Patents

Literature

95results about How to "Reduce sound transmission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

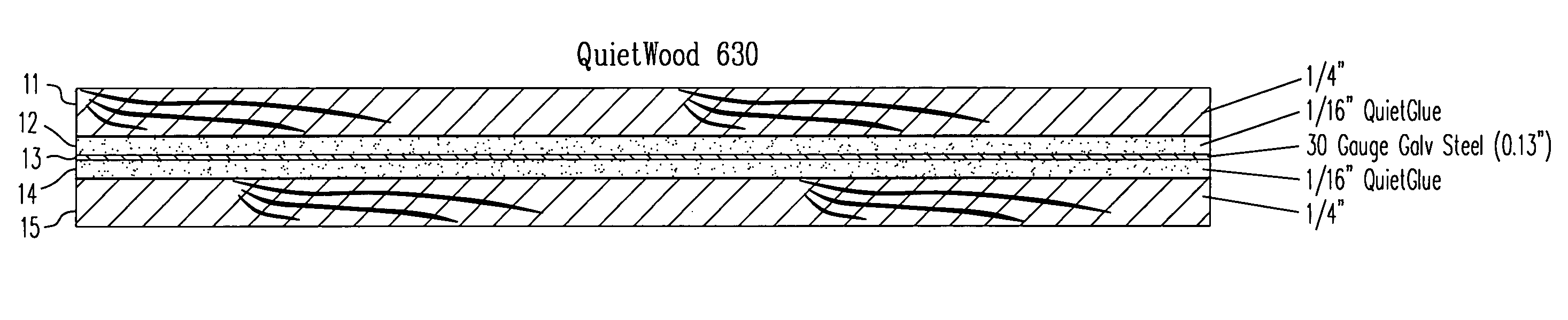

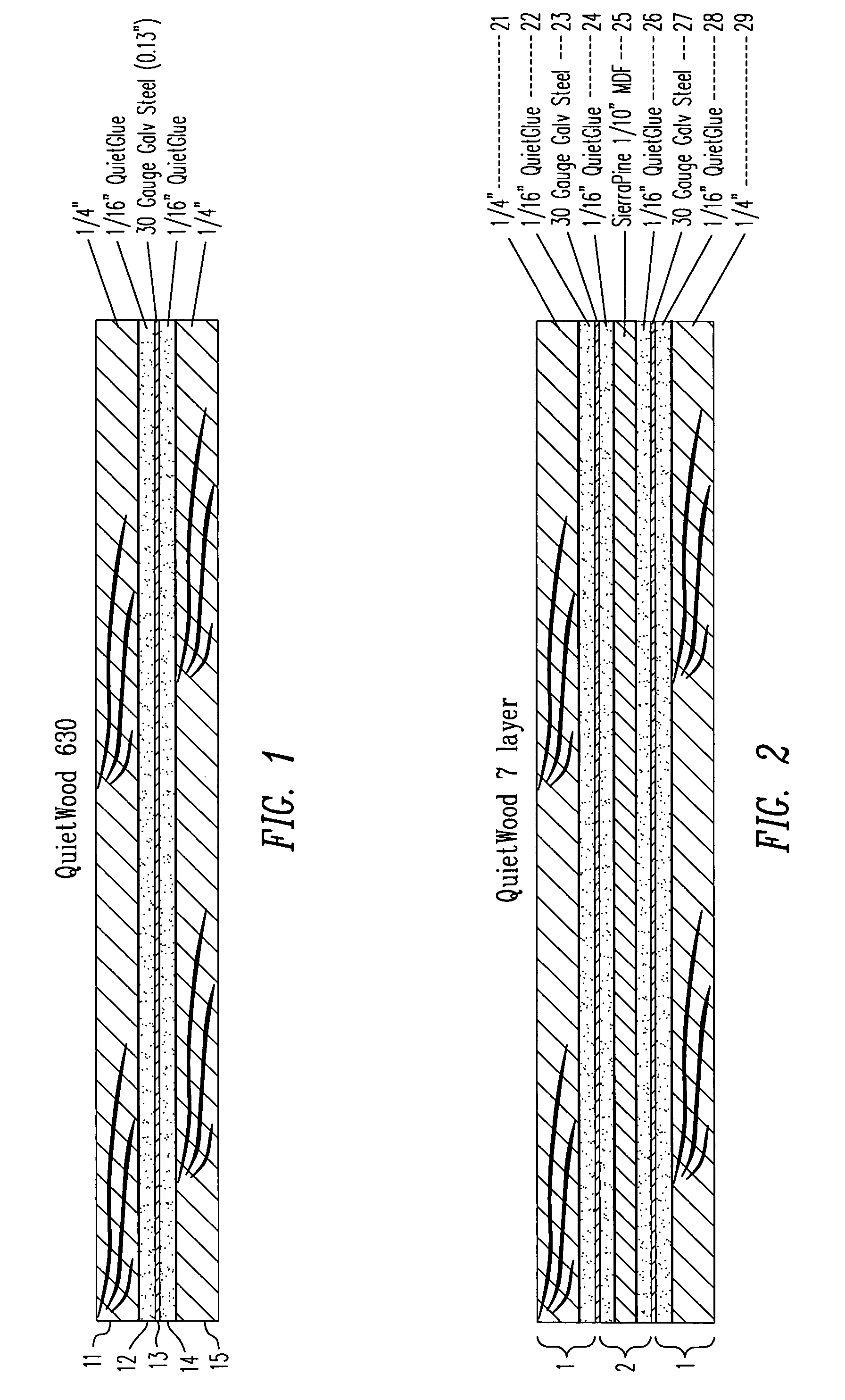

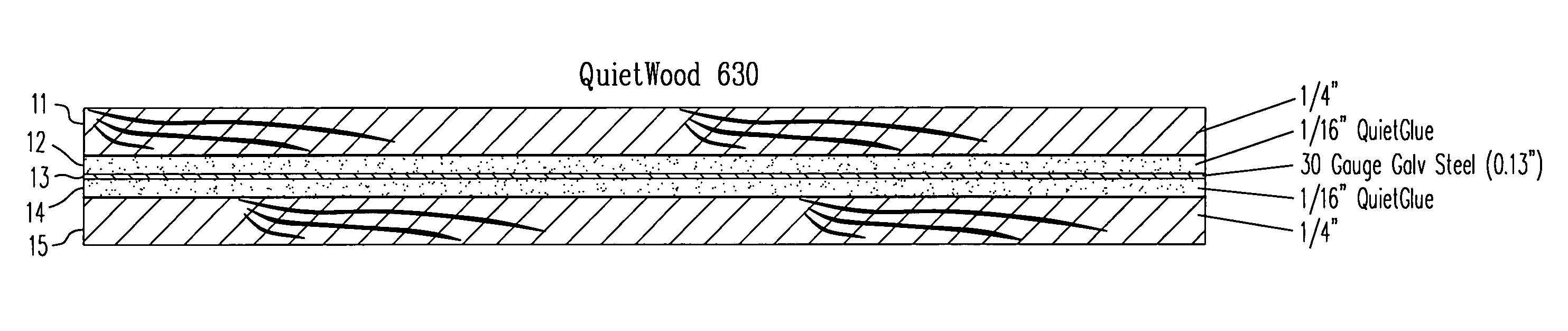

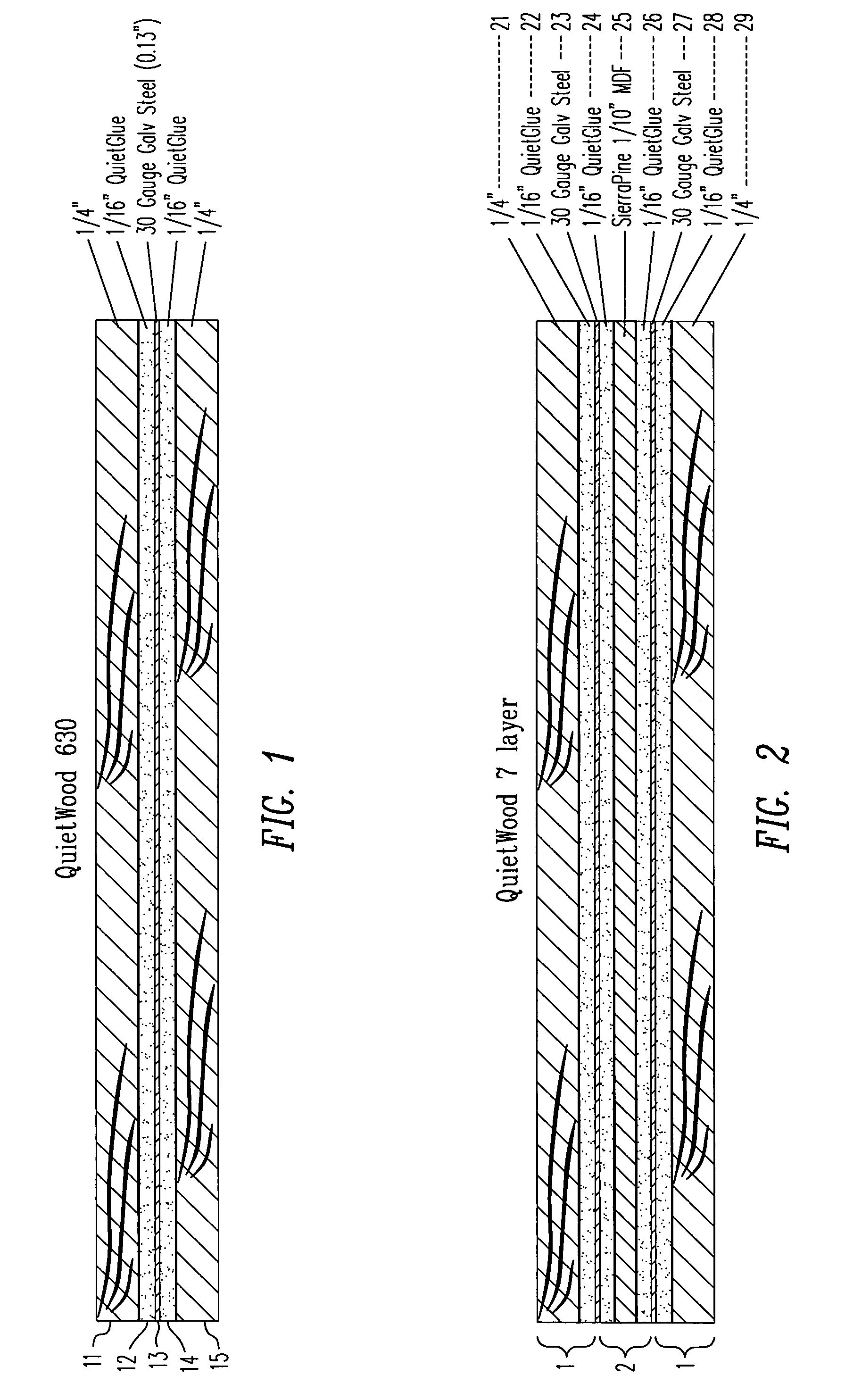

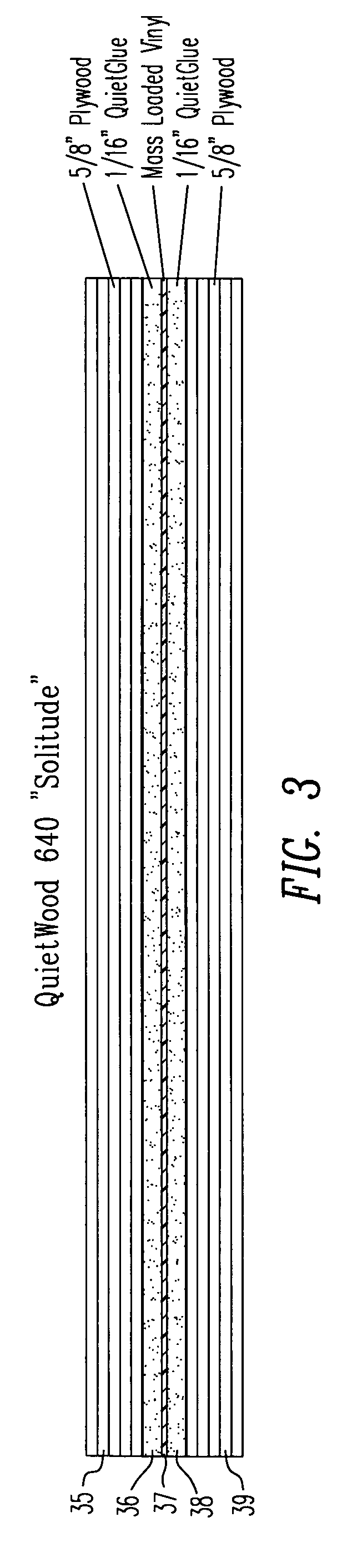

Acoustical sound proofing material and methods for manufacturing same

ActiveUS7181891B2Improve abilitiesReduce sound transmissionBuilding roofsCeilingsUltrasound attenuationCellulose

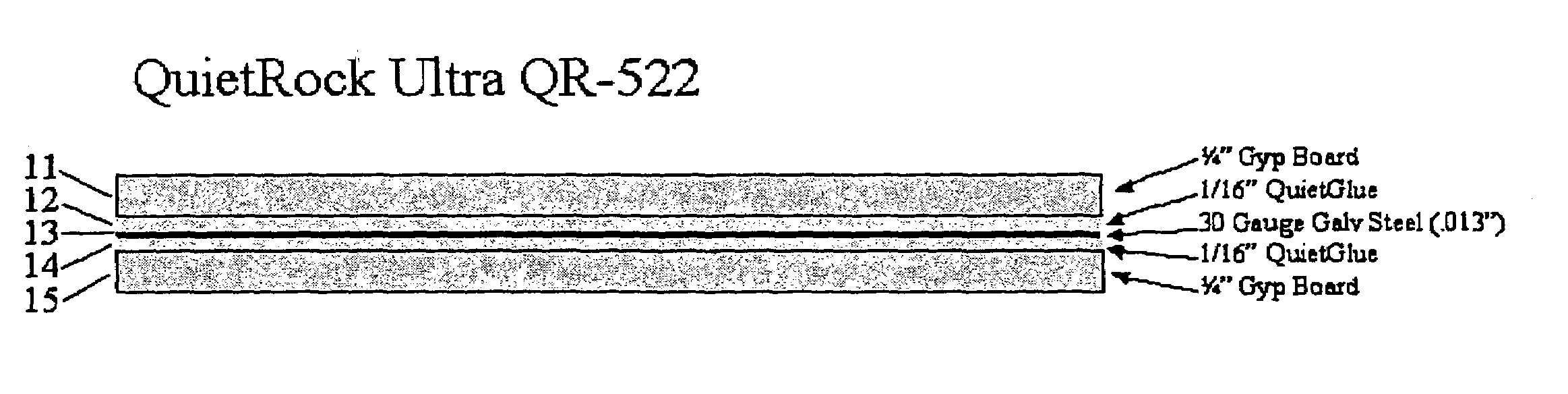

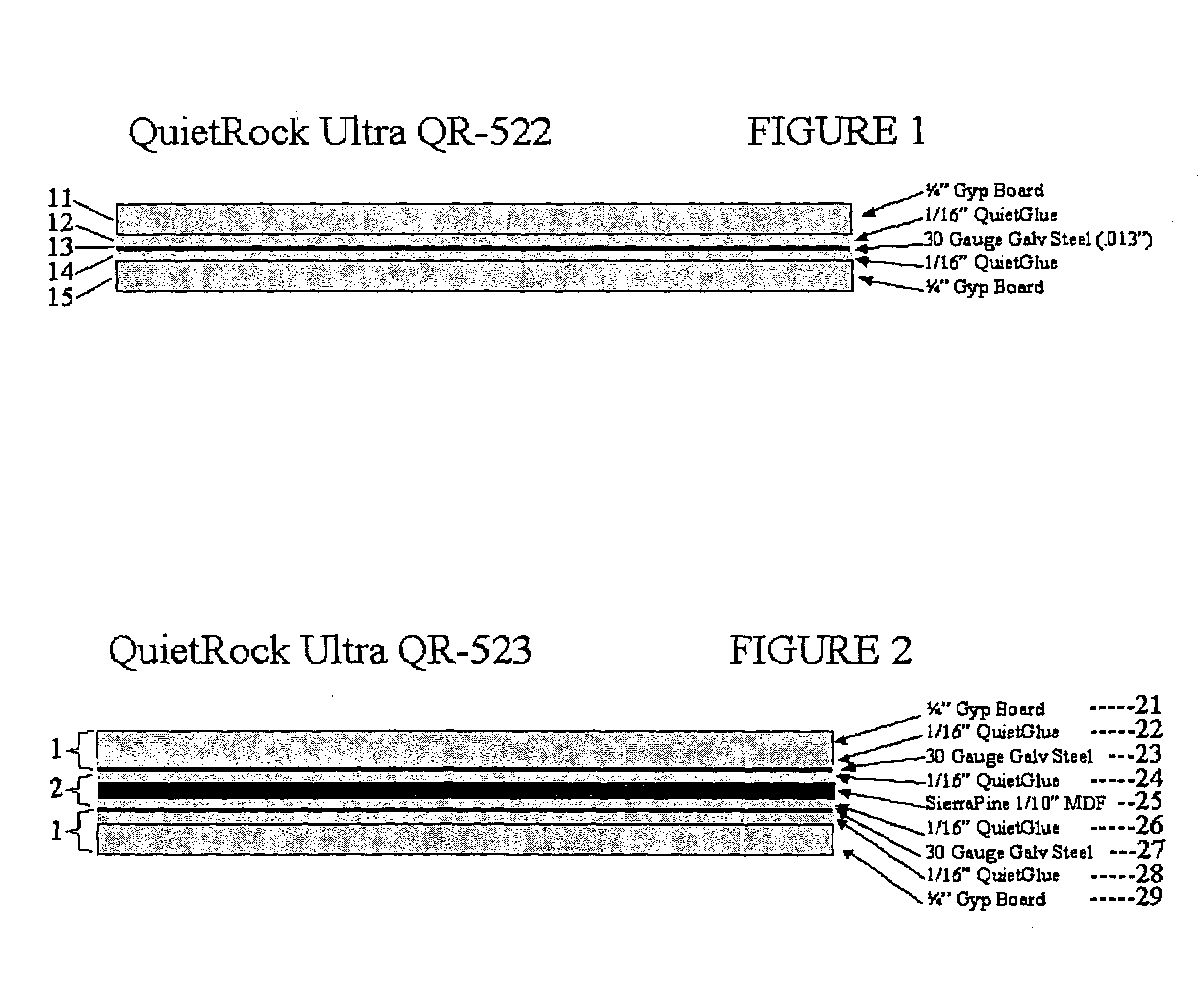

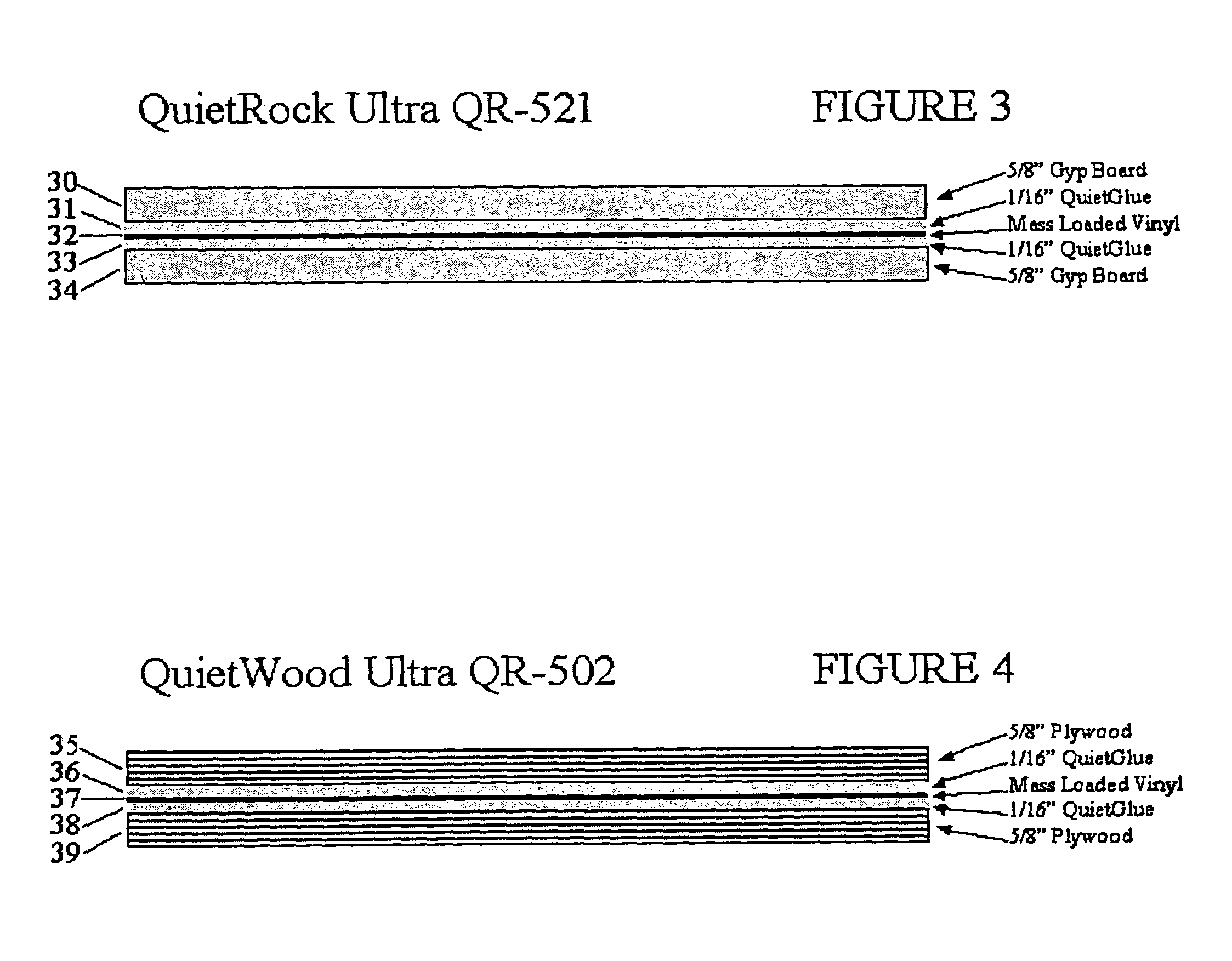

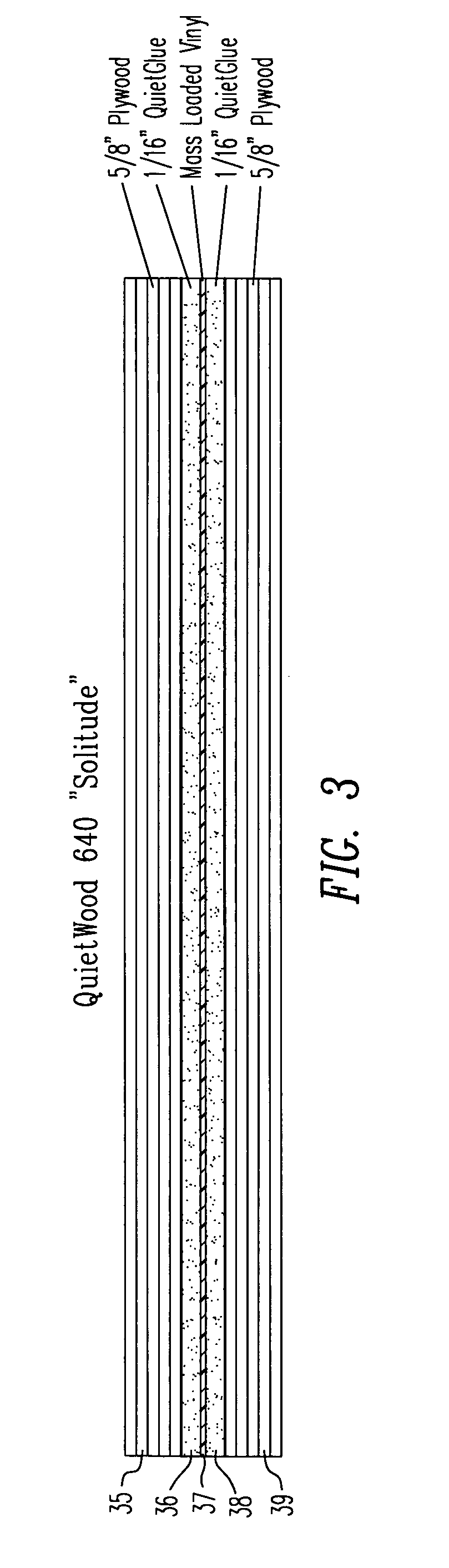

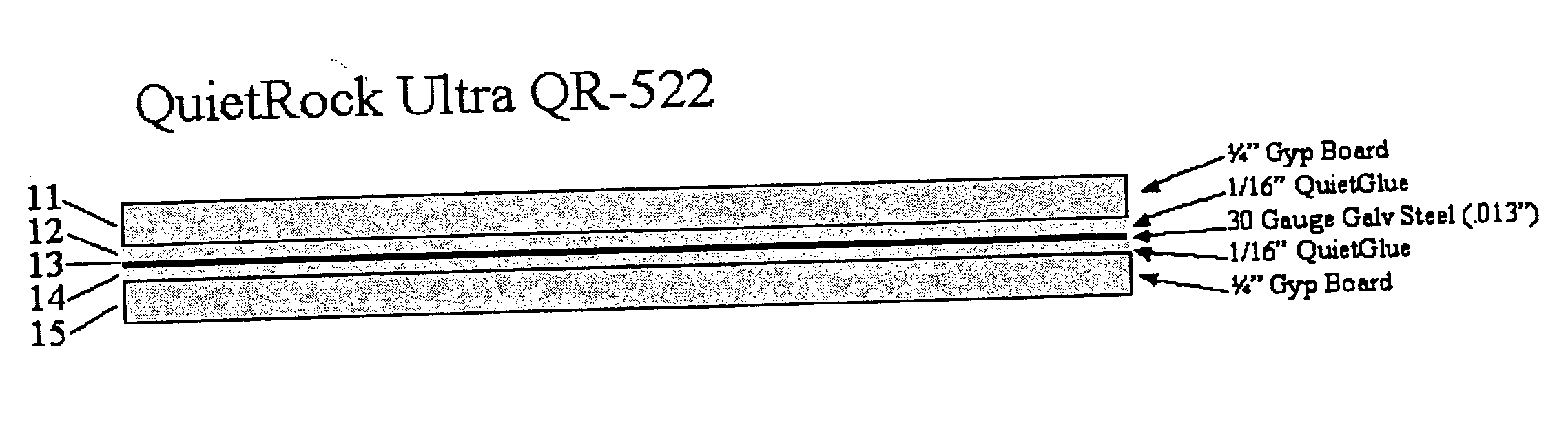

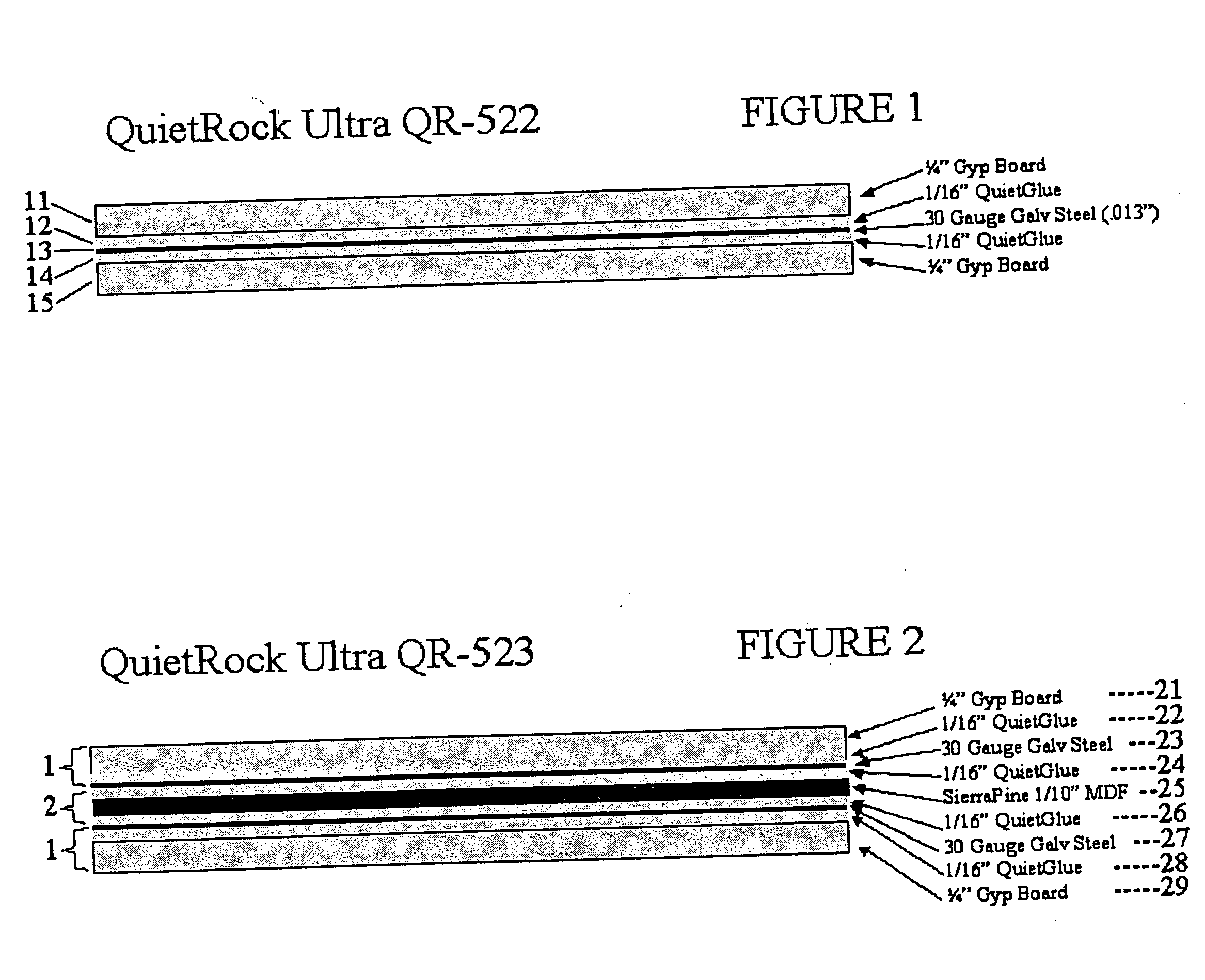

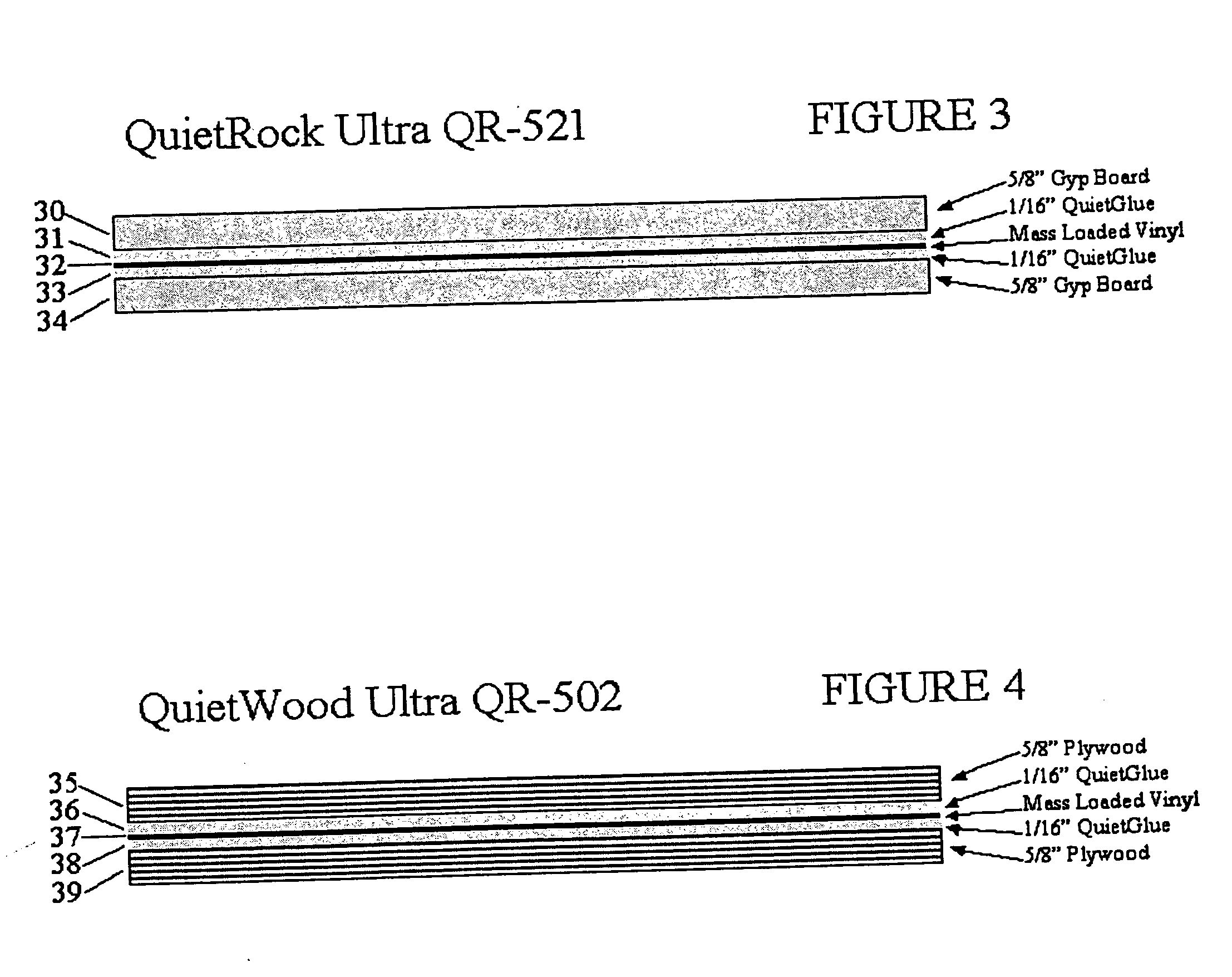

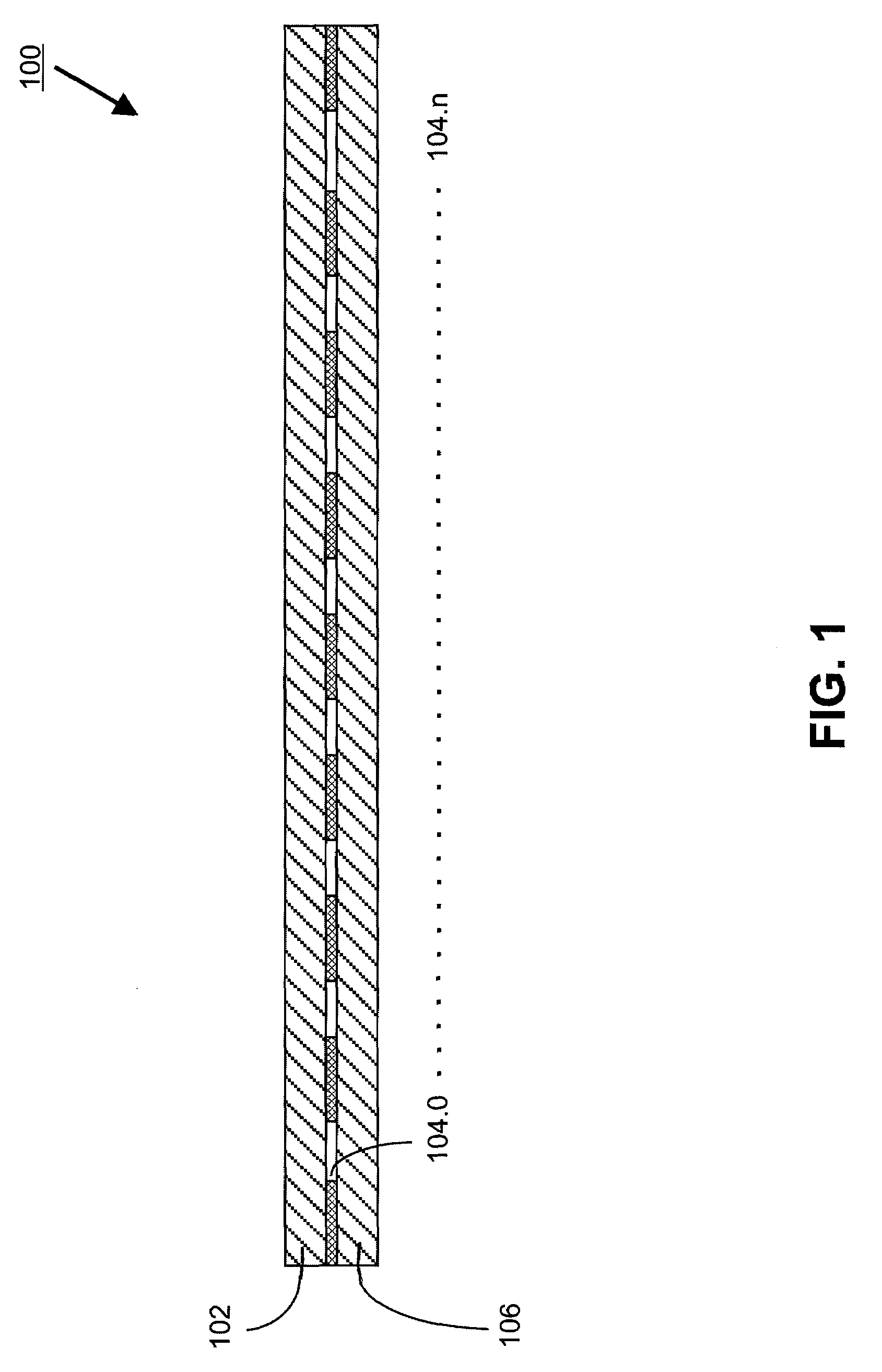

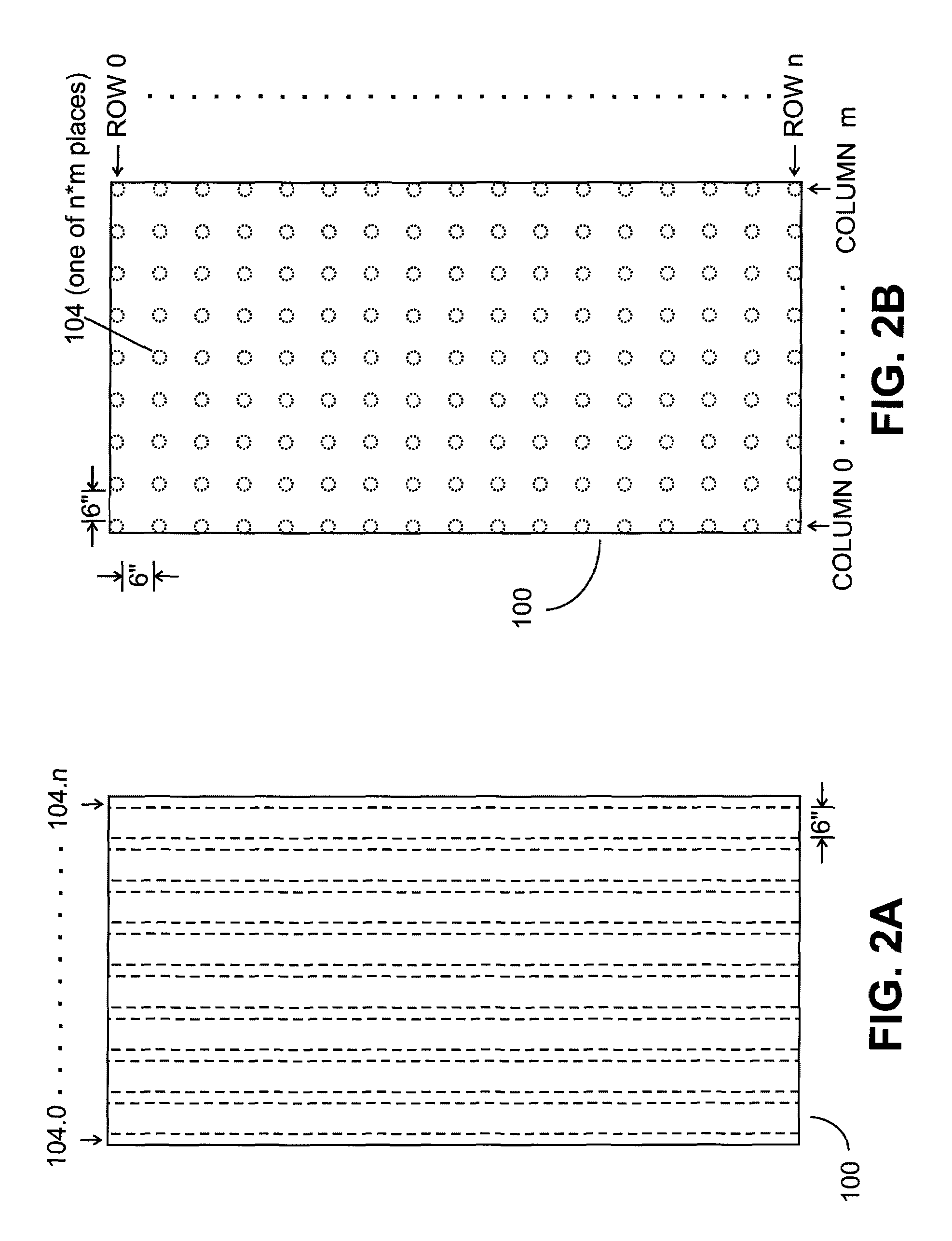

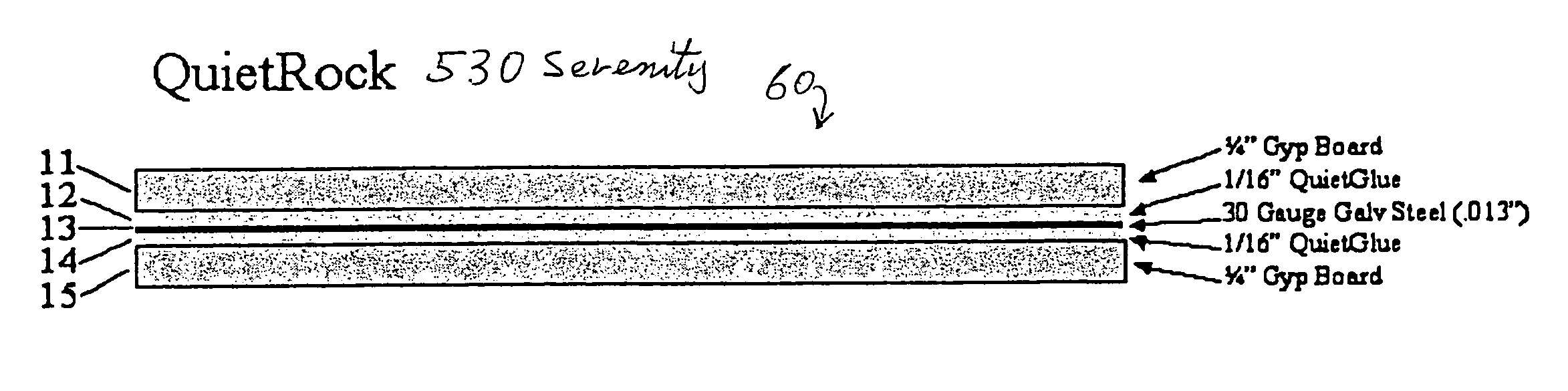

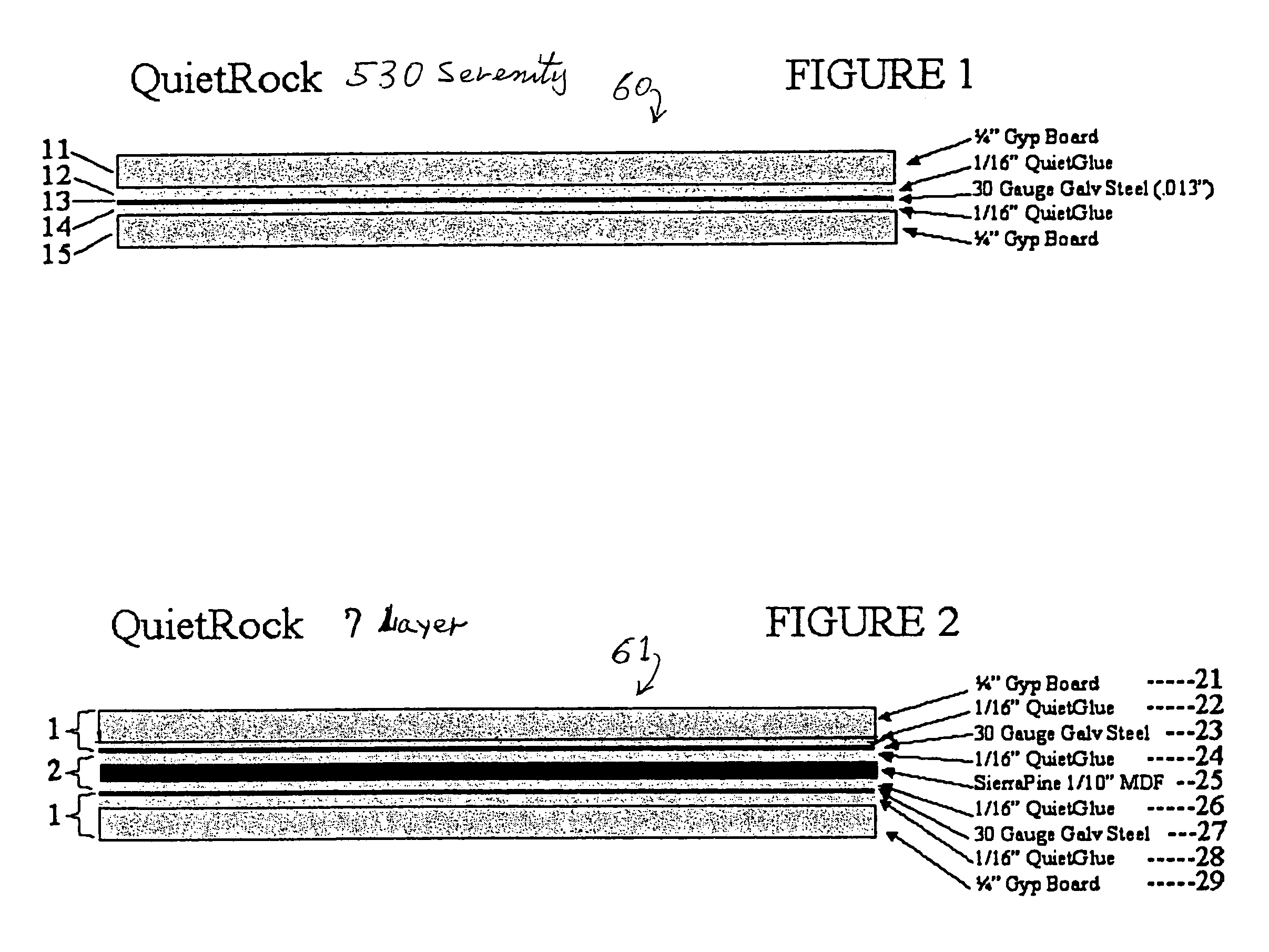

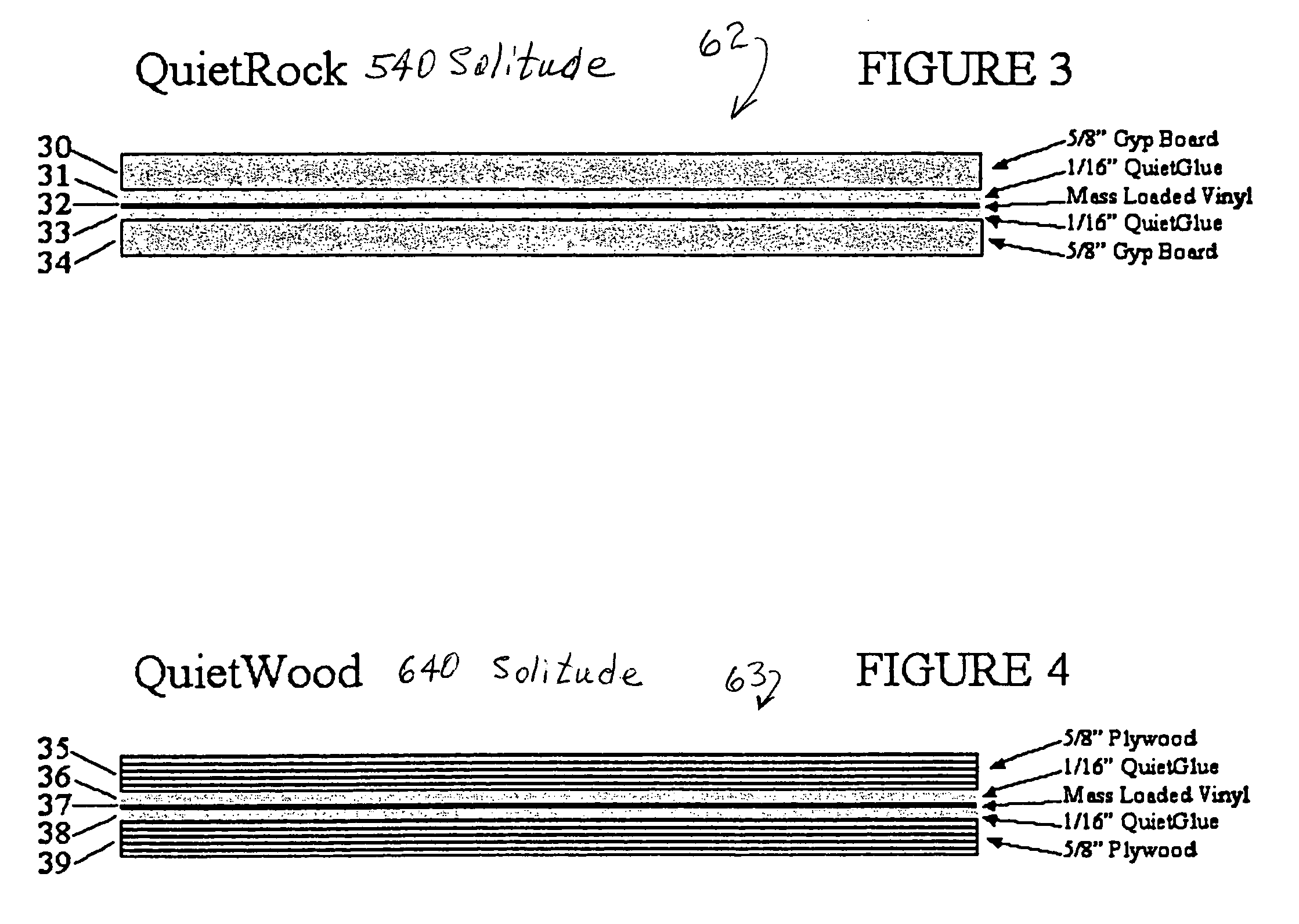

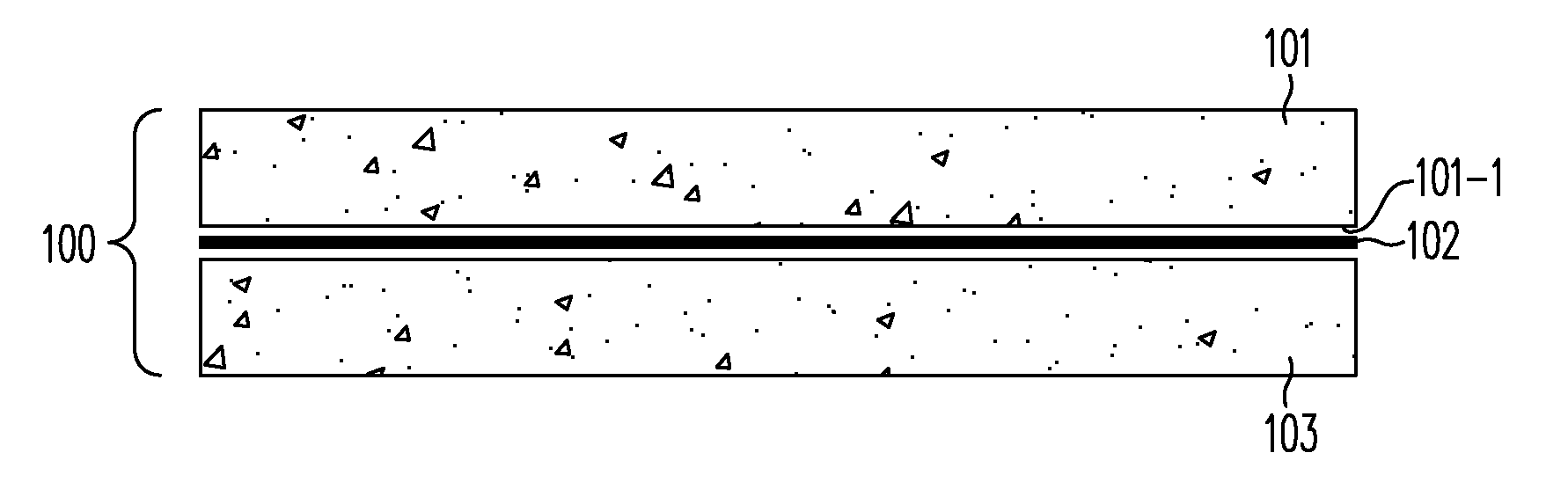

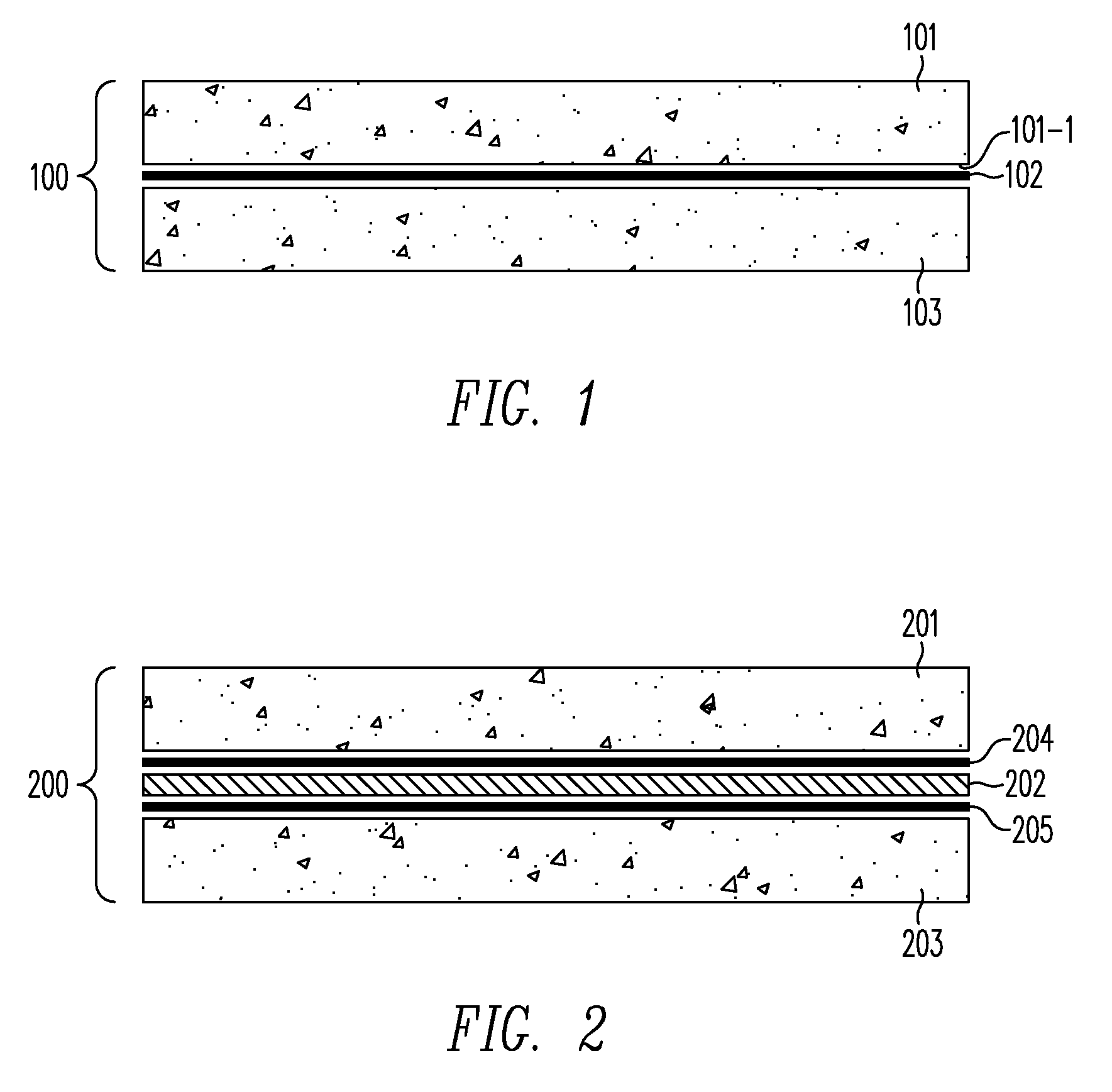

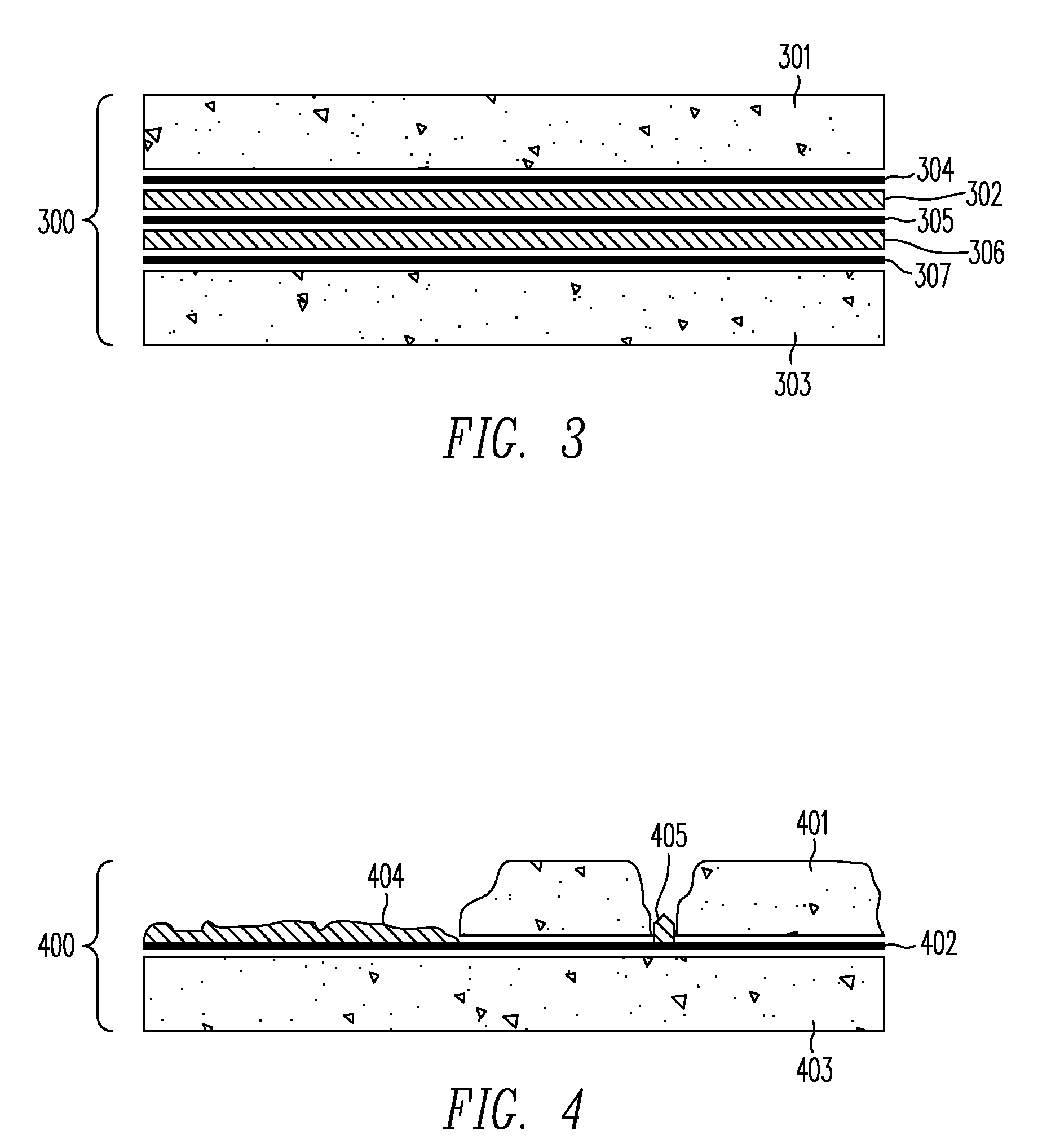

An improved acoustical damping wall (ceiling or floor) or door material comprises a laminar structure having as an integral part thereof one or more layers of viscoelastic material which also functions as a glue and one or more constraining layers, such as metal, cellulose, wood, or petroleum-based products such as plastic, vinyl, plastic or rubber. In one embodiment, standard wallboard, typically gypsum, comprises the external surfaces of the laminar structure; and one or more constraining layers are fabricated between the gypsum exterior. The resulting structure improves the attenuation of sound transmitted through the structure.

Owner:PACIFIC COAST BUILDING PRODS

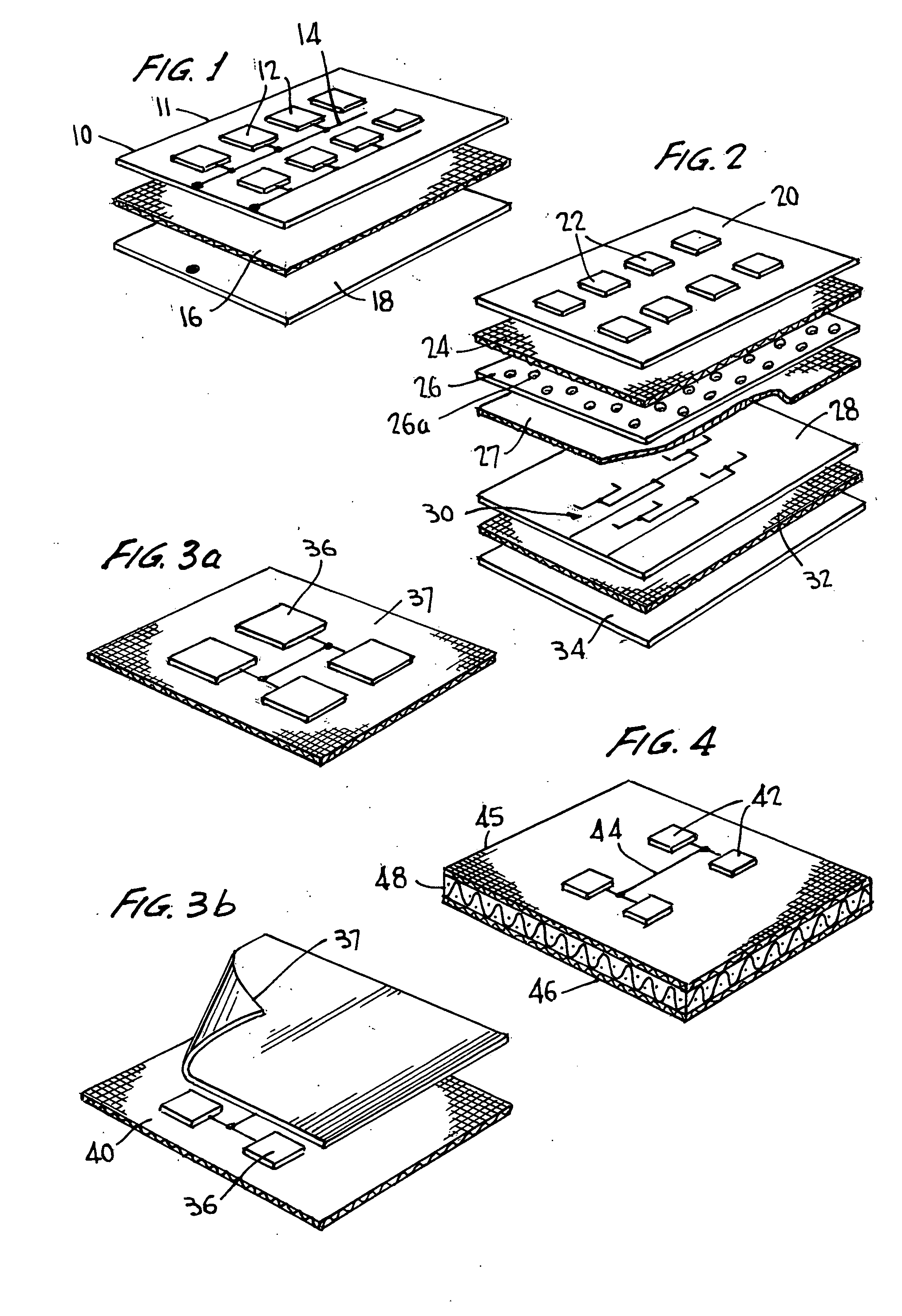

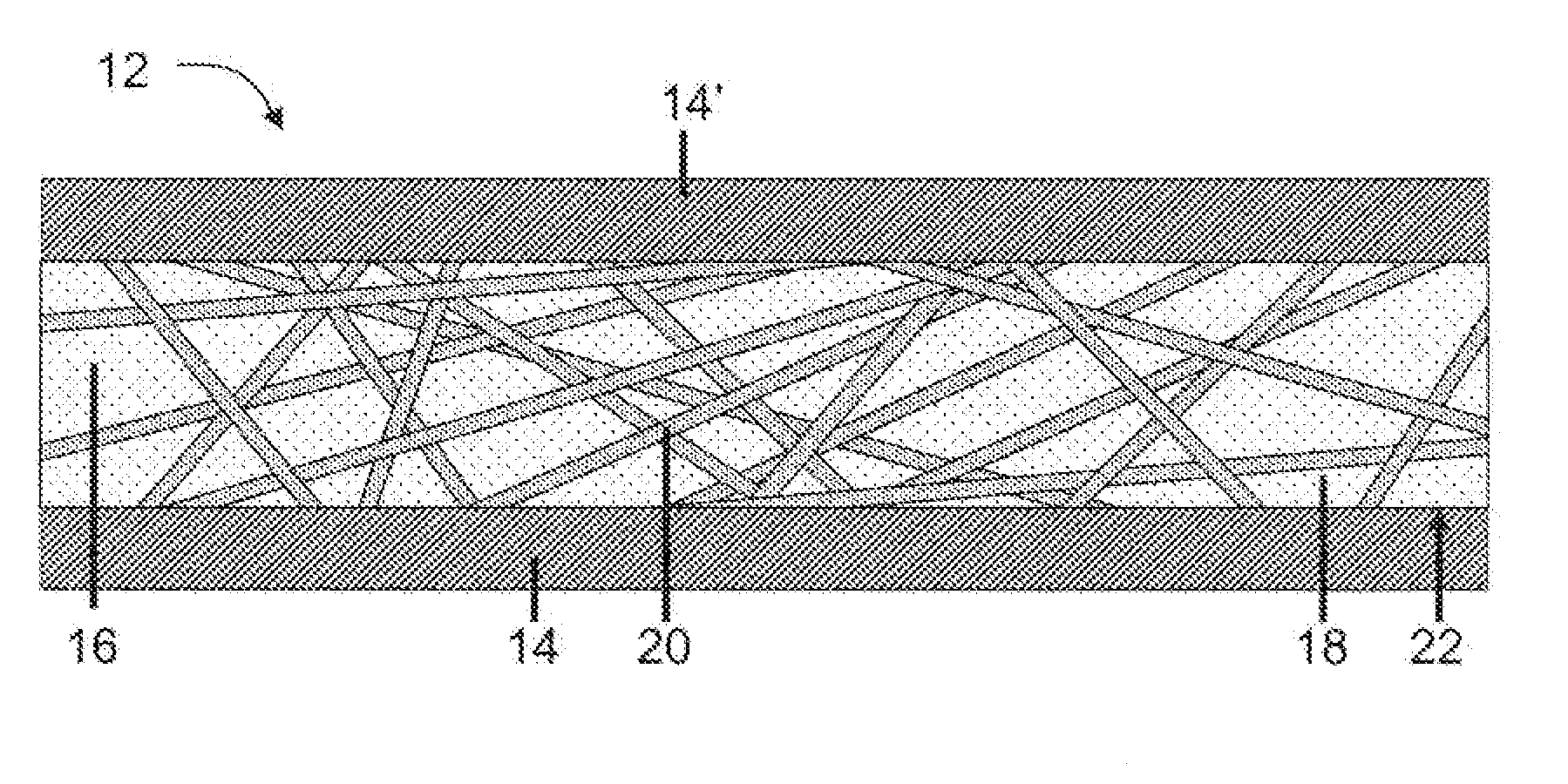

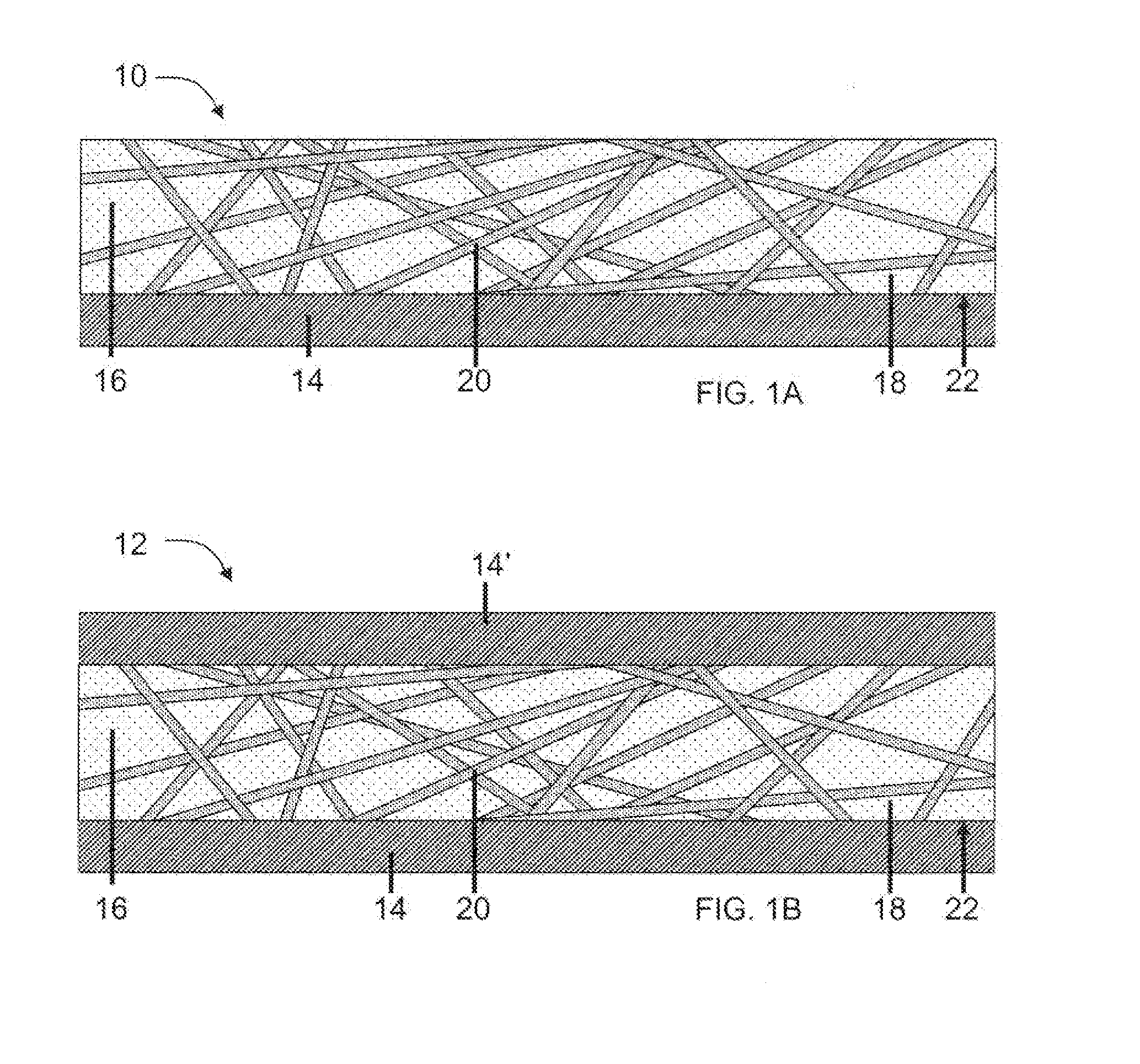

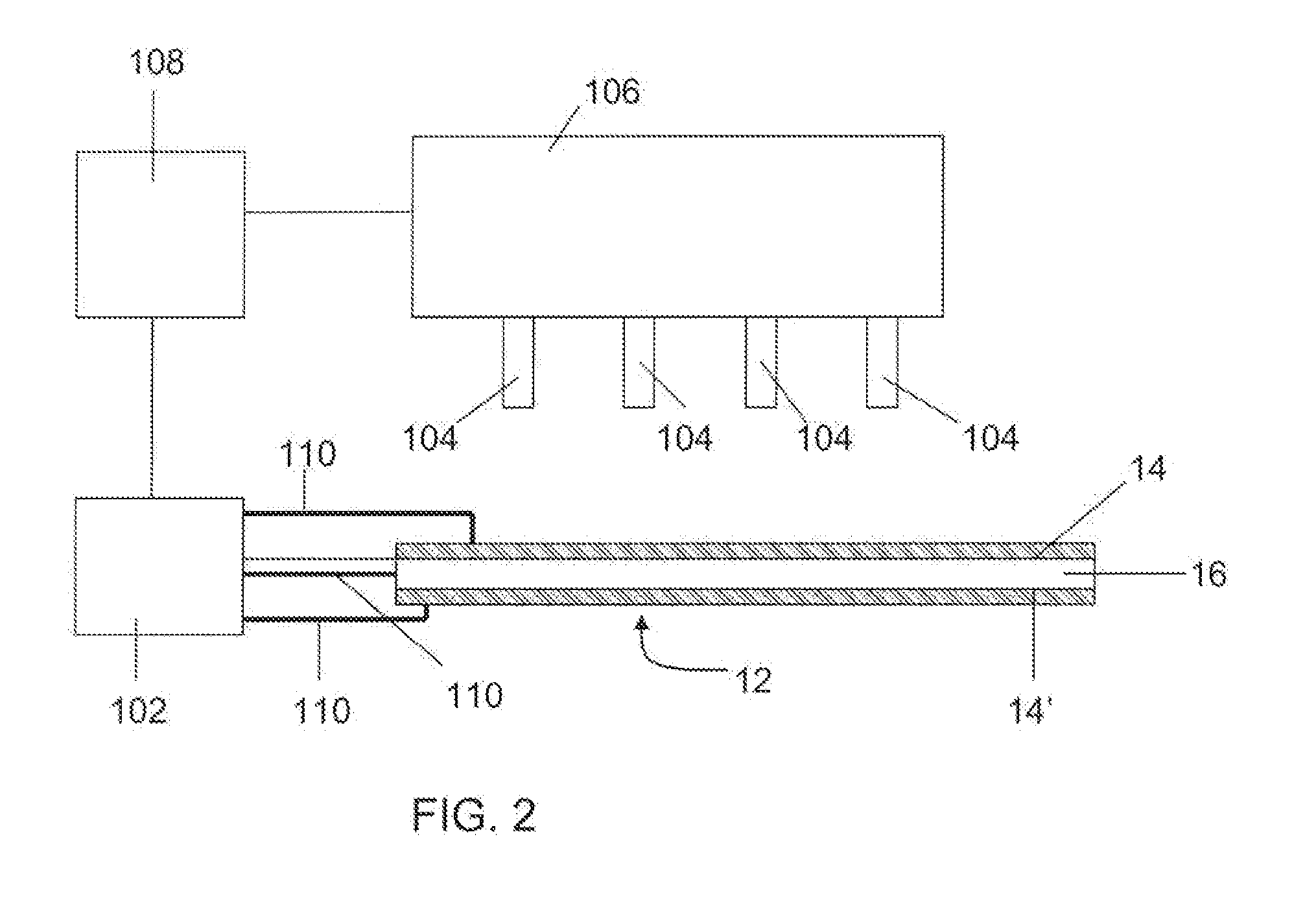

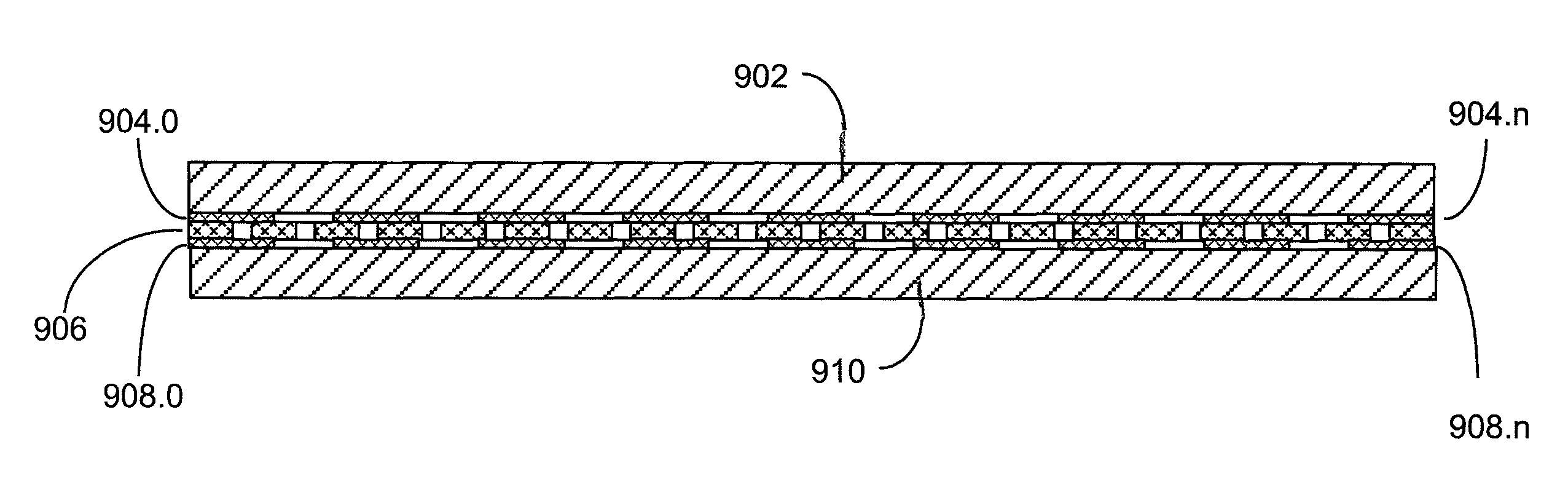

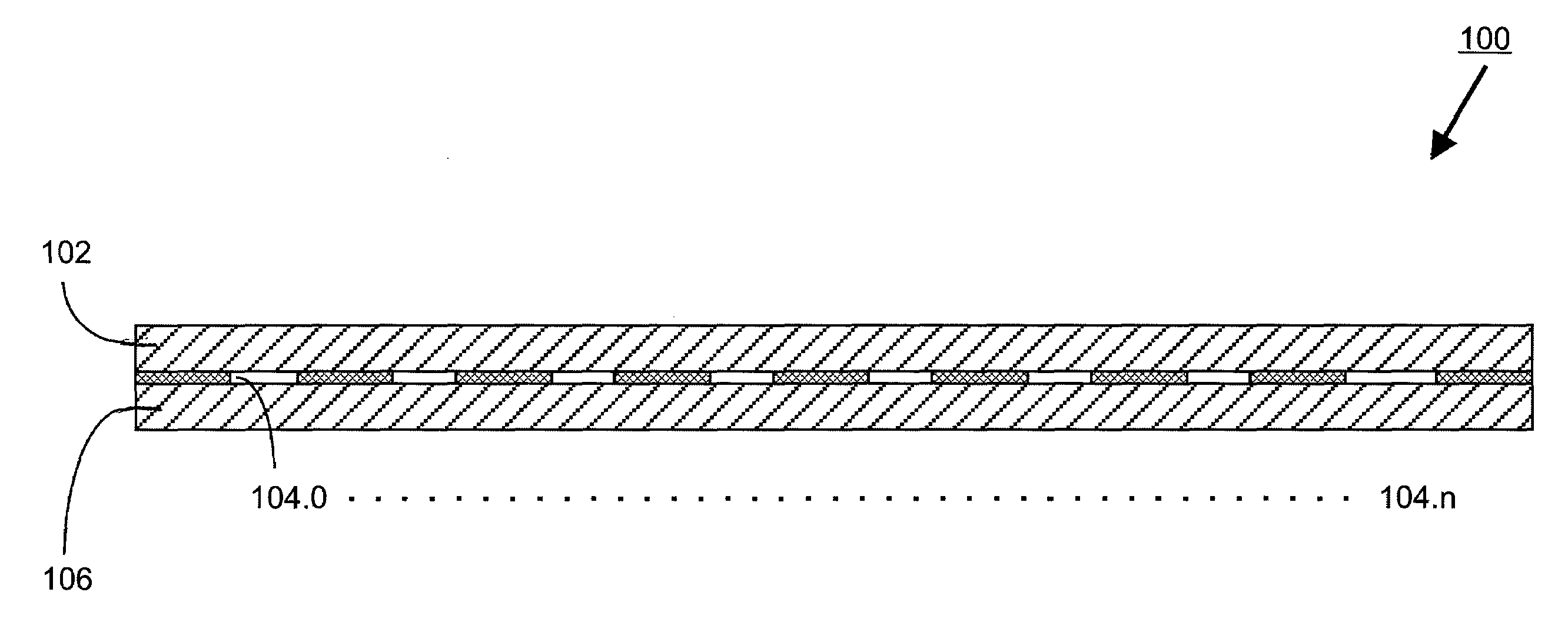

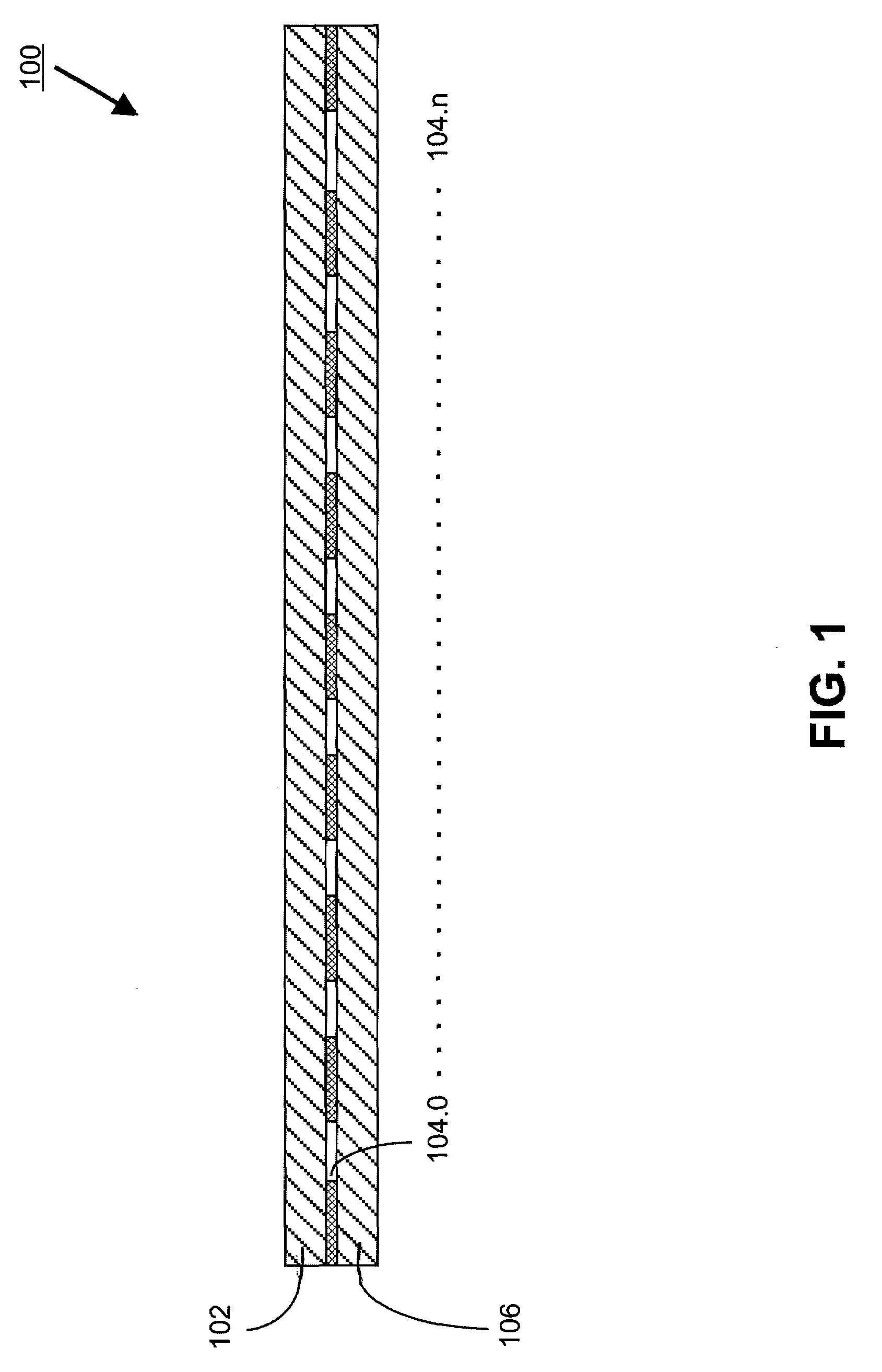

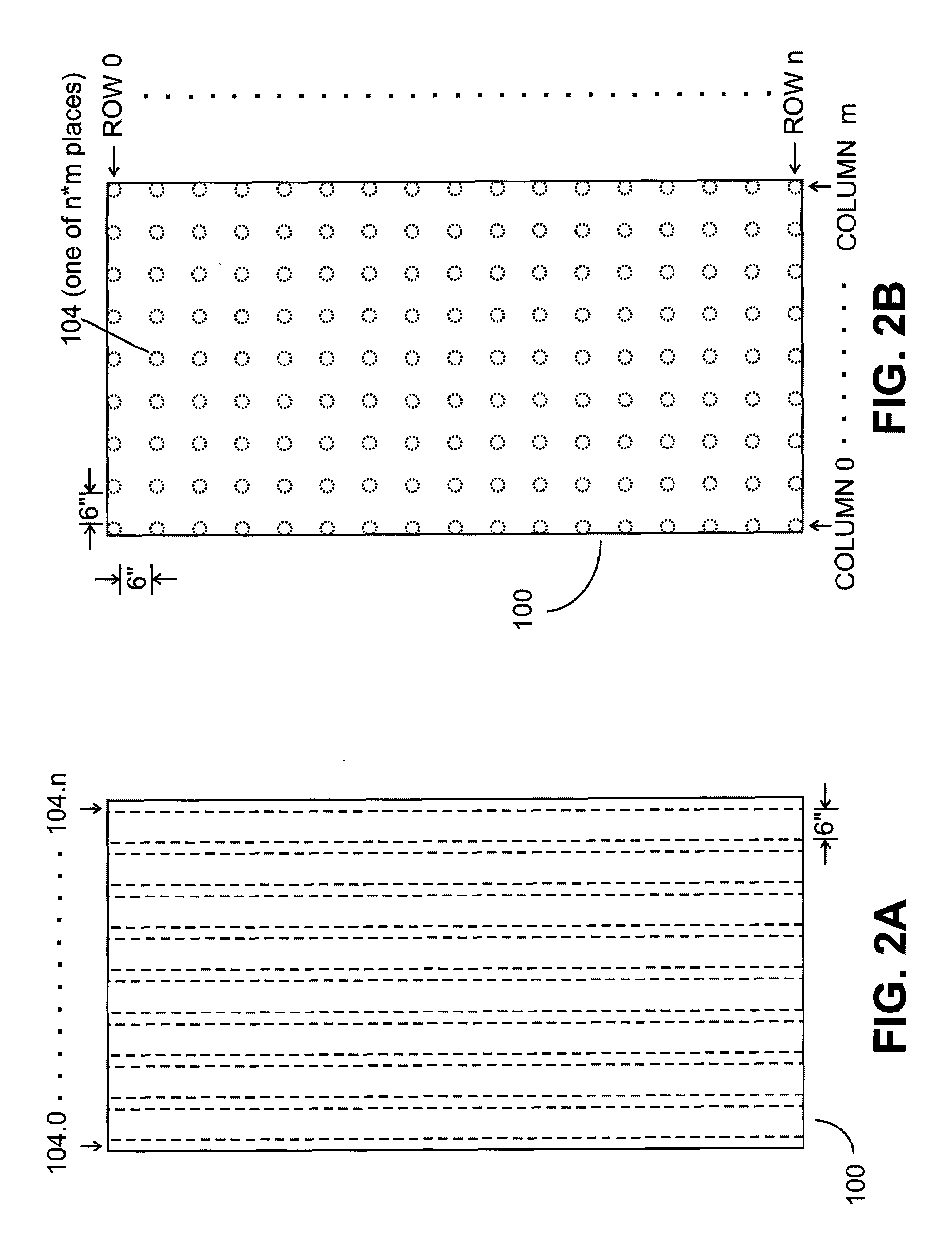

Method for constructing antennas from textile fabrics and components

InactiveUS20050235482A1Reduce sound transmissionReduce vibrationSimultaneous aerial operationsRadiating elements structural formsGround planeYarn

Antennas are fabricated using fabric substrates, and, in some embodiments, known stitching techniques to fabricate the conductive members required, including connecting wiring and radiating and / or receiving elements. In one embodiment, one or more “patch antennas”, that is, planar radiating and / or receiving elements, are connected to transmitting and / or receiving electronics by means of a connector and feed line structure. The antenna structure comprises multiple layers of fabric, some of which may contain patch antenna and / or feedline patterns made of conductive fabric, made by embroidery using conductive thread or yarn, or onto which patch antennas may be bonded. A ground plane layer may be fabricated similarly. Between the fabric layers containing the conductive patterns, there are one or more layers of insulating fabrics that separate the conductive fabric layers by a dielectric layer. Additional sheets of adhesive between the fabric layers may be used to attach the fabric layers. Alternatively, stitching of insulating thread can be used to attach the multiple fabric layers together. Conductive thread may be used where a connection is desired, that is, the microwave antenna may include a “via” (an interlayer electrical connection) of conductive thread sewn through insulating fabric layers to connect one or more conductive components, typically of conductive fabric. The antenna may be flexible, so as to be used on clothing and the like, or may be impregnated with a curable resin, for forming a rigid structure for incorporation into a larger structure.

Owner:APPLIED RADAR

Acoustical sound proofing material and methods for manufacturing same

ActiveUS20060057345A1Reduce sound transmissionImprove abilitiesBuilding roofsCoatingsCelluloseEngineering

An improved acoustical damping wall (ceiling or floor) or door material comprises a laminar structure having as an integral part thereof one or more layers of viscoelastic material which also functions as a glue and one or more constraining layers, such as metal, ceramics, composites, cellulose, wood, or petroleum-based products such as plastic, vinyl, plastic or rubber.

Owner:PACIFIC COAST BUILDING PRODS

Acoustical sound proofing material and methods for manufacturing same

ActiveUS20050050846A1Reduce transmission rateImprove abilitiesBuilding roofsCeilingsCelluloseUltrasound attenuation

An improved acoustical damping wall (ceiling or floor) or door material comprises a laminar structure having as an integral part thereof one or more layers of viscoelastic material which also functions as a glue and one or more constraining layers, such as metal, cellulose, wood, or petroleum-based products such as plastic, vinyl, plastic or rubber. In one embodiment, standard wallboard, typically gypsum, comprises the external surfaces of the laminar structure; and one or more constraining layers are fabricated between the gypsum exterior. The resulting structure improves the attenuation of sound transmitted through the structure.

Owner:PACIFIC COAST BUILDING PRODS

Formable light weight composite material systems and methods

ActiveUS20110200816A1Attractive performance characteristicHigh strengthConductive materialSoldering apparatusElectrical resistance and conductancePolymer science

The present invention relates to filled polymeric materials including a polymer and a mass of metallic fibers distributed within the polymer, and to light weight composites which comprise at least a pair of metallic layers and a polymeric layer interposed between the pair of metallic layers, the polymeric layer containing the filled polymeric material. The composite materials of the present invention may be formed using conventional stamping equipment at ambient temperatures. Composite materials of the present invention may also be capable of being welded to other metal materials using a resistance welding process such as resistance spot welding. Preferred composite materials include one or any combination of the following features: metallic fibers that are ribbon fibers; a polymer selected from a polyolefin, a polyamide, or a combination thereof; or a metallic layer (e.g., one or both of the pair of metallic layers) having a surface facing the filled polymeric material that is untreated.

Owner:PRODIVE RES

Acoustical sound proofing material with controlled water-vapor permeability and methods for manufacturing same

ActiveUS7883763B2Reduce sound transmissionImprove abilitiesCeilingsWallsWater vapor permeabilityMoisture

A laminated structure appropriate for use in constructing walls, floors, ceilings or doors, has a selected area and in one embodiment comprises two external layers of one or more materials such as, but not limited to, gypsum, at least one internal constraining layer having less than said selected area, and two or more internal layers of a viscoelastic glue separated by said at least one internal constraining layer, wherein each of said layers of viscoelastic glue is patterned to cover a selected percentage, but not all, of said area of said laminated structure thereby to allow moisture to pass through said structure.

Owner:SERIOUS MATERIALS +1

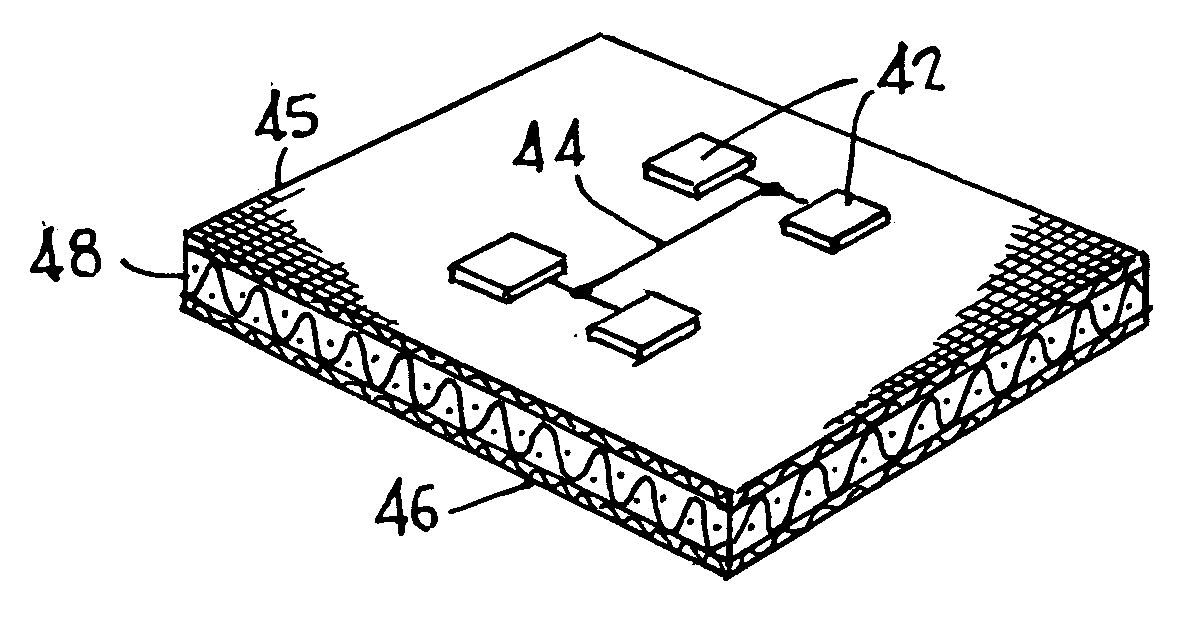

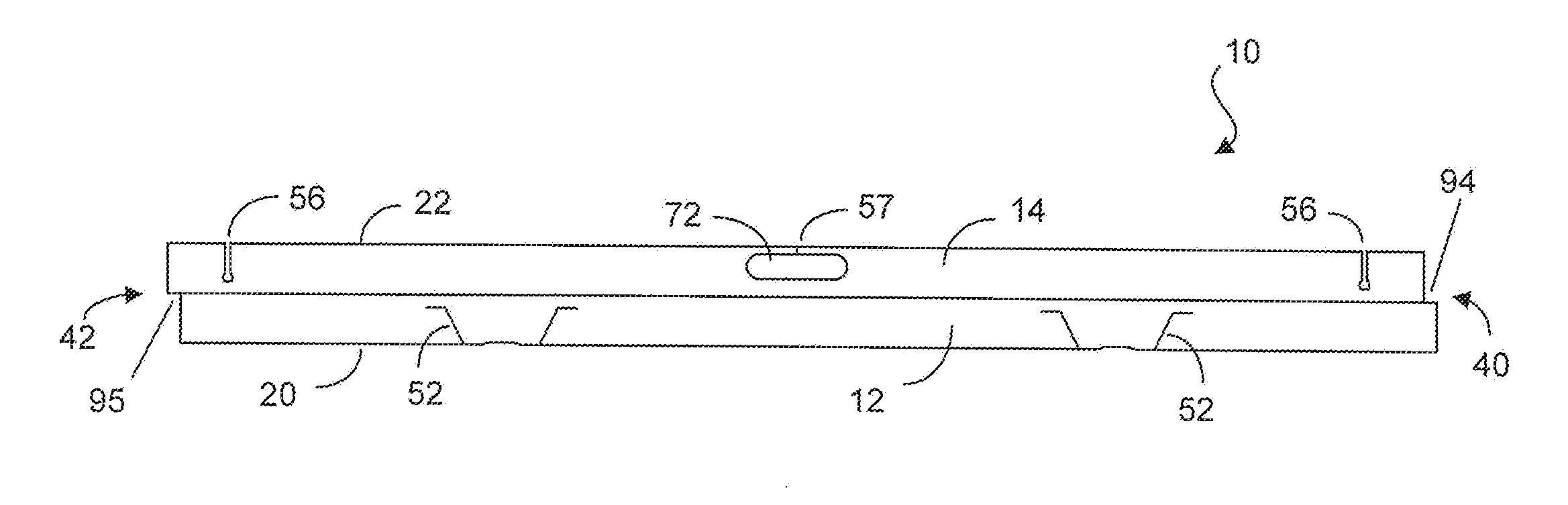

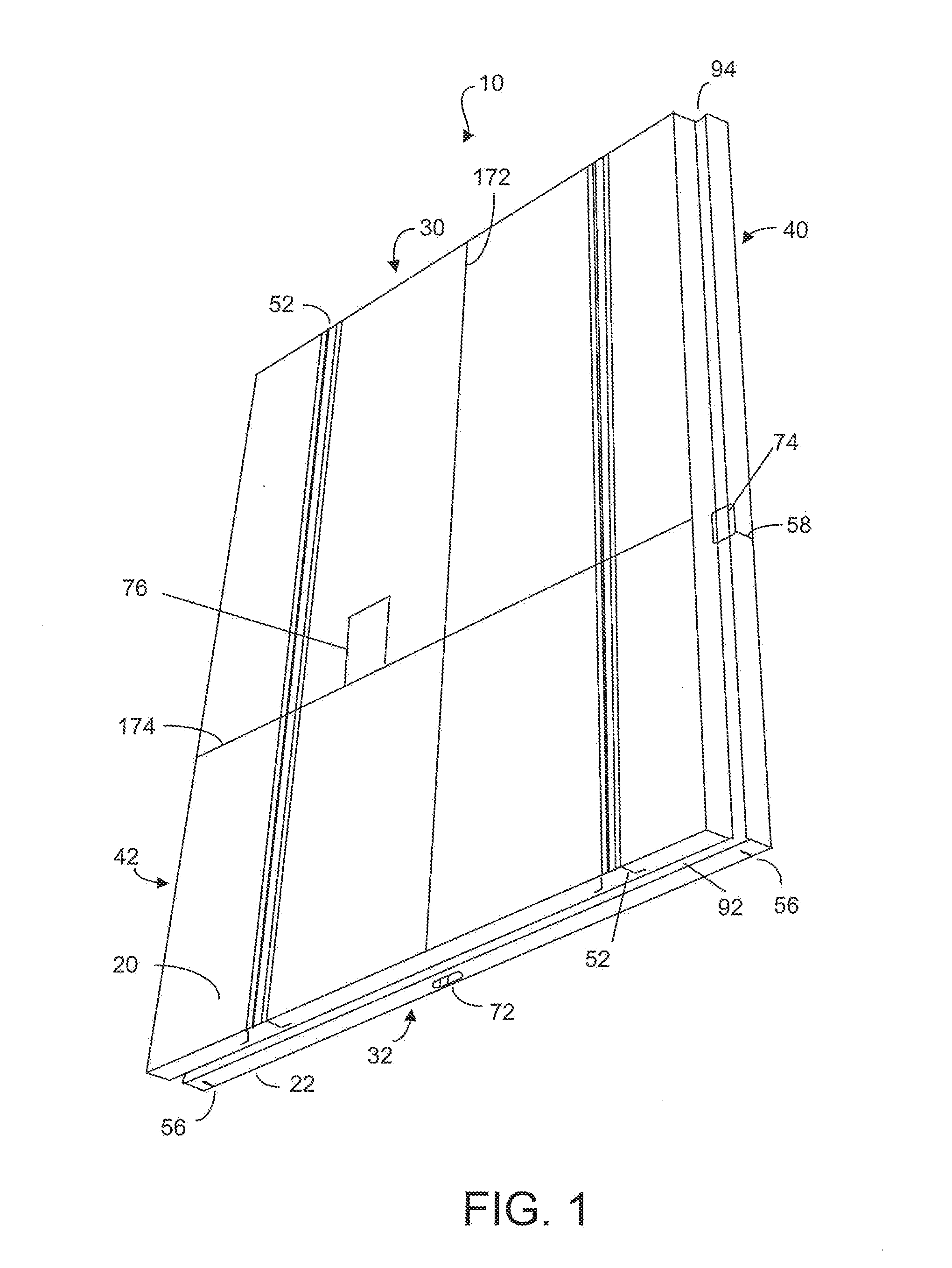

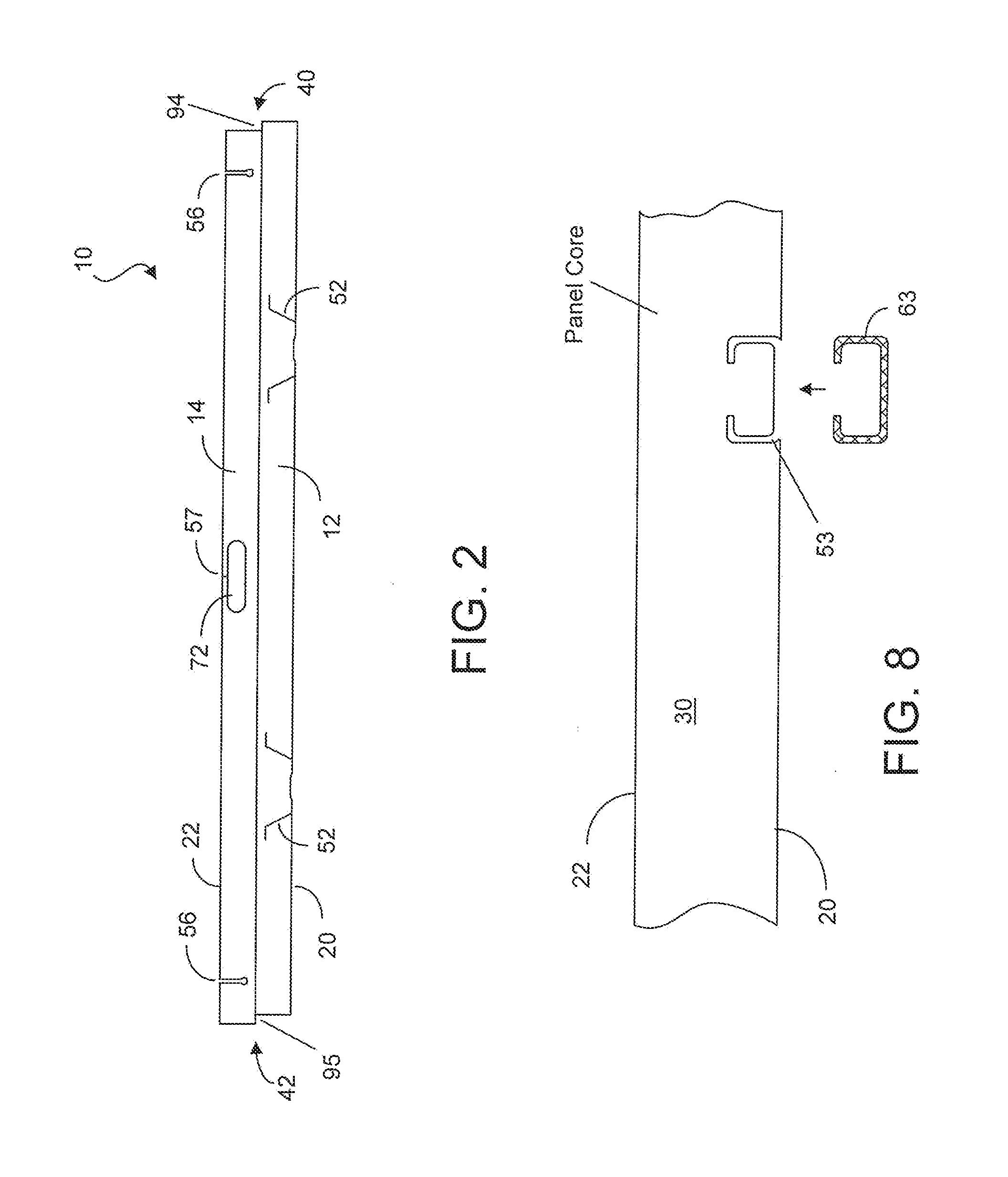

Soundproof assembly and methods for manufacturing same

An improved acoustical floor / ceiling, or wall assembly affixed to a support structure, the assembly using laminar panels. A first one of the laminar panels includes a constraining layer of material with a layer viscoelastic glue on the constraining layer and a layer of material of a first composition on the layer of viscoelastic glue. A second one of the laminar panels includes a constraining layer of material with a layer of viscoelastic glue on the constraining layer of material and a layer of material of a composition different than that of the layer of material in the other laminar panel. In one assembly the material in the first laminar panel is cellulose-based material or wood, and the material in the second laminar panel is gypsum board. Constraining layers of material of metal, cellulose-based material, wood and petroleum-based products such as plastic, vinyl or rubber, ceramic, composite are employed.

Owner:PACIFIC COAST BUILDING PRODS

Insulating Wall Panel System

An insulating panel to be used in a panelized insulation system for insulating and finishing walls, including basement walls has a foam core made of inorganic materials. The system incorporates a capillary break, an integrated water drainage system and an electrical wire chase system within an insulating wall panel. Vertical slots are provided for insertion of metal studs for use in attaching the interior finish panel, such as inorganic fiber cement board with a vinyl laminate finish, onto the insulating panels. Embedding metal studs in the panel core reduces the sound transmission though the panel and eliminates thermal bridging between warm and cold surfaces. Steps on the edges and the top / bottom surfaces of the insulating panel allow more panels to join together with shiplap joints.

Owner:LEWIS DAVID L

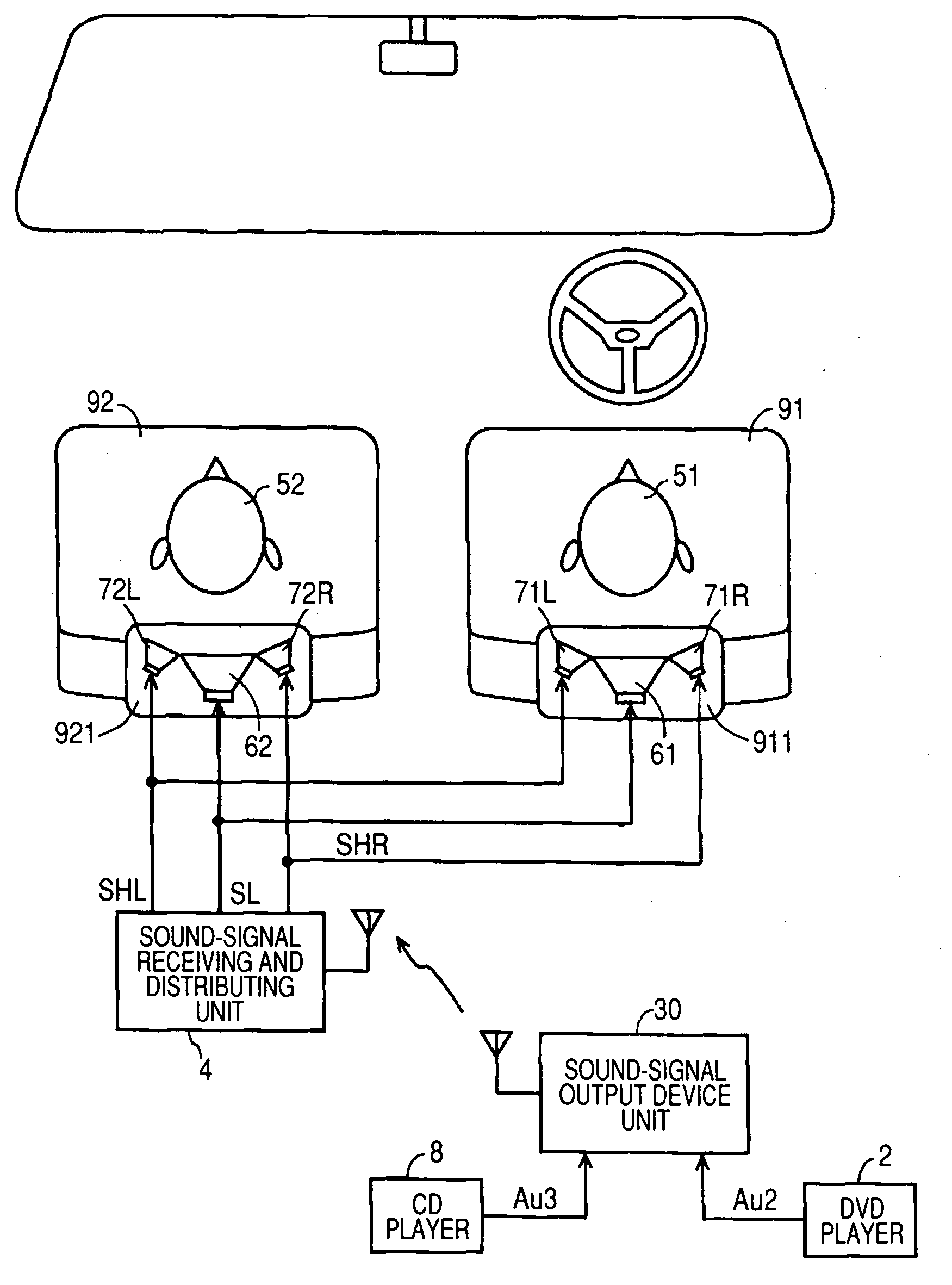

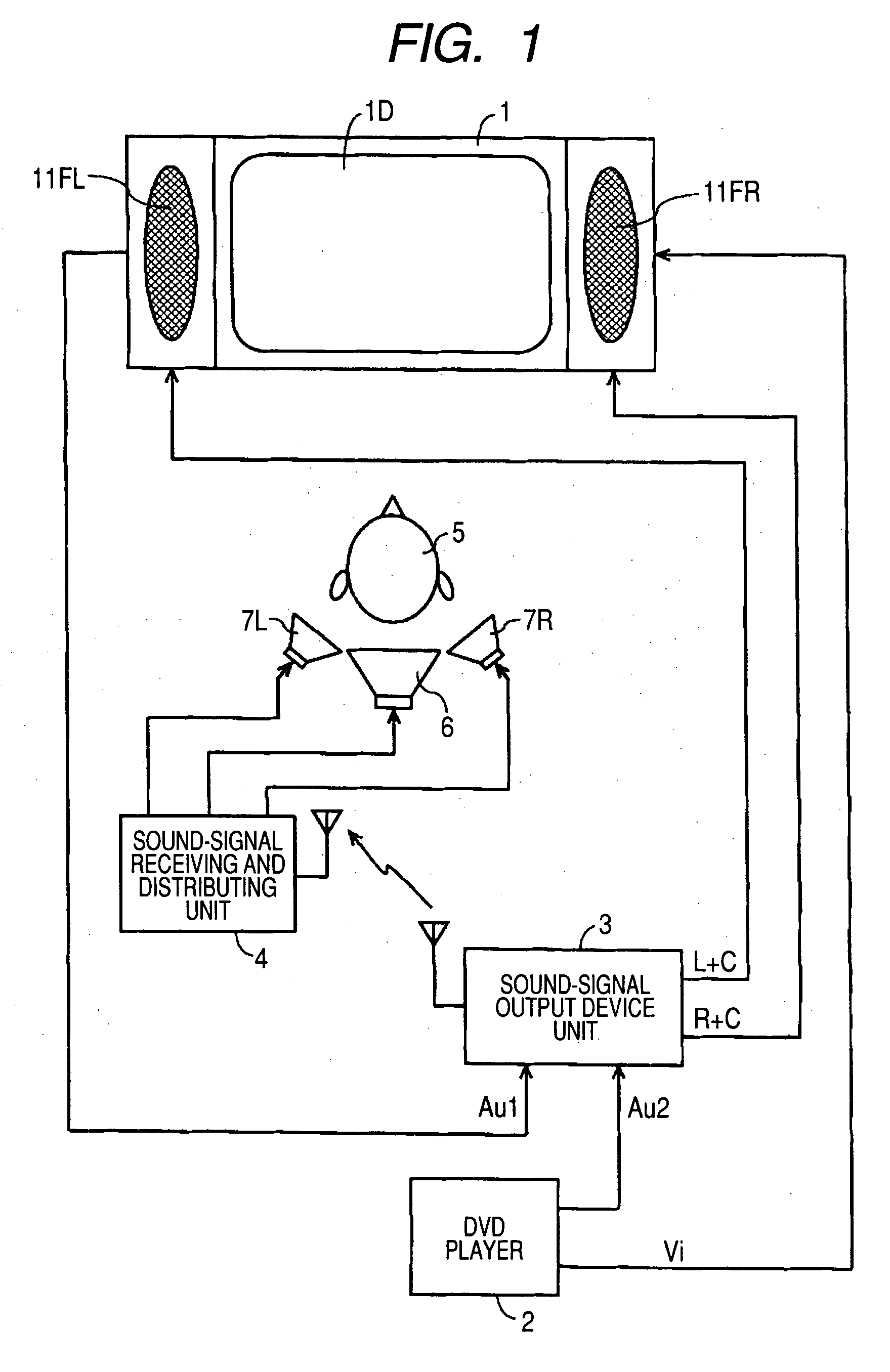

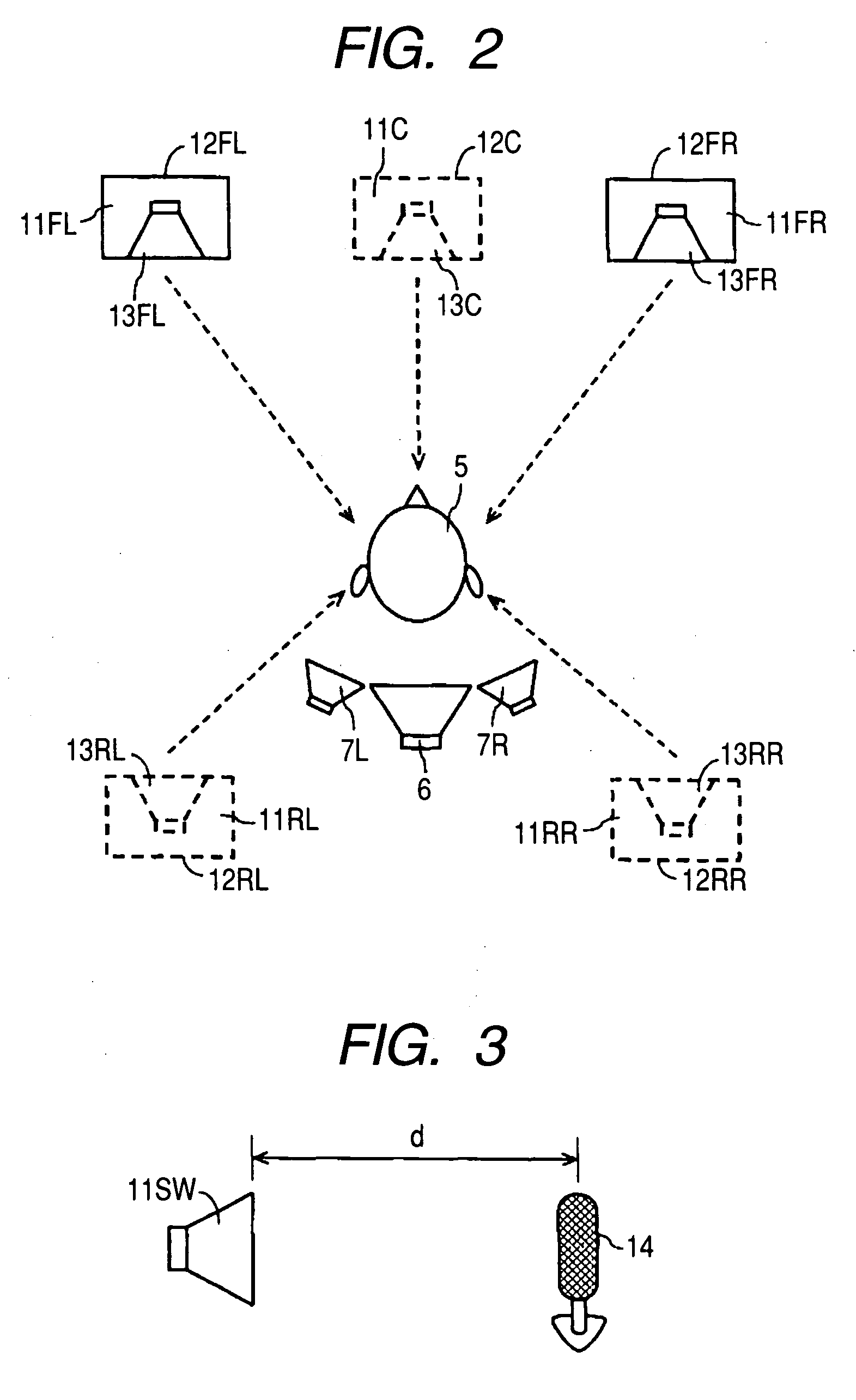

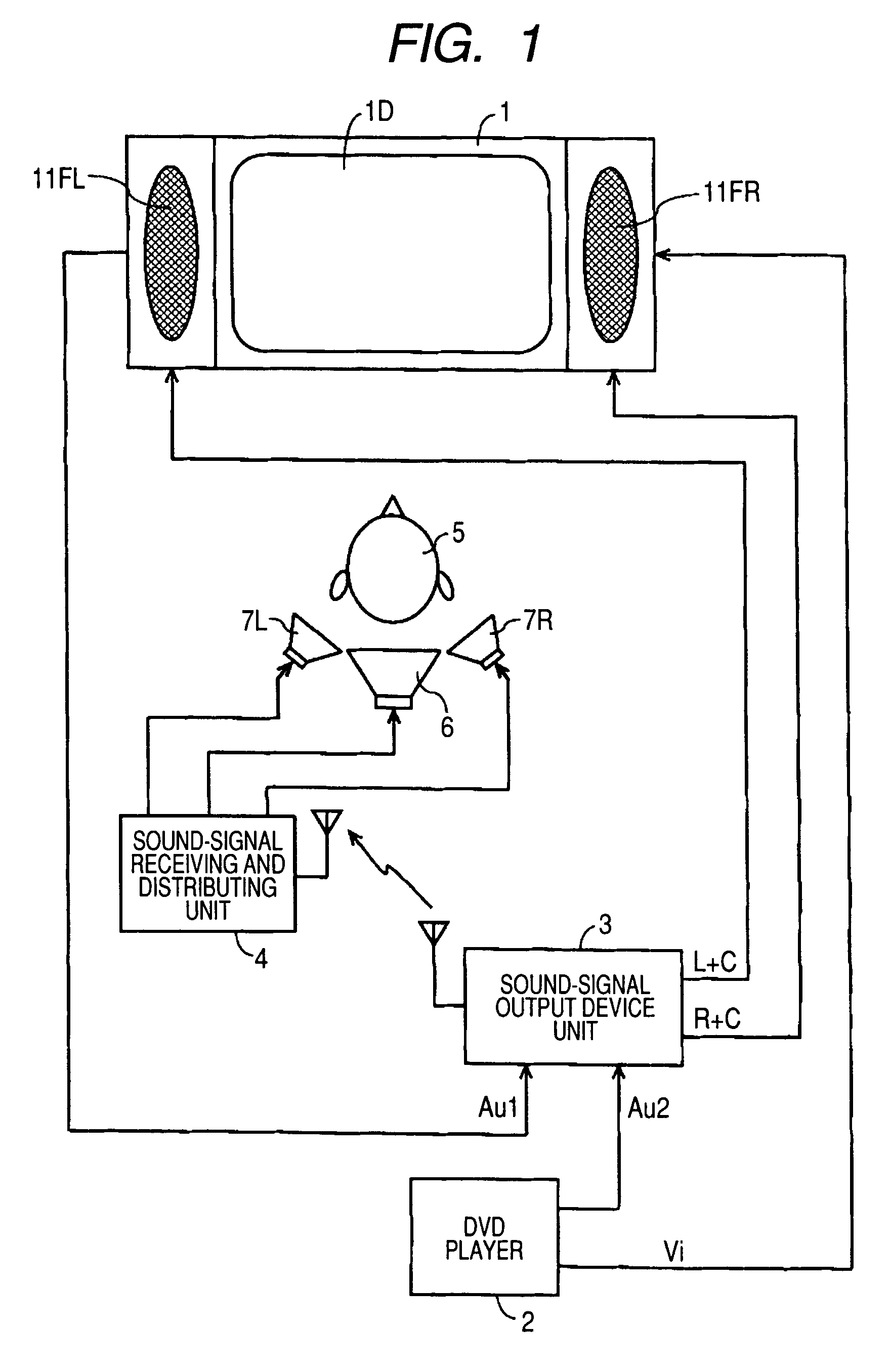

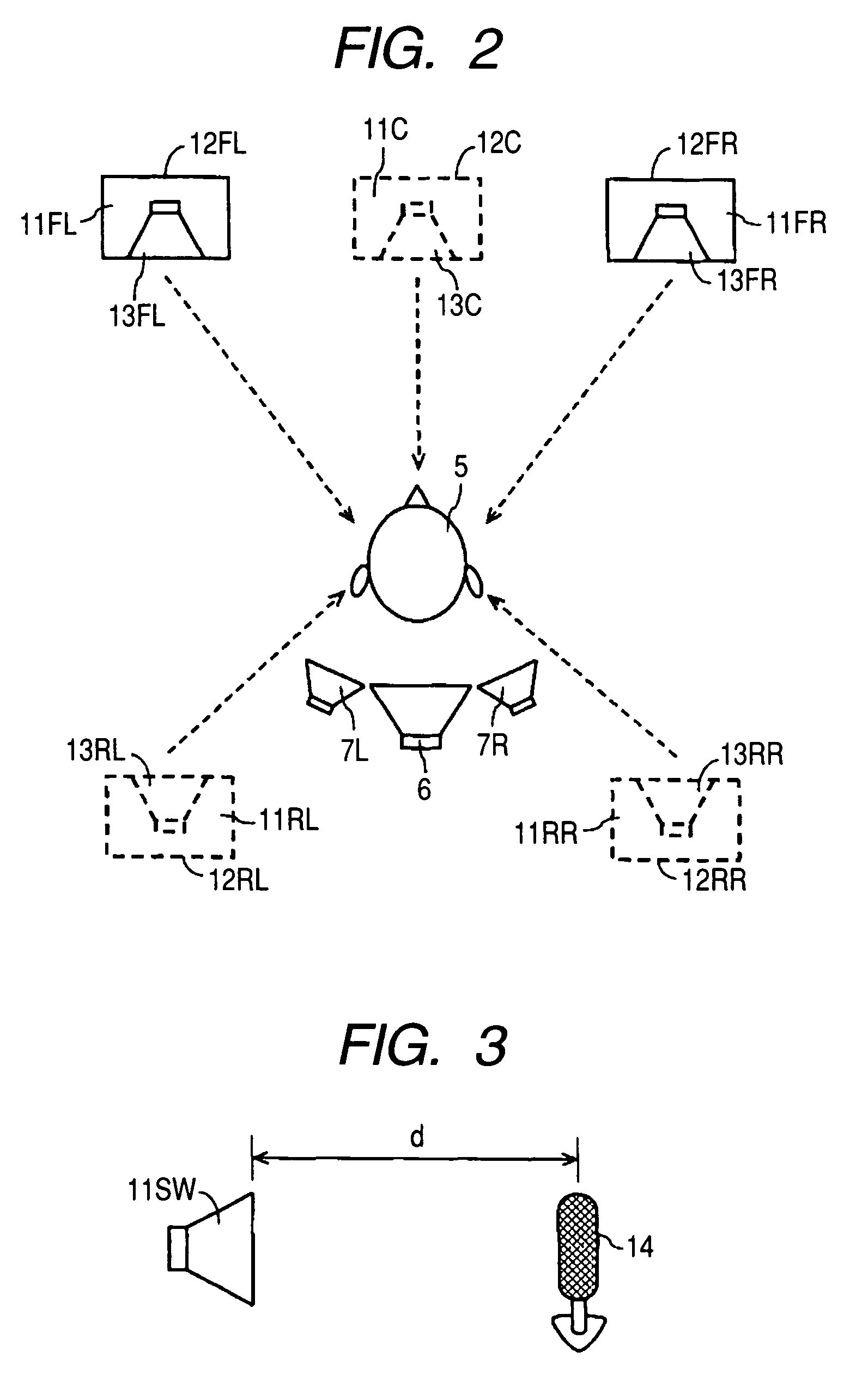

Audio reproduction system and speaker apparatus

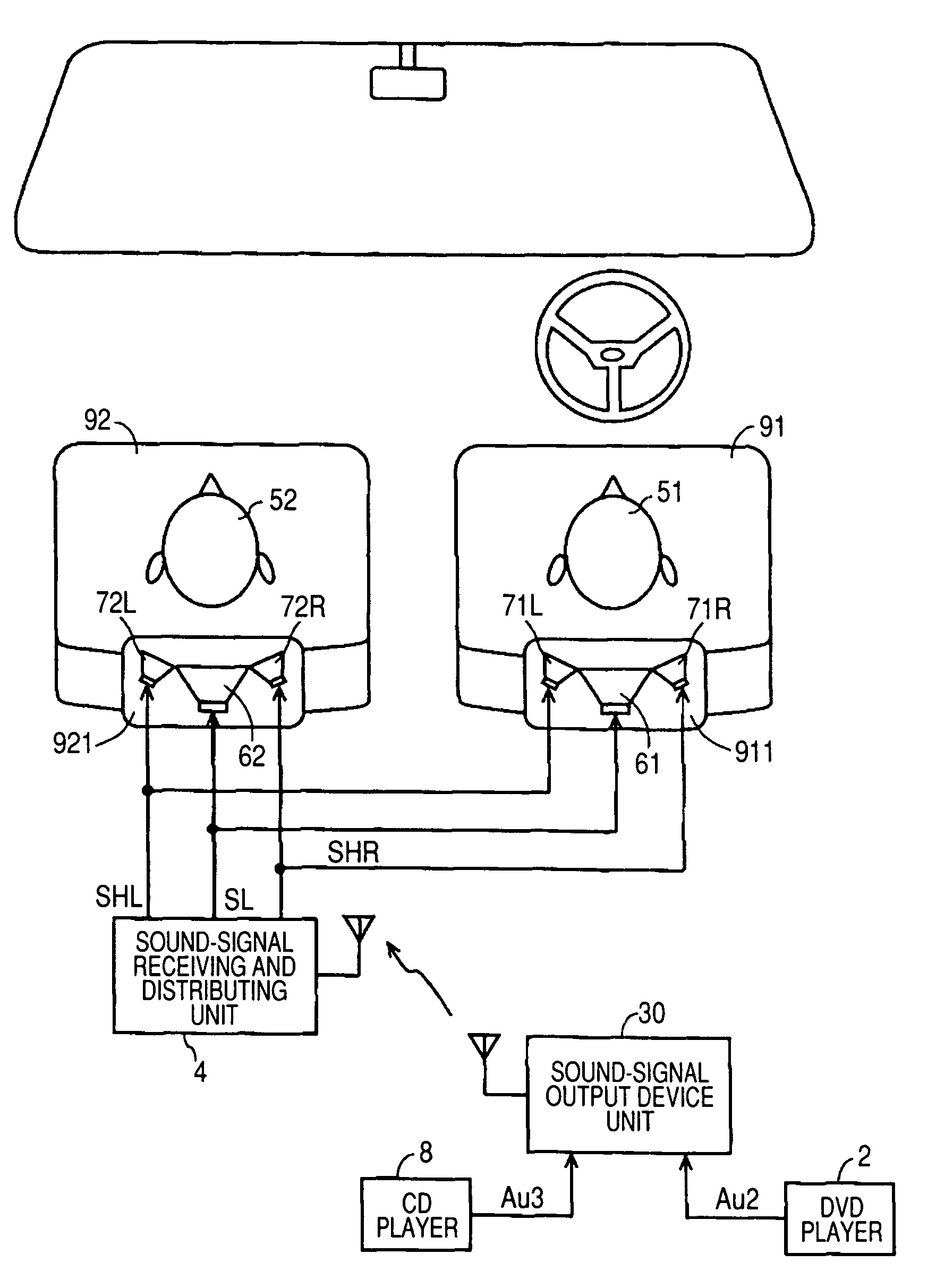

InactiveUS20080292121A1Satisfactory reproduced sound fieldReduce low-frequency reproduced soundSignal processingTransducers for sound channels pluralityIntermediate frequencyEngineering

An audio reproduction system includes: a first speaker arranged near a listener and behind a head of the listener with a speaker unit being held by first holding means to make it possible to mix sounds emitted from front and rear of a vibration plate of the speaker; second and third speakers held by second holding means and arranged near the listener and on left and right of the first speaker; separating means for separating and obtaining low-frequency components and medium- and high-frequency components for left and right channels from an input audio signal; means for supplying the low-frequency components separated by the separating means to the first speaker; and means for supplying the medium- and high-frequency components for the left and right channels separated by the separating means to the second and third speakers.

Owner:SONY CORP

Acoustical sound proofing material with controlled water-vapor permeability and methods for manufacturing same

ActiveUS20080251198A1Dissipating soundDissipating vibrationCeilingsWallsWater vapor permeabilityEngineering

A laminated structure appropriate for use in constructing walls, floors, ceilings or doors, has a selected area and in one embodiment comprises two external layers of one or more materials such as, but not limited to, gypsum, at least one internal constraining layer having less than said selected area, and two or more internal layers of a viscoelastic glue separated by said at least one internal constraining layer, wherein each of said layers of viscoelastic glue is patterned to cover a selected percentage, but not all, of said area of said laminated structure thereby to allow moisture to pass through said structure.

Owner:SERIOUS MATERIALS +1

Heat-insulating and soundproofing lining for an engine compartment of a motor vehicle

InactiveUS6749929B1Reduce sound transmissionReduced stabilityWallsMachines/enginesBiomedical engineeringIncrease temperature

A heat-insulating an soundproofing lining for an engine compartment is disclosed, and a method of manufacturing the same, are disclosed. According to one embodiment of the present invention, the lining includes a first covering layer facing the engine. A duroplastic foam layer contacts the covering layer. A soundproofing layer contacts the duroplastic foam layer. A second covering layer contacts the soundproofing layer. According to another embodiment, a method of manufacturing a heat-insulating and soundproofing lining for an engine compartment is disclosed. The method includes the steps of (1) providing a first covering layer; (2) providing a duroplastic foam layer on the first covering layer; (3) providing a soundproofing layer on the first covering layer; (4) providing a second covering layer; and (5) pressing the layers together at an increased temperature and an increased pressure.

Owner:HP - CHEM PELZER RES & DEV

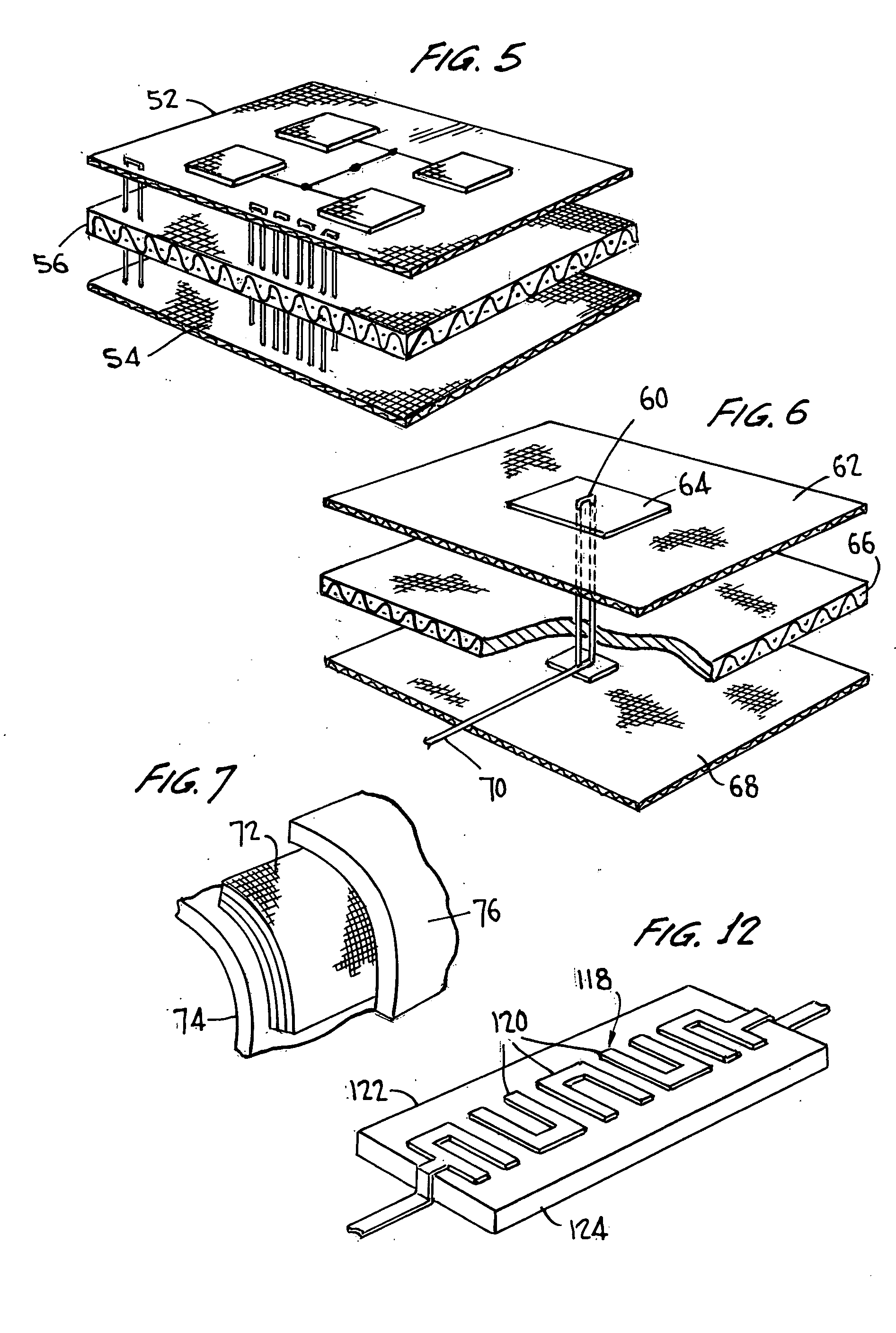

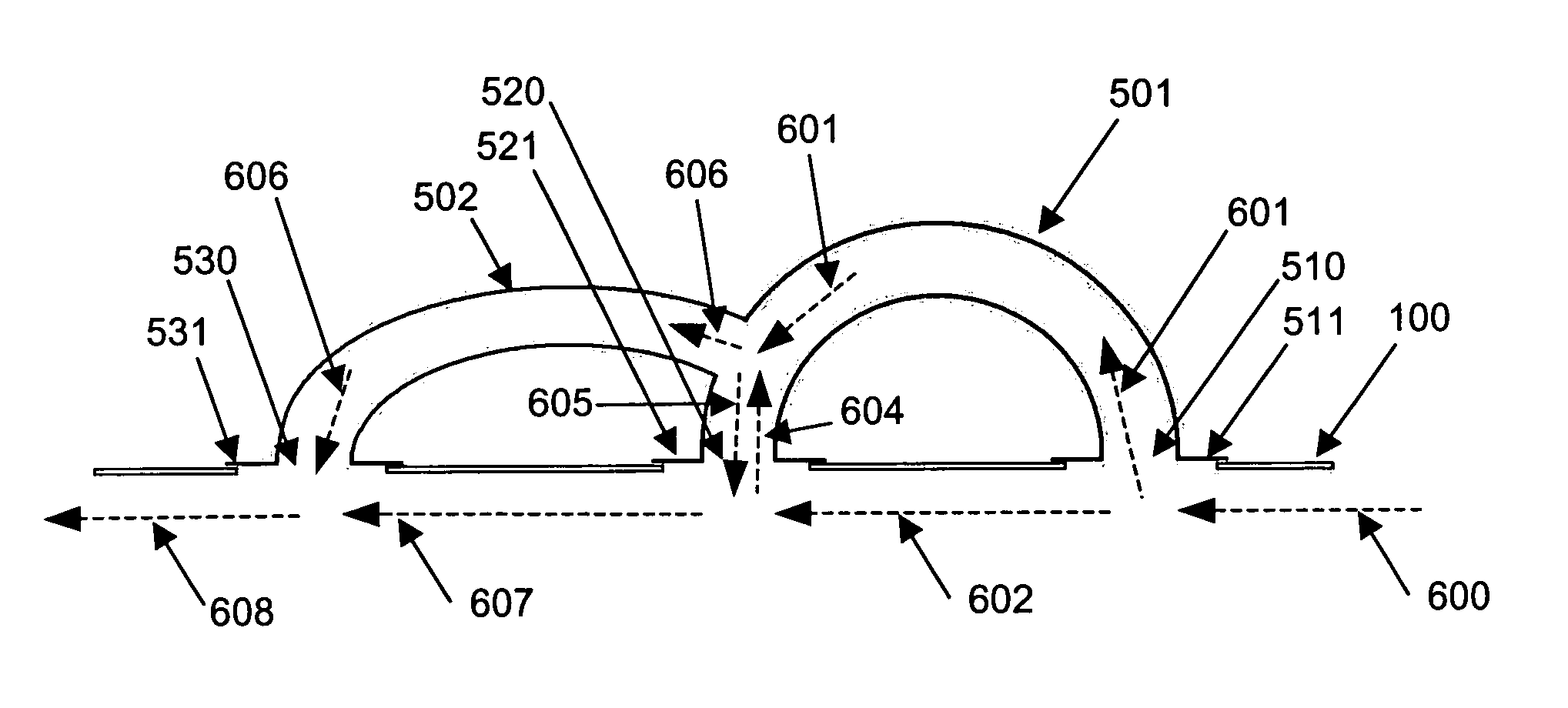

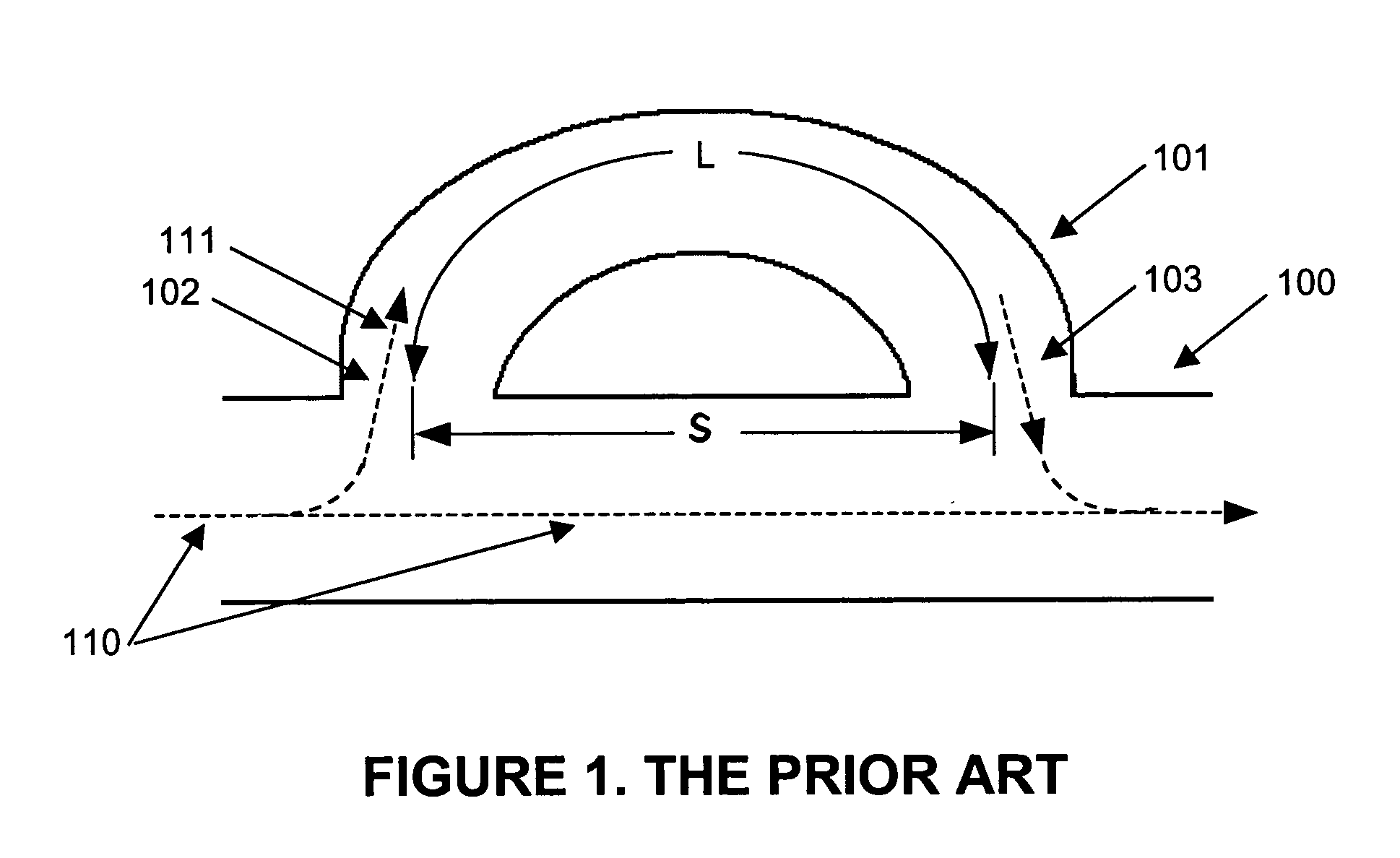

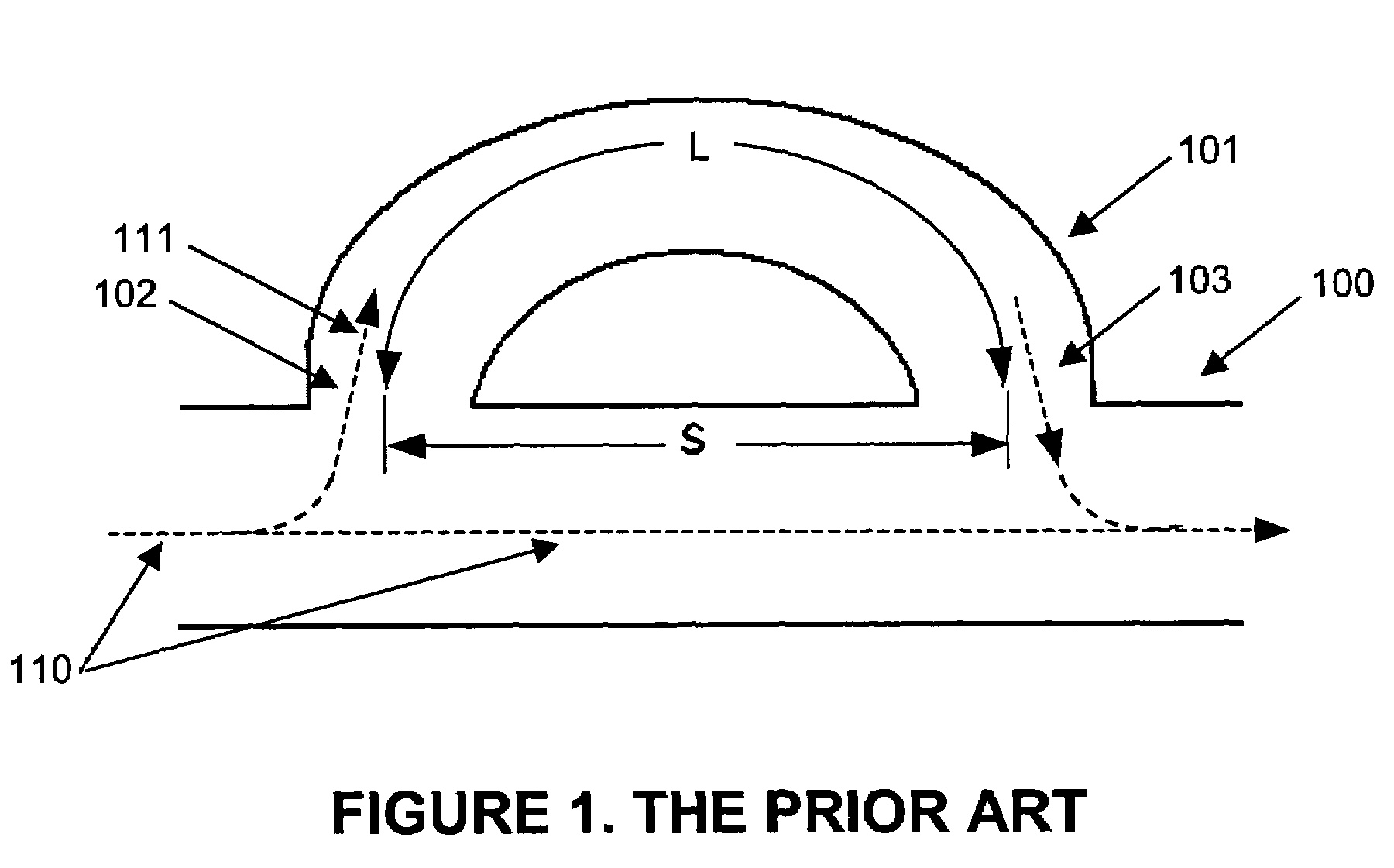

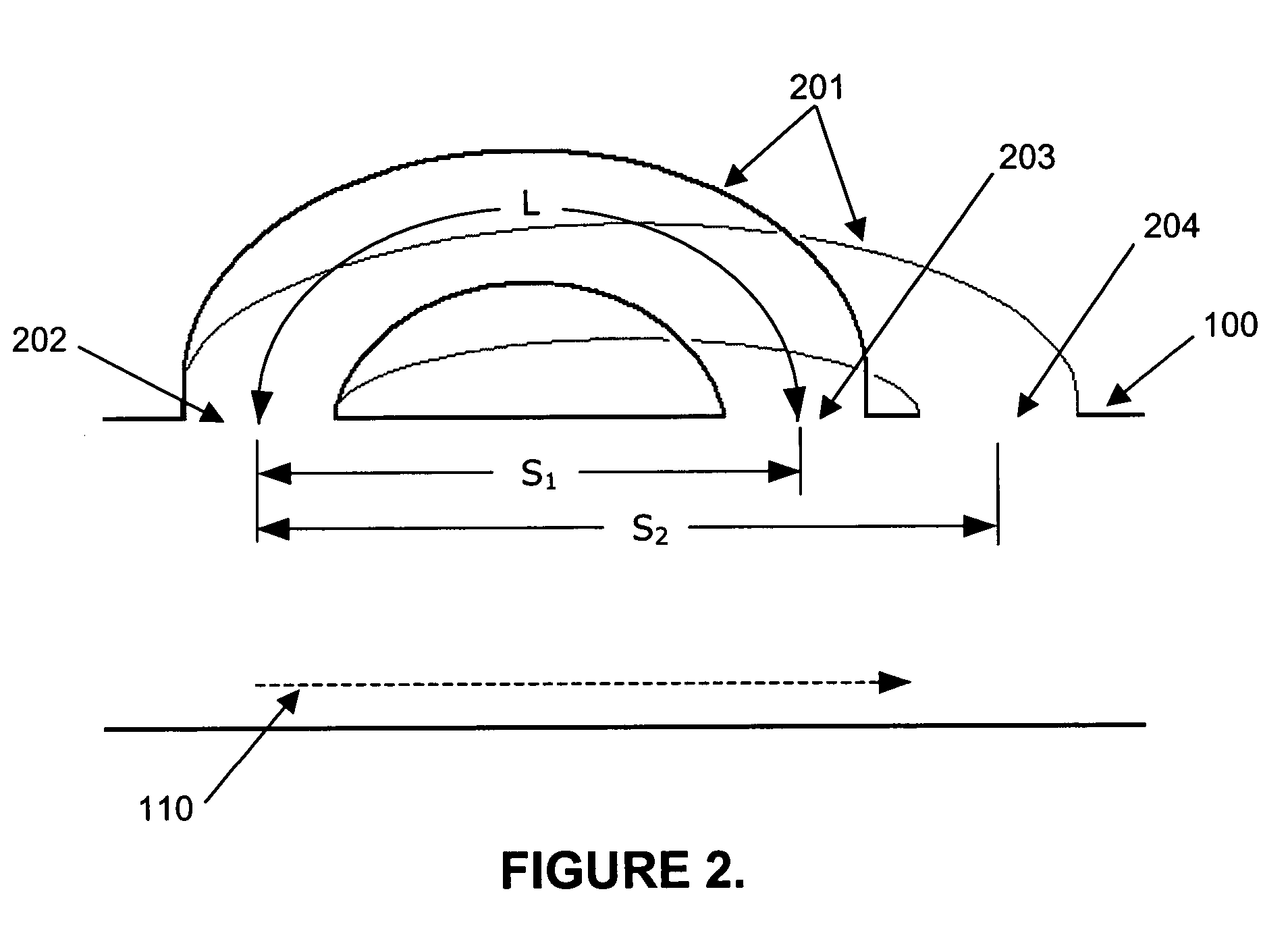

Noise reduction tubes

InactiveUS20050205351A1Reduces unwanted noise propagatingReduce sound propagationPump componentsEngine fuctionsOut of phaseUltrasound attenuation

The invention uses tubes for the reduction of radiated duct noise. The tubes may be used to attenuate narrow band noise by diverting a portion of the acoustic energy through the tubes back into the duct. Upon reintroducing the diverted flow out of phase with the primary flow, acoustic cancellation is achieved. The frequency at which this occurs is dependent on the difference in the path lengths through the tubes and the separation distance—the distance separating the inlet and outlet of the tube. This invention can be used over varying frequency ranges by using an arrangement of flexible, constant length tubes. The effective frequency range is tailored by varying the separation distance and also allows the varying the angular arrangement of the tubes for more effective attenuation of spinning modes having varying propagation angle.

Owner:DANGELO JOHN P

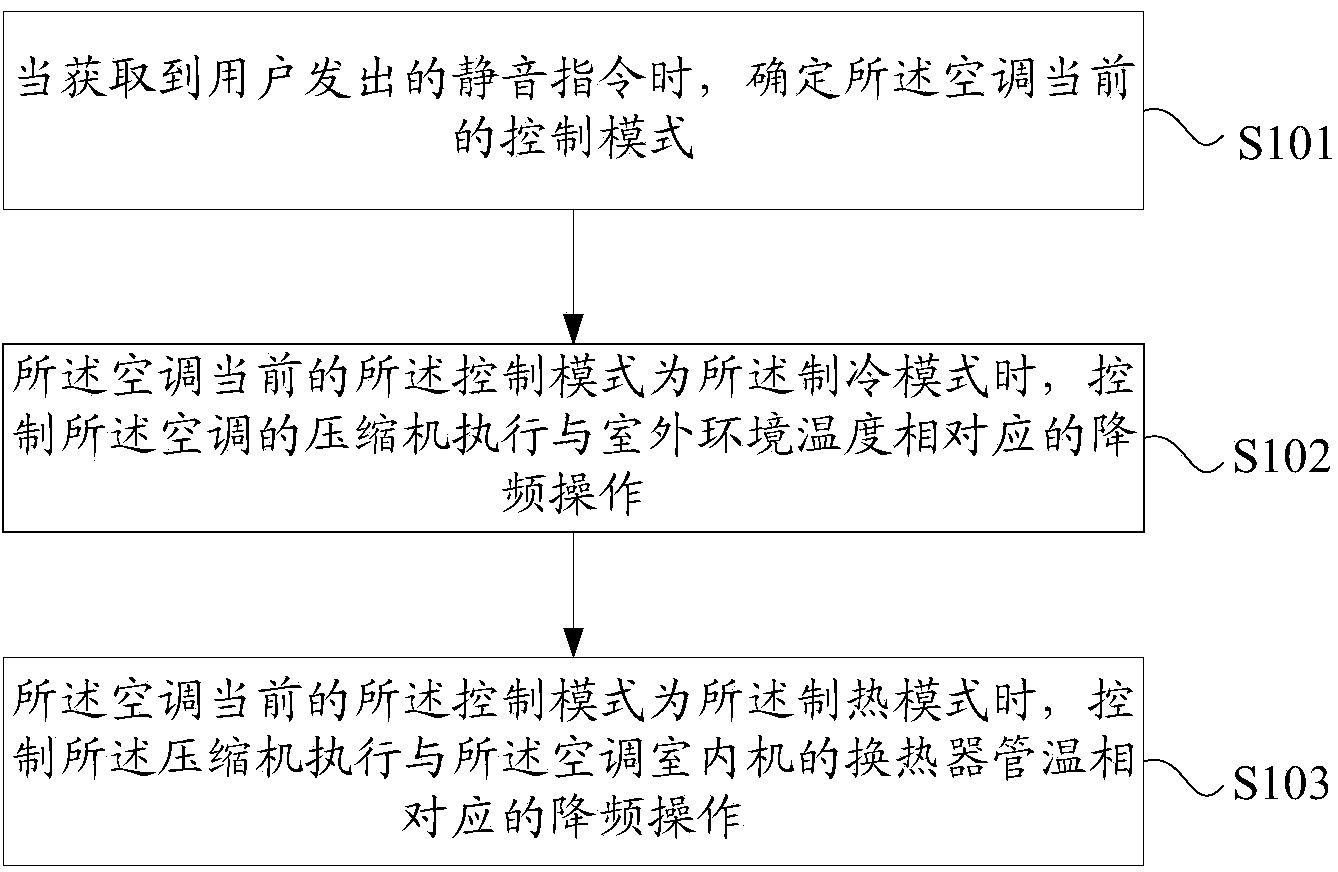

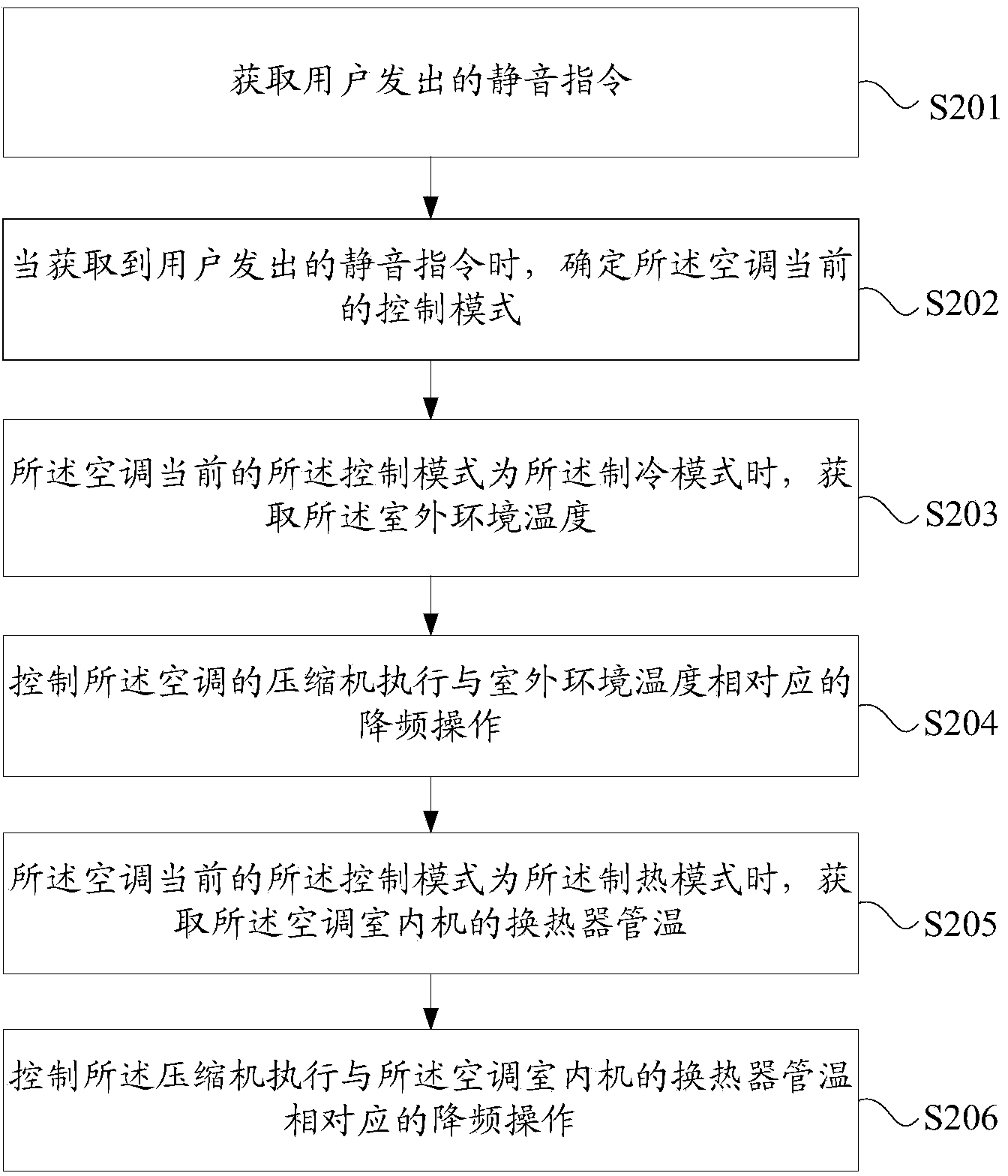

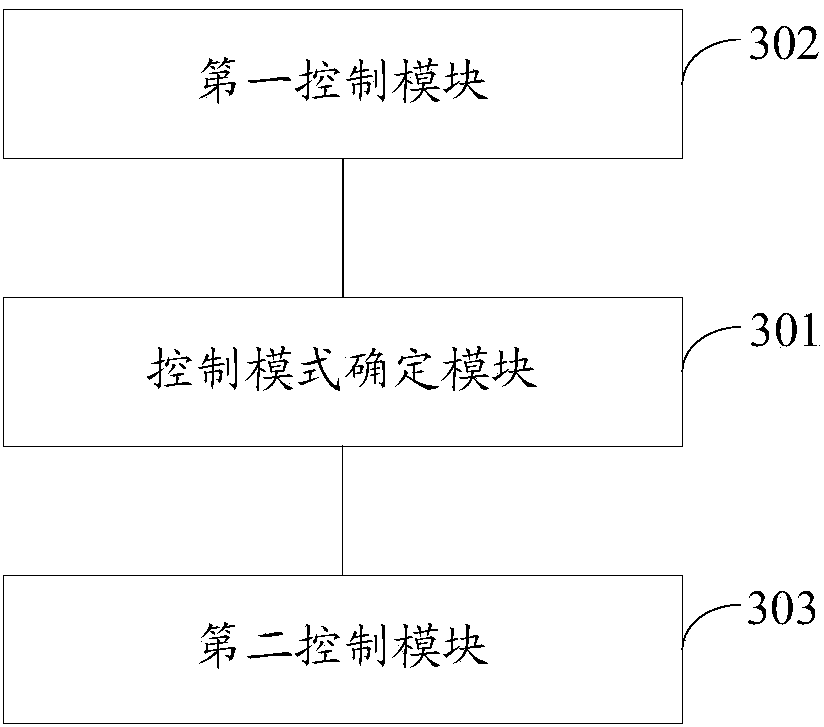

Air conditioner indoor unit running noise control method and system

ActiveCN104033996AReduce noiseQuiet sound environmentSpace heating and ventilation safety systemsLighting and heating apparatusControl modeHeat exchanger

The invention discloses an air conditioner indoor unit running noise control method and system. The method comprises the steps that when a silence instruction given out by a user is obtained, and the current control mode of an air conditioner is determined, wherein the control modes include the refrigeration mode and the heating mode; when the current control mode of the air conditioner is the refrigeration mode, a compressor of the air conditioner is controlled to execute frequency-reducing operation corresponding to the outdoor environment temperature; when the current control mode of the air conditioner is the heating mode, the compressor is controlled to execute frequency-reducing operation corresponding to a heat exchanger tube of the indoor unit of the air conditioner. When the air conditioner indoor unit running noise control method and system are adopted, noise generated when the air conditioner runs can be lowered, and a relatively quiet sound environment is provided for the user.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

Acoustical sound proofing material with improved fire resistance and methods for manufacturing same

ActiveUS8397864B2Improve abilitiesReduce sound transmissionWallsMetal-working apparatusCelluloseEngineering

A material for use in building construction (partition, wall, ceiling, floor or door) that exhibits improved acoustical sound proofing and fire resistance. The material comprises a laminated structure having as an integral part thereof one or more layers of intumescent viscoelastic material which also functions as a glue, energy dissipating layer, and a fire resistive layer; and one or more constraining layers, such as gypsum, cement, metal, cellulose, wood, or petroleum-based products such as plastic, vinyl, plastic or rubber. In one embodiment, standard wallboard, typically gypsum, comprises the external surfaces of the laminated structure.

Owner:PACIFIC COAST BUILDING PRODS

Audio reproduction system and speaker apparatus

InactiveUS8199940B2Reduce noiseReduce sound transmissionSignal processingTransducers for sound channels pluralityIntermediate frequencyEngineering

An audio reproduction system includes: a first speaker arranged near a listener and behind a head of the listener with a speaker unit being held by first holding means to make it possible to mix sounds emitted from front and rear of a vibration plate of the speaker; second and third speakers held by second holding means and arranged near the listener and on left and right of the first speaker; separating means for separating and obtaining low-frequency components and medium- and high-frequency components for left and right channels from an input audio signal; means for supplying the low-frequency components separated by the separating means to the first speaker; and means for supplying the medium- and high-frequency components for the left and right channels separated by the separating means to the second and third speakers.

Owner:SONY CORP

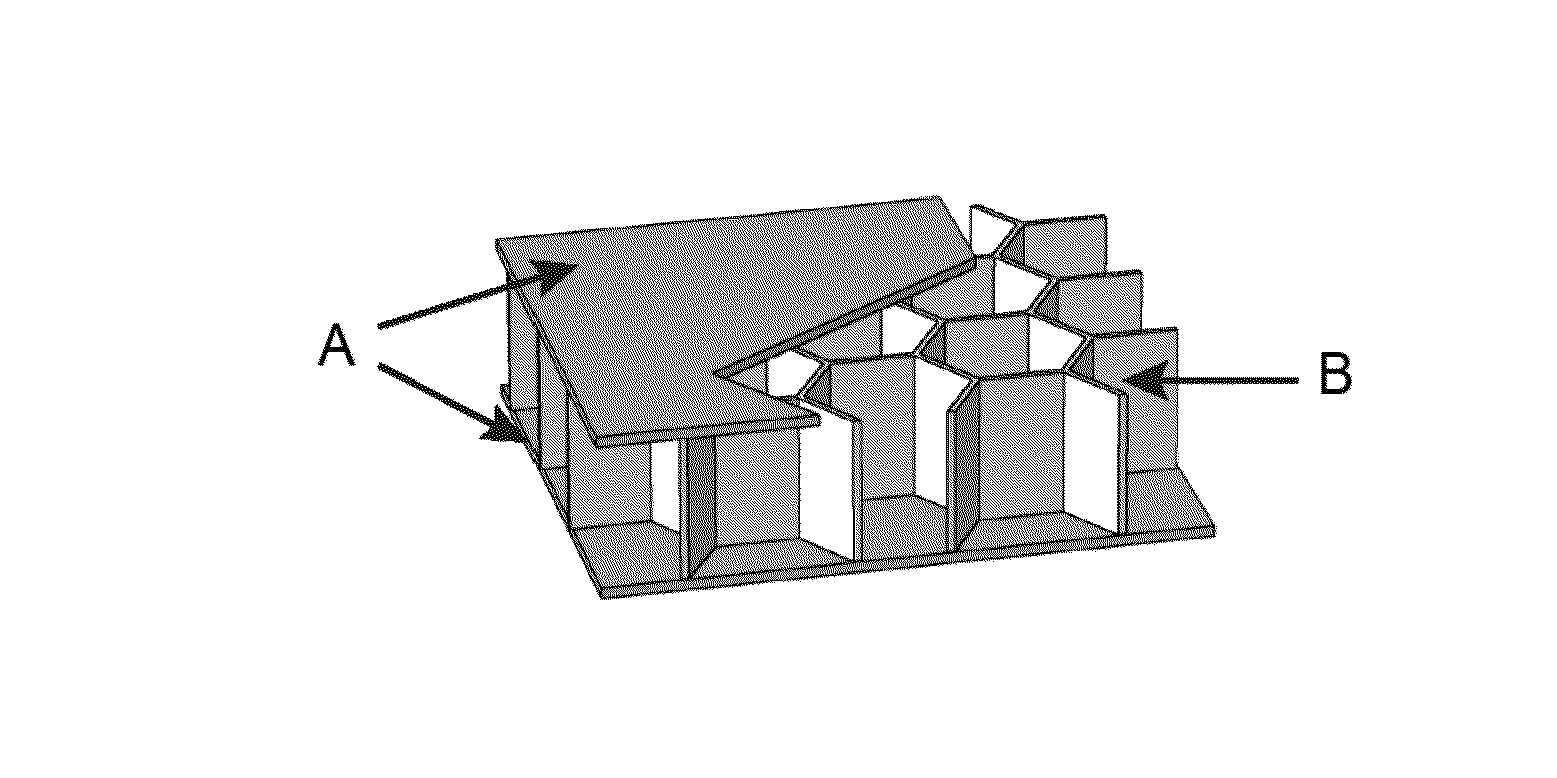

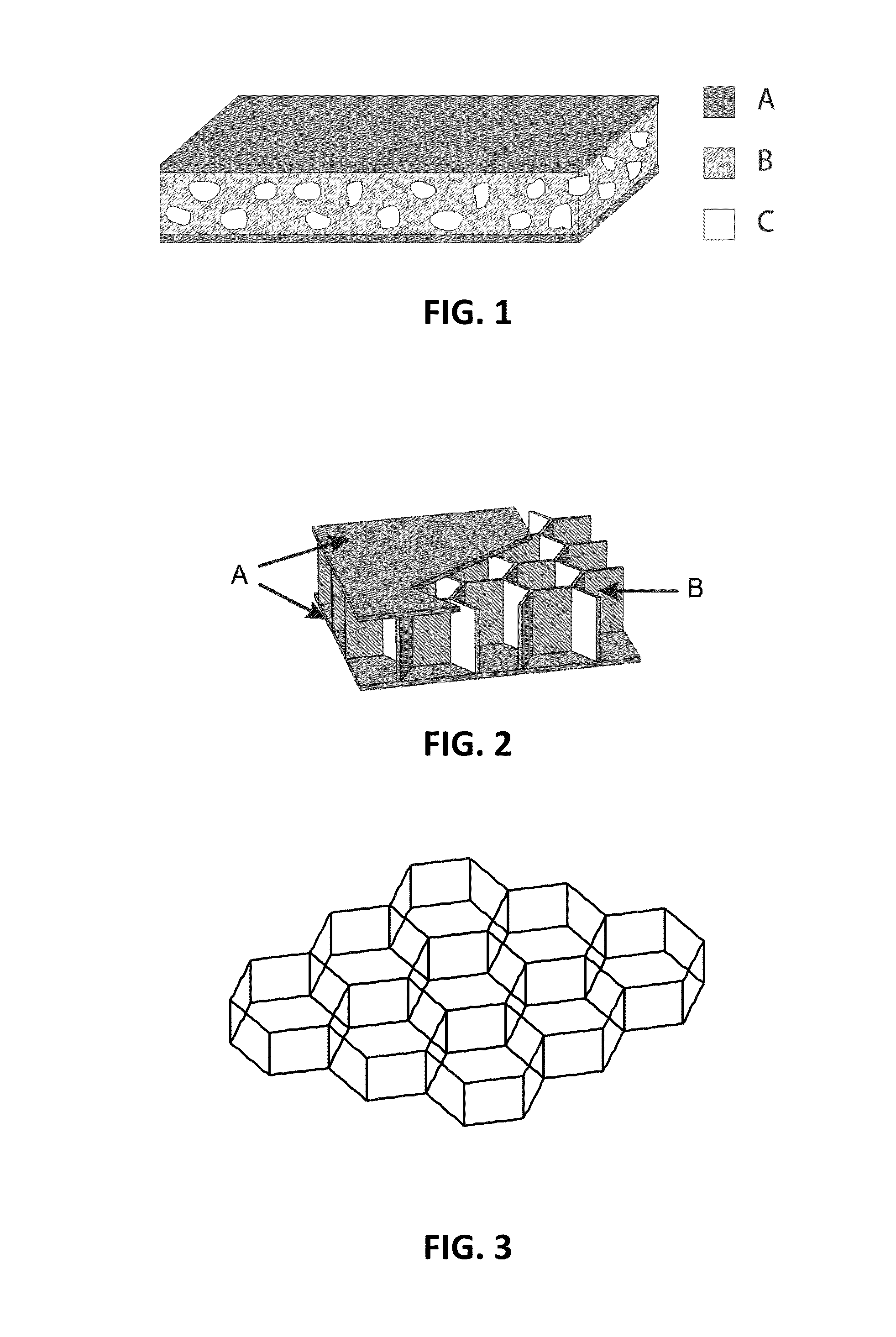

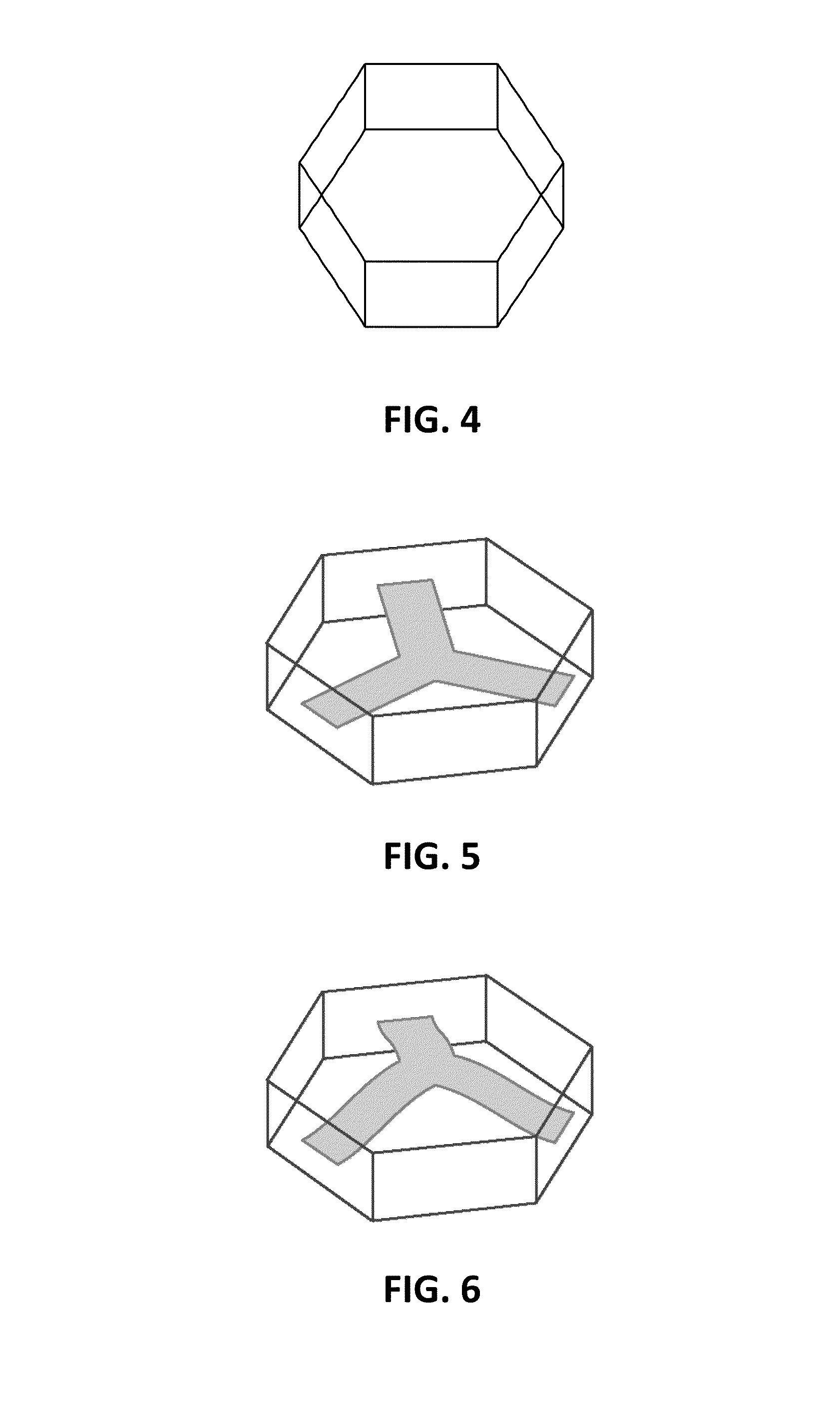

Vibro-Acoustic Attenuation or Reduced Energy Transmission

ActiveUS20140027199A1Reduction of energy transmissionReduce sound transmissionAdditive manufacturing apparatusWallsEngineeringMechanical property

Vibro-acoustic attenuation or reduced energy transmission. The present invention relates to devices that display frequency zones of strong vibro-acoustic attenuation or reduced energy transmission. This can be used in particular, although not necessarily solely, in applications that require lightweight materials with good mechanical properties and good vibro-acoustic response or in applications that require materials with high sound reflection, absorption or sound isolation in a certain frequency band.

Owner:KATHOLIEKE UNIV LEUVEN

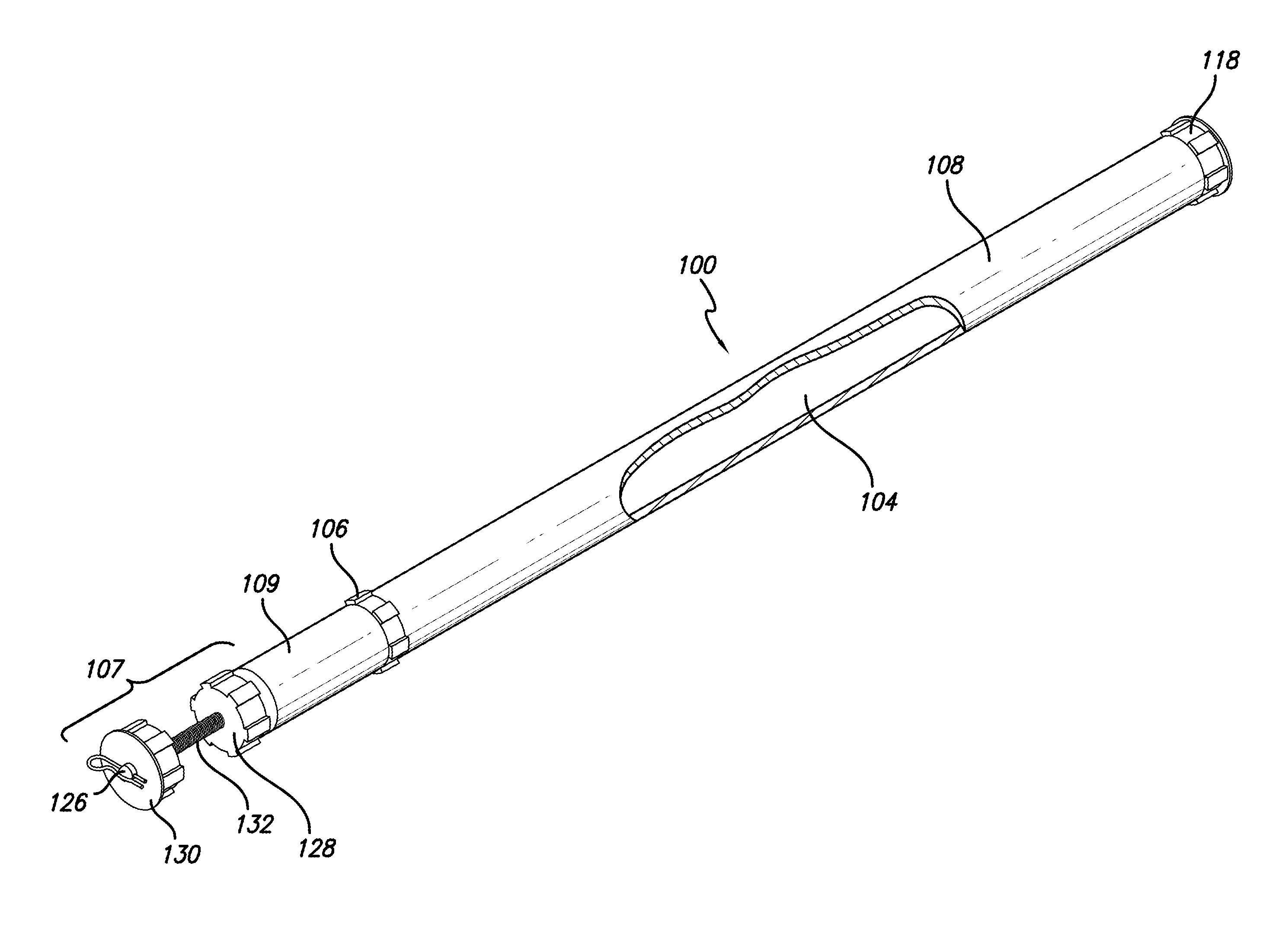

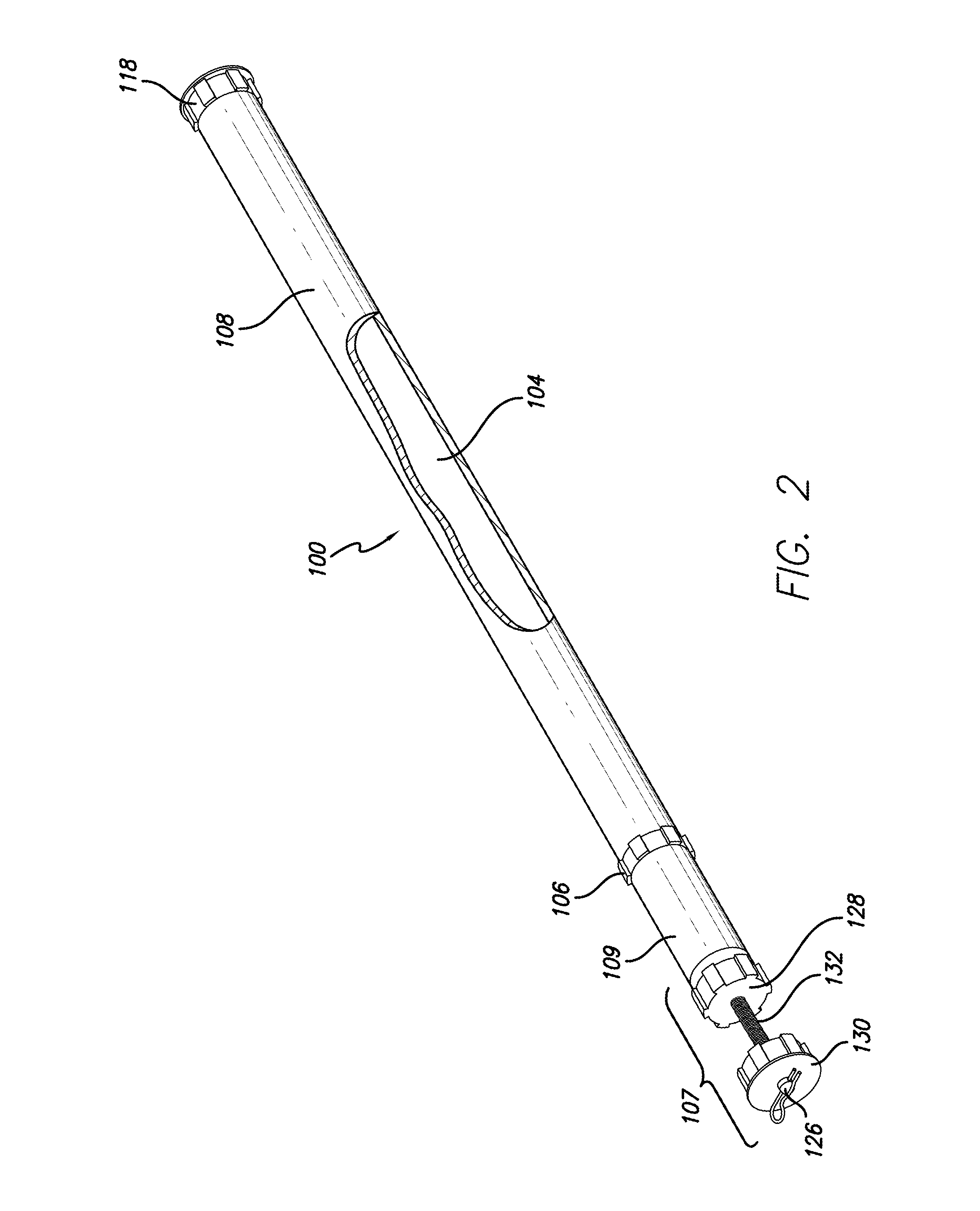

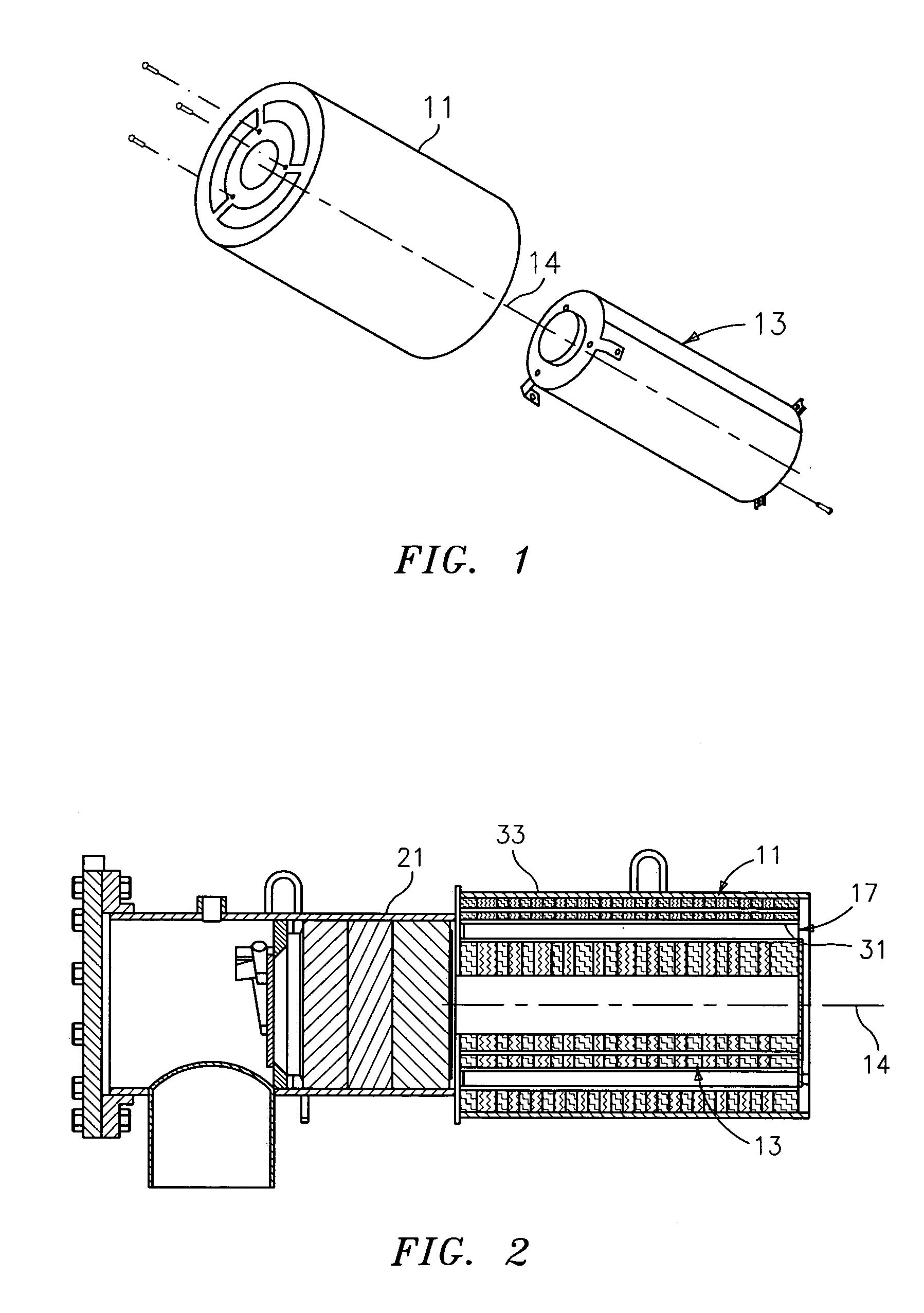

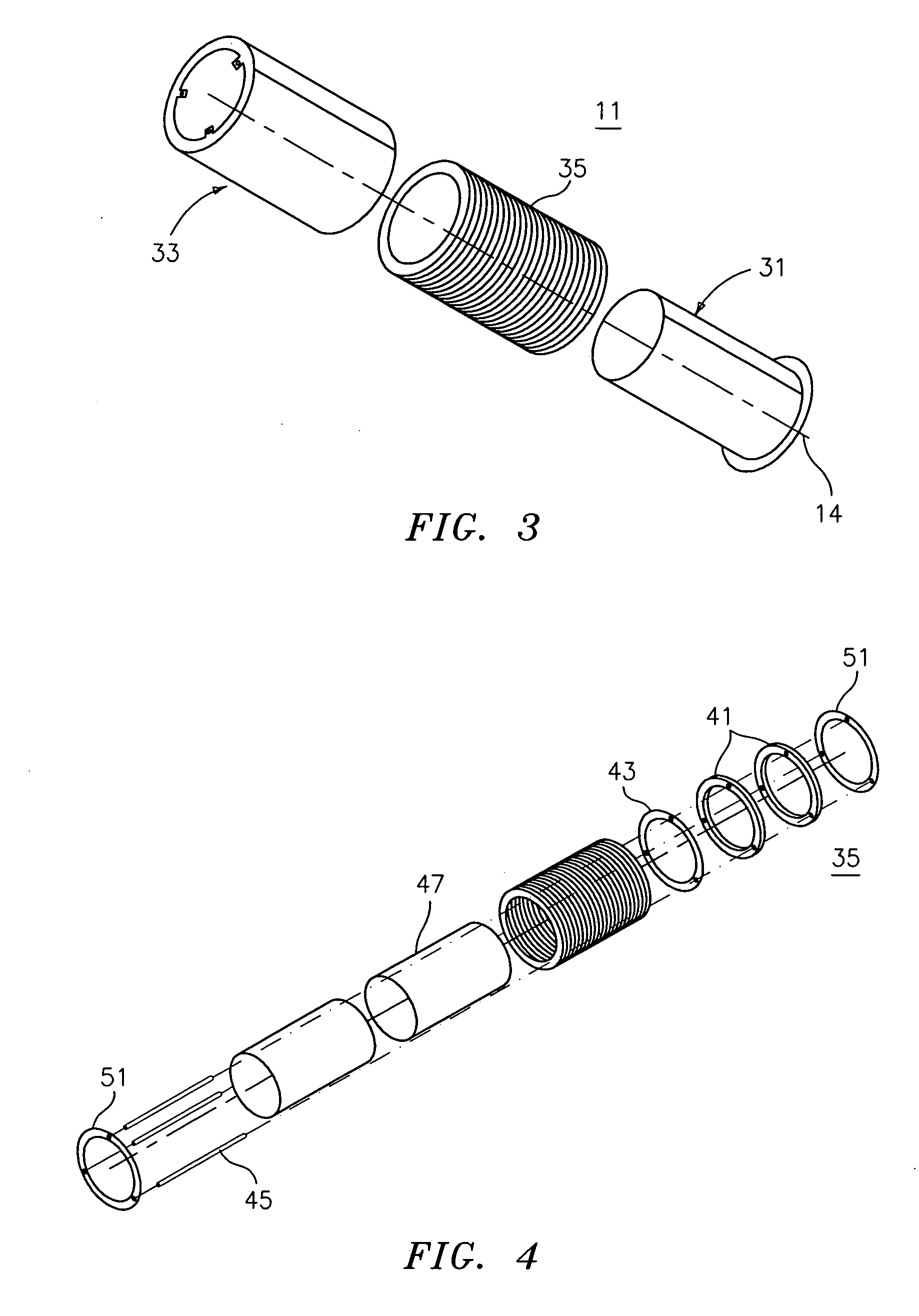

Integrated quiet Motorized Roller Shade System

InactiveUS20100307701A1Reduce vibrationReduce transmission of soundScreensPortable framesEngineeringDrive wheel

A quiet motorized roller shade assembly has a roller tube for reeling and unreeling a reelable shade and an internal electric motor. The motor turns a drive wheel that mates with a the interior of the roller tube so that the roller tube rotates in response to the rotation of the drive wheel. The electric motor disposed within a motor sleeve for reducing sound transmission within the roller tube. A crown is disposed on one end of the roller tube. The drive wheel and the crown maintain a space between the electric motor and the roller tube so that the motor does not directly contact the roller tube. An idler assembly is disposed proximate the end of the roller tube opposite the crown. The idler assembly includes a spring member for reducing vibration between roller shade assembly and the mounting bracket during operation of the electric motor.

Owner:PETERSON THOMAS

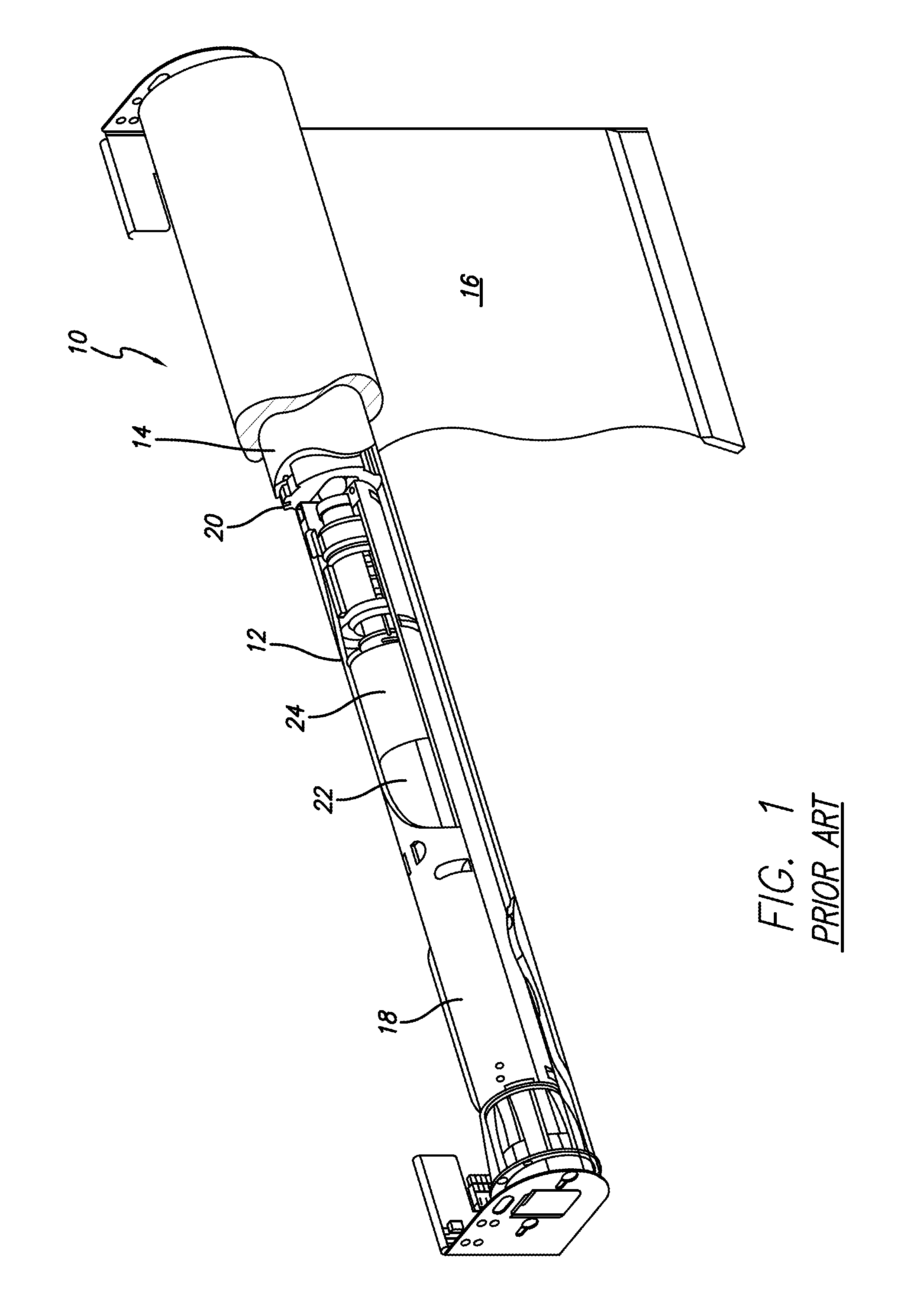

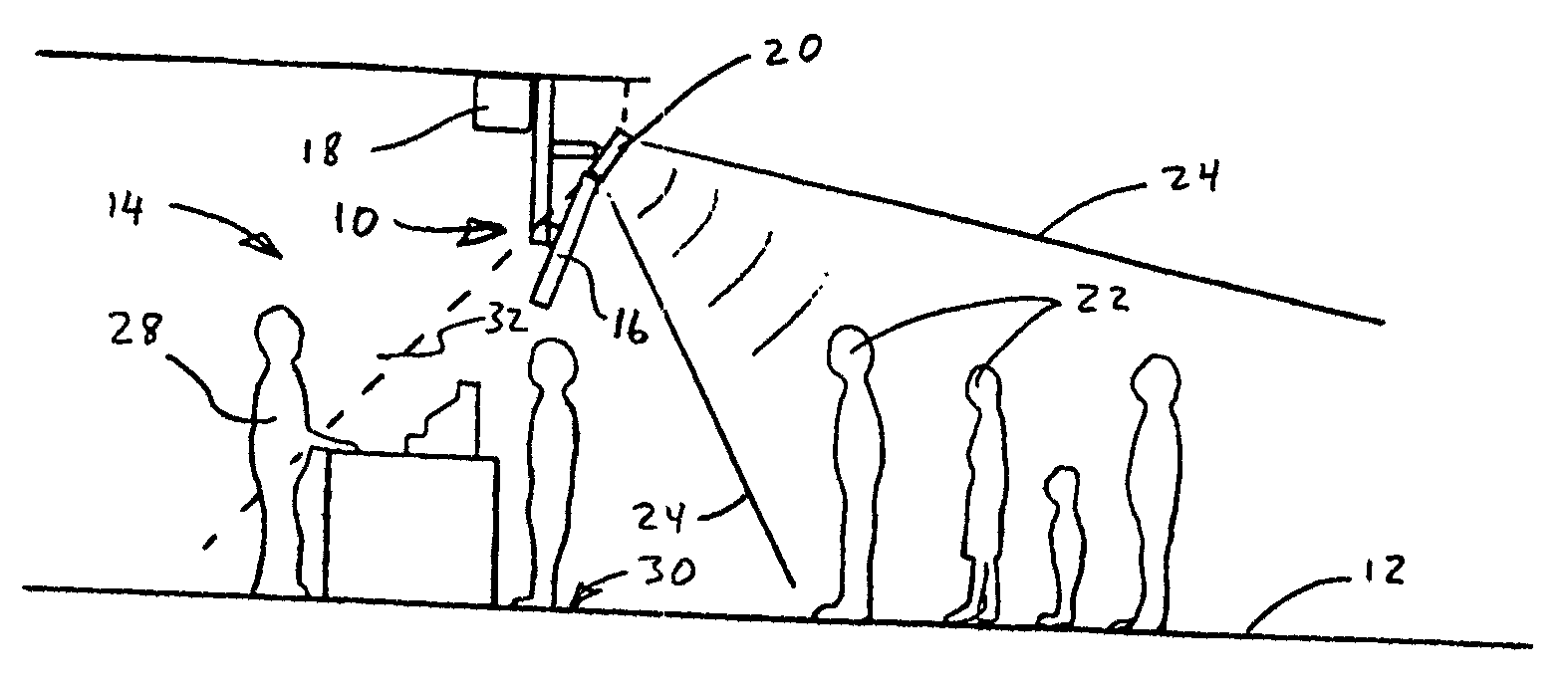

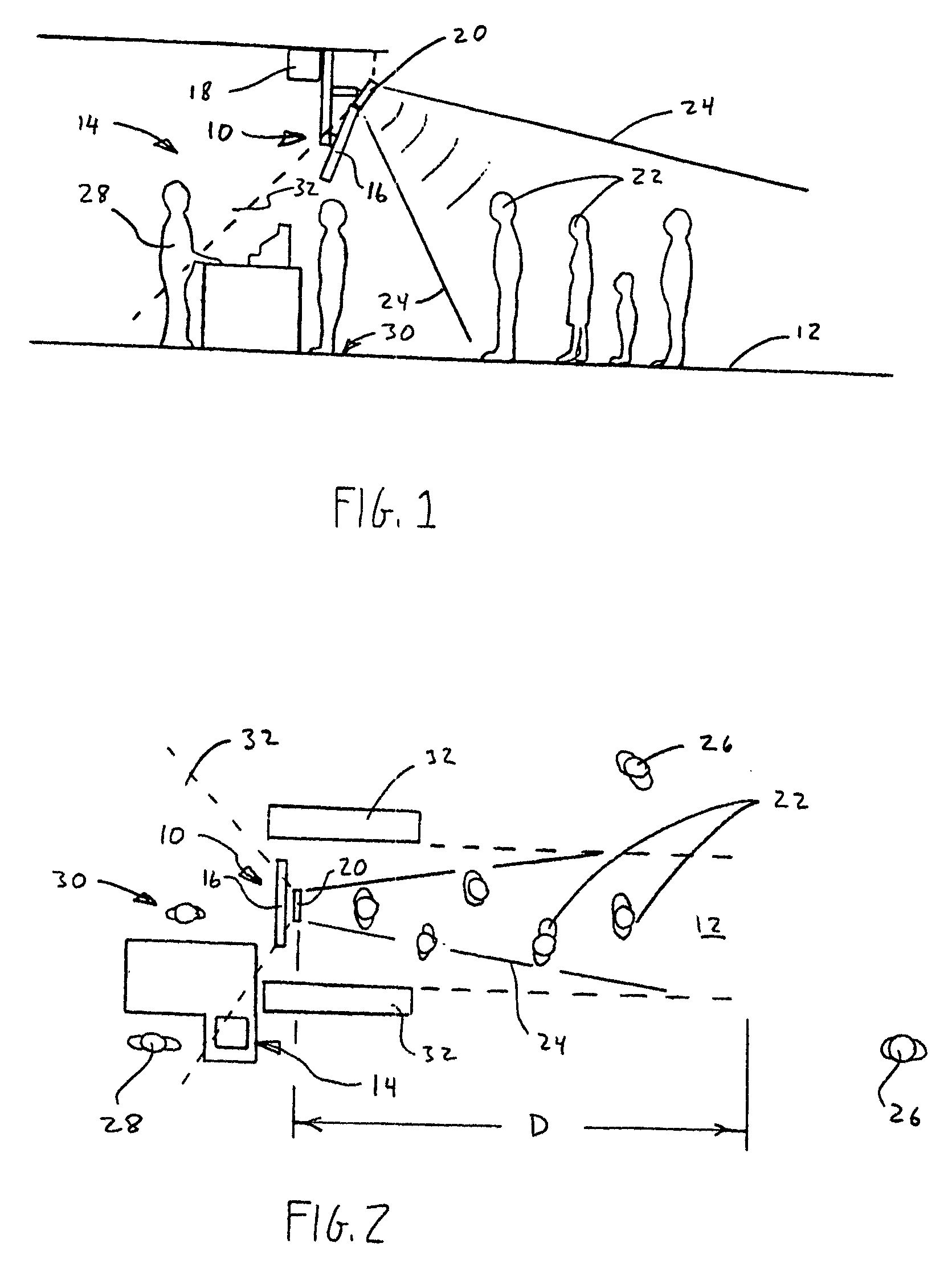

System and method for delivering audio-visual content along a customer waiting line

InactiveUS20060280315A1Minimize distractionContributes to background noiseMicrophonesSignal processingInteraction pointDisplay device

A system for providing audio information to persons in an approach path (12) includes an interaction point (14), and an approach path (12) leading to the interaction point. A parametric sound system (18) is provided, which includes a parametric speaker (20) disposed adjacent to the interaction point. The parametric sound system is configured for limited delivery of sound in a spatially limited audio zone (24) along the approach path (12), within a decibel level above ambient noise levels in the area of the interaction point (14), and sufficiently high to be heard primarily by a person progressing along the approach path (12). The interaction point can be a cashier station, and the system can also include a video display (16) configured to provide video information to persons in the approach path along with the audio information.

Owner:AMERICAN TECH

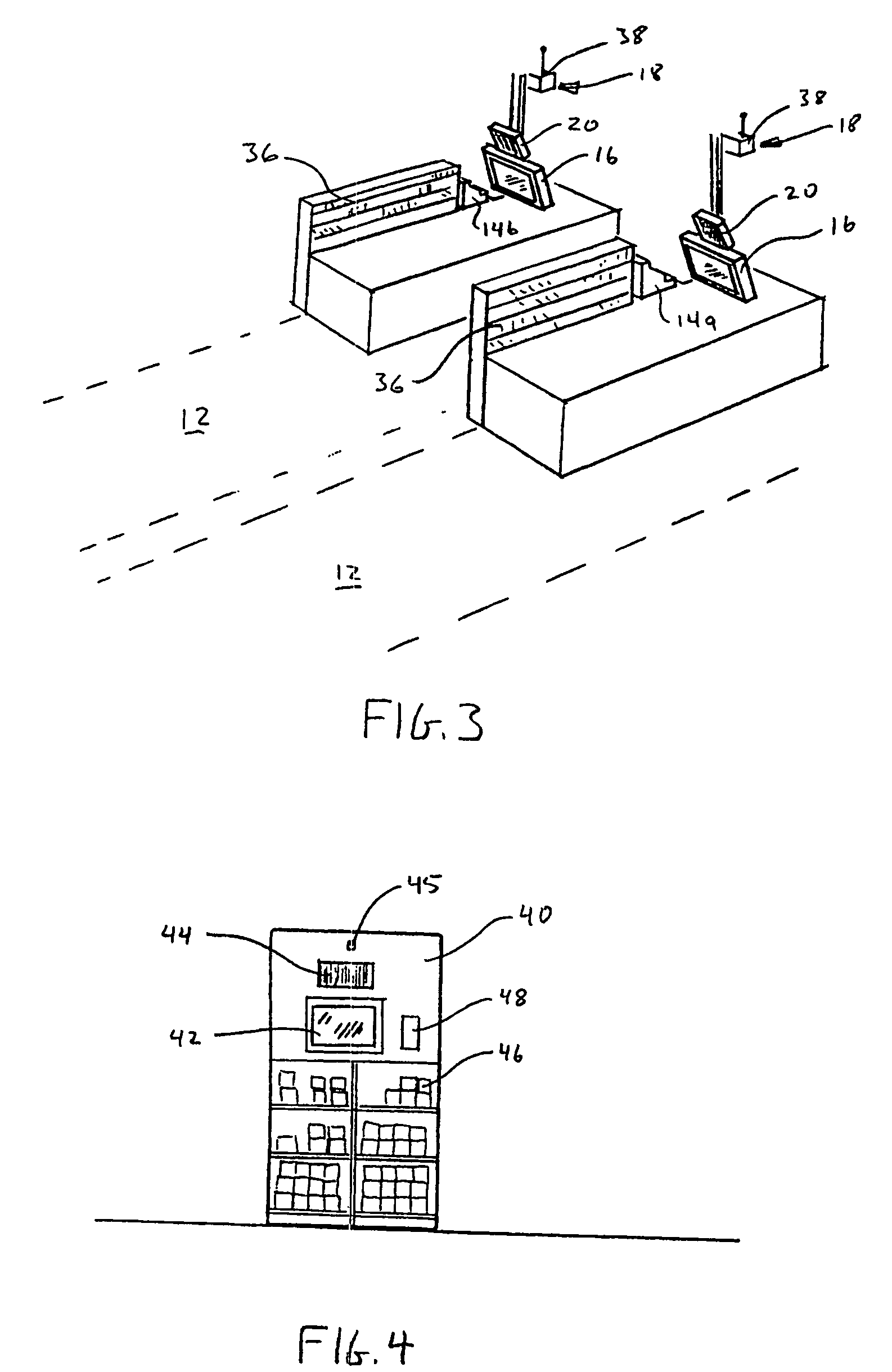

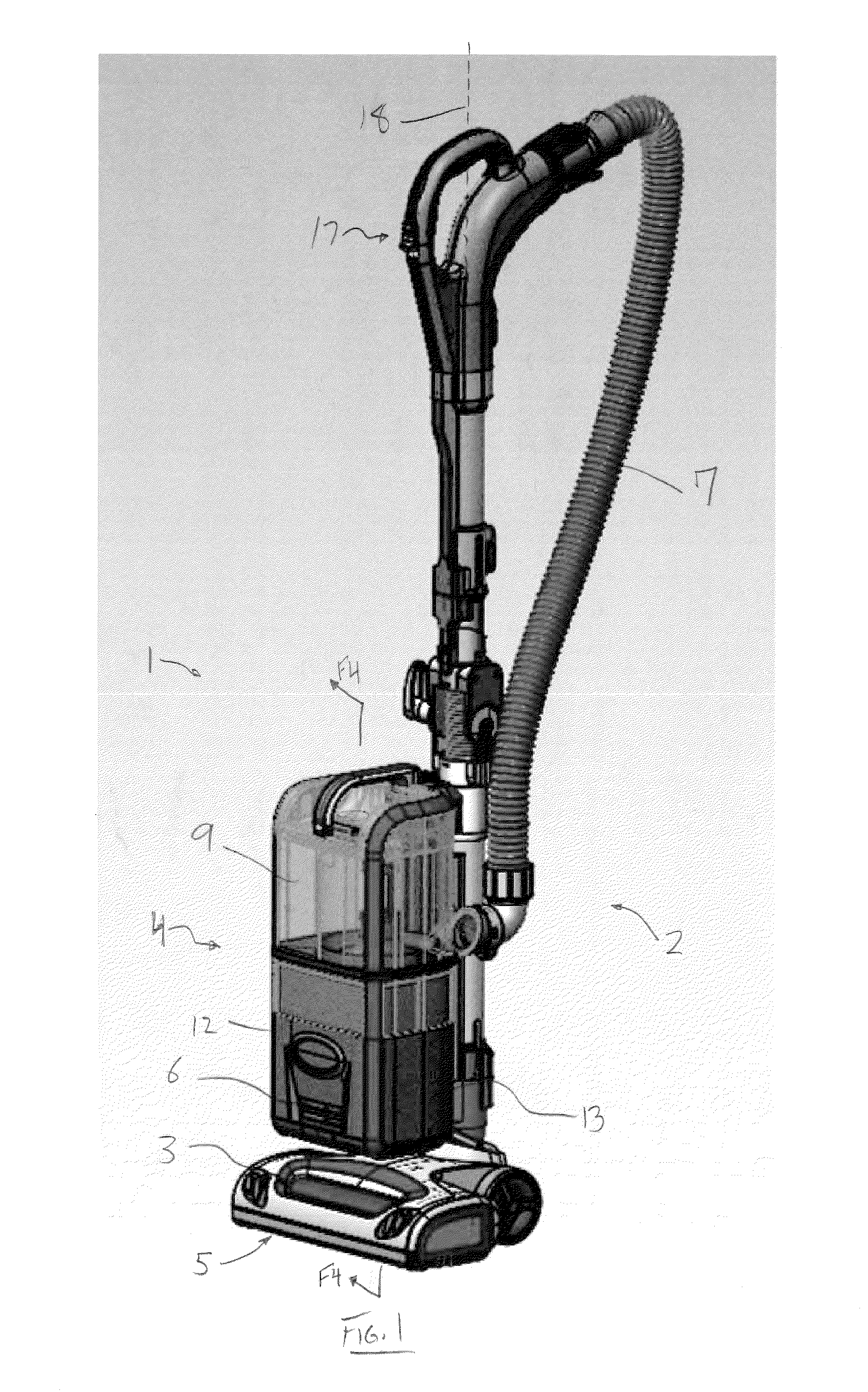

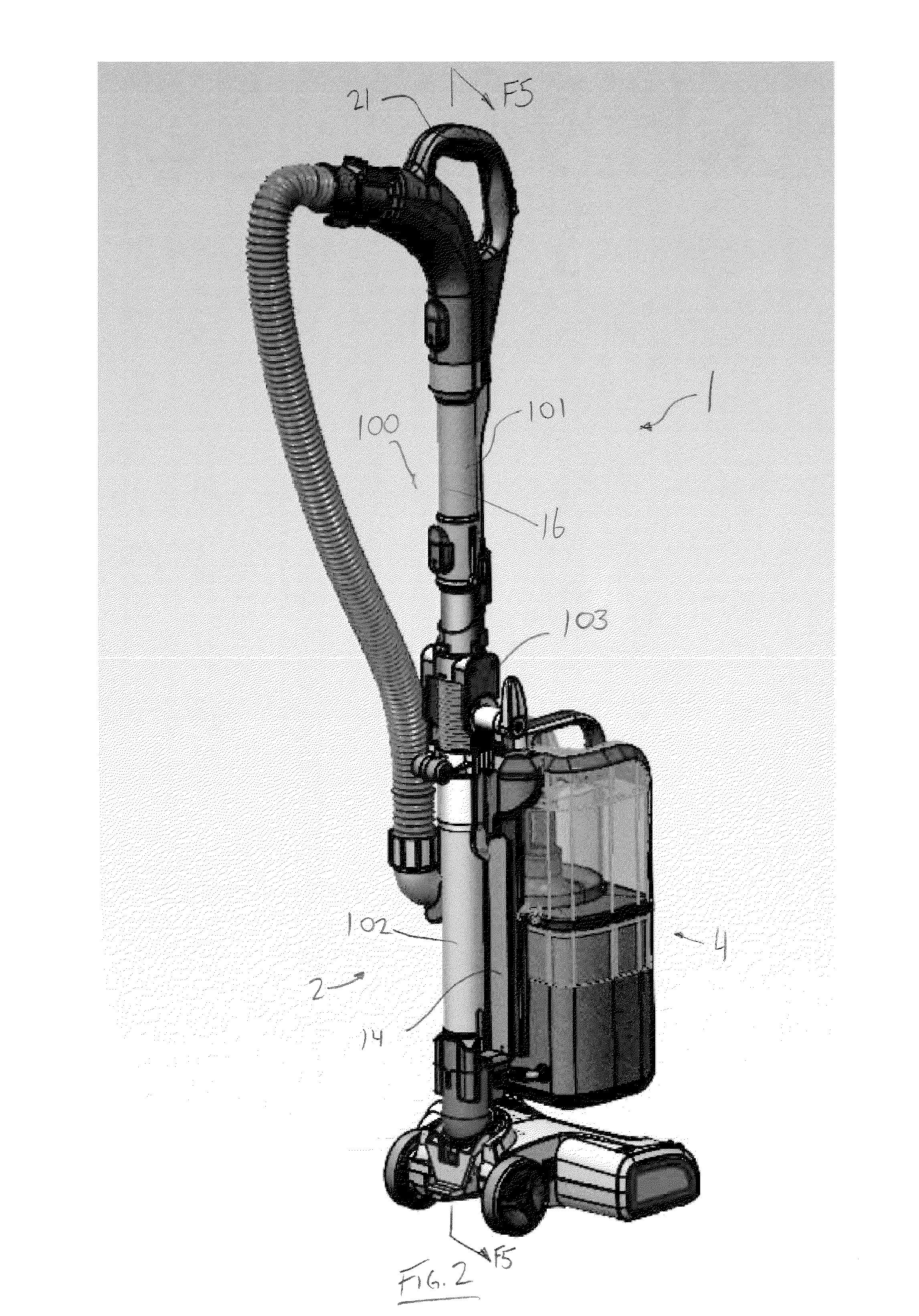

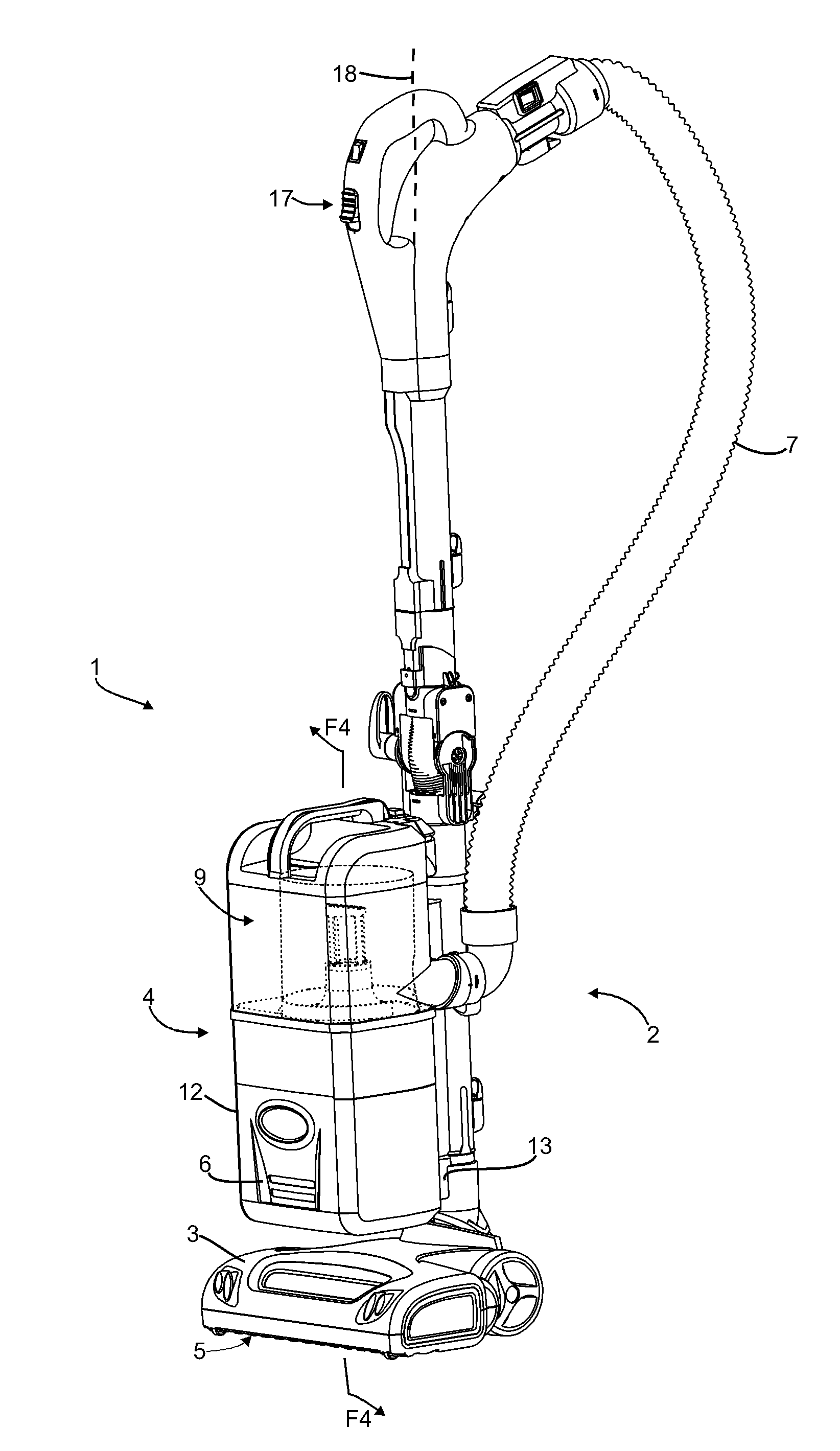

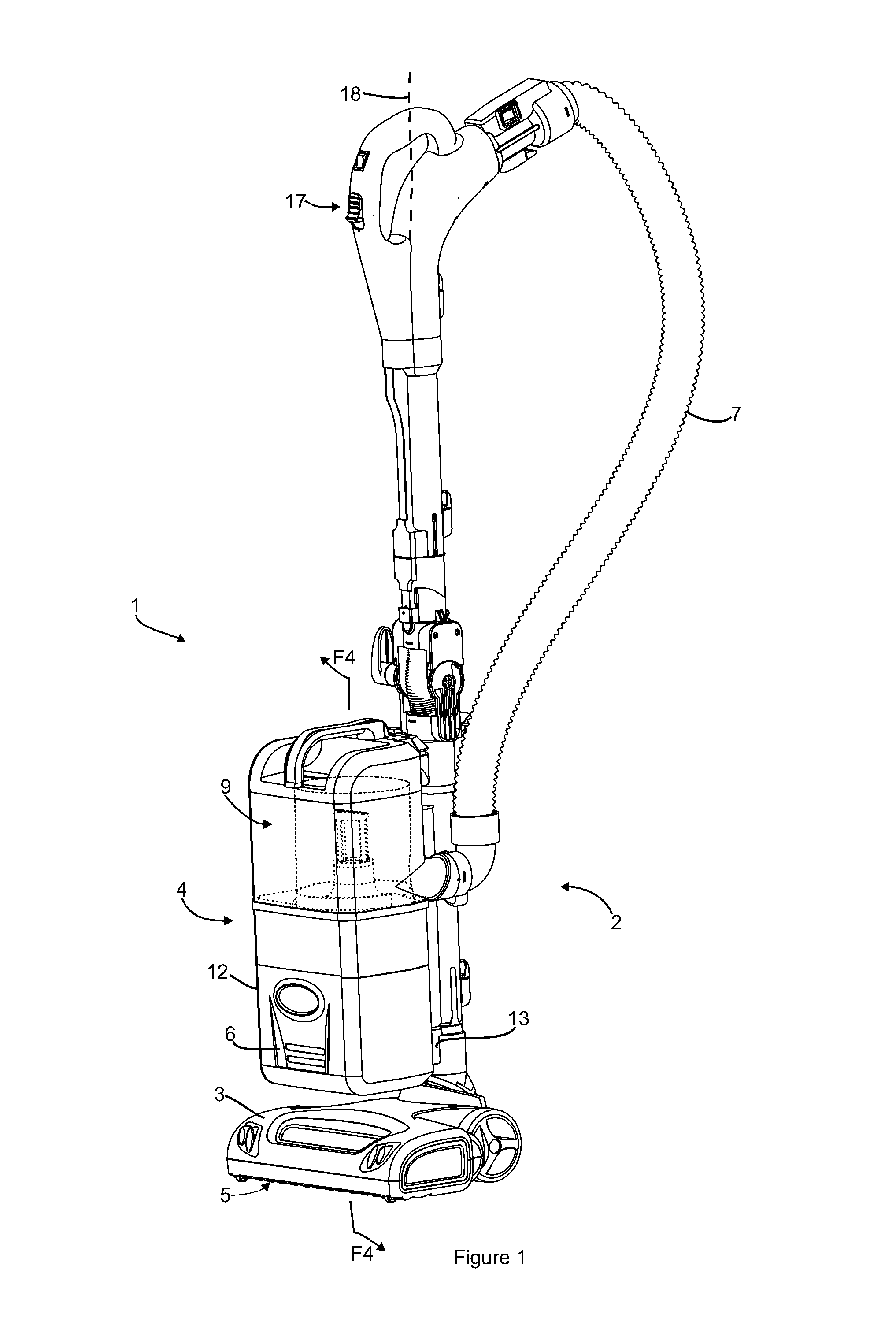

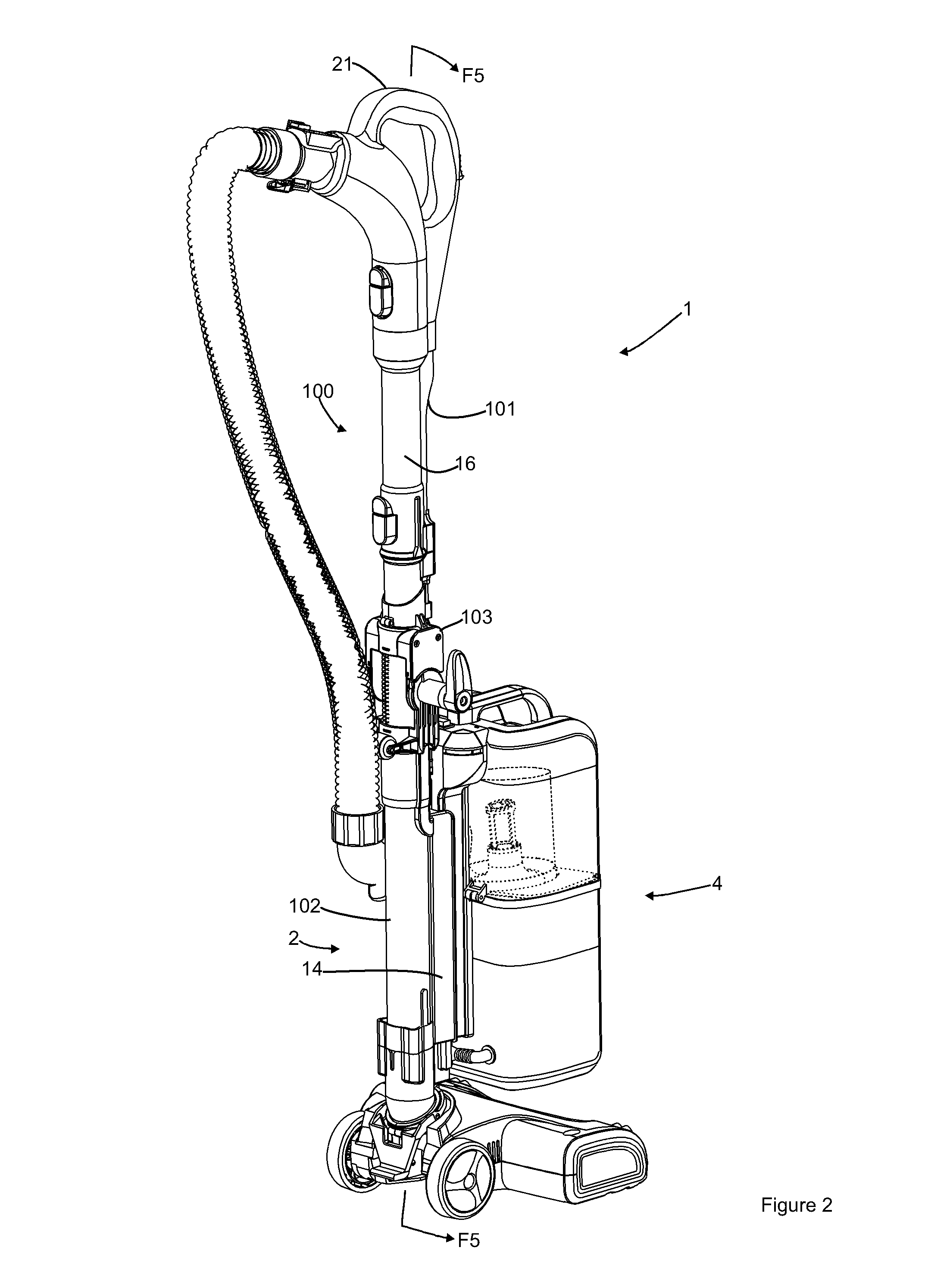

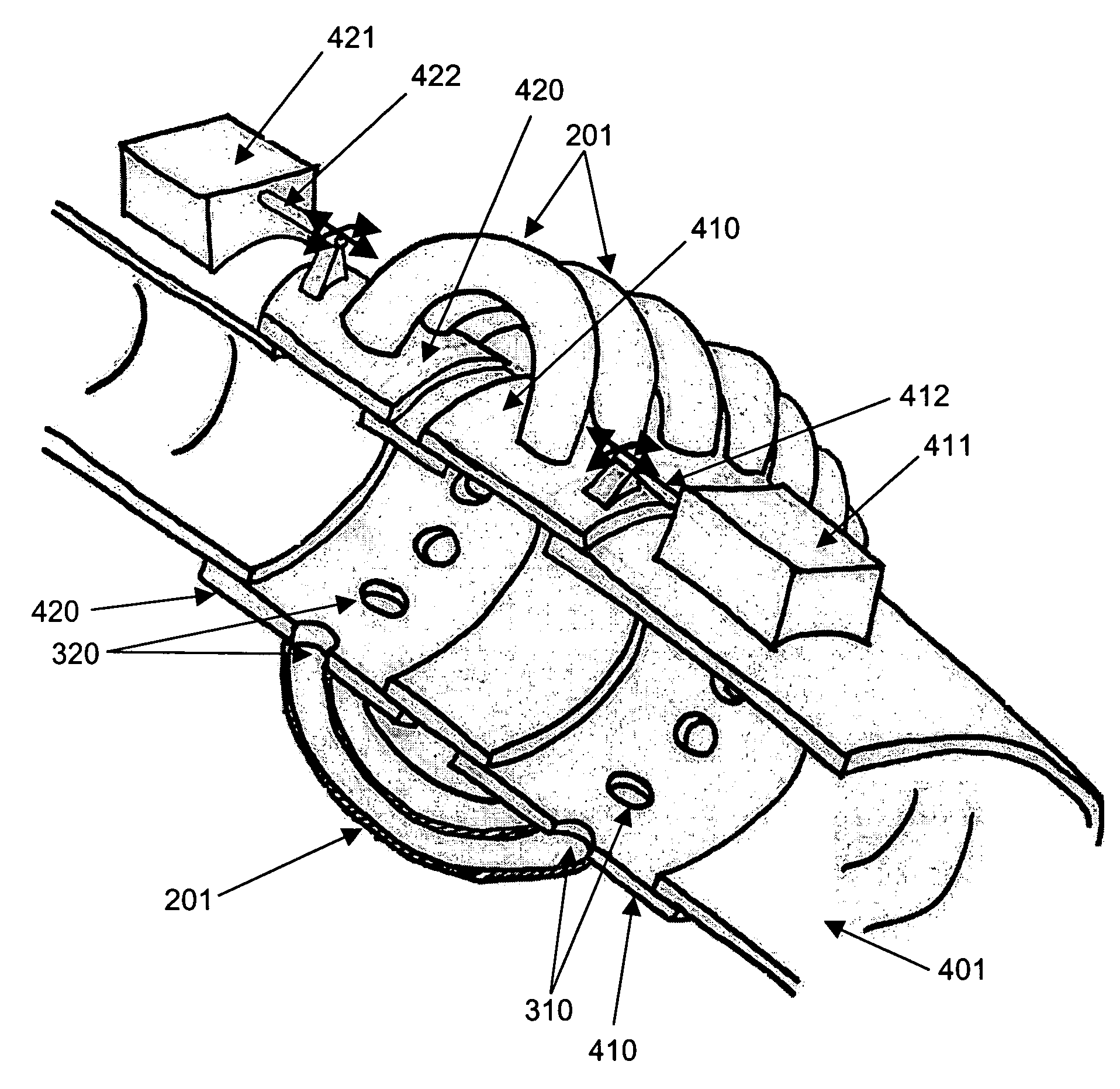

Cyclone such as for use in a surface cleaning apparatus

ActiveUS20140237965A1Reduces suctionReduce back pressureReversed direction vortexDispersed particle separationEngineeringPhencyclone

A cyclone comprises a cyclone chamber having a first end having a first end wall, a second end having a second end wall, a sidewall, an air inlet at the first end, an air outlet and a first central insert member extending away from a center of the second end wall into the cyclone chamber wherein the first central insert member comprises a central member wall extending away from the second end wall and the central member wall and the second end wall meet at a first juncture that extends at an angle to both the central member wall and the second end wall

Owner:OMACHRON INTPROP

Acoustical sound proofing material and methods for manufacturing same

ActiveUS8495851B2Improve abilitiesReduce sound transmissionBuilding roofsCoatingsCelluloseEngineering

An improved acoustical damping wall (ceiling or floor) or door material comprises a laminar structure having as an integral part thereof one or more layers of viscoelastic material which also functions as a glue and one or more constraining layers, such as metal, ceramics, composites, cellulose, wood, or petroleum-based products such as plastic, vinyl, plastic or rubber.

Owner:PACIFIC COAST BUILDING PRODS

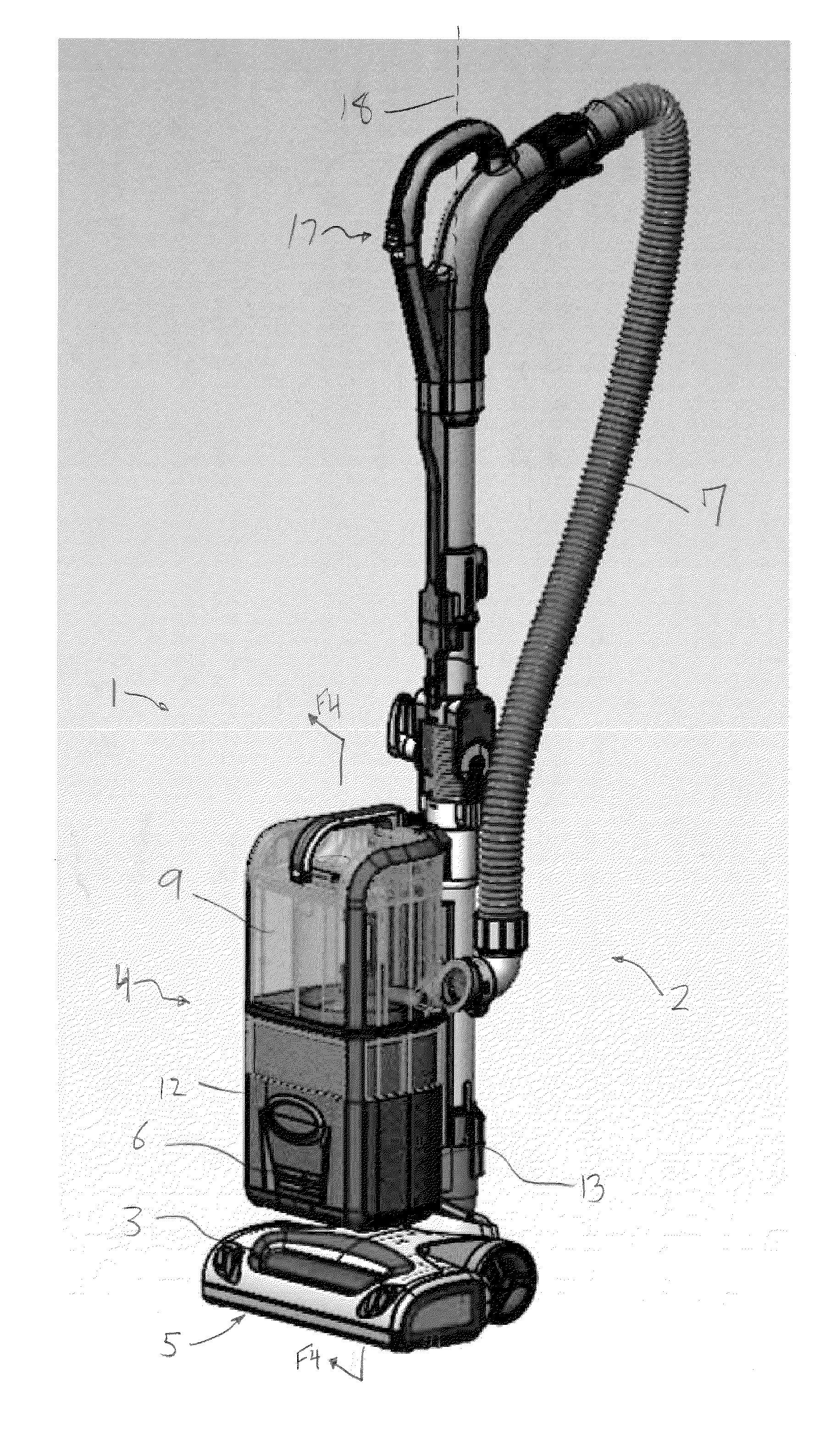

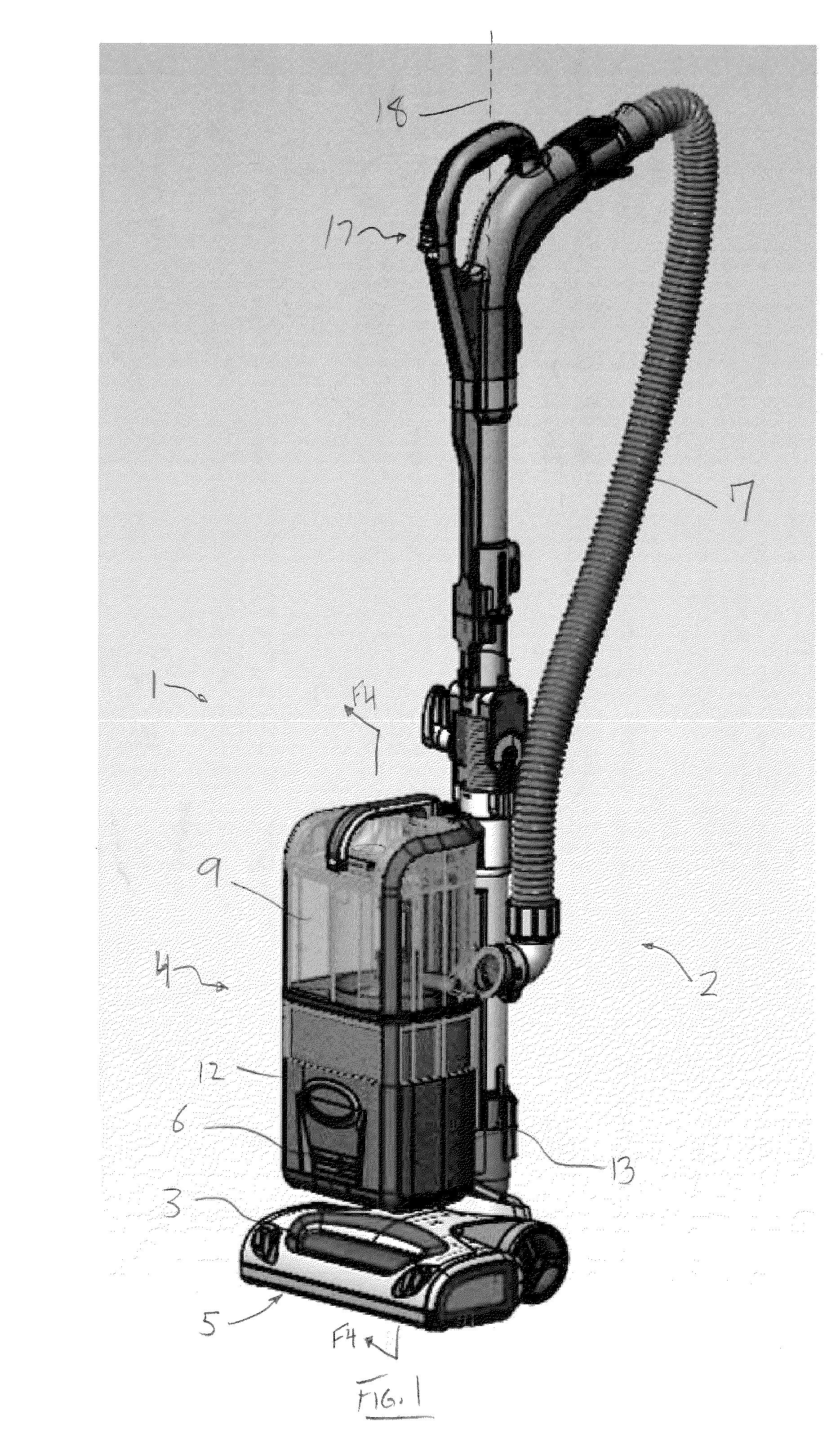

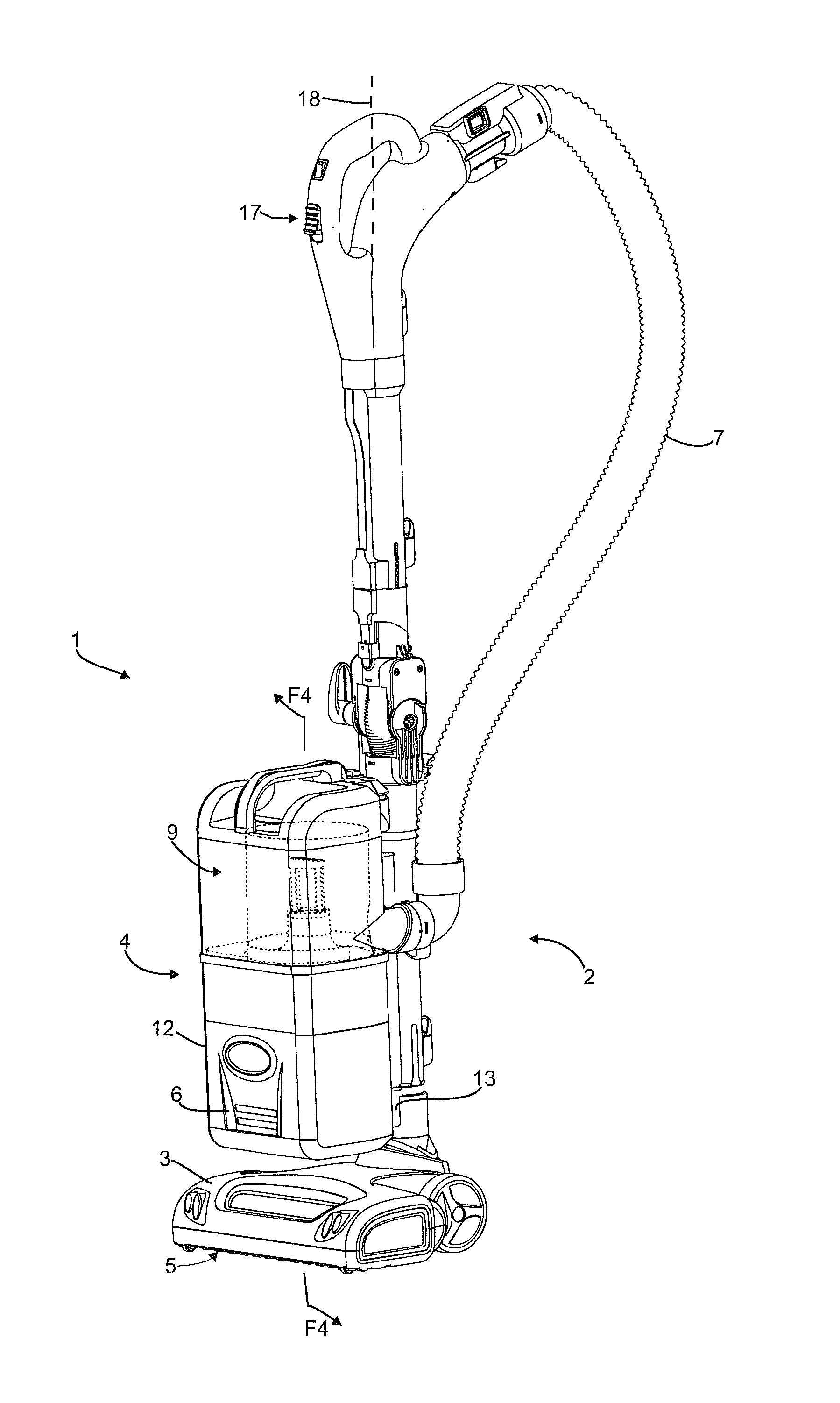

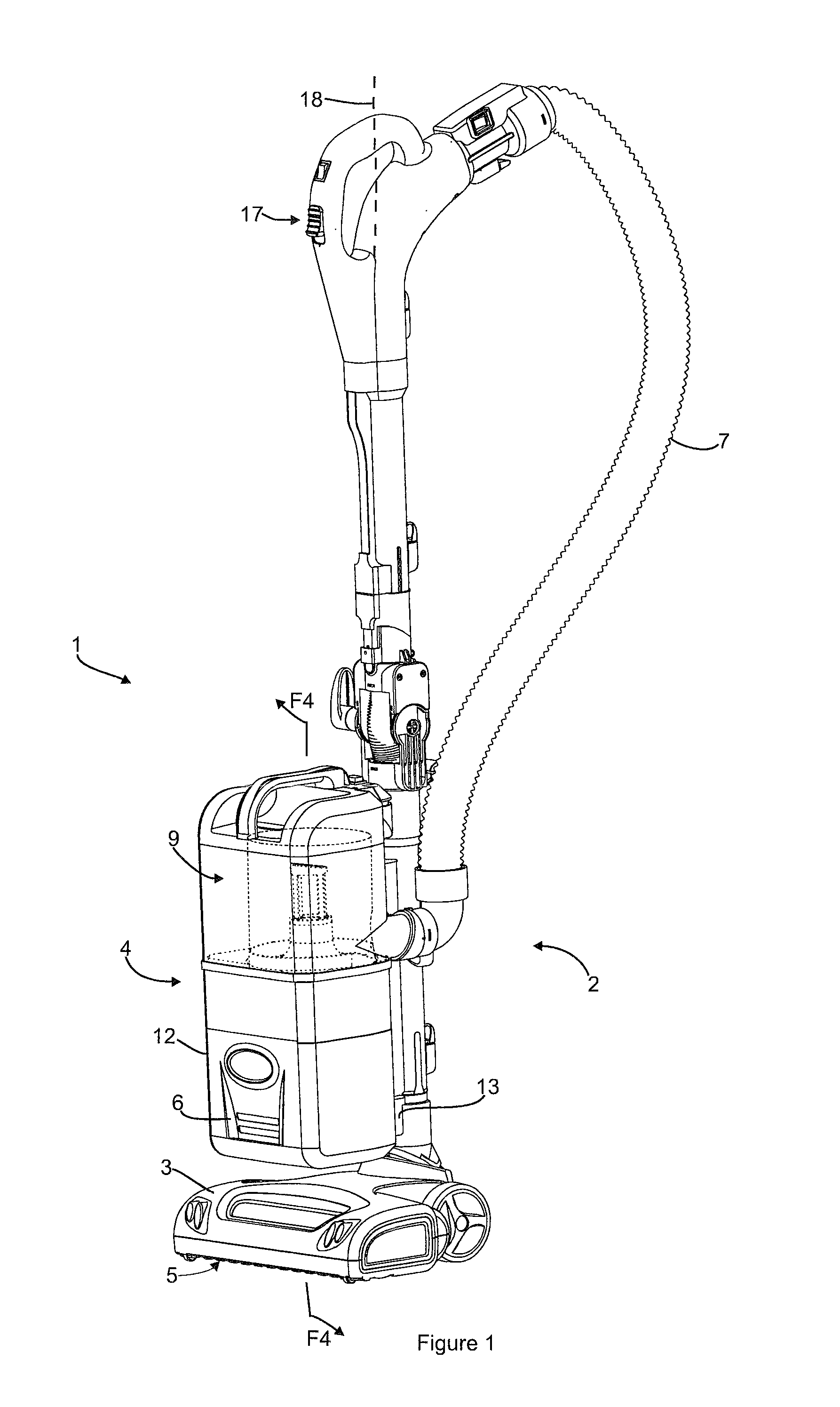

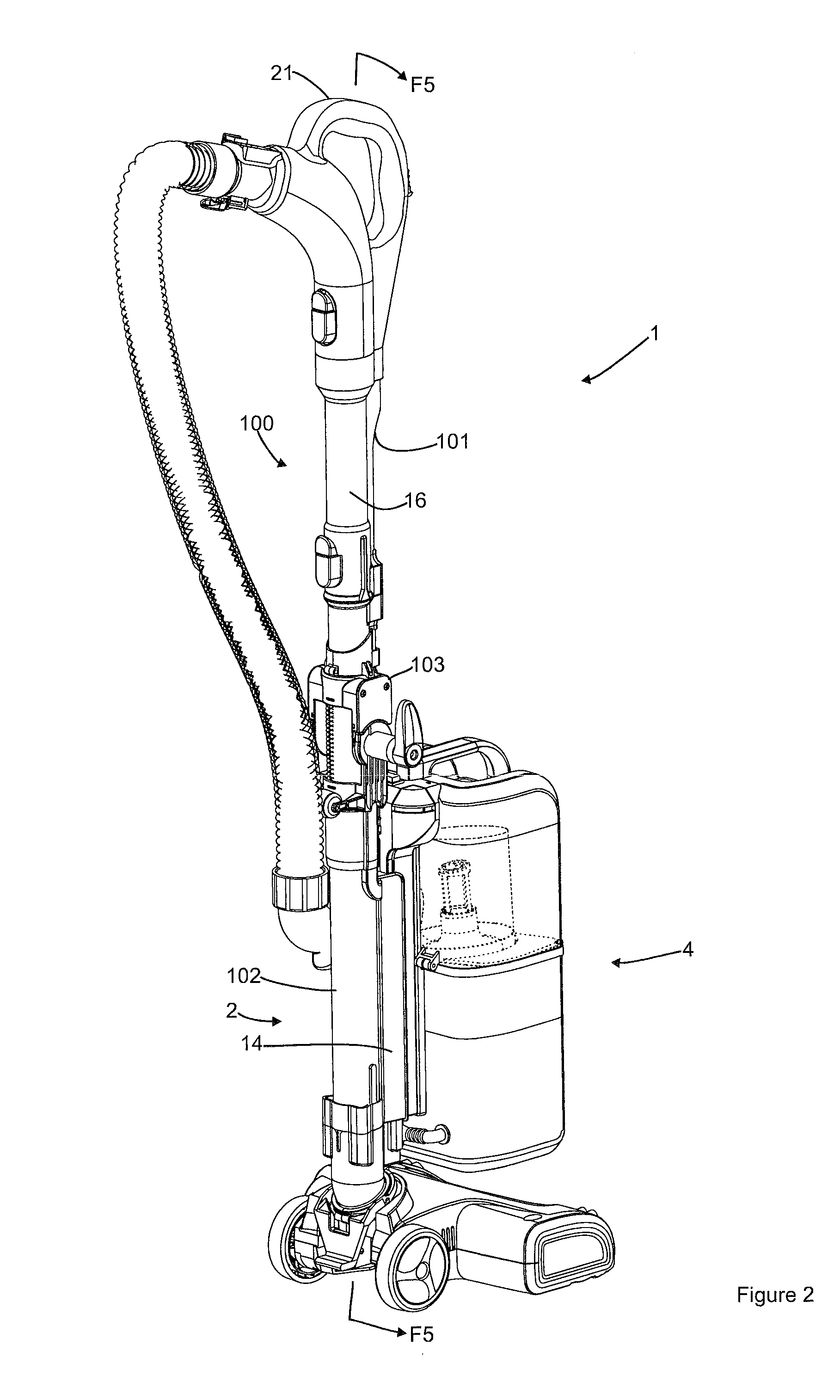

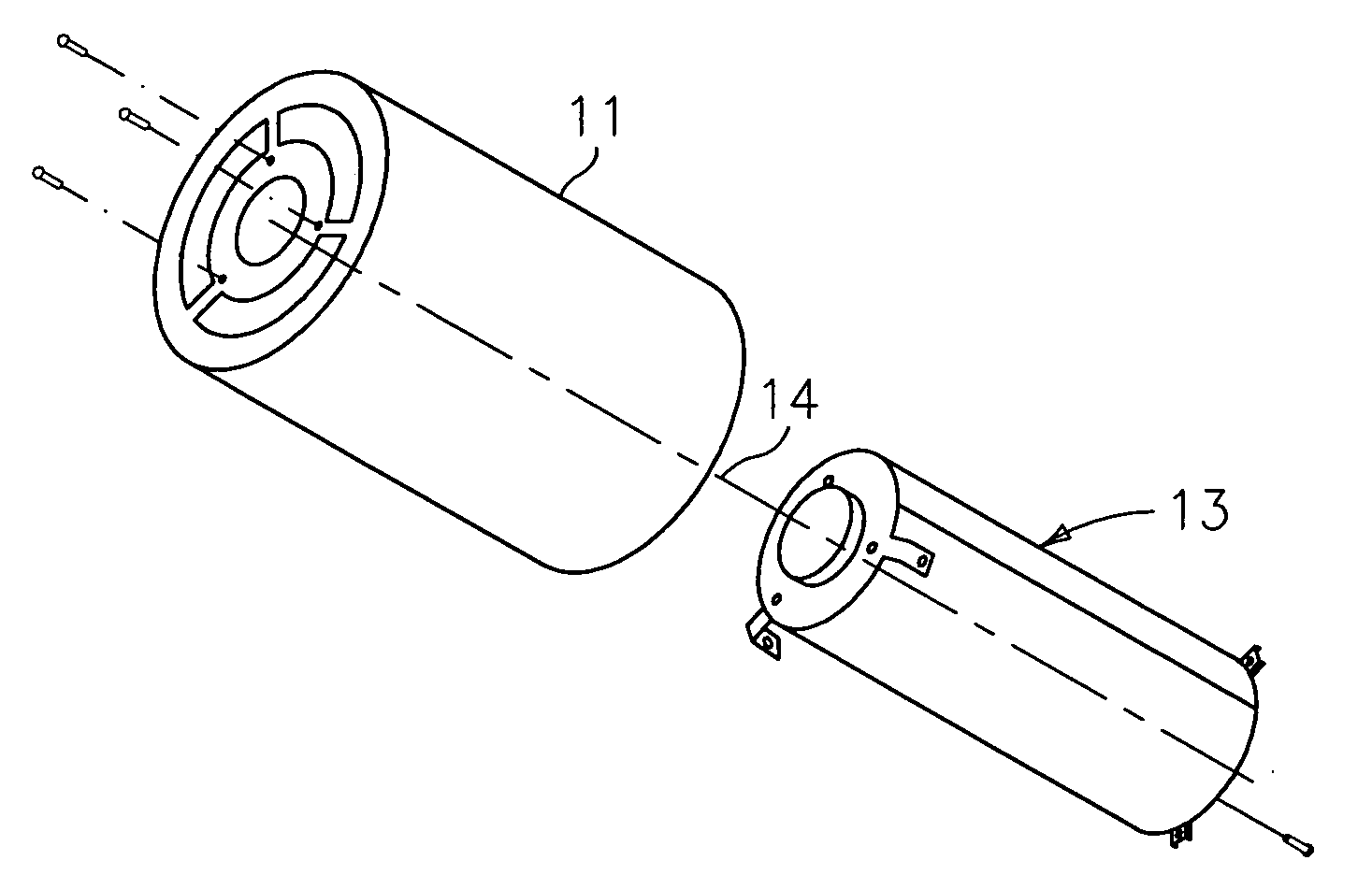

Surface cleaning apparatus

ActiveUS9326652B2Low efficiencySpeed up the air flowSuction filtersSuction hosesCycloneSurface cleaning

A surface cleaning apparatus is provided wherein a uniflow cyclone comprises a cyclone chamber defined by a longitudinal axis, the cyclone chamber having a dirt outlet that has a variable length in the direction of the longitudinal axis. A cyclone chamber having a barrier wall facing the dirt outlet of the cyclone chamber is also provided.

Owner:OMACHRON INTPROP

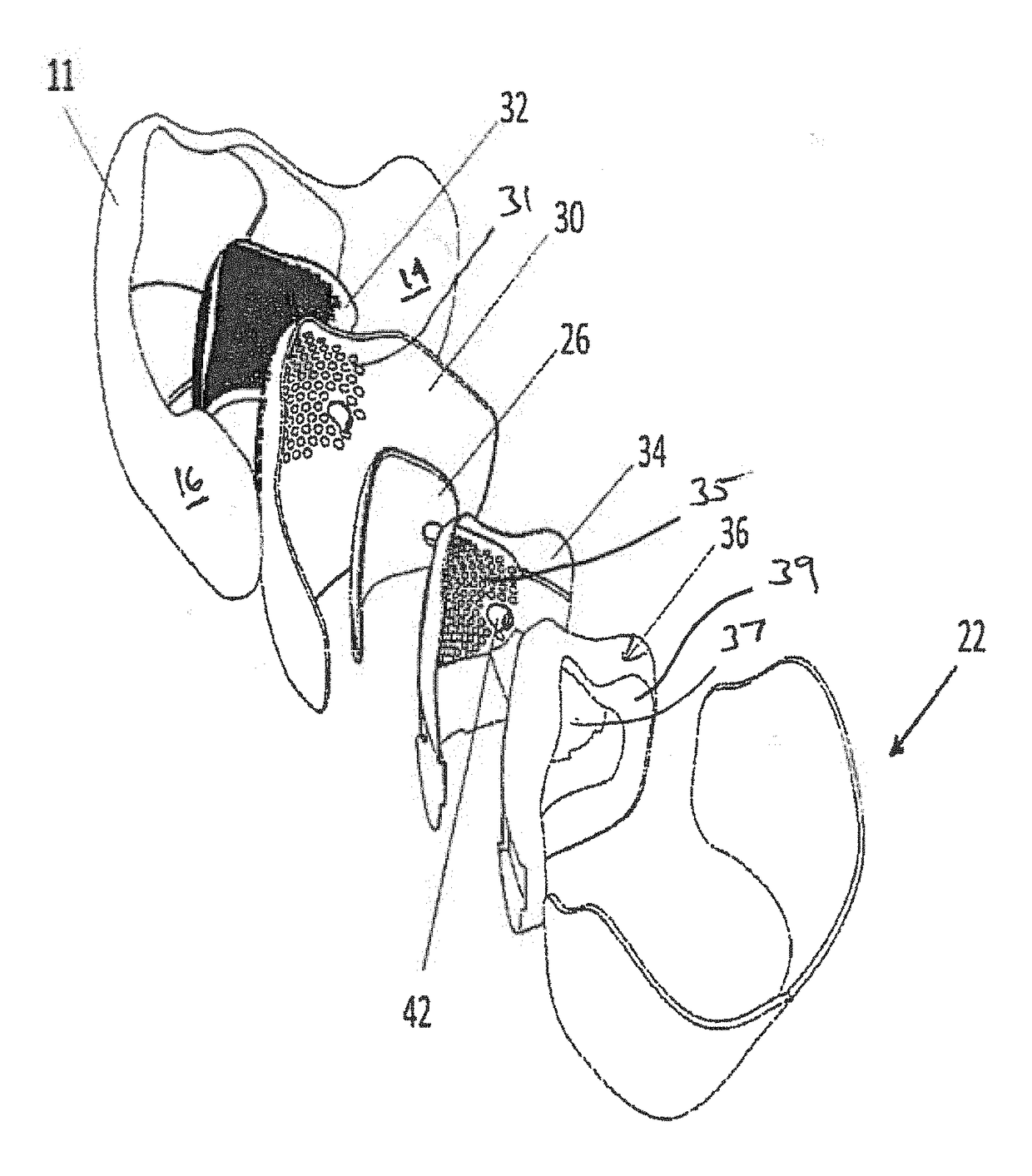

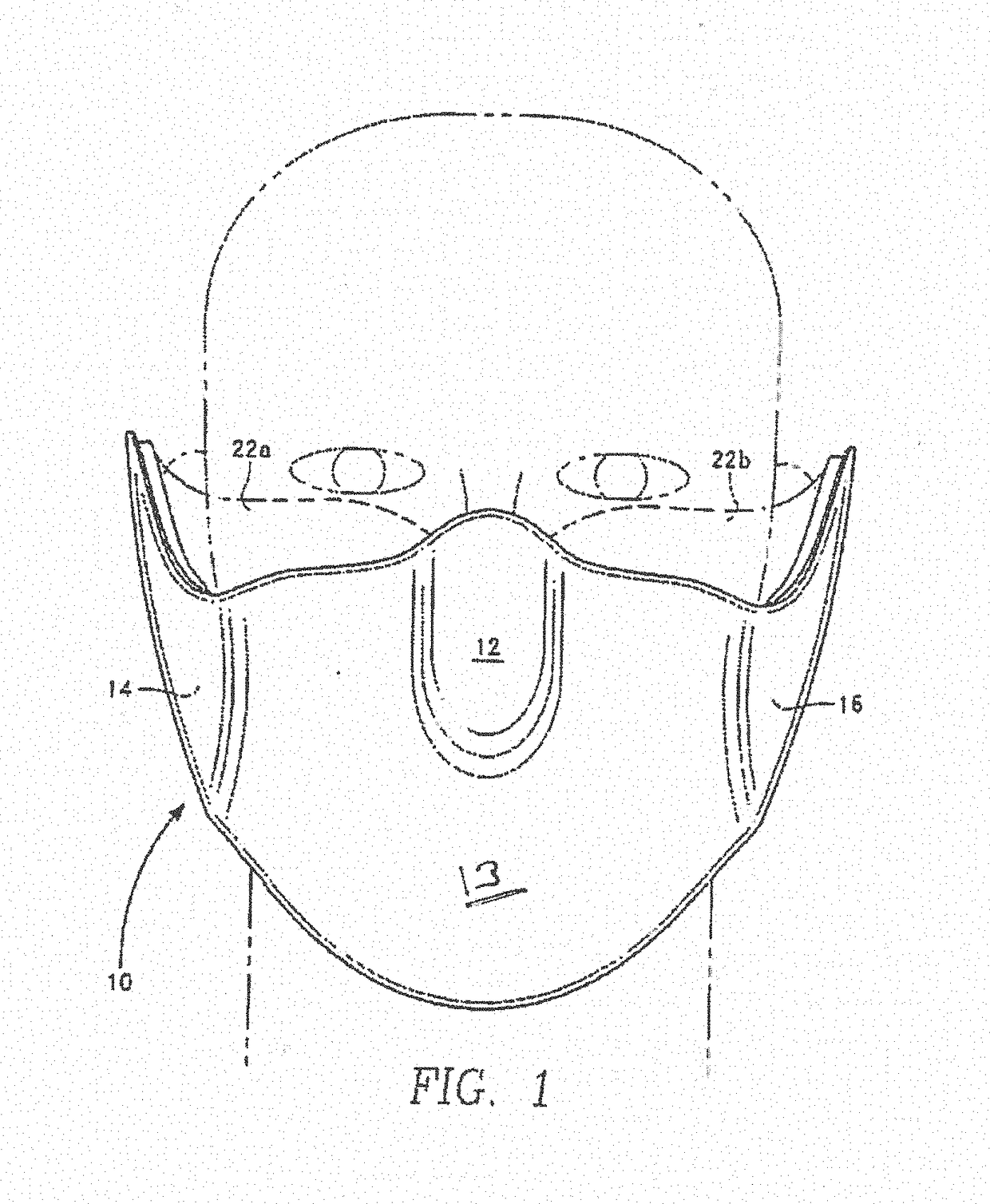

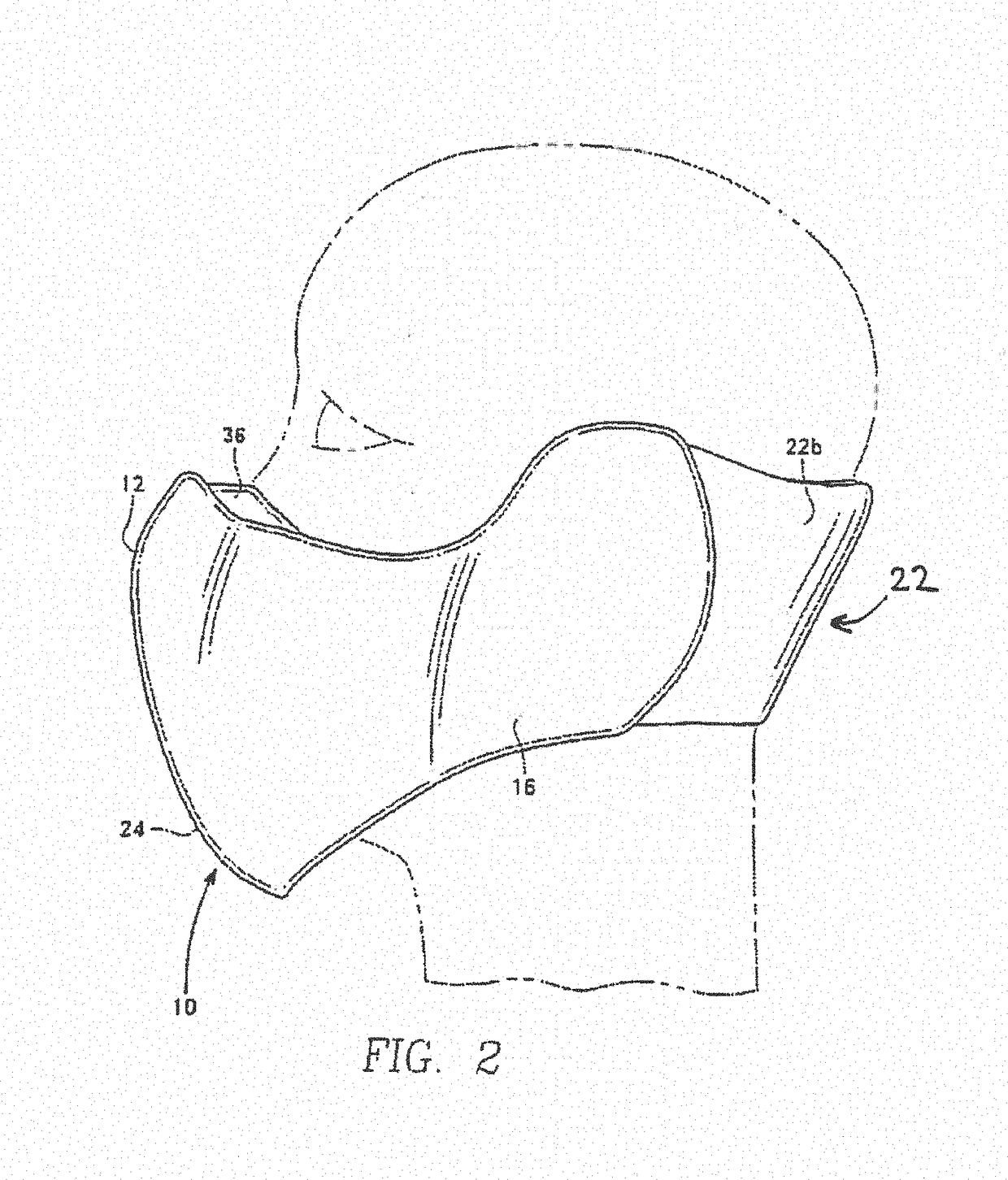

Protective Face Covering

An apparatus which may be used to protect a user's mouth, nose, chin, ears, and jaw from projectiles, direct impacts, air contaminants, and reduce concussive impact to the ears. Before air flowing into the apparatus is filtered by a filter member upstream of a mouthpiece, the air flow first passes through a plurality of conduits in a nose and protection member, where the nose and chin protection member is fabricated from an impact resistant material. Each of the conduits has a deflection member which changes the direction of the air flow. The user's exhalations do not flow back through the filter member but are rather redirected through side ports in the mouth piece.

Owner:GHOSTSTAR LLC

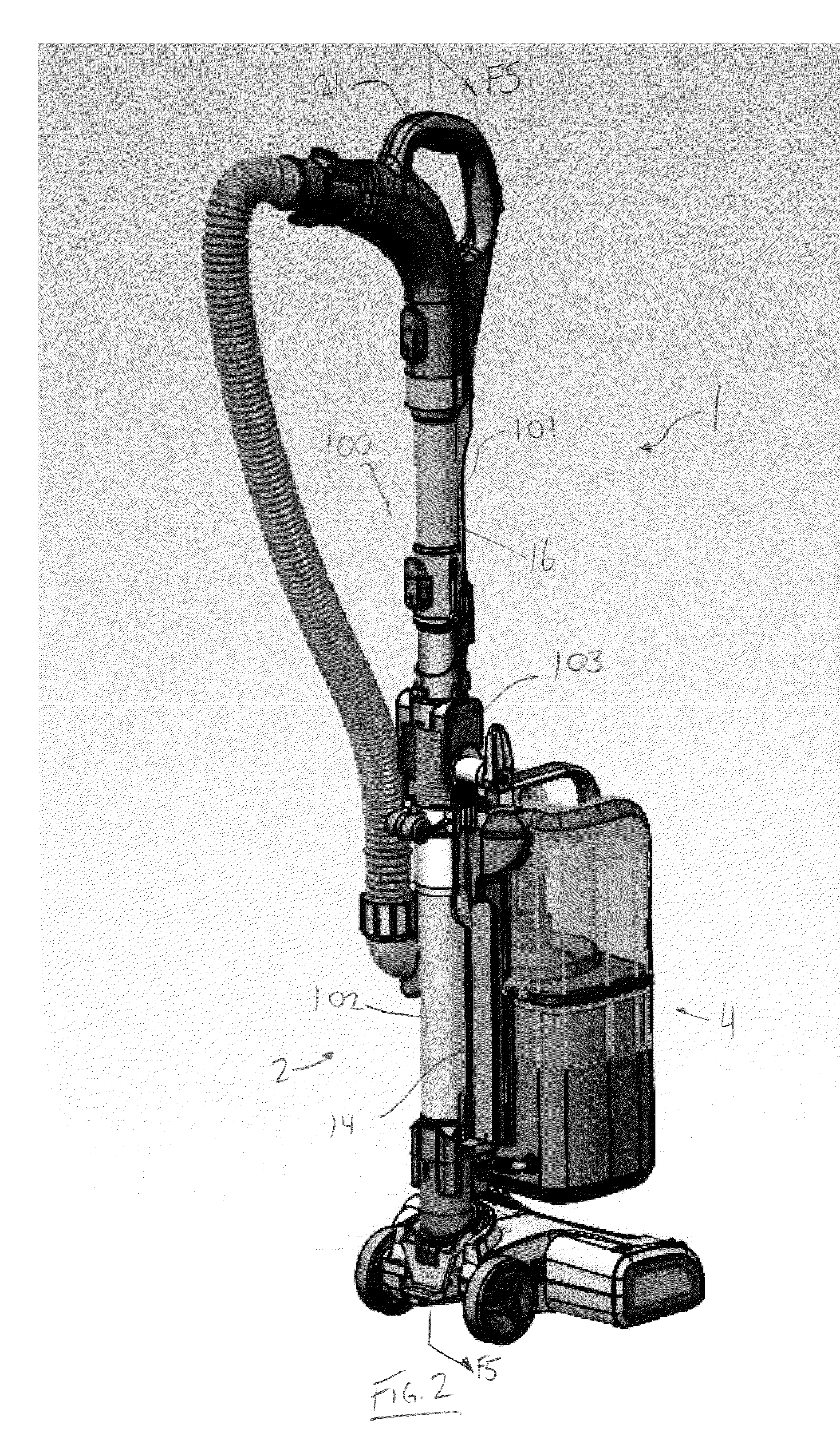

Surface cleaning apparatus

ActiveUS20140237765A1Low efficiencySpeed up the air flowCleaning filter meansSuction filtersSurface cleaningWaste management

A surface cleaning apparatus is provided wherein at least one of an upstream air plenum that is positioned upstream of the pre-motor filter, and a downstream air plenum that is positioned downstream of the pre-motor filter comprises an end wall spaced from the pre-motor filter and comprises a first portion having an air flow port and a second portion proximate the outer perimeter of the pre-motor filter, wherein the first portion and the second portion meet at a first juncture that extends at an angle to the first portion and the second portion.

Owner:OMACHRON INTPROP

Noise reduction tubes

InactiveUS7497300B2Decrease their propagationReduce sound transmissionPump componentsEngine fuctionsUltrasound attenuationPath length

The invention uses tubes for the reduction of radiated duct noise. The tubes may be used to attenuate narrow band noise by diverting a portion of the acoustic energy through the tubes back into the duct. Upon reintroducing the diverted flow out of phase with the primary flow, acoustic cancellation is achieved. The frequency at which this occurs is dependent on the difference in the path lengths through the tubes and the separation distance—the distance separating the inlet and outlet of the tube. This invention can be used over varying frequency ranges by using an arrangement of flexible, constant length tubes. The effective frequency range is tailored by varying the separation distance and also allows the varying the angular arrangement of the tubes for more effective attenuation of spinning modes having varying propagation angle.

Owner:DANGELO JOHN P

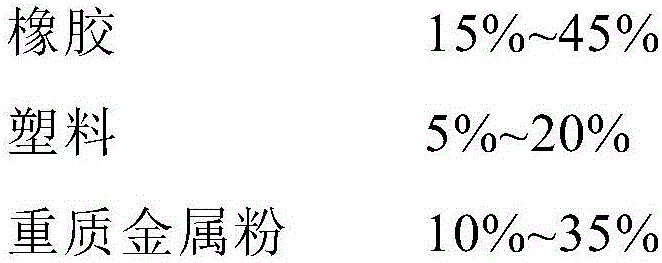

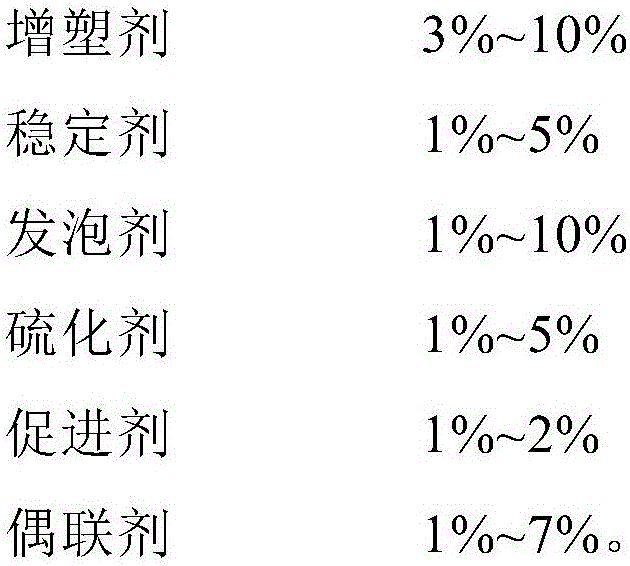

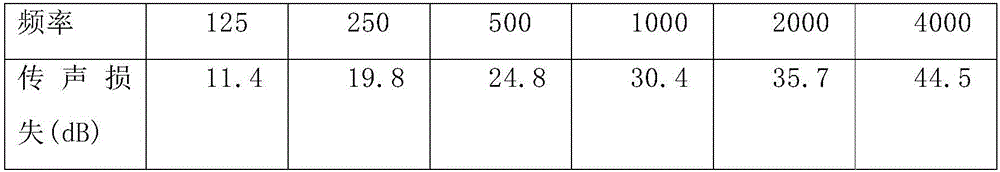

Soft high-specific-gravity rubber-plastic foam material for insulating sound and reducing noise

A related soft high-specific-gravity rubber-plastic foam material for insulating sound and reducing noise consists of the following components in percent by weight: 15%-45% of rubber, 5%-20% of plastic, 10%-30% of a heavy metal powder, 3%-10% of a plasticizer, 1%-5% of a stabilizer, 1%-10% of a foaming agent, 1%-5% of a sulfurizing agent, 1%-2% of an accelerator and 1%-7% of a coupling agent. Compared with the prior art, the soft high-specific-gravity rubber-plastic foam material possesses good elasticity of rubber and good glutinousness of plastic, also possesses relatively high surface density demanded by sound-proof mass action law and additional action of "foam damping", avoids the sound-proof low ebb of a conventional sound-proof material under the effect of resonant frequency and a coincident effect, and is extremely suitable for quality improvement of all kinds of sound environments and noise-controlling places.

Owner:SHANGHAI JIAO TONG UNIV

Cyclone such as for use in a surface cleaning apparatus

ActiveUS20140237955A1Low efficiencySpeed up the air flowCombination devicesSuction filtersCycloneSurface cleaning

A cyclone comprises a cyclone chamber having an air inlet, an air outlet, a first end wall, a second end wall and a sidewall, the air inlet has an inlet end having a shape and a cross sectional area in a plane transverse to a direction of airflow through the air inlet, and the air inlet is provided at a first juncture of the sidewall and the first end wall, the first end wall has a vortex finder having a wall that meets the first end wall at a second juncture, wherein the inlet is spaced from the vortex finder

Owner:OMACHRON INTPROP

Muffler for noise reduction

InactiveUS20050023077A1Dampening acoustic transmissionReduce sound transmissionExhaust apparatusSilencing apparatusGlass fiberNoise reduction

A muffler assembly, comprising an outer muffler assembly comprising a plurality of fiberglass discs and a plurality of reactive plates, and an inner muffler assembly comprising a plurality of fiberglass discs and a plurality of reactive plates the inner muffler assembly generally surrounded by the outer muffler assembly and defining therebetween a gas flow gap.

Owner:CARRIER CORP

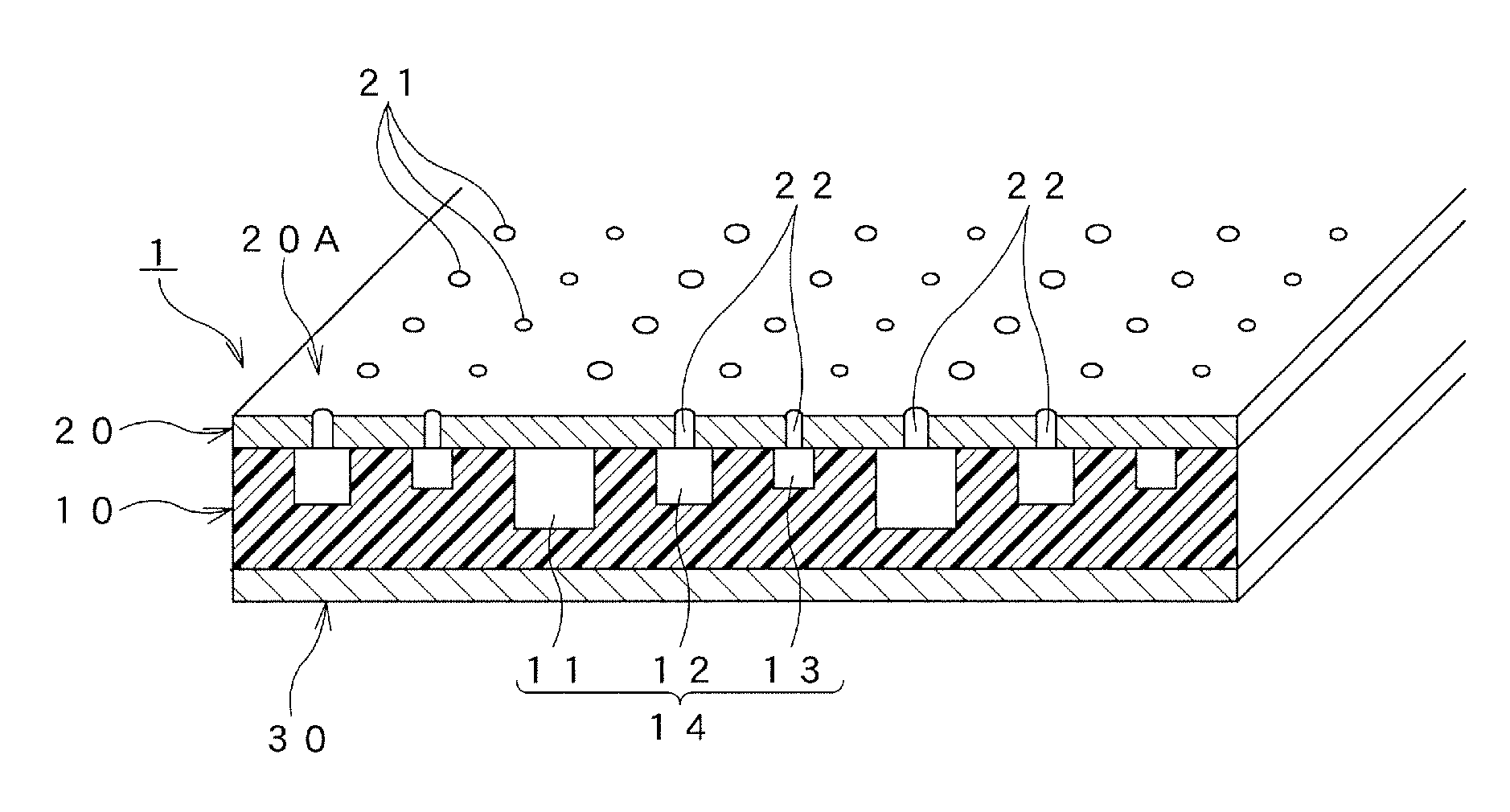

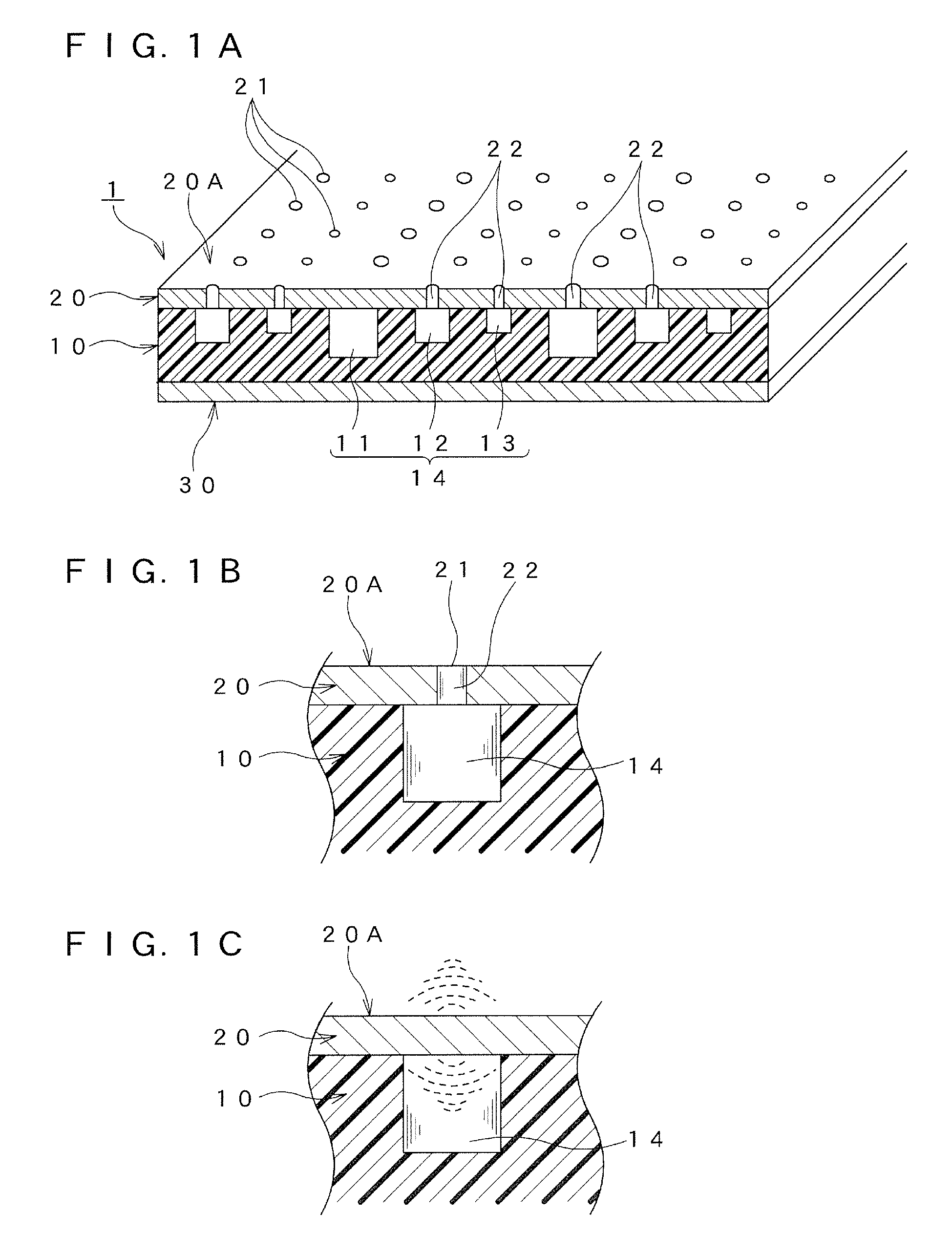

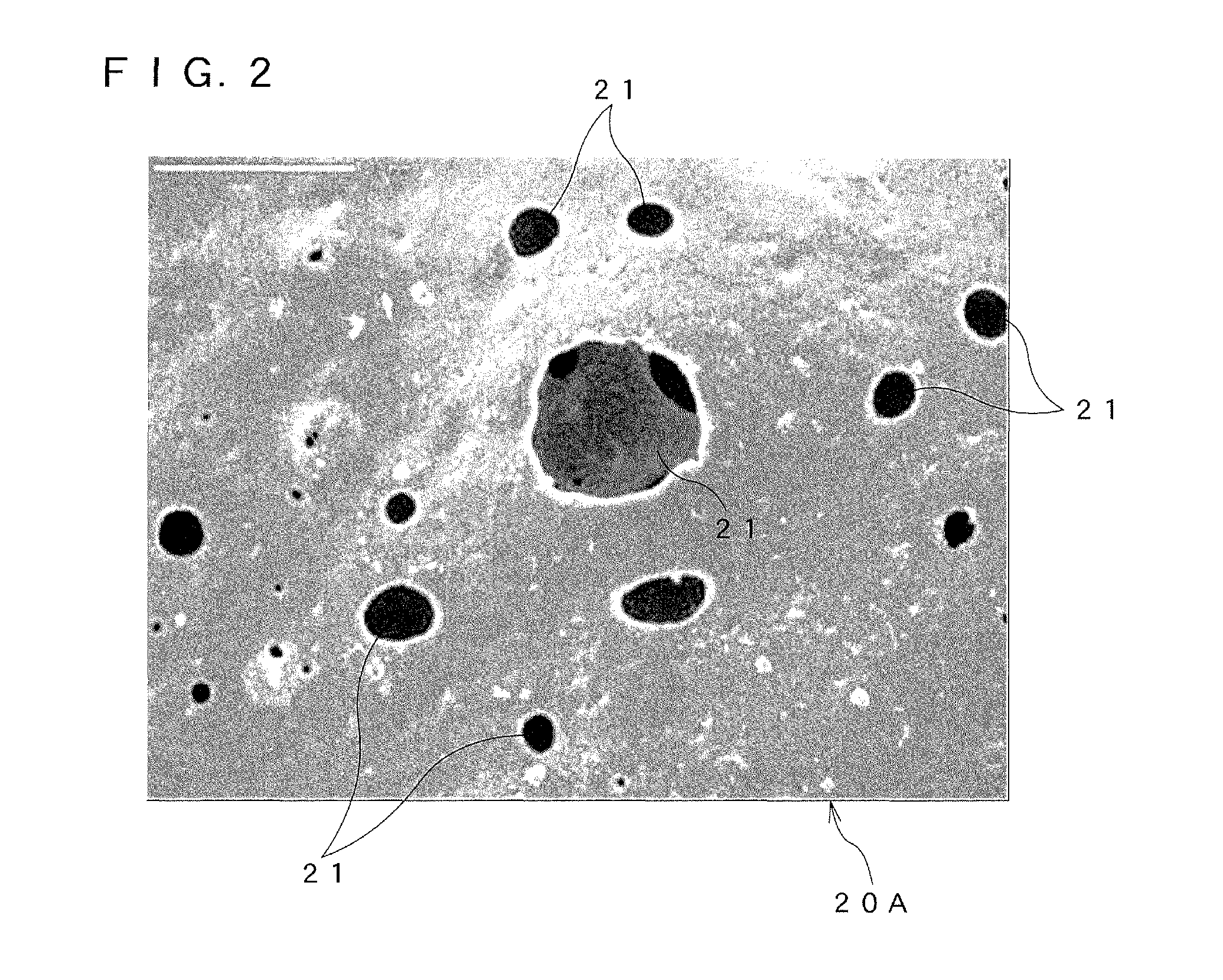

Structure having sound absorption characteristic

To absorb a noise produced by an external force that generates an audio frequency even if it is applied thereto, and to make it hard to become a noise source to a surrounding area.It includes a surface layer 20 having microscopic pores 21 formed on a surface 20A, communicating passages 24 communicating with the microscopic pores 21 and a porous layer 10 having sound pores 14 that are formed at an inner part deeper than the surface layer 20 having the microscopic pores 21 formed, communicate with the communicating passage 24 and that have a volume larger than volumes of the microscopic pore 21 formed on the surface 20A and the communicating passage 24. A sound absorption characteristic and / or a sound insulation characteristic is provided by the microscopic pores 21 of the surface 20A, the communicating passages 24 of the porous layer 10, and the sound pores 14 of the porous layer 10. Accordingly, sound absorption control including sound insulation in a predetermined audio frequency band can be achieved and a high sound absorption characteristic can be provided.

Owner:AISIN CHEM CO LTD

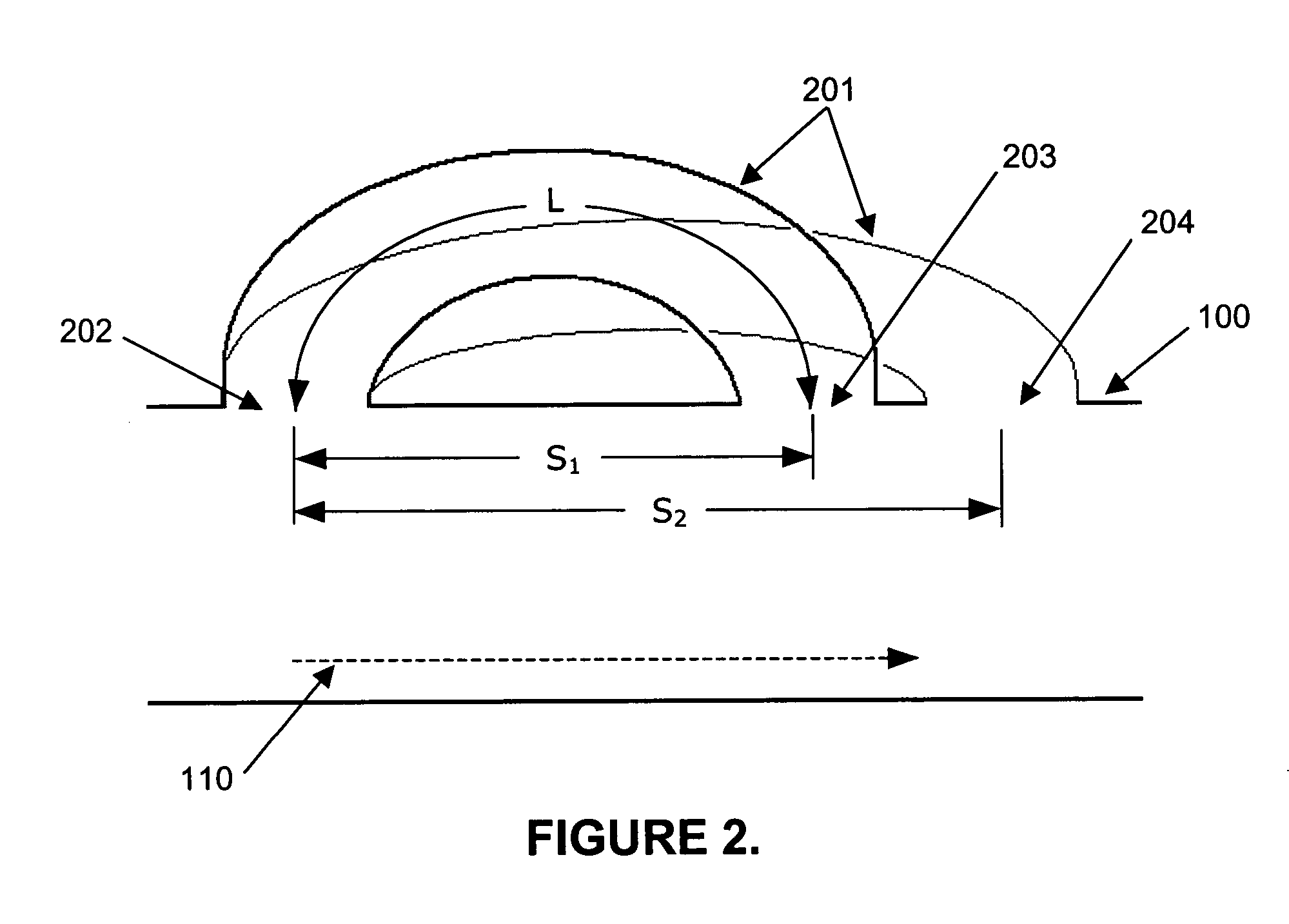

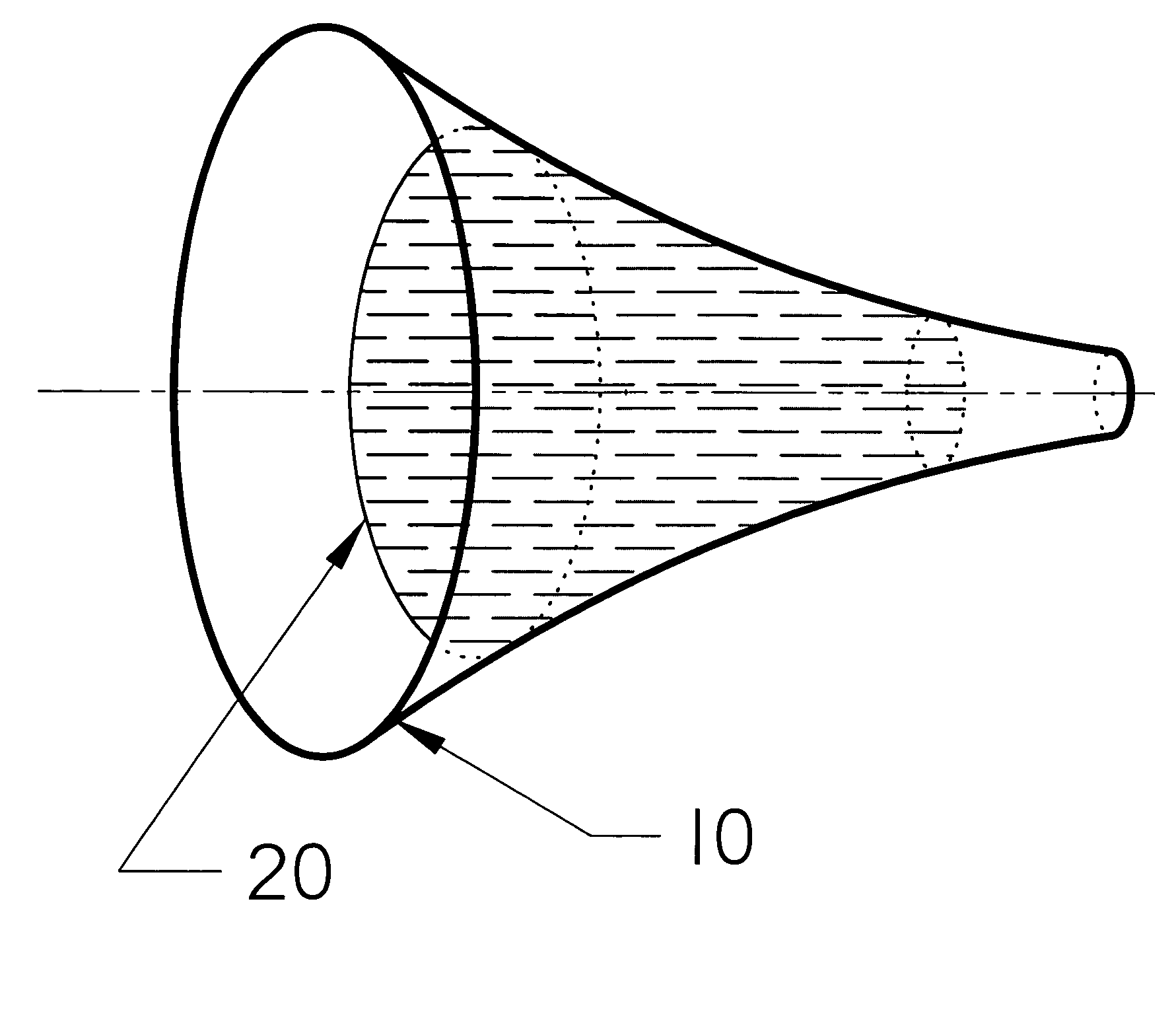

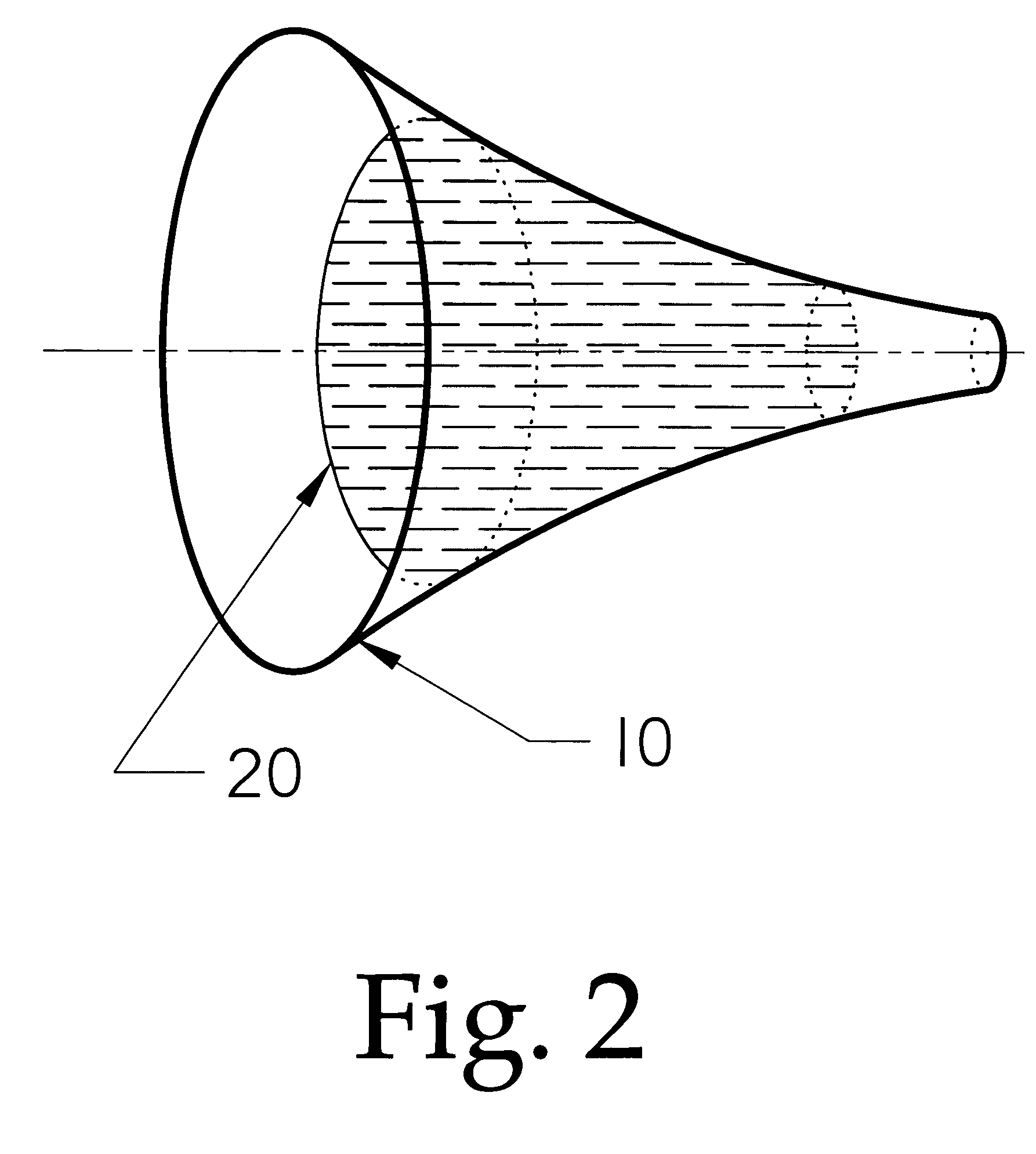

Waveguide phase plug

InactiveUS7708112B2Increase in perceived sound quality of deviceReduce sound transmissionSound producing devicesFrequency/directions obtaining arrangementsAcousticsRadiation pattern

An improved horn for a compression driver which has an interior foam plug for reducing the amplitude of unwanted non-fundamental wave propagation and better control over the sound radiation pattern of the device.

Owner:GEDDES EARL RUSSELL

Anti-cracking plastering gypsum mortar

The invention discloses anti-cracking plastering gypsum mortar. The anti-cracking plastering gypsum mortar is prepared from the following raw materials: high-temperature calcined gypsum, ash calcium powder, composite portland cement, expanded perlite, fly ash, hydroxypropyl methyl cellulose ether, a retarder, a water reducing agent, starch ether, redispersible latex powder, polypropylene fibers and a waterproof agent. The invention provides the environment-friendly type lightweight bottom-layer plastering gypsum mortar which has good anti-cracking performance, has good heat insulation performance and can automatically adjusting temperature and humidity. By adopting the anti-cracking plastering gypsum mortar, the density of the mortar and the self weight of buildings can be effectively reduced; the anti-cracking plastering gypsum mortar has good sound insulation and noise reduction effects and has the advantages of uniformity in material preparation, convenience for construction, capability of being firmly stuck with a base layer, no hollowing, no falling, no cracks, fireproof and heat-resisting performance, heat insulation and sound insulation, greenness and environment protection,low cost and the like.

Owner:安徽省万帮新型建材科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com