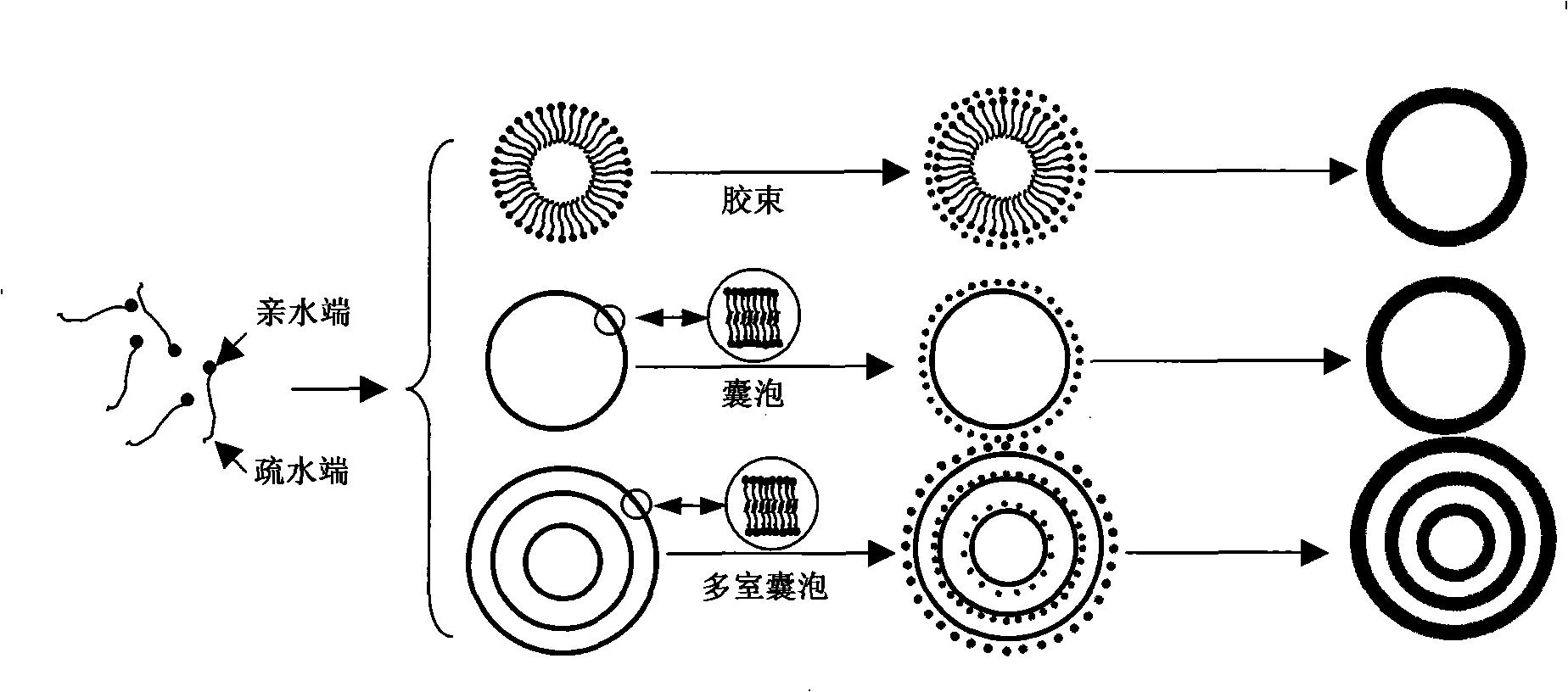

Method for producing multi-layer hollow pellet or stephanoporate pellet with multi-chamber vesicle mould plate method

A technology of hollow spheres and porous spheres, applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of unsuccessful reports and achieve the effect of easy control of the structure and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

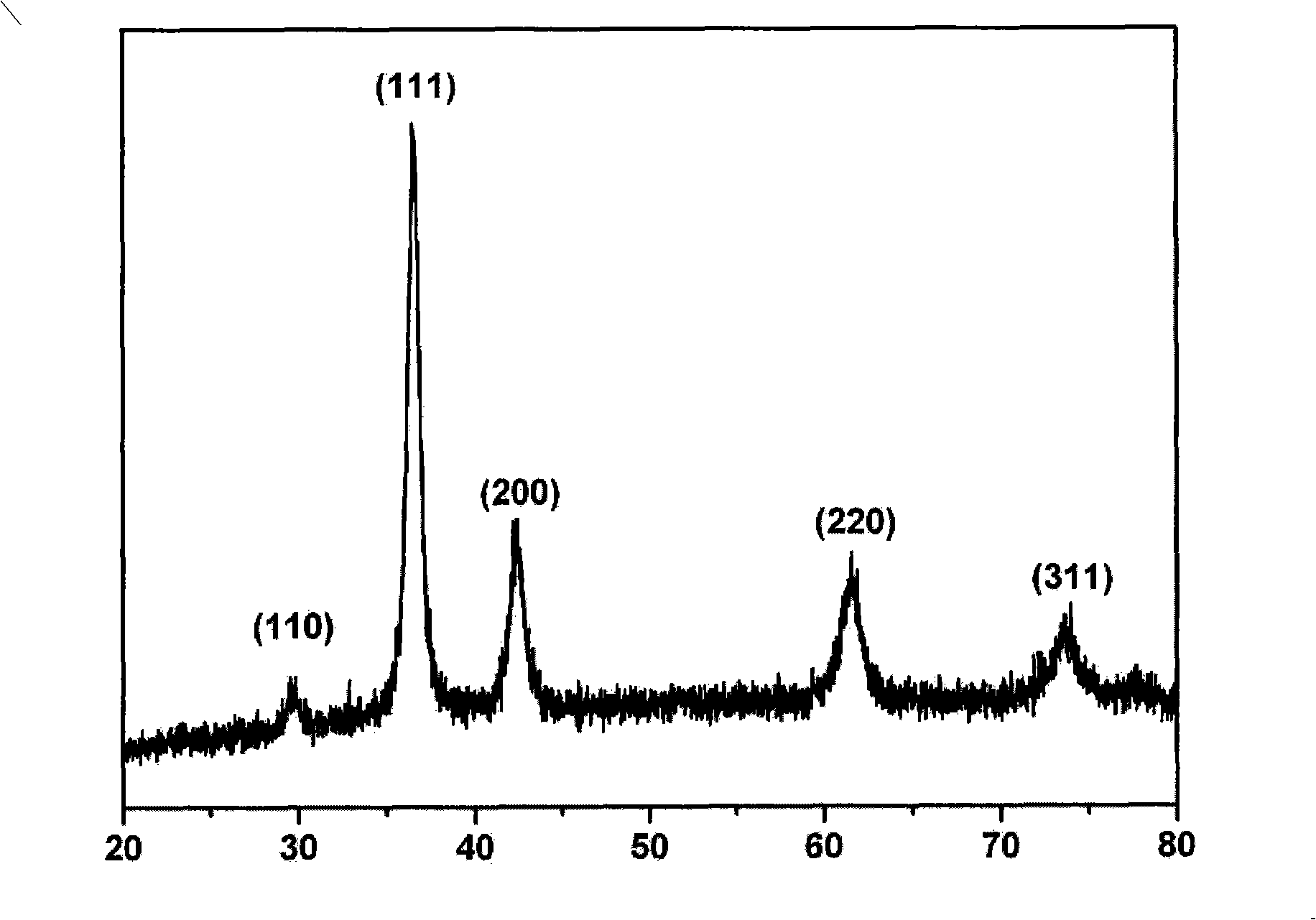

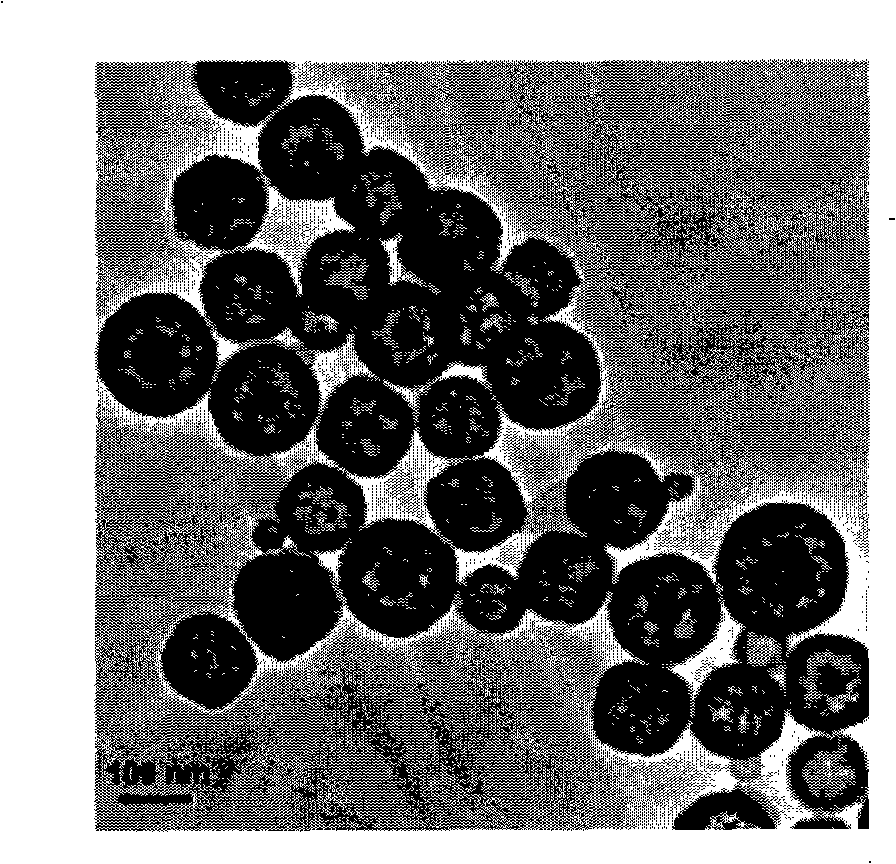

[0025] to prepare Cu 2 O multi-layer hollow ball as an example. Dissolve 3.64 g of cetyltrimethylammonium bromide (CTAB) in 100 mL of water, then add 0.05 g of CuSO 4 ·5H 2 O, add 0.18g ascorbic acid again. The mixed solution was heated to 55°C and stirred for 20 minutes. Add NaOH solution dropwise to the above mixed solution until Cu 2 O is completely precipitated. Continue stirring for 5-10 minutes. The obtained yellow precipitate was centrifuged, washed three to five times with deionized water and absolute ethanol, and then dried at 50°C. figure 2 It is the XRD pattern of the product, which proves that the product is cuprous oxide in the cubic phase. image 3 The morphology of the product under this concentration condition is mainly single-layer hollow spheres, and there are also a small amount of double-layer, three-layer and four-layer hollow spheres. The single-layer hollow spheres have a size of 100-120 nm, while the double-layer hollow spheres have a size of 1...

Embodiment 2

[0027]Take the preparation of ZnS porous spheres and porous hollow spheres as an example. Dissolve 1-4g of cetyltrimethylammonium bromide (CTAB) in 100mL of water, then add 0.15g of Zn(CH 3 COO) 2 2H 2 O. The mixed solution was heated to 60° C. and stirred for 20 minutes. Add excess thiourea or thioacetamide solution dropwise to the above mixed solution. Continue to heat up to 90°C and stir for 2-10 hours. The obtained white precipitate was centrifuged, washed three to five times with deionized water and absolute ethanol, and then dried at 50°C. Figure 7 It is the XRD pattern of the product, which proves that the product is zinc sulfide. Figure 8 (a) and (b) are the morphology of the product under the condition of low concentration of CTAB, mainly porous spherical structure. The size of such porous spheres is 120-180nm. Figure 8 The electron diffraction pattern in (b) shows that the porous spherical structure is polycrystalline. Figure 8 (c) is a high-magnificatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com