Patents

Literature

7292 results about "Dislocation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In materials science, a dislocation or Taylor's dislocation is a crystallographic defect or irregularity within a crystal structure. The presence of dislocations strongly influences many of the properties of materials.

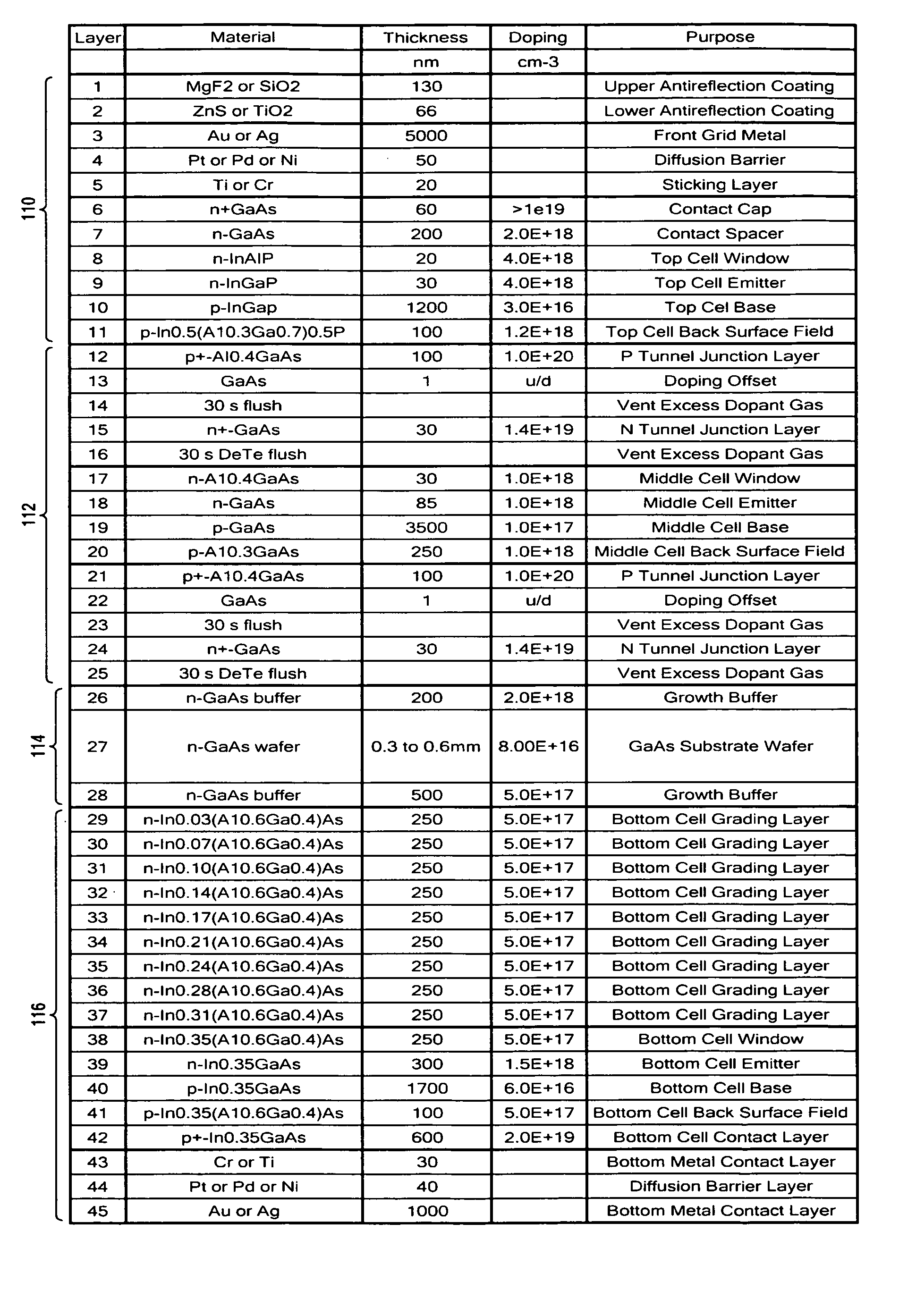

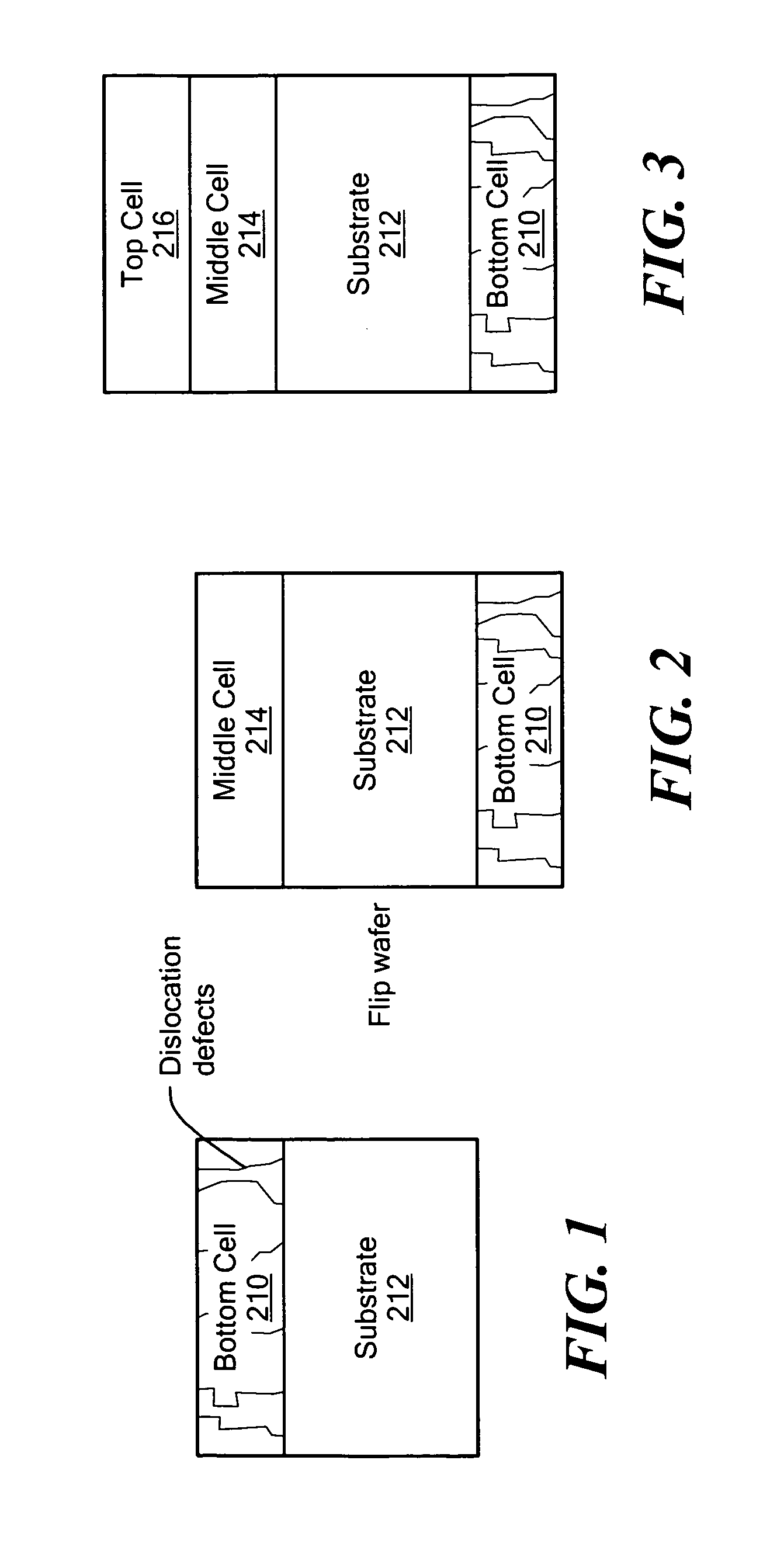

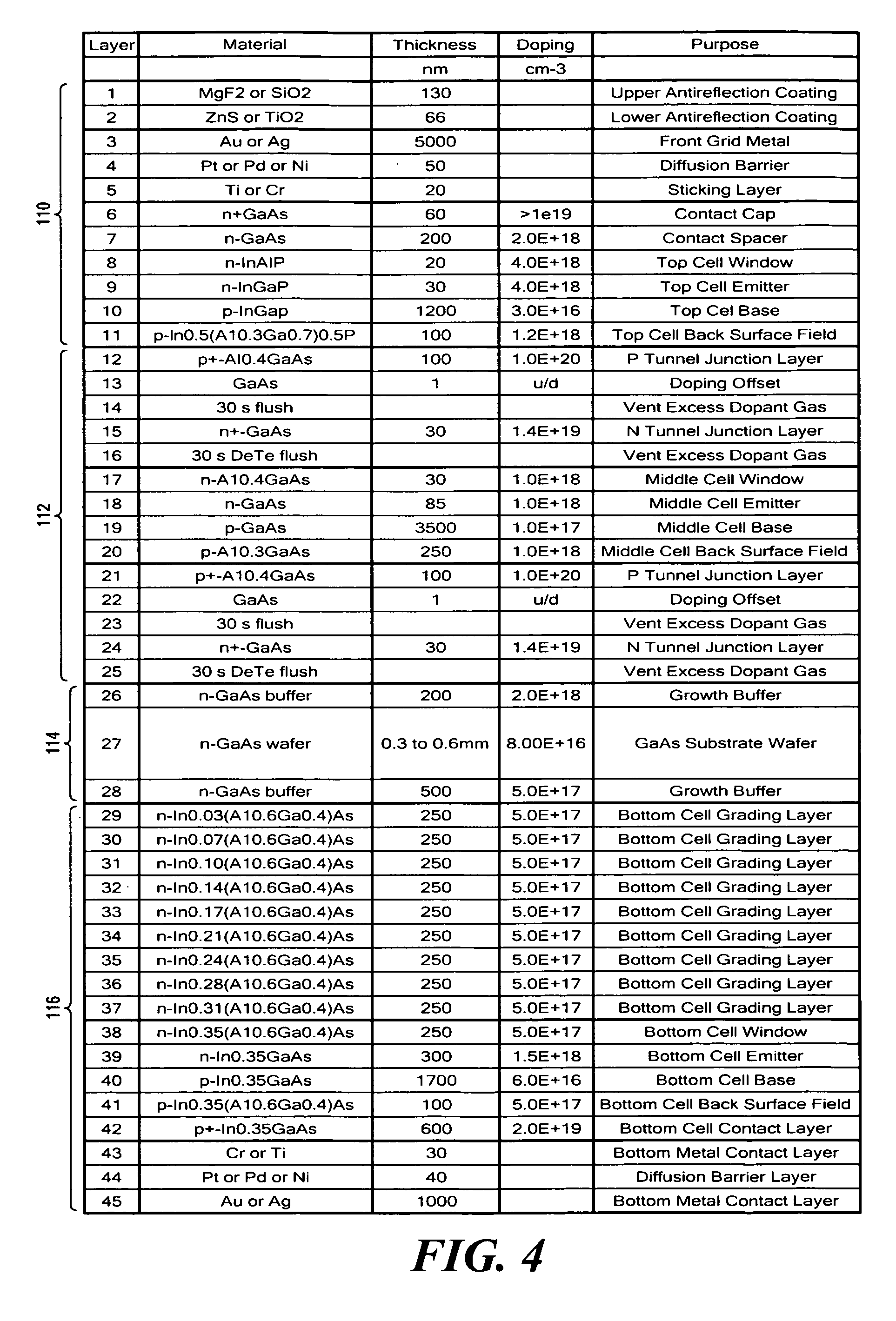

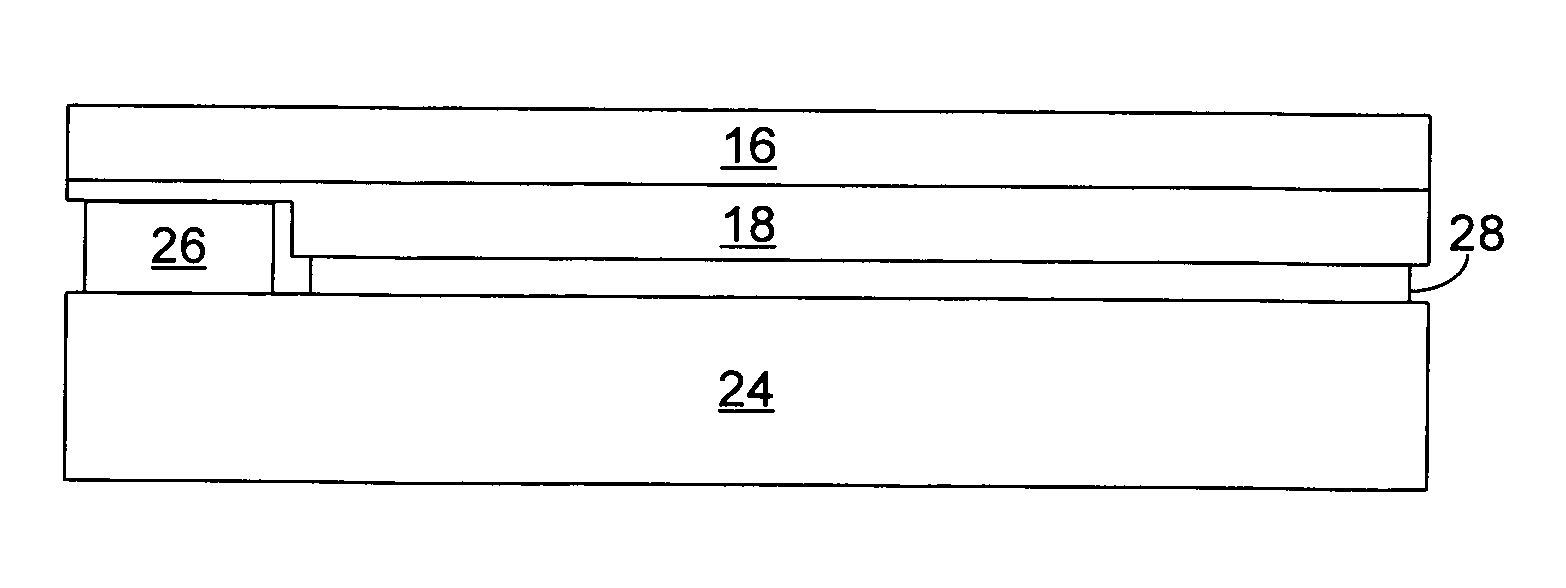

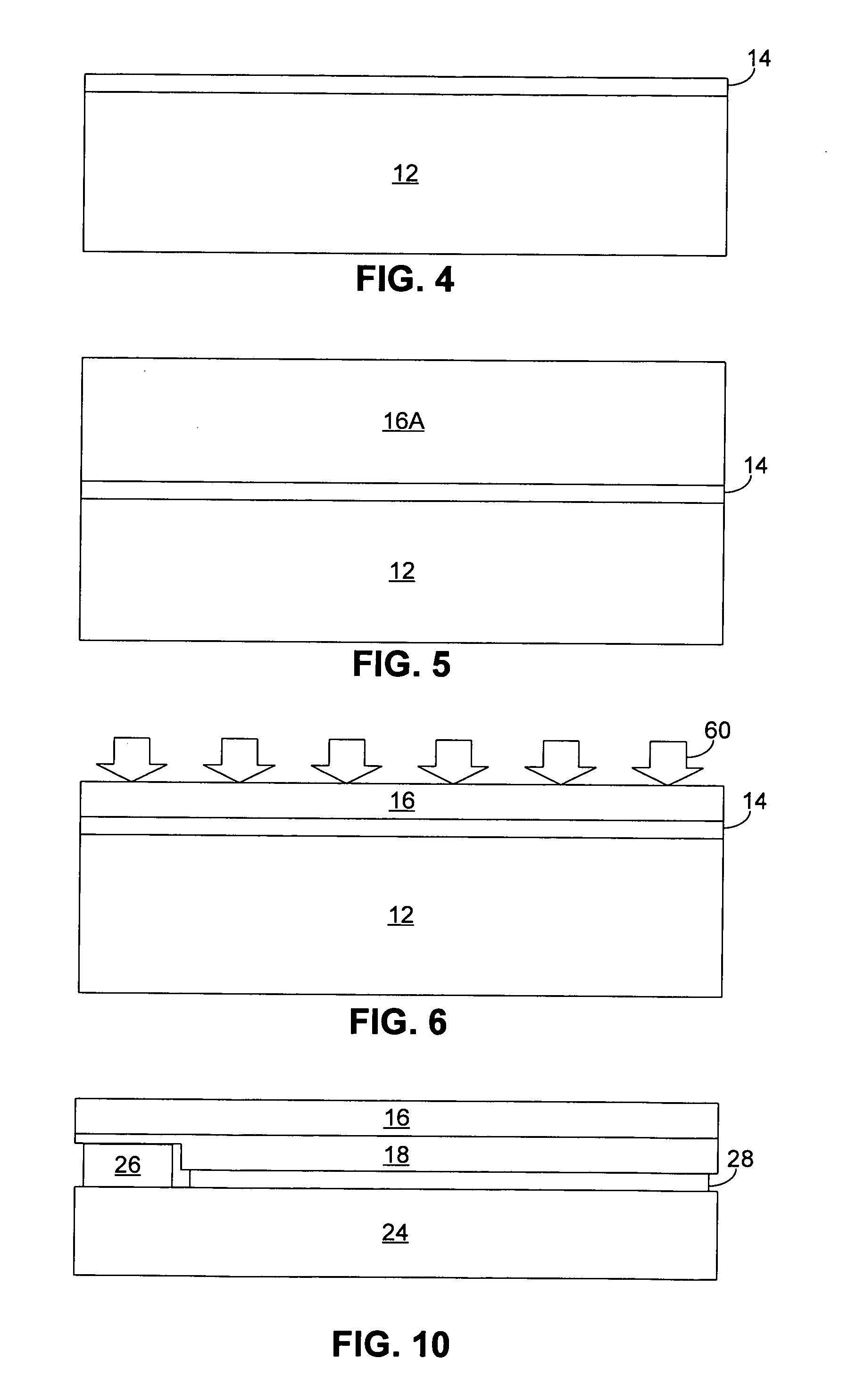

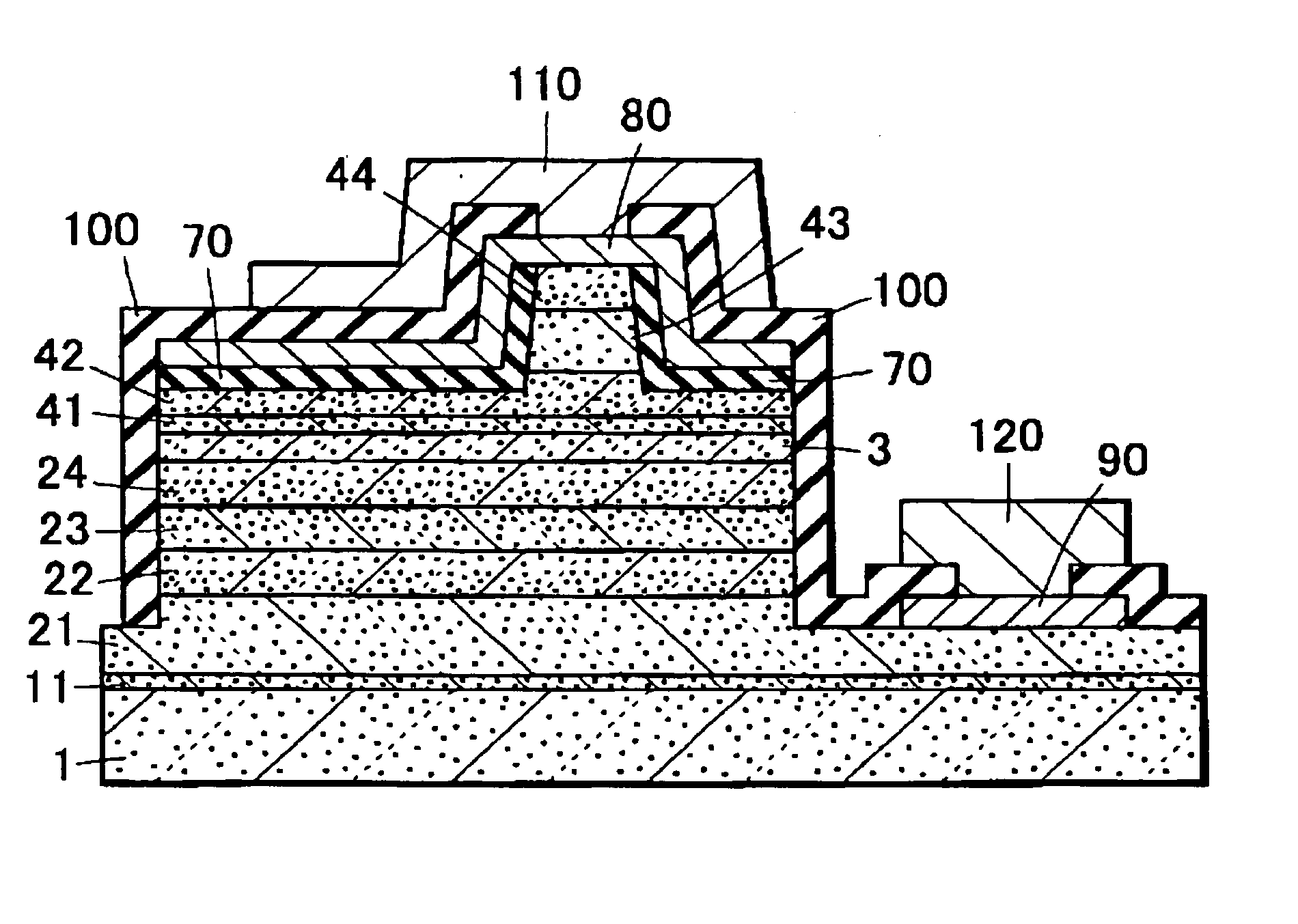

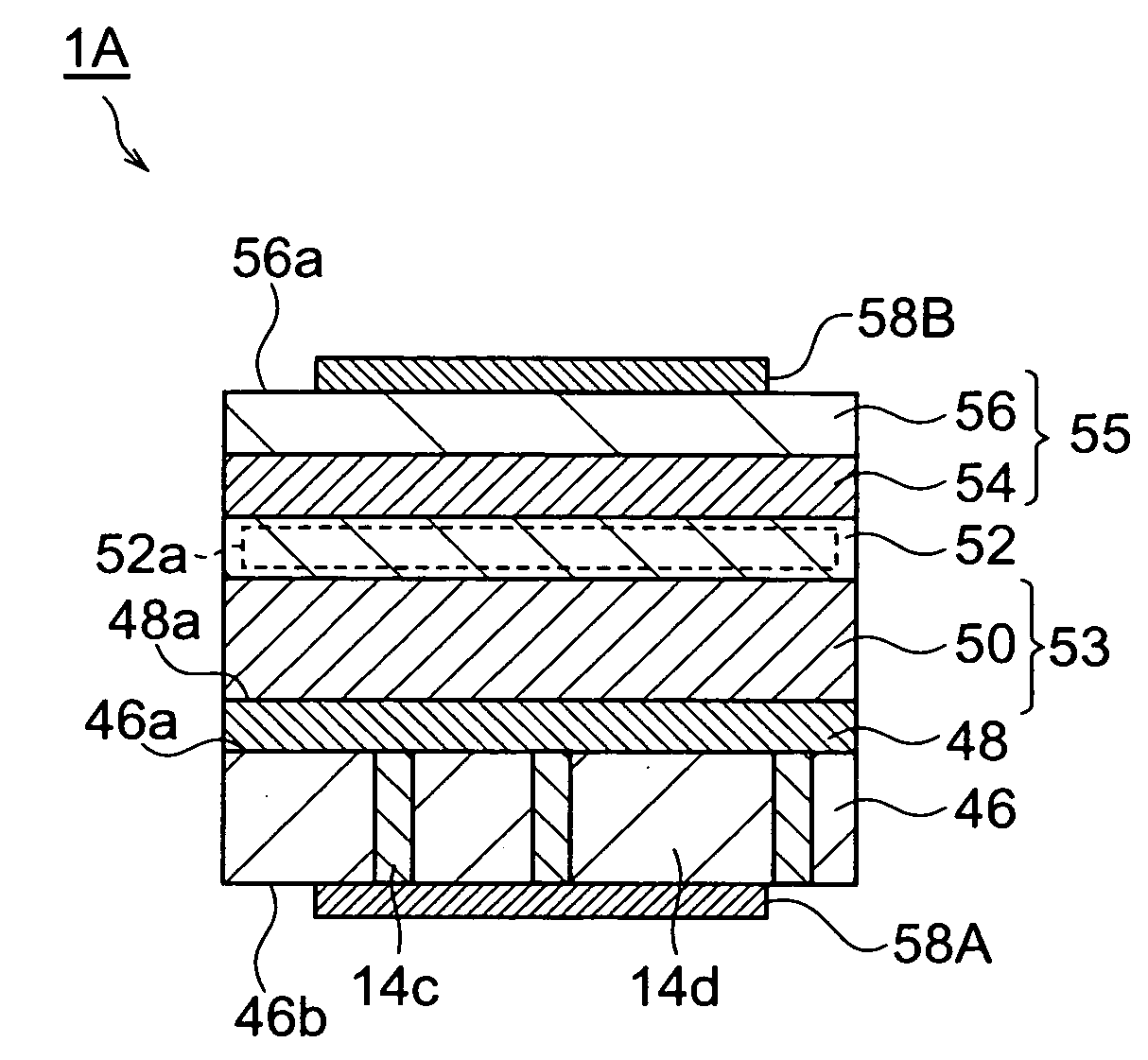

Method of fabricating bifacial tandem solar cells

ActiveUS8852994B2Easy and simpler and reliableSemiconductor/solid-state device manufacturingPhotovoltaic energy generationTandem solar cellOptoelectronics

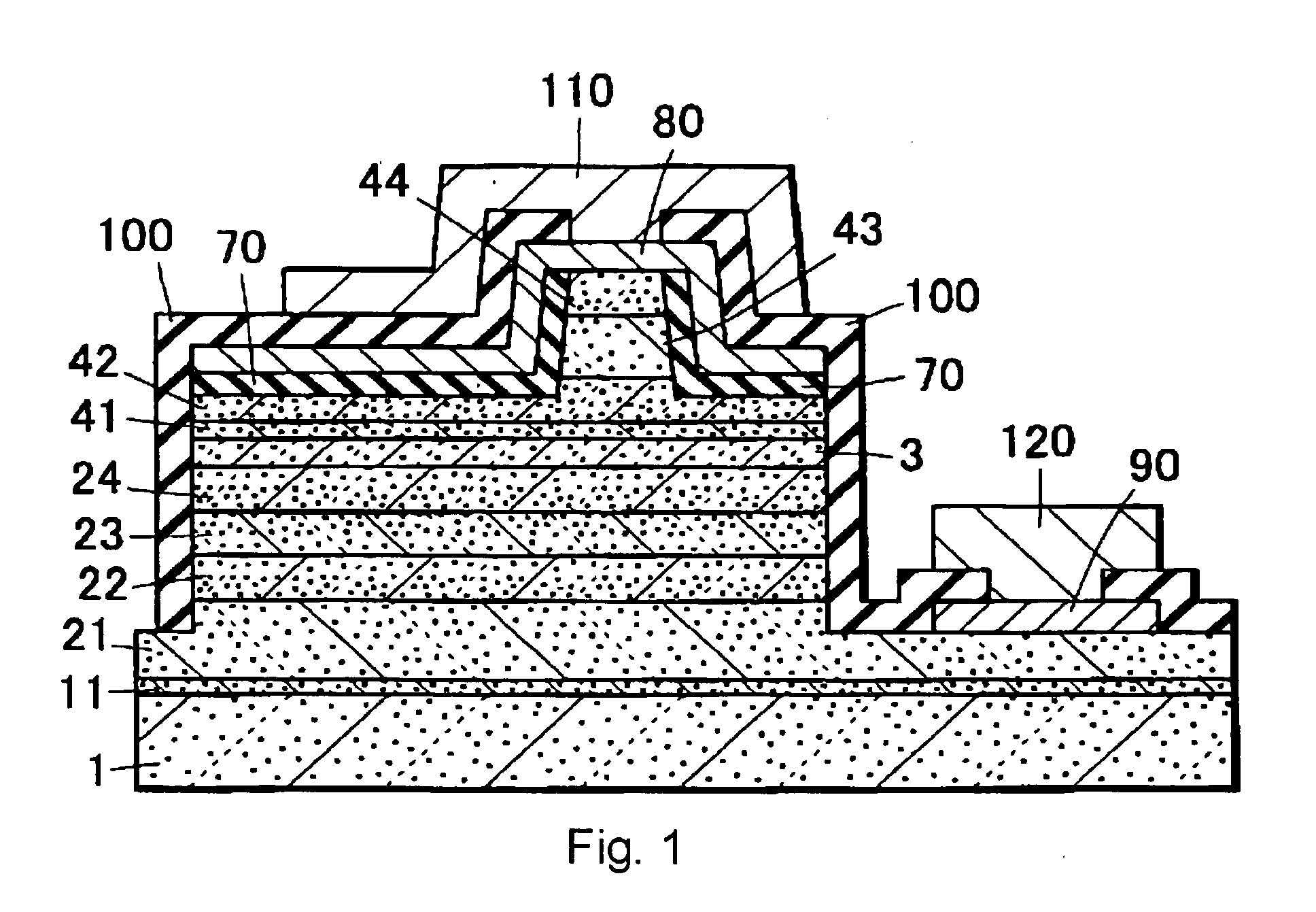

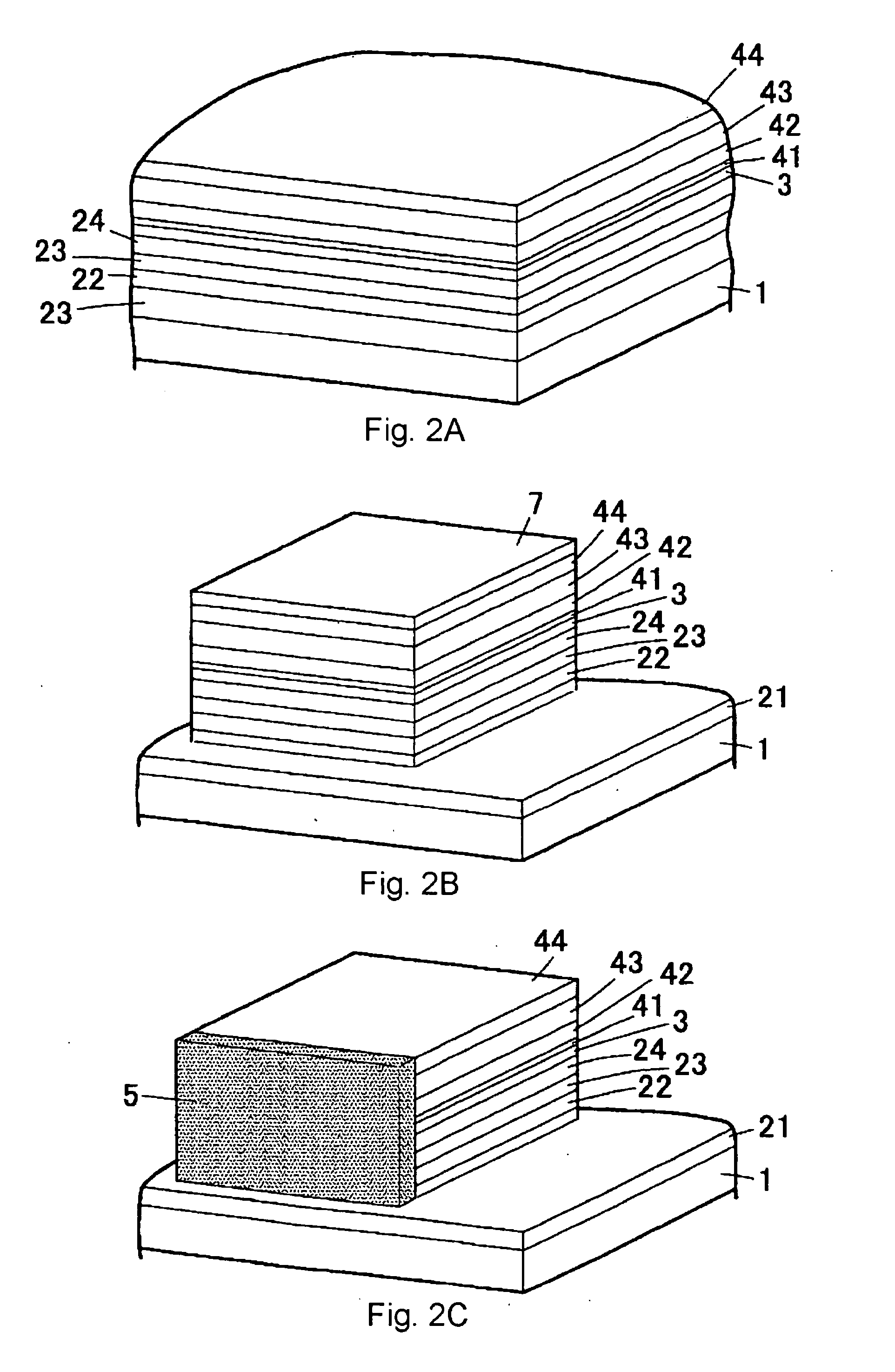

A method of fabricating on a semiconductor substrate bifacial tandem solar cells with semiconductor subcells having a lower bandgap than the substrate bandgap on one side of the substrate and with subcells having a higher bandgap than the substrate on the other including, first, growing a lower bandgap subcell on one substrate side that uses only the same periodic table group V material in the dislocation-reducing grading layers and bottom subcells as is present in the substrate and after the initial growth is complete and then flipping the substrate and growing the higher bandgap subcells on the opposite substrate side which can be of different group V material.

Owner:MASIMO SEMICON +1

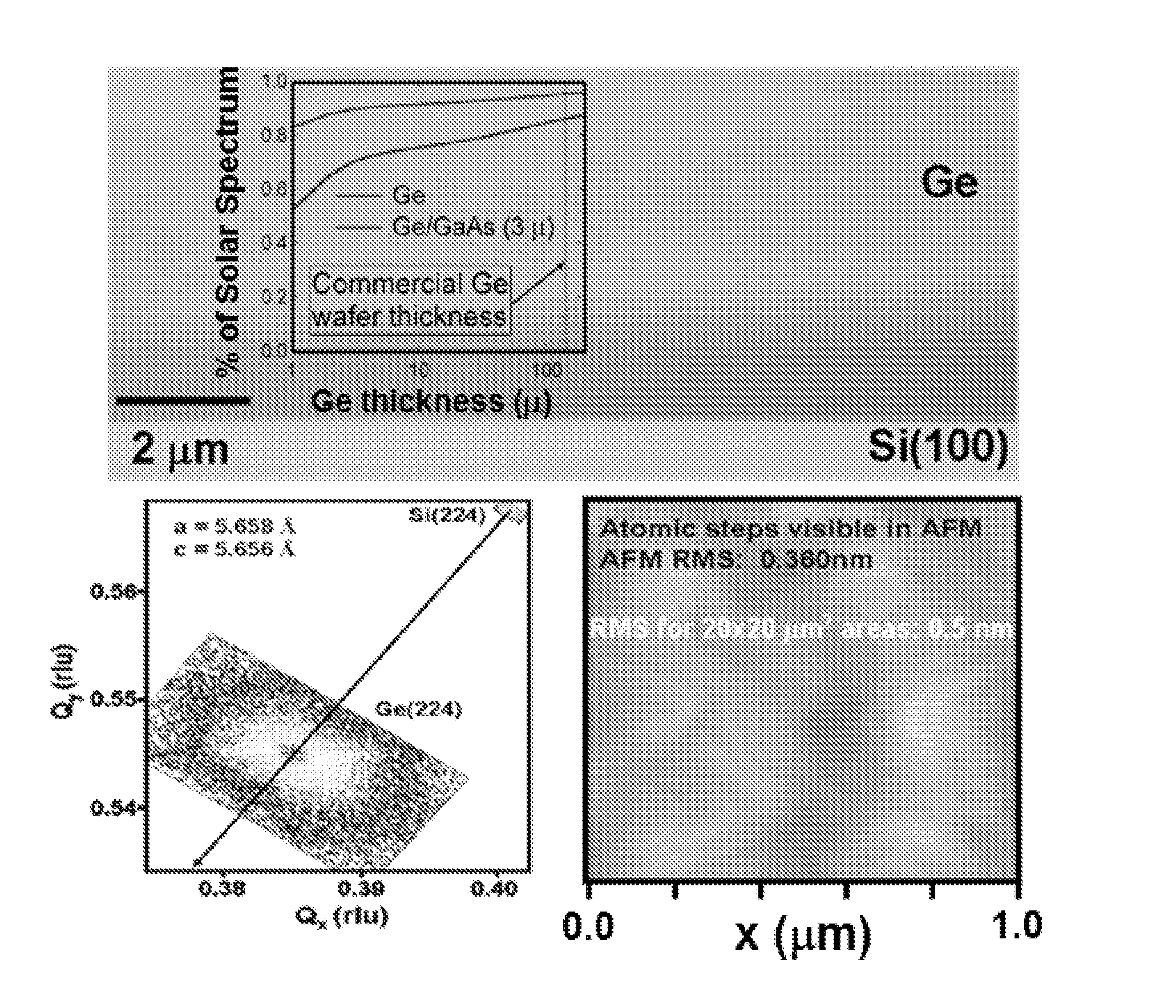

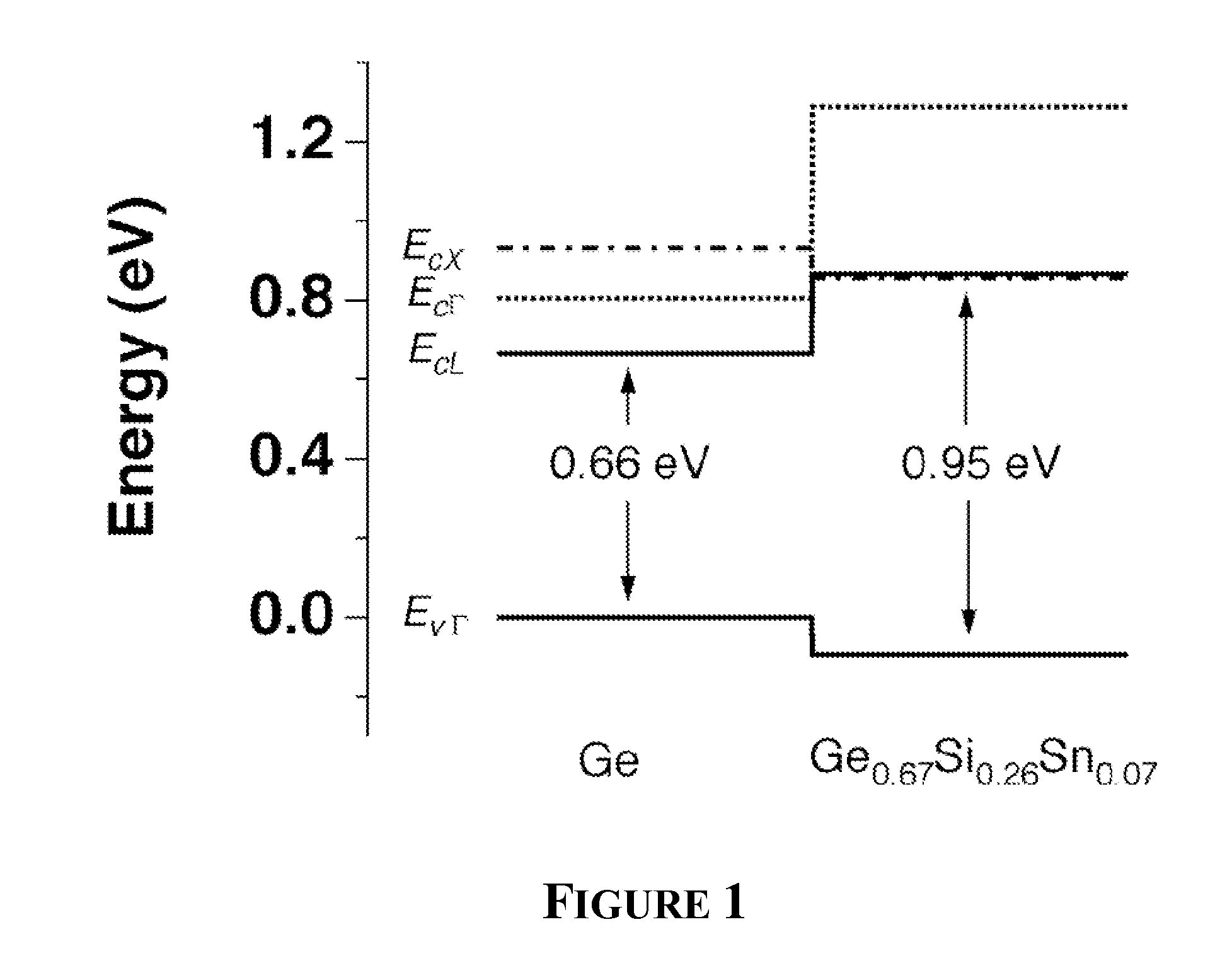

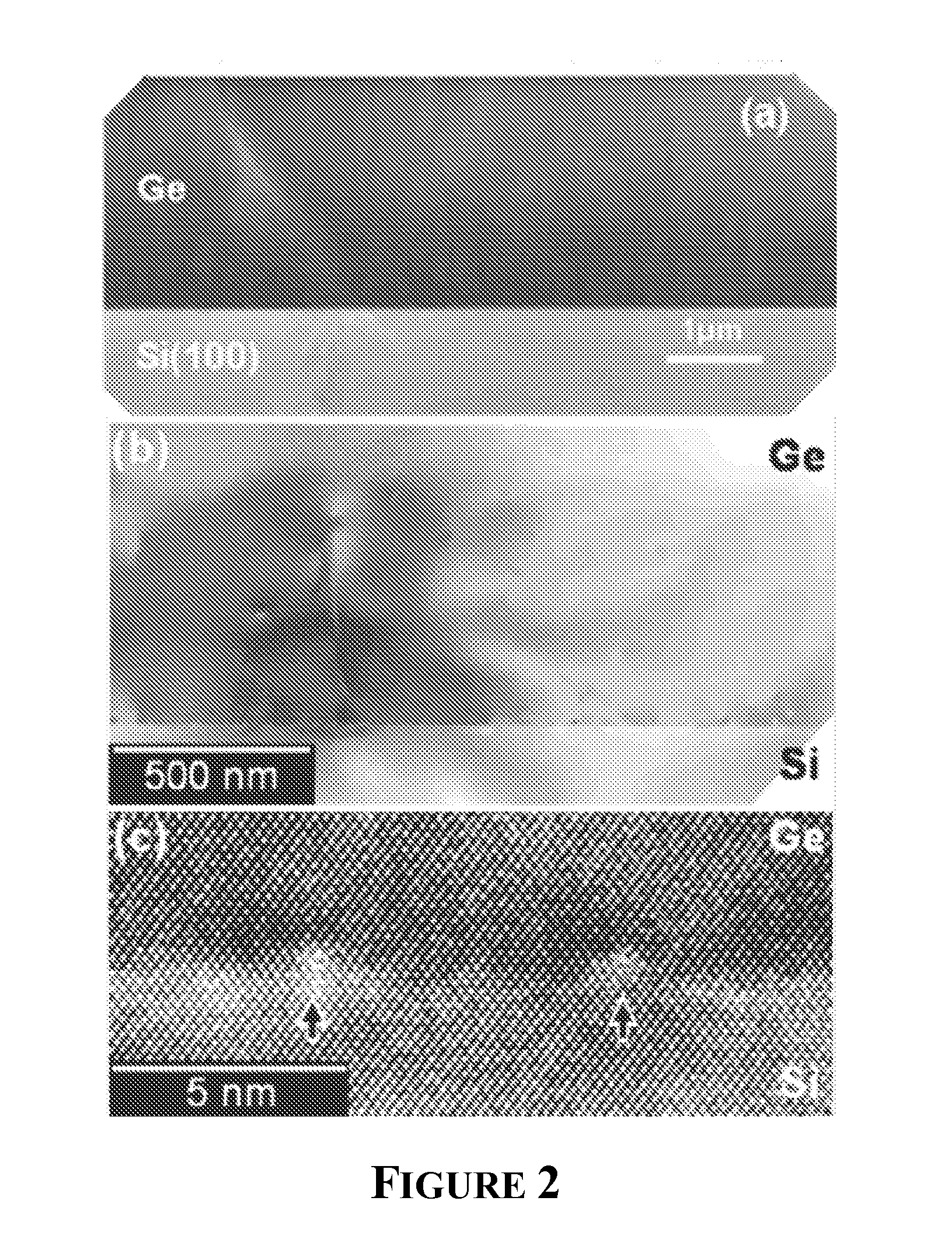

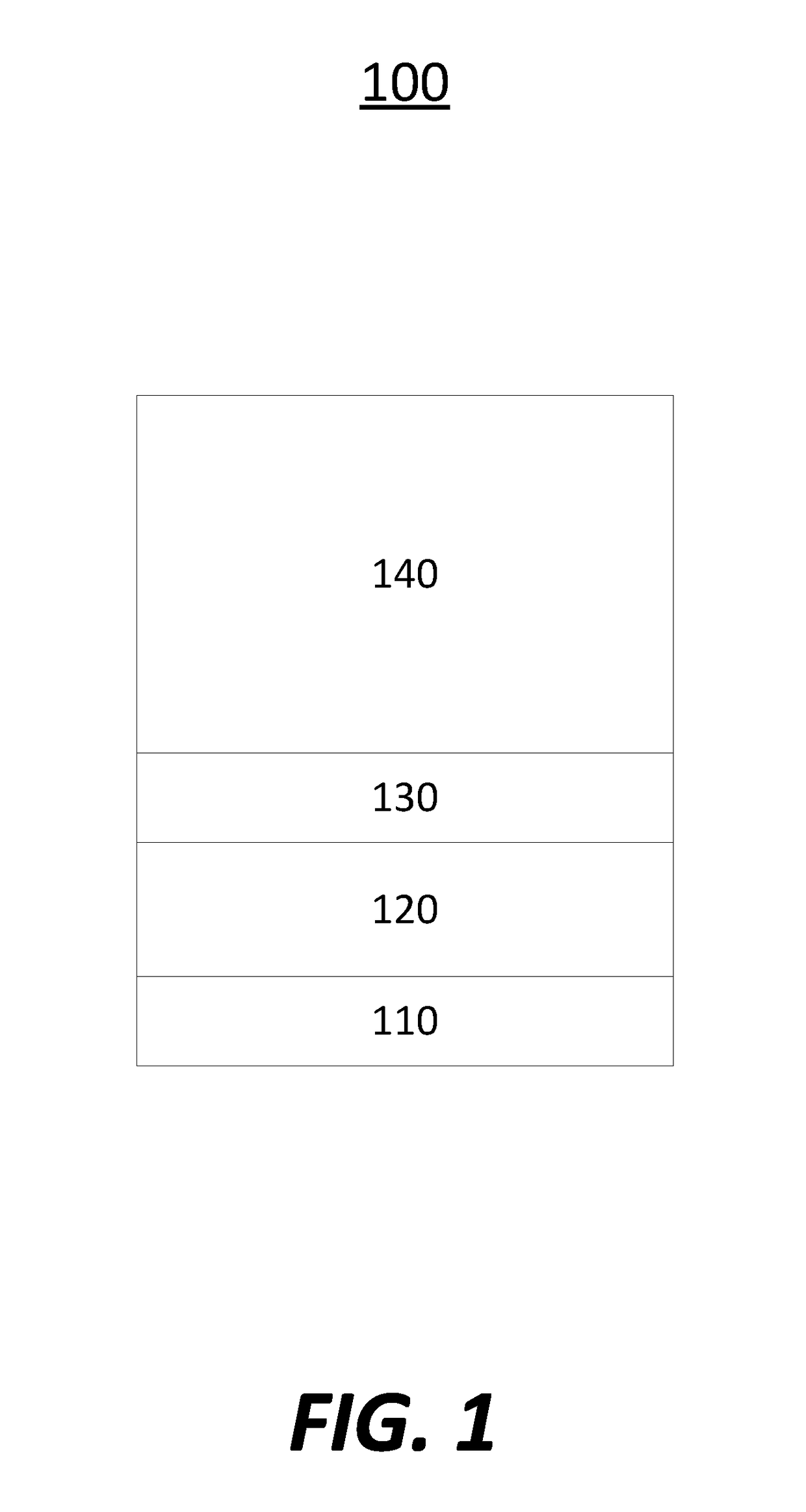

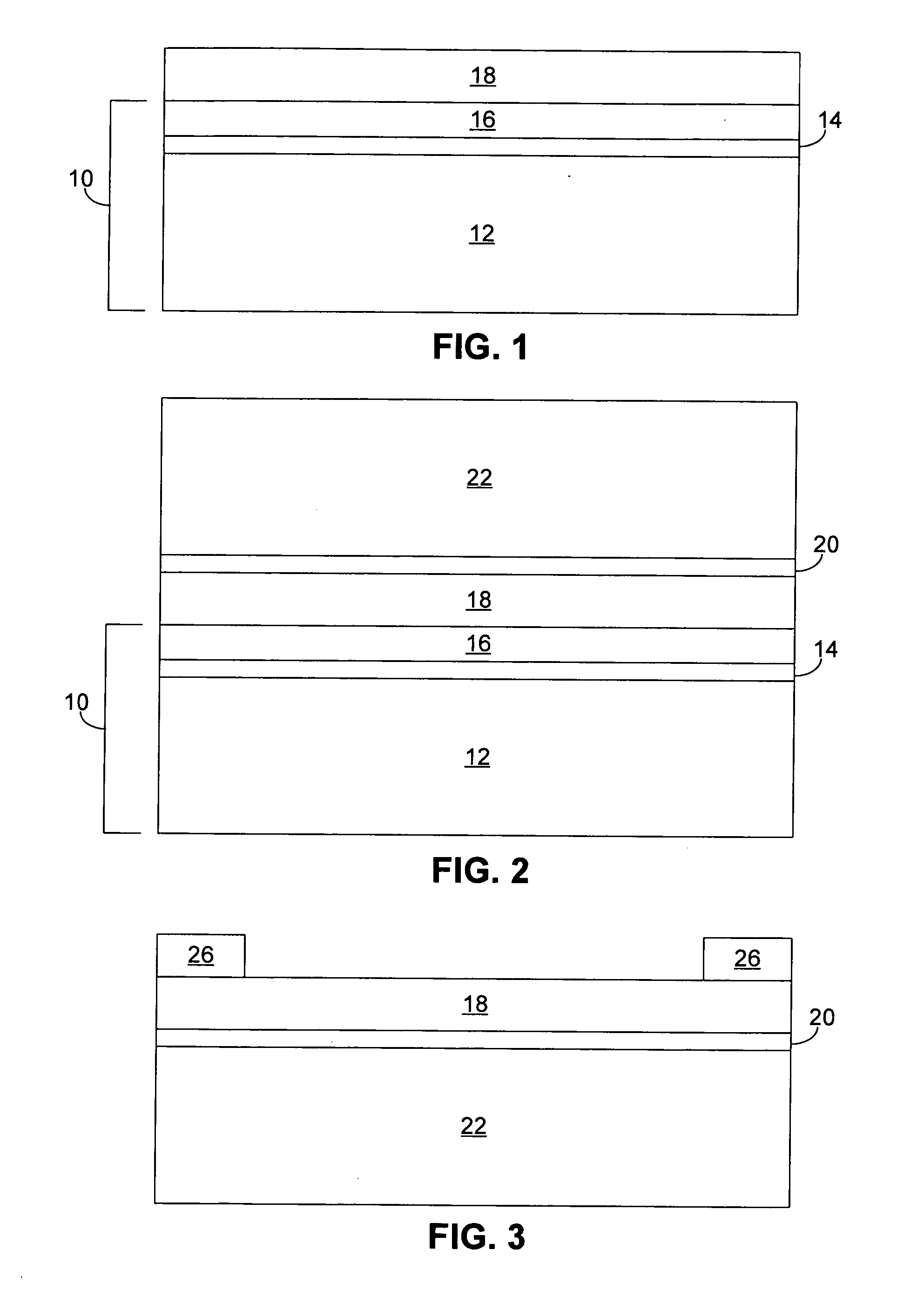

Hybrid Group IV/III-V Semiconductor Structures

InactiveUS20110254052A1Low costImprove efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingSemiconductor structureAlloy

Described herein are semiconductor structures comprising (i) a Si substrate; (ii) a buffer region formed directly over the Si substrate, wherein the buffer region comprises (a) a Ge layer having a threading dislocation density below about 105 cm−2; or (b) a Ge1-xSnx layer formed directly over the Si substrate and a Ge1-x-ySixSny layer formed over the Ge1-xSnx layer; and (iii) a plurality of III-V active blocks formed over the buffer region, wherein the first III-V active block formed over the buffer region is lattice matched or pseudomorphically strained to the buffer region. Further, methods for forming the semiconductor structures are provided and novel Ge1-x-ySixSny, alloys are provided that are lattice matched or pseudomorphically strained to Ge and have tunable band gaps ranging from about 0.80 eV to about 1.4O eV.

Owner:ARIZONA STATE UNIVERSITY

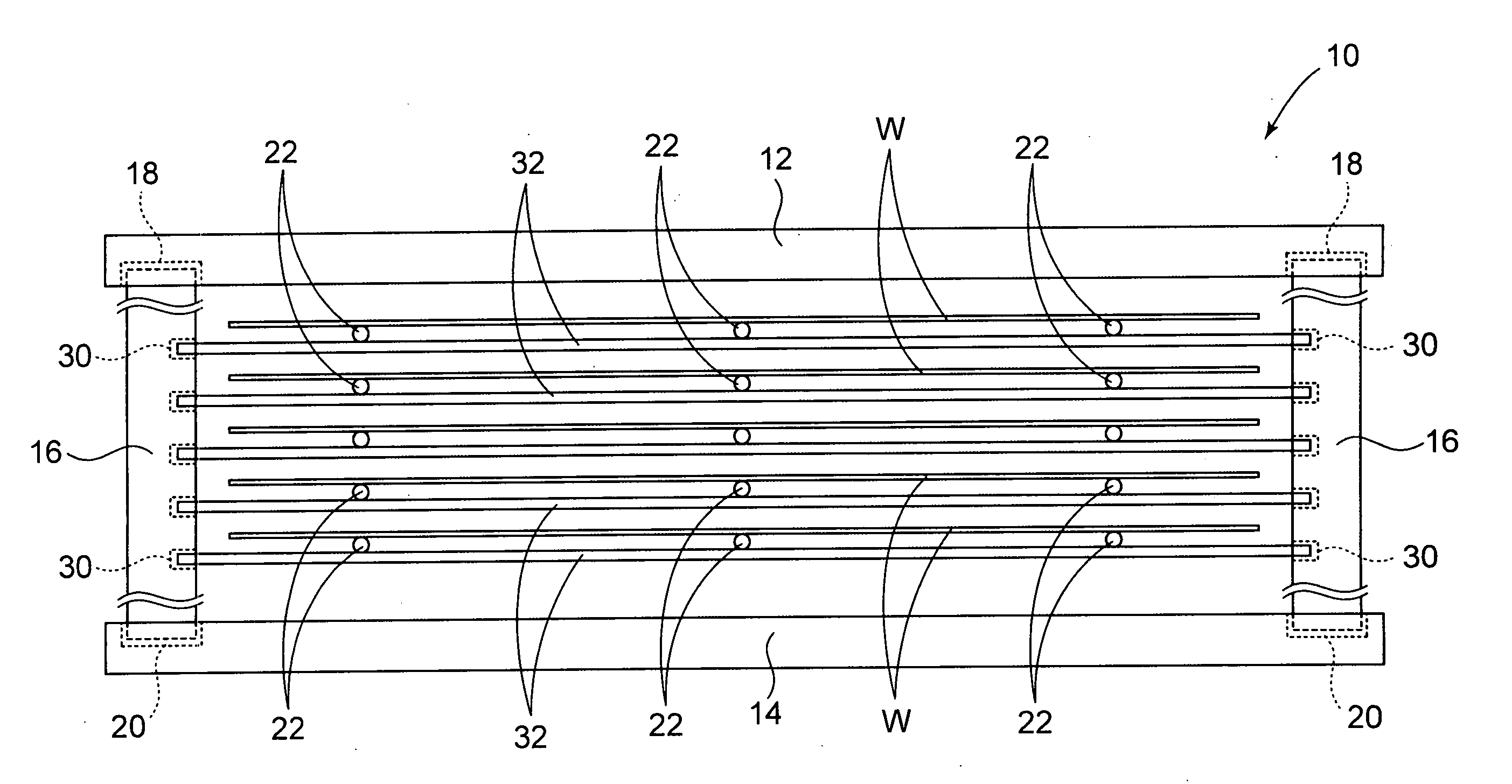

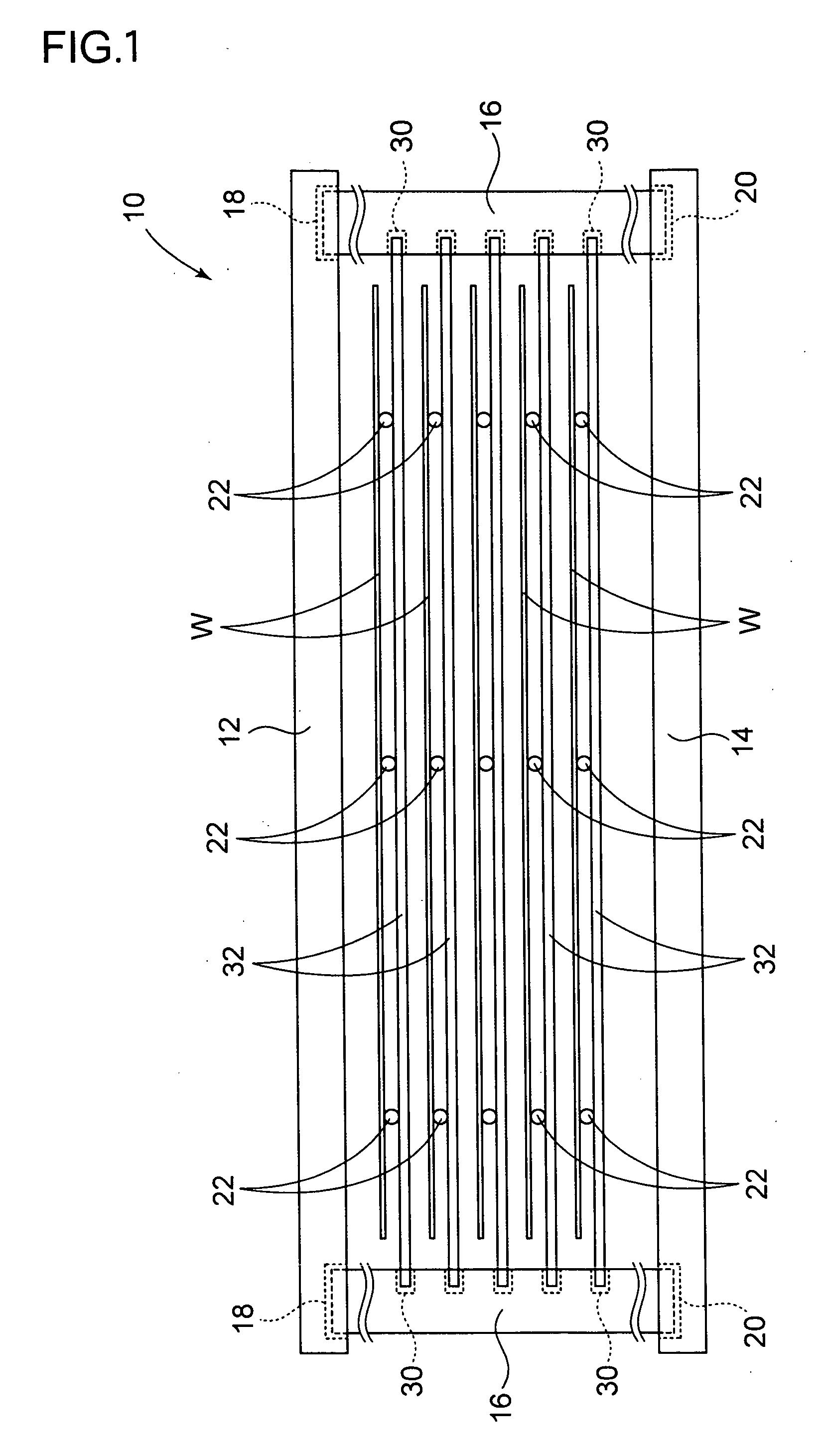

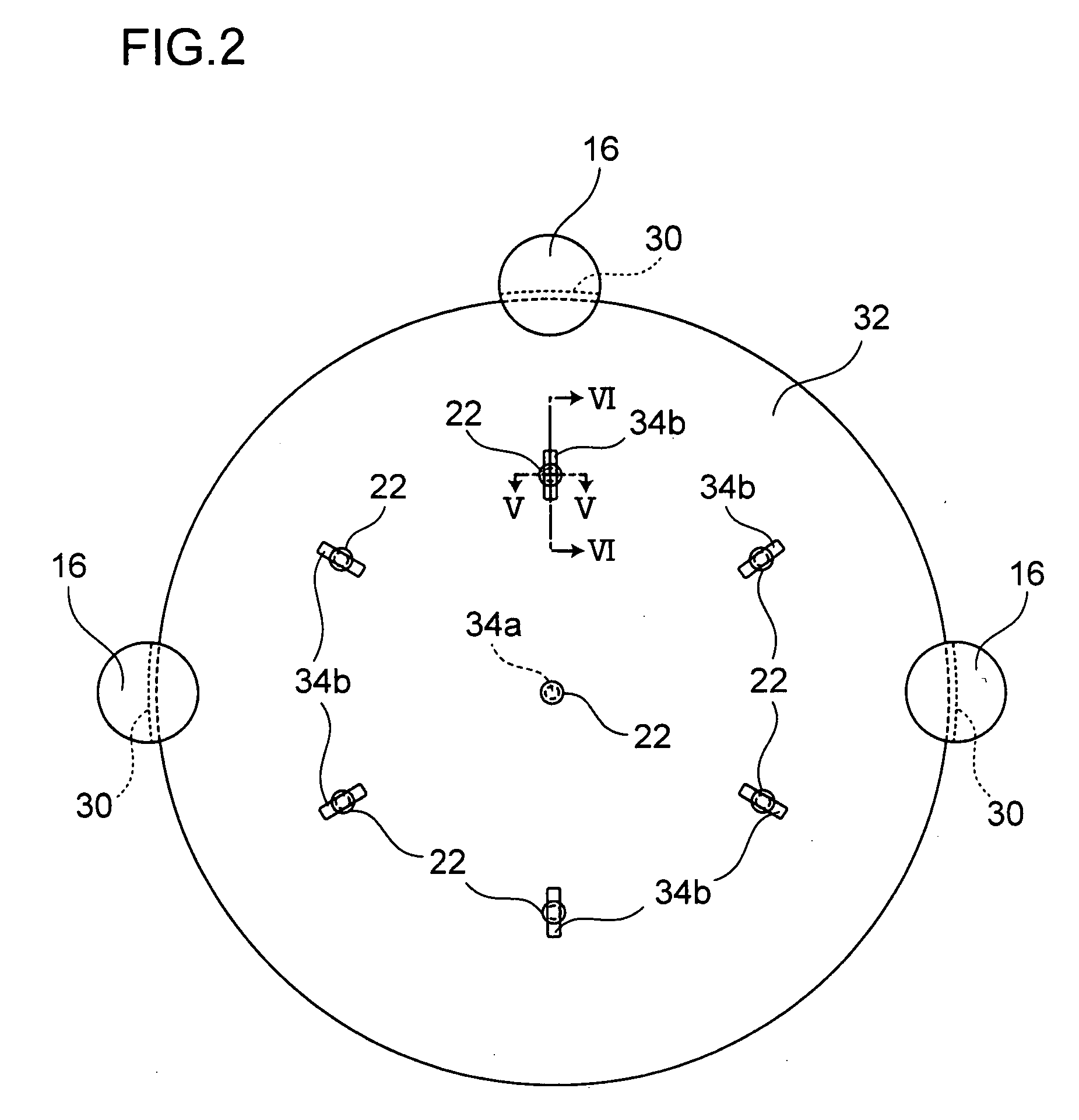

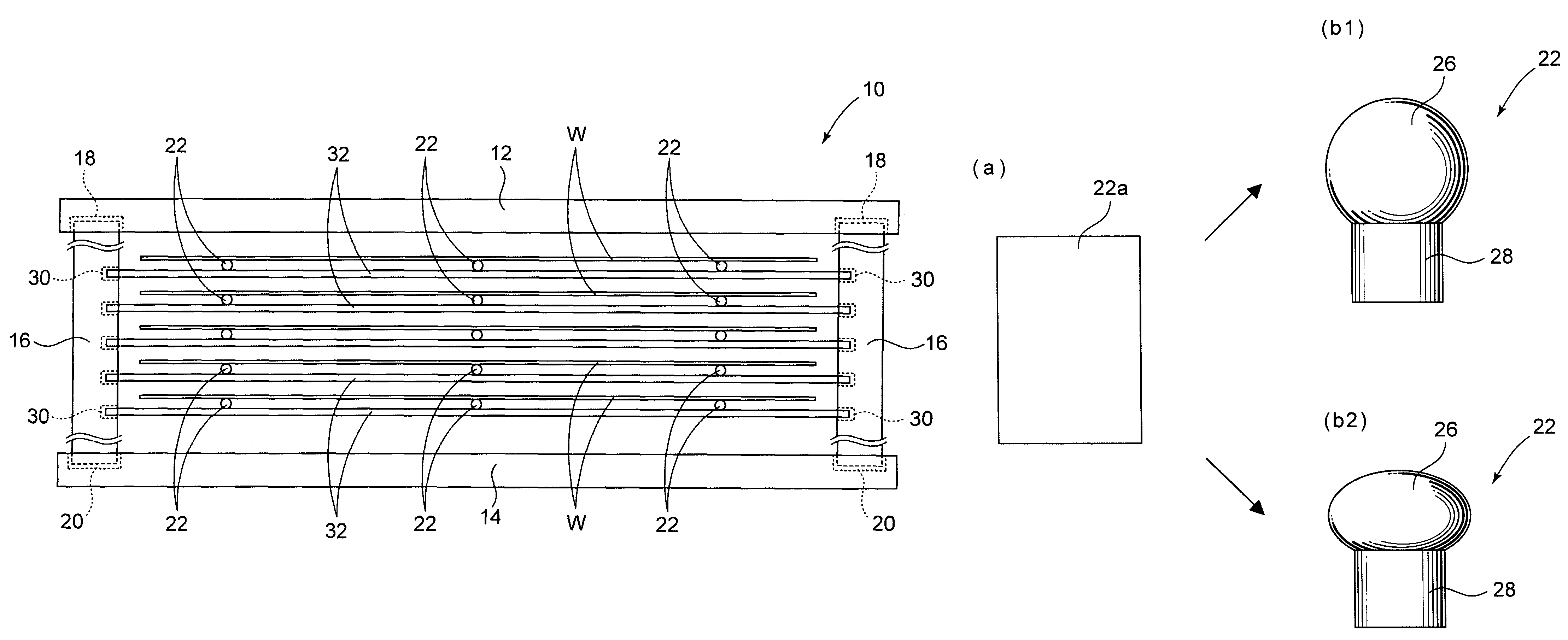

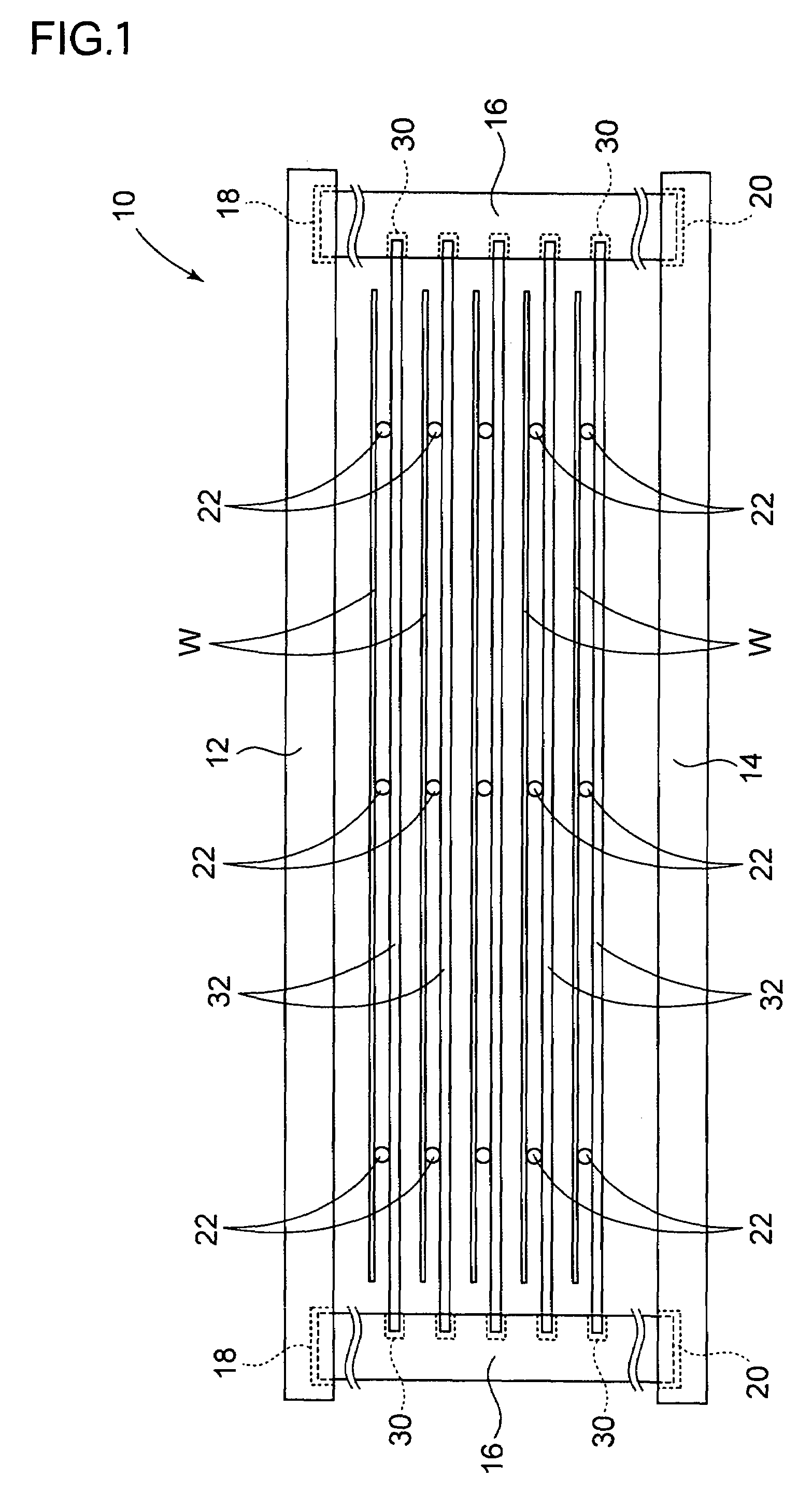

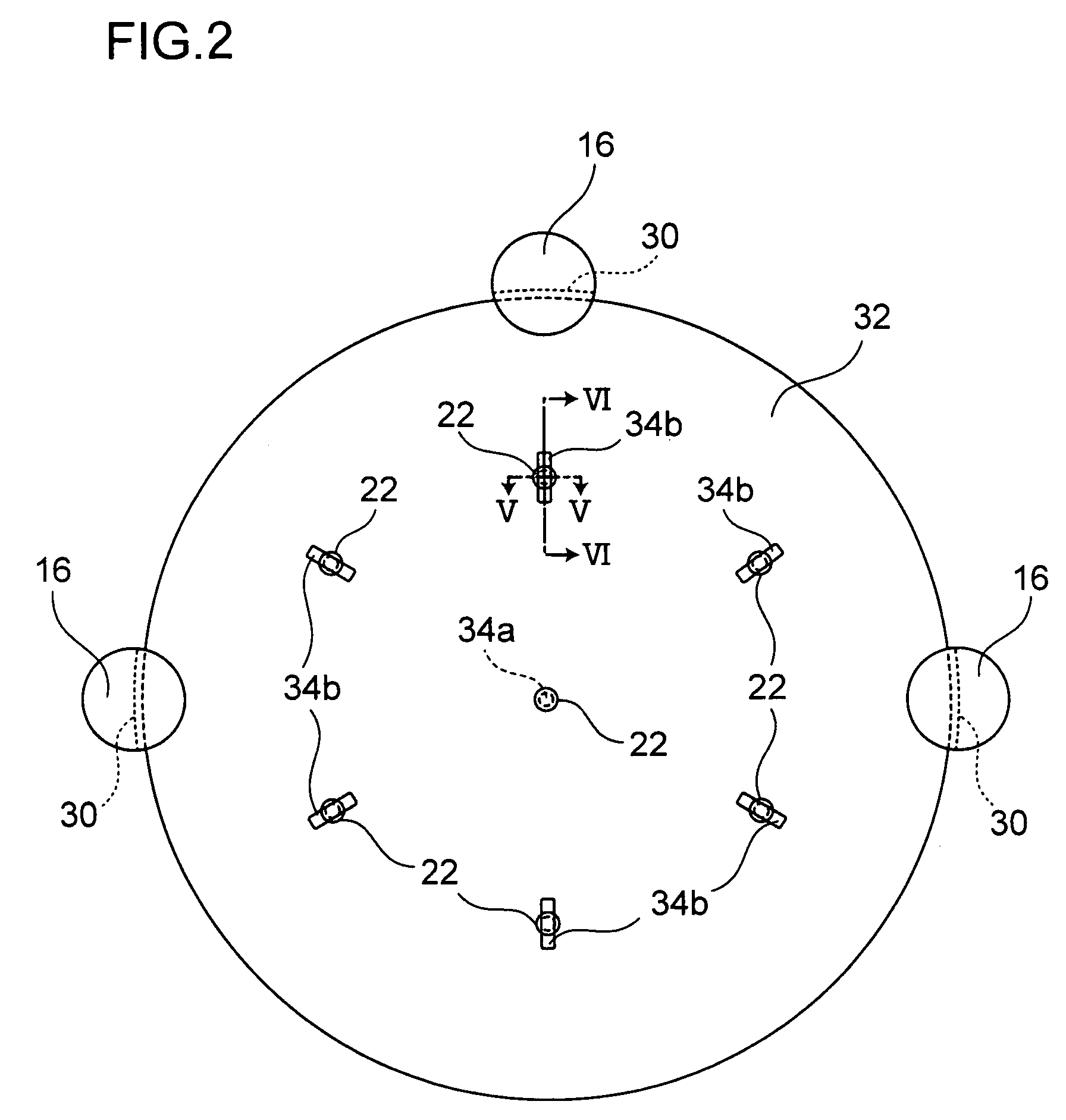

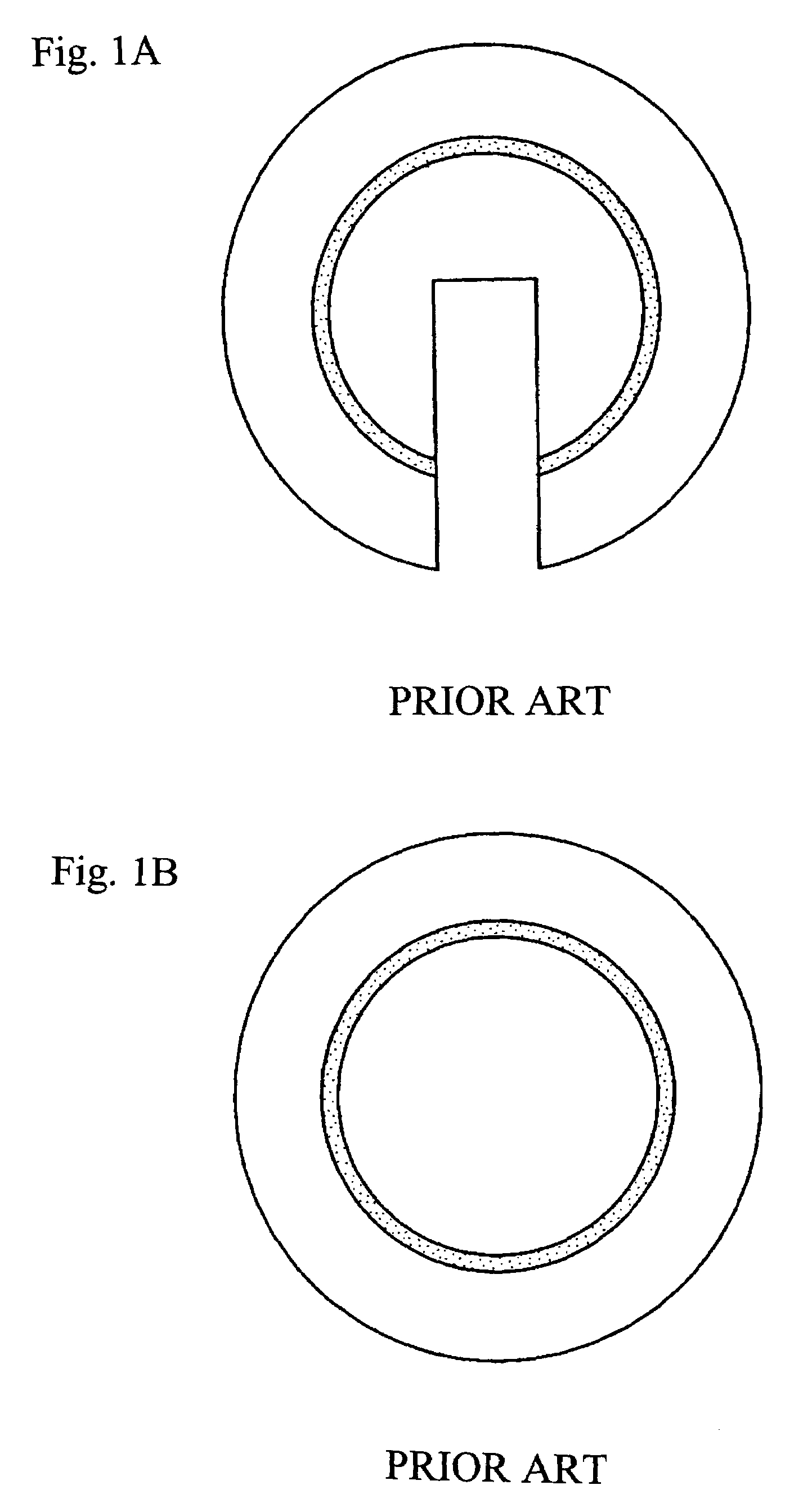

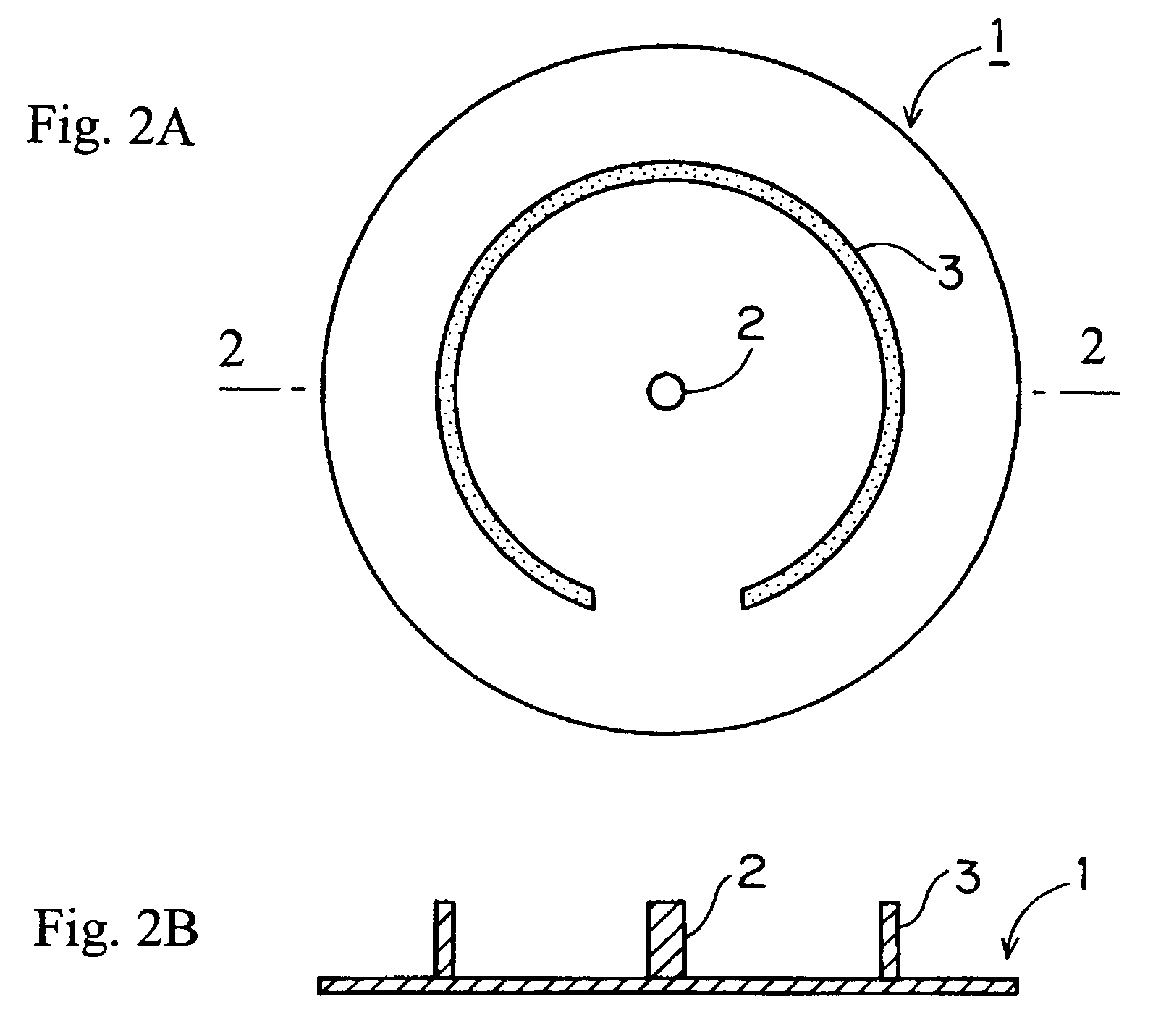

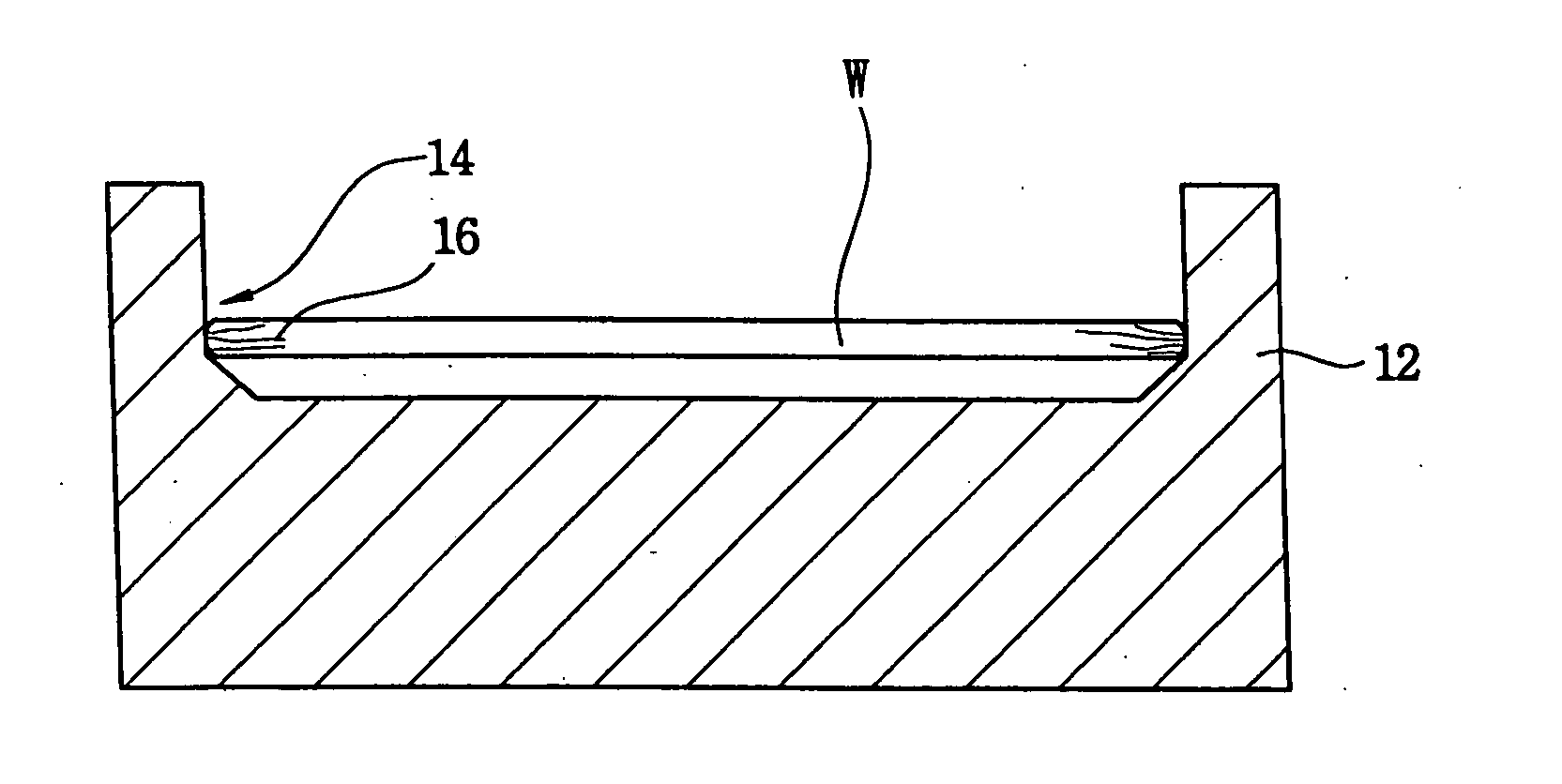

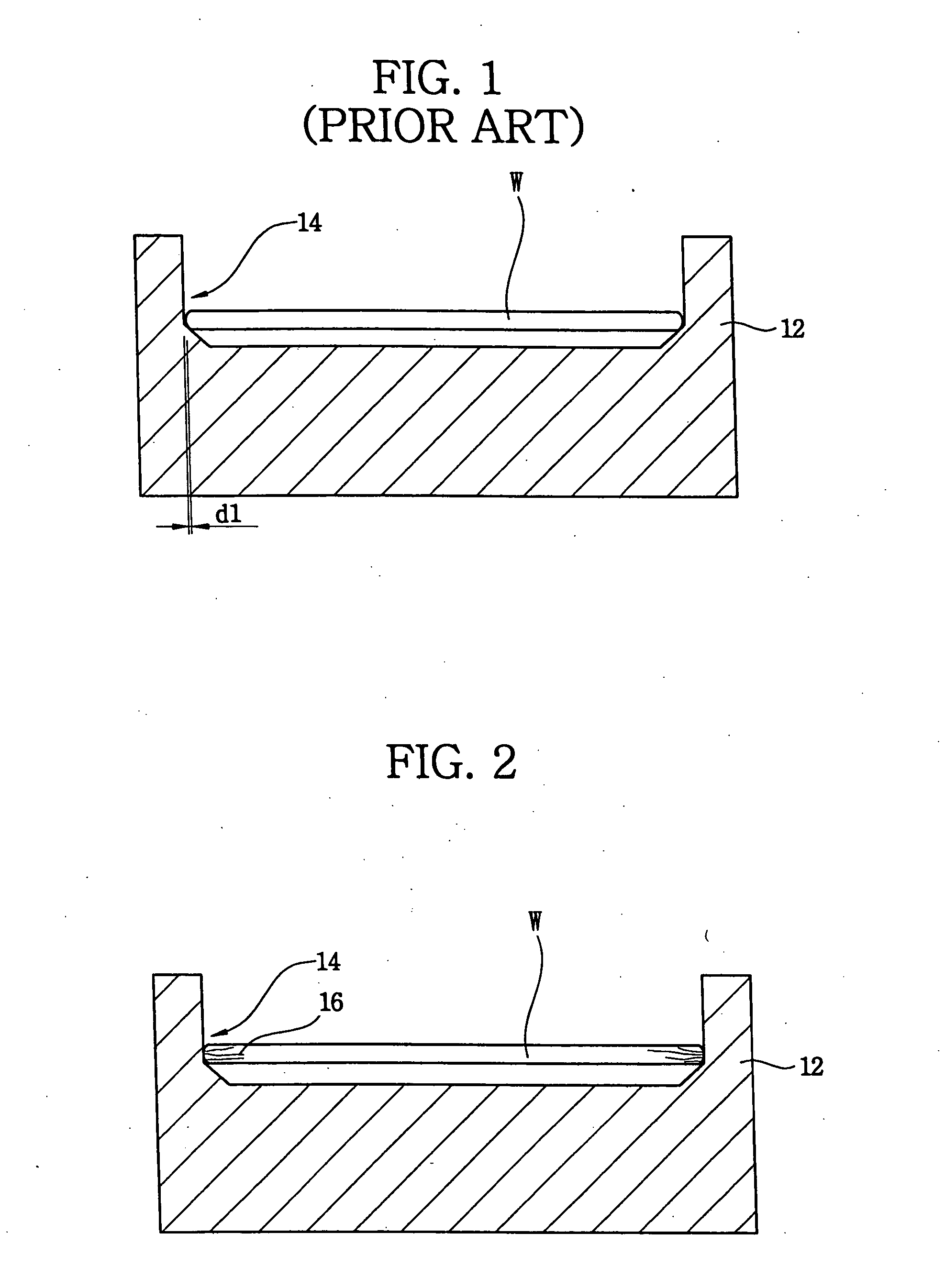

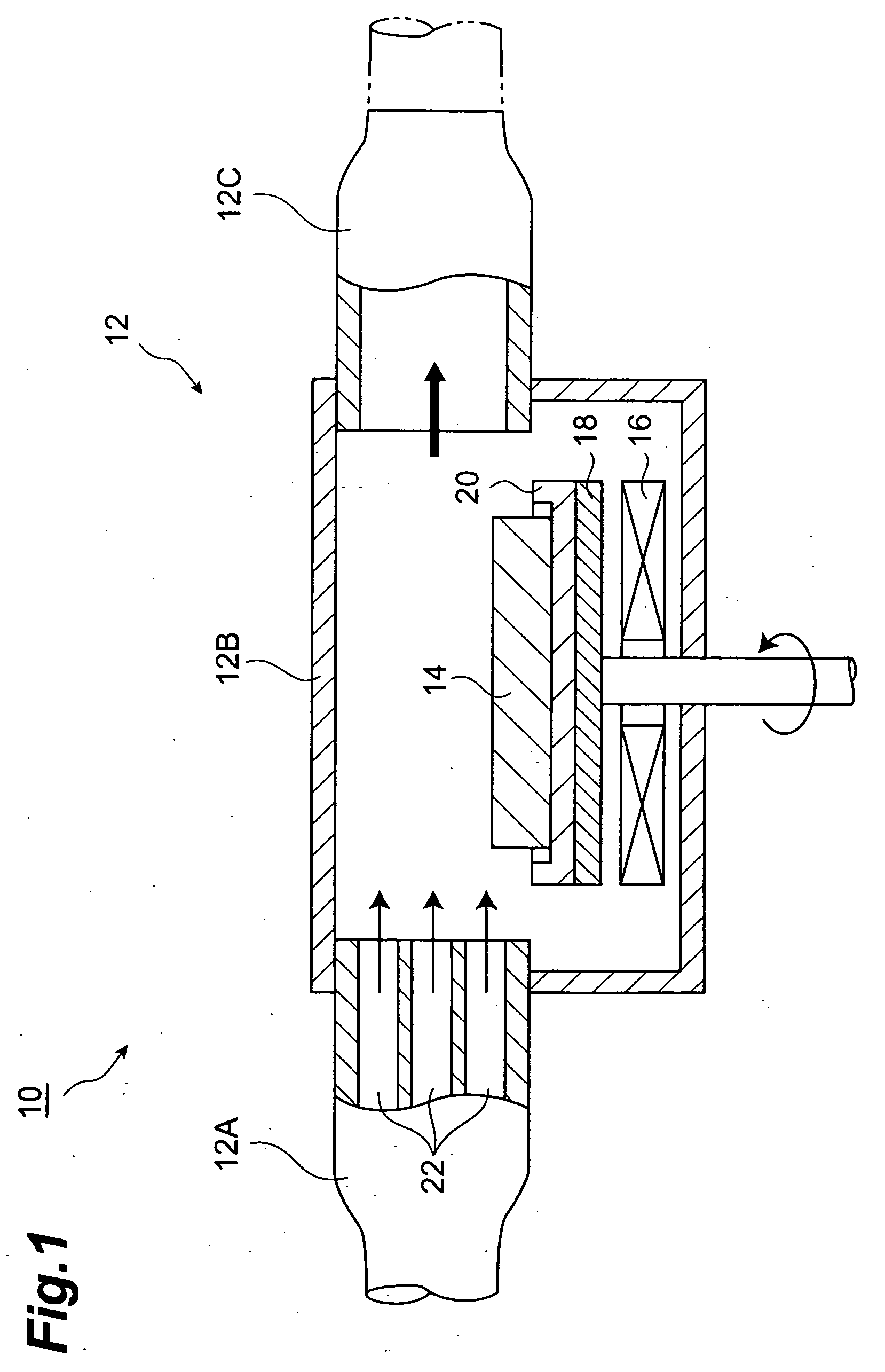

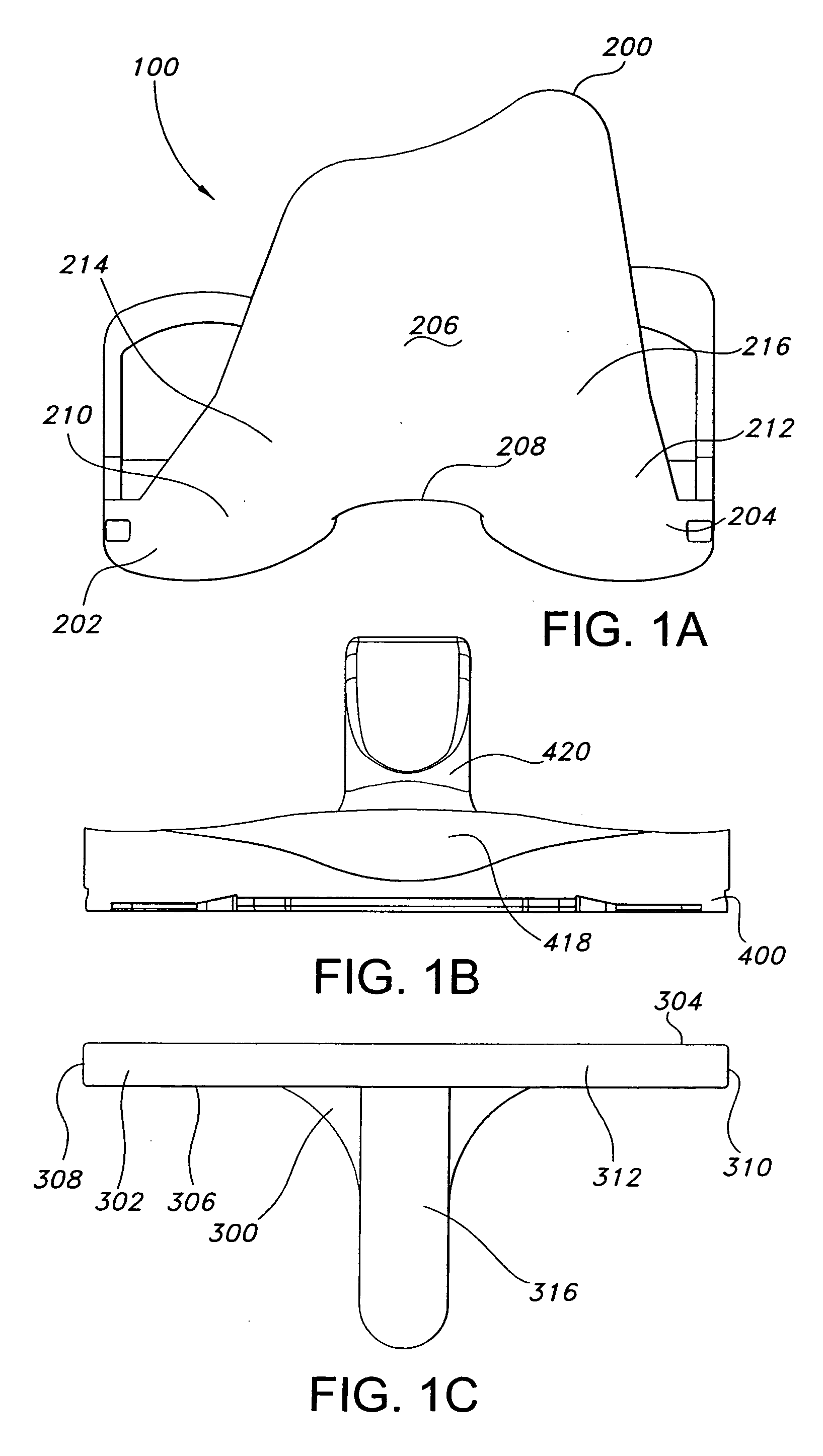

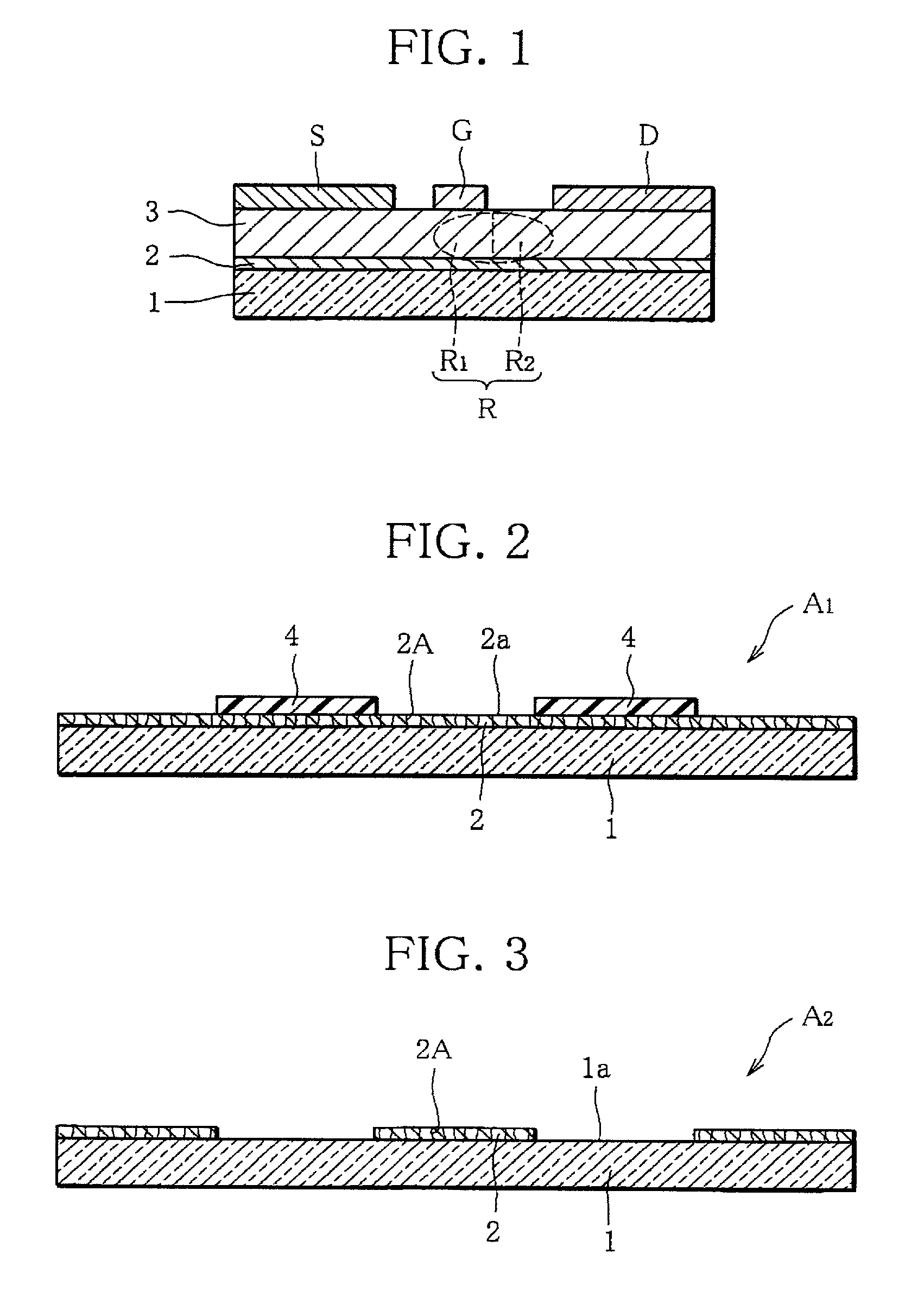

Wafer Support Tool for Heat Treatment and Heat Treatment Apparatus

ActiveUS20070006806A1Simple working processLow costLiquid surface applicatorsCharge supportsMechanical engineeringDislocation

The present invention provides a wafer support tool for heat treatment easy in working and capable of realizing reduction in cost without generating damages or slip dislocations that would be otherwise caused by high temperature heat treatment and a heat treatment apparatus. The present invention is directed to a wafer support tool for heat treatment comprising: a plurality of wafer support members for supporting a wafer to be heat treated; and a support member holder for holding the wafer support members, wherein the wafer support members each has a contact portion with the wafer, at least one of the contact portions being movable relative to the support member holder.

Owner:SHIN-ETSU HANDOTAI CO LTD

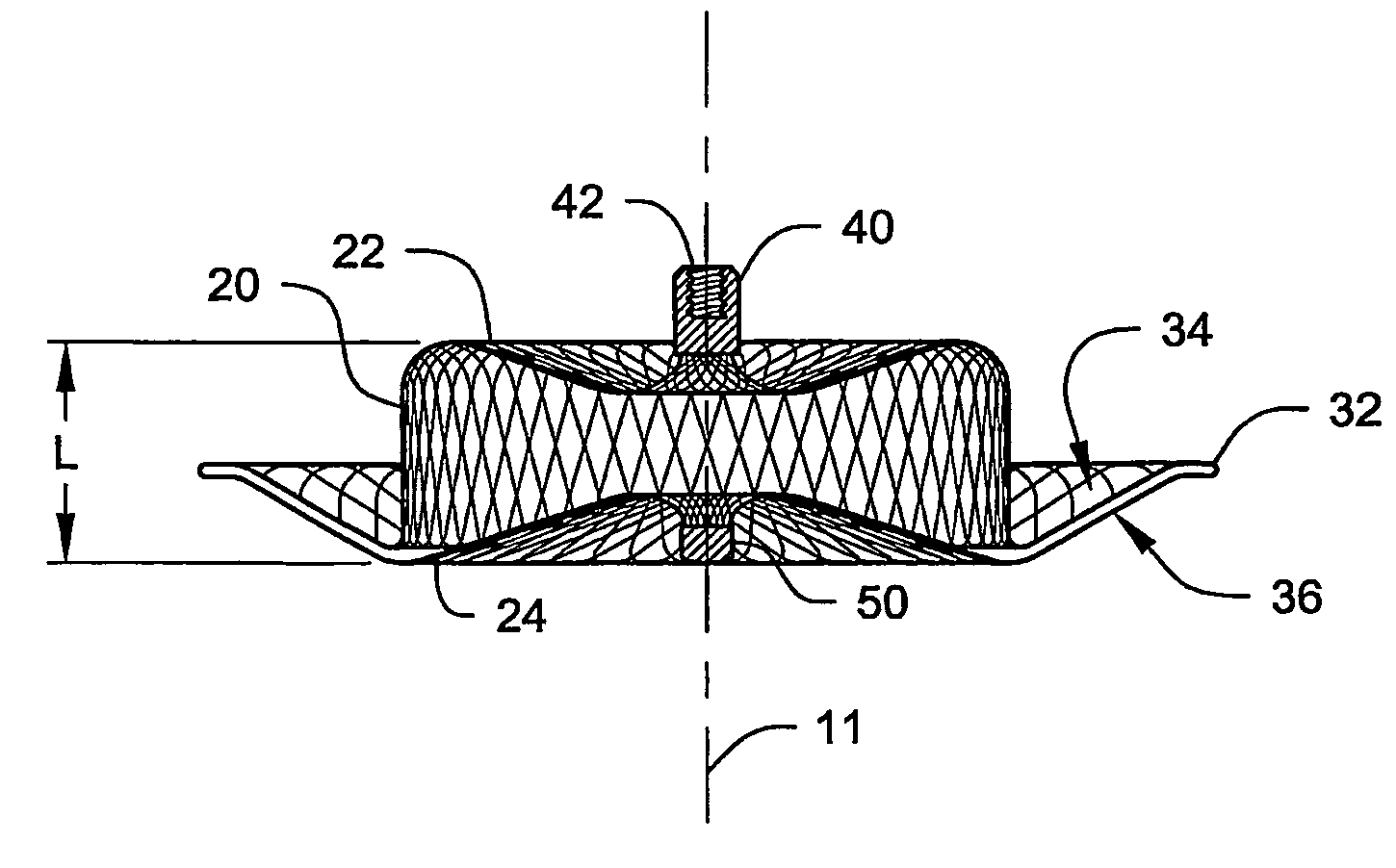

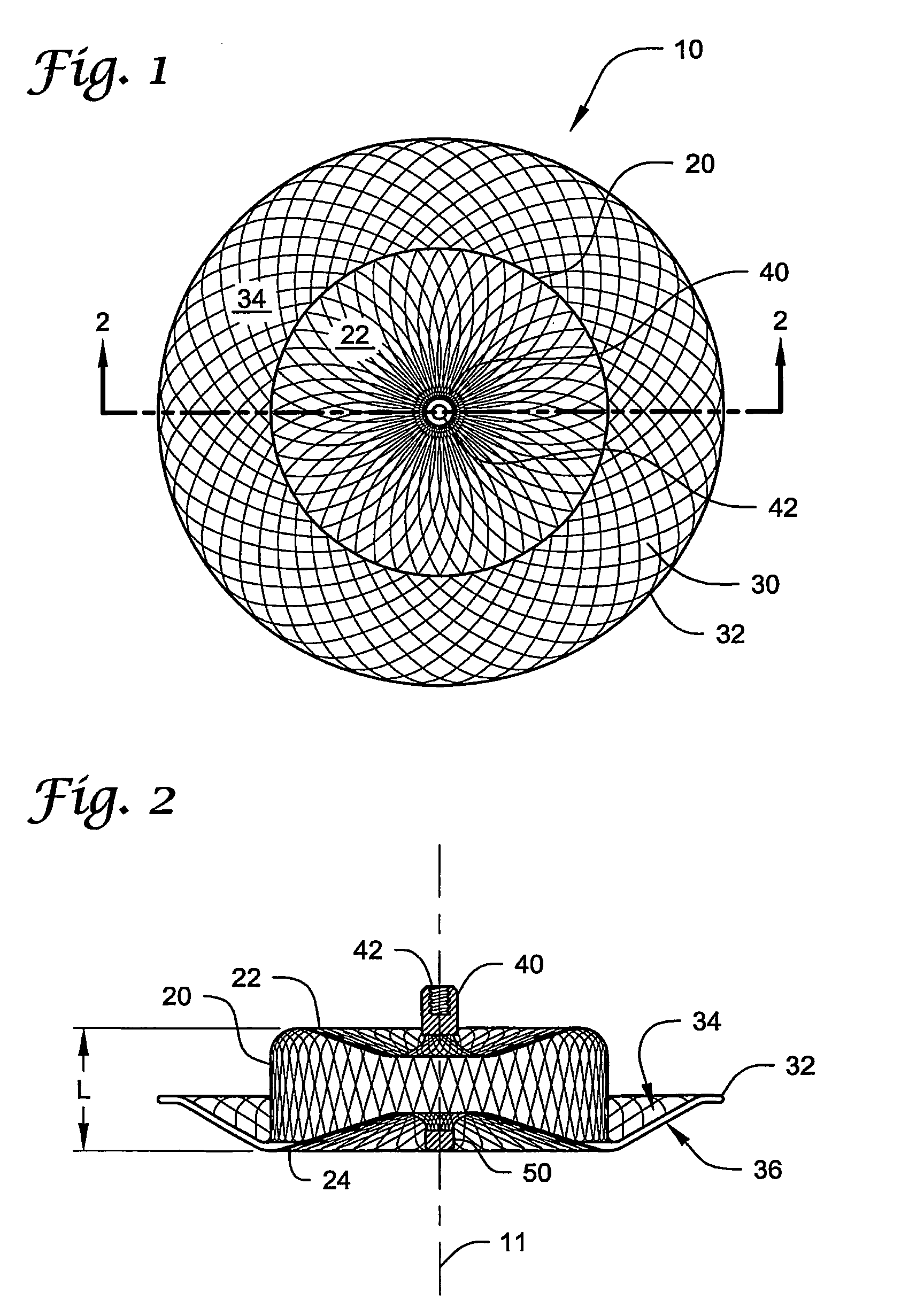

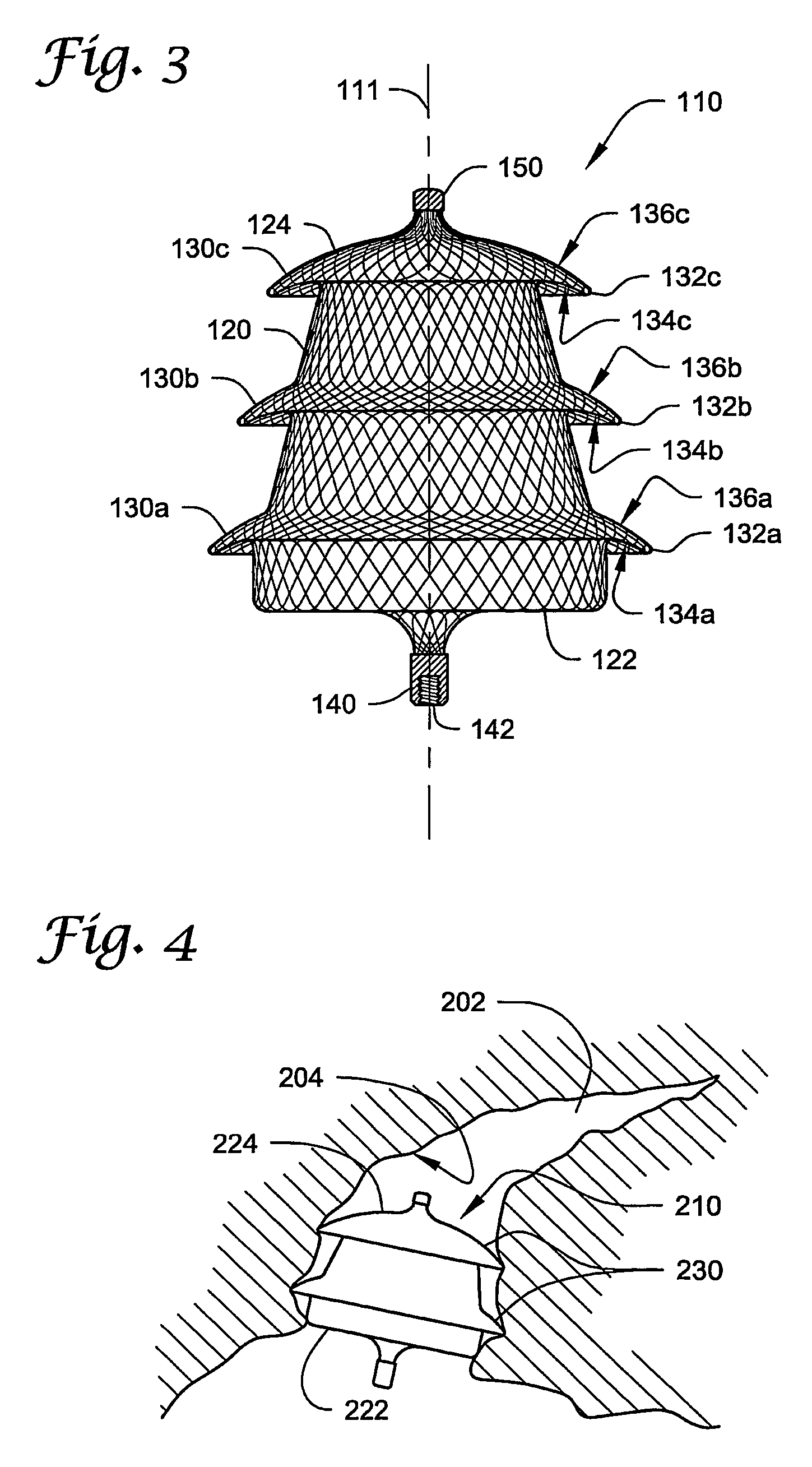

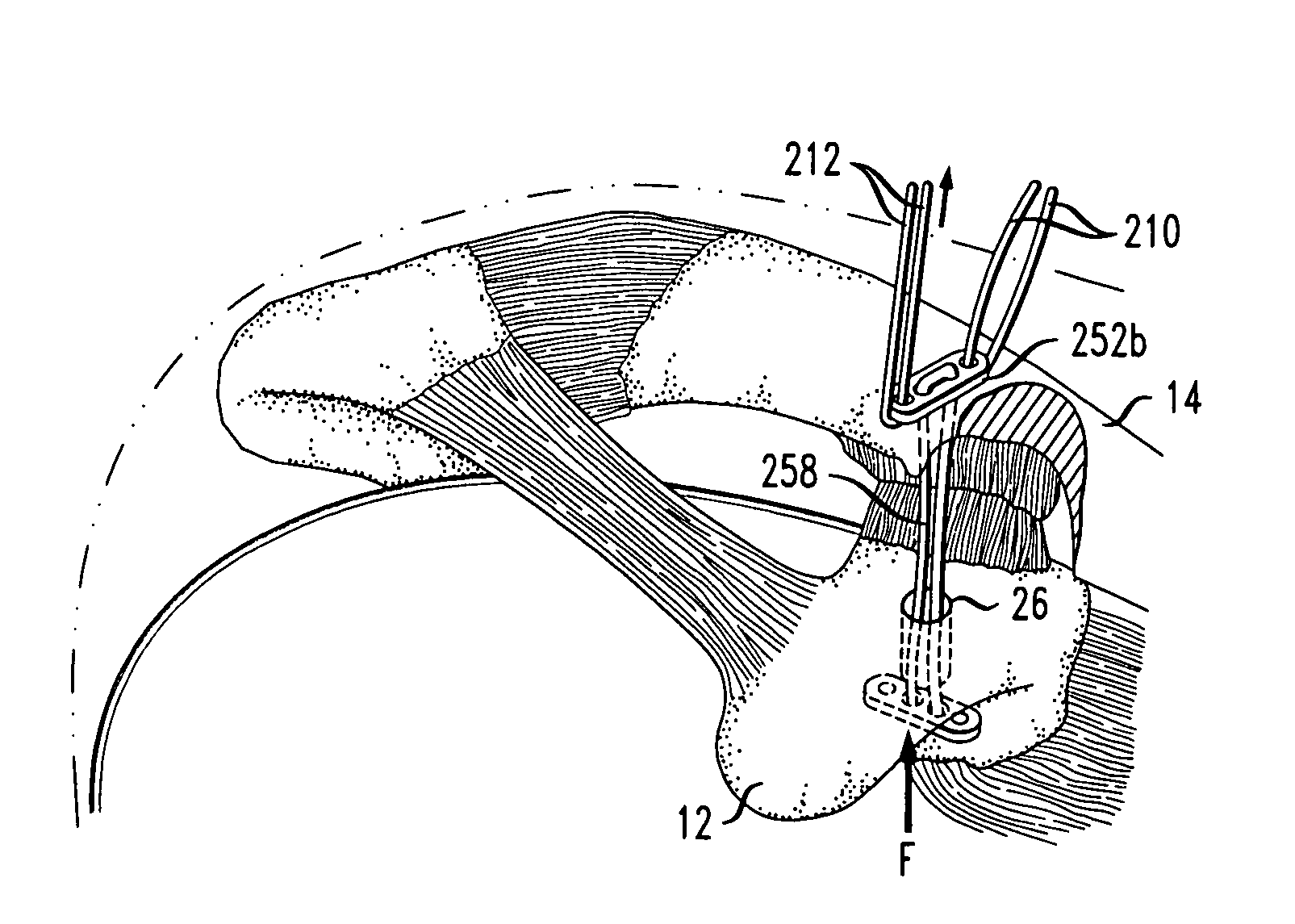

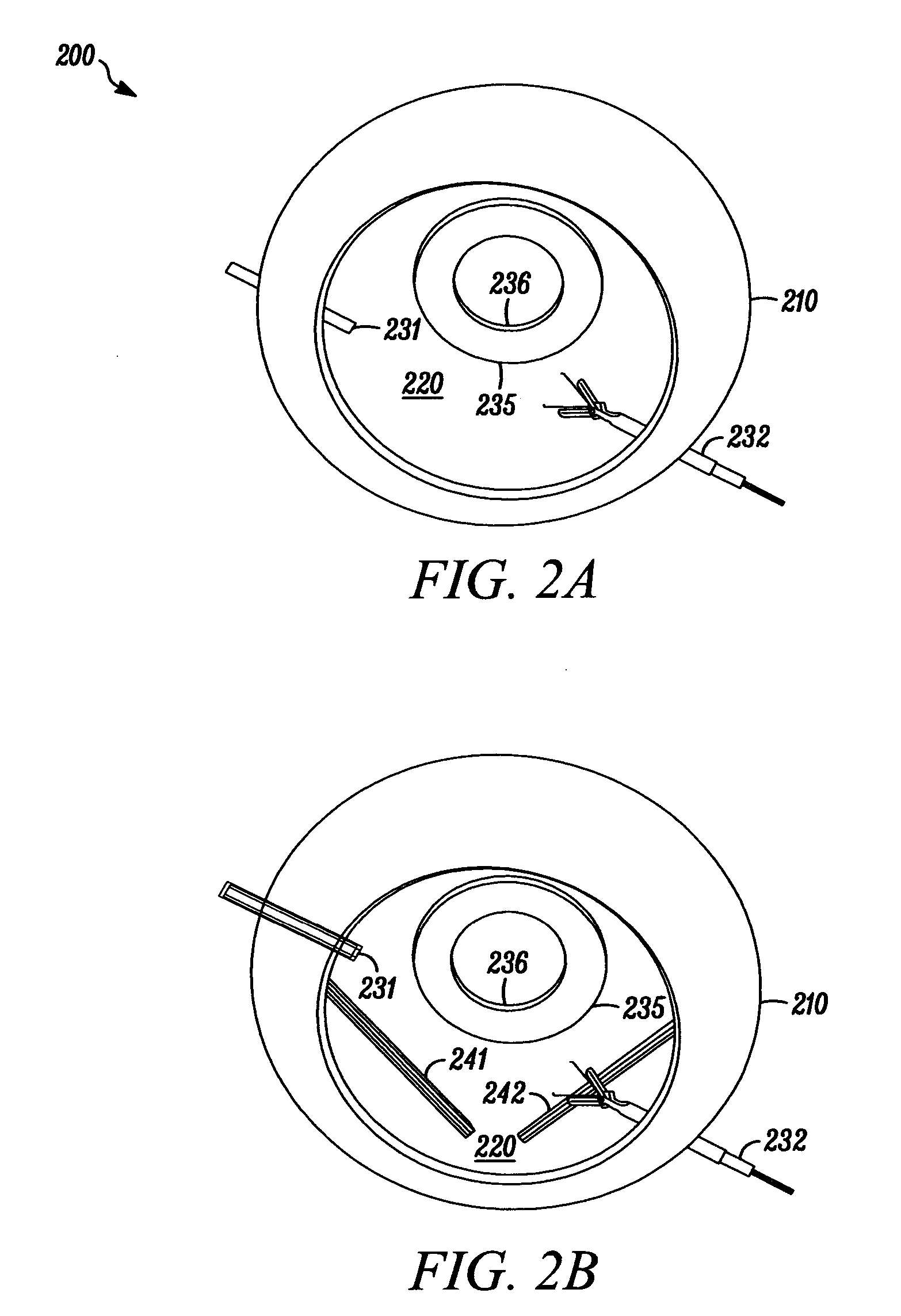

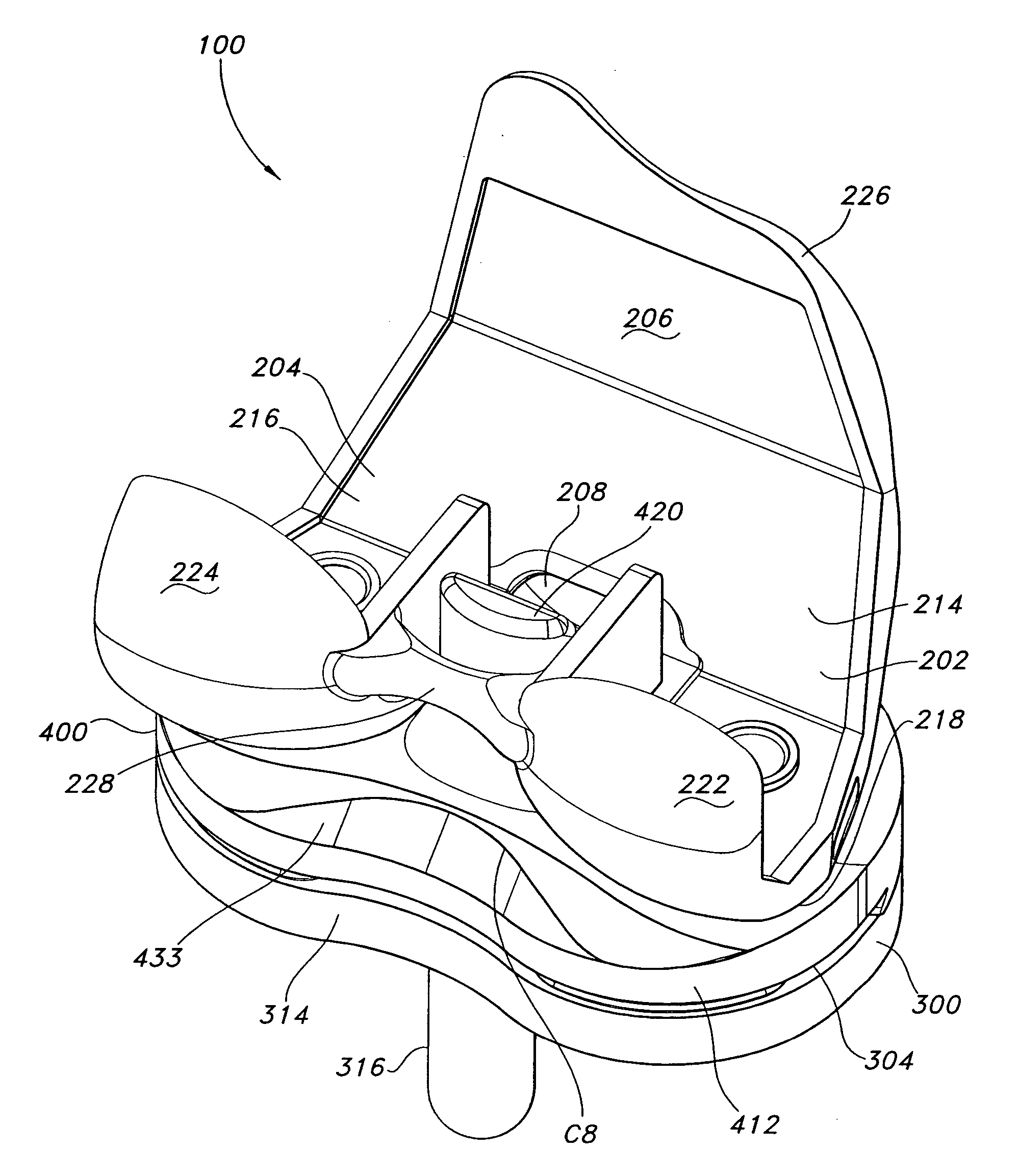

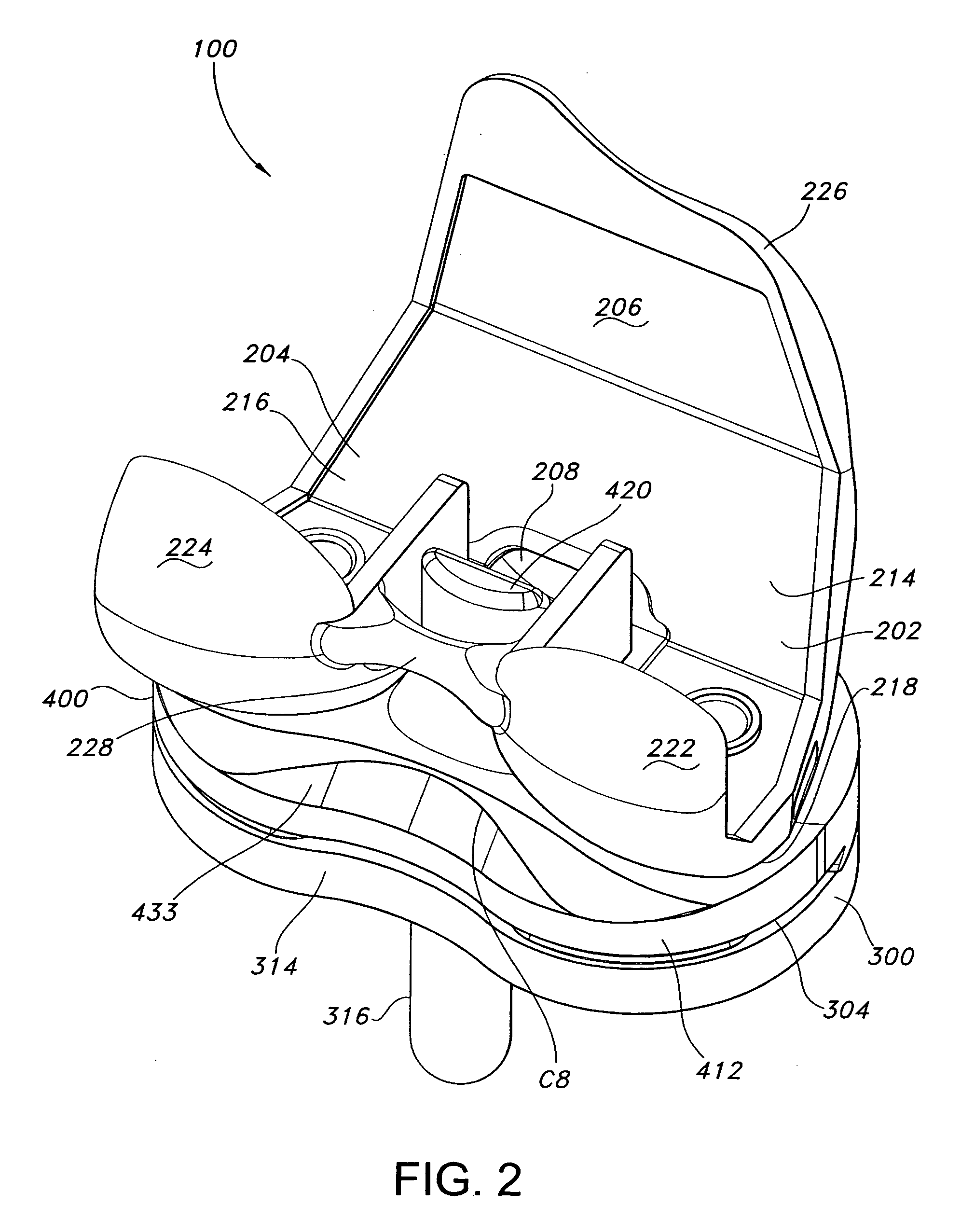

Flanged occlusion devices and methods

Implantable occlusion devices that include one or more flanges extending from a tubular body are disclosed. The flange or flanges may assist in retention of the device within a vessel, cavity, appendage, etc. At least one flange on the occlusion device may include a concave surface proximate one end of a body. Because of the shape of the flange, e.g., its concavity, the occlusion device may resist dislocation due to e.g., the forces generated within the left atrial appendage during atrial filbrillation.

Owner:ST JUDE MEDICAL CARDILOGY DIV INC

Wafer support tool for heat treatment and heat treatment apparatus

ActiveUS7393207B2Simple working processLow costLiquid surface applicatorsCharge supportsEngineeringMechanical engineering

The present invention provides a wafer support tool for heat treatment easy in working and capable of realizing reduction in cost without generating damages or slip dislocations that would be otherwise caused by high temperature heat treatment and a heat treatment apparatus. The present invention is directed to a wafer support tool for heat treatment comprising: a plurality of wafer support members for supporting a wafer to be heat treated; and a support member holder for holding the wafer support members, wherein the wafer support members each has a contact portion with the wafer, at least one of the contact portions being movable relative to the support member holder.

Owner:SHIN-ETSU HANDOTAI CO LTD

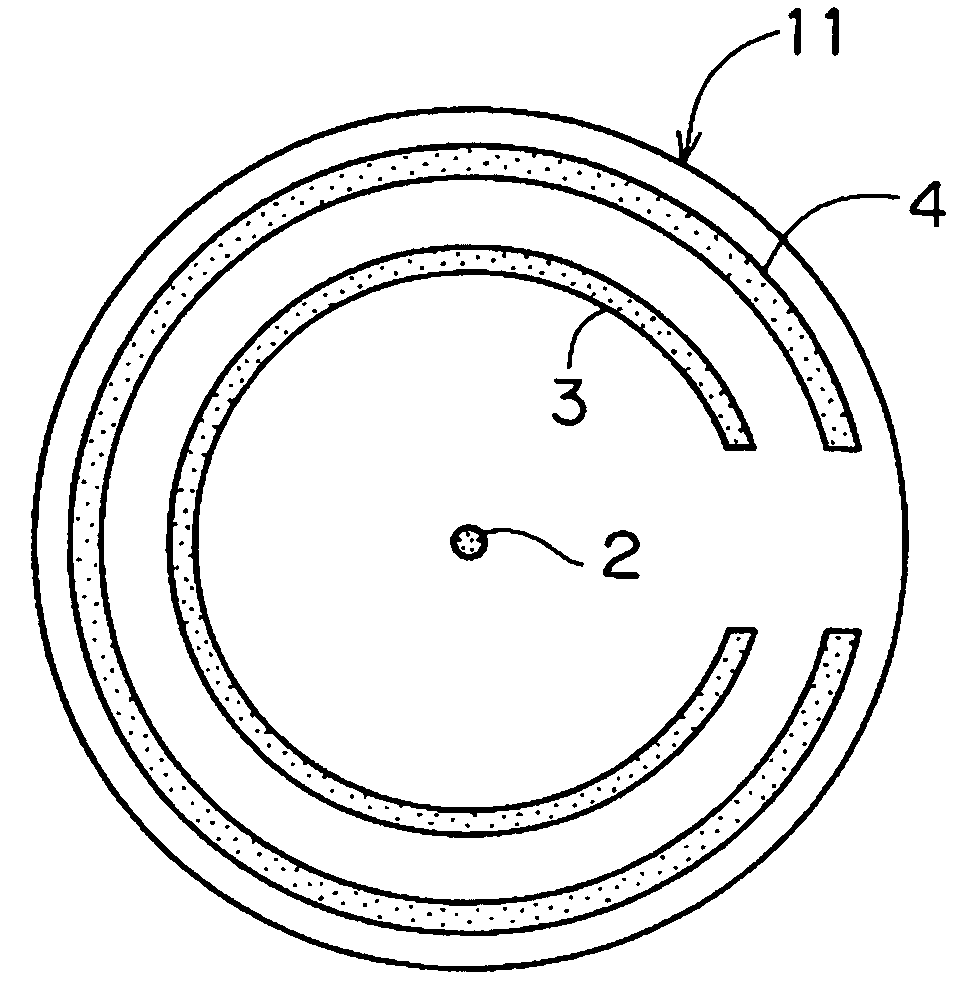

Heat treatment jig for semiconductor silicon substrate

ActiveUS7163393B2Charge supportsSemiconductor/solid-state device manufacturingDislocationHydrogen annealing

Owner:SUMITOMO MITSUBISHI SILICON CORP

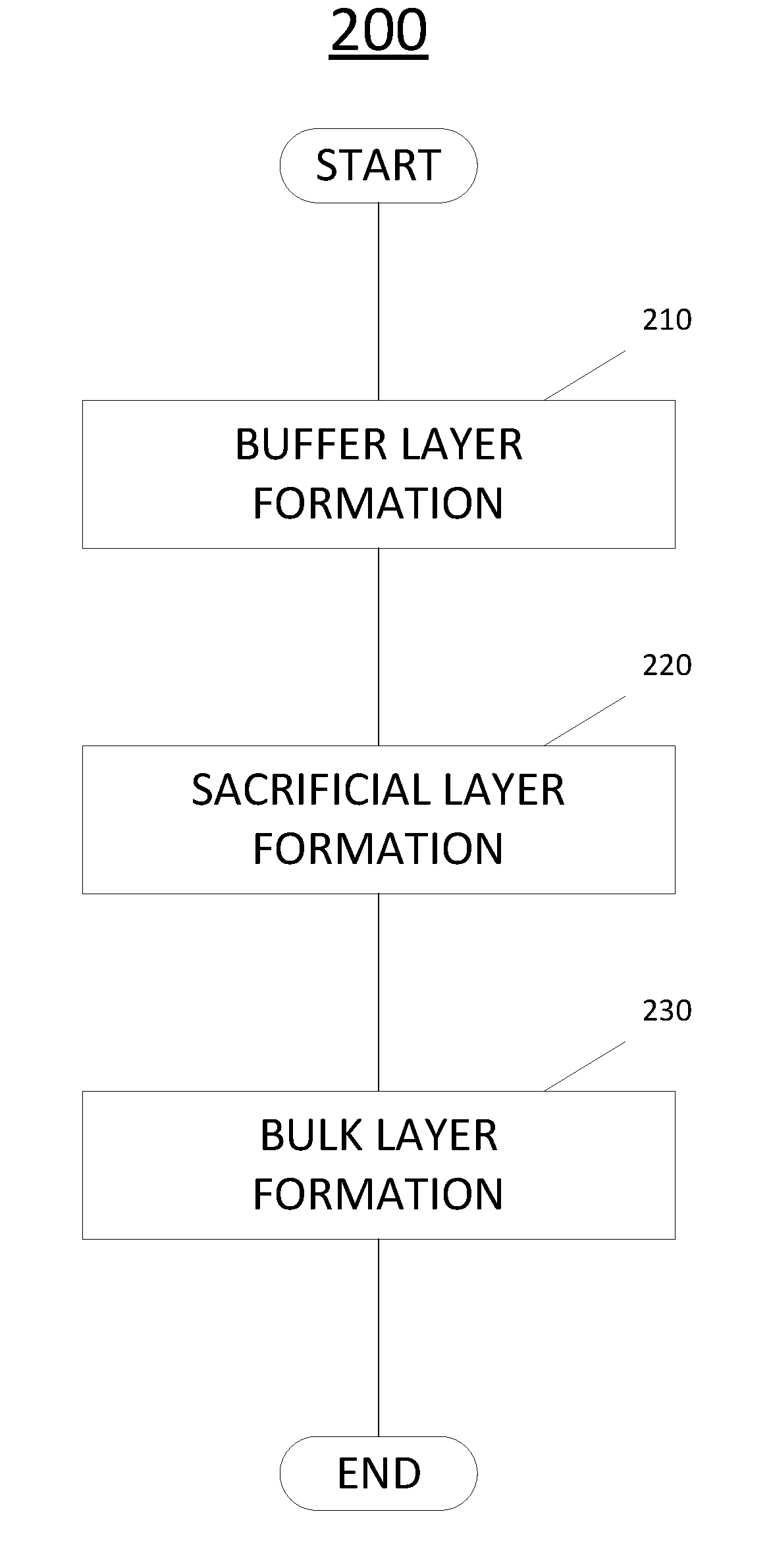

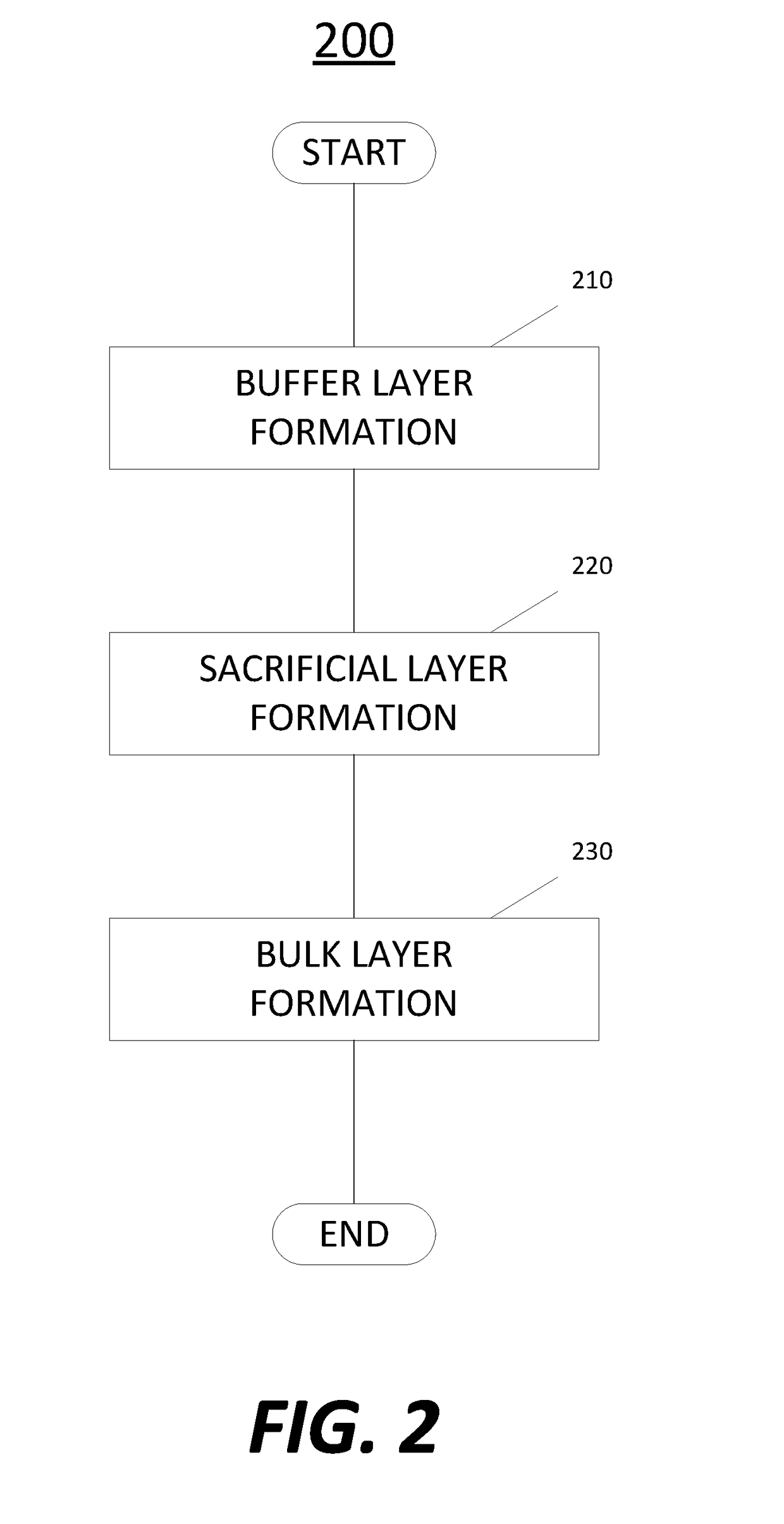

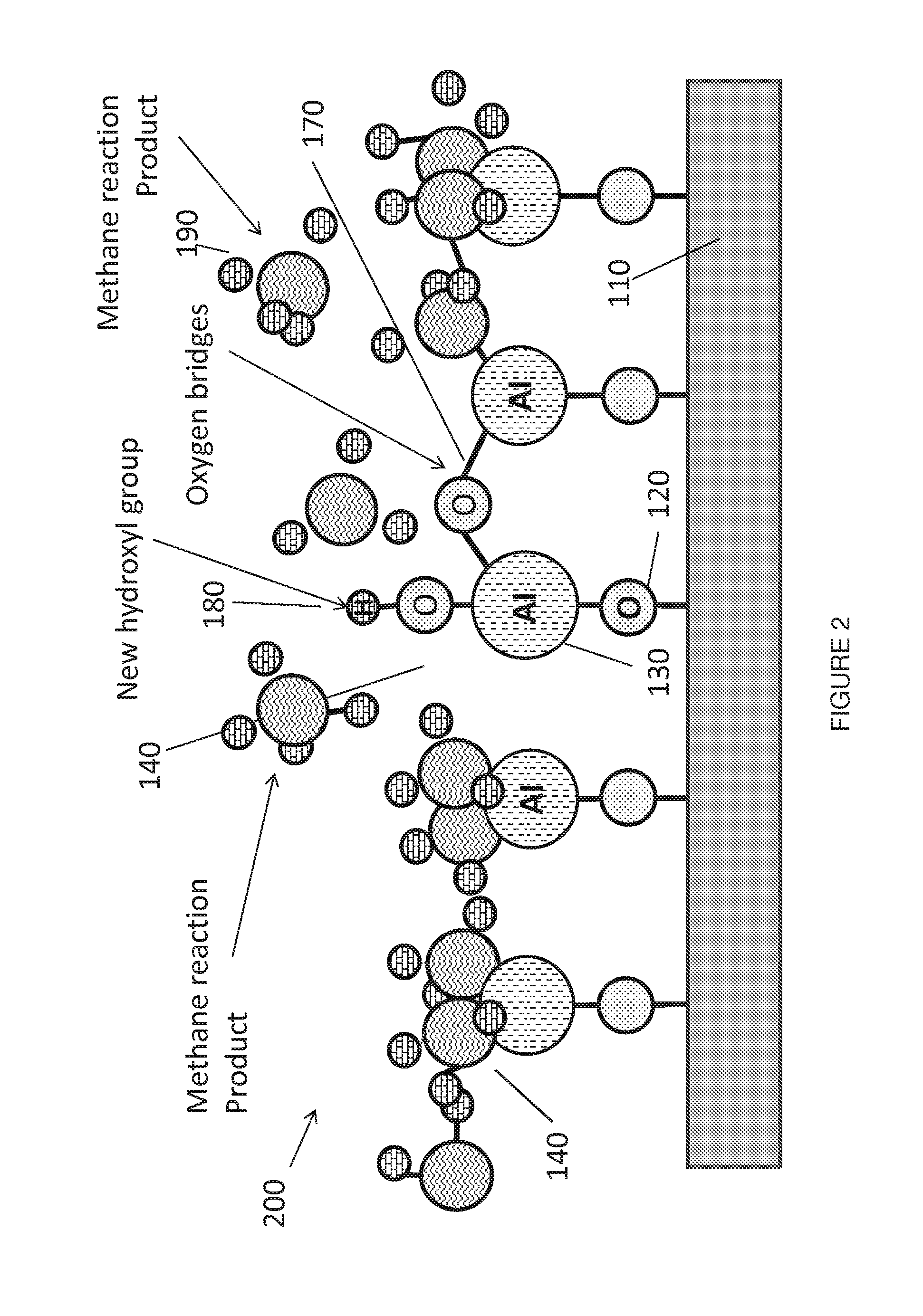

Formation of epitaxial layers via dislocation filtering

ActiveUS20170372884A1Semiconductor/solid-state device manufacturingSemiconductor devicesProcess conditionsDislocation

A process for forming a thick defect-free epitaxial layer is disclosed. The process may comprise forming a buffer layer and a sacrificial layer prior to forming the thick defect-free epitaxial layer. The sacrificial layer and the thick defect-free epitaxial layer may be formed of the same material and at the same process conditions.

Owner:ASM IP HLDG BV

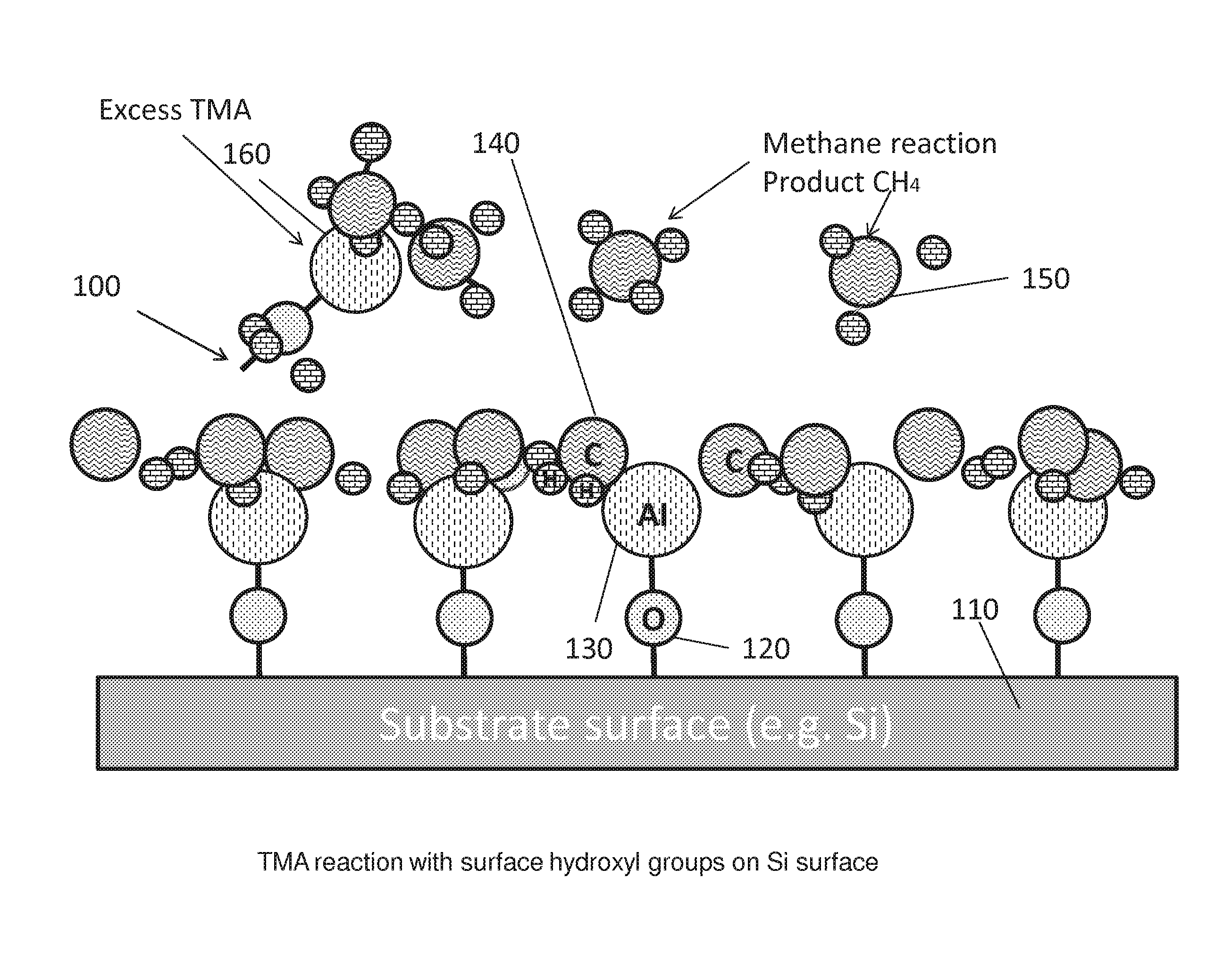

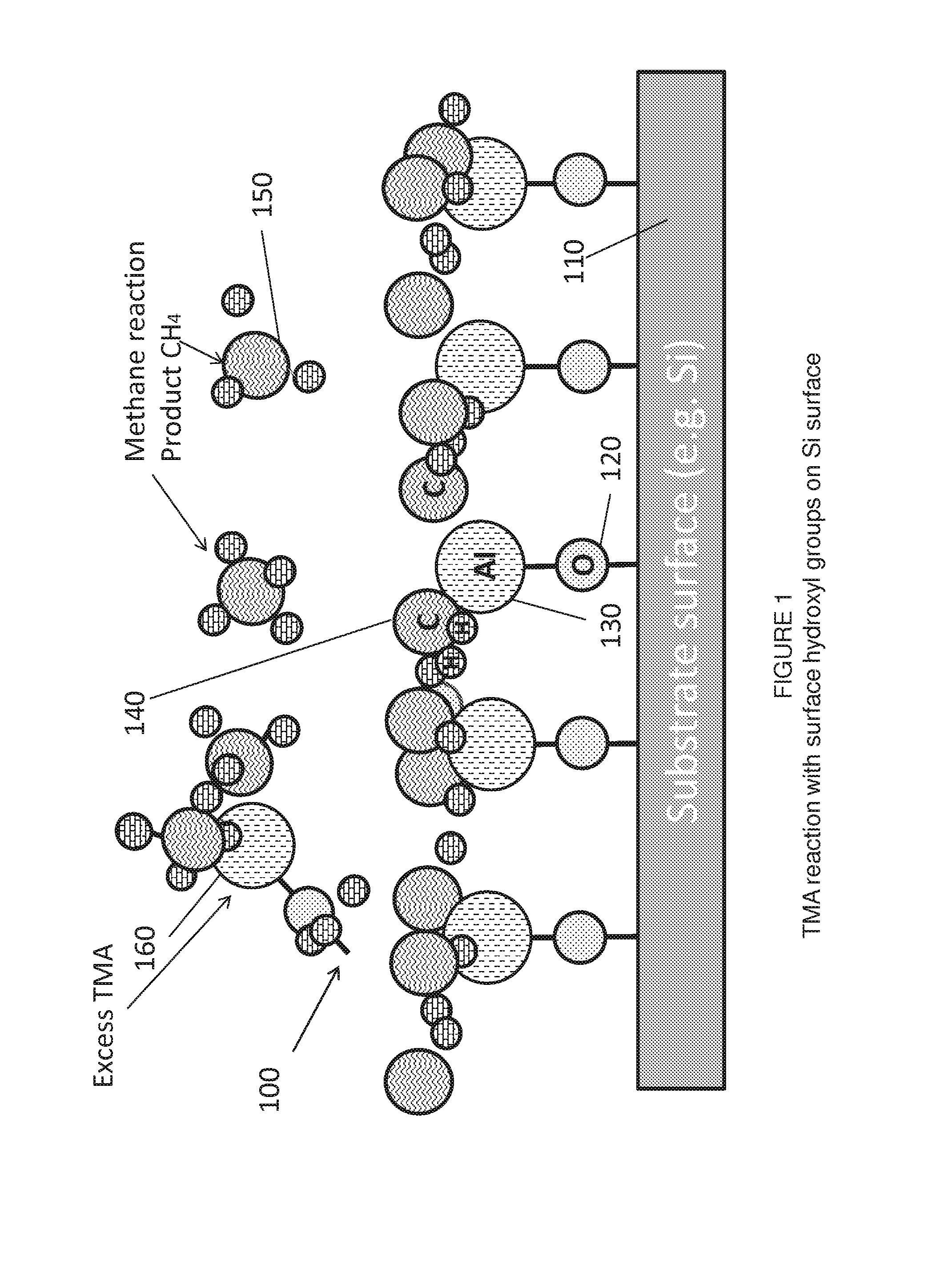

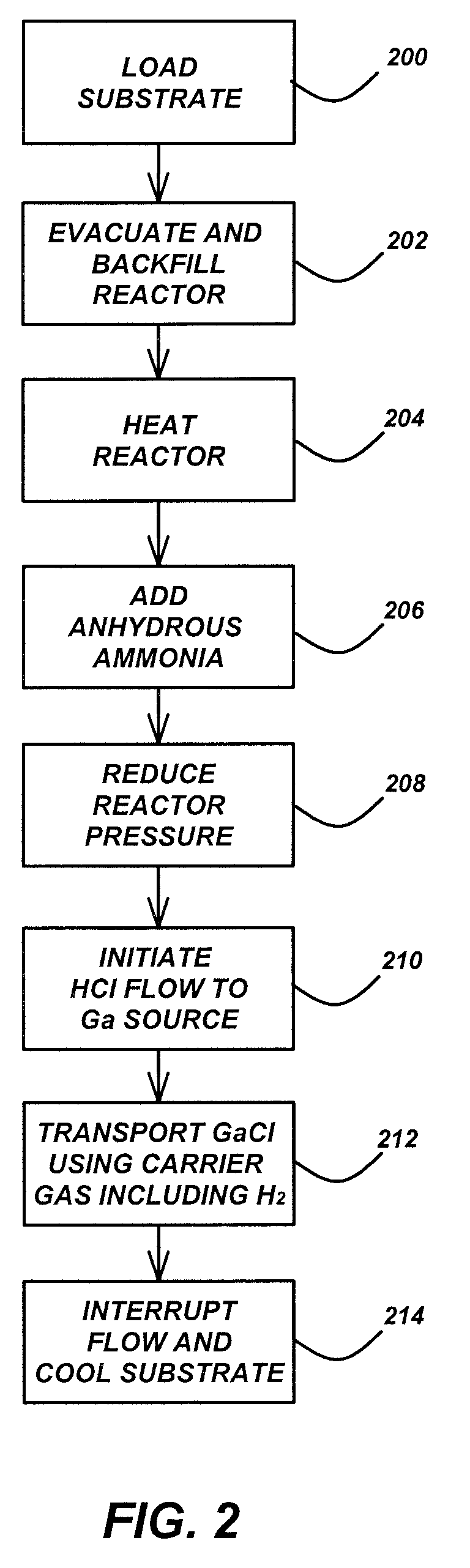

Formation of heteroepitaxial layers with rapid thermal processing to remove lattice dislocations

InactiveUS20160155629A1Semiconductor/solid-state device manufacturingWelding/soldering/cutting articlesReaction temperatureGallium nitride

Method and devices are disclosed for device manufacture of gallium nitride devices by growing a gallium nitride layer on a silicon substrate using Atomic Layer Deposition (ALD) followed by rapid thermal annealing. Gallium nitride is grown directly on silicon or on a barrier layer of aluminum nitride grown on the silicon substrate. One or both layers are thermally processed by rapid thermal annealing. Preferably the ALD process use a reaction temperature below 550° C. and preferable below 350° C. The rapid thermal annealing step raises the temperature of the coating surface to a temperature ranging from 550 to 1500° C. for less than 12 msec.

Owner:VEECO INSTR

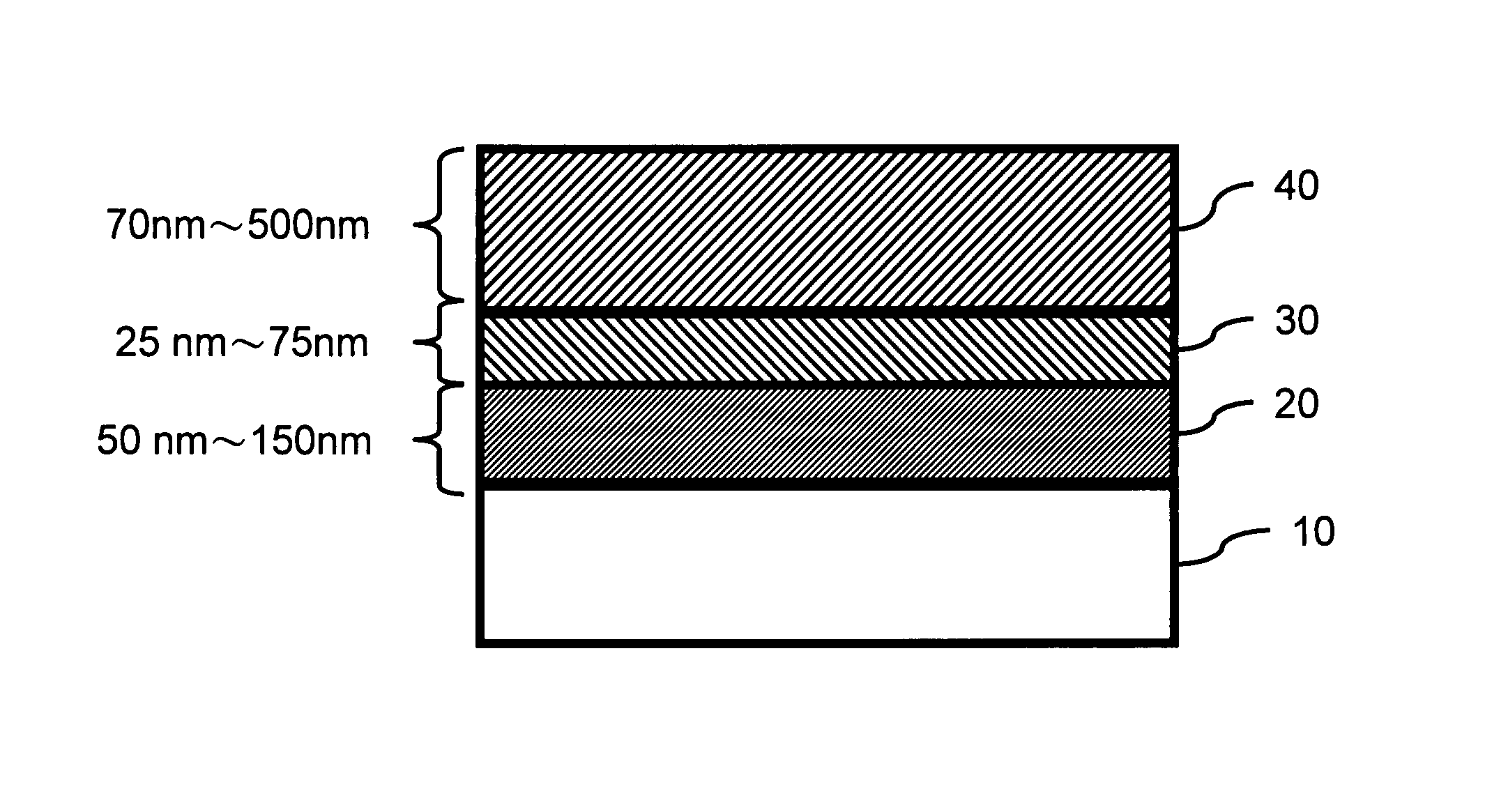

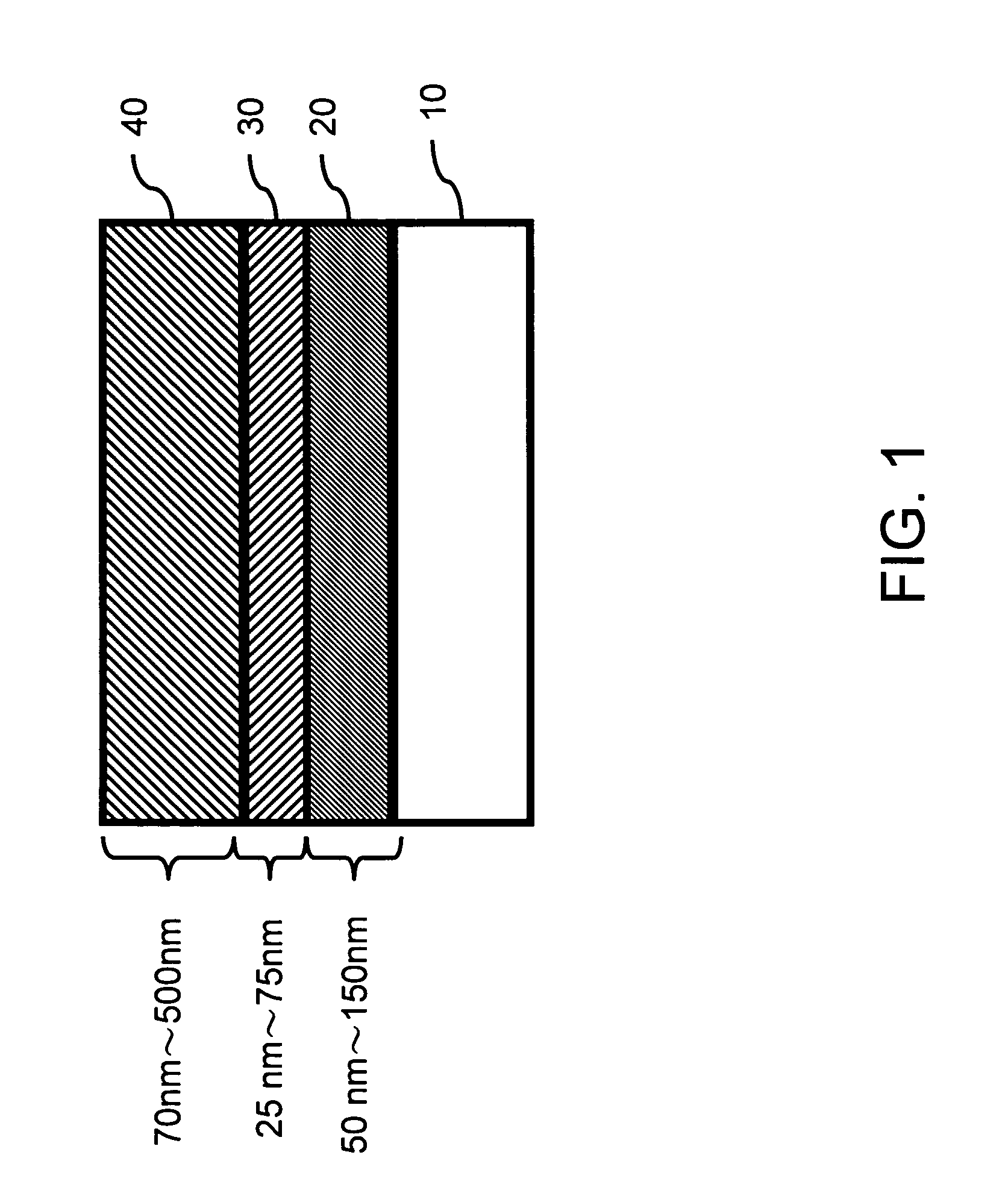

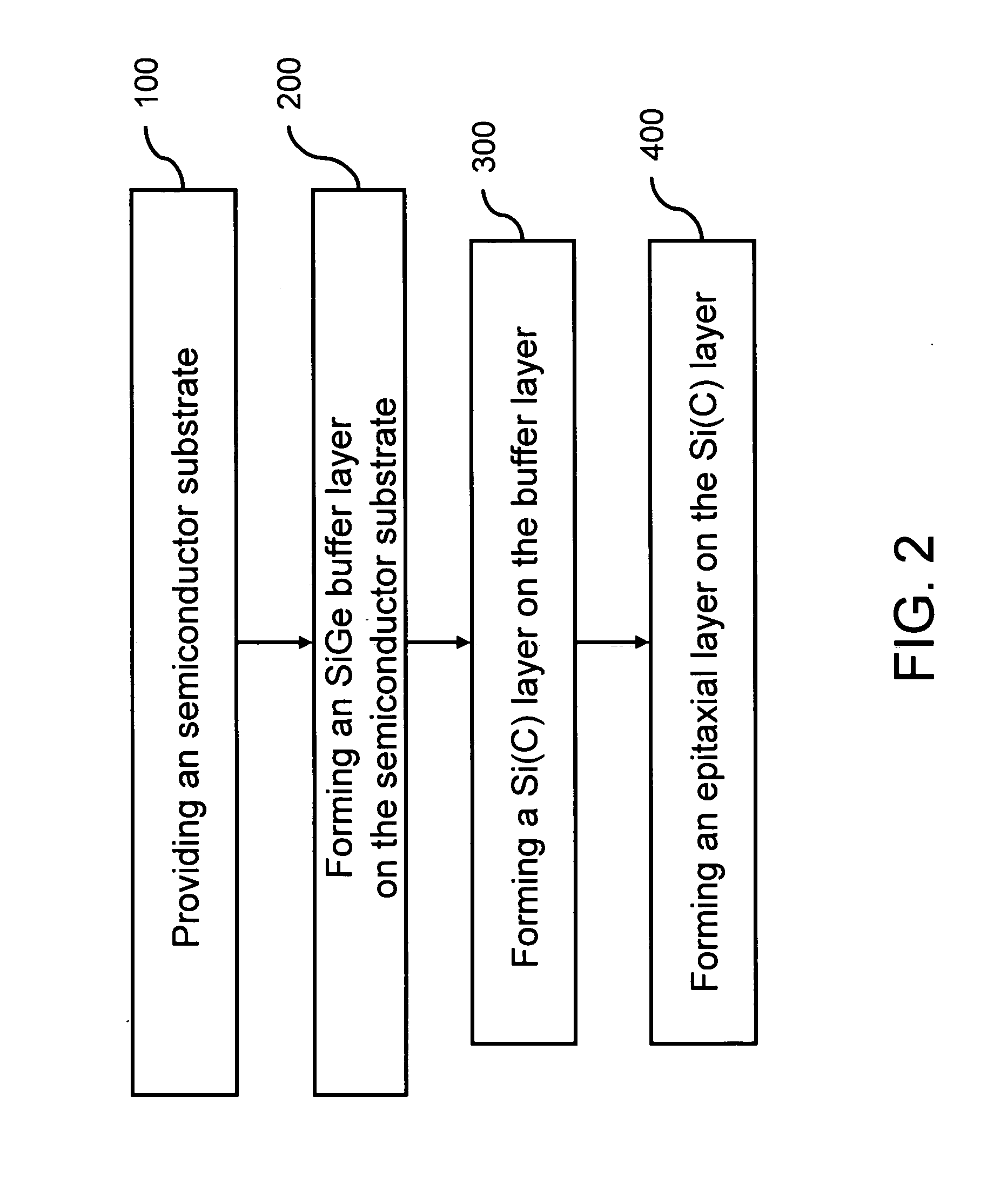

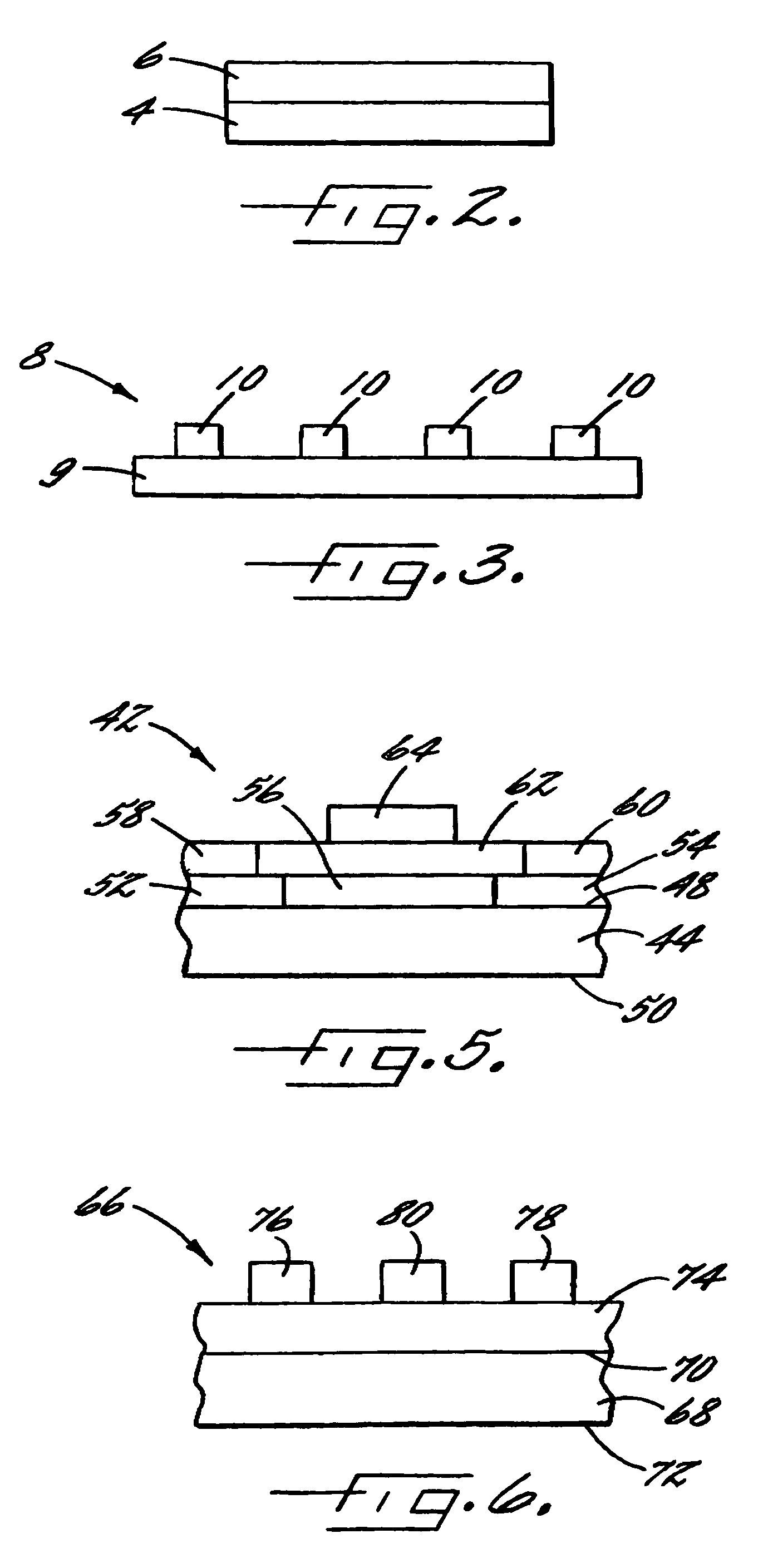

Construction of thin strain-relaxed SiGe layers and method for fabricating the same

InactiveUS7202512B2High degreeReduction of threadingSemiconductor/solid-state device manufacturingSemiconductor devicesSurface roughnessDislocation

A construction of thin strain-relaxed SiGe layers and method for fabricating the same is provided. The construction includes a semiconductor substrate, a SiGe buffer layer formed on the semiconductor substrate, a Si(C) layer formed on the SiGe buffer layer, and an relaxed SiGe epitaxial layer formed on the Si(C) layer. The Si(C) layer is employed to change the strain-relaxed mechanism of the relaxed SiGe epitaxial layer formed on the Si(C) layer. Therefore, a thin relaxed SiGe epitaxial layer with low threading dislocation density, smooth surface is available. The fabricating time for fabricating the strain-relaxed SiGe layers is greatly reduced and the surface roughness is also improved.

Owner:IND TECH RES INST

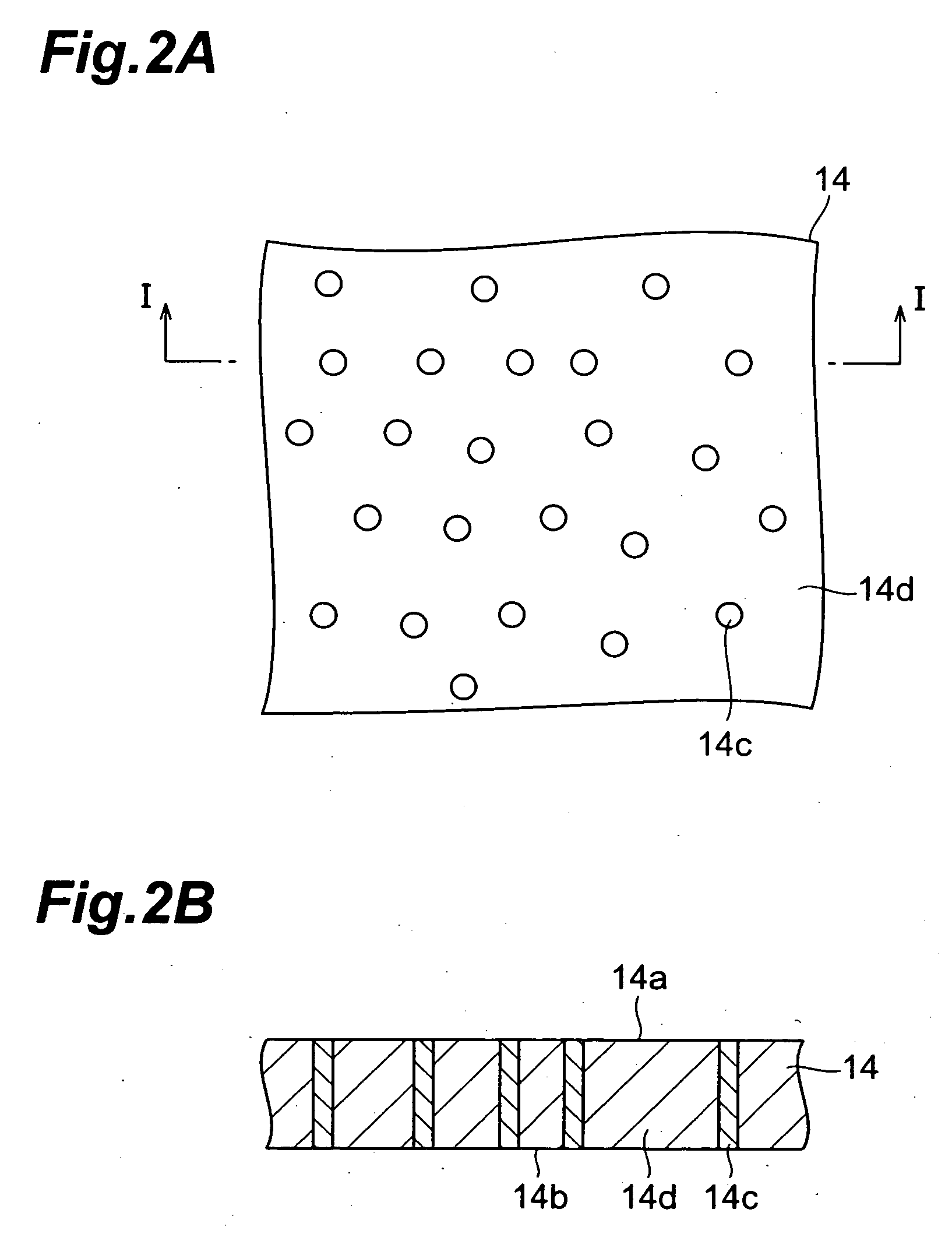

Method of growing GaN crystal, method of producing single crystal GaN substrate, and single crystal GaN substrate

InactiveUS7303630B2Resist invasionImprove stabilityPolycrystalline material growthFrom chemically reactive gasesSeed ImplantRegular pattern

Owner:SUMITOMO ELECTRIC IND LTD

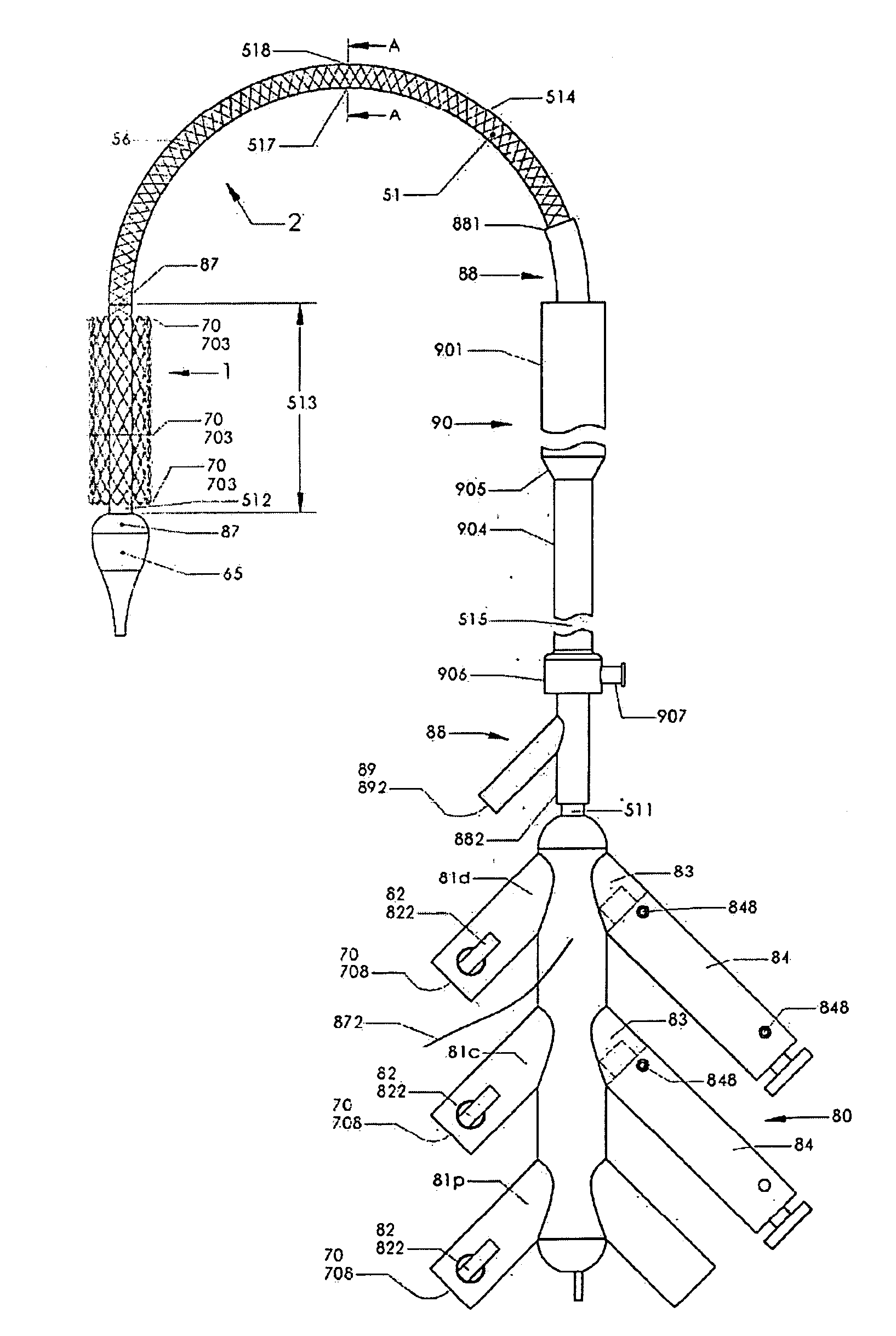

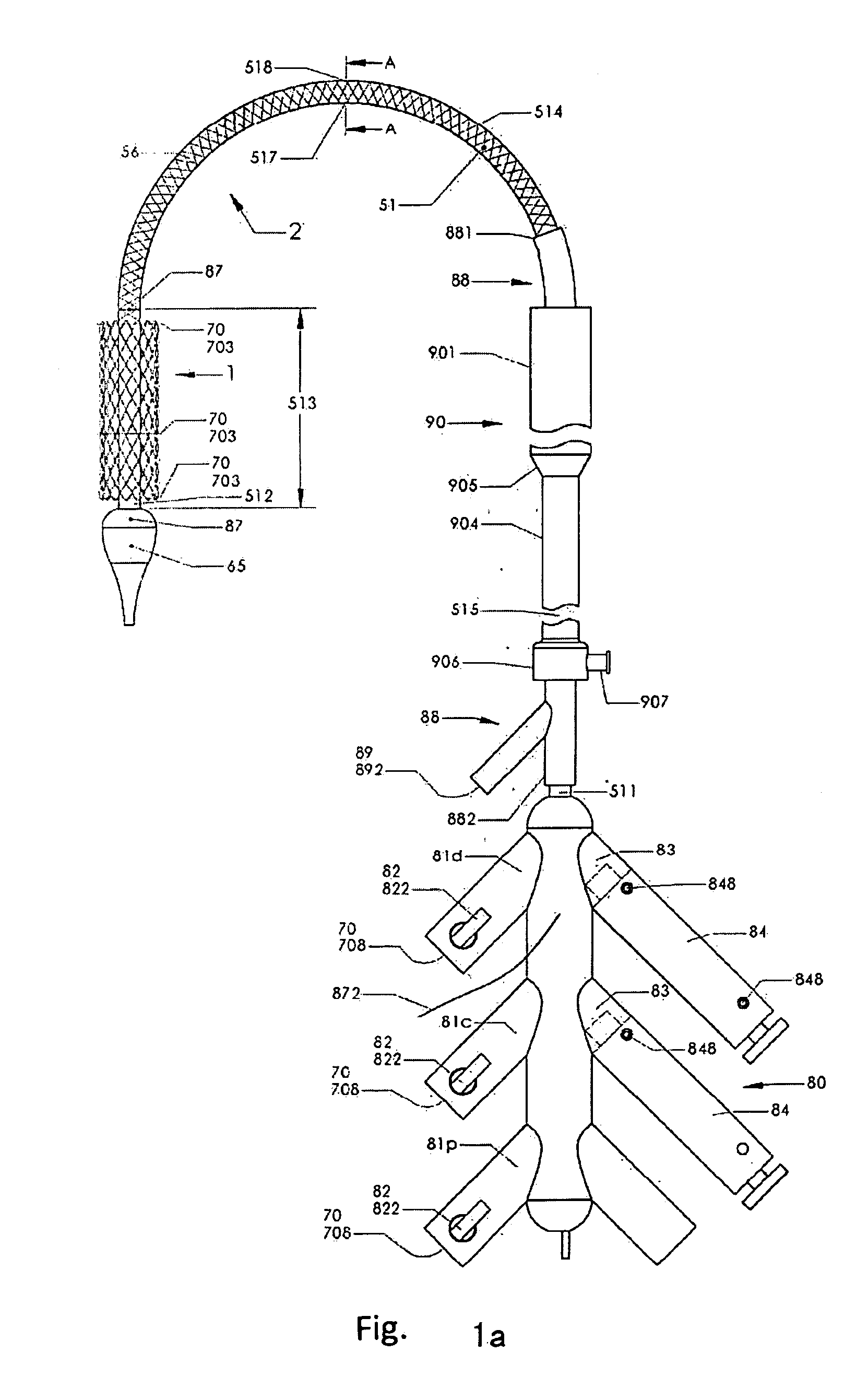

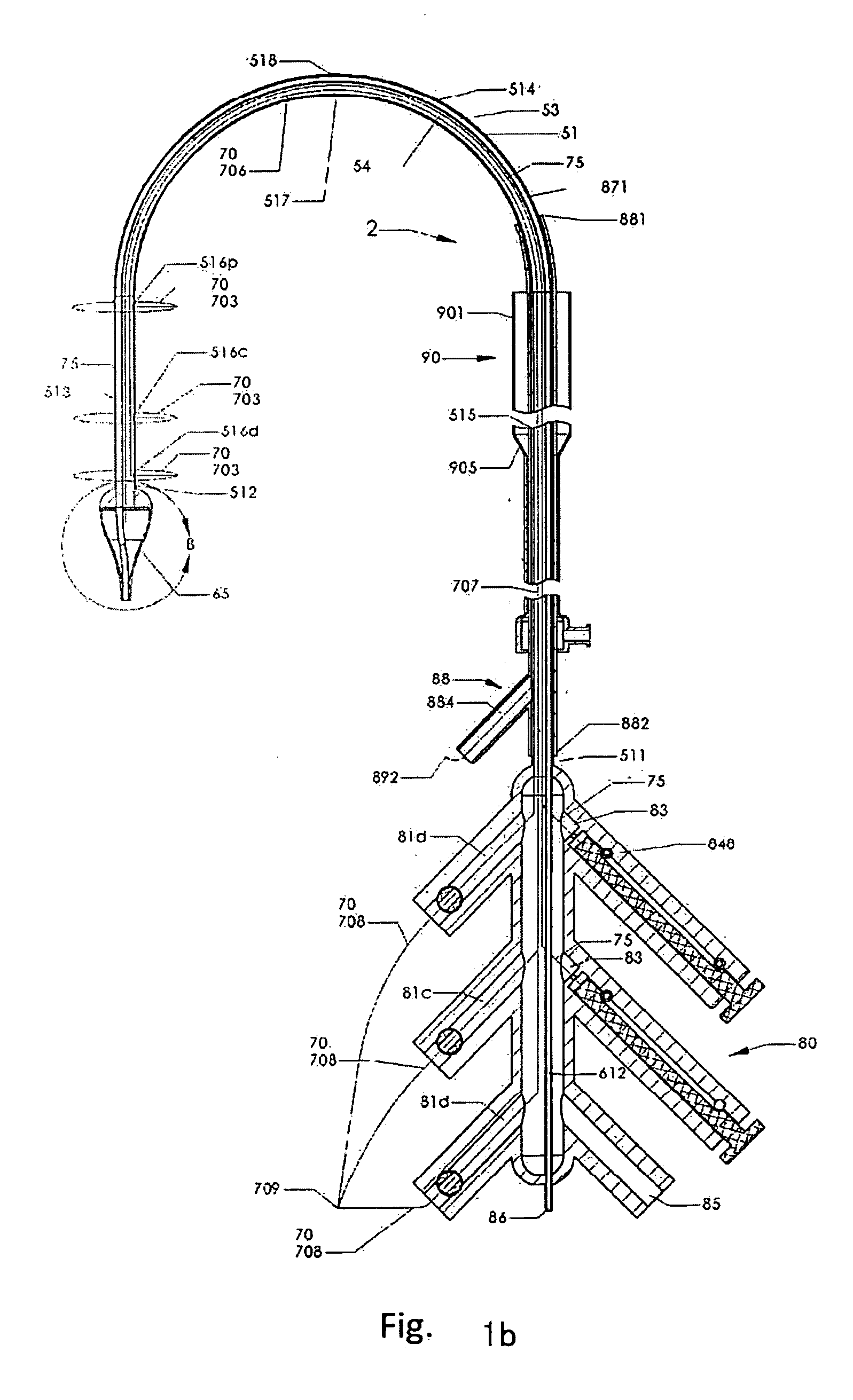

Delivery Device for Delivering a Self-Expanding Stent

The present invention provides a delivery device for self-expanding stent. The delivery device includes pipe head, inner pipe, near end controller, medium pipe, texturing tube, external protection apparatus, at least one locked coil and at least one stayguy. The external protection apparatus is a tearable external protection apparatus or a flexible connects collar hold-down mechanism or a stayguy hold-down mechanism. The present invention has a plenty of following advantages: to locate the stent rotarily, to fix the expanded stent effectively, to reduce the valvular abrasion of artificial cardiac stent, to reduce the abrasion of stayguy, to avoid the dislocation of stayguy and so on.

Owner:WEN NING +1

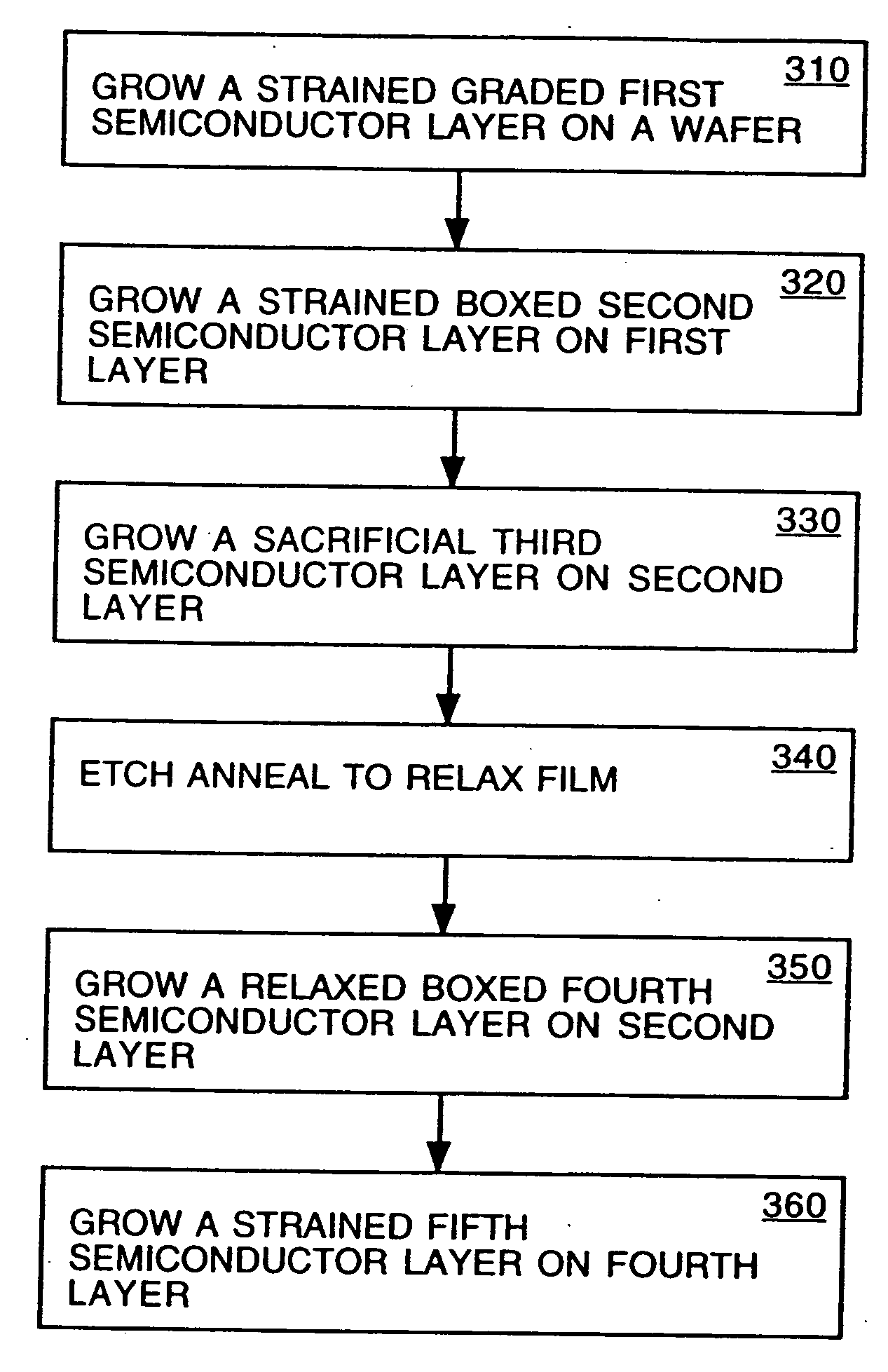

Non-contact etch annealing of strained layers

InactiveUS20070051299A1Reduce misalignmentReduce dislocation densityPolycrystalline material growthAfter-treatment detailsDopantElectrical conductor

The present invention provides a method of forming a strained semiconductor layer. The method comprises growing a strained first semiconductor layer, having a graded dopant profile, on a wafer, having a first lattice constant. The dopant imparts a second lattice constant to the first semiconductor layer. The method further comprises growing a strained boxed second semiconductor layer having the second lattice constant on the first semiconductor layer and growing a sacrificial third semiconductor layer having the first lattice constant on the second semiconductor layer. The method further comprises etch annealing the third and second semiconductor layer, wherein the third semiconductor layer is removed and the second semiconductor layer is relaxed. The method may further comprises growing a fourth semiconductor layer having the second lattice constant on the second semiconductor layer, wherein the fourth semiconductor layer is relaxed, and growing a strained fifth semiconductor layer having the first semiconductor lattice constant on the fourth semiconductor layer. The method controls the surface roughness of the semiconductor layers. The method also has the unexpected benefit of reducing dislocations in the semiconductor layers.

Owner:SILICON GENERAL CORPORATION

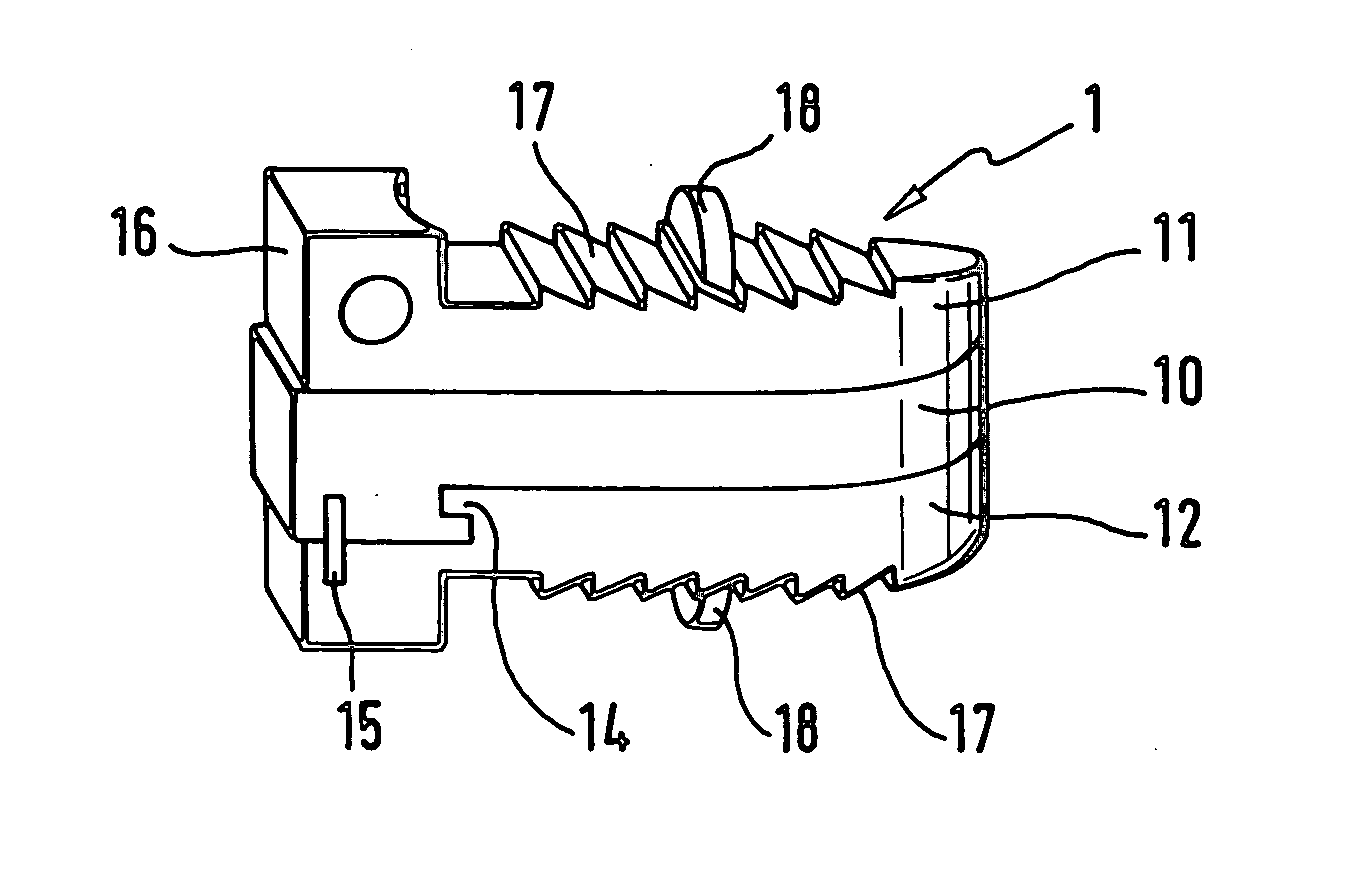

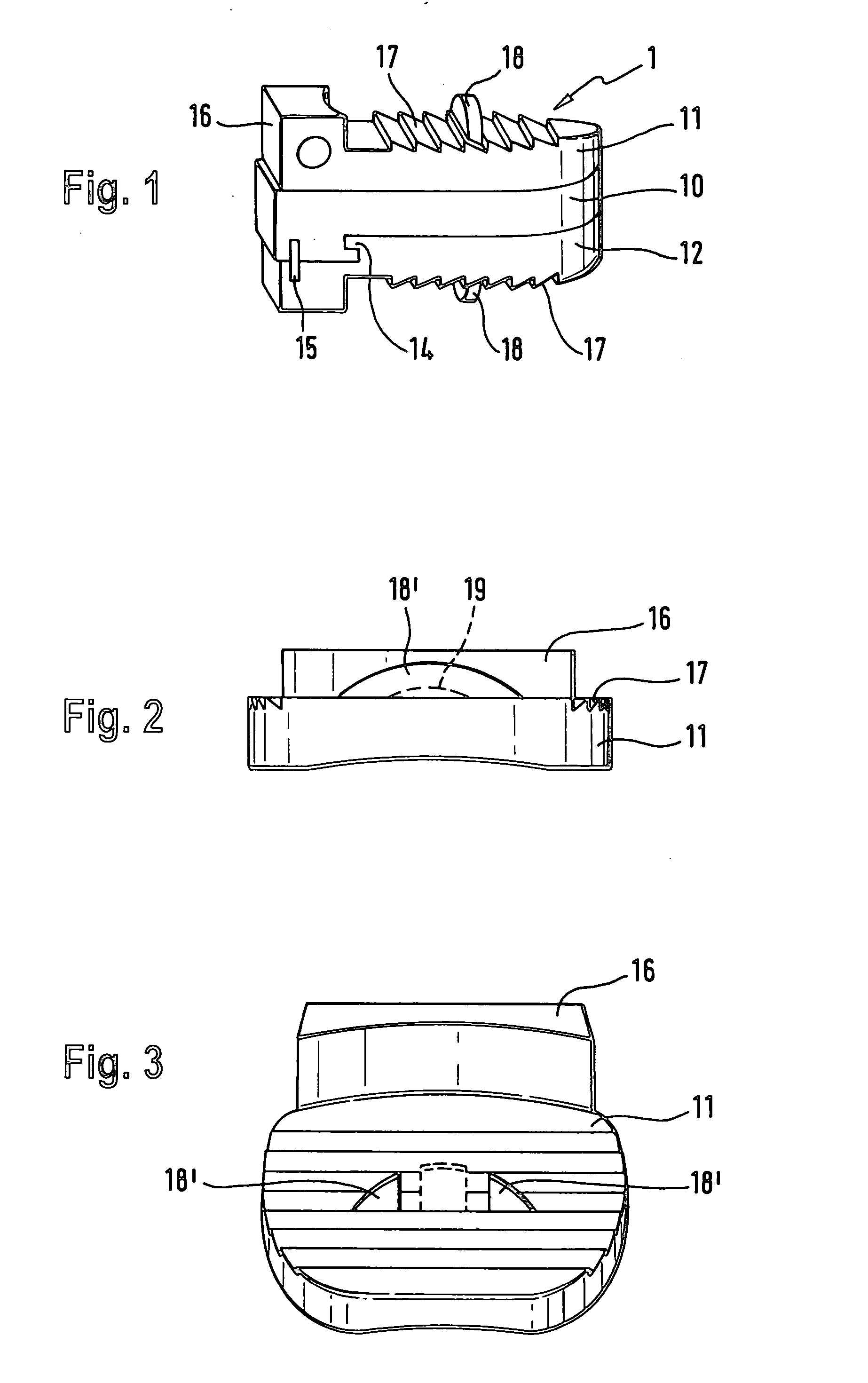

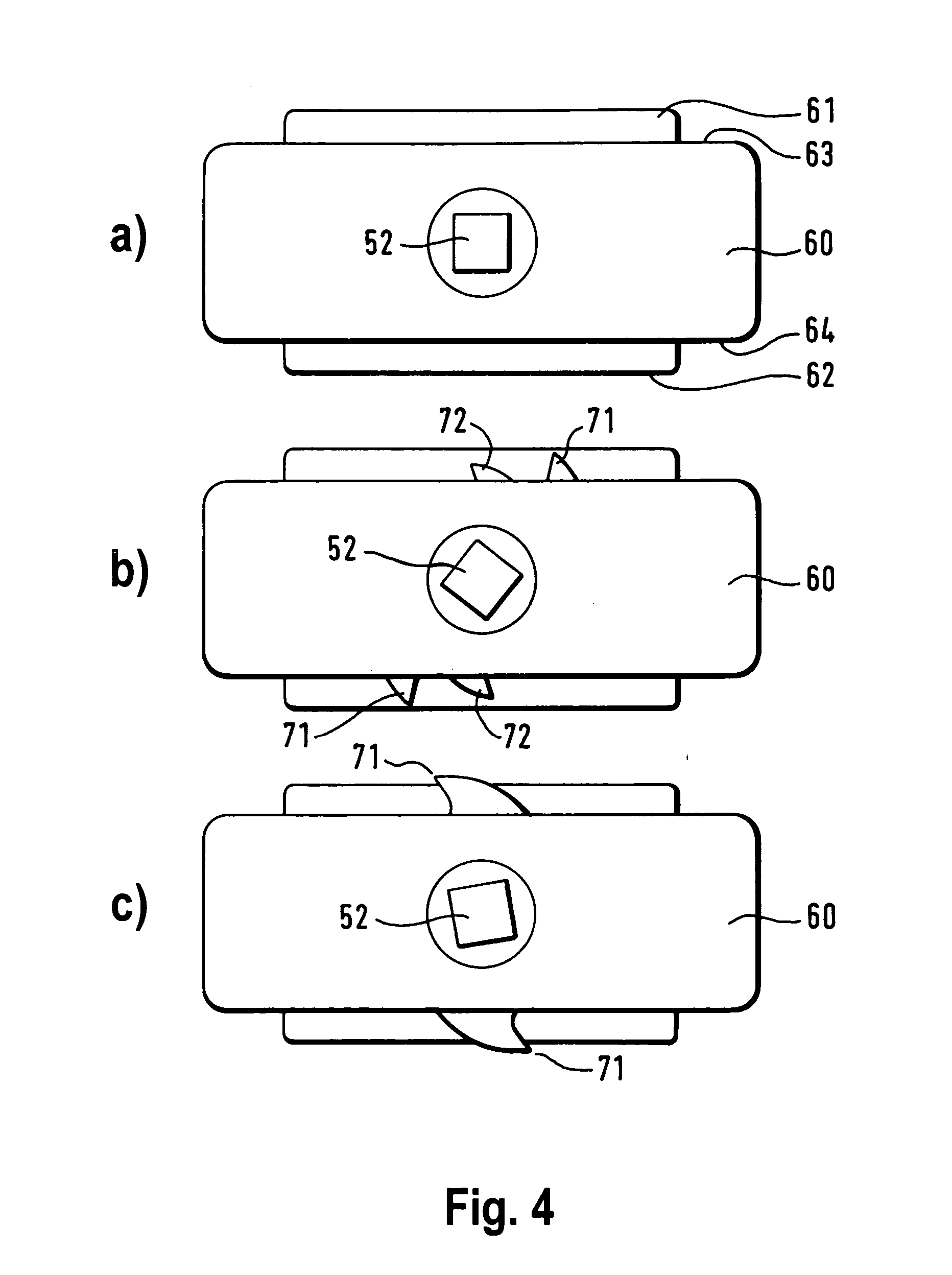

Cervical Intervertebral Disc Prosthesis Comprising An Anti-Dislocation Device And Instruments

InactiveUS20080027550A1Easily advancedImprove connection reliabilityInternal osteosythesisJoint implantsUnintended MovementSpinal column

A cervical intervertebral prosthesis includes lower and upper anchoring plates with a prosthesis core arranged between them to create an articulated connection. The anchoring plates are designed to bear with their anchoring plate surfaces on adjacent vertebral bodies. At least one anchoring plate surface has a rib-like projection thereon which can be used to engage in the vertebral body with a form fit. In order to produce a corresponding recess in the vertebral body, an instrument having a handle, a stem, a head part and an excavating element that can be retracted into the head part may be used. This permits considerably improved securing of the cervical intervertebral prosthesis against unintended movement. The medullary canal running along the posterior margin of the vertebral column is in this way protected from damage.

Owner:CERVITECH INC

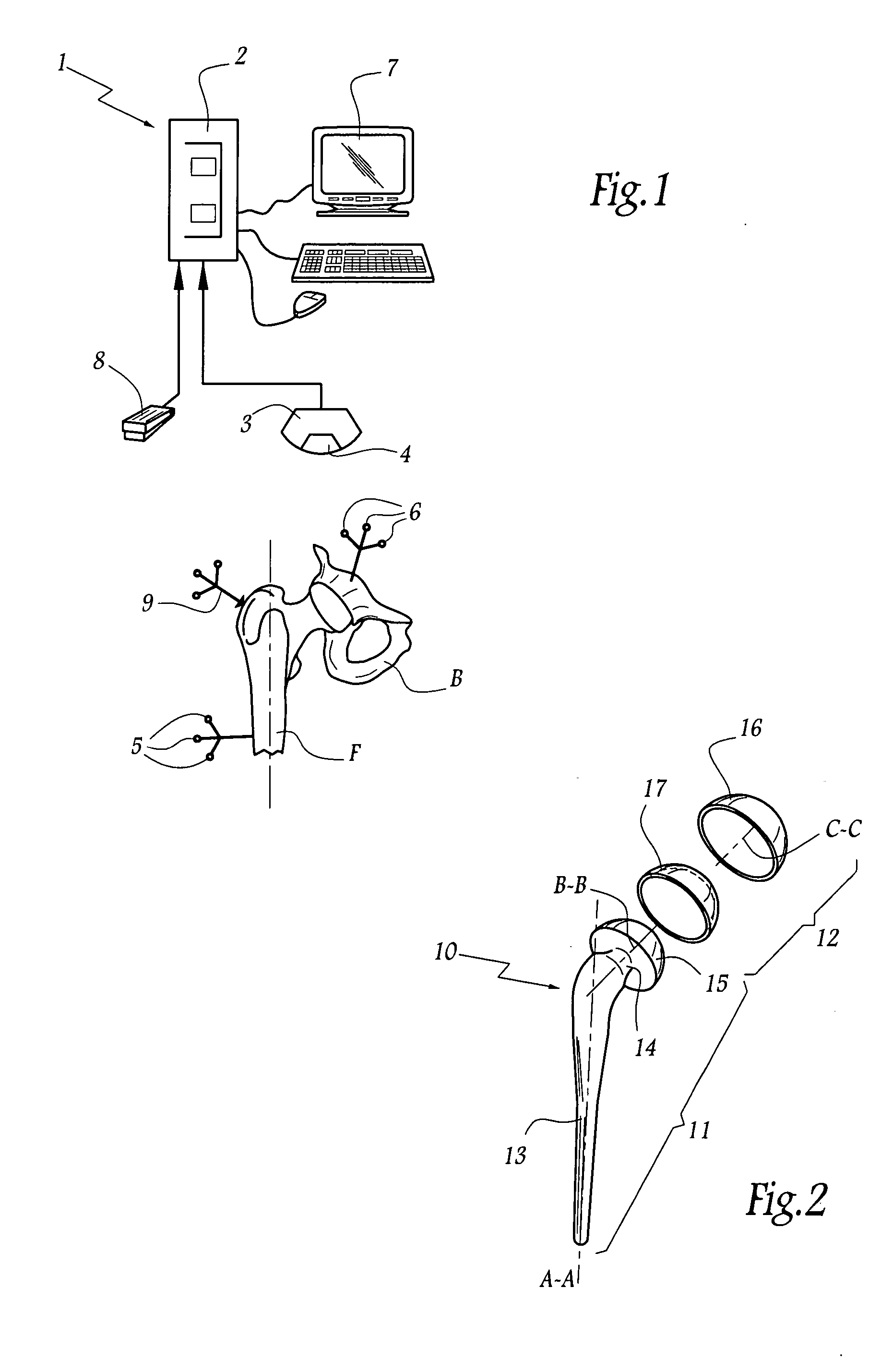

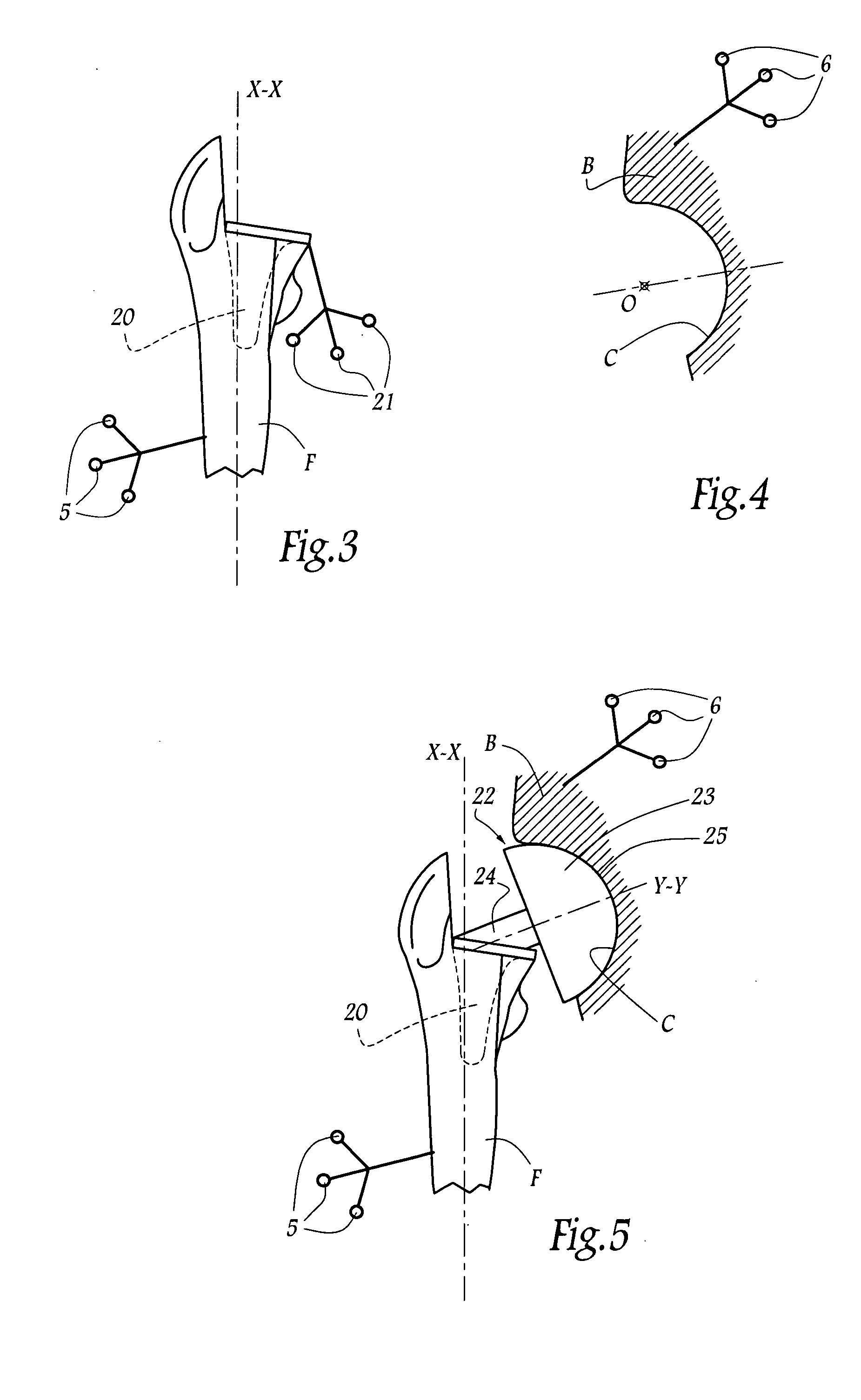

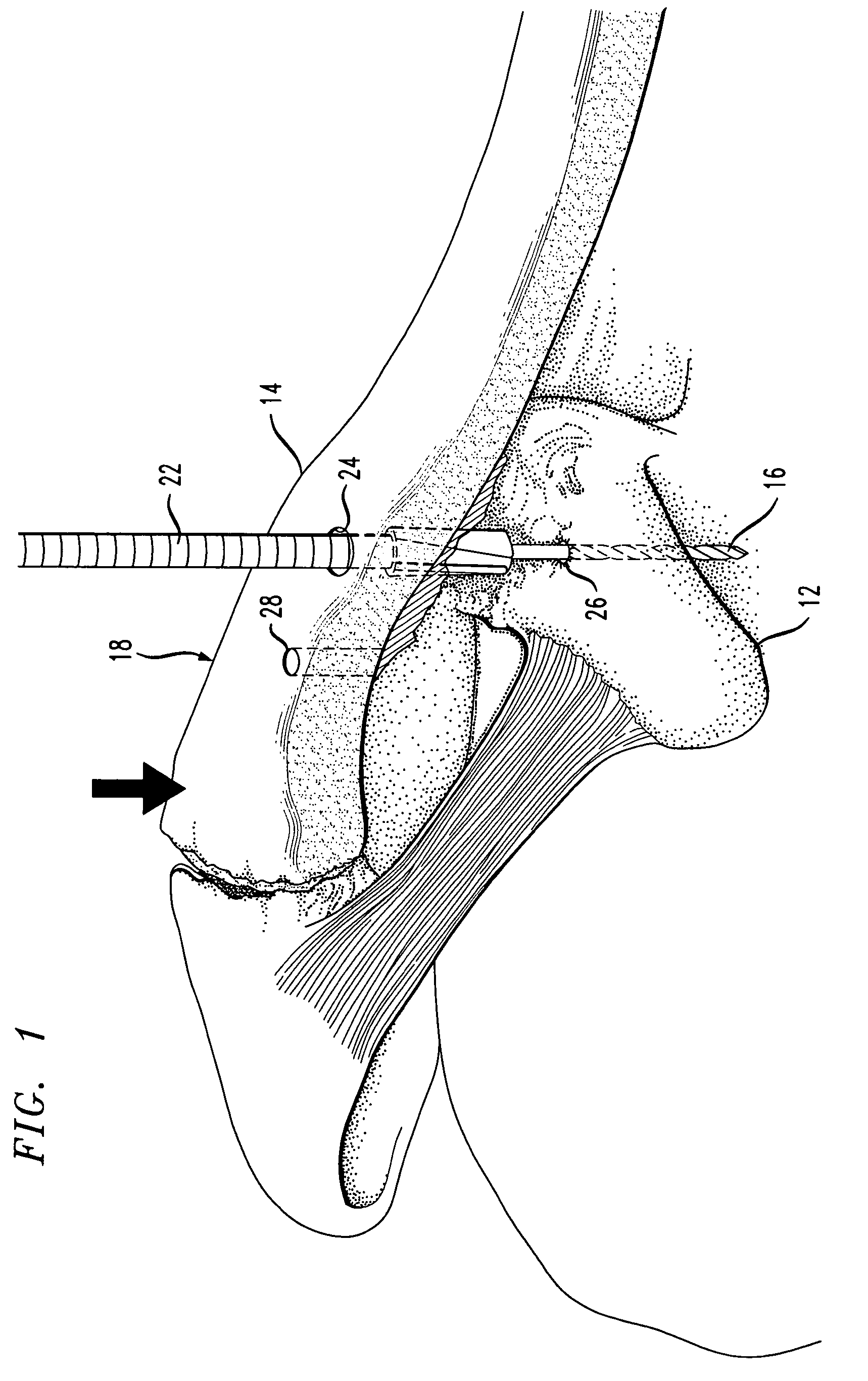

Surgical device for implanting a total hip prosthesis

The surgical device according to the invention comprises both means for per-operative measurement and for memorization of a plurality of positions of a given femoral prosthetic direction and means for per-operative comparison of these positions with the cone of mobility of the prosthesis to be implanted, the position of the axis of revolution of this cone being, during the implantation of the prosthesis, adjustable with respect to the zone of the pelvis where the implantation of an acetabulum of the prosthesis is provided. By using this device, the surgeon can easily and rapidly determine, in the course of the surgical operation, a preferential direction for implanting the prosthetic acetabulum in order to reduce the subsequent risks of dislocations of the implanted prosthesis.

Owner:CORIN

Substrate for growing a III-V light emitting device

ActiveUS20070072324A1Relieve pressurePolycrystalline material growthLight-sensitive devicesSemiconductor structureCritical thickness

A substrate including a host and a seed layer bonded to the host is provided, then a semiconductor structure including a light emitting layer disposed between an n-type region and a p-type region is grown on the seed layer. In some embodiments, a bonding layer bonds the host to the seed layer. The seed layer may be thinner than a critical thickness for relaxation of strain in the semiconductor structure, such that strain in the semiconductor structure is relieved by dislocations formed in the seed layer, or by gliding between the seed layer and the bonding layer an interface between the two layers. In some embodiments, the host may be separated from the semiconductor structure and seed layer by etching away the bonding layer.

Owner:LUMILEDS

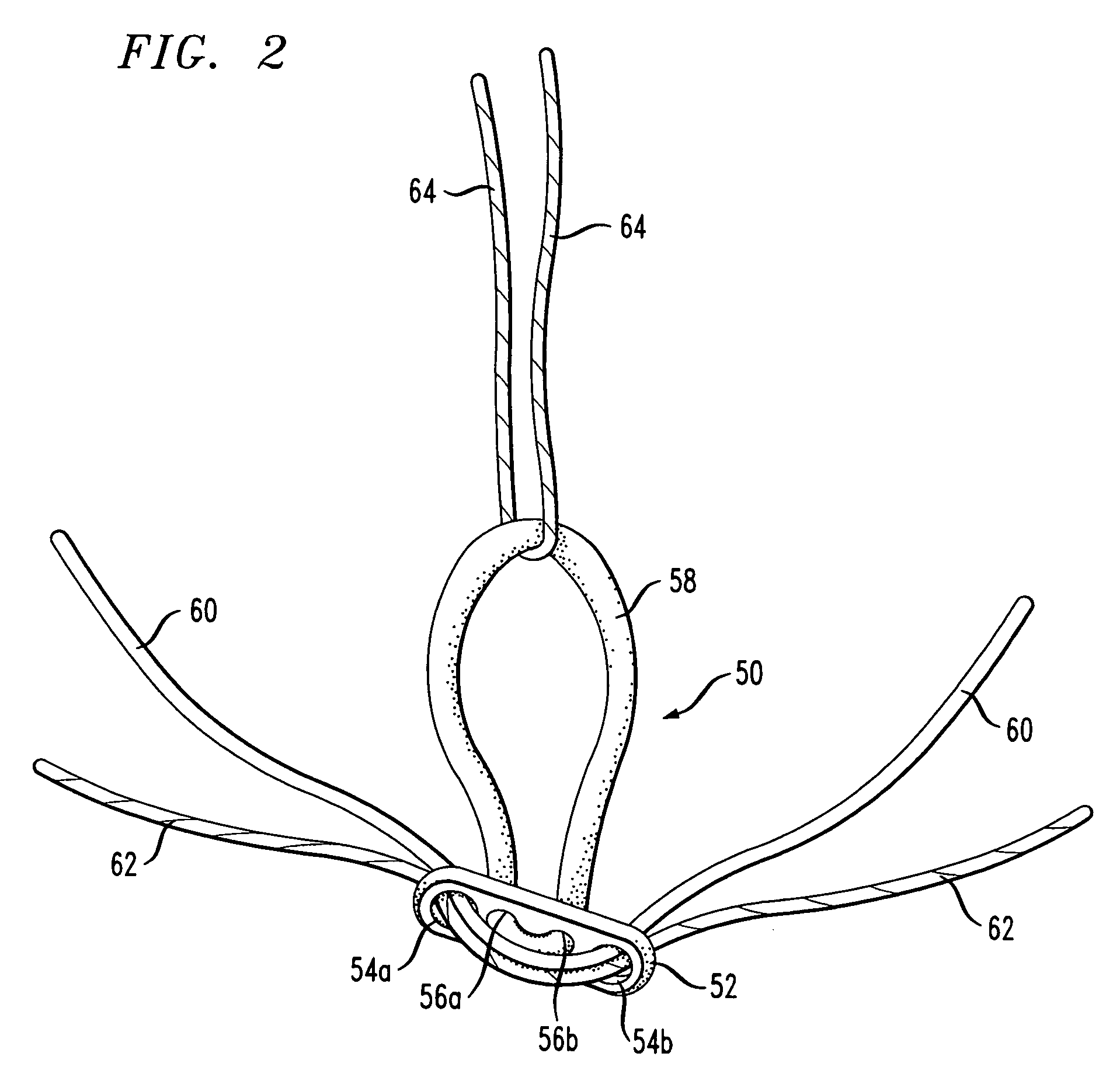

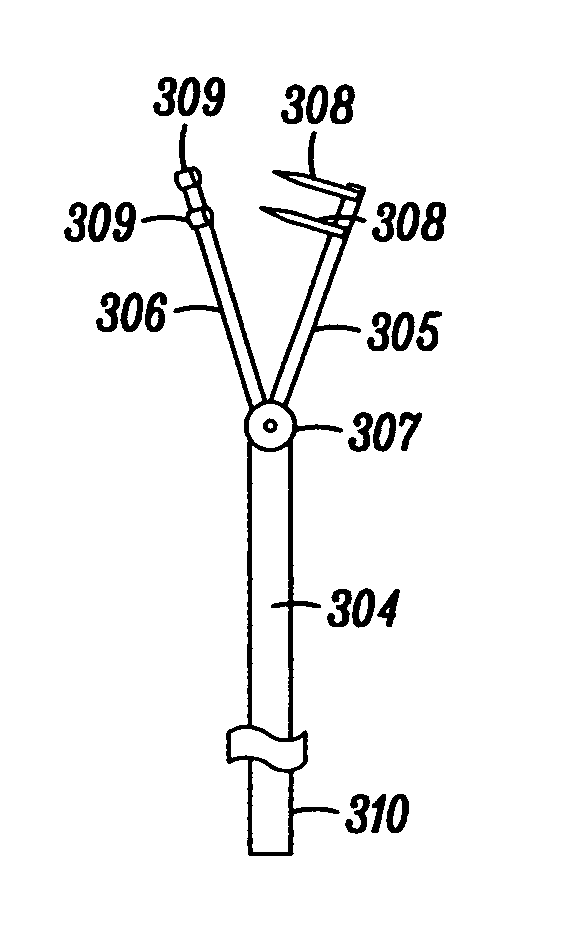

Device for treatment of acromioclavicular joint dislocations

A surgical fastener system for acromioclavicular (AC) joint dislocations, includes a first fastener having an elongate body, and an inner pair of openings centered on the long axis of the body. A closed loop stitch passes through the openings, and the length of the stitch corresponds to the depth of a passage defined between the top of a first hole bored through a patient's clavicle, and the bottom of a second hole bored through the coracoid in axial alignment with the first hole. A second fastener has an elongate body arranged to slide under a portion of the loop stitch that protrudes from the top of the hole in the clavicle, after the first fastener is set beneath the coracoid and the stitch is pulled upward through the passage. In an alternate embodiment, the second fastener also has an inner pair of openings for passing and engaging the loop stitch.

Owner:SMITH & NEPHEW INC

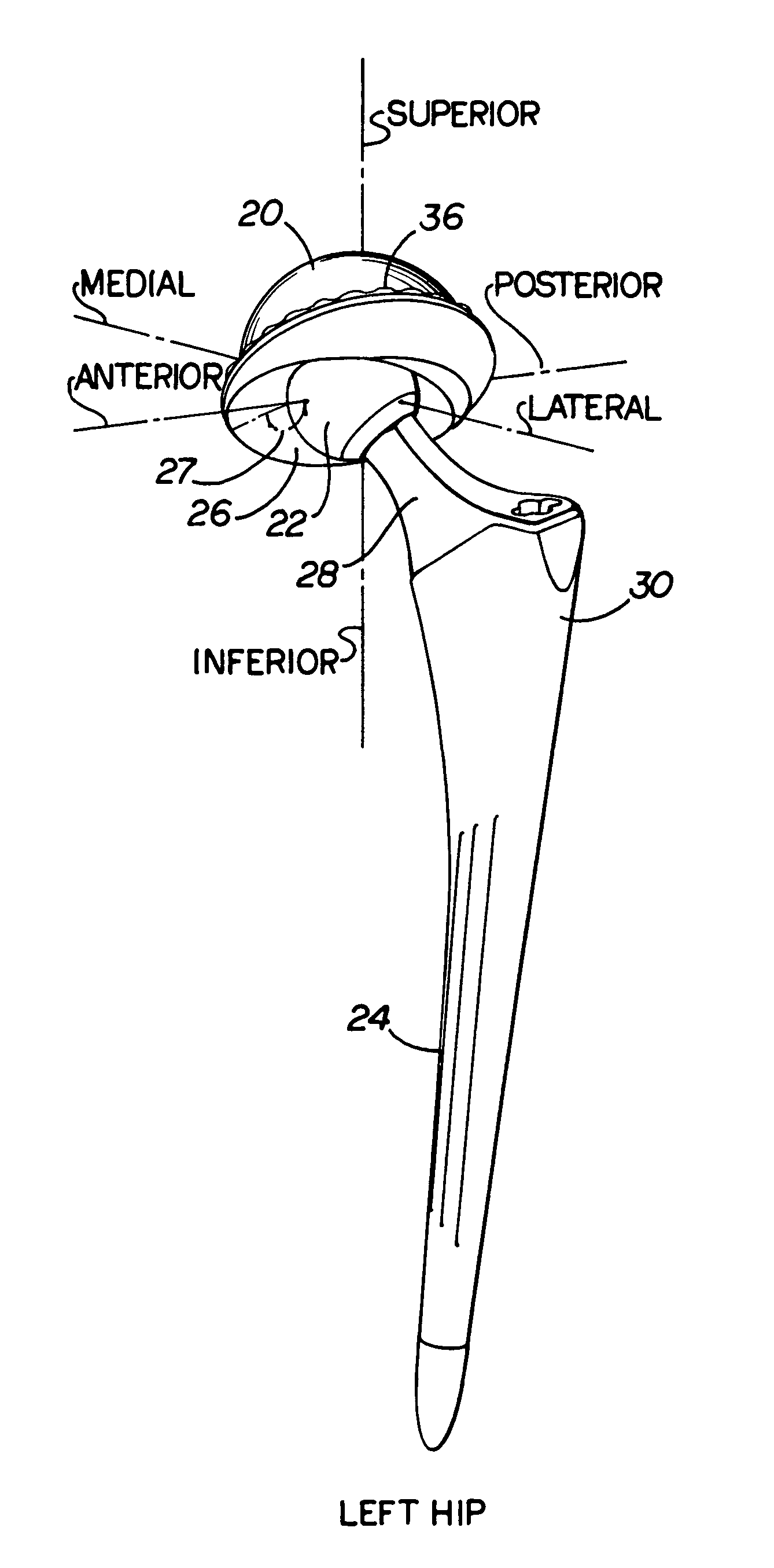

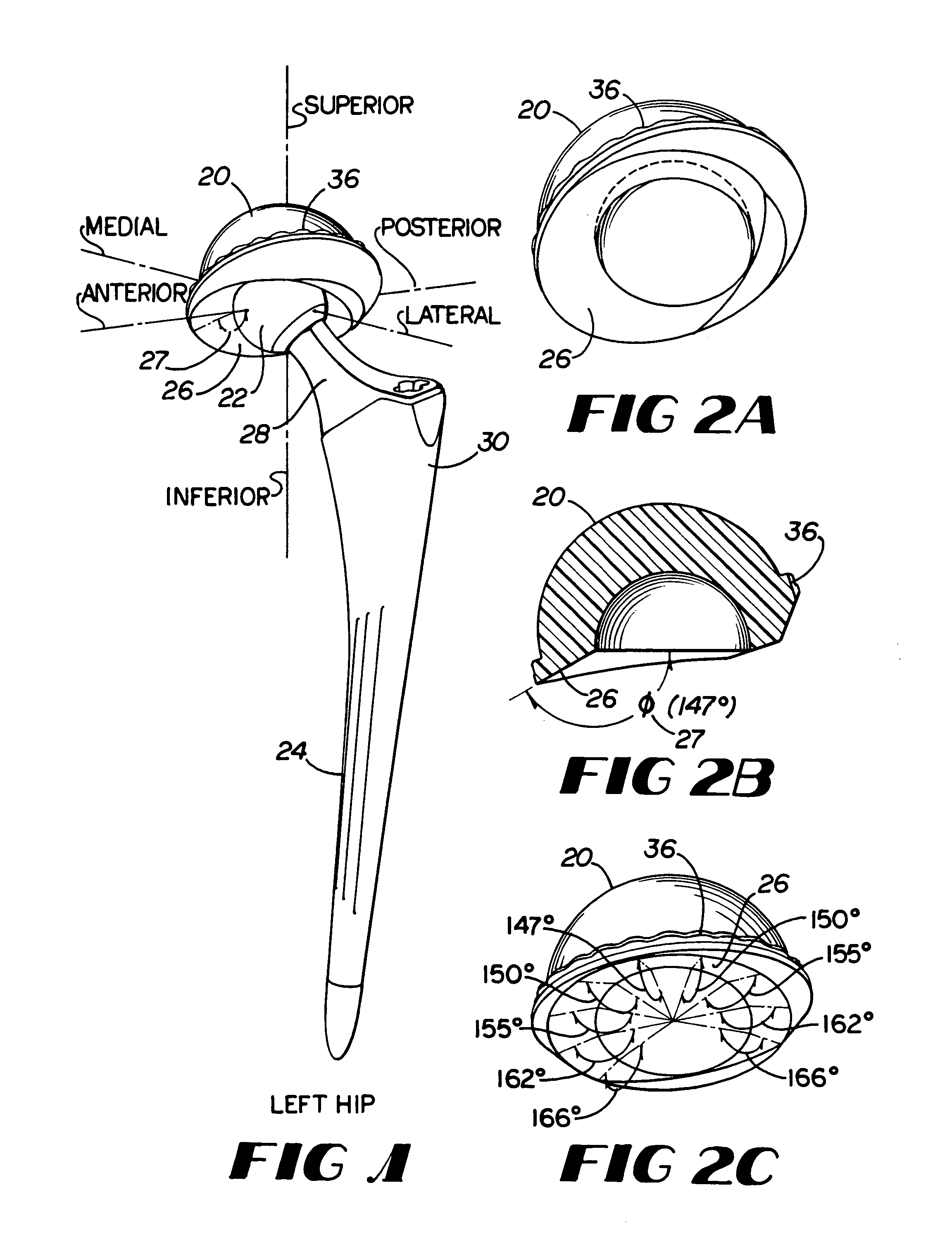

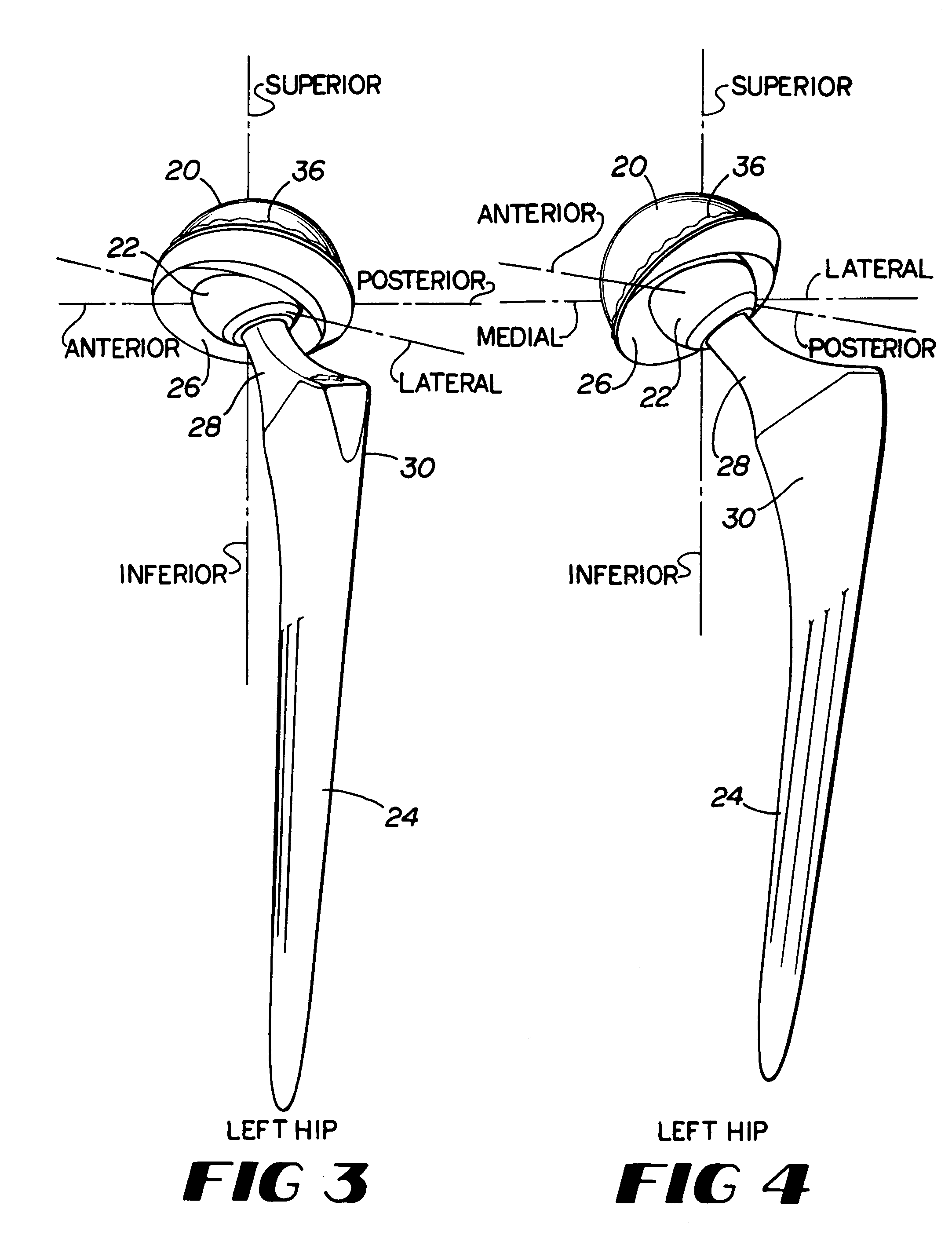

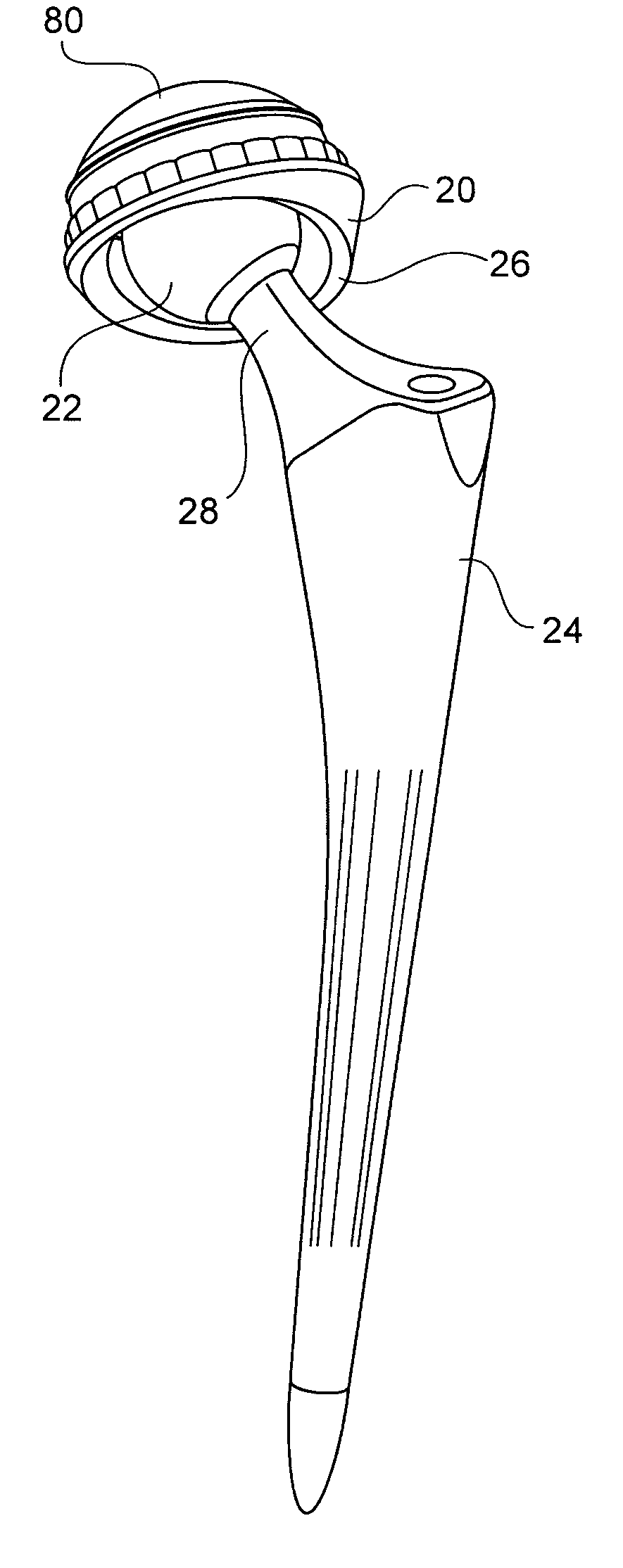

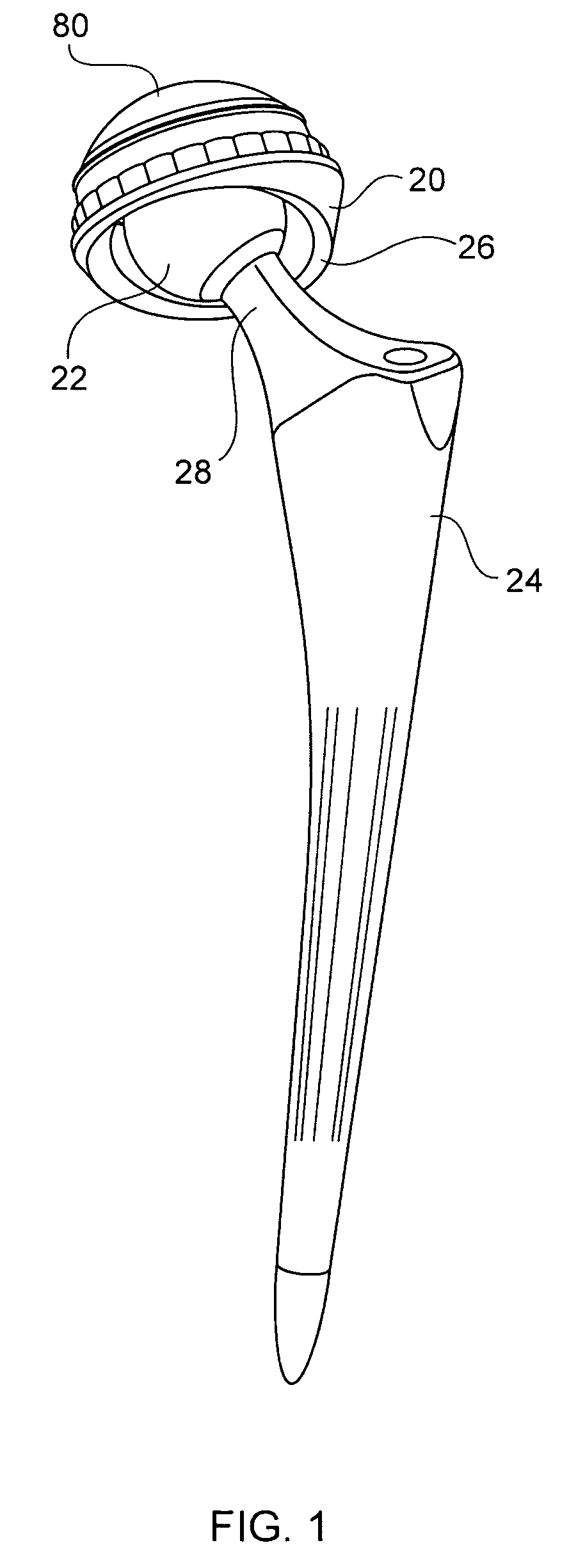

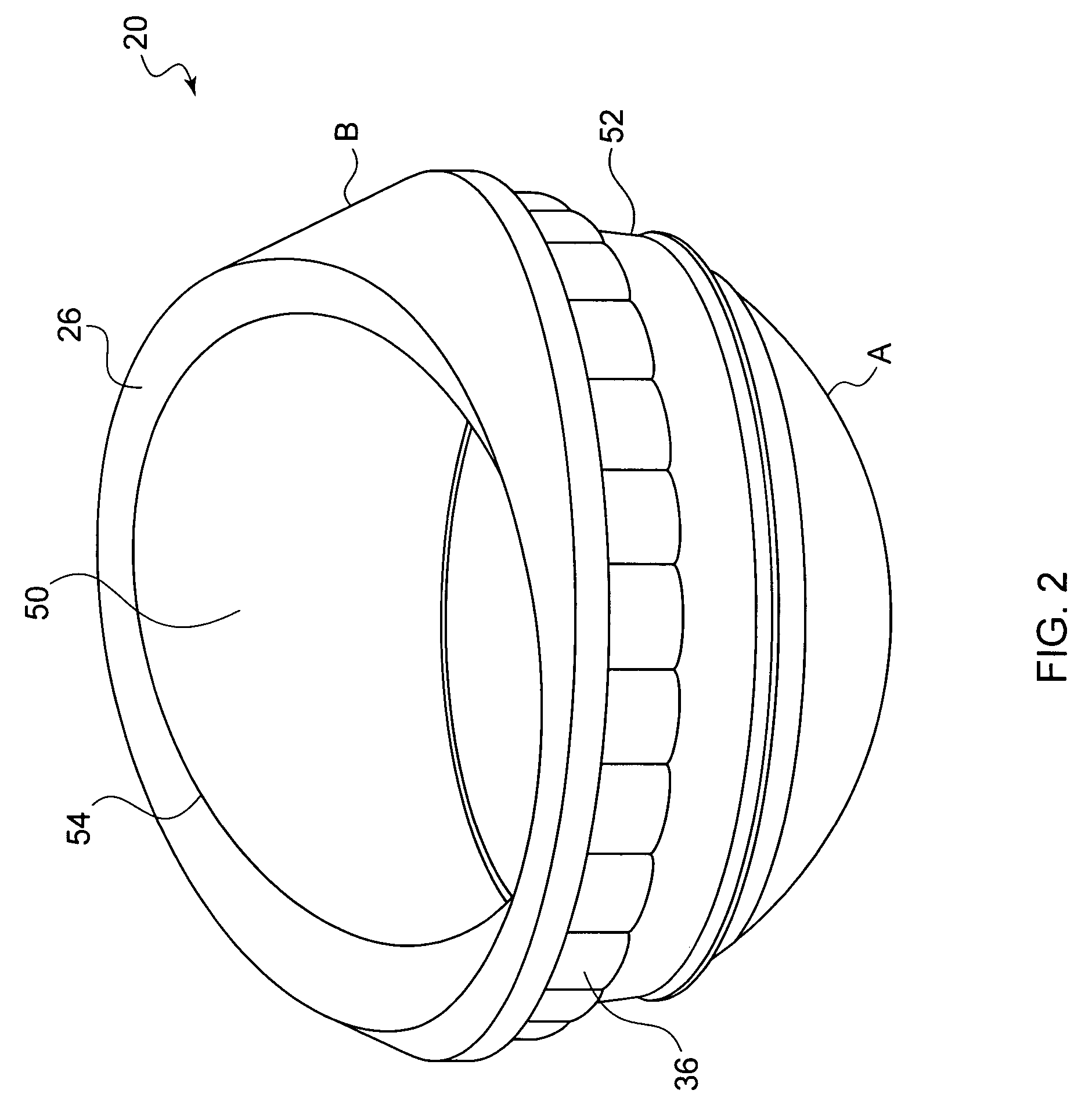

Variable geometry rim surface acetabular shell liner

InactiveUS7074241B2Extended range of motionMinimize interferenceJoint implantsFemoral headsEdge surfaceCoxal joint

An acetabular shell liner having a variable rim surface geometry, which improves range of motion of the femoral component within the liner and decreases the incidence of dislocation and subluxation, and methods of making and using the acetabular shell liner. Prosthetic devices, more particularly hip joint prostheses, containing the acetabular shell liner having a variable rim surface geometry are also provided.

Owner:SMITH & NEPHEW INC

Variable geometry rim surface acetabular shell liner

InactiveUS7682398B2Minimize interferenceExtended range of motionJoint implantsFemoral headsEdge surfaceRange of motion

There is provided an acetabular shell liner, and particularly a constrained liner, having a variable rim surface geometry to improve the range of motion of a femoral component within the liner and decrease the incidence of dislocation and subluxation. There are also provided methods of making and using the acetabular shell liner. Prosthetic devices, and particularly hip joint prostheses, containing the acetabular shell liner having a variable rim surface geometry are also provided.

Owner:SMITH & NEPHEW INC

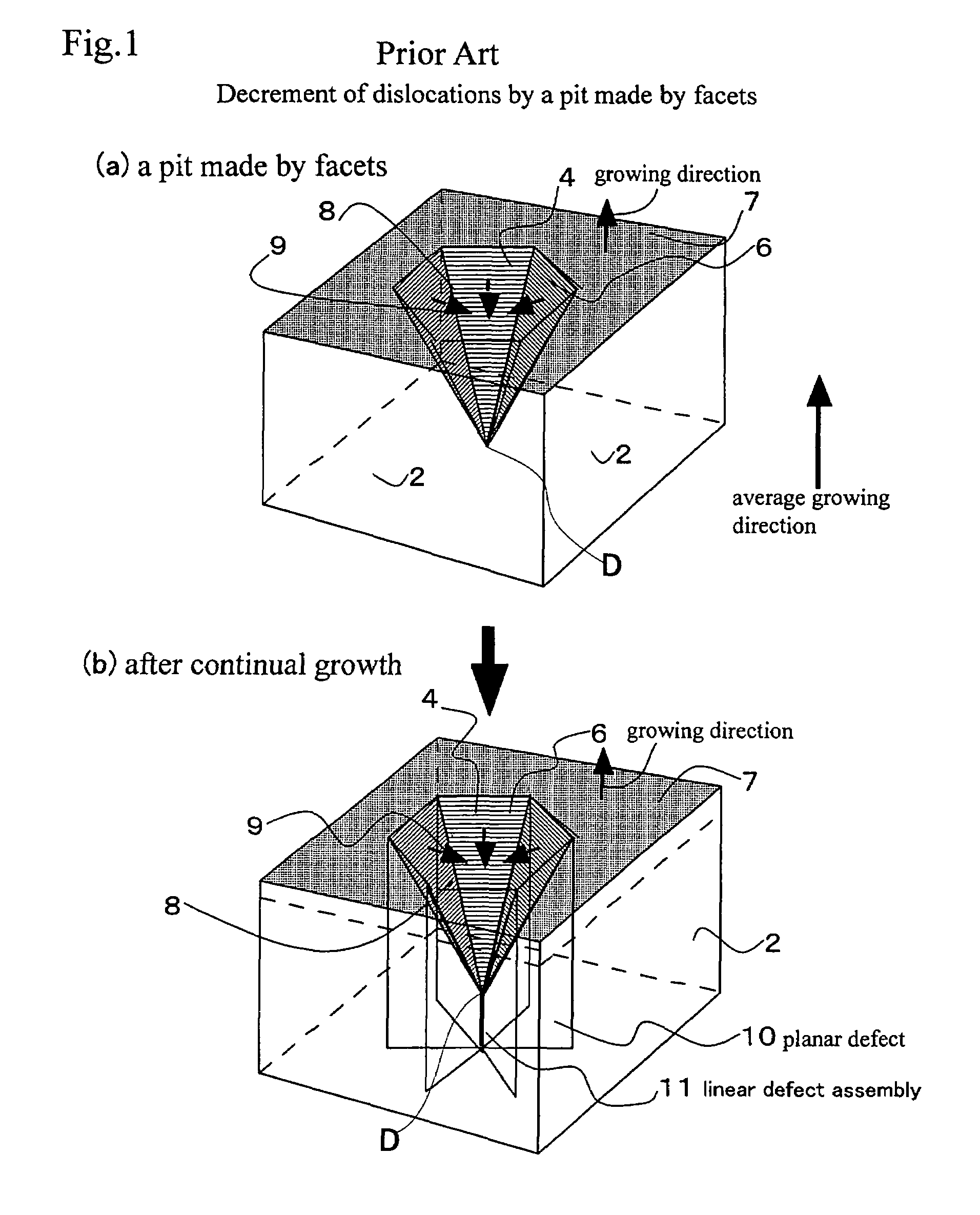

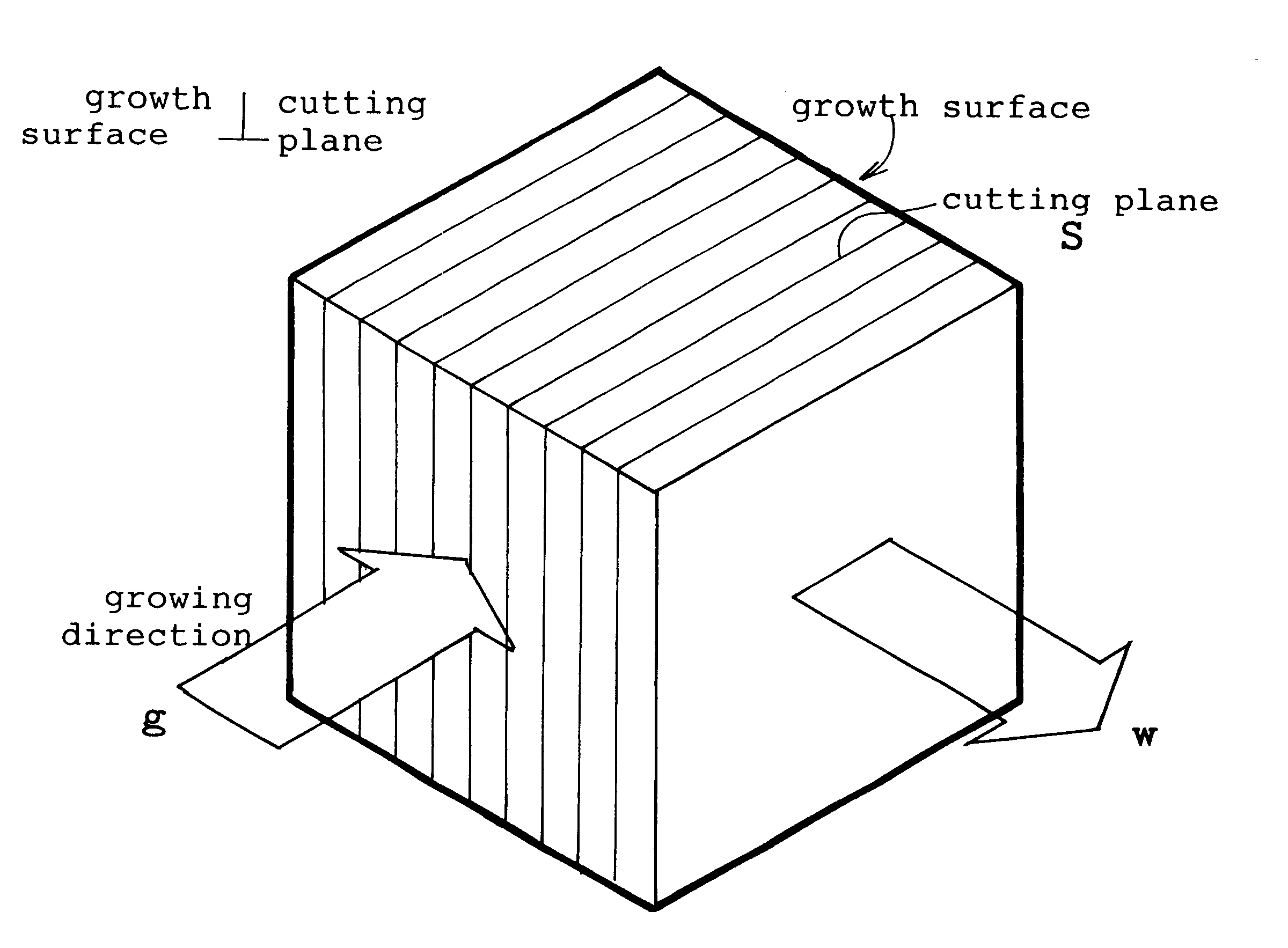

Method of producing a single crystal gallium nitride substrate and single crystal gallium nitride substrate

InactiveUS6468882B2Increase the number ofPolycrystalline material growthLaser detailsThreading dislocationsSingle crystal substrate

GaN single crystal substrates are produced by slicing a GaN single crystal ingot in the planes parallel to the growing direction. Penetration dislocations which have been generated in the growing direction extend mainly in the bulk of the GaN substrate. A few of the threading dislocations appear on the surface of the GaN substrate. GaN substrates of low-dislocation density are obtained.

Owner:SUMITOMO ELECTRIC IND LTD

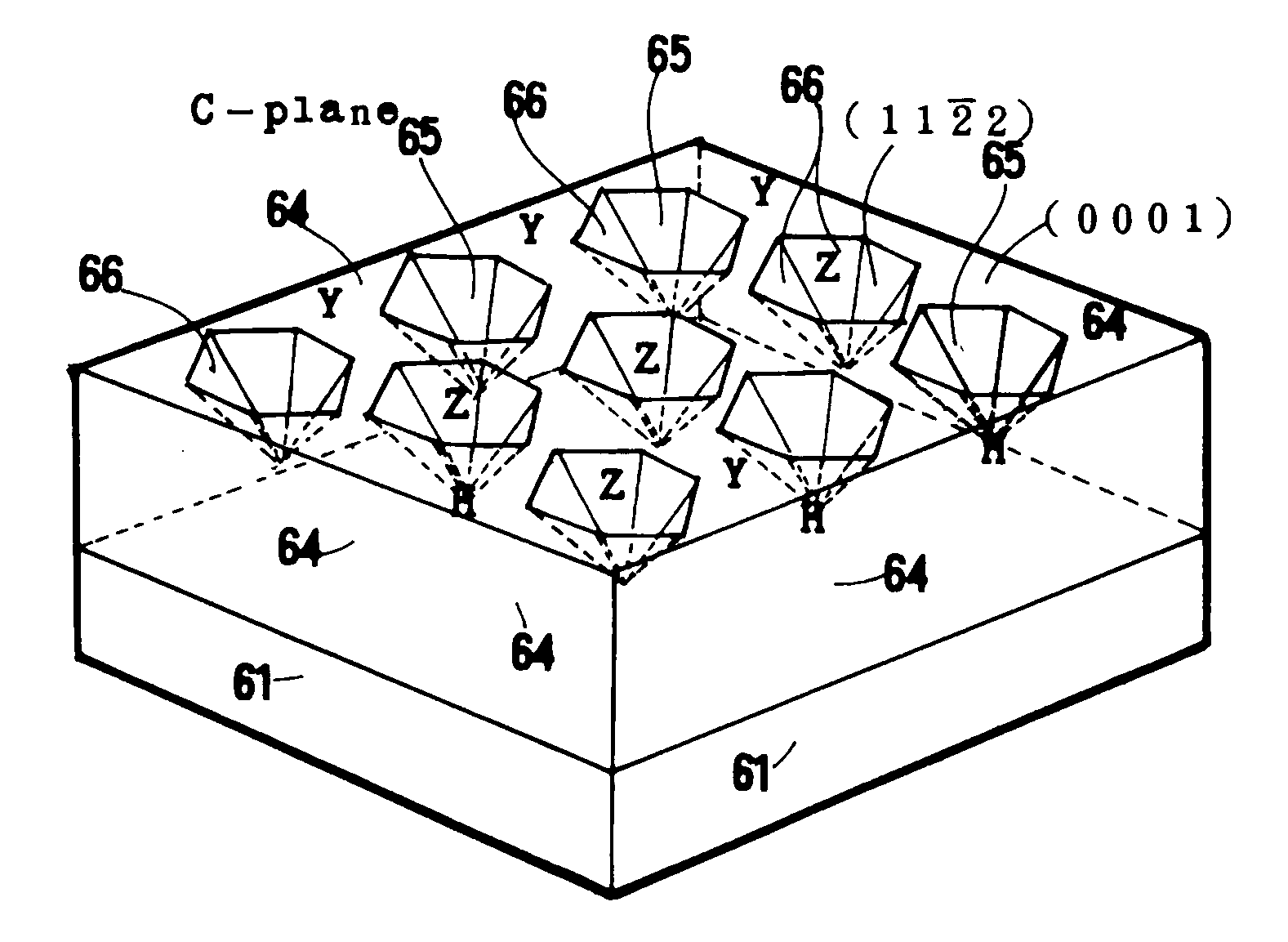

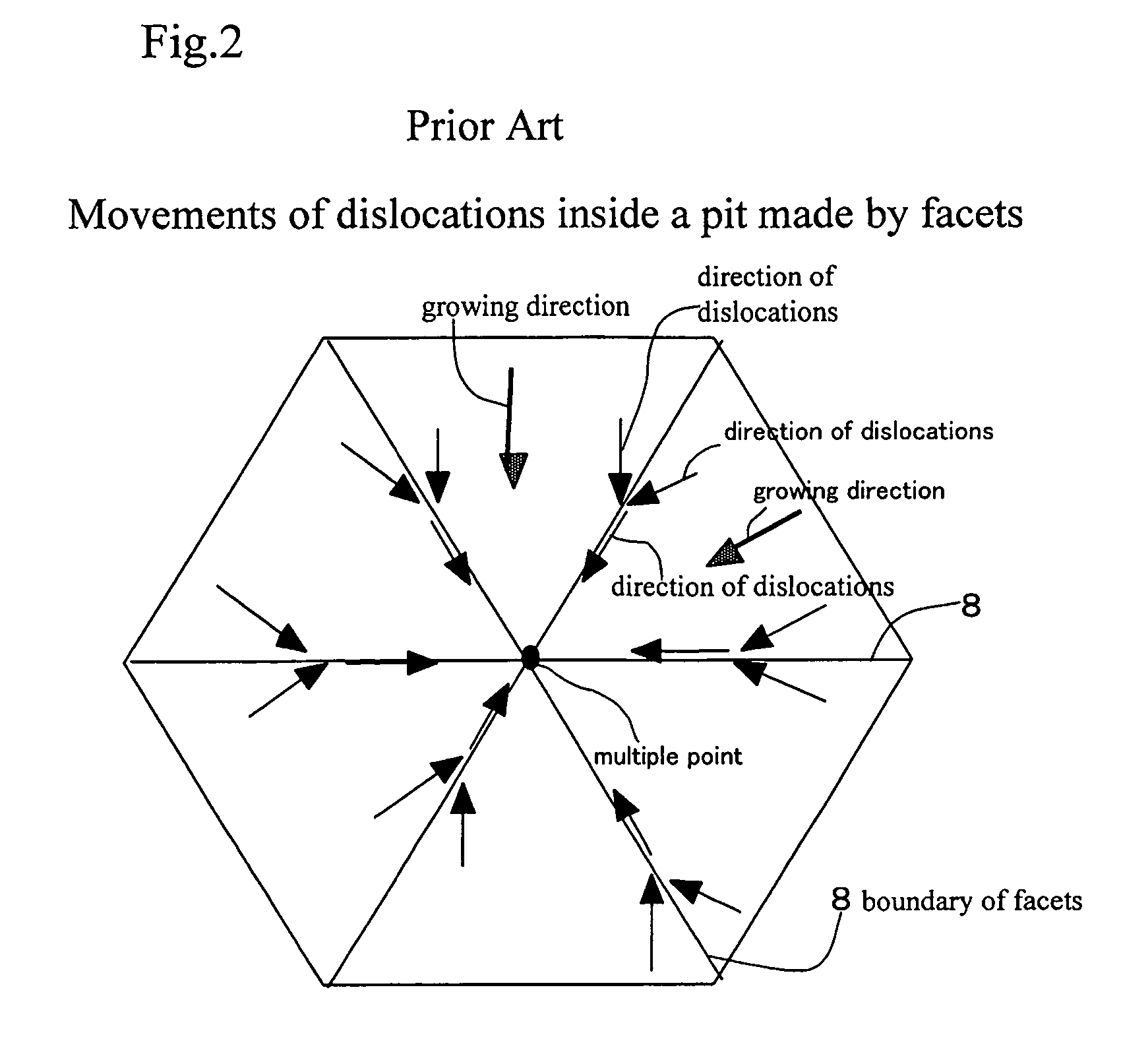

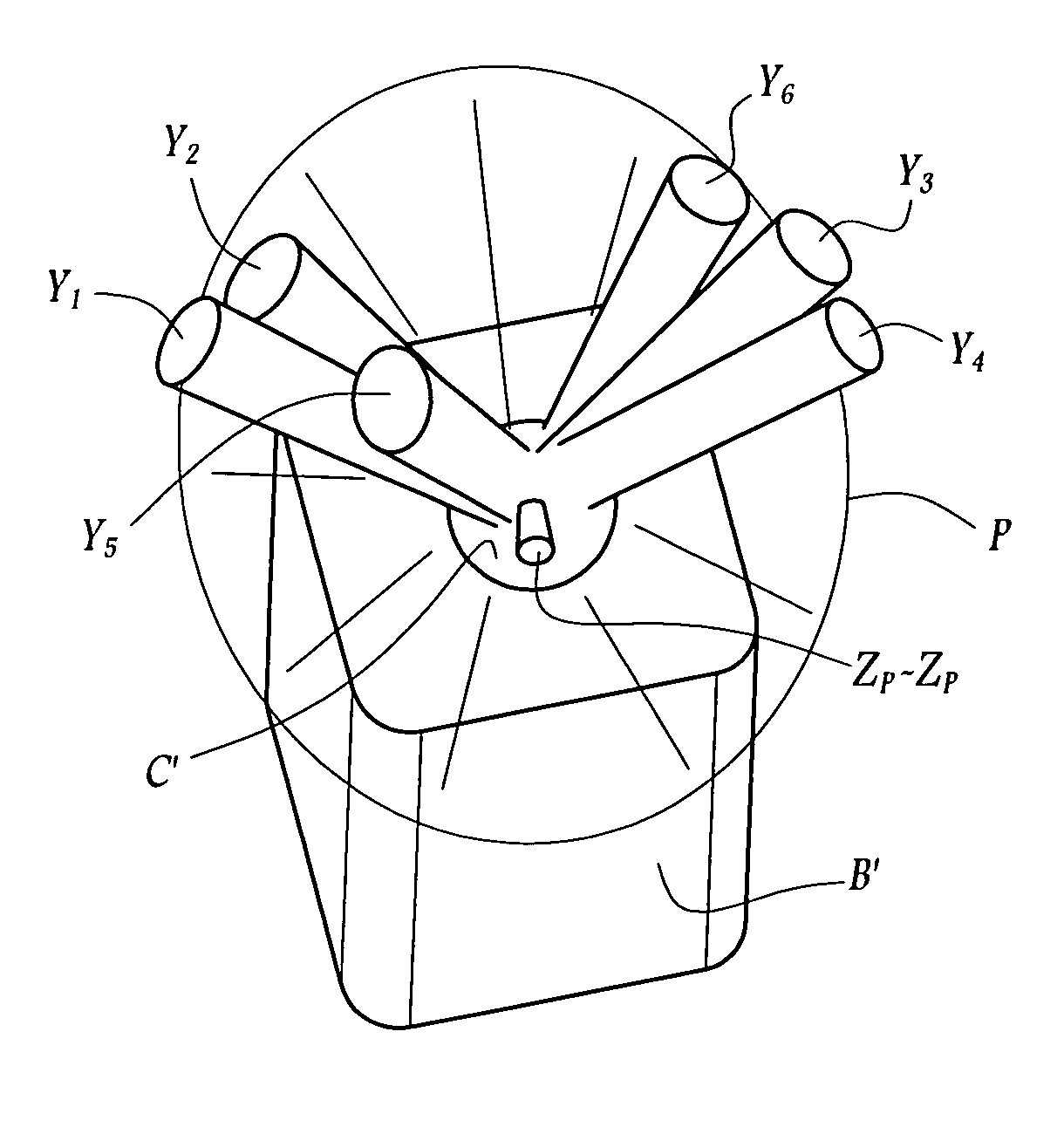

Single crystal GaN substrate, method of growing single crystal GaN and method of producing single crystal GaN substrate

InactiveUS20060213429A1Large capacityMany dislocationPolycrystalline material growthSemiconductor/solid-state device manufacturingSingle crystal substrateSingle crystal

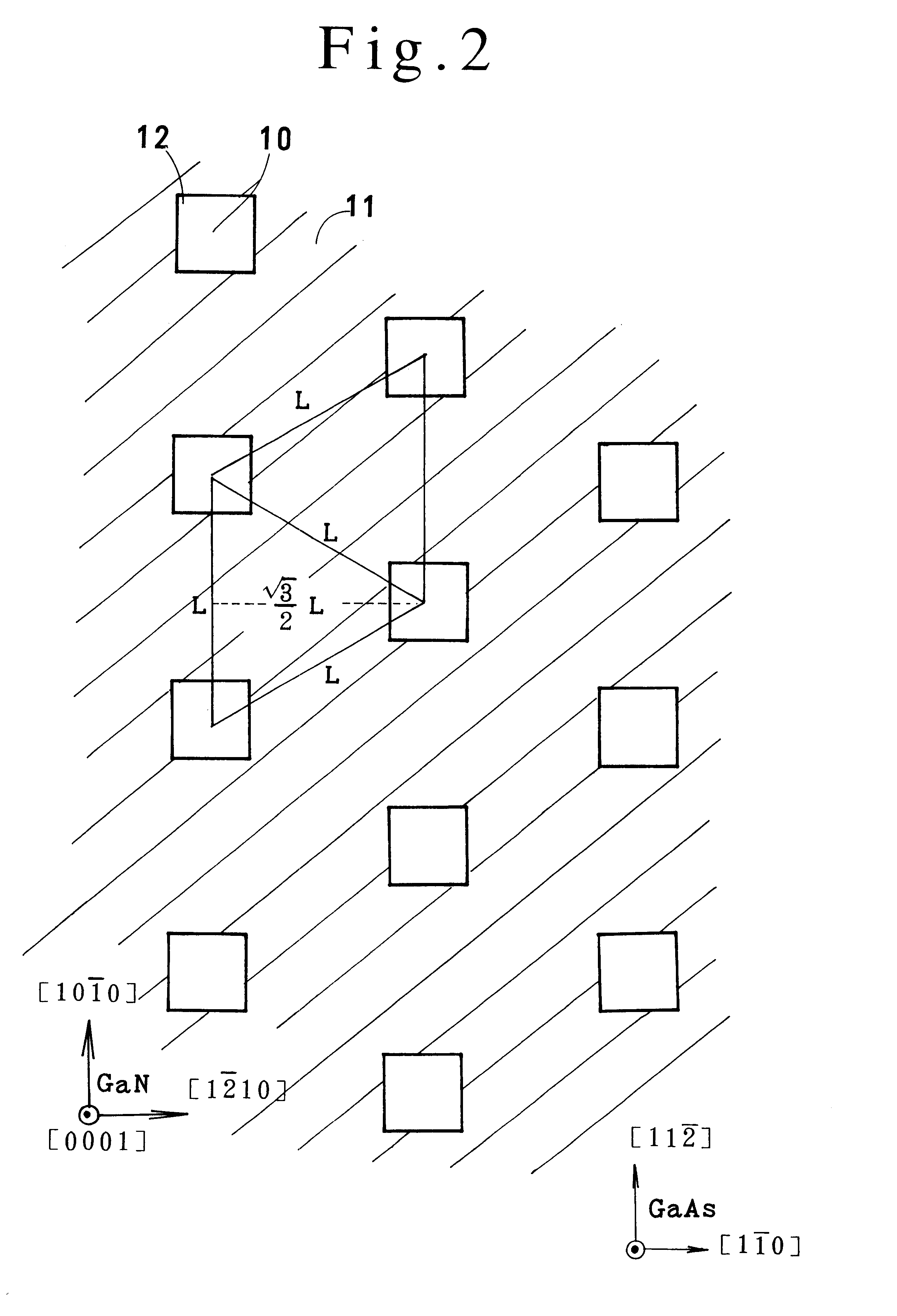

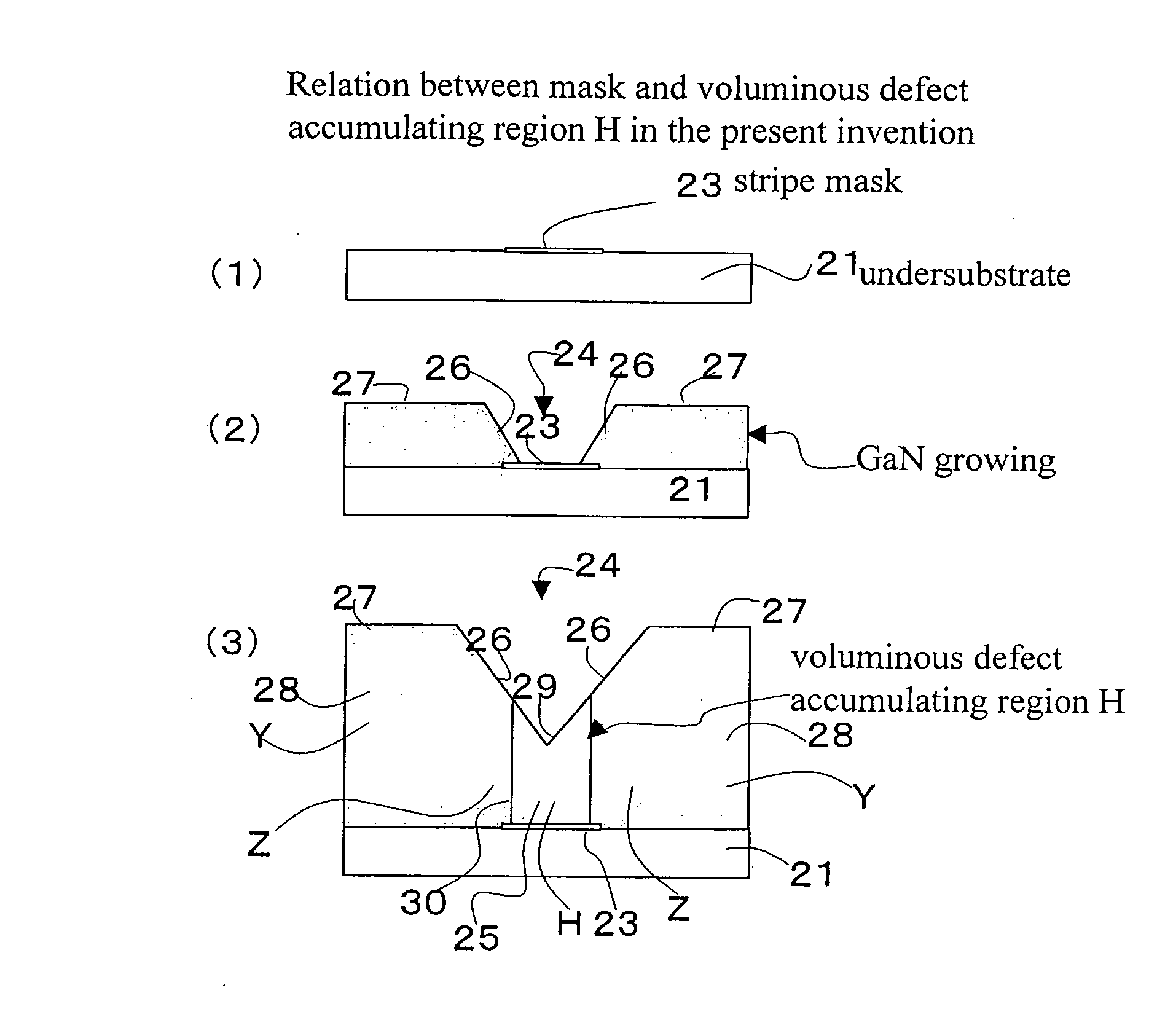

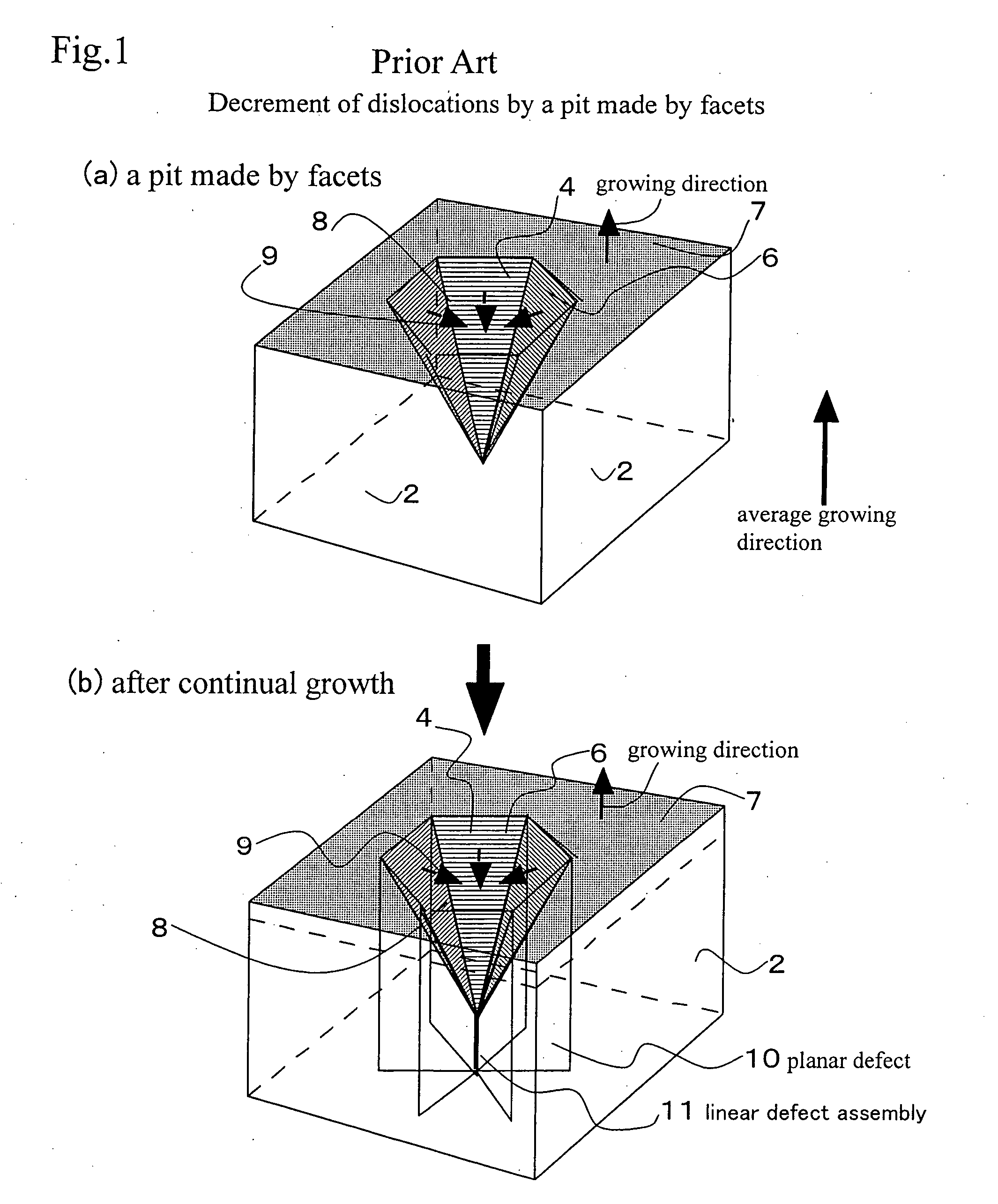

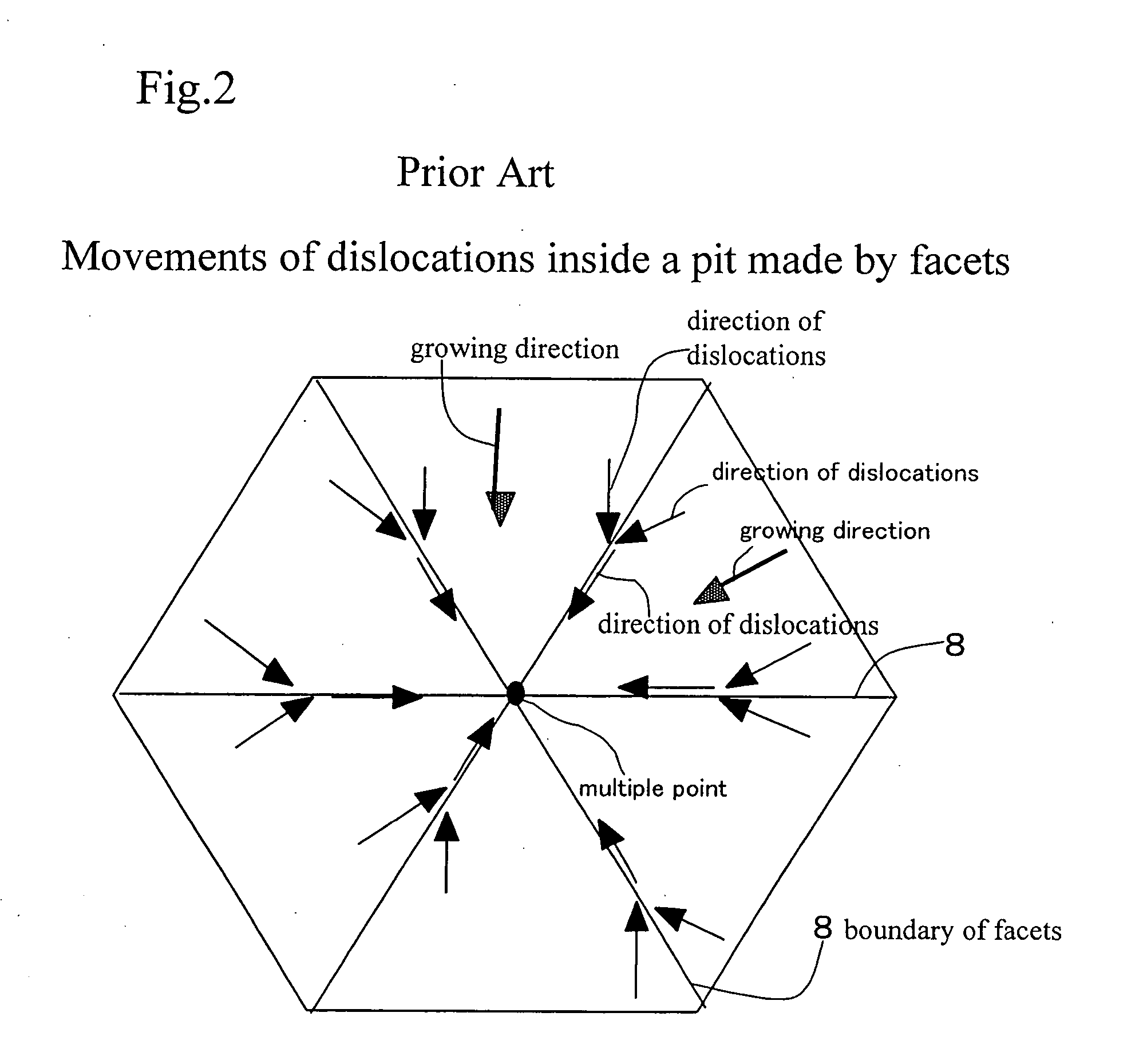

A low dislocation density GaN single crystal substrate is made by forming a seed mask having parallel stripes regularly and periodically aligning on an undersubstrate, growing a GaN crystal on a facet-growth condition, forming repetitions of parallel facet hills and facet valleys rooted upon the mask stripes, maintaining the facet hills and facet valleys, producing voluminous defect accumulating regions (H) accompanying the valleys, yielding low dislocation single crystal regions (Z) following the facets, making C-plane growth regions (Y) following flat tops between the facets, gathering dislocations on the facets into the valleys by the action of the growing facets, reducing dislocations in the low dislocation single crystal regions (Z) and the C-plane growth regions (Y), and accumulating the dislocations in cores (S) or interfaces (K) of the voluminous defect accumulating regions (H).

Owner:SUMITOMO ELECTRIC IND LTD

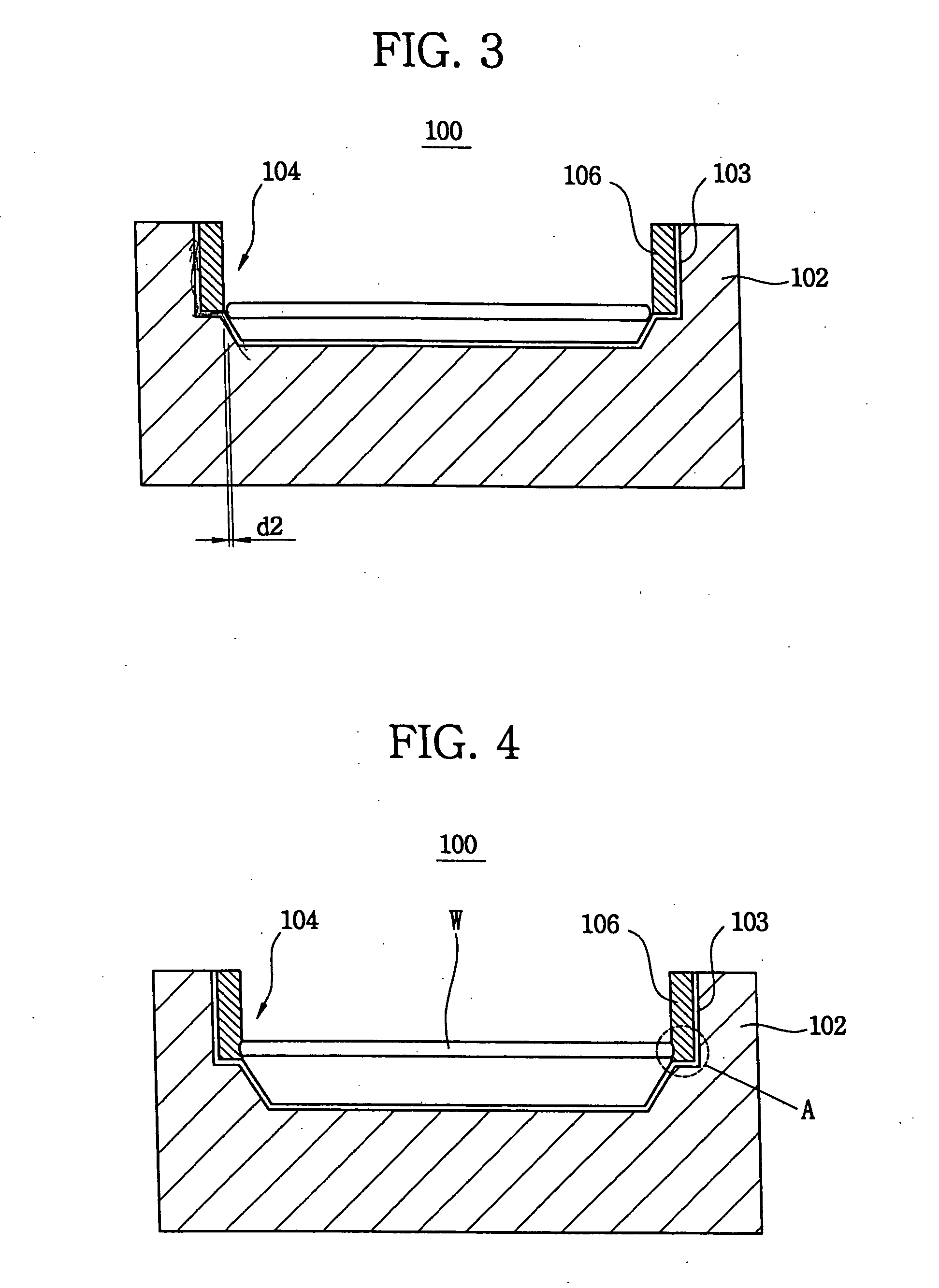

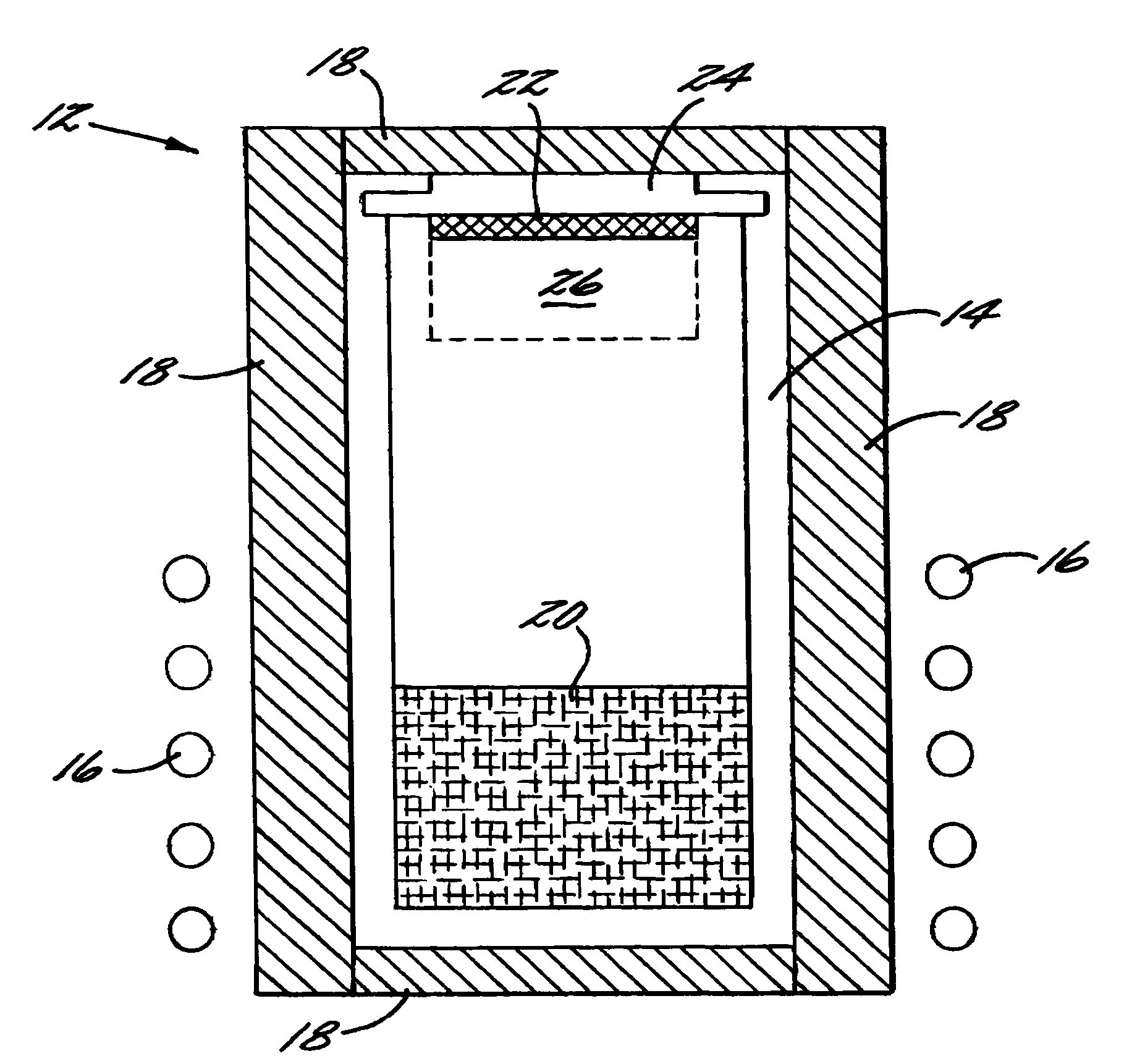

Susceptor and deposition apparatus including the same

InactiveUS20050016470A1Minimize physical impactMinimizing slip dislocationDiffusion/dopingSemiconductor/solid-state device manufacturingSusceptorEngineering

A susceptor for use in a deposition apparatus includes a recess in which a wafer is received, and a stress-reducing bumper disposed along the side of the recess. The stress-reducing bumper is of material having ductility at a relatively high temperature. Therefore, when the wafer contacts the stress-reducing bumper, such as may occur due to thermal expansion of the wafer during processing, the force of the impact on the wafer is minimized by an elastic deformation of the stress-reducing bumper. As a result, defects, such as slip dislocations at the outer peripheral edge of the wafer, are prevented.

Owner:SAMSUNG ELECTRONICS CO LTD

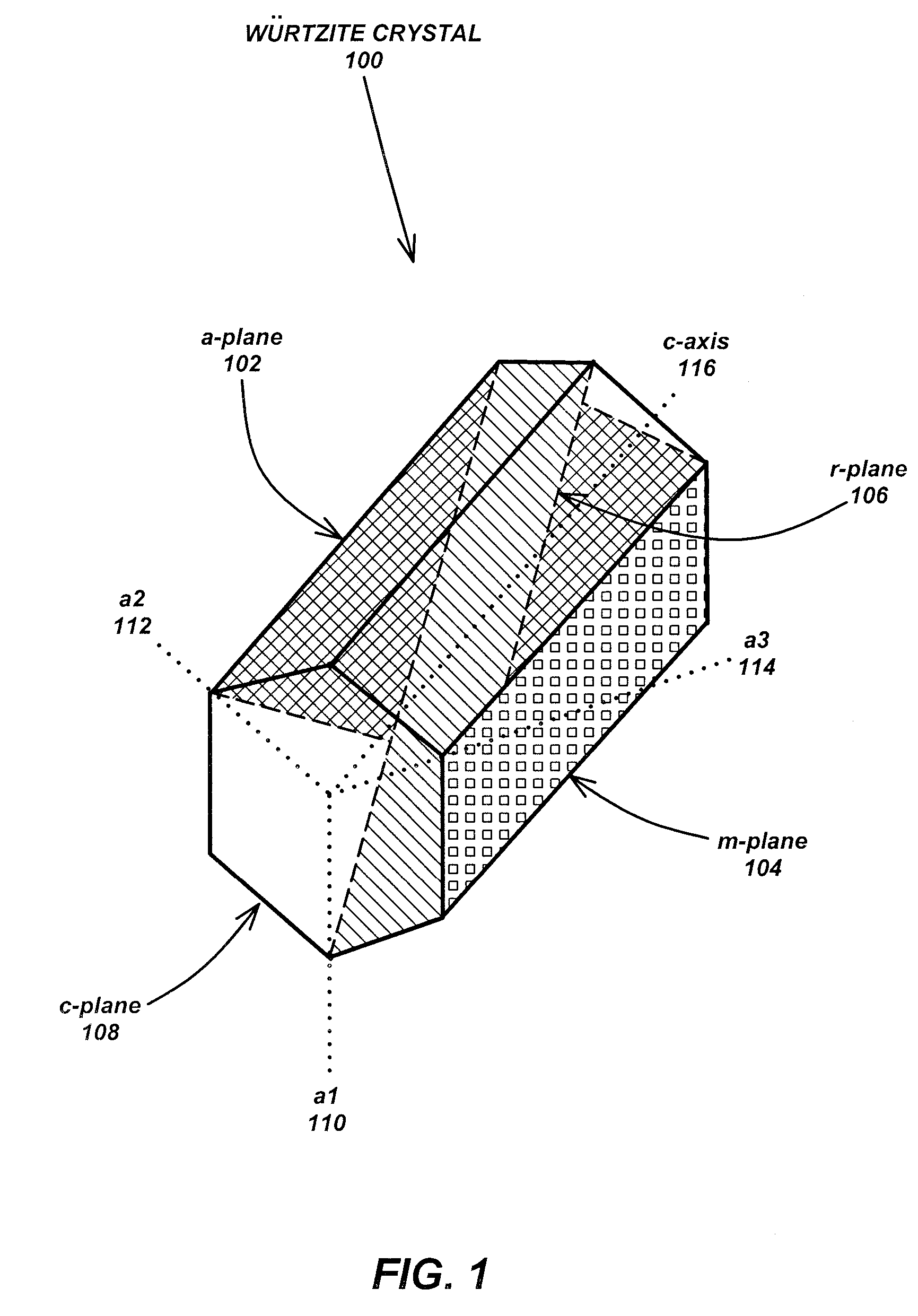

Light emitting element structure using nitride bulk single crystal layer

InactiveUS20040251471A1Improve crystal qualitySimple structureOptical wave guidancePolycrystalline material growthSingle crystalActive layer

The object of this invention is to provide a high-output type nitride light emitting device. The nitride light emitting device comprises an n-type nitride semiconductor layer or layers, a p-type nitride semiconductor layer or layers and an active layer therebetween, wherein a gallium-containing nitride substrate is obtained from a gallium-containing nitride bulk single crystal, provided with an epitaxial growth face with dislocation density of 10<5> / cm<2 >or less, and A-plane or M-plane which is parallel to C-axis of hexagonal structure for an epitaxial face, wherein the n-type semiconductor layer or layers are formed directly on the A-plane or M-plane. In case that the active layer comprises a nitride semiconductor containing In, an end face film of single crystal AlxGa1-xN (0<=x<=1) can be formed at a low temperature not causing damage to the active layer.

Owner:AMMONO SP Z O O (PL) +1

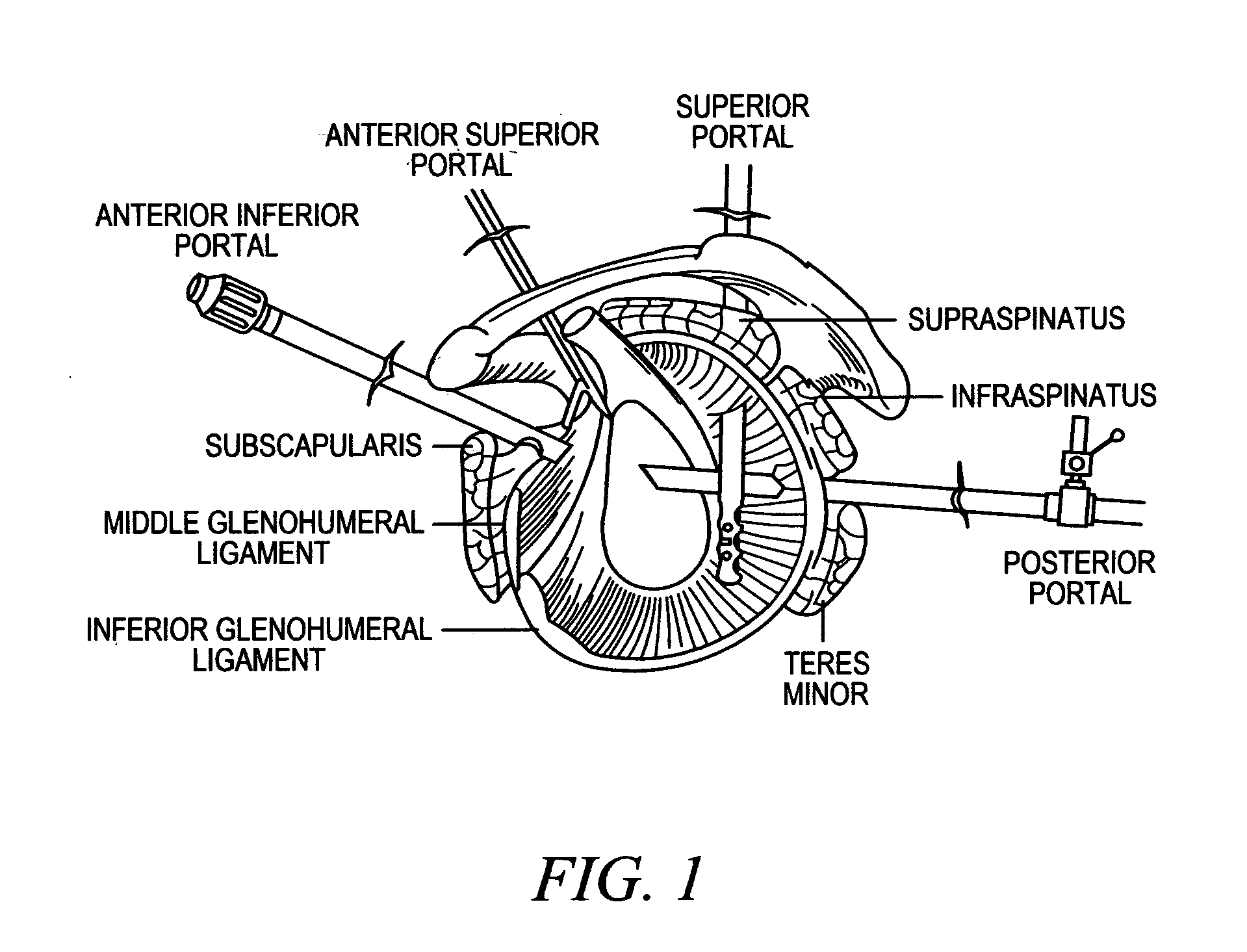

Devices, systems and methods for tissue repair

InactiveUS20050267529A1Good for healthFunction increaseSuture equipmentsSurgical needlesTissue repairEngineering

Devices, systems and methods are disclosed for repairing soft tissue. The surgical system allows for the creation of tissue repair by grasping, aligning and sewing or fixing tissue. For example, this system may be used for clipping together excessive capsular tissue and reducing the overall capsular volume. The deployment device includes a central grasping mechanism and an outer clip delivery system. The clip embodiments may be single or multi-component (penetration and locking base components) that penetrate tissue layers and deploy or lock to clip the tissue together. An example of the system is used to reduce the joint capsule tissue laxity and reduces the potential for subluxation or dislocation of the joint by either restricting inferior laxity (anterior or posterior) and resolving or eliminating pathologic anterior or posterior translation.

Owner:BAY INNOVATION GROUP

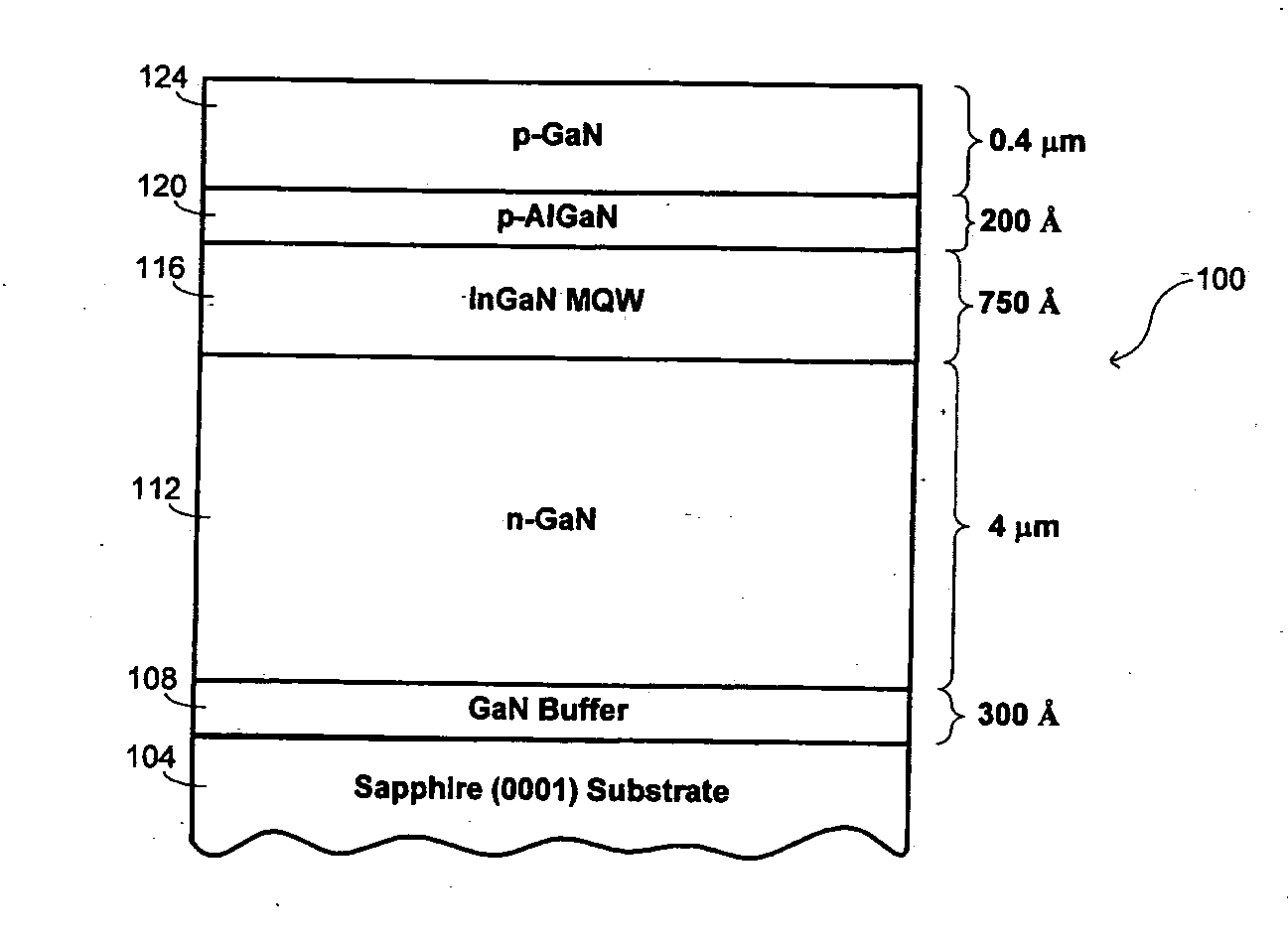

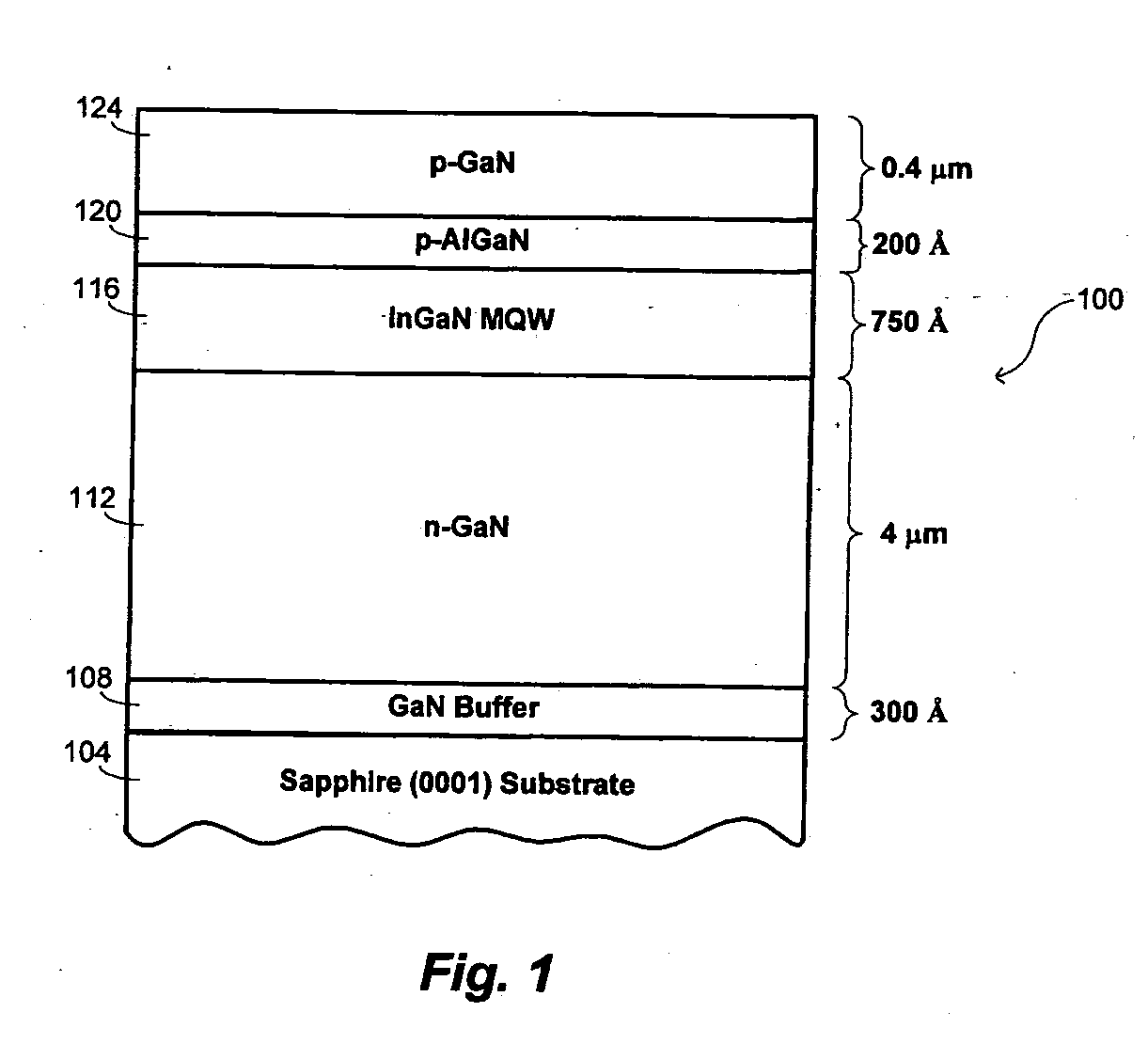

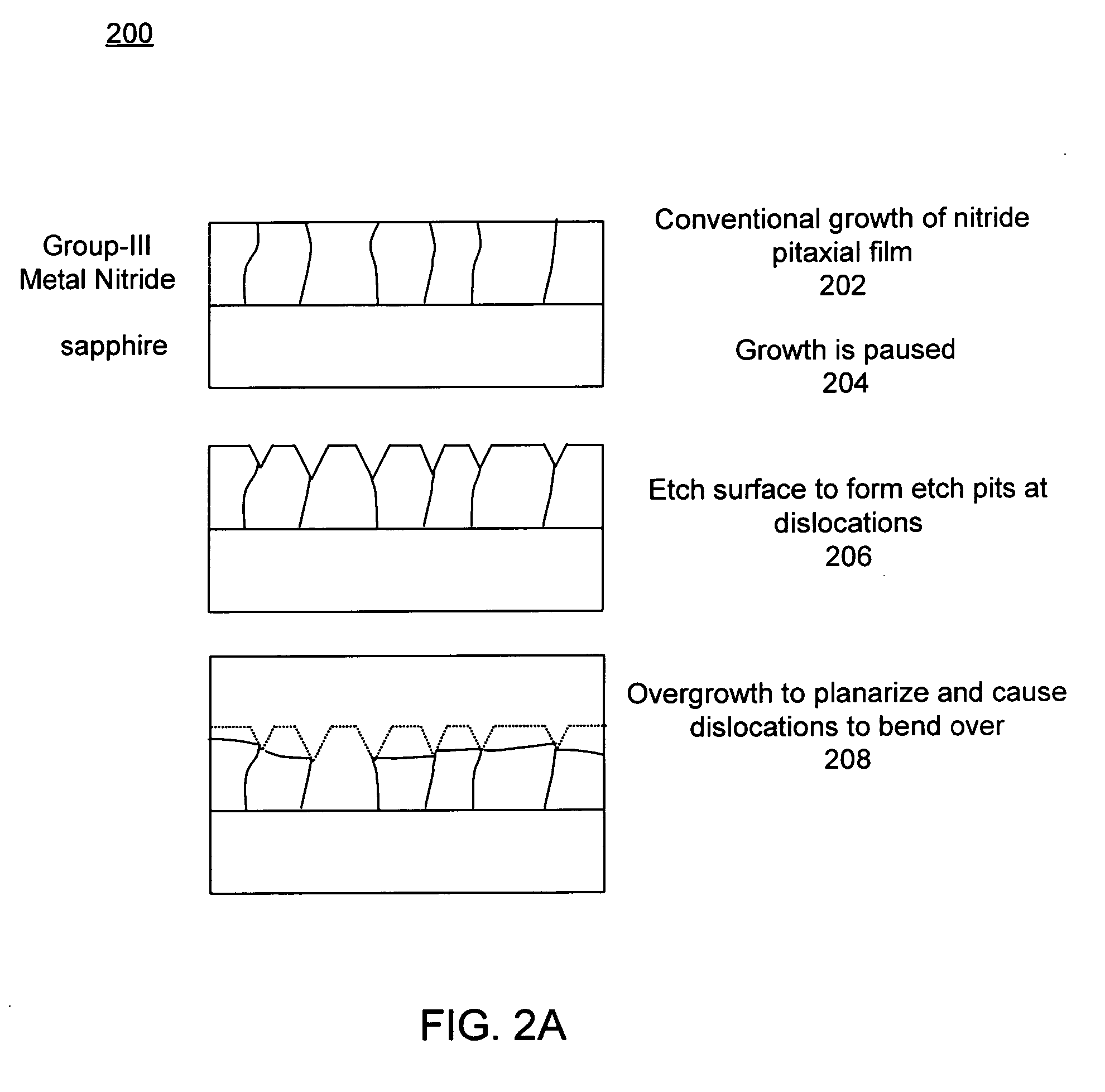

Dislocation-specific dielectric mask deposition and lateral epitaxial overgrowth to reduce dislocation density of nitride films

InactiveUS20070259464A1Inhibit threading of the lattice mismatchSemiconductor/solid-state device manufacturingSemiconductor devicesDielectricEtching

In accordance with the present invention, improved methods for reducing the dislocation density of nitride epitaxial films are provided. Specifically, an in-situ etch treatment is provided to preferentially etch the dislocations of the nitride epitaxial layer to prevent threading of the dislocations through the nitride epitaxial layer. Subsequent to etching of the dislocations, an epitaxial layer overgrowth is performed. In certain embodiments, the etching of the dislocations occurs simultaneously with growth of the epitaxial layer. In other embodiments, a dielectric mask is deposited within the etch pits formed at the dislocations prior to the epitaxial layer overgrowth.

Owner:APPLIED MATERIALS INC

GaN substrate and method of fabricating the same, nitride semiconductor device and method of fabricating the same

InactiveUS20040262624A1Polycrystalline material growthSemiconductor/solid-state device manufacturingSingle crystal substrateSingle crystal

A GaN substrate comprises a GaN single crystal substrate, an AlxGa1-xN intermediate layer (0<x<=1) epitaxially grown on the substrate, and an GaN epitaxial layer grown on the intermediate layer. The intermediate layer is made of AlGaN and this AlGaN grows over the entire surface of the substrate with contaminants thereon and high dislocation regions therein. Thus, the intermediate layer is normally grown on the substrate, and a growth surface of the intermediate layer can be made flat. Since the growth surface is flat, a growth surface of the GaN epitaxial layer epitaxially grown on the intermediate layer is also flat.

Owner:SUMITOMO ELECTRIC IND LTD

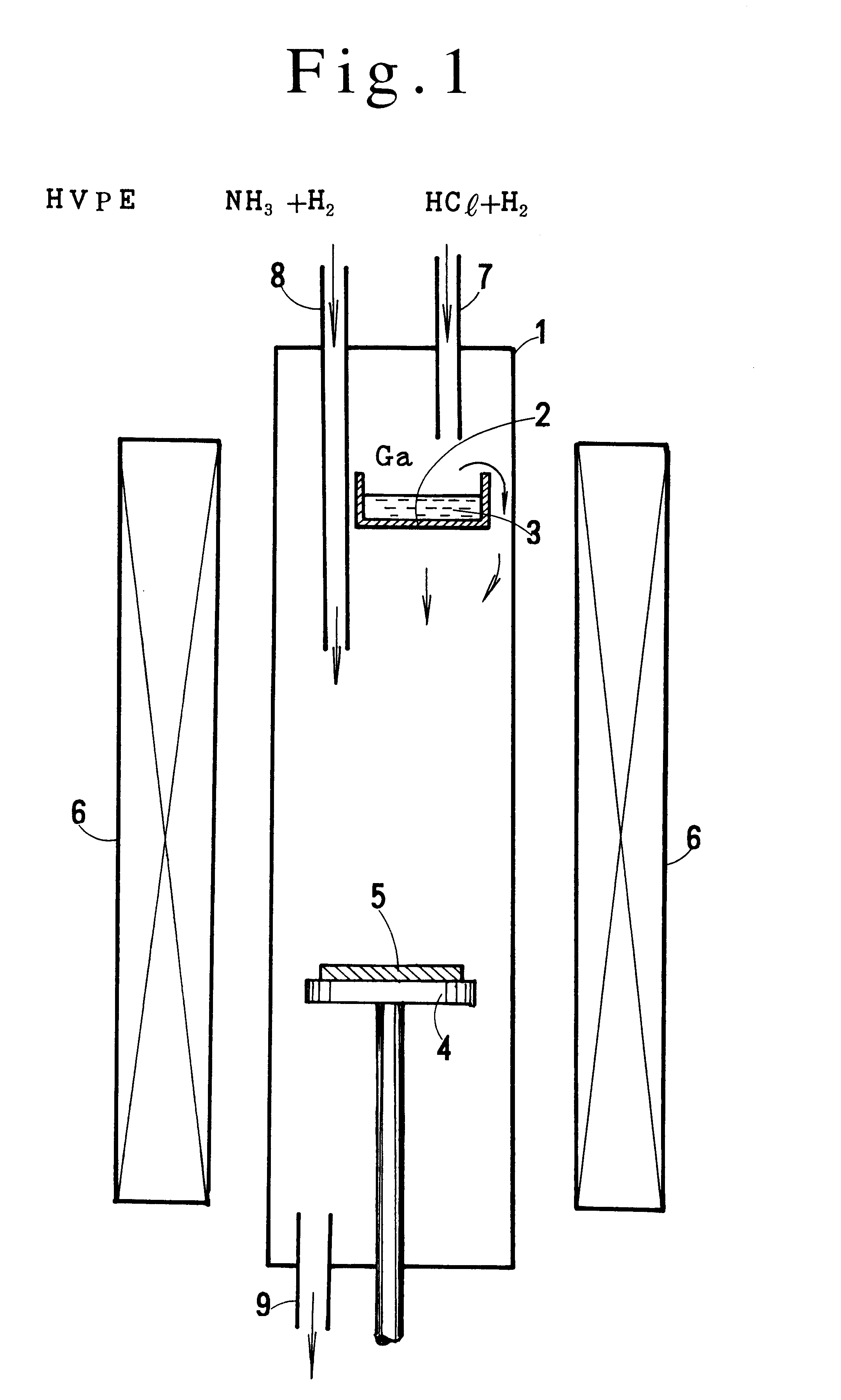

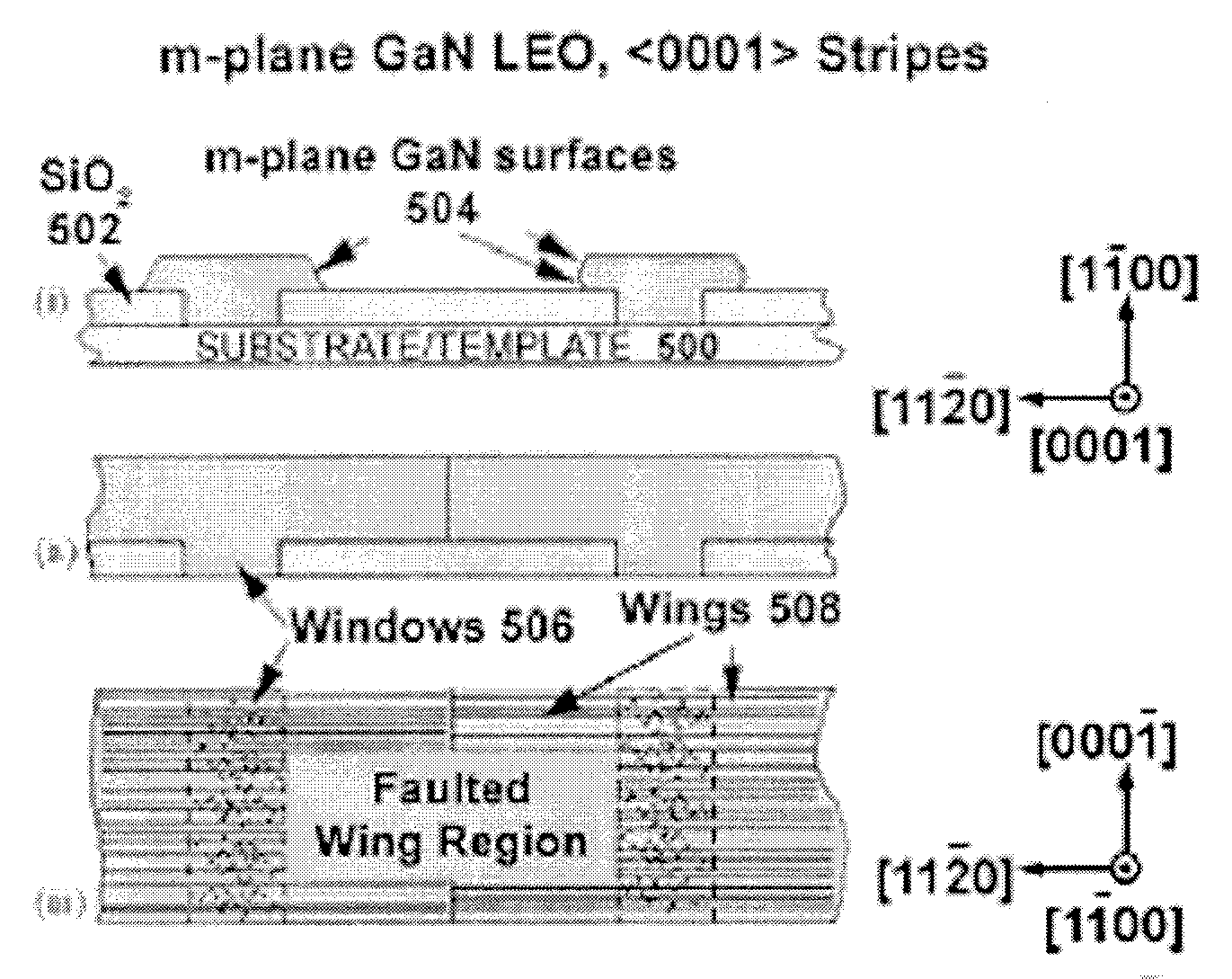

Growth of planar reduced dislocation density m-plane gallium nitride by hydride vapor phase epitaxy

ActiveUS20070184637A1Reduction in structural defect densityReduce defect densitySemiconductor/solid-state device manufacturingSemiconductor devicesLateral overgrowthVolumetric Mass Density

A method of growing highly planar, fully transparent and specular m-plane gallium nitride (GaN) films. The method provides for a significant reduction in structural defect densities via a lateral overgrowth technique. High quality, uniform, thick m-plane GaN films are produced for use as substrates for polarization-free device growth.

Owner:JAPAN SCI & TECH CORP

High flexion articular insert

A knee prosthesis is provided that allows for increased flexion. The knee prosthesis includes (a) a femoral component adapted to fit on a distal end of the femur which includes a lateral condylar structure and a medial condylar structure and (b) an intermediate structure configured to cooperate with a femoral component of a knee prosthesis. The intermediate structure includes at least one surface for contacting the femoral component and a transition of a sagittal curvature of the at least one contact surface from a concave surface into a convex surface at the contact interface of the femoral component and the intermediate structure when the knee is flexed at approximately 120° to 140°. The knee prosthesis minimizes impingement on the femoral posterior cortex in deep flexion, increases the dislocation safety factor and allows for easier reengagement of the articular surface should the femoral component externally rotate off of the tibial plateau.

Owner:SMITH & NEPHEW INC

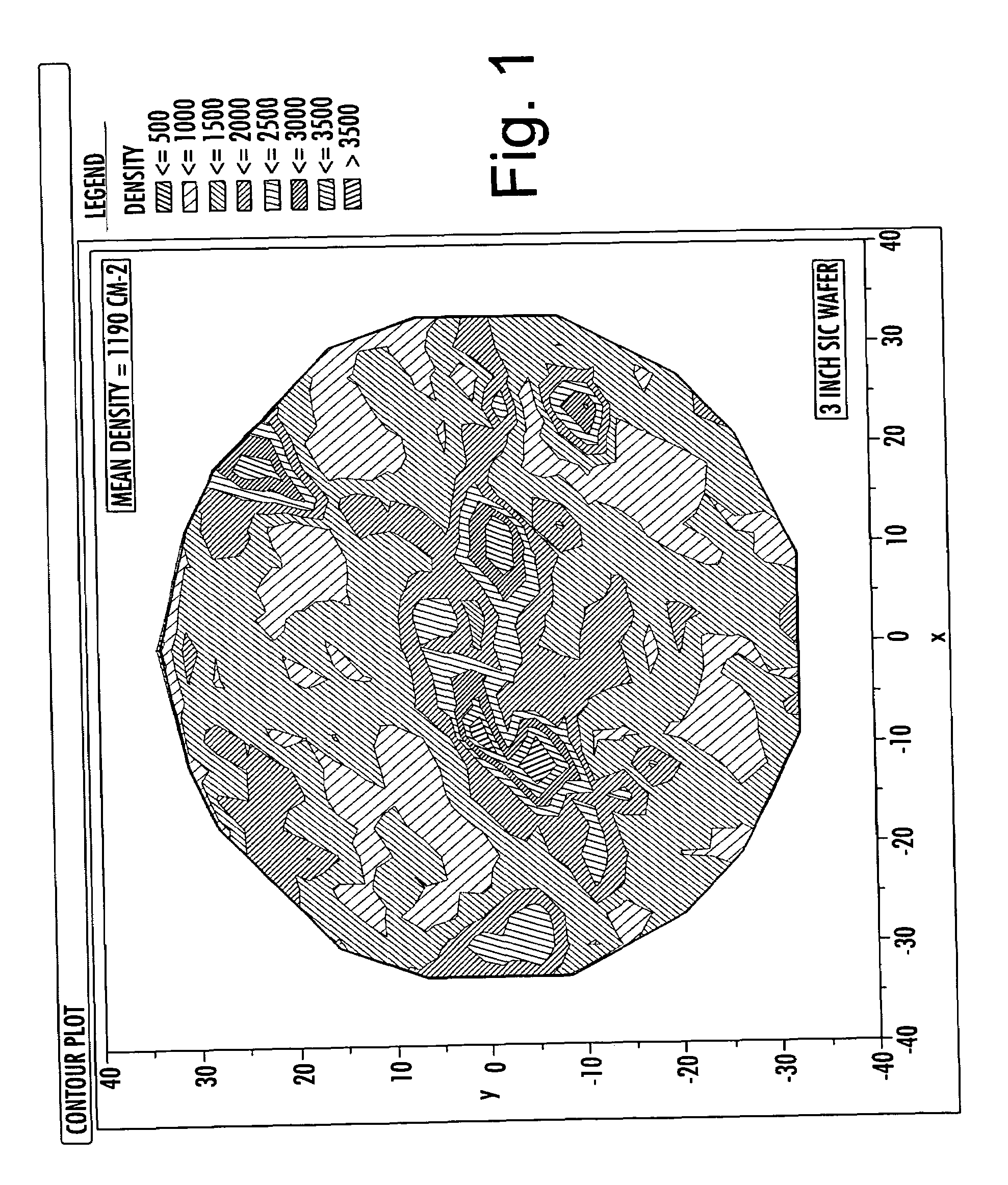

Low 1c screw dislocation 3 inch silicon carbide wafer

ActiveUS7314520B2Polycrystalline material growthSemiconductor/solid-state device manufacturingSingle crystalDislocation

A high quality single crystal wafer of SiC is disclosed having a diameter of at least about 3 inches and a 1 c screw dislocation density of less than about 2000 cm−2.

Owner:CREE INC

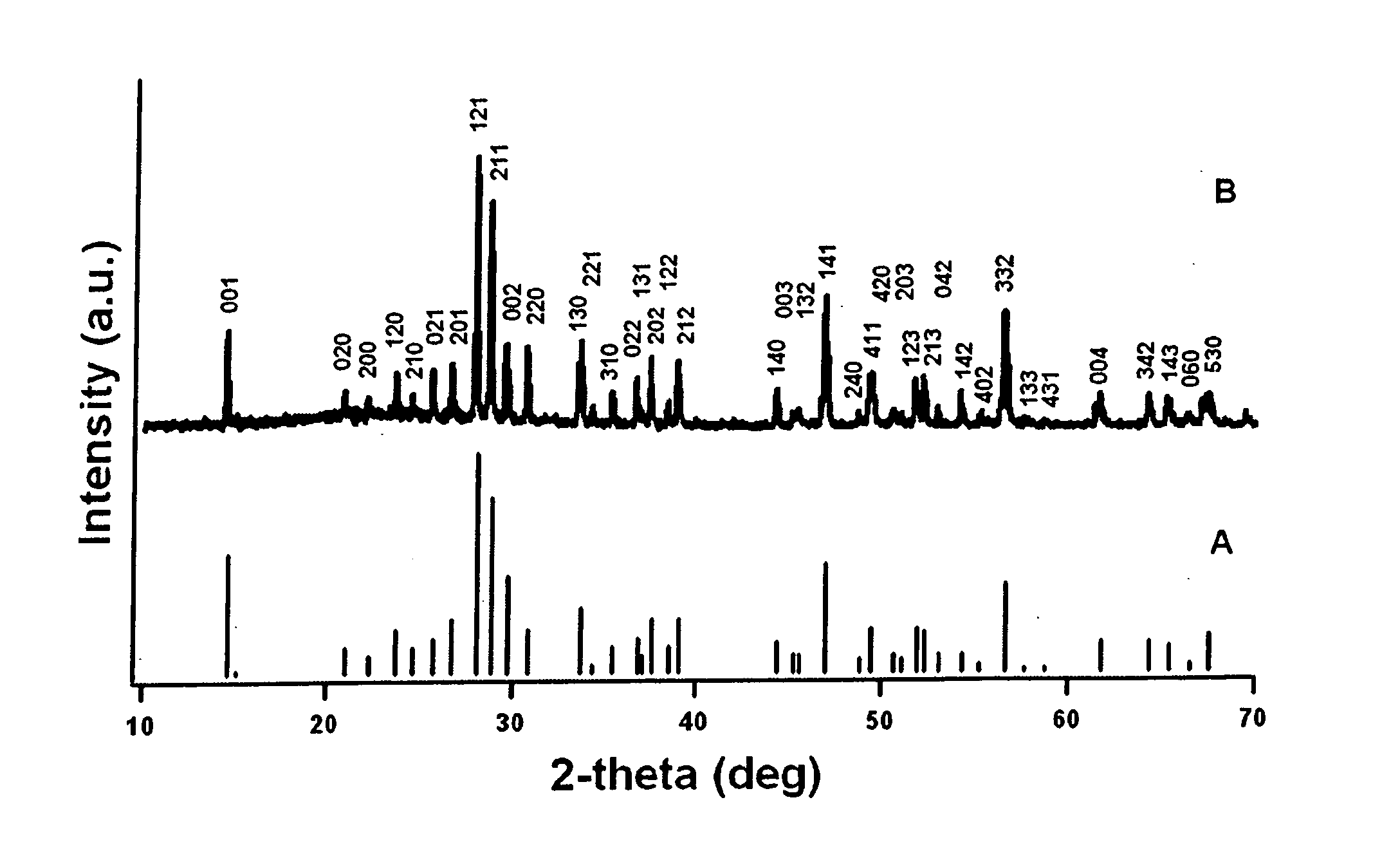

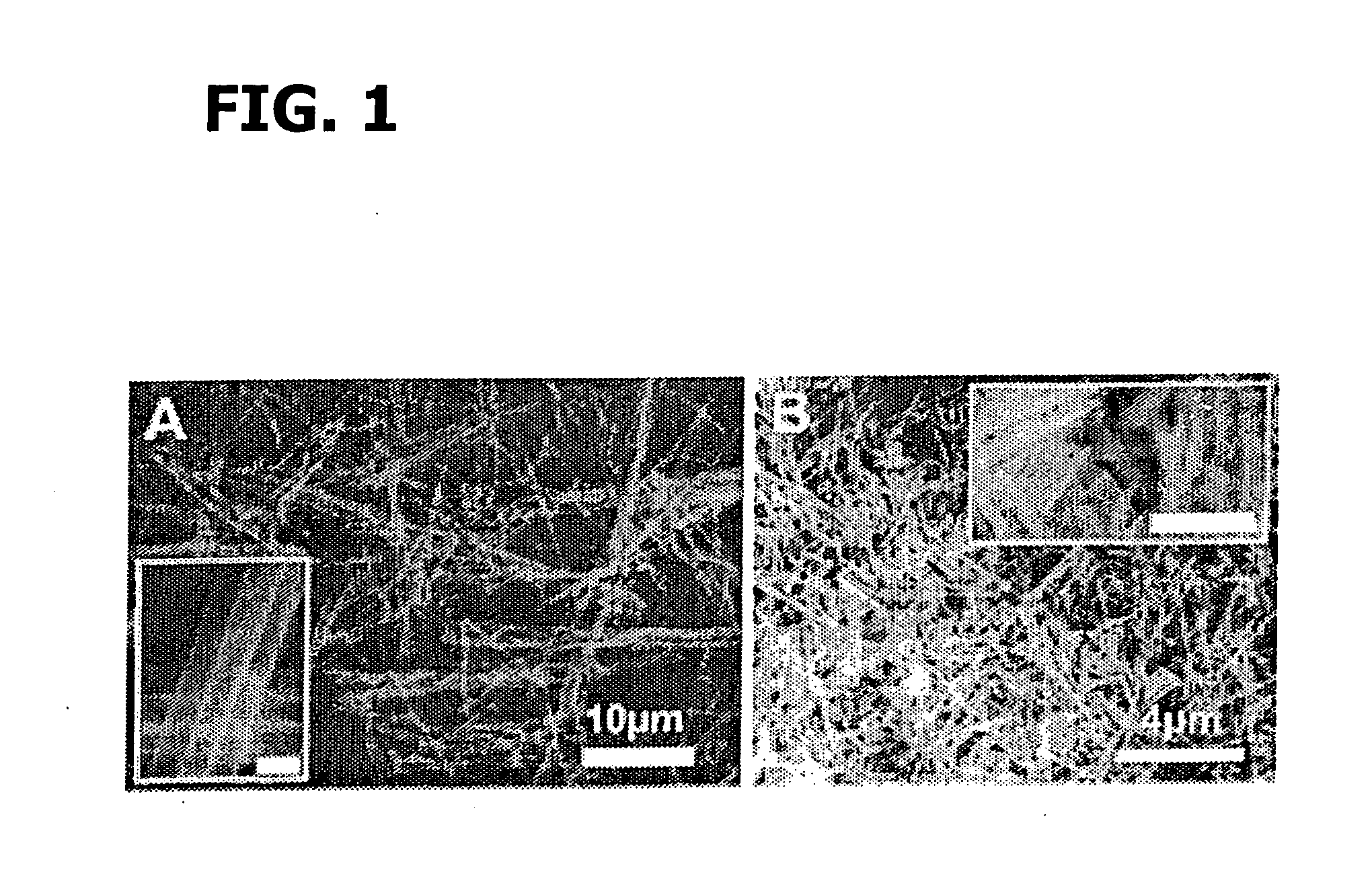

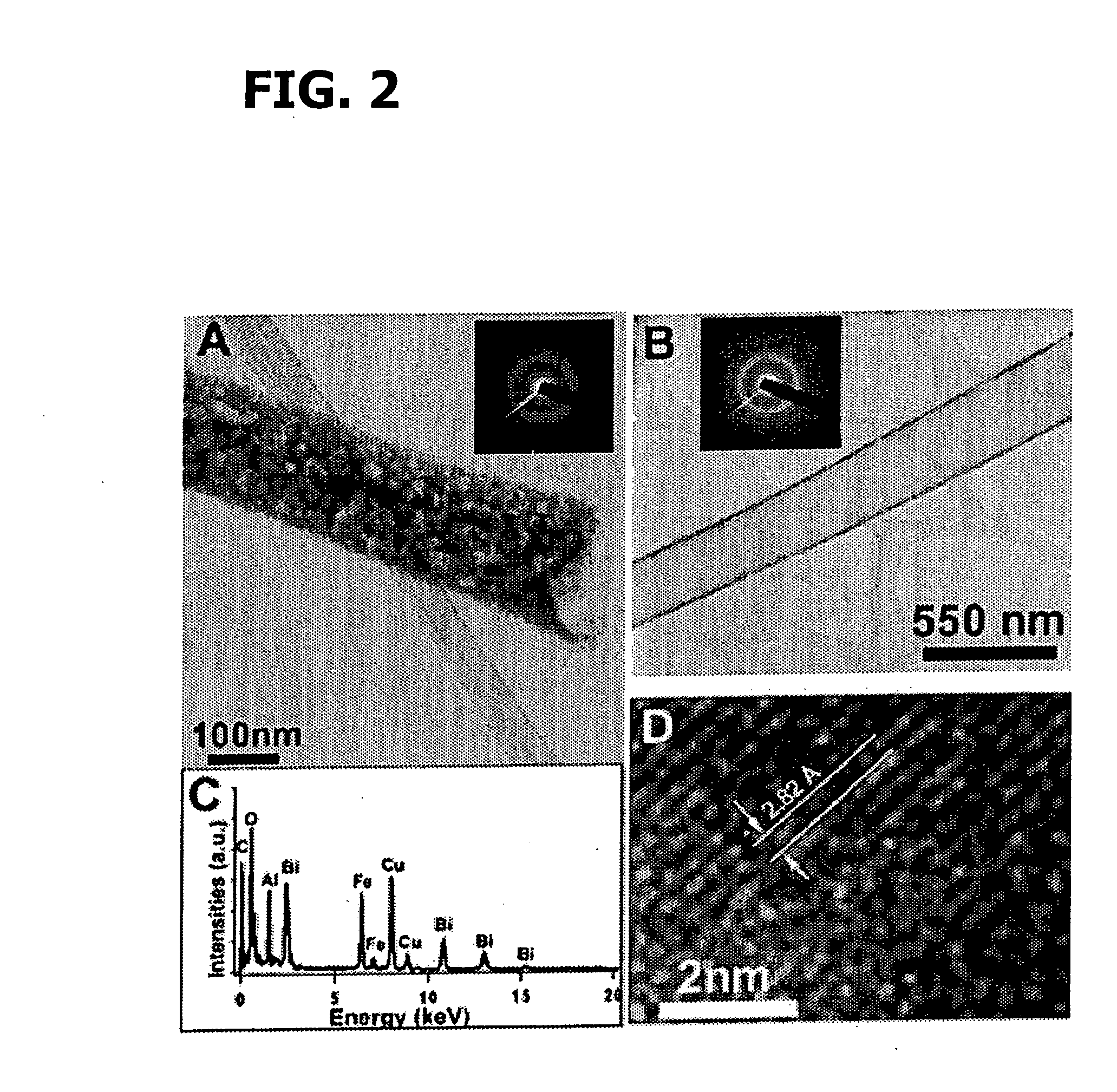

Ternary oxide nanostructures and methods of making same

InactiveUS20070138459A1Suitable for preparationFrom gel stateAlkaline earth titanatesNanostructureDislocation

A single crystalline ternary nanostructure having the formula AxByOz, wherein x ranges from 0.25 to 24, and y ranges from 1.5 to 40, and wherein A and B are independently selected from the group consisting of Ag, Al, As, Au, B, Ba, Br, Ca, Cd, Ce, Cl, Cm, Co, Cr, Cs, Cu, Dy, Er, Eu, F, Fe, Ga, Gd, Ge, Hf, Ho, I, In, Ir, K, La, Li, Lu, Mg, Mn, Mo, Na, Nb, Nd, Ni, Os, P, Pb, Pd, Pr, Pt, Rb, Re, Rh, Ru, S, Sb, Sc, Se, Si, Sm, Sn, Sr, Ta, Tb, Tc, Te, Ti, Ti, Tm, U, V, W, Y, Yb, and Zn, wherein the nanostructure is at least 95% free of defects and / or dislocations.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

GaN field-effect transistor and method of manufacturing the same

InactiveUS20010040246A1Reduce dislocation densityTransistorPolycrystalline material growthLateral overgrowthEngineering

There are provided a GaN field effect transistor (FET) exhibiting an excellent breakdown voltage owing to the high quality of GaN crystal in a region where the electric lines of force concentrate during operation of the same, and a method of manufacturing the same. The FET has a layer structure formed of a plurality of GaN epitaxial layers. A gate electrode and a source electrode are disposed on the surface of the layer structure, and a drain electrode is disposed on the reverse surface of the same. A region of the layer structure in which the electric lines of force concentrate during operation of the FET has a reduced dislocation density compared with the other regions in the layer structure. The GaN FET is manufactured by forming, on a crystal-growing substrate having a surface formed with a plane pattern of a material other than a GaN-based material in an identical design to a plane pattern of an electrode determining the region in which the electric lines of force concentrate, a plurality of GaN epitaxial layers, one upon another, by using the epitaxial lateral overgrowth technique, thereby forming a layer structure, and then forming operational electrodes on the surface of the layer structure.

Owner:FURUKAWA ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com