Patents

Literature

857 results about "Cenosphere" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

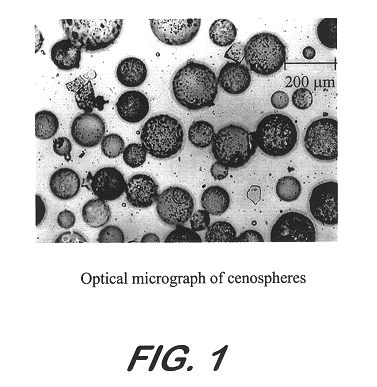

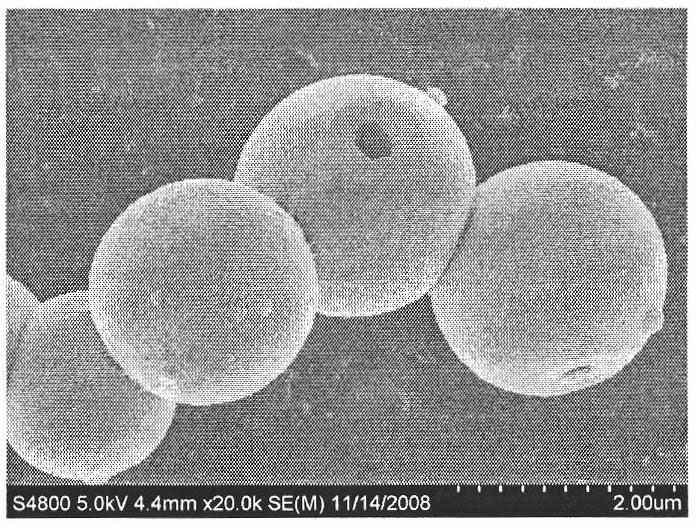

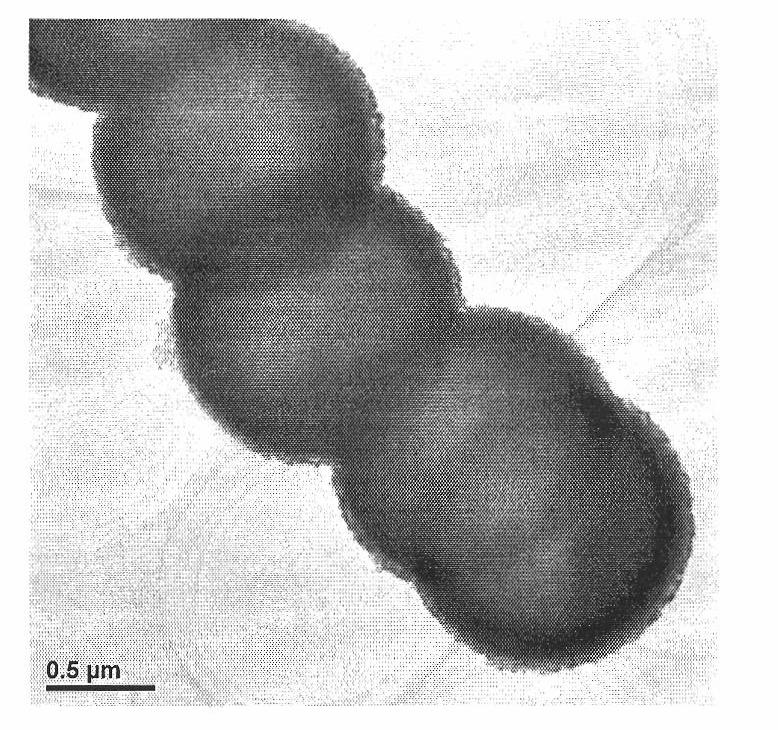

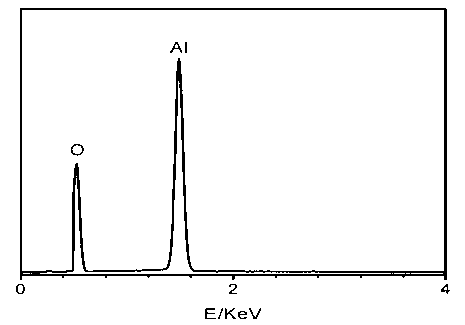

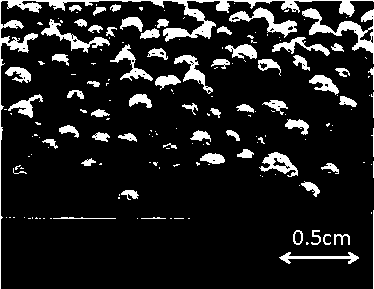

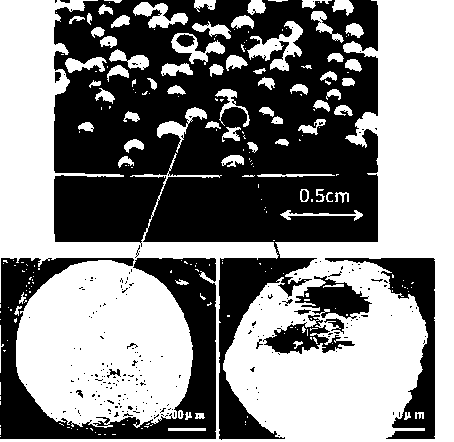

The word cenosphere is a combination of two Greek words:kenos (hollow) and sphaira (sphere) which describes the major characteristic of this material. A cenosphere is a lightweight, inert, hollow sphere made largely of silica and alumina and filled with air or inert gas, typically produced as a byproduct of coal combustion at thermal power plants. The color of cenospheres varies from gray to almost white and their density is about 0.4–0.8 g/cm³ (0.014–0.029 lb/cu in), which gives them a great buoyancy. Cf. glass microspheres...

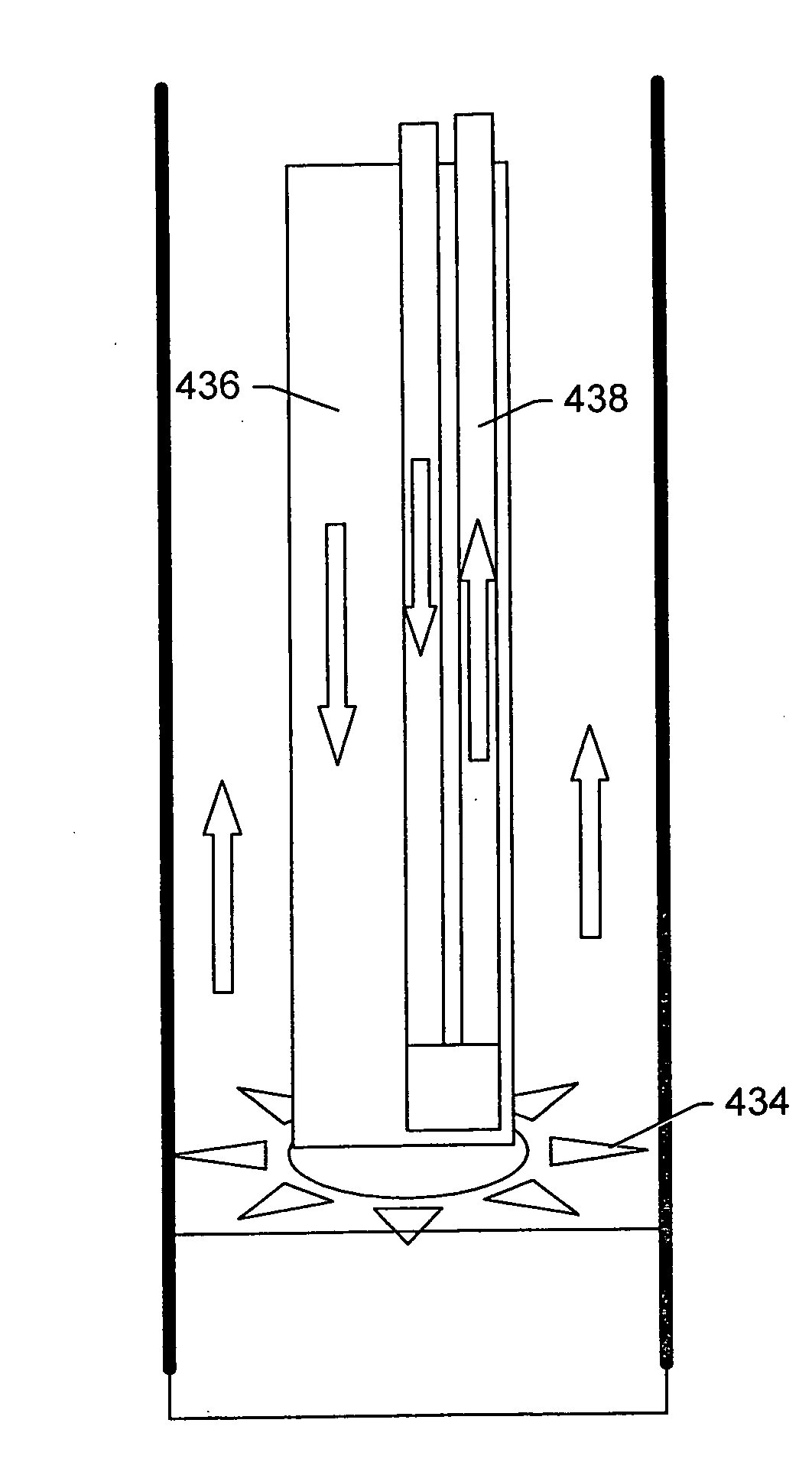

Compositions produced using an in situ heat treatment process

Owner:SHELL OIL CO

Cementing compositions and methods of cementing in a subterranean formation using an additive for preventing the segregation of lightweight beads.

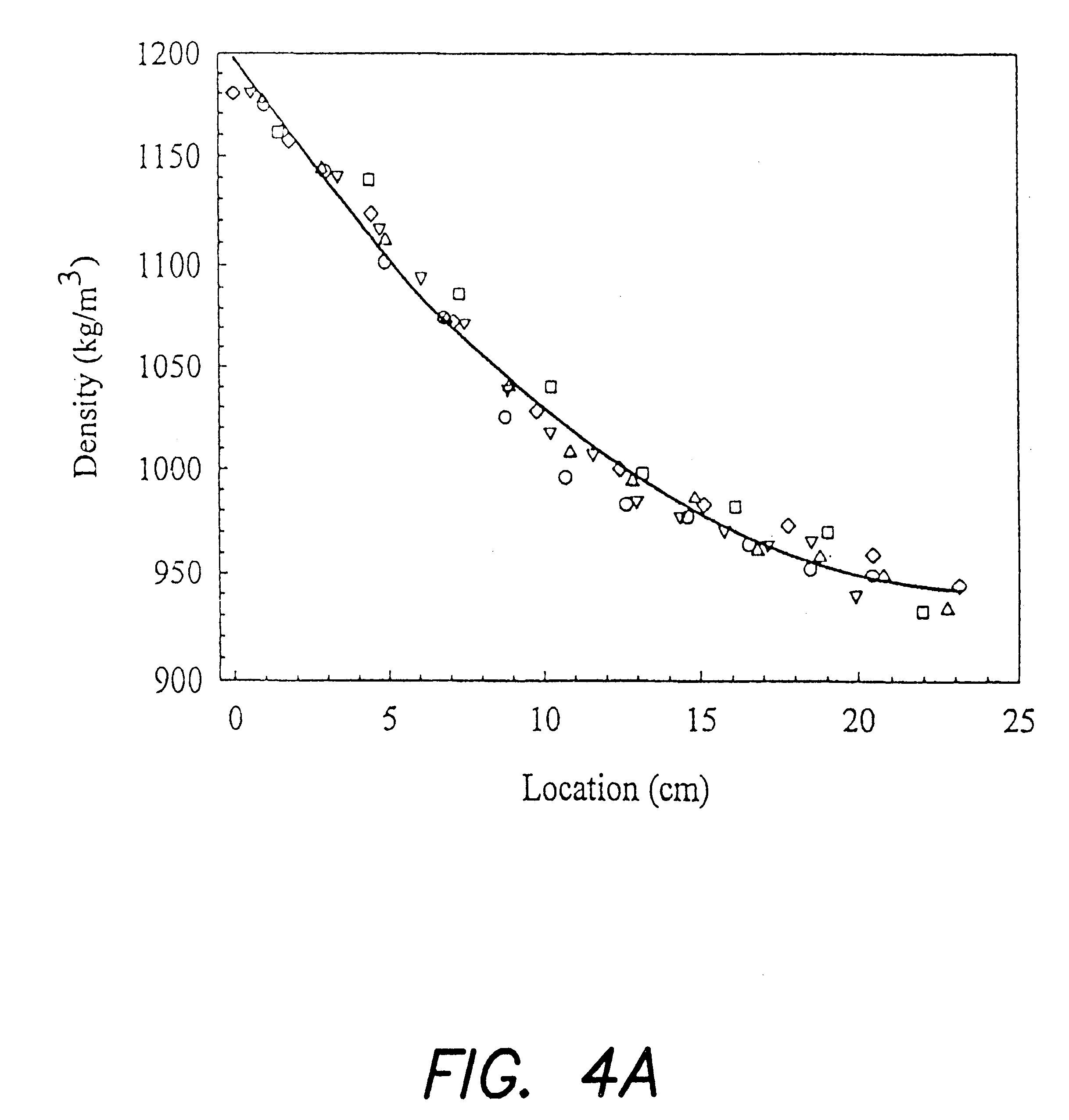

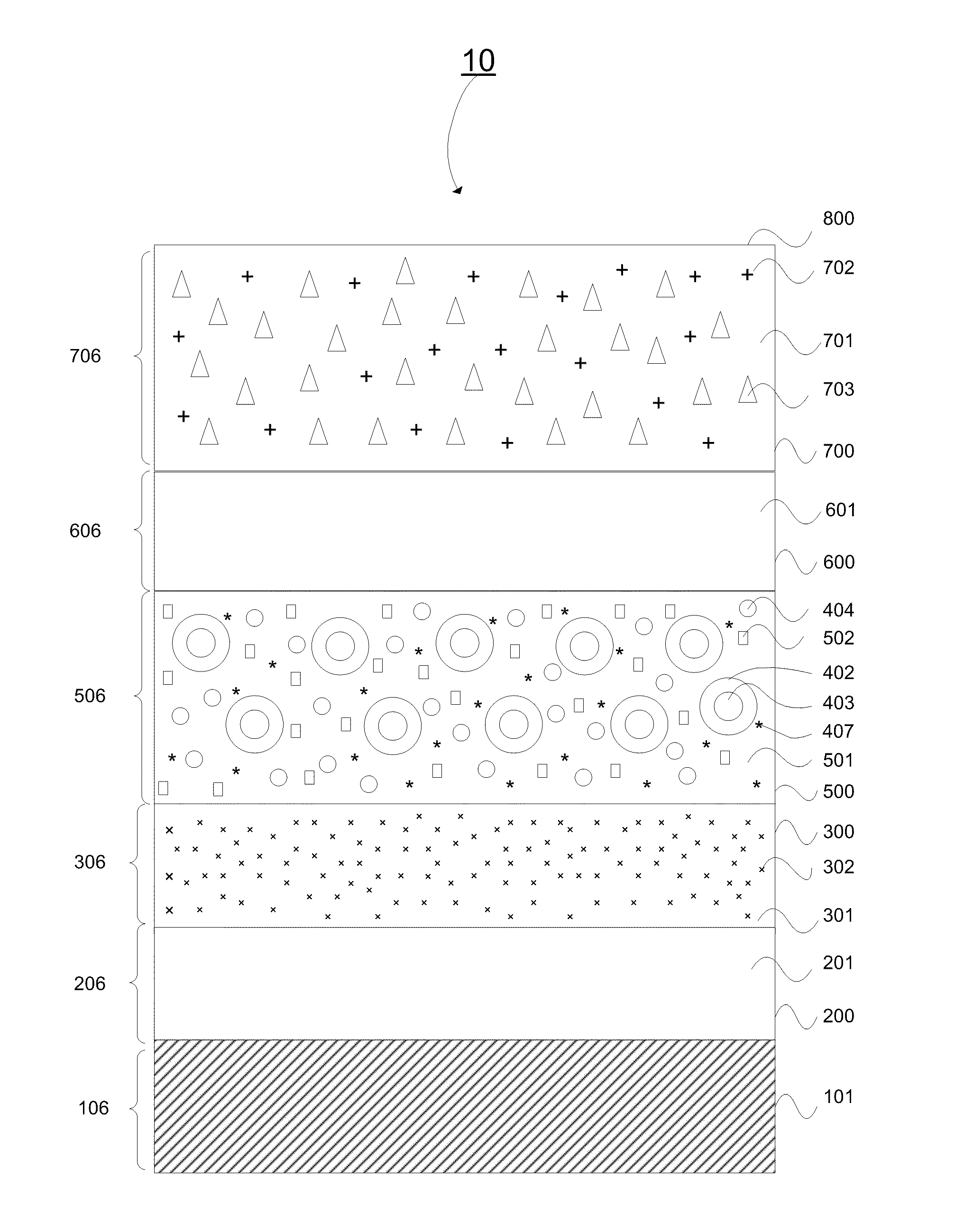

Cementing compositions and methods of cementing in a subterranean formation are provided. The cement composition includes a hydraulic cement, lightweight beads, and a desegregating agent for inhibiting segregation of the beads. The lightweight beads may be, for example, cenospheres, glass spheres, and ceramic spheres. The desegregating agent comprises a particulate substrate such as precipitated silica. It also comprises a polar molecule producing chemical disposed on the particulate substrate. Preferably, the polar molecule producing chemical is absorbed on the particulate substrate. The polar molecule producing chemical comprises at least one of a polar molecule producing acid such as glacial acetic acid, a salt of such an acid, and an acid anhydride. The method of cementing includes forming a pumpable slurry using the cement composition, pumping the slurry into a subterranean formation, and allowing the slurry to set.

Owner:HALLIBURTON ENERGY SERVICES INC

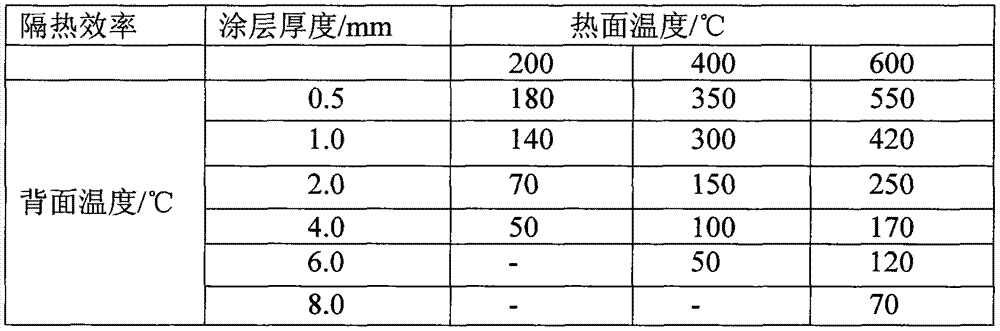

Corrosion resistant water permeable brick

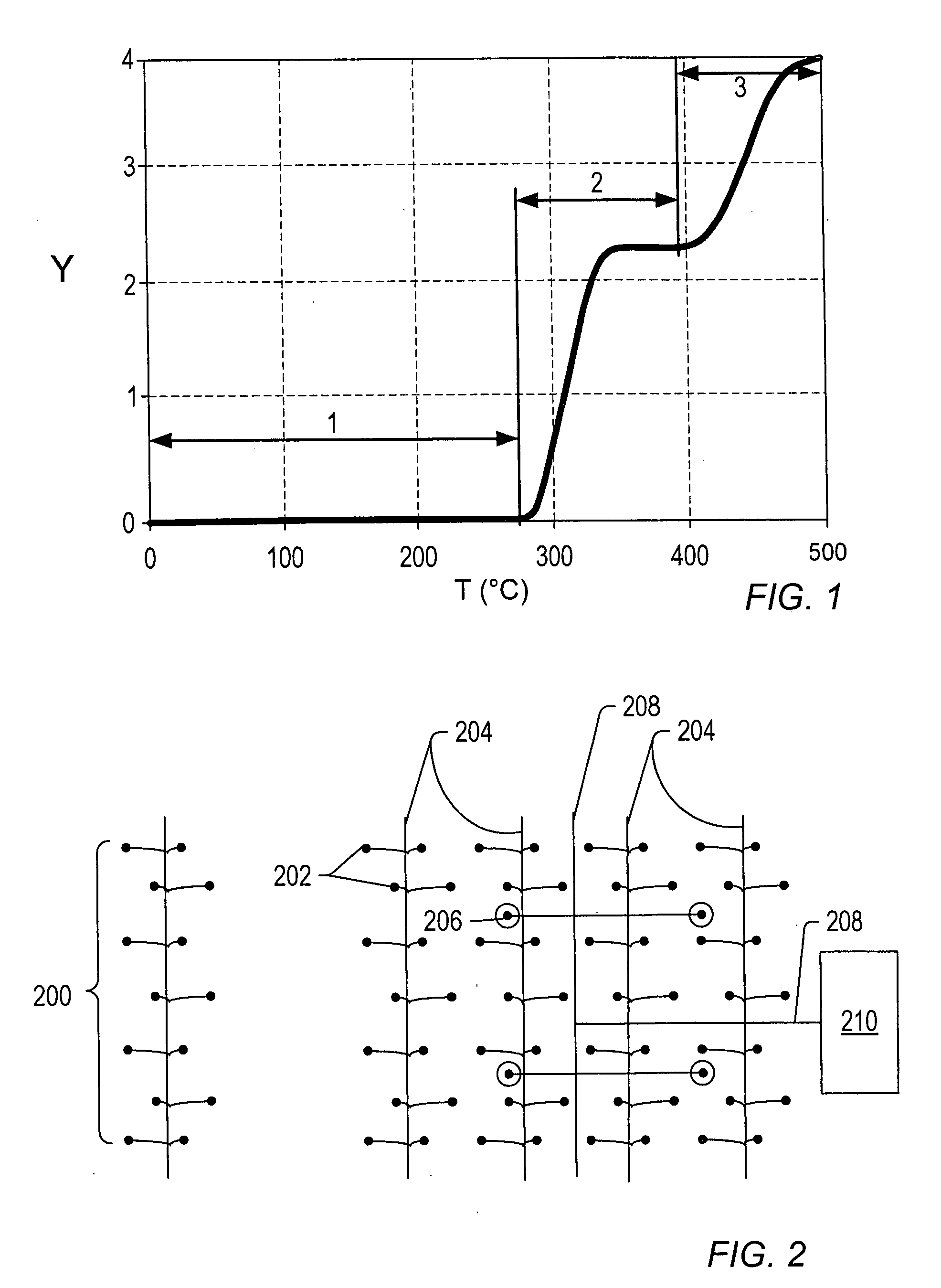

ActiveCN105016765AHigh permeability coefficientHigh compressive strengthCeramicwareCompressive resistanceBrick

The present invention relates to a corrosion resistant water permeable brick, and belongs to the technical field of building materials. The corrosion corrosion resistant water permeable brick comprises 20-25wt% of Portland cement, 1.0-1.2wt% of anhydrite powder, 15.0-20.0wt% of slag pellets, 10-12wt % of cenospheres, 1.5-2.1wt% of admixtures, and the balance of quartz sand. Under the premise that the porosity and water permeability coefficient of the corrosion resistant water permeable brick are significantly higher than that of a water permeable brick, the compressive strength of the corrosion resistant water permeable brick is still higher than that of the conventional water permeable brick, the corrosion resistant water permeable brick has good corrosion resistance, and service life is significantly increased.

Owner:江苏溧阳建设集团有限公司

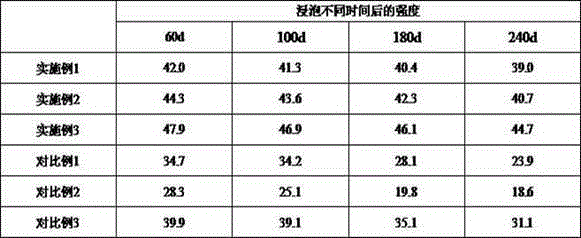

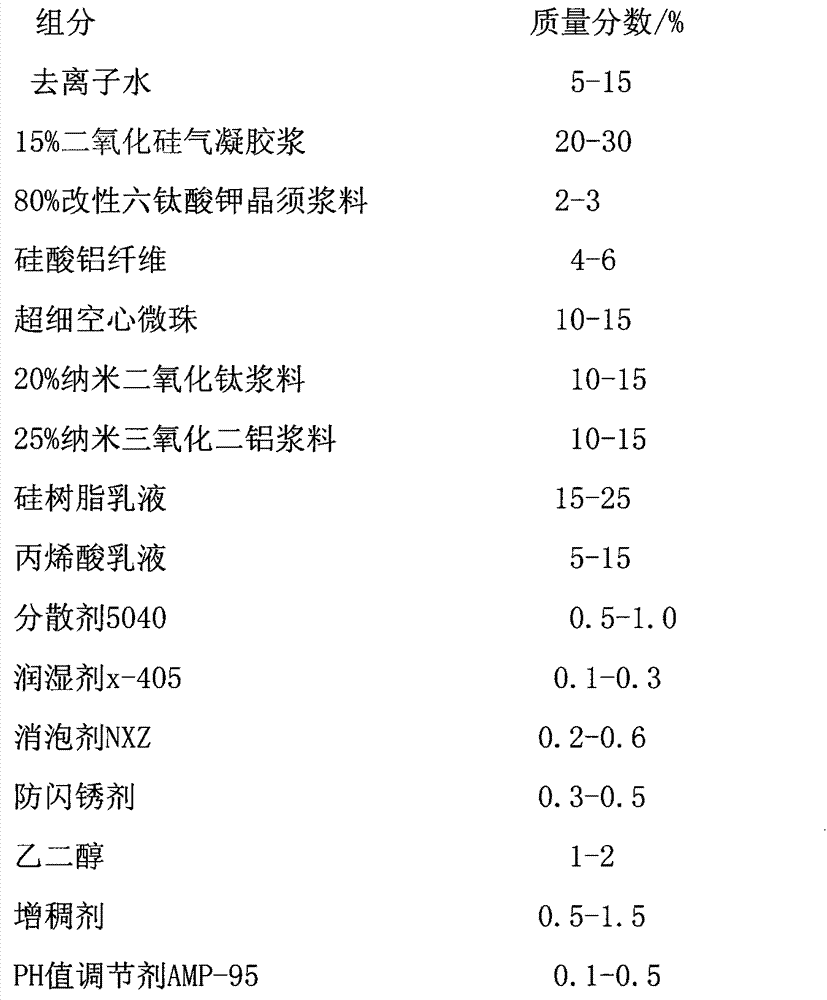

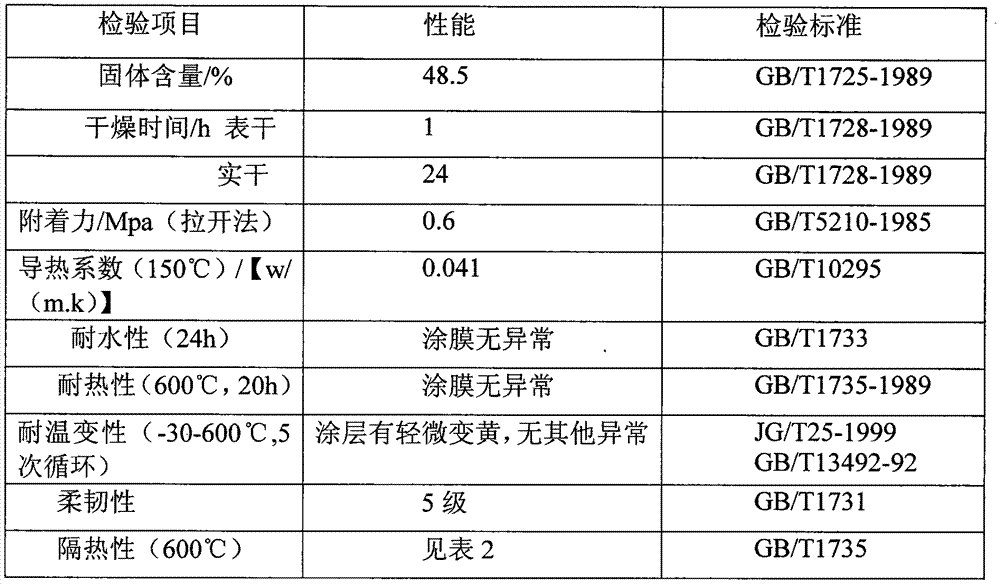

Nanometer high temperature resistant thermal insulation and prevention coating

The invention discloses a nanometer high temperature resistant thermal insulation and prevention coating. SiO2 aerogel, modified potassium hexatitanate whisker, aluminum silicate fiber, ultra-fine cenosphere, nanometer TiO2 and nanometer Al2O3 are used as a thermal insulation filler. A vacuum thermal insulation layer is formed by nano porous structures of SiO2 aerogel and cenosphere. The aluminum silicate fiber is used as a reinforcing and toughening material. The infrared shading performance of potassium hexatitanate whisker, nanometer TiO2 and nanometer Al2O3 are used as a thermal radiation shielding layer. A silicon resin emulsion and an acrylic emulsion are compounded to be an adhesive. Therefore, the nanometer 600 DEG C temperature resistant thermal insulation and prevention coating is prepared with matching of a variety of functional additives. The nanometer high temperature resistant thermal insulation and prevention coating has the characteristics of scumbling, thermal insulation, waterproofing, anti-crack, anti-corrosion, high temperature resistance, weather-proofing, durability and the like and is applicable to the field of industrial high temperature resistant thermal insulation energy conservation.

Owner:株洲中铁中南制造有限公司

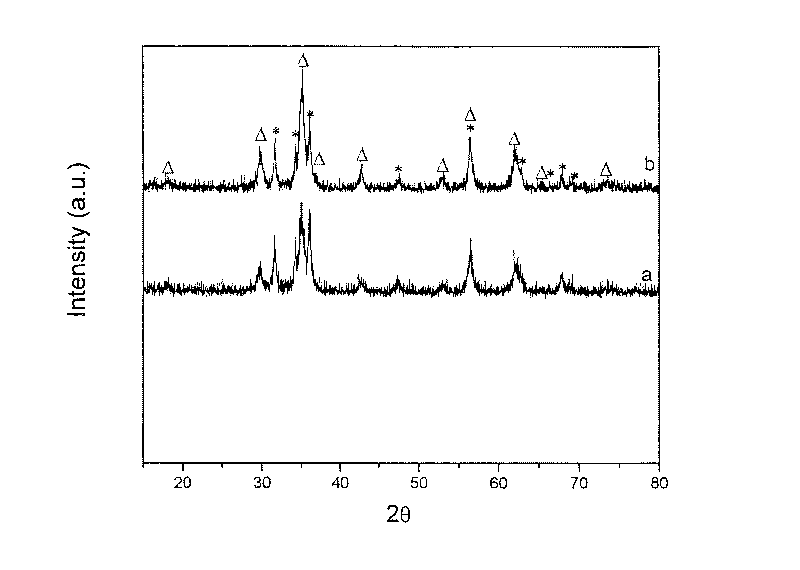

Multi-shell-layer metal oxide hollow ball and preparation method thereof

ActiveCN102464304AHigh specific surface areaSimple processOxide/hydroxide preparationZinc oxides/hydroxidesControllabilityNanoscopic scale

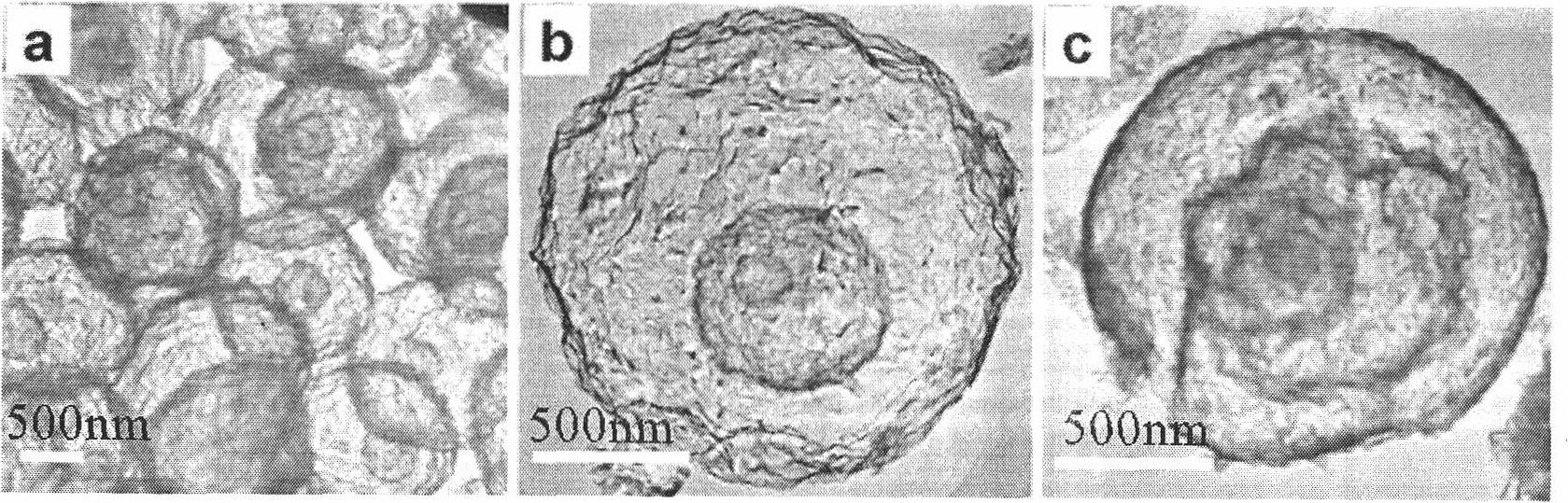

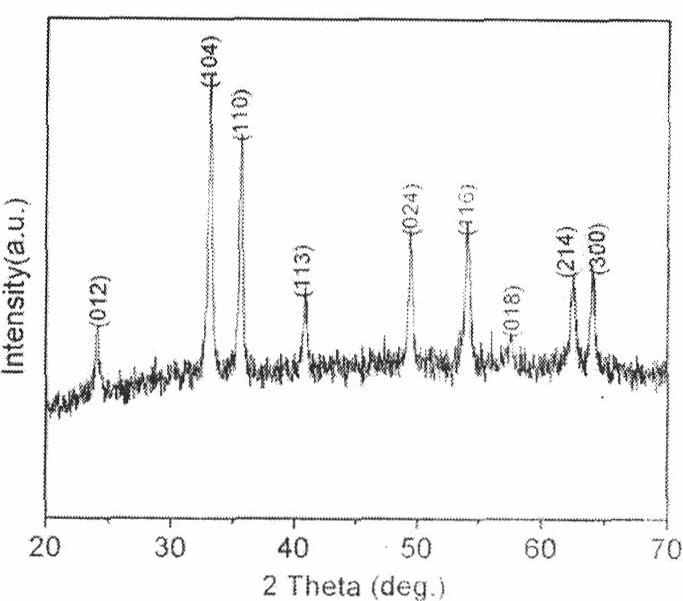

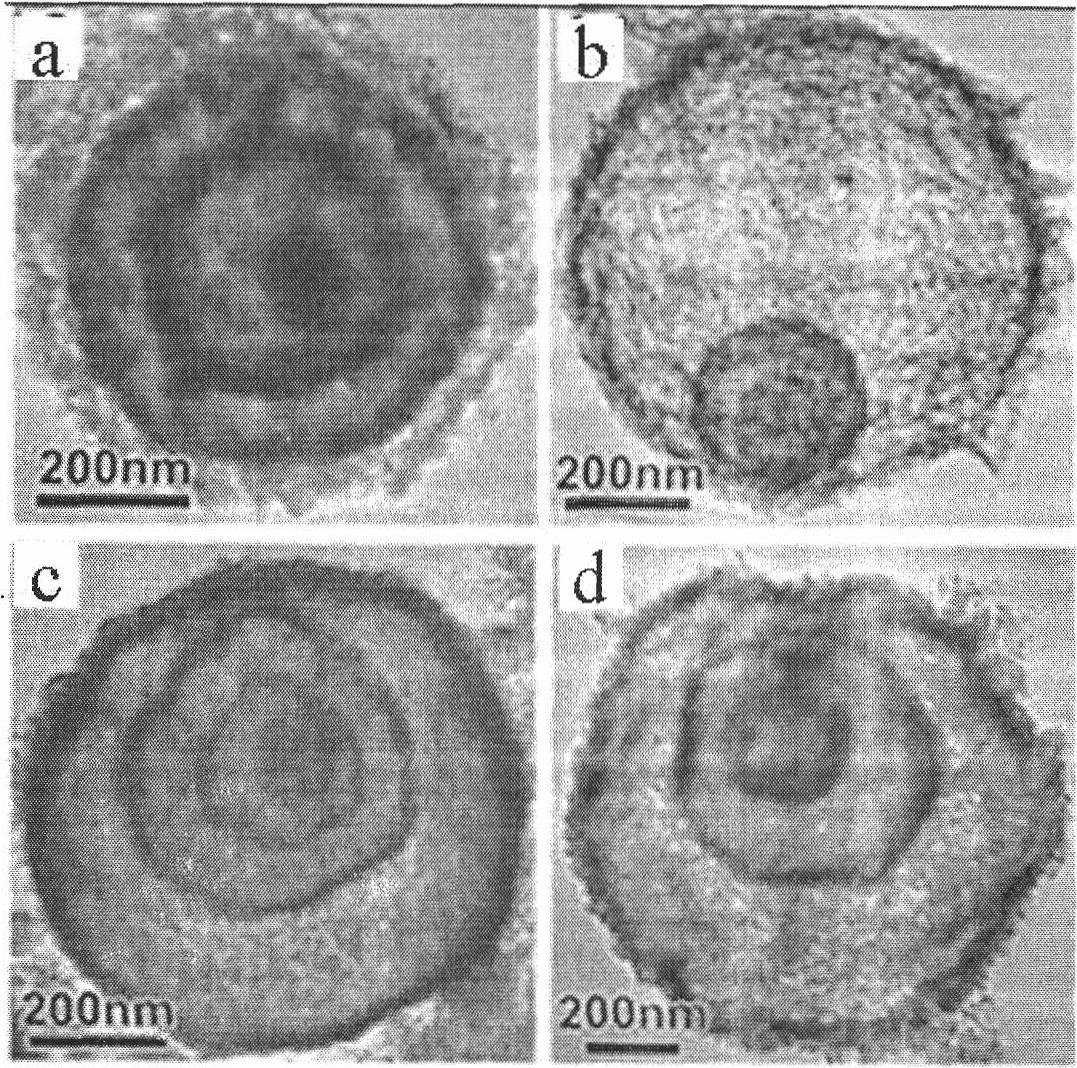

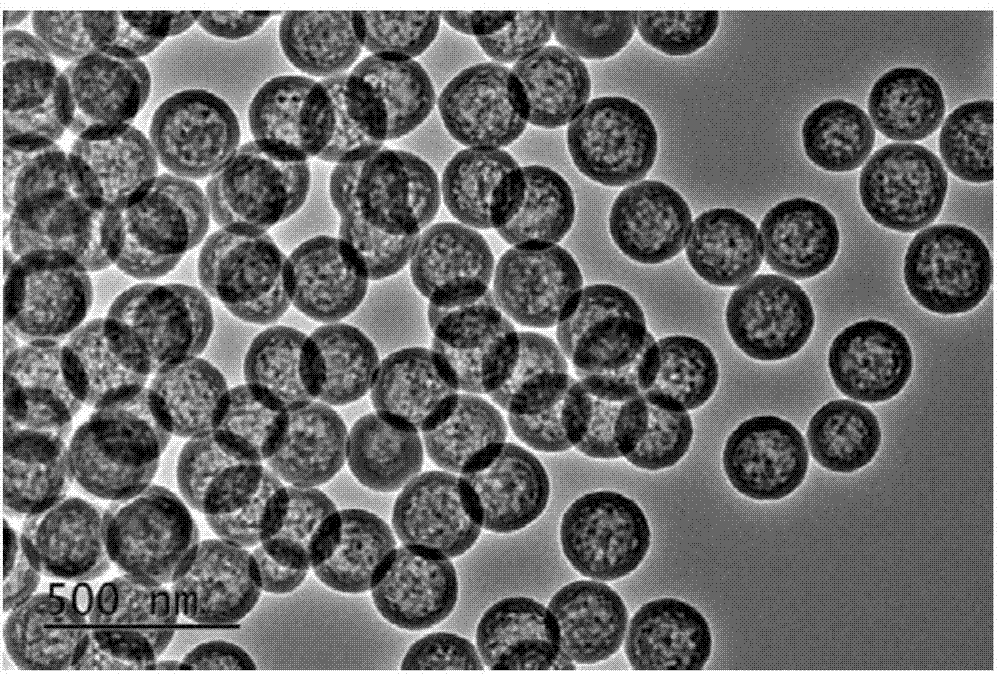

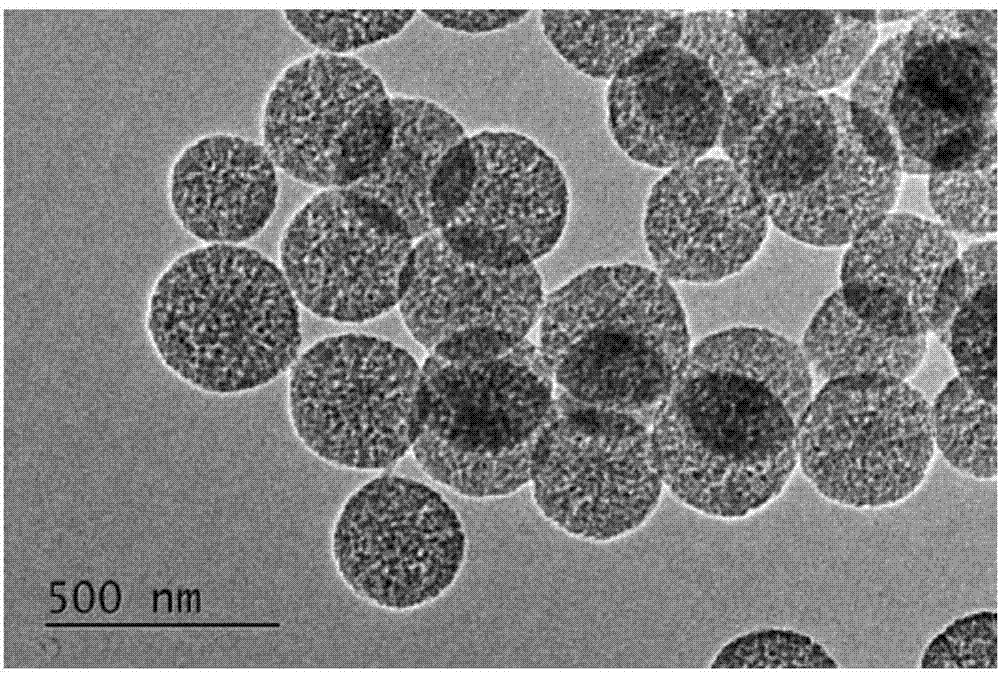

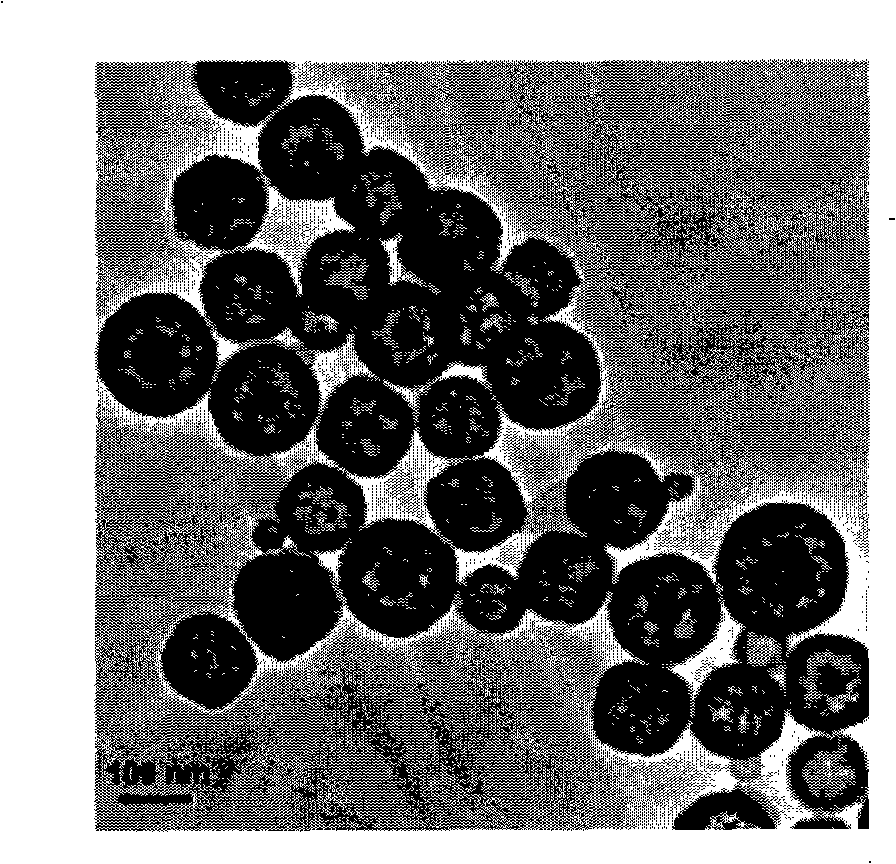

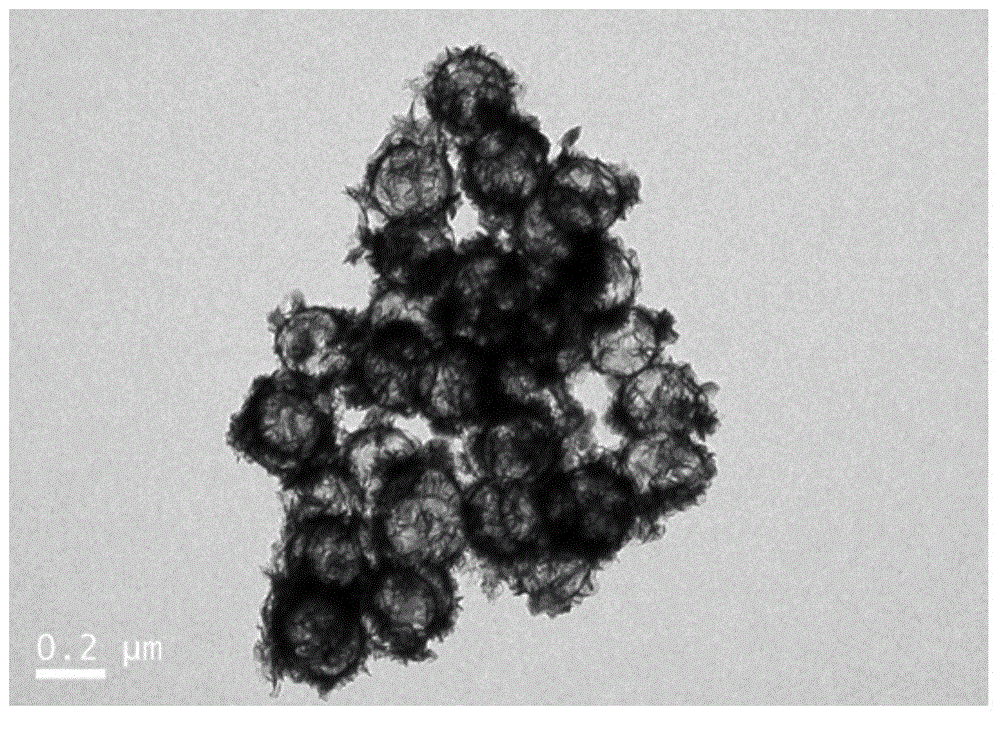

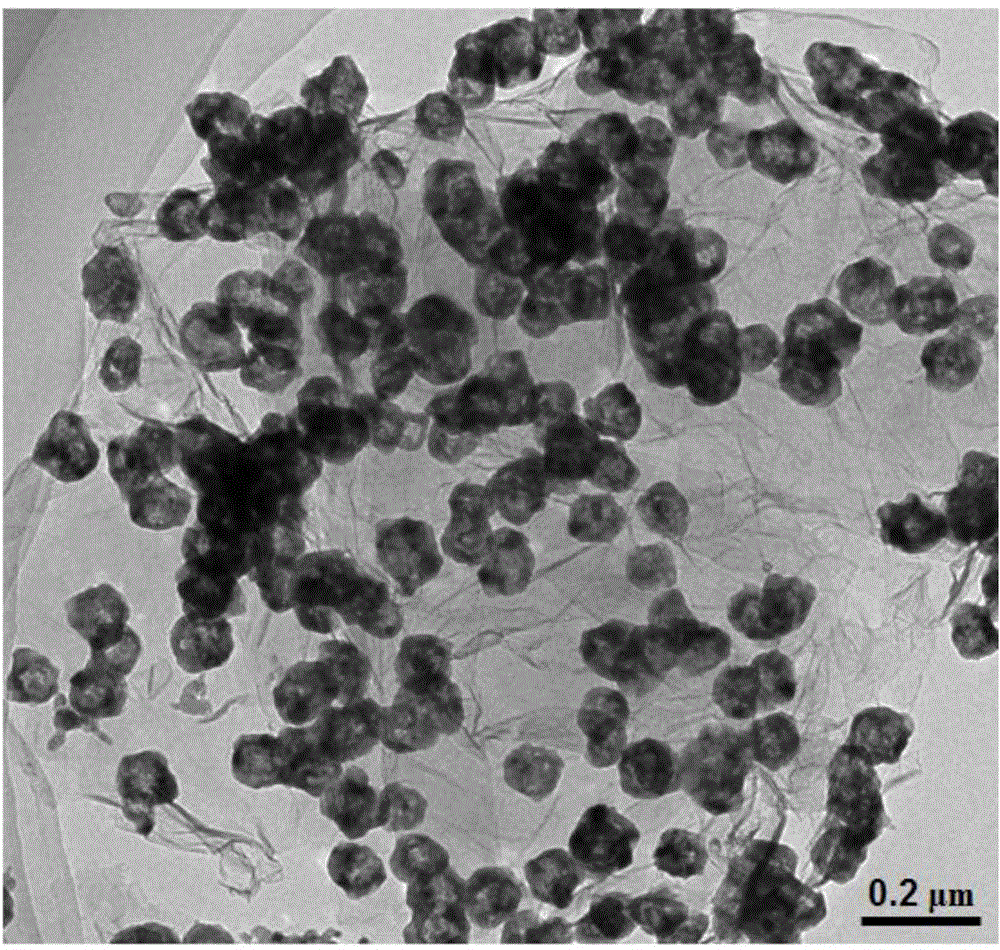

The invention provides a multi-shell-layer metal oxide hollow ball and a preparation method thereof. A hydrothermal method is used for preparing a carbon ball template; metal salts are dissolved in carbon ball suspension liquid, and the gradient distribution, the depth and the number of metal salts entering carbon balls are controlled through regulating adsorption conditions such as metal salt concentration, solution pH value, soaking temperature and time and the like; and the heat treatment is carried out on the carbon balls adsorbing metal ions, and the multi-shell-layer metal oxide hollow ball can be obtained. The shell-layer of the hollow ball prepared by the method is formed by accumulating nanometer crystal particles of metal oxides, the shell layer number can be regulated and changed from two to four, and both the size of the hollow ball and the thickness of the shell layers are controllable. The method provided by the invention is simple and is easy to implement, the controllability is high, the pollution is little, the cost is low, and in addition, the general applicability is realized. The prepared product has a hollow structure and the shell layers with the thickness inthe nanometer level, simultaneously, the internal space can be effectively utilized through the multilayer structure, and the multi-shell-layer metal oxide hollow ball is applied to gas sensitivity and photocatalysis and has the more excellent performance through being compared with the traditional nanometer material and a single-layer hollow ball.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Single-layer and multi-layer hollow carbon nanosphere and preparation method and application thereof

ActiveCN104843665AEasy to operateMild reaction conditionsMaterial nanotechnologySolubilityIn situ polymerization

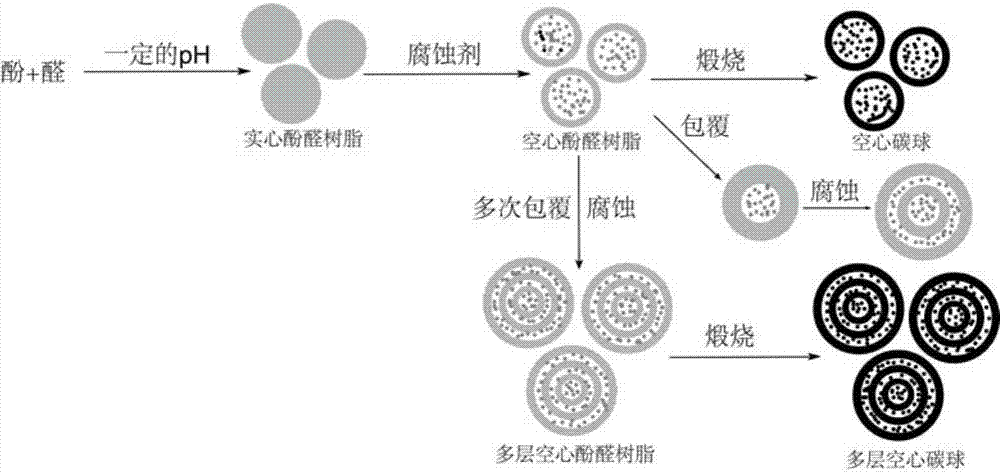

The invention discovers and proposes a characteristic that interior species of phenolic resin are nonuniform in distribution in a polymerization process, and discloses a method for preparing a hollow carbon sphere by utilizing the characteristic of phenolic resin. The method comprises: (1) putting phenol into water or a solvent, adjusting the pH, then adding aldehyde and stirring at a certain temperature for a period of time; (2) adding a corrosive agent in a reaction system, stirring at a certain temperature, and selectively removing a part with a relatively low polymerization degree inside a polymer by utilizing a solubility difference of interior species for different solvents, to obtain an intermediate product, that is, a hollow sphere of phenolic resin polymer; and (3) calcining the intermediate product that is obtained in step (2) in an inertia or reducing atmosphere, naturally cooling to room temperature, and thus completing preparation of the hollow carbon sphere. The method is simple and practicable, and the prepared hollow carbon sphere is uniform in shape and controllable in dimension. Moreover, by utilizing a characteristic that the phenolic resin can be in-situ polymerized on surfaces of different nanometer particles, on one hand, a multi-layer hollow structure can be prepared in a multi-cladding and layer-by-layer corrosion manner, and on the other hand, the different nanometer particles can also be packaged in a cavity in an in-situ mode, so as to prepare a nuclear shell or egg yolk-nuclear structure. The prepared hollow carbon sphere has a potential application value in aspects of silicon-carbon negative electrode material, Li-S battery, supercapacitor, heavy metal ion adsorption, and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

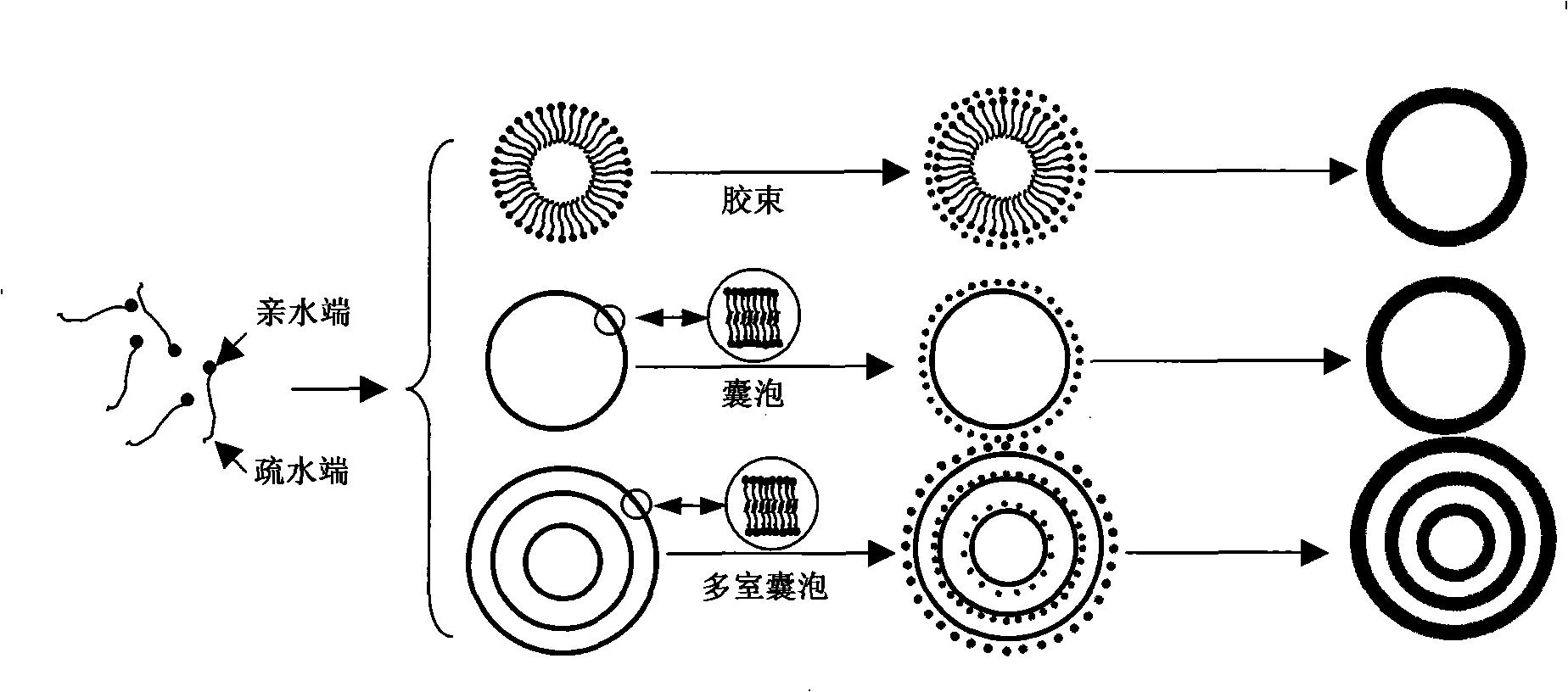

Method for producing multi-layer hollow pellet or stephanoporate pellet with multi-chamber vesicle mould plate method

InactiveCN101293192AEasy to makeControllable structureMicroballoon preparationMicrocapsule preparationActive agentSingle crystal

The present invention relates to a hollow sphere or porous sphere preparation method through vesicle and multi-chamber vesicle template method. The preparation method is characterized in that a surface active agent forms vesicle and multi-chamber as the soft template under certain conditions; inorganic material carries out nucleus growth on the surface of the soft template so as to copy the shape of the vesicle and multi-chamber vesicle and obtain a single-layer hollow sphere and multi-layer hollow sphere structure; due to different growing ways of crystal, the formed hollow sphere can be single crystal, polycrystal or multiaperture. The surface active agent is anion surface active agent, cation active agent or a mixer of the two surface active agents. The deposited inorganic material includes oxide, sulfide, simple metal substance, selenide, hydroxid or inorganic salts, which form core and grow on the surface of the vesicle and multi-chamber vesicle and finally obtain the single-layer and multi-layer hollow sphere structure and the porous sphere structure. Cu2O and ZnS hollow sphere or porous sphere is taken as the embodiment for detailed description.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Emulsion containing organosilicon-based portions of hollow spheres

The present invention relates to a composition in the form of an emulsion containing portions of hollow spheres of organosilicon-based material, the portions of hollow spheres having a mean diameter ranging from 0.05 to 10 μm. The invention also relates to physiologically acceptable emulsion compositions comprising hollow spheres, and to a process for fading out skin surface defects, in particular to reduce the sheen of the skin and / or to fade out pores, shadows under the eyes, marks, wrinkles and / or fine lines, comprising the topical application to the skin of the above-mentioned compositions.

Owner:LOREAL SA

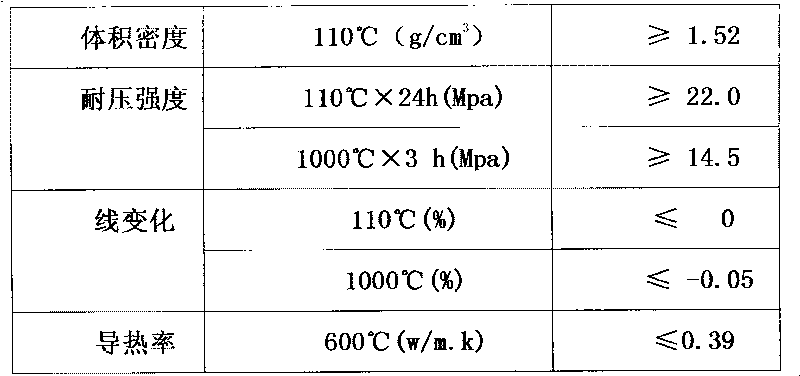

Exterior wall composite insulation heat-proof plastering material

InactiveCN101229970ARealize resource utilizationImprove protectionSolid waste managementFiberResource utilization

The invention relates to compound thermal insulation plastering material for external wall, which consists of a compound cementing material and a lightweight aggregate. The compound cementing material consists of cement, active admixture, lime powder, promoter, surfactant, anti-crack and waterproof agent, water retaining agent, flame retardant, re-dispersible emulsion powder, alkali-resistance fiber and coal flying ash cenosphere; the lightweight aggregate consists of EPS grain and expanded perlite. The invention has the advantages of low density, thermal performance, high strength, good impact resistance, bond strength and low shrinkage. The compound cementing material adopts a plurality of polymeric cementing materials, allows the insulation material to have good bond performance and simultaneously ensures falling and slipping resistance performance. The invention has good water resistance and high softening coefficient. By using cement-based cementing material as main material and organic reinforced material and waterproof component as auxiliary materials, the invention has a hydrophobic rate more than 98 percent and a softening coefficient more than 0.7. The invention can save energy and protect environment. A great deal of industrial waste residue is used in the materials, which can save a great number of energy, realize resource utilization of the waste residue and is in favor of environmental protection.

Owner:SHANGHAI TONGBIAO INSULATION TECH

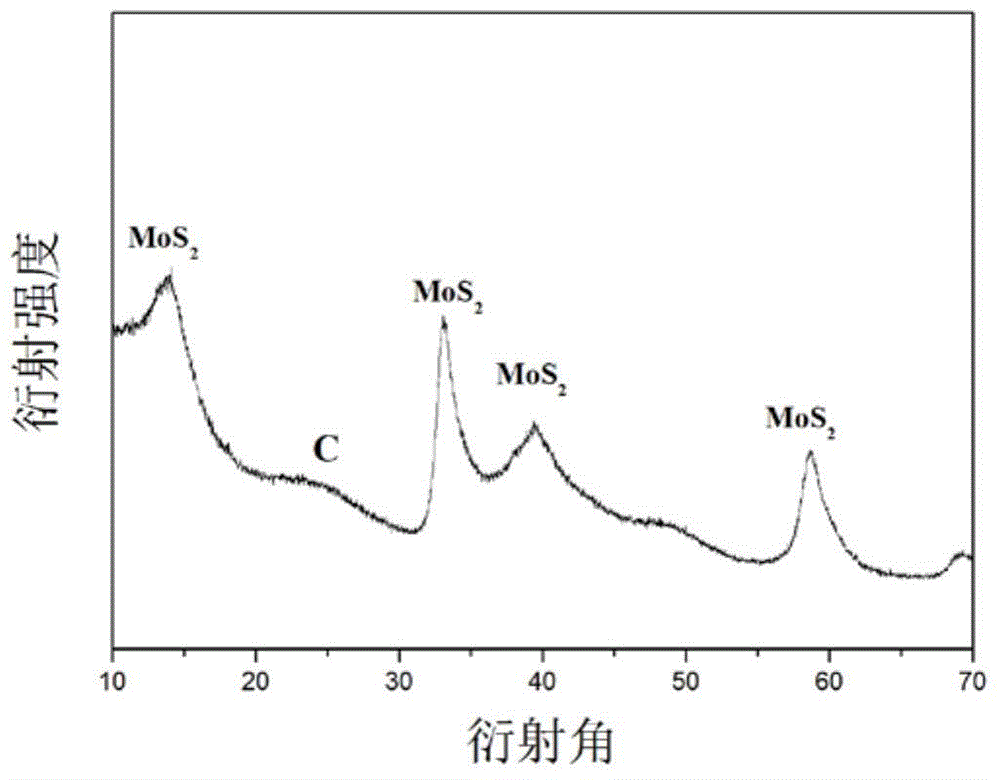

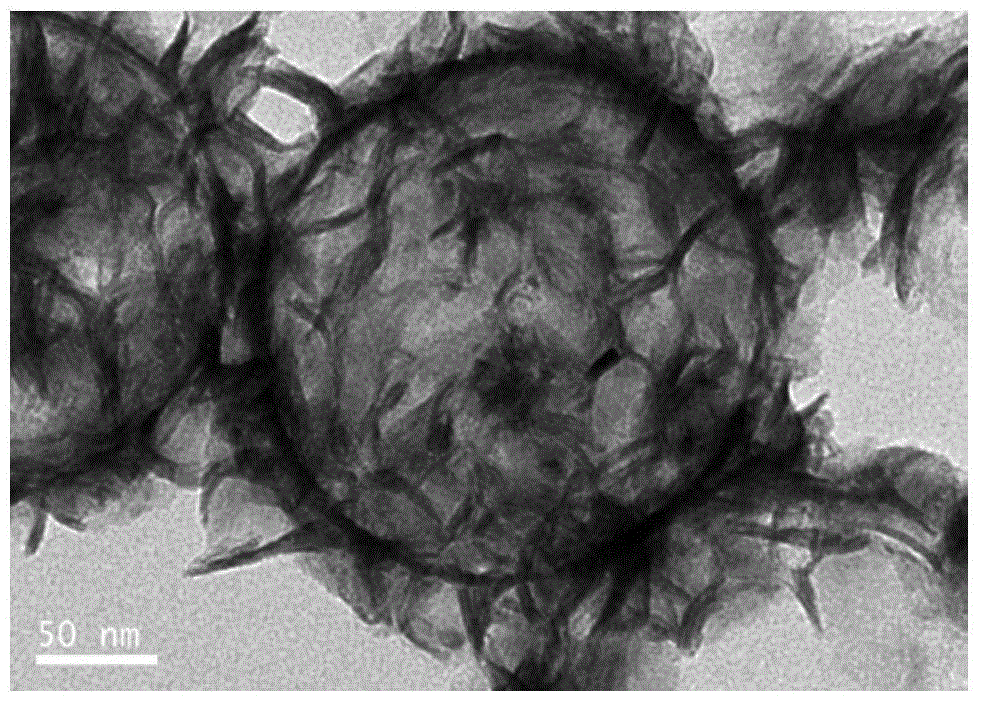

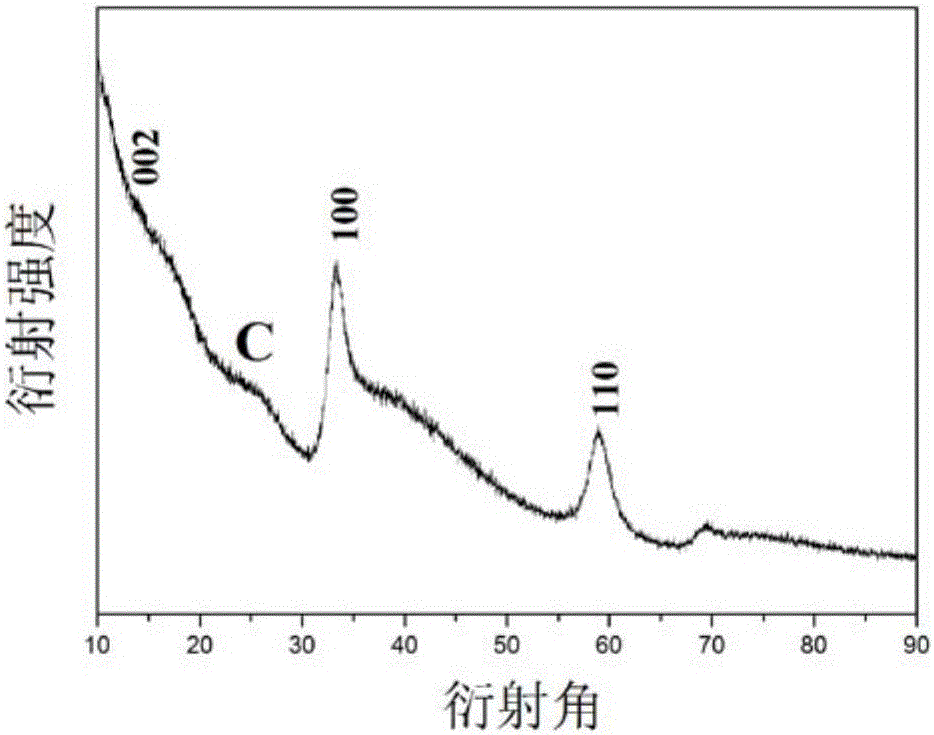

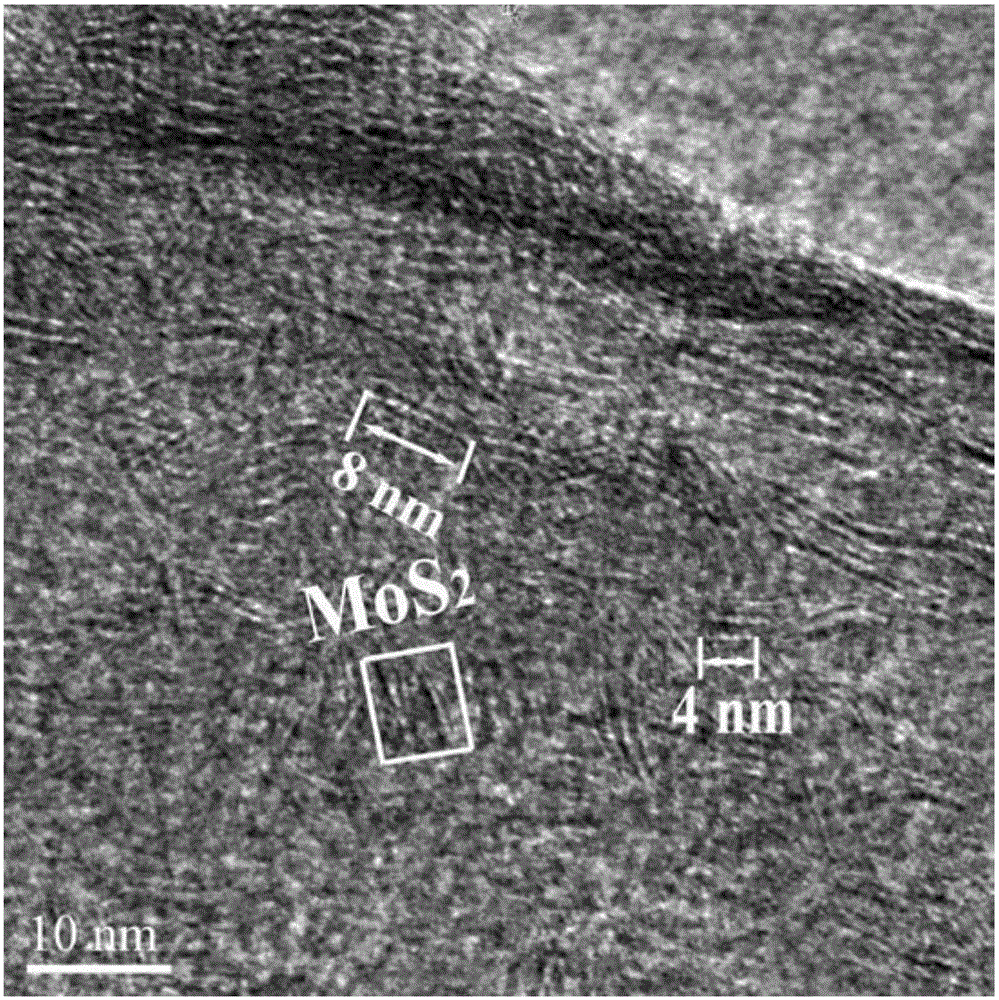

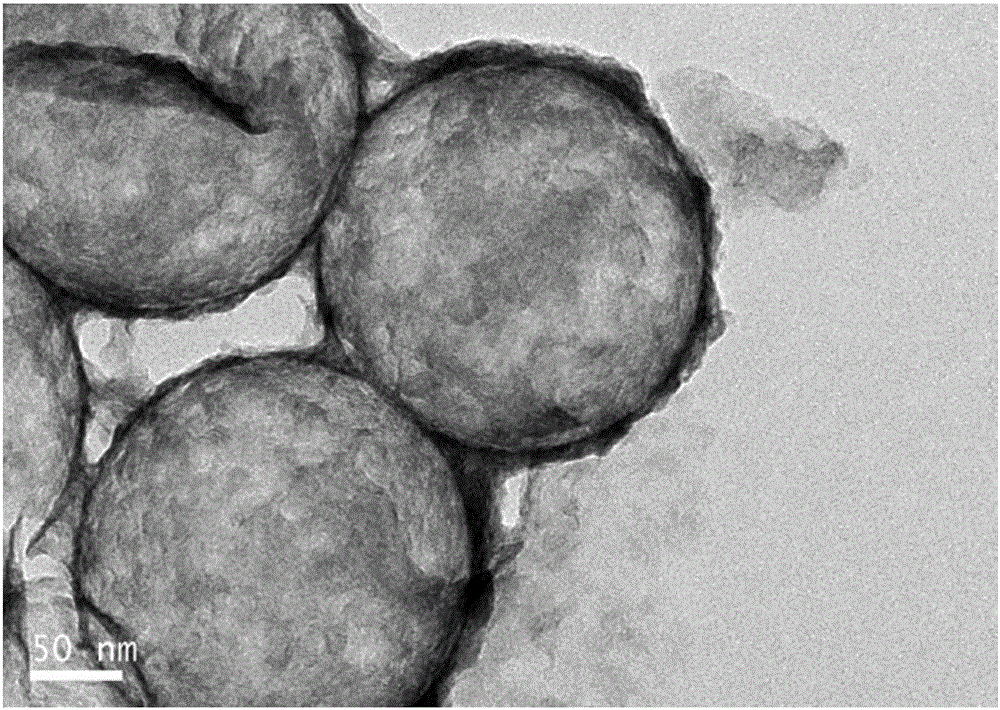

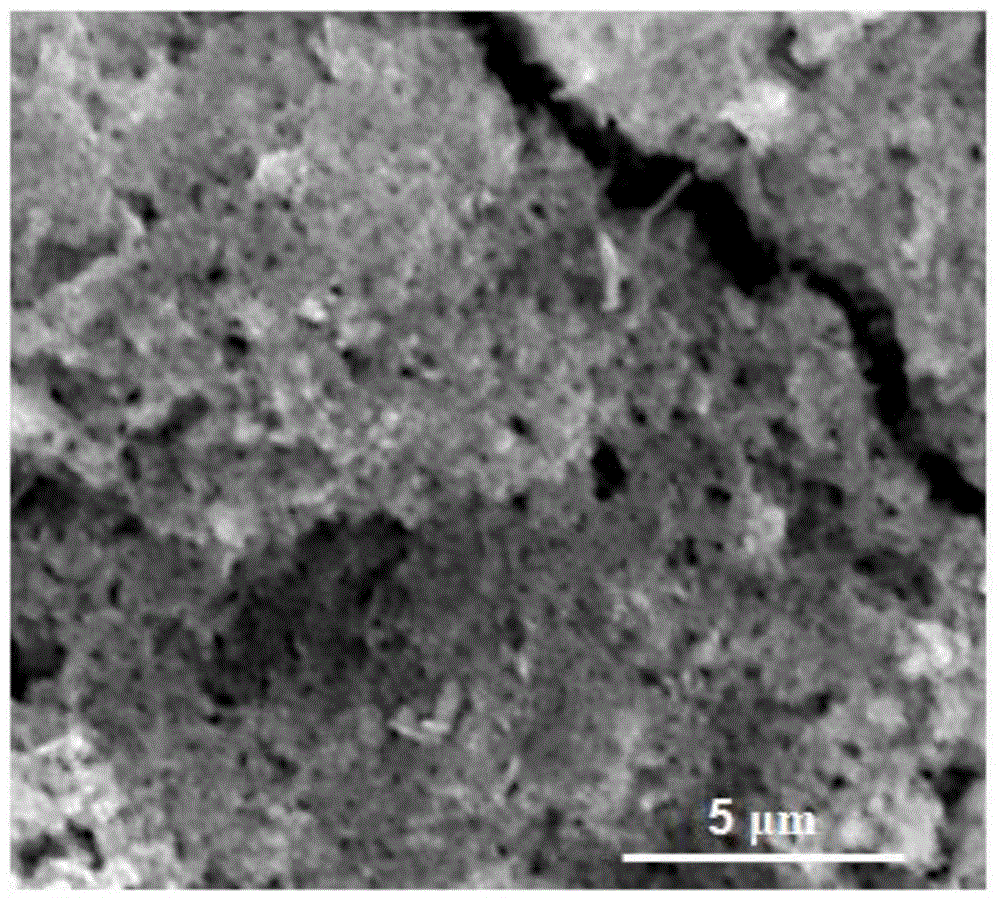

Molybdenum disulfide/carbon composite material and preparation method thereof

InactiveCN104934602AImprove poor conductivityNot easy to reuniteCell electrodesSecondary cellsCarbon compositesCarbonization

The invention discloses a molybdenum disulfide / carbon composite material. The molybdenum disulfide / carbon composite material comprises a molybdenum disulfide layer and a carbon hollow ball, wherein the molybdenum disulfide layer is positioned outside the carbon hollow ball; and the carbon hollow ball has a hollow structure. The invention also discloses a preparation method of the molybdenum disulfide / carbon composite material. The preparation method comprises the following steps of using amino modified silica spheres as a template; wrapping the template by pyrolyzation of an organic carbon source; performing thermal reaction on the template and ammonium tetrathiomolybdate through solvent; performing high-temperature carbonization in an inert atmosphere; and removing the silicon oxide template to obtain the molybdenum disulfide / carbon composite material. The lithium-intercalation capacity of the molybdenum disulfide / carbon composite material is 1467mAh / g for the first time, and the specific capacity of the molybdenum disulfide / carbon composite material can be kept at 733mAh / g after 30 times of repeated charging and discharging cycles.

Owner:SHANGHAI JIAO TONG UNIV

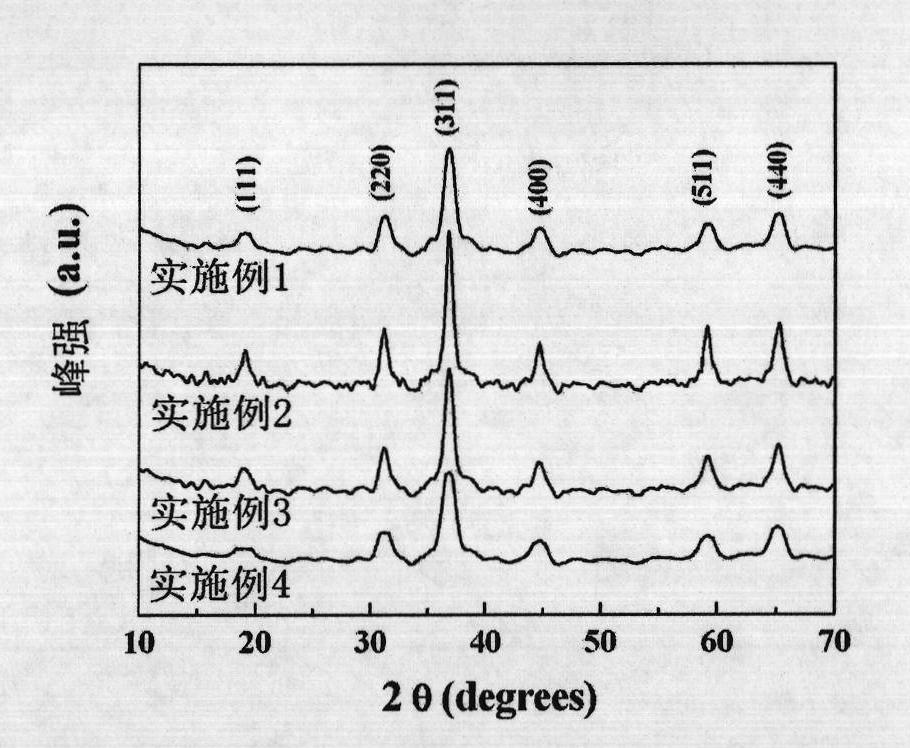

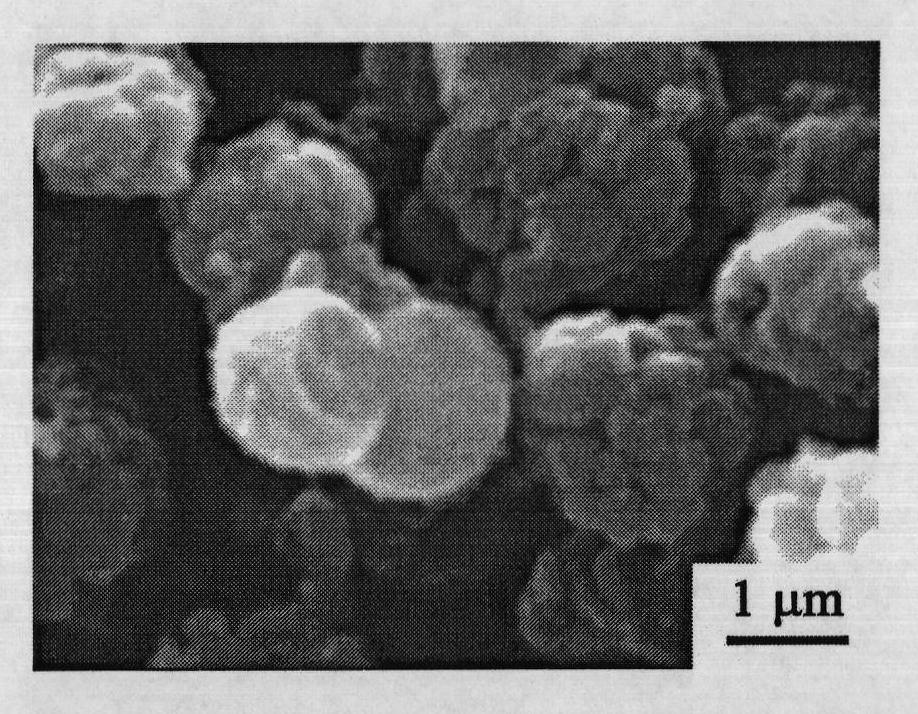

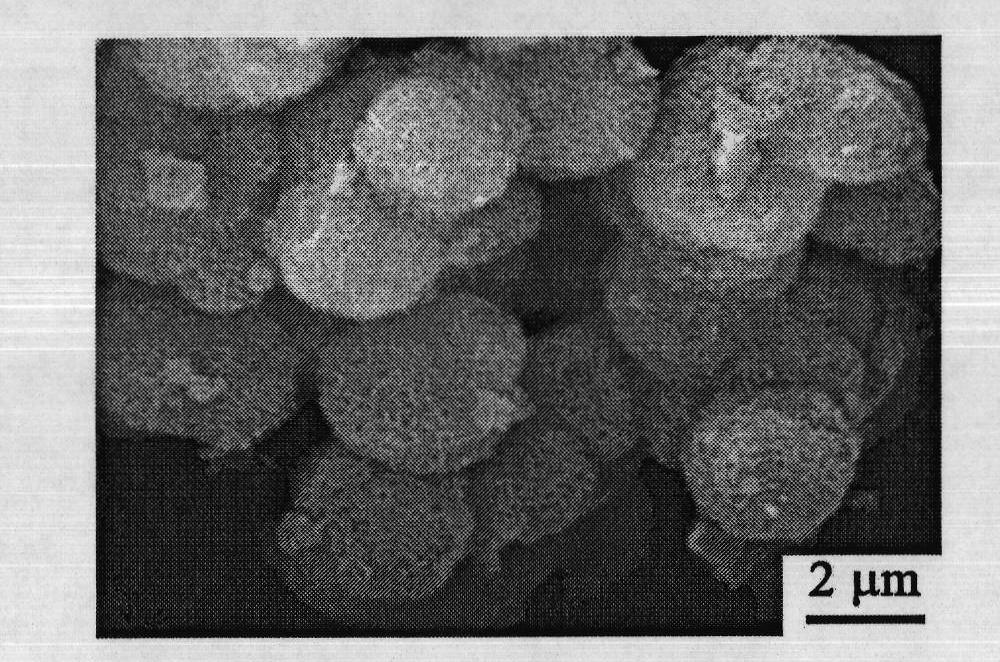

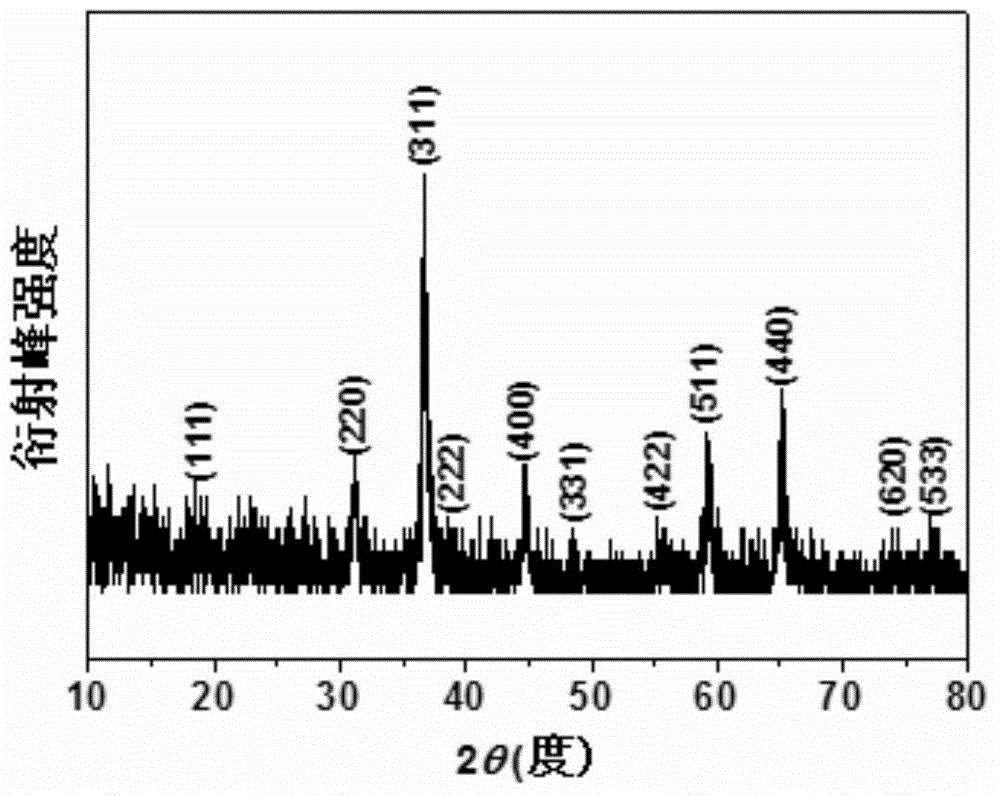

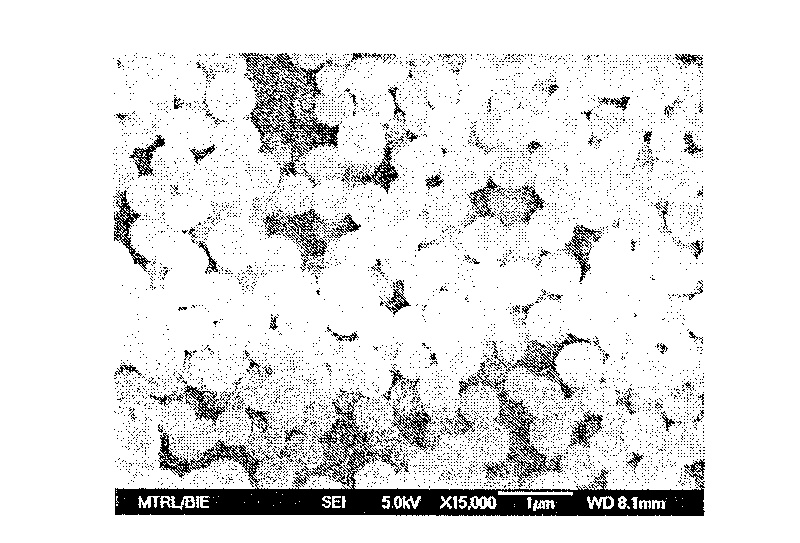

Co3O4 nano hollow sphere material and preparation method and application thereof

InactiveCN101863518AGood electrochemical behaviorGood intercalation/extraction electrochemical behaviorCell electrodesCobalt oxides/hydroxidesElectrochemistrySurface-active agents

The invention provides a Co3O4 nano hollow sphere material and a preparation method and the application thereof. The preparation method of the Co3O4 nano hollow sphere material comprises the following steps of: mixing cobalt salt, surface active agent, precipitant with water according to stoichiometric ratio; putting mixed solution into a reaction kettle to perform hydro-thermal reaction, washing and drying to obtain a powdered mixed precursor; and heat treating the precursor in air to finally obtain the Co3O4 nano hollow sphere material. The obtained Co3O4 nano hollow sphere material has a regular surface nano piece layer and an internal hollow network structure, has a better electrochemical behavior, can be used for a cathode of a rechargeable lithium ion battery, can guarantee the electrolyte to be sufficiently permeated, can provide more electric active points with an increased contact surface, guarantees the lithium ion to better perform an embedding / withdrawing electrochemical behavior, enlargers the specific surface area, and improves the lithium storage capability. The internal network structure also shortens the reaction path of the lithium ion, i.e. shortens the conduction path of the e-and the Li+, thereby improving the characteristic of multiplying power.

Owner:SHANGHAI INSTITUTE OF TECHNOLOGY

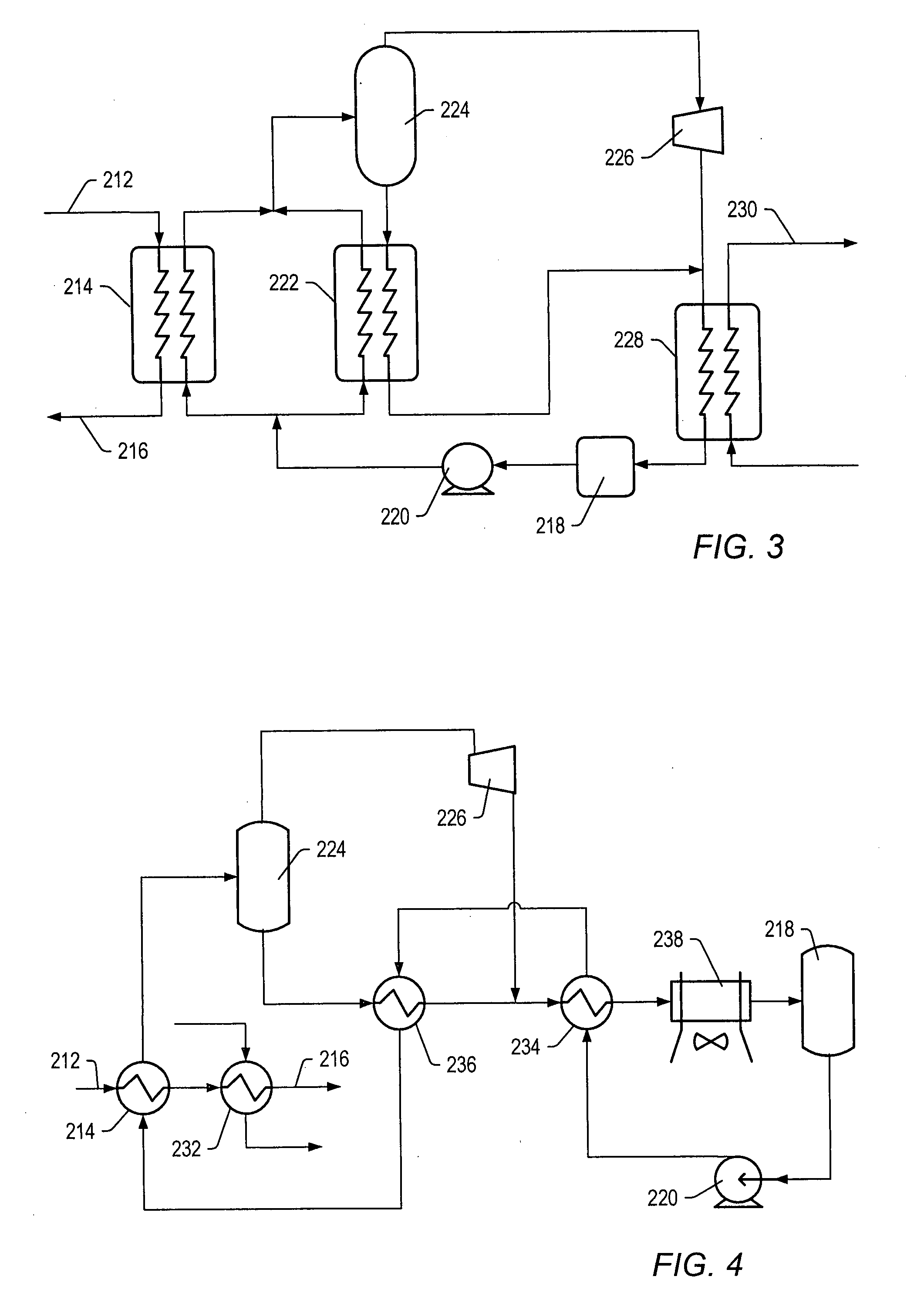

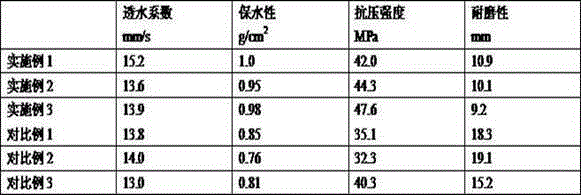

Foams Made of Amorphous Hollow Spheres and Methods of Manufacture Thereof

ActiveUS20120241073A1Minimizes pressure differentialImprove bindingDecorative surface effectsWood working apparatusVitrificationConfined space

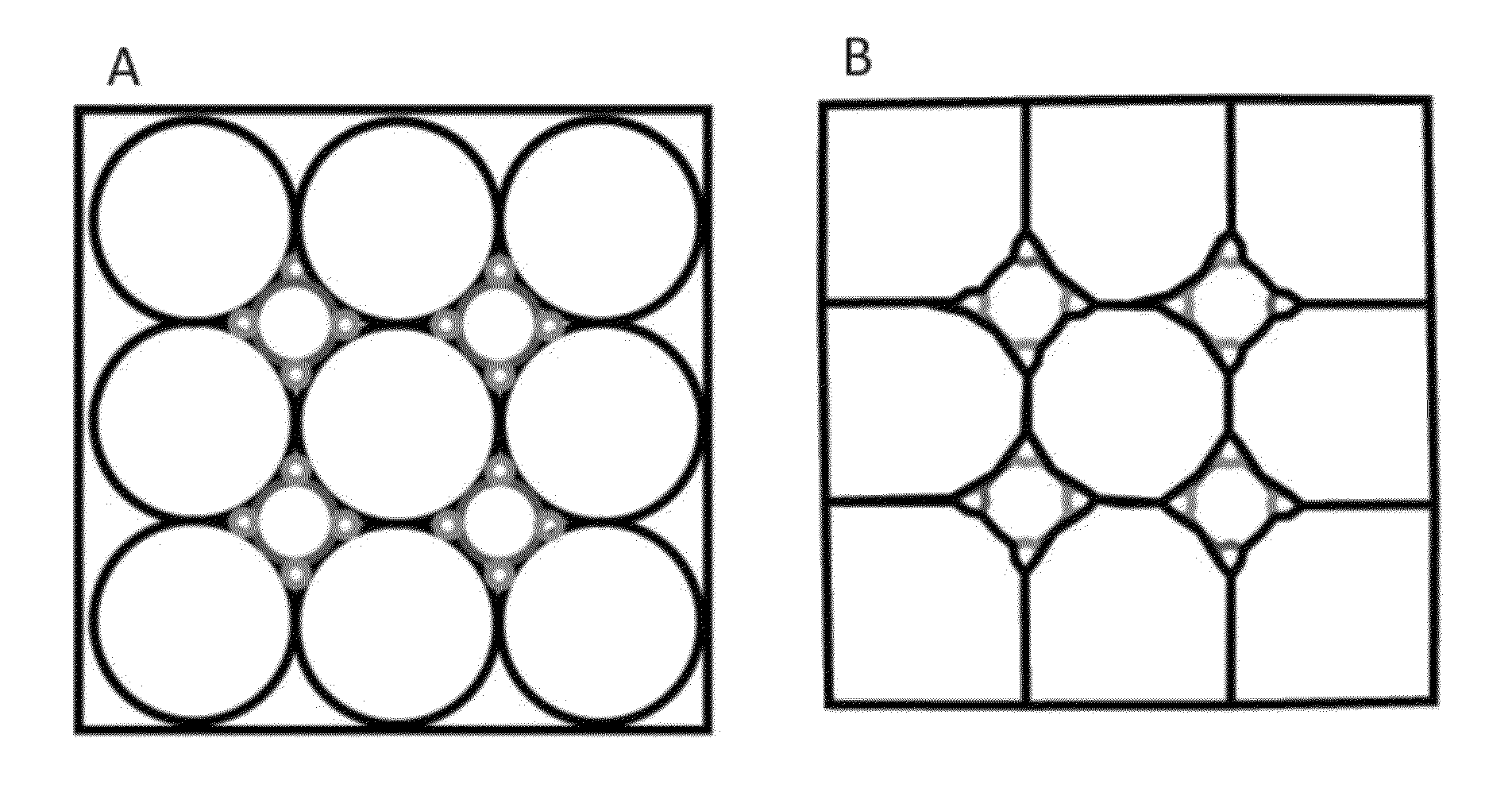

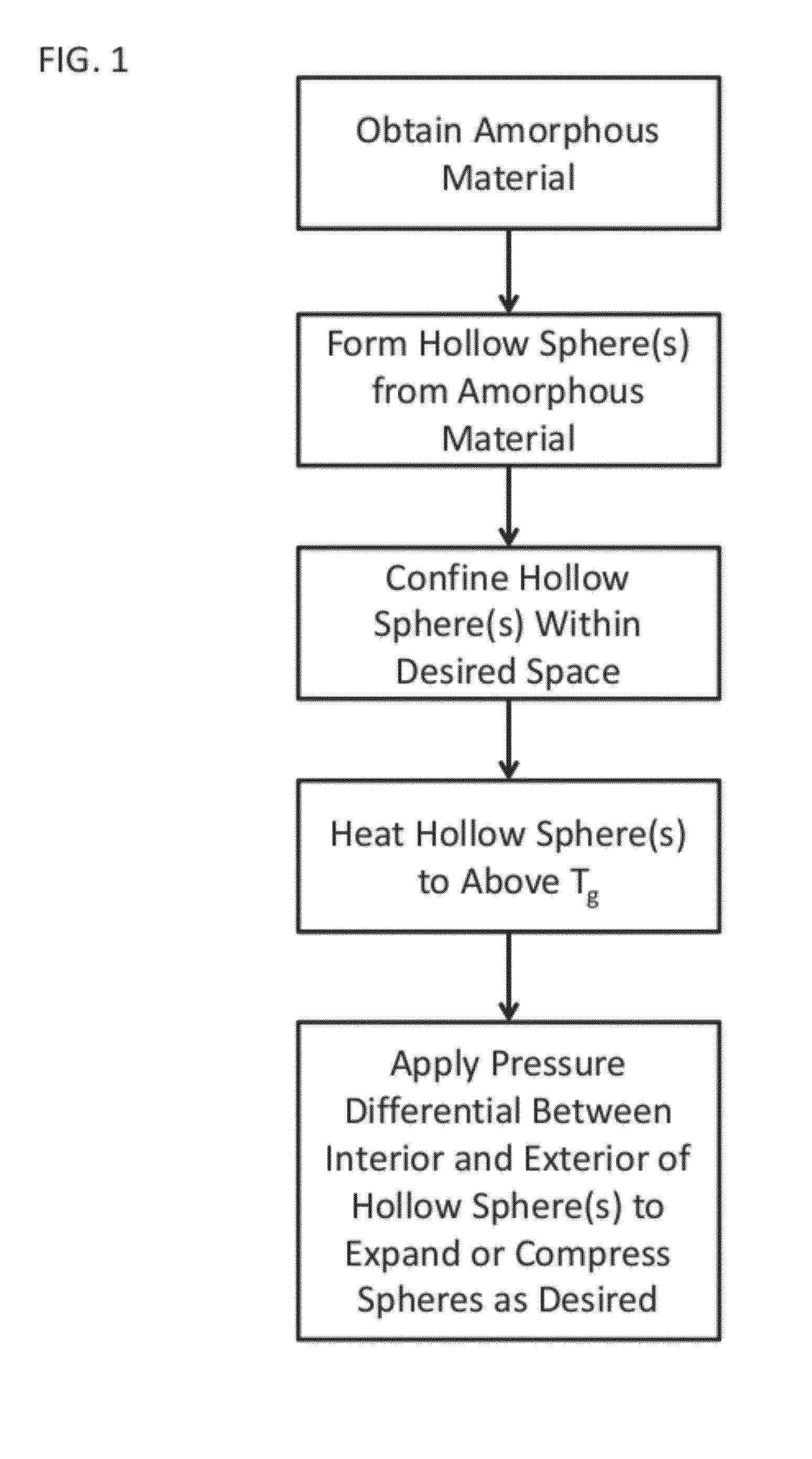

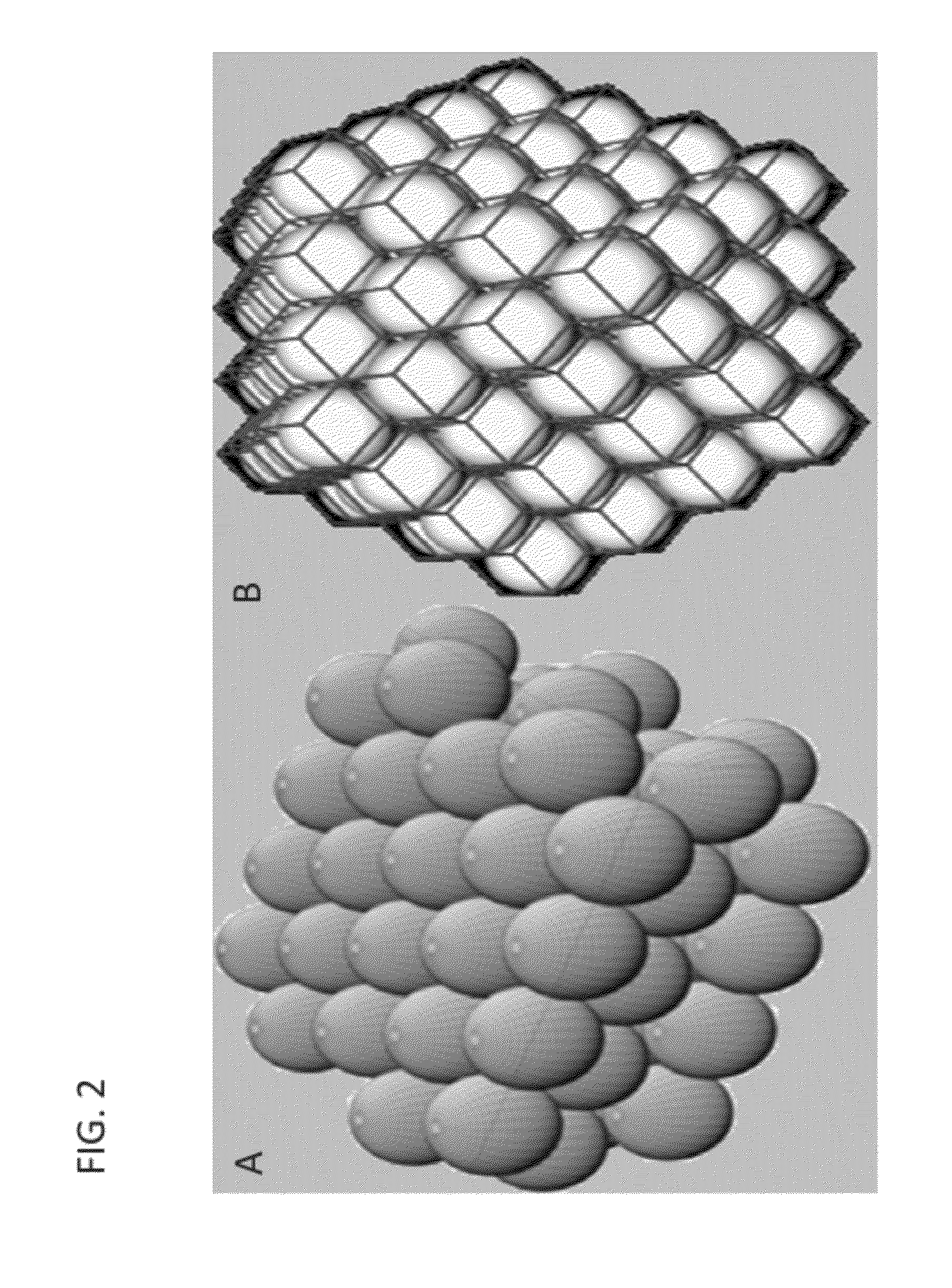

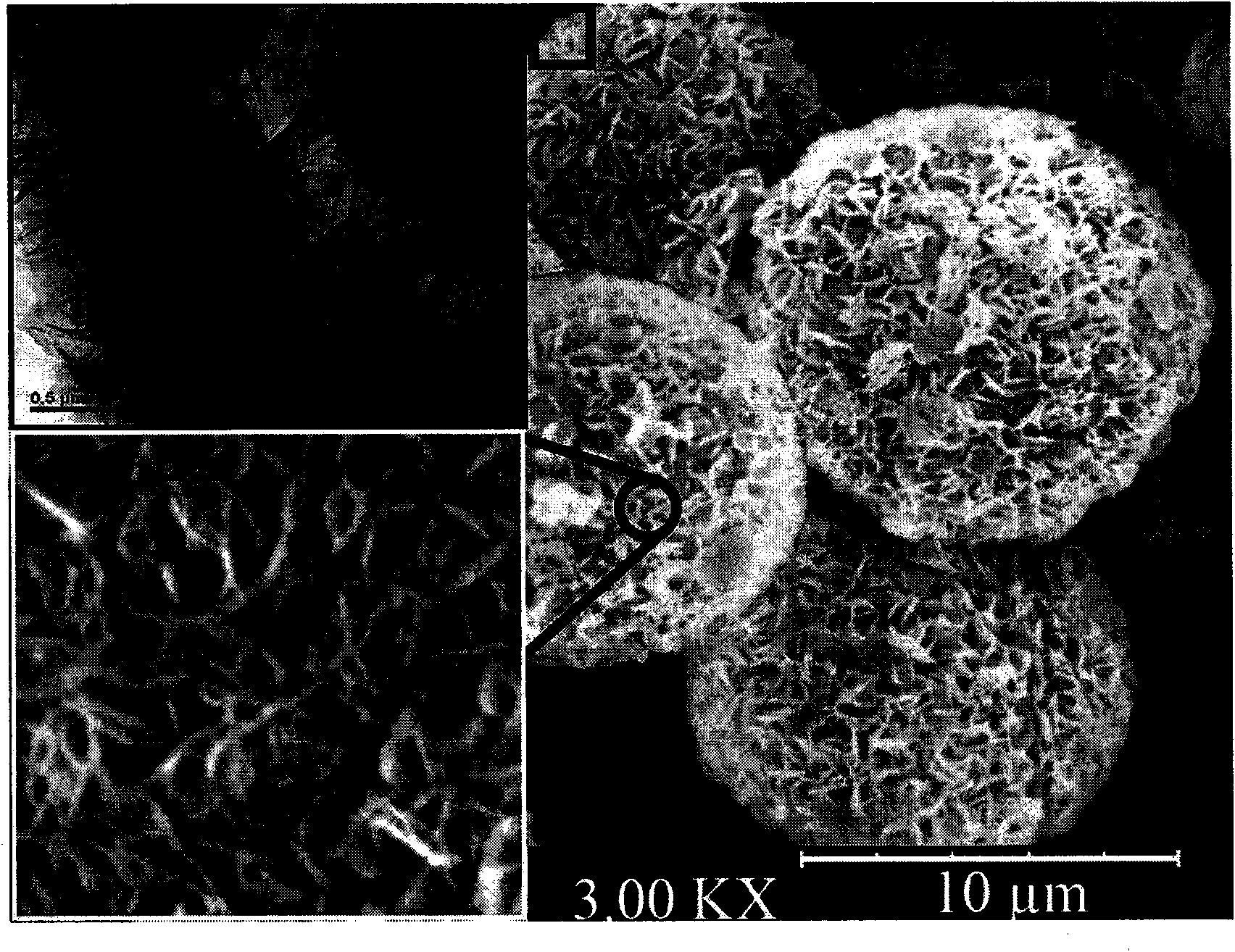

Novel cellular solids and foams from amorphous materials with a glass transition temperature (Tg) and methods of forming such materials are provided. In particular, foams are formed by expanding or compressing hollow spheres made of a high strength amorphous material, which is defined as a material having high strength characteristics, but also possessing a glass transition within a confined space. Using such a method, it has been unexpectedly found that it is possible to make cellular structures, including both open and closed cell foams, with customizable properties from materials that have been inaccessible with conventional methods. Moreover, based on calculations high specific strengths and stiffnesses are expected.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Metal supported MCM-22 molecular sieve hollow sphere bifunctional catalyst preparation method and application thereof

ActiveCN101618336AHigh reactivityHigh selectivityMolecular sieve catalystsCatalyst activation/preparationMolecular sieveActive component

The invention relates to a metal supported MCM-22 molecular sieve hollow sphere bifunctional catalyst preparation method and an application thereof, belonging to the molecular sieve catalysis technology. The method is characterized in that carbon black sphere particles are used as template, molecular sieve hollow spheres with multi-stage pore path structure is prepared by rotation hydrothermal crystallization and by using metal active components the prepared molecular sieve hollow spheres are loaded and modified. The prepared Mo / HMCM-22 molecular sieve hollow sphere bifunctional catalyst can be used in methane non-oxidative aromatization reaction system. The effect and the benefit of the invention is that the preparation method of the molecular sieve hollow spheres has simple operation and low cost, and the prepared hollow sphere catalyst has excellent catalytic performance in the methane non-oxidative aromatization reaction, high methane conversion rate and aromatics yield and very long catalyst life.

Owner:DALIAN UNIV OF TECH

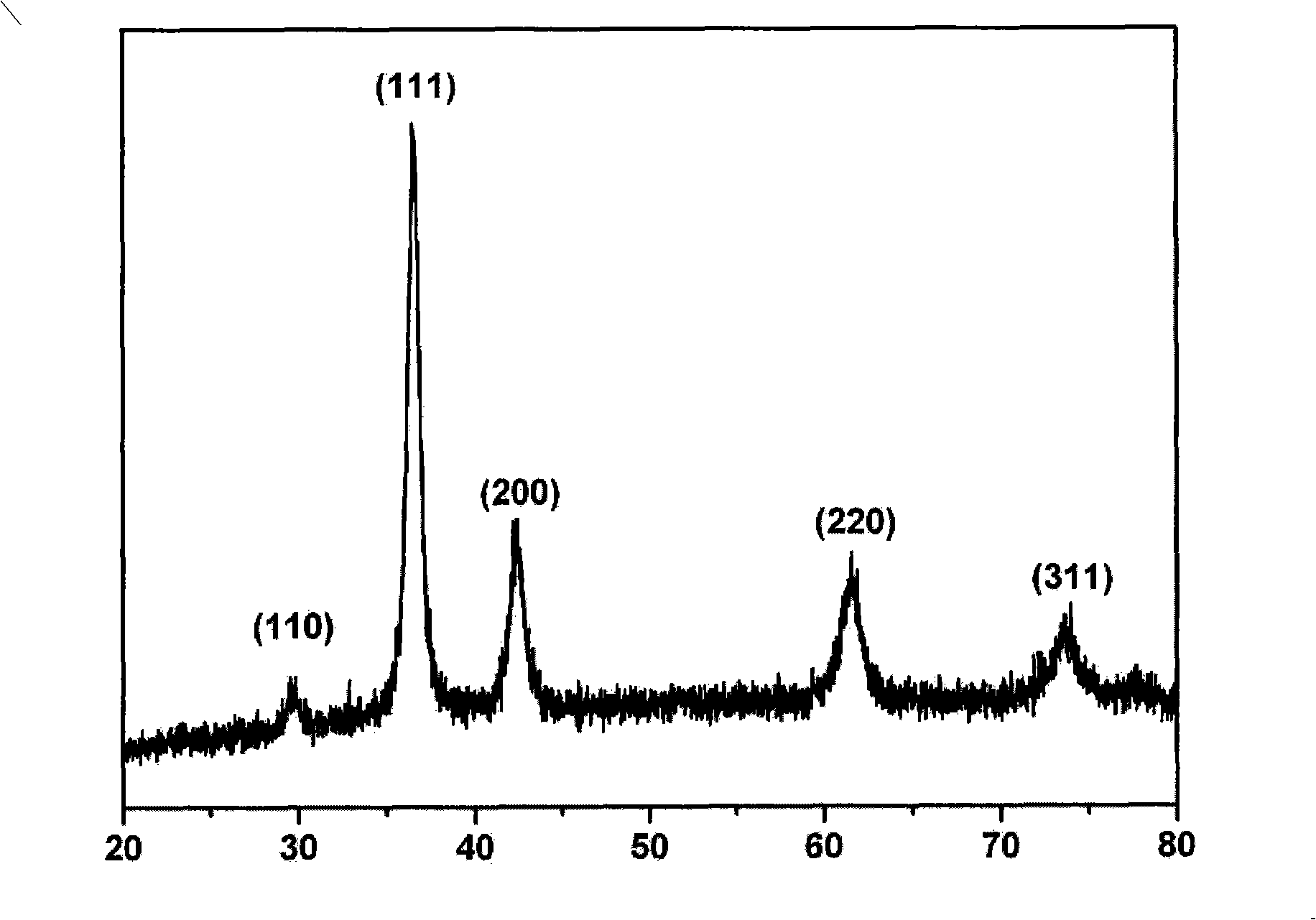

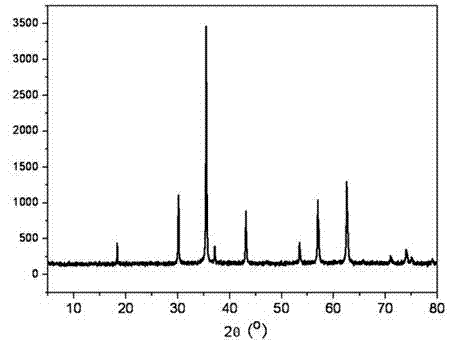

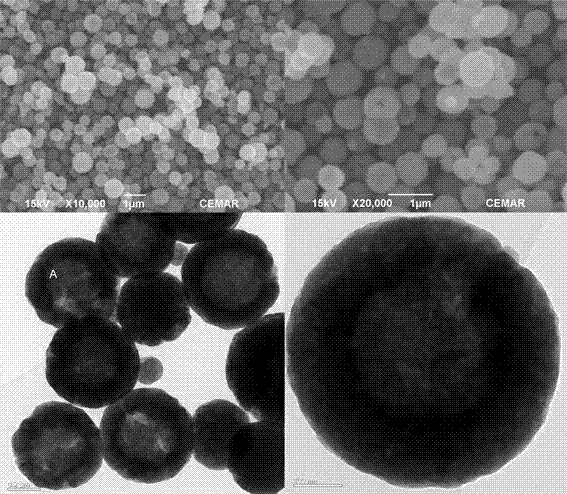

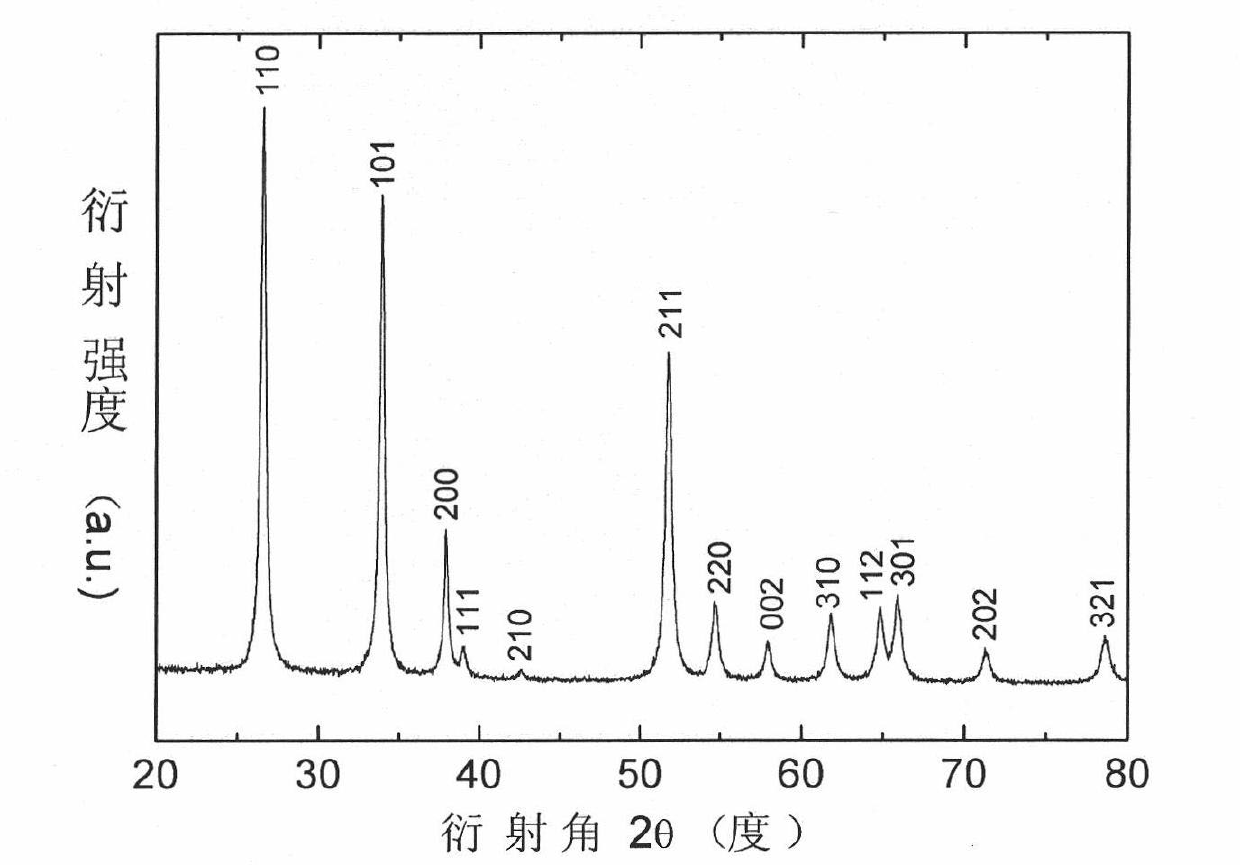

Method for synthesizing Fe3O4/C lithium ion battery cathode material with hollow sphere structure by one-step process

The invention discloses a preparation method of a lithium-stored composite material Fe3O4 / C with a hollow sphere structure and an application of the lithium-stored composite material Fe3O4 / C with a hollow sphere structure in a lithium ion battery, belonging to the technical fields of material synthesis and high-energy lithium-ion storage batteries. The preparation method is characterized in that a solvothermal method or hydrothermal method is utilized to prepare the Fe3O4 / C composite material with a hollow sphere and narrower particle size distribution, wherein the Fe3O4 / C composite material is high in purity; and the mean particle size of the Fe3O4 / C composite material is 750 nanometers and the wall thickness of the Fe3O4 / C composite material is 250 nanometers. An electrochemical test proves that the first discharging specific capacity of the Fe3O4 / C composite material prepared by the method can be 1157mAh / g, and the discharging specific capacity of the Fe3O4 / C composite material can be 900mAh / g after being circulated for 65 times, thus showing the perfect cyclical stability. The Fe3O4 / C composite material has good rate performance; and the charging specific capacity of the Fe3O4 / C composite material is 620mAh / g and 460mAh / g respectively under 2C and 5C charge-discharge rates, thus the rate performance is superior to that of an existing commonly-used carbon cathode material (theoretical specific capacity is 372mAh / g). The Fe3O4 / C lithium ion battery cathode material is low in cost, simple in process and easy to industrialize, and has wide application prospects in the high-energy lithium ion battery field.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST

Molybdenum disulfide-carbon hollow ball hybrid material and preparation method thereof

InactiveCN105098151AShorten the transmission distanceImproved magnification performanceCell electrodesSecondary cellsSolventSilicon dioxide

The invention discloses a molybdenum disulfide-carbon hollow ball hybrid material. The molybdenum disulfide-carbon hollow ball hybrid material has a hollow ball structure; and the hybrid material formed by embedding a single layer of molybdenum disulfide nanosheet or a few of layers of molybdenum disulfide nanosheets into a carbon material is a shell layer of the hollow ball. The invention further discloses a preparation method of the molybdenum disulfide-carbon hollow ball hybrid material. The method comprises the following steps: with amino-modified silica particles as a template, coating the template with an organic pyrolytic carbon material and ammonium tetrathiomolybdate through solvothermal reaction; carrying out high-temperature treatment in an inert atmosphere; and finally removing a silicon dioxide template, so as to obtain the molybdenum disulfide-carbon hollow ball hybrid material disclosed by the invention. The initial lithium insertion capacity of the molybdenum disulfide-carbon hollow ball hybrid material disclosed by the invention is close to 1010mAh / g; and the specific capacity can still be kept at 662mAh / g after 40 repeated charge and discharge cycles.

Owner:SHANGHAI JIAO TONG UNIV

Nitrogen-doped graphene and Co3O4 hollow nanosphere composite material as well as preparation method and application of composite material

ActiveCN104681823AImprove conductivityLarge specific surface areaMaterial nanotechnologyPhysical/chemical process catalystsDoped grapheneNitrogen doped graphene

The invention relates to a novel composite material, and particularly relates to a preparation method and application of a nitrogen-doped graphene and cobaltosic oxide hollow nanosphere composite material. The novel composite material comprises a doped graphene substrate and cobaltosic oxide hollow nanospheres which is attached to the surface of the doped graphene substrate. Melamine resin is taken as a cross-linking reagent for integrating graphite oxide with Co<2+> into a single coordination precursor. The preparation method comprises the following steps: in a pyrolysis process of the precursor, taking the melamine resin as a new nitrogen source to uniformly dope the graphene with nitrogen, fixing cobalt oxide which is generated in situ, and finally preparing the nitrogen-doped graphene / Co3O4 hollow nanosphere composite material with a sandwich structure. The composite material has a graded porous structure, is high in specific surface area, more in active sties, good in electron conductivity and ion conductivity, and good in application prospect in the field of new energy resources and catalysis.

Owner:CHINA WEST NORMAL UNIVERSITY

Light weight particulate composite materials with cenospheres as reinforcements and method for making the same

This invention provides a particulate composite comprising a polyester resin, a plasticizer, and a plurality of cenospheres. The polyester resin and the plasticizer form a matrix wherein the cenospsheres are distributed nonhomogeneously in the matrix. The nonhomogenous distribution of cenospheres further comprises a continuously varying particle volume fraction along a single dimension.

Owner:BOARD OF GOVERNORS FOR HIGHER EDUCATION STATE OF RHODE ISLAND & PROVIDENCE PLATATIONS THE

Production method of high strength polycrystalline ceramic spheres

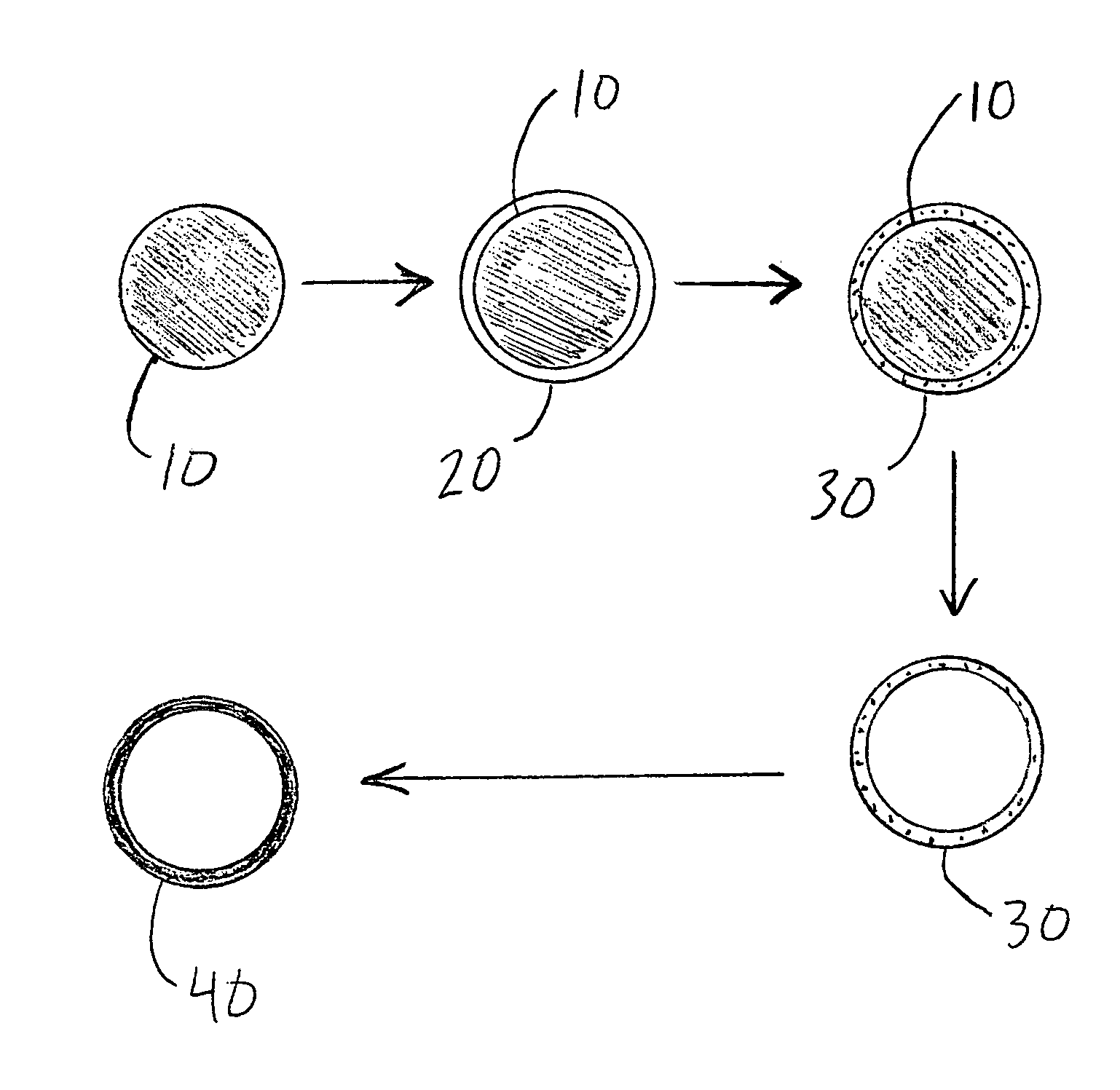

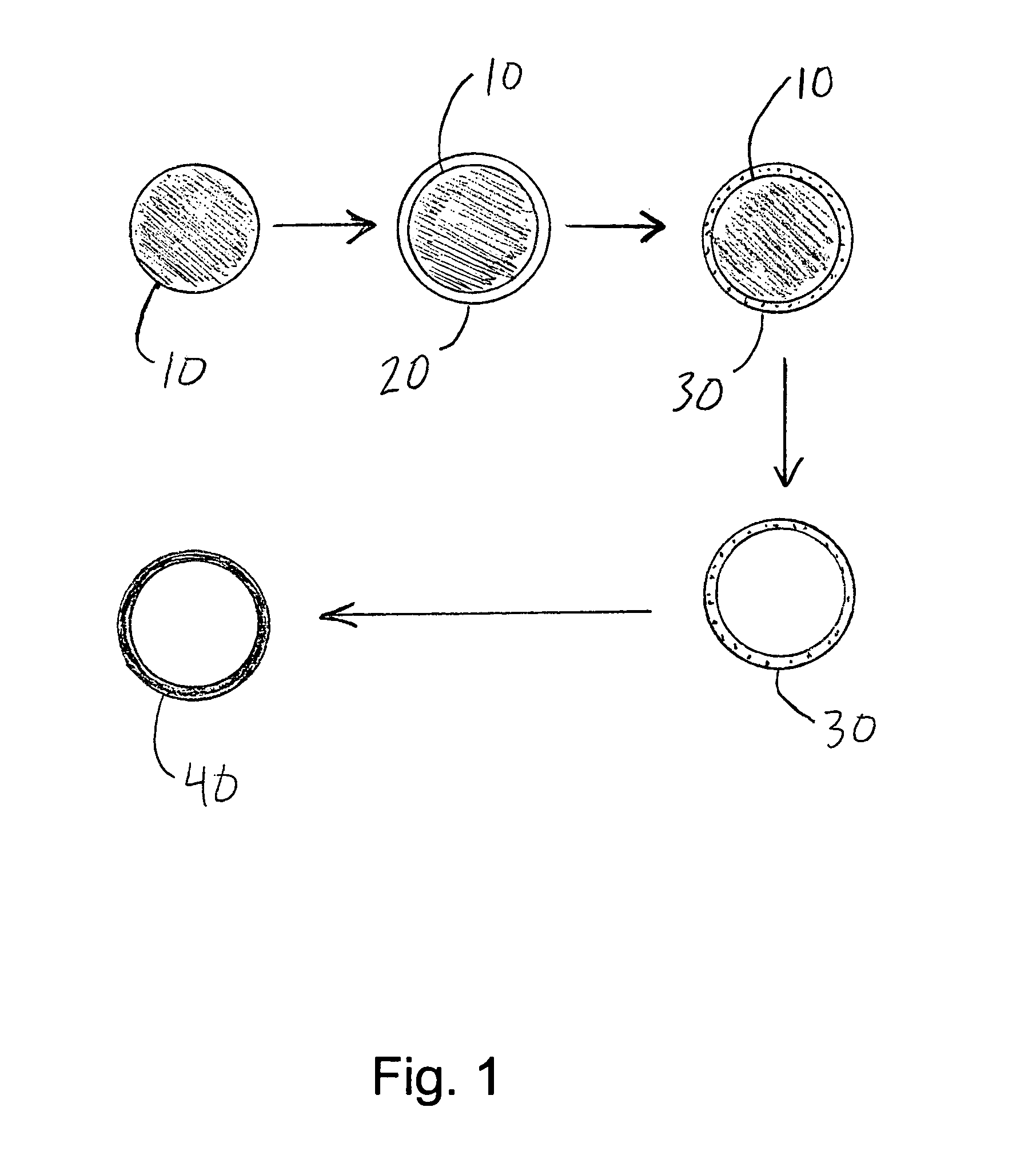

InactiveUS7220454B2High mechanical strengthImprove tolerancePretreated surfacesGlass/slag layered productsAluminatePorous membrane

A method for making hollow spheres of alumina or aluminate comprises: coating polymeric beads with an aqueous solution of an alumoxane, drying the beads so as to form an alumoxane coating on the beads; heating the beads to a first temperature that is sufficient to convert the alumoxane coating to an amorphous alumina or aluminate coating and is not sufficient to decompose the polymeric beads; dissolving the polymeric bead in a solvent; removing the dissolved polymer from the amorphous alumina or aluminate coating; and heating the amorphous alumina or aluminate coating to a second temperature that is sufficient to form a hollow ceramic sphere of desired porosity and strength. The hollow spheres can be used as proppants or can be incorporated in porous membranes.

Owner:RICE UNIV

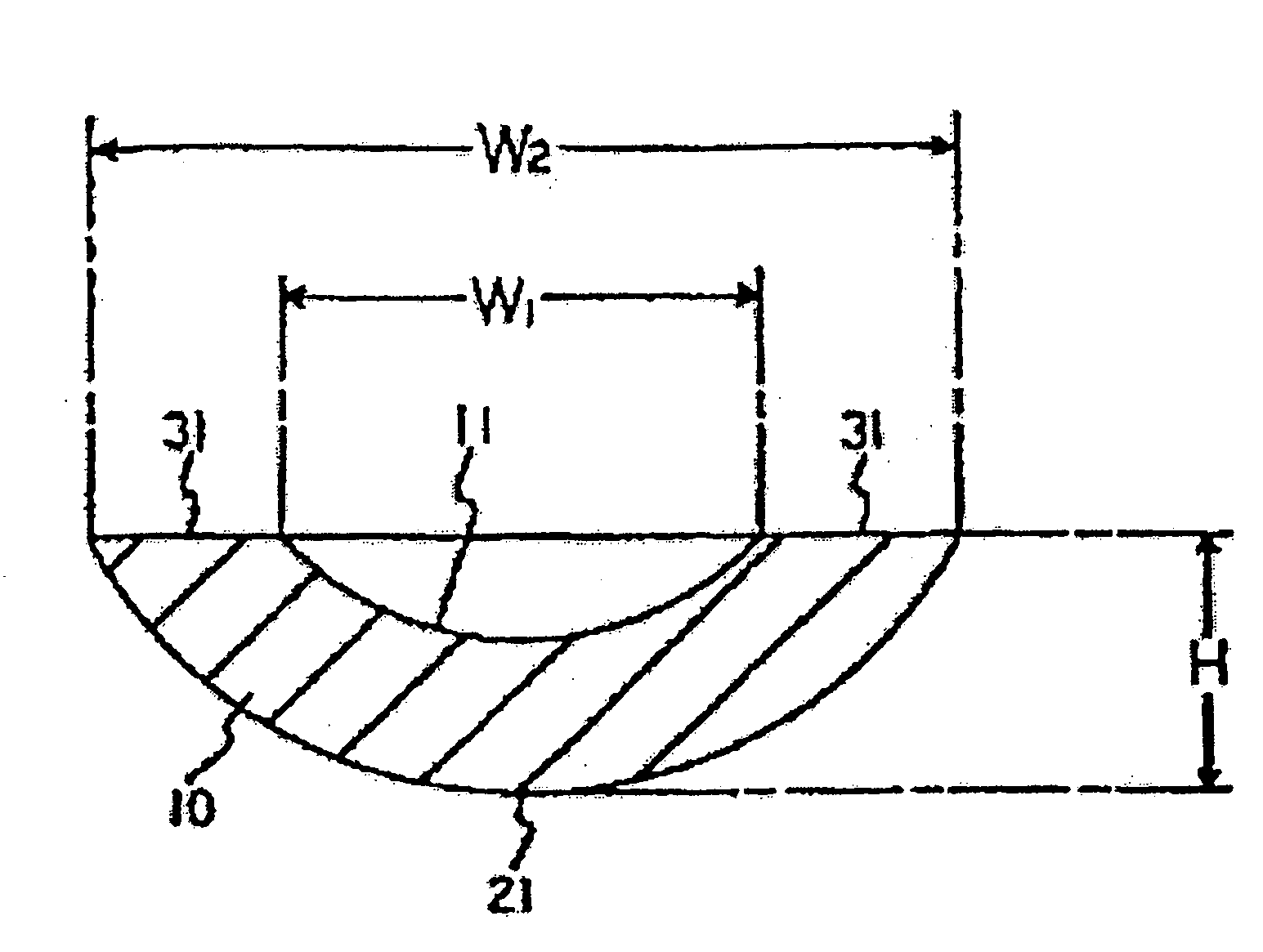

Siliceous mullite structure-insulating integrated composite brick and preparation method thereof

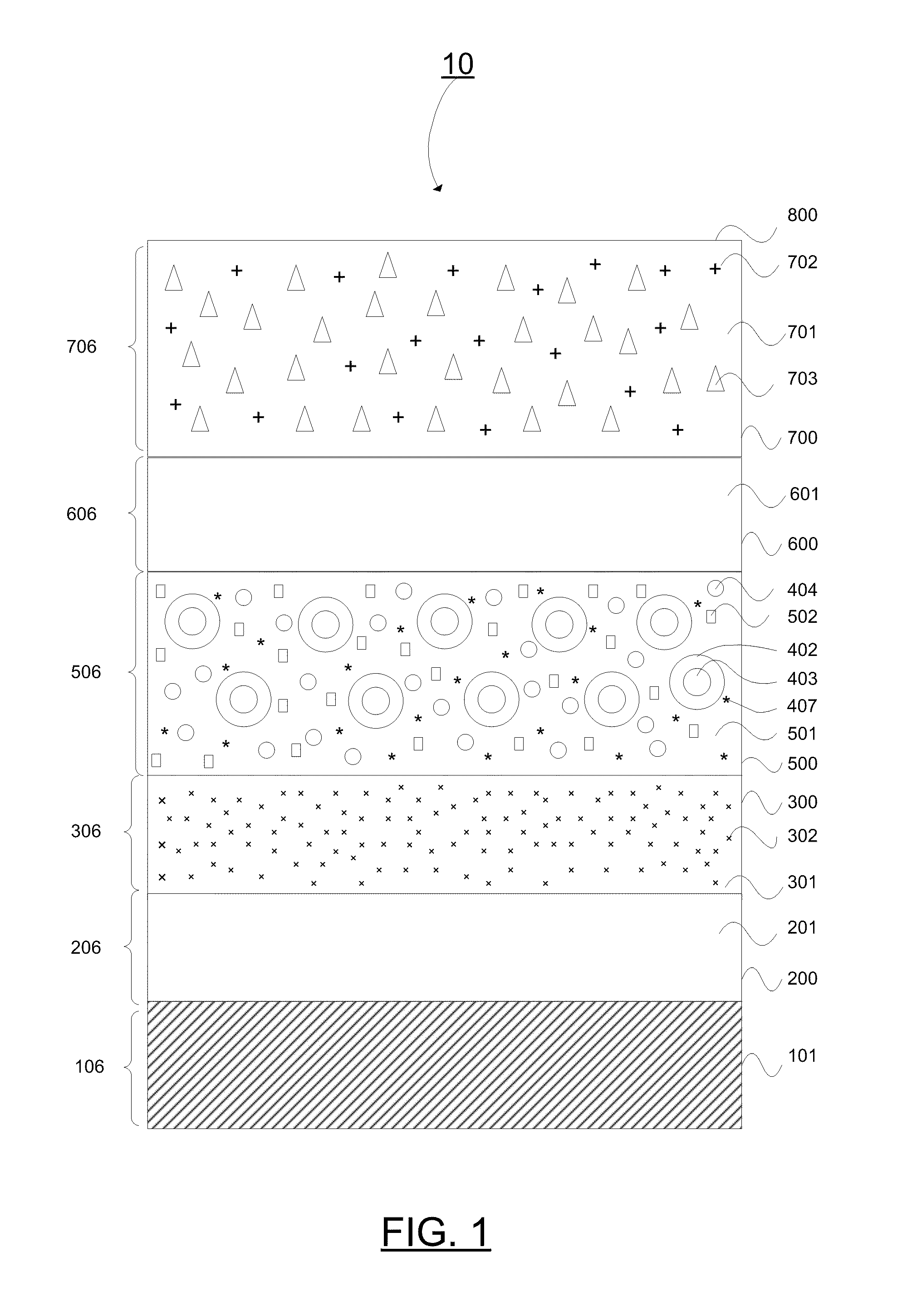

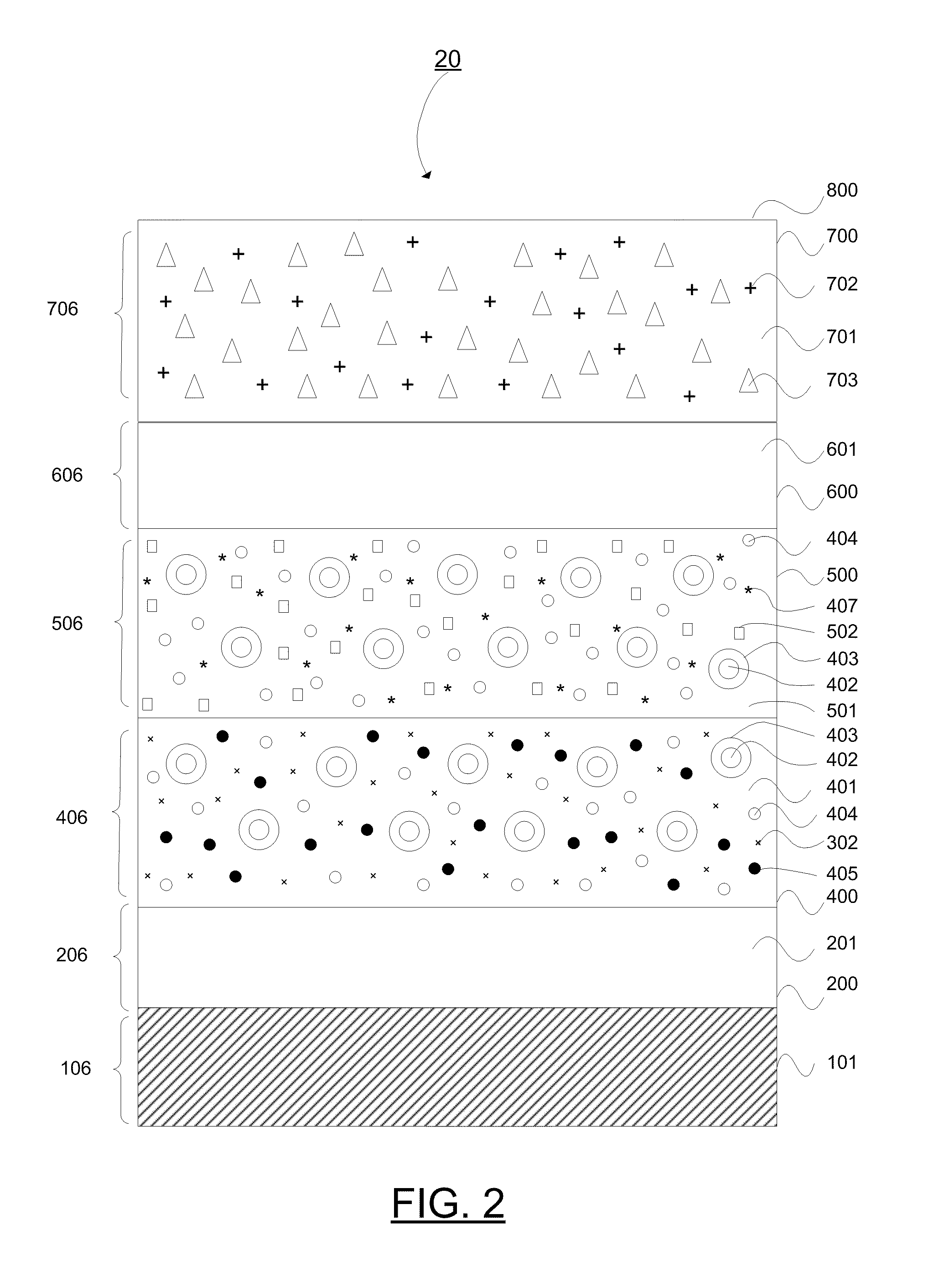

The invention discloses a siliceous mullite structure-insulating integrated composite brick and a preparation method thereof. The brick consists of a heavy working layer and a high-strength light insulating layer, wherein the main materials of the heavy working layer are dense bauxite and silicon carbide material, the aggregate of the high-strength light insulating layer is one or the mixture of alumina hollow balls, alumina-magnesia hollow balls, corundum hollow balls, hollow microspheres and light ceramisite, the heavy working layer and the light insulating layer are combined together by adopting vibratory pressing or mechanical pressing, and the length proportion between the heavy working layer and a light insulating layer is 1 to 5:2 to 1. The invention overcomes the defect of the abrasion-resistant siliceous mullite brick for rotary kilns, i.e. high coefficient of heat conductivity, and the defects of the light part of the conventional siliceous mullite composite brick, i.e. low strength and low refractoriness, and the structure-insulating integrated composite brick has the advantages of high abrasion resistance, high refractoriness, high structure strength and high insulating property.

Owner:浙江盛旺耐火材料股份有限公司

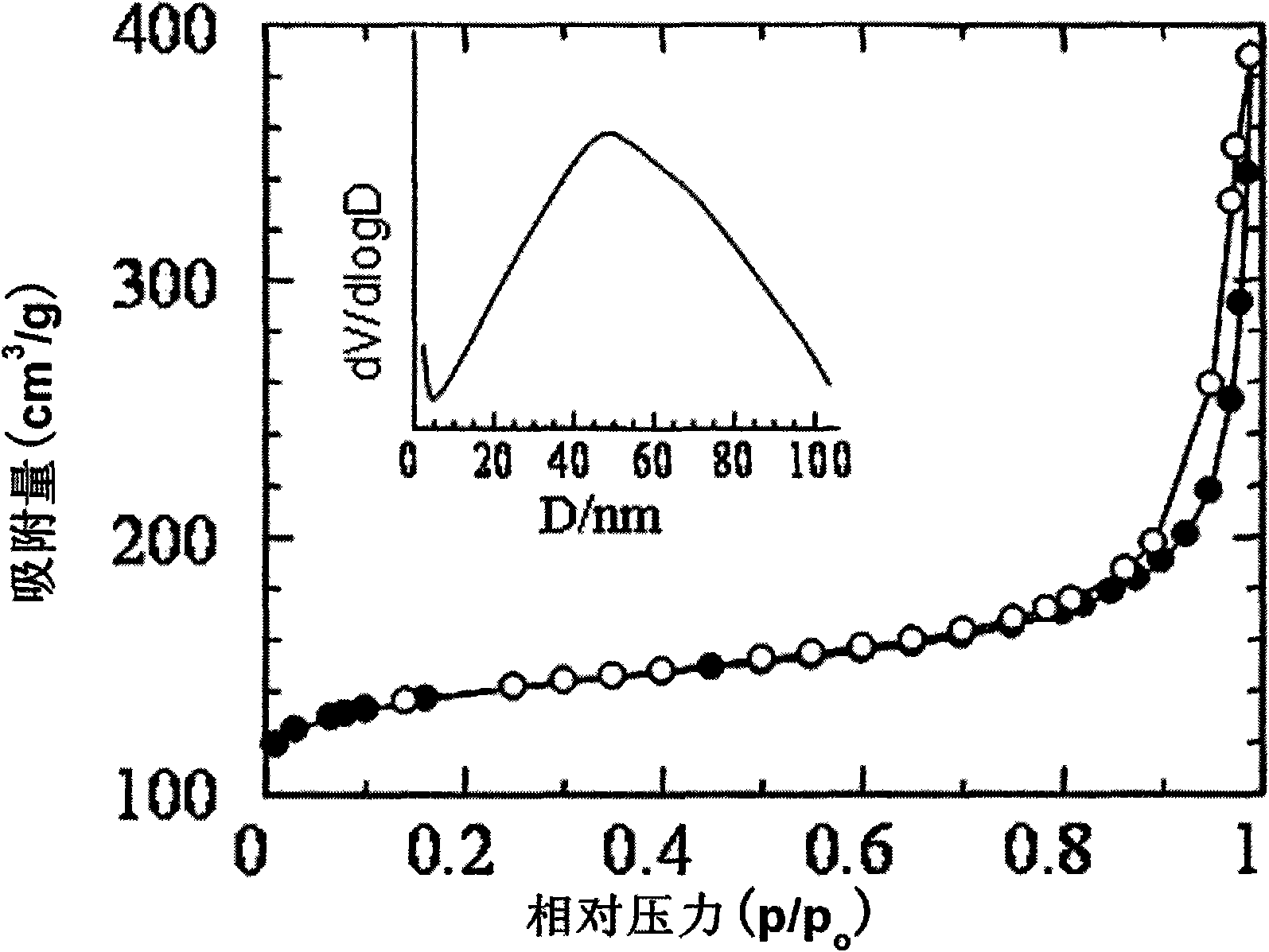

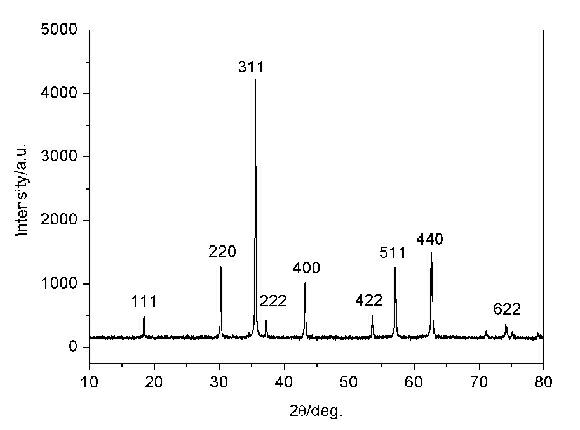

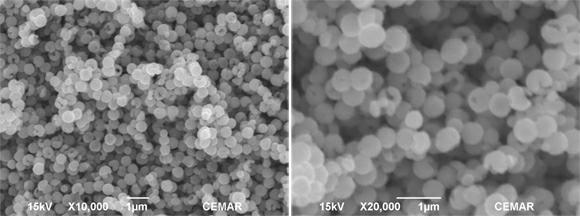

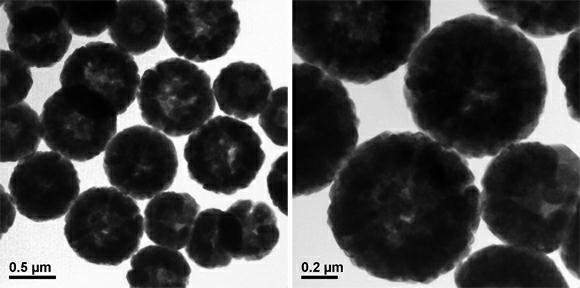

ZnFe2O4/C composite cathode material with hollow sphere structure and one-step preparation method thereof

The invention relates to a technology on a cathode material for a lithium ion secondary battery, and in particular relates to an iron-based composite oxide cathode material ZnFe2O4 / C with a hollow sphere structure and a preparation method thereof. The iron-based composite oxide cathode material is characterized in that the general formula is ZnFe2O4 / C, wherein the content of carbon element is 1-10%; and a solvothermal one-step method is utilized to prepare the ZnFe2O4 / C composite cathode material with the hollow sphere structure and narrower particle size distribution. The ZnFe2O4 / C composite cathode material is high in purity; and the mean particle size of the ZnFe2O4 / C composite cathode material is 500 nanometers and the wall thickness is 150 nanometers. An electrochemical test proves that the charging specific capacity of the ZnFe2O4 / C composite cathode material at the first cycle can be 911mAh / g and the charging specific capacity of the ZnFe2O4 / C composite cathode material can be 826mAh / g after being circulated for 30 times as well as the retention rate of the capacity can be 91%. In addition, the ZnFe2O4 / C composite cathode material can keep good charge-discharge reversibility under different charge-discharge current densities. The charge-discharge capacity of the ZnFe2O4 / C composite cathode material is superior to that of an existing commonly-used carbon cathode material (theoretical specific capacity is 372mAh / g). The ZnFe2O4 / C composite cathode material is low in price of raw materials, simple in process and easy to industrialize, and has wider application prospects as well as meets practical production.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST

Method for preparing ligh high strength aluminium oxide hollow ball ceramic

InactiveCN1554616AWith shrinkageWith thermal shock resistanceCeramicwarePhosphoric acidShock resistance

The light high-strength alumina ceramic ball has phosphoric acid solution as binding agent, alpha-alumina powder as basic material and hollow alumina ball as aggregate. Compared with dense refractory material, it has low density, high heat shock resistance, good heat insulating performance, low heat capacity and other features; and compared with common heat insulating material, it has high compression strength, high loaded softening temperature, low re-burning linear shrinkage and other features. It may be used as heat insulating material directly and may be also used in direct contact with flame, such as being used as lining material in high temperature furnace and kiln. In addition, its strength may be further raised in secondary sintering.

Owner:ZHEJIANG UNIV

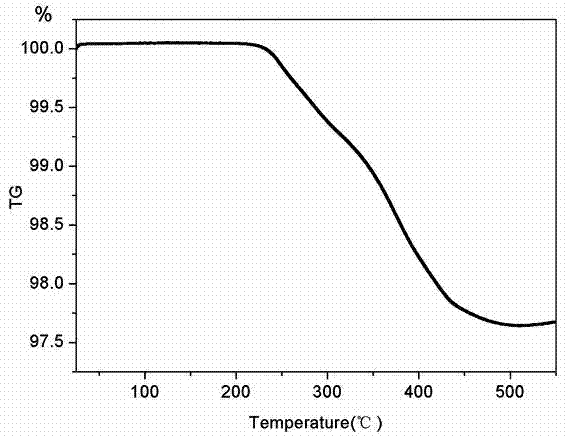

Low heat conductance silicon rubber foam material and manufacture method thereof

The invention provides a low heat conductance silicon rubber foam material which is composed of a silicon rubber foam base body and a gas gel, wherein the silicon rubber foam base body is made of a silicon rubber tackiness agent and cenospheres. Low heat conductance silicon rubber foam has the advantages of being wide in applicable temperature, even in structure, large in nanometer aperture, low in heat conductivity and the like, and is suitable for requirements for heat preservation materials of civilian fields, space flight and aviation fields and the like. Meanwhile, a manufacture method is simple, technology is stable, effective control of a product structure can be performed as required, and the low heat conductance silicon rubber foam material and the manufacture method of the low heat conductance silicon rubber foam material are suitable for mass production.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

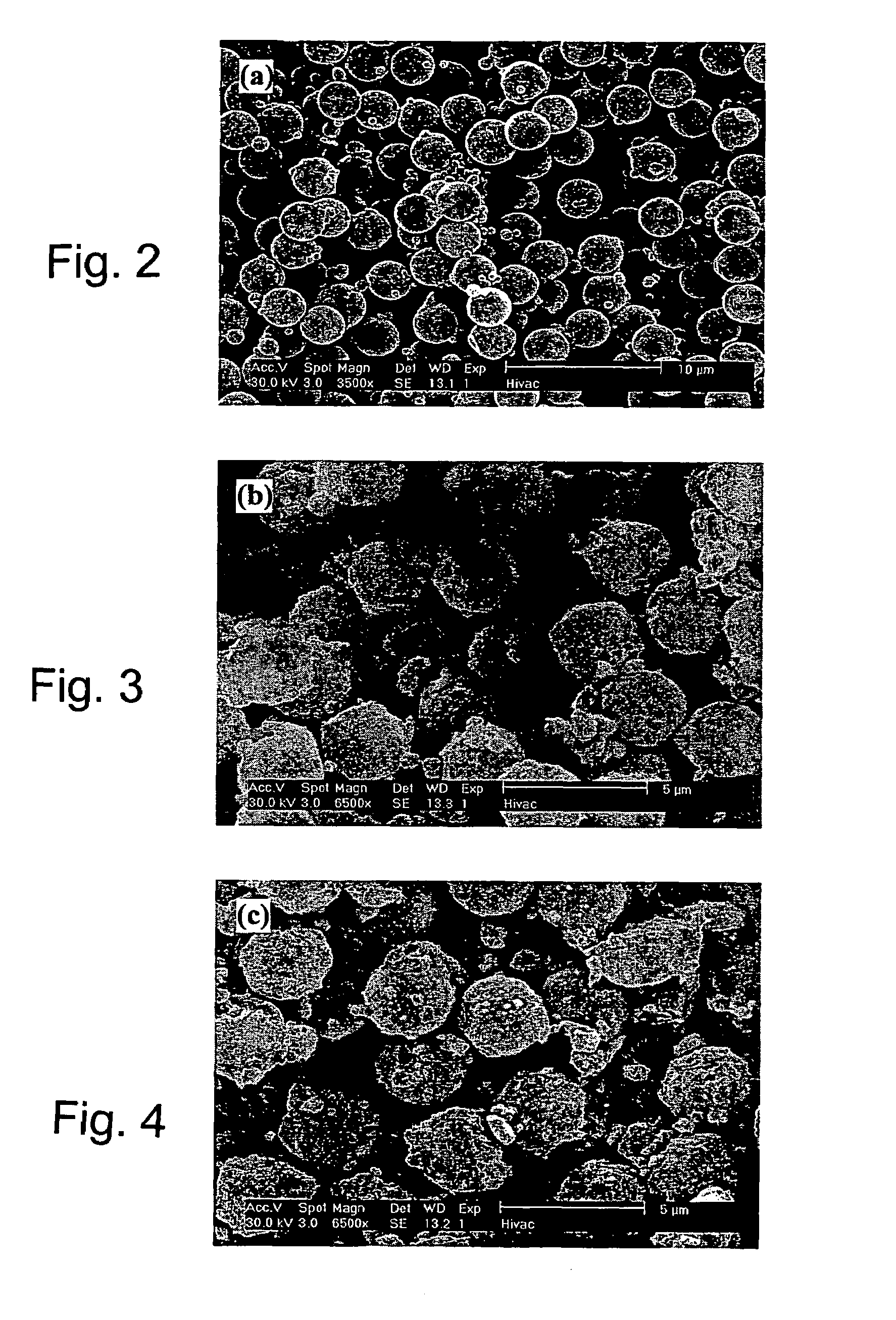

Synthetic microspheres comprising aluminosilicate and methods of making same

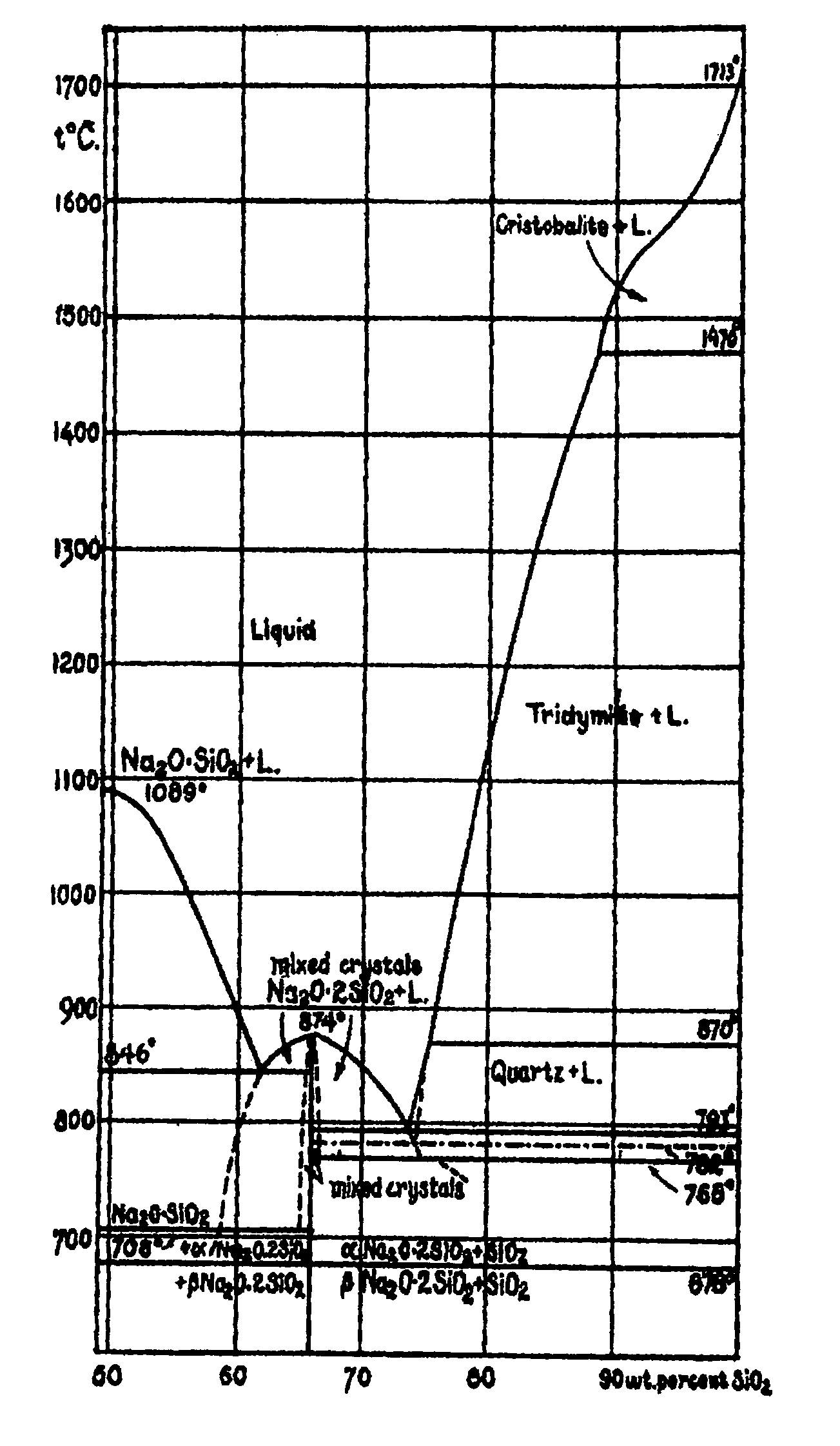

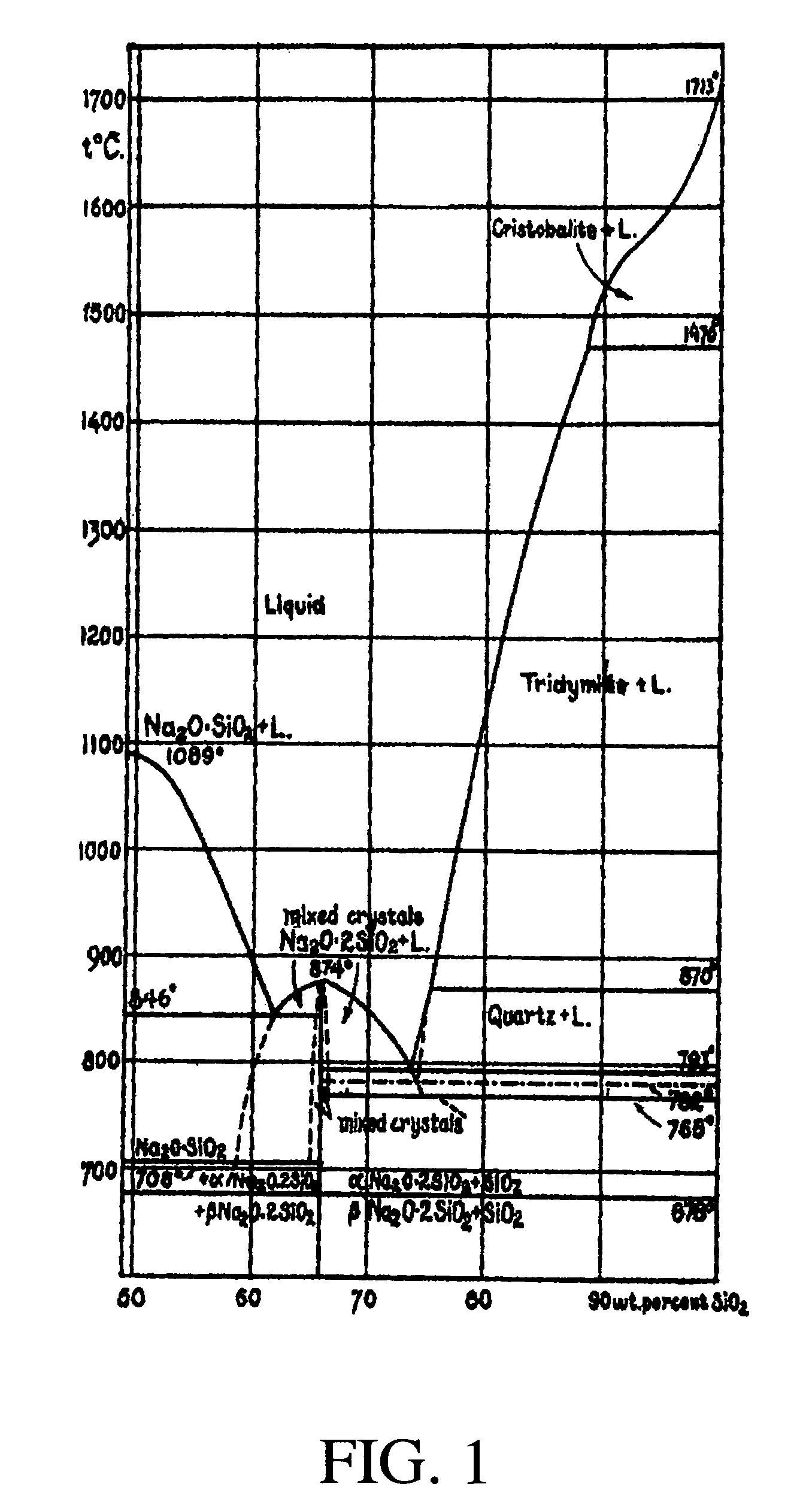

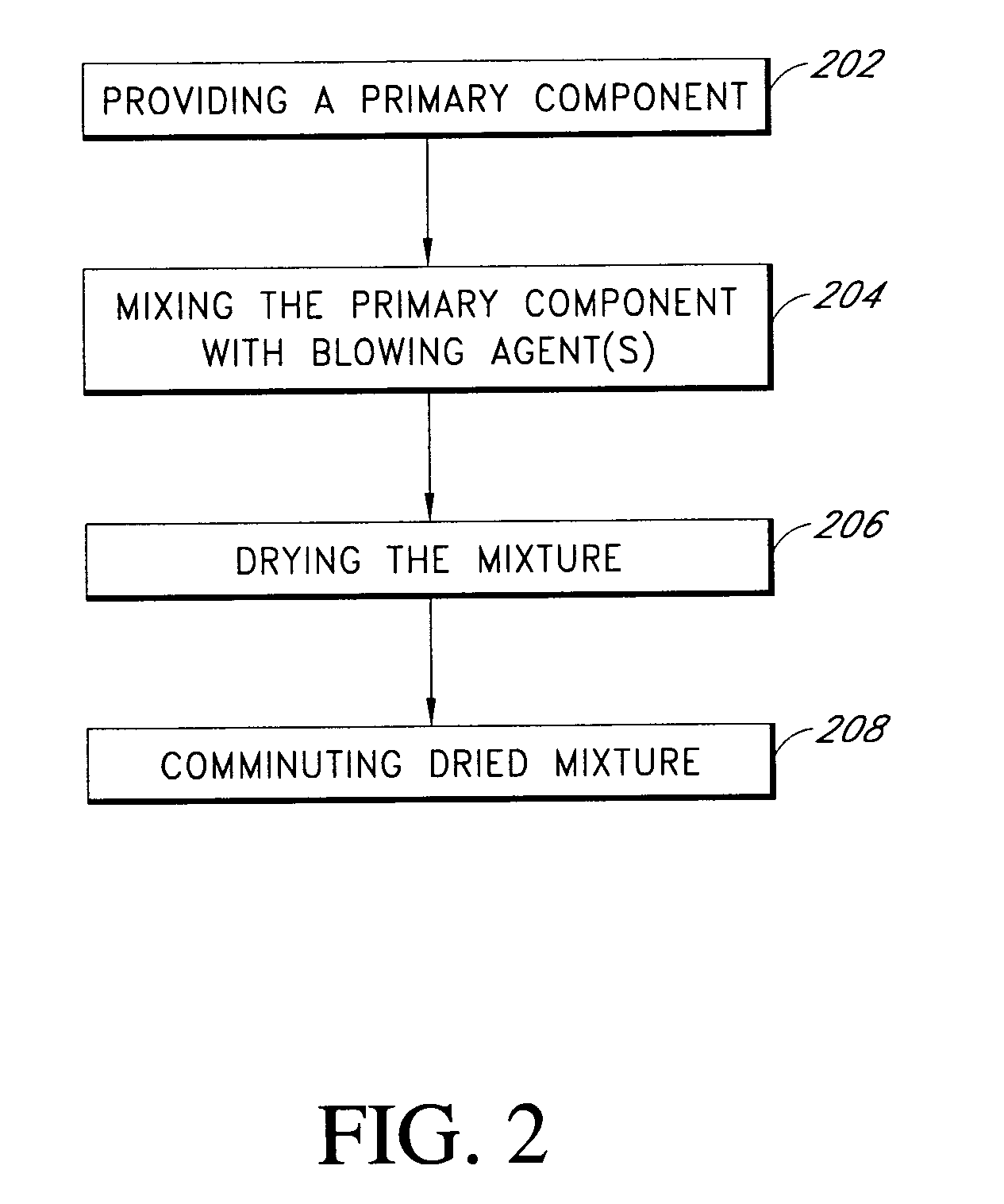

A synthetic microsphere having a low alkali metal oxide content and methods of forming the microsphere and its components are provided. The synthetic microsphere is substantially chemically inert and thus a suitable replacement for natural cenospheres, particularly in caustic environments such as cementitious mixtures. The synthetic microsphere can be made from an agglomerate precursor that includes an aluminosilicate material, such as fly ash, a blowing agent such as sugar, carbon black, and silicon carbide, and a binding agent. The synthetic microsphere is produced when the precursor is fired at a pre-determined temperature profile so as to form either solid or hollow synthetic microspheres depending on the processing conditions and / or components used.

Owner:JAMES HARDIE TECH LTD

Method for preparing hollow spherical stannic oxide nano powder

InactiveCN102086044AAvoid destructionEasy to makeNanostructure manufactureTin oxidesTin dioxidePrill

The invention provides a method for preparing hollow spherical stannic oxide nano powder and belongs to the technical field of preparation of nano materials. The preparation method mainly comprises the steps of: respectively preparing tin salt and an alkali source into solution; uniformly dripping the solution of the alkali source into the solution of tin salt with stirring of a magnetic force, and stirring to obtain uniform precursor solution; performing hydrothermal treatment on the precursor solution in a reaction kettle; washing and drying the hydrothermal product to obtain the hollow spherical powder consisting of nano SnO2 particles. The prepared SnO2 hollow spheres have uniform size, regular shape, good crystallization and uniform thickness of a spherical shell. In the method, an expendable template is not needed, the process is simple and reaction conditions are mild, and the method has the characteristics of short preparation period, high product quality, high yield, low costand the like, and is an environmentally-friendly synthesis method.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Alumina bubble lightweight insulating refractory casting material

The invention discloses an alumina bubble lightweight insulating refractory casting material, which comprises the following components in percentage by weight: 10 to 50 percent of alumina bubbles, 5 to 15 percent of mullite with the grain diameter of 5 to 3 millimeters, 5 to 20 percent of mullite with the grain diameter of 1 to 3 millimeters, 10 to 20 percent of mullite with the grain diameter of 0 to 1 millimeter, 1 to 13 percent of swelling agent, 10 to 25 percent of fine powder, 10 to 20 percent of micro powder, 0.1 to 1 percent of water reducing agent and 5 to 20 percent of composite aluminate cement. The casting material has the characteristics of carrier weight reduction, high temperature resistance, good heat insulation effect, large strength, convenient and practical operation, and suitability for being used at the temperature of between 1,000 and 2,000, can be used for integrally casting, spraying, coating and repairing, and not only meet the requirement of smelting special steel, but also meet the requirements of refractory materials for hot-blast stoves, furnace tops, furnace walls, petrochemical cracking furnaces, systems for chlorine and sulfur removal, slag discharge and catalytic cracking, electric fluidized bed boilers, flues and the like.

Owner:营口丰华耐火材料有限公司

Water gap lining layer material for continuous casting

The invention discloses a water gap lining layer material for continuous casting. The material is prepared from the following components in percent by weight: 20-60 percent of corundum, 0-30 percent of electrofusion zirconium mullite, 0-40 percent of fused silica, 3-40 percent of ceramic hollow sphere, 1-10 percent of light burning alumina, 2-6 percent of sintering assistant, 2-6 percent of phosphate bonding agent and 4-8 percent of solid phenolic resin bonding agent. A water gap for continuous casting produced by adopting the material is suitable for cold casting, and a lining basically has no nodule blocking phenomenon; the lining has high strength and does not have phenomena of chambering and abnormal erosion; a water gap has long service life; and the continuous casting production efficiency is improved.

Owner:SHANGHAI BAOMING REFRACTORIES CO LTD

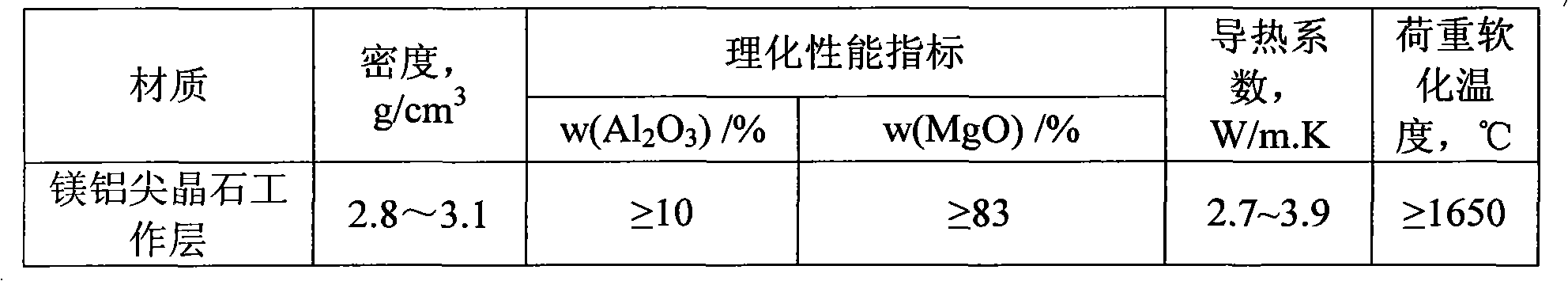

Magnesia-alumina spinel structure heat insulation integral composite brick and preparation method thereof

The invention discloses a magnesia-alumina spinel structure heat insulation integral composite brick and a preparation method thereof. The heat insulation integral composite brick comprises a heavy work layer and a light heat insulation layer, wherein the heavy work layer is made of compact magnesia-alumina spinel, the light heat insulation layer is made of light aggregate of alumina hollow ballsor magnesia-alumina hollow balls or corundum hollow balls or a mixture of the alumina hollow balls, the magnesia-alumina hollow balls and the corundum hollow balls, the heat insulation integral composite brick is formed through vibration compression or mechanical compression, and the length size proportion of the heavy work layer and the light heat insulation layer is 1 to 5 / 2 to 1. The inventionovercomes the defect of high heat conduction coefficient of magnesia-alumina spinel bricks used for a rotary kiln, and provides the magnesia-alumina spinel structure heat insulation integral composite brick with the advantages of good wear resistance performance, high refractoriness, high structural intensity and excellent heat insulation and thermal isolation performance.

Owner:浙江盛旺耐火材料股份有限公司

Method for preparing ZnO/ZnFe2O4 compound nano hollow sphere

InactiveCN101759146AAvoid formingEasy to operateNanostructure manufactureMaterials preparationAlcohol

The invention relates to the technical field of nano material preparation, in particular to a method for preparing ZnO / ZnFe2O4 compound nano hollow spheres. The method comprises the following steps of: (1) preparing a water solution of glucide compound; (2) placing the prepared water solution of glucide compound into a reaction container; (3) sealing the reaction container containing the prepared water solution of a glucide compound, after the heating, the reaction and the cooling of the sealed container, conduct centrifugal separation to obtain a product, washing the product with distilled water and absolute ethyl alcohol, and drying the washed product to obtain carbon spheres with the diameter of 200 nm to 4 mu m; (4) preparing an alcoholic solution containing the carbon spheres; (5) after the reaction of the prepared alcoholic solution containing the carbon spheres, conducting cooling and centrifugal separation to obtain carbon nano spheres cladded with metal hydroxides; (6) calcining the obtained arbon nano spheres clad with metal hydroxides to obtain the ZnO / ZnFe2O4 compound nano hollow spheres. The invention has the characteristics of simple operation and low technological requirements.

Owner:ZHEJIANG NORMAL UNIVERSITY

Preparation method for alumina hollow spheres

The invention discloses a preparation method for alumina hollow spheres. The preparation method comprises the steps of preparing a chitosan-acetic acid-water solution; weighing raw materials according to a mass ratio of polystyrene spheres to the chitosan-acetic acid-water solution 5:1 to 10:1 and a mass ratio of the polystyrene spheres to alpha-alumina powder of 1:5 to 1:15; mixing and stirring the polystyrene spheres and the chitosan-acetic acid-water solution to make the surfaces of the polystyrene spheres uniformly coated by a layer of the chitosan-acetic acid-water solution; putting the polystyrene spheres coated by the chitosan-acetic acid-water solution and the alpha-alumina powder in a ball-milling device, rotating at a rotation speed of 5-30 r / s to coat for 2-24 h so as to prepare core-shell spheres; and sintering the core-shell spheres to obtain the alumina hollow spheres with the diameter of 0.2-2 mm and wall thickness of 20-100 [mu]m. The preparation method is low in cost of the raw materials, simple in process and safe and simple in operations, and can realize industrial production easily.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com