Patents

Literature

1664results about "Ceramics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organoaminosilane Precursors and Methods for Depositing Films Comprising Same

Owner:VERSUM MATERIALS US LLC

Niobium suboxide powder

ActiveUS20050013765A1High currentReduce residual currentOxide/hydroxide preparationLiquid electrolytic capacitorsCapacitorTungsten

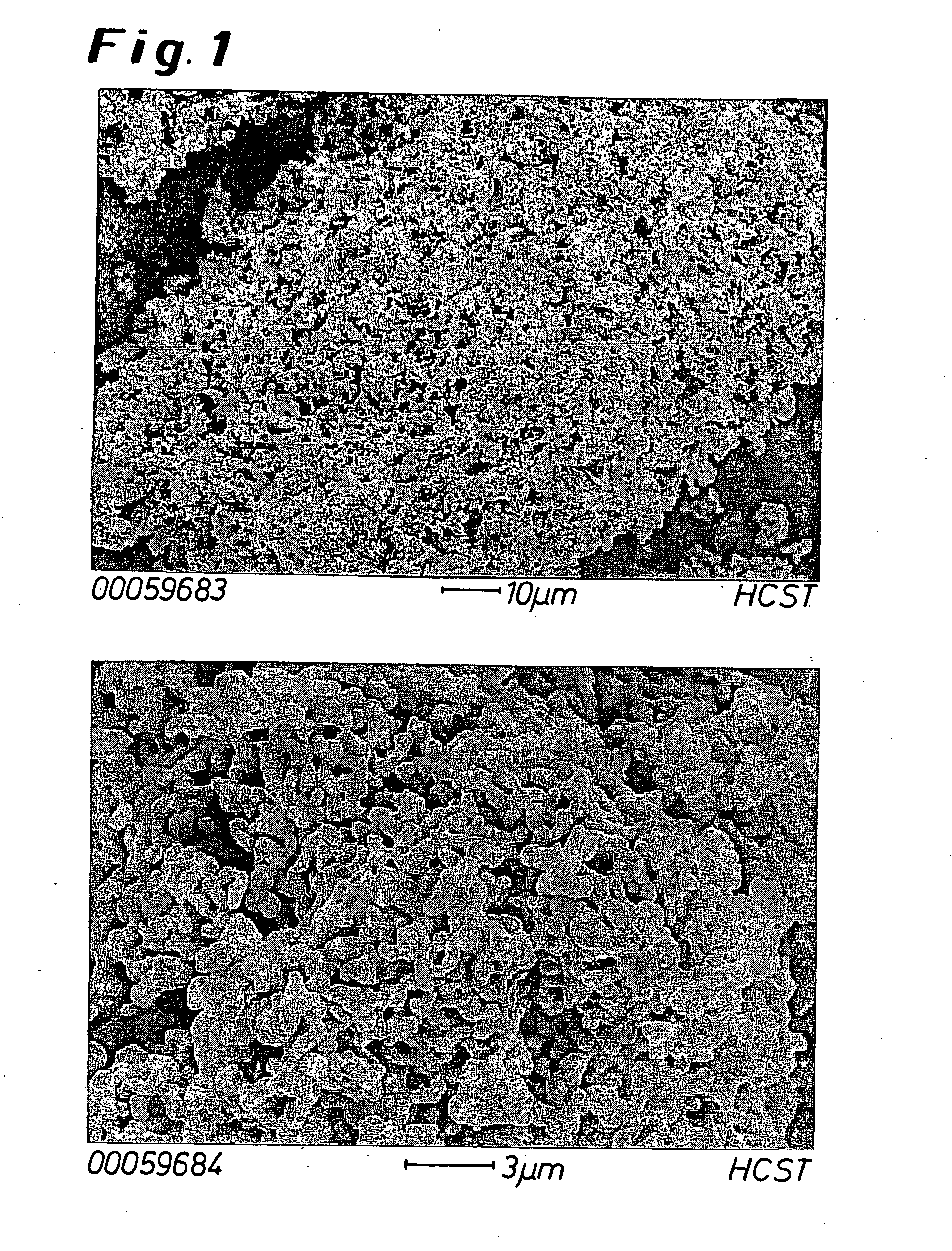

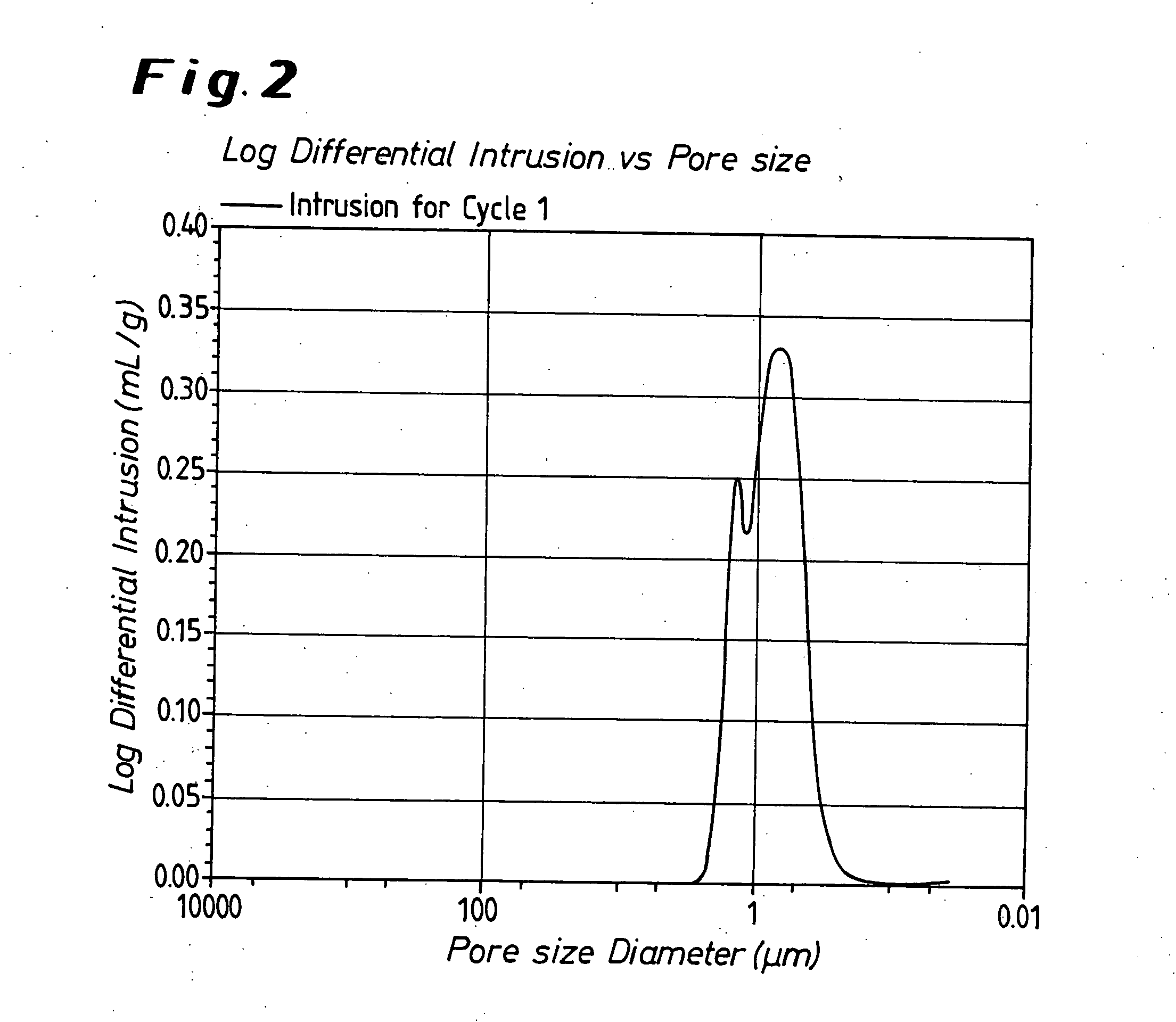

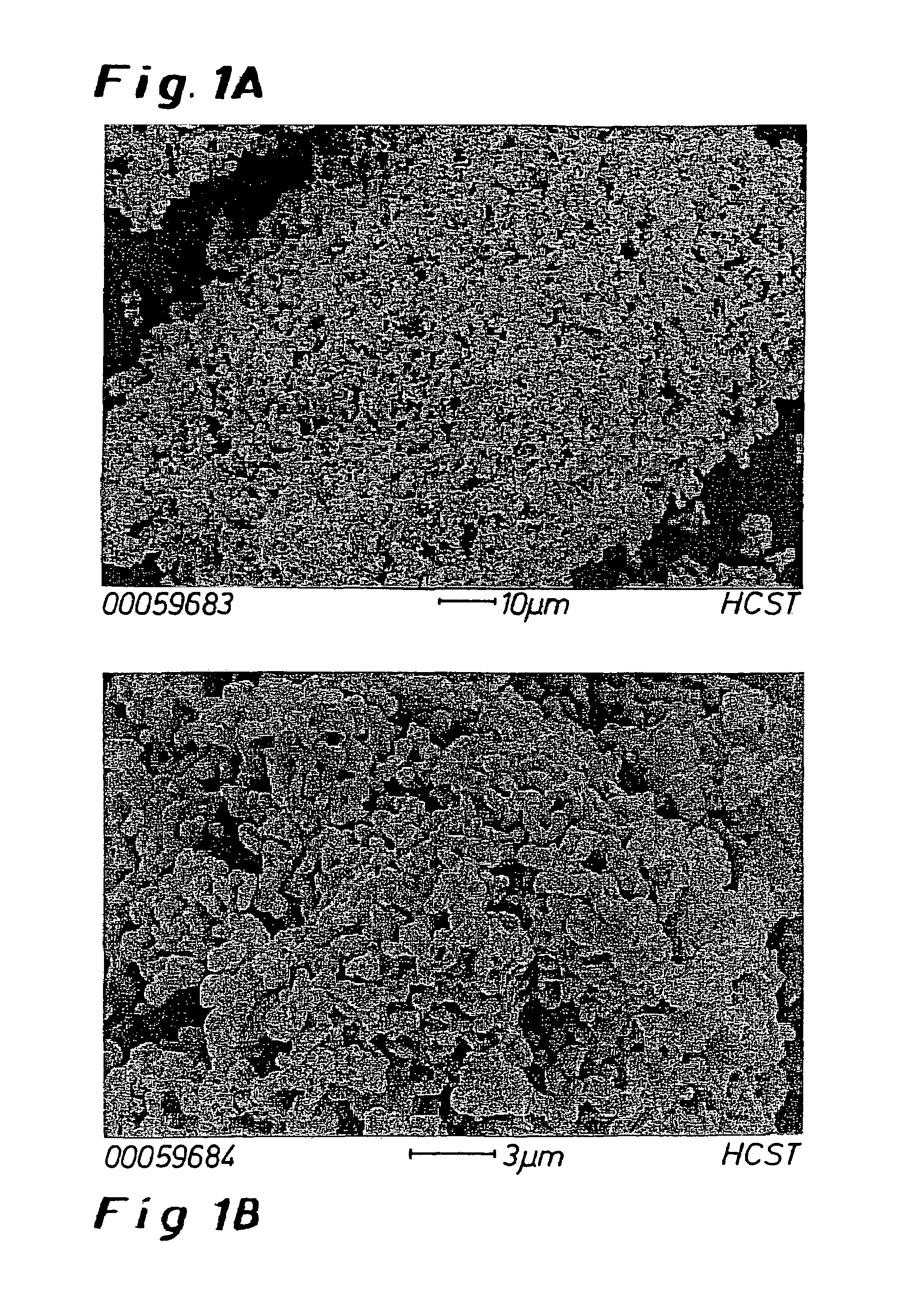

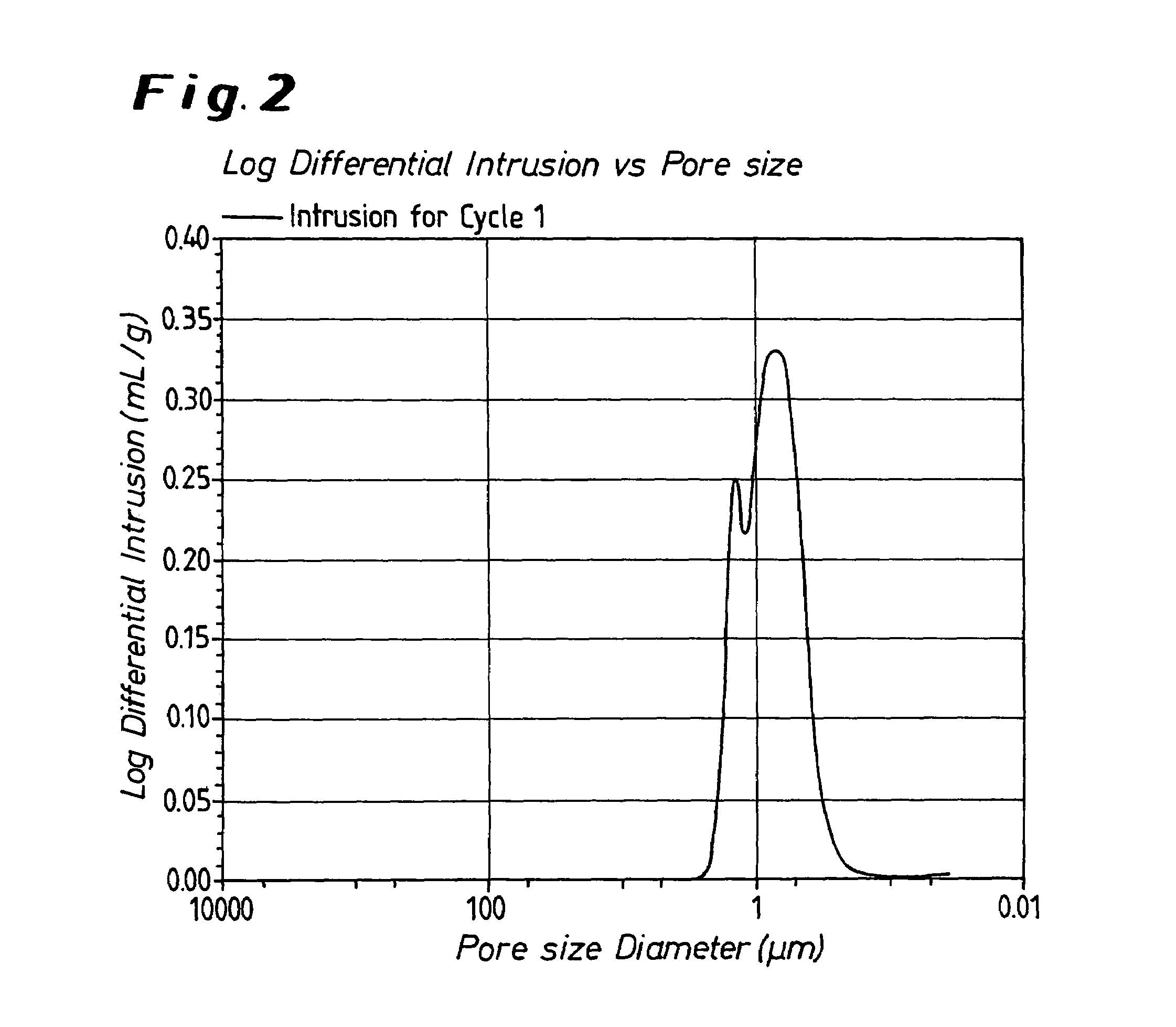

A niobium suboxide powder comprising 100 to 600 ppm of magnesium is described. The niobium suboxide powder may (alternatively or in addition to 100 to 600 ppm of magnesium) further include 50 to 400 ppm of molybdenum and / or tungsten. The niobium suboxide powder is suitable for the production of: capacitors having an insulator layer of niobium pentoxide; capacitor anodes produced from the niobium suboxide powder; and corresponding capacitors.

Owner:TANIOBIS GMBH

Insulating film, method of manufacturing the same, and semiconductor device

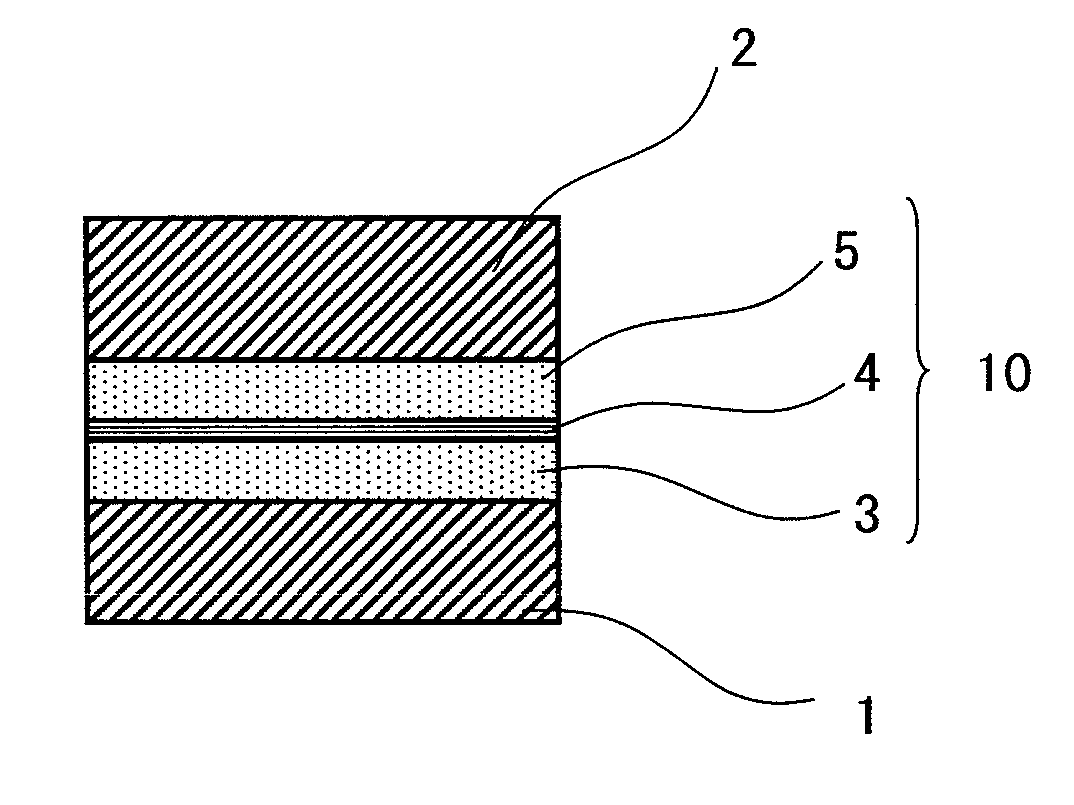

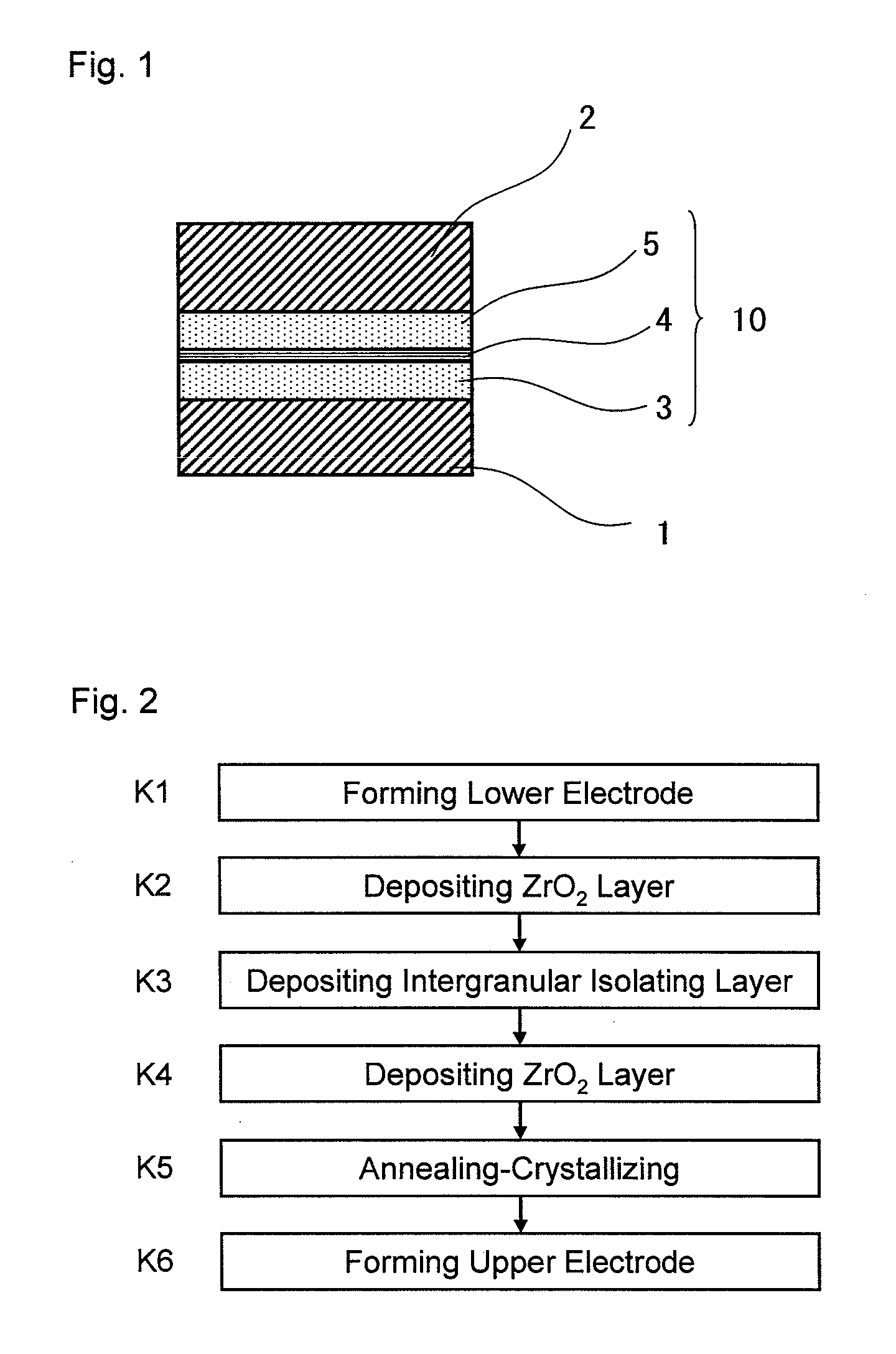

InactiveUS20110048769A1High dielectric constantSmall currentThin/thick film capacitorCeramicsCapacitanceSemiconductor

An exemplary aspect of the invention provides an insulating film which has a high dielectric constant and has small leakage current even when it is sandwiched between electrodes. The insulating film comprises two zirconium oxide layers in crystallized state; and an intergranular isolating layer composed of an amorphous material having a dielectric constant higher than that of zirconium oxide in crystallized state; wherein the intergranular isolating layer is sandwiched between the two zirconium oxide layers. The insulating film is properly used as a capacitive insulating film in a semiconductor device comprising a memory cell including a capacitor element having the capacitive insulating film between an upper electrode and a lower electrode, or as an intergate insulating film in a semiconductor device comprising a nonvolatile memory device having the intergate insulating film between a control gate electrode and a floating gate electrode.

Owner:ELPIDA MEMORY INC

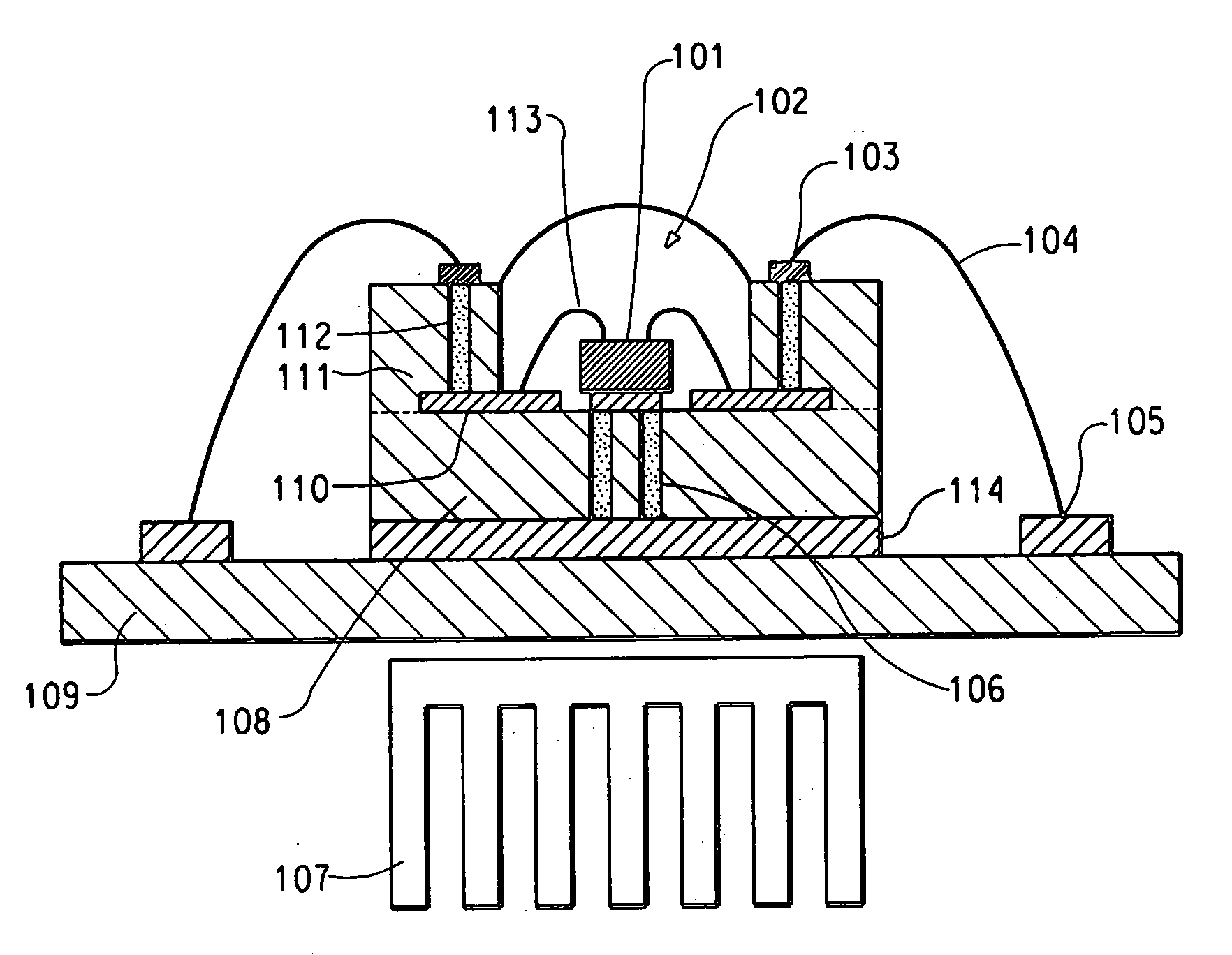

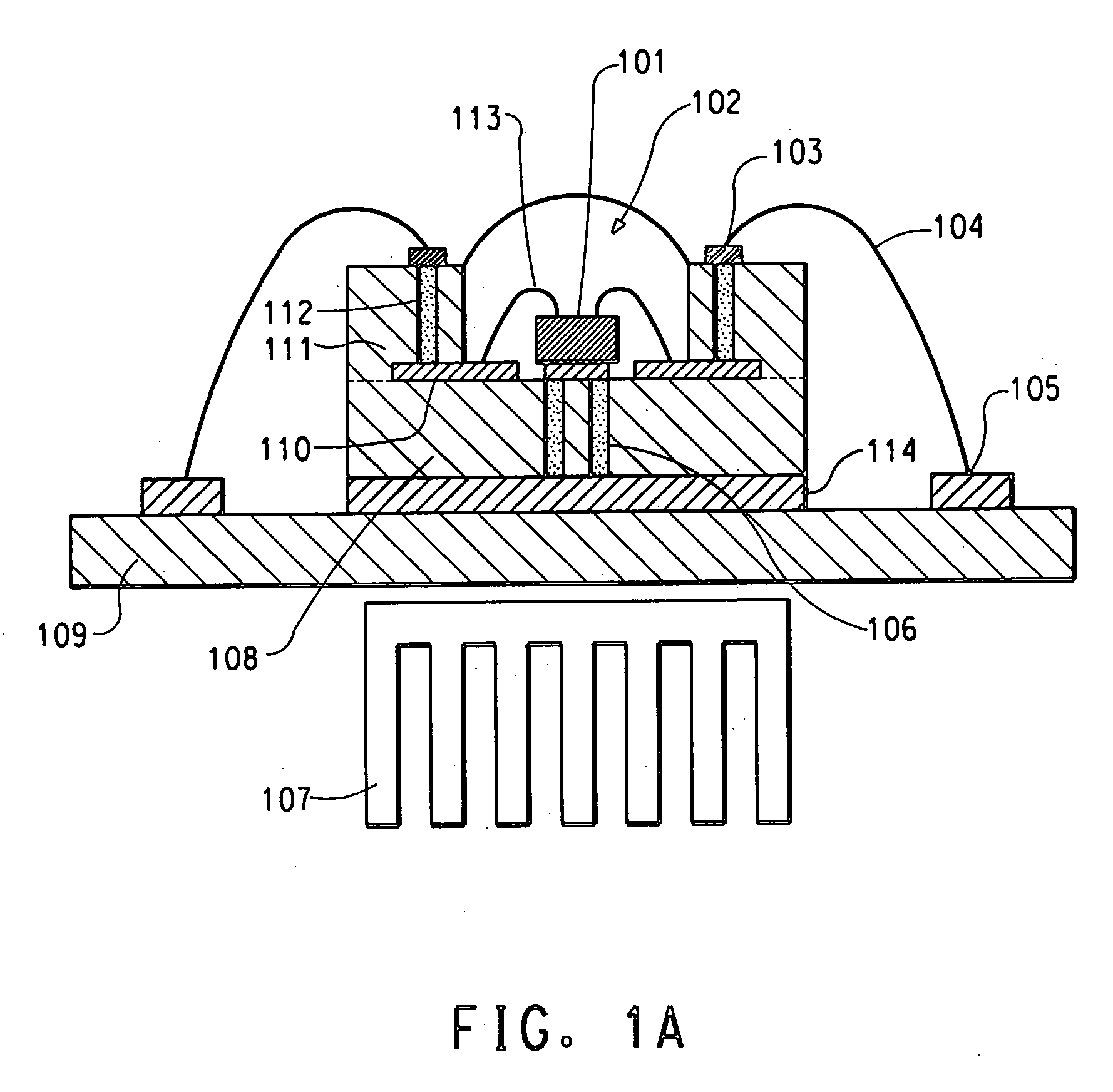

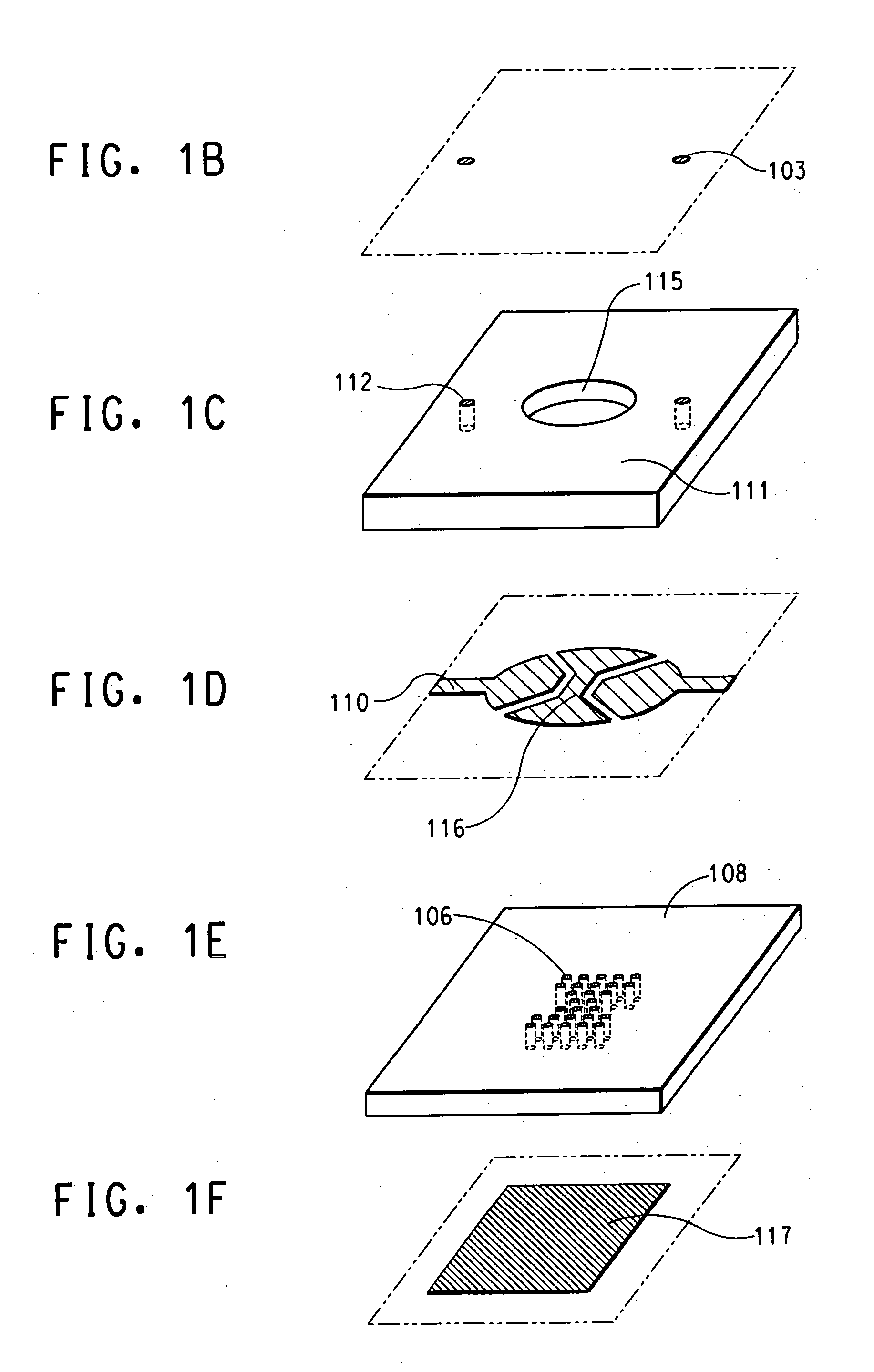

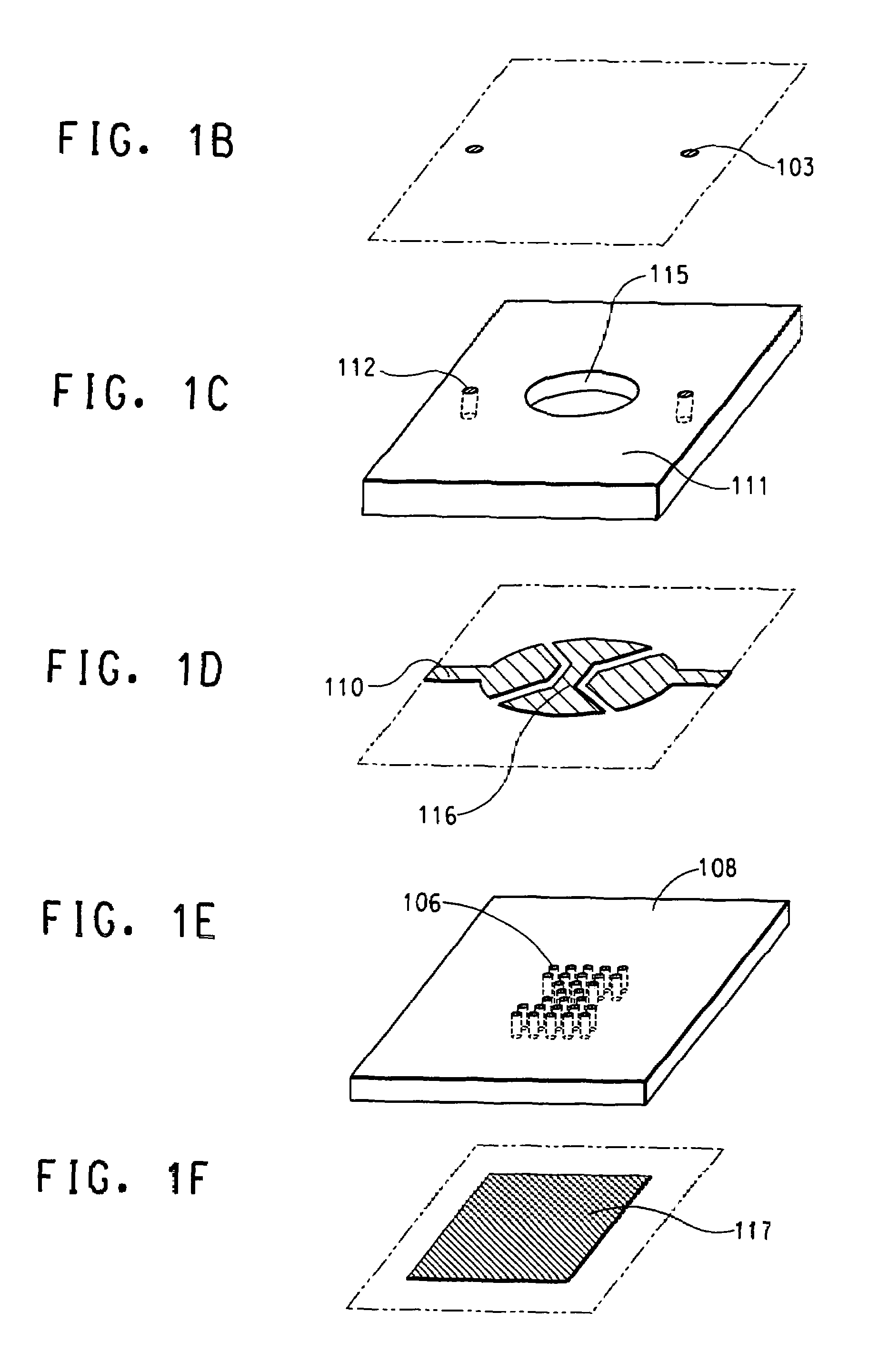

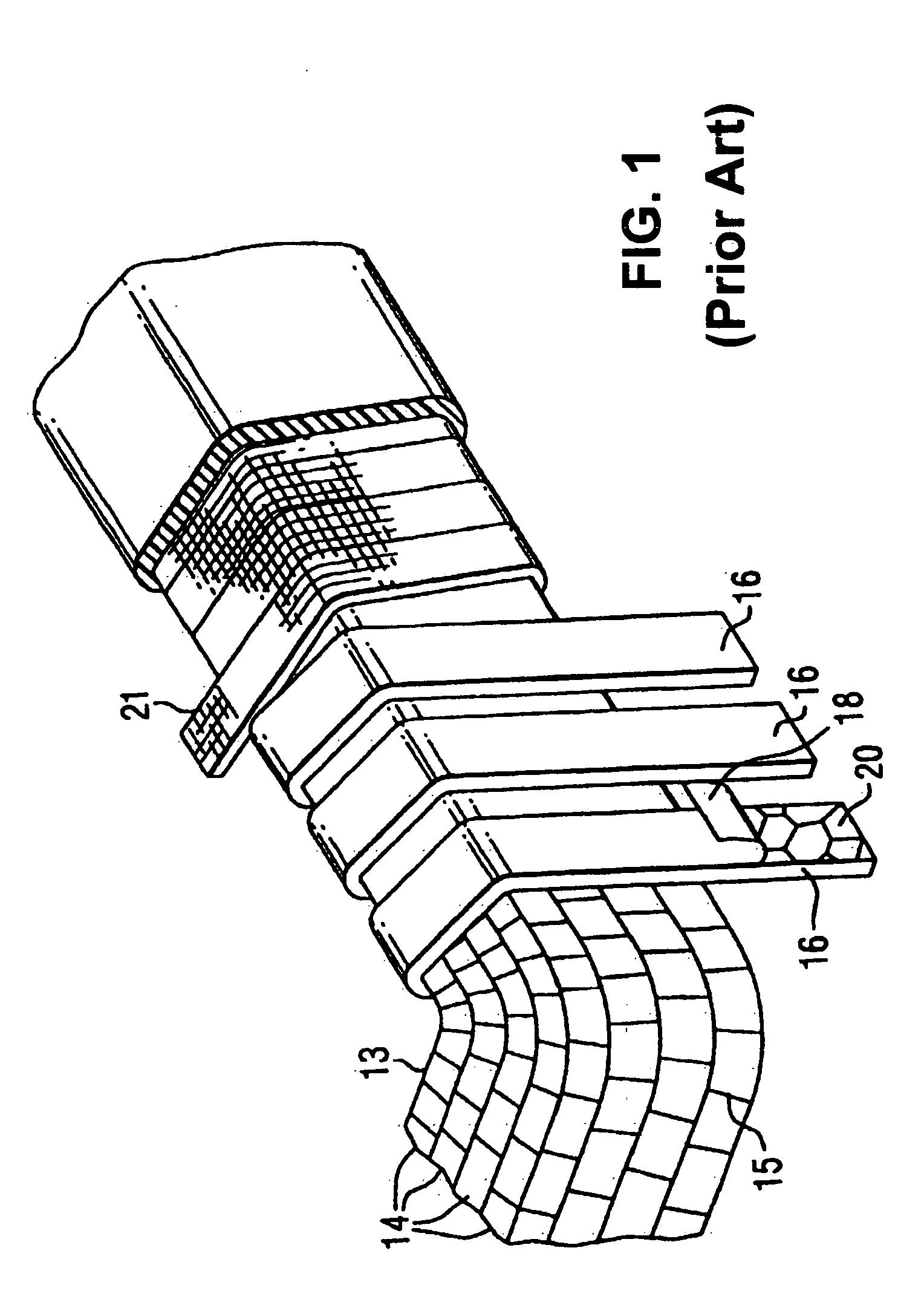

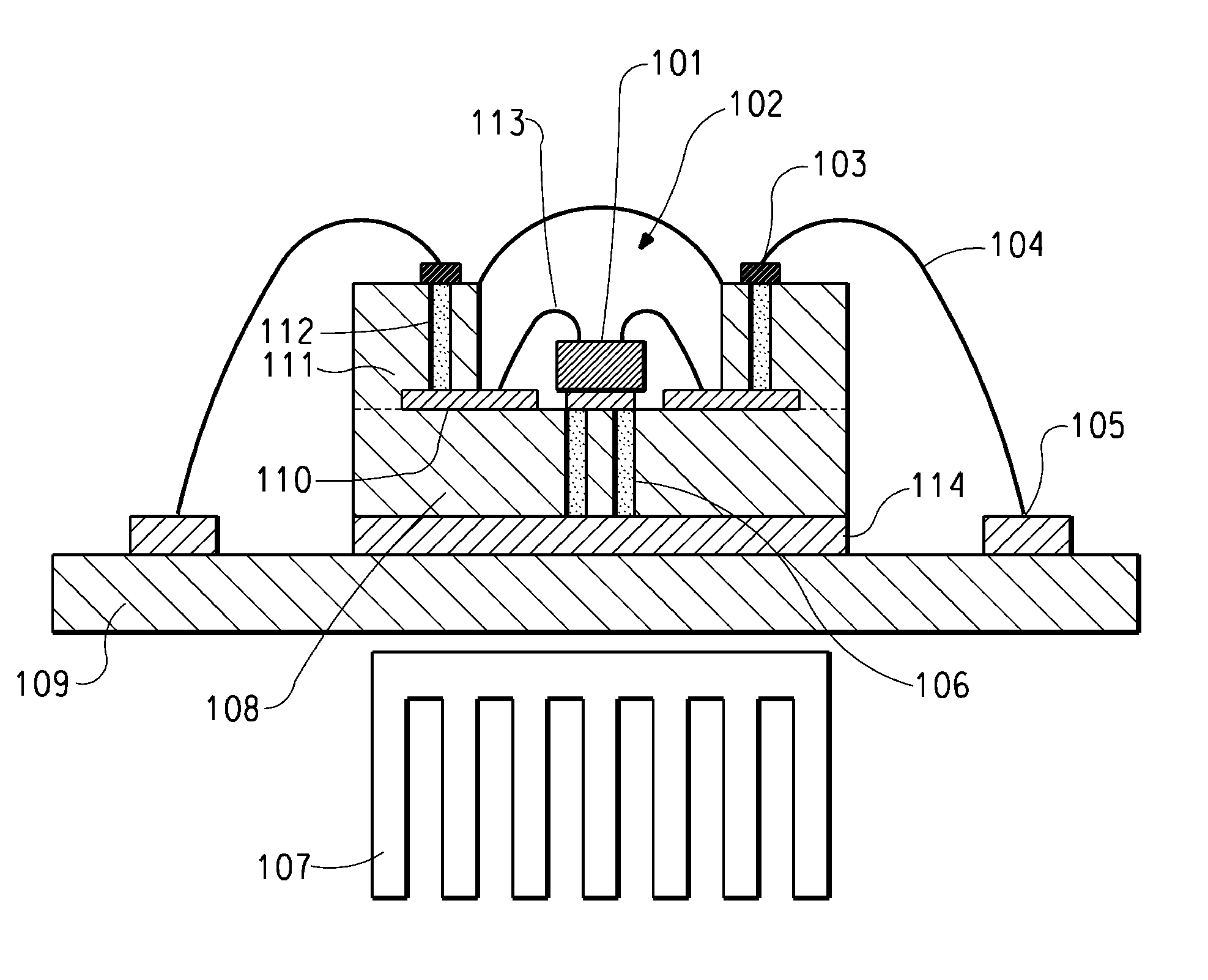

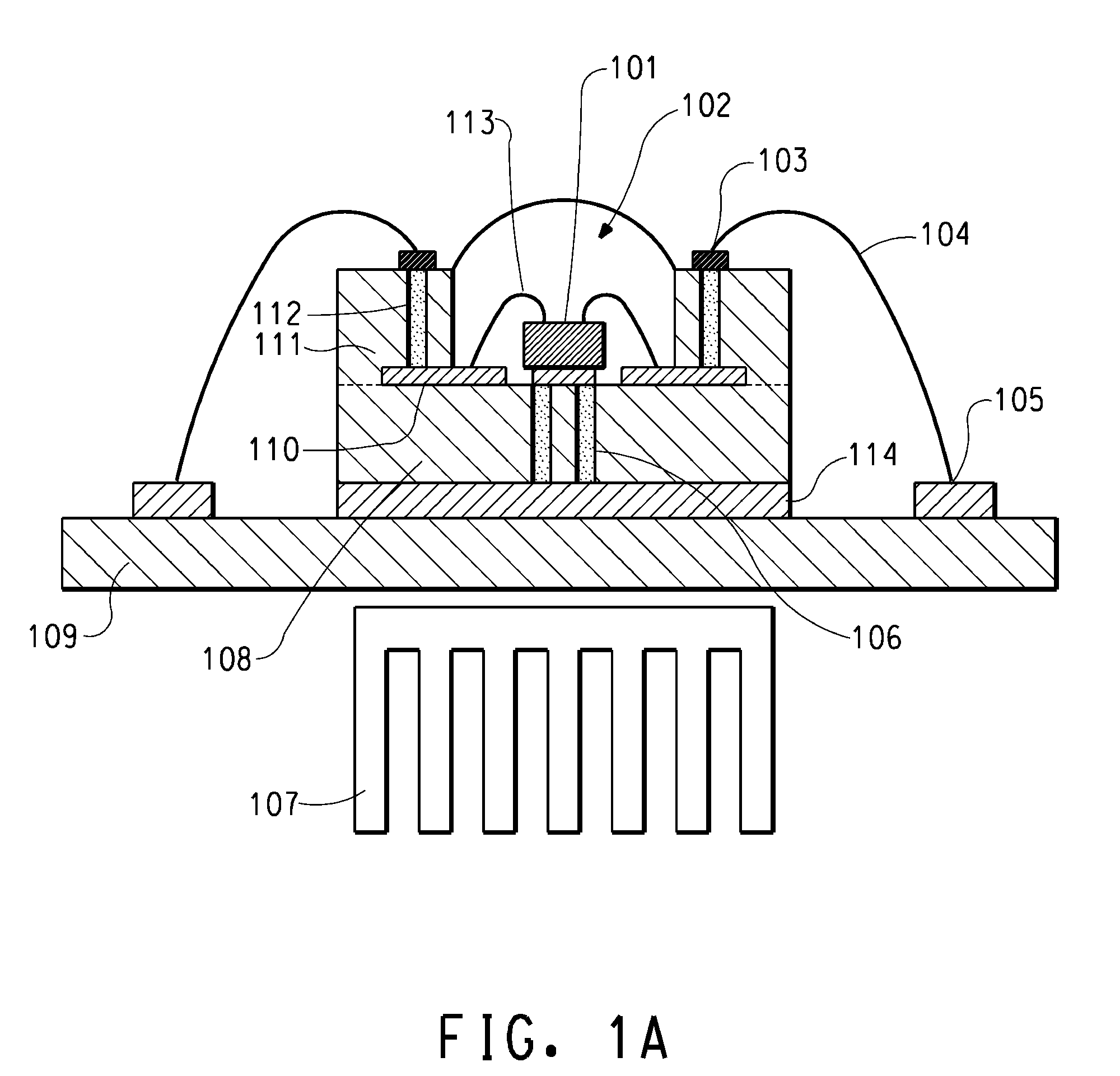

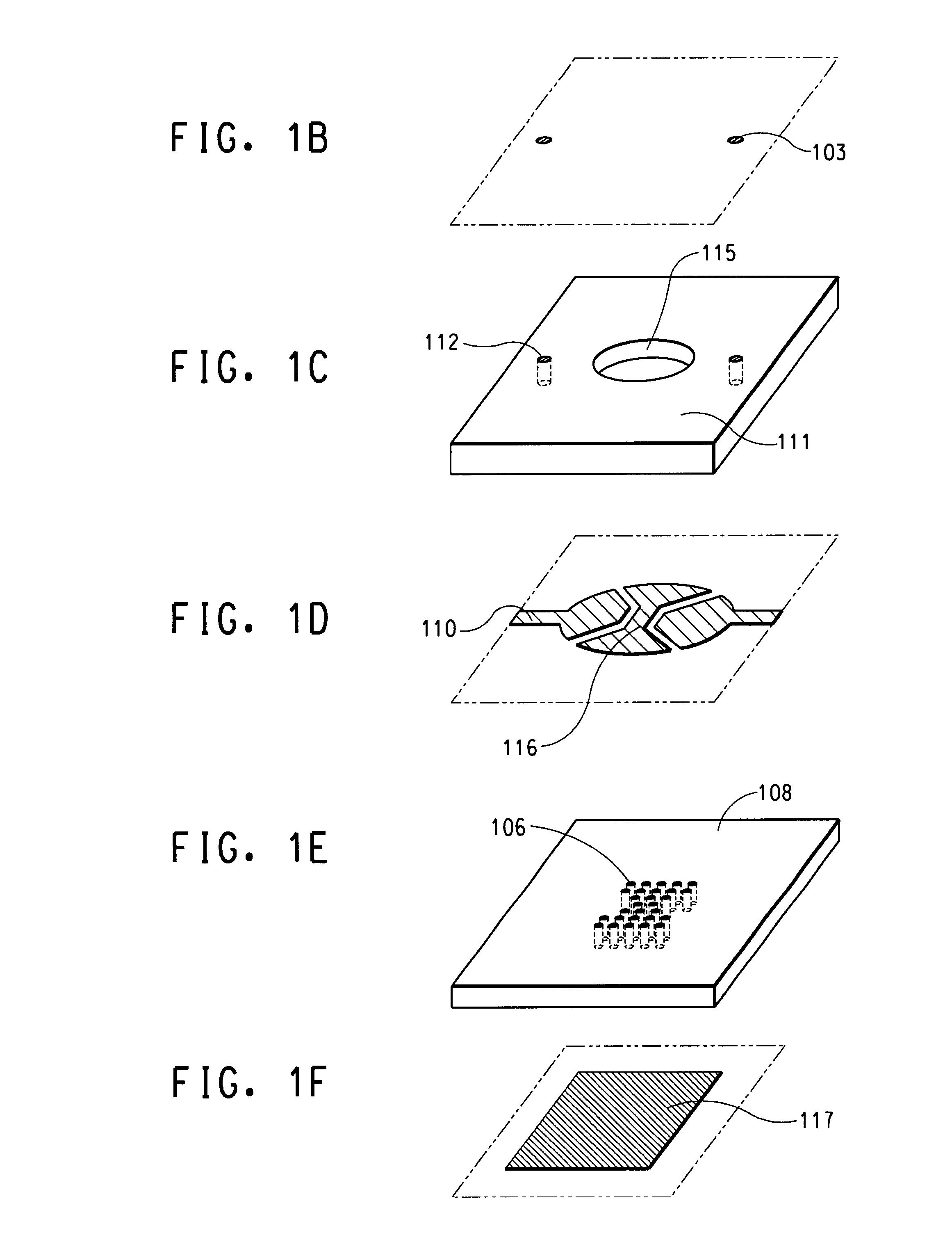

Low temperature co-fired ceramic (LTCC) tape compositions, light emitting diode (LED) modules, lighting devices and method of forming thereof

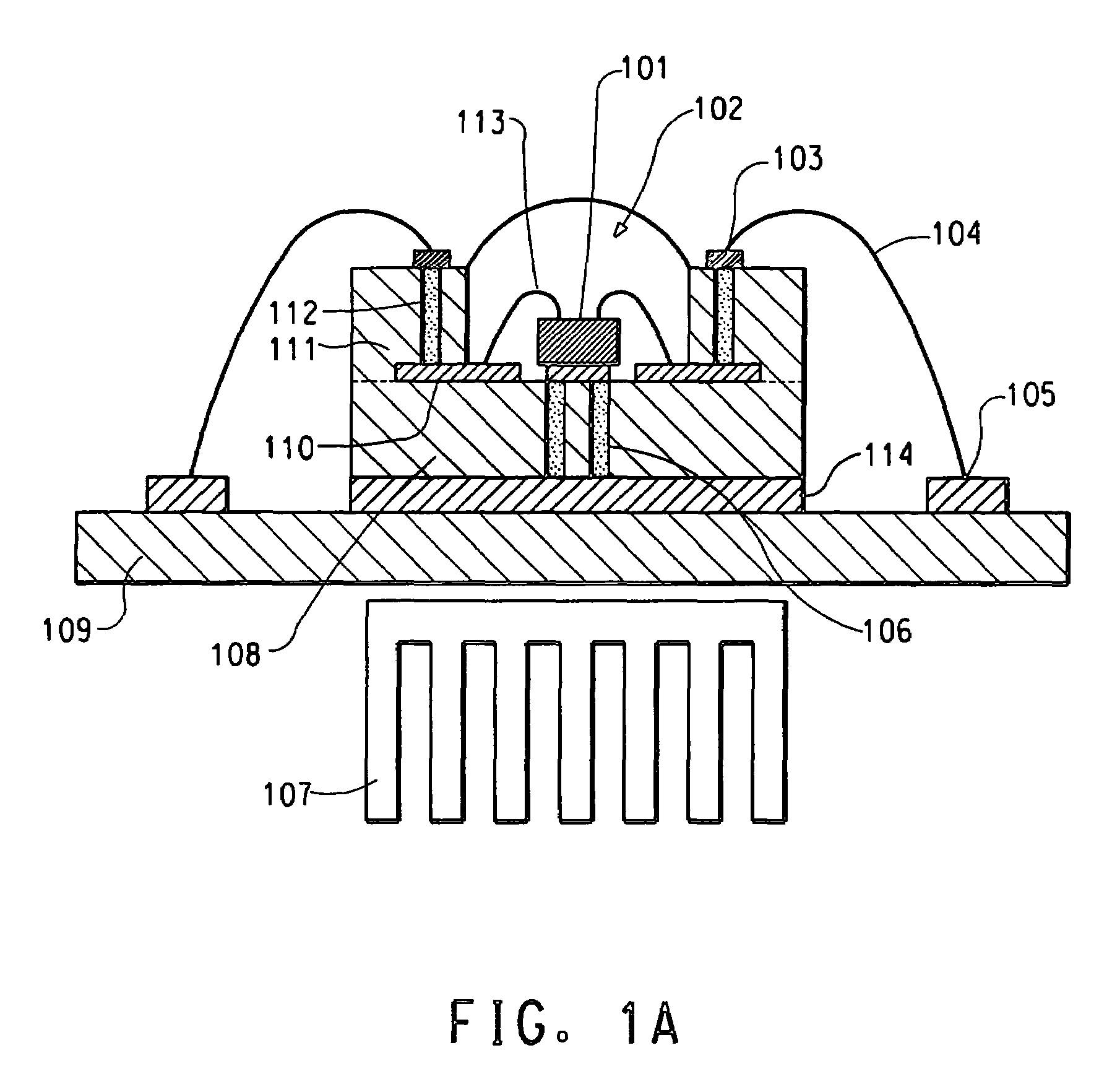

The present invention provides LTCC (low temperature co-fired ceramic) tape compositions and demonstrates the use of said LTCC tape(s) in the formation of Light-Emitting Diode (LED) chip carriers and modules for various lighting applications. The present invention also provides for the use of (LTCC) tape and LED modules in the formation of lighting devices including, but not limited to, LED devices, High Brightness (HB) LED backlights, display-related light sources, automotive lighting, decorative lighting, signage and advertisement lighting, and information display lighting.

Owner:EI DU PONT DE NEMOURS & CO

Niobium suboxide powder

ActiveUS7381396B2Reduce residual currentReduce volatilityOxide/hydroxide preparationLiquid electrolytic capacitorsTungstenSuboxide

A niobium suboxide powder comprising 100 to 600 ppm of magnesium is described. The niobium suboxide powder may (alternatively or in addition to 100 to 600 ppm of magnesium) further include 50 to 400 ppm of molybdenum and / or tungsten. The niobium suboxide powder is suitable for the production of: capacitors having an insulator layer of niobium pentoxide; capacitor anodes produced from the niobium suboxide powder; and corresponding capacitors.

Owner:TANIOBIS GMBH

Low temperature co-fired ceramic (LTCC) tape compositions, light emitting diode (LED) modules, lighting devices and method of forming thereof

InactiveUS7550319B2Extended service lifeSemiconductor/solid-state device detailsCeramicsEffect lightDisplay device

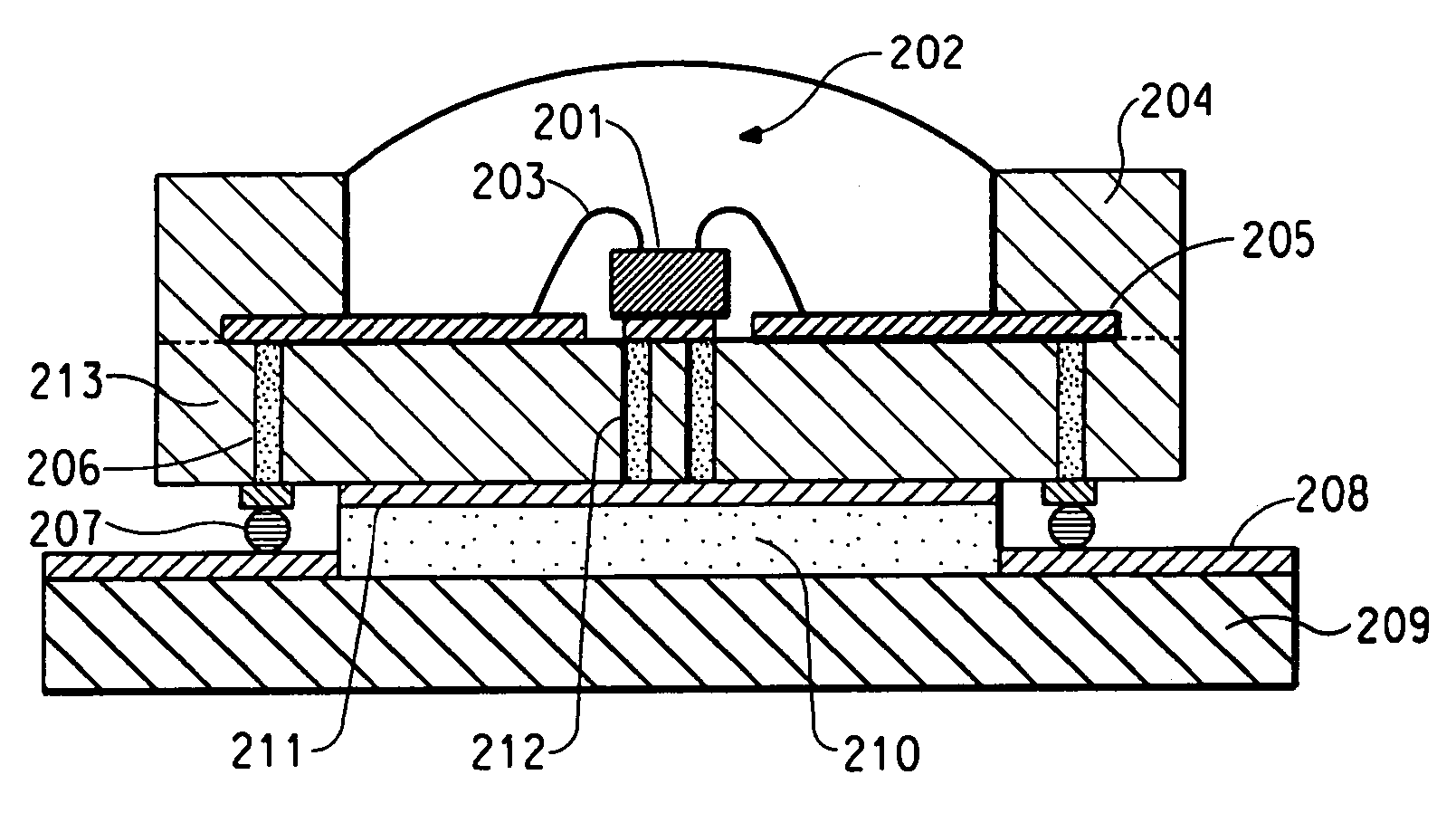

The present invention provides LTCC (low temperature co-fired ceramic) tape compositions and demonstrates the use of said LTCC tape(s) in the formation of Light-Emitting Diode (LED) chip carriers and modules for various lighting applications. The present invention also provides for the use of (LTCC) tape and LED modules in the formation of lighting devices including, but not limited to, LED devices, High Brightness (HB) LED backlights, display-related light sources, automotive lighting, decorative lighting, signage and advertisement lighting, and information display lighting.

Owner:EI DU PONT DE NEMOURS & CO

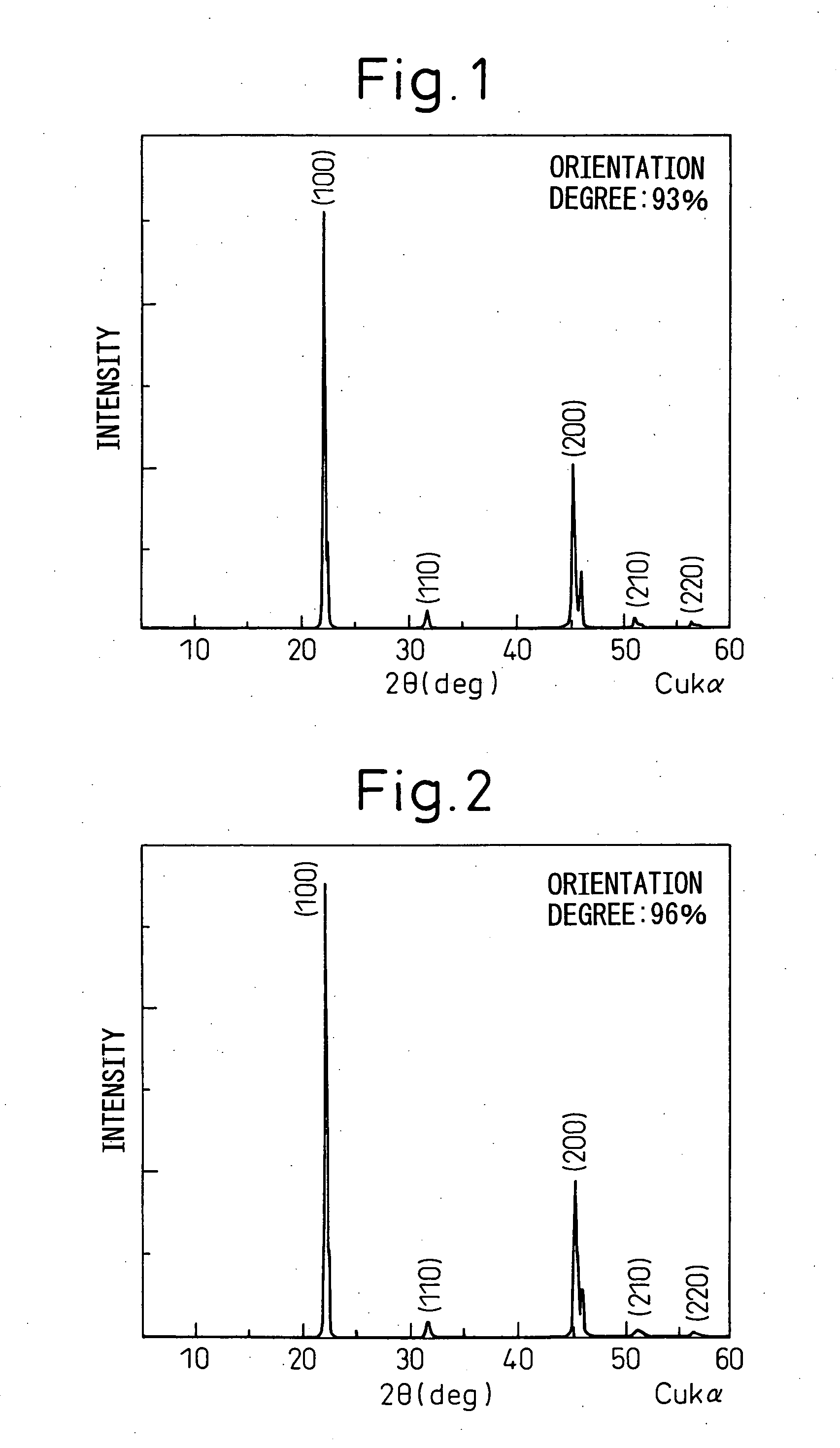

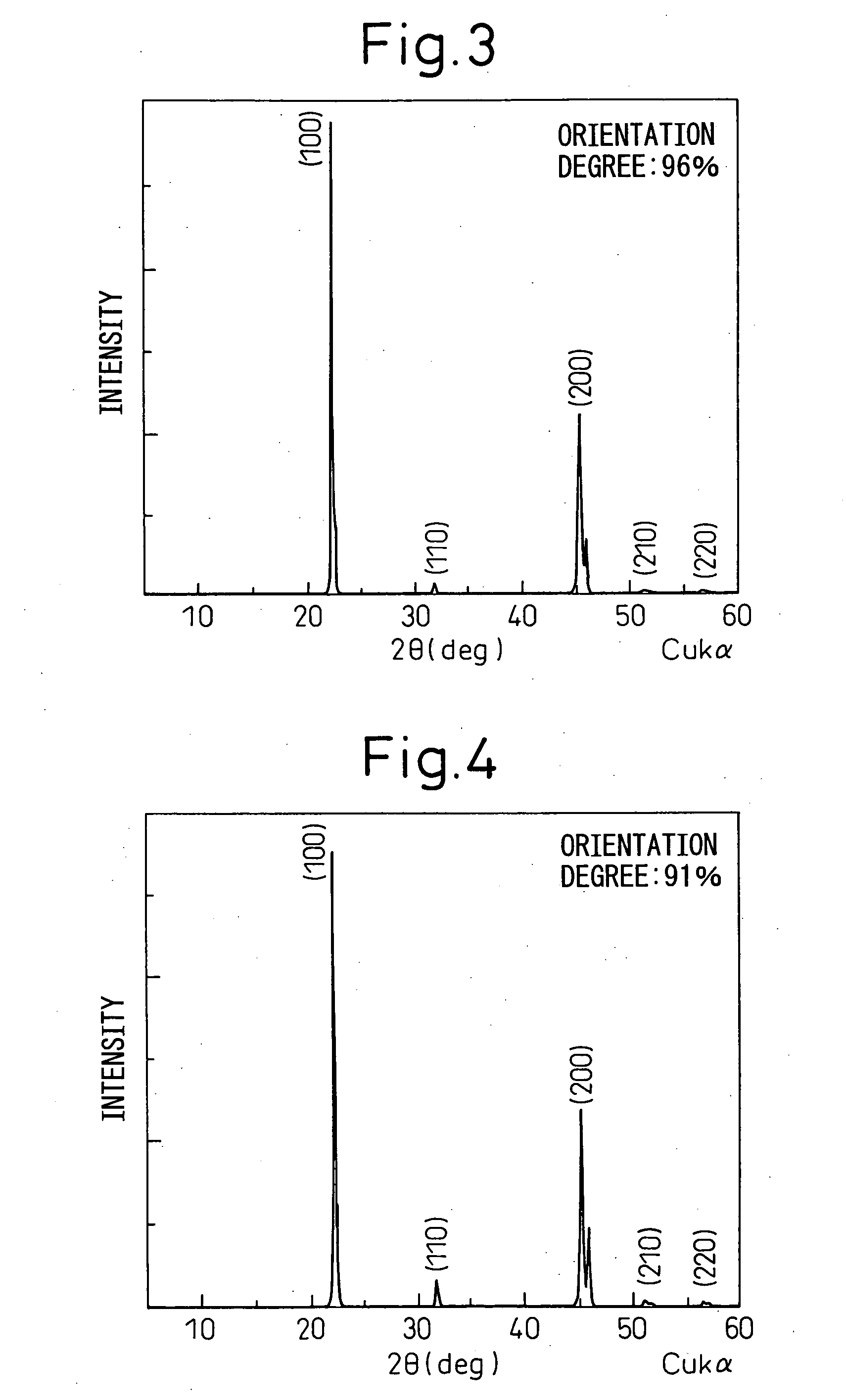

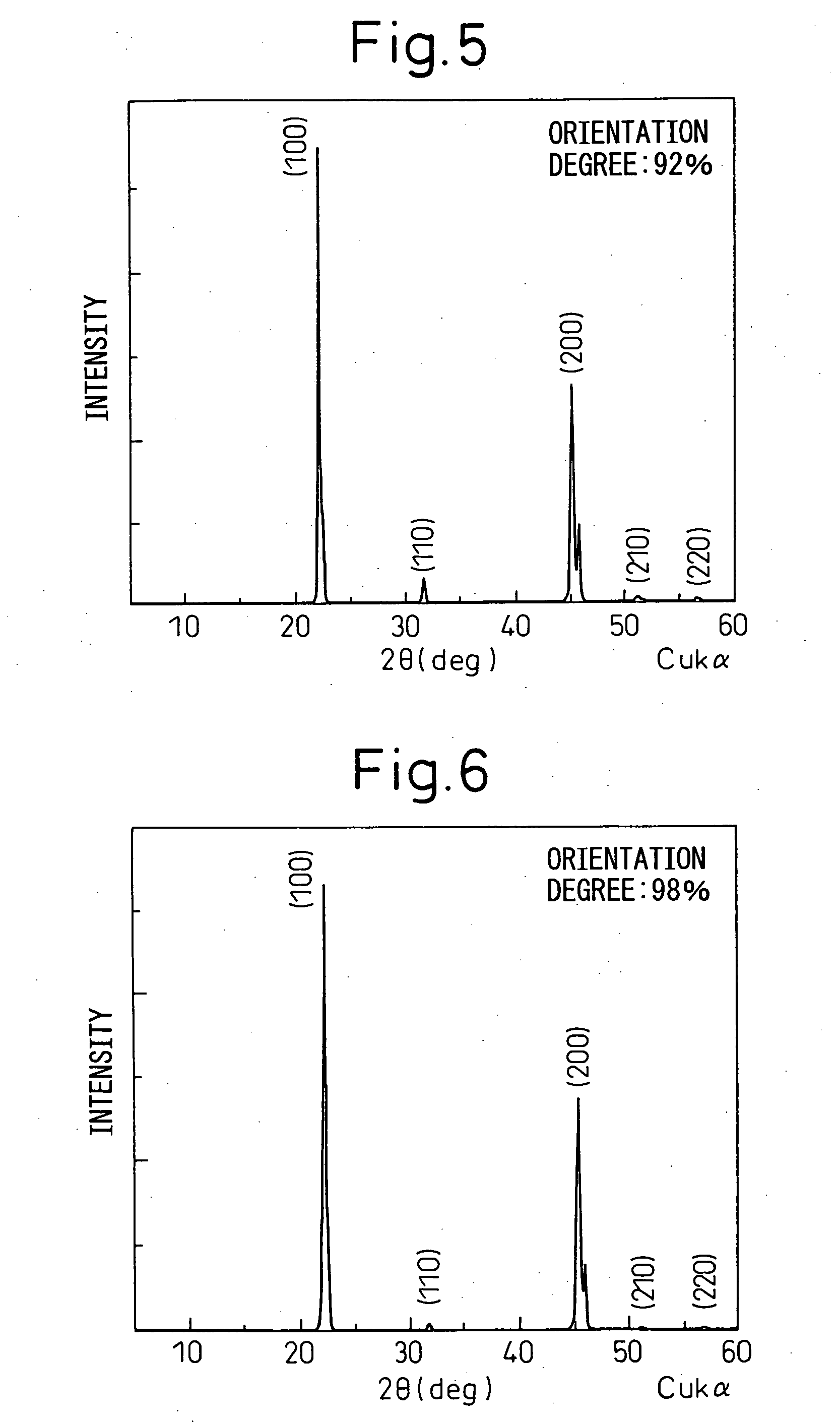

Grain oriented ceramics and production method thereof

InactiveUS20060006360A1Excellent piezoelectric propertiesEnvironment safetyPiezoelectric/electrostrictive device manufacture/assemblyCeramicsAlkaline earth metalCrystal plane

To provide a grain oriented ceramic capable of exerting excellent piezoelectric properties, a production method thereof, and a piezoelectric material, a dielectric material, a thermoelectric conversion element and an ion conducting element each using the grain oriented ceramic, there is provided a grain oriented ceramic comprising, as the main phase, an isotropic perovskite-type compound which is represented by formula (1): {Lix(K1−yNay)1−x}(Nb1−z−wTazSbw)O3 in which x, y, z and w are in respective composition ranges of 0≦x≦0.2, 0≦y≦1, 0≦z≦0.4, 0≦w≦0.2 and x+z+w>0. The main phase comprises a polycrystalline body containing from 0.0001 to 0.15 mol of any one or more additional element selected from metal elements, semimetal elements, transition metal elements, noble metal elements and alkaline earth metal elements belonging to Groups 2 to 15 of the Periodic Table, per mol of the compound represented by formula (1). A specific crystal plane of each crystal grain constituting said polycrystalline body is oriented.

Owner:DENSO CORP

Dielectric materials

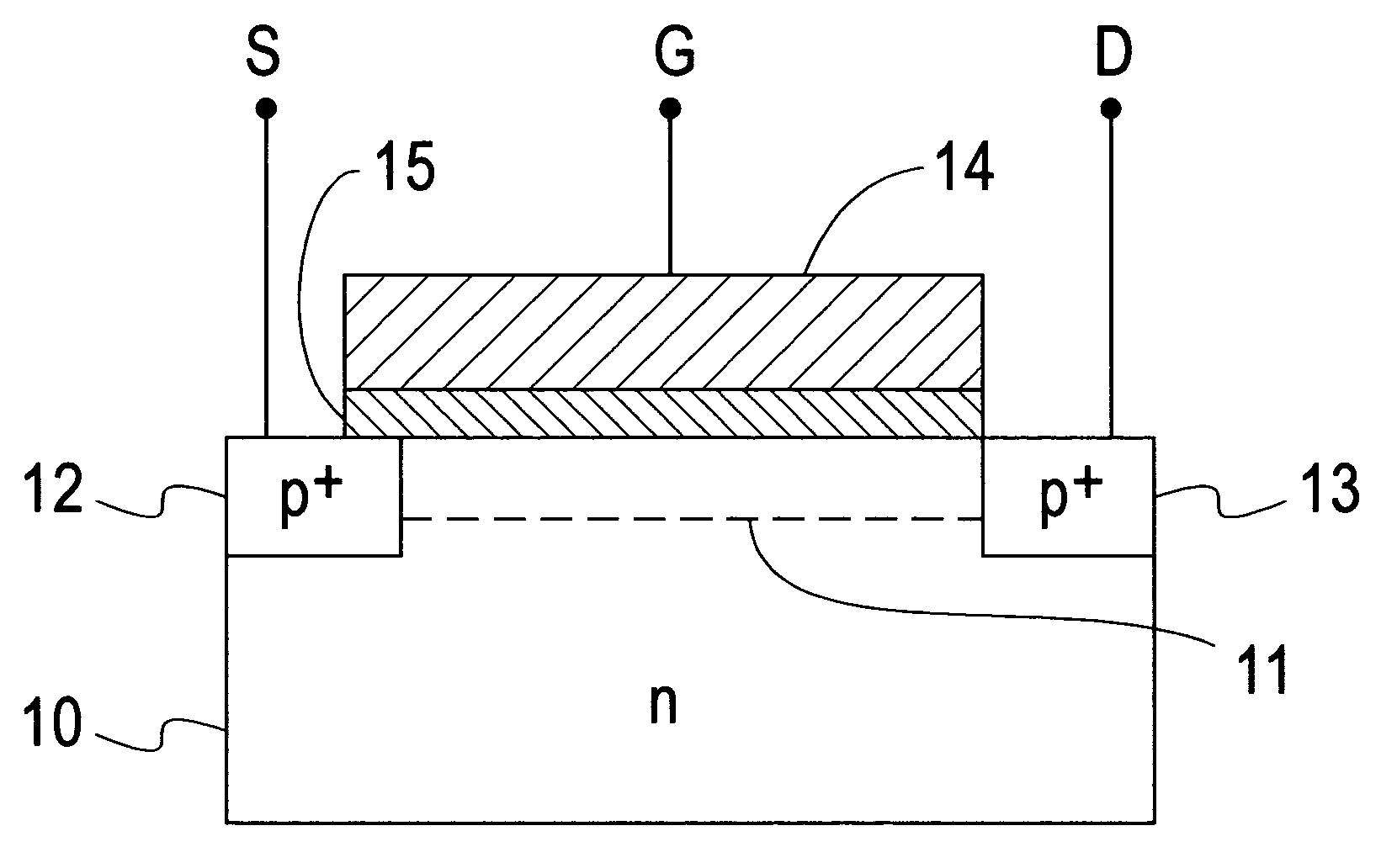

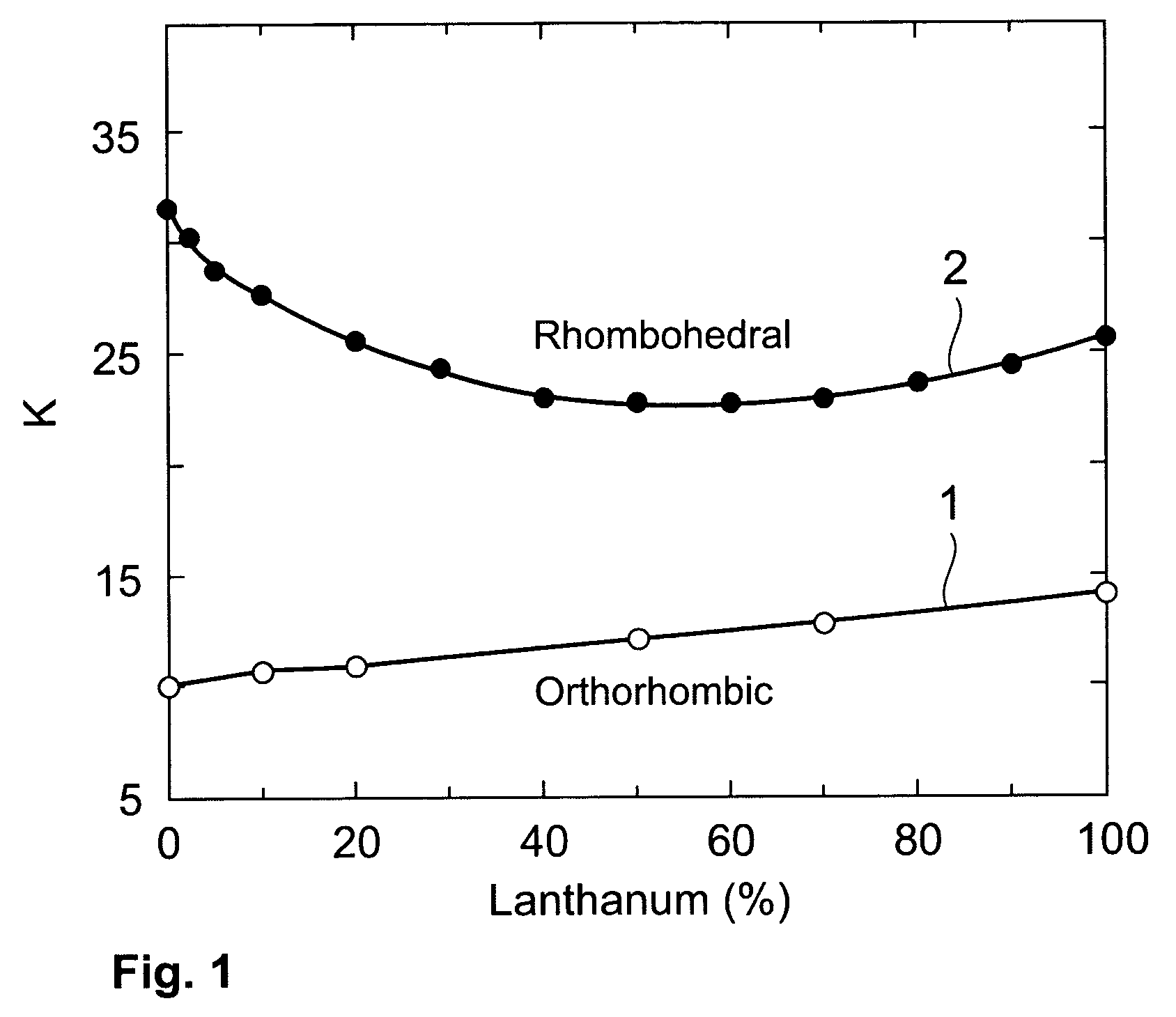

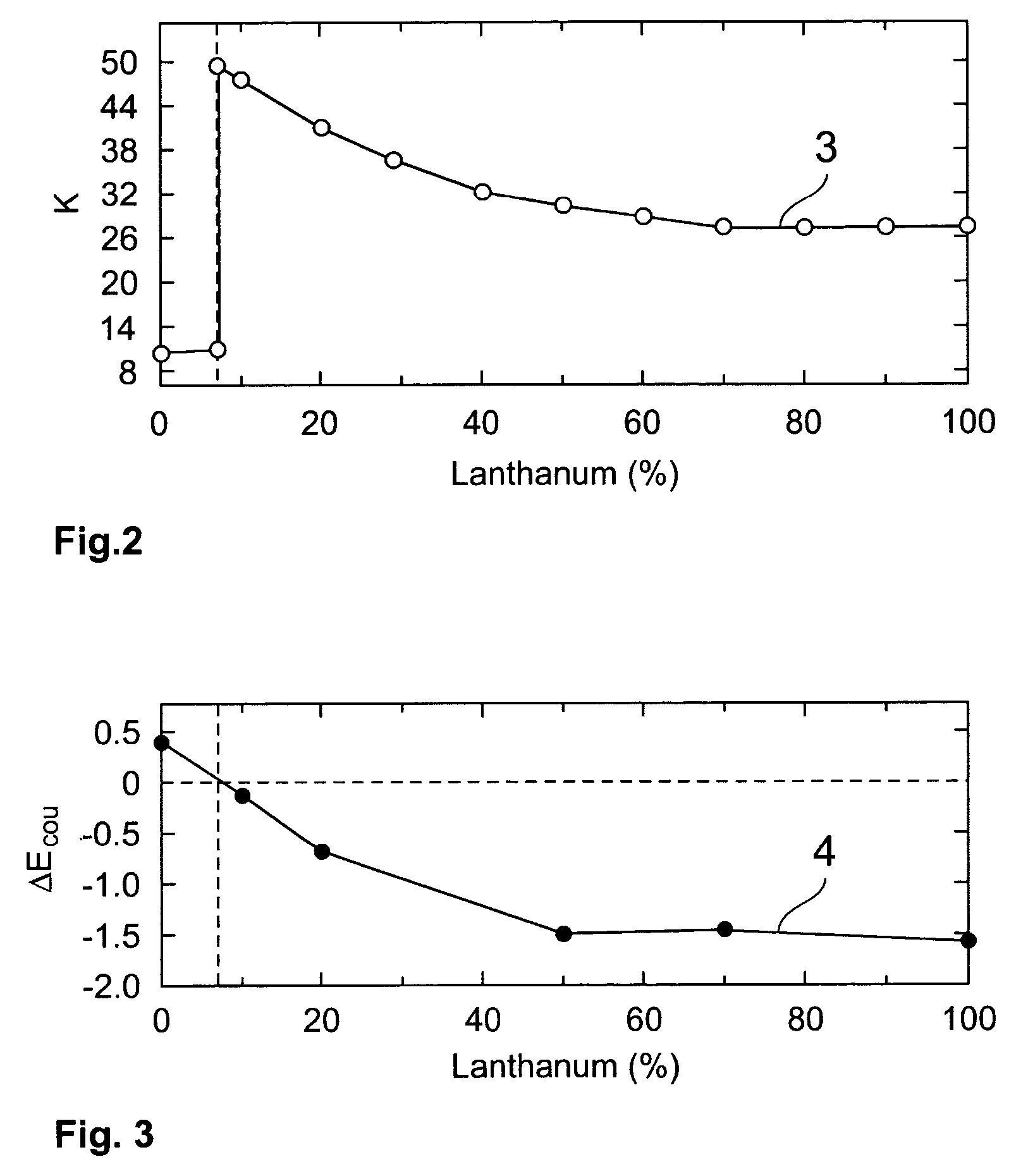

InactiveUS7057244B2High spatial anisotropyHigh thermodynamic stabilityPolycrystalline material growthCeramicsOptoelectronicsField-effect transistor

An article of manufacture comprises a substrate and a layer of N(x)Y(1−x)AlO3 on the substrate where x is a molar fraction greater than zero and less than one, and N is an element selected from La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, and Lu. The article may be an electronic device further comprising an electrode electrically isolated from the substrate by the layer. In particular, the dielectric properties of the layer are such that the layer is especially although by no means exclusively useful for electrically isolating gate electrodes in field effect transistor devices. The layer may be formed on the substrate via molecular beam epitaxy.

Owner:IBM CORP

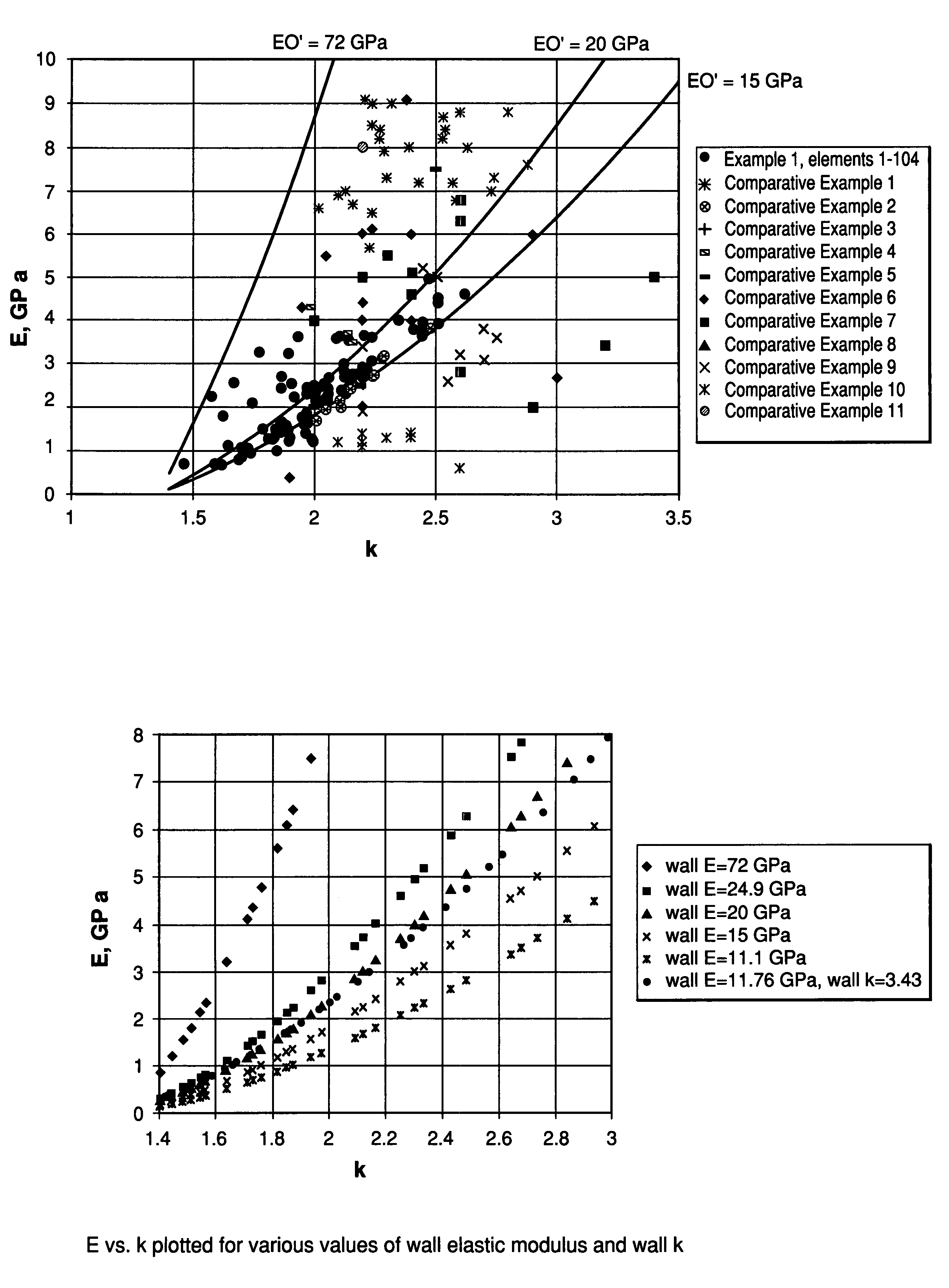

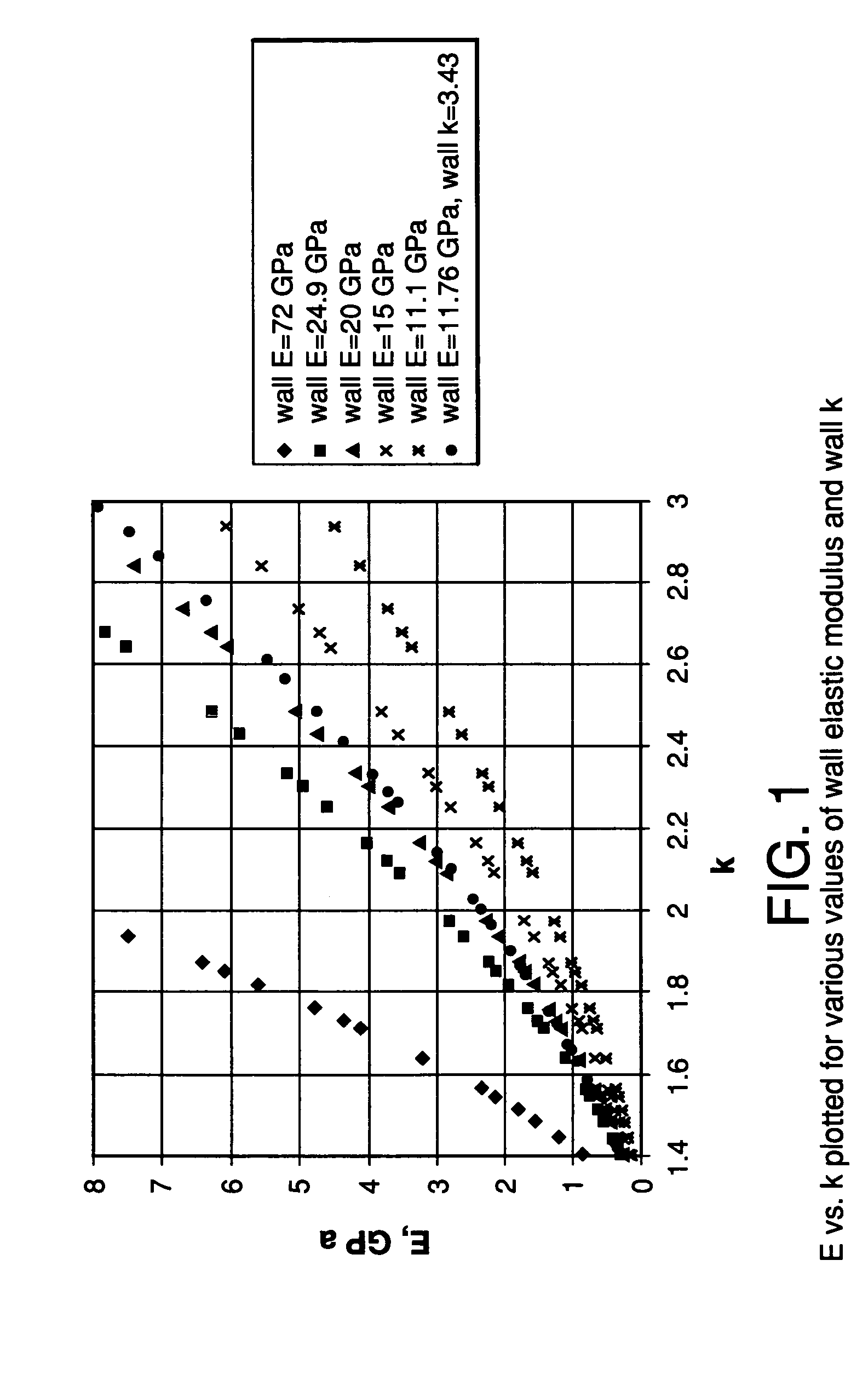

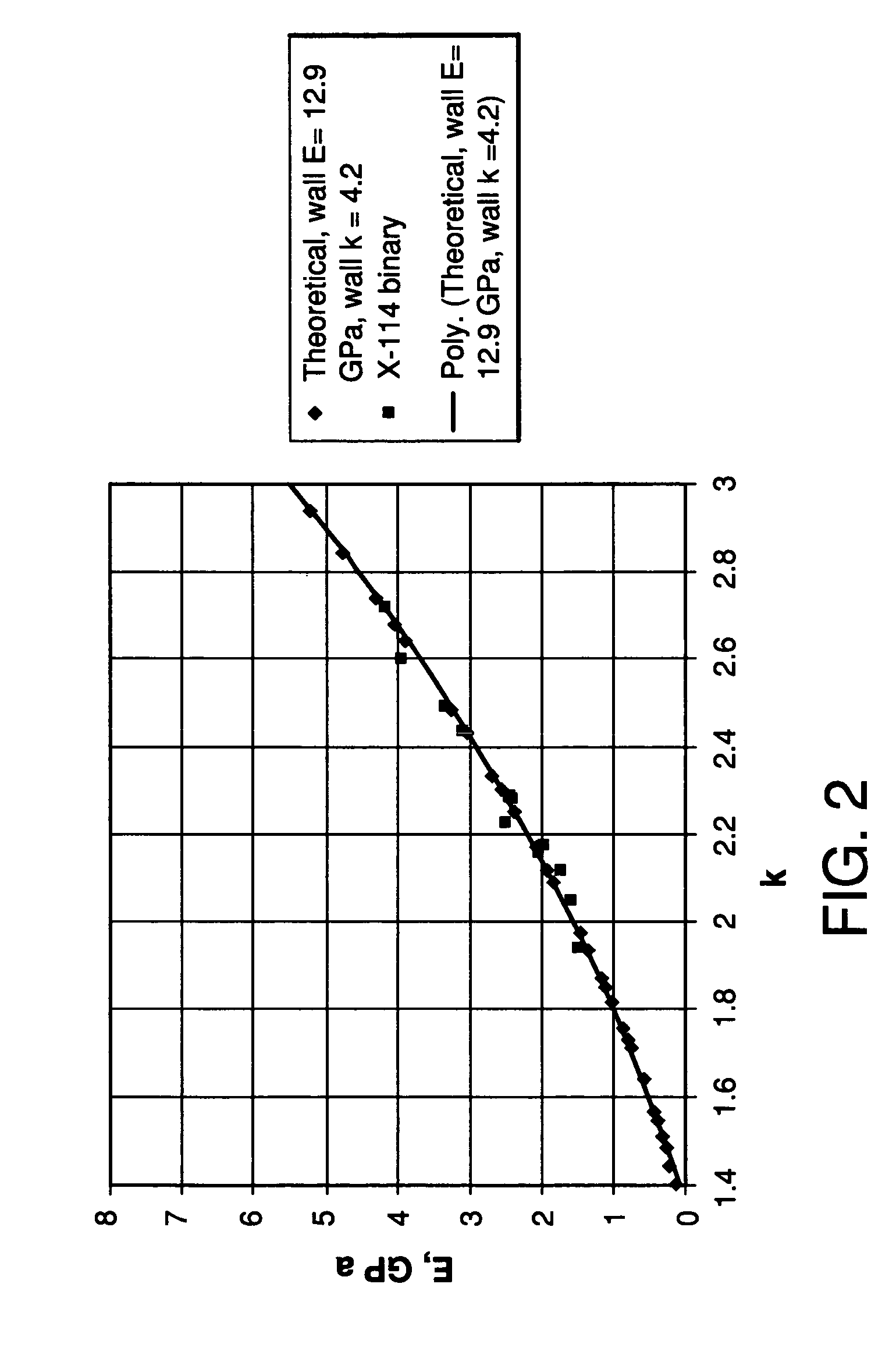

Low dielectric materials and methods for making same

Low dielectric materials and films comprising same have been identified for improved performance when used as interlevel dielectrics in integrated circuits as well as methods for making same. These materials are characterized as having a dielectric constant (κ) a dielectric constant of about 3.7 or less; a normalized wall elastic modulus (E0′), derived in part from the dielectric constant of the material, of about 15 GPa or greater; and a metal impurity level of about 500 ppm or less. Low dielectric materials are also disclosed having a dielectric constant of less than about 1.95 and a normalized wall elastic modulus (E0′), derived in part from the dielectric constant of the material, of greater than about 26 GPa.

Owner:SYMYX SOLUTIONS +1

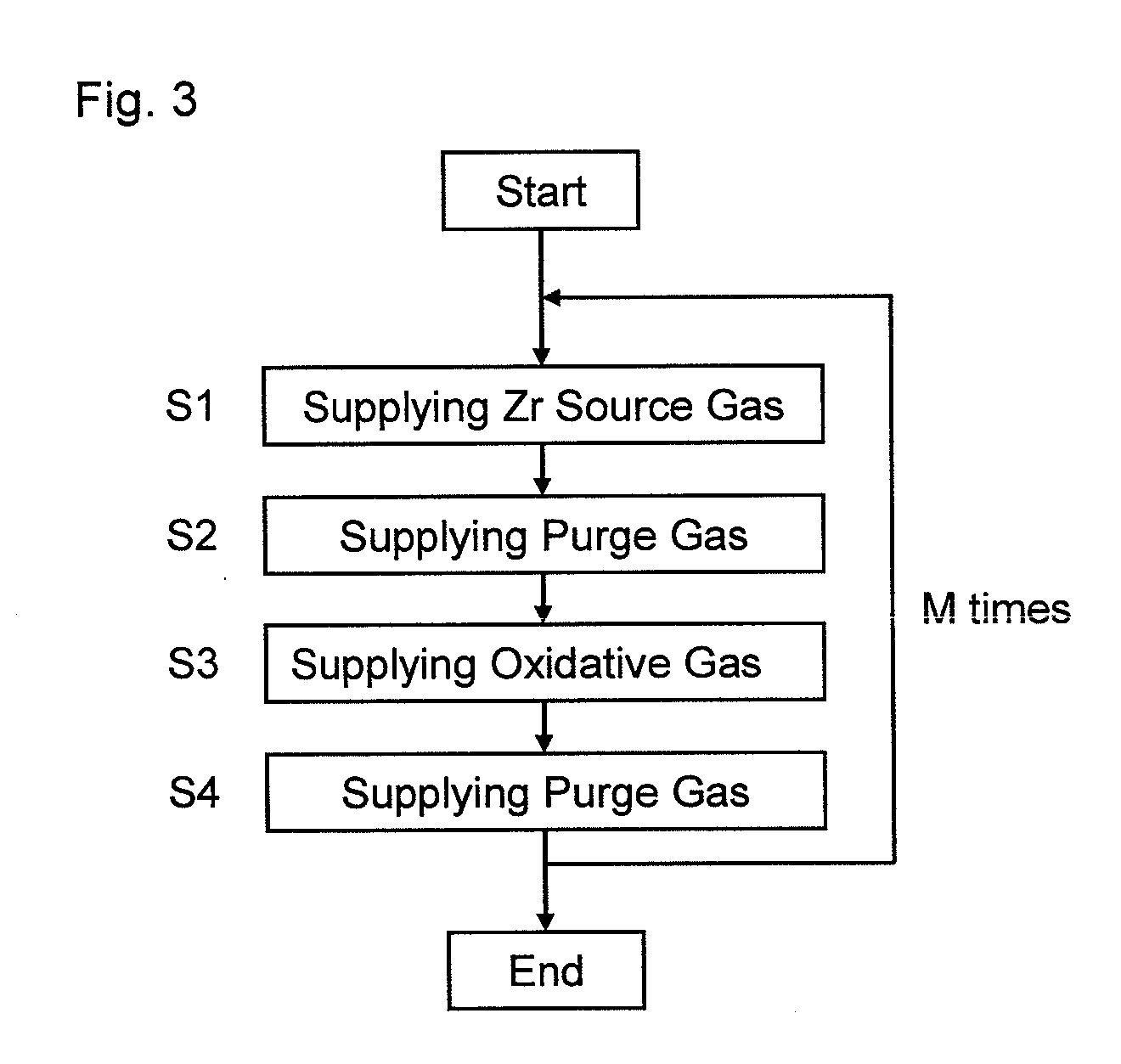

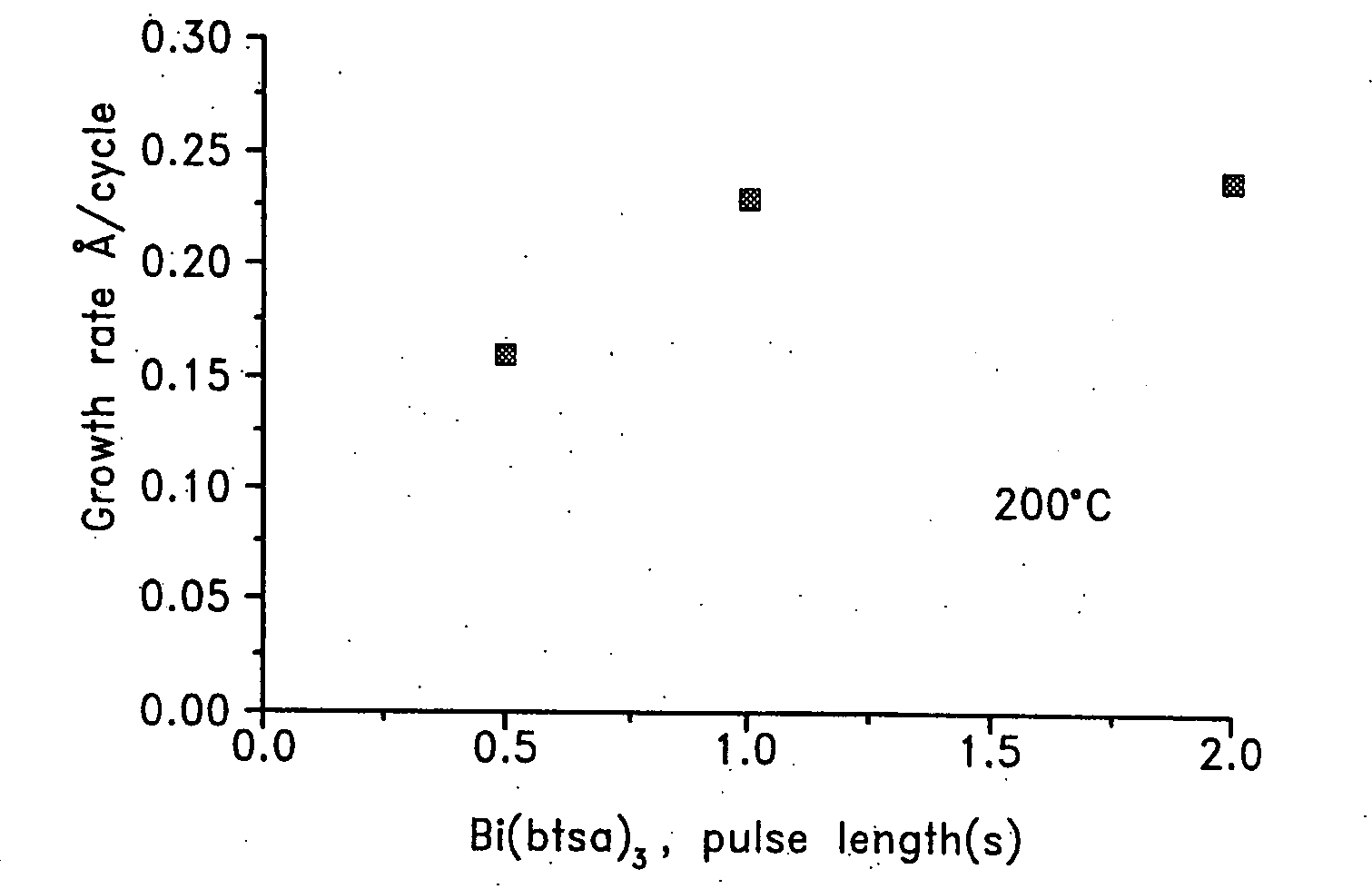

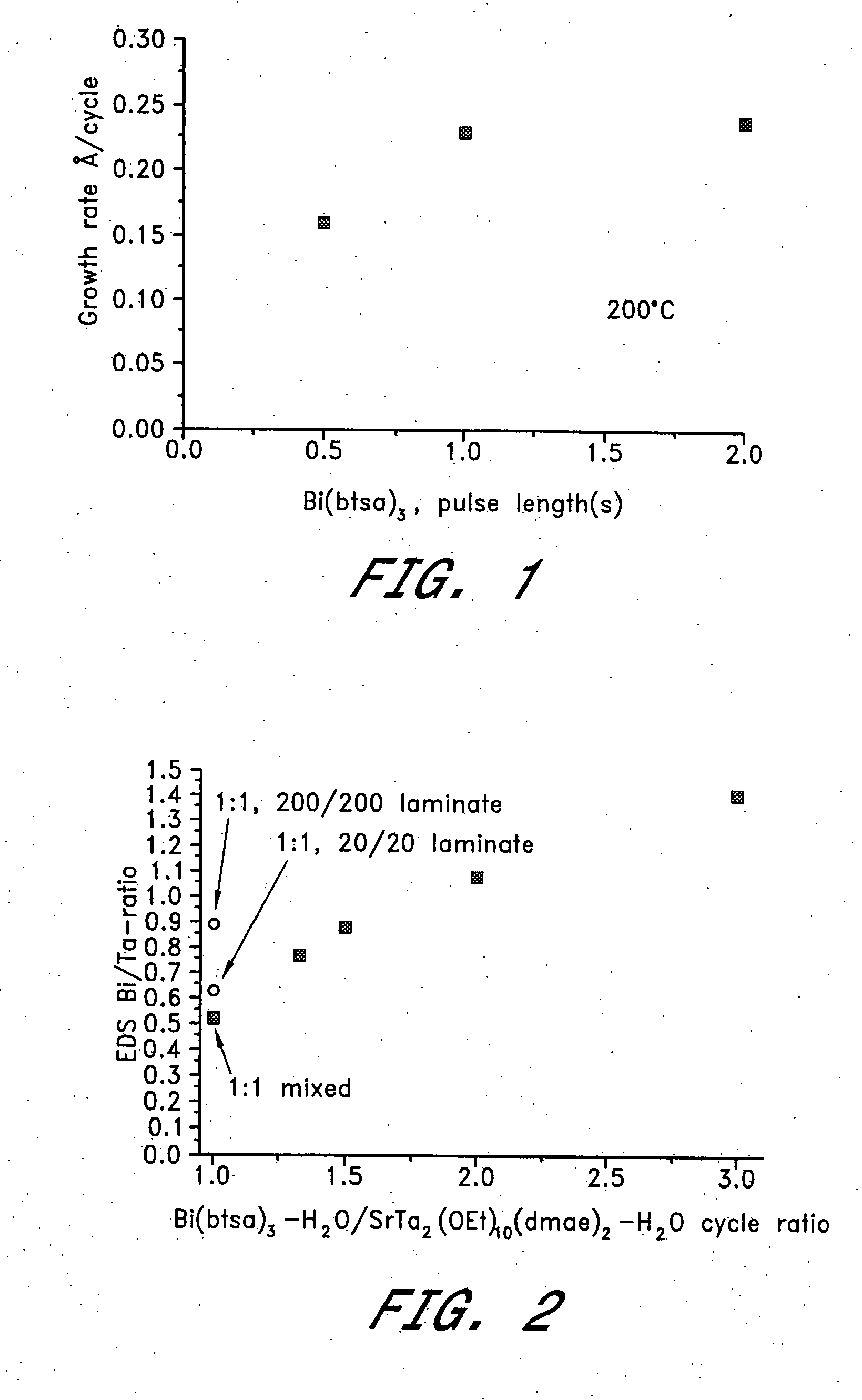

Process for producing oxide films

ActiveUS20050089632A1Reduce decreaseImprove film propertiesCeramicsSolid-state devicesSilyleneBismuth compound

A process for producing bismuth-containing oxide thin films by Atomic Layer Deposition, including using an organic bismuth compound having at least one silylamido ligand as a source material for the bismuth oxide. Bismuth-containing oxide thin films produced by the preferred embodiments can be used, for example, as ferroelectric or dielectric material in integrated circuits and / or as superconductor materials.

Owner:ASM INTERNATIONAL

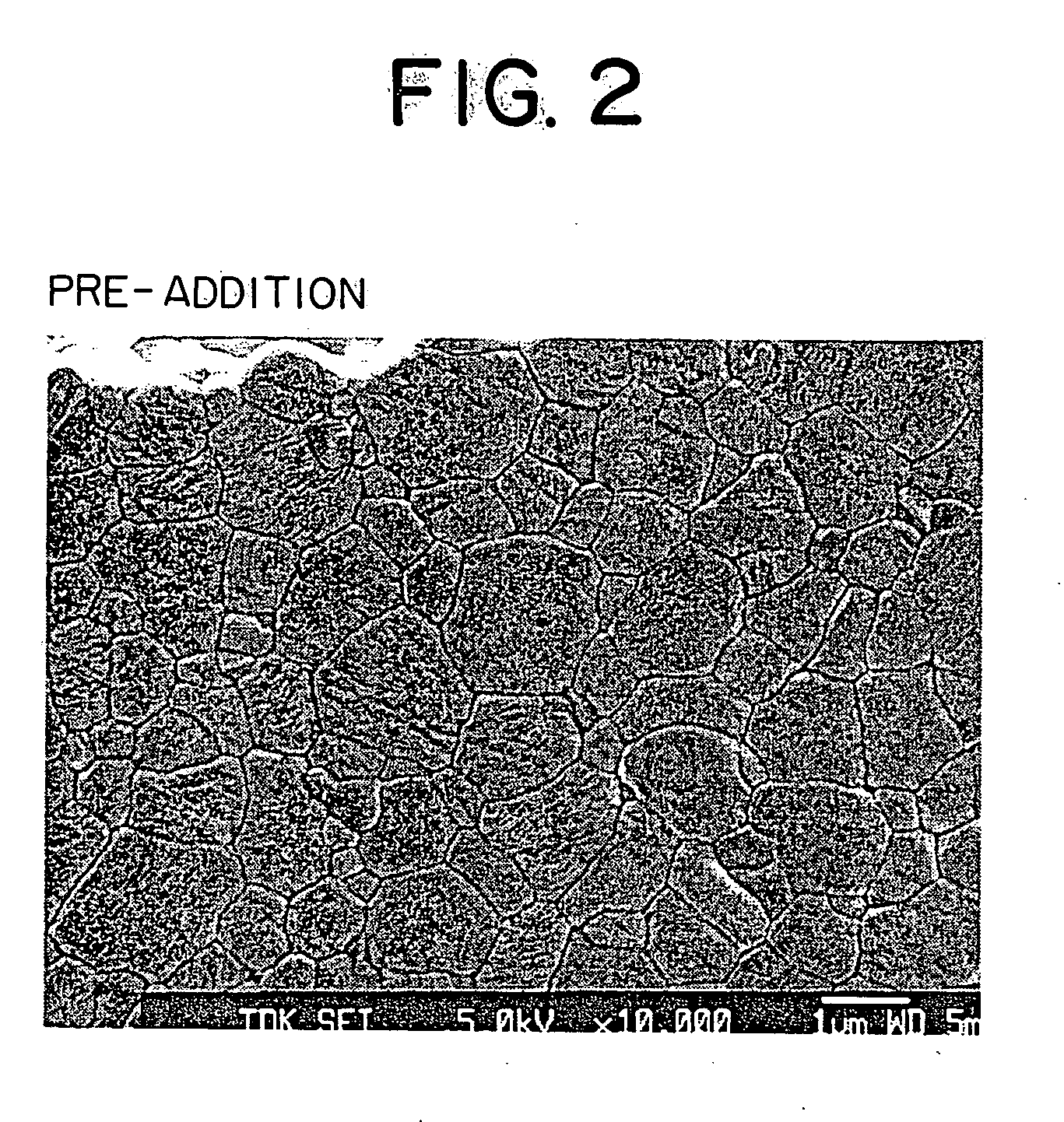

Dielectric ceramic composition and method of production and electronic device of the same

ActiveUS20050128683A1Superior low frequency dielectric characteristicImproved more accelerated lifetimeLayered productsFixed capacitor dielectricDielectricElectrical resistance and conductance

A method of production of a reduction resistant dielectric ceramic composition having a superior low frequency dielectric characteristic and further improved in accelerated lifetime of insulation resistance, specifically a method of production of a dielectric ceramic composition containing a main component including a dielectric oxide of a specific composition, a first subcomponent including a V oxide, a second subcomponent containing an Al oxide, a third subcomponent containing an Mn oxide, and a fourth subcomponent containing a specific sintering aid in a specific ratio, including a step of mixing at least part of the materials of the subcomponents excluding one or both of at least the material of the third subcomponent and material of the fourth subcomponent with the starting materials prepared for obtaining the material of the main component to prepare the pre-reaction material, a step of causing the prepared pre-reaction material to react to obtain a reacted material, and a step of mixing the materials of the subcomponents excluded when preparing the pre-reaction material with the obtained reacted material to obtain a dielectric ceramic composition.

Owner:TDK CORPARATION

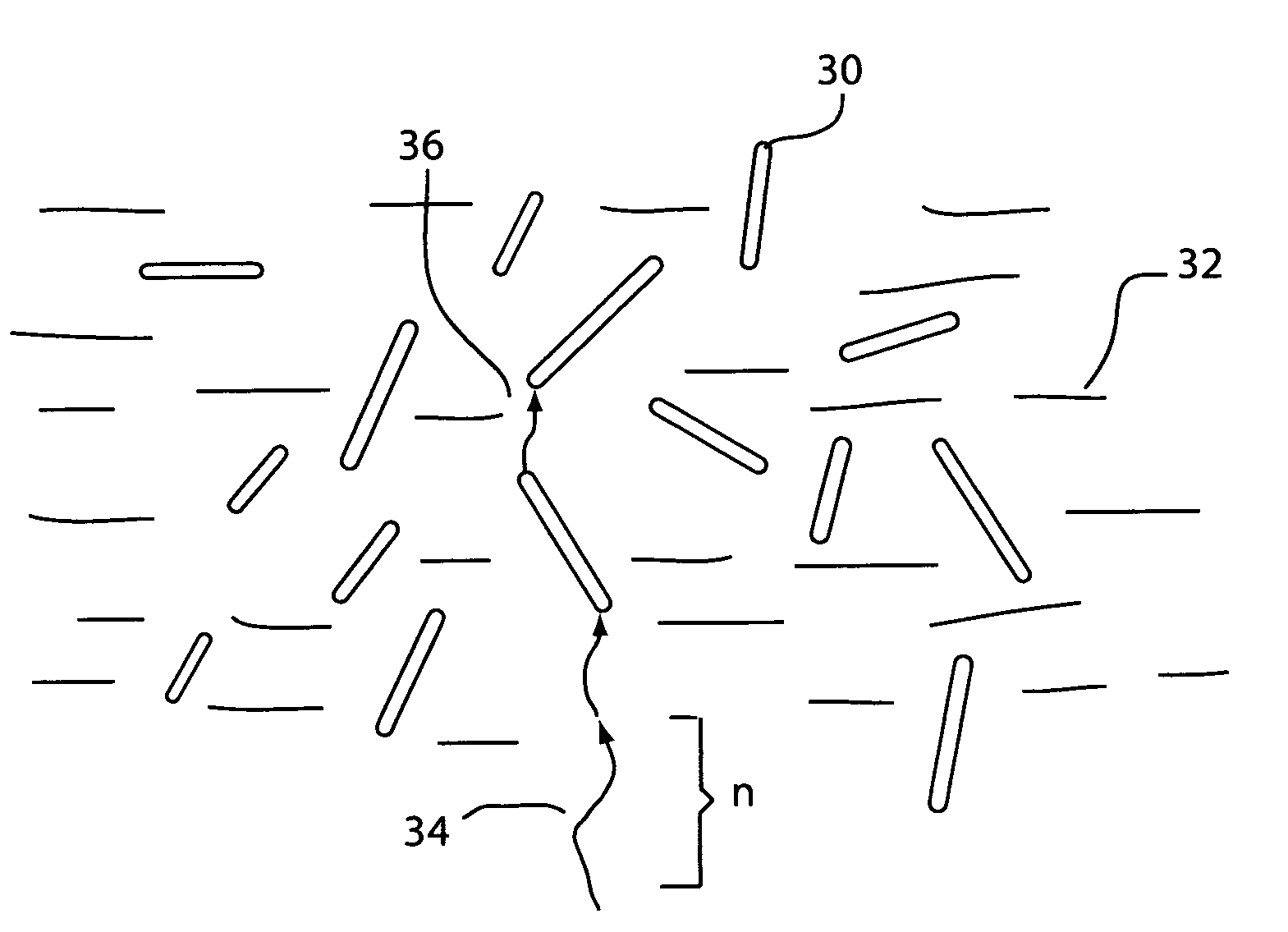

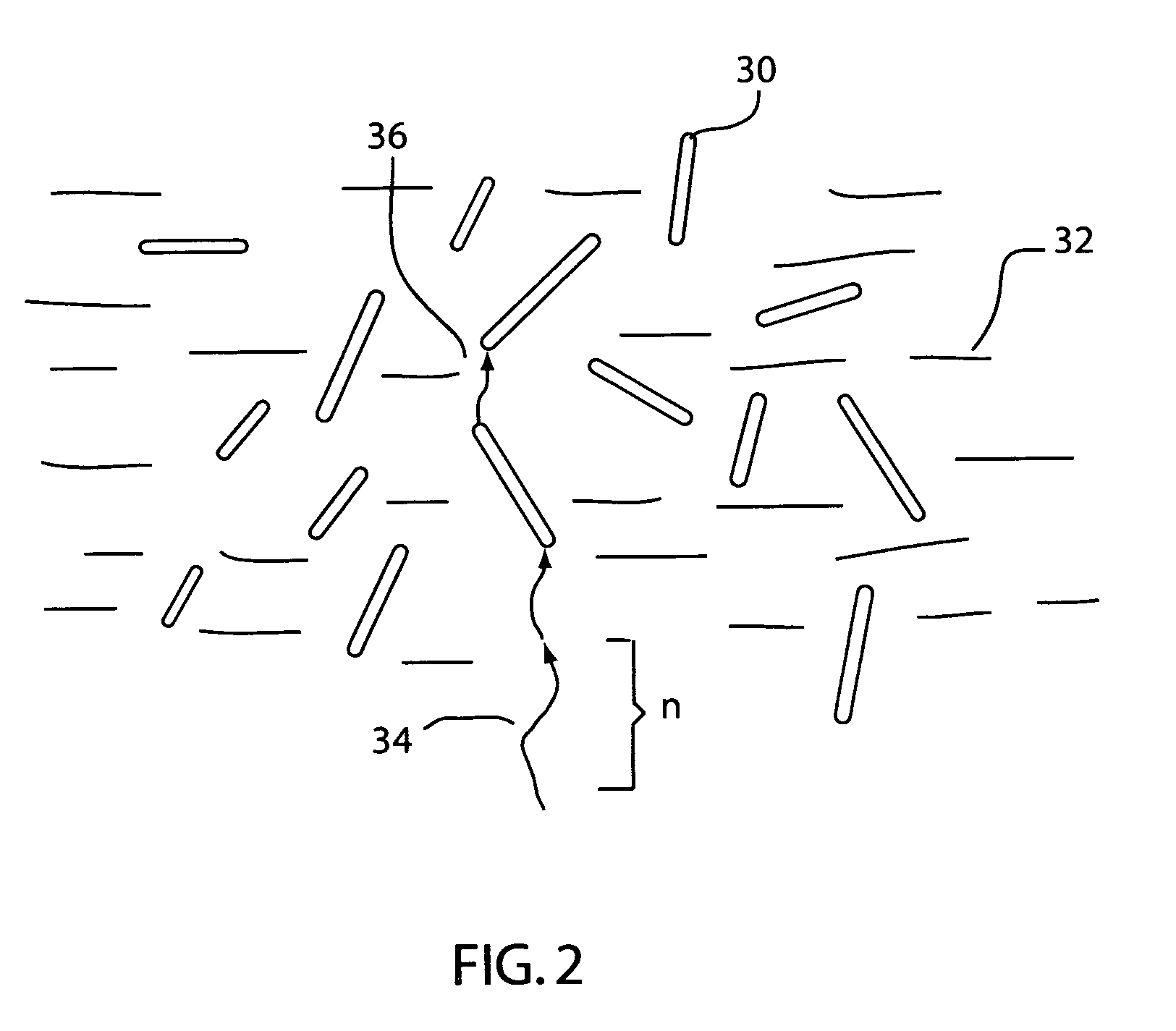

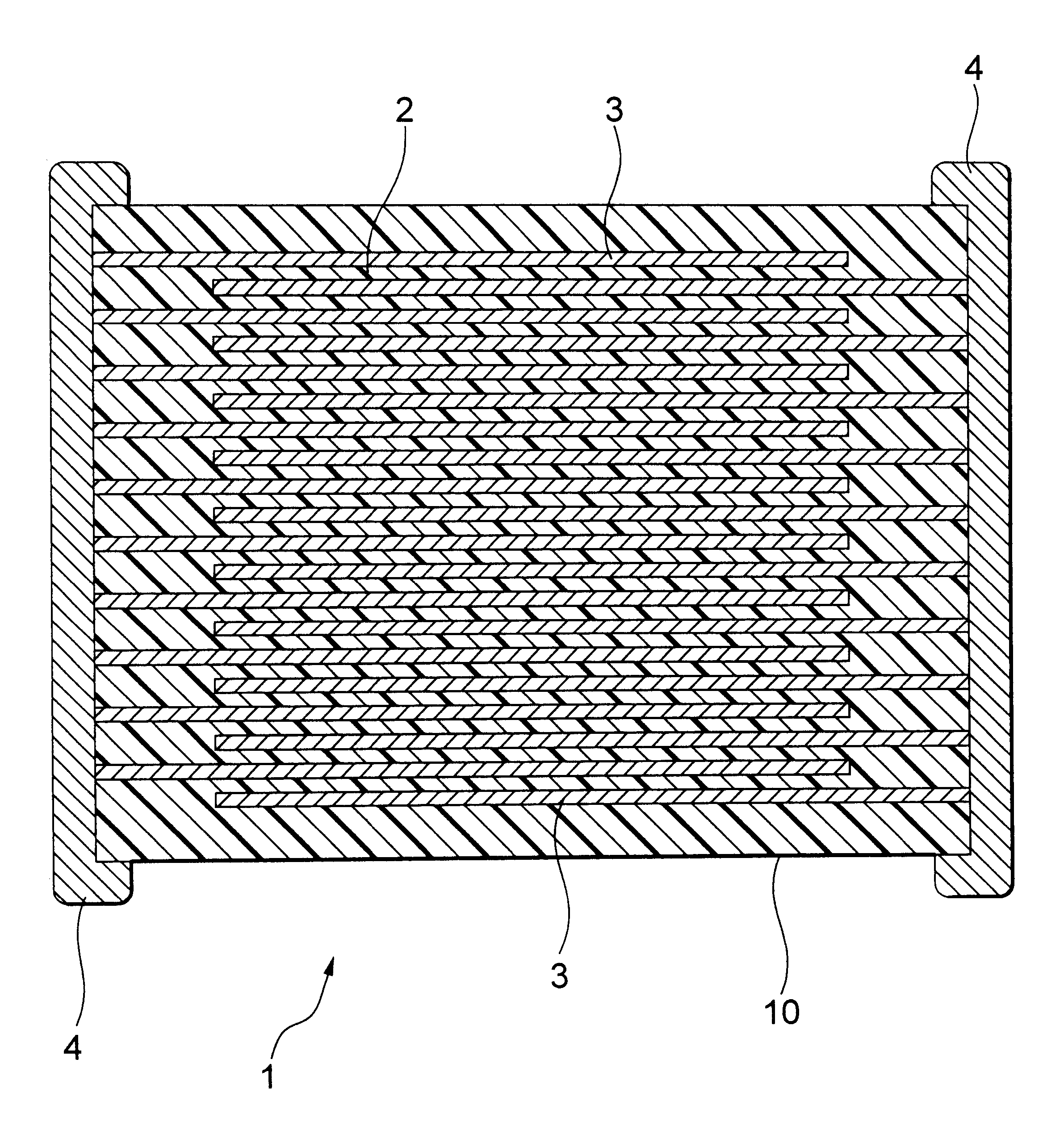

Compression of resin impregnated insulating tapes

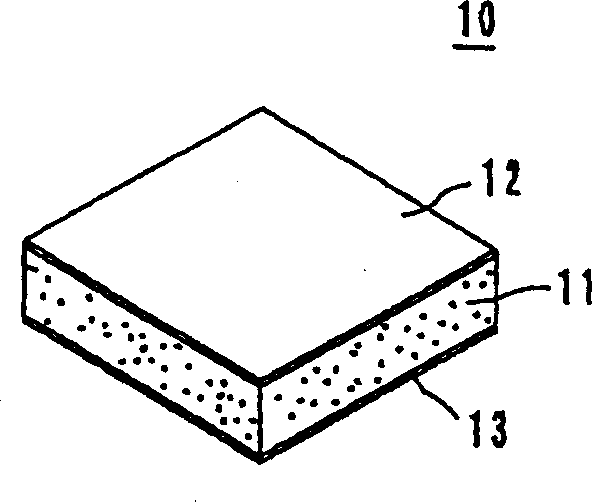

ActiveUS20050274450A1Easy to disperseReduces phonon scatteringWindings insulation materialAdhesive processes with surface pretreatmentThermal conductivity

The present invention provides for a method of impregnating a matrix with a high thermal conductivity filled resin 32, which produces a resin impregnated matrix. The high thermal conductivity material 30 comprises 5-60% by volume of the resin 32. This is compressed by approximately 5-30%, and the distances between the high thermal conductivity materials loaded in the resin are reduced, and the resin is then cured.

Owner:SIEMENS ENERGY INC

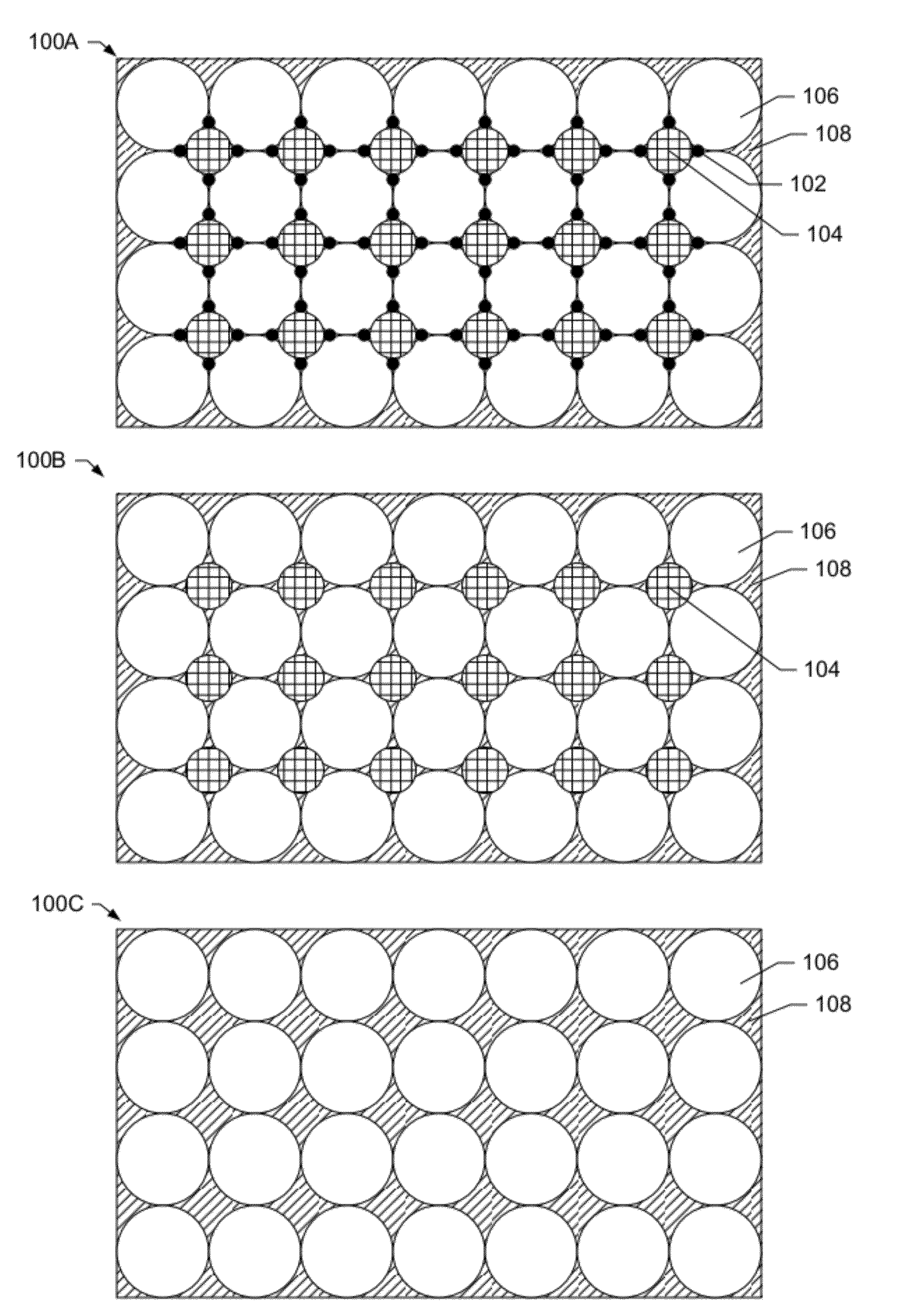

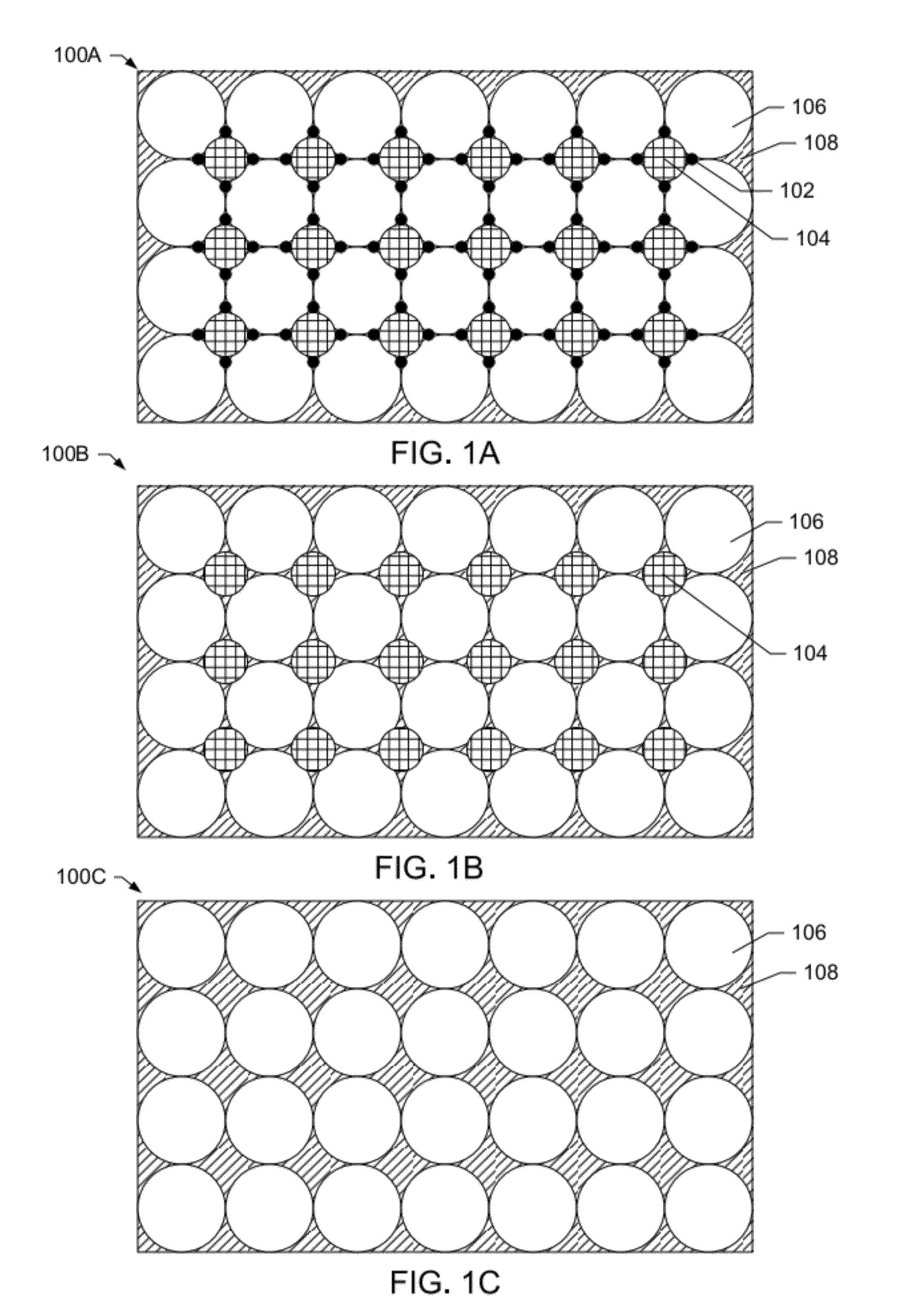

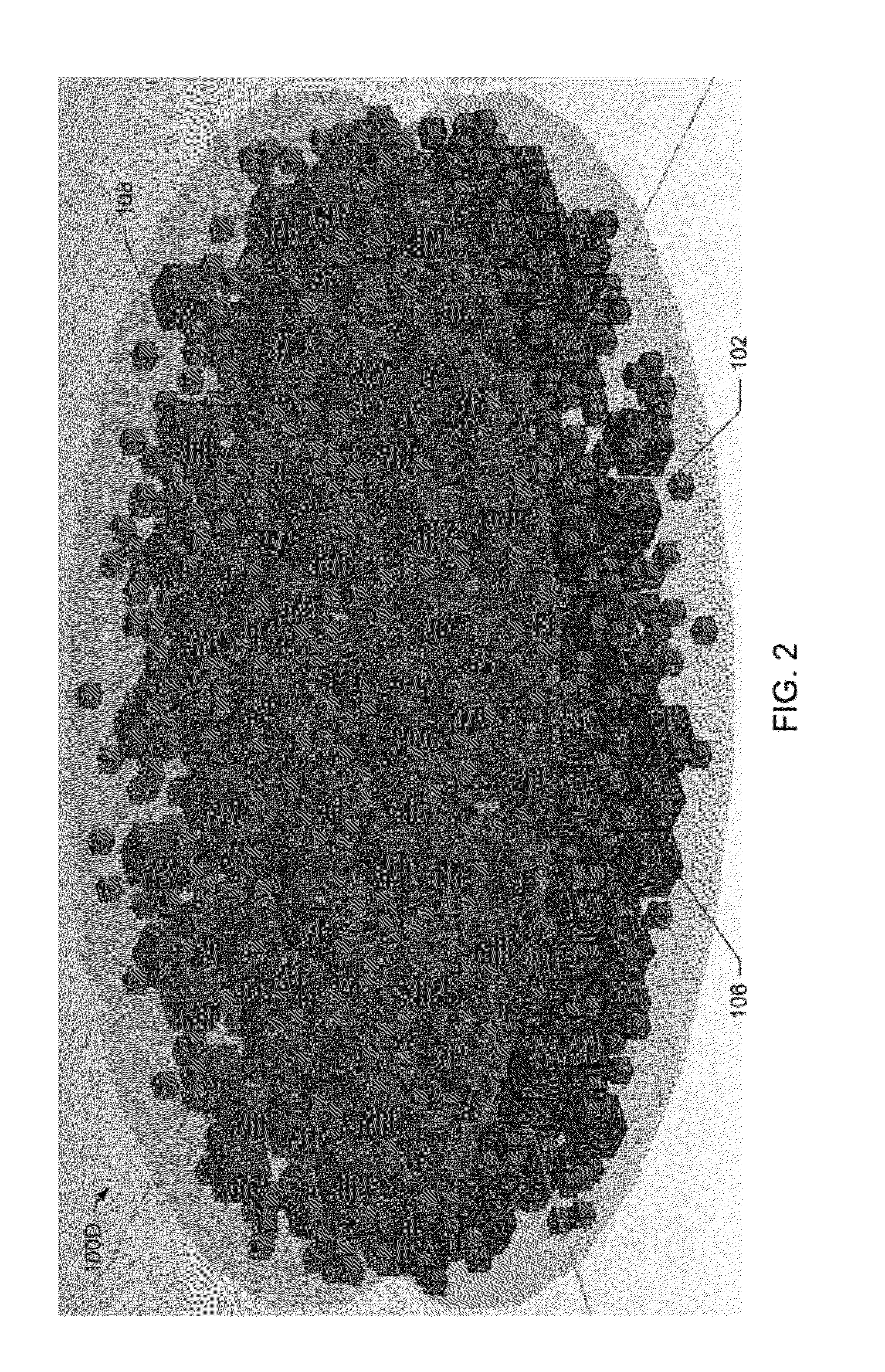

High dielectric constant composite materials and methods of manufacture

ActiveUS20120245016A1High composite strengthHigh dielectric constantMaterial nanotechnologyLiquid surface applicatorsBarium strontium titanateBarium titanate

The present invention relates to composite materials with a high dielectric constant and high dielectric strength and to methods of producing the composite materials. The composite materials have high dielectric constants at a range of high frequencies and possess robust mechanical properties and strengths, such that they may be machined to a variety of configurations. The composite materials also have high dielectric strengths for operation in high power and high energy density systems. In one embodiment, the composite material is composed of a trimodal distribution of ceramic particles, including barium titanate, barium strontium titanate (BST), or combinations thereof and a polymer binder.

Owner:UNIVERSITY OF MISSOURI

Low Temperature Co-Fired Ceramic (LTCC) Tape Compositions, Light-Emitting Diode (LED) Modules, Lighting Devices and Methods of Forming Thereof

The present invention provides LTCC (low temperature co-fired ceramic) tape compositions and demonstrates the use of said LTCC tape(s) in the formation of Light-Emitting Diode (LED) chip carriers and modules for various lighting applications. The present invention also provides for the use of (LTCC) tape and LED modules in the formation of lighting devices including, but not limited to, LED devices, High Brightness (HB) LED backlights, display-related light sources, automotive lighting, decorative lighting, signage and advertisement lighting, and information display lighting.

Owner:EI DU PONT DE NEMOURS & CO

Semiconductor ceramic with negative resistance temperature coefficient and negative temperature coefficient thermistor

InactiveCN1348192ALittle change in characteristicsInhibit swellingCeramicsNegative temperature coefficient thermistorsElectrical resistance and conductanceNegative temperature

A semiconductor ceramic having a negative temperature coefficient of resistance, the element comprising about 0.1 to 20 mol % of AMnO3 (A represents at least one of Ca, Sr, Ba, La, Pr, Nd, Sm, Eu, Gd, Th, Dy and Ho) and to a spinel composite oxide made of a solid solution of Mn and at least one element in Ti, V, Cr, Fe, Co, Ni, Cu, Zn, Mg and Al. As a perovskite Mn composite oxide, one or more of CaMnO3, SrMnO3, BaMnO3, LaMnO3, PrMnO3, NdMnO3, SmMnO3, EuMnO3, GdMnO3, TbMnO3, DyMnO3 and HoMnO3 may be used.

Owner:MURATA MFG CO LTD

Low-temperature sintering Ti-base microwave medium ceramic material and preparation thereof

InactiveCN101186496ALower sintering temperatureHigh dielectric constantCeramicsMicrowaveDielectric loss

The invention discloses a Ti-based microwave medium ceramics material by low-temperature sintering. The Ti-based microwave medium ceramics material takes rutile TiO2 as a main phase. The general formula of the prescription of the invention is that: (AxM2x)(NyTi1-y)1-3xO2, (BxM3x)(NyTi1-y)1-4xO2, (CxMx)(NyTi1-y)1-2xO2 or (1-m) TiO2-mBi2Ti4O11, wherein, the A is one of bivalent ions such as Zn<2+>, Cu<2+>, Ni<2+>, the B one of univalent ions such as Li<+>, the C one of trivalent ions such as Al<3+>, Fe<3+>, M is one of pentavalent ions such as Nb<5+>, Ta<5+>, Sb<5+>, N one of quadrivalent ions such as Zr< 4+ >, Sn< 4+ >, Mn< 4+ >; the X is more than or equal to 0 and less than or equal to 0.25, the Y more than or equal to 0 and less than or equal to 0.5, the m more than or equal to 0 and less than or equal to 0.15, the n is more than or equal to 0 and less than or equal to 2. The microwave medium ceramics material by low-temperature sintering has the advantages of high dielectric constant, low dielectric loss, wide covering range of temperature coefficient of resonant frequency, low sintering temperature, simple preparation technique and adjustable temperature coefficient of resonant frequency according to materials. The invention can be used for Low Temperature Co-fired Ceramics System (LTCC system) and used for producing microwave devices such as multi-media resonators, filters, etc.

Owner:XI AN JIAOTONG UNIV

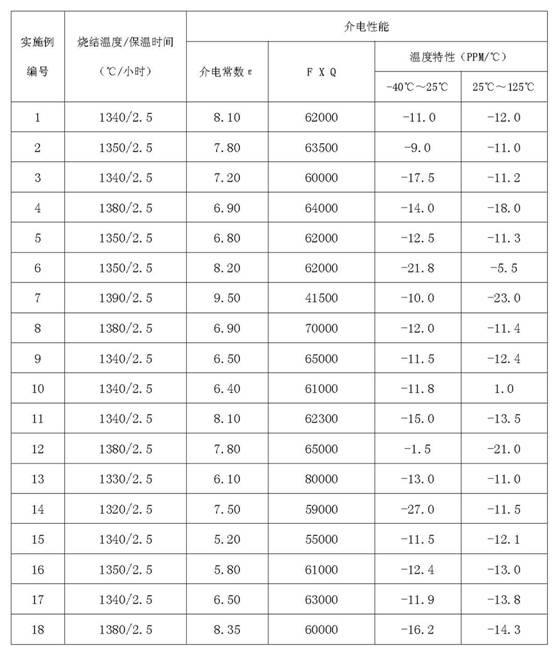

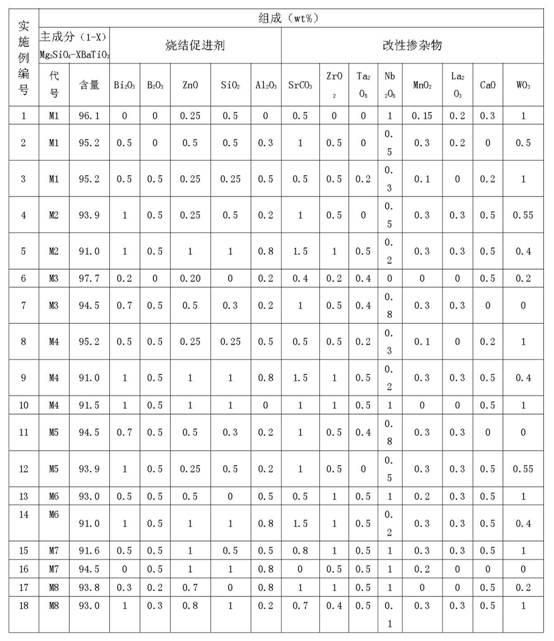

Low-dielectric constant microwave ceramic dielectric material and preparation method thereof

This invention provides a microwave ceramic dielectric material with a low dielectric constant [epsilon]r of 3-8 and a preparation method thereof, and the material is composed of (1-X)Mg2SiO4-XBaTiO3 as a main component, a modification adulterant and a sintering promoter. 1) The said major constituent is a (1-X)Mg2SiO4-XBaTiO3 solid solution, wherein the X=0.001-0.25; 2) The said modification adulterant comprises one or a mixture of more than one of SrCO3, ZrO2, Ta2O5, Nb205, MnO2, CaO, La2O3 and WO3; 3) The said sintering promoter comprises low-melting oxides such as Bi2O3, B2O3, ZnO, SiO2, Al2O3 and Nb2O5,and one or more kinds of the glass powder with a low melting point. After reasonably reasonable formulation, optimizing synthesis and ball milling, the microwave medium material prepared from the method can be sintered at a relatively low temperature of 1340 DEG C to 1380 DEG. C.A microwave capacitor made by this method has an excellent dielectric property: [epsilon]r=3-8>Qf) 60000GHZ, [epsilon] f(-40DEG C. -25DEG C. / 25 DEG C-125 DEG C)<=20PPM / DEG C.

Owner:XIAMEN SUNYEAR ELECTRONICS CO LTD

Medium low temperature sintered high voltage ceramic capacitor medium

InactiveCN1619726ALow costNo pollution in the processFixed capacitor dielectricCeramicsCapacitanceLithium

A formula for medium of intermediate and low temperature sintering high voltage ceramic capacitor is (by weight) BaTiO3 60-90%, SrTiO3 1-20%, CaZrO3 0.1-10%, Nb2O5 0.01-1%, MgO 0.01-1%, CeO2 0.01-0.8%, ZnO 0.01-0.6%, Co2O3 0.03-1%, bismuth lithium solid solution 0.05-10% wherein the BaTiO3, SrTiO3 and CaZrO3 are synthesized from conventional chemical material by solid phase method. Said medium is no lead, no cadmic and no toxicity sintered at 1100-1150 degree centigrade with greater than 6.0 KV / mm of voltage resisting, 2000-3000 dielectric constant etc properties.

Owner:JIANGSU UNIV

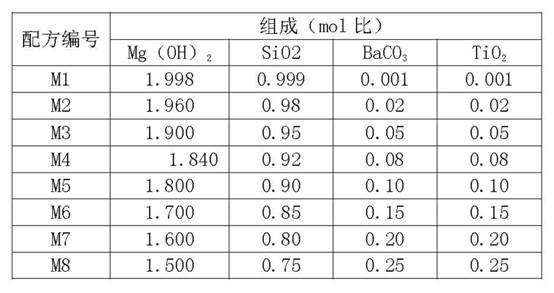

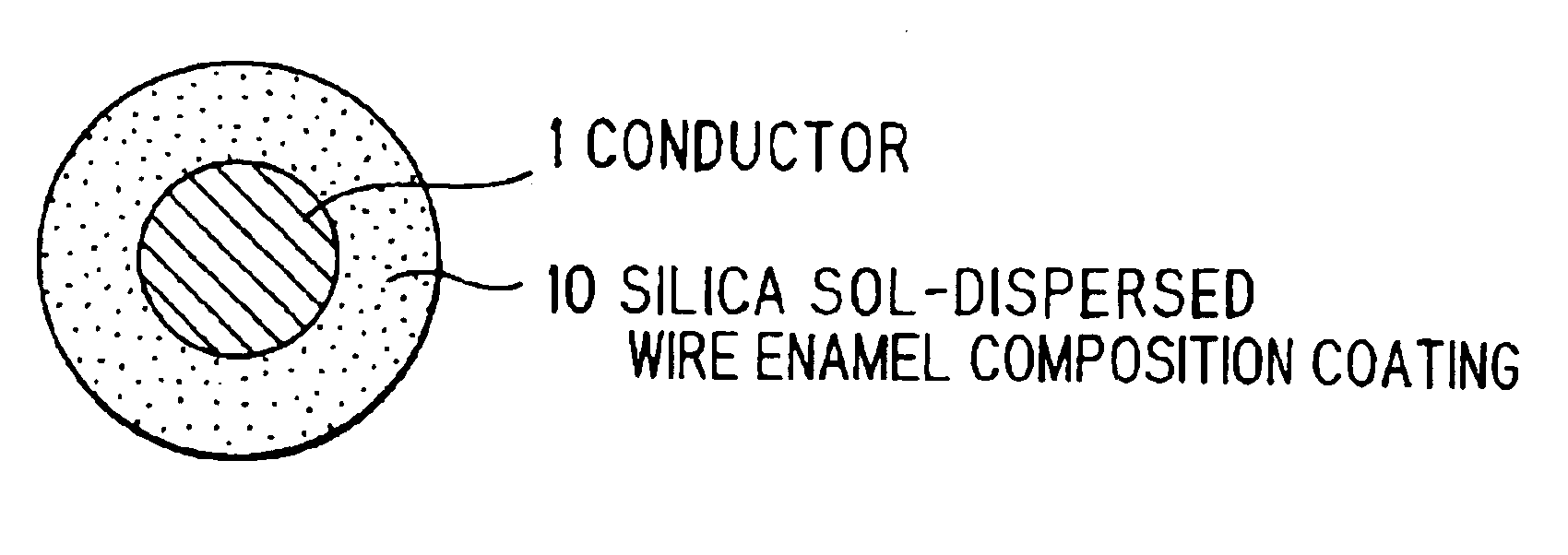

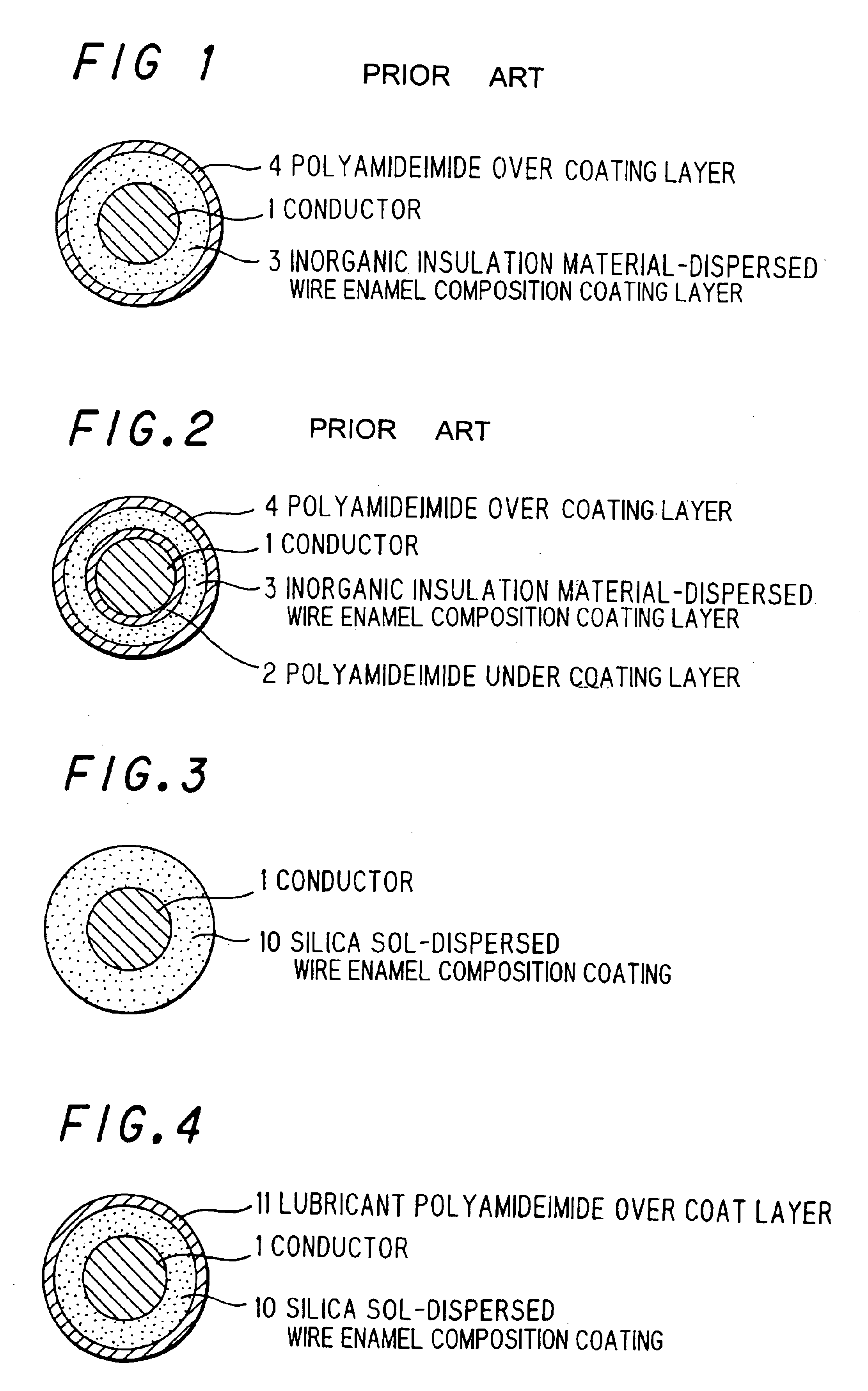

Partial discharging-resistant wire enamel composition and partial discharging-resistant magnet wire

Owner:HITACHI METALS LTD

Electroluminescence wire

InactiveCN1798459AIncrease brightnessWith repeated useElectroluminescent light sourcesCeramicsDielectric layerLight-emitting diode

The invention consists of a baseline body, a metal decorating layer covering on outside of the baseline body, a dielectric layer covering on the metal decorating layer, a light emitting layer covering on the dielectric layer, a transparent conducting layer covering on the light emitting layer and connected to an out-guard wire. All layers are sealed by fluoroplast.

Owner:SHANGHAI KERUN PHOSPHOR TECH

Microwave dielectric ceramic material and preparation method thereof

The invention provides a microwave dielectric ceramic material and a preparation method thereof, belonging to the technical field of electronic materials. The microwave dielectric ceramic material comprises the following components in percentage by mass: 25-35% of MgO, 60-68% of TiO2, 1-10% of CaO, 0-2% of SiO2, 0-2% of MnO2, 0-2% of Nb2O5 and 0-2% of CeO2; the microwave dielectric ceramic material is prepared by proportioning the MgO, TiO2, CaO, SiO2, MnO2, Nb2O5 and CeO2 according to the mass percentage of each component; performing ball milling and mixing; pre-calcining a mixture at a temperature in a range of 1050-1200 DEG C and sintering the mixture at the temperature in a range of 1250-1360 DEG C. In the invention, the microwave dielectric ceramic material is prepared by utilizing atraditional solid-phase sintering method, the process is simple and the cost is low; according to the prepared microwave dielectric ceramic material, the Q*f value is in a range of 63,000-83,000 GHz,the relative dielectric constant epsilon r is in a range of 20-22, and the temperature coefficient of resonance frequency is within + / -10 ppm / DEG C, so that the preparation requirements of a high-performance microwave device can be met.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

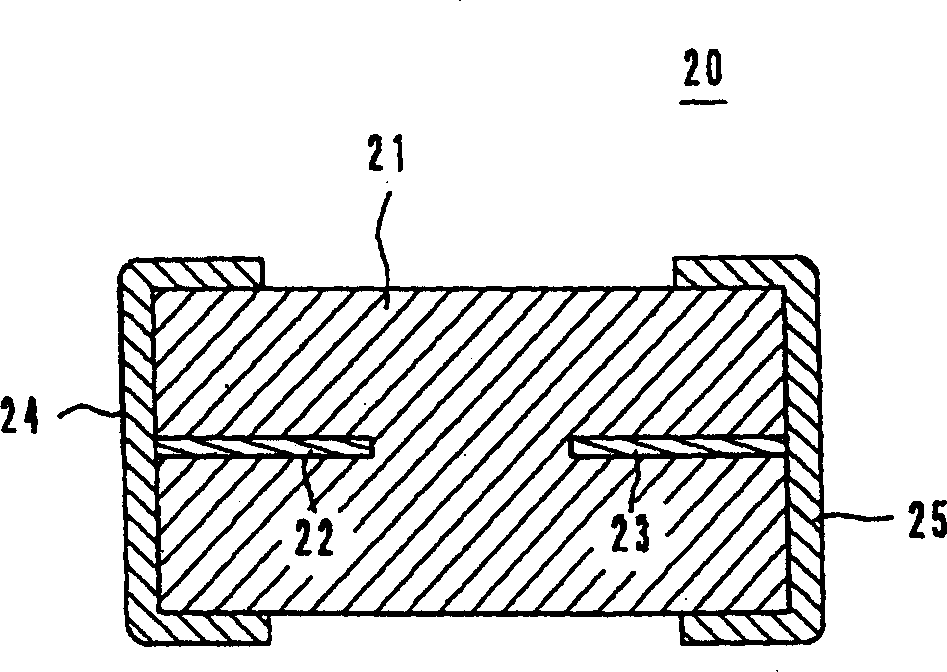

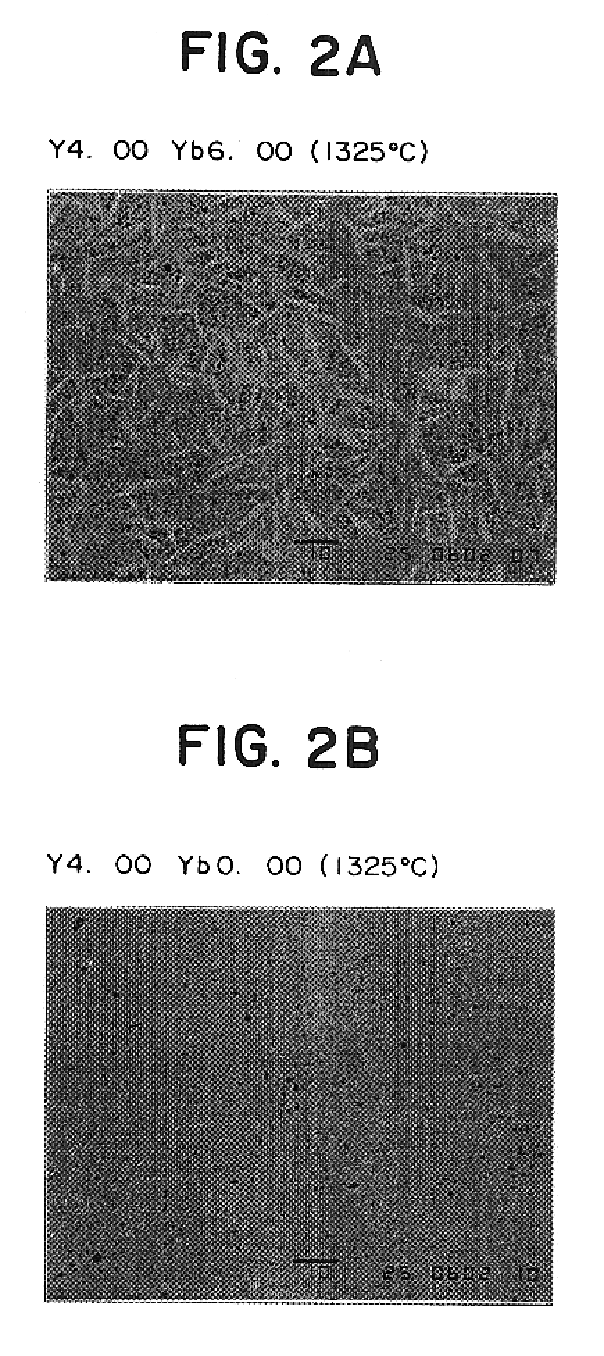

Dielectric ceramic composition and electronic device

InactiveUS6699809B2Increase resistanceHigh strengthFixed capacitor dielectricCeramicsMaterials scienceOxide

A dielectric ceramic composition including a dielectric base phase containing BaTiO3 as a main component, and plate-shaped or acicula deposition phase existing together in the dielectric base phase. Preferably, the dielectric ceramic composition includes a main component of BaTiO3, a first subcomponent including at least one compound selected from MgO, CaG, BaG, SrO and Cr2O3, a second subcomponent of (Ba, Ca)xSiO2+x (where, x=0.8 to 1.2), a third subcomponent including at least one compound selected from V2O5, MoO3, and WO3, and a fourth subcomponent including an oxide of R1 (where R1 is at least one element selected from Sc, Er, Tm, Yb, and Lu), a fifth subcomponent including an oxide of R2 (where R2 is at least one element selected from Y, Dy, Ho, Tb, Gb and Eu), wherein the ratios of the subcomponents to 100 moles of the main component of BaTiO3 are first subcomponent of 0.1 to 3 moles, second subcomponent of 2 to 10 moles, third subcomponent of 0.01 to 0.5 mole, fourth subcomponent of 0.5 to 7 moles, and fifth subcomponent of 2 to 9 moles (where the number of moles of the fourth and fifth subcomponents are respectively the ratio of R1 and R2 alone).

Owner:TDK CORPARATION

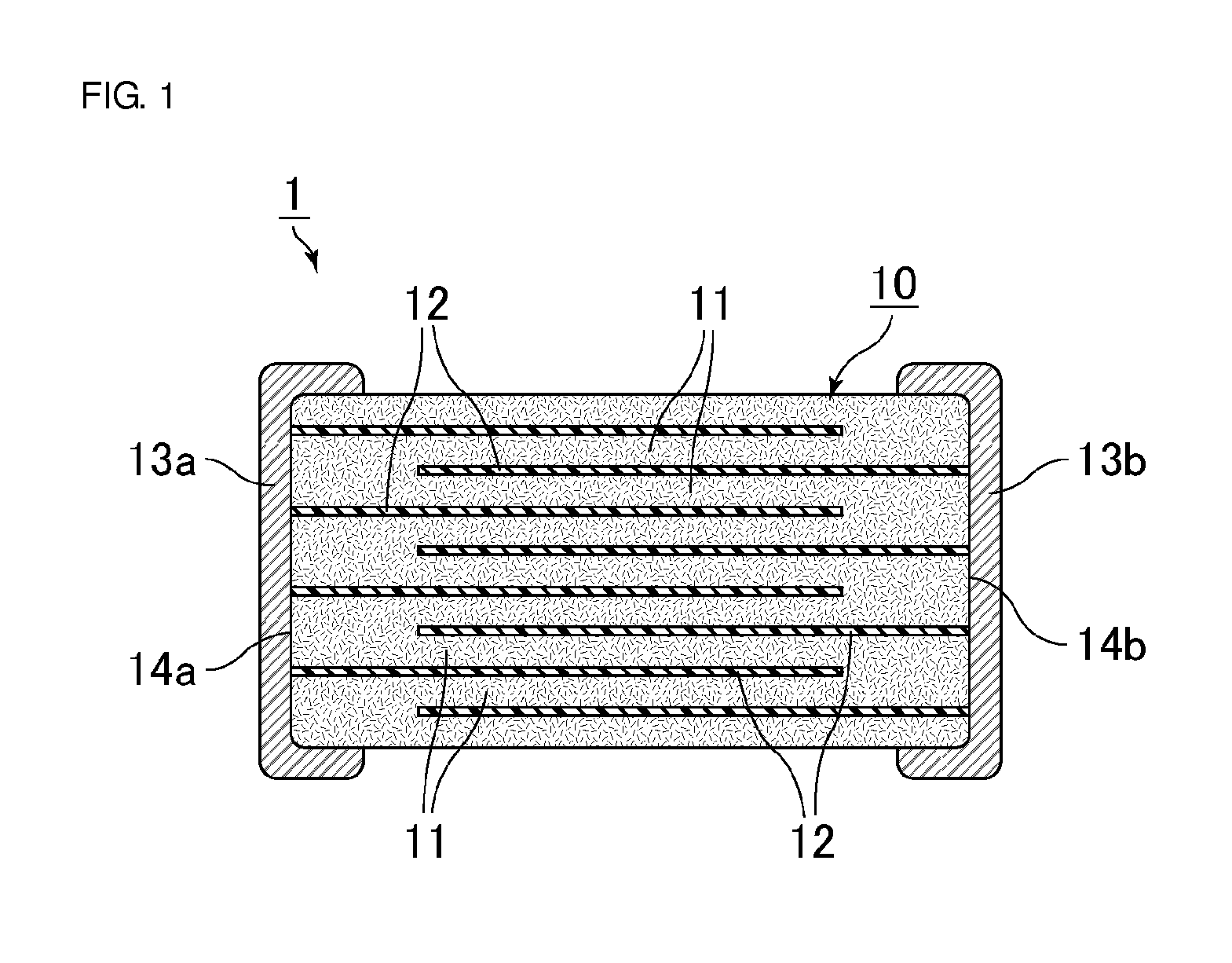

Dielectric ceramic and multilayer ceramic capacitor using the same

ActiveUS20090207551A1Increased Curie temperatureSmooth changeAlkaline earth titanatesFixed capacitor dielectricDielectricCeramic capacitor

A dielectric ceramic is provided which is can be stably used for a multilayer ceramic capacitor even at a high temperature of approximately 175° C. The dielectric ceramic includes a perovskite type compound represented by the composition formula (B1-x-yCaxSny)m(Ti1-zZrz)O3 (where x, y, z, and m satisfy 0≦x≦0.20, 0.02≦y≦0.20, 0≦z≦0.05, and 0.990≦m≦1.015, respectively) as a primary component; and RE as an accessory component (where RE is at least one selected from the group consisting of Y, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, and Lu), wherein 0.5 to 20 molar parts of RE is contained with respect to 100 molar parts of the primary component.

Owner:MURATA MFG CO LTD

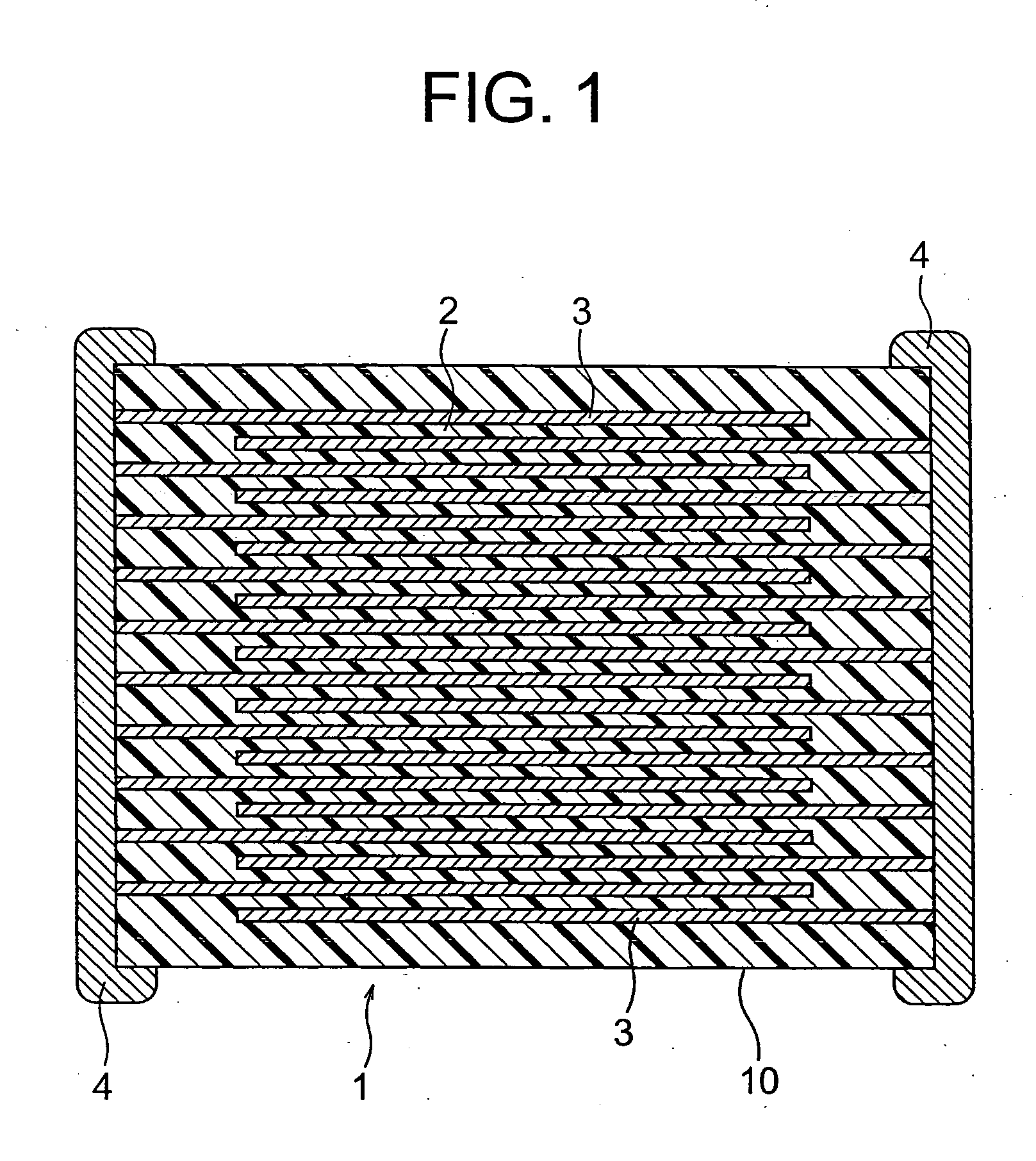

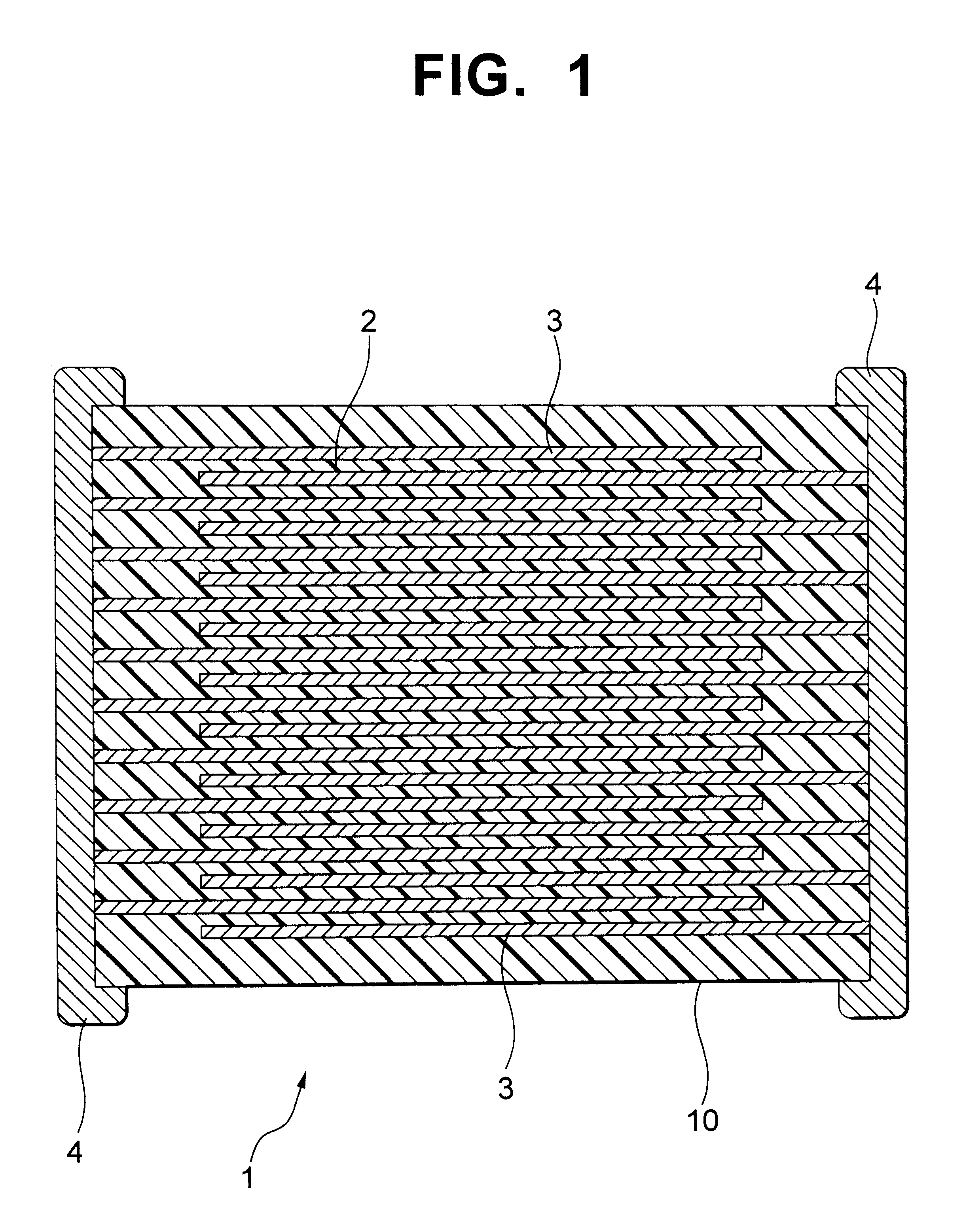

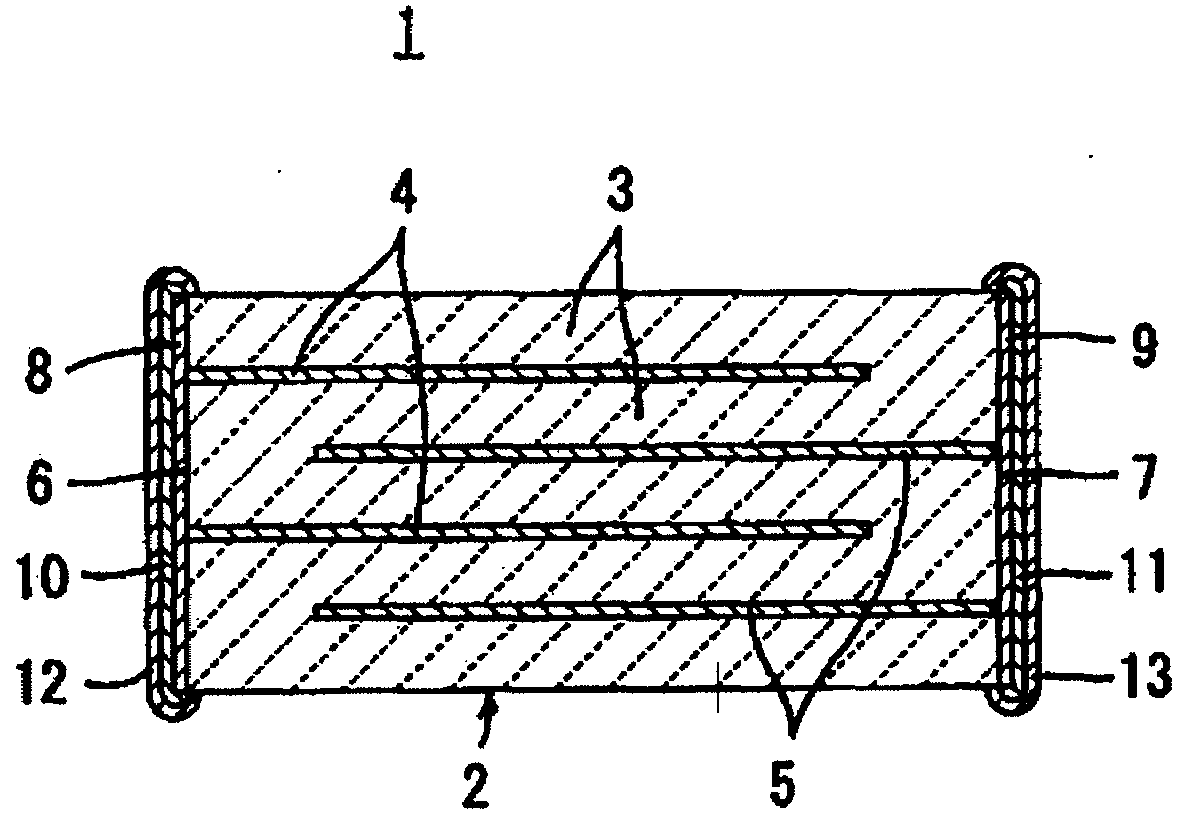

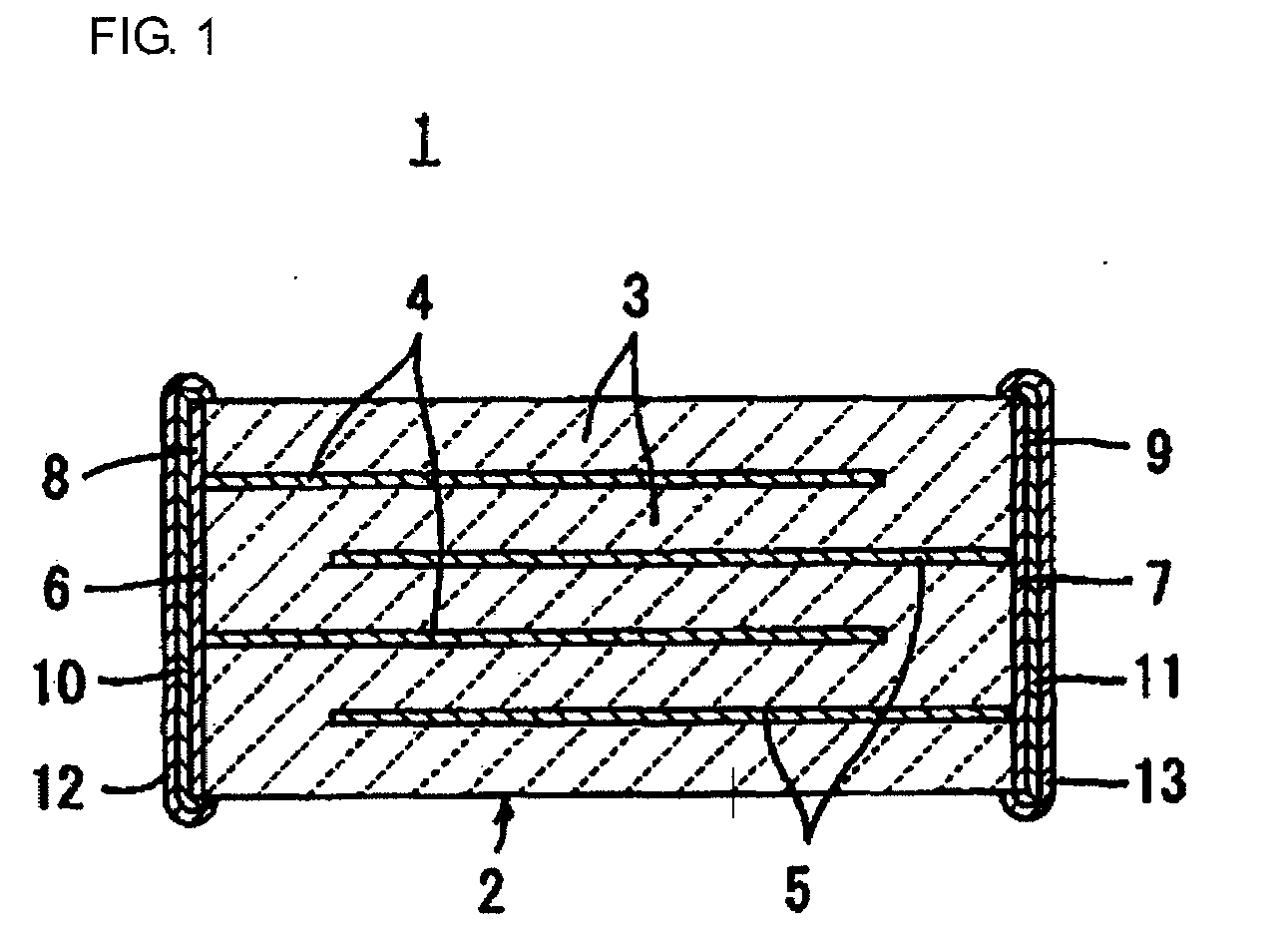

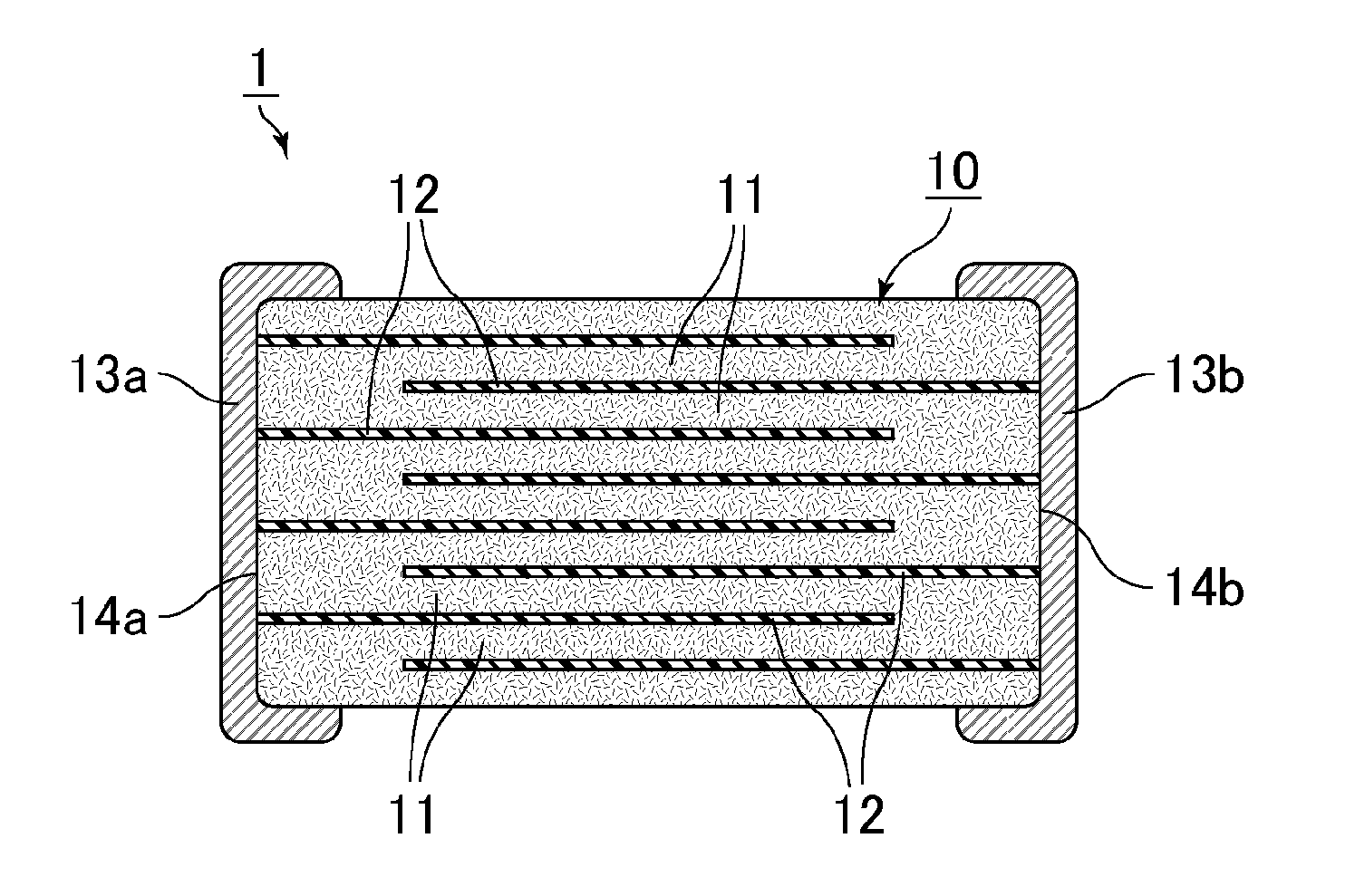

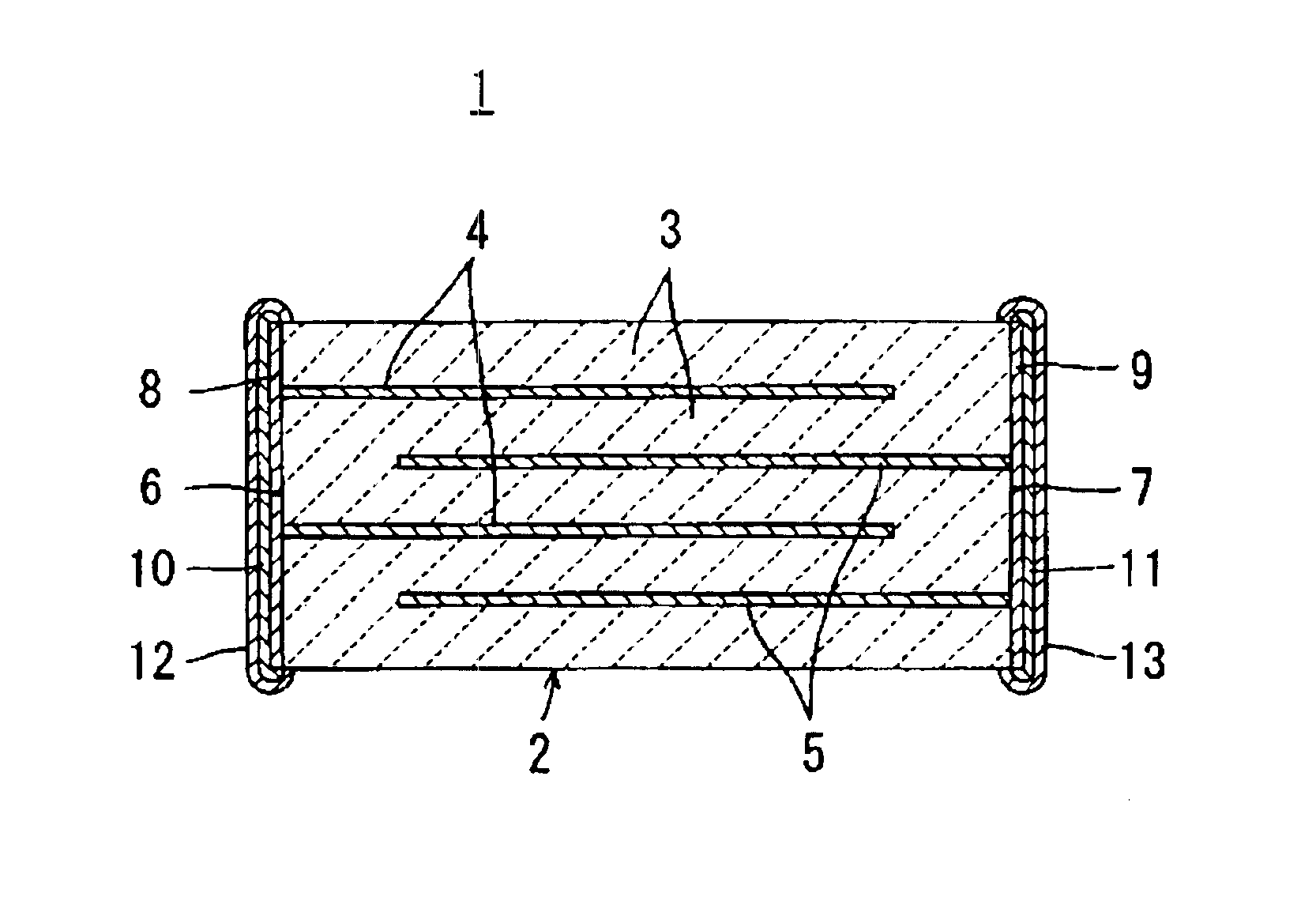

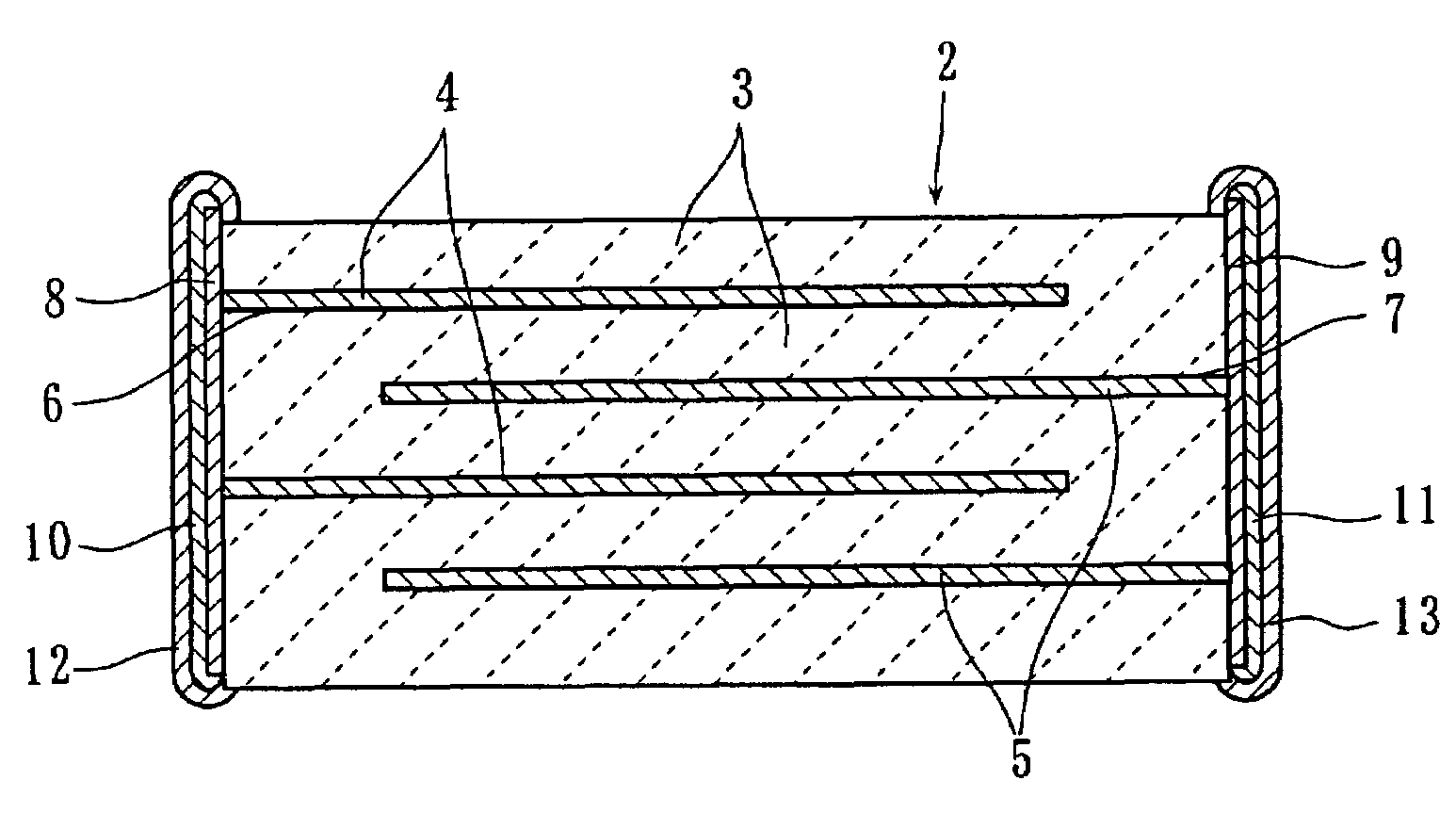

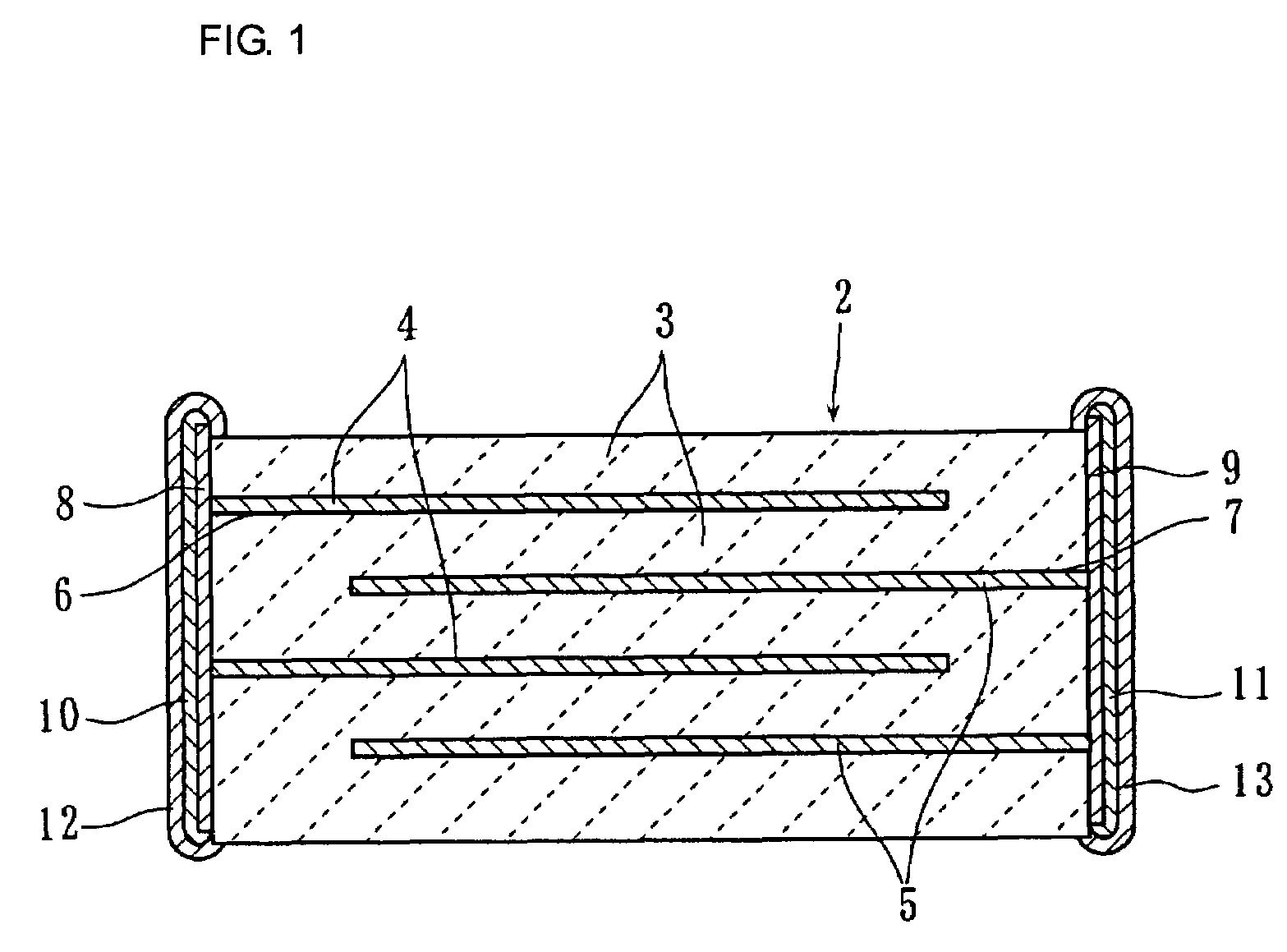

Multilayer ceramic capacitor and method for producing multilayer ceramic capacitor

ActiveUS20160155570A1Prevent movementImprove reliabilityFixed capacitor electrodesFixed capacitor dielectricDielectricCeramic capacitor

A multilayer ceramic capacitor includes a multilayer body including dielectric ceramic layers and inner electrode layers containing Ni and electrically connected to outer electrodes. The dielectric ceramic layers contain a Ba- and Ti-containing perovskite compound, Ca, Mg, R (at least one rare earth metal selected from La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, and Y), M (at least one selected from Zr, Mn, Co, Fe, Cr, Cu, Al, V, Mo, and W), and Si. The number of parts by mole of each element relative to Ti as 100 parts is as follows:Ca, approximately 0.10 to 5.00 parts;Mg, approximately 0.0010 to 0.0098 parts;R in total, approximately 0.50 to 4.00 parts;M in total, approximately 0.10 to 2.00 parts; andSi, approximately 0.5 to 2.0 parts.

Owner:MURATA MFG CO LTD

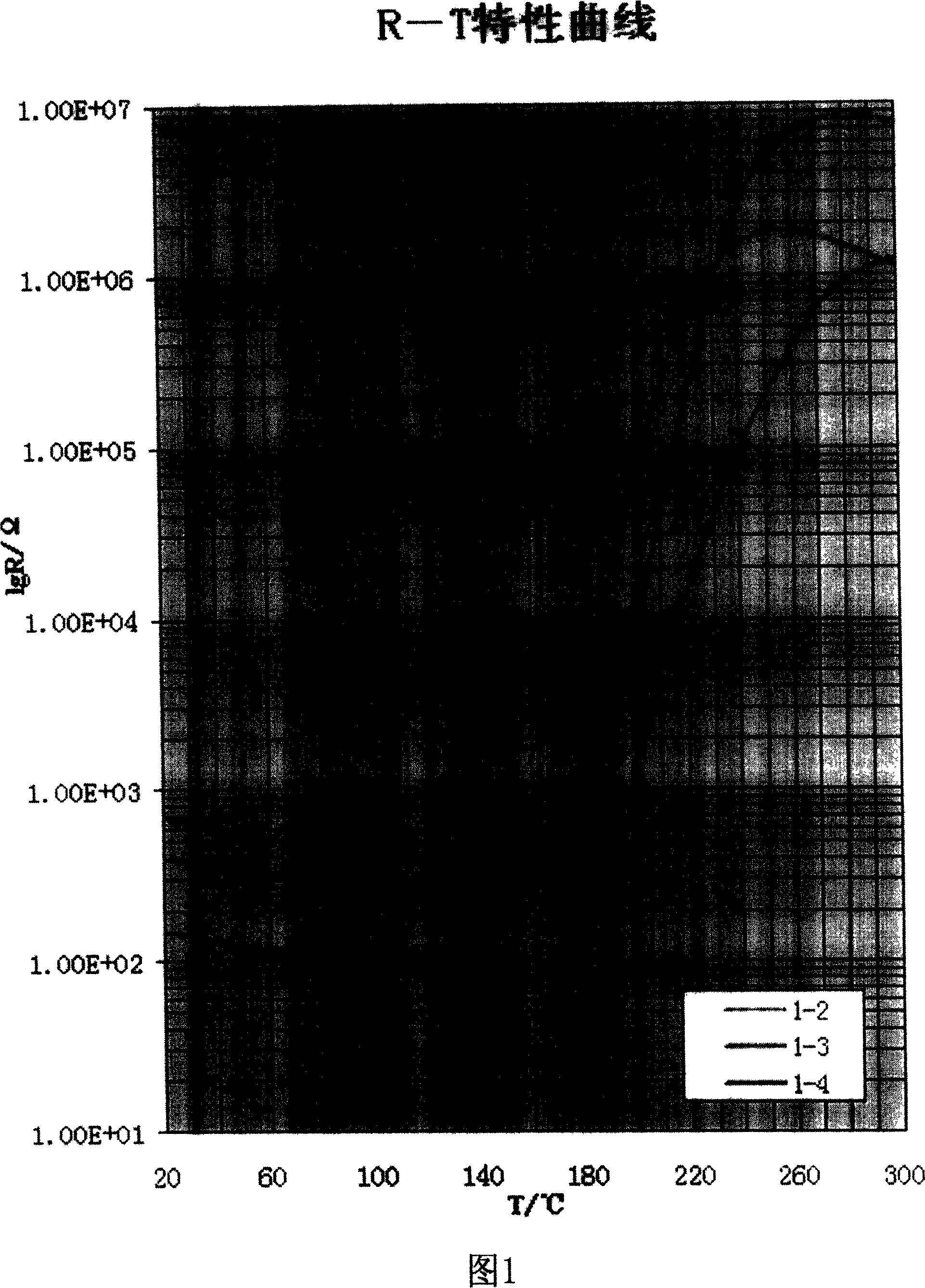

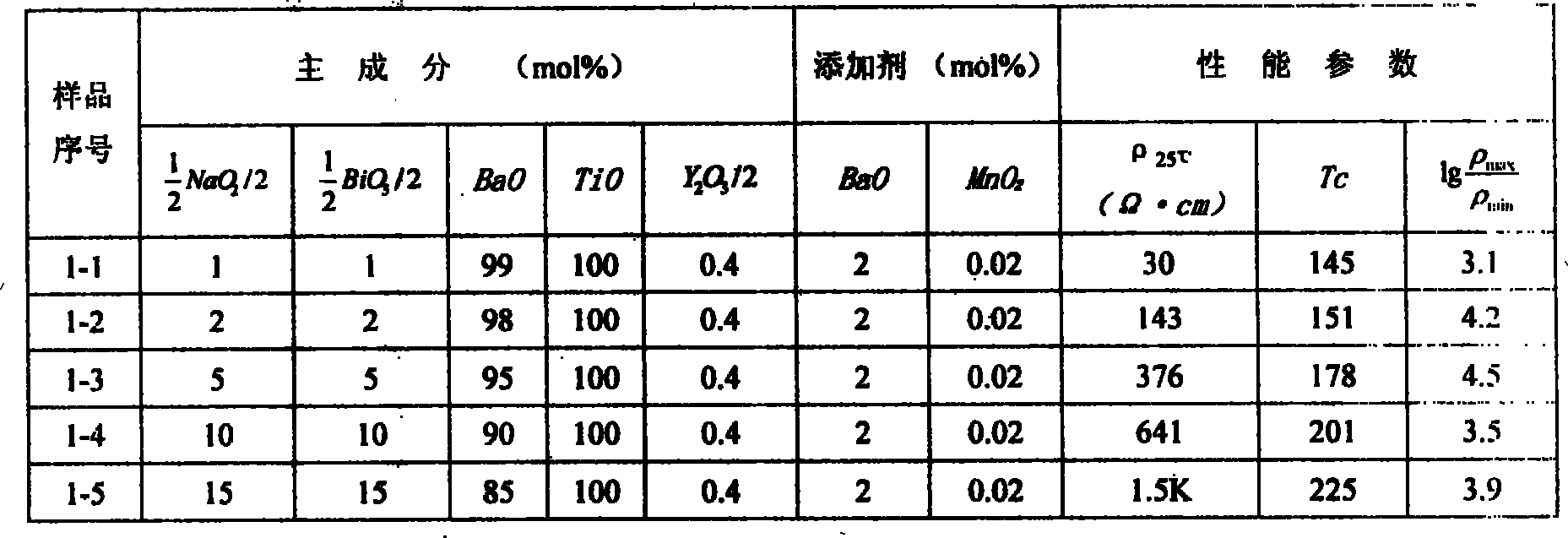

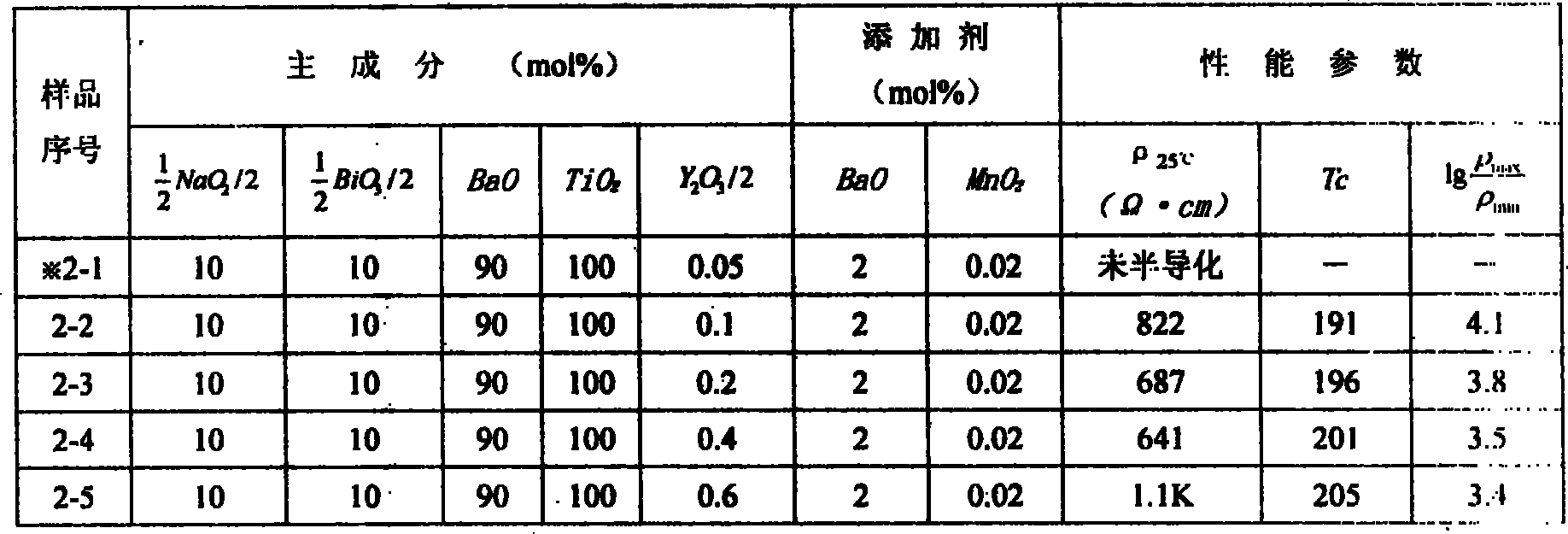

Leadless PTC thermistor material with high Curie point

InactiveCN101013618AAchieve lead-freeAchieve semiconductingCeramicsOxide conductorsElectrical resistance and conductanceSemiconductor materials

The invention relates to one semi-conductor materials to realize semi-conductive process meeting the high Curie piezoelectricity ceramics materials without lead, which comprises the following parts: (Na1 / 2Bi1 / 2)x(Ba1-x-y+z)TiO3+yM1+zM2O+0.02MnO2mol%, wherein, x=0.01-0.15; y=0.001-0.006; z=0.005-0.05; M1=0.0001-0.006; M2=0.005-0.05; Formula comprises micro semi-conductive element and additive components.

Owner:杨敬义 +1

Dielectric material for thermostable laminated ceramic capacitor with basic-metal inner electrode

InactiveCN1404080AImprove uniformityImprove performanceFixed capacitor dielectricCeramicsDielectric lossCeramic capacitor

The present invention is material for laminated ceramic capacitor with high temperature stability and basic material inner electrodes. The inner electrode is made of low cost metal, such as Ni, Cu and their alloy. The dielectric material comprises BaTiO3 as main component, and additives in cludes CaO, CaTiO3, BaO, SiO2, SrO2, MnO2, MgO, Co2O3, Co3O4, Fe2O3 and Y2O3 as well as one or more RE oxide and salt in certain proportion and is prepared through mixing, sintering in reducing atmosphere of mixed nitrogen and hydrogen. The dielectric has excellent performance, including room temperature dielectric constant of 2000-3000, etc. The material of the present invention is suitable for producing great capacity superthin laminated ceramic capacity with high insulating resistivity and stable performance.

Owner:TSINGHUA UNIV

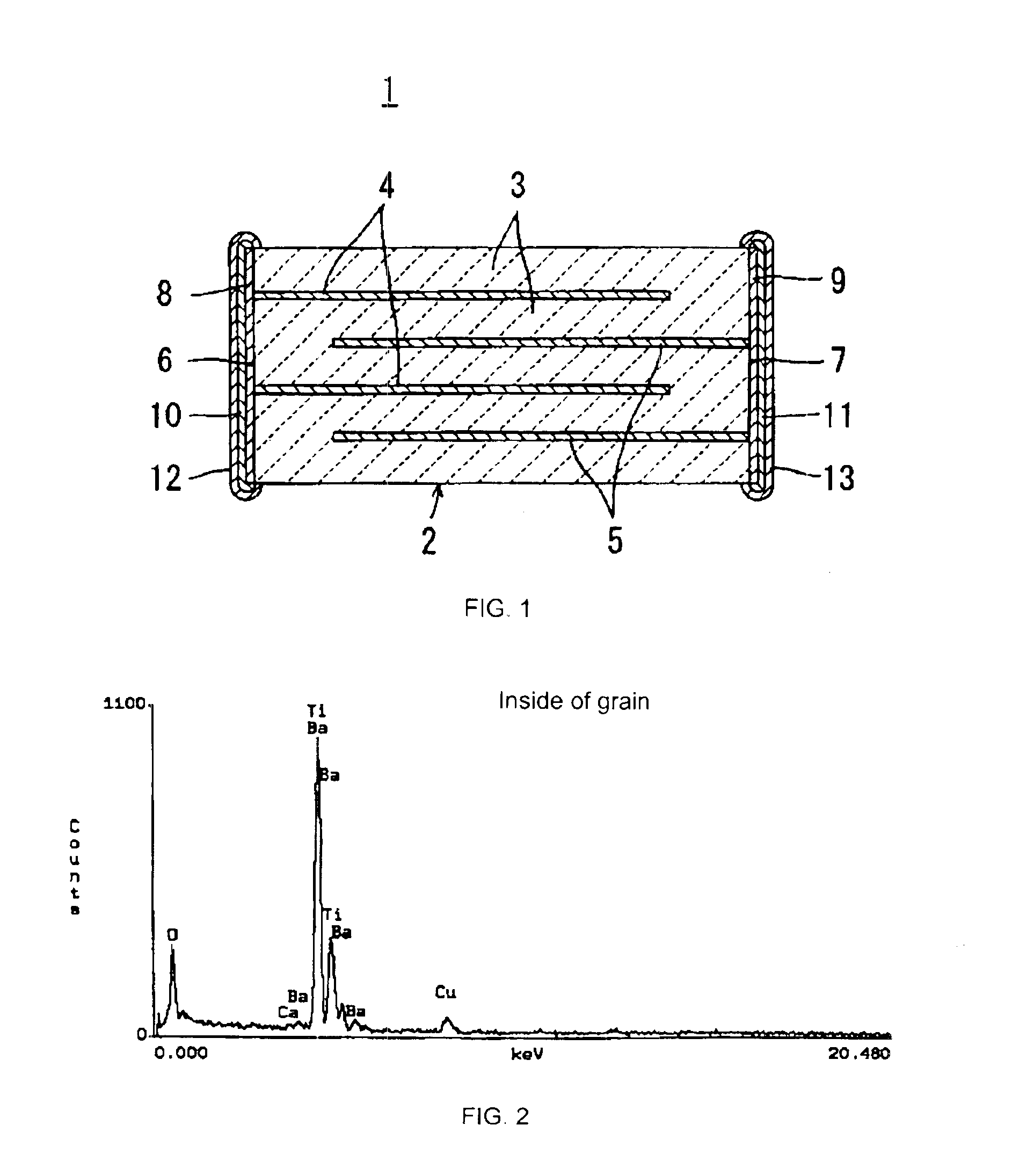

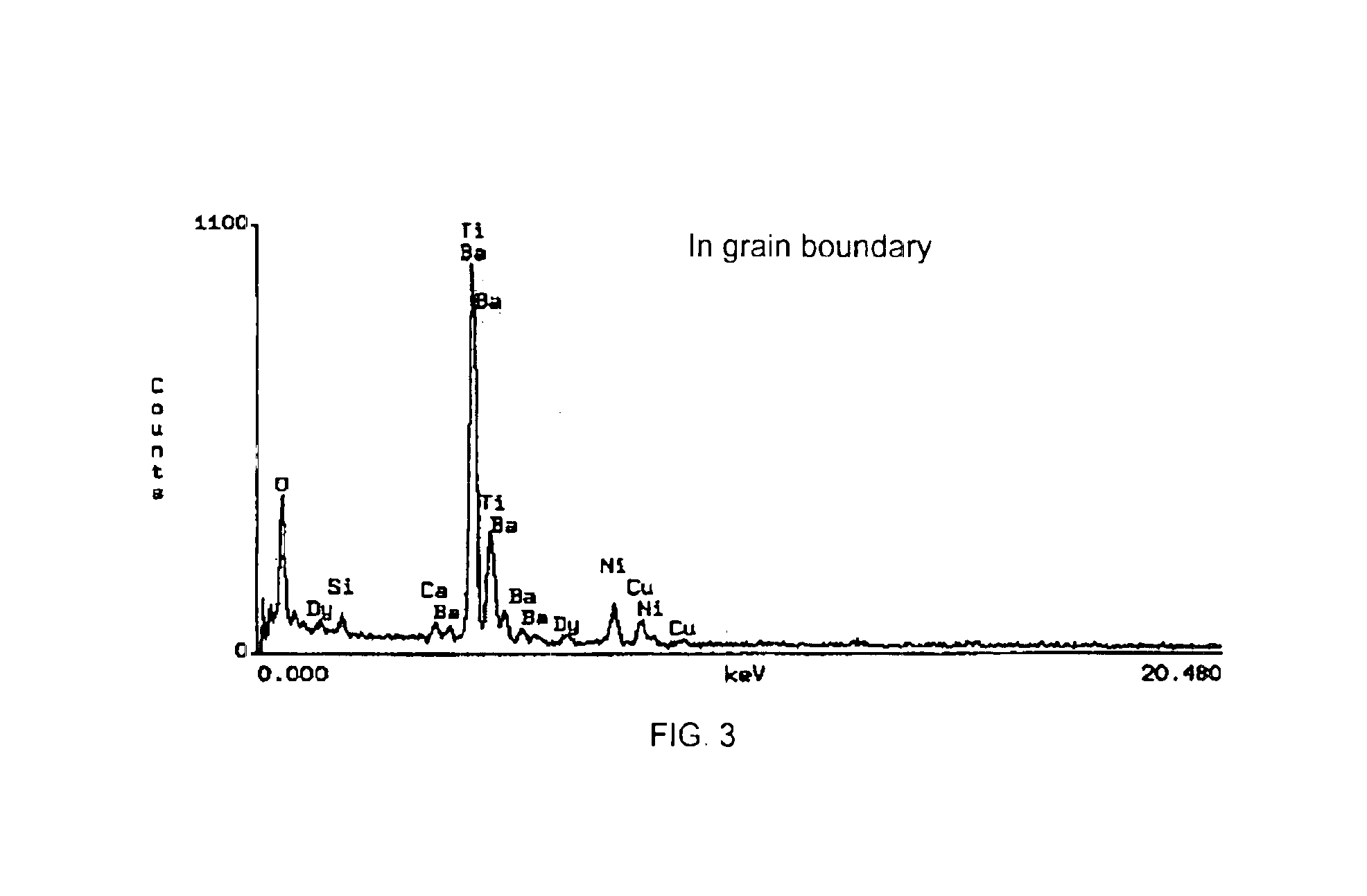

Dielectric ceramic, method of producing the same, and monolithic ceramic capacitor

ActiveUS6853536B2Improve reliabilityProduced easily and securelyFixed capacitor dielectricStacked capacitorsDielectric ceramicsCeramic capacitor

A dielectric ceramic includes, in composition, a perovskite-type compound having the general formula ABO3 containing Ba, Ca and Ti, and an additive component containing Si, R(La or the like), and M (Mn or the like), the additive component not being solid-dissolved and, moreover, the major component existing in at least 90% of the cross-section of each of the crystal grains of which the number is equal to at least 85% of that of all of the crystal grains contained in the dielectric ceramic, at least the Ba, the Ca, the Ti, the Si, the R, and the M being contained at at least 85% of the analytical points in the crystal grain boundaries of the dielectric ceramic.

Owner:MURATA MFG CO LTD

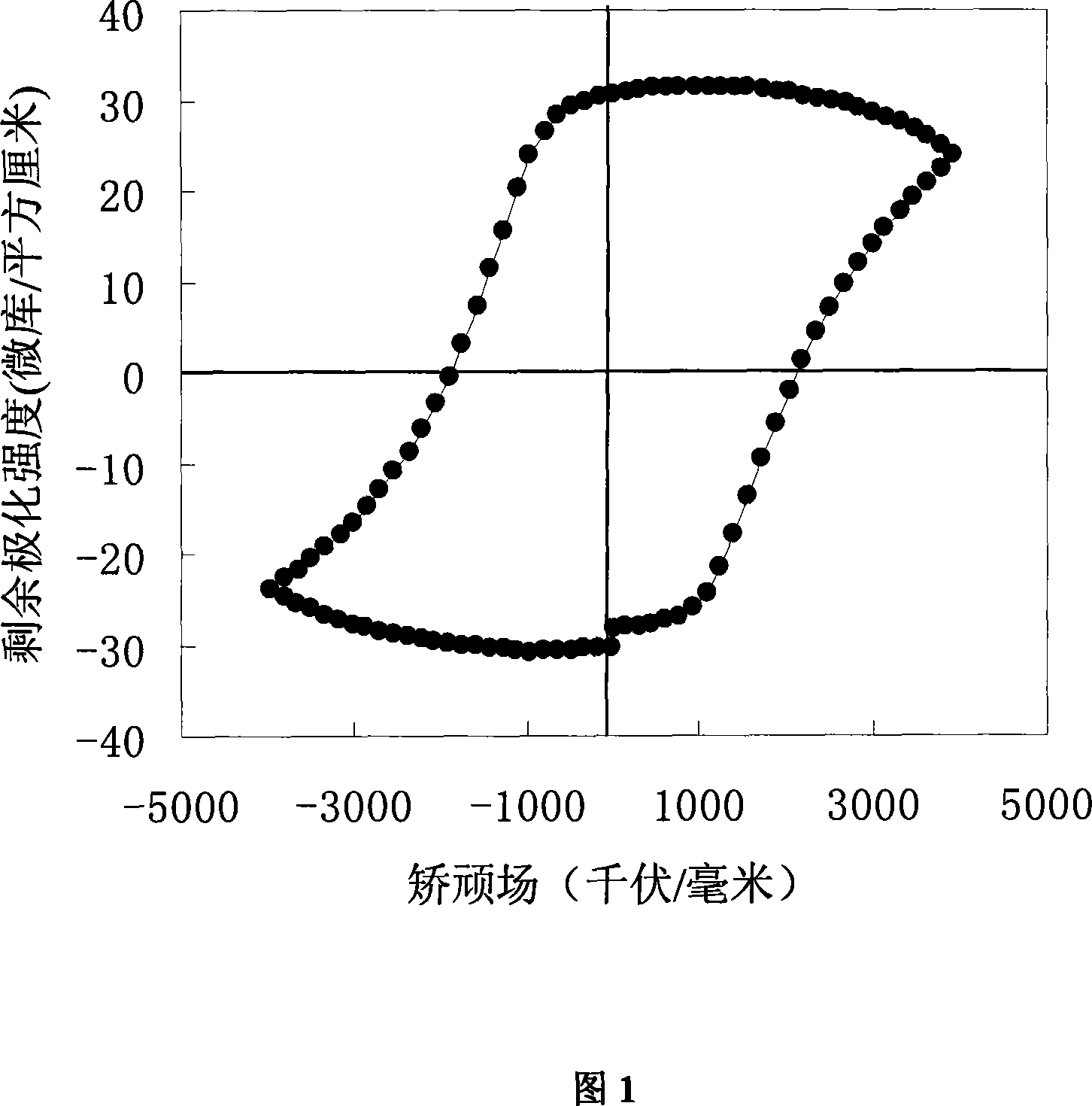

Niobic acid sodium potassium lithium radical leadless piezo-electric ceramic and preparation method thereof

InactiveCN101062864AExcellent piezoelectric propertiesImprove ferroelectric propertiesCeramicsPiezoelectric/electrostrictive/magnetostrictive devicesLithiumPotassium

The invention discloses a preparing method of niobic acid sodium potassium lithium group leadless piezoelectric ceramic in green energy source material domain, which comprises the following steps: expressing component of niobic acid sodium potassium lithium group as non-stoichiometric ratio general formula (NaaKbLic)(NbxTaySbz)O3 or -nM; expressing a, b, c as A bit element; expressing x, y, z as mole fraction of B bit element; setting the selective rage as (0<=a<=1. 5, 0<=b<=1. 5, 0 C04B 35 / 495 C04B 35 / 64 H01B 3 / 12 H01L 41 / 187 1 6 1 2007 / 5 / 28 101062864 2007 / 10 / 31 100465131 2009 / 3 / 4 2009 / 3 / 4 2009 / 3 / 4 University of Science and Technology Beijing Beijing 100083 Zhang Boping Zhao Pei Li Songjie Ding Xiaonian Zhang Hailong liuru e 11207 The Patent Agency of Beijing University of Science and Technology No.30 Xueyuan Road, Beijing 100083

Owner:UNIV OF SCI & TECH BEIJING

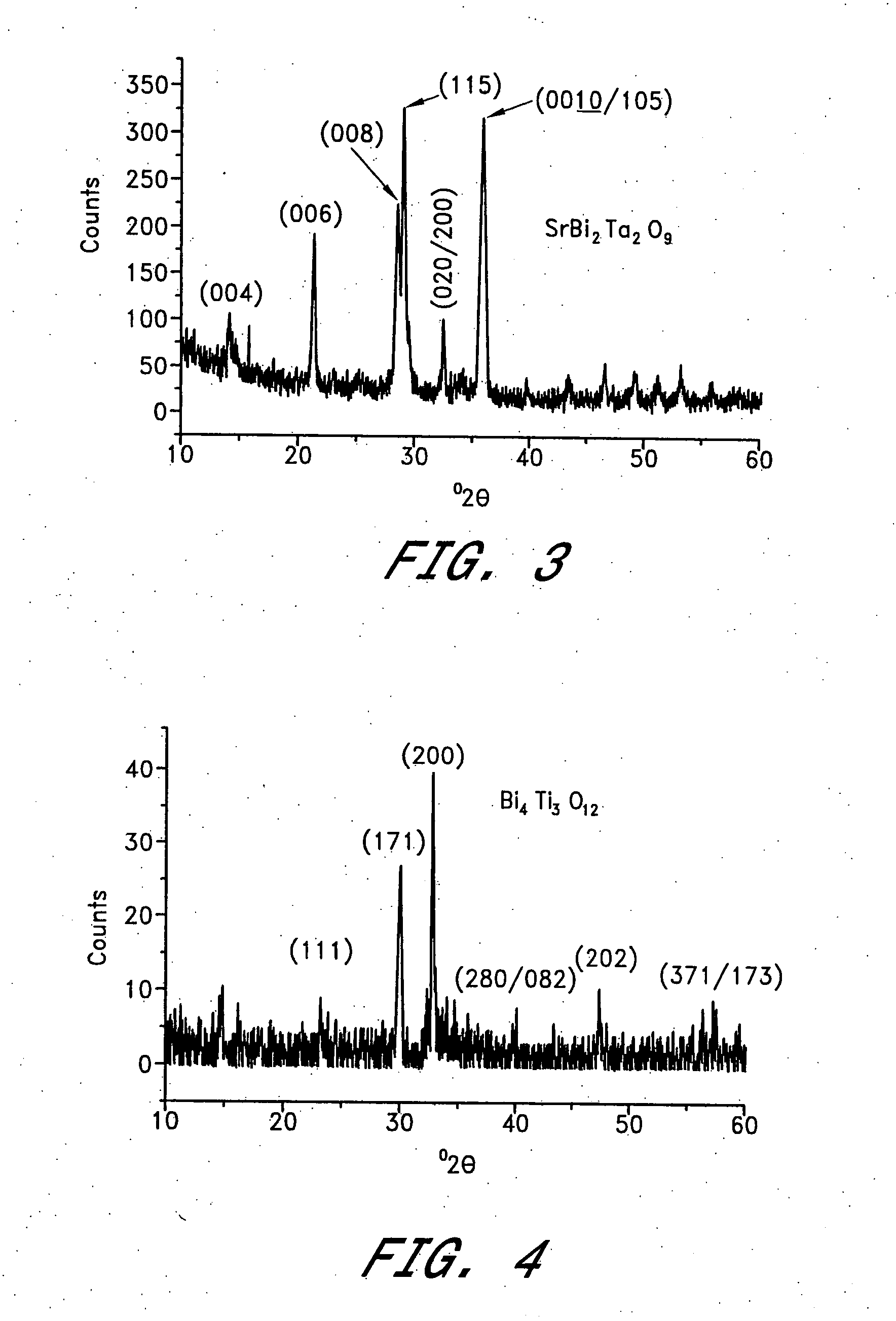

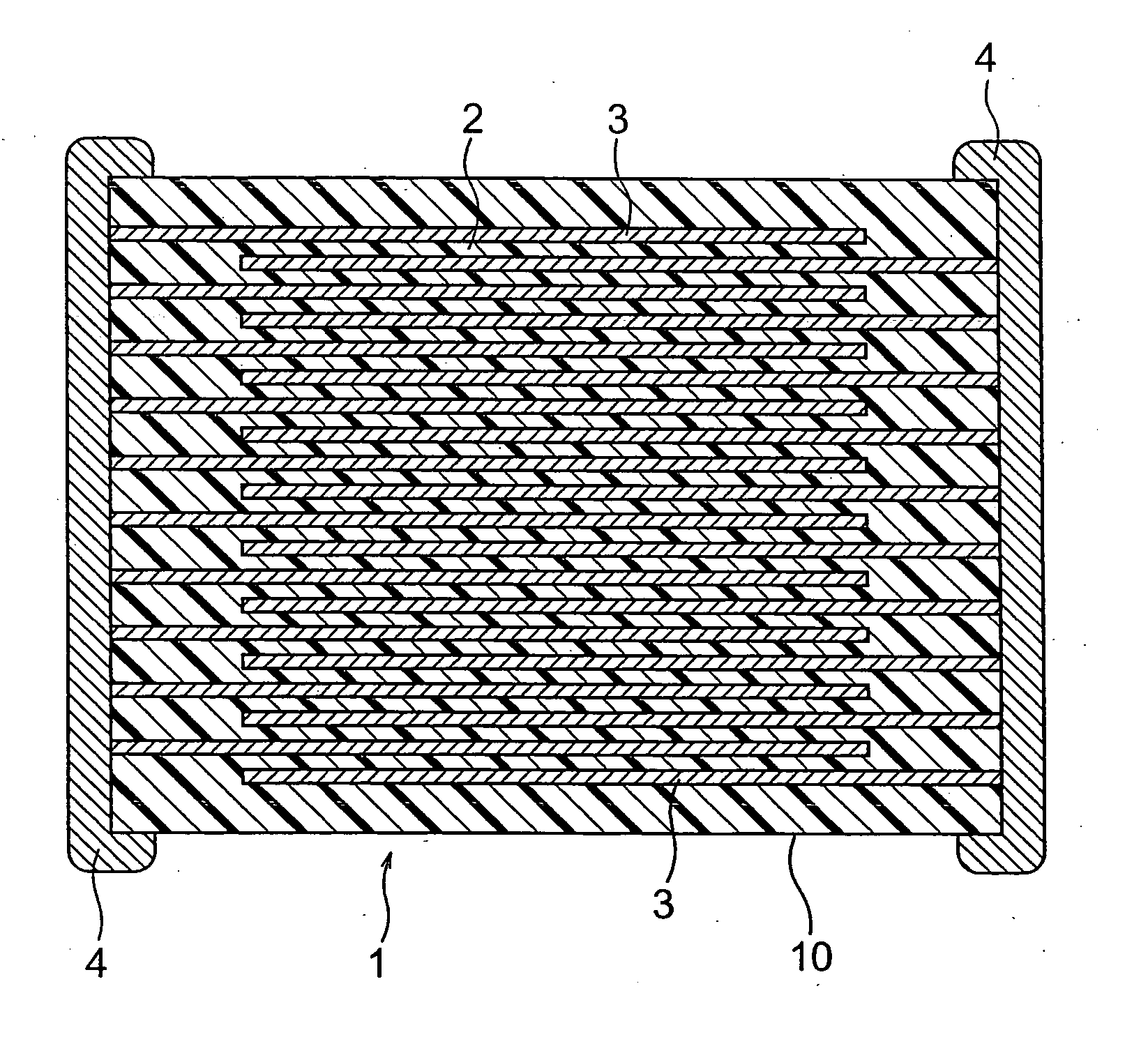

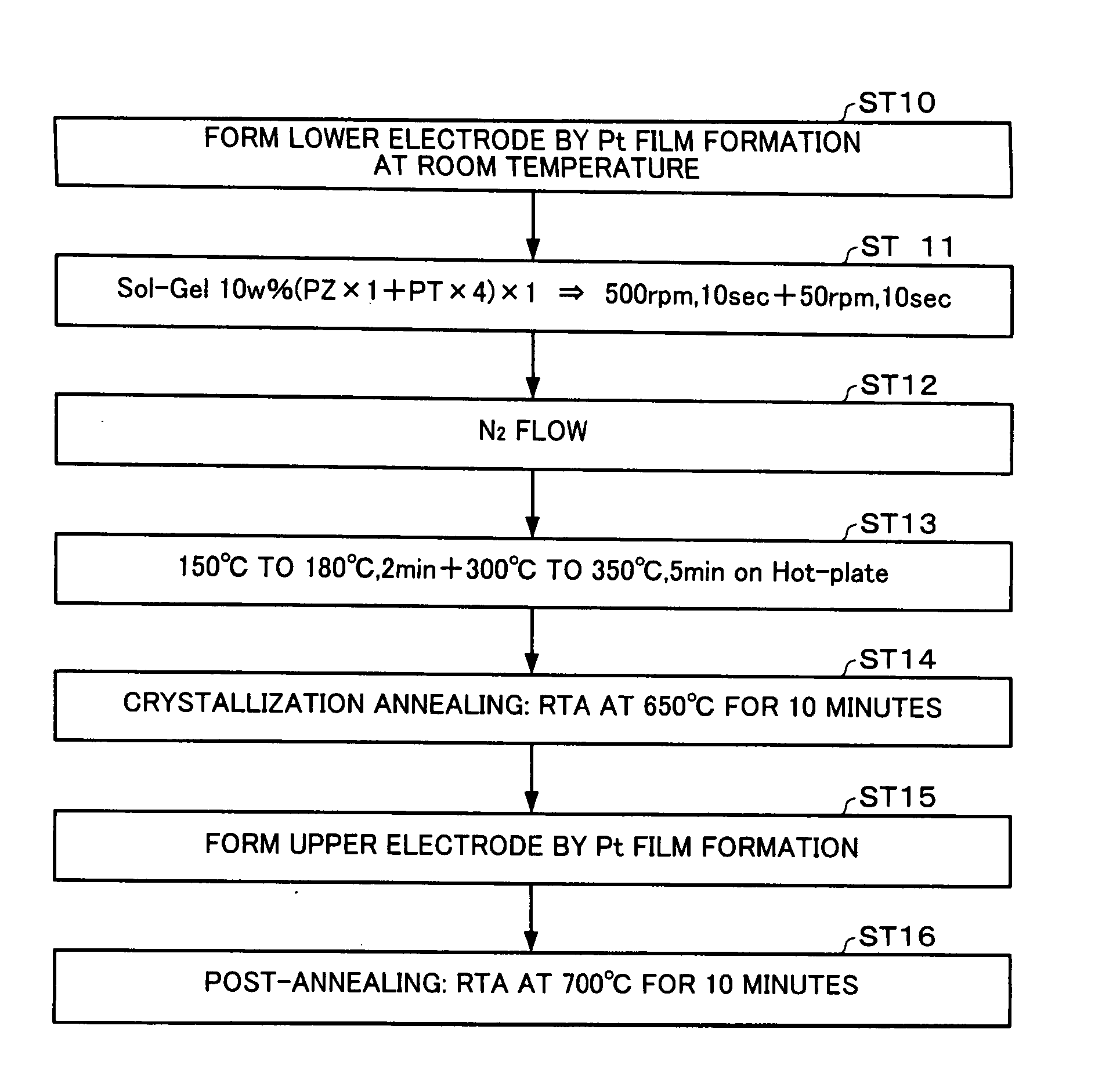

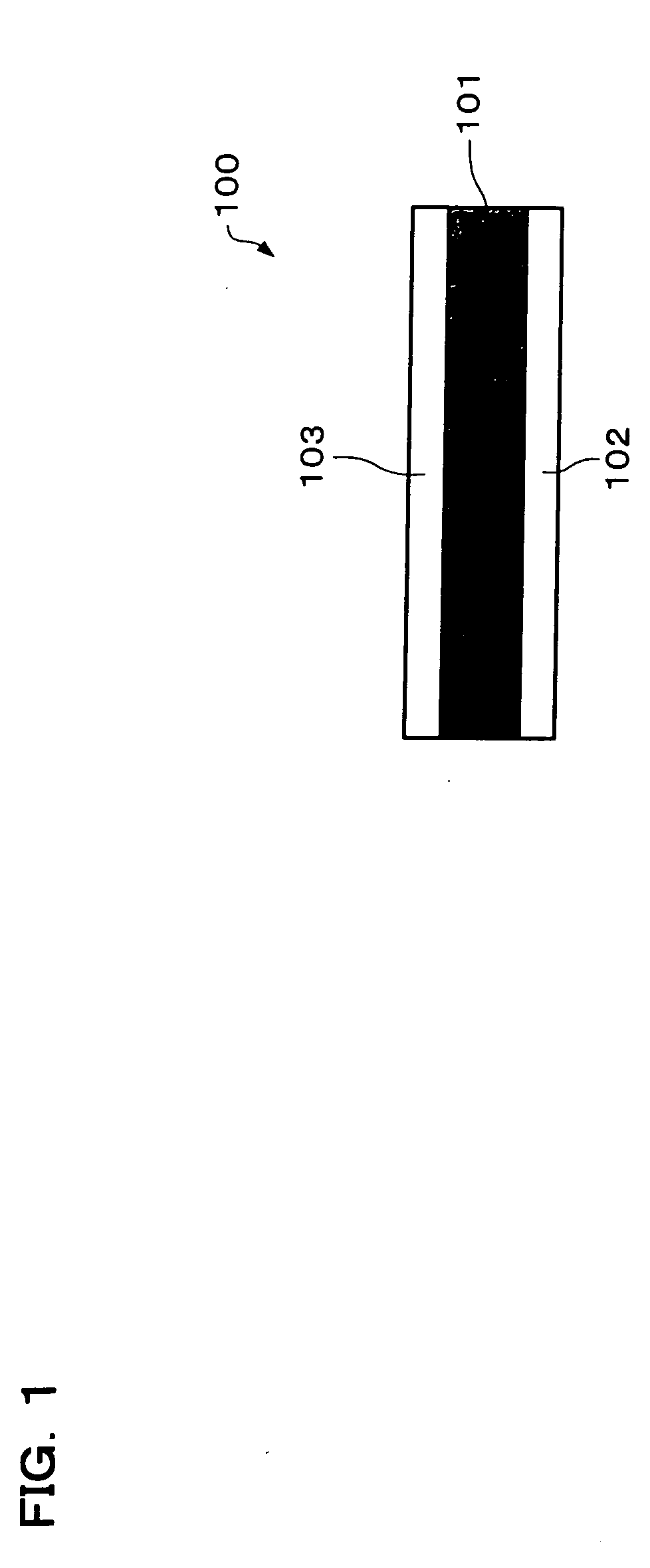

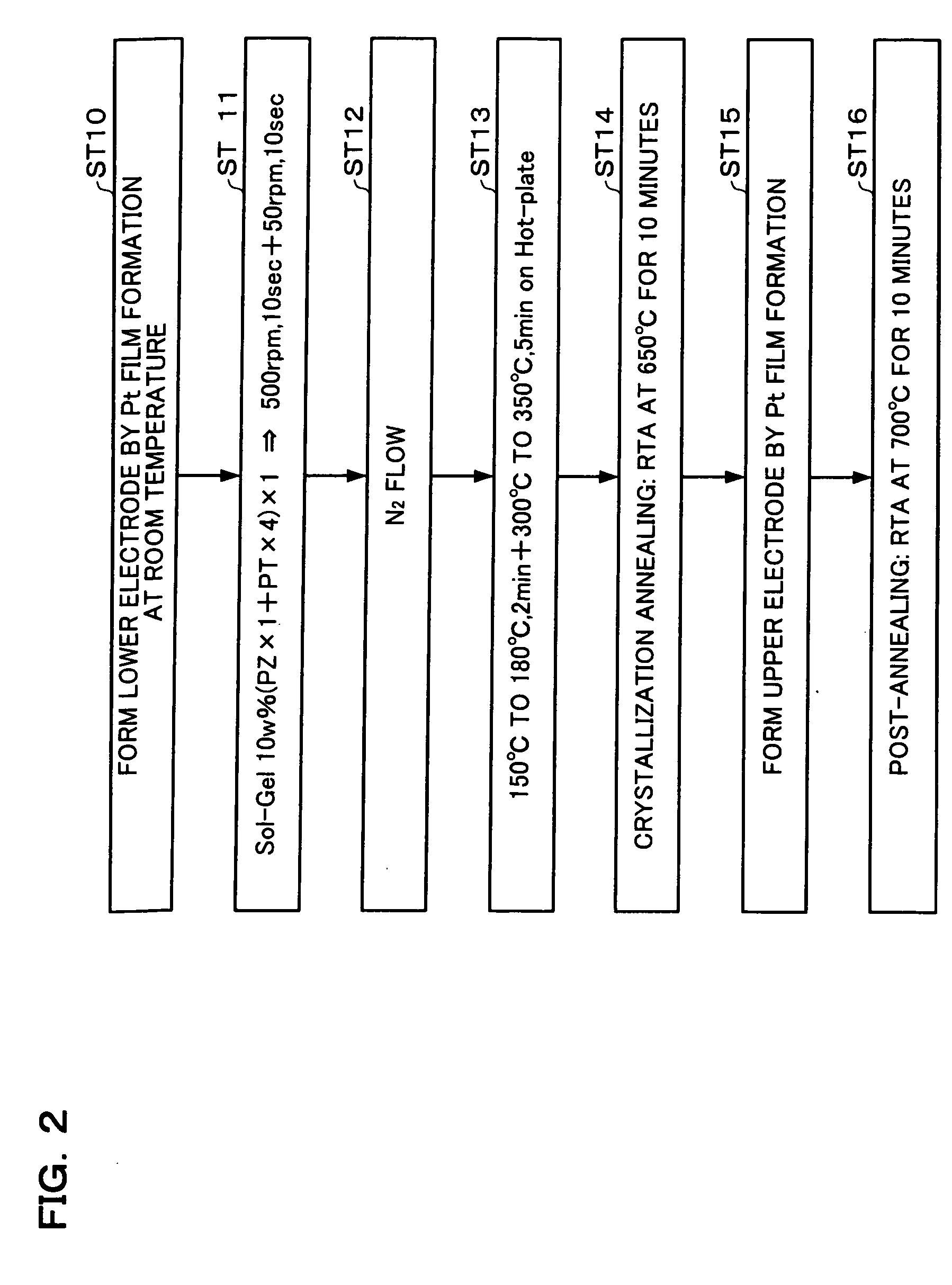

Ferroelectric film, ferroelectric capacitor, ferroelectric memory, piezoelectric element, semiconductor element, method of manufacturing ferroelectric film, and method of manufacturing ferroelectric capacitor

InactiveUS20060088731A1Satisfactory characteristicPiezoelectric/electrostriction/magnetostriction machinesTantalum compoundsOptoelectronicsFerroelectric capacitor

A ferroelectric film is formed by an oxide that is described by a general formula AB1-xNbxO3. An A element includes at least Pb, and a B element includes at least one of Zr, Ti, V, W, Hf and Ta. The ferroelectric film includes Nb within the range of: 0.05≦x<1. The ferroelectric film can be used for any of ferroelectric memories of 1T1C, 2T2C and simple matrix types.

Owner:SEIKO EPSON CORP

Dielectric ceramic and multilayer ceramic capacitor

ActiveUS7397649B2Good temperature characteristicsLittle changeFixed capacitor dielectricStacked capacitorsCapacitanceRare-earth element

A dielectric ceramic includes a compound represented by the general formula: (Ba1-tCat)m(Ti1-u-xZruCux)O3 (where 0.96≦m≦1.02, 0.001≦x≦0.03, 0≦t≦0.1, and 0≦u≦0.06) as a primary component, a rare earth element Re such as Dy, a metal element M such as Mn, Mg, and Si. In the dielectric ceramic, the Cu is uniformly and dispersedly present in the primary phase grain forming the primary component, and the contents of the accessory components with respect to 100 molar parts of the primary component are 0.1 to 1.5 molar parts of Re, 0.1 to 0.6 molar parts of M, 0.1 to 1.5 molar parts of Mg and 0.1 to 2.0 molar parts of Si. Accordingly, a multilayer ceramic capacitor can be realized which has a high dielectric constant, superior temperature properties, and a high reliability, and also has a small change in electrostatic capacitance with time.

Owner:MURATA MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com