Middle-temperature sintering high temperature stabilization type ceramic capacitor dielectric material

A ceramic capacitor, high-temperature stable technology, applied in ceramics, inorganic insulators, etc., can solve the problems of inability to use low-Pd inner electrode slurry and high sintering temperature, and achieve simple and adjustable formula, low firing temperature and good uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] The invention provides the first additive, a preparation method (processing method 1) of glass-ceramic, comprising the following steps:

[0062] 1) According to the stoichiometric ratio, weigh calcium, boron, magnesium, phosphorus and zinc compounds respectively and dissolve them in concentrated nitric acid to obtain solution A. Compound; The "stoichiometric ratio" mentioned here refers to the ratio of calcium compound, boron compound, magnesium compound, phosphorus compound and zinc compound calculated according to the requirements of glass composition for Ca, B, Mg, P and Zn content. This point can be deduced completely based on the component requirements of the product.

[0063] 2) Measure tetraethyl orthosilicate, stabilizer, and absolute ethanol in proportion and mix them uniformly to form solution B;

[0064] 3) Heat and evaporate solution A at 65-95°C. When the volume ratio of solution A to solution B is: solution A / solution B=1.0-2.5, mix solution A and solutio...

Embodiment 1

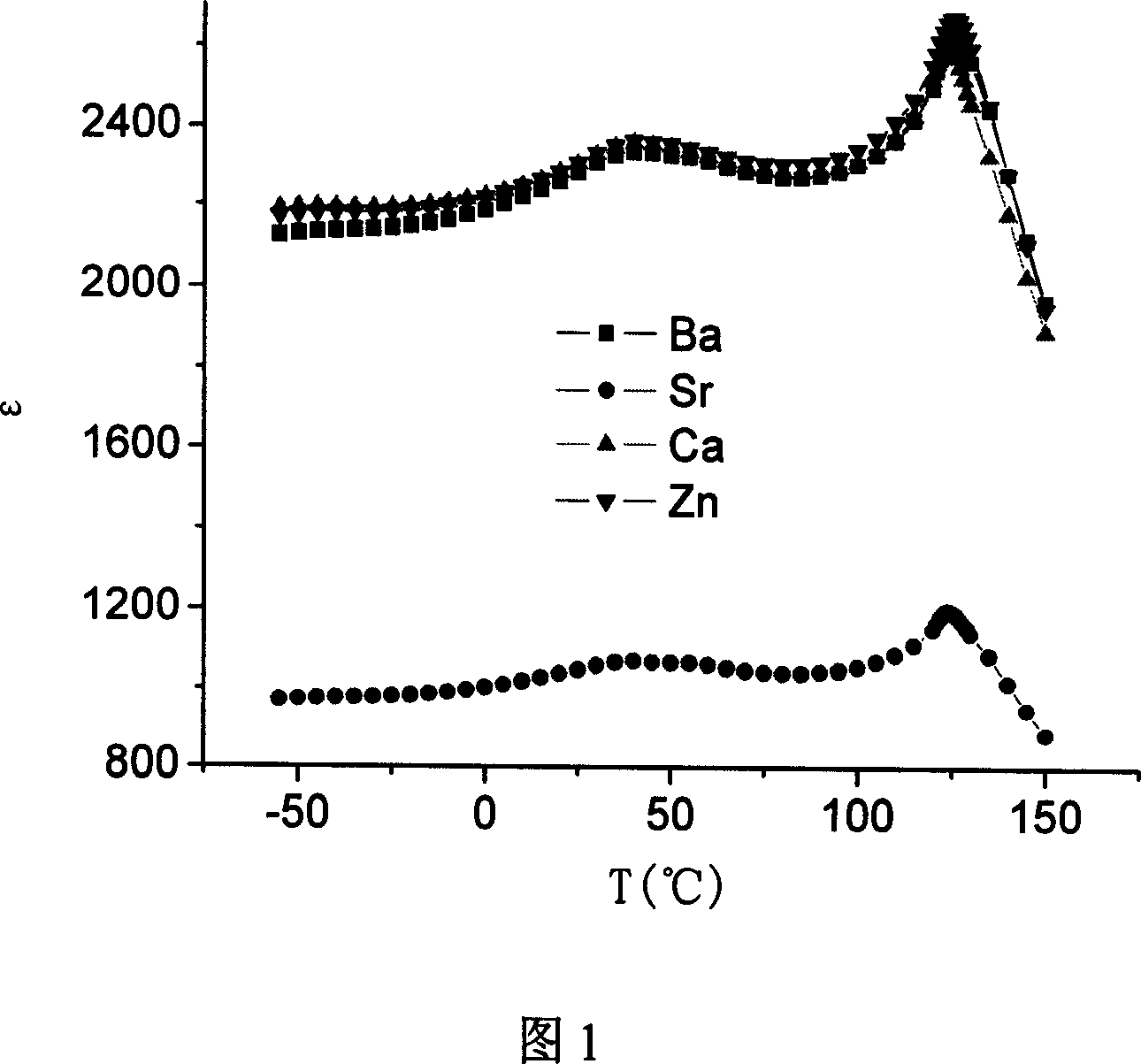

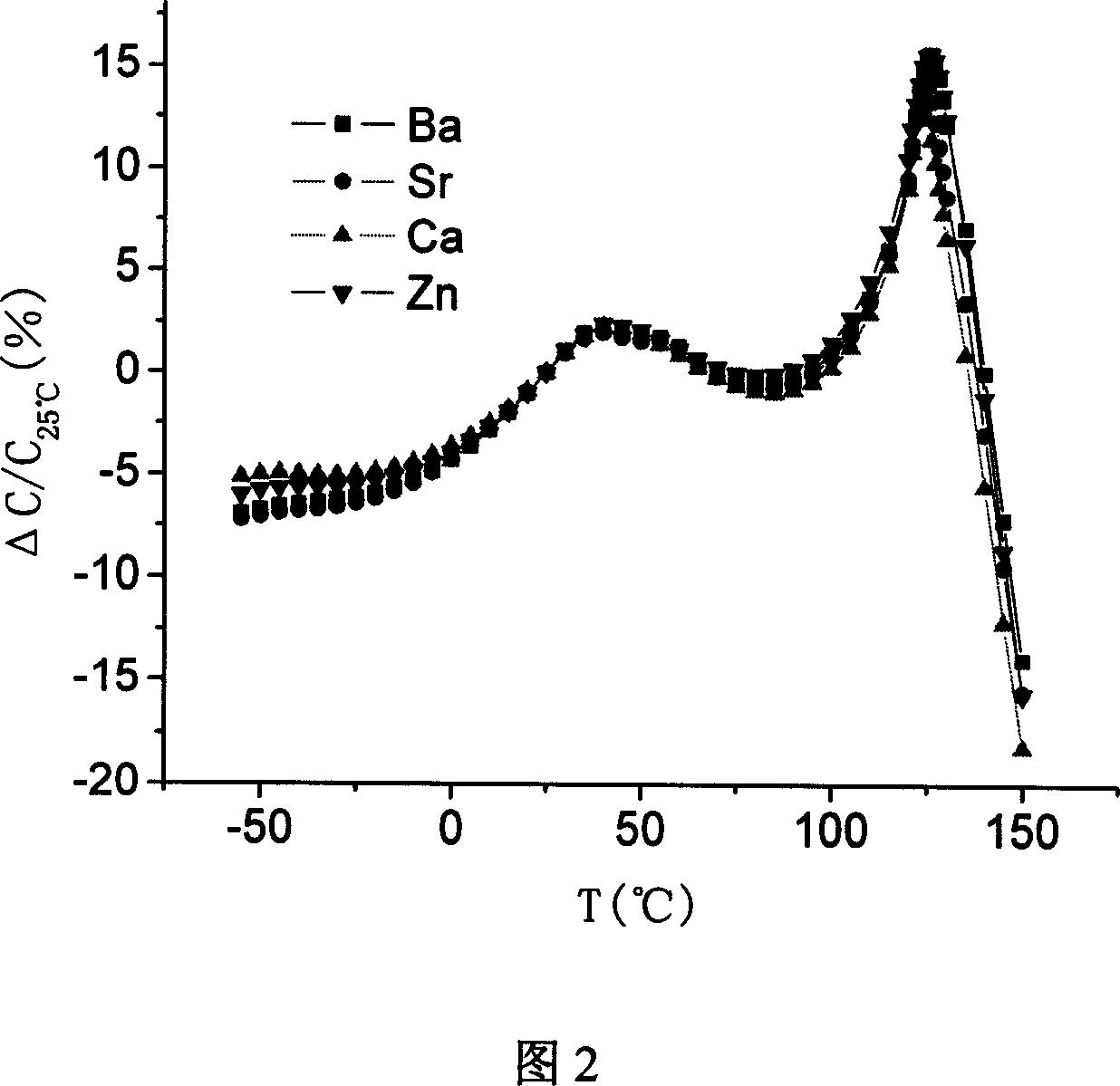

[0082] Example 1: (Comparison of different composition A when the solid-phase dopant is XBS) Process method 3 was used to prepare the dielectric material of ultra-fine medium-temperature sintered temperature-stable multilayer ceramic capacitor. First according to 97.5wt% BaTiO 3 (average particle size 0.5μm), 0.8wt% Nb 2 o 5 , 0.9wt% ZnO, 0.2wt% CBS, 0.6wt% CeO 2Proportional weighing. Then add the solid phase dopant XBS with different composition A, accounting for 1.2wt% of the above mixture. After the obtained sample was dried, it was mixed with 5wt% PVA and granulated, and pressed under a pressure of 10 MPa to form a disc with a diameter of 10 mm and a thickness of 1 mm, and then placed in the air for sintering at a temperature of 1140° C. for 2.5 hours. The heating rate is 3°C / min, and the furnace is cooled. The dielectric properties of the obtained ceramic samples are shown in Table 1. Figures 1 and 2 show the ε-T curves and ΔC curves when the composition A of the soli...

Embodiment 2

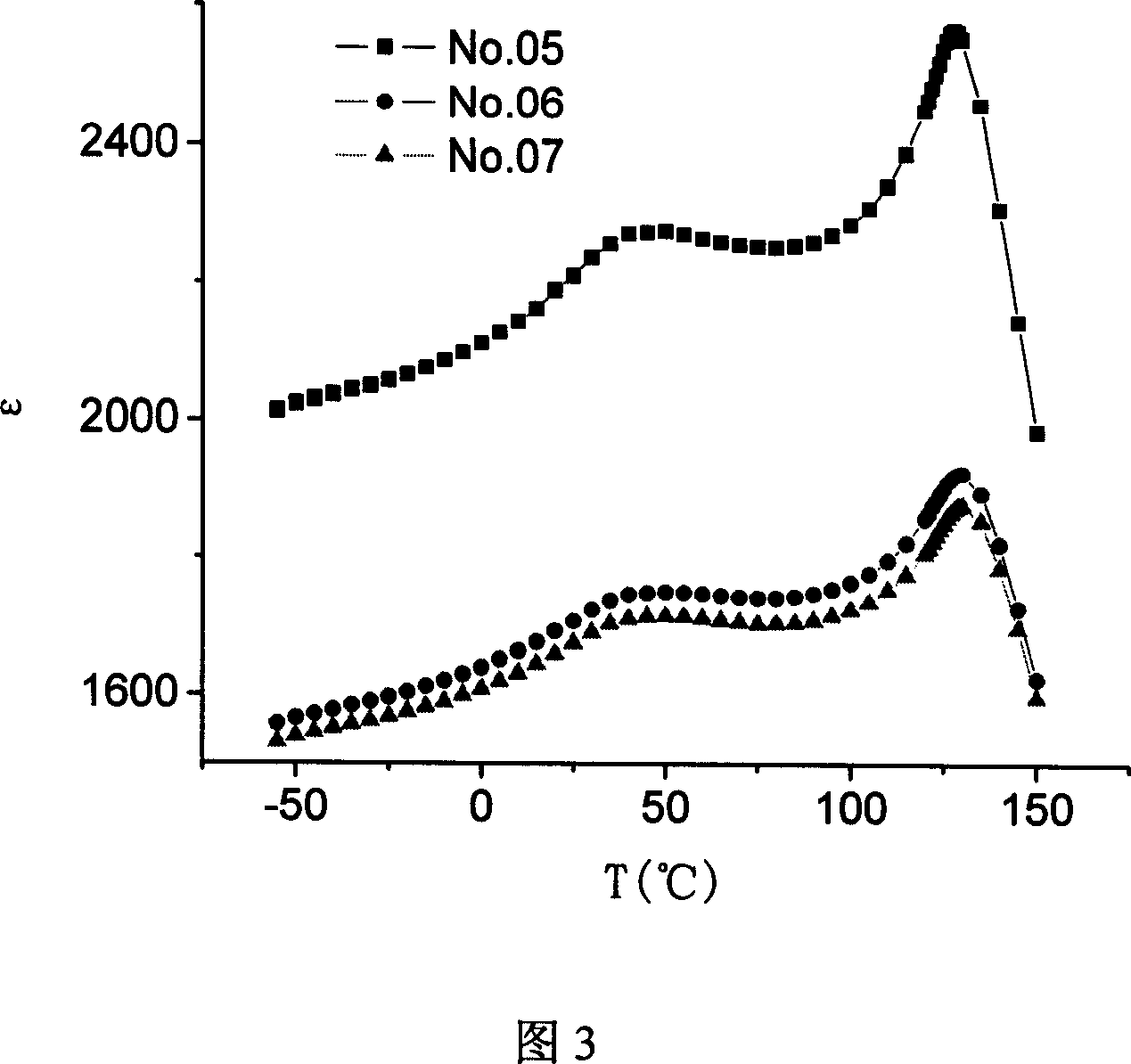

[0084] Example 2: (Comparison of different Nb2O5 dosages when the solid-phase dopant composition A is fixed) Process method 3 was used to prepare the dielectric material of ultra-fine medium-temperature sintered temperature-stable multilayer ceramic capacitor. First according to 97.4wt% BaTiO 3 (average particle size is 0.4μm), 0.9wt% ZnO, 0.2wt% CBS, 0.5wt% Nd 2 o 3 , 1.0wt% ZBS (at this time, A in XBS is Zn, so ZBS is called for short here) proportioning and weighing. Then add different mass percentages of Nb 2 o 5 , accounting for 1.4wt%, 2.2wt%, 3.0wt% of the above-mentioned mixture respectively. After the obtained sample was dried, it was mixed with 5wt% PVA and granulated, and pressed under a pressure of 10 MPa to form a disc with a diameter of 10 mm and a thickness of 1 mm, and then placed in the air for sintering at a temperature of 1100° C. for 2.5 hours. The heating rate is 3°C / min, and the furnace is cooled. The dielectric properties of the obtained ceramic sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com