Preparation method of Co-Mg-Mn oxide for lithium ion power battery and product

A cobalt-magnesium-manganese oxide, power battery technology, applied in battery electrodes, secondary batteries, electrochemical generators, etc., can solve the problems of difficult insertion and removal, deterioration of battery cycle performance, high energy consumption, and simple COD treatment. , the effect of improving electrochemical performance and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

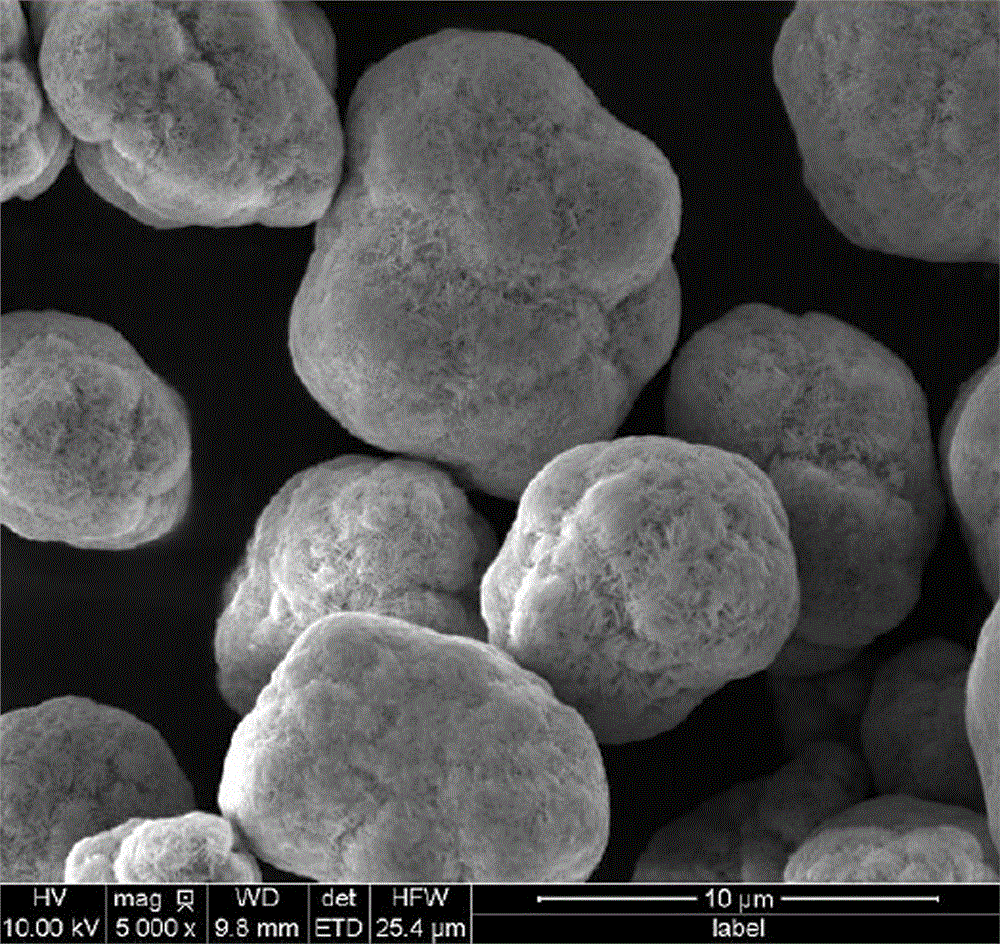

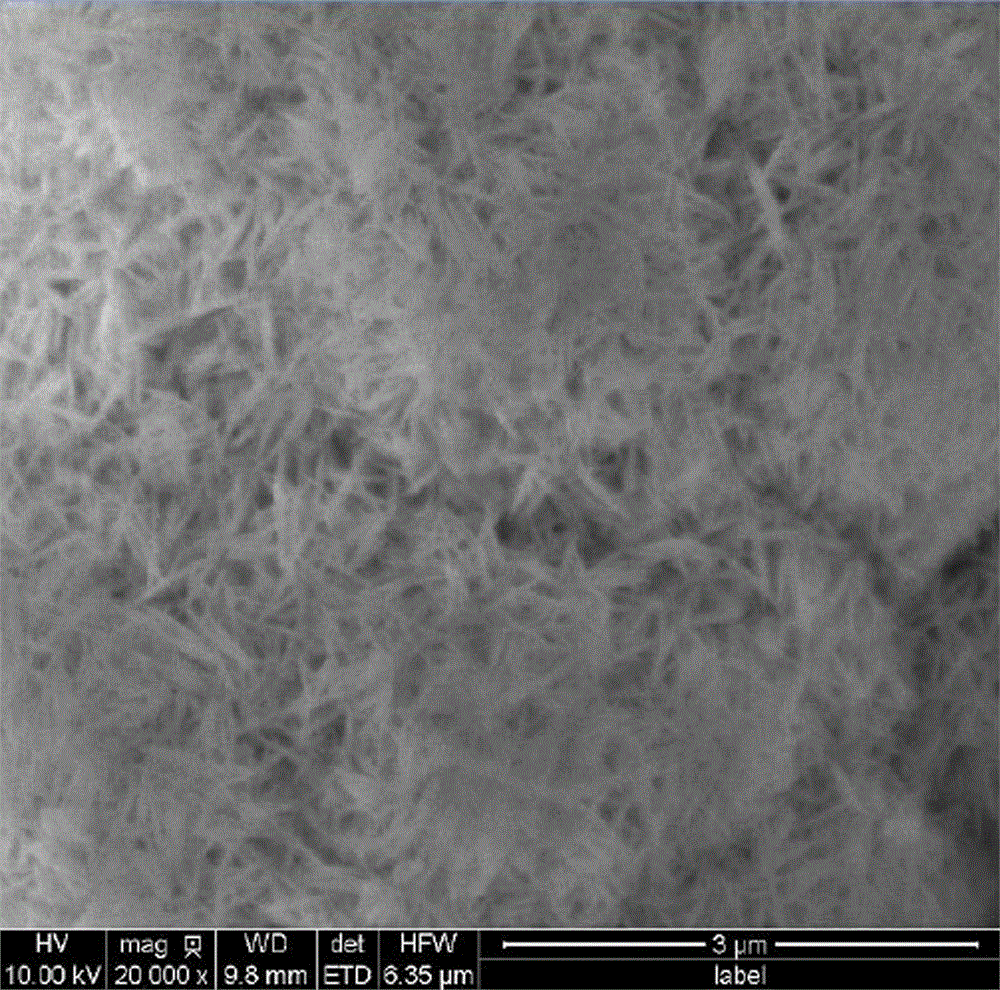

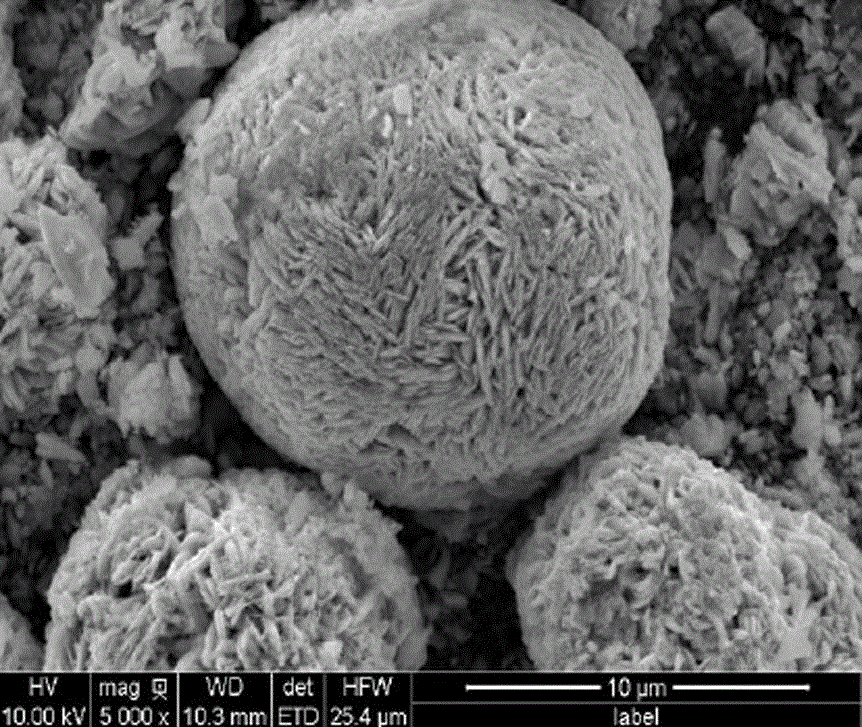

Image

Examples

Embodiment 1

[0032]Embodiment 1: The preparation method of the cobalt-magnesium-manganese oxide for the lithium-ion power battery is prepared by co-precipitation method, and the specific steps are as follows:

[0033] (1) Preparation of reaction solution: add cobalt chloride 1039.5g, magnesium chloride 9.6g and manganese chloride 239.3g respectively in 1200ml water, mix well, and add 1.8g citric acid C 6 h 8 o 7 The slow control agent is stirred for 1h and mixed evenly to obtain a reaction solution;

[0034] (2) Purification treatment: the reaction solution is purified in a non-magnetic box-type ultrafiltration container, and the treatment time is 5h to obtain a purified reaction solution; the precipitant 40% sodium hydroxide solution is purified in a non-magnetic box-type ultrafiltration Purify in the container to obtain the purified precipitant;

[0035] (3) Co-precipitation reaction: The reaction solution is dispersed at a speed of 1.6L / h, and the precipitant is dispersed at a speed ...

Embodiment 2

[0043] Embodiment 2: The preparation method of the cobalt-magnesium-manganese oxide for the lithium-ion power battery is prepared by co-precipitation method, and the specific steps are as follows:

[0044] (1) Preparation of reaction solution: Add 649.7g of cobalt chloride, 8.6g of magnesium chloride and 674.2g of manganese chloride to 3000ml of water, mix well, and add 2.2g of citric acid C with a weight ratio of 2:1 6 h 8 o 7 , 2-ethylhexanoic acid H 18 C 8 o 2 The mixture was stirred for 2.5h and mixed evenly to obtain a reaction solution;

[0045] (2) Purification treatment: the reaction solution is purified in a non-magnetic box-type ultrafiltration container, and the treatment time is 2h to obtain a purified reaction solution; the precipitant 40% sodium hydroxide solution is purified in a non-magnetic box-type ultrafiltration Purify in the container to obtain the purified precipitant;

[0046] (3) Co-precipitation reaction: The reaction solution is dispersed at a s...

Embodiment 3

[0049] Embodiment 3: The preparation method of the cobalt-magnesium-manganese oxide for the lithium-ion power battery is prepared by the co-precipitation method, and the specific steps are as follows:

[0050] (1) Prepare the reaction solution: add 520g of cobalt chloride, 3.2g of magnesium chloride and 752.2g of manganese chloride respectively in 1900ml of water, mix well, and add 2.2g of citric acid C 6 h 8 o 7 Stir for 2h and mix evenly to obtain a reaction solution;

[0051] (2) Purification treatment: the reaction solution is purified in a non-magnetic box-type ultrafiltration container, and the treatment time is 2h to obtain a purified reaction solution; the precipitant 40% sodium hydroxide solution is purified in a non-magnetic box-type ultrafiltration Purify in the container to obtain the purified precipitant;

[0052] (3) Co-precipitation reaction: The reaction solution is dispersed at a speed of 1.5L / h, and the precipitant is dispersed at a speed of 0.6L / h into a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com