Heat-curable resin composition

A resin composition, thermosetting technology, applied in the field of thermosetting resin composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0094] Embodiments of the present invention are exemplified below.

[0095] 1. A thermosetting resin composition containing the following (A) to (D) components, and relative to the total of the following (A) component, the following (B) component, and the following (D) component, containing 10 to 45% by mass of the following (D) component,

[0096] (A) component: epoxy resin;

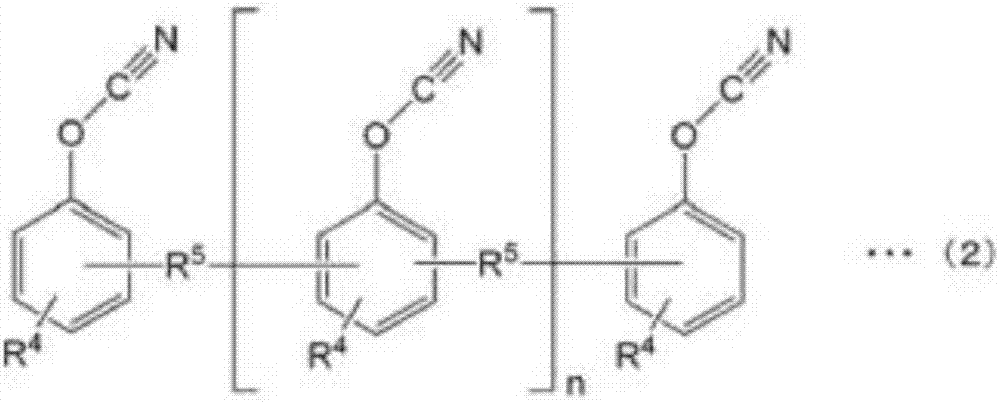

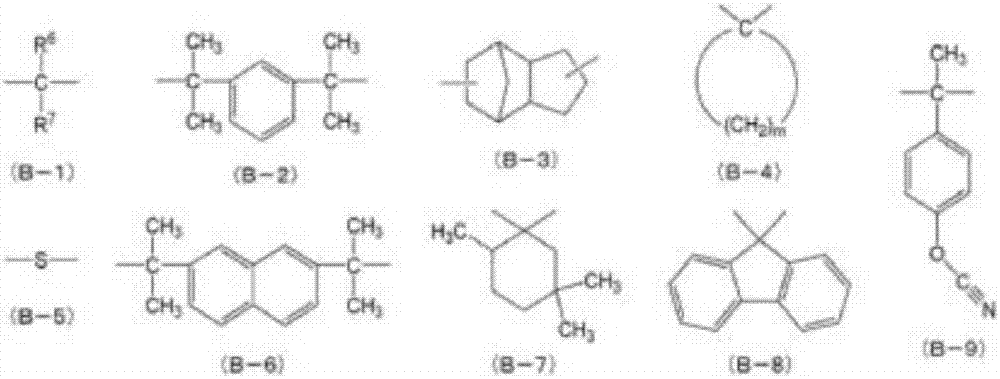

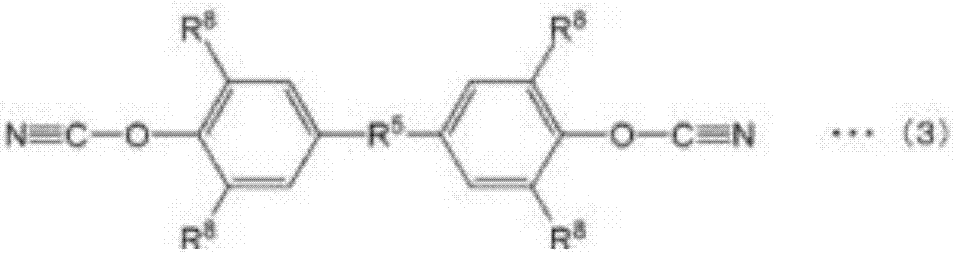

[0097] (B) component: cyanate resin;

[0098] (C) component: curing agent;

[0099] (D) component: the polyol compound whose viscosity in 25 degreeC atmosphere is 50000 mPa*s or less.

[0100] 2. The thermosetting resin composition as described in said 1 further containing an organic filler as (E) component.

[0101] 3. The thermosetting resin composition according to 1 or 2 above, wherein the component (C) includes a curing agent comprising a modified amine compound and a phenolic resin of the component (C1) below, and ( C2) A curing agent made of a modified amine compound and a phenolic resin,

...

Embodiment 1~13、 comparative example 1~5

[0119] In order to prepare the thermosetting resin composition of Examples 1-13 and Comparative Examples 1-5, the following components were prepared (Hereinafter, a thermosetting resin composition is also simply called a composition).

[0120] (A) component: epoxy resin

[0121] ・Bisphenol A type and F type mixed epoxy resin (EXA-835LV DIC Co., Ltd.) (hereinafter referred to as EP.)

[0122] (B) Component: Cyanate resin

[0123] ・1,1-bis(4-cyanatophenyl)ethane (hereinafter referred to as CY.)

[0124] (C) Component: curing agent

[0125] ・Preparation of the first curing agent made of modified amine compound and phenolic resin containing the component (C1): put 130 g of N,N-dimethylaminopropylamine in the flask, keep it at 80°C, Secondary addition of bisphenol A type epoxy resin (EP-4100E manufactured by ADEKA Co., Ltd., epoxy equivalent 190) 213g ([bisphenol A type epoxy resin relative to the epoxy equivalent of 1 mole of N,N-dimethylaminopropylamine 1.12]). After adding ...

Embodiment 7~13、 comparative example 5

[0174] In order to prepare the composition of Examples 7-13 and the comparative example 5, after stirring the said (A) component, (B) component, and (D) component (or (D') component) for 15 minutes, add (E) component, Stir for a further 15 minutes. Finally, (C)component was added, and it stirred for 30 minutes. The detailed preparation amount is according to Table 3, and all numerical values are expressed in parts by mass.

[0175] table 3

[0176]

[0177]

[0178] Regarding the compositions of Examples 1, 7 to 13 and Comparative Examples 4 and 5, 90° C. curing time measurement, peel resistance confirmation, and flexibility confirmation were performed. The results are summarized in Table 4 below.

[0179] [Confirmation of peel resistance]

[0180] On an aluminum plate (A1050P) of width 25 mm x length 100 mm x thickness 0.5 mm, the composition was applied so as to be width 10 mm x length 30 mm x thickness 1 mm. Then, the composition was left to stand for 1 hour in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com