Patents

Literature

1657results about "Disk carriers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

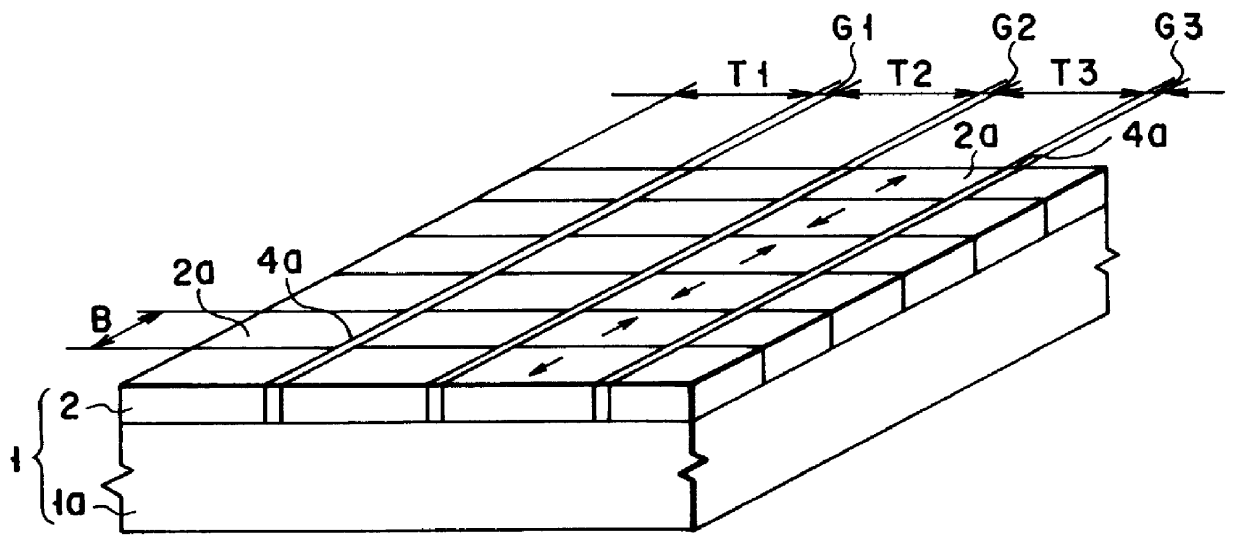

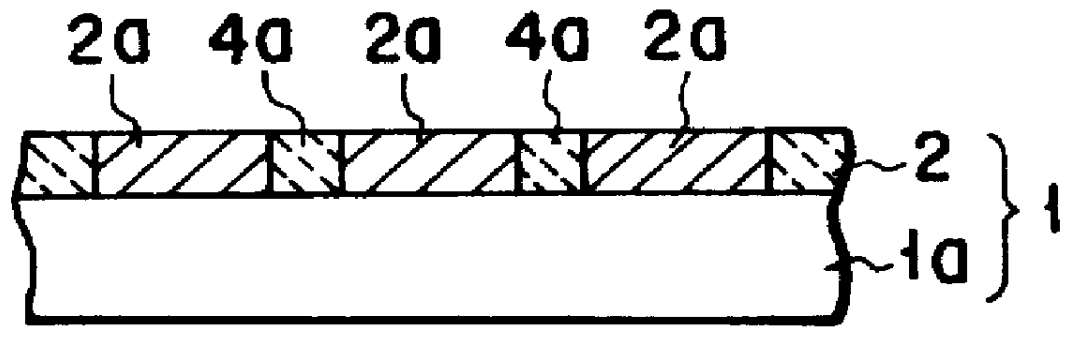

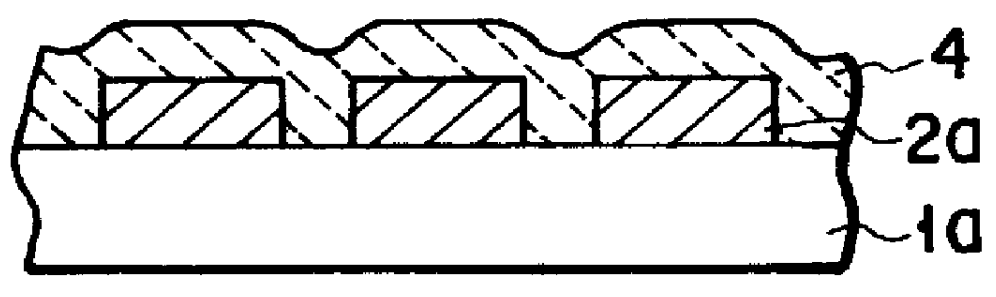

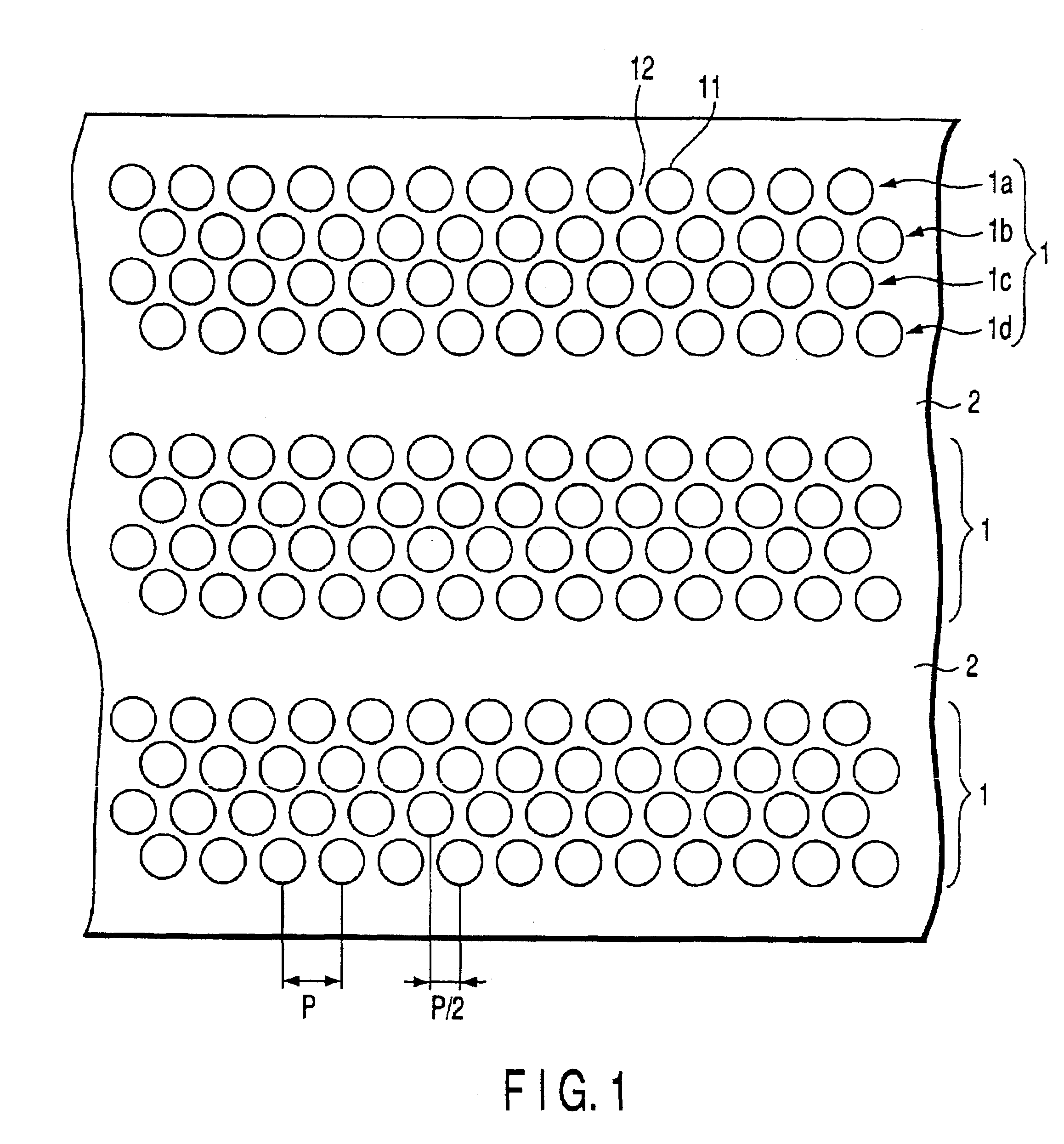

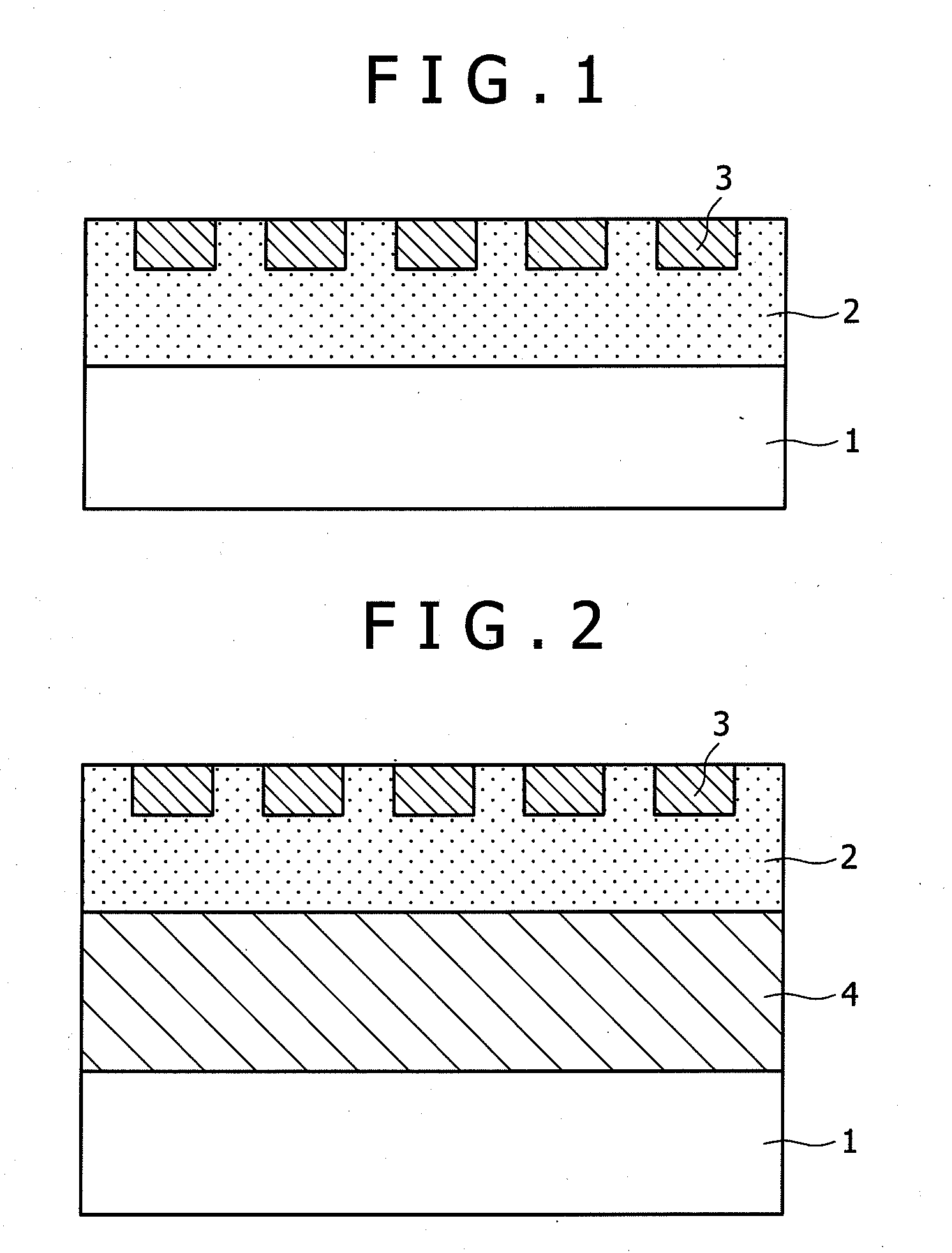

Magnetic disk with a guard band arrangement

A magnetic disk including a substrate, a recording track section which is made of a magnetic member for recording and reproducing information magnetically and is provided on the substrate, and a guard band member which is provided between the recording track sections adjacent to each other so that they are substantially continued in a track direction and is harder than the magnetic member and is made of a non-magnetic material. Moreover, the magnetic member is not provided or magnetic members with a different thickness from the magnetic member forming the recording track section is provided on a lower area of the guard band member.

Owner:KK TOSHIBA

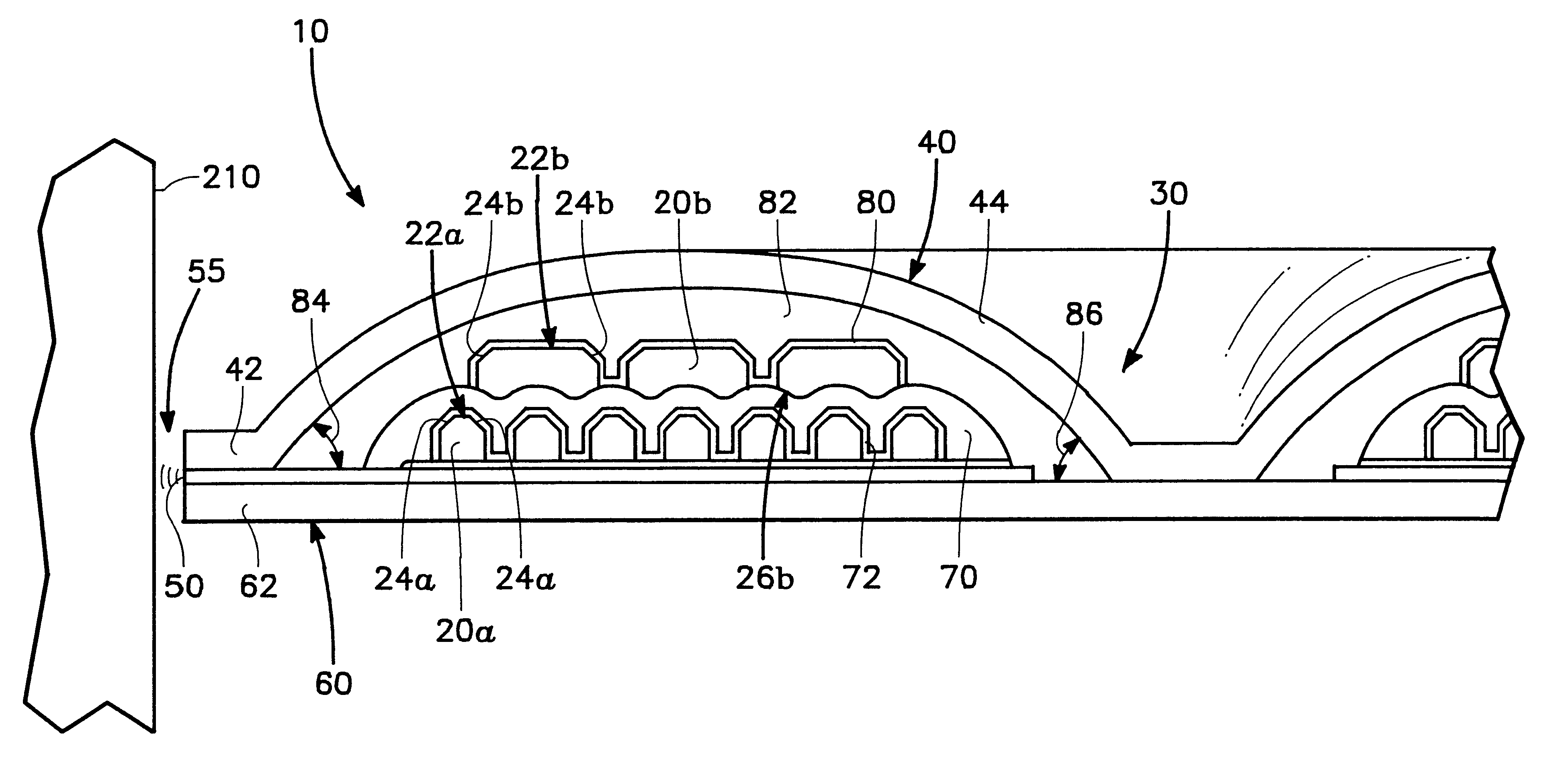

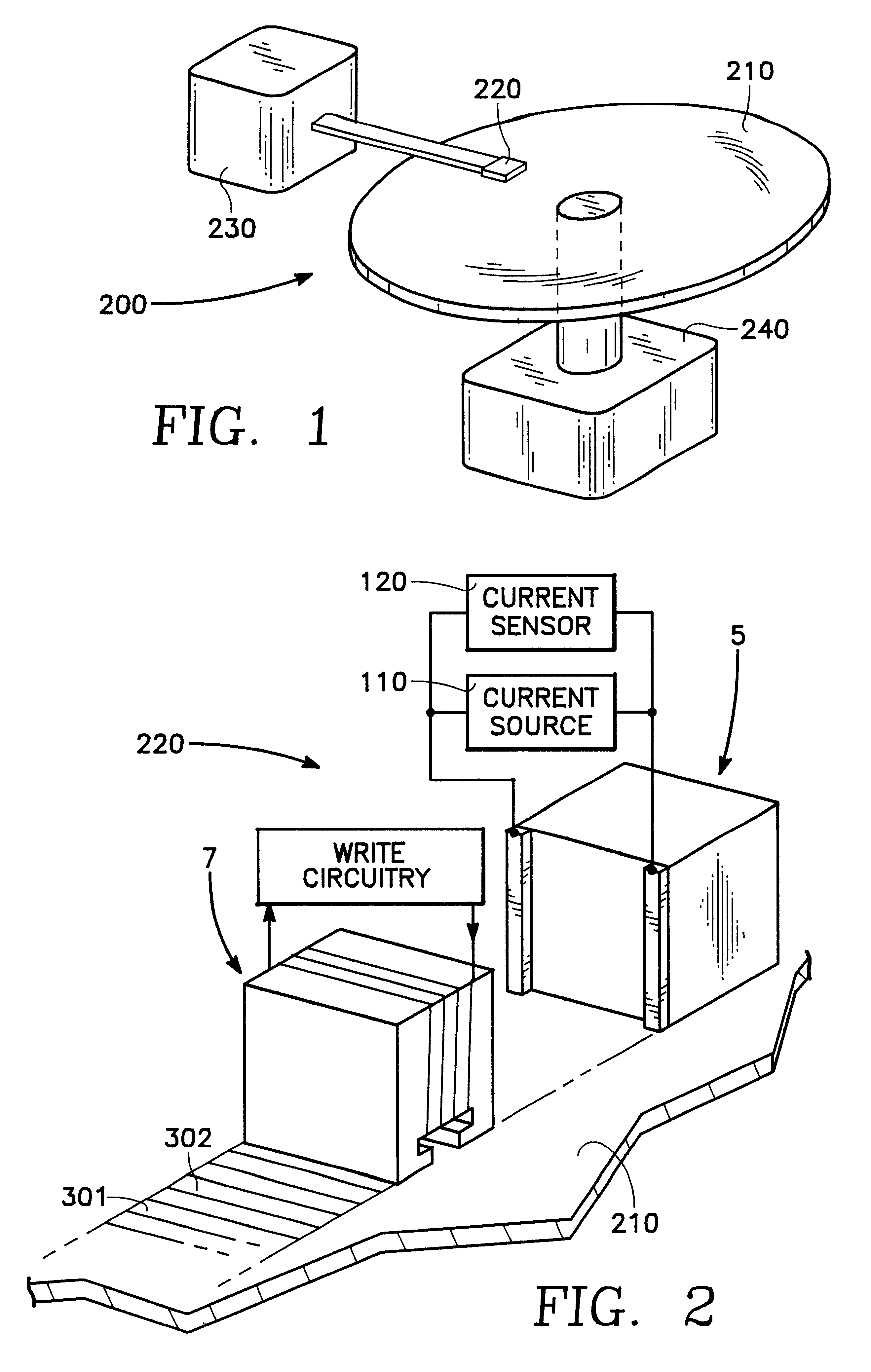

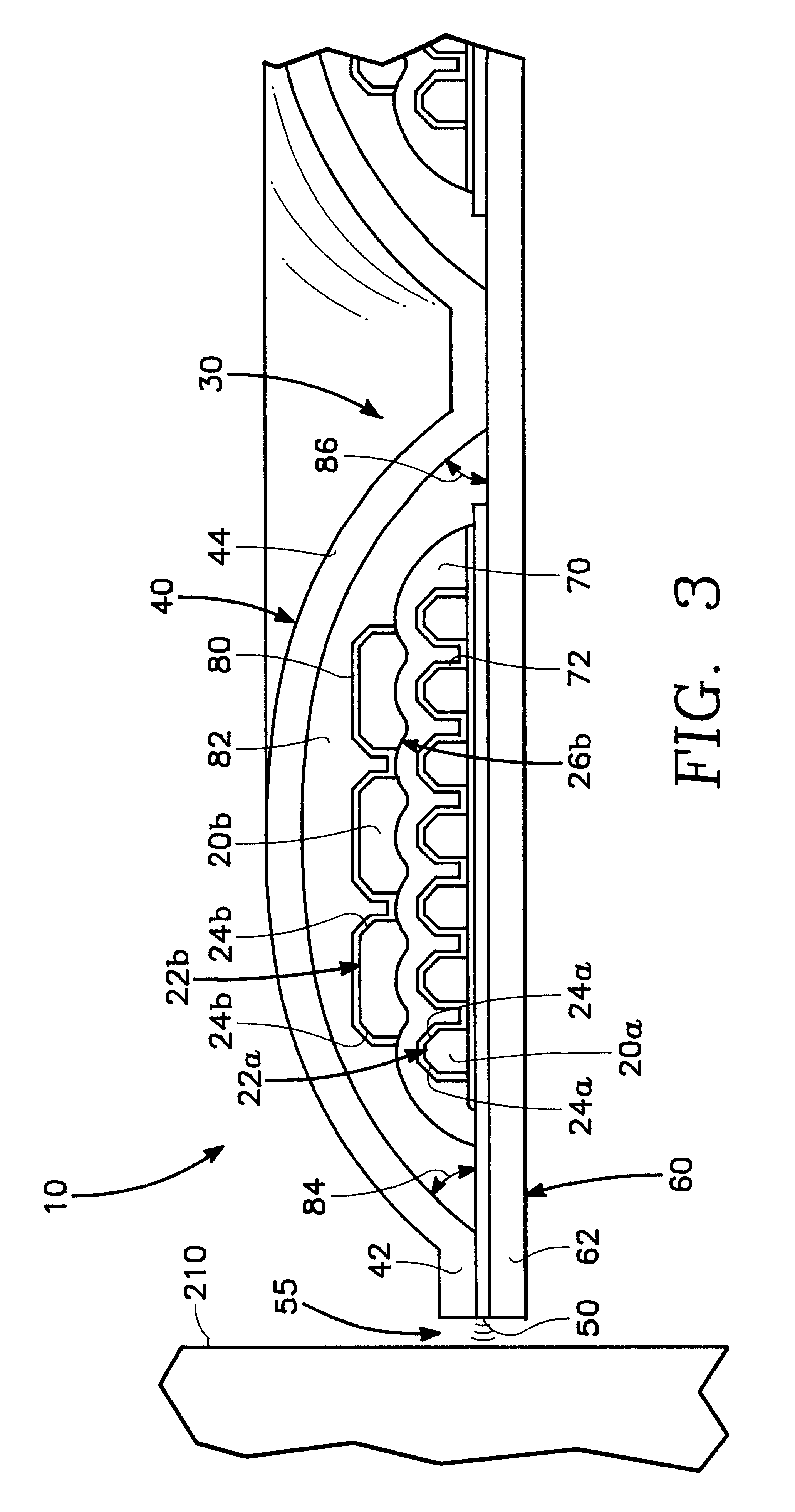

Low resistance coil structure for high speed writer

InactiveUS6333830B2Lower coil resistanceReduce dissipationConstruction of head windingsHeads using thin filmsElectrical conductorLower pole

The present invention provides a thin film write head having an upper and lower pole structures and conductor turns forming a winding for generating magnetic flux. The conductor is formed with a non-planar top surface. The winding of the present invention may be formed of lower and upper turns. The upper turns may be formed with a non-planar top surface, a non-planar bottom surface, or both. It is preferred that the bottom surface of the upper conductor turns be coherent with the non-planar top surface of the lower conductor turns. The non-planar top surface may be formed by removing corners formed during deposition between a generally planar top surface and abutting side walls. The corners may be removed by ion milling to form the non-planar top surface. The conductor may be copper with the non-planar top surface having sloping facets. The thin film write head of the present invention may be utilized to provide an improved data storage and retrieval apparatus. The preferred embodiment provides reduced coil resistance thereby reducing Johnson Thermal Noise and power dissipation. It also allows for reduced yoke length and reduced stack height while providing low apex angles to expand and improve yoke material deposition thereby improving head response and operational frequency.

Owner:WESTERN DIGITAL TECH INC

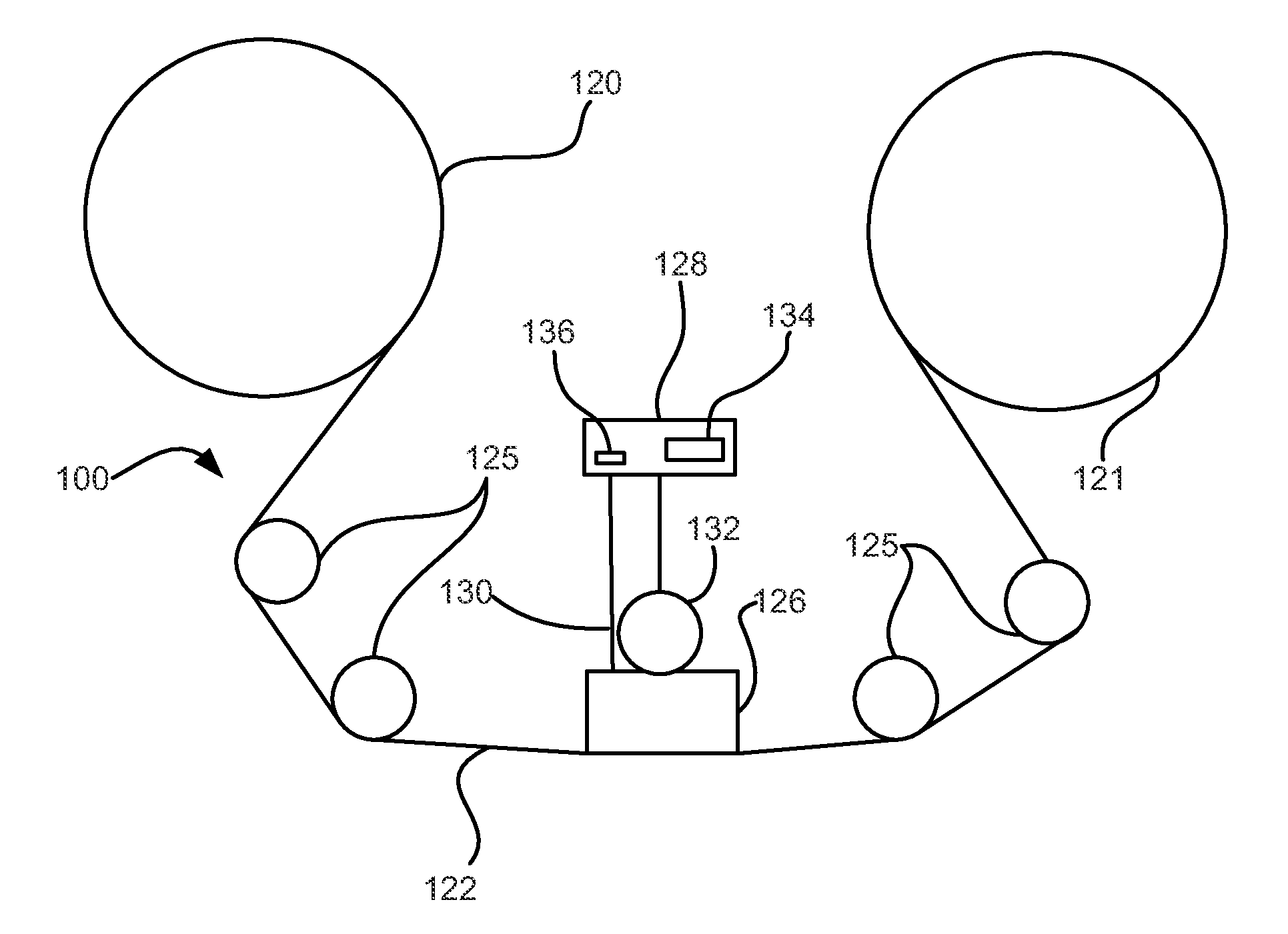

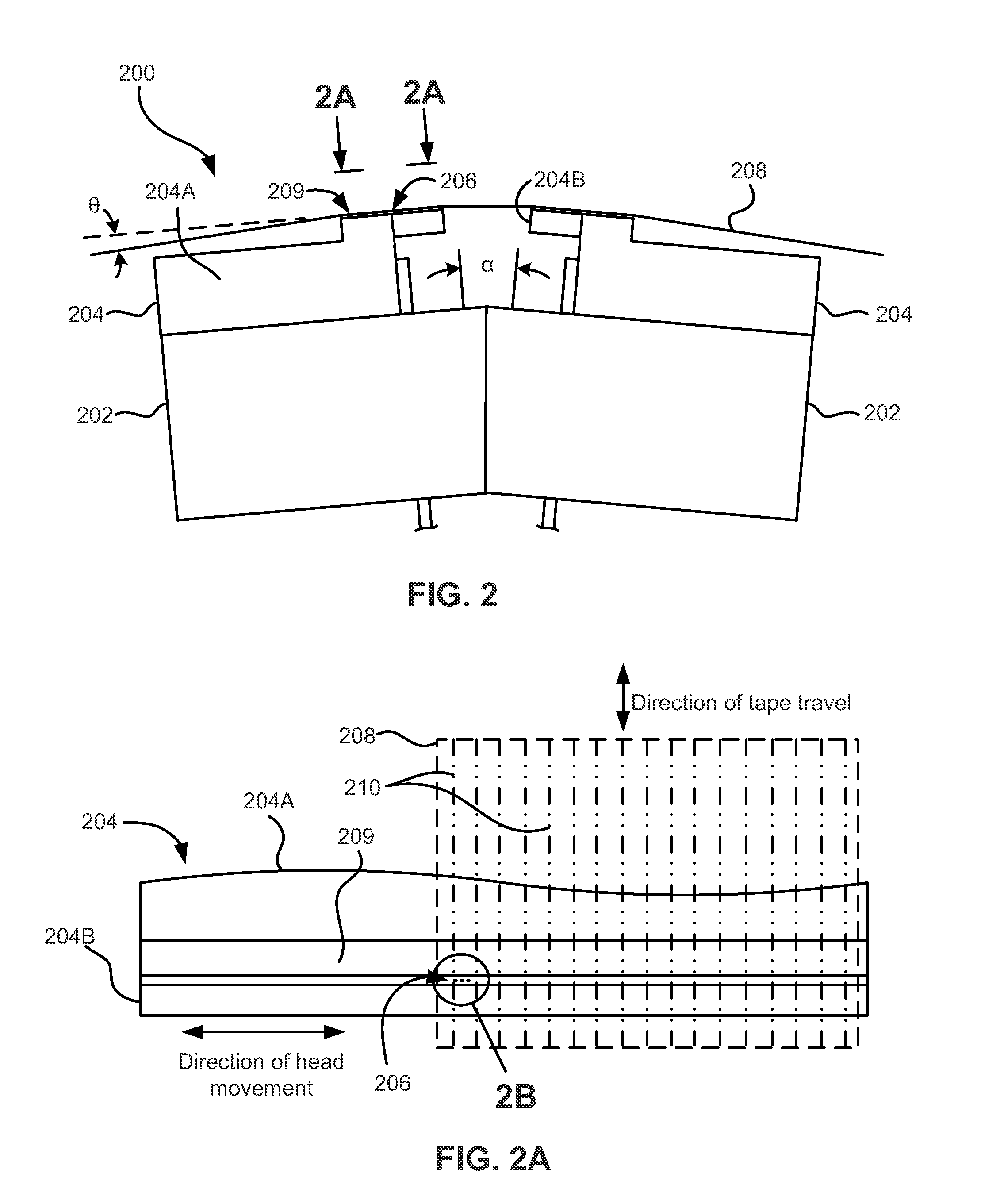

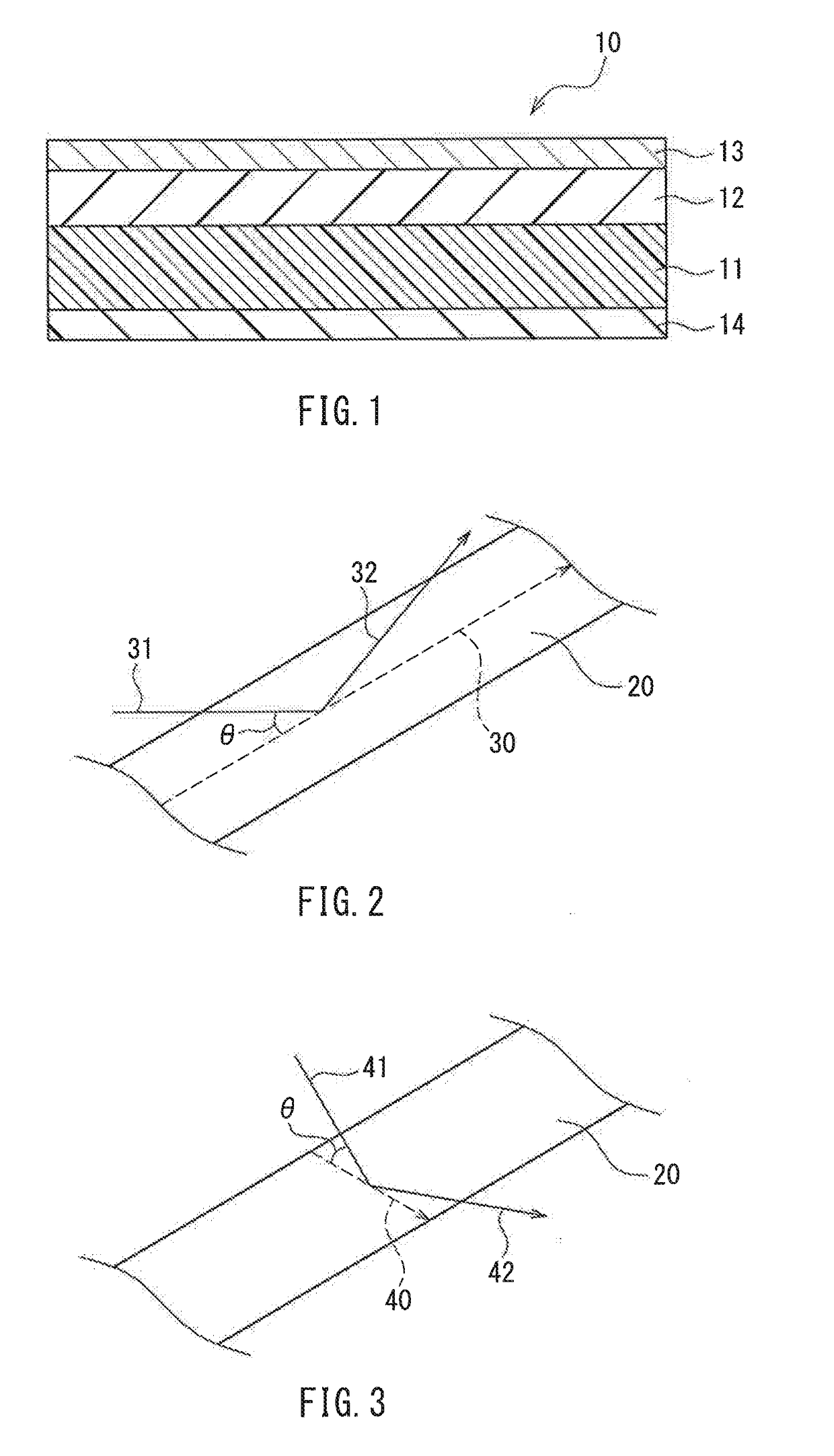

High density timing based servo format for use with tilted transducer arrays

A product, according to one embodiment, includes a magnetic recording tape having opposite ends, a longitudinal axis of the magnetic recording tape being defined between the ends. The magnetic recording tape has at least one servo track, the at least one servo track having a plurality of first magnetic bars and a plurality of third magnetic bars oriented to form chevron-like patterns with the first magnetic bars. The first magnetic bars each have a longitudinal axis oriented at a first angle between 2 and 88 degrees from the longitudinal axis of the magnetic recording tape. The third magnetic bars each have a longitudinal axis oriented at a second angle between 2 and 88 degrees from the longitudinal axis of the magnetic recording tape, the second angle having a different numerical absolute value than the first angle.

Owner:GLOBALFOUNDRIES US INC

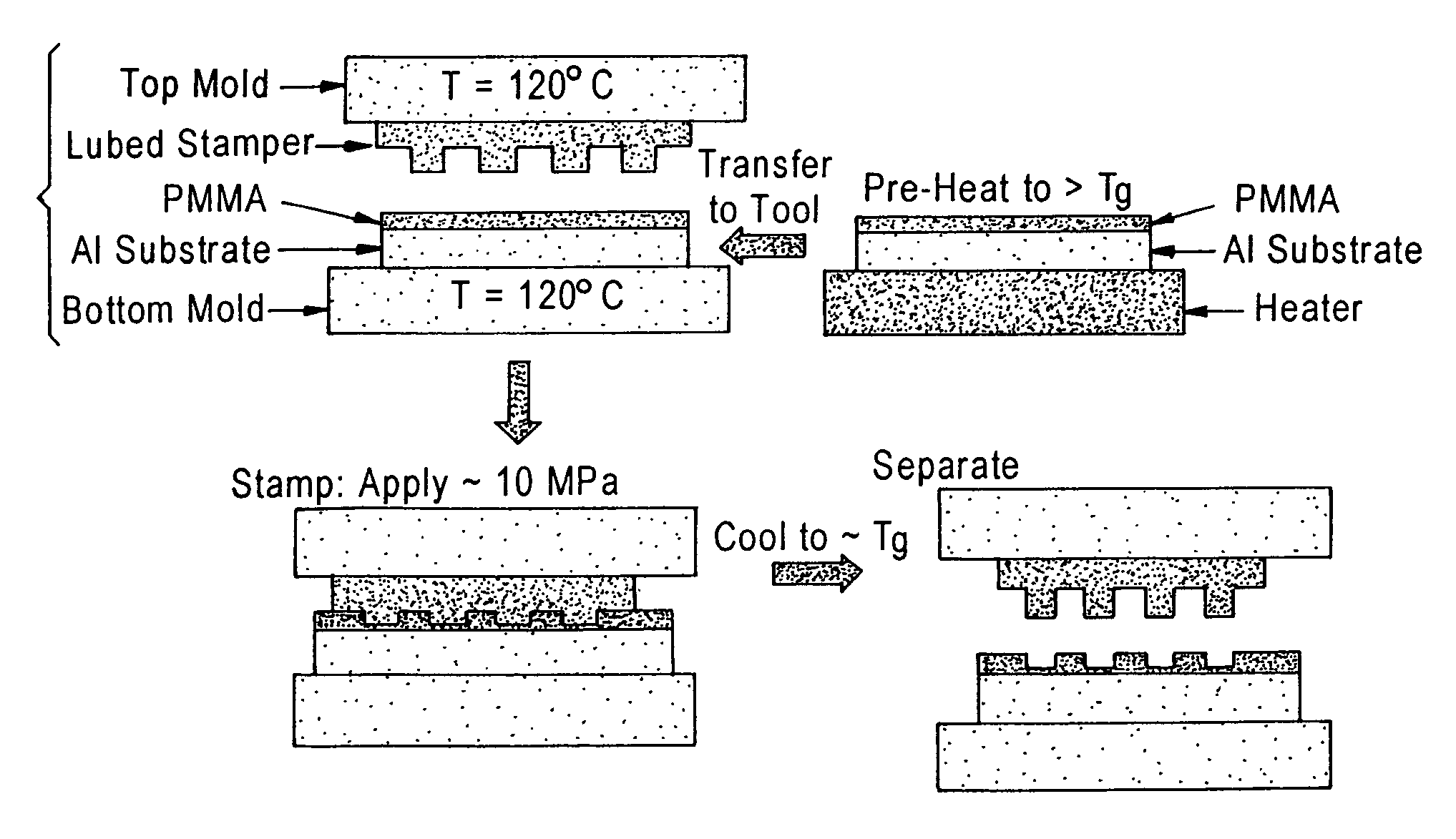

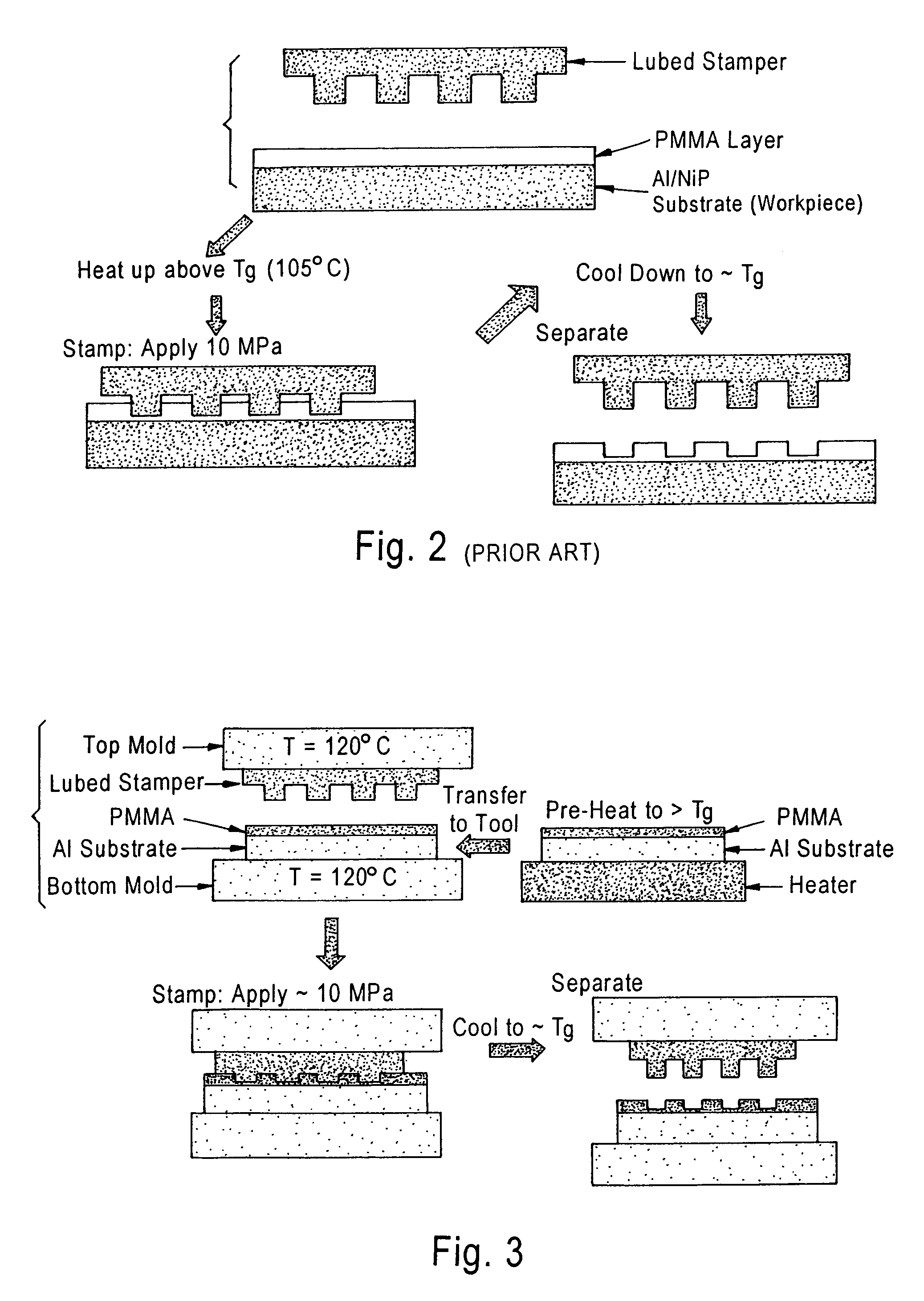

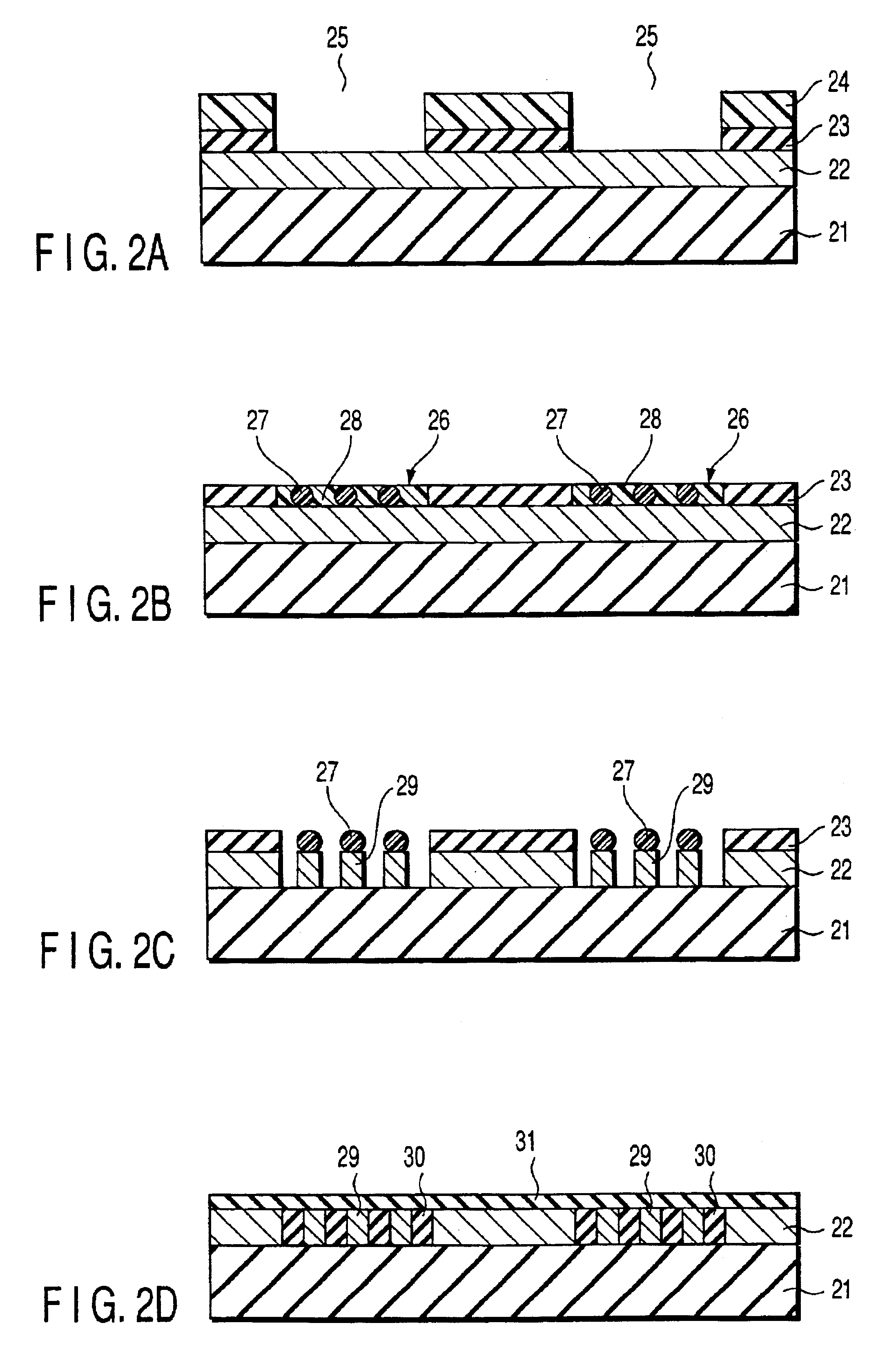

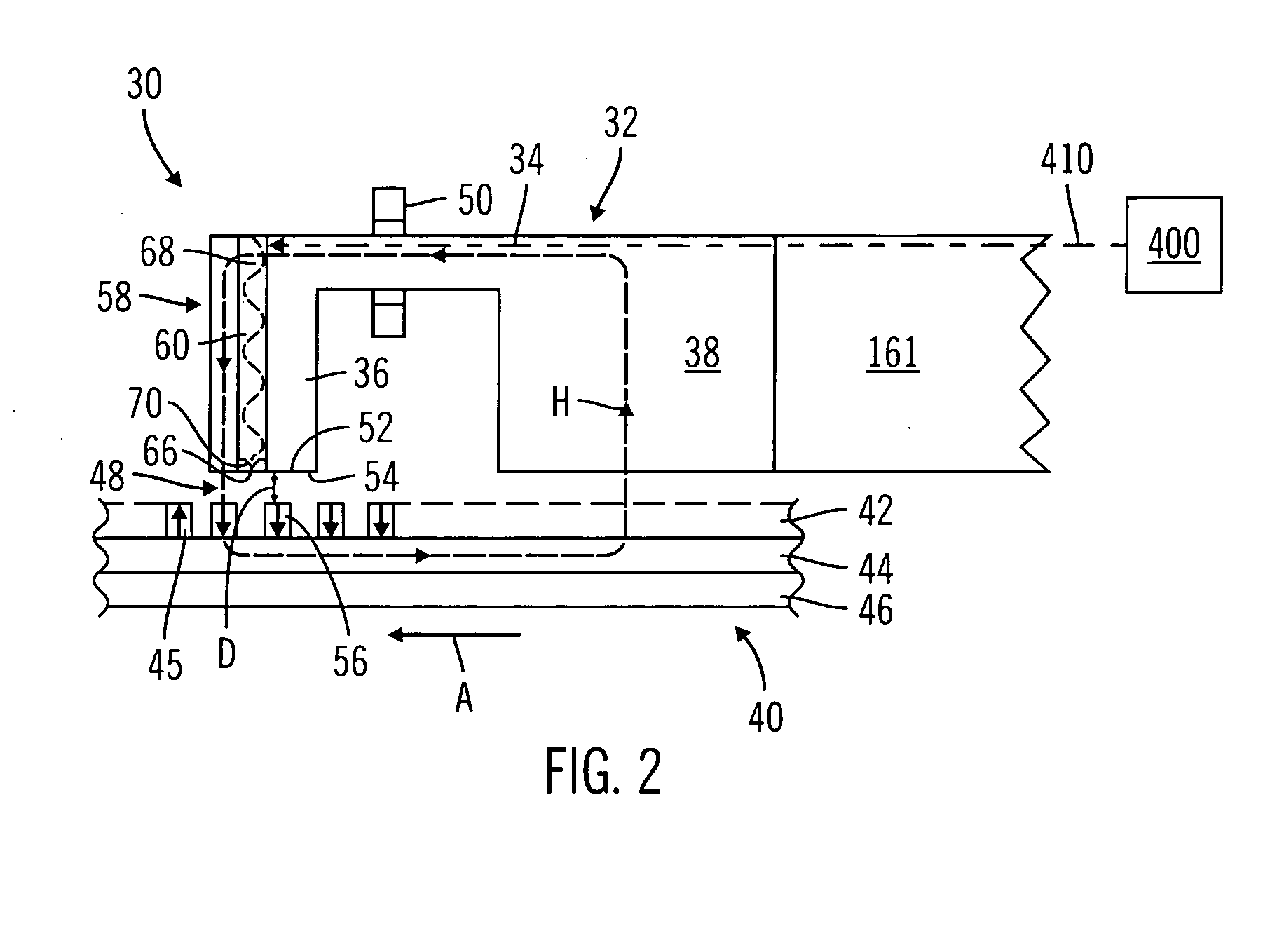

Heat-transfer-stamp process for thermal imprint lithography

InactiveUS6949199B1Eliminate disadvantagesSimple methodNanostructure manufactureDecorative surface effectsStamping processPlanographic printing

A method of performing thermal imprint lithography of a surface of a thermoplastic layer-coated workpiece for forming a pattern therein comprises pre-heating the workpiece to a pre-selected high temperature prior to inserting the workpiece in a stamping / imprinting tool maintained at a predetermined lower temperature, whereby the interval for thermal cycling of the stamping / imprinting tool between higher and lower temperatures is eliminated or at least reduced. Applications of the method include forming servo patterns in disk-shaped substrates for hard disk recording media.

Owner:SEAGATE TECH LLC

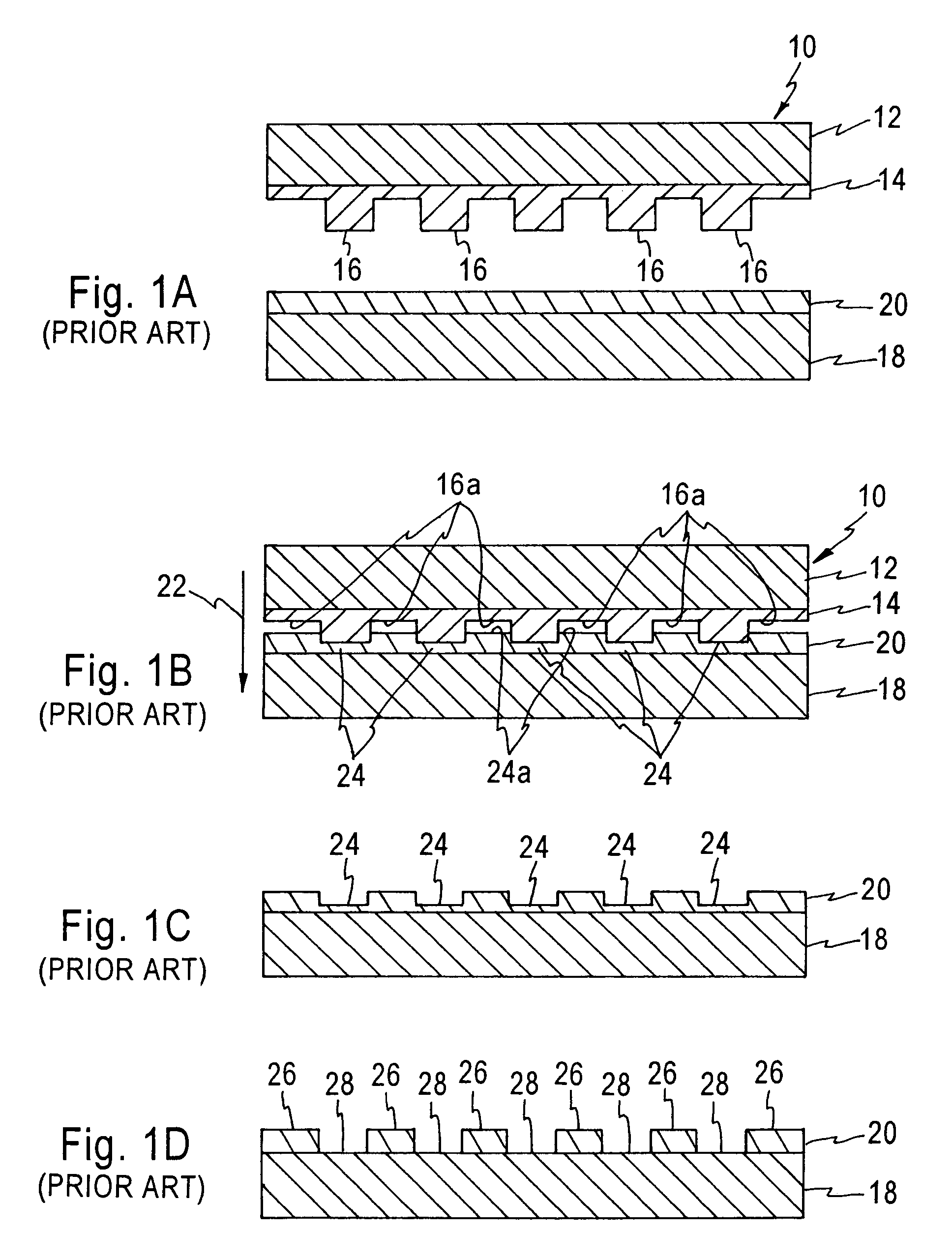

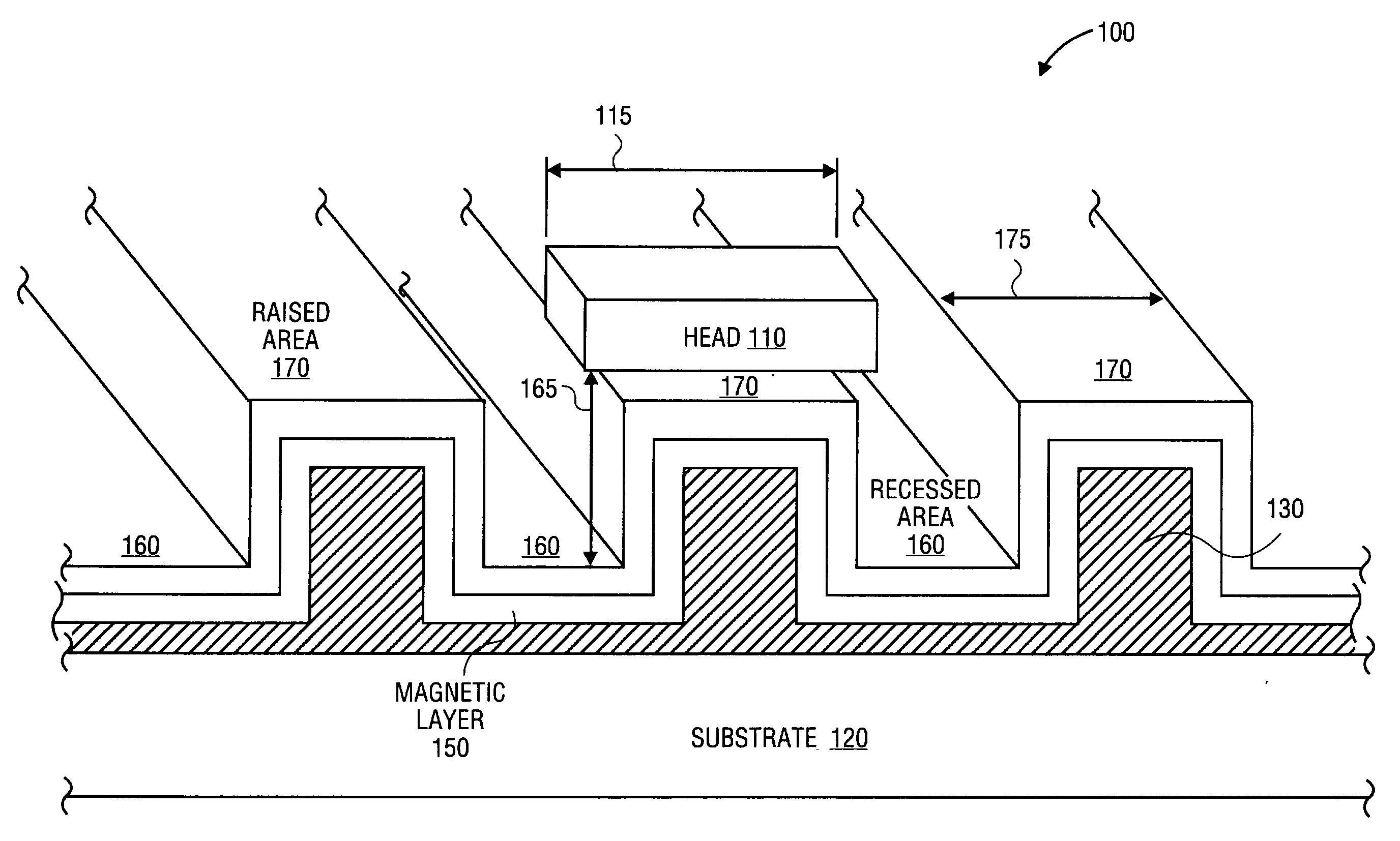

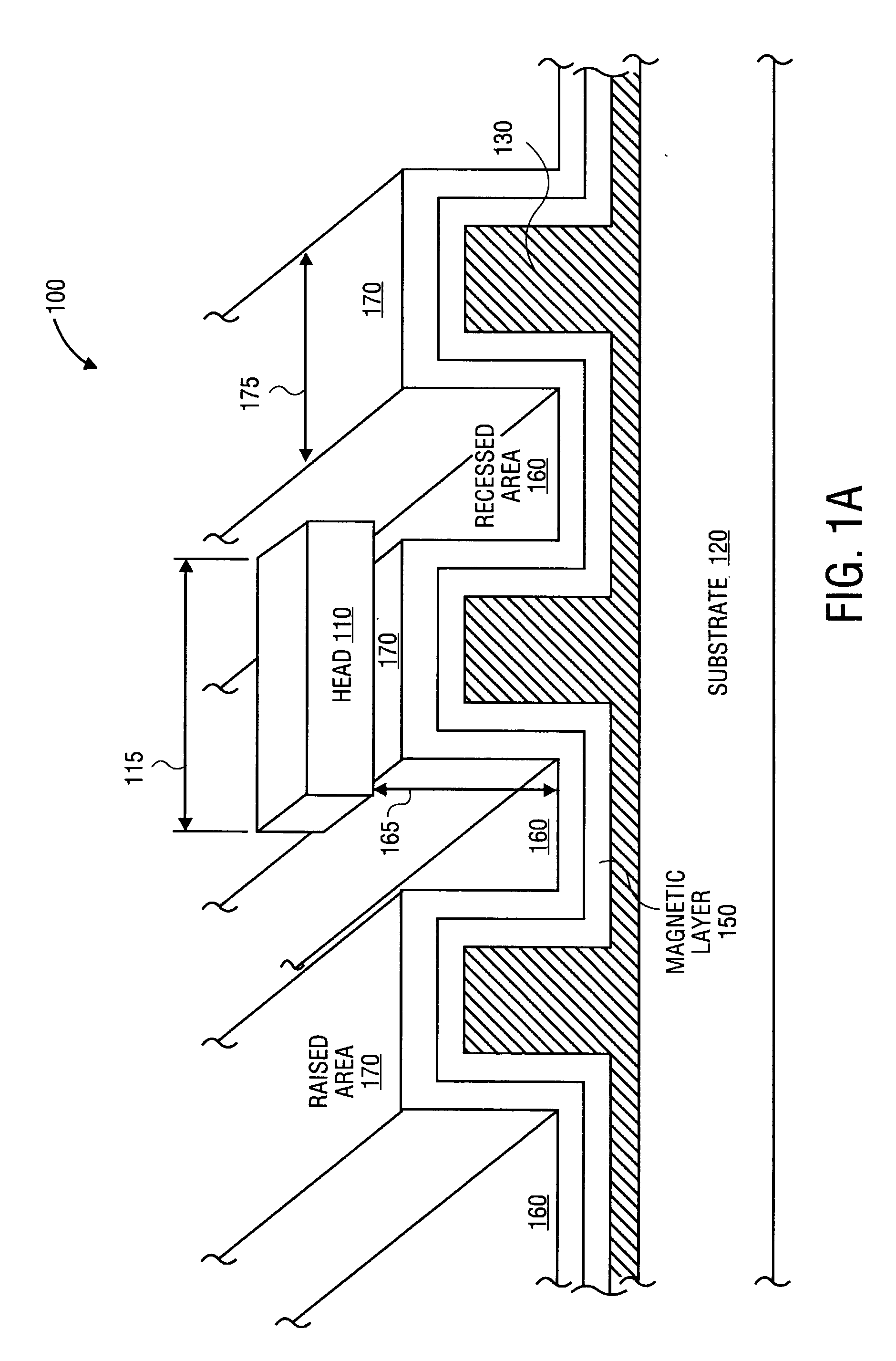

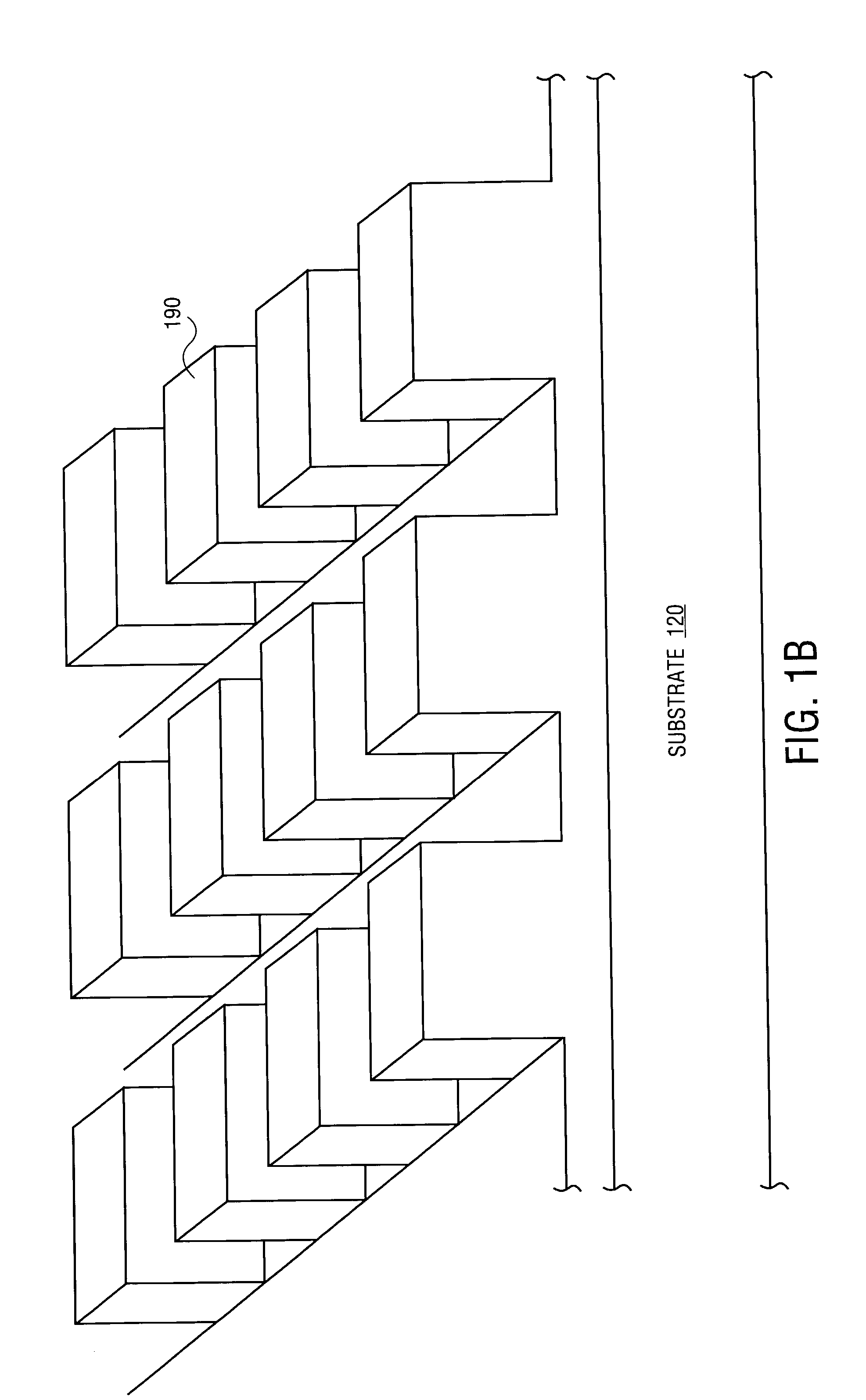

Magnetic discrete track recording disk

InactiveUS20050036223A1Protective coatings for layersBase layers for recording layersComputer science

Owner:KOMAG

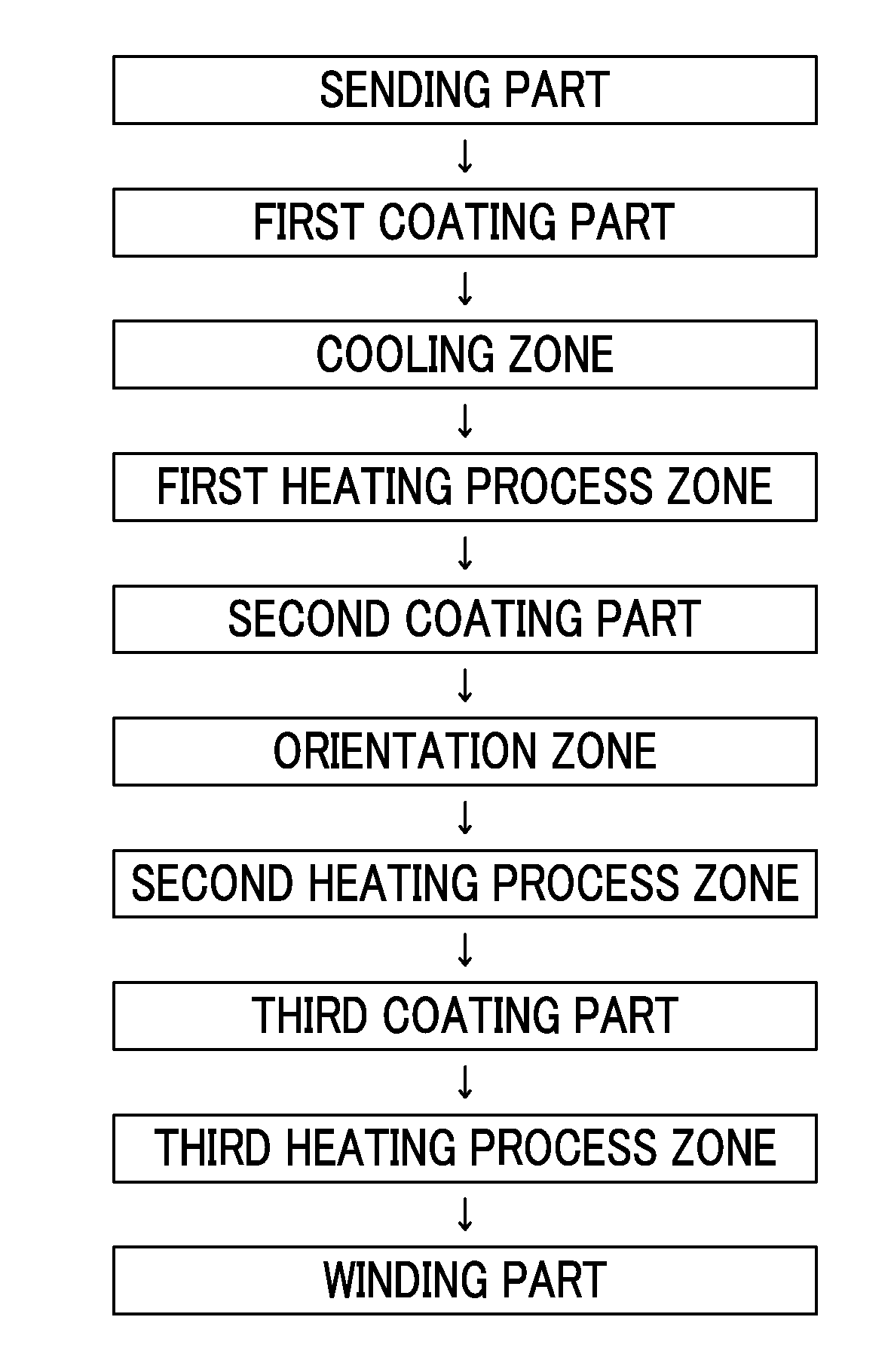

Magnetic recording medium

InactiveUS20070020490A1Excellent electromagnetic characteristic and error rate and durabilityImproved electromagnetic characteristic and error rate and durabilityBase layers for recording layersRecord information storageHigh densityMicrometer

Provided is a magnetic recording medium for high-density recording, that has excellent electromagnetic characteristics, error rates, and durability. The magnetic recording medium comprises a magnetic layer comprising a ferromagnetic powder, a binder and an abrasive on a nonmagnetic support and is employed for recording a magnetic signal on the medium and reproducing the recorded signal with a reproduction head. The abrasive has a Vickers hardness ranging from 18 to 80 GPa and a mean particle diameter ranging from 10 to 100 nm. The magnetic layer comprises the abrasive in a quantity of 5 to 60 weight parts per 100 weight parts of the ferromagnetic powder and has a thickness ranging from 10 to 100 nm. The number of abrasive present on the surface of the magnetic layer ranges from 0.01 to 1 per {(minimum bit length of the recorded signal)×(read track width of the reproduction head)} micrometer2.

Owner:FUJIFILM HLDG CORP +1

Magnetic tape device and magnetic reproducing method

ActiveUS20180286449A1Improve signal-to-noise ratioIncrease recording capacityRecord information storageManufacture of flux-sensitive headsMagnetic tapeX-ray

The magnetic tape device includes a magnetic tape and a TMR head, in which the magnetic tape includes a non-magnetic support, and a magnetic layer including ferromagnetic powder and a binding agent on the non-magnetic support, the ferromagnetic powder is ferromagnetic hexagonal ferrite powder, an intensity ratio of a peak intensity Int(110) of a diffraction peak of a (110) plane with respect to a peak intensity Int(114) of a diffraction peak of a (114) plane of a hexagonal ferrite crystal structure obtained by an X-ray diffraction analysis of the magnetic layer by using an In-Plane method is 0.5 to 4.0, and a vertical direction squareness ratio of the magnetic tape is 0.65 to 1.00.

Owner:FUJIFILM CORP

Recording medium including patterned tracks and isolation regions

InactiveUS6977108B2Easy to manufactureIncrease speedTrack finding/aligningMagnetic materials for record carriersEngineeringRecording layer

Owner:KK TOSHIBA

Magnetic tape device and magnetic reproducing method

ActiveUS20180286450A1Improve smoothnessImprove surface smoothnessMaterials with ironRecord information storageIn planeX-ray

The magnetic tape device includes a magnetic tape including a magnetic layer; and a TMR head (reproducing head), in which an intensity ratio of a peak intensity of a diffraction peak of a (110) plane with respect to a peak intensity of a diffraction peak of a (114) plane of a hexagonal ferrite crystal structure obtained by an X-ray diffraction analysis of the magnetic layer by using an In-Plane method is 0.5 to 4.0, a vertical direction squareness ratio of the magnetic tape is 0.65 to 1.00, Ra measured regarding a surface of the magnetic layer is equal to or smaller than 2.0 nm, and a C—H derived C concentration calculated from a C—H peak area ratio of C1s spectra obtained by X-ray photoelectron spectroscopic analysis performed on the surface of the magnetic layer at a photoelectron take-off angle of 10 degrees is 45 to 65 atom %.

Owner:FUJIFILM CORP

Apparatus and method for improving chamfer quality of disk edge surfaces with laser treatment

A carbon dioxide laser is used as a non-mechanical means for smoothing and polishing the as-cut chamfer surface at the edge of the disk. Applying laser radiation to the glass surface causes transient melting and resolidification. Due to surface tension effects, the glass resolidifies to produce a surface that is significantly smoother than it was before irradiation. If scratches or abrasive marks are present on the glass surface prior to irradiation, the irradiation process "polishes out" these defects as long as they are not too deep. At a wavelength near 10 mum, the penetration depth of the radiation into the glass is approximately 1 mum. Therefore, scratches and defects of this order of magnitude are eliminated. The quality of the resulting modified chamfer surface is far superior to the original mechanically ground and polished surface.

Owner:WESTERN DIGITAL TECH INC

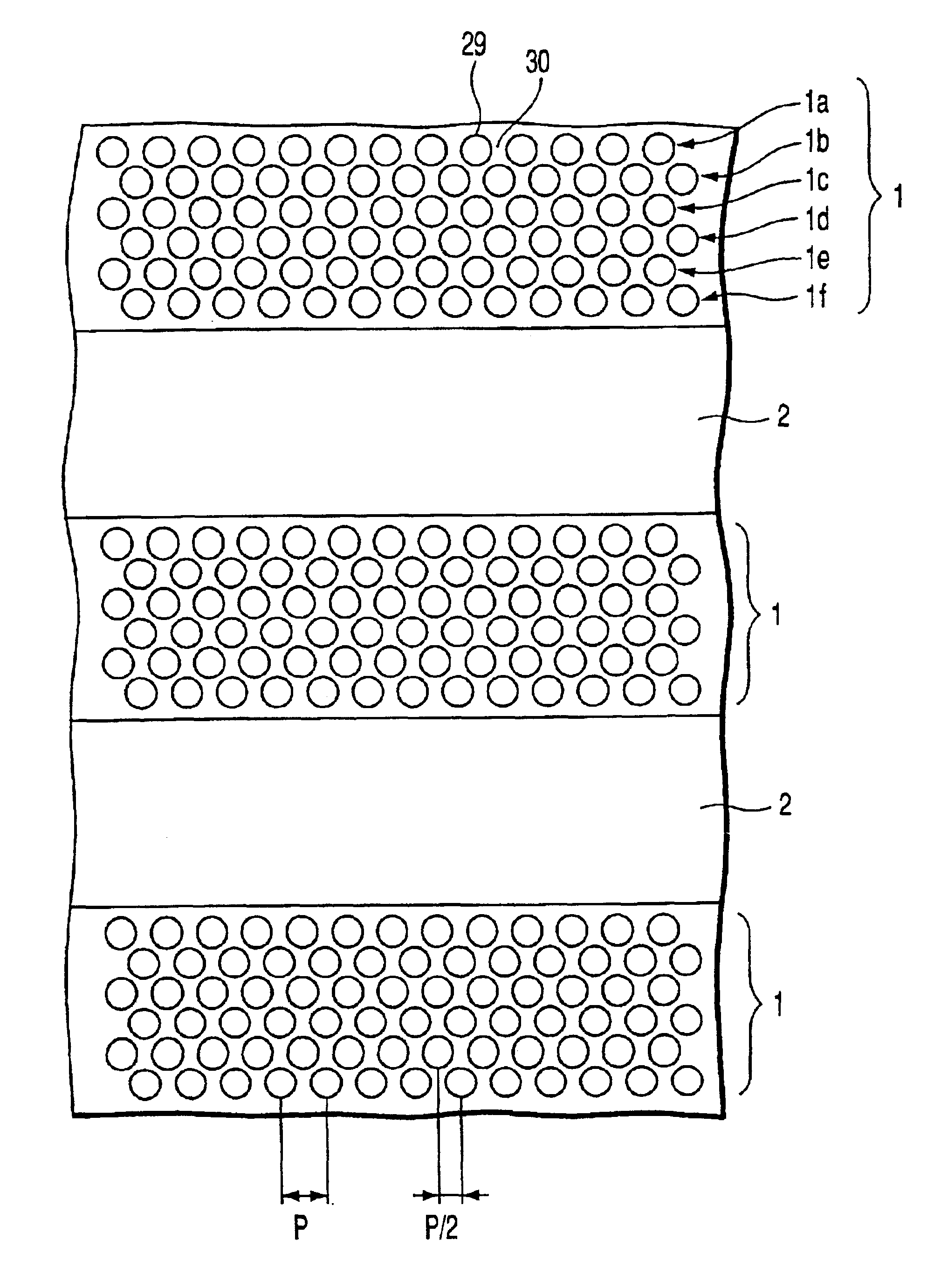

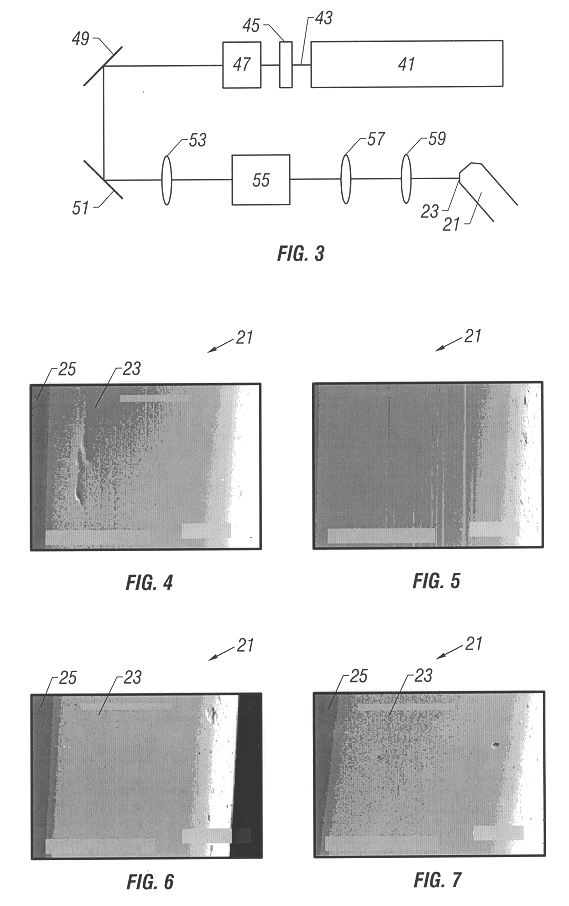

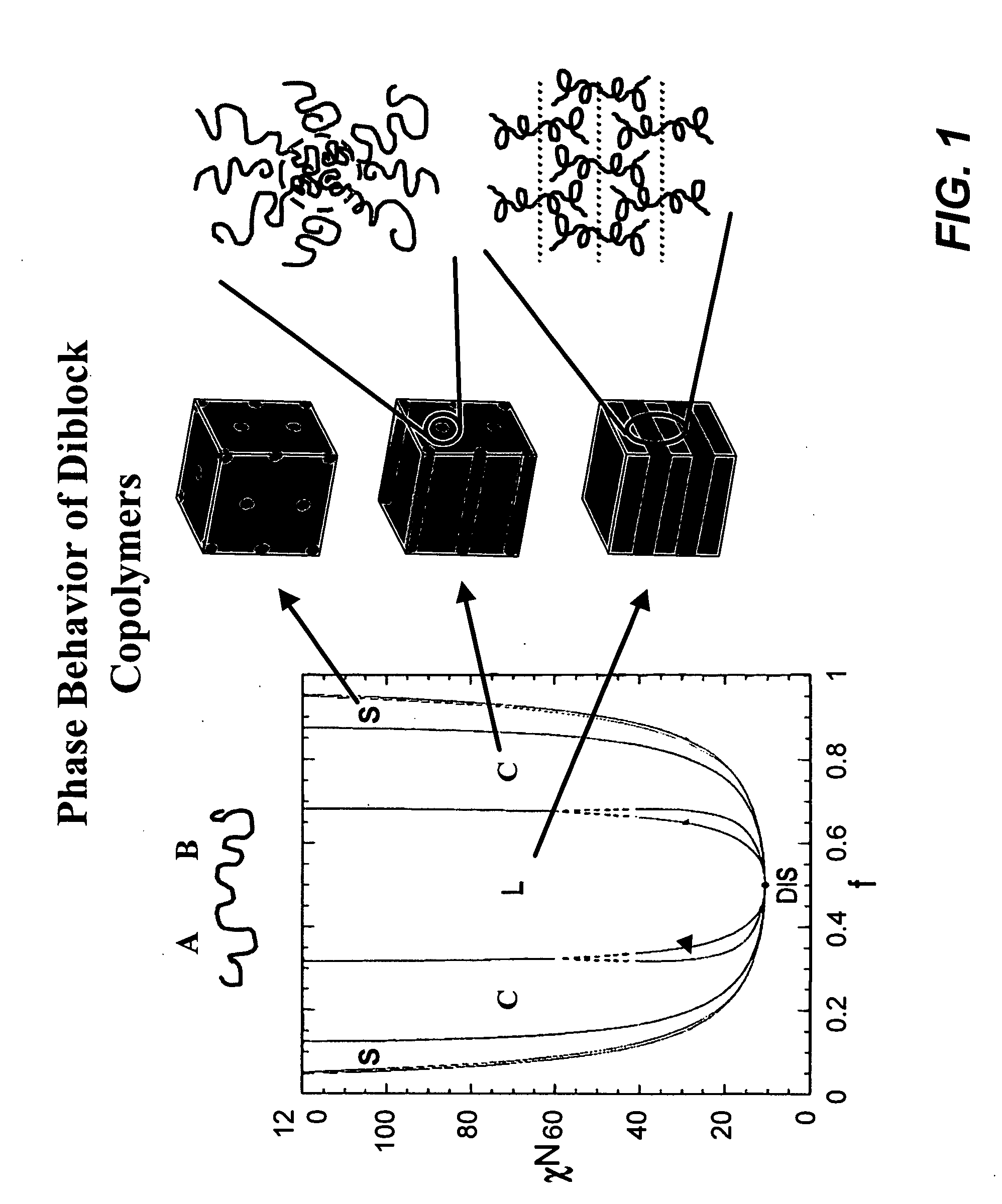

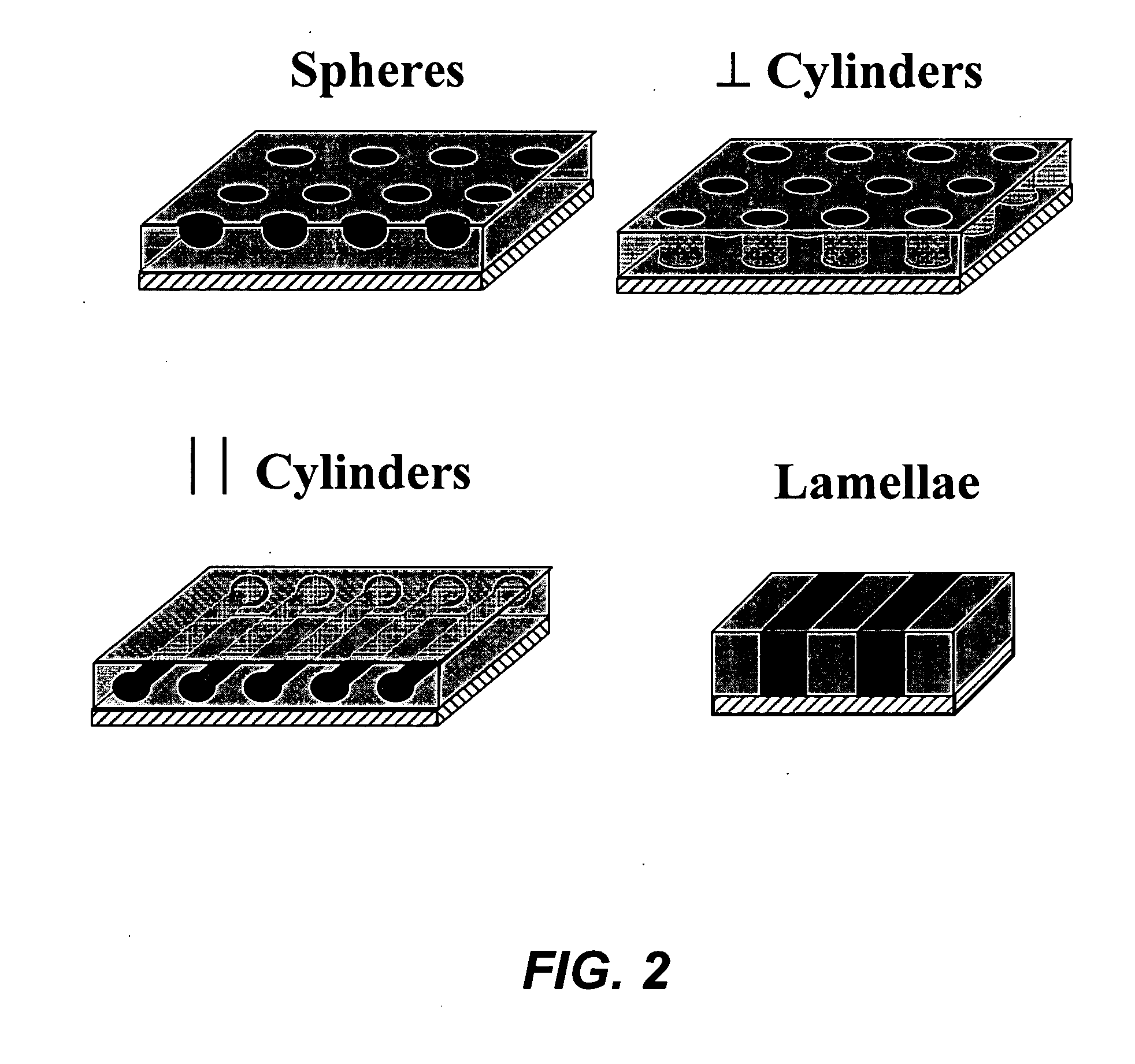

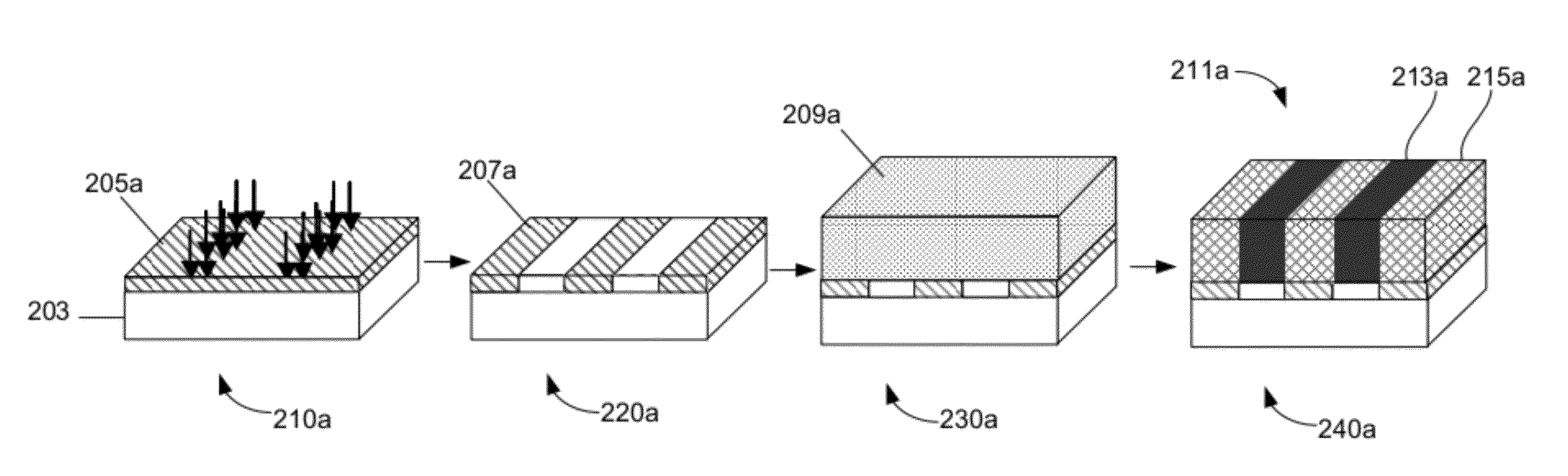

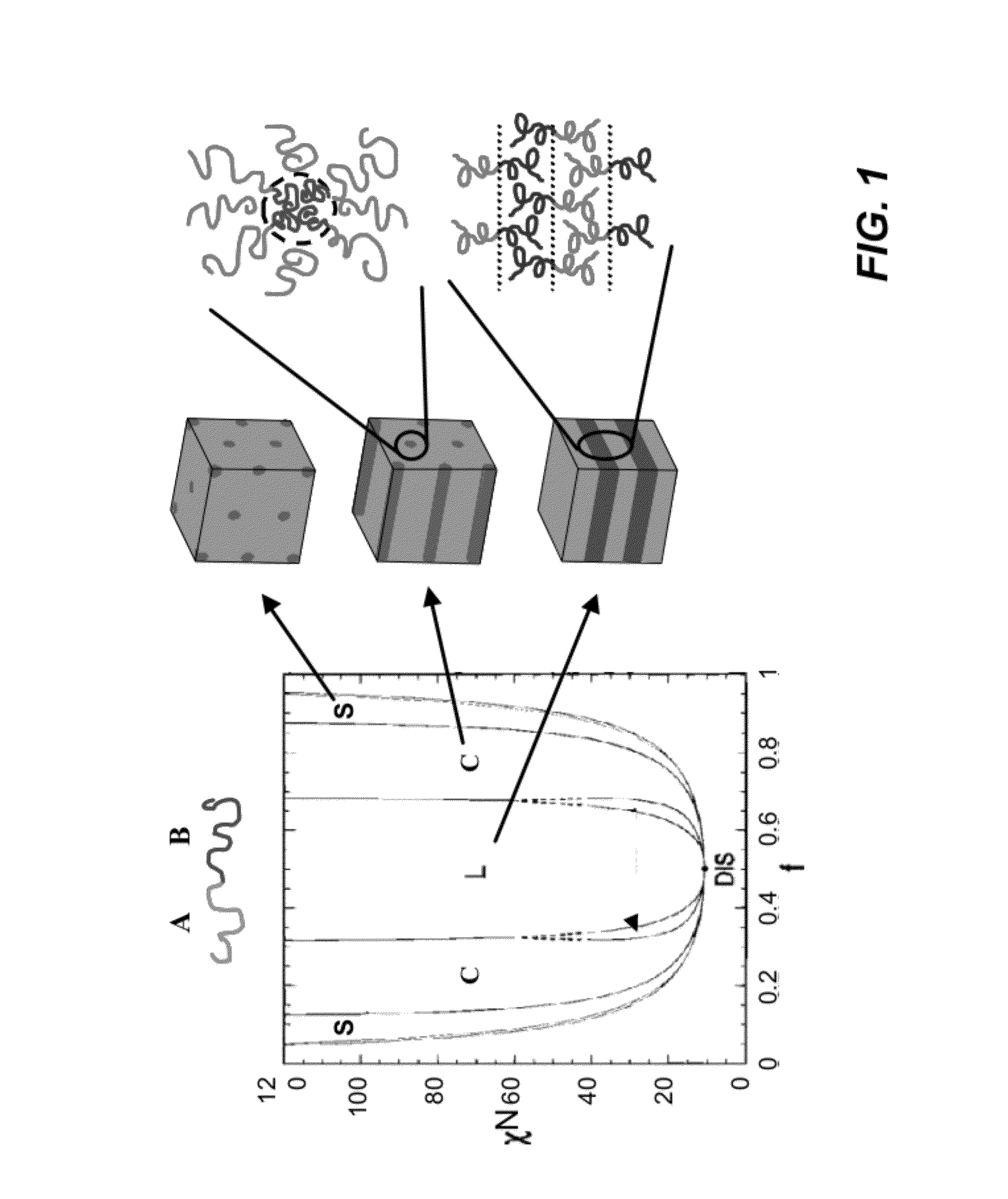

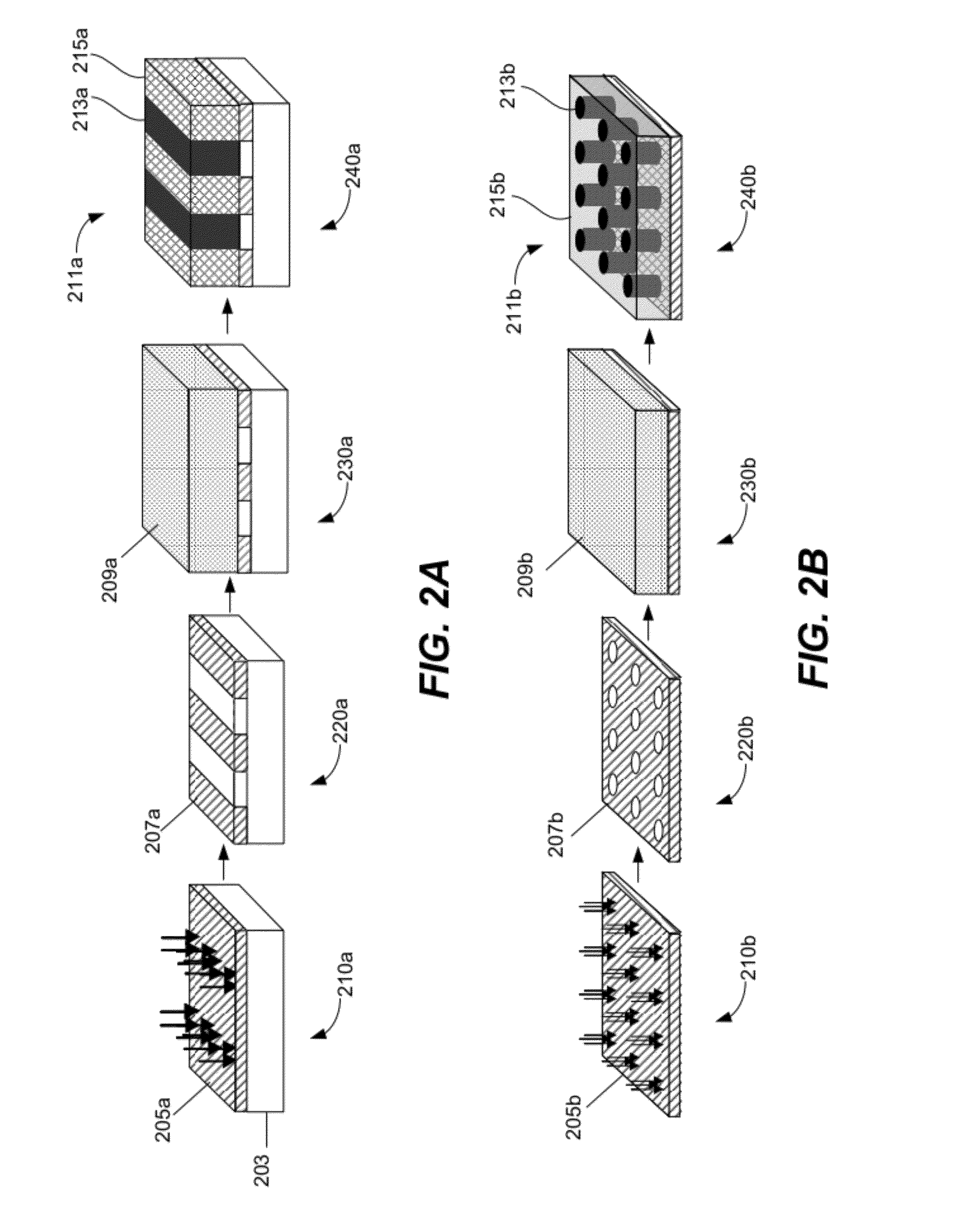

Density multiplication and improved lithography by directed block copolymer assembly

ActiveUS20090196488A1High densityQuality improvementMaterial nanotechnologyPatterned record carriersHigh densityPeriodic nanostructures

Methods to pattern substrates with dense periodic nanostructures that combine top-down lithographic tools and self-assembling block copolymer materials are provided. According to various embodiments, the methods involve chemically patterning a substrate, depositing a block copolymer film on the chemically patterned imaging layer, and allowing the block copolymer to self-assemble in the presence of the chemically patterned substrate, thereby producing a pattern in the block copolymer film that is improved over the substrate pattern in terms feature size, shape, and uniformity, as well as regular spacing between arrays of features and between the features within each array compared to the substrate pattern. In certain embodiments, the density and total number of pattern features in the block copolymer film is also increased. High density and quality nanoimprint templates and other nanopatterned structures are also provided.

Owner:WISCONSIN ALUMNI RES FOUND +1

High recording density magnetic recording medium and recording/reproduction mechanism for the same

ActiveUS20180350398A1Improve recording densityMaintain good propertiesRecord information storageManufacture of flux-sensitive headsUltrasound attenuationRefractive index

A refractive index nL and an attenuation rate kL of a magnetic layer are obtained by irradiating linearly polarized light at an irradiation angle of 70° from a lengthwise direction of the magnetic layer to the surface of the magnetic layer, and a vertical reflectance RL during vertical incidence of the linearly polarized light in the lengthwise direction is obtained based on nL and kL. A refractive index nT and an attenuation rate kT of the magnetic layer are obtained by irradiating linearly polarized light at an irradiation angle of 70° from a width direction of the magnetic layer to the surface of the magnetic layer, and a vertical reflectance RT during vertical incidence of the linearly polarized light in the width direction is obtained from nT and kT. If a variation rate A (%) of RL and RT is A=|RL / RT−1|×100, the relationship A≤10% is established.

Owner:MAXELL HLDG LTD

Dot-patterned structure magnetic recording medium and method for production thereof

InactiveUS20090098413A1Function increaseHigh crystallinityRecord information storageDisk carriersCrystallinityRecording layer

Disclosed herein are a dot-patterned structure for magnetic recording bits and a magnetic recording medium provided therewith. The former exhibits high functionality and high performance owing to good crystallinity. The dot-patterned structure is composed of a first layer, which is continuous, and a second layer, which is discrete. The magnetic recording medium having a dot-patterned recording layer is formed by the steps of treating an underlying layer by lithography, thereby forming grooves, filling the grooves by epitaxial growth with the same material as the underlying layer, removing the photoresist used for lithography in a solvent, thereby forming pits, and filling the pits by epitaxial growth with a magnetic film as the recording layer.

Owner:HITACHI LTD

Magnetic recording medium

InactiveUS20050260459A1Increased durabilityStorage stabilityMagnetic materials for record carriersBase layers for recording layersPolyesterNon magnetic

A magnetic recording medium comprising: a nonmagnetic support having a first surface and a second surface; and a magnetic layer containing ferromagnetic powder and a binder, so that the magnetic layer, the first surface and the second surface are in this order, wherein the nonmagnetic support contains polyester, a difference between largest ratio and smallest ratio among peak intensity ratios of gauche / trans on the first and second surfaces of the support in a machine direction and a transverse direction obtained by ATR-FT-IR method is 0.030 or less in an absolute value, and a shrinkage factor of the magnetic recording medium after preservation at 70° C. 5% RH for one week is 0.040% or less.

Owner:FUJIFILM CORP +1

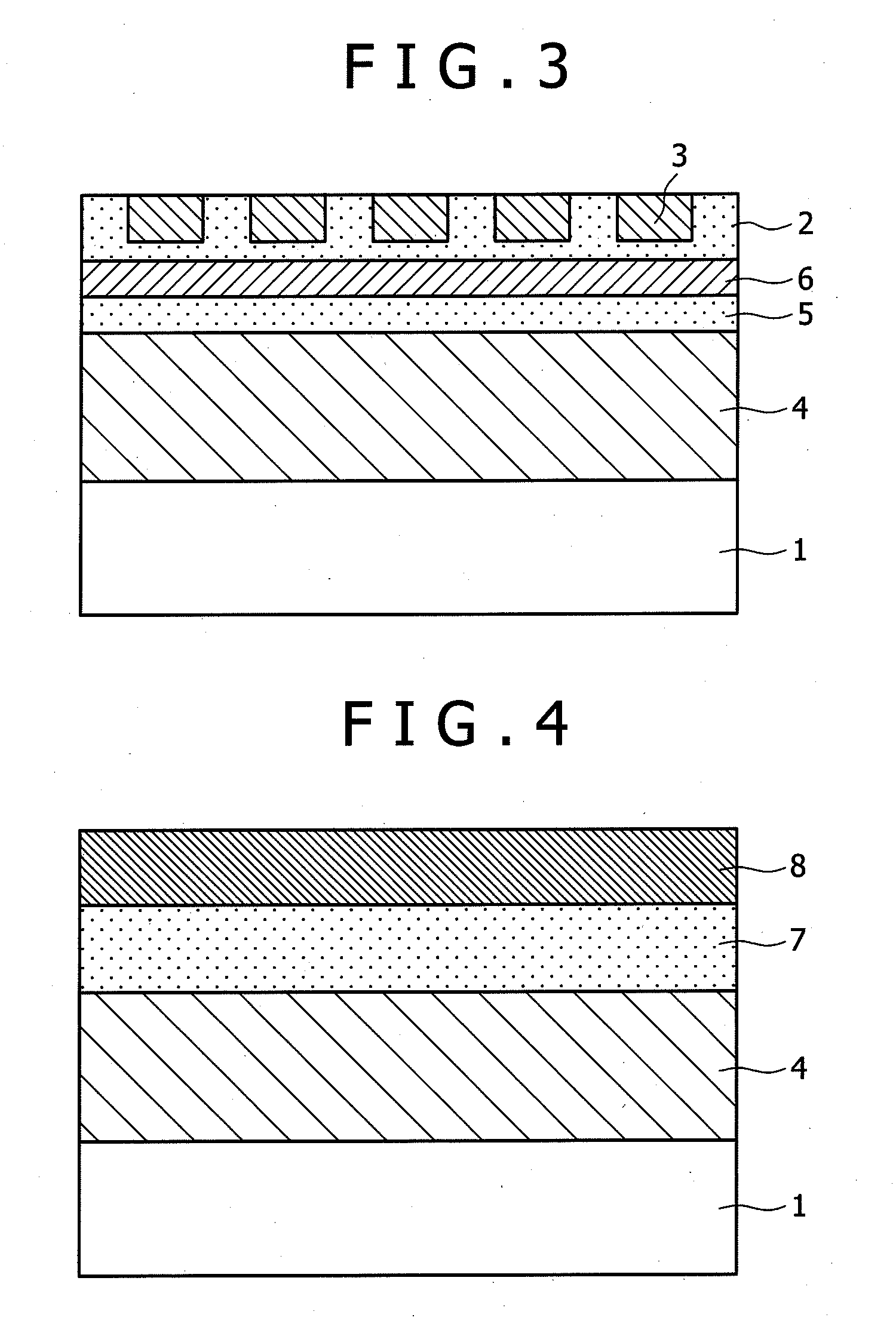

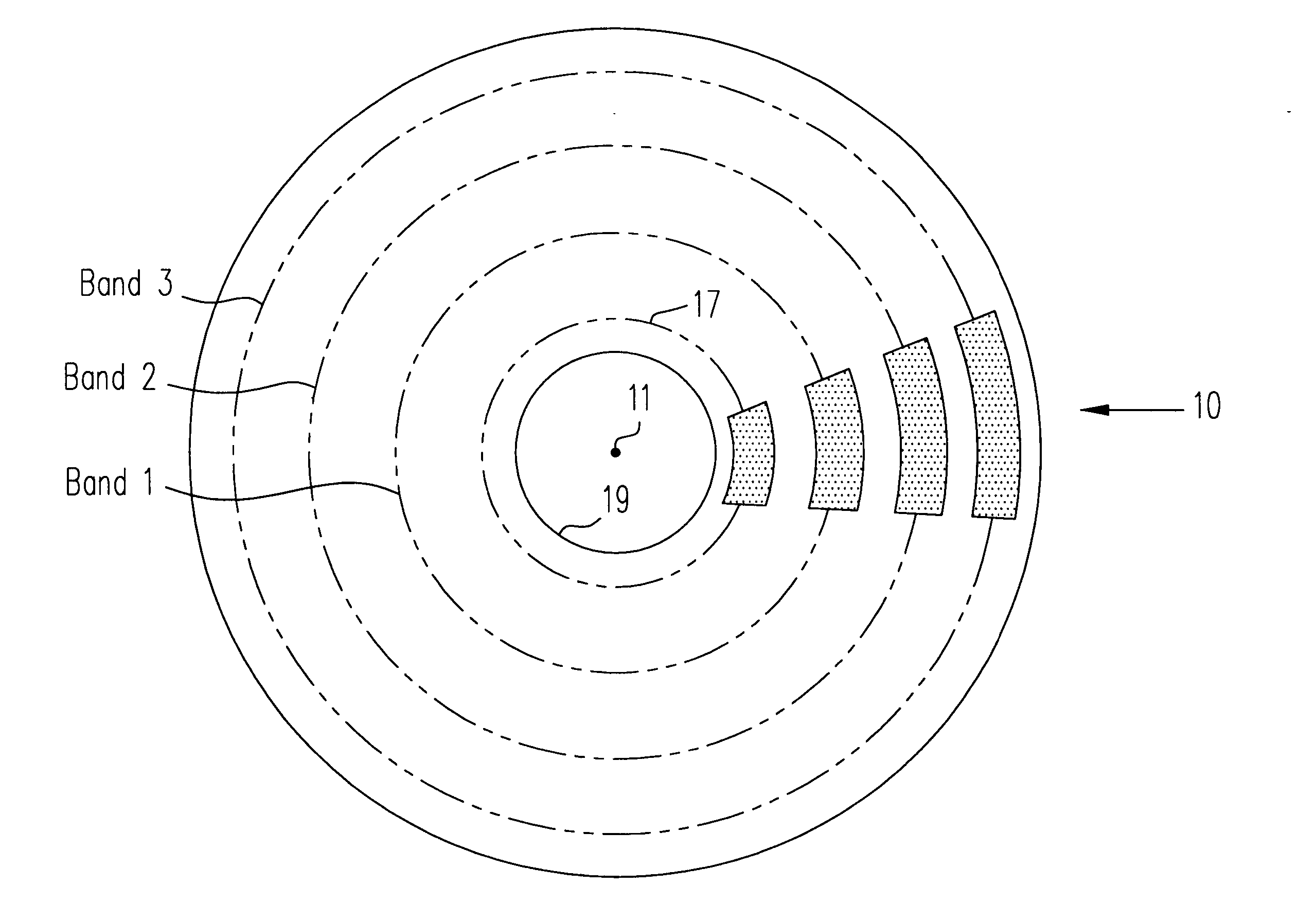

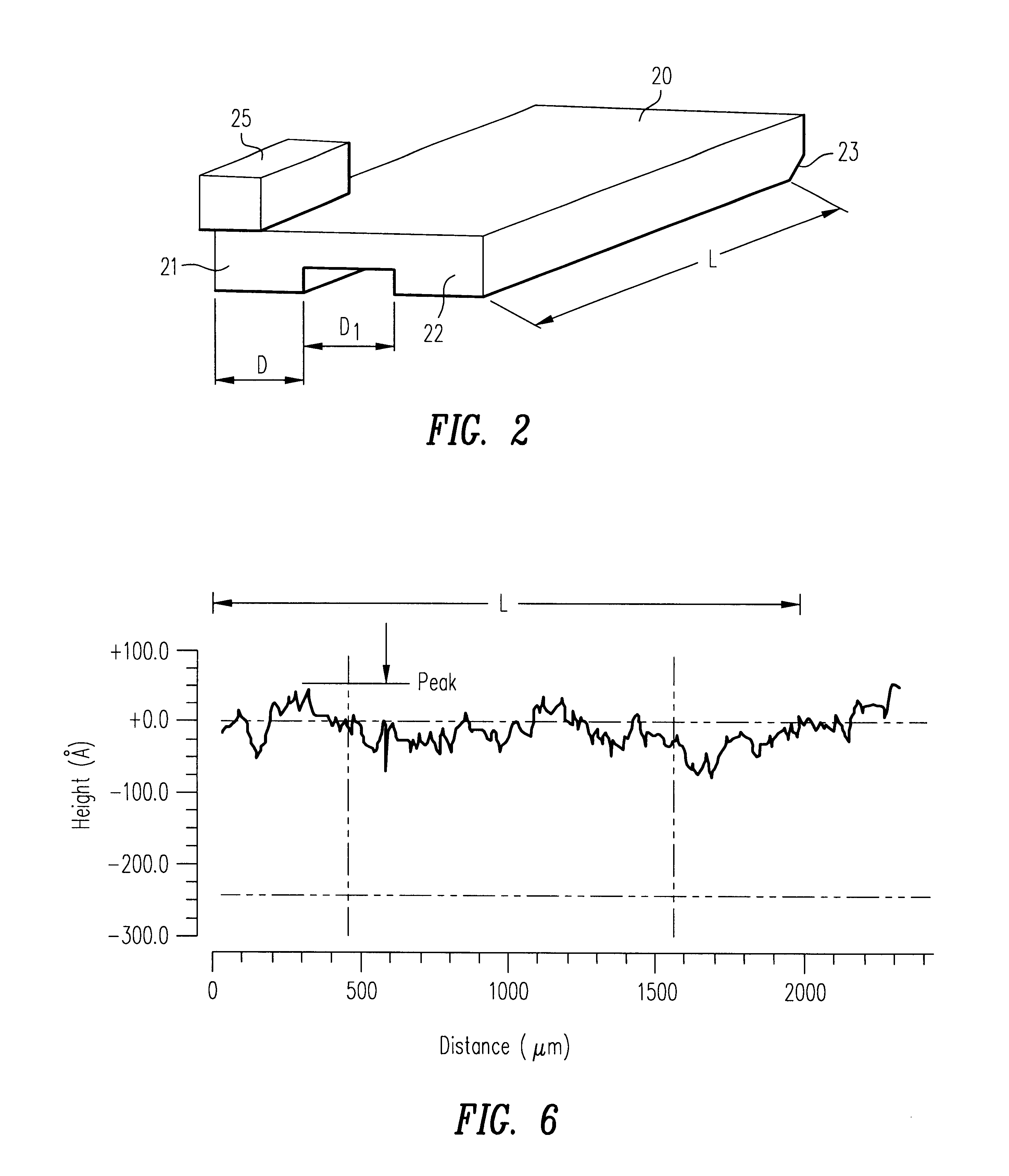

Calibration disk having discrete bands of composite roughness

InactiveUS6408677B1Carrier indicating/warning arrangementsRecord information storageEngineeringFlying height

A calibration disk includes calibration areas that allow a glide head to be calibrated as to the glide's head's avalanche height, fly height and the like. The calibration areas may be, for example, configured in a circumferential band (or, alternatively, a series of circumferential bands extending substantially concentric to one another), one or more spiral bands or some other suitable configuration. Such bands can, for example, extend from adjacent an outer diameter of the calibration disk to adjacent an inner portion of the calibration disk. Each of the circumferential bands is a textured area on the calibration disk having a given degree of composite roughness, as measured by the given circumferential band's average composite roughness height, and as such is referred to herein as a calibration band. Preferably, the given circumferential band is textured in a uniform manner, sufficient to produce a constant and continuous output signal from a sensor mounted on a glide head when the glide head flies lower than a maximum composite roughness height. Also preferably, the average composite roughness height within an individual calibration band is substantially uniform, and the average composite roughness height of each calibration band is slightly different from that of the other calibration bands.

Owner:KOMAG CORP

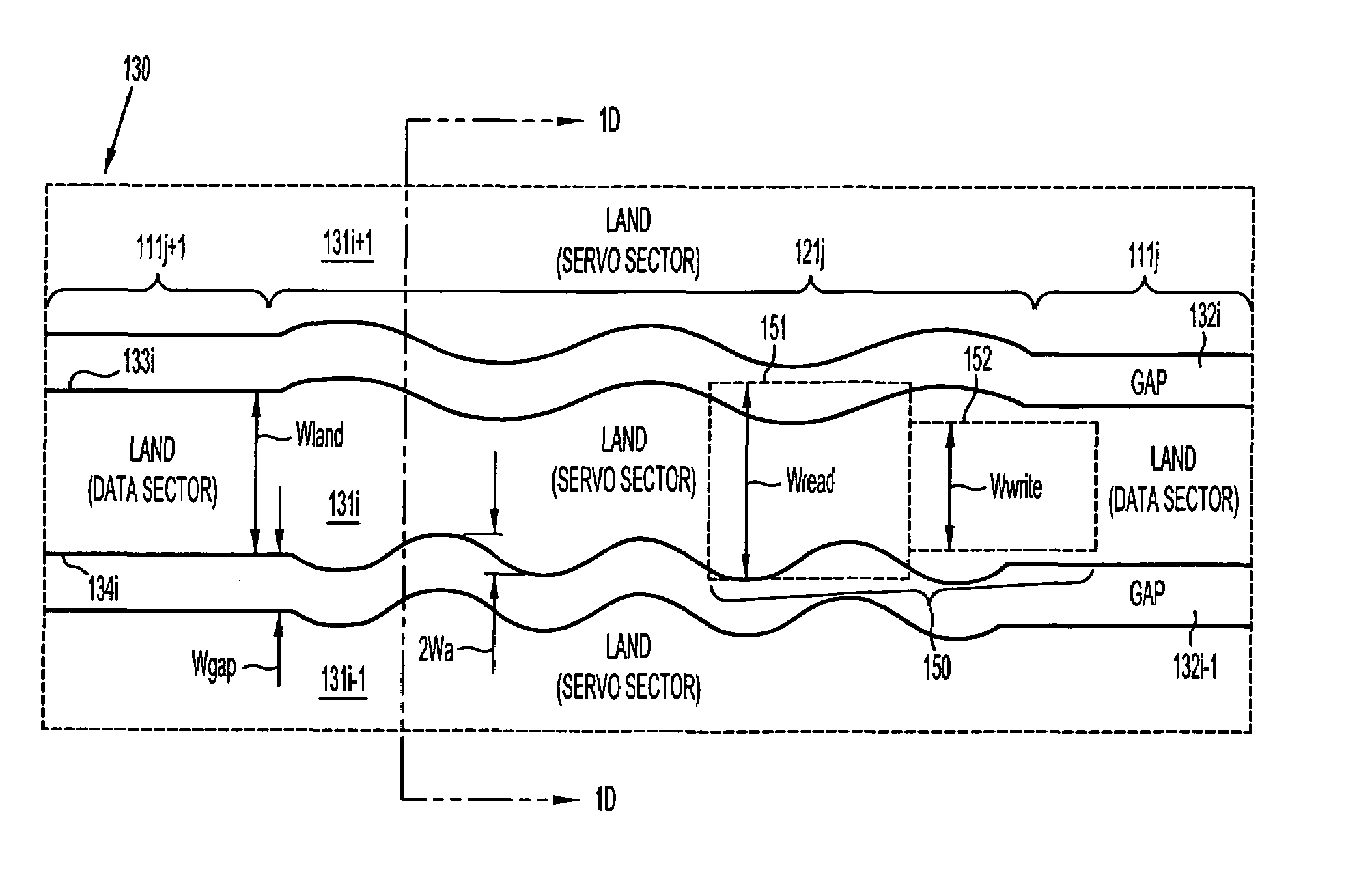

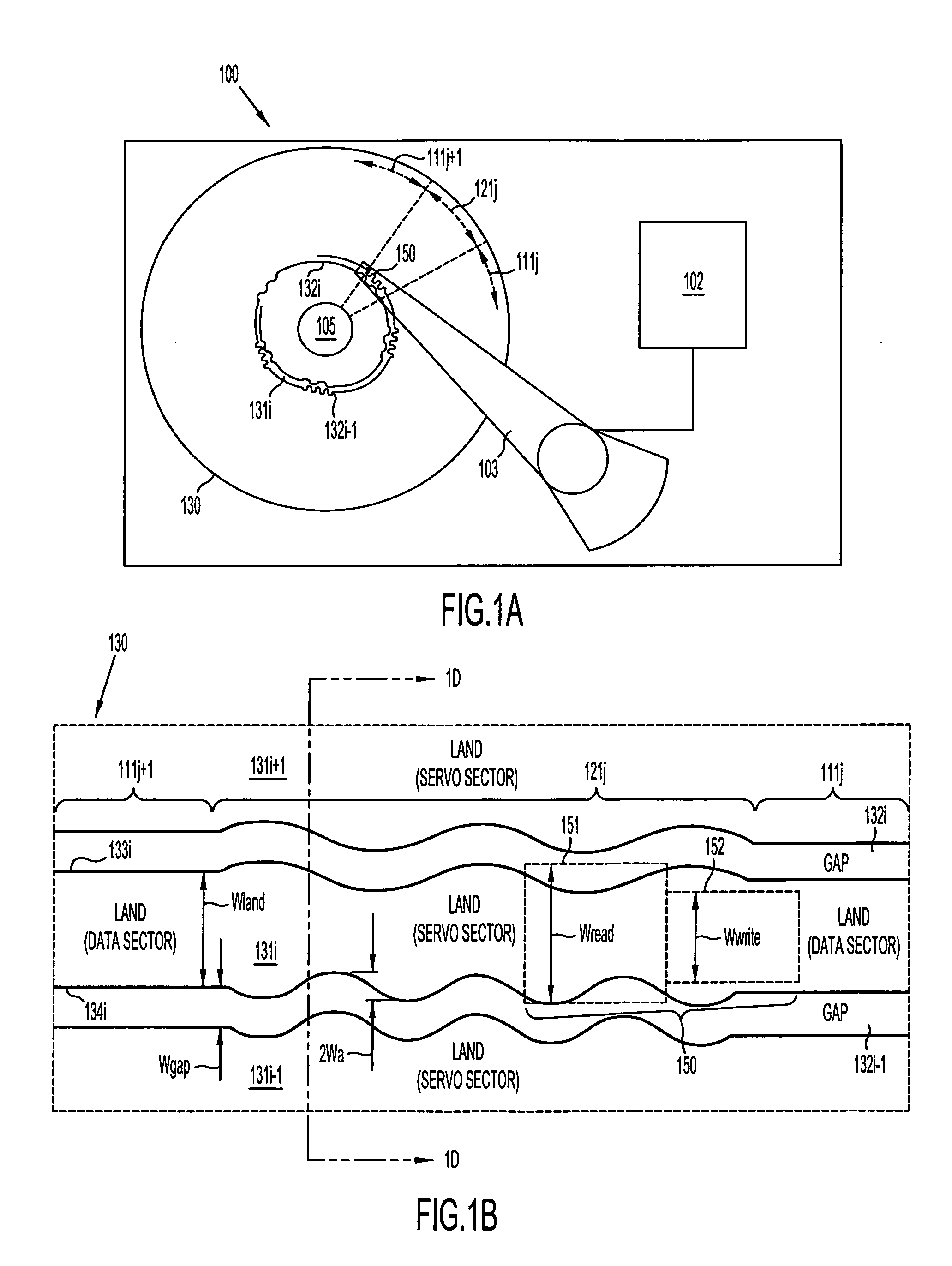

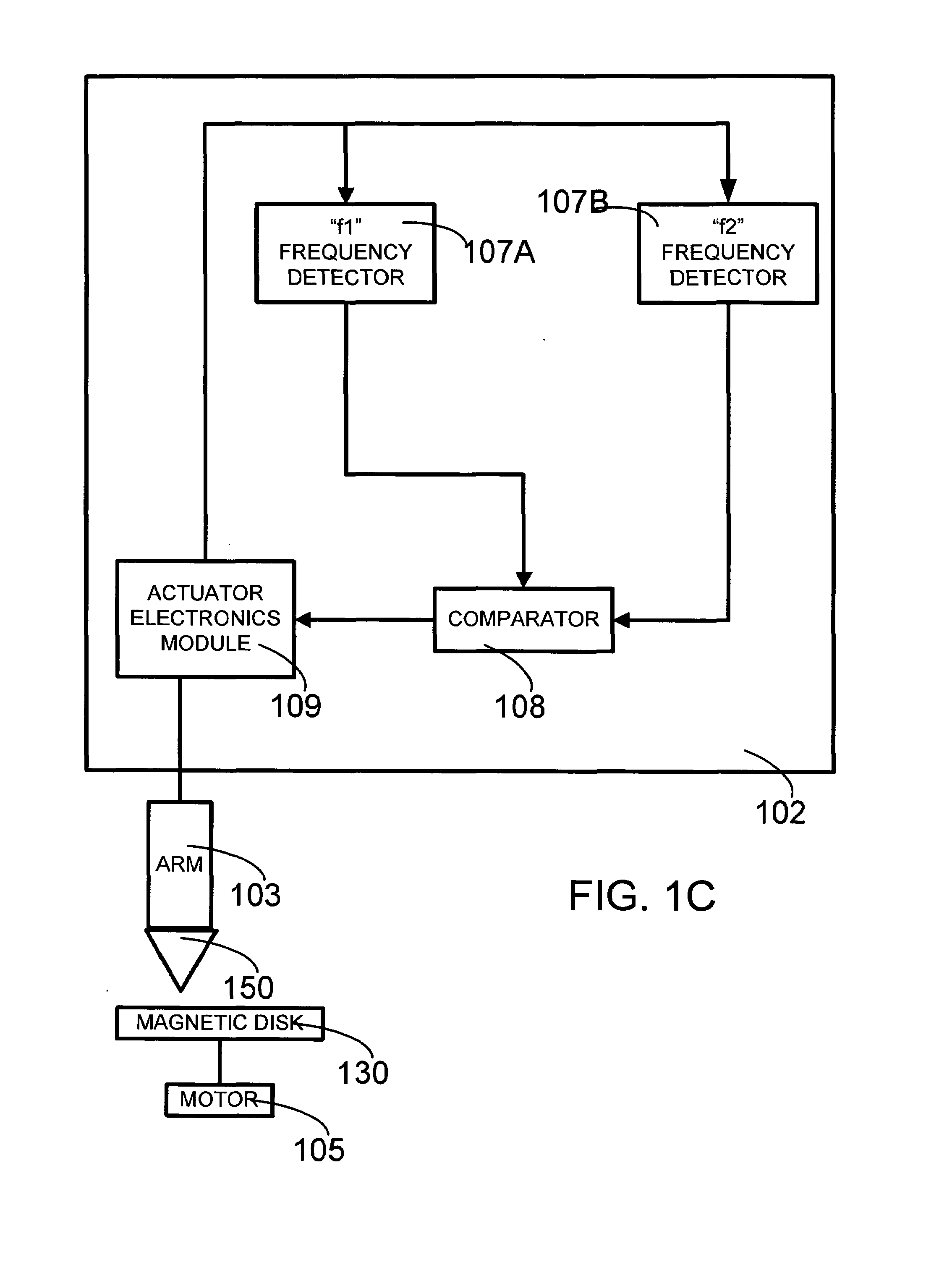

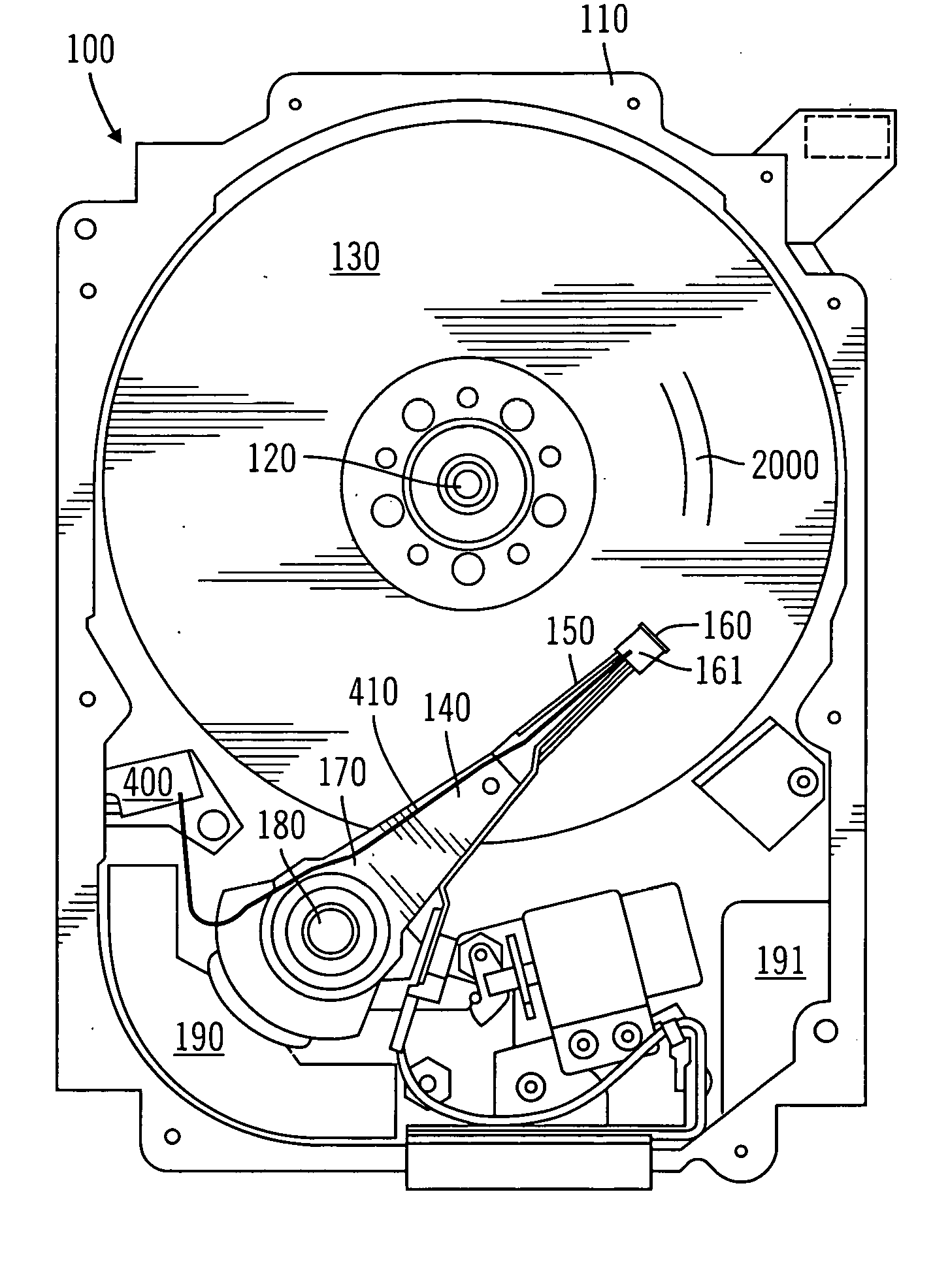

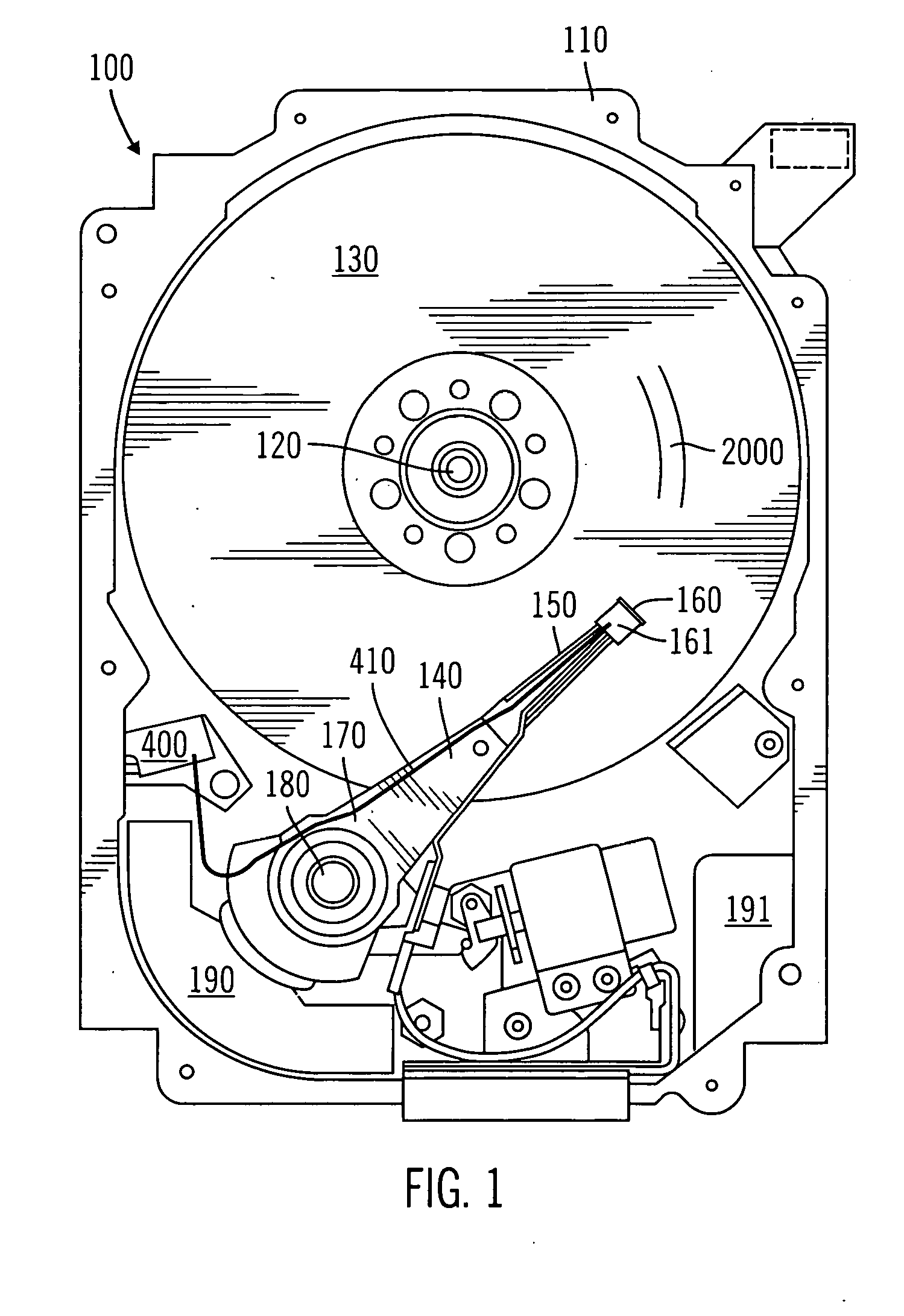

Modulation of sidewalls of servo sectors of a magnetic disk and the resultant disk

A discrete-track-recording (DTR) disk (also called “patterned” disk) has a sectored servo formed by modulation of its sidewalls in a predetermined manner, whereas sidewalls of data sectors are not modulated in this manner. Each servo sector has two side walls that are each respectively modulated in two different ways. Hence, a readback signal from a given servo sector contains components of each of the two different modulations, even in case of “DC” erase initiation. Therefore, the just-described modulated servo sectors eliminate servowriting. Moreover, data signals are read without filtering the modulation, because data sector sidewalls are not modulated.

Owner:WD MEDIA

Optimized media grain packing fraction for bit patterned magnetic recording media

InactiveUS20050157597A1Optimizes optical coupling efficiencyOptimizes medium grain packing fractionCombination recordingNanoinformaticsEngineeringOptical coupling

A bit patterned magnetic recording medium for use in HAMR, which is optimized for optical coupling efficiencies and improved magnetic read-back coupling. The medium comprises bit-patterned magnetic recording elements, each corresponding to a magnetic data bit, and each comprising a cluster of discrete and separated magnetic grains. The desired packing fraction may be obtained by defining the number of grains within a bit, while bit-patterning provides efficient optical transmission. The grains have an effective packing fraction that enhances magnetic read-back signals, and the bits are distributed in a pattern having a packing fraction that enhances the optical coupling efficiency. The bits and / or the grains may be substantially thermally and optically isolated.

Owner:SEAGATE TECH LLC

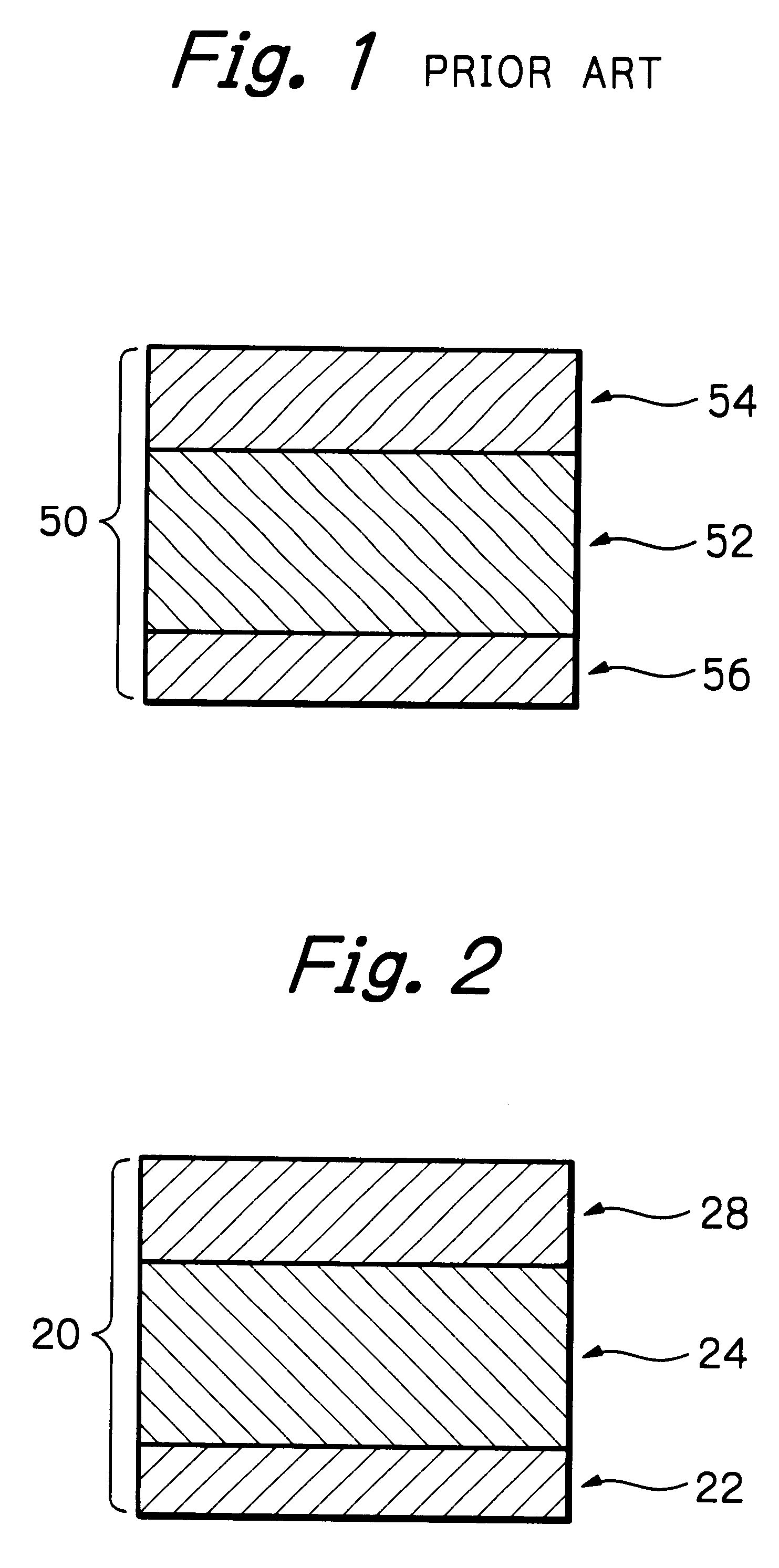

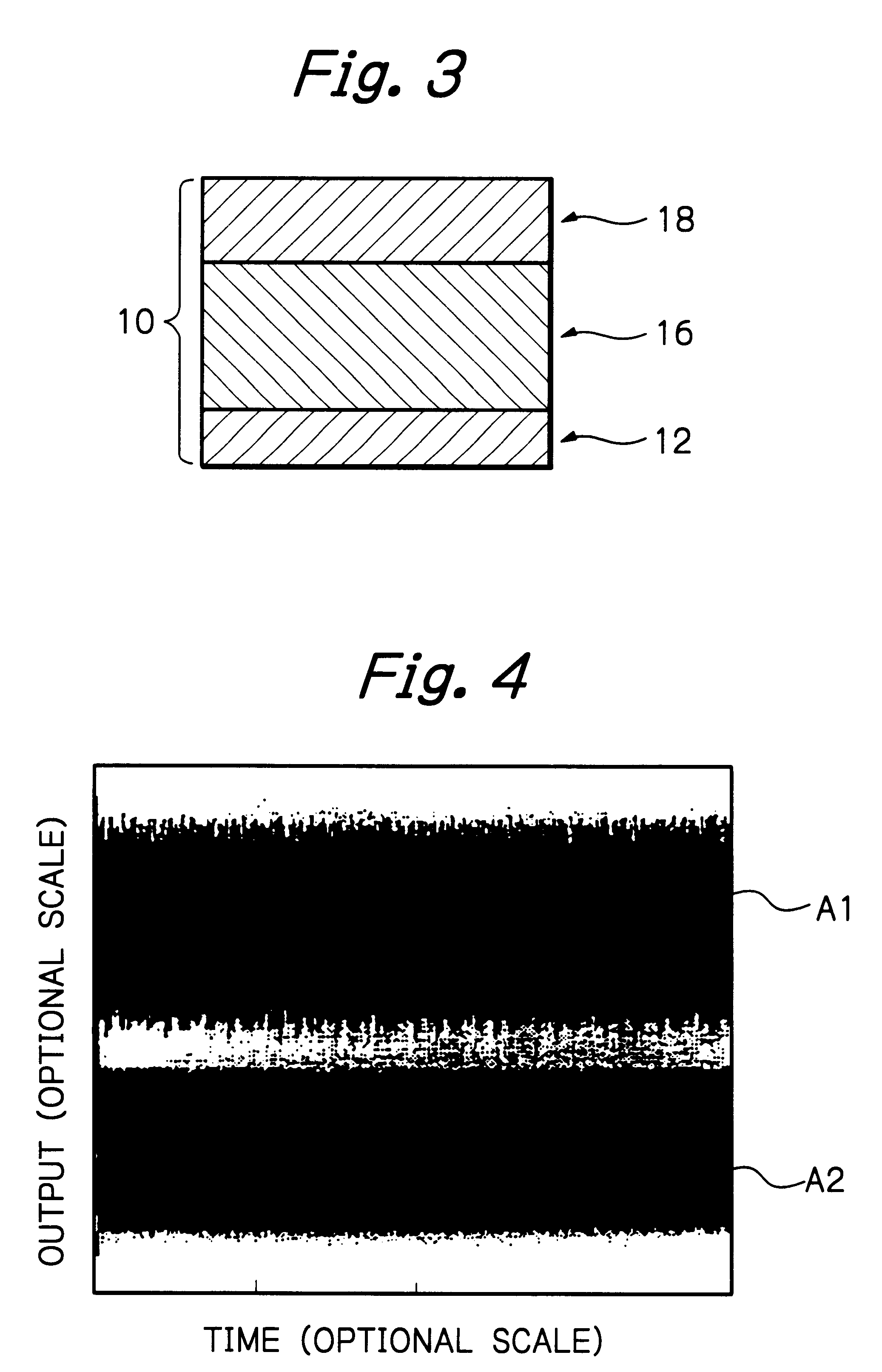

Perpendicular magnetic recording medium

InactiveUS6270885B1Decrease cancellationReduce noiseRecord information storageDisk carriersPerpendicular magnetizationMagnetization

In a perpendicular magnetic recording medium, a soft magnetic film playing the role of an back layer, but not having a domain wall structure, is positioned beneath a perpendicular magnetization film. Such a back layer improves the envelope characteristic of the medium at the time of recording and reproduction. Moreover, the medium is free from spike noise and the decrease or cancellation of recorded magnetization ascribable to the movement of the domain wall of a back layer. The medium of the present invention is therefore a drastic solution to the problems particular to a conventional perpendicular magnetic recording medium and realizes desirable recording and reproducing characteristics.

Owner:WD MEDIA SINGAPORE PTE

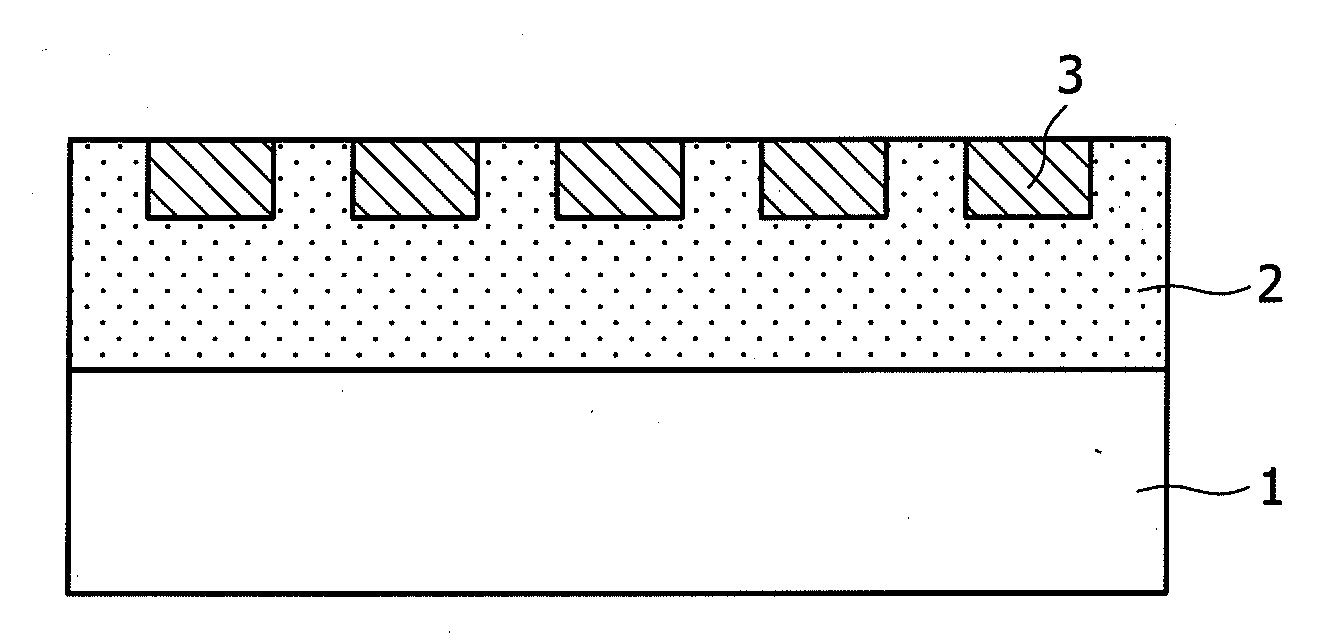

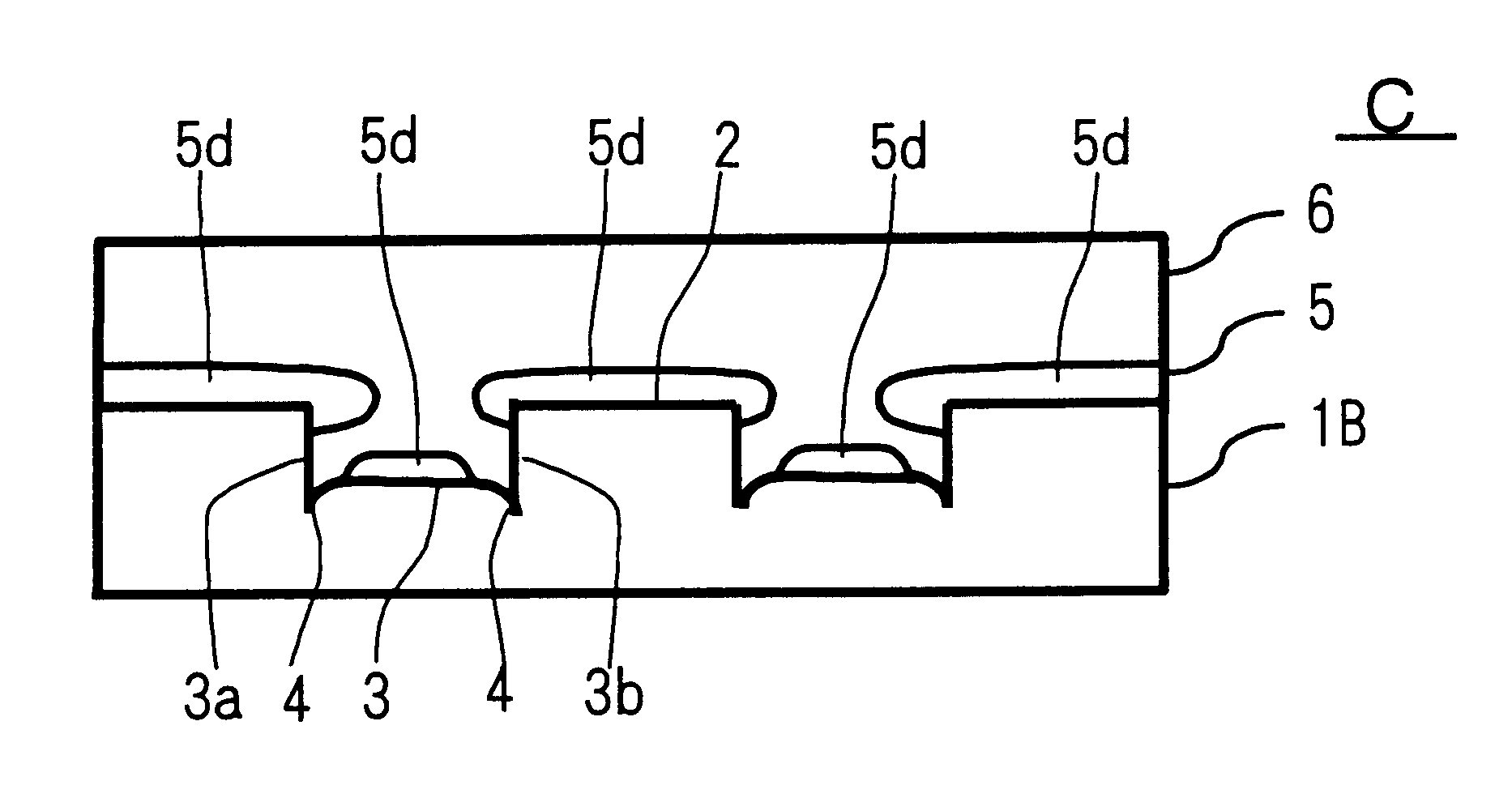

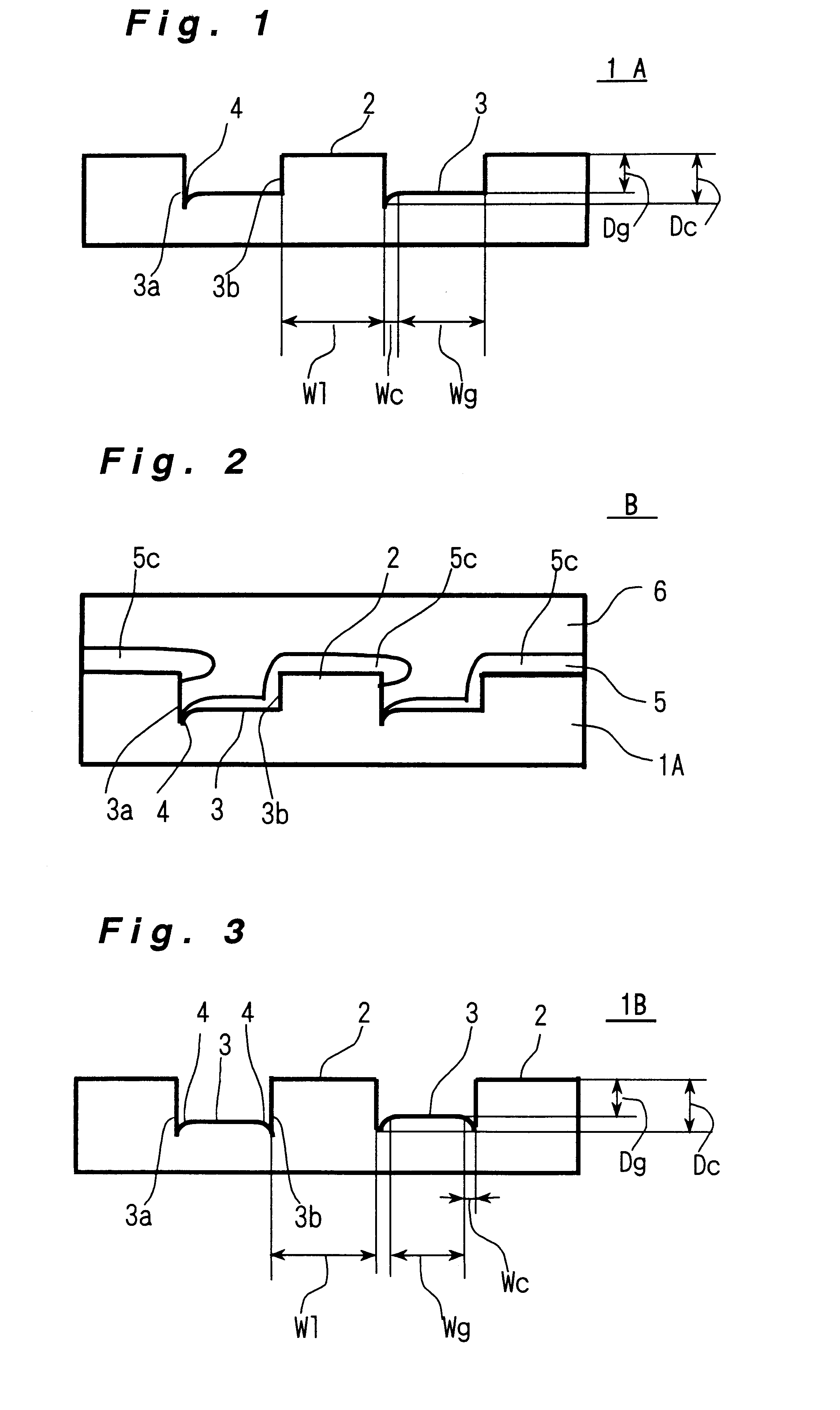

Information recording mediums, supporter used in the mediums, manufacture methods of the supporter, manufacturing apparatus of the supporter and stampers for producing the mediums

InactiveUS6254966B1Magnetic materials for record carriersLayered productsHigh densityManufactured apparatus

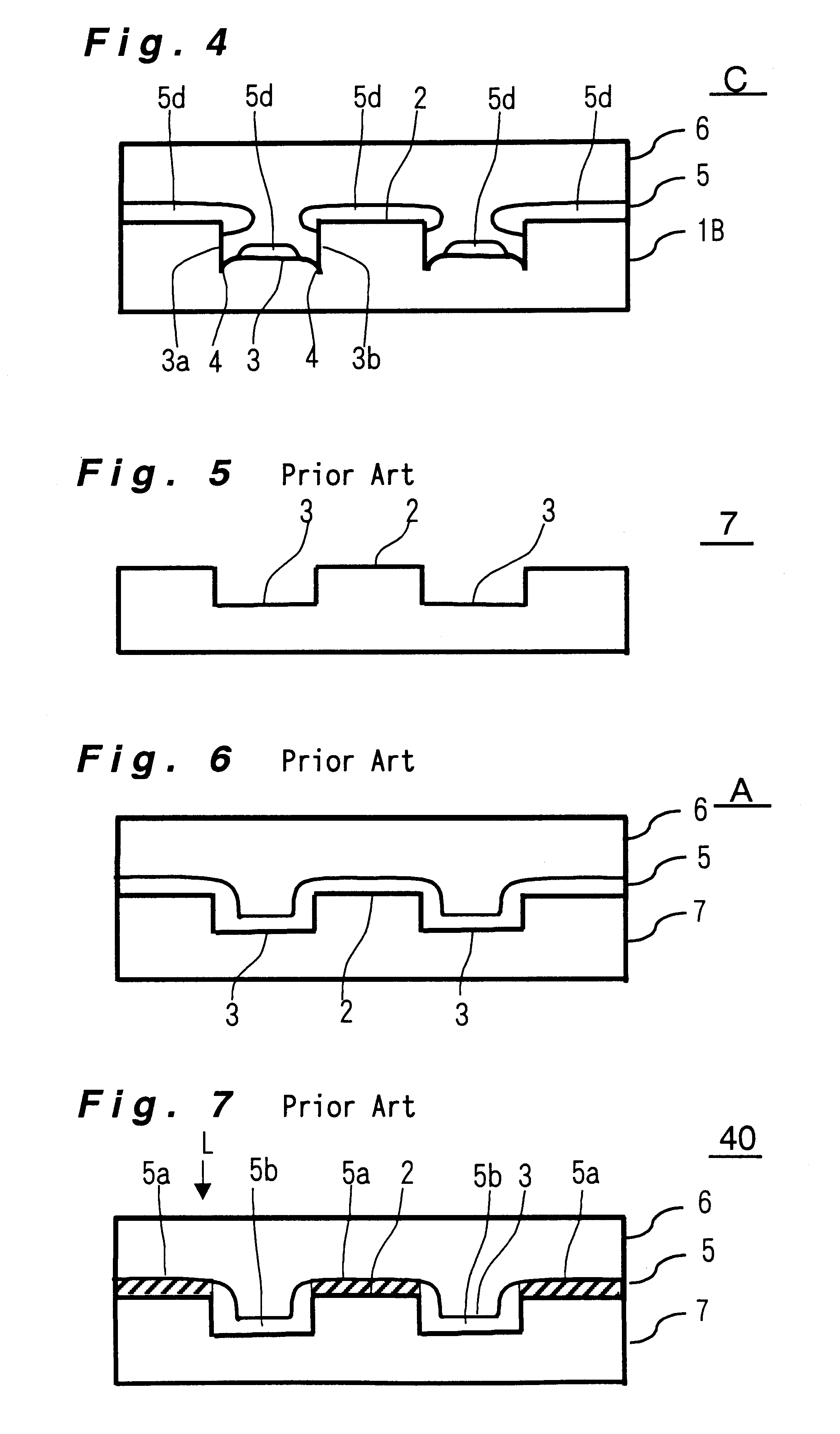

An information recording medium and a supporter used for the information recording medium capable of recording a land / groove recording by using a high density recording technique such as a super-resolution, resulting in a high density recording. An information recording medium B has a supporter 1A, on which a recording layer 5 is formed. On the supporter 1A, lands 2 and groove 3 are alternately formed as a minute track pattern. A crevice 4 having a depth Dc larger than a depth Dg of the respective grooves 3 is formed in the respective grooves 3 at one end of the respective grooves 3 in a width direction of the respective grooves.

Owner:RAKUTEN INC

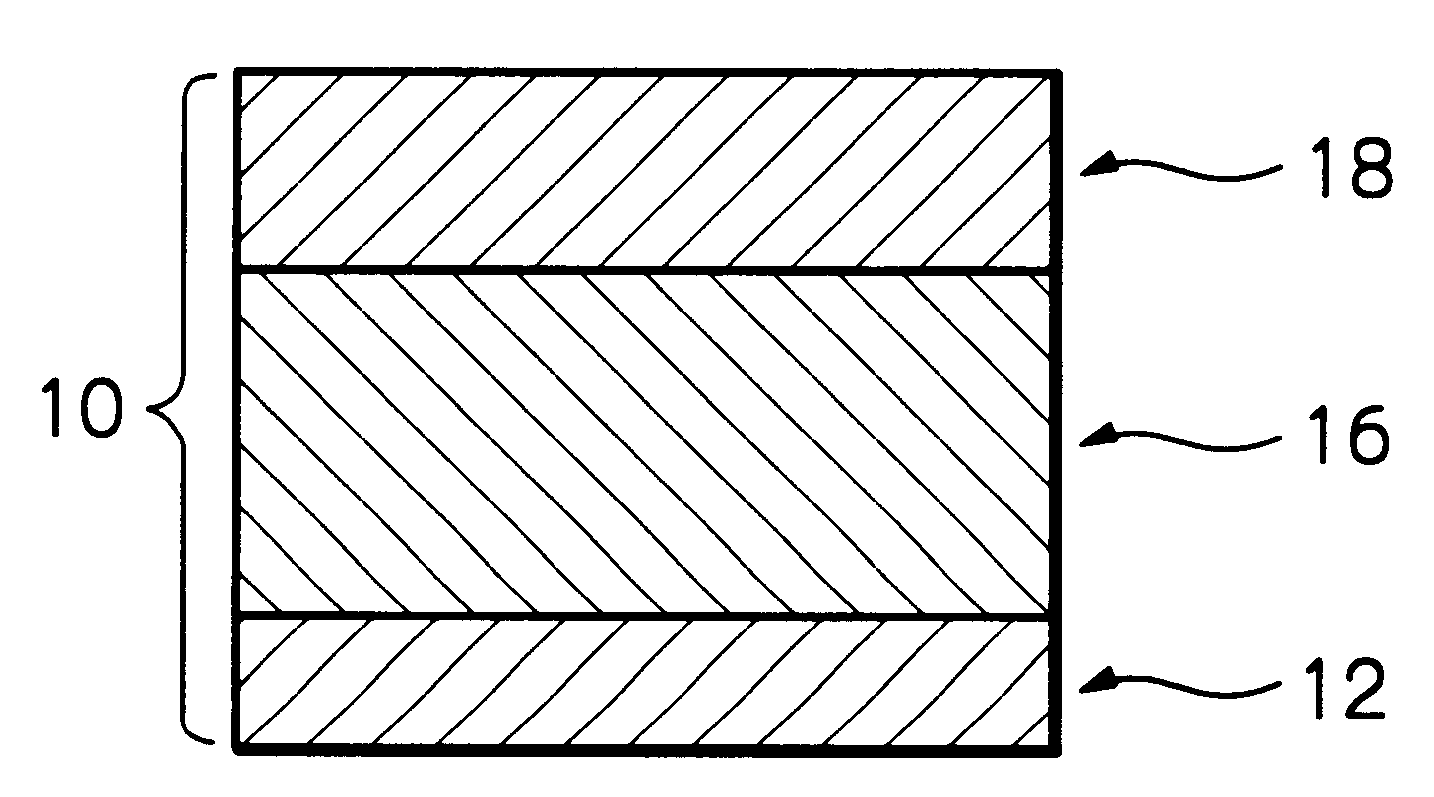

Magnetic recording medium, magnetic recording medium manufacturing method, and magnetic disk

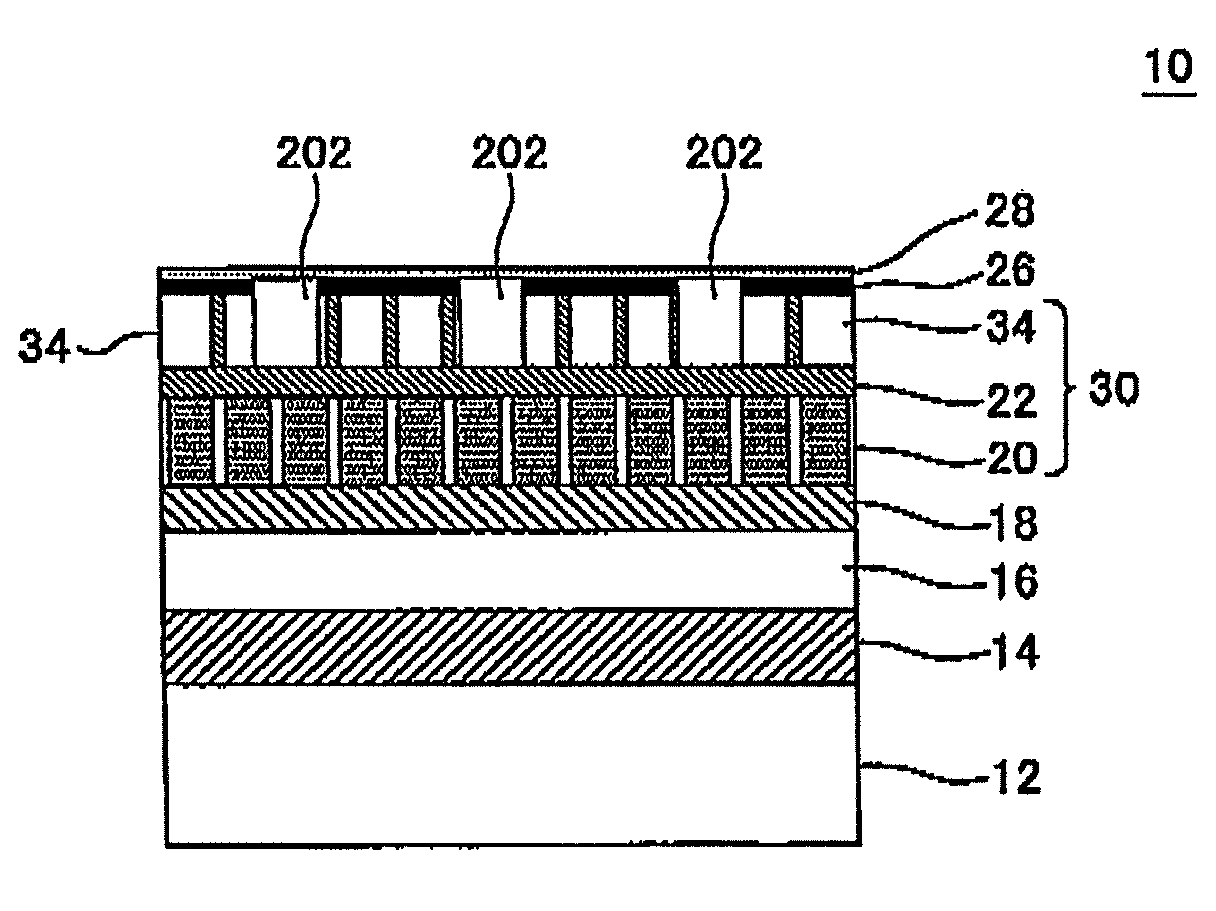

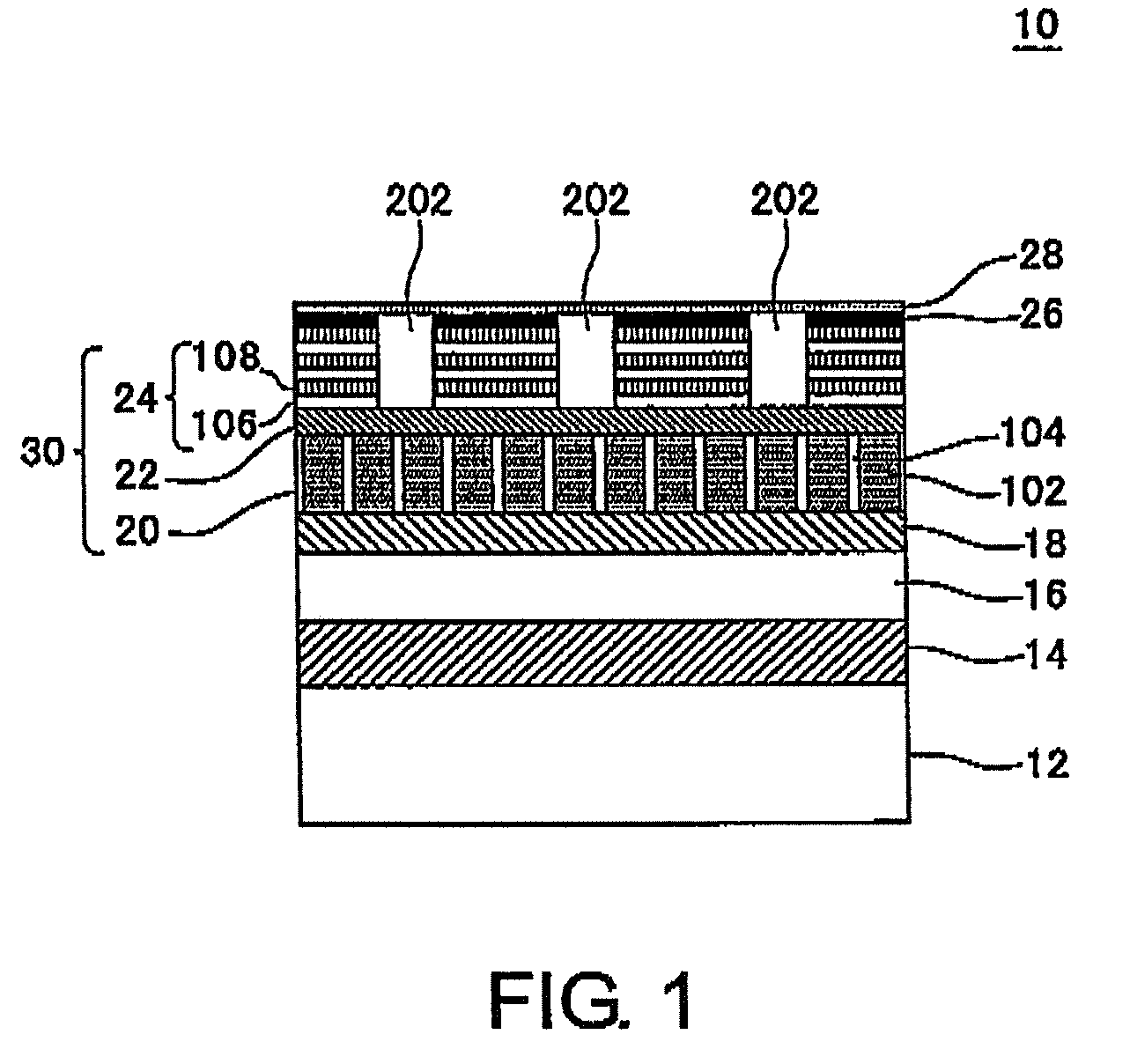

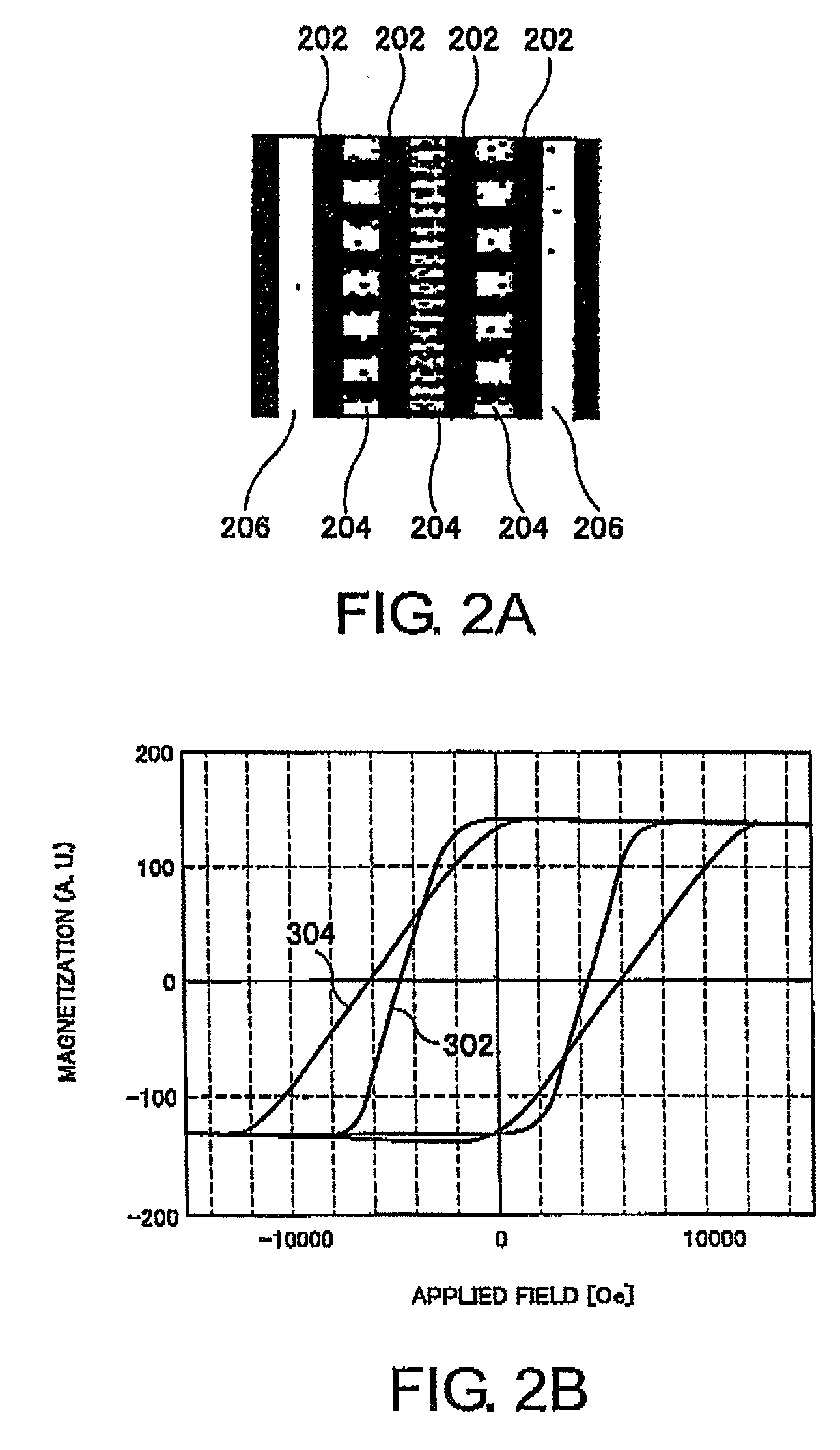

ActiveUS8076013B2Reduce noiseHigh track densityPretreated surfacesRecord information storageMagnetization curveMagnetic shield

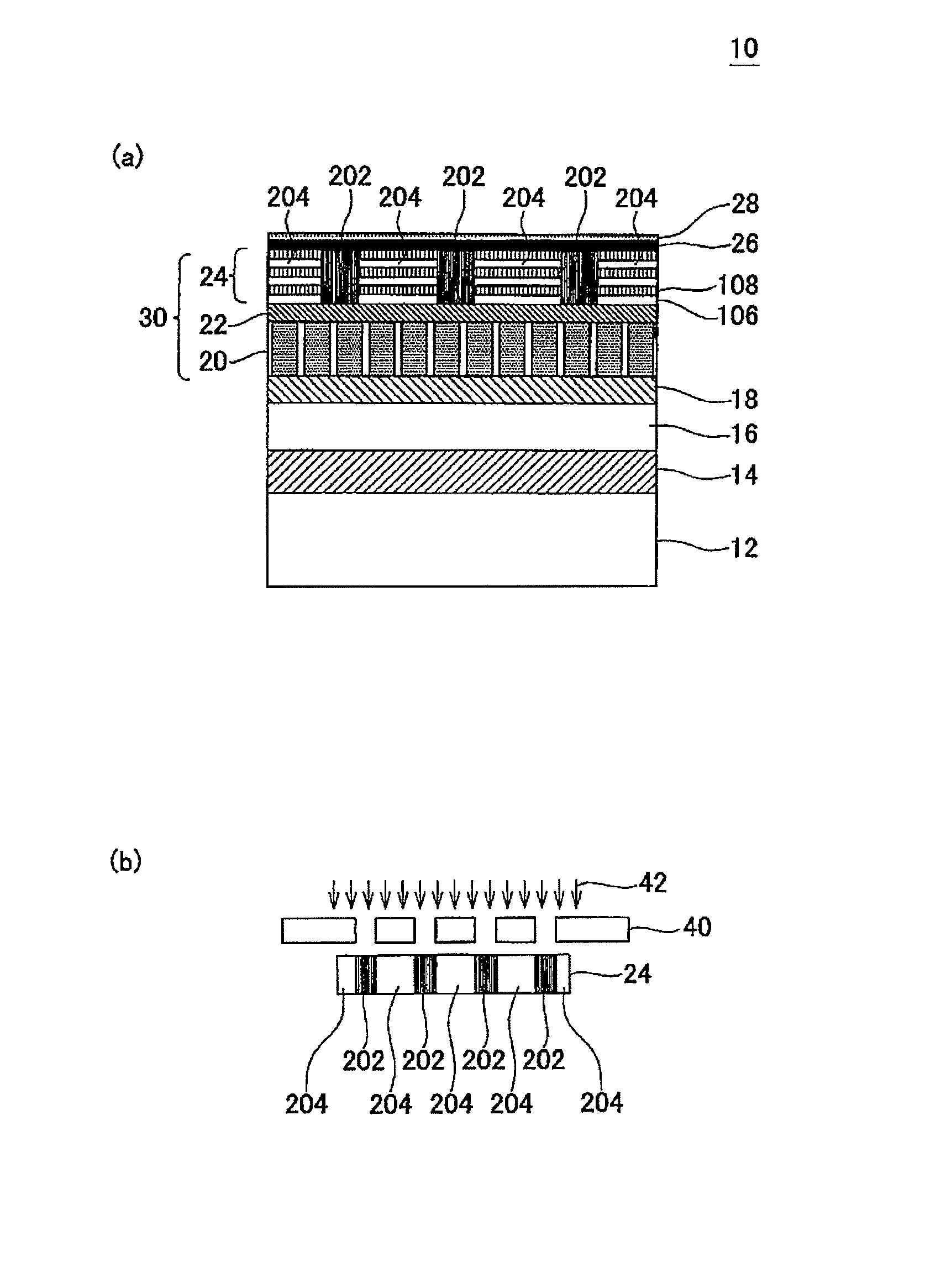

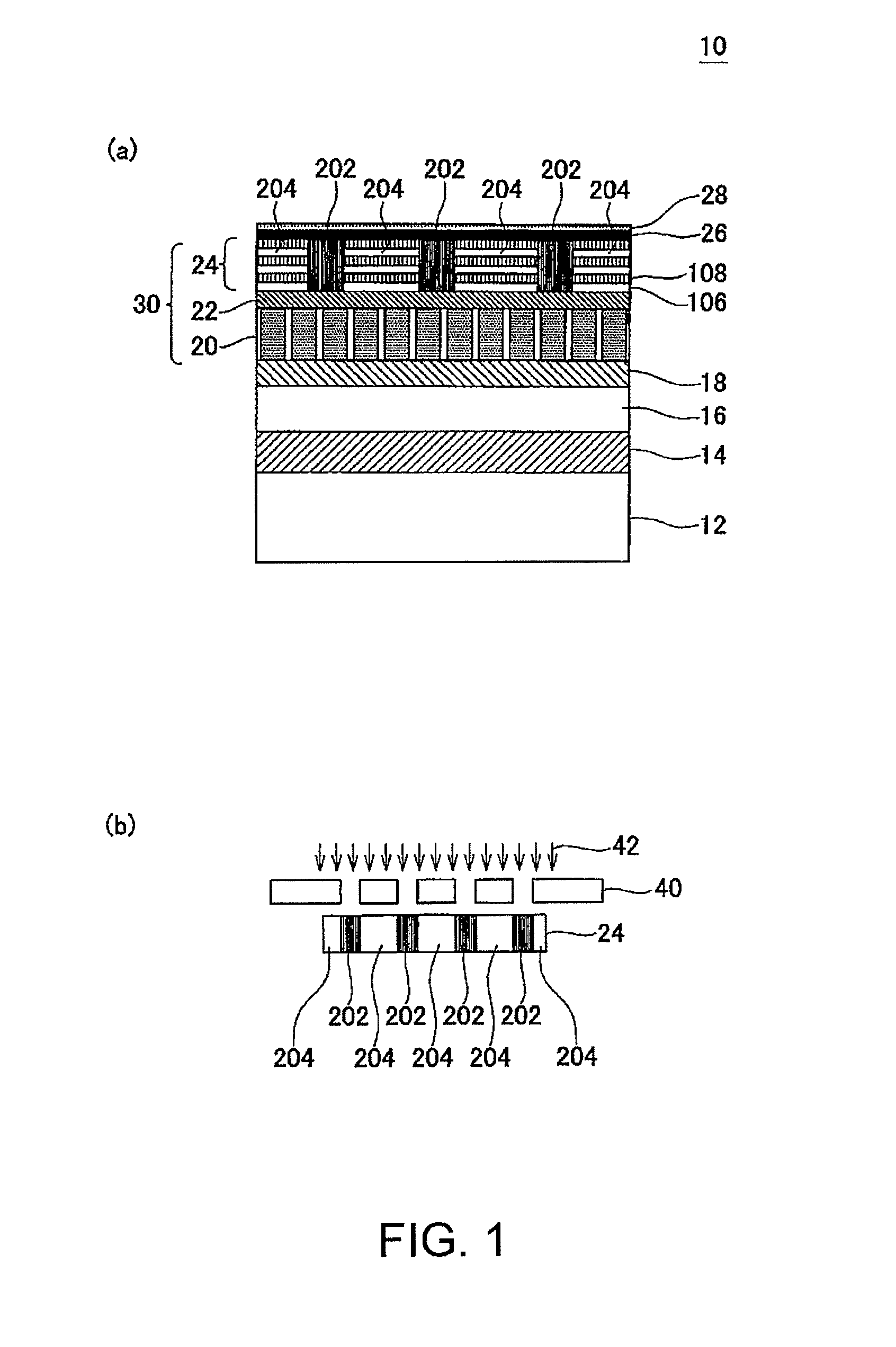

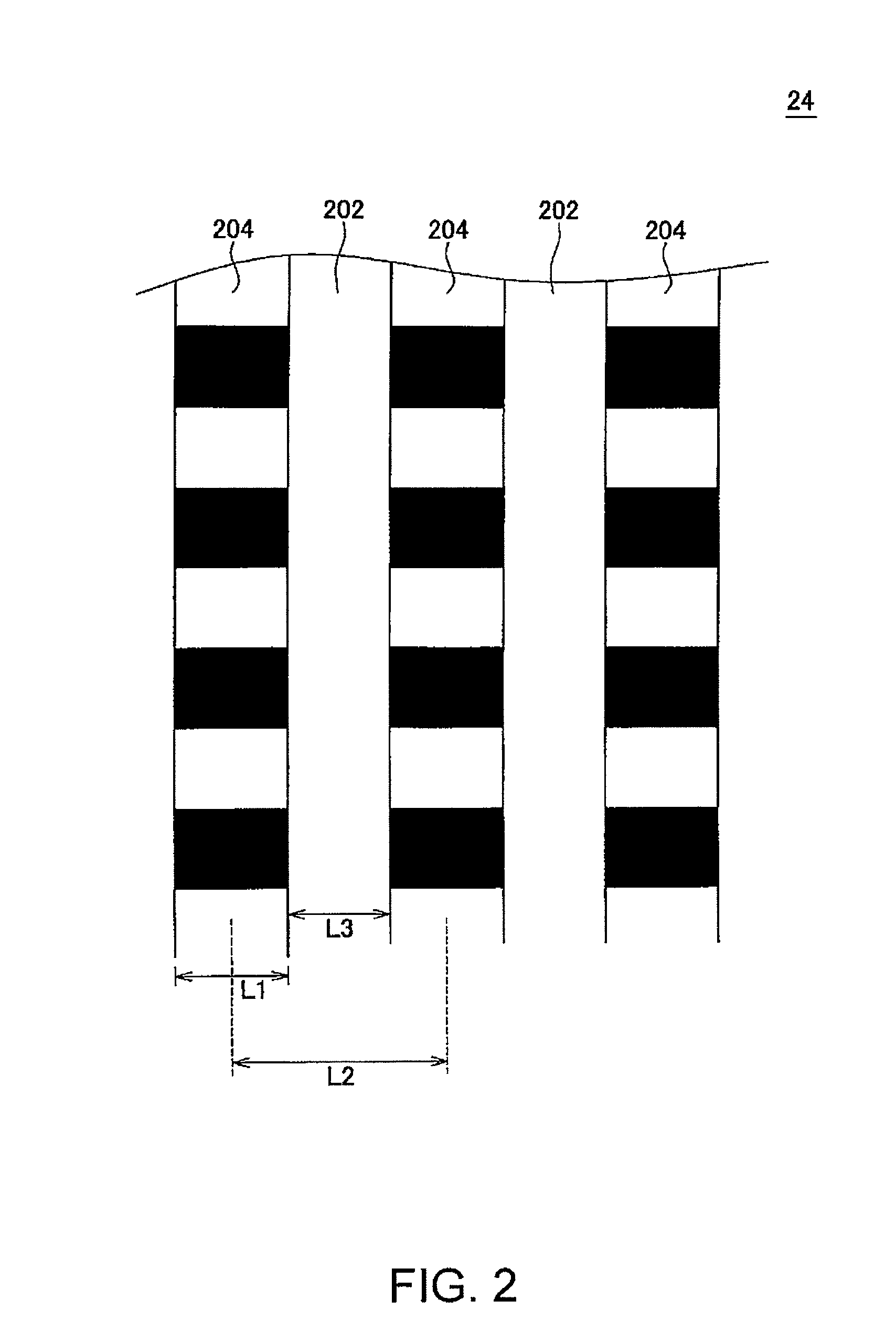

A magnetic recording medium (10) has a substrate (12) and a perpendicular magnetic recording layer (30) formed over the substrate (12). The perpendicular magnetic recording layer (30) has a granular layer (20) in which a magnetic signal is recorded and a continuous film layer (24) magnetically coupled to the granular layer (20). The continuous film layer (24) has hard magnetic portions (204) formed in positions corresponding to the recording regions where magnetic signals are recorded in the granular layer (20) and magnetic shield portions (202) formed between the hard magnetic portions (204), each having a magnetization curve whose slope is larger than those of the hard magnetic portions in the region where the applied magnetic filed is zero when the magnetization curve is measured, and each having a residual magnetic polarization smaller than those in the hard magnetic portions.

Owner:WESTERN DIGITAL TECH INC

Magnetic recording medium and method for manufacturing magnetic recording medium

InactiveUS7833639B2Delay transitionImprove thermal stabilityPatterned record carriersNanoinformaticsGrain boundaryCrystallite

Owner:WD MEDIA SINGAPORE PTE

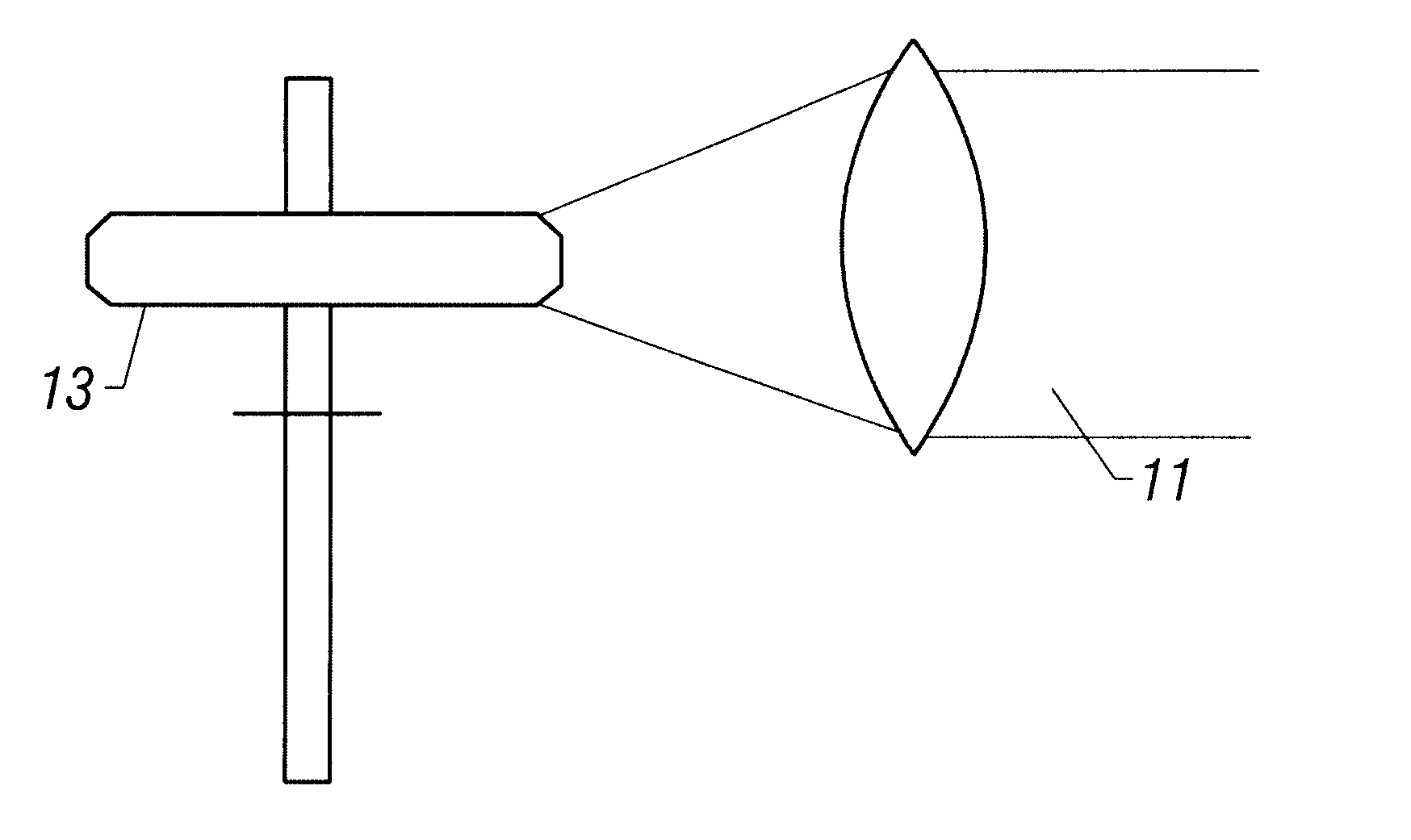

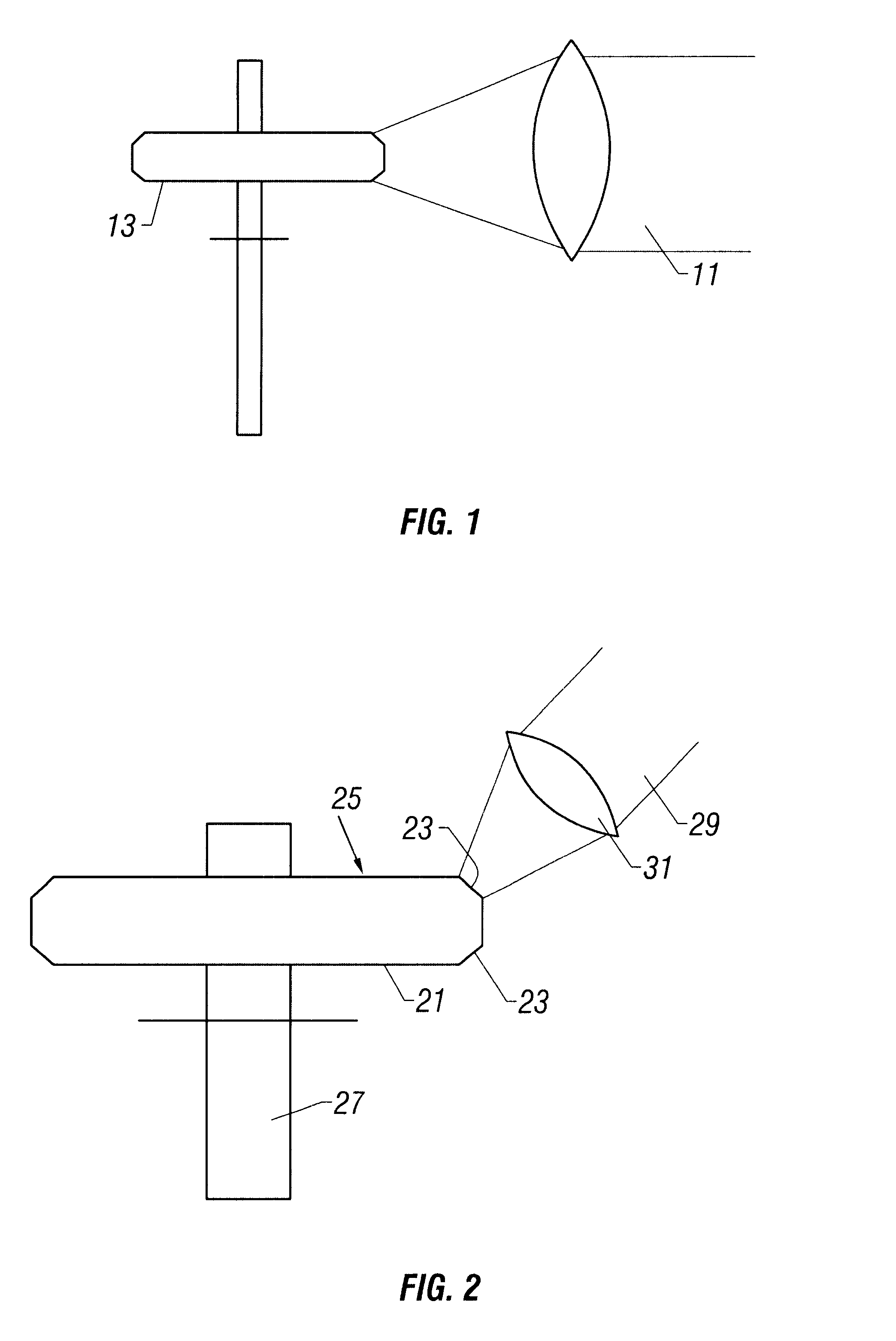

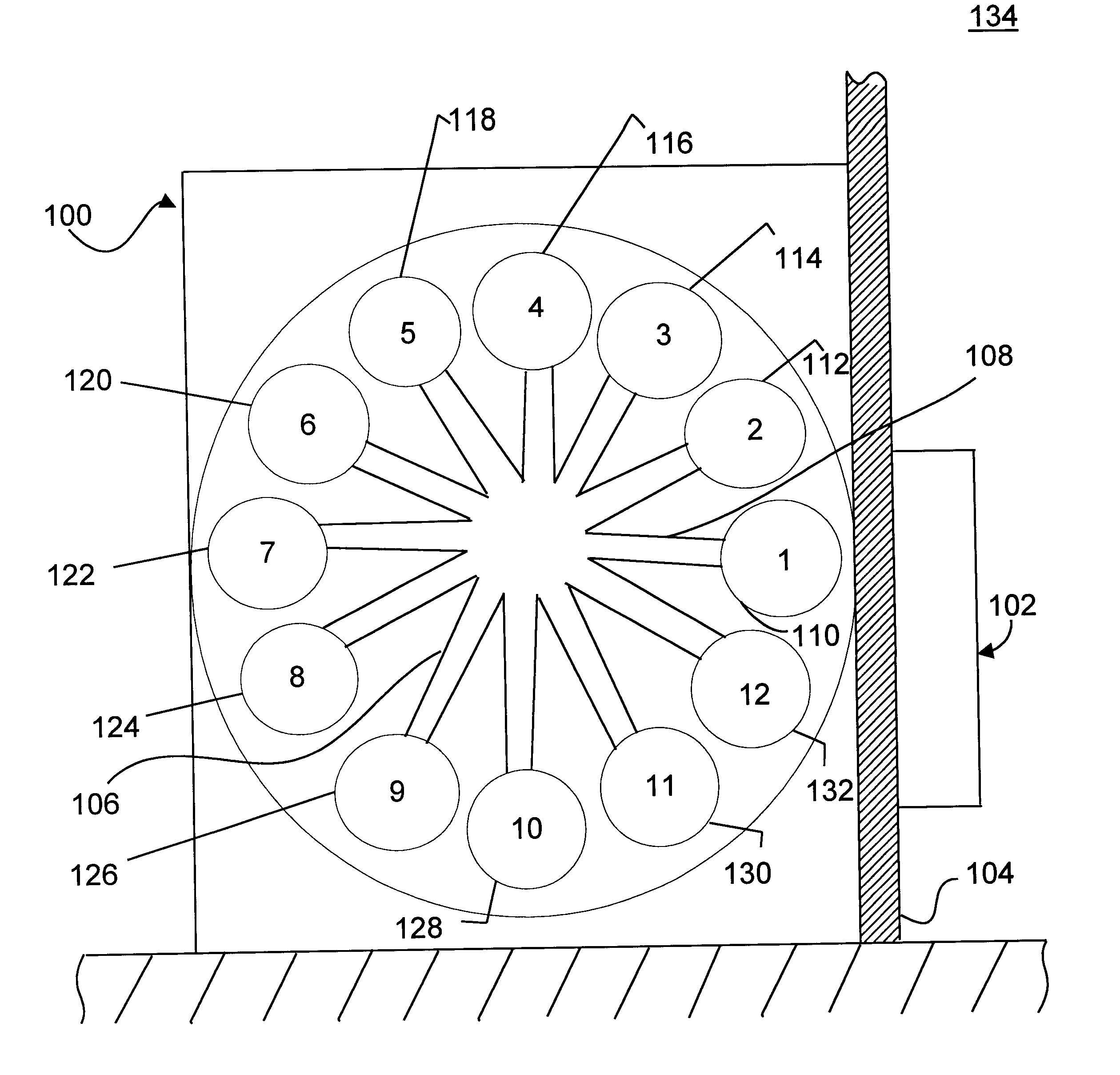

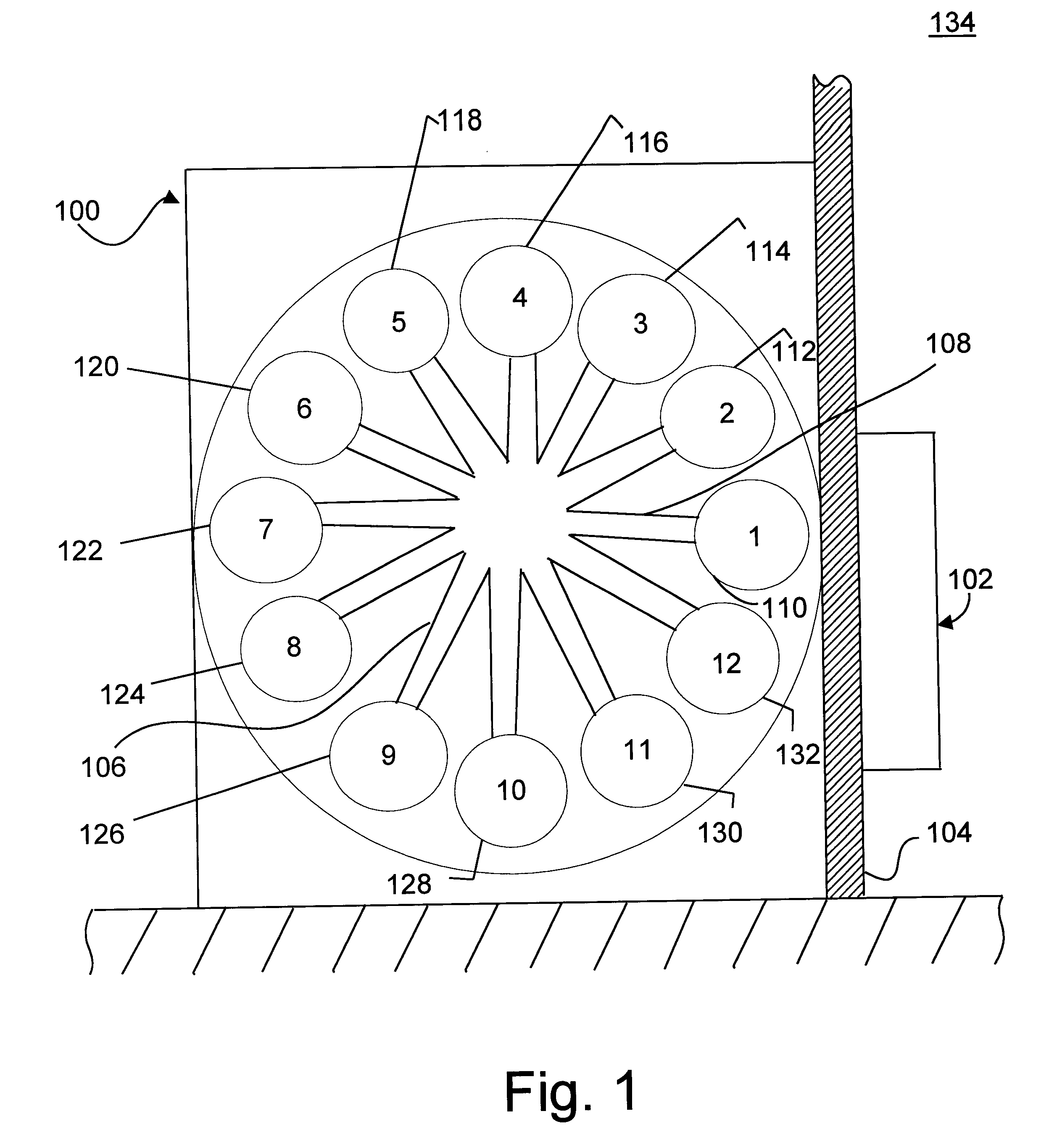

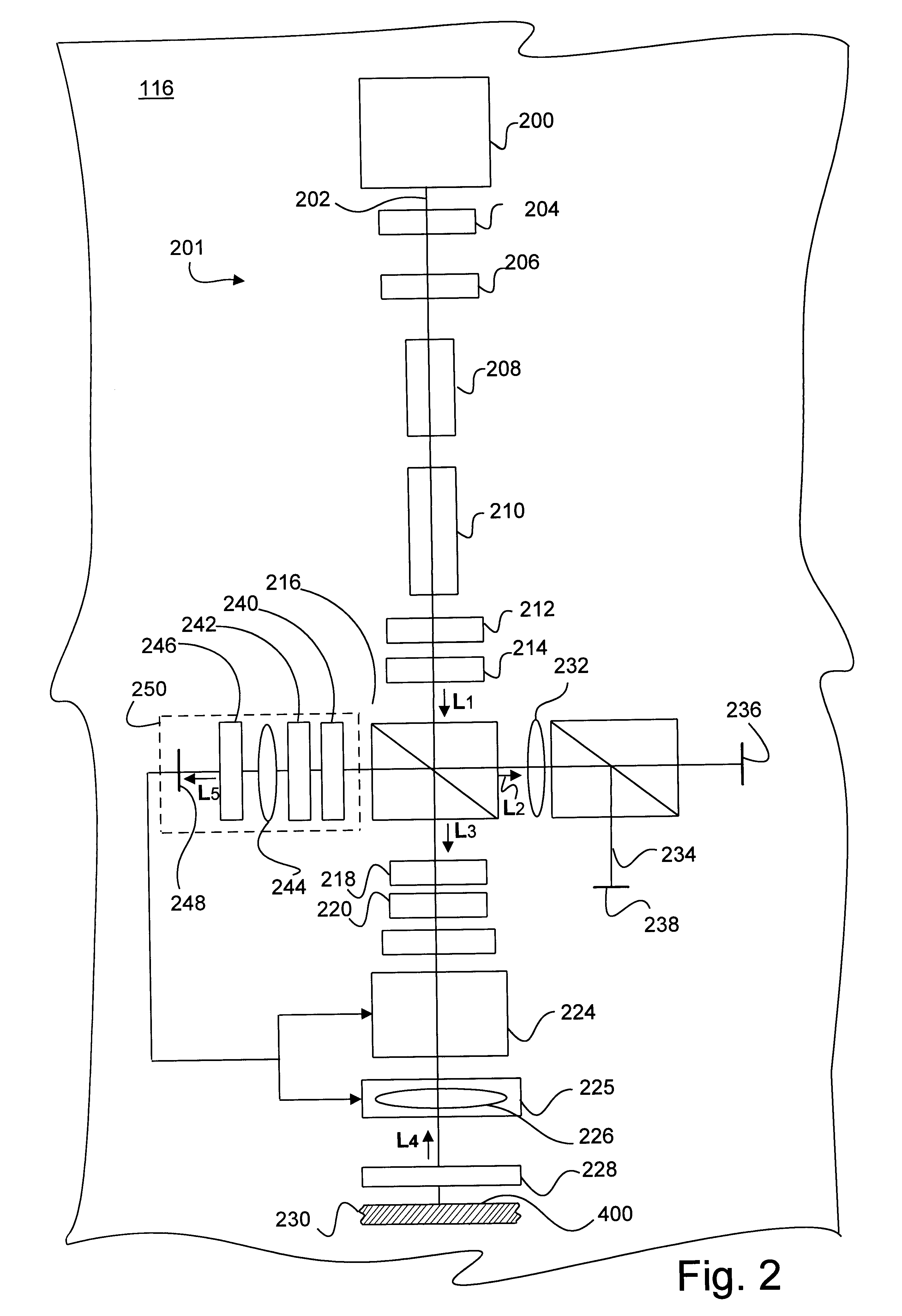

Multiple station vacuum deposition apparatus for texturing a substrate using a scanning beam

A stationary vacuum deposition machine for use in a method for processing substrates to make magnetic hard disks includes a series of stations and a transport. The series of stations includes an entrance station for receiving substrates into the machine and a predetermined station. The transport operates in a cycle with each cycle including a transport phase and a stationary phase. The transport causes all the substrates that are in the machine to be moved during the transport phase, and be temporarily held stationary during the stationary phase, such that during each stationary phase a predetermined one of the stations is occupied by one of the substrates while each of a plurality of others of the stations is occupied by a respective one of a plurality of others of the substrates. The machine further includes a plurality of vacuum deposition stations and a scanning beam generator. Each vacuum deposition station operates during each stationary phase such that each station causes a thin film to be deposited on a respective one of the substrates. The scanning beam generator directs a scanning beam at the substrate occupying the predetermined station while the substrate is held stationary to produce a textured pattern.

Owner:WESTERN DIGITAL TECH INC

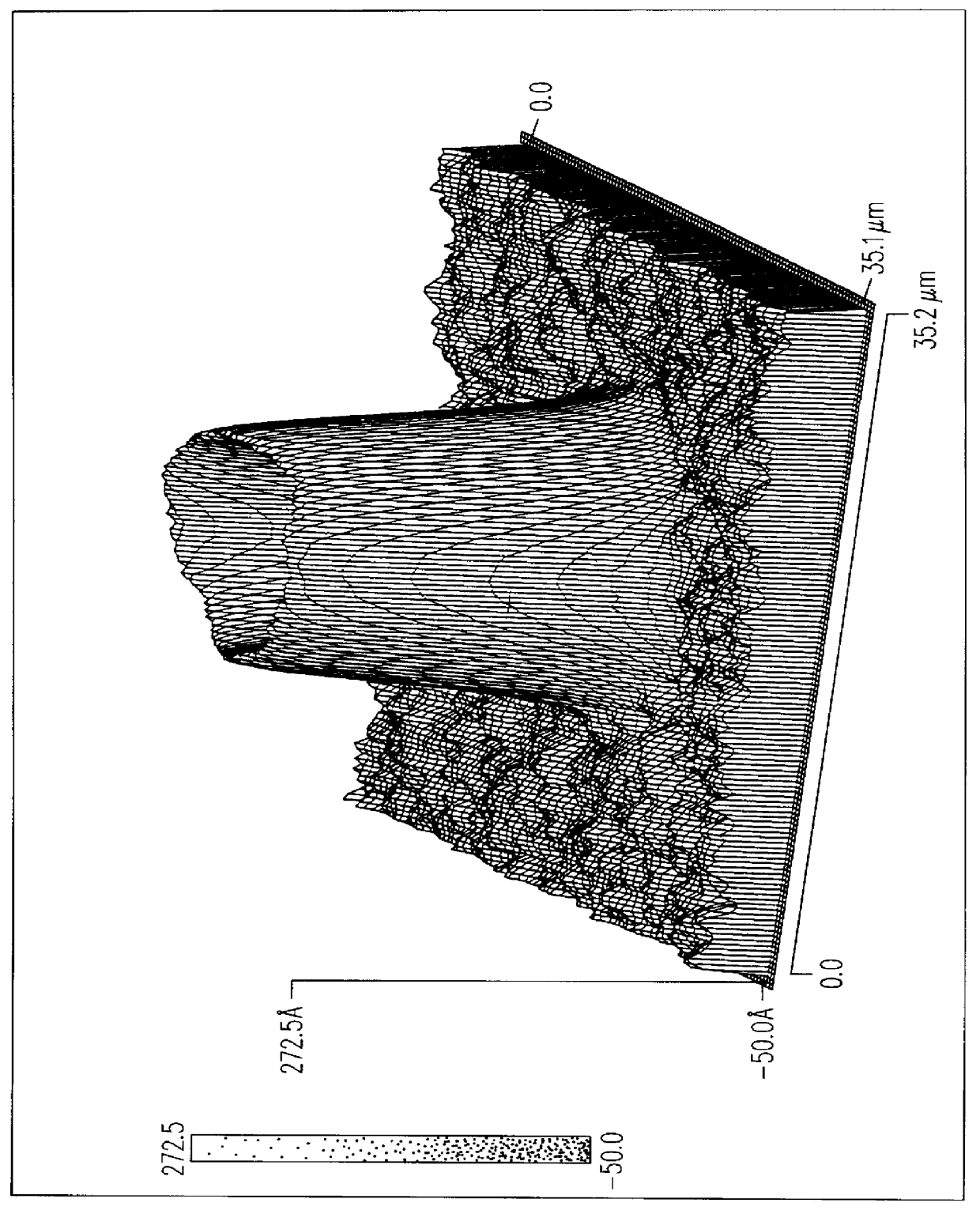

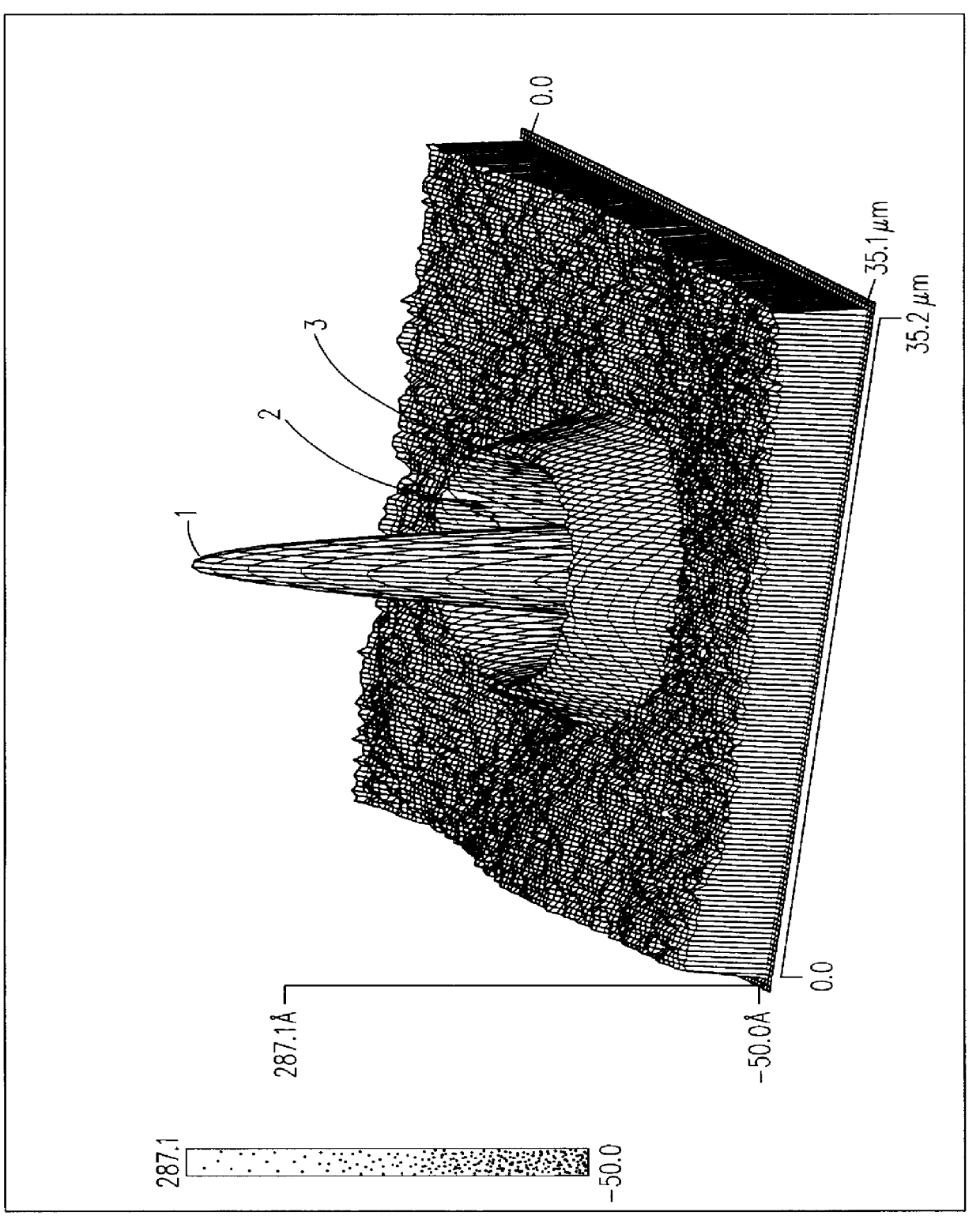

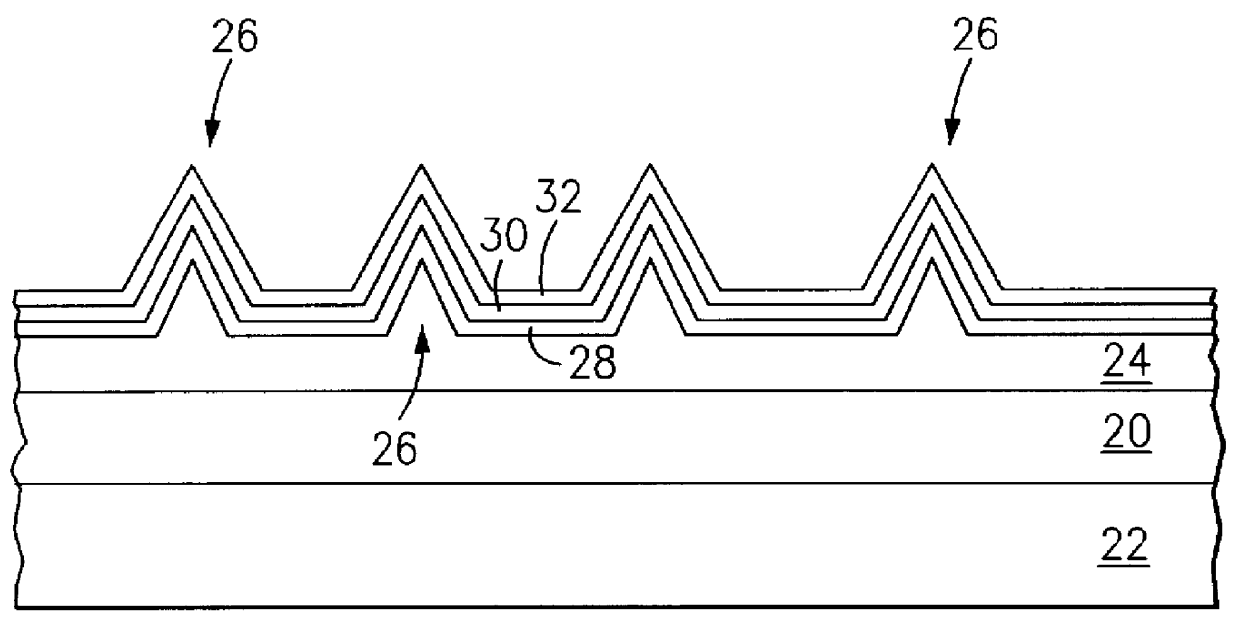

Laser textured magnetic disk comprising NiNb

A method for manufacturing a magnetic disk comprises the steps of depositing NiP (20) on a substrate (22); depositing NiNb (24) on the NiP; and laser texturing the NiNb. "Sombrero" shaped texture features are more easily formed on the substrate / NiP / NiNb structure than a substrate / NiP structure. The disk is completed by depositing an underlayer (e.g. sputtered Cr or NiP), a magnetic layer (e.g. a Co alloy) and a protective overcoat (e.g. by hydrogenated carbon).

Owner:KOMAG

Solvent annealing block copolymers on patterned substrates

ActiveUS20120202017A1High degreeImproved size controlMaterial nanotechnologyDecorative surface effectsImage resolutionLine width

Provided herein are block copolymer thin film structures and methods of fabrication. Aspects described herein include methods of directed self-assembly of block copolymers on patterns using solvent annealing, and the resulting thin films, structures, media or other compositions. According to various embodiments, solvent annealing is used direct the assembly of block copolymers on chemical patterns to achieve high degrees of pattern perfection, placement of features at the precision of the lithographic tool used to make the chemical pattern, improved dimensional control of features, improved line edge and line width roughness, and resolution enhancement by factors of two to four or greater.

Owner:WISCONSIN ALUMNI RES FOUND

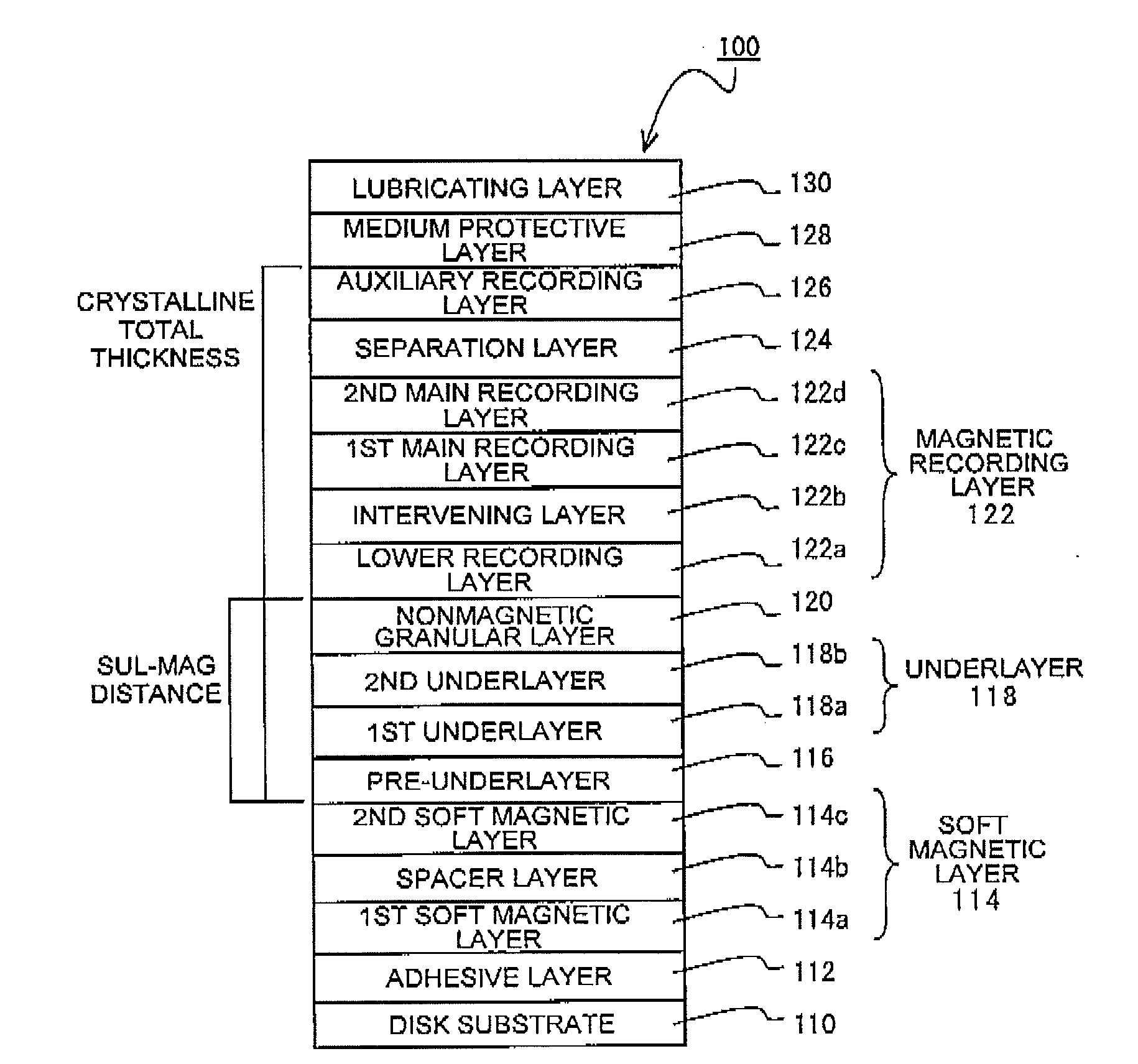

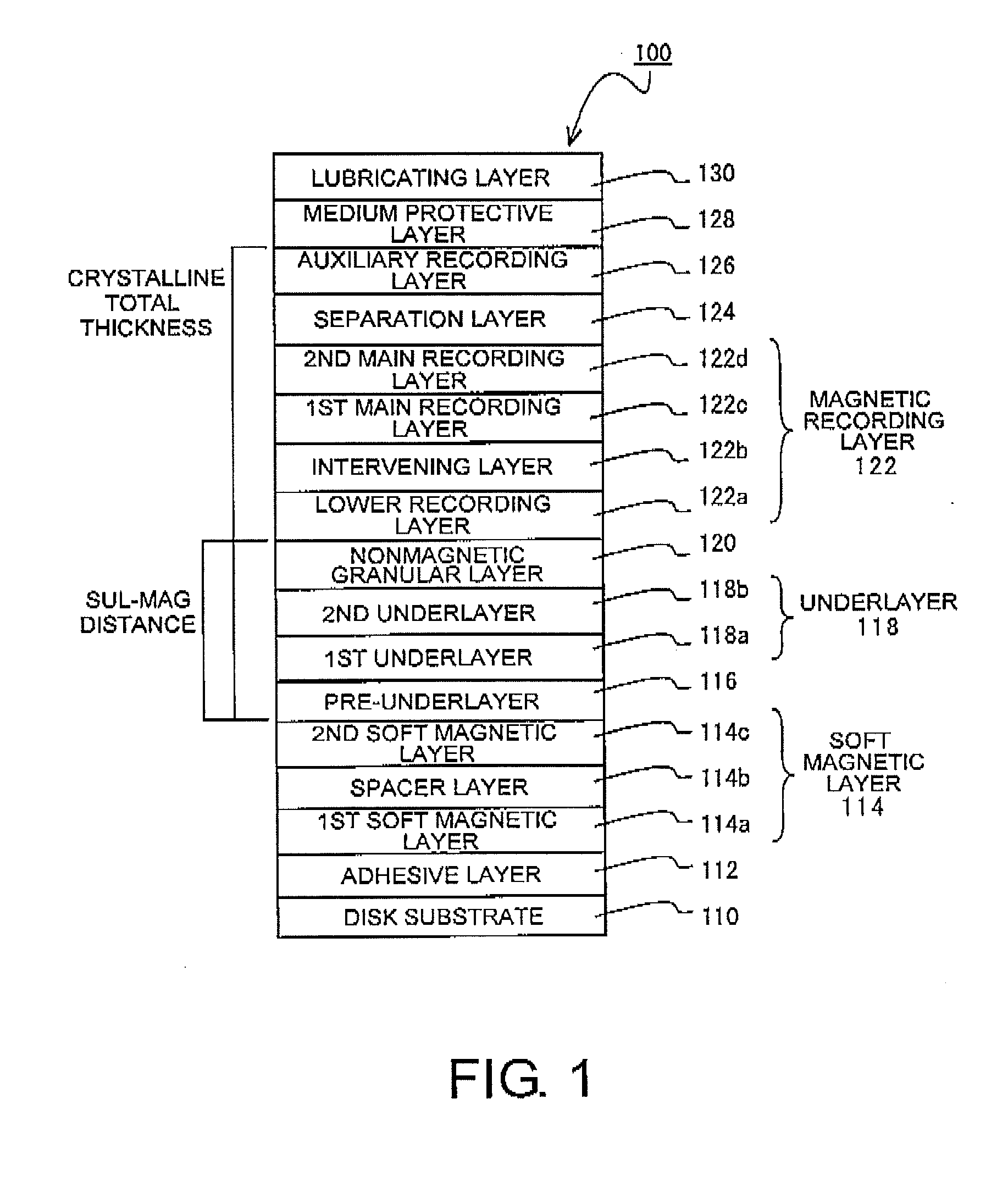

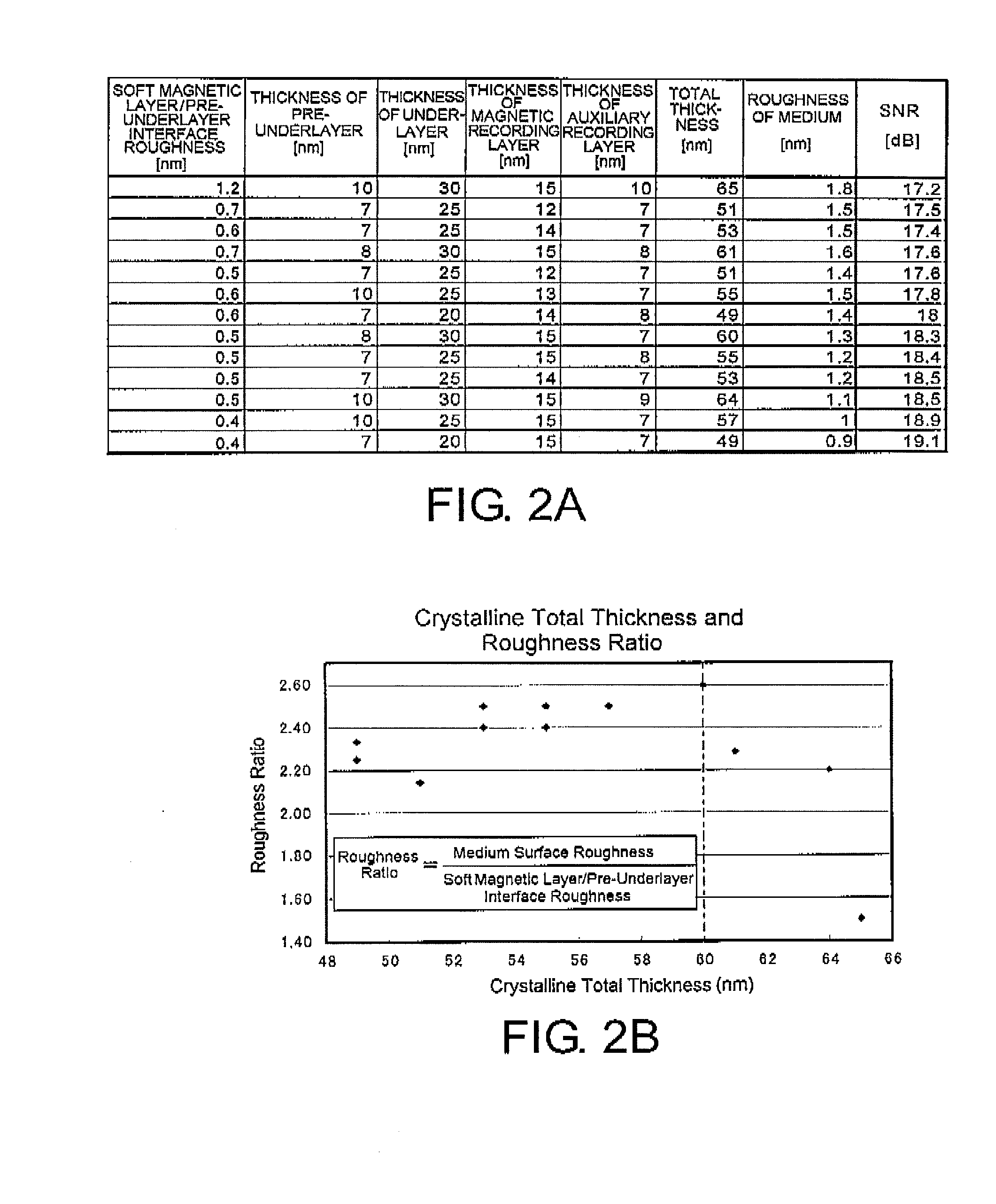

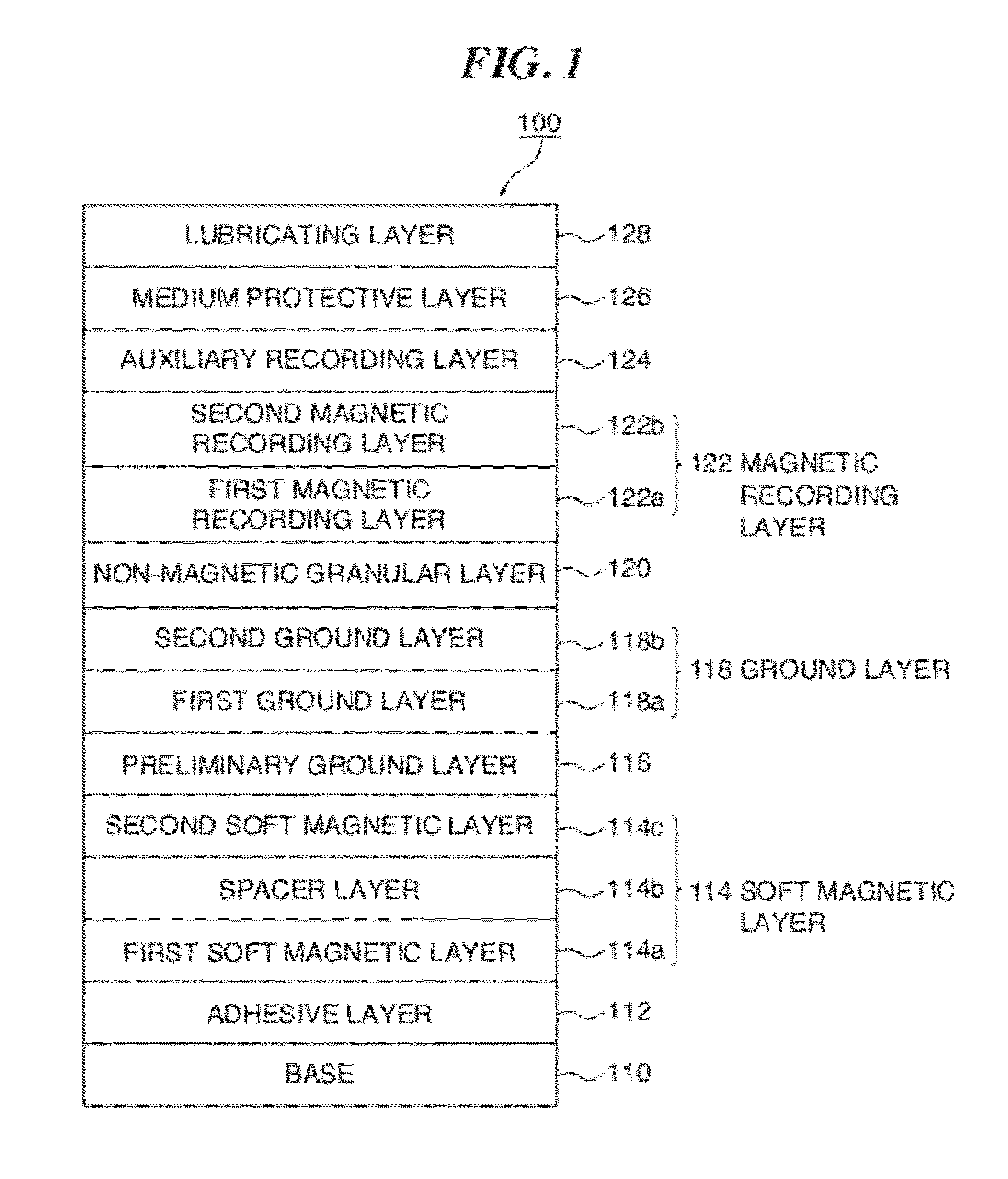

Perpendicular magnetic recording medium

ActiveUS20100247965A1Reduce surface roughnessImprove recording densityRecord information storageManufacture of flux-sensitive headsCrystalline materialsNon magnetic

In a perpendicular magnetic recording medium having, over a substrate, a magnetic recording layer, an underlayer made of Ru or a Ru compound and provided below the magnetic recording layer, a pre-underlayer made of a nonmagnetic crystalline material, and a soft magnetic layer provided below the pre-underlayer, when the difference between the highest point and the lowest point of unevenness of the interface between the soft magnetic layer and the pre-underlayer, derived by a cross-sectional TEM image, is given as an interface roughness (nm) and the distance between the soft magnetic layer and the magnetic recording layer, excluding the soft magnetic layer and the magnetic recording layer, is given as a SUL-MAG distance (nm), interface roughness (nm)≦0.4 (nm) and interface roughness×SUL-MAG distance (nm)≦12 (nm) are satisfied.

Owner:WESTERN DIGITAL TECH INC

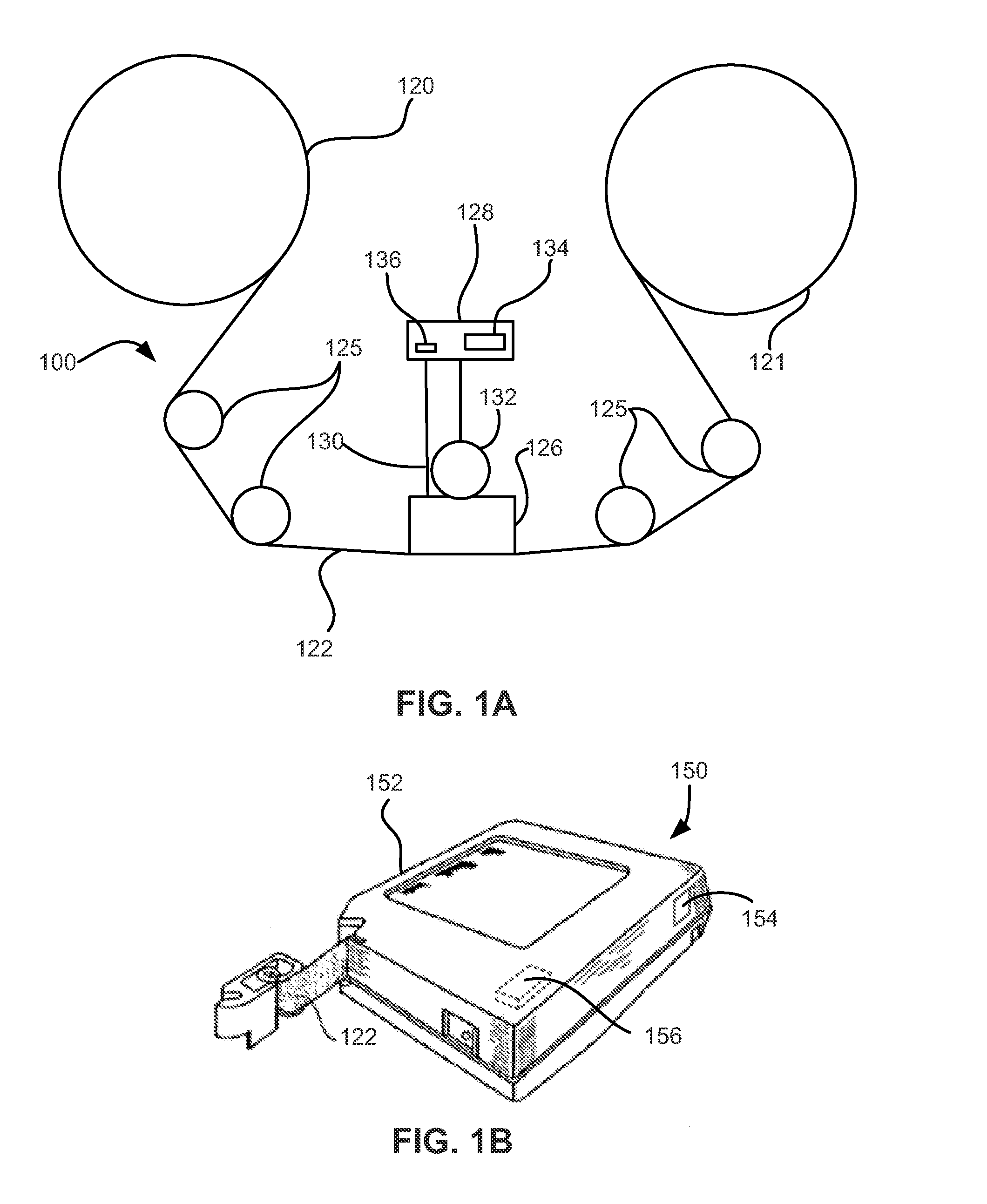

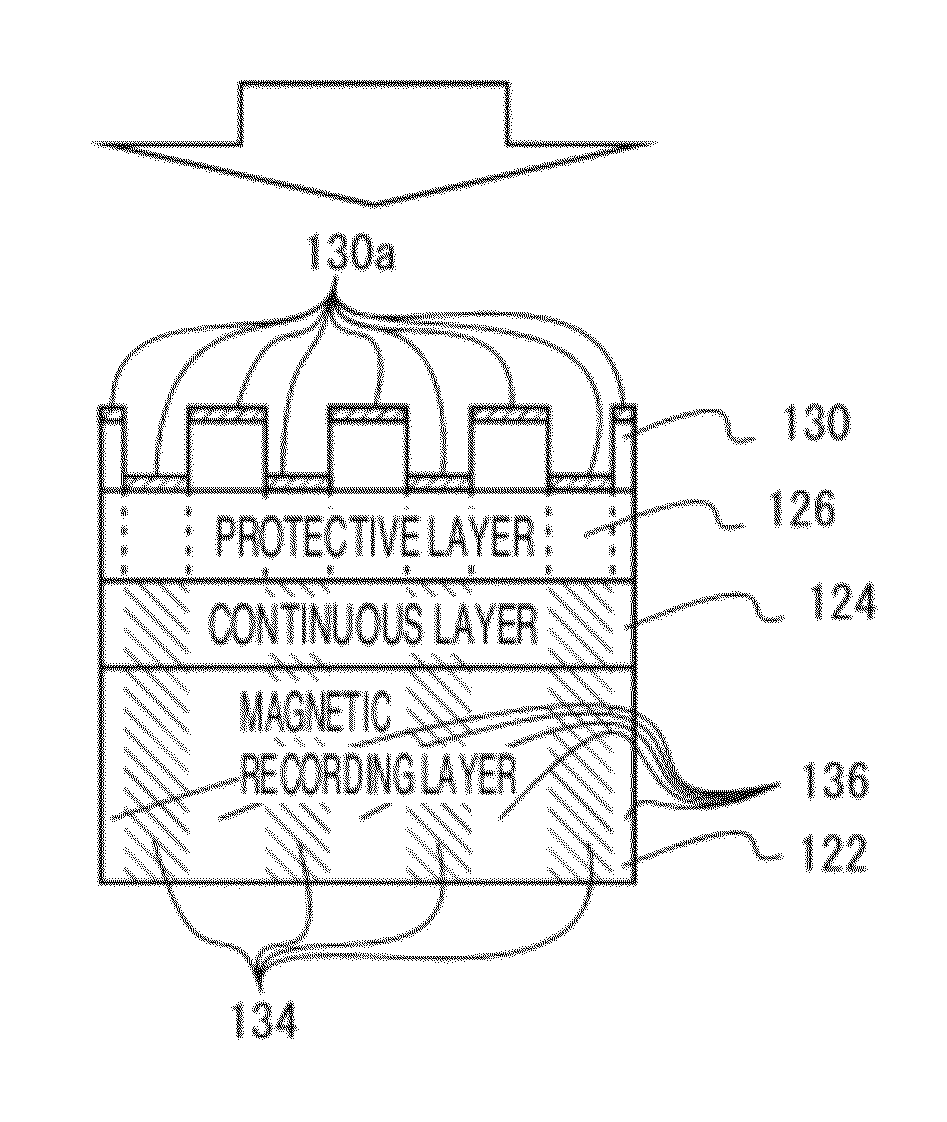

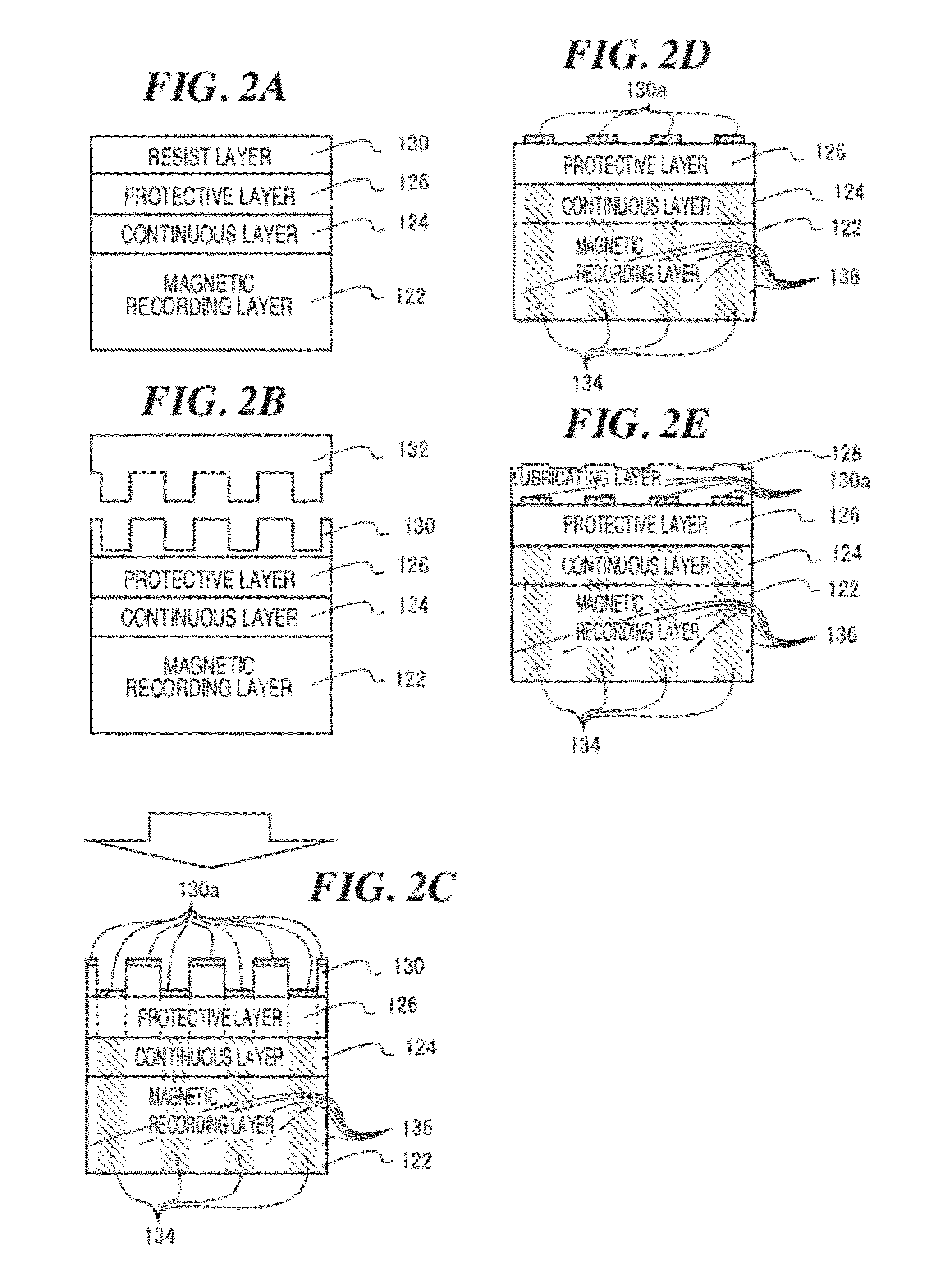

Magnetic recording medium and magnetic recording medium manufacturing method

InactiveUS20120170152A1Reduced durabilityPatterned record carriersNanoinformaticsIn planeRecording layer

[Problem] An object is to provide a magnetic recording medium with improved HDI characteristics, such as impact resistance, and its manufacturing method.[Solution] A typical structure of a magnetic recording medium 100 according to the present invention includes, on a base, at least a magnetic recording layer 122, a protective layer 126, and a lubricating layer 128, wherein the magnetic recording layer 122 includes, in an in-plane direction, a magnetic recording part 136 configured of a magnetic material and a non-recording part 134 magnetically separating the magnetic recording part 136, and a surface corresponding to the non-recording part 134 protuberates more than a surface corresponding to the magnetic recording part 136.

Owner:WD MEDIA SINGAPORE PTE +1

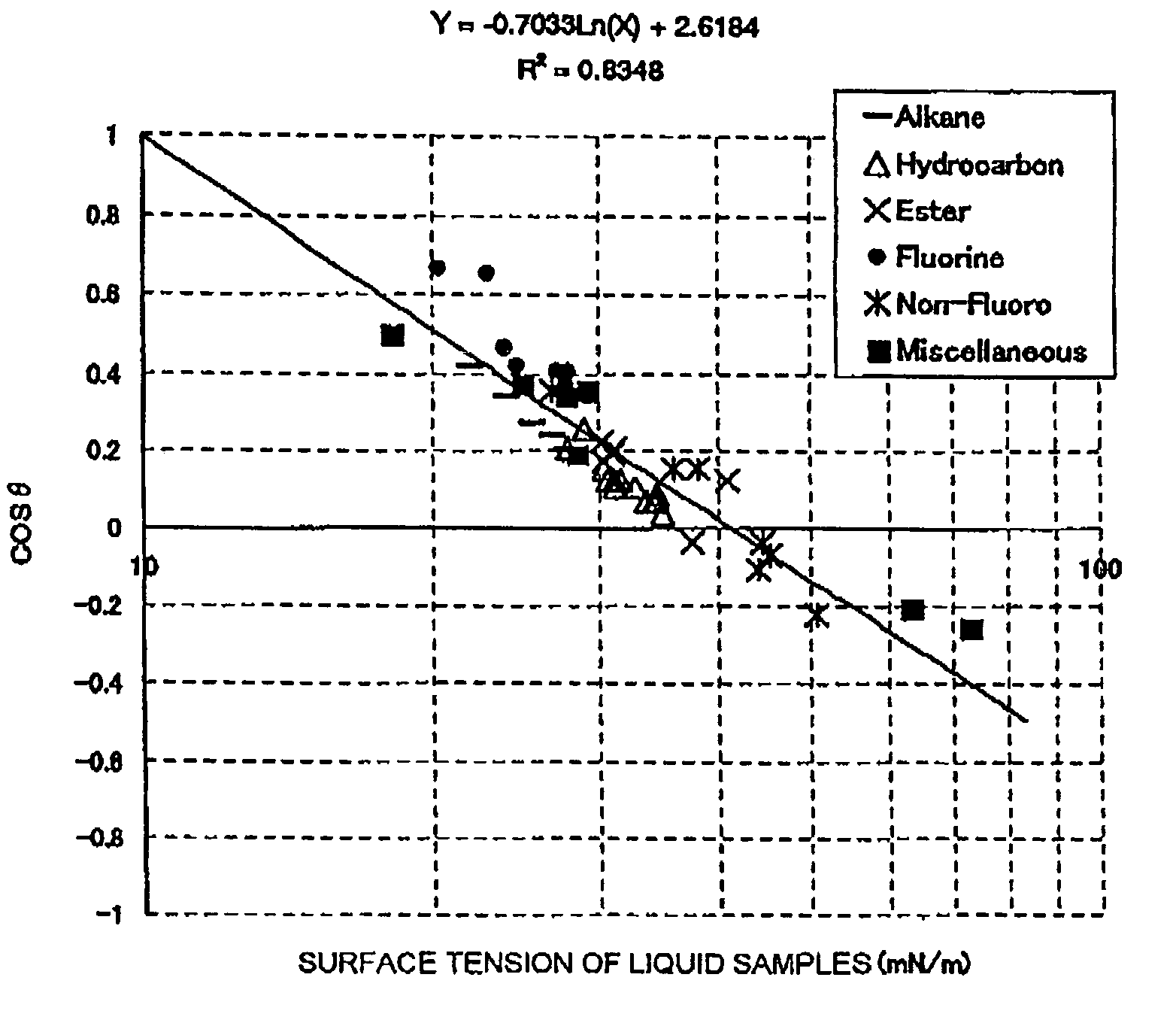

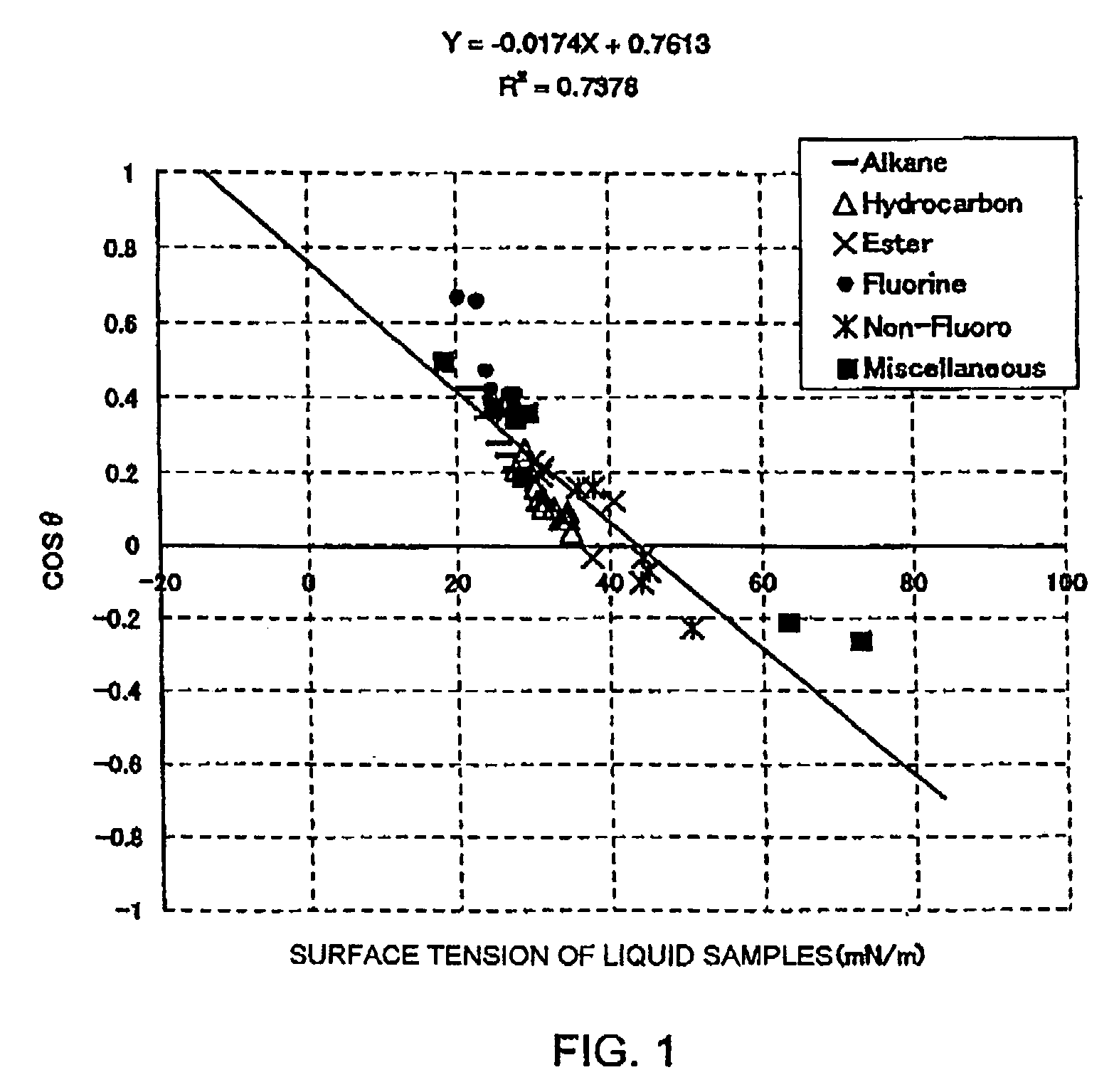

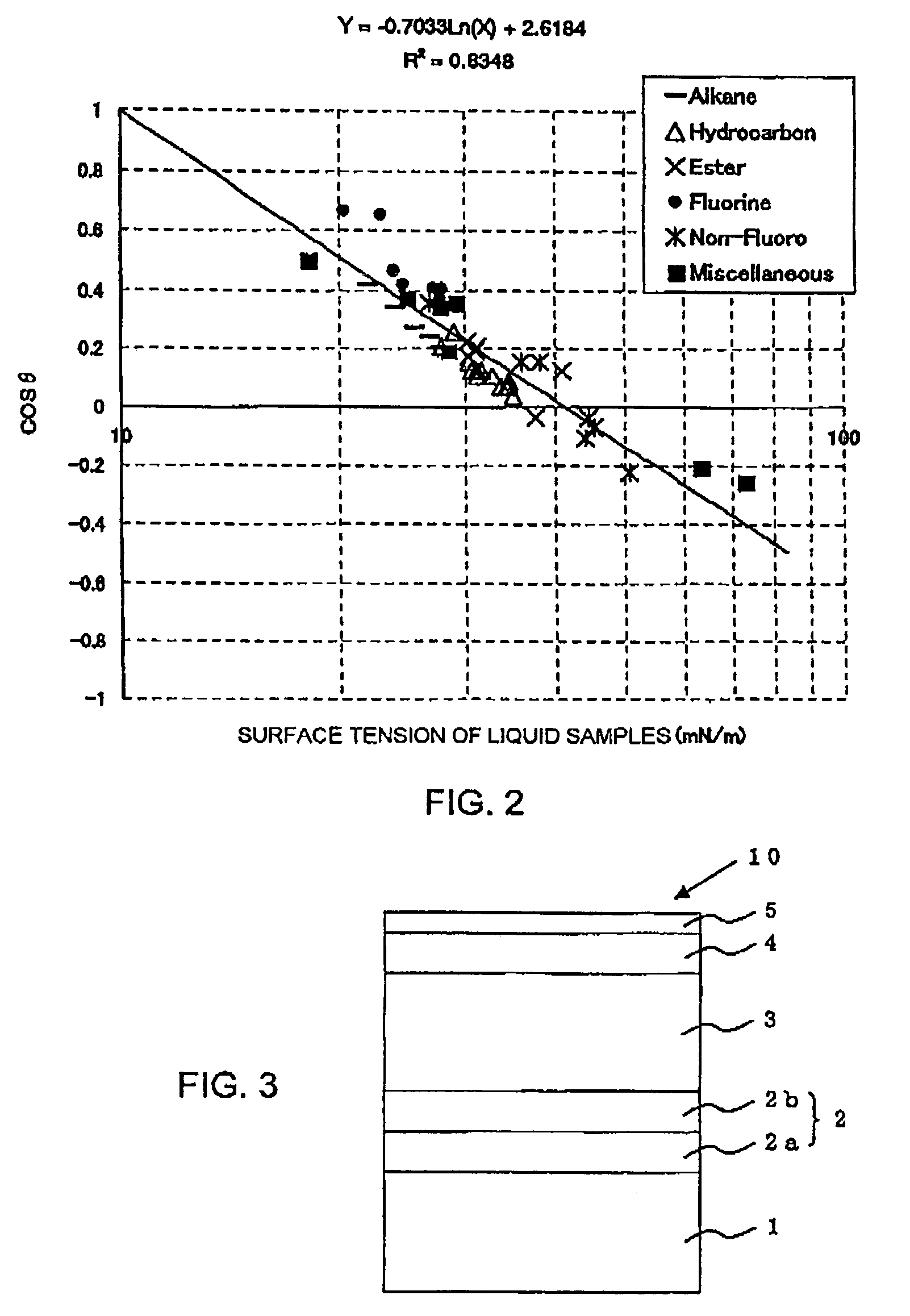

Solid body surface evaluation method, magnetic disk evaluation method, magnetic disk, and manufacturing method thereof

InactiveUS7174775B2Effective tensionSolve the real problemVehicle testingElectronic circuit testingBiomedical engineeringBody surface

In a method of evaluating surface tension of a solid body surface, selection is made of at least three liquid samples having different surface tensions, and contact angles between the respective liquid samples and the solid body surface are measured. Thereby, a correlation between cosines (Y) of the contact angles and surface tensions (X) of the liquid samples is derived as a logarithmic function. Surface tension of the solid body surface is evaluated by the use of a value of X that is calculated by substituting 1 for Y in the correlation. When evaluated by the foregoing evaluation method, a magnetic disk has a surface where the value of X, when 1 is substituted for Y, is greater than 0 and no greater than 17 mN / m.

Owner:WD MEDIA SINGAPORE PTE

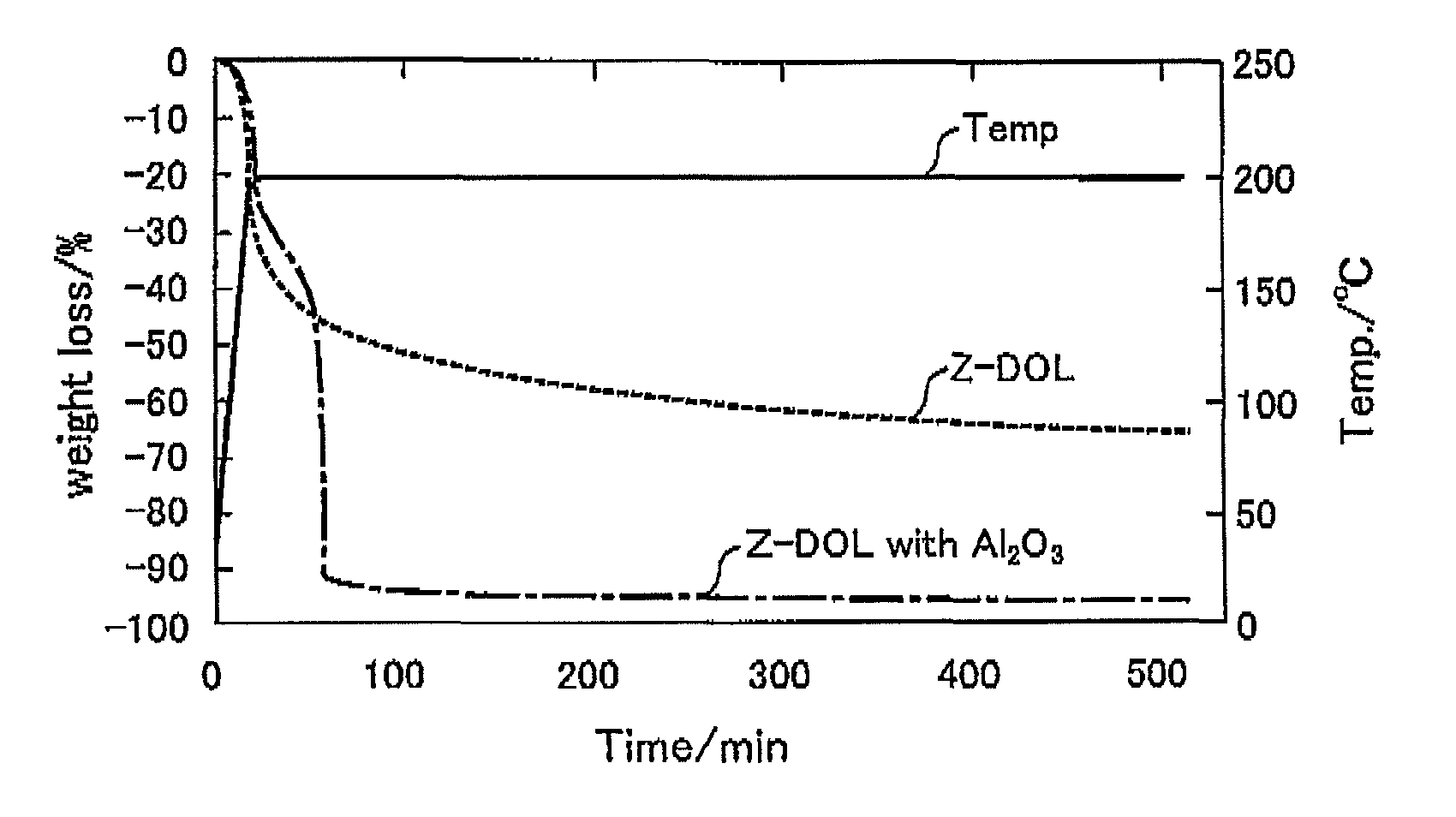

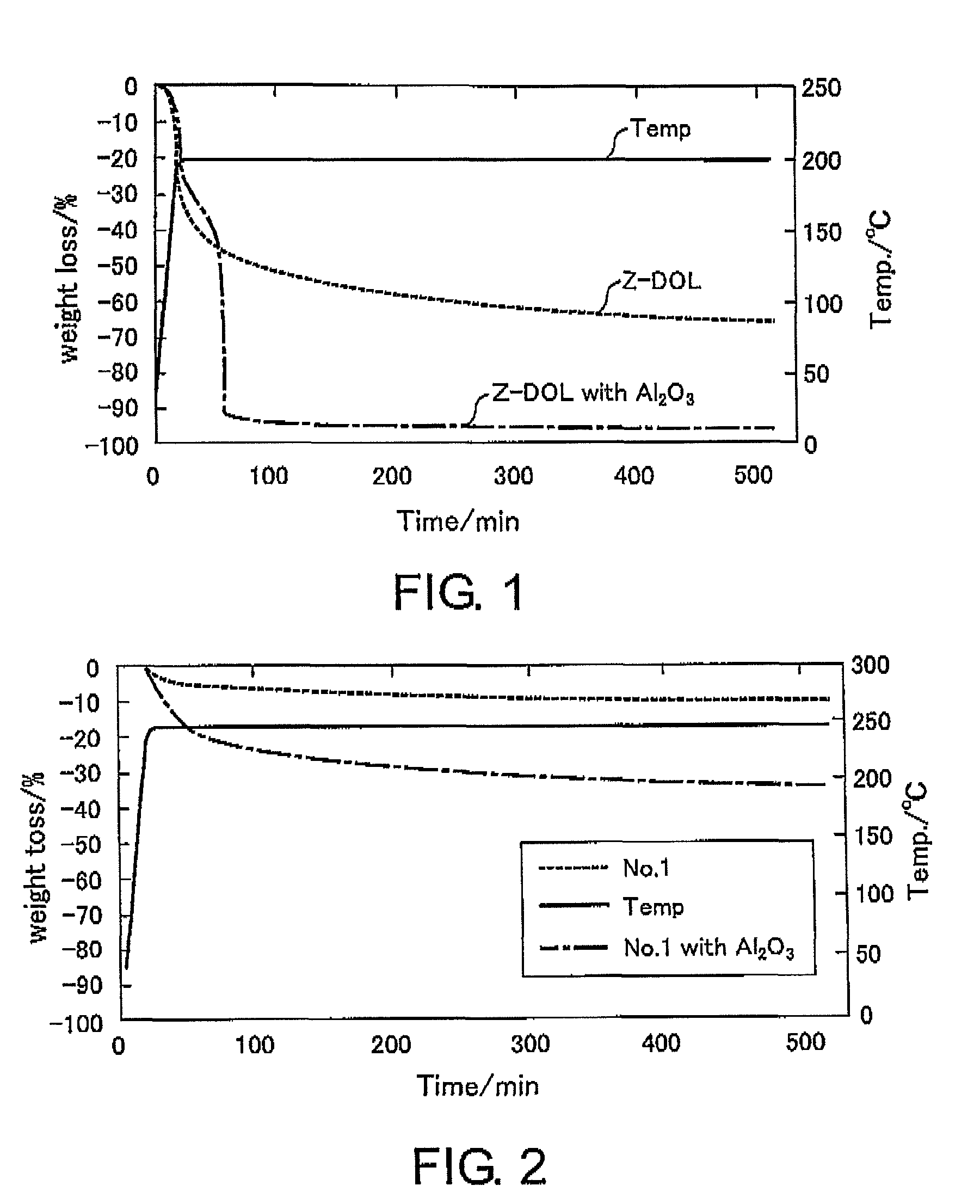

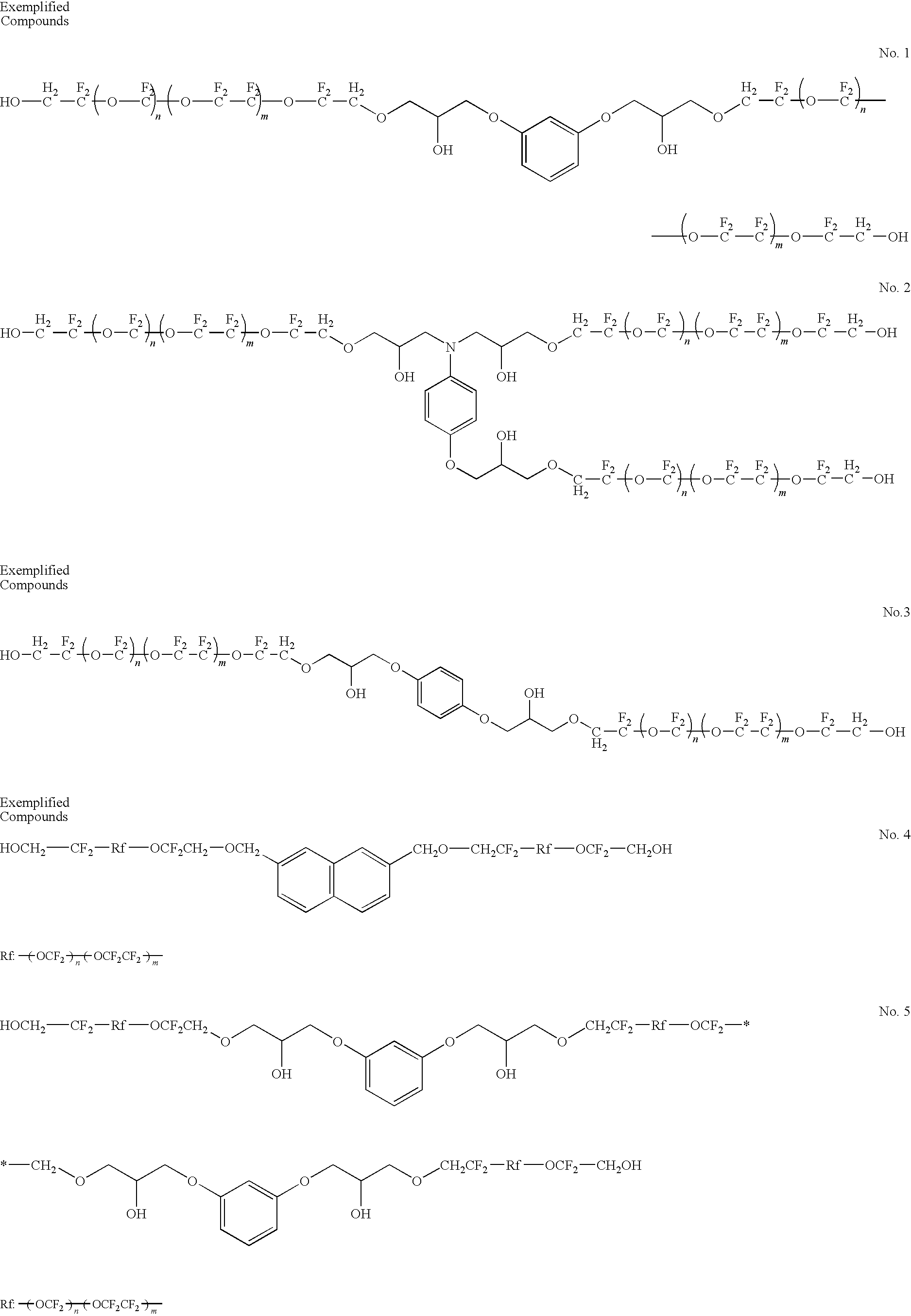

Lubricant compound for a magnetic disk, magnetic disk, and method of manufacturing the same

InactiveUS8492011B2Increased durabilityImprove reliabilitySnowboard bindingsRecord information storagePerfluoropolyetherEngineering

In a magnetic disk that has at least a magnetic layer, a carbon-based protective layer, and a lubricating layer formed in this order over a substrate, the lubricating layer contains a lubricant compound including a compound which has a perfluoropolyether main chain in a structure thereof, an aromatic group located at a position except each end of a molecule thereof, and a polar group at each end of the molecule.

Owner:WESTERN DIGITAL TECH INC

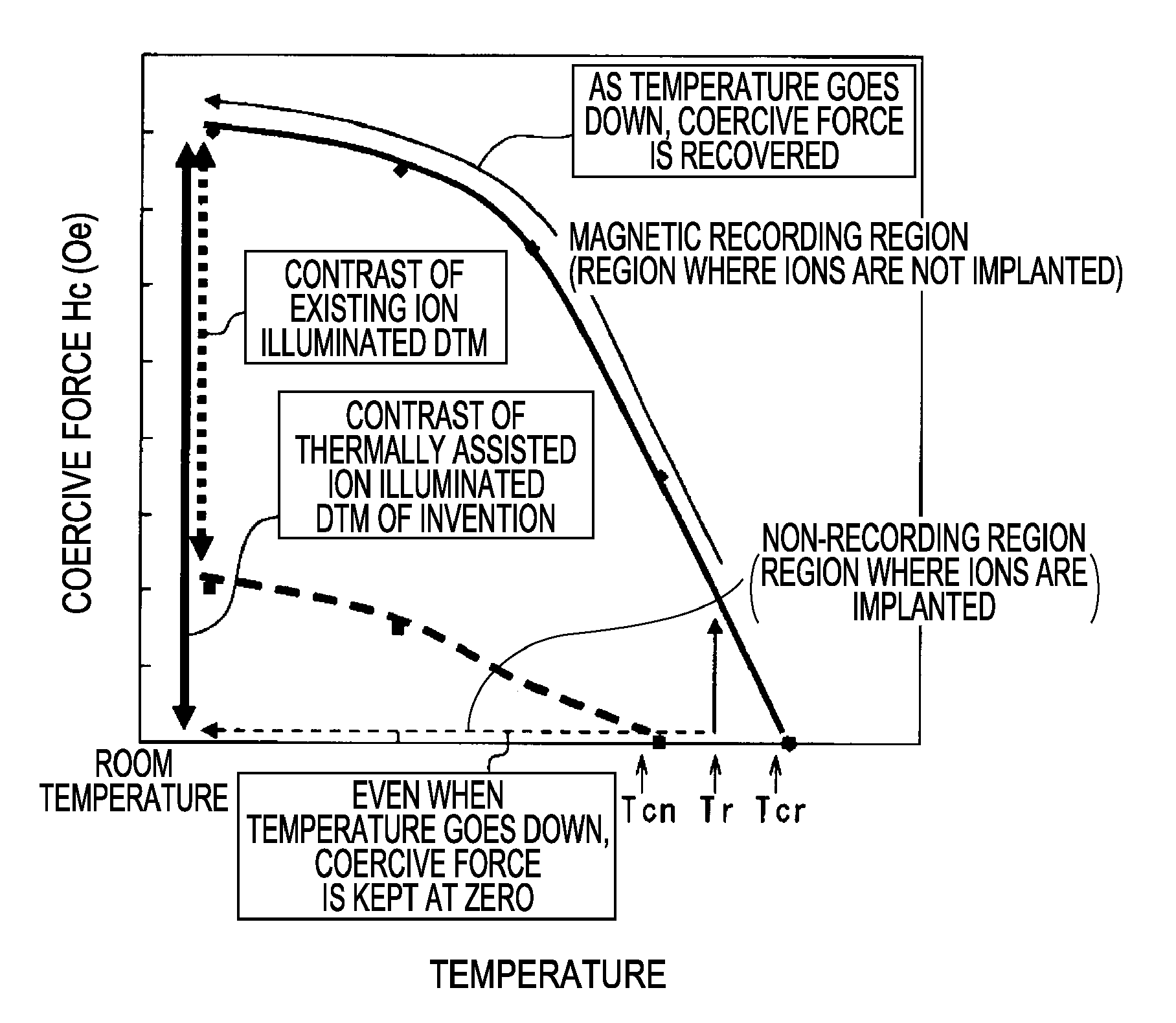

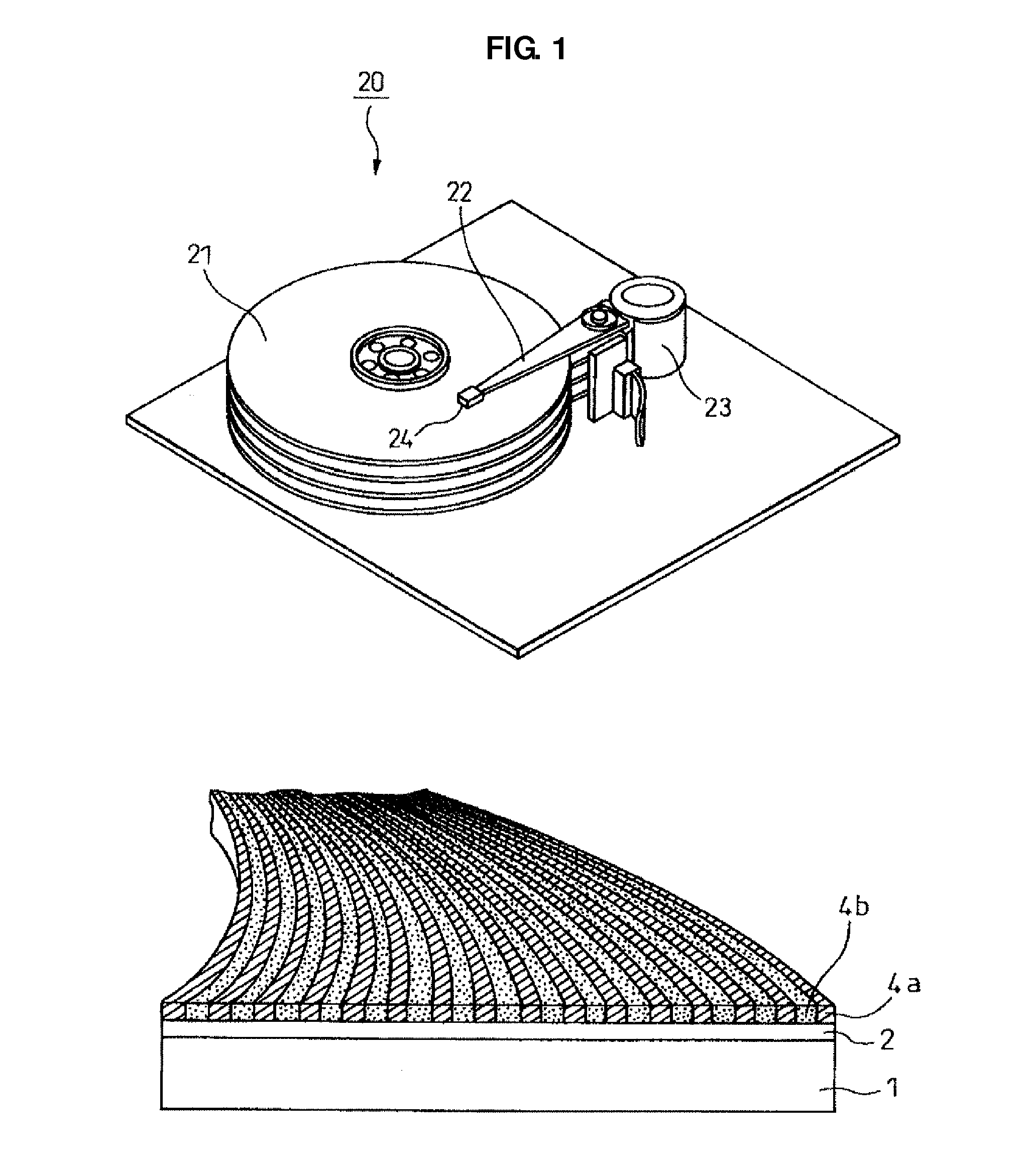

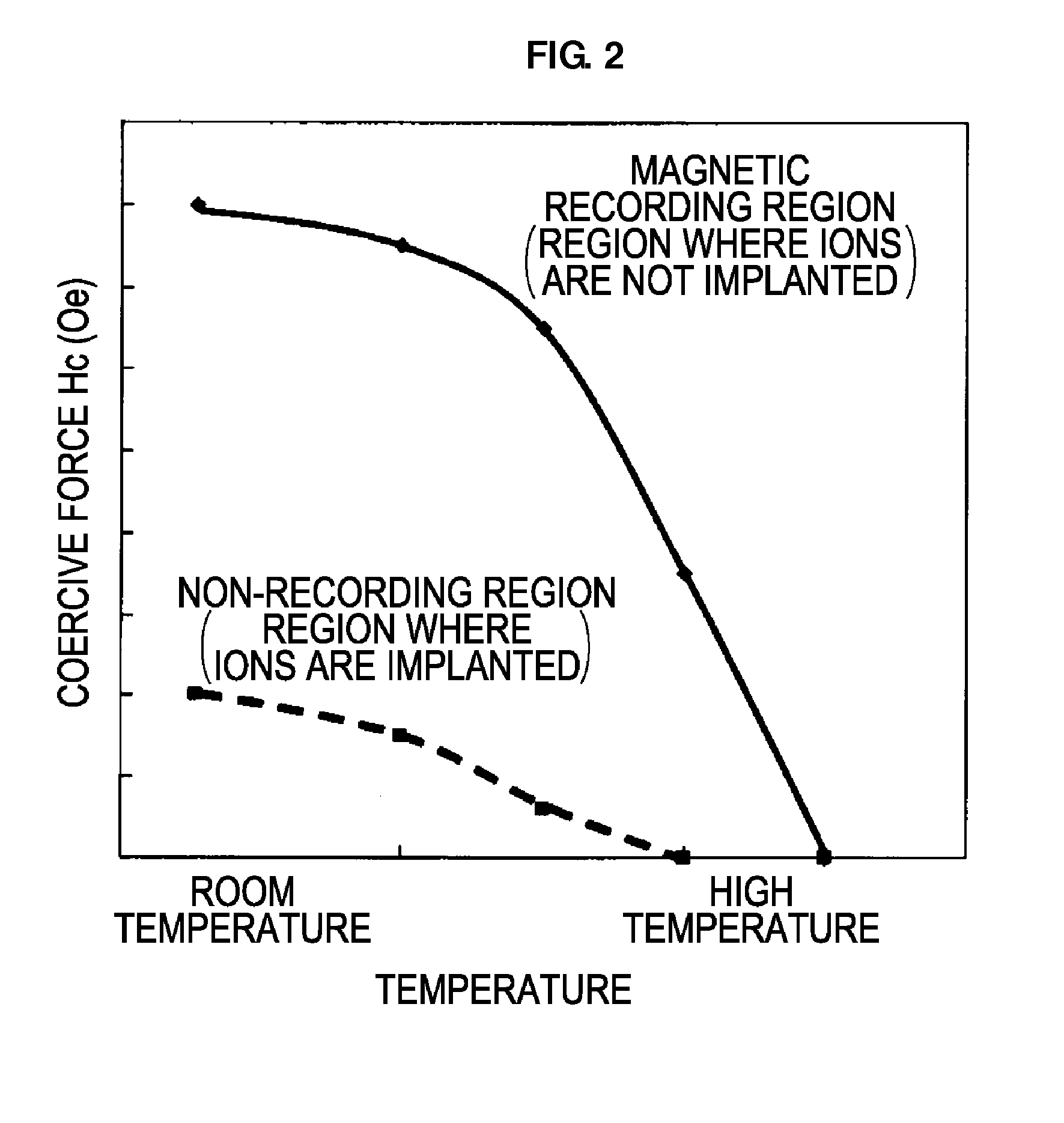

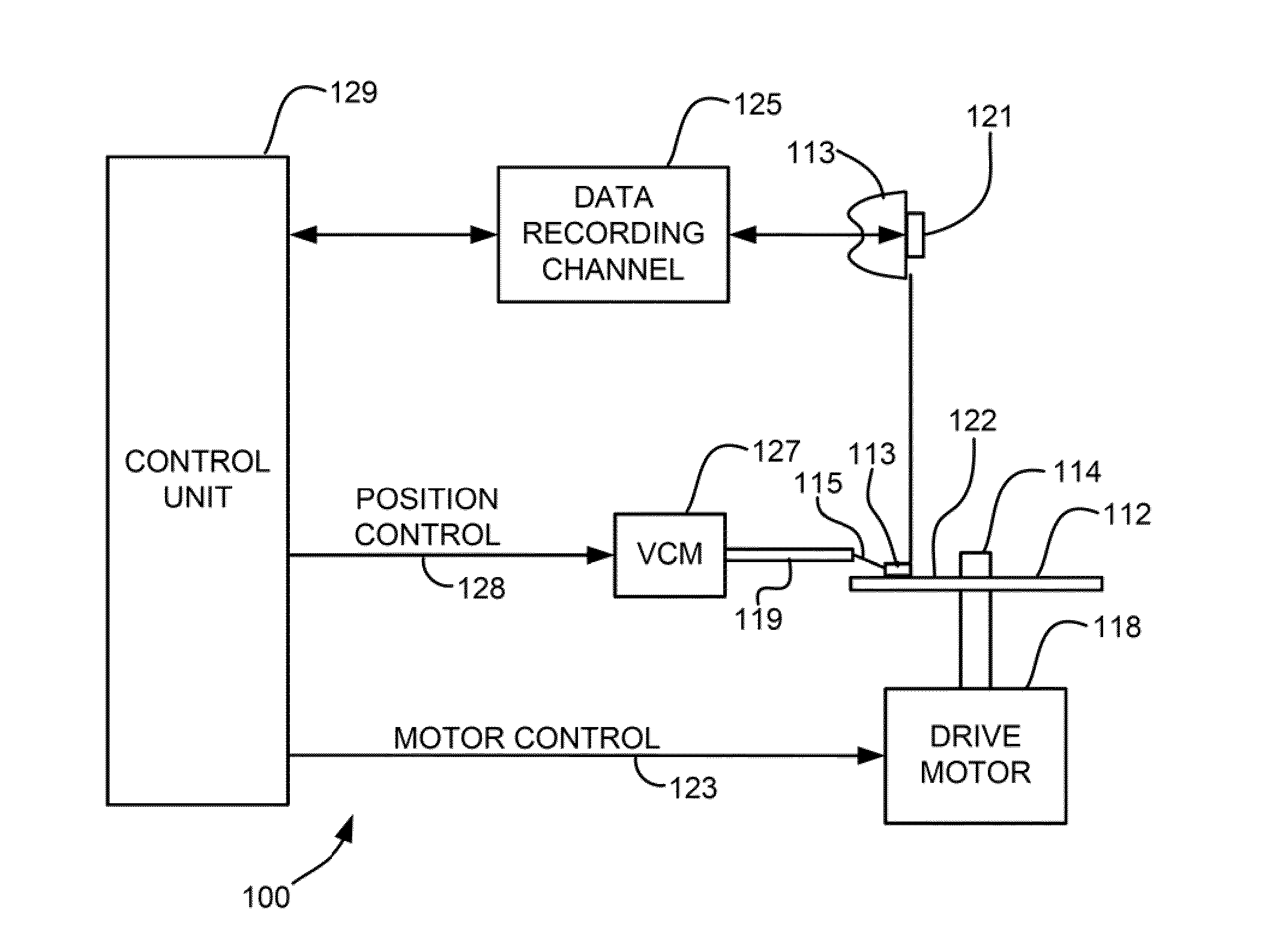

Thermally assisted magnetic recording disk with ion-implant facilitated non-magnetic regions, manufacturing method thereof, and magnetic recording method

ActiveUS8634155B2Low coercivityPatterned record carriersNanoinformaticsHeat-assisted magnetic recordingThermal expansion

The invention provides a magnetic disk that solves (1) a problem of cross-talk that cannot be solved even by an existing thermally assisted recording method or a discrete method (DTM or the like), (2) a problem of surface flatness, which an existing embedding type DTM or the like has, and (3) a problem of a difference in thermal expansion coefficient between materials when a thermally assisted method is applied to the DTM, and that (4) does not necessitate a special medium structure, and is excellent in a surface flatness and economically and functionally high in realizability. A DTM manufactured by ion implantation is excellent in the surface flatness, and can solve the cross-talk problem by conducting the thermally assisted recording at a temperature between a Curie temperature (Tcn) of a portion where ions are implanted (non-recording region) and a Curie temperature (Tcr) of a portion where ions are not implanted (recording region).

Owner:WESTERN DIGITAL TECH INC

Joint design of thermally-assisted magnetic recording head and patterned media for high optical efficiency

ActiveUS20110096431A1Combination recordingPatterned record carriersHeat-assisted magnetic recordingEngineering

A system according to one embodiment includes a magnetic recording medium having a magnetic layer with features in a discrete track configuration or a bit patterned configuration and an underlayer adjacent the magnetic layer, the underlayer comprising a material capable of forming surface plasmon resonance; and a magnetic head having: a writer for writing to the medium; and a near-field transducer for heating the medium for thermally assisted recording. Additional systems and methods are also presented.

Owner:WESTERN DIGITAL TECH INC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com