Patents

Literature

439 results about "Andalusite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Andalusite is an aluminium nesosilicate mineral with the chemical formula Al₂SiO₅. This mineral was called andalousite by Delamétehrie, who thought it came from Andalusia. It soon became clear that it was a locality error, and that the specimens studied were actually from El Cardoso de la Sierra, in the province of Guadalajara, not Andalusia.

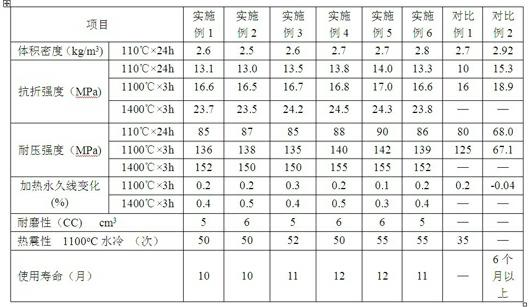

Special pouring material for coal injection pipe

The invention discloses a special pouring material for a kiln opening and belongs to the field of a refractory material. The special pouring material comprises the following components by weight percent: 10-25% of silicon carbide, 15-30% of andalusite, 20-35% of corundum, 5-15% of spinel powder, 5-10% of zircon mullite powder, 5-15% of aluminum oxide micro powder, 3-8% of silicon micro powder, 2-5% of pure calcium aluminate cement, and 0.5% and 0.2% of anti-explosion fibers and sodium tripolyphosphate serving as additives. The special pouring material is capable of efficiently improving the wear resistance and avoiding the hot peeling phenomenon of the cement kiln coal injection pipe, has the characteristics of high temperature resistance, heat vibration resistance, wear resistance, high strength, irreversible micro inflation, and the like, and is capable of greatly prolonging the service life of the cement kiln coal injection pipe.

Owner:ZHEJIANG KINGCRED NEW MATERIAL CO LTD

Sagger with coatings capable of resisting high-temperature lithium battery corrosion and method for preparing sagger

InactiveCN105777090AReduce erosionExtended service lifeElectrode thermal treatmentAndalusiteSillimanite

The invention relates to sagger with coatings capable of resisting high-temperature lithium battery corrosion and a method for preparing the sagger, and belongs to the field of refractory materials. Thesagger with the coatings capable of resisting high-temperature lithium battery corrosion comprises a sagger blank, and is characterized in that a layer of glaze with the coatings capable of resisting high-temperature lithium battery corrosion is impregnated on the surface of the sagger blank, and then the sagger blank is baked in a high-temperature furnace to obtain the sagger; the glaze with the coatings capable of resisting high-temperature lithium battery corrosion comprises dry materials and solvents which are mixed with one another, and the solid content of the glaze is 30-40vol%; the dry materials comprise, by weight, 20-50% of Al2O3, 20-50% of SiO2, 15-35% of ZrO2, 10-25% of MgO and 5-16% of Li2O. Micro-powder is further added into the sagger blank, and the weight percentage of the micro-powder is 2-10%; the micro-powder comprises one of andalusite, kyanite and sillimanite or mixture of more than two of the andalusite, the kyanite and the sillimanite. The sagger has the advantage that erosion of the sagger due to lithium ion solution can be effectively prevented.

Owner:WUHAN UNIV OF TECH

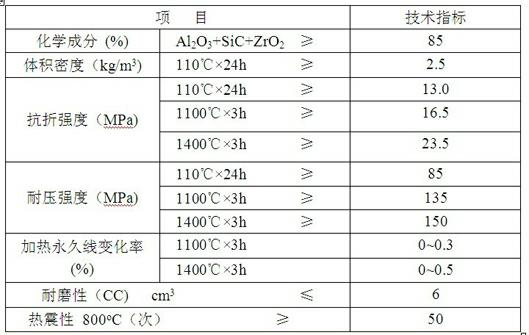

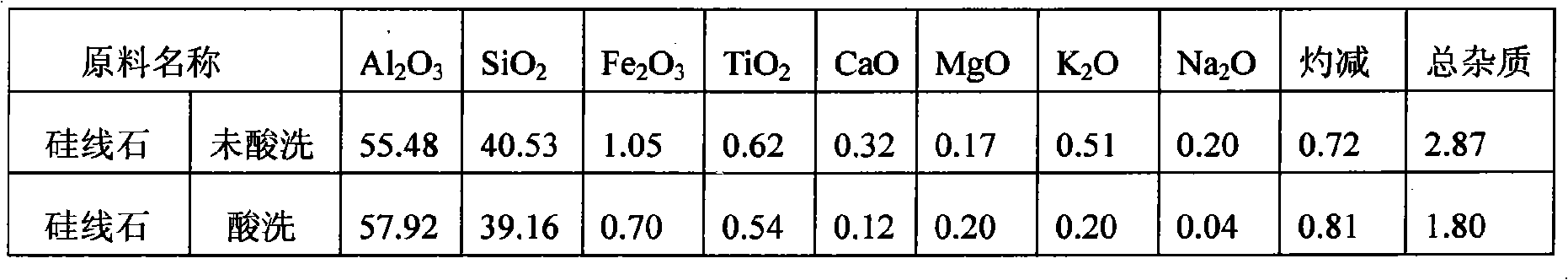

Sillimanite brick for large-scale blast furnace hot blast stove and method of manufacturing the same

InactiveCN101343190AImproved and enhanced high temperature performanceImprove and improve qualityBrickMullite

The invention discloses a sillimanite brick used in the large blast furnace stove and a production method thereof. The raw material of the sillimanite brick contains 30 to 60 percent of mullite, 30 to 60 percent of sillimanite or / and andalusite and 10 to 40 percent of common milling powder, and additionally, a binder, whose weight accounts for 2 to 5 percent of the total weight of the above raw materials, is added into the above raw materials. The production method of the brick comprises mulling, aging, molding, drying and firing processes; and green bricks are heat preserved for 8 to 12 hours under 1480 to 1520 DEG C to be fired, and are taken out of the kiln after being cooled naturally. The creep rate of the sillimanite brick is only 0.179 percent in the conditions of 1450 DEG C and 50 hours, the compressive strength reaches 76.2 Mpa, and the service life of the product is long. Thus, the product can completely meet the performance requirements of the sillimanite brick used in the blast furnace stove, and the product surpasses the performances of the same kind products at home and abroad and ends the history that the product has been imported from foreign countries all the time.

Owner:巩义市第五耐火材料总厂 +1

Alumina base andalusite-SiC-C brick, manufacturing method and its application

InactiveCN101045636AImprove medium and high temperature physical propertiesImprove antioxidant capacityAl powderBrick

An alumine-based andalusite-SiC-C brick used for the 300-ton molten iron ladle with long service life features that two kinds of andalusite are used to take part in mullite reaction to form the mullite network frame, and Al powder and Si powder are used for improving its antioxidizing performance and medium-and high-temp physical properties. Its preparing process includes pugging, shaping, baking, etc.

Owner:上海柯瑞冶金炉料有限公司

Ceramic honeycomb structures

InactiveUS20100300053A1High mechanical strengthImprove thermal shock resistanceInternal combustion piston enginesDispersed particle filtrationAndalusiteMullite

Ceramic honeycomb structures may include a mullite phase and a tialite phase, and methods for manufacturing ceramic honeycomb structures may include making ceramic honeycomb structures including a mullite phase and a tialite phase. Ceramic honeycomb structures may include andalusite, and methods for manufacturing ceramic honeycomb structures may include using andalusite and making ceramic honeycomb structures including andalusite.

Owner:IMERYS SA

Layered composite carrier for producing shell shaped catalyst

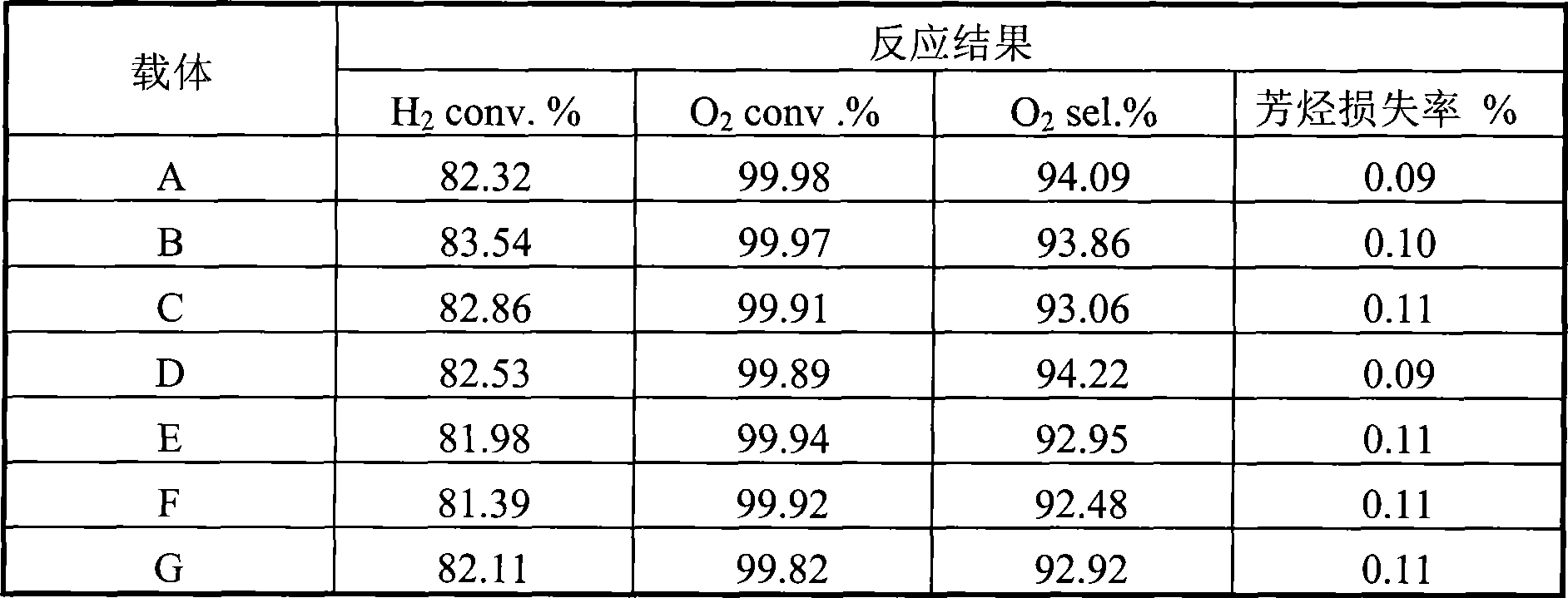

The invention relates to a layered composite carrier used for preparing thin-shell catalysts, and solves the technical problems that the prior layered composite carrier has small specific surface area, and the relevant thin-shell noble metal catalyst has low dispersity, poor utilization rate and low selectivity. In order to solve the problems, the technical scheme is as follows: the layered composite carrier used for preparing thin-shell catalysts, comprises an inert carrier inner core and a porous coating as outer layer conjugated on the inner core. The carrier inner core is at least one substance selected from alpha-Al2O3, theta-Al2O3, metals, SiC, cordierite, zirconium oxide, titanium oxide, quartz, mullite and Al-rich andalusite. The porous coating is at least one substance selected from gamma-Al2O3, delta-Al2O3, eta-Al2O3, theta-Al2O3, silicon oxide / aluminum oxide, zeolite, non-zeolite molecular sieves, titanium oxide and zirconium oxide. The layered composite carrier is applied to the industrial production of thin-shell catalysts.

Owner:CHINA PETROLEUM & CHEM CORP +1

Zirconium oxide sandwich composite calcining-endure plate and preparation process thereof

The invention discloses a zirconium oxide sandwich composite calcining-endure plate. The zirconium oxide sandwich composite calcining-endure plate comprises a matrix mullite calcining-endure plate and zirconium oxide paint. The matrix mullite calcining-endure plate comprises the following raw materials in percentage by mass: 20 to 25 percent of andalusite with thickness degree between 1 and 1.5 mm, 5 to 10 percent of andalusite with thickness degree between 0.5 and 1 mm, 5 to 8 percent of andalusite with thickness degree less than 0.5 mm, 10 to 15 percent of plate-shaped corundum with thickness degree between 0.5 and 1 mm, 5 to 10 percent of plate-shaped corundum with thickness degree less than 0.5 mm, 5 to 10 percent of electrical melting mullite with thickness degree between 0.5 and 1 mm, 8 to 12 percent of sillimanite powder, 15 to 20 percent of alpha-aluminium oxide (Al2O3) powder, 2 to 3 percent of silica micropowder, 3 to 4 percent of clay and 3 to 4 percent of binding agent. The zirconium oxide paint comprises the following raw materials in percentage by mass: 75 to 80 percent of zirconium oxide with granularity less than or equal to 600 meshes and 20 to 25 percent of silicasol. In addition, the invention also provides a process for preparing the zirconium oxide sandwich composite calcining-endure plate. The zirconium oxide sandwich composite calcining-endure plate has the advantages of high-temperature resistance, high mechanical strength, stable chemical properties, high stability of thermal shock resistance, long service life and high anti-stripping property.

Owner:夏卫平

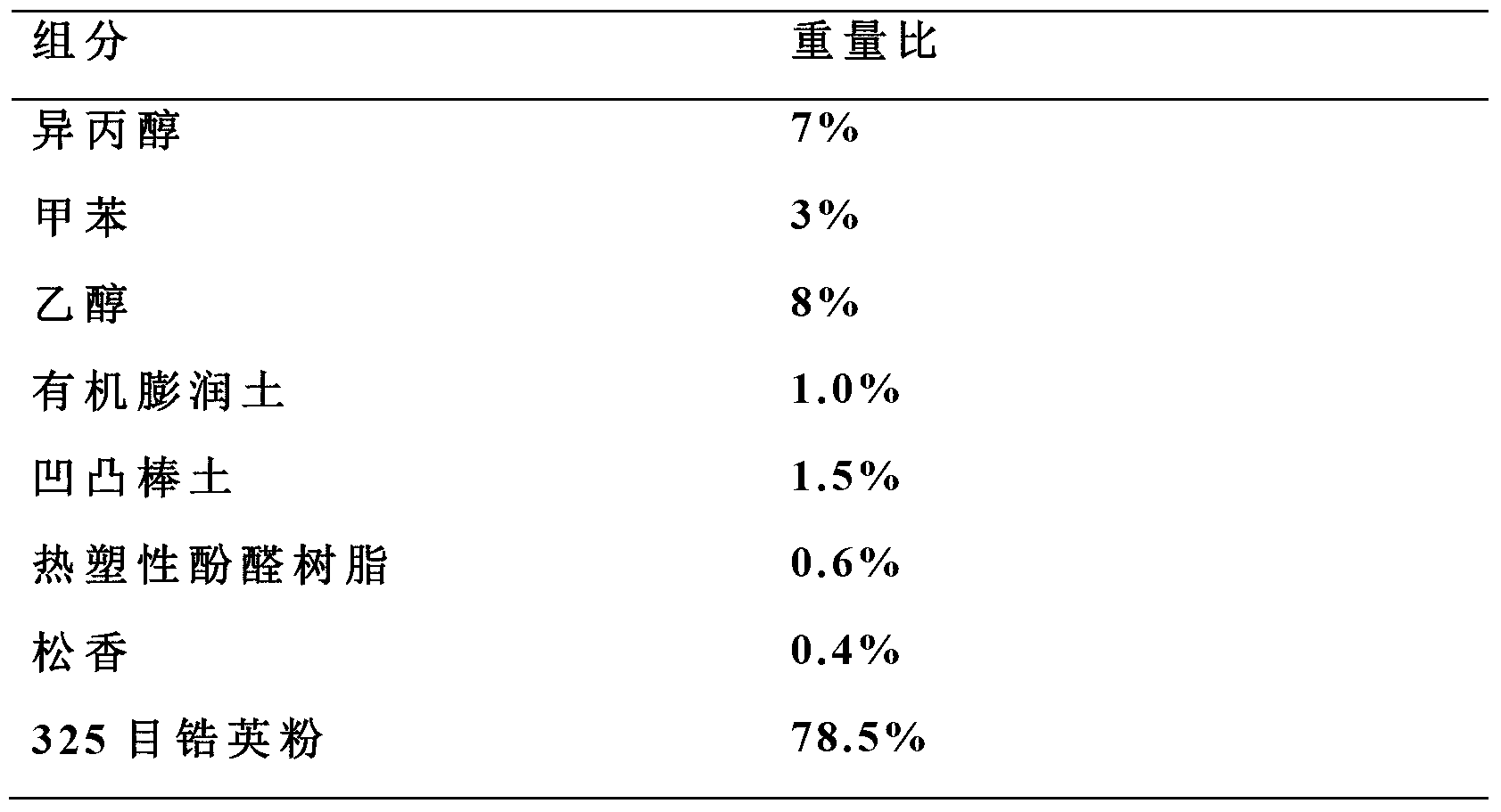

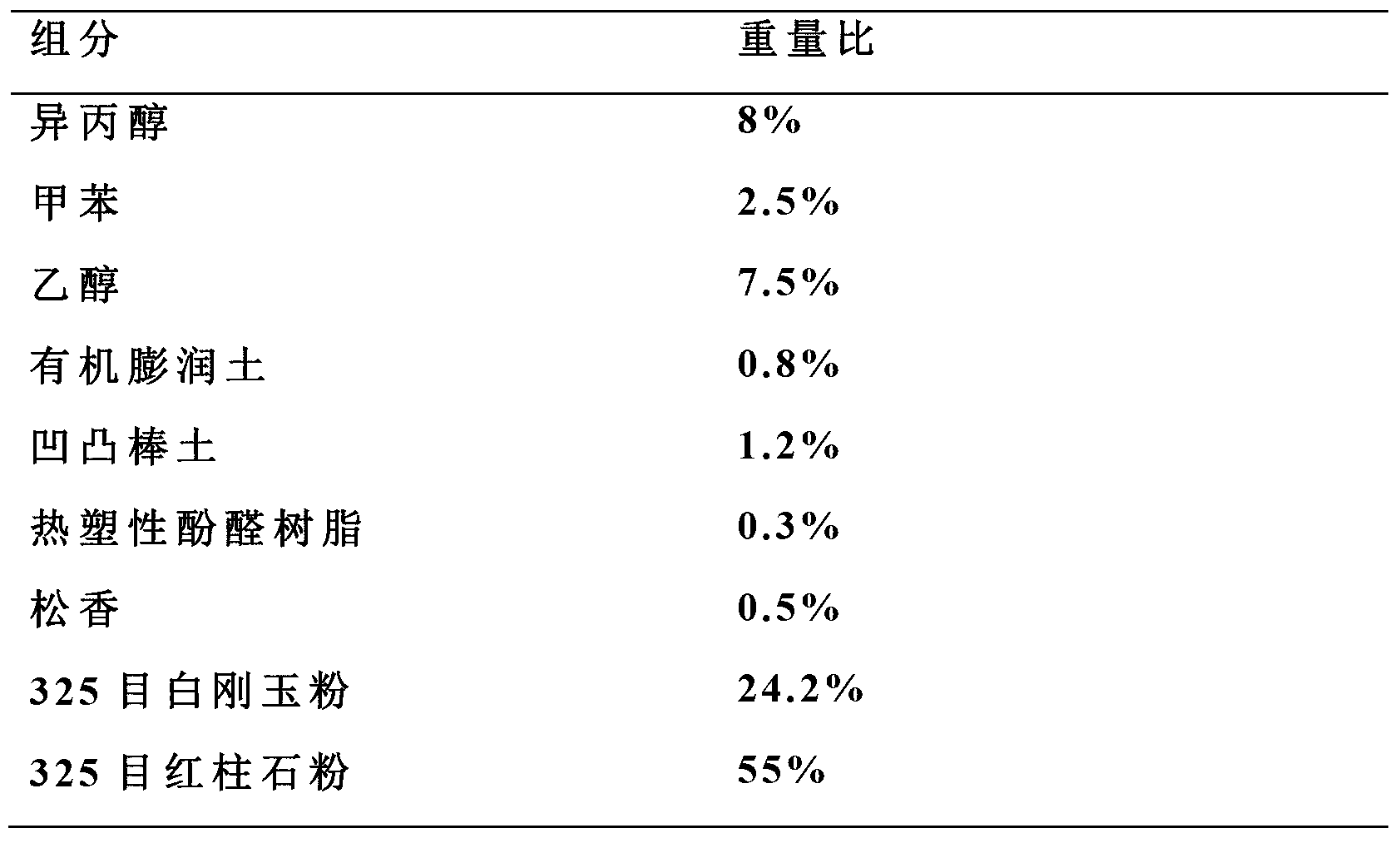

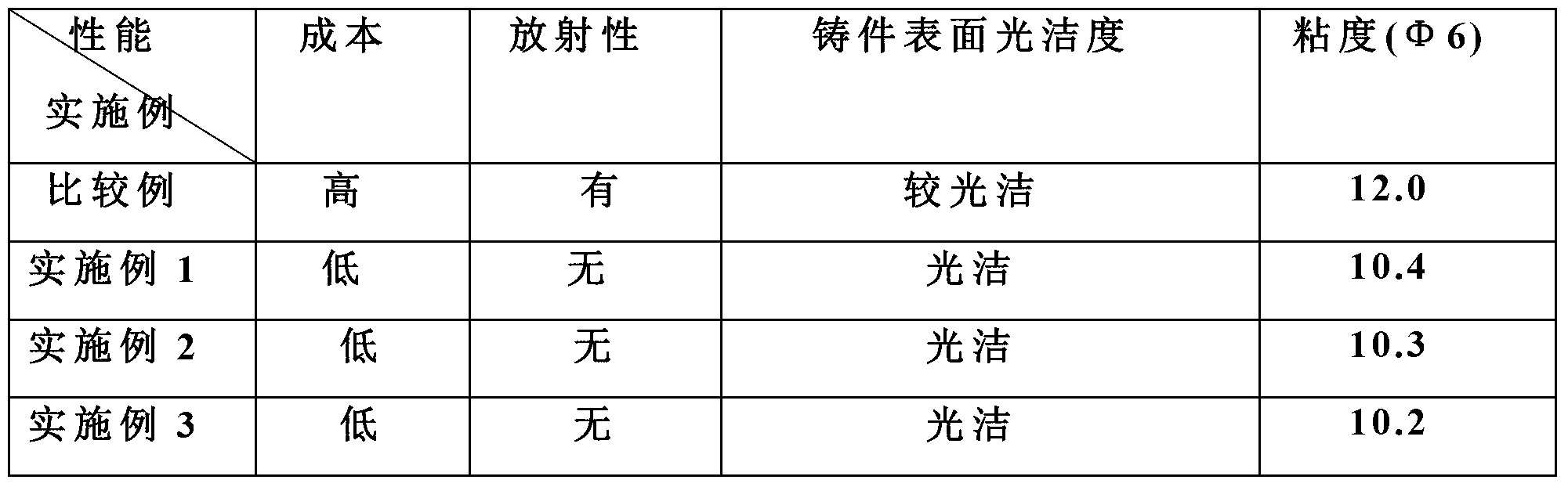

Zircon power alternative coating for casting and preparation method thereof

The invention discloses a zircon power alternative coating for casting, which is characterized in that a coating composition comprises carrier liquid consisting of isopropyl alcohol, toluene and ethanol, a suspending agent consisting of organobentonite and attapulgite, an adhesive consisting of thermoplastic phenolic resin and rosin, and refractory aggregate consisting of white alundum powder and andalusite powder. The coating composition comprises the following components by weight percent: 6-10 percent of isopropyl alcohol, 2-4 percent of toluene, 6-10 percent of ethanol, 0.5-1.5 percent of organobentonite, 1-2 percent of attapulgite, 0.2-1.0 percent of thermoplastic phenolic resin, 0.2-1.0 percent of rosin, 15-55 percent of white alundum powder and 15-55 percent of andalusite powder. Compared with the conventional common cast steel zircon power coating, the coating has high thixotropy and leveling property, is smooth and dense and has enough normal temperature and high-temperature strength, so that the casting roughness meets the quality requirement; and moreover, the zircon power alternative coating is low in gas outlet quantity and has proper shielding property, and the defects of the casting air holes can be obviously reduced.

Owner:SUZHOU XINGYE MATERIALS TECH

Ceramic Al203SiC refractory and preparation method thereof

A refractory ceramic Al2O3-SiC brick with high strength and low porosity is prepared through proportionally mixing high-Al alumine, white corundum, brown corundum, industrial silicon carbide, andalusite, ceramic additive, adhesive and water, stirring or grinding, die pressing, drying at 60-110 deg.C for 12-24 hr or natural drying, and calcining at 1400-1470 deg.C.

Owner:WUHAN UNIV OF SCI & TECH

Thermal-shock resistant fireproof brick and production process thereof

The invention relates to a heat shock resistance firebrick and the manufacture method. The method is that it adopts mullite, corundum, alpha-Al2O3 powder, andalusite and clay as base material, adding 3-15wt% binding agent. The process includes the following steps: adding binding agent into the base material, grinding to equal, molding, sintering at 1450 degree centigrade. The invention has good heat shock resistance, long useful life, etc. It has great economic and social benefits.

Owner:ZHENGZHOU YUXING REFRACTORY MATERIAL

Sintering bearing plate for sintering kiln, and preparation method of sintering bearing plate

The invention discloses a sintering bearing plate for a sintering kiln, and a preparation method of the sintering bearing plate. The sintering bearing plate structurally comprises a substrate, a transition layer covering the surface of the substrate, and a spraying surface layer covering the surface of the transition layer, wherein the substrate comprises the following components by weight percentage: 20-30% of andalusite, 30-45% of corundum, 20-30% of alumina micropowder, 5-10% of kaoline and 1-2% of binding agent; the transition layer comprises the following components by weight percentage: 60-80% of yttria-stabilized zirconia and 20-40% of alumina; and the spraying surface layer is yttria-stabilized zirconia. According to the sintering bearing plate for the sintering kiln, a material of the substrate is adjusted and the transition layer is sprayed before the surface layer and the substrate are sprayed, so that the adhesion between the material layers is improved obviously, and each thermal expansion coefficient is approximate; and compared with the existing sintering bearing plate, the sintering bearing plate has the advantages of good thermal shock resistance, high high-temperature creep resistance, high coating stripping resistance, long service life and the like.

Owner:广东羚光新材料股份有限公司

Wear-resistant pouring material used for tertiary air pipe elbow of cement kiln

The invention relates to a pouring material, in particular to a wear-resistant pouring material used for a tertiary air pipe elbow of a cement kiln. The pouring material comprises the following components: brown fused alumina, andalusite, SiC, SiC fine powder, andalusite powder, white alundum powder, alpha-Al2O3 micro powder, SiO2 micro powder, pure calcium aluminate cement, heat resistant steel fibers, polypropylene fibers and sodium tripolyphosphate. The wear-resistant pouring material used for the tertiary air pipe elbow of the cement kiln has the advantages of high fracture resistance and compression strength, good abrasion resistance, erosion resistance and thermal shock stability, outstanding abrasion resistance, low water absorption rate and good flowability.

Owner:JIANGSU HENGNAI FURNACE CHARGE GRP

Micro-porous mullite-silicon carbide multiphase fire resistant material and preparation method thereof

InactiveCN102432312AWith high strength and wear resistanceImprove insulation effectThermal insulationMullite

The invention relates to a micro-porous mullite-silicon carbide multiphase fire resistant material and a preparation method thereof. The micro-porous mullite-silicon carbide multiphase fire resistant material comprises the following ingredients: 25-30 wt% of super-grade bauxite particles having a particle size of no less than 1 mm and less than 3 mm, 24-27 wt% of super-grade bauxite particles having a particle size of no less than 0.1 mm and less than 1 mm, 10-15 wt% of SiC particles having a particle size of no less than 0.1 mm and less than1 mm, 10-15 wt% of super-grade bauxite fine powder having a particle size of less than 0.074 mm, 5-10 wt% of andalusite fine powder having a particle size of less than 0.088 mm, 2-5 wt% of pyrophyllite fine powder having a particle size of less than 0.088 mm, 3-5 wt% of active alpha-Al2O3 micro powder, 3-5 wt% of SiO2 micro powder, 4-6 wt% of Guangxi white clay, 1-3 wt% of elemental Si powder, and 1-2 wt% of Al powder, 1-2 wt% of dextrin, 0.4-0.6 wt% of calcium lignosulphonate, and 2-4 wt% of water. The micro-porous mullite-silicon carbide multiphase fire resistant material is prepared by mixing the ingredients, aging the mixture, moulding, drying and sintering. The prepared material has a uniform structure, has the average aperture less than 5 mum, has the characteristics of high strength, wear resistance, good thermal insulation performance, and excellent anti-alkali, chlorine, and sulfur compound erosion performance, and can meet the requirement of novel dry method cement production.

Owner:WUHAN UNIV OF SCI & TECH

Blast furnace main iron channel castable

The invention relates to a blast furnace main iron channel castable and belongs to the field of refractory castables. The blast furnace main iron channel castable comprises the following components in part by weight: 50-65 parts of tabular corundum, 10-15 parts of andalusite, 1-8 parts of alumina hollow ball, 3-10 parts of electric smelting zirconia, 10-25 parts of alumina micro powder, 10-15 parts of silicon carbide, 8-12 parts of ferro silicon nitride, 3-10 parts of alumina micro powder, 4-8 parts of alumina and silica sol composite suspension, 1-2 parts of nano ceramic powder, 0.1-0.3 part of mixture of sodium tripolyphosphate and sodium hexametaphosphate and 0.3-0.4 part of explosion-proof fiber. A blast furnace main iron channel prepared by the castable has the advantages of long service life, low melting loss rate and strong oxidation resistance.

Owner:ZHEJIANG KINGCRED NEW MATERIAL CO LTD

Wear resistant and high-hardness diamond glaze, preparation method and application

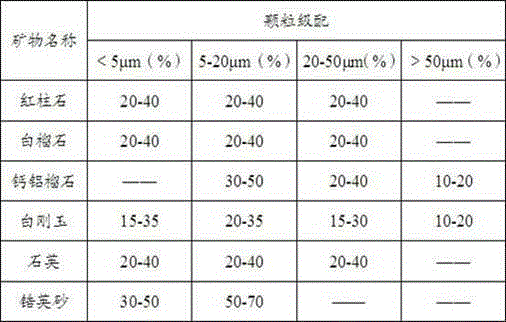

The invention discloses a wear resistant and high-hardness diamond glaze, a preparation method and application. The wear resistant and high-hardness diamond glaze is prepared from the following raw materials according to mass percent: 5 to 15% of kaolin, 5 to 10% of andalusite, 5 to 10% of orthoclase, 5 to 12% of leucite, 1 to 3% of essonite, 10 to 18% of nepheline, 5 to 15% of spodumene, 2 to 8% of wollastonite, 3 to 7% of quartz, 5 to 10% of zircon sand, 5 to 10% of white corundum, 1 to 3% of dolomite, 1 to 3% of calcined white talc, 0.1 to 0.5% of zinc oxide and 0.5 to 3% of additive. According to the wear resistant and high-hardness diamond glaze, the preparation method and the application, the selection of mineral raw materials of the glaze is optimized, firstly, the wear resistant and high-hardness mineral raw materials such as the andalusite (the hardness is 6.9 to 7.4), the white corundum (the hardness is 9.0), the leucite (the hardness is 5.5 to 6) and the essonite (the hardness is 7 to 7.5) are selected, the grain fineness and addition of the wear resistant and high-hardness mineral raw materials are controlled through reasonable grain composition, and by adopting the subsequent preparation process and application process, the wear resistance and hardness of the diamond glaze are greatly increased.

Owner:FOSHAN ZHONGCHENG SILICATE TECH CO LTD

Iolite-mullite-andalusite thermal-shock-resistant brick and preparation method thereof

The invention relates to an iolite-mullite-andalusite thermal-shock-resistant brick, which is characterized by being basically produced by sintering the following base materials for 16 hours at a temperature of 1400 DEG C. The base materials comprise 15-42 wt% of electrofused mullite, 5-18 wt% of brown corundum, 10-32 wt% of plate corundum, 5-20 wt% of andalusite, 3-10 wt% of aluminum oxide micropowder, 5-12 wt% of iolite, and 3-6 wt% of clay; in the finished product of the thermal-shock-resistant brick, Al2O3 is not less than 60 wt%, Fe2O3 is not more than 0.4 wt%, and the sum of K2O and Na2O is not more than 0.3 wt%. According to the iolite-mullite-andalusite thermal-shock-resistant brick and the preparation method thereof, the plate corundum and the brown corundum are adopted, therefore, on basis of improvement in refractoriness under load and high temperature creep property of firebricks, the thermal-shock-resistant stability of the product is improved, and the service life of the iolite-mullite-andalusite thermal-shock-resistant brick serving as the martial of the firebricks in high-temperature-resistant ceramic burners can be obviously prolonged.

Owner:任健均

A method for making a sealing cover for the observation and operation hole of the flue wall of a carbon roasting furnace

ActiveCN102276263AImproved thermal shock stabilityExcellent softening temperature under loadFiberFlexural strength

The invention provides a manufacturing method of a seal cover for an operation observation aperture on a carbon calciner fire wall. Raw materials consist of three parts of aggregate, matrix and additive. The aggregate comprises three or more components selected from: granular mullite, high aluminium corundum, bauxite chamotte, flint clay and andalusite; the matrix comprises fine-powdered mullite,bauxite chamotte, andalusite or kyanite or sillimanite, alumina, high-alumina cement, silicon micro powder and high temperature heat resistant steel fiber; the additive is a mixture comprising two ormore components selected from sodium tripolyphosphate, sodium hexametaphosphate, CMC, FDN and sodium lignosulfonate. The manufacturing method includes steps of: proportioning raw materials; mixing bya mixer; adding water with stirring; putting into a die; partitioning into blocks and moulding; carrying out natural maintenance; and drying at 110 DEG C-300 DEG C for 24-48h. The invention has beneficial effect that the seal cover produced by the method has excellent physical and chemical performance indexes, such as high high-temperature flexural strength, good thermal shock stability and refractoiness under load.

Owner:河南鑫诚耐火材料股份有限公司

Refractory castable for rotary kiln mouth and kiln head hood

The invention provides a refractory castable for a rotary kiln mouth and a kiln head hood. The refractory castable comprises the following components in parts by weight: 40-50 parts of aggregate, 25-40 parts of fine powder, 6-15 parts of oxide micro powder, 1-3 parts of binding agent and 2-2.5 parts of additives, wherein the aggregate is composed of 30 parts of special-grade alumina, 10 parts of corundum, 30 parts of mullite, 15 parts of andalusite and 15 parts of spinel; the fine powder is composed of 60 parts of zirconite powder and 40 parts of silicon carbide powder; the oxide micro powder comprises aluminum oxide micro powder; the binding agent is calcium aluminate cement in which the content of aluminum oxide is 80%; and the additives are composed of 30 parts of metal aluminum powder, 30 parts of organic anti-explosion fibers, 30 parts of sodium hexametaphosphate and 10 parts of heat-resistant steel fibers.

Owner:NINGXIA TIANZONG HONGGUANG COGENERATION TECH

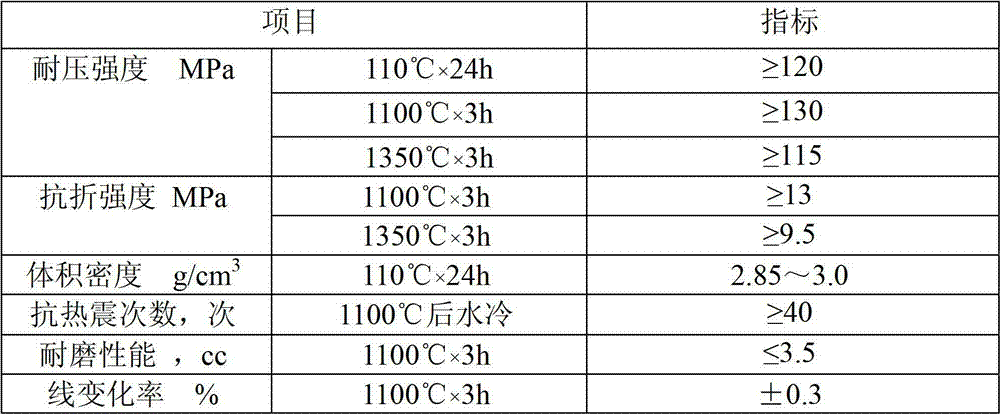

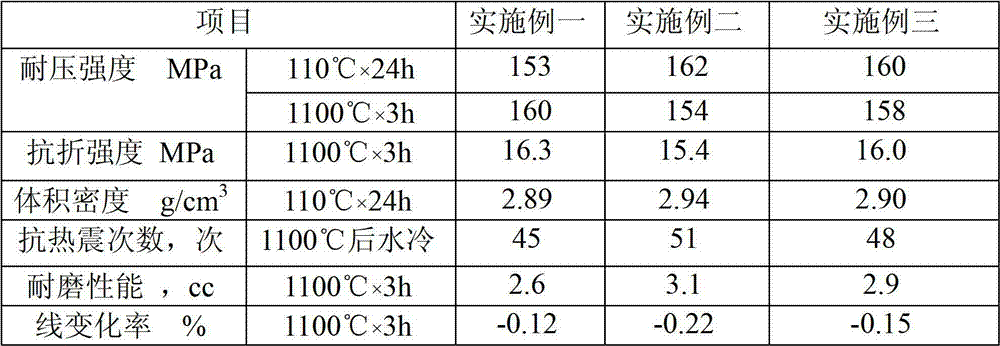

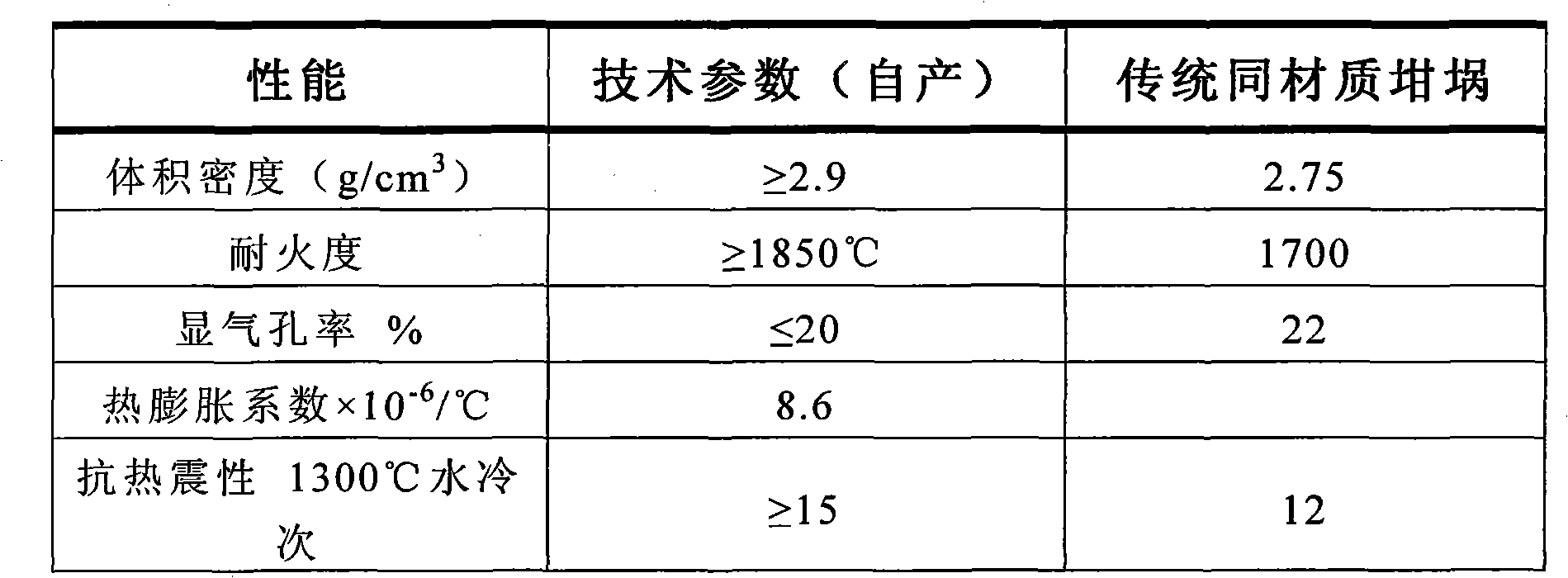

Method for producing kiln furniture product of andalusite

This invention discloses a method for manufacturing andalusite kiln mold product from andalusite particles 10-80%, corundum particles 5-40%, mullite particles 5-40%, aluminum micropowders 5-30% and silicon micropowders 5-15%. Silicon sol 4% the weight of the raw materials is used as the binding agent. The method comprises: (1) mixing aluminum micropowders and silicon micropowders, and ball-milling; (2) dry-mixing andalusite particles, corundum particles and mullite particles, adding silicon sol, and mixing; (3) mixing the mixed powders obtained in step 1 with the mixture obtained in step 2, pressing for molding, drying, calcining at 1500-1550 deg.C for 8-20 h. The andalusite kiln mold product thus manufactured has such advantages as high strength, good heat shock resistance.

Owner:ZHEJIANG UNIV

Preparation method of high-strength wear-resistant pouring material combined with ceramics

The invention relates to a preparation method of a high-strength wear-resistant pouring material combined with ceramics. The technical scheme is as follows: firstly taking 30-70w% of fused mullite particles, 5-25w% of andalusite, 5-20w% of tabular alumina particles, 2-15w% of alumina micro-powder, 3-12w% of pure aluminate cement and 1-5w% of silicon dioxide micro-powder as raw materials, further adding 0.2-3w% of feldspar group mineral fine powder, 1-3w% of heat-resistant stainless steel fiber, 0.02-0.1w% of polypropylene fiber, 0.1-0.5w% of water reducing agent and 3-12w% of water into the raw materials, uniformly stirring, pouring, molding, curing for 24 hours at room temperature, standing for 24 hours in air, and keeping the temperature for 8-24 hours at the temperature of 110 DEG C-300 DEG C so as to get the wear-resistant pouring material combined with the ceramics. A composite material prepared according to the invention has high strength and good wear resistance, and can betteradapt to using environments with the greater temperature change range and be used as easy-to-wear parts of equipment in cement, electric power, petrochemistry, metallurgy, coal, machinery and other industries.

Owner:WUHAN UNIV OF SCI & TECH

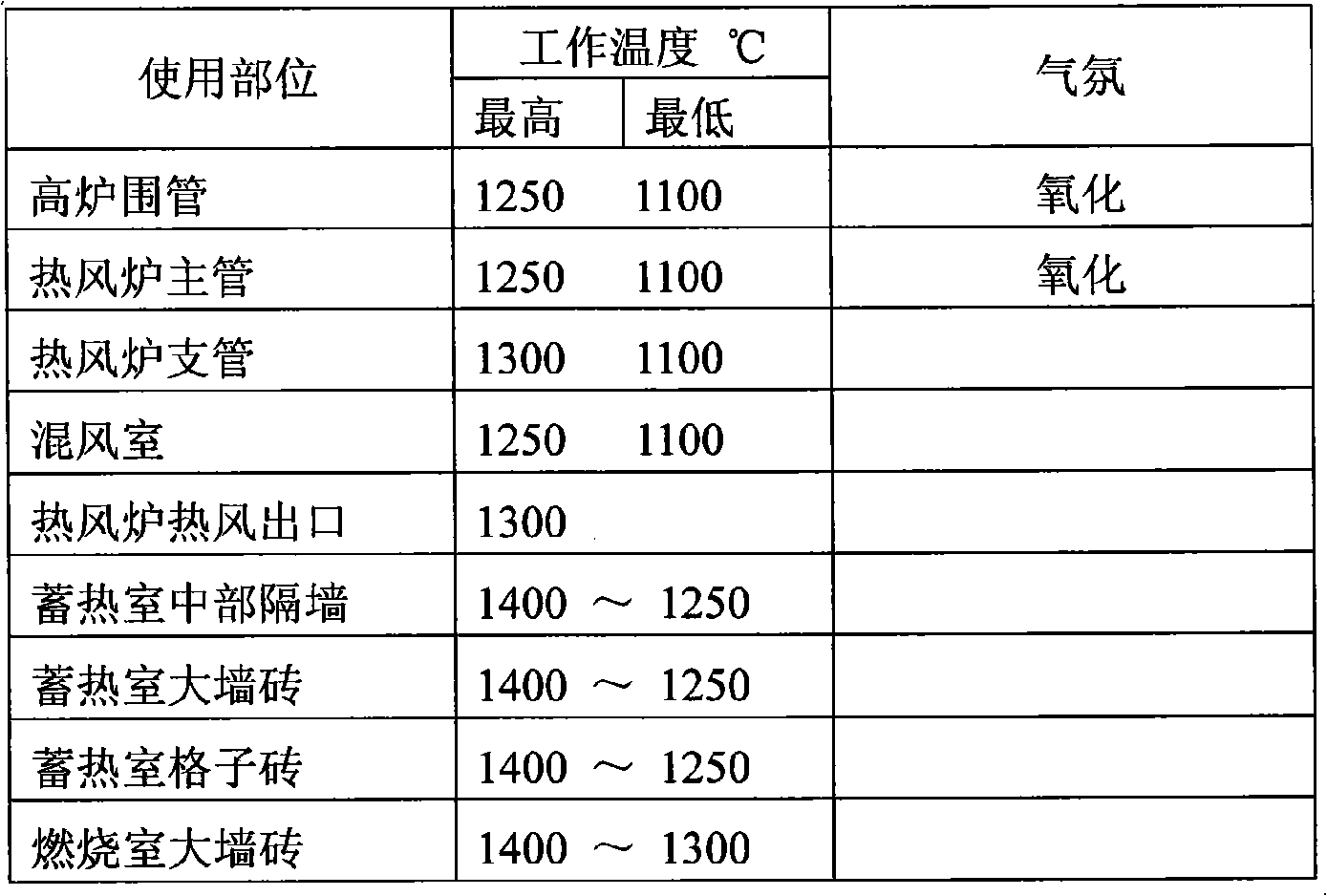

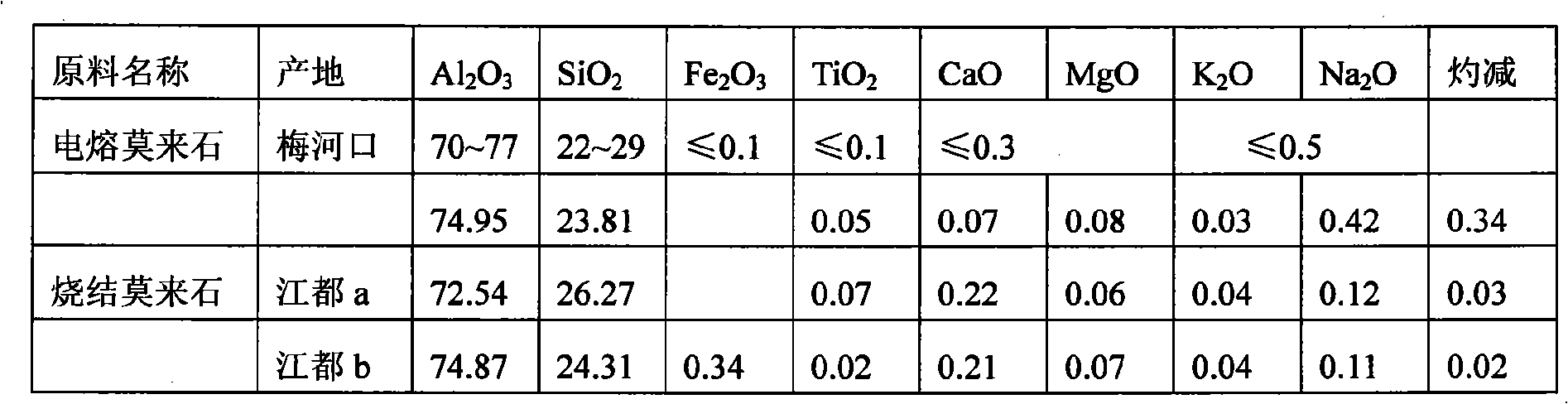

High-temperature resistant thermal shock resistant pipeline used in iron-making hot blast heater and preparation method of high-temperature resistant thermal shock resistant pipeline

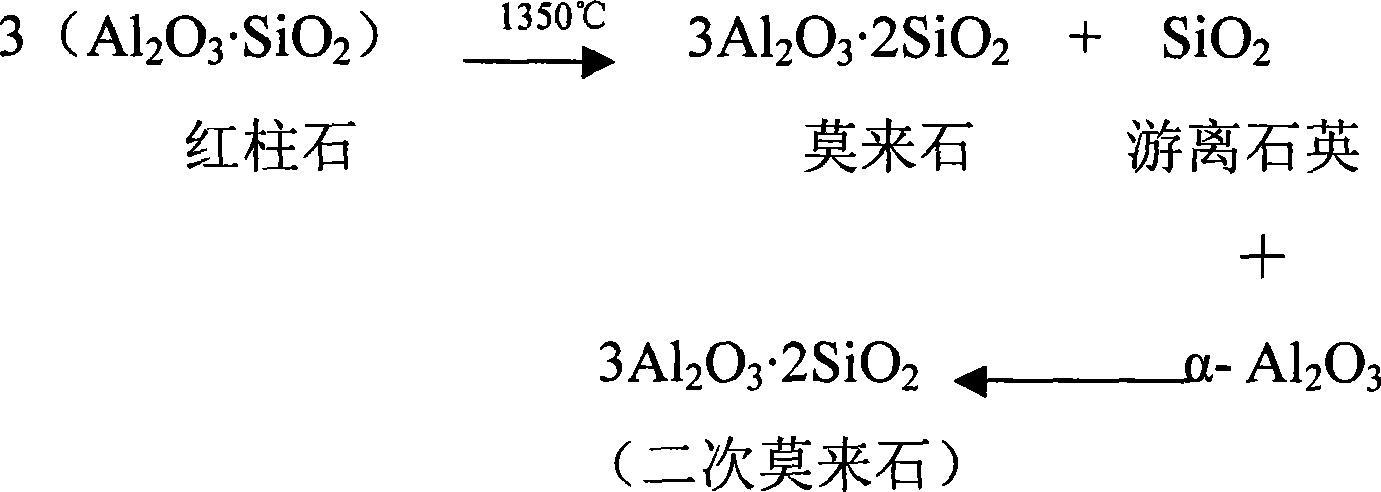

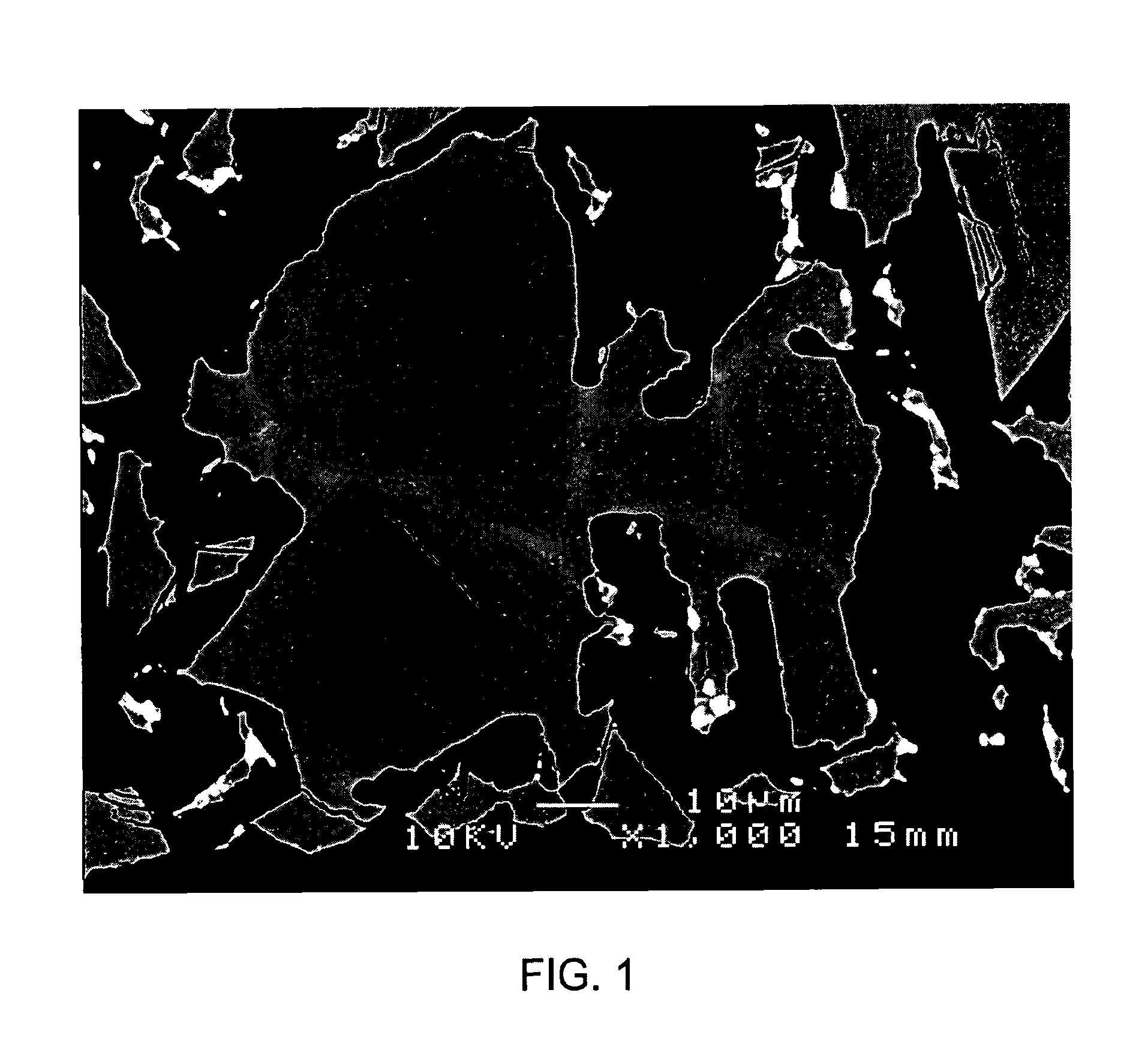

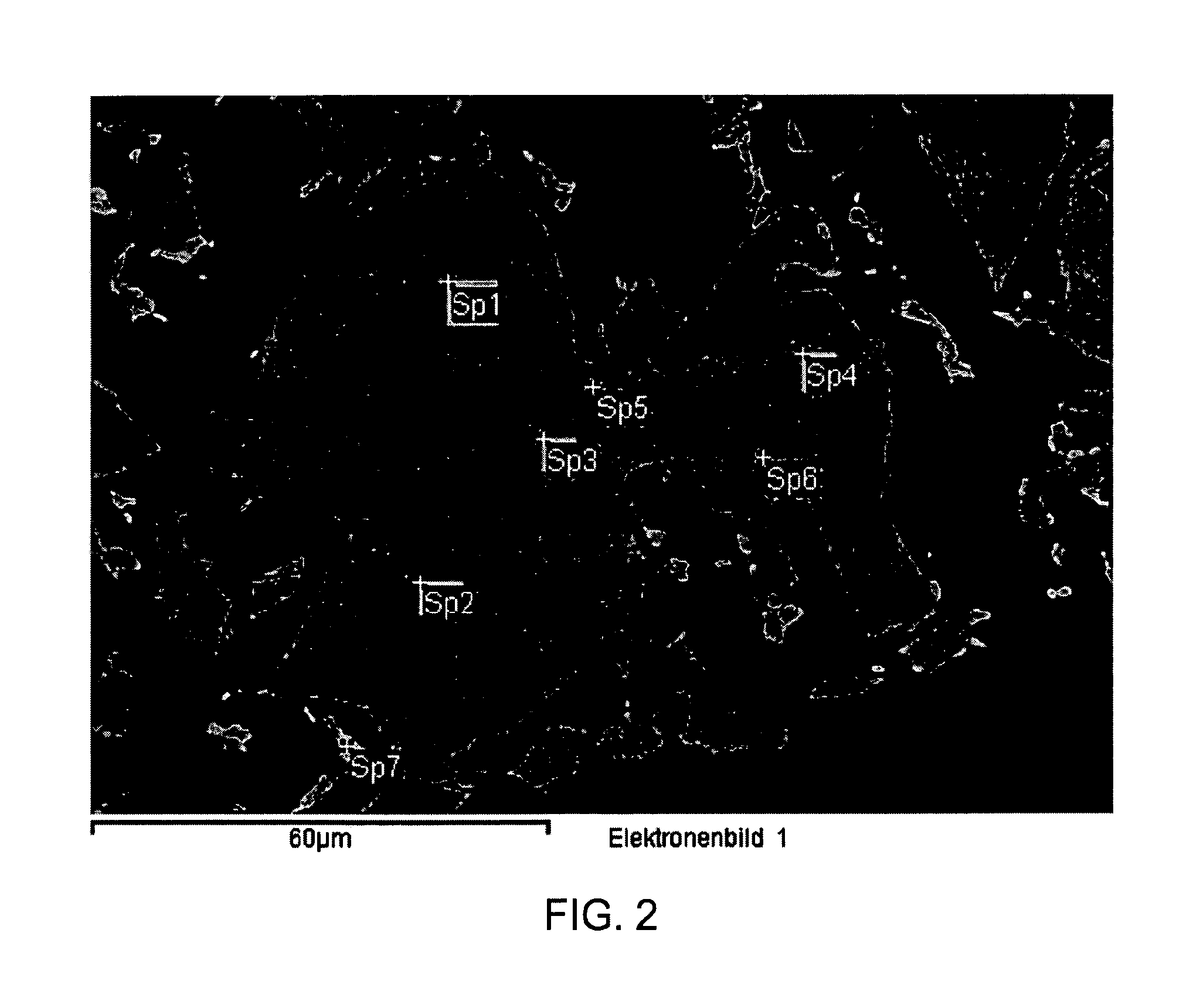

The invention discloses a high-temperature resistant thermal shock resistant pipeline used in an iron-making hot blast heater, and relates to the technical field of refractory materials. The high-temperature resistant thermal shock resistant pipeline is prepared from bauxite chamotte clinker granules, andalusite, fine corundum powder, pure calcium aluminate cement, Al2O3 micro powder, SiO2 micro powder, a dispersing agent, organic anti-explosion fiber and stainless steel fiber, wherein andalusite consists of fine powder of 200 meshes and granules of 3-0.074mm; and the weight of the granules of 3-0.074mm is greater than 65% of the total weight of andalusite. A preparation method of the high-temperature resistant thermal shock resistant pipeline comprises the following steps: performing on-site casting or preparing the above raw materials into precast blocks, and subsequently combining and building the precast blocks on site. The mullitization of andalusite is a lasting process, columnar and needle-shaped mullite converted from andalusite can be formed into pilotaxitic texture with other raw materials and can be solidly combined, and when a raw material product is broken because of thermal stress and other mechanical stress, a bridging and toughening function is achieved, and the thermal shock resistance of the raw material product is improved.

Owner:ZHENGZHOU ANNEC IND

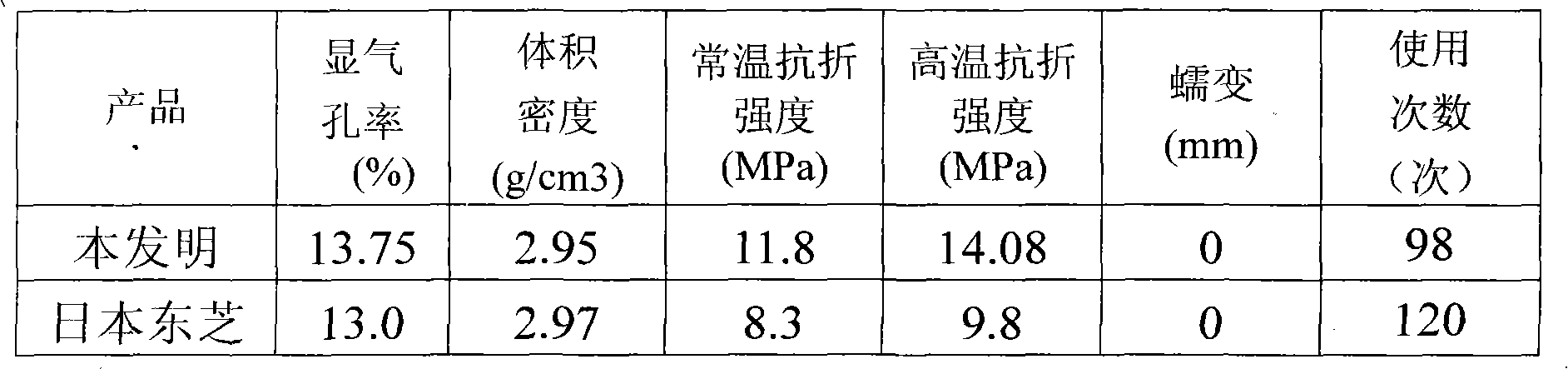

High-temperature corundum-porzite pushing plate and manufacture method thereof

The invention belongs to the technical field of fireproof materials and provides a high-temperature corundum-porzite pushing plate and a manufacture method thereof. The pushing plate is prepared by using fused porzite, corundum, andalusite, alumina powder and ultrafine fused silica powder as raw materials through mixing, tapping, forming, drying and finally sintering at a high temperature. The pushing plate manufactured by utilizing the invention has higher high-temperature strength, wear resistance, favorable creep resistance, favorable product use performance similar to imported products and low production cost. The popularization of the technical scheme can effectively decrease the production cost of domestic high-temperature ceramic industry.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Silicon mullite red brick for large cement kiln and its producing method

The present invention is silicon mullite red brick for large cement kiln and belongs to the field of refractory material technology. The silicon mullite red brick is made with alum as aggregate, silicon carbide, electrocast white alundum powder, andalusite powder, clay, yellow dextrin, methyl cellulose and water, and through mixing, pressing and sintering. Practical application in large cement kiln shows that the silicon mullite red brick has high heat insulating effect and long service life.

Owner:江苏君耀耐磨耐火材料有限公司

Heat shock resistant refractory brick formed with slurry binding agent and production process thereof

InactiveCN1792950AIncrease productivityAvoid falling bricksCeramic shaping apparatusAl powderAndalusite

A heat shock resistant refractory brick with long service life is prepared from high-Al powder, mullite, sillimanite, cordierite, andalusite, argil and mud as adhesive through grinding, shaping and sintering.

Owner:ZHENGZHOU YUXING REFRACTORY MATERIAL

Special casting material of coal-injection duct

The invention discloses a special-purpose casting material of a coal-injection duct. The special-purpose casting material comprises the following components in percentage by weight: 5%-15% of silicon carbide, 15%-30% of andalusite, 10%-25% of corundum, 5%-15% of spinel powder, 15%-20% of silicon boride powder, 5%-10% of zirconite powder, 5%-10% of mullite powder, 5%-15% of aluminum oxide micro powder, 3%-8% of silicon micro powder, 2%-5% of pure calcium aluminate cement, as well as anti-explosion fiber and sodium hexametaphosphate which respectively account for 0.3% of the total weight of the components. The special casting material of the coal-injection duct disclosed by the invention has seismic stability, high temperature resistance, volume stability and abrasive resistance, has high strength, and can be used for improving the defects that the coal-injection duct is not wear-resisting and not thermal-spalling-resistant, so that the service life of a cement kiln coal-injection duct is prolonged to about 12-15 months from about 6-8 months at present.

Owner:NINGXIA TIANZONG HONGGUANG COGENERATION TECH

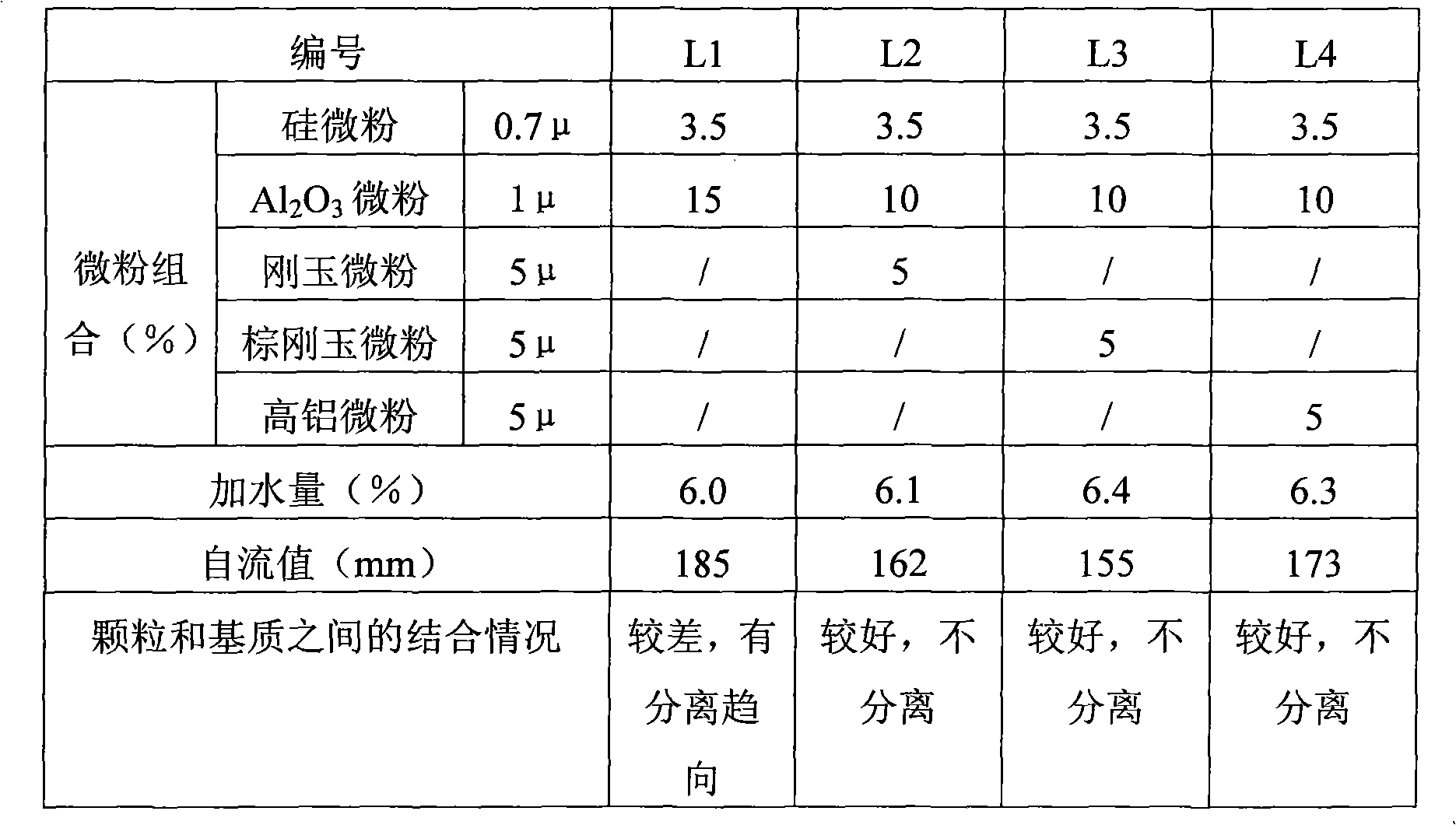

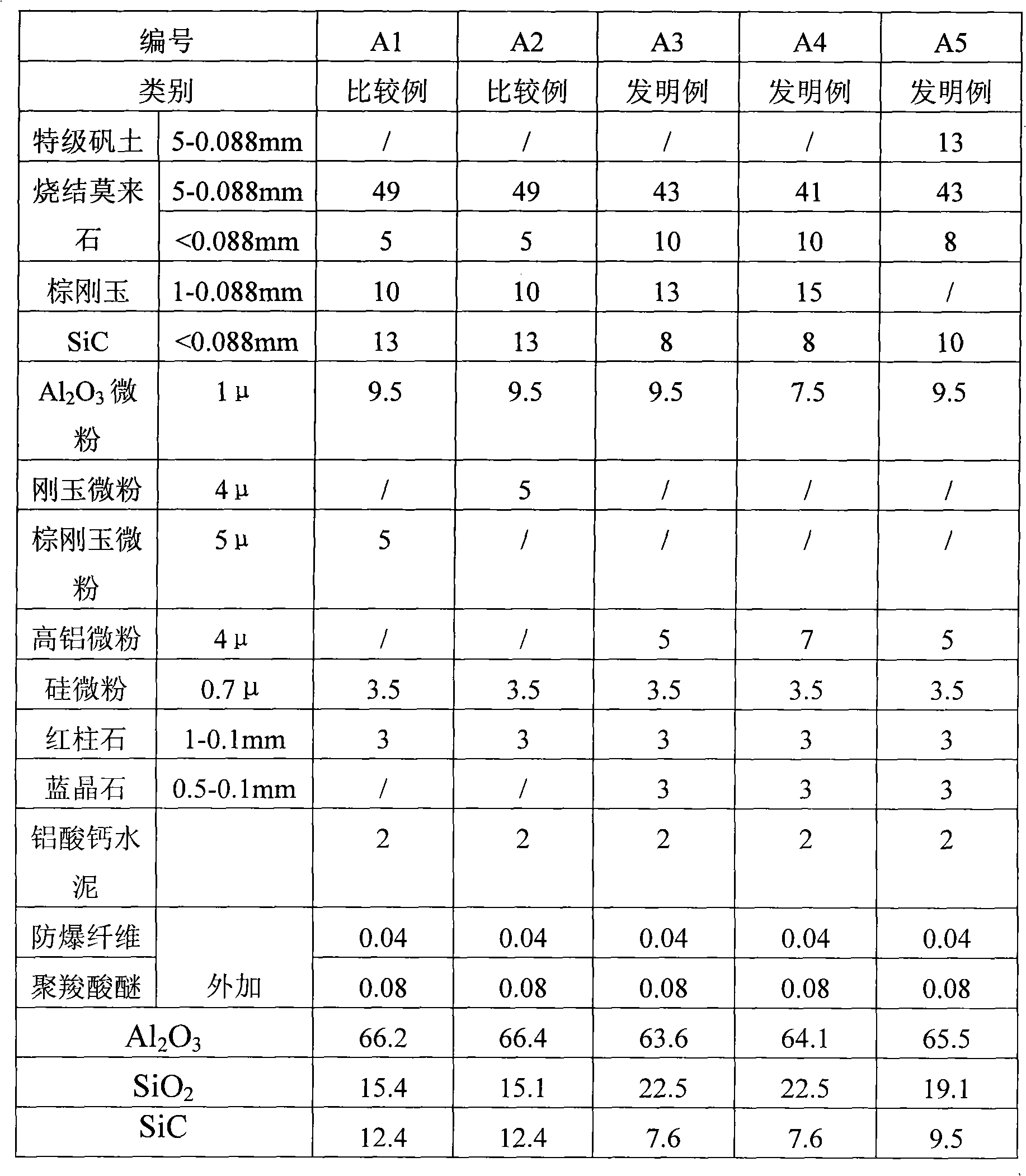

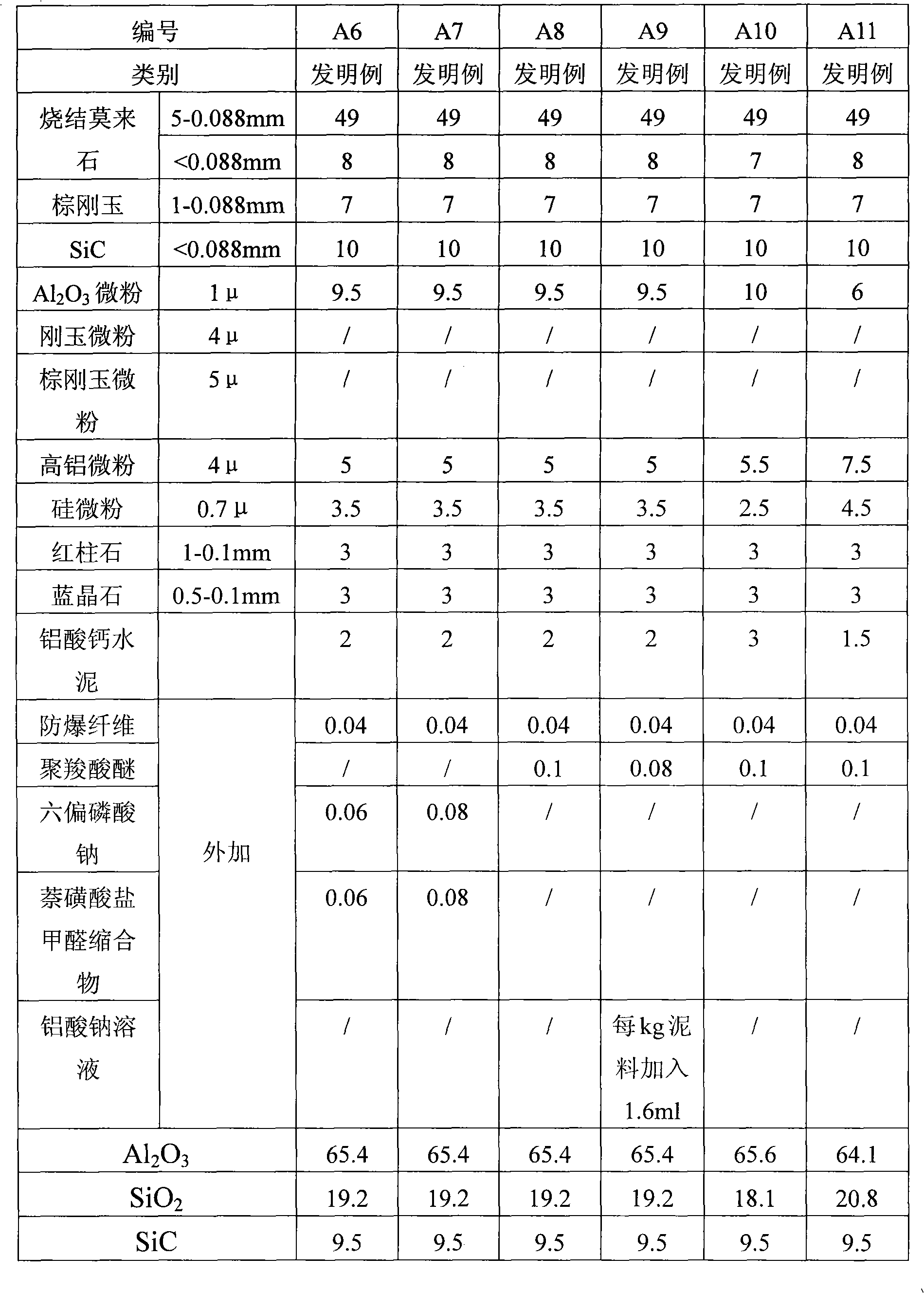

Al2O3-SiO2-SiC-based jet material for foundry ladle

The invention relates to an Al2O3-SiO2-SiC-based refractory material, in particular to an Al2O3-SiO2-SiC-based jet material for wet jet construction of a foundry ladle. The Al2O3-SiO2-SiC-based jet material for the foundry ladle comprises the following components in percentage by weight: 45 to 65 percent of sintered mullite, 5 to 15 percent of SiC, 7 to 18 percent of brown aluminium oxide or special-grade alumina, 5 to 10 percent of Al2O3 super-micro powder, 4 to 8 percent of high-aluminum micro powder, 2 to 5 percent of silicon micro powder, 1.5 to 3 percent of calcium aluminate cement, and 6 percent of balance. The granularity of the Al2O3 super-micro powder is leas than or equal to 2 microns; the purity of Al2O3 in the high-aluminum micro powder is more than or equal to 88 percent, and the granularity is less than or equal to 5 microns; and the purity of SiO2 in the silicon micro powder is more than or equal to 92 percent, and the granularity is less than 1 micron. The balance comprises 3 percent of andalusite and 3 percent of cyanite. The jet material has high strength and good thermal shock stability and corrosion resistance, and ensures good self-flowing property and pumping property.

Owner:BAOSHAN IRON & STEEL CO LTD

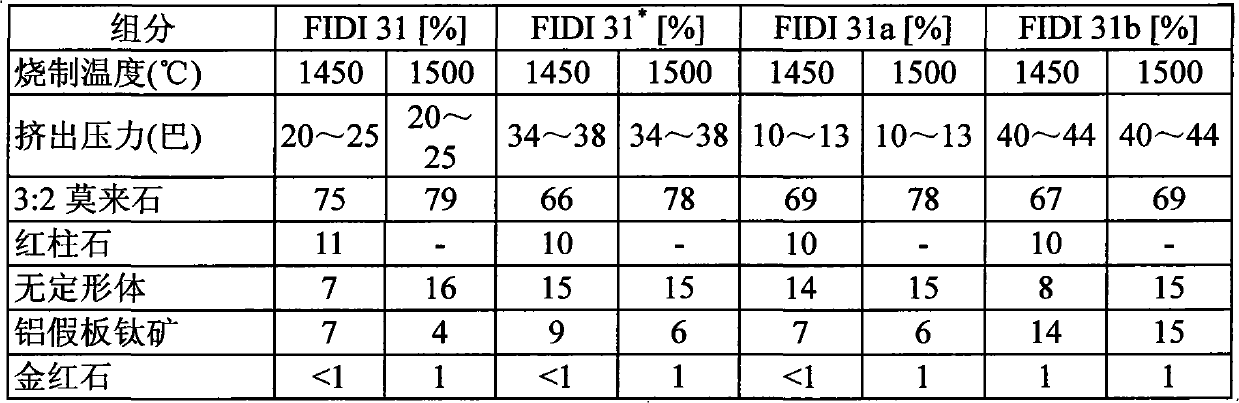

Ceramic honeycomb structures

The invention relates to ceramic honeycomb structures comprising a mullite phase and a tialite phase, and methods for manufacturing these honeycomb structures. The invention also relates to the use of andalusite for the manufacture of a ceramic honeycomb structure, as well as to the ceramic honeycomb structures containing andalusite, and to the methods for manufacturing these ceramic honeycomb structures.

Owner:IMERYS SA

Special silicon brick

The invention discloses a special silicon brick. The special silicon brick is prepared from a main material, an auxiliary material and a binding agent, wherein the main material comprises the following components in percentages by weight: 20-25 percent of bauxite chamotte with granularity of more than 2 mm and not less than 4 mm, 2-20 percent of bauxite chamotte with granularity of more than 1 mm and not less than 2 mm, 15-20 percent of bauxite chamotte with granularity of not more than 1 mm and 10-20 percent of silicon carbide with granularity of not more than 1 mm; the auxiliary material comprises the following components in percentages by weight: 5-10 percent of electrofused corindon thinner than 325 meshes, 5-10 percent of sialon thinner than 200 meshes, 5-10 percent of andalusite with granularity of not more than 1 mm, 3-5 percent of soft binding clay thinner than 200 meshes; and the binding agent is a spent pulping liquor at the concentration of 1.18-1.25 g / cm<3> and accounts for 4-4.5 percent of the sum of the weight of the main material and the auxiliary material. In the invention, by utilizing a strict scientific proportioning, high intensity ceramic combination is finally obtained for various materials, thereby the intensity of the product is greatly enhanced, the high temperature performance is stable and the high temperature wear resistance is better.

Owner:郑州瑞泰耐火科技有限公司

Corundum-mullite crucible

The invention discloses a corundum-mullite crucible. The crucible is characterized by comprising the following raw materials in percentage by weight: 56 to 75 percent of corundum, 5 to 15 percent of mullite, 5 to 15 percent of andalusite, 1 to 10 percent of cement, 5 to 15 percent of calcined alumina, proper silicon micropowder and proper fiber; and the crucible is prepared by the following steps: mixing and stirring the raw materials; preparing slurry by adding water into the raw materials; injecting the slurry into a die for molding, and shaking the die simultaneously; naturally airing the formed blank, and baking the blank for further drying; and finally sintering the blank to obtain the corundum-mullite crucible. The corundum-mullite crucible has the advantages of excellent high-temperature strength, excellent thermal shock and corrosion resistance, small thermal expansion coefficient, high thermal stability, oxidation resistance, certain thermal shock fatigue resistance, outstanding slag resistance, high use temperature (1,750 DEG C), long service life and excellent chemical stability, and has excellent industrial prospect.

Owner:中山市华山特种陶瓷有限公司

High-strength high thermal-shock-resistance low-aluminium mullite brick

The invention relates to a high-strength high thermal-shock-resistance low-aluminium mullite brick, which comprises the following components in percentage by weight: 15-50% of raw material sintered mullite, 5-15% of electric melted mullite, 10-40% of superfine flint clay, 10-30% of sillimanite, 10-30% of andalusite, 2-10% of activated alumina, 2-15% of zirconite, 2-12% of silica and 3-10% of bond clay. The high-strength high thermal-shock-resistance low-aluminium mullite brick provided by the invention made from the above raw material components has the advantages of high refractoriness under load (larger than or equal to 1500 DEG C) and heated volume stability, high thermal-shock resistance (larger than or equal to 50 times under water cooling at 1100 DEG C), low creep rate (smaller than or equal to 0.15 in 20-50 hours), good compressive strength (larger than or equal to 70Mpa), good volume stability and low impurity content at high temperature and the like; and at the same time, the CO corrosion resistance of the product provided by the invention is unaffected, so that the product provided by the invention can meet the use requirements of the medium and large blast furnace hot blast stove and other high-temperature kilns.

Owner:GONGYI HONGYU FIREPROOFING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com