Patents

Literature

7675results about How to "Improve crack resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

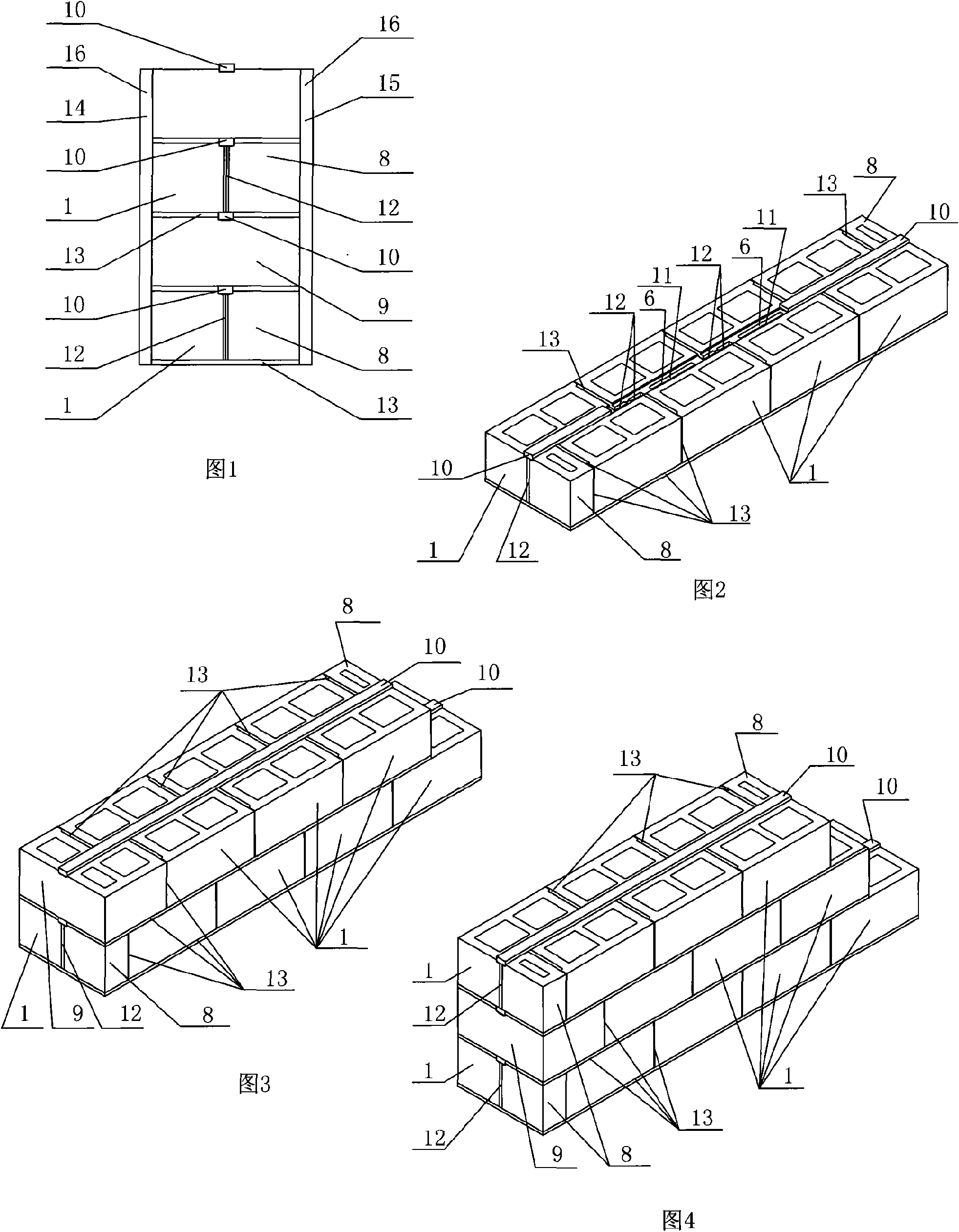

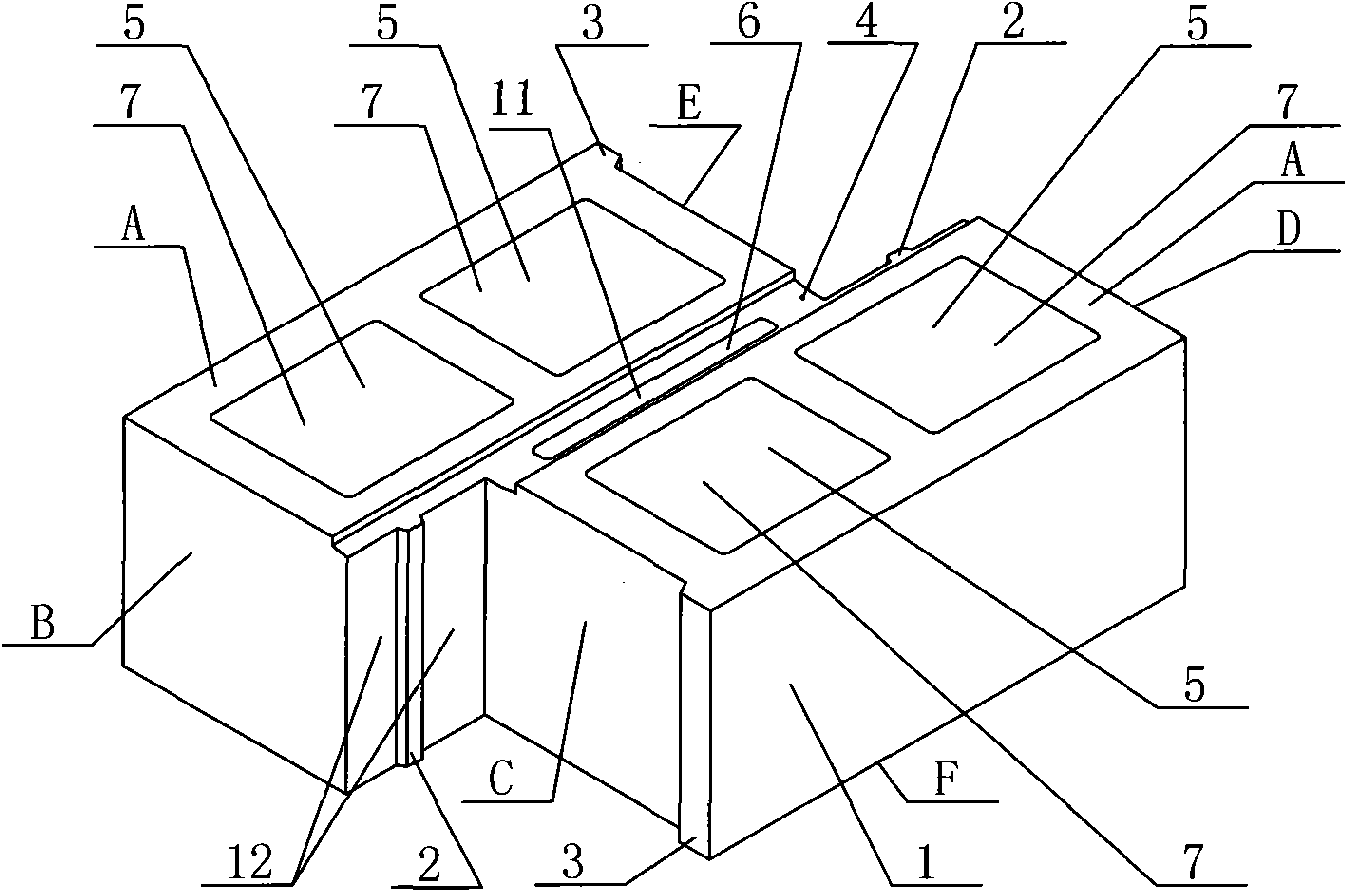

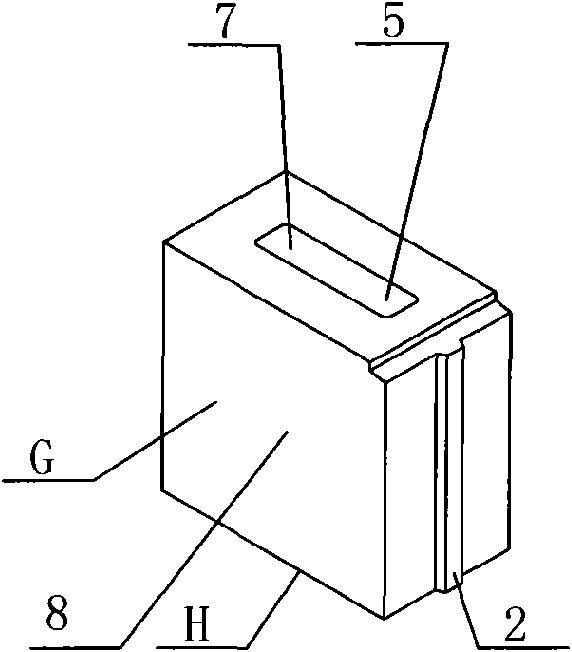

Technical method for building self-insulating and energy-saving wall with Z-shaped energy-saving building blocks

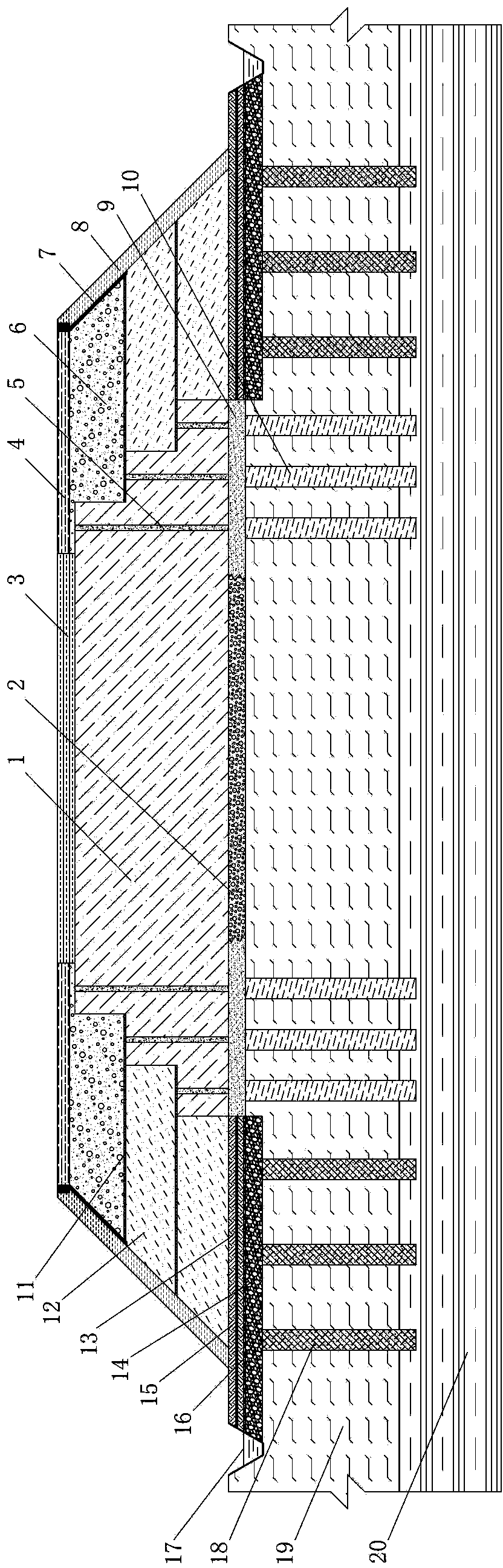

In the invention, the same clad bricks are laid in the forward direction, and a positioning convex platform 2 and a longitudinal positioning convex platform 3 are used for realizing transverse and longitudinal self-locking positioning, thereby naturally ensuring the designed thickness and surface smoothness of the wall, forming a combined still air layer 12 which is 9mm to 10mm wide and vertical to the ground, and further blocking heat bridges in vertical bricklaying seams. The cavity of a 28-30mm-wide groove 4 in the horizontal bricklaying seam between two clad bricks is filled with a broken bridge insulation board 10 which is as wide as the groove and has a thickness of 15mm; the broken bridge insulation board 10 is used for sealing a long-strip groove still air layer 11 and the combined still air layer 12 and cutting off the heat bridges in the horizontal bricklaying seams; the exposed part of broken bridge insulation board with a height of 10mm, is used for controlling the coating thickness of anti-crack masonry mortar 13 to be even and uniform. When the self-insulating and energy-saving wall is built, Z-shaped energy-saving building blocks 1 of the upper clad bricks and the lower bricks are laid in a staggered manner so as to cut off heat bridges in vertical bricklaying seams. The structure of the invention, with a reasonable thickness, can satisfy the requirement of saving 50 percent of energy in various regions, or even higher requiremets without an internal or external insulating layer of walls. Simultaneously, the structure is easy to build and the formation of the block shape effectively ensures the thickness of walls and the smoothness of wall surfaces. The thermal insulation function of the still air layer with a thickness of 10mm to 12mm strengthens the heat insulation effect. The insulation boards (28-30mm wide and 15mm thick) between the two clad bricks is capable of cutting off the heat bridge effects.

Owner:康玉范

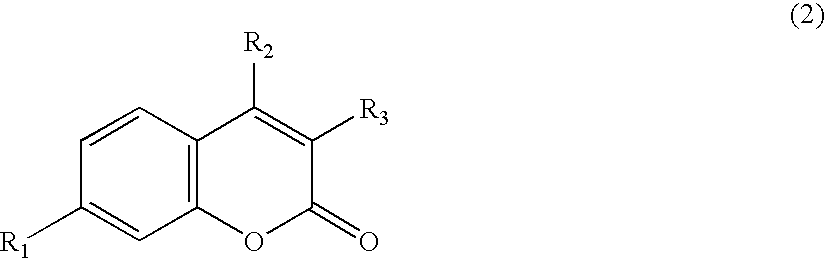

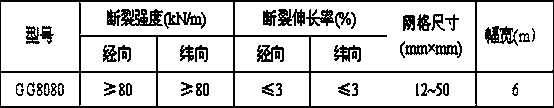

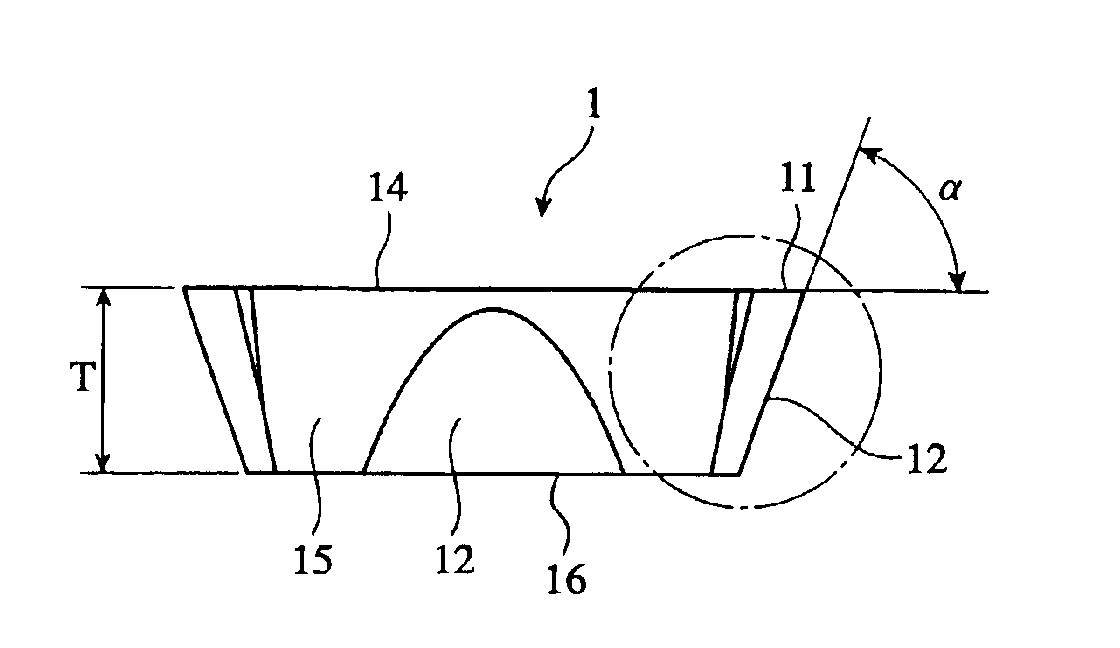

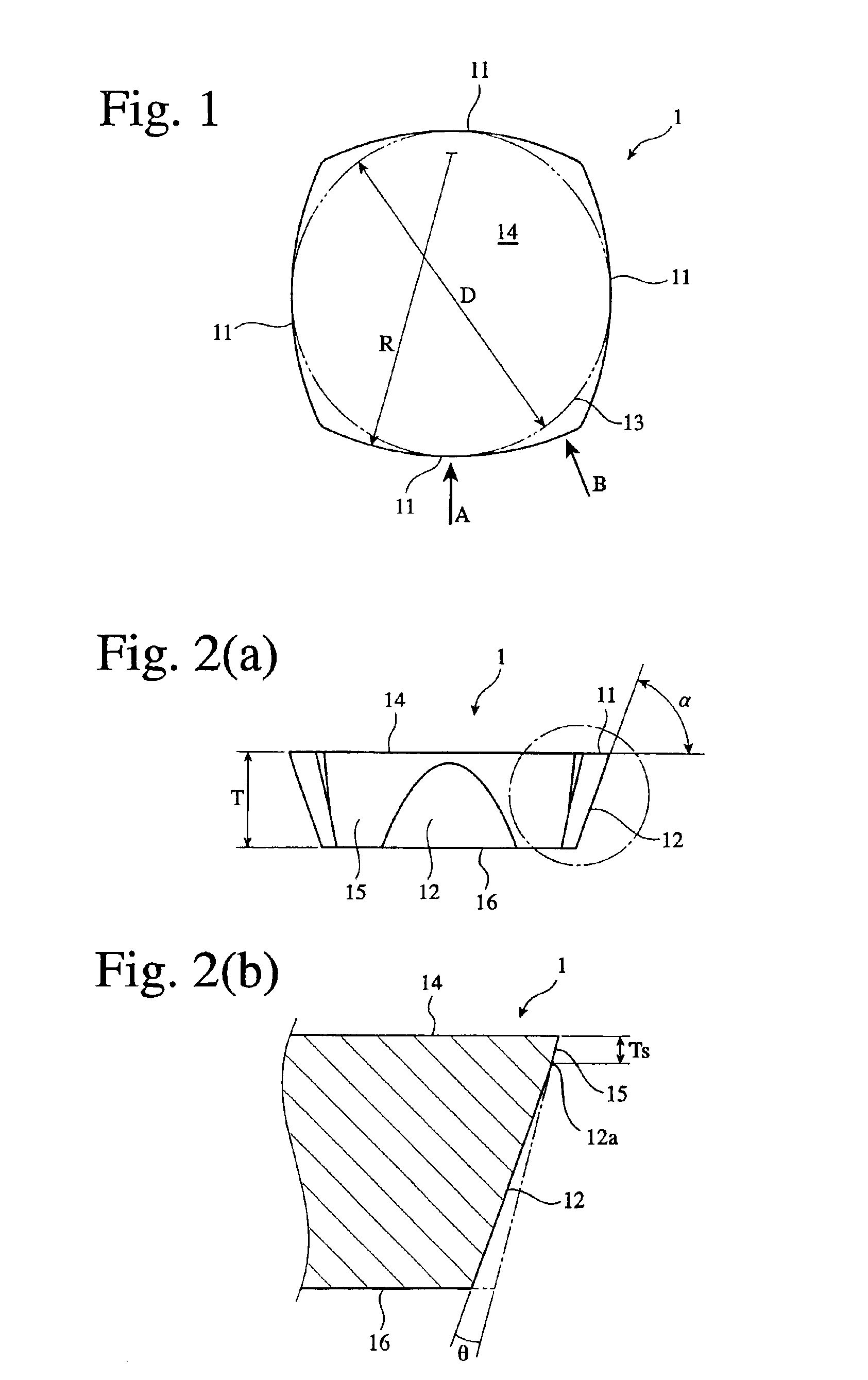

Solid golf ball

InactiveUS20080194357A1Improve spin performanceIncrease distanceGolf ballsSolid ballsThermoplasticPolymer science

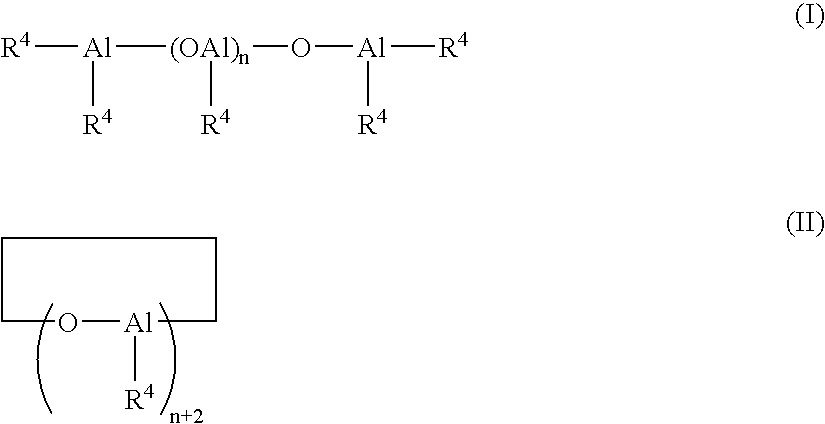

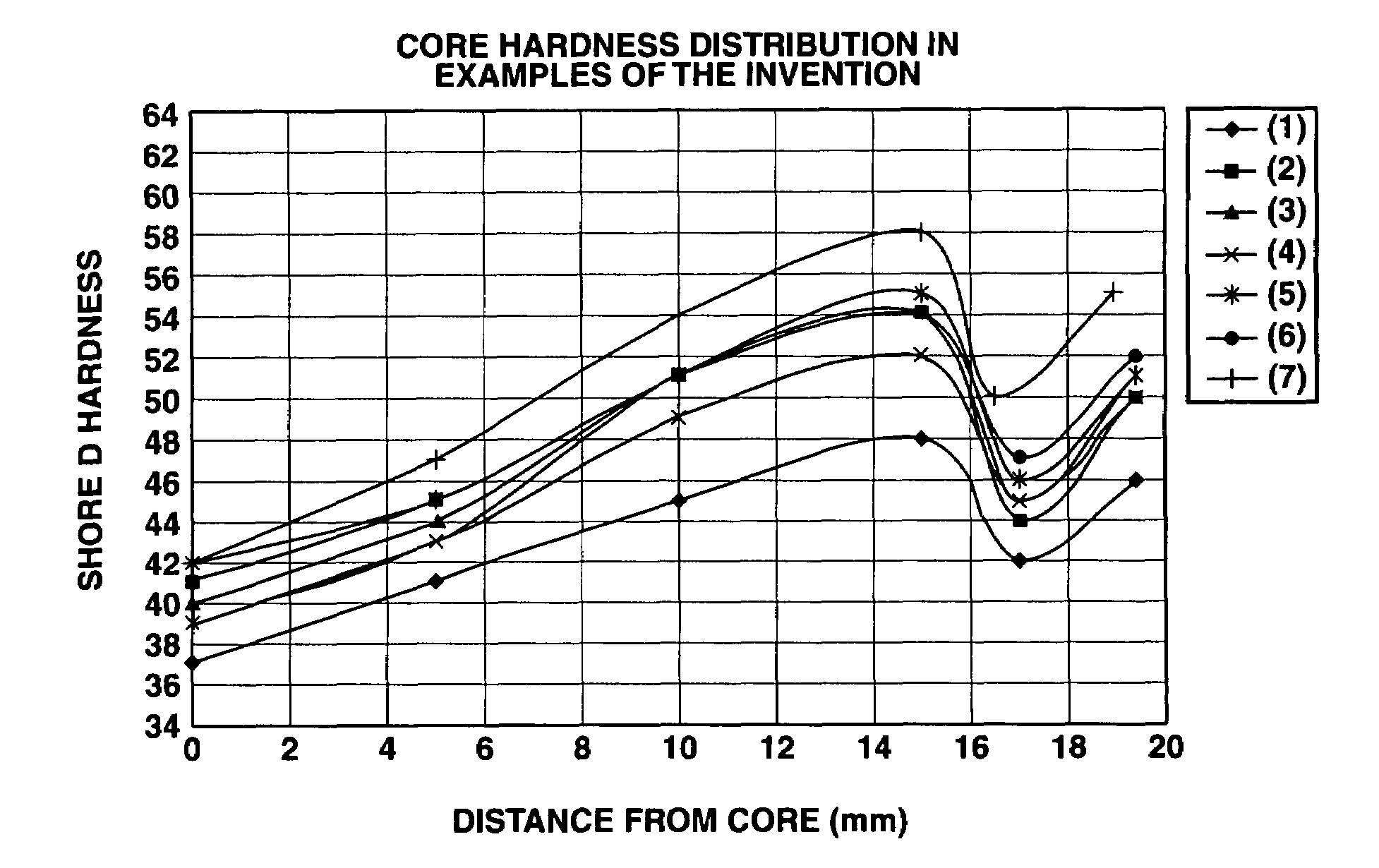

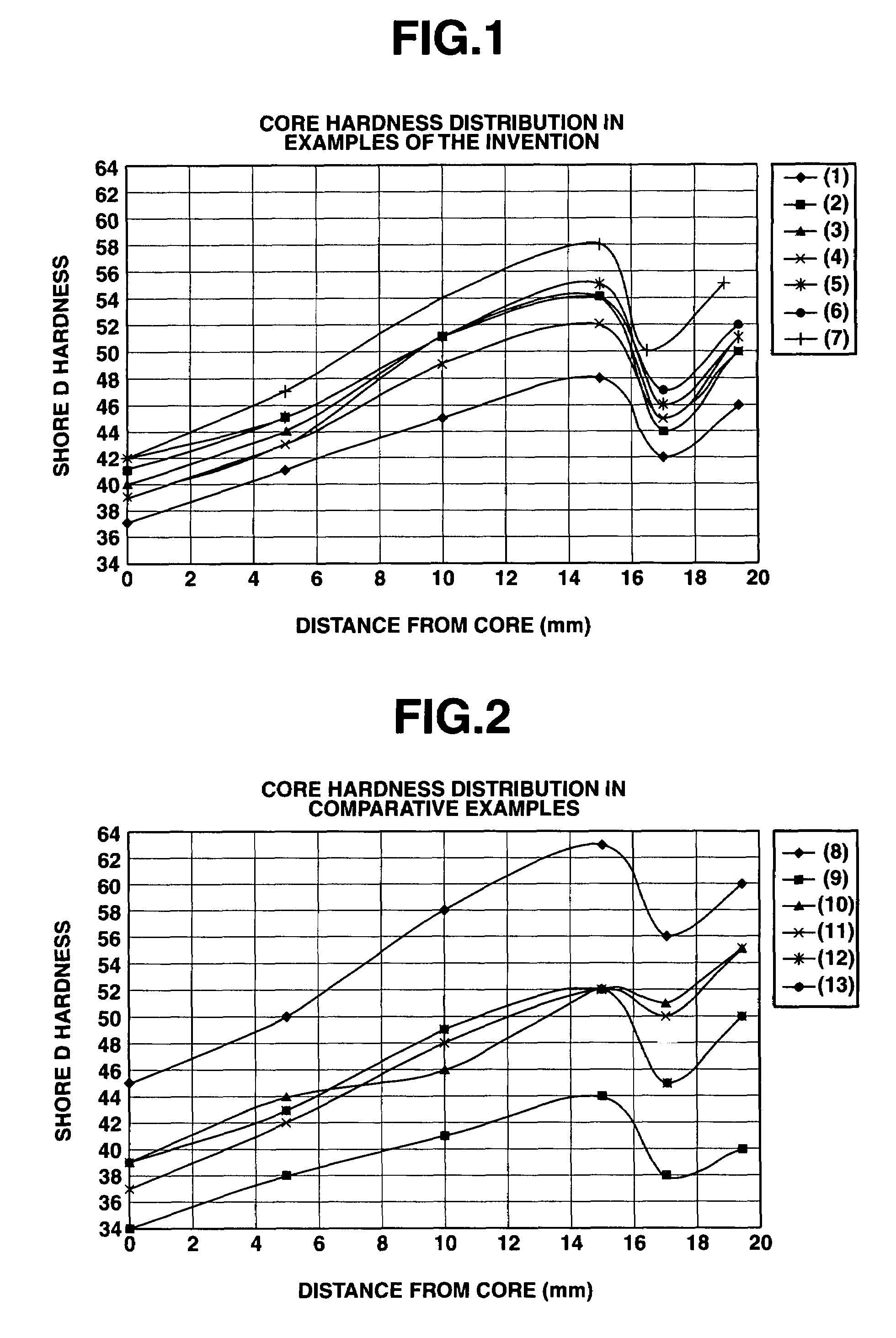

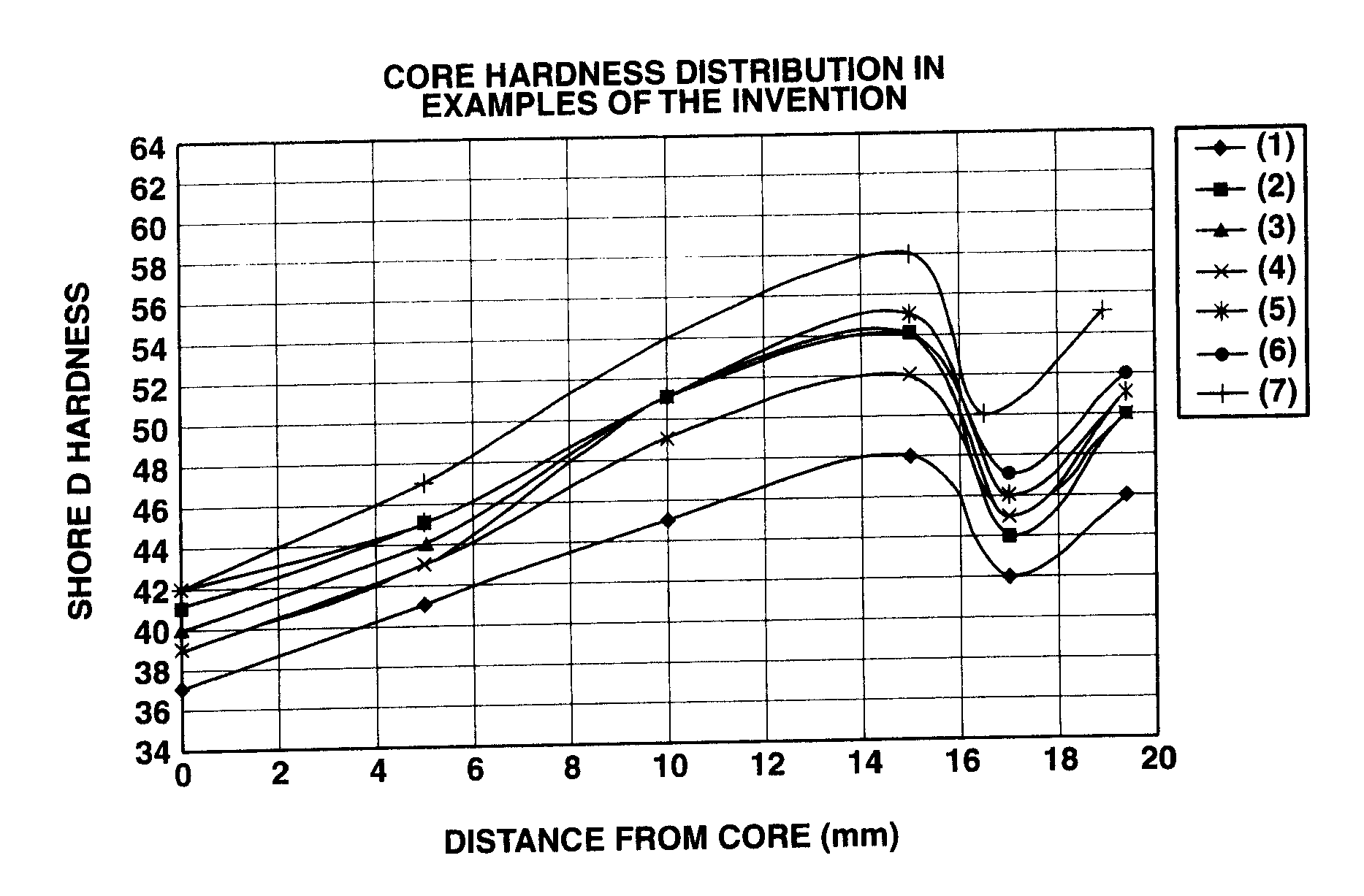

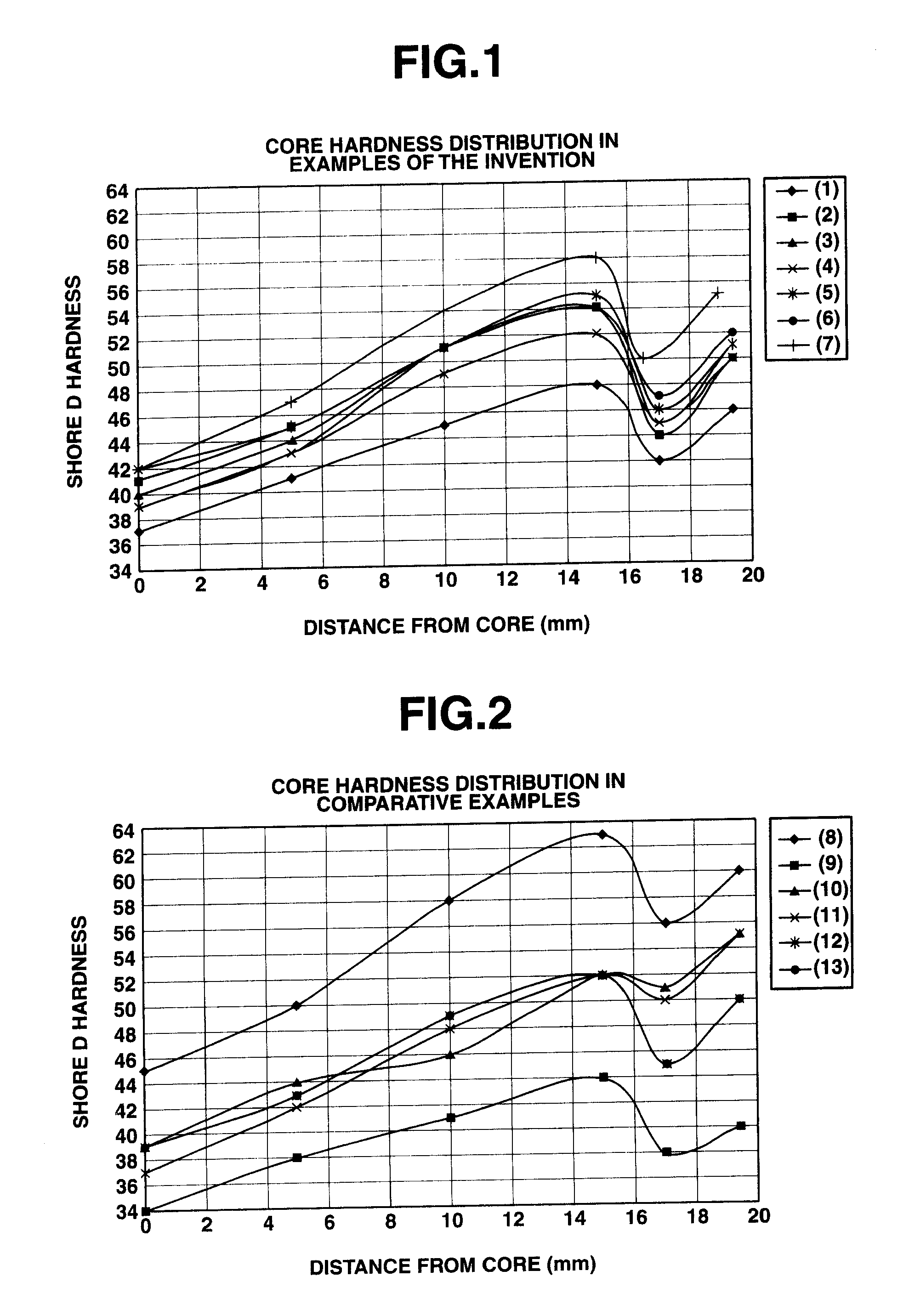

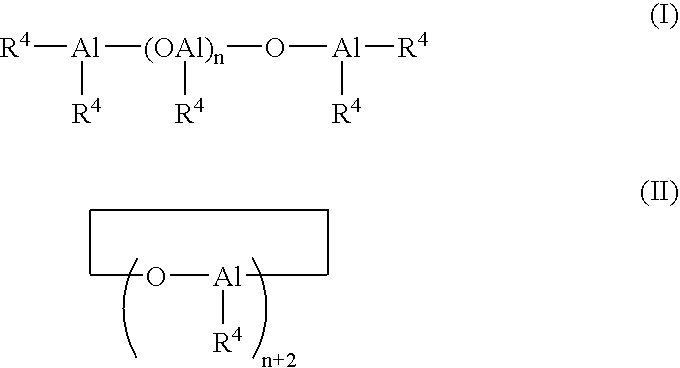

The invention provides a solid golf ball having a solid core and a cover layer that encases the core and has an outermost layer on an outside surface of which are formed a plurality of dimples. The solid core is formed of a rubber composition composed of 100 parts by weight of a base rubber that includes 60 to 100 parts by weight of a polybutadiene rubber having a cis-1,4 bond content of at least 60% and synthesized using a rare-earth catalyst, 0.1 to 5 parts by weight of an organosulfur compound, an unsaturated carboxylic acid or a metal salt thereof, and an inorganic filler. The solid core has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of 2.0 to 4.0 mm, and has a specific hardness distribution. The cover layer is formed primarily of a thermoplastic or thermoset polyurethane material and has a thickness of 0.5 to 2.5 mm, a Shore D hardness at the surface of 50 to 70 and a flexural rigidity of 50 to 300 MPa. The golf ball has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of 2.0 to 3.8 mm. The solid golf ball is advantageous overall in competitive use.

Owner:BRIDGESTONE SPORTS

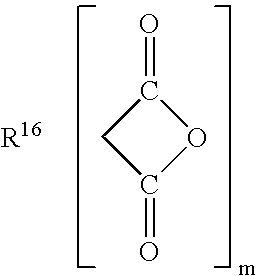

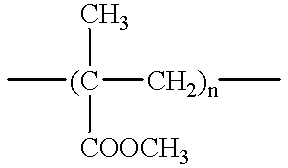

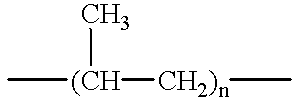

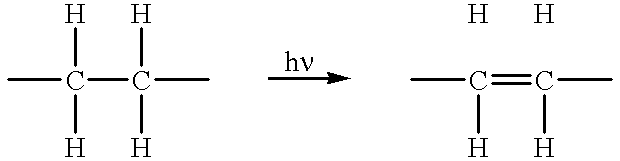

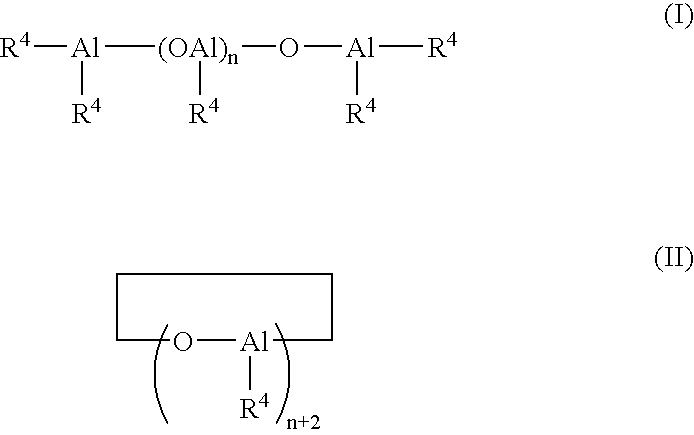

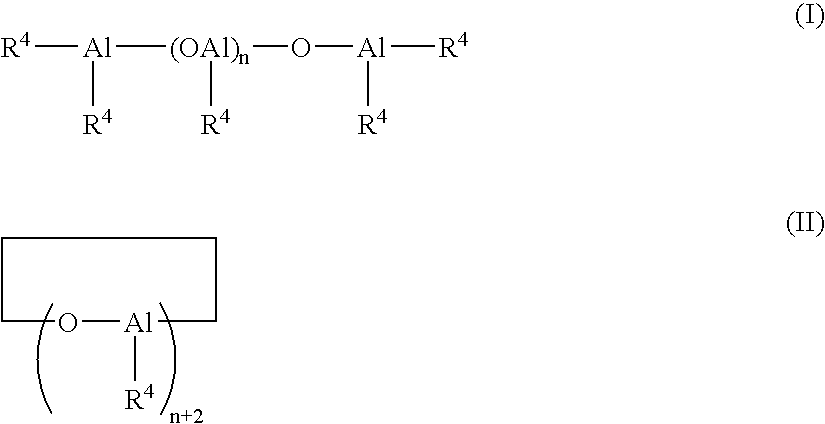

Method of device having biostable elastomeric polymers having quaternary carbons

An article of manufacture and method of making and implanting the article made of a polyolefin star or linear copolymer are disclosed in which the polyolefin copolymer is biostable and crack-resistant when implanted in vivo. The polyolefin copolymer is the reaction product of a rubbery component which when homopolymerized produces a polymer having a low level of hardness, and a hardening component which when homopolymerized produces a polymer having a high level of hardness. The polyolefin copolymer is elastomeric, has a hardness intermediate the low and high levels of hardness, and has a backbone in which the majority of polymer linkages along the copolymer chain are alternating quaternary and secondary carbon atoms.

Owner:LIFESHIELD SCI

Solid golf ball

InactiveUS7344455B1Reduce rigidityImprove performanceGolf ballsSolid ballsPolymer scienceAntioxidant

The invention provides a solid golf ball having a solid core and a cover layer that encases the core and has an outermost layer on an outside surface of which are formed a plurality of dimples. The solid core is formed of a rubber composition composed of 100 parts by weight of a base rubber that includes 60 to 100 parts by weight of a polybutadiene rubber having a cis-1,4 bond content of at least 60% and synthesized using a rare-earth catalyst, 0.1 to 5 parts by weight of an organosulfur compound, an unsaturated carboxylic acid or a metal salt thereof, an inorganic filler, and an antioxidant. The solid core has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of 2.0 to 4.0 mm, and has a specific hardness distribution. The cover layer is formed primarily of a polyurethane material and has a thickness of 0.5 to 2.5 mm, a Shore D hardness at the surface of 50 to 70 and a flexural rigidity of 50 to 300 MPa. The golf ball has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of 2.0 to 3.8 mm. The solid golf ball is advantageous overall in competitive use.

Owner:BRIDGESTONE SPORTS

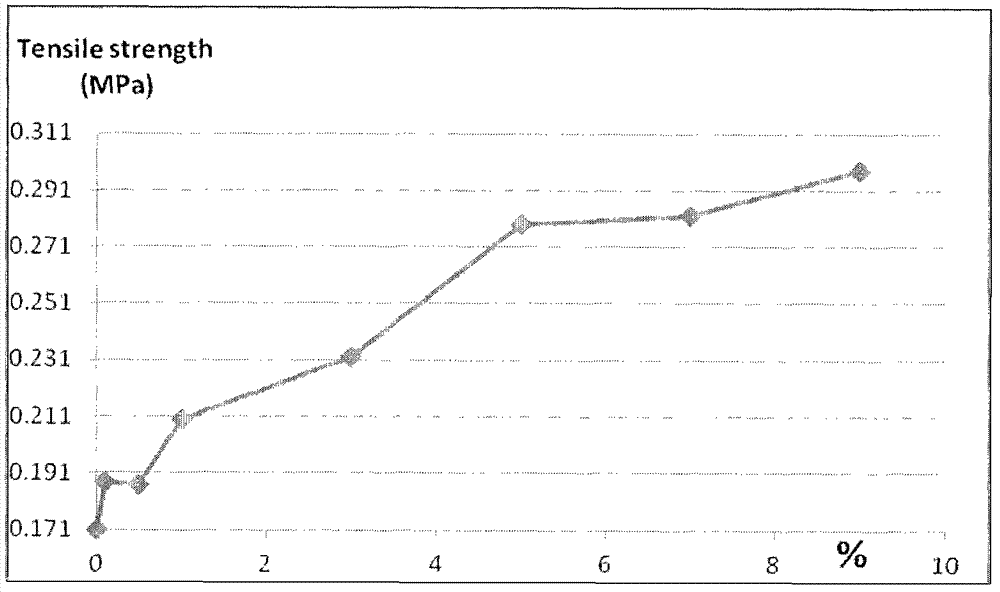

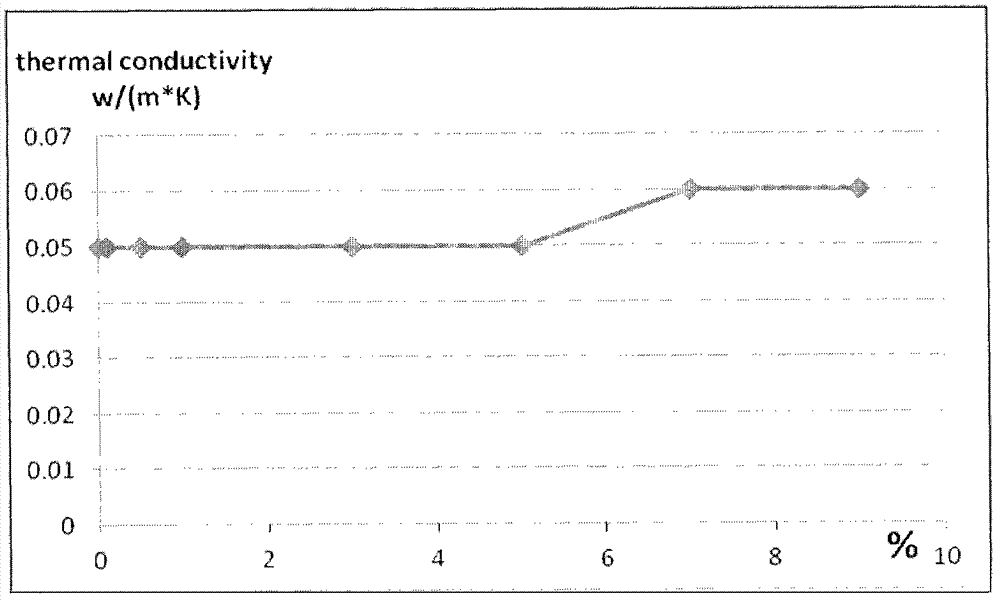

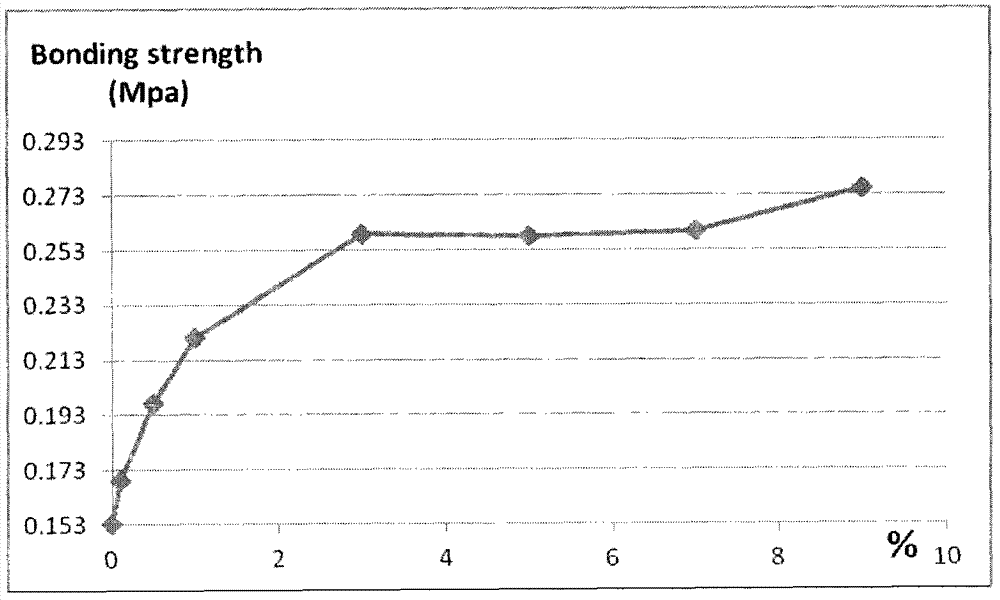

Nano-material-containing high-strength high-heat insulation exterior wall inorganic heat-retaining face brick

The invention belongs to the field of building materials, relates to a use of a nano-material in a building exterior wall heat-retaining system and provides a nano-material-containing high-strength high-heat insulation exterior wall inorganic heat-retaining face brick. The nano-material-containing high-strength high-heat insulation exterior wall inorganic heat-retaining face brick is characterized in that nano-particles are used so that compressive strength, tensile strength and bonding strength are improved. The nano-material-containing high-strength high-heat insulation exterior wall inorganic heat-retaining face brick is prepared by adding a nano-material having a nanoscale particle size into a mixed system of cement, an auxiliary gel material, a polymer binder, an inorganic light heat-retaining material, fibers and water, uniformly mixing, carrying out pressing molding of the mixture, carrying out organic polymer crosslinking and cement hydration drying, and carrying out waterproof layer coating. The nano-material-containing high-strength high-heat insulation exterior wall inorganic heat-retaining face brick has the advantages of excellent flame resistance, high compressive strength, high tensile strength, high bonding strength and good insulation effects.

Owner:平湖市法而特建筑保温科技有限公司

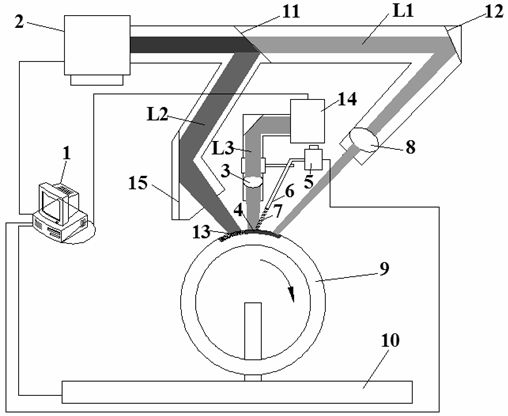

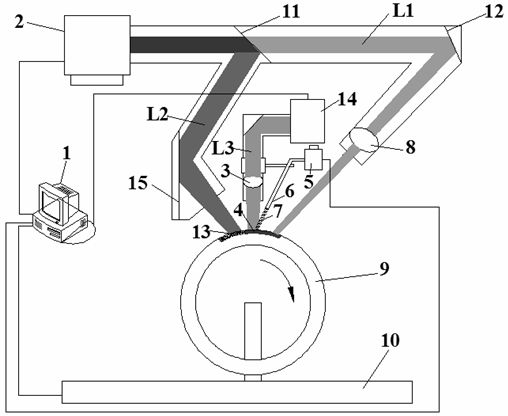

Method with functions of preheating and postheating for forming crack-free coating with high efficiency by three-light-beam laser-cladding technique

InactiveCN102383126ALow and adjustable dilution rateSmall heat affected zoneMetallic material coating processesLaser beam welding apparatusMelting tankHeat-affected zone

The invention discloses a method with functions of preheating and postheating for forming crack-free coating with high efficiency by a three-light-beam laser-cladding technique. The method comprises the following steps of: splitting a laser beam emitted by an Nd: YAG laser into two laser beams by using a laser beam splitter, namely a preheating laser beam for preheating the surface of a base material and a postheating laser beam for postheating the formed coating; then blowing alloy powder into a molten pool which is formed by focusing a laser beam emitted by a CO2 laser and acting the focused laser beam on the surface of the base material by using a powder nozzle, wherein after the CO2 laser beam moves away, a molten layer is cured and crystallized quickly to form the coating; and postheating the formed coating by adopting the postheating laser beam. The method has the advantages that: (1) the dilution rate of the coating is low and adjustable, and the coating is metallurgically combined with the base material, so the base material has a small thermal influence area and is deformation-free and crack-free; (2) residual inner stress in the coating can be eliminated effectively, a tissue can be improved, and the coating has high abrasion resistance, high corrosion resistance, high anti-cracking performance and high thermal shock resistance; and (3) relative to the processing efficiency in the conventional laser cladding technology, the processing efficiency in the method can be improved by 50 times to the maximum extent, so the processing cost is reduced greatly, and a large-scale industrialized application potential is realized.

Owner:NANCHANG HANGKONG UNIVERSITY

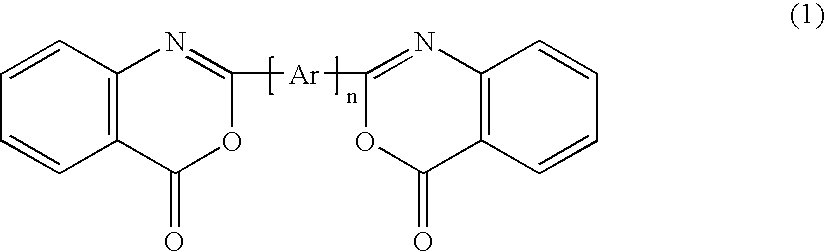

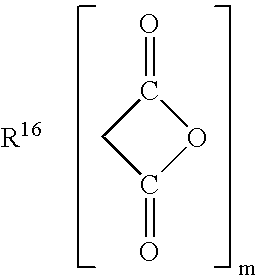

Polycarbonate resin composition, pellets thereof and molded article thereof

InactiveUS20040152806A1Increased durabilityHigh transparencySynthetic resin layered productsAbsorbent padsAlcoholCrack resistance

The object of the present invention is to provide a polycarbonate resin composition which has excellent transparency and durability against molding heat, which gives a molded article having an excellent mold release property, reduced strains, improved cracking resistance and, preferably, weatherability, and which is particularly suitable for a transparent member for a vehicle, pellets thereof and a molded article thereof, and the present invention provides a polycarbonate resin composition obtained by blending 100 parts by weight of a polycarbonate resin (Component A) and 0.005 to 2 parts by weight of a full ester (Component B) from an aliphatic polyhydric alcohol having 4 to 8 hydroxyl groups and 5 to 30 carbon atoms and an aliphatic carboxylic acid having 10 to 22 carbon atoms, said Component B having a 5% weight loss temperature, measured by TGA (thermogravimetric analysis), of 250 to 360° C. and having an acid value of 4 to 20, pellets thereof and a molded article thereof.

Owner:TEIJIN KASEK KK

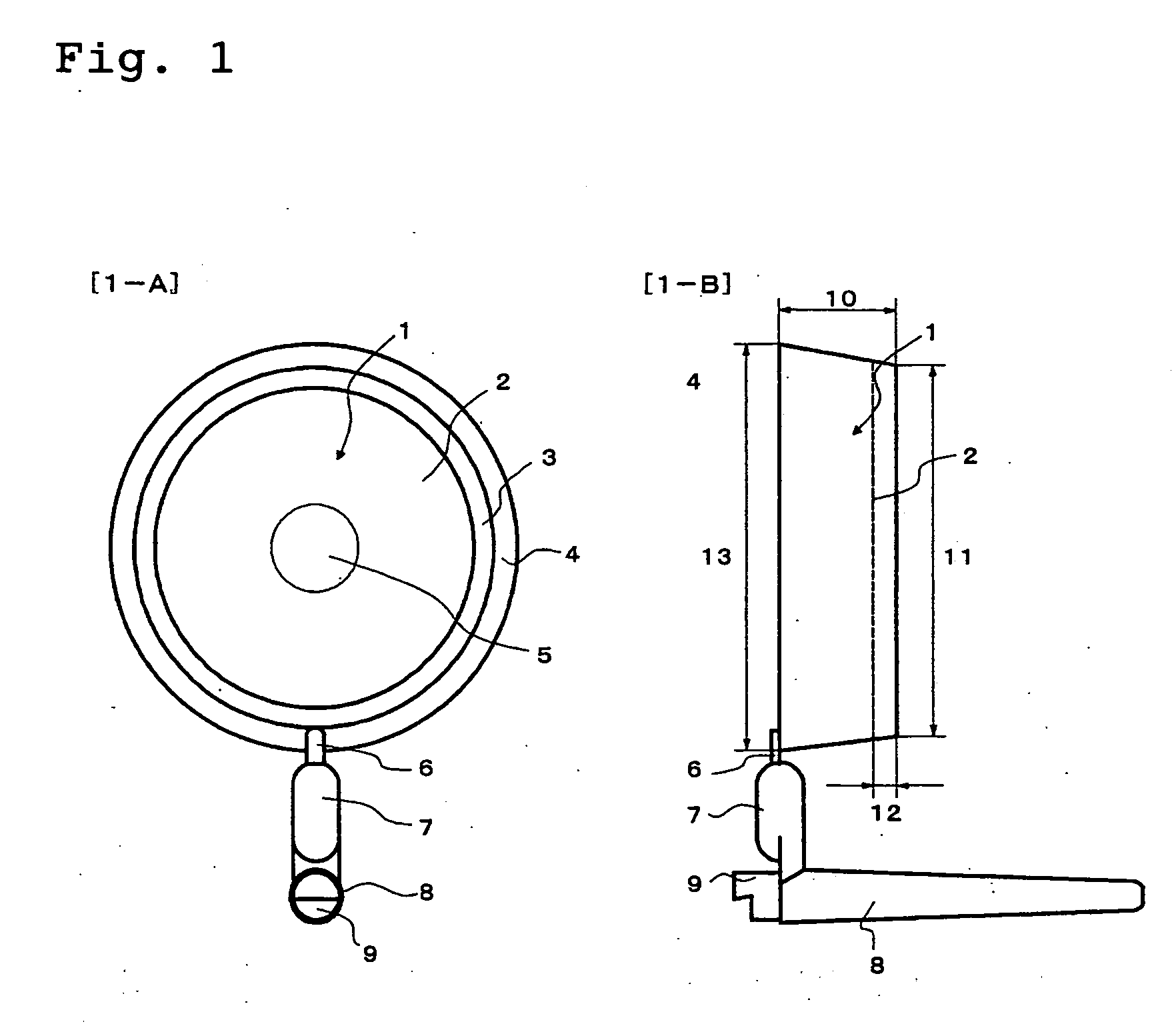

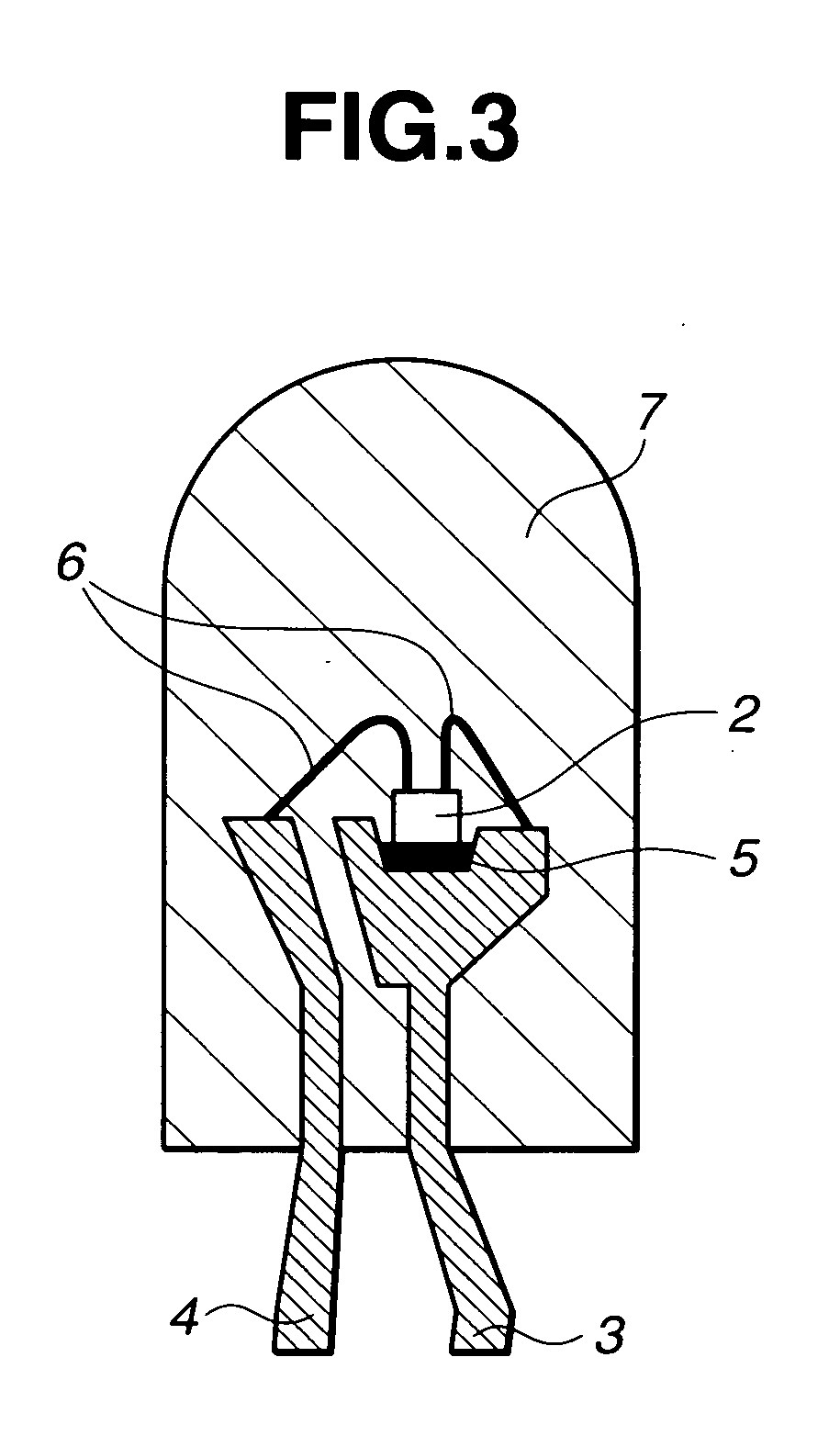

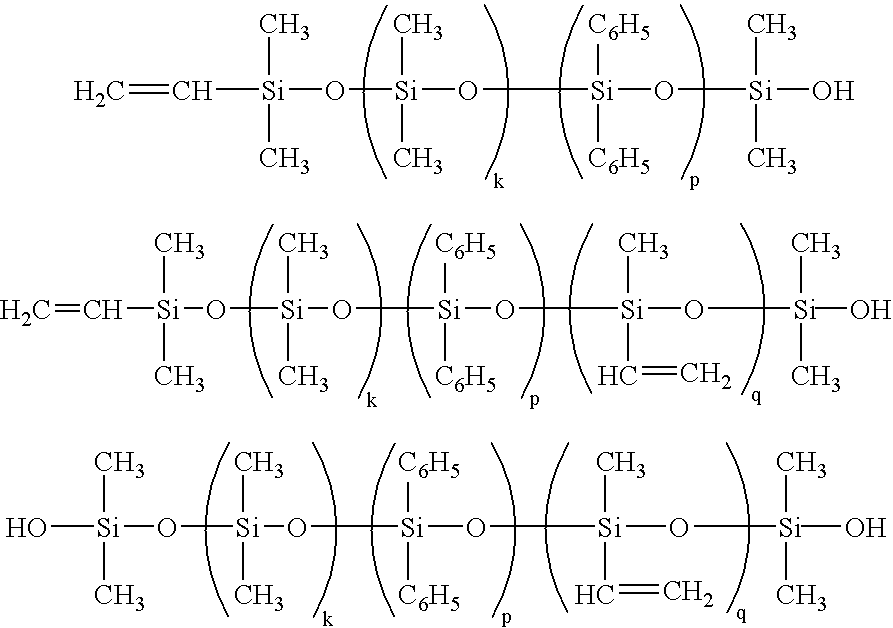

Epoxy-silicone mixed resin composition and light-emitting semiconductor device

ActiveUS20050244649A1Little surface tackinessGood adhesivenessLaser detailsSynthetic resin layered productsEpoxyRefractive index

An epoxy-silicone mixed resin composition to give a transparent cured product which comprises [I] 100 parts by weight of a curable resin composition containing an organosilicon compound and an epoxy resin as essential components, and [II] 0.1 to 50 parts by weight of a silicone elastomer having a refractive index within 10% of that of a cured product of the curable resin composition. It is suitable for use as an encapsulator for light-emitting semiconductors.

Owner:SHIN ETSU CHEM IND CO LTD

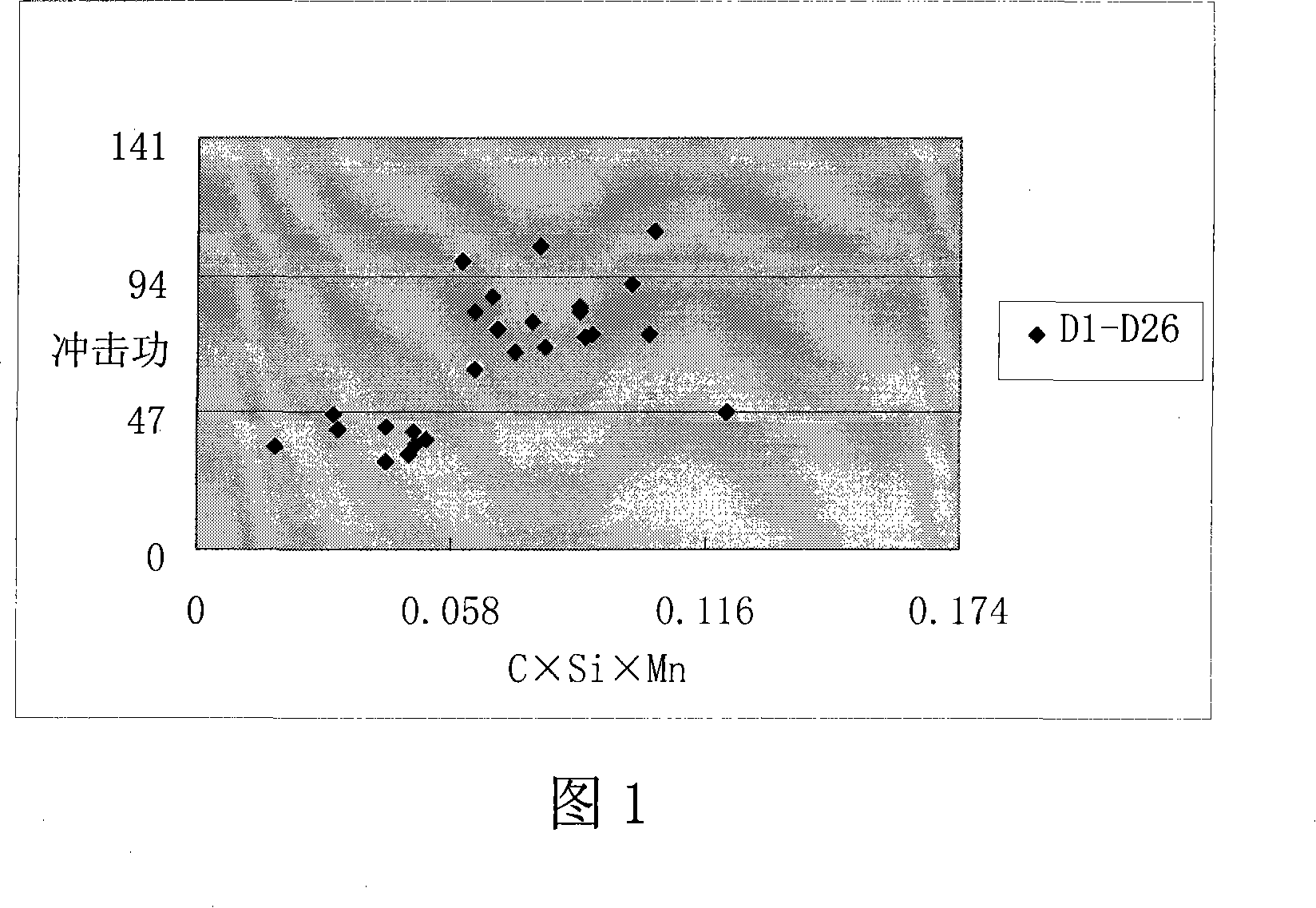

Low alloy steel flux-cored welding wire for carbon dioxide gas protection welding

InactiveCN101104232AImprove impact toughnessAccelerated corrosionArc welding apparatusWelding/cutting media/materialsArc stabilityCrack resistance

Disclosed is a low alloy steel drug core welding wire used in the carbon dioxide arc welding. The components of the drug core and the content occupying the total weight of the welding wire(percent ratio) are as following: Ti01 3-6, Si 0.3-0.5, Mn 1.5-3.2, Si02 0.1-0.8,Zr02 0.1-0.5, Fe 2-7, Al plus Mg 0.5-1.2, Ni 0.5 -5, B 0.002-0.015, Ti 0.1-0.3; oxide or fluoride of alkali metal K, Na and Li is converted into the content of K, Na and Li, that is, 0.1-0.35; the content of fluoride F is 0.05-0.2; fluoride or oxide of rare earth metal is converted into the content of the rare earth metal, that is, 0.005-0.2; the product of the contents of C, Si and Mn in the welding wire is 0.058-0.11. The invention has good process property for the whole position welding of high strength low alloy steel, and can keep good stability of electric arc and welding operating property in the conditions of large current and fast-speed welding with smooth welding seam, high connecting intensity, good impact toughness minus 40 DEG C low temperature and good crack resistance.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

Single-component high-performance mortar for repairing and reinforcing concrete

InactiveCN101935201AShrinkage controlImprove bindingSolid waste managementFlexural strengthPollution

The invention provides single-component t high-performance mortar for repairing and reinforcing concrete, which comprises the following components in part by mass: 200g of sand, 55 to 75 parts of ordinary portland cement, 10 to 30 parts of sulphate aluminium cement, 3 to 7 parts of siliceous dust, 8 to 12 parts of flyash, 0.18 to 0.22 part of water reducing agent, 2 to 4 parts of flexibilizer, 0.04 to 0.06 part of water-retaining agent, 1.0 to 2.0 parts of swelling agent and 0.1 to 0.2 part of polymer synthetic fiber. The single-component t high-performance mortar has the advantages of high initial strength, good adhesion, excellent cracking resistance, low ratio of compressive strength to flexural strength, excellent toughness, simple and convenient construction, single component, no toxin or smell, no harm to human bodies, and environmental protection without pollution.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

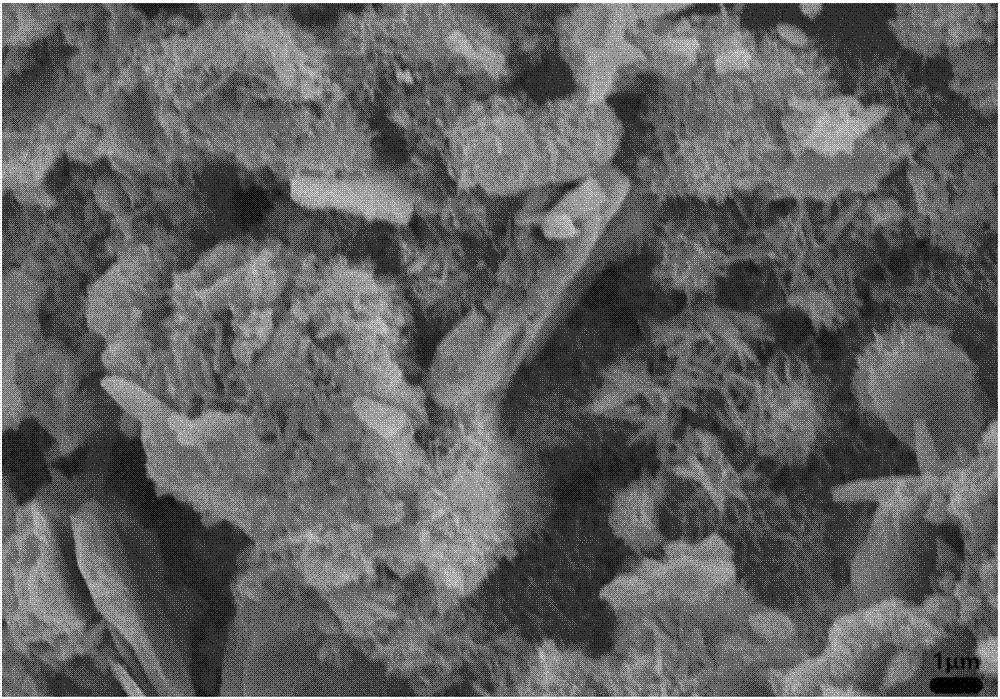

Powdery alloy processing material in site by movable laser smelt-coating process

A movable field processing alloy powder material for the laser melting is to reinforce the nickel-base alloy using the below elements: Cr, W, Mo, Al, Ti, Co; also it can be added with the Co, C, N, Nb, Cu, B, Si and the minim rare-earth metal which can be the Ce, Y and the Hf. The invention has the high hardness, the strength and the low melting point, high wearing resistance. It has improved the cracking resistance, moldability, the stability and the uniformity of the laser melting layer. So it can repair the high temperature alloy, the carbon steel, the structural steel and the stainless steel by the laser melting.

Owner:SHENYANG DALU LASER TECH

Exterior wall composite insulation heat-proof plastering material

InactiveCN101229970ARealize resource utilizationImprove protectionSolid waste managementFiberResource utilization

The invention relates to compound thermal insulation plastering material for external wall, which consists of a compound cementing material and a lightweight aggregate. The compound cementing material consists of cement, active admixture, lime powder, promoter, surfactant, anti-crack and waterproof agent, water retaining agent, flame retardant, re-dispersible emulsion powder, alkali-resistance fiber and coal flying ash cenosphere; the lightweight aggregate consists of EPS grain and expanded perlite. The invention has the advantages of low density, thermal performance, high strength, good impact resistance, bond strength and low shrinkage. The compound cementing material adopts a plurality of polymeric cementing materials, allows the insulation material to have good bond performance and simultaneously ensures falling and slipping resistance performance. The invention has good water resistance and high softening coefficient. By using cement-based cementing material as main material and organic reinforced material and waterproof component as auxiliary materials, the invention has a hydrophobic rate more than 98 percent and a softening coefficient more than 0.7. The invention can save energy and protect environment. A great deal of industrial waste residue is used in the materials, which can save a great number of energy, realize resource utilization of the waste residue and is in favor of environmental protection.

Owner:SHANGHAI TONGBIAO INSULATION TECH

High-polymer modified pitch, its water-proof roll material and use thereof

ActiveCN101070434AImprove standardsHigh standard waterproof functionOther chemical processesRoof covering using flexible materialsPolymer modifiedCrack resistance

The invention provides a polymer modified asphalt, and the weight of the components comprising as follows :45-55% matrix asphalt, 4 - 8% blend oil, 12 - 14% of SBS ,5-9 % APAO, 2-7% of High-temperature improvement and 15-20% filler. It also offers polymer modified asphalt, which made of waterproof membrane and the railway bridge, highway bridge deck waterproofing project applications. The invention of these waterproofing membrane have a high standard of waterproof function, it can withstand high intensity of railway bridge and particularly high stress dynamic load .It also have excellent performance on water-resistance, high and low temperature resistance, adhesion, crack resistance, fatigue resistance and other aspects .it can be used for railway bridge and the road deck waterproofing works.

Owner:JINZHOU DONGFANG YUHONG BUILDING MATERIALS +1

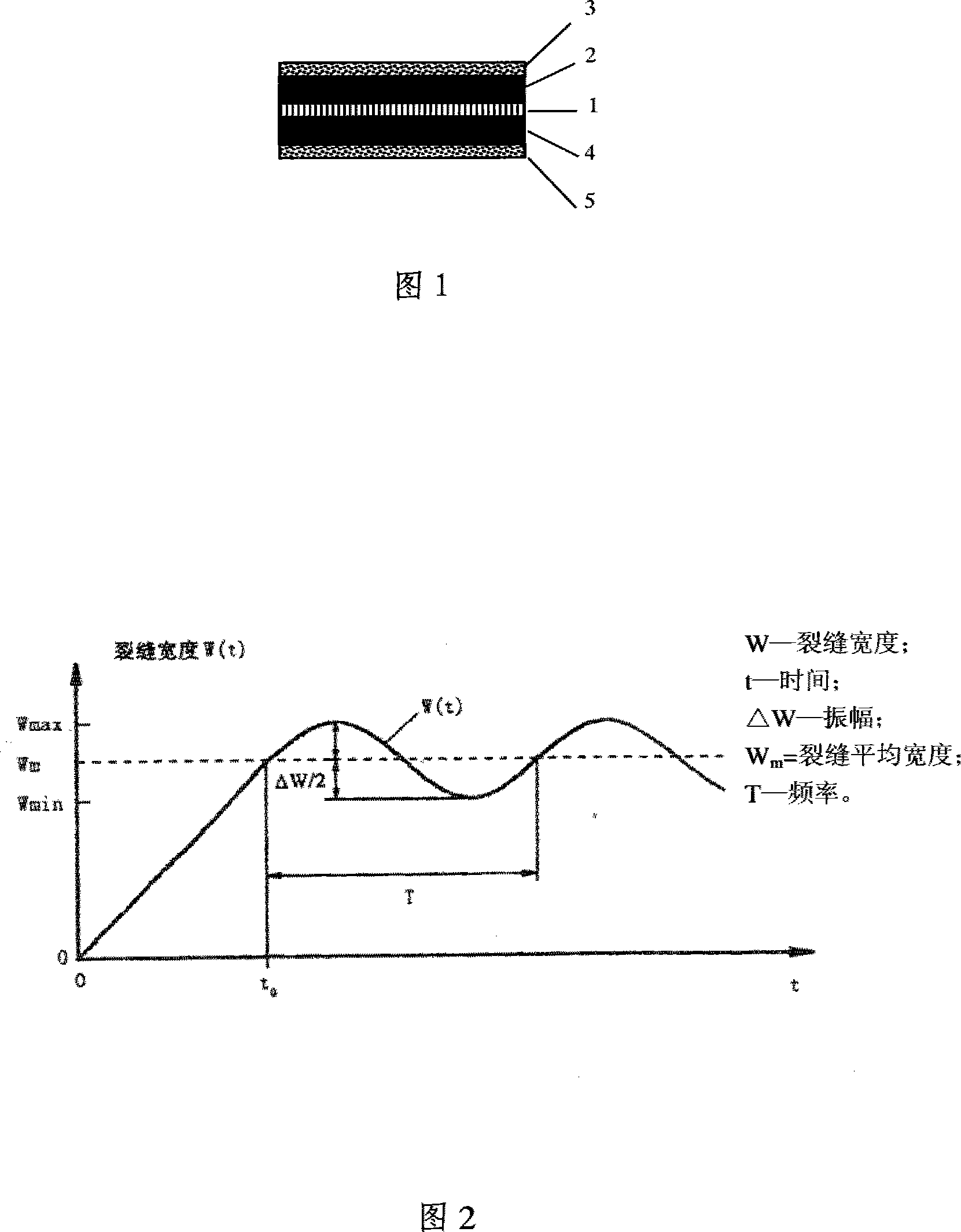

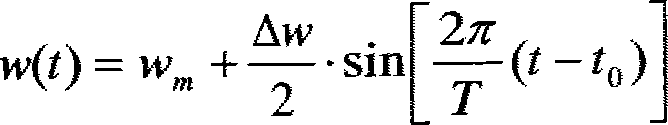

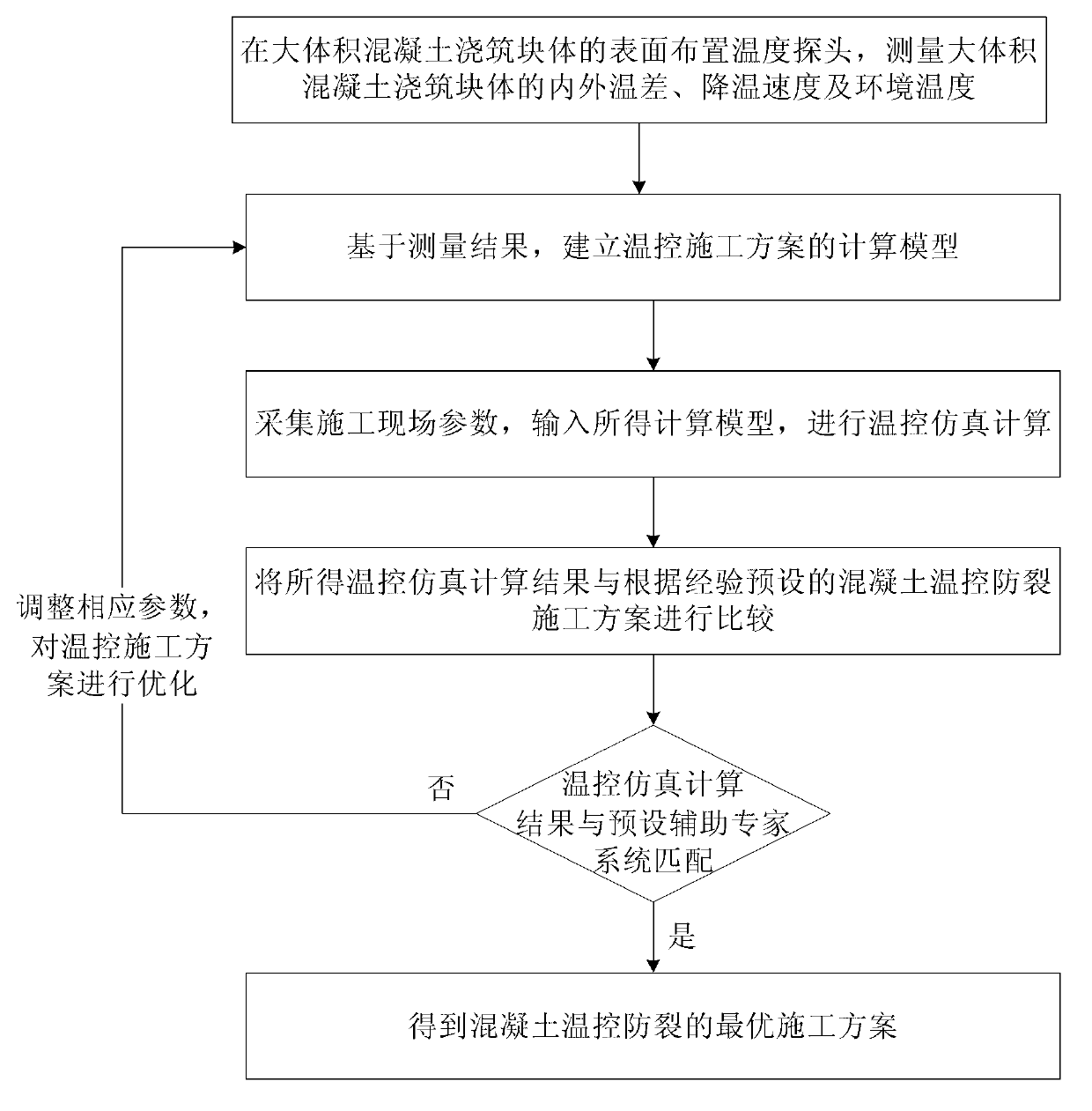

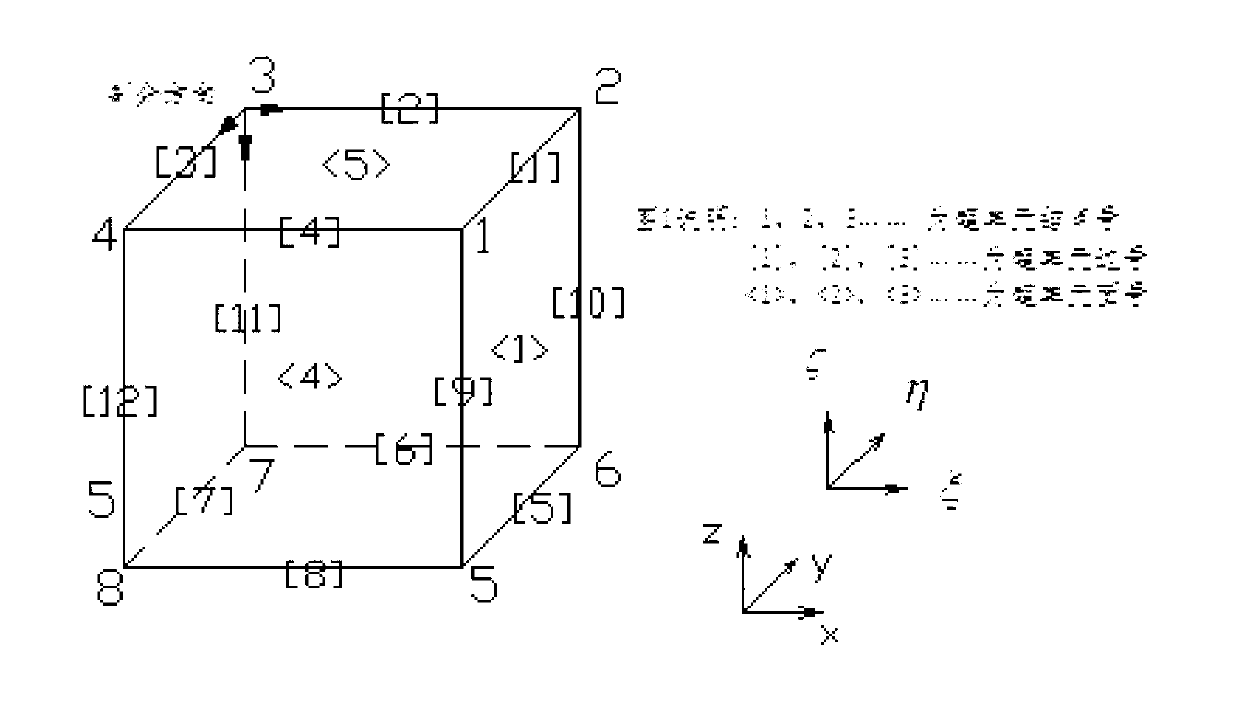

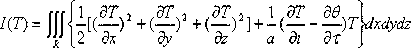

Temperature-controlled crack prevention construction method for concrete structure

ActiveCN102979307AOvercoming easy cracksOvercoming reliabilityFoundation engineeringBuilding material handlingTemperature controlTemperature difference

The invention discloses a temperature-controlled crack prevention construction method for a concrete structure. The method comprises the steps of (1) arranging temperature probes on the surface of a large-size concrete pouring block to measure the temperature difference between inside and outside, the cooling rate of the large-size concrete pouring block and the environment temperature; (2) establishing a calculation model for the temperature-controlled construction scheme based on the obtained measuring result; (3) collecting the construction site parameters, and inputting the parameters into the obtained calculation model for temperature-controlled simulation calculation; and (4) comparing the temperature-controlled simulation calculation result obtained in the step (3) with the preset auxiliary expert system, repeating the step (2) to adjust the corresponding parameters when the temperature-controlled simulation calculation result obtained in the step (3) and the preset auxiliary expert system mismatch, and optimizing the temperature-controlled crack prevention construction scheme for concrete preset based on experience until the optimal temperature-controlled crack prevention construction scheme for the concrete is obtained. The temperature-controlled crack prevention construction method for the concrete structure disclosed by the invention has the advantages that the concrete is not prone to crack, the crack prevention reliability is high, and the crack prevention commonality is good.

Owner:JINLAI CONSTR ENG TECH RES & DEV CO LTD OF THE XINJIANG PRODION & CONSTR CORPS

High hardness ferritic stainless steel wearable surfacing flux-cored wire

InactiveCN101224527AOvercome the disadvantage of poor wear resistanceHigh hardnessWelding/cutting media/materialsSoldering mediaHigh carbonBoron carbide

The invention provides a high hardness ferrite stainless steel wearable flux-cored wire, which takes a low carbon steel H08A cold rolling thin steel strip as an external wrapper; furthermore, the wrapper is internally provided with a powder core which is composed of graphite, metal and alloy powder; the weight percentages of all ingredients of the powder core are 50-75% of high carbon ferrochrome, 10-16% of ferrovanadium, 6-10% of ferrotitanium, 2-10% of tungsten carbide, 2-3% of nickel powder, 1.5-2.5% of silver graphite, 1-3.5% of boron carbide, 1-2% of aluminium magnesium powder, 0-10% of metallic chromium, and the residual quantity of reduced iron powder; the filling proportion of the powder core is 46-50%; the invention adopts the technical proposal that high-content ferrovanadium and adequate alloy powders such as tungsten carbide and boron carbide, etc. are added into the flux-cored wire, changes the microstructure of the existing ferrite stainless steel flux-cored wire surfacing alloy, overcomes the shortages of poor wearability and ductility, and can be applied to submerged arc bead weld manufacture or repair of the parts which has high requirement of abrasion and the corrosion resistance of the wearable grain.

Owner:XIANGTAN UNIV

Solid golf ball

InactiveUS20080194358A1Reduce rigidityImprove performanceGolf ballsSolid ballsPolymer scienceAntioxidant

The invention provides a solid golf ball having a solid core and a cover layer that encases the core and has an outermost layer on an outside surface of which are formed a plurality of dimples. The solid core is formed of a rubber composition composed of 100 parts by weight of a base rubber that includes 60 to 100 parts by weight of a polybutadiene rubber having a cis-1,4 bond content of at least 60% and synthesized using a rare-earth catalyst, 0.1 to 5 parts by weight of an organosulfur compound, an unsaturated carboxylic acid or a metal salt thereof, an inorganic filler, and an antioxidant. The solid core has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of 2.0 to 4.0 mm, and has a specific hardness distribution. The cover layer is formed primarily of a polyurethane material and has a thickness of 0.5 to 2.5 mm, a Shore D hardness at the surface of 50 to 70 and a flexural rigidity of 50 to 300 MPa. The golf ball has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of 2.0 to 3.8 mm. The solid golf ball is advantageous overall in competitive use.

Owner:BRIDGESTONE SPORTS

Process for welding 800MPa high-strength steel without preheating

ActiveCN1962151AStrong resistance to crack generation and propagationImprove crack resistanceArc welding apparatusFurnace typesWeld seamEngineering

The invention relates to a non-preheat welding method of high-strength steel whose tensile strength 800MPa, wherein it comprises (1), the connector has V-shape slope cut; (2), cleaning the slope before welding; (3), using impulse welding power source to weld in Ar+CO2 mixed gas or CO2 gas, while the welding voltage is 30-34V, the welding current is 200-240A, the welding speed is 0.4cm / s-0.6cm / s, the welding heat input is 10kJ / cm-20kJ / cm, and the protect gas flux is 15L / min-25L / min;(4), using 600MPa or 700MPa drug welding or solid welding wire to weld bottom, while other welding channels use 800MPa drug welding wire to multilayer weld, without intermission; (5), using alumina silicate plate to cover the welding head, to cool. The invention can avoid preheat and following thermal treatment, with low cost, while the welding seam has high flexibility.

Owner:BEIJING CHONGLEE MACHINERY ENG

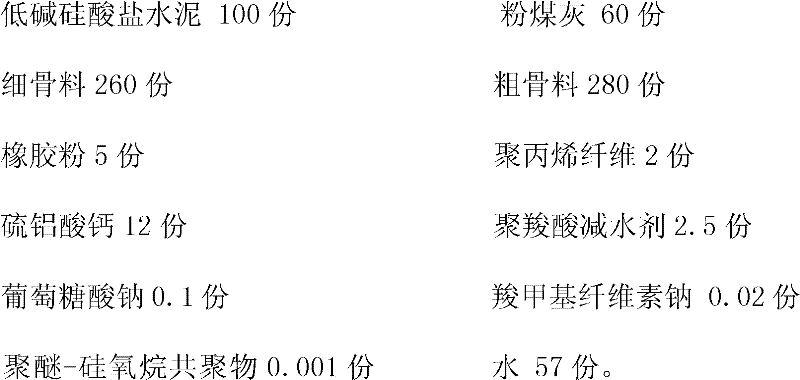

Self-compacting concrete mixture for plate-type ballastless track of railway

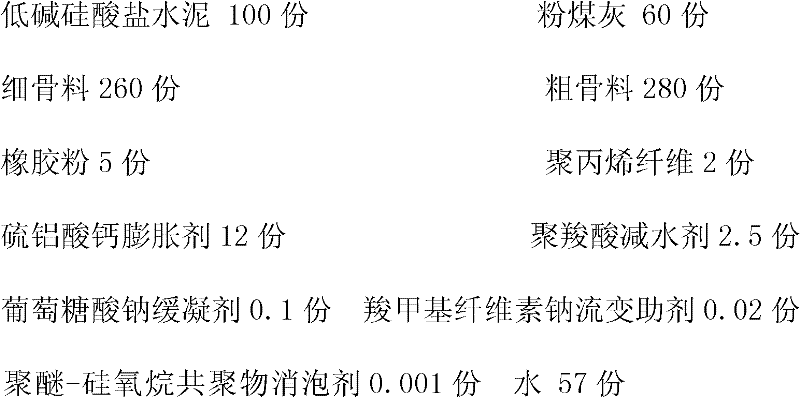

The invention discloses a self-compacting concrete mixture for a plate-type ballastless track of a railway, which is composed of the following ingredients in part by weight: 100 parts of cement, 20-80 parts of mineral admixture, 200-300 parts of fine aggregate, 250-350 parts of coarse aggregate, 2-10 parts of parts of rubber powder, 1-3 parts of polypropylene fiber, 10-25 parts of expansion agent, 1.0-3.0 parts of water reducing agent, 0.1-1 part of retarder, 0.01-0.05 parts of rheology accessory agent, 0.001 part of antifoaming agent and 60-80 parts of water; and the self-compacting concretemixture is prepared by blending and stirring the materials. The self-compacting concrete mixture disclosed by the invention has the advantages of large flow state, self-compacting property, non-segregation, low shrinkage, high anti-cracking property and vibration adsorption, and the like, so that the self-compacting concrete mixture can be used as filler between a rail board and a soleplate in a plate-type ballastless track and can also be used as filler between a turnout board and the soleplate in a turnout structure.

Owner:SOUTHWEST JIAOTONG UNIV

Exterior wall color surface decoration mortar and preparation method thereof

The invention relates to a building material, and in particular relates to an exterior wall color surface decoration mortar and a preparation method thereof. The exterior wall color surface decoration mortar comprises the following raw materials by weight: 20%-30% of white cement, 50%-60% of quartz sand, 0.1%-0.5% of chopped fiber, 10%-20% of heavy calcium carbonate, 0.2%-1% of latex powder, 0.3%-0.5% of cellulose ether, 1%-5% of an inorganic pigment, 0.2%-0.4% of a water repellent, 5%-10% of coal powder ash, 0.1%-0.15% of a defoaming agent, 1%-3% of metakaolin, 0.2%-0.5% of a thixotropic lubricant and 1%-2% of a water reducing agent. The exterior wall color surface decoration mortar has the advantages of crack resistance, weather resistance, good ultraviolet resistance, permanent and uniform color, good whiskering resistance, and the like, can be well combined with various inorganic base layer materials, is good in coating density, and can be widely used in the building fields such as exterior wall decoration and the like.

Owner:KUNSHAN JIANGUO CONCRETE PROD CO LTD

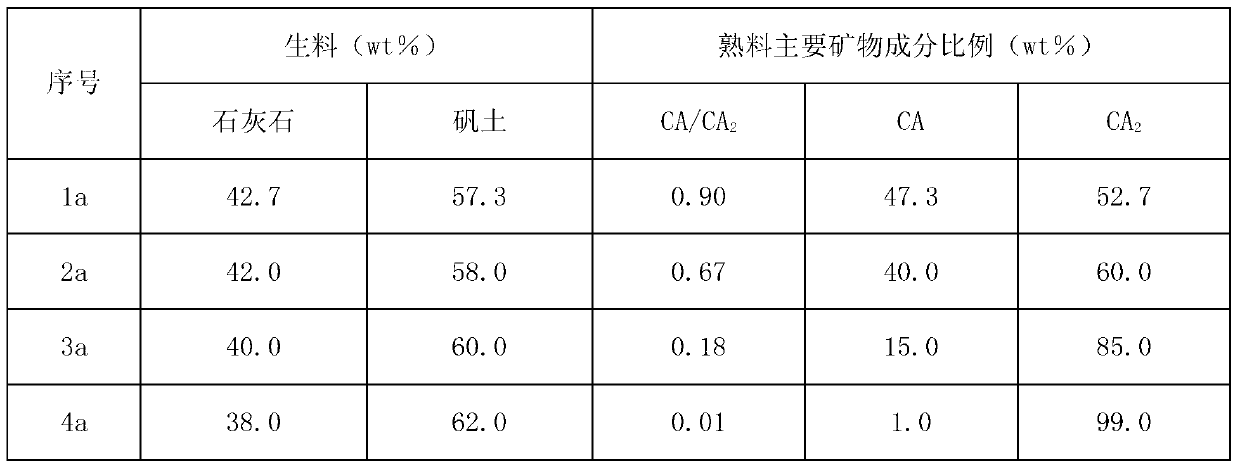

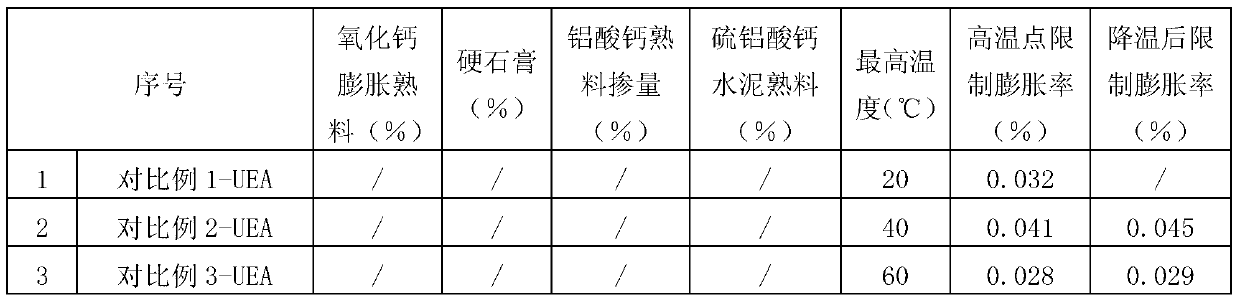

Hydration heat inhibited concrete expanding material as well as preparation method and applications thereof

The invention discloses a hydration heat inhibited concrete expanding material as well as a preparation method and applications thereof. The hydration heat inhibited concrete expanding material is implemented by complexly using first two or three of an expanding agent, a hydration heat inhibitor and an inner curing agent. The hydration heat inhibited concrete expanding material disclosed by the invention fully plays the superimposed effect of the three types of materials, so that the dry shrinkage resistance and cold shrinkage resistance of concrete can be maximized. Experiments prove that concrete with the hydration heat inhibited concrete expanding material disclosed by the invention produces a large expansion in the temperature-fall period, thereby considerably improving the temperature shrinkage (caused by hydration heat) resistance of the concrete; the temperature rise of concrete can be effectively reduced; high relative humidity can be kept in the concrete for a long time, thereby providing a good hydration reaction environment for the expanding agent, and reducing dry shrinkage.

Owner:CHINA BUILDING MATERIALS ACAD

Novel highway embankment widened structure and construction method

InactiveCN104278608ACoordinated settlement deformationImprove carrying capacityRoadwaysClimate change adaptationMesh reinforcementSoil cement

The invention relates to a novel highway embankment widened structure. The original roadbed slope of the structure is trimmed into a step shape, a high pressure jet grouting pile is disposed below an original roadbed slope cushion layer, pressurized continuous grouting is employed at an original roadbed cushion layer to form a slurry solid bearing plate, parts of pore cavities of the original roadbed are recharged with fine aggregate concrete or mortar; foundation treatment piles are employed to reinforce the foundation of a widened area, a drainage cushion layer is laid throughout the top of the foundation treatment piles; an earthwork cloth is laid on the drainage cushion layer, a cement soil plate is disposed on the earthwork cloth, high strength reinforcing mesh sheets are disposed in the cement soil plate; and the widened area embankment is formed by layered filling of excavation soil and light filler in a construction process. The structure provided by the invention can reinforce the bearing capacity of roadbed soil on both sides of the widened area and the original roadbed slope strength, and enhance the integrality of the embankment structure, reduce longitudinal cracks induced by differential settlement and the like at the juncture of new and old roadbeds, thus having good technical and economic benefits. The invention also discloses a construction method of the novel highway embankment widened structure.

Owner:HANGZHOU HUASHUI MUNICIPAL ENG

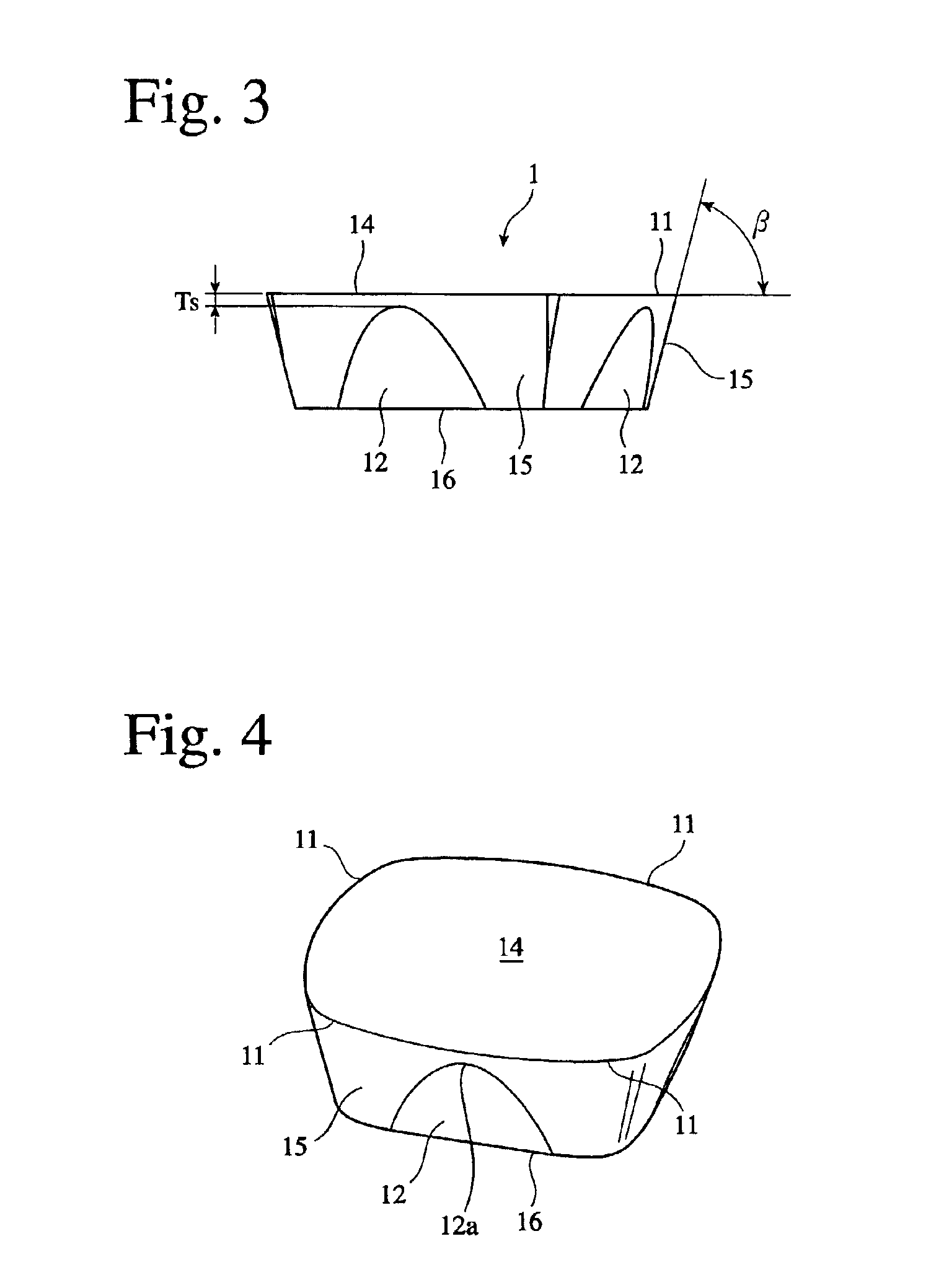

Insert-exchangeable, rotary tool and throwaway insert

InactiveUS6884006B2High operating requirementsStable cuttingMilling cuttersShaping cuttersPositive typeEngineering

Owner:HITACHI TOOL ENG LTD

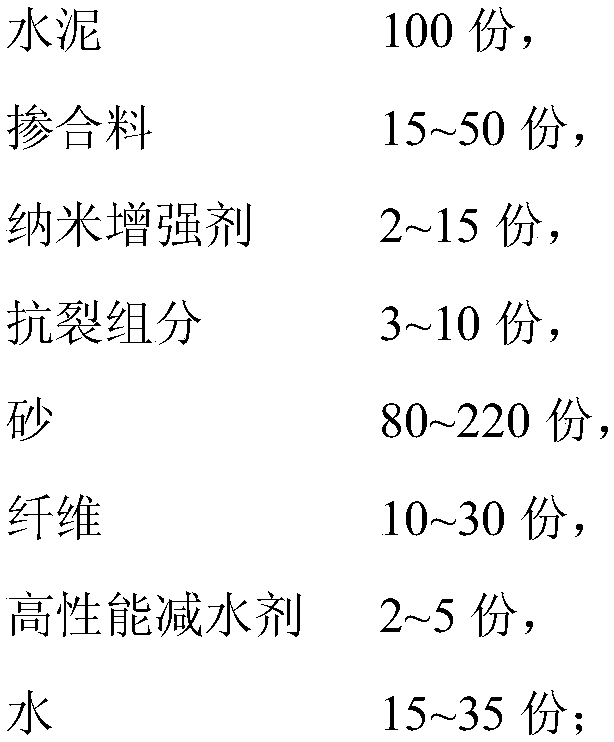

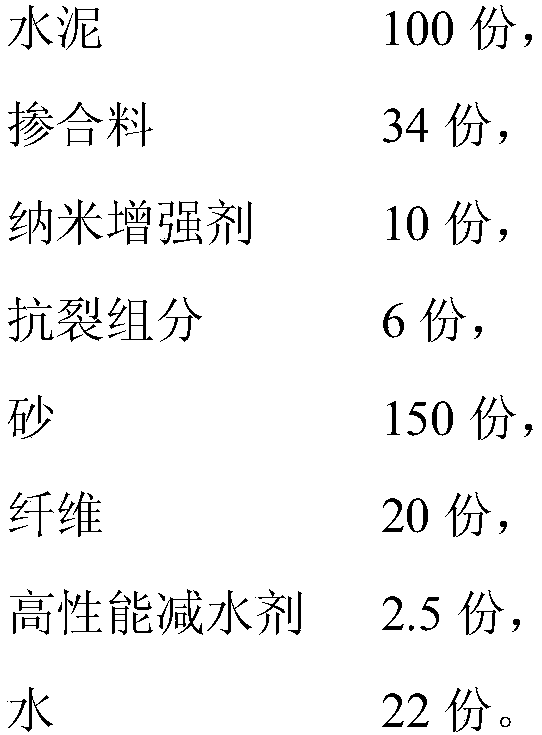

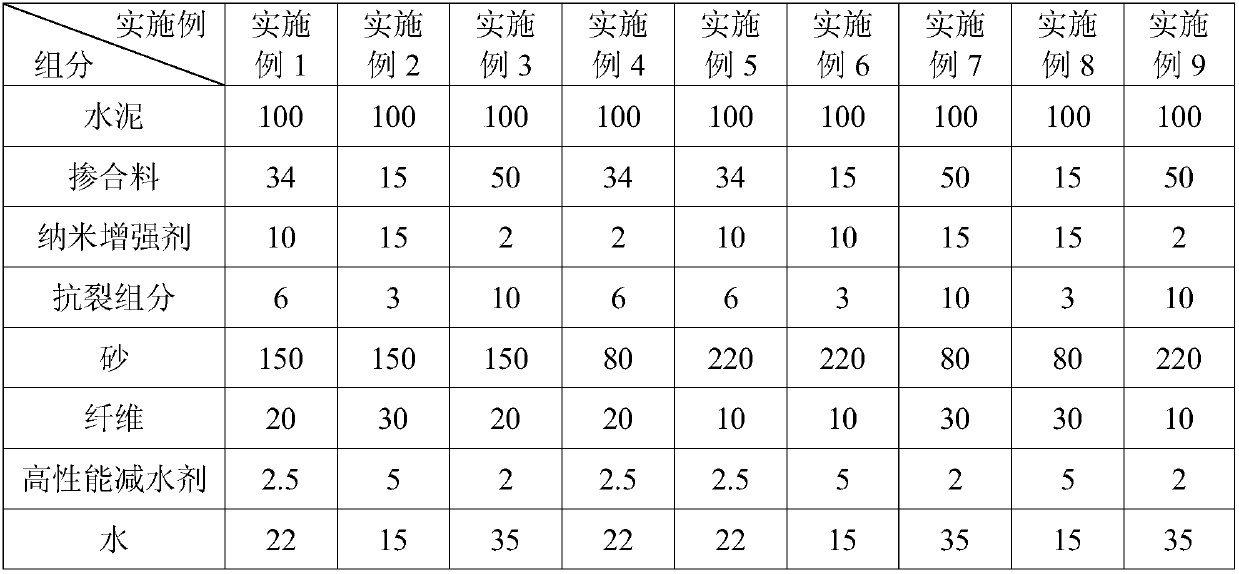

Super-high-performance cement base repairing material and preparing method thereof

The invention discloses a super-high-performance cement base repairing material and a preparing method thereof. The repairing material is prepared from, by mass, 100 parts of cement, 15-50 parts of admixture, 2-15 parts of nanometer reinforcing agent, 3-10 parts of crack resistance component, 80-220 parts of sand, 10-30 parts of fiber, 2-5 parts of high-performance water reducing agent and 15-35 parts of water. The super-high-performance cement base repairing material has super-high tensile strength, bending resistance and adhesive strength and extremely low shrinkage performance, and has excellent construction performance, high elasticity modulus and super-high durability. The material has effects of repairing, reinforcing, seepage preventing, preventing and the like, and therefore the service life of the repairing material and a structure is prolonged. In addition, the material can be used as a joint material of a structural joint.

Owner:JIANGSU SOBUTE NEW MATERIALS

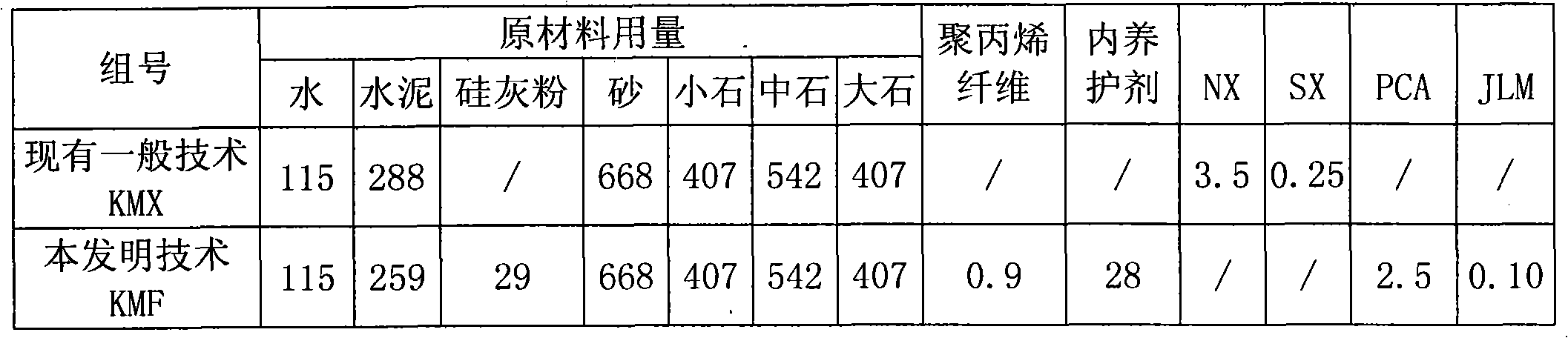

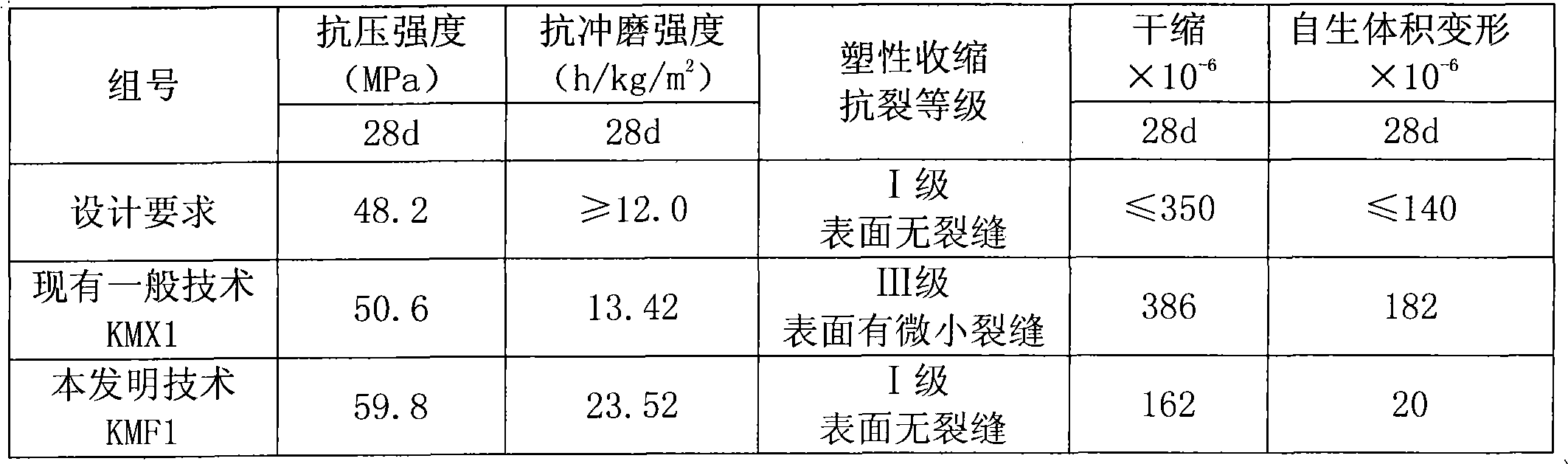

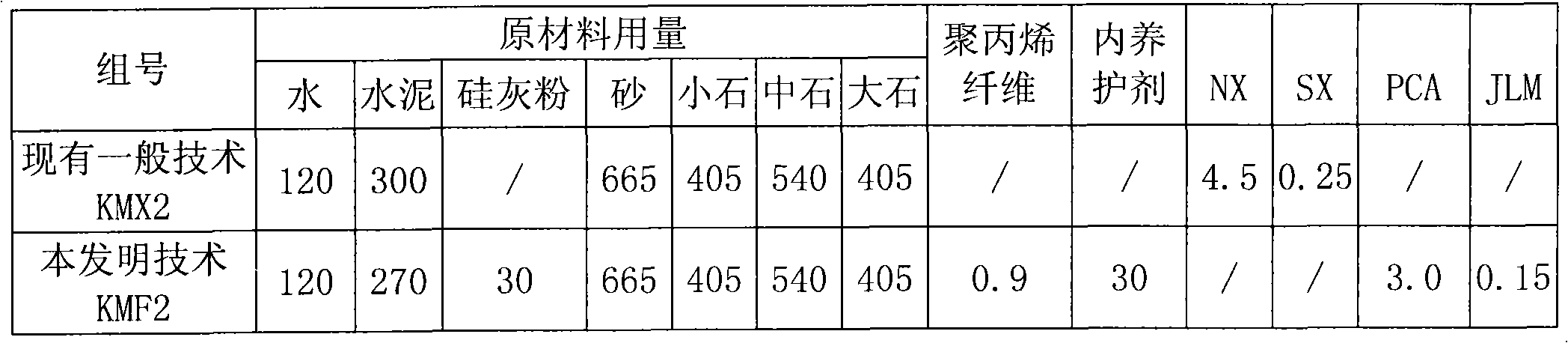

Crack-resistant abrasion-resistant hydraulic concrete and preparation method thereof

InactiveCN102010160AImprove performanceImprove abrasion resistanceSolid waste managementCrack resistanceVolume deformation

The invention discloses crack-resistant abrasion-resistant hydraulic concrete and a preparation method thereof. The hydraulic concrete comprises materials of cement, sand, stones, a polypropylene fiber, a water reducing agent, an air entraining agent and water, and is characterized in that: an internal curing agent and silica fume powder are added; by adopting the internal curing agent as a super absorbent resin, internal maintenance of the concrete is enhanced, the concrete shrinkage is reduced, the abrasion resistance of the concrete is improved, and the crack resistance of the concrete is improved; by adopting the silica fume powder, the concrete mixture performance and abrasion resistance are improved, the comprehensive utilization of industrial wastes and resource and energy conservation are realized, and the environment is protected; and taking concrete at C40 strength grade as an example, the abrasion resistance is 23.52h / kg / m<2>, the early plastic shrinkage crack resistance reaches the first grade, cracks are not formed on the surface of the concrete, an air shrinkage value within 28 days is 162*10<-6>, and the autogenous volume deformation within 28 days is 20*10<-6>. The technical scheme is simple in technical operation, readily available in raw materials, lower in production cost and better in economic and social benefits.

Owner:广西壮族自治区水利科学研究院

Aerogel composite material with surface subjected to dust-free treatment and preparation method

The invention relates to an aerogel composite material with a surface subjected to dust-free treatment and a preparation method thereof, in particular to a method using an aerogel felt, an aerogel plate, an aerogel cylinder and an aerogel shaped piece as the base material and coating the substrate surface with compact coating so as to avoid shedding of aerogel surface dust. The method is simple and practicable, can effectively solve the problem of easy generation of dust on the aerogel surface, significantly improves the working environment, and can satisfy the use condition of aerogel in clean space. By adopting different ratios, a rigid coating and a flexible coating can be obtained, high temperature and low temperature application can also be achieved, compound proportioning of an inorganic film-forming agent and an organic film-forming agent also can give consideration to flexibility and fire resistance, and significantly improves the adaptability of the coating paste to different types of aerogel materials. The aerogel subjected to dust-free treatment can be applied to heat preservation of various industrial equipment and pipeline, and also can be applied to thermal insulation of high speed rail, vessels, electronics and pharmaceutical workshops and building field.

Owner:浙江圣润纳米科技有限公司

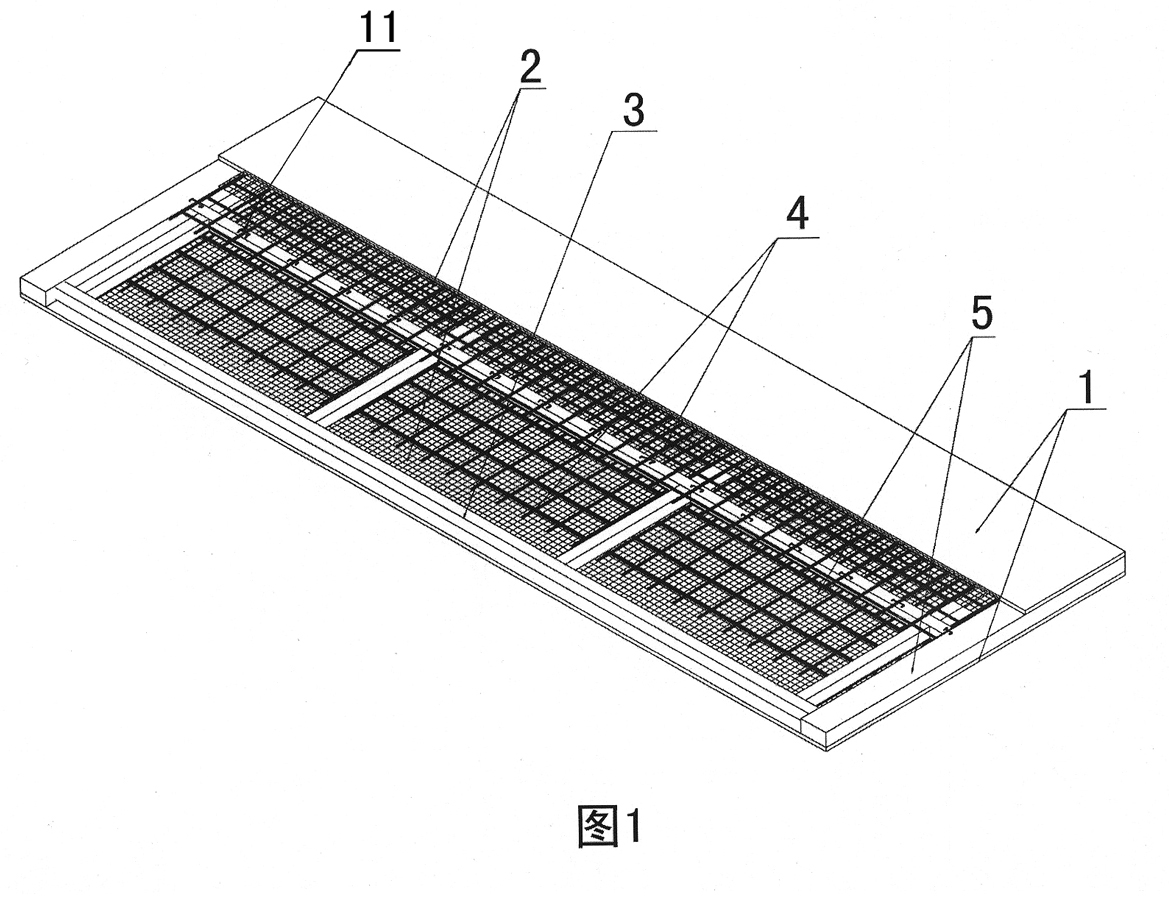

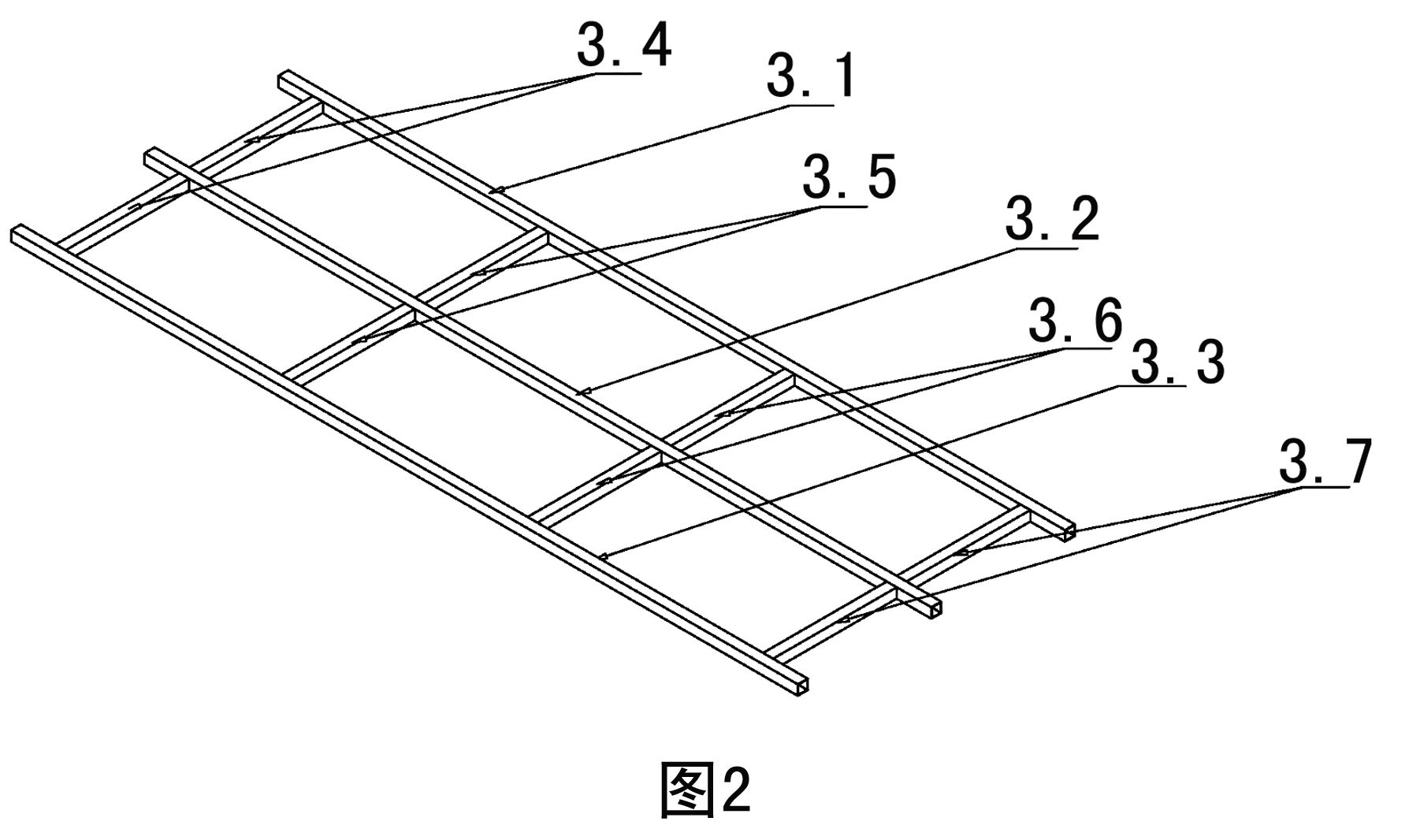

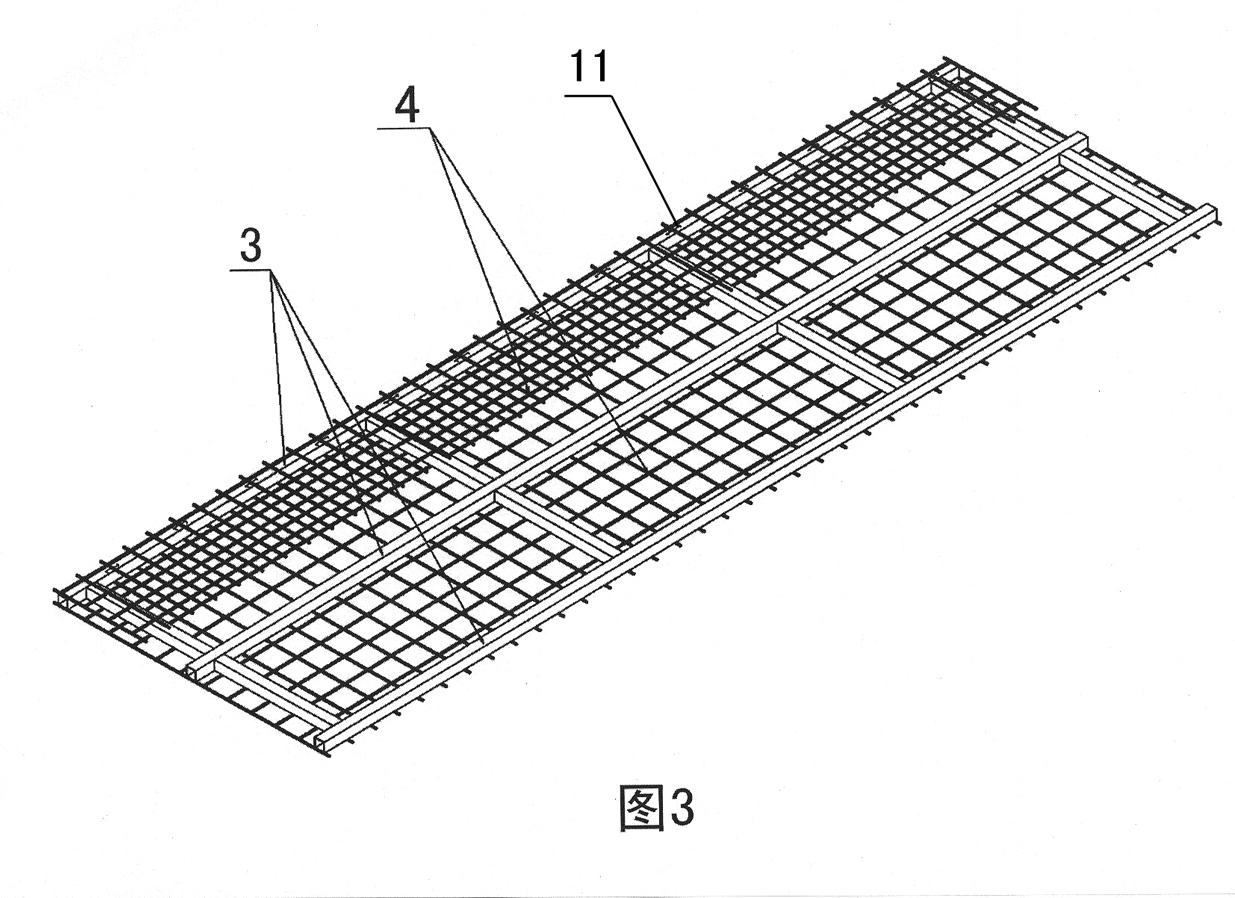

Built-in latticed steel frame exterior protected structural slab as well as building and production and construction method thereof

The invention discloses a built-in latticed steel frame exterior protected structural slab as well as a building and a production and construction method thereof. The built-in latticed steel frame exterior protected structural slab is of a solid core sandwich structure; the intermediate layer of the structural slab is a foamed cement filled layer; the two sides of the intermediate layer are combined with surface layers; the inner part of the foamed cement filled layer is provided with a built-in latticed steel frame; one side or two sides of the built-in latticed steel frame is or are covered with a steel wire mesh sheet or steel wire mesh sheets; the surface layer is a high-strength and anti-crack mortar strengthening surface layer internally doped with fiber silks and laid with fiber meshes; and a latticed steel frame net is formed by welding square steel tubes which are arranged vertically and horizontally at crossing intervals. The structural slab of the invention solves the problems that the existing building cover panel has low strength, is not convenient to be connected with a keel, is easy to fragment and has poor heat insulation property and the like, has the performances of energy conservation, environment protection, earthquake resistance, heat protection, heat preservation, heat insulation and sound insulation and the like, and can be widely applied in house buildings with lightweight-steel-construction wall bodies, floors and roofs.

Owner:筑巢(北京)科技有限公司

Solid golf ball

InactiveUS7481722B2Improve spin performanceIncrease distanceGolf ballsSolid ballsThermoplasticPolymer science

Owner:BRIDGESTONE SPORTS

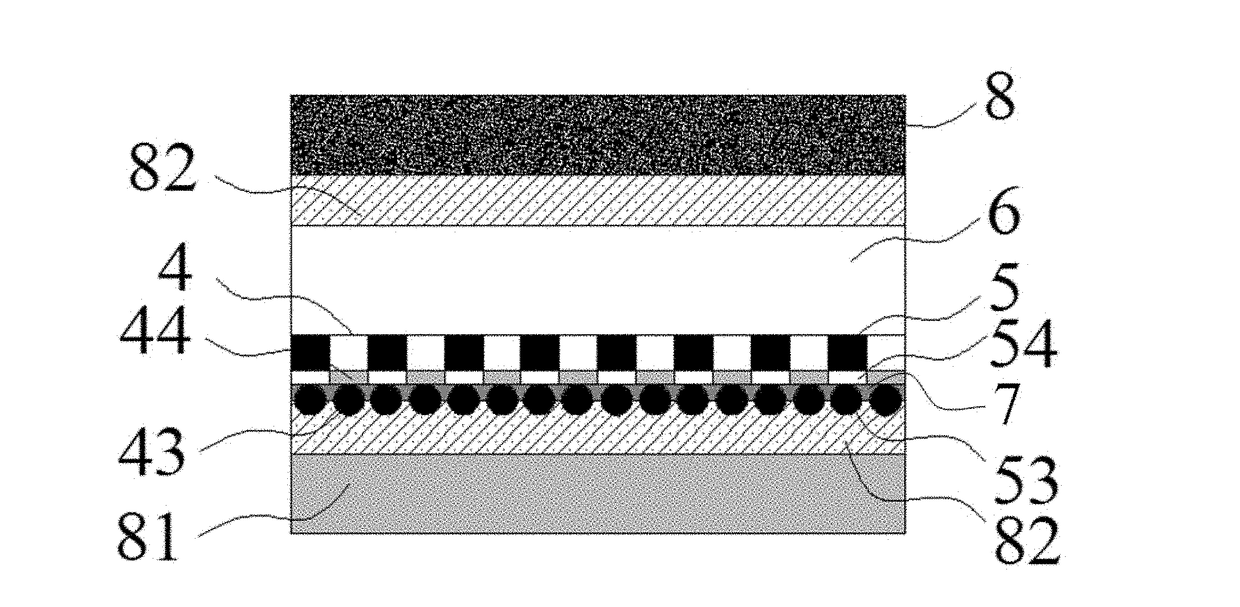

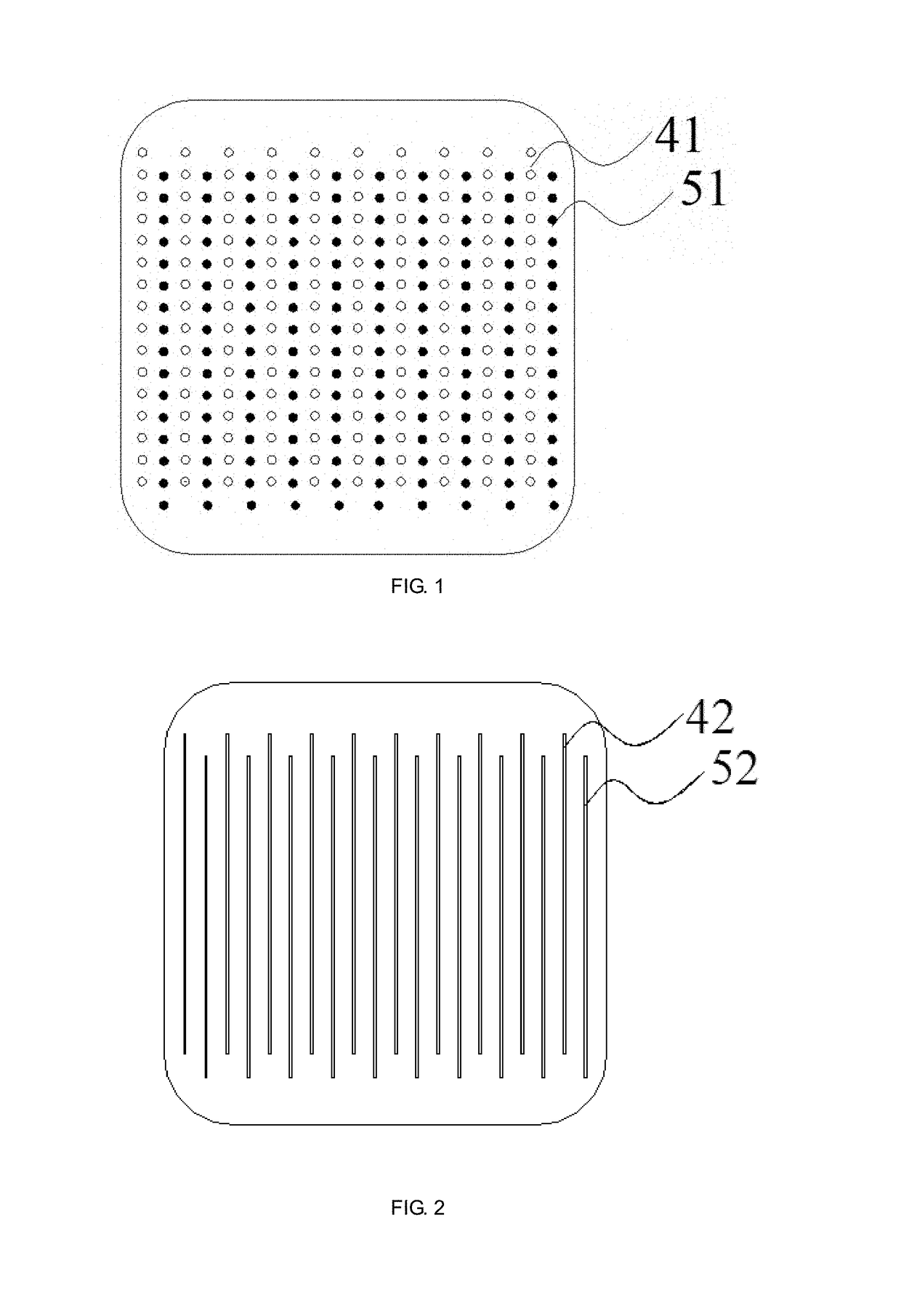

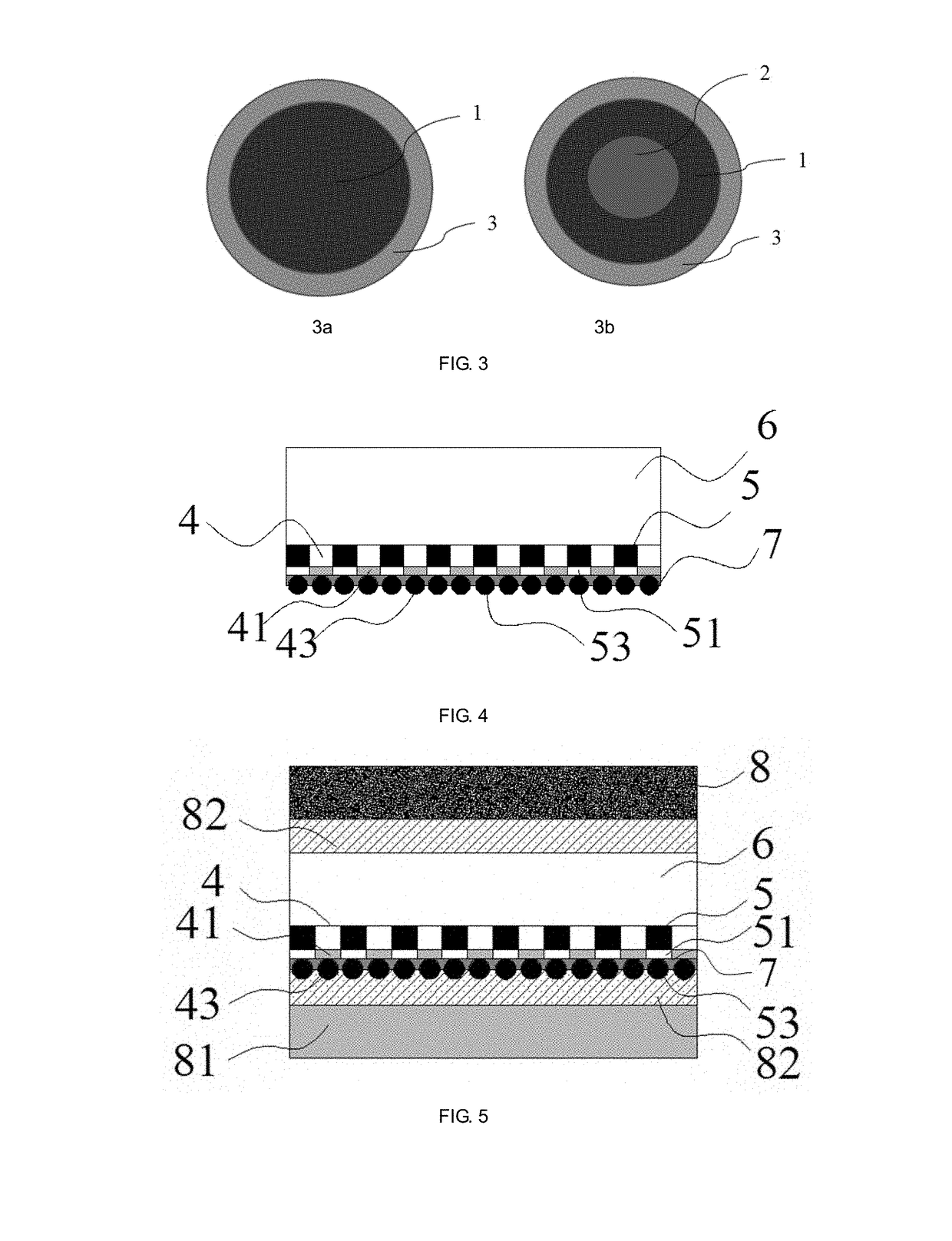

Main-gate-free and high-efficiency back-contact solar cell module, main-gate-free and high-efficiency back-contact solar cell assembly, and preparation process thereof

ActiveUS20170222082A1Reduces electron collection distanceReduced series resistanceFinal product manufacturePV power plantsElectricityCrack resistance

The present invention relates to the field of solar cells, and in particular to a main-gate-free and high-efficiency back-contact solar cell module, a main-gate-free and high-efficiency back-contact solar cell assembly, and a preparation process thereof. The solar cell module, comprising cells and an electrical connection layer, a backlight side of the cells having P-electrodes connected to a P-type doping layer and N-electrodes connected to a N-type doping layer, is characterized in that the electrical connection layer comprises a number of parallel leads each electrically connected to the P-electrodes or the N-electrodes. The present invention has the beneficial effect that a main-gate-free and high-efficiency back-contact solar cell module, a main-gate-free and high-efficiency back-contact solar cell assembly, and a preparation process thereof are provided, which can effectively the short-circuiting of the P-electrodes and the N-electrodes and has the advantages of low cost, high hidden-cracking resistance, high efficiency and high stability.

Owner:JOLYWOOD SUZHOU SUNWATT

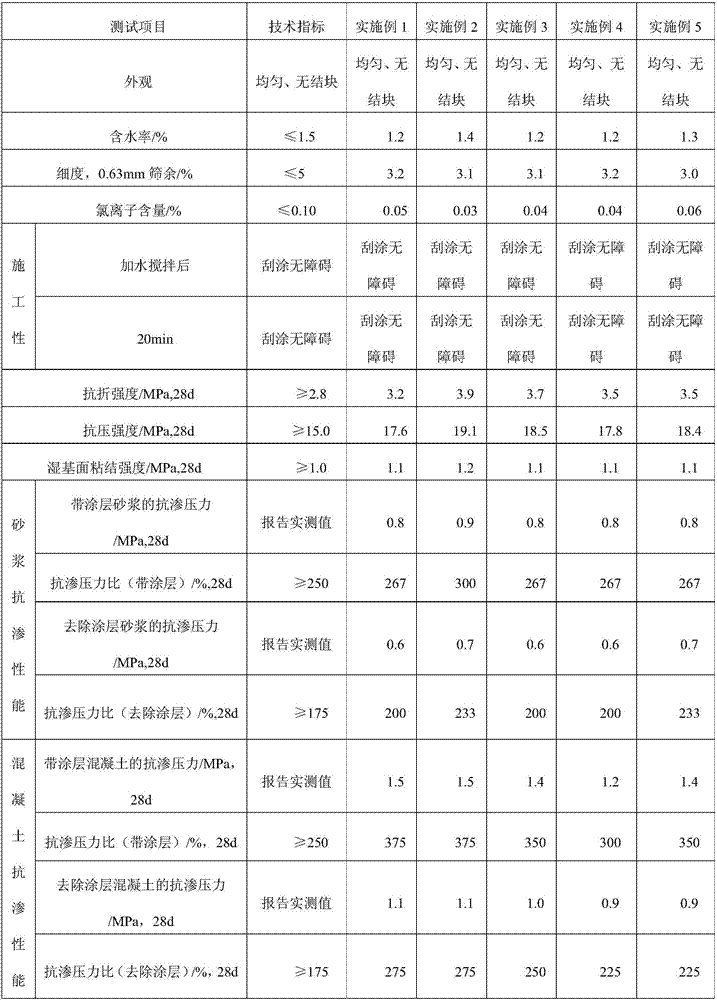

Quick-setting cement-based capillary crystalline self-repairing waterproofing material and preparation method therefor

ActiveCN106946518AAchieve waterproof effectImprove flexural and compressive capacityIon contentBULK ACTIVE INGREDIENT

The invention discloses a quick-setting cement-based capillary crystalline self-repairing waterproofing material and a preparation method therefor. The quick-setting cement-based capillary crystalline self-repairing waterproofing material is prepared from the following ingredients in parts by weight: 55-75 parts of silicate cement, 25-45 parts of quartz sand, 3-10 parts of buffering agent, 4-12 parts of active ingredient A, 4-15 parts of active ingredient B, 2-6 parts of expanding agent, 1-12 parts of calcium ion supplement and 1-4 parts of water reducing agent. The waterproofing material disclosed by the invention is prepared by a simple physical mixing method, is short in initial setting time and low in chloride ion content and can infiltrate into the interior of a cement-based material to form crystals so as to block up microcracks, thus, the folding and compressing resistance and secondary infiltrating resistance are improved, and meanwhile, the cement-based material is endowed with long-lasting self-repairing performance and good waterproof and durable performance. In addition, the preparation method for the quick-setting cement-based capillary crystalline self-repairing waterproofing material is simple, has low requirements on equipment and processes and has very high application power.

Owner:SOUTH CHINA UNIV OF TECH +1

Series flux cord welding rod used for pile-up welding reparing and remanufacturing large type medium high carbon steel parts

InactiveCN100999041AImprove crack resistanceHigh carbon contentArc welding apparatusWelding/cutting media/materialsHigh carbonRare earth

The present invention discloses a series flux-cored wire for reparation and refabrication of large-size medium-high carbon steel components and parts. Its chemical composition includes (wt%) 5-10 of fluorite, 25-45% of high-carbon ferrochrome, 2-10% of high-carbon manganese iron, 5-8% of tantiron, 10-15% of ferro-molybdenum, 8-14% of rare earth oxide, 5-15% of metal nickel, 2-5% of ferrovanadium, 0.5-2% of graphite, 2-4% of chloride and 1-2.5% of aluminium-magnesium alloy. Its external covering adopts low-carbon steel tape.

Owner:QINHUANGDAO WEIERDE SPECIAL WELDING IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com