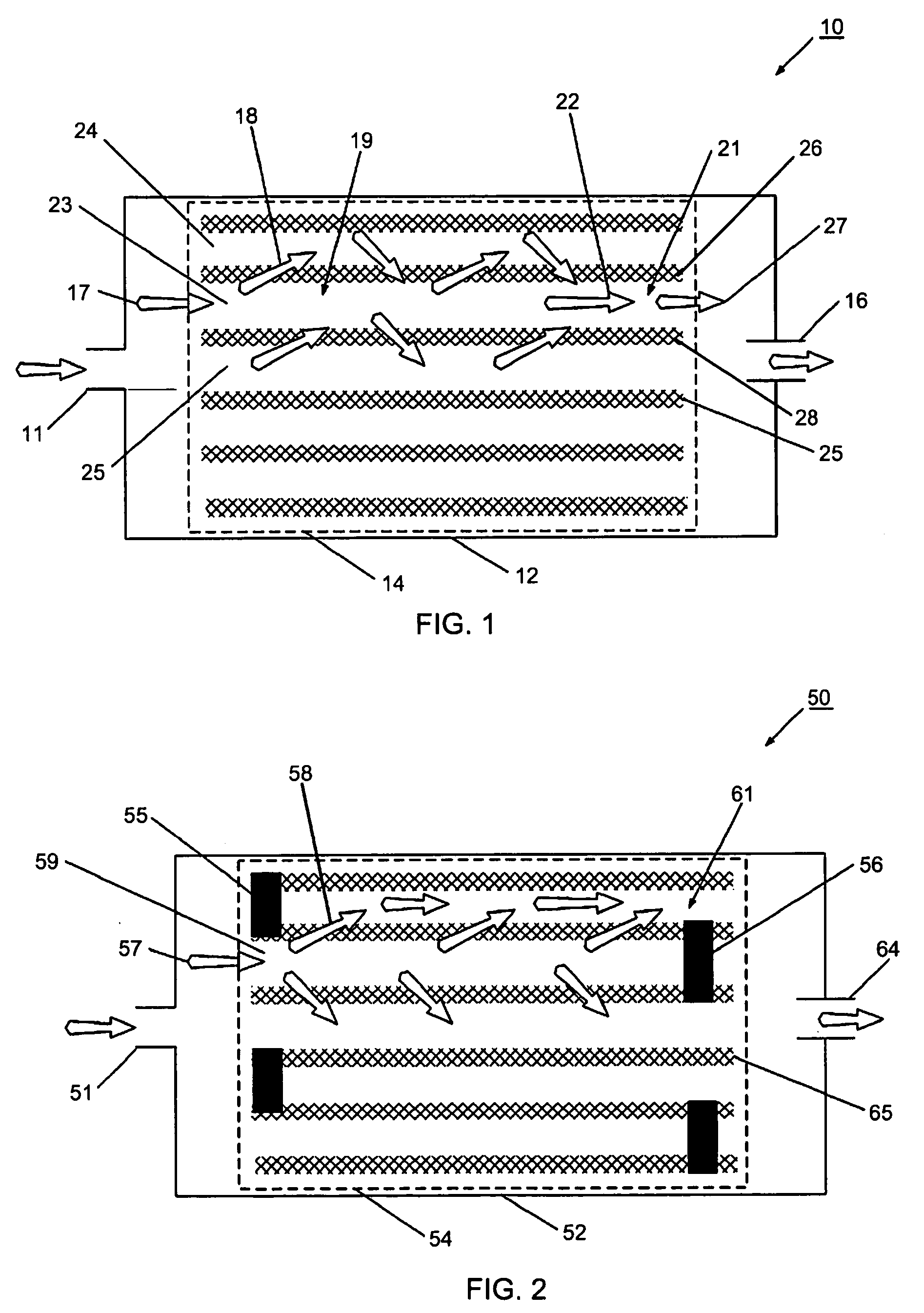

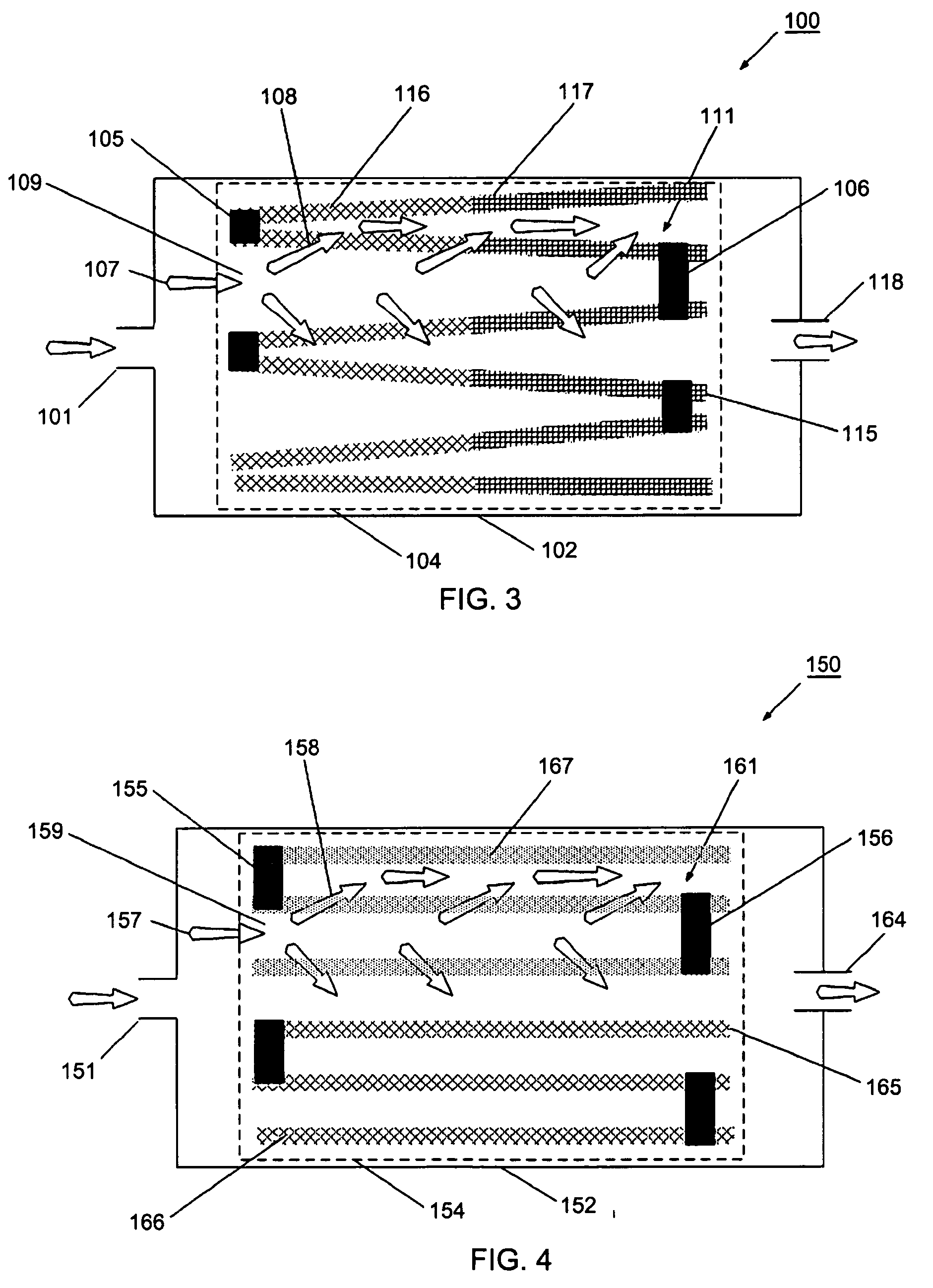

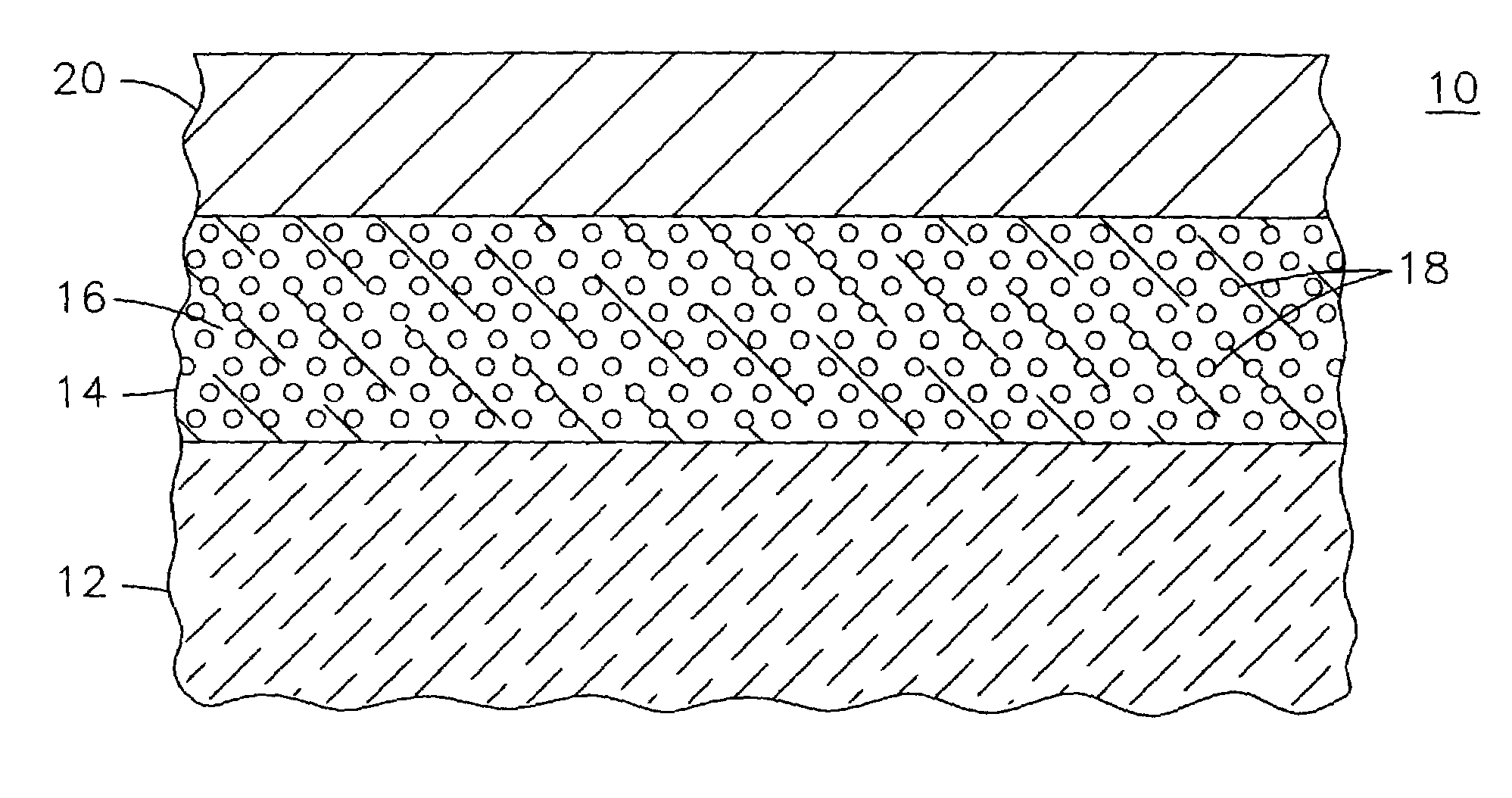

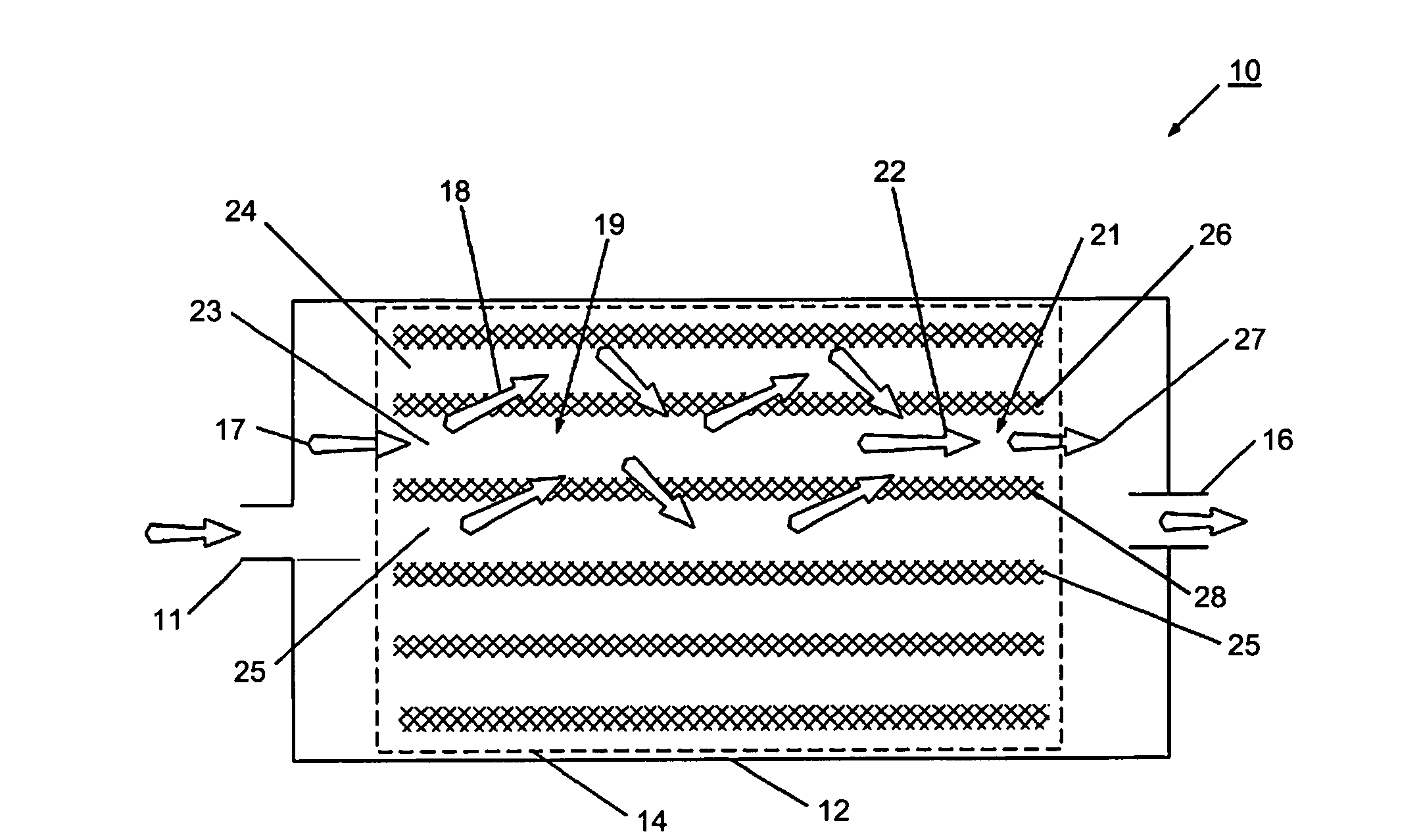

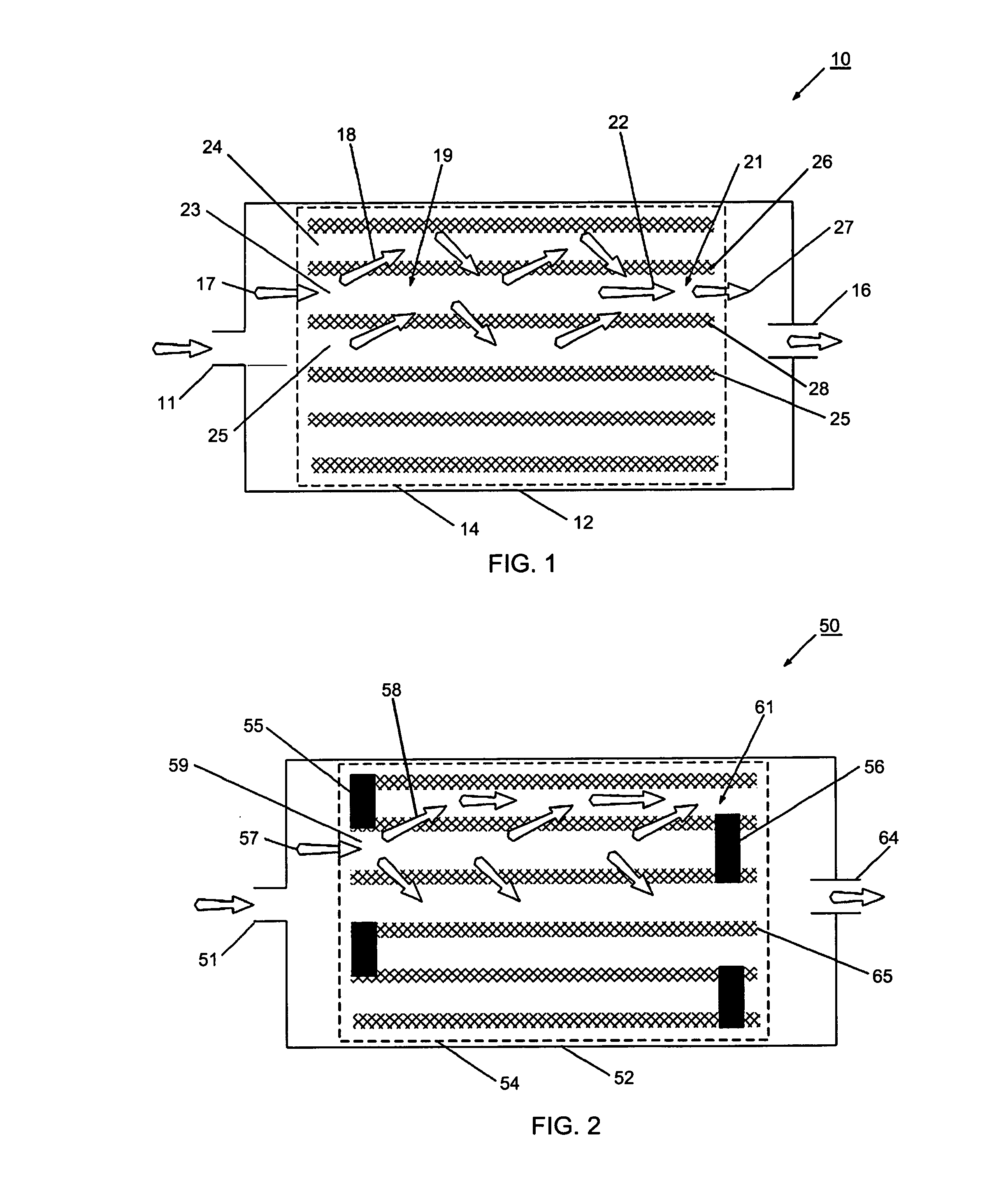

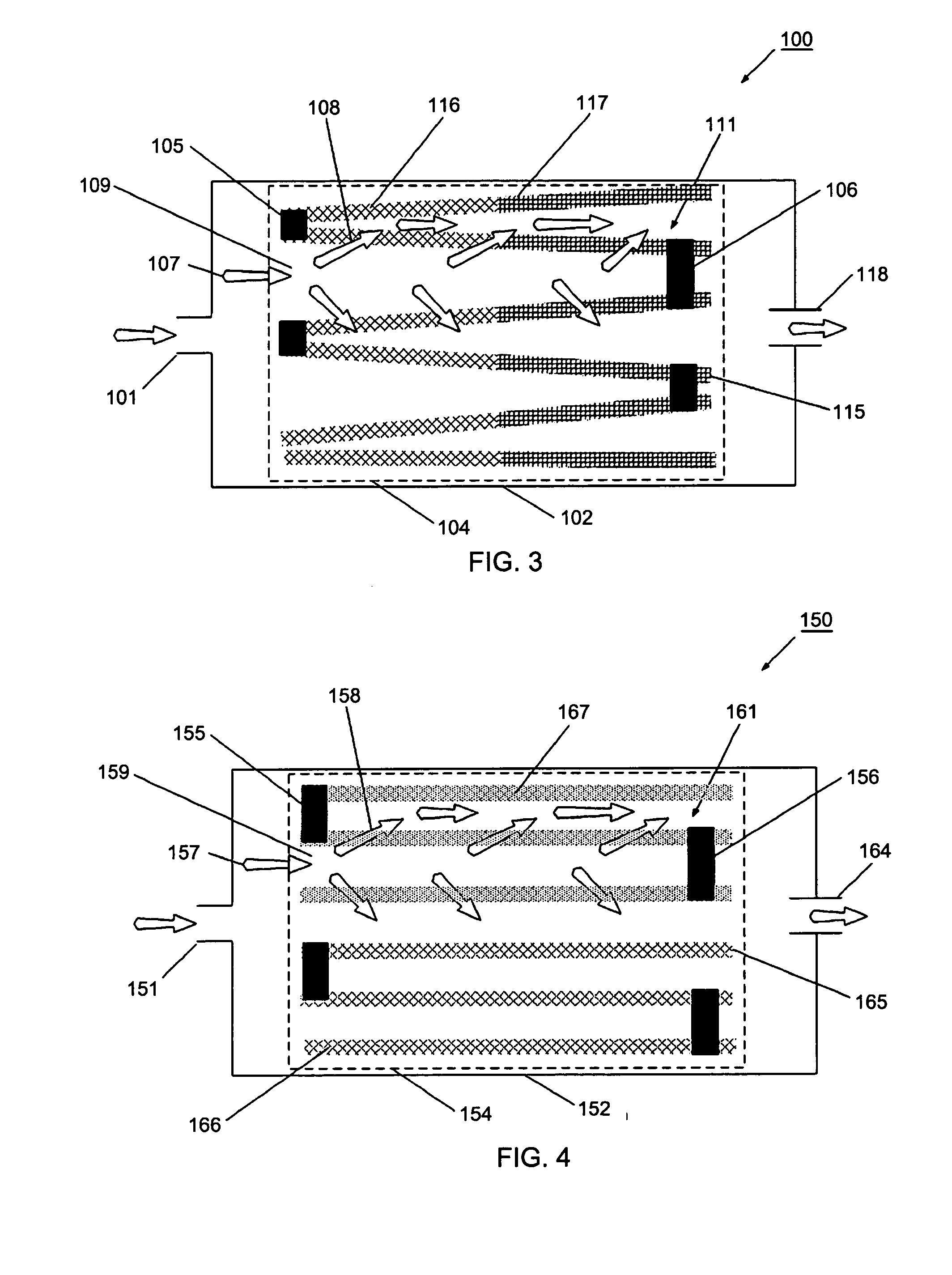

Multi-functional substantially fibrous mullite filtration substates and devices

InactiveUS20060120937A1Small surface areaRapid back-pressure increaseCombination devicesInternal combustion piston enginesFiberFiltration

A diesel particulate filter assembly, including a housing having an inlet end and an outlet end, a particulate filter portion consisting essentially of mullite fibers and positioned in the housing, channels in the filter, a porous wall between adjacent channels, and an exhaust path extending through the inlet end, through the particulate filter portion and though the outlet end.

Owner:GE02 TECH INC

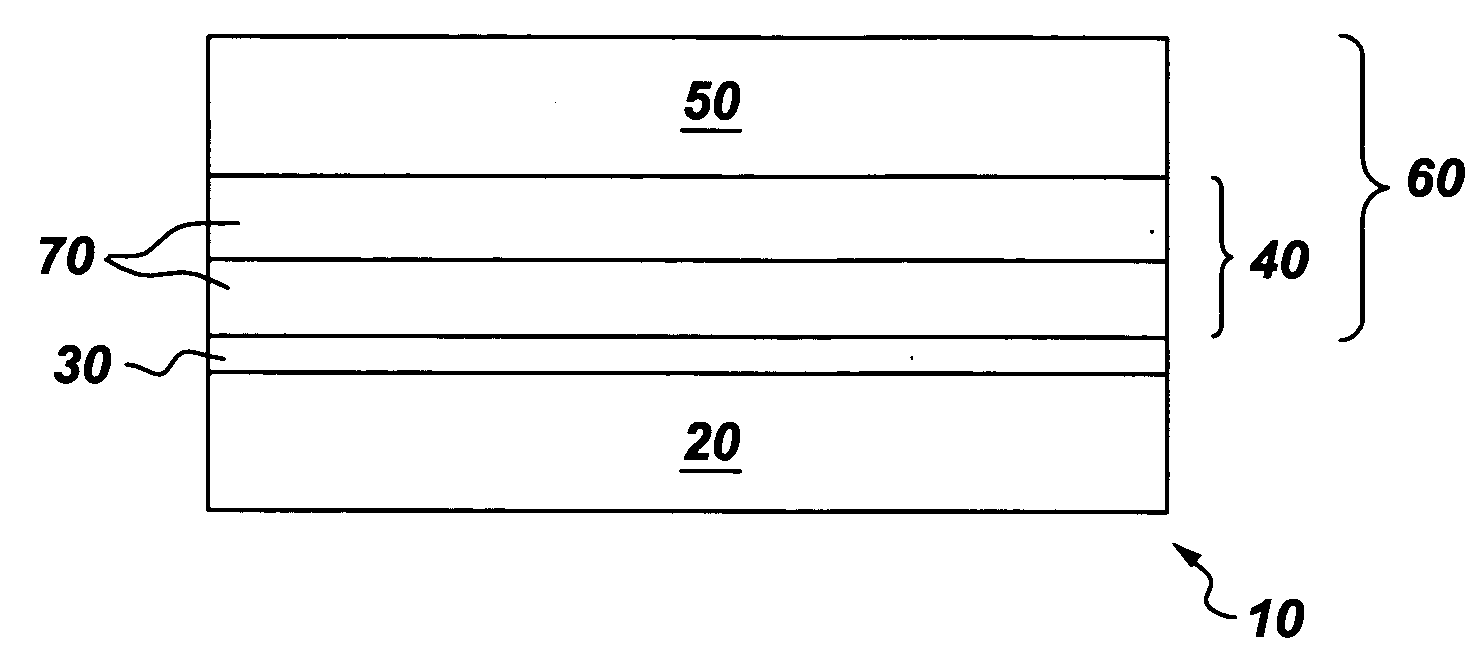

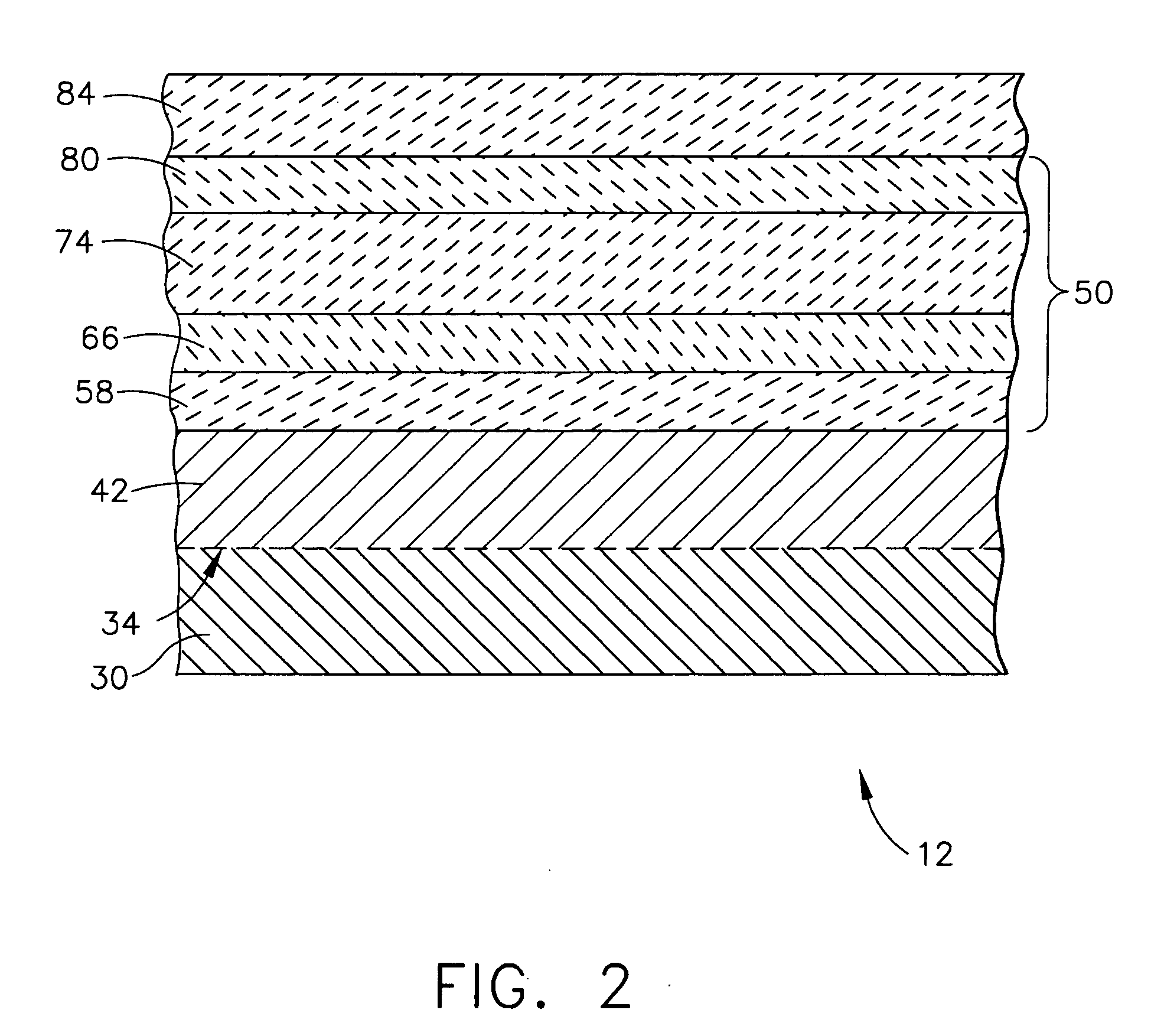

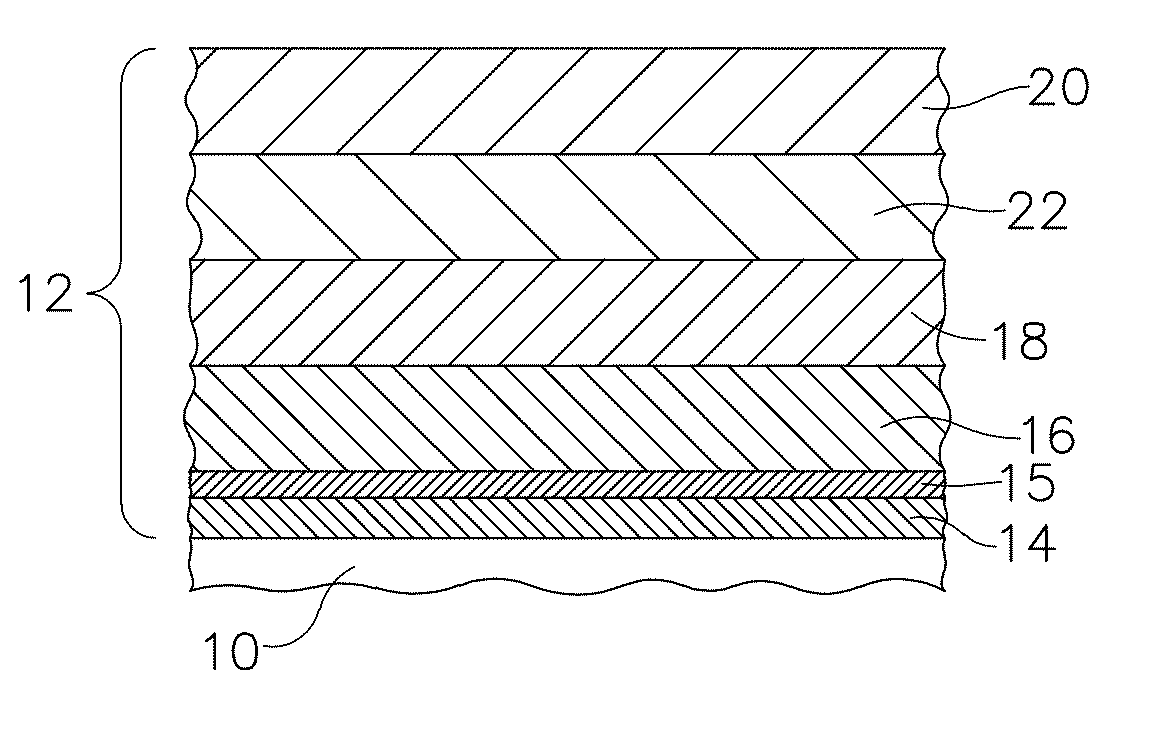

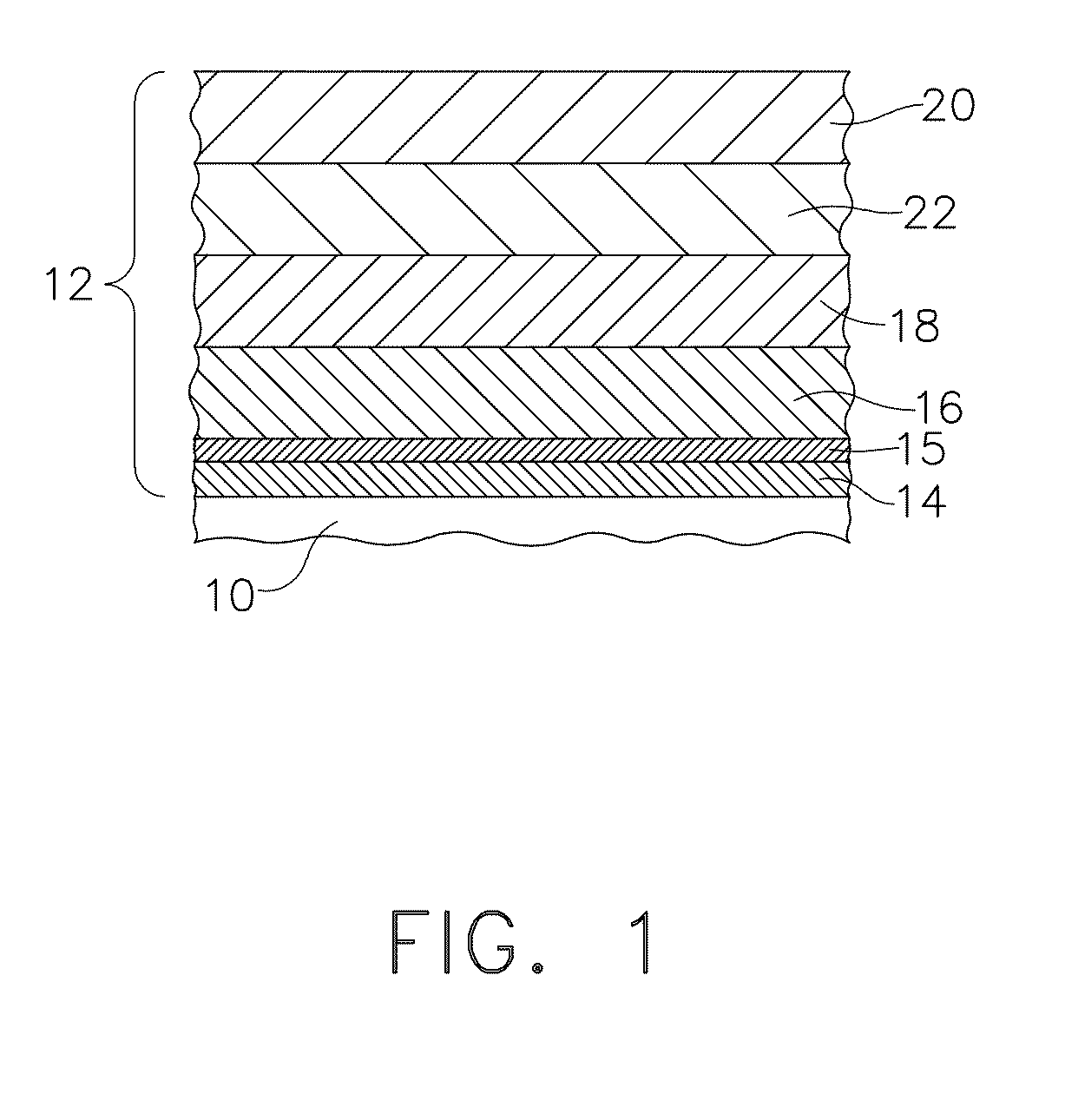

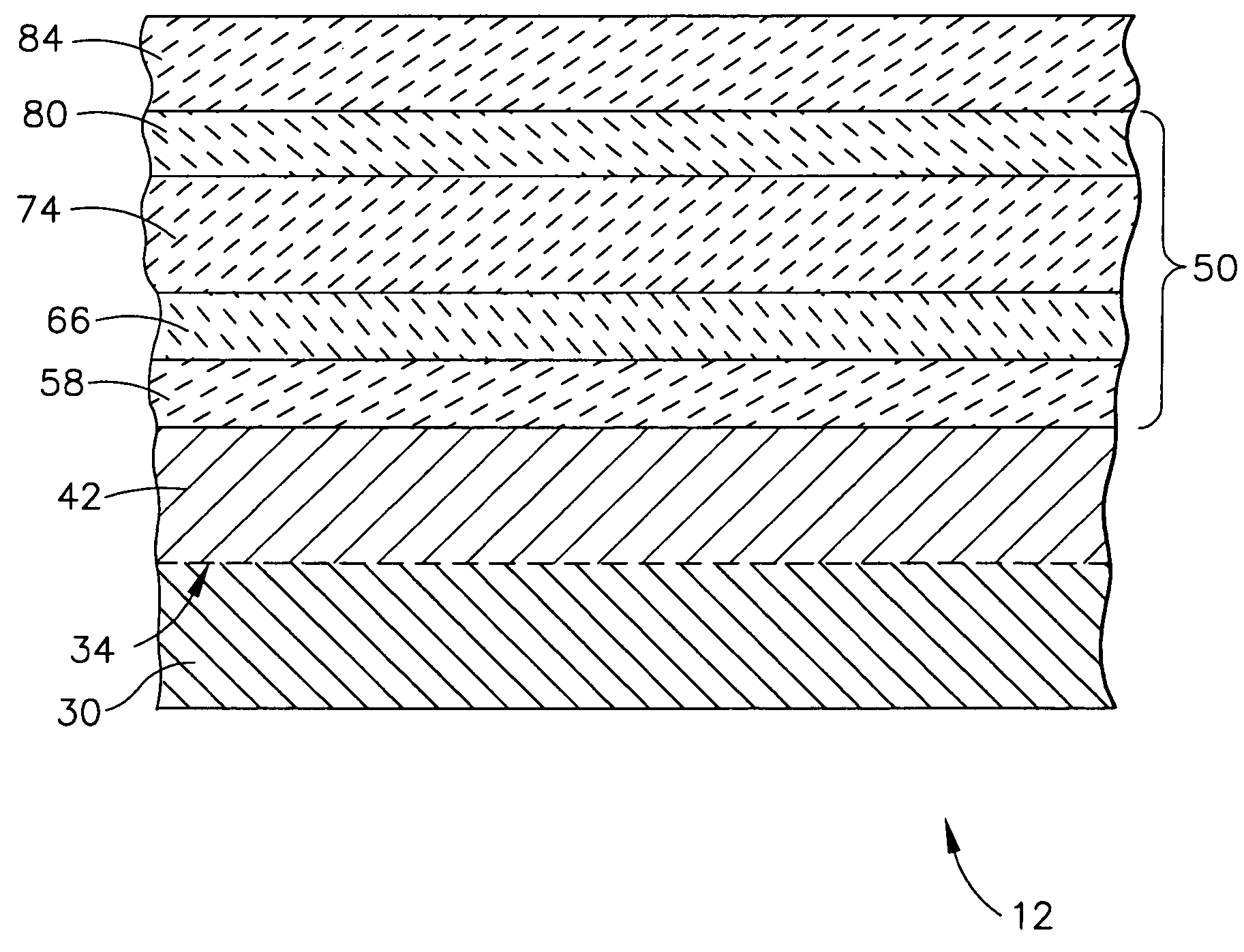

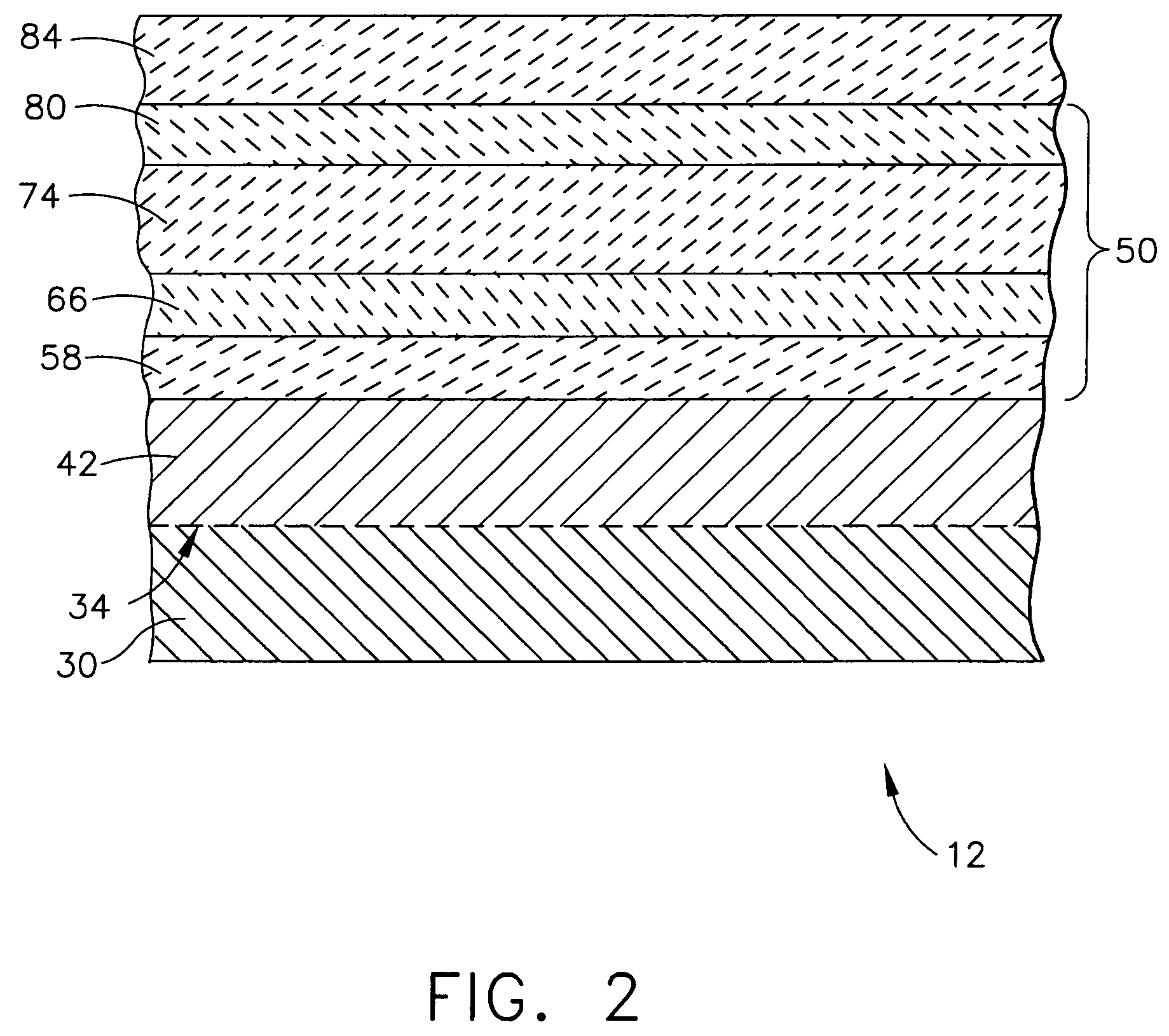

Article including environmental barrier coating system, and method for making

InactiveUS20060014029A1Need be addressLiquid surface applicatorsEngine manufactureCoating systemRare earth

Articles for use in a high temperature environment, and methods for protecting articles in such environments, are provided. The article comprises a substrate comprising silicon; a bondcoat comprising silicon, disposed over the substrate; an intermediate barrier disposed over the bondcoat, the barrier comprising at least one layer, wherein the at least one layer comprises a rare-earth silicate and is substantially free of mullite; and a topcoat disposed over the intermediate barrier, the topcoat comprising a rare-earth monosilicate. The method comprises providing a substrate, the substrate comprising silicon; disposing a bondcoat comprising silicon over the substrate; disposing an intermediate barrier over the bondcoat, the barrier comprising at least one layer, wherein the at least one layer comprises a rare-earth silicate and is substantially free of mullite; and disposing a topcoat over the intermediate barrier, the topcoat comprising a rare-earth monosilicate.

Owner:GENERAL ELECTRIC CO

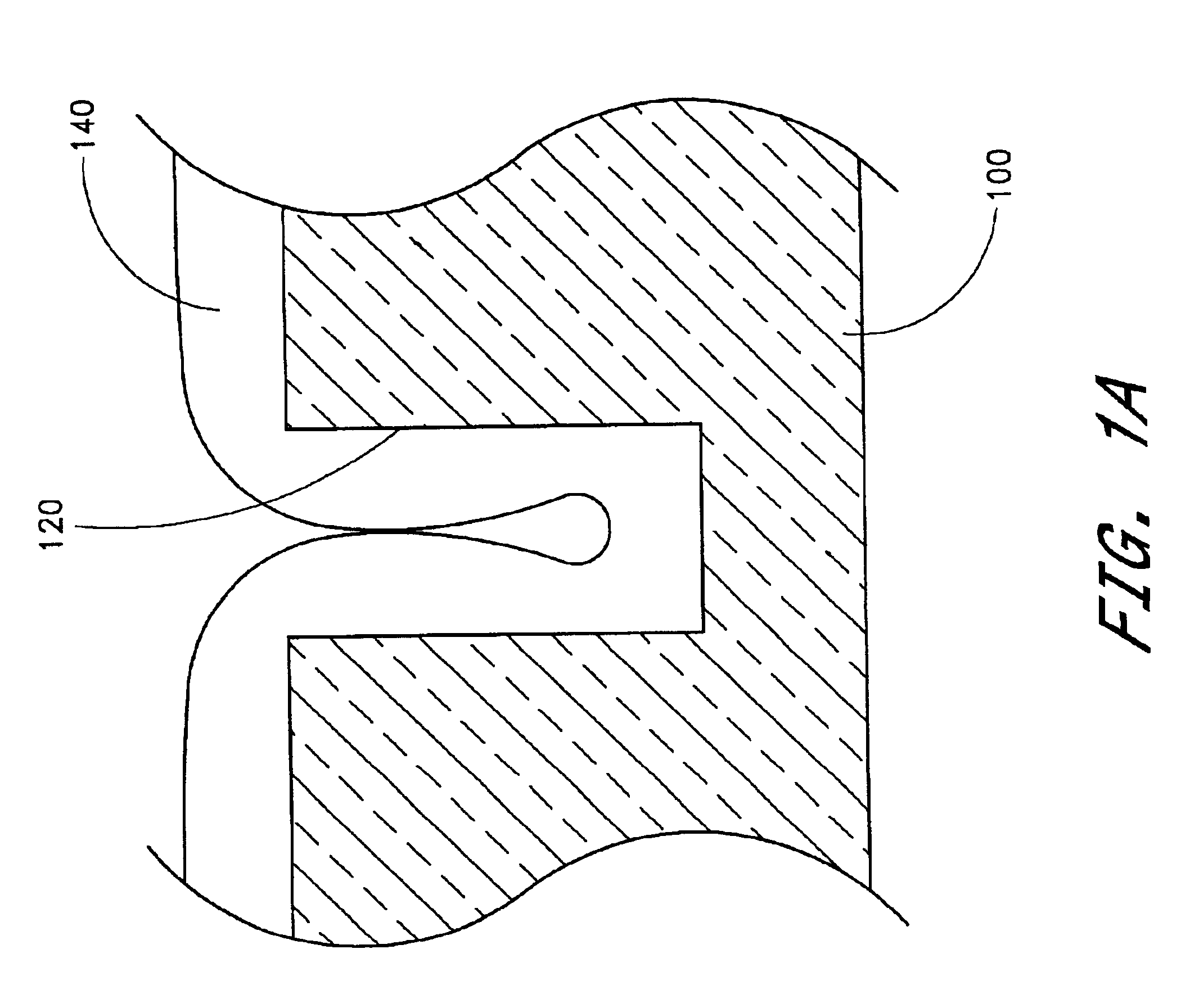

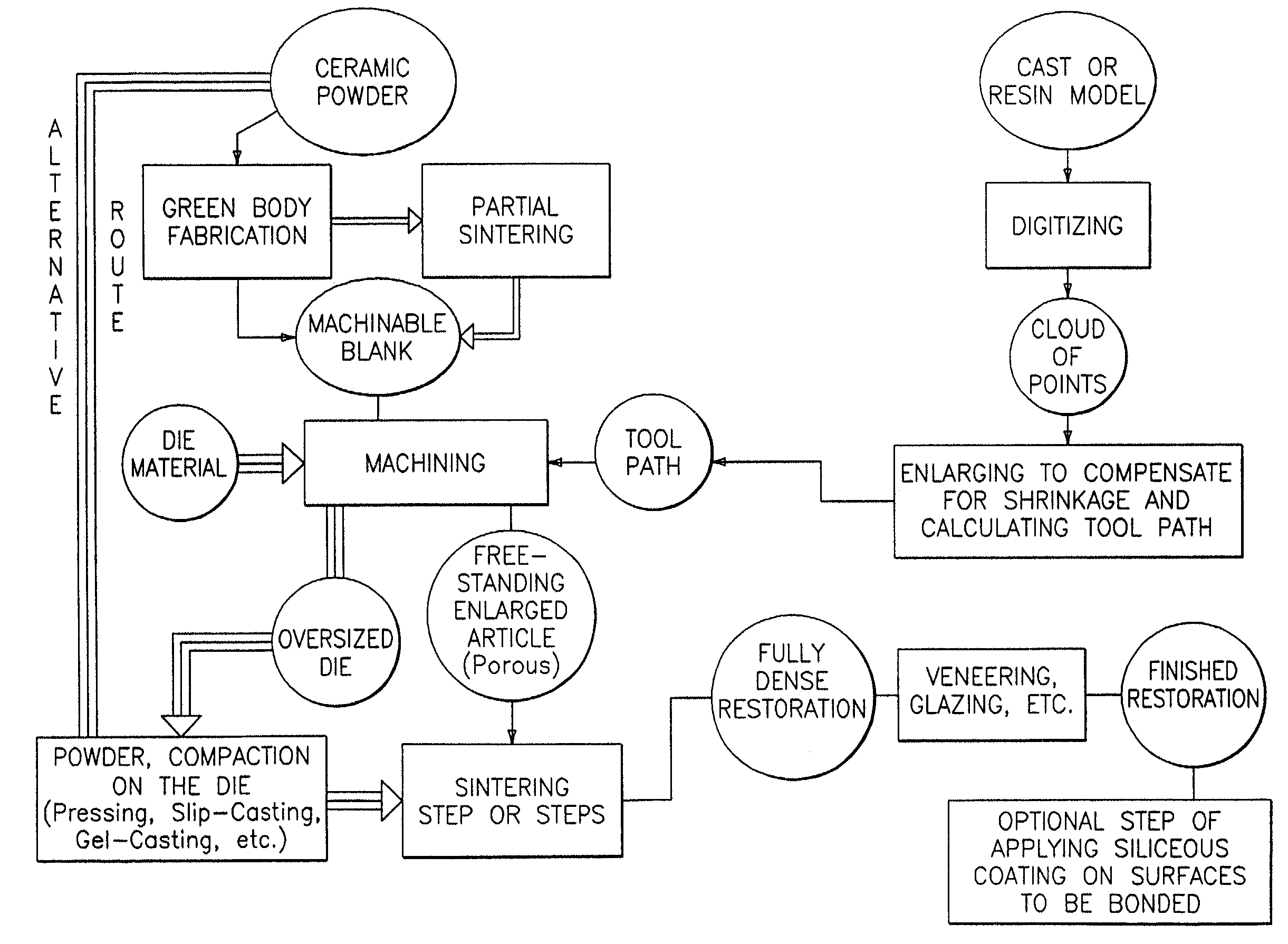

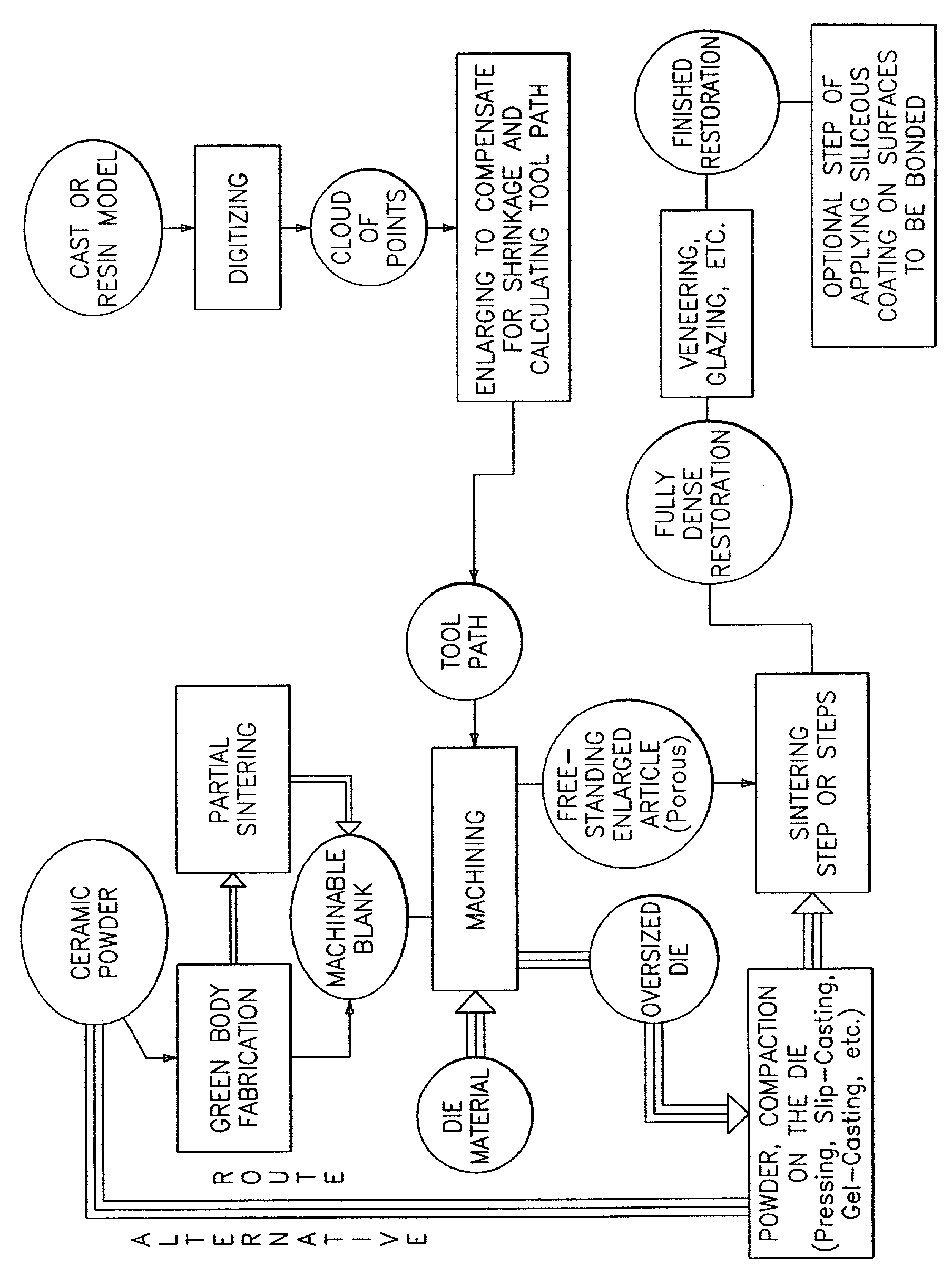

Methods of producing dental restorations using CAD/CAM and manufactures thereof

InactiveUS7011522B2High strengthEasy millingTeeth fillingArtificial teethMulliteVolumetric Mass Density

Ceramic precursor powders are combined with a binder and pressed into blocks or similar shapes to form green bodies. The ceramic powders consist of fairly uniform particles thoroughly dispersed to be essentially free of agglomerates such that it will sinter predictably and isotropically without appreciable distortion. The green bodies may be soft-sintered to a bisque density less than about eighty five percent of the final density. The soft-sintered blocks are then milled to a desired shape and sintered to a final density rendering a high strength dental restorative material. The material may be aluminum oxide, partially stabilized zirconium oxide, mixtures of the two, mullite or any suitable oxide that may be sintered to high strength (i.e., greater than 250 MPa).

Owner:IVOCLAR VIVADENT MFG

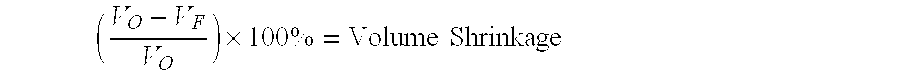

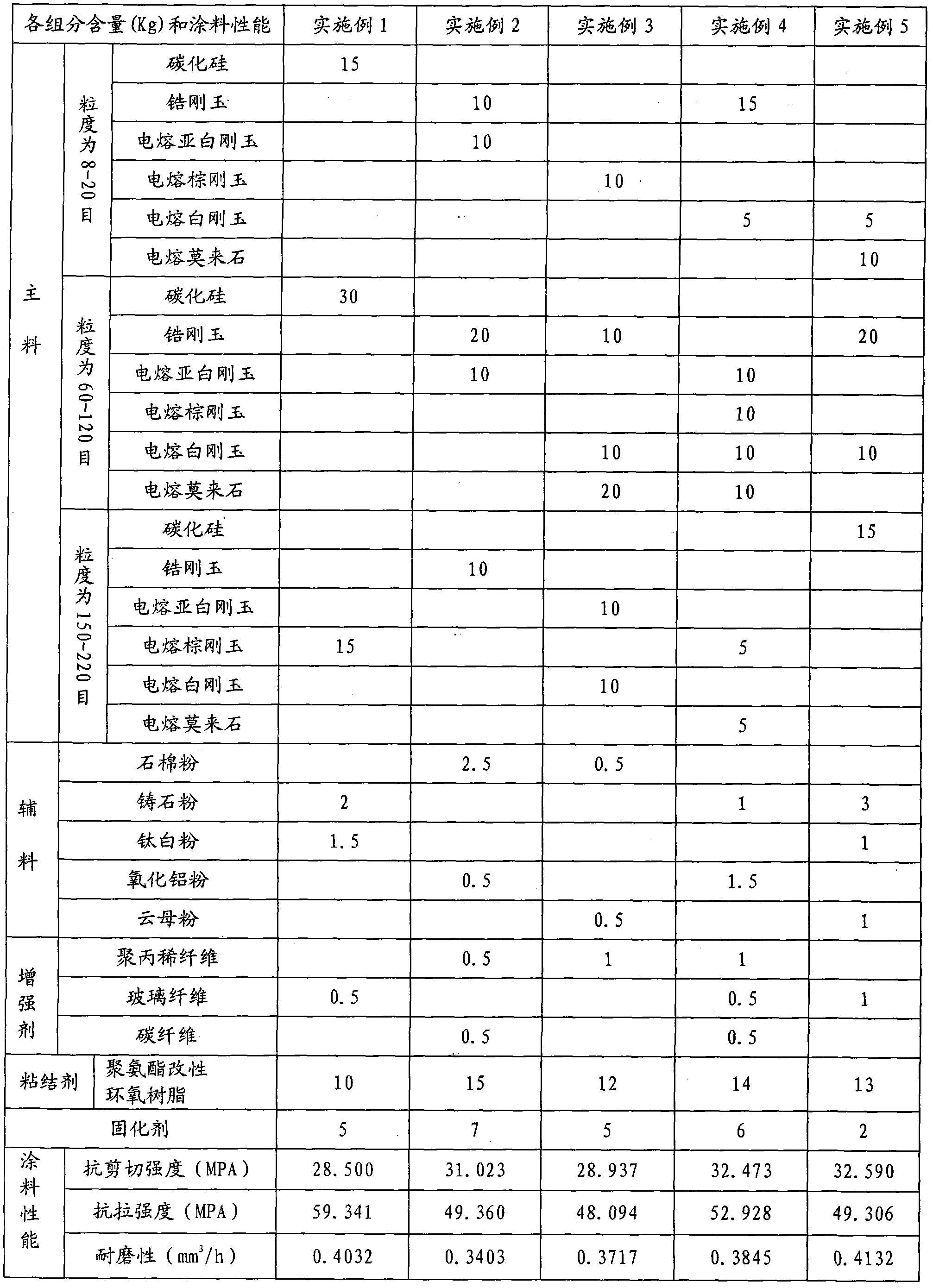

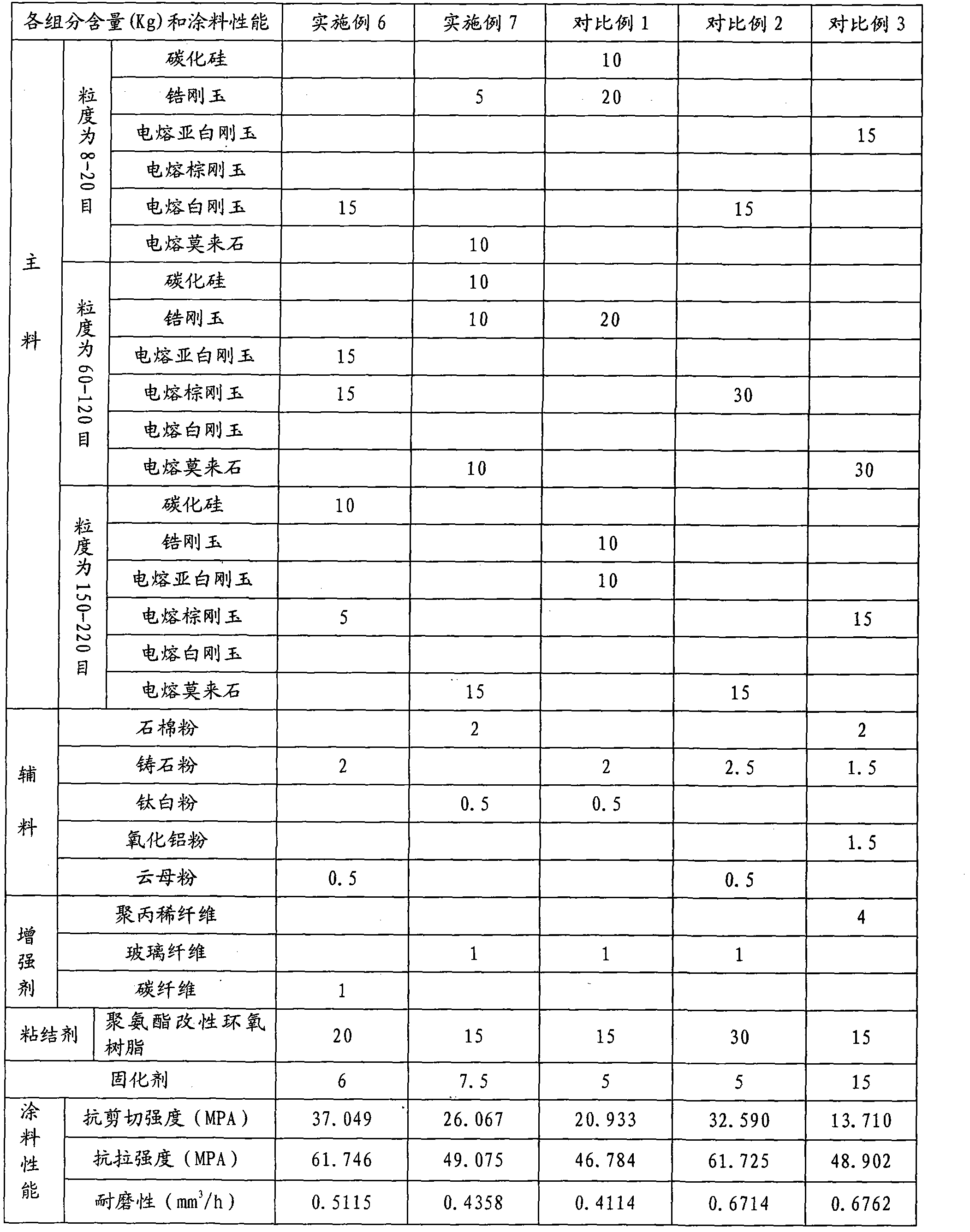

Polymer wear-resistance coating material

ActiveCN102040901AReduce operating costsReduce labor intensityEpoxy resin coatingsEpoxyCarbon fibers

The invention relates to a polymer wear-resistance coating material, which is a coating material consisting of a component A and a component B, wherein the component B is a solidifier, and the weight part of the component B is 2 to 10 percent of that of the component A; the component A consists of 40 to 80 weight parts of a main ingredient which is one or more mixed in random ratio of silicon carbide, fused zirconia alumina, fused sub-white corundum, fused brown aluminium oxide, fused white corundum and fused mullite, 1 to 5 weight parts of an auxiliary material which is one or more mixed in a random ratio of asbestos powder, glass-ceramic powder, titanium white, aluminium oxide powder and mica powder, 0.5 to 2 weight parts of reinforcing agent which is one ore more mixed in a random ratio of polypropylene fibers, glass fibers and carbon fibers, and 10 to 20 weight parts of a bonding agent which is polyurethane modified epoxy resin. The construction and use of the coating material are convenient and quick, the bonding strength of the coating material is high and the use cost of the coating material is low; and the coating material has high wear resistance, corrosion resistance and air corrosion resistance.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

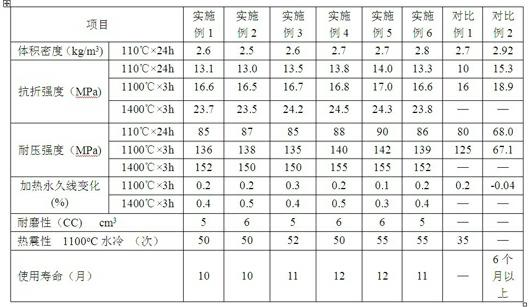

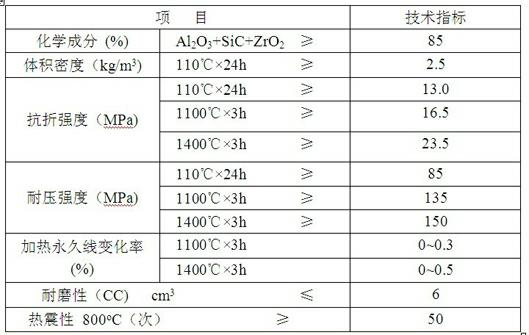

High-temperature wearable composite dope for electric power boiler flue

The invention relates to a high-temperature wear-resistant composite coating for the flue of an electrical furnace, belonging to the high-temperature coating field. The invention enhances the strength and toughness of the material, improves the high-temperature performance of the material and forms mullite net compound structure under high temperature condition by using modern composite material principle and a coupling method by particle enhancing and fiber toughness increasing and adding high-performance material and using nano-compound powder as bonding and using hard high-strength particle as enhancer, further, the invention can also improves the volume stability and the rear resistant performance in high temperature, and prolongs service life. The invention is especially suitable for the flue of a furnace, and has the advantages of high refractoriness, wear-resistant performance, excellent high temperature performance, stable volume, high strength, good toughness, prolonging service life of the material, reducing maintenance times for the flue, and labor saving.

Owner:LUOYANG KENAI HIGH TEMPERATURE MATERIAL

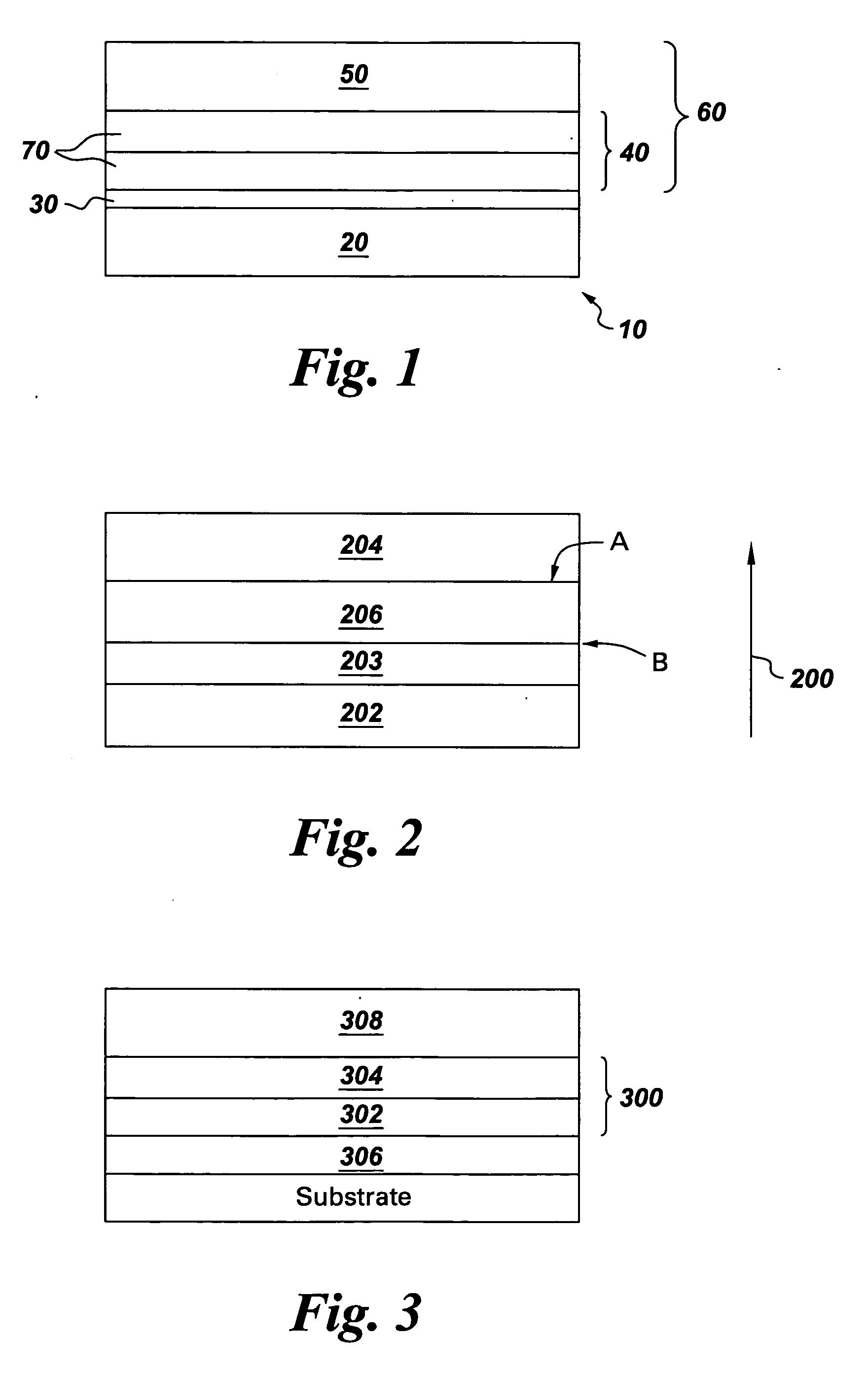

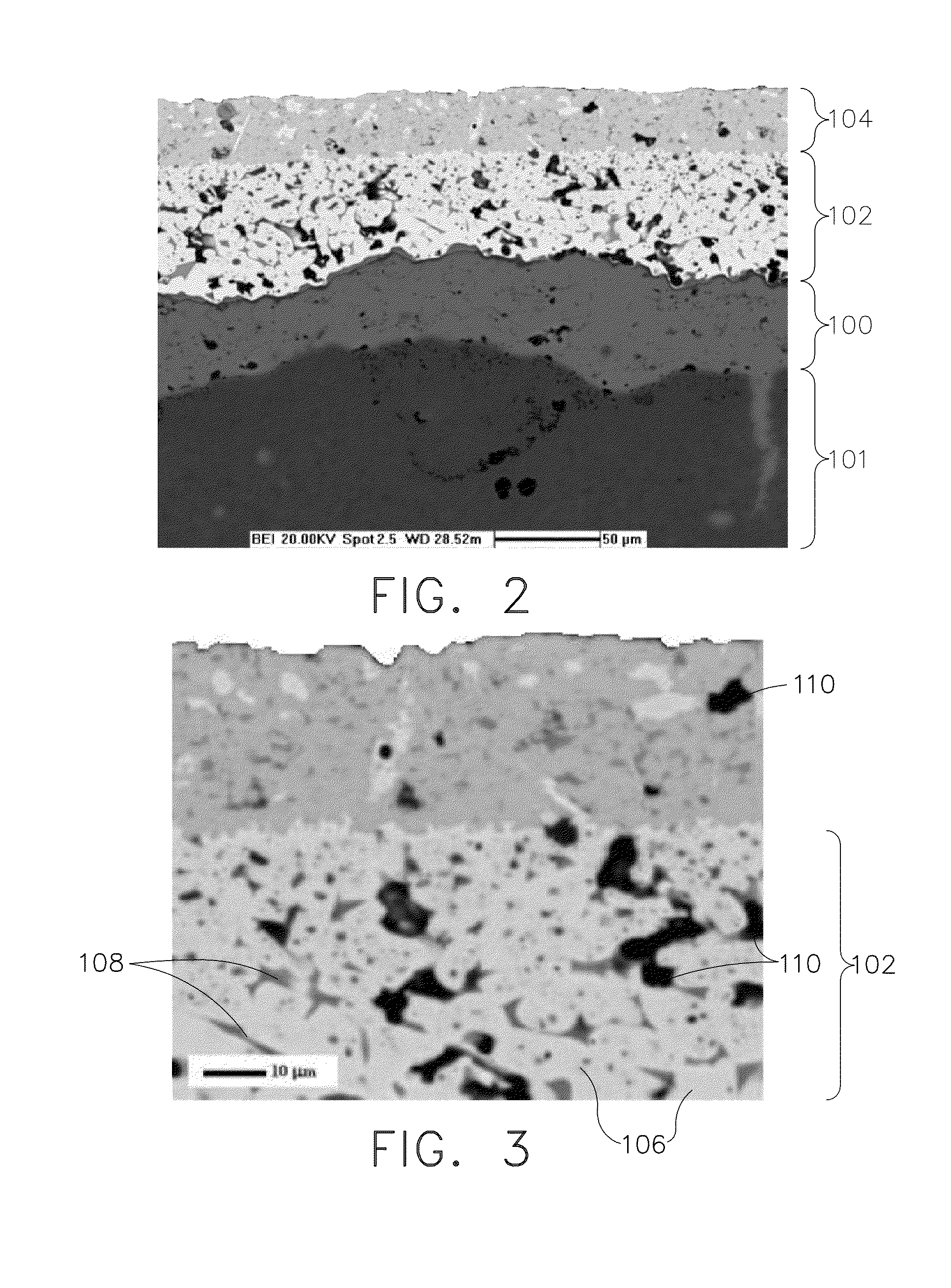

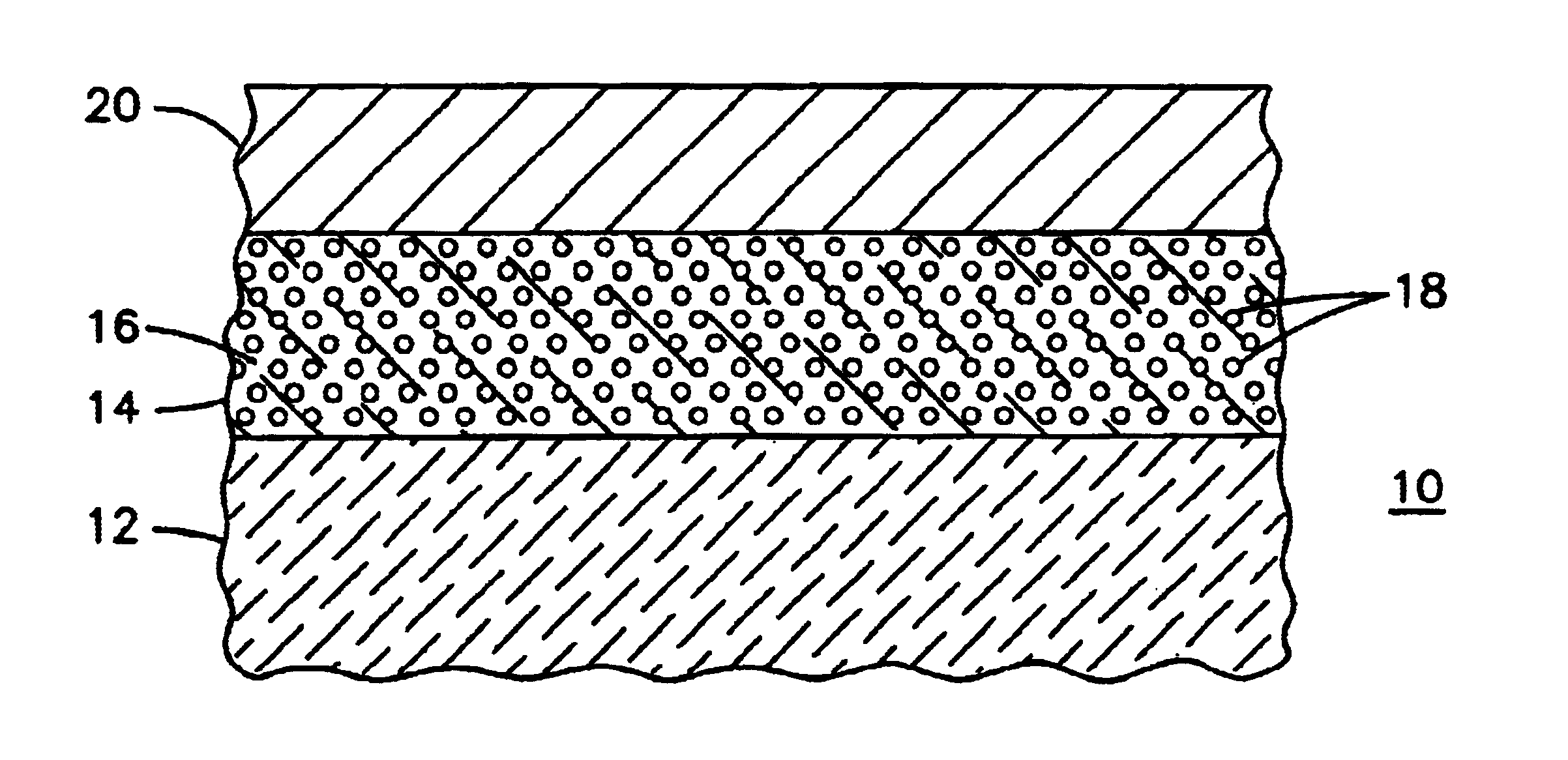

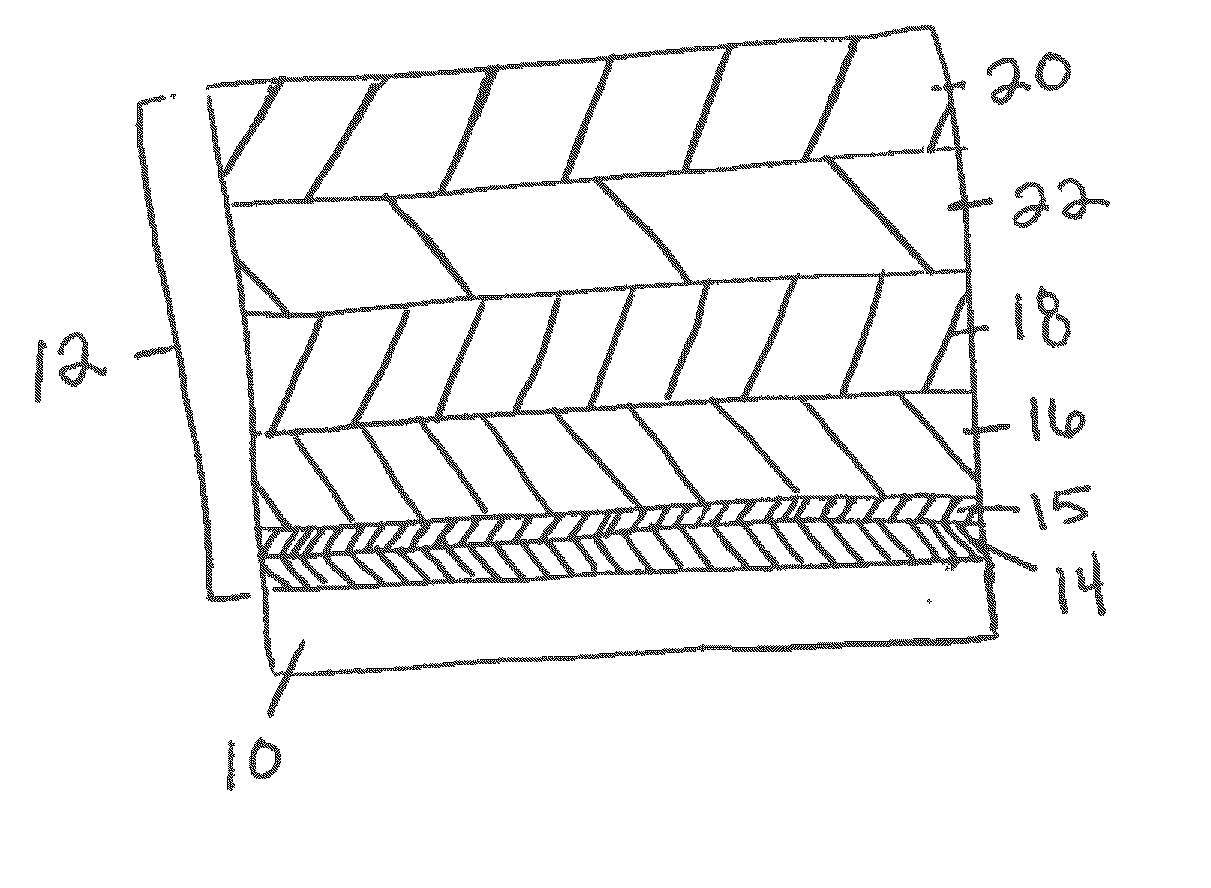

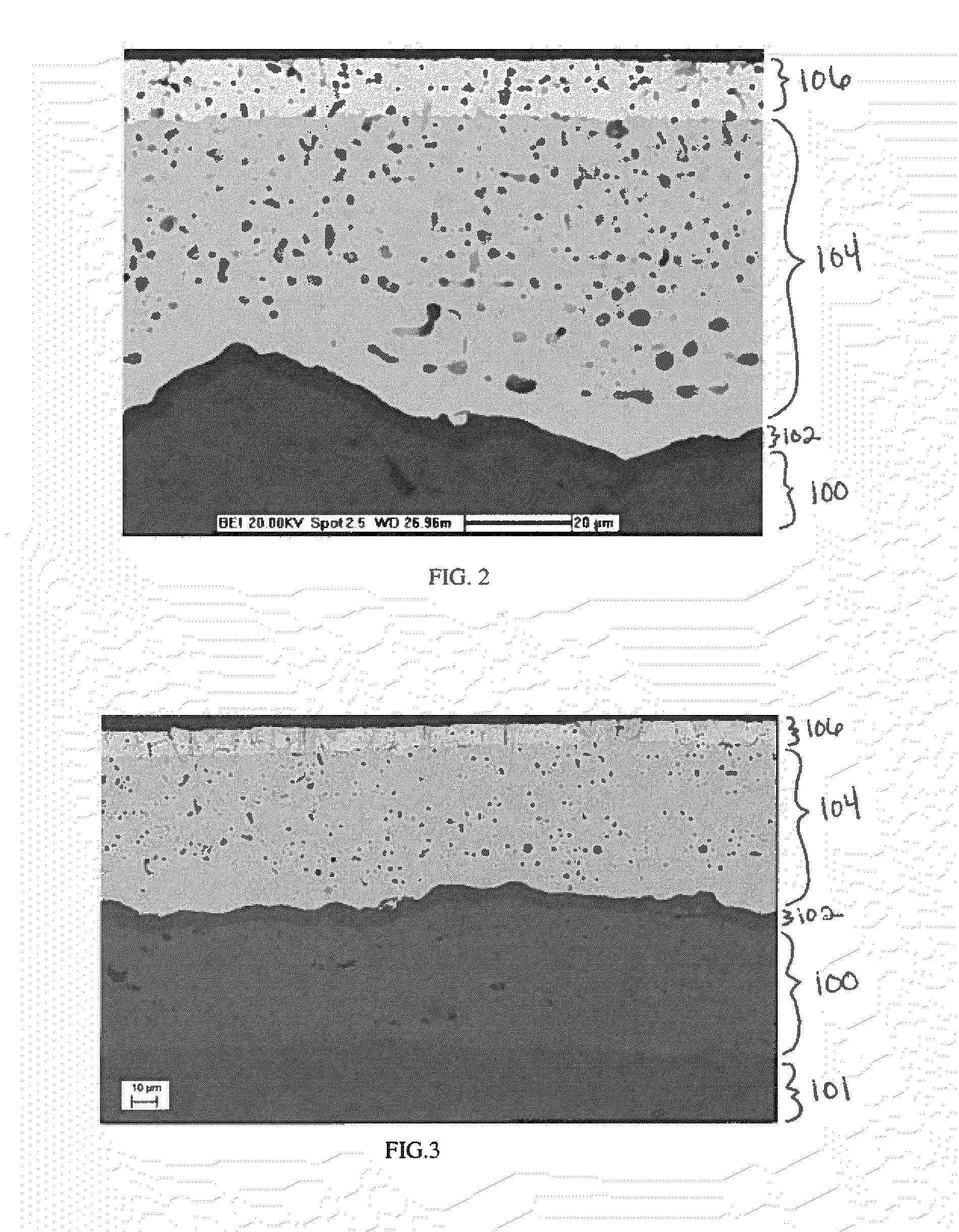

Bond coat for silicon-containing substrate for EBC and processes for preparing same

ActiveUS20060280953A1Improve adhesionHigh melting pointLiquid surface applicatorsMolten spray coatingCalcium silicateAlkaline earth metal

An article comprising a silicon-containing substrate, a silicide-containing bond coat layer overlying the substrate, and typically an environmental barrier coating overlaying the bond coat layer. An article is also provided wherein the environmental barrier coating comprises: (1) an optional inner silica scale layer overlaying the bond coat layer; (2) intermediate layer overlaying the inner silica scale layer, or the bond coat layer in the absence of the inner silica scale layer, and comprising mullite, or a combination of mullite with a barium strontium aluminosilicate, a yttrium silicate, or a calcium aluminosilicate; and (3) an outer steam-resistant barrier layer overlaying the intermediate layer and consisting essentially of an alkaline earth silicate / aluminosilicate. Processes are also provided for forming the silicide-containing bond coat layer over the substrate, followed by forming the environmental barrier coating over the bond coat layer.

Owner:GENERAL ELECTRIC CO

Abrasion-proof fire-resistant moldable refractory

The invention relates to an improvement to abrasion-resistant fireproof plastic, which is characterized in that the invention comprises 60-80wt percent of corundum and / or porzite and / or Al2O3 larger than or equal to 80 percent of bauxite clinker, 5-10wt percent less than or equal to4 micron of alumina micro-powder, 6-15wt percent less than or equal to 0.025mm of chromium corundum fine powder, 2-6wt percent less than or equal to1micron of silicon fine powder, 5-10wt percent of kyanite or andalusite or silimanite, 12-15wt percent of aluminium dihydrogen phosphate or aluminium sulfate wedding agent, and 0.5-3wt percent of calcium aluminate or bauxite cement coagulant. Compared with the prior art, the abrasion-resistant fireproof plastic has the advantages of high compressive strength, good wear-resisting property, high temperature used and strong slag resistance and anti-etching power, thereby greatly prolonging the service life and meeting the use with higher requirements.

Owner:江苏国窑科技有限公司

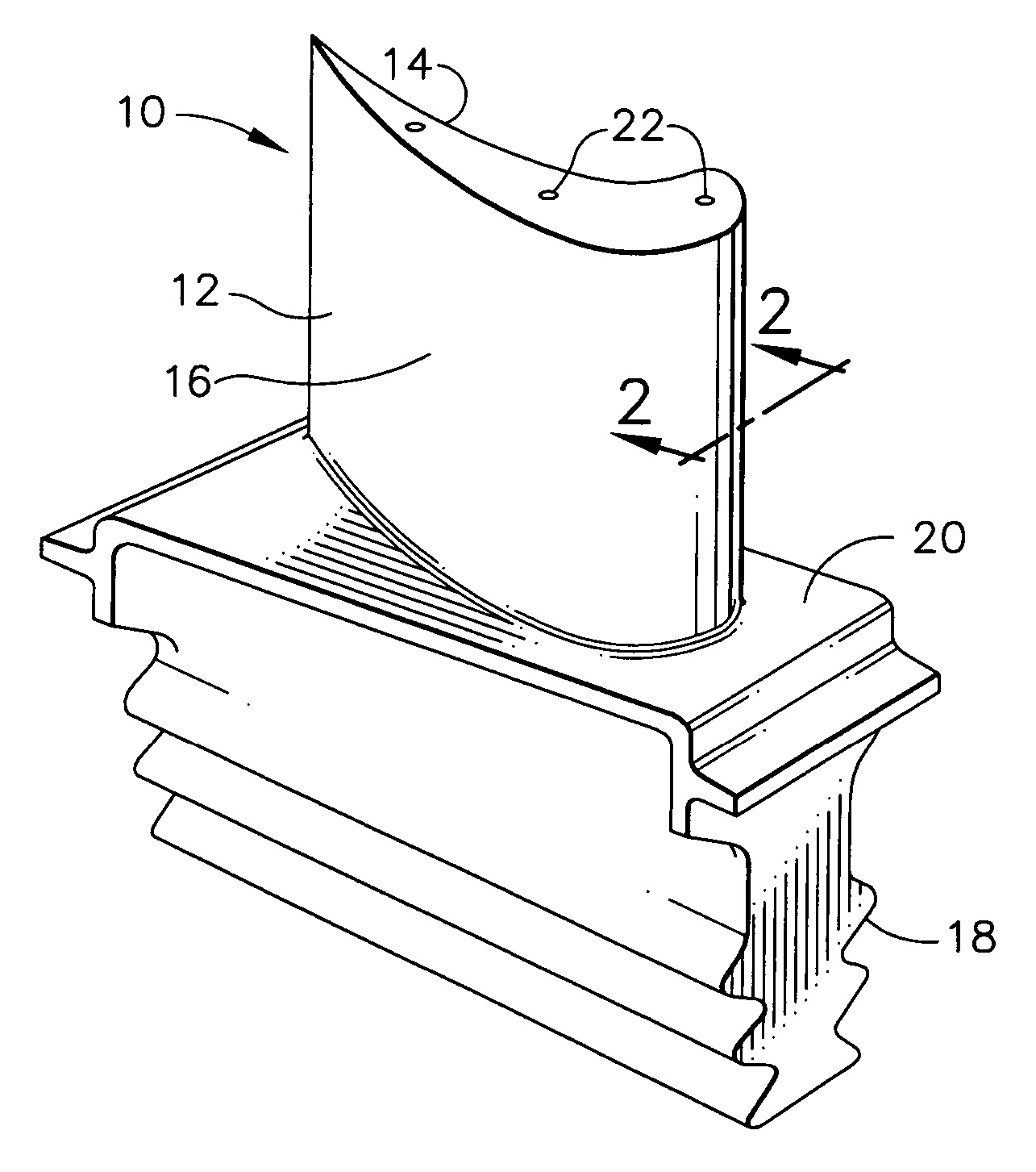

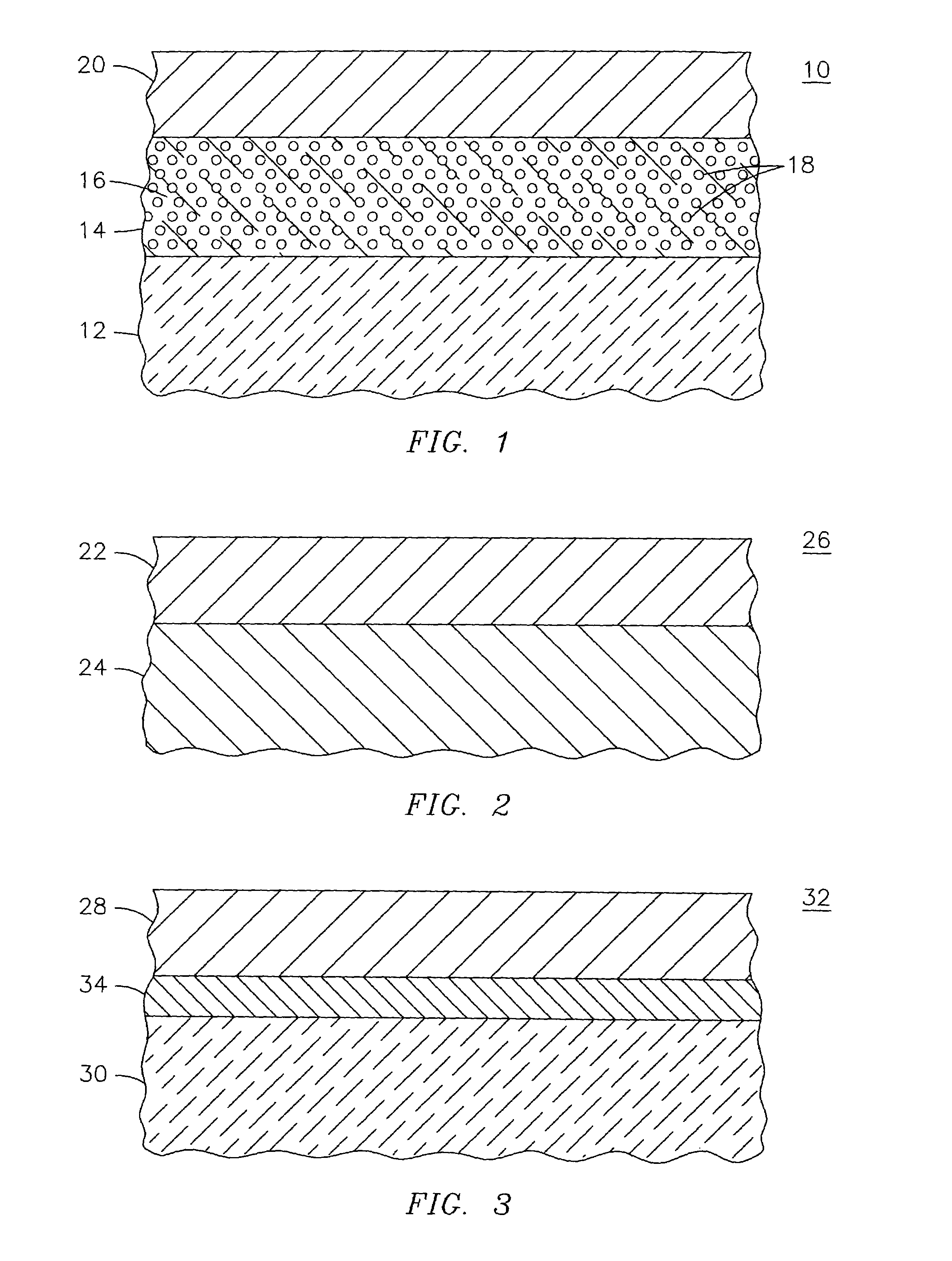

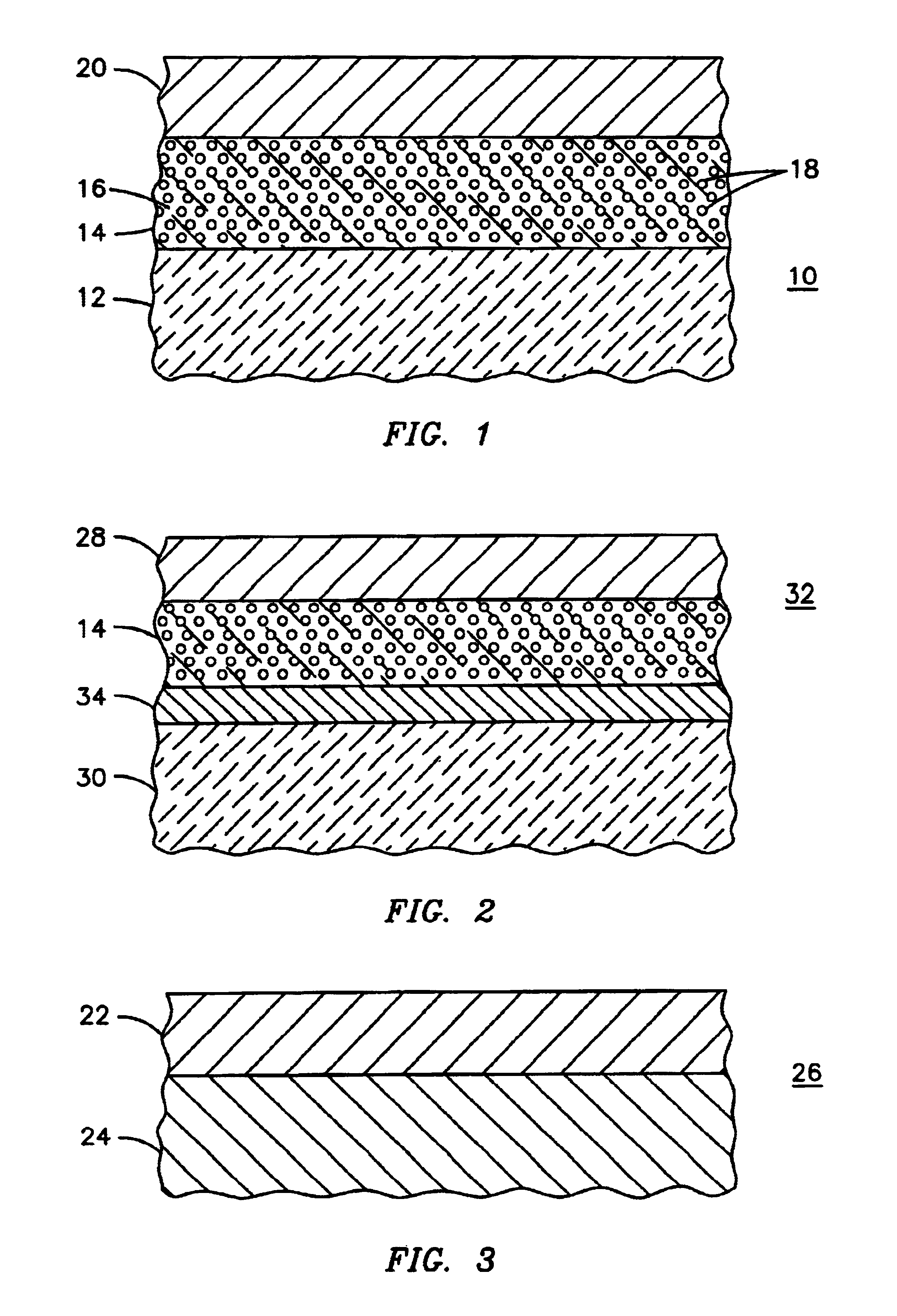

Protective overlayer for ceramics

A xenotime phosphate protective overlayer (22) for protecting a ceramic material (24) from a high temperature, moisture-containing environment. Yttrium phosphate may be used as a protective overlayer to protect an underlying mullite layer to temperatures in excess of 1,500° C. The coating may have porosity of greater than 15% for improved thermal shock protection. To prevent the ingress of oxygen to an underlying ceramic non-oxide material, such as silicon carbide or silicon nitride, an oxygen barrier layer (34) is disposed between the xenotime phosphate coating and the non-oxide material. Such a protective overlayer may be used for an article having a ceramic matrix composite substrate.

Owner:SIEMENS ENERGY INC

Water based environmental barrier coatings for high temperature ceramic components

Environmental barrier coatings for high temperature ceramic components including: a bond coat layer; an optional silica layer; and at least one transition layer including: from about 85% to about 100% by volume of the transition layer of a primary transition material selected from a rare earth disilicate, or a doped rare earth disilicate; and from 0% to about 15% by volume of the transition layer of a secondary material selected from Fe2O3, iron silicates, rare earth iron oxides, Al2O3, mullite, rare earth aluminates, rare earth aluminosilicates, TiO2, rare earth titanates, Ga2O3, rare earth gallates, NiO, nickel silicates, rare earth nickel oxides, Lnb metals, Lnb2O3, Lnb2Si2O7, Lnb2SiO5, borosilicate glass, alkaline earth silicates, alkaline earth rare earth oxides, alkaline earth rare earth silicates, and mixtures thereof; where the transition layer is applied to the component as a slurry including at least water, the primary transition material and at least one slurry sintering aid, and where a reaction between the slurry sintering aid and the primary transition material results in the transition layer having a porosity of from 0% to about 15% by volume of the transition layer.

Owner:GENERAL ELECTRIC CO

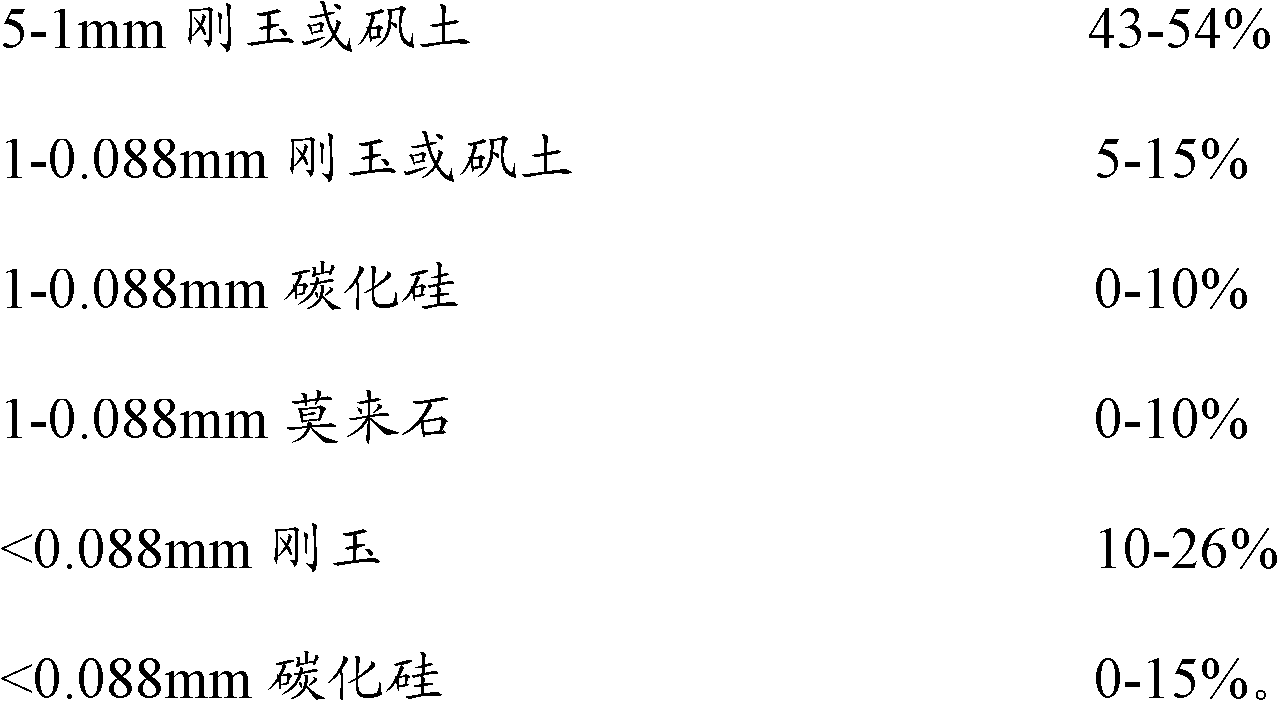

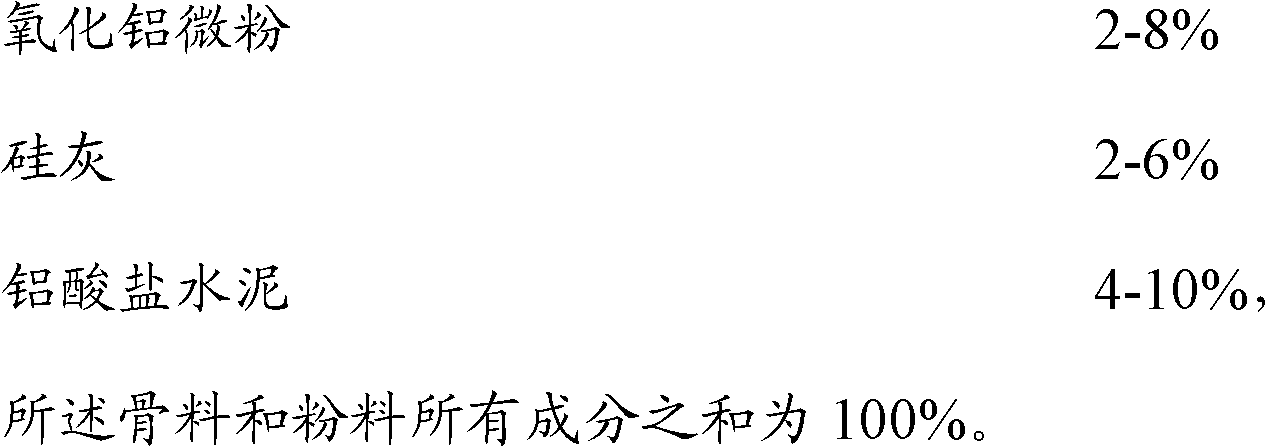

Abrasion resistant ceramic coating

The invention discloses a brushing-proof abrasion-proof and erosion-proof ceramic paint, which is characterized by the following: selecting at least one of electric-melting brown corundum, electric-melting subwhite corundum, electric-melting white corundum, carborundum and electric melting mullite with different grain sizes as main material and at least one of compact corundum, electric-melting subwhite corundum, electric-melting white corundum, carborundum, silicon nitride and boron nitride as auxiliary material; using CA50 calcium aluminate cement or pure calcium aluminate cement as binder and nanometer micro-silica powder and active alpha-Al2O3 micropowder as reinforcer; making hyperdrying active high-effective dehydragent, sodium citrate and sodium hexametaphosphate as composite additive; loading in the strength stirrer to stir 12-17min; blending evenly; packing.

Owner:CHONGQING LUOMAN NEW MATERIAL TECH CO LTD

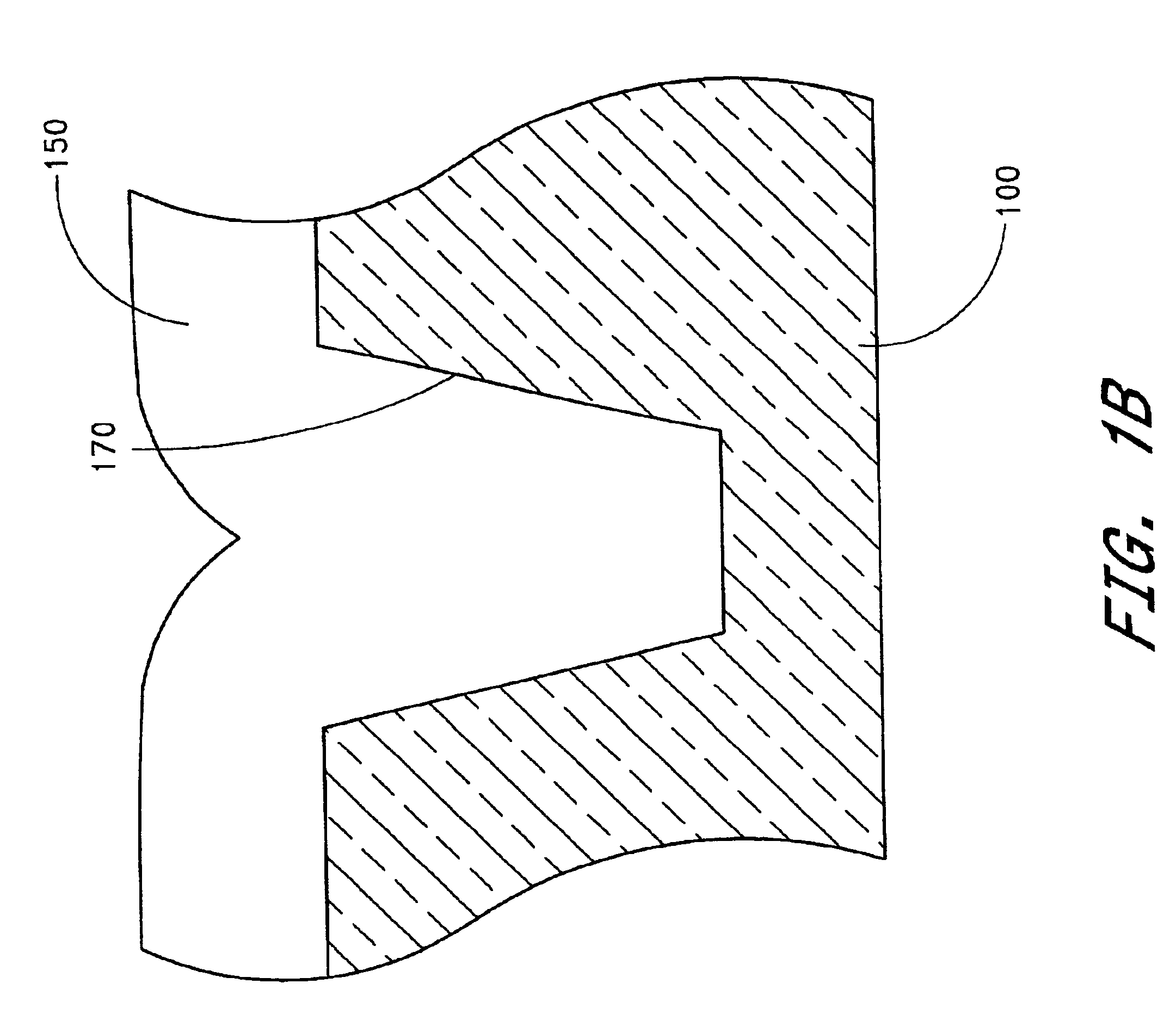

Highly porous mullite particulate filter substrate

A typically monolithic particulate filter including a highly porous block made primarily of intertangled polycrystalline mullite fibers, a set of channels formed through the block, and a set of porous walls separating adjacent channels. Exhaust gas is flowed through the channels and interacts with the walls such that particulate matter carried in the exhaust gas, such as soot particles, is screened out by porous fibrous mullite walls.

Owner:GE02 TECH INC

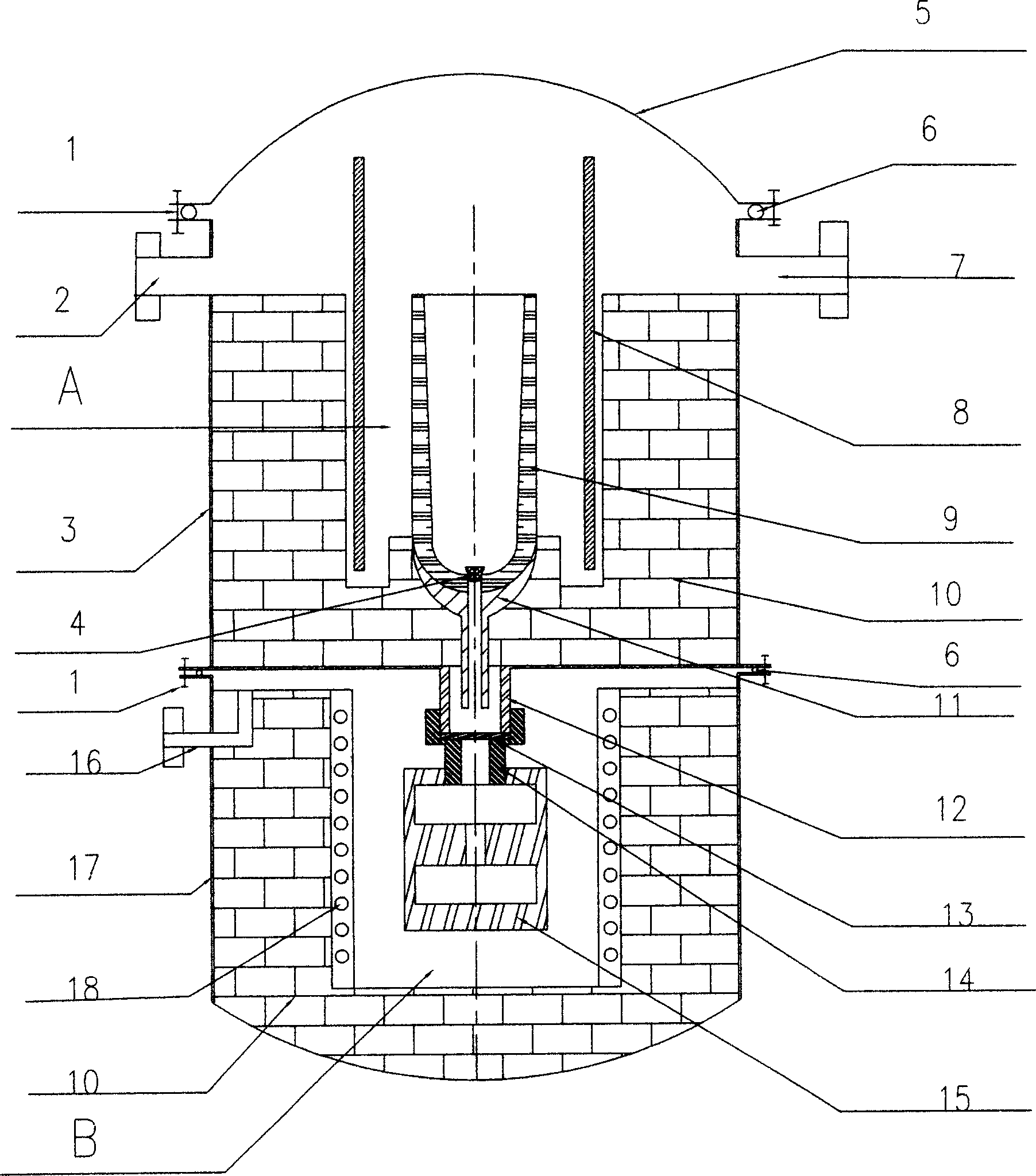

3D networked vacuum-air pressure method for casting friction composite material of ceramics-metals

A vacuum-pneumatic casting method for the 3D network shaped ceramic-metal friction material includes such steps as pretreating the 3D network shaped ceramic skeleton made of SiC, B4C, Si3N4, Al2O3, ZrO2, or mullite ceramic by surficial preoxidizing, inorganic modifying, electroplating, or powder metallurgical, providing metal chosen from Al, Al alloy, Cu alloy, Ti alloy and iron or steel, pretreating mould, and smelting-casting in vacuum-pneumatic furnace.

Owner:NORTHEASTERN UNIV

Lightweight dry refractory

A dry refractory composition having superior insulating value. The dry refractory composition also may have excellent resistance to molten metals and slags. The composition includes filler lightweight material, which may be selected from perlite, vermiculite, expanded shale, expanded fireclay, expanded alumina silica hollow spheres, bubble alumina, sintered porous alumina, alumina spinel insulating aggregate, calcium alumina insulating aggregate, expanded mulllite, cordierite, and anorthite, and matrix material, which may be selected from calcined alumina, fused alumina, sintered magnesia, fused magnesia, silica fume, fused silica, silicon carbide, boron carbide, titanium diboride, zirconium boride, boron nitride, aluminum nitride, silicon nitride, Sialon, titanium oxide, barium sulfate, zircon, a sillimanite group mineral, pyrophyllite, fireclay, carbon, and calcium fluoride. The composition also may include dense refractory aggregate, which may be selected from calcined fireclay, calcined Chamotte, a sillimanite group mineral, calcined bauxite, pyrophyllite, silica, zircon, baddeleyite, cordierite, silicon carbide, sintered alumina, fused alumina, fused silica, sintered mullite, fused mullite, fused zirconia, sintered zirconia mullite, fused zirconia mullite, sintered magnesia, fused magnesia, sintered spinel, and fused spinel refractory grog, a heat activated bonding agent, and a dust suppressant.

Owner:ALLIED MINERAL PROD

Bond coat for silicon-containing substrate for EBC and processes for preparing same

ActiveUS7442444B2Improve adhesionHigh melting pointMolten spray coatingVacuum evaporation coatingCalcium silicateAlkaline earth metal

An article comprising a silicon-containing substrate, a silicide-containing bond coat layer overlying the substrate, and typically an environmental barrier coating overlaying the bond coat layer. An article is also provided wherein the environmental barrier coating comprises: (1) an optional inner silica scale layer overlaying the bond coat layer; (2) intermediate layer overlaying the inner silica scale layer, or the bond coat layer in the absence of the inner silica scale layer, and comprising mullite, or a combination of mullite with a barium strontium aluminosilicate, a yttrium silicate, or a calcium aluminosilicate; and (3) an outer steam-resistant barrier layer overlaying the intermediate layer and consisting essentially of an alkaline earth silicate / aluminosilicate. Processes are also provided for forming the silicide-containing bond coat layer over the substrate, followed by forming the environmental barrier coating over the bond coat layer.

Owner:GENERAL ELECTRIC CO

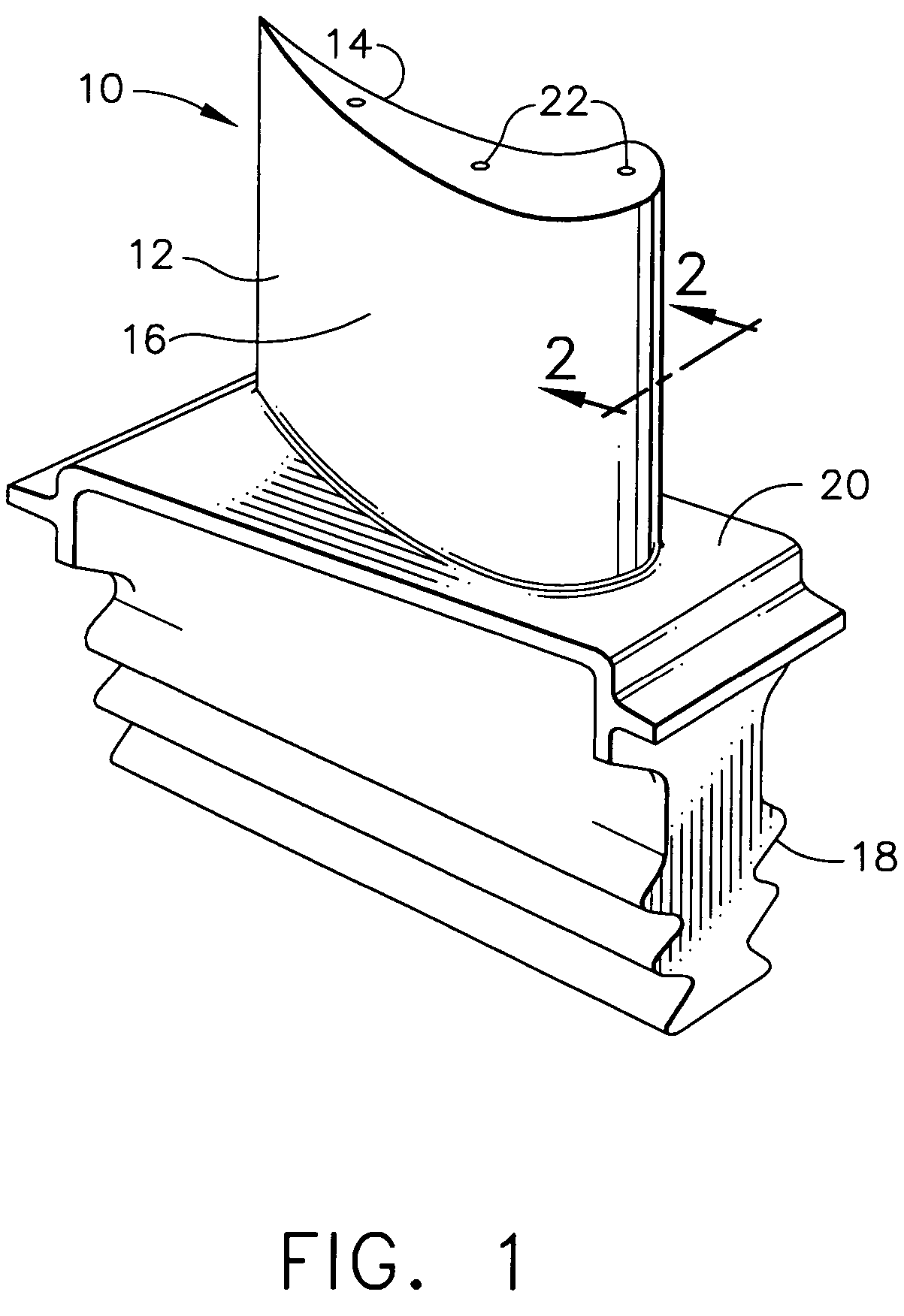

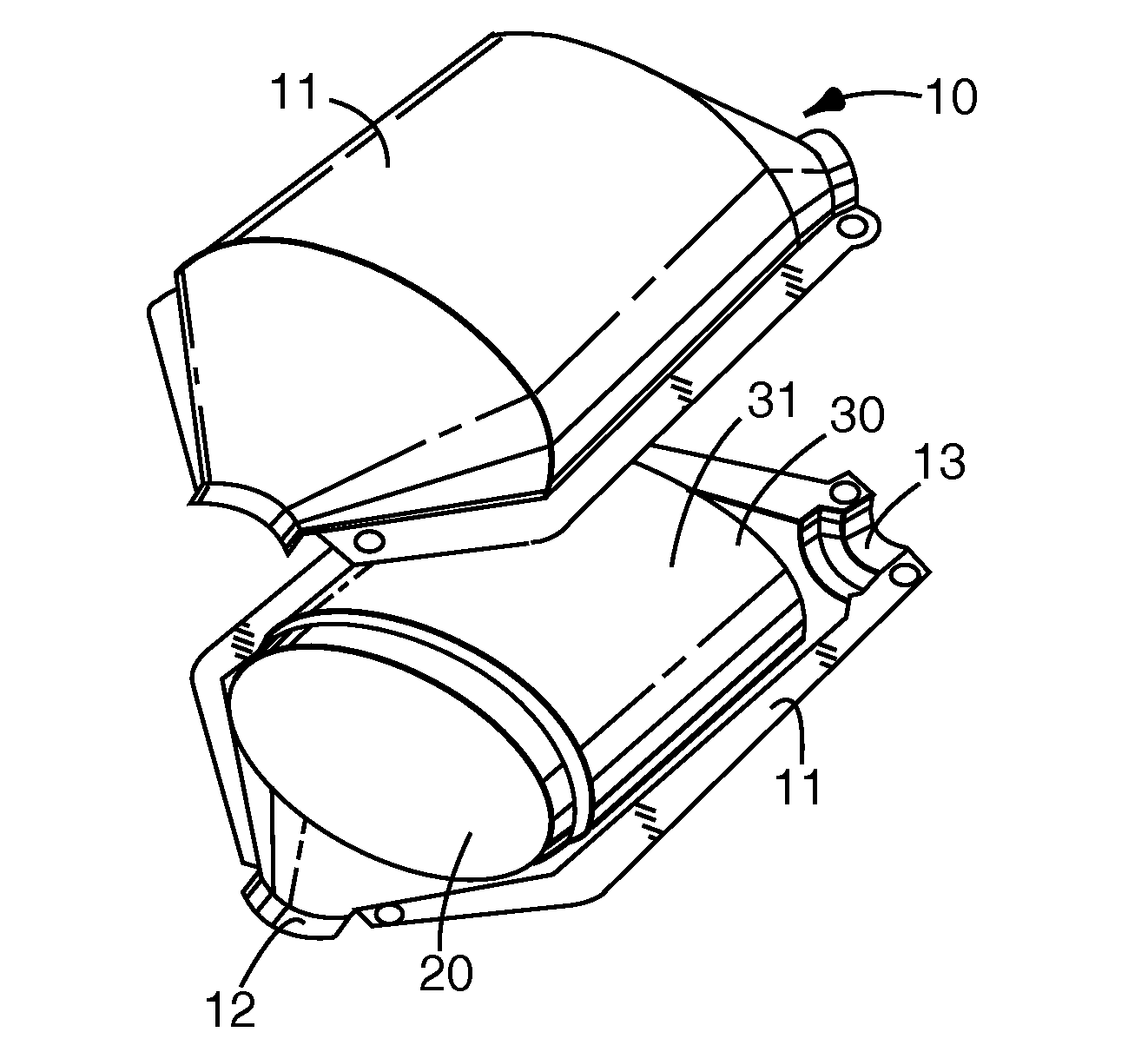

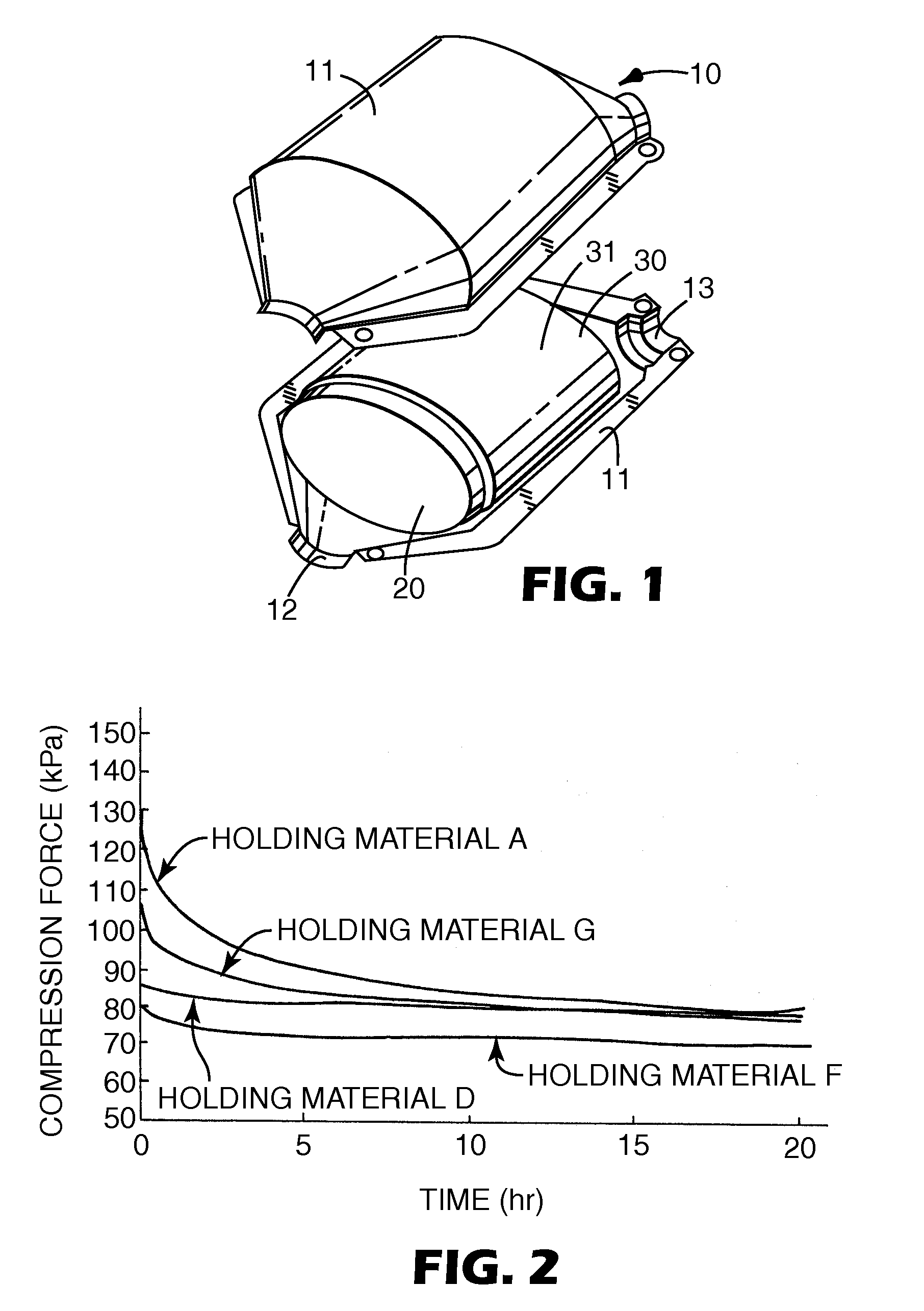

Catalyst carrier holding material and catalytic converter

ActiveUS7261864B2Improve stress resistanceExcellent wind erosion resistanceCombination devicesPhysical/chemical process catalystsFiberHeat resistance

To provide a catalyst carrier holding material which is particularly useful for catalytic converters, by exhibiting heat resistance and high compression resistance in high temperature ranges, as well as excellent wind erosion resistance. The catalyst carrier holding material comprises inorganic fibers comprising alumina and silica, and the mullite ratio of the inorganic fibers is in the range of greater than 30% and less than 75%, and preferably in the range of 35% to 70%.

Owner:3M INNOVATIVE PROPERTIES CO

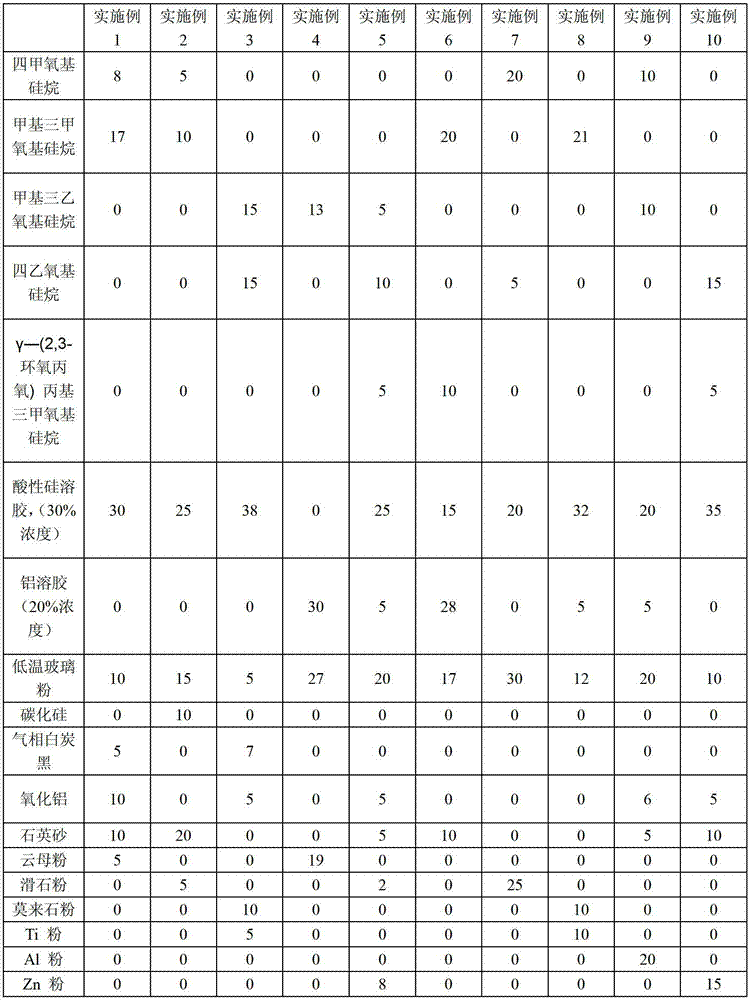

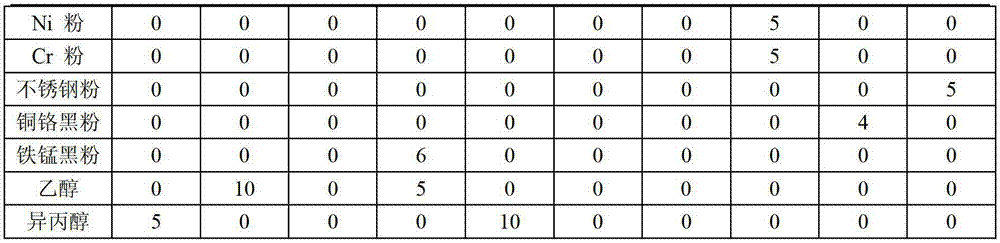

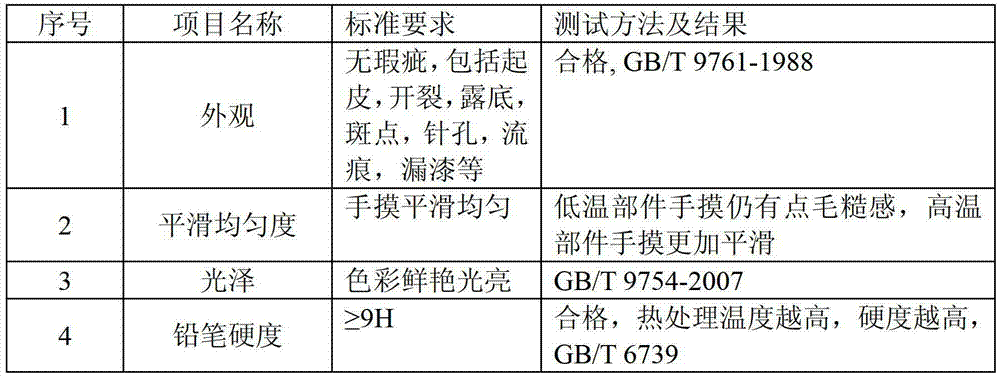

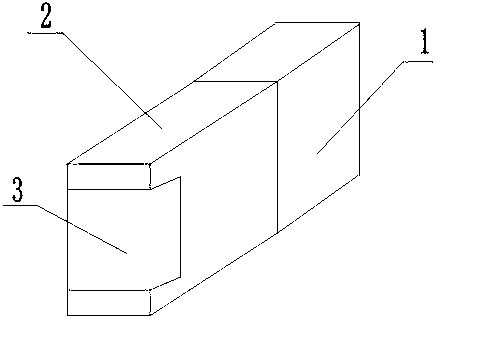

High temperature resistant coating for engine exhaust system

The invention relates to a high temperature resistant coating for an engine exhaust system. The high temperature resistant coating is characterized by being prepared through at least one step by mixing the following raw materials in parts by weight: 10-80 parts of base materials, 10-80 parts of ceramic materials and 5-30 parts of low-temperature glass powder, wherein the base materials include 10-50 parts by weight of silicon sol and 0-30 parts by weight of aluminum sol; and the ceramic materials include at least one of quartz sand, aluminum oxide, silicon carbide, talcum powder, kaolin powder, mullite powder and mica powder.Compared with an organic silicon coating, the high temperature resistant coating disclosed by the invention has better high temperature resistance because the silicon sol or the mixture of the silicon sol and the aluminum sol is used as the base material in the raw materials; the high temperature resistant coating disclosed by the invention is compact in structure, can be used at a temperature higher than 600 DEG C, has the advantages of anti-corrosive properties, namely salt-fog resistance, acid resistance, and the like, higher rigidity and abrasion resistance because various raw materials are mixed in appropriate proportion and synergistically play a role; and the high temperature resistant coating is matched with an engine material in thermal expansion coefficient, has good temperature and denaturalization resistance and is particularly suitable for engine anticorrosion.

Owner:SUZHOU NANODISPERSIONS

Low-heat-conduction multi-layer mullite brick and preparation method thereof

ActiveCN103234346ALow thermal conductivityHigh strengthFurnace componentsRotary drum furnacesBrickMullite

Owner:郑州瑞泰耐火科技有限公司

Special pouring material for coal injection pipe

The invention discloses a special pouring material for a kiln opening and belongs to the field of a refractory material. The special pouring material comprises the following components by weight percent: 10-25% of silicon carbide, 15-30% of andalusite, 20-35% of corundum, 5-15% of spinel powder, 5-10% of zircon mullite powder, 5-15% of aluminum oxide micro powder, 3-8% of silicon micro powder, 2-5% of pure calcium aluminate cement, and 0.5% and 0.2% of anti-explosion fibers and sodium tripolyphosphate serving as additives. The special pouring material is capable of efficiently improving the wear resistance and avoiding the hot peeling phenomenon of the cement kiln coal injection pipe, has the characteristics of high temperature resistance, heat vibration resistance, wear resistance, high strength, irreversible micro inflation, and the like, and is capable of greatly prolonging the service life of the cement kiln coal injection pipe.

Owner:ZHEJIANG KINGCRED NEW MATERIAL CO LTD

Porous ceramic membrane support with flat structure and preparation method thereof

ActiveCN102688700AReduce frictionAvoid accumulationSemi-permeable membranesPolyvinyl alcoholAdhesive

The invention relates to a porous ceramic membrane support with a flat structure and a preparation method thereof, and belongs to the technical field of ceramic membrane supports. The ceramic membrane support is flat and consists of two flat membrane supports; a certain space is reserved between the two flat membrane supports; at least one supporting column is distributed in the space; and at least one water outlet passage is formed in each flat membrane support, so that flowing resistance of filtrate in the support with the flat structure is reduced. The ceramic aggregate of the support is one or more of alumina, zirconia, silicon dioxide, silicon carbide, titanium oxide, mullite and cordierite; the pore-forming agent is starch, graphite, phenolic resin spheres and the like; and the adhesive is methylcellulose, polyvinyl alcohol and the like. The porosity of the prepared porous ceramic membrane support with the flat structure can reach 30 to 50 percent, the aperture is 20 to 200 nanometers, and the compressive strength can reach 20 to 40MPa; and the support can be used for substituting an organic hollow fiber membrane bioreactor, and has great potential application in the fields of sewage treatment, fine chemical industry and the like.

Owner:TSINGHUA UNIV +1

Composite bonding low-temperature constructional castable refractory

The invention relates to a composite bonding low-temperature constructional castable refractory, which can be used for high-temperature kiln engineering. According to the castable refractory, corundum, alumina, mullite and silicon carbide are used as an aggregate, silica sol is used as a bonding agent, aluminate cement is used as a curing agent and a bonding aid, and alumina micro powder, wollastonite, a deflocculant, a retarder, water and the like are added. The composite bonding low-temperature constructional castable refractory has high low-temperature constructional performance, high performance of high-temperature resistance, erosion resistance, thermal shock resistance and high mechanical performance, and meets the requirements of overhauling in winter on the premise that the service life of the castable refractory is not influenced.

Owner:ANHUI RUITAI NEW MATERIALS TECH

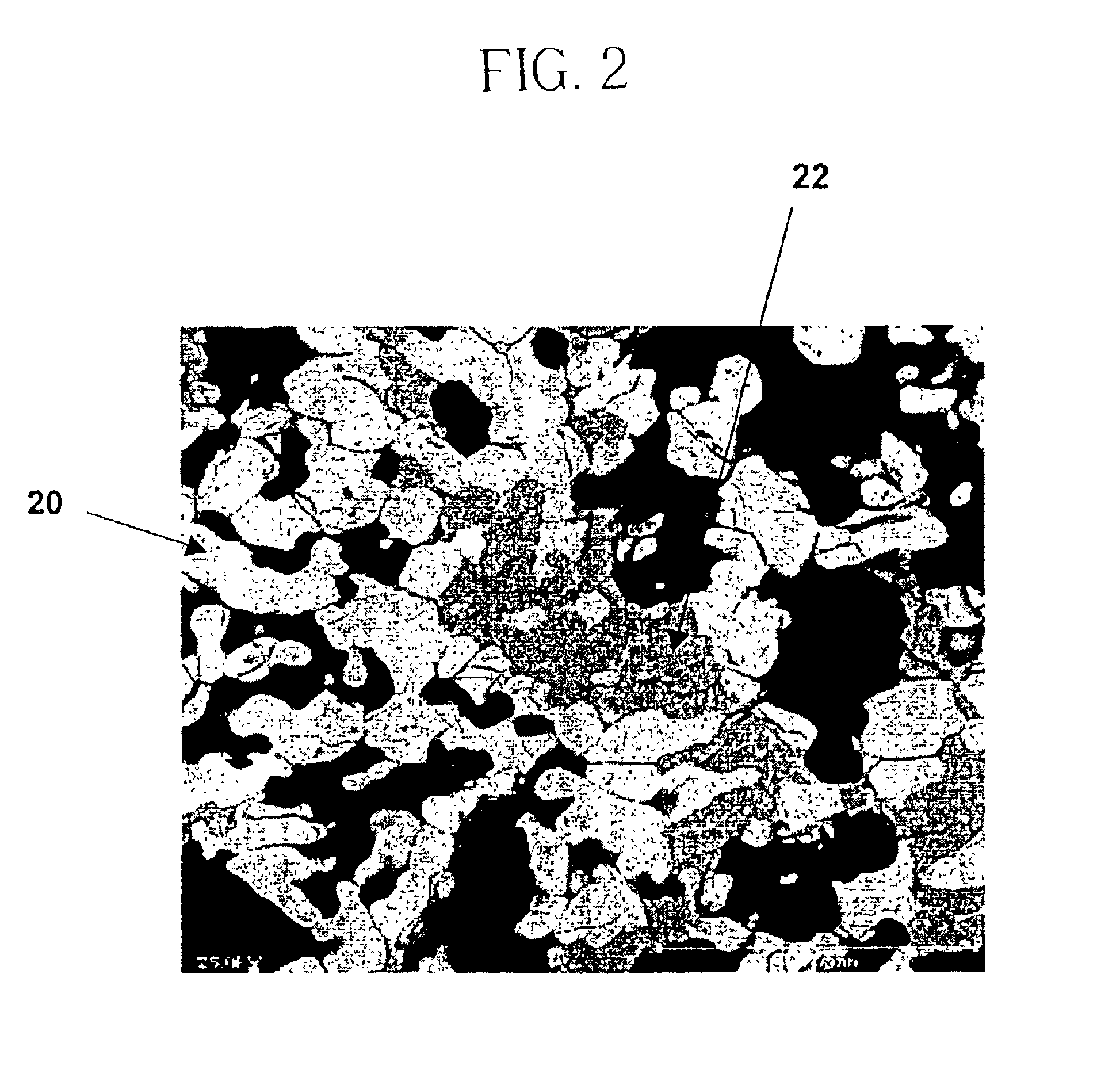

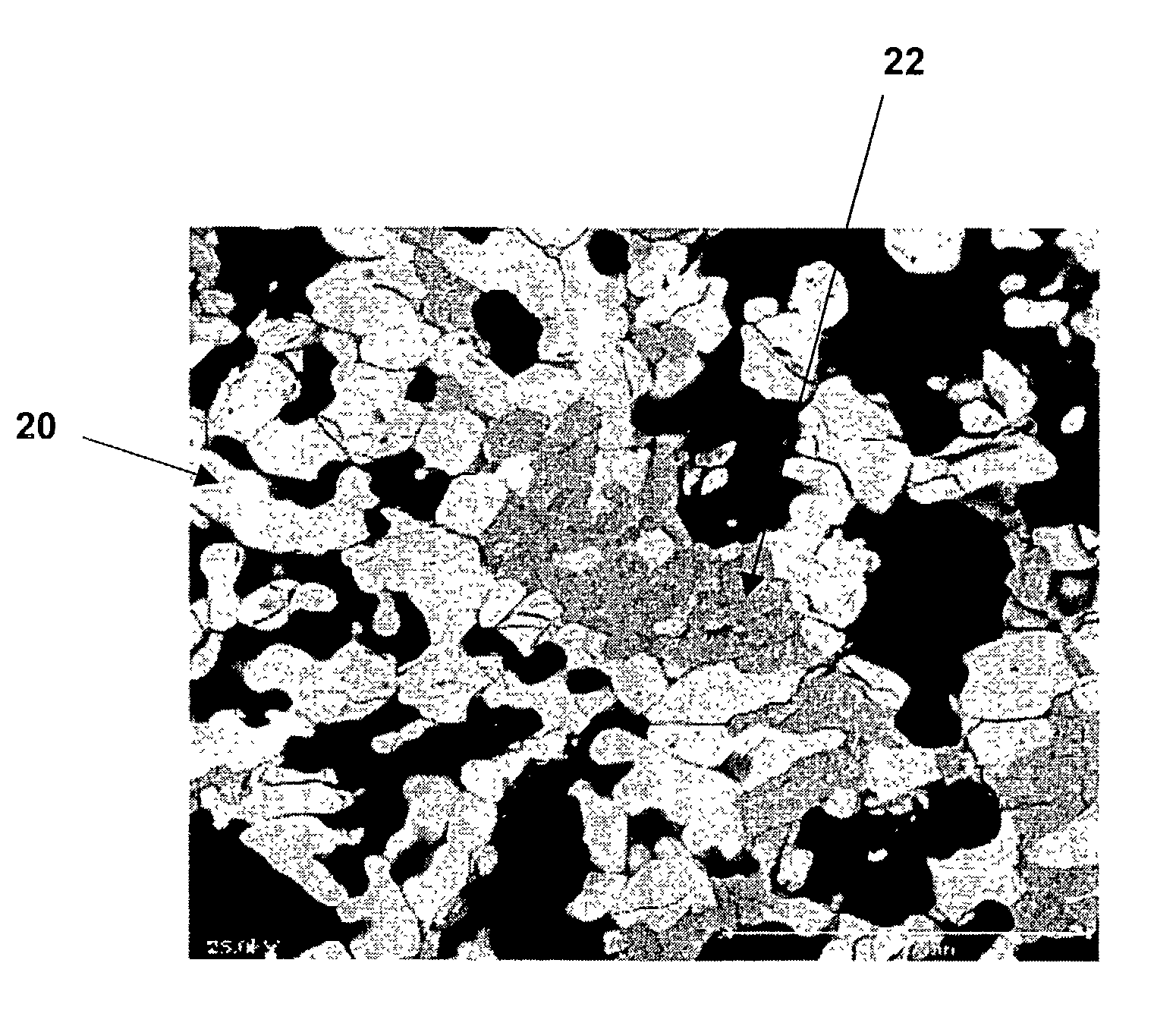

Porous mullite bodies and methods of forming them

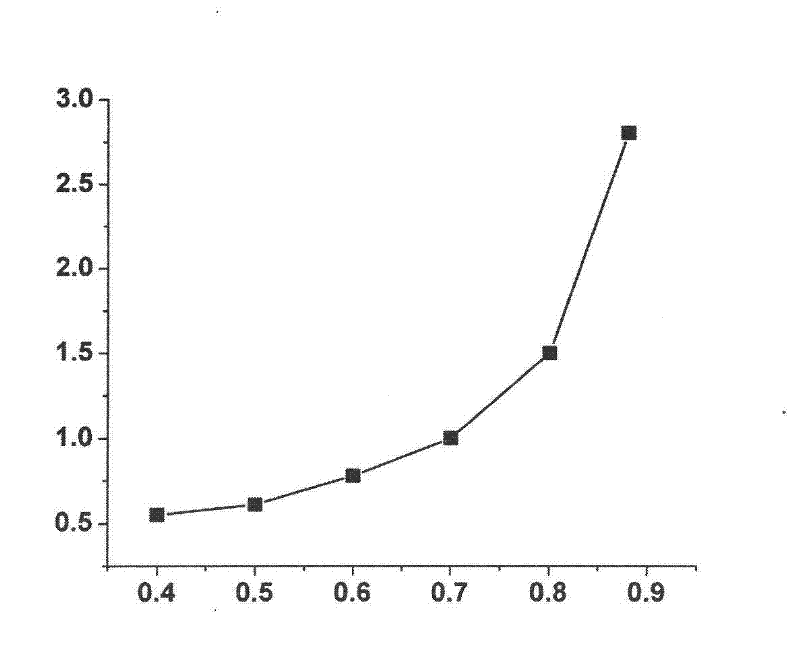

InactiveUS7485594B2Improved thermal shock factorCombination devicesCeramic shaping apparatusMulliteSilicon dioxide

A porous mullite composition is made by forming a mixture of one or more precursor compounds having the elements present in mullite (e.g., clay, alumina, silica) and a property enhancing compound. The property enhancing compound is a compound having an element selected from the group consisting of Mg, Ca, Fe, Na, K, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, B, Y, Sc, La and combination thereof. The mixture is shaped and to form a porous green shape which is heated under an atmosphere having a fluorine containing gas to a temperature sufficient to form a mullite composition comprised substantially of acicular mullite grains that are essentially chemically bound.

Owner:DOW GLOBAL TECH LLC

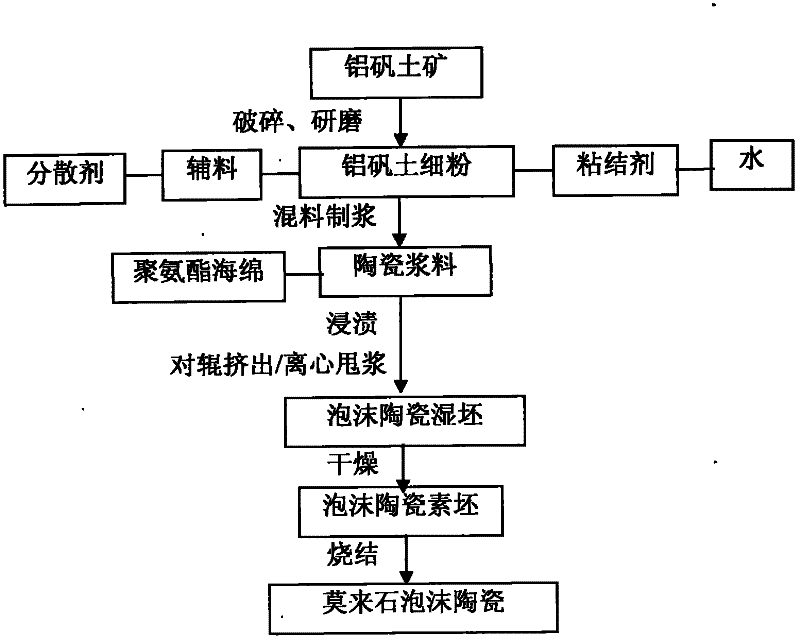

Mullite ceramic foam filter for casting and preparation method thereof

InactiveCN102173856AGood purification effectImprove filtering effectFiltration separationCeramicwareMulliteSlurry

The invention belongs to the field of porous ceramic, and provides a mullite ceramic foam filter for casting. The mullite ceramic foam filter for casting comprises the following chemical components: 40-80 wt% of Al2O3, 10-50 wt% of SiO2 and 1-10 wt% of alkali-earth oxide. The mullite ceramic foam filter for casting is in a mutually-communicated mesh porous structure. The preparation method comprises the following steps: using natural alumina containing 40-80 wt% of Al2O3 as the main raw material, adding one or more of silicon dioxide, aluminum oxide, kaolin, bentonite and talcum powder as the auxiliary material, and adding adhesive, dispersant and water to obtain a ceramic slurry; and immersing polyurethane sponge foam into the slurry, removing the excessive slurry, drying, and sintering at high temperature to obtain the mullite ceramic foam filter. The invention has excellent thermal impact resistance and molten metal attack resistance, and can be widely used for filtering, purifying and rectifying aluminum, aluminum alloy, copper, iron or any other molten metal liquid, thereby greatly enhancing the quality and yield of castings.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Refractory cast material for desulfurizing gunite

The present invention relates to a refractory cast material for desulfurizing gunite, and refractory material for desulfurizing pre-treatment of molten iron before steel-making in converter. Two kinds of cast materials in different components are provided for molten iron with temperature not lower than 1320 deg.c and that lower than 1320 deg.c separately. The aggregate for the cast material consists of three kinds of raw material including pyrojewel, common electrically molten mullite and andalusite; and proper amount of refractory steel fiber, mineralizing agent, water reducer and antinock agent are added into the cast material to improve the construction performance and use performance of the refractory cast material. The present invention is suitable for casting the refractory material layer of desulfurizing and dephosphorizing gunite and other thermal member.

Owner:武钢集团有限公司

Roasting sagger for circulating type lithium battery anode material and preparation method thereof

ActiveCN103311498AGood chemical inertnessStrong alkali corrosion resistanceElectrode manufacturing processesCharge supportsMulliteCordierites

The invention discloses and provides a roasting sagger for a circulating type lithium battery anode material, which is simple in manufacturing process and structure, does not easily react with a lithium battery material, can avoid polluting the lithium battery material, does not pollute the environment and can be recycled, and a preparation method thereof. The preparation method of the roasting sagger for the circulating type lithium battery anode material comprises the following steps of: (1) uniformly mixing mullite, cordierite, aluminum oxide, corundum, kaolin, active magnesium oxide, spodumene and a bonding agent; adding the materials into a metal mould according to the weight; and pressing and molding a blank by pressing and molding equipment; (2) uniformly mixing zirconium oxide, the spodumene, cerium oxide, the corundum and the bonding agent; uniformly distributing the materials on the surface of the blank by a material distribution machine or manpower and pressing again by the pressing and molding equipment to obtain a semi-finished sagger product; and (3) drying the sagger semi-finished product and sintering. The roasting sagger disclosed by the invention can be widely applied to the field of the sagger for the lithium battery anode material.

Owner:李艳晖

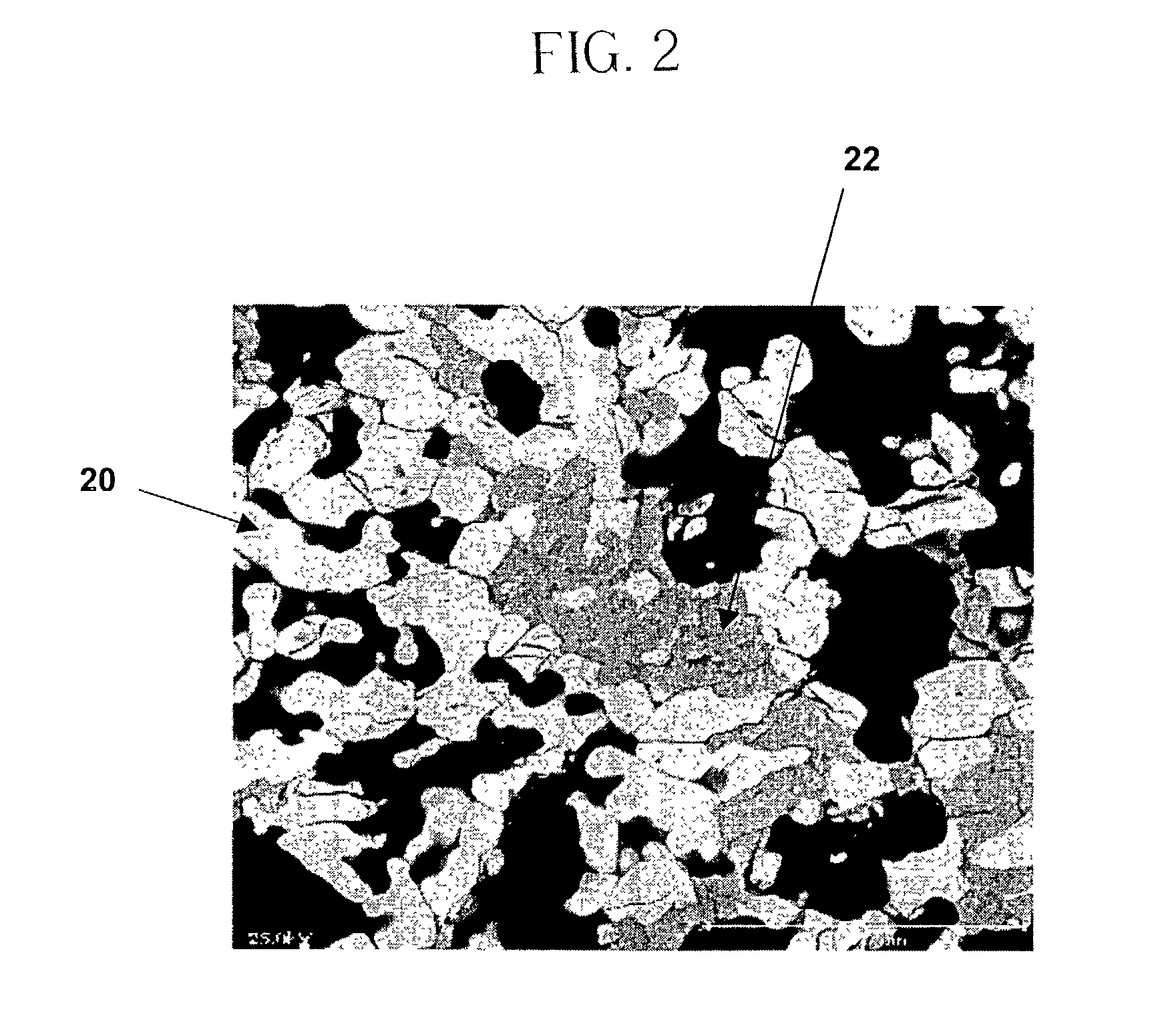

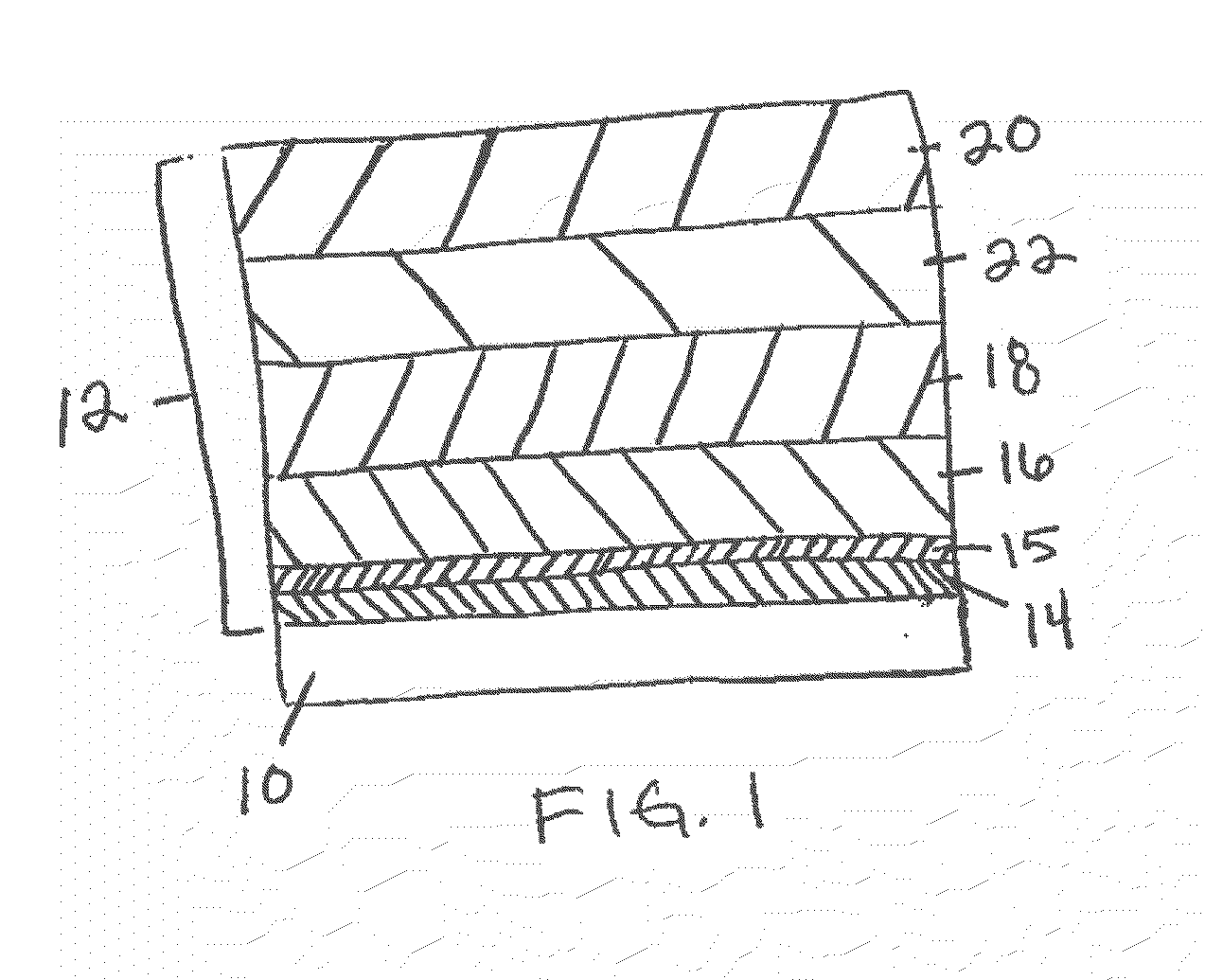

Protective overlayer for ceramics

An alumina comprising composition protective overlayer (20) for protecting a ceramic matrix composite material (12) from a high temperature, moisture-containing environment. Alumina may be used as a protective overlayer to protect an underlying mullite layer to temperatures in excess of 1,500° C. The coating may have porosity of greater than 15% for improved thermal shock protection. To prevent the ingress of oxygen to an underlying ceramic material, an oxide barrier layer may be optionally disposed between the alumina coating and the ceramic material. Such a protective overlayer may be used for an article having a ceramic oxide or non-oxide substrate.

Owner:SIEMENS ENERGY INC

Solvent based environmental barrier coatings for high temperature ceramic components

InactiveUS20110027557A1Suitable for useEfficient propulsion technologiesGlass/slag layered productsPorosityAluminate

Environmental barrier coatings for high temperature ceramic components including a bond coat layer; an optional silica layer; and at least one transition layer including: from about 85% to about 100% by volume of the transition layer of a primary transition material including a rare earth disilicate, or a doped rare earth disilicate; and from 0% to about 15% by volume of the transition layer of a secondary material selected from Fe2O3, iron silicates, rare earth iron oxides, Al2O3, mullite, rare earth aluminates, rare earth aluminosilicates, TiO2, rare earth titanates, Ga2O3, rare earth gallates, NiO, nickel silicates, rare earth nickel oxides, Lnb metals, Lnb2O3, Lnb2Si2O7, Lnb2SiO5, borosilicate glass, alkaline earth silicates, alkaline earth rare earth oxides, alkaline earth rare earth silicates, and mixtures thereof; where the transition layer is applied to the component as a slurry including at least an organic solvent, the primary transition material and at least one slurry sintering aid, and where a reaction between the slurry sintering aid and the primary transition material results in the transition layer having a porosity of from 0% to about 15% by volume of the transition layer.

Owner:GENERAL ELECTRIC CO

Siliceous mullite structure-insulating integrated composite brick and preparation method thereof

The invention discloses a siliceous mullite structure-insulating integrated composite brick and a preparation method thereof. The brick consists of a heavy working layer and a high-strength light insulating layer, wherein the main materials of the heavy working layer are dense bauxite and silicon carbide material, the aggregate of the high-strength light insulating layer is one or the mixture of alumina hollow balls, alumina-magnesia hollow balls, corundum hollow balls, hollow microspheres and light ceramisite, the heavy working layer and the light insulating layer are combined together by adopting vibratory pressing or mechanical pressing, and the length proportion between the heavy working layer and a light insulating layer is 1 to 5:2 to 1. The invention overcomes the defect of the abrasion-resistant siliceous mullite brick for rotary kilns, i.e. high coefficient of heat conductivity, and the defects of the light part of the conventional siliceous mullite composite brick, i.e. low strength and low refractoriness, and the structure-insulating integrated composite brick has the advantages of high abrasion resistance, high refractoriness, high structure strength and high insulating property.

Owner:浙江盛旺耐火材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com