Layered composite carrier for producing shell shaped catalyst

A layered composite, catalyst technology, applied in physical/chemical process catalysts, hydrocarbons, hydrocarbons, etc., can solve the problems of low selectivity, low dispersion of precious metals, and small specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

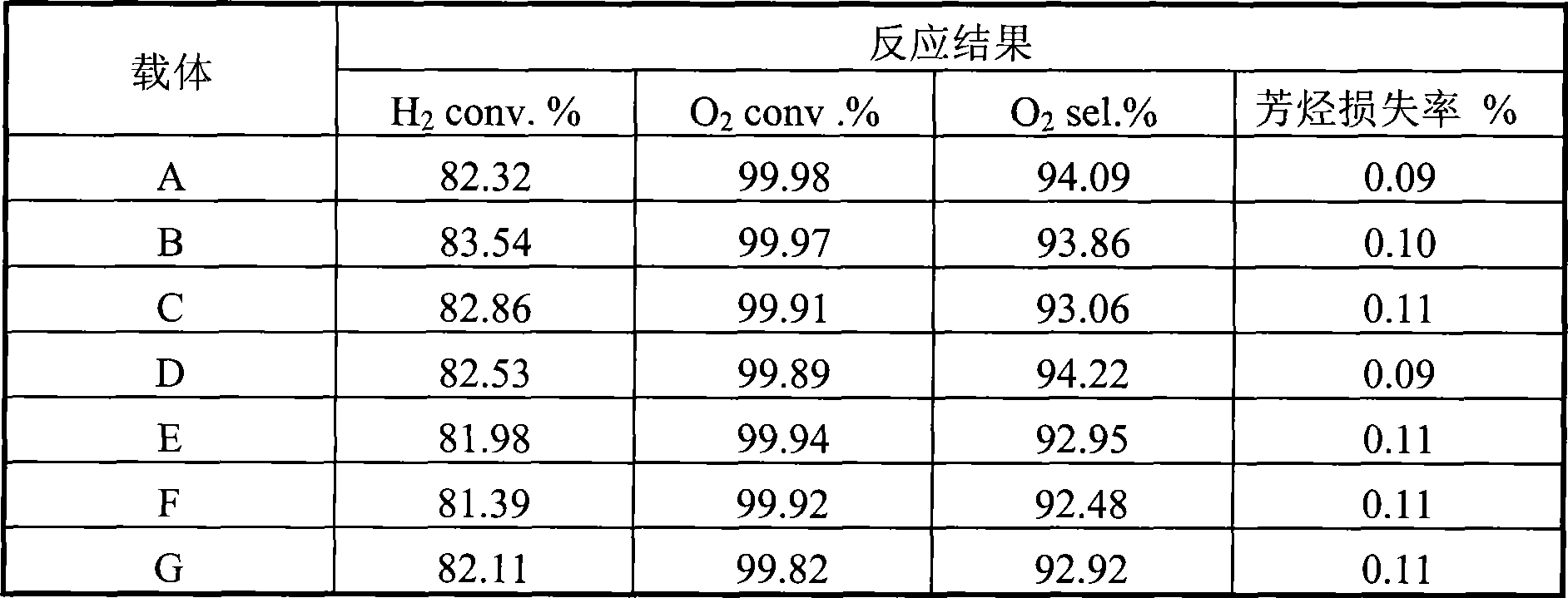

Embodiment 1

[0018]40 grams of alumina sol (containing 15% alumina by mass ratio), 60 grams of 2% glycerin solution, and 0.5 grams of Span 80 were made into a slurry. Then add 0.5 grams of potassium feldspar and 40 grams of jet-milled γ-Al with a particle size below 100 microns to this mixture. 2 o 3 powder (specific surface area 230 m 2 / gram). After stirring for about ten minutes, the slurry was ball milled at room temperature for 4 hours to control the particle size below 20 microns. The slurry was sprayed onto quartz pellets with a particle size of 4 mm, and the coating loading was controlled by controlling the spraying time. After spraying, dry at 80°C for 2 hours, then raise the temperature to 100°C and dry again for 2 hours, and finally bake at 900°C for 6 hours to obtain a layered composite carrier A. The physical and chemical properties are shown in Table 1.

Embodiment 2

[0020] θ-Al 2 o 3 (Specific surface area 180 meters 2 / g) the powder is pulverized and sieved by air flow, and its particle size is controlled below 20 microns to obtain ultrafine θ-Al 2 o 3 pink. 40 grams of alumina sol (containing 15% by mass ratio of alumina), 60 grams of 3% polyacrylamide solution, and 0.4 grams of betaine were prepared into slurry. Then add 0.3 grams of calcium silicate, 40 grams of ultrafine θ-Al to this mixture 2 o 3 pink. After stirring for about ten minutes, the slurry was ball milled at room temperature for 2 hours to control the particle size below 10 microns. Slurry spraying to α-Al with a particle size of 4 mm 2 o 3 On the pellets, dry at 80°C for 2 hours, then raise the temperature to 150°C and dry again for 2 hours, and finally bake at 800°C for 10 hours to obtain a layered composite carrier B. The physical and chemical properties are shown in Table 1.

Embodiment 3

[0022] 30 grams of alumina sol (containing 25% aluminum oxide by mass ratio), 5 grams of 40% silica sol, 60 grams of 4% cyclodextrin solution, and 1.0 gram of cetyltrimethylammonium bromide are made into slurry . Then add 0.4 grams of calcium silicate, 0.3 grams of potassium carbonate and 50 grams of δ-Al with a particle size of less than 100 microns after ball milling to this mixed solution. 2 o 3 powder (specific surface area 160 m 2 / gram). After stirring for about twenty minutes, the slurry was ball milled at room temperature for 3 hours to control the particle size below 1 micron. The slurry was sprayed onto mullite pellets with a particle size of 4 mm, dried at 80°C for 2 hours, then heated to 150°C and dried again for 2 hours, and finally calcined at 950°C for 6 hours to obtain a layered composite carrier C. The physical and chemical properties are shown in Table 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com