Patents

Literature

341 results about "Bismuth titanate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bismuth titanate or bismuth titanium oxide is a solid inorganic compound of bismuth, titanium and oxygen with the chemical formula of Bi₁₂TiO₂₀, Bi ₄Ti₃O₁₂ or Bi₂Ti₂O₇

Amorphous dielectric capacitors on silicon

InactiveUS6255122B1Improve conformityReduce leakage currentTransistorSemiconductor/solid-state device manufacturingLead zirconate titanateMaterials science

High-capacity capacitors and gate insulators exhibiting moderately high dielectric constants with surprisingly low leakage using amorphous or low temperature films of perovskite type oxides including a titanate system material such as barium titanate, strontium titanate, barium strontium titanate (BST), lead titanate, lead zirconate titanate, lead lanthanum zirconate titanate, barium lanthanum titanate, a niobate, aluminate or tantalate system material such as lead magnesium niobate, lithium niobate lithium tantalate, potassium niobate and potassium tantalum niobate, a tungsten-bronze system material such as barium strontium niobate, lead barium niobate, barium titanium niobate, and Bi-layered perovskite system material such as strontium bismuth tantalate, bismuth titanate deposited directly on a silicon surface at temperatures about 450° C. or less.

Owner:GLOBALFOUNDRIES INC

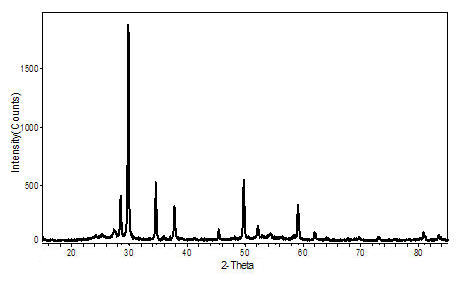

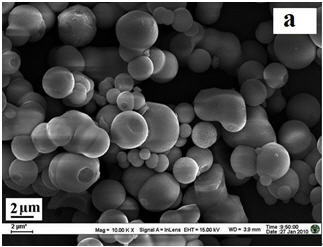

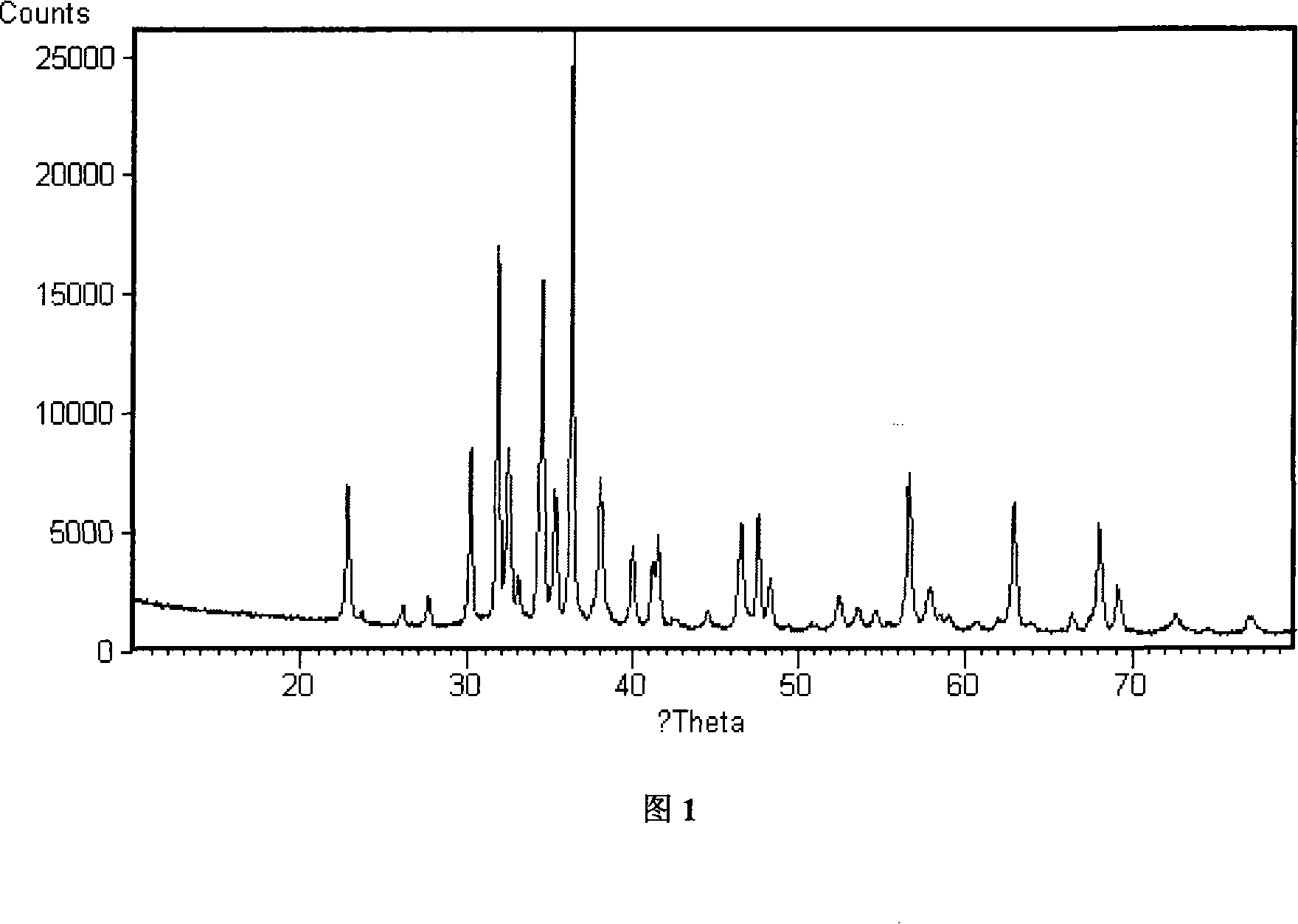

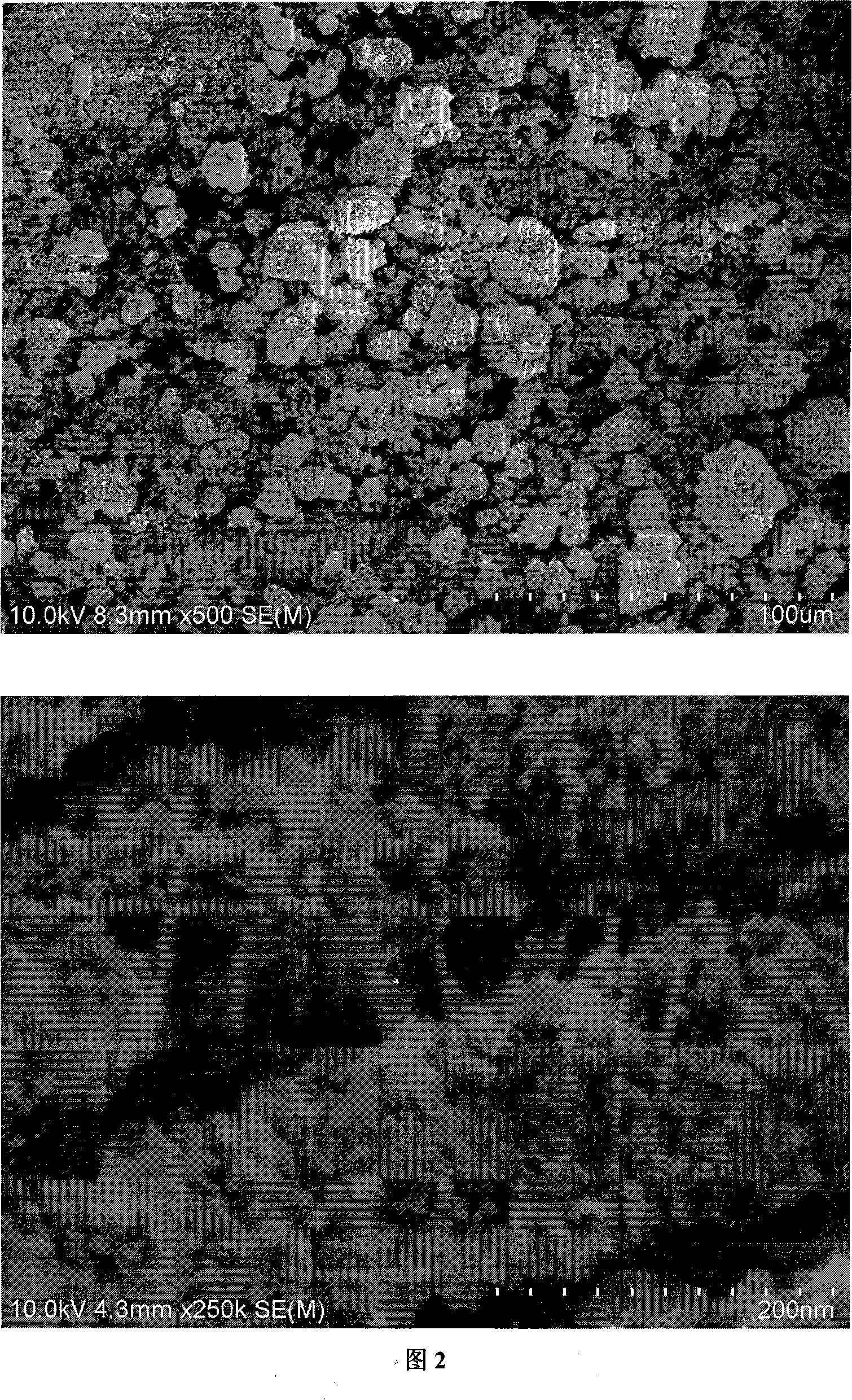

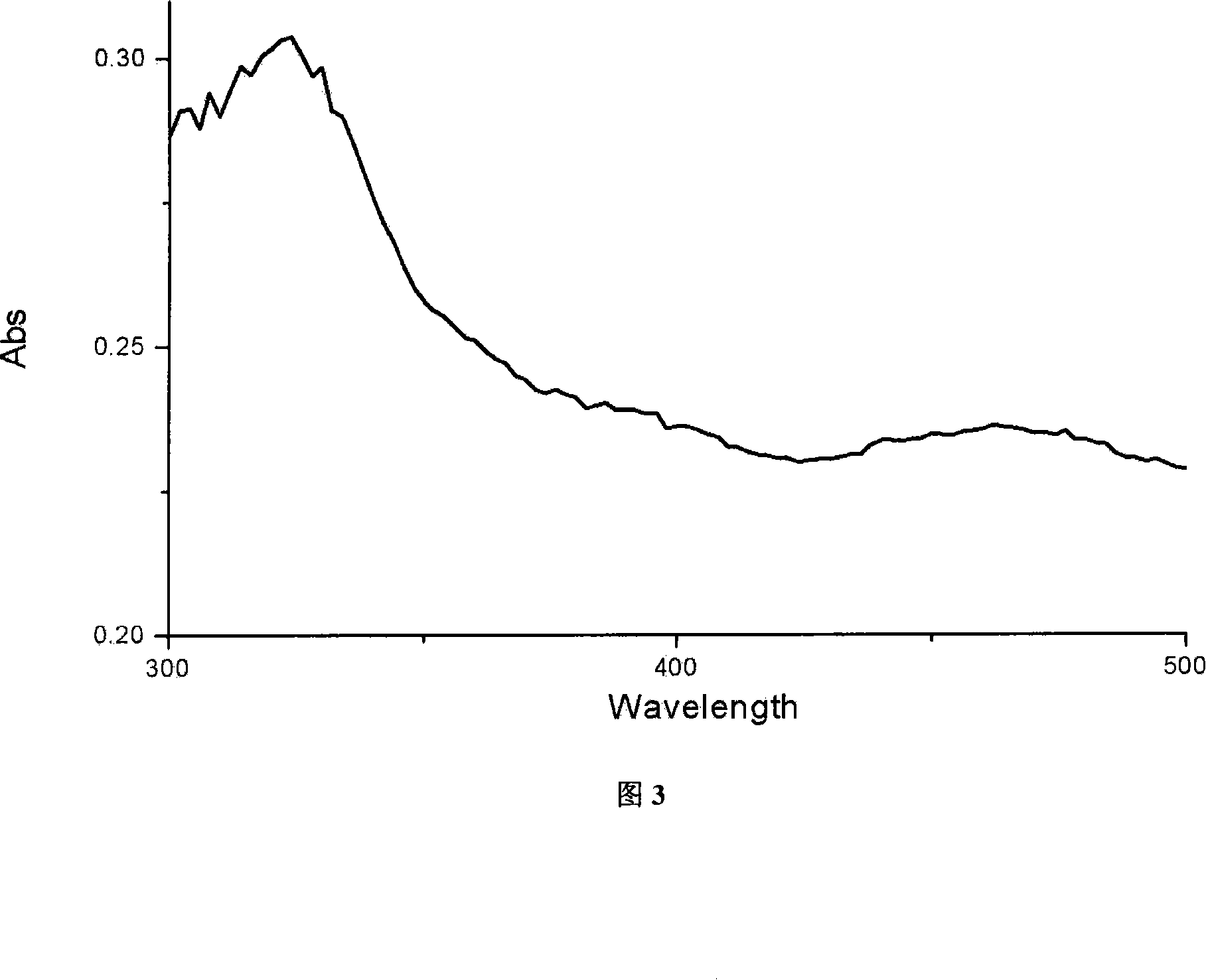

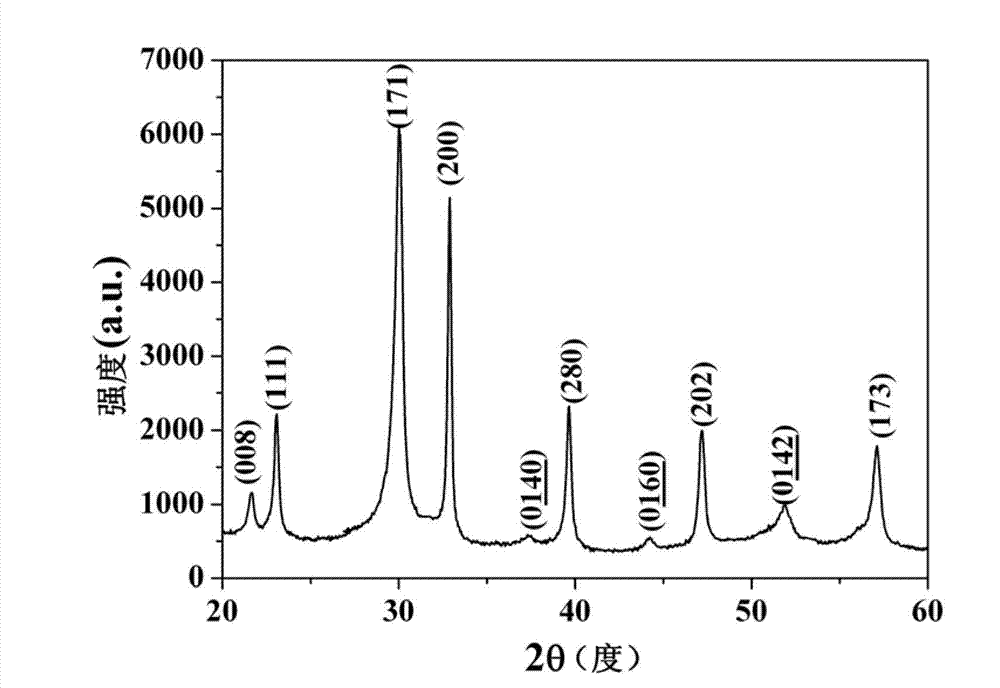

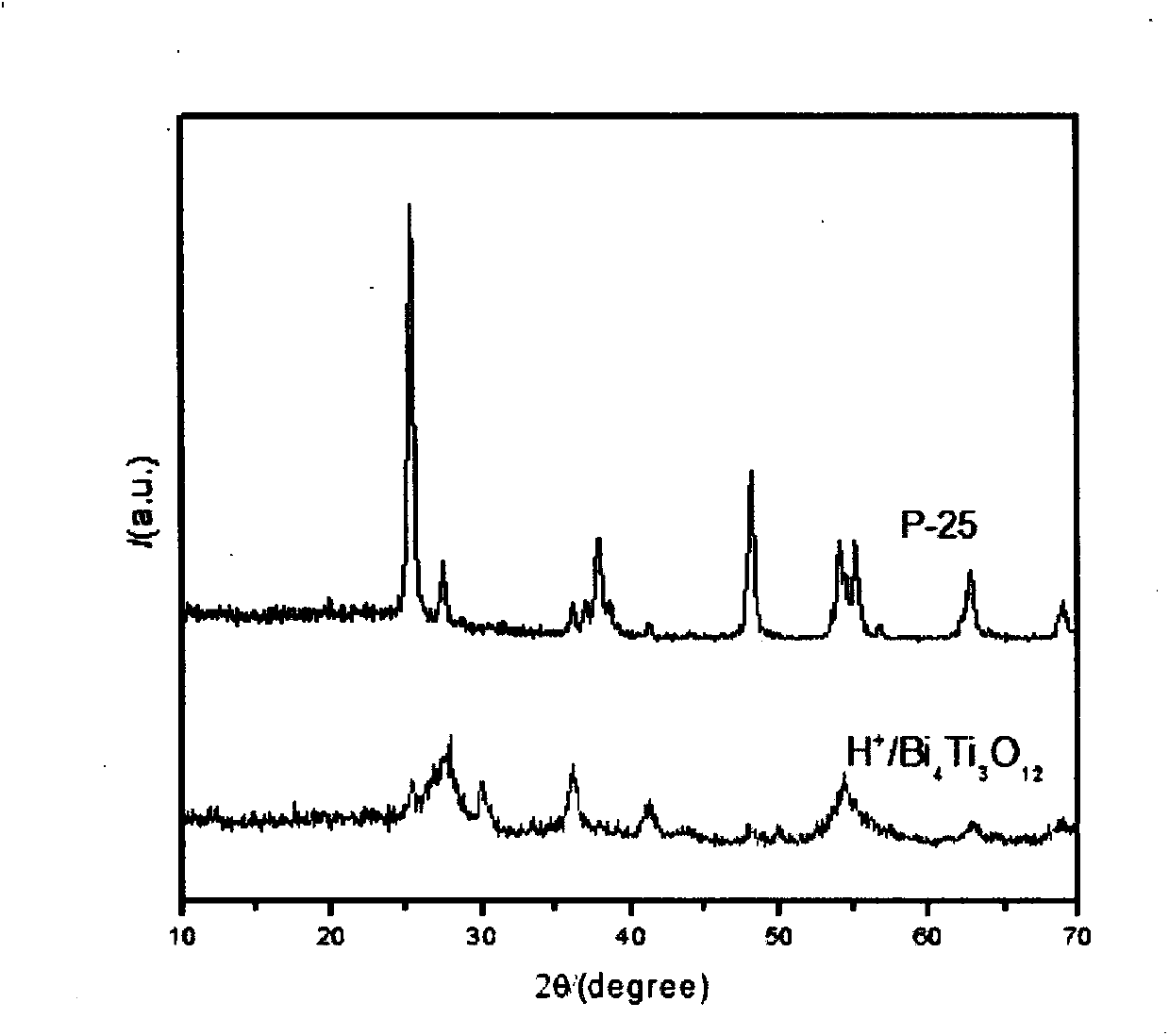

Solvent-thermal method for preparing single-phase bismuth titanate Bi2Ti2O7

InactiveCN102351242AExcellent solar photocatalytic activityHigh purityTitanium compoundsMetal/metal-oxides/metal-hydroxide catalystsSolar photocatalysisPhoto catalytic

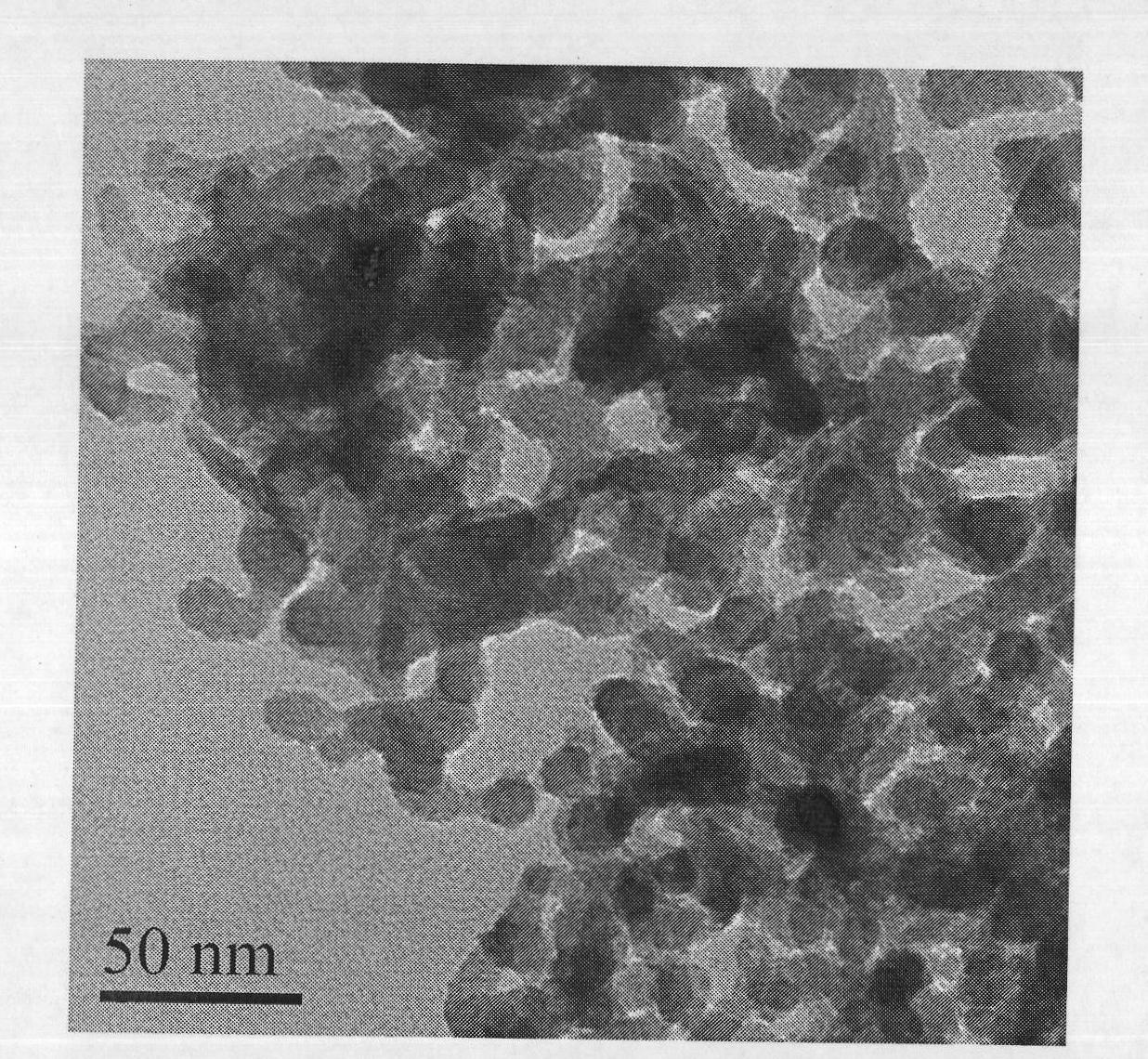

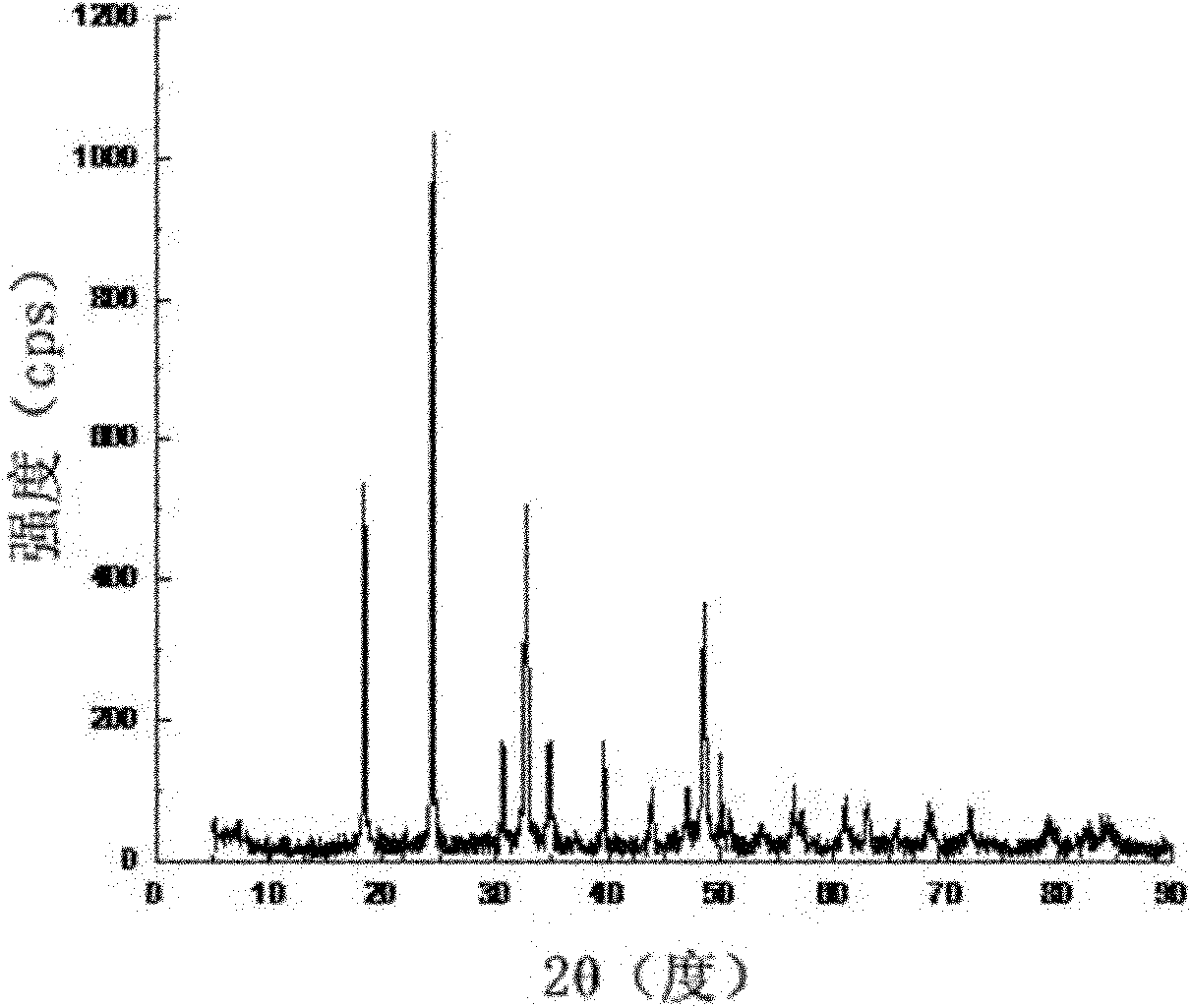

The invention discloses a solvent-thermal method for preparing single-phase bismuth titanate Bi2Ti2O7. Bismuth nitrate and butyl titanate are taken as raw materials, and the method is characterized by comprising the following steps of: dissolving the bismuth nitrate in alcohol serving as a solvent, and adding the butyl titanate and ether, wherein the using amount of the bismuth nitrate is lower than the stoichiometric ratio; uniformly mixing, and reacting at the temperature of between 110 and 230DEG C in an enclosed reaction kettle; and cooling, filtering and drying a solid, and calcining at the temperature of between 450 and 550DEG C to obtain the single-phase Bi2Ti2O7. The prepared bismuth titanate compound has a single-phase structure, is spherical nanoparticles, and has excellent solar photo-catalytic activity. The method has the advantages of low synthesis temperature, high powder purity and the like, the preparation process is simple, the raw materials are readily available, thecost is low, and the equipment is simple, and easy to operate.

Owner:NANJING NORMAL UNIVERSITY

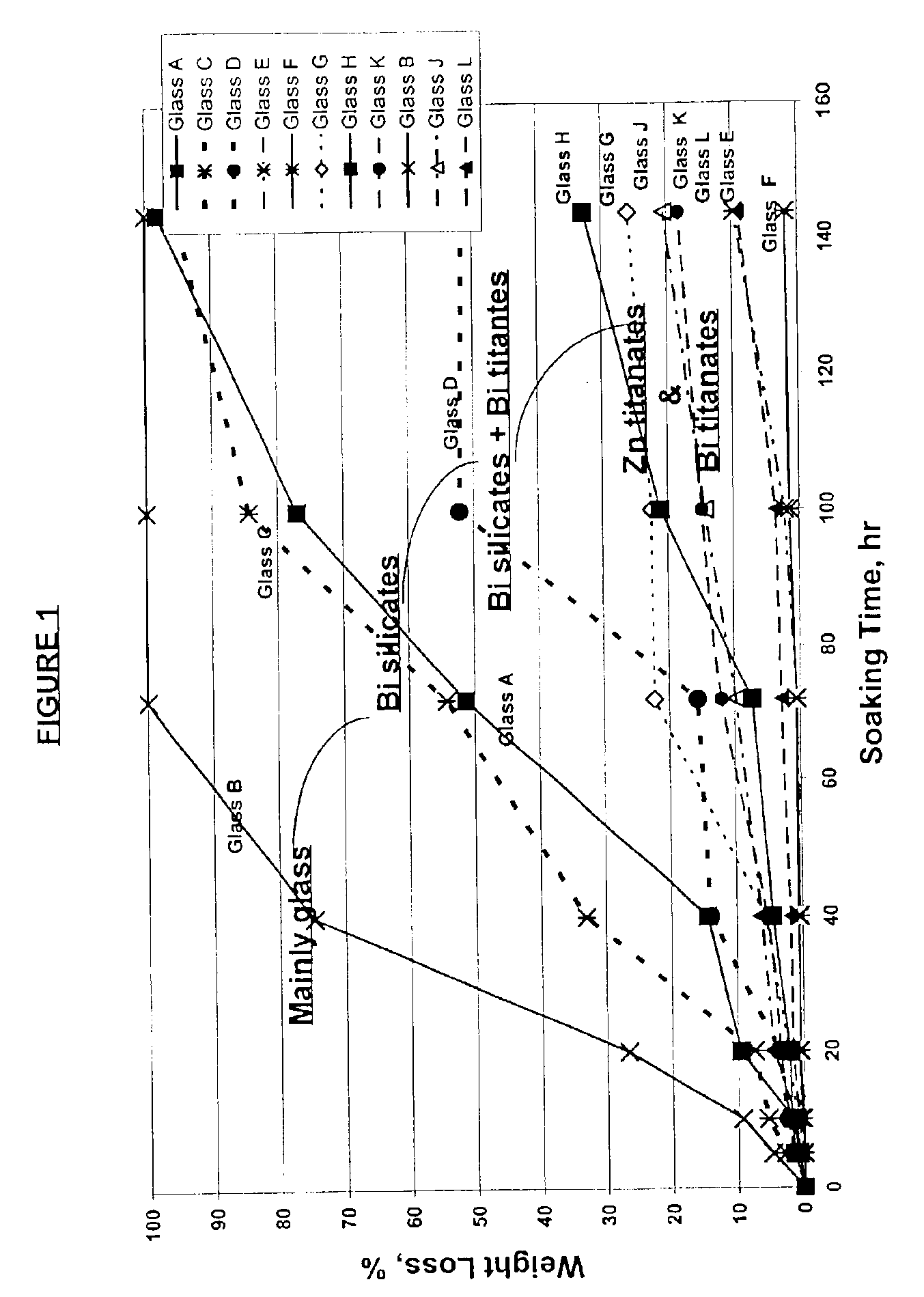

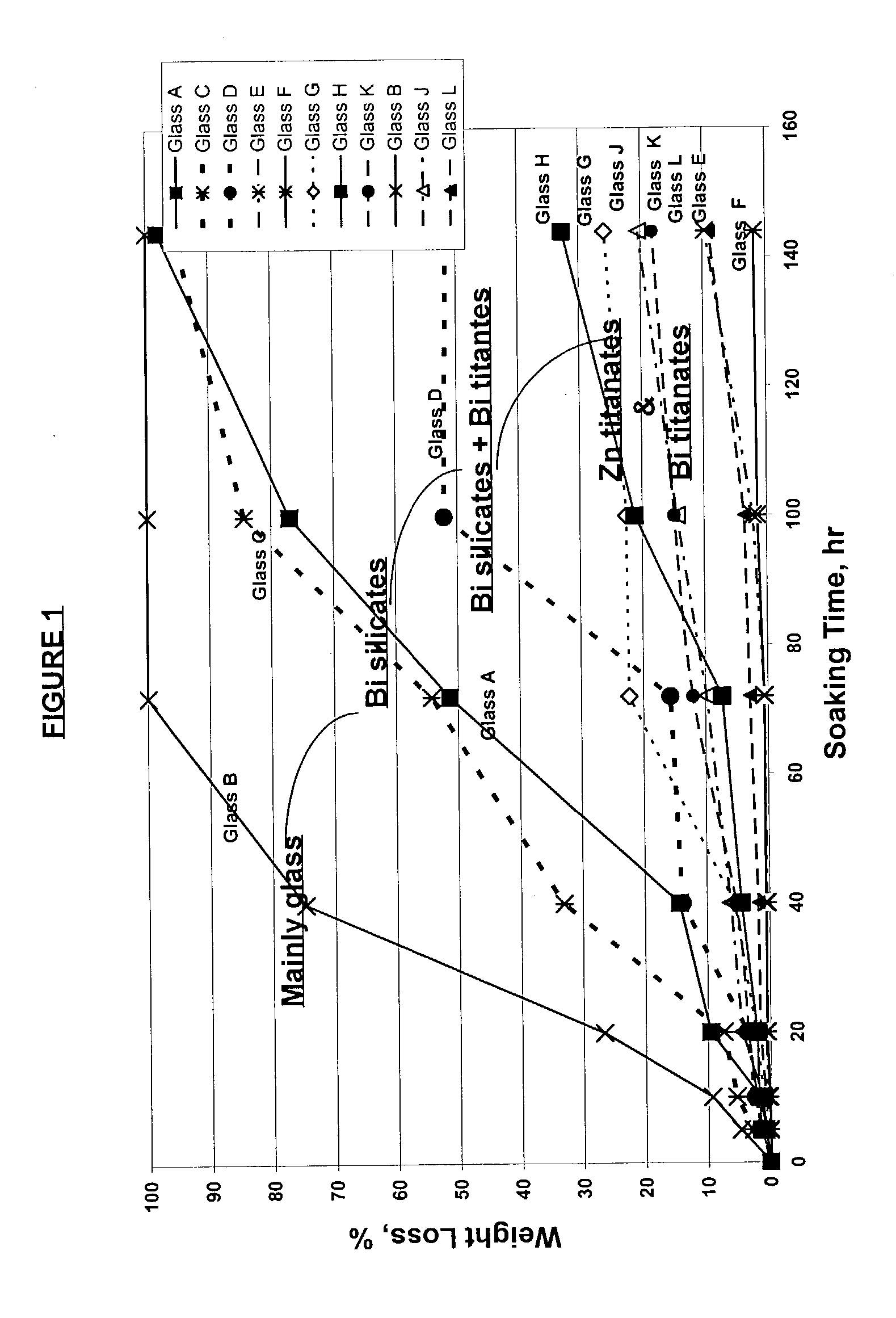

Durable glass enamel composition

The present invention provides partially crystallizing lead-free and cadmium-free glass enamel composition that fuse at low temperatures. Glass enamel compositions according to the present invention form predominantly bismuth titanate and optionally zinc titanate crystals upon firing. Preferably, glass enamel compositions according to the invention include a glass component that includes by weight from about 11% to about 52% SiO2, from 10.2% to about 40% TiO2, from about 5% to about 75% Bi2O3, up to about 8% B2O3, up to about 14% BaO+SrO, and up to about 45% by weight ZnO, where the sum of Bi2O3 and ZnO comprises from about 30% to about 85% of the glass component by weight.

Owner:FERRO CORP

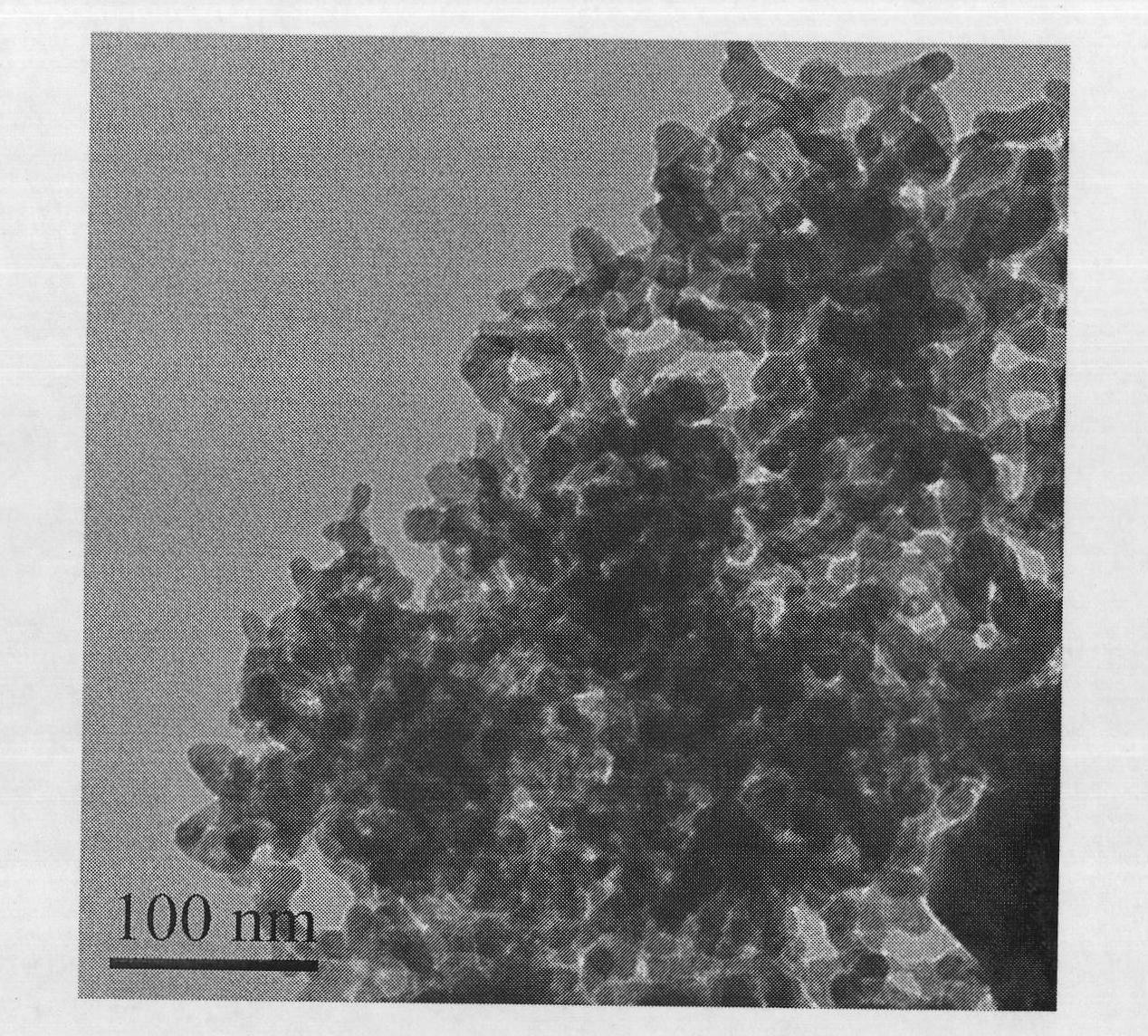

Method for preparing porous bismuth titanate photocatalyst

InactiveCN101147859AHydrolysis reaction easedUnique mesoporous structureWater/sewage treatment by irradiationEnergy based wastewater treatmentSynthesis methodsSolvent

The present invention belongs to the field of environmental science and engineering technology, in the concrete, it relates to a preparation method of new-type mesopore bismuth titanate photacatalyst for degrading organic pollutant. Said method includes the following steps: using bismuth nitrate and titanate as main raw material, using block interpolymer surfactant as structure guide agent, adopting acetic acid as hydrolysis catalyst, utilizing solvent thermal synthesis method to prepare titanium-bismuth composite oxide gel, making said gel undergo the processes of filtering, drying, high-temperature calcining and crystallizing so as to obtain the mesopore bismuth titanate material with photocatalytic activity.

Owner:BEIJING NORMAL UNIVERSITY

Middle-temperature sintering high temperature stabilization type ceramic capacitor dielectric material

InactiveCN101033132ARealize separate mass productionCompliant with large capacityCeramicsBarium titanateRare earth

This invention relates to a mid-temperature calcined and high temperature stabilized ceramic medium material of capacitors composed of barium titanate main material, a first additive, a second additive and a third additive, in which, the first additive is a microcrystal glass, the second additive includes lead-free piezoelectric material bismuth titanate sodium or boron silicate and the third additive includes: a rare earth oxide, ZnO and Nb2O5, and said rare earth oxide includes Ce or Nd oxide. Advantage: batch production is realized to basic materials and dopants so as to simplify the production process.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

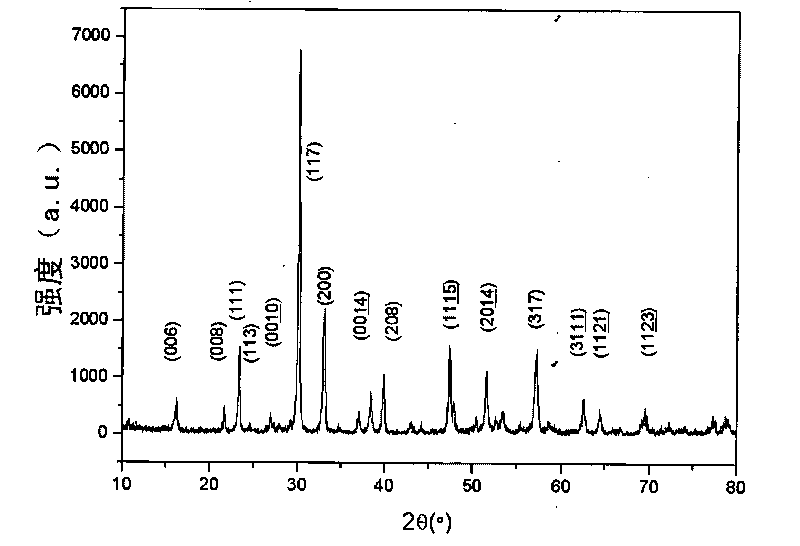

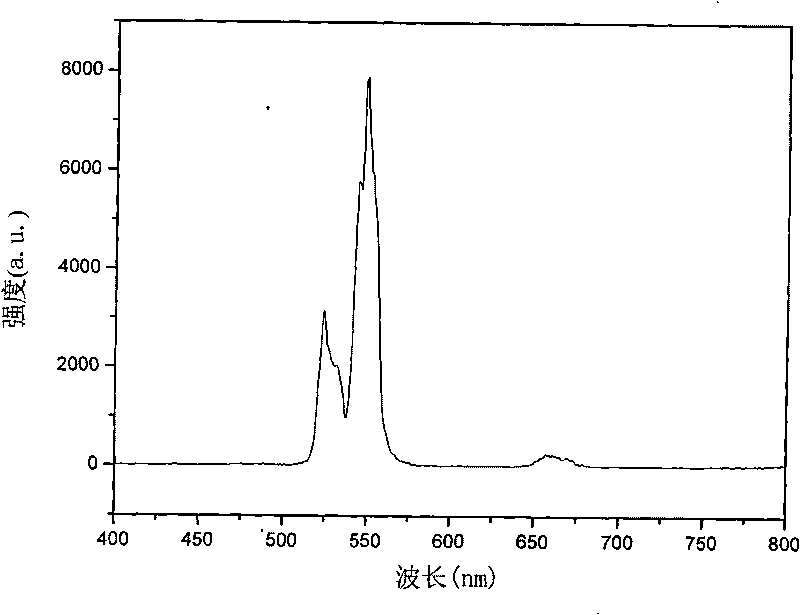

Rare-earth doped bismuth titanate up-conversion luminescence nanometer crystal material

InactiveCN101724397AImprove performanceHigh luminous intensityLuminescent compositionsLuminous intensityFluorescence

The invention relates to a rare-earth doped bismuth titanate up-conversion luminescence nanometer crystal material which relates to a bismuth titanate luminescence nanometer crystal material. The invention solves the problem of low luminous intensity of the rare-earth doped bismuth titanate up-conversion luminescence nanometer crystal material. The rare-earth doped bismuth titanate up-conversion luminescence nanometer crystal material is obtained by doping Er, Er / Yb, Yb / Tm and Er / Yb / Tm to the bismuth titanate matrix by a sol-gel method. The up-conversion luminescence nanometer crystal material can realize up-conversion luminescence of different colours of red, green, yellow, blue and white under the excitation of infrared radiation with the wavelength of 980nm and has high luminous intensity. The rare-earth doped bismuth titanate up-conversion luminescence nanometer crystal material can be widely applied in the fields of infrared radiation detection, anti-counterfeit, bimolecular fluorescent mark, and the like.

Owner:HARBIN INST OF TECH

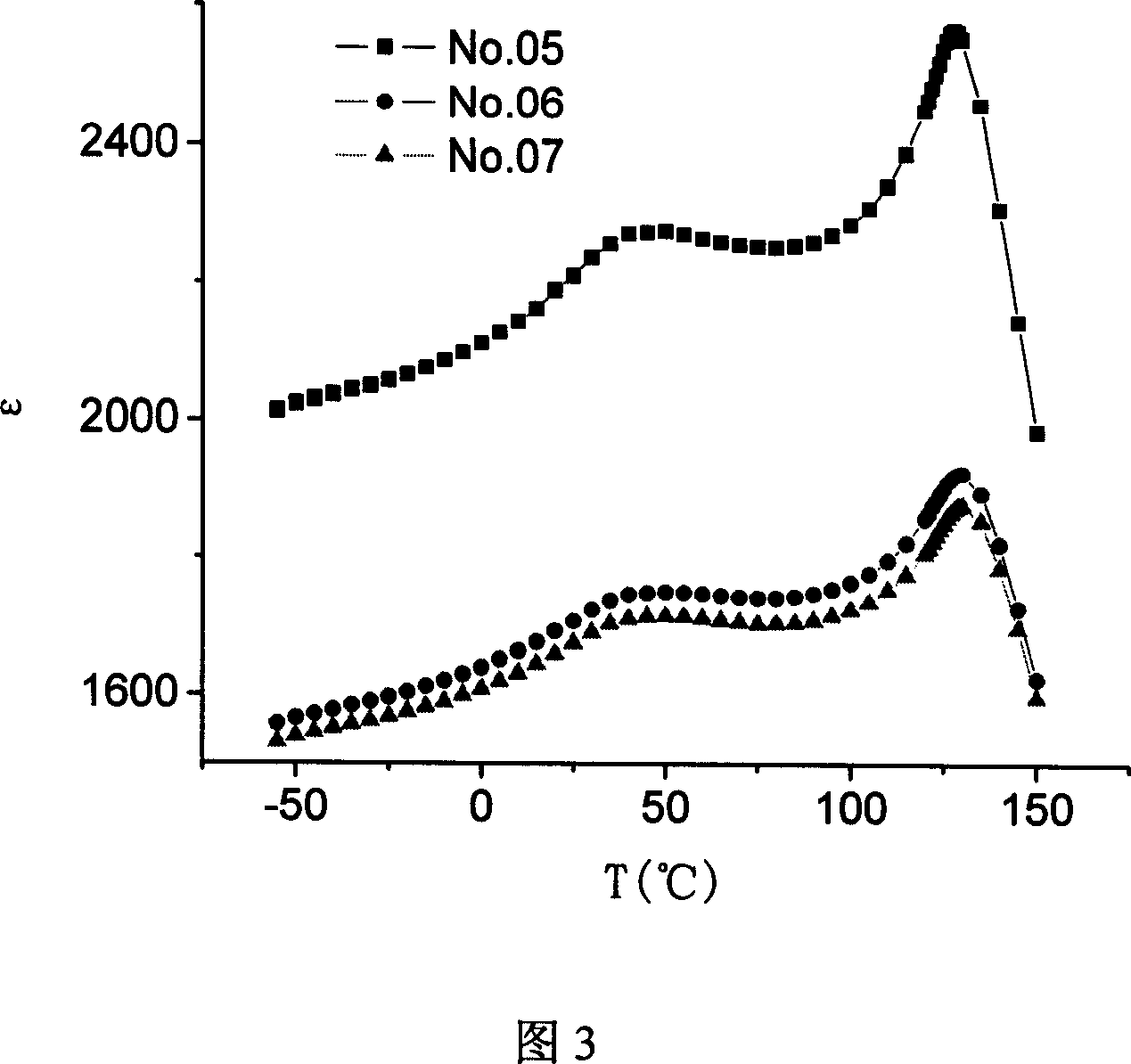

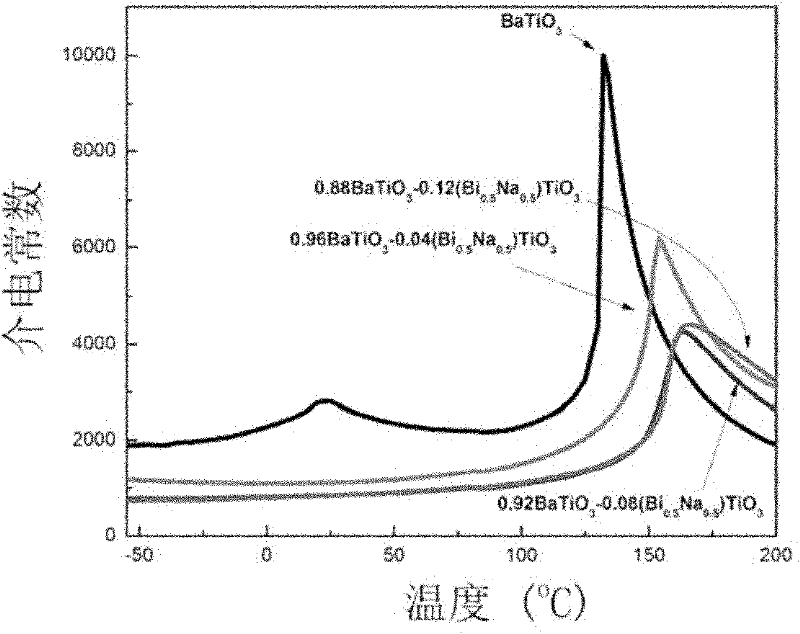

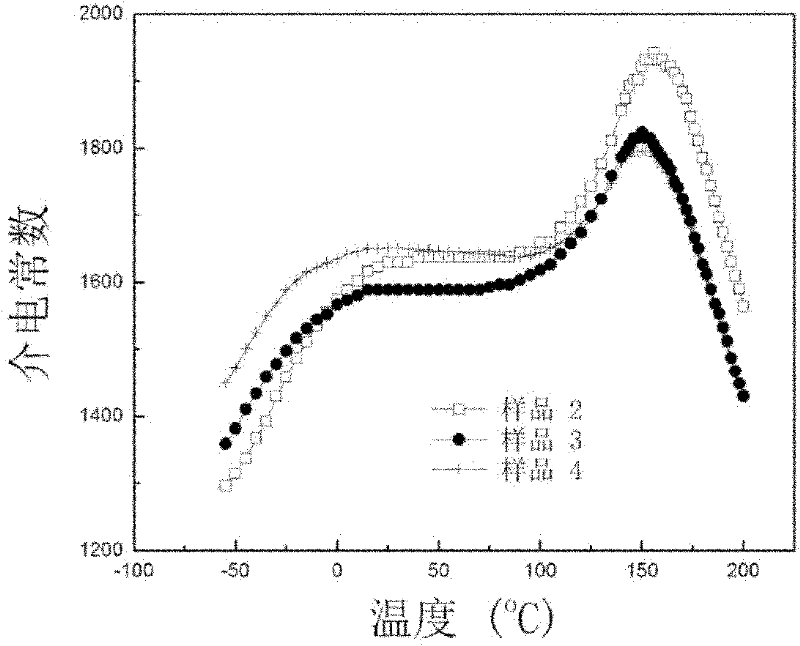

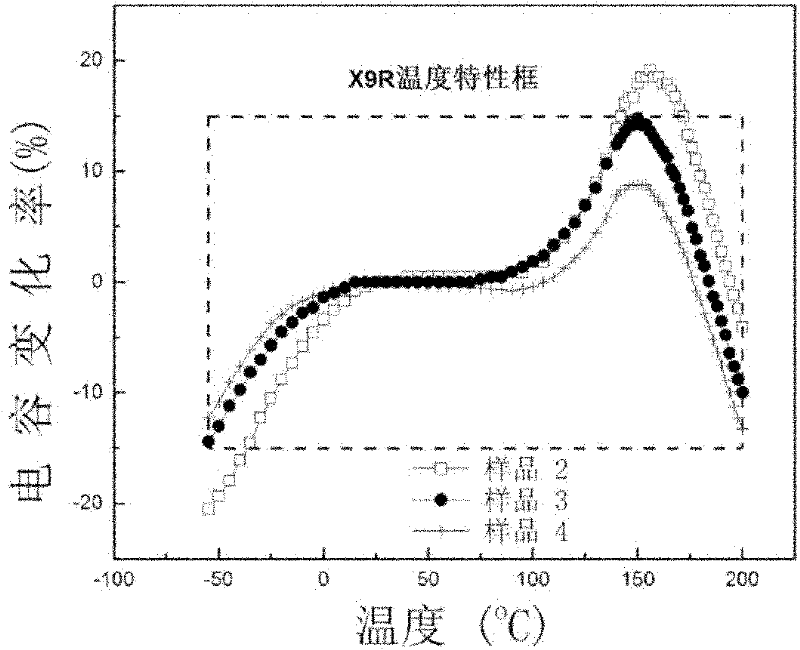

X9R ceramic capacitor dielectric material and preparation method thereof

ActiveCN102199035AImprove temperature stabilityRaise the Curie transition temperatureBarium titanatePotassium

The invention discloses an X9R ceramic capacitor dielectric material and a preparation method thereof. The material comprises 95 to 98 molar percent of barium titanate-sodium bismuth titanate complex or barium titanate-potassium bismuth titanate complex serving as a main component, and 2 to 5 molar percent of secondary additive consisting of at least one of Nb2O5, CaZrO3 and SrZrO3. According to the preparation method of the invention, the dielectric ceramic material with high property can be obtained, meeting the electronic industries association (EIA) X9R standard; the process is simple, and intermediate temperature sintering can be performed; and the material has the room temperature dielectric constant of 1,500 to 1,700, the room temperature loss of about 2 percent, the room temperature resistivity of more than or equal to 1,013omega.cm, the breakdown voltage of more than or equal to 5kV / mm, and a good industrial prospect.

Owner:TSINGHUA UNIV

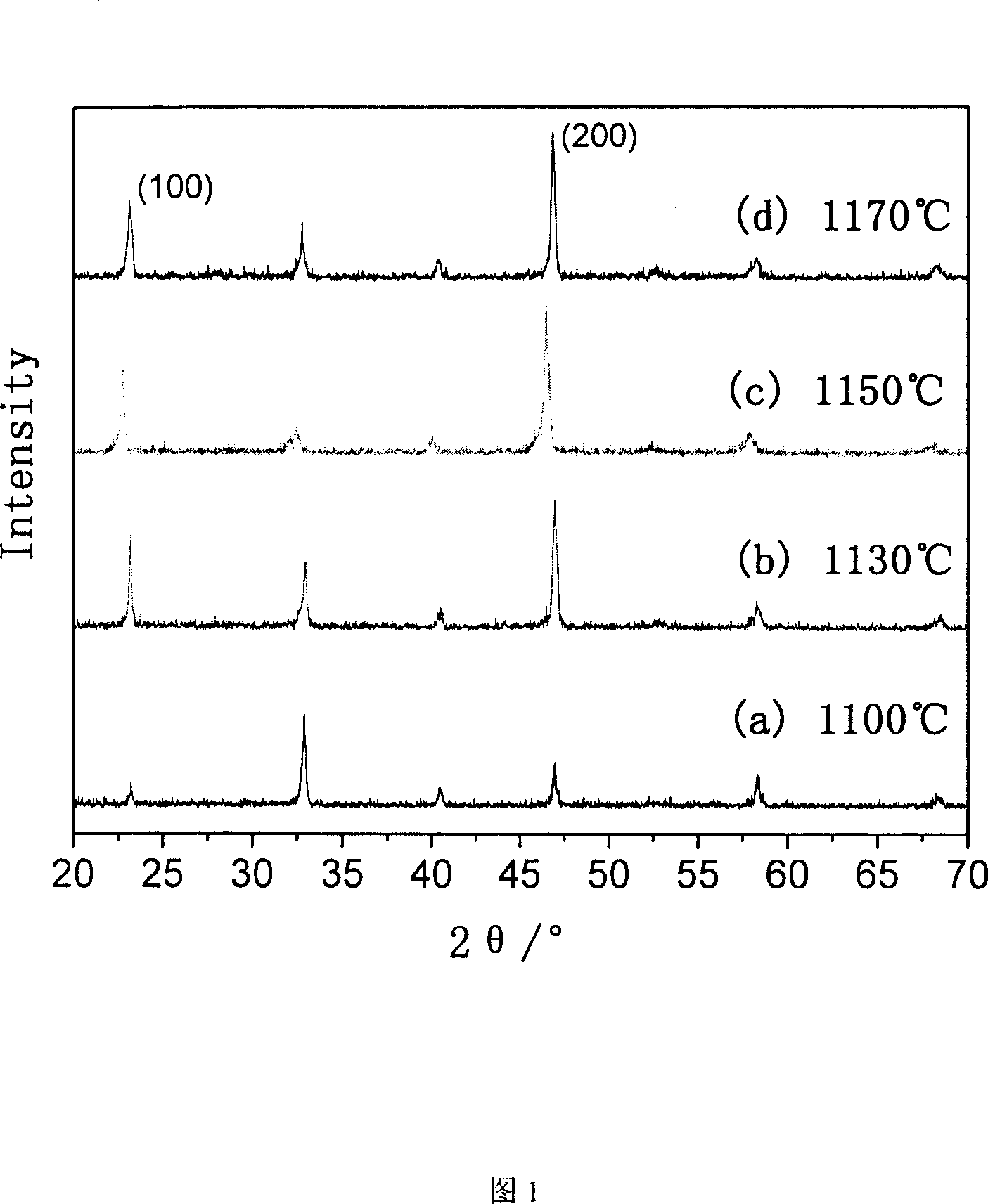

Bi.Na.Ag Ba titanate series lead-free piezoelectric ceramics

InactiveCN1814569AImprove performancePromote polarizationPiezoelectric/electrostrictive/magnetostrictive devicesElectromechanical coupling coefficientDielectric loss

The invention relates to bismuth titanate natrium-silver-barium series piezoelectric ceramics with ABO3 structure. The general equation of the compound is [Bi0.5(Na1-xAgx)0.5] 1-yBayTiO3+aM alpha O beta (wt%), and in the equation, 0 alpha Obeta is one or plural doping oxide. The main constituent is 0-5 of Biw(Na1-x-y-zKxLiyAgz)1-wTiO3, M could be Na, K, Li, Ni, Zn, Cr, Co, Nb, Ta, Al, Cu, Fe, Ce, Pr, Nd, Sm, Gd, Dy, Er, Yb, In, Y, Sc, La, Ho, Lu, Sn, Sb, Mn, Ca, Ba, Sr, Mg, Si, Bi, Ag, etc. Alpha and beta mean the M element and atomicity corresponding to the relative oxide. The sintering temperature is 1100-1200 degree centigrade, keeping for 1-4 hours. The optimal value of the compound of d33 could be over 160pC / N, kp could be over 31%, dielectric loss could be below 0.03. And the technology is stable, and it would be made from traditional technology and raw material.

Owner:SICHUAN UNIV

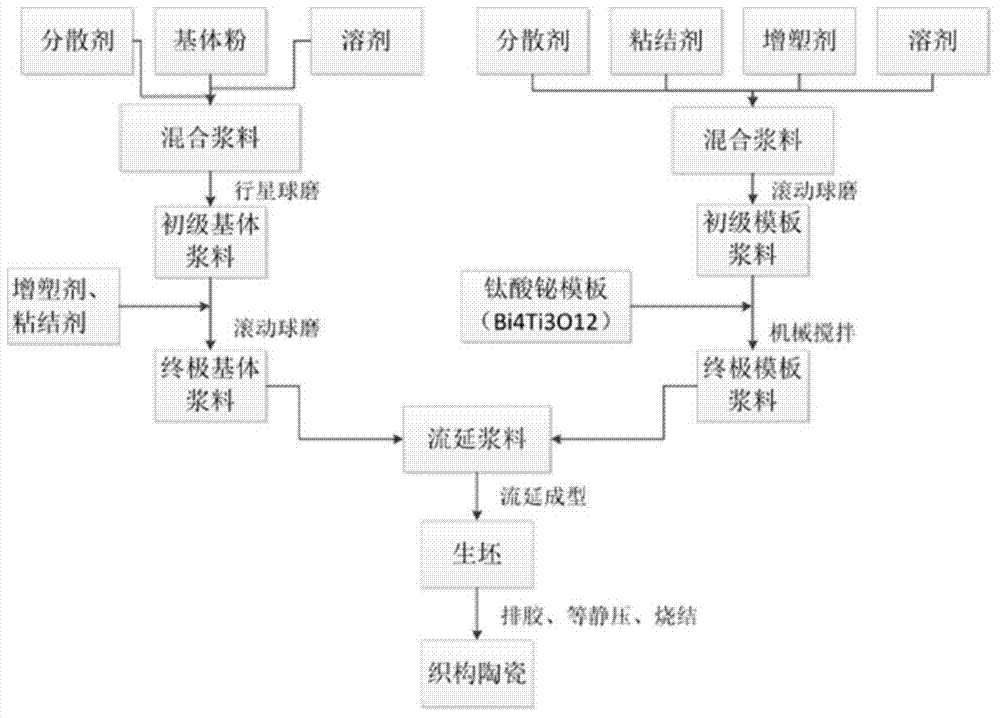

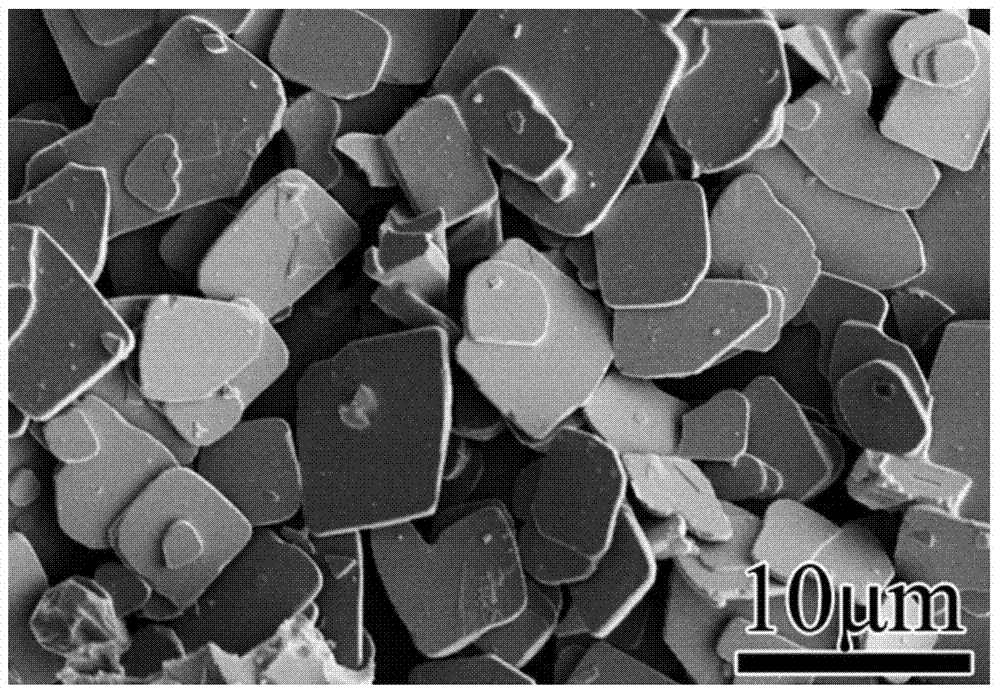

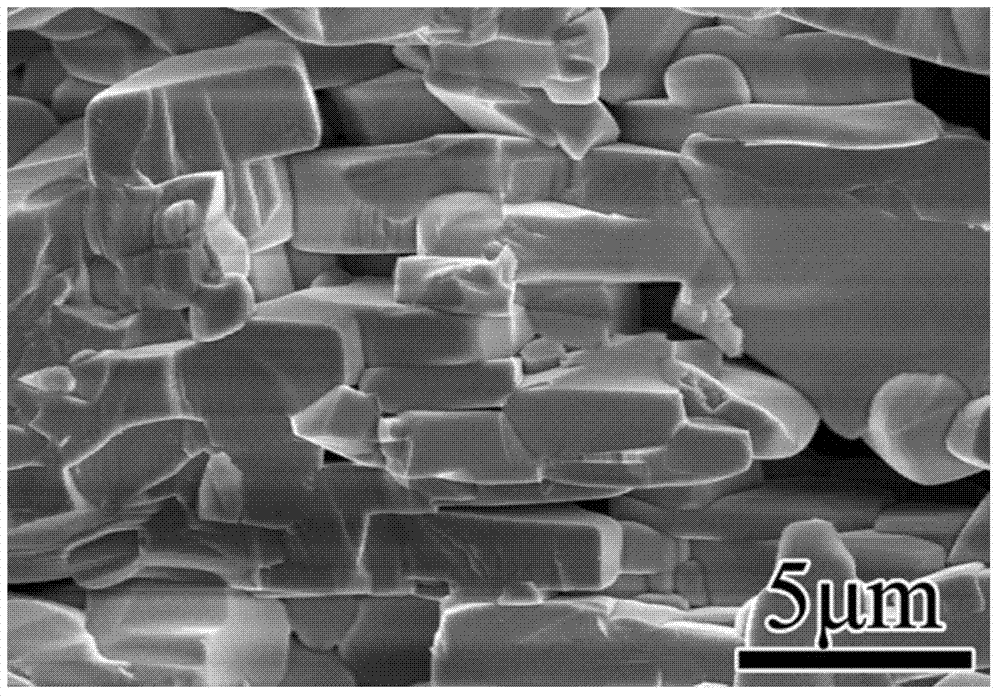

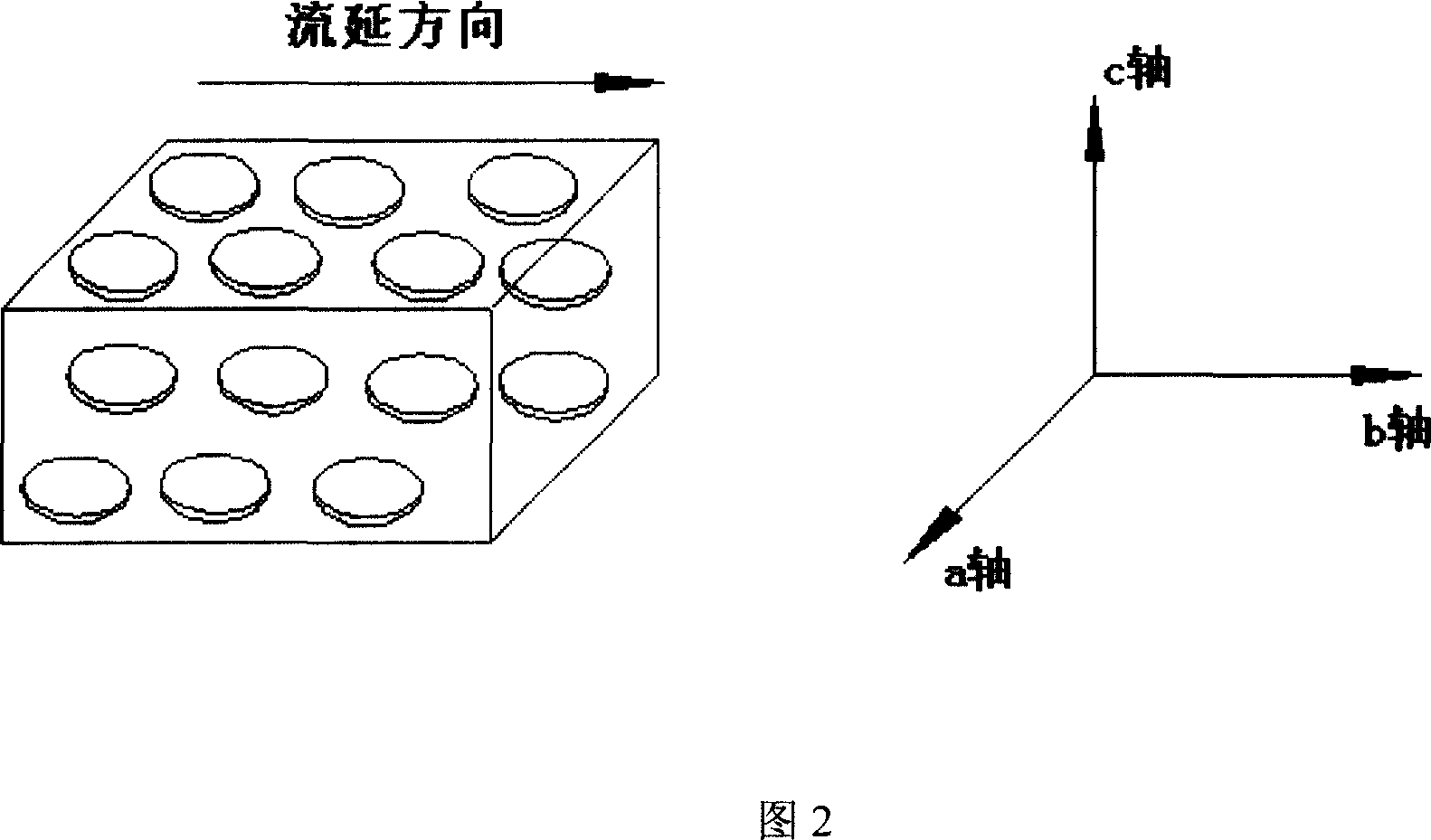

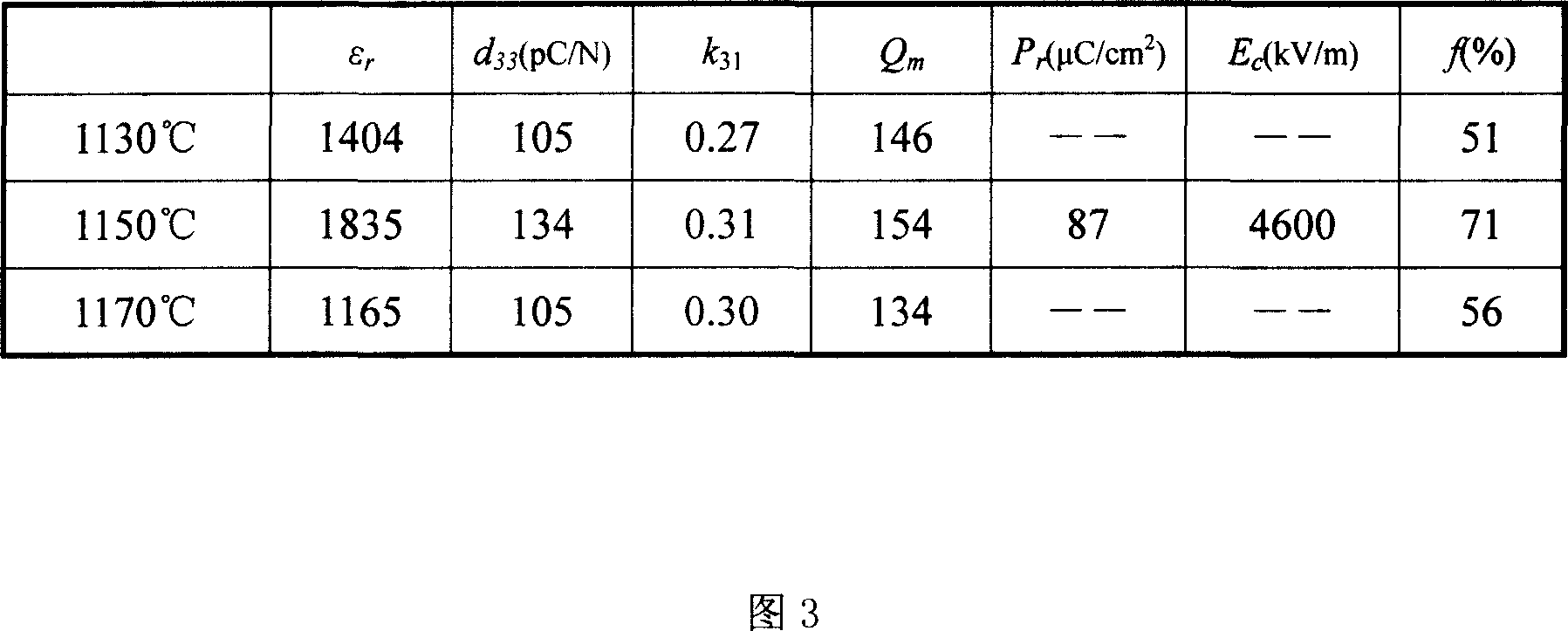

Sodium bismuth titanate-barium titanate-potassium bismuth titanate lead-free piezoelectric texture ceramic and preparation method thereof

InactiveCN103613382AExcellent piezoelectric propertiesThe original composition does not changeBarium titanatePotassium

The invention provides sodium bismuth titanate-barium titanate-potassium bismuth titanate lead-free piezoelectric texture ceramic and a preparation method thereof. The preparation method comprises the following steps: mixing a template with organic additives such as matrix powder, an organic solvent and a binder to obtain slurry by taking a Bi4Ti3O12 crystal as the template; preparing the slurry into a film sheet with thickness of 30 mu m-60 mu m through a curtain coating process; and sintering the film sheet after laminating, cutting, rubber exhausting and isostatic cool pressing to prepare a BNBK texture ceramic material with high oriented growth, wherein original components of the materials are not changed due to precise control in the process. The prepared sodium bismuth titanate-barium titanate-potassium bismuth titanate lead-free piezoelectric texture ceramic constitutes a (1-x-y)Na0.5Bi0.5TiO3-xBaTiO3-Yk0.5Bi0.5TiO3 ternary system, has good crystalline grain orientation effect, excellent performances in the lead-free piezoelectric field, a piezoelectric constant of over 210 pC / N and a Curie temperature of over 320 DEG C.

Owner:TIANJIN UNIV

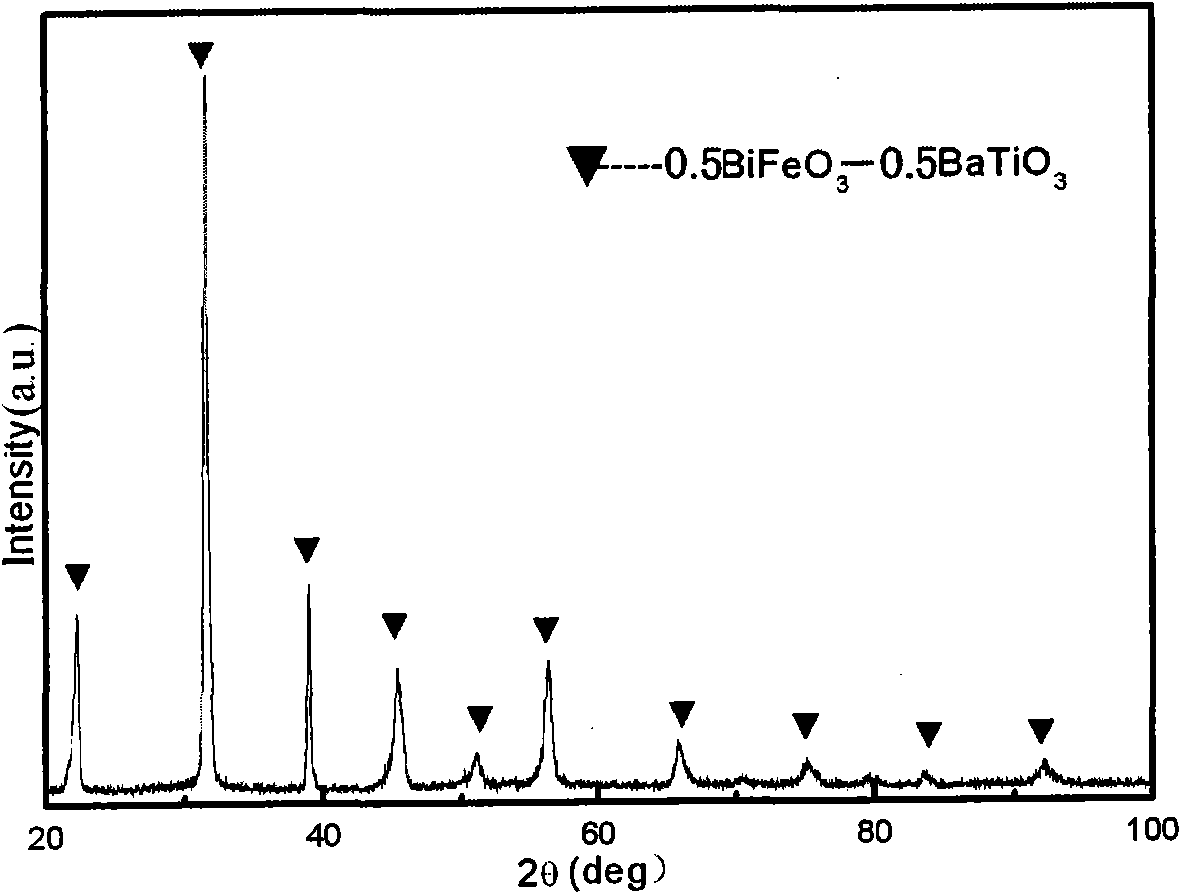

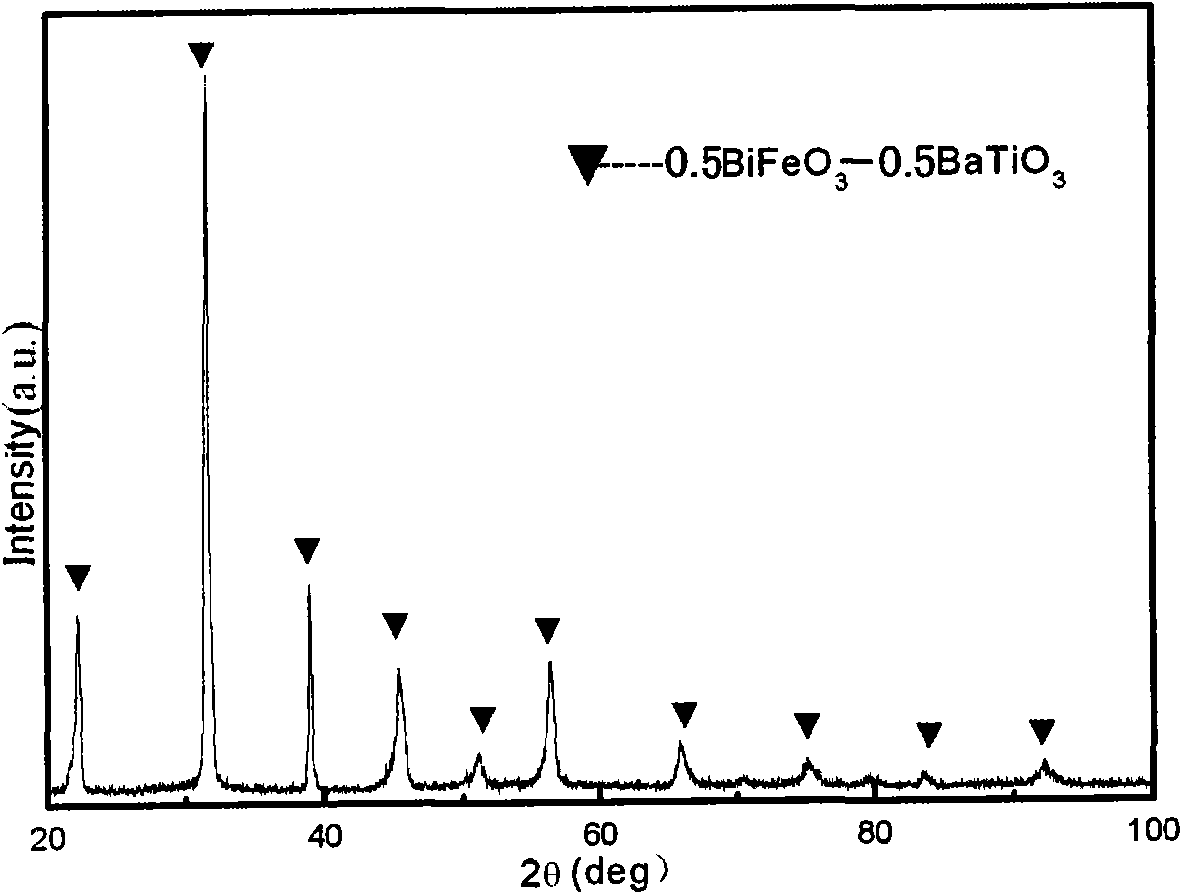

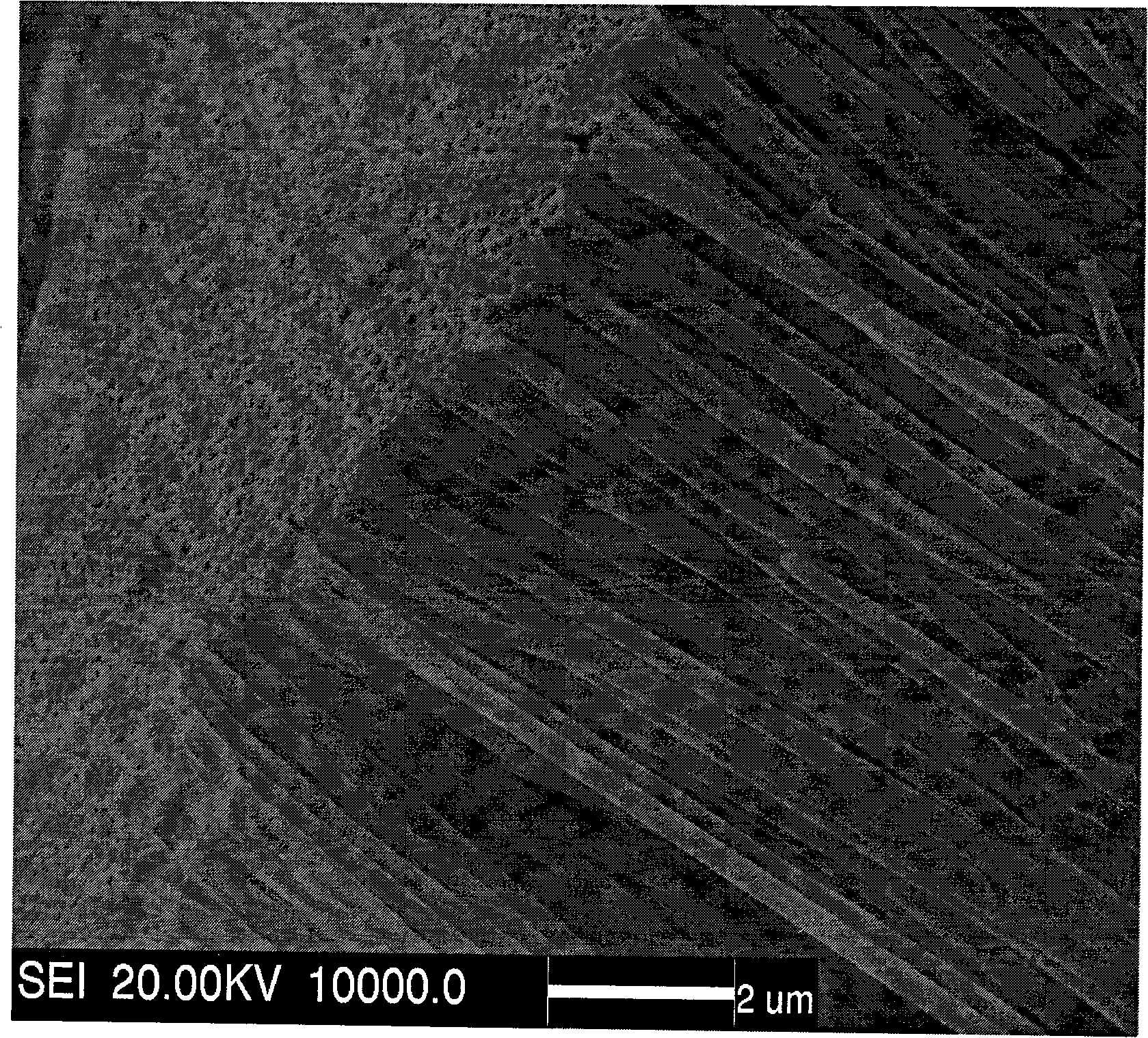

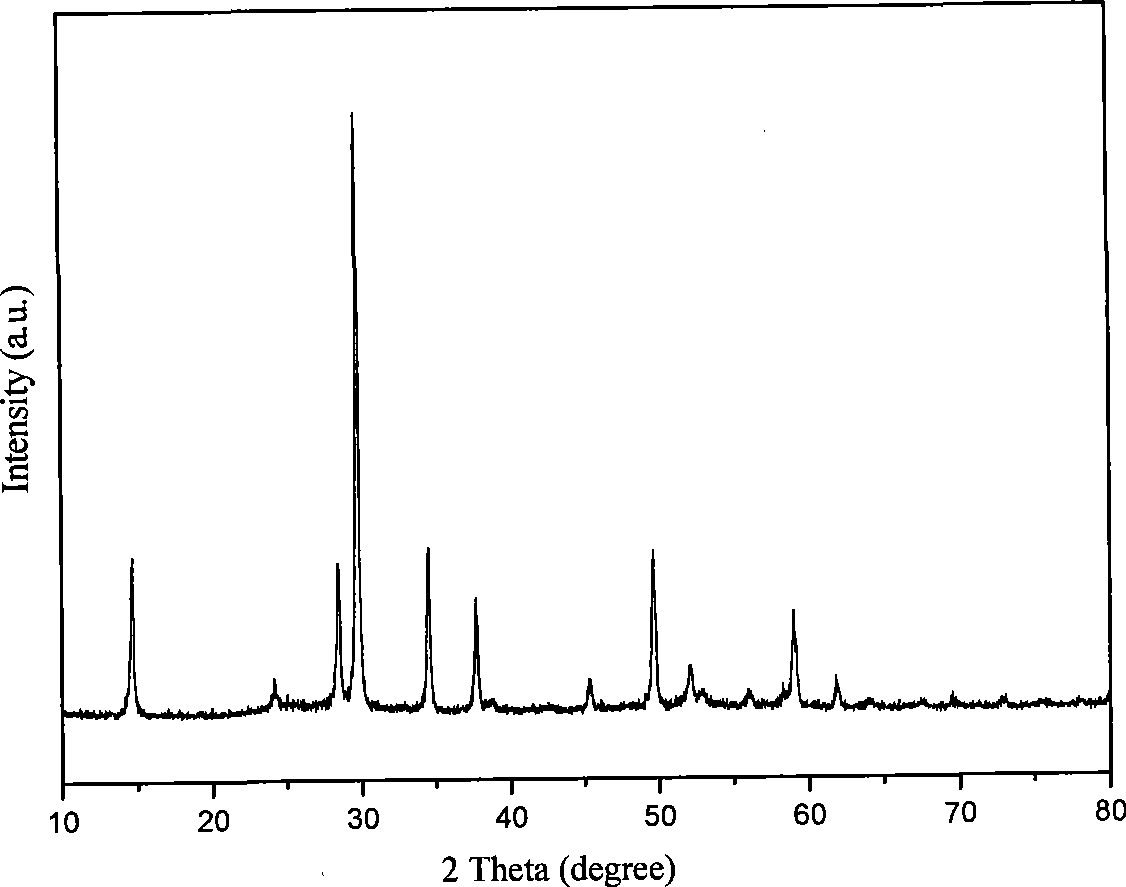

Method for preparing bismuth titanate-barium titanate powder by hydrothermal method

InactiveCN101913853AShort reaction timeReaction is easy to controlBarium titanateParticle-size distribution

The invention provides a method for preparing bismuth titanate-barium titanate powder by hydrothermal method. The method is characterized by belonging to the hydrothermal synthesis technique and the field of functional ceramics. The method comprises the following steps of: preparing KOH and deionized water into mineralizer solution of which the concentration is 4 to 10mol / L; blending Bi(NO3)3.5H2O, Fe(NO3)3.9H2O, BaCl2 and TiCl4, which serve as raw materials, according to the following chemical formula: xBiFeO3-(1-x)BaTiO3 (x is more than or equal to 0.1 and less than or equal to 0.9), addinghydrochloric acid and the deionized water dropwise into the raw materials, and uniformly stirring to completely dissolve the raw materials; slowly adding the mixture into the KOH mineralizer solutiondropwise, and uniformly stirring to obtain fulvous precursor solution; and adding the precursor solution into a reactor, putting the reactor in a 200 DEG C oven for keeping the temperature for 6 to 36 hours, and naturally cooling and filtering to the reactor to obtain the reaction product, namely the bismuth titanate-barium titanate powder. The bismuth titanate-barium titanate powder solid solution powder prepared by the invention has the advantages of good crystallization, uniform grain distribution, simple process flow, short reaction time and energy conservation.

Owner:UNIV OF SCI & TECH BEIJING

Preparation of lanthanide series rare-earth doped bismuth titanate nano-tube

InactiveCN101279767APrecise size controlThe higher the yieldNanostructure manufactureTitanium compoundsRare earthLanthanide

Disclosed is a method for the production of a lanthanide rare-earth doping bismuth titanate nano-tube, which relates to a method for the production of a bismuth titanate nano-tube. The method solves the problems of complex technique and equipment, long preparation cycle, high cost, low yield and being unable to control the size of the nanostructure material accurately when preparing the lanthanide rare-earth doping bismuth titanate nanostructure material by the prior art. The method of preparation has steps of: firstly, weighting nitrate and tetrabutyl titanate in bismuth salt and lanthanide rare-earth; secondly, preparing a lanthanide rare-earth doping bismuth titanate sol, thirdly, dripping the lanthanide rare-earth doping bismuth titanate sol on the surface of an aluminum oxide template and drying the template after being soaked; fourthly, repeating the third step and preserving the heat of the dried template at a certain temperature; and fifthly, repeating the third and the fourth steps and taking out the template at a certain temperature and then placing the template in a KOH or NaOH solution, thereby obtaining the lanthanide rare-earth doping bismuth titanate nano-tube. The method of preparation has advantages of simple process and equipment, short preparation cycle, low cost, high yield and being able to control the size of the nano-tube accurately.

Owner:HARBIN INST OF TECH

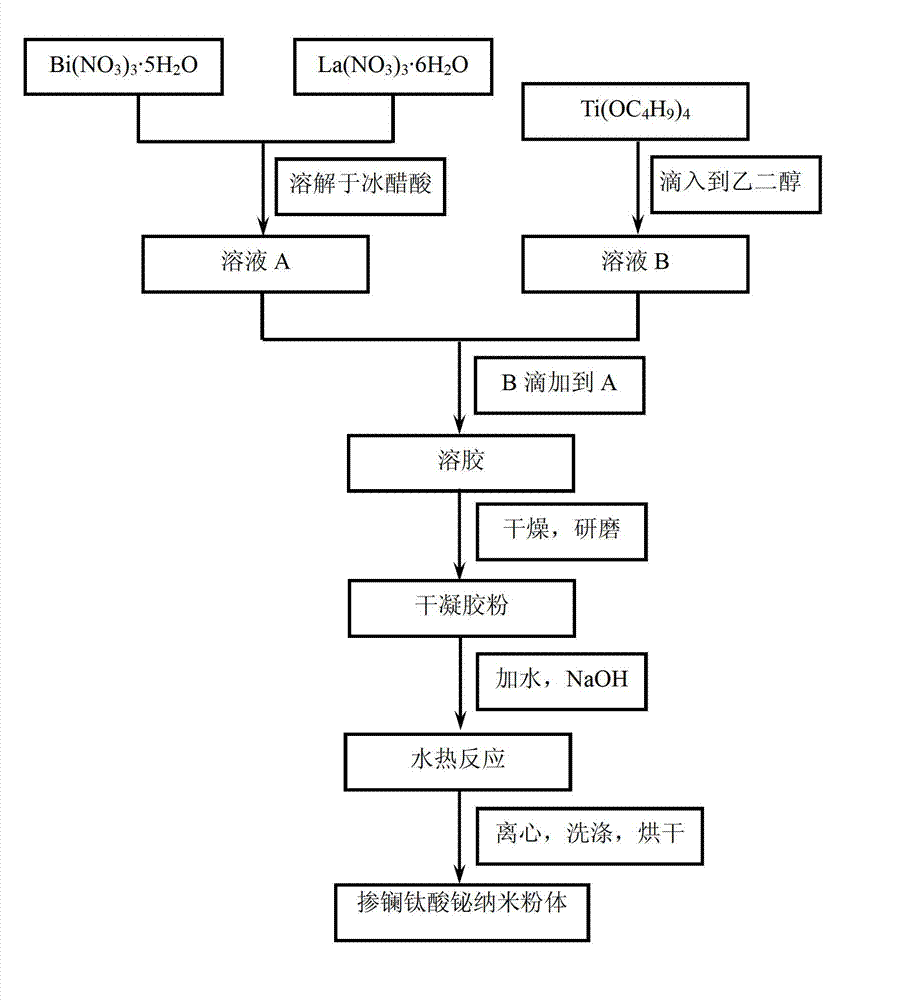

Method for preparing lanthanum-doped bismuth titanate nano powder by sol-gel hydrothermal method

ActiveCN102963929ASave energySimple equipmentMaterial nanotechnologyChemical industryOrganic solventAcetic acid solution

The invention discloses a method for preparing lanthanum-doped bismuth titanate nano powder by a sol-gel hydrothermal method, which comprises the following steps of: dissolving Bi (NO3) 3.5H2O and La (NO3) 3.6H2O into glacial acetic acid solution to obtain solution A; dropwise adding Ti (OC4H9) 4 into organic solvent to obtain solution B; dropwise adding the solution B into the solution A, and preparing even sol by magnetic stirring; putting the sol into a drying oven, and drying to obtain xerogel; grinding to obtain powdered hydrothermal reaction precursor; putting the hydrothermal reaction precursor into a hydrothermal kettle, and adding pure water taken as solvent and NaOH taken as mineralizer into the hydrothermal kettle; sealing the reaction kettle, and putting the reaction kettle into the drying oven at 160-170 DEG C; taking out products after reaction, and filtering to obtain precipitate; and finally, washing and drying the precipitate to obtain the lanthanum-doped bismuth titanate nano powder. The method can be used for preparing the lanthanum-doped bismuth titanate nano powder under the condition of low temperature, so that the energy is saved, and lanthanum-doped bismuth titanate is perfect in crystallization.

Owner:SOUTH CHINA UNIV OF TECH

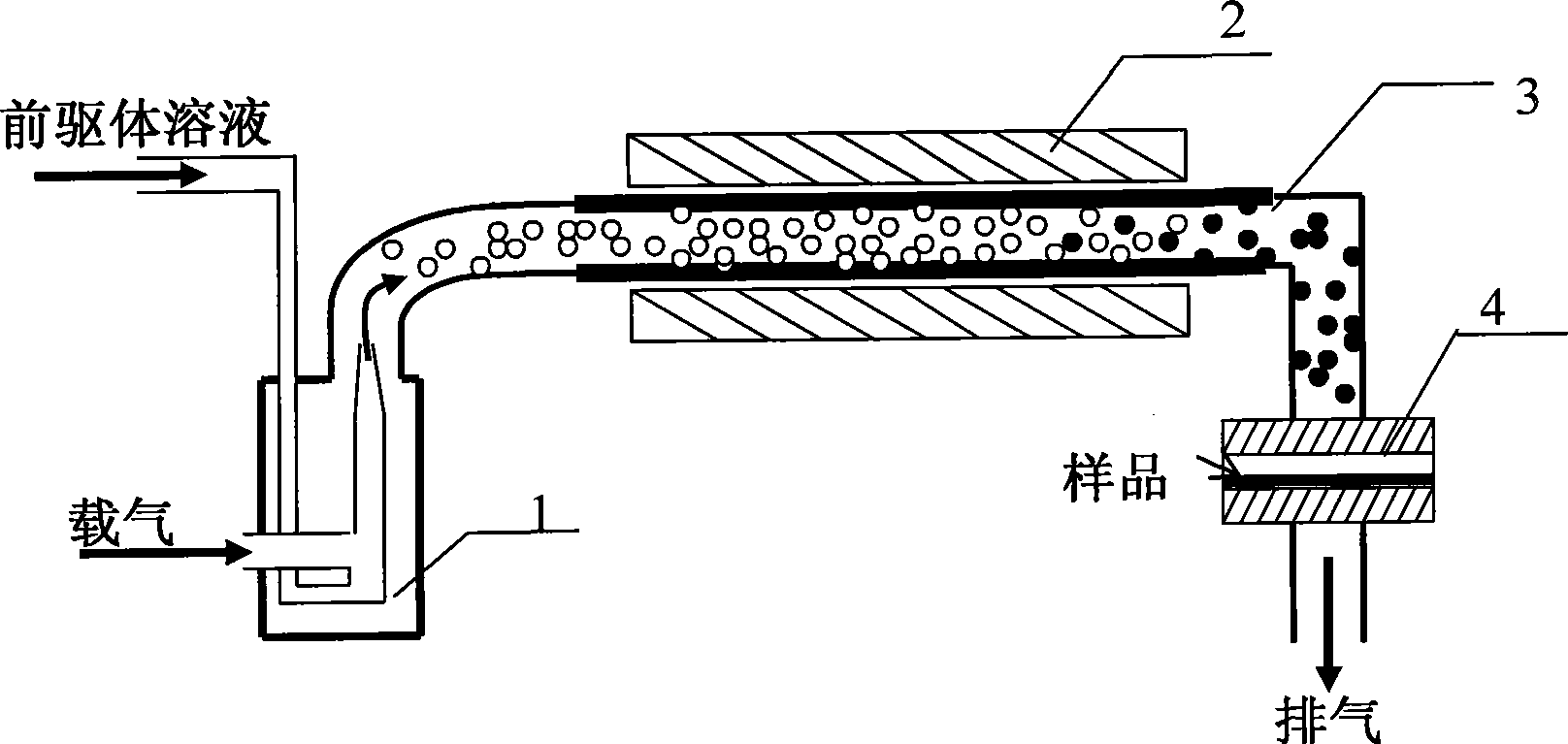

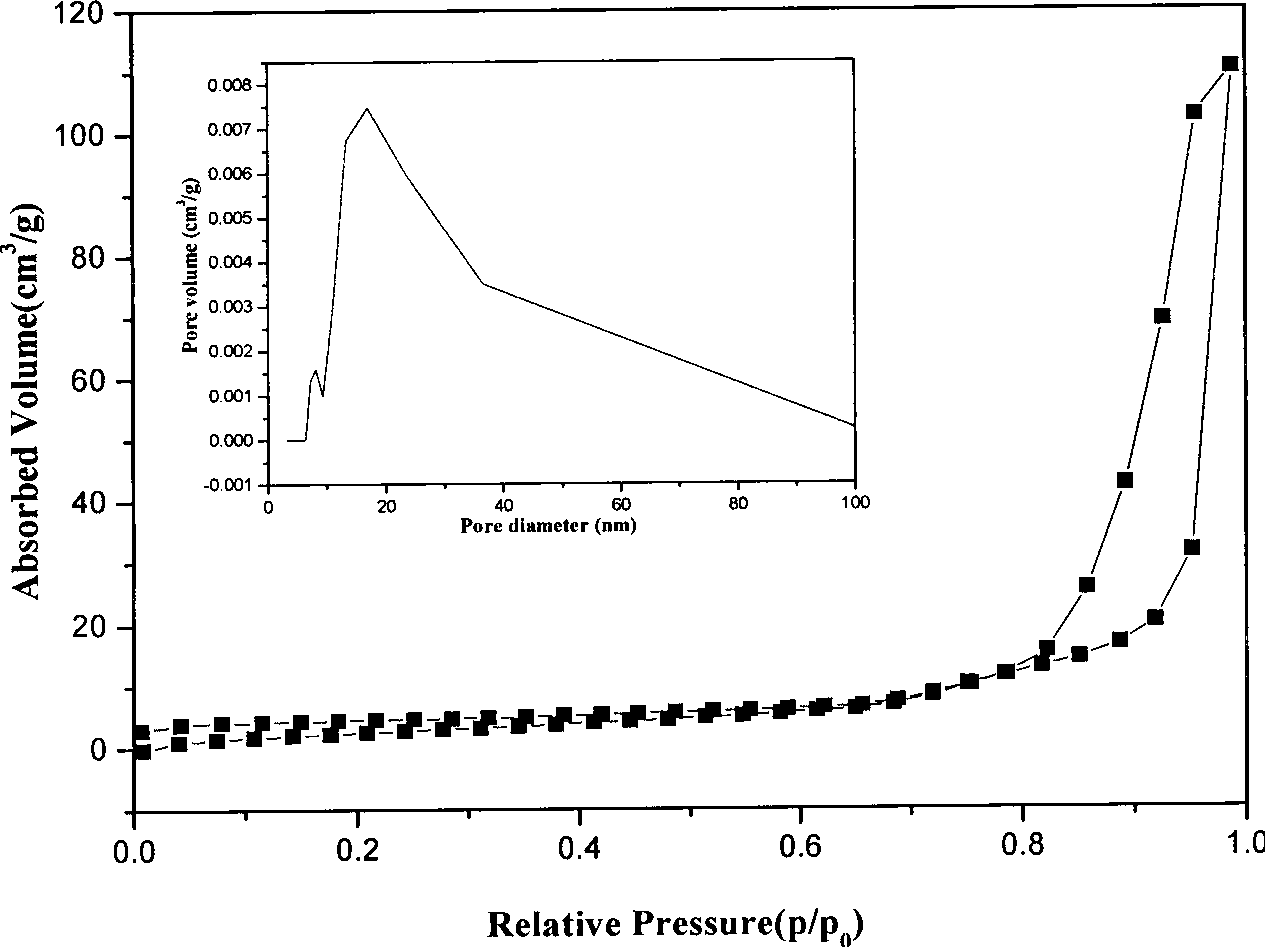

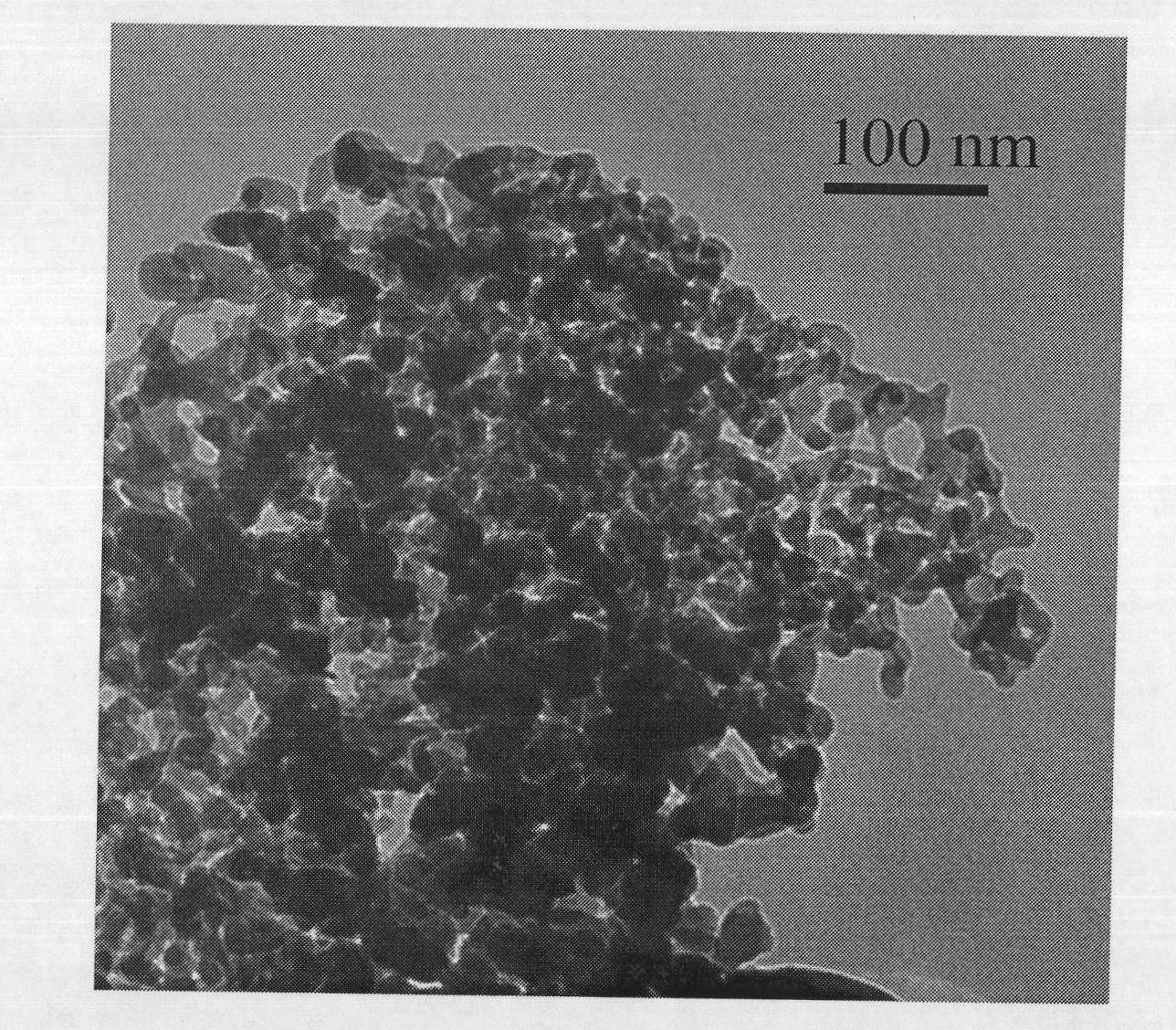

Porous structured bismuth titanate microsphere, preparation method and application thereof

InactiveCN101428210ASimple preparation processEasy to operateMetal/metal-oxides/metal-hydroxide catalystsAcetic acidMicrosphere

The invention discloses a bismuth titanate microsphere with a porous structure, as well as a preparation method and the application thereof. The porous-structure bismuth titanate microsphere is characterized in that the molecular formula thereof is Bi2Ti2O7, the grain diameter thereof is 0.5-2.0 Mum, the aperture thereof is 3.1-23.8 nm, the pore volume thereof is 0.02-0.20 cm<3> / g, and the specific surface area thereof is 8.4-47.1 m<2> / g. The preparation method comprises the following steps: using glacial acetic acid of bismuth salt or a glycerin solution, a surface active agent aqueous solution and titaniumivbutoxide or titanyl sulfate to form a precursor solution, in which the spray drying technique is applied to obtain a porous-structure bismuth titanate photocatalyst. The porous-structure bismuth titanate obtained can effectively degrade organic pollutants such as para-chlorophenol and the like through photocatalysis in visible light, so that the porous-structure bismuth titanate has a potential prospect of application. The invention has the advantages of easy attainment of raw materials, low preparation cost, simple process and easy control of conditions, and meanwhile provides a preparation process, from which synthesis of other photocatalyst materials can draw on experience.

Owner:SHANGHAI NORMAL UNIVERSITY

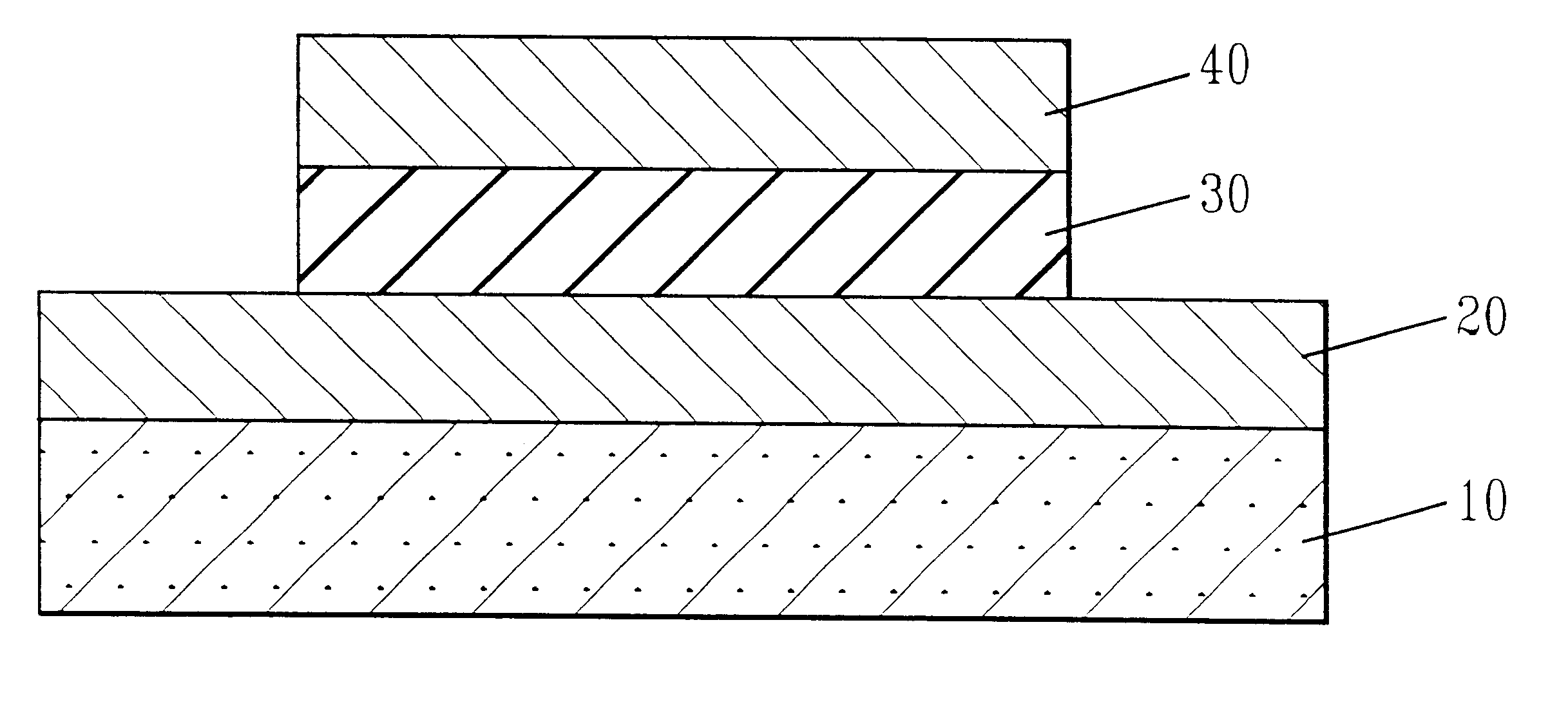

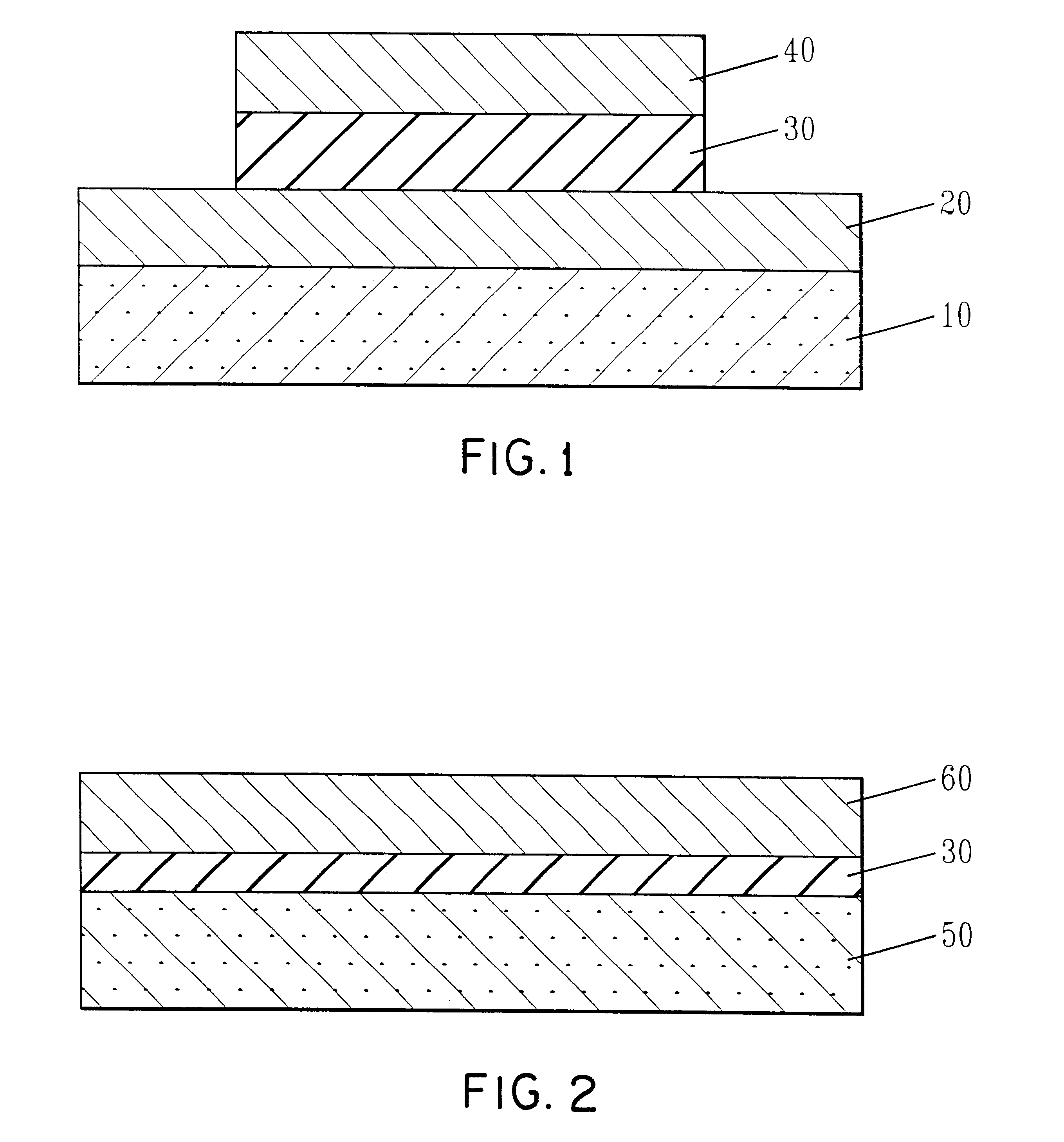

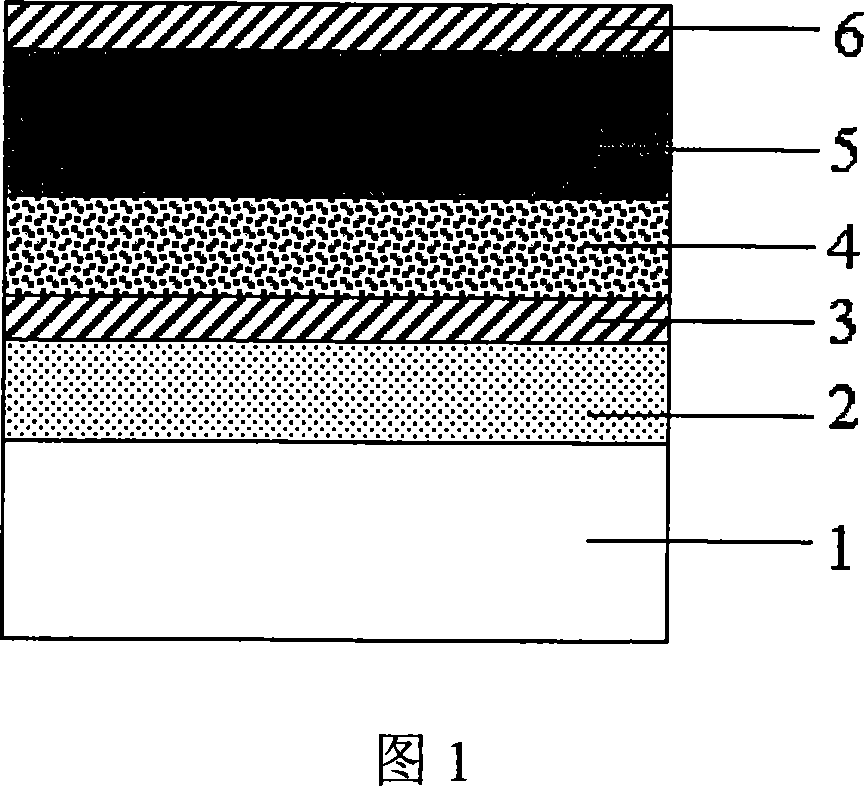

Bismuth ferric/bismuth titanate laminated construction electric capacity and method for preparing the same

InactiveCN101136404AMaximum polarizationGood anti-fatigue propertiesSolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceFerroelectric capacitor

This invention relates to a BFO / BXT laminated capacitor and its preparing method, in which, the capacitor includes: a substrate made of silicon and orderly combined with an oxidation layer, a lower electrode metal layer, a BFO film and an upper metal layer, in which, a BXT induction film is set between the lower electrode metal layer and the BFO film. The method includes: preparation of sol of RFO and BXT precursors and preparation of the capacitor of its laminated structure and the ferroelectric capacitor prepared with this method includes excellent property of anti-fatigue, high residual polarized intensity, low operational voltage and better dielectric property.

Owner:TSINGHUA UNIV

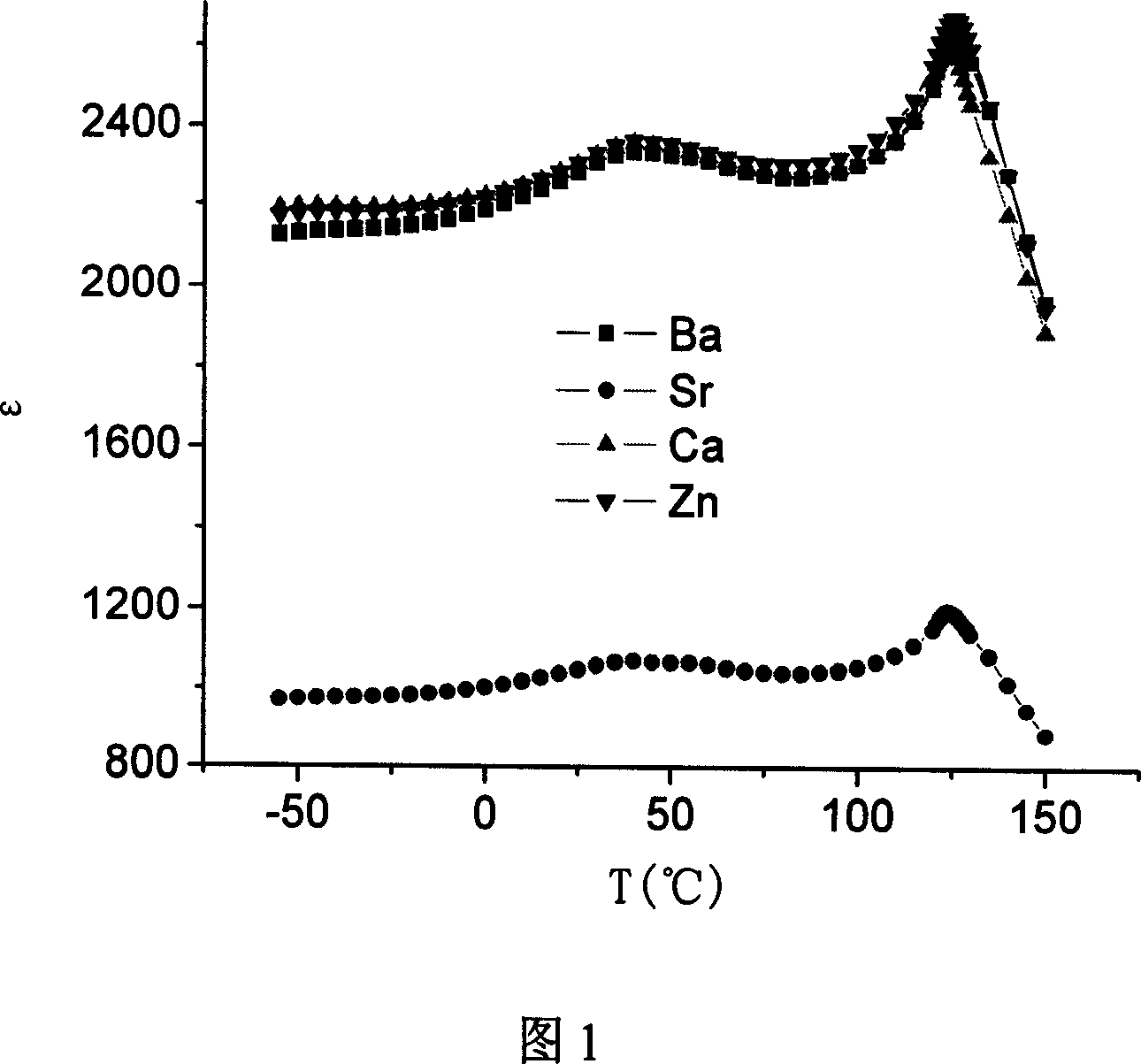

Barium titanate-based lead-free high-voltage ceramic capacitor material

The invention provides a barium titanate-based lead-free high-voltage ceramic capacitor material, which takes barium titanate, bismuth titanate, strontium titanate and calcium titanate as raw materials. After the materials are mixed, polyvinyl alcohol is added, the obtained mixture is pressed and formed, and the obtained product is sintered under about 1220 DEG C to obtain the high-pressure lead-free ceramic capacitor material. The voltage resistance of the capacitor material sintered by using the ceramic material formula is improved to 16.9kv / mm, the dielectric constant (Xir) is equal to 2089, and the dielectric loss (tan Delta) is equal to 0.0006 under 1MHz AC working current.

Owner:钱云春

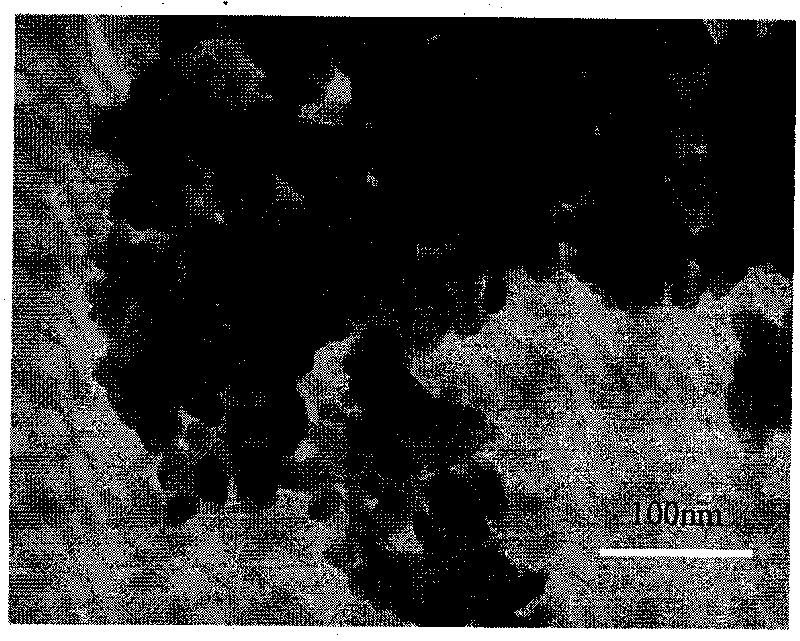

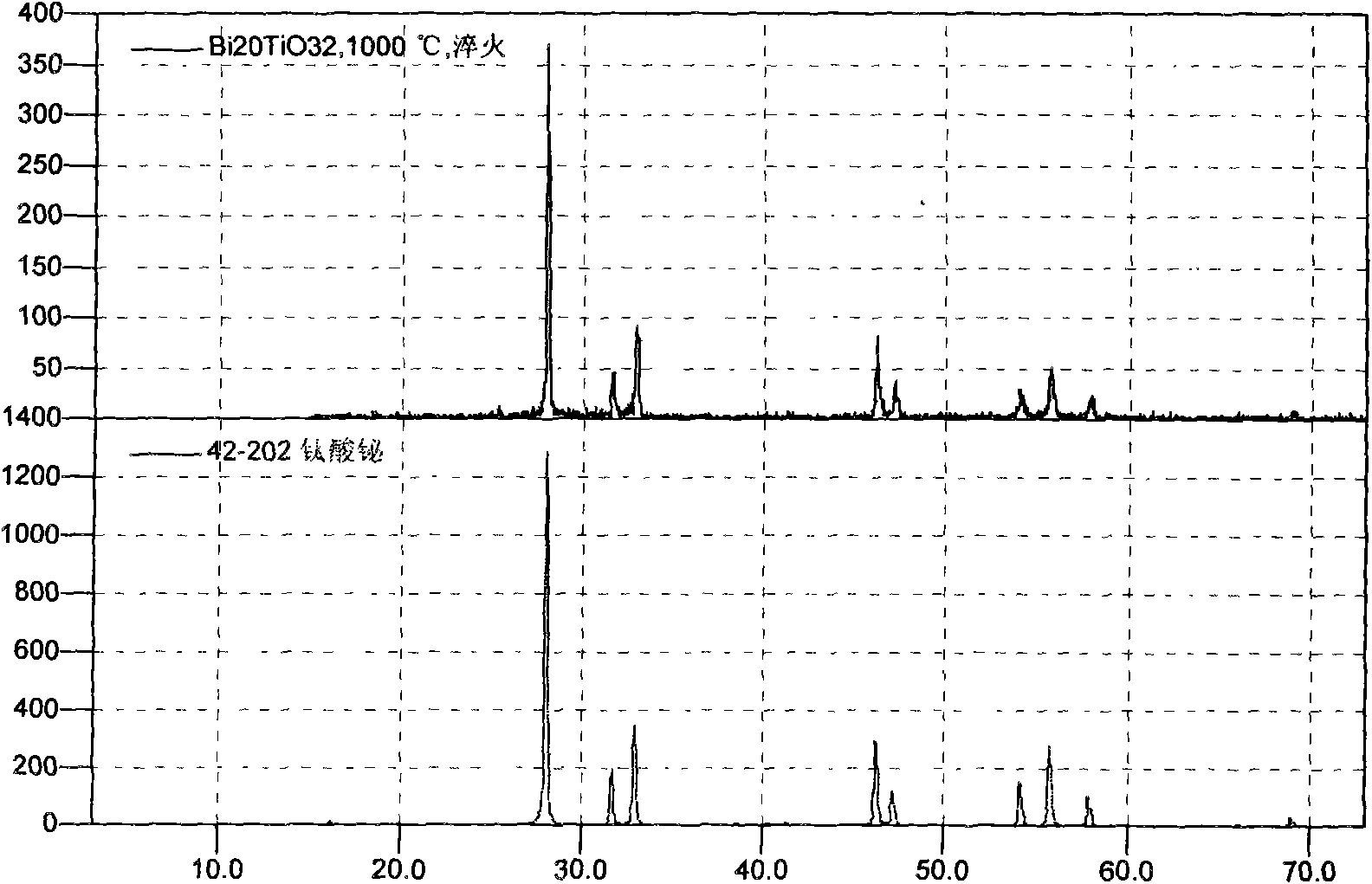

Preparation method and application of single-phase bismuth titanate nano-material

ActiveCN101862649ALow costSimple processCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsNanostructureBismuth preparation

The invention discloses a preparation method and application of a single-phase bismuth titanate nano-material. The single-phase nano-material with the formula Bi20TiO32 which can not be easily obtained through conventional synthesis is prepared in a supercritical method with soluble bismuth salts and titanate as main raw materials, the crystalline state of the nano-material is good, and the image obtained by the transmission electron microscope shows that the nano-material is of a sheet-shaped nano structure with holes. The method for synthesis of the single-phase Bi20TiO32 nano-material has the advantages of low cost, mild reaction conditions, high yield, easy large-scale production in the industry and the like. The Bi20TiO32 nano-material obtained in the method shows high photocatalytic activity in the experiment of catalytic degradation of common organic pollutants under the sunlight. Moreover, the catalyst has high regenerability and still has good catalytic performance after being repeatedly used for eight times. Therefore, the catalyst has high industrial practicality.

Owner:浙江绿色德环保科技股份有限公司

Method for preparing bismuth titanate as visible light response semiconductor photochemical catalyst

InactiveCN101972645AHigh photocatalytic degradation rateLarge specific surface areaWater/sewage treatment by irradiationWater contaminantsPolyethylene glycolVanadate

The invention discloses a method for preparing bismuth titanate as a visible light response semiconductor photochemical catalyst, which comprises the steps of: dissolving bismuth salts in nitric acid at room temperature, dissolving vanadate or metavanadate same mol with the bismuth salts in 60-90 DEG C hot water, and respectively adding benzene or polyethylene glycol or a mixed solution of the benzene and the polyethylene glycol in two solutions obtained from the steps; and dropping vanadium-containing liquid into bismuth-containing liquid under the stirring state, stirring, ageing, filtering, washing and drying to prepare the bismuth titanate BiVO4 as a visible light response semiconductor photochemical catalyst. The BiVO4 prepared by the steps has the advantages of strong response of visual light, high photocatalytic oxidation degrading capability, simple preparation method, short reaction time and easy industrialized production.

Owner:南通宏洋化工有限公司 +1

Potassium-bismuth titanate-based solid solution lead-free piezoelectric ceramic and manufacturing method thereof

InactiveCN101973763AImprove performanceGood environmental coordinationPiezoelectric/electrostrictive/magnetostrictive devicesElectricityPotassium

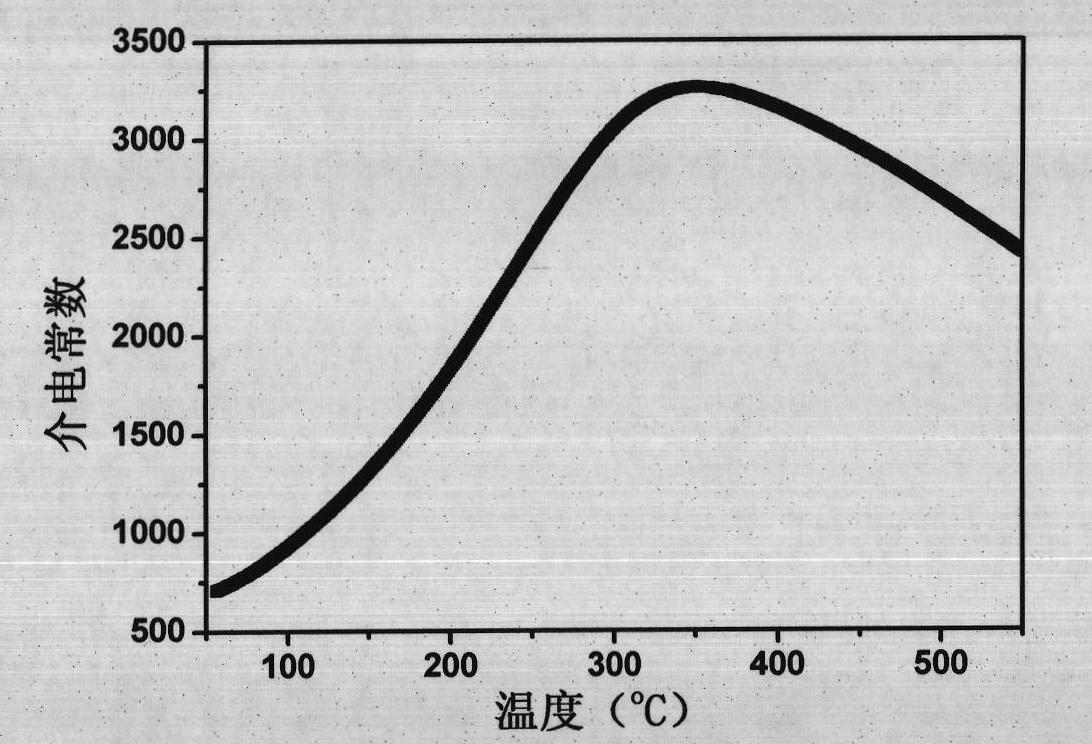

The invention discloses a potassium-bismuth titanate-based solid solution lead-free piezoelectric ceramic and a manufacturing method thereof. The components are represented by the general formula of (1-n){(1-u)(Bi0.5K0.5)TiO3+u[(1-z)Bi(CxDy)O3+zBiEO3]}+nM. The ceramic components of the invention have a morphotropic phase boundary of the rhombic ferroelectric phase and the cubic ferroelectric phase, good piezoelectric performance and higher Curie temperature. The ceramic components have the characteristic of environmental protection, can realize the replacement of a part of the traditional lead-containing piezoelectric ceramics, and can be manufactured by using the manufacturing method of the traditional piezoelectric ceramic and the industrial materials, thereby having practical application.

Owner:HEFEI UNIV OF TECH

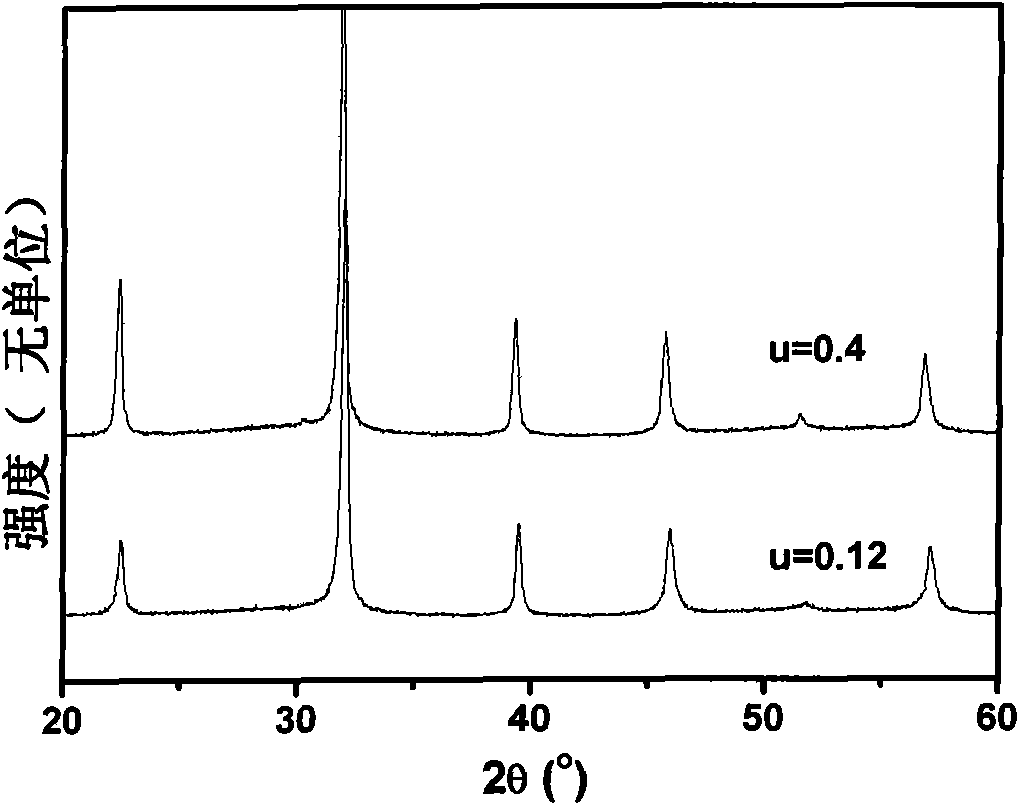

Bismuth titanate photocatalytic material with visible light response and preparation method thereof

InactiveCN101574653ASimple preparation processLow costCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsLight responseQuenching

The invention discloses a bismuth titanate photocatalytic material with visible light response, which is a pure phase material with a chemical formula of Bi20TiO32 and prepared by the steps of preparation of raw materials, heating reaction, and quenching and cooling. The material has the advantages of good photocatalytic activity, low cost, capability of recycling catalyst, simple method, easy large-scale production, and the like.

Owner:SHANDONG UNIV

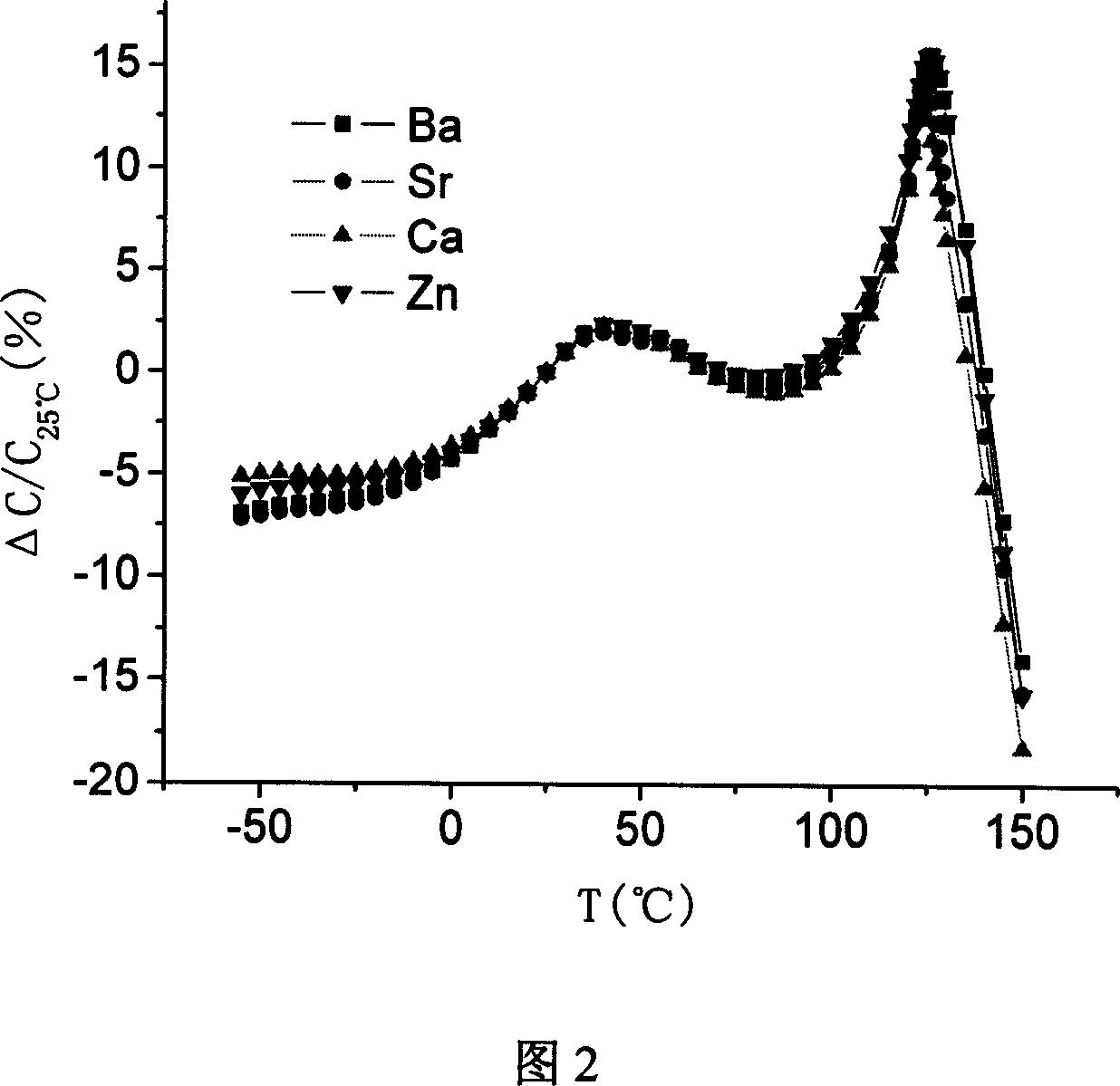

Preparation method of two-phase low-temperature co-sintered temperature stable dielectric ceramic material

The invention discloses a preparation method of two-phase low-temperature co-sintered temperature stable dielectric ceramic material. The preparation method comprises the steps of: (1) calcining BaCO3 and TiO2 through at a high temperature of 1250 DEG C which is close to the sintering temperature of BaTiO3 ceramic, so as to synthesize BaTiO3; (2) calcinating Na2CO3, Bi2O3 and TiO2 at 800 DEG C to synthesize Na0.5Bi0.5TiO3; (3) evenly mixing (1-x)BaTiO3 and xNa0.5Bi0.5TiO3 together by weight percentage, wherein x is greater than 0.05 and less than 0.2, and the mixer is used as a substrate material; (4) adding y wt% of Y2O3 by weight of the substrate material in the mixing process, wherein y is greater than 0.1 and less than 0.5; and (5) performing washing-out, drying and compression moulding operations on the powder, and sintering at a temperature of 1100-1150 DEG C, so as to obtain a two-phase low-temperature co-sintered ceramic sample piece. According to the preparation method, different from a BT-BNT composite material, a BT-BNT (Bismuth Titanate-Bismuth Na Titanate) mixed two-phase coexistence dielectric material is prepared by a step-by-step solid phase method. The two-phase low-temperature co-sintered temperature stable dielectric ceramic material has the characteristics of low loss and high dielectric constant of BT at a temperature lower than 120 DEG C and BNT at a temperature higher than 120 DEG C. The preparation method is capable of realizing multiphase medium coexistence and co-sintering without adding any sintering aid, and also capable of realizing co-sintering with a metal internal electrode; therefore, a new preparation method of the temperature stable ceramic is realized; and the preparation method has great application value.

Owner:HUBEI UNIV

Preparation method for bismuth titanate nanowire solar cells

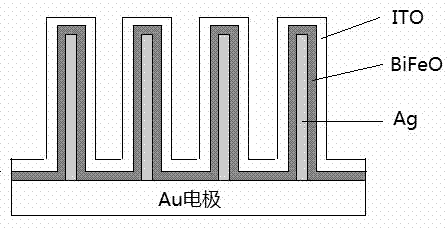

ActiveCN102856430APromote absorptionImprove collection effectFinal product manufactureSemiconductor devicesSemiconductor materialsNanowire

The invention belongs to the technical field of semiconductor materials, and in particular relates to a preparation method for bismuth titanate nanowire solar cells. By utilizing a BiFeO3 nanowire structure, the optical band gap is decreased and the absorption on sunshine is improved; the collection capacity of carriers is improved by utilizing Ag nanowires and electrodes on an ITO, so that the purpose of improving the photoelectricity conversion efficiency of the bismuth titanate nanowire solar cells can be achieved.

Owner:南通东湖国际商务服务有限公司

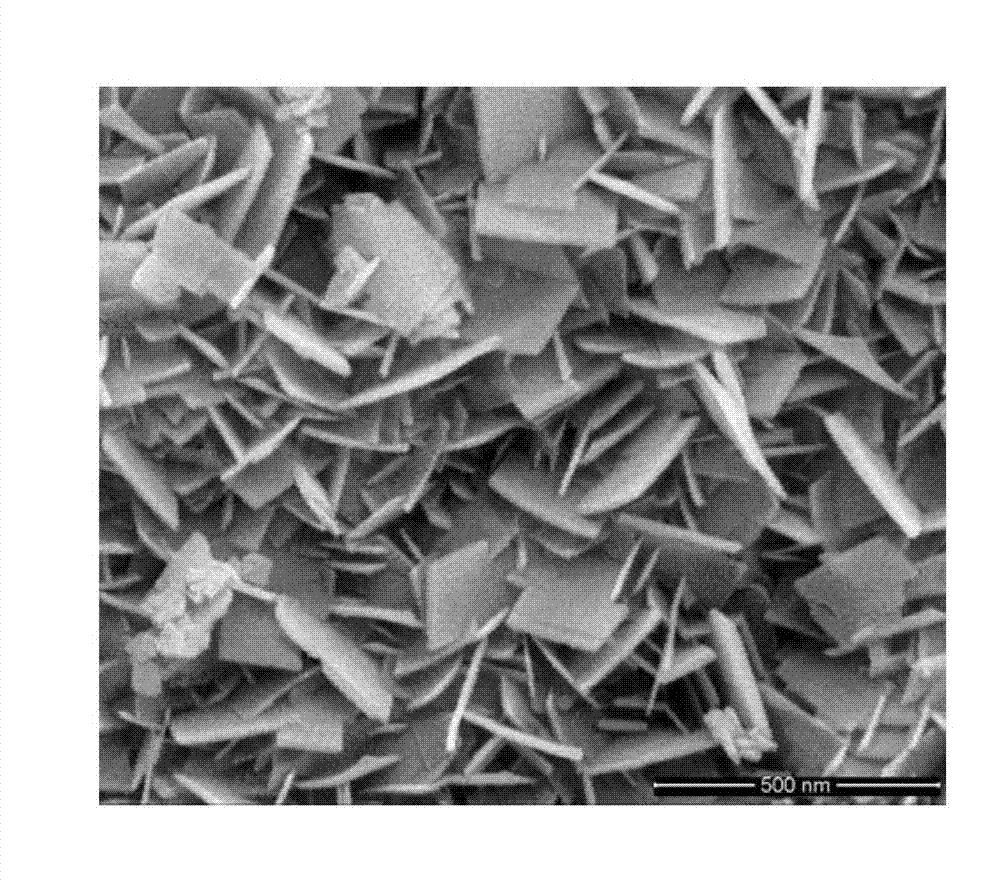

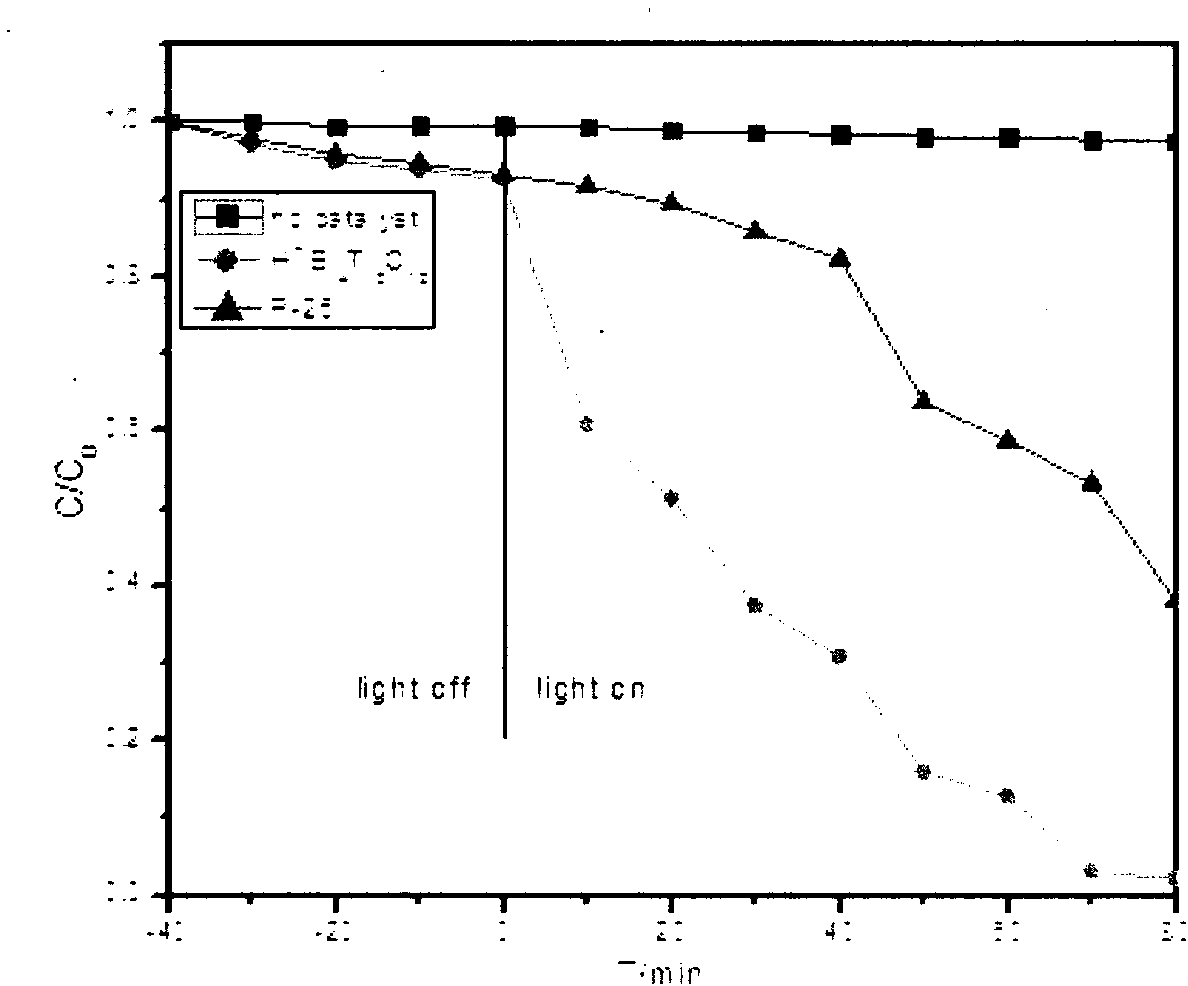

Bismuth titanate catalyst with sunlight photocatalytic activity

InactiveCN103990447AEfficient photocatalytic activitySimple production processWater/sewage treatment by irradiationWater contaminantsSolar photocatalysisChemical solution

The invention provides a preparation method of a acidic bismuth titanate photocatalyst with photocatalytic activity under sunlight. The invention adopts a chemical solution decomposition method (CSD), and uses bismuth nitrate and P25 as the main raw materials to prepare bismuth titanate (Bi4Ti3Oi2), which is then subjected to acid treatment to obtain the bismuth titanate photocatalyst with sunlight photocatalytic activity. The photocatalyst has excellent methyl orange (MO) degradation performance in the sunlight irradiation. The production process involved in the invention is simple and has cheap and easily available raw materials; the obtained powder has efficient light response degree, and widens the application range of bismuth titanate in photocatalysis field.

Owner:NANJING UNIV OF TECH

Process for producing fine particles of bismuth titanate

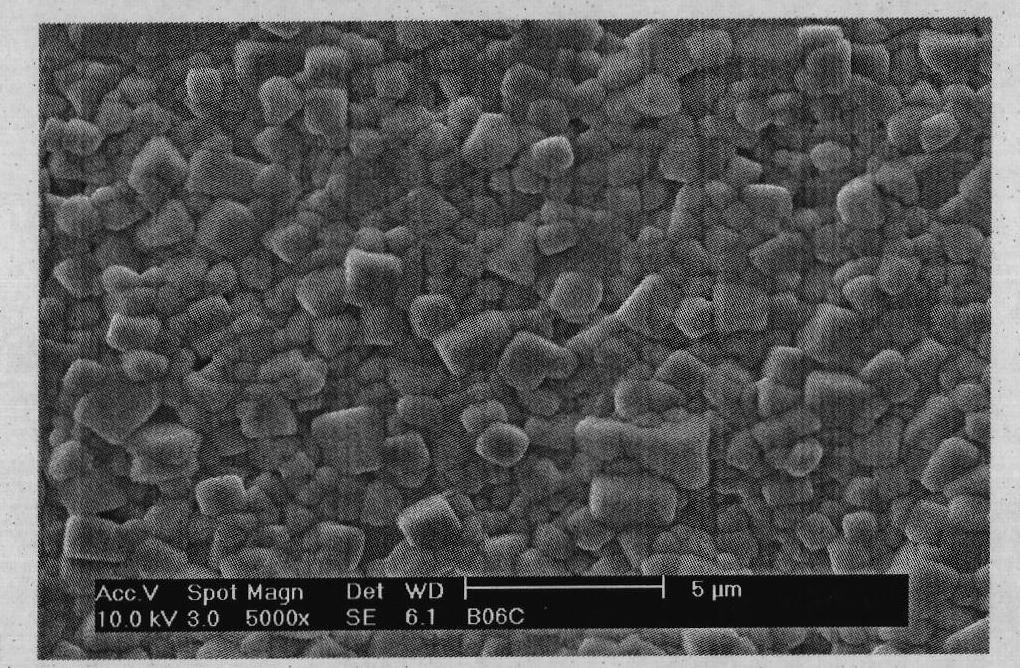

InactiveUS20060008928A1Excellent dielectric propertiesHigh crystallinityMaterial nanotechnologySemiconductor/solid-state device manufacturingMicroparticleCrystallinity

It is an object to provide fine particles of bismuth titanate having excellent dielectric characteristics, high crystallinity and a small particle diameter, and a process for their production. The object is accomplished by a process which comprises a step of obtaining a melt comprising, as represented by mol % based on oxides, from 23 to 72% of Bi2O3, from 4 to 64% of TiO2 and from 6 to 50% of B2O3, a step of quickly quenching this melt to obtain an amorphous material, a step of crystallization of bismuth titanate crystals from the above amorphous material, and a step of separating the bismuth titanate crystals from the obtained crystallized material, in this order.

Owner:ASAHI GLASS CO LTD

Bi.Na.K.Li Ag titanate series lead-free piezoelectric ceramics

InactiveCN1814570AExcellent piezoelectric propertiesThe preparation process is stablePiezoelectric/electrostrictive/magnetostrictive devicesLithiumPotassium

The invention relates to bismuth titanate natrium-potassium-lithium-silver series leadless piezoelectric ceramics. The general equation of the compound is Bi0.5(Na1-x-y-zKxLiyAgz)0.5TiO3+aM alpha O beta(wt%), and in the equation, 0 alpha Obeta is one or plural doping oxide. The main constituent is 0-5 of Bi0.5(Na1-x-y-zKxLiyAgz)SUB>0.5TiO3, M could be Na, K, Li, Ni, Zn, Cr, Co, Nb, Ta, Al, Cu, Fe, Ce, Pr, Nd, Sm, Gd, Dy, Er, Yb, In, Y, Sc, La, Ho, Lu, Sn, Sb, Mn, Ca, Ba, Sr, Mg, Si, Bi, Ag, etc. Alpha and beta mean the M element and atomicity corresponding to the relative oxide. The optimal value of the compound of d33 could be over 210pC / N, kp could be over 40%. And the technology is stable, and it would be made from traditional technology and raw material.

Owner:SICHUAN UNIV

Transparent rare-earth-doped bismuth titanate luminous ferro-electricity thin film and method for preparing same

Owner:SUN YAT SEN UNIV

Durable glass enamel composition

The present invention provides partially crystallizing lead-free and cadmium-free glass enamel composition that fuse at low temperatures. Glass enamel compositions according to the present invention form predominantly bismuth titanate and optionally zinc titanate crystals upon firing. Preferably, glass enamel compositions according to the invention include a glass component that includes by weight from about 11% to about 52% SiO2, from 10.2% to about 40% TiO2, from about 5% to about 75% Bi2O3, up to about 8% B2O3, up to about 14% BaO+SrO, and up to about 45% by weight ZnO, where the sum of Bi2O3 and ZnO comprises from about 30% to about 85% of the glass component by weight.

Owner:FERRO CORP

Method for preparing aluminum electrolytic capacitor anode foil

InactiveCN1731549AHigh specific capacitanceAnodisationElectrolytic capacitorsAluminium electrolysisMetallurgy

Disclosed is a method for making anode foil of aluminum electrolytic capacitor which comprises steps of: preparing bismuth titanate or its predecessors with sol-gel processing; coating the predecessors on the etched aluminum foil surface with leaching method; forming a bismuth titanate nanometer file of high dielectric constant after heating; forming a compound dielectric membrane on the etched aluminum foil by anode oxidation processing. The inventive method has the advantage of increasing the specific capacity of anode aluminum foil.

Owner:XI AN JIAOTONG UNIV

Lead-free piezoelectric knitting ceramic of titanic acid bismuth sodium-titanic acid bismuth potassium and its production

InactiveCN101028979AMeet environmental protection requirementsMeet practical requirementsPiezoelectric/electrostrictive/magnetostrictive devicesAdhesivePotassium

A lead-free piezoelectric sodium bismuth titanate-potassium bismuth titanate texture ceramics is prepared from the microcrystalline template (bismuth titanate) prepared from TiO2, bismuth oxide, sodium chloride and potassium chloride, the raw powder of sodium carbonate, potassium carbonate, TiO2 and bismuth oxide, organic solvent, and adhesive through mixing, ball grinding, doctor blading, laminating, isostatic pressing in hot water, cutting pre-calcining, and coating Ag.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

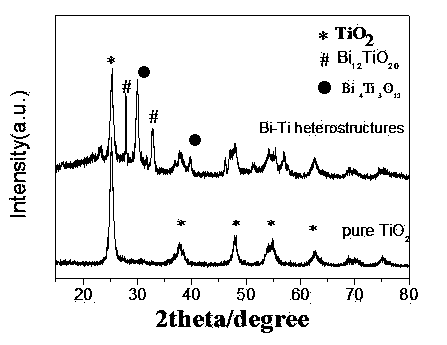

Preparation method and application of bismuth titanate-titanium oxide heterojunction nano-material

InactiveCN103523823ASynthesis temperature is lowImprove stabilityMaterial nanotechnologyWater/sewage treatment by irradiationHeterojunctionTitanium oxide

The invention discloses a preparation method of a bismuth titanate-titanium oxide heterojunction nano-material and a method for preparing a membrane electrode by utilizing the bismuth titanate-titanium oxide heterojunction nano-material so as to perform photoelectrocatalytic treatment on bacteria in ballast water. By adopting the process disclosed by the invention to prepare the bismuth titanate-titanium oxide heterojunction nano-material, the synthesis temperature is low and the preparation process is simple; by applying the bismuth titanate-titanium oxide heterojunction nano-material to prepare the membrane electrode, the preparation method is simple, the membrane electrode has relatively good stability, and the electrode can be reused; by utilizing a photoelectrocatalytic technology to apply the membrane electrode in the field of sterilization of the ballast water, equipment is simple, the sterilization time is short, the efficiency is high, the required externally applied voltage is small, and the application is favorable for ballast operation of a ship; furthermore, the sterilization treatment energy consumption is low, the process is simple, the scale is controllable, and the secondary pollution is avoided.

Owner:NANJING NORMAL UNIVERSITY

Method for manufacturing bismuth lanthanum titanate (BLT) ferro-electricity film at low-temperature

The invention relates to a method for preparing a BLT ferroelectric film used for a ferroelectric storage at a low temperature. The preparation method consists of the complexing agent technique and the hydro-thermal reaction low temperature preparation technique. Firstly, the complexing agent technique is adopted, a BLT precursor solution is prepared by taking inorganic salt as a raw material and a film with required thickness is coated on the cleaned Pt / Ti / SiO2Si underlay rotationally, the thermal treatment is performed at a temperature of between 350 and 450 DEG C, and then the film after the thermal treatment is put into a high pressure reaction kettle to perform the hydro-thermal chemical reaction; the reaction temperature is between 150 and 300 DEG C, the reaction time lasts for 2 to 48 hours; the product is cooled in the furnace, washed and dried at a temperature of 80 DEG C so that the BLT ferroelectric film with the thickness between 400 and 900 nanometers is produced. The method has simple preparation technology, low preparation temperature, convenient operation and low cost and can be compatible with the microelectronic technology.

Owner:CHINA JILIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com