Patents

Literature

549 results about "Diacrylate ester" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

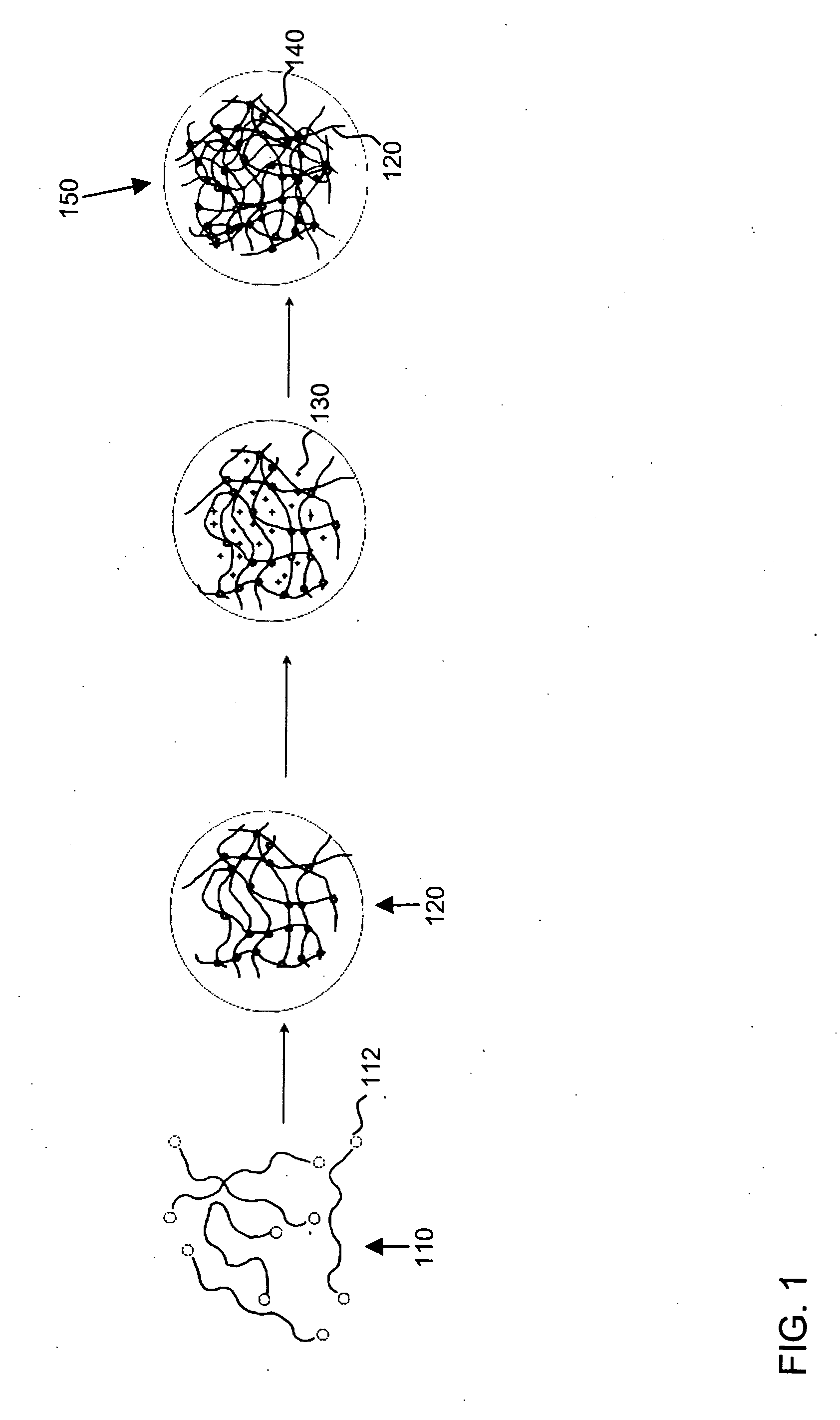

Efficient microencapsulation

InactiveUS20110223314A1Increase radiusChannel widthMixersPharmaceutical containersPolymer scienceDiacrylate ester

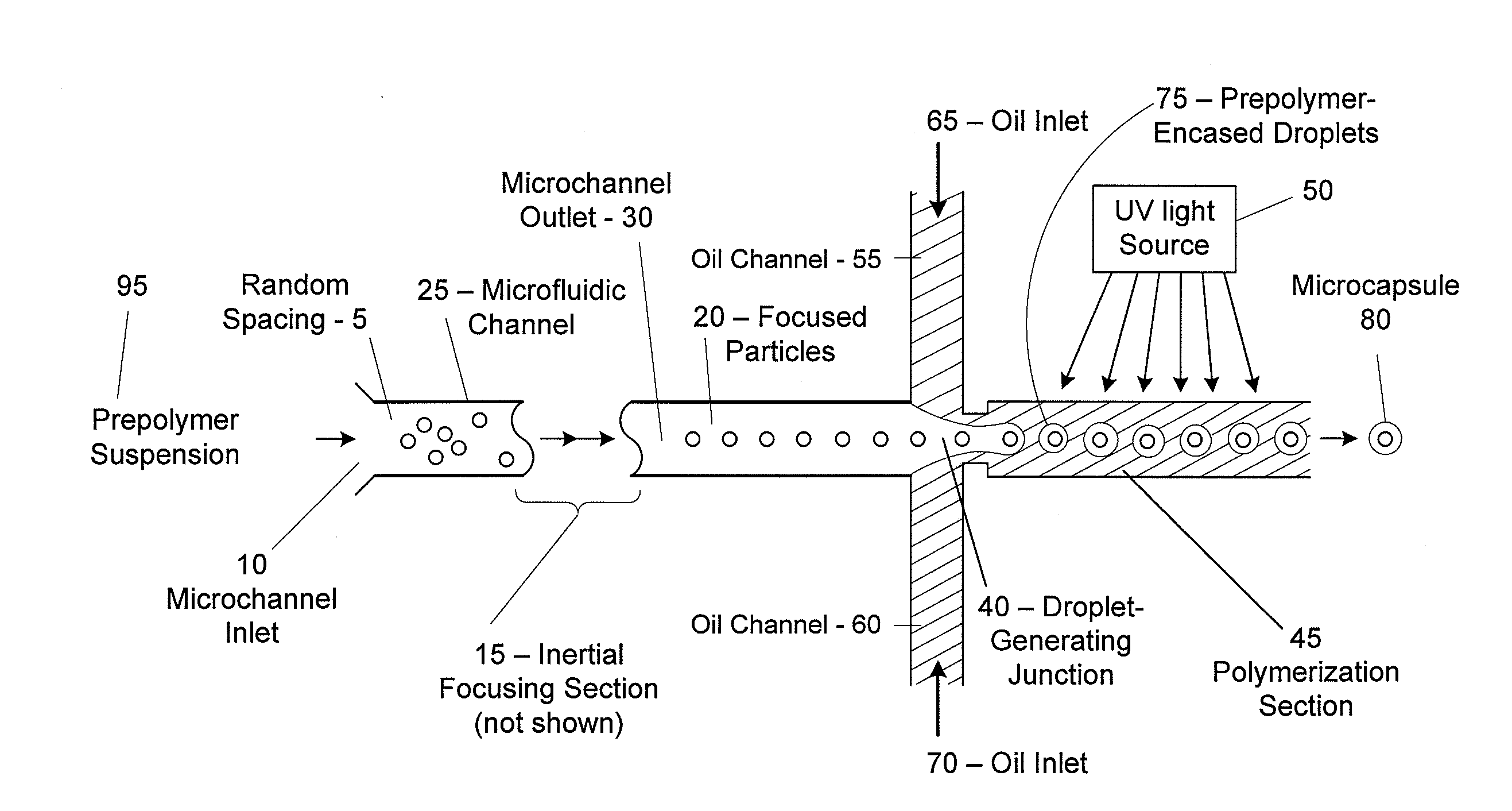

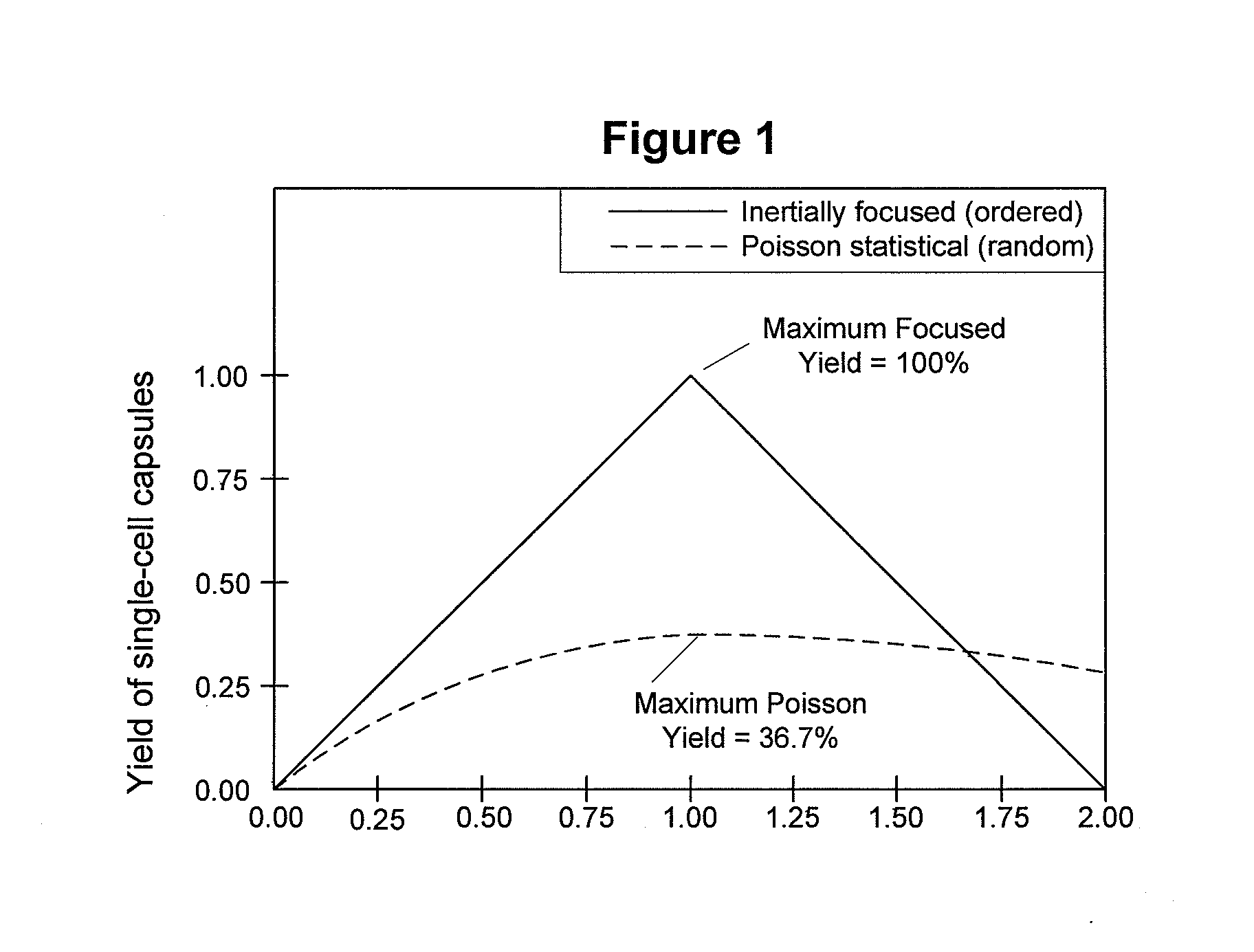

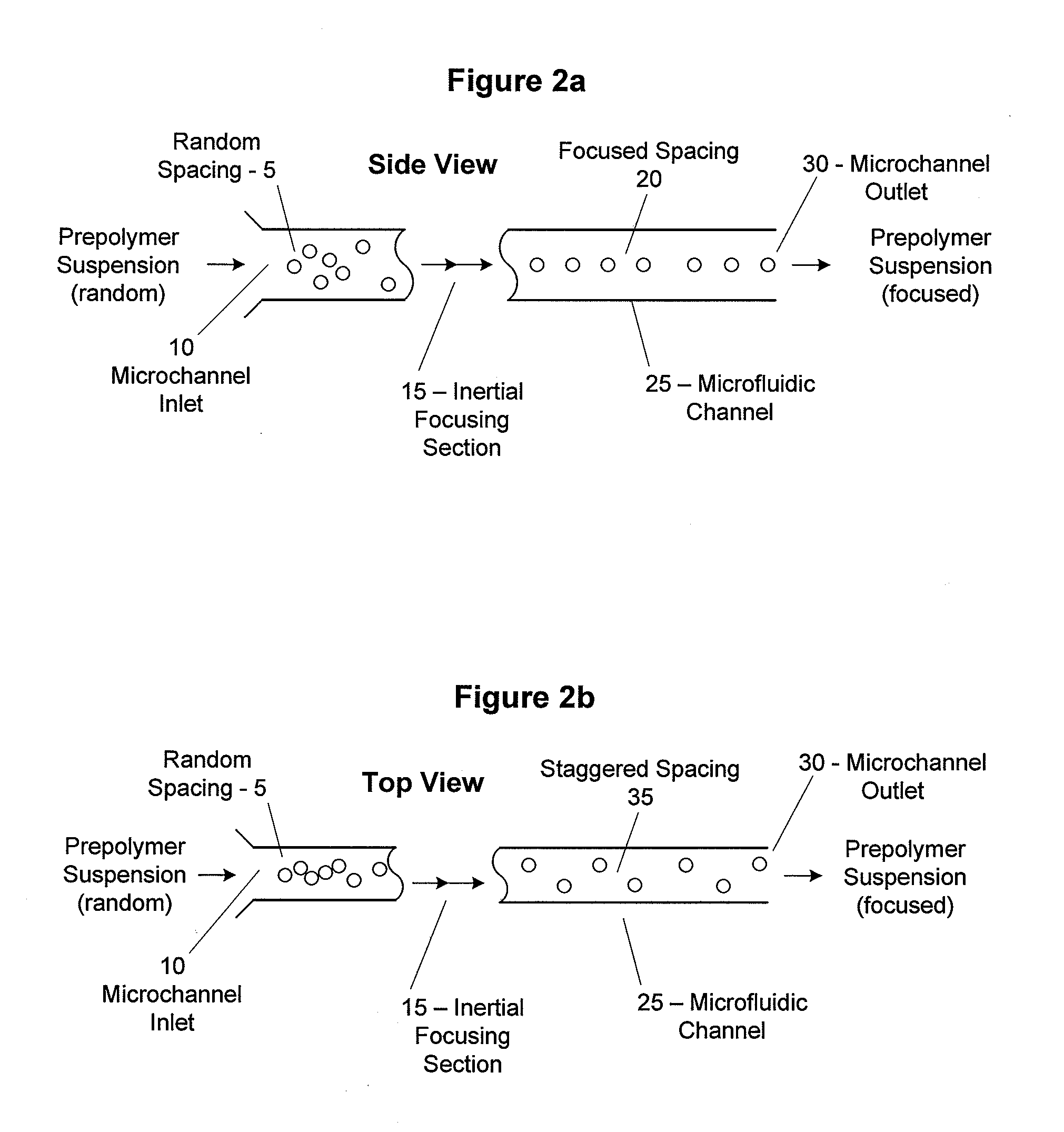

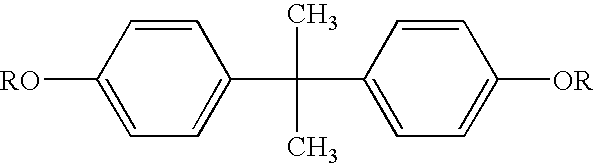

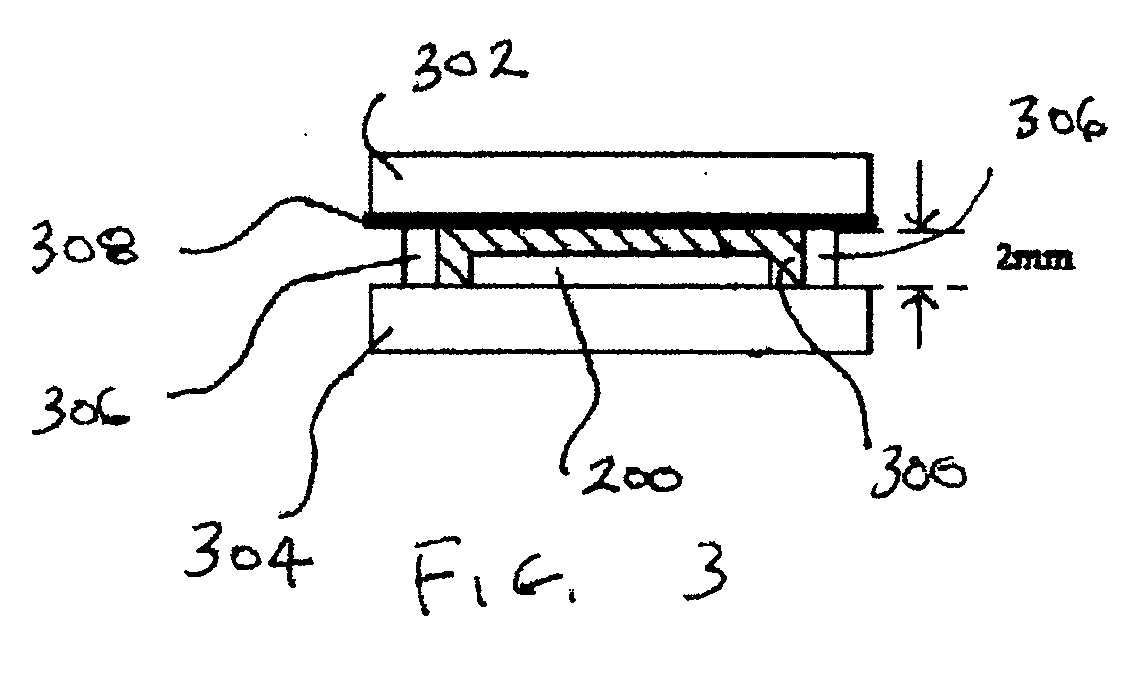

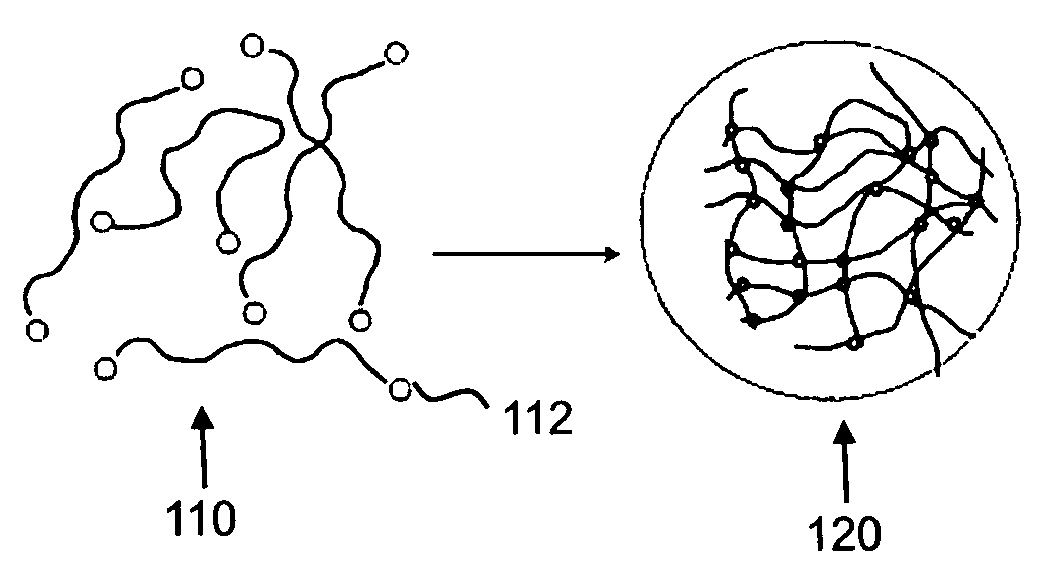

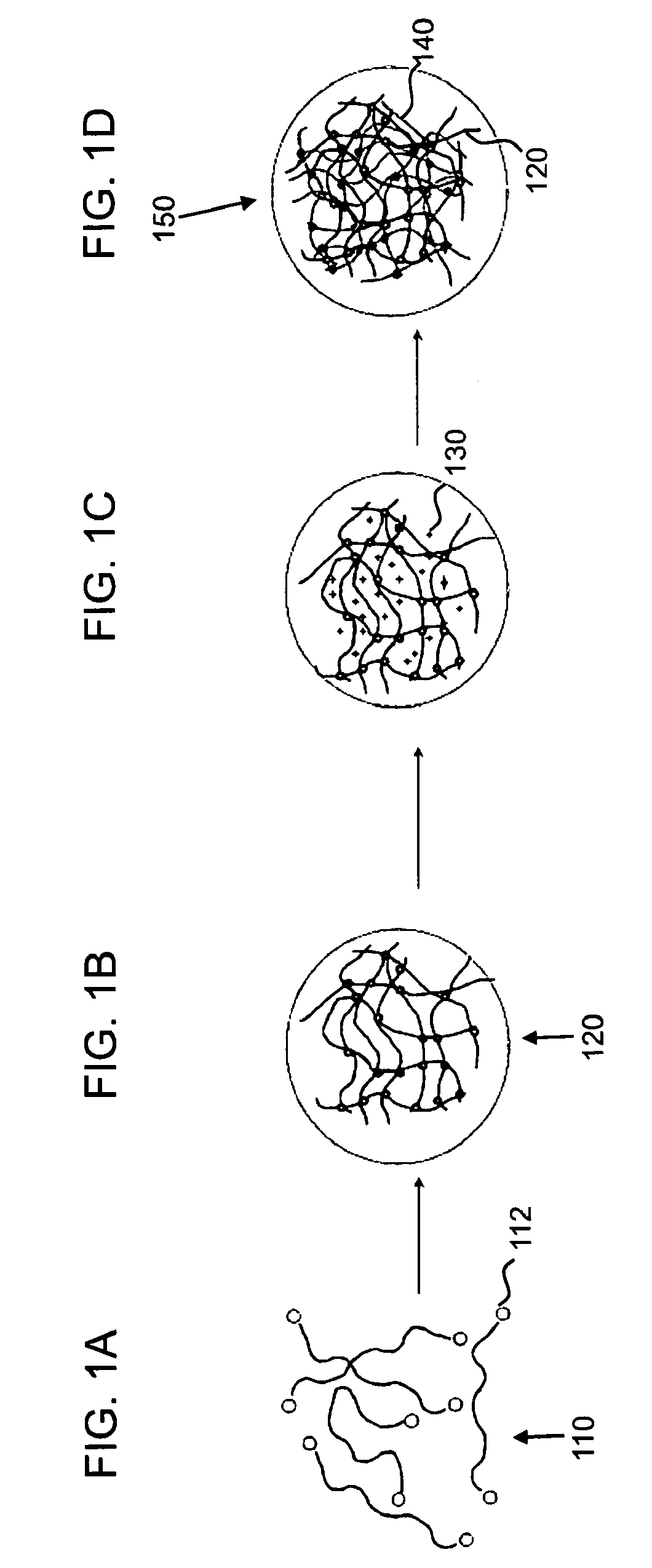

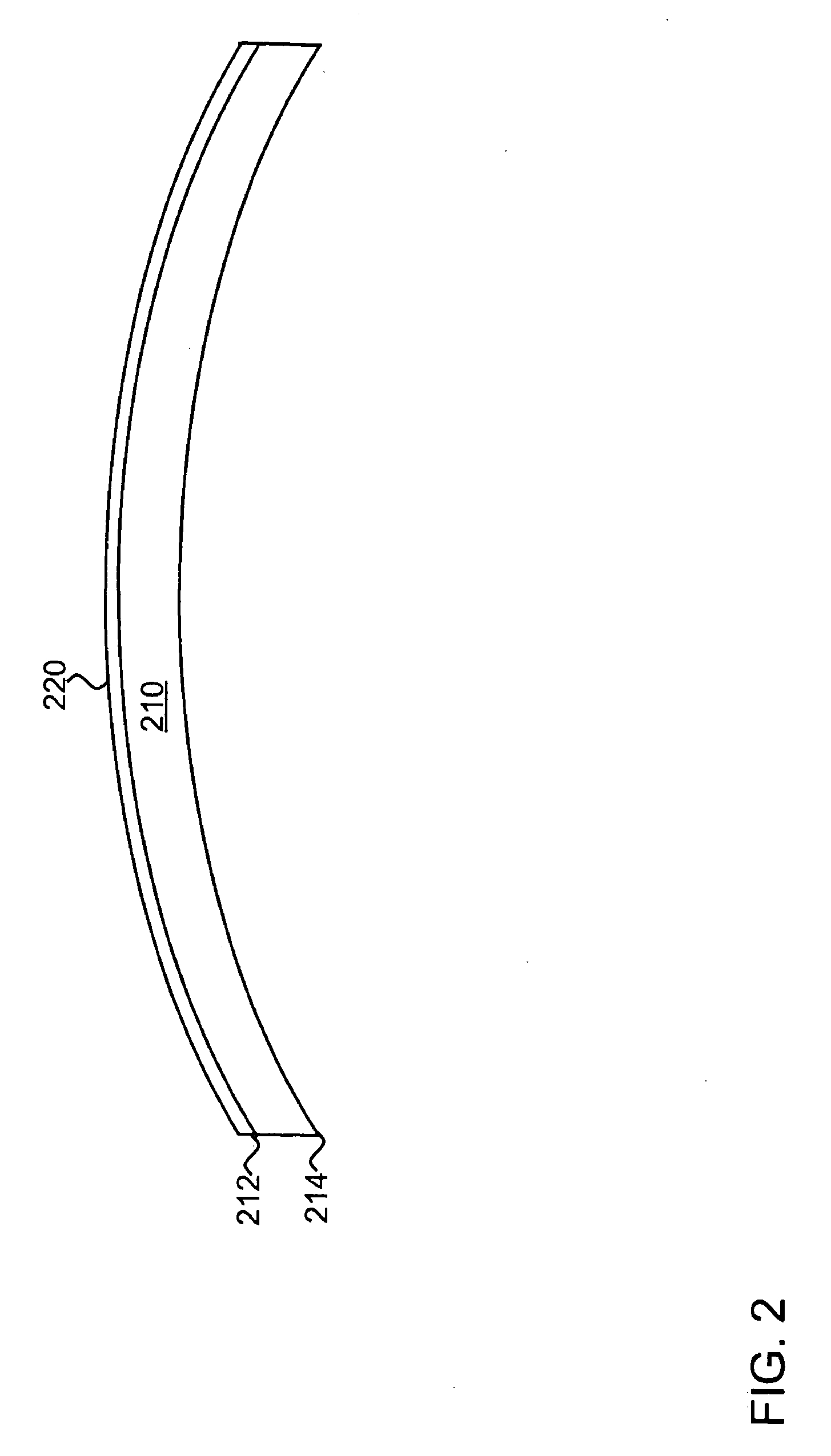

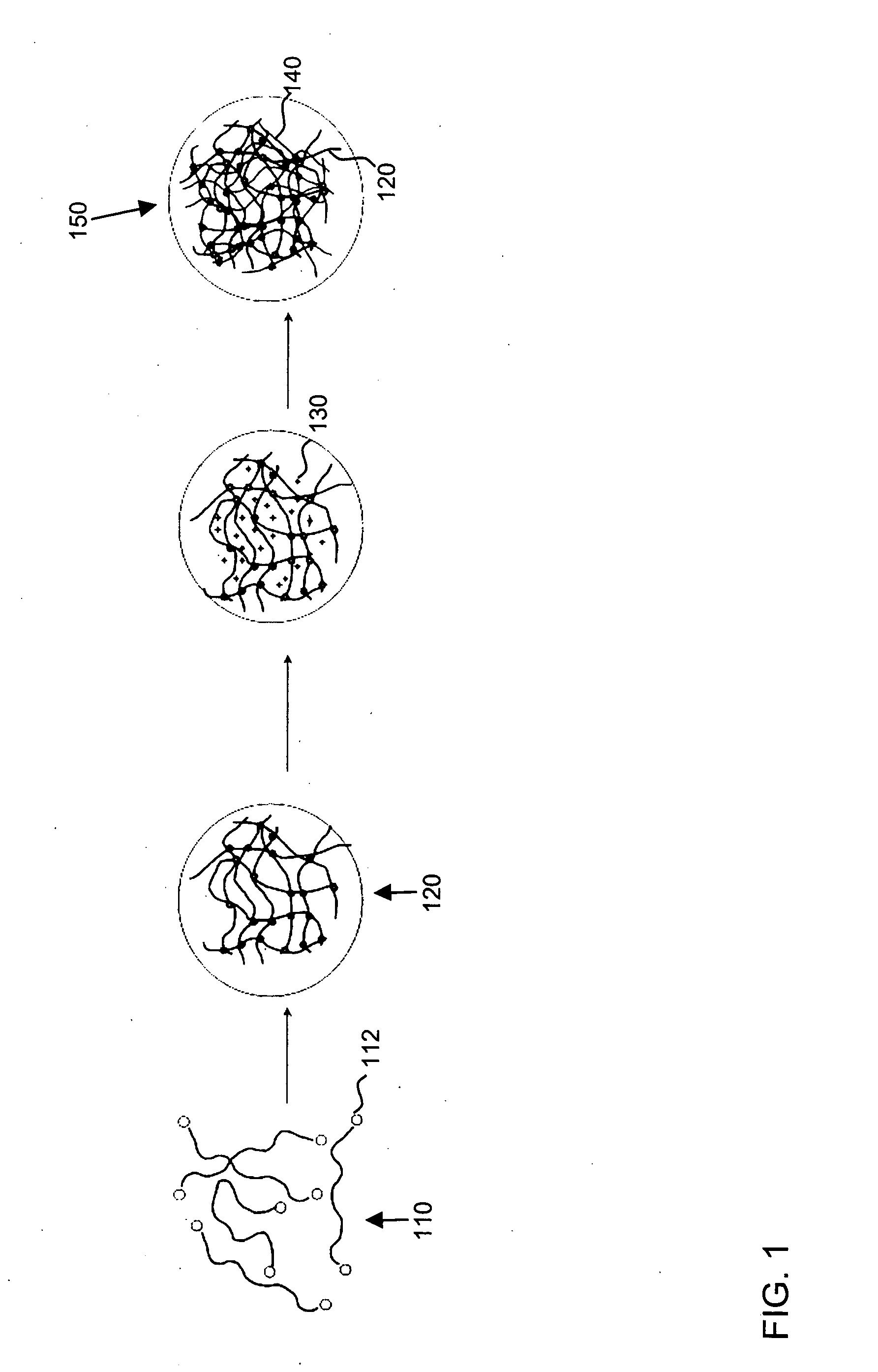

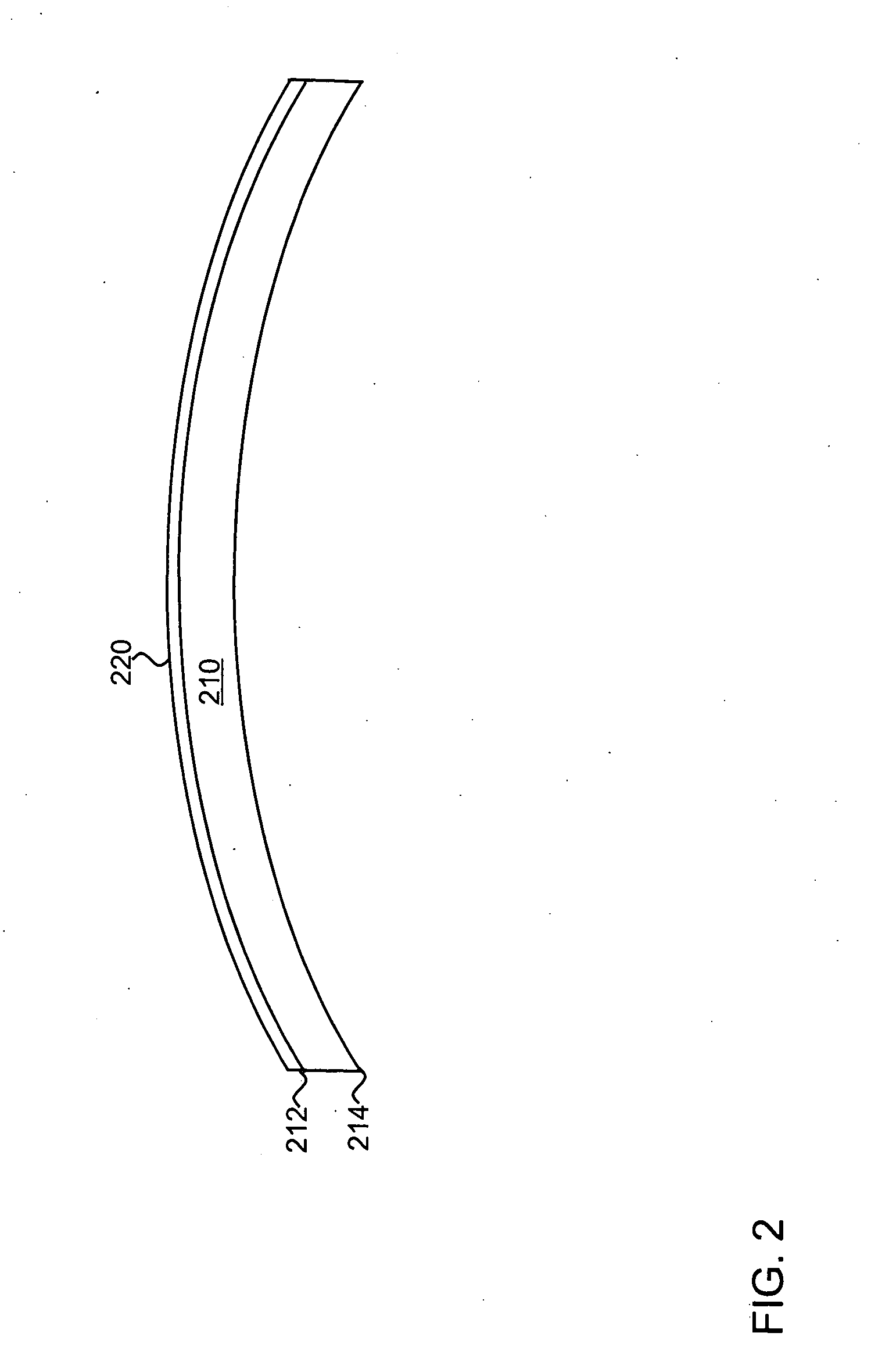

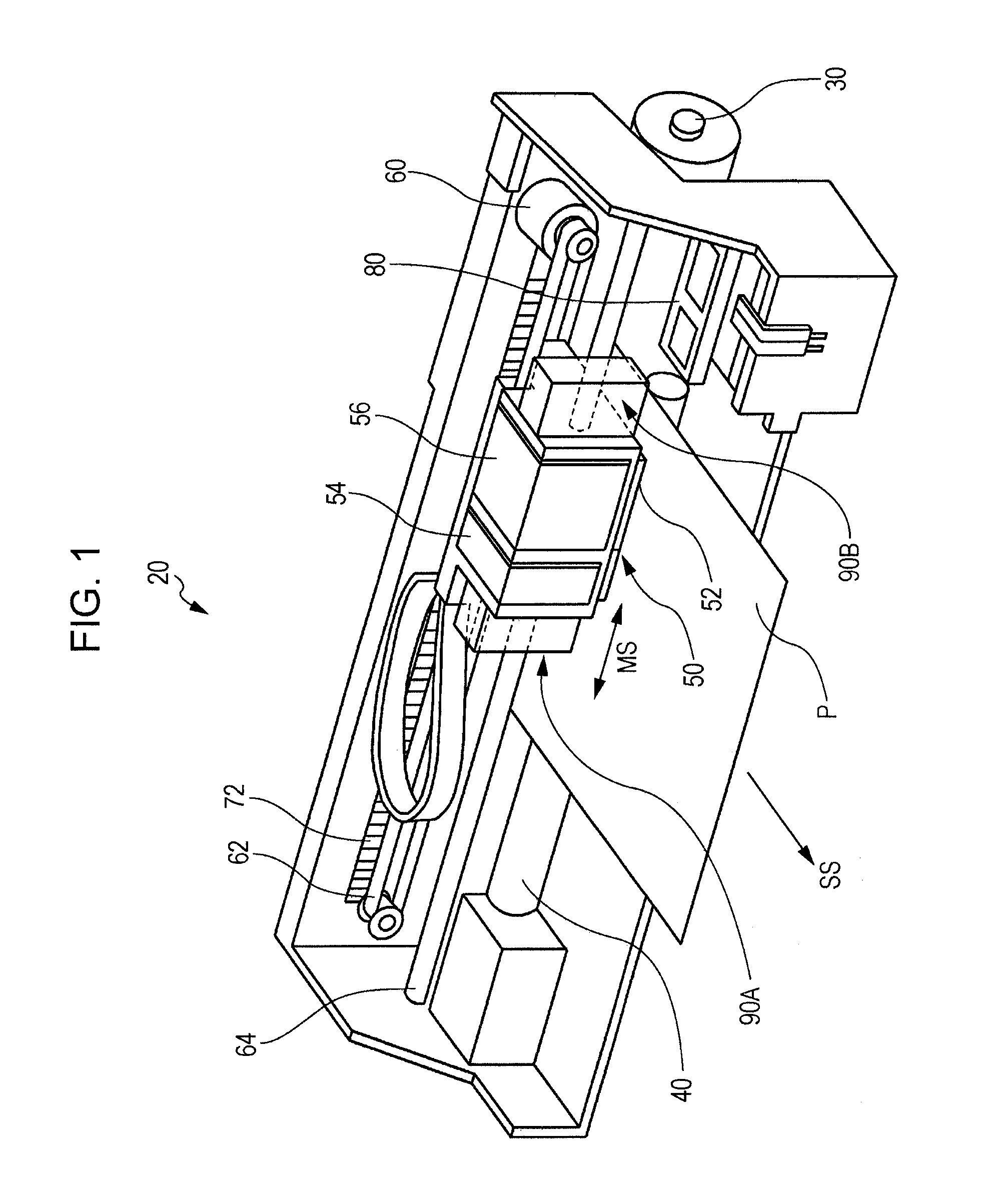

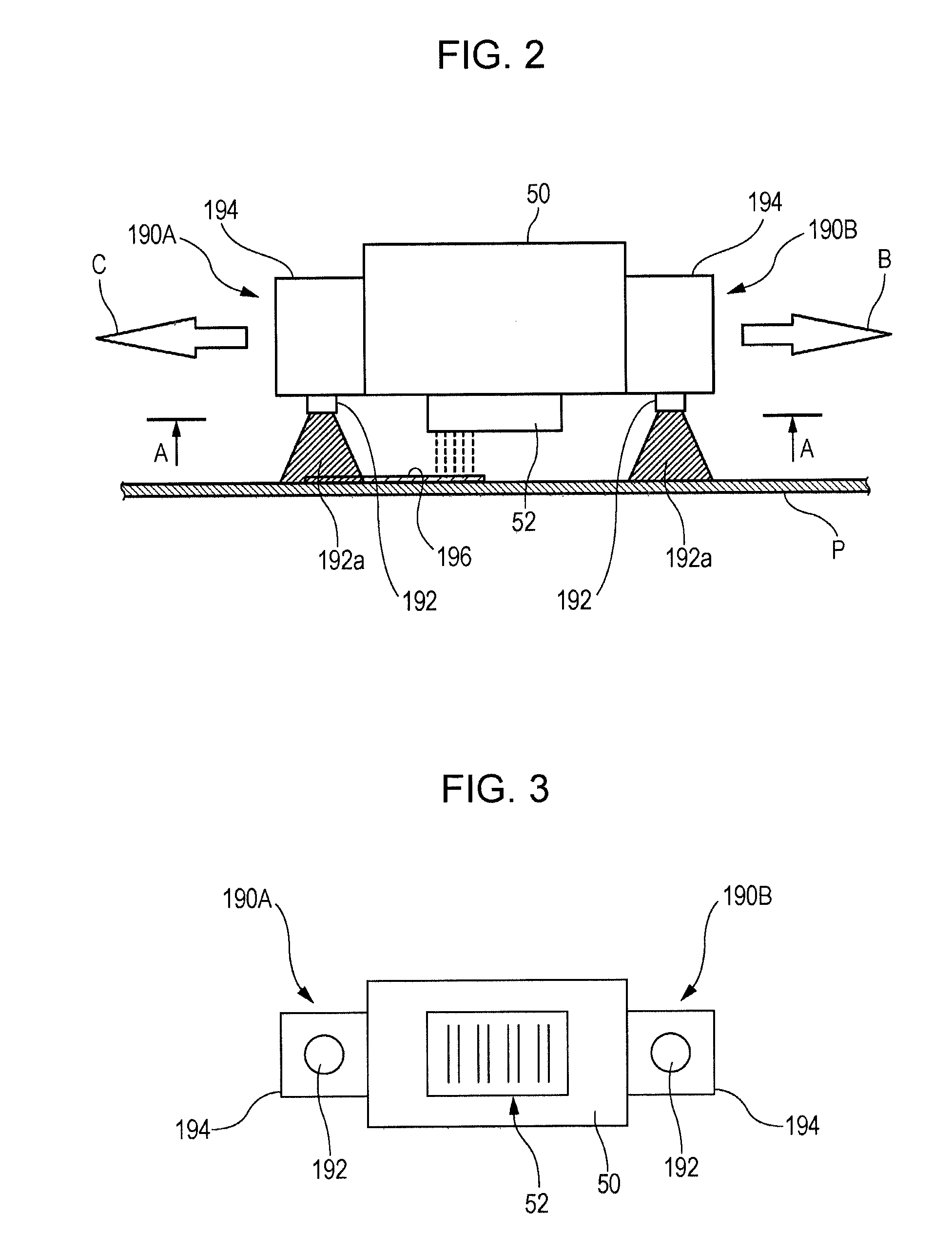

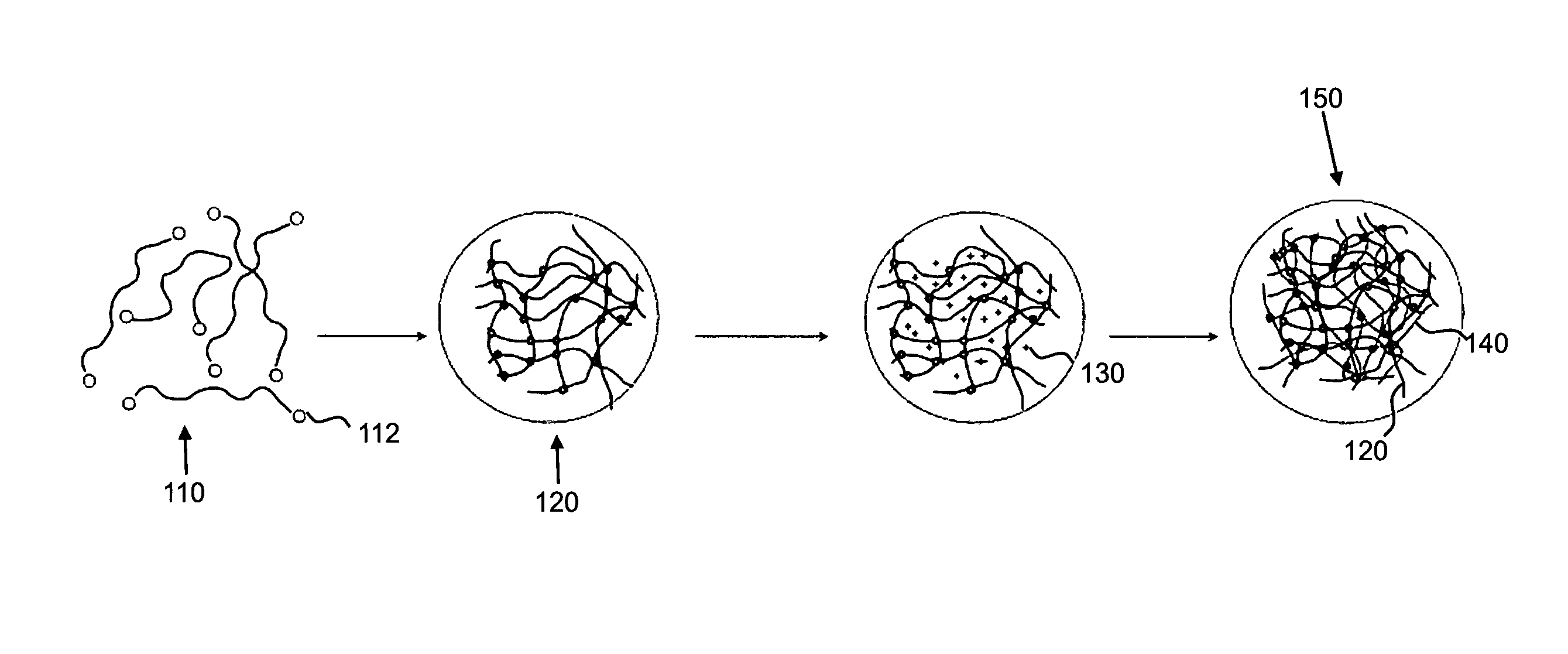

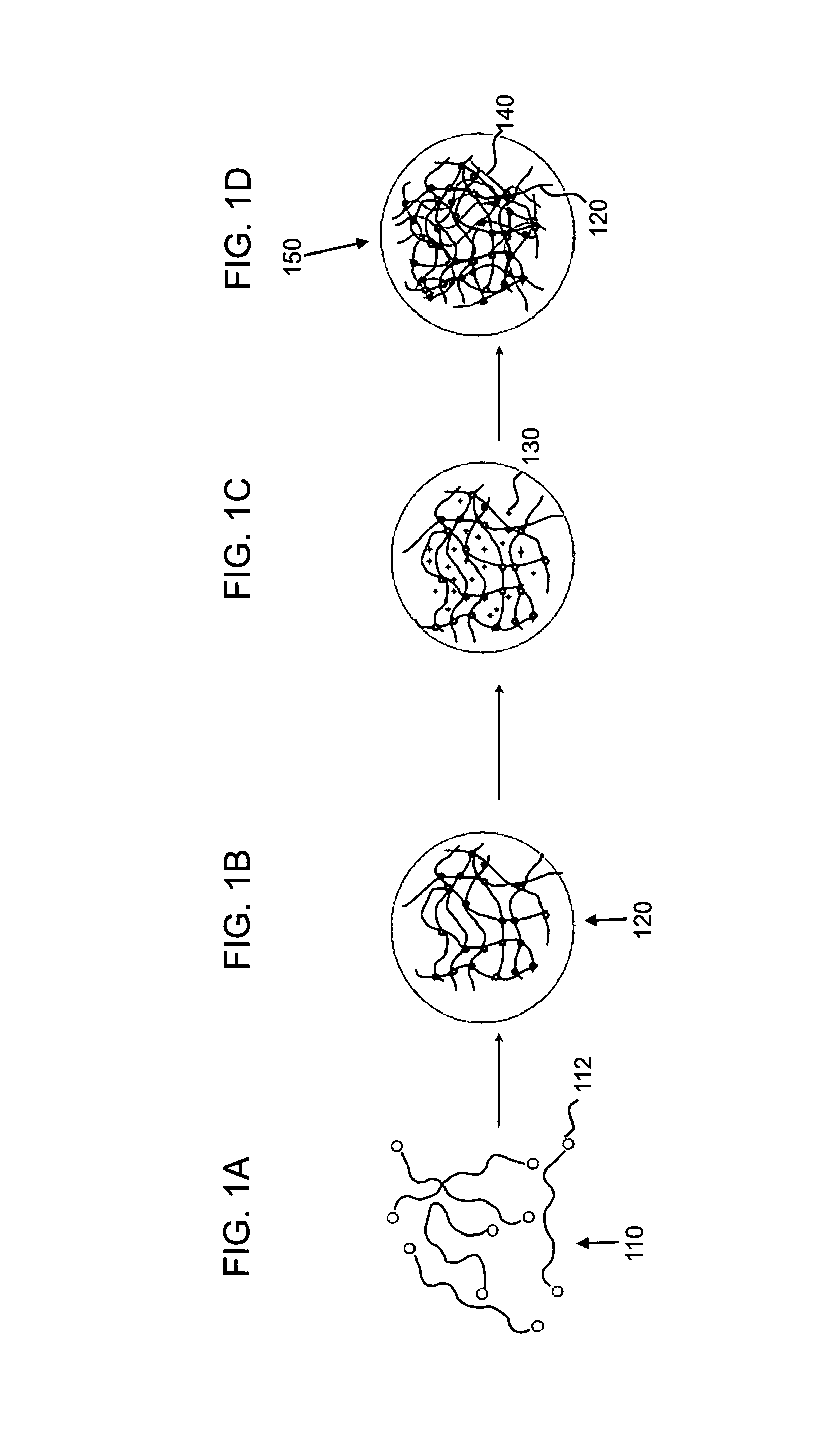

A device and method for generating microcapsules employs an inertial-focusing channel for introducing particles dispersed in a prepolymer suspension fluid, a droplet-generating junction for introducing oil evenly onto the flow of particles to create separated droplets of prepolymer suspension fluid encapsulating respective particles in a streamline flow, and a polymerization section for exposing the droplets to UV light or heat to cause polymerization of a polymer coating on separate microcapsules each containing a respective particle. Preferred suspension fluids may be aqueous solution of poly(ethylene-glycol)-diacrylate (PEGDA), or poly(N-isopropyl-acryalmide) (PNIPAAM). The preferred device may employ a curved or linear inertial-focusing microchannel. Functional tags and / or handles may be added to the microcapsules allowing easy detection, measurement and handling of the microcapsules.

Owner:UNIV OF HAWAII

Abrasion resistant coatings

InactiveUS7375144B2Enhanced resistance to abrasion and chemicalImprove clarityOrganic chemistryMixing methodsDiacrylate esterUrethane acrylate

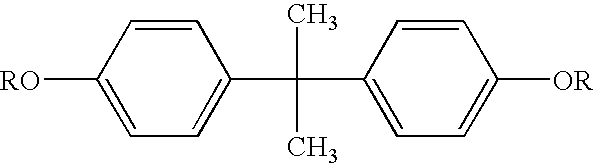

Disclosed are radiation-curable, abrasion resistant coating compositions for thermoplastic substrates which provides superior abrasion, chemical, and impact resistance properties. The coating composition includes at least one flexible diacrylate component, at least one aromatic diacrylate component, and at least one urethane acrylate. Also disclosed are shaped articles having the coating composition applied to at least one surface and cured by exposure to radiation.

Owner:EASTMAN CHEM CO

Interpenetrating polymer network hydrogel corneal prosthesis

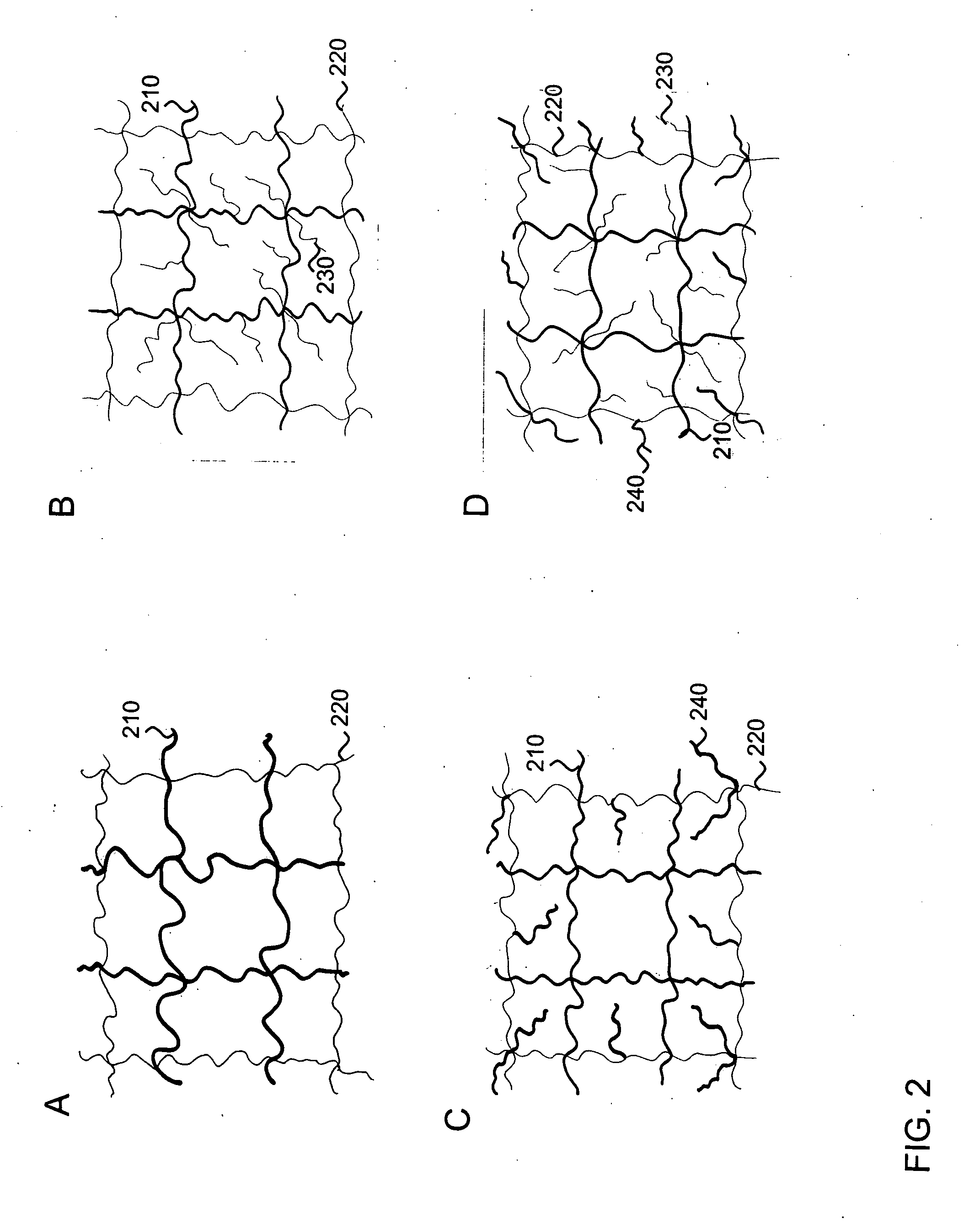

InactiveUS20070179605A1High tensile strengthHigh nutrient permeabilityNervous system cellsArtificial cell constructsCross-linkHydrophilic monomer

The present invention provides materials that have high glucose and oxygen permeability, strength, water content, and resistance to protein adsorption. The materials include an interpenetrating polymer network (IPN) hydrogel that is coated with biomolecules. The IPN hydrogels include two interpenetrating polymer networks. The first polymer network is based on a hydrophilic telechelic macromonomer. The second polymer network is based on a hydrophilic monomer. The hydrophilic monomer is polymerized and cross-linked to form the second polymer network in the presence of the first polymer network. In a preferred embodiment, the hydrophilic telechelic macromonomer is PEG-diacrylate or PEG-dimethacrylate and the hydrophilic monomer is an acrylic-based monomer. Any biomolecules may be linked to the IPN hydrogels, but are preferably biomolecules that support the growth of cornea-derived cells. The material is designed to serve as a corneal prosthesis.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Abrasion resistant coatings

InactiveUS20060286383A1Enhanced resistance to abrasion and chemicalImprove clarityOrganic chemistryMixing methodsPolymer scienceDiacrylate ester

Disclosed are radiation-curable, abrasion resistant coating compositions for thermoplastic substrates which provides superior abrasion, chemical, and impact resistance properties. The coating composition includes at least one flexible diacrylate component, at least one aromatic diacrylate component, and at least one urethane acrylate. Also disclosed are shaped articles having the coating composition applied to at least one surface and cured by exposure to radiation.

Owner:EASTMAN CHEM CO

Hydrophilic membrane and process for making the same

InactiveUS7067058B2Practical and convenientEconomical and simpleMembranesSemi-permeable membranesDiacrylate esterEthylene oxide

A process for imparting hydrophilic properties to a polymeric membrane by exposing the membrane to an acrylate monomer containing hydrophilic segments, such as ethylene oxide, and a hydrophilic functional group, a diacrylate monomer containing hydrophilic functional groups, and an initiator for facilitating crosslinking and polymerization reactions.

Owner:3M INNOVATIVE PROPERTIES CO

Chemical vapor deposition of hydrogel films

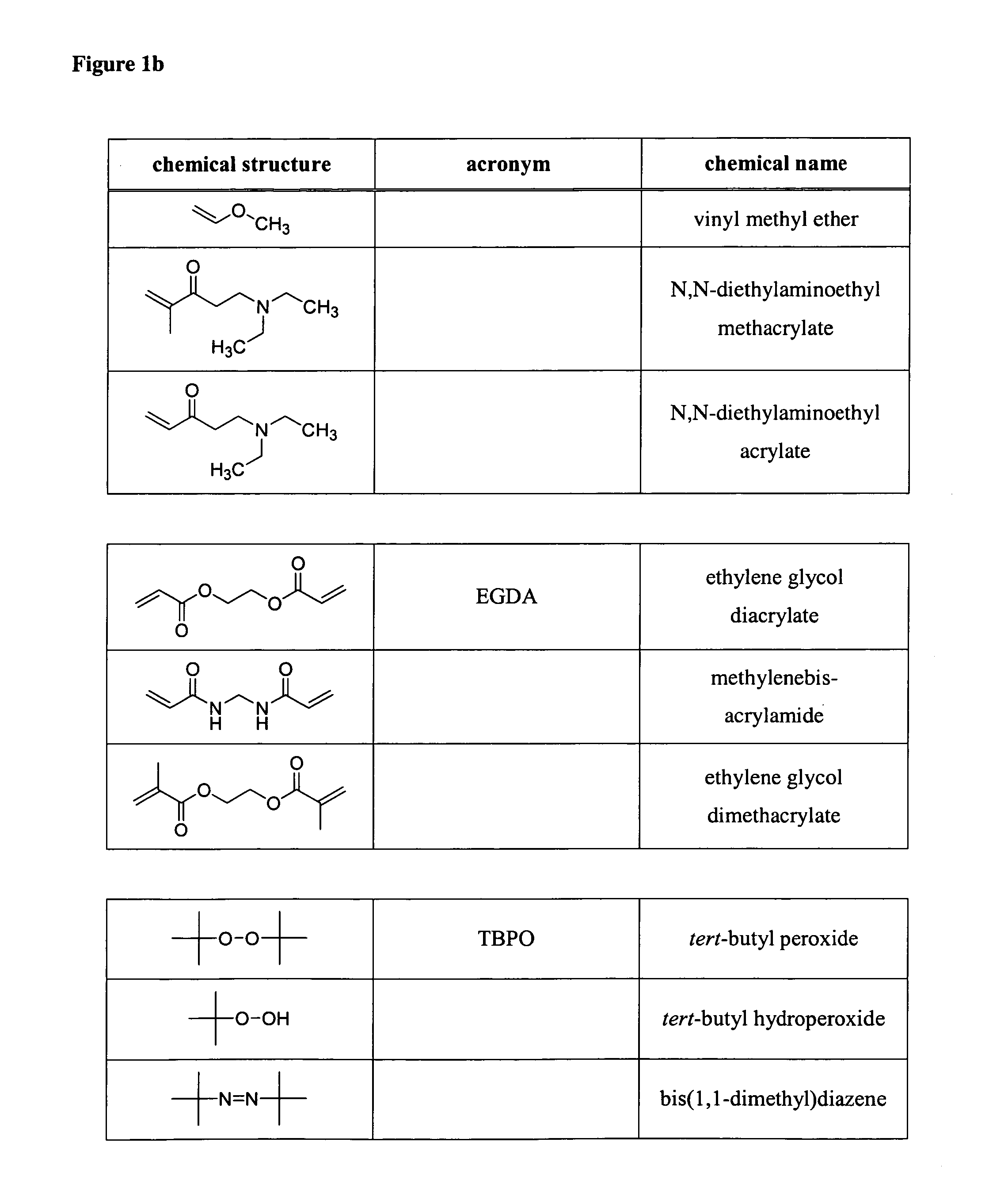

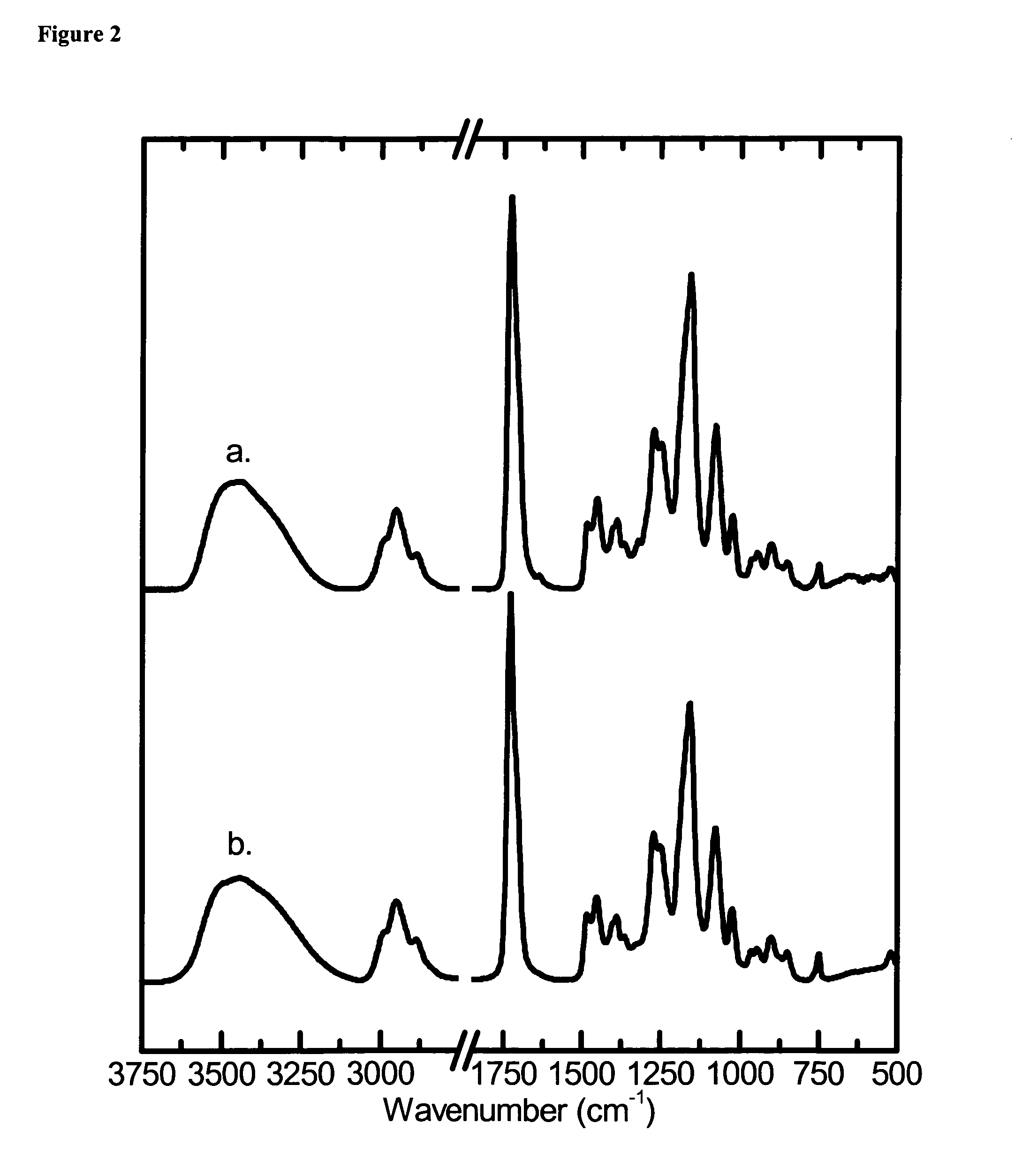

ActiveUS20070032620A1Add partsLiquid surface applicatorsChemical vapor deposition coatingDiacrylate esterGas phase

In one embodiment of the invention, iCVD is used to form linear thin films using a radical initiator and an alkene. In another embodiment, iCVD is used to form crosslinked thin films by the addition of a crosslinking agent (e.g., a diacrylate or a dimethyacrylate). The incorporation of a crosslinking agent into the thin films is shown to increase systematically with its partial pressure. In one embodiment, when the crosslinker is EDGA and the monomer is HEMA it results in crosslinked P(HEMA-co-EGDA) copolymer. In another embodiment, when the crosslinker is EDGA and the monomer is VP, it results in crosslinked P(VP-co-EGDA). Disclosed are the effects of crosslinker incorporation on the thermal and the wetting properties of the polymers. The unique swelling properties of these films are also described; certain films of the present invention are hydrogels when soaked in water.

Owner:MASSACHUSETTS INST OF TECH

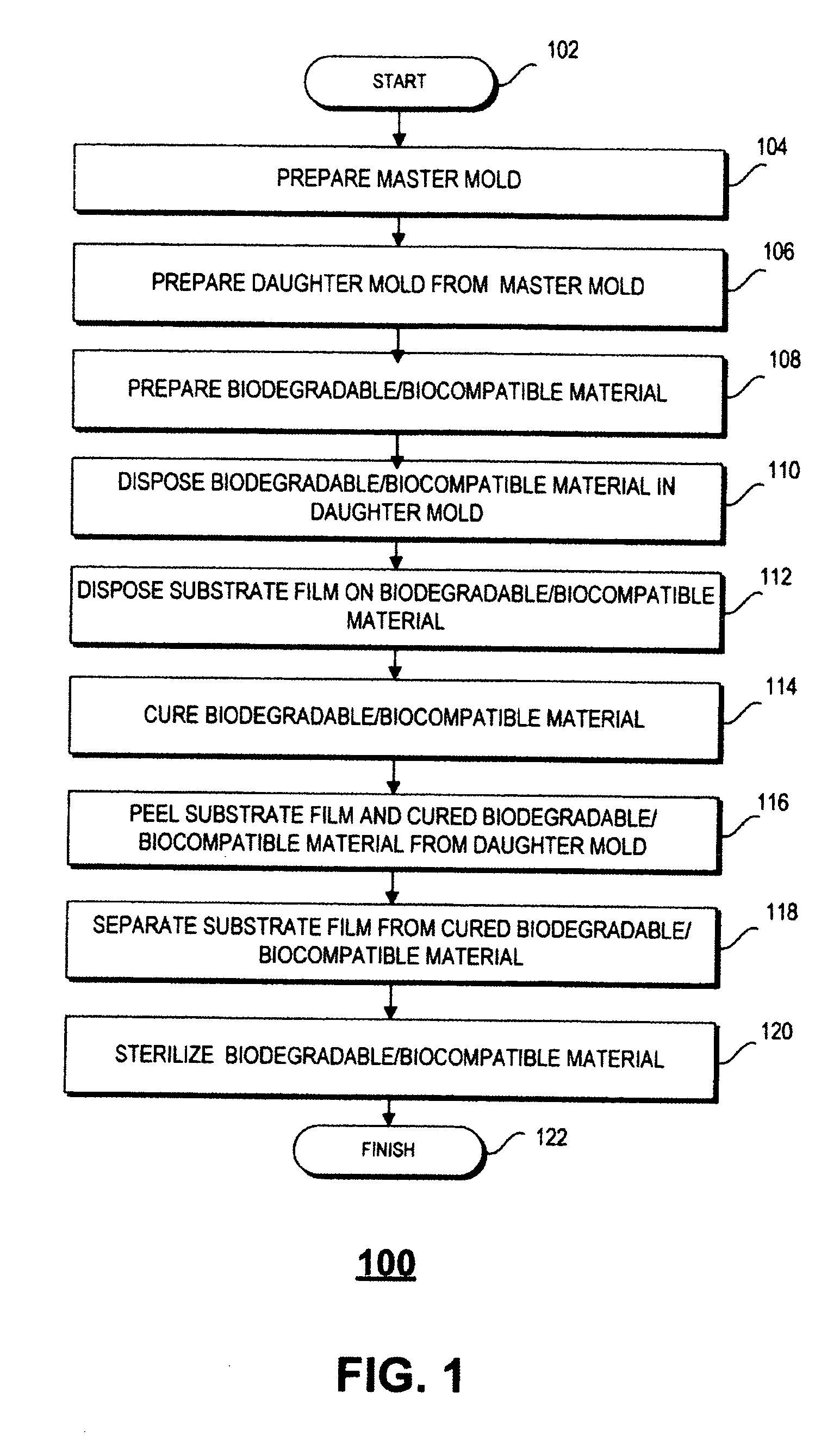

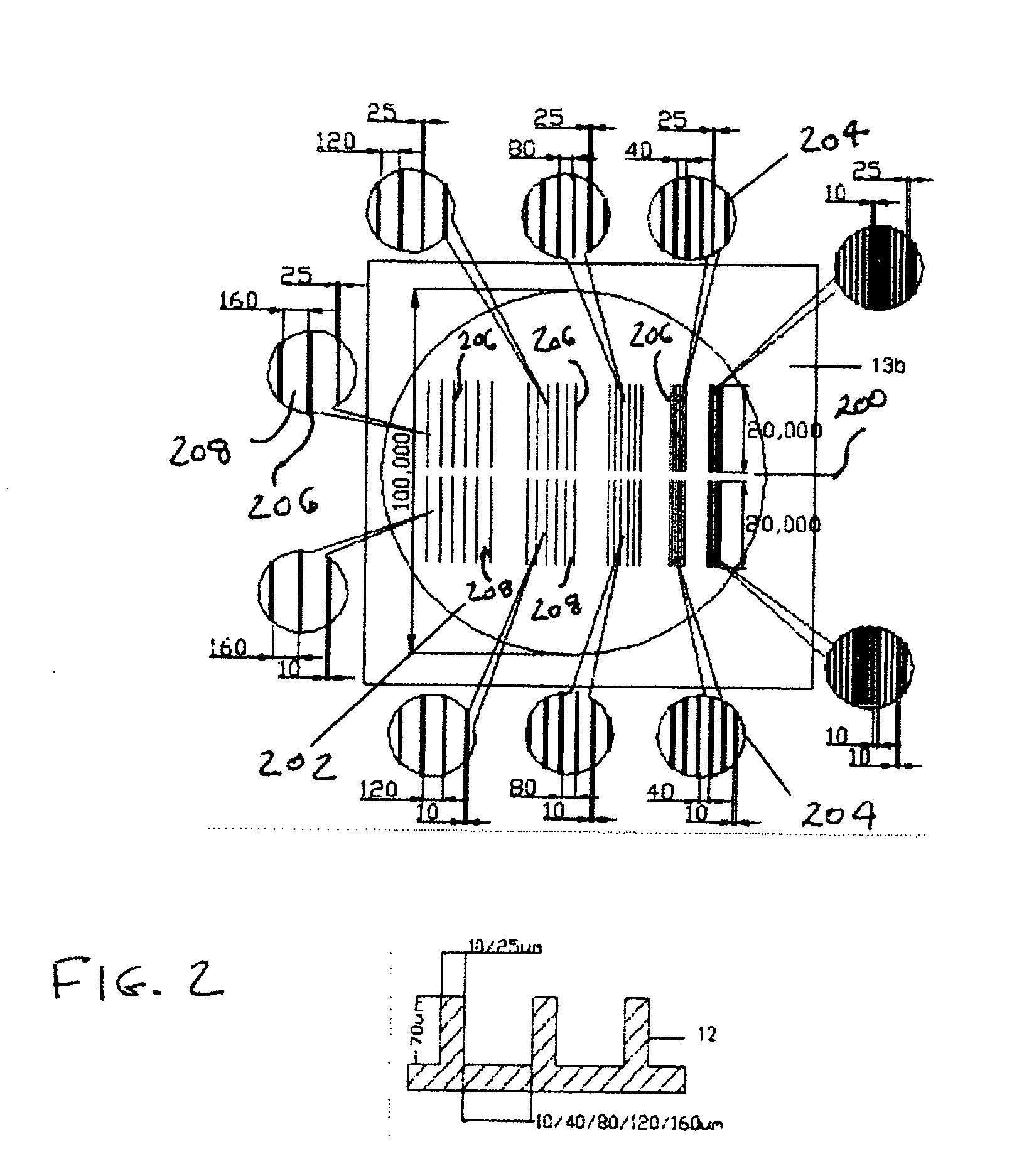

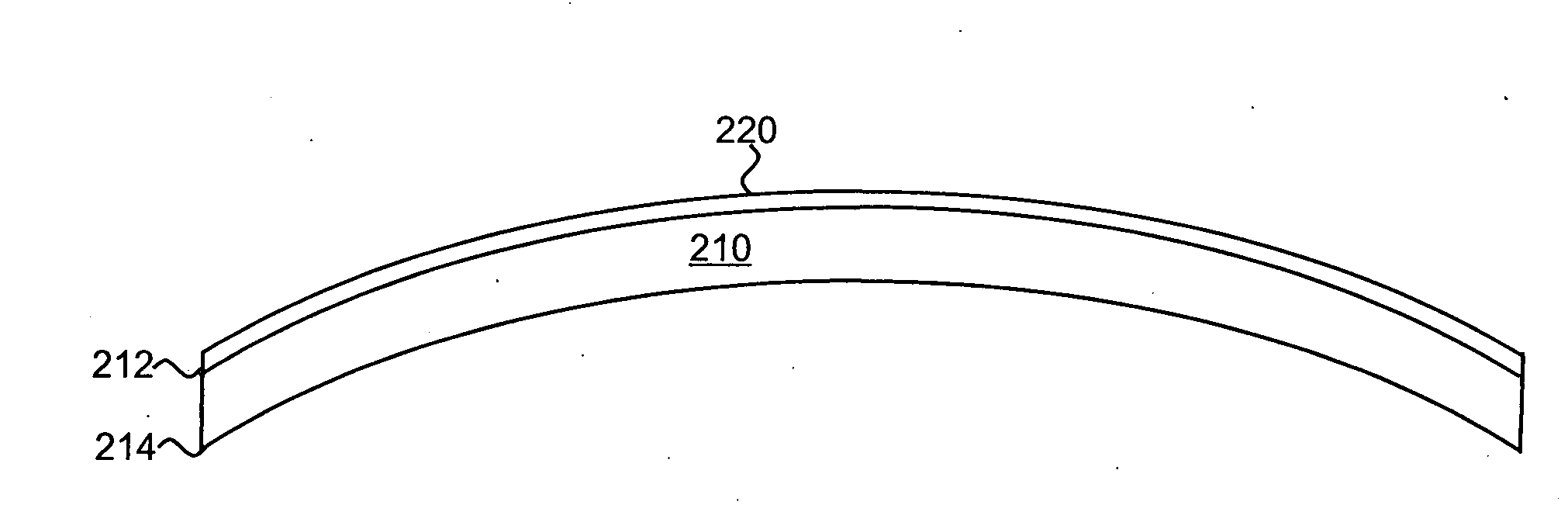

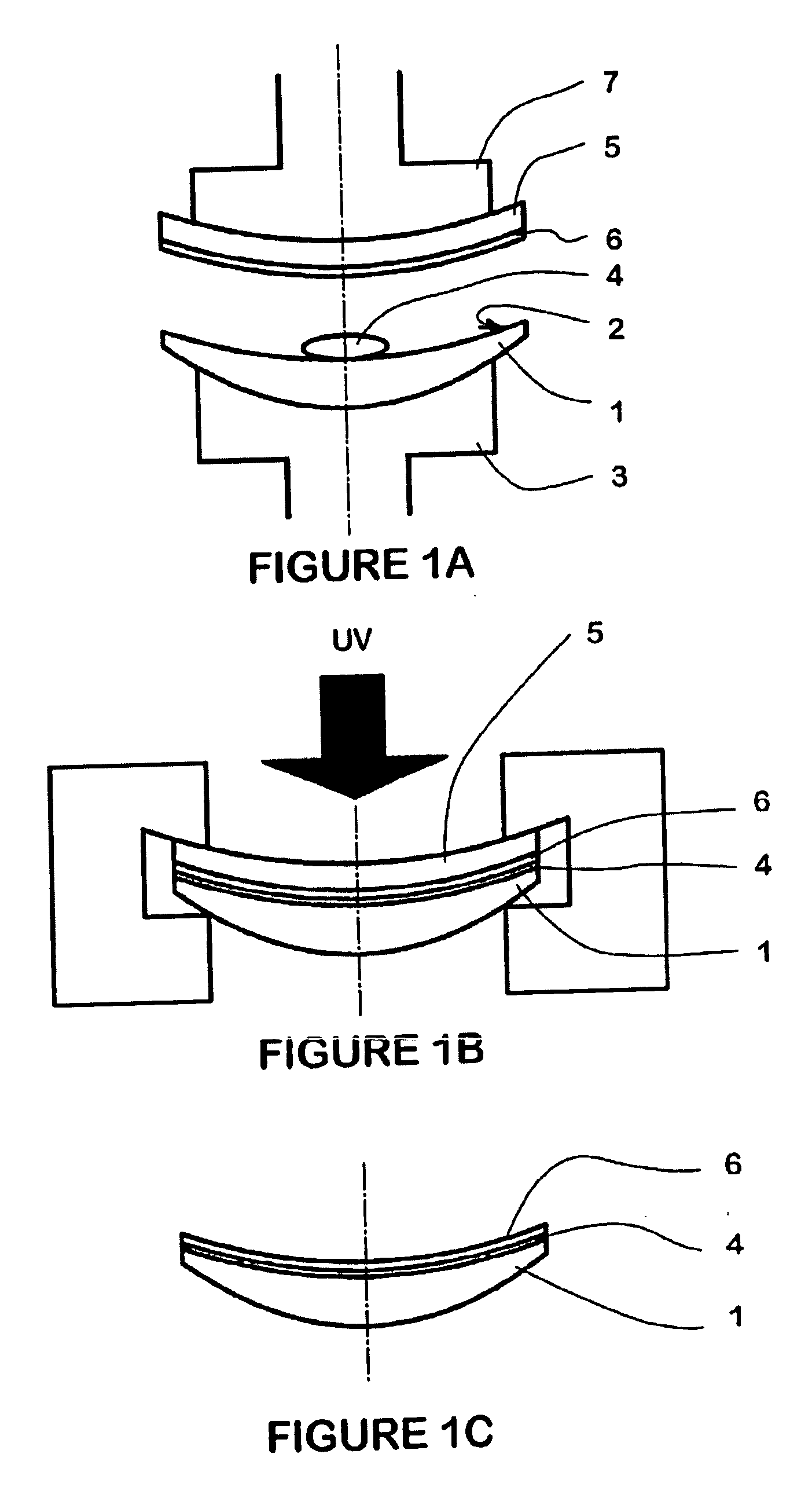

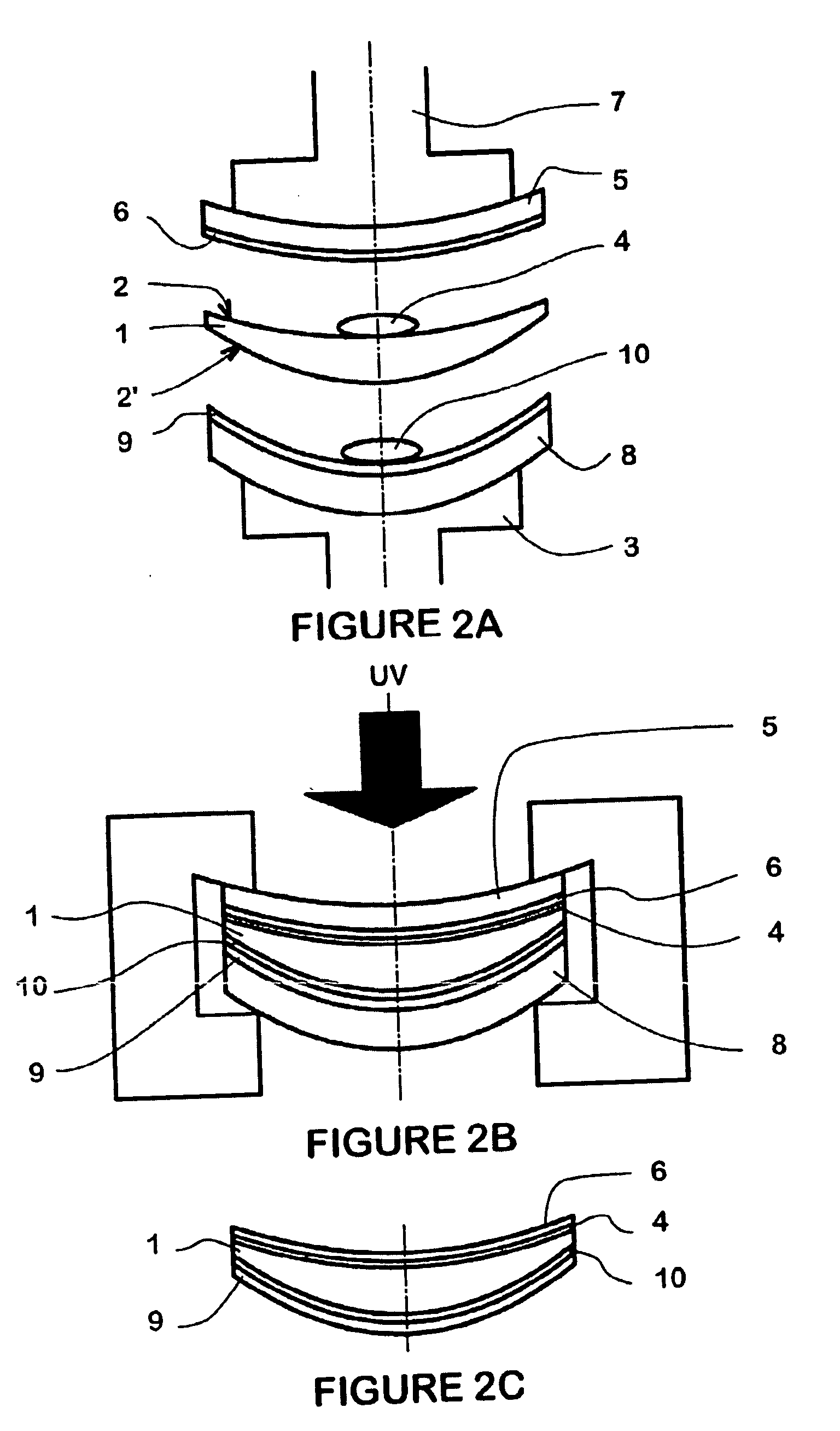

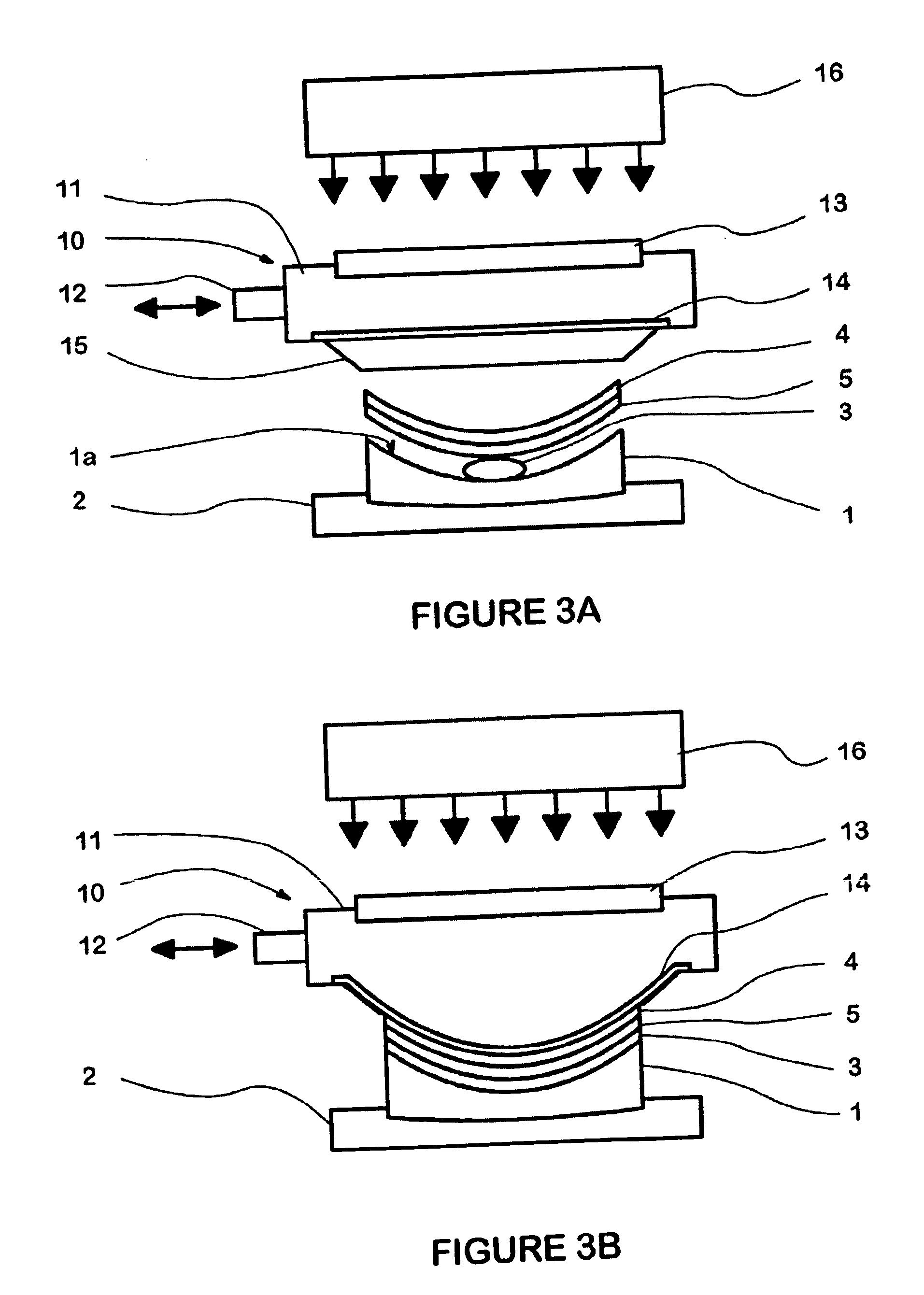

Micro-structured and nano-structured surfaces on biodegradable polymers

In embodiments of the present invention, a biodegradable / biodegradable polymer film may be used as a scaffold for tissue engineering scaffolds for engineering organized organs, such as vascular grafts, for example. In one embodiment, an ultraviolet (UV) resin made from a diacrylated biodegradable oligomer is molded into a flexible scaffold having cavities and / or channels. Channel / cavity size may be on the order of micrometers and / or nanometers, and thus the walls may have high aspect ratios. Smooth muscle cells may be deposited in the channels and because of the high aspect ratios, the cells may align along the channels / cavities as confluence is reached.

Owner:NANYANG TECH UNIV

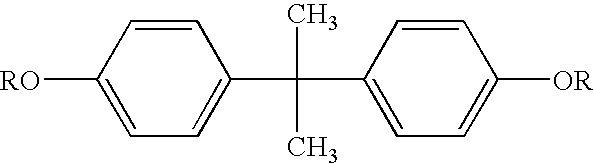

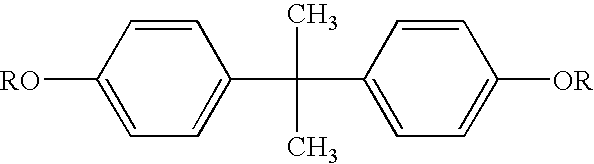

Biocompatible polymeric compositions for use in making anterior chamber intraocular lenses

Biocompatible polymers useful for making anterior chamber intraocular lenses (AC-IOL) are provided. The biocompatible polymers are generally composed of one or more acrylate monomers, crosslinked with at least one diacrylate ester and may include one or more additional components such as ultraviolet light and / or blue-violet light absorbing dyes. The AC-IOLs made using the biocompatible polymers disclosed herein are suitable for placement in phakic or aphakic eyes and are intended for refractive correction including myopia, hyperopia, presbyopia and astigmatisms.

Owner:JOHNSON & JOHNSON SURGICAL VISION INC

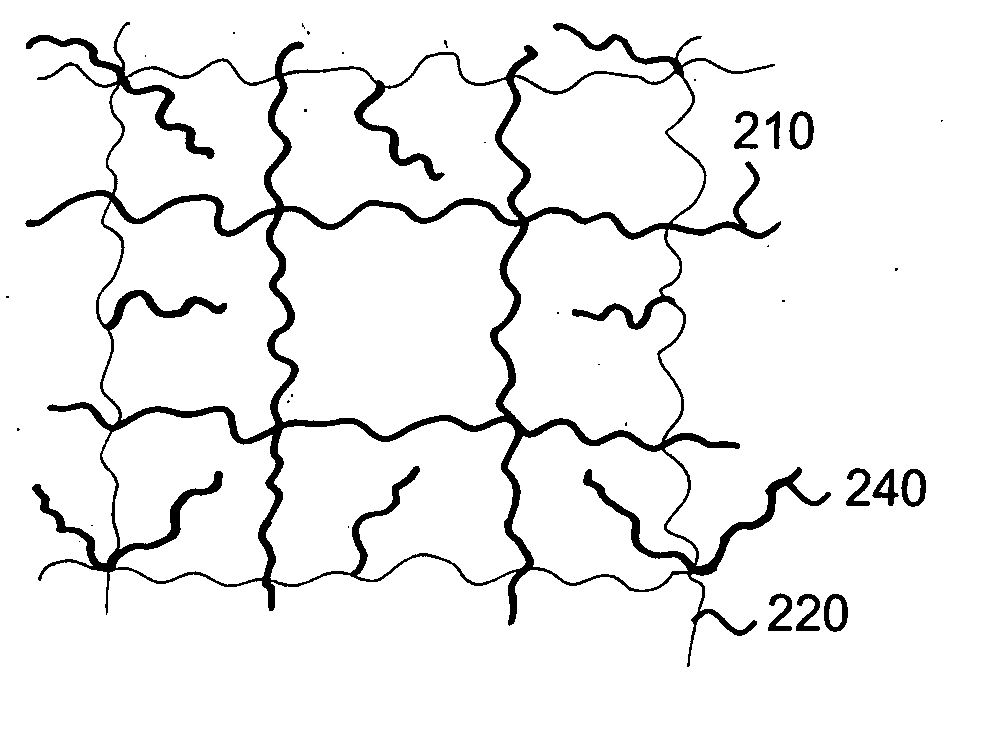

Interpenetrating polymer network hydrogel contact lenses

InactiveUS7857447B2High tensile strengthHigh oxygen permeabilityIntraocular lensOptical partsCross-linkHydrophilic monomer

The present invention provides interpenetrating polymer network hydrogels that have high oxygen permeability, strength, water content, and resistance to protein adsorption. The hydrogels include two interpenetrating polymer networks. The first polymer network is based on a hydrophilic telechelic macromonomer. The second polymer network is based on a hydrophilic monomer. The hydrophilic monomer is polymerized and cross-linked to form the second polymer network in the presence of the first polymer network. The telechelic macromonomer preferably has a molecular weight of between about 575 Da and about 20,000 Da. Mixtures of molecular weights may also be used. In a preferred embodiment, the hydrophilic telechelic macromonomer is PEG-diacrylate or PEG-dimethacrylate and the hydrophilic monomer is an acrylic-based monomer. The material is designed to serve as a contact lens.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

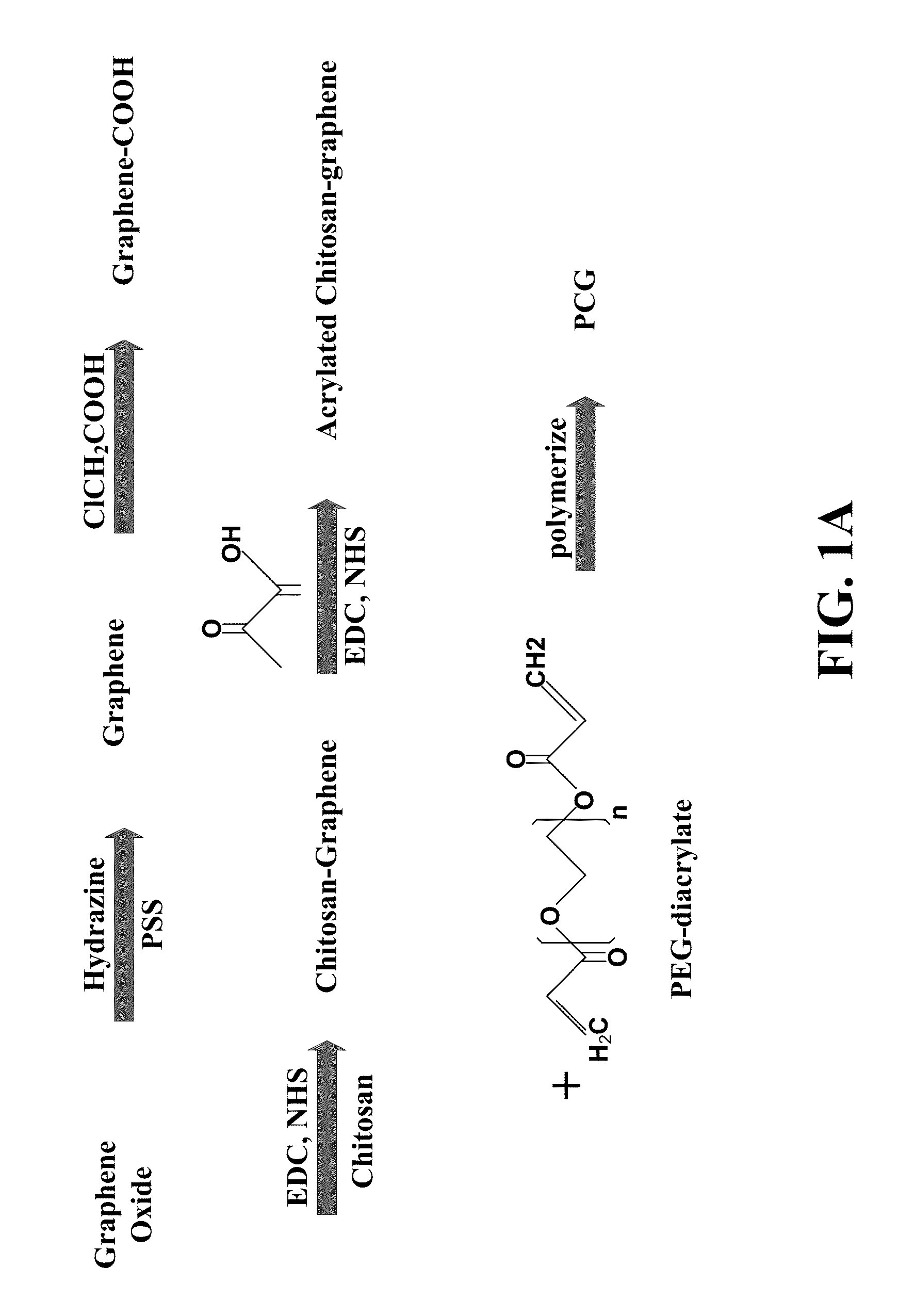

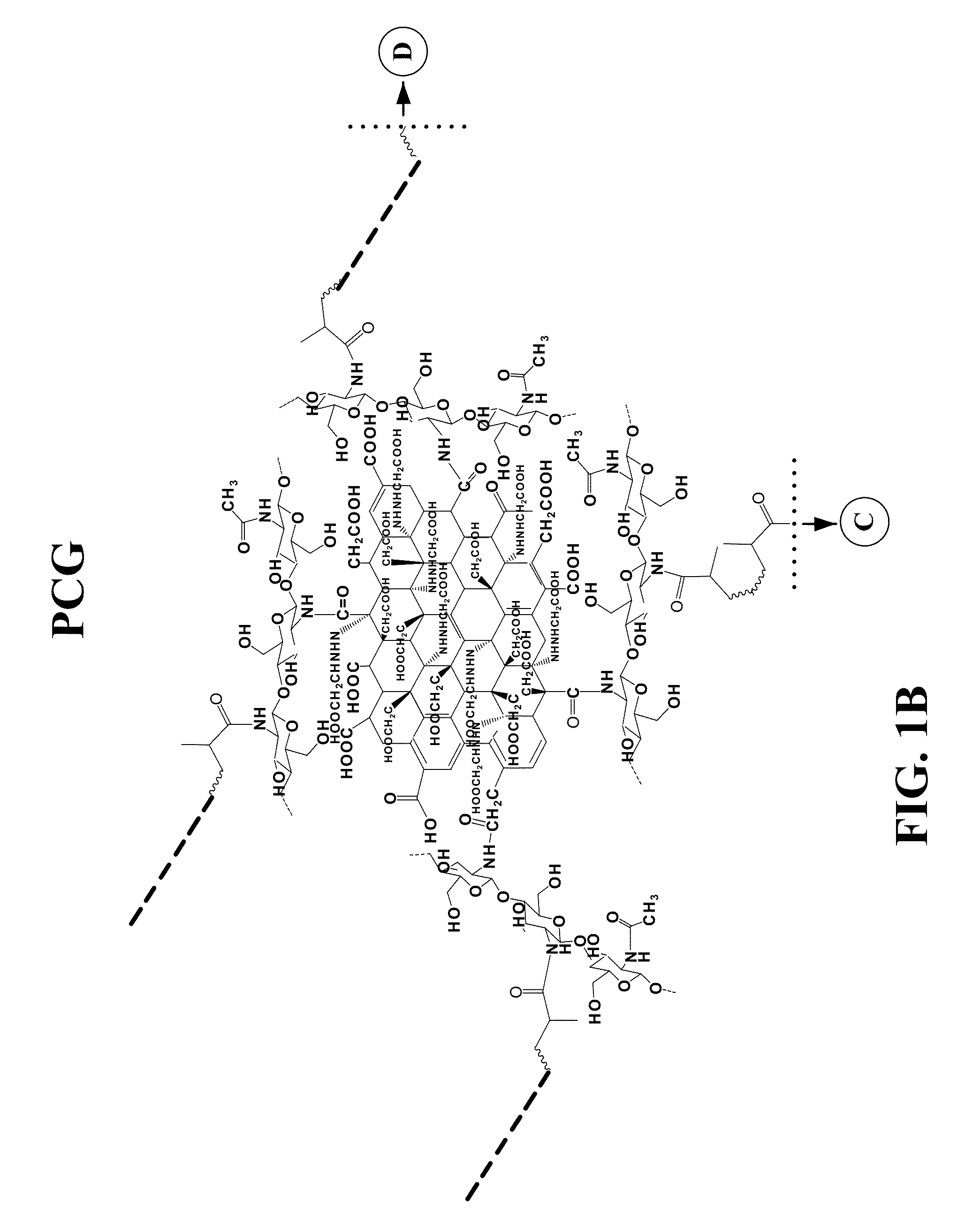

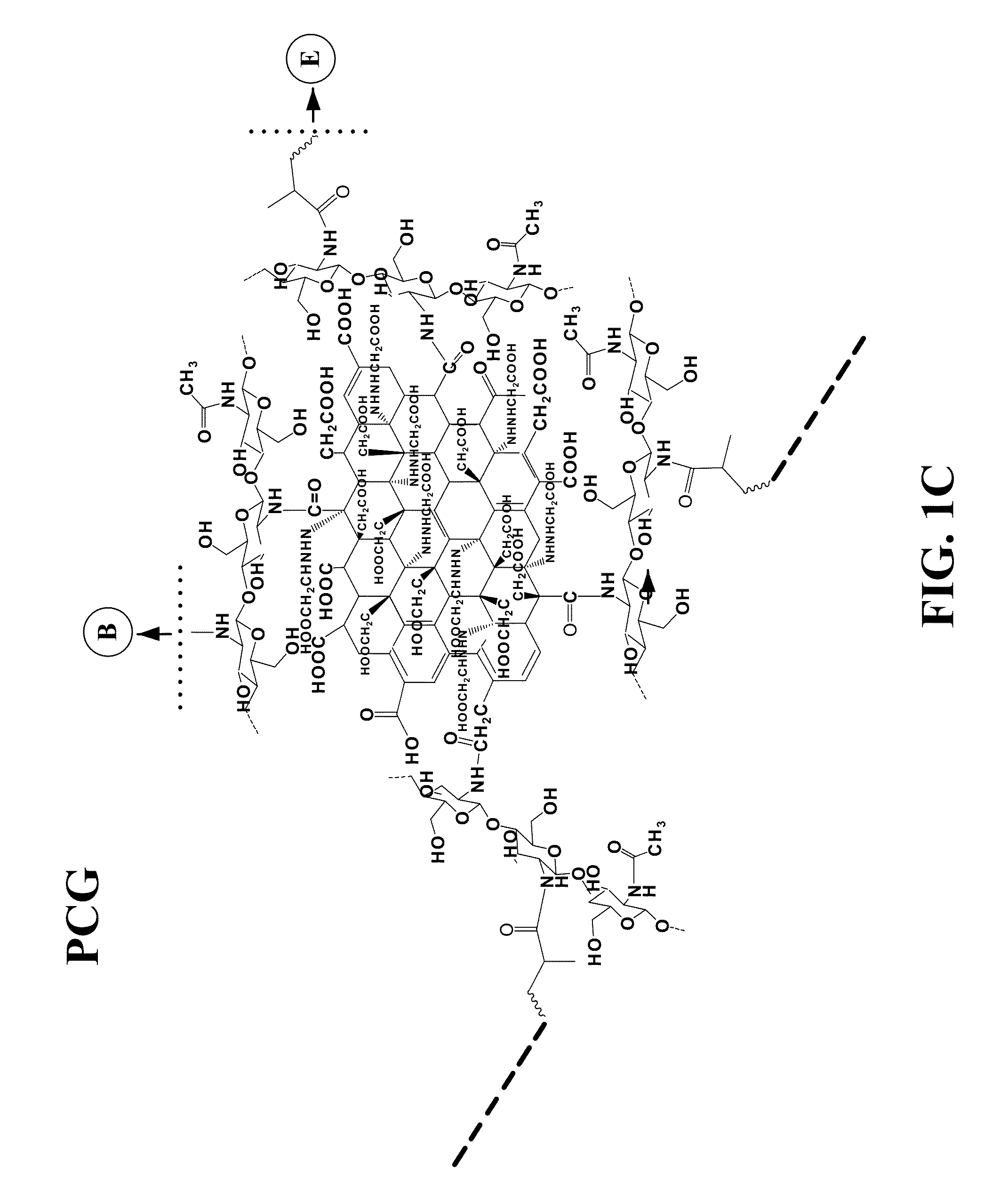

Graphene hydrogel and method for using the same

Provided herein is a hydrogel composition comprising a graphene, a chitosan, and a polyethylene (glycol) diacrylate (PEGDA) (PCG hydrogel). In some embodiments, the hydrogel further comprises a N-isopropylacrylamide (NIPAM) (TPCG hydrogel). Also provided is a method for differentiating a mesenchymal stem cell comprising contacting the cell with the PCG hydrogel. Further provided herein is a method for delivering a pharmaceutical composition to a cell comprising administering to the cell a TPCG hydrogel and the pharmaceutical composition.

Owner:UNIV OF SOUTH FLORIDA

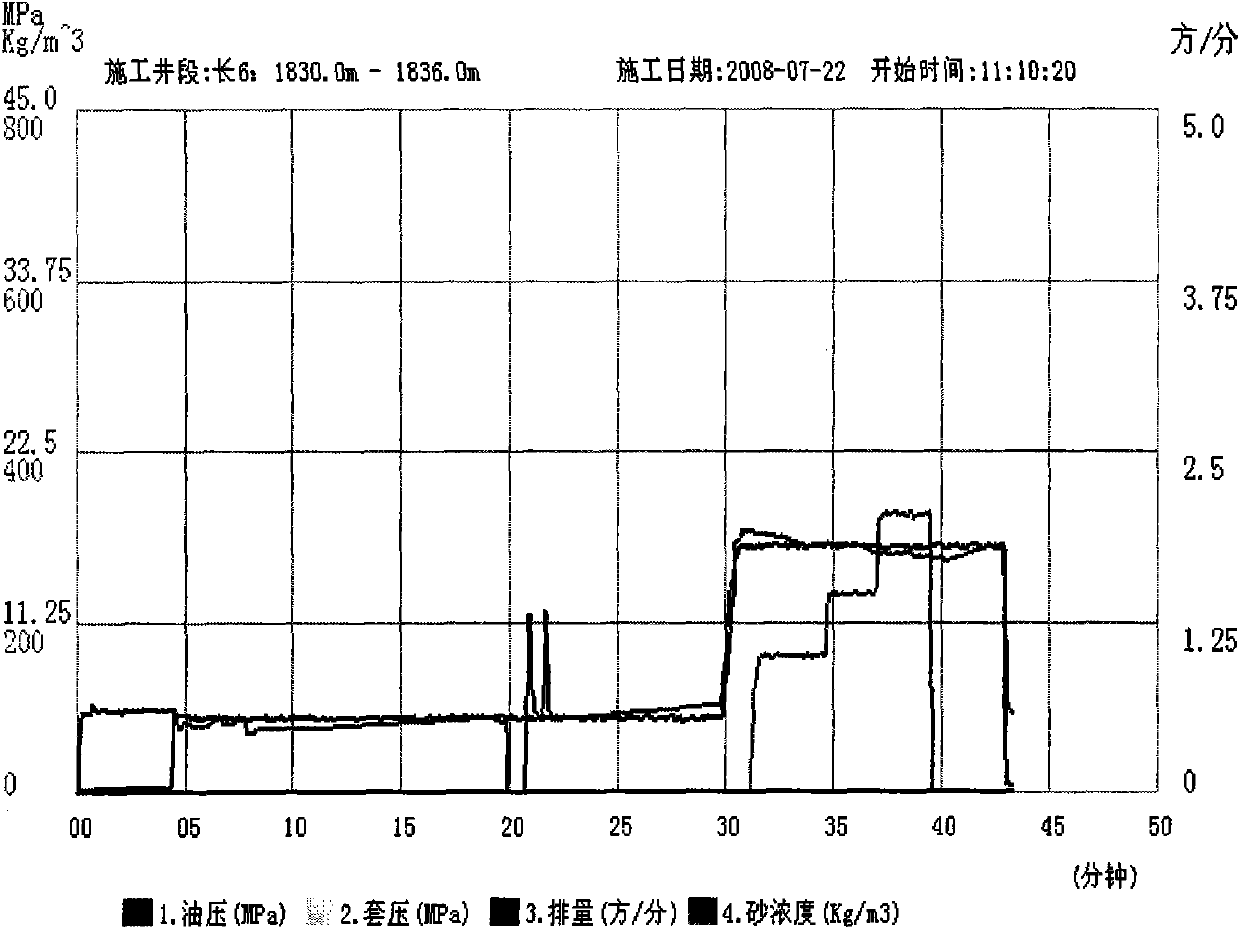

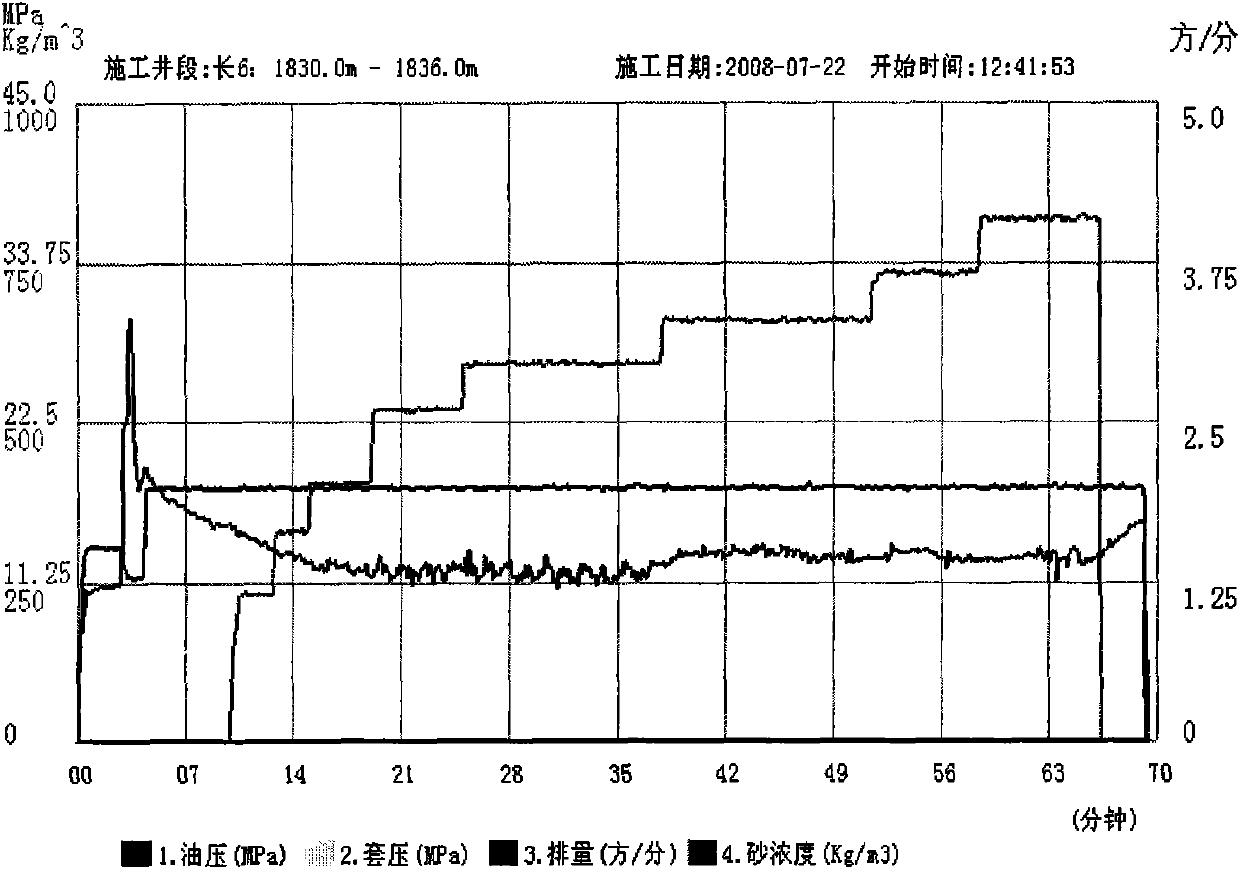

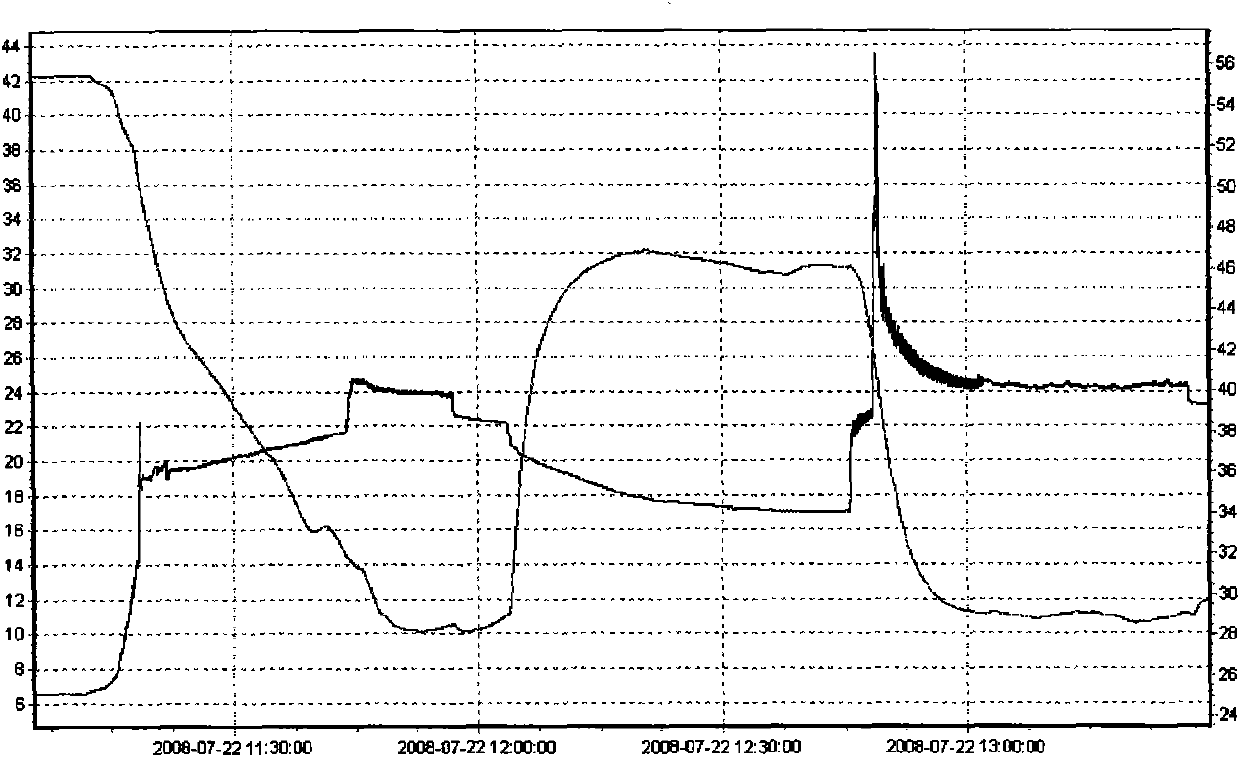

In-fissure diversion fracturing temporary blocking agent for low-permeability oilfield, and preparation method and application thereof

The invention relates to an in-fissure diversion fracturing temporary blocking agent for a low-permeability oilfield, and a preparation method and application thereof. The temporary blocking agent is prepared by the following steps of: mixing 92 mass percent of bone glue powder, 0.2 mass percent of benzoic acid, 5 mass percent of modified starch, 1.3 mass percent of hydroxyethyl cellulose, 1.0 mass percent of F-containing surfactant and 0.5 mass percent of cross-linking agent; adding polyoxyethylene diacrylate with concentration of between 5 and 100mg / L and an initiator with concentration of between 100 and 500mg / L and reacting at the temperature of 80 DEG C under the pressure of 1.2MPa for gelling; and granulating, applying oil and drying, wherein the maximum expansion ratio is 1.33; the agent has high temperature resistance stability and stable adhesion; the maximum elongation is 64 percent; the breakthrough pressure gradient reaches 30.0MPa / m; the viscosity is 35mPa.s after the agent is completely dissolved at the temperature of 60 DEG C; and the agent can be completely flowed back under the action of the carrying of fracturing liquid.

Owner:PETROCHINA CO LTD

Injectable hydrogel microspheres from aqueous two-phase system

InactiveUS7776240B2Big lossSustained releaseLiquid surface applicatorsPeptide/protein ingredientsSolubilityEmulsion

Injectable hydrogel microspheres are prepared by forming an emulsion where hydrogel precursors are in a disperse aqueous phase and polymerizing the hydrogel precursors. In a preferred case, the hydrogel precursors are poly(ethylene glycol) diacrylate and N-isopropylacrylamide and the continuous phase of the emulsion is an aqueous solution of dextran and a dextran solubility reducer. The microspheres will load protein, e.g., cytokines, from aqueous solution.

Owner:CORNELL RES FOUNDATION INC

Interpenetrating polymer network hydrogel contact lenses

InactiveUS20070126982A1High tensile strengthHigh oxygen permeabilityIntraocular lensOptical partsHydrophilic monomerCross-link

The present invention provides interpenetrating polymer network hydrogels that have high oxygen permeability, strength, water content, and resistance to protein adsorption. The hydrogels include two interpenetrating polymer networks. The first polymer network is based on a hydrophilic telechelic macromonomer. The second polymer network is based on a hydrophilic monomer. The hydrophilic monomer is polymerized and cross-linked to form the second polymer network in the presence of the first polymer network. The telechelic macromonomer preferably has a molecular weight of between about 575 Da and about 20,000 Da. Mixtures of molecular weights may also be used. In a preferred embodiment, the hydrophilic telechelic macromonomer is PEG-diacrylate or PEG-dimethacrylate and the hydrophilic monomer is an acrylic-based monomer. The material is designed to serve as a contact lens.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

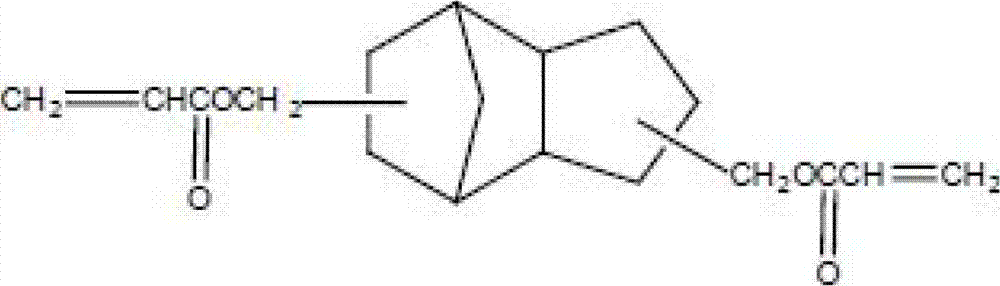

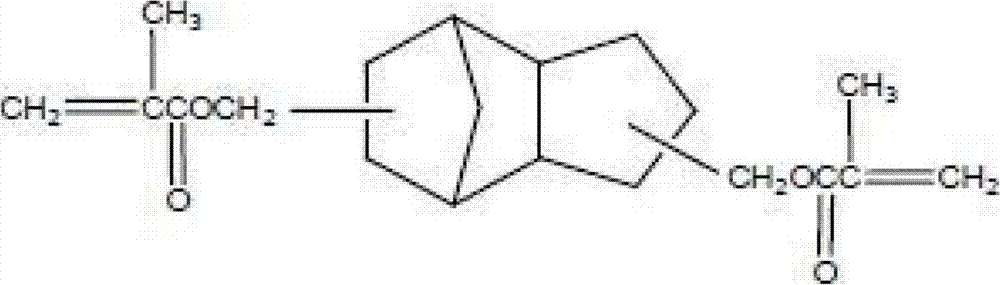

Optical resin composition, optical resin material using the same, optical filter for image display device, and image display device

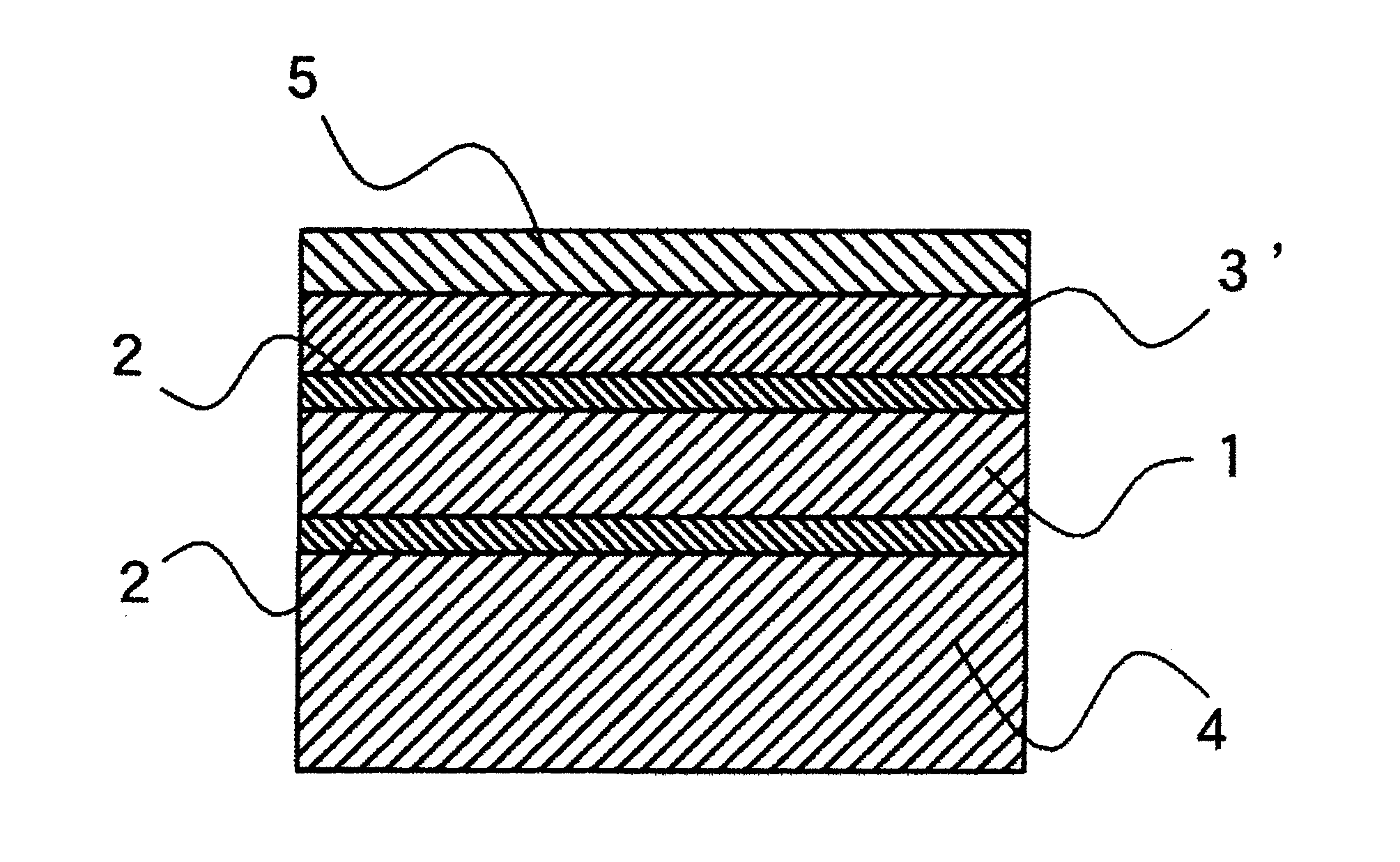

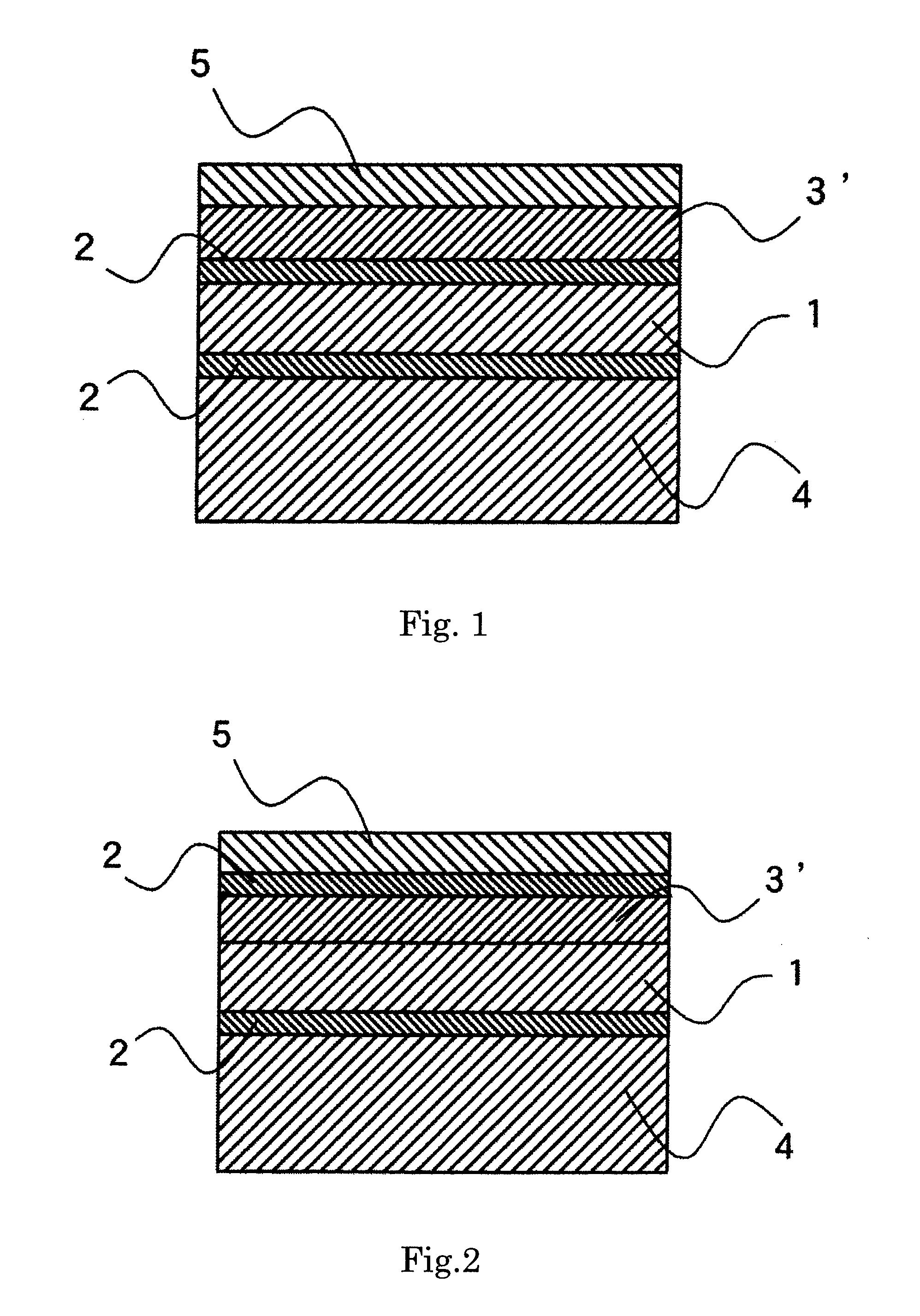

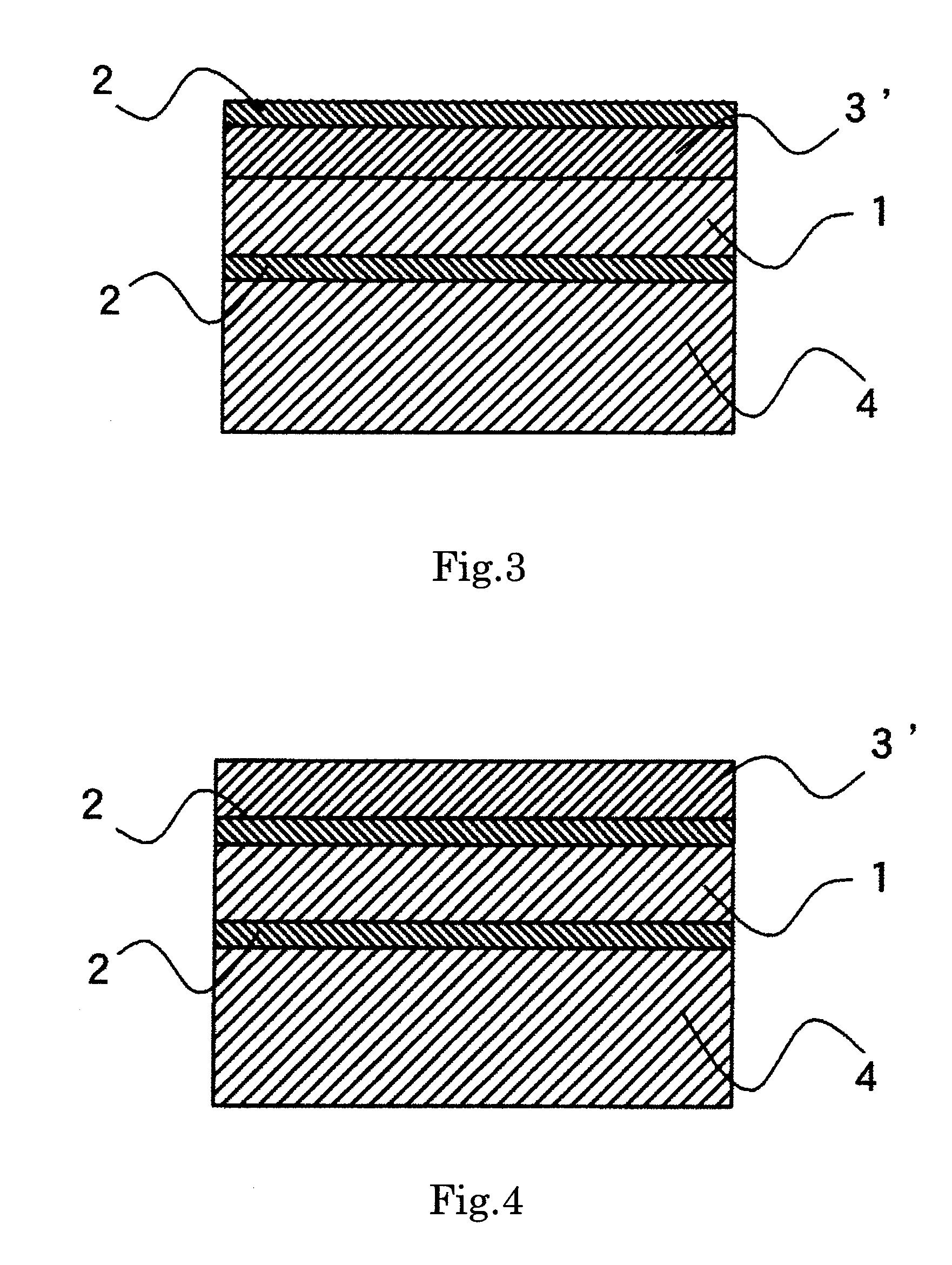

InactiveUS20100247940A1Improve impact absorption performanceHigh transparencyImpression capsOptical filtersDiacrylate esterBiopolymer

The invention provides an optical resin composition being transparent, having suitable adhesion and necessary impact absorption for protection of an image display device etc., not affecting constituent materials of a image display panel, and being excellent in reliability, and an optical resin material using the same.Disclosed is an optical resin composition containing (A) a first acrylate derivative that is a compound having one polymerizable unsaturated bond in its molecule, (B) a second acrylate derivative that is a compound having two or more polymerizable unsaturated bonds in its molecule, and (C) an acrylate derivative polymer, and an optical resin material produced by curing reaction of the optical resin composition.

Owner:HITACHI CHEM CO LTD

Non-whitening emulsion pressure sensitive adhesives

InactiveCN1284106ALow hazeAdhesiveNon-macromolecular adhesive additivesEster polymer adhesivesMethacrylateEmulsion

Water resistant, low haze acrylic emulsion pressure sensitive adhesive compositions for use in decorative, light management or optical articles are disclosed. These emulsion pressure sensitive adhesives comprise (a) 50-90% by weight n-butyl acrylate, and (b) 10-50% by weight 2-hydroxy ethyl acrylate, or 2-hydroxy ethyl methacrylate, hydroxy propyl acrylate monomer, or mixtures thereof. These emulsion pressure sensitive adhesives can be used in wet lamination processes, and exhibit less than 2% increase in haze, less than 2% increase in opacity and greater than 95% transmittance after the wet lamination process.

Owner:3M CO

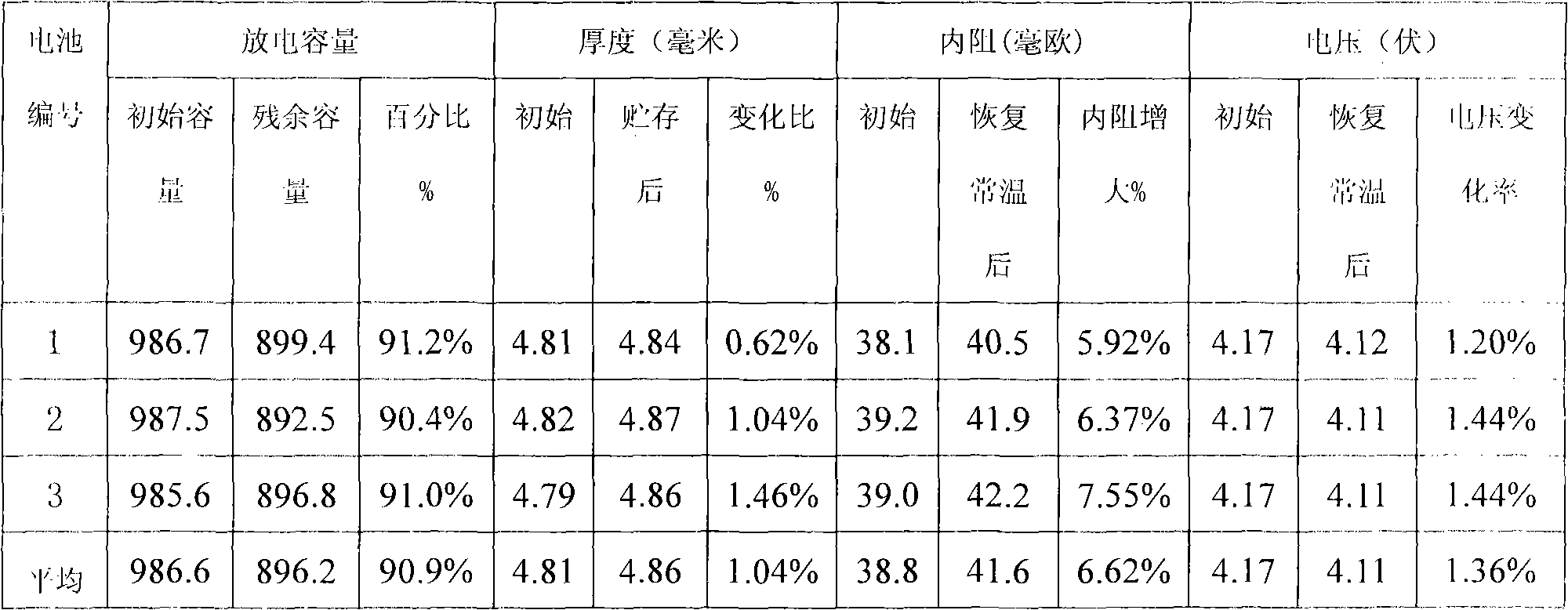

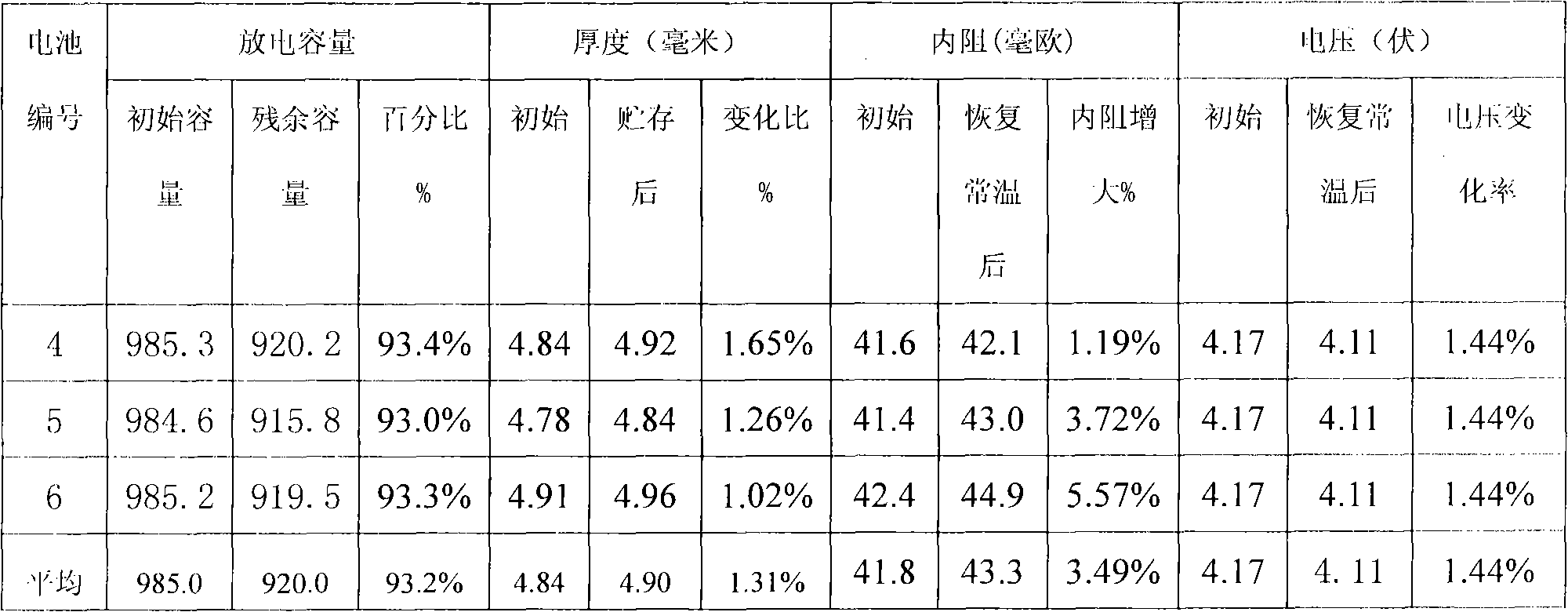

Acrylic ester pressure-sensitive adhesive tape and preparation method thereof and lithium ion battery

ActiveCN103911088ASticky enoughEnough durabilityNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceDiacrylate ester

The invention provides an acrylic ester pressure-sensitive adhesive tape and a preparation method of the acrylic ester pressure-sensitive adhesive tape and a lithium ion battery using the acrylic ester pressure-sensitive adhesive tape. The acrylic ester pressure-sensitive adhesive tape comprises a substrate and pressure-sensitive adhesive on the surface of the substrate, wherein the pressure-sensitive adhesive comprises an acrylic ester copolymer and a crosslinking and curing agent; the acrylic ester copolymer is obtained by the polymerization of acrylic ester monomers; the acrylic ester monomers comprise a first acrylic ester monomer, a second acrylic ester monomer and a third acrylic ester monomer; the first acrylic ester monomer comprises the acrylic ester monomer with low glass-transition temperature; the second acrylic ester monomer comprises the acrylic ester monomer with high glass-transition temperature; the third acrylic ester monomer comprises functional acrylic ester monomer. The acrylic ester pressure-sensitive adhesive tape is easy to produce, convenient to use, and low in cost, has sufficient viscosity and durability, and can withstand long-time soaking in electrolyte.

Owner:SHENZHEN MEIXIN ELECTRONICS

Preparation method and application of hydrogel

InactiveCN103665397ARealize non-invasive surgeryFacilitate dissociationProsthesisPolymer scienceDiacrylate ester

The invention belongs to the technical field of polymer materials, relates to water-insoluble hydrogel based on high-molecular-weight polyethylene glycol diacrylate (PEGDA), and in particular relates to a method for preparing hydrogel by performing polymerization on high-molecular-weight PEGDA and thiolated hyaluronic acid and an application of the hydrogel. The method is simple, convenient and efficient, a variety of different gels can be prepared according to different requirements, and the application of a situ gel can be performed.

Owner:广州恩柯肽医药科技有限公司

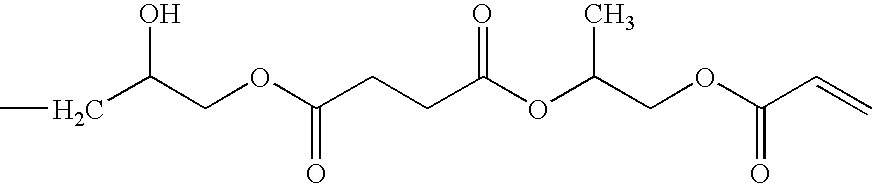

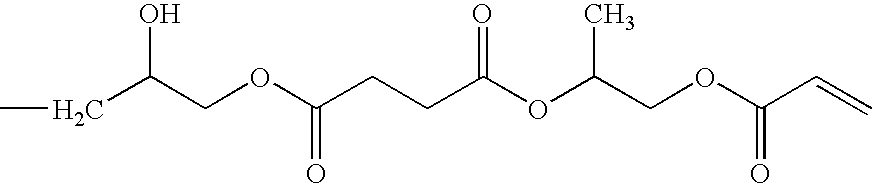

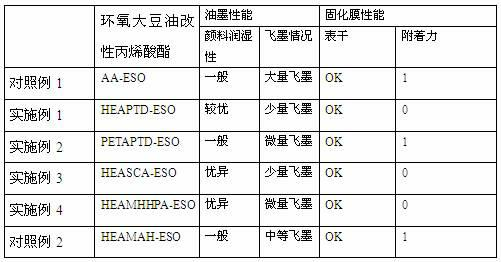

Acrylic acid ester modified epoxy soybean oil, its preparation method and application thereof

ActiveCN102660387ANovel structureImprove adhesionOrganic chemistryFatty acid chemical modificationPolymer scienceMeth-

The invention discloses an acrylic acid ester modified epoxy soybean oil, its preparation method and an application thereof. According to the preparation method of the acrylic acid ester modified epoxy soybean oil, acrylate monomer bearing a hydroxyl group reacts with acid anhydride to obtain a half-ester intermediate, and the half-ester intermediate reacts with epoxy soybean oil to obtain the acrylic acid ester modified epoxy soybean oil. The acrylate monomer bearing a hydroxyl group is hydroxyethyl acrylate, hydroxyethyl methacrylate, pentaerythritol triarylate, hydroxypropyl acrylate, hydroxypropyl methacrylate, trimethylol propane diacrylate or trimethylol propane dimethacrylate. Acid anhydride is o phthalic anhydride, succinic anhydride, methyl hexahydrophthalicanhydride, hexahydrophthalic anhydride or tetrahydrophthalic anhydride. The acrylic acid ester modified epoxy soybean oil has a novel structure. When applied in paper printing ink, the acrylic acid ester modified epoxy soybean oil can improve adhesive force of a cured film and also can improve wetability of pigments and remarkably minimize occurrence of misting. The preparation method helps widen the application range of the modified epoxy soybean oil.

Owner:GUANGDONG BOSSIN NOVEL MATERIALS TECH CO LTD

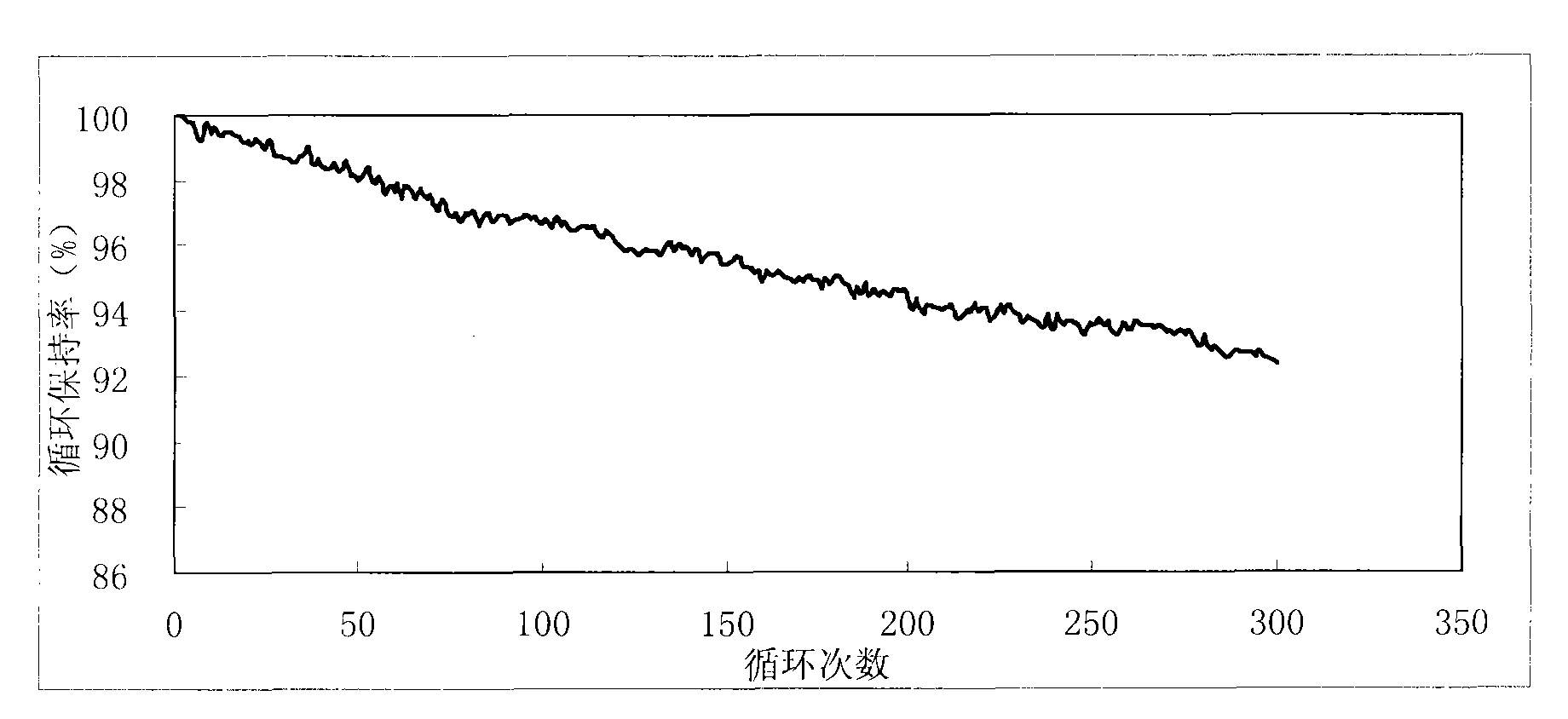

Preparation method of polymer lithium ion battery

ActiveCN101685878AStable structureMeet capacityCell electrodesFinal product manufactureHigh temperature storagePolymer science

The invention belongs to a preparation method of a polymer lithium ion battery in the technical field of battery product development, which is characterized in that the polymer lithium ion battery comprises an anode system, a cathode system and gel polymer electrolyte, wherein, the anode system adopts lithium manganate and lithium nickelate cobaltate manganate in a weight ratio of 1:1-4, the cathode system adopts natural graphite and / or artificial graphite in a weight ratio of 0-100:100-0, the gel polymer electrolyte comprises a monomer / an initiator / organic electrolyte, the monomer is methyl acrylate / tetraethenol diacrylate, the initiator is a radical initiator, the organic electrolyte is ethylene carbonate / methyl ethyl carbonate / diethyl carbonate. The product prepared by the invention canmeet the requirements of the battery on capacity and overcharge protection, is excellent in high temperature storage and cyclicity and is widely applied to such electronic equipment as MP3, MP4, portable DVD and the like.

Owner:ZHENGZHOU BAK BATTERY CO LTD

Active energy ray-curable inkjet ink composition and printed material using same

InactiveUS20140212634A1Good compatibilityExcellent property discharge propertyDecorative surface effectsDuplicating/marking methodsDiacrylate esterEthyl acrylate

Provided is an ink composition used in active energy ray-curable inkjet printing, which has excellent curing property, discharge property, storage stability, and compatibility with various substrates. The inkjet ink composition of the present invention includes at least two types of polymerizable compounds selected from a group consisting of (A) 2-(2-vinyloxyethoxy)ethyl acrylate, (B) N-vinyl caprolactam, and (C) at least one type of bifunctional acrylate monomer including at least a diacrylate having a molecular weight of 250 or less.

Owner:TOYOCOLOR CO LTD +1

Photo-curable resin composition

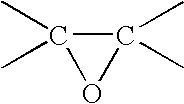

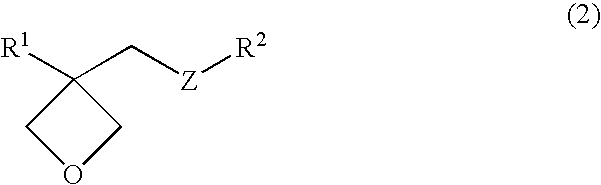

InactiveUS20080103226A1Additive manufacturing apparatus3D object support structuresPolyolDiacrylate ester

The invention relates to a radiation curable composition comprising from about 50 wt % to about 70 wt % of a cycloaliphatic diepoxide, from about 5 wt % to about 15 wt % of a polyol, from about 5 wt % to about 15 wt % of an oxetane, from about 10 wt % to about 20 wt % of an aromatic diacrylate, a radical photoinitiator and a cationic photoinitiator. The invention further relates to a process for making a three dimensional article from the resin composition of the invention, to the three-dimensional article itself and to the use of the composition of the invention.

Owner:DSM IP ASSETS BV

Anisotropic conductive film composition, the anisotropic conductive film thereof and semiconductor device

ActiveCN103160217APrevents reduction in electrical connection reliabilityStrong adhesionNon-insulated conductorsFilm/foil adhesivesAnisotropic conductive filmPolyester

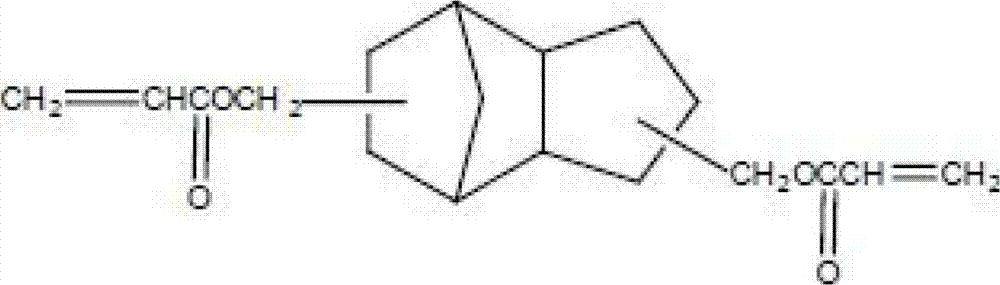

The invention discloses an anisotropic conductive film composition comprising a binding agent containing at least one of polyester type polyurethane resin, polyurethane acrylate resin, and carbamic acid ester resin; ethylene-acetic acid vinyl ester copolymer; materials capable of free radical polymerization containing tricyclodecane dimethanol diacrylate or tricyclodecane dimethanol dimethyl methacrylate; and organic particles. To be specific, the invention relates to a resin composition used for connection of the circuit and a film, which is provided with an extension rate in a range from 10 to 100% after the solidification and has no obvious retraction and expansion in the connection structure. The reliability of the electric connection under the high temperature and high humidity condition can be reduced. The invention also provides a semiconductor device containing the above mentioned anisotropic conductive film.

Owner:KUKDO ADVANCED MATERIALS CO LTD

Amino silicone oil emulsions crosslinked by reactions similar to a Michael addition

InactiveUS6177511B1Improve heat resistanceGood shear stabilityFibre treatmentDrageesWater insolubleIon

Novel organopolysiloxane compositions comprising(A) organopolysiloxanes which contain at least one SiC-bonded organic radical containing basic nitrogen, where the basic nitrogen is optionally present in part as a salt of a water-soluble organic acid, water-soluble inorganic acid, or water-insoluble organic acid,(B) anionic, cationic, nonionic or amphoteric surfactants, which are in soluble or soluble in (A)(C) substituted or unsubstituted diacrylates and / or oligoacrylates, and optionally,(C') substituted or unsubstituted acrylates, and(D) water are described.

Owner:WACKER CHEM GMBH

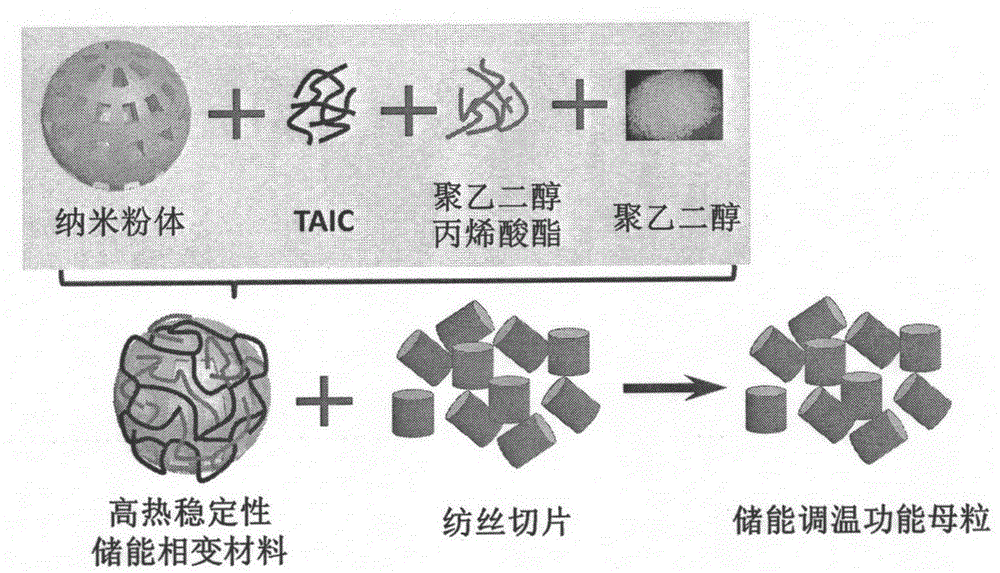

Preparation method for energy-storing and temperature-adjusting phase-change material and fibres thereof

ActiveCN104910334AStrong energy storage and temperature control abilityReduce manufacturing costHeat-exchange elementsArtifical filament manufacturePolymer scienceHigh energy

The invention provides a preparation method for an energy-storing and temperature-adjusting phase-change material and fibres thereof. The preparation method for the energy-storing and temperature-adjusting phase-change material is characterized by comprising the following specific steps: placing porous nano-powder, triallyl isocyanurate, polyethylene glycol acrylate, polyethylene glycol and an initiator in solvent water, reacting for 2-5 hours at 65-75 DEG C by means of reduced pressure ultrasonic dispersion, and finally centrifugally dewatering to obtain the energy-storing and temperature-adjusting phase-change material. The energy-storing and temperature-adjusting phase-change material is subjected to drying treatment, then sliced with polymers and blended and granulated through a double-screw extruder, and then subjected to melt-spinning to obtain the energy-storing and temperature-adjusting fibres. The phase-change energy-storing material prepared by the preparation method provided by the invention has the characteristic of high energy-storing and temperature-controlling capacity, and has the advantages of low preparation cost, good heat-resistant stability and simple operation.

Owner:DONGHUA UNIV

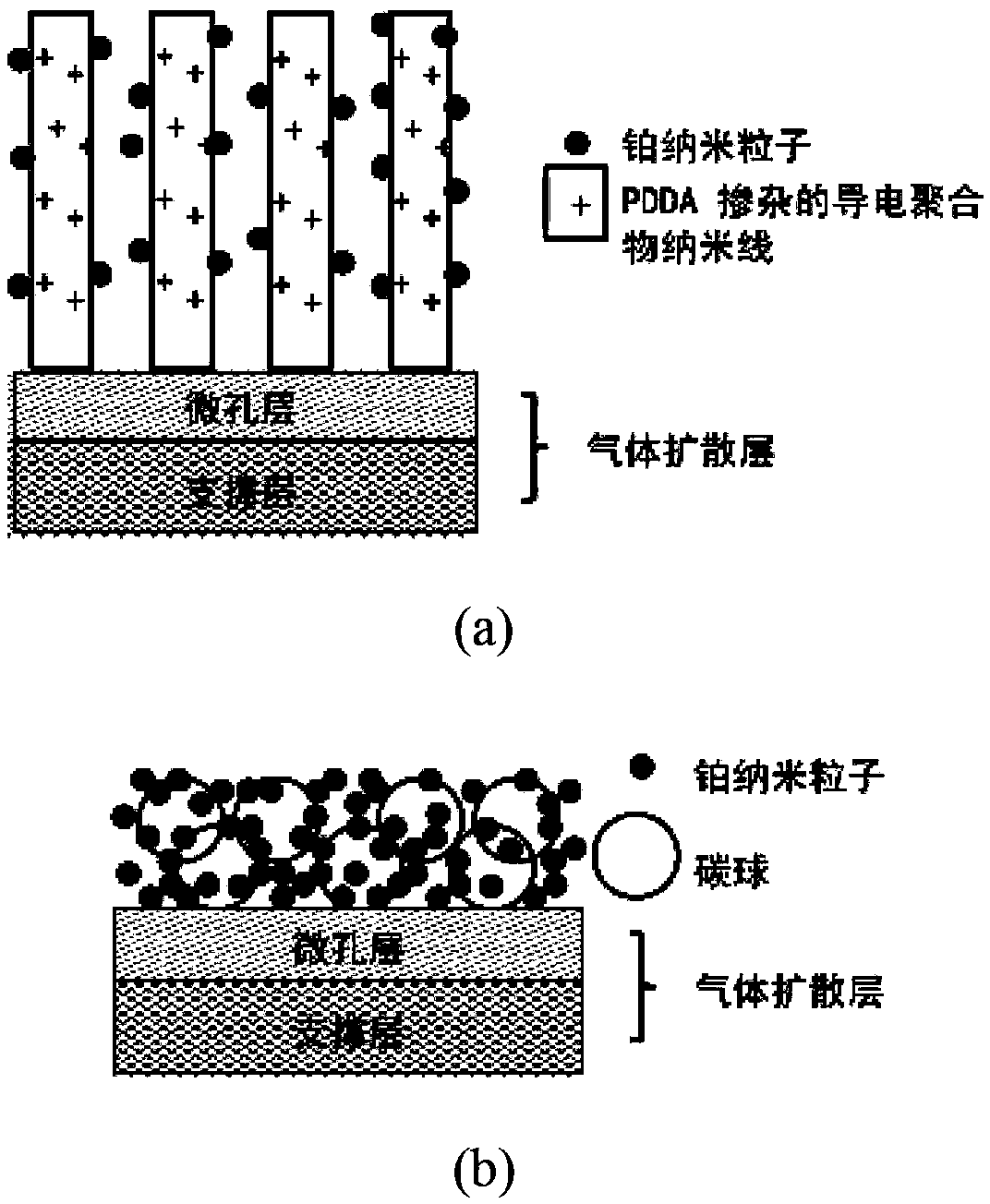

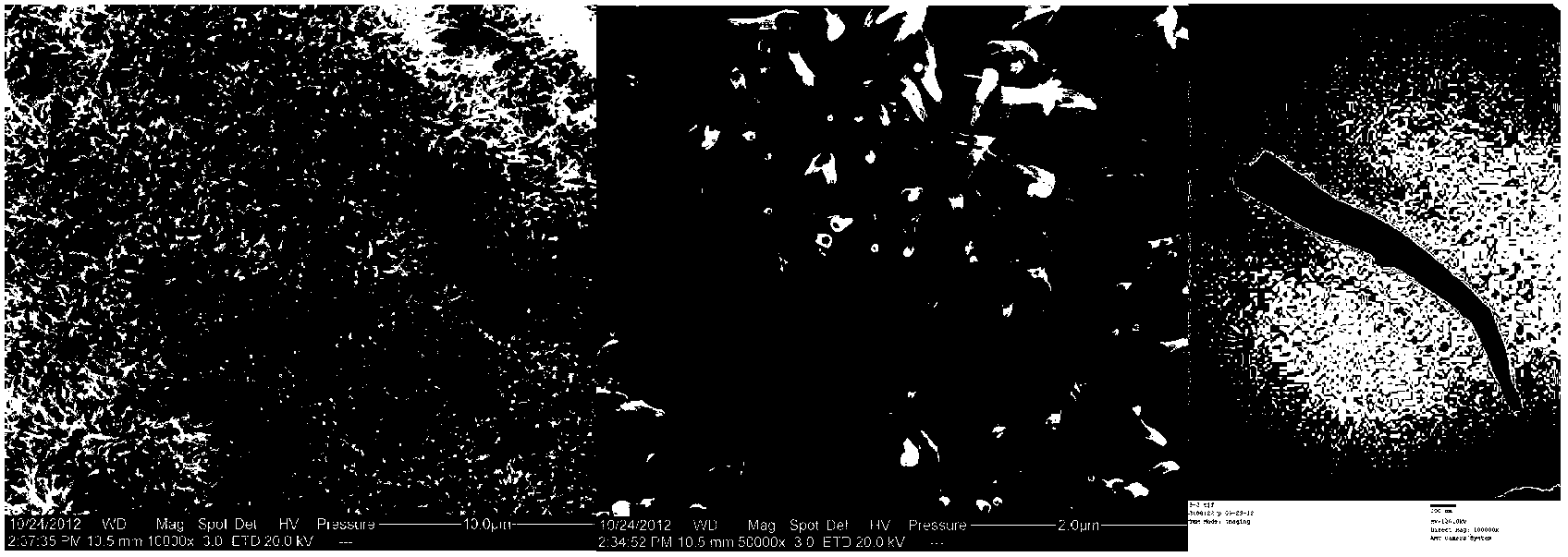

Ordered gas diffusion electrode and preparation and application thereof

The invention relates to an ordered gas diffusion electrode, preparation and application thereof. The membrane electrode comprises a gas diffusion layer and a catalysis layer; the catalysis layer is an ordered catalysis layer, and is formed by interaction of conductive polymer nanowires arranged in an ordered array manner on the gas diffusion layer surface and phthalic acid diethylene glycol diacrylate (PDDA) doped on the surface of the conductive polymer nanowires with Pt catalyst particles. The ordered membrane electrode of the invention has the advantages of high utilization rate of precious metal Pt, high stability, and the like, can effectively reduces catalyst cost of fuel cells, and can improve the service life of fuel cells; meanwhile, the membrane electrode of the invention can effectively enhance the mass transfer of fuel in the catalysis layer, thereby improving the fuel utilization rate; the ordered membrane electrode of the invention can be used as a membrane electrode of proton exchange membrane fuel cells, direct liquid fuel cells, and proton exchange membrane water-type electrolytic baths.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Curable adhesive composition and its use in the optical field

InactiveUS20050250870A1Improve adhesionMechanical properties are not damagedOptical articlesInksOligomerMeth-

The invention concerns a photocurable adhesive composition comprising, based on total weight of photopolymerizable monomers and / or oligomers of the composition: (A1) 20 to 80 wt % of at least one diacrylate monomer or oligomer thereof (A1); (A2) 80 to 20 wt % of at least one dimethacrylate monomer or oligomer thereof; (B) 0 to 50 wt %, of at least one copolymerizable monomer different from components (A1) and (A2); with the proviso that the composition is free from any thio(meth)acrylate (—SCOCR′=CH2, with R′=H or CH3) monomer or oligomer thereof.

Owner:ESSILOR INT CIE GEN DOPTIQUE

Photopolymerizable inkjet ink

ActiveUS20140240414A1Low viscosityImprove curing effectImpression capsMixing methodsPentaerythritolDiacrylate ester

To provide a photopolymerizable inkjet ink, which contains photopolymerizable monomers containing at least one selected from the following compound group (A) compounds of which are negative for skin sensitization, and at least one selected from the following compound group (B) compounds of which are negative for skin sensitization, wherein the compound group (A) is a compound group consisting of caprolactone-modified dipentaerythritol hexaacrylate, polyethoxylated tetramethylol methane tetraacrylate, ethylene oxide-modified bisphenol A diacrylate, caprolactone-modified hydroxy pivalic acid neopentyl glycol diacrylate, polypropylene glycol diacrylate [CH2═CH—CO—(OC3H6)n-OCOCH═CH2 (n≈12)], hydroxyethyl acryl amide, trimethylol propane trimethacrylate, and tricyclodecane dimethanol dimethacrylate, and the compound group (B) is a compound group consisting of ethylene oxide-modified phenolacrylate, isostearyl acrylate, ethylene oxide-modified trimethylol propane trimethacrylate, stearyl methacrylate, and glycerin dimethacrylate.

Owner:RICOH KK

High gloss high abrasion resistance ultra-violet curing overprinting varnish of mobile phone and preparation method thereof

InactiveCN101967338AImprove wear resistanceHigh gloss and high wear resistancePolyurea/polyurethane coatingsPolyester coatingsIsooctyl acrylatePolyester

The invention discloses a high gloss high abrasion resistance ultra-violet (UV) curing overprinting varnish of mobile phone and a preparation method thereof. The method of the invention uses low-viscosity polyester acrylate and aliphatic polyurethane acrylate as base resin which combines with ethoxylated pentaerythritol tetraacrylate, Trimethylolpropane triacrylate, Tri(propylene glycol) diacrylate, 1,6-hexanediol diacrylate and 2-ethylhexyl acrylate which are used as active diluent, alcohol and ethyl acetate which are used as diluent, benzophenone and 1-hydroxycyclohexyl phenyl ketone which are used as photoinitiator, reactive amine coinitiator, defoaming agent, flatting agent, slip agent and other agents to mix evenly and prepare the UV overprinting varnish. The overprinting varnish of the invention adopts the special raw material formula and has good lustrousness, adhesive force and mechanical stability; as some polyfunctional resins and resins with special functional groups are added, the crosslink density of the UV varnish is increased in the curing process and the hardness of the product is up to 5-7H; and as solid wax powder used as the slip agent is added, the coefficients of friction can be reduced and the product can have extremely high wear resistance.

Owner:苏州凯康化工科技有限公司

Radiation-curable ink composition, ink jet recording method, and recorded matter

ActiveUS20110251298A1Increase flexibilityExcellent in elongation durabilityLiquid surface applicatorsDuplicating/marking methodsDiacrylate esterPhosphine oxide

Owner:SEIKO EPSON CORP

Interpenetrating polymer network hydrogel corneal prosthesis

InactiveUS7909867B2High tensile strengthImprove permeabilityNervous system cellsArtificial cell constructsHydrophilic monomerCross-link

The present invention provides materials that have high glucose and oxygen permeability, strength, water content, and resistance to protein adsorption. The materials include an interpenetrating polymer network (IPN) hydrogel that is coated with biomolecules. The IPN hydrogels include two interpenetrating polymer networks. The first polymer network is based on a hydrophilic telechelic macromonomer. The second polymer network is based on a hydrophilic monomer. The hydrophilic monomer is polymerized and cross-linked to form the second polymer network in the presence of the first polymer network. In a preferred embodiment, the hydrophilic telechelic macromonomer is PEG-diacrylate or PEG-dimethacrylate and the hydrophilic monomer is an acrylic-based monomer. Any biomolecules may be linked to the IPN hydrogels, but are preferably biomolecules that support the growth of cornea-derived cells. The material is designed to serve as a corneal prosthesis.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com