Patents

Literature

94 results about "Mn oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manganese(II,III) oxide is the chemical compound with formula Mn 3O 4. Manganese is present in two oxidation states +2 and +3 and the formula is sometimes written as MnO.Mn 2O 3. Mn 3O 4 is found in nature as the mineral hausmannite.

Complex Li-Mn-oxide, manufacture method and battery made of this material

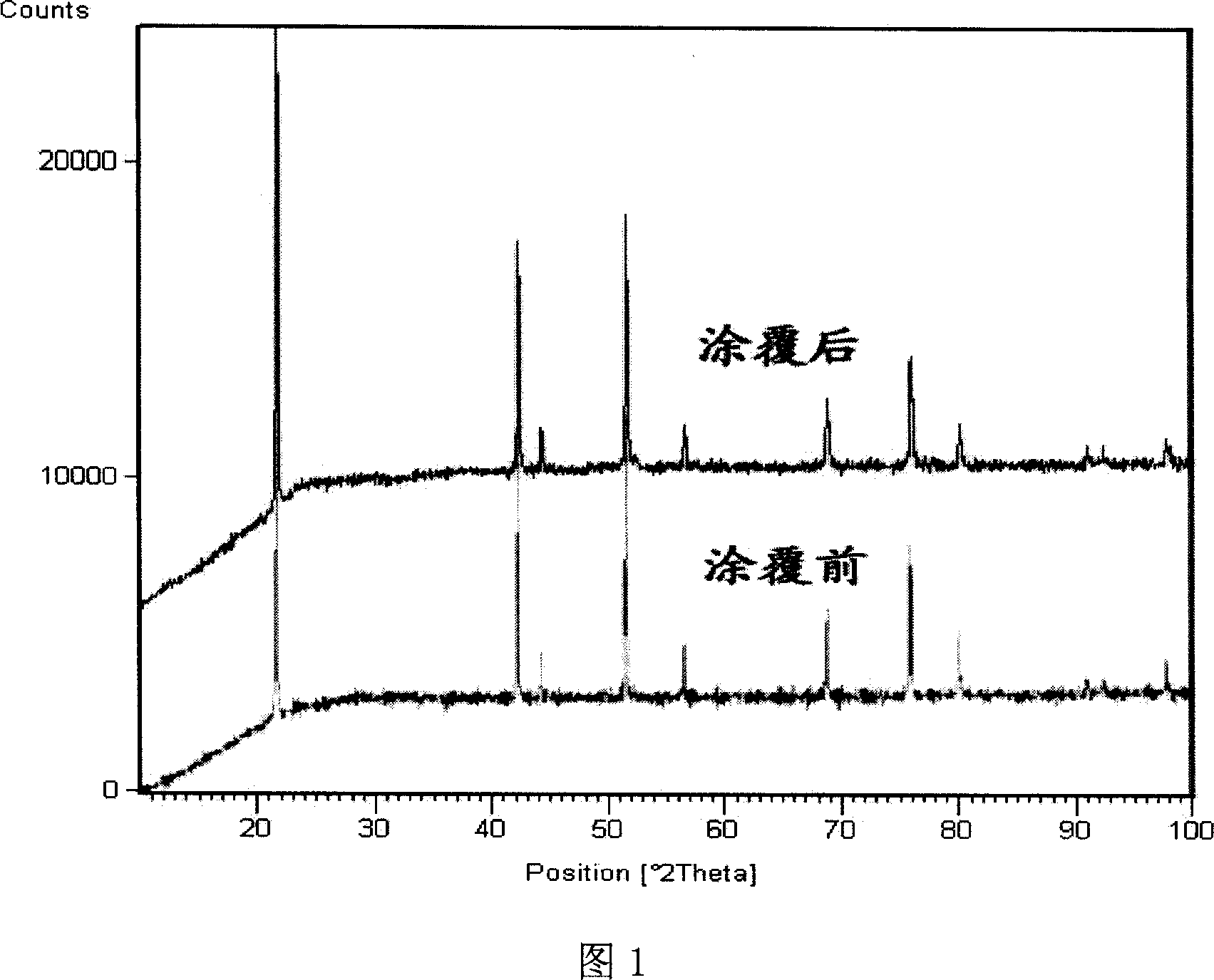

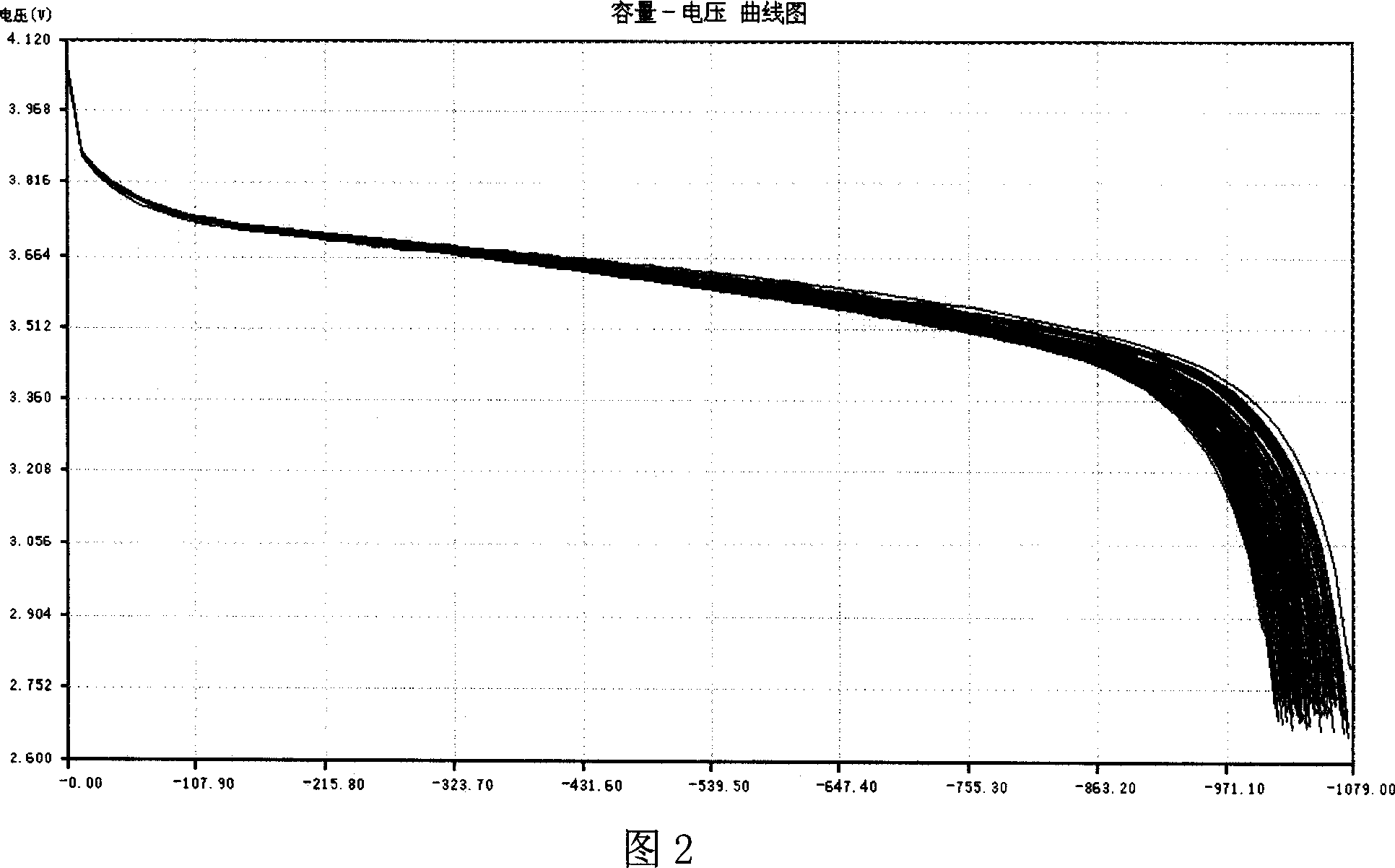

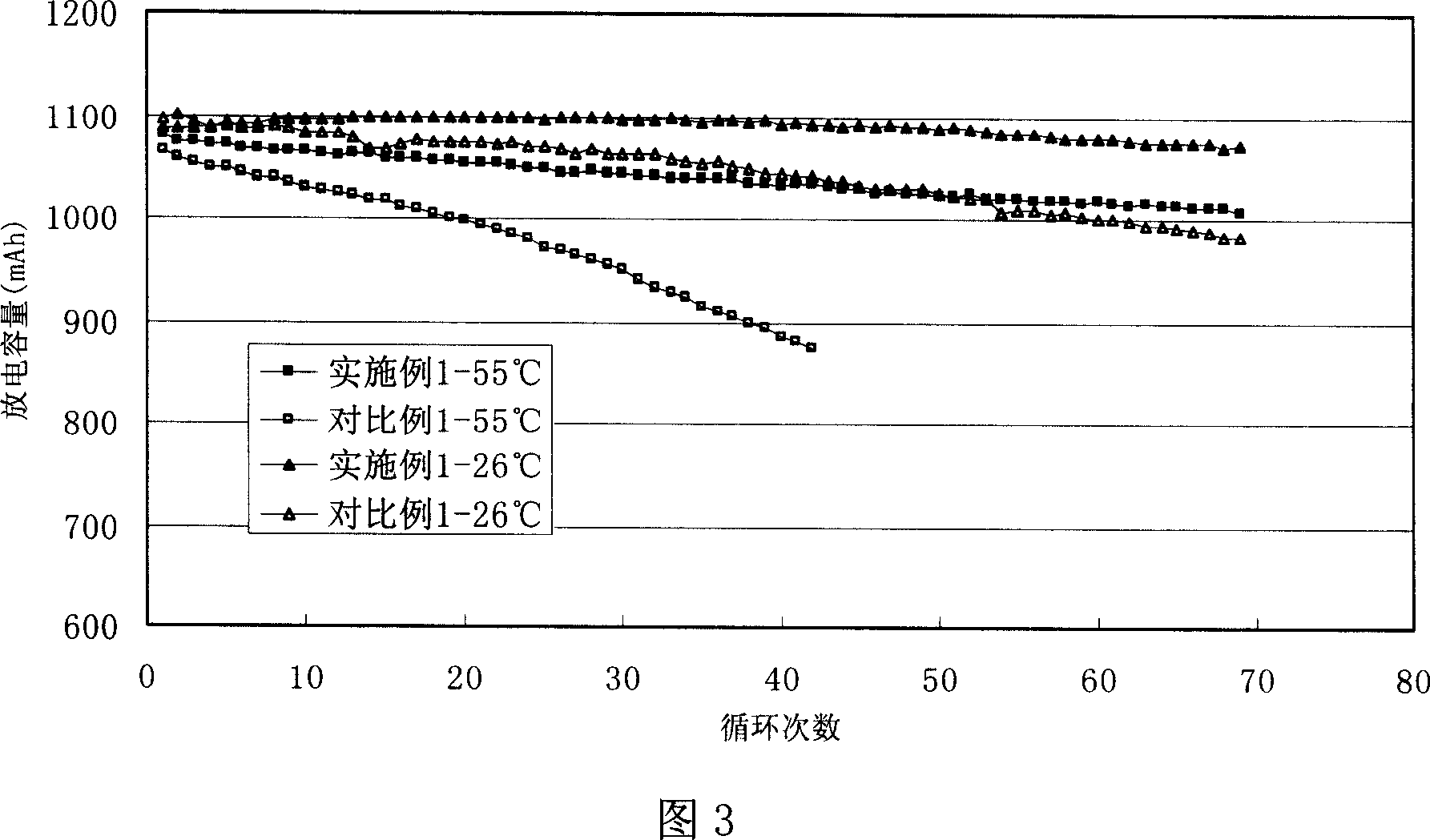

ActiveCN101060173AImprove rate charge and discharge performanceEasy to prepareElectrode manufacturing processesSecondary cellsPhosphateComposite oxide

The disclosed Li-Mn composite oxide for positive of secondary Li cell comprises the core LiaMn2-bXbO4 and a coating layer, wherein 0. 97<=a<=1. 06, 0 <=b<=0. 5, X for other metal (except Li and Mn) or Si; the coating layer comprises one of more of Li-B composite oxide, Li-Co oxide, Li-V oxide, Al oxide, Al phosphate, Ti oxide, Cr. Oxide, Mg oxide, and Ca oxide This invention improves material performance, special the circulation performance at high temperature.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

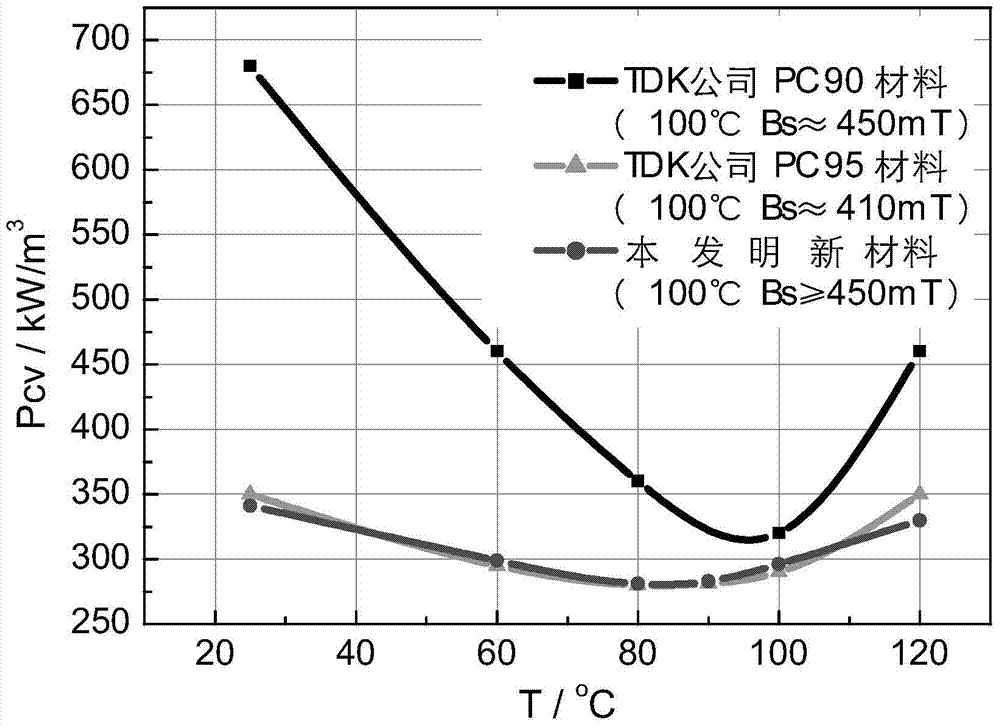

Ni-free MnZn ferrite magnetic core with double characteristics and manufacture method

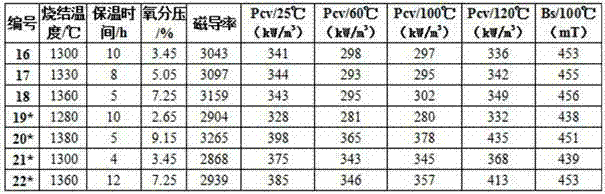

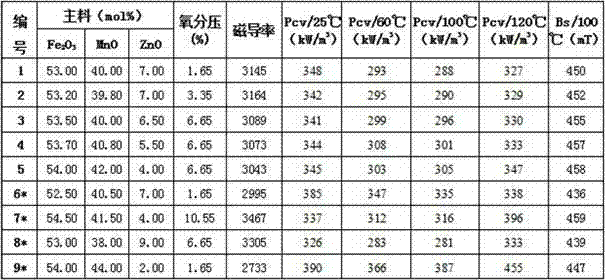

ActiveCN103496963AOvercome the inability to take into account multiple featuresImprove performanceFerrite (magnet)Condensed matter physics

The invention provides a Ni-free MnZn ferrite magnetic core with double characteristics and a manufacture method thereof, wherein the double characteristics mean high temperature and high Bs, and wide temperature and low loss. The ferrite magnetic core comprises main components and auxiliary components. The main components comprise: 53 mol%-54 mol% of Fe2O3, 39 mol%-42 mol% of MnO and 4 mol%-7 mol% of ZnO; and the auxiliary components comprise: Co2O3 or CoO or Co3O4 as a first auxiliary component, SiO2 and CaCO3 as a second auxiliary, and a third auxiliary component which is one or more selected from MoO3, TiO2, SnO2, Nb2O5, V2O5, Sm2O3 and ZrO2. The provided MnZn ferrite magnetic core with double characteristics has unit volume loss Pcv (100kHz, 200mT) less than 350 kW / m<3> at the temperature of 25 DEG C to 120 DEG C, lowest loss of 300 kW / m<3> at the temperature of about 90 DEG C, and saturation magnetic flux density up to 450 mT at the temperature of 100 DEG C.

Owner:江门安磁电子有限公司

Catalyst of composite oxides of copper and manganese and application

InactiveCN1660491AUniform surface distributionIncrease surface areaOrganic compound preparationCarbonyl compound preparationCopperToluene

A composite Cu-Mn oxide catalyst used for the liquid-phase oxidization of toluene under existance of molecular oxygen is prepared from the metallic oxides, acidic oxides, alkaline oxides, or others of Cu, Mn and others chosen from Co, Zn, Ni, Cr, Fe, Ce and V through deposition. It has high oxidizing activity, selectivity and stability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

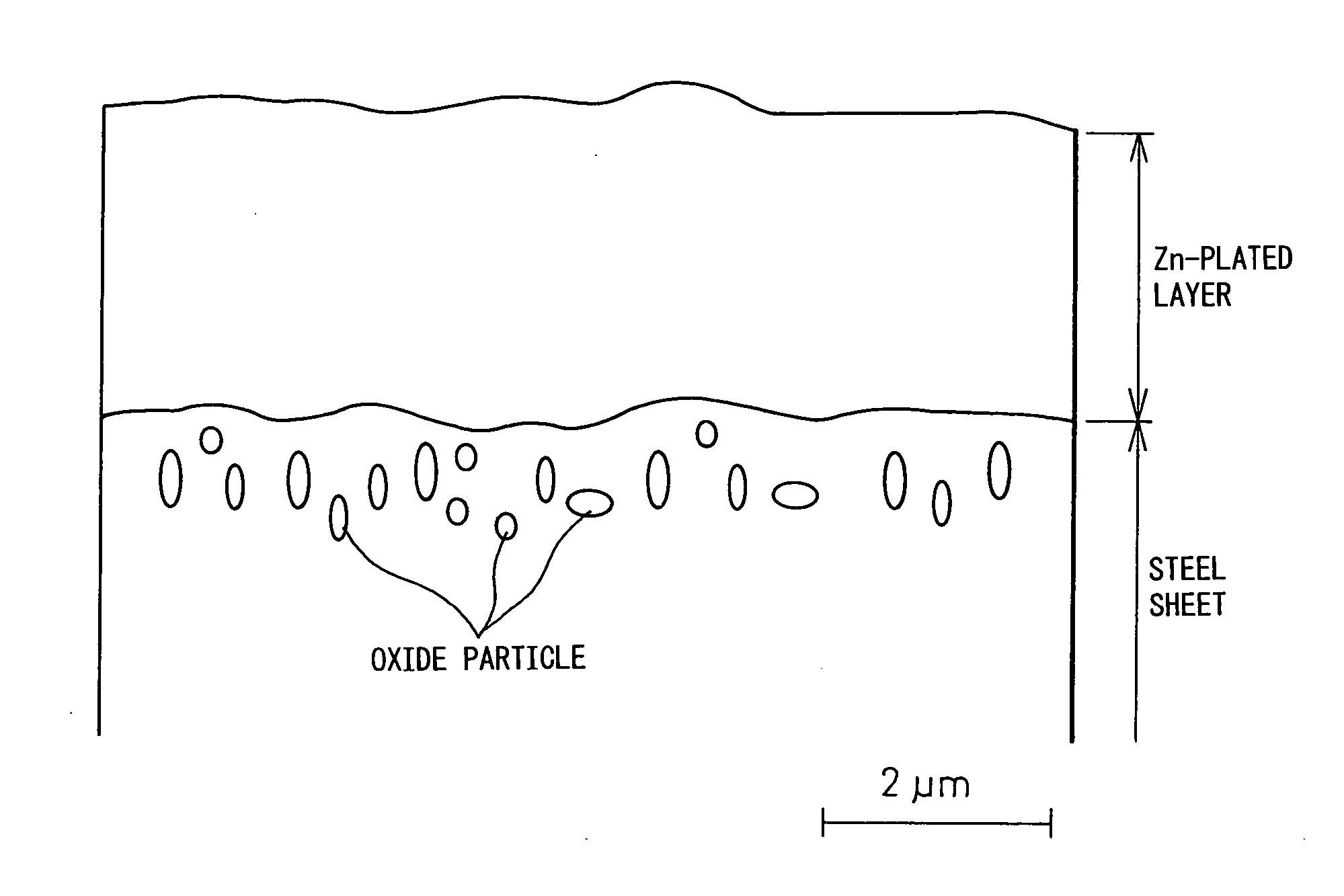

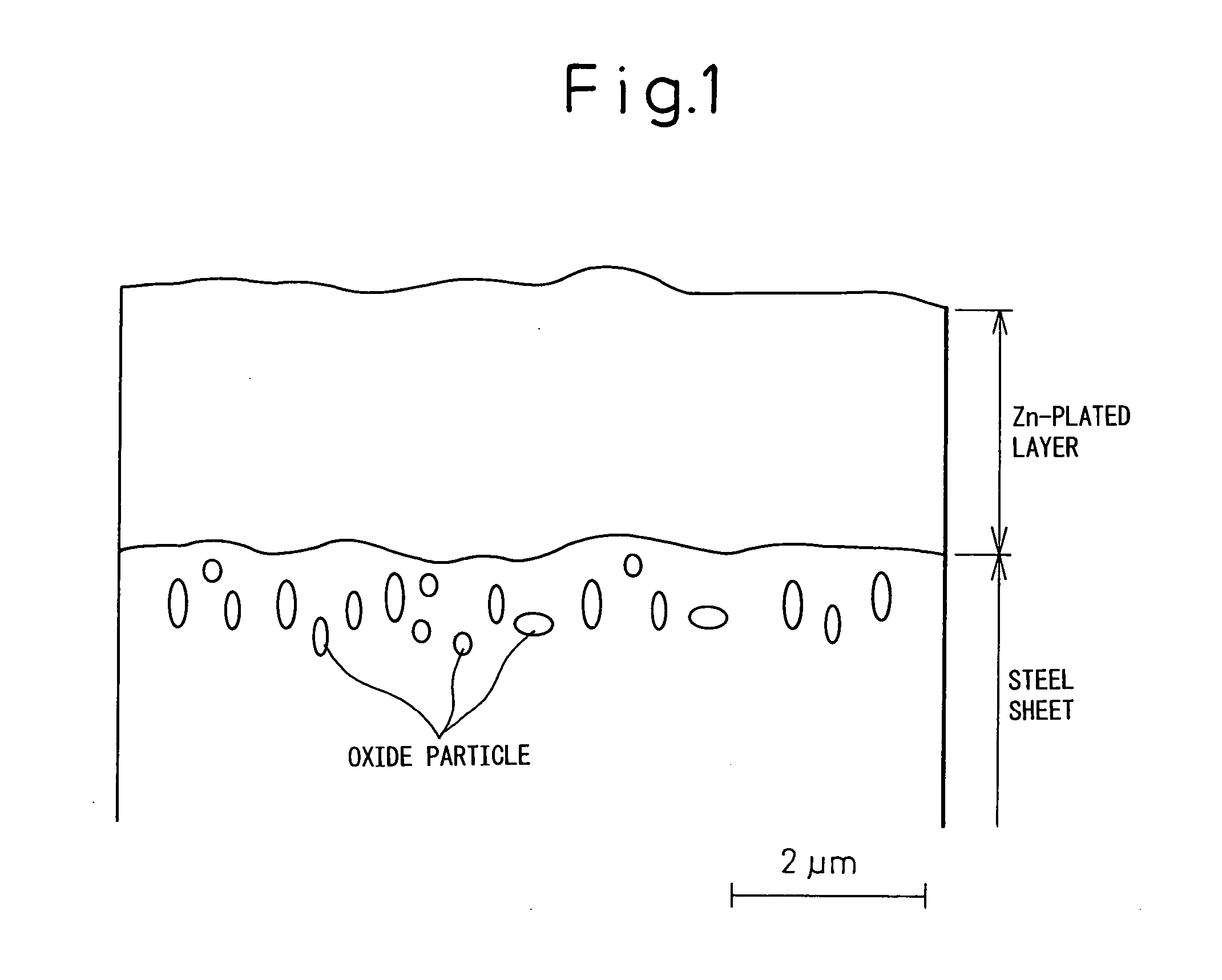

Hot-dip zinc steel sheet having high strength and method for production thereof

ActiveUS20060292391A1Superior in strength and shapeabilityImprove adhesionHot-dipping/immersion processesLiquid surface applicatorsSheet steelHigh intensity

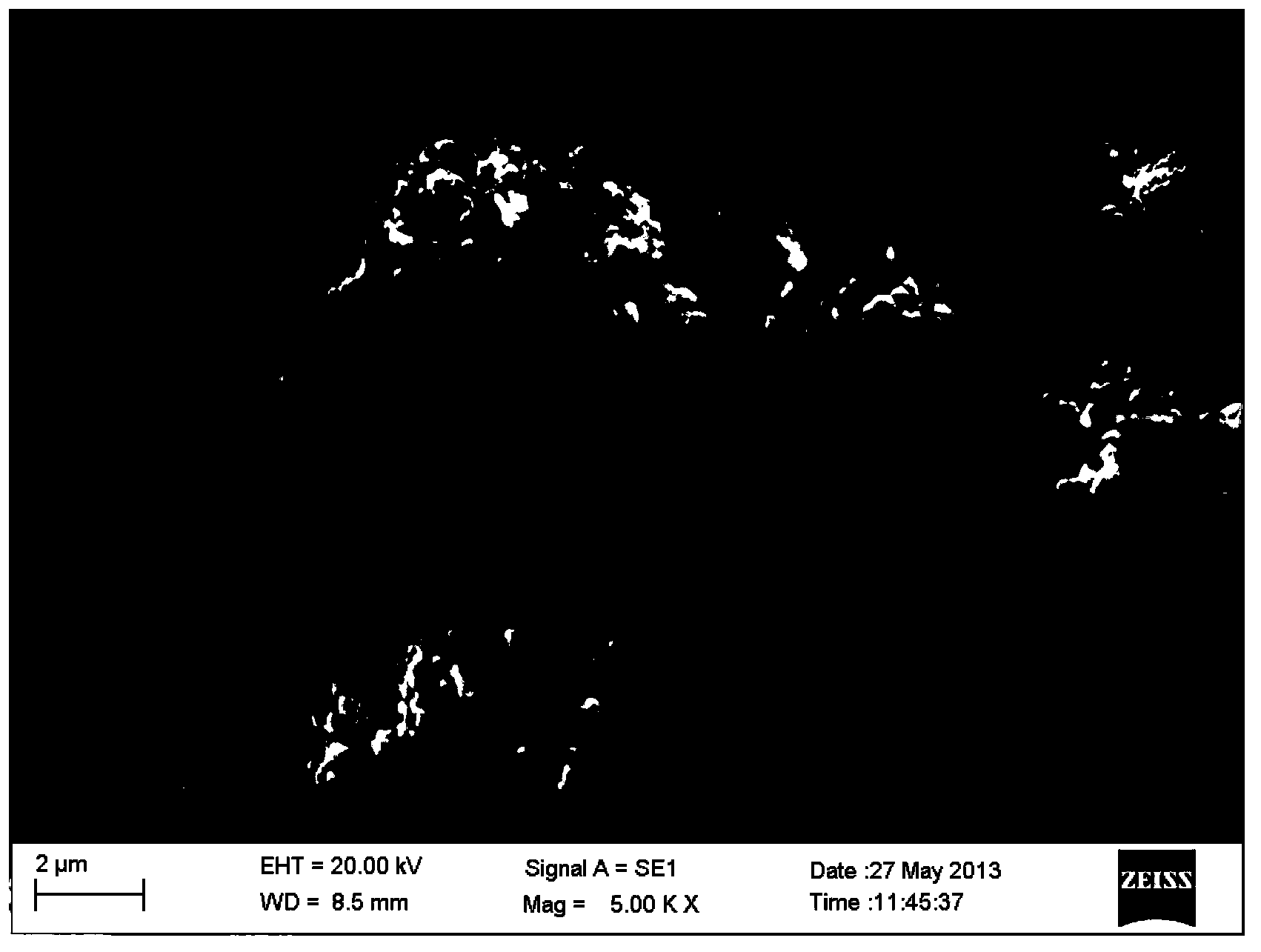

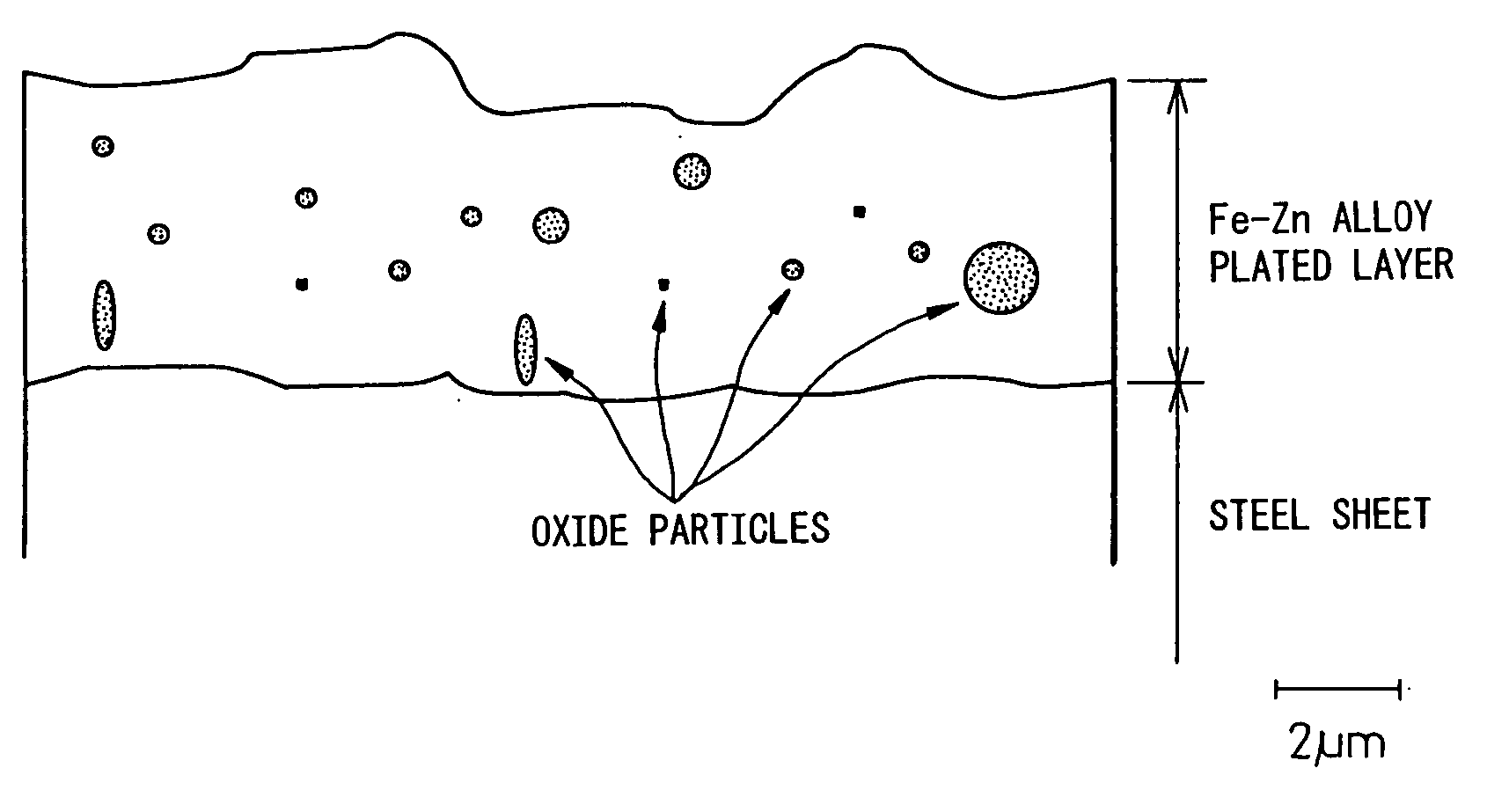

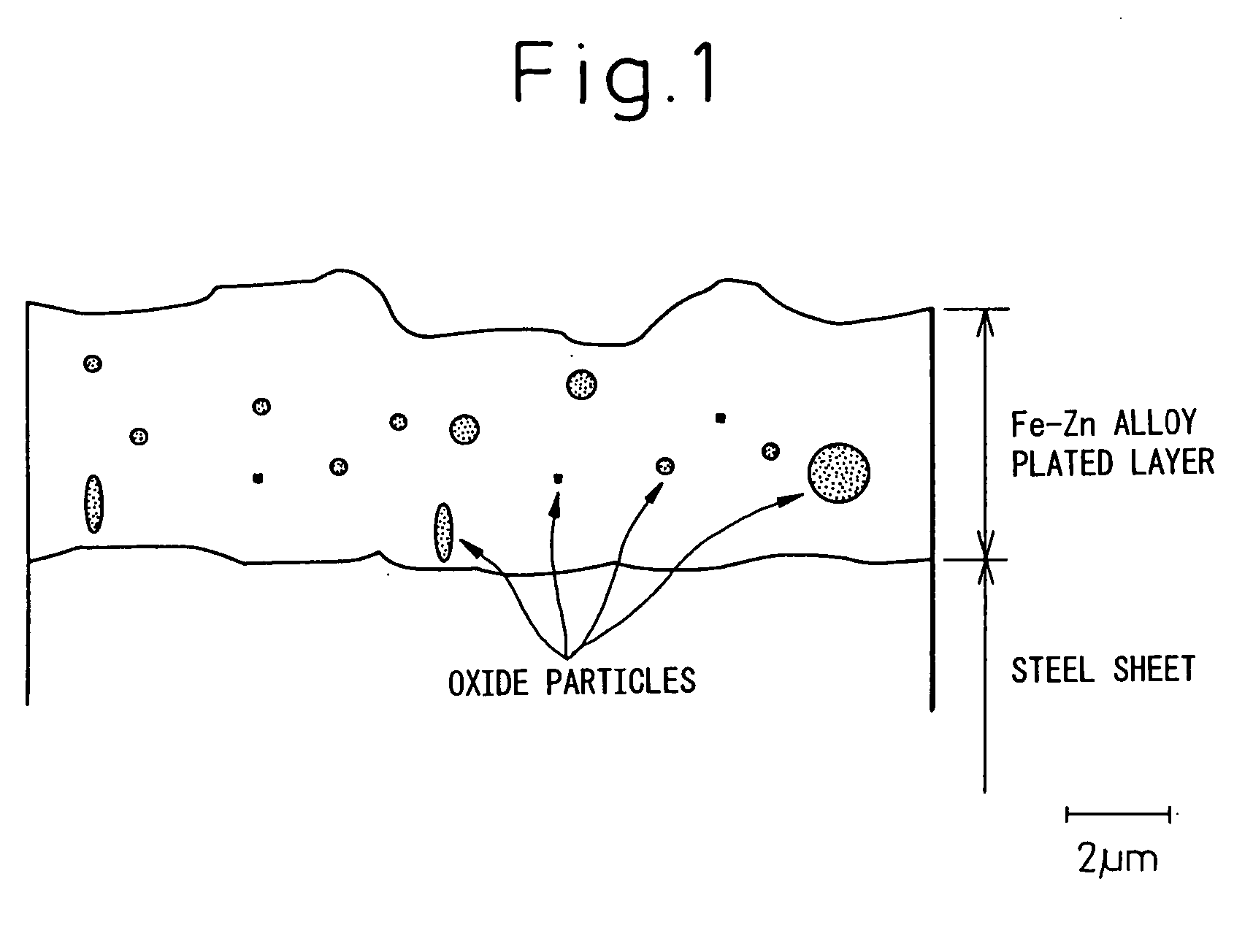

A molten zinc plated steel sheet superior in plating bondability and provided with both strength and shapeability is provided and a method of producing this molten zinc plating steel sheet by a continuous zinc plating production system which enables production at a low cost without modification of the system or addition of steps is provided, said molten zinc plated steel sheet characterized by comprising, by wt %, a steel sheet including C: 0.05 to 0.40%, Si: 0.2 to 3.0%, and Mn: 0.1 to 2.5%, the balance comprised of Fe and unavoidable impurities, having on its surface a Zn plating layer containing Al: 0.01 to 1% and the balance of Zn and unavoidable impurities and containing inside the steel sheet within 2 μm from the interface of said plating layer and steel sheet oxide particles of at least one type of oxide selected from an Al oxide, Si oxide, Mn oxide, or complex oxide comprised of at least two of Al, Si, and Mn.

Owner:NIPPON STEEL CORP +1

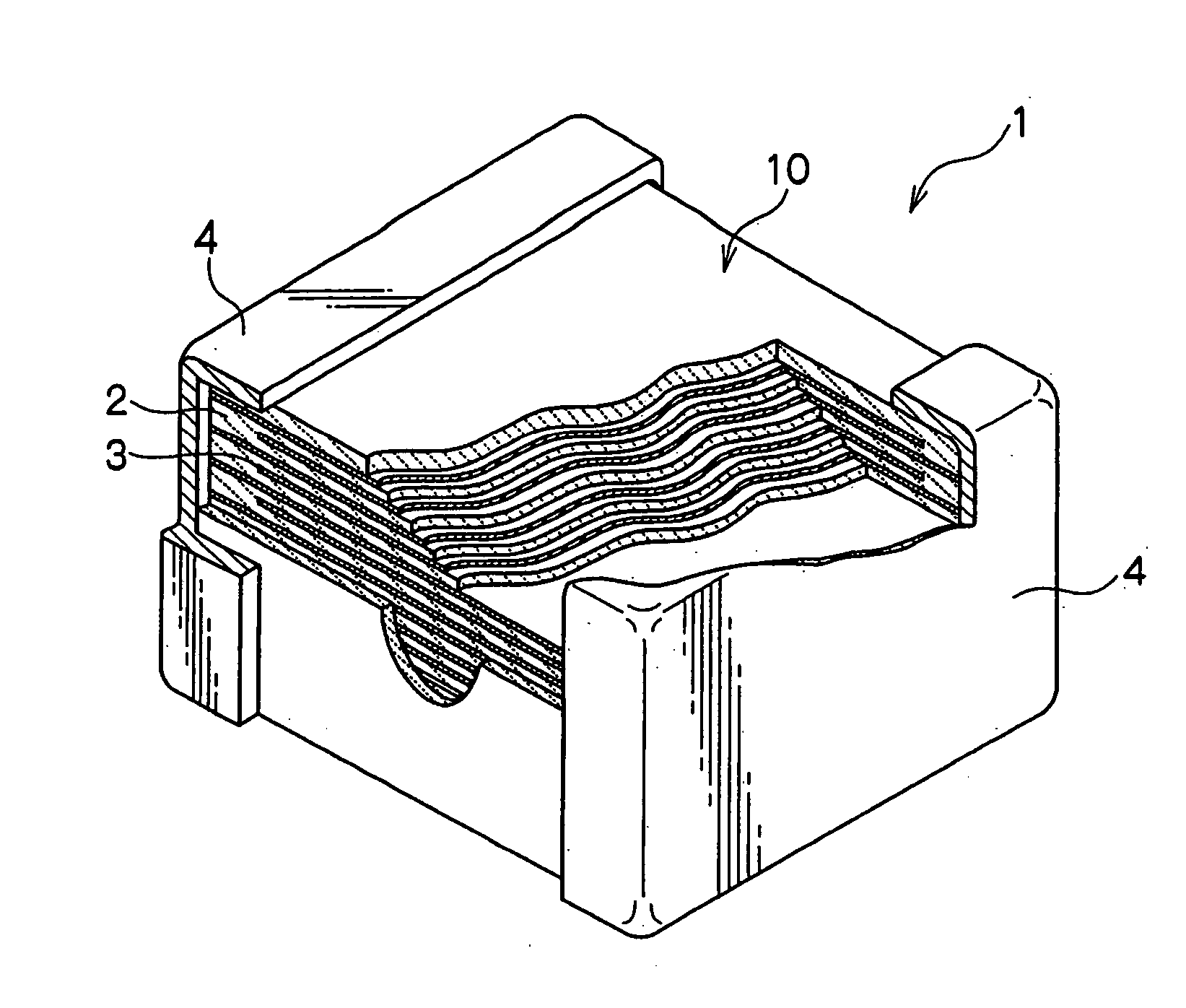

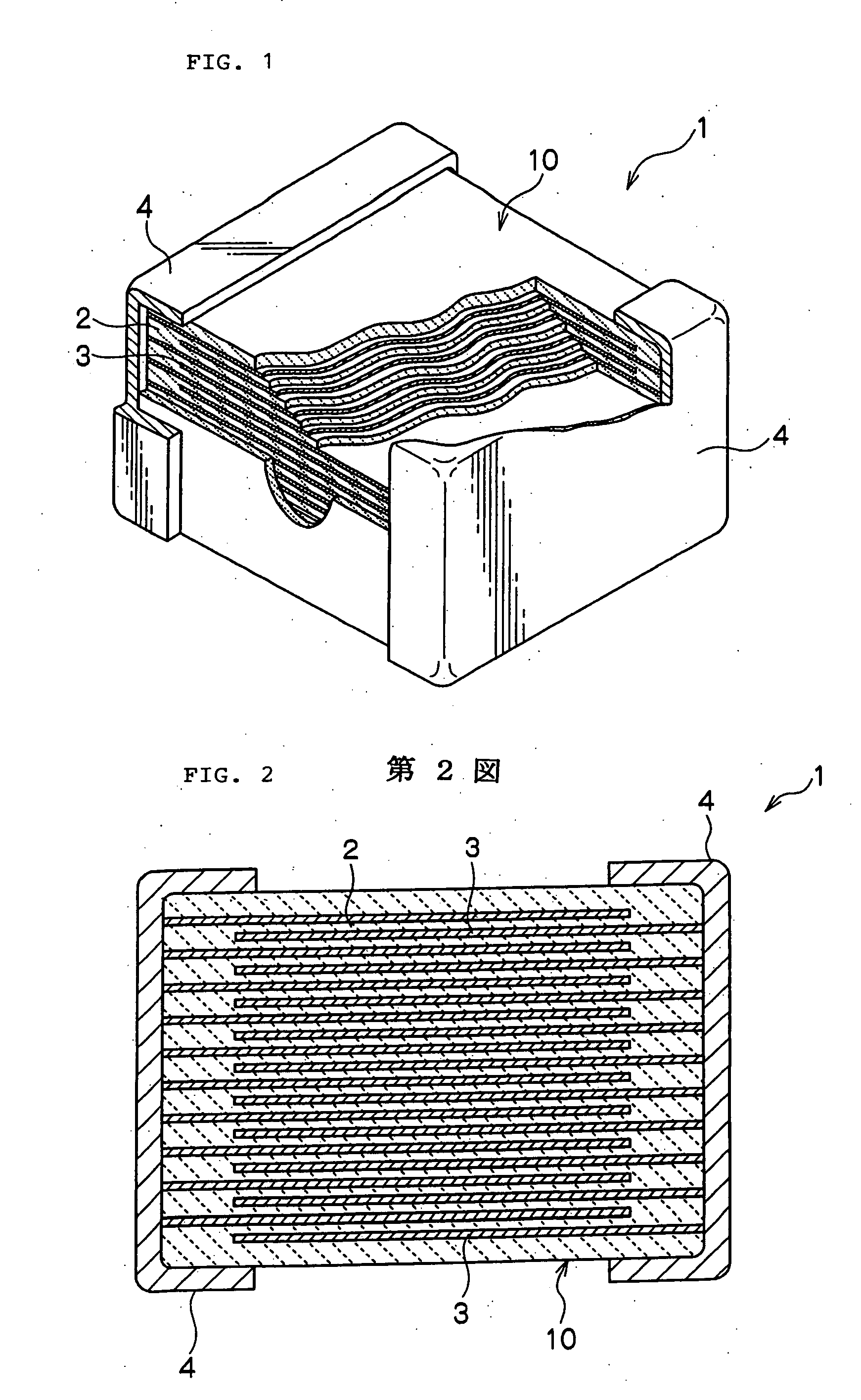

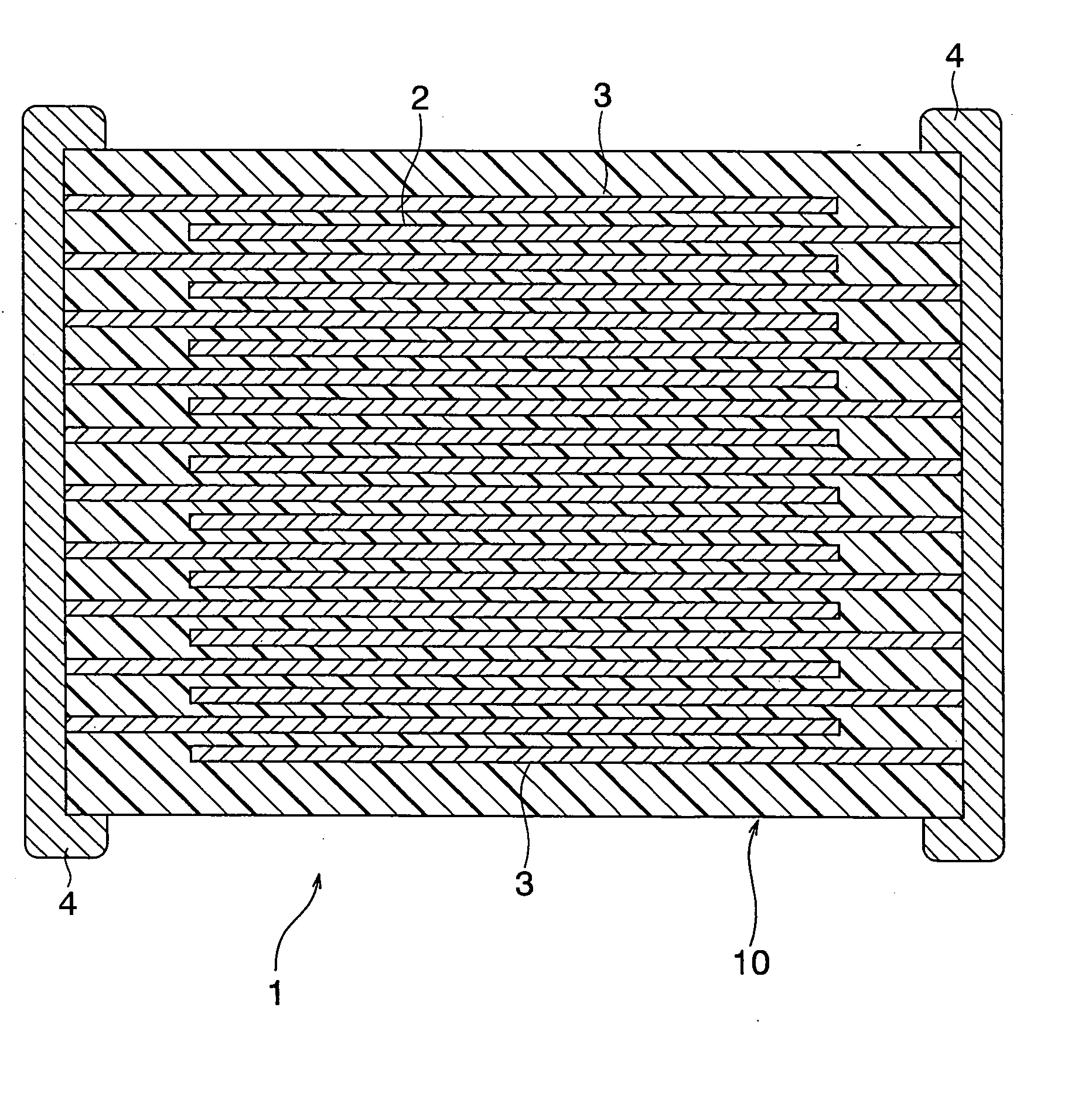

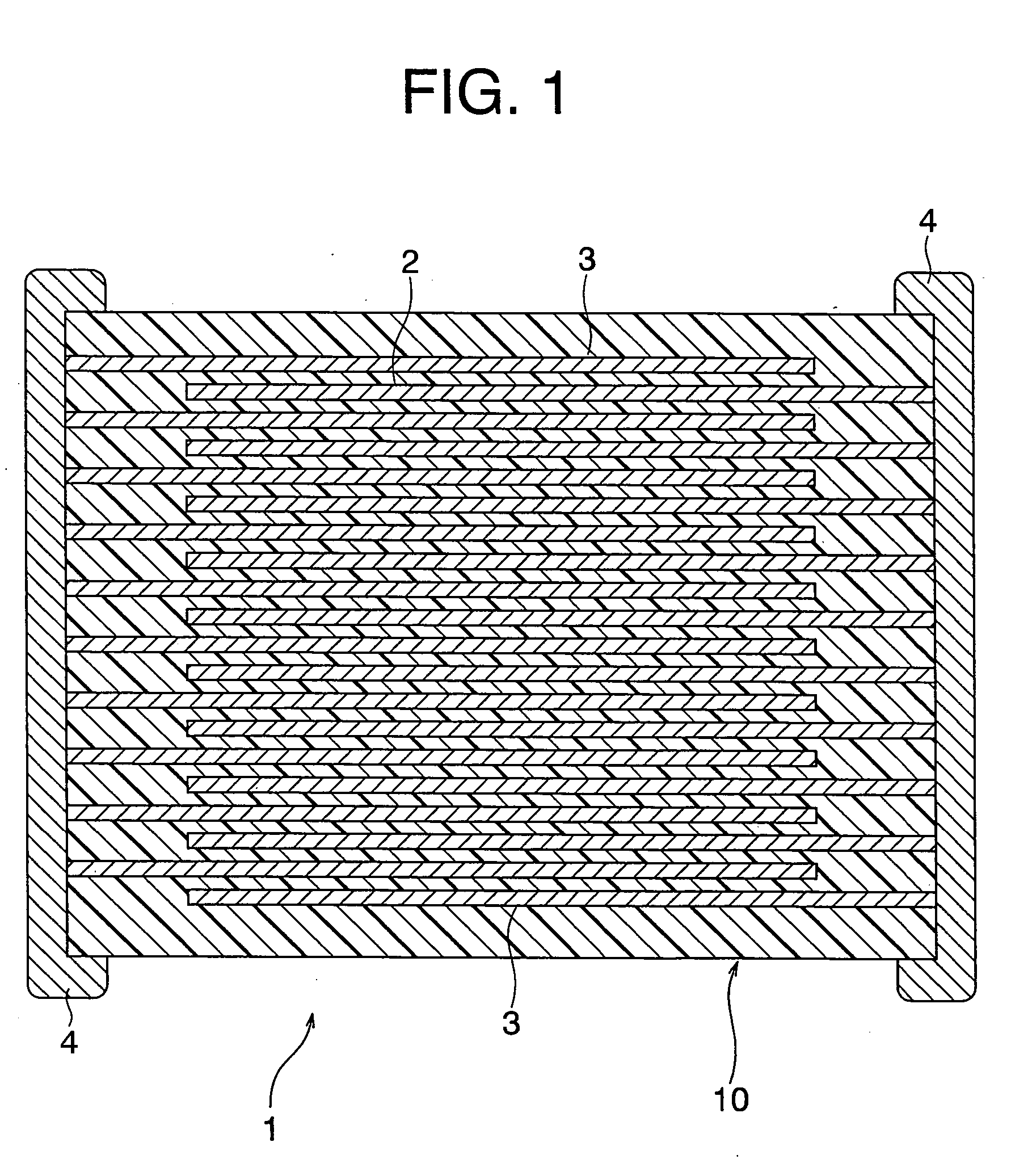

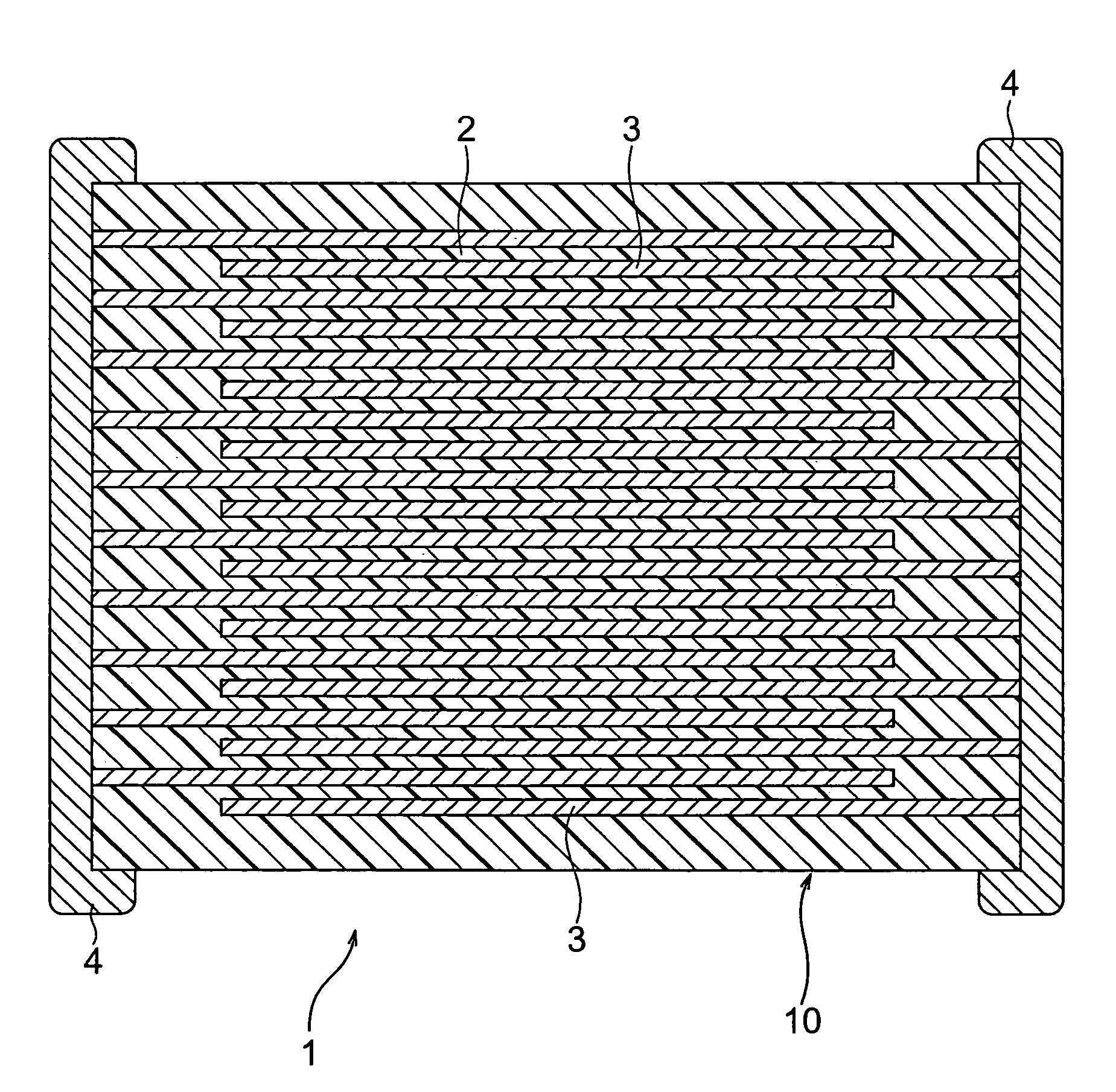

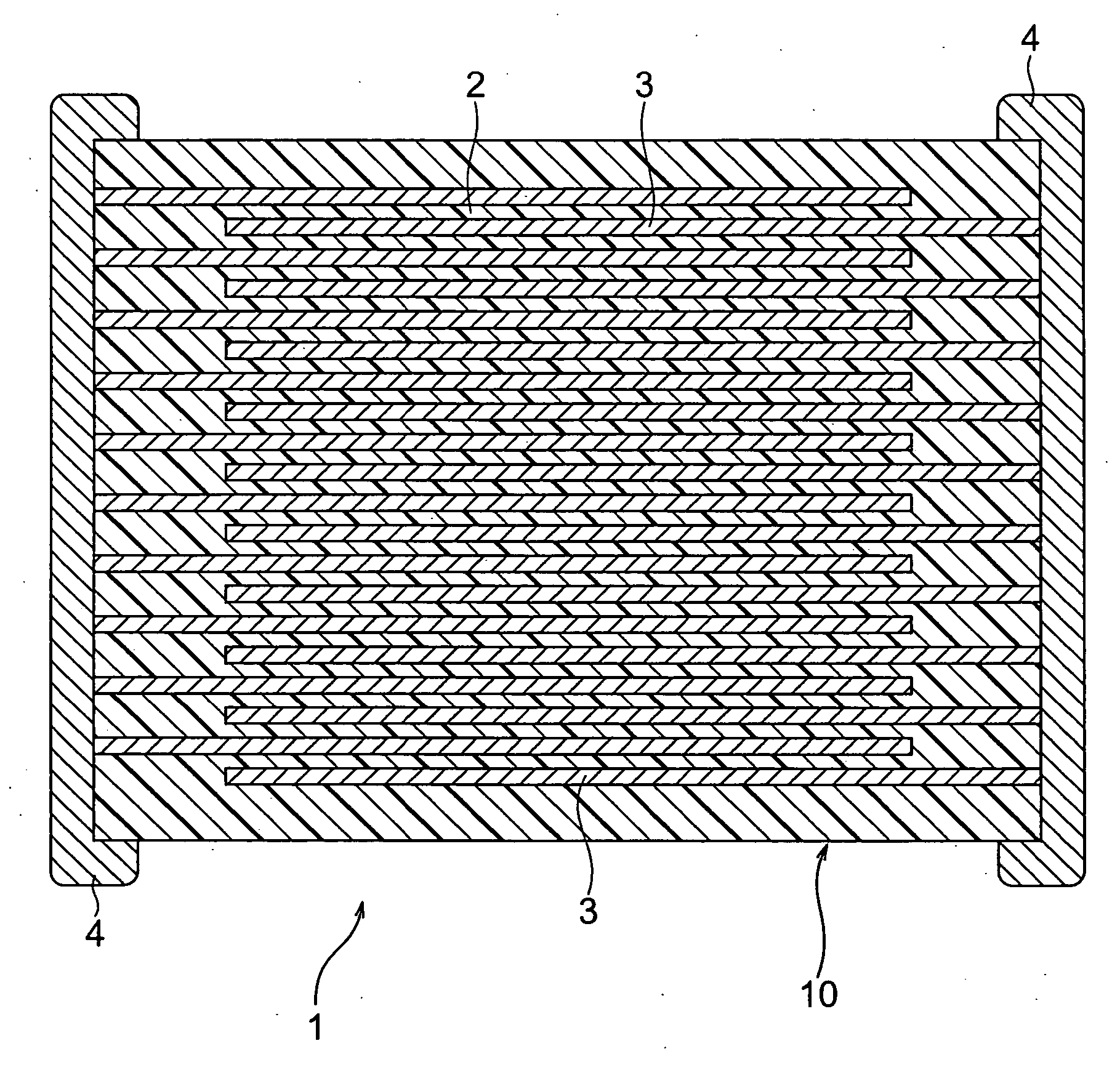

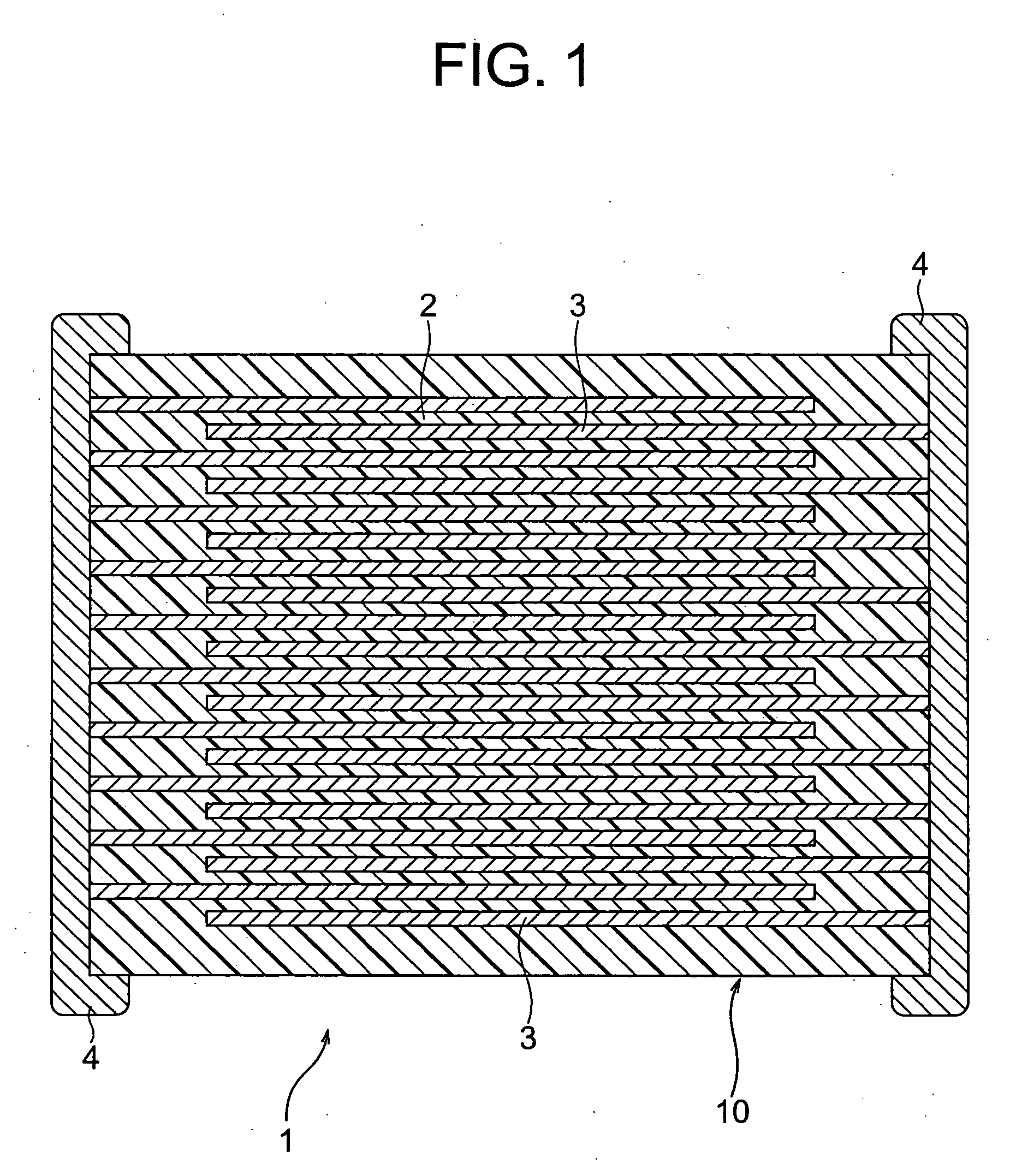

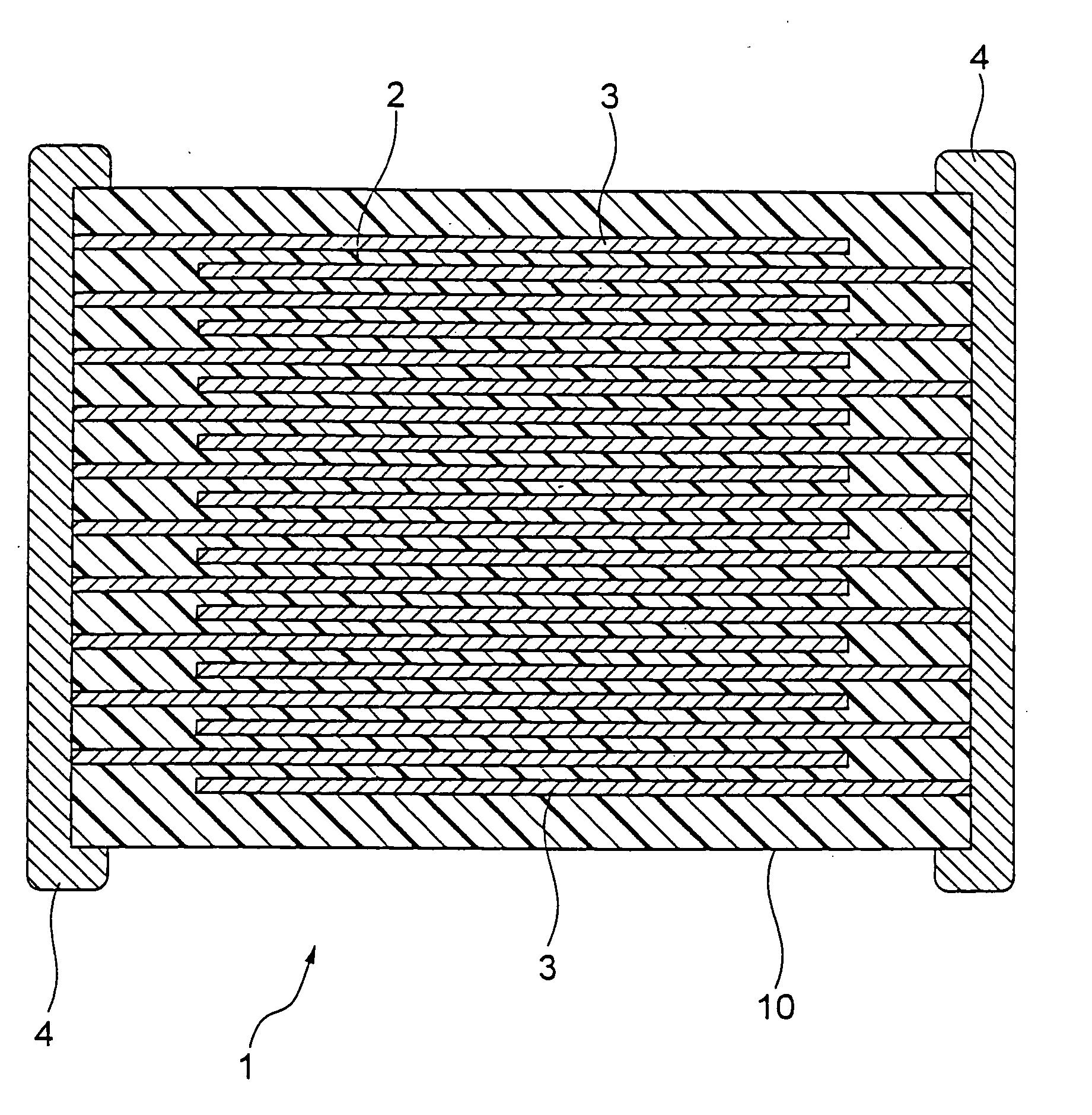

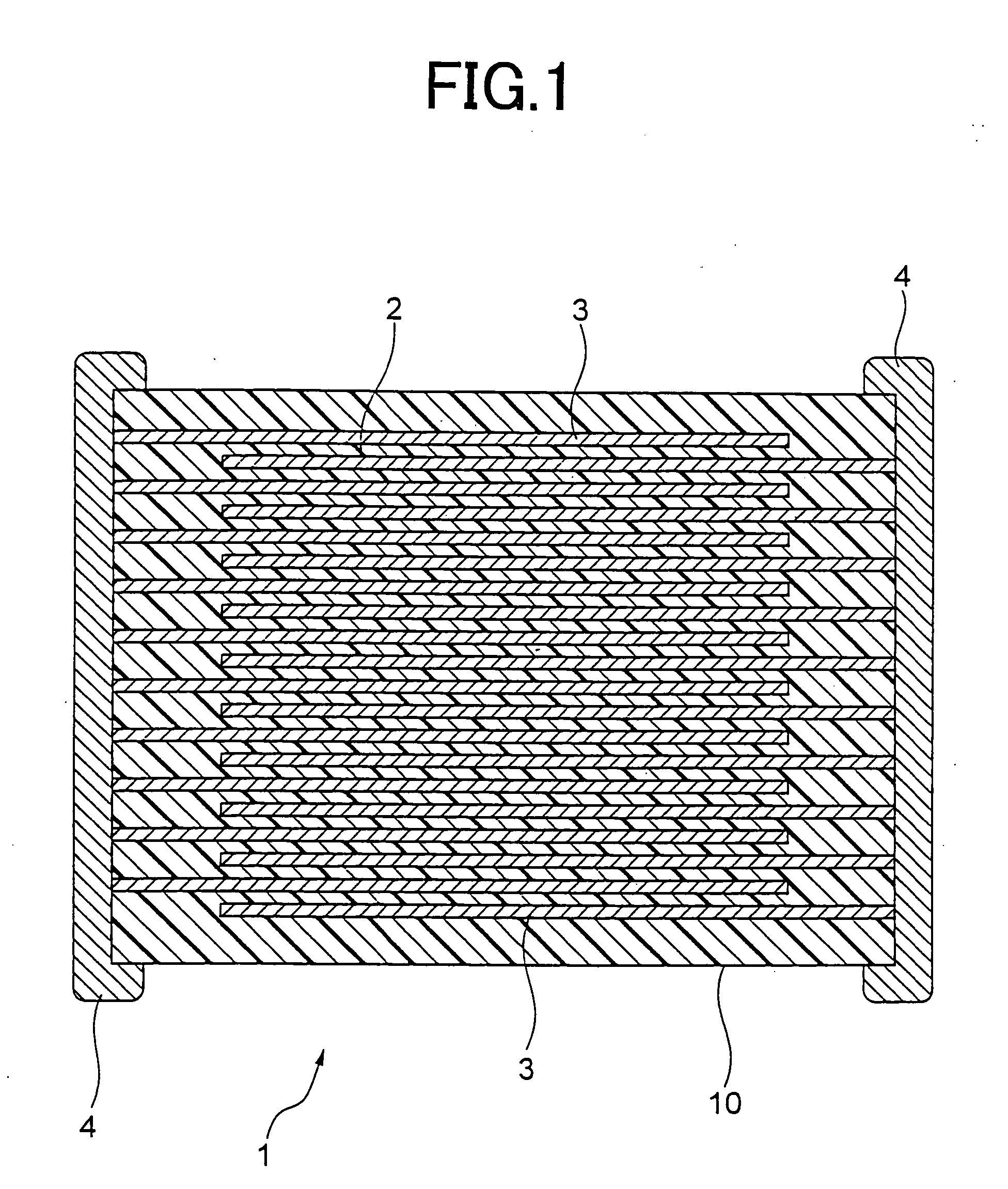

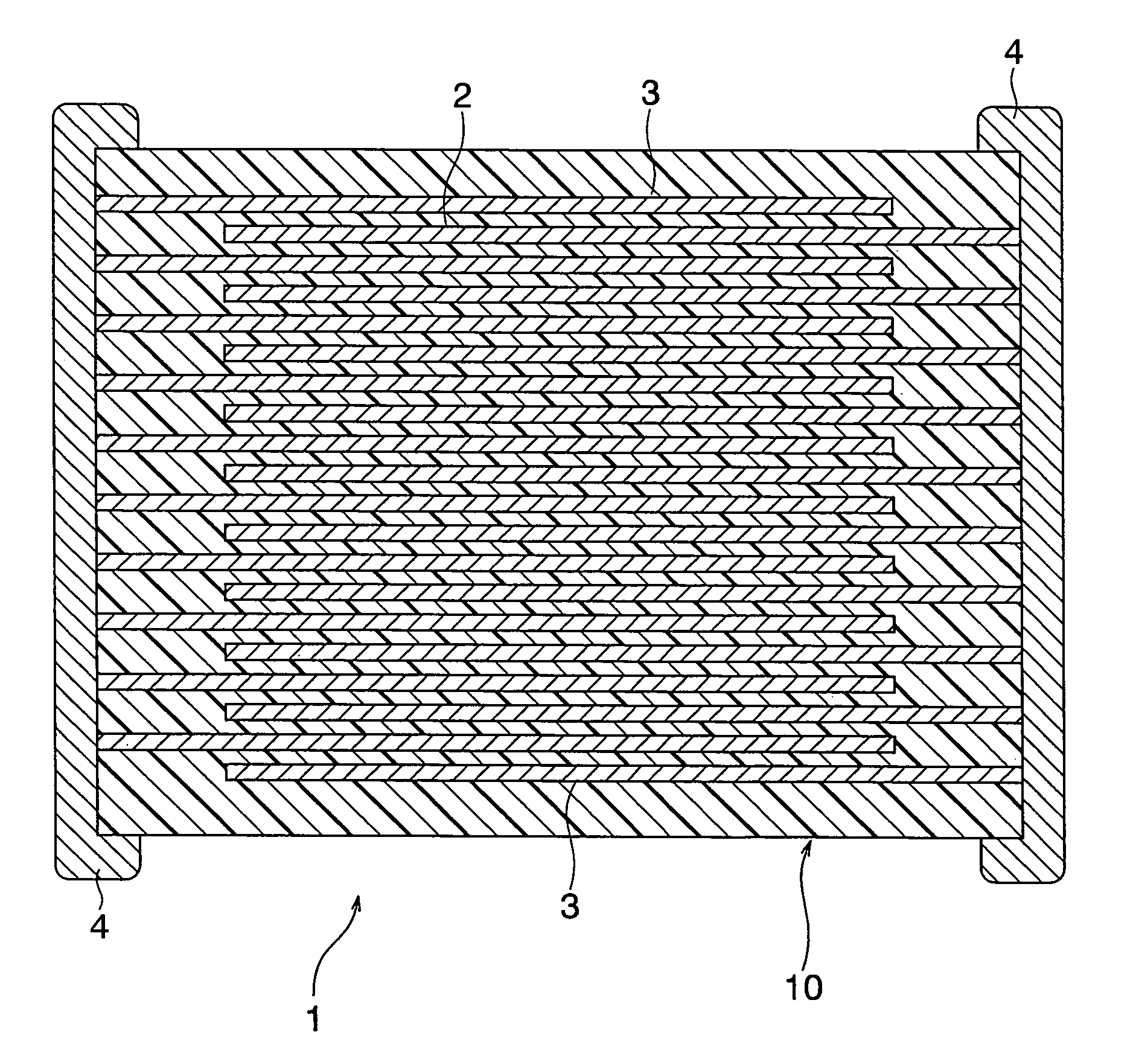

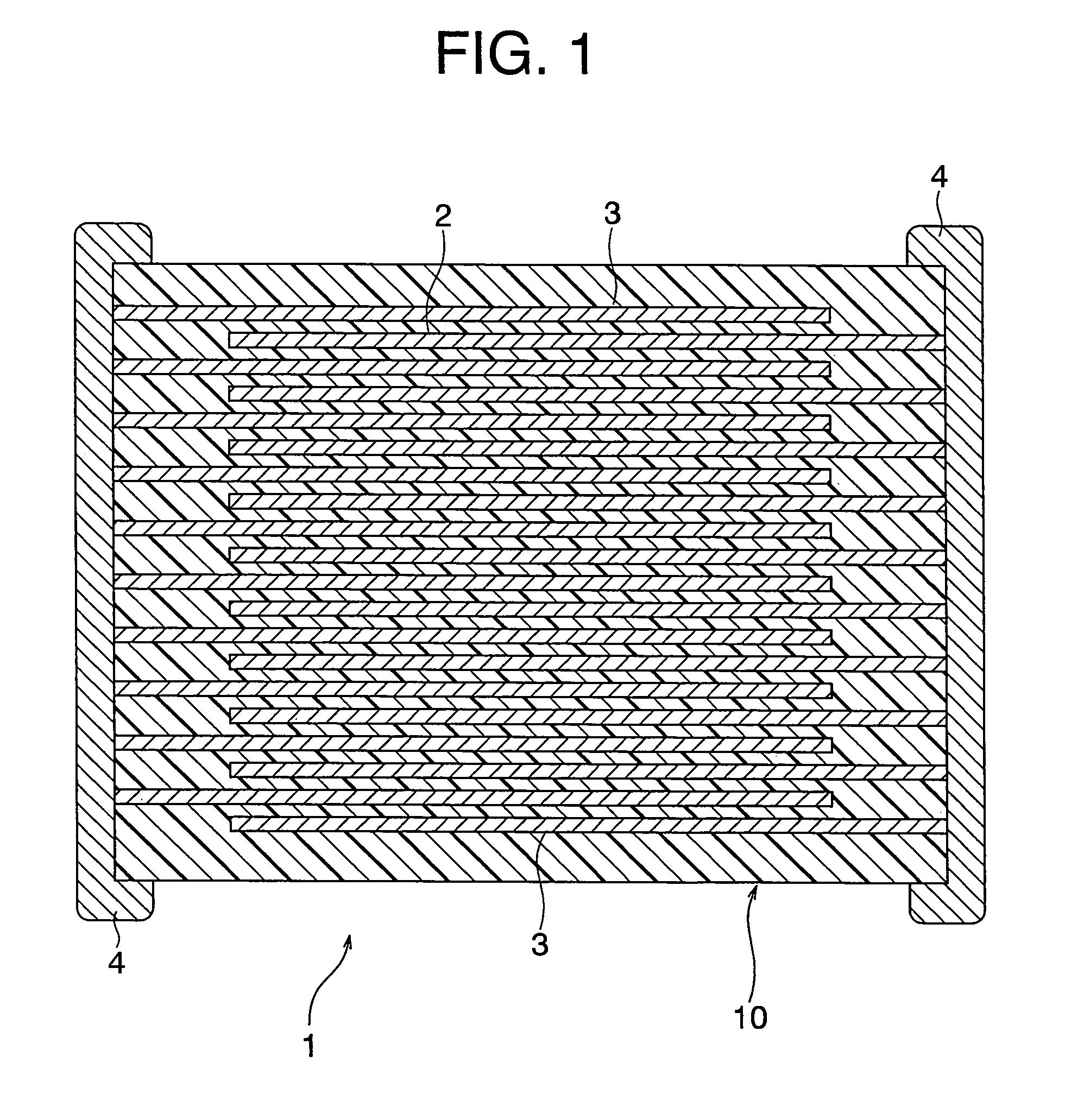

Dielectric ceramic composition, multilayer ceramic capacitor, and method for manufacturing the same

InactiveUS20050219794A1Keep for a long timeSmall variation in lifetimeFixed capacitor dielectricStacked capacitorsBarium titanateCeramic capacitor

A dielectric ceramic composition contains components, with respective numbers of moles relative to 100 moles of barium titanate, including barium titanate, a first sub-component containing at least one oxide selected from a Mg oxide, a Ca oxide, a Ba oxide, and Sr oxide, a second sub-component containing an oxide containing 1 mol of Si atoms per mol, a third sub-component containing at least one oxide selected from a V oxide, a Mo oxide, and a W oxide, a fourth sub-component containing at least one R1 oxide (wherein R1 is at least one selected from Sc, Er, Tm, Yb, and Lu), a fifth sub-component containing at least one R2 oxide (wherein R2 is at least one selected from Y, Dy, Ho, Tb, Gd, and Eu), a sixth sub-component containing at least one selected from a Mn oxide and a Cr oxide, and a seventh sub-component containing at least one selected from calcium zirconate and a mixture of a Ca oxide and Zr oxide. The ratio (A / B) of the number of moles A of the second sub-component to the total number of moles B of the fourth and fifth sub-components is 0.7 or more. Alternatively, the ratio (C / D) of the number of moles C of Si atoms in the second sub-component to the total number of moles of the atoms in the first to seventh sub-components excluding the Si atoms and oxygen atoms being 0.2 or more, and the total number of moles of the fourth and fifth sub-components being 3 or more.

Owner:TDK CORPARATION

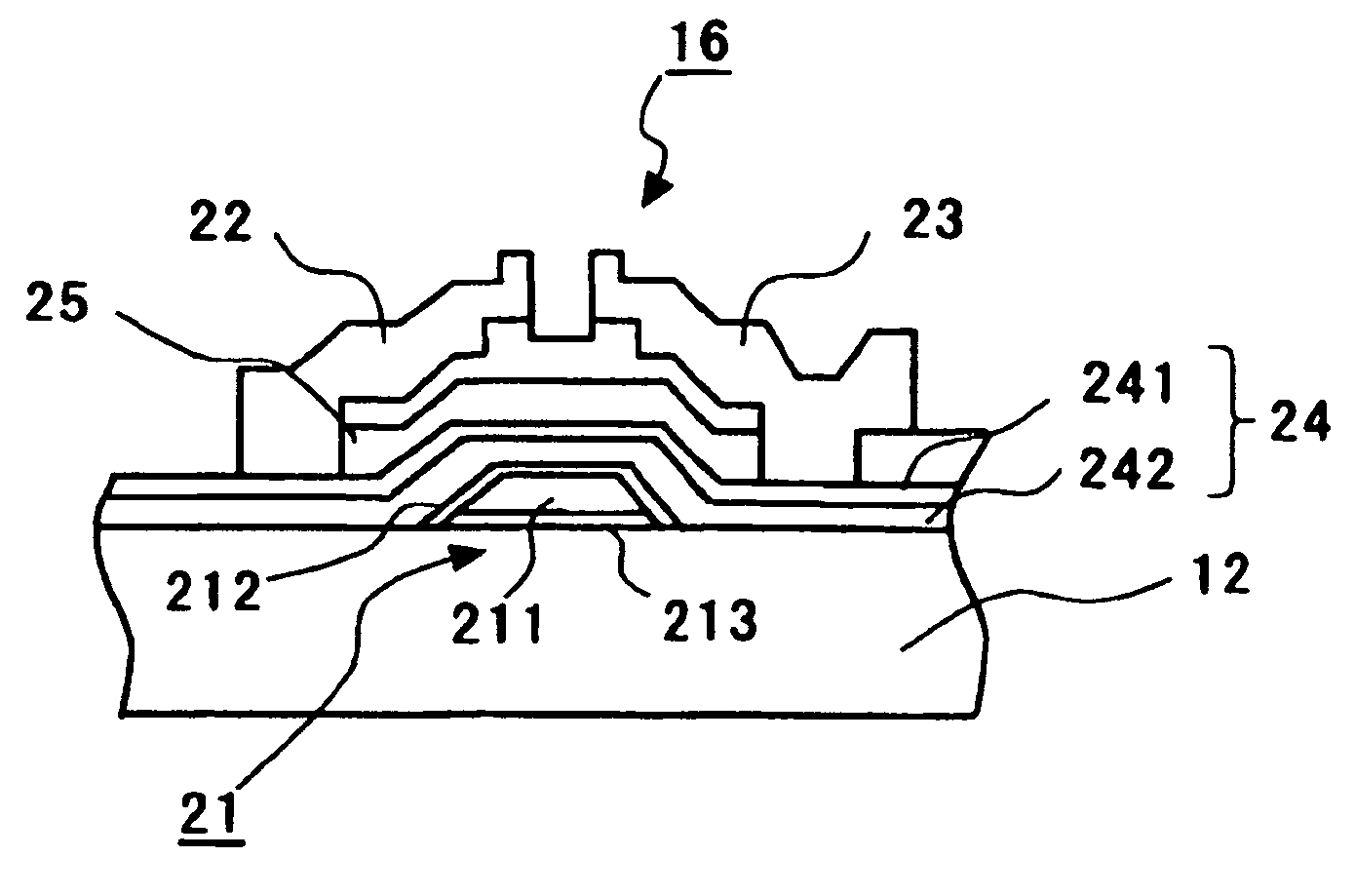

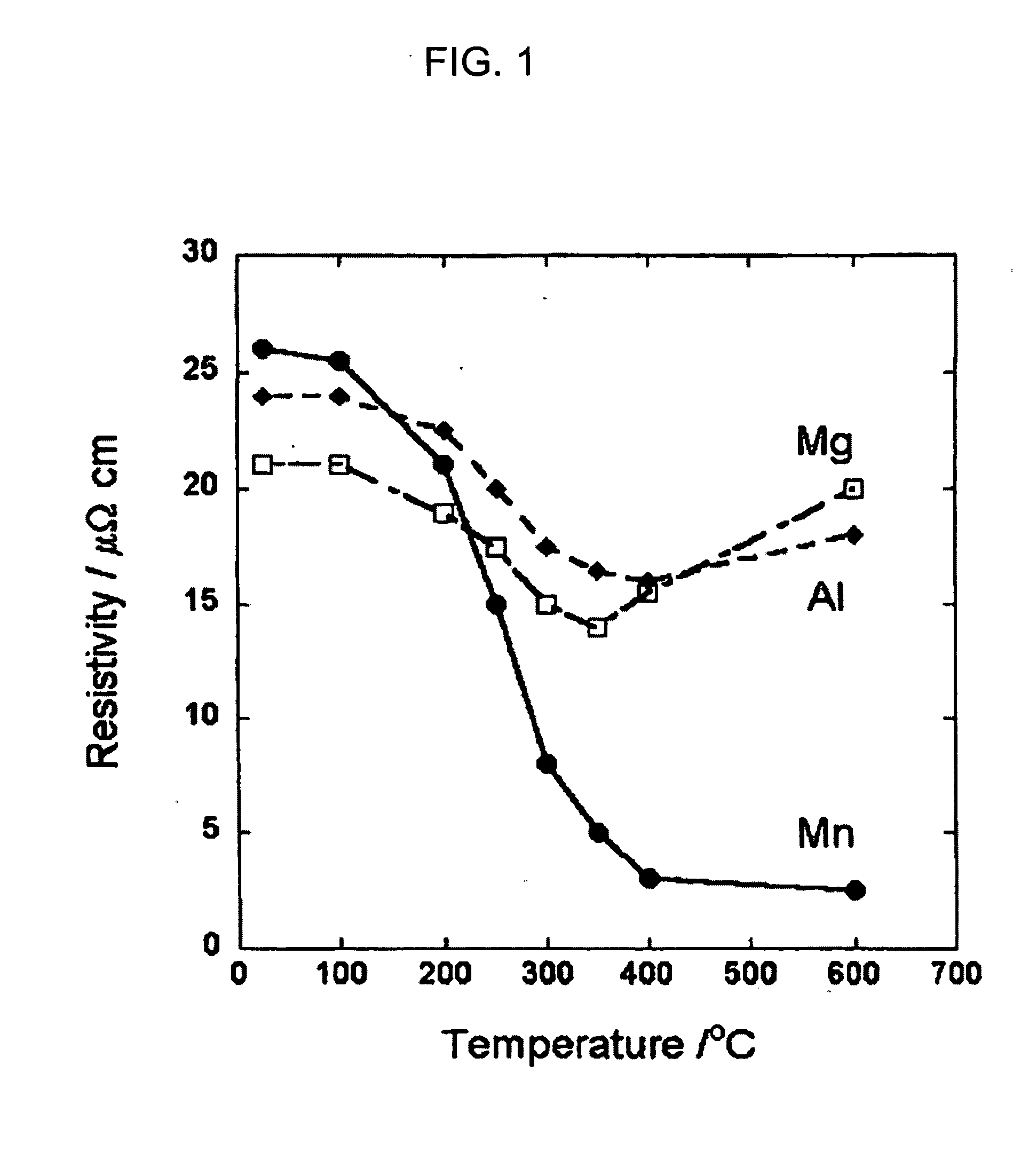

Copper alloy and liquid-crystal display device

ActiveUS20110032467A1Well formedSemiconductor/solid-state device detailsSolid-state devicesSolubilityLiquid-crystal display

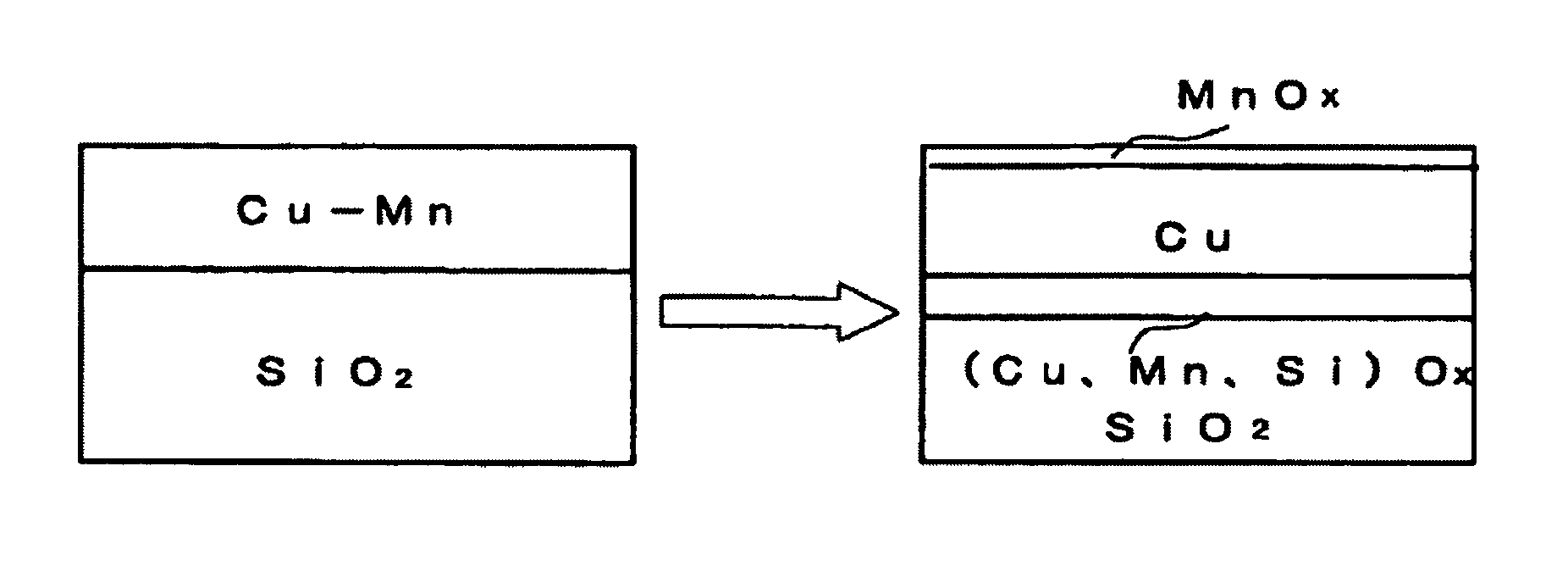

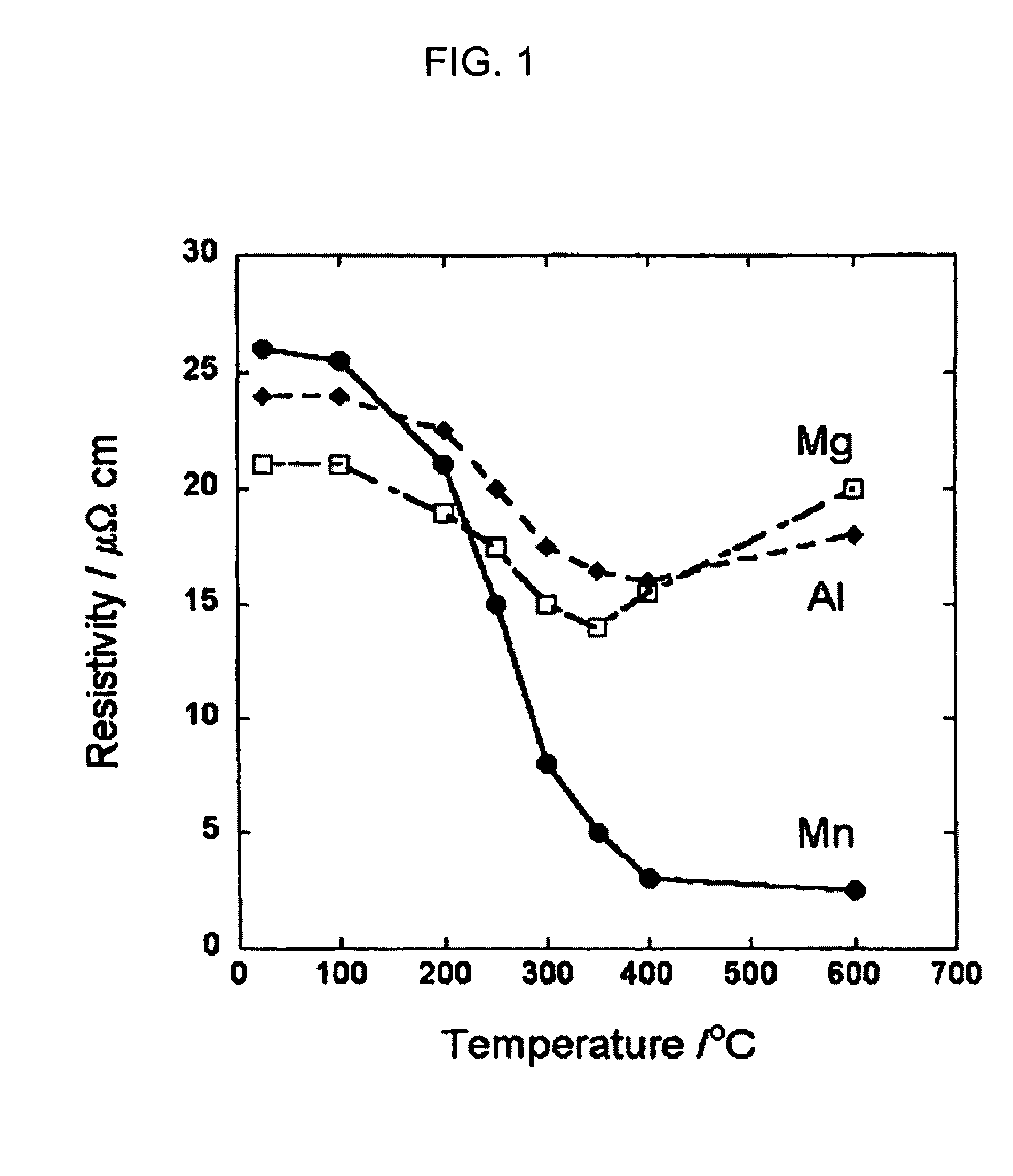

A liquid crystal display device including, a pair of substrates, a gate electrode of a thin film transistor (TFT) formed on one of the substrates, and a wiring layer connected to the gate electrode or an electrode of the thin film transistor, wherein at least a part of the gate electrode or a part the wiring layer is formed by a layer structured by a pure copper layer and a Cu—Mn alloy layer including Mn, wherein a concentration of Mn in the Cu—Mn alloy layer is more than 0.1 and not more than 20 atomic percentage within a solubility limit of Mn in the copper, and wherein a boundary surface between the Cu—Mn alloy layer and said one of the substrate includes an oxide layer having a Mn oxide layer.

Owner:XENOGENIC DEV LLC

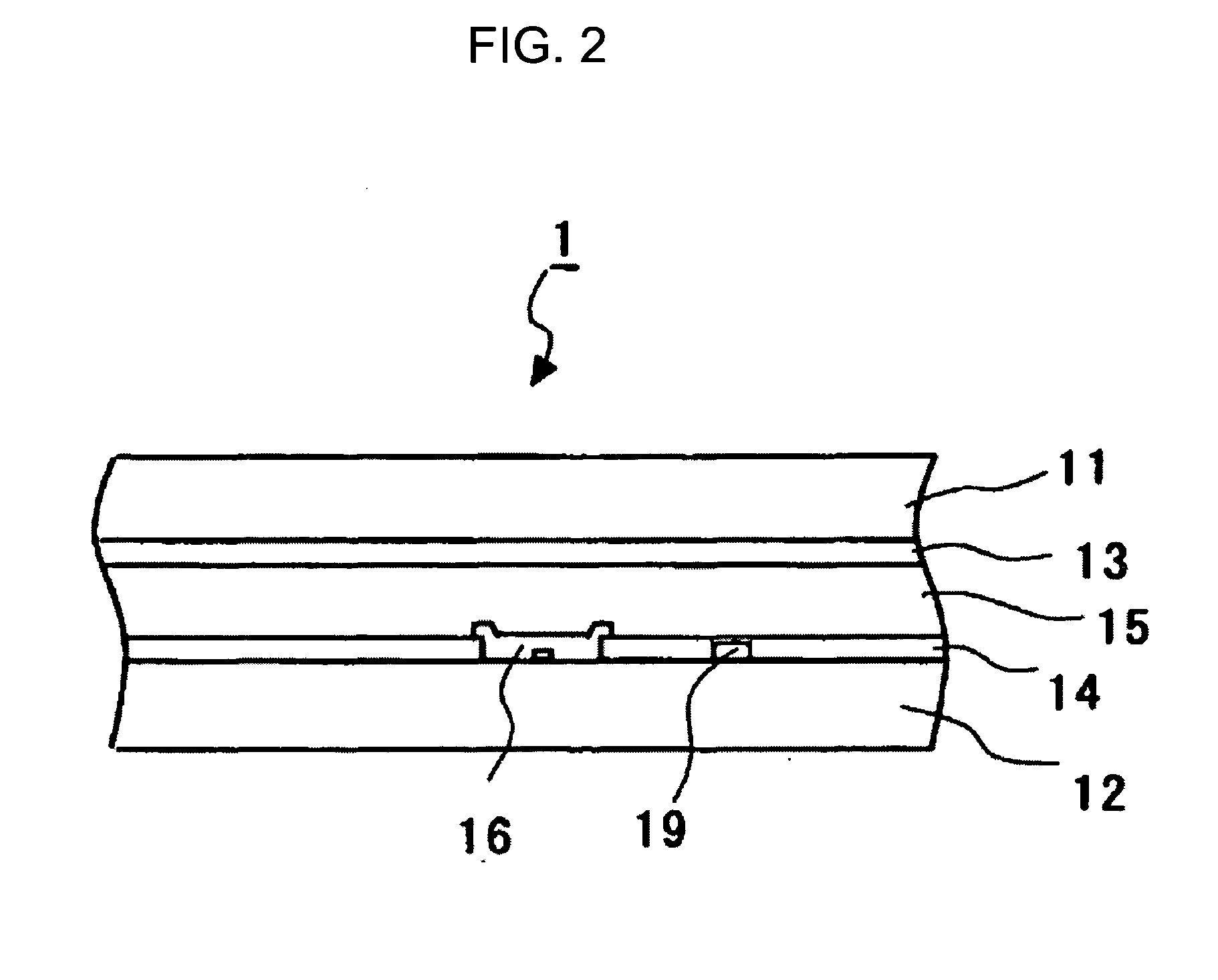

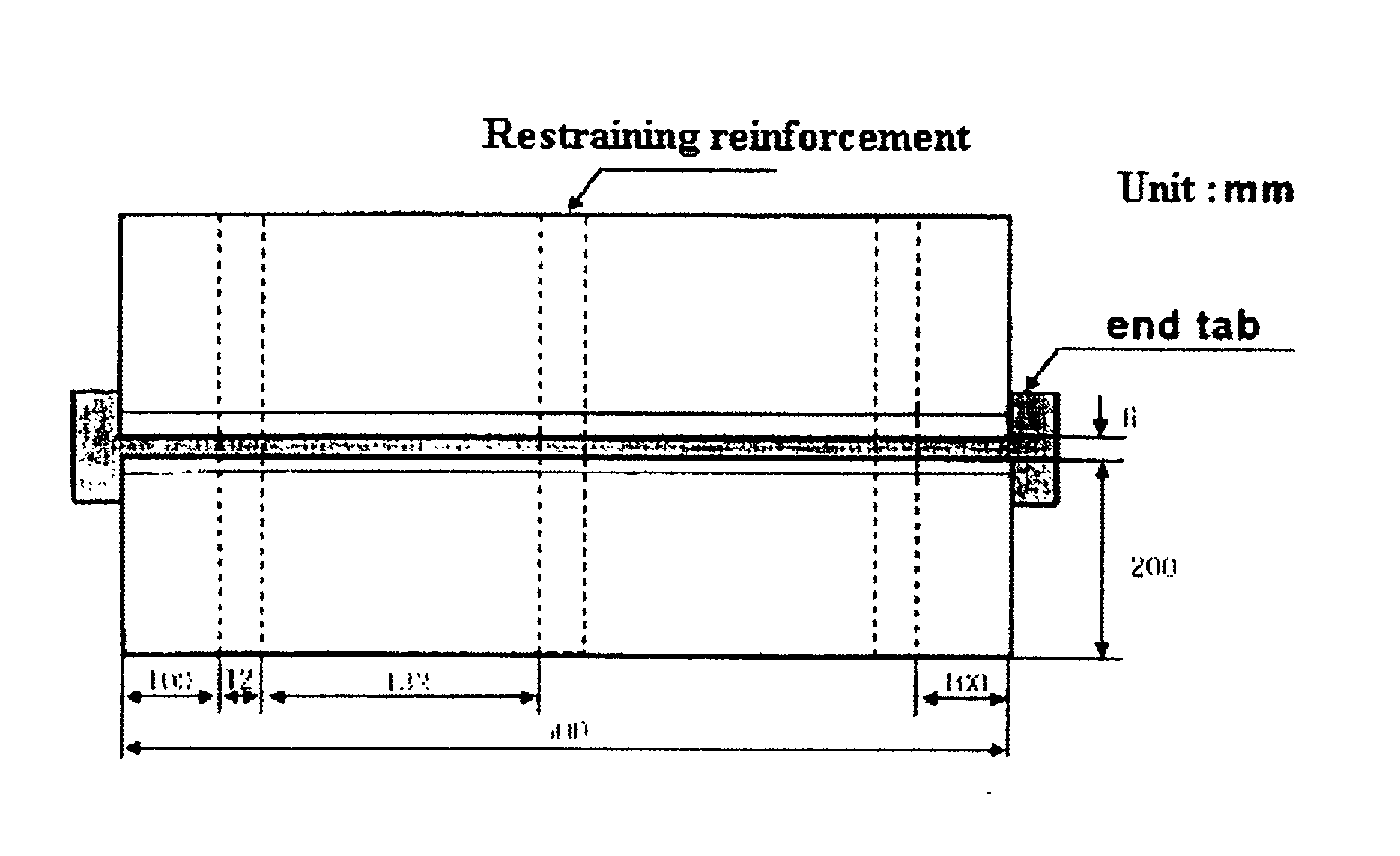

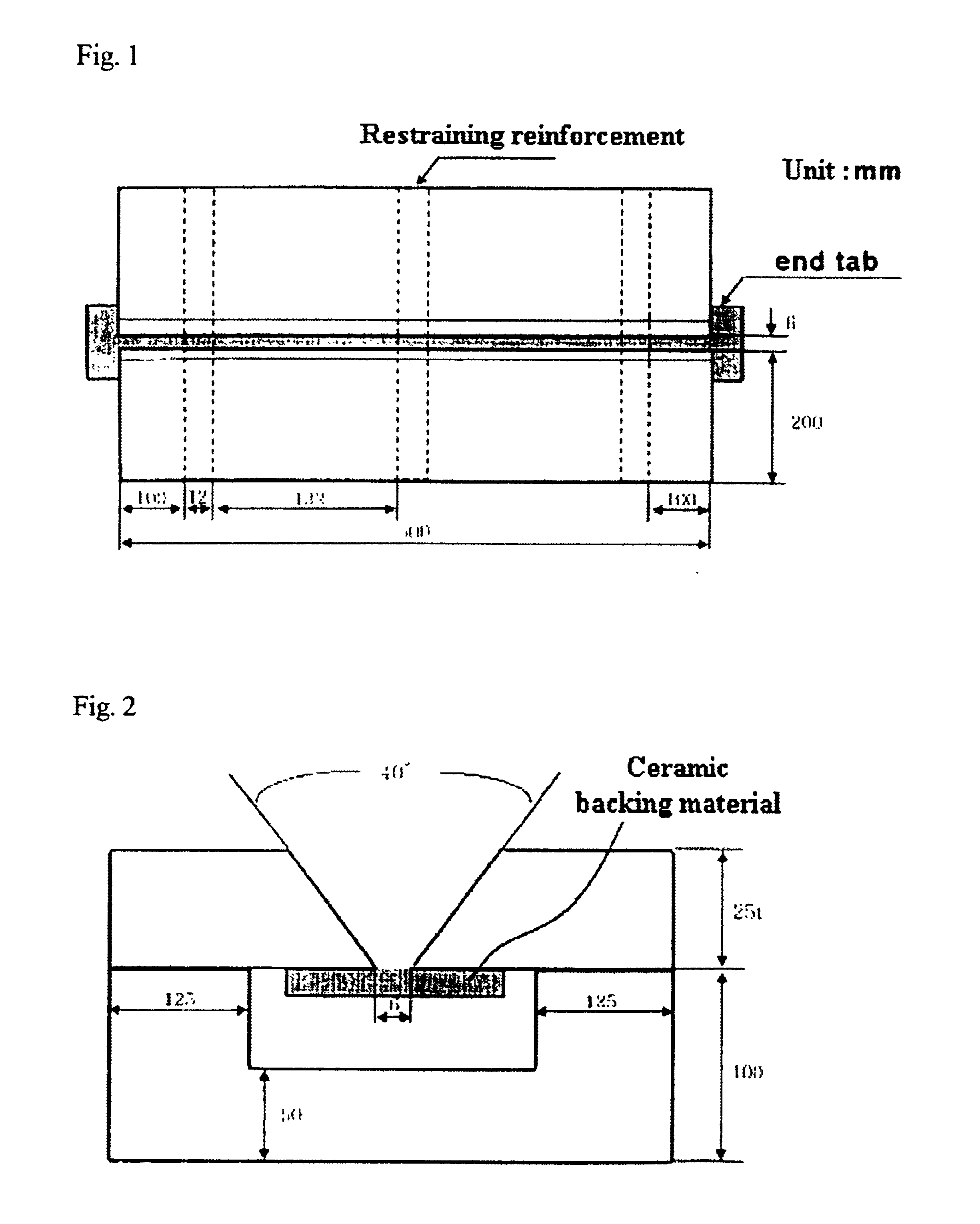

Basic flux cored wire with excellent weldability

InactiveUS6713723B2Improve crack resistanceLow toughnessWelding/cutting media/materialsSoldering mediaCrack resistanceShielding gas

Disclosed is a basic flux cored wire having a mild steel or an alloy steel sheath filled with flux, characterized in that the flux essentially consists of, with respect to the total weight of the wire: 0.3 to 3.0% Ti and Ti oxide (TiO2-converted value); 1.0 to 2.5% Si and Si oxide (SiO2-converted value); 0.1 to 1.5% Mg and Mg oxide (MgO-converted value); 1.5 to 4.0% Mn and Mn oxide (MnO-converted value); 0.2 to 1.5% Al and Al oxide (Al2O3-converted value); 0.1 to 1.0% Zr and Zr oxide (ZrO2-converted value); 0.2 to 3.5% CaF2; and 0.01 to 0.5% K2O, with the proviso that the components satisfy the basicity of 0.5 to 4.5 in the basicity equation (1) defined as B=(CaF2+MgO+MnO+K2O) / (TiO2+SiO2+Al2O3+ZrO2). The basic flux cored wire of the present invention is excellent in crack resistance and low temperature toughness, and exhibits excellent welding workability in all welding positions, ensuring an improvement in the efficiency of welding work. Furthermore, the basic flux cored wire according to the present invention exhibits excellent welding workability even under a shield gas of 100% CO2.

Owner:KISWEL LTD

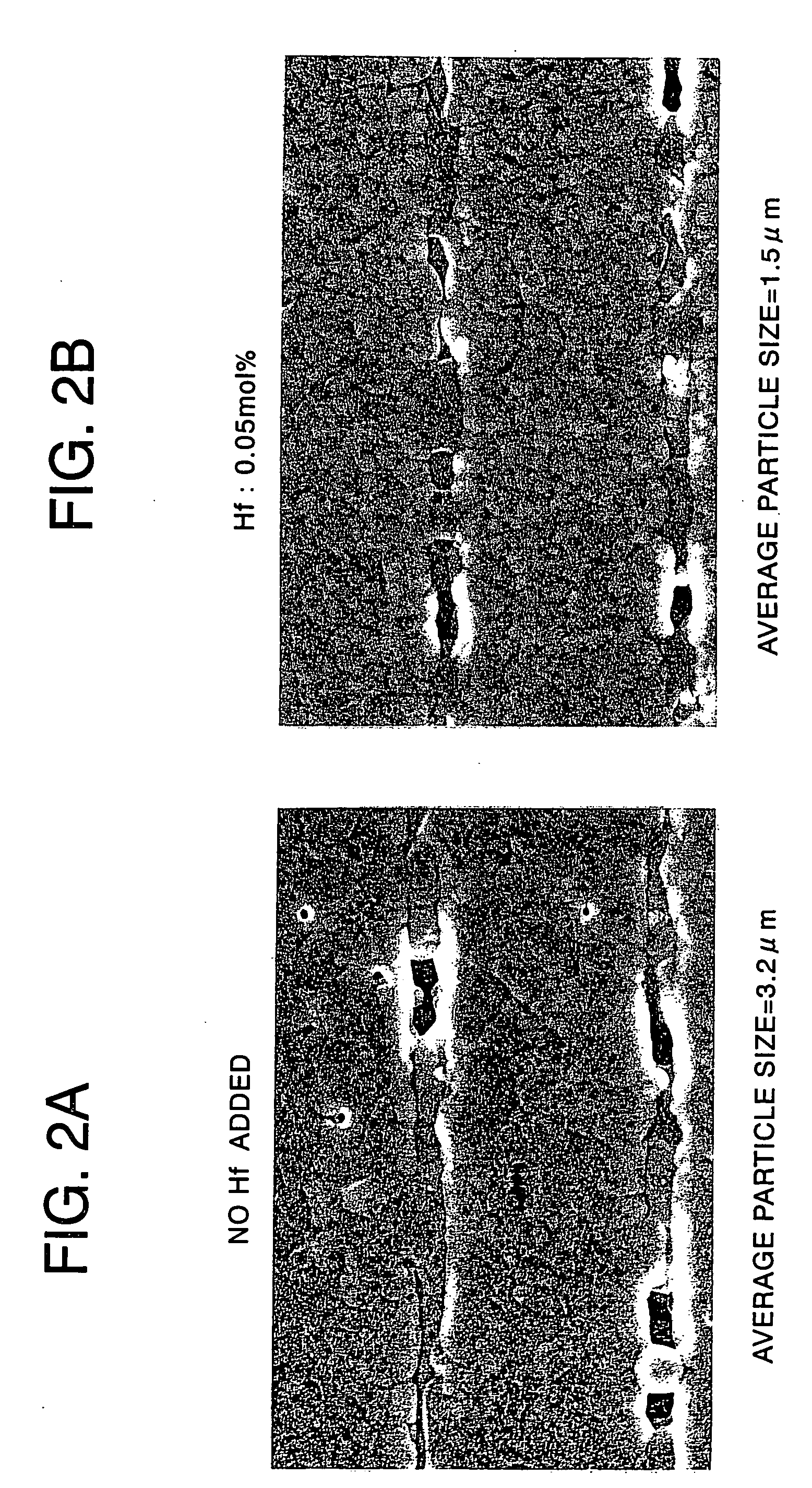

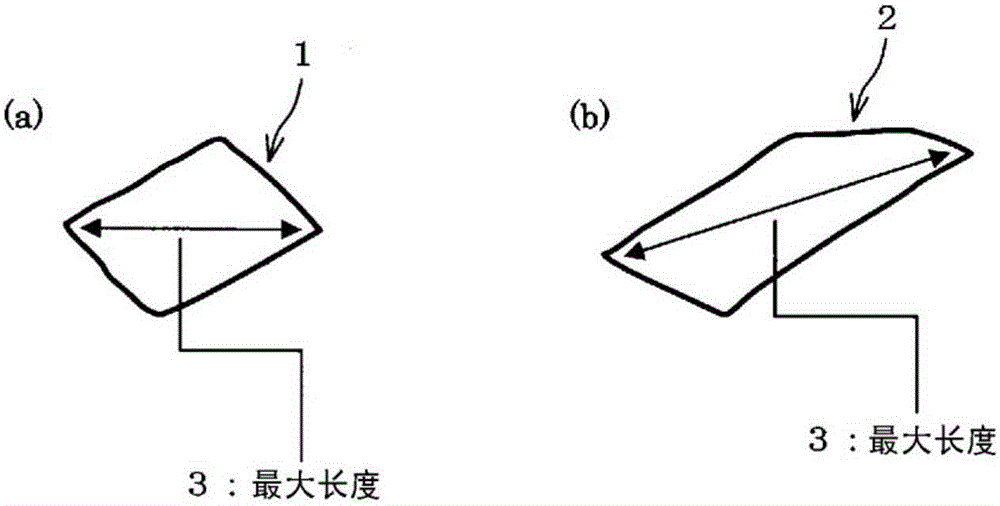

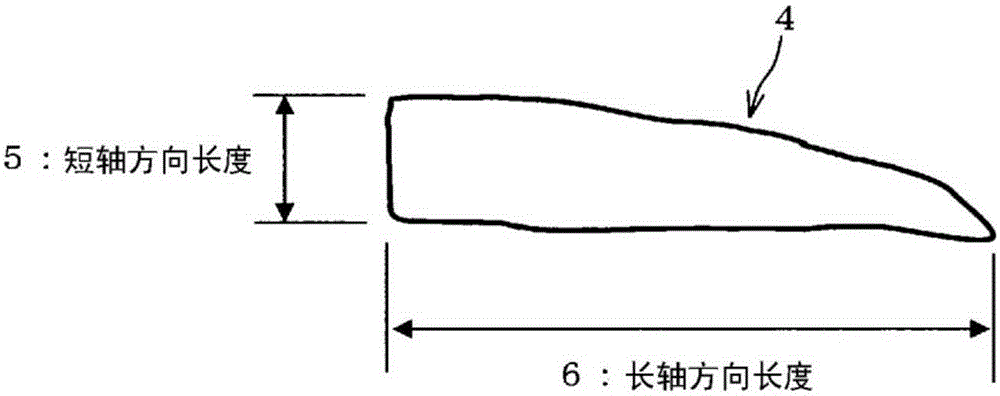

Steel sheet for hot stamping, method for production thereof, and hot stamping steel material

ActiveUS20150024237A1Improve hydrogen embrittlement resistanceEasy to practiceHot-dipping/immersion processesFurnace typesHot stampingChemical composition

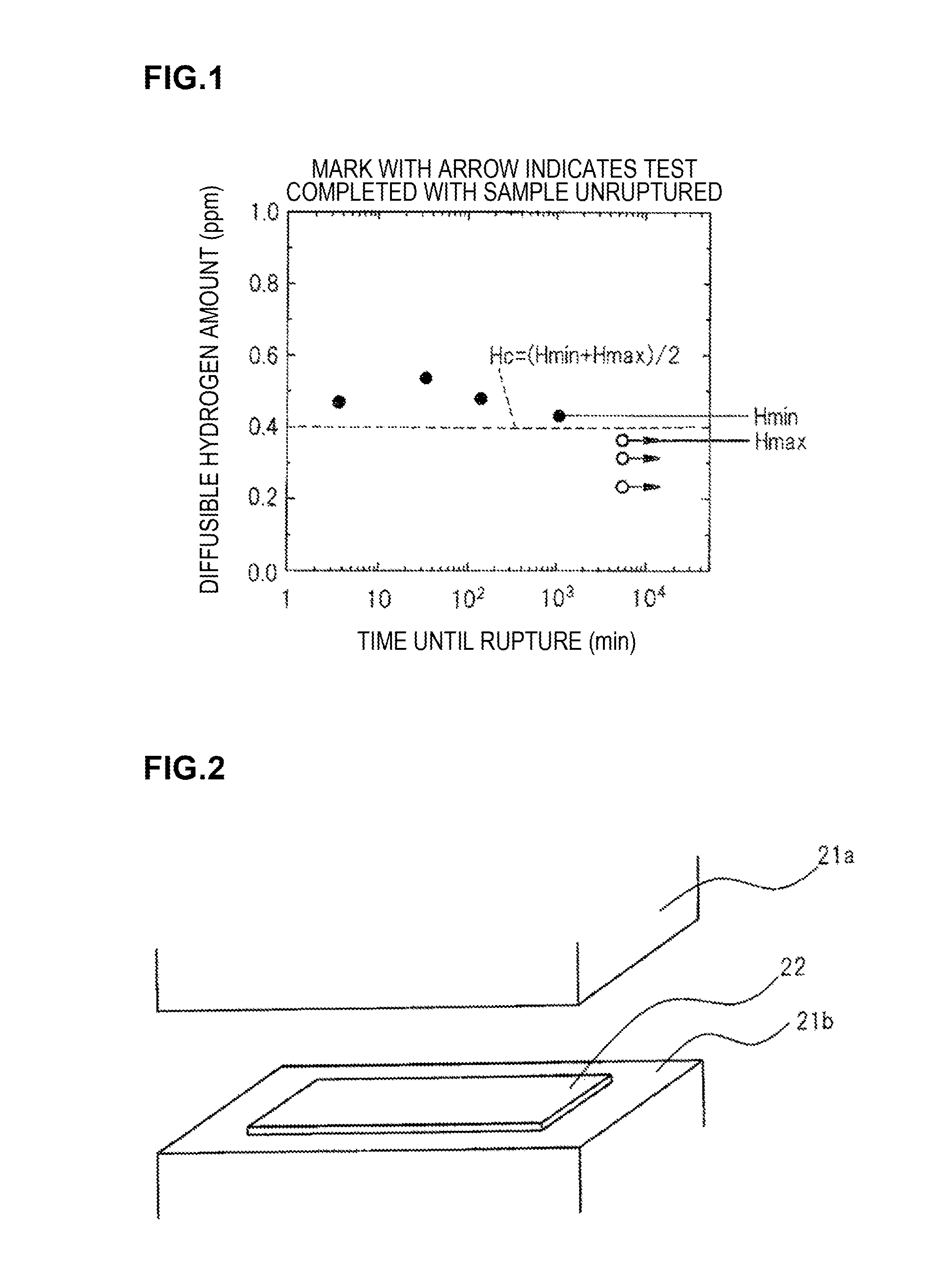

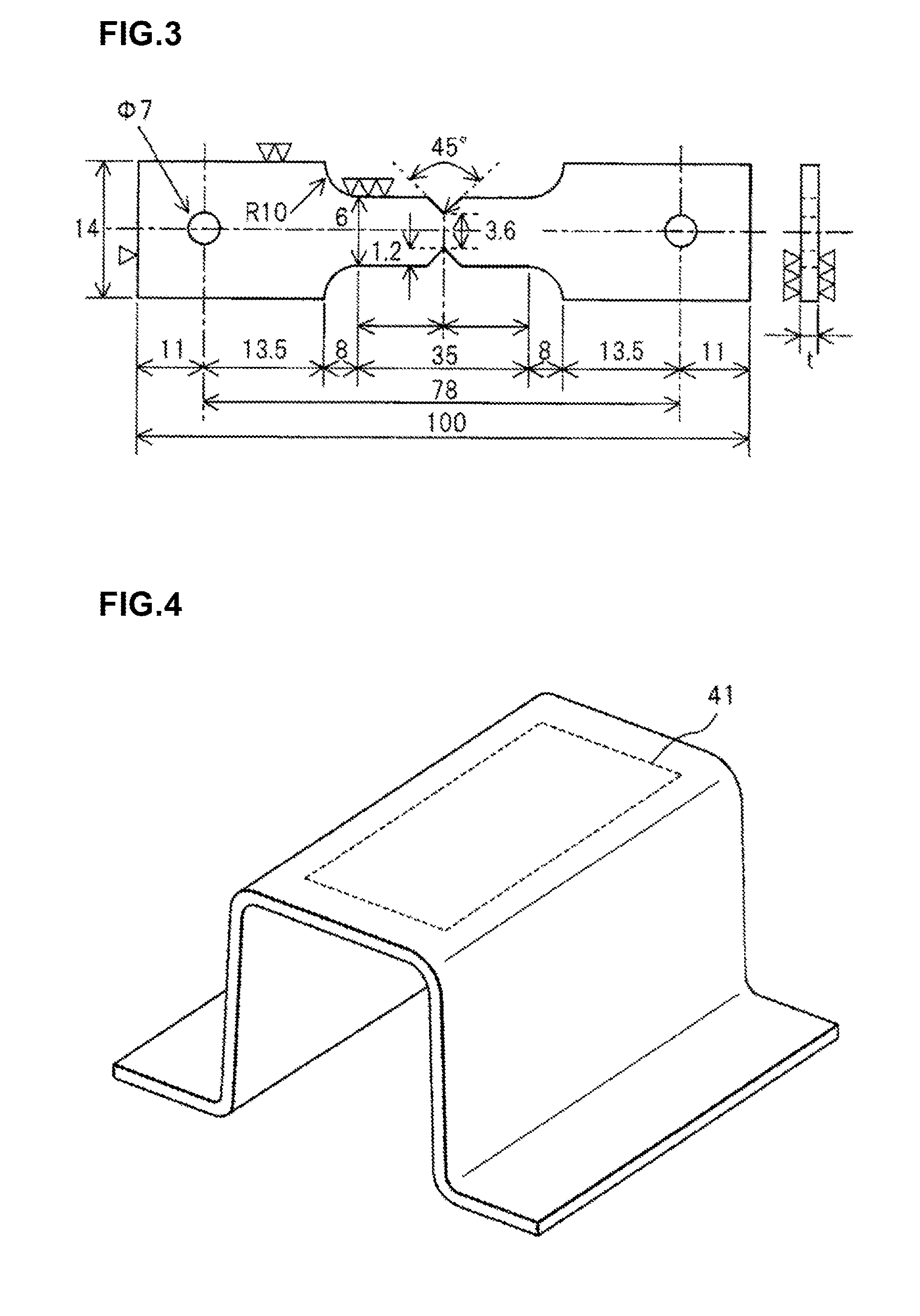

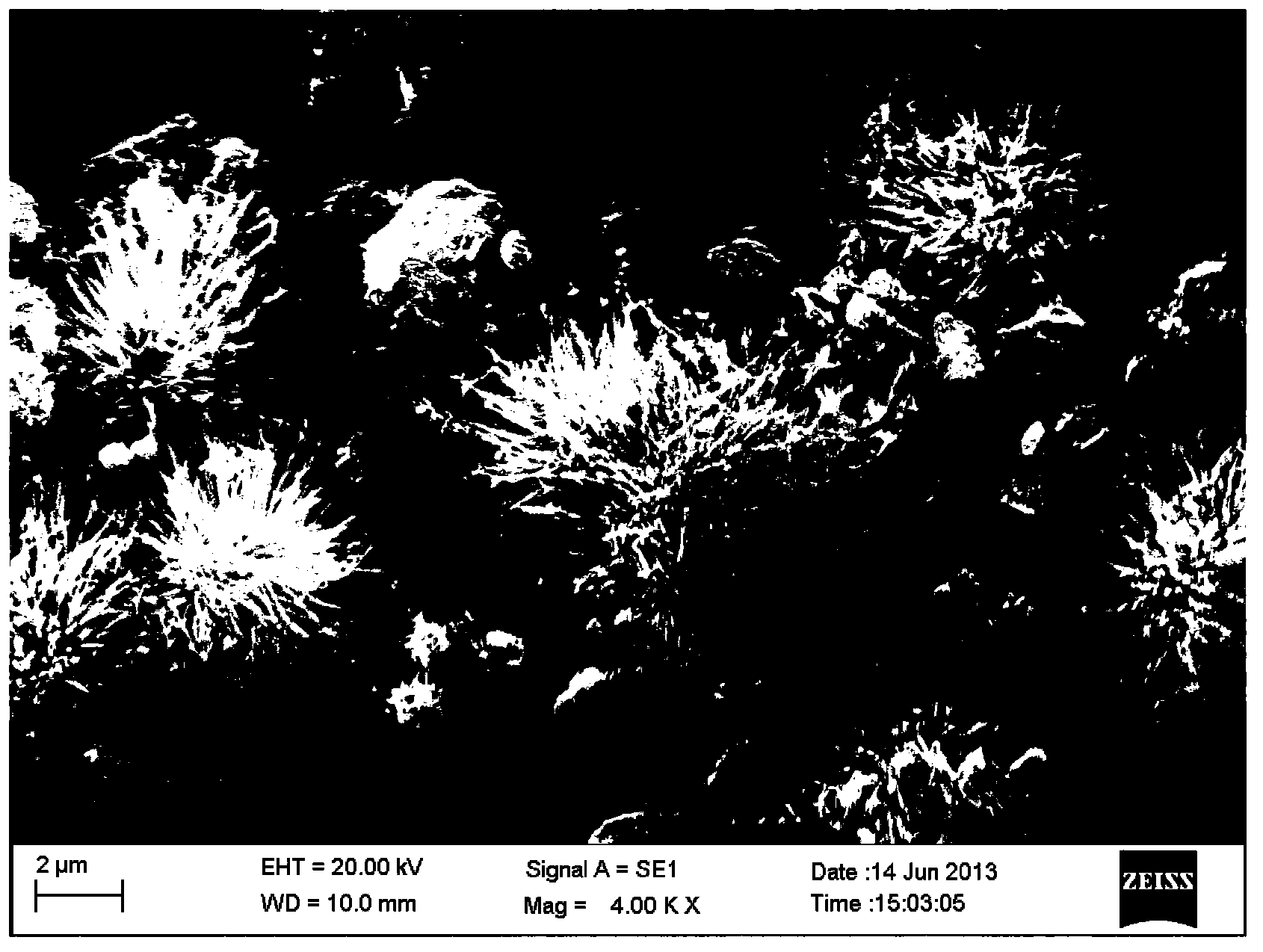

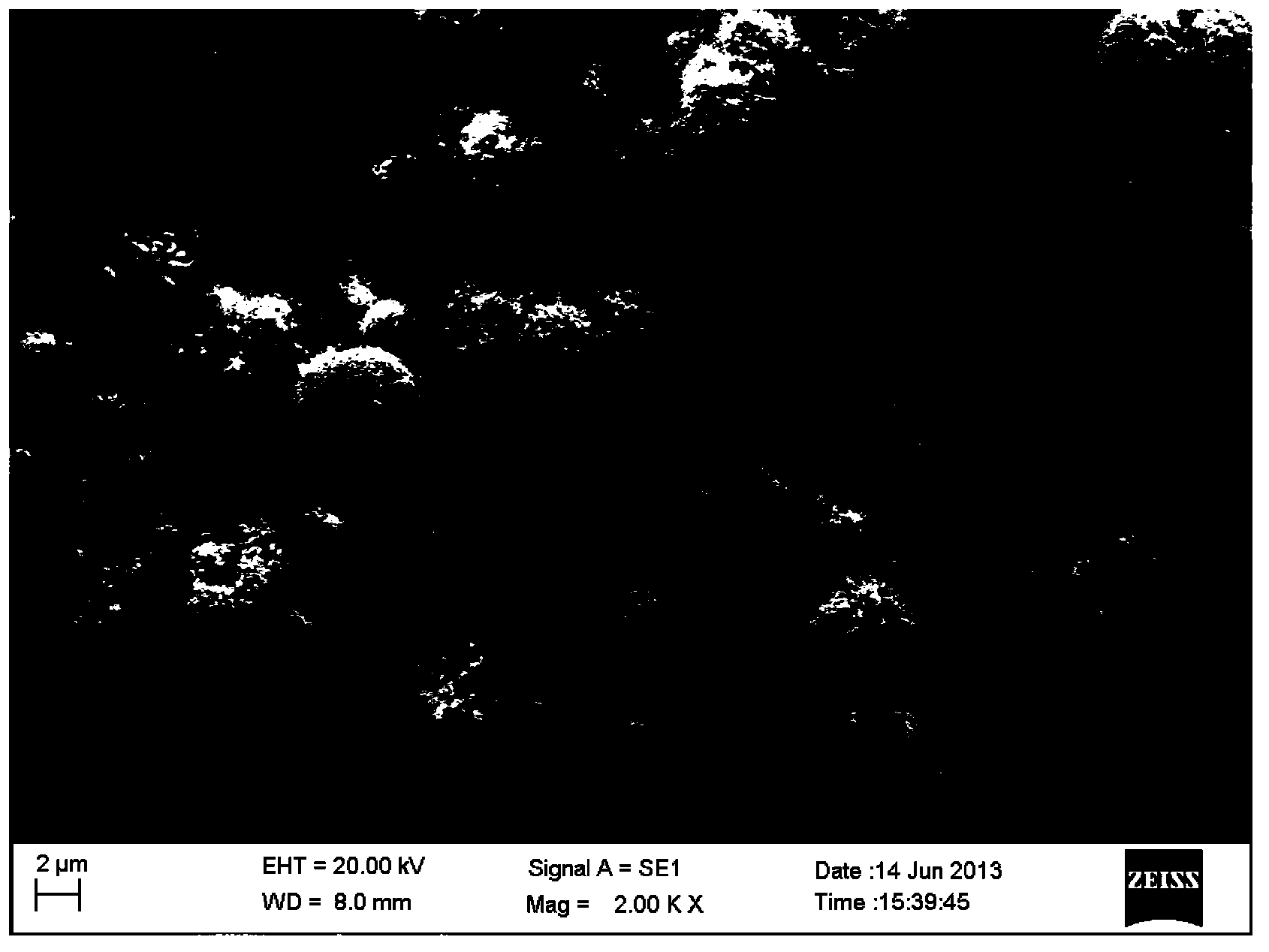

A hot stamping steel material, which secures good hydrogen embrittlement resistance even when the steel sheet after hot stamping is subjected to processing leading to remaining of stress, such as piercing and which is easily practicable, wherein the steel sheet has the chemical composition of: C: 0.18 to 0.26%; Si: more than 0.02% and not more than 0.05%; Mn: 1.0 to 1.5%; P: 0.03% or less; S: 0.02% or less; Al: 0.001 to 0.5%; N: 0.1% or less; O: 0.001 to 0.02%; Cr: 0 to 2.0%; Mo: 0 to 1.0%; V: 0 to 0.5%; W: 0 to 0.5%; Ni: 0 to 5.0%; B: 0 to 0.01%; Ti: 0 to 0.5%; Nb: 0 to 0.5%; Cu: 0 to 1.0%; and balance: Fe and impurities, in terms of % by mass, the concentration of a Mn-containing inclusion is not less than 0.010% by mass and less than 0.25% by mass, and the number ratio of a Mn oxide to the inclusion having a maximum length of 1.0 to 4.0 μm is 10.0% or more.

Owner:NIPPON STEEL CORP

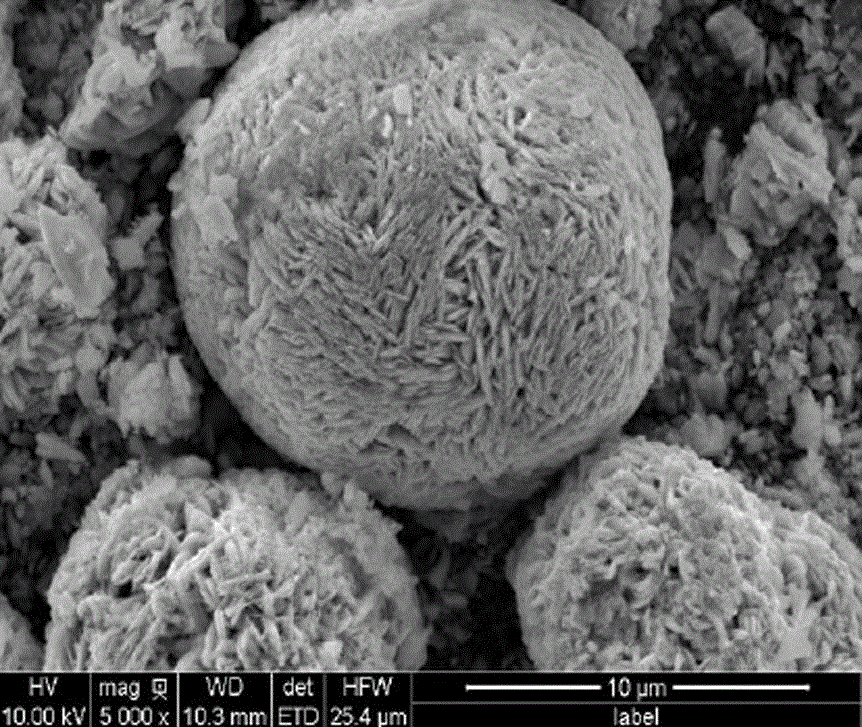

Preparation method and application of high-capacity high-temperature-resistant lithium manganate

ActiveCN103384003AImprove charging capacityImprove cycle performanceCell electrodesPhosphateManganate

The invention discloses a preparation method and application of high-capacity high-temperature-resistant lithium manganate. The preparation method comprises a first step of enabling manganese sulfate, ammonium persulfate and aluminum sulfate to undergo a hydrothermal reaction and then be heated in air, and obtaining aluminum-doped nanometer gamma-manganese dioxide; a second step of enabling products in the first step and lithium carbonate to be dispersed in an organic solvent and undergo ball-milling crushing and drying, performing primary sintering in the presence of oxygen, and obtaining an aluminum-doped lithium manganate precursor; a third step of mixing aluminum nitrate, the aluminum-doped lithium manganate precursor and water to obtain suspension liquid, adding phosphate and polymeric dispersants in the suspension liquid, evaporating the solvent after mixing, performing secondary sintering in the presence of oxygen, and obtaining the product. The invention further discloses application of the high-capacity high-temperature-resistant lithium manganate in batteries. The product has the advantages of high charge-discharge capacity and small in circulation attenuation. The initial charge gram volume is 137.7mAh / g, and the charge gram volume is kept at 121.1 mAh / g after circulation for 30 circles. The preparation process is free of pollution, and the preparation method is high in yield and suitable for industrialized production.

Owner:ADVANCED ELECTRONICS ENERGY LIMITED GUANGDONG

Hot dip alloyed zinc coated steel sheet and method for production thereof

ActiveUS20060269776A1Good shapeabilityHigh strengthHot-dipping/immersion processesLiquid surface applicatorsAlloyUltimate tensile strength

The present invention provides an alloyed molten zinc plated steel sheet having an area of the Fe and Zn alloy phase in the unformed parts in the plating layer of less than 10% of the area of the steel sheet as a whole and superior in strength and shapeability and a method of producing this alloyed molten zinc plating steel sheet by a continuous zinc plating production system which enables production at a low cost without modification of the system or addition of steps, said alloyed molten zinc plated steel sheet characterized by comprising a steel sheet including C: 0.05 to 0.40%, Si: 0.2 to 3.0%, and Mn: 0.1 to 2.5%, the balance comprised of Fe and unavoidable impurities, having on its surface a Zn alloy plating layer comprised of Fe in a concentration of 7 to 15 wt %, Al in a concentration of 0.01 to 1 wt %, and the balance of Zn and unavoidable impurities, said plating layer containing oxide particles of at least one type of oxide selected from an Al oxide, Si oxide, Mn oxide, and complex oxides of the same alone or in combination.

Owner:NIPPON STEEL CORP +1

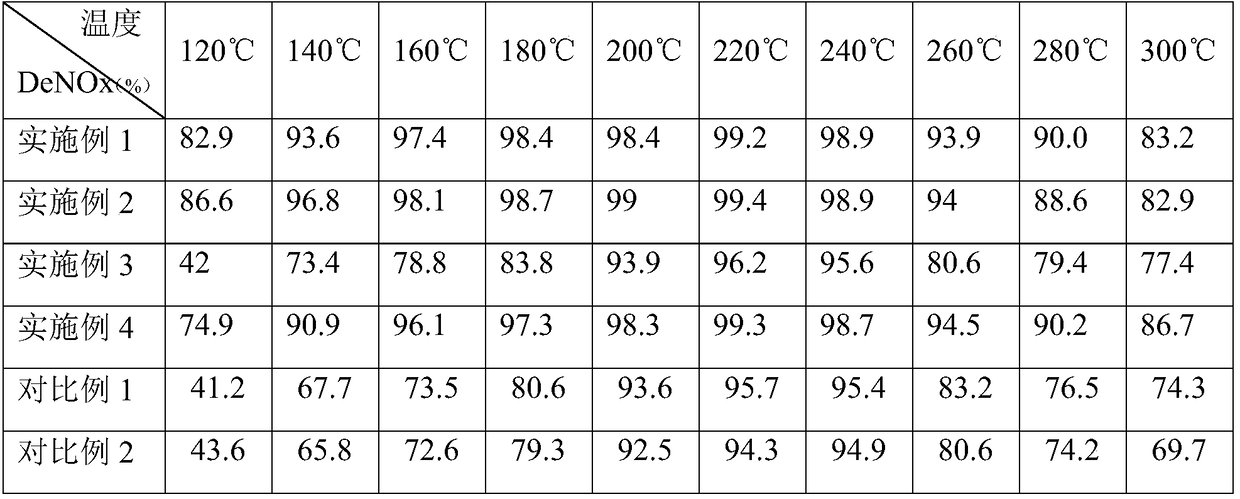

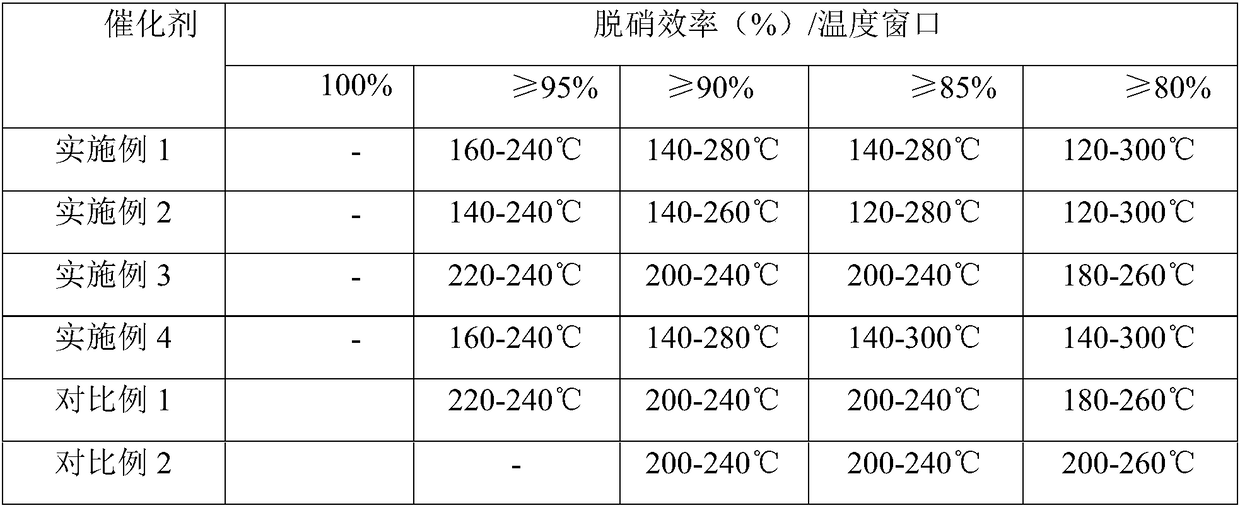

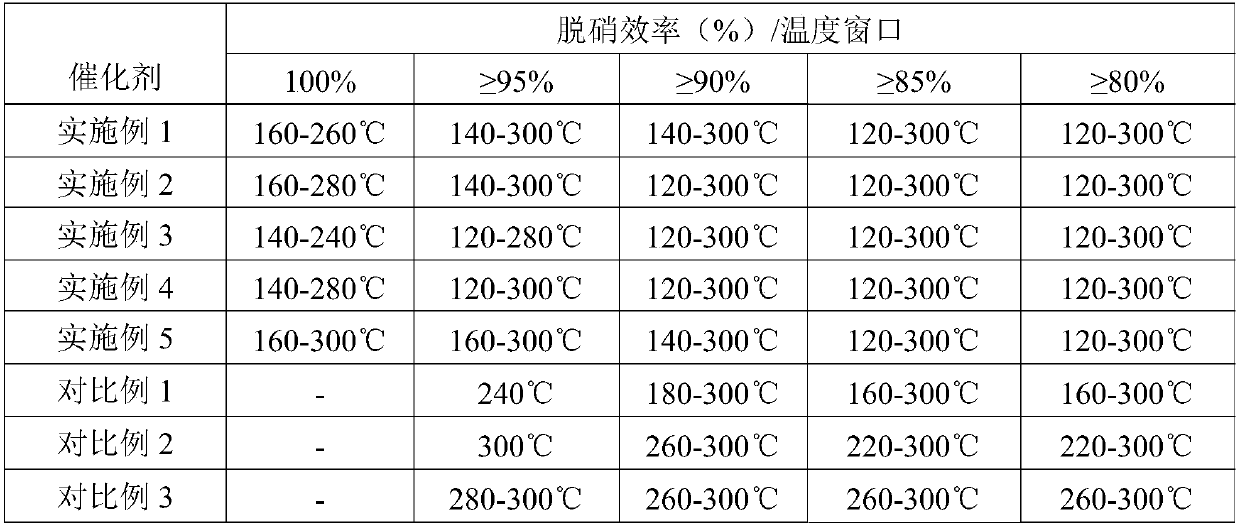

Low-temperature SCR flue gas denitrification catalyst and preparation method and application thereof

InactiveCN109092323AAvoid hydrolysisIncreased dispersionGas treatmentHeterogenous catalyst chemical elementsFlue gasActive component

The invention belongs to the technical field of environmental protection and catalysis, and discloses a low-temperature SCR flue gas denitrification catalyst and a preparation method and application thereof. The catalyst comprises a carrier, a first metallic oxide and a second metallic oxide, wherein the first metallic oxide and the second metallic oxide are immobilized on the carrier, the carrierrefers to nanometer titanium dioxide, the first metallic oxide refers to a Fe oxide, and the second metallic oxide is a Mn oxide. The catalyst has an excellent SCR catalytic activity in a wide-temperature (from 140 DEG C to 240 DEG C) window, and has a high NOx removal rate in the low-temperature range from 140 DEG C to 240 DEG C. Besides, the vanadium-free metallic oxides serve as the active components of the catalyst, and the catalyst has a positive significance in control over environmental pollution and secondary pollution of catalyst wastes.

Owner:CHINA PETROLEUM & CHEM CORP +1

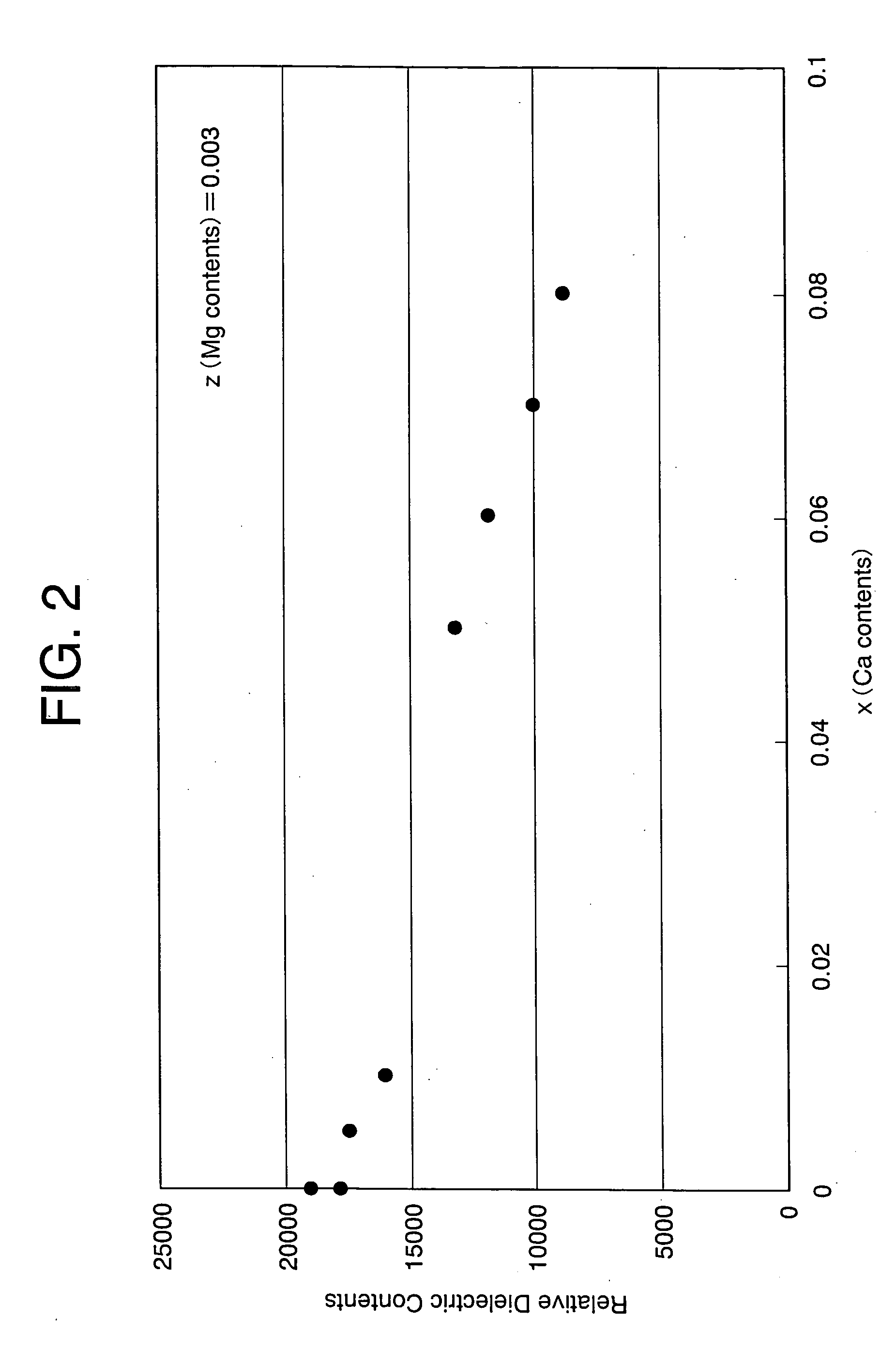

Dielectric ceramic compositions and electronic devices

ActiveUS20050111163A1Low IR defect rateHigh dielectric constantFixed capacitor dielectricStacked capacitorsDielectricCeramic capacitor

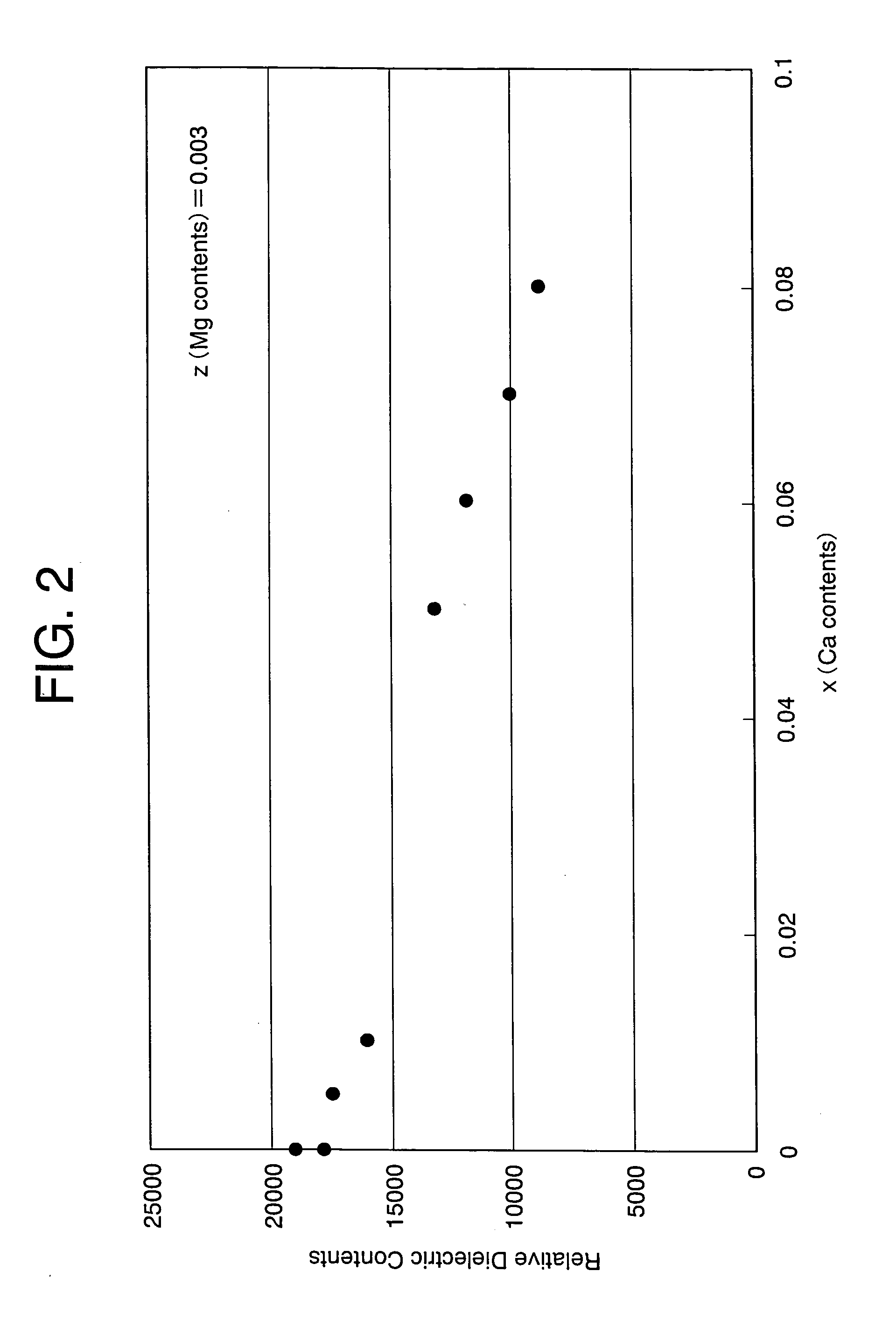

In order to provide dielectric ceramic composition having low IR defect rate and high relative dielectric constant even when the multilayer ceramic capacitor is made thinner, dielectric ceramic composition including a main component expressed by a composition formula {{Ba(1-x)Cax}O}A{Ti(1-y-z)ZryMgz}BO2 and subcomponents of Mn oxide, Y oxide, V oxide and Si oxide is provided. In the above formula, A, B, x , y and z are as follows: 0.995≦A / B≦1.020, 0.0001≦x≦0.07, preferably 0.001≦x≦0.05, 0.1≦y≦0.3 and 0.0005≦z≦0.0 1, preferably 0.003≦z≦0.0 1.

Owner:TDK CORPARATION

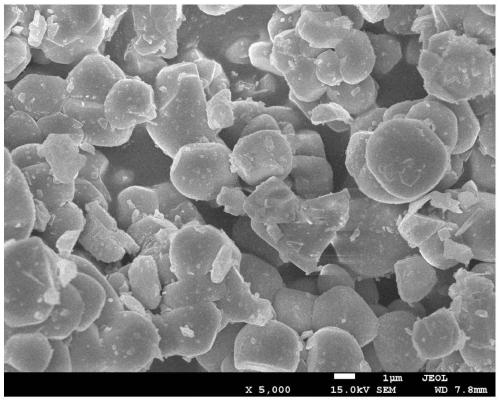

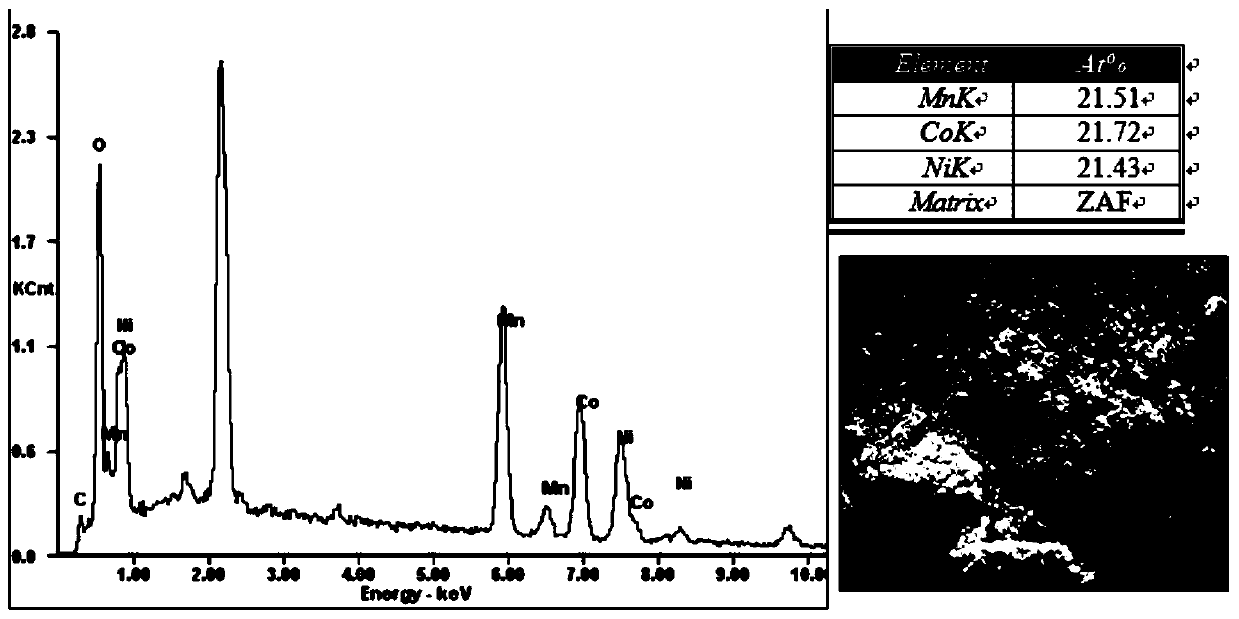

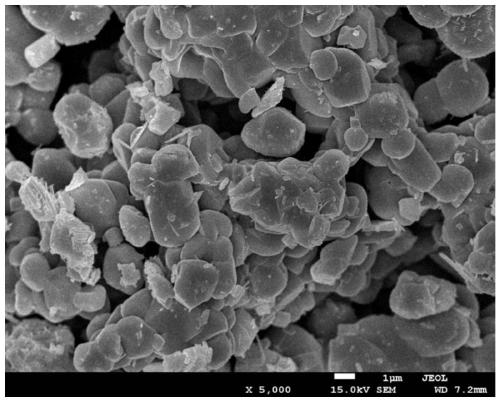

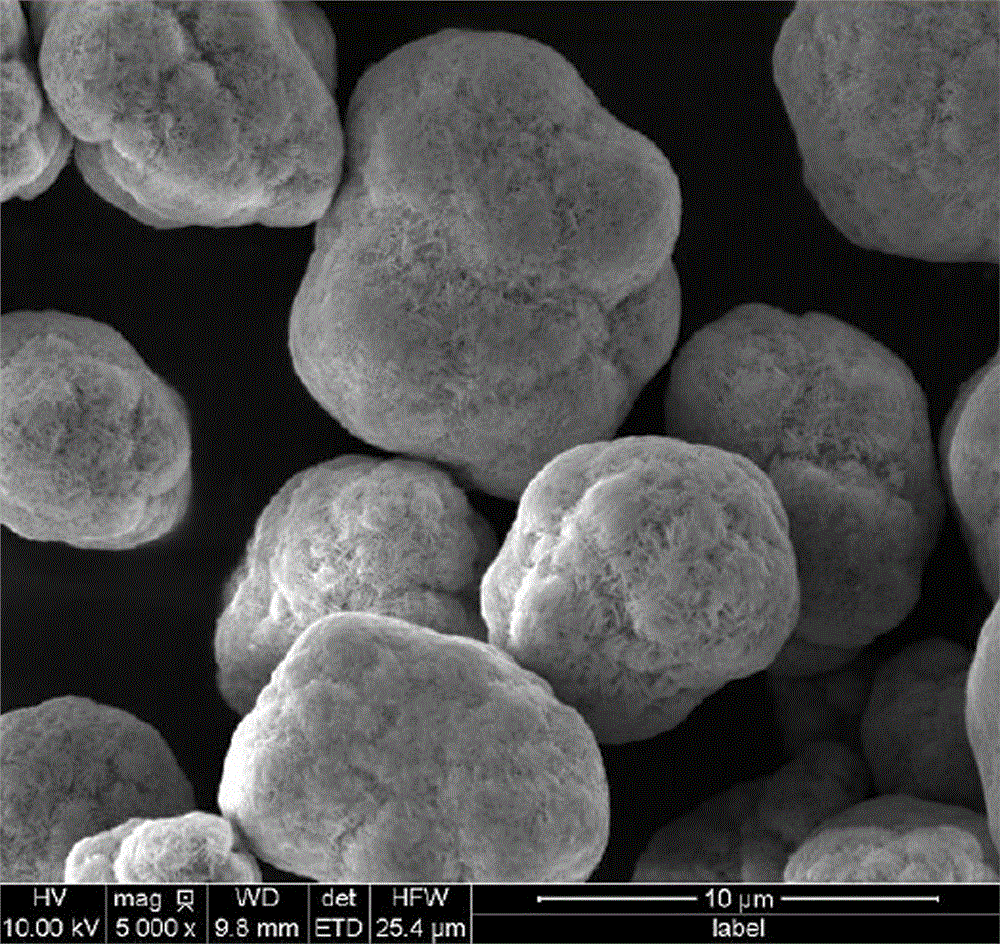

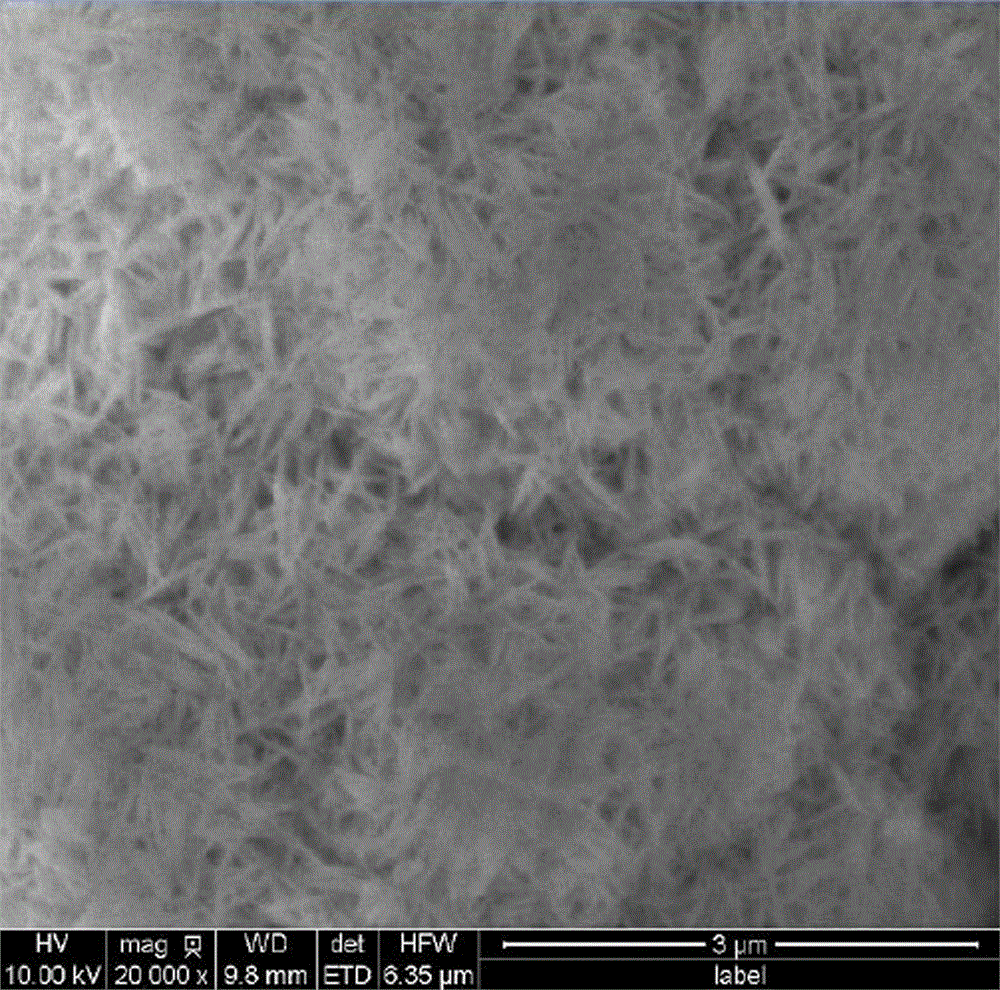

Preparation method of ternary Ni-Co-Mn precursor and ternary Ni-Co lithium manganate material

InactiveCN109809501AHigh specific capacityIncrease compaction densityPolycrystalline material growthCell electrodesNickel oxide hydroxideManganate

The invention discloses a preparation method of a ternary Ni-Co-Mn precursor and a ternary Ni-Co lithium manganate material. The preparation method of the ternary Ni-Co-Mn precursor comprises the following steps: (1) preparing a Ni-Co-Mn hydroxide solid solution through a co-precipitation method by taking a Ni-Co-Mn salt solution as a raw material and an alkaline solution as a precipitator; (2) sintering the Ni-Co-Mn hydroxide solid solution, thus obtaining a Ni-Co-Mn oxide precursor; (3) drying after sanding and dispersing the Ni-Co-Mn oxide precursor obtained in step (2) by using a sand mill, thus obtaining the ternary Ni-Co-Mn precursor. The preparation method of the ternary Ni-Co lithium manganate material comprises the following steps: adding the Ni-Co-Mn oxide precursor into a lithium source, entering a ball mill for uniformly mixing, and entering an atmosphere furnace for sintering, thus obtaining a ternary material after sintering, i.e., the ternary Ni-Co lithium manganate material. A ternary anode material prepared through the preparation method is high in specific capacity and high in compaction density, the Mn dissolution quantity of an electrode plate in a total batterycan be reduced to a large extent, and high / low-temperature cycle performance can also be effectively increased.

Owner:深圳道童新能源有限公司

Process for manufacturing a galvannealed steel sheet by DFF regulation

ActiveCN101809182AAvoid Surface Appearance IssuesHot-dipping/immersion processesFurnace typesImpurityMn oxide

The invention deals with a process for manufacturing a hot-dip galvannealed steel sheet having a TRIP microstructure, and comprising, by % by weight, 0.01 <= C <= 0.22%, 0.50 <= Mn <= 2.0%, 0.5 < Si <= 2.0%, 0.005 <= Al <= 2.0%, Mo < 0.01 %, Cr <=1.0%, P < 0.02%, Ti <= 0.20%, V <= 0.40%, Ni <= 1.0%, Nb <= 0.20%, the balance of the composition being iron and unavoidable impurities resulting from the smelting, said process comprising the steps consisting in: - oxidizing said steel sheet in order to form a layer of iron oxide on the surface of the steel sheet, and to form an. internal oxide of at least one type of oxide selected from the group consisting of Si oxide, Mn oxide, Al oxide, complex oxide comprising Si and Mn, complex oxide comprising Si and Al complex oxide comprising Al and Mn, and complex comprising Si, Mn and Al, - reducing said oxidized steel sheet in order to reduce the layer of iron oxide, - hot-dip galvanising said reduced steel sheet to form a zinc-based coated steel sheet, and - subjecting said zinc-based coated steel sheet to an alloying treatment to form a galvannealed steel sheet.

Owner:ARCELORMITTAL INVESTIGACION Y DESARROLLO SL +1

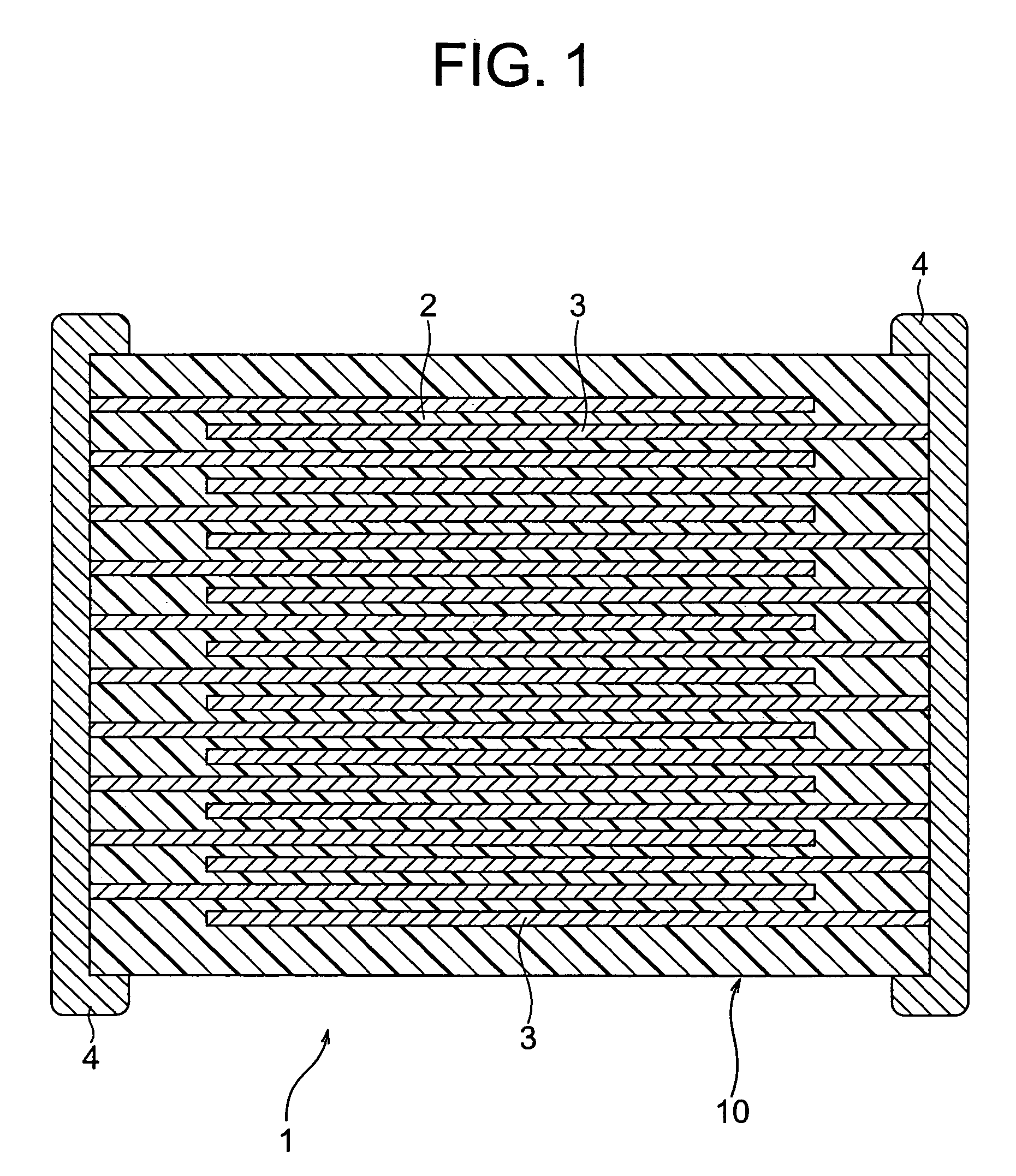

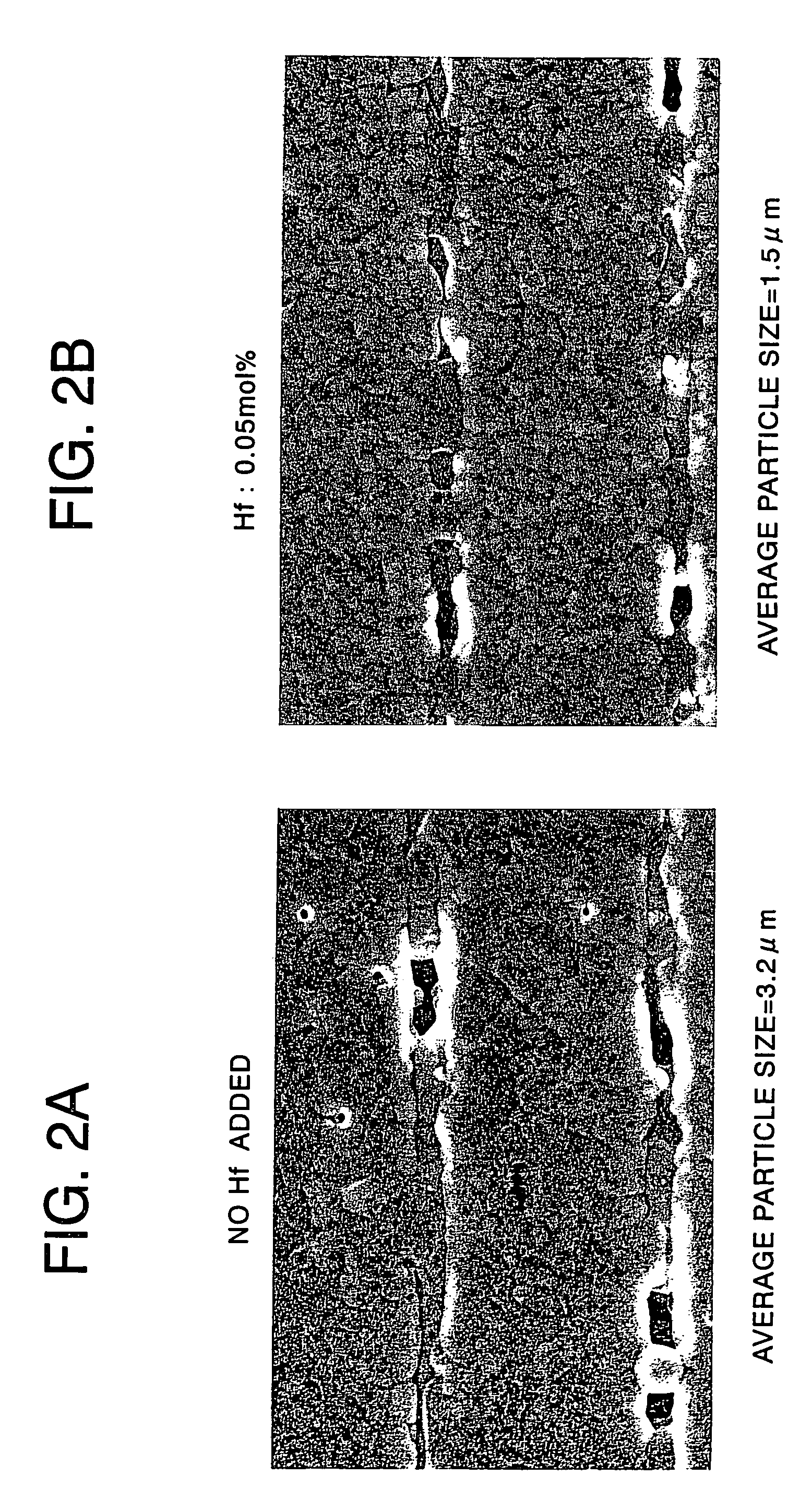

Dielectric ceramic composition, electronic device and production methods of the same

ActiveUS7312172B2Improve reliabilityReduced frequency dependenceFixed capacitor dielectricStacked capacitorsMn oxideMole ratio

A dielectric ceramic composition, comprising a main component including at least a dielectric oxide having a composition expressed by [(CaxSr1-x)O]m[(TiyZr1-y-zHfz)O2], a first subcomponent including a Mn oxide and / or an Al oxide and a glass component, wherein “m”, “x”, “y” and “z” indicating composition mole ratios in the formula included in the main component are in relationships of 0.90≦m≦1.04, preferably 1.005≦m≦1.025, 0.5≦x<1, preferably 0.6≦x≦0.9, 0.01≦y≦0.10, preferably 0.02≦y≦0.07 and 0<z≦0.20, preferably 0<z≦0.10.

Owner:TDK CORPARATION

Reduced catalyst of mono fluorin, and preparation method and usage

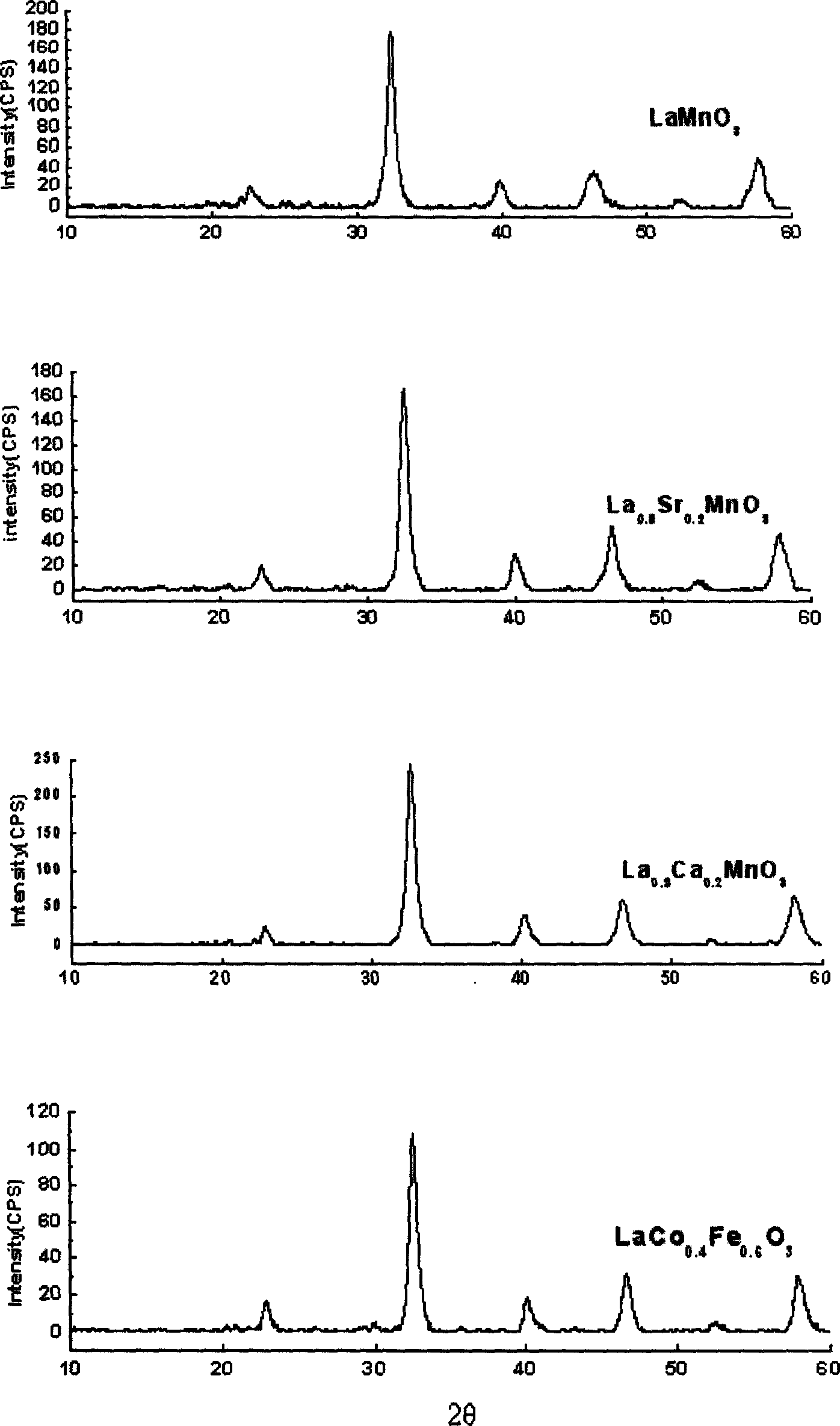

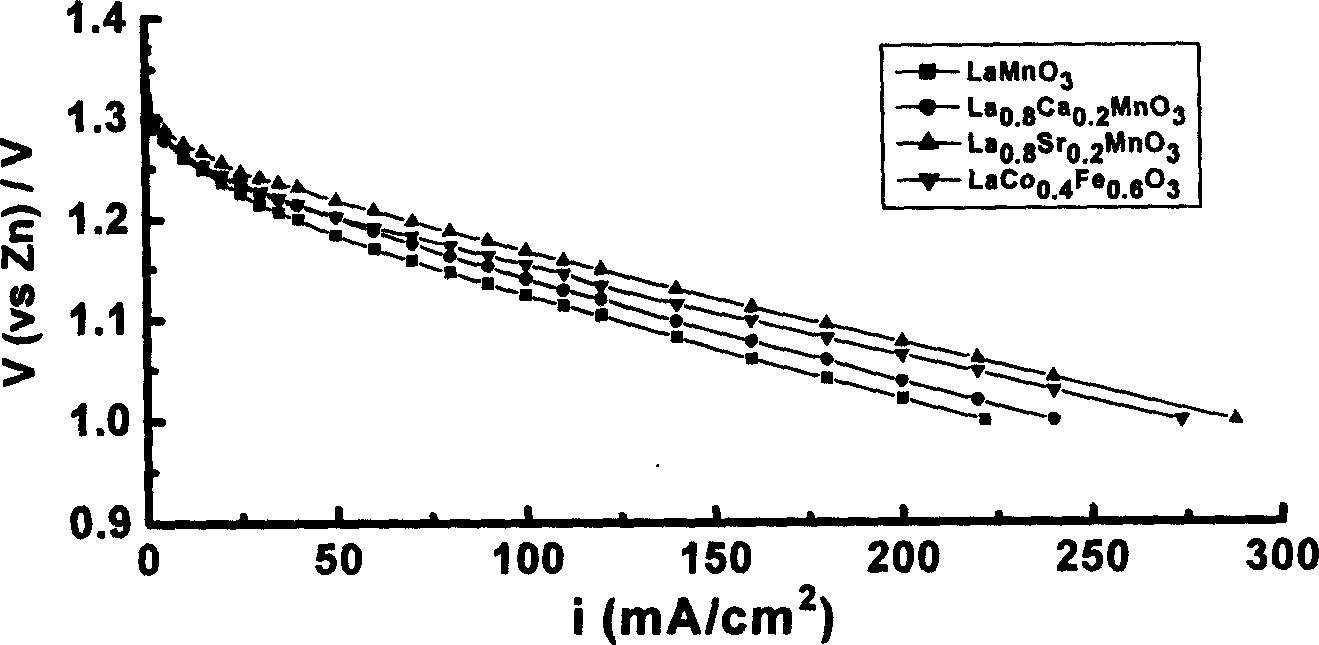

InactiveCN1872414AImprove performanceThe characteristic diffraction peaks are obviousMetal/metal-oxides/metal-hydroxide catalystsStrontium oxideCerium oxide

An oxygen reducing catalyst is prepared from lanthanum oxide, praseodymium oxide, strontium oxide, calcium oxide, MnO2, Mn2O3, Fe2O3, Co3O4, nickel oxide and chromium oxide through swinging-vibrating type ball grinding while reaction for 0.5-12 hr. Its chemical formula is ABO3 or A1-xMxB1-yO3. It can be used to prepare air electrode with high oxygen reducing power in air and high stability in alkaline medium.

Owner:WUHAN HONGYUAN WEILI NEW ENERGY TECH

Dielectric porcelain composition, electronic device and methods for producing these

ActiveUS20060234853A1Grain growth can be suppressedReduce crackingFixed capacitor dielectricStacked capacitorsMn oxideMole ratio

A dielectric ceramic composition, comprising a main component including at least a dielectric oxide having a composition expressed by [(CaxSr1-x)O]m[(TiyZr1-y-zHfz)O2], a first subcomponent including a Mn oxide and / or an Al oxide and a glass component, wherein “m”, “x”, “y” and “z” indicating composition mole ratios in the formula included in the main component are in relationships of 0.90≦m≦1.04, preferably 1.005≦m≦1.025, 0.5≦x<1, preferably 0.6≦x≦0.9, 0.01≦y≦0.10, preferably 0.02≦y≦0.07 and 0<z≦0.20, preferably 0<z≦0.10.

Owner:TDK CORPARATION

High strength steel plate with excellent delayed destruction resistance characteristics and low temperature toughness, and high strength member manufactured using same

ActiveCN105189798AImprove featuresImprove low temperature toughnessHot-dipping/immersion processesFurnace typesSheet steelHigh intensity

Owner:NIPPON STEEL CORP

Method for electroplating metal on surface of insulating base material

ActiveCN108977862AImprove surface propertiesImprove bindingPrinted circuit manufactureConductive polymerWater soluble

The invention relates to a method for electroplating metal on the surface of an insulating base material. The method comprises the following steps that the surface of the insulating base material makes contact with a water-soluble anionic compound, so that a modified surface is produced; the modified surface makes contact with an aqueous solution containing permanganate ions, so that a manganese dioxide adsorption layer is formed on the modified surface; a conducting polymer layer is formed on the surface of the manganese dioxide adsorption layer; and electroplating is carried out on the surface of the conducting polymer layer, and thus a metal layer is formed. According to the method, the anionic compound is deposited on the surface of the insulating base material so as to form a coatinglayer tightly combined with the surface of the base material, after the modification and adsorption, an even film with a certain thickness is formed on the surface, thus, under the metal electroplating liquid and electroplating condition are the same, the deep plating capacity and dispersing capacity of the electroplating liquid can be greatly improved, the obtained metal plating layer has the characteristics of being flat, even and good in backlighting effect, and the hole breakout phenomenon and the phenomenon that certain parts of the electroplating metal layer in holes are too thin are avoided.

Owner:GUANGDONG TONESET SCI & TECH

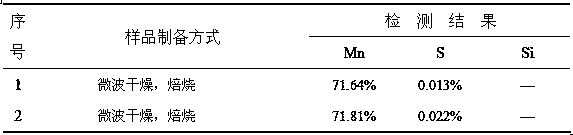

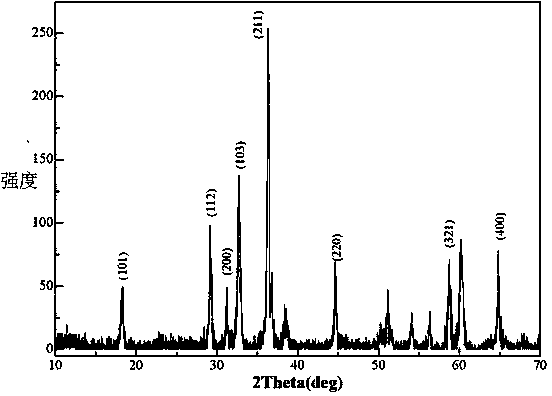

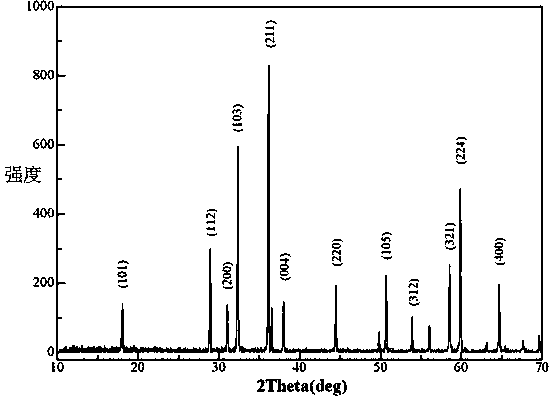

Technology for preparing high-purity manganous-manganic oxide with manganous sulfate solution

ActiveCN103466712AHigh purityLarge specific surface areaManganese oxides/hydroxidesManganese sulphateSulfate

The invention discloses a technology for preparing high-purity manganous-manganic oxide with a manganous sulfate solution. The technology is characterized by comprising the following steps that the manganous sulfate solution is heated; the temperature is controlled to be 50-90 DEG C; ammonia water is added to the manganous sulfate solution, and stirred; a PH (potential of hydrogen) value of the solution is controlled to be 9.5; stirring is continued for 1-2h after the ammonia water is stopped; filtering is performed; a manganous hydroxide filter cake is obtained; the manganous hydroxide filter cake is activated in a drying oven; deionized water is added to the activated manganous hydroxide filter cake; a solution is prepared; air is supplied for oxidation; after the PH value of the solution is 6.5, and no manganous ion is detected from the solution, the stirring is continued for 1-2h; cooling to a room temperature is performed; the filtering is performed; the filter cake is washed by the deionized water; the filtered filter cake is a manganous-manganic oxide precursor; manganous-manganic oxide is heated, dried, roasted and cooled; and high-purity manganous-manganic oxide is obtained. The technology is simple to operate and low in production cost; and produced manganous-manganic oxide is high in purity and large in specific surface area.

Owner:DAXIN MANGANESE MINE BRANCH OF CITIC DAMENG MINING IND

Solder Alloy, Solder Ball, Chip Solder, Solder Paste and Solder Joint

ActiveUS20170216975A1Increase in thickness of oxide film is preventedPrevent discolorationPrinted circuit assemblingWelding/cutting media/materialsHigh humiditySolder ball

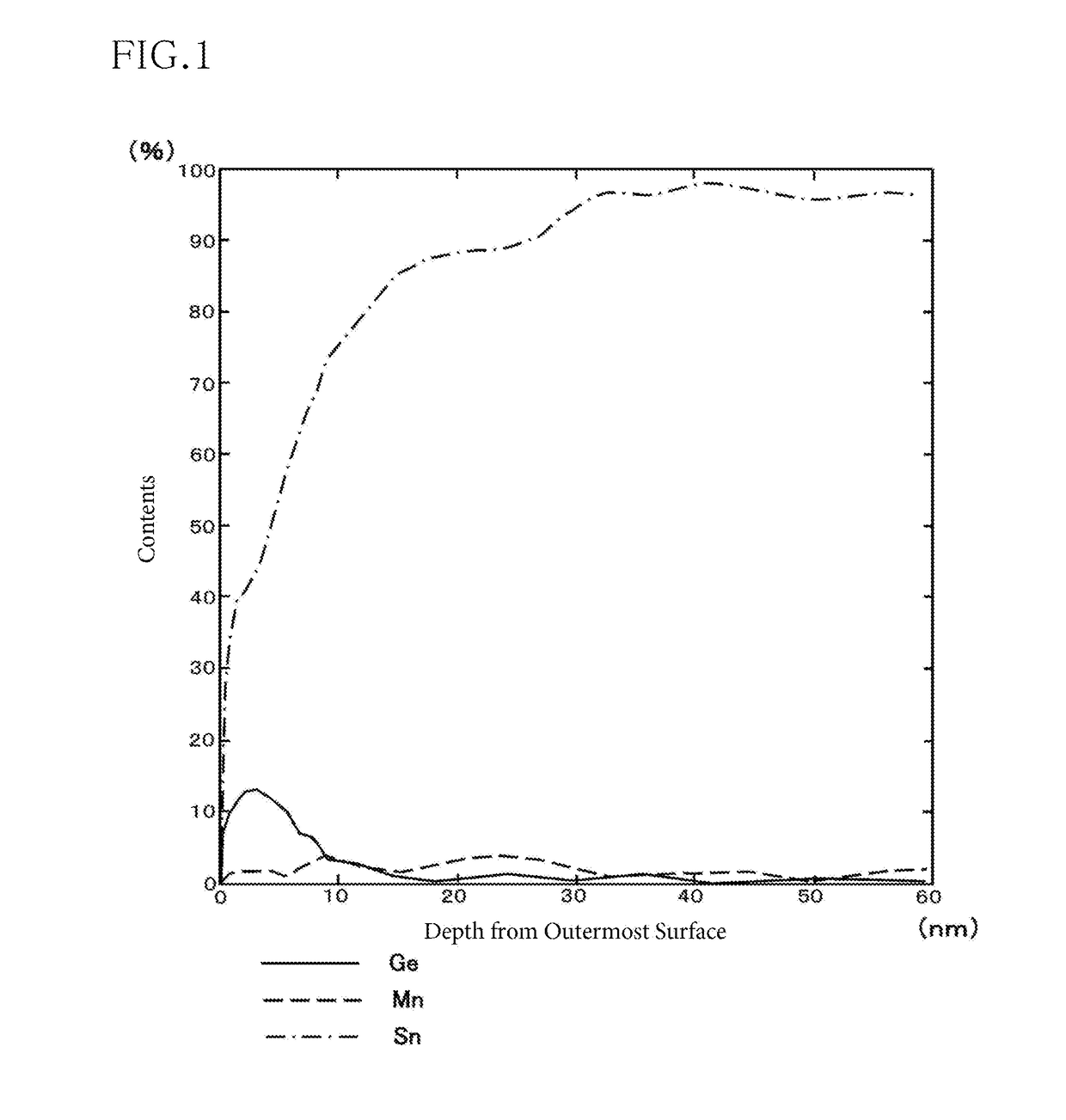

A solder alloy that contains 0.005 mass % or more and 0.1 mass % or less of Mn, 0.001 mass % or more and 0.1 mass % or less of Ge, and a balance of Sn. A plurality of Ge oxides is distributed on an outermost surface side of an oxide film including Sn oxide, Mn oxide and Ge oxide by adding 0.005 mass % or more and 0.1 mass % or less of Mn, 0.001 mass % or more and 0.1 mass % or less of Ge to the solder alloy having a principal ingredient of Sn, so that it is possible to obtain the discolor-inhibiting effect even under the high-temperature and high-humidity environment.

Owner:SENJU METAL IND CO LTD

Copper alloy and liquid-crystal display device

ActiveUS7940361B2Well formedSemiconductor/solid-state device detailsVacuum evaporation coatingSolubilityLiquid-crystal display

A liquid crystal display device including, a pair of substrates, a gate electrode of a thin film transistor (TFT) formed on one of the substrates, and a wiring layer connected to the gate electrode or an electrode of the thin film transistor, wherein at least a part of the gate electrode or a part the wiring layer is formed by a layer structured by a pure copper layer and a Cu—Mn alloy layer including Mn, wherein a concentration of Mn in the Cu—Mn alloy layer is more than 0.1 and not more than 20 atomic percentage within a solubility limit of Mn in the copper, and wherein a boundary surface between the Cu—Mn alloy layer and said one of the substrate includes an oxide layer having a Mn oxide layer.

Owner:XENOGENIC DEV LLC

Dielectric porcelain composition and electronic part

ActiveUS20060234854A1Extended service lifeImprove reliabilityFixed capacitor dielectricStacked capacitorsDielectricSilicon dioxide

A dielectric ceramic composition comprising a main component including a dielectric oxide expressed by a composition formula of {(Ca1-x Mex)O}m·(Zr1-y Tiy)O2, wherein “Me” indicating an element name in the composition formula is at least one of Sr, Mg and Ba, and “m”, “x” and “y” indicating composition mole ratios in the composition formula are in relationships of 0.8≦m≦1.3, 0≦x≦1.00 and 0≦y≦1.00; a first subcomponent including a V oxide; a second subcomponent including an Al oxide; a third subcomponent including a Mn oxide; and a fourth subcomponent including a composite oxide expressed by a composition formula of {(Baz, Ca1-z)O}v SiO2, wherein “z” and “v” indicating composition mole ratios in the composition formula are in relationships of 0≦z≦1 and 0.5≦v≦4.0; wherein ratios of respective components with respect to 100 moles of the main component are the first subcomponent by 0 mole<first subcomponent<7 moles (wherein a value of a V oxide is in terms of V2O5); the second subcomponent by 0 mole<second subcomponent<15 moles (wherein a value of an Al oxide is in terms of Al2O3); the third subcomponent by 0 mole third subcomponent 5 moles (wherein a value is in terms of a Mn element in the oxide); and the fourth subcomponent by 0 mole<fourth subcomponent<20 moles (wherein a value is in terms of a composite oxide). According to the invention, a reduction-resistance dielectric ceramic composition having an excellent low frequency dielectric characteristic and a furthermore improved accelerated lifetime of insulation resistance can be provided.

Owner:TDK CORPARATION

Magnesium-zine-series ferrite and preparing method

This invention relates to a ferrite of Mg-Zn series and its preparation method including a primary composition and a sub-composition, in which, said primary composition includes Fe2O3, ZnO and MgO in the following mol percentages: Fe203: 47.5mol%-52.3mol%, ZnO: 23mol%-27mol%, MgO:21mol-25.8mol%, said sub-composition includes Mn oxide and Cu oxide, which provides a ferrite of Mg-Zn series similar to that of Ni-Zn series having strong wicking and anti-cracking performance and suitable for IF and HF transformers, inductors and filters.

Owner:RUYUAN DONGYANGGUANG MAGNETIC MATERIAL

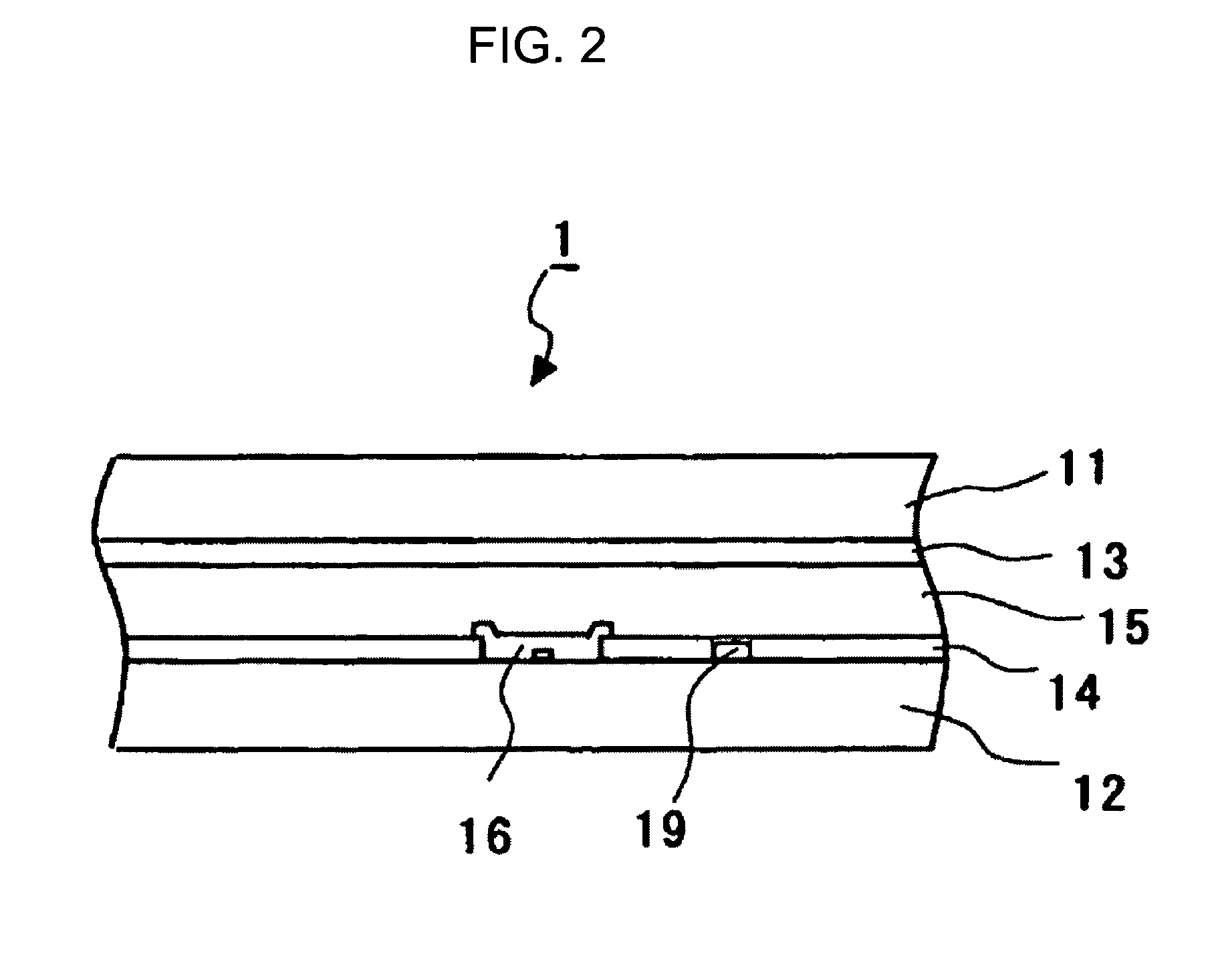

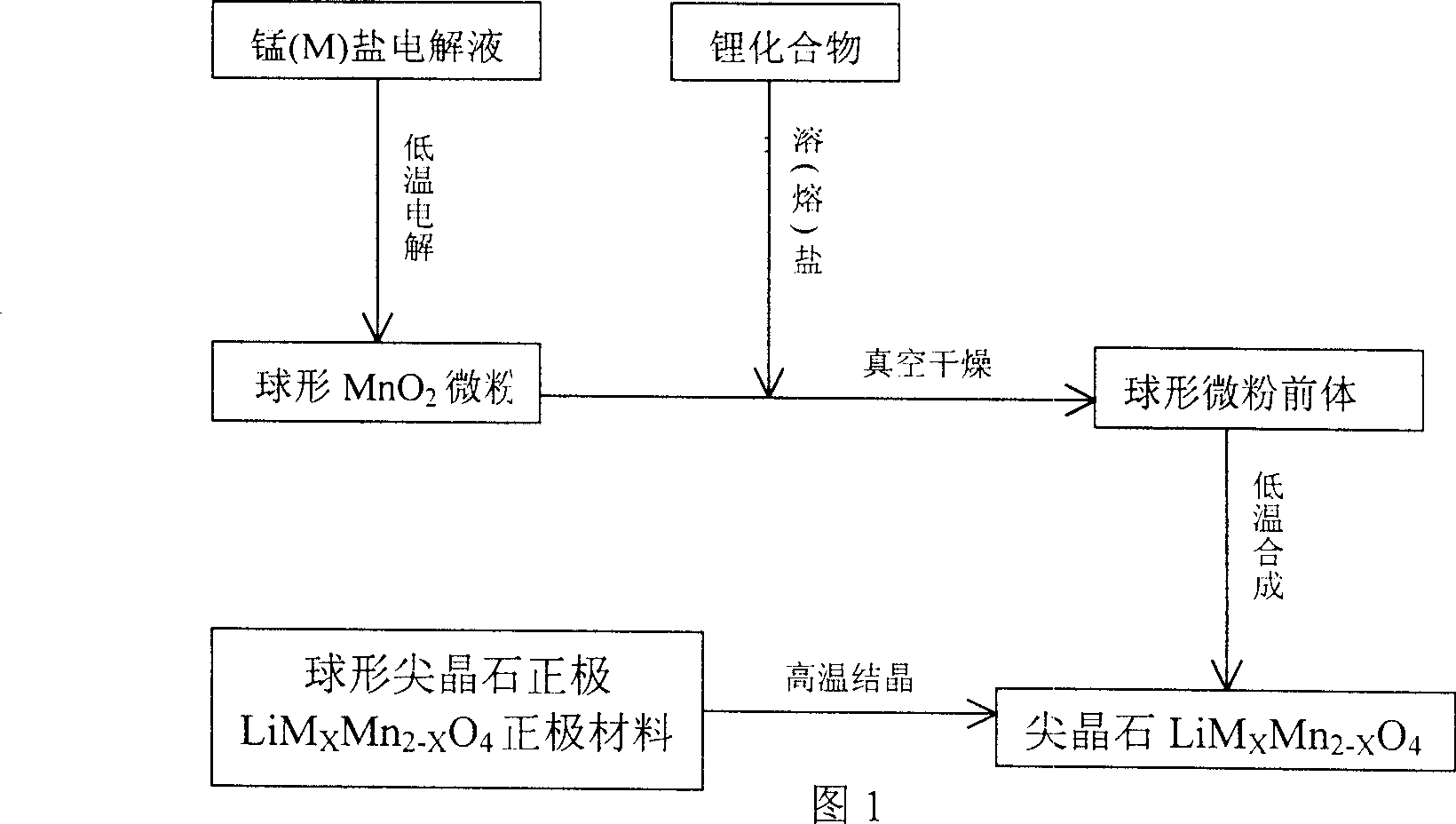

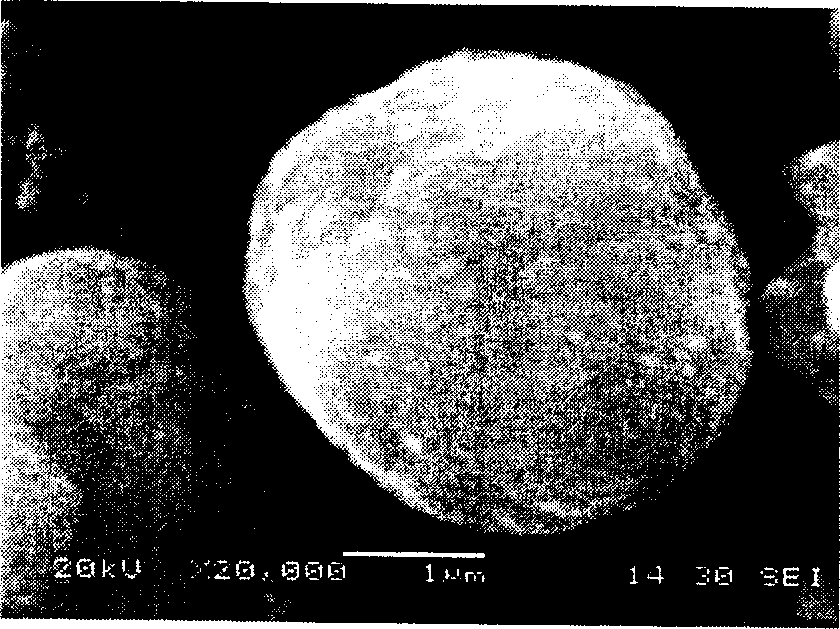

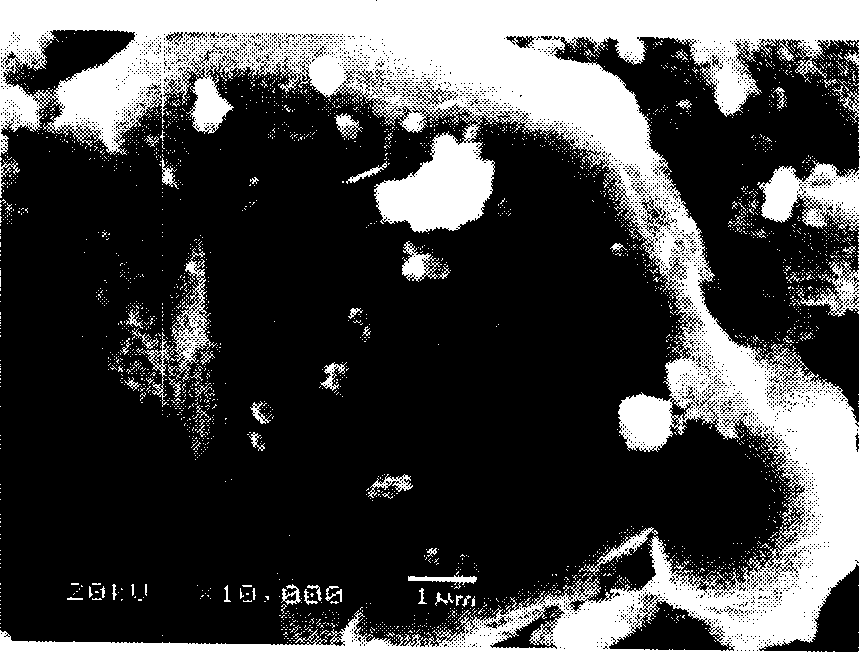

Method for preparnig spherical spinel Li-Mn-oxide lithium ion cell anode material

InactiveCN1744353ASmall surface areaEliminate protrusionsElectrode manufacturing processesLithium oxides/hydroxidesElectrolysisDecomposition

First, using special electrolytic technology in low temperature, the method prepares spherical MnO2 fine grain of pure or composite M metallic oxide. Then, through diffusion process of dissolution (melt), lithium ion is led in; and through thermal reaction, anode material of spinel LiMxMn2-xO4 is obtained. Spherical Li-Mn-Oxide anode material of lithium ion cell prepared by the invention is different from material of polyhedral columnar material prepared by traditional solid phase method, combustion method, coprecipitation method, sol-gel method, and hydrothermal method etc. Spherical form possesses minimal external surface per unit volume. Thus, Spherical form can reduce surface area exposed in electrolyte solution so as to avoid point active effect and restrain Mn2+ from dissolution and running out as well as decomposition of electrolyte. The invention raises performance of anode material LiMn2O4 and improves allover properties of pole pieces.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

High-efficiency cold catalyst room temperature complete removal of formaldehyde technology

ActiveCN102284288AGood removal effectImprove stabilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPlatinumHollandite

The invention provides a high-efficiency humidity-resistance room-temperature formaldehyde removing catalyst technology, and relates to the field of catalyst and environmental protection. The technology is characterized in that: honeycomb ceramic adopted as a carrier first loads channel gold-doped hollandite type crystal structured manganese dioxide (MnO2) to serve as a substrate, and then loads platinum (Pt) as an active component, wherein the doped hollandite type MnO2 substrate is characterized in that: chemical general formula of the substrate can be shown as Aux(A)y[MzMn8-z]O16 (M is Mg2+ and Zn2+, A is K+ and H+, x is less than or equal to 2, y is less than or equal to 2, and z is less than or equal to 3, [MzMn8-z]O16 represents the framework composition of the hollandite type MnO2, and Aux(A)y represents the channel composition of MnO2; and the weight ratio of Pt to doped MnO2 is between 0 and 10 percent. The integral catalyst can effectively, stably and completely remove the formaldehyde in the air in a room-temperature constant-humidity real environment, has no adverse side effect to a human body, and thus can be widely applied to the preparation of various air purifiers to remove formaldehyde.

Owner:上海复翼环保科技有限公司

Dielectric ceramic compositions and electronic devices

ActiveUS6995968B2Reduce defective rateHigh dielectric constantFixed capacitor dielectricStacked capacitorsDielectricCeramic capacitor

In order to provide dielectric ceramic composition having low IR defect rate and high relative dielectric constant even when the multilayer ceramic capacitor is made thinner, dielectric ceramic composition including a main component expressed by a composition formula {{Ba(1-x)Cax}O}A{Ti(1-y-z)ZryMgz}BO2 and subcomponents of Mn oxide, Y oxide, V oxide and Si oxide is provided. In the above formula, A, B, x, y and z are as follows: 0.995<=A / B<=1.020, 0.0001<=x<=0.07, preferably 0.001<=x<0.05, 0.1<=y<=0.3 and 0.0005<=z<=0.01, preferably 0.003<=z<=0.01.

Owner:TDK CORPARATION

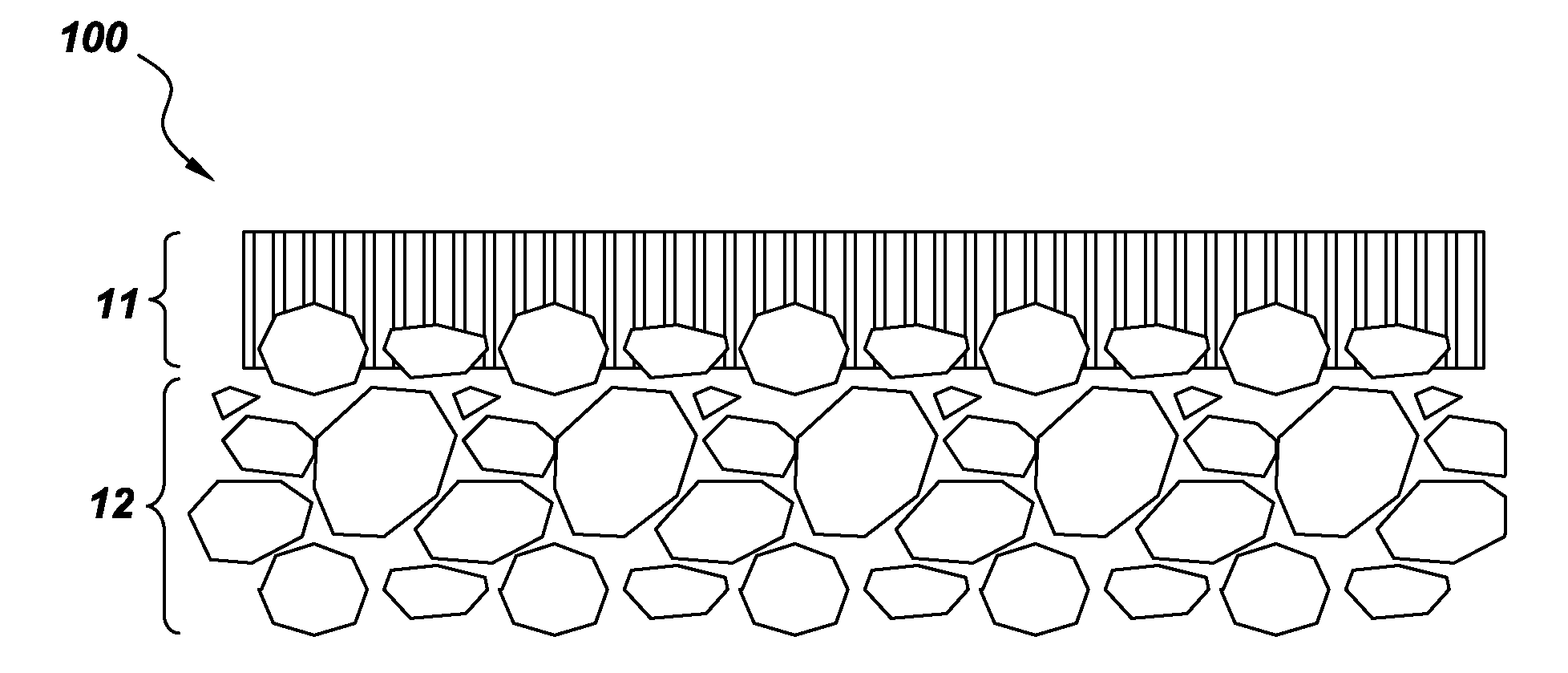

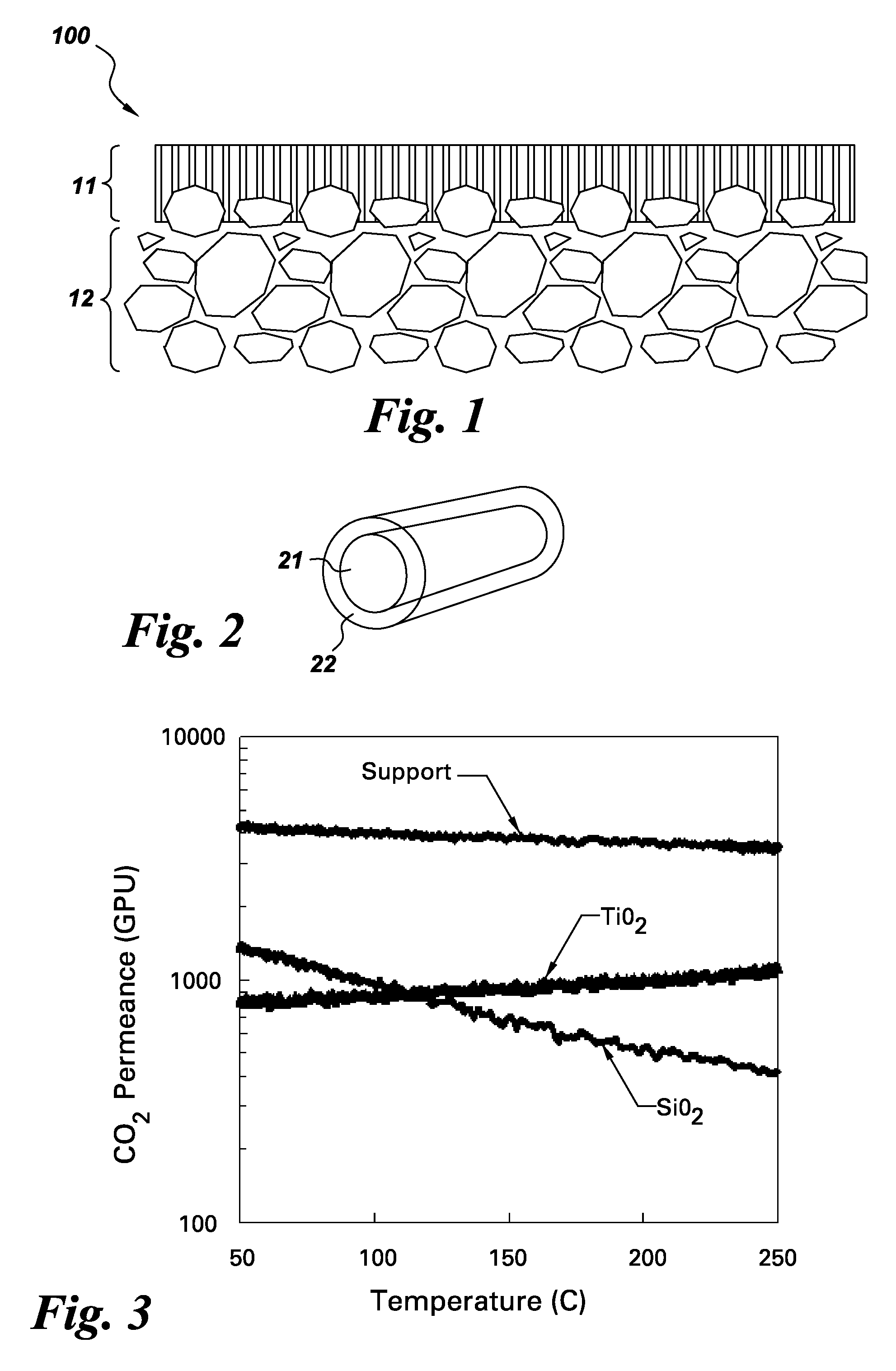

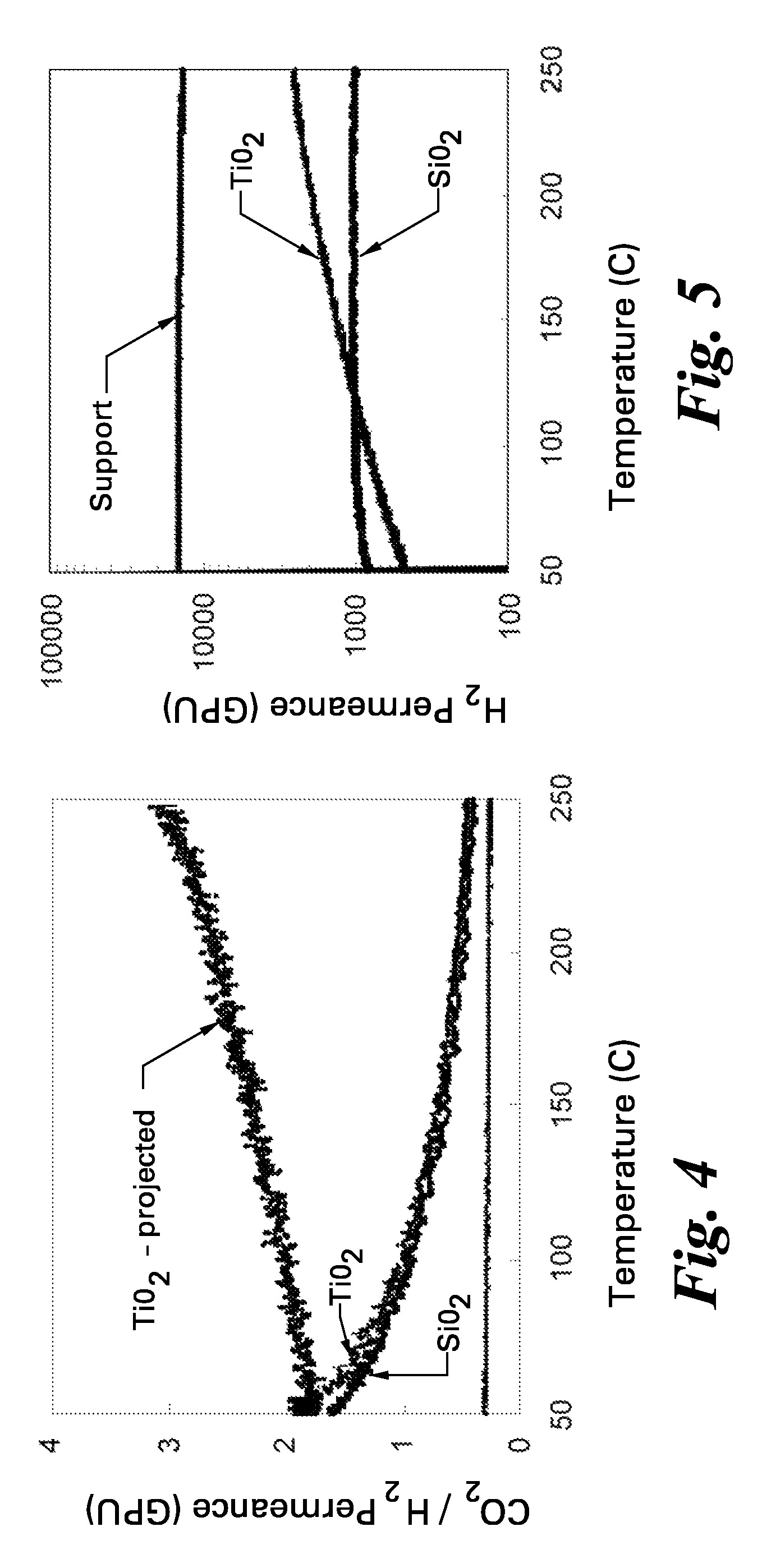

Membranes for separation of carbon dioxide

Methods for separating carbon dioxide from a fluid stream at a temperature higher than about 200° C. with selectivity higher than Knudsen diffusion selectivity include contacting a porous membrane with the fluid stream to preferentially transport carbon dioxide. The porous membrane includes a porous support and a continuous porous separation layer disposed on a surface of the porous support and extending between the fluid stream and the porous support layer. The porous support comprises alumina, silica, zirconia, stabilized zirconia, stainless steel, titanium, nickel-based alloys, aluminum-based alloys, zirconium-based alloys or a combination thereof. Median pore size of the porous separation layer is less than about 10 nm, and the porous separation layer comprises titania, MgO, CaO, SrO, BaO, La2O3, CeO2, HfO2, Y2O3, VOz, NbOz, TaOz, ATiO3, AZrO3, AAl2O4, A1FeO3, A1MnO3, A1CoO3, A1NiO3, A2HfO3, A3 CeO3, Li2ZrO3, Li2SiO3, Li2TiO3, Li2HfO3, A4N1yOz, YxN1yOz, LaxN1yOz, HfN2yOz, or a combination thereof;whereinA is La, Mg, Ca, Sr or Ba;A1 is La, Ca, Sr or Ba;A2 is Ca, Sr or Ba;A3 is Sr or Ba;A4 is Mg, Ca, Sr, Ba, Ti or Zr;N1 is V, Nb, Ta, Cr, Mo, W, Mn, Si or Ge;N2 is V, Mo, W or Si;x is 1 or 2;y ranges from 1 to 3; andz ranges from 2 to 7.

Owner:AIR PROD & CHEM INC

Preparation method of Co-Mg-Mn oxide for lithium ion power battery and product

InactiveCN105140507AEvenly distributedUniform treatmentCell electrodesSecondary cellsPower batteryMagnesium salt

The invention relates to a preparation method of a Co-Mg-Mn oxide for a lithium ion power battery. A co-precipitation method is adopted and the preparation method comprises the following steps of: (1) preparing a reaction solution; (2) carrying out purification treatment; (3) carrying out co-precipitation reaction; (4) removing impurities; and (5) carrying out heat stabilizing. Chemical precipitation reaction of a certain molar concentration of a cobalt salt, a magnesium salt and a manganese salt according to a certain proportion with a precipitator is carried out in a reaction kettle compatible with a radial flow and an axial flow under conditions of a certain temperature, a flow rate, a pH value, a stirring speed and the like and in a system of a mixture with the presence of a slow controlled agent to form an atomic-scale uniform mixture of cobalt hydroxide, magnesium hydroxide and manganese hydroxide for precipitation, and then low-temperature dehydration and high-temperature reconstitution are carried out to form the Co-Mg-Mn oxide, the formula of the Co-Mg-Mn oxide is Co<X>Mn<Y>Mg<Z>O4, wherein (X+Y+Z) is more than 0 but less than or equal to 3, X is more than 0, (X+Y) is more than 0 and less than 2, and Z is more than 0 but less than or equal to 0.1.

Owner:浙江亿利泰钴镍材料有限公司

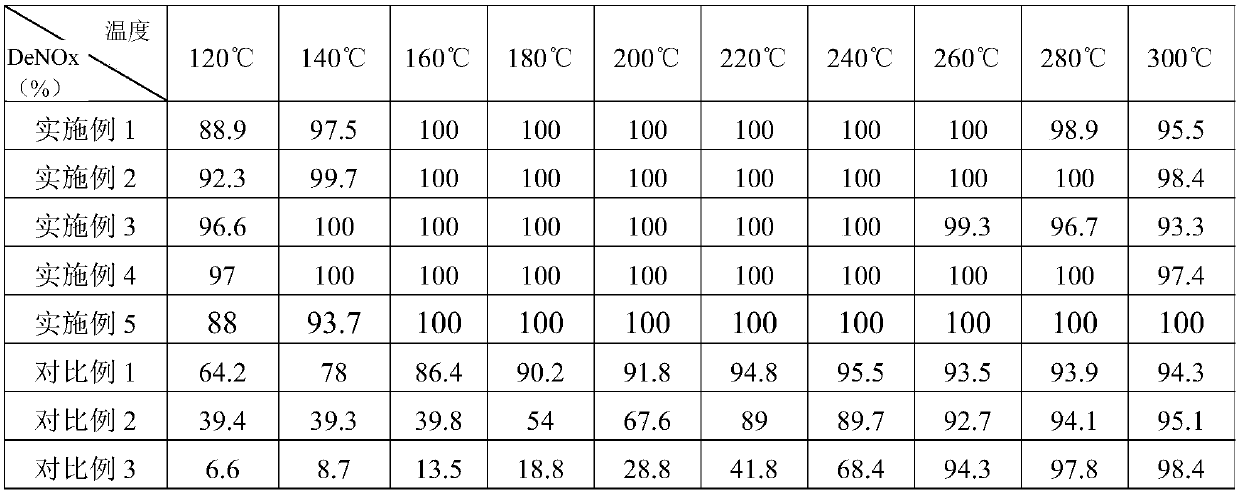

SCR flue gas denitration catalyst with wide temperature window, preparation method and application of catalyst

ActiveCN109745995AExcellent low temperature SCR catalytic activityReduce contentDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsFlue gasActive component

The invention belongs to the technical field of environmental protection and catalysis, and discloses an SCR flue gas denitration catalyst with a wide temperature window, a preparation method and an application of the catalyst, wherein the catalyst comprises a carrier and a first metal oxide, a second metal oxide and a third metal oxide which are supported on the carrier; the carrier is nano titanium dioxide; the first metal oxide is Fe oxide; the second metal oxide is Mn oxide; and the third metal oxide is V oxide. The catalyst has excellent SCR catalytic activity in a wide temperature windowof 120-300 DEG C, and simultaneously has excellent NOx removal rate in a low temperature section of 120-200 DEG C and a medium temperature section of 200-300 DEG C; and in addition, the active component of the catalyst has low vanadium content and has positive significance in controlling environmental pollution and secondary pollution of catalyst wastes.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com