Patents

Literature

654 results about "Thin shells" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

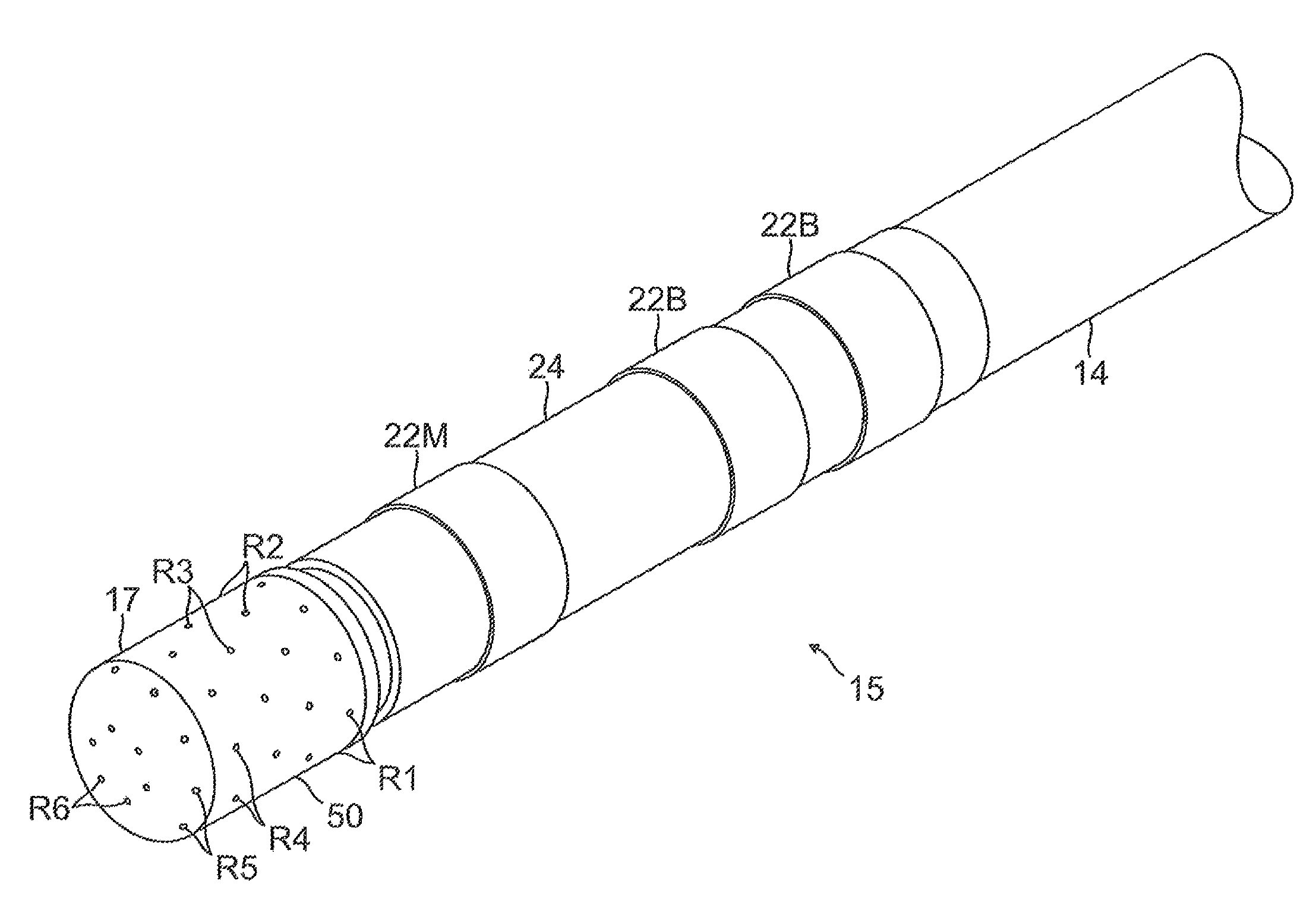

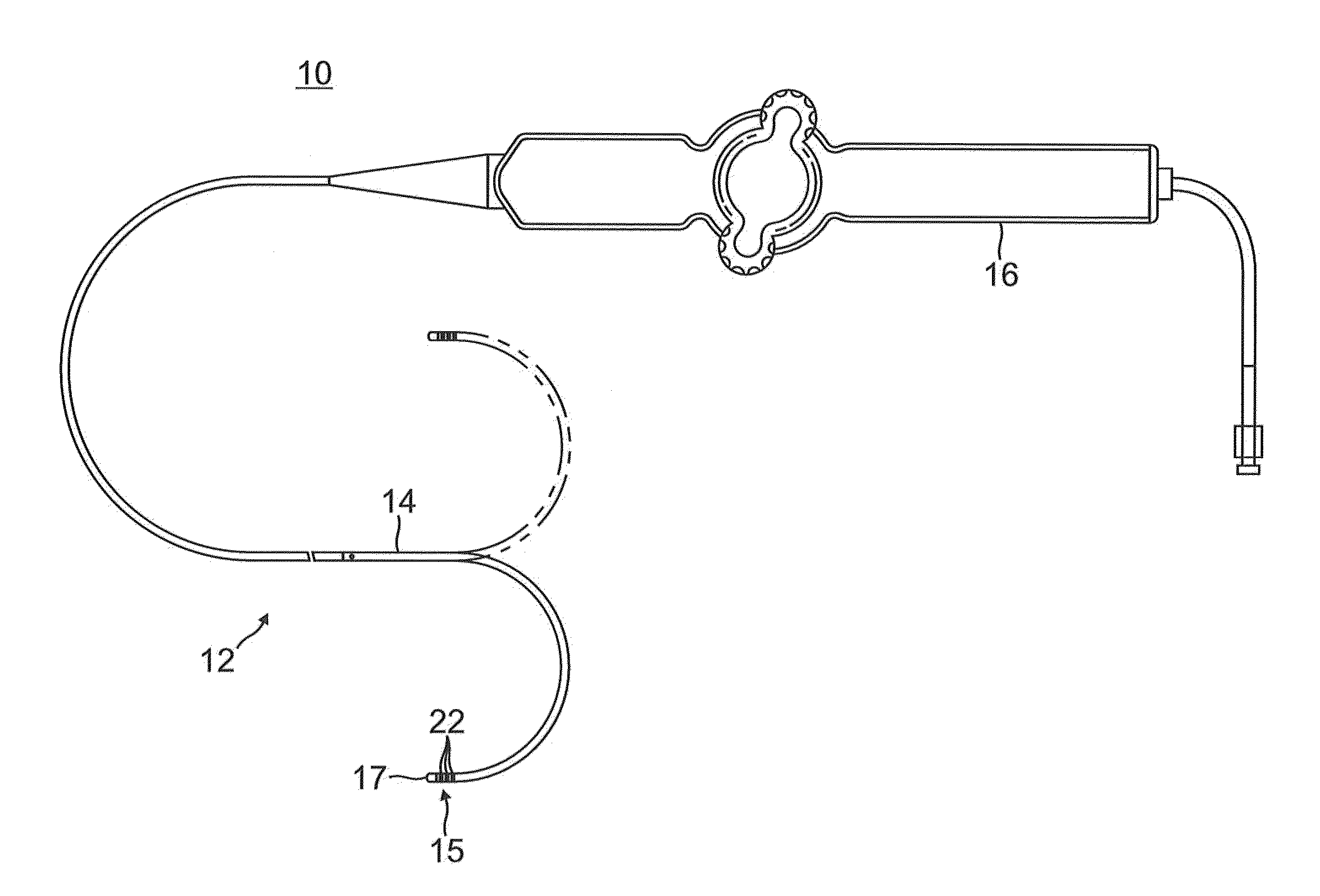

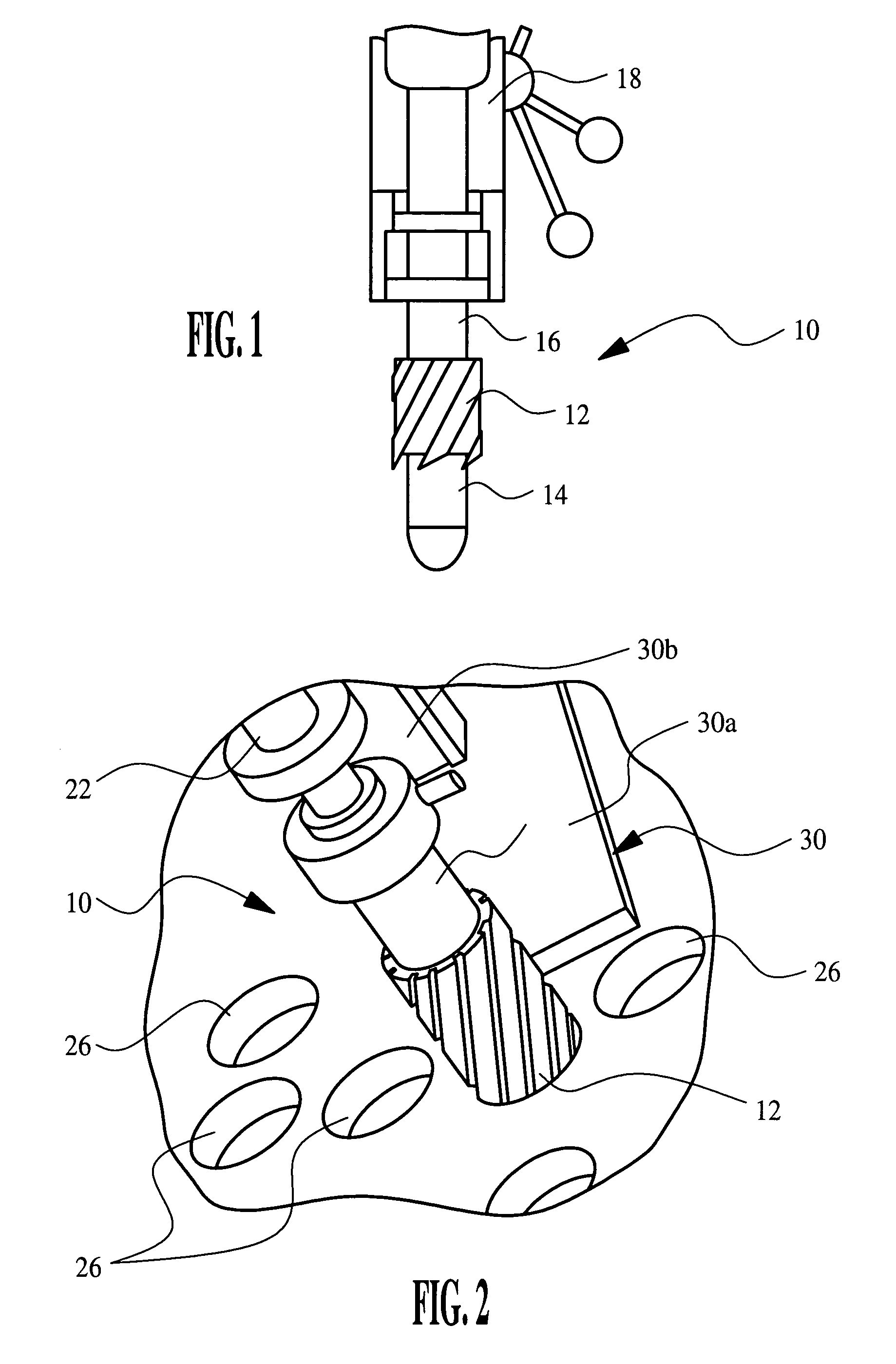

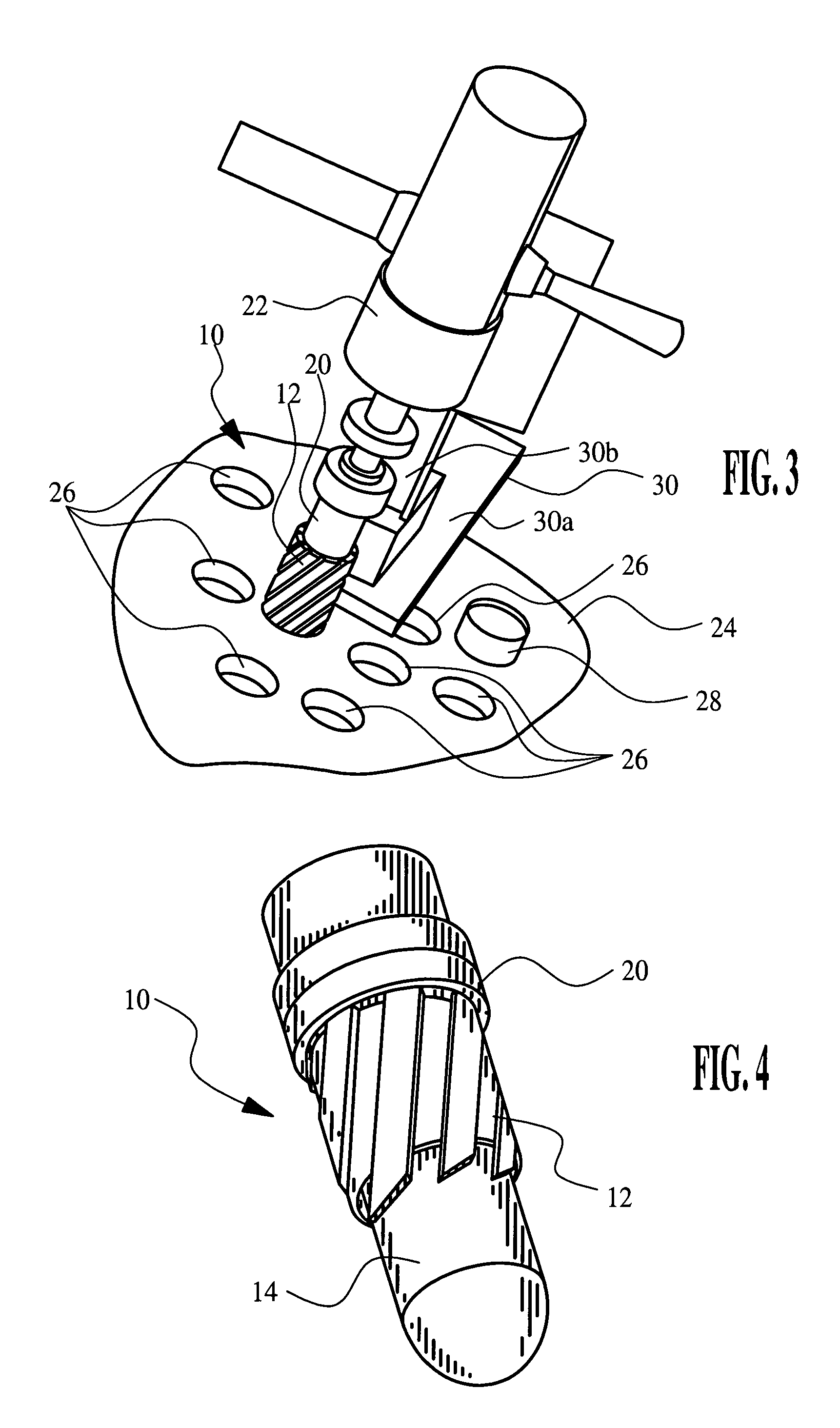

Irrigated ablation catheter with improved fluid flow

ActiveUS20110270246A1High trafficIncrease speedSurgical instruments for heatingComputer-aided surgeryFluid inputThin shells

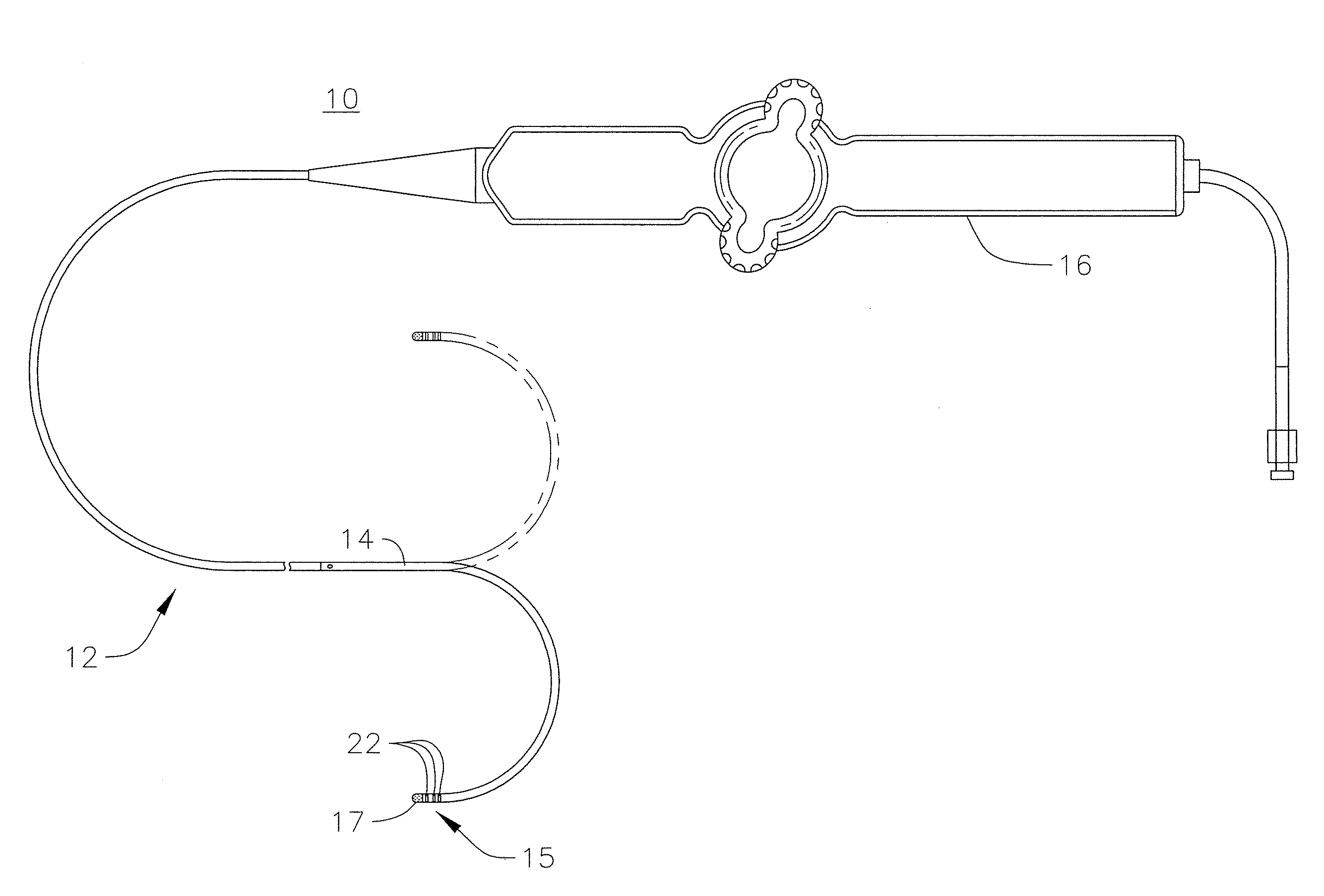

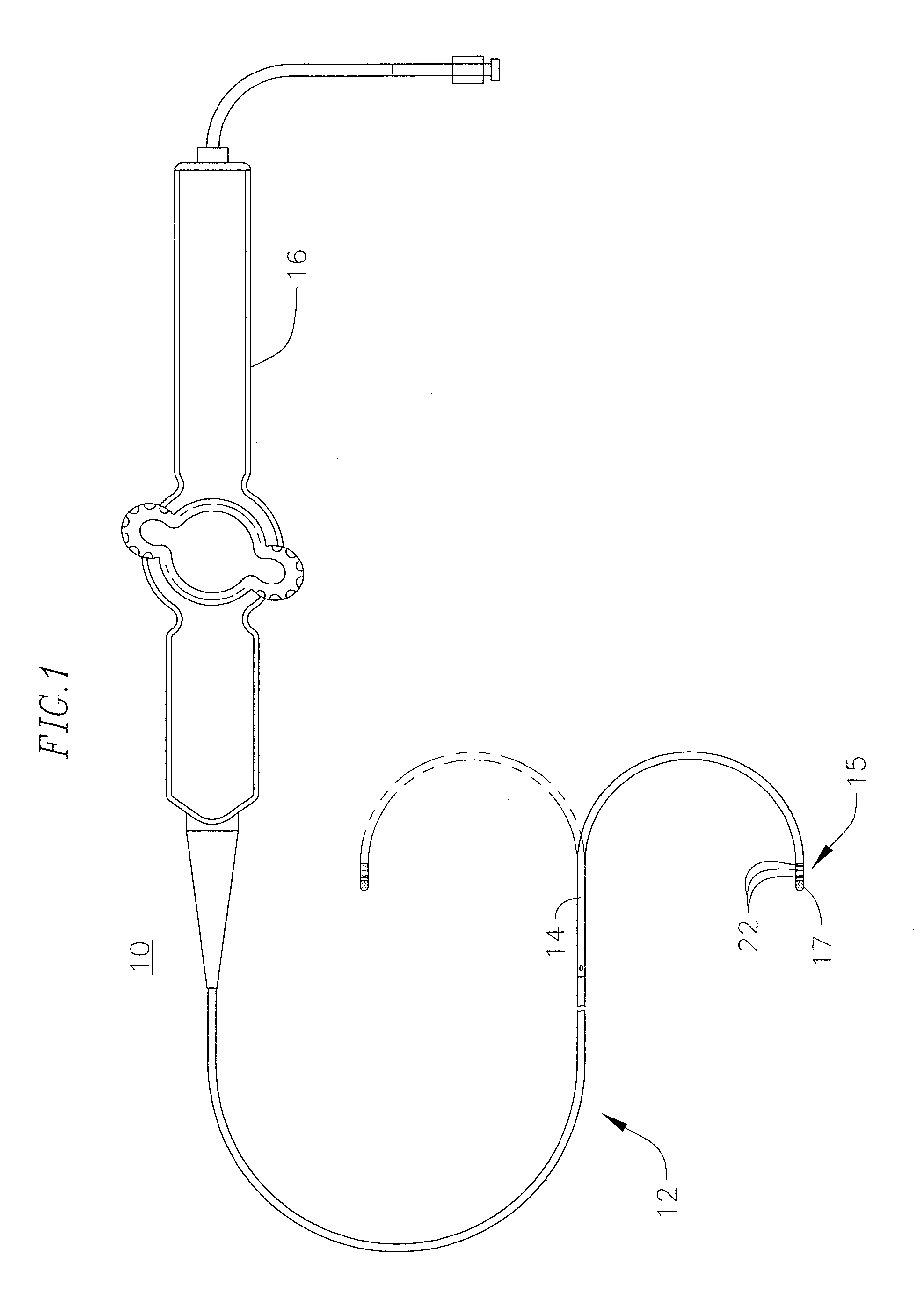

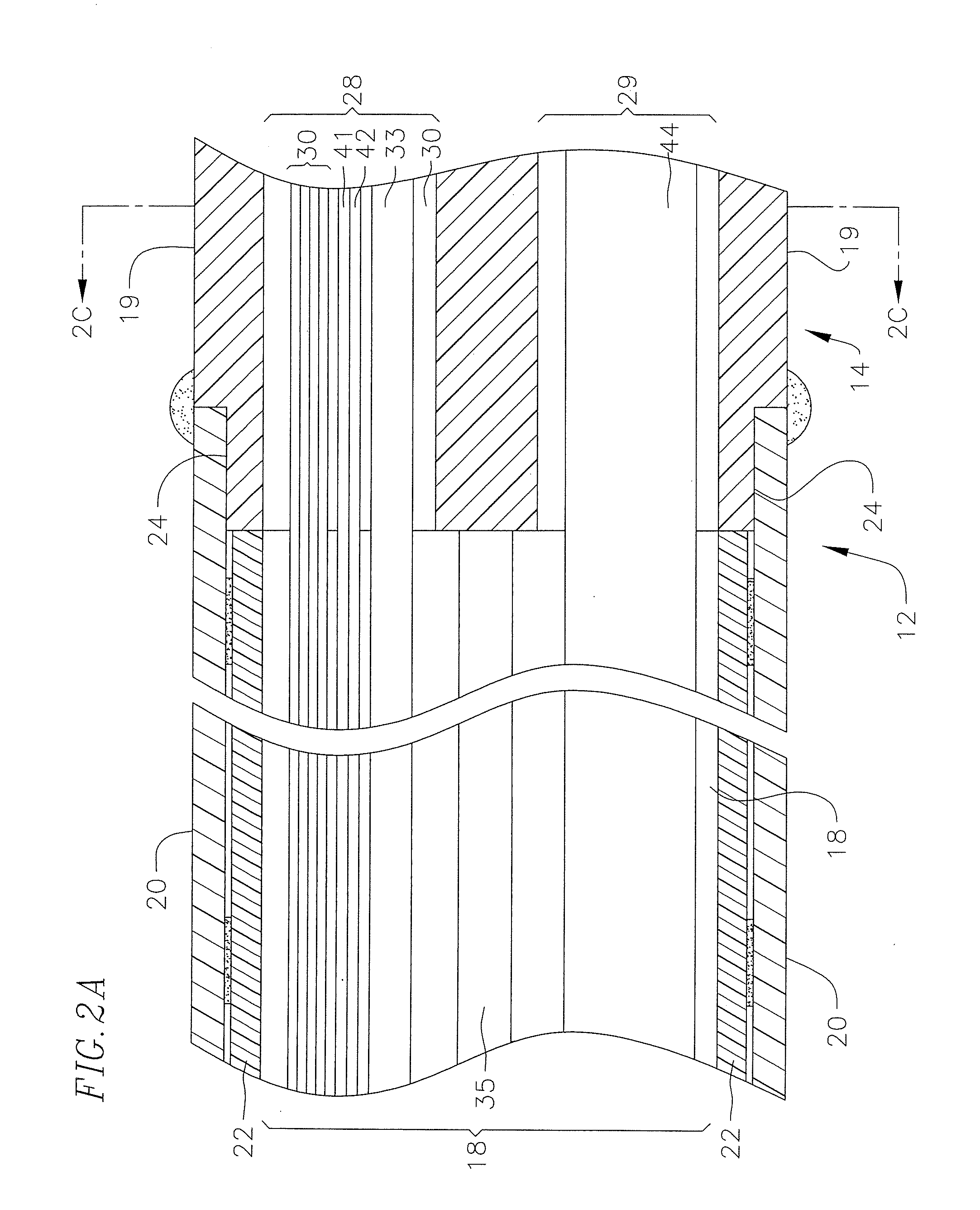

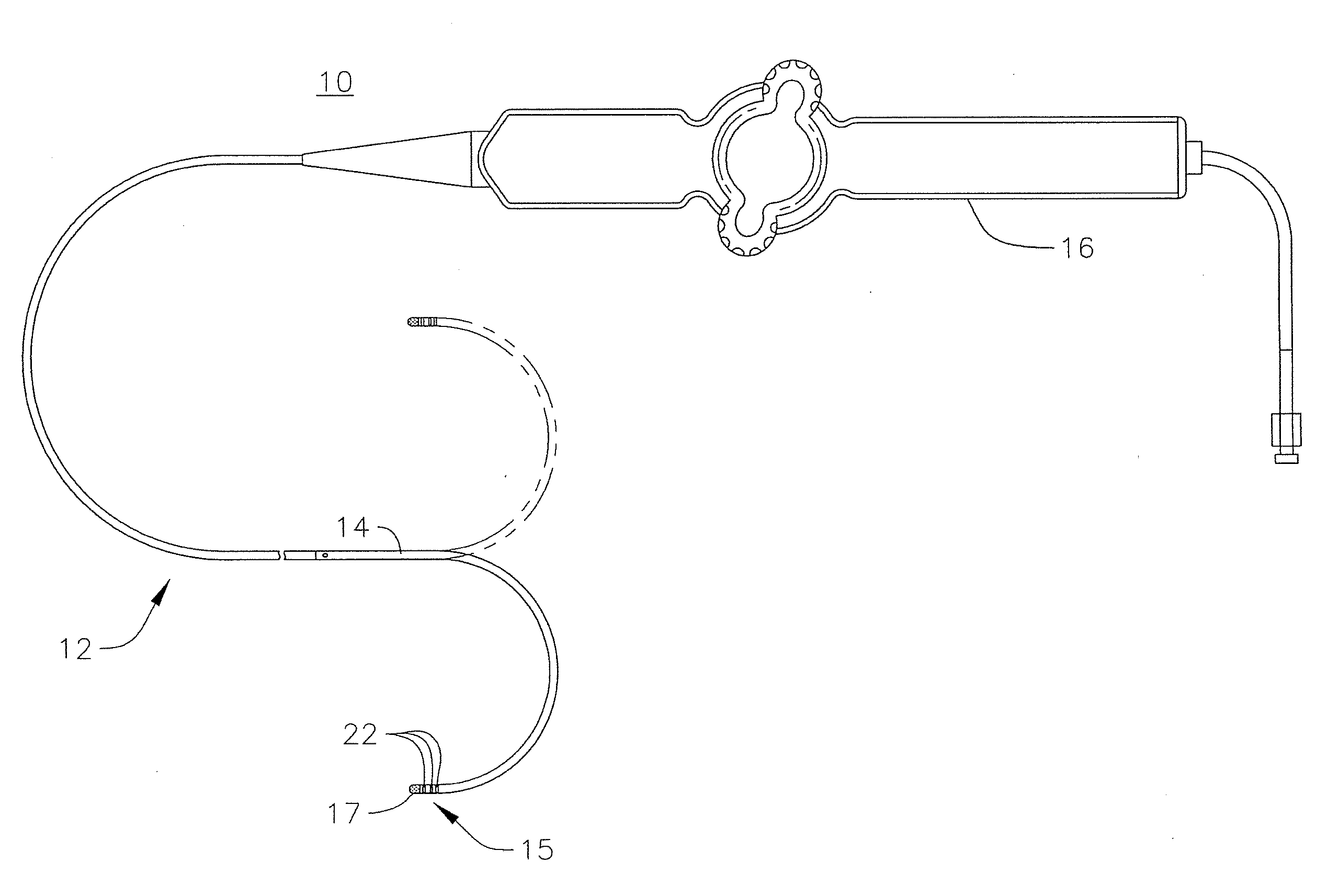

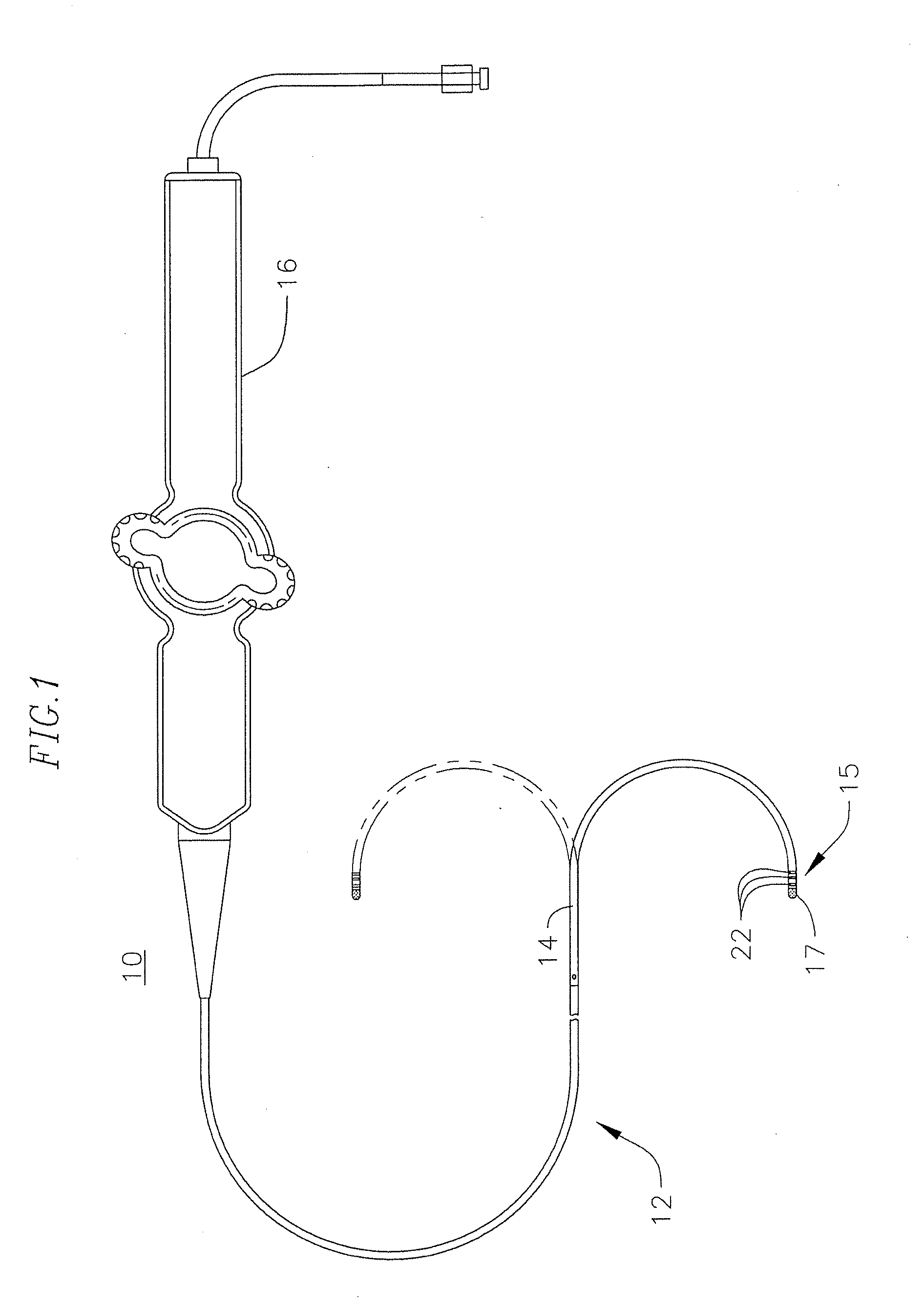

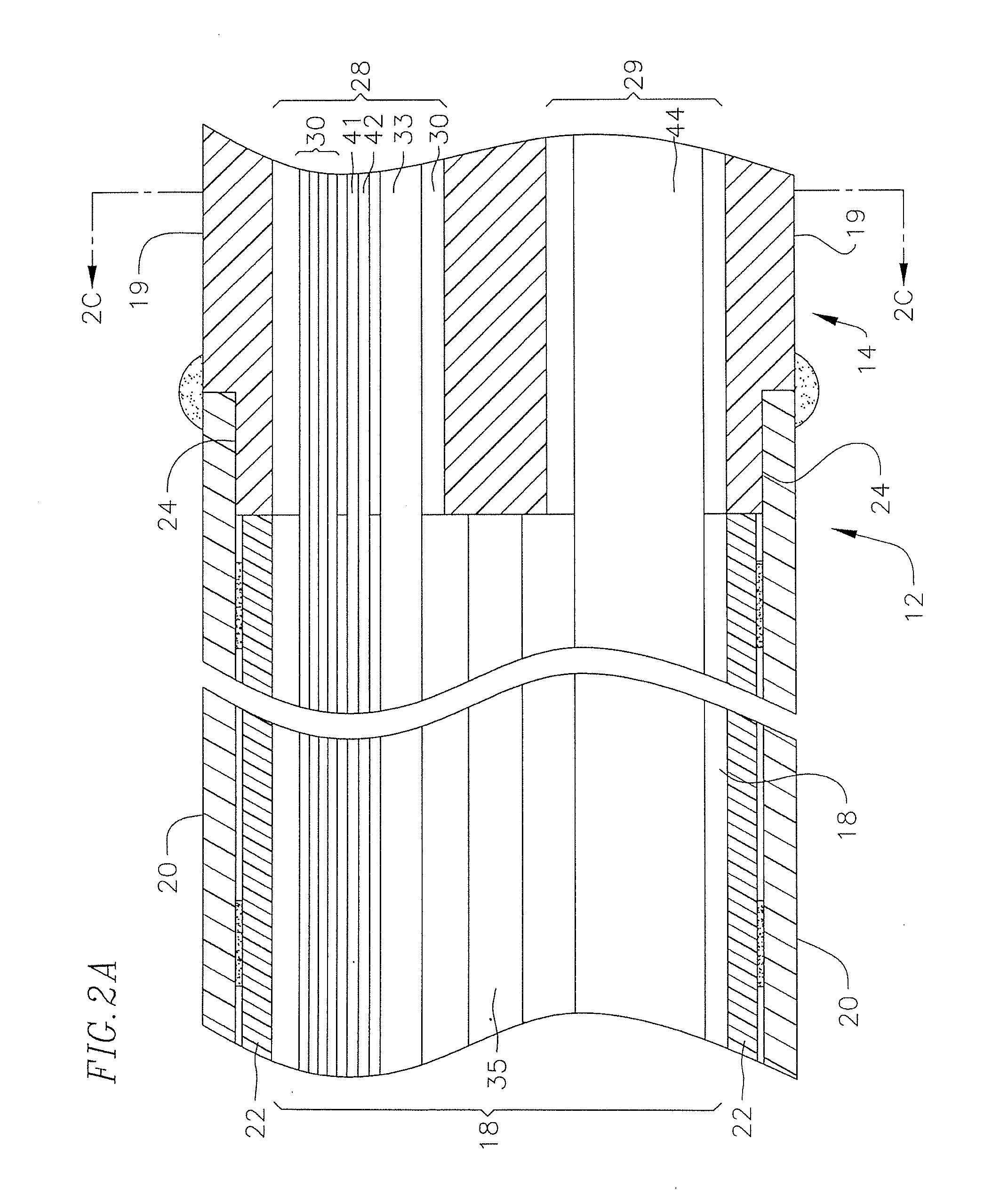

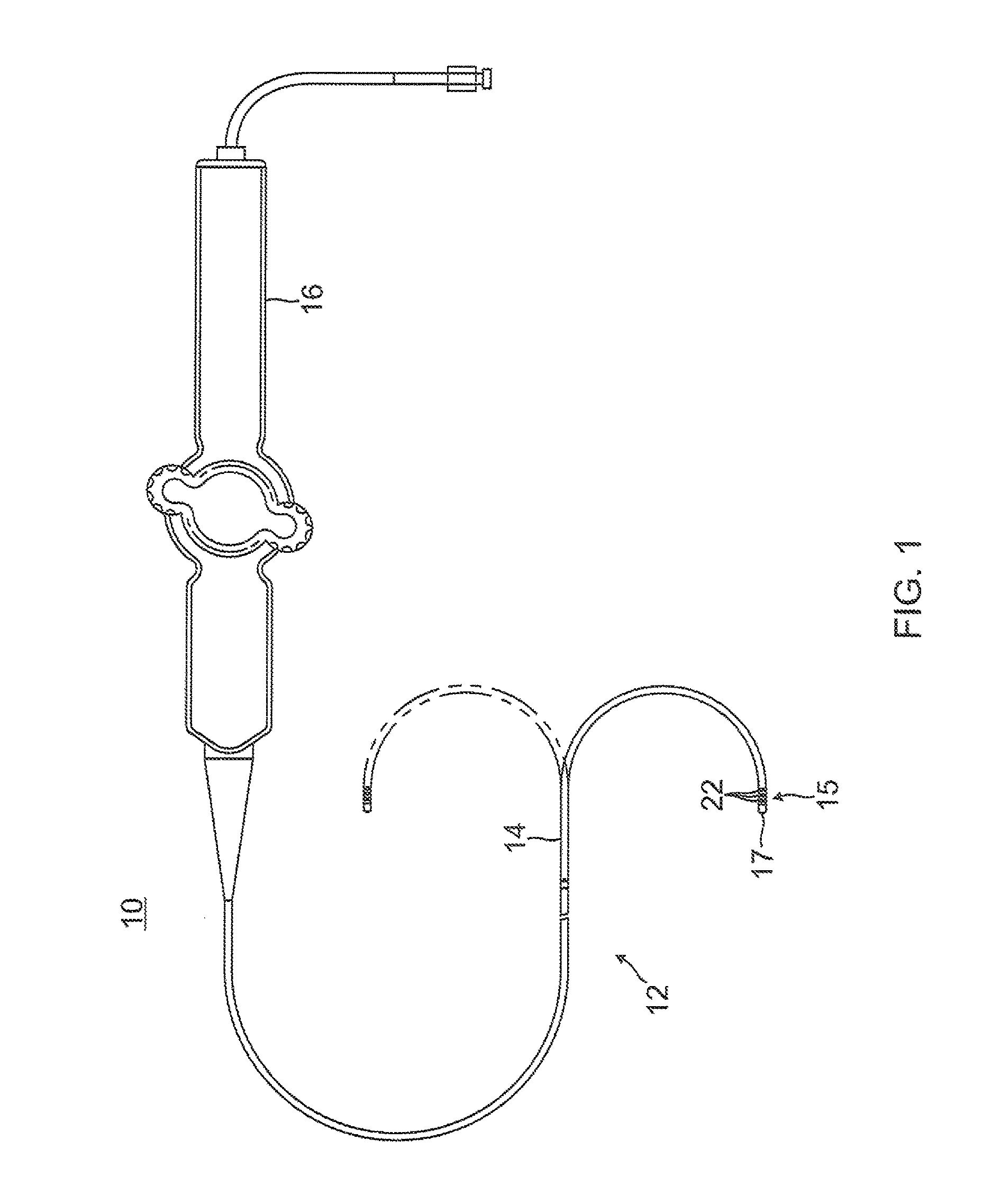

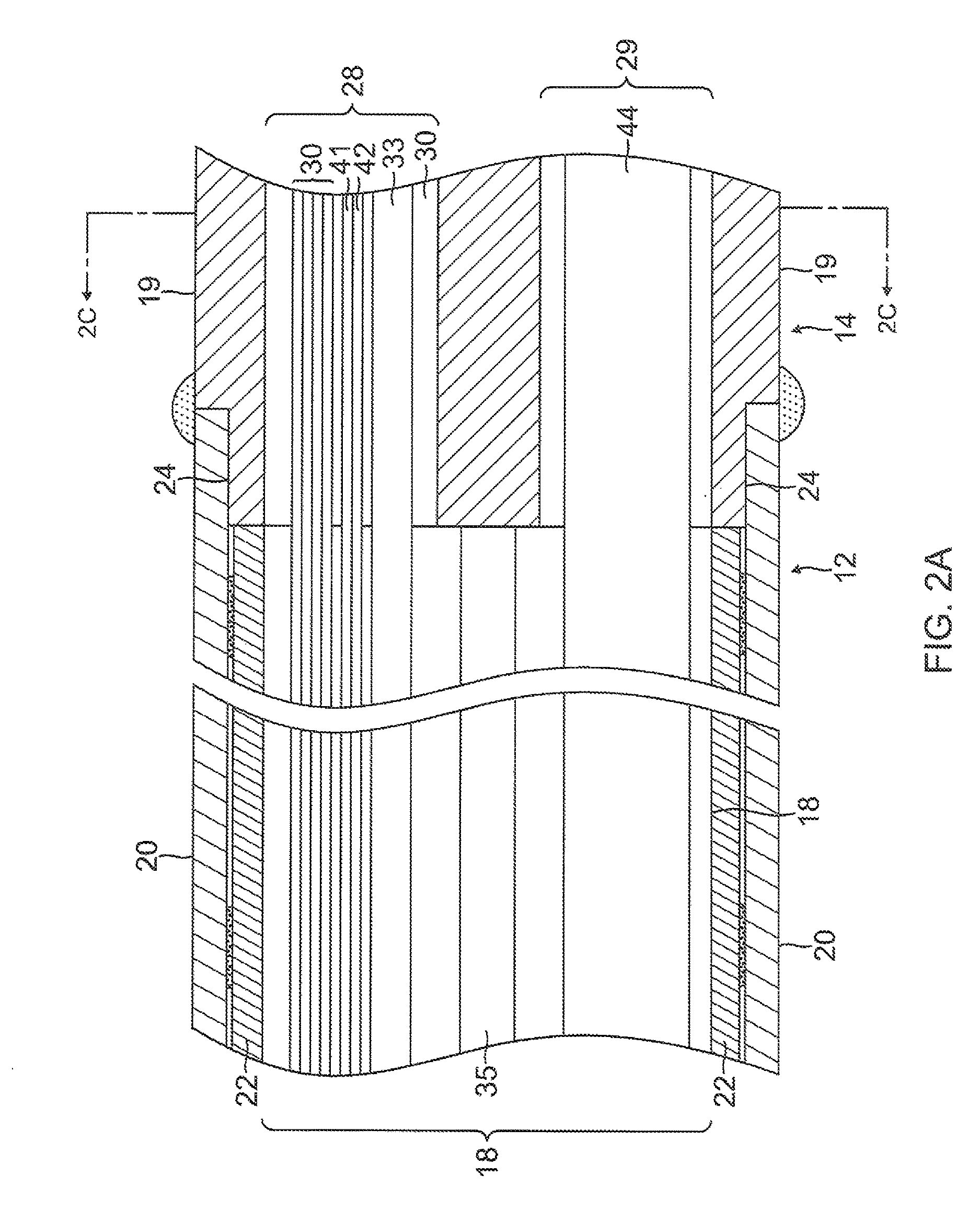

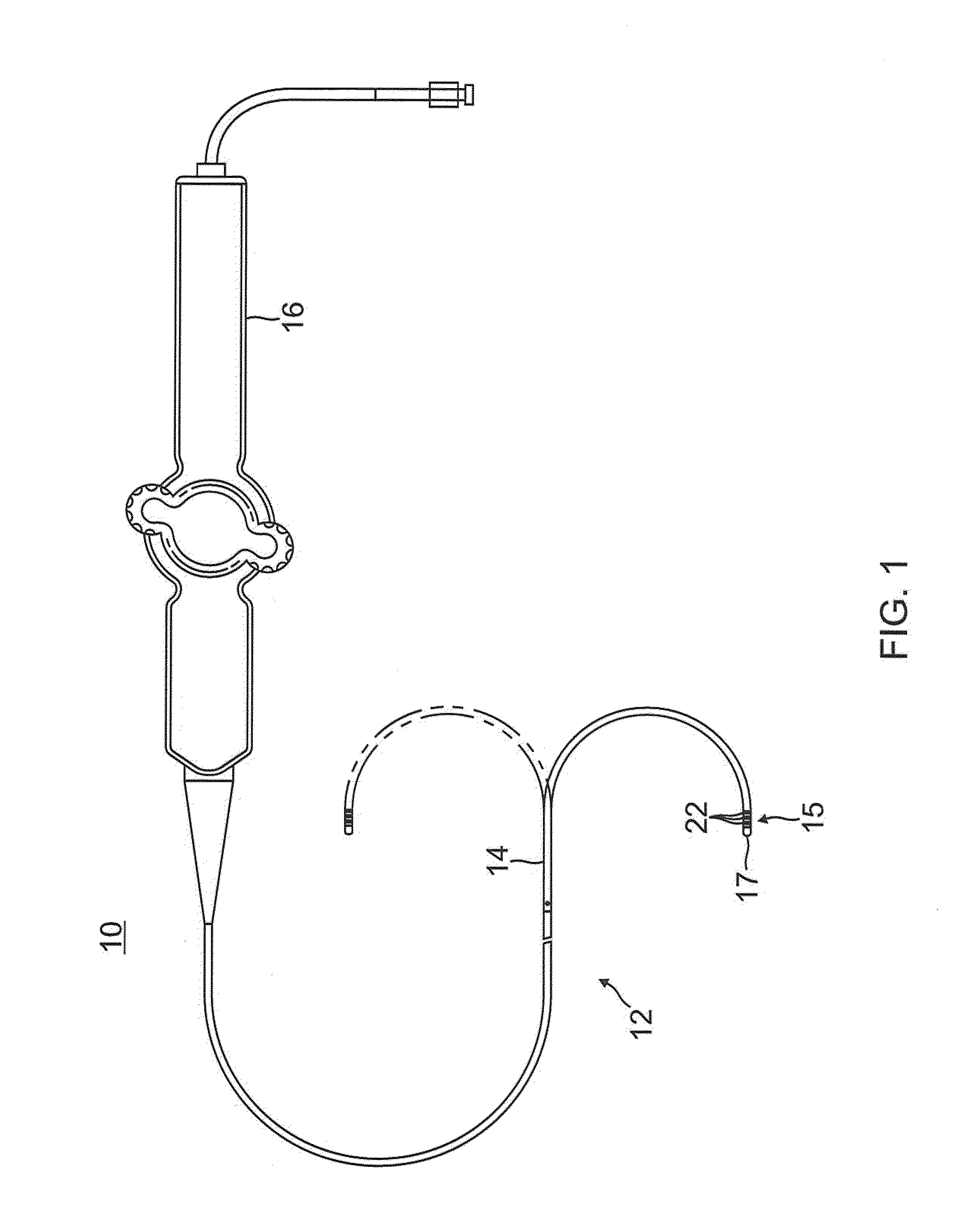

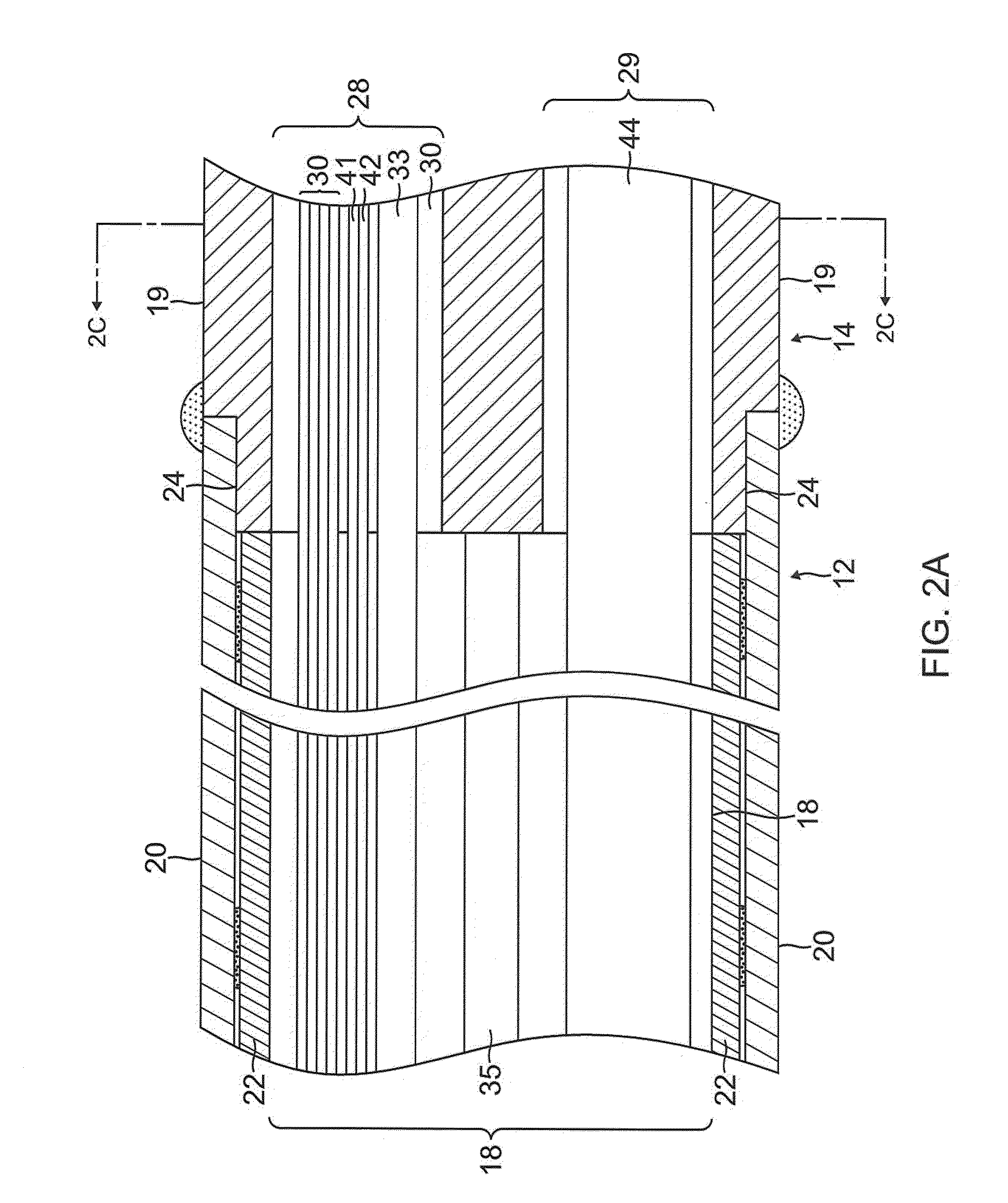

An irrigated ablation catheter includes a tip electrode with a thin shell and a plug to provide a plenum chamber. The tip electrode has an inlet of a predetermined size and noncircular shape, and outlets in the form of fluid ports formed in the thin shell wall. The plurality of the fluid ports is predetermined, as is their diameter. The tip electrode thus considers a diffusion ratio of total fluid output area to fluid input area, and a fluid port ratio. The tip electrode also considers a fluid inlet aspect ratio where the fluid inlet has a noncircular (for example, oval or elliptical) radial cross-section. The plenum chamber has a narrow proximal portion opening to a wider distal portion so that fluid pressure decreases while fluid velocity increases with the desired effect of increased turbulence which decreases momentum for a more uniform distribution of fluid in the tip electrode. Extending distally from the plug is a baffle member shaped to diffuse fluid entering the tip electrode and to house an electromagnetic position sensor.

Owner:BIOSENSE WEBSTER (ISRAEL) LTD

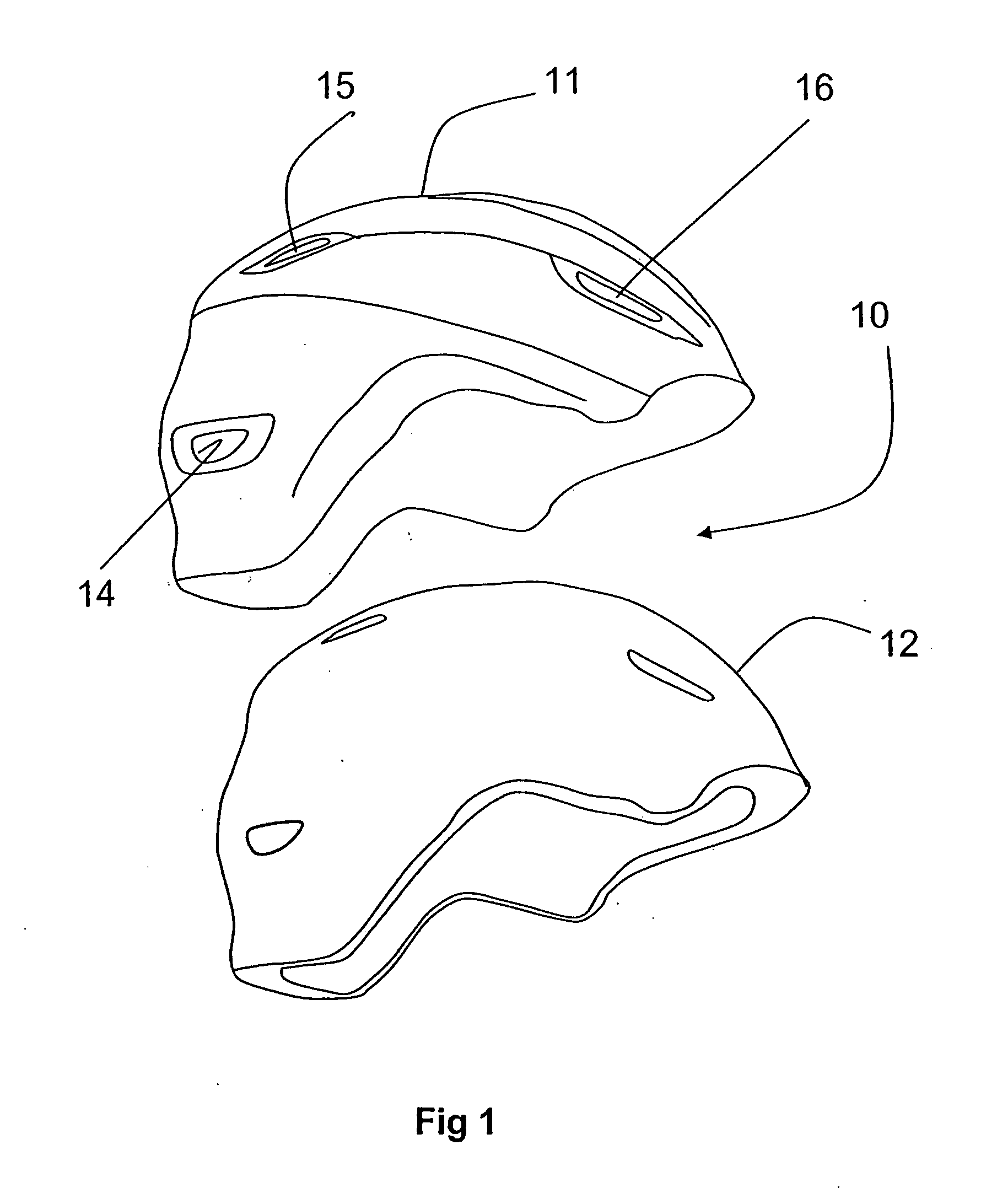

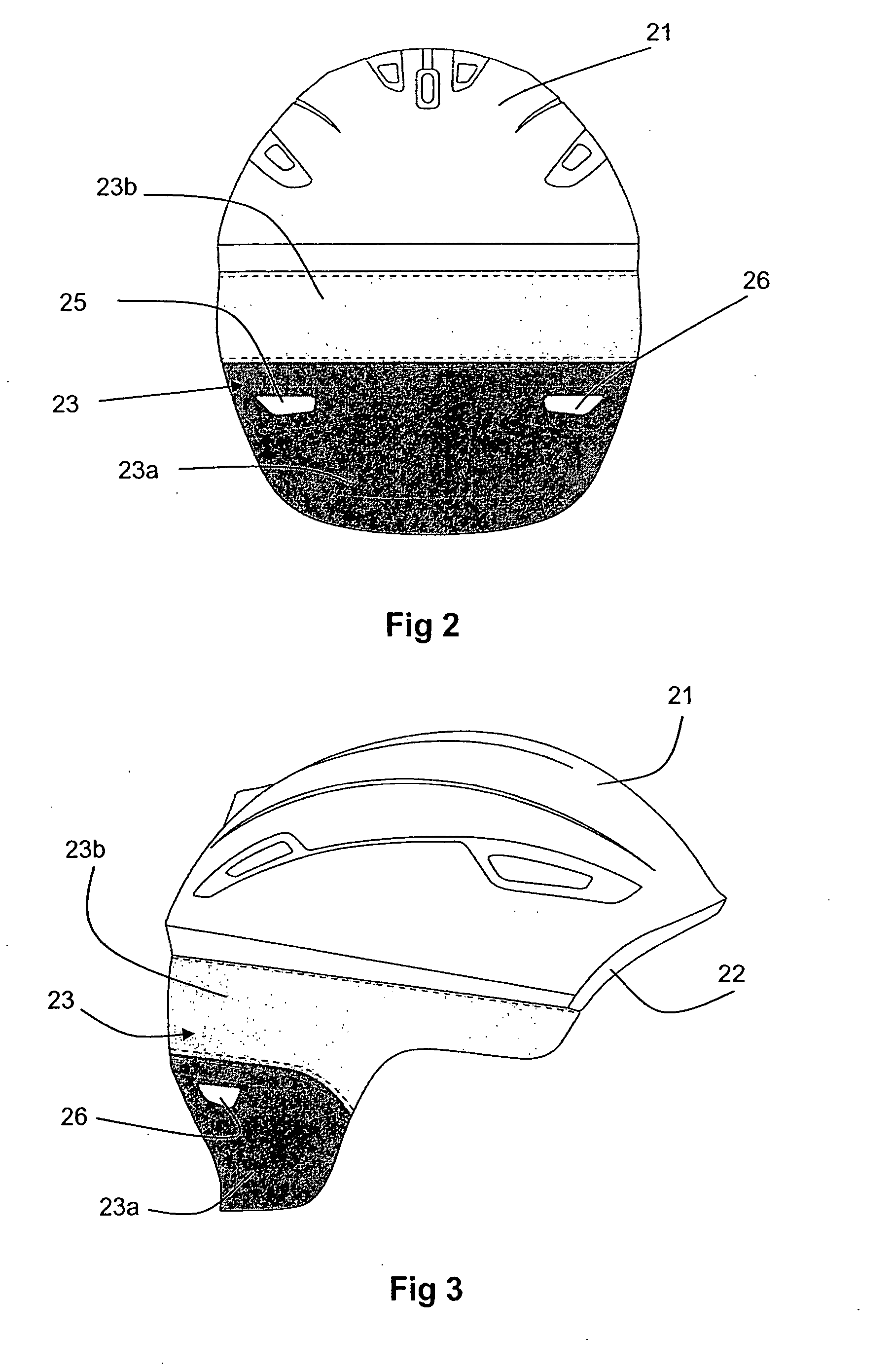

Protective helmet and method of manufacture thereof

Owner:SALOMON SA

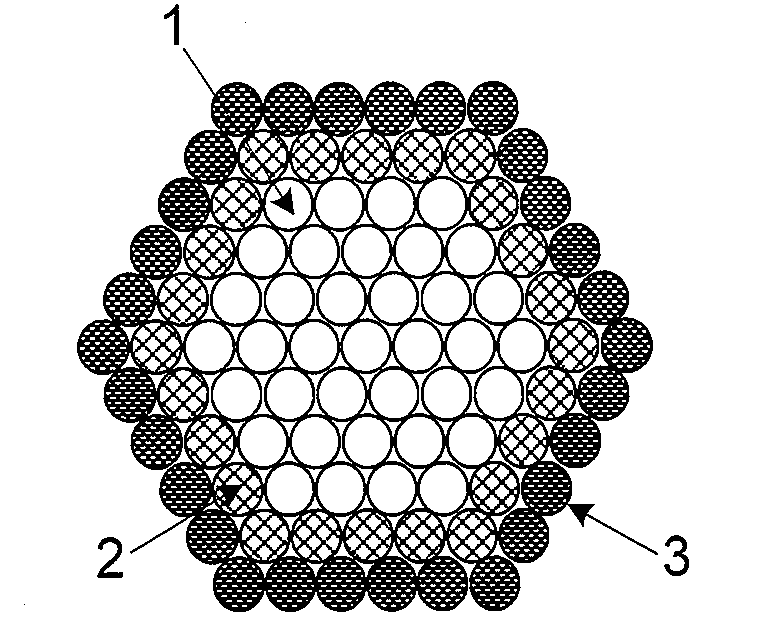

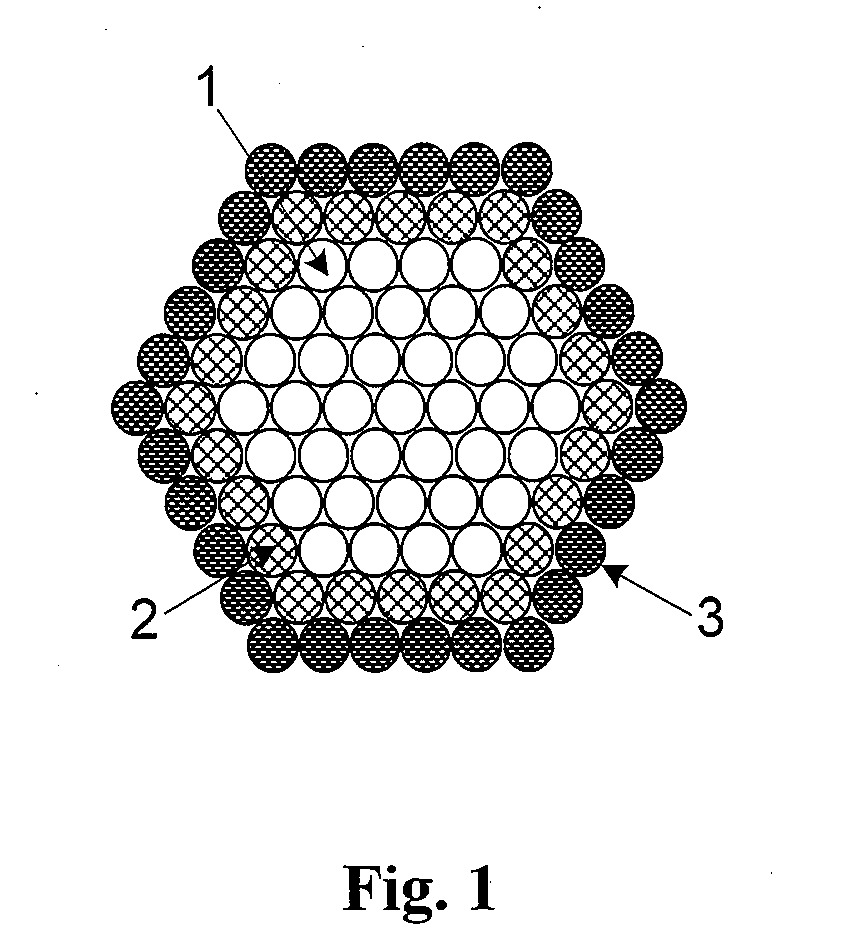

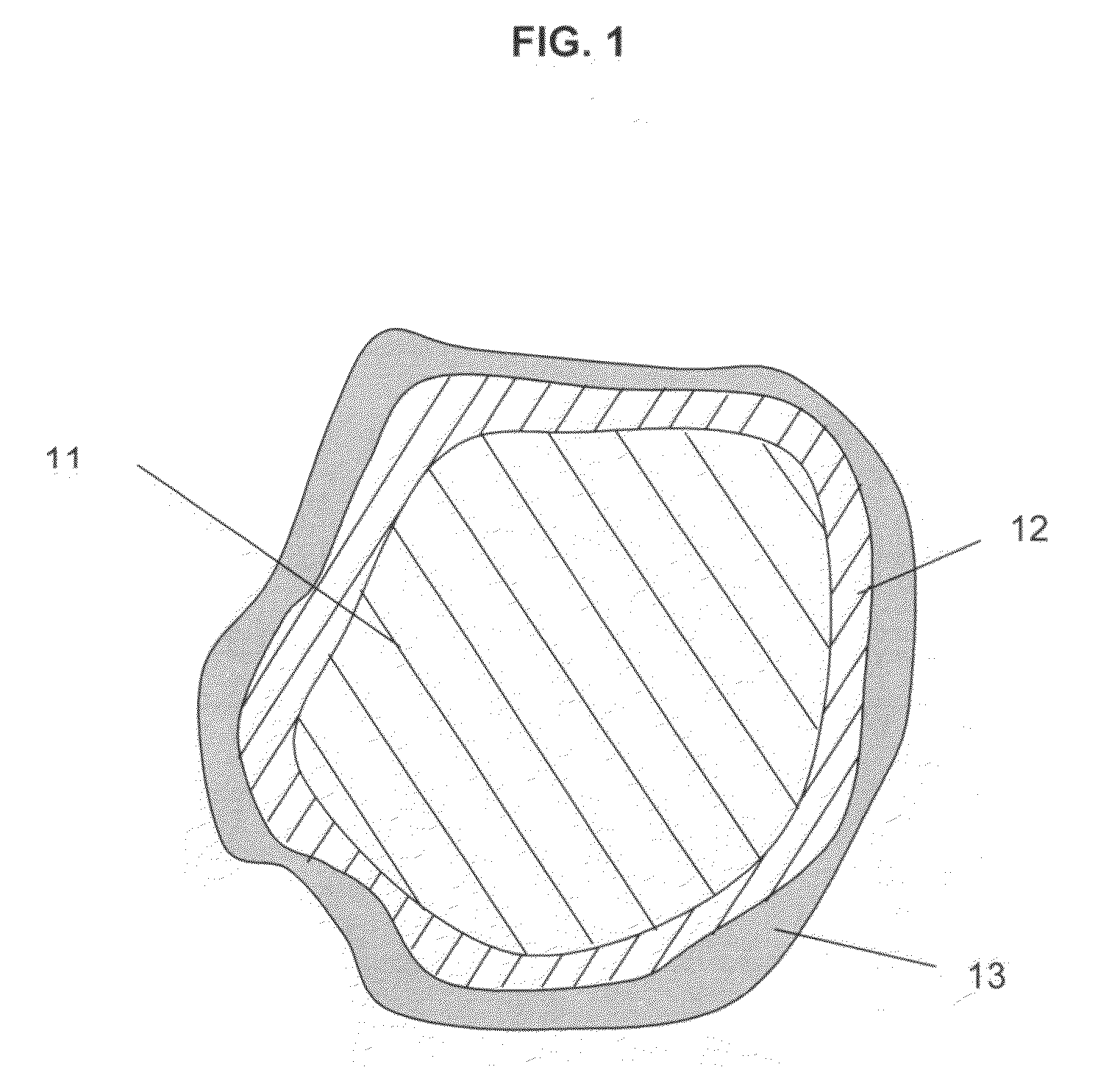

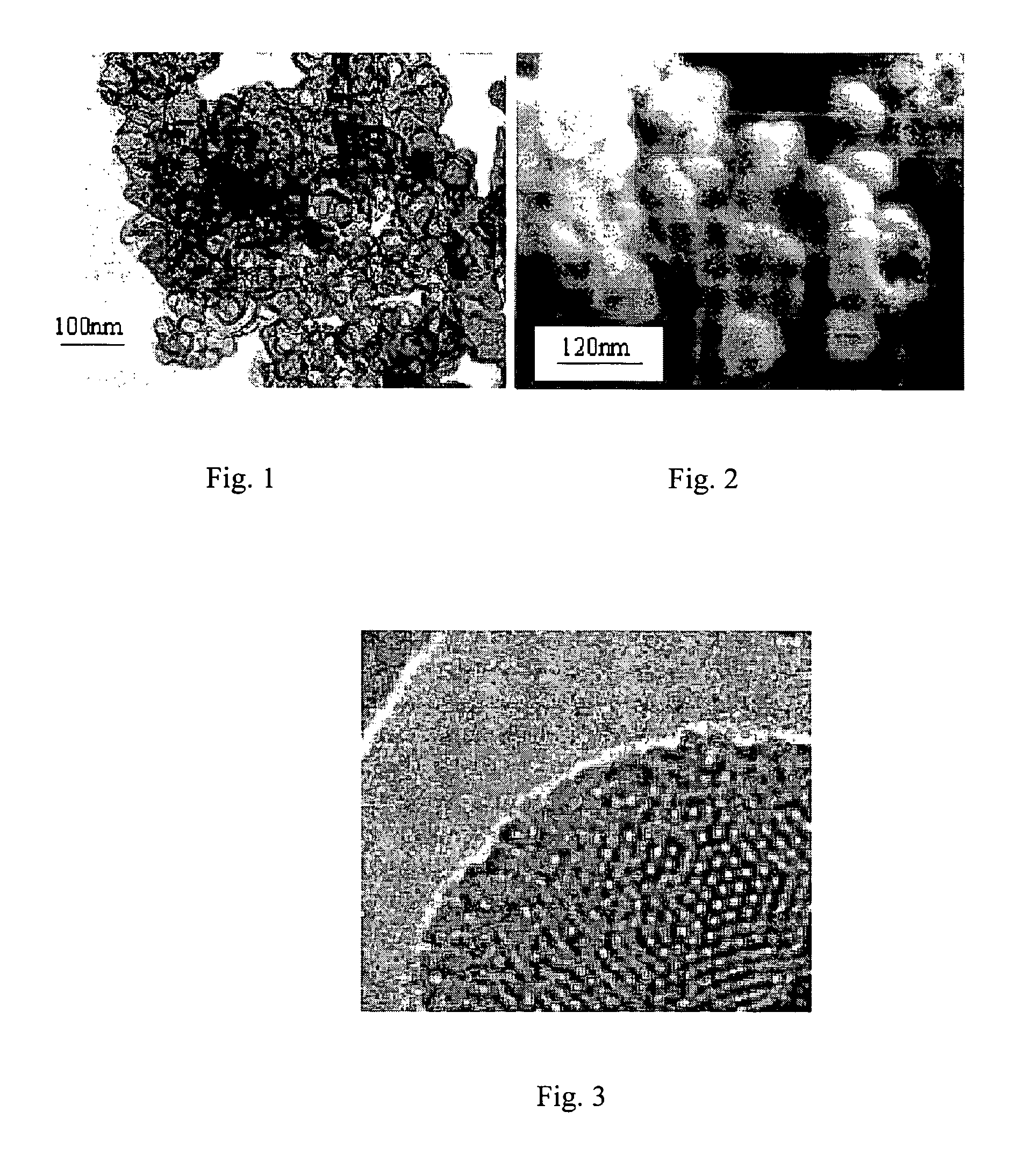

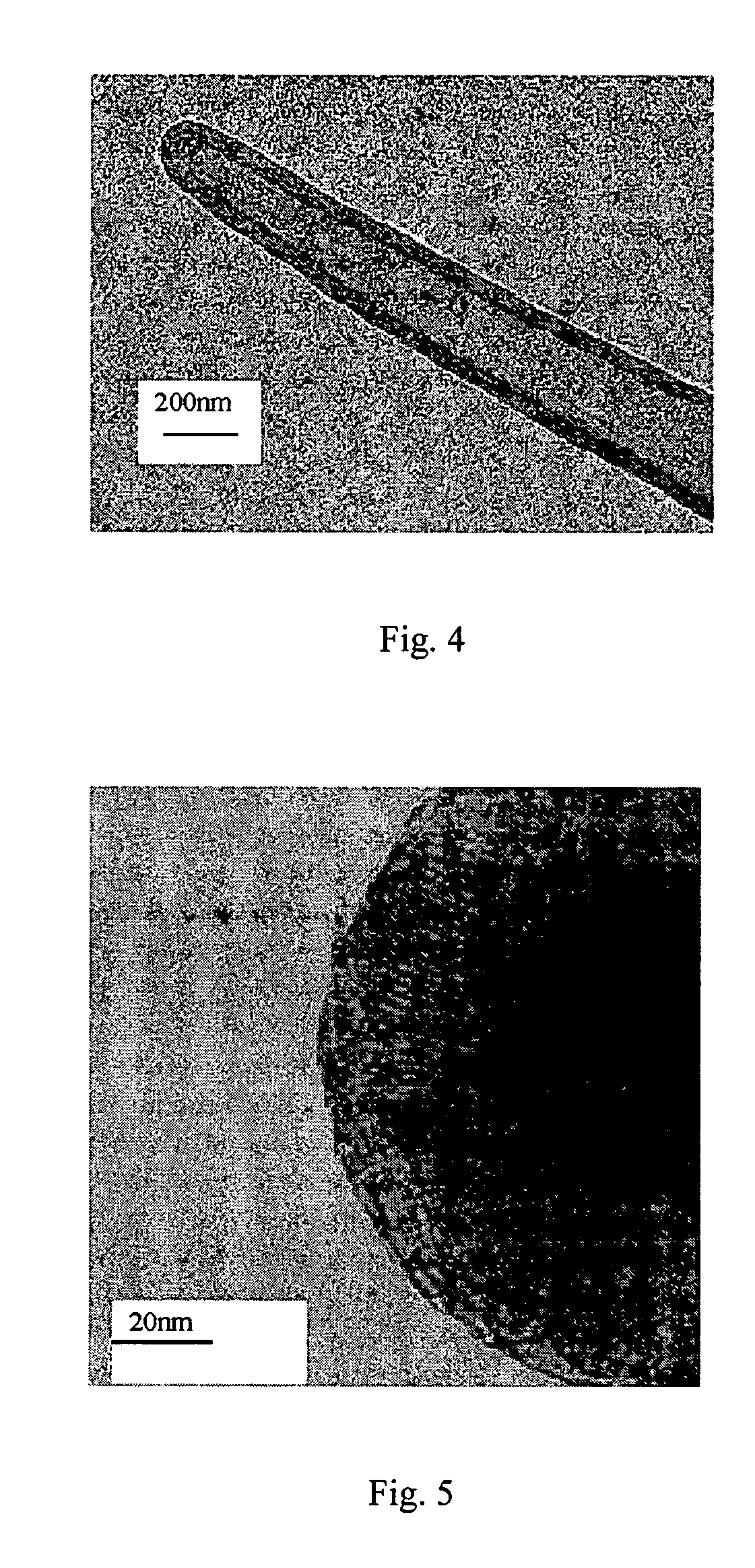

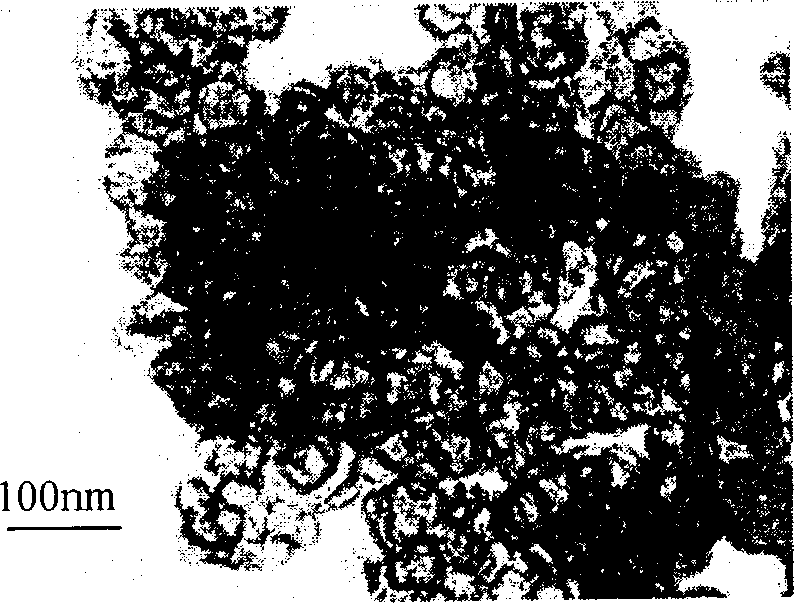

Platinum-Coated Non-Noble Metal-Noble Metal Core-Shell Electrocatalysts

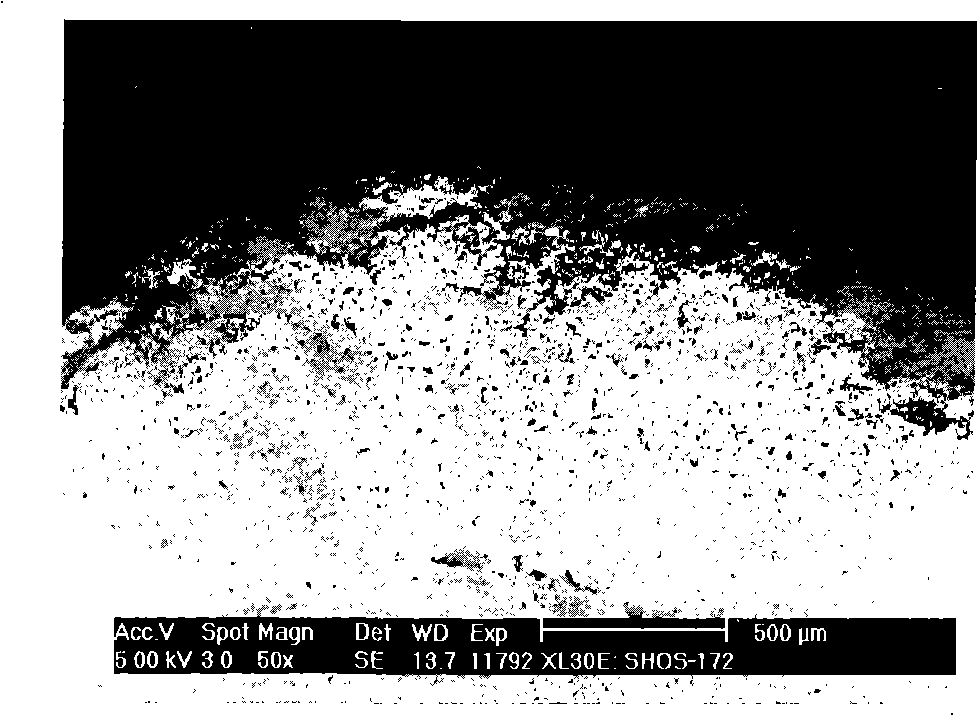

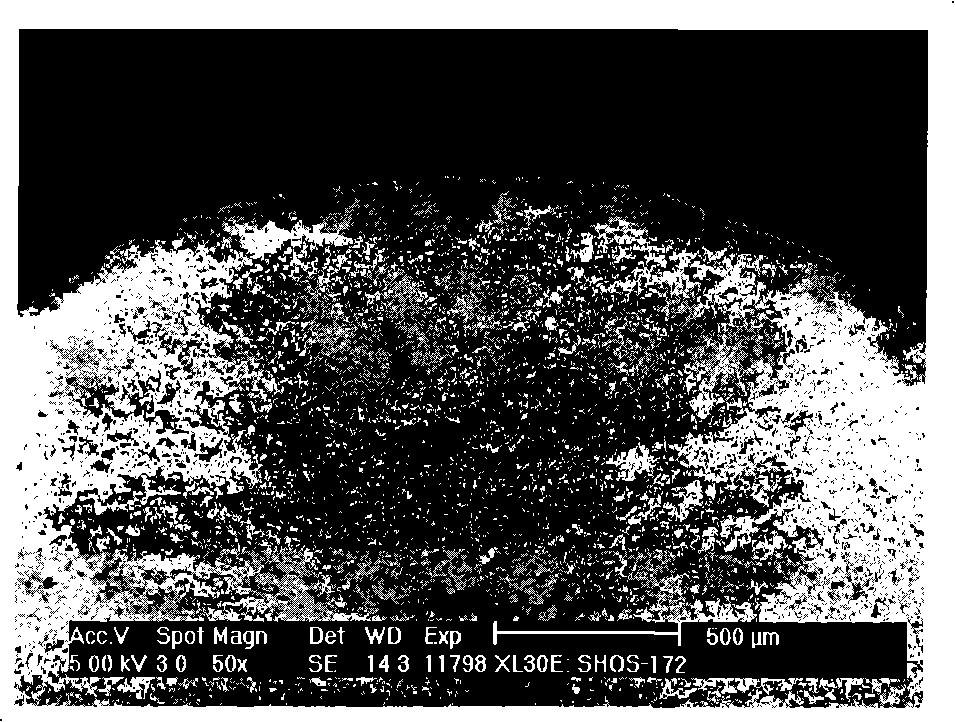

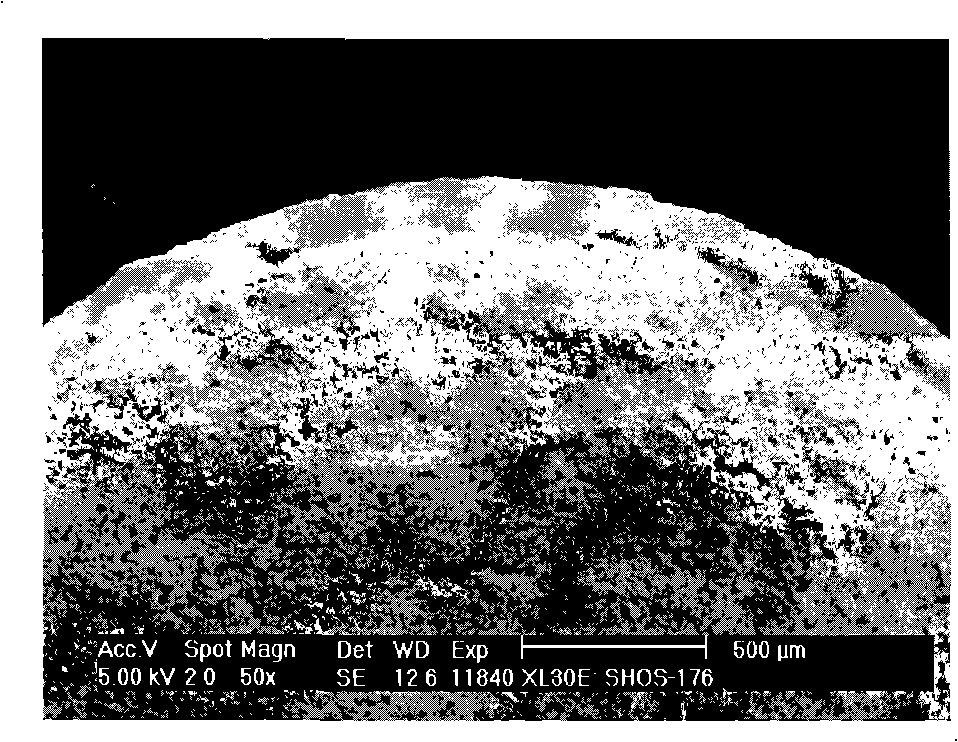

InactiveUS20100197490A1Minimal loadingEfficiently formedMaterial nanotechnologyCell electrodesAlloyPt element

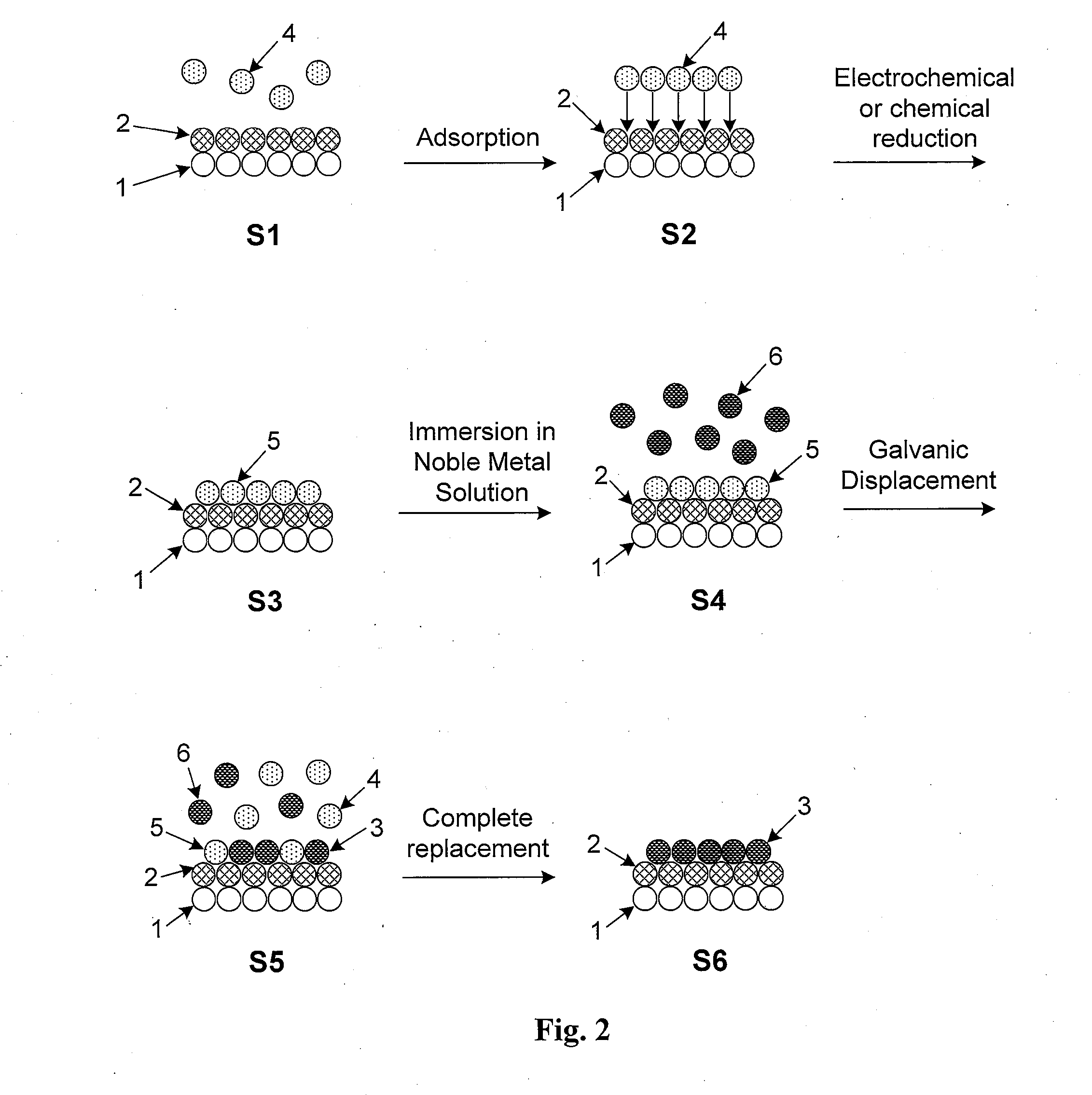

Core-shell particles encapsulated by a thin film of a catalytically active metal are described. The particles are preferably nanoparticles comprising a non-noble core with a noble metal shell which preferably do not include Pt. The non-noble metal-noble metal core-shell nanoparticles are encapsulated by a catalytically active metal which is preferably Pt. The core-shell nanoparticles are preferably formed by prolonged elevated-temperature annealing of nanoparticle alloys in an inert environment. This causes the noble metal component to surface segregate and form an atomically thin shell. The Pt overlayer is formed by a process involving the underpotential deposition of a monolayer of a non-noble metal followed by immersion in a solution comprising a Pt salt. A thin Pt layer forms via the galvanic displacement of non-noble surface atoms by more noble Pt atoms in the salt. The overall process is a robust and cost-efficient method for forming Pt-coated non-noble metal-noble metal core-shell nanoparticles.

Owner:BROOKHAVEN SCI ASSOCS

Irrigated ablation catheter with improved fluid flow

ActiveUS20110270244A1Increase speedImprove fluid flowDiagnosticsSurgical instruments for heatingFluid inputThin shells

An irrigated ablation catheter includes a tip electrode with a thin shell and a plug to provide a plenum chamber. The tip electrode has an inlet of a predetermined size and noncircular shape, and outlets in the form of fluid ports formed in the thin shell wall. The plurality of the fluid ports is predetermined, as is their diameter. The tip electrode thus considers a diffusion ratio of total fluid output area to fluid input area, and a fluid port ratio. The tip electrode also considers a fluid inlet aspect ratio where the fluid inlet has a noncircular (for example, oval or elliptical) radial cross-section. The plenum chamber has a narrow proximal portion opening to a wider distal portion so that fluid pressure decreases while fluid velocity increases with the desired effect of increased turbulence which decreases momentum for a more uniform distribution of fluid in the tip electrode. Extending distally from the plug is a baffle member shaped to diffuse fluid entering the tip electrode and to house an electromagnetic position sensor.

Owner:BIOSENSE WEBSTER (ISRAEL) LTD

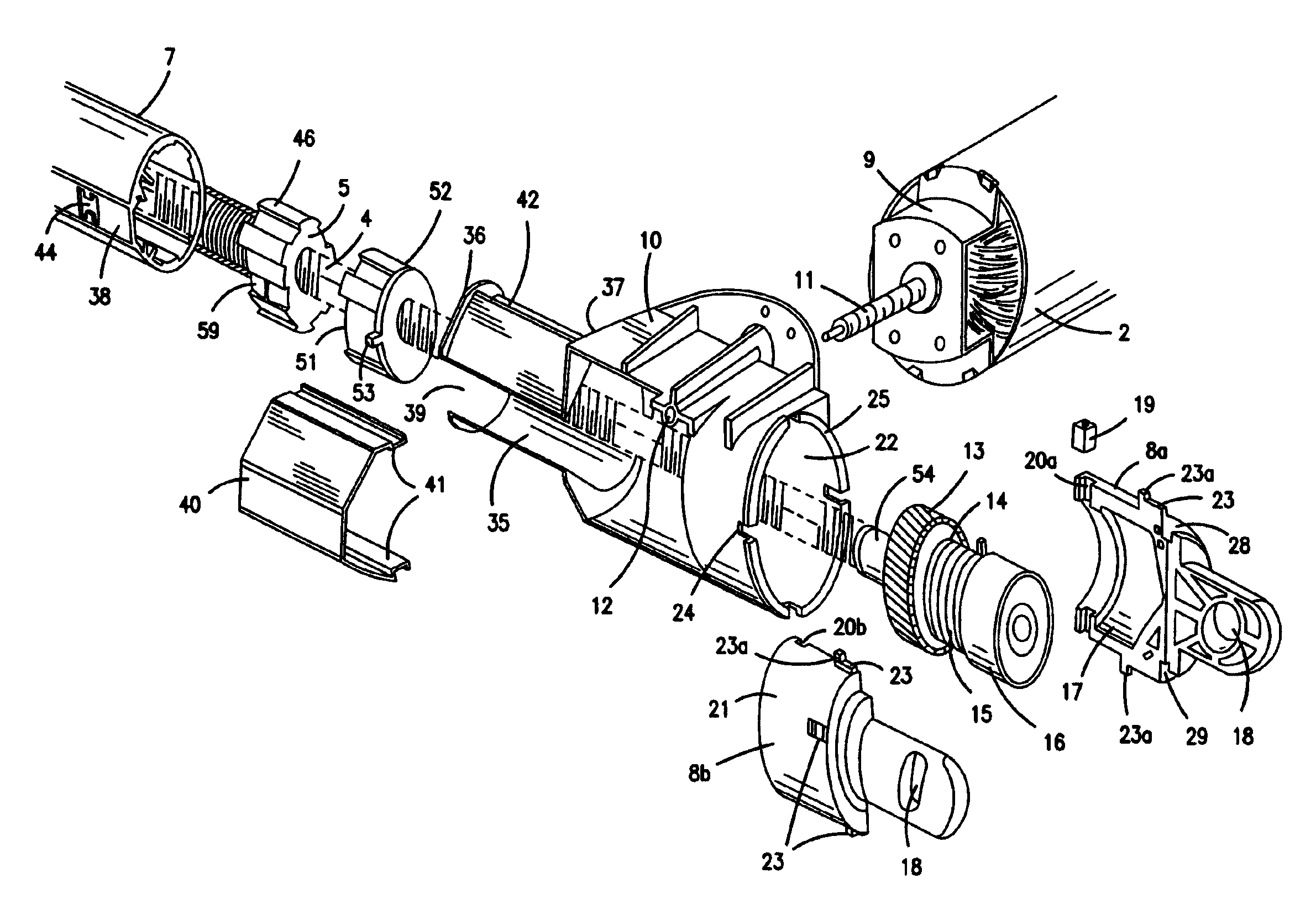

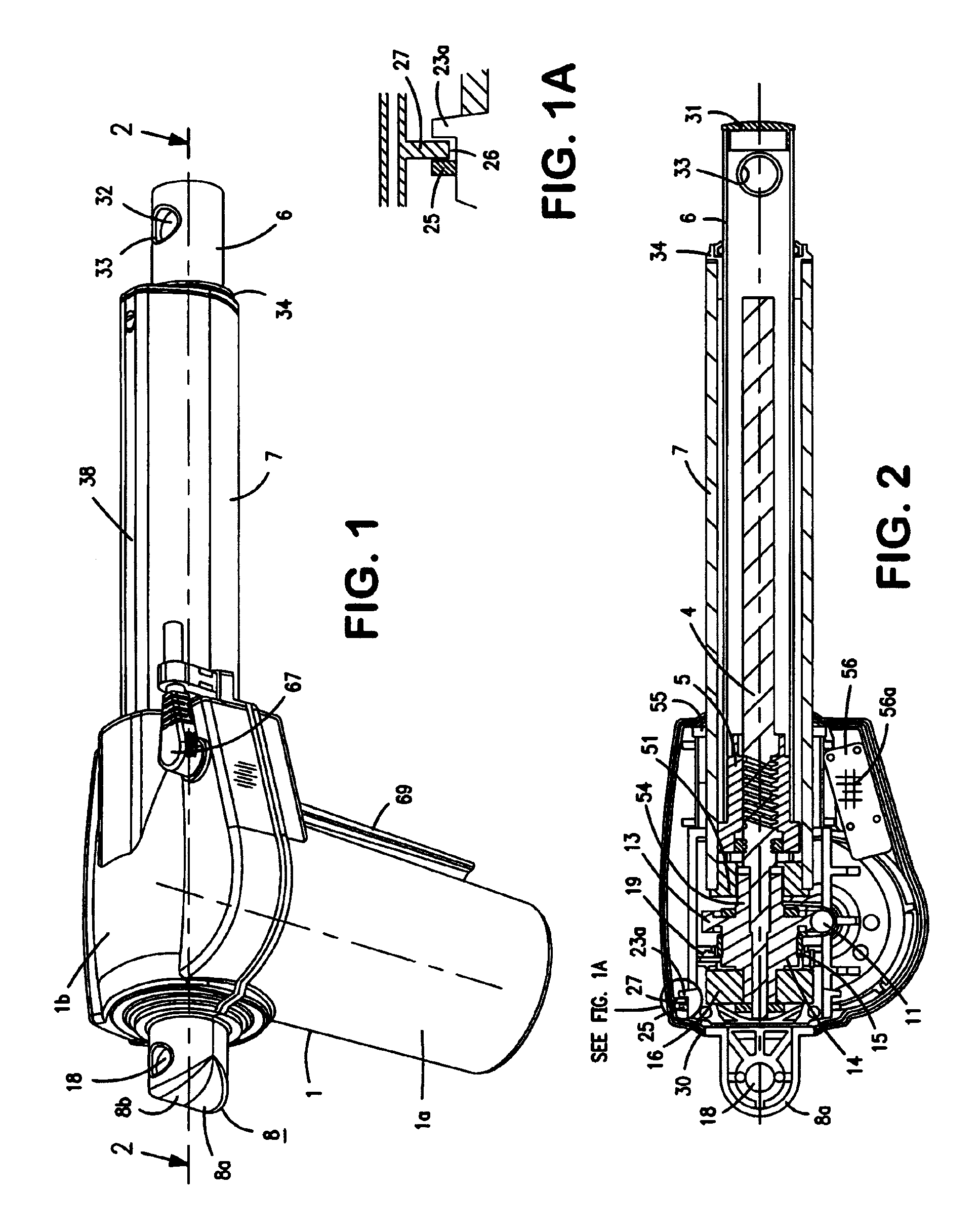

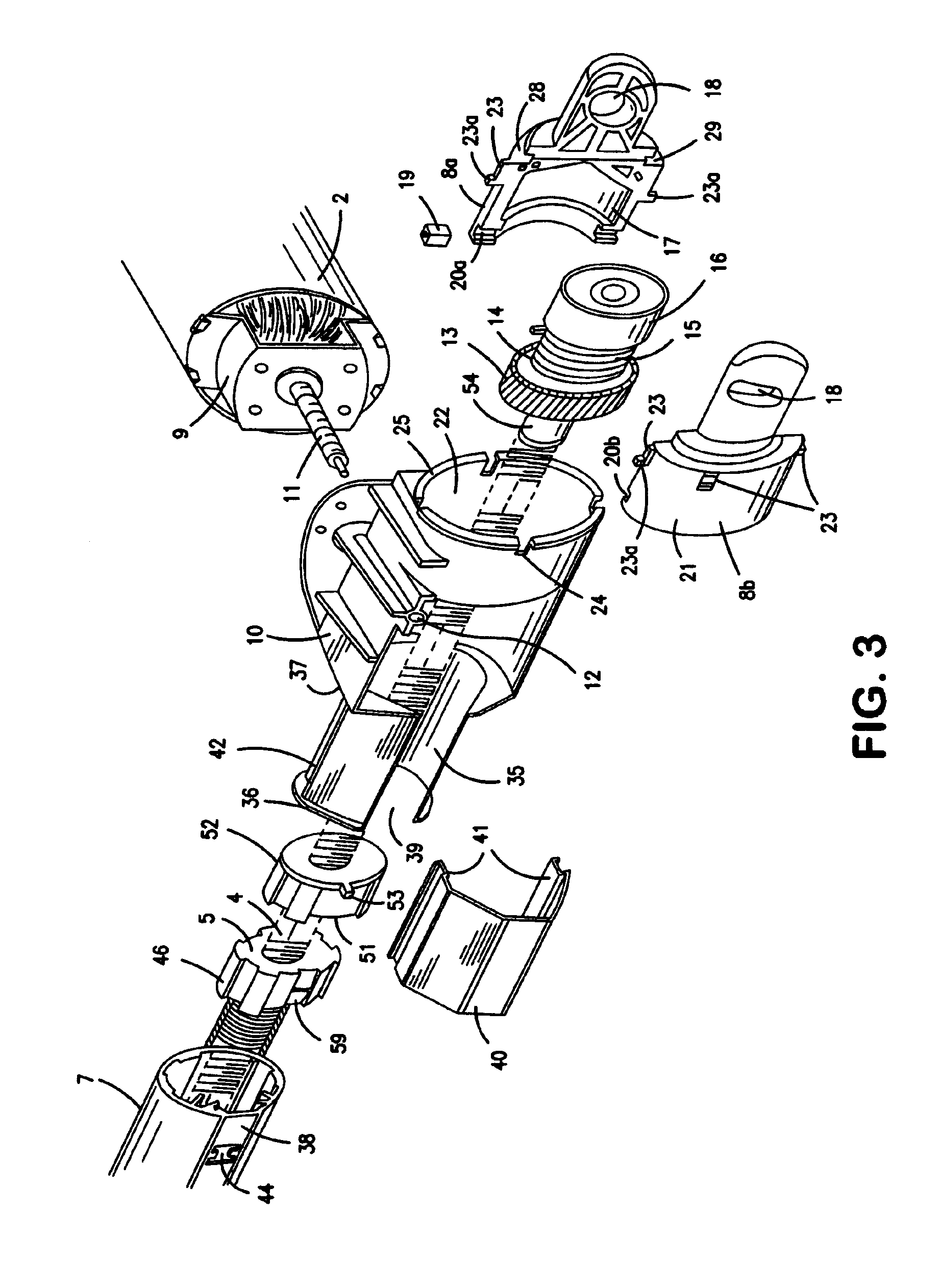

Linear actuator

A linear actuator useful for adjusting furniture includes a housing (1) with a reversible electric-motor (2) which, via a transmission (11, 13), drives a spindle (4) with a force absorbing bearing (16). On the spindle there is a nut (5) to which an actuation rod (86) is fixed surrounded by an outer tube (7). The actuator is with the actuation rod and a rear mounting mounted in the construction into which the actuator should be built-in. The motor housing is part of the supporting construction, as a console is fixed to this (10) with a fixing for the outer tube, spindle bearing and a rear mounting and is designed to absorb the forces occurring hereon. As the housing, as with previously known actuators, need not absorb and transfer forces, this can be made as a thin shell.

Owner:LINAK AS

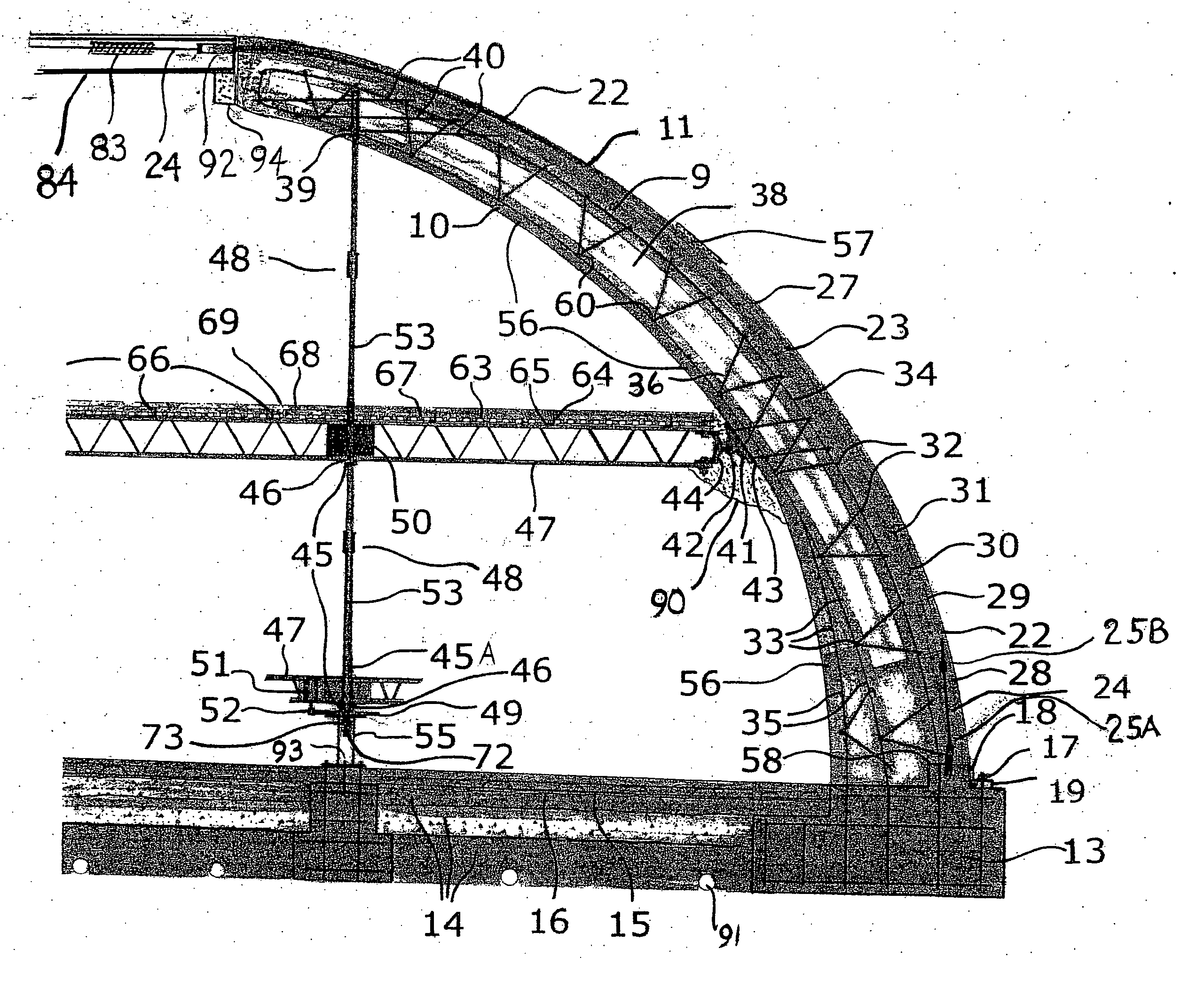

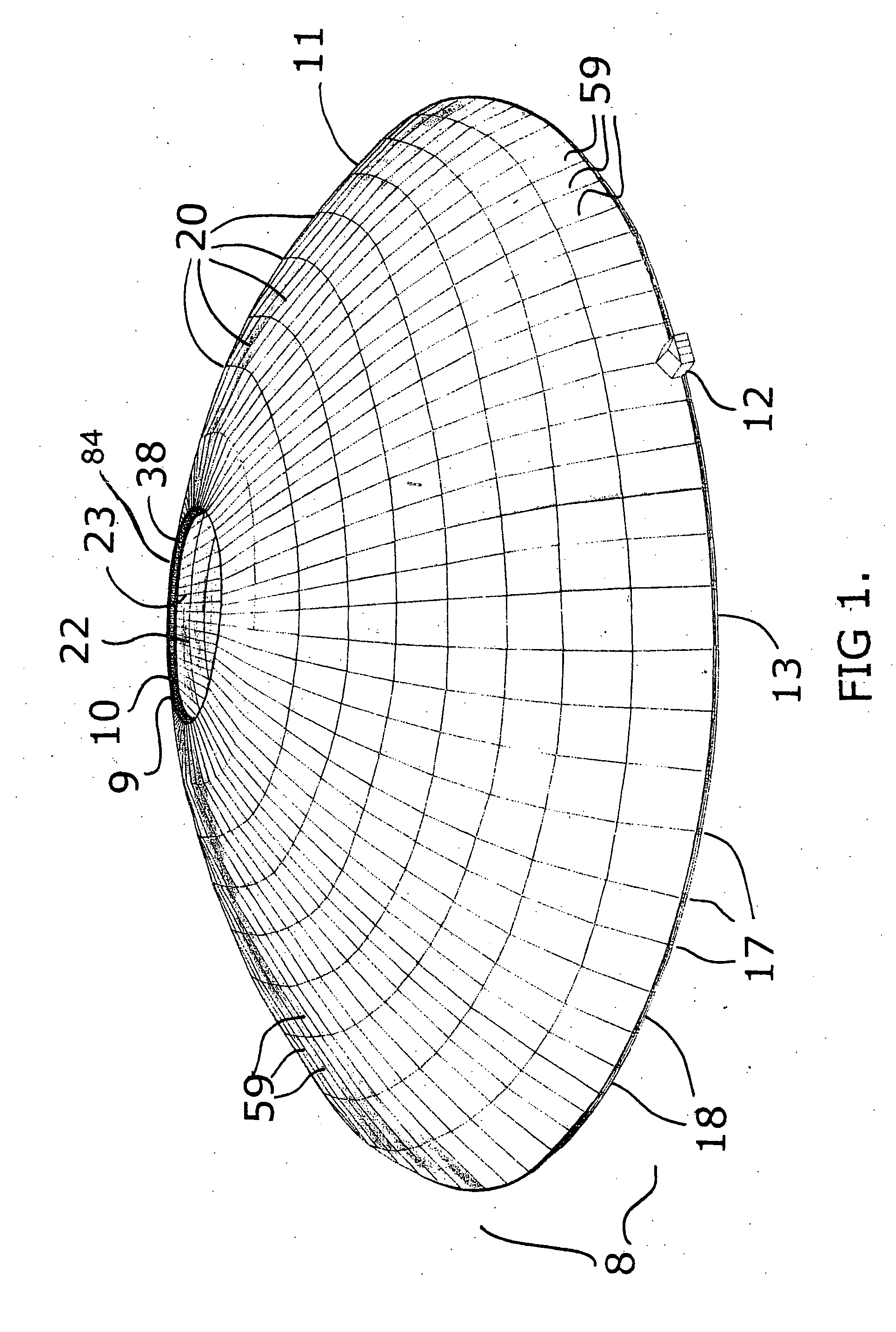

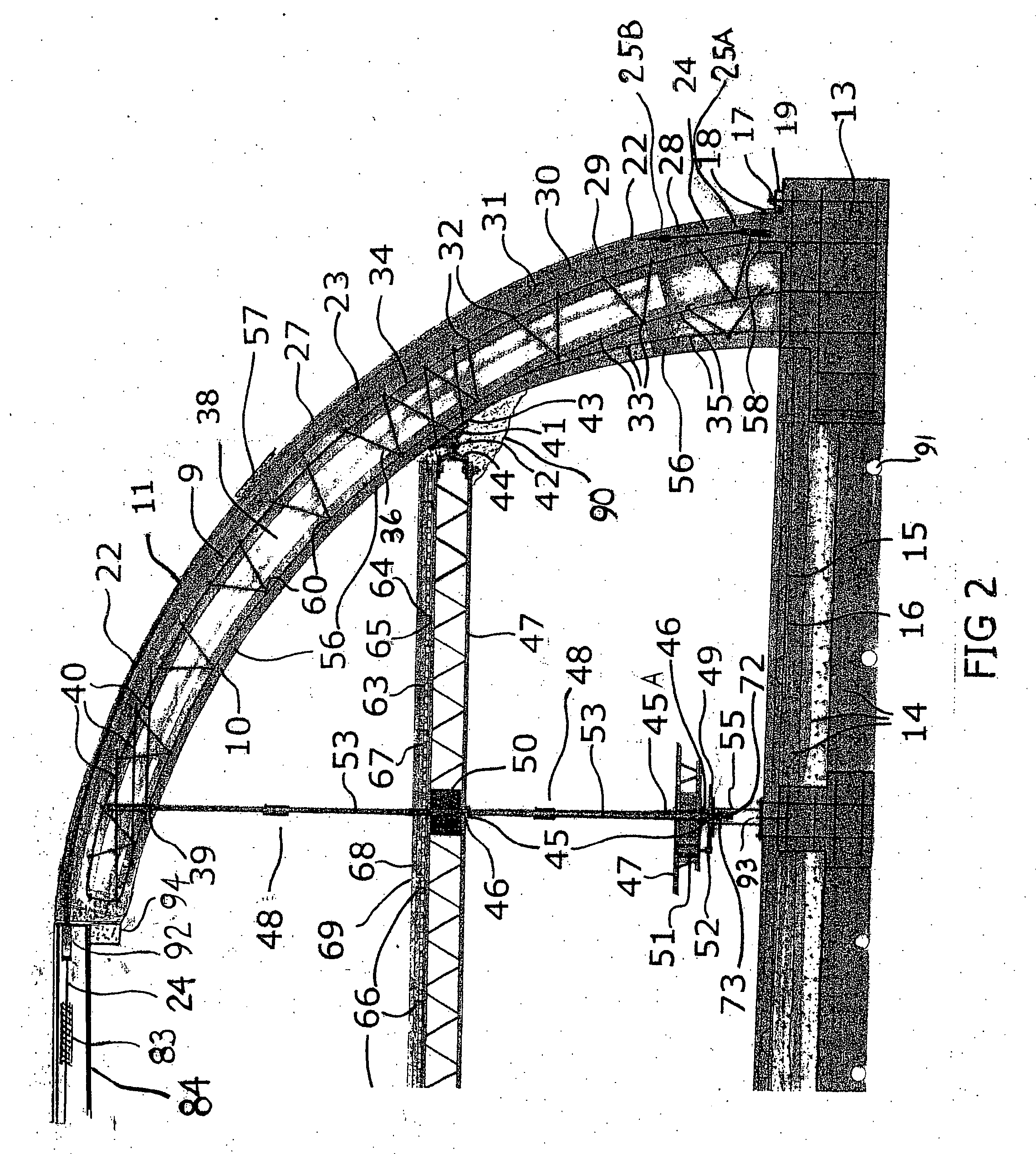

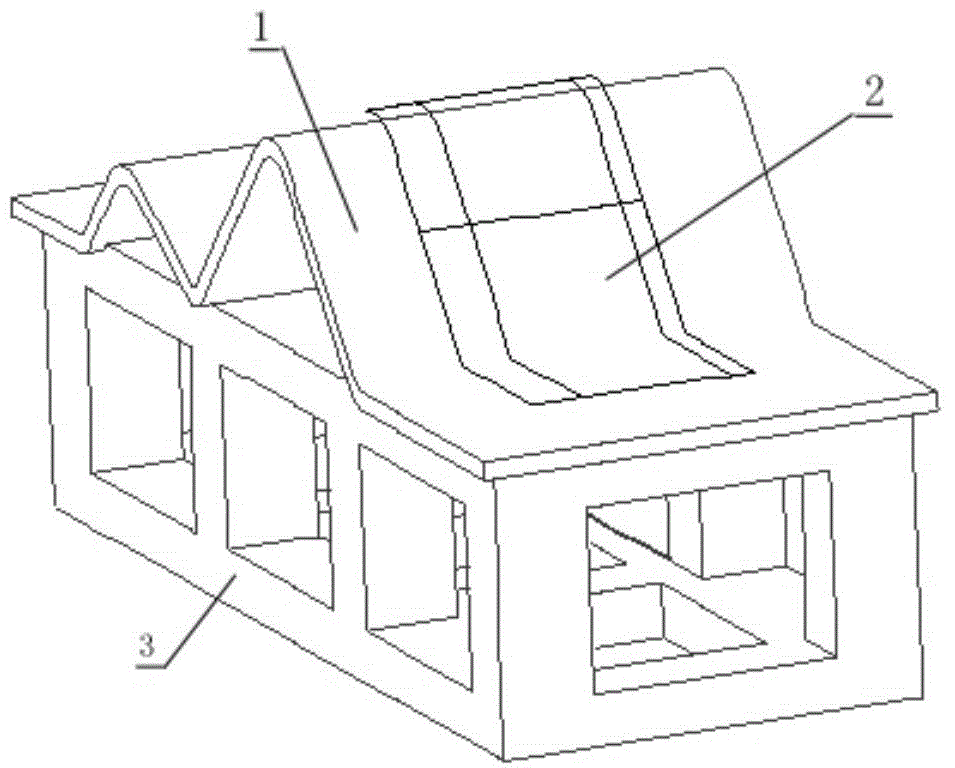

Trilithic and/or twin shell dome type structures and method of making same

InactiveUS20050210767A1Quick connectionImprove load-bearing strengthBuilding roofsArched structuresShotcreteThin shells

Trilithic Shell, Twin Shell, Multiple Shell, Curvilinear Shell as well as Free-formed Structures described herein each employ an inflatable membrane having a peripheral edge secured to an outer foundation base. An ultra-light membrane (air-form) having a network of internal cross connecting restraints is additionally secured to the inner foundation base to permit a novel and unique curvilinear surface. Pressurization then creates the backdrop upon which various urethane layers are applied which when laced with rigidifying tubes become the defining backdrop beneath which numerous cross connecting braces which when snapped into position effectively lock an inner framework to an outer framework thereby producing a self supporting truss like structure both compatible with either current dome construction and / or conventional construction practices. Shotcrete being then sprayed from the interior over said urethane coated backdrop forms highs at framework intersections and natural lows in between followed by the insertion of inflated cell tubes which span the created network of horizontal and vertical cavities are next over sprayed with urethane foam necessary to form the next natural backdrop over which two or more shotcrete / steel reinforced separate yet cross connected planes may be achieved. Such multiple yet independent rigid layers now having thousands of inner-connecting cross braces through which interior voids become natural chase-ways effectively displace 50% or more of what might otherwise be solid concrete as would be the case with all prior art thin shell structures and / or conventional stem wall construction practices. Such Free Formed curve-linear structures effectively reduce material and labor costs by as much as 50%, eliminate snap-through or oil-can buckling tendencies, enhance overall structural capacity, eliminate all height to diameter restraints, permit larger structures, facilitate floor suspension and attachment, and allow mechanical, electrical and HVAC distribution through interior chase-ways which cannot be achieved with prior art concrete thin shell single thickness structures and / or conventional stem wall, construction practices to date.

Owner:DEFEVER MICHAEL D +1

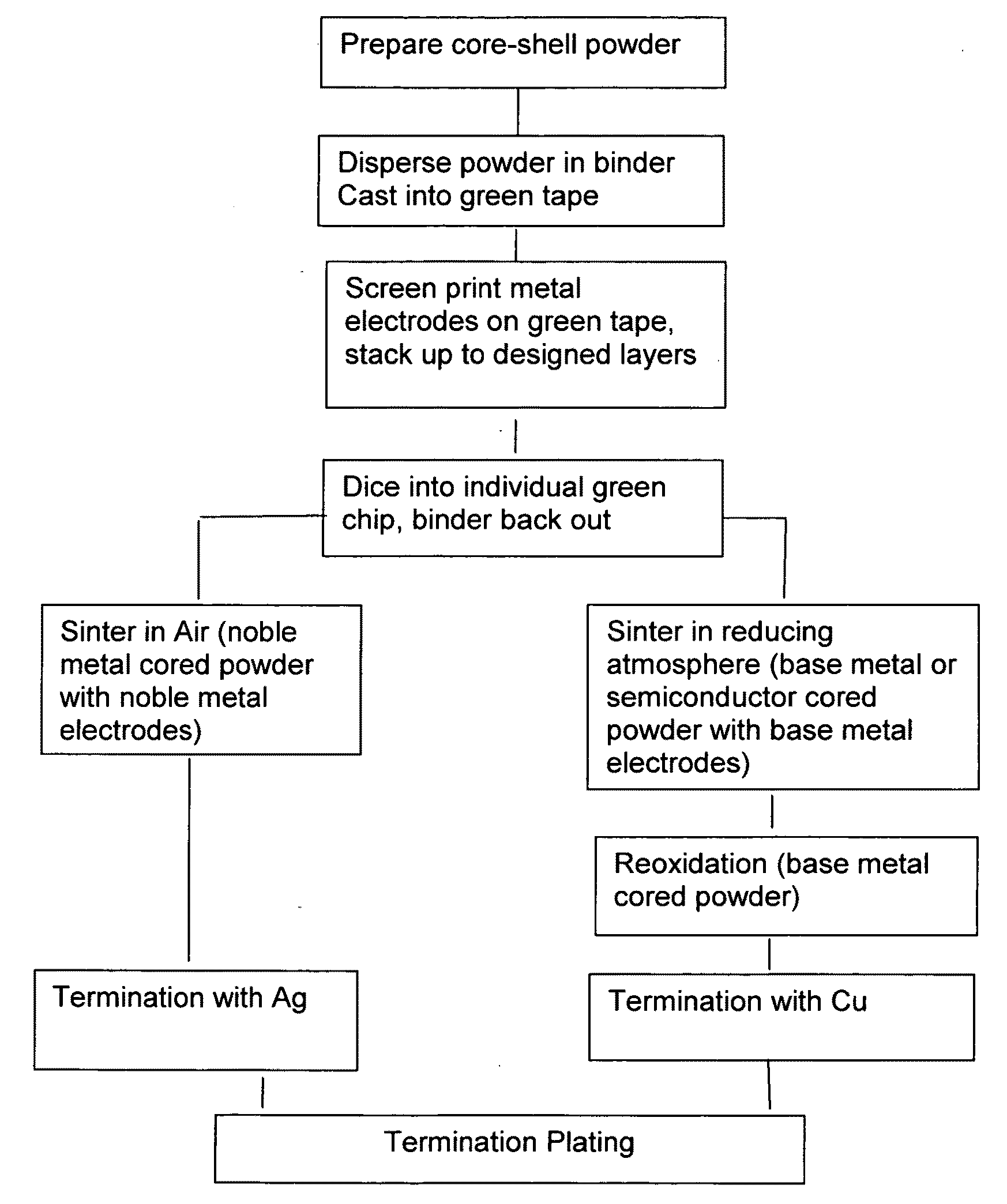

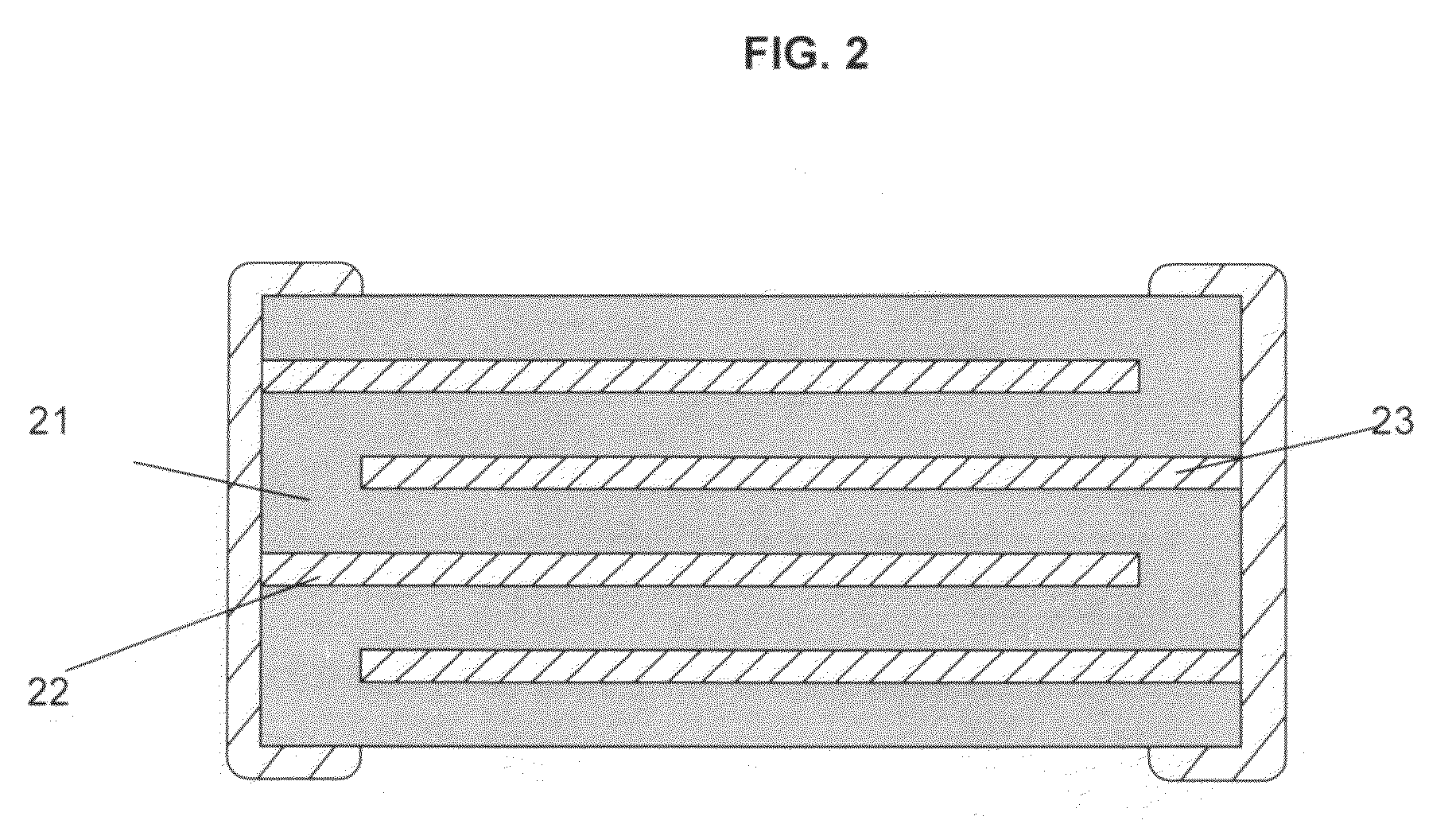

Core-shell structured dielectric particles for use in multilayer ceramic capacitors

InactiveUS20100110608A1Simplifies MLCC manufacturing processImprove propertiesFixed capacitor dielectricStacked capacitorsCapacitanceThin shells

This invention provides a method to make core-shell structured dielectric particles which consist of a conductive core and at least one layer of insulating dielectric shell for the application of multilayer ceramic capacitors (MLCC). The use of said core-shell instead of conventionally solid dielectric particles as the capacitor's active layers simplifies the MLCC manufacturing processes and effectively improves the MLCC properties. In particular, the use of core-shell particles with a thin shell of high permittivity dielectric material improves the capacitance volumetric efficiency, and the use of core-shell particles with a thick shell of dielectric will improve capacitor device's energy storage capacity as the results of improved electrical and mechanical strength.

Owner:WEI FRANK +1

Hollow-structured mesoporous silica material and preparation process

A hollow-structured mesoporous silica material composed of hollow silica particles that have a shell having radial-arrayed channels, and a process for its preparation. The thin-shell type of mesoporous materials with different morphologies are prepared by growing and synthesizing mesoporous silica on the surface of calcium carbonate nanoparticles with different shapes as inorganic templates, and then removing the inorganic templates. The hollow-structure mesoporous silica material can be used in many fields such as the preparation of catalyst, pesticide and optical fiber.

Owner:BEIJING UNIV OF CHEM TECH +1

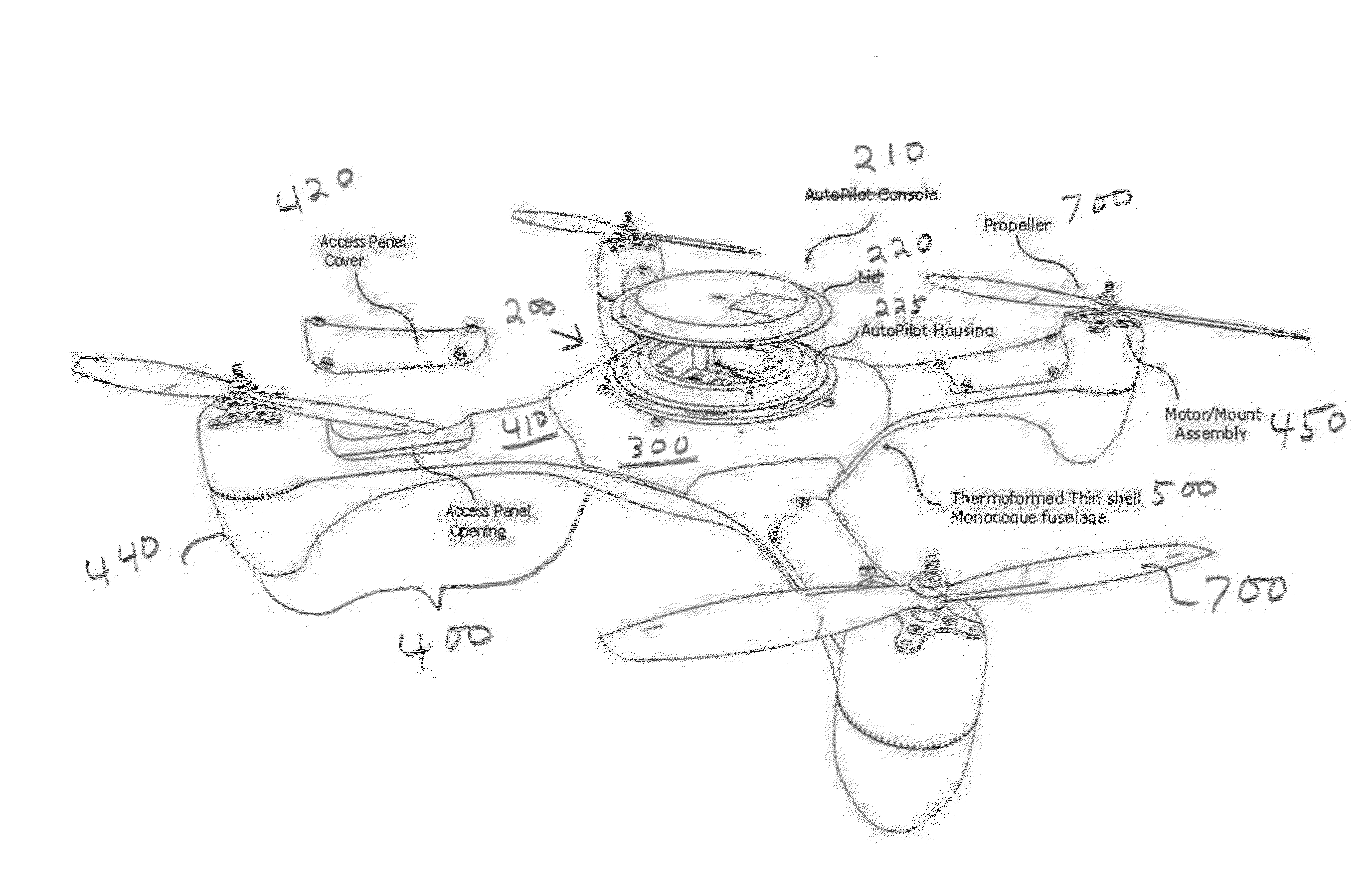

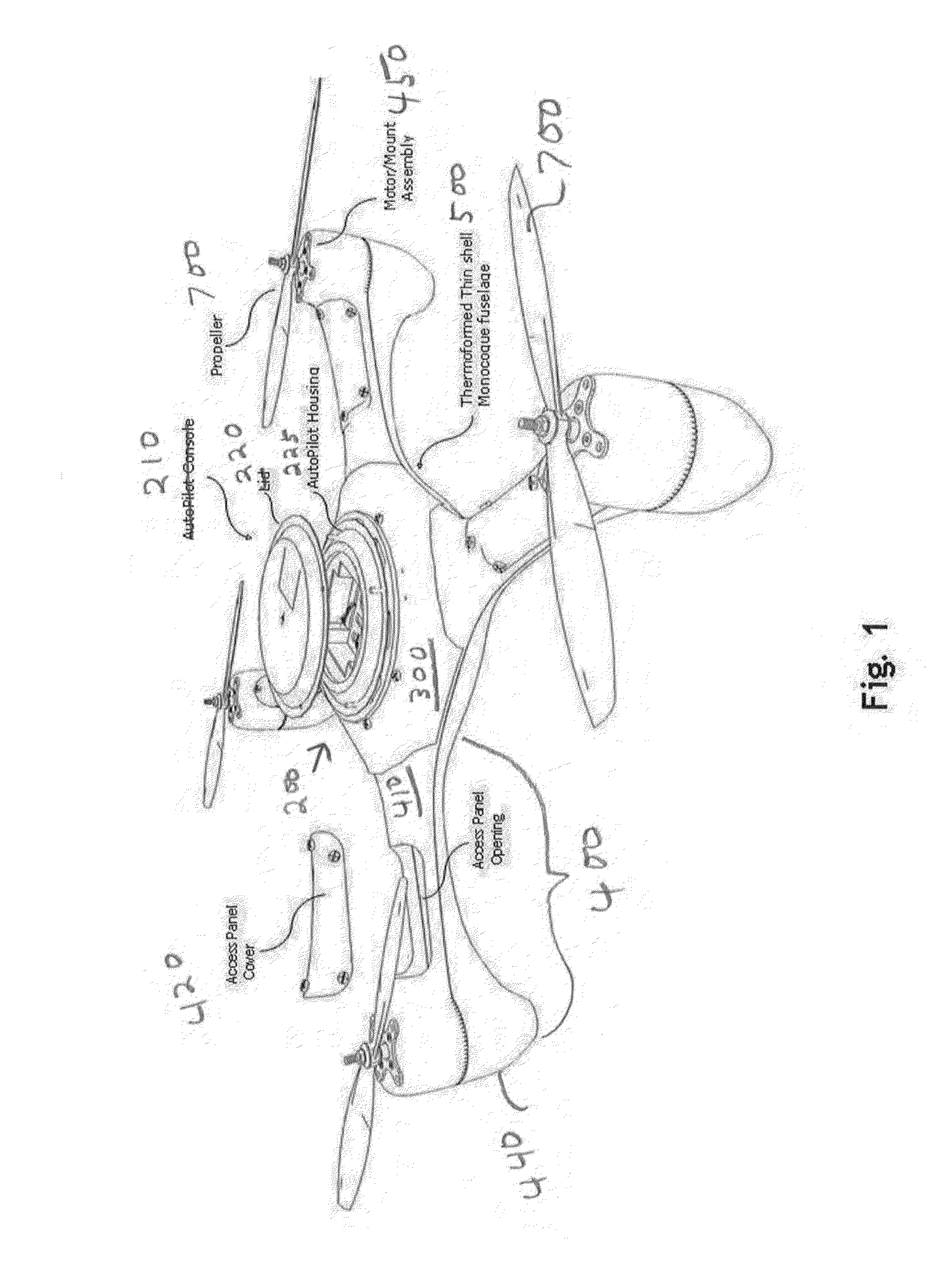

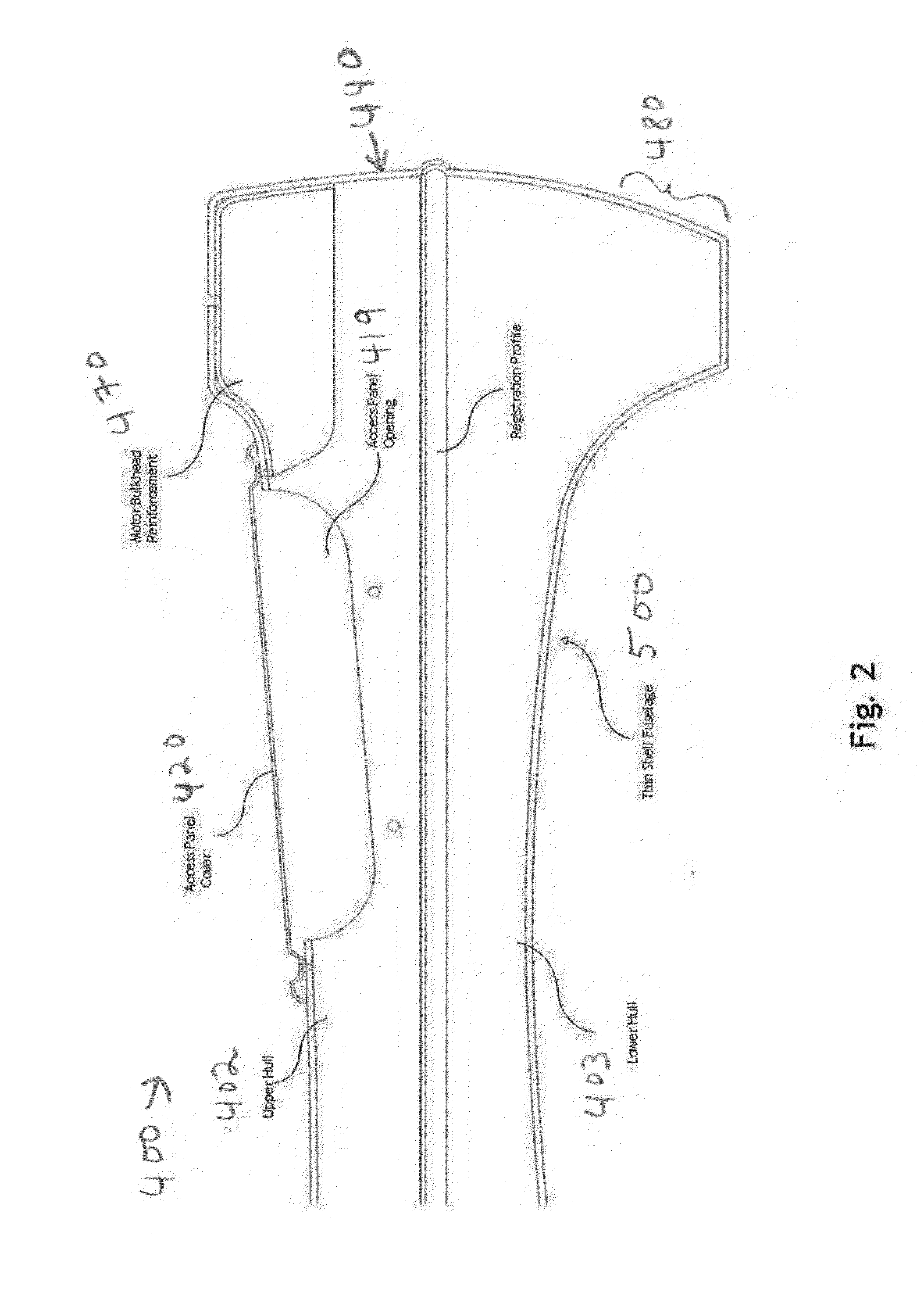

Methods and Systems of Constructing a Multi Rotor Aircraft Fuselage

InactiveUS20140231582A1Dissipating loadImprove efficiencyPower plant arrangements/mountingRemote controlled aircraftThin shellsFuselage

A lower hull 403 and an upper hull 402 may form a multi rotor aircraft fuselage system comprising a comprising a thermoformed thin shell monocoque fuselage 500, center console assembly 200, the center console assembly comprising a center console cover 210, an auto pilot housing cover 220 and an auto pilot housing 225. A center fuselage area 300 contains the center console assembly 200. The center fuselage area is part of a plurality of arm assemblies 400. Each arm assembly may comprise a distal end 440 and a proximal end 410, an access panel cover 420 which may expose a access panel opening 419. An access panel opening 419 may lead to an arm void area 430, with the arm void area 430 further defined by the interior sections of the thin shell fuselage 500.

Owner:HEADRICK SEAN

Silicon dioxide mesoporous material and its preparing method

The mesoporous silica material consists of hollow silica grains with radically radial arranged hole canal in the wall. The present invention also provides the preparation process of the said mesoporous silica material, and the preparation process includes adopting calcium carbonate in different forms as inorganic template; growing and synthesizing mesoporous material on the surface and subsequent eliminating the inorganic template to obtain thin shell type mesoporous material in different forms. The present invention also provides the application of the mesoporous silica material in preparing catalyst, pesticide and optical fiber.

Owner:XIAMEN NANOTECH +1

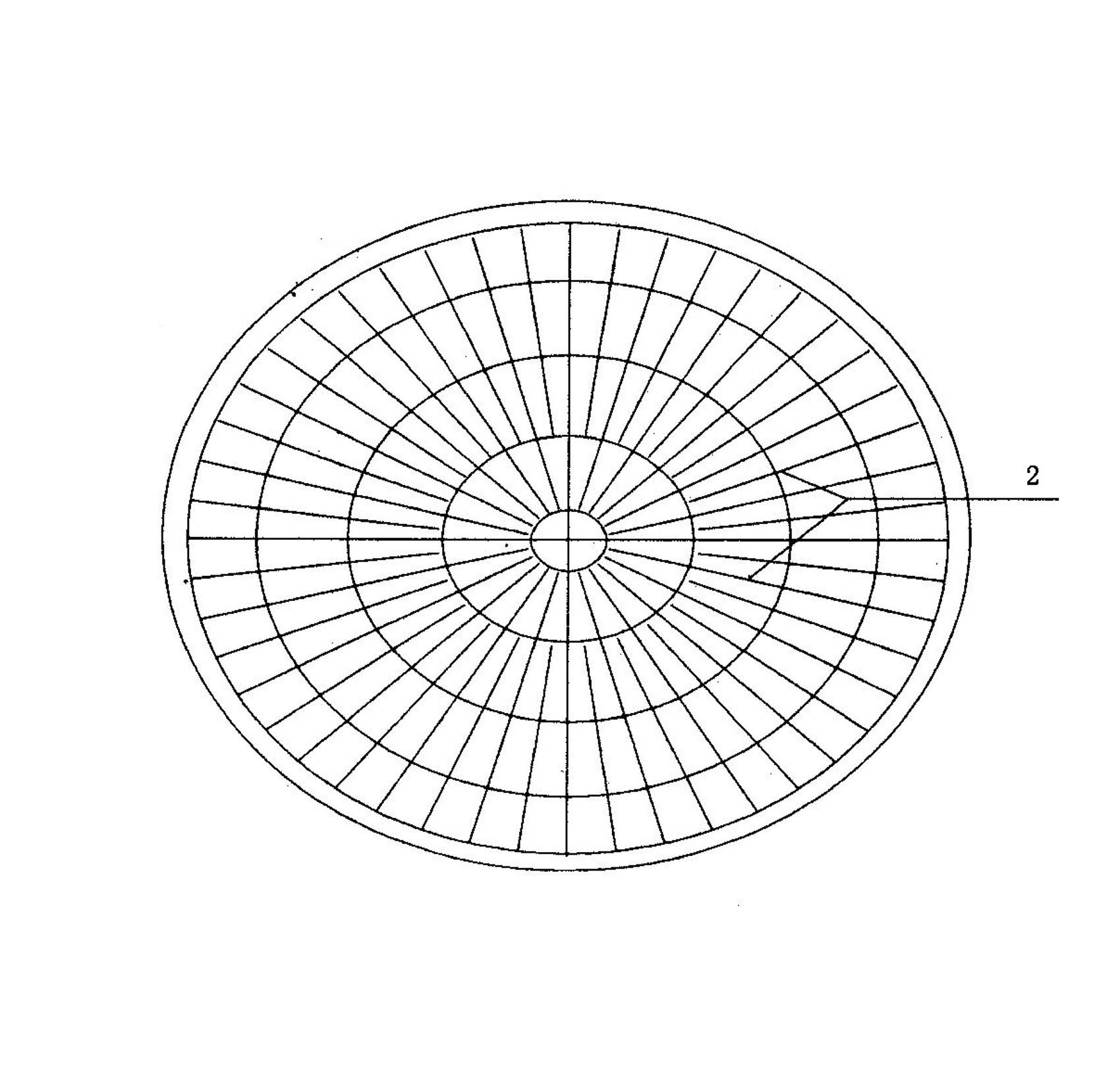

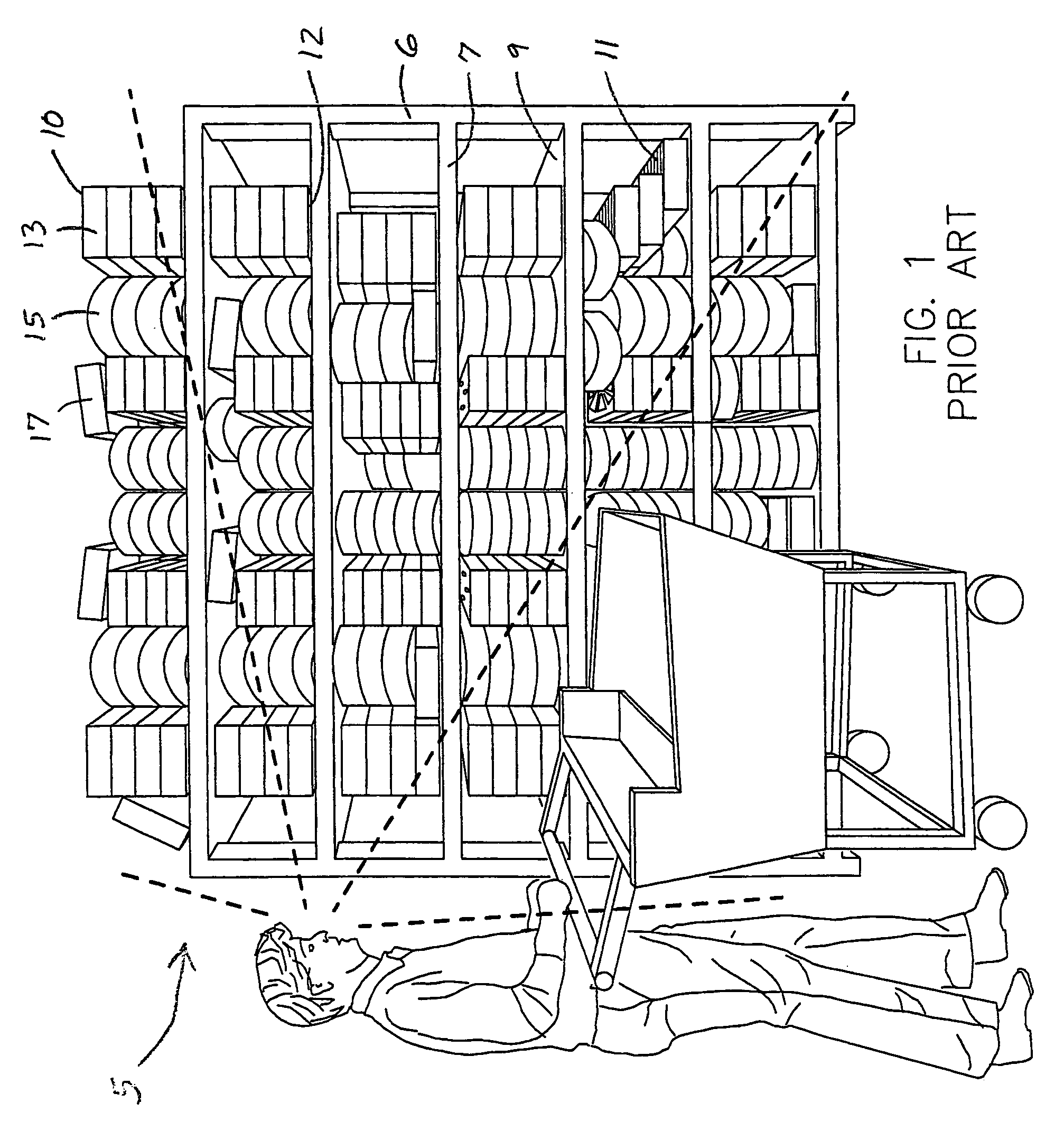

Three-dimensional detection system for surface of large thin-shell object and detection method thereof

ActiveCN101995231ASimple structureFlexible structureUsing optical meansThin shellsComputer Aided Design

The invention is applied to the technical field of three-dimensional sensing, and provides a three-dimensional detection system for the surface of a large thin-shell object and a detection method thereof. The detection method comprises that: three groups of sensors project fringes to the surface of an object to be detected in the upper, middle and lower directions of the object to be detected, acquire a deformation fringe graph, acquires phase distribution information, and acquires three-dimensional depth data of each viewing field by combining phase and depth mapping principle; multi-sensor calibration information is matched with the depth data acquired by the three sensors, and multi-angle data is matched to the same coordinate system; and dimensions are acquired and models are compared, namely the measured three-dimensional data is matched with a computer-aided design (CAD) model, distances from all measuring point to the CAD model are calculated, error distribution pseudo-color pictures of the inner side face, outer side face, inner bottom surface and outer bottom surface of the object, and the related dimension of the object, such as the length, width, height, wall thickness and the like are calculated by methods such as ray tracing and the like.

Owner:SHENZHEN ESUN DISPLAY

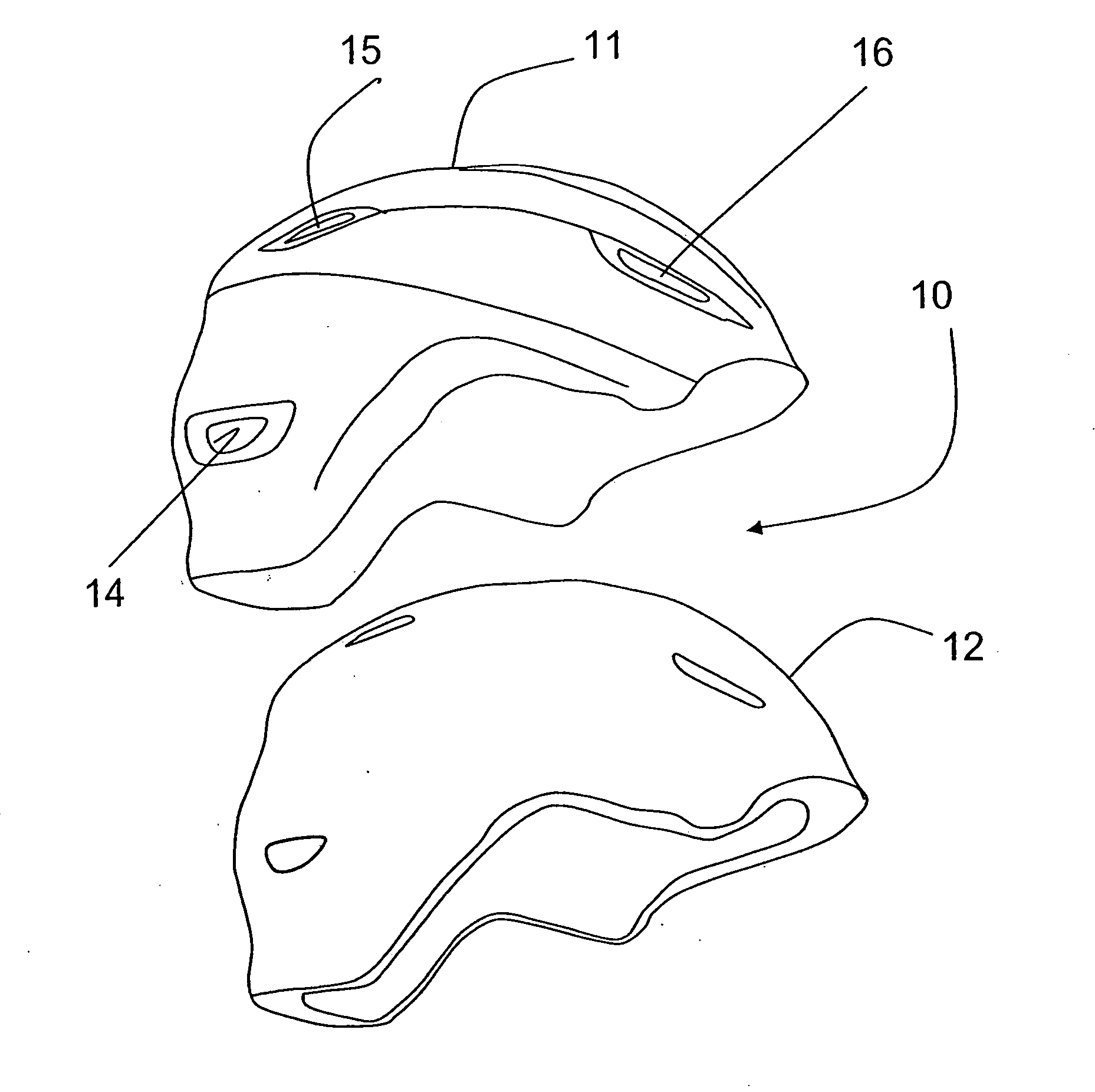

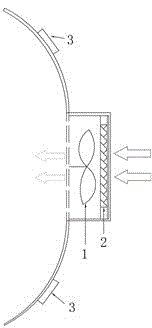

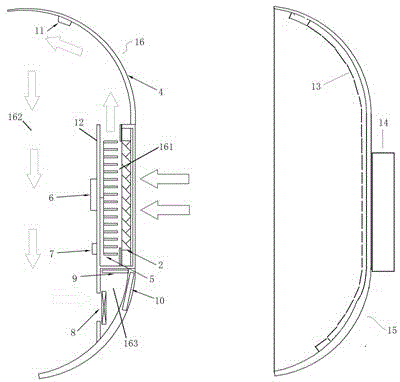

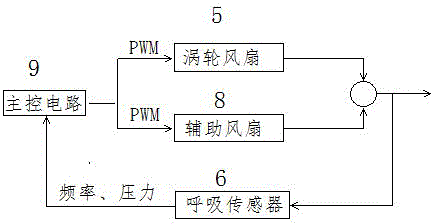

Smog-proof intelligent mask

The invention discloses a smog-proof intelligent mask, which is provided with a shell body (15) and a main mask frame (16); an ultraviolet disinfector (13) and a wireless charging transmitter (14) are arranged on the shell body (15); the main mask frame (16), which is a thin shell, is divided into two parts, i.e. a main frame (4) and a breathing partition wall (12); an auxiliary fan (8) is mounted on the breathing partition wall (12); an air filter screen (2) is mounted on the thin shell; while a turbofan (5) is mounted at a position, which is opposite to the air filter screen (2), on the breathing partition wall (12) of the area; a master control circuit (9) and a wireless charging receiving circuit (10) are mounted on the breathing partition wall (12) of an exhalation area (163). Since the smog-proof intelligent mask adopts the two active suction and exhaust fans, breathing is smooth without the feeling of suffocation, the smog-proof intelligent mask can effectively proof smog, calls can be easily answered and made as well, and the smog-proof intelligent mask is clean and sanitary, and is convenient to carry.

Owner:上海圆天电子科技有限公司

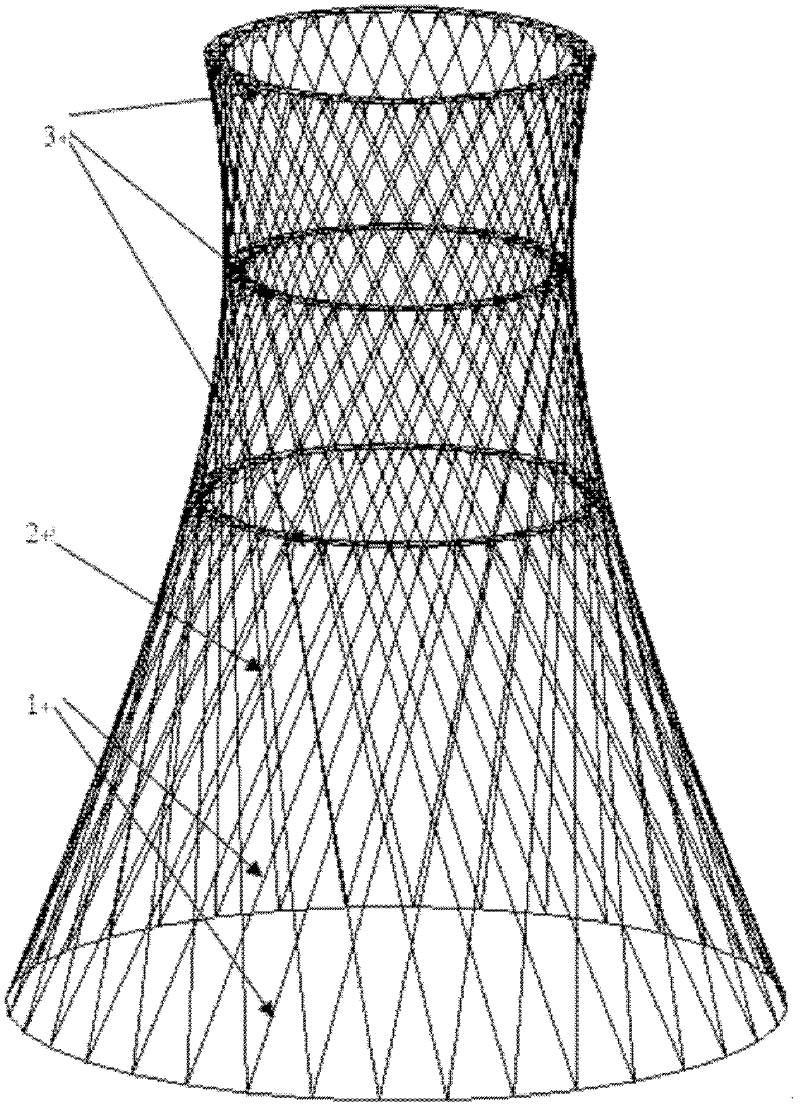

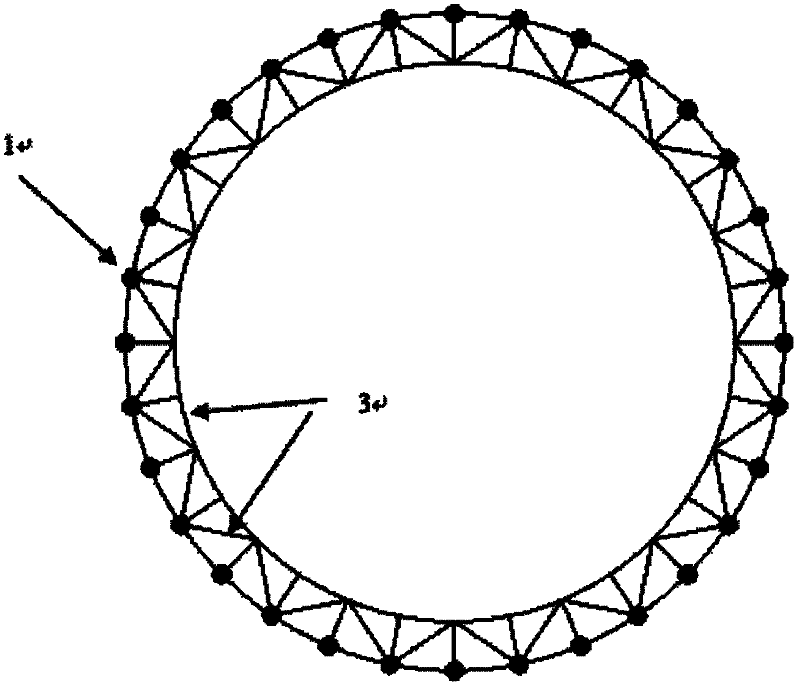

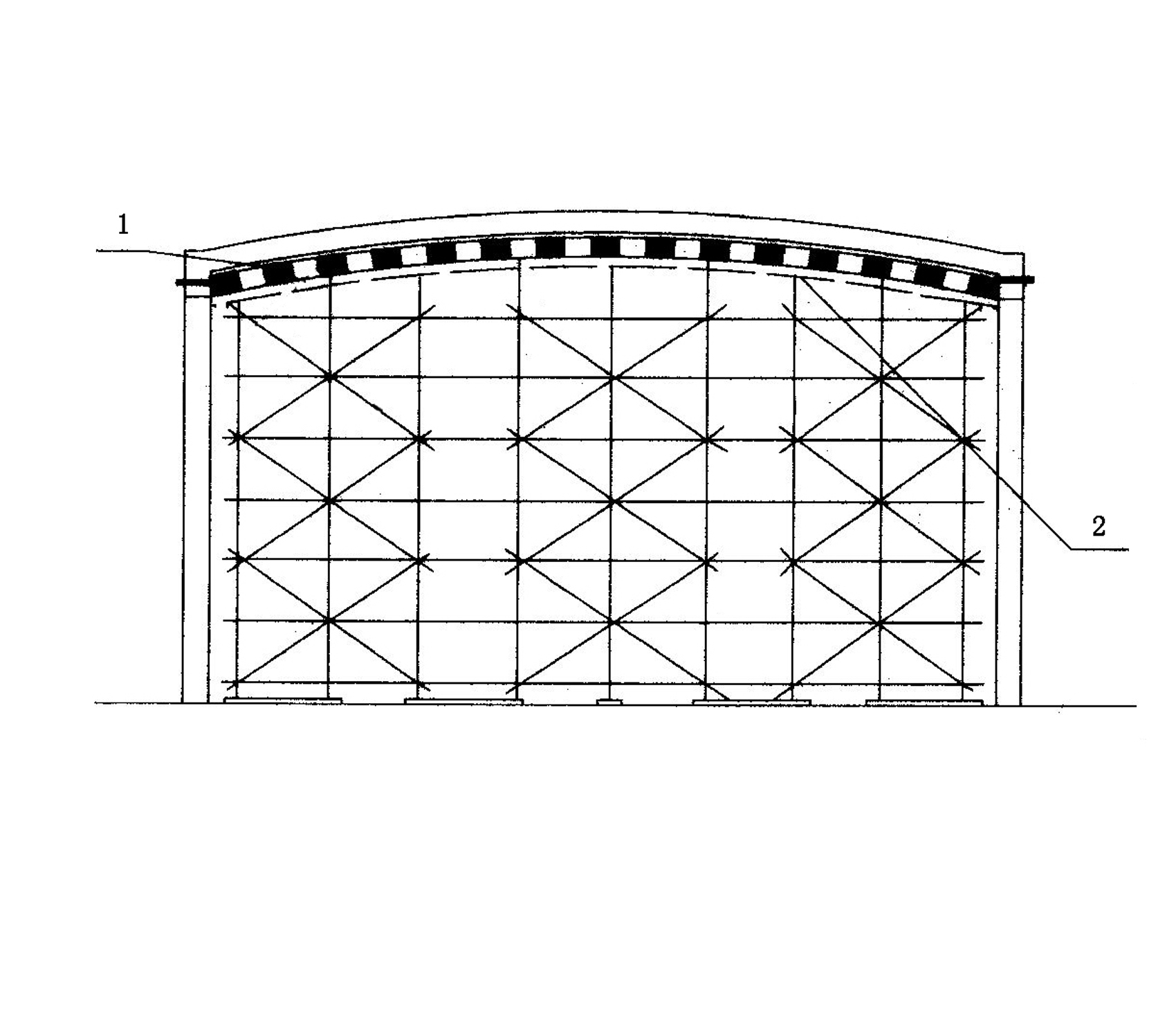

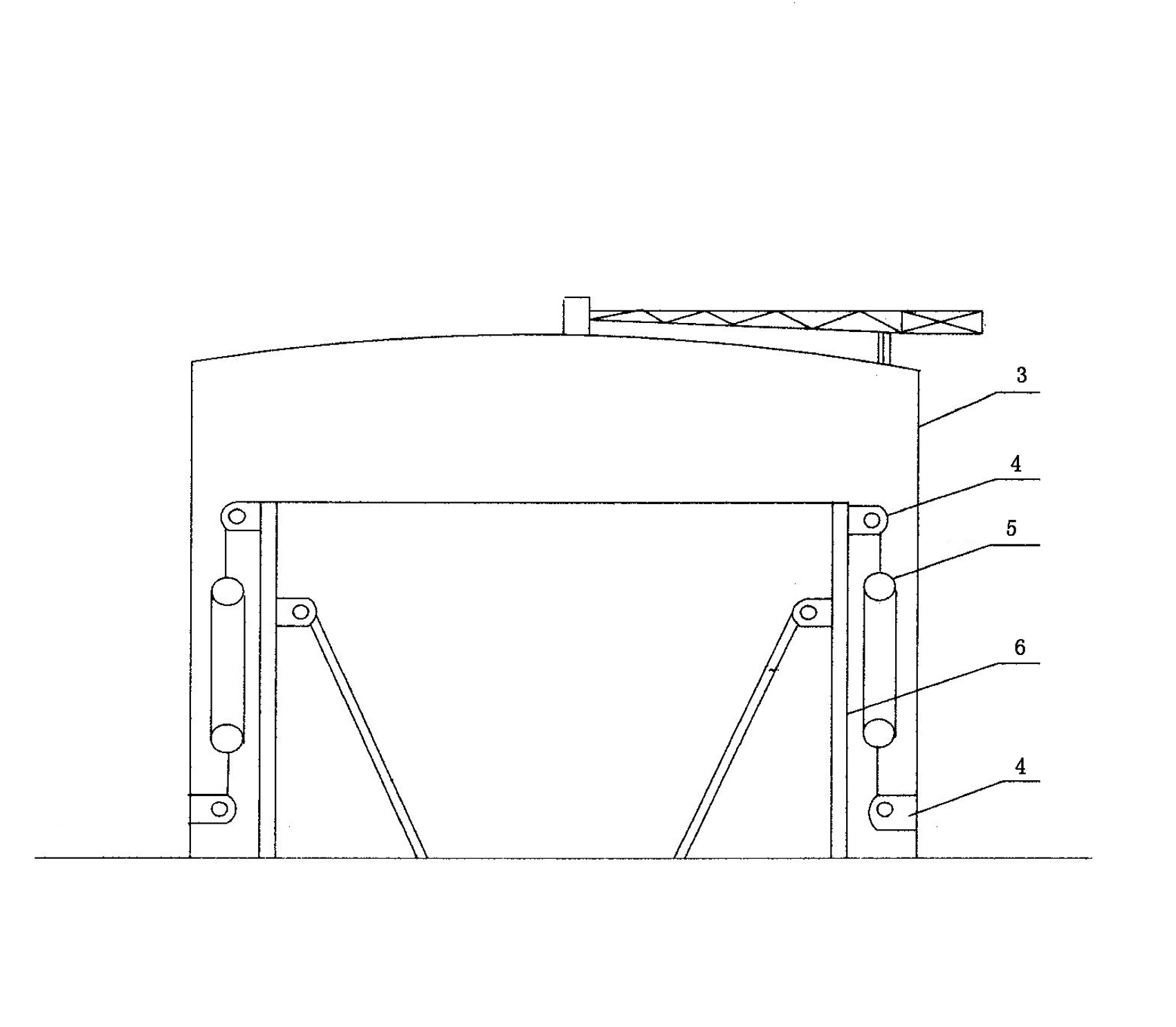

Large double-curve steel structure cooling tower for power plant

ActiveCN102505880AReduce processing difficultyReduce processingTowersCooling plantsThin shellsCooling tower

The invention discloses a large double-curve steel structure cooling tower for a power plant. The large double-curve steel structure cooling tower comprises linear inclined vertical columns, intersected nodes and reinforcing rings, wherein a steel structure cooling tower framework consists of a vertical line rotary array formed by encircling the linear inclined vertical columns around an upper circle center and a lower circle center of the tower; intersected positions of the linear inclined vertical columns are the nodes; and along the height direction of the tower, 3 to 5 reinforcing rings are required to be arranged. The tower is over 150 meters high, and the diameter of the lower part of the tower is about 150 meters. The large double-curve steel structure cooling tower is a novel steel structure cooling tower replacing a concrete thin-shell double-curve cooling tower, is suitable for indirect cooling units with the capacities of 125 MW or over 125 MW, can be applied to those extremely cold places in which the concrete cooling tower cannot be used, and has the characteristics of low gravity, high construction speed, simple foundation treatment operation, low comprehensive manufacturing cost, high anti-seismic and anti-wind performance, low post-maintenance cost and the like.

Owner:NORTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP

Irrigated ablation catheter having irrigation ports with reduced hydraulic resistance

ActiveUS9510894B2High trafficIncrease speedCatheterSurgical instruments for heatingThin shellsPlenum chamber

Owner:BIOSENSE WEBSTER (ISRAEL) LTD

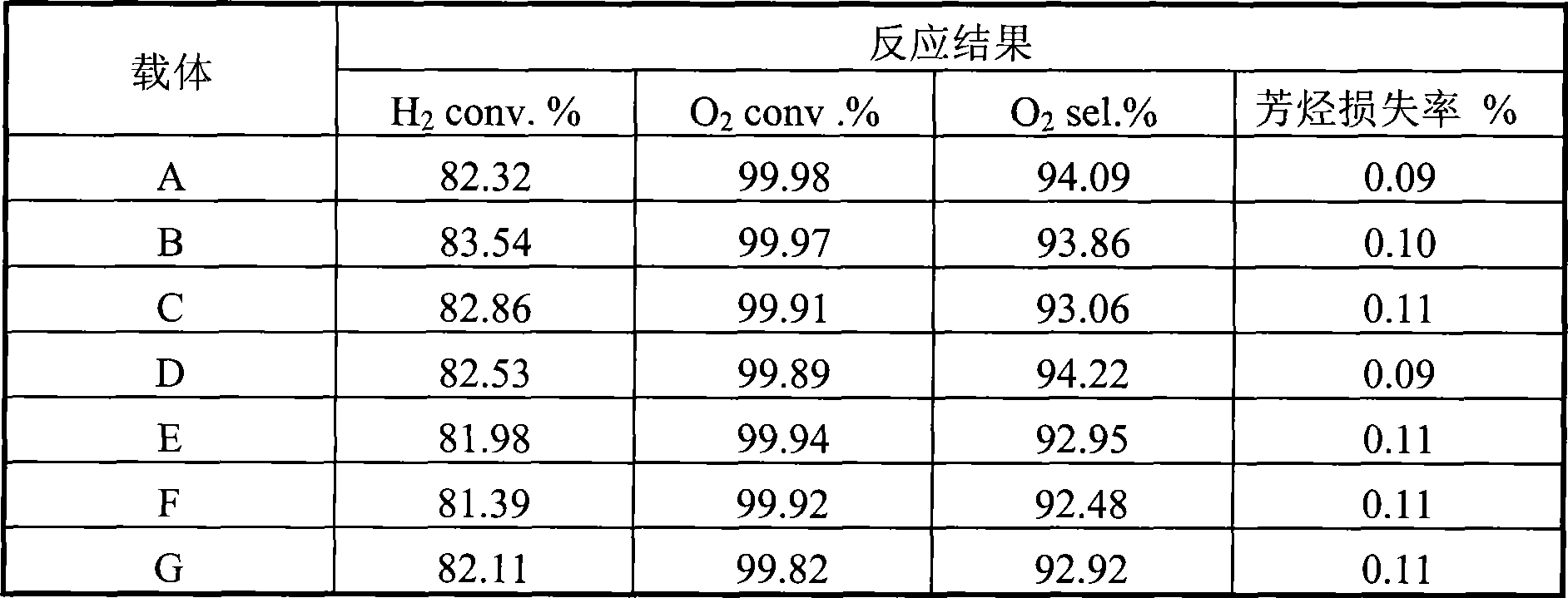

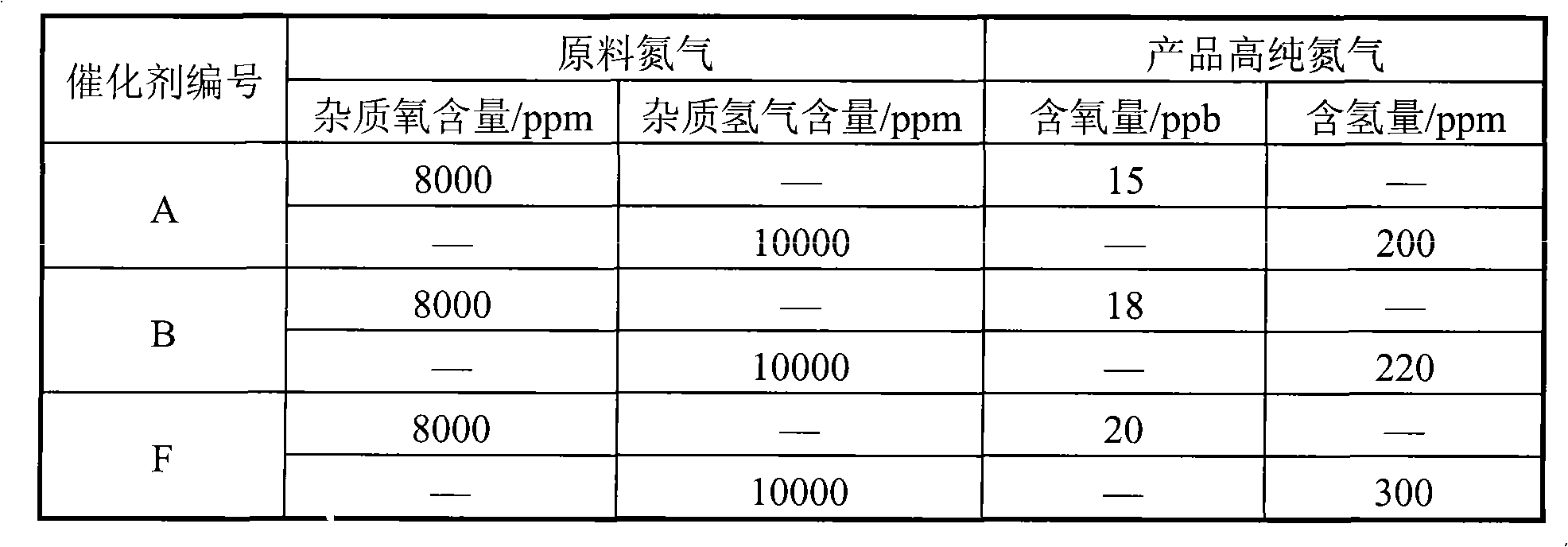

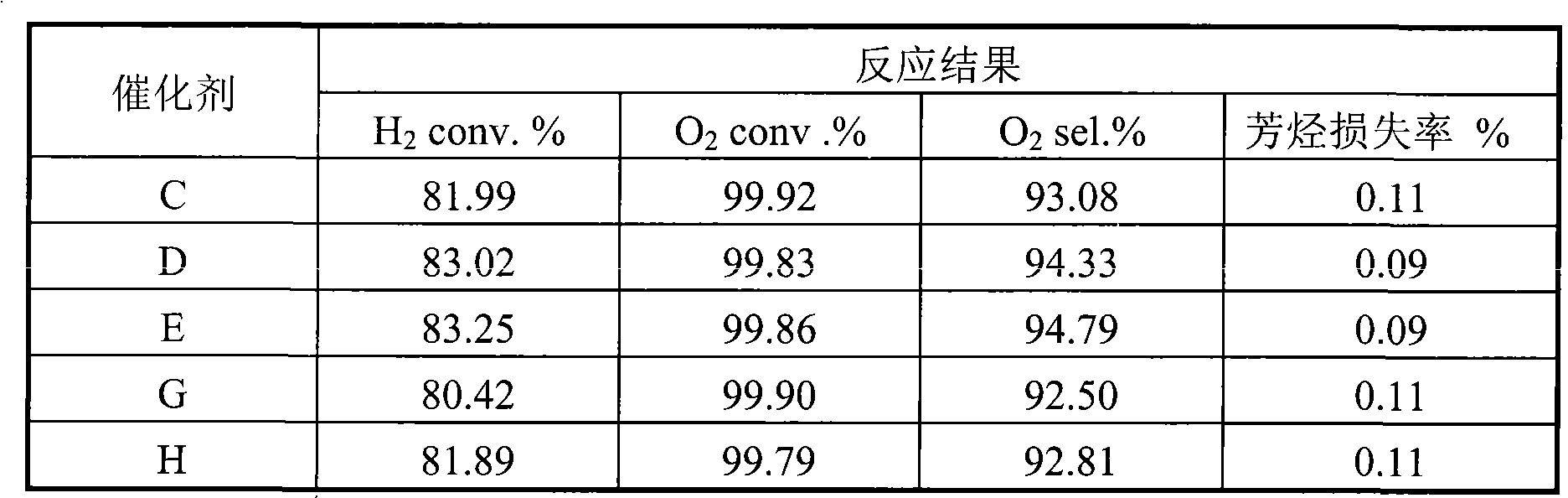

Noble metal catalyst based on spherical silicon-containing alumina, and preparation method thereof

InactiveCN101543778AGood dispersionImprove thermal stabilityOrganic compound preparationHydroxy compound preparationIridiumHigh activity

The invention provides a noble metal catalyst based on spherical silicon-containing alumina, and a preparation method thereof. The noble metal catalyst based on silicon-containing alumina takes the spherical silicon-containing alumina as a carrier, and loaded active components can be nickel, platinum, palladium, ruthenium, rhodium or iridium and other noble metal. The adopted spherical silicon-containing alumina carrier is spherical particles of which the particle size is 0.5 to 5 millimeters, wherein the SiO2 content is 1 to 20 percent by weight, and the crystal form of alumina is gamma, delta, eta or theta. The catalyst is characterized in that the active components are distributed in a surface layer of the carrier with 5 to 400 mu m, and an active layer is reasonable in thickness distribution and belongs to a high-dispersion thin-shell type. The catalyst has the advantages of high activity, good selectivity and good stability, is beneficial to bed mass transfer and recovery and long in life span, and is a novel hydrogenation catalyst applicable to the development of a hydrogenation production process.

Owner:BEIJING UNIV OF CHEM TECH

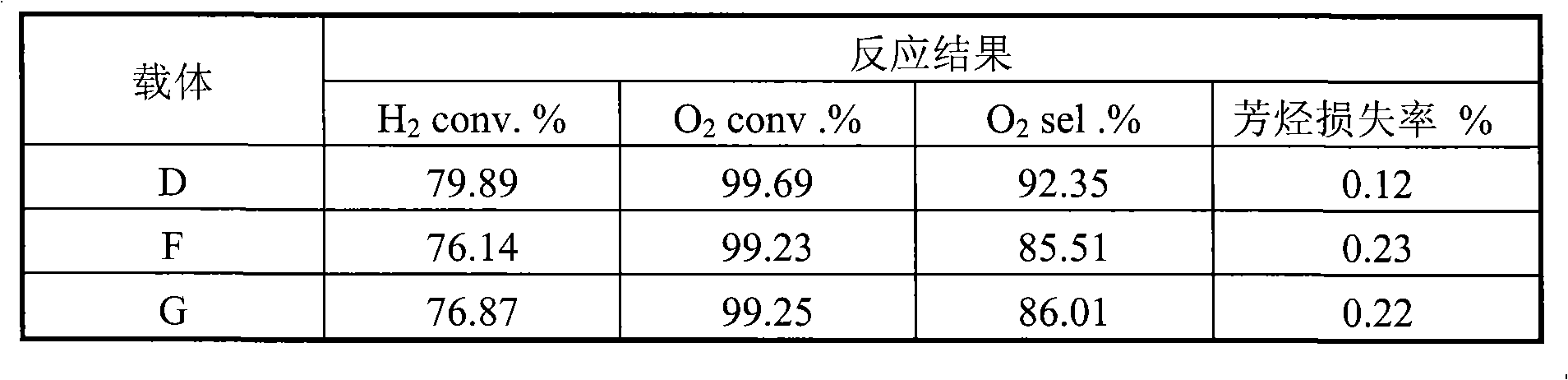

Layered composite carrier for producing shell shaped catalyst

The invention relates to a layered composite carrier used for preparing thin-shell catalysts, and solves the technical problems that the prior layered composite carrier has small specific surface area, and the relevant thin-shell noble metal catalyst has low dispersity, poor utilization rate and low selectivity. In order to solve the problems, the technical scheme is as follows: the layered composite carrier used for preparing thin-shell catalysts, comprises an inert carrier inner core and a porous coating as outer layer conjugated on the inner core. The carrier inner core is at least one substance selected from alpha-Al2O3, theta-Al2O3, metals, SiC, cordierite, zirconium oxide, titanium oxide, quartz, mullite and Al-rich andalusite. The porous coating is at least one substance selected from gamma-Al2O3, delta-Al2O3, eta-Al2O3, theta-Al2O3, silicon oxide / aluminum oxide, zeolite, non-zeolite molecular sieves, titanium oxide and zirconium oxide. The layered composite carrier is applied to the industrial production of thin-shell catalysts.

Owner:CHINA PETROLEUM & CHEM CORP +1

Construction method of soil covering tank

ActiveCN101852031AReduce construction intensityEmission reductionArtificial islandsUnderwater structuresRebarDust emission

The invention relates to a construction method of a soil covering tank for storing product oil and the like, which comprises the following steps of: (A) building a tank chamber of a soil covering tank: firstly, carrying out earth excavation with a method combining a back-acting shovel and manual excavation; then, manufacturing a ring beam, precasting concrete blocks on the spot according to the radian of the ring beam, and building the concrete blocks; carrying out the engineering of steel bars: welding steel bars by machining, and manually binding the steel bars on the spot; carrying out the engineering of templates and scaffolds: taking a bamboo plywood as a top plate template of a concrete thin shell of the tank chamber, designing a camber at the middle part, and taking scaffold tubes as bottom template brackets of the thin shell of the tank; then, carrying out concrete engineering and asphalt sand construction; and finally, carrying out waterproof engineering, thereby completing the construction of the tank chamber of the soil covering tank; and (B) installing a storage tank body of the soil covering tank: firstly, precasting the storage tank body; then, installing a tank bottom plate; installing the tank body, and welding the storage tank; and finally, testing and inspecting to complete the whole construction process of the soil covering tank after the construction is qualified. The invention reduces the occurrence of accidents, increases the benefit and reduces the dust emission.

Owner:中国化学工程第四建设有限公司

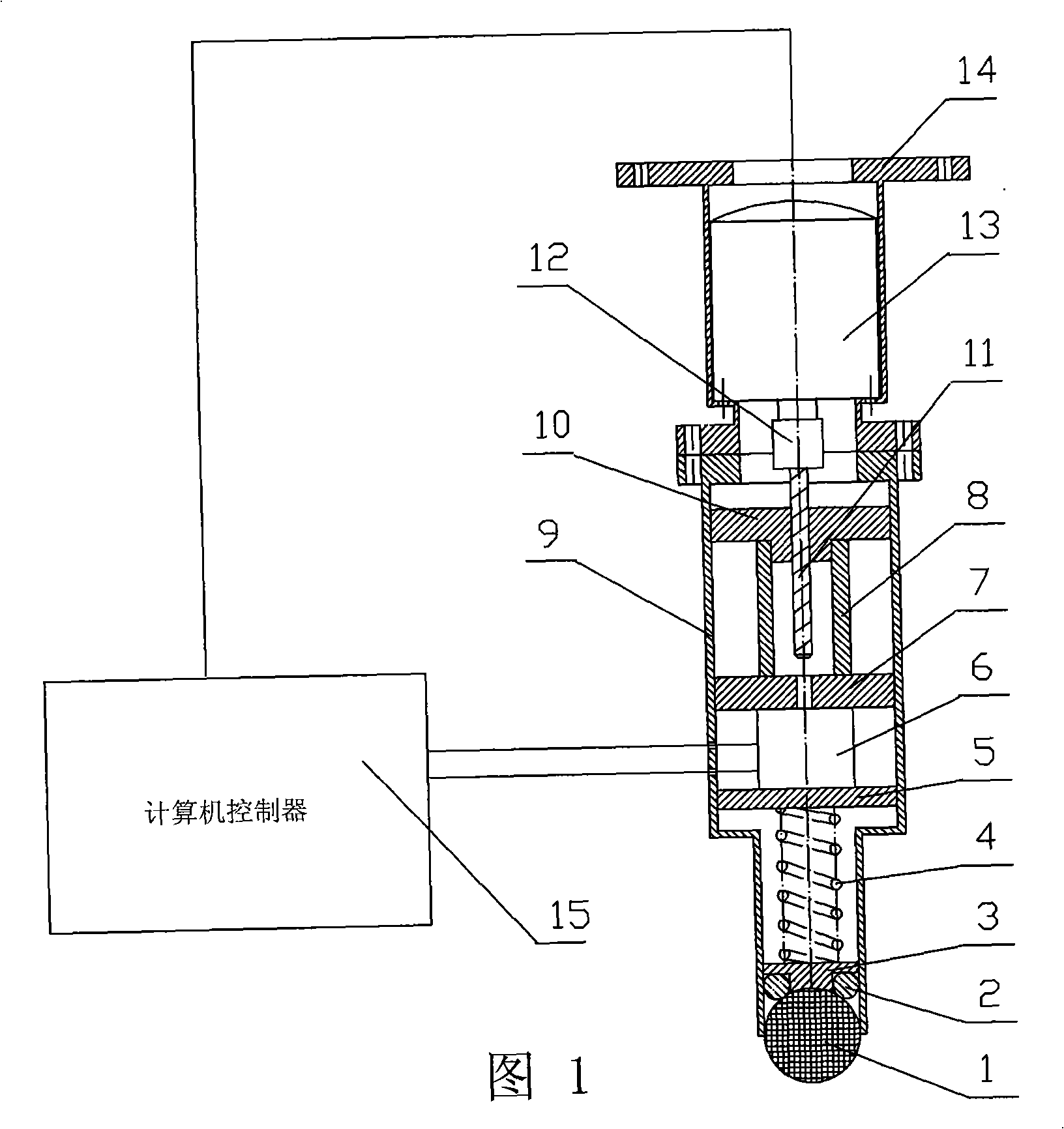

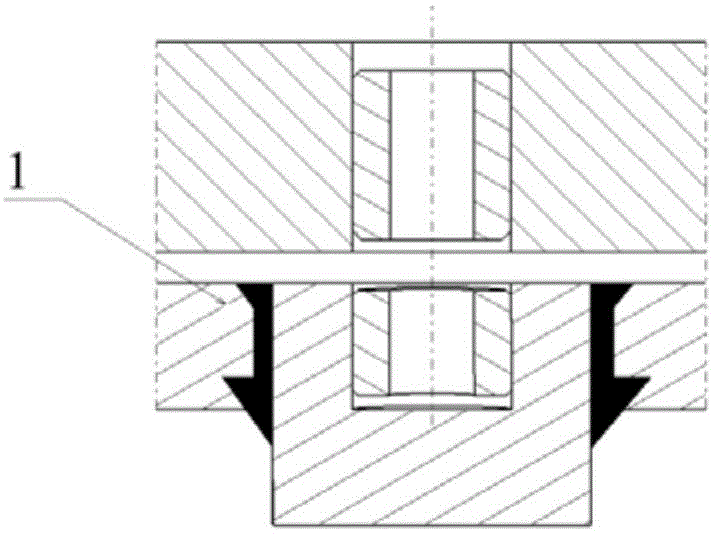

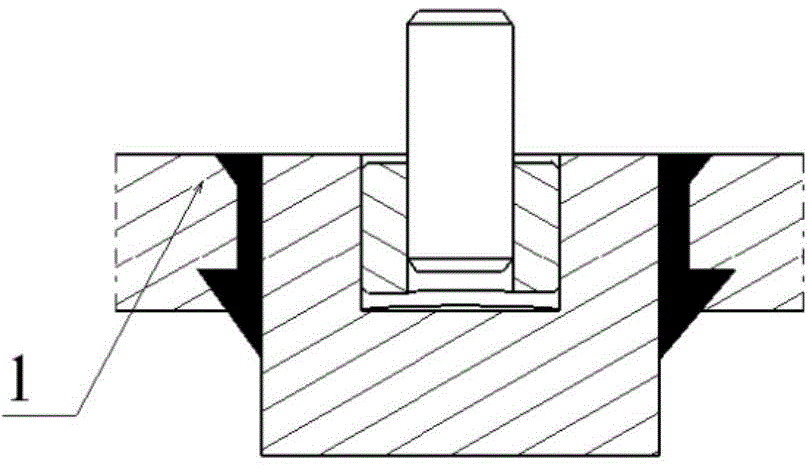

Pressure-tunable plate gradual shaping pressure head and shaping device thereof

The invention discloses an incremental forming indenter for sheet material with an adjustable pressure. The indenter comprises a forming indenter cylinder body, wherein a forming motor is fixedly mounted at the upper end of the cylindrical forming indenter cylinder body; a forming ball head is moveably arranged at the lower end of the forming indenter cylinder body via a ball cup, and the forming ball head is provided with an overhang ball cap part which extends out of the lower end of the forming indenter cylinder body; a transmission pair composed of a screw rod and a screw nut, and a pressure sensor are sequentially arranged from top to bottom in an inner cavity of the forming indenter cylinder body, and the pressure sensor is positioned between an upper backing plate and a lower backing plate; the screw rod is connected with an output shaft of the forming motor, and the screw nut is supported on the upper backing plate; and a ball head spring is supported between the lower backing plate and the ball cup. Based on the principle of 'layered manufacture', a thin-shell piece with a required shape is produced by adopting the layered incremental forming, therefore, the indenter is characterized by high machining accuracy, good surface quality, accurate and stable forming, adjustable and controllable pressure, etc., and is widely applicable to the forming processes of various complex curved shapes and various trial-manufacture stamping parts in small amount.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Early fructification and high yield method of American Illinois nut early

InactiveCN101322468AImprove the survival rate of graftingStrong and rapid growthBiocideAnimal repellantsThin shellsFruit tree

The invention relates to a method for the early fruition and luxuriant production of fruit trees, in particular to a method for early fruition and luxuriant production of American thin-shell kiskatoms. The technical proposal of the invention is as follows: cions of American thin-shell kiskatoms of a second year are grafted in parental stocks of American thin-shell kiskatoms of the last year; a part of soil is then dug out to expose partial root of the parental stock for crab rooting cultivation that adopts a growth regulator; the growth regulator used by each strain of American thin-shell kiskatom plantlet is 0.18mg rhodofix and 0.12mg indoleacetic acid; the use method is that mixed liquid is made and mixed by adding 200g water in the rhodofix for dissolving and adding 200g water in the indoleacetic acid for dissolving; the mixed liquid is sprayed at the exposed root of each strain of American thin-shell kiskatom plantlet. The method of the invention has the effect of early fruition and luxuriant production. The mixed growth regulator by adopting the rhodofix and indoleacetic acid can further improve the effect of early fruition and luxuriant production.

Owner:邱富兴

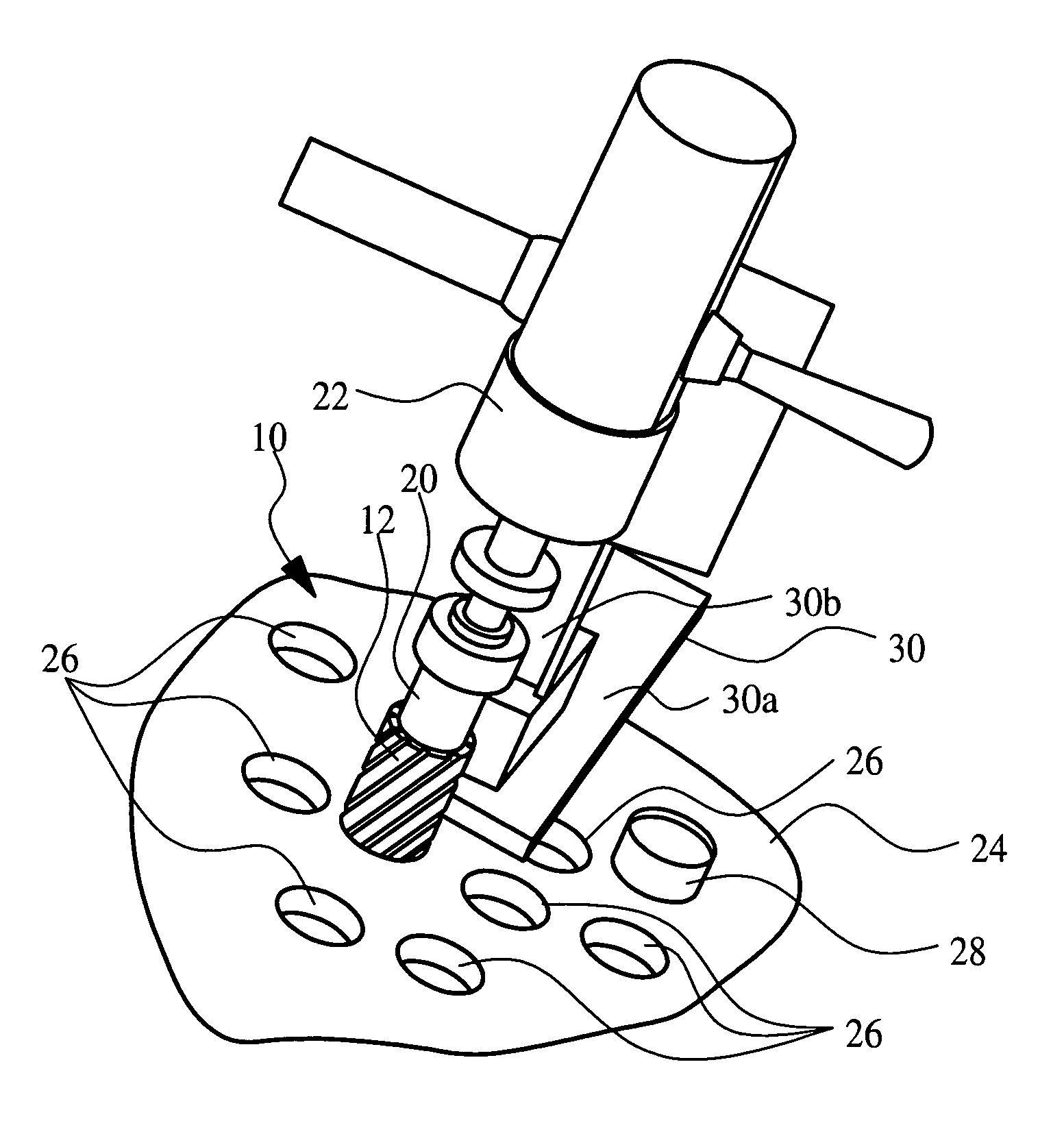

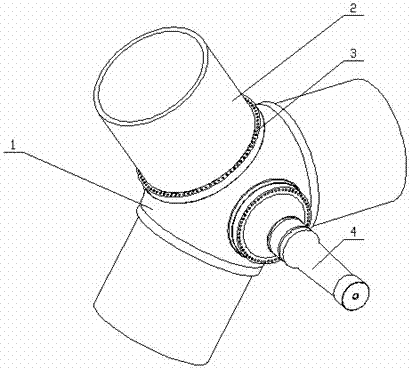

Irrigated ablation catheter having irrigation ports with reduced hydraulic resistance

ActiveUS20140058386A1High trafficIncrease speedCatheterSurgical instruments for heatingThin shellsPlenum chamber

An irrigated ablation catheter includes a tip electrode with a thin shell and a plug to provide a plenum chamber. The tip electrode has an inlet of a predetermined size and noncircular shape, and outlets in the form of fluid ports formed in the thin shell wall. The plurality of the fluid ports is predetermined, as is their diameter. Each fluid port has a tapered configuration, for example, a frustoconical configuration, with a smaller inlet diameter and a larger outlet diameter.

Owner:BIOSENSE WEBSTER (ISRAEL) LTD

Display dispenser

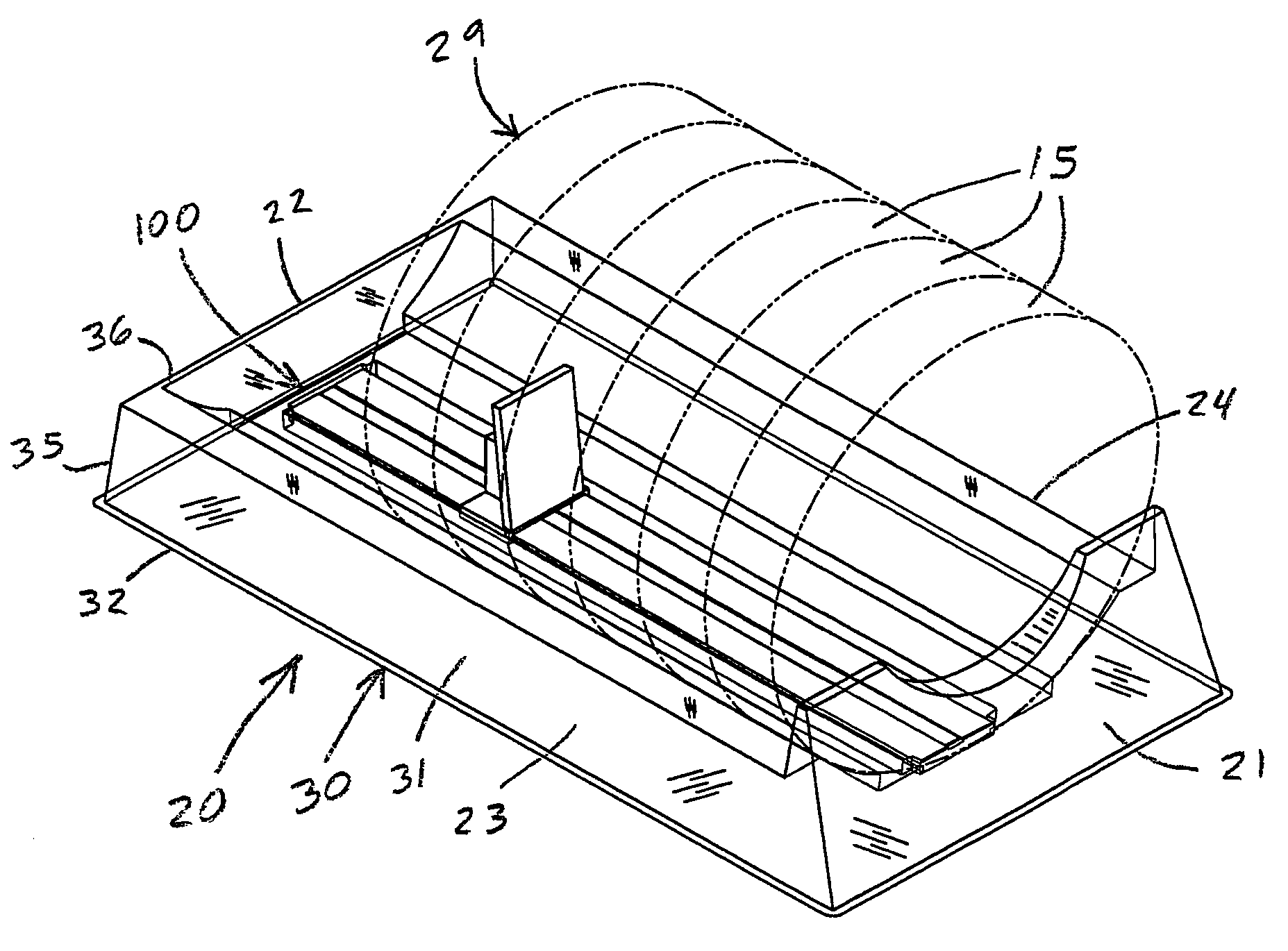

InactiveUS7017778B2Maximizes shelving space and shoppabilityEasy to addRacksCoin-freed apparatus detailsThin shellsCardboard

The present invention pertains to a display dispenser having a disposable molded tray with a thin shell, unibody construction that firmly receives a removable pusher assembly. The tray is formed from a unitary sheet of plastic that forms inner and outer shells. Each shell forms the inside or outside half of a continuous wall around the perimeter of the tray. The two wall halves are integrally joined along a top portion, but otherwise spaced apart to provide a double-walled construction. Each wall has a frustoconical shape so that the trays nest into each other when stacked. The inner shell has an interior portion with two symmetrical side ledges that support and align the sides of the packages. The top of the package faces forward to show the artistic design on the article such as the paper plates or paper napkins inside. The inner shell has a central recess that snuggly receives the unified pusher assembly. A rim extending from the wall and a floor of the recess lay flat on a surface of a shelf.

Owner:SOLO CUP OPERATING CORP

Preparation method of thin shell shaped noble metal catalyst

InactiveCN101491778AExtended service lifeGood dispersionMolecular sieve catalystsCatalyst activation/preparationAlkaneThin shells

The invention relates to a preparation method of thin-shelled noble metal catalyst, and mainly solves the problems of the prior art of high dosage, poor selectivity and short service life of noble metal. The preparation method better solves the technical problems of the prior art by adopting the technical proposal comprising the following steps of: (a) coating the slurry of a coat porous material on the inner core of an inert carrier, drying the slurry coating and baking the slurry coating at a temperature of between 700 and 1,200 DEG C for 0.5 to 10 hours to obtain a laminar composite carrier; (b) impregnating the surface of the laminar composite carrier with a solution containing noble metal and cocatalyst components, drying the laminar composite carrier, and baking the laminar composite carrier in the air at a temperature of between 200 and 700 DEG C for 1 to 24 hours to obtain a thin-shelled catalyst precursor; and (c) reducing the thin-shelled catalyst precursor in a reducing atmosphere at a temperature between 300 and 800 DEG C for 1 to 24 hours to obtain the thin-shelled noble metal catalyst. The preparation method can be used in the industrial production of gas purification materials which are dehydrogenation-deoxidization catalysts, alkanes and aromatic hydrocarbons for selective hydrogen oxidation in a dehydrogenation process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Alumina coats pulp and preparation method thereof

ActiveCN101491776AHigh bonding strengthHigh hydrothermal stabilityCatalyst carriersDispersed particle separationThin shellsAdhesive

The invention relates to alumina coat slurry and a preparation method thereof, and mainly solves the problems of the prior art of poor stability of a prepared laminar composite carrier and short service life of a prepared thin-shelled noble metal catalyst. The alumina coat slurry comprises the following components: aluminum sol with an average granularity of less than 20 micrometres, active alumina, an organic adhesive, an inorganic adhesive, a surfactant, a pH modifying agent and the balance being water, wherein the average granularity of the slurry is less than 10 micrometres. The preparation method comprises the following steps: dissolving the aluminum sol, the organic adhesive, the surfactant and the pH modifying agent in water; mixing the mixture evenly with stirring at a high speed; then adding the inorganic adhesive and active alumina powder for high-speed dispersion; and regrinding the obtained alumina coat slurry to prepare the alumina coat slurry. Thus, the preparation method better solves the problems by adopting the technical proposal, and can be used in the industrial production of laminar composite carrier.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of removing boiler tubes

Boiler tubes are removed from a boiler vessel without damaging the vessel by severing the boiler tube near the exterior periphery of the vessel, and using a piloted rotary cutting tool fixtured with respect to the longitudinal axis of the severed boiler tube to remove all but a very thin shell of the severed tube. The rotary cutting tool is then withdrawn, and the remaining thin shell of the boiler tube is manually peeled away from the periphery of the boiler vessel opening. In a preferred implementation, the rotary cutting tool is annular, and a tapered cylindrical pilot having an outside diameter slightly smaller than the inside diameter of the expanded portion of the boiler tube is retractably mounted within the annulus of the cutting tool.

Owner:CRAIG MERRILL C

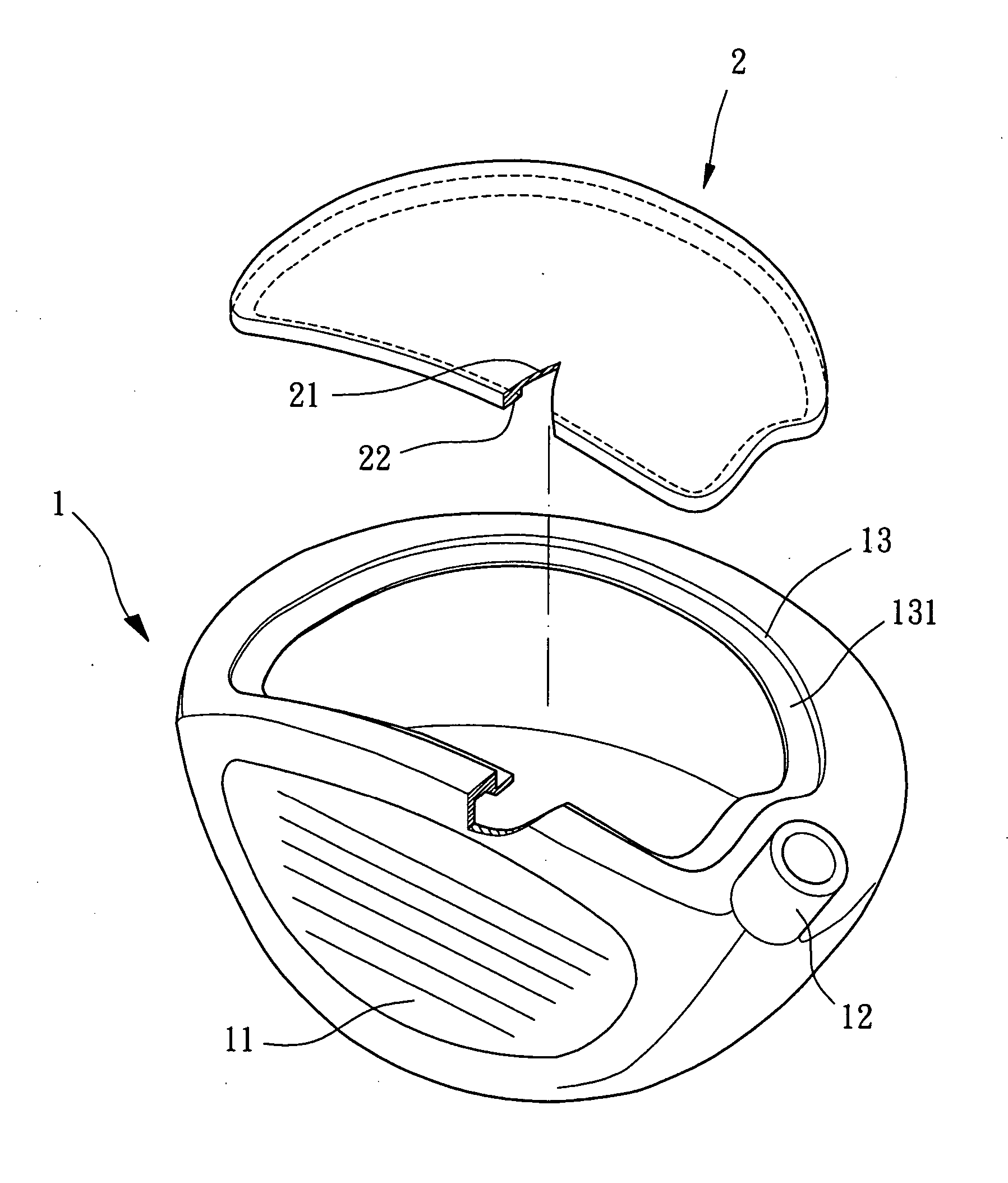

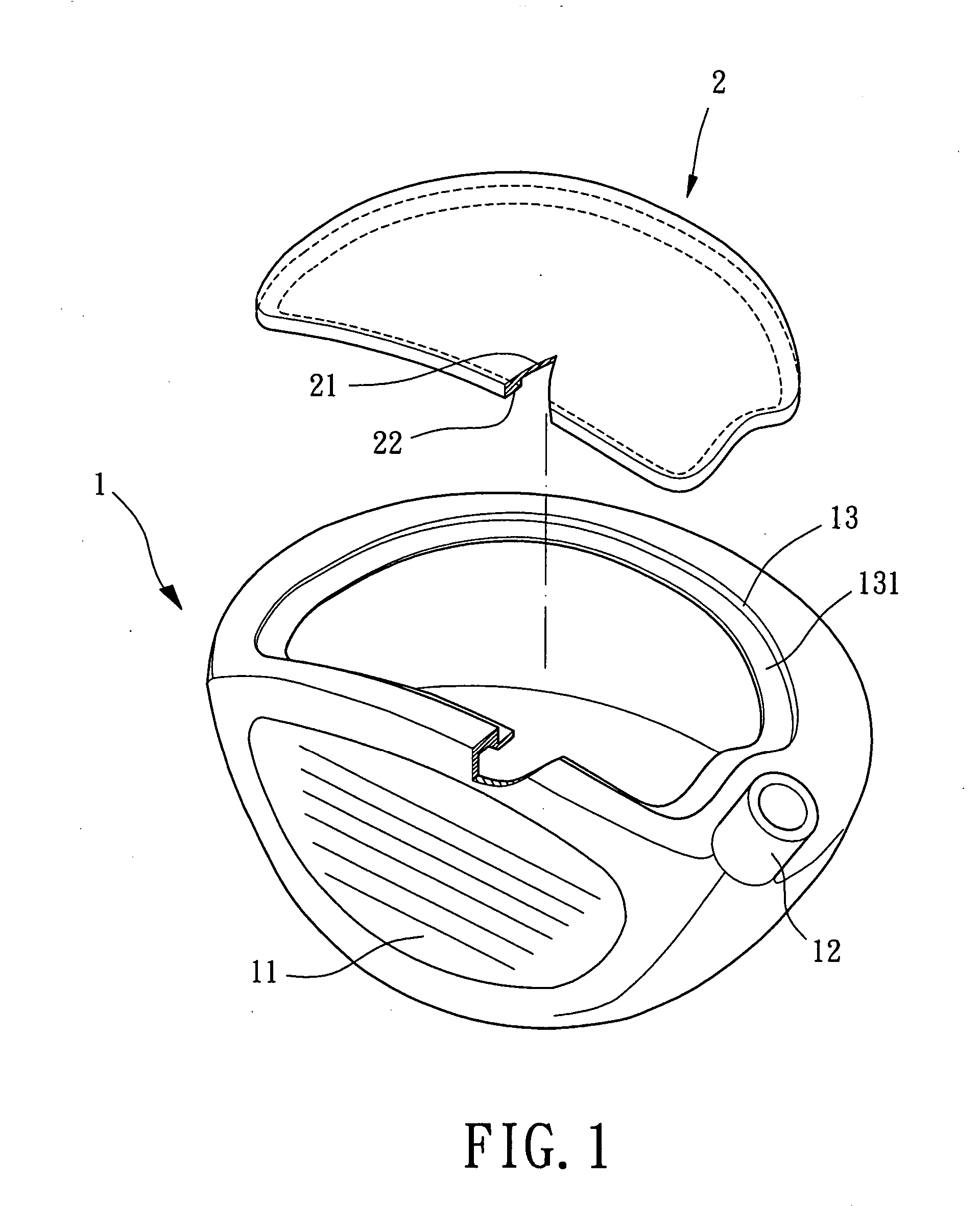

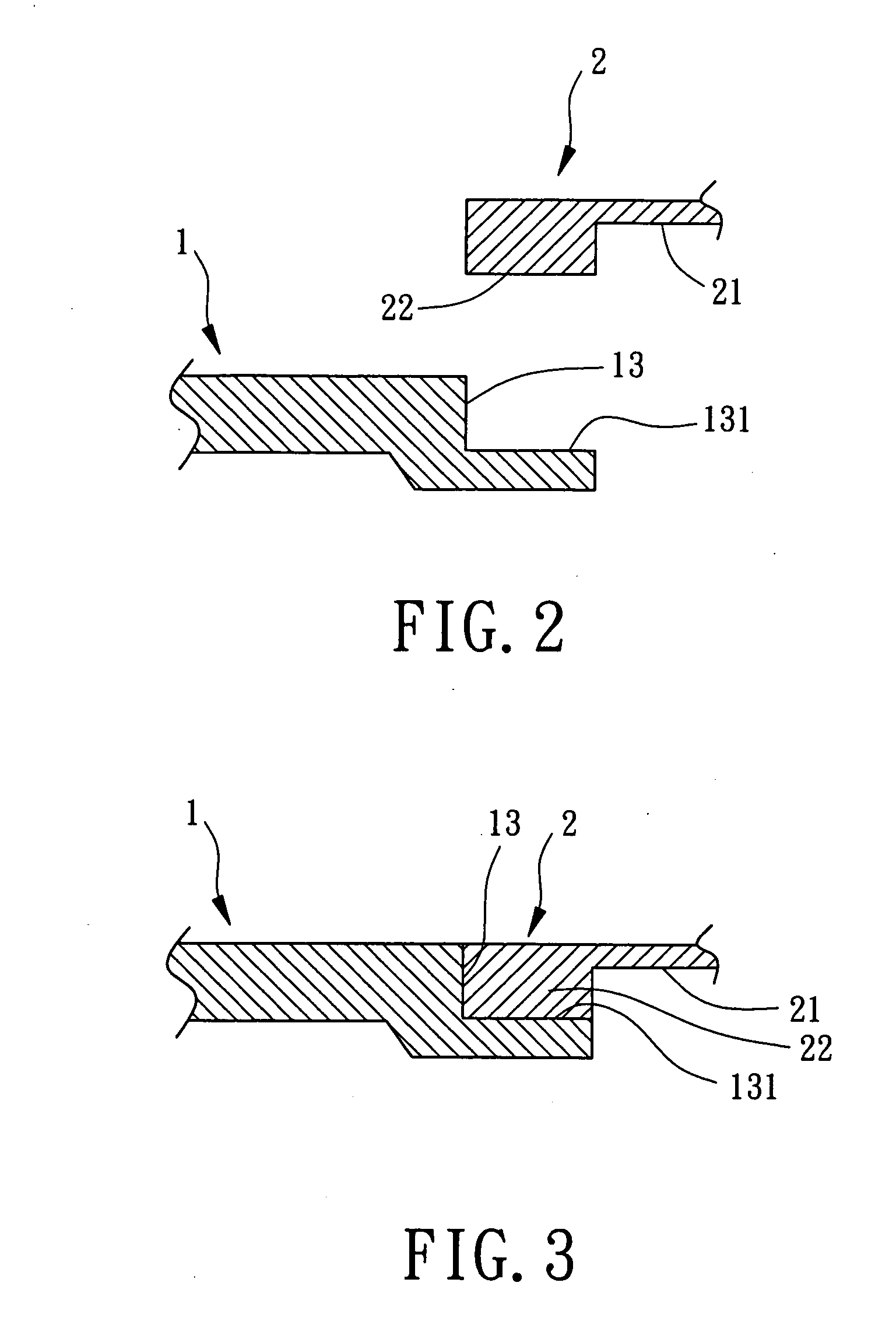

Golf club head having a thin-type cover plate structure

InactiveUS20060270490A1Simple structureImprove reliabilityGolf clubsRacket sportsThin shellsGolf club

A golf club head includes a golf club head body and a cover plate mechanically connected thereto. The golf club head body provides with a striking plate and at least one assembling opening. The cover plate provides with a reinforcing outer edge and a relatively thin shell portion. The reinforcing outer edge is partially arranged on an outer periphery of the relatively thin shell portion of the cover plate. In assembling, the reinforcing outer edge of the cover plate securely connects with an inner periphery of the assembling opening of the golf club head body.

Owner:FUSHENG IND CO LTD

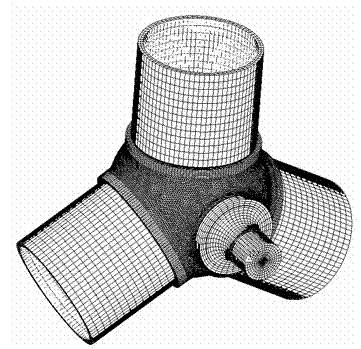

Method for casting thin-shell nodular-cast-iron turbocharger

The invention relates to a method for casting a thin-shell nodular-cast-iron turbocharger, in particular to a method for casting the thin-shell nodular-cast-iron turbocharger and the like products, which is characterized by comprising the following steps of: process method design, three-dimensional model design of the casting process, mold-filling / solidifying simulation, analysis treatment for a simulated result, selection of mold materials, mold assembling simulation, molding, core making, mold assembling, molten iron melting, spheroidizing inoculation, and pouring. The process method provided by the invention is unique, which can solve the problem of shrinkage porosity because the partially overlarge part of an inner cavity cannot be fed by a riser, and can ensure the dimensional accuracy of air cavity, water cavity and oil cavity which are intersected one another in the inner cavity of the casting shell.

Owner:KOCEL EQUIP +1

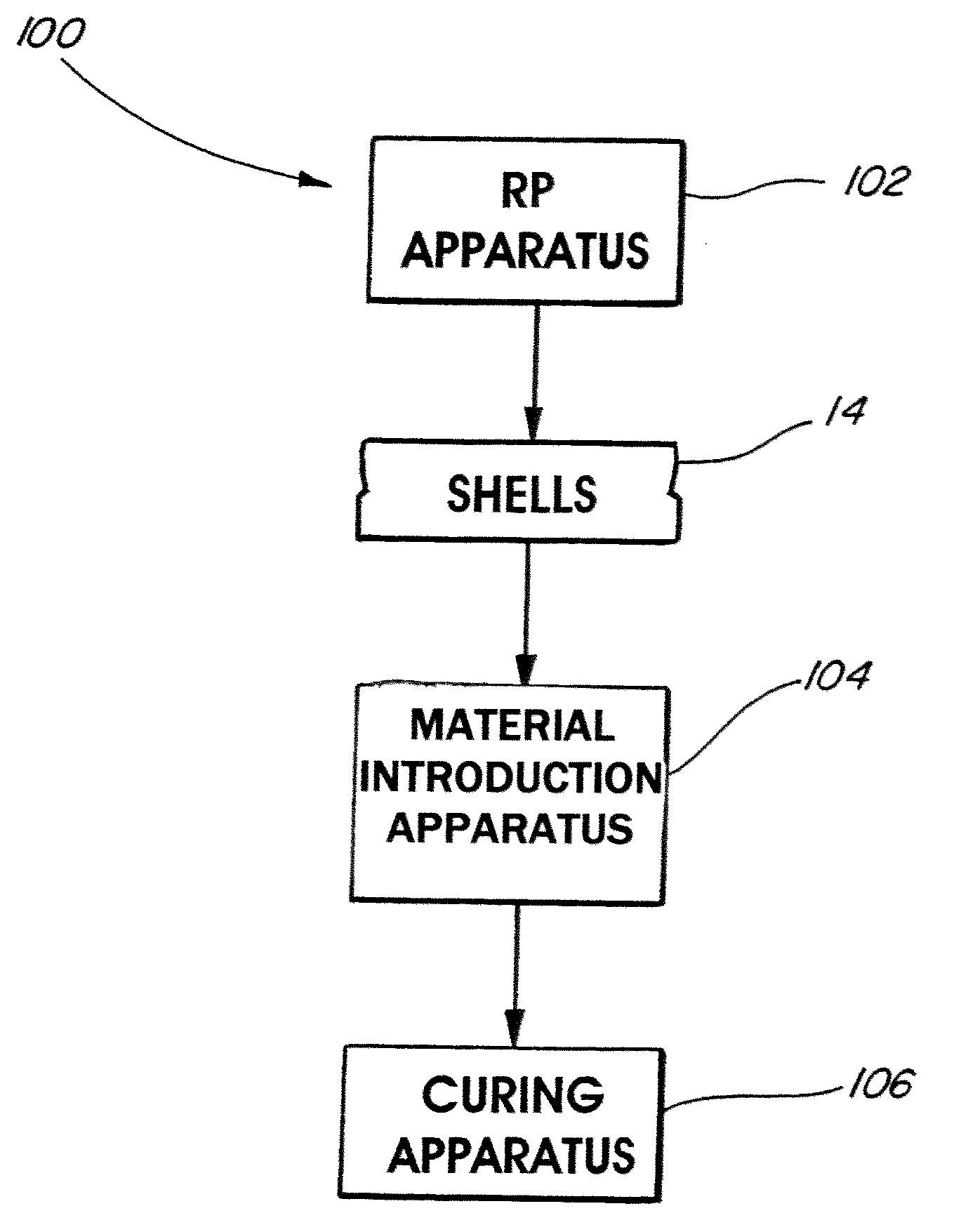

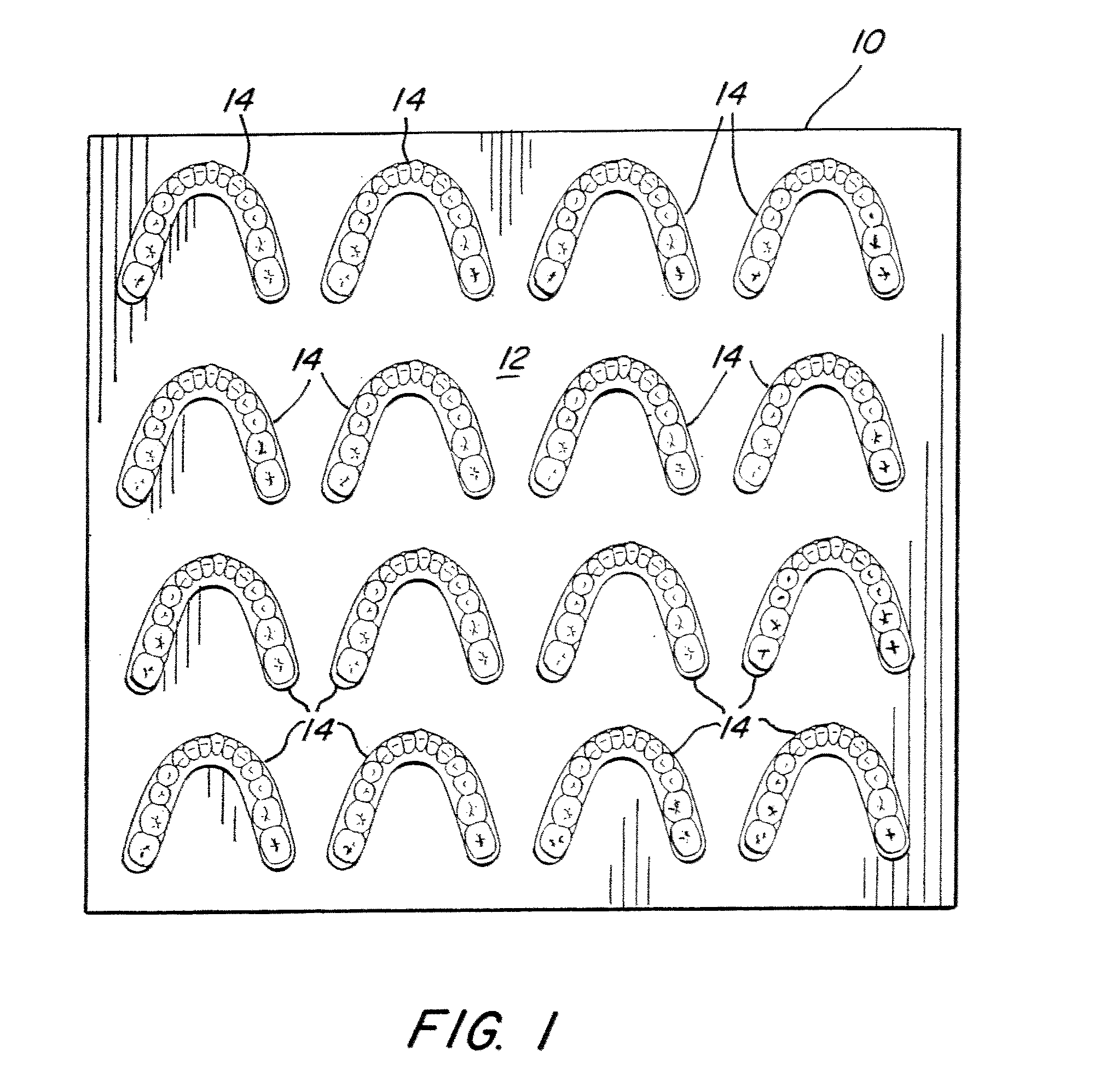

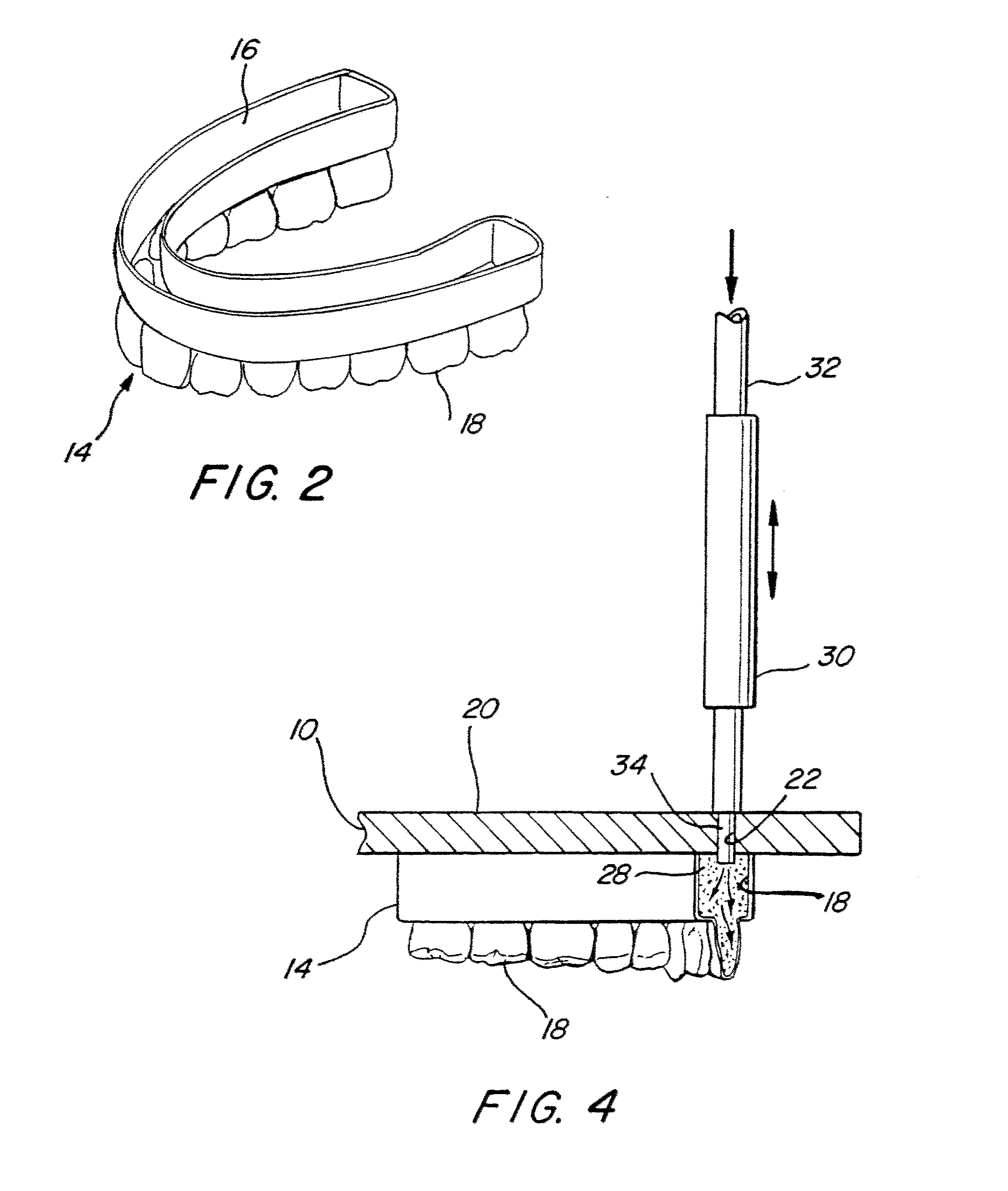

Reinforced thin-shell molds

A method and a system for forming a polymeric resin mold for molding plastic items, wherein the method includes: (a) using a rapid-prototyping process to create a polymeric resin shell having a configuration in the form of the mold; (b) introducing a reinforcing material into the shell; and (c) curing the shell. The system includes a rapid-prototyping apparatus that creates a plurality of the polymeric resin shells on a platform; a reinforcing material introduction apparatus that introduces a reinforcing material into each of the shells while the shells are on the platform to form a plurality of uncured molds on the platform; and a curing apparatus that cures the shells while they are on the platform.

Owner:ALIGN TECH

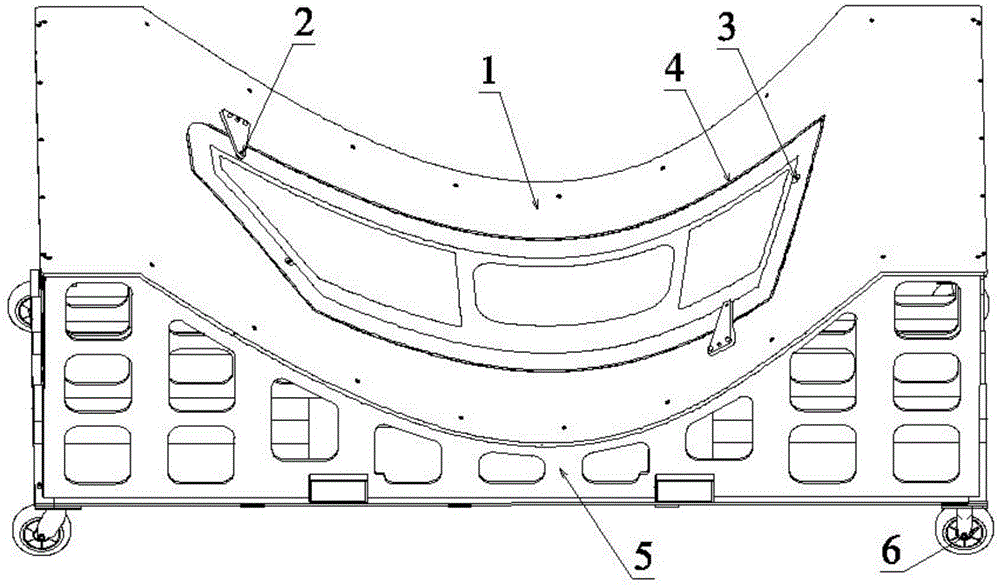

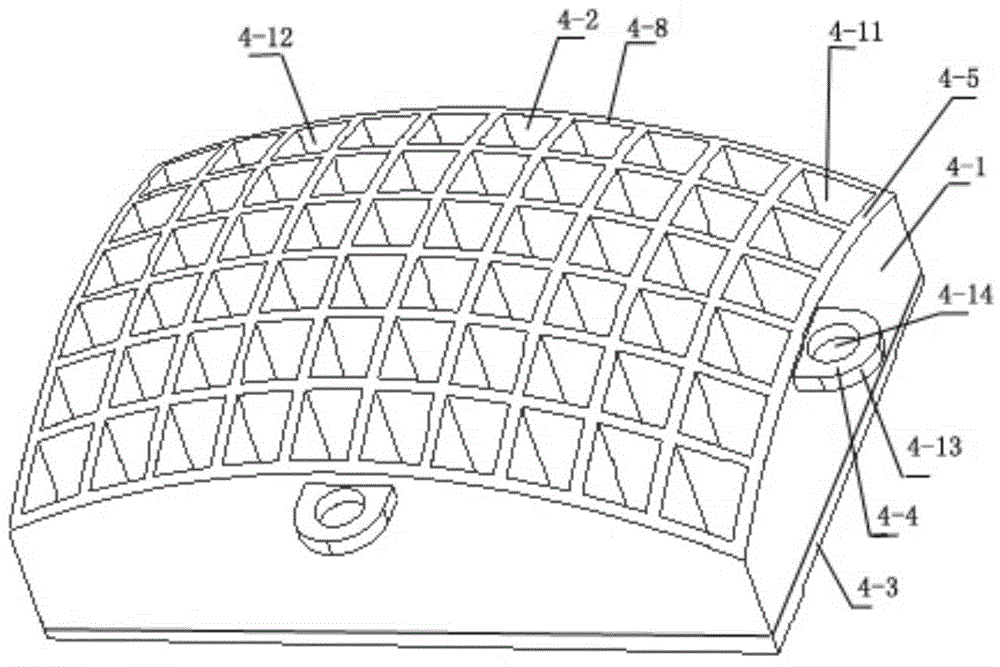

Carbon fiber composite material forming tool

ActiveCN104626606AExtended service lifeGood dimensional stabilityMetal working apparatusThin shellsMaterials science

The invention belongs to the technology of airplane assembly tools and relates to a carbon fiber composite material forming tool, aiming at solving the problem that a product is inconsistent with the design in shape due to great difference of heat expansion coefficients of the product and a tool when a large-sized carbon fiber composite material airplane member with a complicated surface is formed. The tool provided by the invention is of a thin shell type structure and mainly comprises a die body and a frame. The tool provided by the invention consists of six parts, namely a structure 1, the die body, a structure 2 for drilling assembling and coordinating positioning holes, a structure 3 for preparing the positioning holes, a structure 4, an anti-skid belt, a structure 5, the frame, and a structure 6, wheels. The carbon fiber composite material forming tool provided by the invention can be used for solving the problem that the product is inconsistent with the design in shape due to great difference of heat expansion coefficients of the product and the tool when the large-sized carbon fiber composite material airplane member with the complicated surface is formed. Moreover, as steel tiles are excellent in dimensional stability, the service life of the tool is prolonged and the production cost is lowered.

Owner:HARBIN

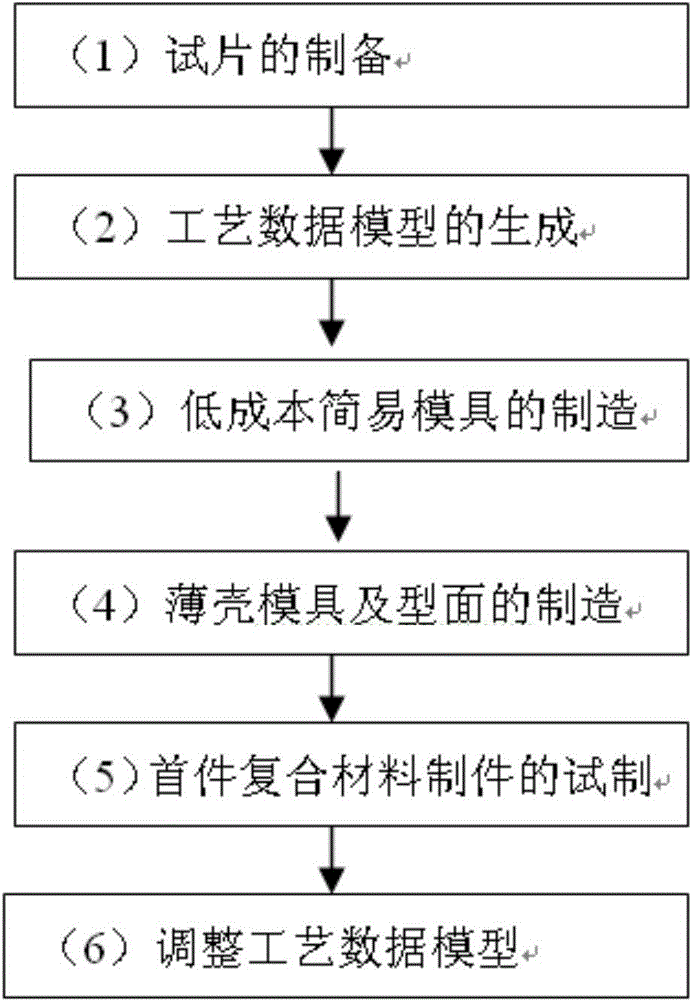

Composite material precision molding tool for airplane and precision molding manufacturing method

The invention relates to a composite material precision molding tool for an airplane and a precision molding manufacturing method. In a single large-scale part composite material molding process, the size precision is affected by many factors such as a mould material and structure, a composite material laying angle, layers and curing processes. The composite material precision molding tool provided by the invention comprises a set of special mould for test piece preparation, a test piece, an easy molding mould, a thin-shell mould and the like; the composite material test piece is prepared on the special test piece preparation mould, a transformative database is built by analyzing the transformation rule of the test piece, and a product digital model is converted into a process digital model by compensating molding errors by using CATIA software. According to the process digital model, a molded surface of the thin-shell mould is manufactured on an easy molding mould transition tool, and the composite material product is manufactured by utilizing the molded surface of the thin-shell mould, so that the molding quality and accuracy of the composite material can be improved, the design difficulty of the molded surface of the mould and the mould manufacturing cost are reduced, the thermal capacity of the mould is effectively reduced, and the optimization of curing reaction is facilitated.

Owner:哈尔滨新科锐工艺装备制造有限公司 +1

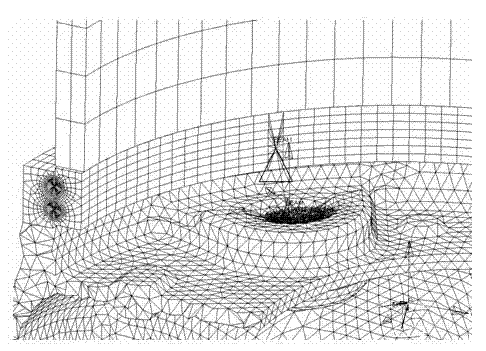

Hub strength calculation method of wind power generating unit

InactiveCN102831260AAccurate force transmissionImprove accuracySpecial data processing applicationsElement modelElement analysis

The invention provides a hub strength calculation method of a wind power generating unit. In a finite element model, variable propeller drive, a roller of a variable propeller bearing, and the like are considered, and a section of blade prosthesis is also used, so that the stress transfer of the model is relatively accurate, and the accuracy of a model calculation result is improved; according to the stress characteristics of a hub, only four limit working conditions are calculated, so that the calculation efficiency is improved; and during the fatigue analysis to a hub body, a layer of very thin shell unit is paved on the surface of the hub body, and the fatigue life of a part is calculated by combining the fatigue life performance of a material and applying a fatigue theory according to a stress strain result obtained in finite element analysis.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com