Anti-cracking plastering gypsum mortar

A plastering gypsum and mortar technology, applied in the field of crack-resistant plastering gypsum mortar, can solve the problems of whitening, poor cohesion, wall bubbles, etc., and achieve increased durability, good workability, and high cohesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

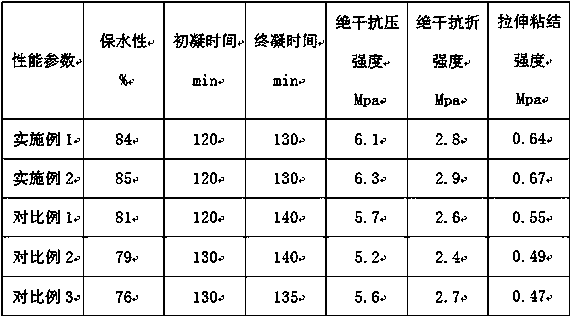

Examples

Embodiment 1

[0022] A crack-resistant plastering gypsum mortar, comprising 60 parts by weight of high-temperature calcined gypsum, 35 parts of lime calcium powder, 15 parts of composite Portland cement, 5 parts of expanded perlite, 28 parts of fly ash, hydroxypropyl 0.04 parts of methyl cellulose ether, 0.02 parts of retarder, 0.02 parts of water reducer, 0.015 parts of starch ether, 13 parts of redispersible latex powder, 1.2 parts of polypropylene fiber, and 1 part of waterproofing agent.

[0023] Further, the fly ash is Class I fly ash and / or Class II fly ash.

[0024] Further, the high-temperature calcined gypsum is desulfurized anhydrite calcined at a temperature above 800 degrees Celsius in a power plant.

[0025] Further, the composite Portland cement is pc32.5 or pc42.5.

[0026] Further, the retarder is 20% of sugar retarder, 20% of organic phosphine retarder, 2% of polyether concrete air-entraining agent, and 58% of water; wherein the sugar retarder is sucrose and lemon A combi...

Embodiment 2

[0032] A crack-resistant plastering gypsum mortar, comprising 70 parts by weight of high-temperature calcined gypsum, 70 parts of lime calcium powder, 18 parts of composite Portland cement, 15 parts of expanded perlite, 28 parts of fly ash, hydroxypropyl 00.06 parts of methyl cellulose ether, 0.03 parts of retarder, 0.03 parts of water reducing agent, 0.015 parts of starch ether, 17 parts of redispersible latex powder, 1.5 parts of polypropylene fiber, and 1 part of waterproofing agent.

[0033] Further, the fly ash is Class I fly ash and / or Class II fly ash.

[0034] Further, the high-temperature calcined gypsum is desulfurized anhydrite calcined at a temperature above 800 degrees Celsius in a power plant.

[0035] Further, the composite Portland cement is pc32.5 or pc42.5.

[0036] Further, the retarder is 20% of sugar retarder, 20% of organic phosphine retarder, 2% of polyether concrete air-entraining agent, and 58% of water; wherein the sugar retarder is sucrose and lemon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com