Patents

Literature

51results about How to "Storage stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

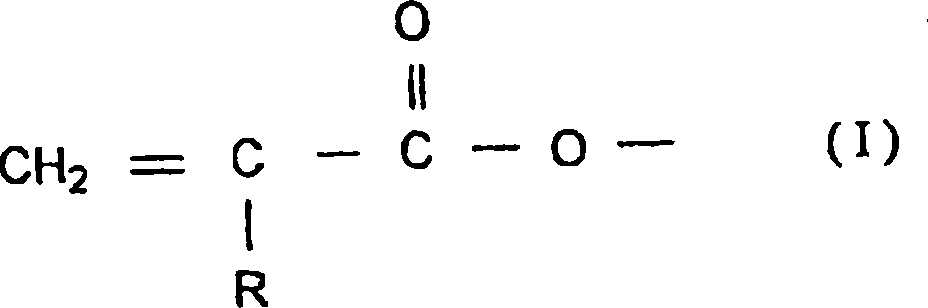

Photo-cured heat-cured resin composition and printed circuit board produced with the same

ActiveCN101320212AExcellent developabilityAvoid inactivationPhotomechanical apparatusPrinted circuit manufactureM-aminoacetophenoneUltraviolet

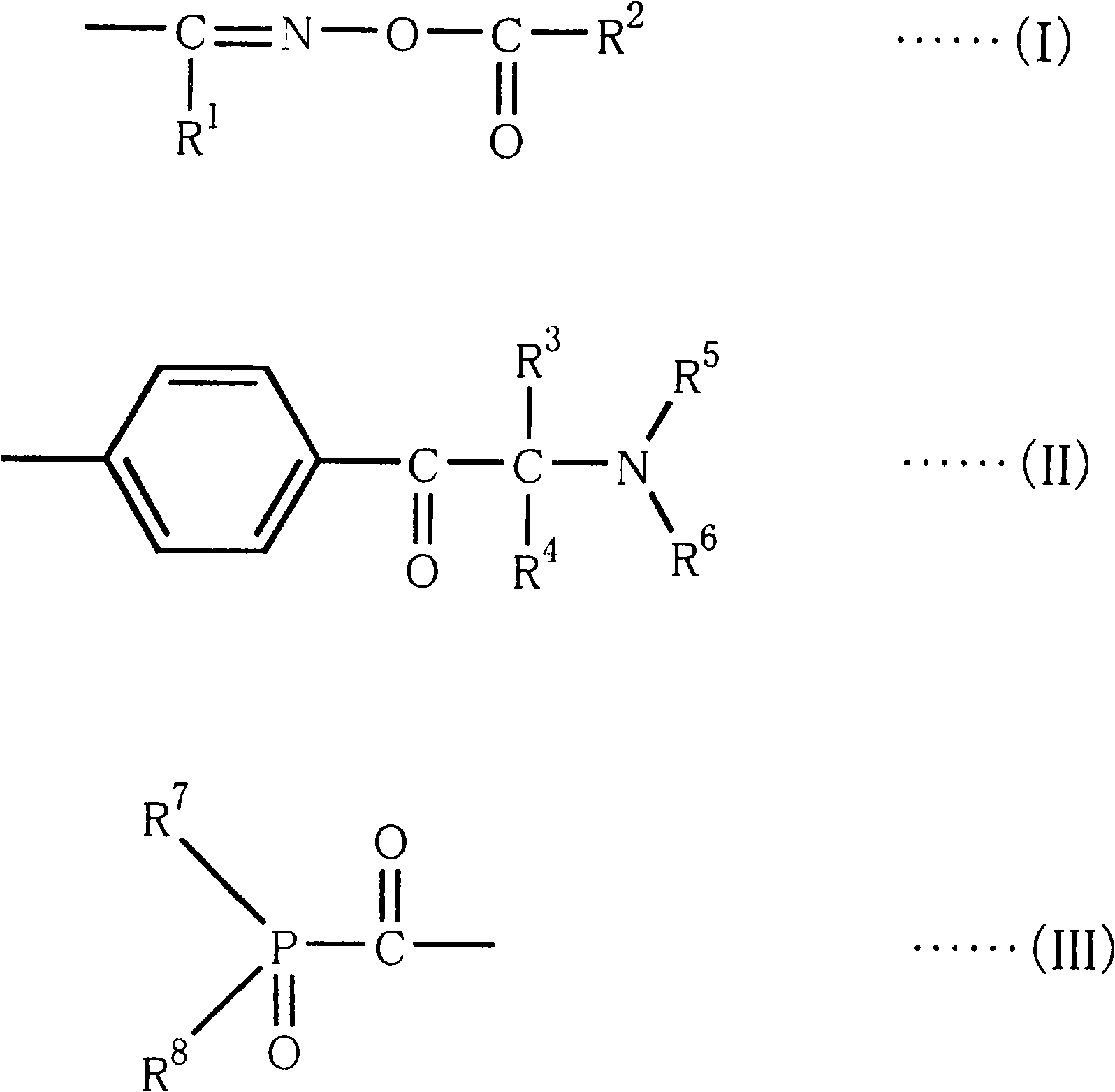

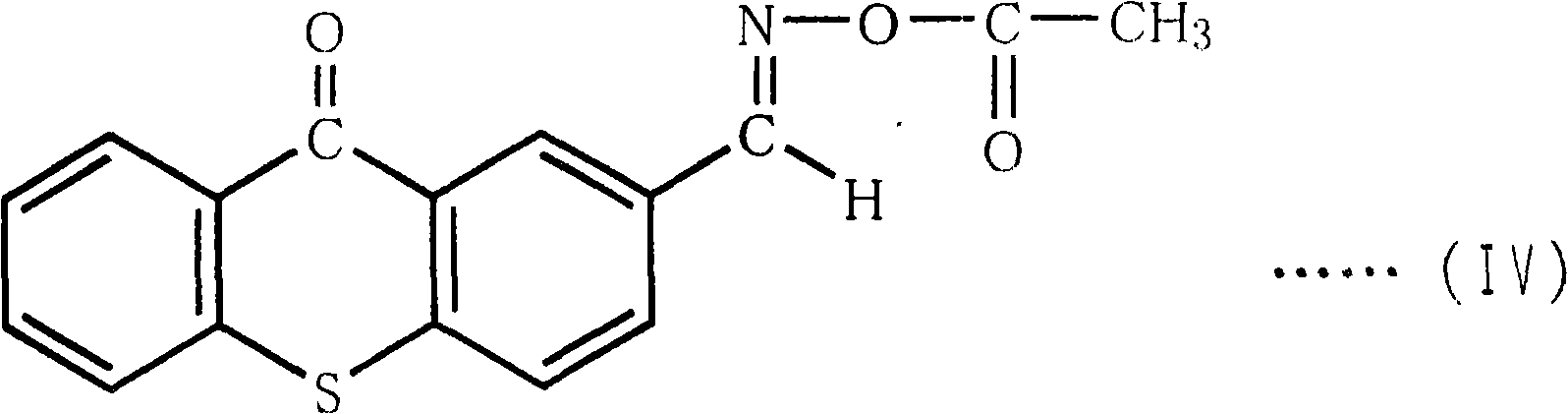

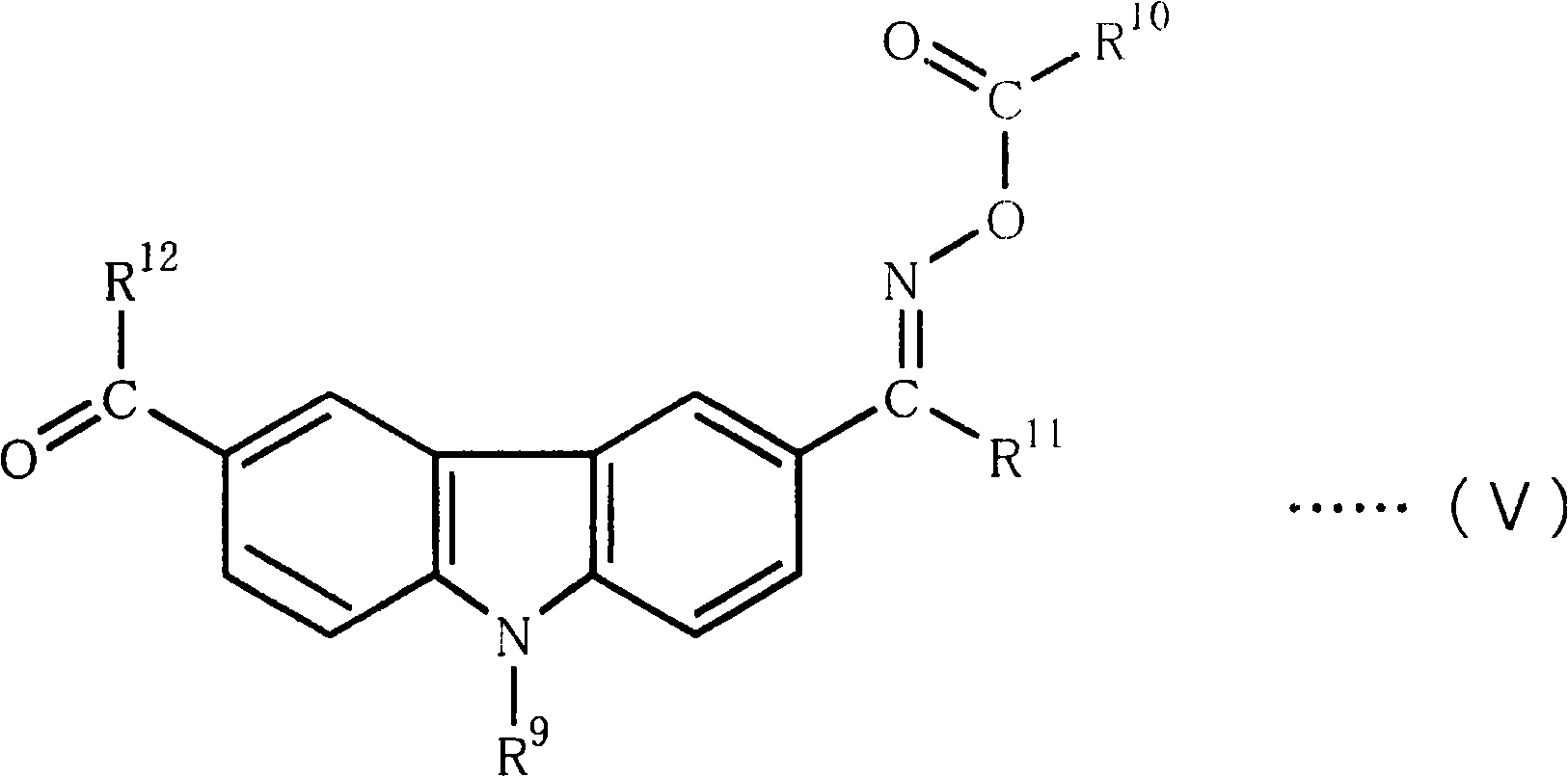

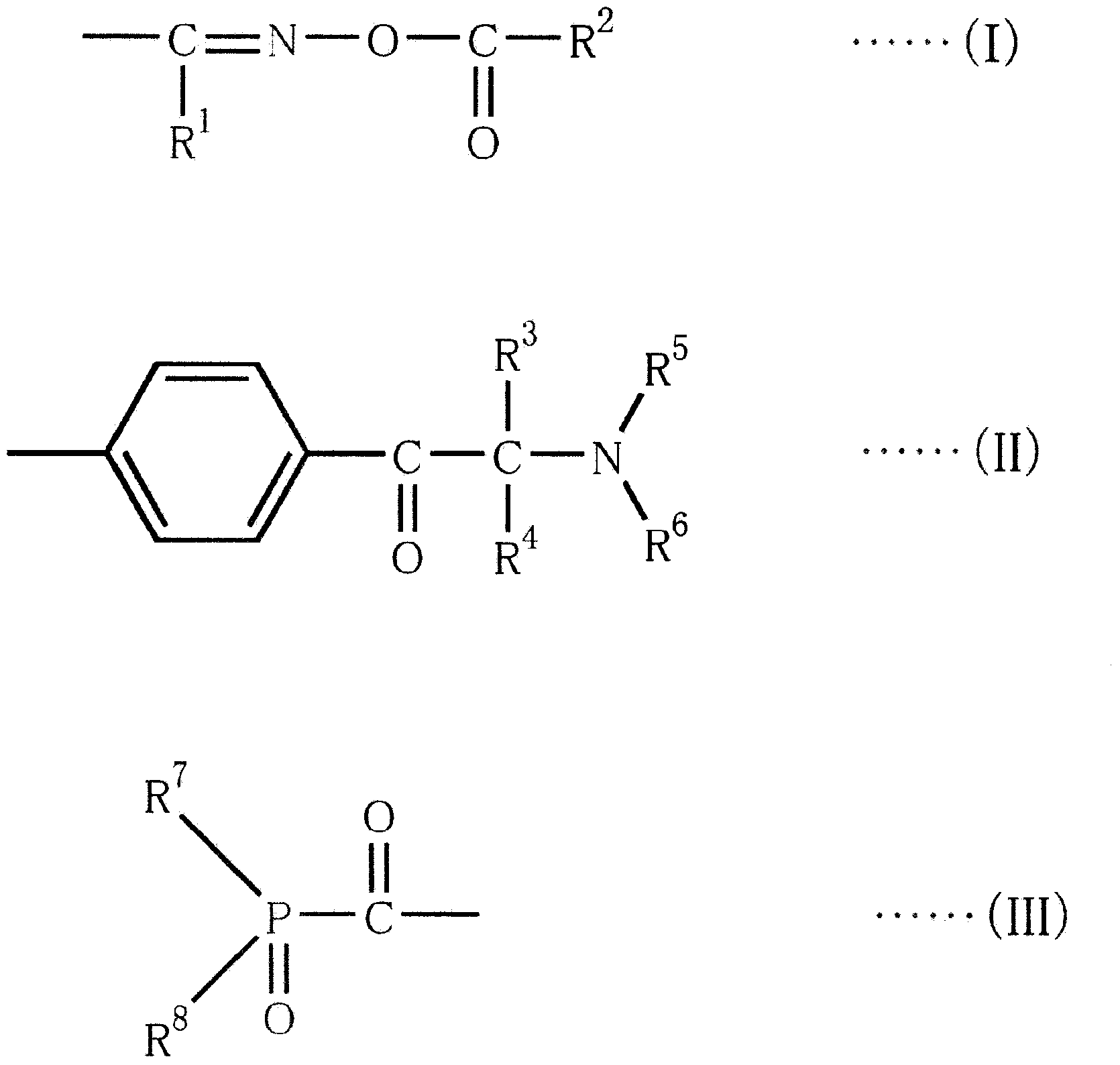

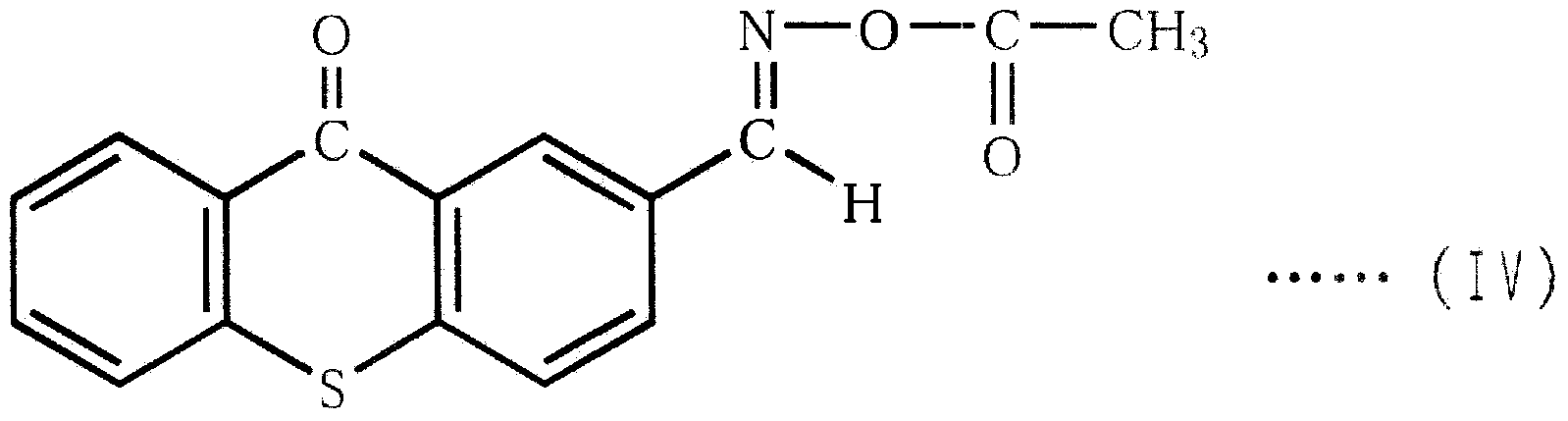

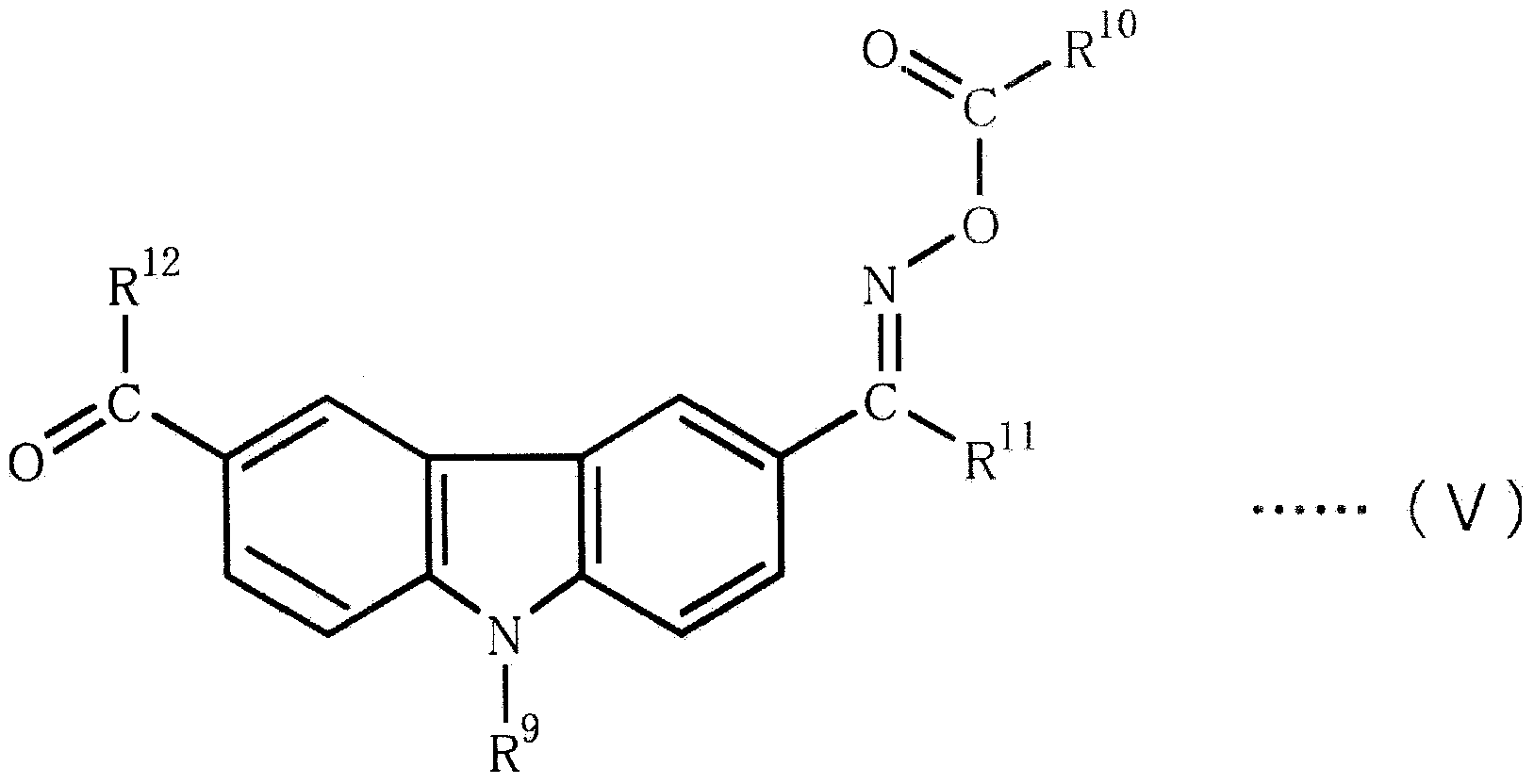

A light-curing thermo-curing resin composition and a printed circuit board obtained using the same are provided, the composition has high light sensitivity and excellent curing depth in ultraviolet ray and laser exposure, thus further having great developing ability to pass through diluted alkaline aqueous solution while being excellent in storage stability and operability, so the composition is suitable for solder resisting agent. The light-curing thermo-curing resin composition comprises (A) carboxyl-containing resin, (B) mercaptobutyric acid or derivatives thereof, (C) photopolymerization initiator, (D) compounds having 2 or more of olefinic unsaturated groups in the molecules, and (E) thermo-curing components. The suitable (A) carboxyl-containing resin is preferably the carboxyl-containing resin capable of free radical polymerization and having unsaturated double bond. In addition, the (C) photopolymerization initiator is preferably oximes photopolymerization initiator (C1), particularly preferably proxetil photopolymerization initiator, aminoacetophenone photopolymerization initiator and / or acyl phosphine oxide photopolymerization initiator.

Owner:TAIYO HLDG CO LTD

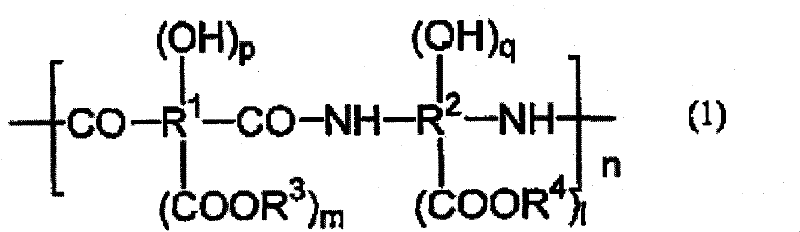

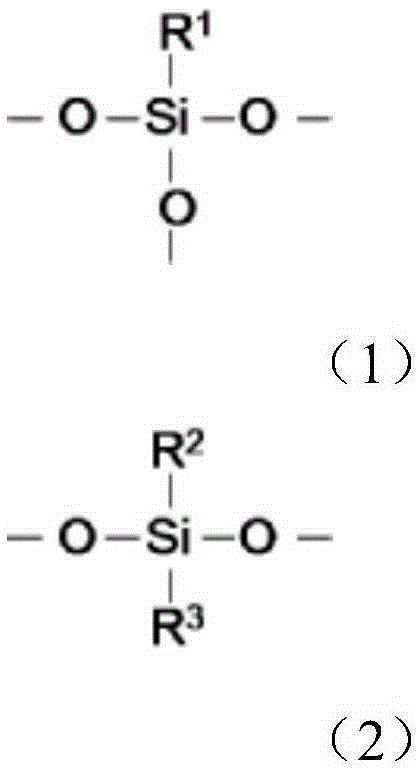

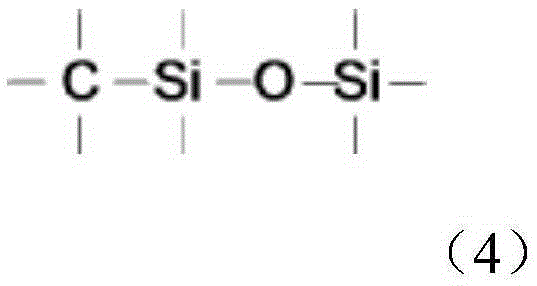

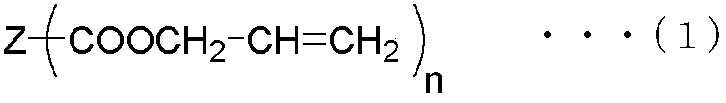

Electrolyte for non-aqueous electrolyte battery, and non-aqueous electrolyte battery using same

ActiveCN104380517AInitial feature improvementReduce free acid concentrationLi-accumulatorsVehicular energy storagePhosphatePhysical chemistry

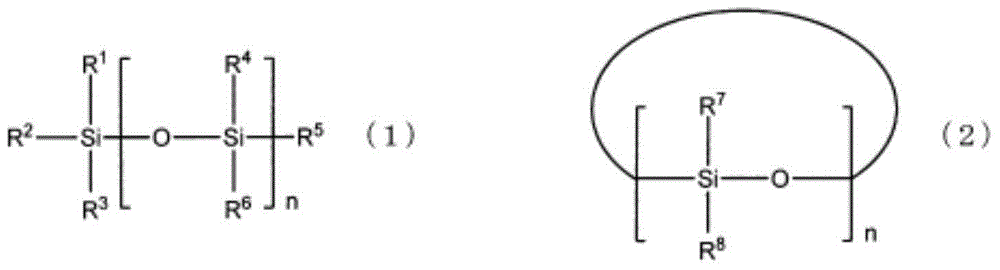

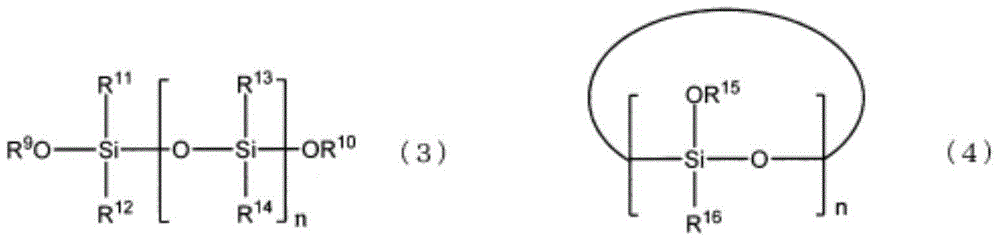

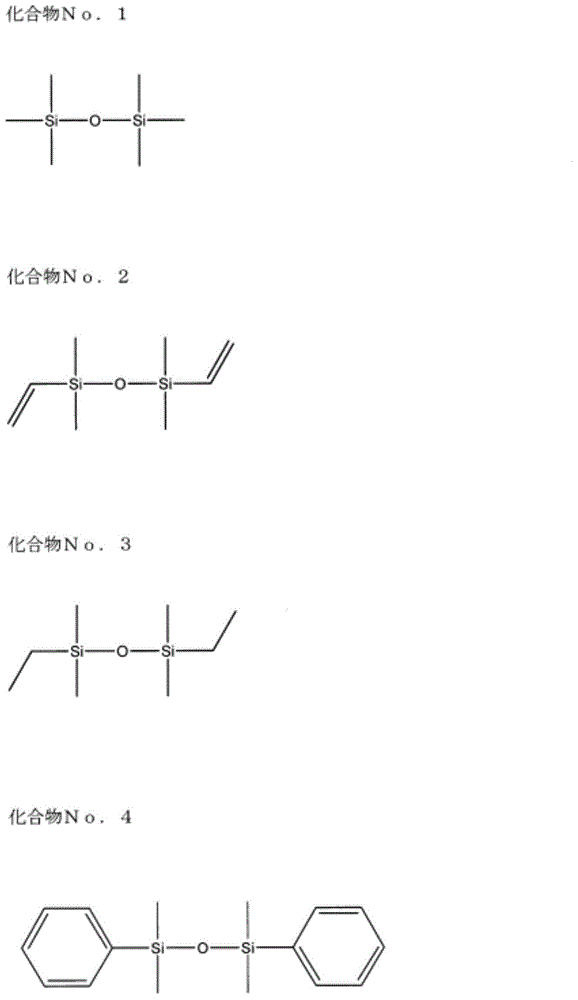

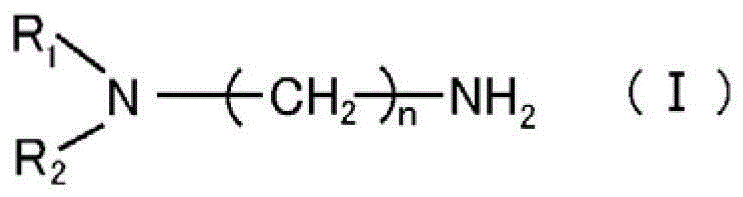

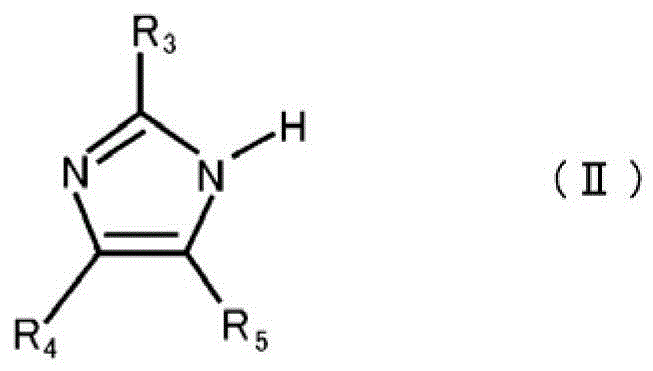

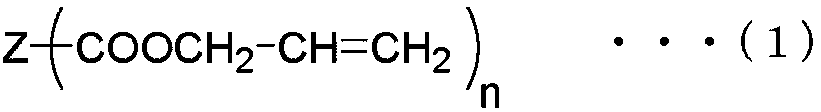

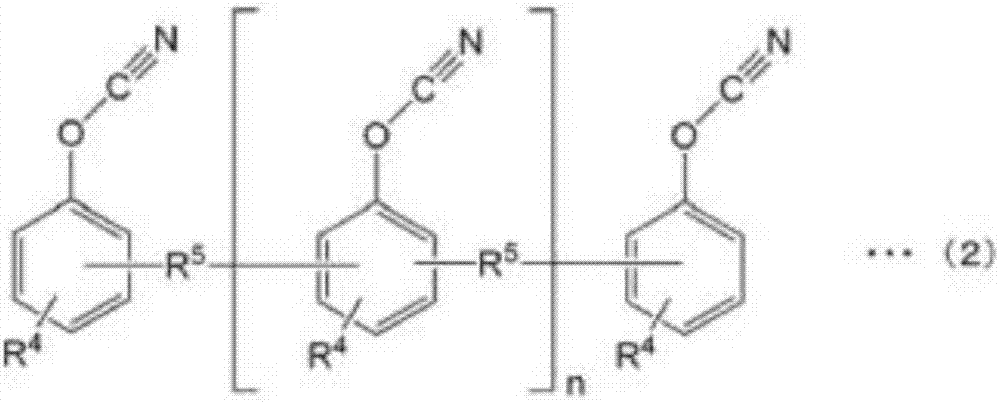

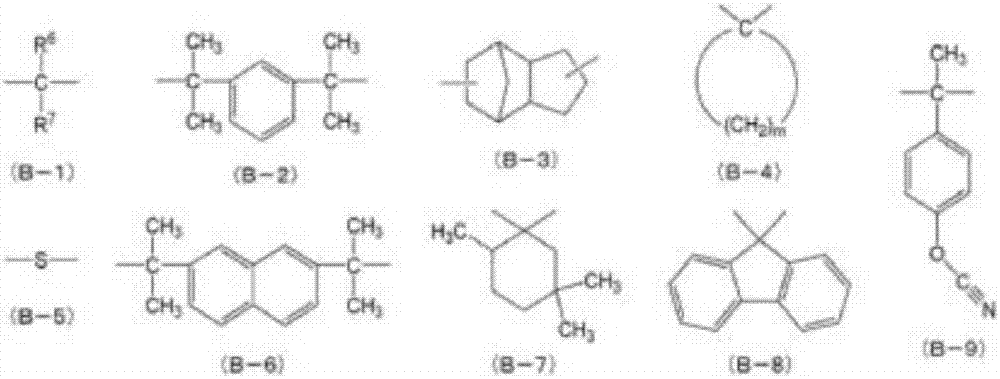

Provided is an electrolyte for a non-aqueous electrolyte battery comprising at least one compound selected from the group consisting of lithium difluoro(bis(oxalato))phosphate, lithium tetrafluoro(oxalato)phosphate, and lithium difluoro(oxalato)borate as a first compound, and at least one of the siloxane compounds represented by formulas (1) and (2) as a second compound. The electrolyte exhibits improved initial characteristics and superior storage stability and low-temperature characteristics, and yields a battery that demonstrates excellent, well-balanced overall performance.

Owner:CENT GLASS CO LTD

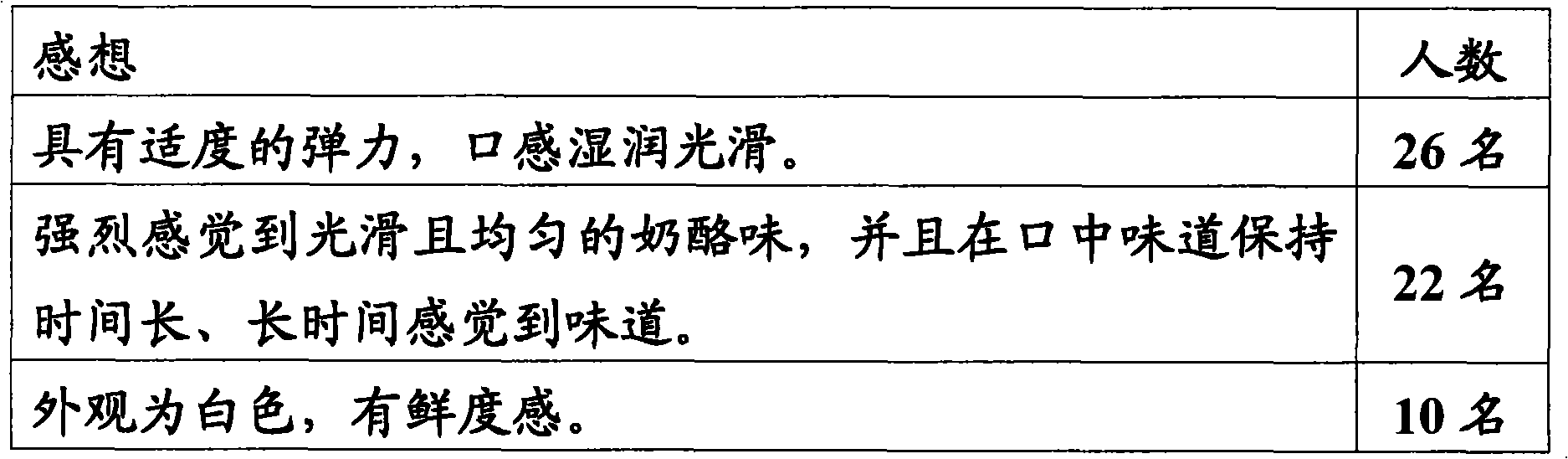

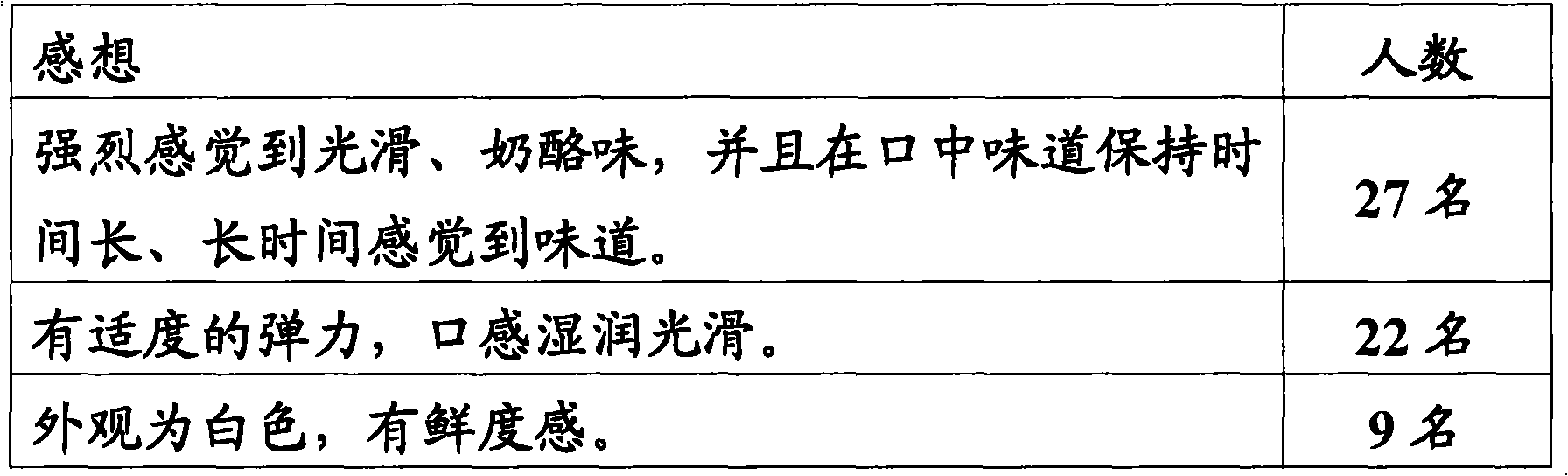

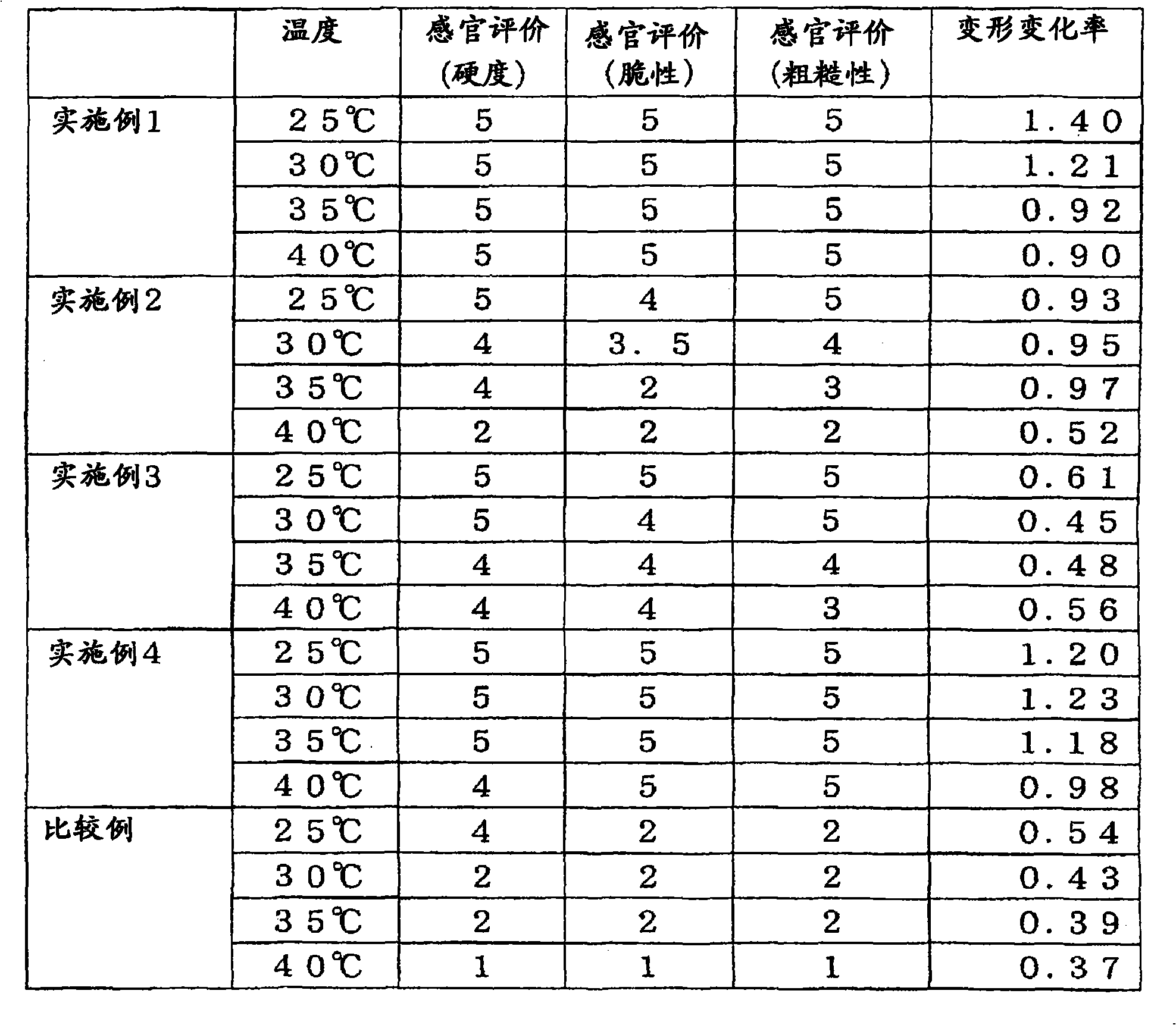

Cheese product capable of long-term storing stability

The subject of the invention is to provide a cheese product which has good storing stability and can maintain flexibility of tissue for a long time at normal temperature. The cheese product is used for solving the subject of the invention and can maintain storing stability and flexibility of tissue at normal temperature, wherein the cheese product contains natural cheese, trehalose, crystalline cellulose and / or modified starch.

Owner:NATORI

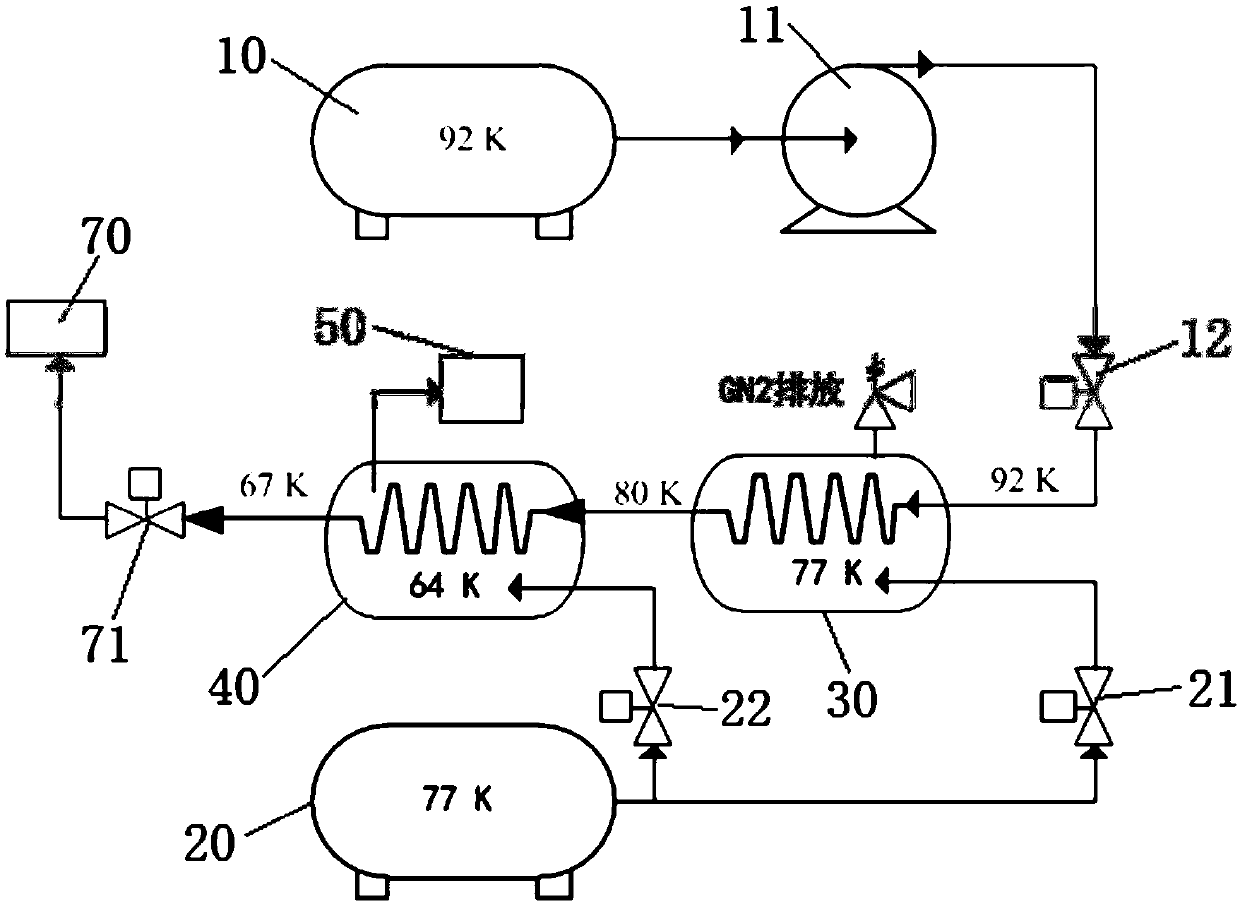

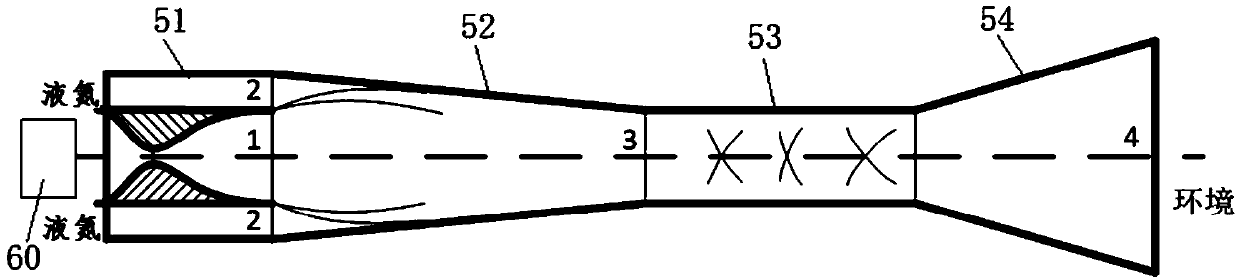

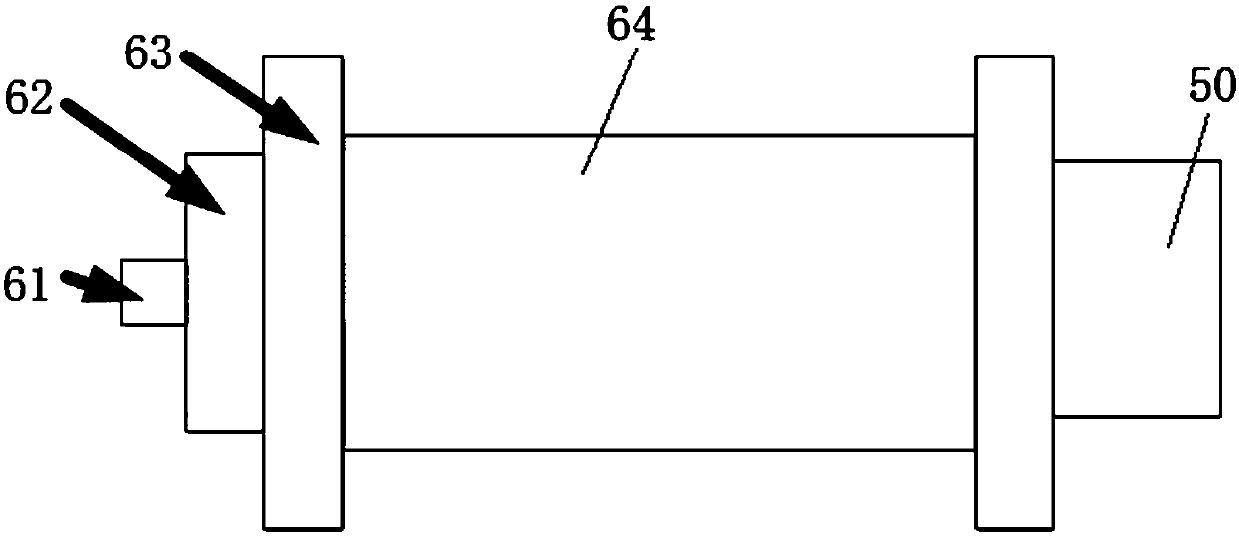

Large flow liquid oxygen supercooling method based on supersonic ejector

InactiveCN109579351ALarge supercooling flowStorage stabilityMechanical apparatusFluid circulation arrangementLiquid nitrogenLiquid oxygen

The invention discloses a large flow liquid oxygen supercooling method based on a supersonic ejector. The large flow liquid oxygen supercooling method comprises the steps that a heat exchanger used inconventional saturated liquid nitrogen supercooling liquid oxygen is used as a primary heat exchanger, and the liquid oxygen with a supercooling flow rate greater than 4500 L / min can be supercooled from 92K to 80K; a secondary heat exchanger is arranged at the downstream position of the primary heat exchanger to supercool the liquid oxygen which is supercooled to 80K and with the supercooling flow rate greater than 4500L / min to below 67K; the secondary heat exchanger is filled with liquid nitrogen in a saturated state, the temperature of the liquid nitrogen in the secondary heat exchanger isno more than 64K, and an air outlet of the secondary heat exchanger is connected with an ejected airflow inlet of the supersonic ejector; an ejector airflow inlet of the supersonic ejector is connected to a gas outlet of a gas generator; the supersonic ejector sequentially includes a mixing section, a super-expansion section and a sub-expansion section which are arranged coaxially in the directionof the airflow; and the mixing section is a conical isobaric mixing chamber with a contracted cross section. The large flow liquid oxygen supercooling method can meet the needs of rapid cooling and filling of large-flow liquid oxygen before launching such as CZ-5. In addition, the pumping capacity of the supersonic ejector can be matched with the load, and more security and reliability are achieved.

Owner:PLA PEOPLES LIBERATION ARMY OF CHINA STRATEGIC SUPPORT FORCE AEROSPACE ENG UNIV

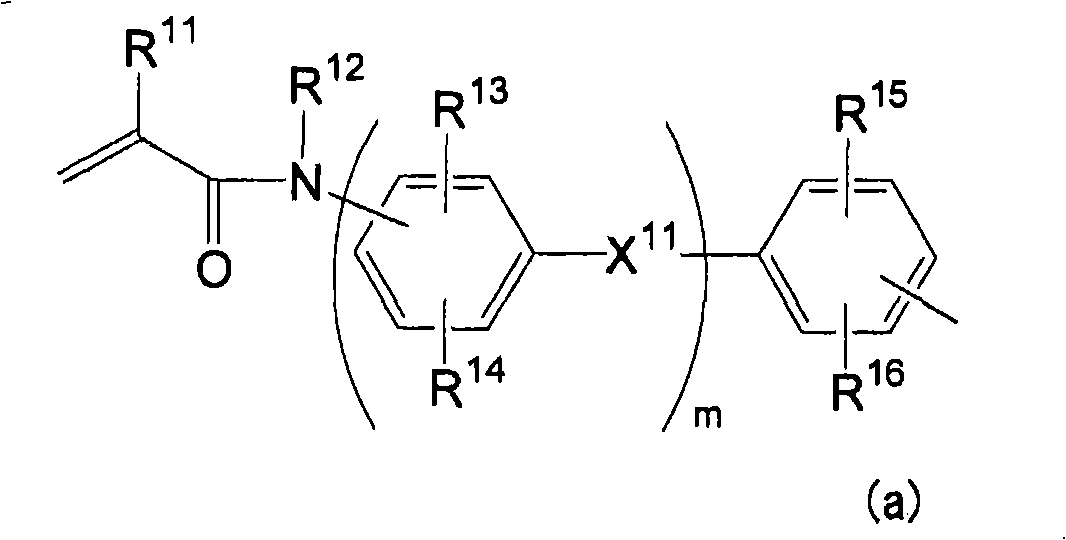

Active energy ray-curable ink composition

InactiveCN101014670AGood dispersionImprove printing qualityDuplicating/marking methodsInksDiluentSolvent

Disclosed is an energy ray-curable ink composition containing a coloring agent, a monomer and a photopolymerization initiator. As the monomer, 10-90% by weight of an acrylamide derivative is contained relative to the total weight of the ink composition, and the viscosity of the ink composition as a whole is 3-35 mPas at 25 DEG C. This ink composition has low viscosity without being diluted with a diluent, while exhibiting good storage stability and good pigment dispersibility in cases where the coloring agent is composed of a pigment. The ink composition further has excellent stability in continuous discharge to a recording medium, and exhibits good curability even when the energy is low and the integrated amount of light is not more than 150 mJ / cm2. Furthermore, the ink composition enables to obtain good print quality on a non-absorptive recording medium, and in particular, it exhibits excellent adhesion to a recording medium base.

Owner:HITACHT MAXELL LTD

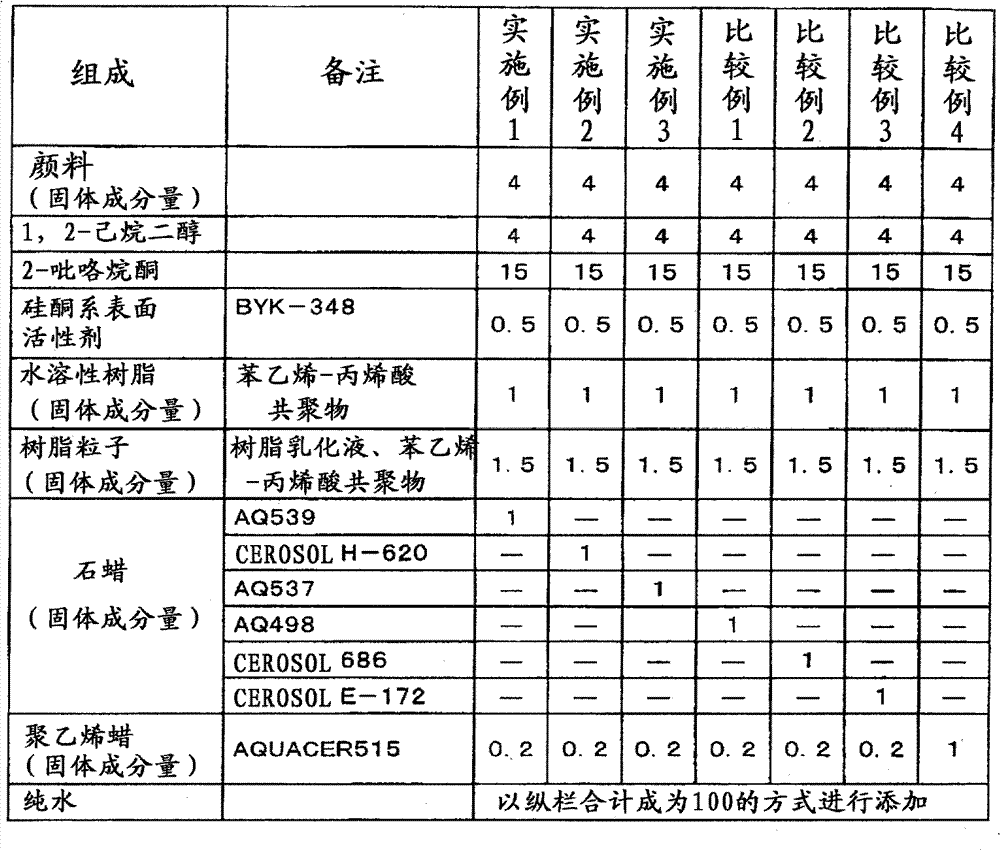

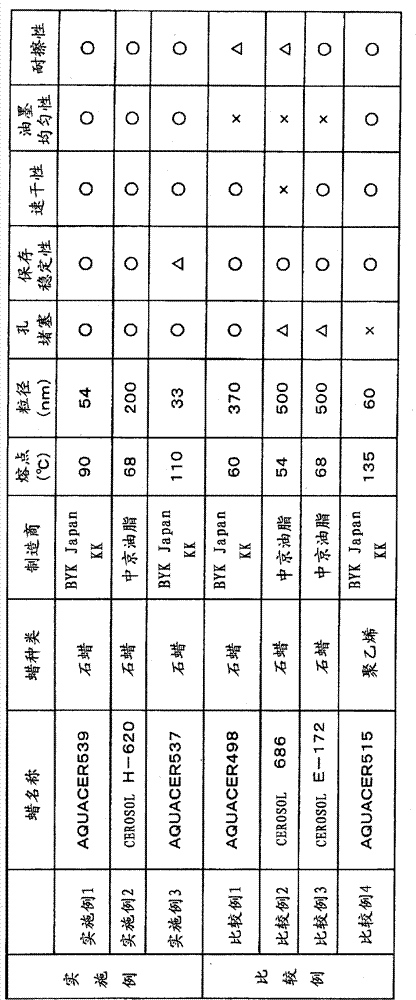

Aqueous ink composition

InactiveCN102732099AGood pore pluggingStorage stabilityDuplicating/marking methodsInksParaffin waxWater insoluble

An aqueous ink composition includes at least one kind of water-insoluble colorant and a wax in which the wax is a paraffin wax with a melting point of 60 DEG C. to 110 DEG C. and an average particle size of 30 nm to 250 nm.

Owner:SEIKO EPSON CORP

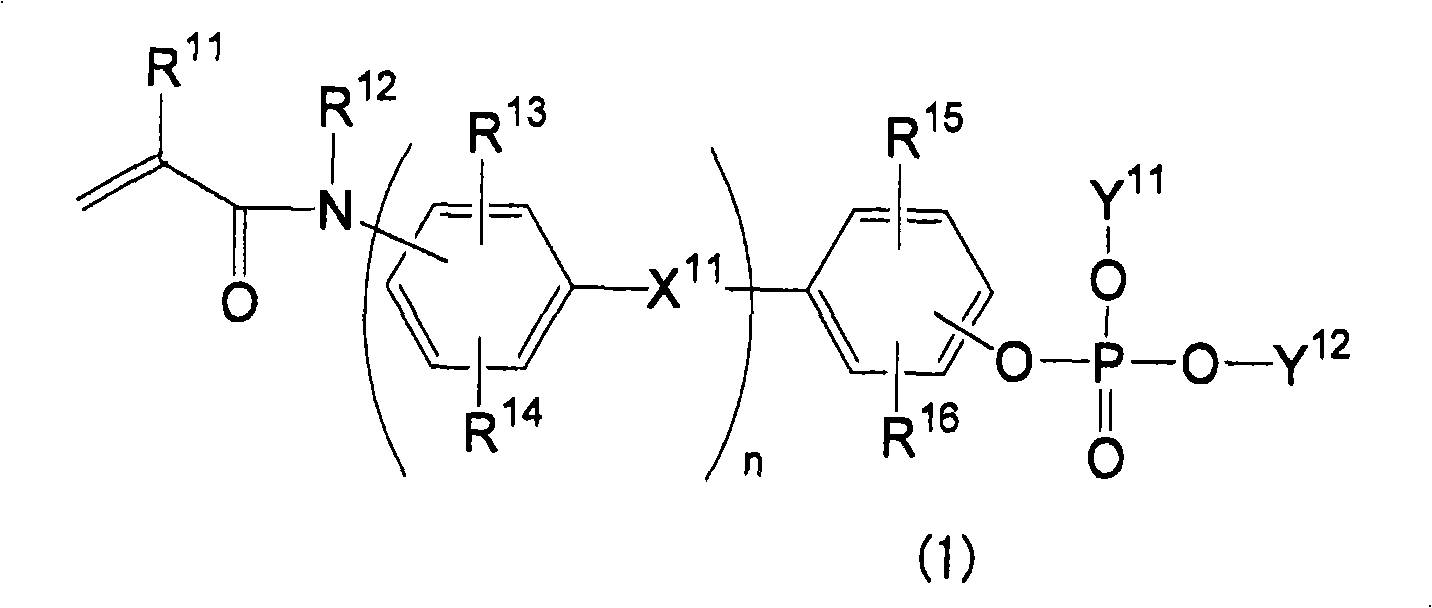

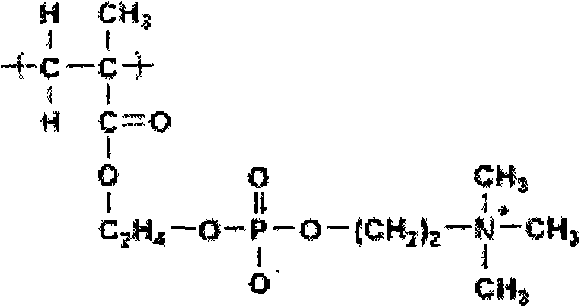

Phosphate ester compound, metal salt thereof, dental material, and demtal composition

ActiveCN101516896APreserve operabilitySimple and fast operationImpression capsMedical preparationsPhosphateChemical compound

The invention provides a phosphate compound having an unsaturated double bond and a metal salt thereof; a dental material containing a phosphate compound having an unsaturated double bond and / or a metal salt thereof; and a dental composition containing a phosphate compound having an unsaturated double bond and / or a metal salt thereof. The phosphate compound of the invention provides a dental material and a dental composition such as a bonding material, adhesive material and a dental luting agent that are highly stable during storage, convenient for handling, and that exhibit higher adhesiveness and bond durability.

Owner:MITSUI CHEM INC

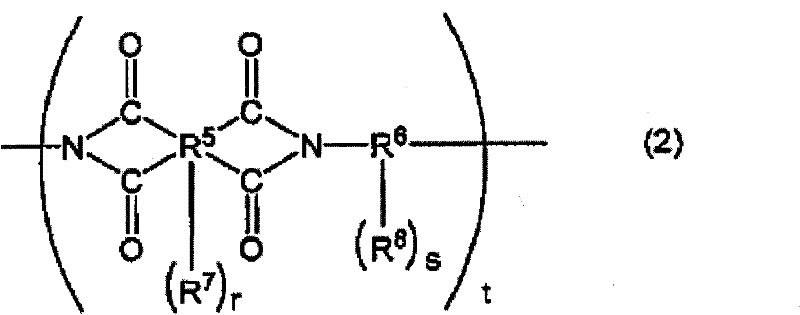

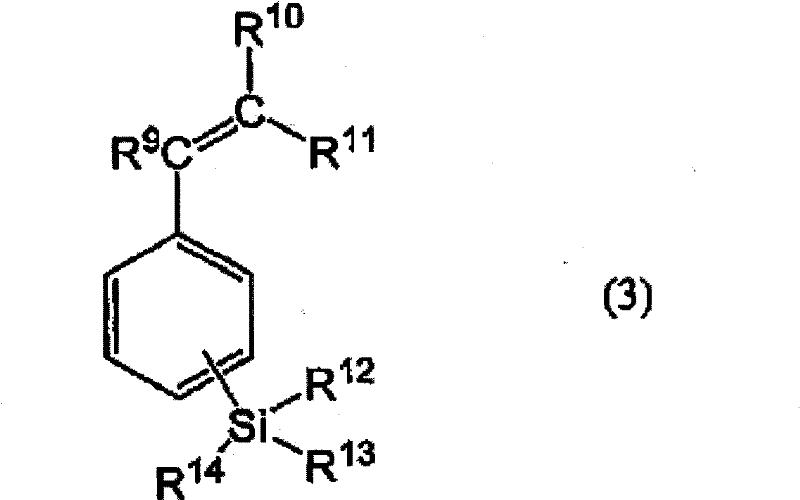

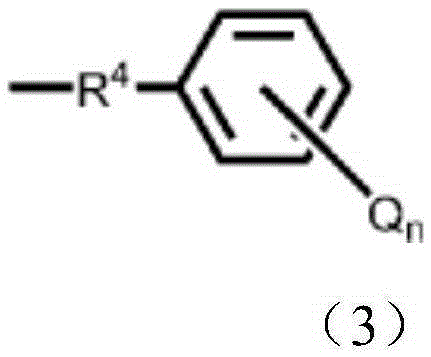

Positive-type photosensitive resin composition

ActiveCN102292675BStorage stabilityExcellent sensitivity stabilityPhotomechanical apparatusSemiconductor/solid-state device manufacturingSilanesPositive type

Disclosed is a positive-type photosensitive resin composition which has excellent storage stability, particularly excellent sensitivity stability, and can be formed into a cured film having excellent adhesion onto a substrate when heated at 350 DEG C or higher or heated in the air. The positive-type photosensitive resin composition comprises (a) a polymer having, as the main component, at least one structure selected from the group consisting of a polyimide precursor structure, a polybenzoxazole precursor structure, and a polyimide structure, (b) a quinonediazide compound, (c) a silane coupling agent having a styryl group, (d) a silane coupling agent having an epoxy group, an oxetanyl group, a methacryloxy group, an acryloxy group, an amino group, an amide group or mercapto group and an alkoxysilyl group, and (e) a solvent.

Owner:TORAY IND INC

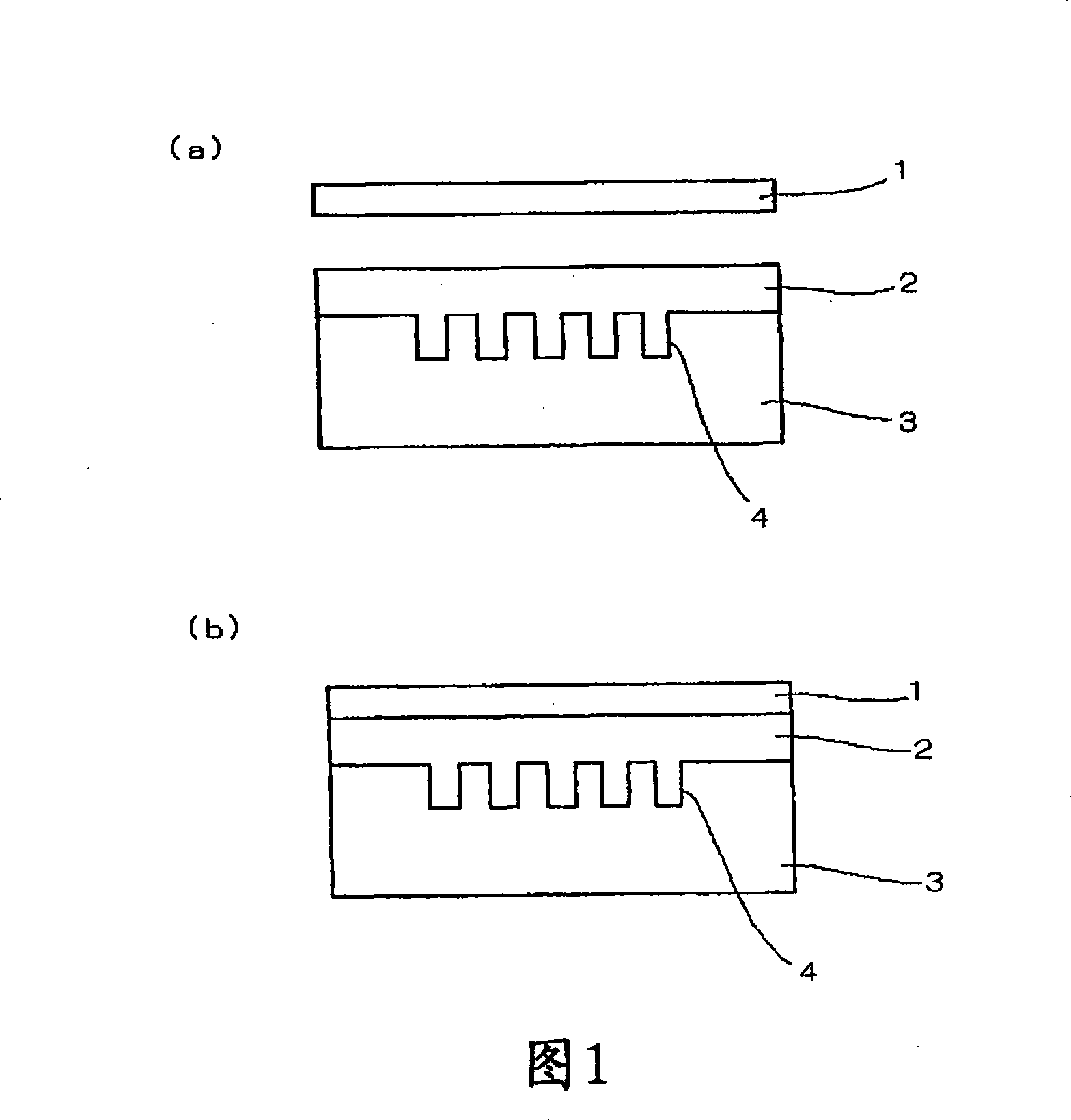

Laminated board comprising photopolymer

InactiveCN101144981AHigh resolutionImprove adhesionSemiconductor/solid-state device manufacturingPhotosensitive materials for photomechanical apparatusChemical compoundMicrometer

The present invention provides a laminate with photosensitive resin, and has excellent performances of corrosion-resistance image shaping, conductor pattern shaping, and preservative stability. The present invention relates to a long-strip-shaped laminate with photosensitive resin; conductive sheets are overlapped on one side or two sides of an insulative resin layer to form a long-strip-shaped structure; the present invention consists of a layer which is formed by photosensitive resins and is arranged on at least one side of the conductive sheet, and the thickness of the layer is arranged thicker than 1 micrometer but thinner than 20 micrometer; the present invention is characterized in that the photosensitive resins contains (a) thermoplastic copolymers, carboxyl content of which is more than 100 but less than 600 if counted by acid equivalent, and the molecular weight on weight average of which is more than 20,000 but less than 500,000; (b) photopolymerisable unsaturated compounds; (c) photopolymerization initiator and specific compounds.

Owner:ASAHI KASEI E-MATERIALS CORPORATION

Stable black nano-water dispersible pigment dispersion

InactiveCN101492585AAvoid reunionImprove stabilityInksParticle size analysisWater dispersibleBULK ACTIVE INGREDIENT

The invention relates to stable black nano water dispersible pigment dispersion liquid and a preparation method thereof. The black nano water dispersible pigment dispersion liquid is characterized by consisting of black pigment C.I.P.B.7, polyurethanes dispersant, bactericide and de-ionized water; wherein, the proportion between the active ingredients which are the black pigment and the dispersant is preferentially within the range of 1.1-1.8. The preparation method comprises the steps: the dispersant and the de-ionized water are mixed in a container to be stirred and then added with the black pigment; the mixed solution is cut for 0.5-8h by a high speed shearing machine and then is ground and dispersed in a circulating way; granularity detection is carried out every 15min until the grain diameter of the dispersion liquid reaches the requirement. The invention has the advantages that the water dispersible pigment dispersion liquid has good dispersibility and storage stability; black pigment cluster is mechanically shattered to be smaller, so that the dispersant can be anchored and fixed on the pigment granules, thus preventing the pigment granules agglomerating together. The stability of the prepared pigment dispersion liquid is enhanced.

Owner:天津兆阳纳米科技有限公司

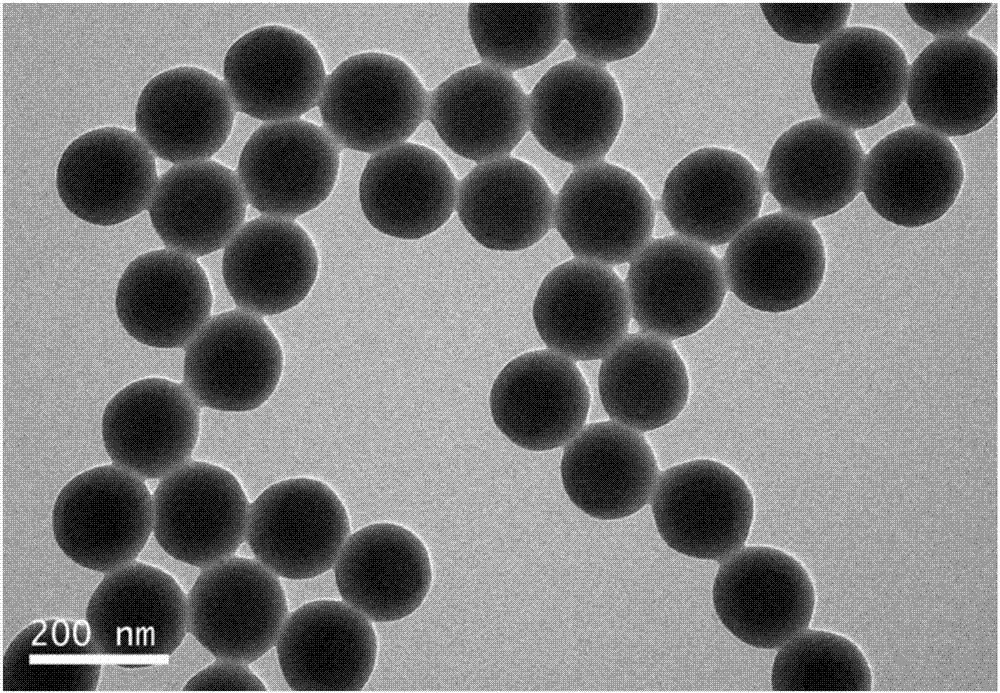

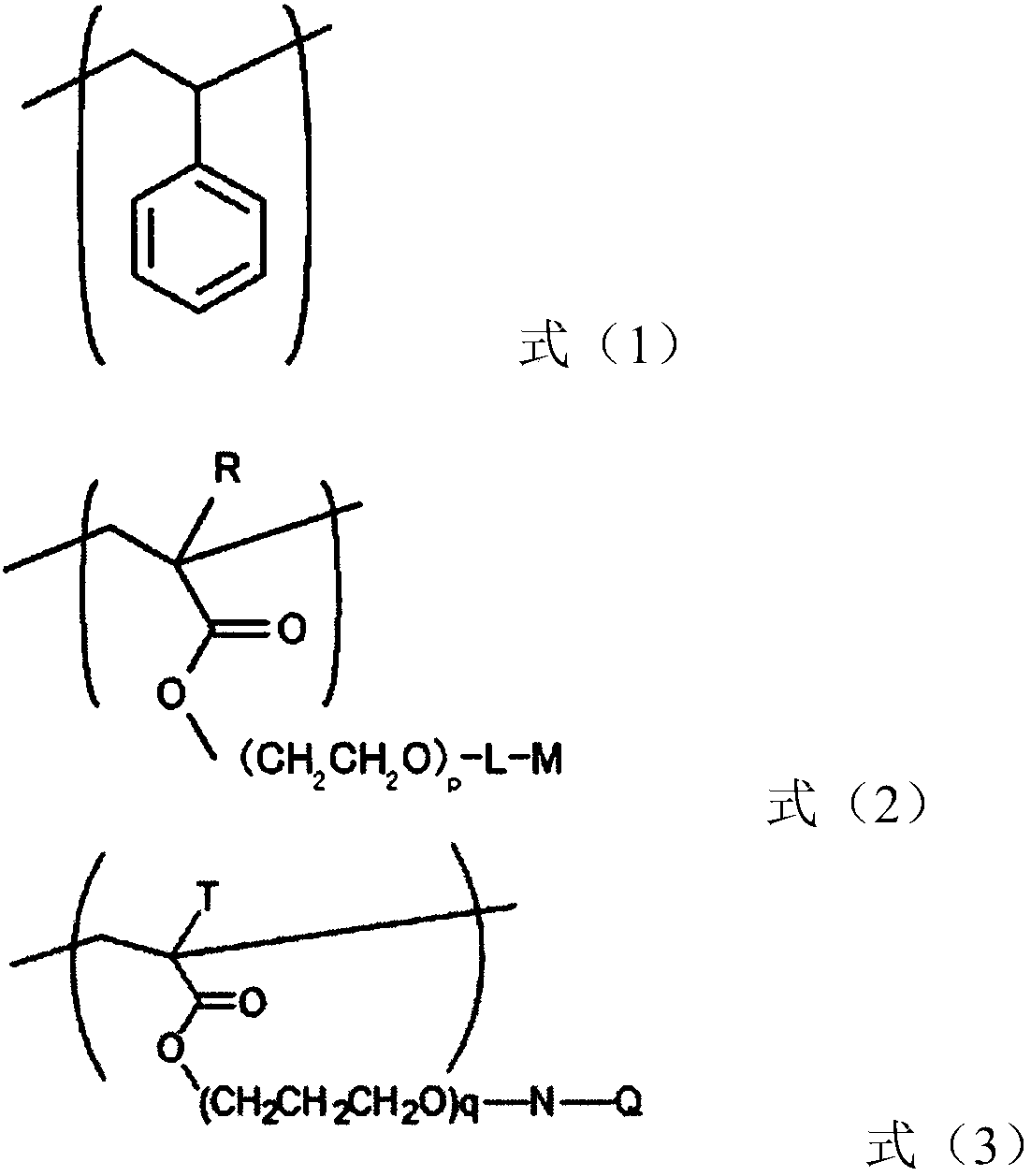

Monodisperse polystyrene microsphere, and preparation method and application thereof

ActiveCN107216421AGood dispersionStorage stabilityPolycrystalline material growthInksColor printingEmulsion

The invention relates to a monodisperse polystyrene microsphere, and a preparation method and application thereof. The polystyrene microsphere is prepared through soap-free emulsion polymerization with styrene as main monomers and N-isopropylacrylamide and vinylpyridine as comonomers, or with N-isopropylacrylamide and 1-vinyl imidazole as comonomers. The preparation method comprises the following steps: adding styrene and N-isopropylacrylamide into a reaction container filled with water; then adding vinylpyridine or 1-vinyl imidazole; introducing inert gas; carrying out heating to 60 to 85 DEG C and maintaining the temperature for 3 to 10 min; then adding an initiator according to the addition amount of styrene; and carrying out a reaction for 4 to 48 h. The monodisperse polystyrene microsphere provided by the invention can be used for preparation of emulsion paint, variable-color printing ink and photonic crystal devices. Compared with the prior art, the polystyrene microsphere provided by the invention has the advantage of good monodispersity; a photonic crystal film with a brilliant color can be prepared from the polystyrene microsphere without addition of other auxiliary agents; and the color of the photonic crystal film varies at different observation angles.

Owner:SHANGHAI JIAO TONG UNIV

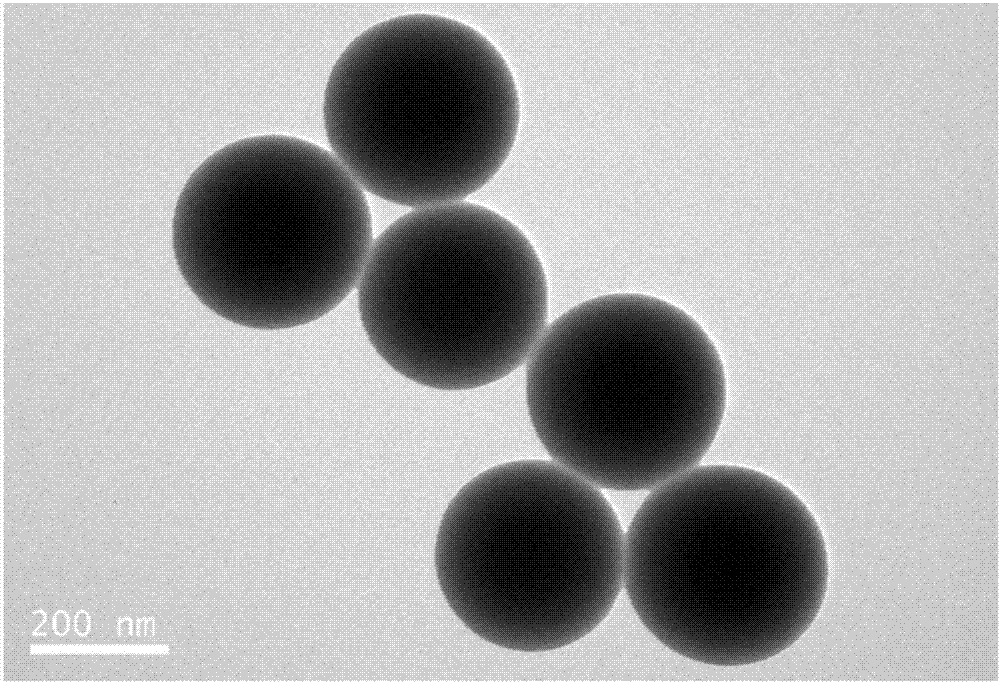

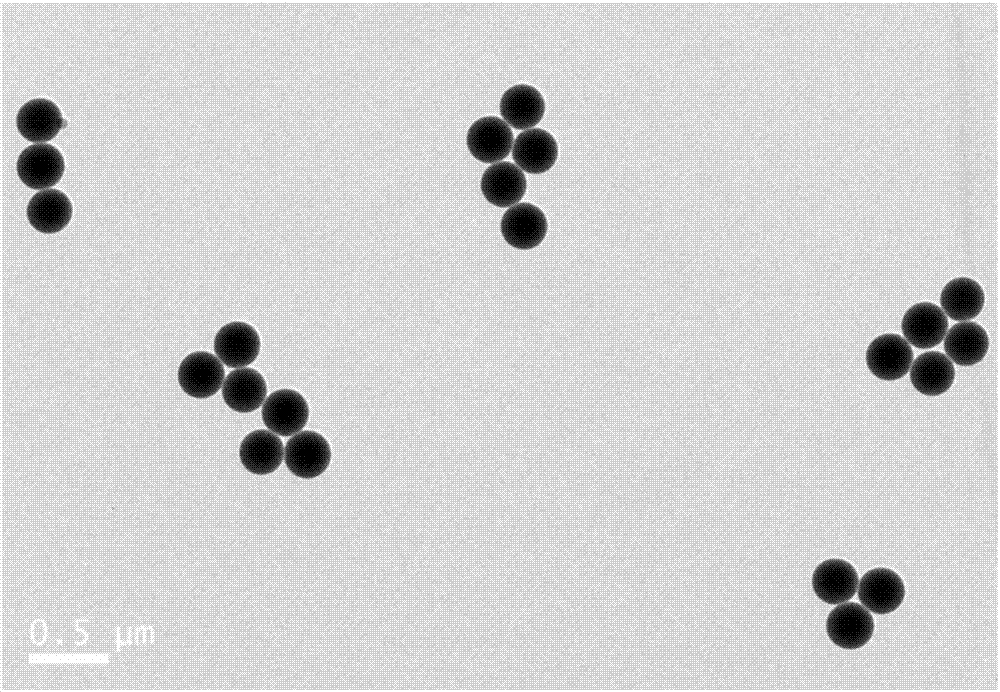

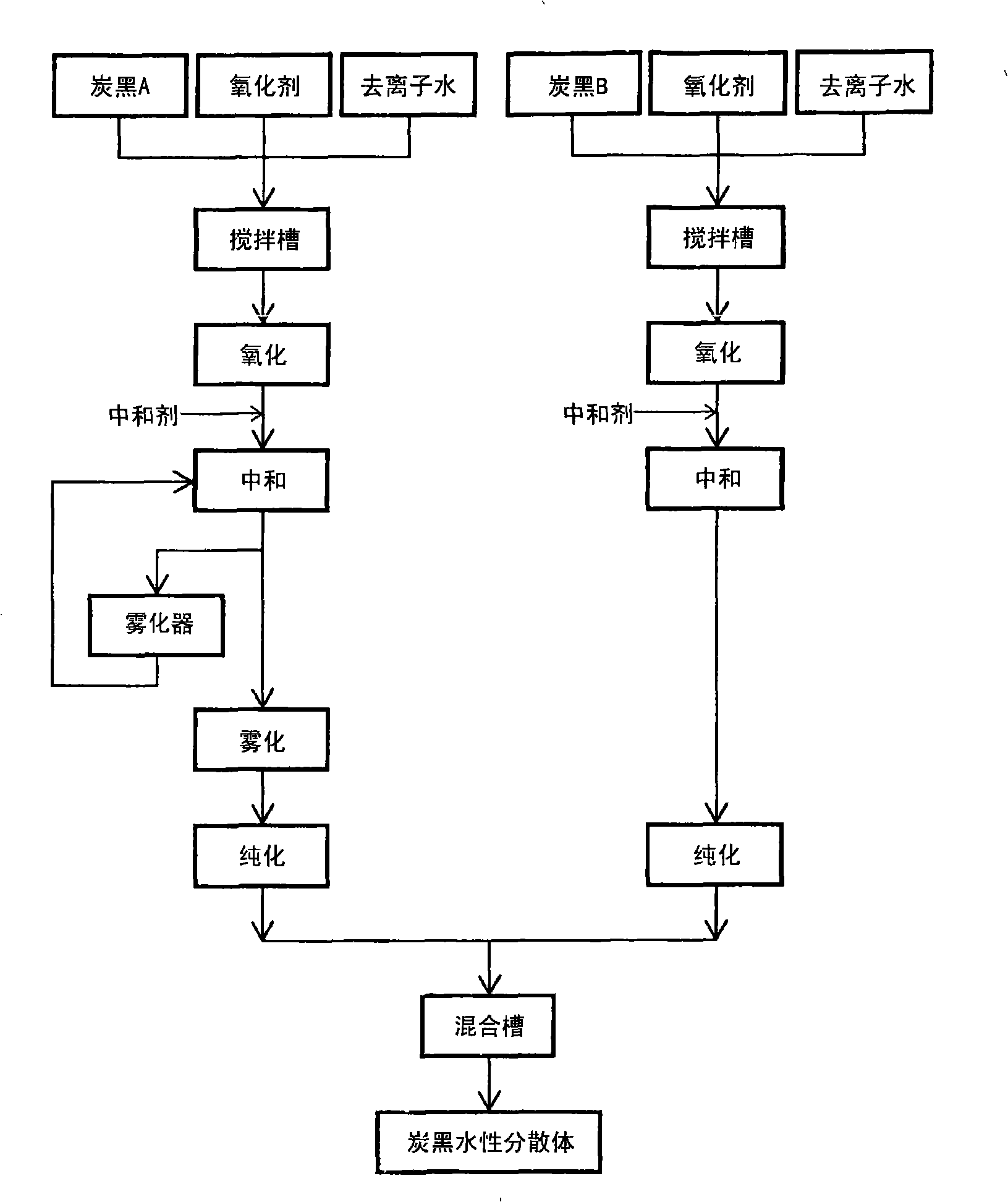

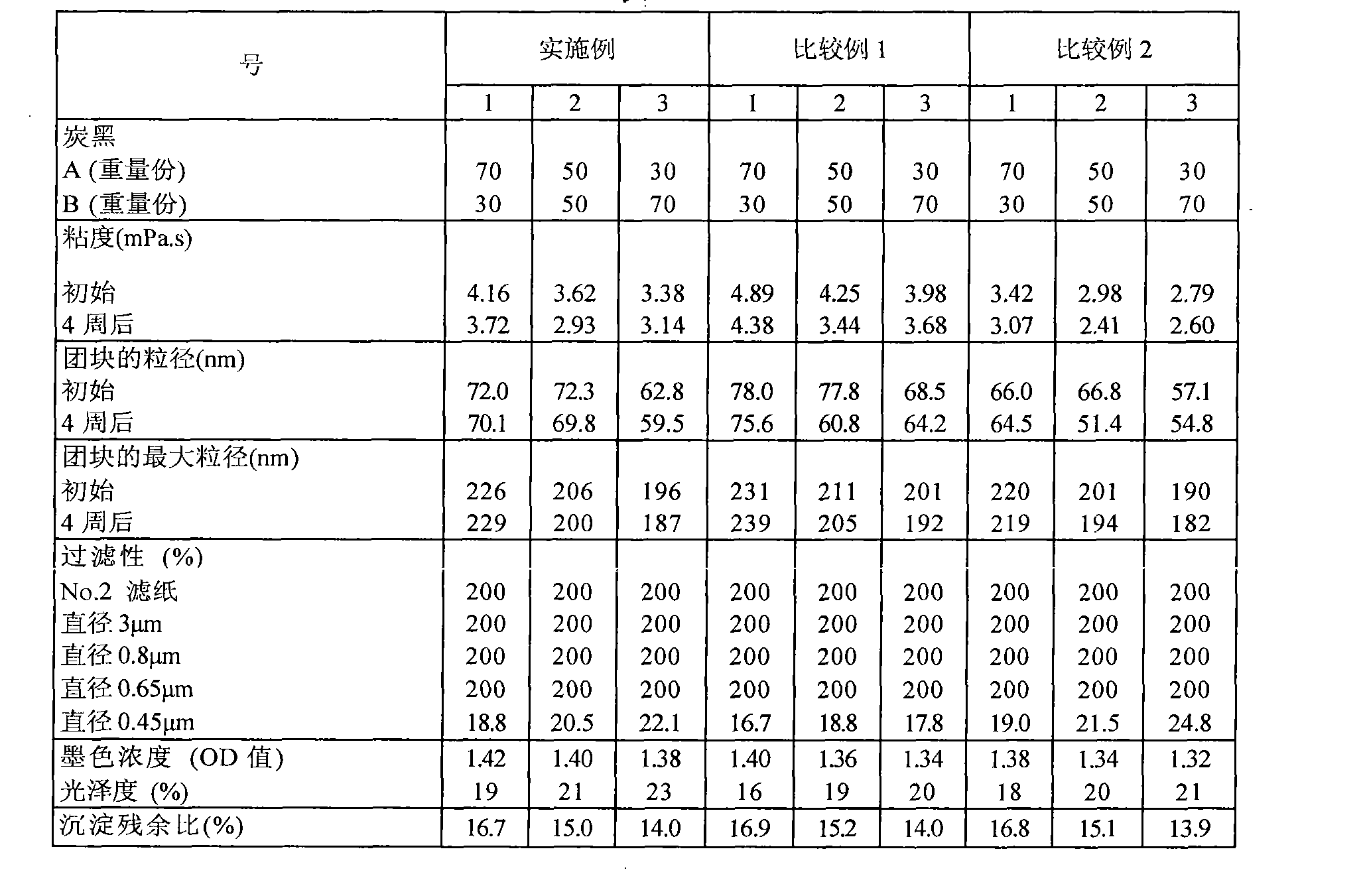

Water-dispersible carbon black pigment and process for producing aqueous dispersion thereof

InactiveCN101283056AGood dispersionHigh blacknessInksPigment pastesWater dispersibleSurface oxidation

A water-dispersible carbon black pigment excellent in water dispersibility and ink performance; and a process for producing an aqueous carbon black dispersion. The water-dispersible carbon black pigment comprises a mixture of a carbon black (A) having a nitrogen-adsorption specific surface area of 150 m<2> / g or larger, a DBP absorption of 95 cm<3> / 100 g or higher, and a specific coloring power of 120% or higher and a carbon black (B) having a nitrogen-adsorption specific surface area smaller than 150 m<2> / g, a DBP absorption less than 95 cm<3> / 100 g, and a specific coloring power of 120% or higher in a proportion of from 20:80 to 80:20 by weight, these carbon blacks having undergone a surface oxidation treatment and a neutralization treatment, and at least the carbon black (A) having undergone a disaggregation treatment. The process comprises separately dispersing the carbon black (A) and the carbon black (B) in an aqueous oxidizing agent solution to conduct an oxidation treatment, subjecting these carbon blacks to a neutralization treatment, subjecting at least the carbon black (A) to a disaggregation treatment, thereafter purifying them, subsequently mixing the carbon black (A) with the carbon black (B) in a proportion of from 20:80 to 80:20 by weight, and then dispersing the resultant water-dispersible carbon black pigment into an aqueous medium.

Owner:TOKAI CARBON CO LTD

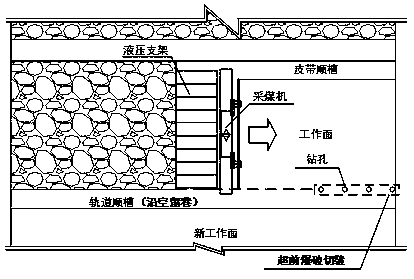

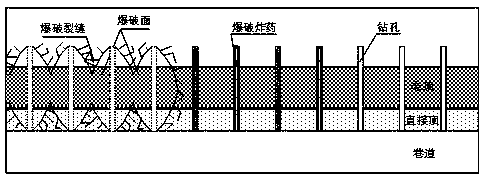

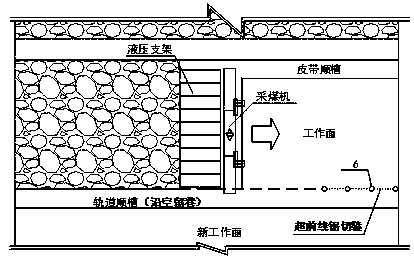

Gob-side entry retaining roof cutting method

InactiveCN111173511AGuaranteed operational safetyImprove operational safetyUnderground miningSurface miningArchitectural engineeringStructural engineering

The invention discloses a gob-side entry retaining roof cutting method. The gob-side entry retaining roof cutting method comprises the following steps that S1, the thickness of a direct roof and basicroof of a roadway is calculated according to mine geological data, a drilling track is designed, and a directional drilling machine is used for conducting directional drilling operation according tothe drilling track; S2, one end of a saw line is connected with a drill pipe end head by using a connector at one end of a drilling hole after the drilling hole is opened, and when the drill pipe is pulled out, the drill pipe drives the saw line to penetrate through the drilling hole to complete saw line layout; and S3, assembly of a wire saw machine is completed, the saw line is arranged on the wire saw machine, the wire saw machine drives the saw line to carry out cutting operation to the direct top and the basic top, and after the saw line penetrates through the direct top and the basic top, gob-side entry retaining roof cutting is completed. According to the gob-side entry retaining roof cutting method, the wire saw machine is used for carrying out static cutting operation, thus the stability and safety of an existing structure can be saved to the greatest extent, power of the wire saw machine is high, the cutting ability and the cutting efficiency are improved, at the same time, the labor intensity of the staff is reduced, and convenience is brought to construction operation of the staff.

Owner:河南明德矿山技术开发有限公司

Processing method of brown sugar and ginger tea

The invention relates to a processing method of brown sugar and ginger tea. The processing method is characterized in that crude ginger powder is soaked into honey and is stored in a cellar at the lowtemperature, so that pungency of ginger is reduced, and the ginger is endowed with rich honeydew fragrance. Adequate homogenizing and degassing are carried out in the processing process, so that themouth feel of the brown sugar and ginger tea is enabled to be uniform and fine, and the storage stability of the brown sugar and ginger tea is facilitated to be improved.

Owner:安徽华健生物科技有限公司

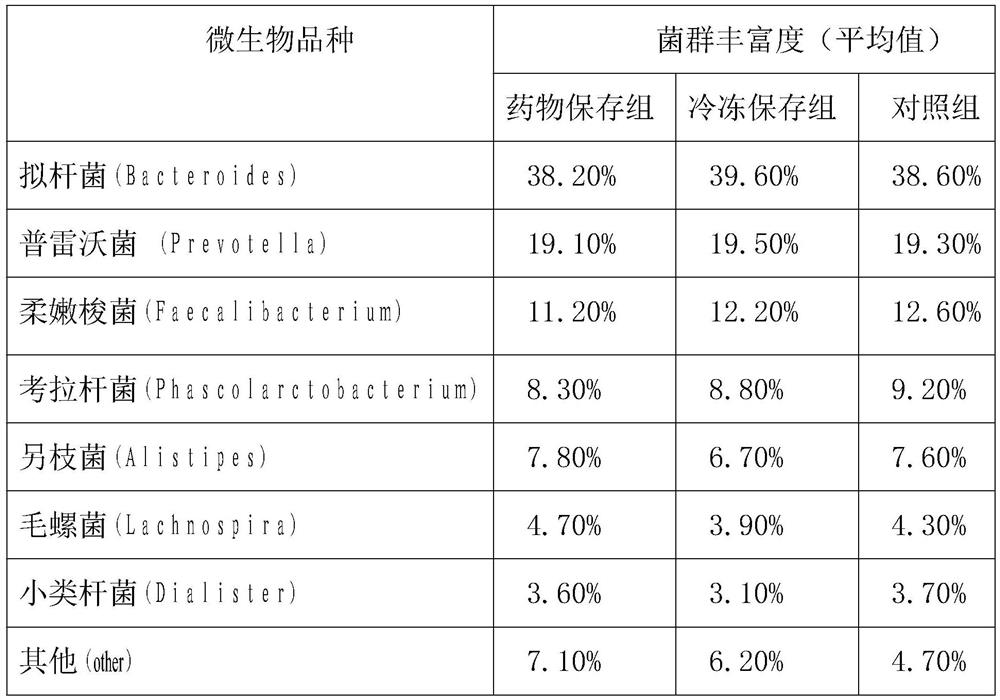

Structure and method for preserving sampling material in gastrointestinal tracts

InactiveCN111631758AStorage stabilityReach preservation levelSurgical needlesVaccination/ovulation diagnosticsPharmaceutical drugCryopreservation

The invention discloses a structure and method for preserving a sampling material in gastrointestinal tracts. The structure comprises a sampling capsule; a wrapping structure is arranged in the sampling capsule; and a medicament is wrapped in the wrapping structure, wherein the interior of the sampling capsule refers to the inner side wall of the capsule, the sampling capsule is pushed to the central position through a support structure, and the wrapping structure is composed of a water-absorption decomposition material, a semi-permeable membrane material or a waterproof material. According tothe invention, the sampling capsule is placed in a simulated gastrointestinal tract device, and experiments show that the flora types and structures of samples sampled in a drug preservation sample group, a cryopreservation sample group and a control group are basically consistent with the flora types and structures of samples which are directly sampled and are refrigerated by a refrigerator, sothat the preservation effect of samples in the sampling capsule is proved.

Owner:WENZHOU FANGZHI BIOTECH

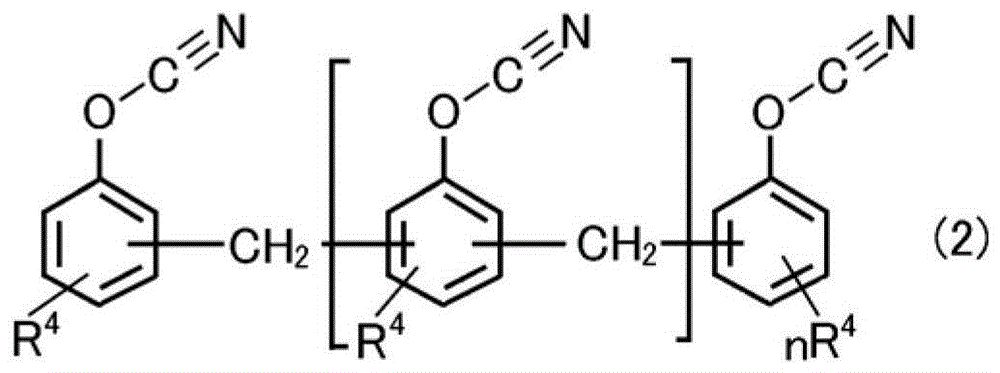

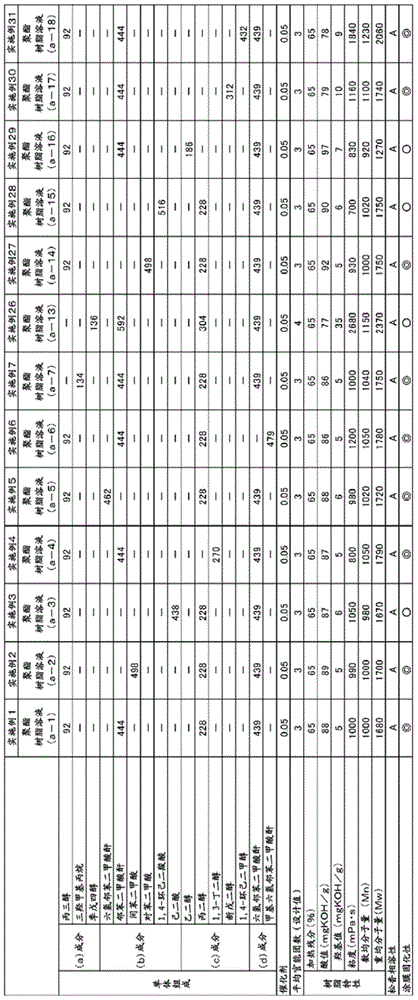

Latent curing agent composition and one-part curable epoxy resin composition

The present invention is a latent curing agent composition comprising (A) an adduct obtained by reacting (a) an amine compound having an active hydrogen group and (b) a polyglycidyl compound, and (B) a curing agent composition for epoxy resin containing phenol resin, characterized in that the phenol resin comprises 10 to 40 mass% of a dikaryon, and the number average molecular weight (Mn) is 900 to 2,000, the weight average molecular weight (Mw) is 2,500 to 5,000, and the molecular weight distribution (Mw / Mn) is 2.0 to 4.0.

Owner:ADEKA CORP

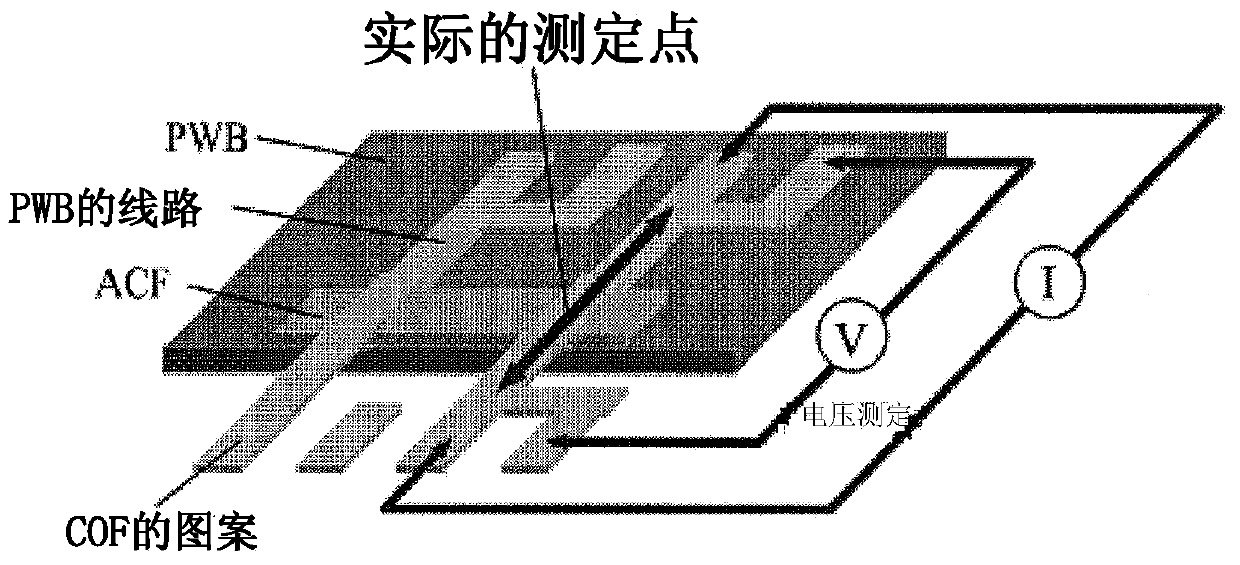

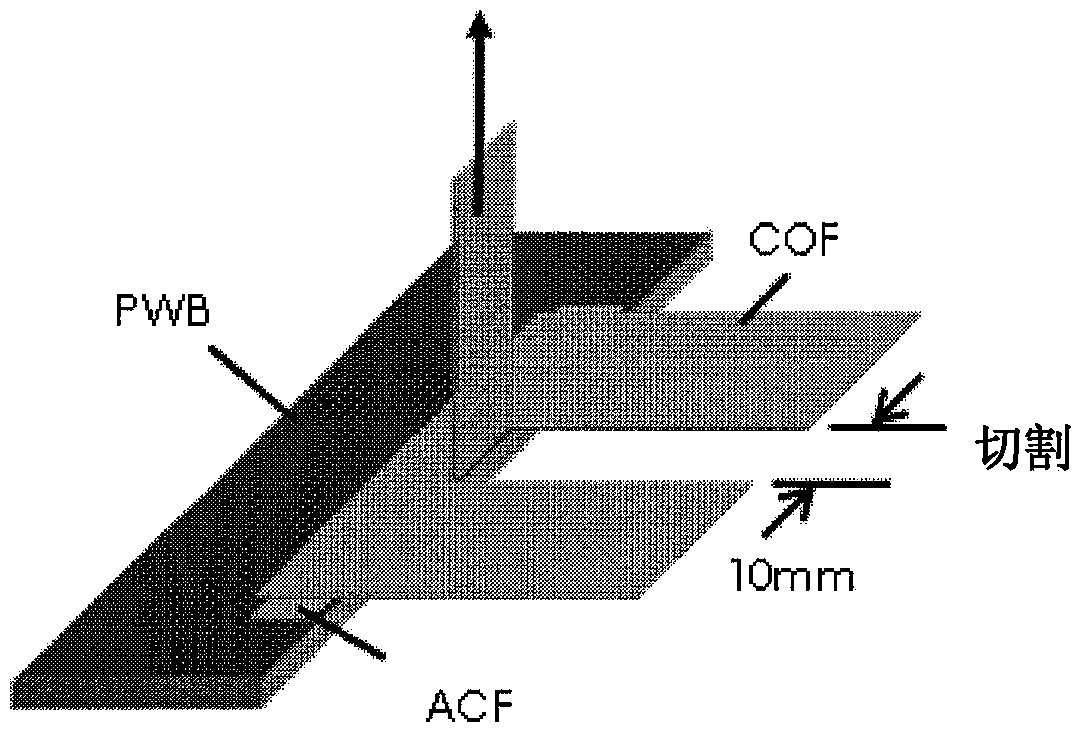

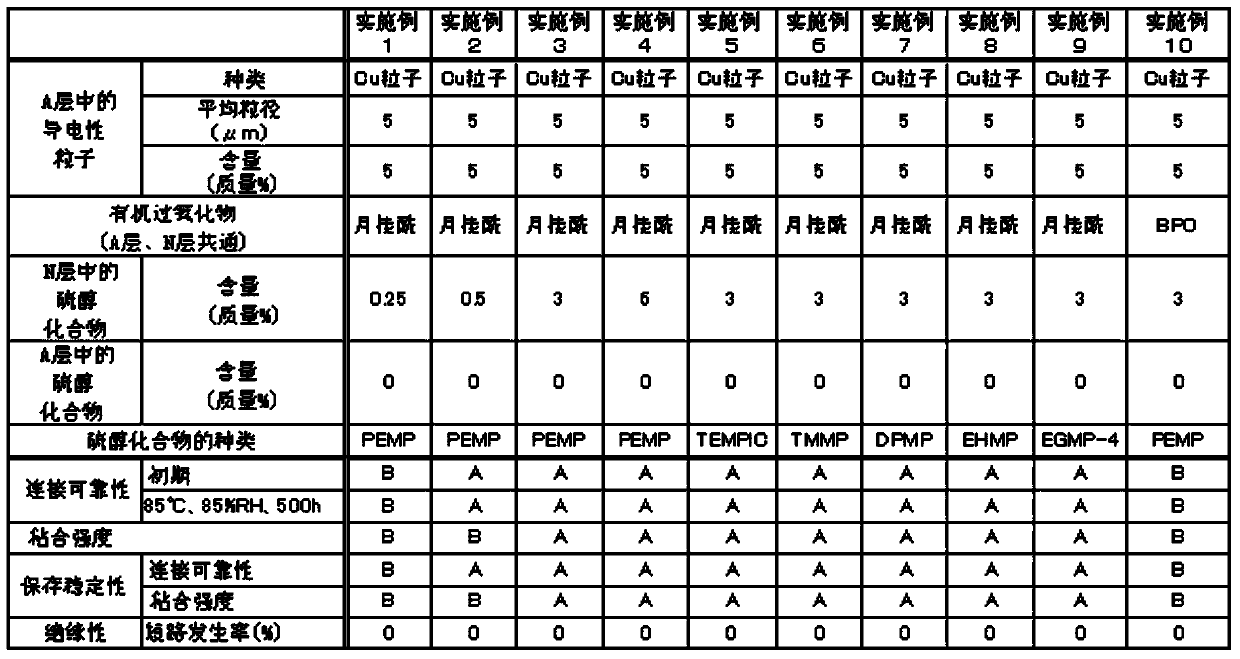

Anisotropic conductive film

ActiveCN103996431AGood connection reliabilityImprove connection reliabilityConductive layers on insulating-supportsNon-macromolecular adhesive additivesComposite materialAnisotropy

The invention discloses an anisotropic conductive film, a connection method and a coalition, comprising a conductive particle layer which comprises conductive electric particles, film forming resin, solidified resin and a curing agent, and an insulation adhesive layer comprising the film forming resin, solidified resin and a curing agent. Only the insulation adhesive layer contains the thiol compounds, and the surface of the conductive particle has Cu.

Owner:DEXERIALS CORP

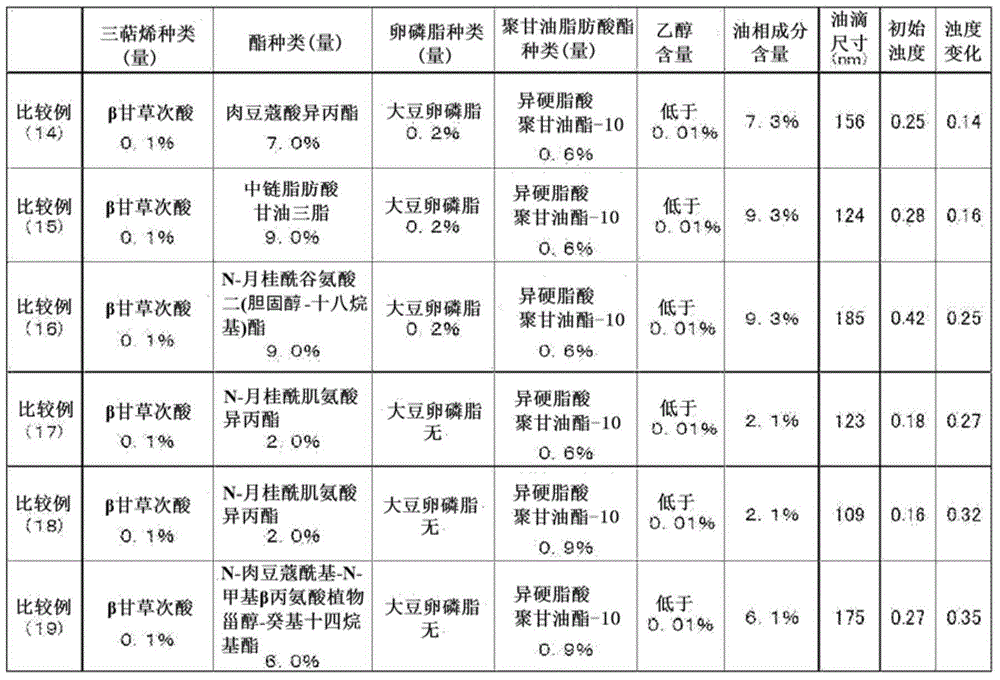

Oil-in-water emulsion composition and use of same

Disclosed is an oil-in-water emulsion composition which contains: an oil phase that contains (a) a pentacyclic triterpene, (b) an N-acylamino acid monoester and (c) lecithin; and an aqueous phase.

Owner:FUJIFILM CORP

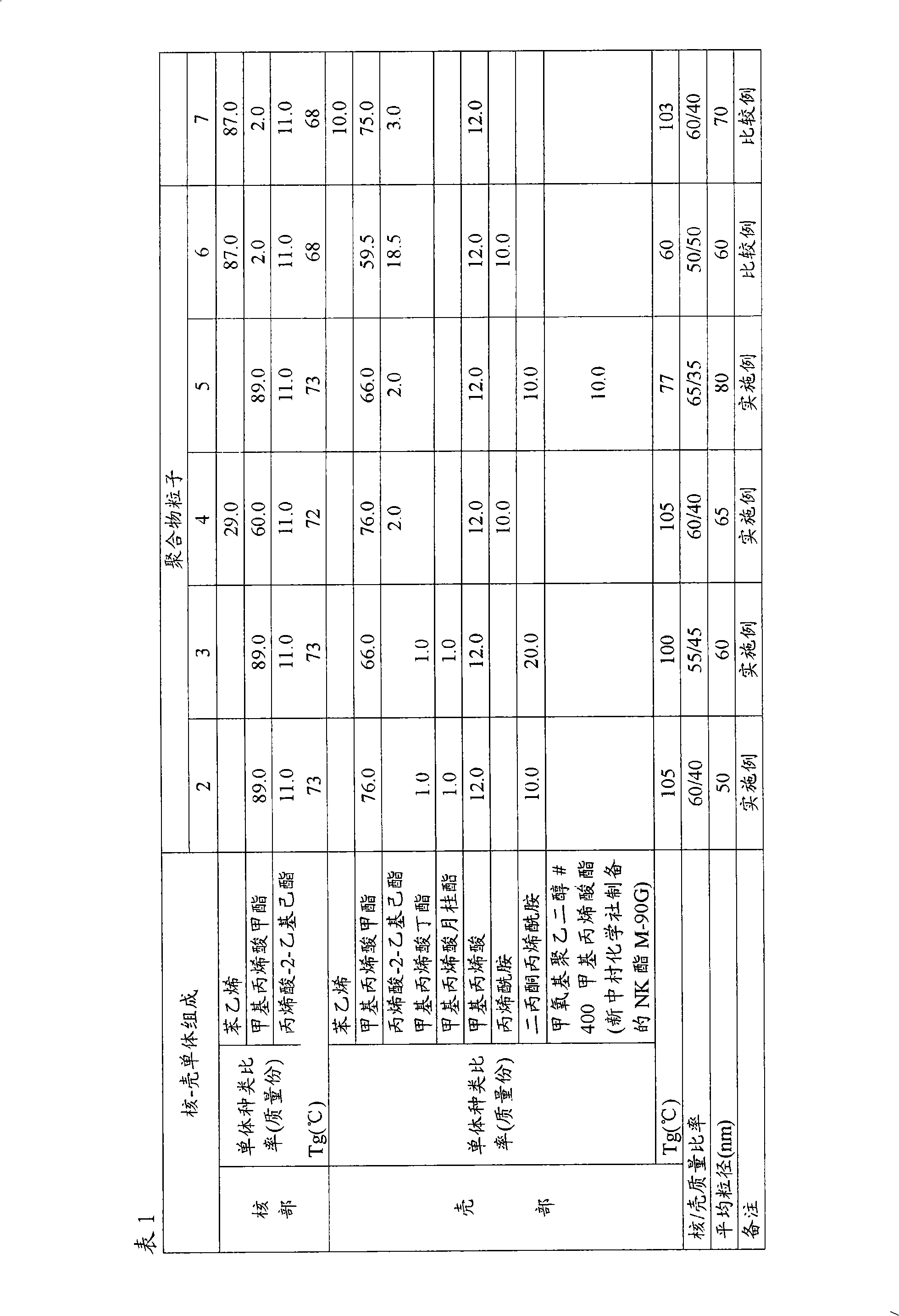

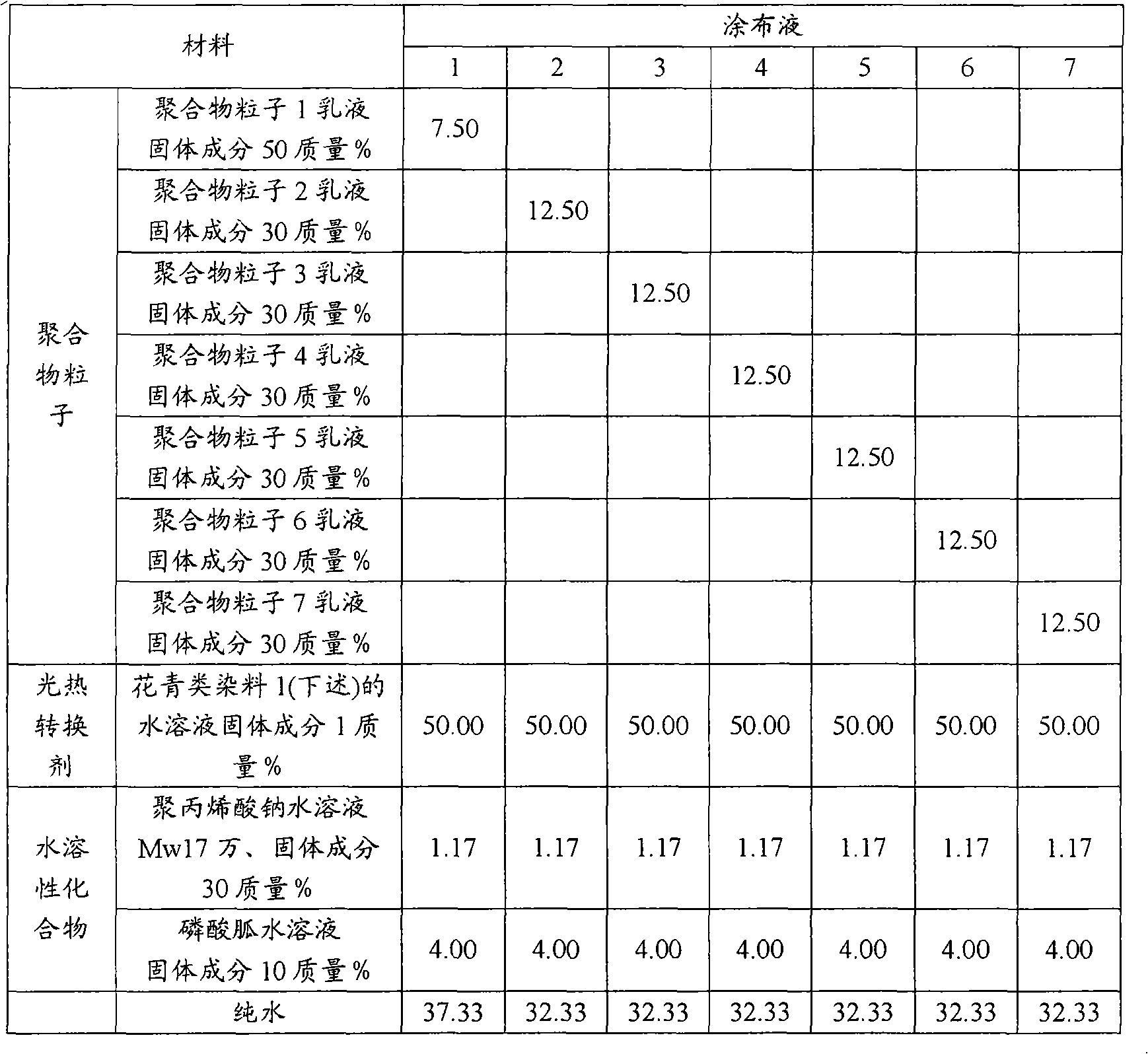

Printing plate material

InactiveCN101573241AExcellent printing resistanceStorage stabilityPlate printingFoil printingVitrificationPolymer science

A printing plate material for use in CTP systems which has high sensitivity and is excellent in printing resistance and storage stability while retaining satisfactory on-press developability. This printing plate material comprises a base and an image-forming layer formed thereon, and is characterized in that the image-forming layer contains the following (A1) or (A2). (A1) Polymer particles having a glass transition temperature (Tg) of 70 DEG C or higher formed by the emulsion polymerization of a polymerizable carboxylated monomer and a polymerizable amidated monomer; (A2) polymer particles having a core / shell structure formed by emulsion polymerization in which the shells of the polymer particles are made of a polymer having a glass transition temperature (Tg) of 70 DEG C or higher obtained by the polymerization of a polymerizable carboxylated monomer and a polymerizable amidated monomer.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

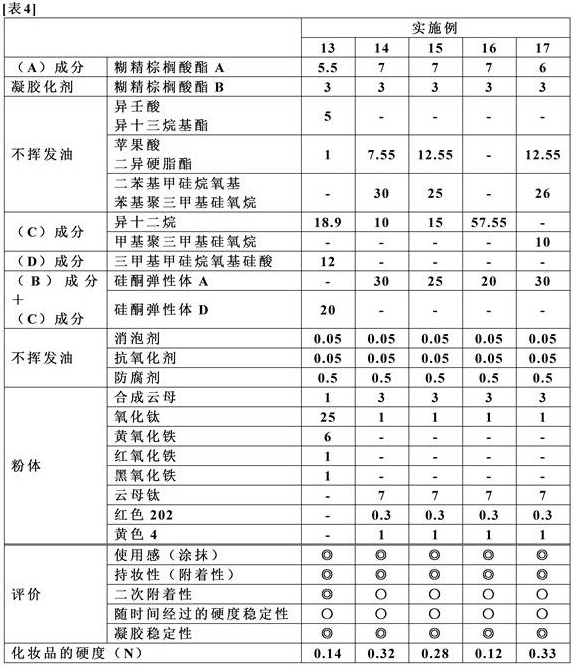

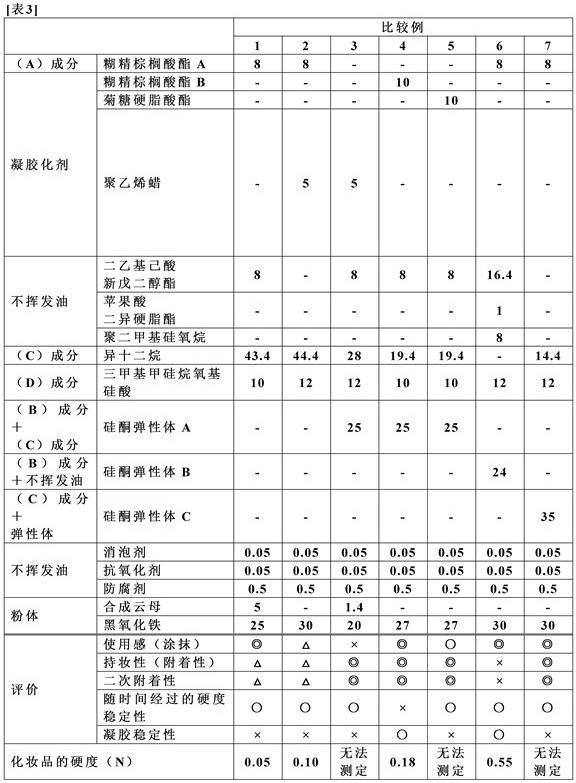

Oil-based gel cosmetic

PendingCN111840129AEase of useMakeup effect is goodCosmetic preparationsMake-upPolymer scienceAcyl group

The present invention provides an oily gel-like cosmetic capable of achieving both an easy-to-apply feeling and good makeup retention and storage stability at a high level. The oil-based gel cosmeticcontains (A) a dextrin fatty acid ester having a degree of acylation of 2.0 or larger, (B) a crosslinked silicone elastomer having an alkyl group with 8 to 30 carbon atoms, and (C) a volatile oil.

Owner:TOKIWA CORP

Inorganic fine particle composite body, method for producing same, composition and cured product

Provided is an inorganic fine particle composite body (M) which is characterized in that a composite resin (A), wherein a polysiloxane segment (a1) having a specific structure and a vinyl polymer segment (a2) are bonded with each other, and inorganic fine particles (m) are bonded with each other at the polysiloxane segment (a1) via a siloxane bond. Also provided are a composition and a hard coat material, each of which contains the inorganic fine particle composite body (M). Also provided are: a cured product which is obtained by curing the composition containing the inorganic fine particle composite body (M); and a laminate which contains the cured product.

Owner:DIC CORP

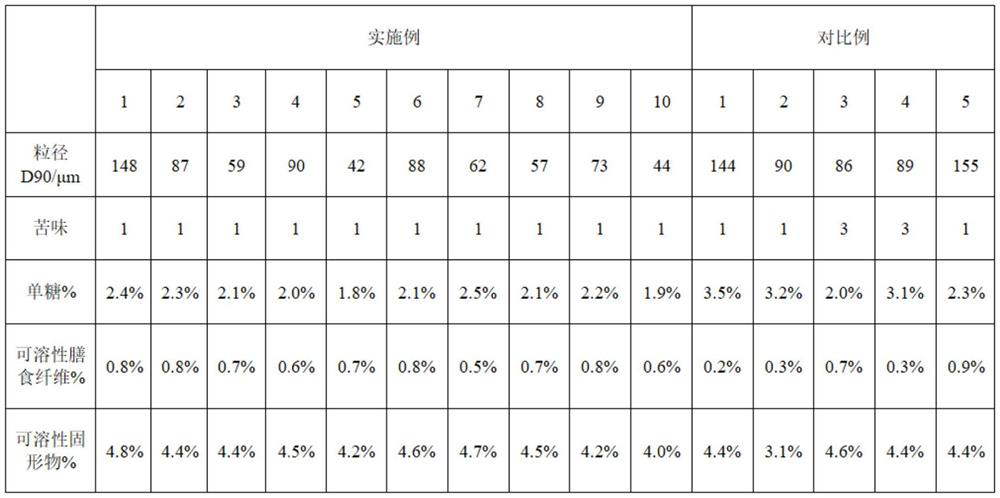

Preparation method and application of corn juice

PendingCN114223822ASource requirements are lowReduce the ratioFood thermal treatmentInorganic compound food ingredientsAmidaseOligosaccharide

The invention relates to a preparation method and application of corn juice, and the preparation method of the corn juice comprises the following steps: a primary enzyme treatment step: enabling crushed corn components to react in the presence of a first enzyme component, the reaction product comprising carbohydrates, and the carbohydrates comprising one or more of monosaccharides or disaccharides; and a secondary enzyme treatment step, in which a product obtained in the primary enzyme treatment step is reacted in the presence of a second enzyme component and a third enzyme component, the second enzyme component converts at least part of monosaccharide and / or disaccharide into oligosaccharide, and the third enzyme component comprises one or more of protein deamidase and excision protease.

Owner:HEILONGJIANG FEIHE DAIRY +2

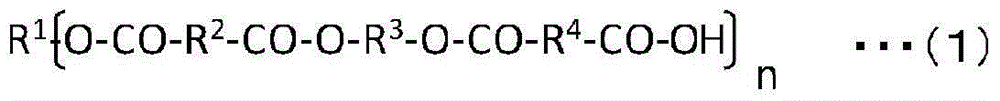

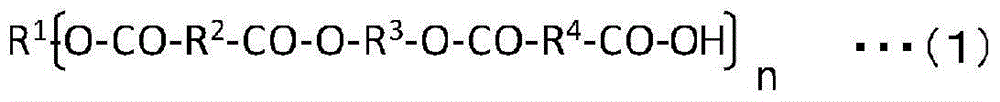

Polyester resin for antifouling coating materials, method for producing same, antifouling coating material composition, antifouling coating film, and antifouling base

ActiveCN104487479AImprove curing effectStorage stabilityAntifouling/underwater paintsRosin coatingsAlcoholPolyester resin

The purpose of the present invention is to provide: a polyester resin for antifouling coating materials, which enables an antifouling coating material to be in a one-pack form by improving storage stability, while maintaining low VOC level, and which is capable of improving curability, while providing long-lasting good antifouling properties and good coating film properties; a method for producing the polyester resin for antifouling coating materials; and an antifouling coating material composition. A polyester resin for antifouling coating materials is obtained by reacting (a) a tri- or higher hydric alcohol, (b) a dibasic acid or an anhydride thereof and (c) a dihydric alcohol, and then reacting the resulting product with (d) an alicyclic dibasic acid or an anhydride thereof.

Owner:CHUGOKU MARINE PAINTS +1

Heat conduction paste

InactiveCN101144007AGood physical propertiesIncrease heat releaseHeat-exchange elementsChemistryThermal conductivity

The invention provides a thermal conductivity paste for screen printing with low viscosity, exothermicity, excellent storage stability and physical property of settability. The thermal conductivity paste is separated into A liquid containing acrylate resin and an epoxy resin hardener and B liquid containing epoxy resin and acrylate resin hardener. A thermally conductive filler is blended with one side or both sides of said A liquid and B liquid at a rate of 100 to 1000 weight section to total amount 100 weight section of said acrylate resin and an epoxy resin and the thermally conductive paste obtaining by mixing at a rate that a rate of a compounding ratio of said acrylate resin and an epoxy resin (however, weight %) is set to 10:90-90:10 before using said A liquid and B liquid.

Owner:TATSUTA ELECTRICWIRE & CABLE

Composition for lining

InactiveCN107835736ALow viscosityEasy to operateSynthetic resin layered productsCoatingsVinyl esterOrganic chemistry

The present invention addresses the problem of providing a composition for lining, which is capable of solving problems such as an environmental problem of marine pollution and a problem of VOC, whilehaving a good curing speed. It is found that the above-described problem is able to be solved by a composition which contains a vinyl ester resin as a prepolymer, while containing an aliphatic or alicyclic polyfunctional allyl ester compound as a crosslinking agent.

Owner:OSAKA SODA CO LTD

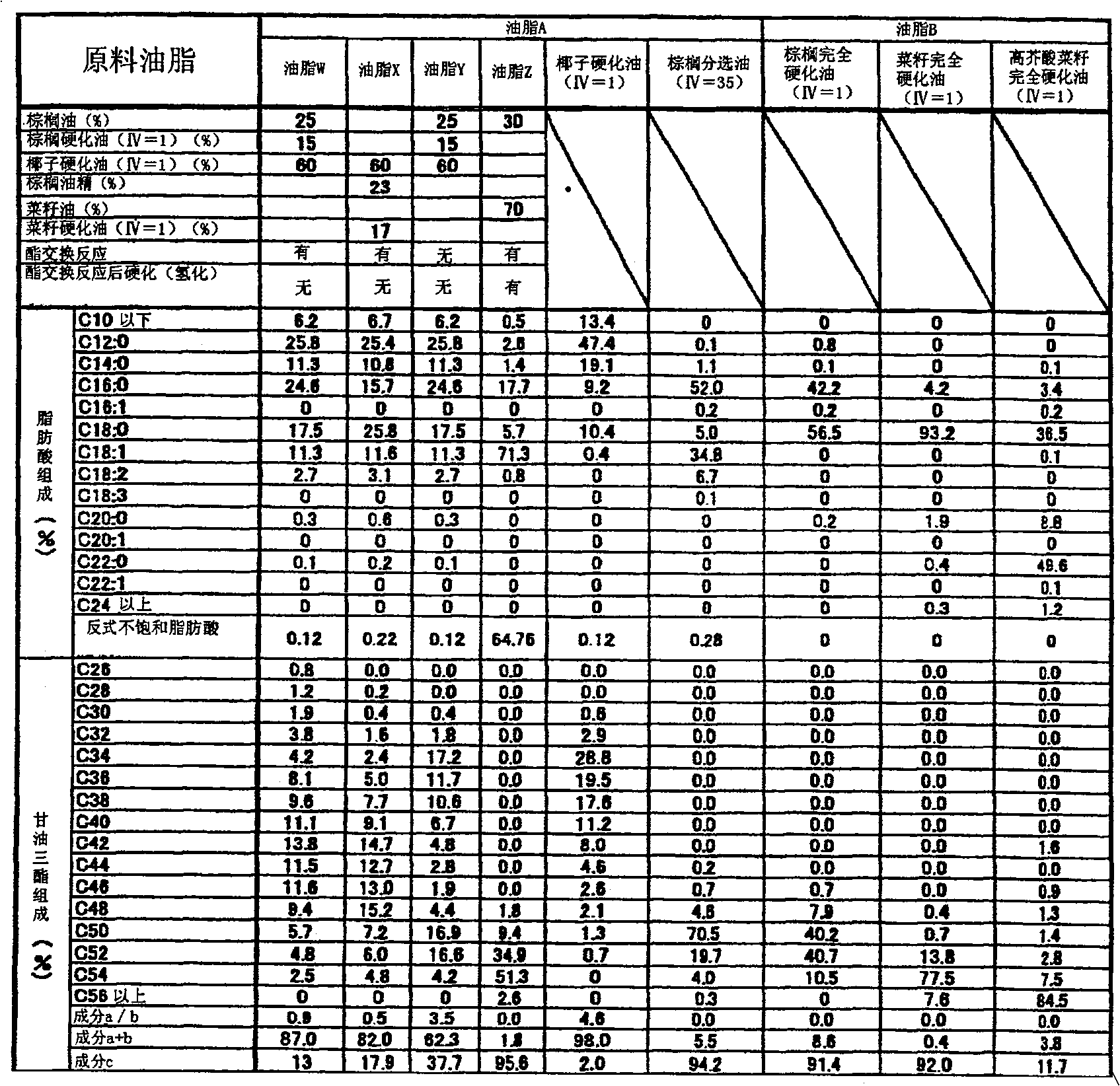

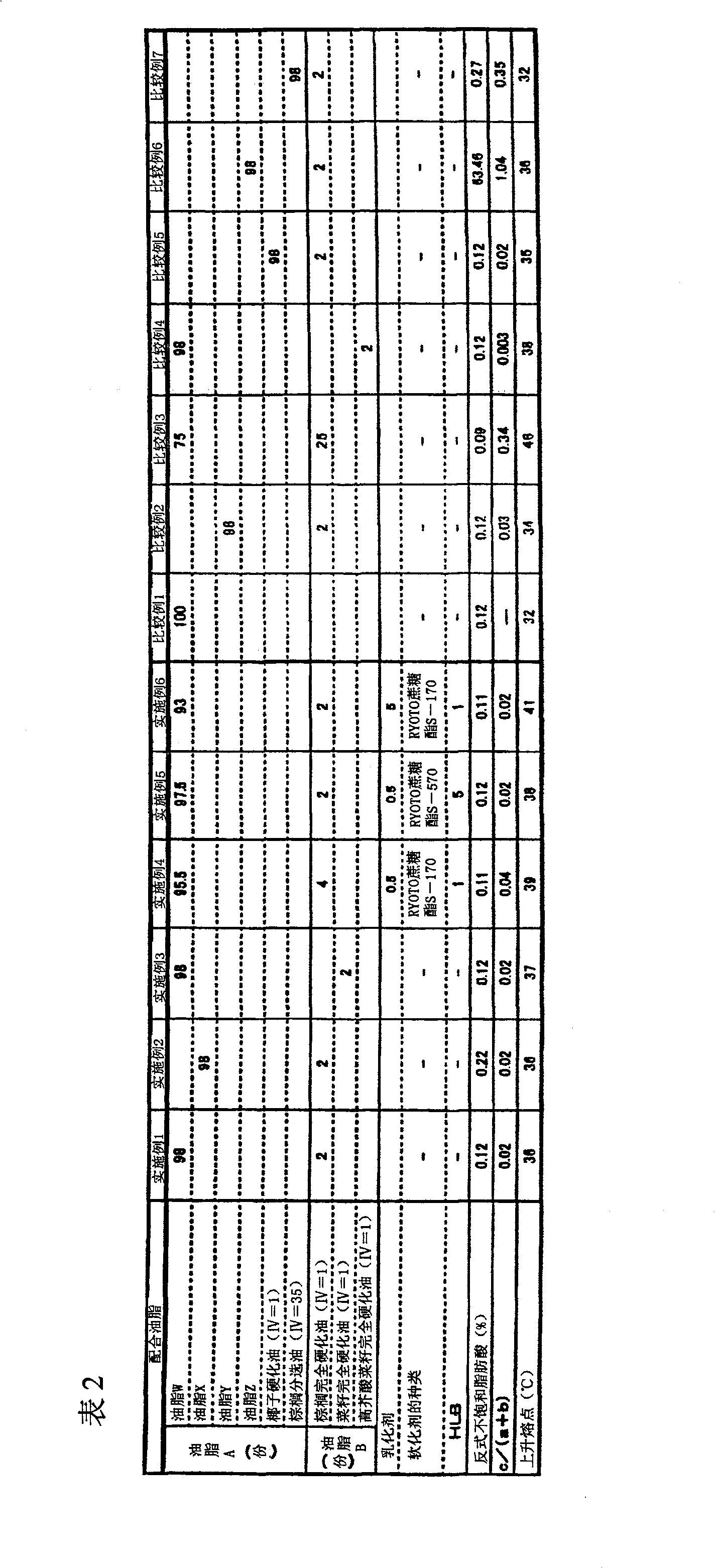

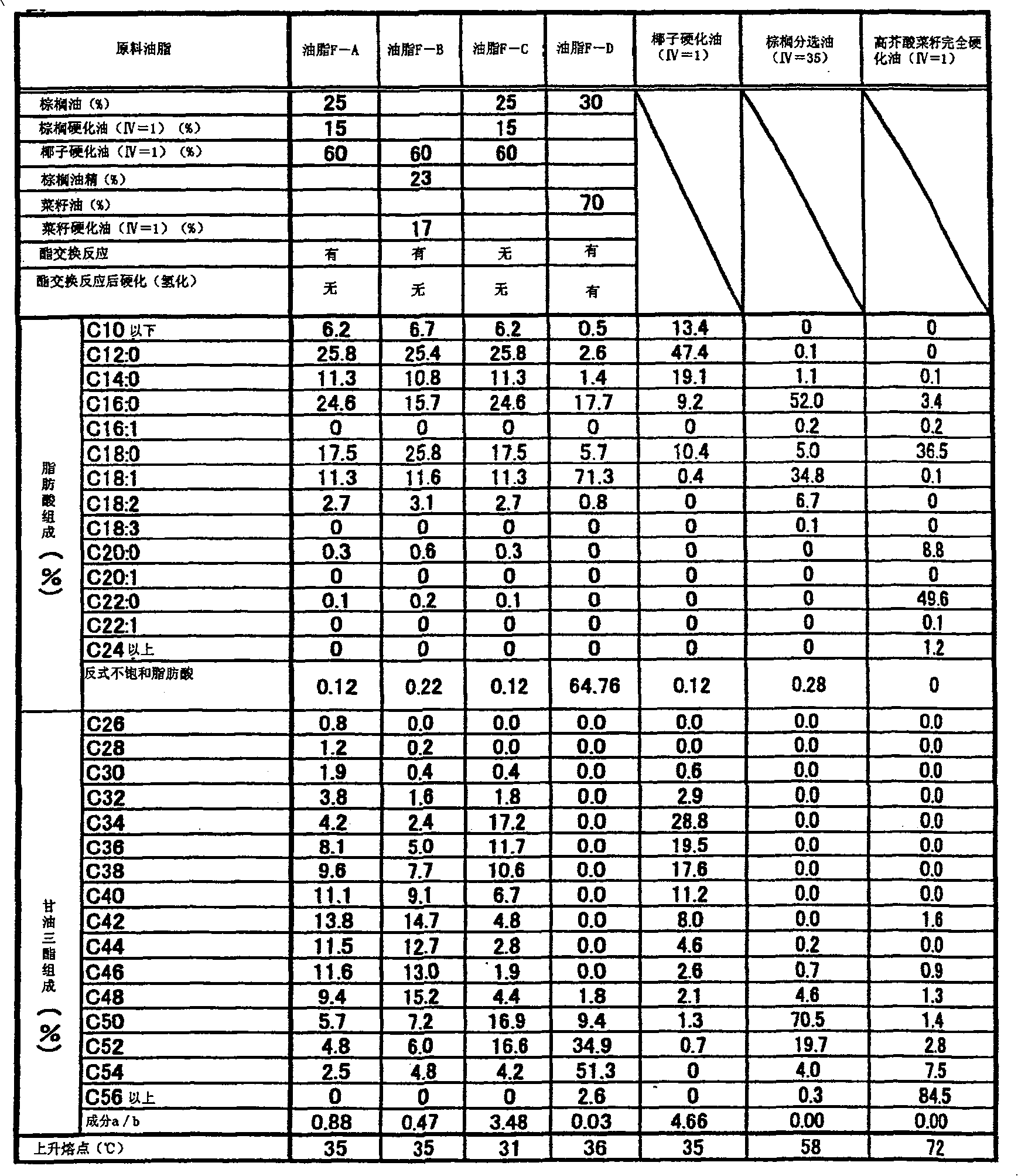

Hard fat and chocolate

ActiveCN101926391BFull hardnessStorage stabilityConfectionerySweetmeatsTriglycerideLipid composition

The invention provides hard fat comprising a lipid composition and chocolate comprising the hard fat. The lipid composition comprises lipid A and lipid B. Trans unsaturated fatty acids account for 5% in mass of all the fatty acids composed of lipid. Mass ratio of components a and b in lipid A to component c in lipid B is shown in following formula: c / a+b=0.001-0.3. Referring to lipid A: (1) in the composing fatty acids, saturated fatty acids with number of carbon atom less than 14 account for 25-60% in mass, and saturated fatty acids with carbon atom number more than 20 account for less than 1% in mass, (2) in triglyceride of the fatty lipid, mass ratio of triglyceride (component a) with number of carbon atoms composing the fatty acid being less than 40 to triglyceride (component b) with number of total carbon atoms composing the fatty acid being 42-48 is shown in the following formula: a / b=0.2-1; referring to lipid B: (3) in the composing fatty acids, saturated fatty acids account for 95% in mass, and fatty acids with carbon number more than 20 account for less than 5% in mass, (4) in triglyceride of lipid, triglyceride with number of carbon atom composing the fatty acids being 50-54 account for 80% in mass.

Owner:KAO CORP

Photo-cured heat-cured resin composition and printed circuit board produced with the same

ActiveCN101320212BExcellent developabilityAvoid inactivationPhotomechanical apparatusPrinted circuit manufacturePolymer scienceAcyl group

A light-curing thermo-curing resin composition and a printed circuit board obtained using the same are provided, the composition has high light sensitivity and excellent curing depth in ultraviolet ray and laser exposure, thus further having great developing ability to pass through diluted alkaline aqueous solution while being excellent in storage stability and operability, so the composition is suitable for solder resisting agent. The light-curing thermo-curing resin composition comprises (A) carboxyl-containing resin, (B) mercaptobutyric acid or derivatives thereof, (C) photopolymerization initiator, (D) compounds having 2 or more of olefinic unsaturated groups in the molecules, and (E) thermo-curing components. The suitable (A) carboxyl-containing resin is preferably the carboxyl-containing resin capable of free radical polymerization and having unsaturated double bond. In addition, the (C) photopolymerization initiator is preferably oximes photopolymerization initiator (C1), particularly preferably proxetil photopolymerization initiator, aminoacetophenone photopolymerization initiator and / or acyl phosphine oxide photopolymerization initiator.

Owner:TAIYO HLDG CO LTD

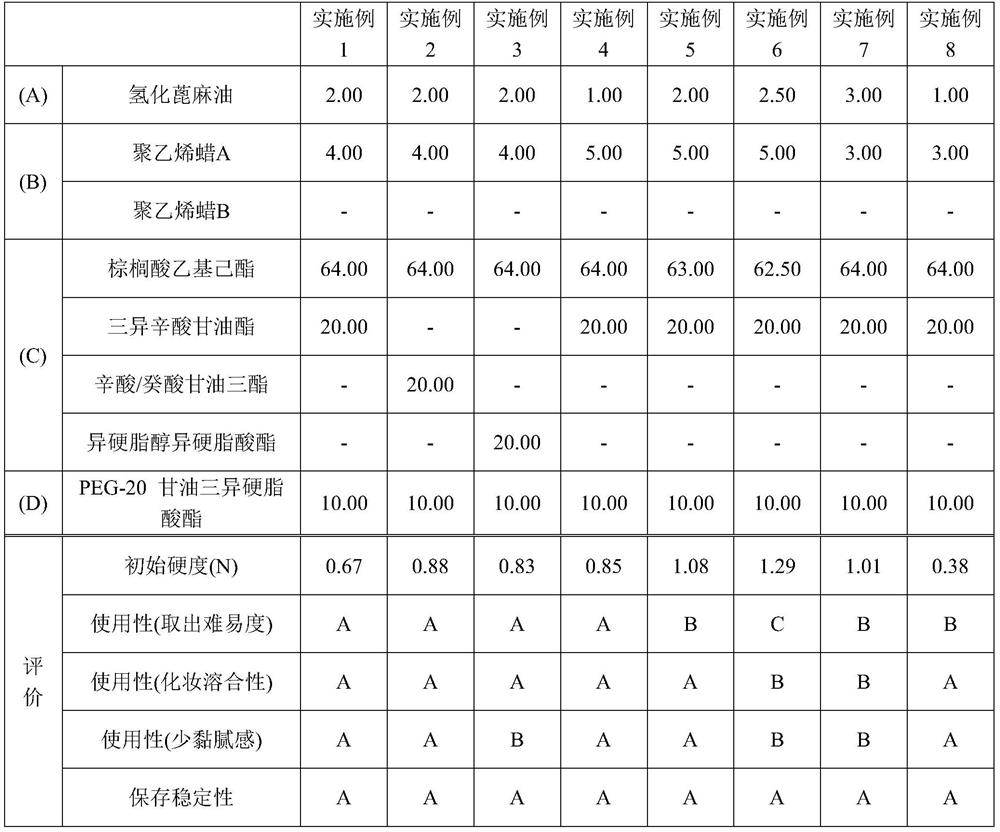

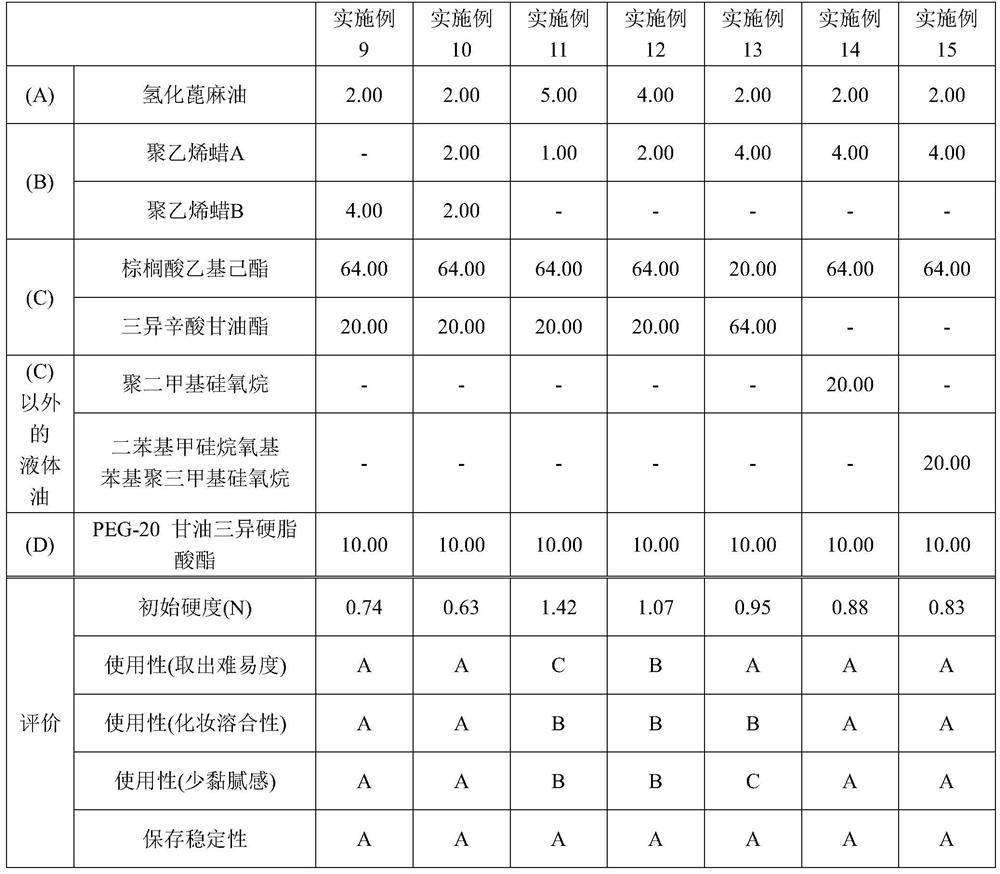

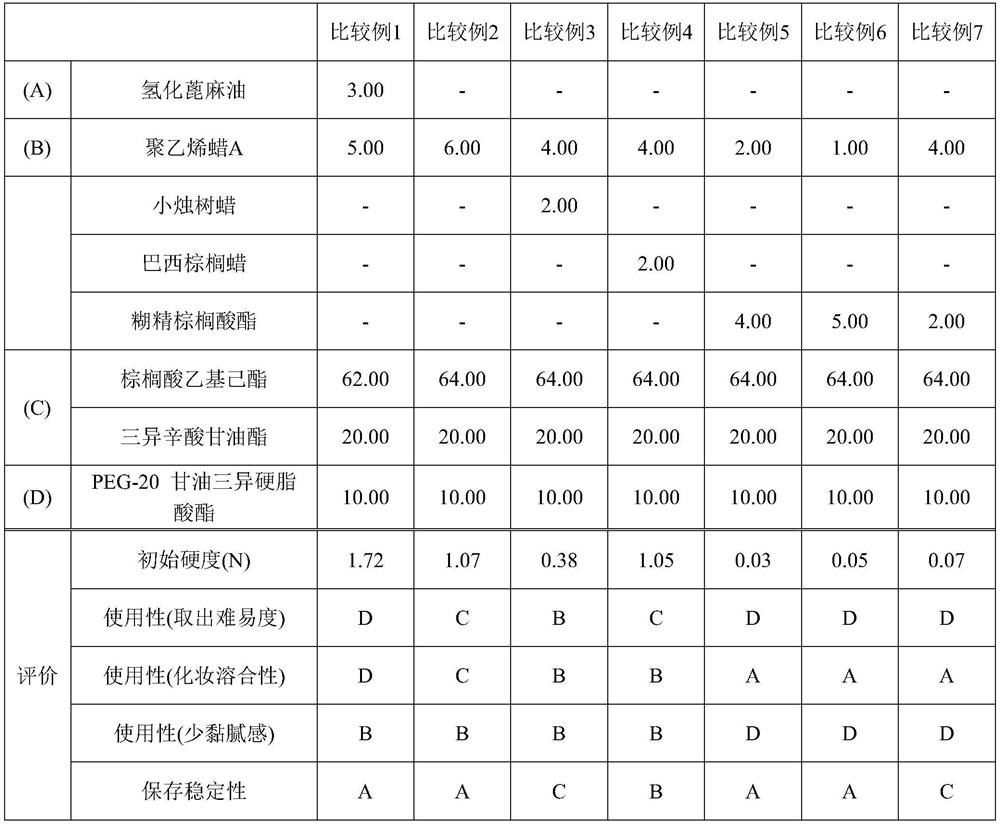

Oily solid cleansing cosmetics

The present invention provides oily solid cleansing cosmetics containing: (A) hydrogenated castor oil; (B) hydrocarbon wax; (C) ester oil with a viscosity of 50 mPa*s or less at 25 DEG C; and (D) nonIonic surfactant. The content of (A) component is 1 to 5% by mass, the content of (B) component is 1 to 5% by mass, the content of (C) component is 60% by mass or more, (A) component and (B) The totalcontent of the components is 4 to 7.5% by mass.

Owner:TOKIWA CORP

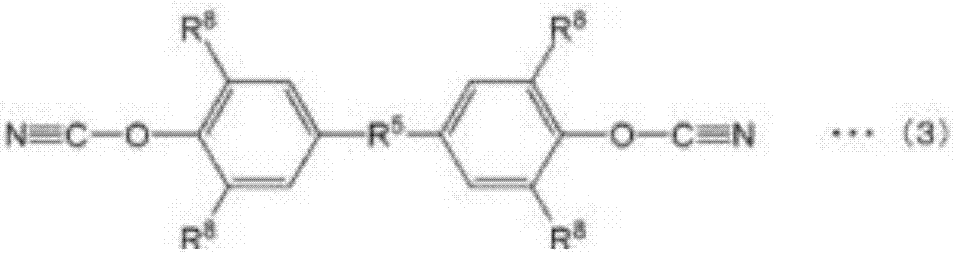

Heat-curable resin composition

To provide a heat-curable resin composition which is rapid-curing while having excellent storage stability, peeling resistance and bendability, and which makes it possible to fix neodymium magnets in a stable manner, even after durability testing. A heat-curable resin composition containing components (A) to (D) below, wherein the content of component (D) with respect to the total of components (A), (B) and (D) falls within the range of 10-45 mass%. Component (A): epoxy resin. Component (B): cyanate ester resin. Component (C): hardener. Component (D): polyol compound having a viscosity not exceeding 50000mPa.s in an atmosphere of 25 DEG C.

Owner:THREE BOND CO LTD

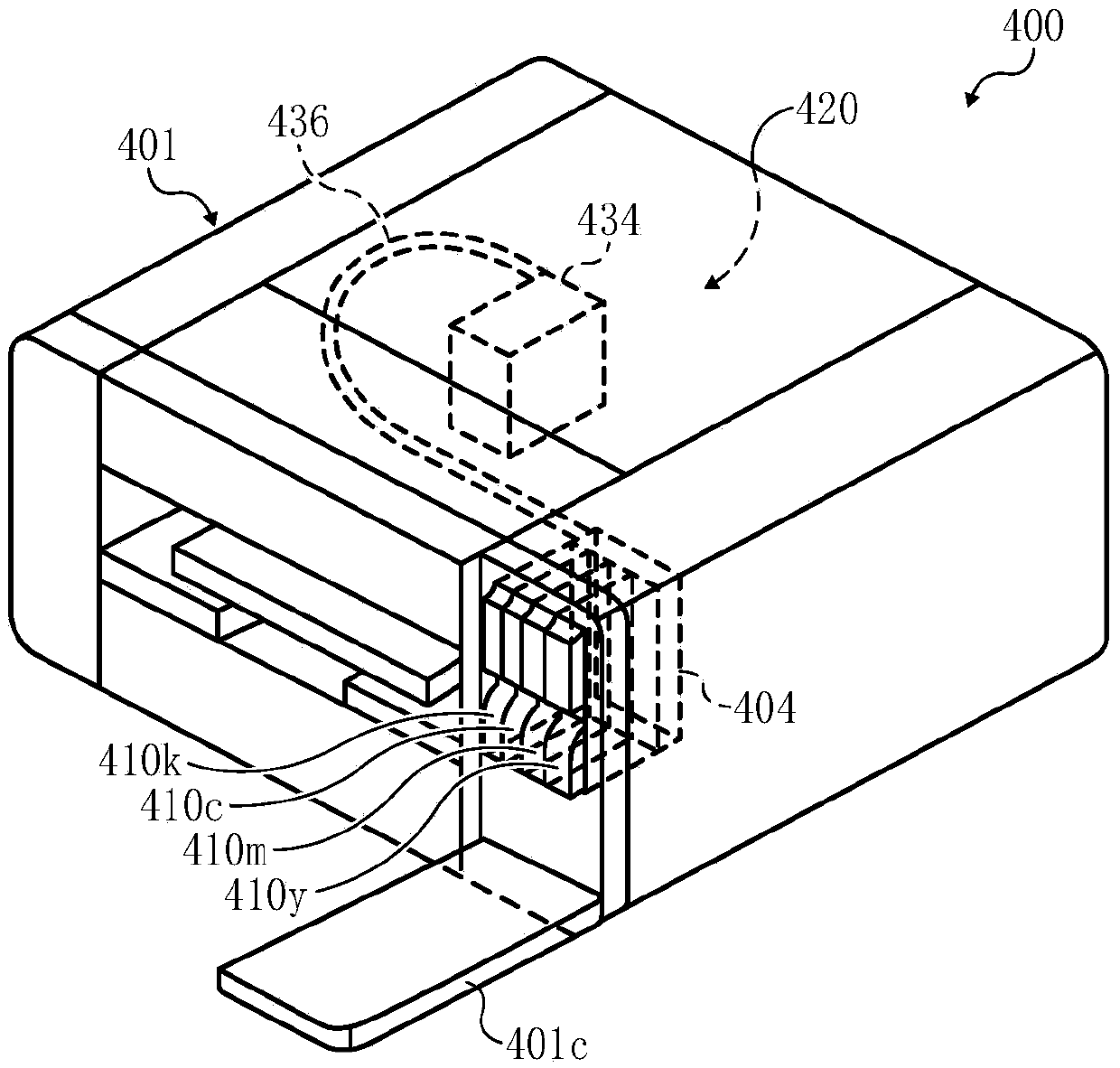

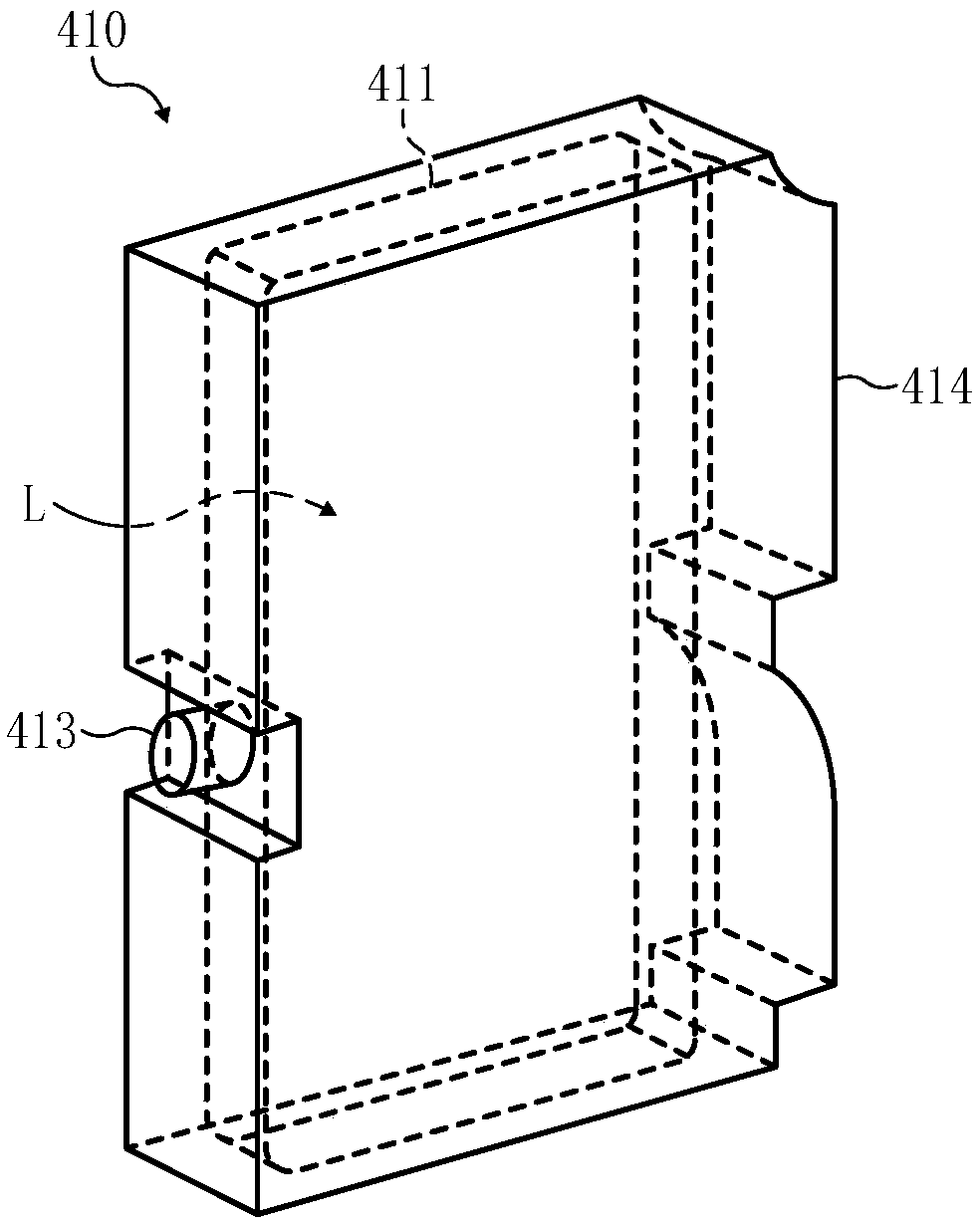

Ink, ink accommodation container, image formation method, and image formation device

The invention relates to an ink, an ink accommodation container, an image formation method and an image formation device. To overcome a situation that there are each proposals for improving one of image concentration, storage stability and beading, but image concentration, storage stability and beading cannot be improved by each proposals. The ink contains water, a coloring material and a copolymer, in which the copolymer has a constitutional unit of styrene and a constitutional unit having a naphthyl group or a biphenyl group.

Owner:RICOH KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com