Patents

Literature

2642 results about "Edge surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

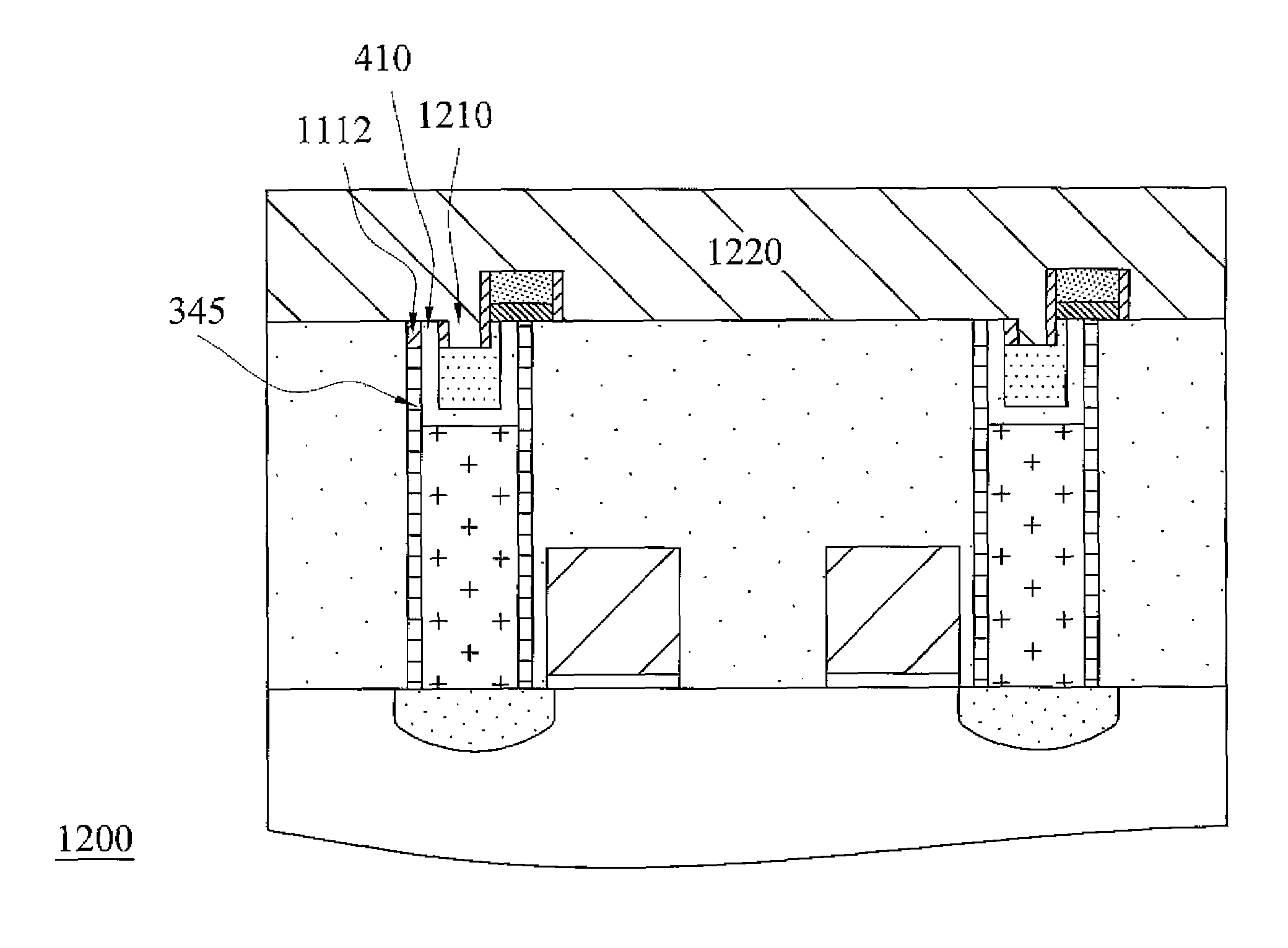

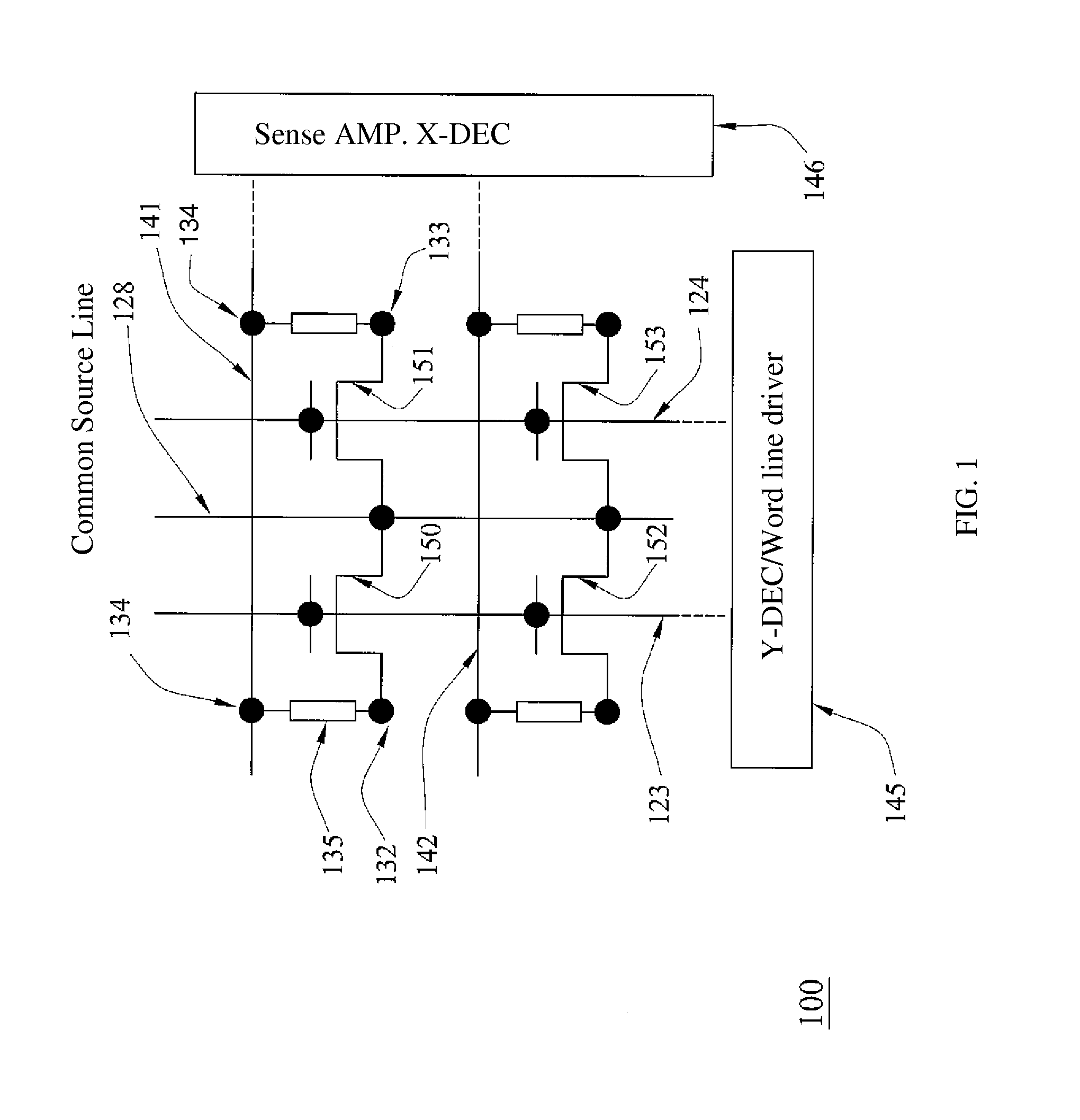

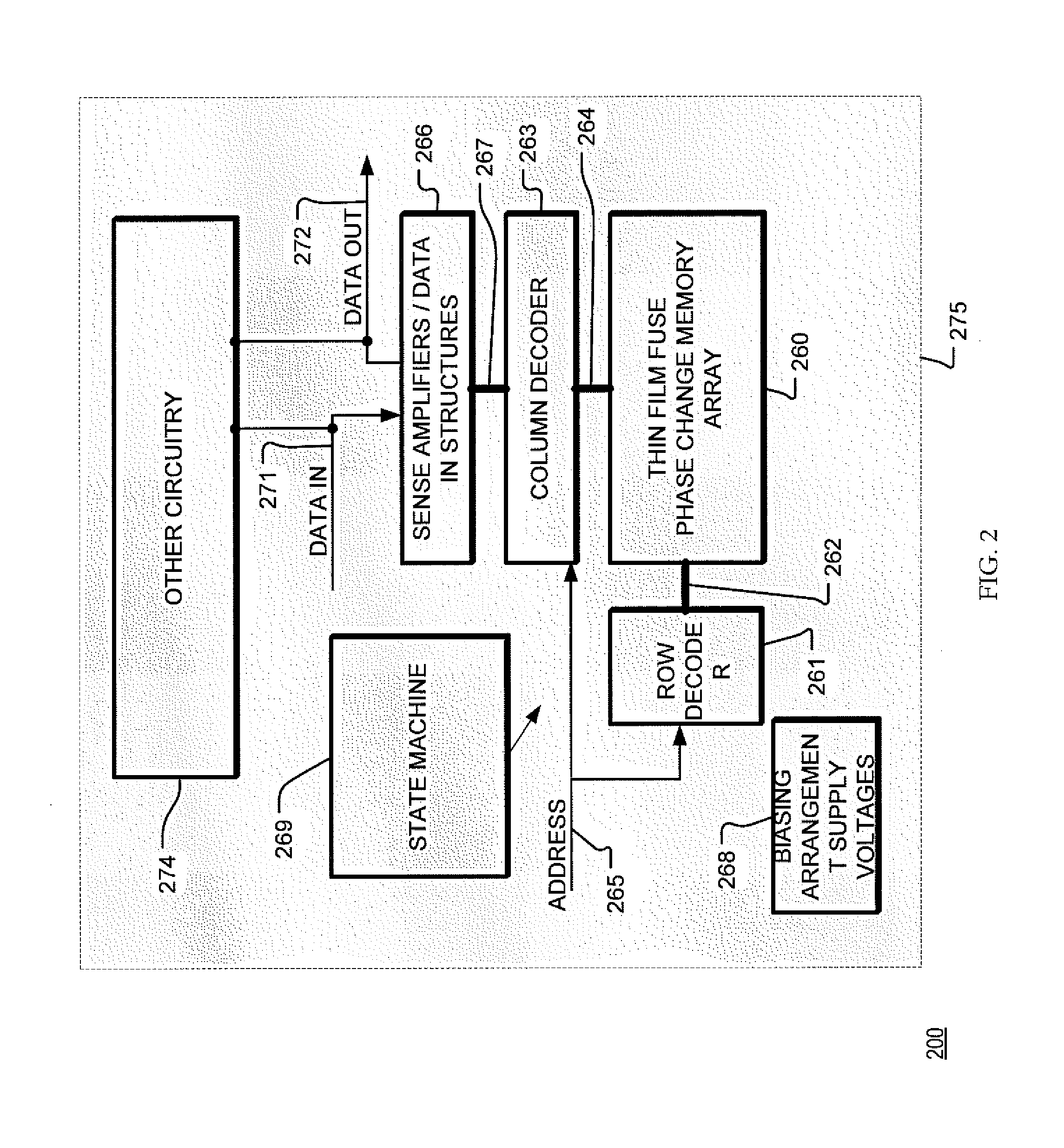

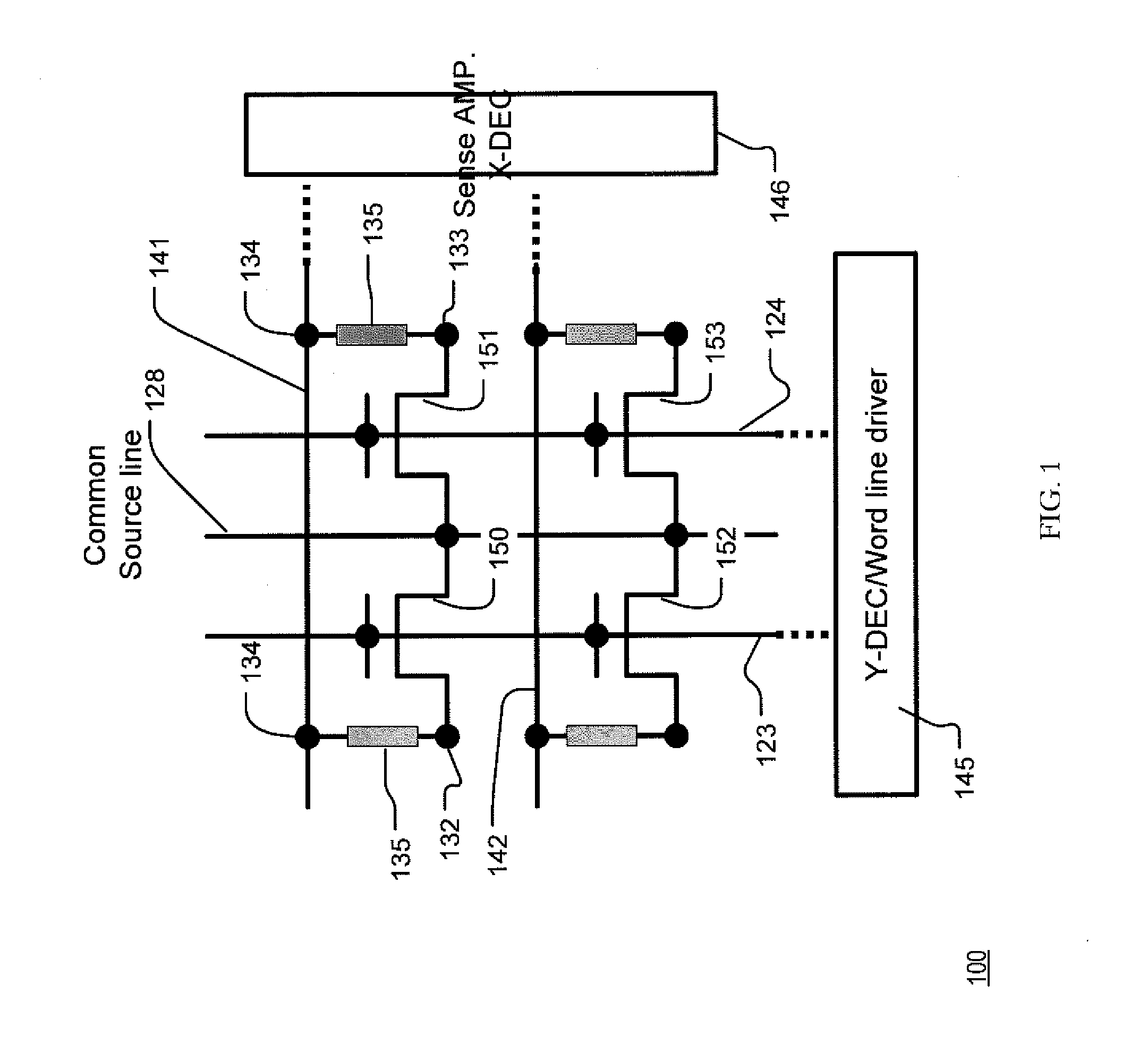

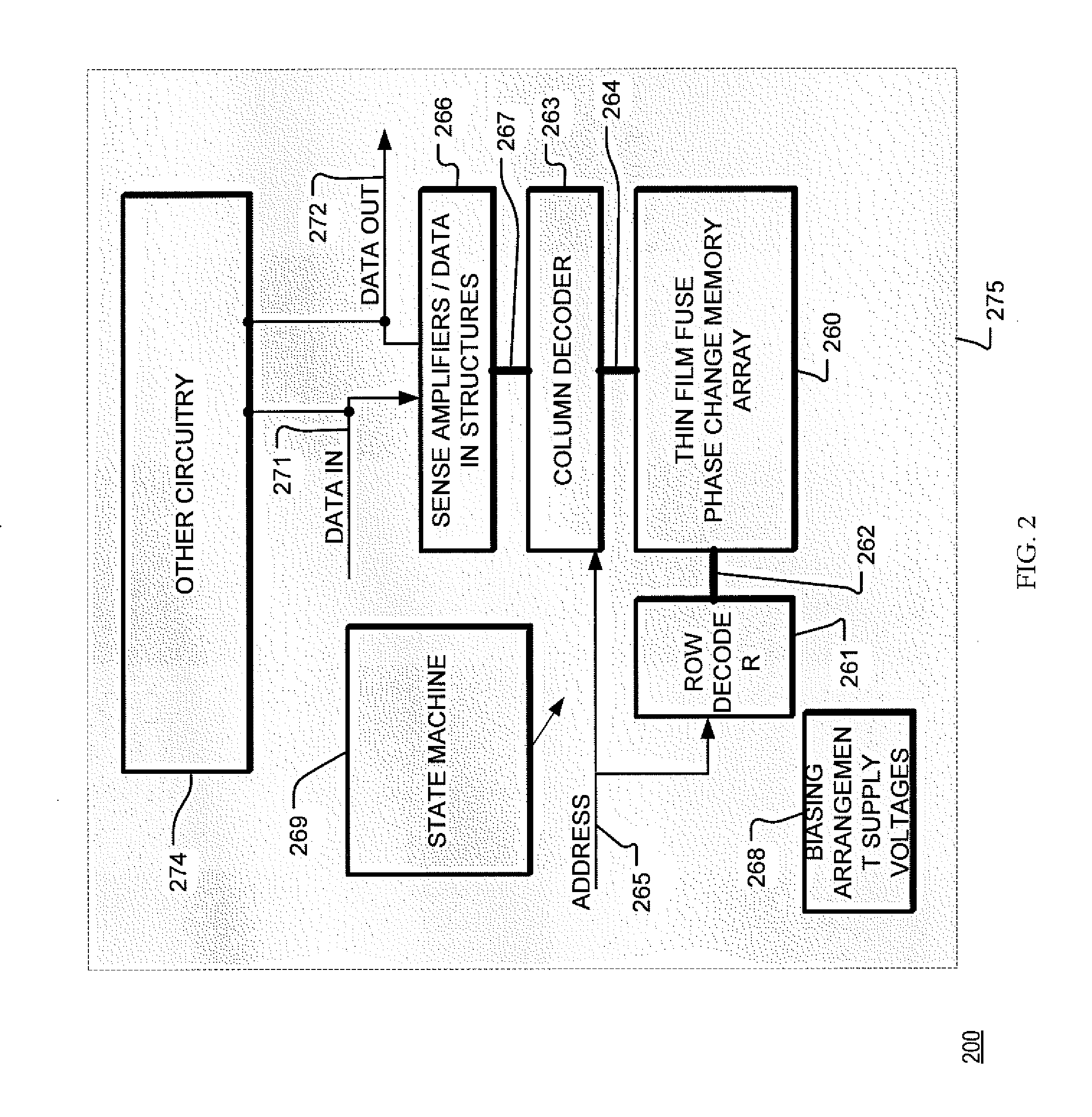

Bridge resistance random access memory device with a singular contact structure

ActiveUS7608848B2Reduced dimensionSolid-state devicesBulk negative resistance effect devicesBit lineEdge surface

A resistance random access memory in a bridge structure is disclosed that comprises a contact structure where first and second electrodes are located within the contact structure. The first electrode has a circumferential extending shape, such as an annular shape, surrounding an inner wall of the contact structure. The second electrode is located within an interior of the circumferential extending shape and separated from the first electrode by an insulating material. A resistance memory bridge is in contact with an edge surface of the first and second electrodes. The first electrode in the contact structure is connected to a transistor and the second electrode in the contact structure is connected to a bit line. A bit line is connected to the second electrode by a self-aligning process.

Owner:MACRONIX INT CO LTD

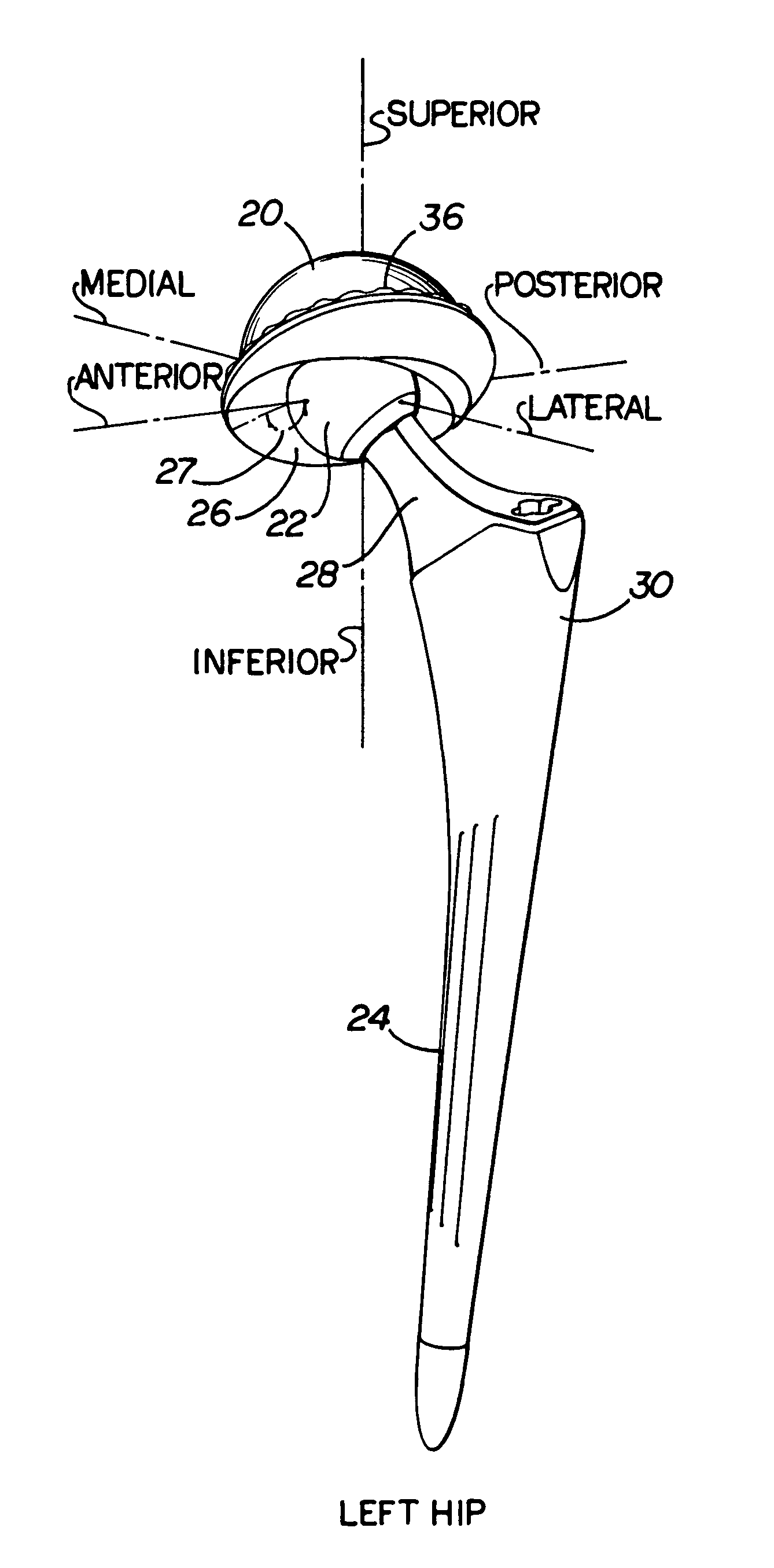

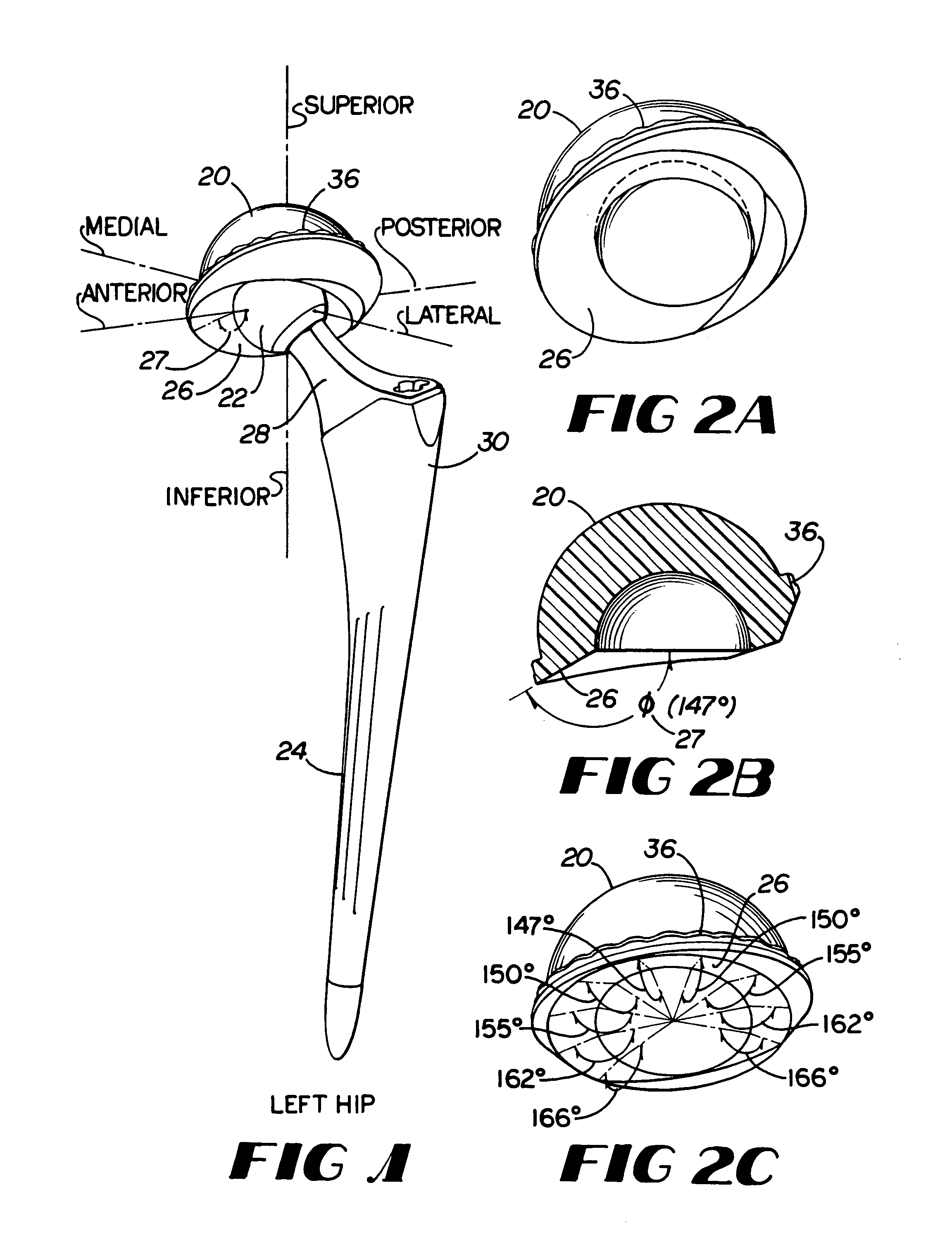

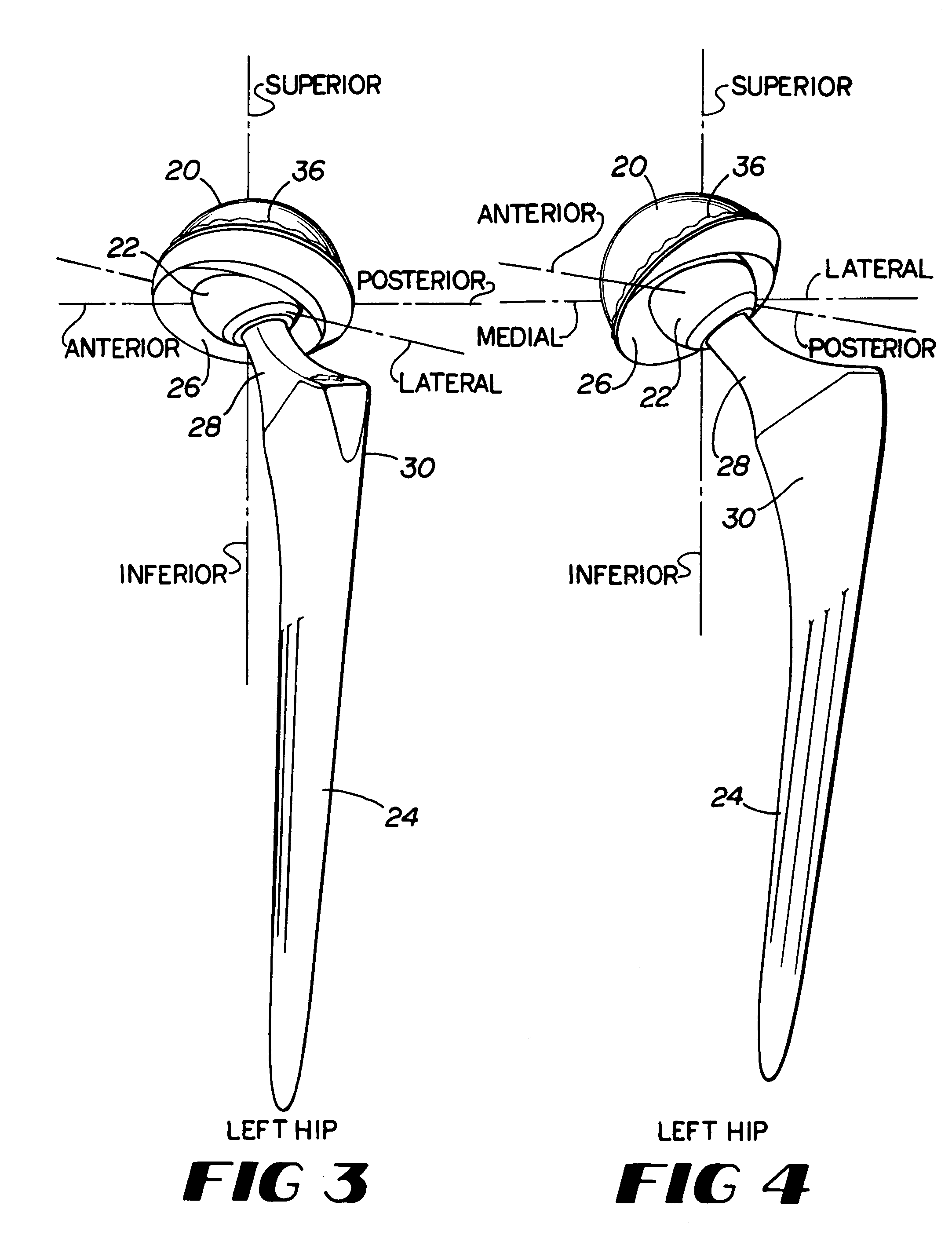

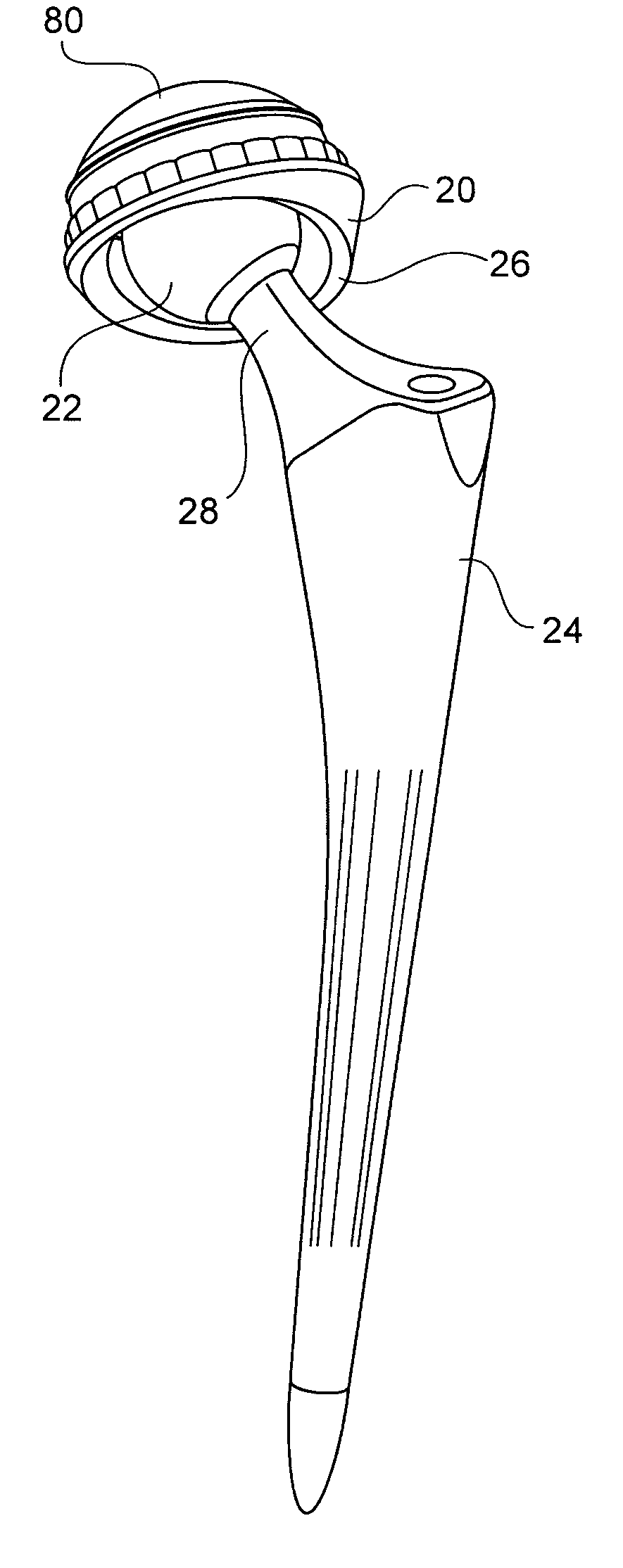

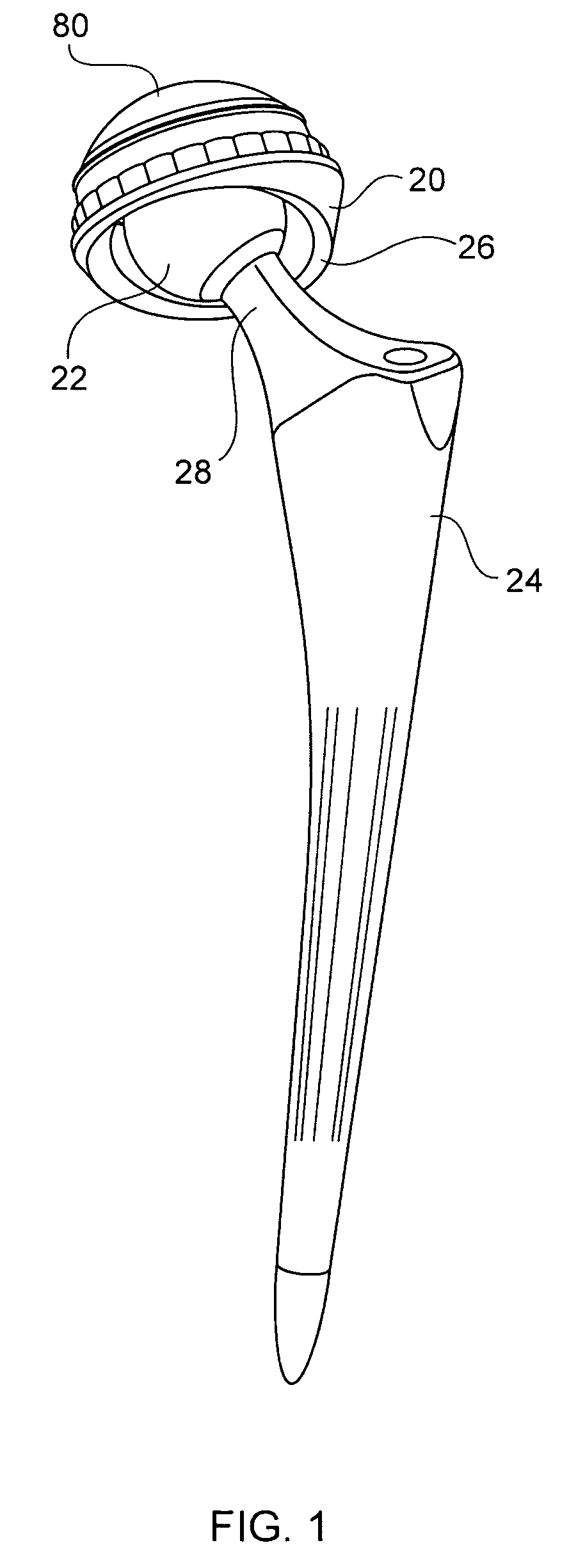

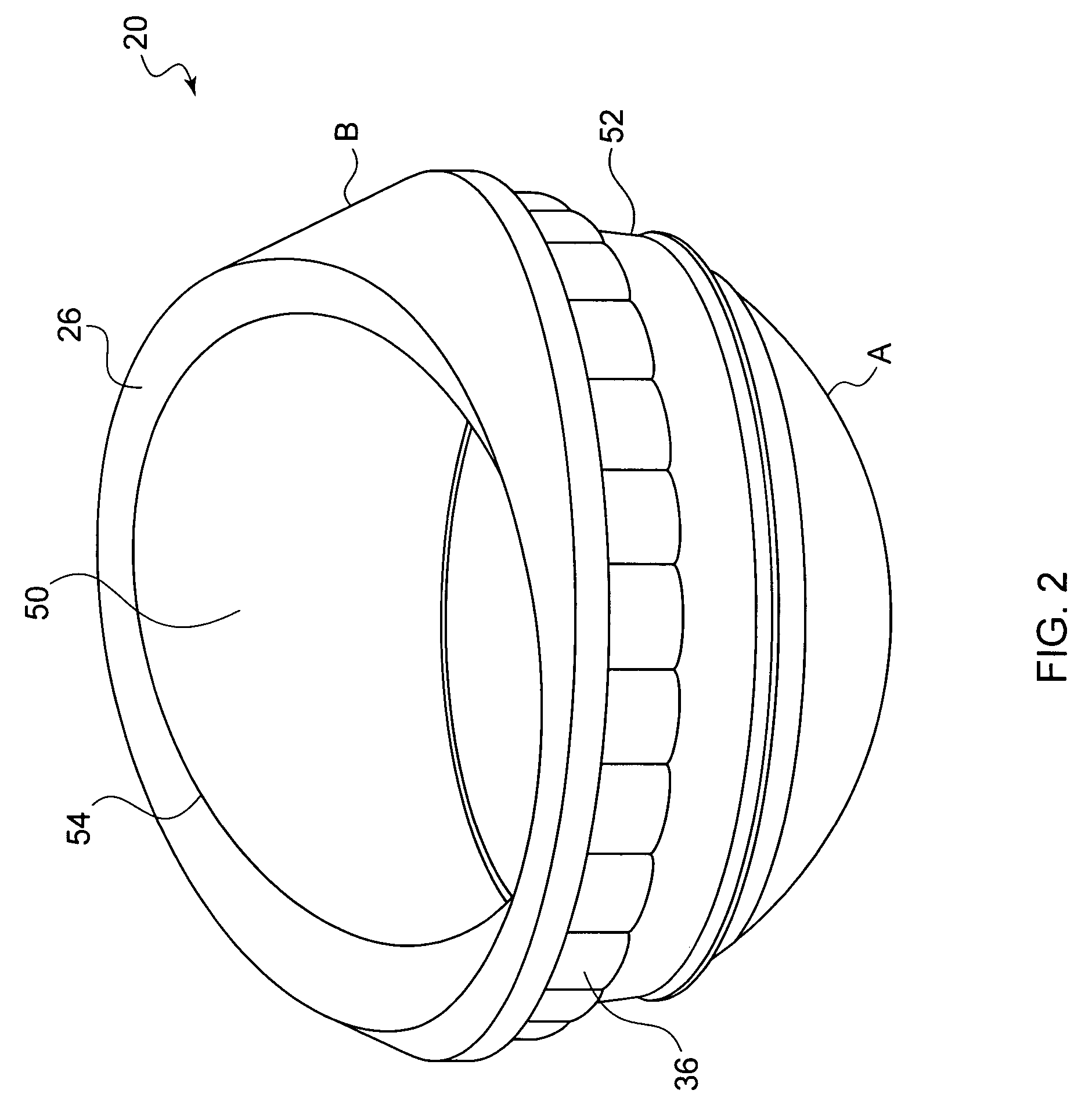

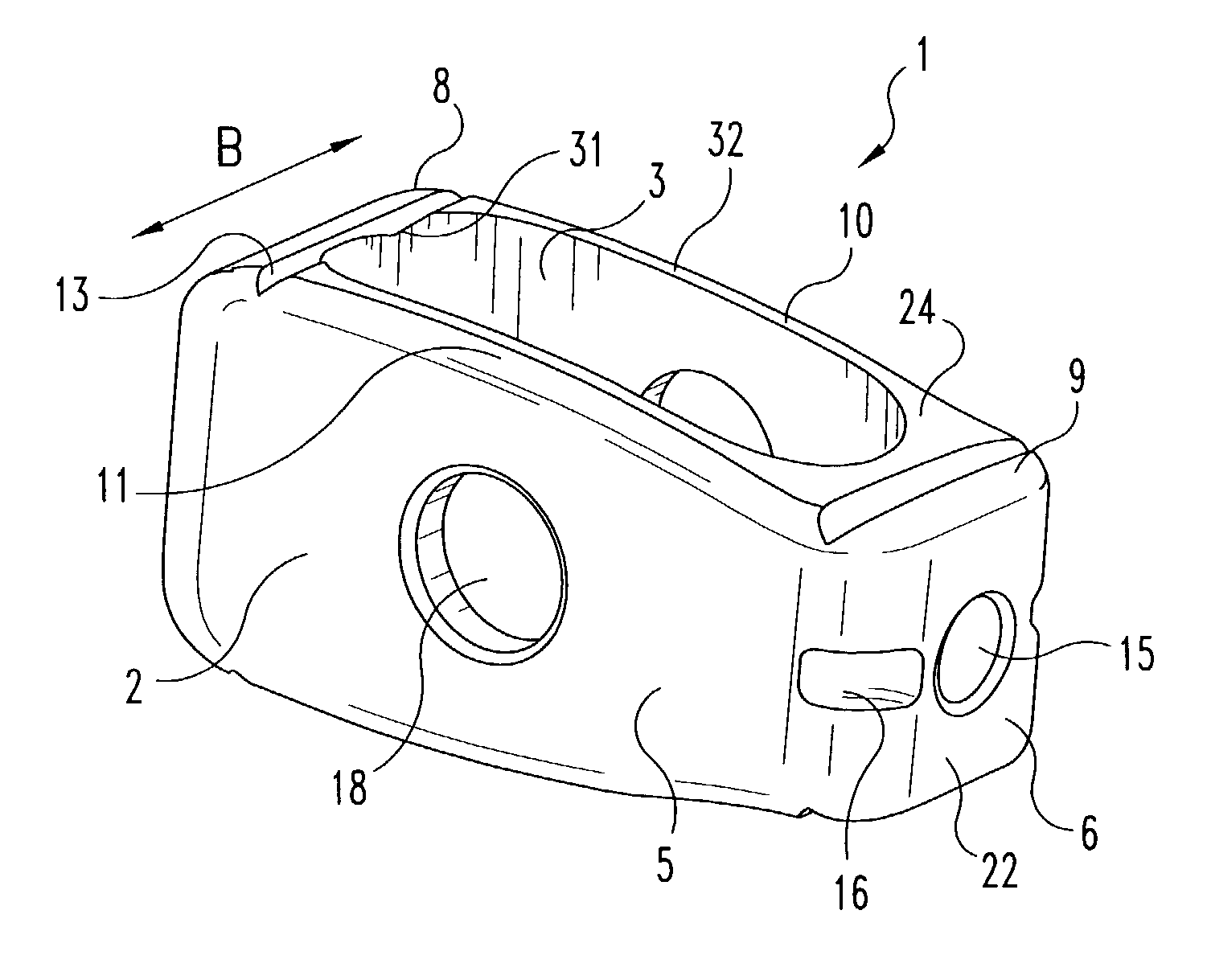

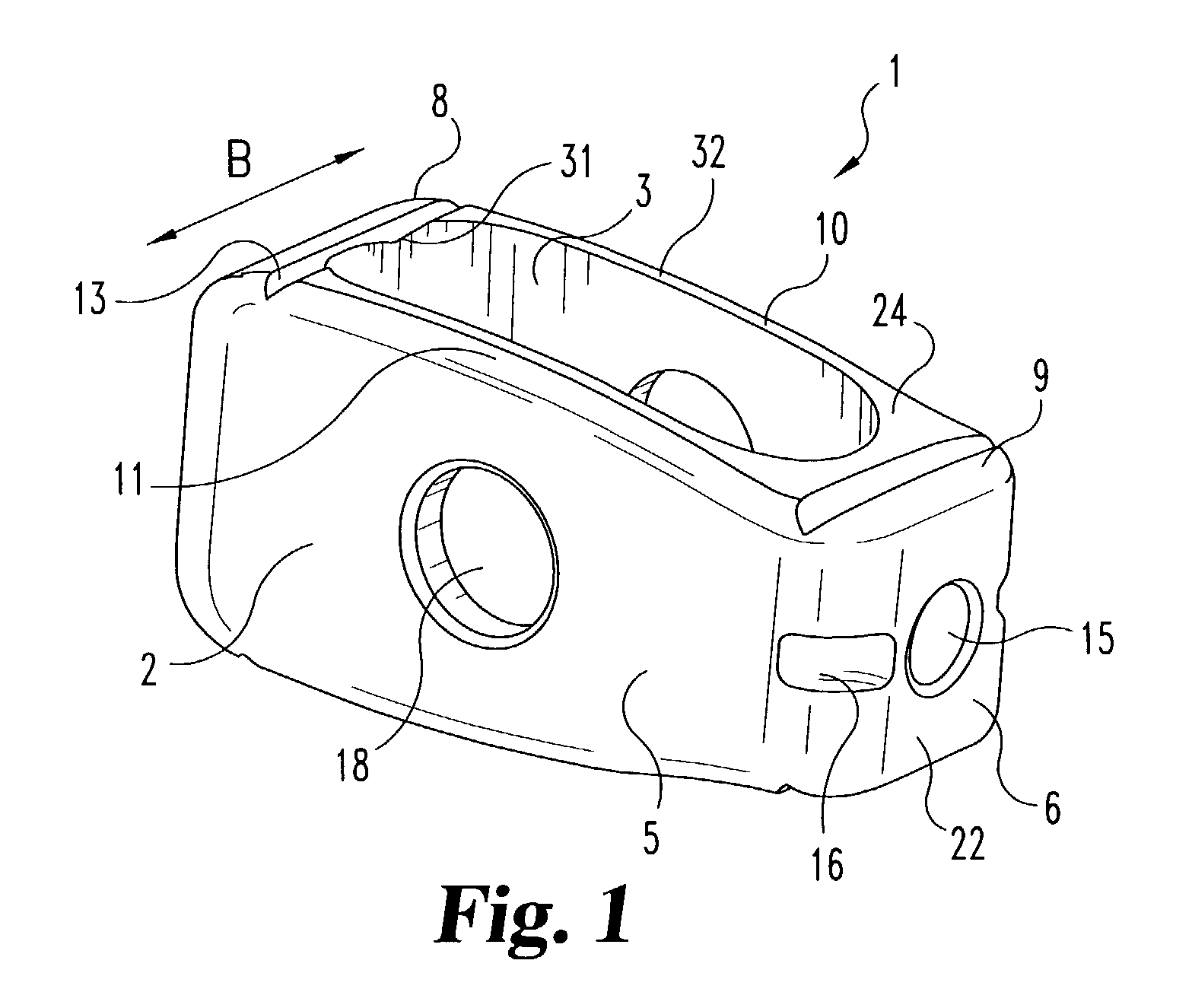

Variable geometry rim surface acetabular shell liner

InactiveUS7074241B2Extended range of motionMinimize interferenceJoint implantsFemoral headsEdge surfaceCoxal joint

An acetabular shell liner having a variable rim surface geometry, which improves range of motion of the femoral component within the liner and decreases the incidence of dislocation and subluxation, and methods of making and using the acetabular shell liner. Prosthetic devices, more particularly hip joint prostheses, containing the acetabular shell liner having a variable rim surface geometry are also provided.

Owner:SMITH & NEPHEW INC

Variable geometry rim surface acetabular shell liner

InactiveUS7682398B2Minimize interferenceExtended range of motionJoint implantsFemoral headsEdge surfaceRange of motion

There is provided an acetabular shell liner, and particularly a constrained liner, having a variable rim surface geometry to improve the range of motion of a femoral component within the liner and decrease the incidence of dislocation and subluxation. There are also provided methods of making and using the acetabular shell liner. Prosthetic devices, and particularly hip joint prostheses, containing the acetabular shell liner having a variable rim surface geometry are also provided.

Owner:SMITH & NEPHEW INC

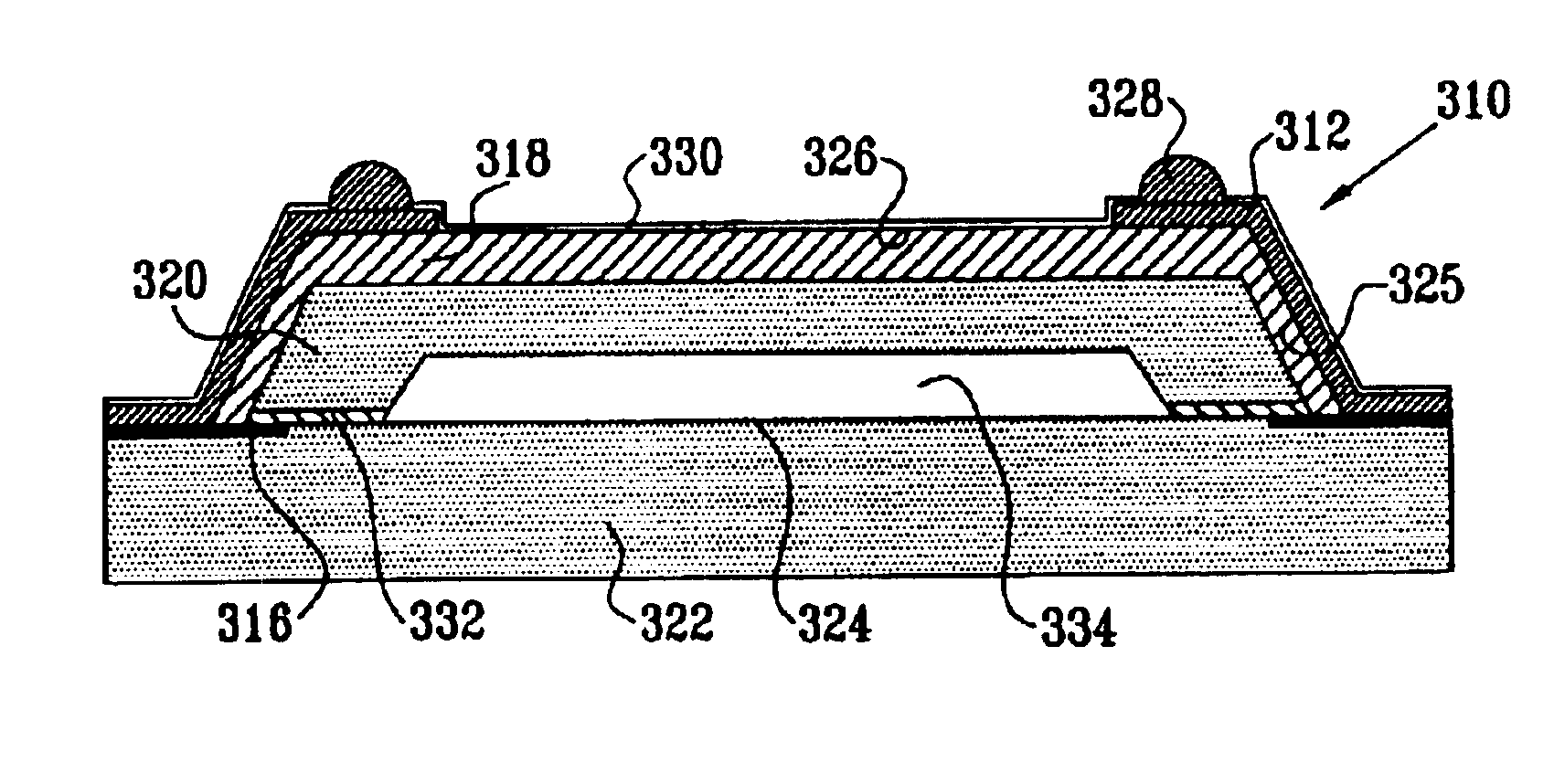

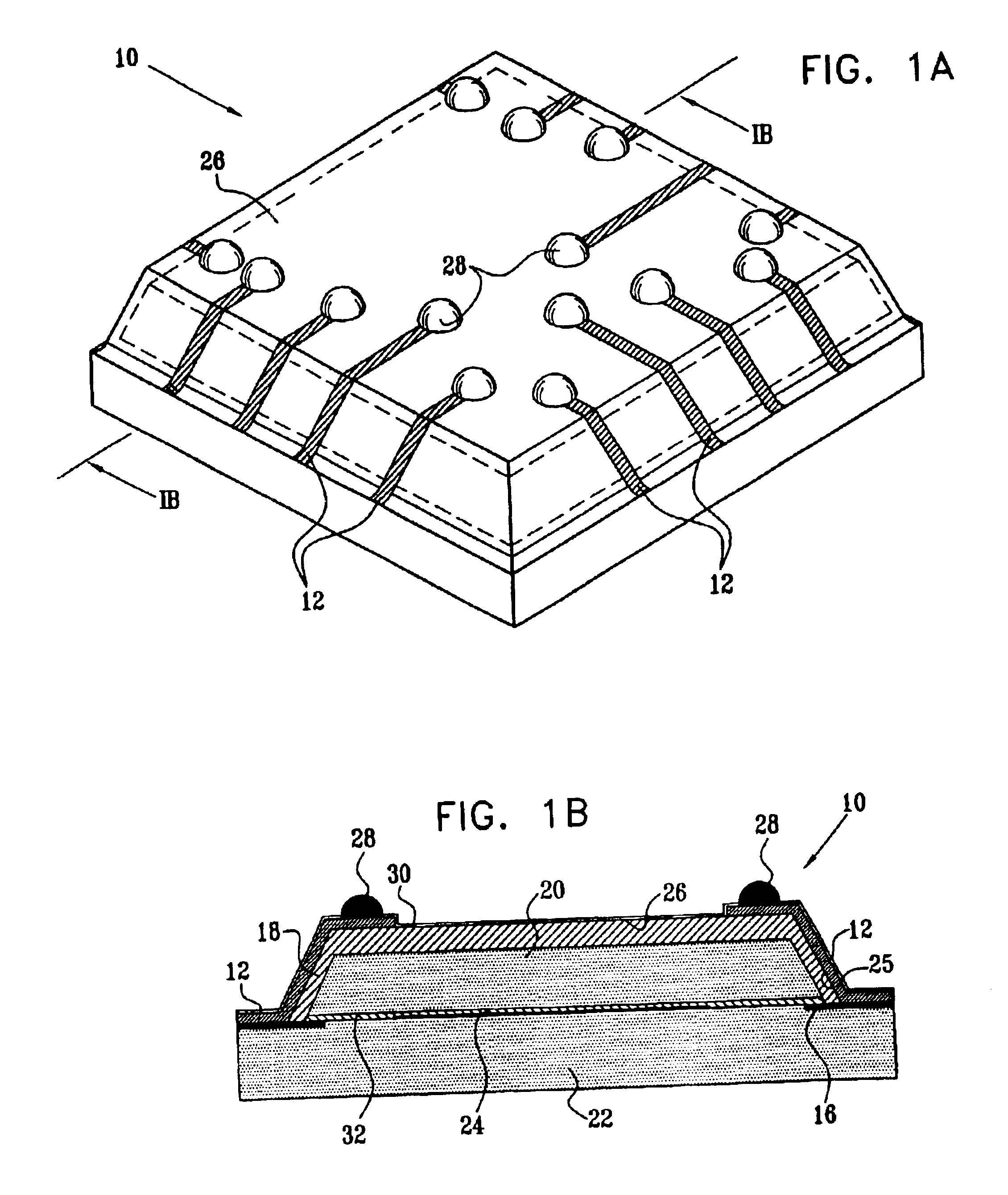

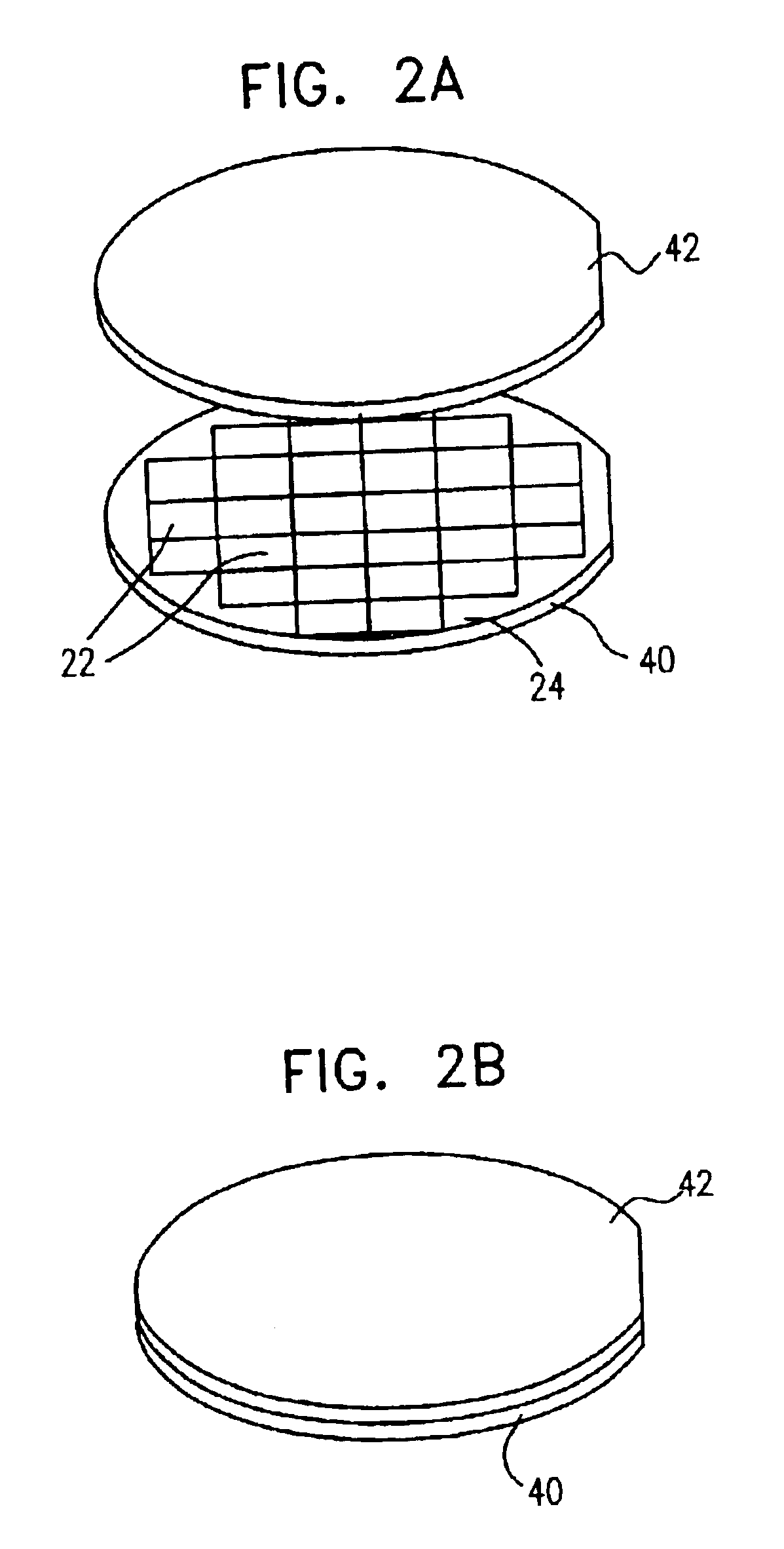

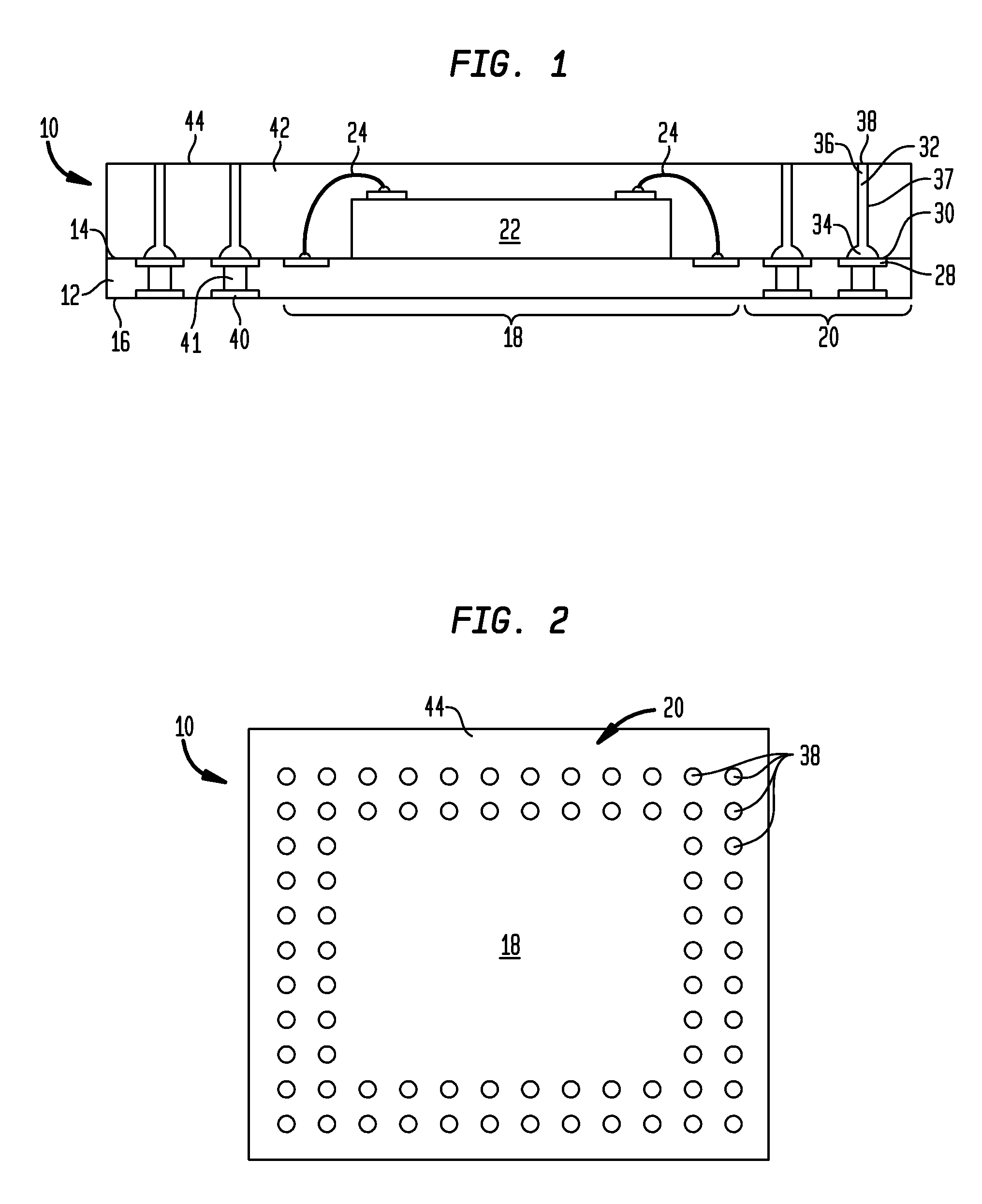

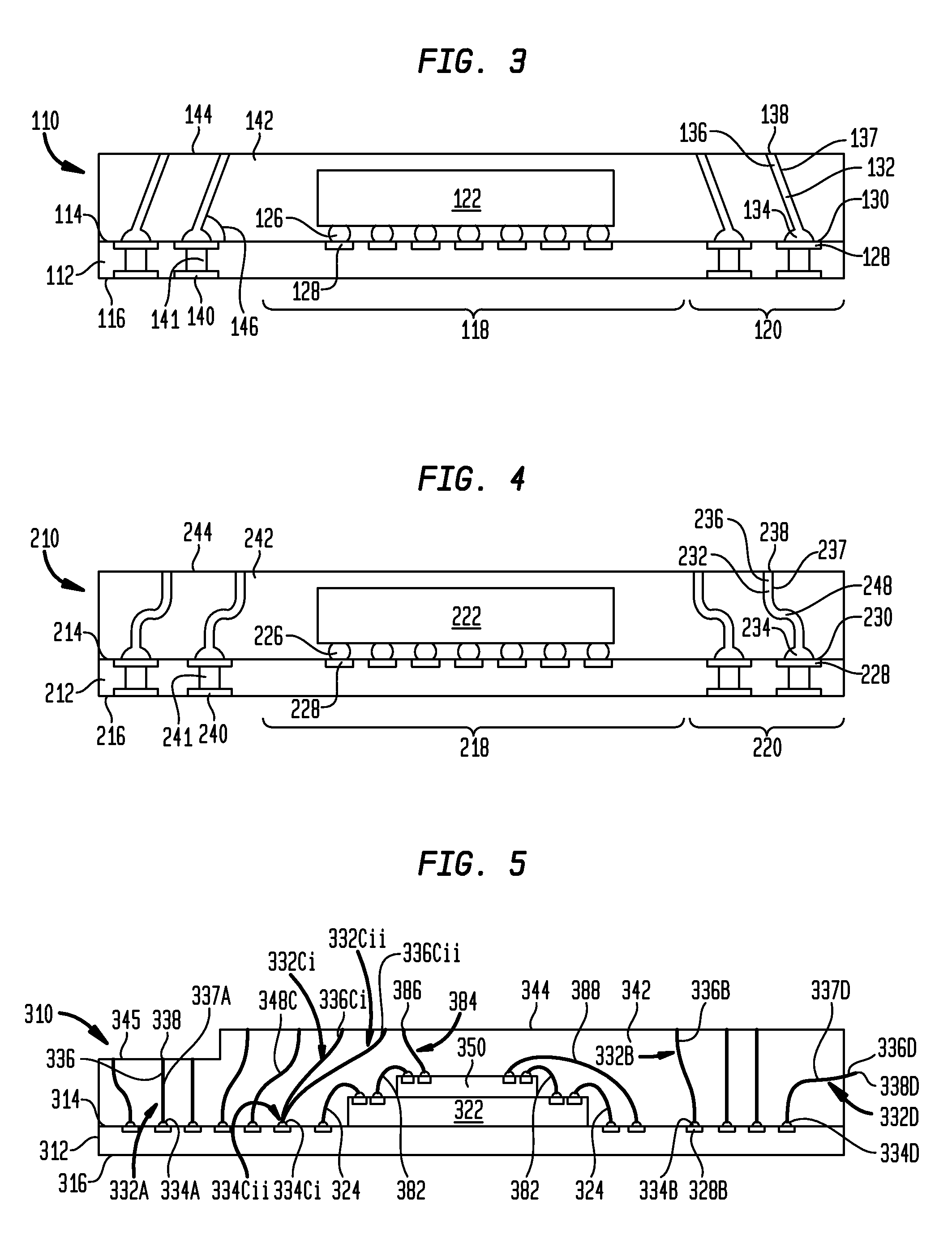

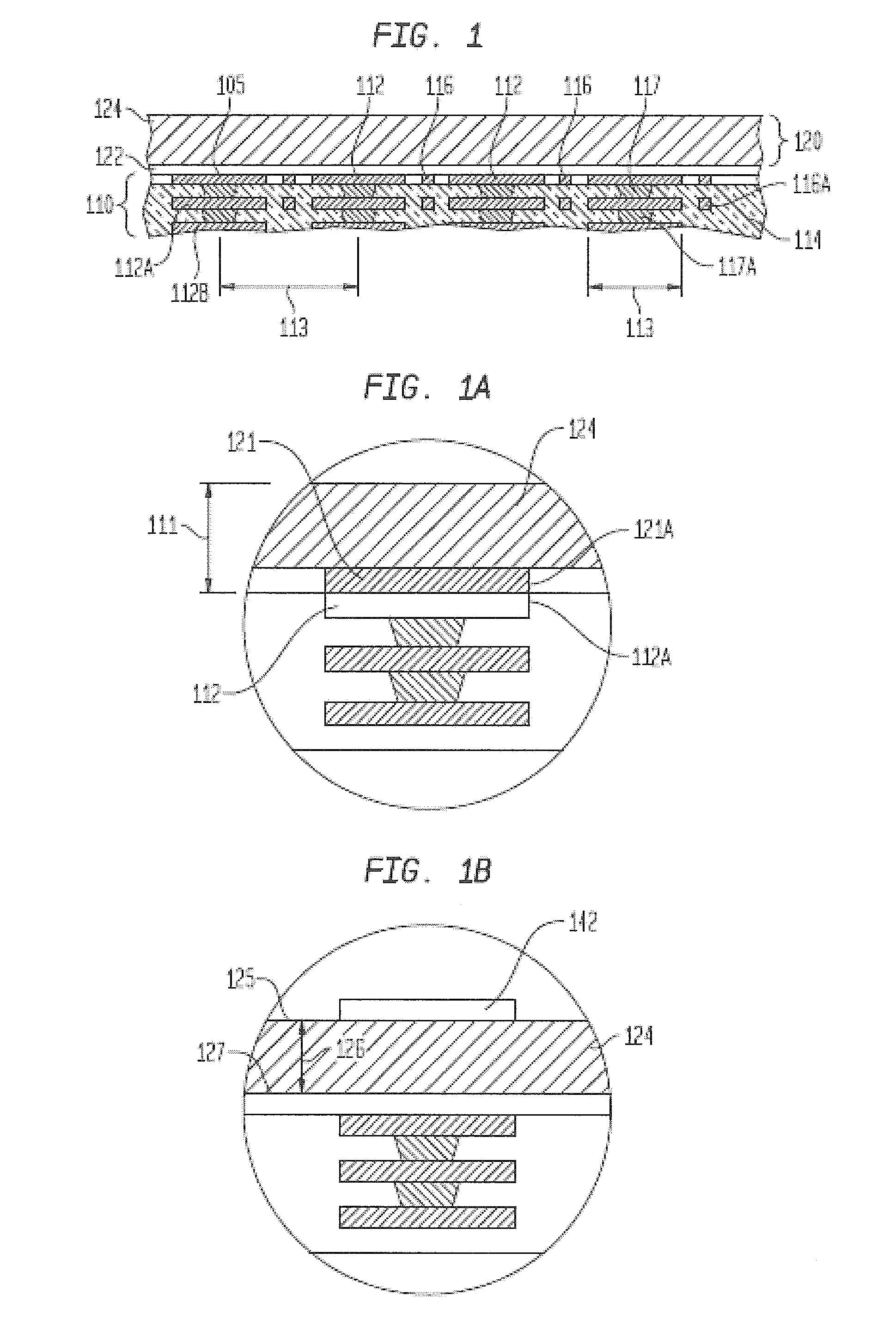

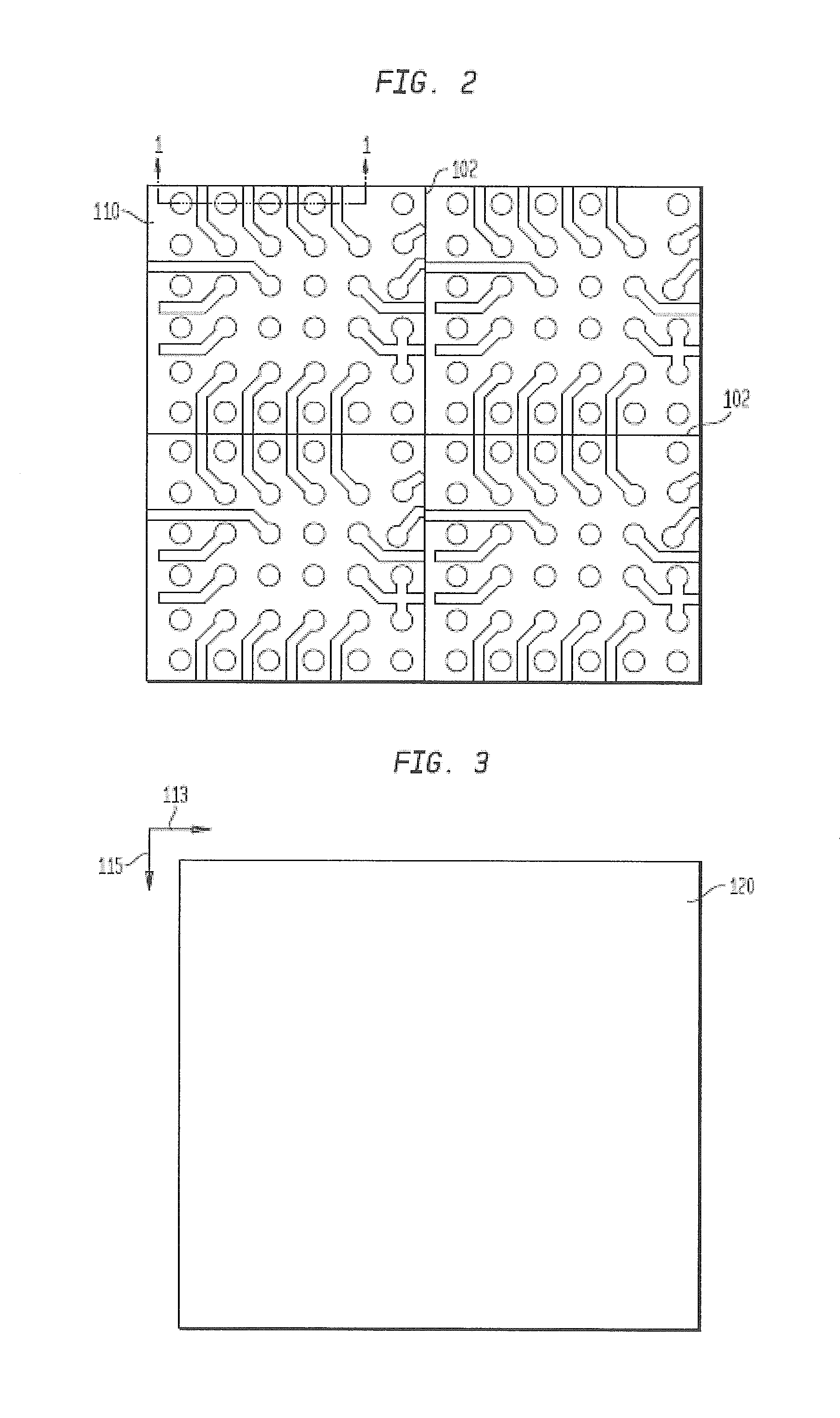

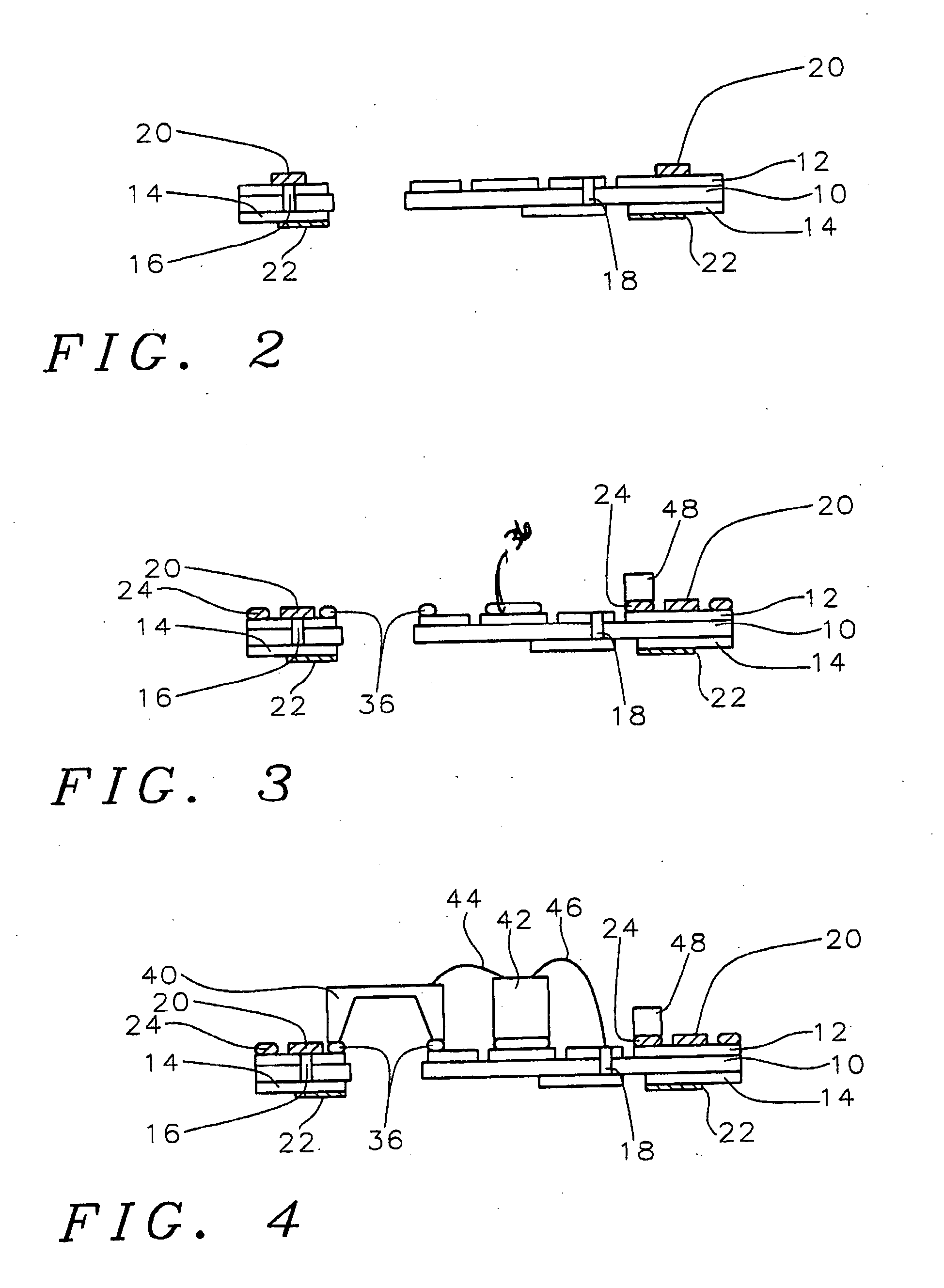

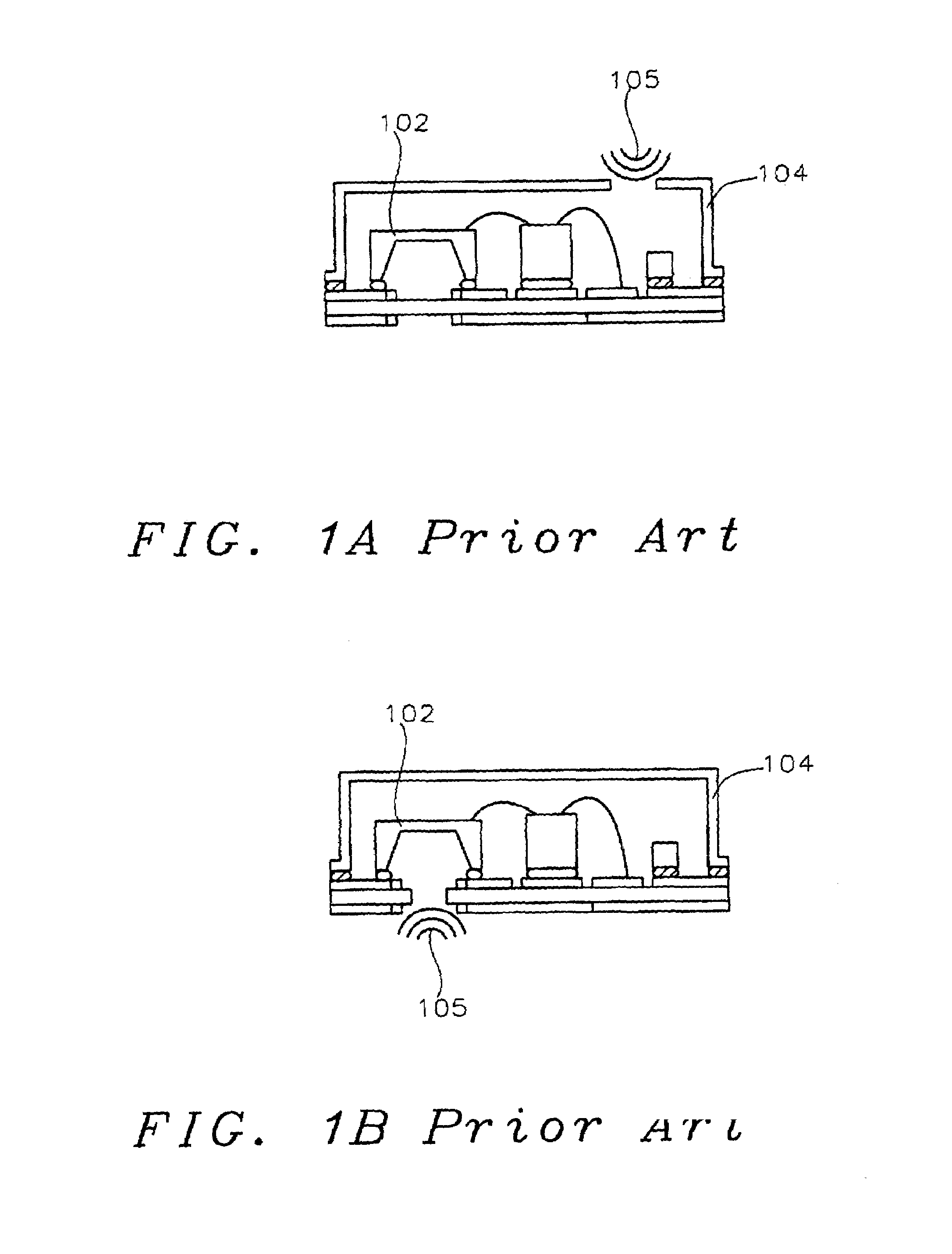

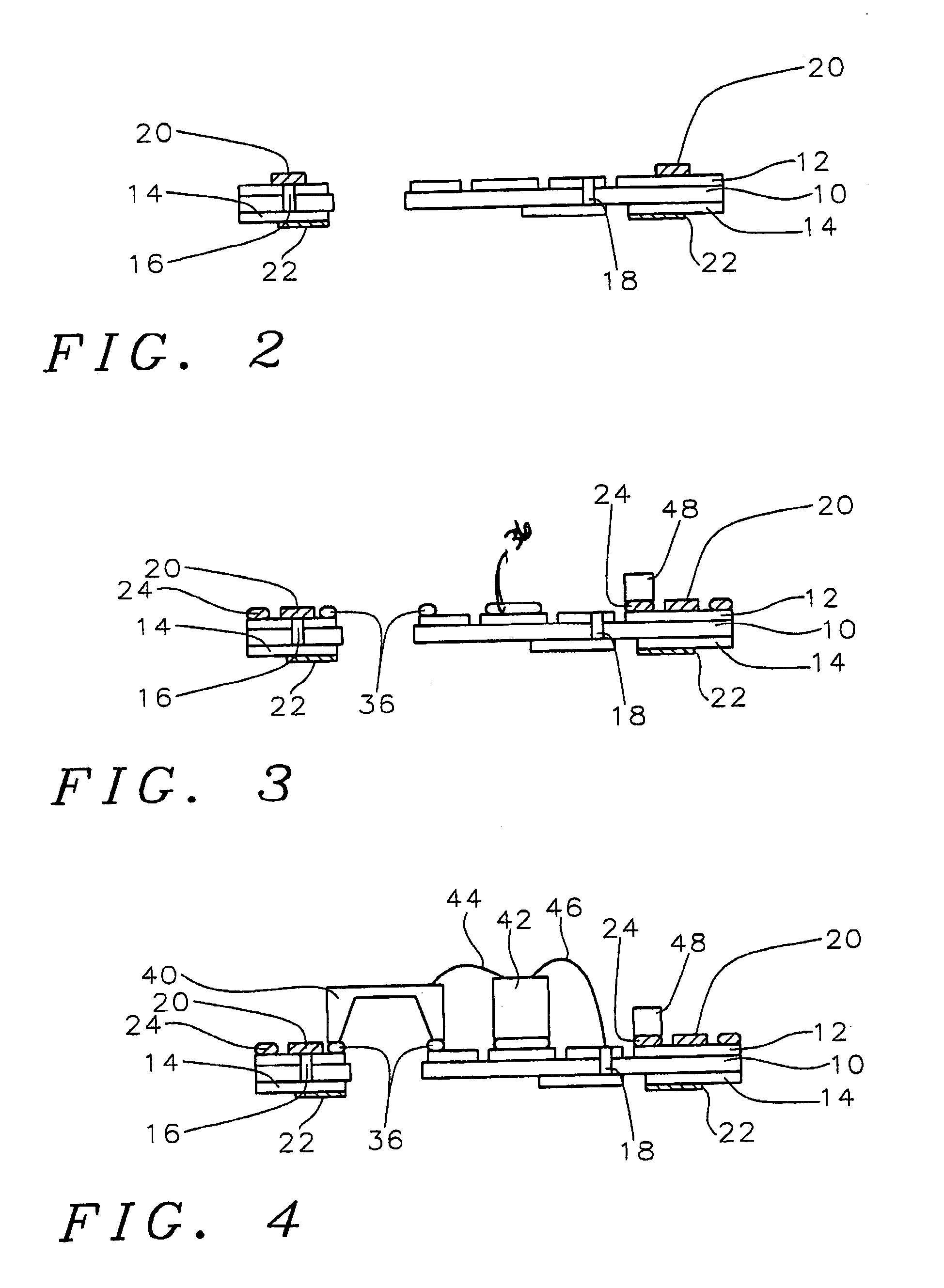

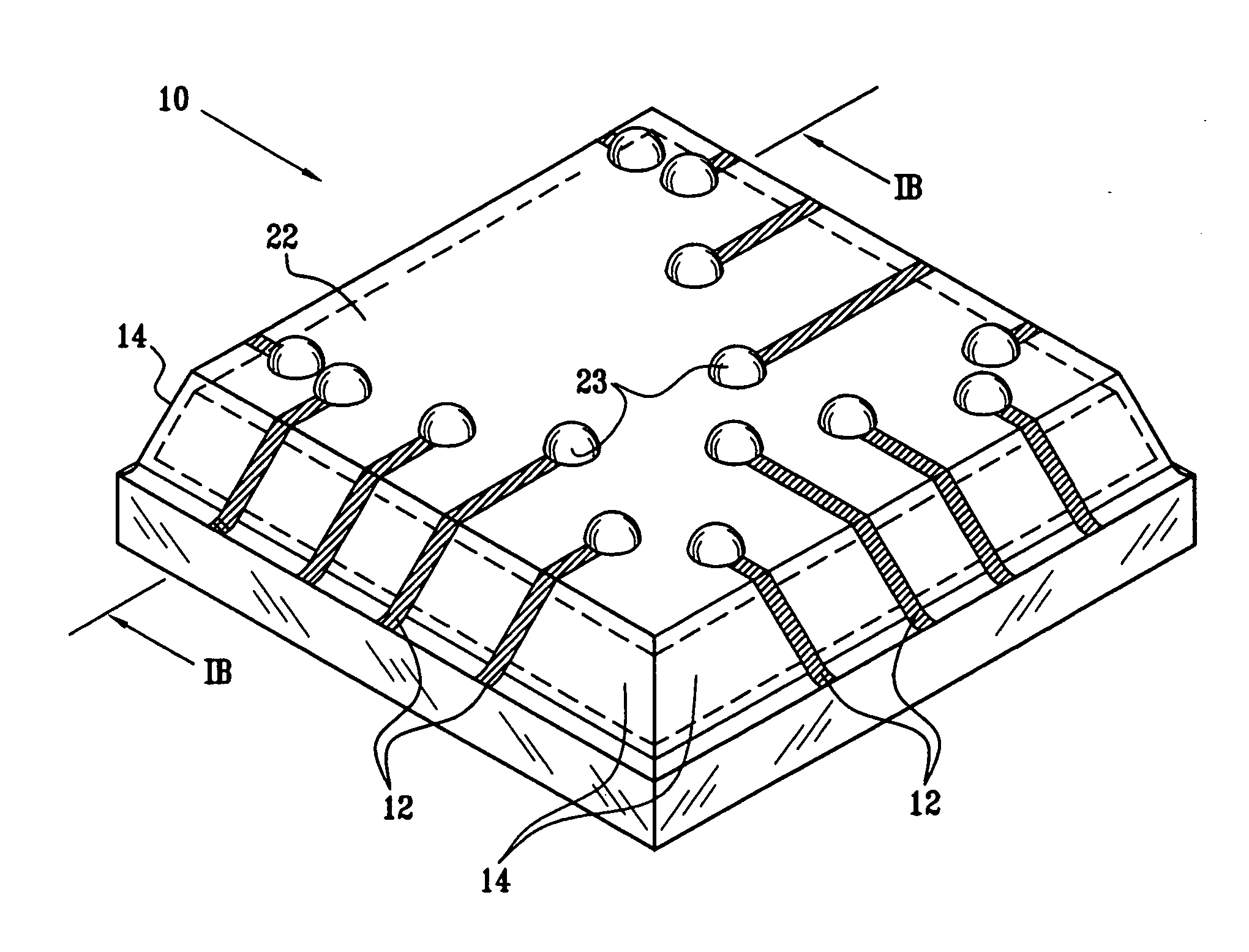

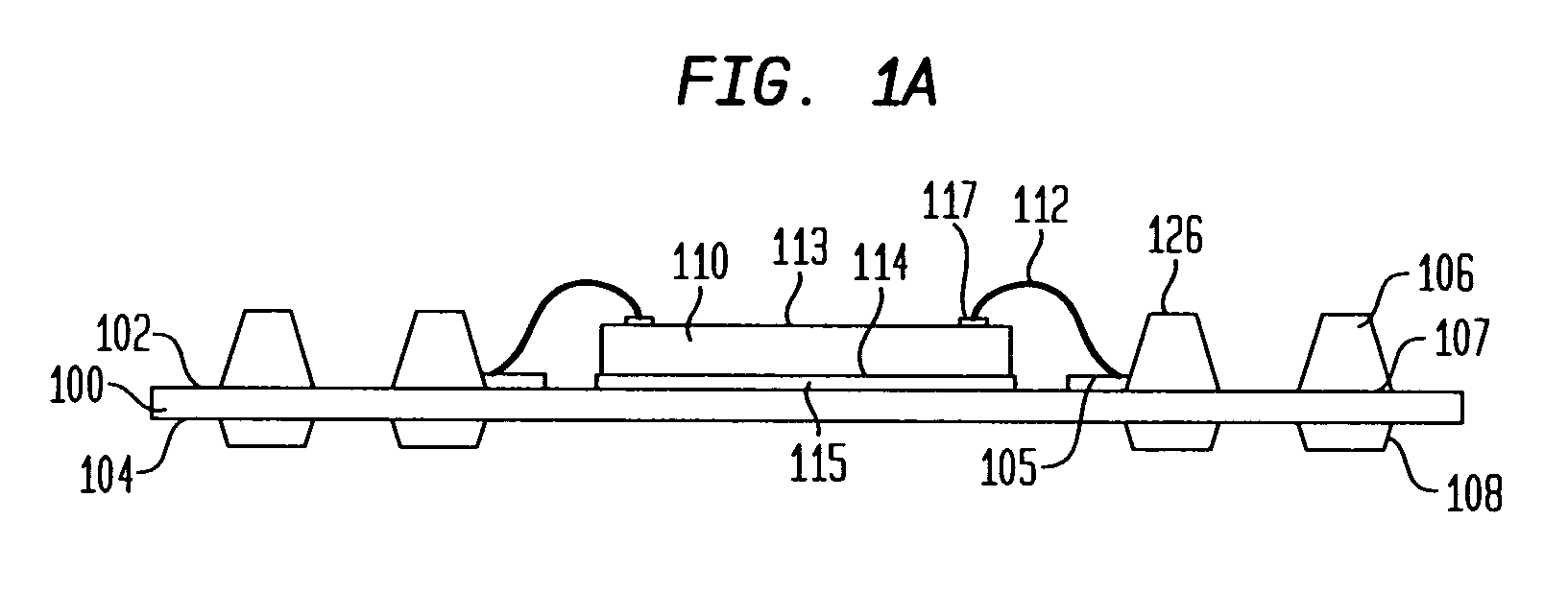

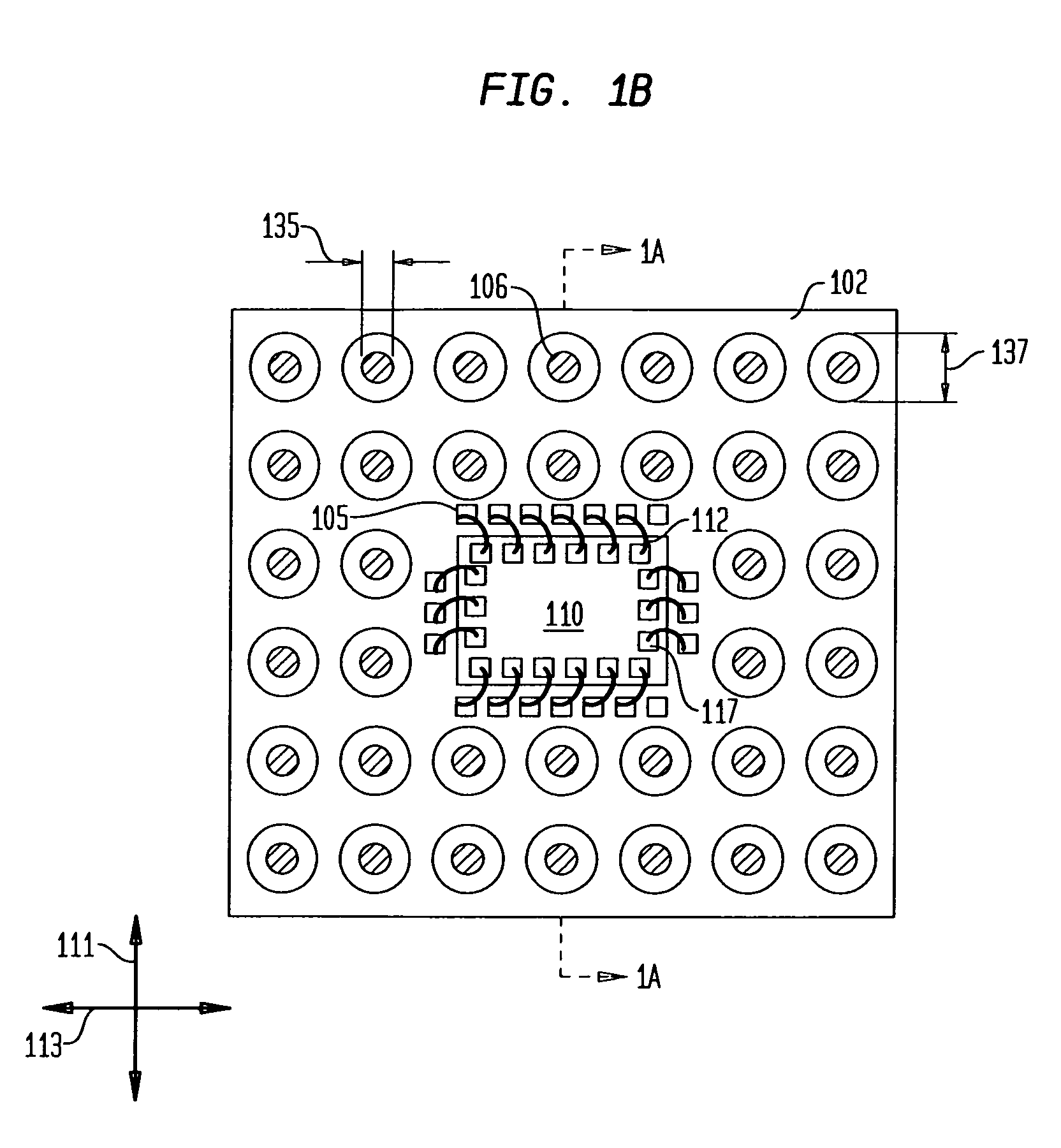

Methods and apparatus for packaging integrated circuit devices

InactiveUS6972480B2Semiconductor/solid-state device detailsSolid-state devicesEdge surfaceEngineering

An integrally packaged integrated circuit device including an integrated circuit die including a crystalline substrate having first and second generally planar surfaces and edge surfaces and an active surface formed on the first generally planar surface, at least one chip scale packaging layer formed over the active surface and at least one electrical contact formed over the at least one chip scale packaging layer, the at least one electrical contact being connected to circuitry on the active surface by at least one pad formed on the first generally planar surface.

Owner:INVENSAS CORP +1

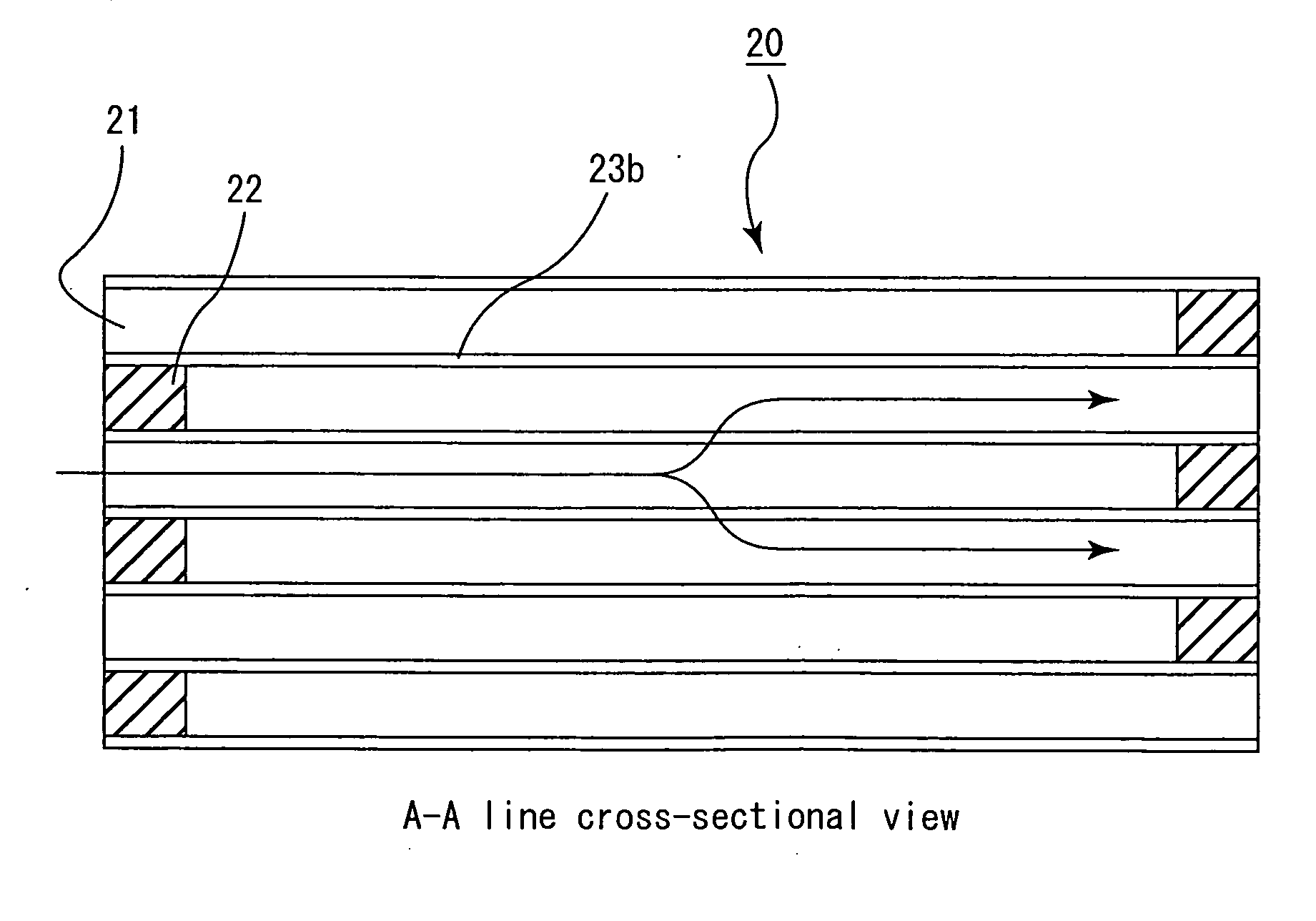

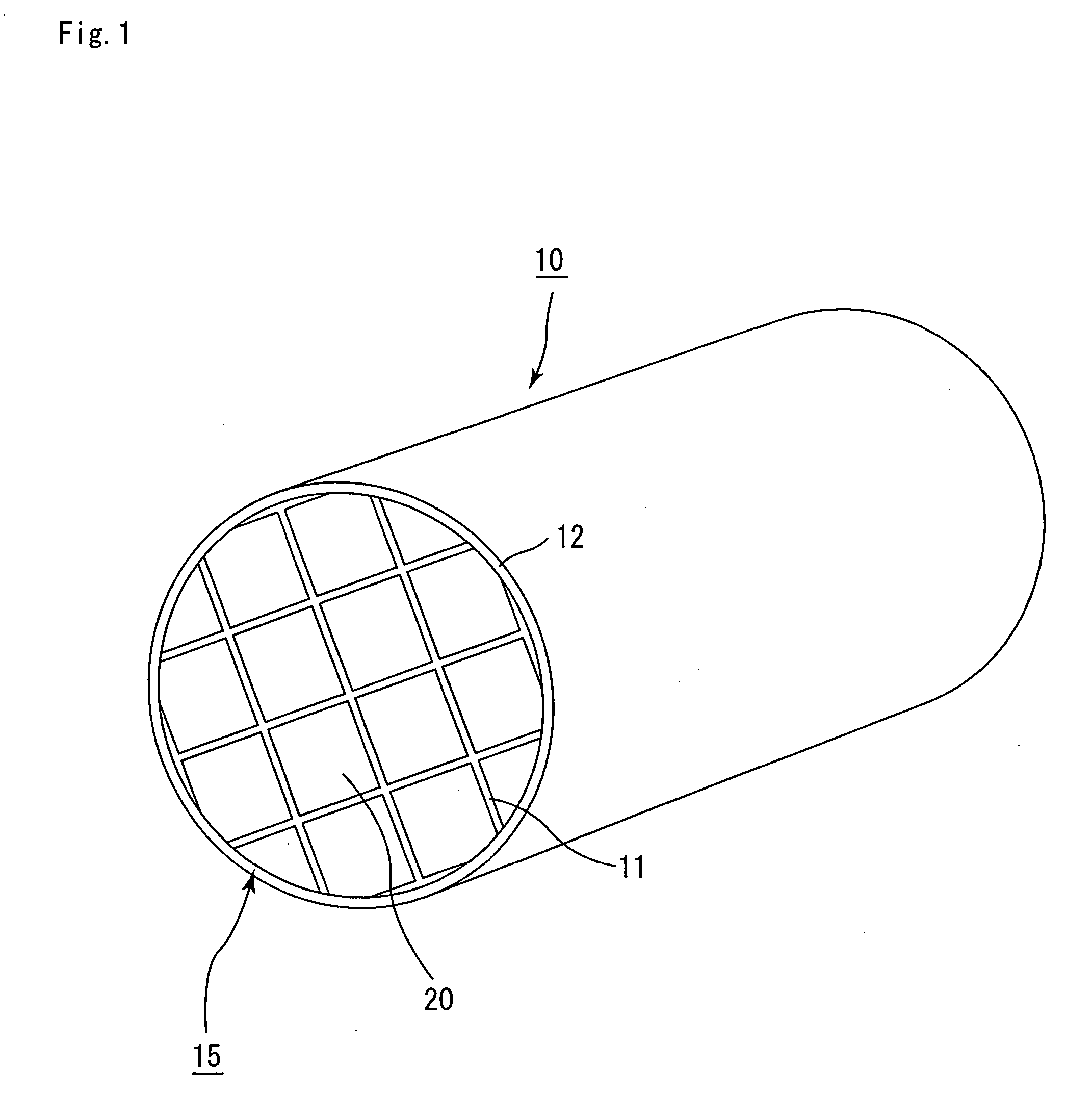

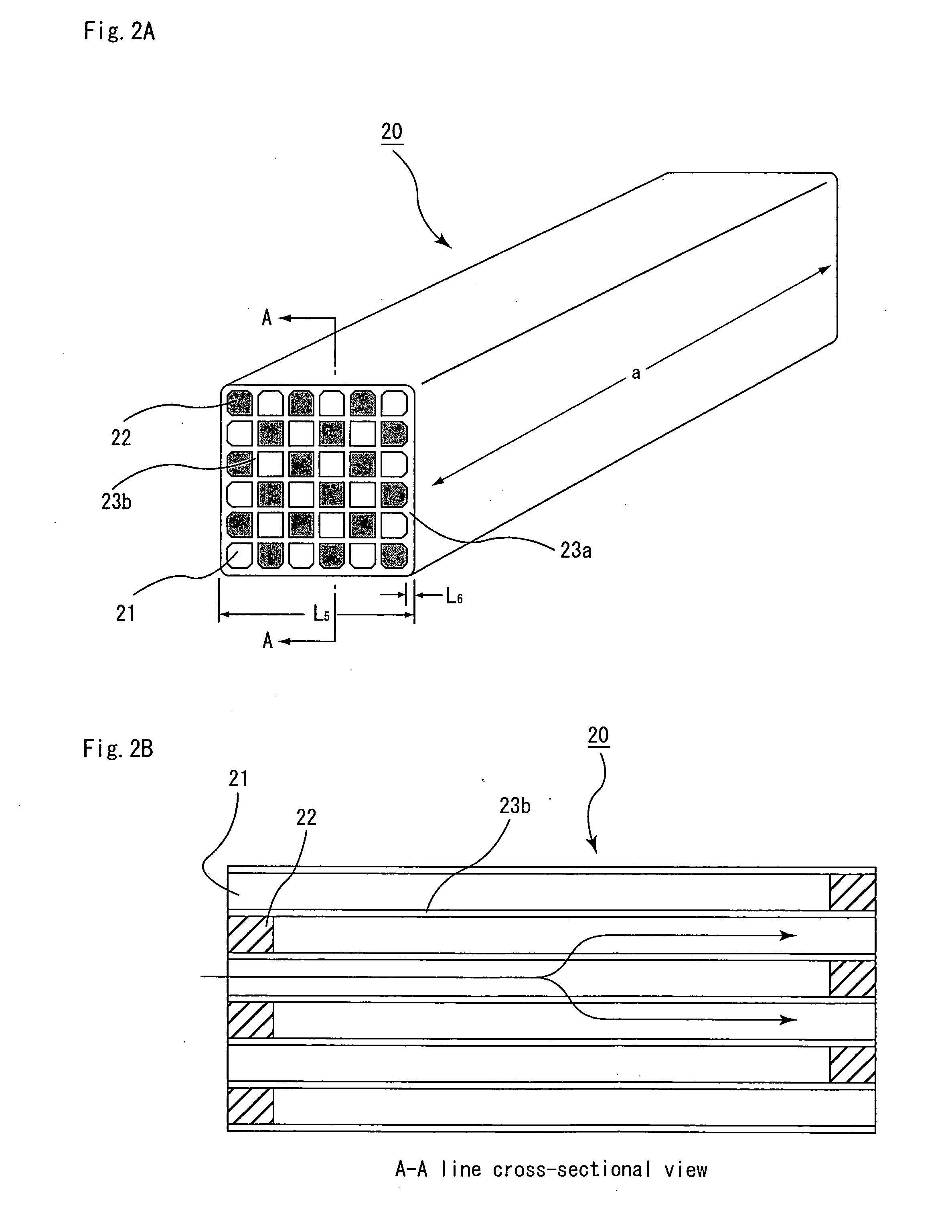

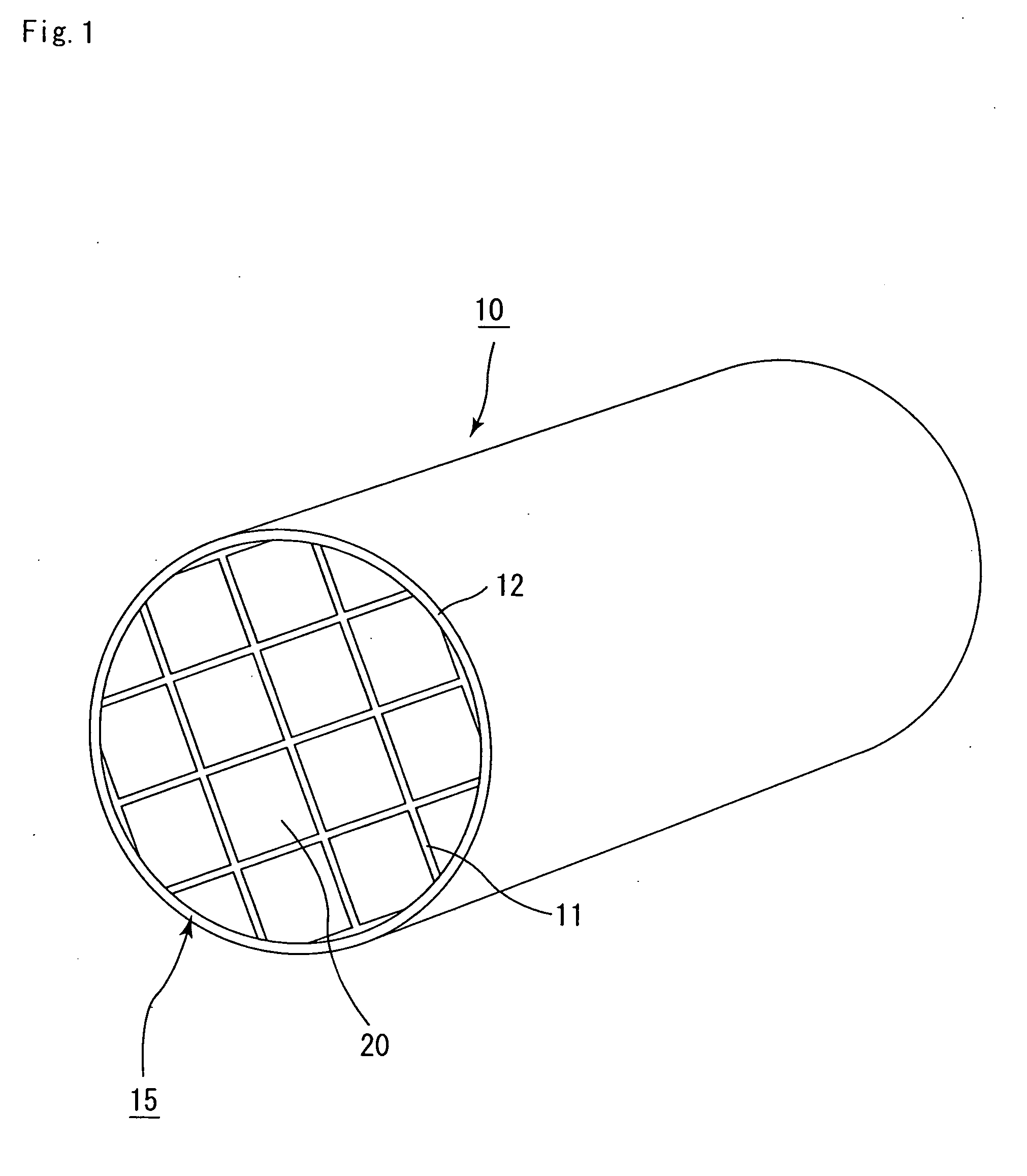

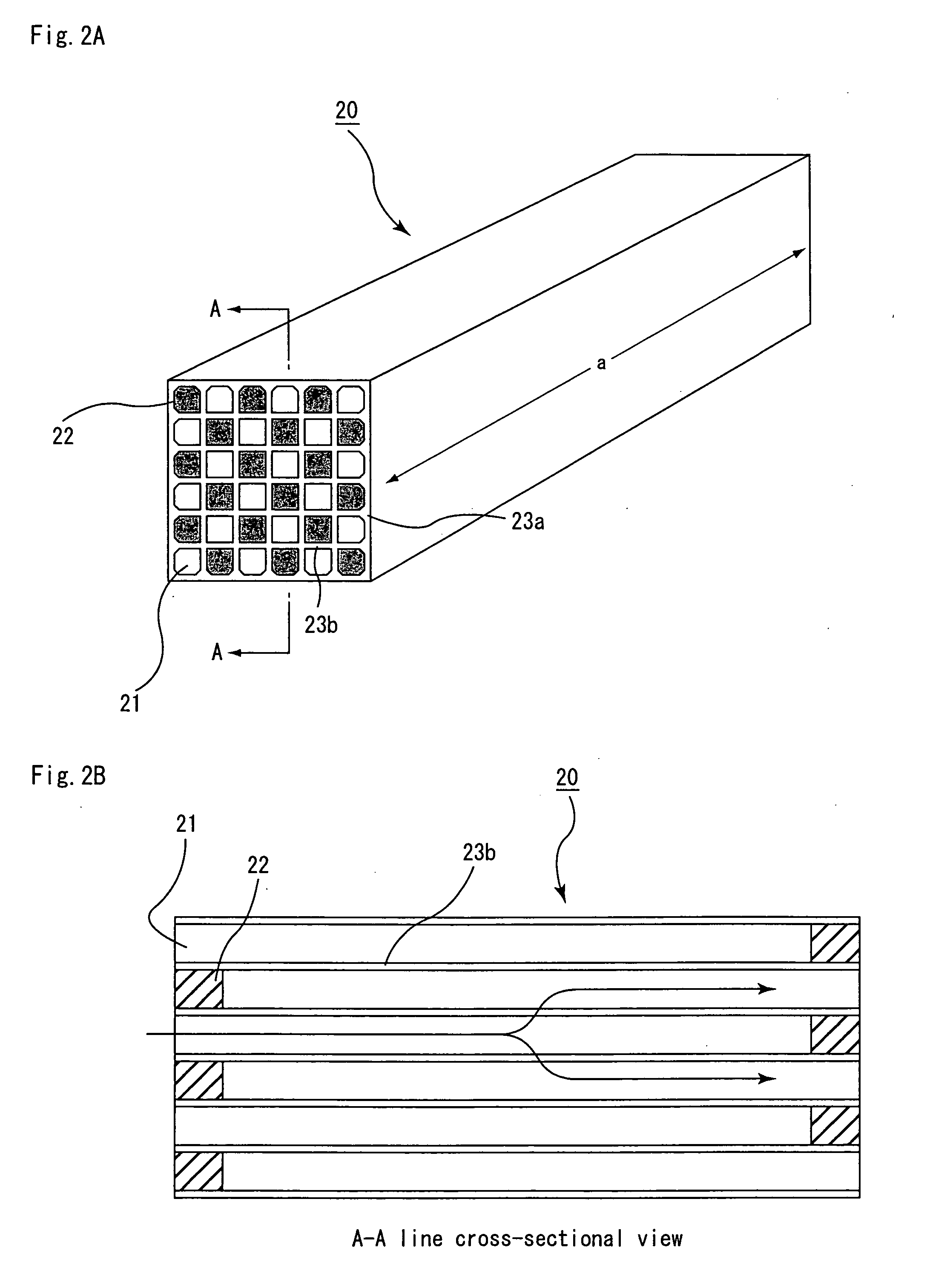

Honeycomb structured body, method for manufacturing honeycomb structured body and exhaust gas purifying device

ActiveUS20070128405A1Secure strengthLoss levelingPhysical/chemical process catalystsInternal combustion piston enginesRight triangleEdge surface

A honeycomb structured body in which a plurality of porous ceramic members are combined with one another by interposing an adhesive layer, each of the porous ceramic members having a plurality of cells placed in parallel with one another in a longitudinal direction with a cell wall therebetween and having an outer edge wall on the outer edge surface thereof, wherein each of the porous ceramic members has a filling body which is provided so as to fill in at least one corner portion of at least one outermost cell of the porous ceramic members, a cross-sectional shape of the outermost cell at the face orthogonal to the longitudinal direction of the cells is an almost tetragon, and a cross-sectional shape of the filling body at the face orthogonal to the longitudinal direction of the cells is an almost right triangle.

Owner:IBIDEN CO LTD

Light emitting diode and lens for the same

A lens for a light emitting diode is formed with a material having a refractive index of n, and the lens includes a base, a first curved circumferential surface extending from the base, a curved center-edge surface extending from the first curved circumferential surface, and a curved centermost surface extending from the curved center-edge surface. The base includes a groove for receiving a light emitting chip therein. In the lens, a distance from a center of the base to a point of the curved center-edge surface is always shorter than the radius of curvature for the point of the curved center-edge surface. The curved centermost surface has a concave shape with respect to the base. In addition, when an obtuse angle formed between a main axis of the lens and a tangent line of a point of the curved centermost surface is A1, and an acute angle formed between a straight line linking the center of the base to the point of the curved centermost surface and the main axis of the lens is A2, the lens satisfies the equation: A1+A2<90+sin−1(1 / n).

Owner:SAMSUNG DISPLAY CO LTD

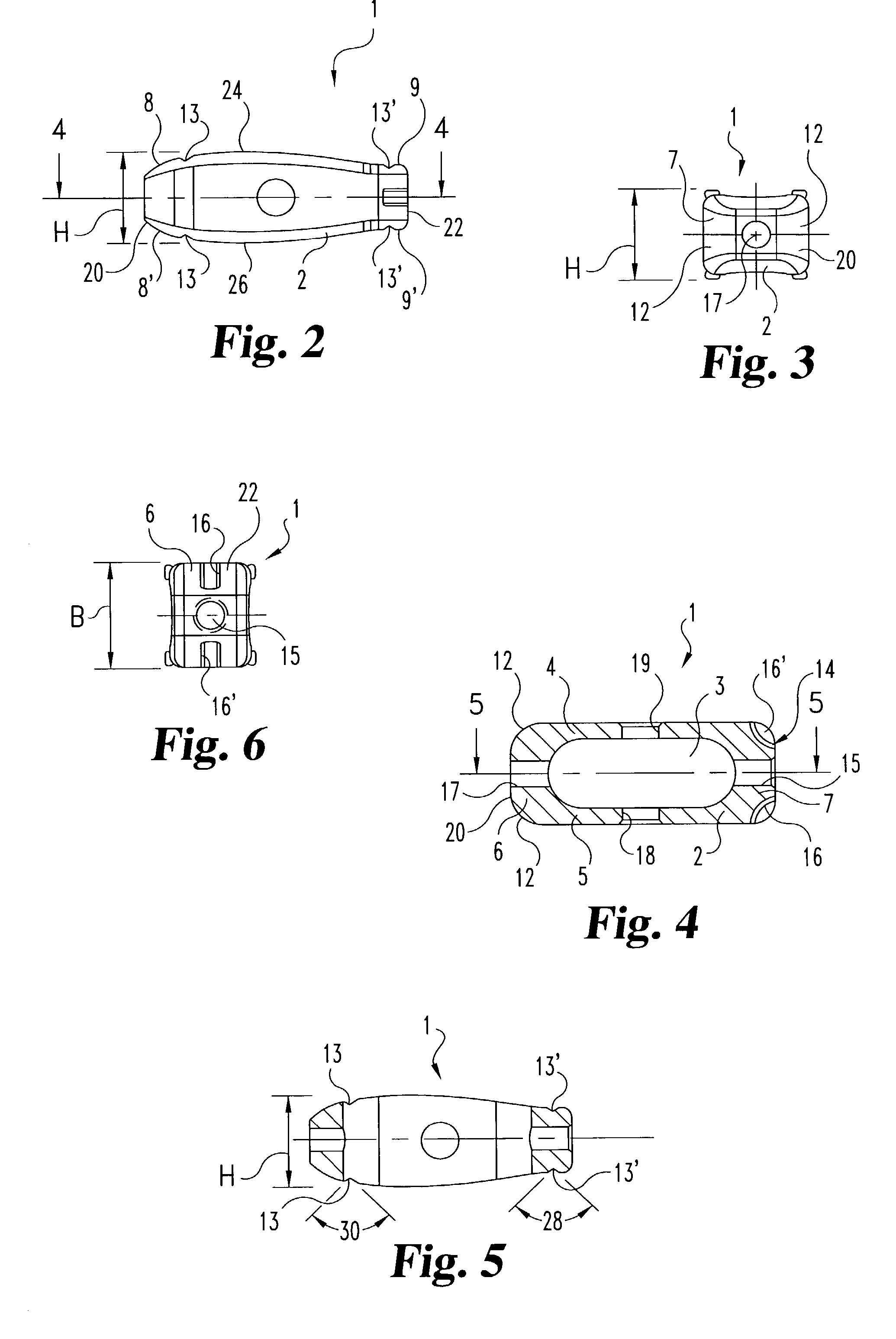

Vertebral implant for promoting arthrodesis of the spine

This invention provides a vertebral implant for impaction in a disc space to restore and / or maintain desired disc space height and spinal orientation. The implant has an elongated basis body having a generally lens-shape provided by convex upper and lower surfaces. Bearing surfaces are provided on the cross-edge surfaces of the endwalls. Grooves are provided in the upper and lower surfaces positioned between the bearing surfaces. The implant can be prepared from a wide variety of materials including metallic materials, synthetic materials, polymeric materials, ceramic materials, and composite materials including reinforced materials i.e. glass, fiber, and / or carbon fiber reinforced materials (CFRP). These preferred materials for fabricating implants in the present invention reduce costs, increase service life and provide excellent physiological compatibility. The non-metallic material can be selected to be either a substantially permanent material, a biodegradable material or a bioerodable material. Further, the implant material can be provided to be radio opaque to facilitate monitoring of bone ingrowth both into the implant and between the opposing endplates of the adjacent vertebrae.

Owner:WARSAW ORTHOPEDIC INC

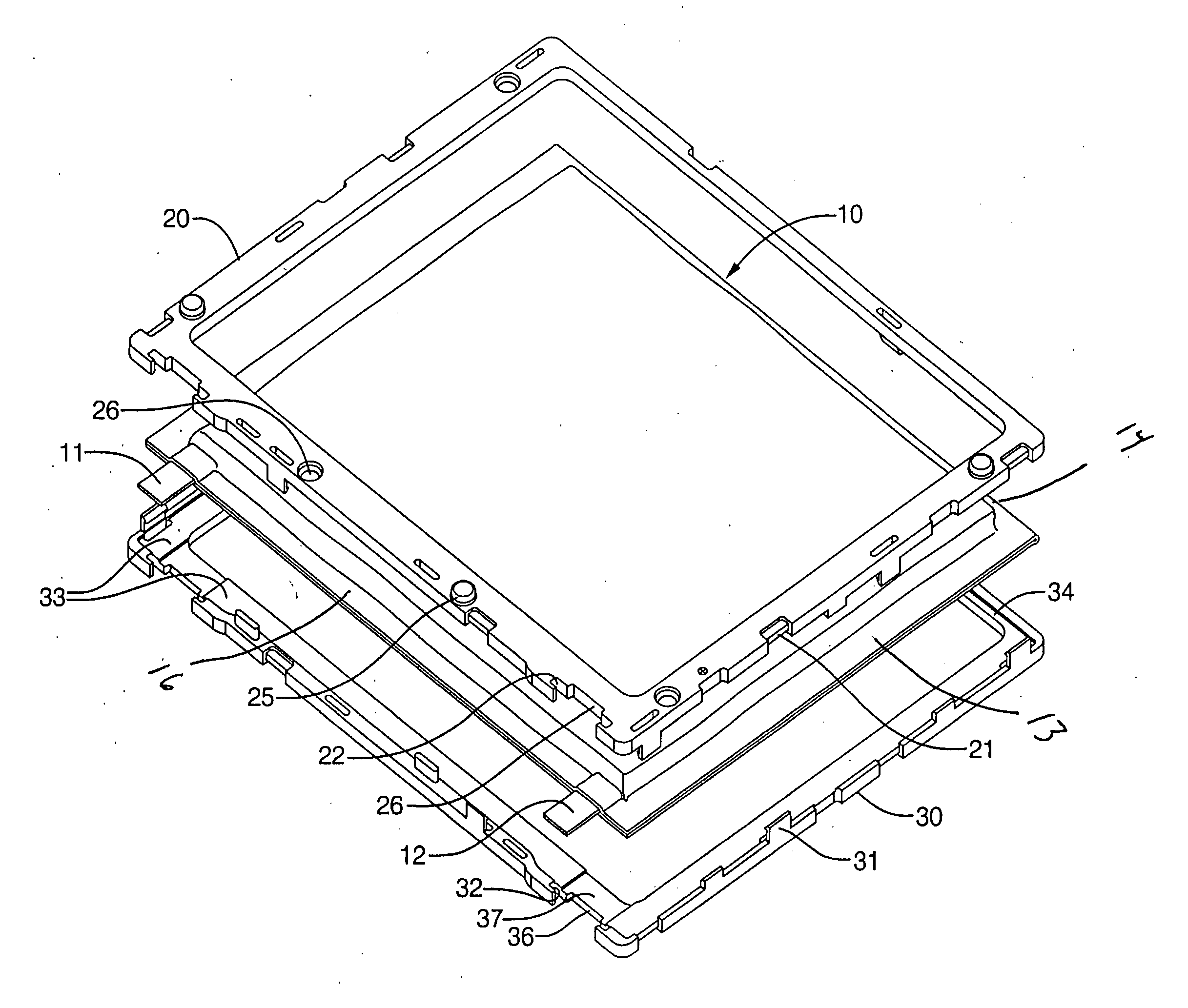

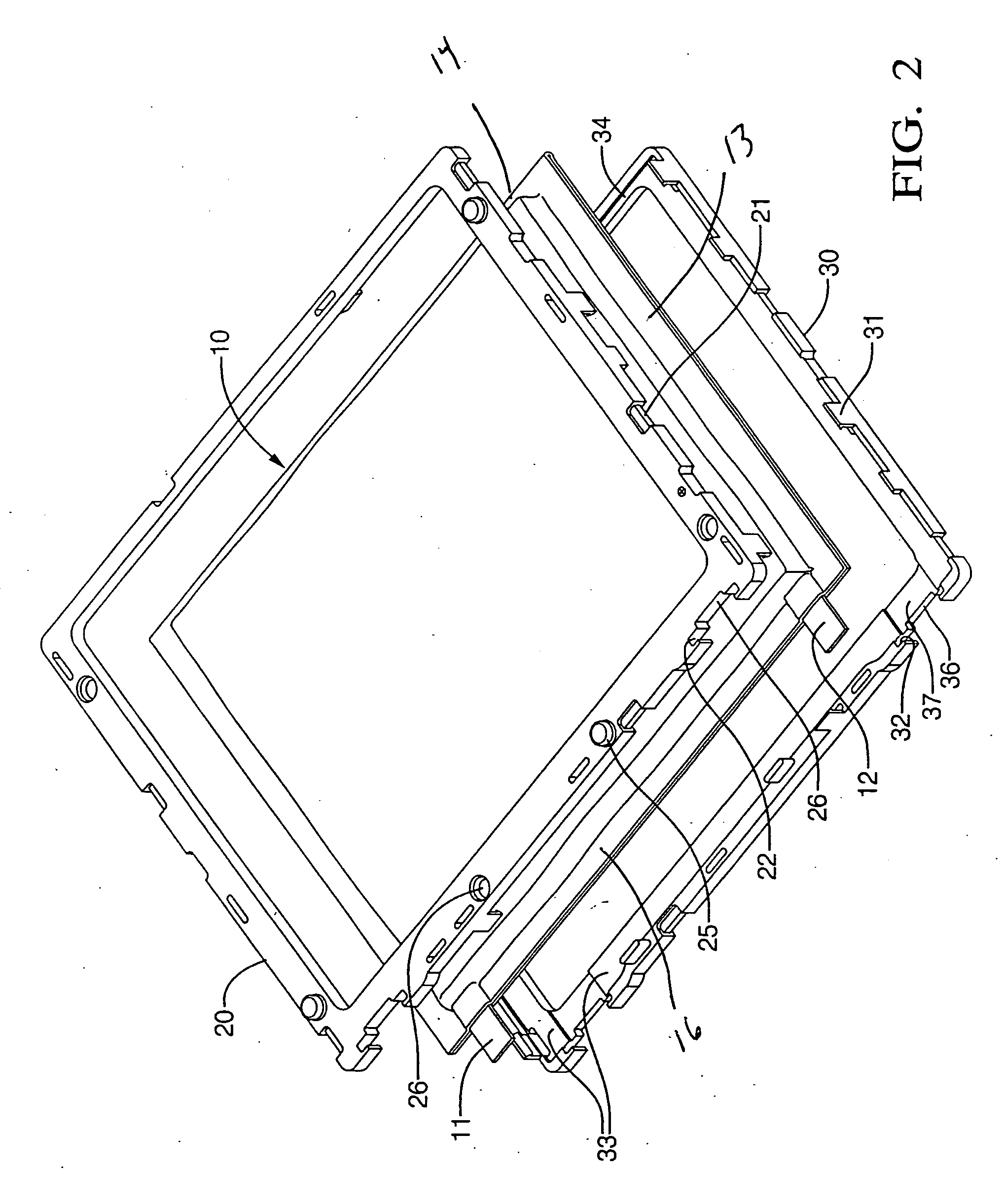

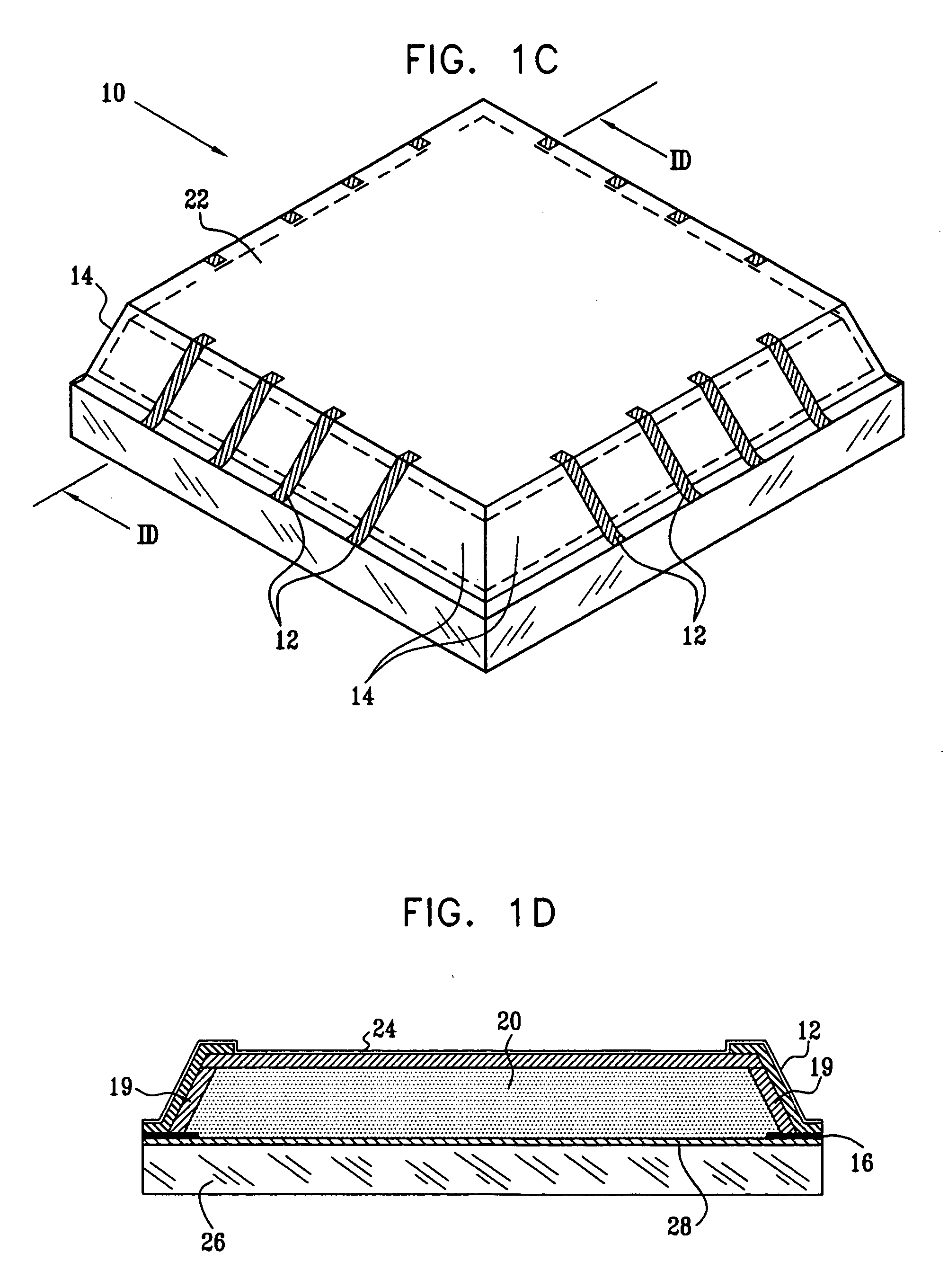

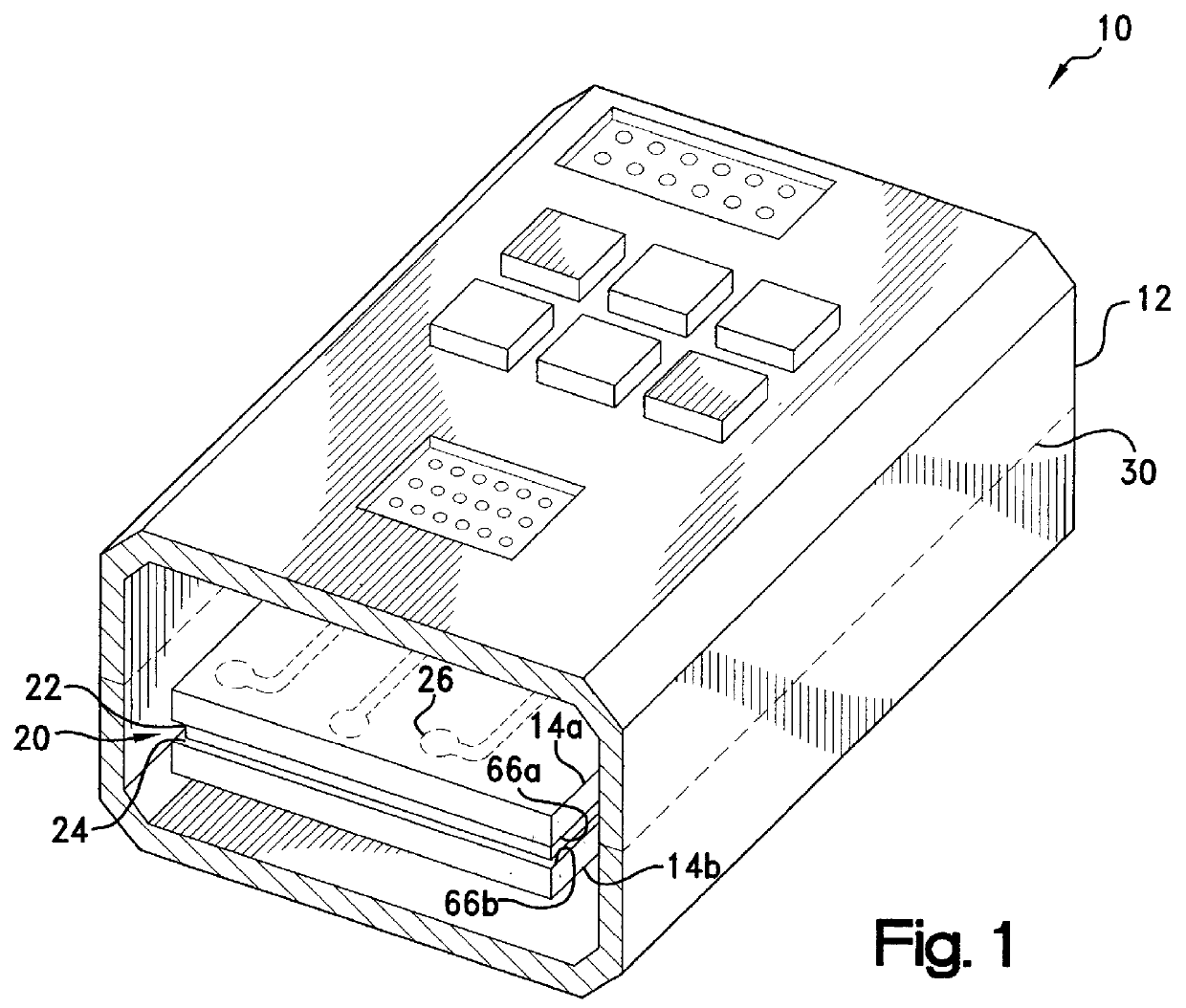

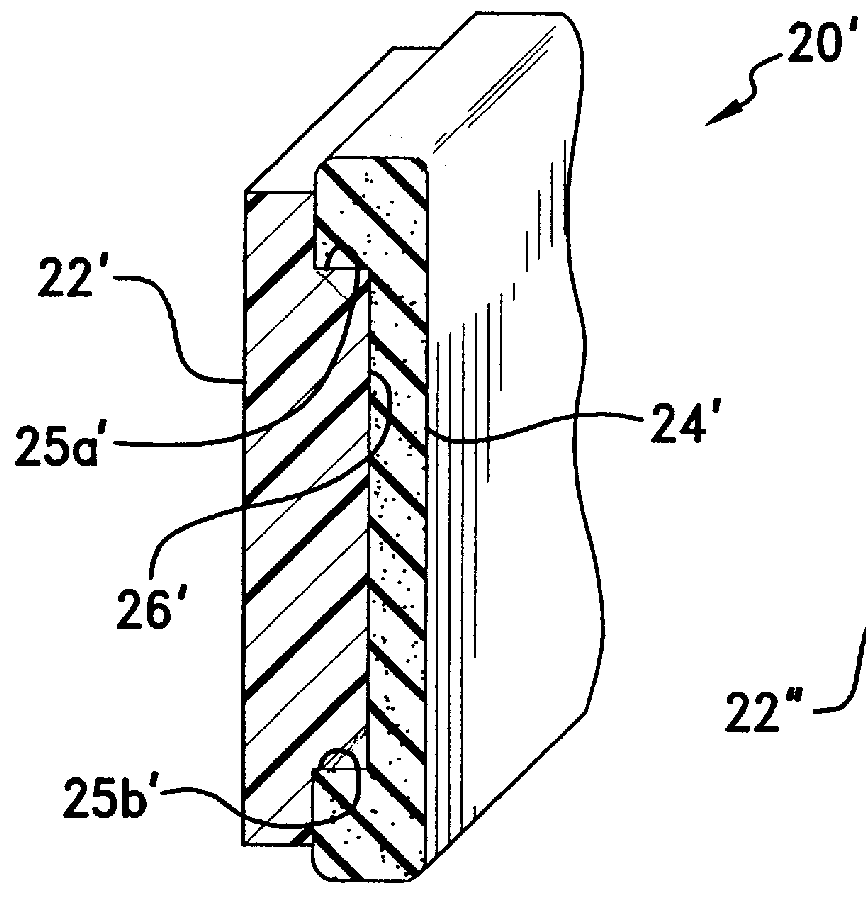

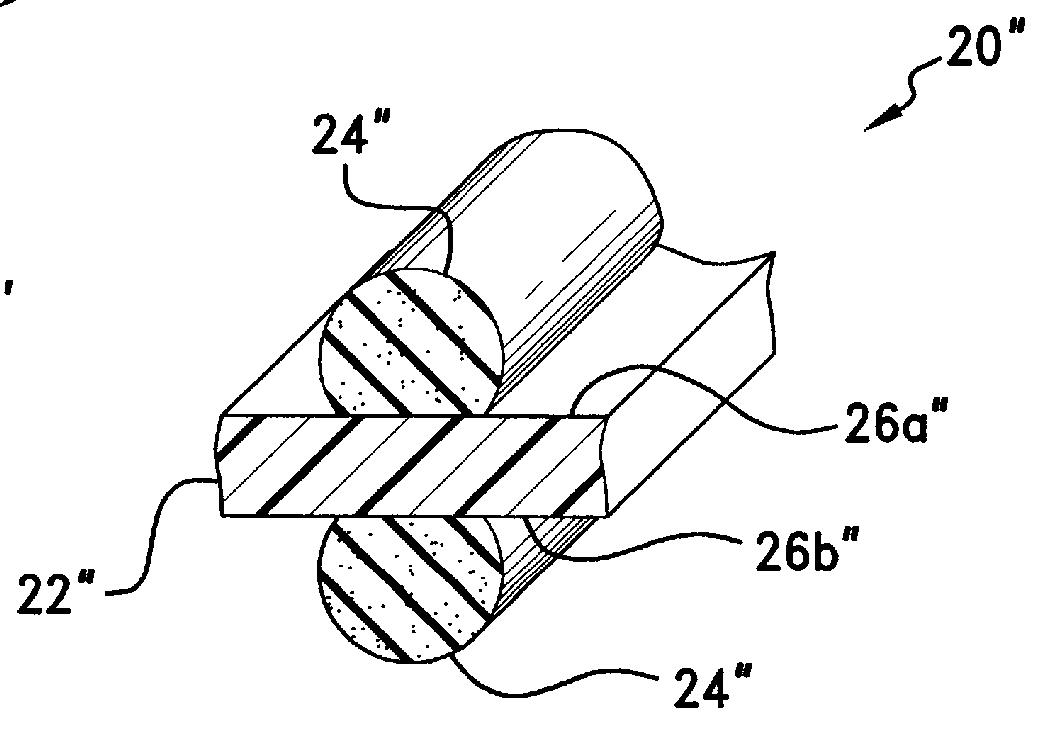

Apparatus and method for securing battery cell packs

ActiveUS20060234119A1Facilitate electrically connectingFacilitate mechanically connectingFinal product manufactureSmall-sized cells cases/jacketsEdge surfaceBattery cell

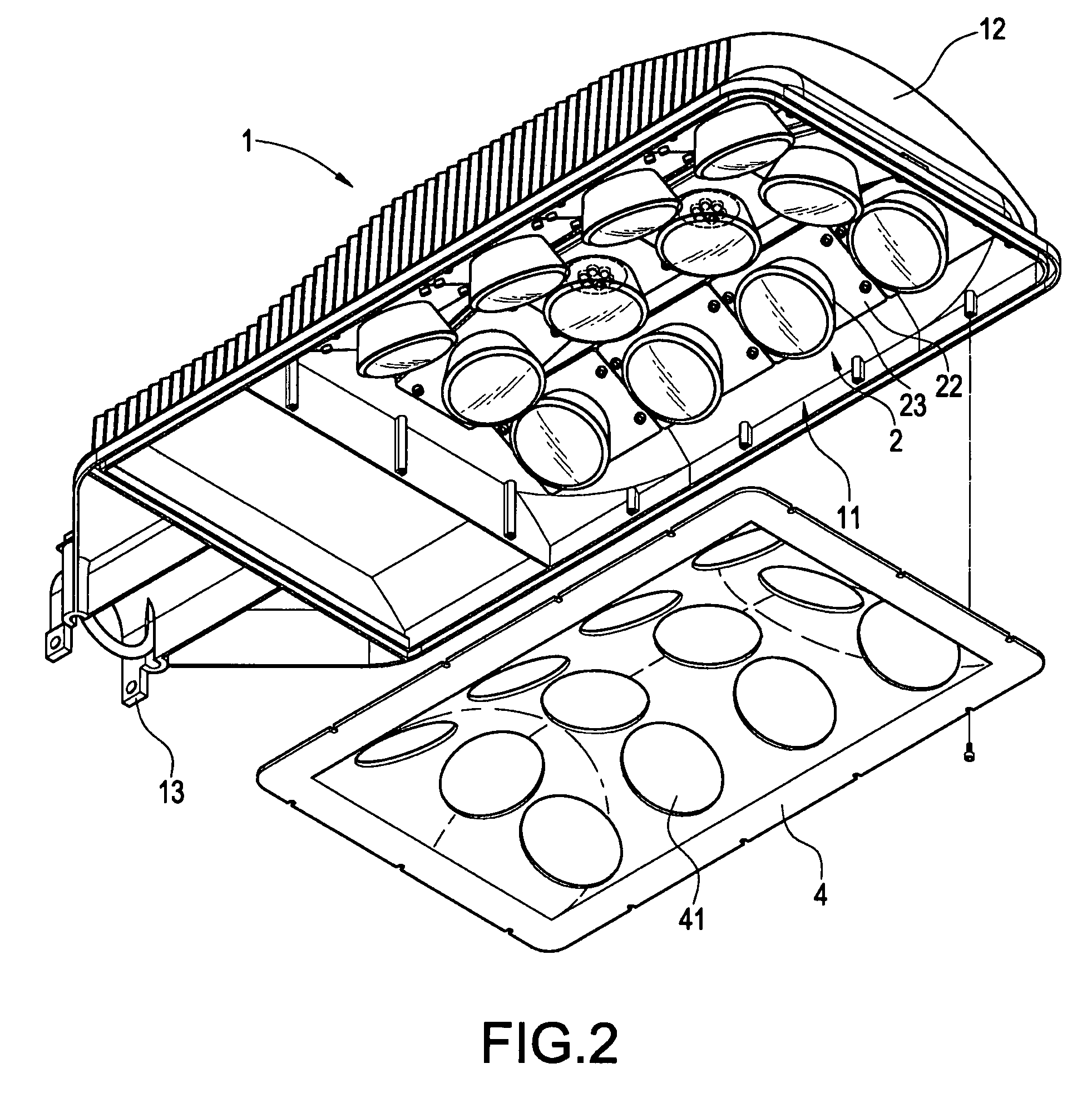

A framed lithium battery cell group includes a first frame member (20) and a second frame member (30). The frame members are locked together, clamping the lithium battery cell pack (10) on the seal edge surfaces (13, 16), thereby providing structural rigidity and protection from damage due to handling and vibration. Each of the frame members (20, 30) has multiple pins (25) and sockets (26) on the side opposite the clamping surface (33) to facilitate aligning and stacking multiple lithium battery cell pack and frame assemblies to form a lithium battery cell group (50). Each of the frame members (20, 30) include a buss bar capture feature (22, 32) having a bus bar (40) inserted therein for electrically connecting all of the terminals for a given lithium battery pack group to the buss bar (40).

Owner:ENERDEL

Honeycomb structured body, method for manufacturing honeycomb structured body, and exhaust gas purifying device

InactiveUS20070130897A1Avoid deformationReduce generationPhysical/chemical process catalystsInternal combustion piston enginesEdge surfaceCell wall

A honeycomb structured body in which a plurality of porous ceramic members are combined with one another by interposing an adhesive layer, each of the porous ceramic members having a plurality of cells placed in parallel with one another in a longitudinal direction with a cell wall therebetween and an outer edgewall on the outer edge surface thereof, wherein the thickness of the outer edge wall of the porous ceramic member is greater than the thickness of the cell wall, and each of the porous ceramic members has a filling body which is provided so as to fill in at least one corner portion of at least one outermost cell of the porous ceramic members.

Owner:IBIDEN CO LTD

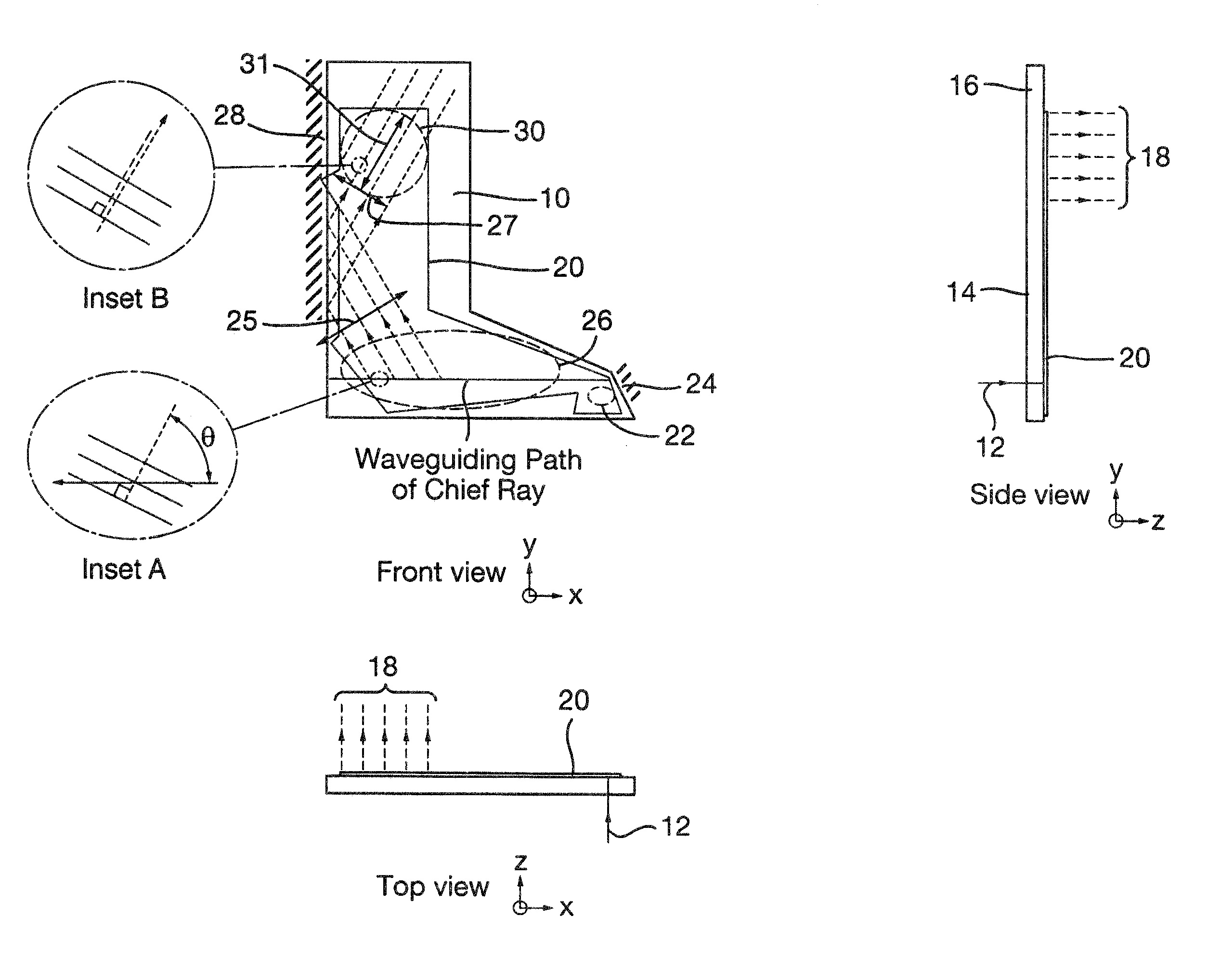

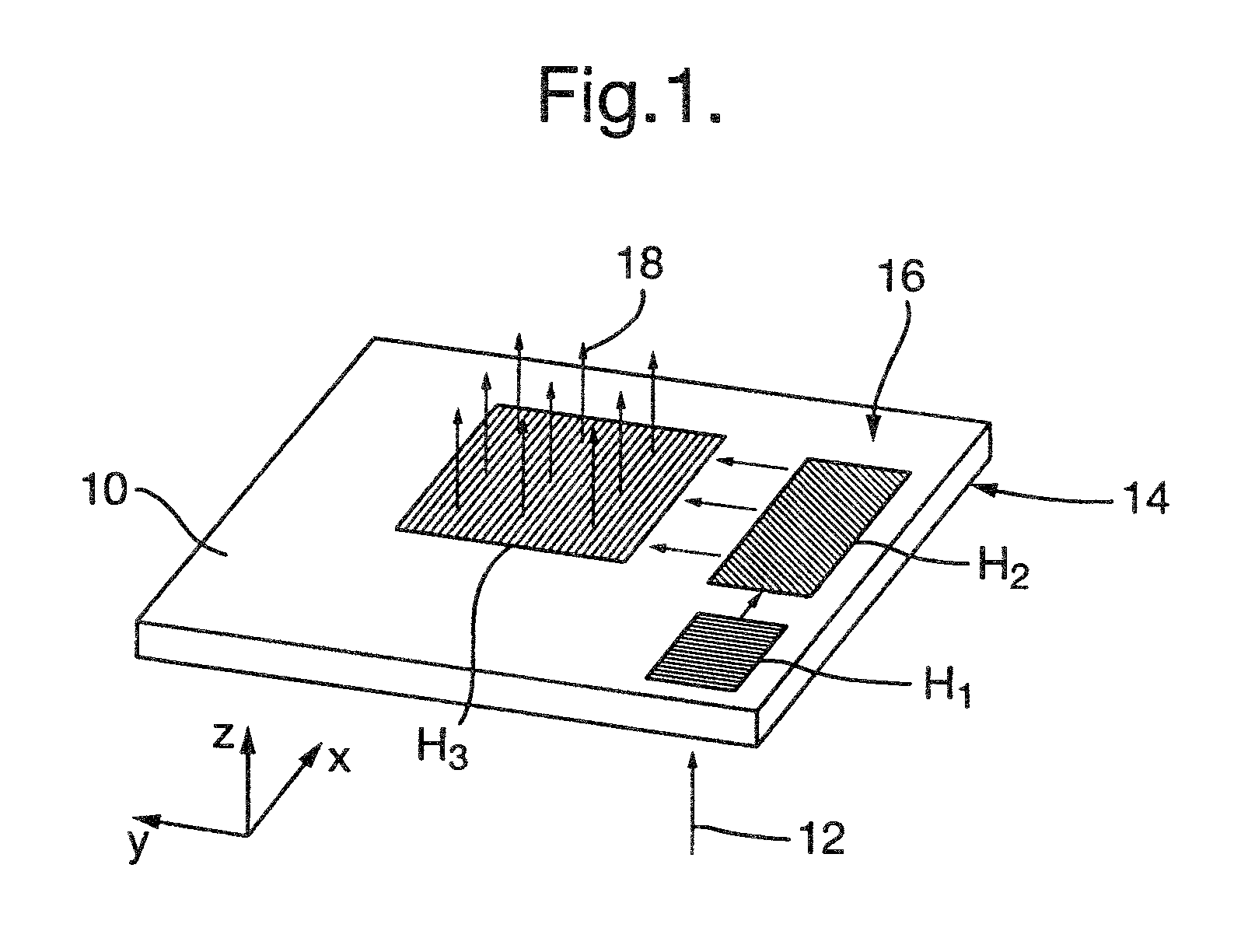

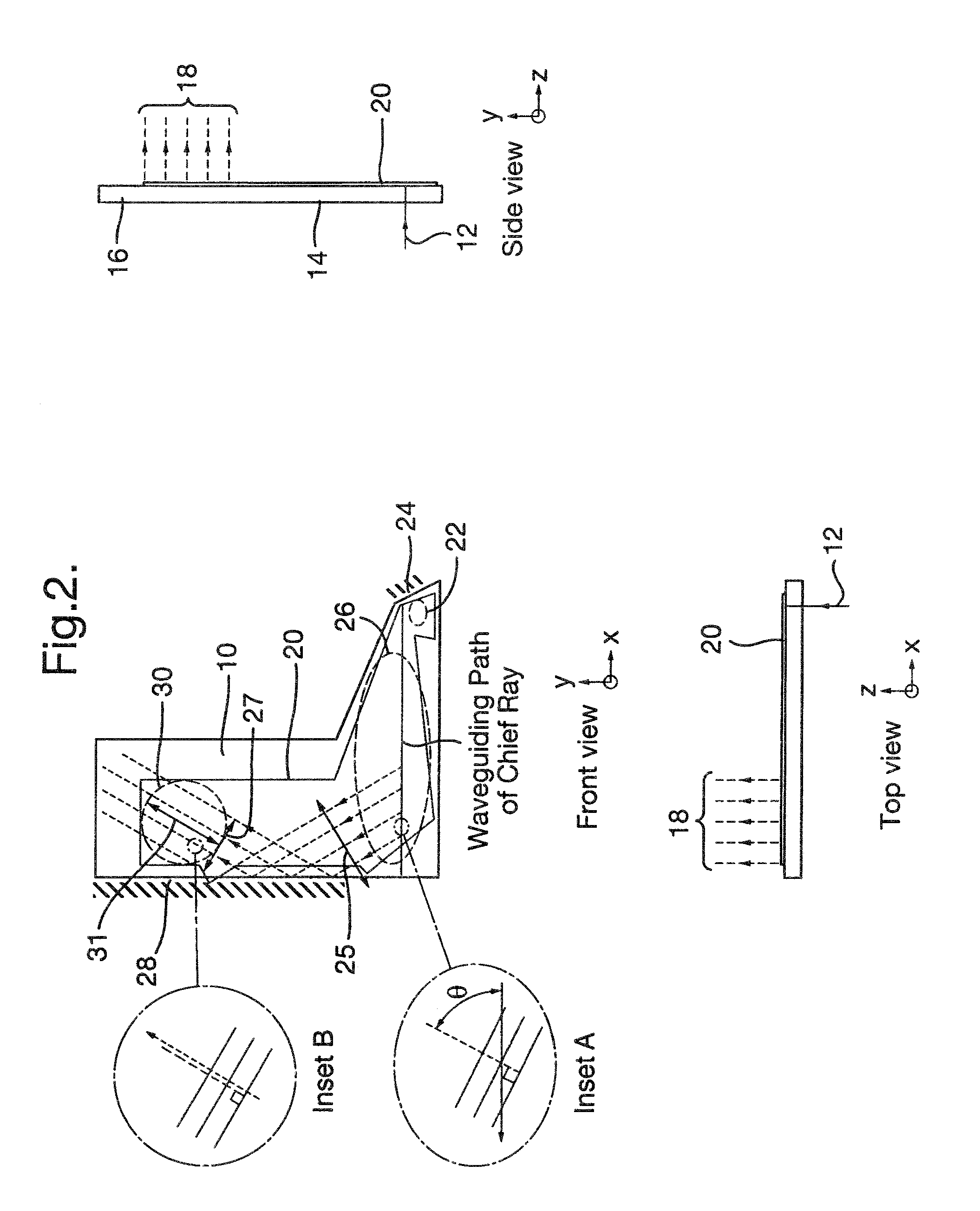

Optical waveguide and display device

In a slab waveguide which expands an image-bearing pupil into a visible image, reflective edge surfaces are used to redirect once-diffracted light back through the same grating structure. The number of separate grating structures thereby can be reduced to two or even one, compared to three in the prior art.

Owner:BAE SYSTEMS PLC

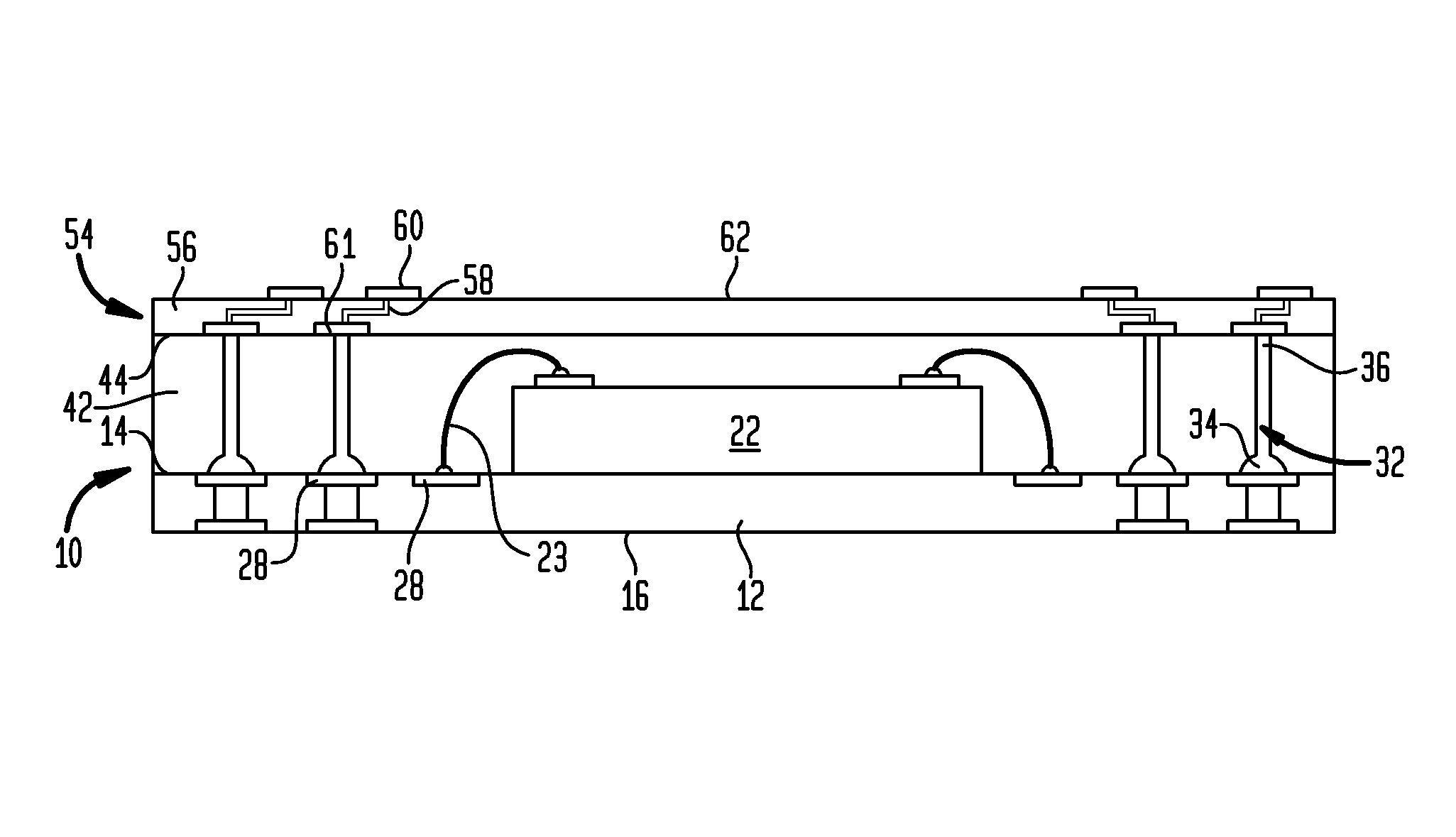

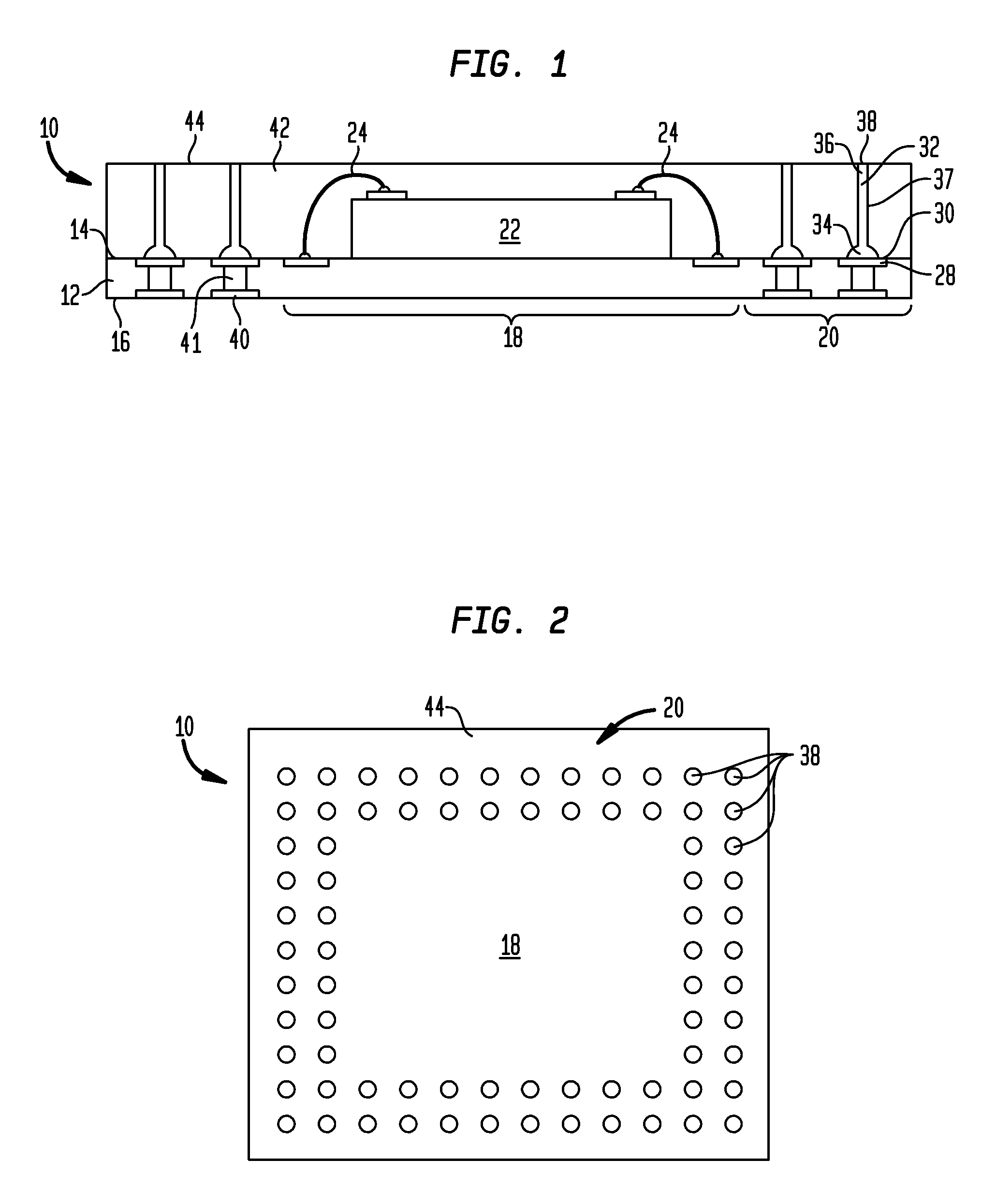

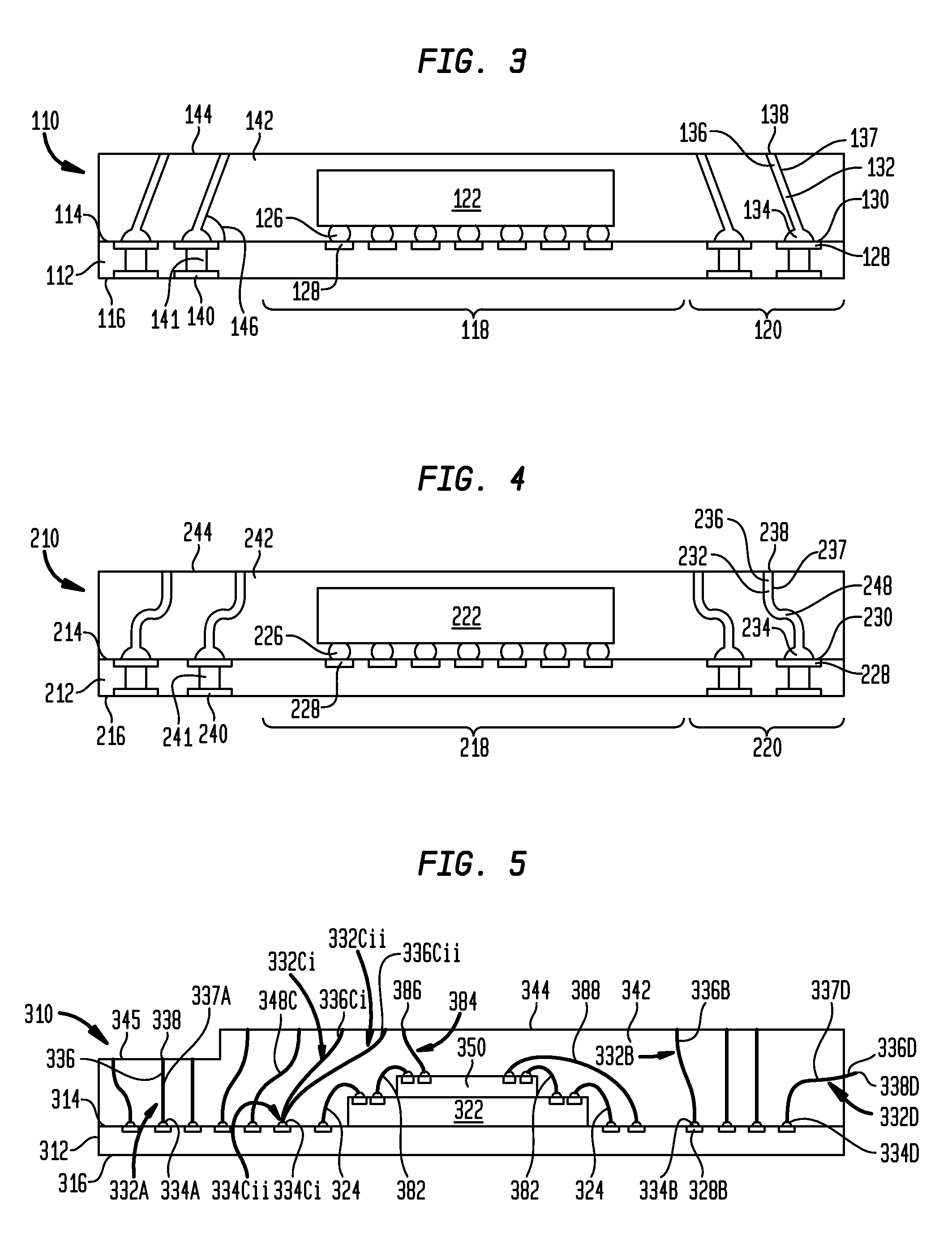

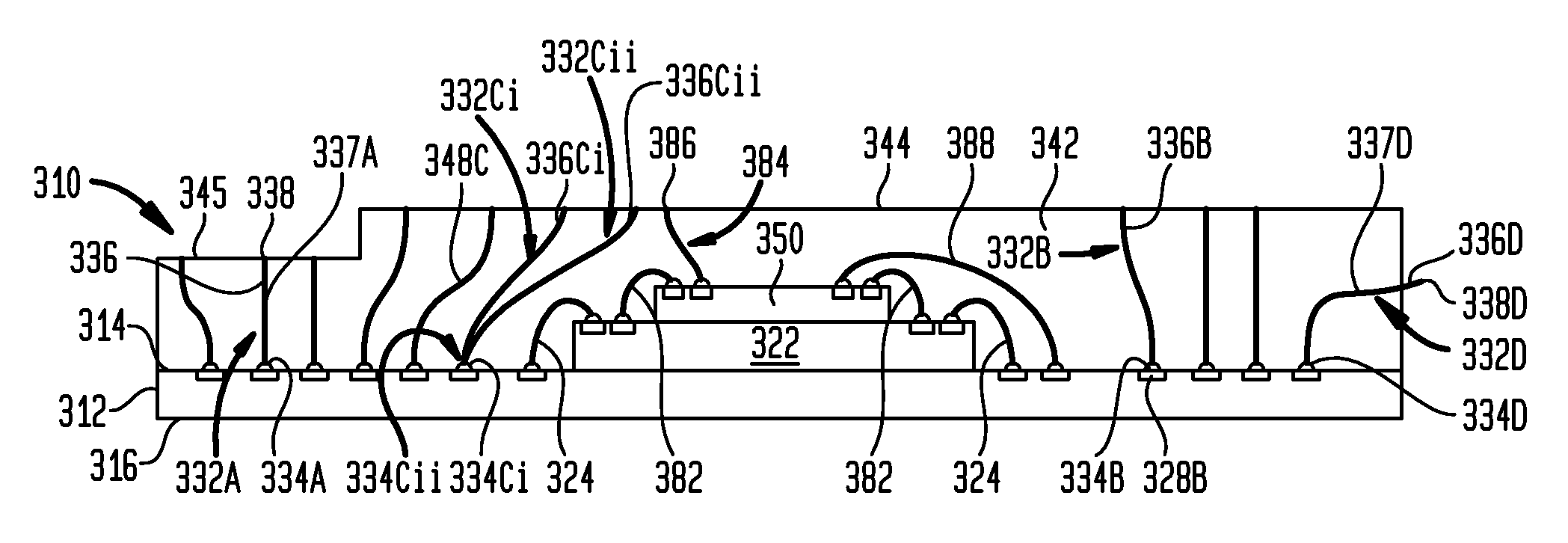

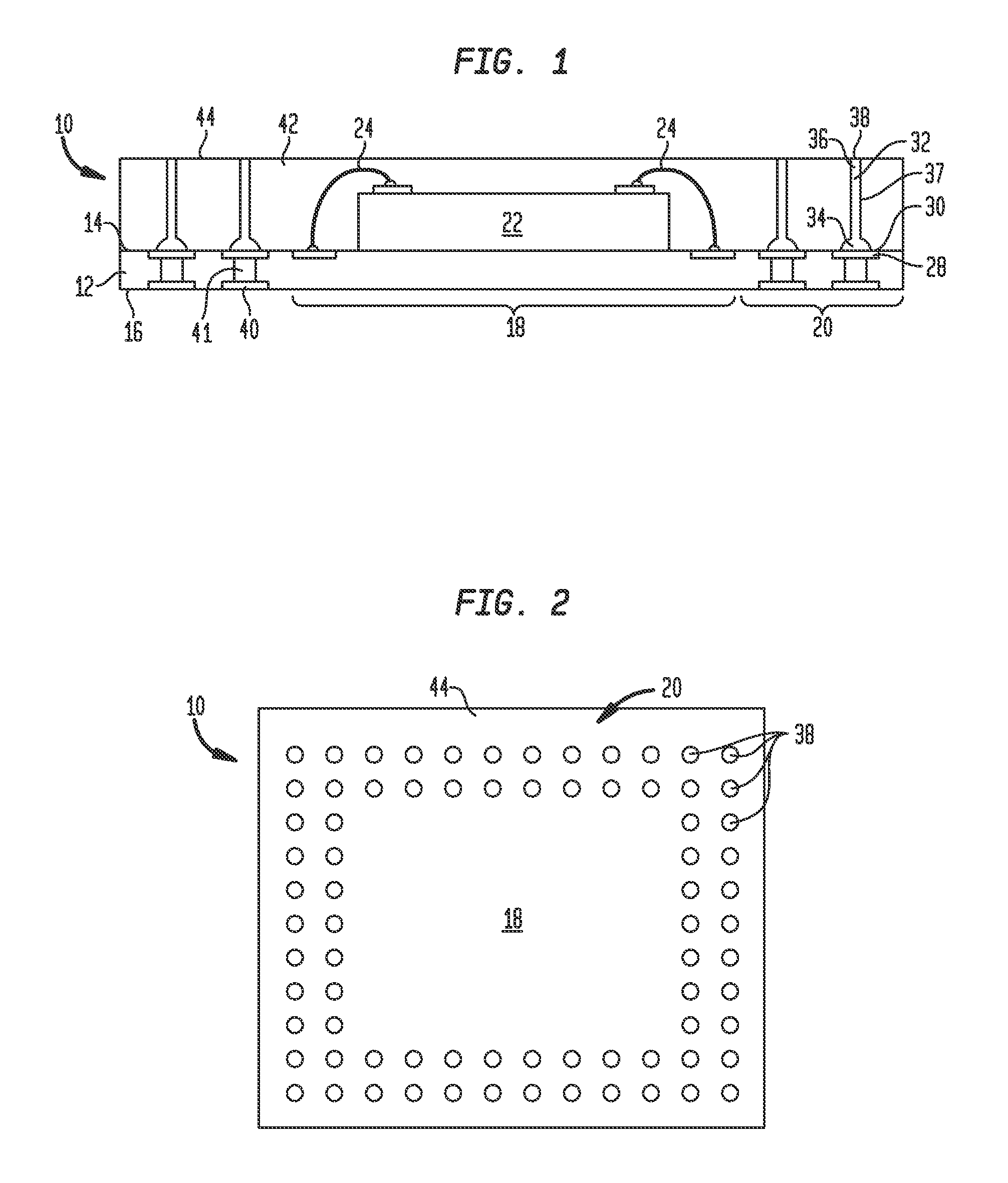

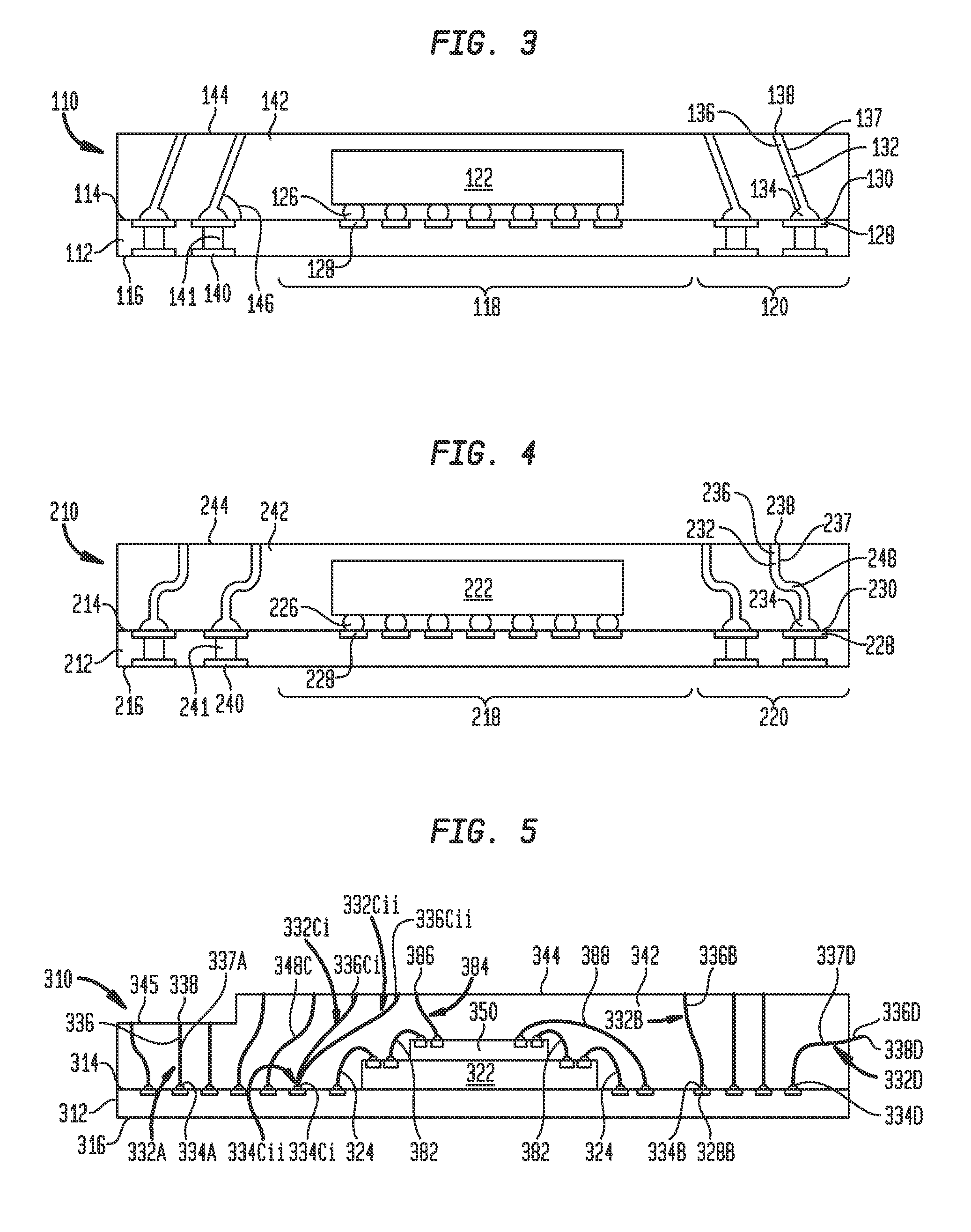

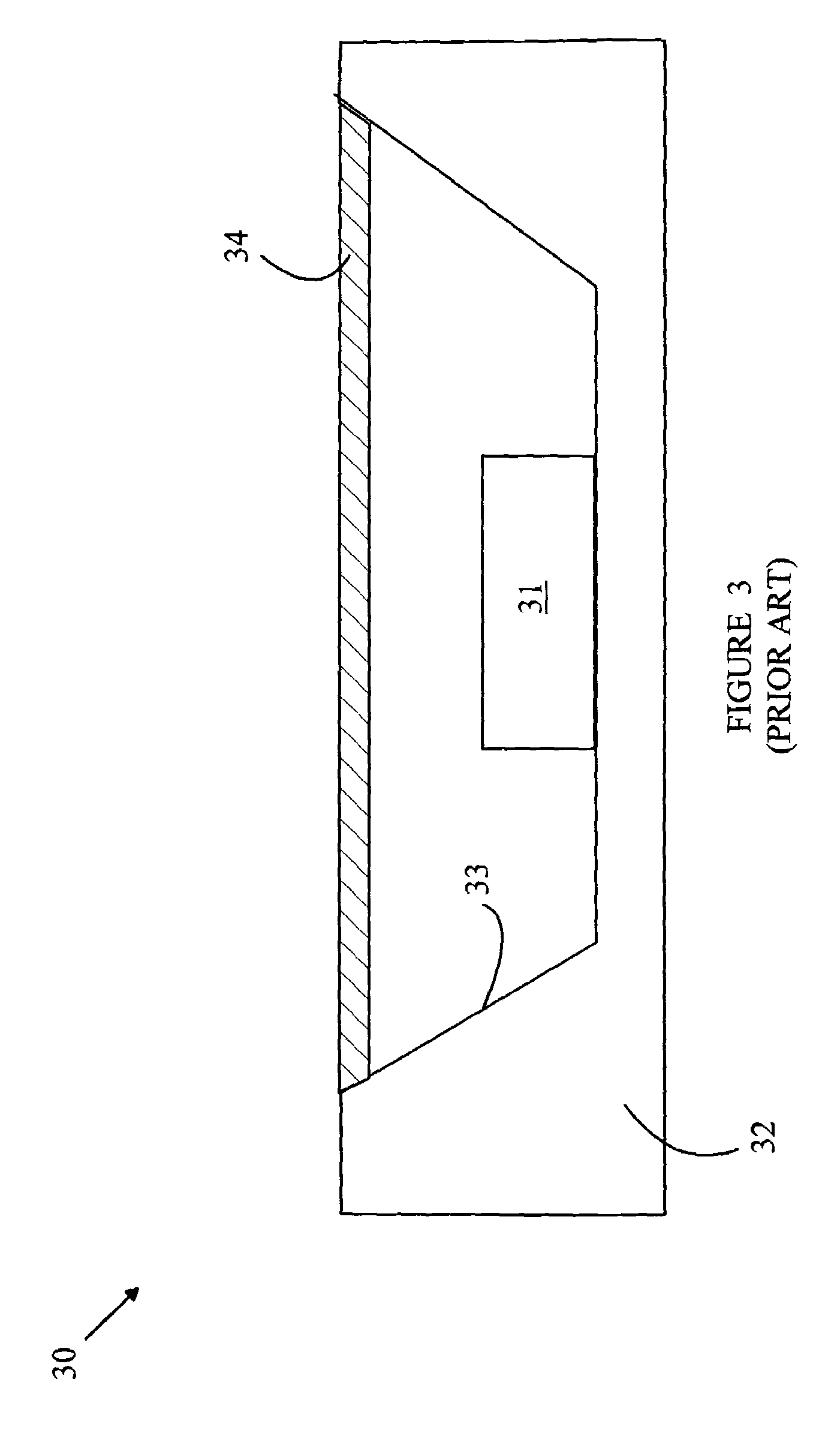

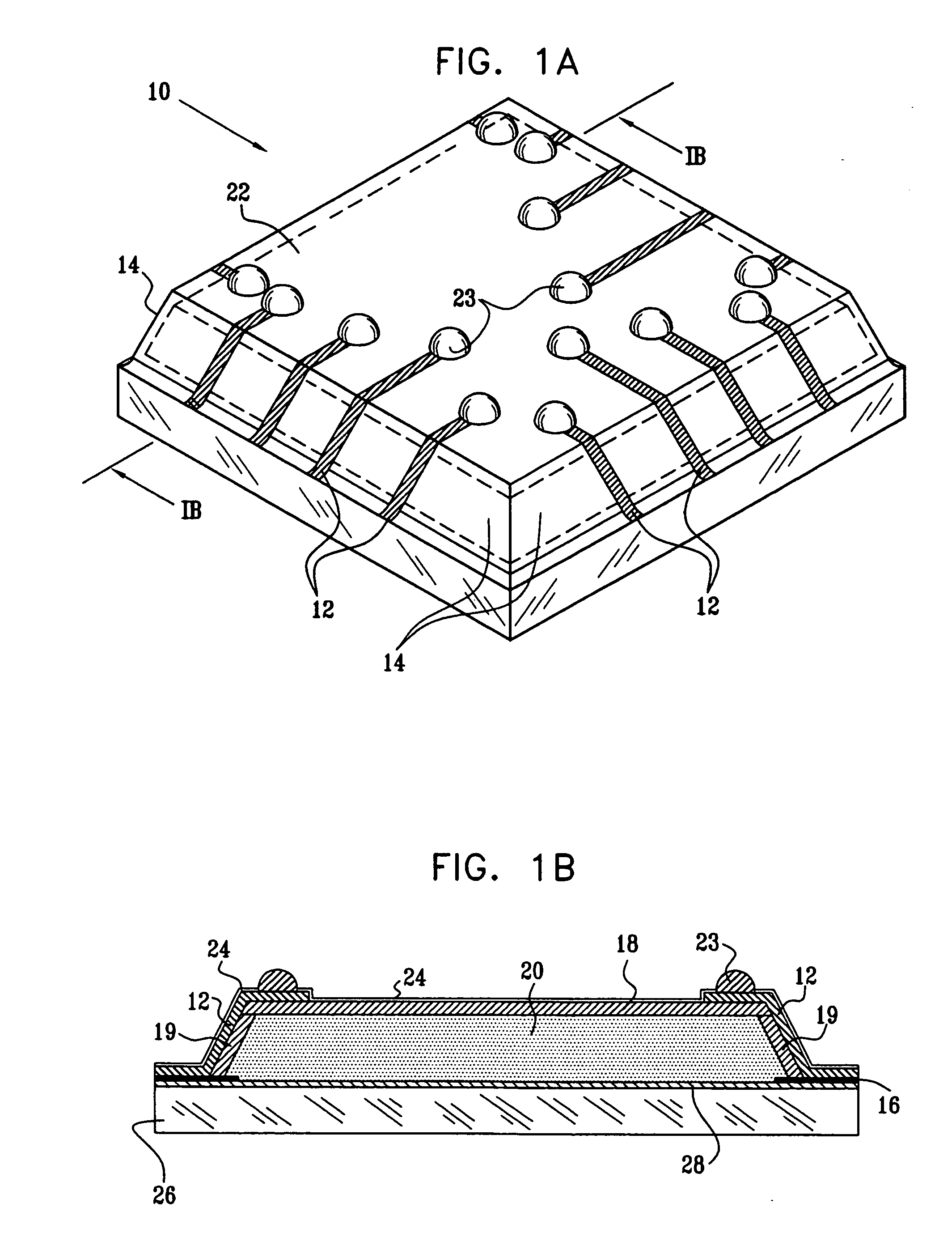

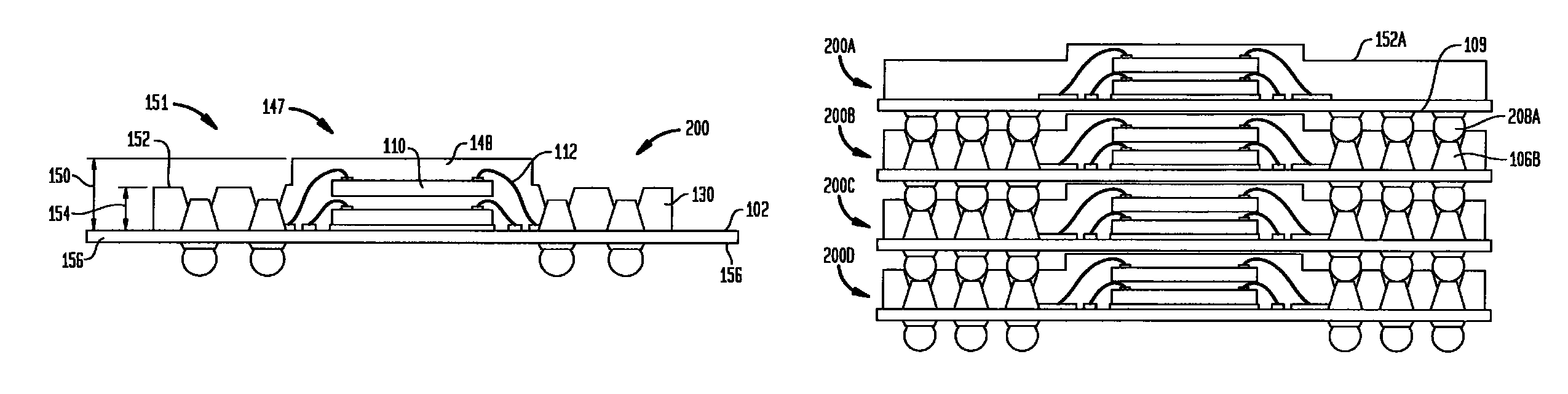

Package-on-package assembly with wire bonds to encapsulation surface

ActiveUS8618659B2Semiconductor/solid-state device detailsSolid-state devicesEdge surfaceLead bonding

A microelectronic assembly includes a substrate having a first surface and a second surface remote from the first surface. A microelectronic element overlies the first surface and first electrically conductive elements are exposed at one of the first surface and the second surface. Some of the first conductive elements are electrically connected to the microelectronic element. Wire bonds have bases joined to the conductive elements and end surfaces remote from the substrate and the bases, each wire bond defining an edge surface extending between the base and the end surface. An encapsulation layer extends from the first surface and fills spaces between the wire bonds such that the wire bonds are separated by the encapsulation layer. Unencapsulated portions of the wire bonds are defined by at least portions of the end surfaces of the wire bonds that are uncovered by the encapsulation layer.

Owner:TESSERA LLC

Package-on-package assembly with wire bonds to encapsulation surface

ActiveUS20120280386A1Semiconductor/solid-state device detailsSolid-state devicesEdge surfaceLead bonding

A microelectronic assembly includes a substrate having a first surface and a second surface remote from the first surface. A microelectronic element overlies the first surface and first electrically conductive elements are exposed at one of the first surface and the second surface. Some of the first conductive elements are electrically connected to the microelectronic element. Wire bonds have bases joined to the conductive elements and end surfaces remote from the substrate and the bases, each wire bond defining an edge surface extending between the base and the end surface. An encapsulation layer extends from the first surface and fills spaces between the wire bonds such that the wire bonds are separated by the encapsulation layer. Unencapsulated portions of the wire bonds are defined by at least portions of the end surfaces of the wire bonds that are uncovered by the encapsulation layer.

Owner:TESSERA LLC

Microelectronic packages with nanoparticle joining

A method of making an assembly includes the steps of applying metallic nanoparticles to exposed surfaces of conductive elements of either of or both of a first component and a second component, juxtaposing the conductive elements of the first component with the conductive elements of the second component with the metallic nanoparticles disposed therebetween, and elevating a temperature at least at interfaces of the juxtaposed conductive elements to a joining temperature at which the metallic nanoparticles cause metallurgical joints to form between the juxtaposed conductive elements. The conductive elements of either of or both of the first component and the second component can include substantially rigid posts having top surfaces projecting a height above the surface of the respective component and edge surfaces extending at substantial angles away from the top surfaces thereof.

Owner:TESSERA INC

Bridge Resistance Random Access Memory Device and Method With A Singular Contact Structure

ActiveUS20070262388A1Reduced dimensionSemiconductor/solid-state device detailsSolid-state devicesBit lineEdge surface

A resistance random access memory in a bridge structure is disclosed that comprises a contact structure where first and second electrodes are located within the contact structure. The first electrode has a circumferential extending shape, such as an annular shape, surrounding an inner wall of the contact structure. The second electrode is located within an interior of the circumferential extending shape and separated from the first electrode by an insulating material. A resistance memory bridge is in contact with an edge surface of the first and second electrodes. The first electrode in the contact structure is connected to a transistor and the second electrode in the contact structure is connected to a bit line. A bit line is connected to the second electrode by a self-aligning process.

Owner:MACRONIX INT CO LTD

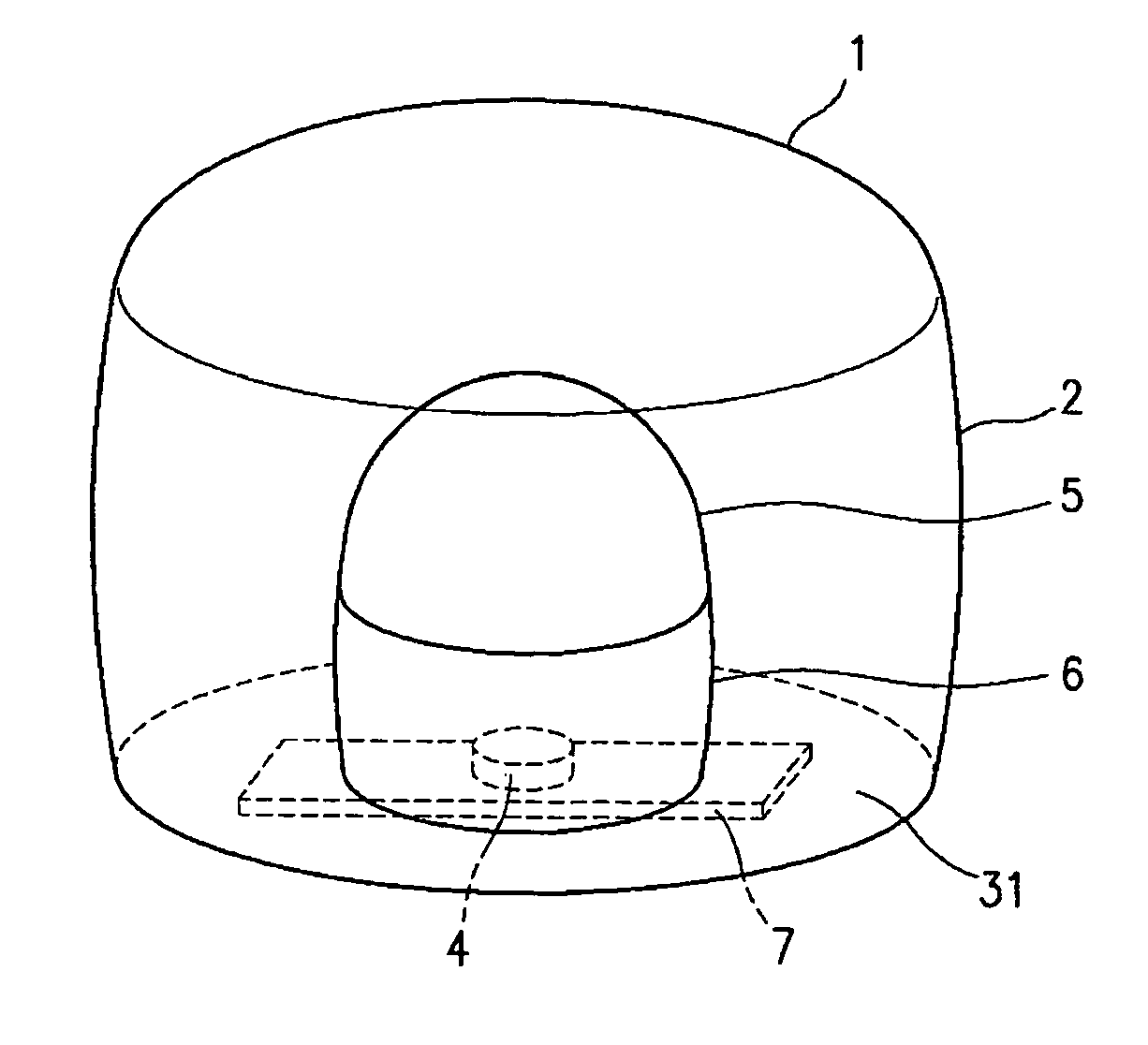

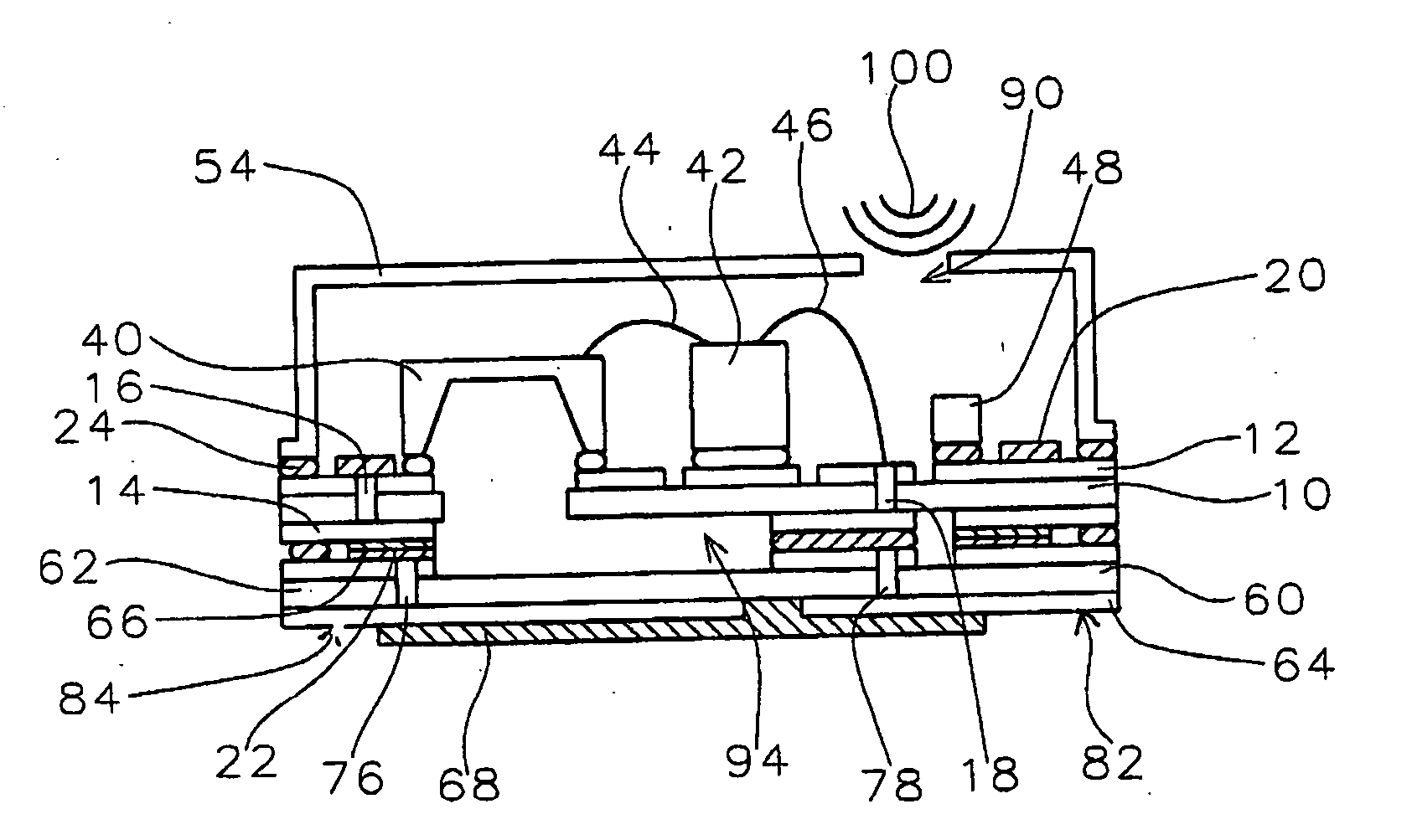

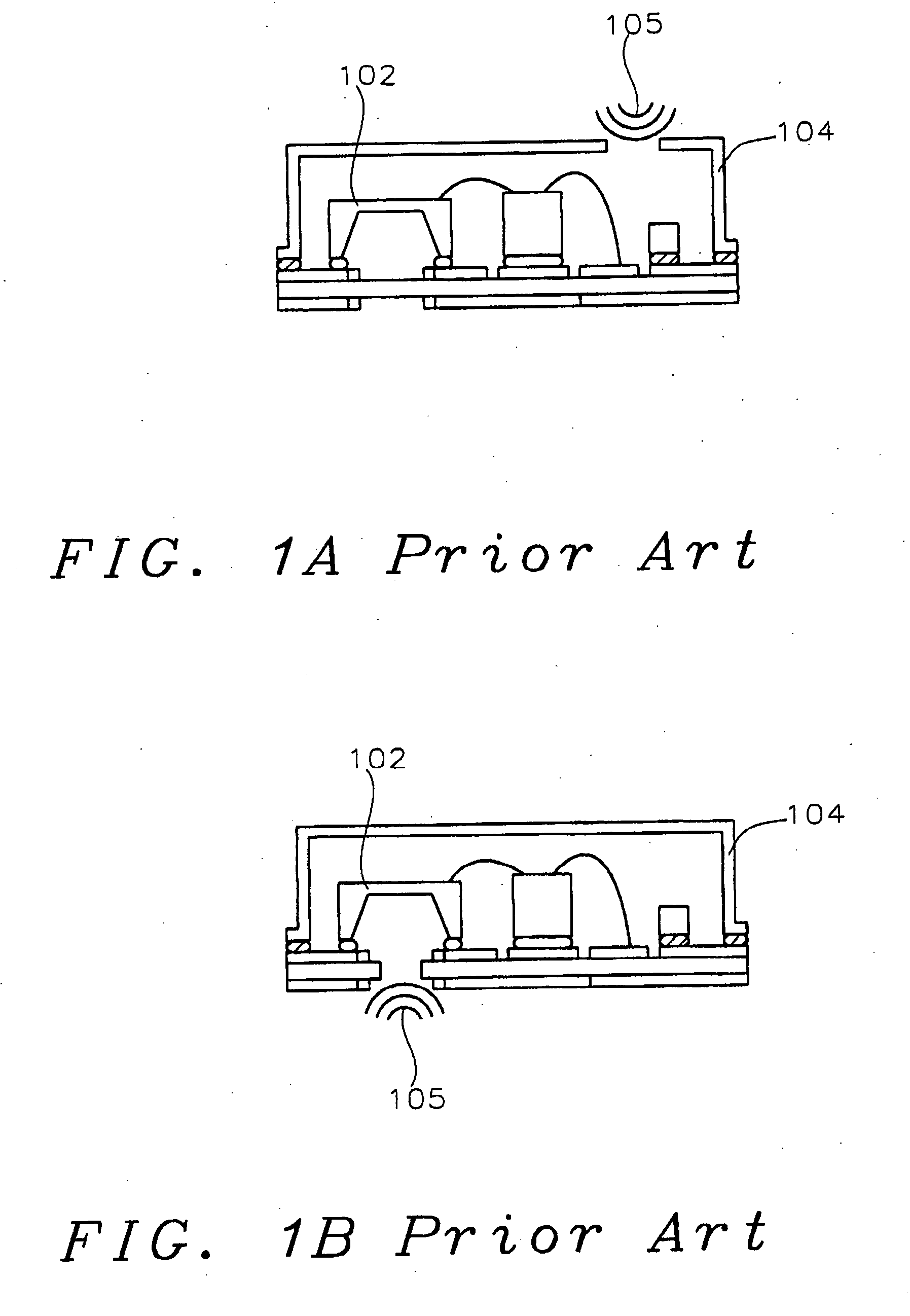

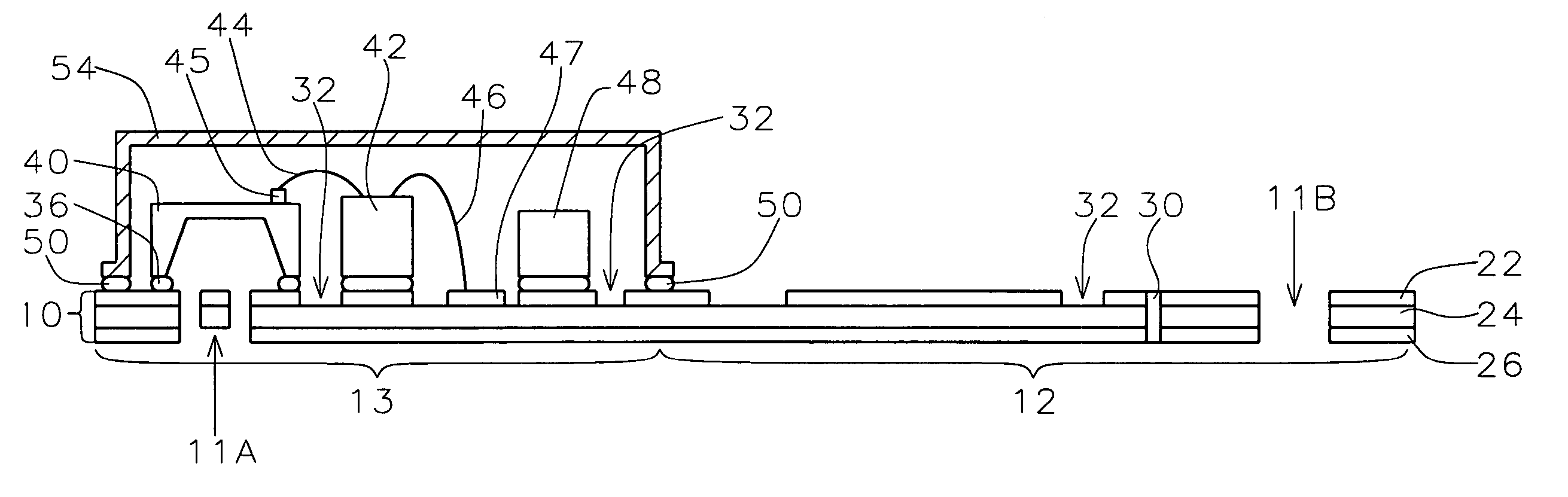

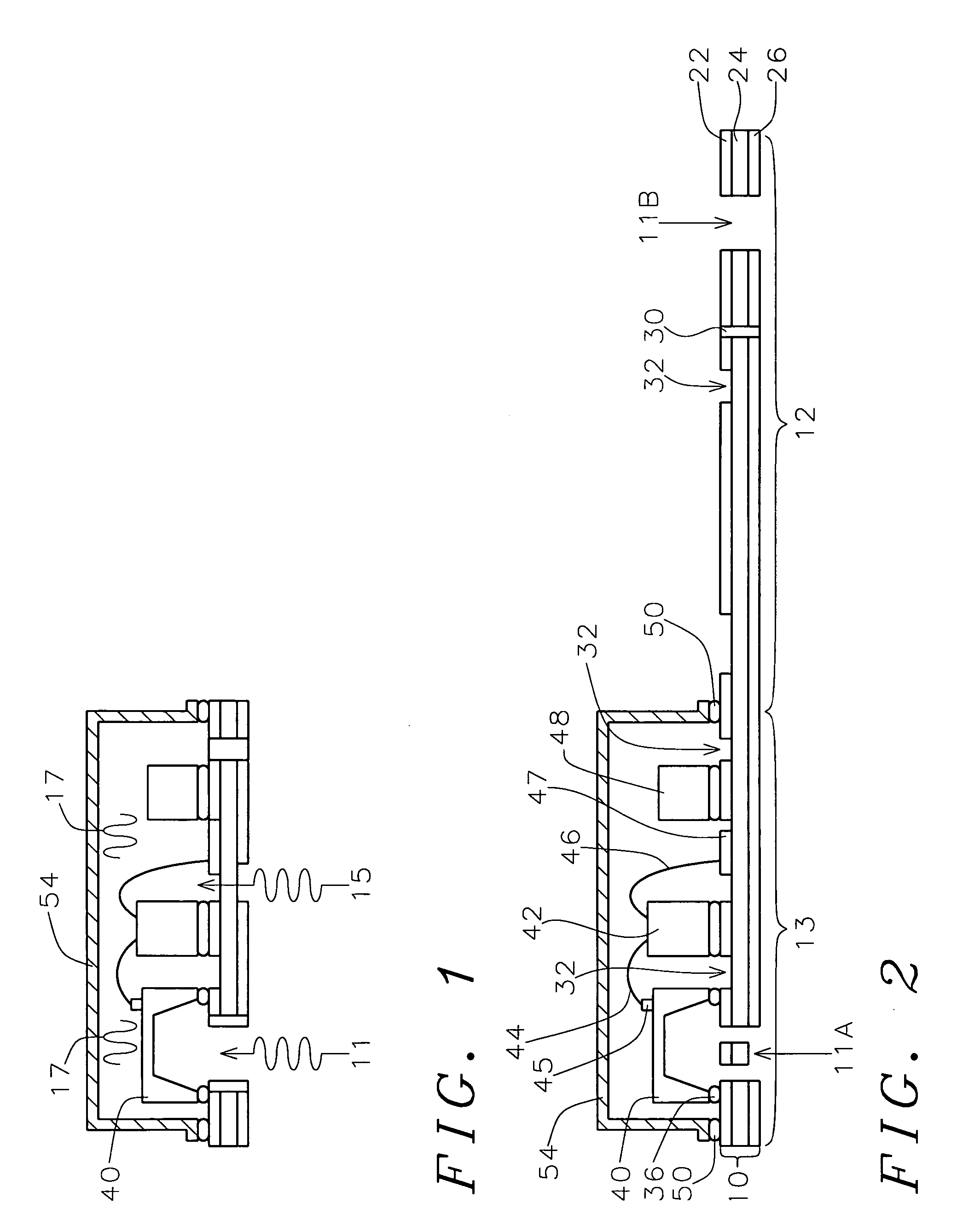

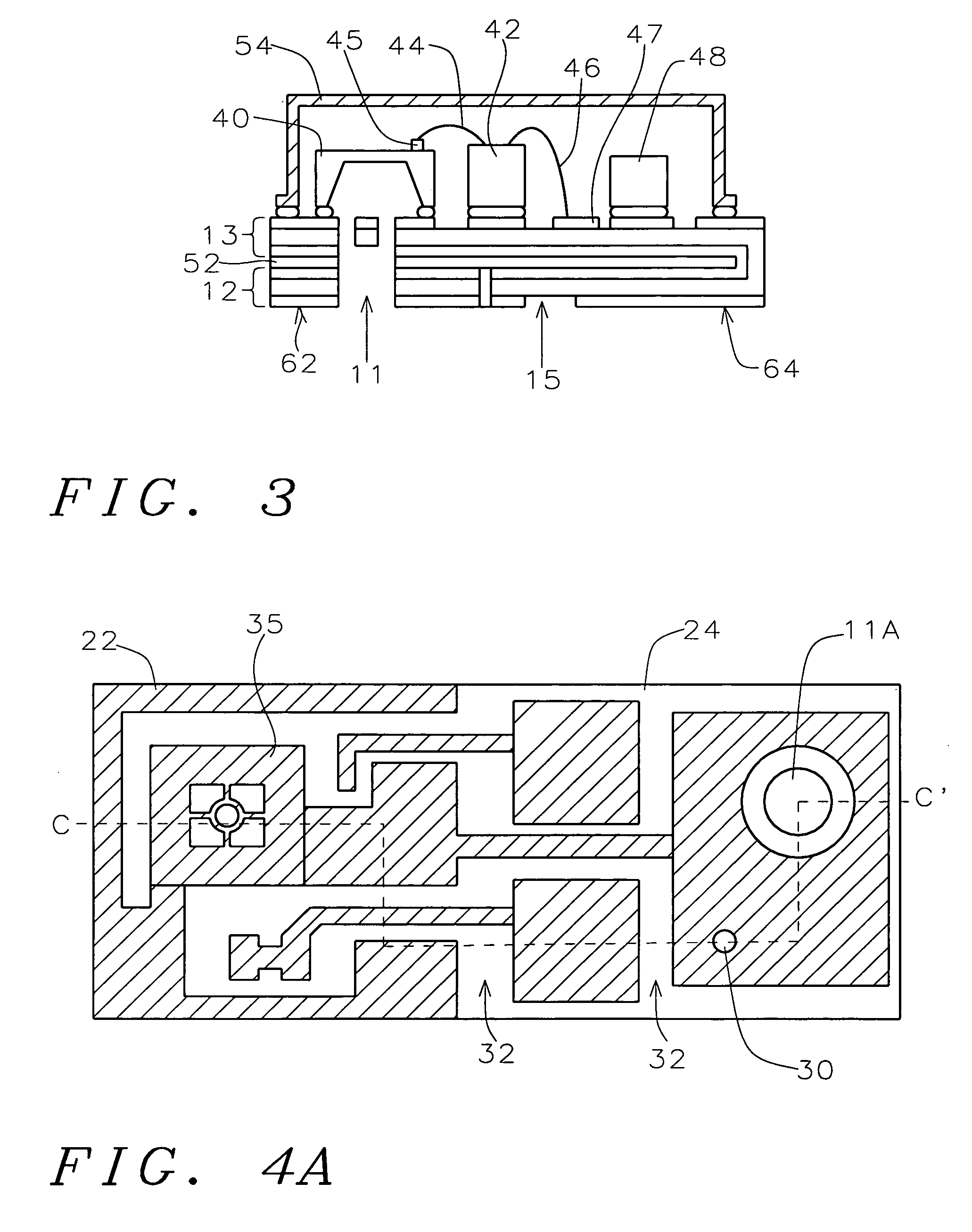

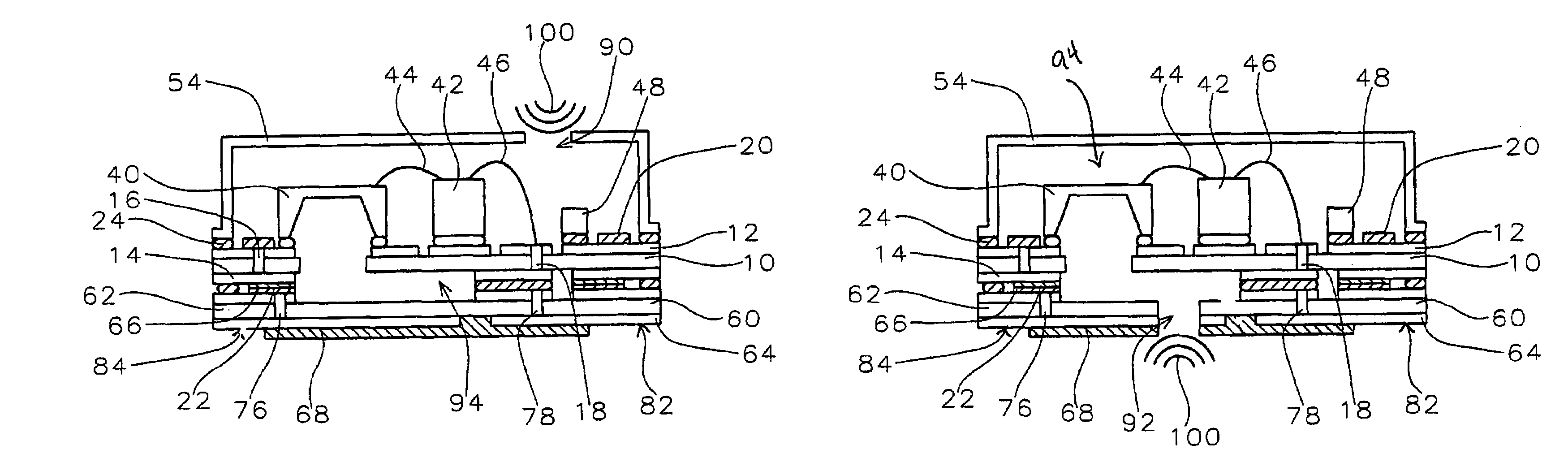

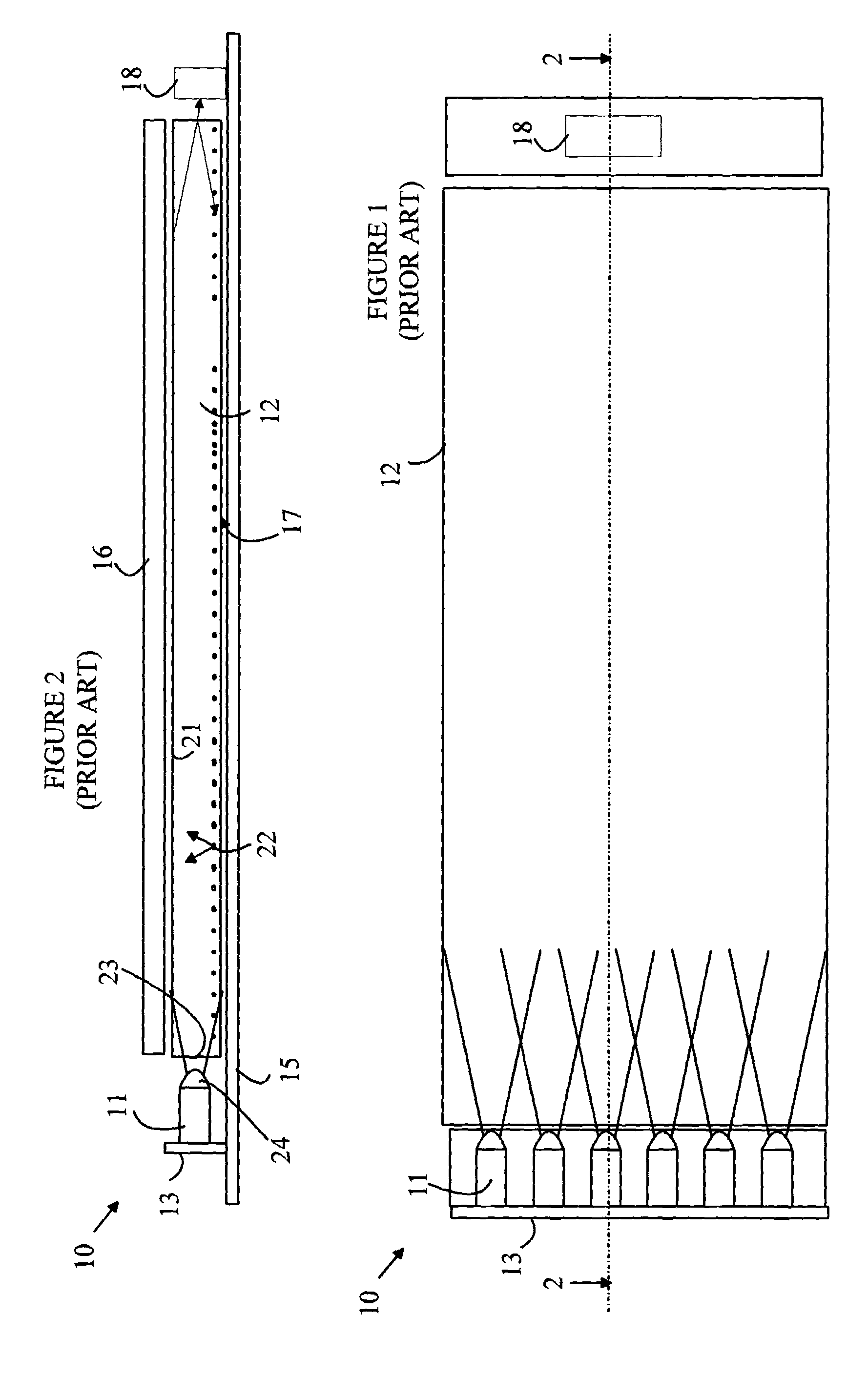

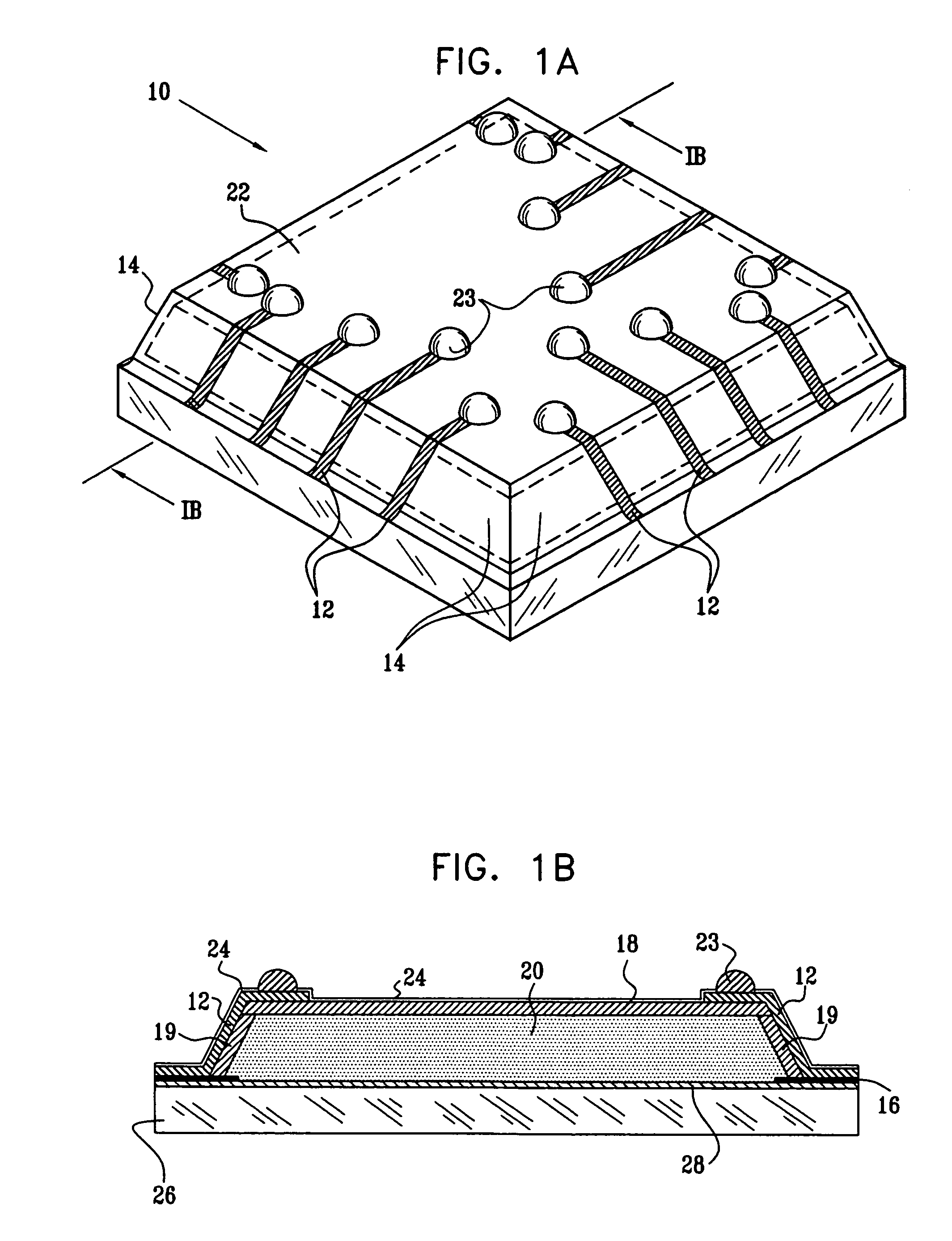

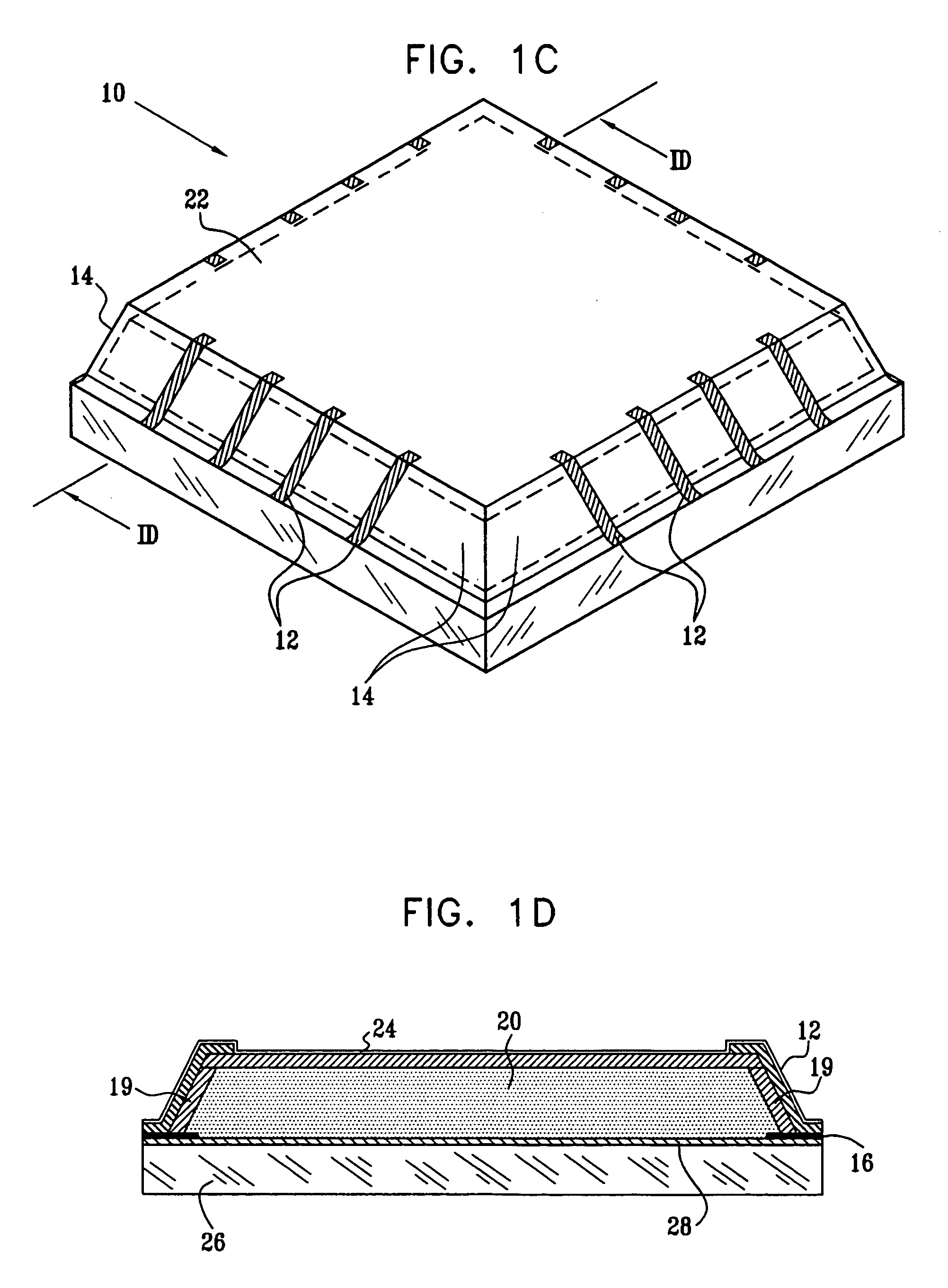

MEMS microphone with a stacked PCB package and method of producing the same

ActiveUS20070205492A1Cost-effectiveSemiconductor/solid-state device detailsSolid-state devicesEdge surfaceAcoustic energy

A MEMS microphone with a stacked PCB package is described. The MEMS package has at least one MEMS acoustic sensor device located on a PCB stack. A metal cap structure surrounds the at least one MEMS acoustic sensor device wherein an edge surface of the metal cap structure is attached and electrically connected to the PCB stack. In a first embodiment, a back chamber is formed underlying the at least one MEMS acoustic sensor device and within the PCB stack wherein an opening underlying the at least one MEMS acoustic sensor device accesses the back chamber. An opening in the metal cap structure not aligned with the at least one MEMS acoustic sensor device allows external fluid, acoustic energy or pressure to enter the at least one MEMS acoustic sensor device. In a second embodiment, a back chamber is formed in the space under the metal cap and over the first PCB. A hollow chamber is formed between the first PCB and the second PCB wherein an opening under the at least one MEMS acoustic sensor device accesses the hollow chamber. An opening in a bottom surface of the PCB stack not aligned with the at least one MEMS acoustic sensor device also accesses the hollow chamber and allows external fluid, acoustic energy or pressure to enter the at least one MEMS acoustic sensor device.

Owner:SHANDONG GETTOP ACOUSTIC

Method for package-on-package assembly with wire bonds to encapsulation surface

ActiveUS8372741B1Less thicknessSemiconductor/solid-state device detailsSolid-state devicesEdge surfaceEngineering

A microelectronic assembly includes a substrate having a first and second opposed surfaces. A microelectronic element overlies the first surface and first electrically conductive elements can be exposed at at least one of the first surface or second surfaces. Some of the first conductive elements are electrically connected to the microelectronic element. Wire bonds have bases joined to the conductive elements and end surfaces remote from the substrate and the bases, each wire bond defining an edge surface extending between the base and the end surface. An encapsulation layer can extend from the first surface and fill spaces between the wire bonds, such that the wire bonds can be separated by the encapsulation layer. Unencapsulated portions of the wire bonds are defined by at least portions of the end surfaces of the wire bonds that are uncovered by the encapsulation layer.

Owner:INVENSAS CORP

MEMS packaging method for enhanced EMI immunity using flexible substrates

ActiveUS20070013052A1Semiconductor/solid-state device detailsSolid-state devicesEdge surfaceElectrical and Electronics engineering

A MEMS package and methods for its embodiment are described. The MEMS package has at least one MEMS device mounted on a flexible and foldable substrate. A metal cap structure surrounds the at least one MEMS device wherein an edge surface of the metal cap structure is attached to the flexible substrate and wherein a portion of the flexible substrate is folded under itself thereby forming the MEMS package. A meshed metal environmental hole underlying the at least one MEMS device provides enhanced EMI immunity.

Owner:SHANDONG GETTOP ACOUSTIC

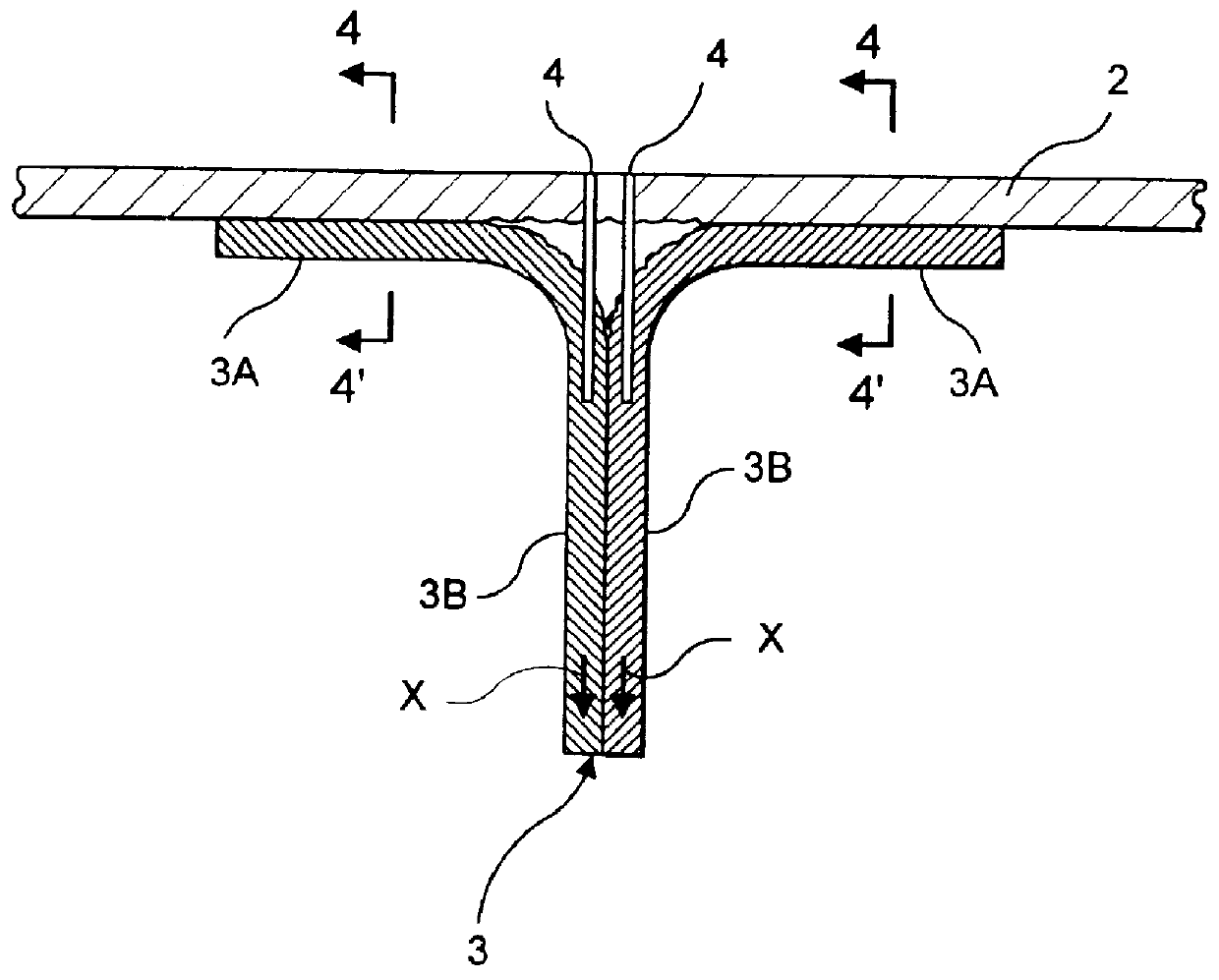

Fiber-reinforced composite materials structures and methods of making same

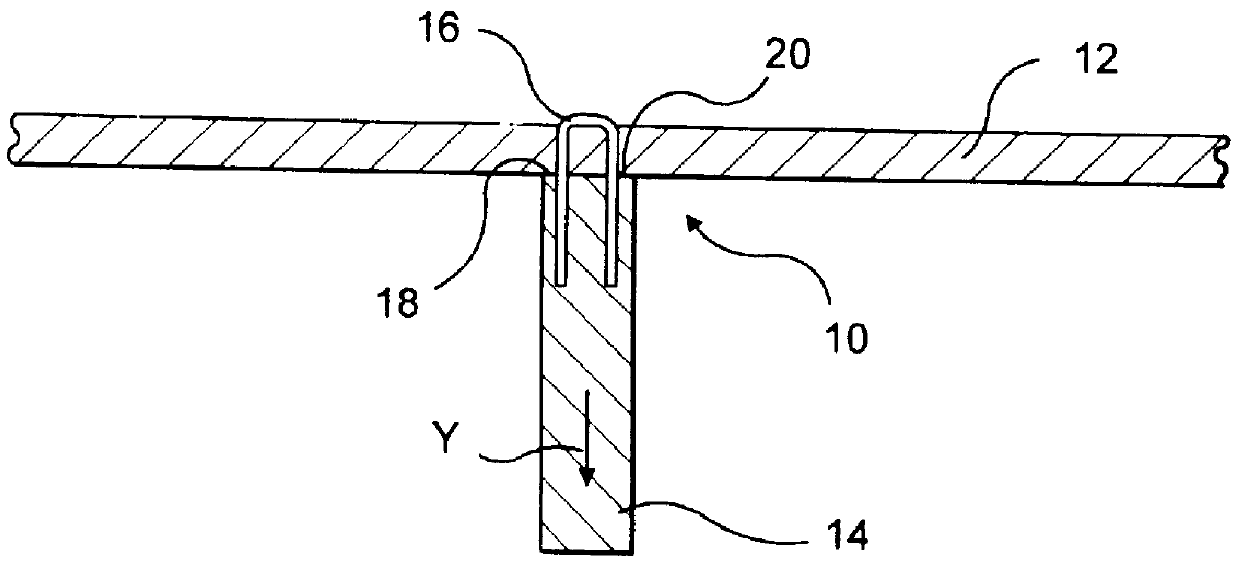

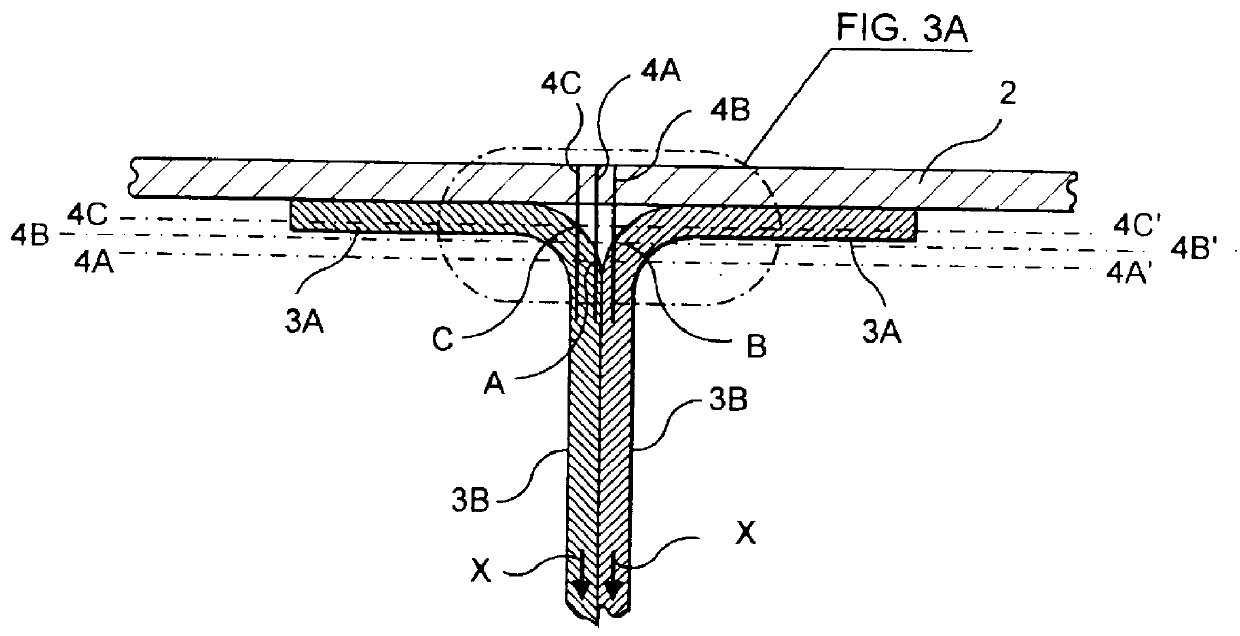

Reinforcement preforms and methods for making same for use in fiber-reinforced composite materials structures are disclosed, in which the reinforcement preforms comprise first and second reinforcement preform elements which include strength reinforcement fibers that are in desired directional orientation. The first element has a cross-fiber surface which extends transverse of its constituent strength reinforcement fibers and is in contacting juxtaposition to a selected surface region of the second element, forming an abutment therebetween. Abutment strength reinforcing fibers, which may optionally be introduced in situ by a continuum of fibers, such as a yarn or thread, extend through at least a portion of said second element and its said selected surface region, the abutment, said cross-fiber edge surface, and into the first element substantially in the direction of orientation to its constituent strength fibers to which its cross-fiber surface is transverse.

Owner:ALBANY ENGINEERED COMPOSITES

MEMS microphone with a stacked PCB package and method of producing the same

ActiveUS7436054B2Cost-effectiveSemiconductor/solid-state device detailsSolid-state devicesEdge surfaceAcoustic energy

Owner:SHANDONG GETTOP ACOUSTIC

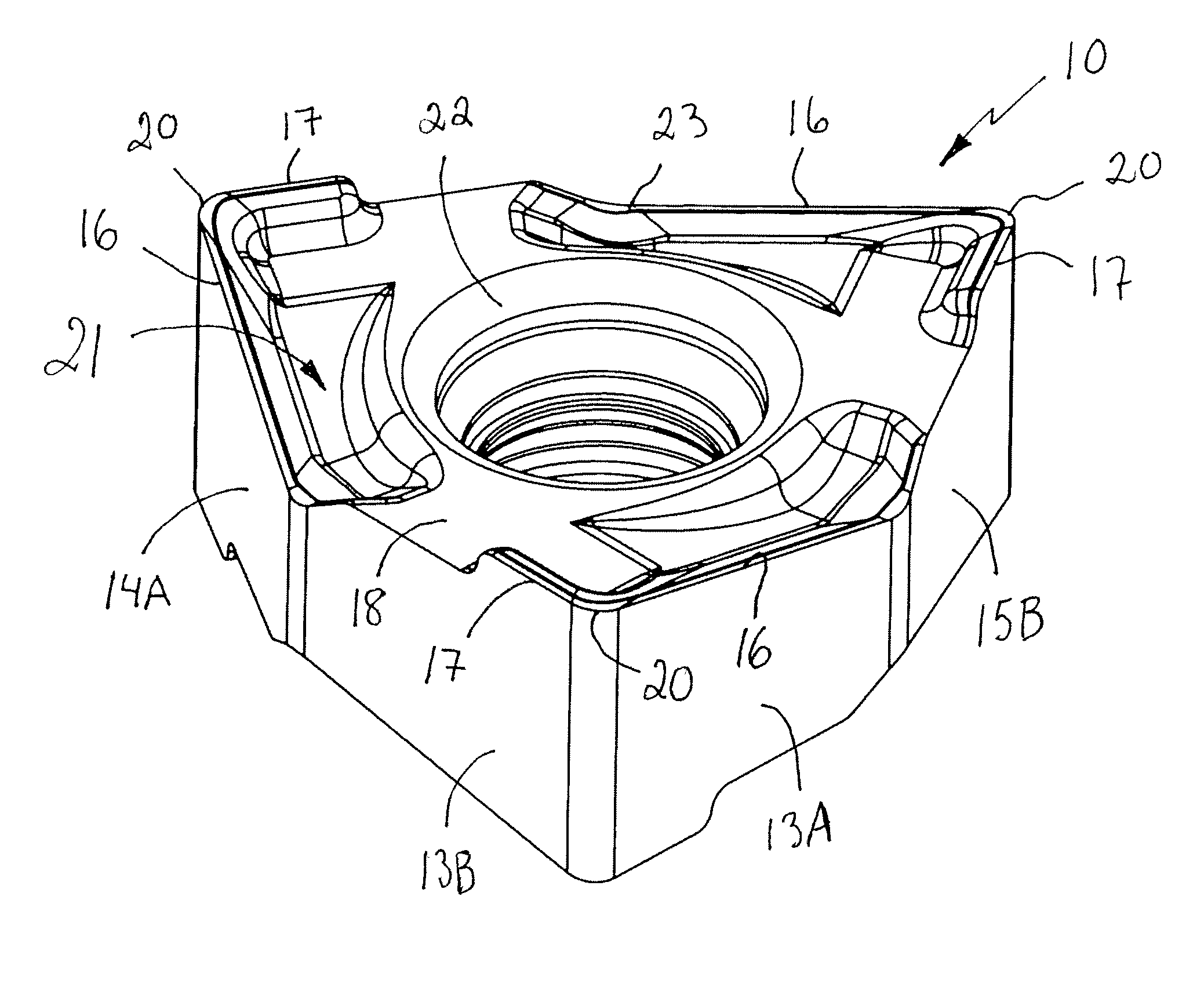

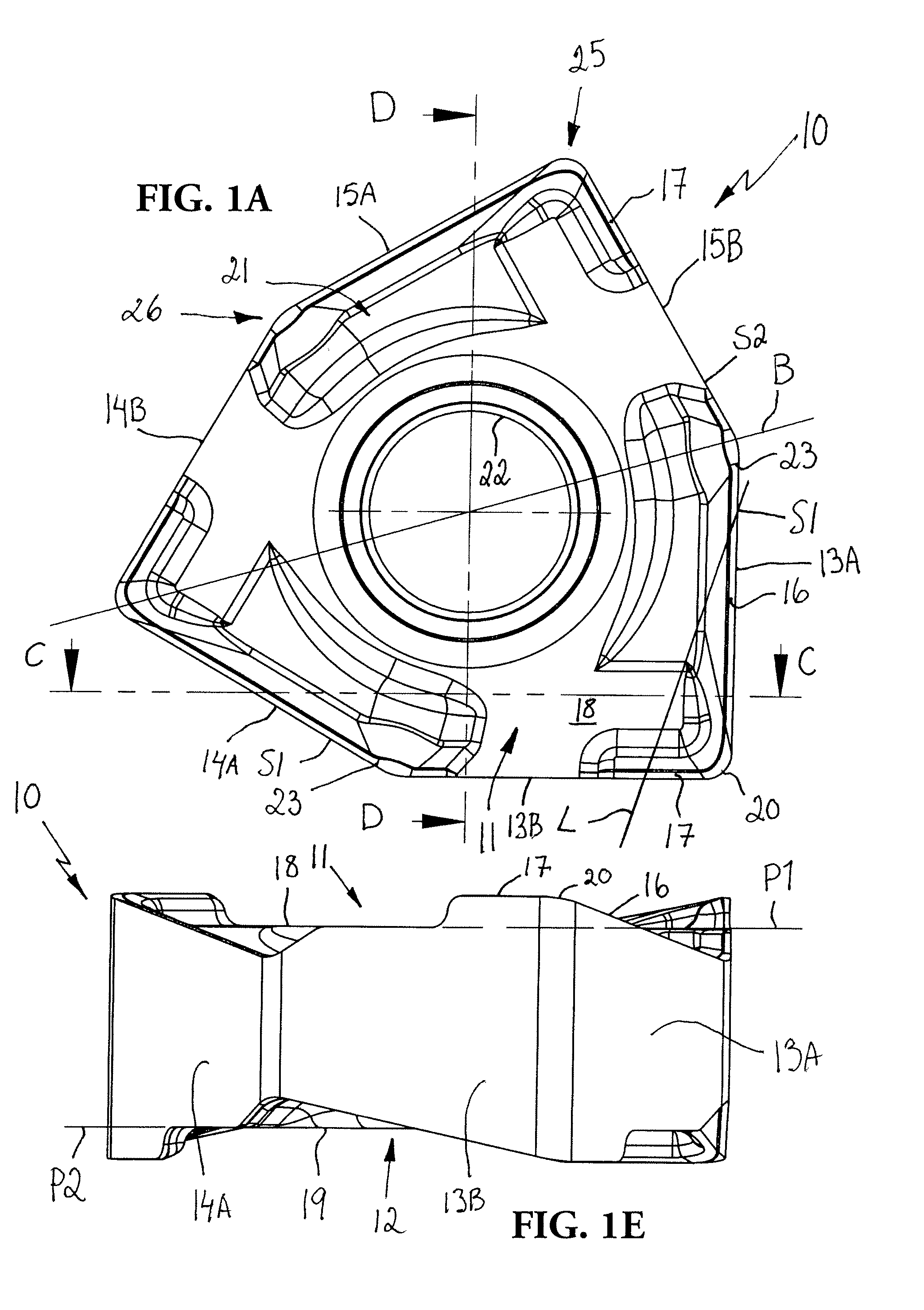

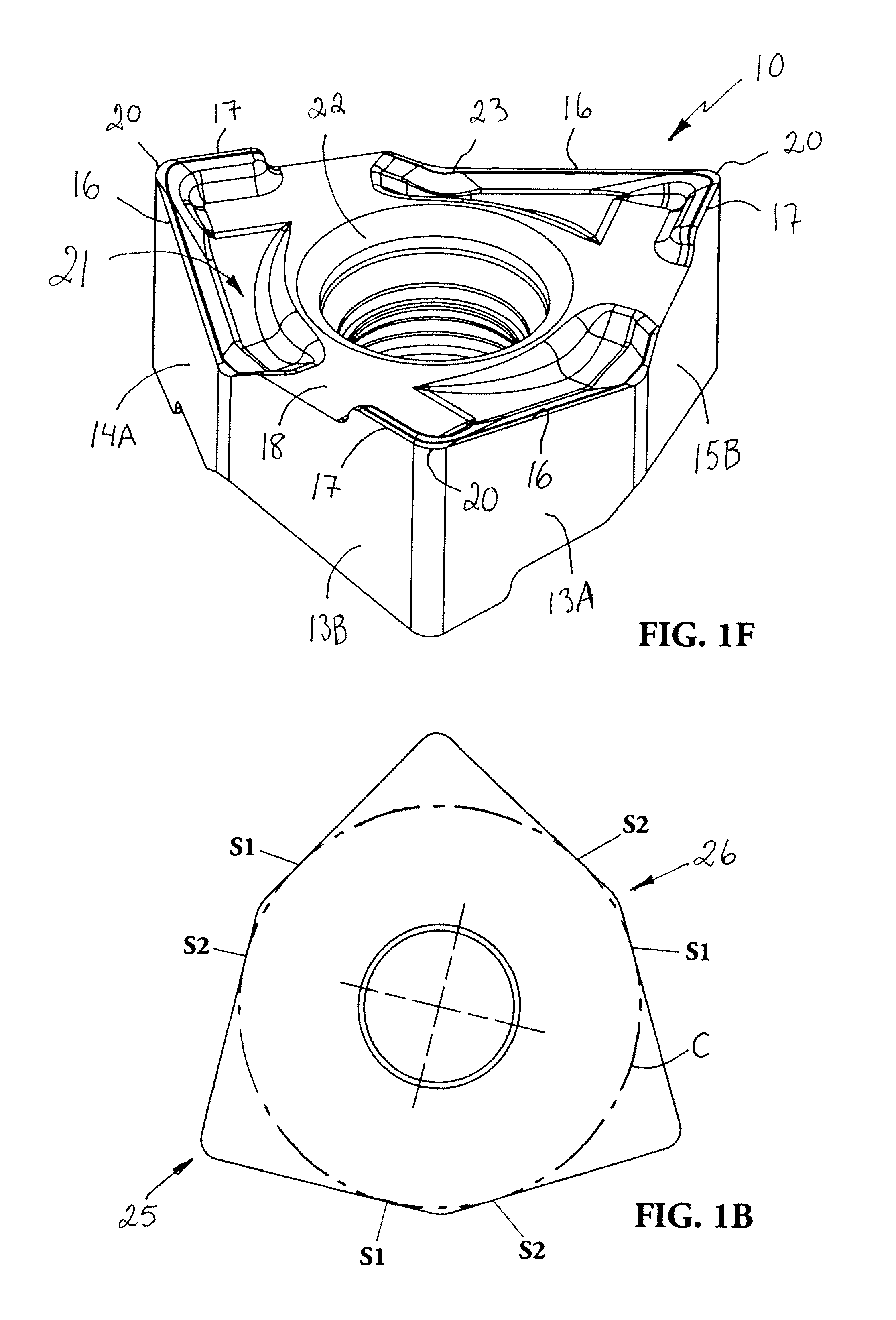

Milling insert and a milling tool

The present invention relates to an indexable milling insert and a milling tool for chip removing machining. The milling insert is intended to be able to mill substantially perpendicular corners in a work piece. The milling insert comprises an upper side, a lower side and edge surfaces extending therebetween. The upper side and the lower side are substantially identical. An imaginary circle inscribed in the milling insert touches the milling insert periphery in four to six points. Lines of intersection between the edge surfaces and the sides form relative to each other substantially perpendicular main cutting edges and minor cutting edges. Each of the sides includes a support surface, each of which being provided in a plane. Each minor cutting edge projects from the plane of the associated support surface. Each major cutting edge intersects the plane of the associated support surface.

Owner:SECO TOOLS AB

Microelectronic packages with dual or multiple-etched flip-chip connectors

ActiveUS20120007232A1Semiconductor/solid-state device detailsSolid-state devicesEdge surfaceEngineering

A packaged microelectronic element includes a microelectronic element having a front surface and a plurality of first solid metal posts extending away from the front surface. A substrate has a major surface and a plurality of conductive elements exposed at the major surface and joined to the first solid metal posts. In particular examples, the conductive elements can be bond pads or can be second posts having top surfaces and edge surfaces extending at substantial angles away therefrom. Each first solid metal post includes a base region adjacent the microelectronic element and a tip region remote from the microelectronic element, the base region and tip region having respective concave circumferential surfaces. Each first solid metal post has a horizontal dimension which is a first function of vertical location in the base region and which is a second function of vertical location in the tip region.

Owner:TESSERA INC

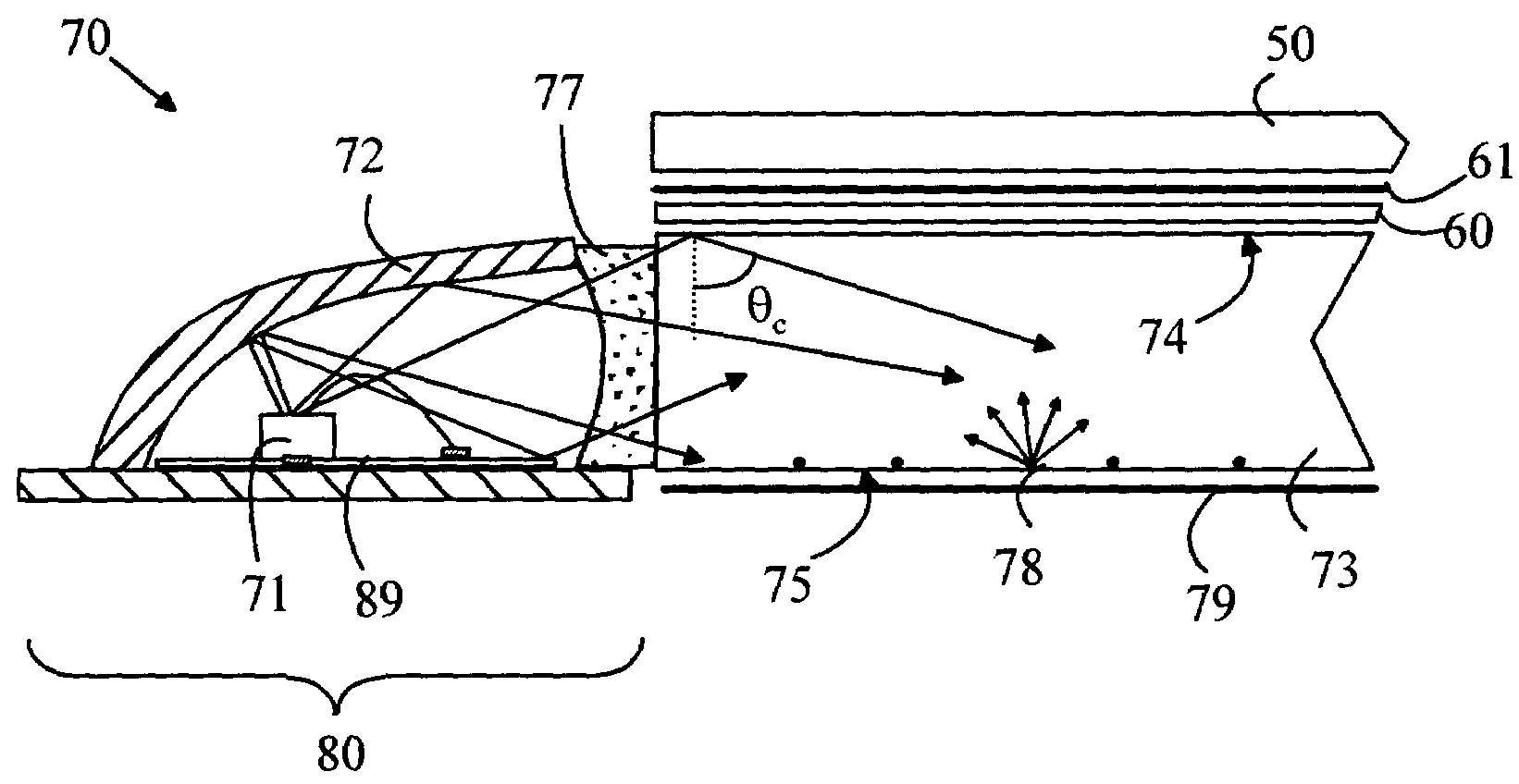

Light source for LCD back-lit displays

An apparatus having a light source, light pipe, and light conversion layer is disclosed. The light source includes a plurality of LED dies arranged in an array, each LED emitting light having an excitation wavelength, the light source emitting light within a cone of angles. The light pipe is positioned to receive the light within the cone of angles through an edge surface such that the light within the predetermined cone of angles is totally reflected from the top surface. The light pipe has features that redirect some of the light at angles such that some of the redirected light exits through the top surface. The light conversion layer overlies the top surface and converts light of the excitation wavelength to light in an output spectrum having wavelengths different from the excitation wavelength. A display layer can be placed such that it is illuminated by light from the light pipe.

Owner:TAIWAN SEMICON MFG CO LTD

Methods and apparatus for packaging integrated circuit devices

ActiveUS20050104179A1Semiconductor/solid-state device detailsSolid-state devicesElectrical conductorInsulation layer

An integrally packaged integrated circuit device including an integrated circuit die including a crystalline substrate having first and second generally planar surfaces and edge surfaces and semiconductor circuitry formed over the first generally planar surface, at least one chip scale packaging layer formed over the semiconductor circuitry and the first generally planar surface, an insulation layer formed over the second generally planar surface and the edge surfaces and at least one electrical conductor formed directly on the insulation layer overlying the second generally planar surface, the at least one electrical conductor being connected to the circuitry by at least one pad formed directly on the first generally planar surface.

Owner:TESSERA TECH HUNGARY KFT +1

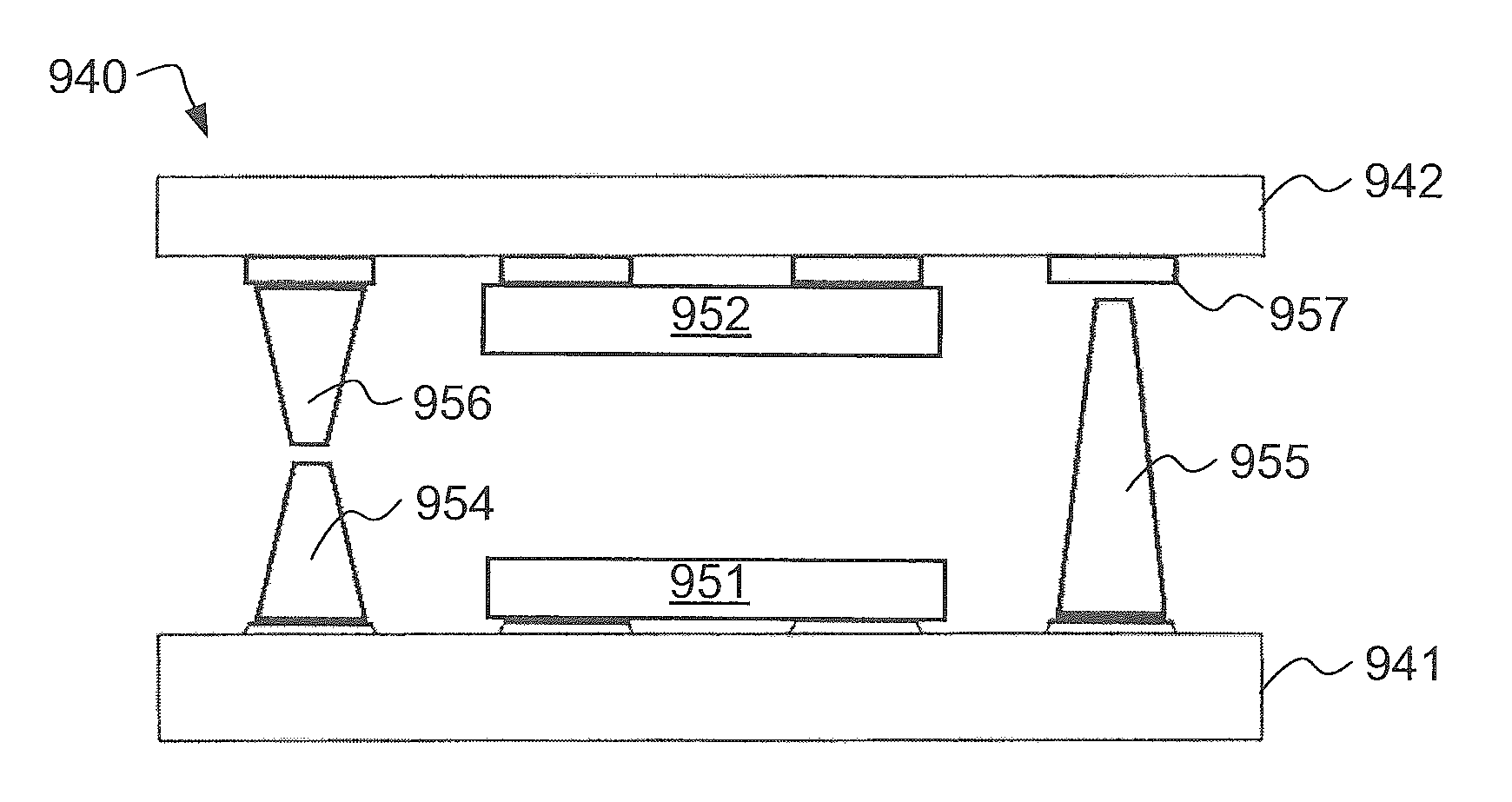

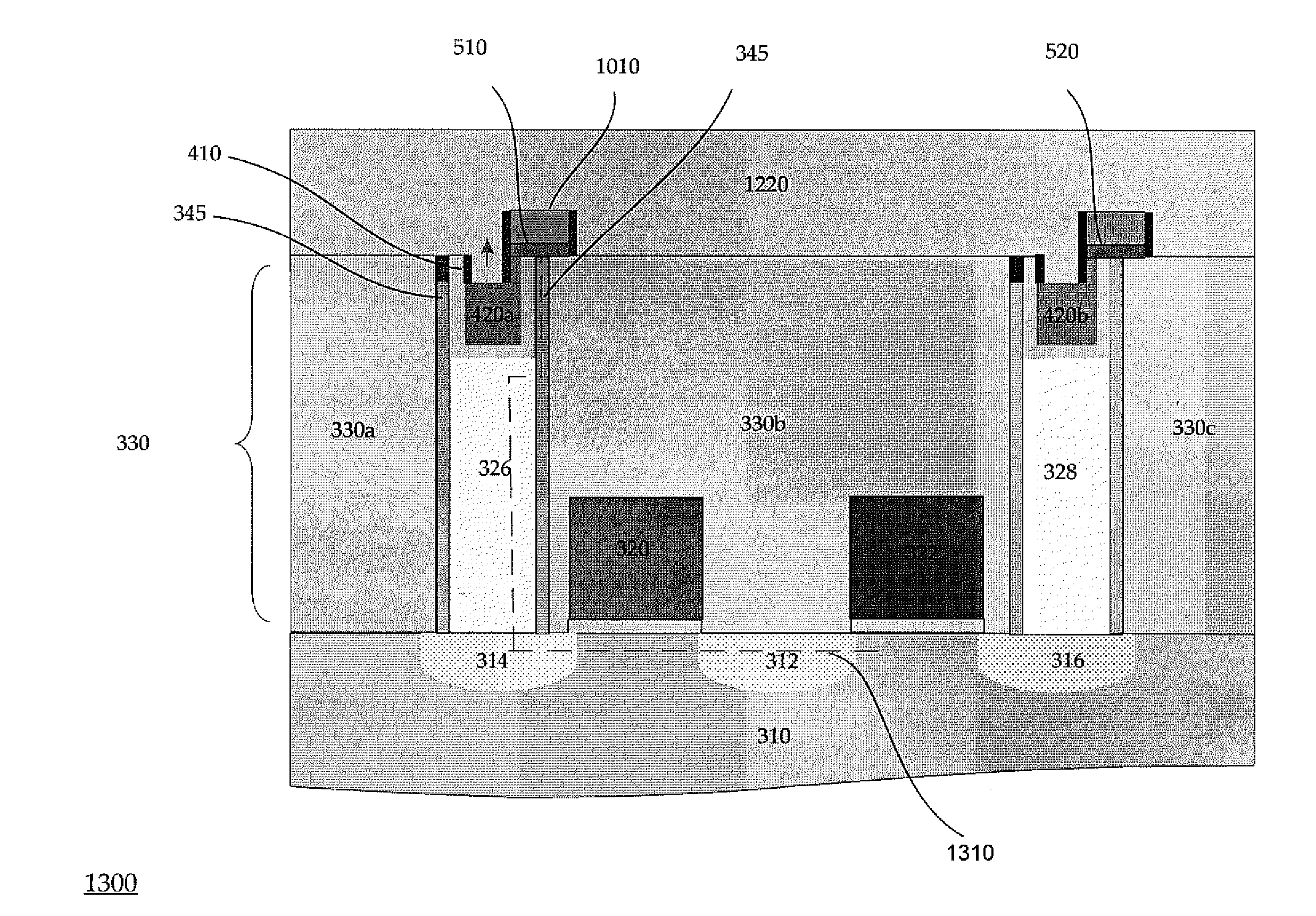

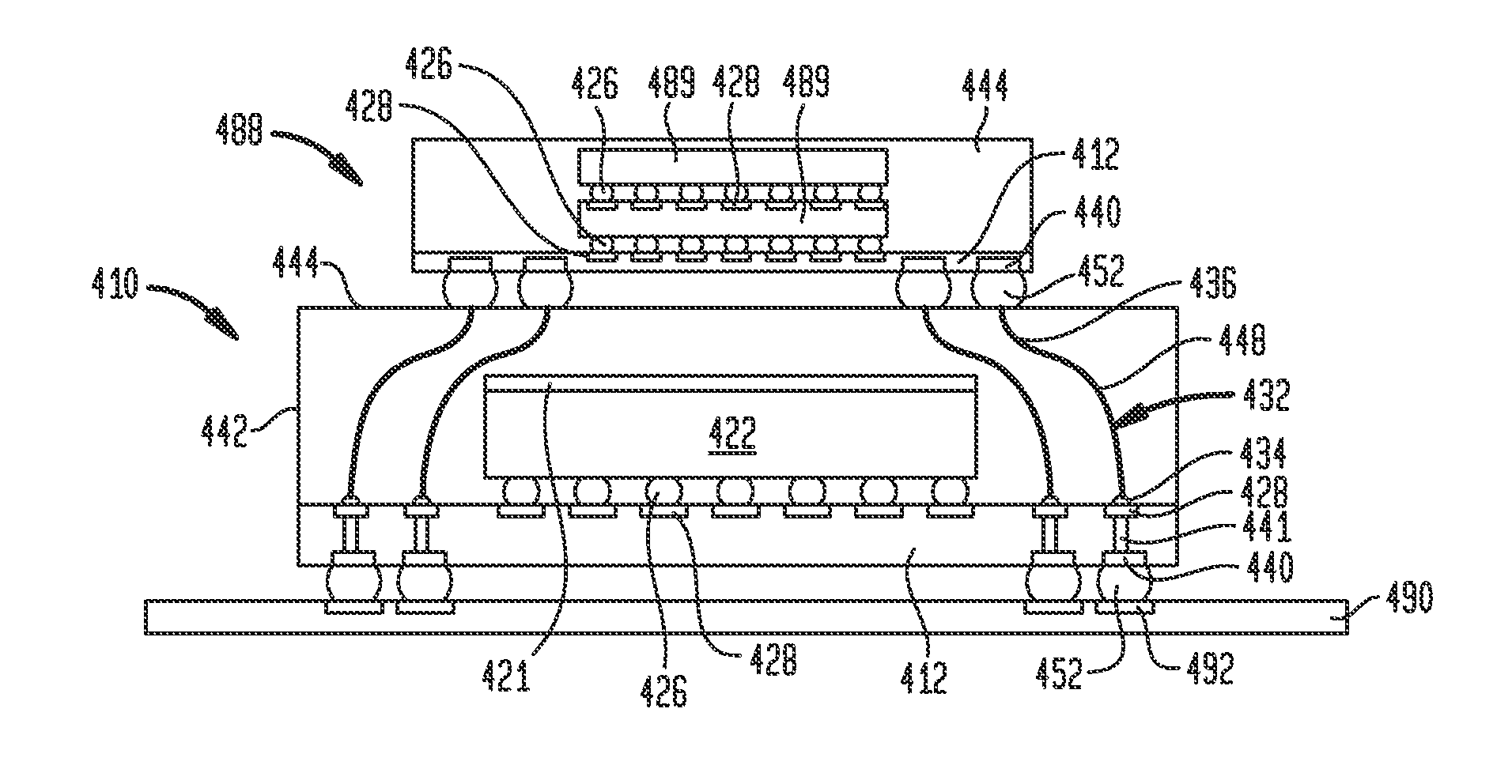

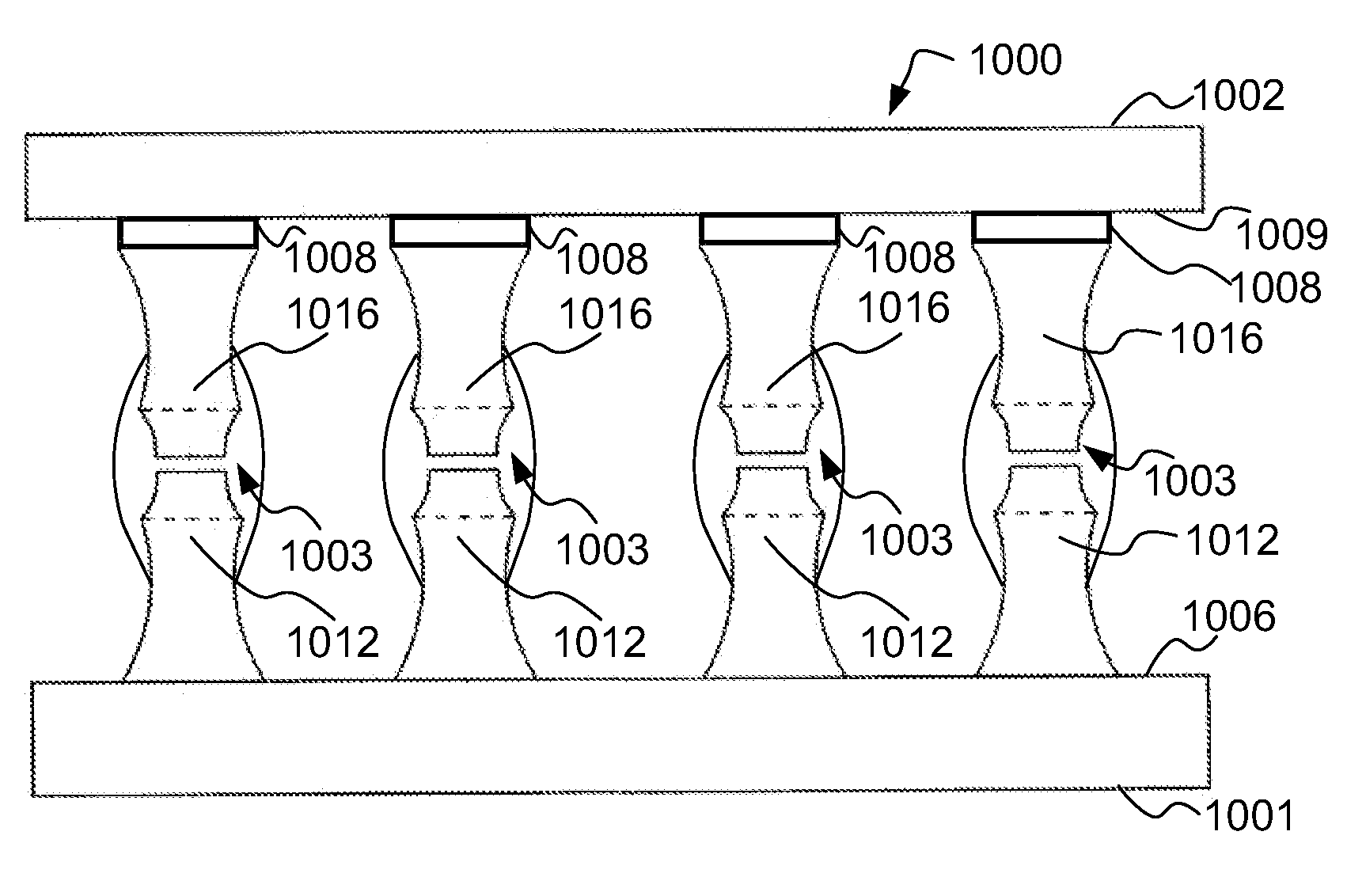

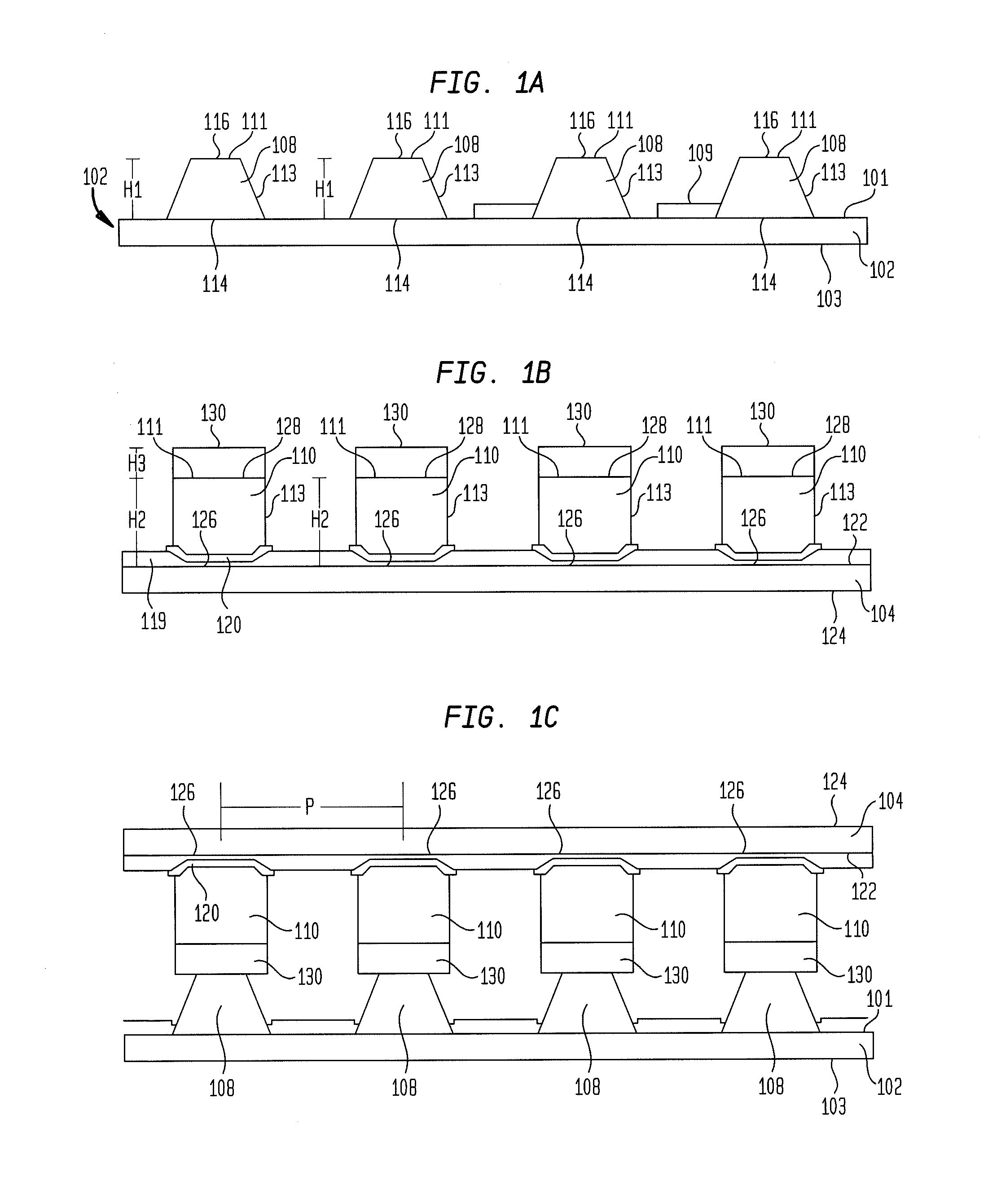

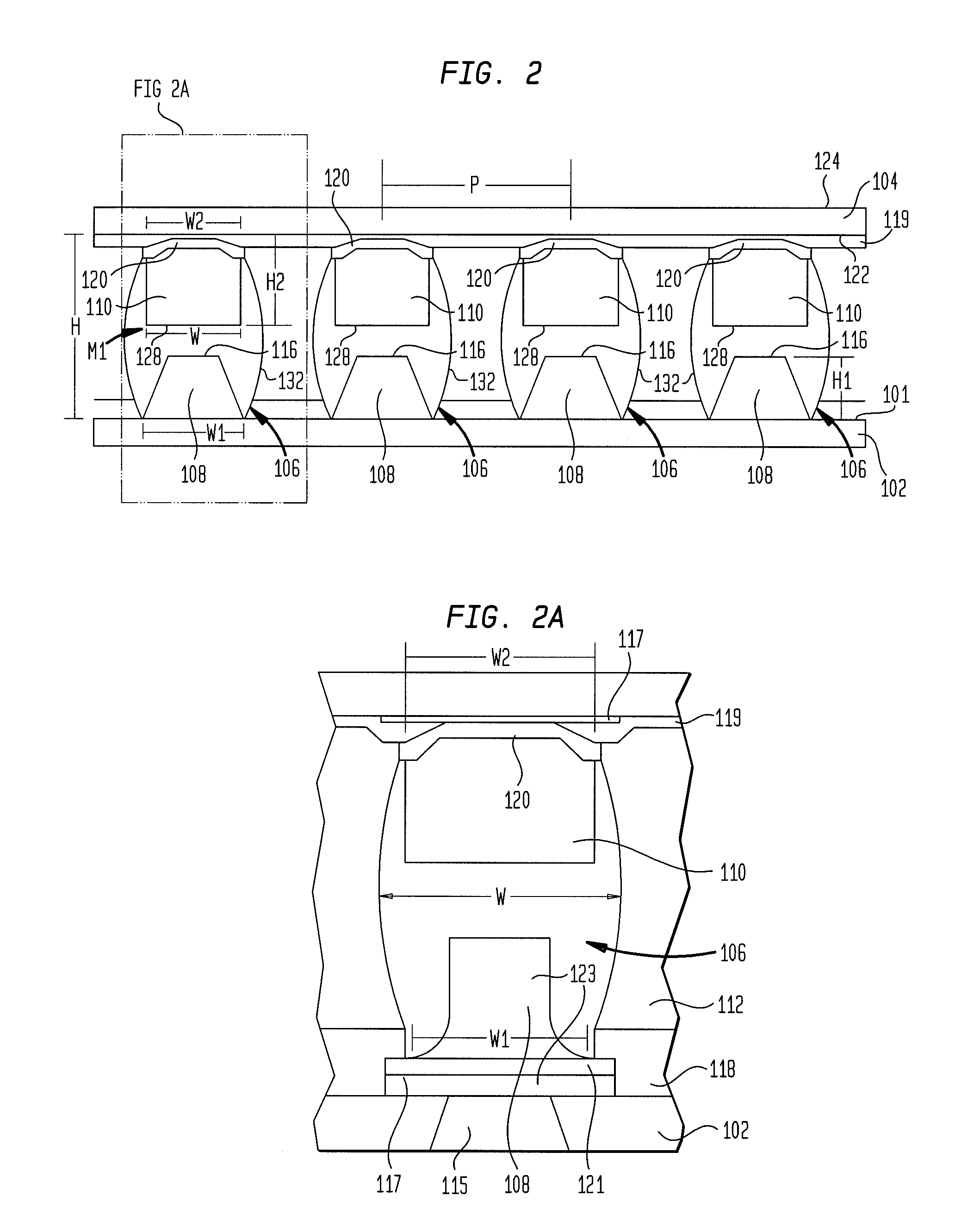

Stackable molded microelectronic packages

ActiveUS8482111B2Semiconductor/solid-state device detailsSolid-state devicesEdge surfaceElectrical connection

A microelectronic package has a microelectronic element overlying or mounted to a first surface of a substrate and substantially rigid conductive posts projecting above the first surface or projecting above a second surface of the substrate remote therefrom. Conductive elements exposed at a surface of the substrate opposite the surface above which the conductive posts project are electrically interconnected with the microelectronic element. An encapsulant overlies at least a portion of the microelectronic element and the surface of the substrate above which the conductive posts project, the encapsulant having a recess or a plurality of openings each permitting at least one electrical connection to be made to at least one conductive post. At least some conductive posts are electrically insulated from one another and adapted to simultaneously carry different electric potentials. In particular embodiments, the openings in the encapsulant at least partially expose conductive masses joined to posts, fully expose top surfaces of posts and partially expose edge surfaces of posts, or may only partially expose top surfaces of posts.

Owner:TESSERA INC

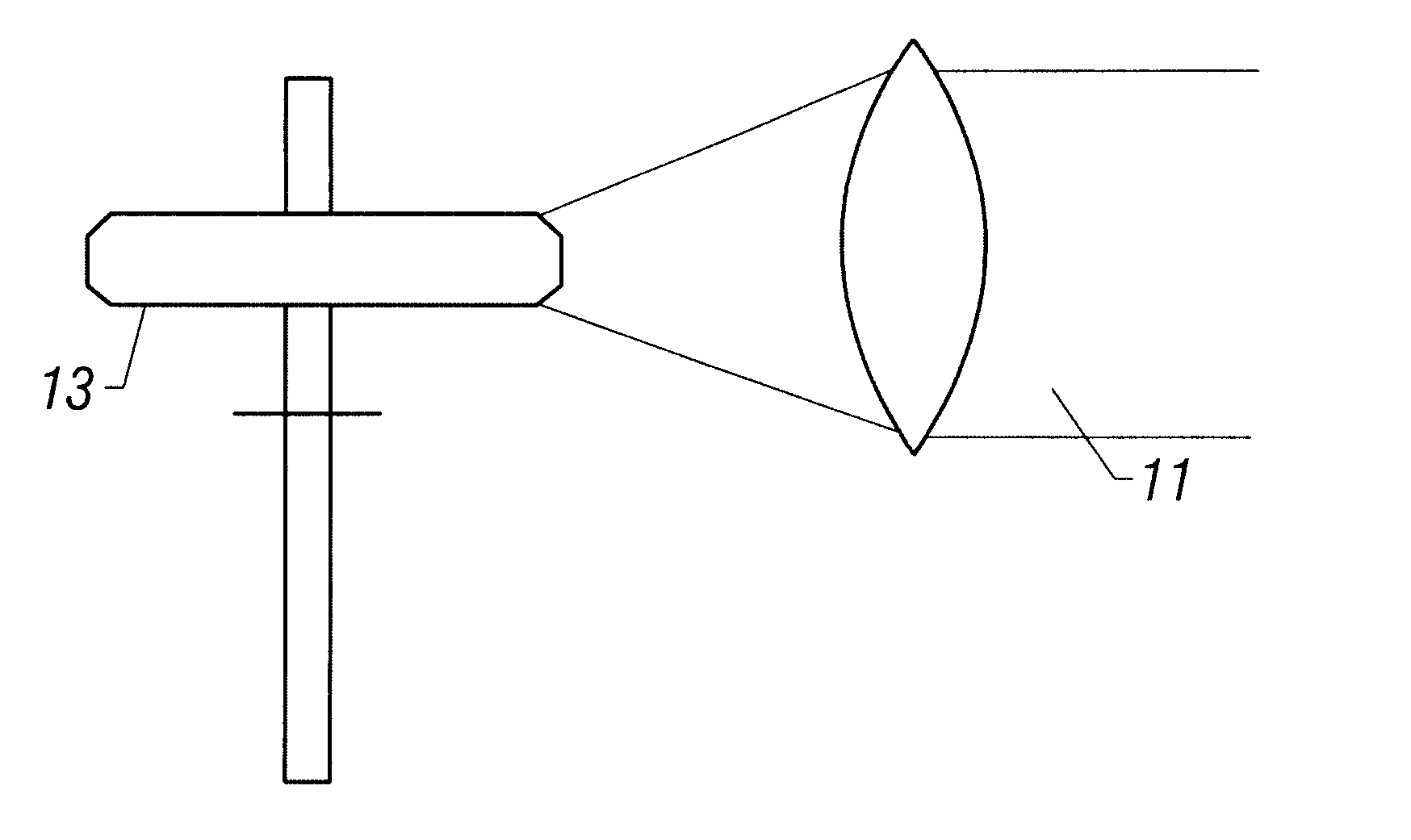

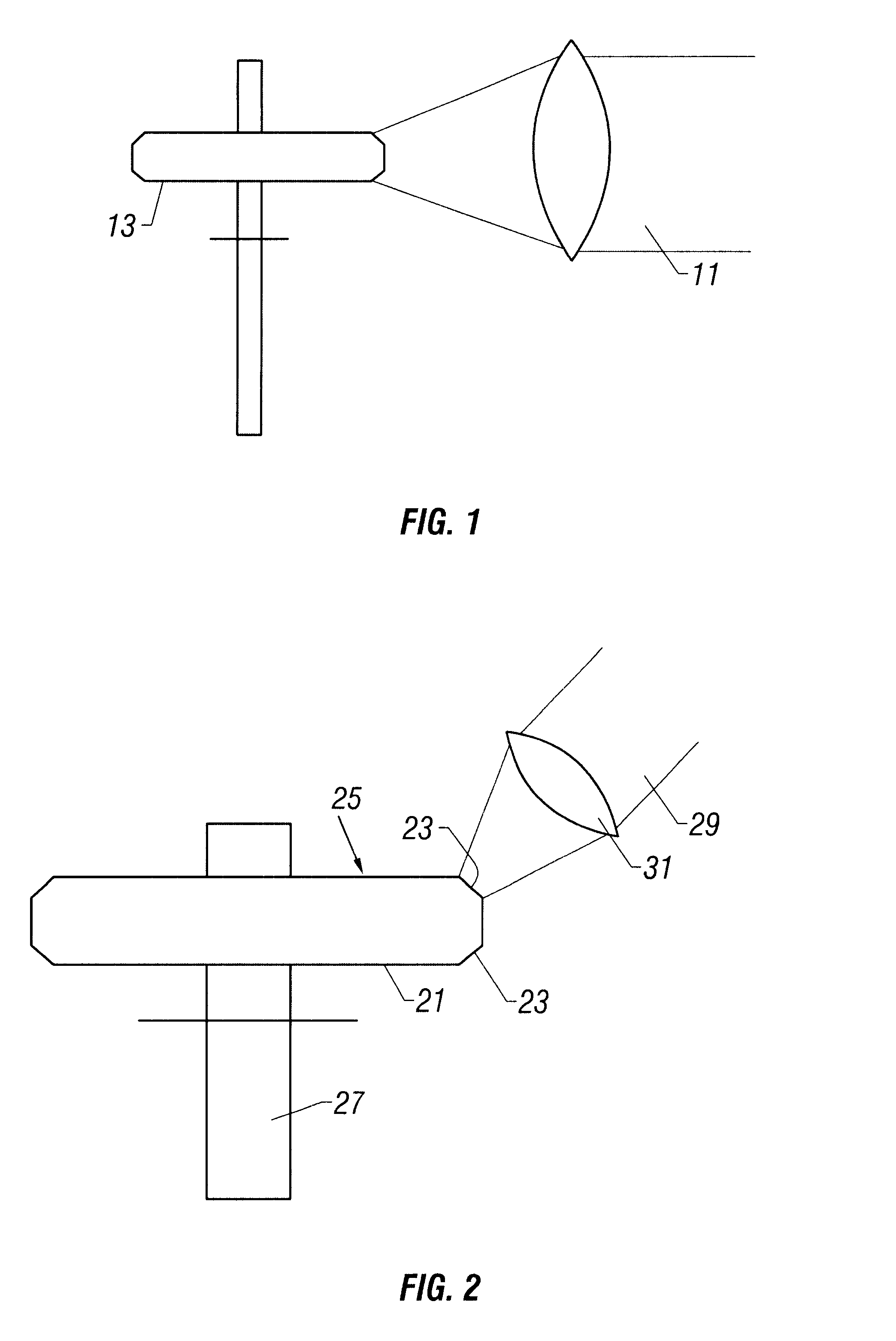

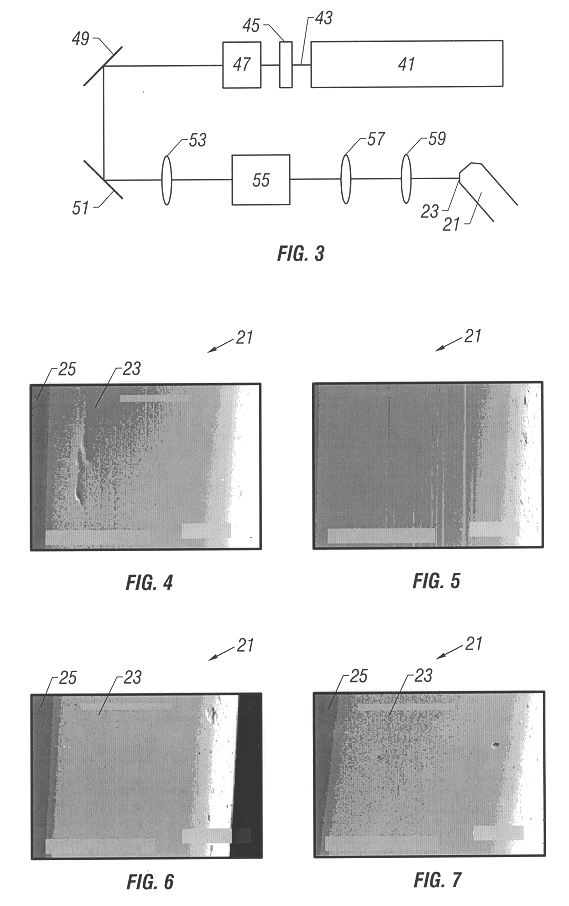

Apparatus and method for improving chamfer quality of disk edge surfaces with laser treatment

A carbon dioxide laser is used as a non-mechanical means for smoothing and polishing the as-cut chamfer surface at the edge of the disk. Applying laser radiation to the glass surface causes transient melting and resolidification. Due to surface tension effects, the glass resolidifies to produce a surface that is significantly smoother than it was before irradiation. If scratches or abrasive marks are present on the glass surface prior to irradiation, the irradiation process "polishes out" these defects as long as they are not too deep. At a wavelength near 10 mum, the penetration depth of the radiation into the glass is approximately 1 mum. Therefore, scratches and defects of this order of magnitude are eliminated. The quality of the resulting modified chamfer surface is far superior to the original mechanically ground and polished surface.

Owner:WESTERN DIGITAL TECH INC

Low closure force EMI shielding spacer gasket

InactiveUS6121545AEnhance the imageEnsure electrical continuityEngine sealsScreening gaskets/sealsEdge surfaceBending moment

An EMI shielding spacer gasket assembly for interposition under a predetermined compressive load within an electronics enclosure between a first surface and an oppositely-disposed second surface of the enclosure. The assembly includes a frame member and an electrically conductive, elastomeric member extending along at least a portion of the perimeter of the frame member as retained on a corresponding peripheral edge surface thereof. The elastomeric member has an outboard side which is compressible axially under the compressive load for providing an electrically conductive pathway between the surfaces of the enclosure. In an uncompressed orientation, the outboard side of the elastomeric member exhibits elongate upper and lower bearing portions which are disposed at a spaced-apart radial distance from the frame member to define a corresponding bending moment arm. Each of the bearing portions is angularly deflectable relative to the moment arm to effect the compression of the elastomeric member under a relatively low compressive load.

Owner:PARKER INTANGIBLES LLC

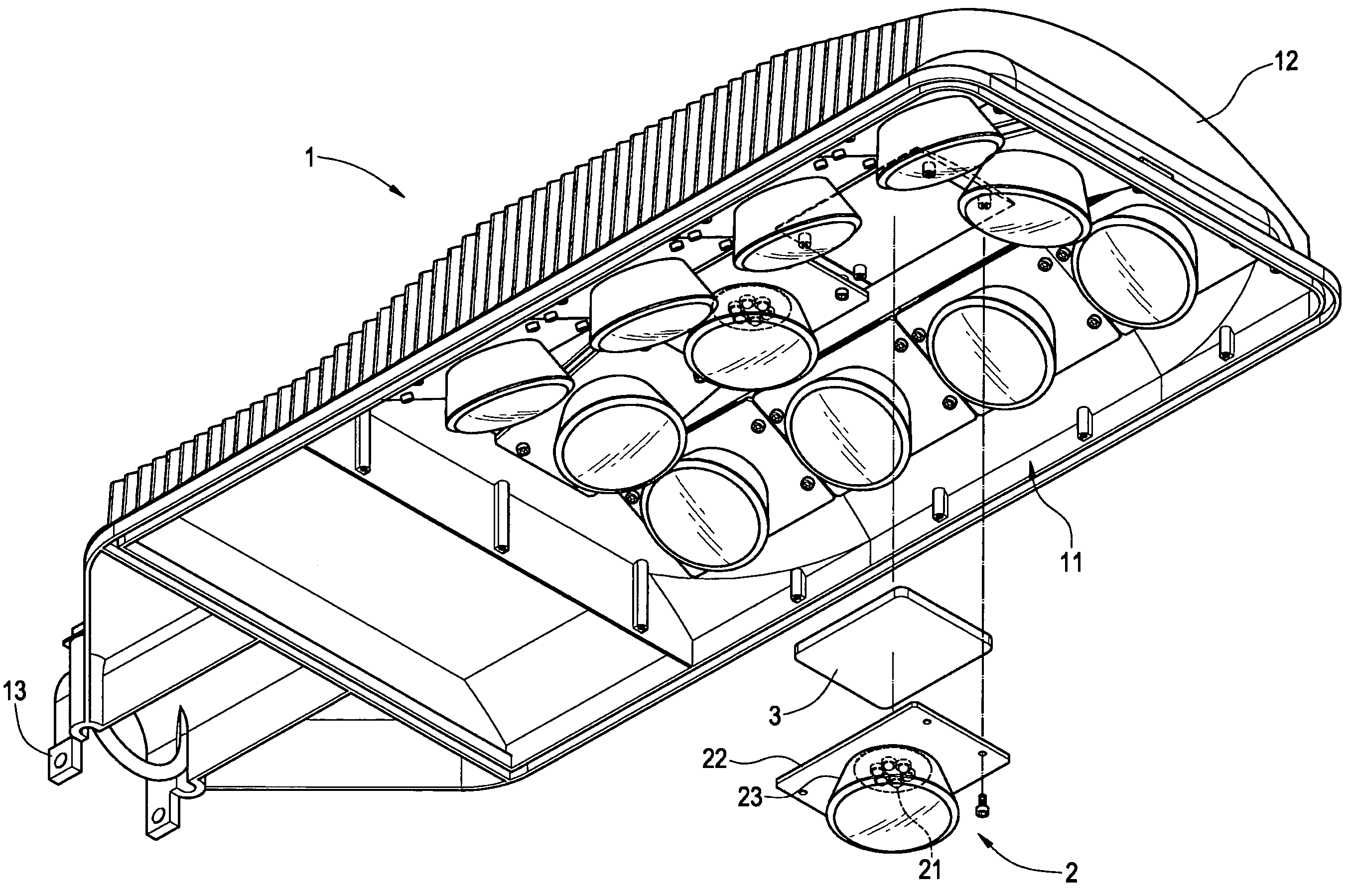

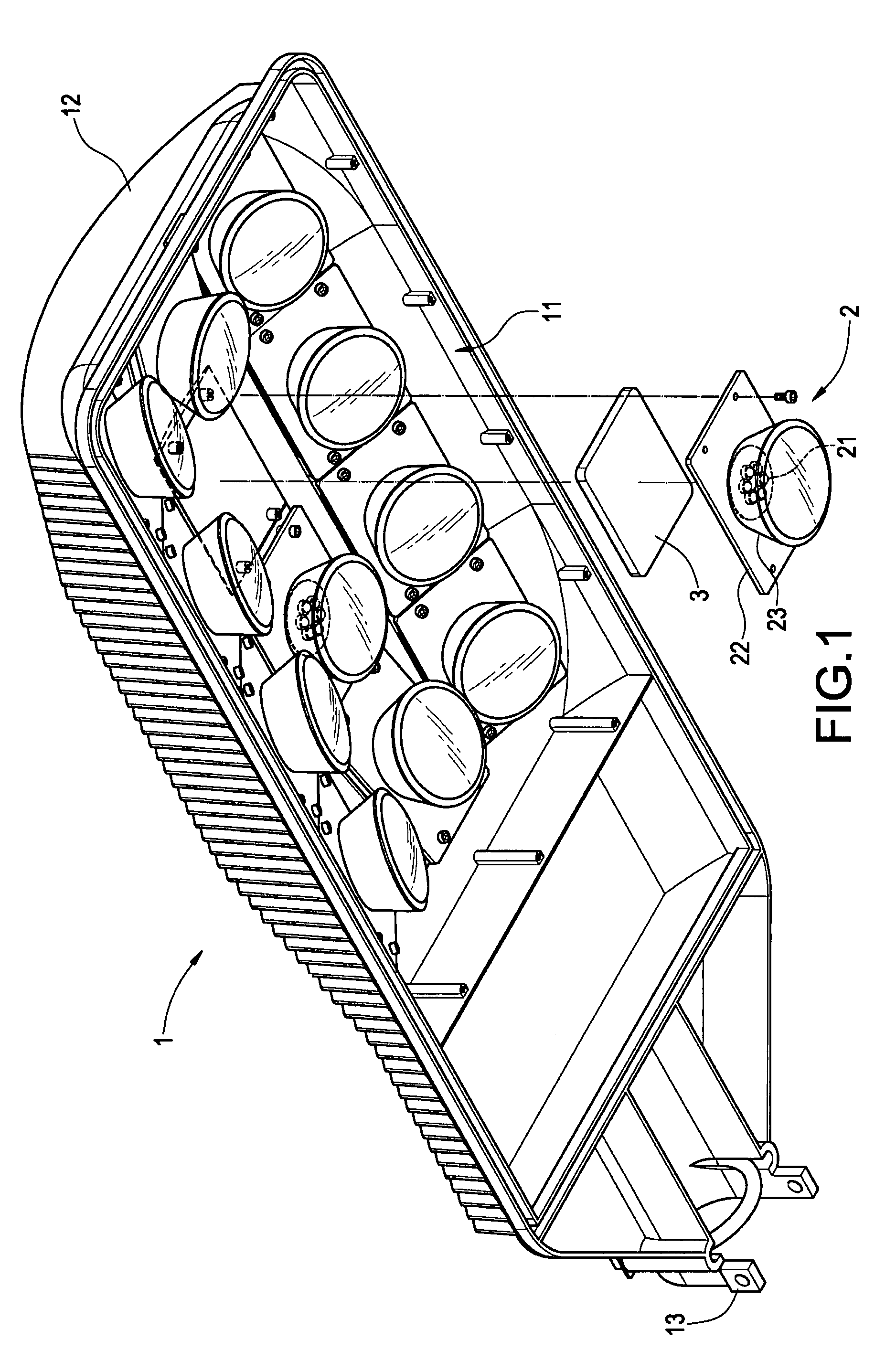

LED lamp device

InactiveUS7434959B1Improve performanceConvenient lightingMechanical apparatusPoint-like light sourceEdge surfaceEngineering

An LED lamp device has a lamp seat, in which a lamp trough is formed by being recessed inwardly, and the inner edge surface of the lamp seat is formed as an arc surface. The front and rear parts in longitudinal direction of the lamp trough are also bent inwardly. Three rows of lamp set are arranged along the longitudinal sides in the lamp trough. These lamp sets have a plurality of LEDs as light-emitting elements. The lamp sets at left and right rows are inclined inwardly according to the curvature of the inner edge surface. In the meantime, the lamp sets at front and rear sides of one row are also inclined inwardly. Under this arrangement, the plural lamp sets not only can enhance the illumination of the lamp, but also can concentrate its light-emitting operation, for solving a shortcoming of light dispersal in most light sources.

Owner:PYROSWIFT HOLDING CO LIMITED

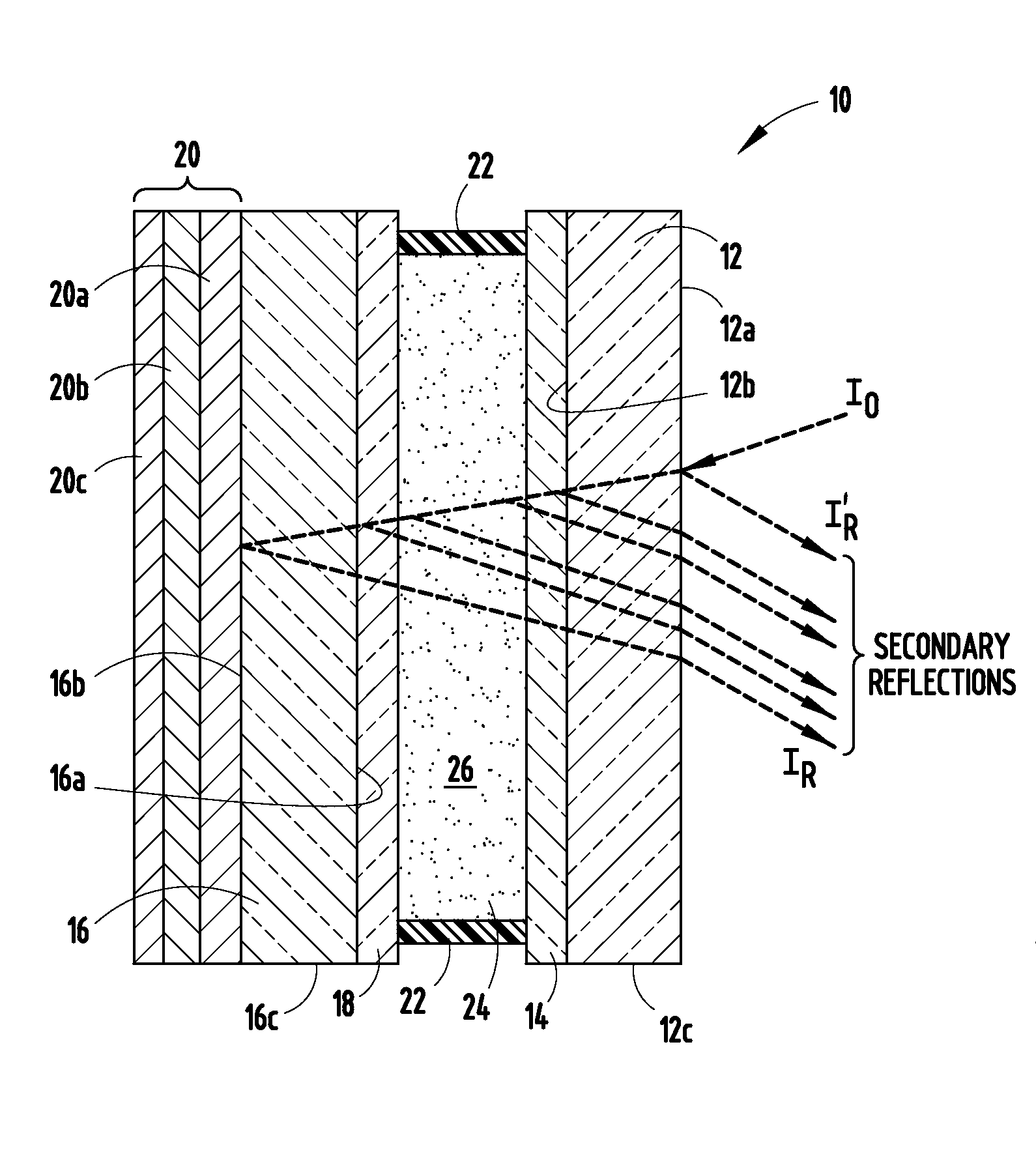

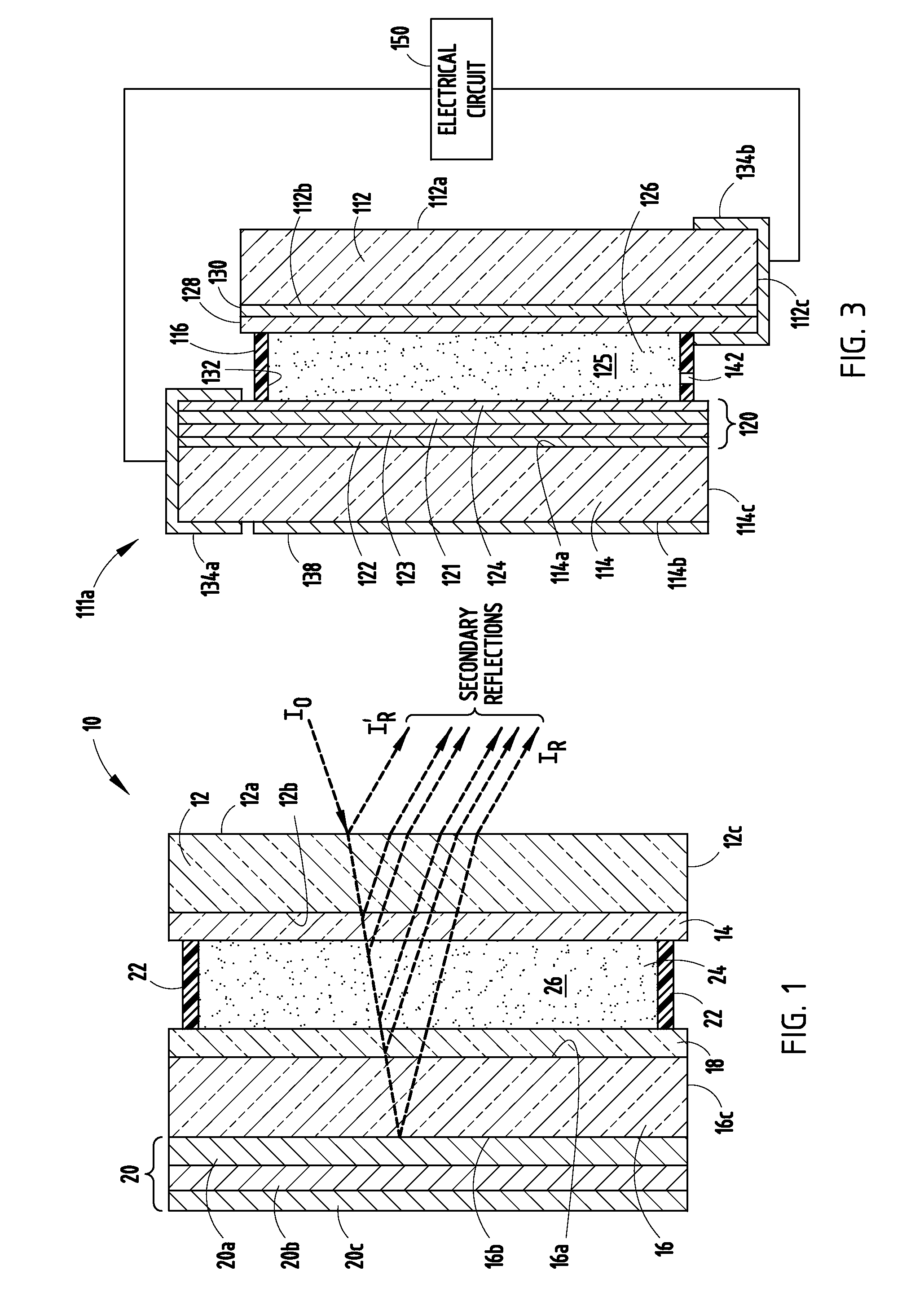

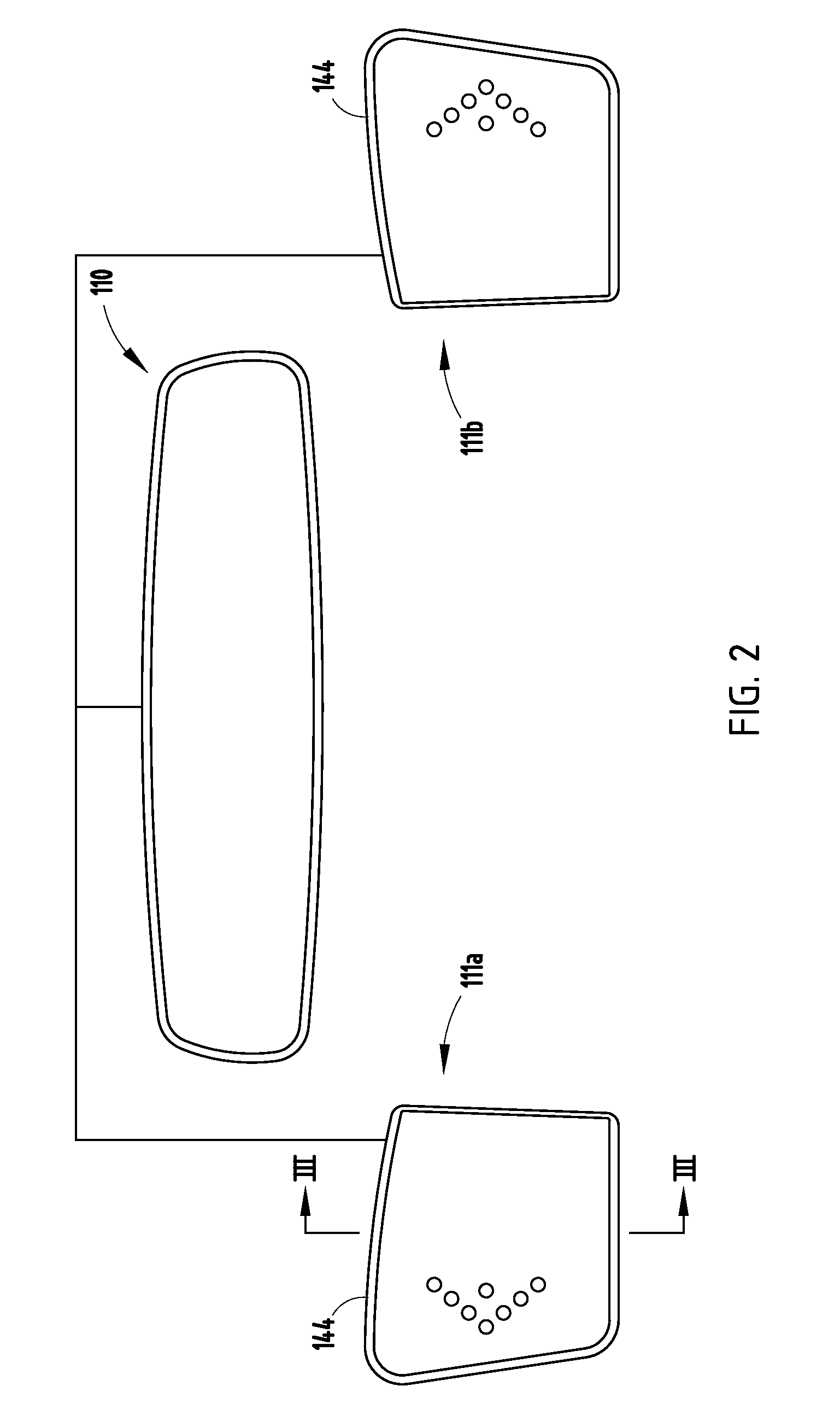

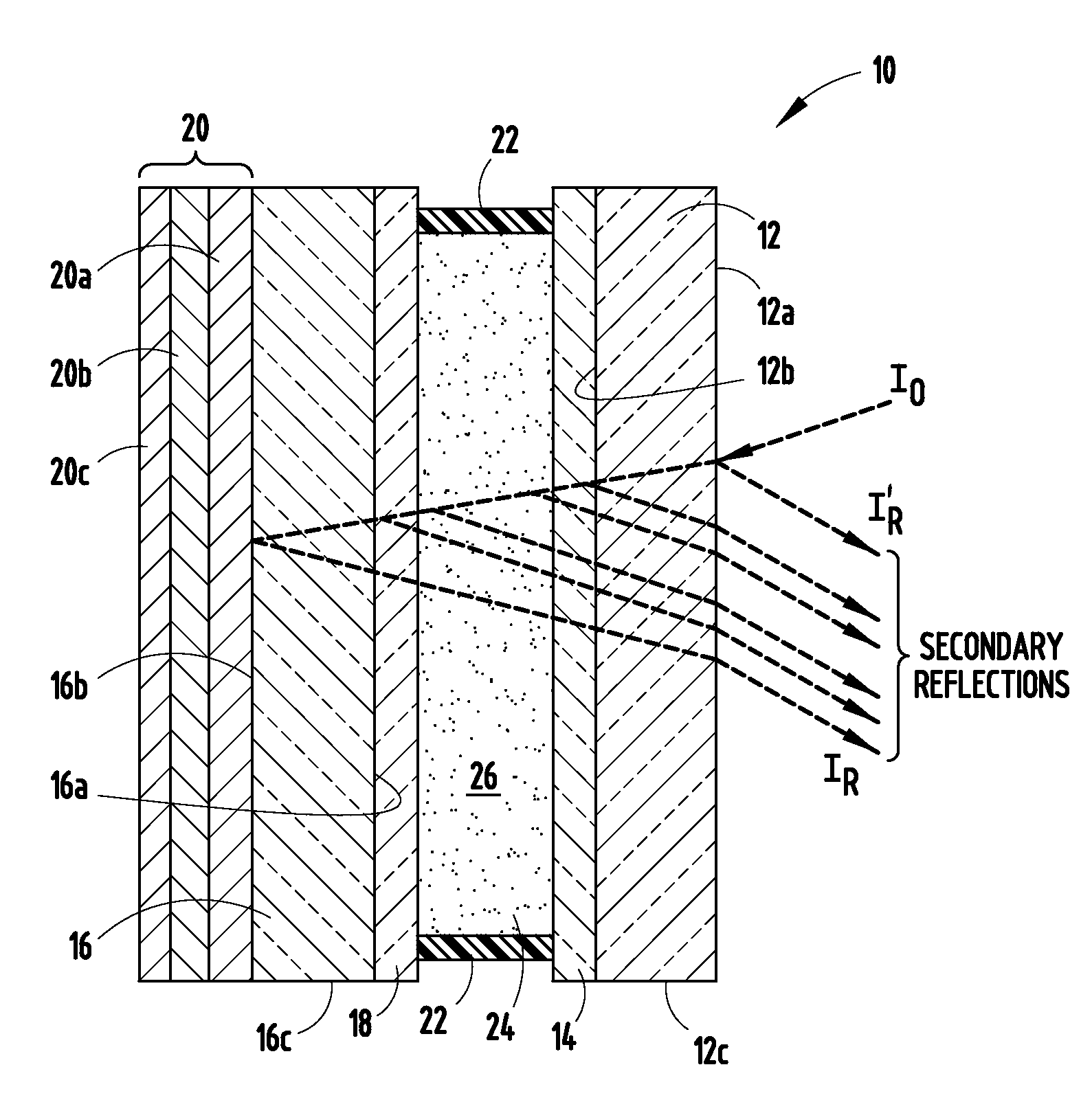

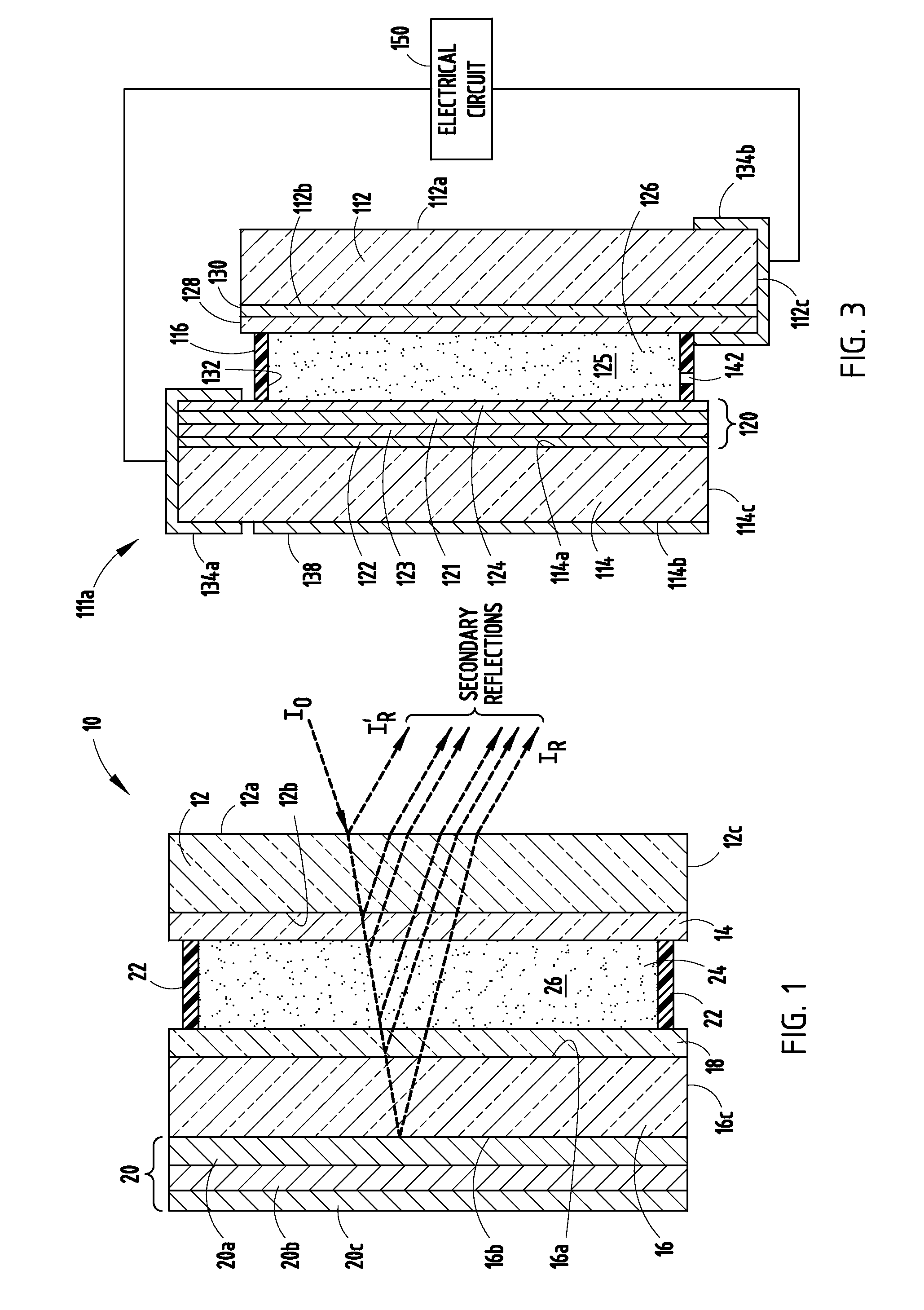

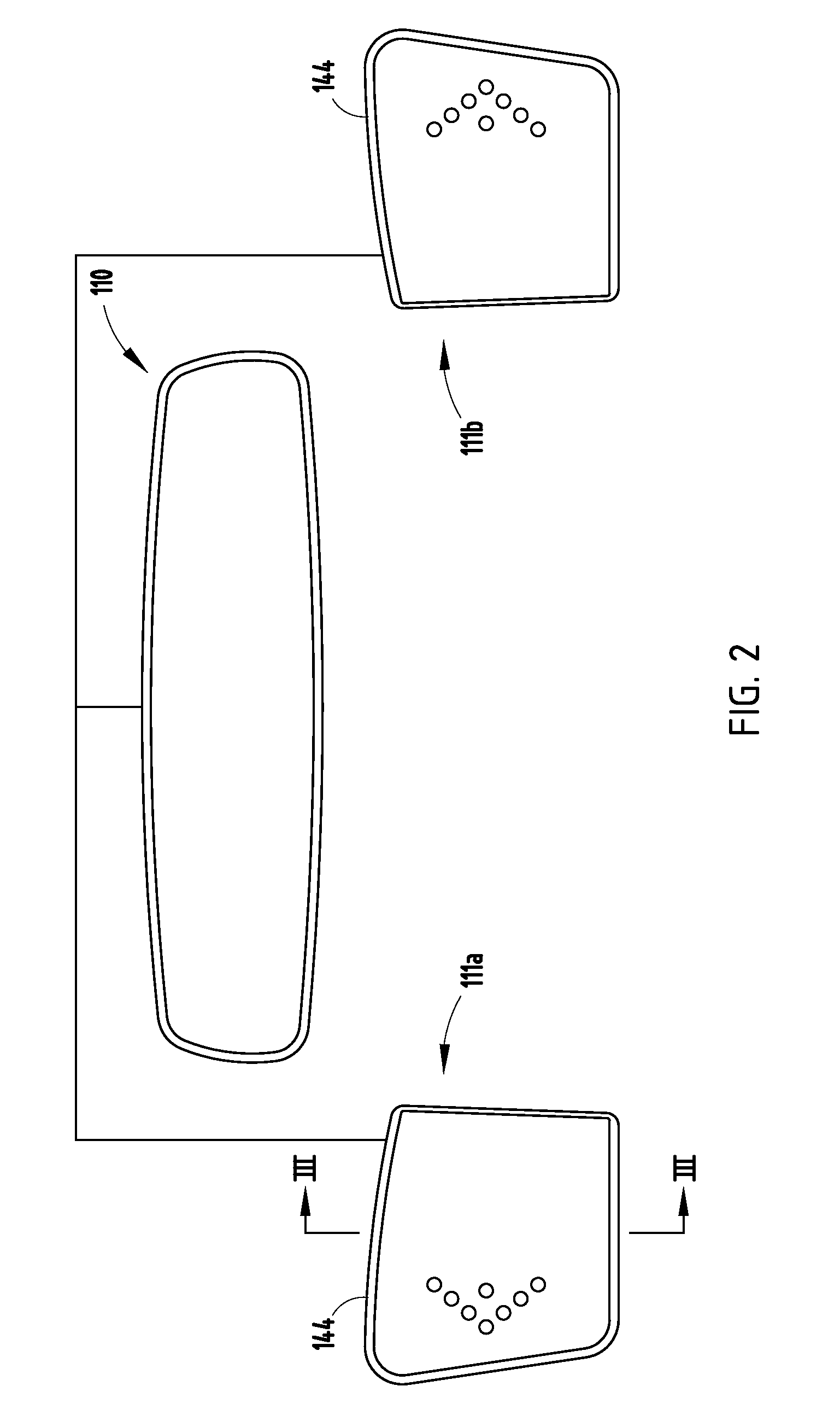

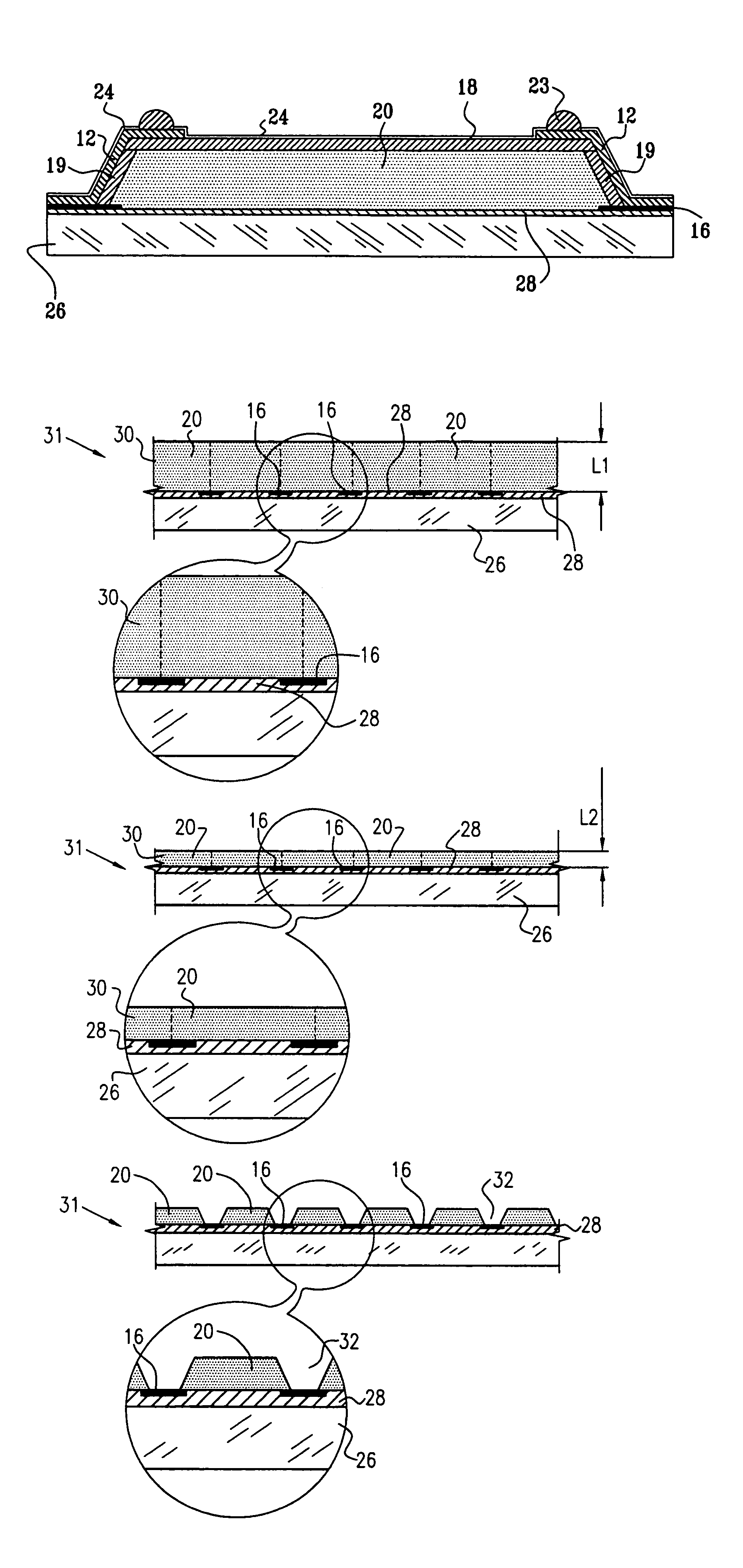

Electro-Optical Element Including Metallic Films and Methods For Applying The Same

A method for manufacturing an electrochromic element comprises providing a first substrate having first and second surfaces and a first edge surface, providing a second substrate having third and fourth surfaces and a second edge surface, the third surfaces facing the second surface, providing an electrochromic medium located between the first and second substrates, the medium having a light transmittance that is variable upon application of electric field thereto, applying a conductive layer on a portion of at least one of the surfaces, wherein applying the layer is accomplished at substantially atmospheric pressure, and applying at least one of metallic particles, an organometallic, a metallo-organic, and combinations thereof, wherein the conductive layer has a bulk resistivity of greater than or equal to 150 μΩ·cm. The conductive layer may be applied via ink jetting, ultrasonic spraying, auger or jet pumping.

Owner:GENTEX CORP

Electro-optical element including metallic films and methods for applying the same

A method for manufacturing an electrochromic element comprises providing a first substrate having first and second surfaces opposite one another and a first edge surface, providing a second substrate having third and fourth surfaces opposite one another and a second edge surface, wherein the third surfaces faces the second surface, and providing an electrochromic medium located between the first and second substrates, wherein the electrochromic medium has a light transmittance that is variable upon the application of electric field thereto. The method further complies applying a conductive layer on at least a portion of at least a select one of a first, second, third, and fourth surfaces and the first and second edge surfaces, wherein applying the conductive layer is accomplished at substantially atmospheric pressure and including applying at least a select one of metallic particles, an organometallic, a metallo-organic, and combinations thereof, and wherein the conductive layer has a bulk resistivity of less than or equal to 150 μΩ·cm. Other aspects of this invention comprise applying the conductive layer via ink jetting, ultrasonic spraying, auger pumping and jet pumping.

Owner:GENTEX CORP

Methods and apparatus for packaging integrated circuit devices

ActiveUS7192796B2Semiconductor/solid-state device detailsSolid-state devicesInsulation layerElectrical conductor

An integrally packaged integrated circuit device including an integrated circuit die including a crystalline substrate having first and second generally planar surfaces and edge surfaces and semiconductor circuitry formed over the first generally planar surface, at least one chip scale packaging layer formed over the semiconductor circuitry and the first generally planar surface, an insulation layer formed over the second generally planar surface and the edge surfaces and at least one electrical conductor formed directly on the insulation layer overlying the second generally planar surface, the at least one electrical conductor being connected to the circuitry by at least one pad formed directly on the first generally planar surface.

Owner:TESSERA TECH HUNGARY KFT +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com