Patents

Literature

1145results about "Arched structures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

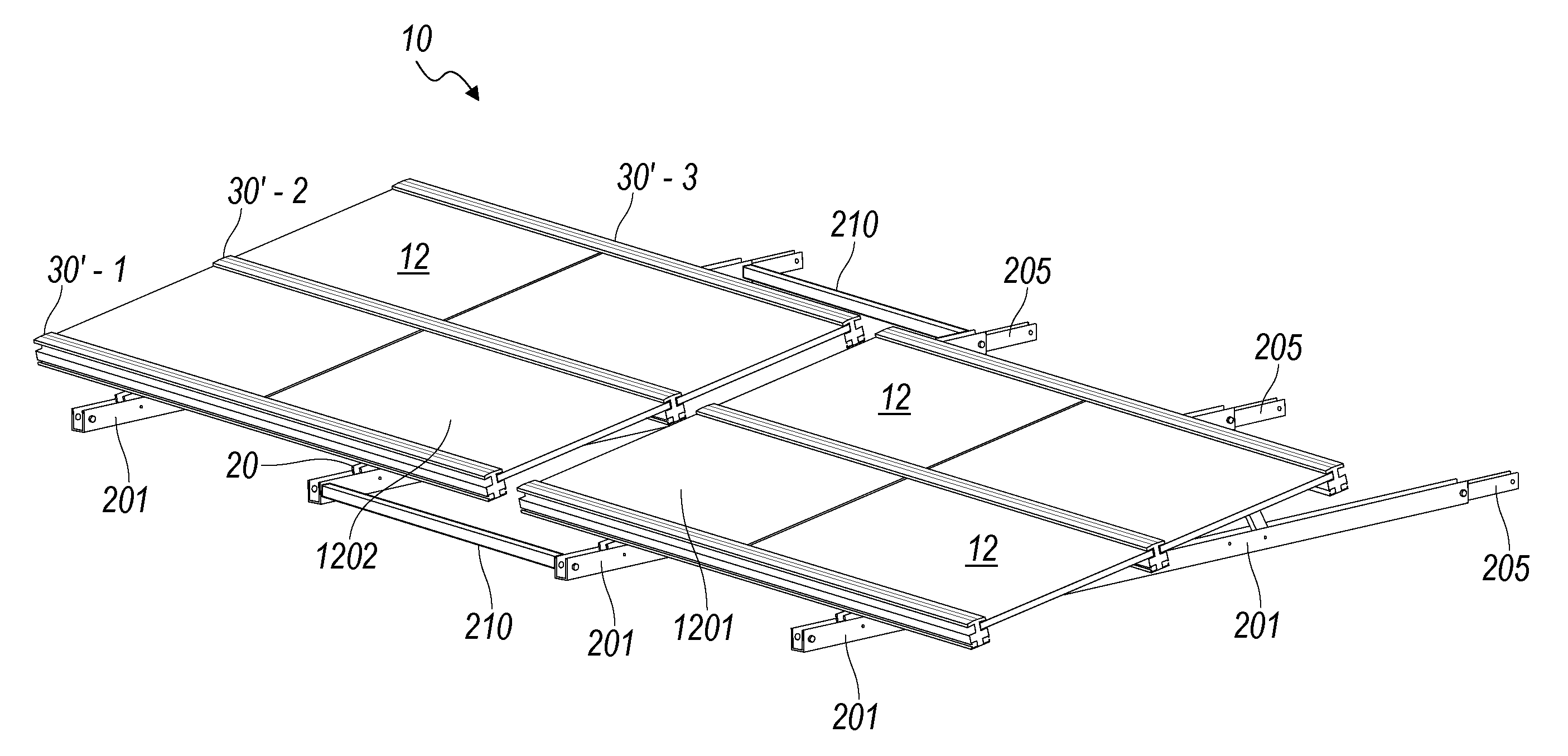

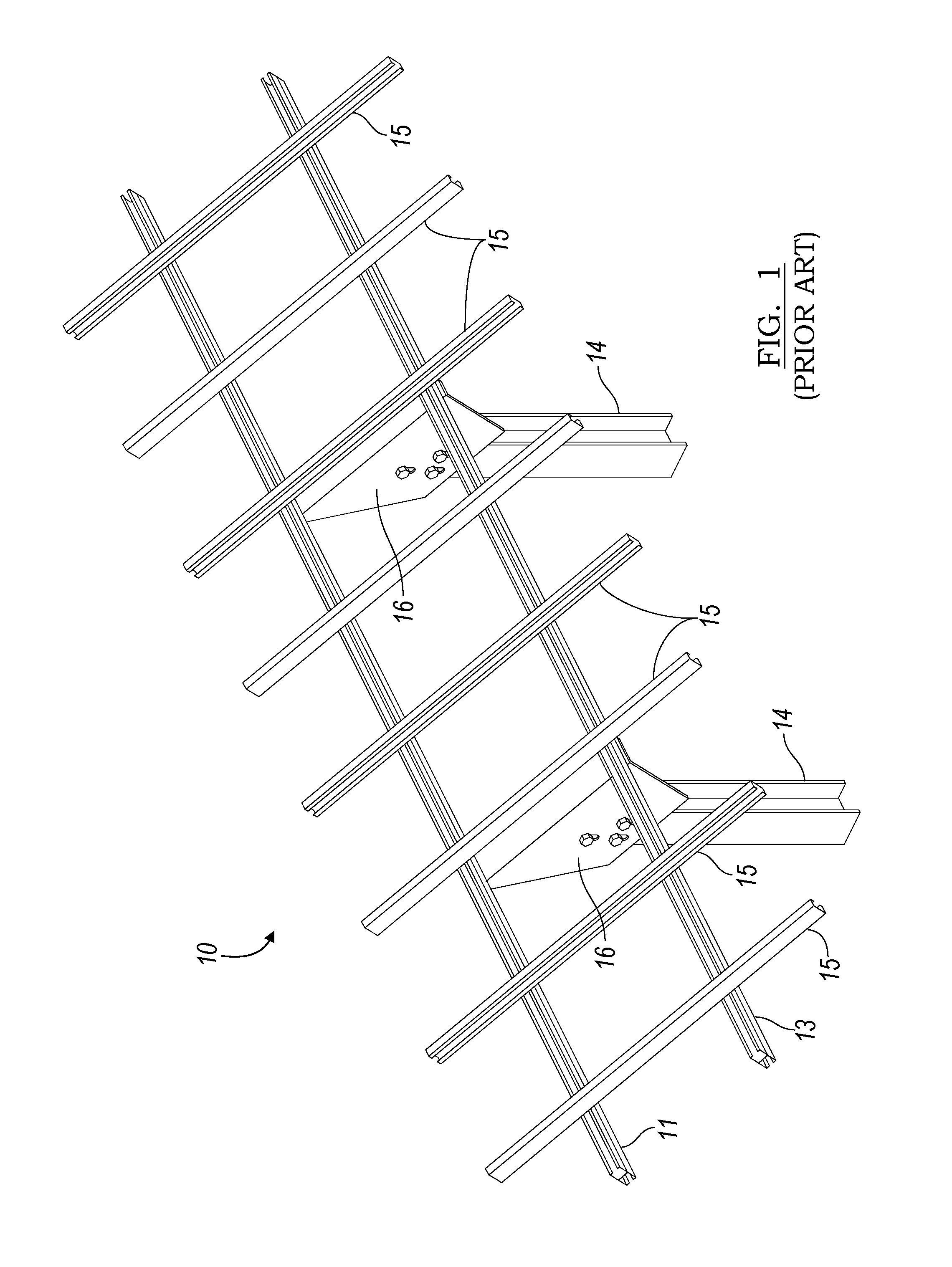

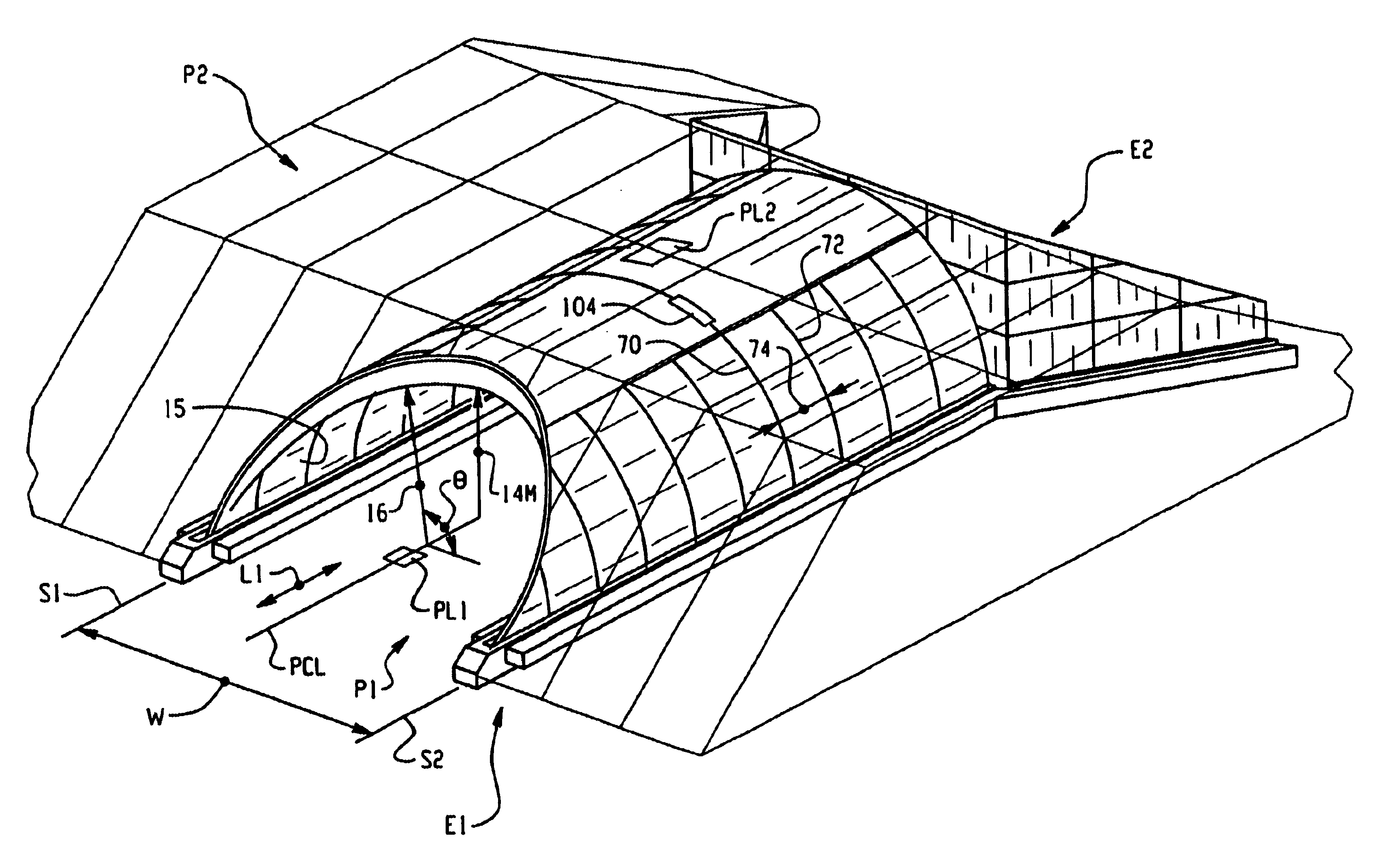

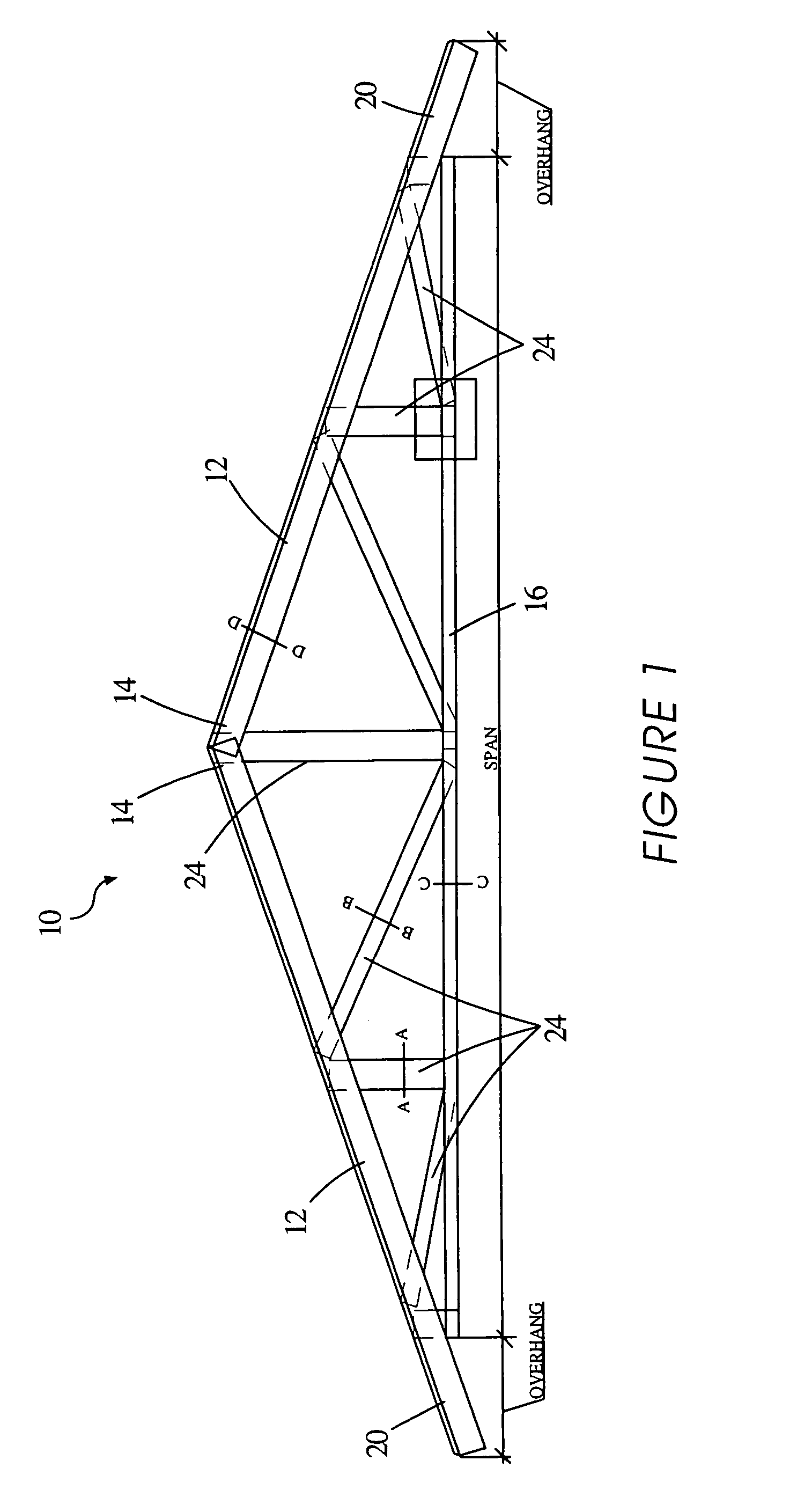

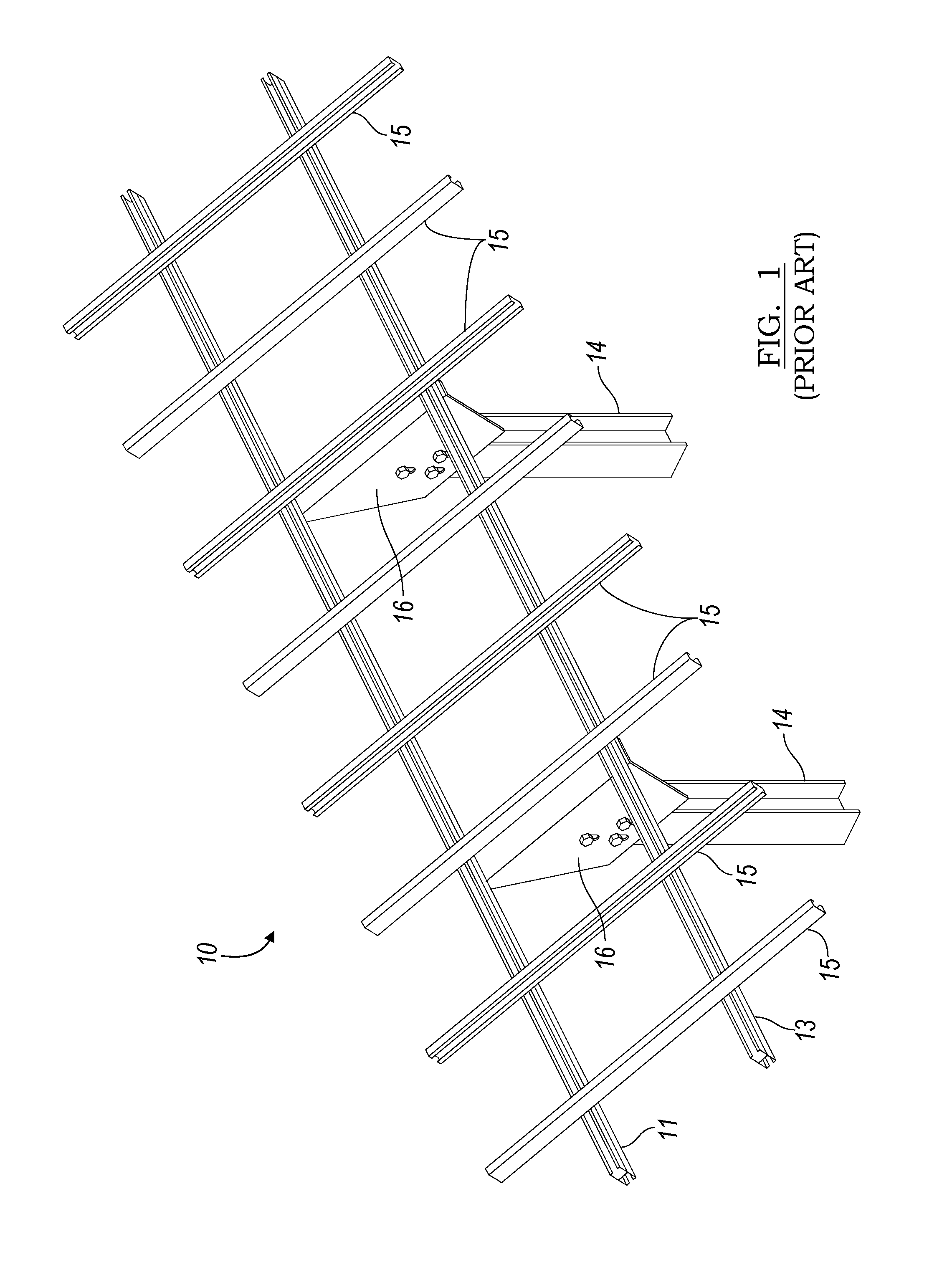

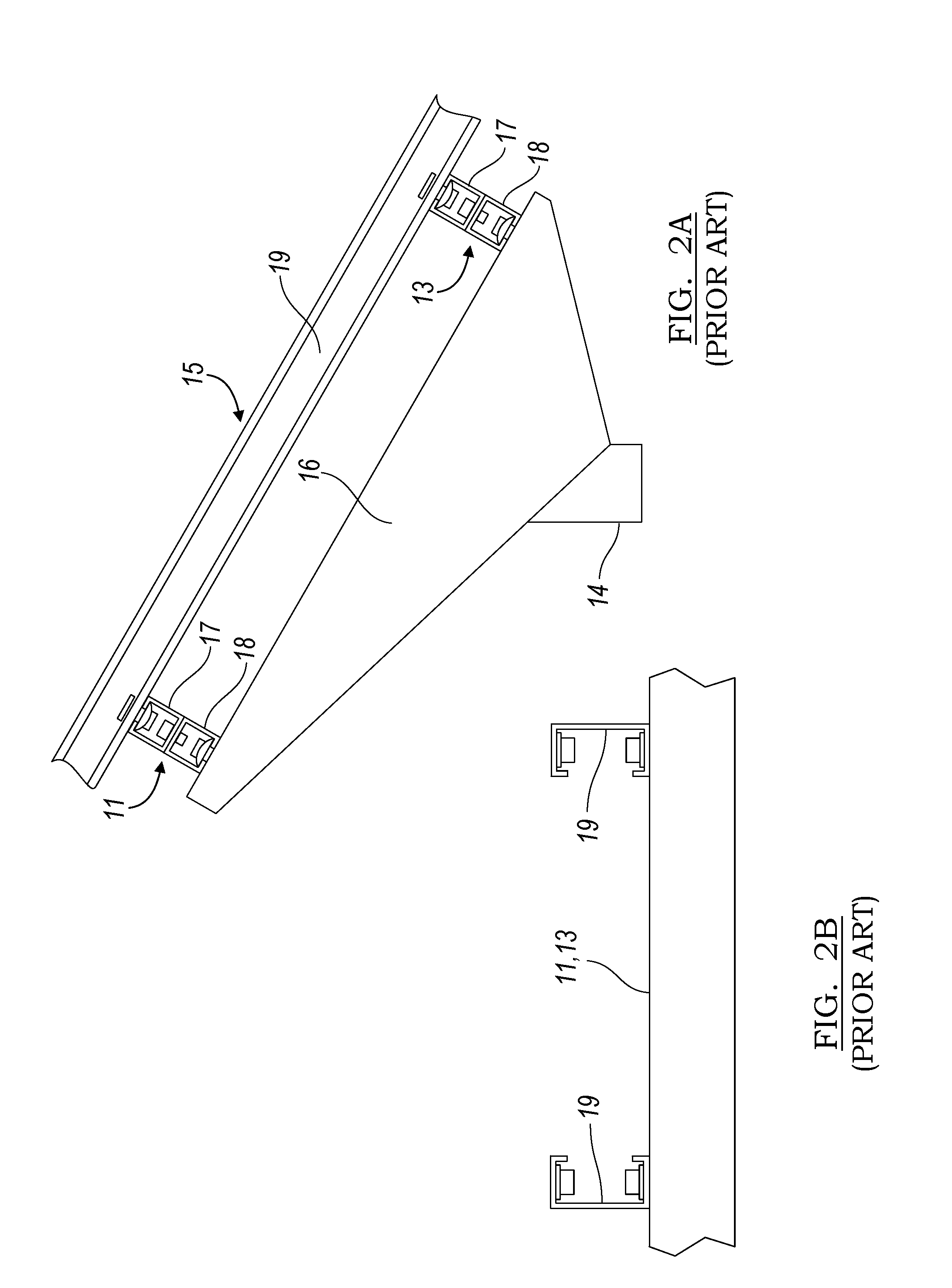

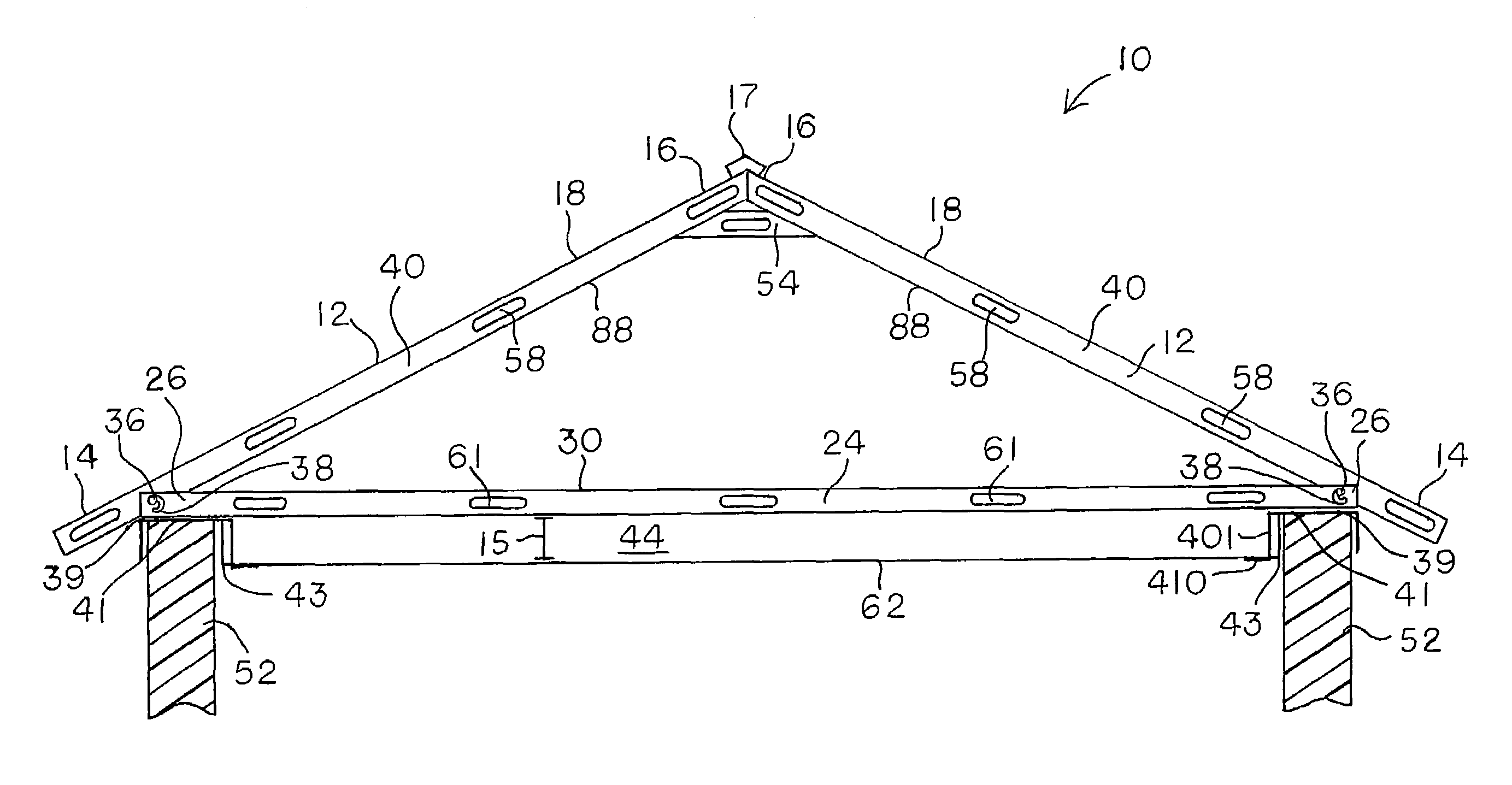

Support System for Solar Panels

ActiveUS20100236183A1Easy to deployEasy to removePhotovoltaic supportsSolar heating energySupporting systemBraced frame

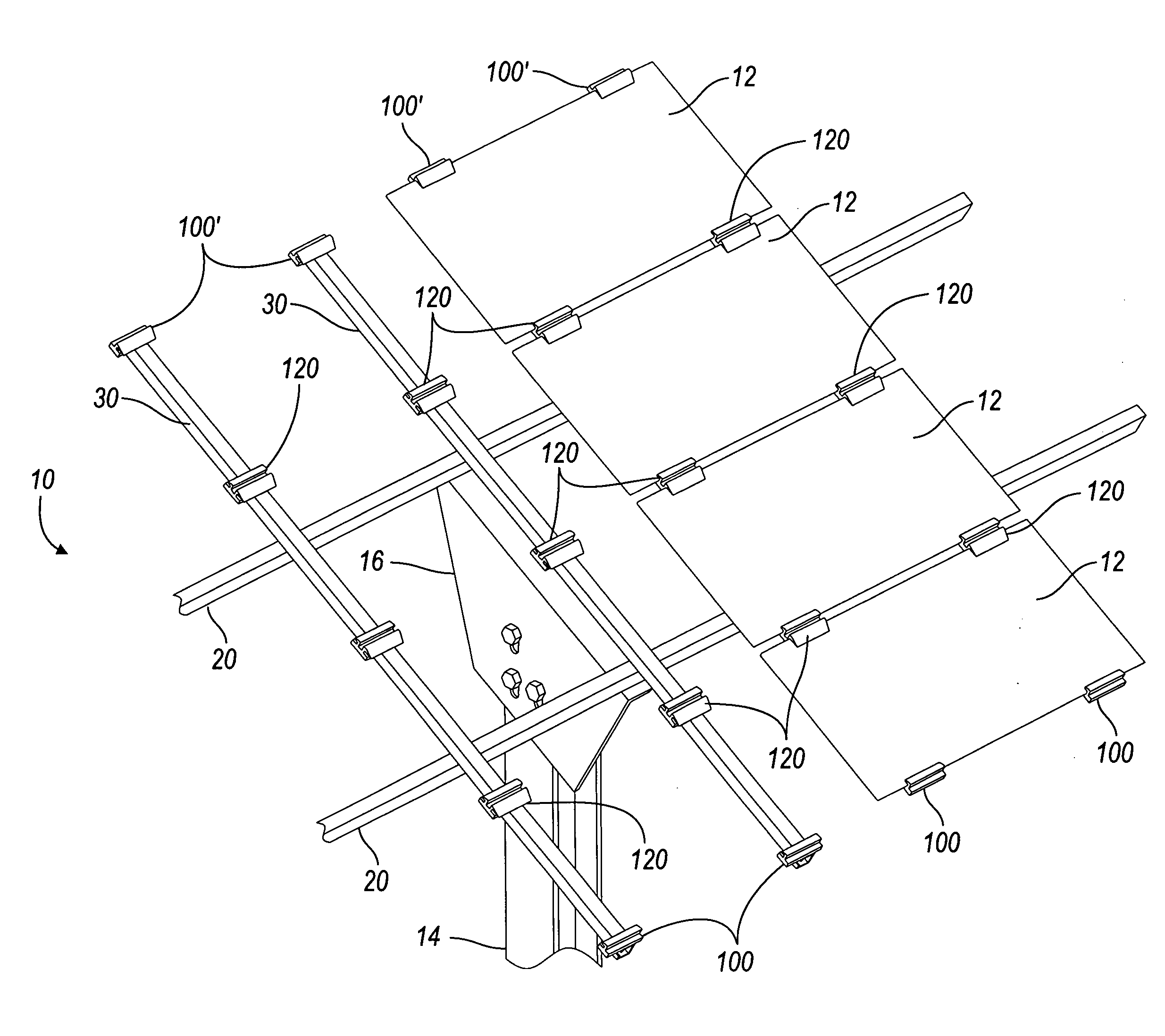

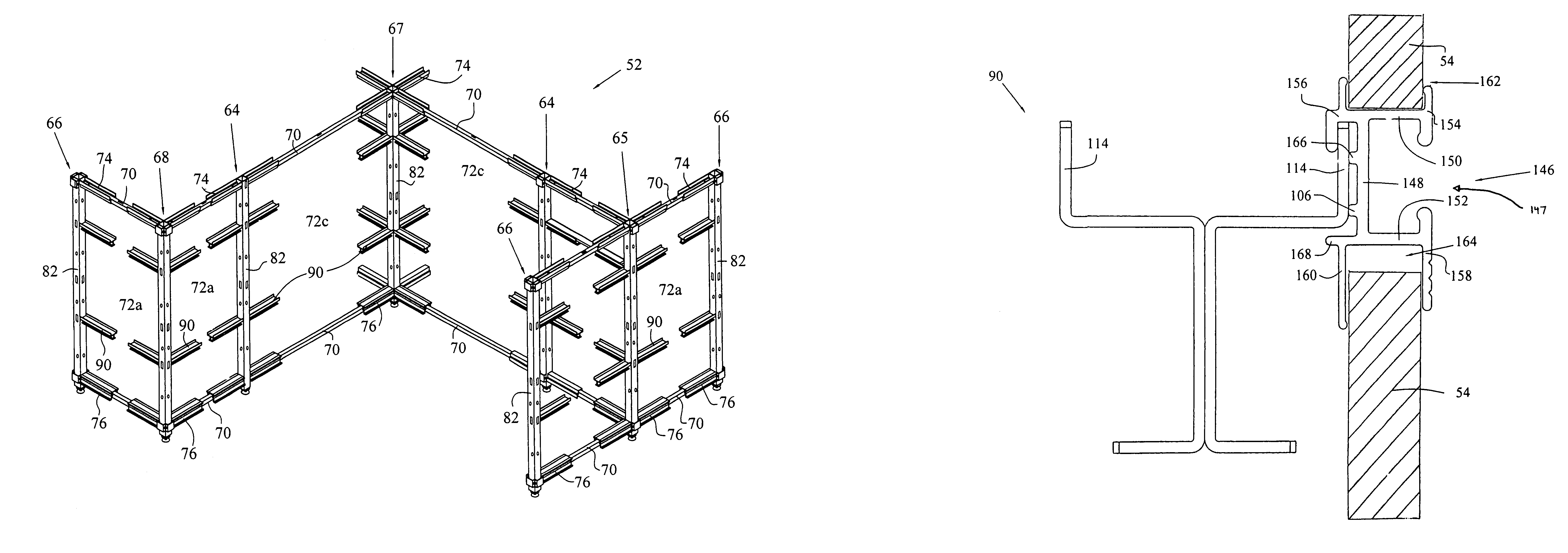

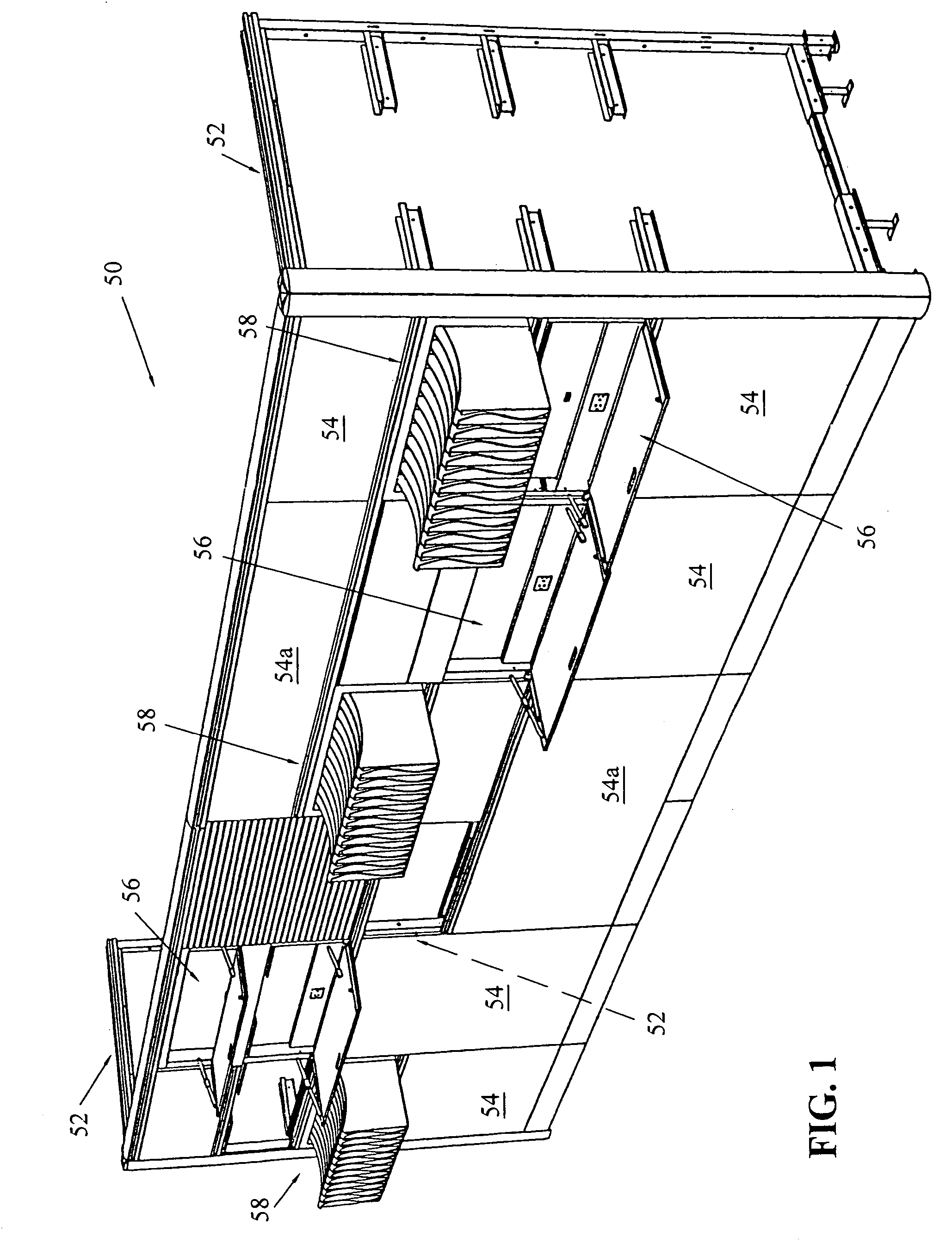

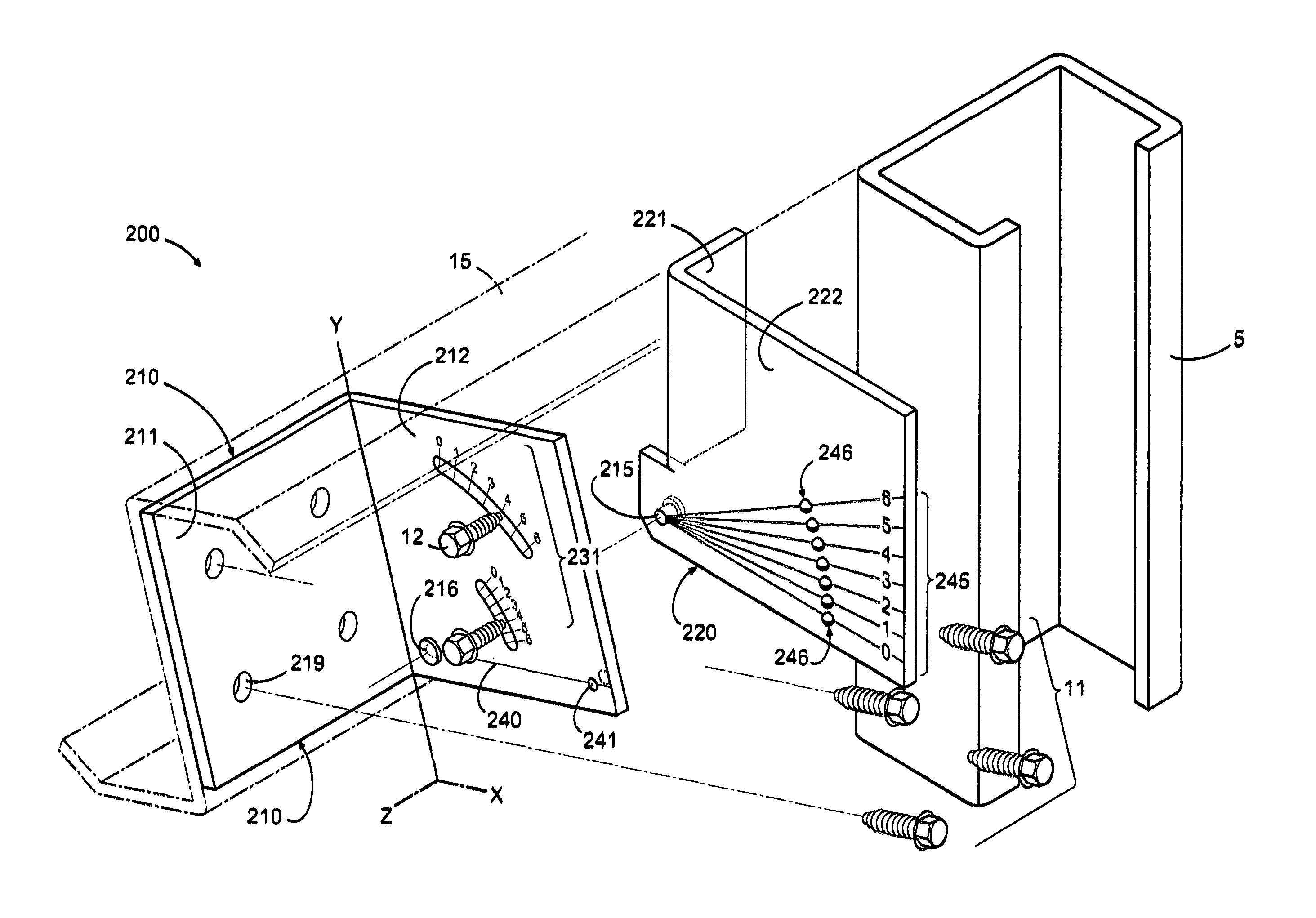

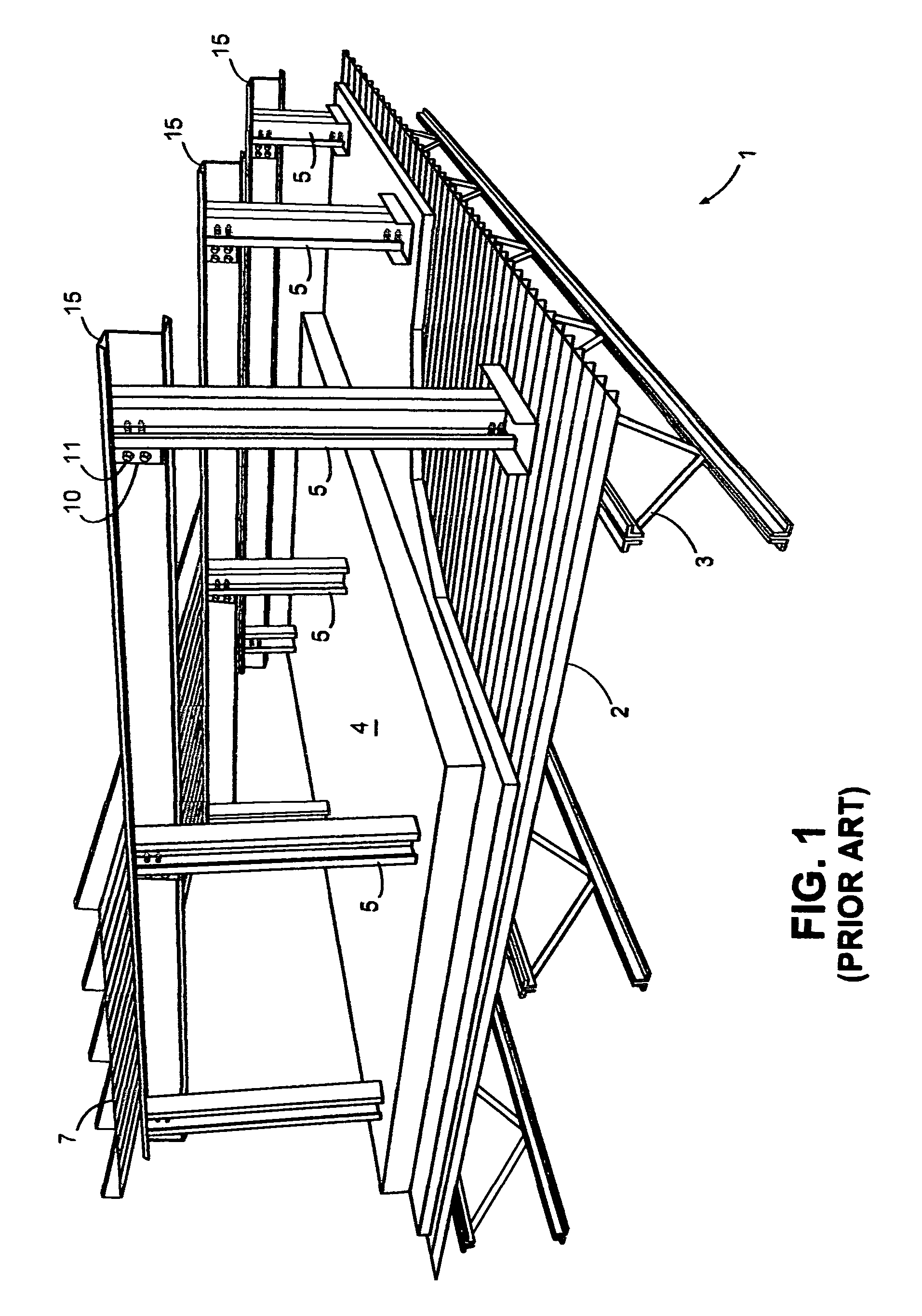

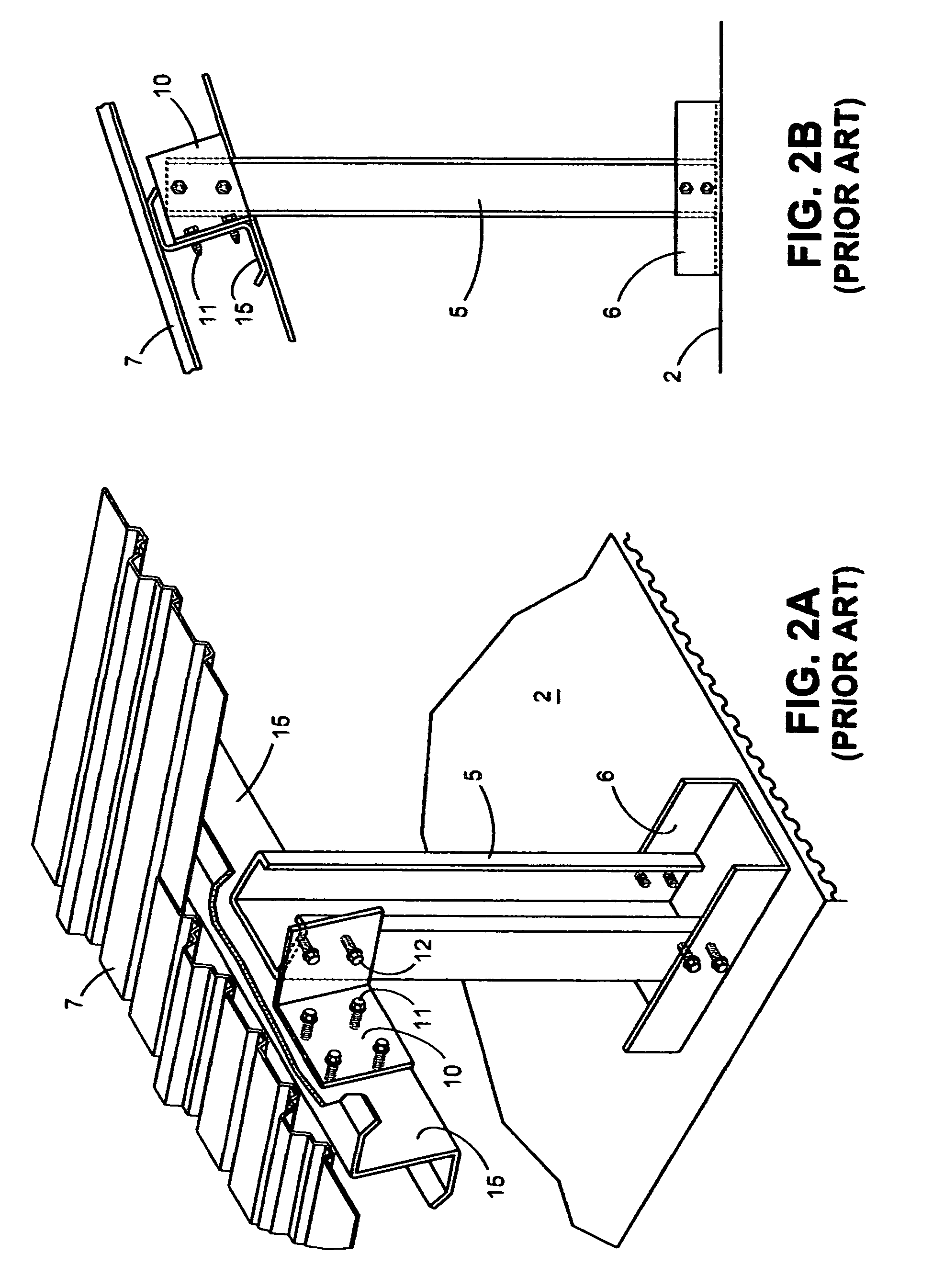

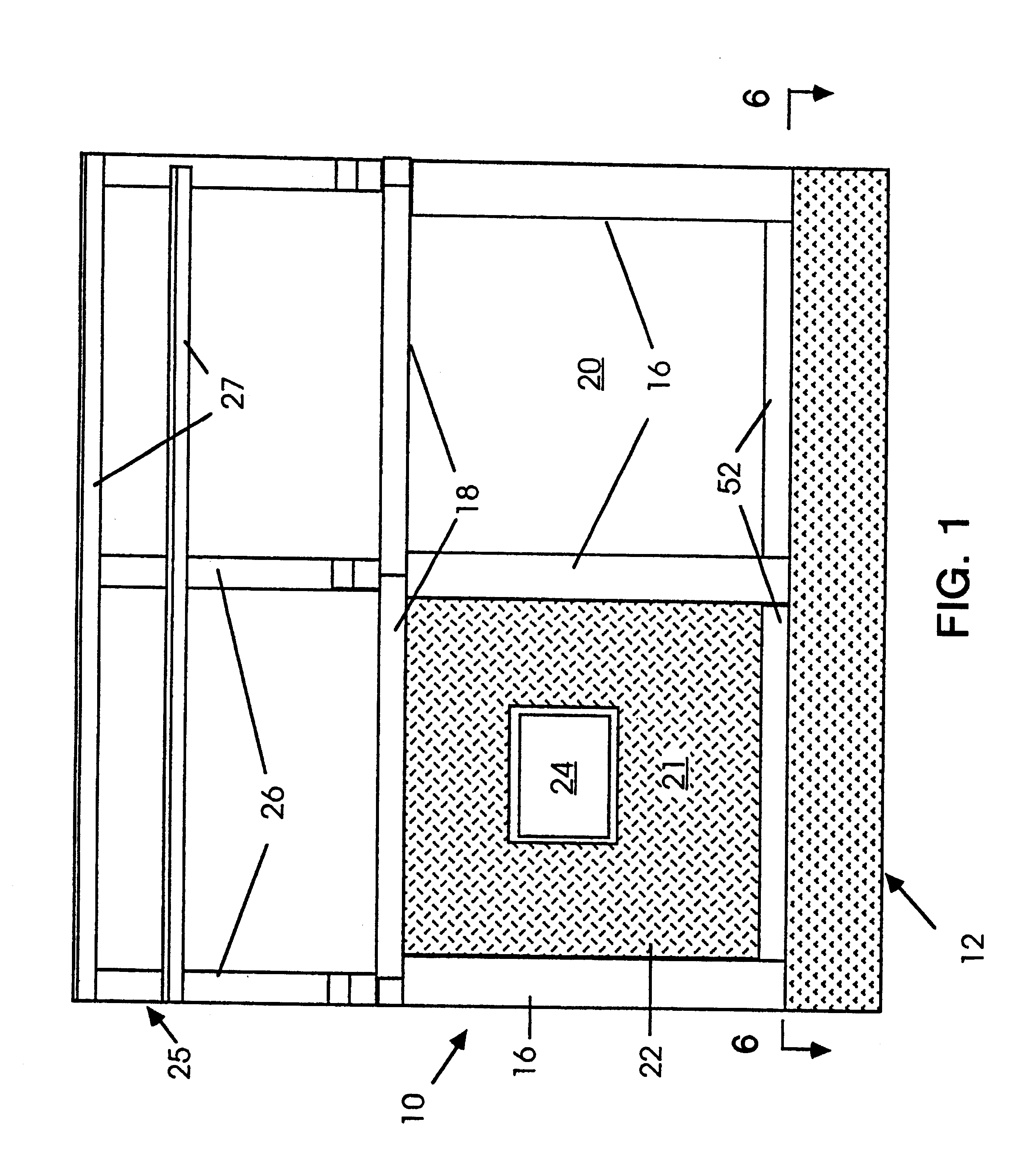

Precise parameters are maintained in a support system for solar panels or other panel-like structures through use of a collapsible folding, support frame which is preassembled to precise tolerances at a convenient staging site before being collapsed for shipment. Installation on flat roofs is also facilitated through the use of a roof interface frame which rotatably supports the panel support frame of the support system and folds along with it at the assembly, staging site.

Owner:NORTHERN STATES METALS

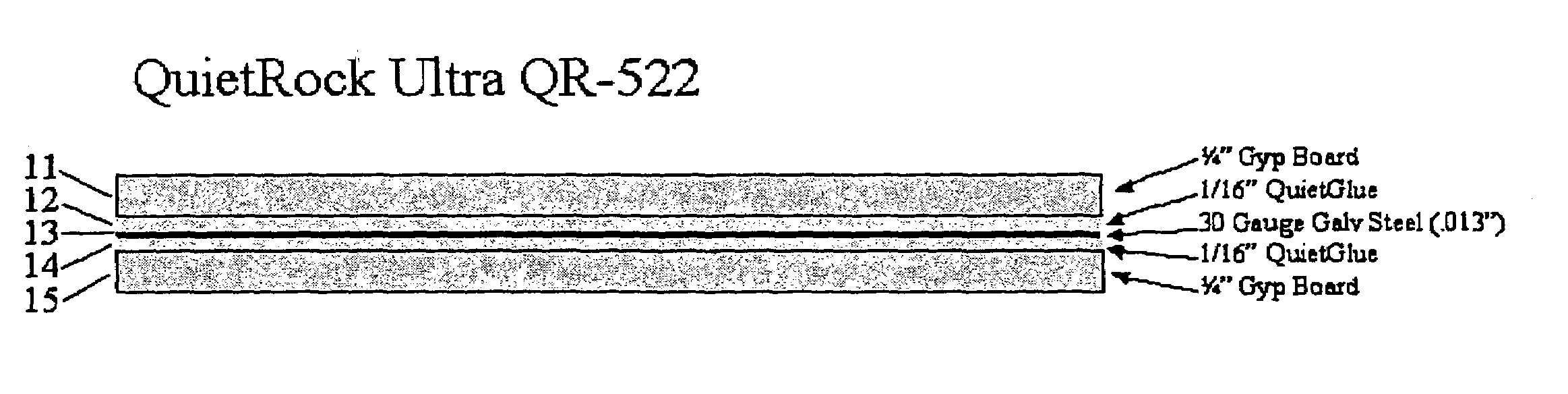

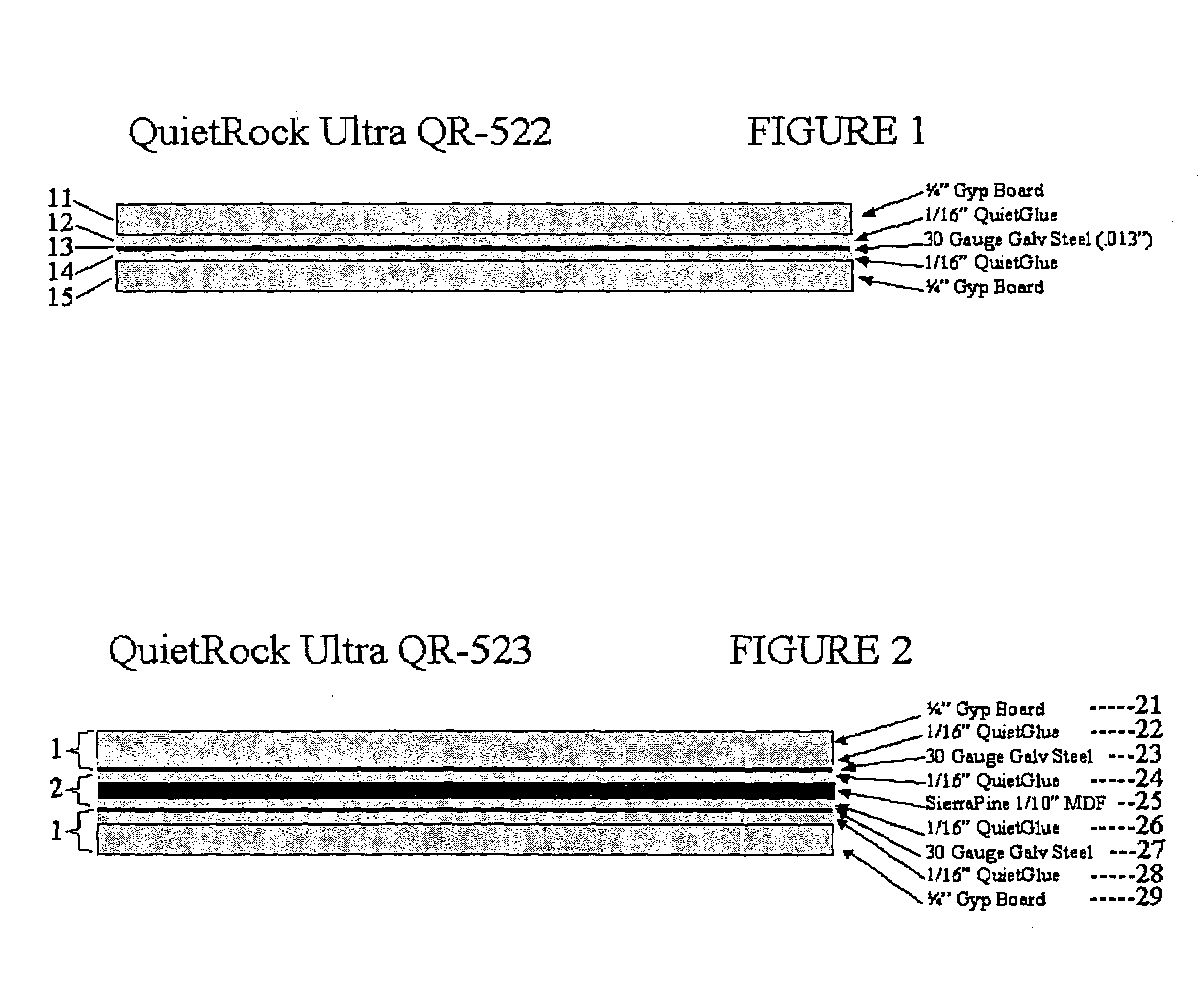

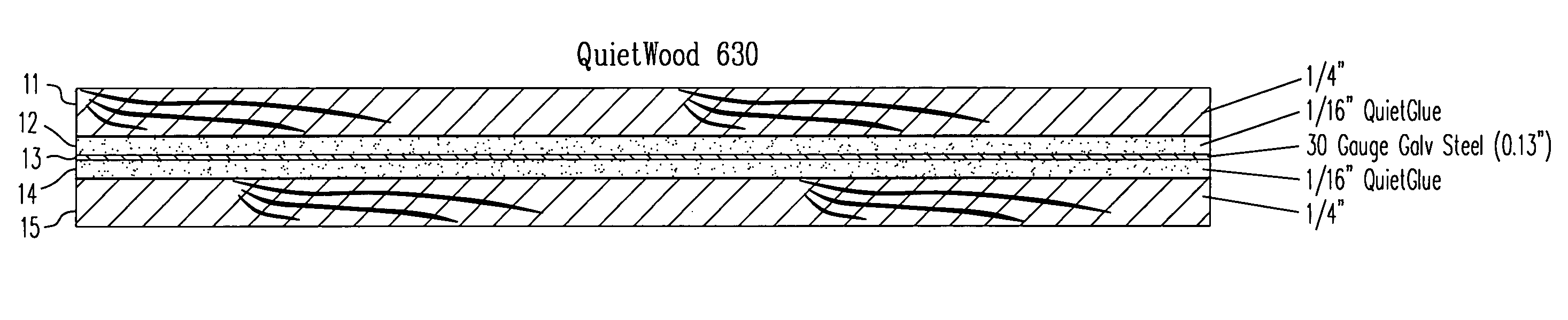

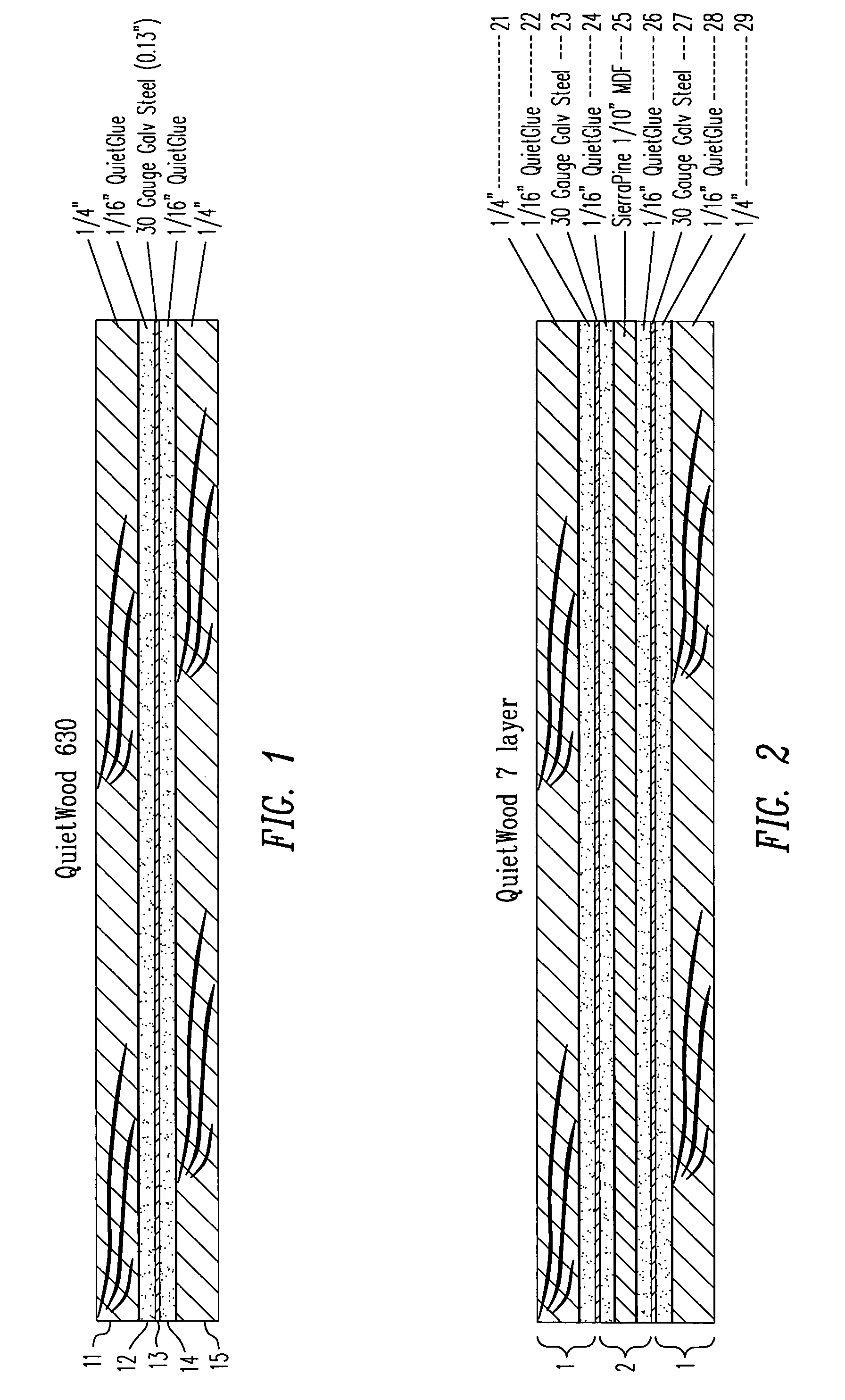

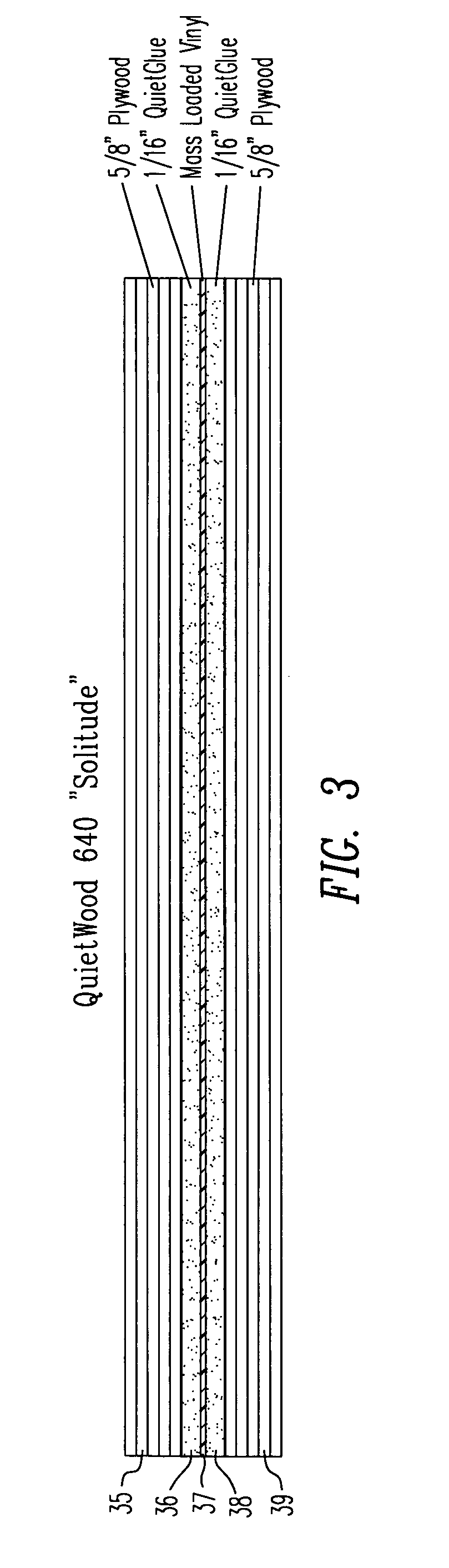

Acoustical sound proofing material and methods for manufacturing same

ActiveUS7181891B2Improve abilitiesReduce sound transmissionBuilding roofsCeilingsUltrasound attenuationCellulose

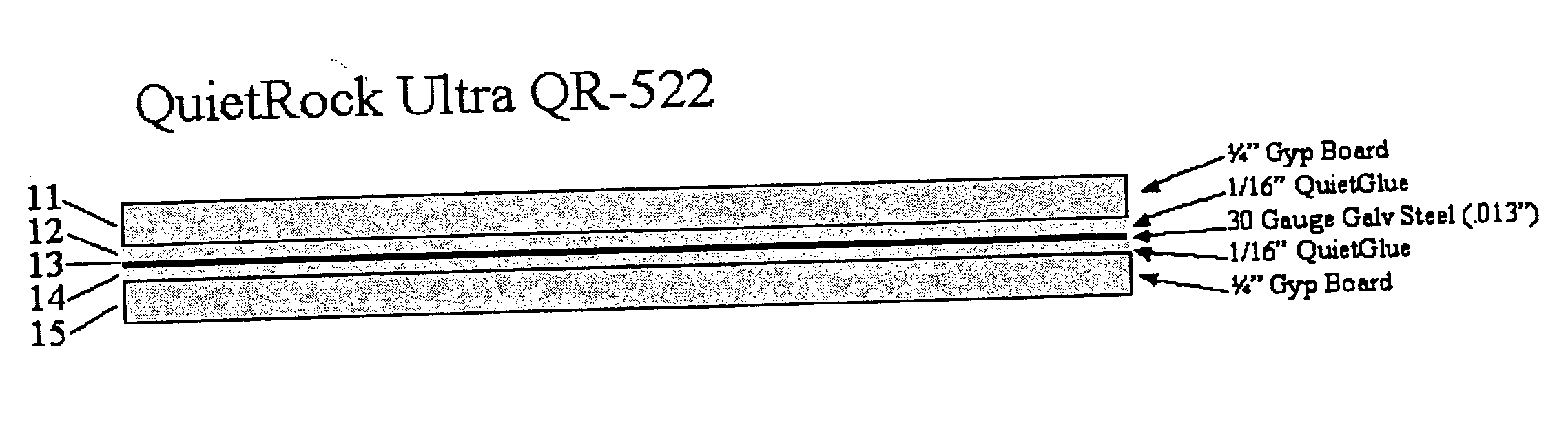

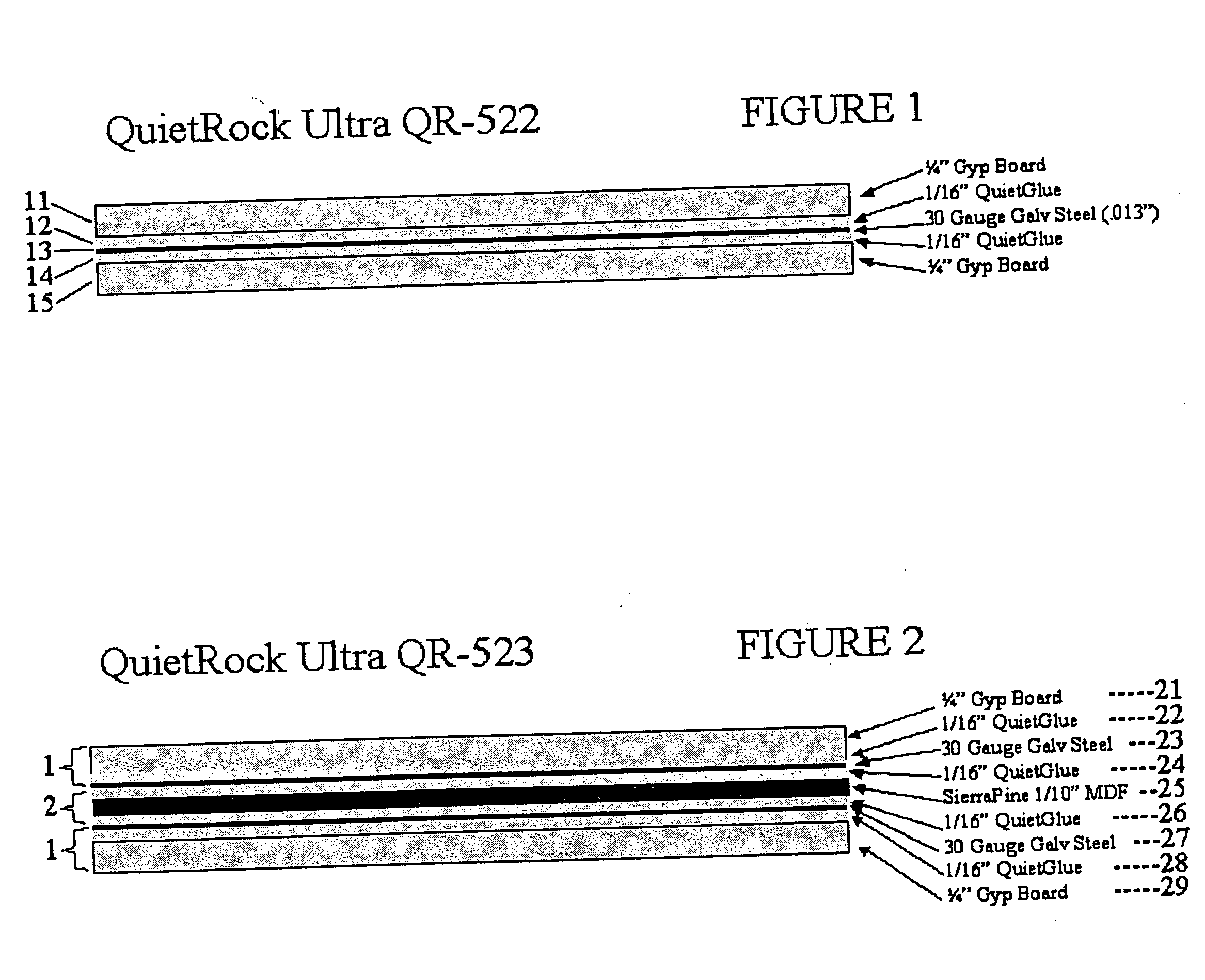

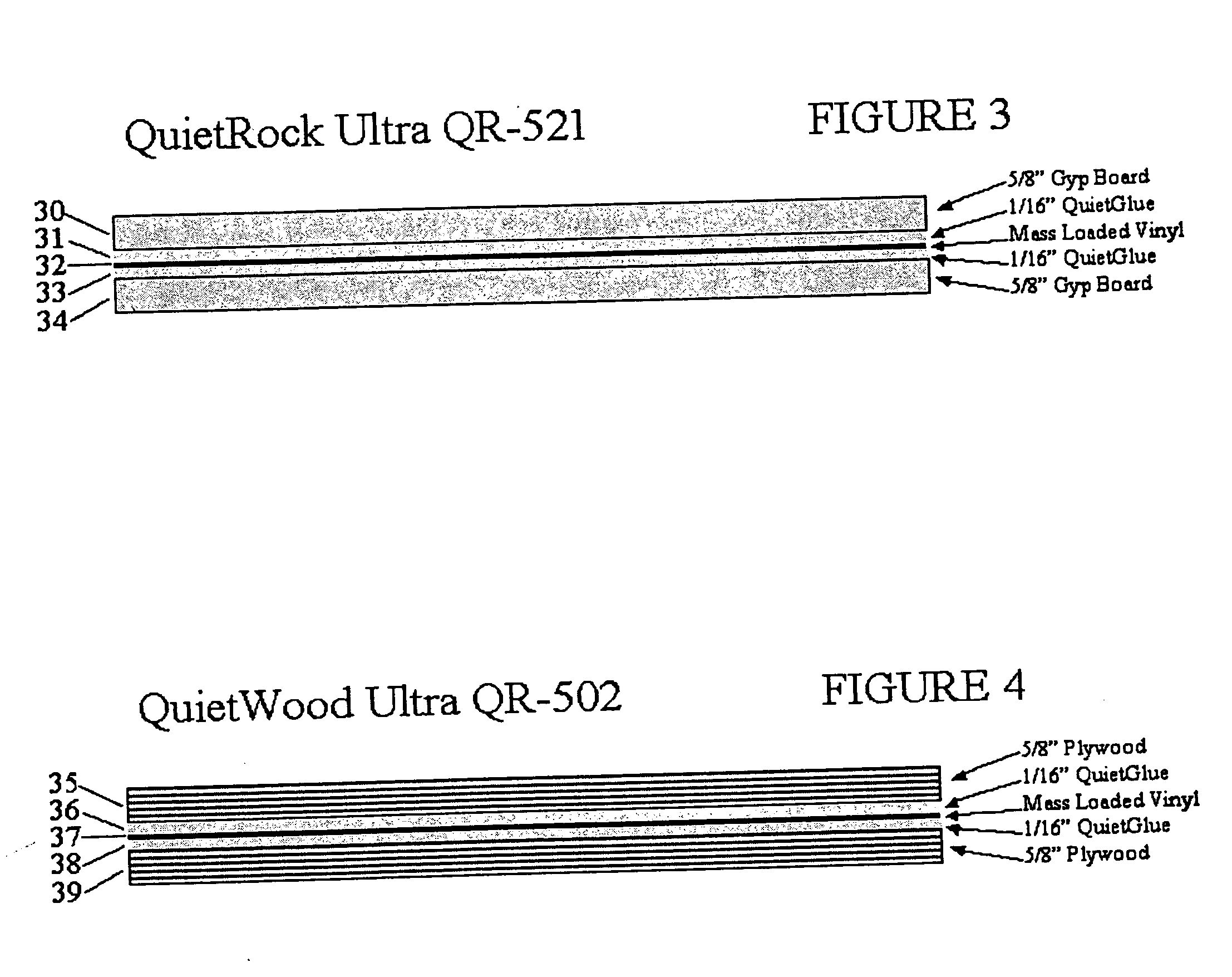

An improved acoustical damping wall (ceiling or floor) or door material comprises a laminar structure having as an integral part thereof one or more layers of viscoelastic material which also functions as a glue and one or more constraining layers, such as metal, cellulose, wood, or petroleum-based products such as plastic, vinyl, plastic or rubber. In one embodiment, standard wallboard, typically gypsum, comprises the external surfaces of the laminar structure; and one or more constraining layers are fabricated between the gypsum exterior. The resulting structure improves the attenuation of sound transmitted through the structure.

Owner:PACIFIC COAST BUILDING PRODS

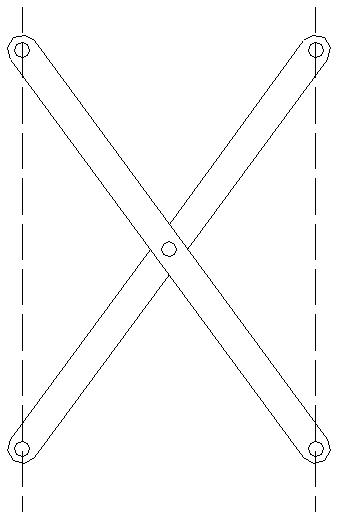

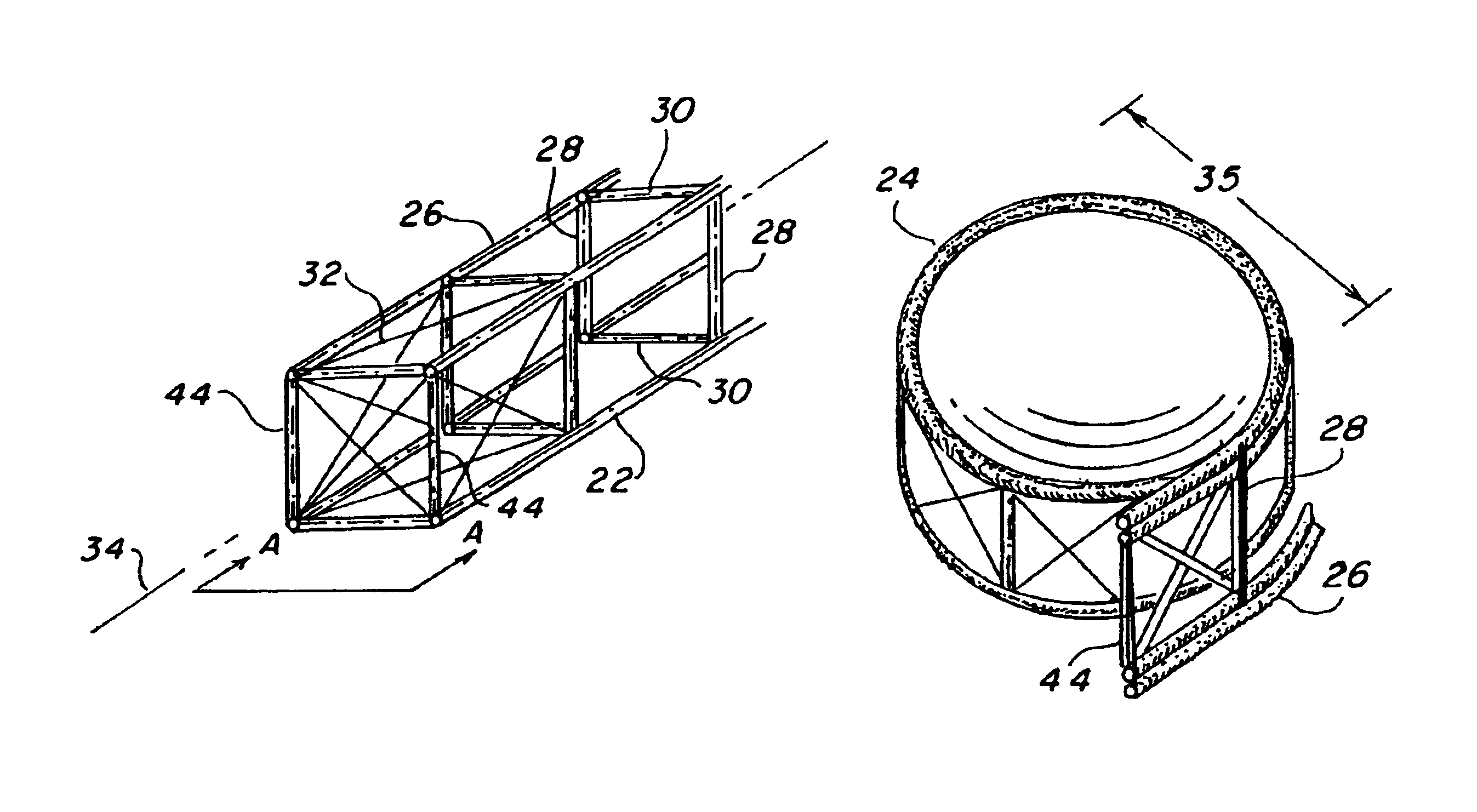

Foldable member

InactiveUS6374565B1Weight increaseDimensional instabilityBuilding roofsCosmonautic vehiclesMechanical engineeringEngineering

Owner:FOSTER-MILLER

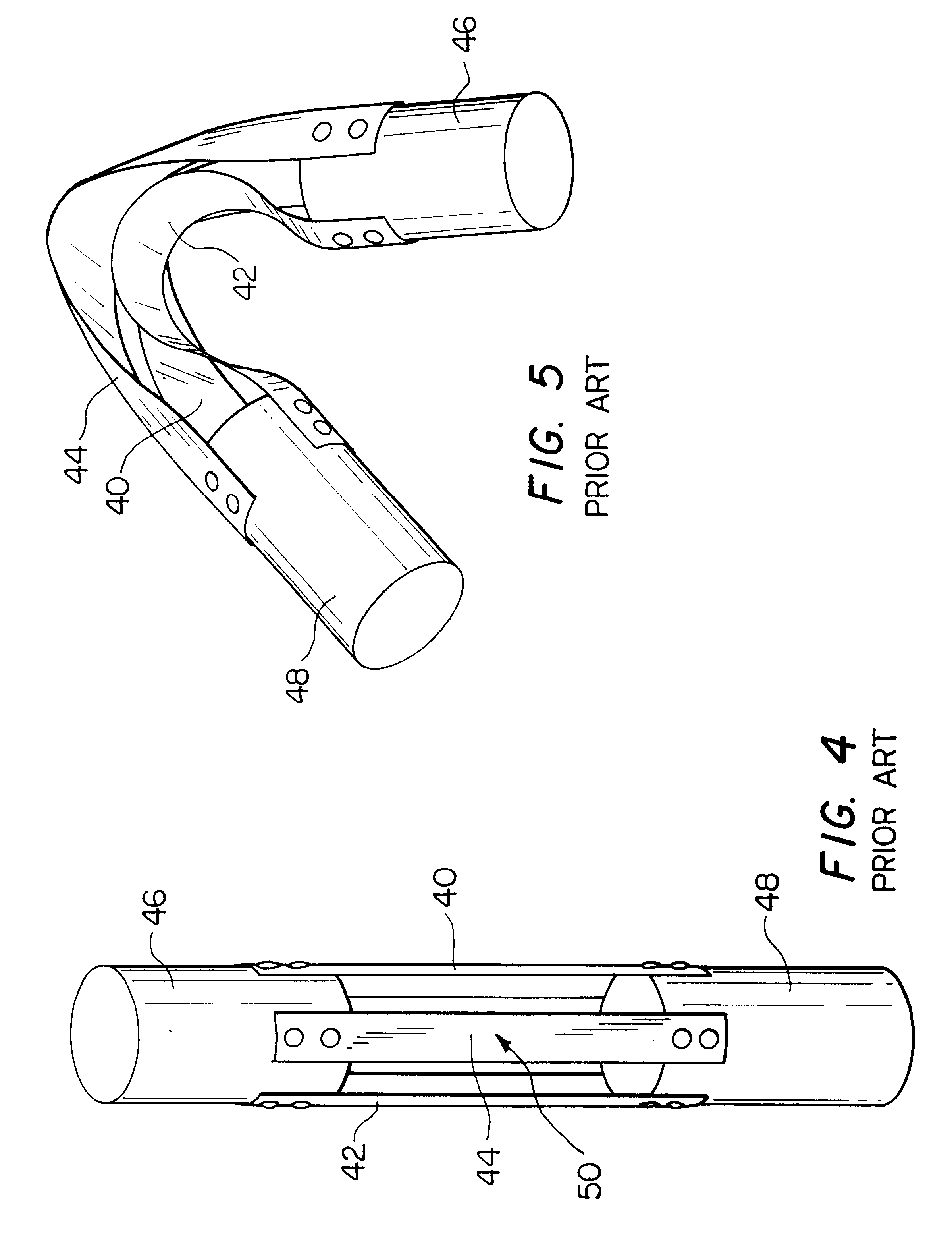

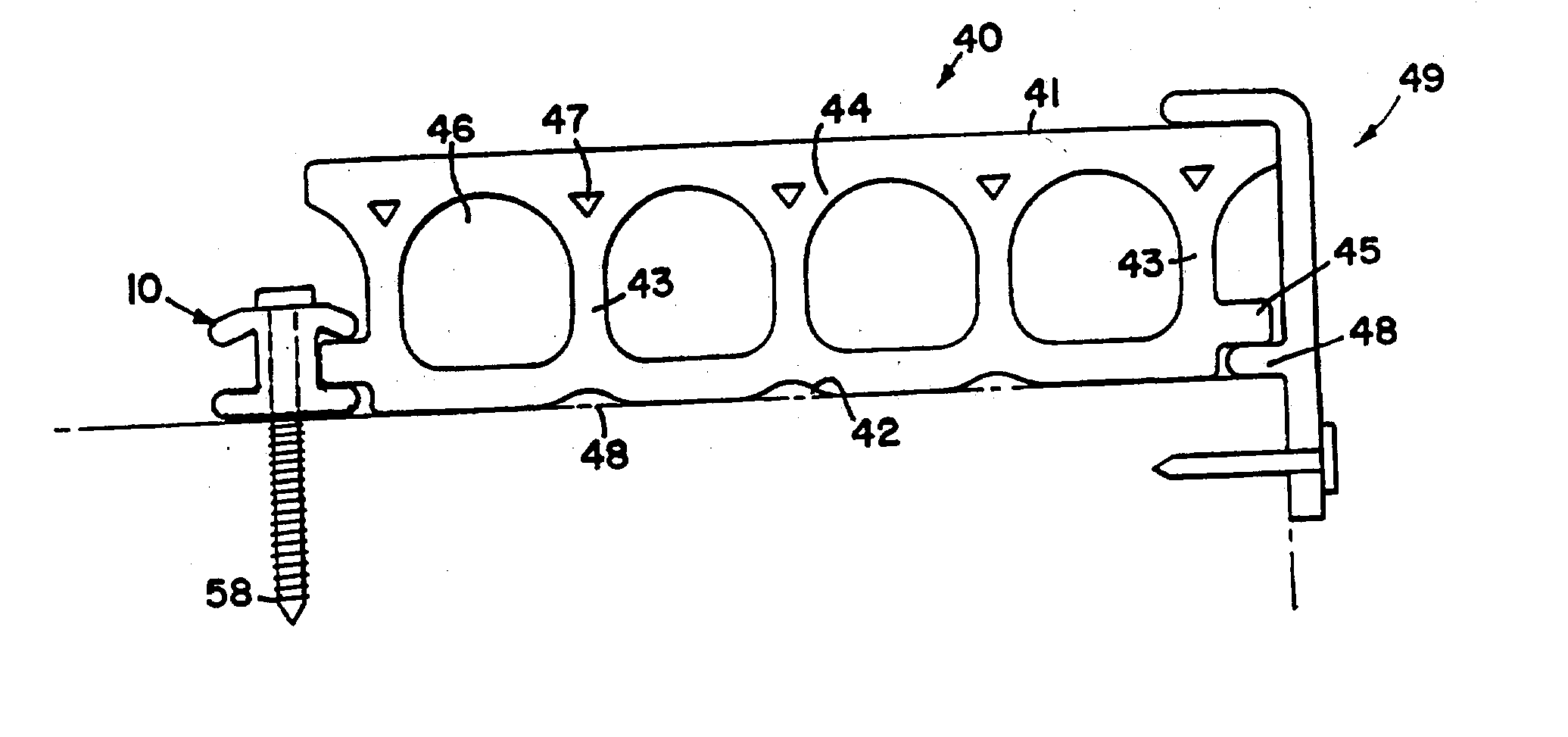

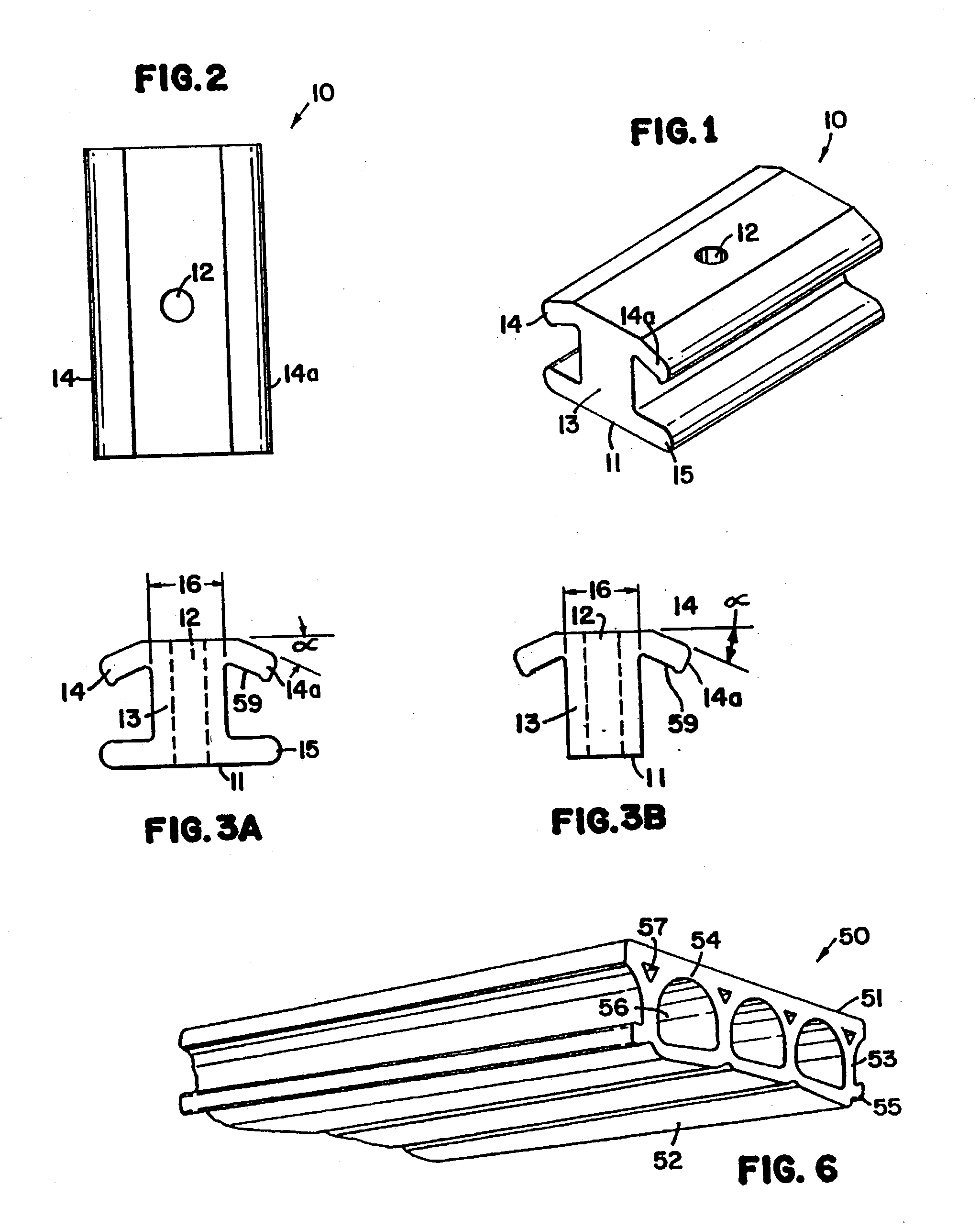

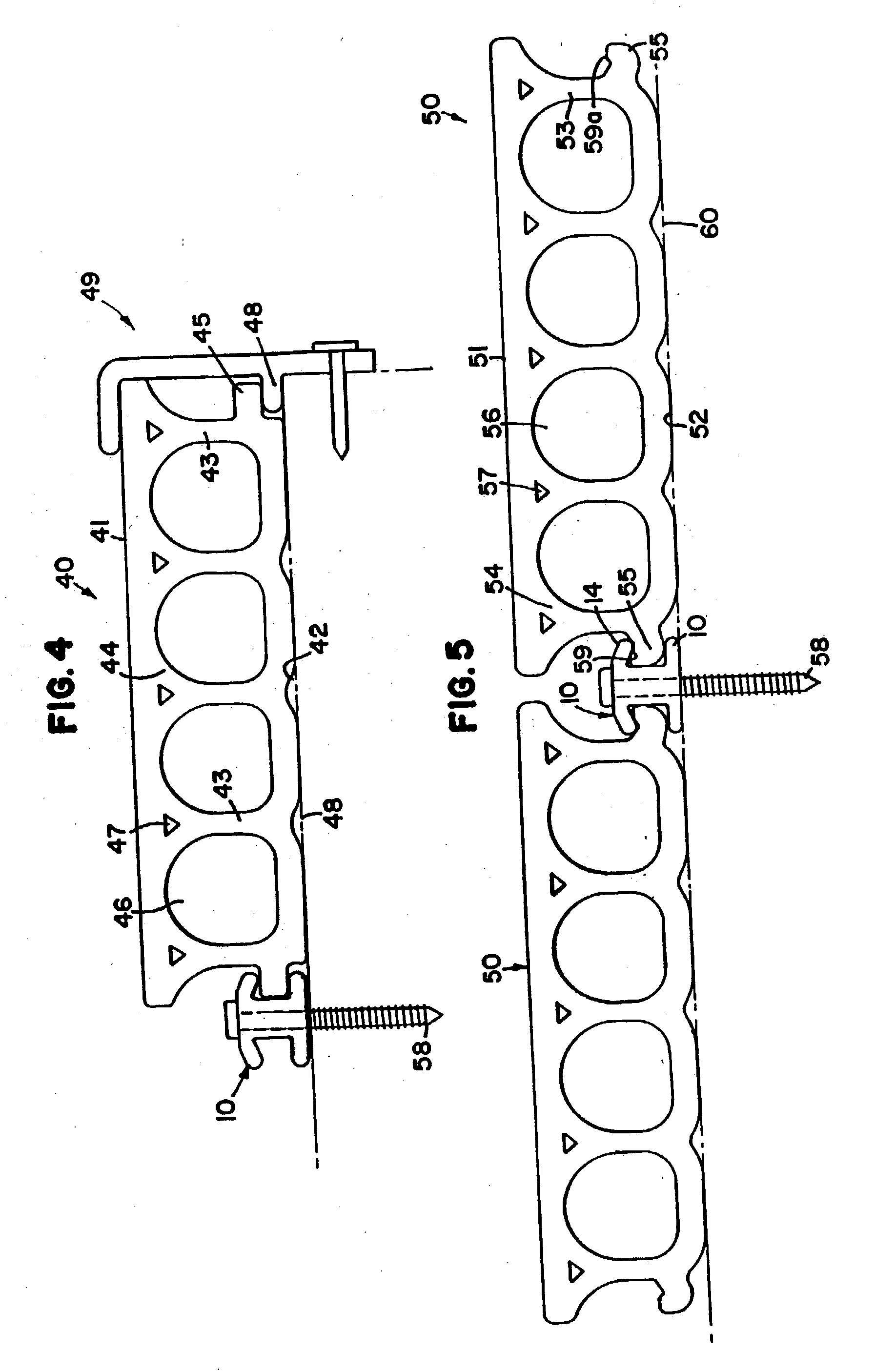

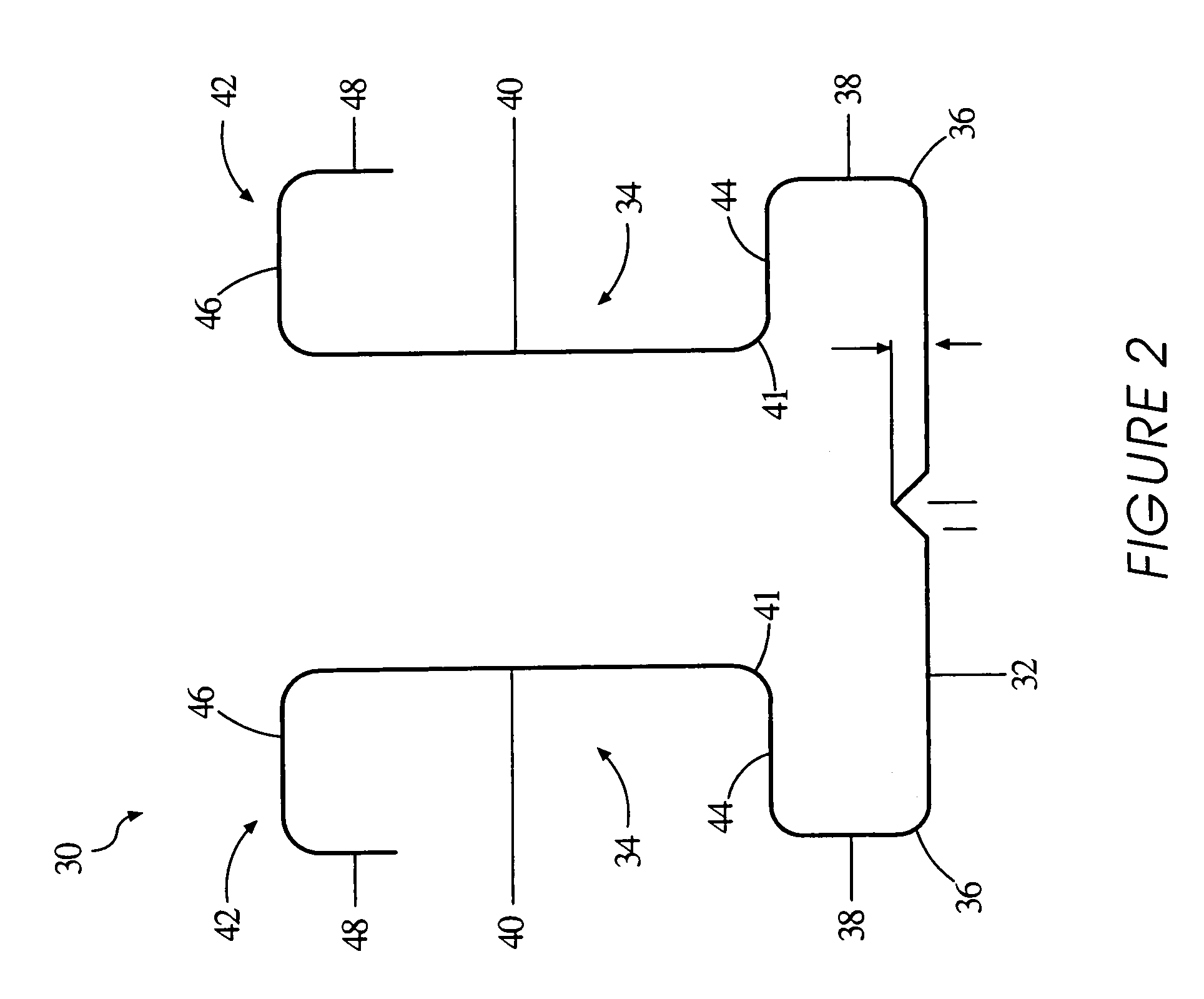

Hollow profile decking system comprising plank and anchor using anchor flange construction

InactiveUS20030154662A1Stable supportImprove stabilityCovering/liningsArched structuresArchitectural engineeringBatten

A decking system, decking components and an installed deck for use on a support structure. The decking system comprises hollow profile planking units having anchor flanges on opposite edges that cooperate with an anchor structure to form a deck or platform. The flanges and the anchor units are shaped and configured to closely interact and form an installed platform structure. The planks comprise an extruded thermoplastic wood fiber composite having an internal structure sufficient to withstand installation, engineering forces placed on the installed platform, weathering and use. The anchor structures have a shape that conforms to the anchor flanges on the decking profiles to hold the deck in place.

Owner:ANDERSEN CORPORATION

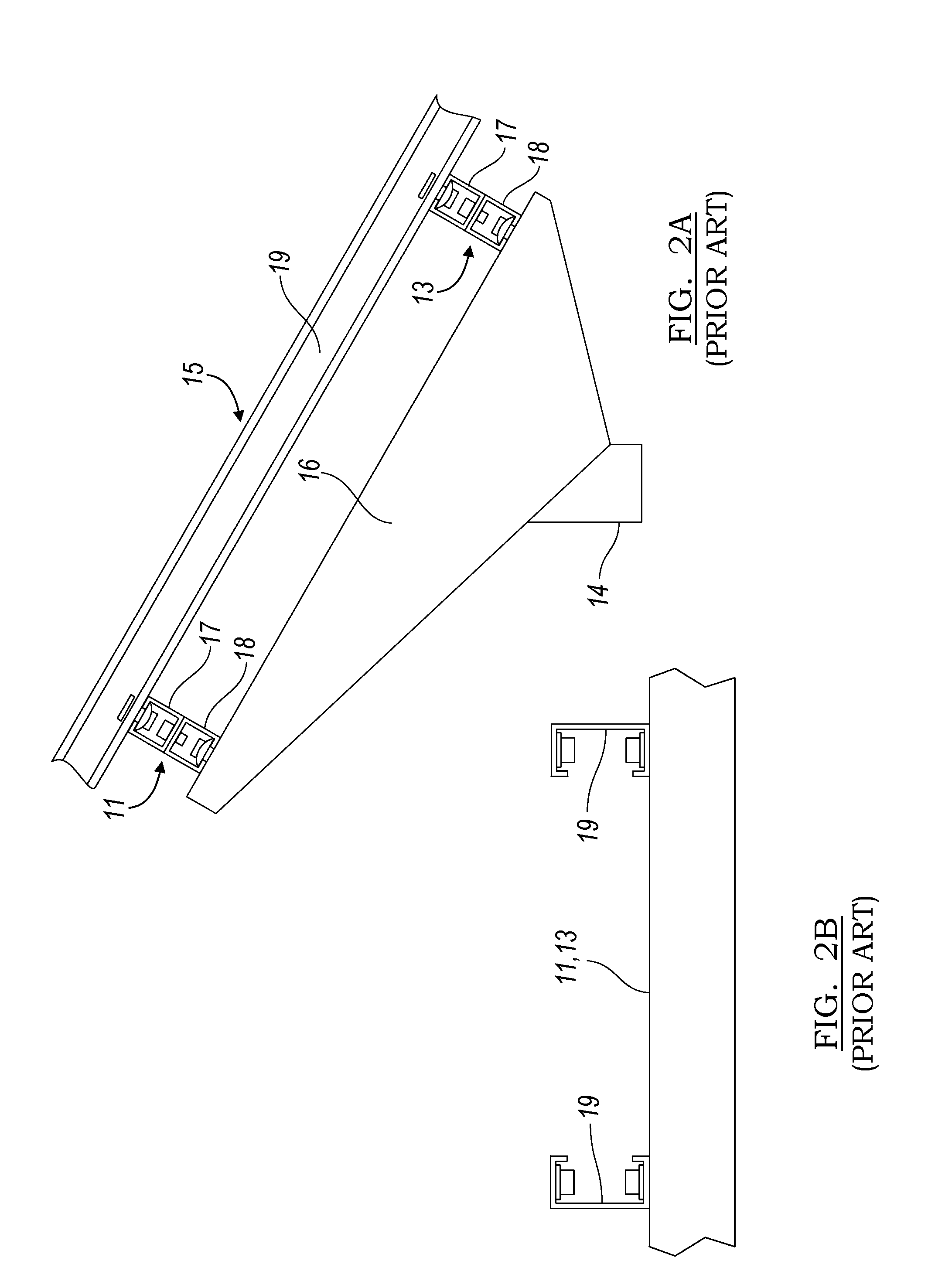

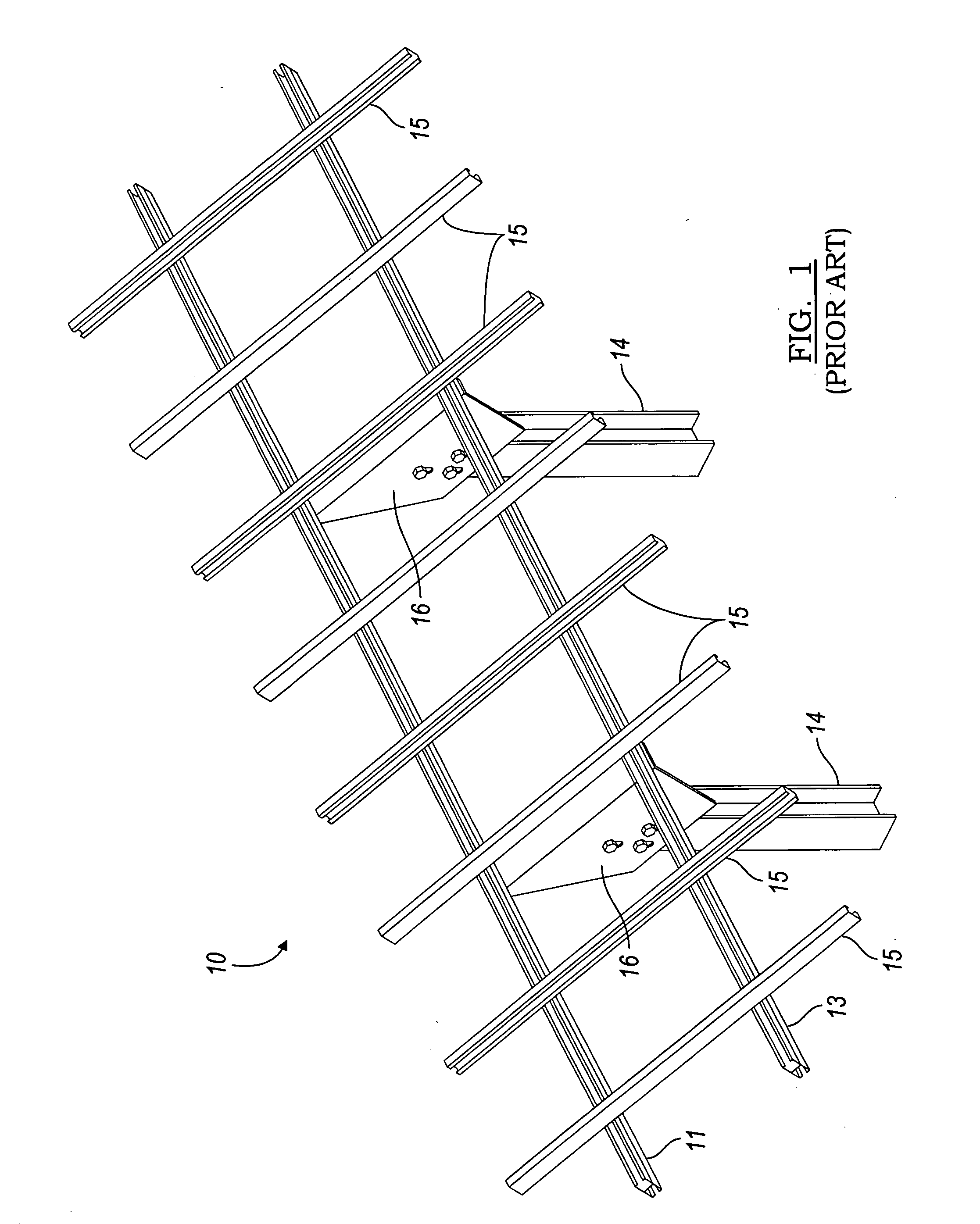

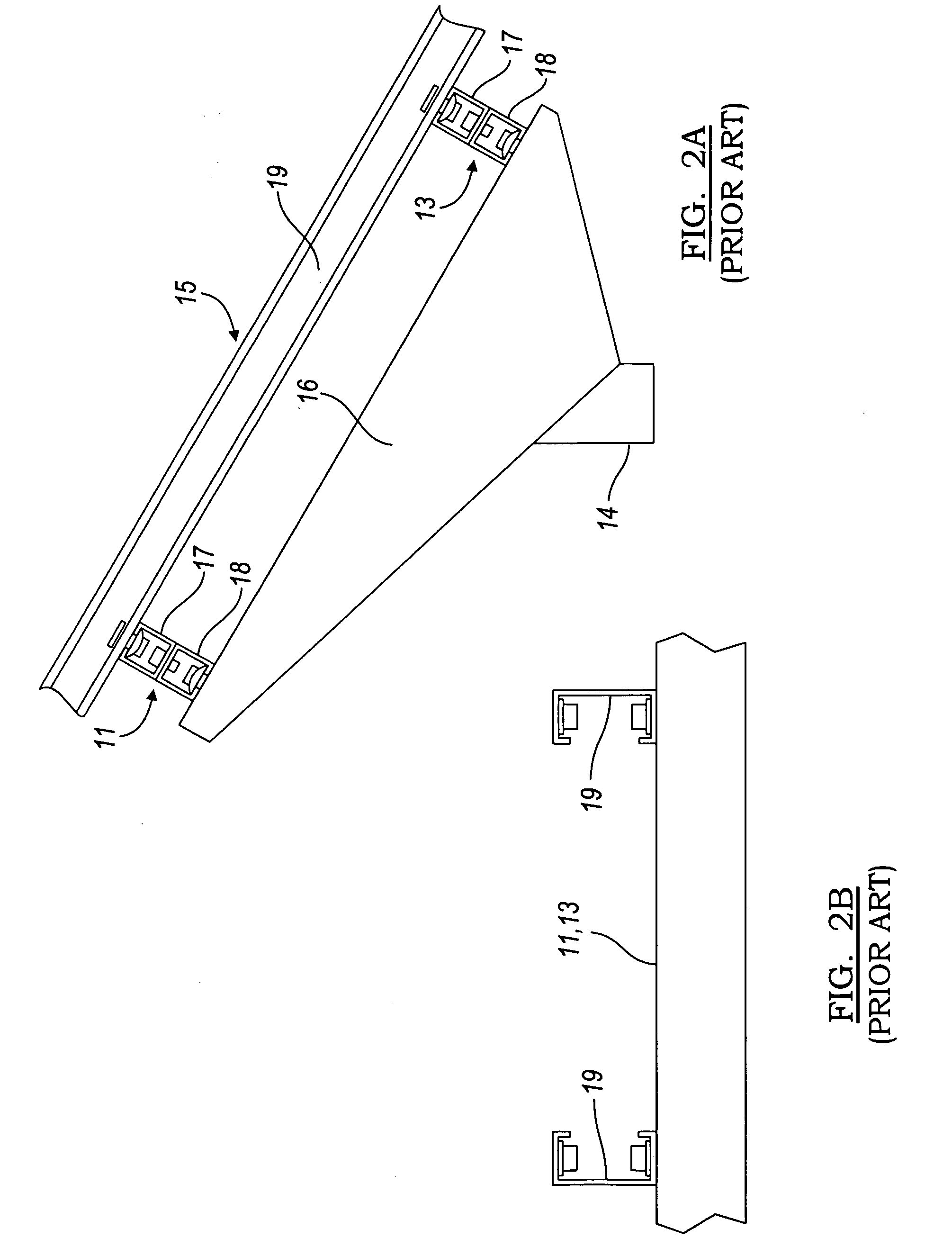

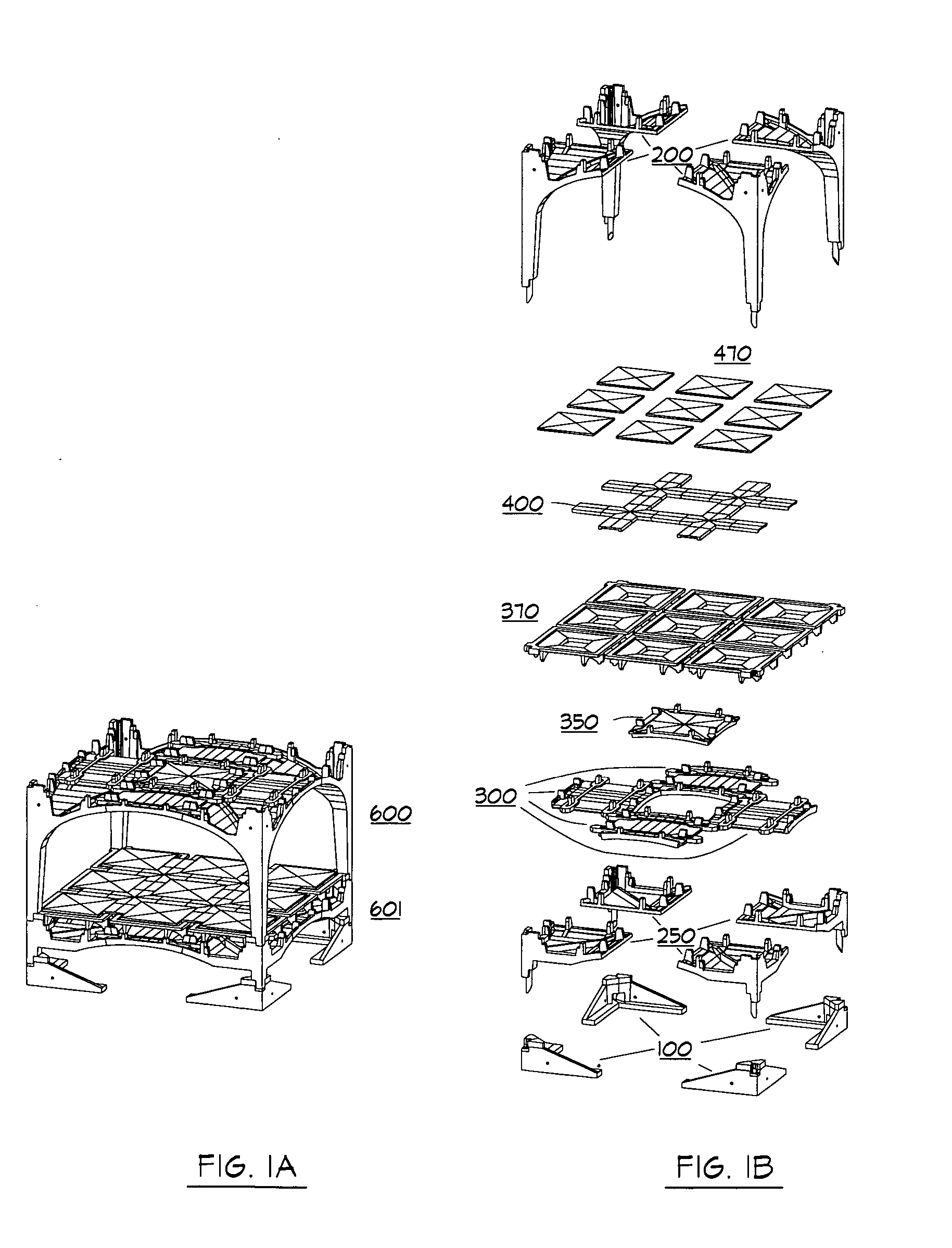

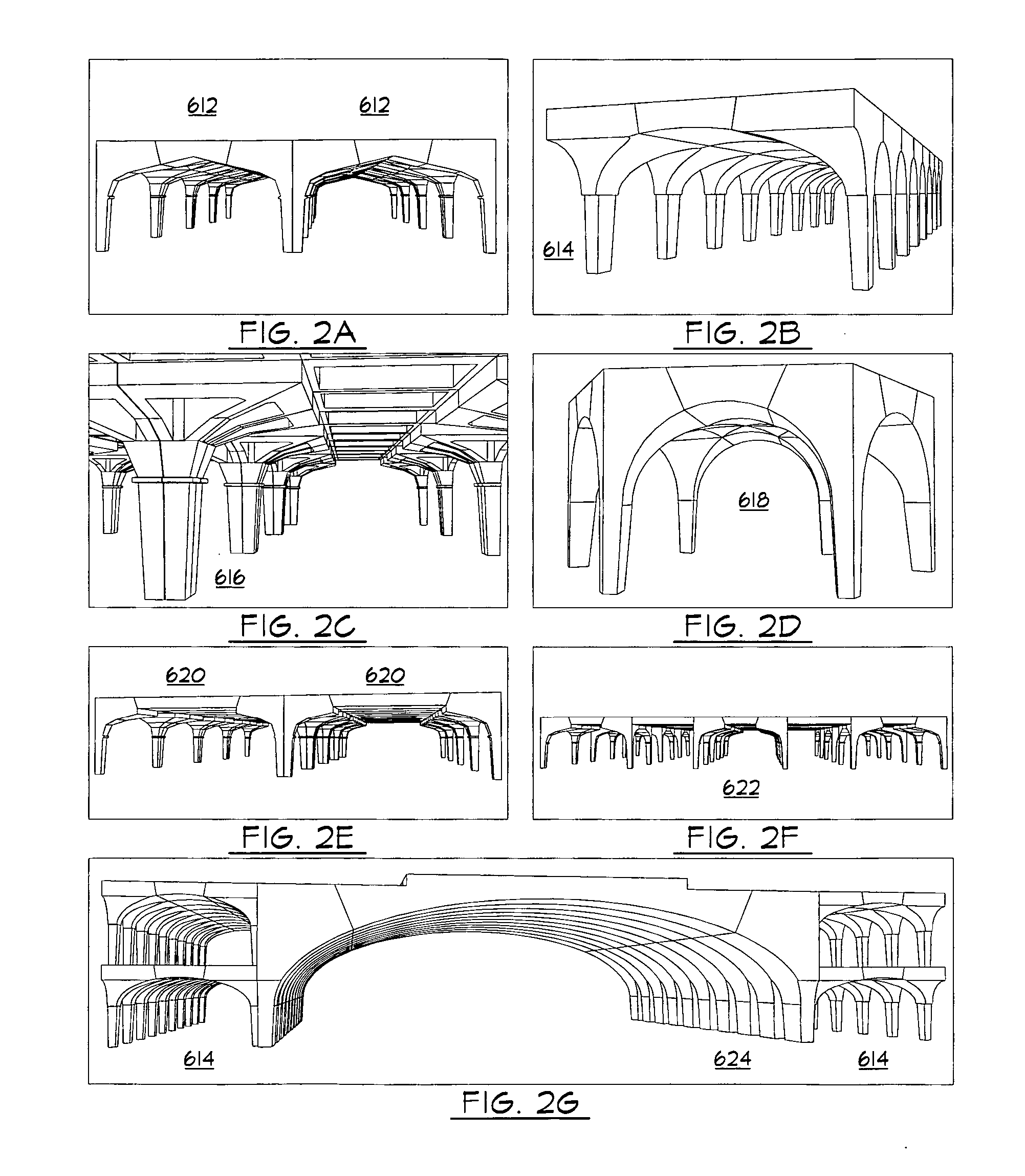

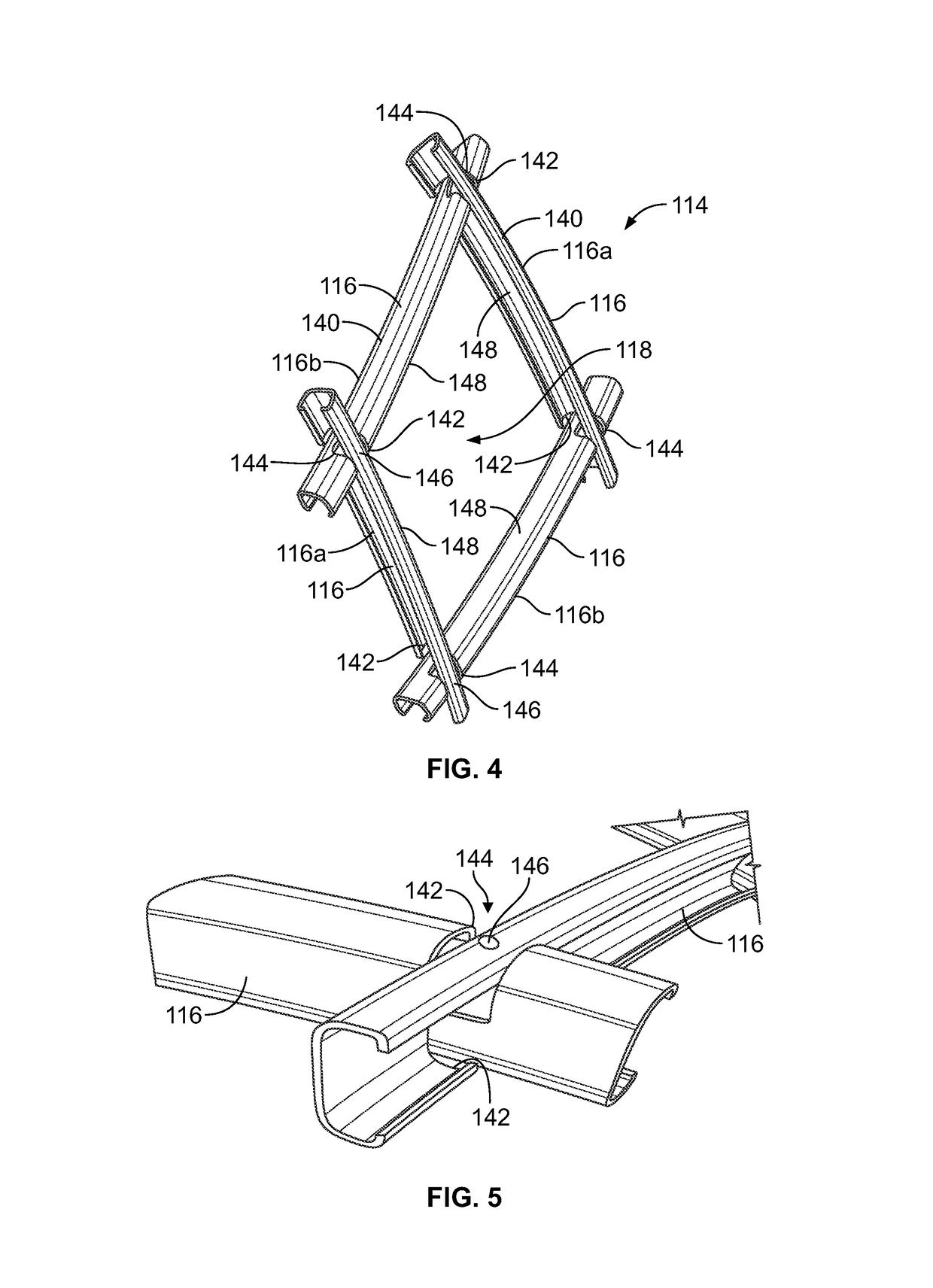

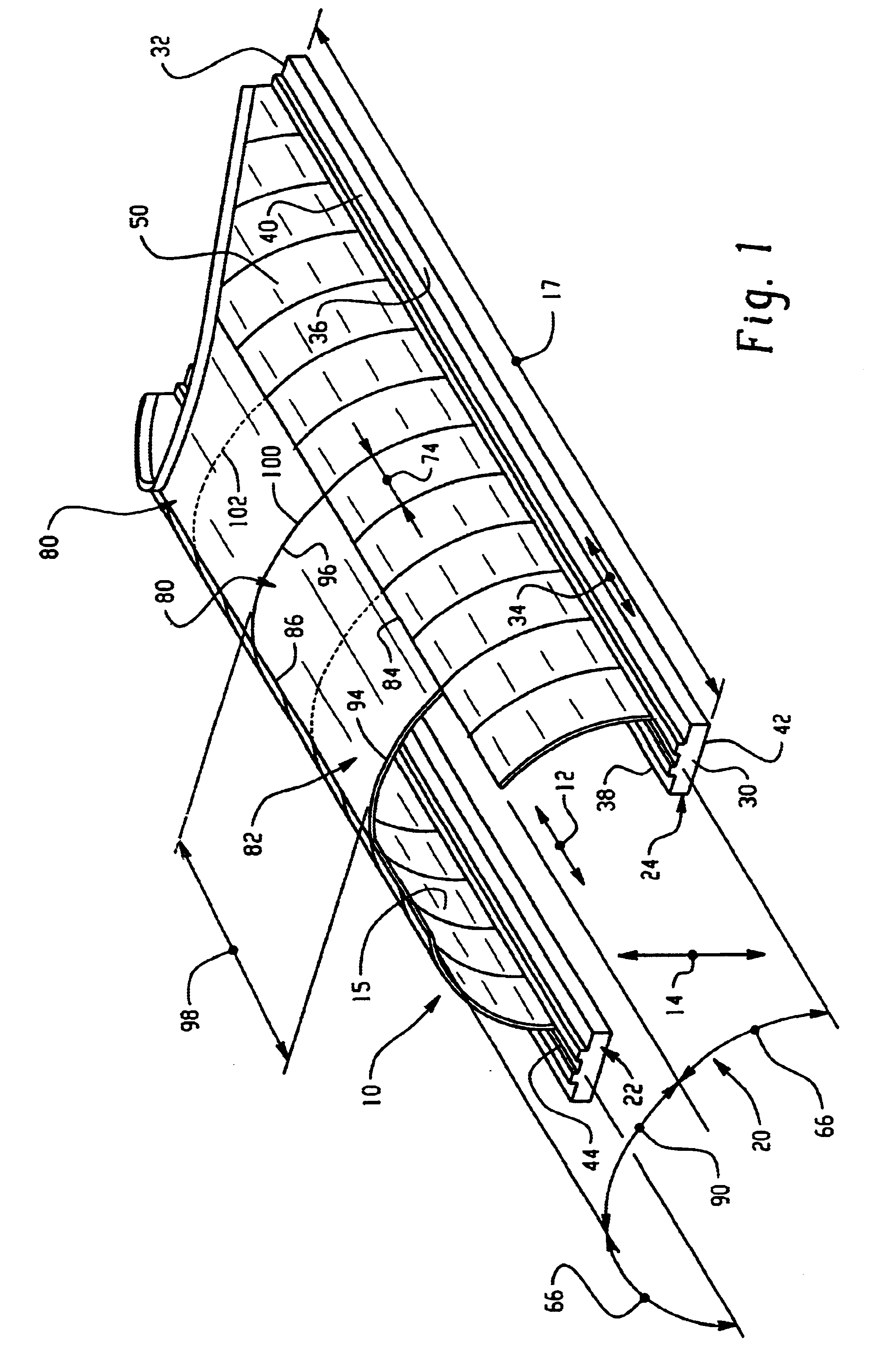

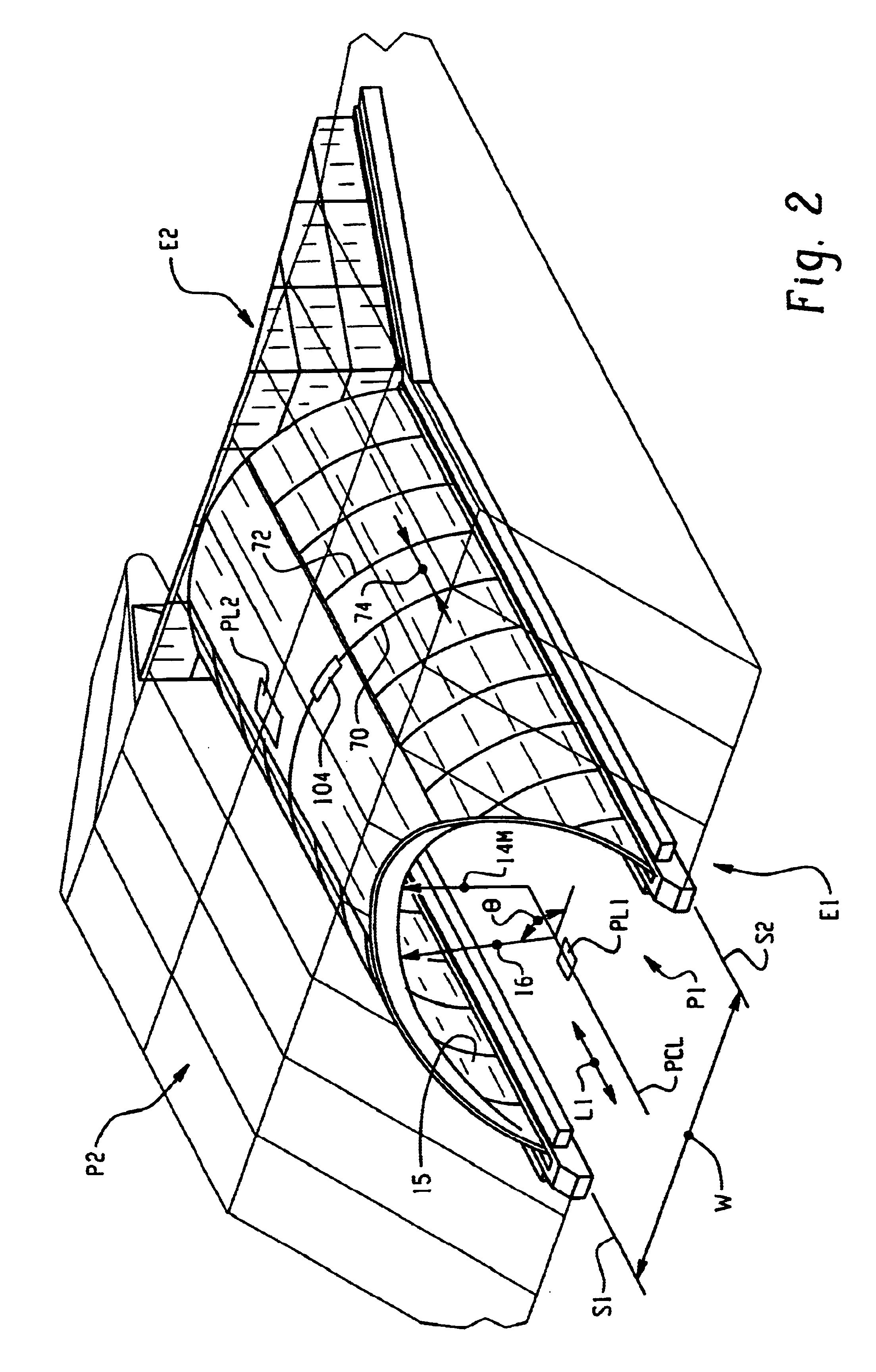

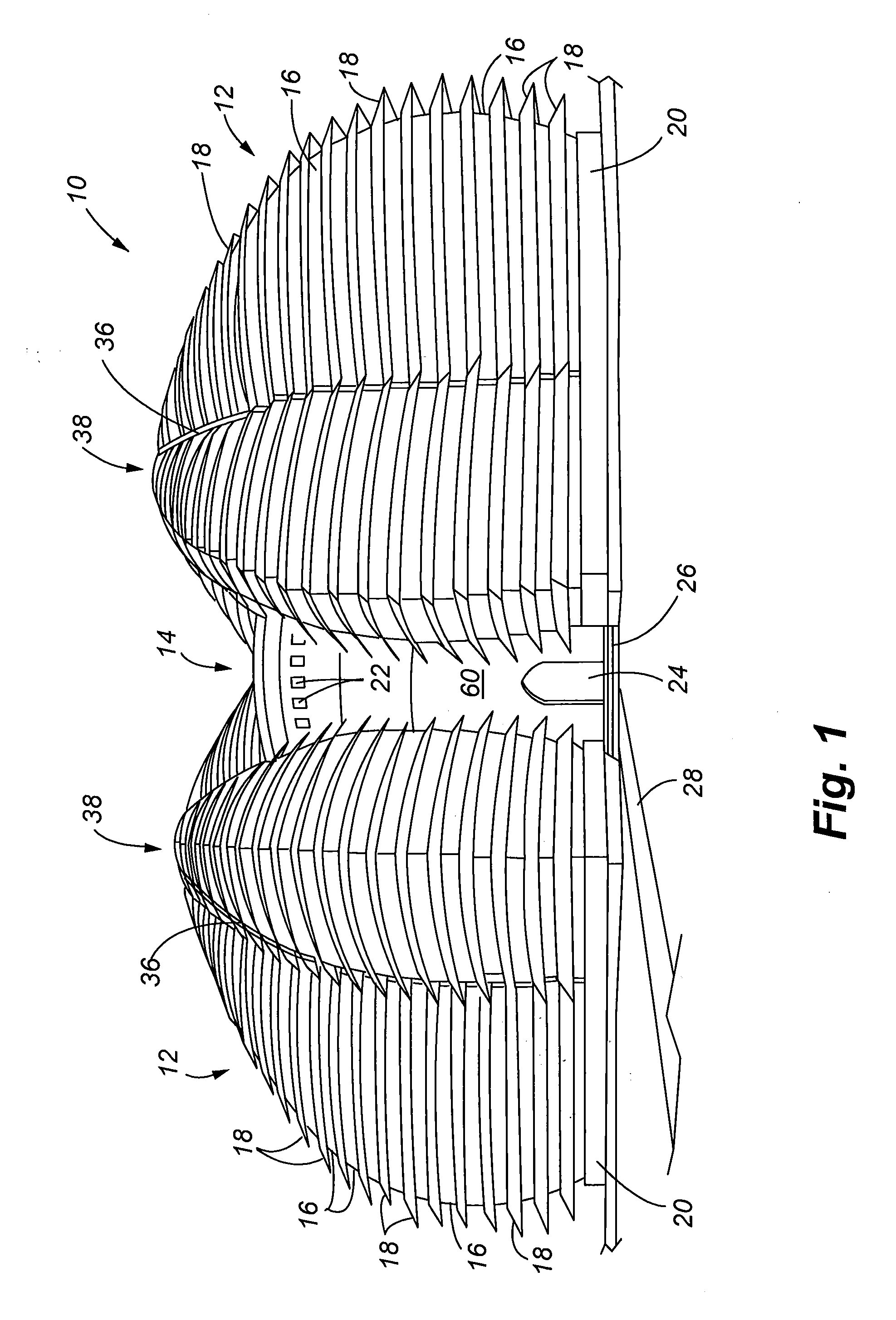

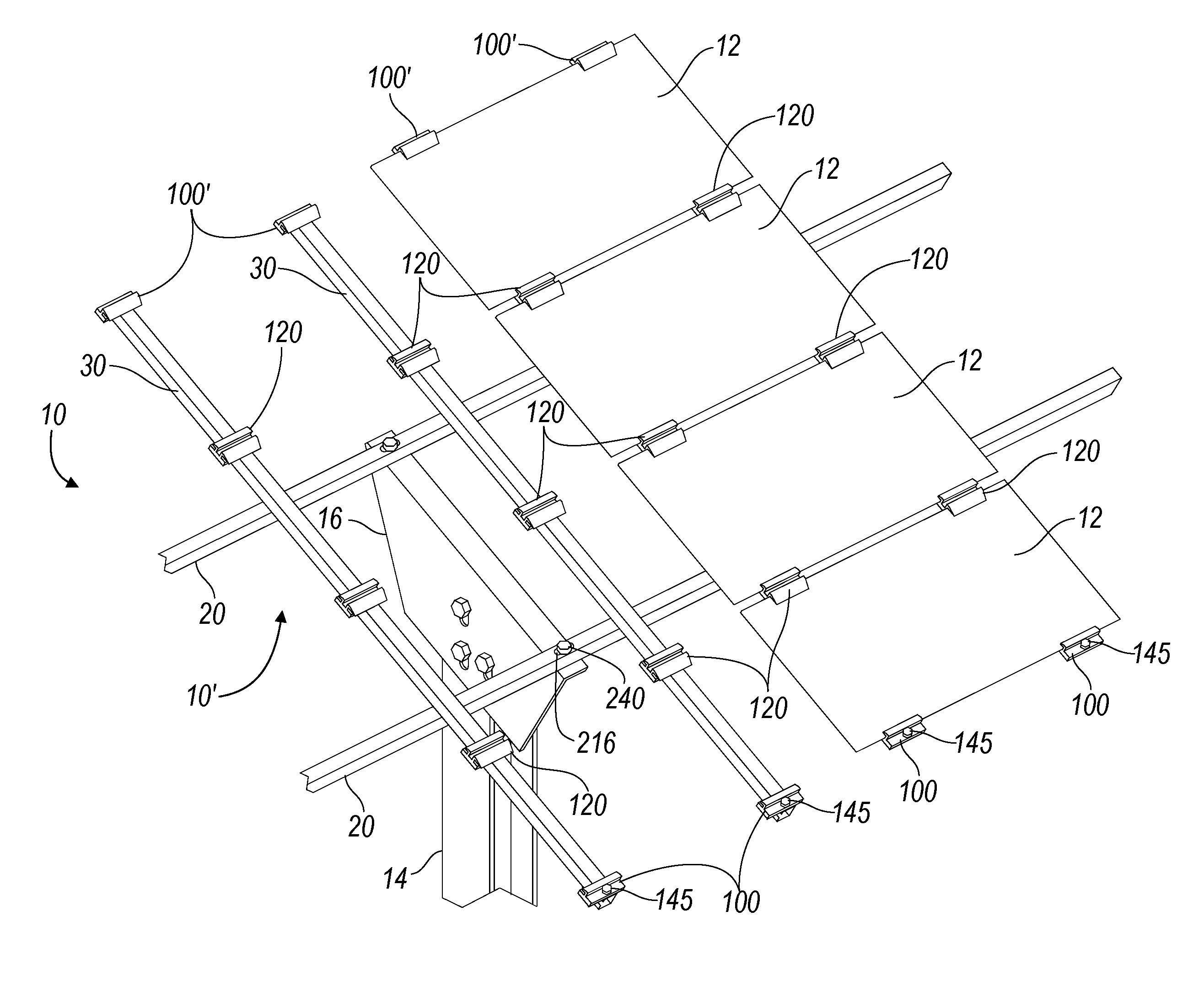

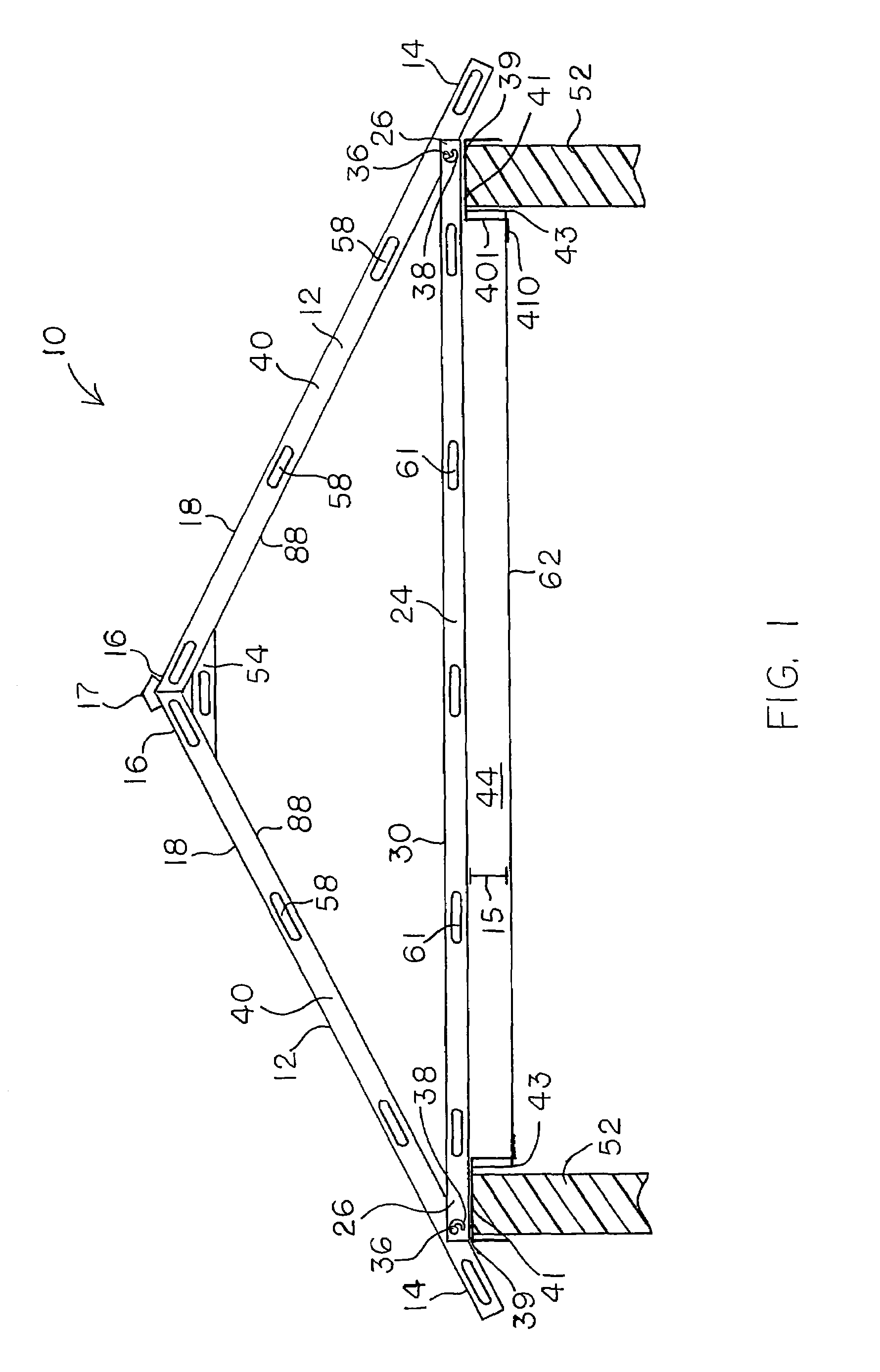

Support system for solar panels

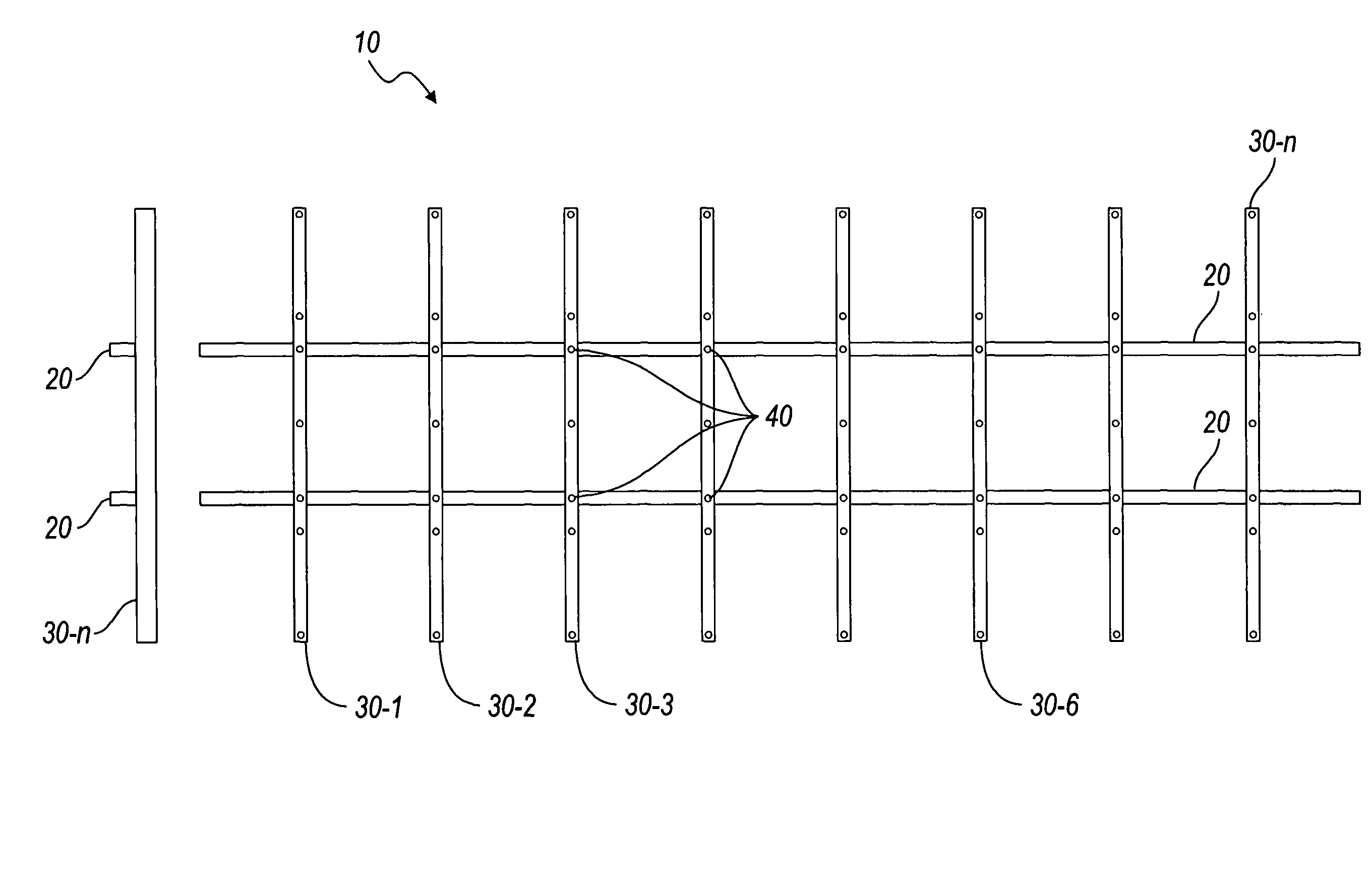

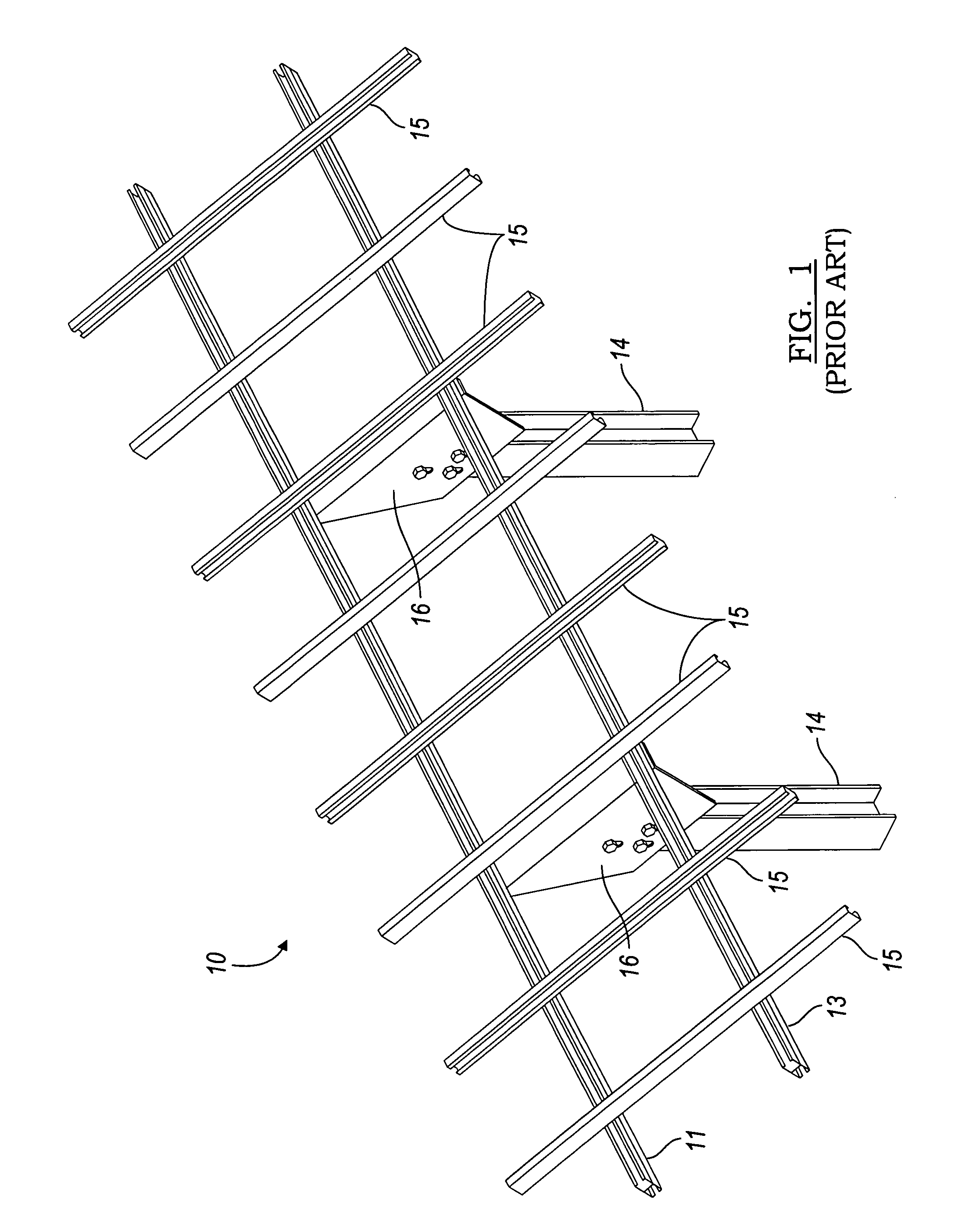

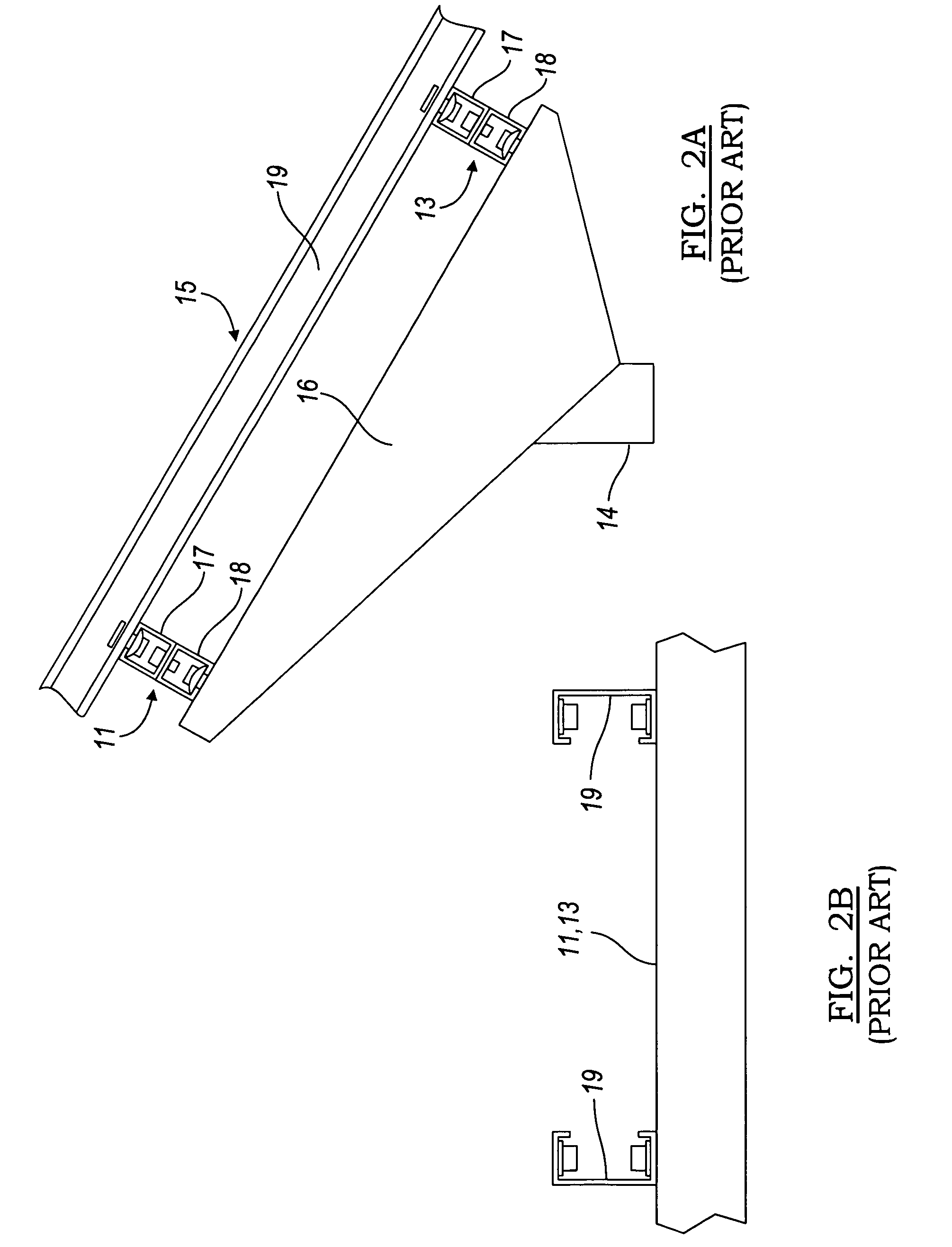

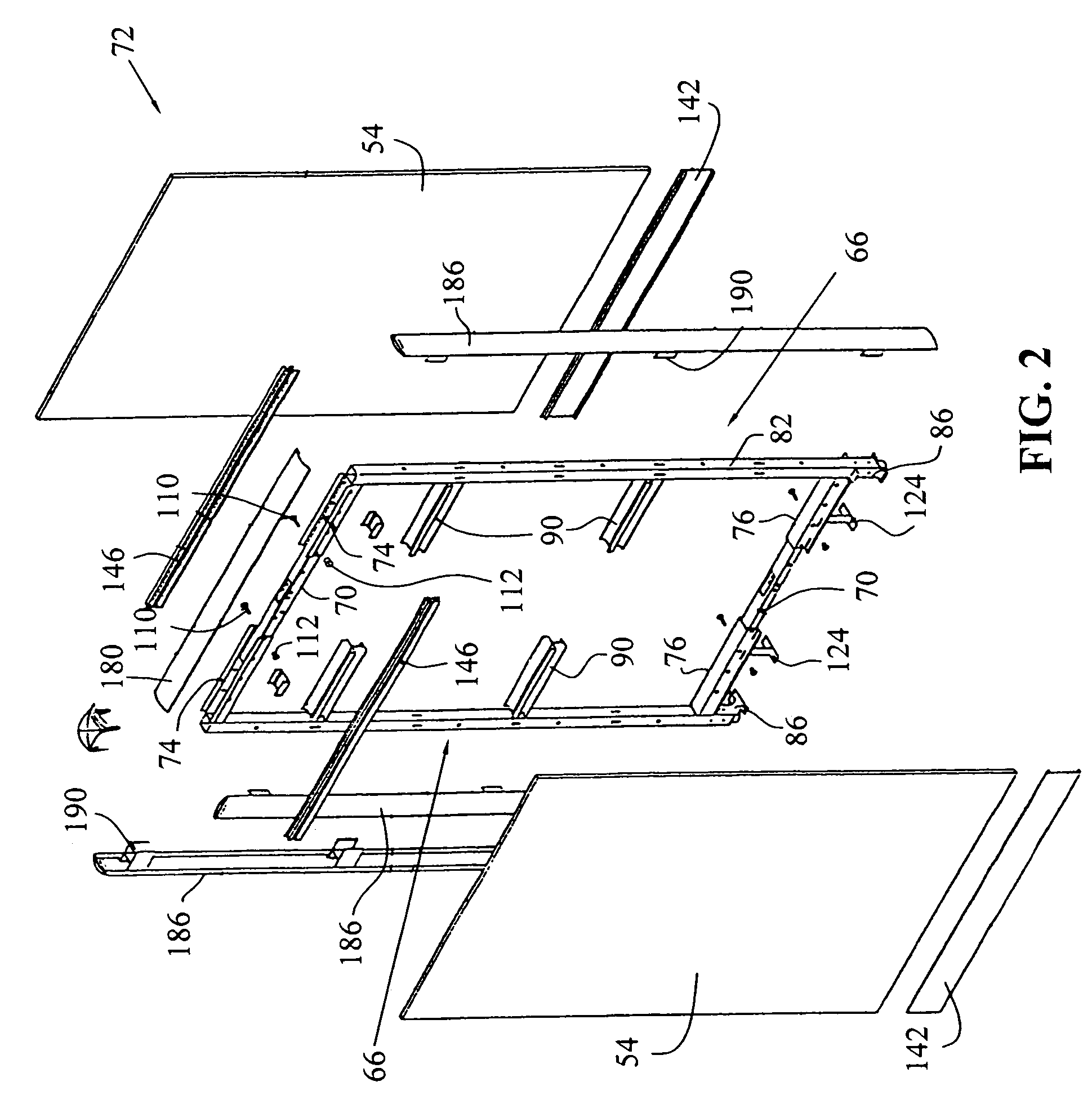

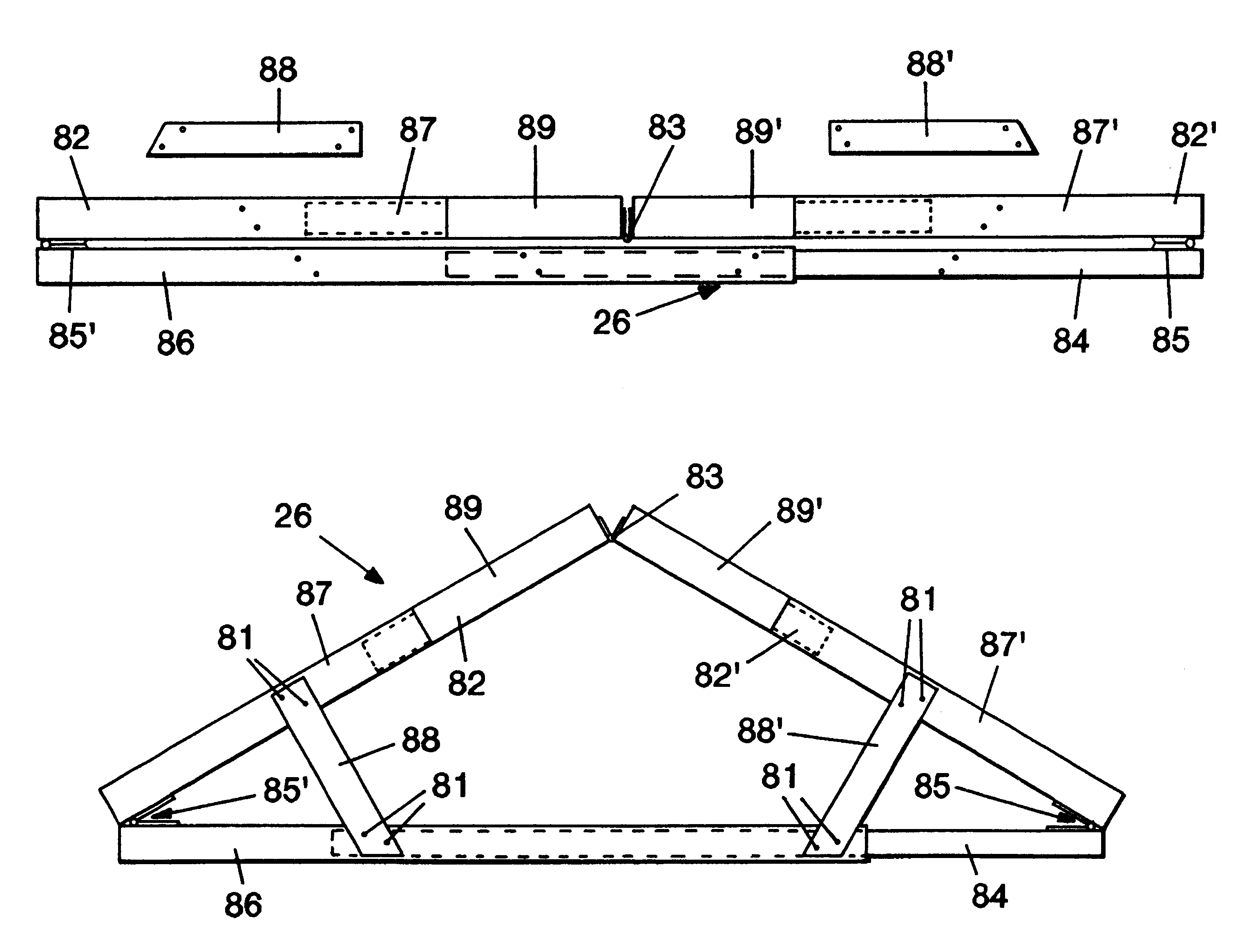

ActiveUS8316590B2Easy to foldReduce spacingPhotovoltaic supportsSolar heating energyRow and column spacesSupporting system

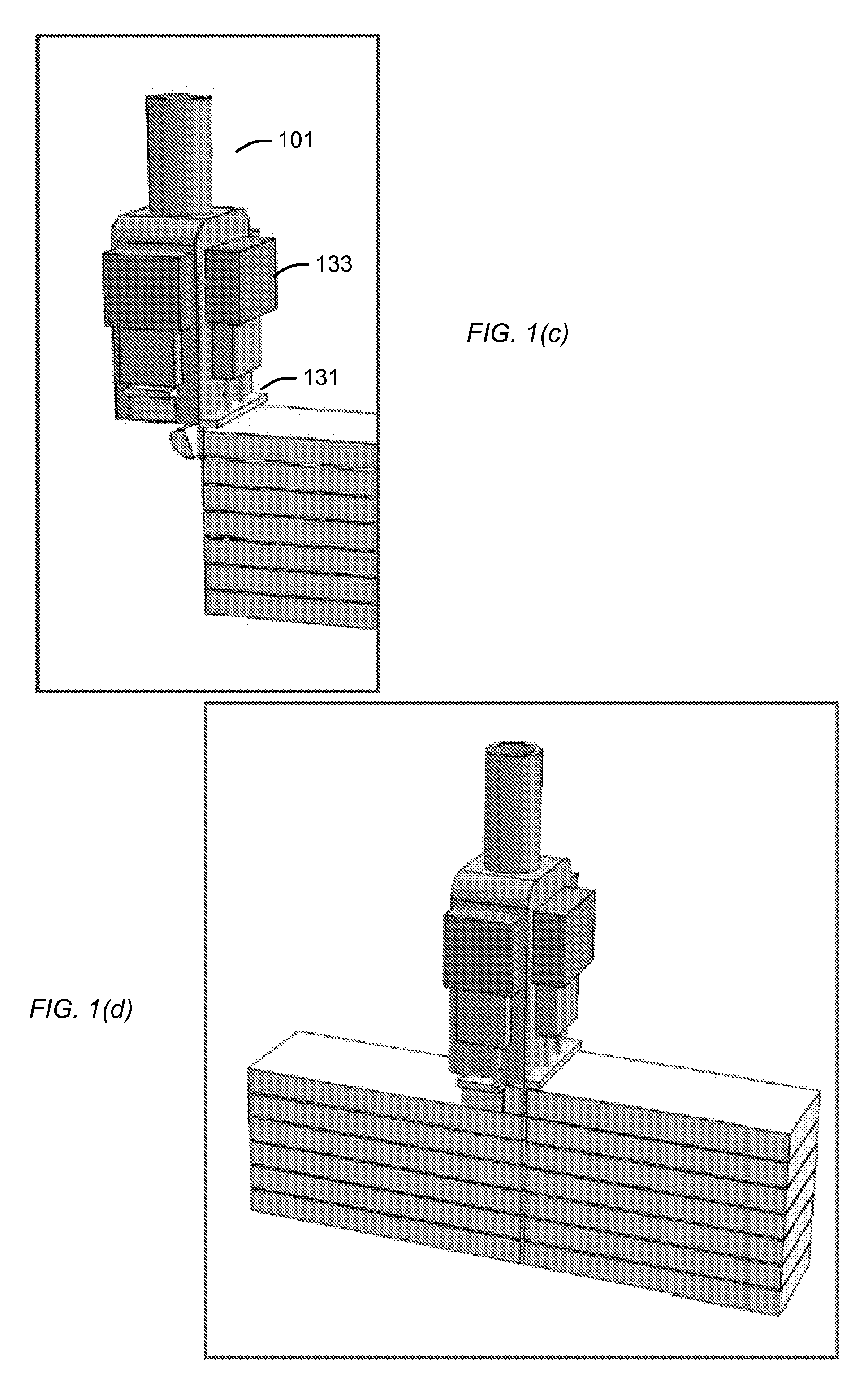

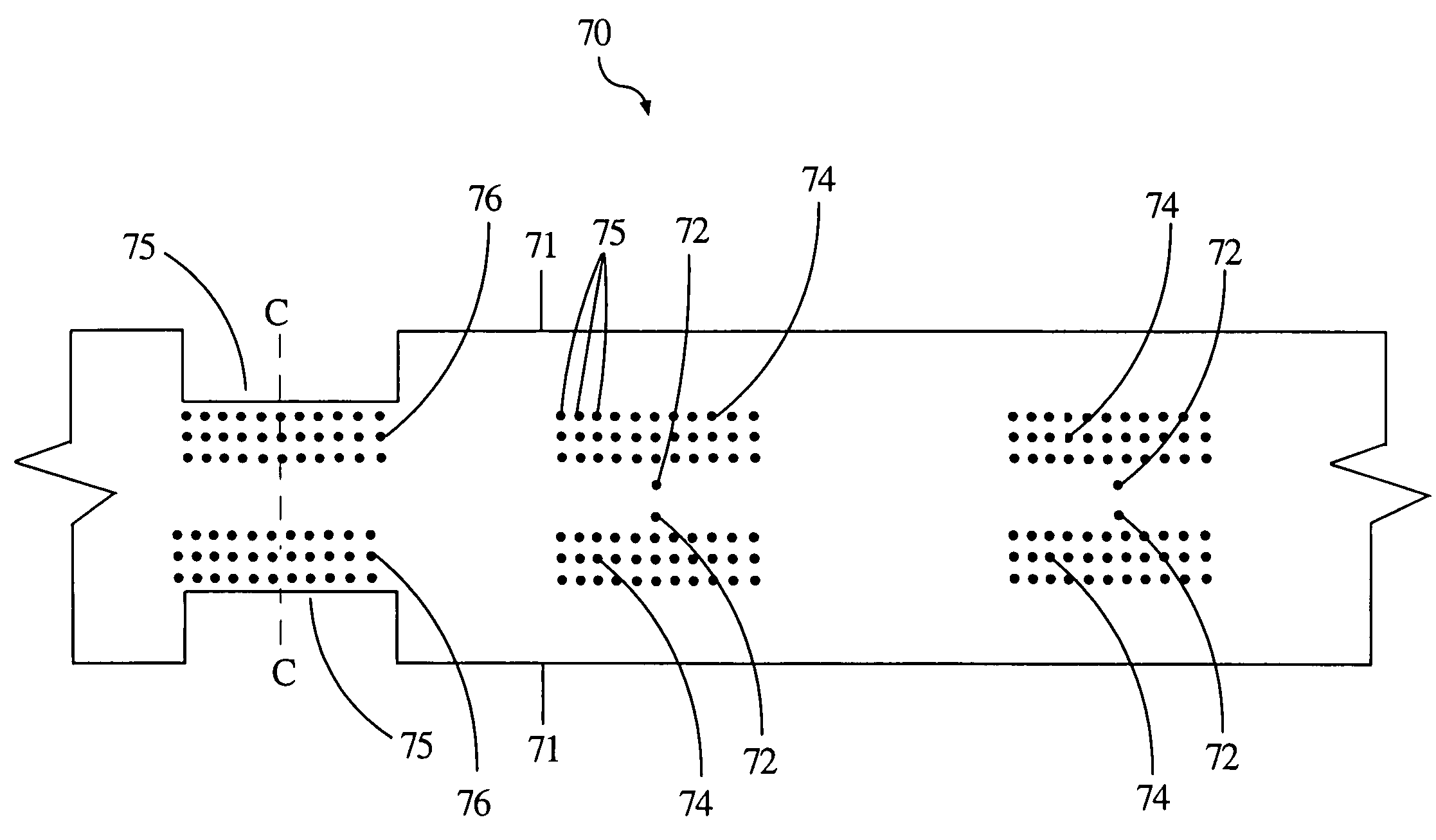

An array of photovoltaic panels is supported in rows and columns spaced from one another using a foldable bi-directional span of support members. The support members include a plurality of support joists and support rails braced at an incline. Each support rail is tubular and generally rectangular, having a lower wall section with a T-slot channel for acceptance of the head of a bolt for adjustable attachment with the support joist. Also, the support rail may have a C-slot channel for retaining electrical wires. Clips are used to secure each panel to upper wall portions of underlying support rails. Each clip has a generally U-shaped gasket and is retained to a corresponding support rail through a threaded hole in a top wall of the support rail that receives a bolt or similar threaded fastener.

Owner:NORTHERN STATES METALS

Support system for solar panels

ActiveUS20100237028A1Easy to foldReduce spacingPhotovoltaic supportsSolar heating energySupporting systemRow and column spaces

An array of photovoltaic panels is supported in rows and columns spaced from one another using a foldable bi-directional span of support members. The support members include a plurality of support joists and support rails braced at an incline. Each support rail is tubular and generally rectangular, having a lower wall section with a T-slot channel for acceptance of the head of a bolt for adjustable attachment with the support joist. Also, the support rail may have a C-slot channel for retaining electrical wires. Clips are used to secure each panel to upper wall portions of underlying support rails. Each clip has a generally U-shaped gasket and is retained to a corresponding support rail through a threaded hole in a top wall of the support rail that receives a bolt or similar threaded fastener.

Owner:NORTHERN STATES METALS

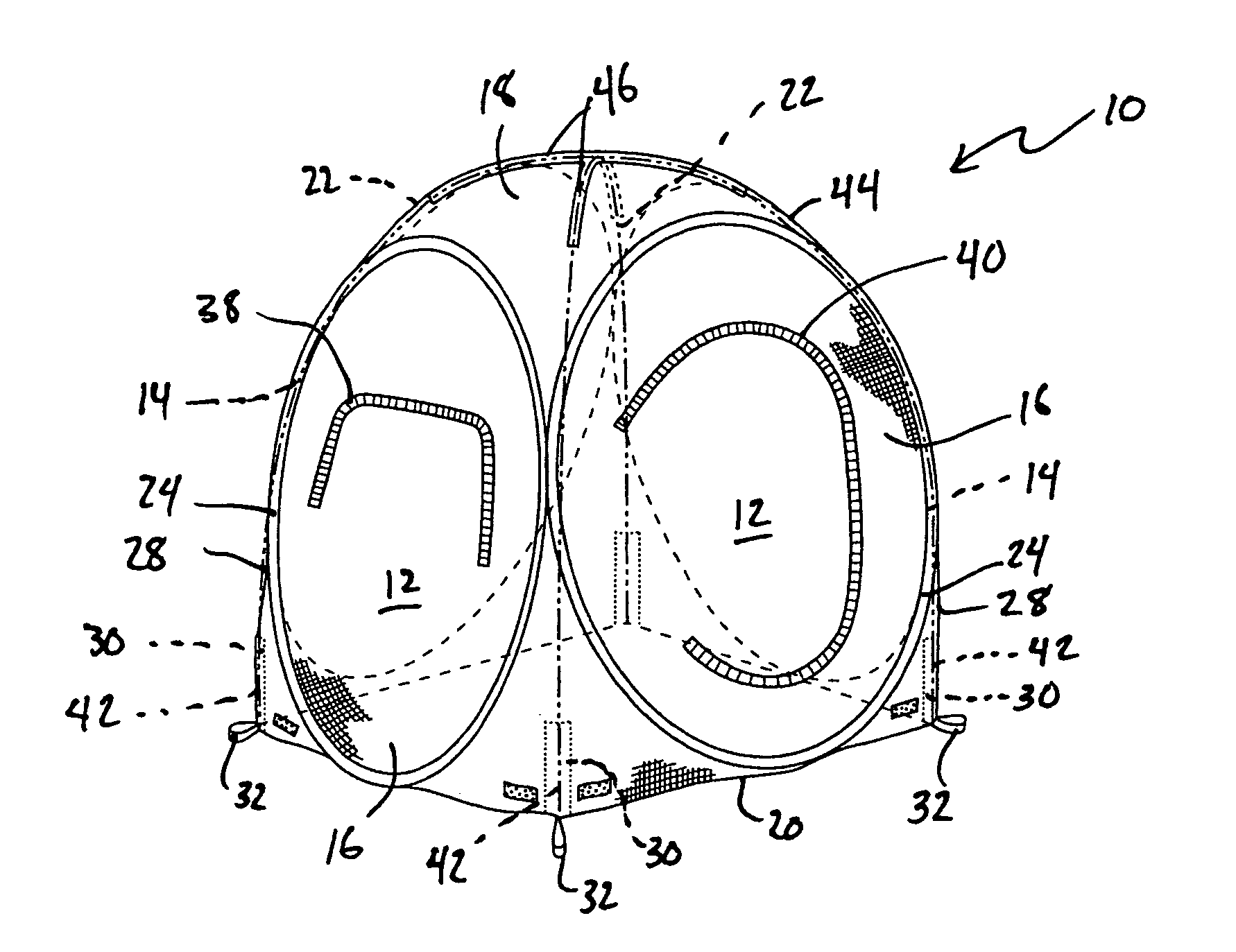

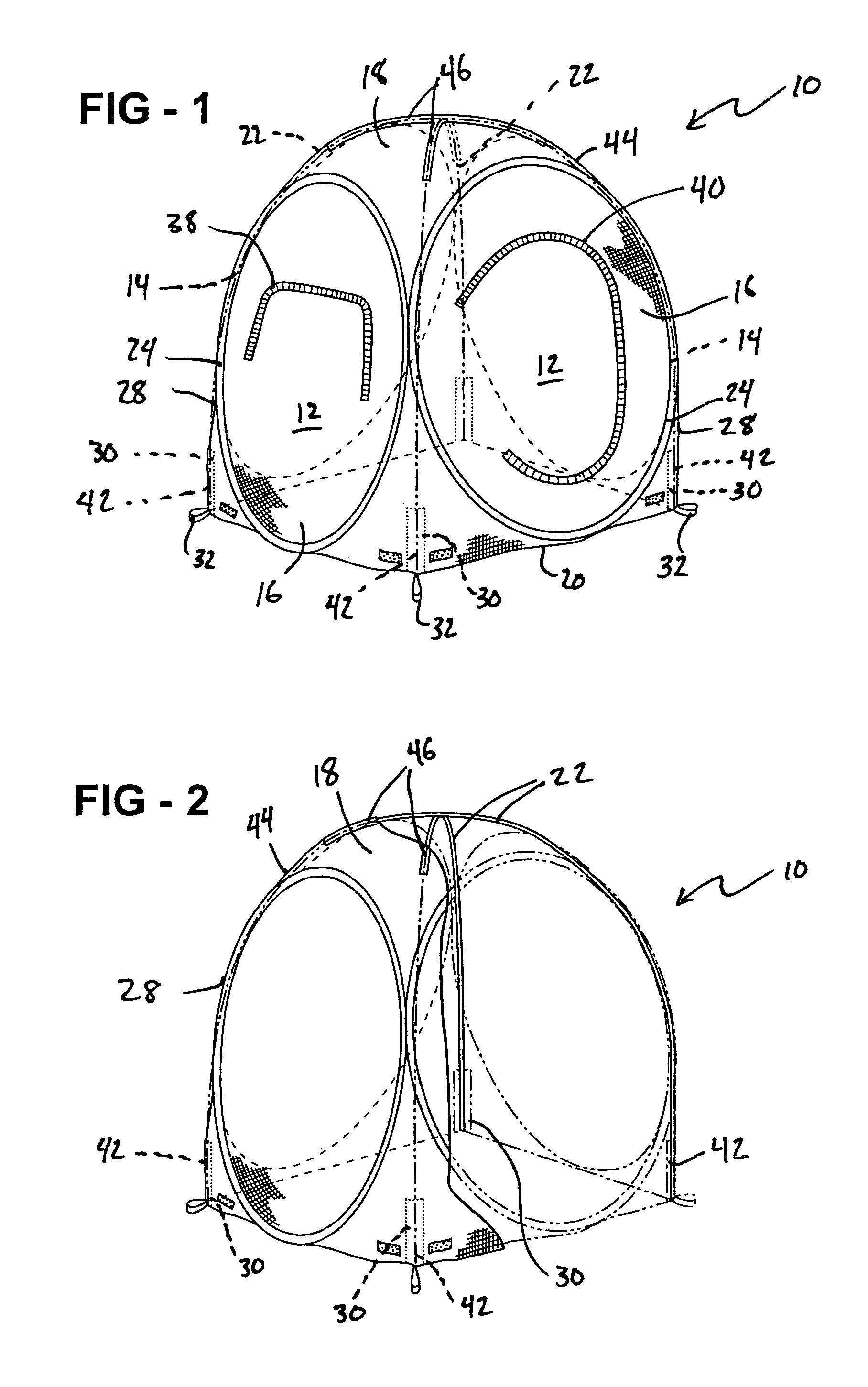

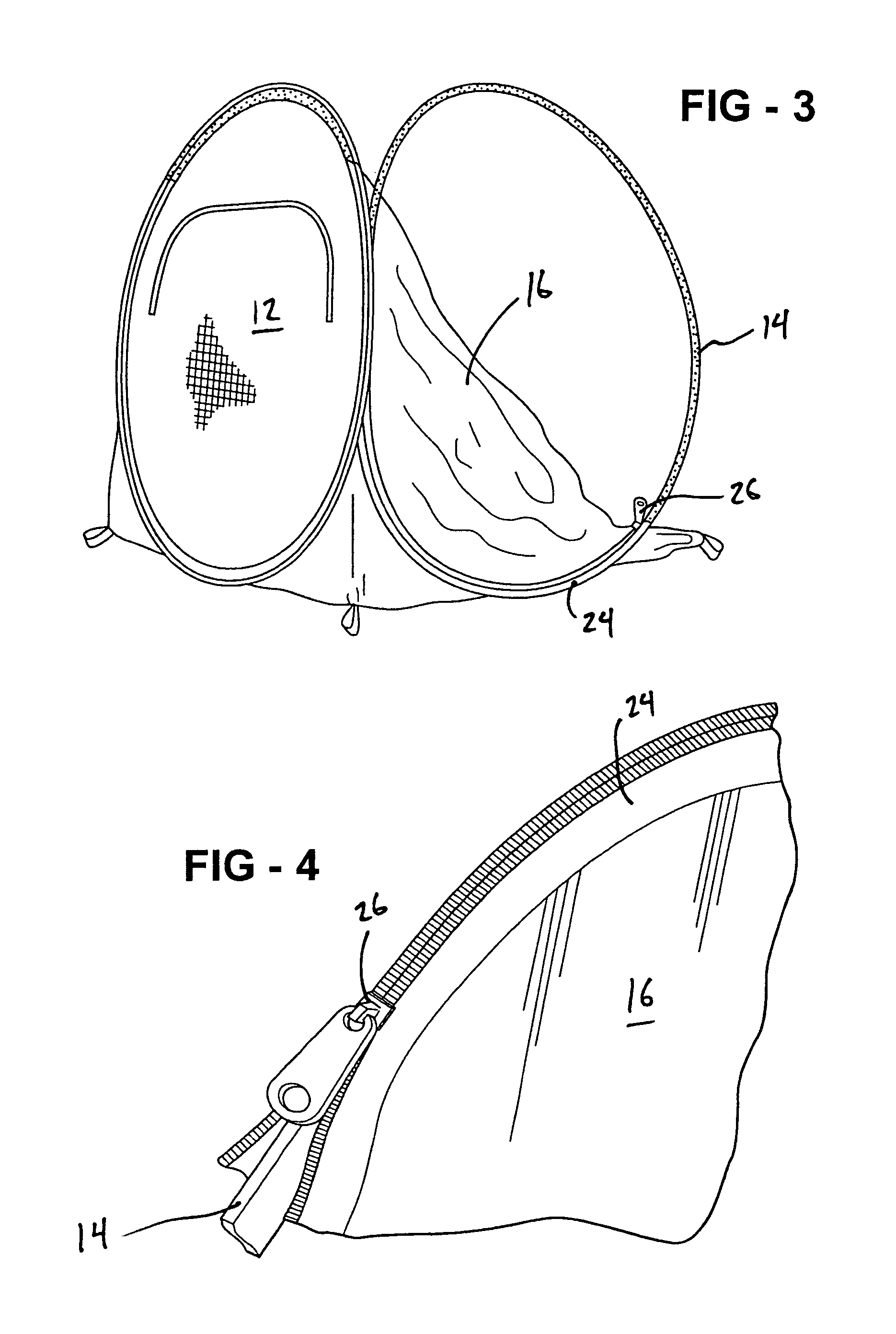

Collapsible structure with top supporting elements

The invention is a collapsible structure comprising a plurality of panel elements, each having a coilable frame element and flexible material attached to the frame element. The panel elements are joined to define an enclosure having a roof portion and a bottom perimeter. The bottom perimeter rests on a supporting surface. The structure has at least one roof support rod having a first end and a second end. The first end of the at least one roof support rod is attached to a first location on the bottom perimeter, and the second end of the at least one roof support rod is attached to a second location on the bottom perimeter. The at least one roof support rod is in supporting contact with the roof portion of the enclosure.

Owner:EVOLVED INGENUITY

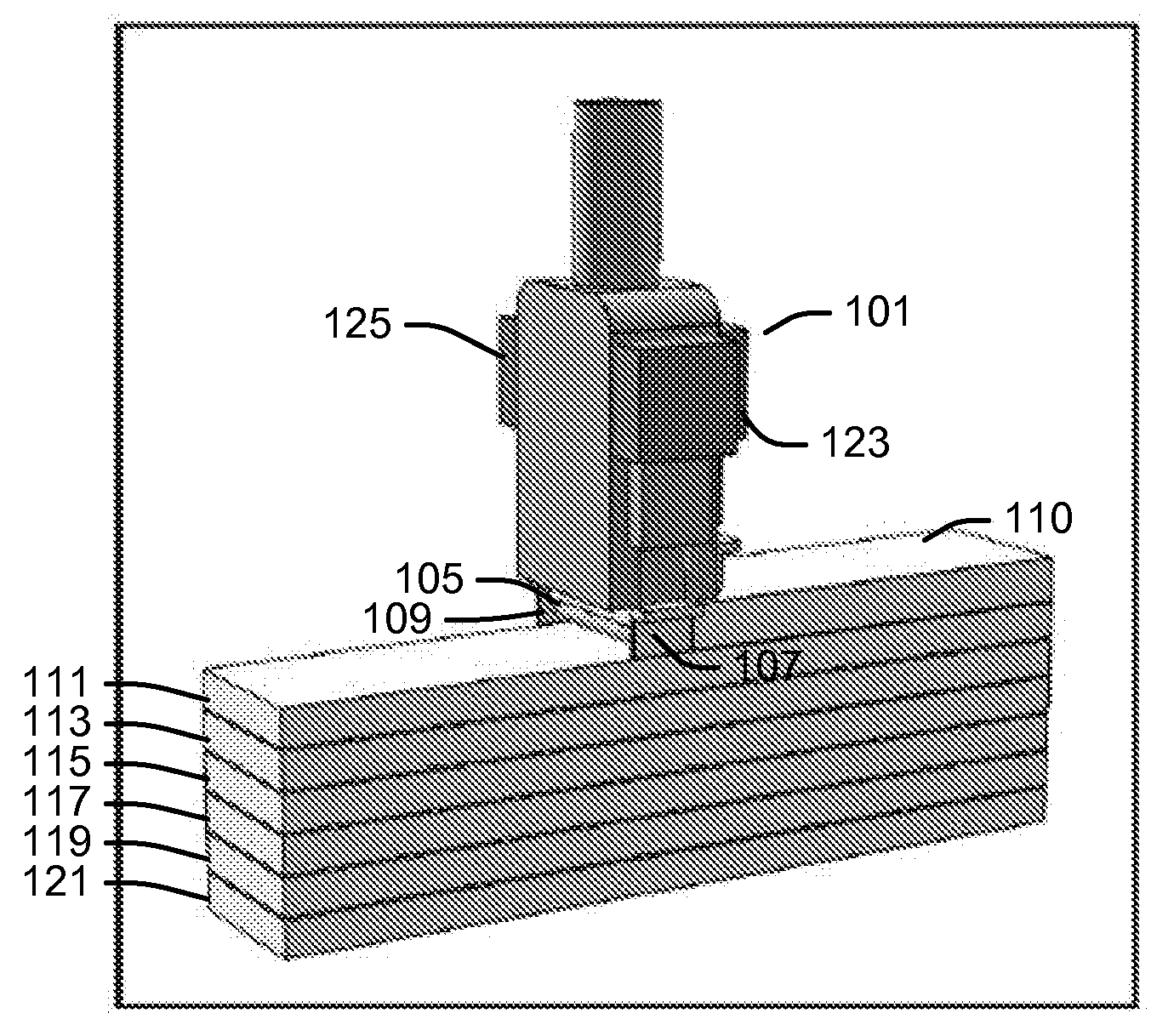

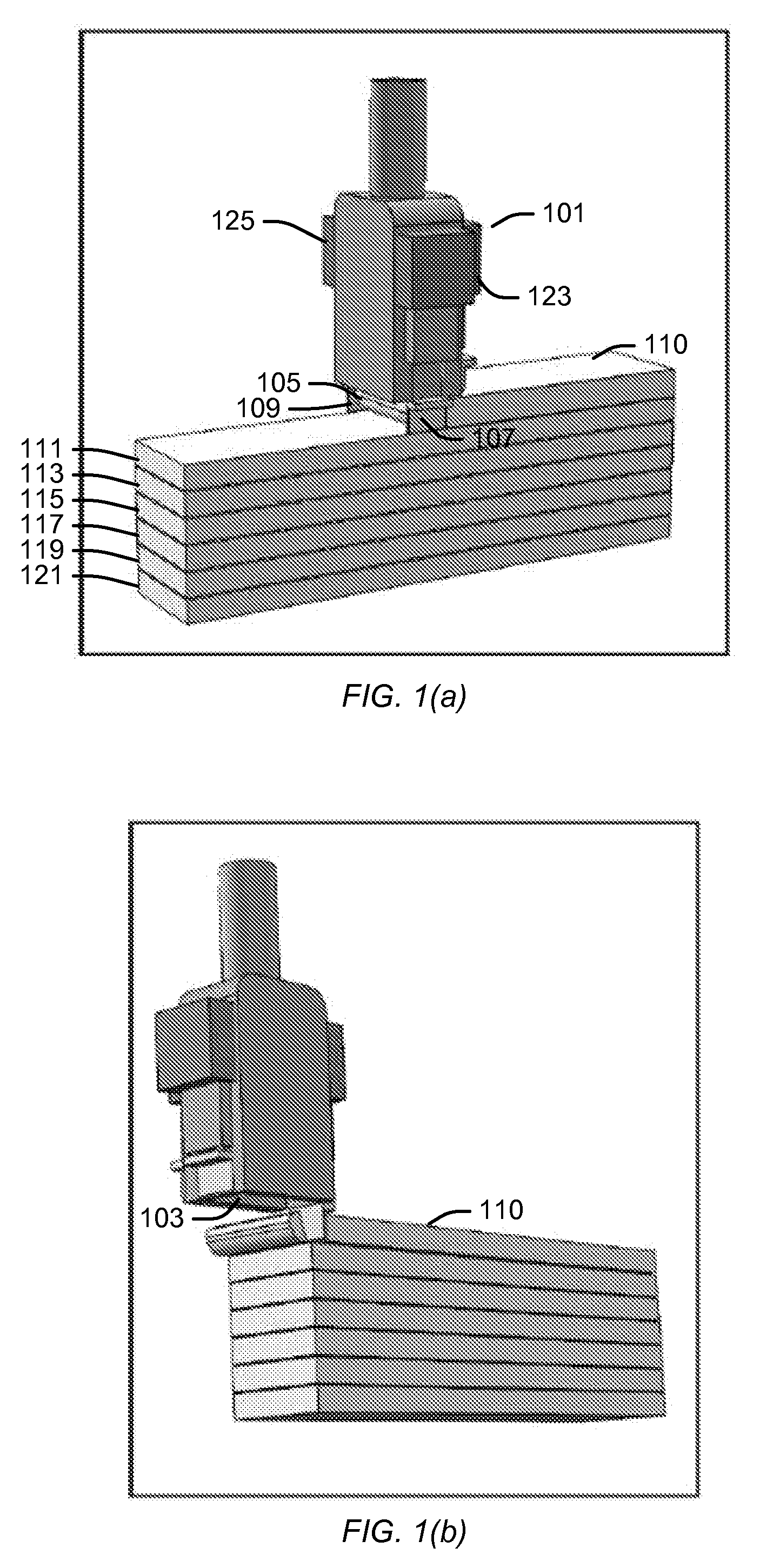

Method of reinforced cementitious constrauction by high speed extrusion printing and apparatus for using same

ActiveUS20180071949A1Low costAdditive manufacturing apparatusConstruction materialReinforced concreteBrick

The present invention relates to methods and apparatuses for an automated reinforced concrete construction system for onsite slip-form molding and casting a variety of cementitious mixes in a cast in place leave in place externally moldable flexible reinforced containment sleeve providing a wide variety of interchangeable full-scale molding configurations simultaneously optimizing a wide variety of cementitious mix curing characteristics, further having optional internal reinforcement net(s), for layer wise interlocking additive printed brick deposition providing improved slip-form mold casting of a wide variety of reinforced concrete structures; the present invention further includes a variety of operating platforms suitable for on and offsite construction as disclosed herein.

Owner:ARMATRON SYST LLC

Partition system

InactiveUS7150127B2Easily attachable to the frameworkEasy to changeCorner/edge jointsLight protection screensBrickEngineering

Owner:KIMBALL INTERNATIONAL

Method and system for prefabricated construction

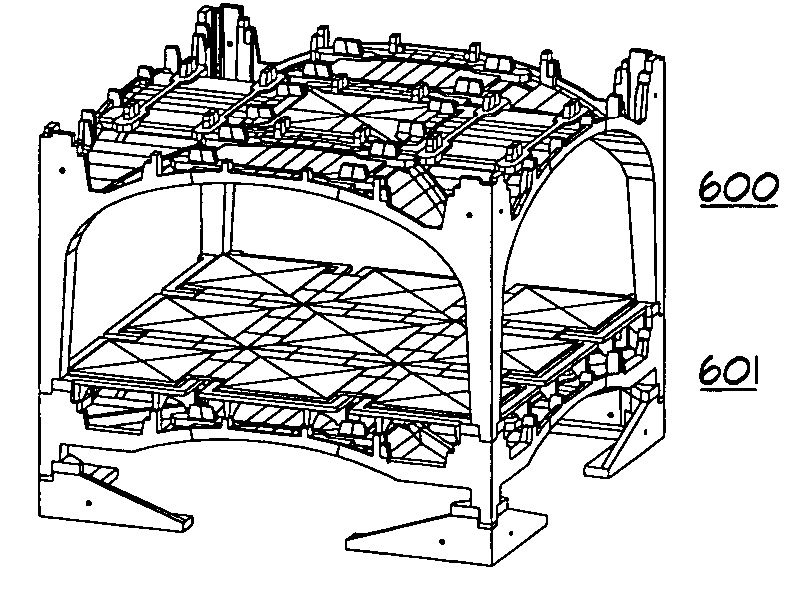

A structure assembled from a combination of stackable modules, each module assembled from multiple prefabricated, transportable blocks. The blocks are typically reinforced cast concrete formed in reusable molds. Module framing blocks may include arched corner blocks, key blocks that interlock with a pair of corner blocks, and optional center blocks. Other structural elements include roof, floor, and wall components that interlock with the framing modules. Modules may be stacked or nested to form structures including buildings, elevated roadways, and parking garages. Utilities may be provided through optional conduits formed in the corner elements. The framing supports raised floor modules for ease in mechanical system installation and modification. The roof elements support usable terraces and rainwater collection. The blocks are demountable and reusable. The modules are self-supporting during erection, and may be assembled without fasteners.

Owner:POWELL DAVID W

Acoustical sound proofing material and methods for manufacturing same

ActiveUS20060057345A1Reduce sound transmissionImprove abilitiesBuilding roofsCoatingsCelluloseEngineering

An improved acoustical damping wall (ceiling or floor) or door material comprises a laminar structure having as an integral part thereof one or more layers of viscoelastic material which also functions as a glue and one or more constraining layers, such as metal, ceramics, composites, cellulose, wood, or petroleum-based products such as plastic, vinyl, plastic or rubber.

Owner:PACIFIC COAST BUILDING PRODS

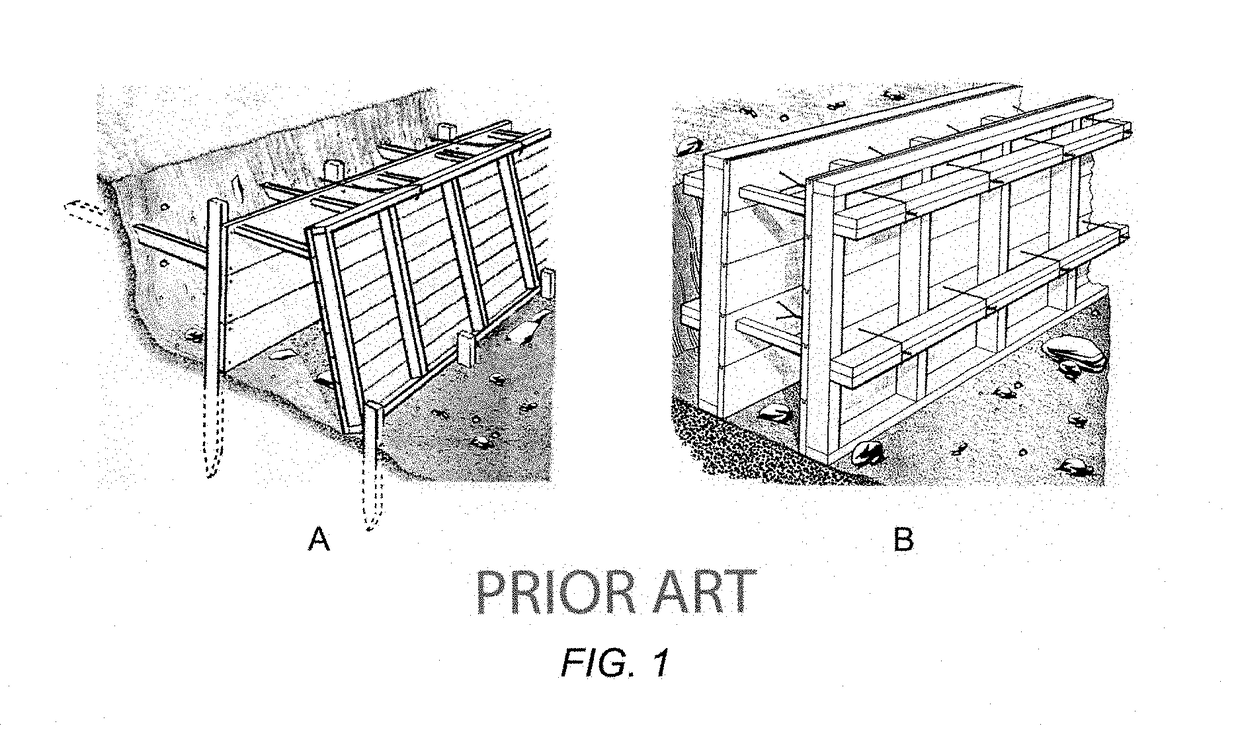

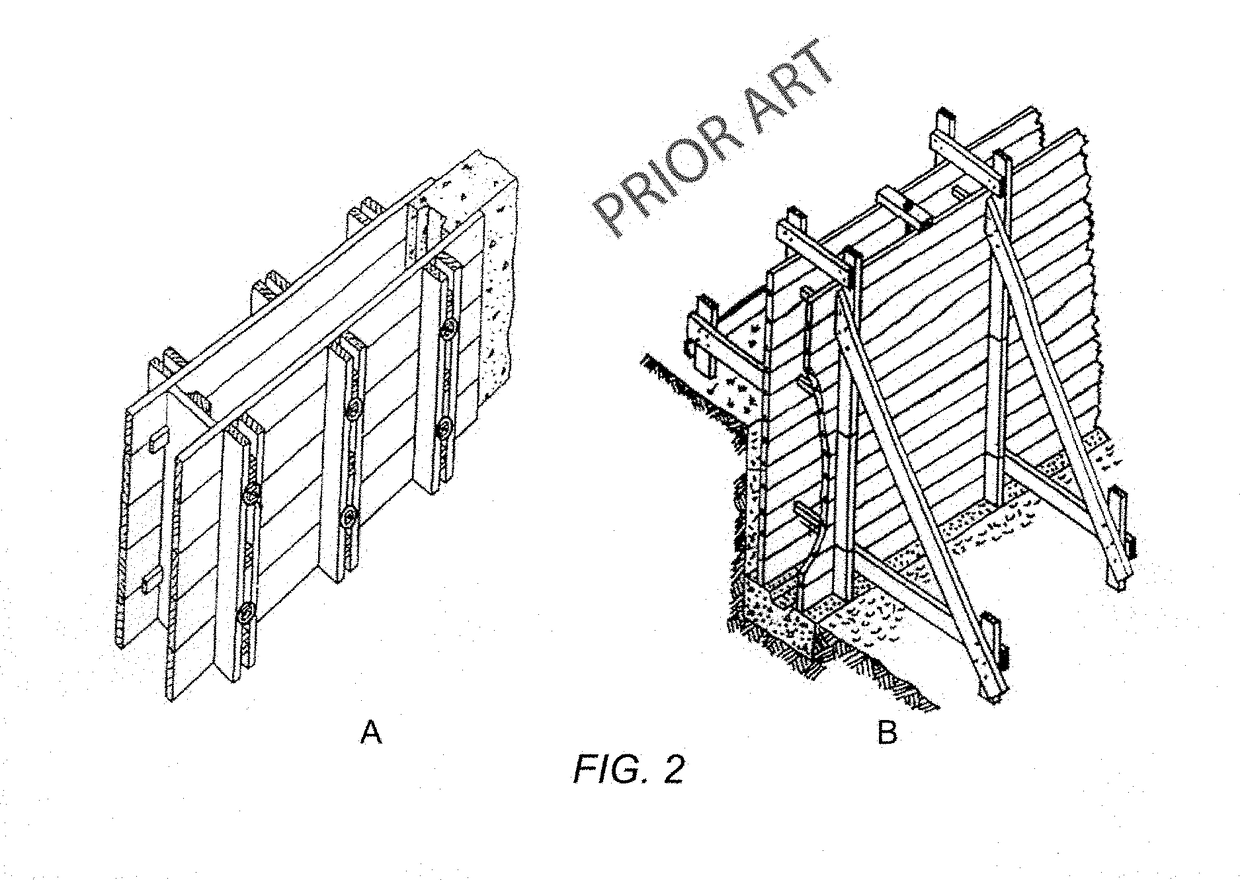

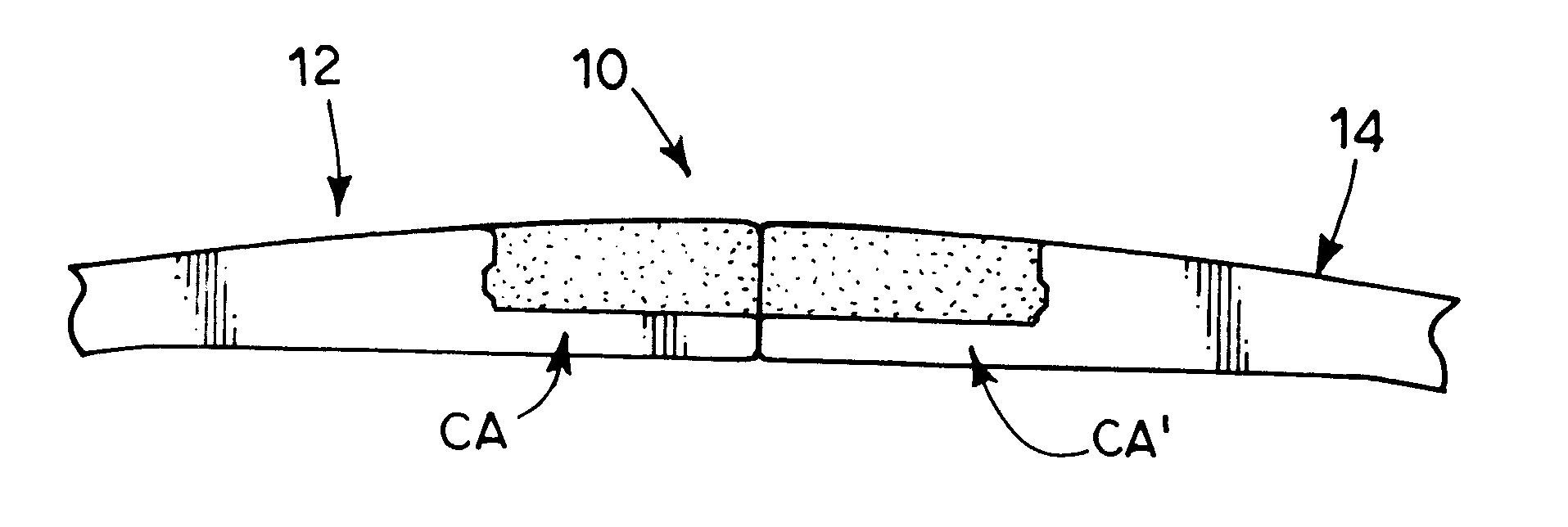

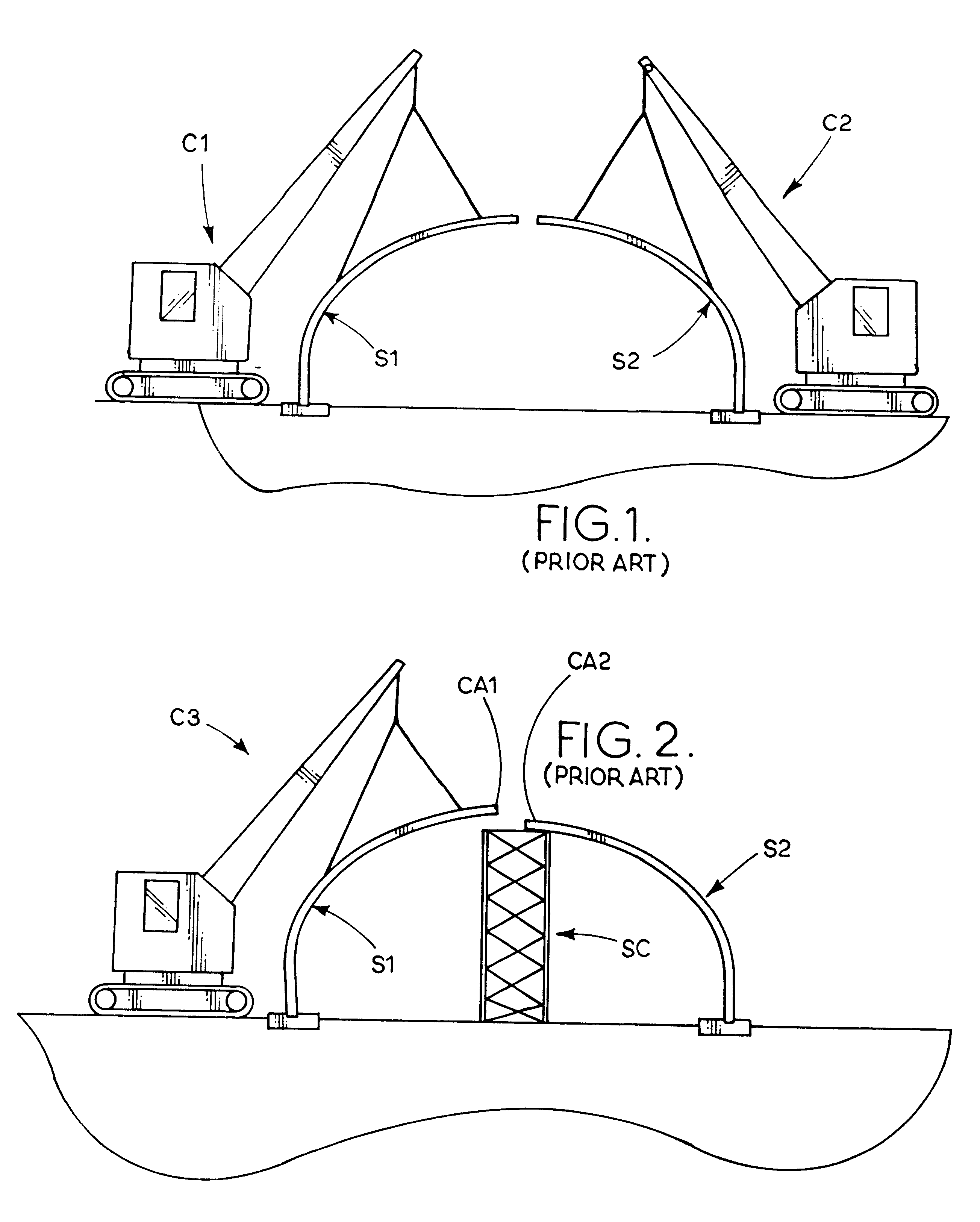

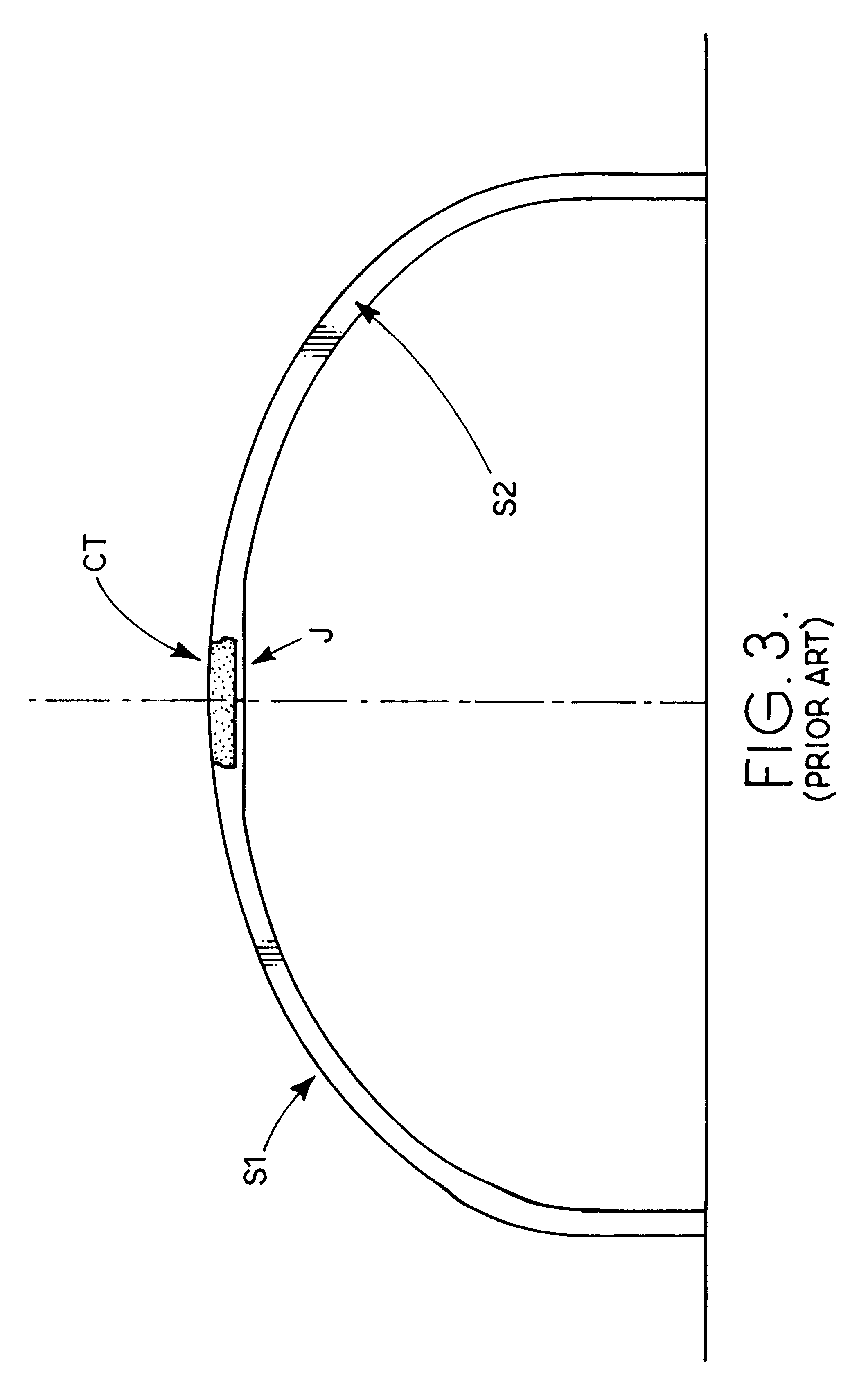

Joint for pre-cast concrete twin-leaf arch sections

InactiveUS6243994B1Efficiently and accurately formForming accuratelyUnderground chambersBuilding material handlingControl theoryPrecast concrete

A joint for pre-cast concrete twin-leaf arch sections is self-aligning when the two arch sections are initially brought into abutting contact with each other. The joint provides a rigid connection between the twin units and is achieved on site by means of re-inforced cast-in-place concrete. Reinforcement splices for the connection are lap splices, and the joint allows pouring the cast-in-place concrete without the need of formwork. For load distributing purposes, a continuous connection of individual arch rings in the longitudinal direction at the arch crown is possible. An initial abutting contact between the twin units is provided by the joint of the present invention. The contact provided by the joint of the present invention is self-aligning, locking, allows the controlled transmission of the abutting force and allows for a temporary connection. The joint includes mechanical elements for aligning and locking the two arch sections together. The mechanical elements include, in the preferred embodiment, a projection on one arch section and a depression on the other arch section. Cast-in-place concrete is placed in boxed-out, or step, sections located adjacent to the mechanical elements and completes the joint.

Owner:CONTECH ENGINEERED SOLUTIONS

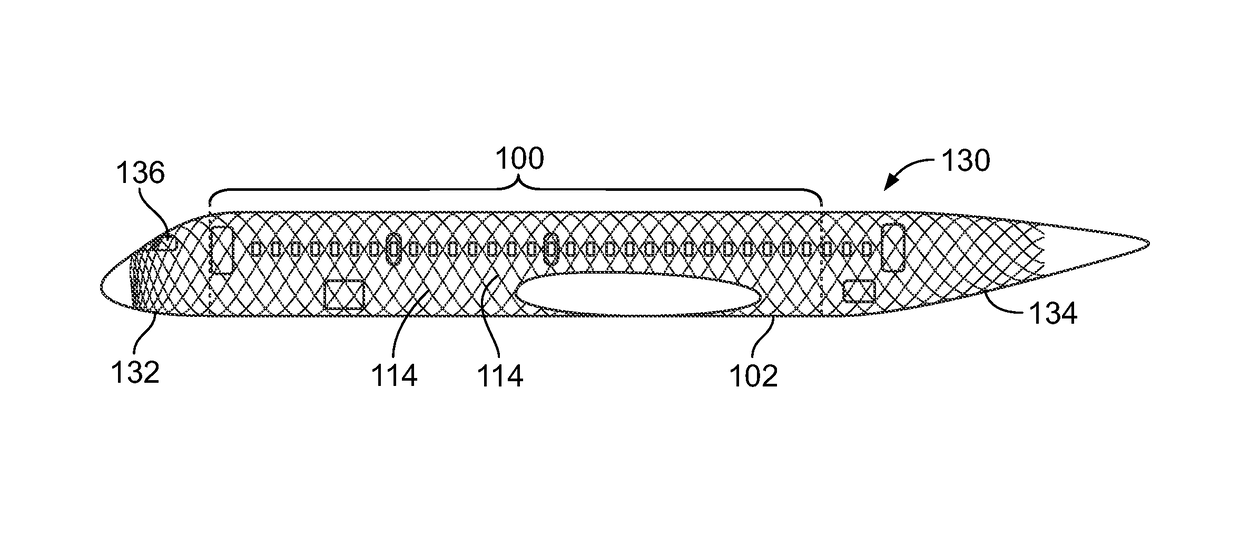

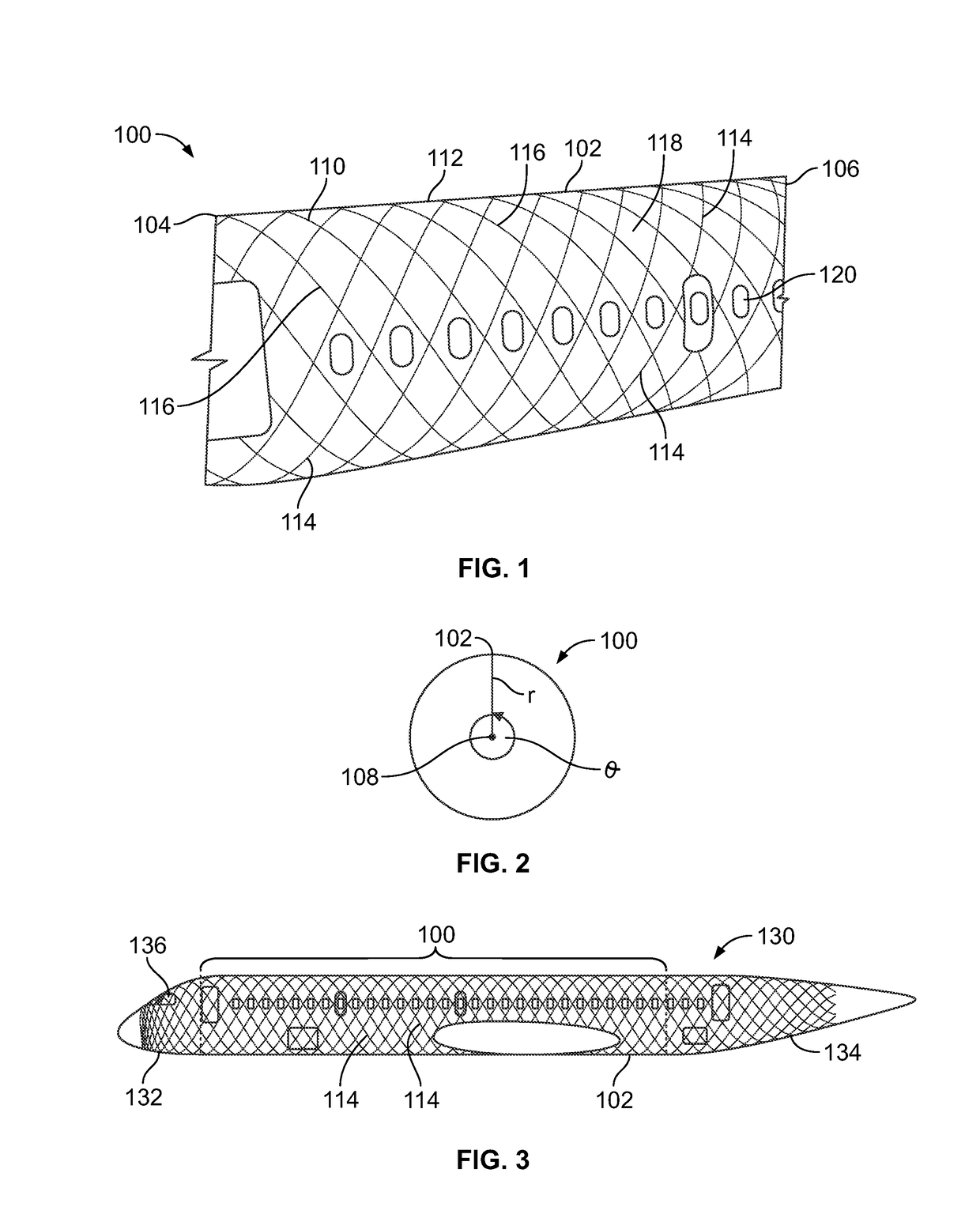

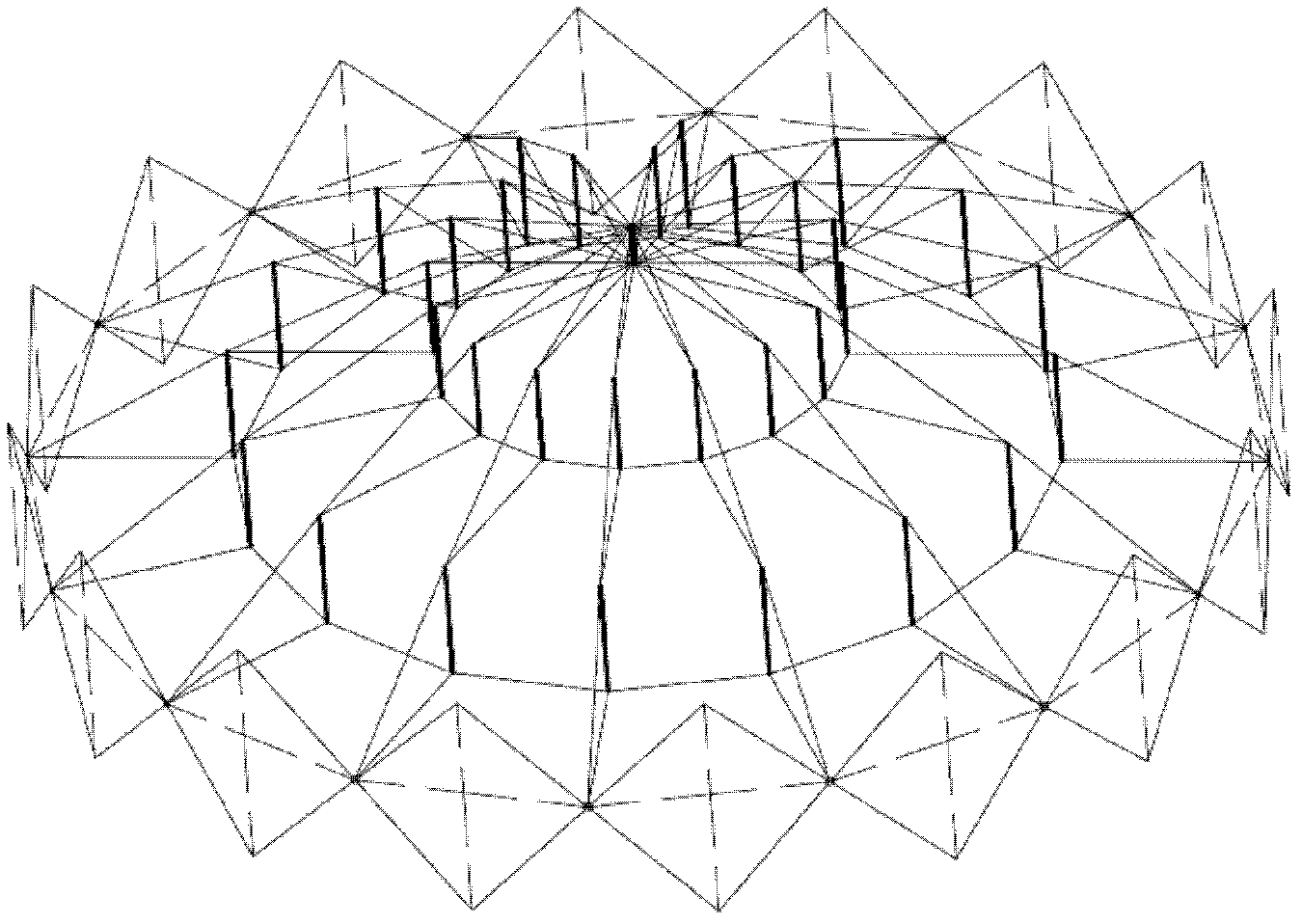

Systems and methods for manufacturing a tubular structure

ActiveUS9957031B2Secure retentionArched structuresVaulted structuresComputer moduleBiomedical engineering

A system and method determine a size and a shape for identical geodesic modules that are used to form a structure. The system and method may include analyzing input data regarding a size and a shape of the structure to be formed, and determining the size and the shape for each of the identical geodesic modules based on the size and the shape of the structure to be formed. The structure may include a framework including the identical geodesic modules. Each of the geodesic modules has a size and a shape that are the same as all of the other of the geodesic modules. A forming system and method position a framework and a covering skin of the structure in relation to a mandrel, and drill and rivet the framework to the covering skin with a plurality of operating heads.

Owner:THE BOEING CO

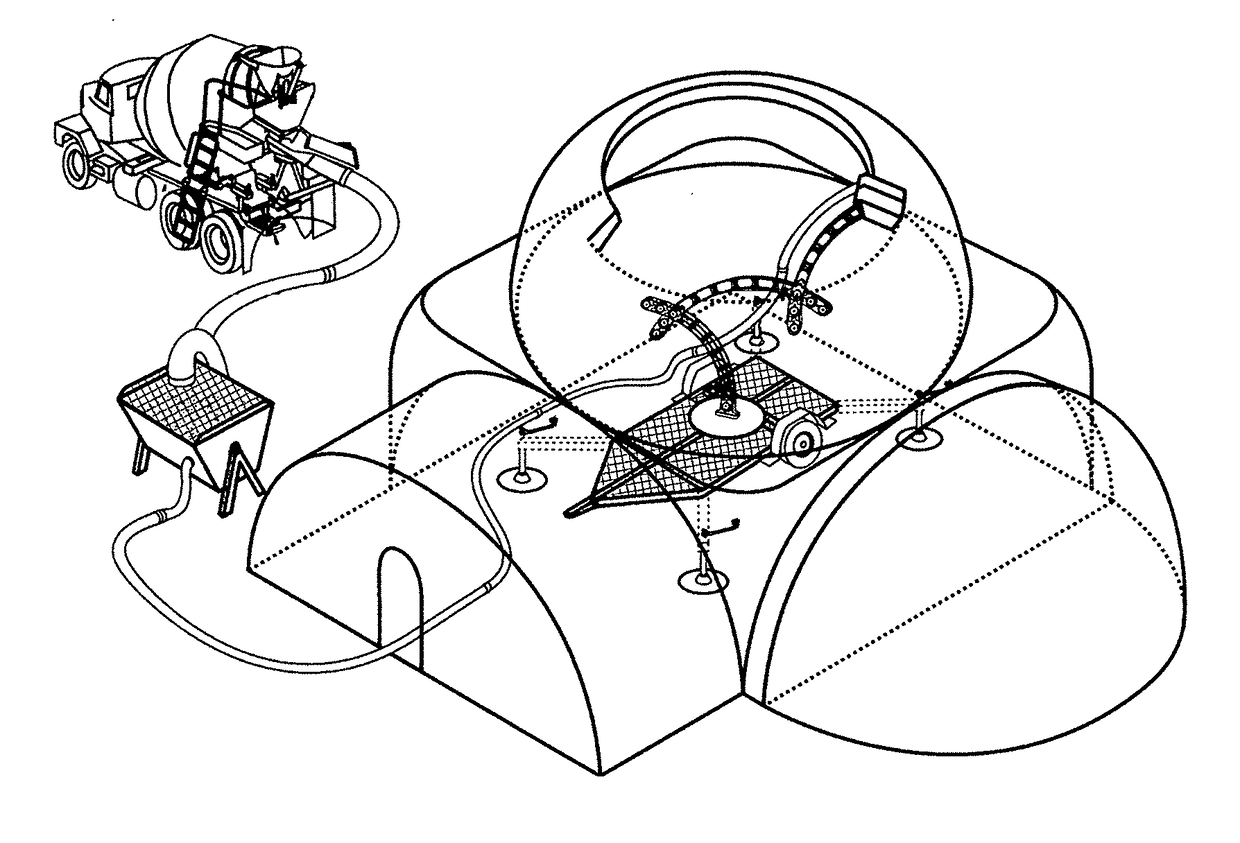

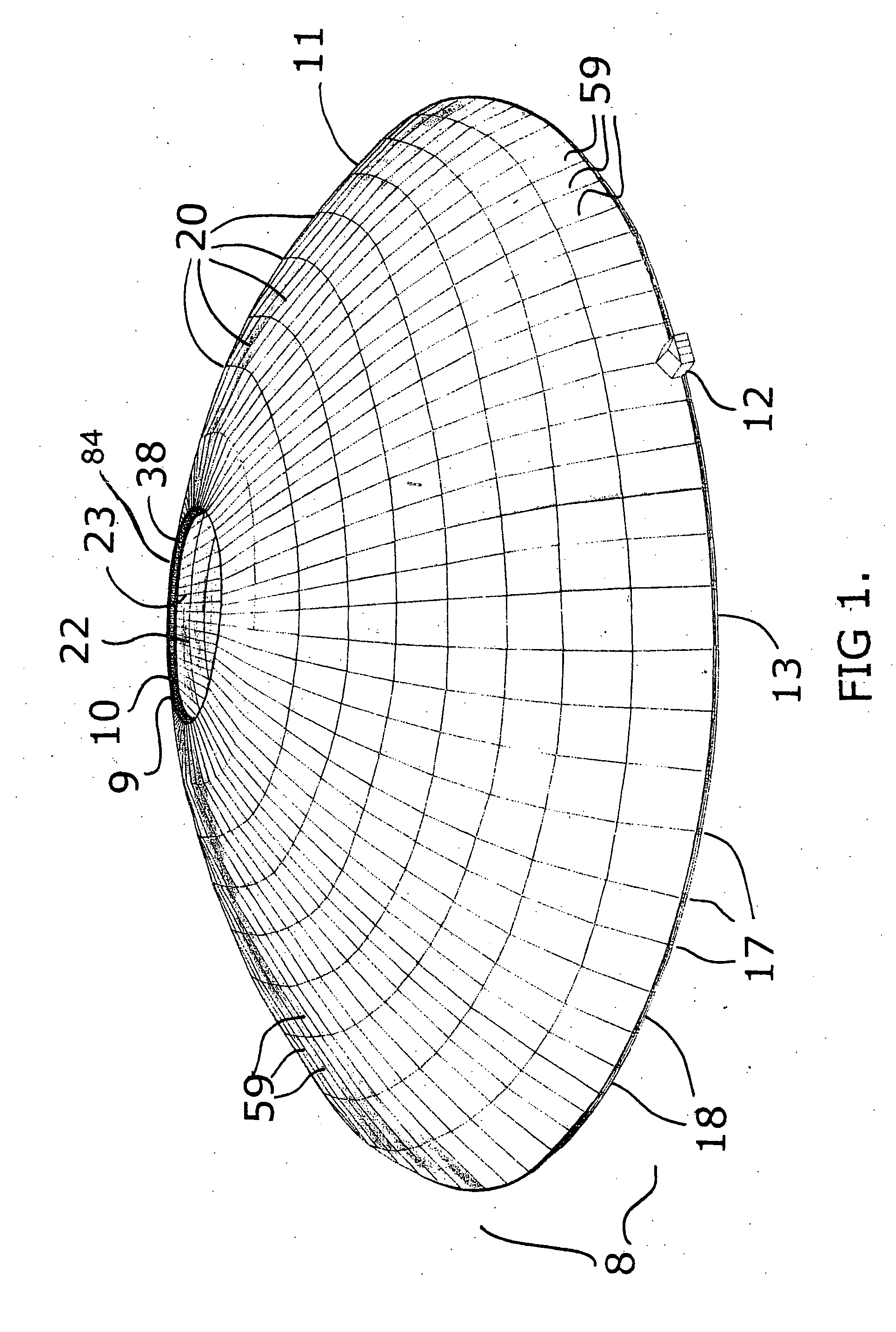

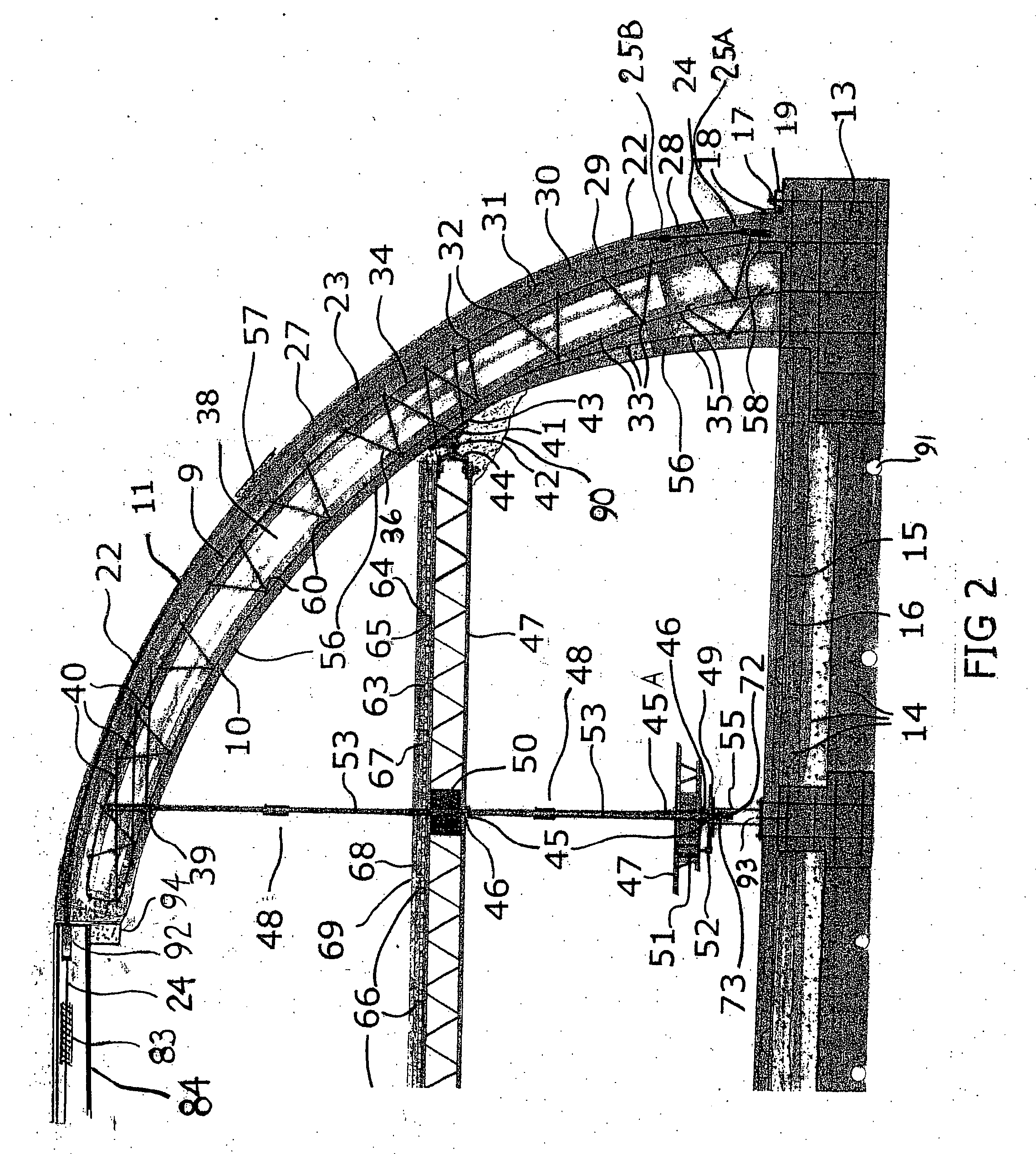

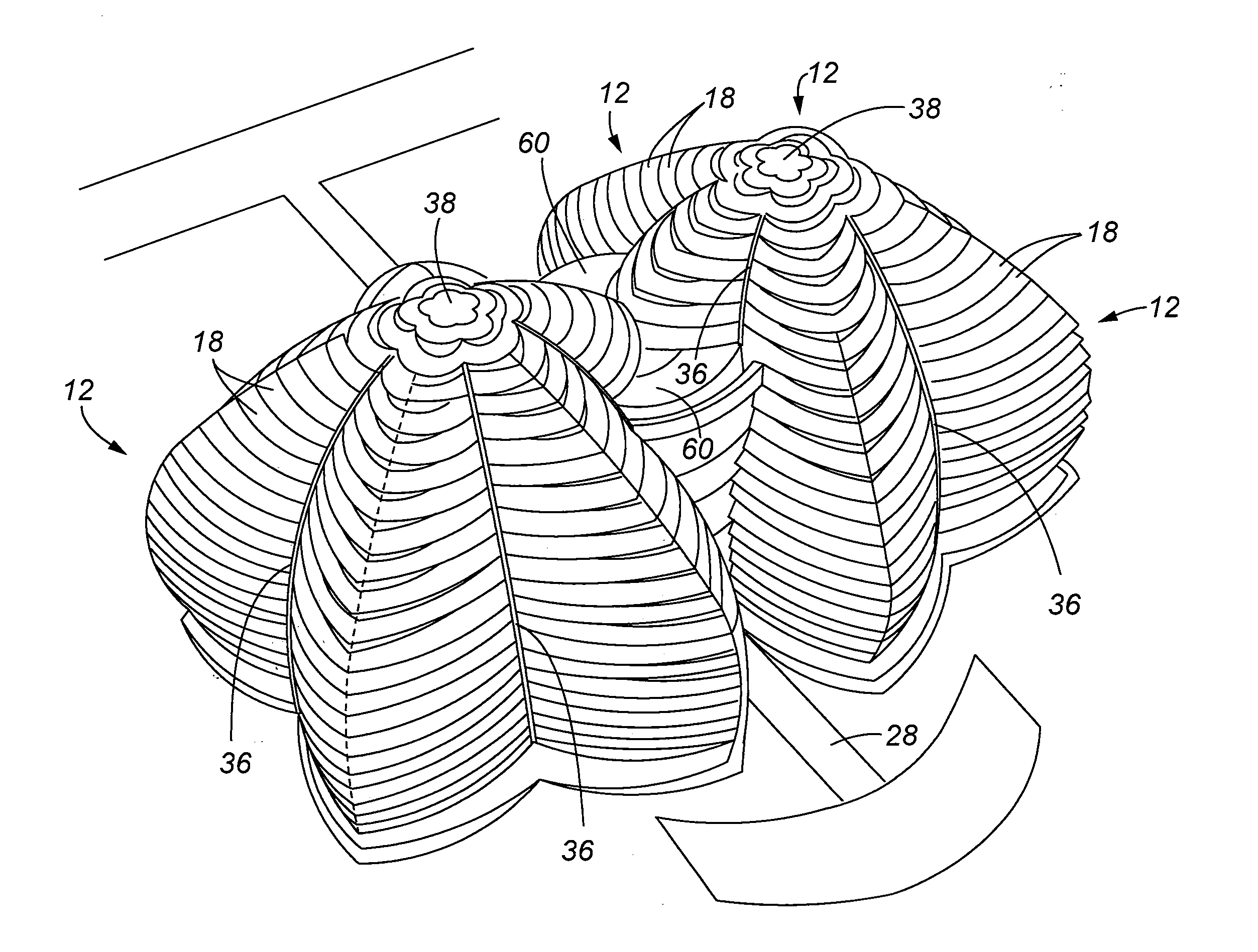

Trilithic and/or twin shell dome type structures and method of making same

InactiveUS20050210767A1Quick connectionImprove load-bearing strengthBuilding roofsArched structuresShotcreteThin shells

Trilithic Shell, Twin Shell, Multiple Shell, Curvilinear Shell as well as Free-formed Structures described herein each employ an inflatable membrane having a peripheral edge secured to an outer foundation base. An ultra-light membrane (air-form) having a network of internal cross connecting restraints is additionally secured to the inner foundation base to permit a novel and unique curvilinear surface. Pressurization then creates the backdrop upon which various urethane layers are applied which when laced with rigidifying tubes become the defining backdrop beneath which numerous cross connecting braces which when snapped into position effectively lock an inner framework to an outer framework thereby producing a self supporting truss like structure both compatible with either current dome construction and / or conventional construction practices. Shotcrete being then sprayed from the interior over said urethane coated backdrop forms highs at framework intersections and natural lows in between followed by the insertion of inflated cell tubes which span the created network of horizontal and vertical cavities are next over sprayed with urethane foam necessary to form the next natural backdrop over which two or more shotcrete / steel reinforced separate yet cross connected planes may be achieved. Such multiple yet independent rigid layers now having thousands of inner-connecting cross braces through which interior voids become natural chase-ways effectively displace 50% or more of what might otherwise be solid concrete as would be the case with all prior art thin shell structures and / or conventional stem wall construction practices. Such Free Formed curve-linear structures effectively reduce material and labor costs by as much as 50%, eliminate snap-through or oil-can buckling tendencies, enhance overall structural capacity, eliminate all height to diameter restraints, permit larger structures, facilitate floor suspension and attachment, and allow mechanical, electrical and HVAC distribution through interior chase-ways which cannot be achieved with prior art concrete thin shell single thickness structures and / or conventional stem wall, construction practices to date.

Owner:DEFEVER MICHAEL D +1

Extruded Wall with Rib-Like Interior

A nozzle for extruding a surface may include a first outlet configured to controllably extrude a first extrudate of unhardened material, a second outlet configured to controllably extrude a second extrudate of unhardened material that is separated from the first extrudate, a third outlet configured to extrude a third extrudate of unhardened material between the first and the second extrudates, and a controller. The third outlet may have a width that is substantially less than the distance between the first and second extrudates. The controller may be configured to cause the third extrudate to repeatedly traverse between the first and second extrudates and / or to cause the third extrudate to leave a plurality of substantial and separated spaces between the first and second extrudates.

Owner:UNIV OF SOUTHERN CALIFORNIA

Acoustical sound proofing material and methods for manufacturing same

ActiveUS20050050846A1Reduce transmission rateImprove abilitiesBuilding roofsCeilingsCelluloseUltrasound attenuation

An improved acoustical damping wall (ceiling or floor) or door material comprises a laminar structure having as an integral part thereof one or more layers of viscoelastic material which also functions as a glue and one or more constraining layers, such as metal, cellulose, wood, or petroleum-based products such as plastic, vinyl, plastic or rubber. In one embodiment, standard wallboard, typically gypsum, comprises the external surfaces of the laminar structure; and one or more constraining layers are fabricated between the gypsum exterior. The resulting structure improves the attenuation of sound transmitted through the structure.

Owner:PACIFIC COAST BUILDING PRODS

Roofing bracket and system

Various novel roofing brackets and roofing systems are disclosed. A first embodiment can be considered a roofing bracket to be coupled to a vertical post and a horizontal purlin of a roofing system whereby the horizontal purlin is positioned to support roof panels at a requisite pitch. The roofing bracket includes a reference brace and a clip. The reference brace includes a first brace face positioned planarly parallel with the vertical post and a second brace face extending at an angle angle from the first brace face and positioned planarly parallel with the vertical post. The clip includes a first clip face positioned to be fastened generally flush with the horizontal purlin and a second clip face extending at an angle from the first clip face and positioned to be fastened planarly parallel with the vertical post. The second clip face is coupled to the first brace face at a pivot point such that the clip can be rotated a particular angle relative to the reference brace. The angle of rotation is consistent with the requisite pitch of the roofing system.

Owner:GP INNOVATIVE CONCEPTS

Framing system for building construction

According to existing methods of frame building construction, a concrete foundation is formed on which wooden floor joists are laid. Walls are constructed on the foundation and floor using wooden wall studs, and a roof is constructed on the walls using wooden rafters, beams and trusses. These methods require skilled carpenters and high quality wood materials, both of which are increasingly expensive. There is therefore a need for a system for framing houses or other buildings which uses prefabricated steel framing and which is quick and easy to construct. The invention provides a prefabricated system for framing a complete building on a foundation. Folding telescopic framing units are used for vertical partitions and horizontal floor panels. The invention therefore provides a prefabricated system of framing units forconstructing a building comprising: a) proving a foundation; b) securing vertical beams having open upper ends to the foundation at spaced locations; c) securing horizontal beams between the upper ends of the vertical beams; d) erecting and securing folding, telescopic floor joists on the foundation; and e) erecting and securing folding, telescopic roof trusts at spaced locations on the horizontal beams. The invention also provides a framed building comprising: a) a foundation; b) vertical beams having open upper ends secured to the foundation at spaced locations; c) horizontal beams secured between the upper ends of the vertical beams; d) erected folding, telescopic floor joists secured on the foundation; and e) erected folding, telescopic roof trusts secured at spaced locations on the horizontal beams.

Owner:CAMPBELL RONALD W

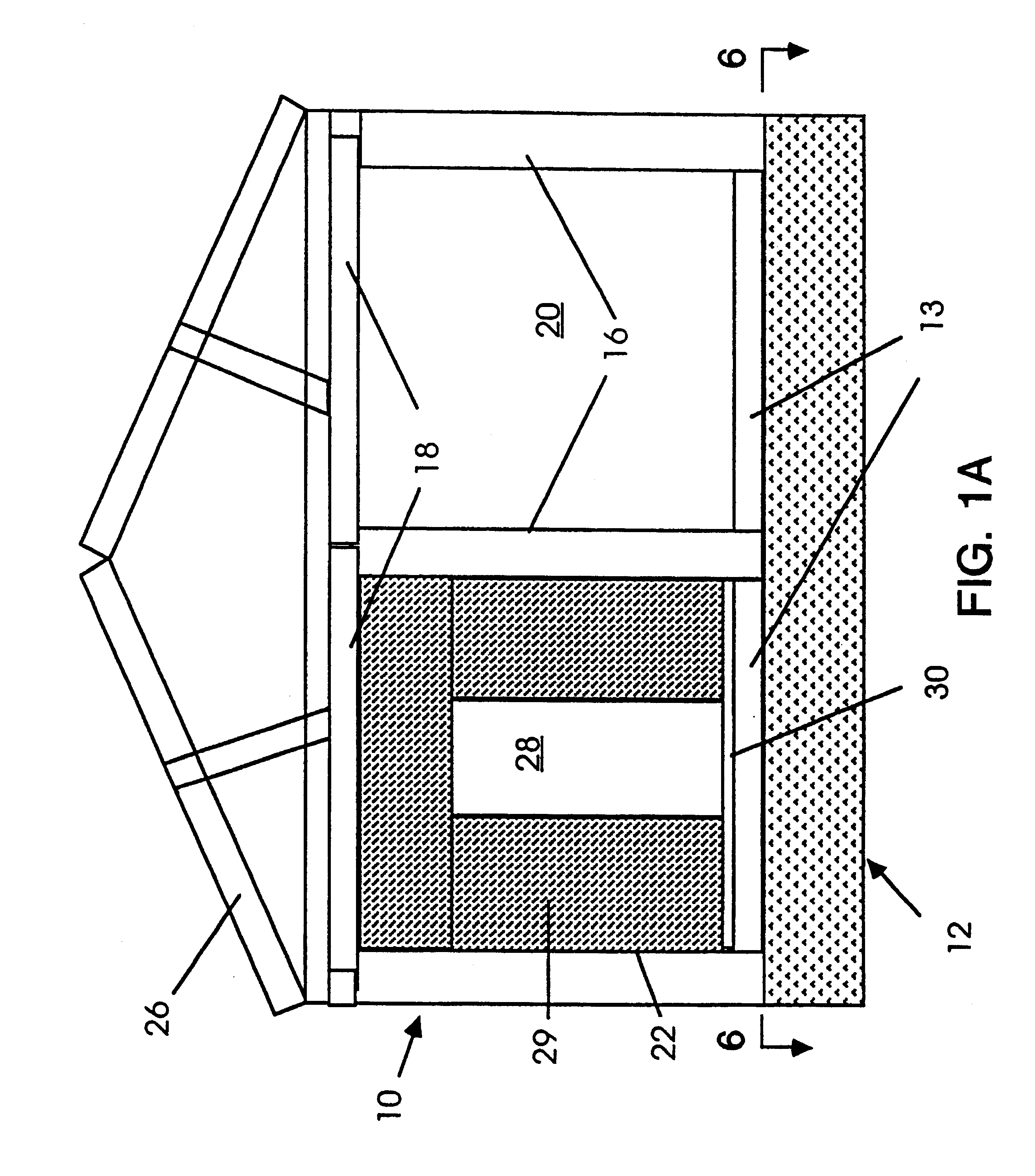

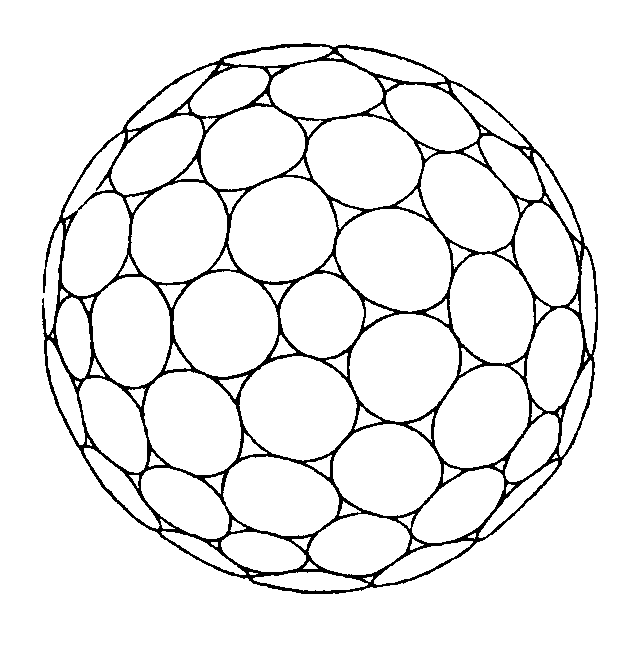

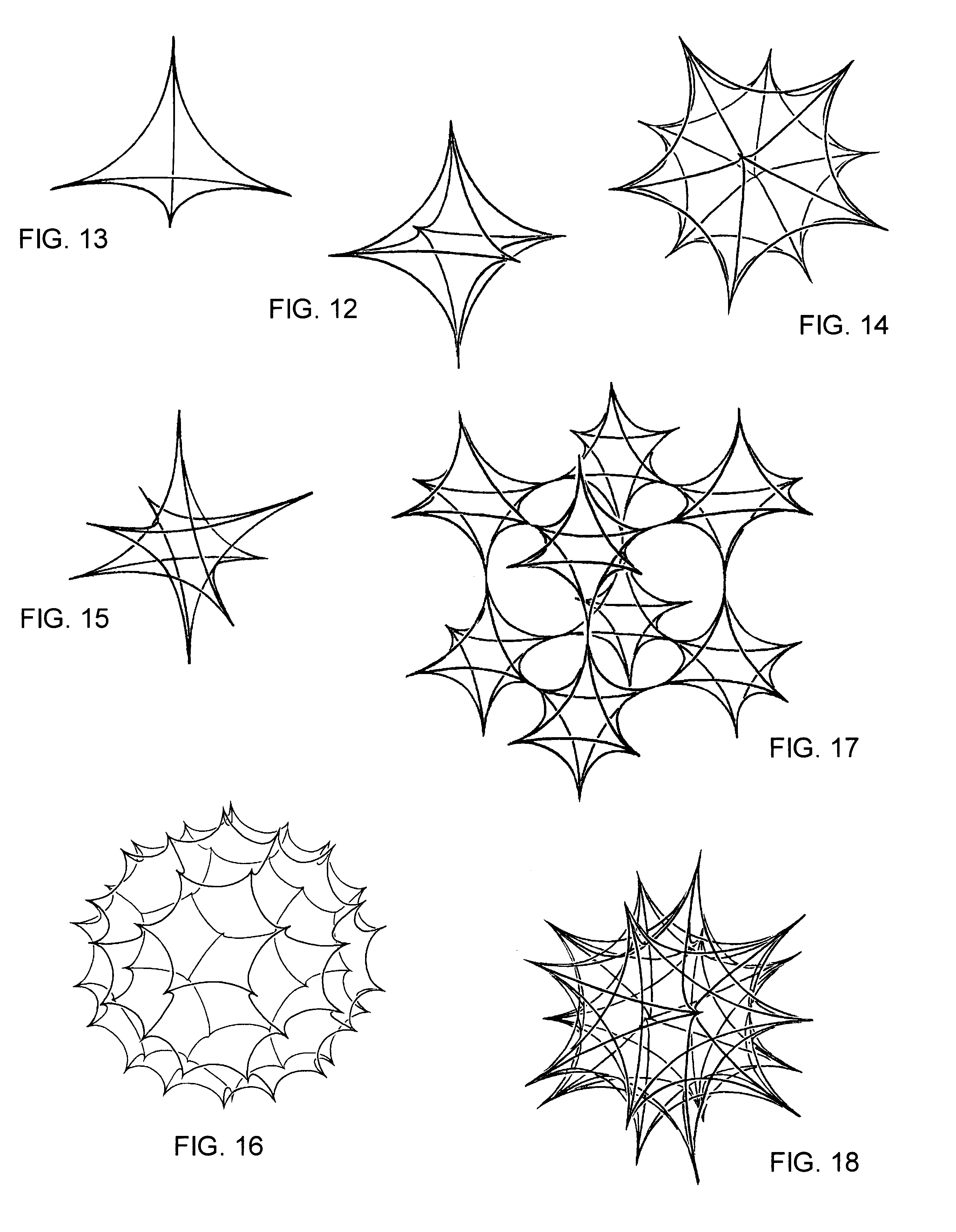

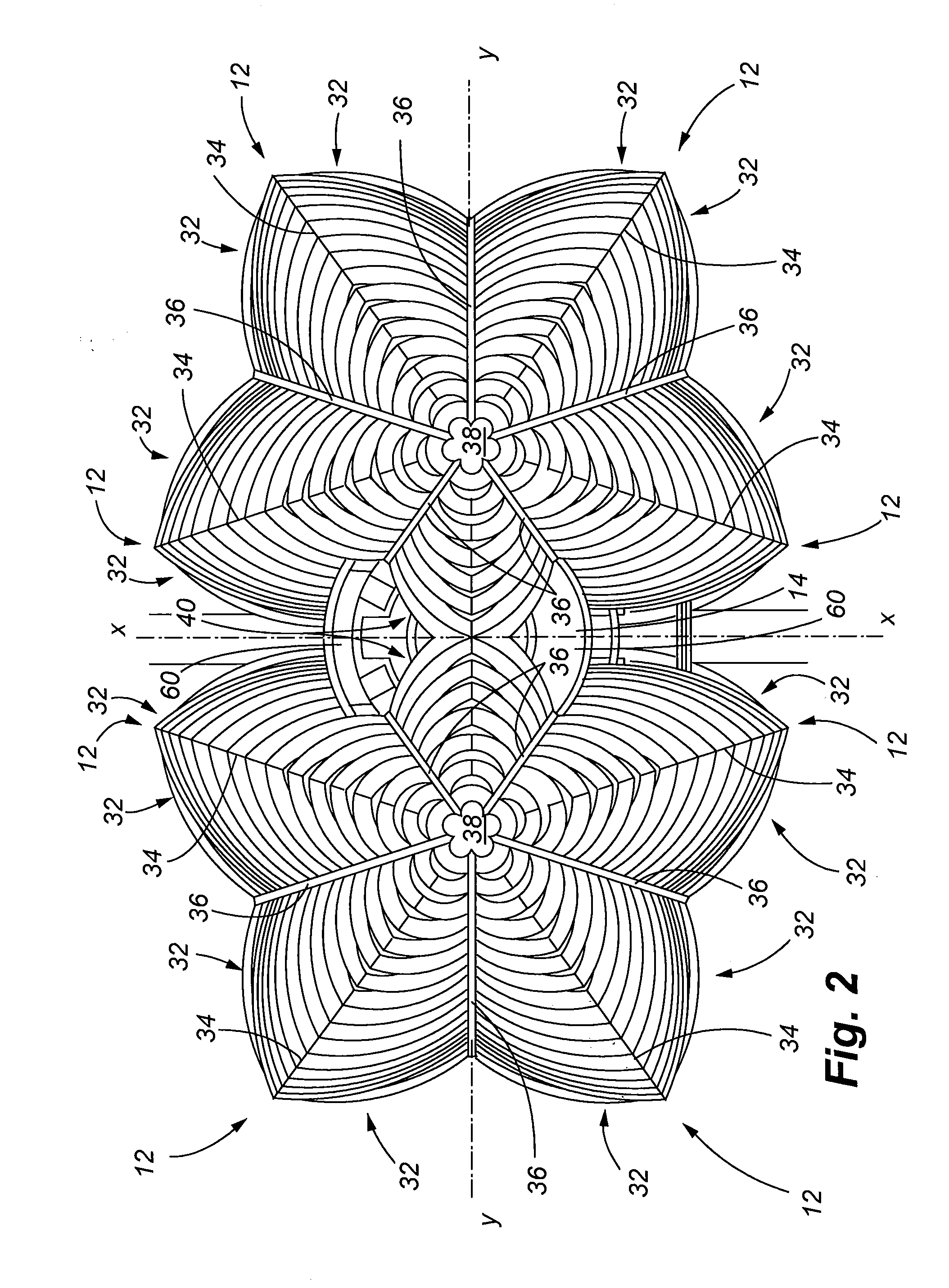

Synetic structural forms and systems comprising same

A strong, lightweight structural system wherein curved structural elements are tangentially joined. Compressive forces are distributed in a near continuous manner throughout the matrix, and tensile forces are present primarily to brace, support and pre-stress the compression net. The system is scalable from molecular through architectural levels, and finds many applications in dome shaped and spherical structures. The structural system also provides a force interaction model that is applicable to a broad array of real and theoretical problems.

Owner:HULTQUIST STEVEN J +1

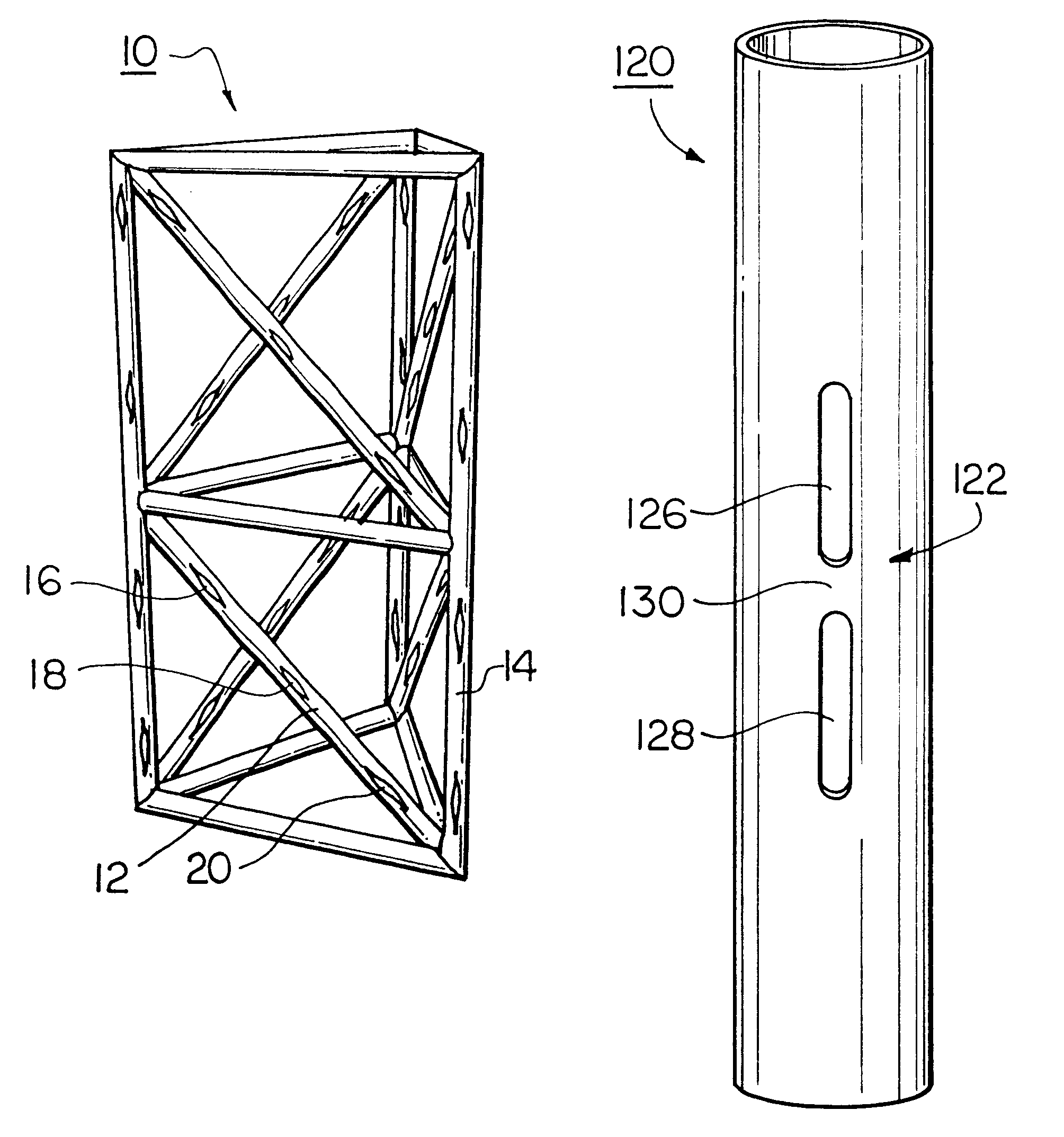

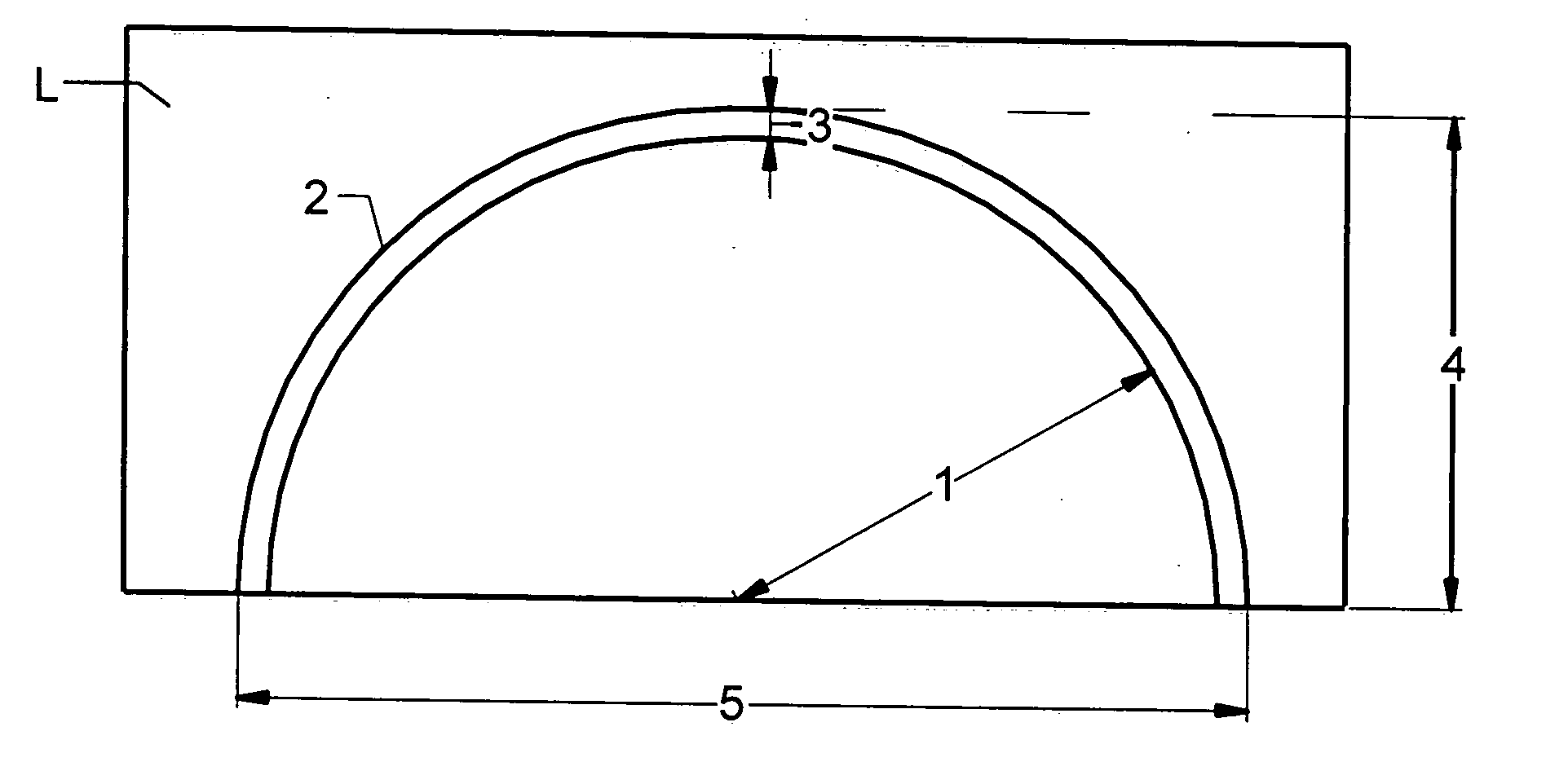

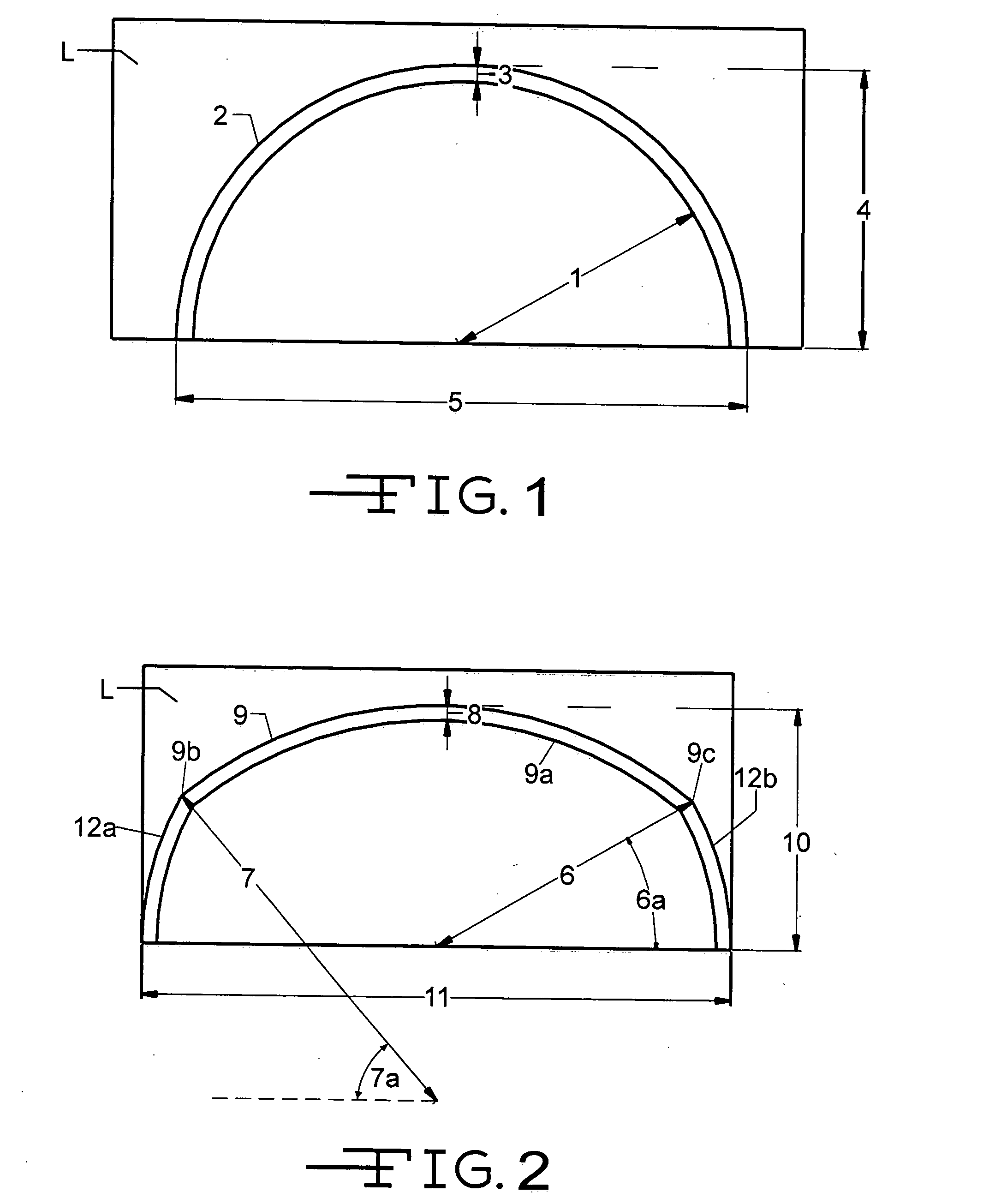

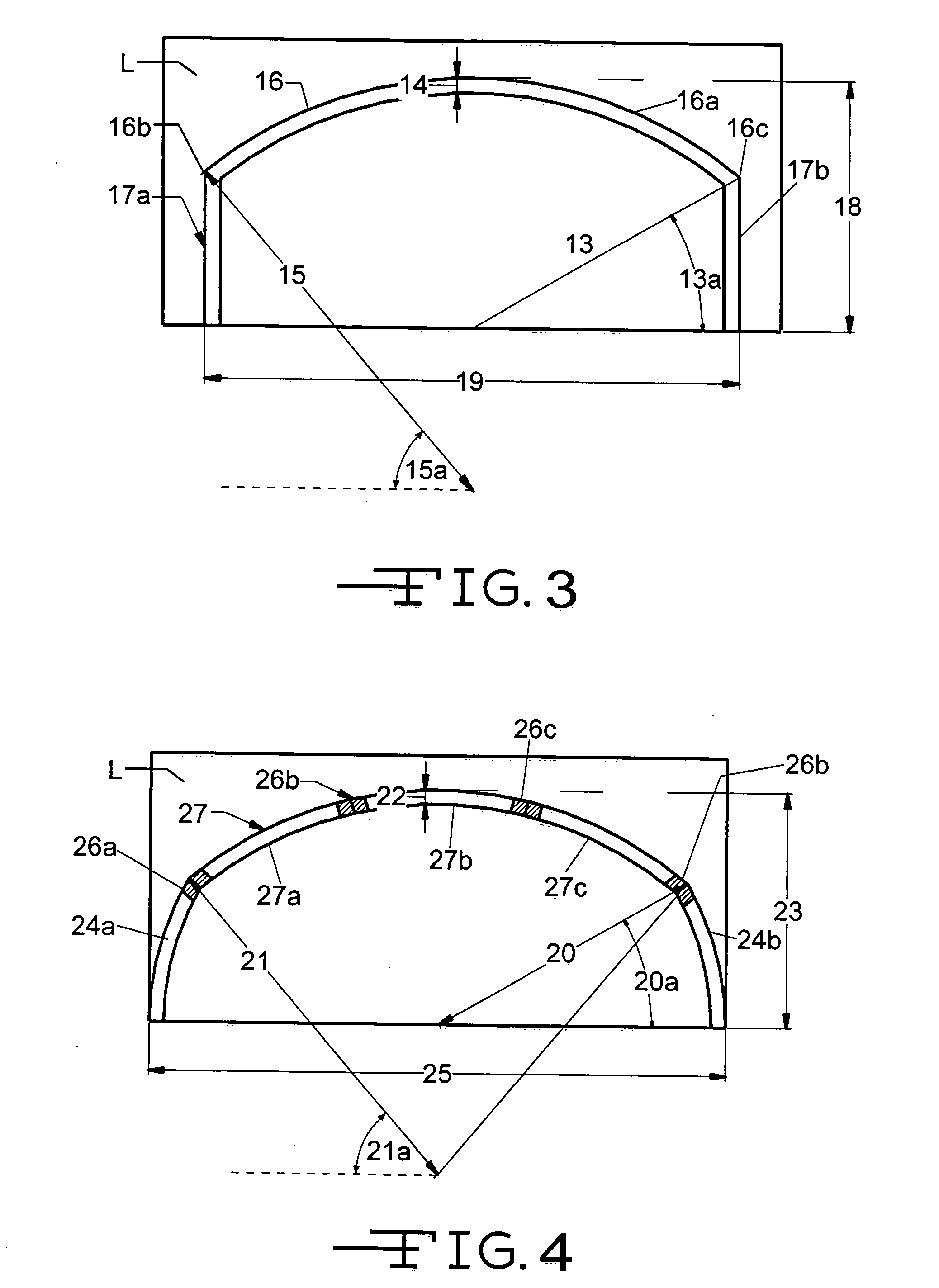

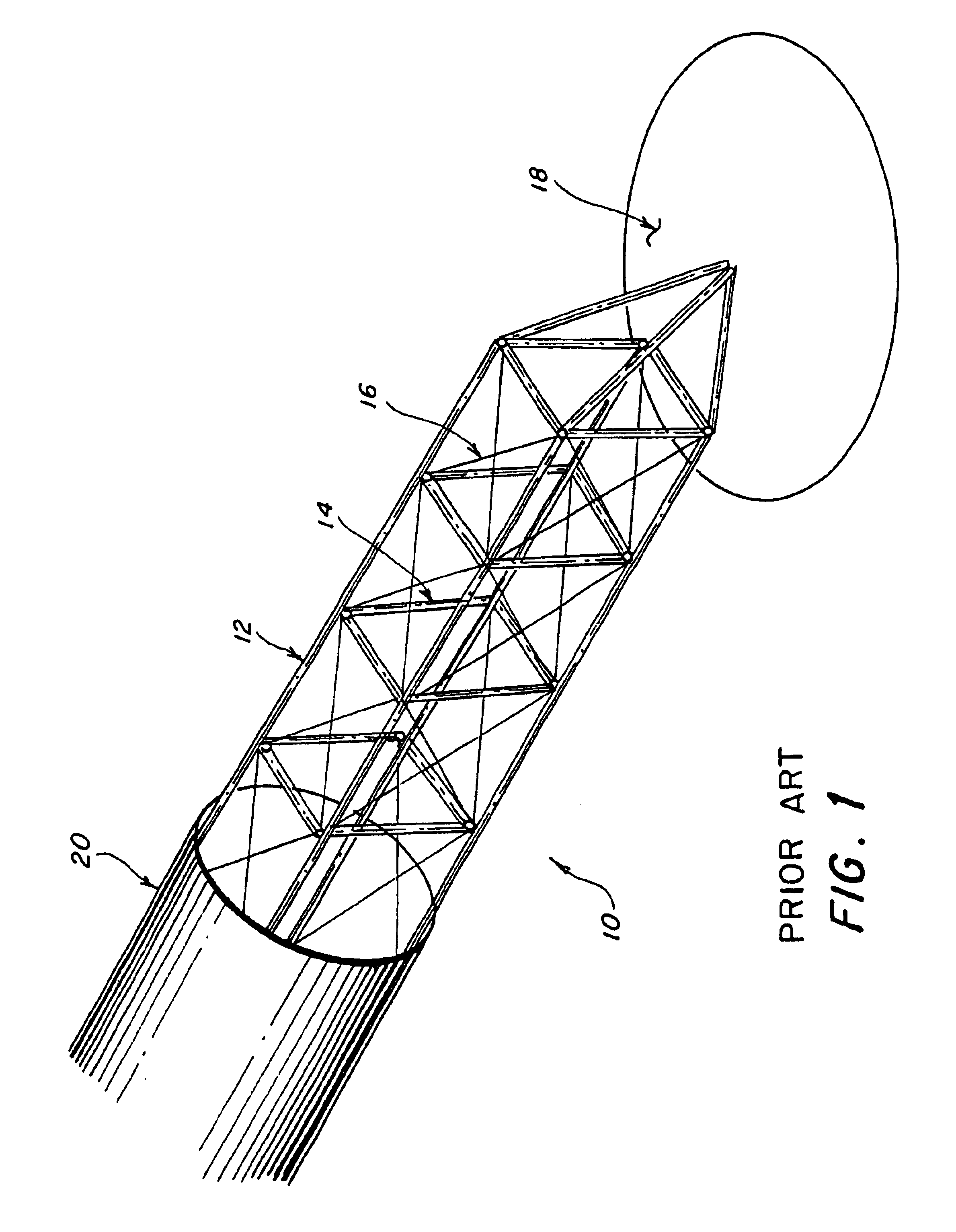

Rapidly-deployable lightweight load resisting arch system

ActiveUS20060174549A1Requires minimizationAdditional strength and stiffnessArched structuresVaulted structuresFiberVertical plane

A rapidly-erectable lightweight load resisting system for the construction of buried arched bridges, tunnels or underground bunkers, has a plurality of lightweight arched tubular support members which are formed of a fiber reinforced polymer material and are substantially oriented in a vertical plane. The lightweight tubular support members are connected by at least one or more lateral force resisting members which are positioned in a direction perpendicular to the vertical plane of the tubular support members, and which are capable of transferring vertical loads to the tubular support members and of providing lateral-load capacity to the load resisting system. The tubular support members are fitted with one or more holes near the top which allows them to be filled with a suitable material to provide additional strength or stiffness.

Owner:UNIVERSITY OF MAINE

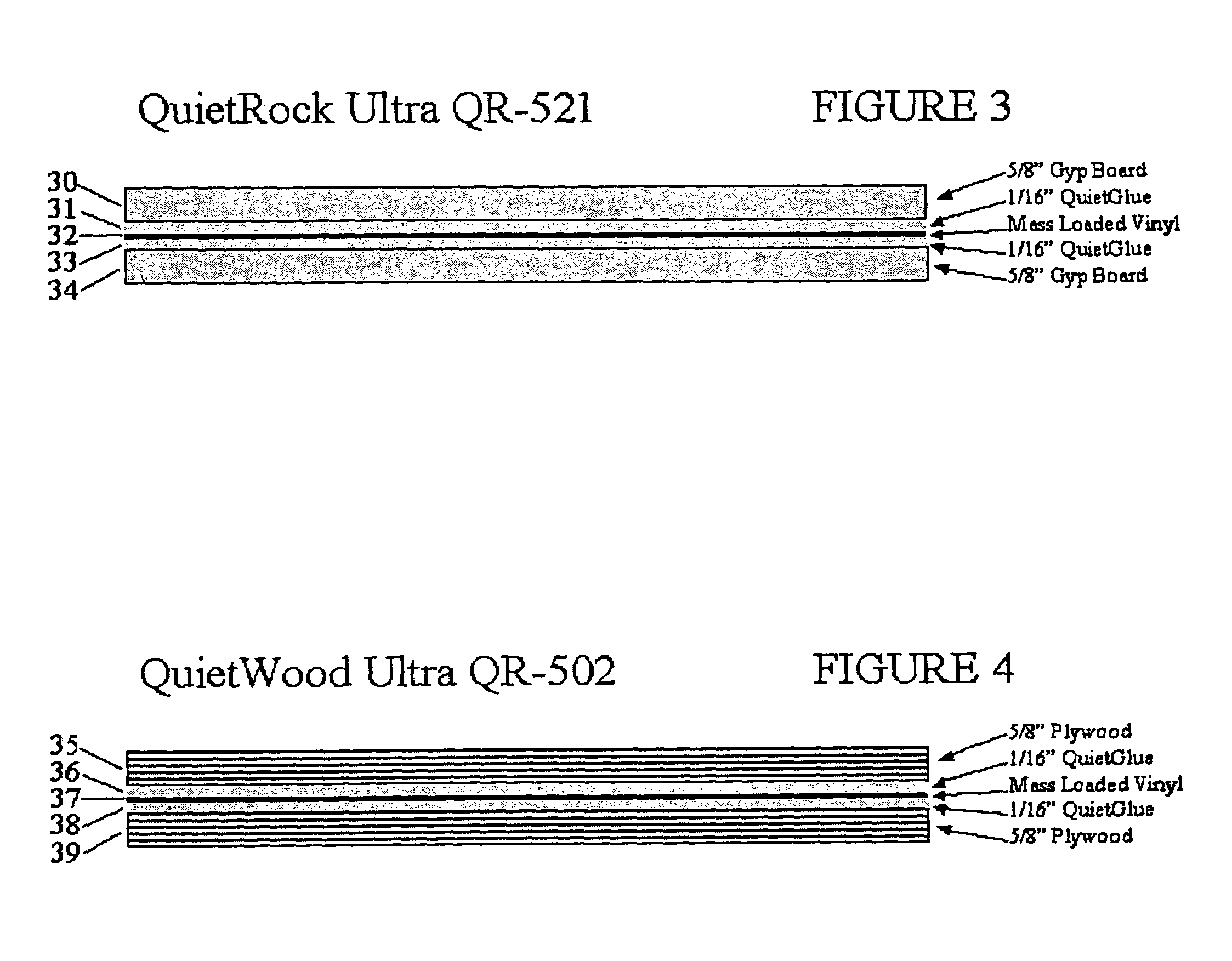

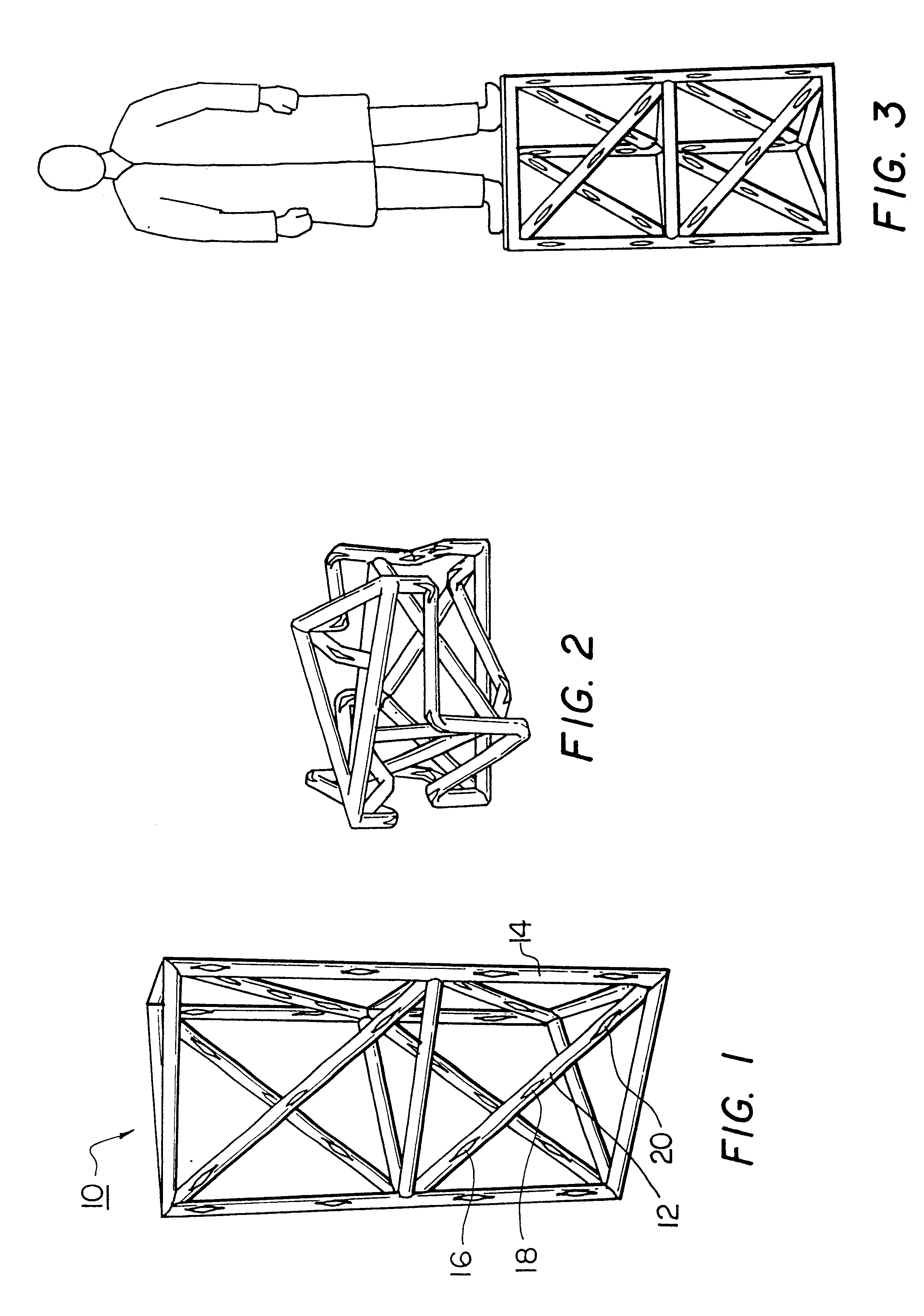

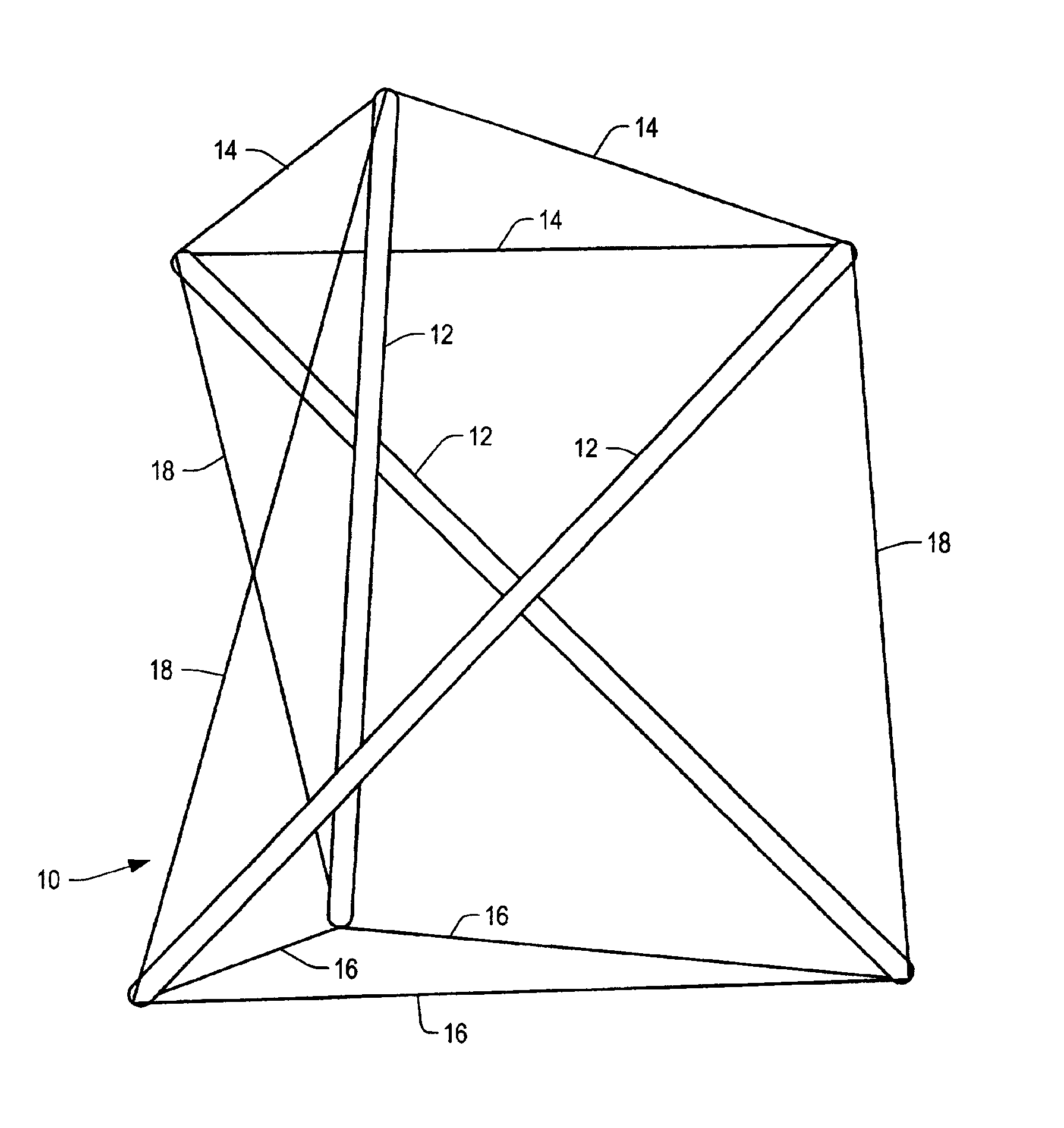

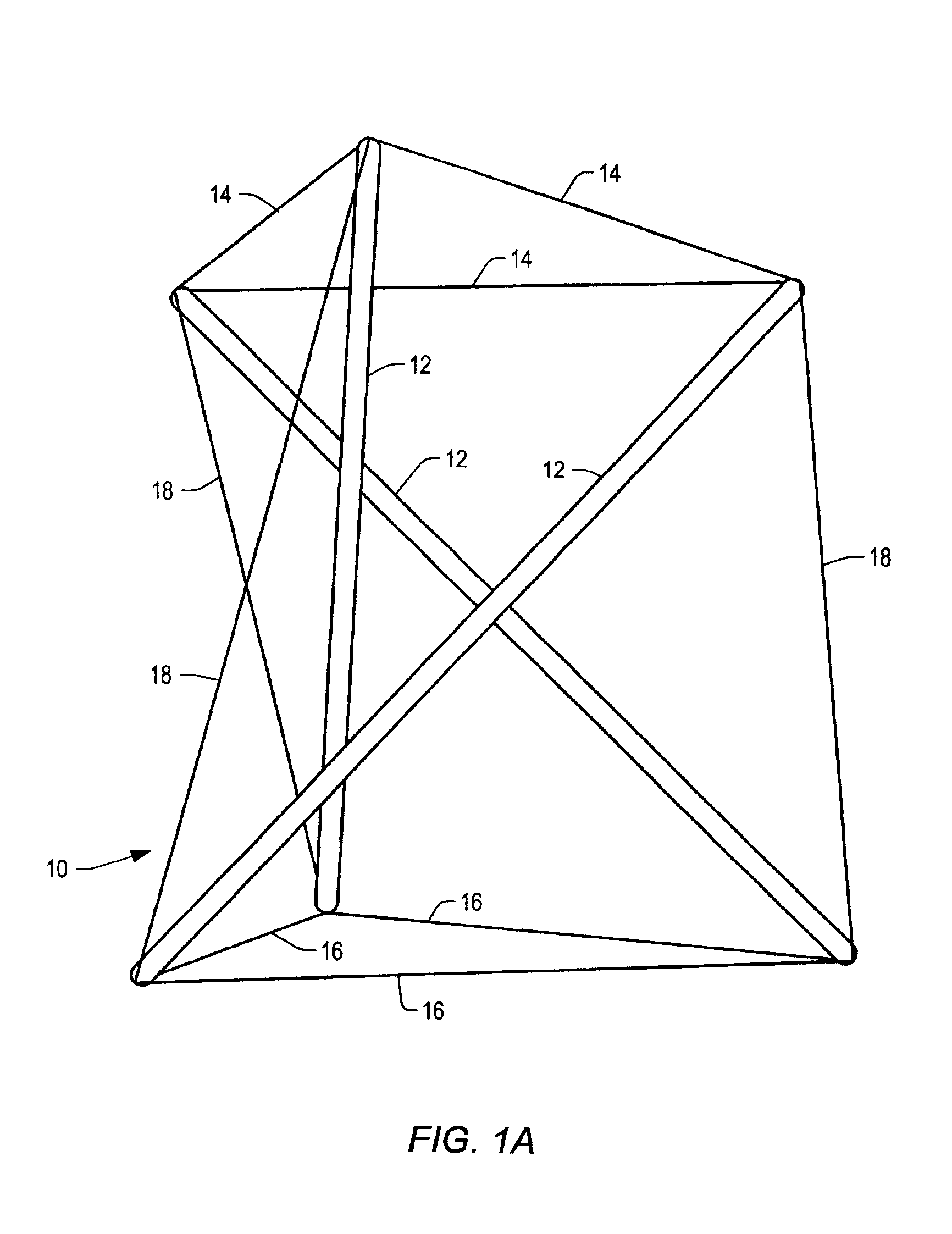

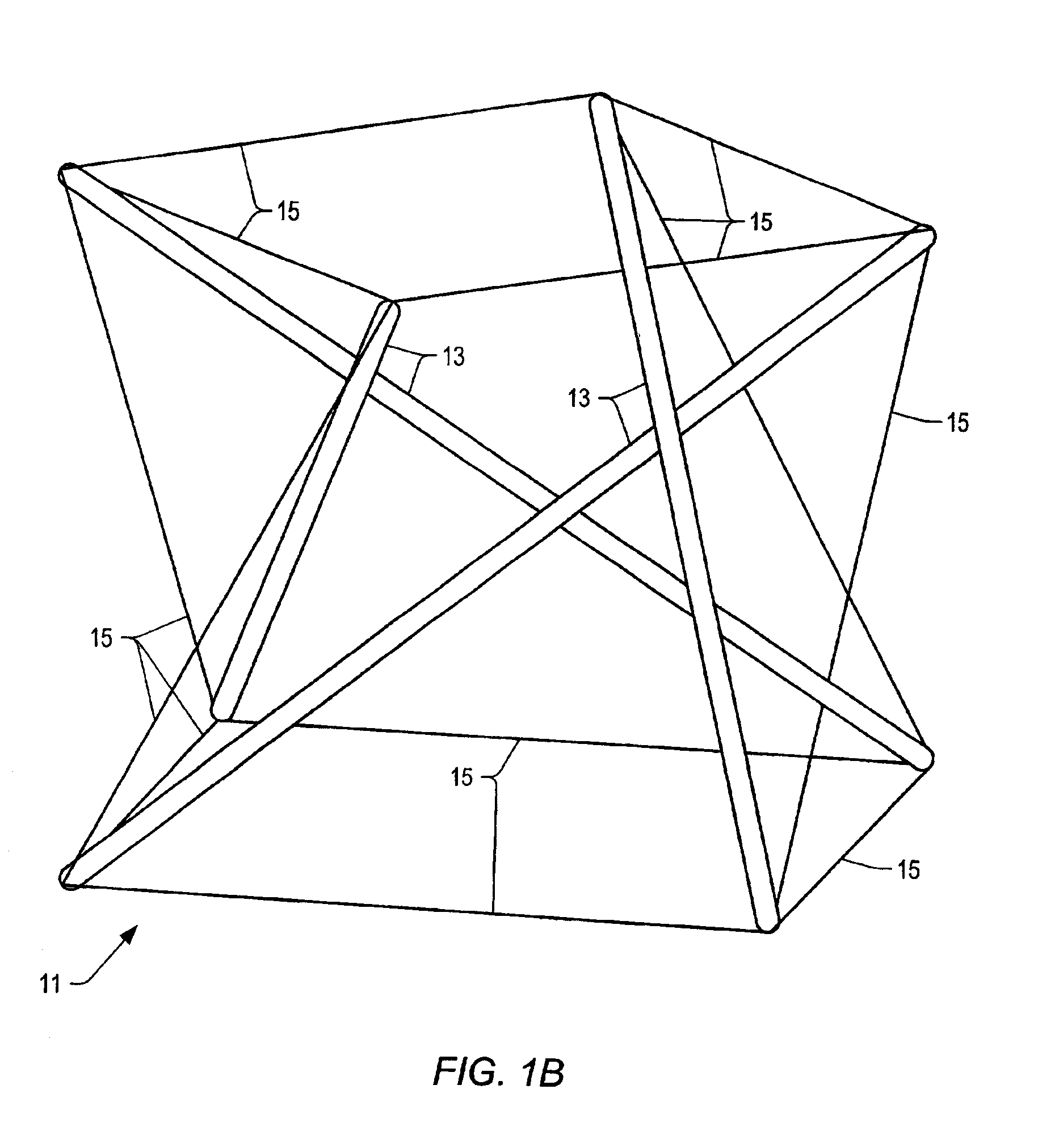

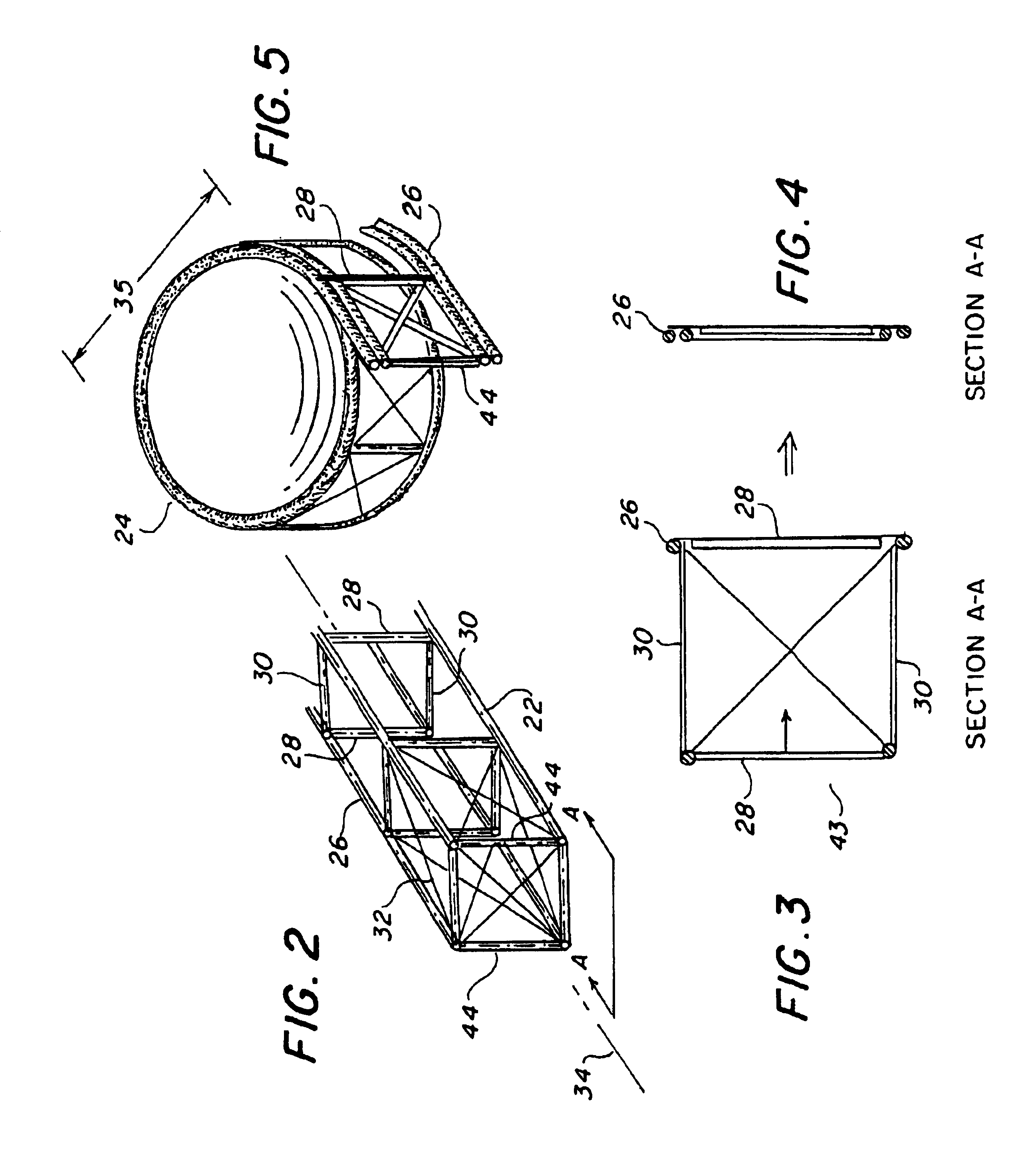

Tensegrity unit, structure and method for construction

Tensegrity units may be used to form a tensegrity structure. Each tensegrity unit may include n face tension members, n continuous tension members, and n compression members. A bracket for the tensegrity unit may allow for adjustment of position of portions of the tension members when the tensegrity unit is not in a deployed state. The tension members may be coupled to the tensegrity unit so that there are no loose tension member ends. The unit may be deployed from a collapsed state by positioning the compression members and tension members in a proper orientation and adjusting the length of at least one compression member. Adjusting the length of at least the one compression member may allow tension to be applied to each tension member. A tensegrity structure may be formed from tensegrity units by joining a number of tensegrity units together.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

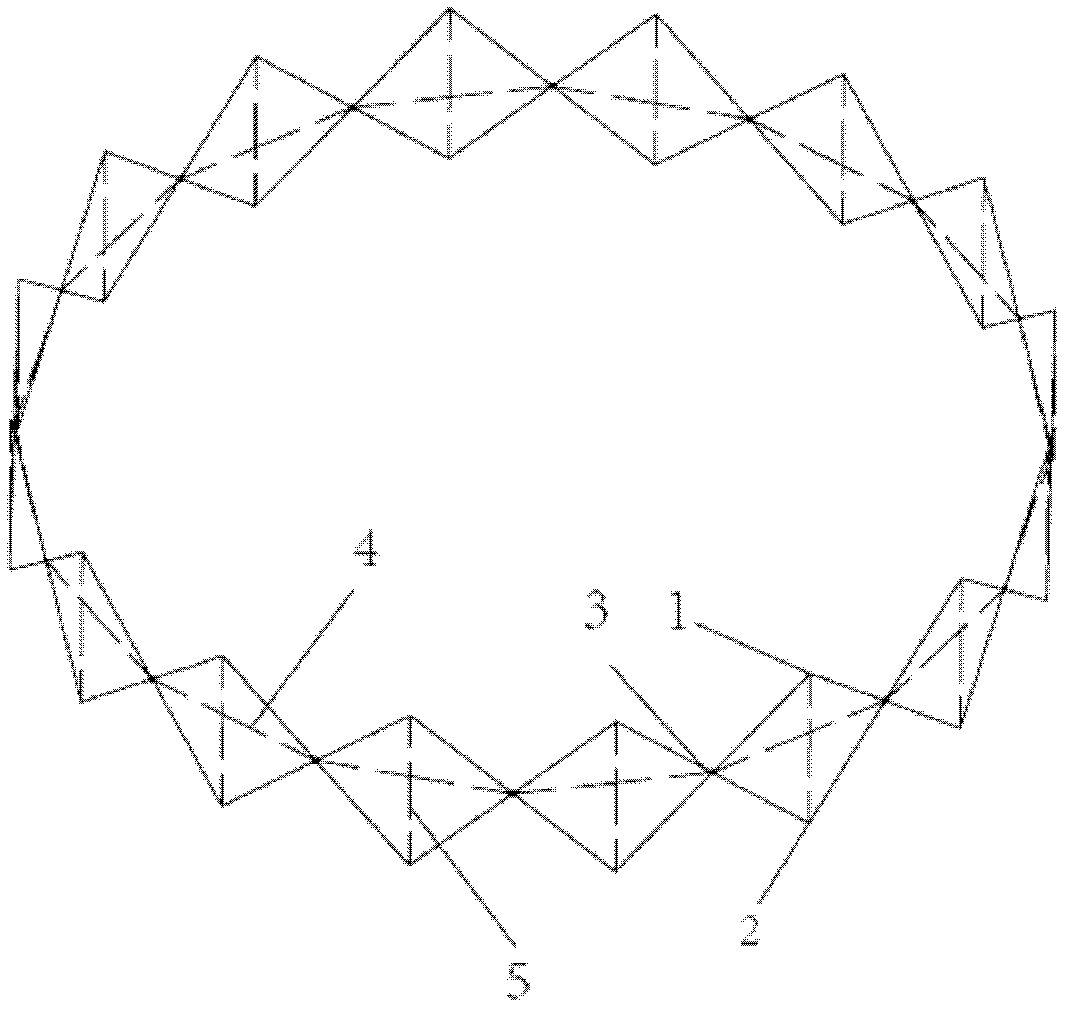

Deployable cable pole dome structure

InactiveCN102605861AIncrease stiffnessReduce in quantityArched structuresVaulted structuresActive cableFull extension

The invention discloses a deployable cable pole dome structure, comprising an inner cable pole body and an external single-freedom-degree annular connecting bar mechanism, wherein the single-free degree annular connecting bar mechanism comprises at least four shearing type units, a passive cable and an active cable. The invention uses the single-freedom-degree annular connecting bar mechanism to drive the dome structure to fold and unfold, thus number of driving devices is reduced; the active cable and the passive cable are arranged in the external annular connecting bar mechanism, and the prestressing force exists at a full extension state, so that the rigidity of the structure is increased and the material does is reduced; only the active cable needs to be fixed at a full extension state, and an additional locking device is not needed; a coverage range of the dome structure is provided by the inner cable pole body, thus, the external load of the structure is mainly born by the inner cable pole body; the inner cable pole body is composed of a high-strength inhaul cable and a pressure bar; the self weight is light; and the rigidity is mainly provided by the prestressing force, and the stress performance is excellent.

Owner:SOUTHEAST UNIV

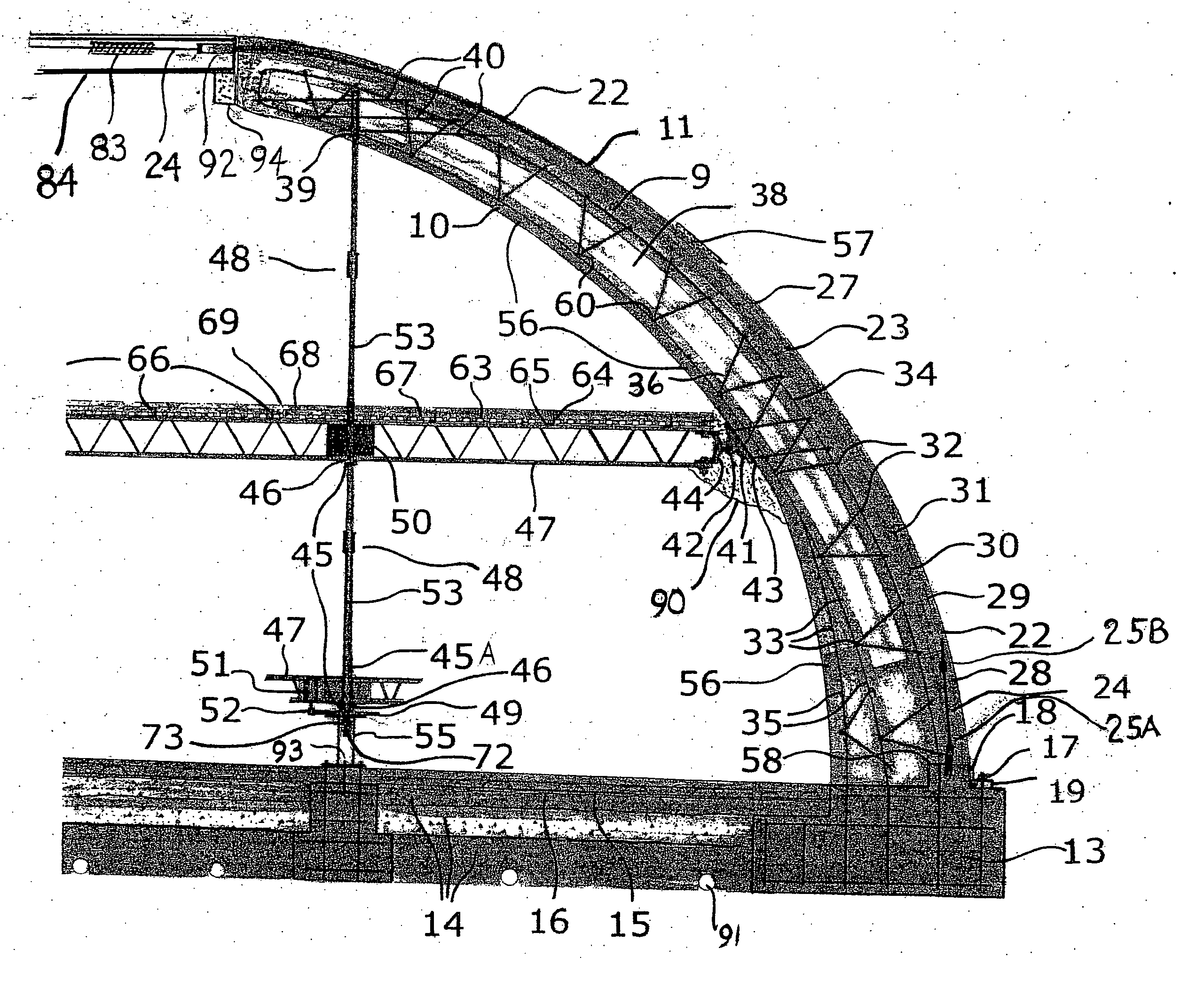

Hybrid arched overfilled structure

InactiveUS6640505B1Reduces initial capital investment requiredLow costBuilding roofsArtificial islandsEngineeringHorizontal orientation

A hybrid arched overfilled structure includes a combination of pre-cast side elements and at least one cast-in-place crown sector element. The side elements are pre-cast generally in a horizontal orientation and subsequently lifted into place. The crown sector element is cast in place between the side elements. In one form of the invention, each of the three sections makes up about one-third of the overall arch span.

Owner:CONTECH ENGINEERED SOLUTIONS

Elongated truss boom structures for space applications

An elongated truss boom structure is adapted to be flattened and coiled to a stowed configuration. The truss boom includes longerons, battens, and diagonals. A fixed ladder shaped structure is formed by a plurality of fixedly coupled battens which interconnect two adjacent longerons. The truss boom is flattened for stowage by arranging all of the longerons coplanar to the plane of the fixed ladder shaped structure. The longerons preferably have a corrugated cross section. For stowage the longeron is heated and compressed into a ribbon shaped cross section, and upon deployment the longeron is heated to restore its corrugated cross section. A mechanical assembly machine includes a drum, a stowed flattened truss boom rolled into a coil around the drum, a device for unrolling the coil, an actuating and locking mechanism, and a control arm which connects the actuating and locking mechanism to the drum.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

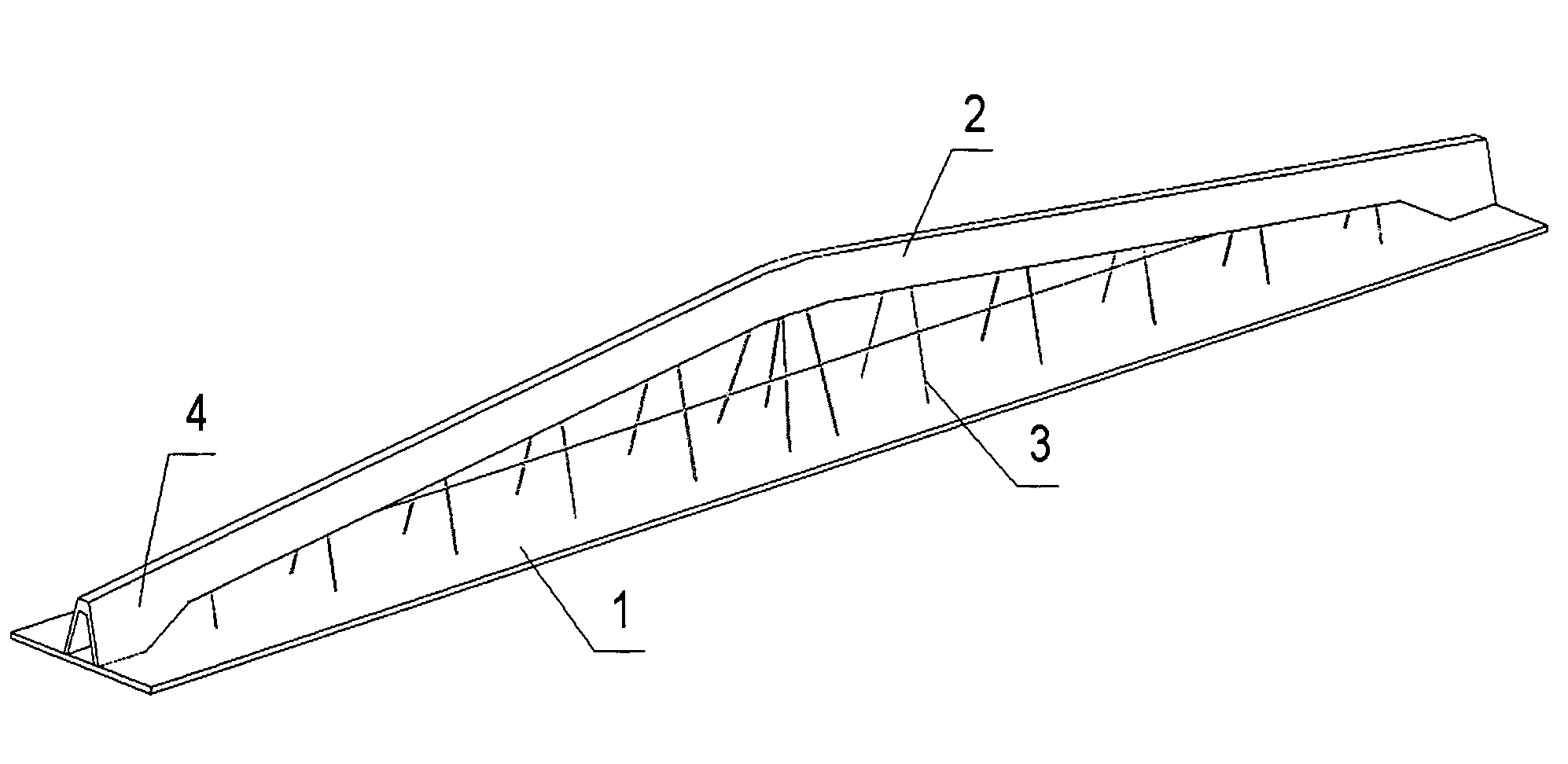

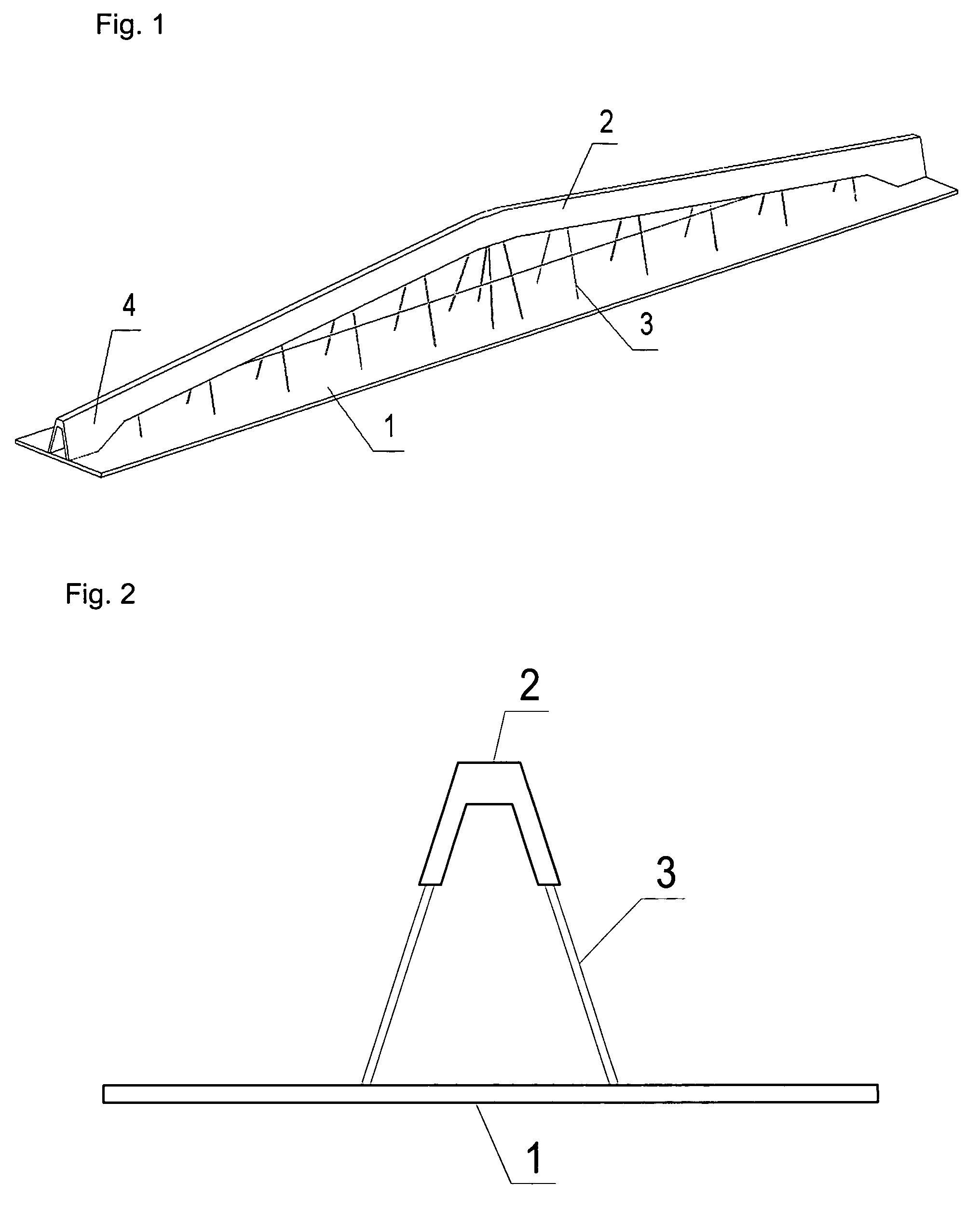

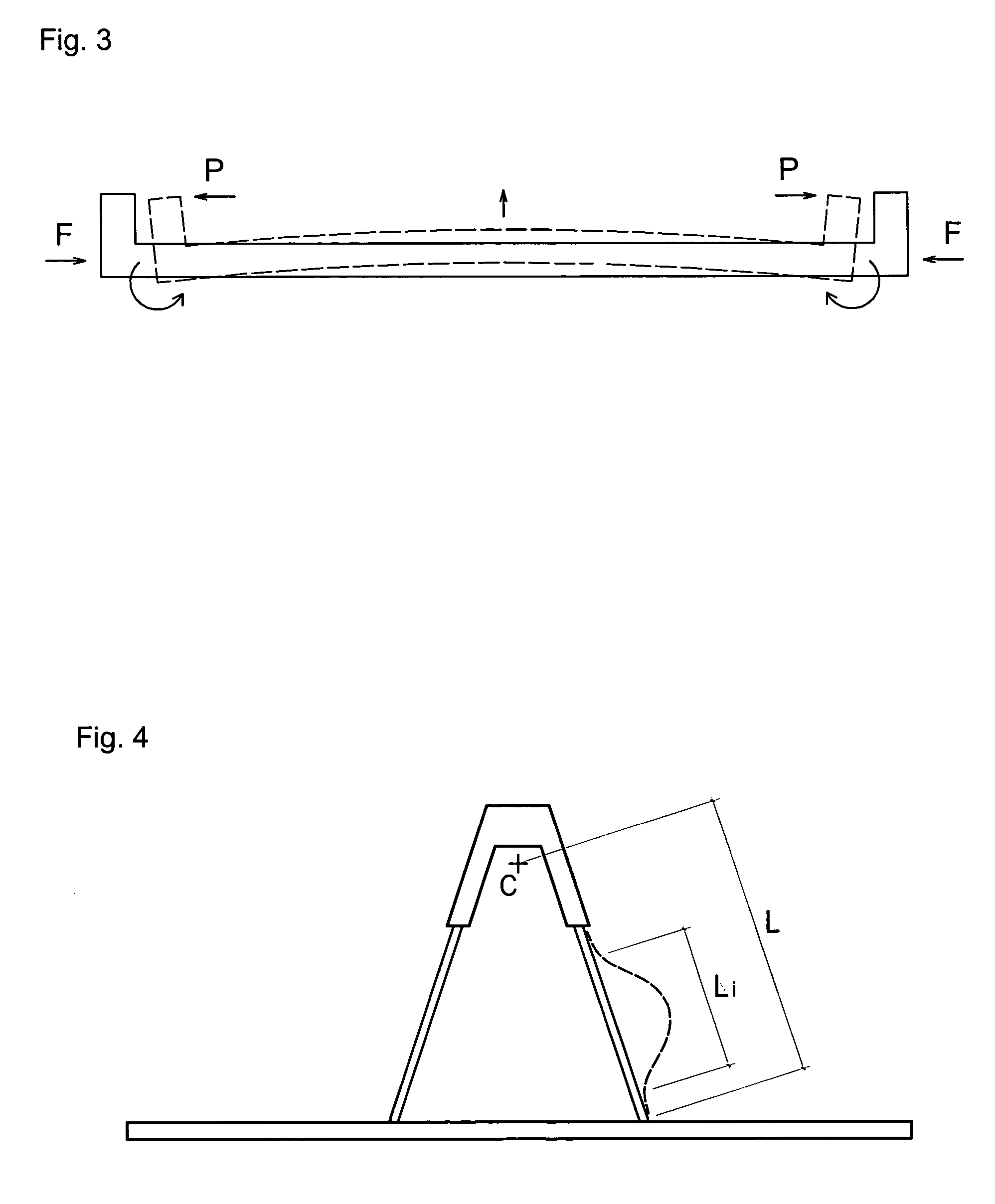

Indirectly prestressed, concrete, roof-ceiling construction with flat soffit

An indirectly prestressed concrete roof-ceiling construction is a prefabricated element for constructing large-span industrial buildings. The construction includes a distinctly wide and thin concrete soffit plate and an upper concrete girder of an inverse “V”-shaped cross section, interconnected by slender steel pipe-rods that are used to stabilize the upper girder against lateral buckling and to prevent the plate and the girder from getting closer or further away from each other. Prestressing of the soffit plate causes compression in the upper girder which passively (indirectly) pushes the ends of the construction, acting on some eccentricity over the center of gravity of the cross section, causing rotation of its ends, bending in that way the soffit plate upwards. There are two efficient methods of prestressing these constructions.

Owner:MARA INST D O O

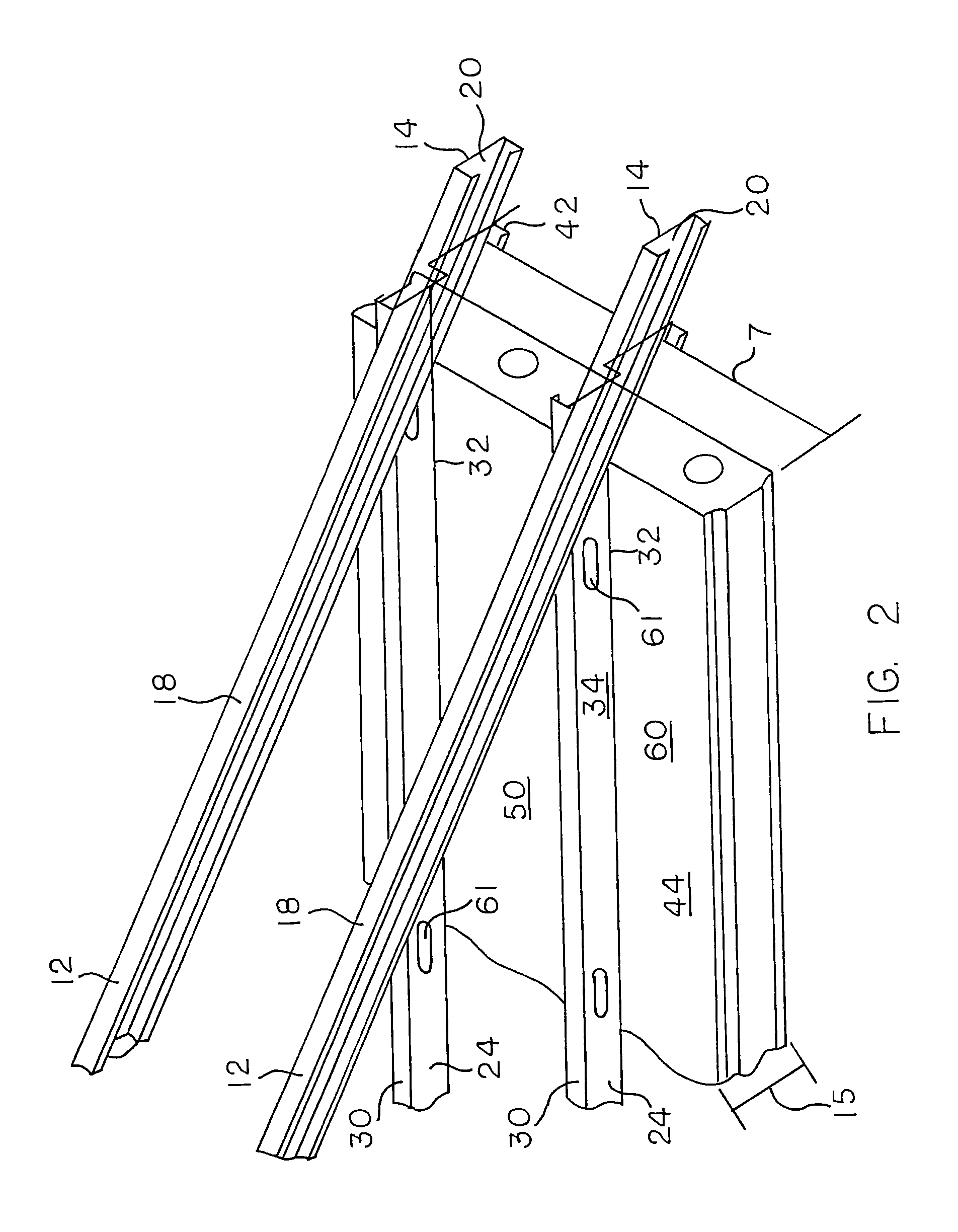

Light gauge metal truss system and method

InactiveUS7093401B2Easy to engageConvenient nestingBuilding roofsLayered productsEngineeringUltimate tensile strength

A truss system wherein the structural components and fixtures are formed from light gauge metal. The trusses are fabricated from roll formed truss chord members and truss web members. The truss chord members are roll formed to have a generally U-shaped cross-section with a base and two substantially parallel legs with recessed web attachment faces and outwardly extending stiffening flanges to improve structural capacity thus improving the strength-to-weight ratio of the chord member and minimizing costs. The truss web members are formed by nesting two roll formed C-shaped members to form a web member which is box-shaped in cross section. The web members provide the structural advantages of a box-shaped member and the ease and flexibility of a roll formed member. The truss system and method provides improved means and methods for positioning and attaching the web members to the chord members as well as improved truss clips for resistance to uplifting forces and improved truss jack clips for forming hip connections.

Owner:INNOVATIVE STEEL TECH

Building with integrated natural systems

InactiveUS20110214364A1Little strengthForce is requiredPhotovoltaic supportsBuilding roofsEnvironmental resource managementGreenhouse

A building is provided with integrated natural systems that reduce dependency on external resources to operate and maintain the building. A source of electricity is provided through an extensive set of solar panels that may be incorporated on louvers mounted to the exterior of the building. The building has a double insulative layer to include an outer airtight membrane or cover, and an internal building structure that defines habitable space within the structure. Rainwater may be collected and stored within a subsurface well. The space between the internal structure and outer membrane may support the growth of vegetation in a greenhouse environment. A flow of temperature regulated air is provided through the structure by a set of underground pipes in which the air is circulated through a central core of the building, into the habitable space, and then outward into the greenhouse space.

Owner:MICHAEL FULLER ARCHITECTS PC

Support system for solar panels

ActiveUS8256169B2Easy to deployEasy to removePhotovoltaic supportsSolar heating energySupporting systemBraced frame

Precise parameters are maintained in a support system for solar panels or other panel-like structures through use of a collapsible folding, support frame which is preassembled to precise tolerances at a convenient staging site before being collapsed for shipment. Installation on flat roofs is also facilitated through the use of a roof interface frame which rotatably supports the panel support frame of the support system and folds along with it at the assembly, staging site.

Owner:NORTHERN STATES METALS

Roof truss system

An adjustable roof truss that includes roof truss members, roof base members and a central body containing a polymer matrix. The roof truss members include a pivot end, a connection end, a roof facing edge, an inside edge, and a pivot surface. The roof base members include a receiving end, a connecting end, a top edge, a bottom edge, and a contact surface. The roof truss members are pivotally connected to the roof base members by a pivot fastener inserted through a pivot opening on the roof base members and a stator opening on the roof truss members. One or both of the roof truss members and the roof base members include an embedded portion extending from the roof facing edge or the bottom edge respectively into the central body. Expansion hole(s) are positioned along the embedded portion such that the polymer matrix expands through the expansion holes.

Owner:SYNTHEON HLDG SPA

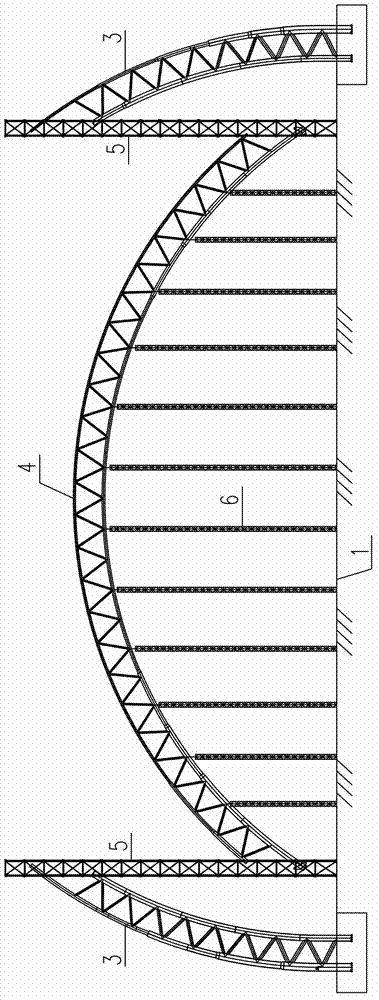

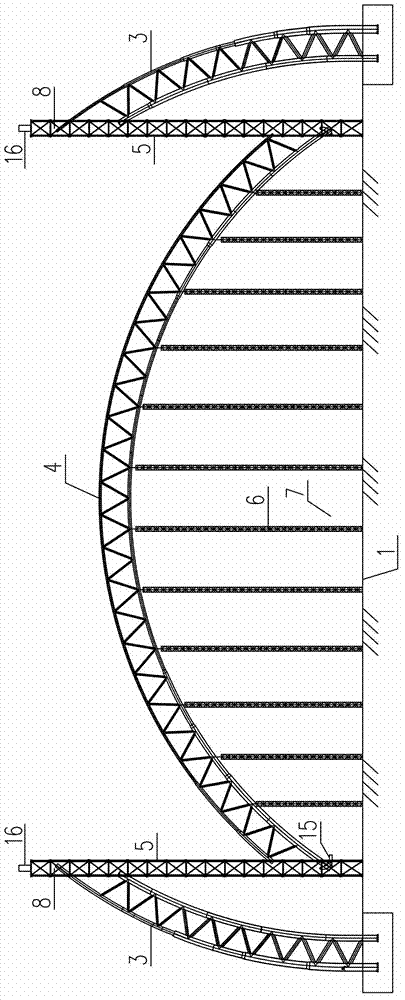

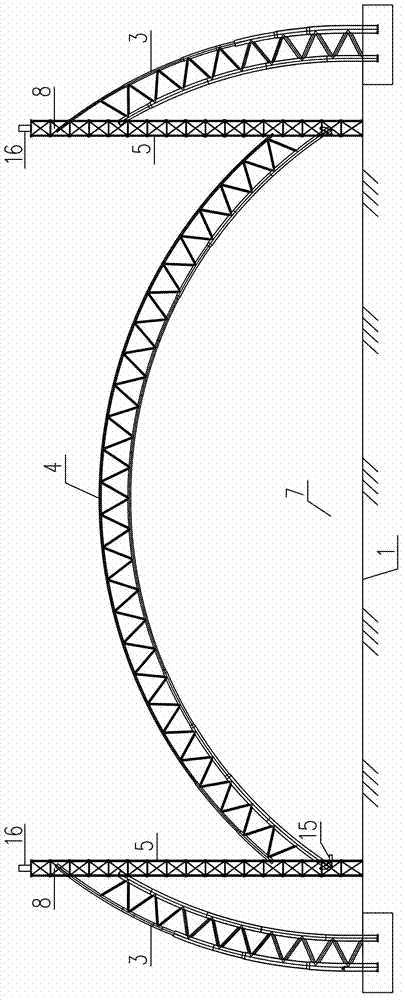

Construction method for lifting arch structure in zero-deformation state

ActiveCN102777043AReduce or even eliminate horizontal thrustHigh precisionArched structuresVaulted structuresButt jointArchitectural engineering

The invention discloses a construction method for lifting an arch structure in a zero-deformation state. The construction method specifically comprises the following steps: 1, sectioning a large-span arch structure into floor arch structures and a lifting construction unit; 2, building up a support bed jig, splicing and assembling the lifting construction unit in situ and simultaneously installing the floor arch structures; 3, installing horizontal steel strands, horizontal jacks and tensioning the horizontal jacks to tension the horizontal steel strands; 4, building up lifting frames, installing lifting jacks and vertical lifting steel strands; 5, alternately tensioning the horizontal steel strands and the vertical lifting steel strands level by level so that the lifting construction unit is separated from the support bed jig; 6, lifting the lifting construction unit to a preset height to be in butt joint with the floor arch structures at two sides, thus forming the large-span arch structure; and 7, unloading and disassembling the horizontal jacks, the horizontal steel strands, the lifting jacks, the vertical lifting steel strands and the lifting frames level by level to finish the construction. The construction method has the advantages of high construction accuracy, high quality, reliable safety and low-cost construction measures.

Owner:ZHEJIANG JINGGONG STEEL BUILDING GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com