Patents

Literature

206results about How to "Controllable structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

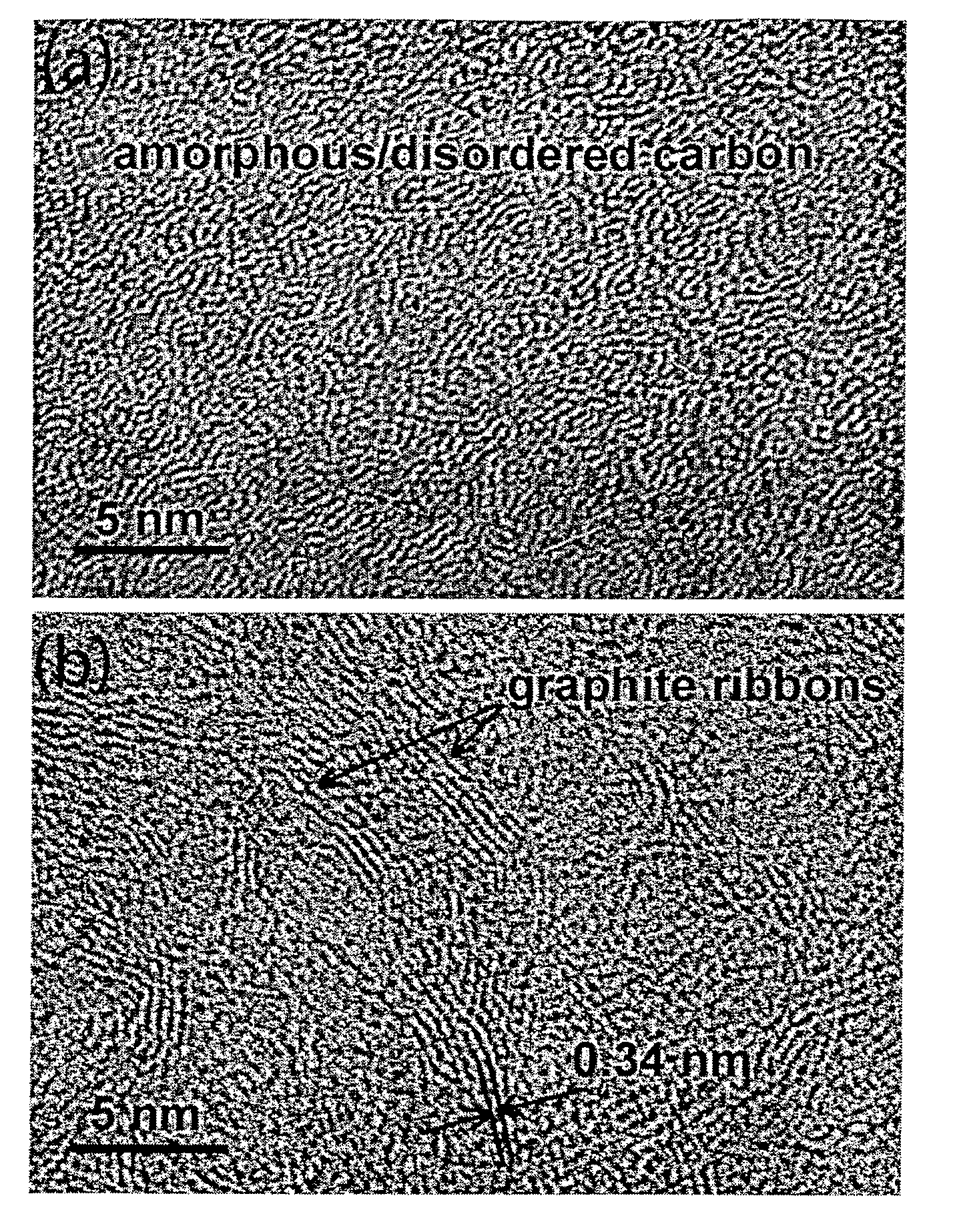

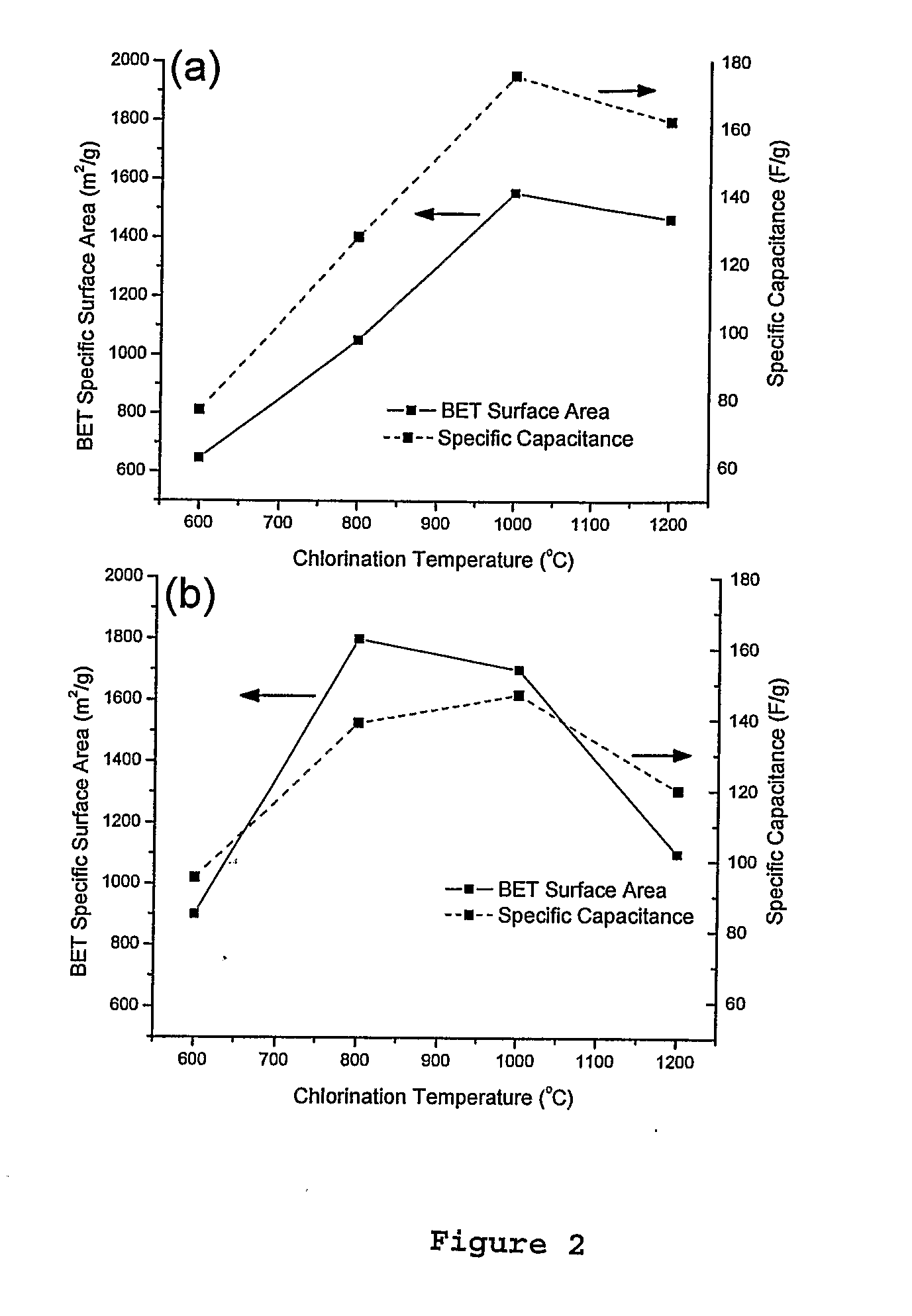

Nanocellular high surface area material and methods for use and production thereof

InactiveUS20090213529A1Improve conductivityHighly structuredElectrolytic capacitorsLayered productsPolymer scienceHoneycomb like

Nanocellular high surface area materials of a carbon material with high surface area that is controllable and which exhibits high conductivity, controllable structure and a precisely controllable pore size and methods for production and use of these materials are provided.

Owner:DREXEL UNIV

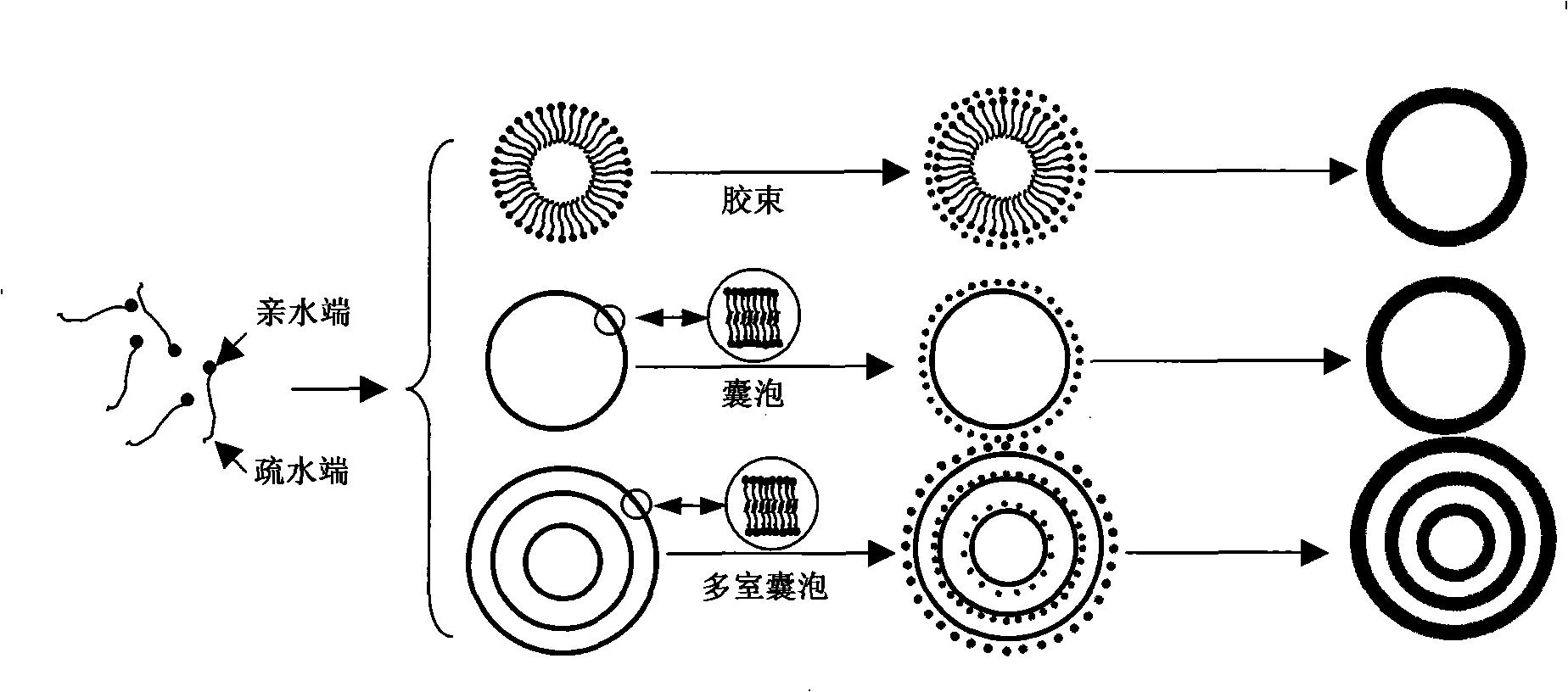

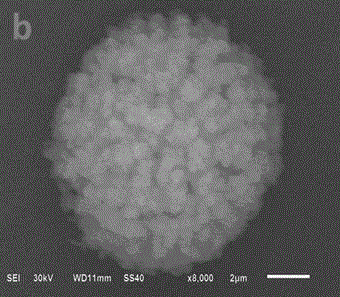

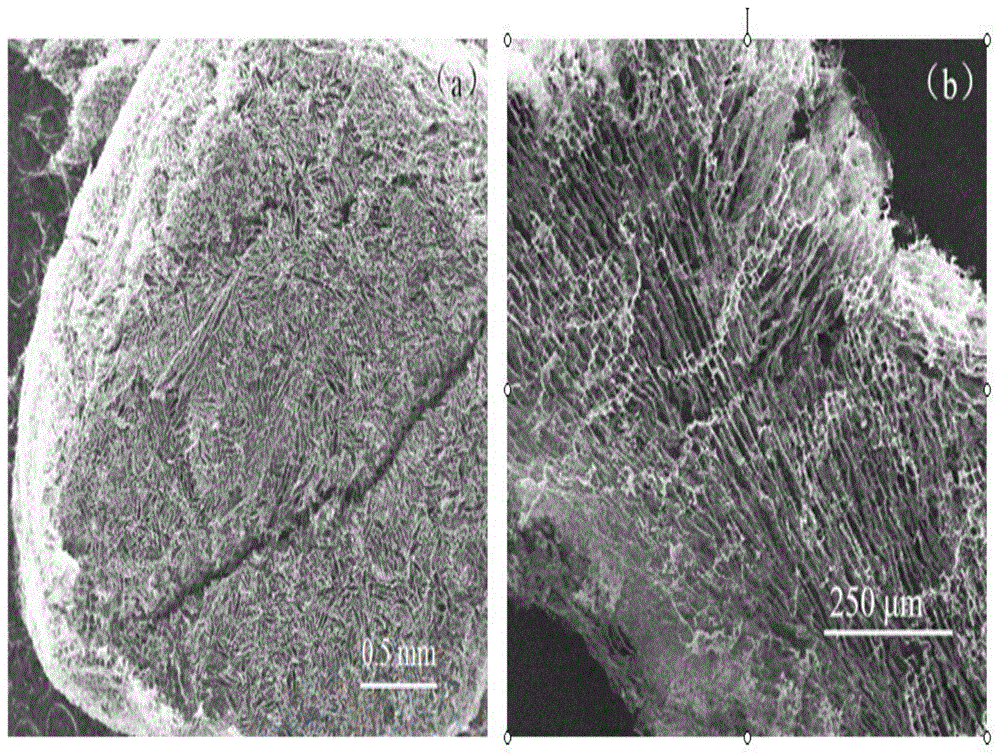

Method for producing multi-layer hollow pellet or stephanoporate pellet with multi-chamber vesicle mould plate method

InactiveCN101293192AEasy to makeControllable structureMicroballoon preparationMicrocapsule preparationActive agentSingle crystal

The present invention relates to a hollow sphere or porous sphere preparation method through vesicle and multi-chamber vesicle template method. The preparation method is characterized in that a surface active agent forms vesicle and multi-chamber as the soft template under certain conditions; inorganic material carries out nucleus growth on the surface of the soft template so as to copy the shape of the vesicle and multi-chamber vesicle and obtain a single-layer hollow sphere and multi-layer hollow sphere structure; due to different growing ways of crystal, the formed hollow sphere can be single crystal, polycrystal or multiaperture. The surface active agent is anion surface active agent, cation active agent or a mixer of the two surface active agents. The deposited inorganic material includes oxide, sulfide, simple metal substance, selenide, hydroxid or inorganic salts, which form core and grow on the surface of the vesicle and multi-chamber vesicle and finally obtain the single-layer and multi-layer hollow sphere structure and the porous sphere structure. Cu2O and ZnS hollow sphere or porous sphere is taken as the embodiment for detailed description.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Recovery method of positive active material in lithium ion battery waste material

InactiveCN103794832AHigh charge and discharge capacityImprove charge and discharge efficiencyWaste accumulators reclaimingBattery recyclingElectrochemistryLithium electrode

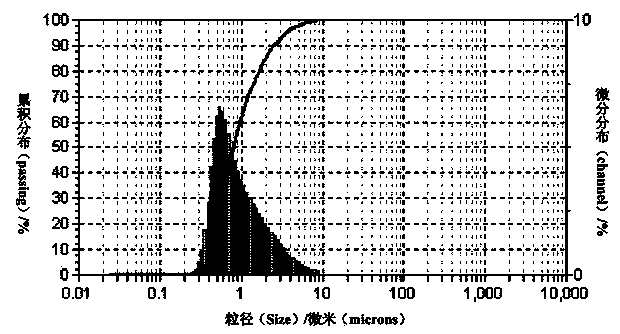

The invention provides a recovery method of a positive active material in a lithium ion battery waste material. The method includes the following steps: S1, heat treatment of the waste material is performed at 350-500DEG C in inert gas or reducing gas atmosphere; S2, powder product obtained in the step S1 is sintered at 600-800DEG C in the inert gas or reducing gas atmosphere; and the positive active material is obtained by recovery; the positive active material is one or multiple substance selected from lithium phosphate, lithium silicate or a vanadium material of lithium. The positive active material obtained by recovery is high in charge and discharge capacity, and high in charge and discharge efficiency, the obtained positive active material is even in particle size distribution, and complete in crystal structure, the technical process of the recovery method is simple, the requirement on equipment is low, the process is easy to control, at the same time, the recovery process may not cause a negative impact on the active material, physical and chemical properties and electrochemical activity of the active material may not be affected, the recovery and reuse of the positive active material raw material can be realized, the cost can be saved, and the recovery method has environmental-friendly benefits.

Owner:BYD CO LTD

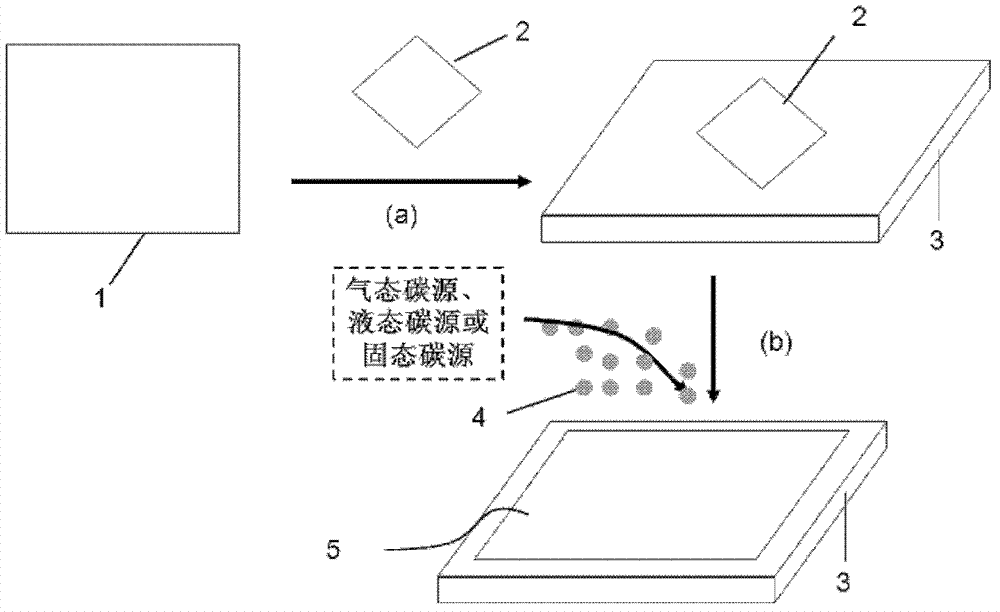

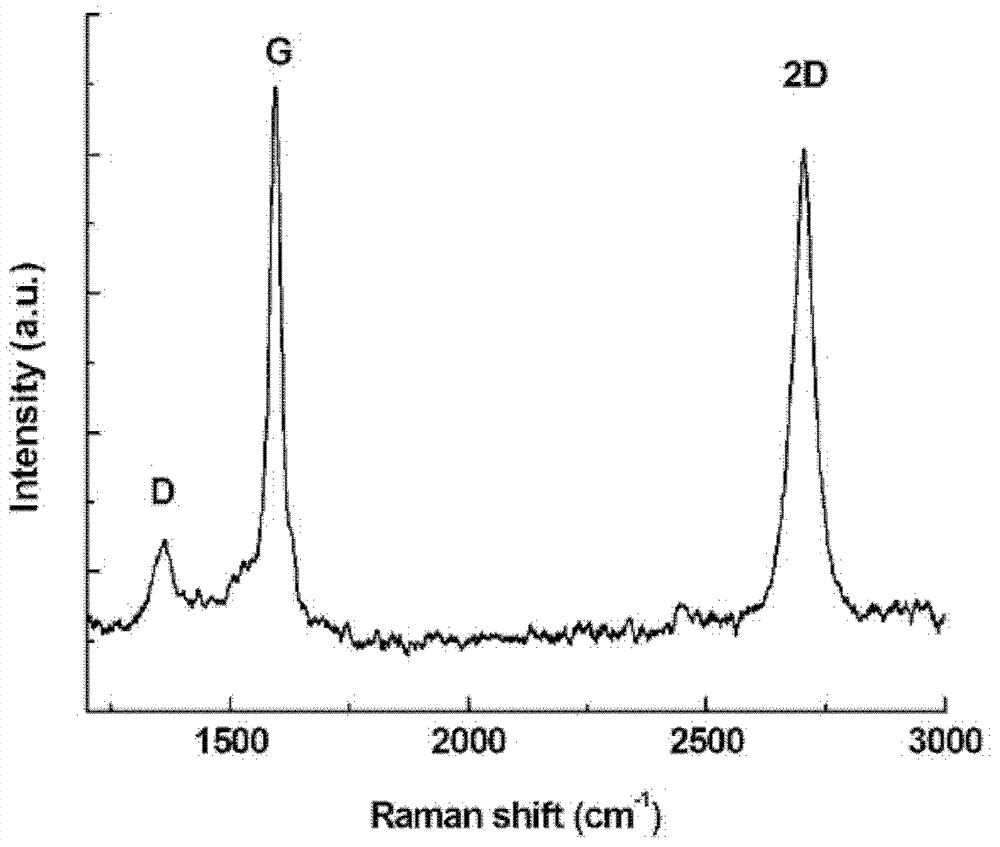

PrPrearation method for graphene film

ActiveCN102897750AThickness is easy to controlControllable structureGrapheneCvd grapheneGraphene foam

The invention discloses a preparation method for a graphene film. The method comprises the steps of putting small sheets of the in advance synthetic graphene film on a substrate, and growing the graphene film on the substrate by using the small sheets of the in advance synthetic graphene film as induced points for the growth of s large-area graphene film and adopting carbon atoms released by carbon atom-containing gas carbon source, solid carbon source, liquid carbon source or composite carbon source materials thereof. The graphene film can directly grow on the substrate of practical application graphene film, so that the graphene film needs not to be transferred when being used. The number of layers, the structure and the size of the prepared graphene film are easy to control; the temperature for growing the graphene film can be 0 DEG C-2000 DEG C; the prepared graphene film has excellent photoelectric characteristics and is suitable for large-scale manufacture of optoelectronic devices.

Owner:ZHEJIANG UNIV

Method for preparing hydrophilic low catching molecular composite ultrafiltering membrane

InactiveCN101053779AImprove hydrophilicityLow molecular weight cut offSemi-permeable membranesPolyelectrolyteSurface structure

The invention relates to a method for preparing a hydrophilic low retain molecular weight composite ultrafiltration membrane. The invention uses polysulfone or polyethersulfone as membrane material to prepare water repellent ultrafiltration membrane-substrate membrane with high retain molecular weight by transfer method; and based on this, the polyelectrolyte multilayer film is assembled on the ultrafiltration membrane-substrate membrane as a composite layer using layers static self-assembly technology to get the hydrophilic low retain molecular weight composite ultrafiltration membrane. The said composite ultrafiltration membrane preparation method in the invention is characterized in low cost and simple process. The surface of the composite ultrafiltration membrane prepared by the said method in the invention is electriferous, electrical property is controlled, and the surface structure is controlled. The invention has good retain performance to the low molecular weight solute, and also has better anti pollution performance.

Owner:SHANGHAI UNIV

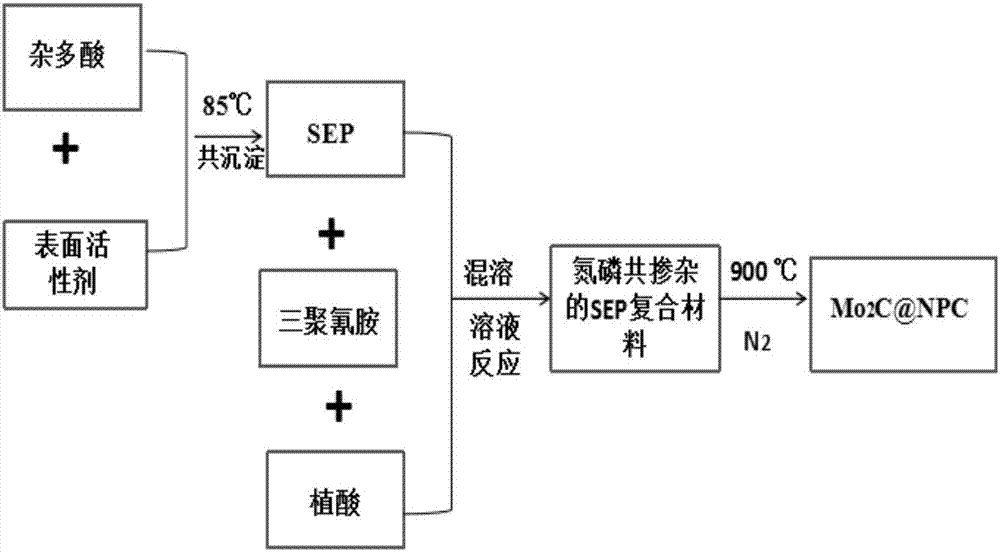

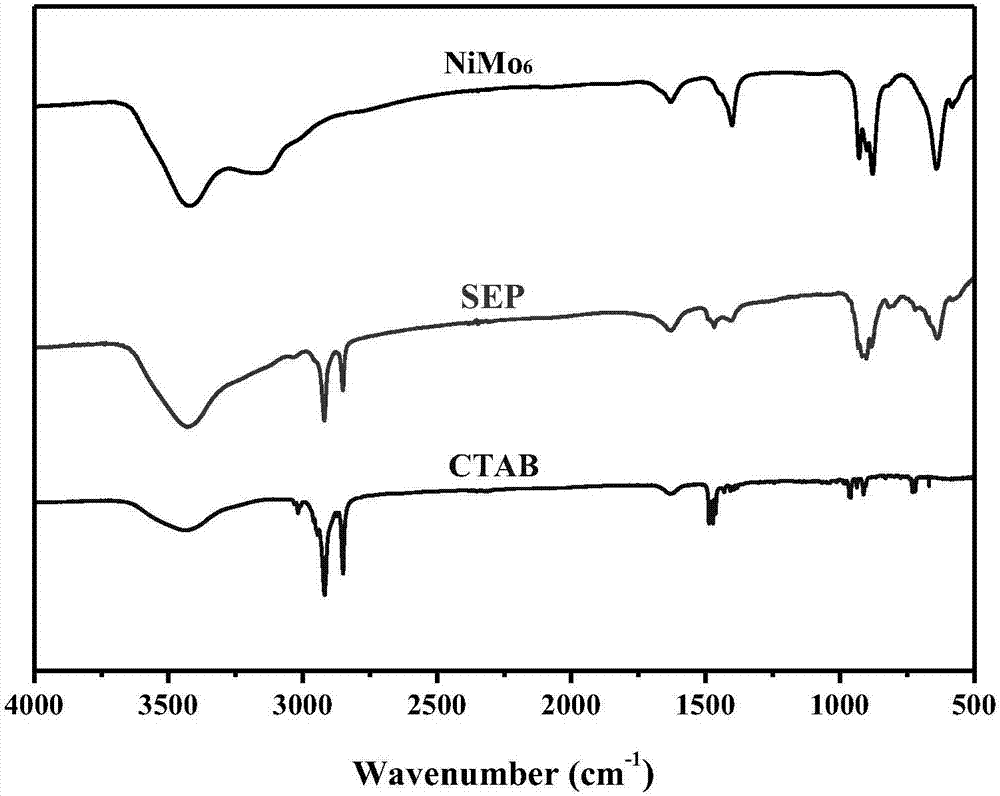

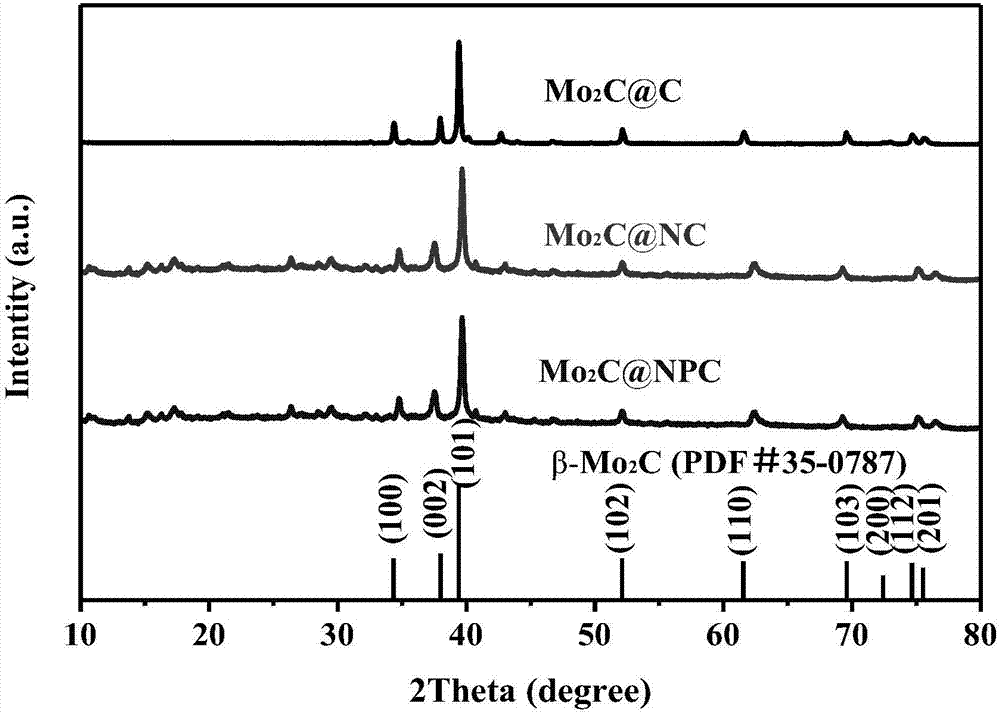

Nitrogen-phosphorus codoped carbon loaded molybdenum carbide or tungsten carbide catalyst and preparing method and application thereof

ActiveCN107999108AClear structureControllable structureCatalyst activation/preparationElectrodesIonTungsten

The invention provides a nitrogen-phosphorus codoped carbon loaded molybdenum carbide or tungsten carbide catalyst and a preparing method and application thereof. The preparing method includes the following steps that a coprecipitation method is used for preparing a SEP compound material from a surfactant and heteropolyacid or polyoxometalate, the surfactant is a cationic surfactant or ionic liquid surfactant, and the heteropolyacid or polyoxometalate contains molybdenum or tungsten; the SEP compound material, melamine and phytic acid are used as raw materials for synthesizing a SEP-MA-PA compound material through a mixing and dissolving method; under protection of inert gas, the SEP-MA-PA compound material is subjected to heat treatment and cooled to obtain the nitrogen-phosphorus codopedcarbon loaded molybdenum carbide or tungsten carbide catalyst. Nanoparticles of the nitrogen-phosphorus codoped carbon loaded molybdenum carbide or tungsten carbide catalyst are small in size and areof a porous structure, by means of nitrogen-phosphorus heteroatom doping, the conductivity of the catalyst is enhanced, and the catalyst has efficient performance of electrolyzing water for preparinghydrogen.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

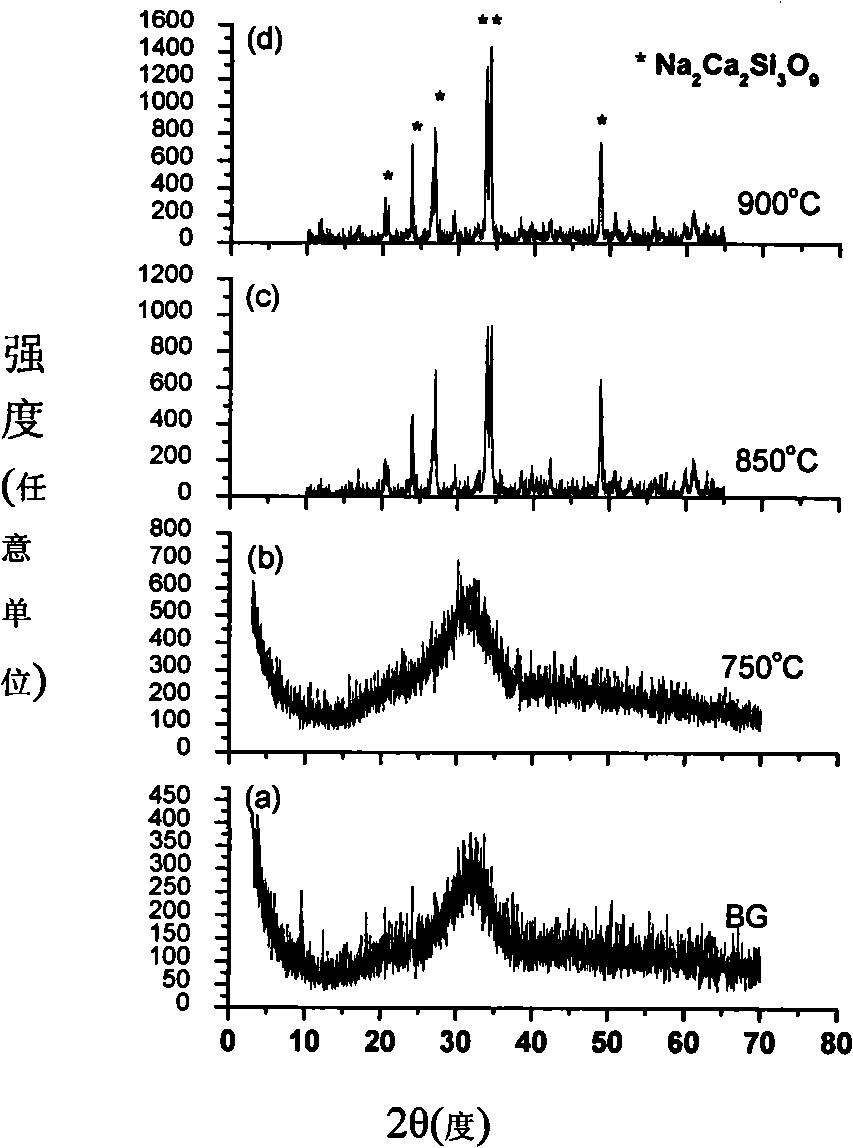

Degradable dynamics enhancement type bioglass radical porous composite material and preparation method thereof

InactiveCN101288780ARaise the sintering temperatureHigh compressive strengthBone implantStress concentrationCell-Extracellular Matrix

The invention relates to a biological glass base porous composite material of a degradable mechanical enhanced type and a preparation method thereof. The material takes a biological glass porous stent which comprises macroporous channels and mediated pore channels as matrix. Adjacent macroporous channels are mutually communicated. The internal and external surfaces of the macroporous channels and mediated pore channels are provided with gel layers which are assembled layer-to-layer by the biomolecules with positive and negative charges alternatively. The biological glass matrix is made from the components with the following weight percentage of 16-38 percent of CaO, 0-10 percent of P2O5, 45-80 percent of SiO2, 0-0.1 percent of SrO and 0-22.5 percent of Na2O. The releasing speed of the biological active ions of the biological glass base porous composite material which is similar to the extracellular matrix and is decorated by the layer-to-layer assembly of the charges of different polarity of the biomolecules can be effectively cut and controlled. The walls of the pore channels are beneficial to the adhesion growth of cells. The mechanical strength, the fracture toughness and the machinability are good. And the application of the regeneration treatment on the bone gear injury home position of a stress concentrated part can be satisfied.

Owner:ZHEJIANG UNIV

Method for preparing Nano silicon dioxide

A process for preparing nano-SiO2 includes such steps as adding water-soluble polymer and / or water-soluble organic C1-C8 alcohol to the solution alkali-metal silicate, stirring adding weak organic acid as catalyst, hydrolyzing reaction to obtain the hydrosol, washing, filter, and natural drying or supercritical extracting. The obtained amorphous nano-SiO2 has high purity and dispersity and large specific surface area.

Owner:BEIJING UNIV OF CHEM TECH +1

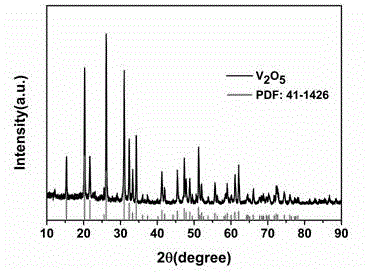

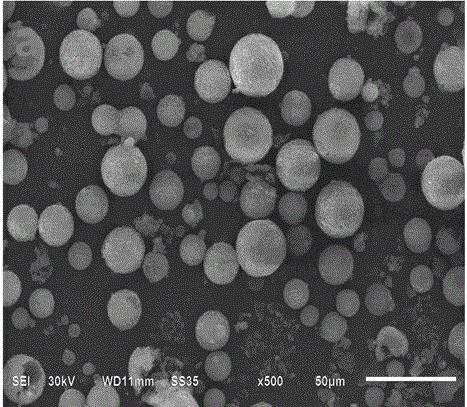

Porous V2O5/C composite microspheres of lithium secondary battery positive electrode material and preparation method of porous V2O5/C composite microspheres

InactiveCN104466102AEffective control of particle sizeEffective control of morphologyCell electrodesMicrospherePolymethyl methacrylate

The invention discloses porous V2O5 / C composite microspheres of a lithium secondary battery positive electrode material and a preparation method of the porous V2O5 / C composite microspheres. The porous V2O5 / C composite microspheres are formed by clustering carbon coated V2O5 nano composite particles with the particle sizes of 5-30 mirons, and the porous V2O5 / C composite microspheres are internally provided with porous structures. The preparation method comprises the following steps of synthesizing crosslinked polymethyl methacrylate PMMA microgel spheres, hydrolyzing partially so as to act as a mold plate for synthesizing the porous V2O5 / C composite microspheres; adsorbing VO<2+> to three-dimensional meshes of the PMMA mold plate, changing the pH value of an adsorption solution, hydrolyzing the VO<2+> to generate V2O5 nano particles, and filling the three-dimensional meshes in situ with the V2O5 nano particles so as to obtain a V2O5 / PMMA precursor; and forging the precursor so as to obtain the porous V2O5 / C composite microspheres. The composite microsphere has the beneficial effects of improving the multiplying performance and the cycle performance and the like; the preparation method is simple in technology, and is suitable for being used in large-scale industrial production.

Owner:XIANGTAN UNIV

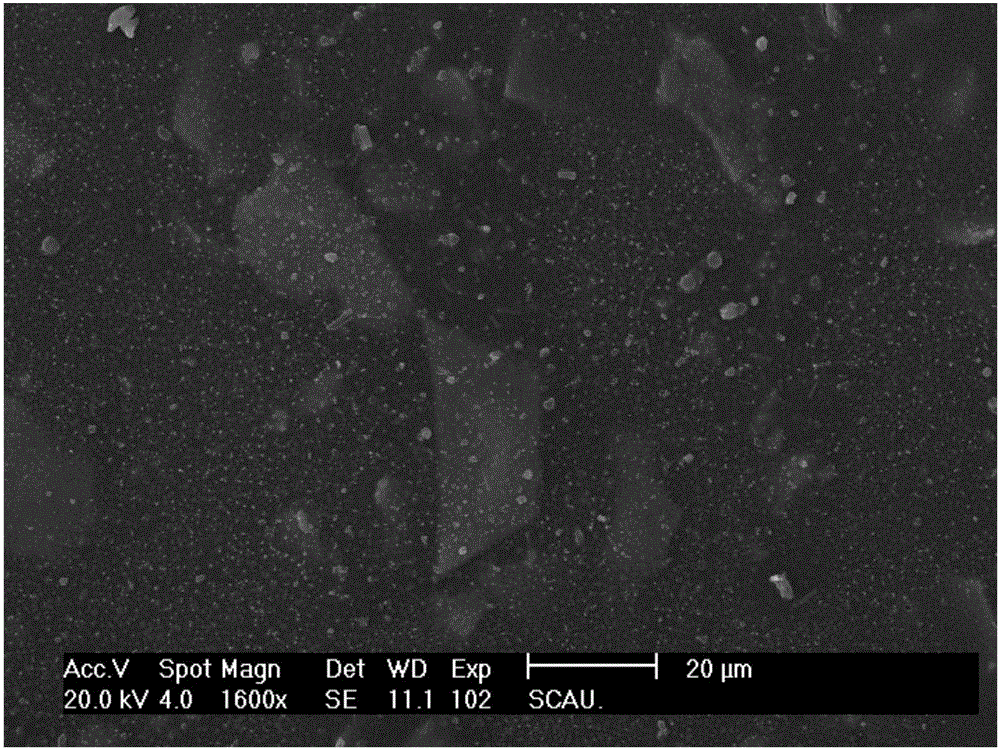

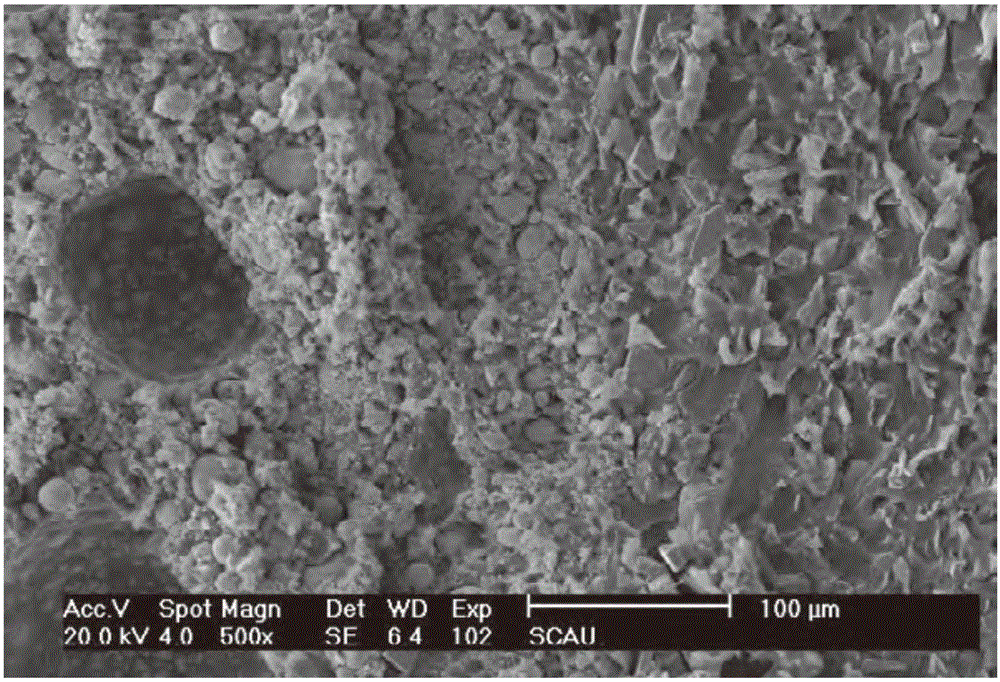

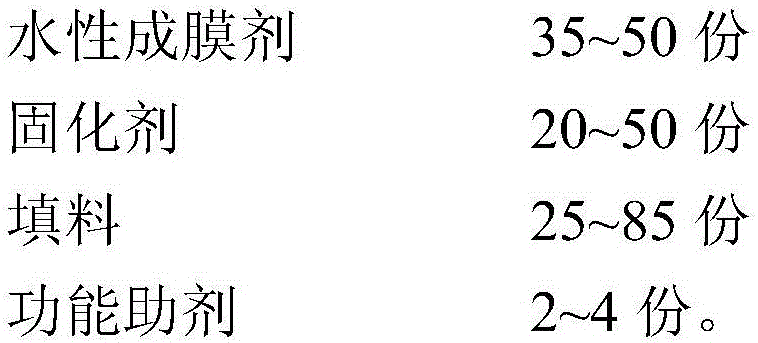

Petrochemical water-based high-temperature-resistant, anticorrosive and abrasion-resistant coating and method for preparing same

InactiveCN105885620AMeet environmental protection requirementsGood adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedPetrochemical

The invention belongs to the field of coating, and discloses petrochemical water-based high-temperature-resistant, anticorrosive and abrasion-resistant coating and a method for preparing the same. The petrochemical water-based high-temperature-resistant, anticorrosive and abrasion-resistant coating comprises a coating of water-based zinc-rich primer, a coating of water-based mica iron oxide intermediate paint and a coating of water-based nanometer abrasion-resistant finish paint. The three coatings respectively comprise, by weight, 35-50 parts of water-based film-forming agents, 20-50 parts of curing agents, 25-85 parts of packing and 2-4 parts of functional auxiliaries. The petrochemical water-based high-temperature-resistant, anticorrosive and abrasion-resistant coating and the method have the advantages that anticorrosive effects can be realized by the water-based zinc-rich primer and the water-based mica iron oxide intermediate paint, the water-based nanometer abrasion-resistant finish paint has high-temperature and abrasion-resistant functions, layer structures of a water-based mica iron oxide intermediate layer, the primer and the finish paint can be effectively adhered with one another, and accordingly the problem of easiness in peeling of existing coatings with multilayer structures can be solved; the three coatings are combined with one another, and accordingly requirements of petrochemical oil refining equipment on high-temperature-resistant, anticorrosive and abrasion-resistant performance of coating can be effectively met.

Owner:广州汤谱建筑装饰材料有限公司 +1

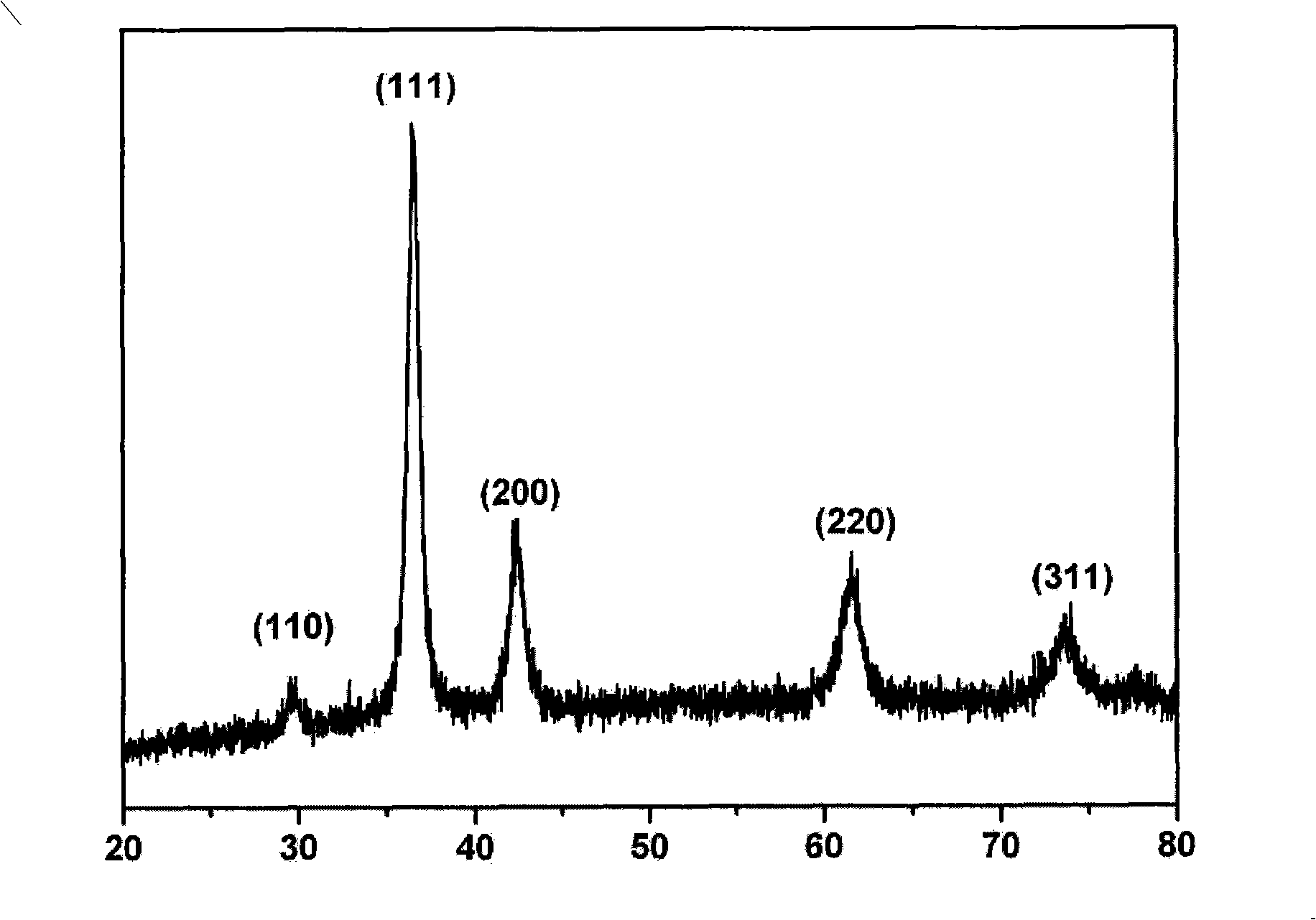

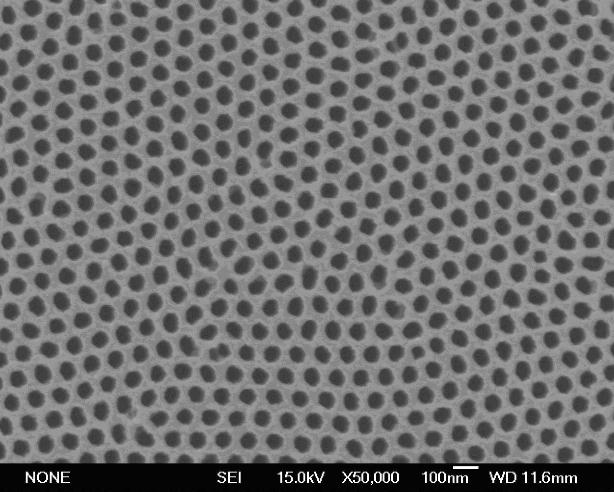

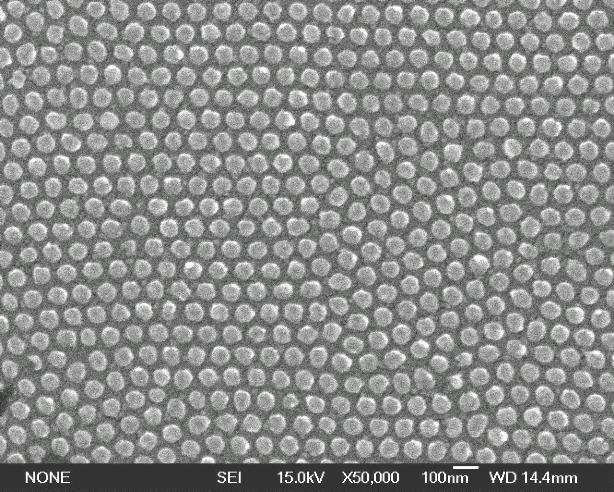

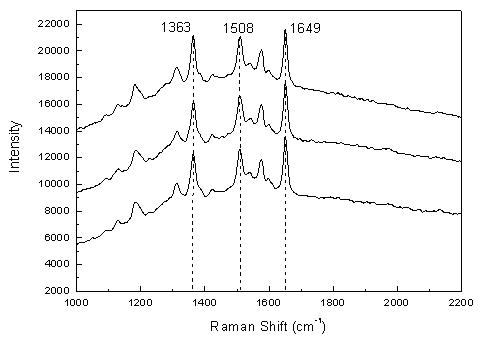

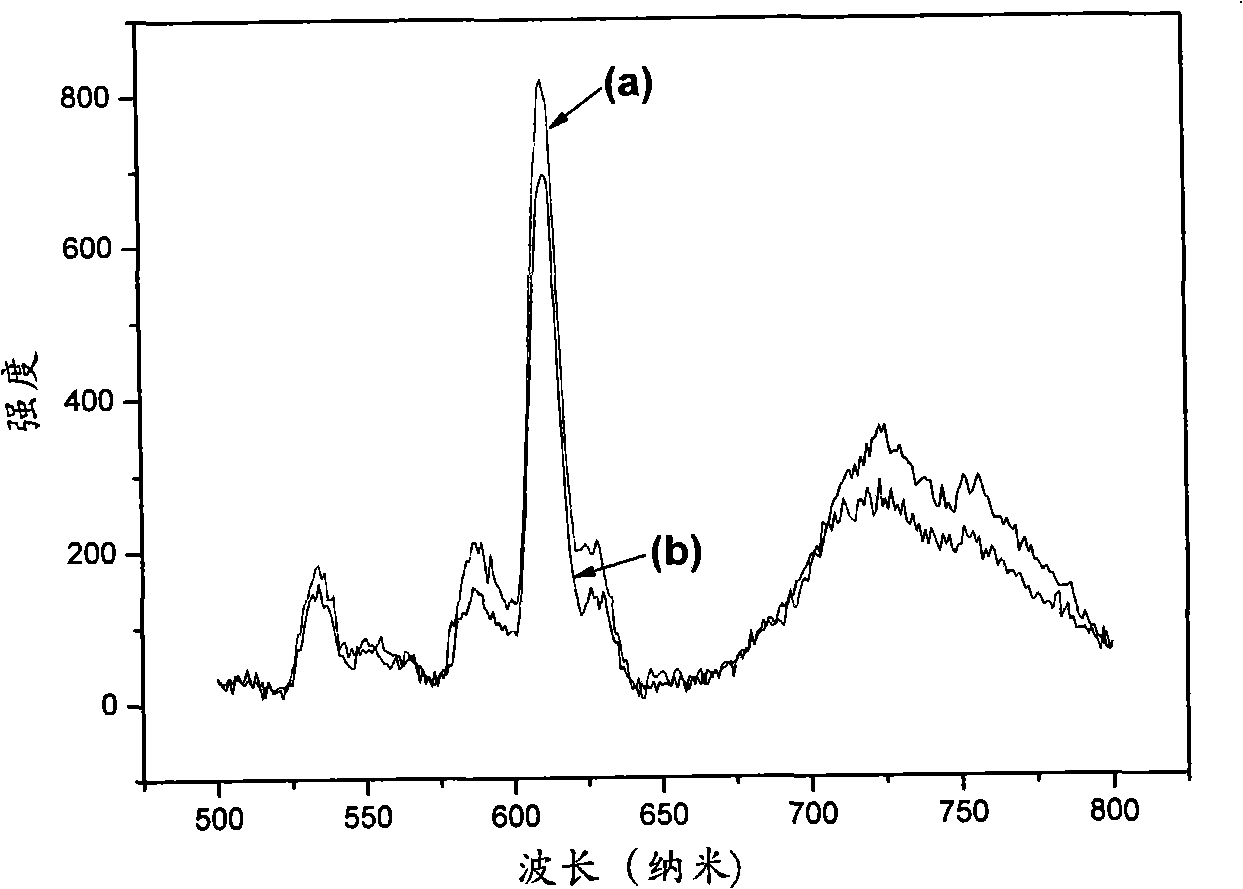

Silver nano lattice surface enhanced raman active substrate and preparation method thereof

InactiveCN102590179AUniform shapeControllable structureRaman scatteringNanotechnologyUnderlaySio2 nanoparticle

The invention discloses a silver nano lattice surface enhanced raman active substrate and a preparation method thereof. According to the substrate, silicon single crystal is used as an underlay; a silver nanoparticle array structure is deposited on the silicon surface; the particle size of the silver nanoparticles is 30-90 nm; and the center distance of the particles is 99-111 nm. The silver nano lattice surface enhanced raman active substrate provided by the invention has a uniform shape and a controllable structure, and has an obvious surface raman enhancement effect on analytes of different concentrations, and an enhancement signal is uniform and stable. According to the method, the structural parameters and the shape of a silver nano lattice can be adjusted according to structural parameters of an ultra-thin aluminum oxide template, so that different influences of different metal nano lattice substrates on a raman surface enhancement effect are realized. The substrate and the method have the advantages of easiness for operation, low cost and easiness for industrial production.

Owner:SHANGHAI UNIV

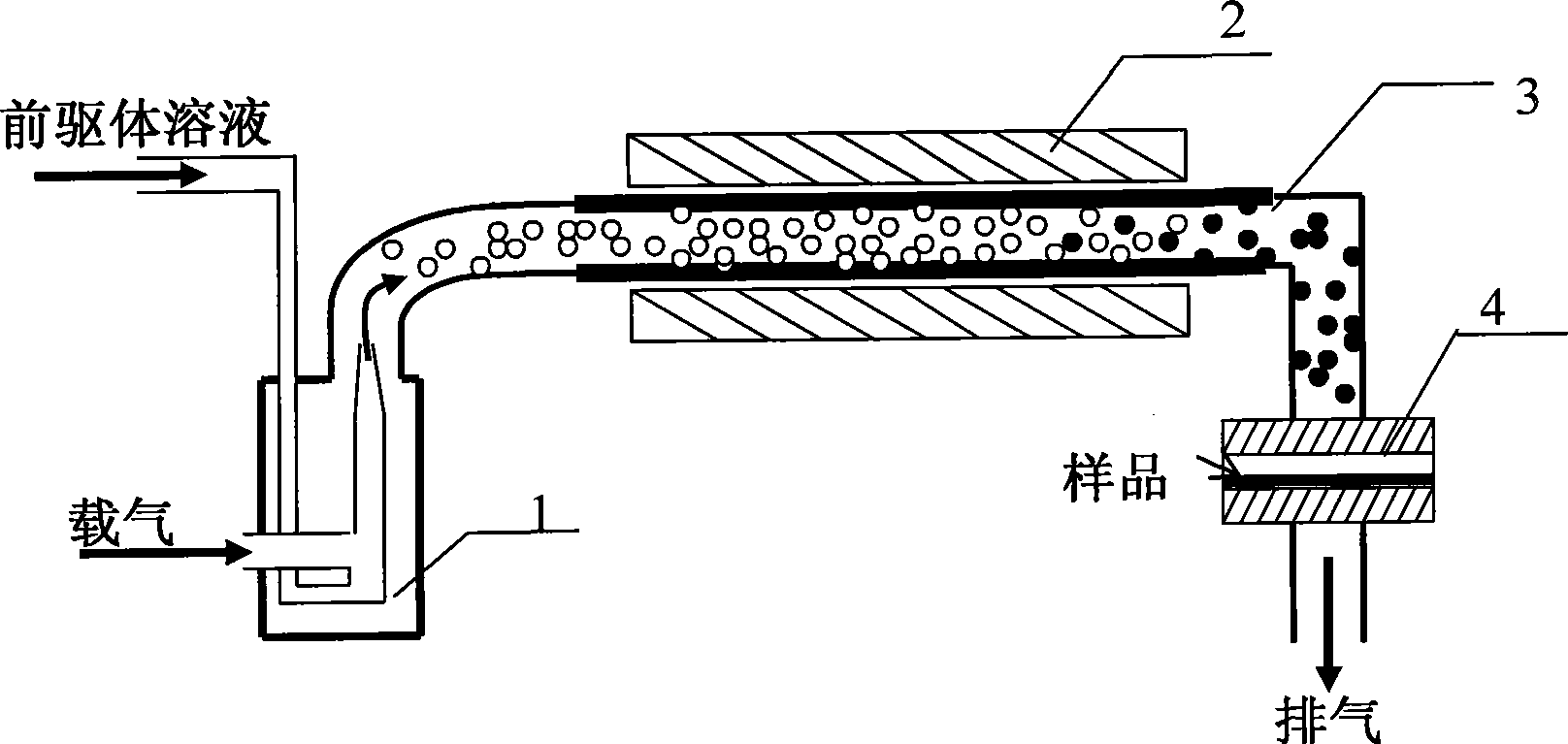

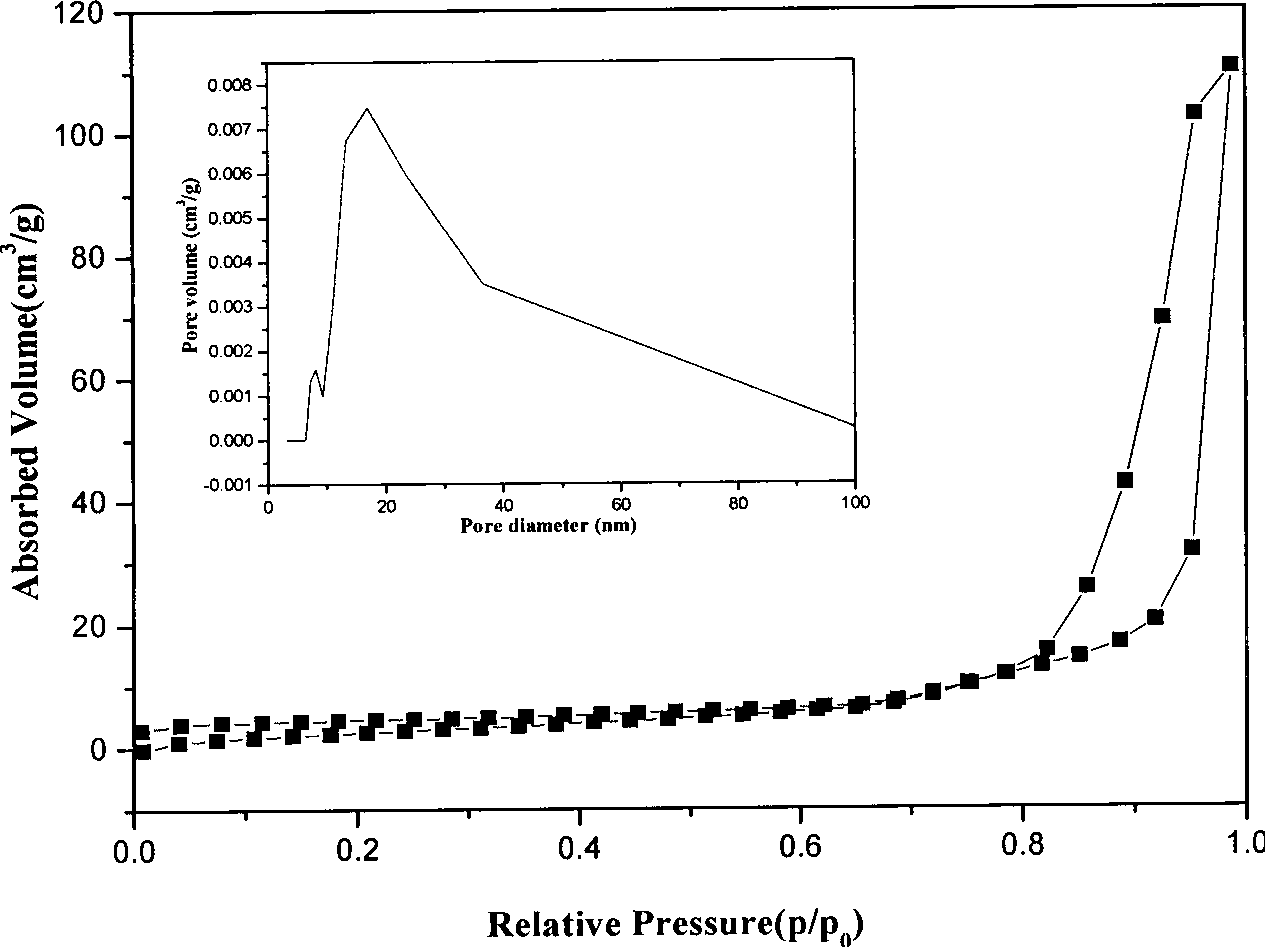

Porous structured bismuth titanate microsphere, preparation method and application thereof

InactiveCN101428210ASimple preparation processEasy to operateMetal/metal-oxides/metal-hydroxide catalystsAcetic acidMicrosphere

The invention discloses a bismuth titanate microsphere with a porous structure, as well as a preparation method and the application thereof. The porous-structure bismuth titanate microsphere is characterized in that the molecular formula thereof is Bi2Ti2O7, the grain diameter thereof is 0.5-2.0 Mum, the aperture thereof is 3.1-23.8 nm, the pore volume thereof is 0.02-0.20 cm<3> / g, and the specific surface area thereof is 8.4-47.1 m<2> / g. The preparation method comprises the following steps: using glacial acetic acid of bismuth salt or a glycerin solution, a surface active agent aqueous solution and titaniumivbutoxide or titanyl sulfate to form a precursor solution, in which the spray drying technique is applied to obtain a porous-structure bismuth titanate photocatalyst. The porous-structure bismuth titanate obtained can effectively degrade organic pollutants such as para-chlorophenol and the like through photocatalysis in visible light, so that the porous-structure bismuth titanate has a potential prospect of application. The invention has the advantages of easy attainment of raw materials, low preparation cost, simple process and easy control of conditions, and meanwhile provides a preparation process, from which synthesis of other photocatalyst materials can draw on experience.

Owner:SHANGHAI NORMAL UNIVERSITY

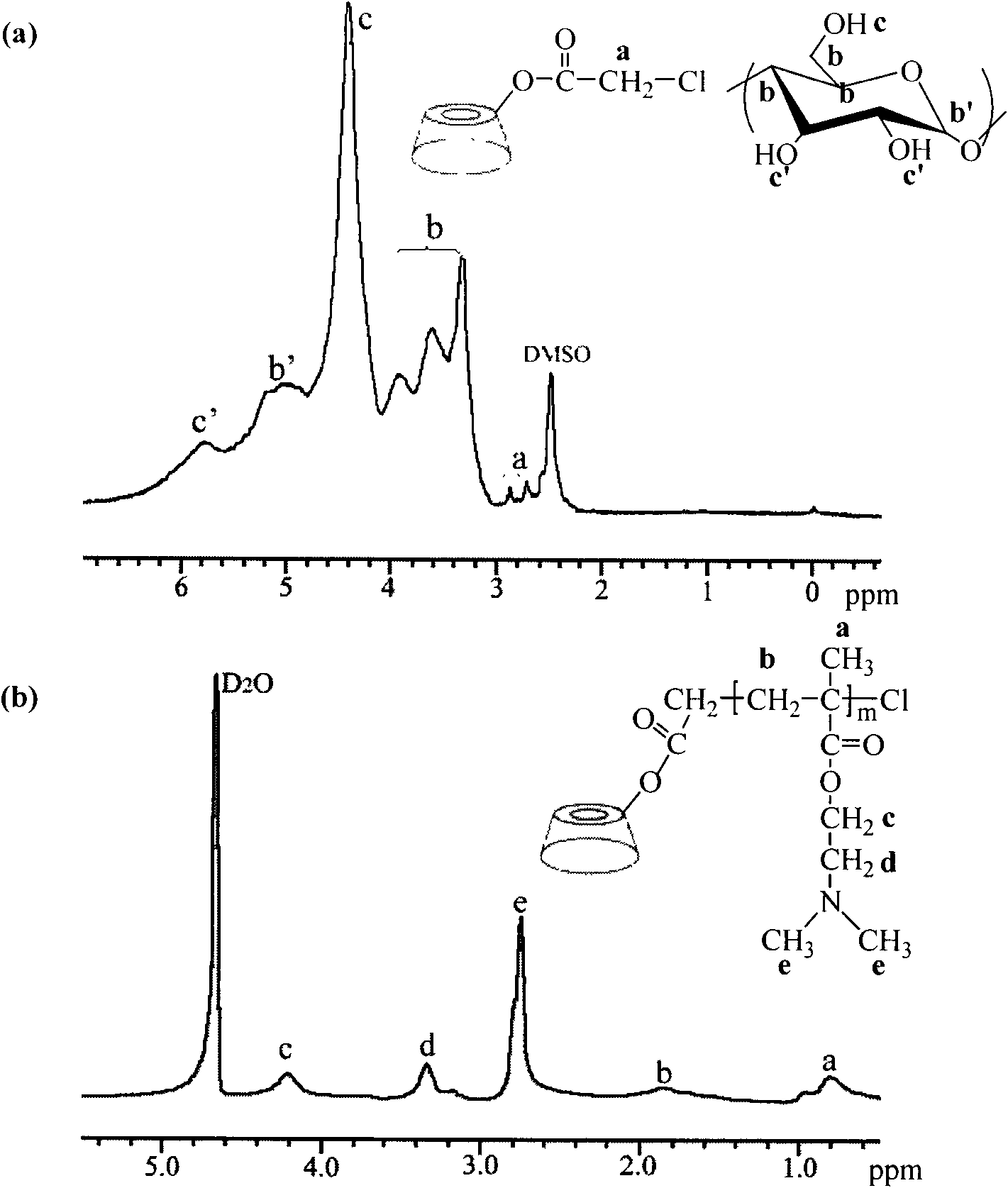

Microgel based on cyclodextrins and preparation method thereof

InactiveCN101665576AThe synthesis steps are simpleQuick responseMacromolecular non-active ingredientsPolymer scienceCationic polyelectrolytes

The invention belongs to the fields of high polymer and biological materials, which discloses a microgel based on cyclodextrins compounds and a preparation method thereof, and star cationic polyelectrolyte based on cyclodextrins (CD) and block anionic polyelectrolyte based on polyethylene glycols (PEG) can be combined to form the microgel under electrostatic effect. The invention uses natural polymer polysaccharide, such as the cyclodextrins, as raw materials for preparing the cationic electrolyte, the microgel has good biocompatibility, low price and convenience in accessibility; and based onthe electrostatic effect, the invention uses the electrostatic effect between a PDMAEMA chain segment in the synthetic cationic polyelectrolyte and a PMAA chain segment in the anionic polyelectrolyteto form a physical microgel without covalent bond crosslinking, and the preparation method is simple and easy to control.

Owner:江苏景越塑料科技有限公司

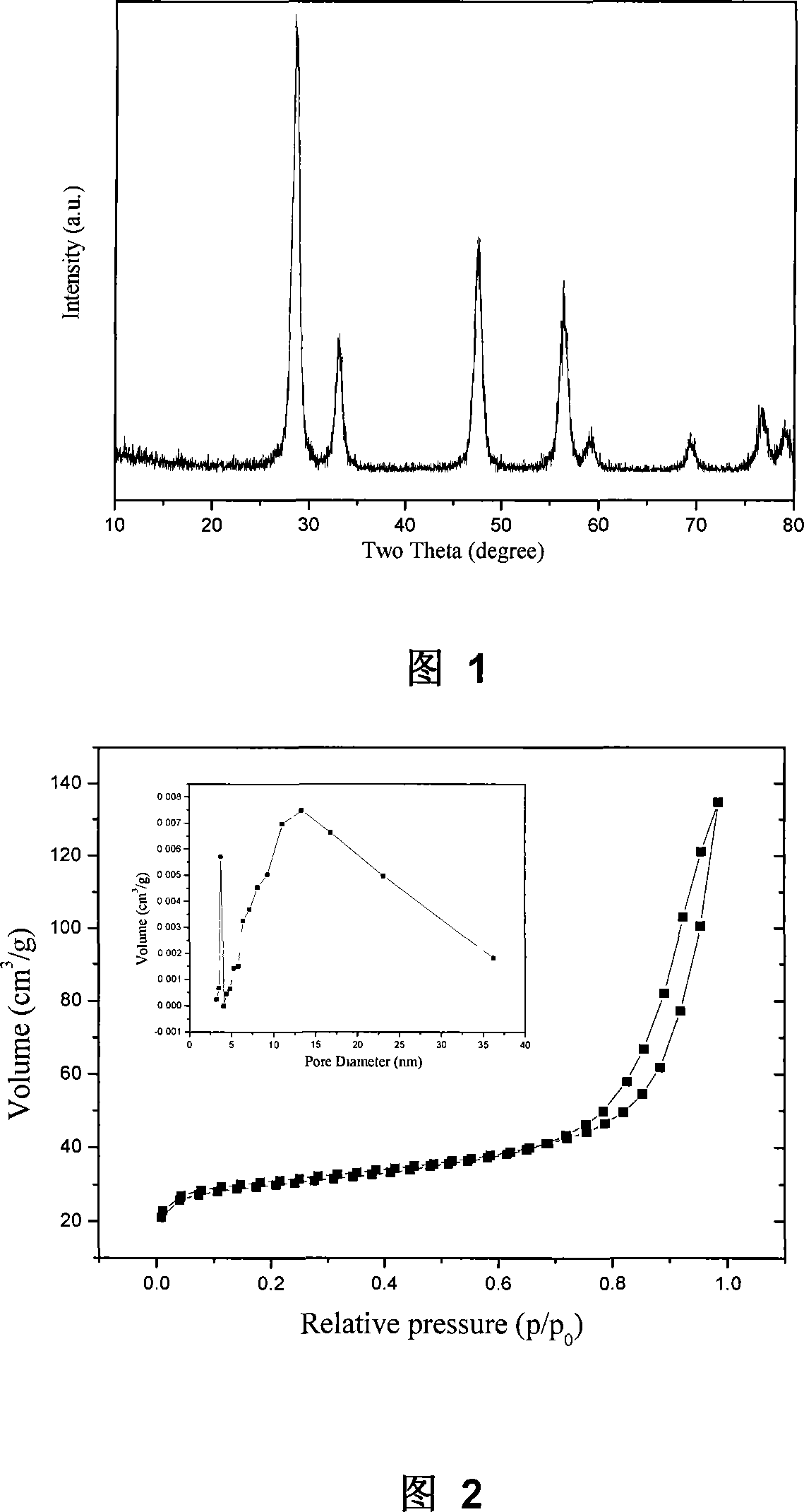

Method of preparing cerium oxide nano-rod

ActiveCN101407330ALarge specific surface areaHigh catalytic activityRare earth metal compoundsCeriumCerium oxide

The invention relates to a method for preparing a cerium oxide nanometer rod at a mild condition, which belongs to the preparation technical field of inorganic nanometer materials, and comprises the main steps as follows: (1) the preparation of a cerium salt liquor: cerium salt is dissolved in an appropriate amount of deionized water and prepared into the 0.1-0.8mol / l cerium salt liquor; (2) the preparation of a concentrated alkali liquor: alkali is dissolved by using the appropriate amount of deionized water and prepared into the 10-15mol / l concentrated alkali liquor; and (3) the mixing of the two liquor for carrying out liquid phase reaction: the cerium salt liquor is quickly poured into the concentrated alkali liquor at the temperature of 10-40 DEG C; the volume ratio of the two used liquor is 1:3 to 1:7; after the reaction is finished, a white precipitate is generated, stayed in the liquor for ageing for 1 hour to 9 days, then washed and dried and finally the cerium oxide nanometer rod is obtained.

Owner:SHANGHAI UNIV

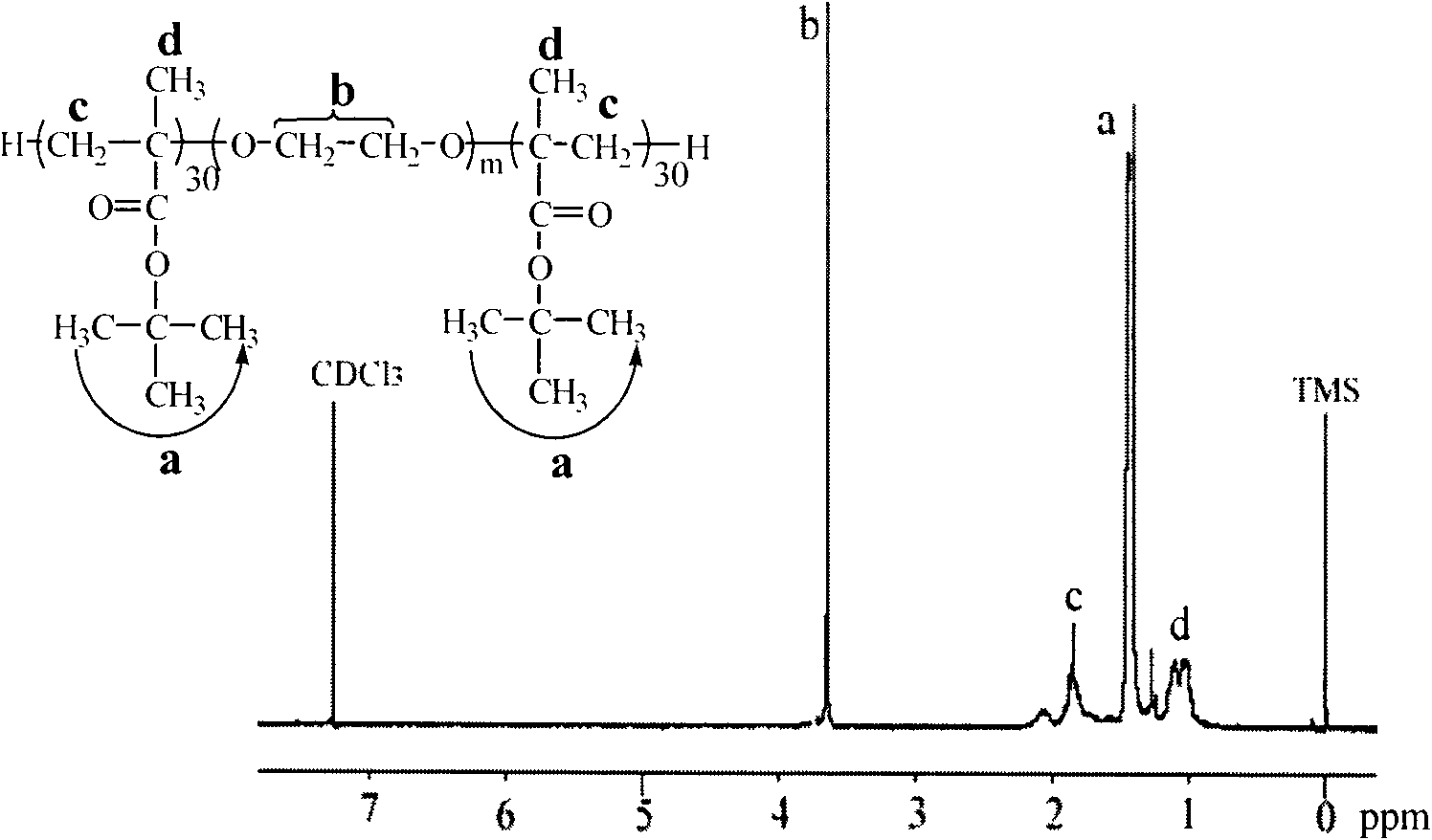

Poly(butylene succinate) and preparation method thereof

The invention discloses a poly(butylene succinate) which is prepared by copolymerizing succinic acid, butylene glycol and cyclic dibasic alcohol. The poly(butylene succinate) comprises succinic acid residue, butylene glycol residue and cyclic diol residue, wherein the butylene glycol residue accounts for 90-98% of the total dibasic alcohol, and the cyclic diol residue accounts for 2-10% of the total dibasic alcohol. The preparation method comprises the following steps: reacting succinic acid, butylene glycol and cyclic dibasic alcohol at 200-230 DEG C under the action of a catalyst to perform direct esterification, thereby obtaining an esterified substance; adding a stabilizer, and carrying out pre-polycondensation reaction at 220-250 DEG C to obtain a prepolymer; carrying out polycondensation reaction on the prepolymer at 235-250 DEG C while gradually reducing the vacuum degree of the reaction system to less than 150Pa; and after the polycondensation finishes, adding carbodiimide compounds into the reaction product, and mixing for 2-15 minutes, thereby obtaining the poly(butylene succinate). The polyester synthesized by the method disclosed by the invention has the advantages of high heat resistance, high melting point, controllable degradation rate, excellent mechanical properties and excellent processability.

Owner:KINGFA SCI & TECH CO LTD +2

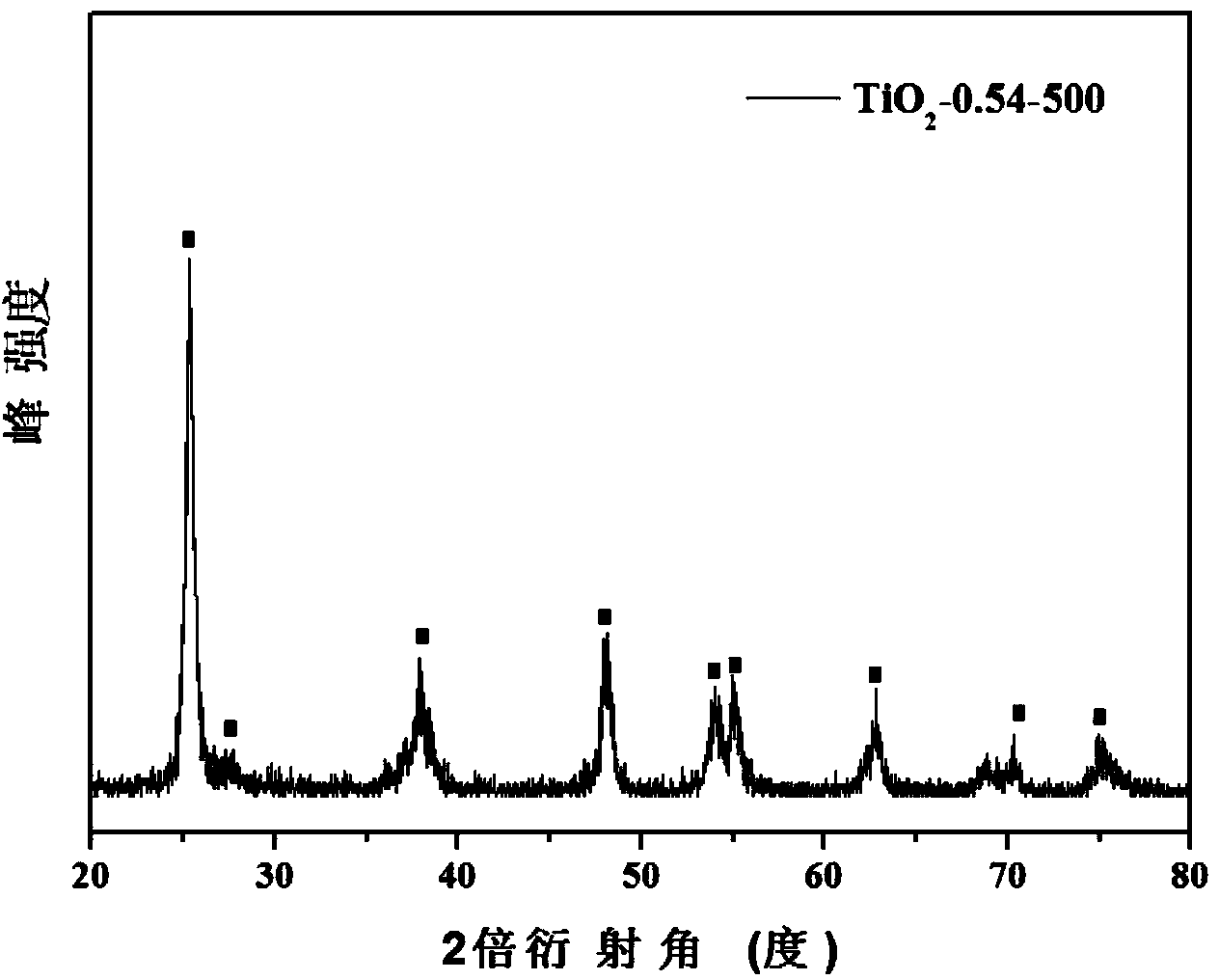

Ti<3+>-self-doped anatase titanium-oxide photocatalyst with large specific surface area, and synthetic method and applications thereof

InactiveCN103285852AIncrease heatAccelerateHydrogenMetal/metal-oxides/metal-hydroxide catalystsPhotocatalytic degradationChemistry

The invention discloses a Ti<3+>-self-doped anatase titanium-oxide photocatalyst with a large specific surface area, and a synthetic method and applications thereof. A microwave-assisted one-step method is used to prepare large specific-surface-area porous anatase TiO2. The catalyst is simple, fast and energy-saving in preparation method, and has environmental pollution in preparation process which meets green synthesis requirement. The prepared TiO2 has a Ti<3+>-self-doped porous structure which is beneficial for separation of a photo electron and a hole in a photocatalytic reaction process, and finally helps to improve quantum efficiency of the material in hydrogen production. The catalyst also is widely applicable to the field of antibiosis, photocatalytic degradation of a pollutant, lithium battery and the like.

Owner:SHANGHAI NORMAL UNIVERSITY

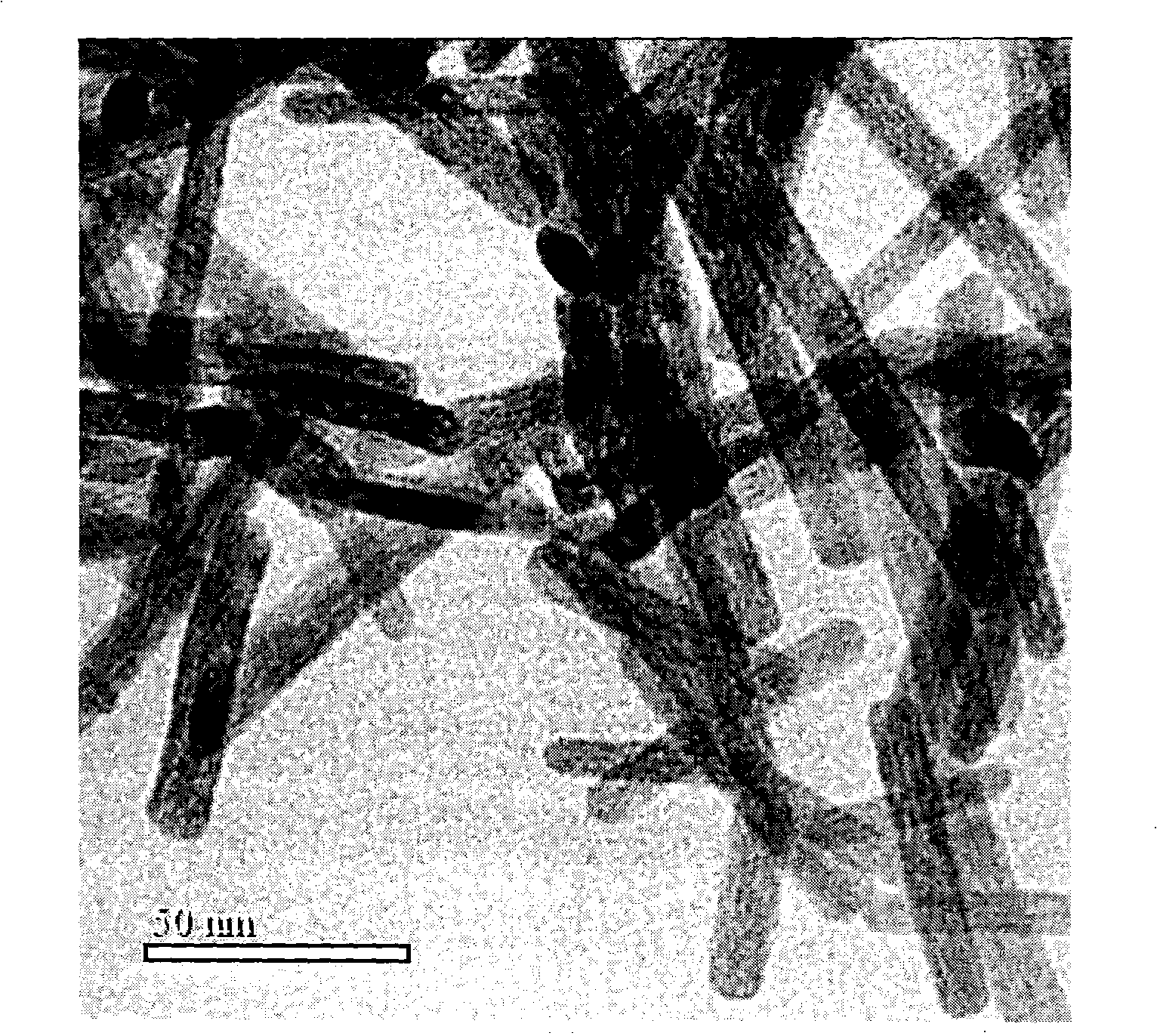

Thermal stable and super-hydrophobic ceramic-carbon nanotube composite membrane and application of membrane distillation water treatment thereof

ActiveCN107096393ALow resistance transmissionGuaranteed bondingMembranesGeneral water supply conservationReaction temperatureCarbon nanotube

The invention relates to a thermal stable and super-hydrophobic ceramic-carbon nanotube composite membrane and application of membrane distillation water treatment thereof, and belongs to the technical field of inorganic membranes. The composite membrane is prepared by the following steps of adopting a chemical vapor deposition method, using a ceramic hollow fiber membrane as a carrier, changing the different preparation conditions, such as a loading amount of a catalyst, reaction temperature and reaction time, and controlling the structure, loading amount and load state of the carbon nanotube, so as to obtain the ceramic-carbon nanotube hollow fiber composite membrane with different structures and properties. The composite membrane has the advantages that by regulating and optimizing the preparation conditions, the thermal stable and super-hydrophobic composite membrane with a carbon nanotube complete covering structure is obtained; the seawater freshening, high-salt wastewater zero drainage, and other wastewater high-efficiency treatment, such as electroplating heavy metal wastewater, dyeing and printing wastewater and antibiotic wastewater, can be realized via the composite membrane; and the good membrane distillation property is realized.

Owner:DALIAN UNIV OF TECH

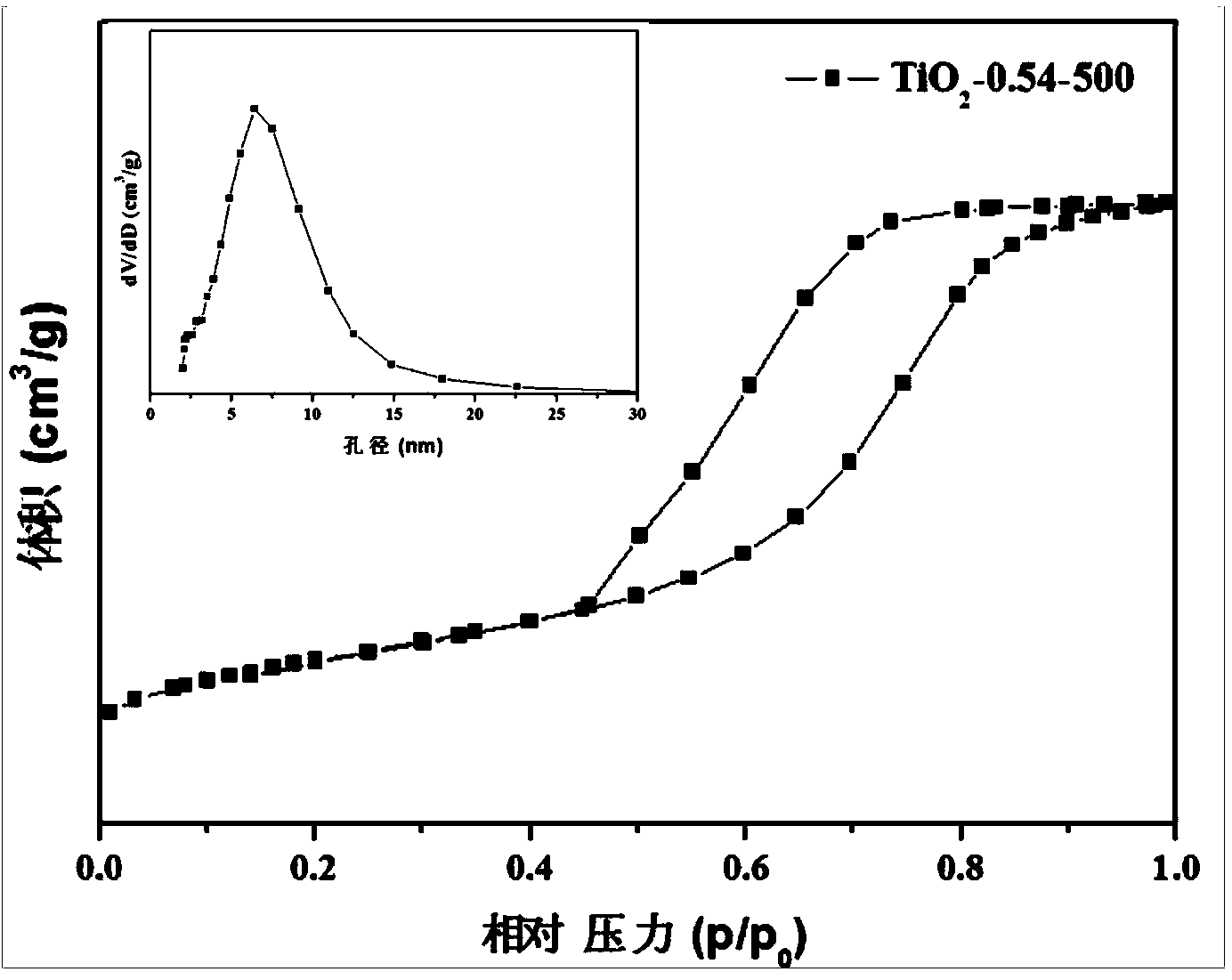

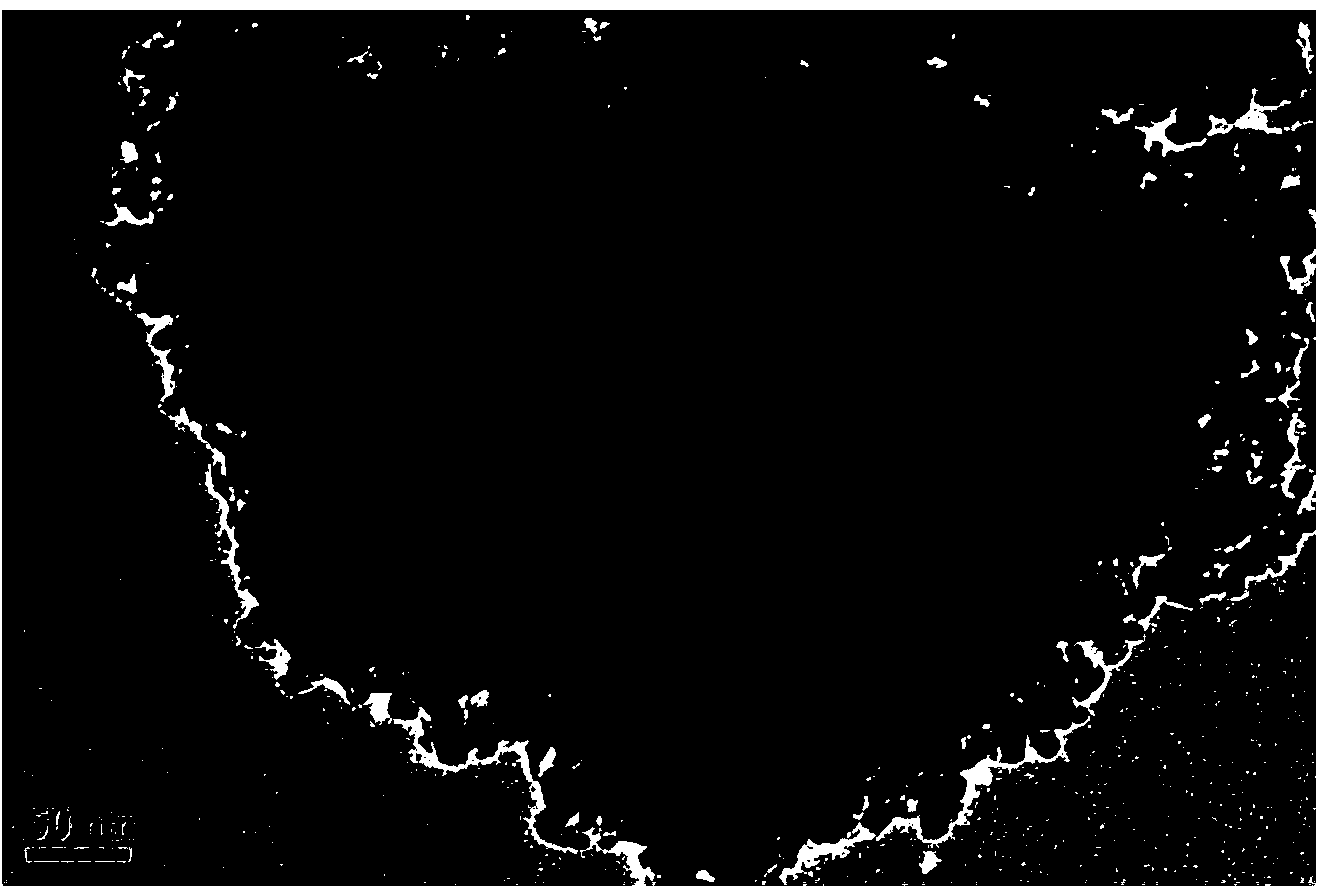

TiO2 photocatalyst with mesoporous structure, as well as preparation method and applications of photocatalyst

InactiveCN103949232ALarge specific surface areaSimple preparation processPhysical/chemical process catalystsDispersed particle separationSolar cellLithium-ion battery

The invention discloses a TiO2 photocatalyst with mesoporous structure, as well as a preparation method and applications of the photocatalyst. The TiO2 photocatalyst with the mesoporous structure can be prepared by adopting a water phase volatilization and induction self-assembling method, the aperture of the prepared TiO2 photocatalyst ranges from 6.6nm to 10.7nm, and the specific surface area of the prepared TiO2 photocatalyst ranges from 72.2m<3> / g to 40.4m<3> / g. The preparation method of the photocatalyst is simple, and mild and clean in conditions, as well as basically free from environmental pollution in the preparation process. The catalyst can be widely applied in the fields of hydrogen production by using photocatalysis, photooxidization of NO, a solar cell, a lithium ion battery, antibacterial and photocatalytic pollutant treatment, and the like.

Owner:SHANGHAI NORMAL UNIVERSITY

Manganese dioxide nanowire @ multidimensional mesoporous metal-organic framework adsorbent and preparation therefor

ActiveUS20180056269A1Improve performanceEfficient use ofOther chemical processesWater contaminantsNanowireSorbent

A manganese dioxide nanowire @ multidimensional mesoporous metal-organic framework adsorbent and application method thereof for removing heavy metals from water. A multidimensional mesoporous metal-organic framework material is prepared from metal ions and organic ligands by means of a self-assembly reaction; a manganese dioxide nanowire is prepared from manganese salt and thiosulfate by means of reaction in a reaction kettle. The adsorbent possesses not only the characteristics of a multidimensional mesoporous metal-organic framework material, such as reticulated pore adaptation, a large specific surface area, and abundant reaction sites, but also the oxidative and catalytic properties of manganese dioxide nanowire.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

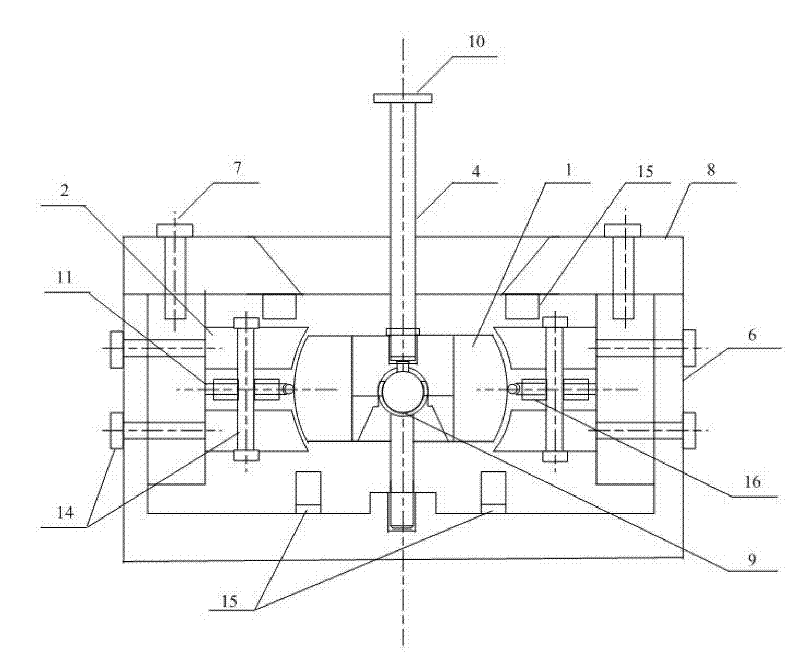

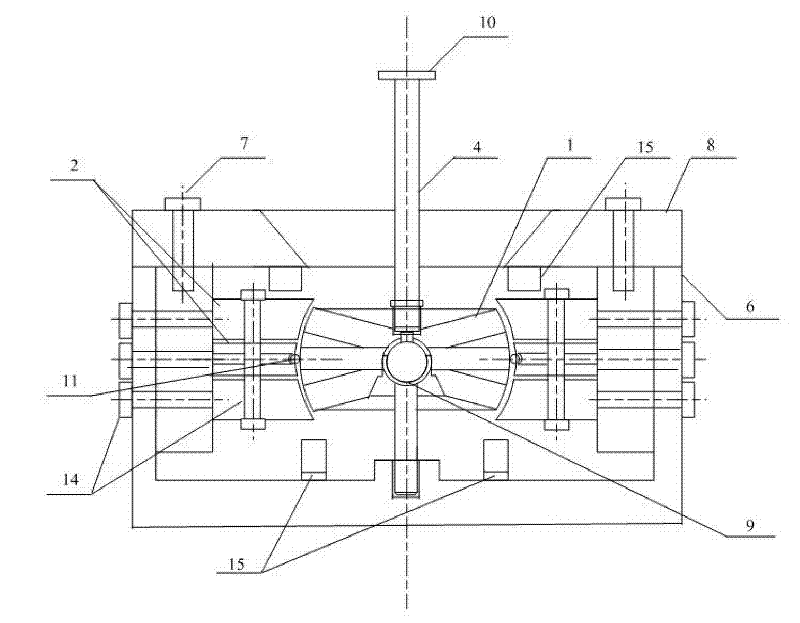

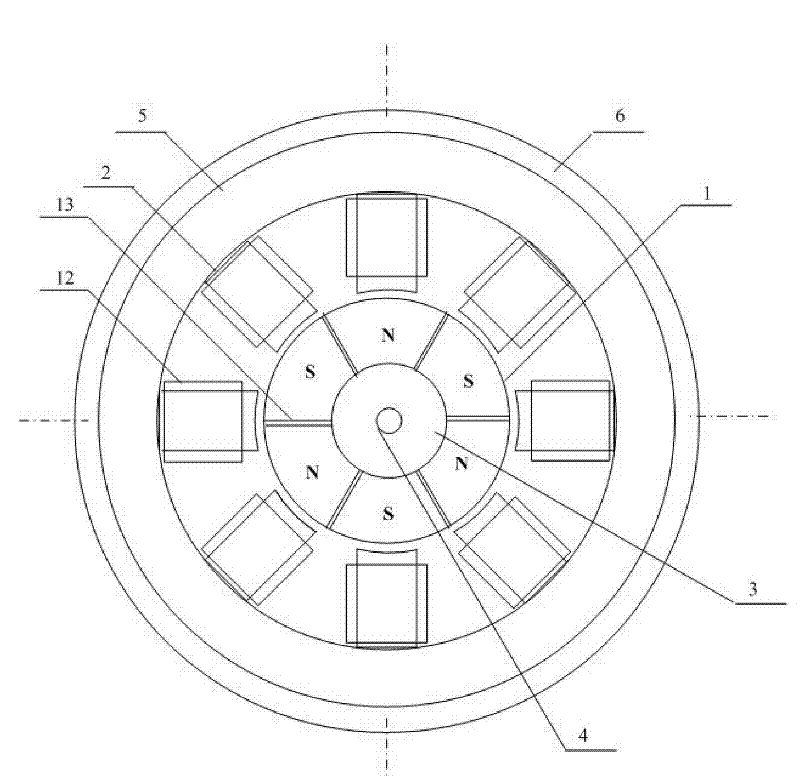

Permanent-magnet rotor deflection-type three-degree-of-freedom motion motor

ActiveCN102480253ASolve wear and tearSolve problems such as poor torque output capabilityMagnetic holding devicesPermanent magnet rotorLoop control

The invention provides a permanent-magnet rotor deflection-type three-degree-of-freedom motion motor, which relates to the technical field of permanent-magnet rotor motors. The motion motor is characterized in that magnetism isolating sheets and permanent magnets consisted of non-magnetic-conduction materials are distributed on the outer side of the inner core of the rotor. N-poles and S-poles are distributed in a staggered way and the outlines of the permanent magnets are spherical. At least two layers of magnetic pole iron cores are provided on the rotor of the periphery. Stator magnetic pole loops are provided on the magnetic pole iron cores. An output shaft is rigidly connected with center of the stator, the center of an outer housing overlaps with center of the rotor and the rotor is supported by a circular ball bearing fixed on the stator. The stator is provided with a transducer for detecting the position and the speed of the rotor so as to realize closed-loop control of the motor. The motion motor of the invention solves the problems of the three-degree-of-freedom motion motor in the prior art, including heavy abrasion, poor torque output capacity and the like. The motion motor of the invention is relatively simple in structure, easy to control, high in mechanical integration level, small in abrasion, strong in torque output capacity, and excellent in static and dynamic performance. In addition, the motion motor can realize suspension control.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

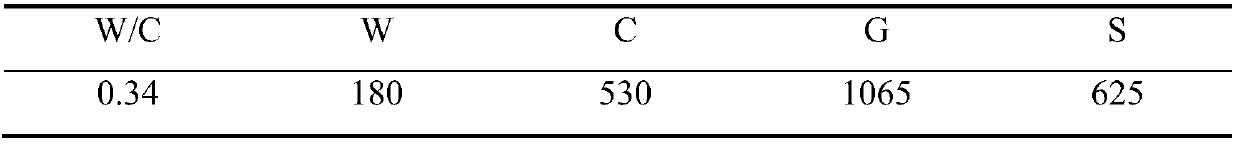

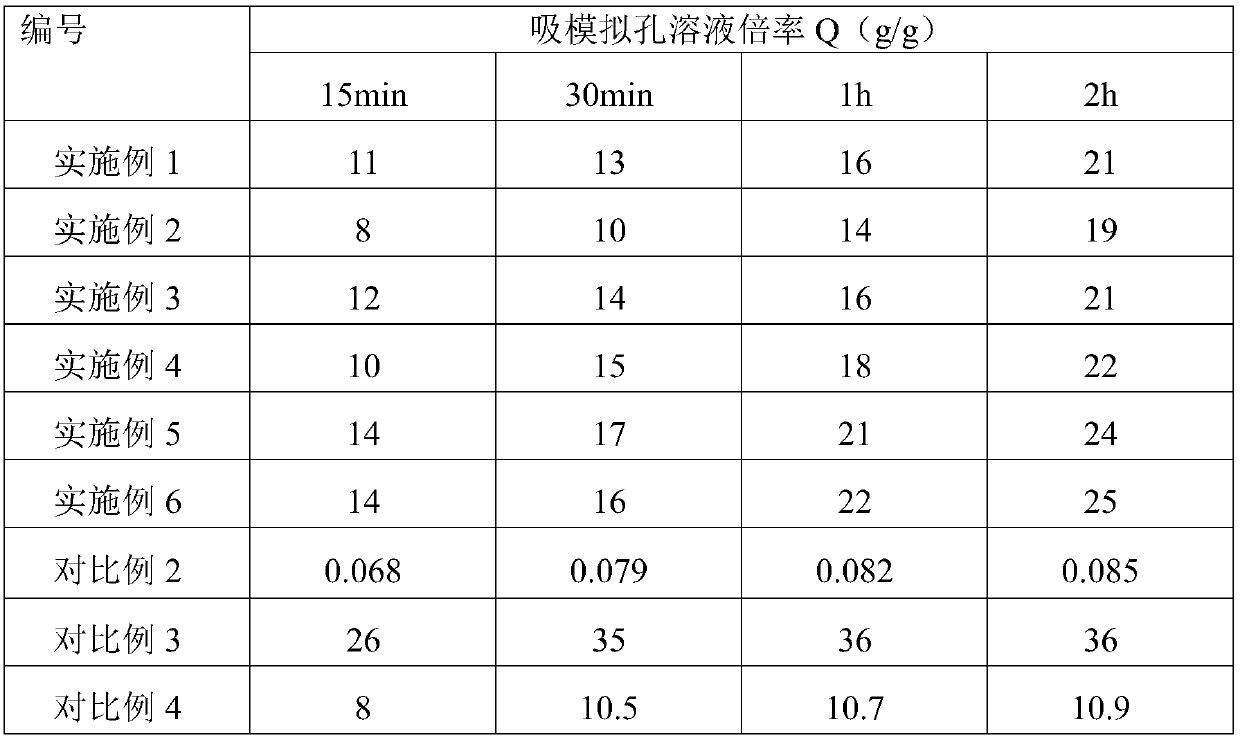

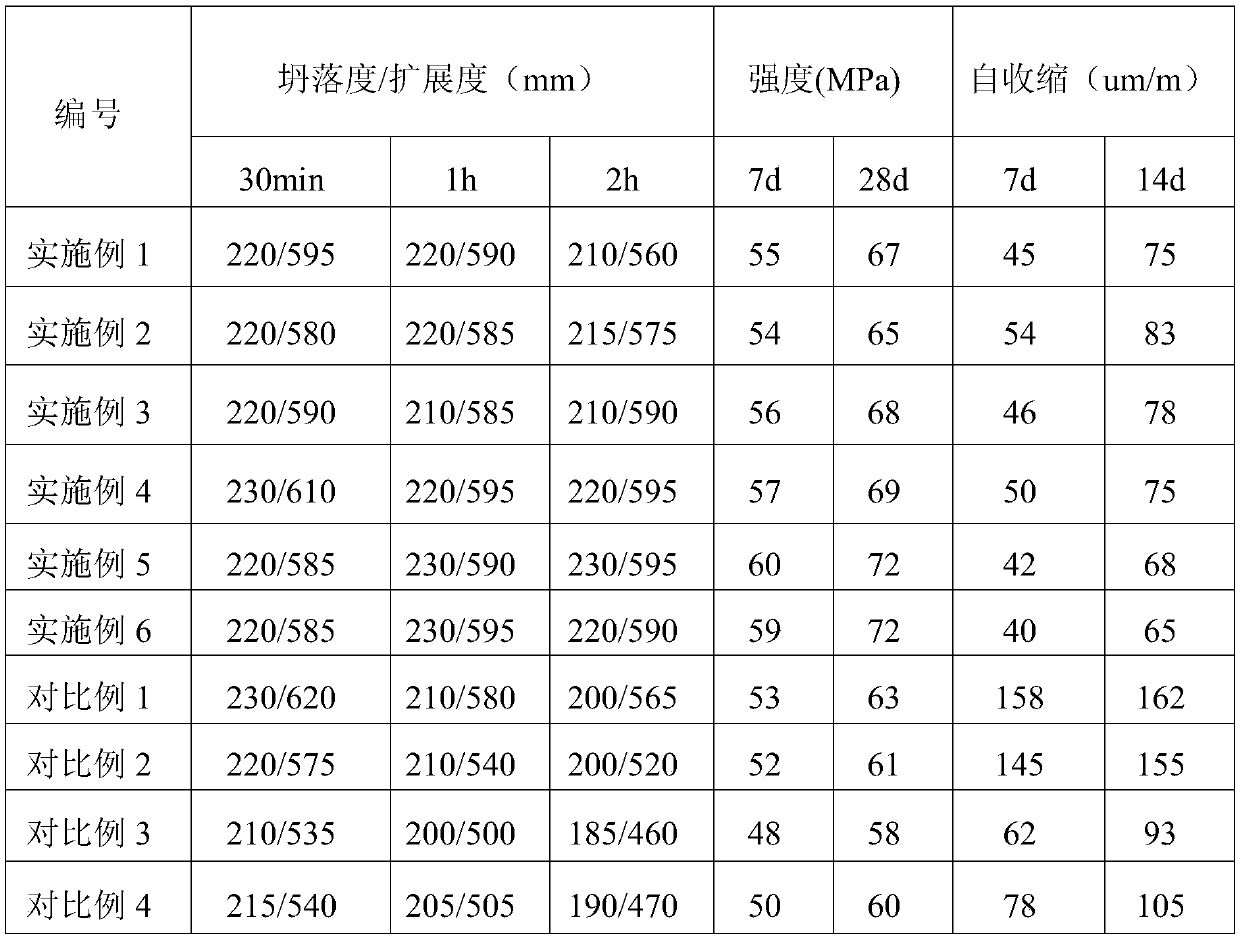

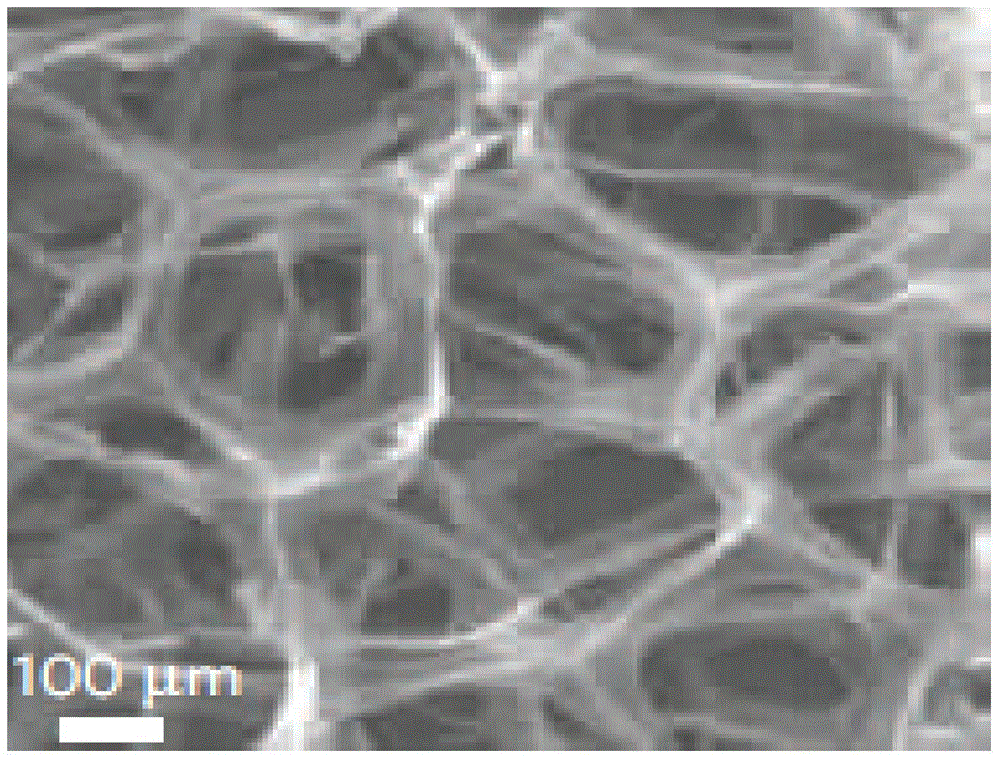

Curing agent in ceramsite carrier concrete and preparation method thereof

ActiveCN109516714AImprove water absorptionEasy to cause loss of work performanceExpanded clay aggregateAbsorption rate

The invention discloses a curing agent in ceramsite carrier concrete. A preparation method of the curing agent comprises the following steps that an acrylic acid solution, 2-acrylamide-2-methacrylic acid, initiators and crosslinking agents are uniformly mixed to prepare a reaction solution a; an etherificated sodium alginate solution, an acrylamide solution, initiators and crosslinking agents areuniformly mixed to prepare a reaction solution b; ceramsite is sequentially soaked in the reaction solution a and the reaction solution b, and is sequentially subjected to microwave treatment. Firstly, the ceramsite is used as a carrier; the polymerization of water absorption resin is performed inside and outside the ceramsite; meanwhile, a hole-inside hole-outside two-step method is used; the building of polymers with different water absorption rates inside and outside holes is realized; the prepared curing agent in the ceramsite carrier concrete can greatly improve the humidity inside the concrete; the early-period reduction and shrinkage effect of the concrete is obvious; meanwhile, the curing agent in the ceramsite carrier concrete has the advantages that the water absorption and waterrelease rate is slow; the use performance such as concrete strength is favorably guaranteed; important application and promotion values are realized.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

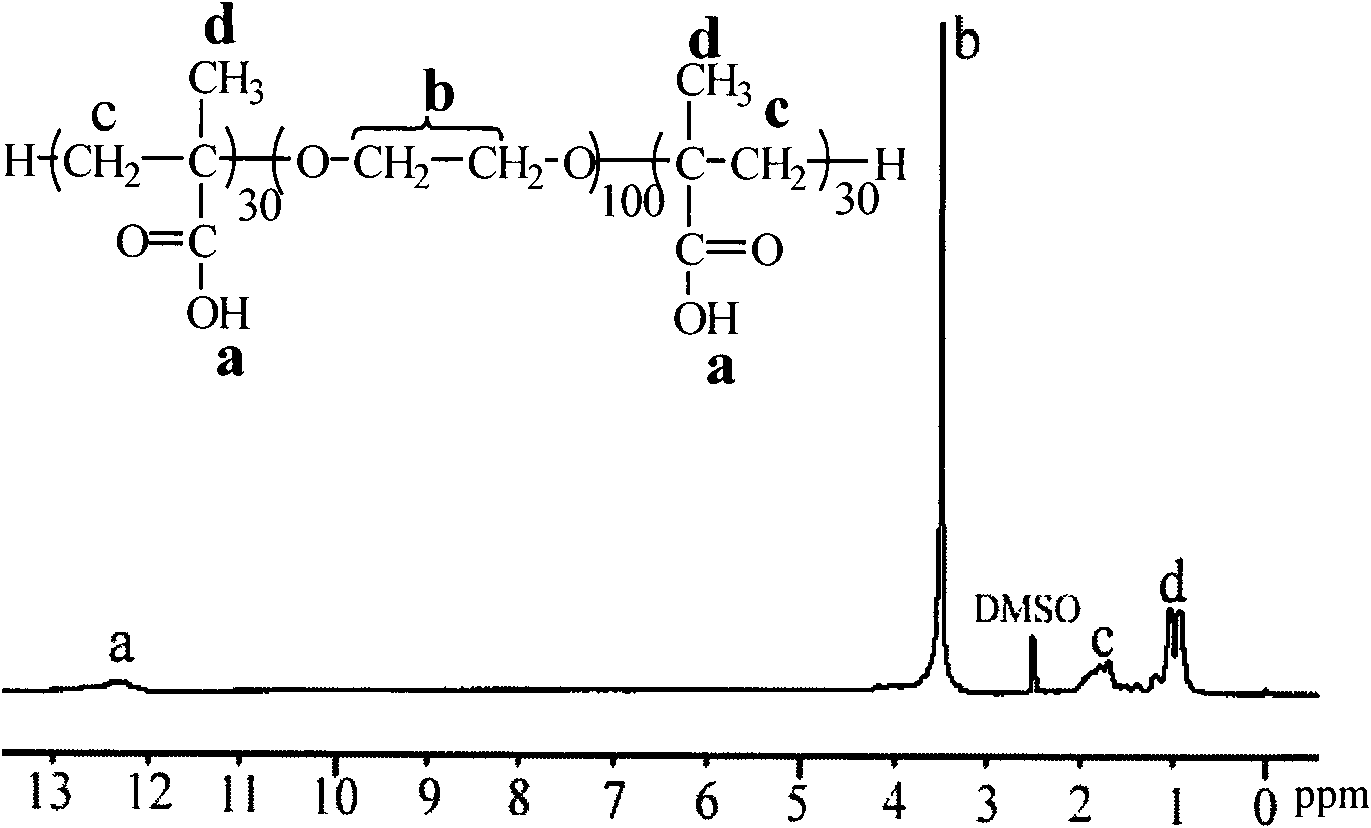

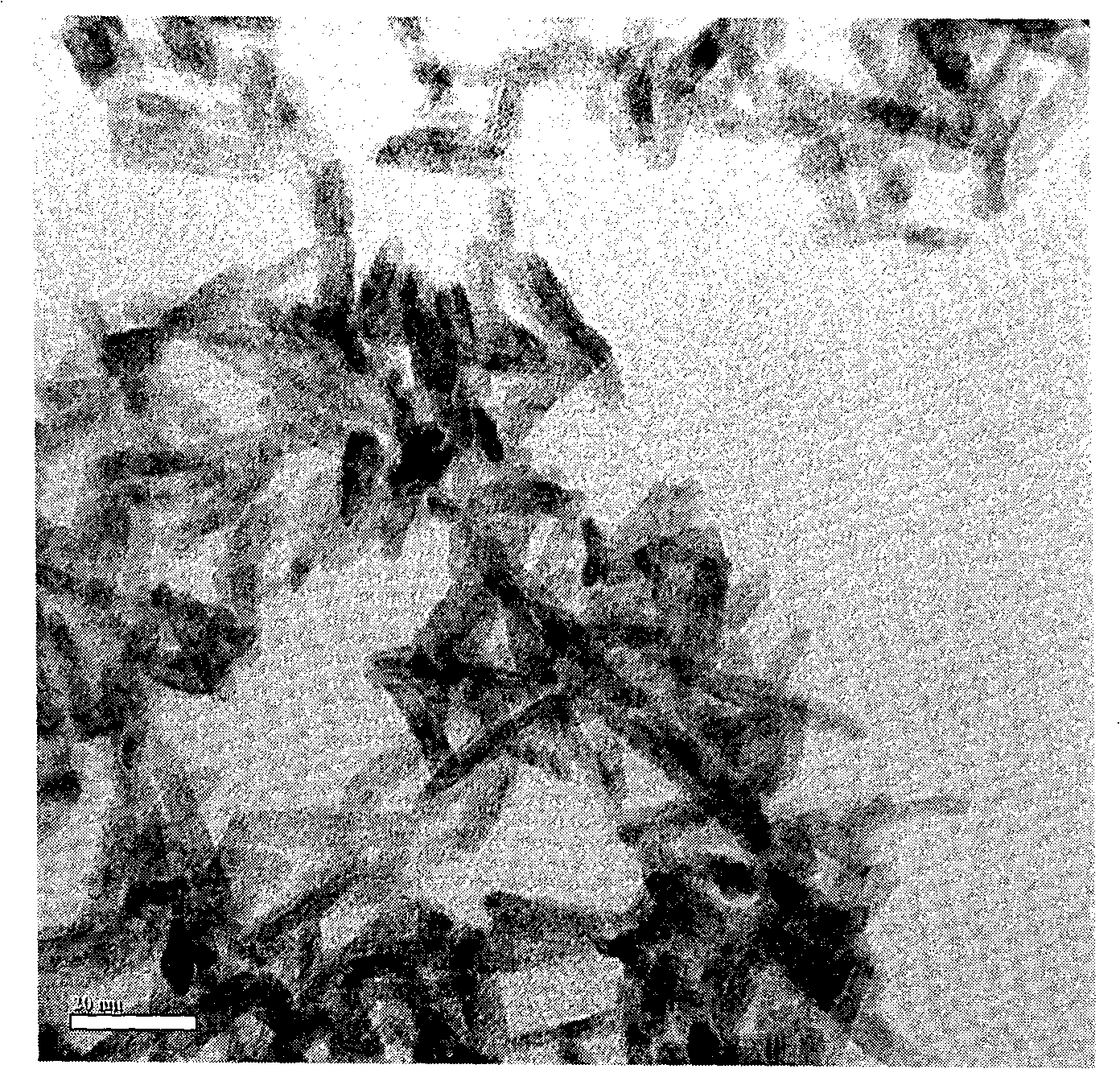

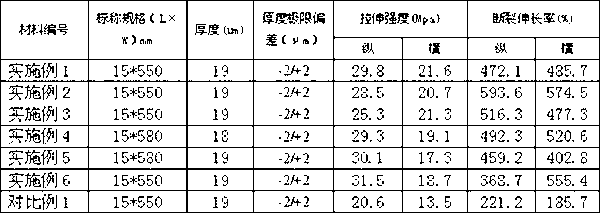

Carbon nanotube three-dimensional network architecture and polymer composite material thereof, and preparation methods thereof

ActiveCN104860293AImprove conductivityImprove thermal conductivityNetwork architectureInterconnection

The invention discloses a carbon nanotube three-dimensional network architecture and a preparation method thereof, and a carbon nanotube / polymer composite material prepared from the carbon nanotube three-dimensional network architecture and having a three-dimensional continuous skeleton structure and a preparation method thereof. The architecture is a three-dimensional network body formed by interconnection of sheet layers composed of carbon nanotubes, and the proportion of the carbon nanotube in the composite material is 0.1 to 10 wt%. The carbon nanotube / polymer composite material with the three-dimensional continuous skeleton structure is constructed by preparing the carbon nanotube architecture with a three-dimensional network by using directional freezing technology, then mixing the carbon nanotube architecture with a polymer and carrying out curing. According to the invention, the carbon nanotube three-dimensional network architecture capable of realizing independent support is used as a conductive additive for a polymer matrix to construct a three-dimensional communicated conductive network in the composite material; and in virtue of good intrinsic conductivity of the carbon nanotube architecture and the characteristics of the inner three-dimensional continuous structure, the conductivity of the polymer composite material is improved.

Owner:DALIAN UNIV OF TECH

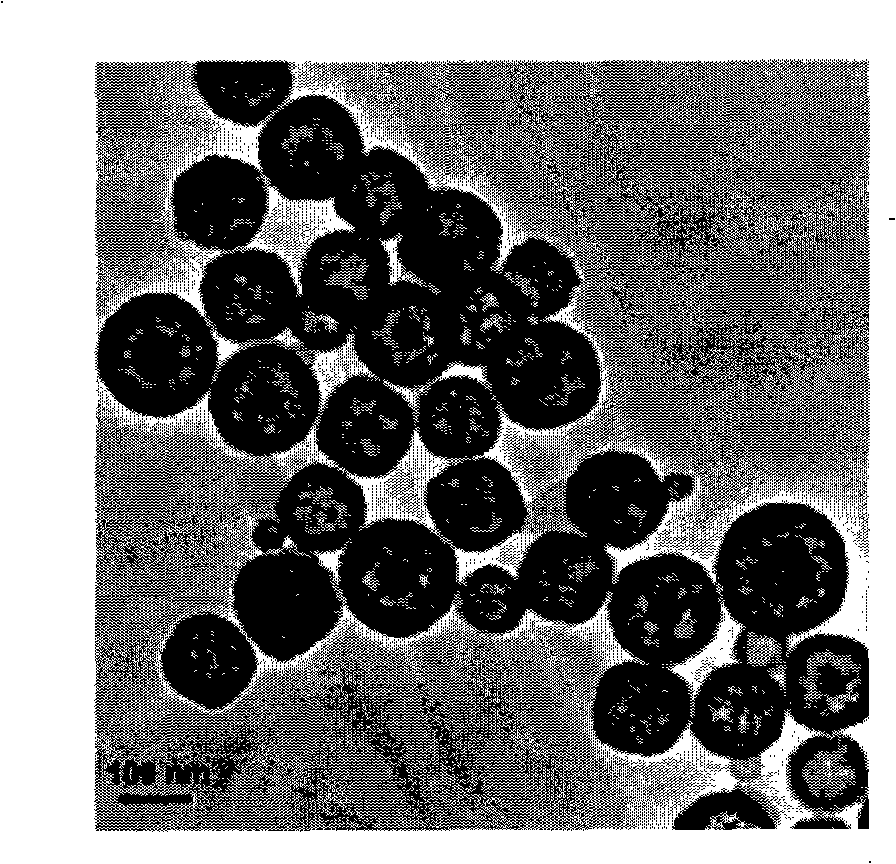

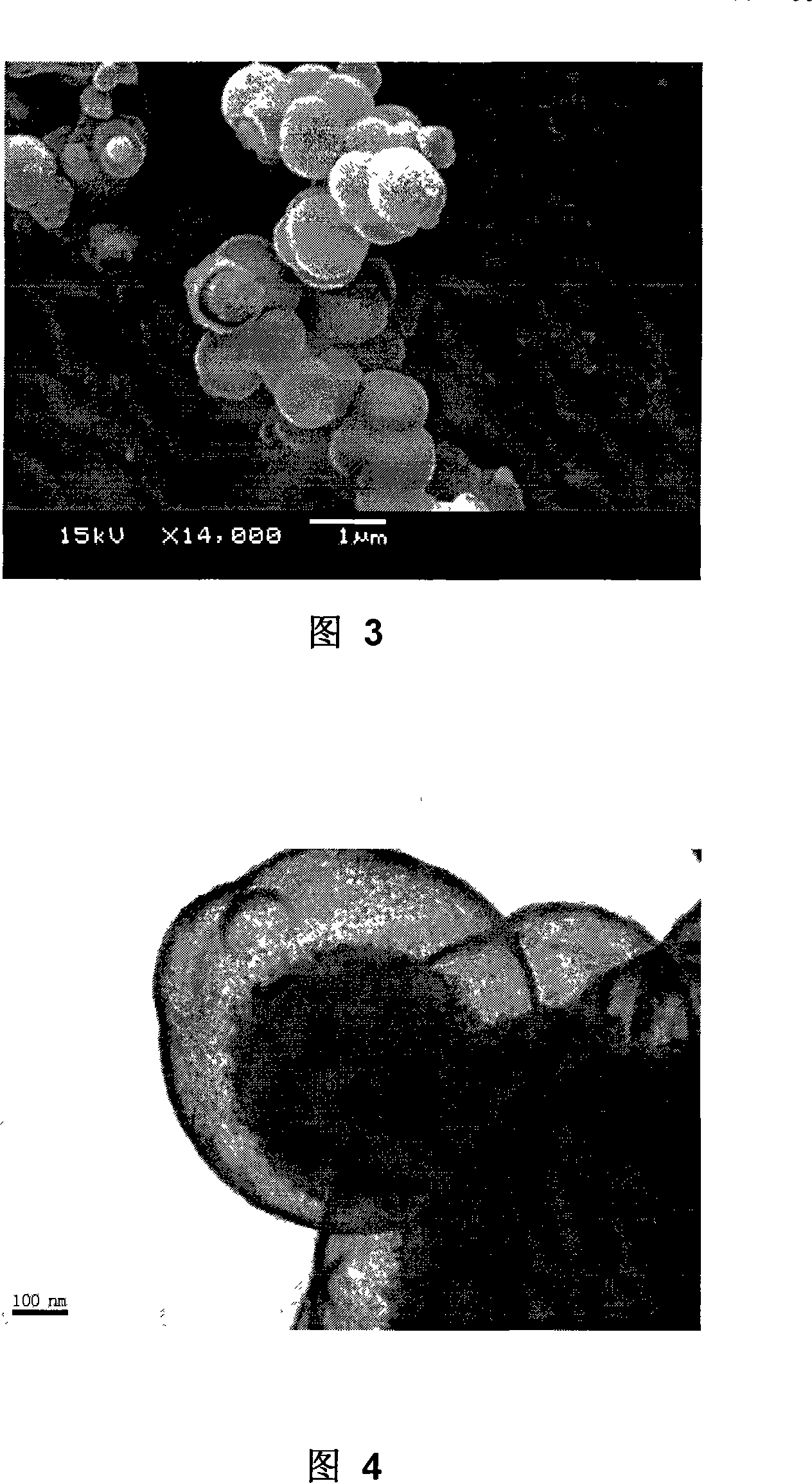

Nano cerium oxide with core-shell structure and preparation method thereof

InactiveCN101164889ALarge specific surface areaSimple preparation processNanostructure manufactureRare earth metal compoundsKernel sizeSolvent

This invention discloses the shell-and-kernel structured nanometer cerium oxide and its preparation method, particularly ball-shaped structure with the grain size of 400-1000nm and the kernel size of 200-700nm and specific surface area of 70-120m2 / g. In this invention method, soluble composite ammonium salt is used as predecessor, mixed with mixture solvent, being heated by heating the solvent making the same being curing to form this inventive product. This invention has advantages of: low cost, simple process, easy to be controlled, providing general technique for synthesis of inorganic oxides, and the inventive product has potential utilization in fields of nanometer device, catalysis, polishing or the like.

Owner:SHANGHAI NORMAL UNIVERSITY

Hollow bead shaped nano-cerium oxide and its preparation method

ActiveCN1948157ALarge specific surface areaLower catalytic temperatureIndividual molecule manipulationRare earth metal compoundsSpherical granuleOrganic solvent

The present invention relates to a hollow pearl nano cerium oxide and its preparation method. The invented nano cerium oxide is a spherical granule whose diameter is 80-200 nm and centre has a through hole whose diameter is 10-60 nm. Said invention utilizes organic solvent to make the cerium salt be dissolved, and further utilizes solvent heat to make the hollow pearl nano cerium oxide be formed on the surface of carbon nano tube, then the template is removed, so that the correspondent hollow pearl nano cerium oxide can be obtained.

Owner:SHANGHAI UNIV

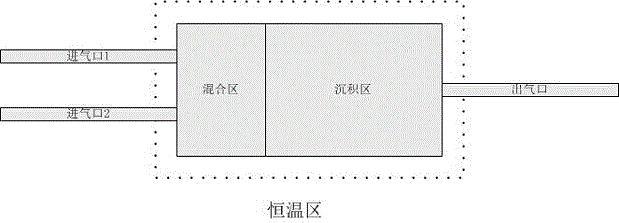

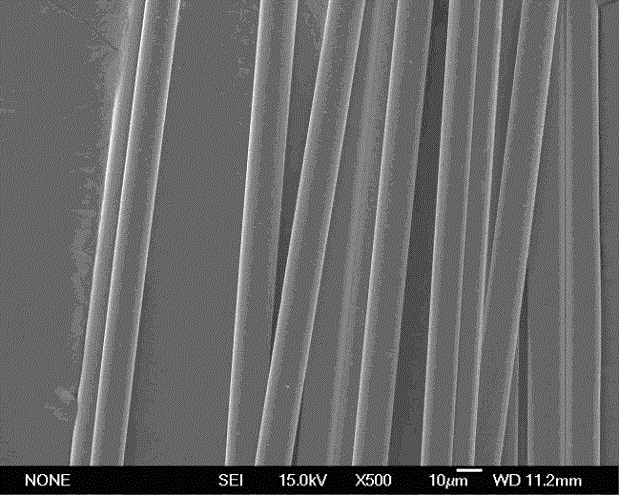

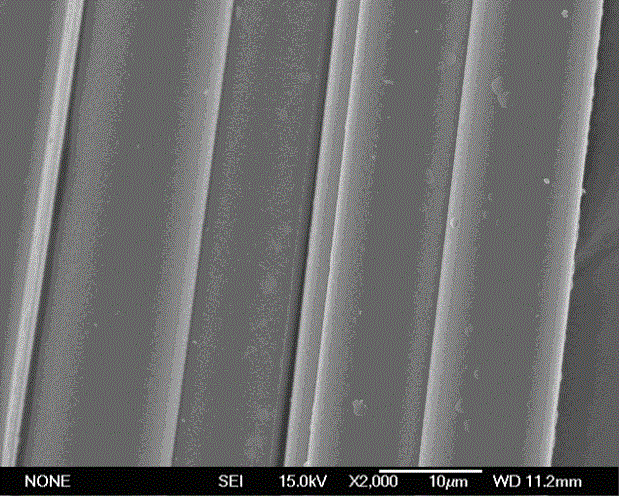

Preparation method of homogenized boron nitride coating

InactiveCN105296960AUniform thicknessThickness is easy to controlChemical vapor deposition coatingBoron trichlorideScanning tunneling microscope

The invention relates to a preparation method of a homogenized boron nitride coating. According to the method, boron trichloride (BCl<3>) and ammonia gas (NH<3>) serve as reaction gases and are fed into a reactor, firstly the reaction gases are evenly mixed in a mixing region and then generate surface deposition in a deposition reaction region, finally an obtained sample is subjected to high-temperature heat treatment, and through a scanning tunneling microscope (SEM), Fourier transform infraRed (FT-IR) and X-ray diffraction (XRD) detection, the boron nitride coating which is even in thickness, singular in ingredient and high in degree of crystallinity is obtained. The method can be used for preparing a boron nitride interface in composite and for preparing boron nitride coatings on the surfaces of other samples and can be further used for researching the boron nitride vapor deposition process and mechanism. The method mainly solves the problem that gases are not evenly mixed in the two-component chemical gas phase sedimentary boron nitride process, so that the uniformity of the boron nitride coating is improved, and the coating thickness is better controlled.

Owner:SHANGHAI UNIV

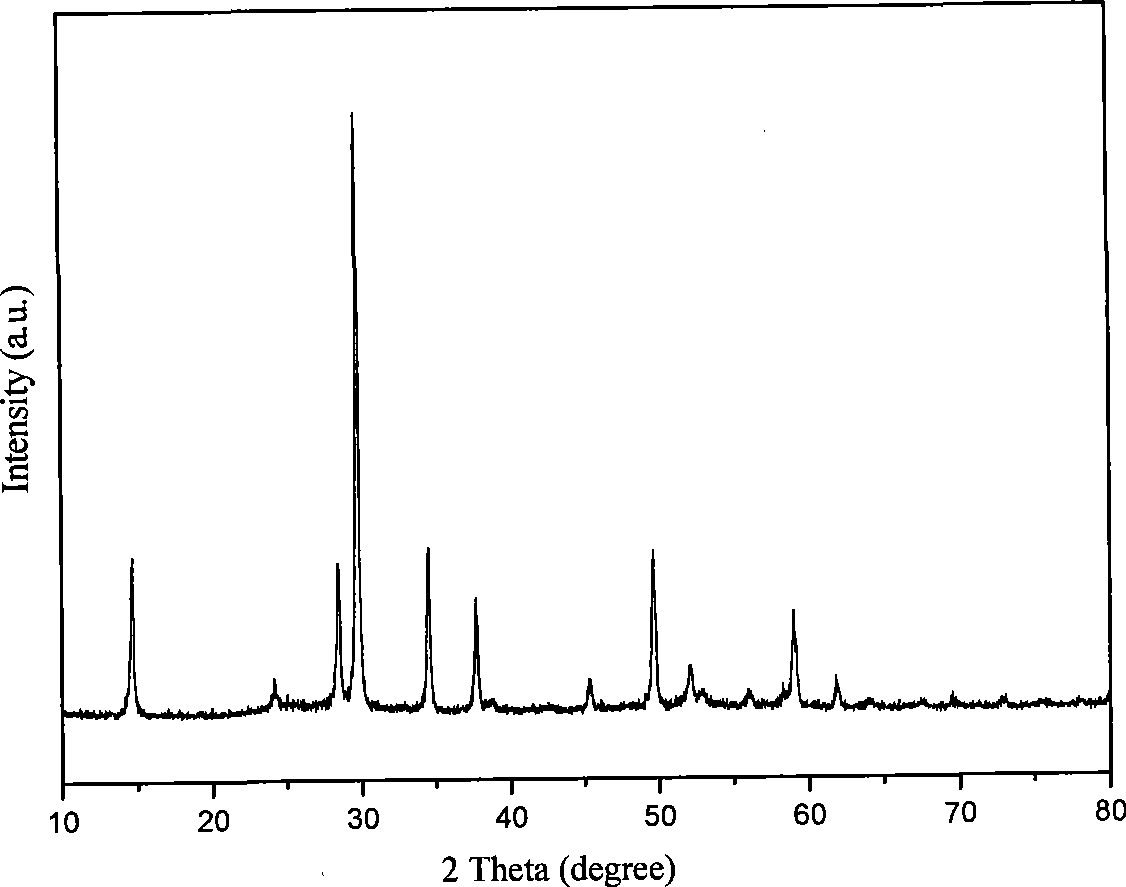

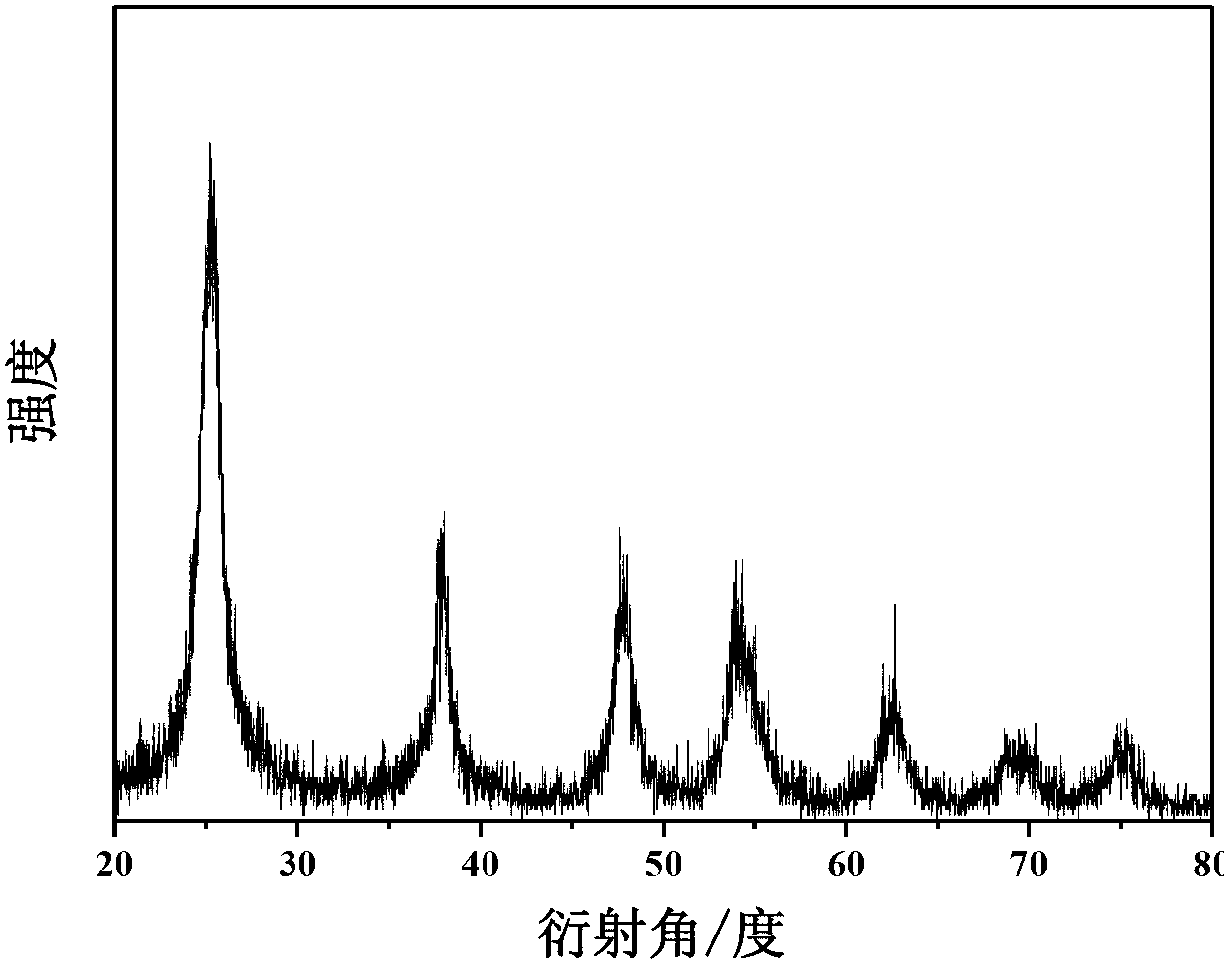

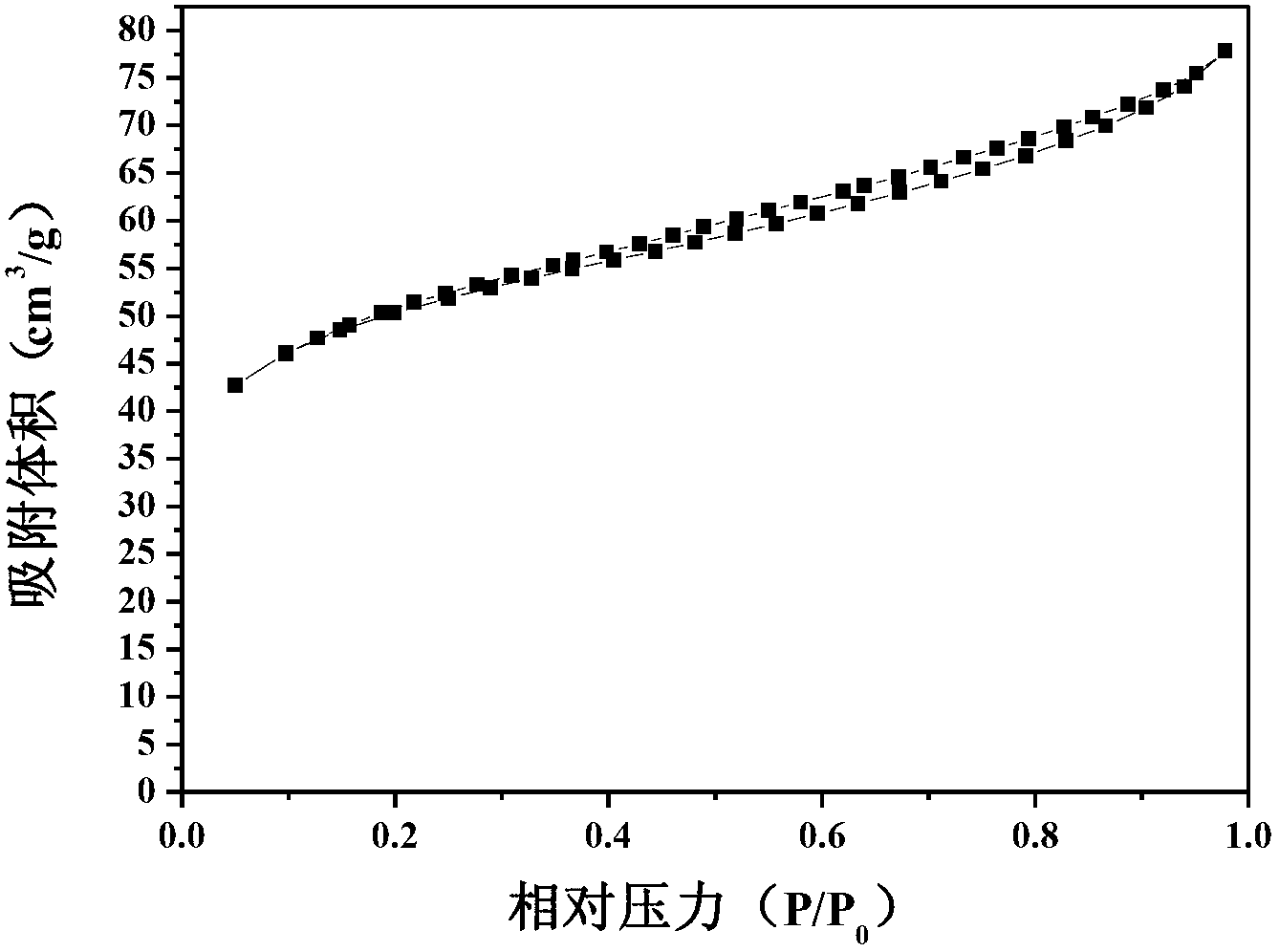

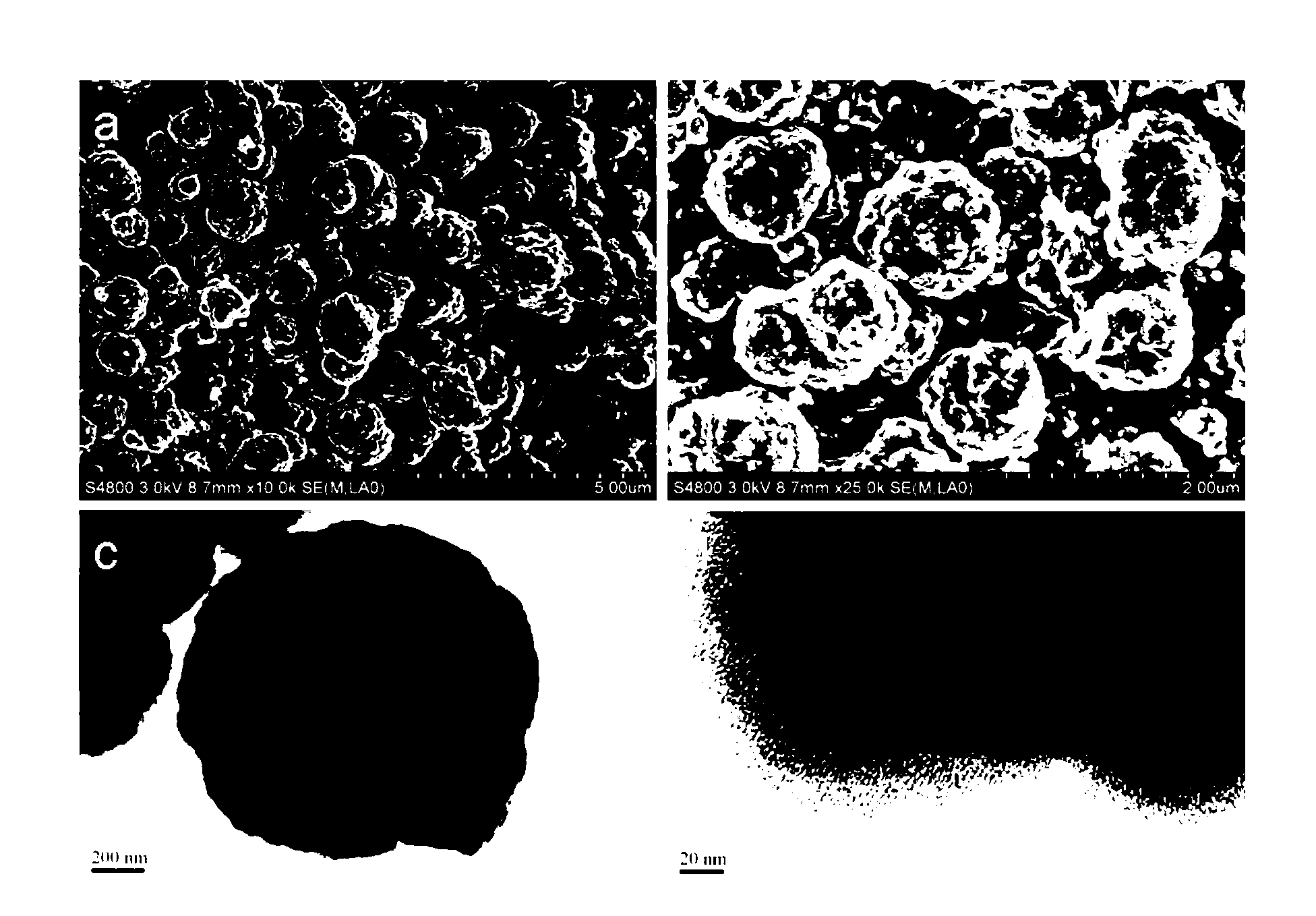

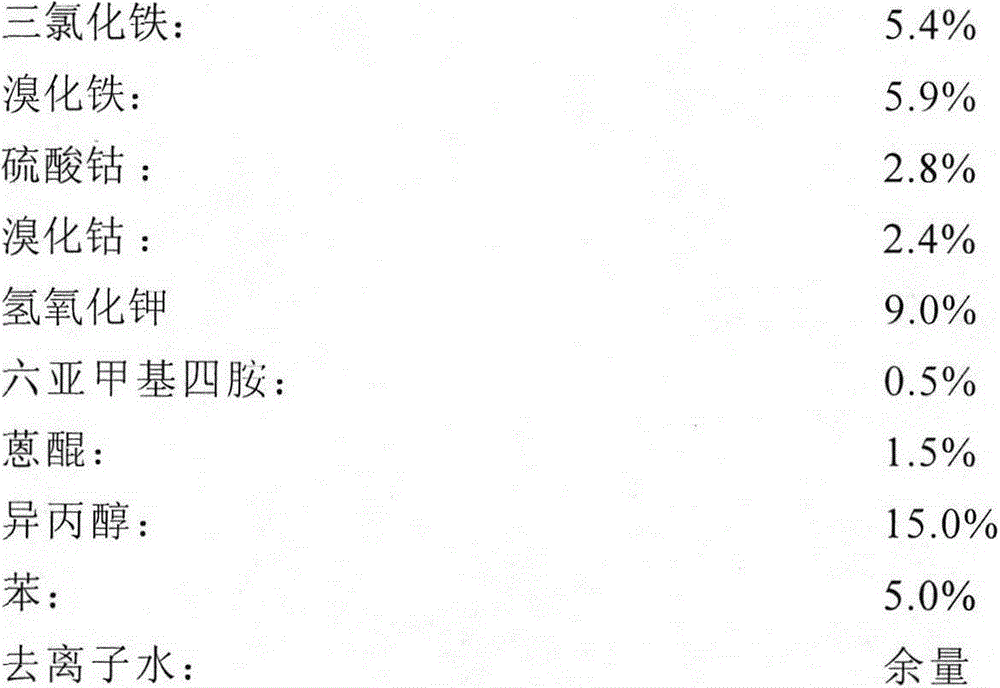

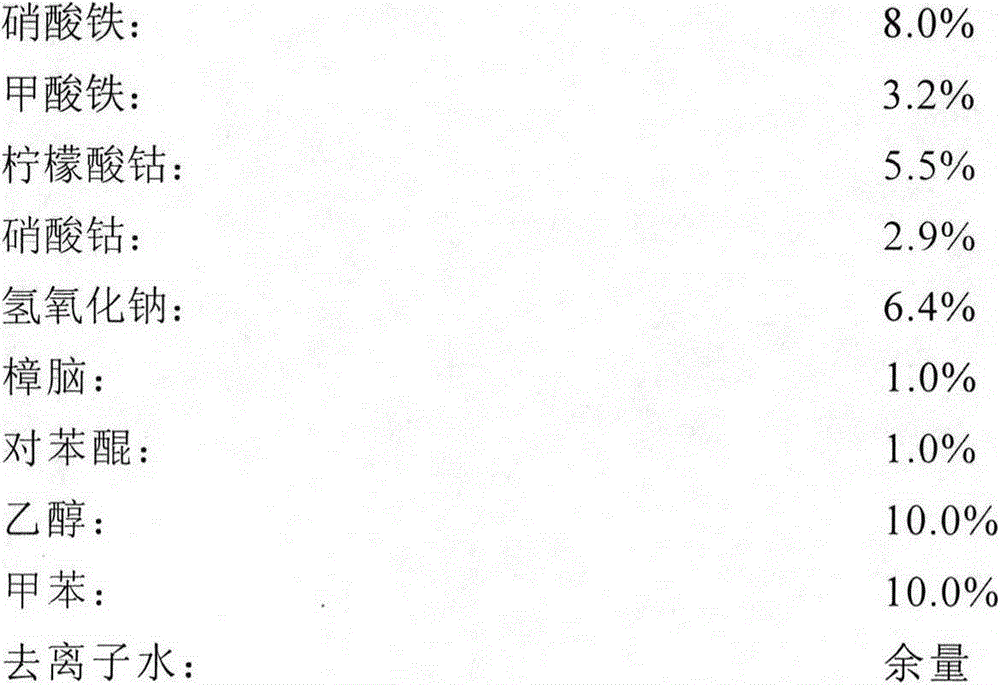

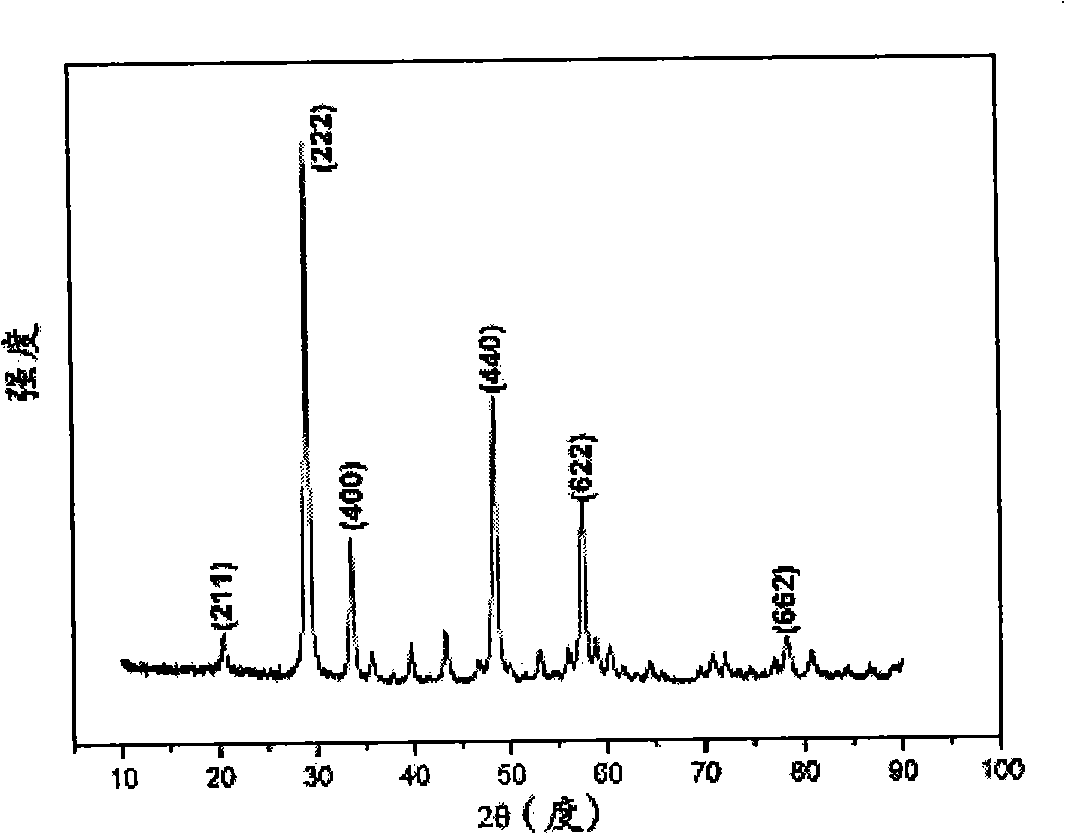

Preparation method of porous nano CoFe2O4

InactiveCN104591301AControllable structureNo tunnel collapseCobalt oxides/hydroxidesMetal/metal-oxides/metal-hydroxide catalystsSolventOrganic solvent

The invention discloses a preparation method of porous nano CoFe2O4. The method comprises the following steps: under the condition that the mass percentage of a ferric salt, a cobalt salt, alkali, deionized water, an organic solvent and a sublimable compound template is (0.001-70%):(0.00001-70%): (0.001-55%): (0.001-90%):(0.001-90%):(0.001-90%), reacting a mixed solution of the ferric salt and the cobalt salt with an alkali solution, and carrying out separation and purification on the obtained object so as to obtain a CoFe2O4 sol; and mixing the CoFe2O4 sol with the deionized water, carrying out ultrasonic dispersion on the obtained mixture, adding the organic solvent and the sublimable compound template, reacting by using a water-organic solvent mixed solvothermal method, distilling the obtained object so as to remove a mixed solvent, carrying out heat treatment on the obtained product so as to remove the sublimable compound template, and then sequentially cooling, grinding, washing, filtering, drying and grinding the obtained product, so that porous nano CoFe2O4 powder is obtained. The method is simple and feasible in process, small in investment, and beneficial for popularization and utilization.

Owner:NANJING UNIV OF TECH

Preparation method for metal / metallic oxide nano-composite materials

ActiveCN103646792AAdjustable thicknessControllable structureHybrid capacitor electrodesHybrid/EDL manufactureAnodic oxidationGrain shape

The invention belongs to the technical field of preparation of nano materials and relates to a preparation method for metal / metallic oxide nano-composite materials. The preparation method for the metal / metallic oxide nano-composite materials is characterized by preparing an oxalic acid solution according to the concentration between 0.01 to 1.5 mole every liter to obtain an electrolyte solution; placing panel metal or foam metal into the prepared electrolyte solution and performing anodic oxidation through a constant pressure method or a current constant method; controlling reaction degrees by controlling reaction conditions such as reaction voltage or current, reaction time, reaction temperature and the like and effectively preparing the metal / metallic oxide nano-composite materials having different shapes, thickness and components in a controllable mode. According to the preparation method for the metal / metallic oxide nano-composite materials, the obtained metal / metallic oxide nano-composite materials comprise the panel or foam state metal substrate and a metallic oxide layer with the thickness between 50 nanometers to 100 micrometers and the metallic oxide which is petal-shaped or grain-shaped with the size between 50 to 500 nanometers is directly formed on the surface of the metal. The preparation method for the metal / metallic oxide nano-composite materials has the advantages of being simple and easy to operate, short in period, strong in adaptability, low in cost and benefited to commercial application.

Owner:SHANDONG UNIV

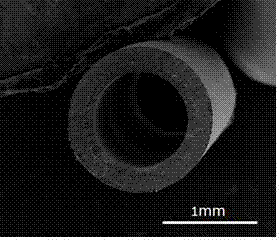

Powder metallurgy fabrication method of hollow metal sphere

The invention discloses a powder metallurgy fabrication method of a hollow metal sphere, which comprises the following steps of placing a polystyrene sphere in a centrifugal mold, preparing slurry 1 with metal powder, adhesive solution and a defoaming agent, pouring the slurry 1 into the centrifugal mold, centrifuging, putting the centrifuged polystyrene sphere in an oven for drying together with the centrifugal mold, preparing slurry 2 with the metal powder, the adhesive solution and the defoaming agent, pouring the slurry 2 into the dried centrifugal mold, centrifuging, putting the centrifuged polystyrene sphere in the oven for drying together with the centrifugal mold, taking out the dried polystyrene sphere from the centrifugal mold, embedding the polystyrene sphere into alumina packing, and then putting in a vacuum furnace for pyrolysis and sintering, thereby obtaining the hollow metal sphere. The method is reasonable in design, simple in process and low in cost. The hollow metal sphere fabricated by the fabrication method has the advantages of uniform, smooth and complete spherical shell wall thickness, facilitation of sphere dimension selection, easiness in overall structure control and the like.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

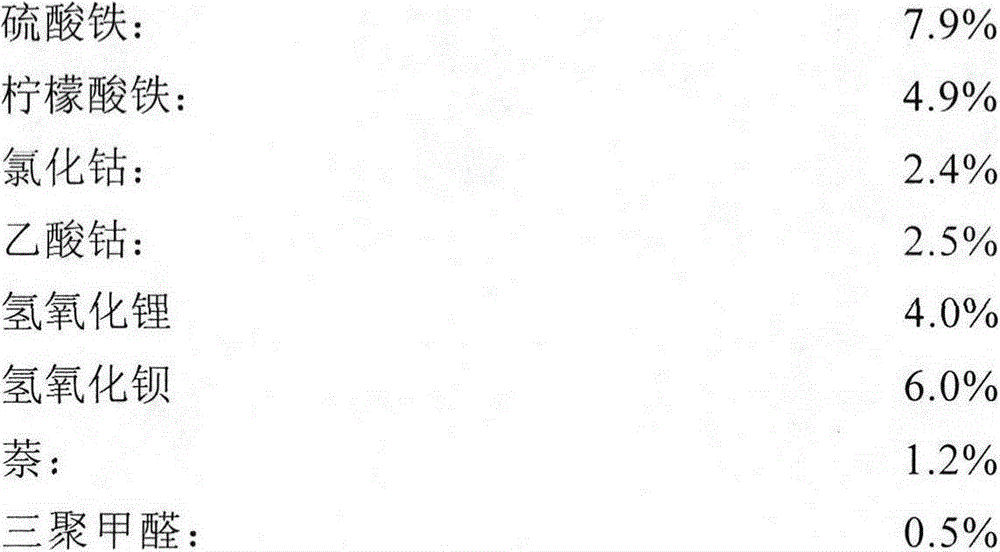

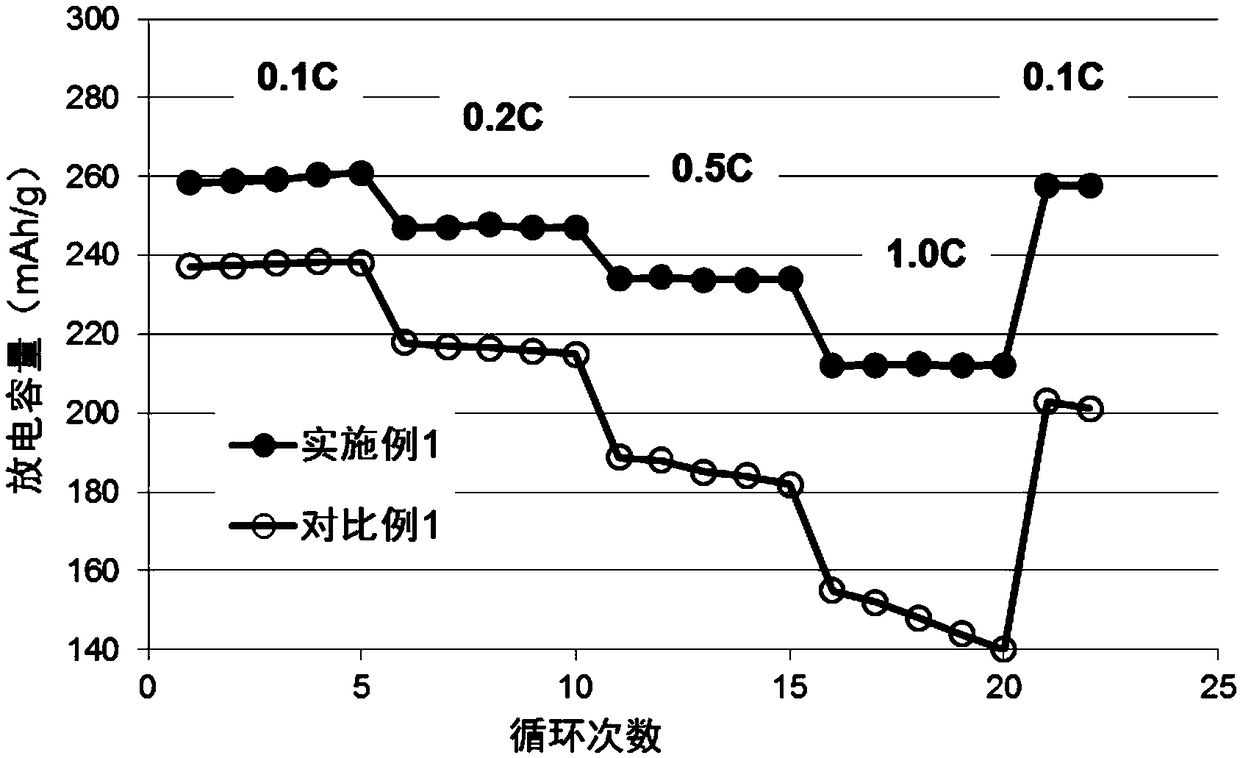

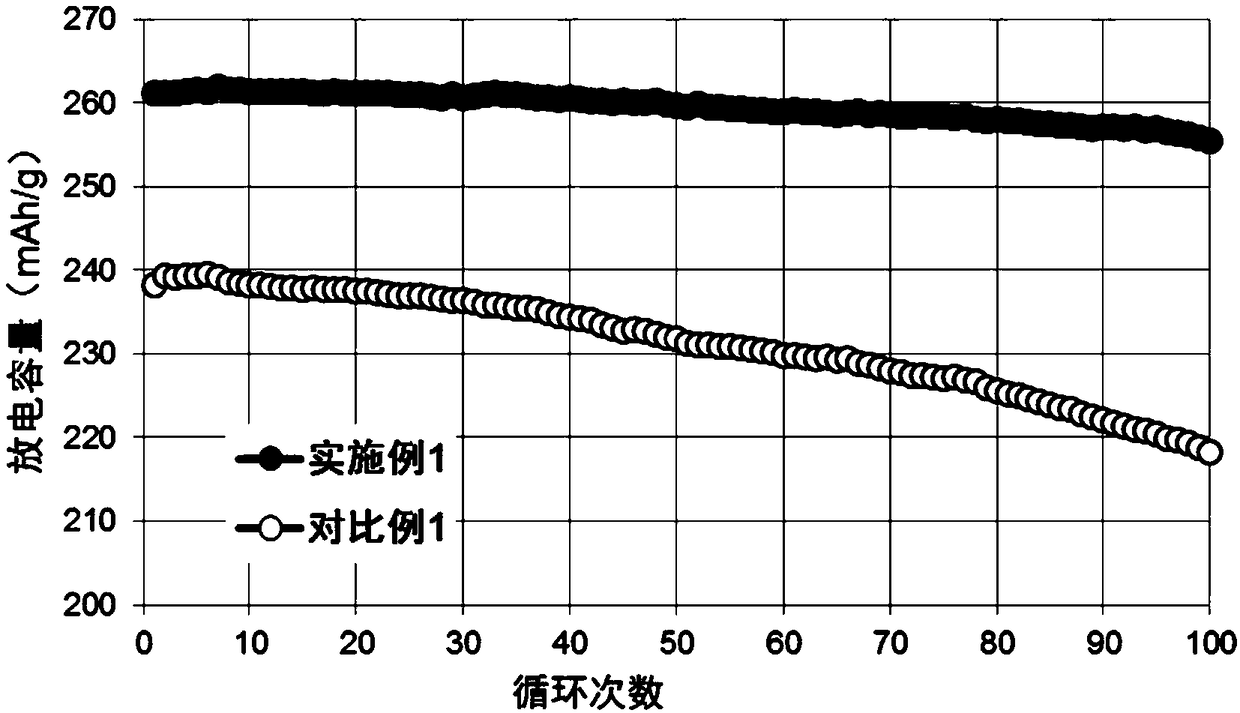

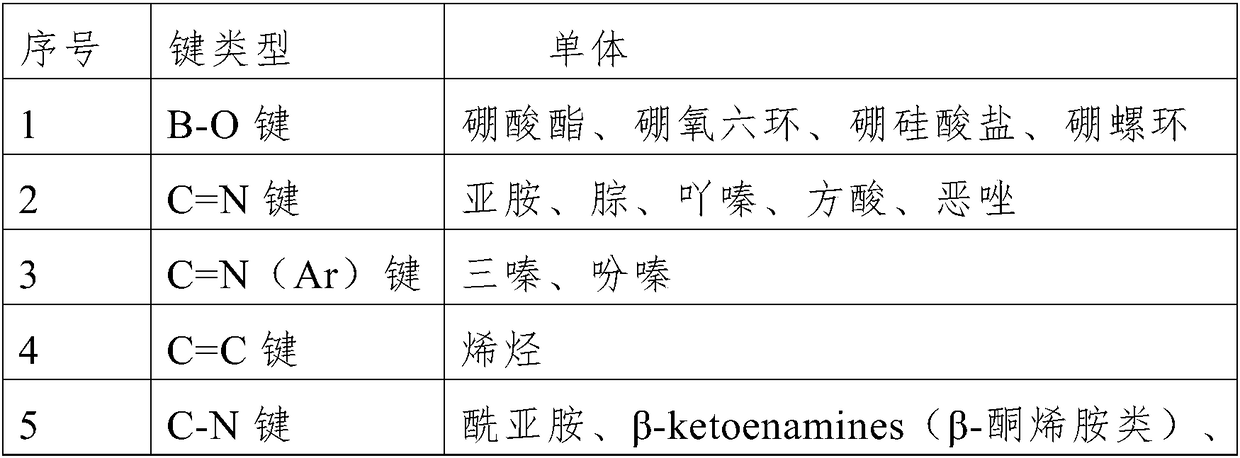

Lithium-rich manganese-based cathode material coated with composite carbon material and preparation method thereof, and lithium battery

ActiveCN109167042AImprove conductivityImproved magnification performanceCell electrodesSecondary cellsPorous carbonManganese

The invention relates to a lithium-rich manganese-based cathode material coated with a composite carbon material derived from a COFs material containing at least one element of N and B, and a preparation method thereof, and a lithium battery, wherein the surface of the lithium-rich manganese-based cathode material is coated with a composite carbon material. The lithium-rich manganese-based cathodematerial coated with the composite carbon material can obviously improve the conductivity of the material and the rate performance and cycle performance of the battery containing the composite carbonmaterial, and the composite carbon material is coated more uniformly. The invention adopts a simple one-step carbonization method to prepare a composite porous carbon material coated with a lithium-rich manganese-based cathode material, the prepared porous carbon has controllable specific surface area and pore size, and the preparation method is simple and efficient, and is suitable for large-scale preparation and synthesis.

Owner:桑德新能源技术开发有限公司 +1

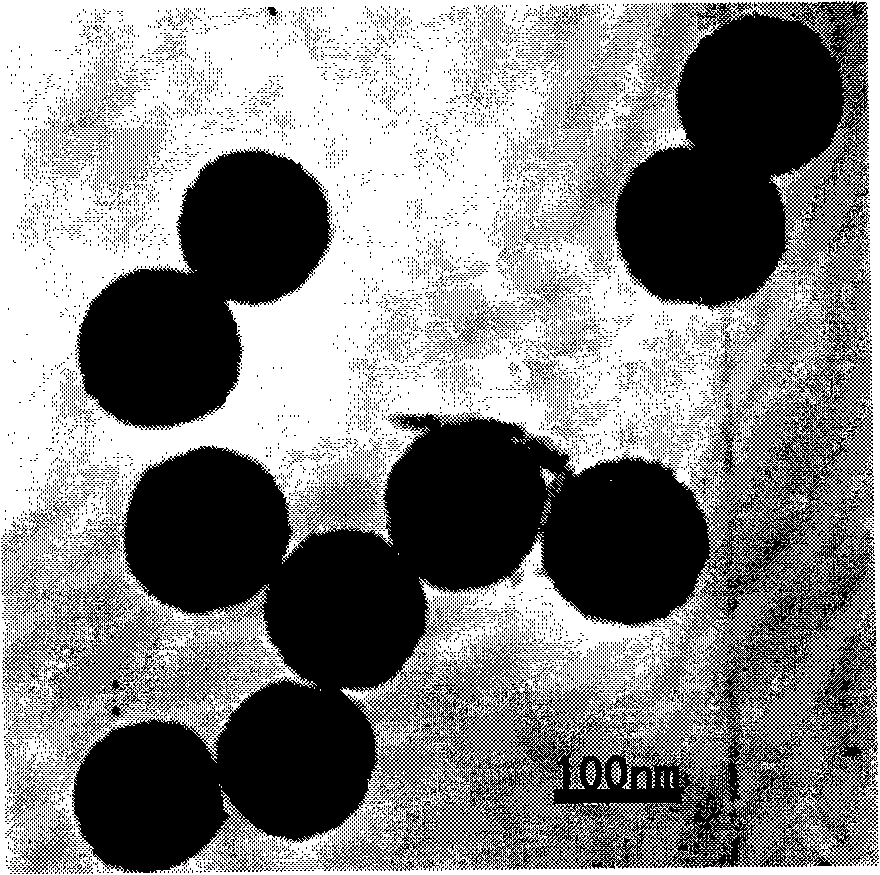

Preparation of Y2O3: Eu3+ nanosphere powder

The invention relates to a method for producing Y2O3:Eu3plus nanometer ball powder, which belongs to the technical field of the inorganic nanophase material. The production method of the invention comprises the following steps of: (1) weighting the raw materials (counted by chemical mass): 1.0-3.0 mmol of yttrium nitrate, 0.05-0.15 mmol of europium nitrate, 20-60mmol of urea and 0.1-0.3mmol of cetyl trimethylammonium bromide, and then dissolving the materials in 40-100ml of de-ionized water; (2) placing the mixed solution into a round flask and leading reflux reaction to carry out without heating under the magnetic stirring for 30-60 min; cooling the solution to normal temperature and then carrying out separation, washing and drying for the obtained precipitate; (3) calcining for 2-4 hours under 600-1000 DEG C and finally obtaining the Y2O3:Eu3plus nanometer ball powder with the average particle diameter of 100 nm. The instrument test indicates that the sample obtained by the method of the invention has good dispersibility, uniform article size and has excellent luminous property.

Owner:SHANGHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com