Preparation method of polymer lithium ion battery

A lithium-ion battery and polymer technology, applied in the manufacture of electrolyte batteries, battery electrodes, secondary batteries, etc., can solve the problems of cobalt resource shortage, high price, toxic promotion and use, etc., and achieve ultra-low cost, small discharge capacity, The effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

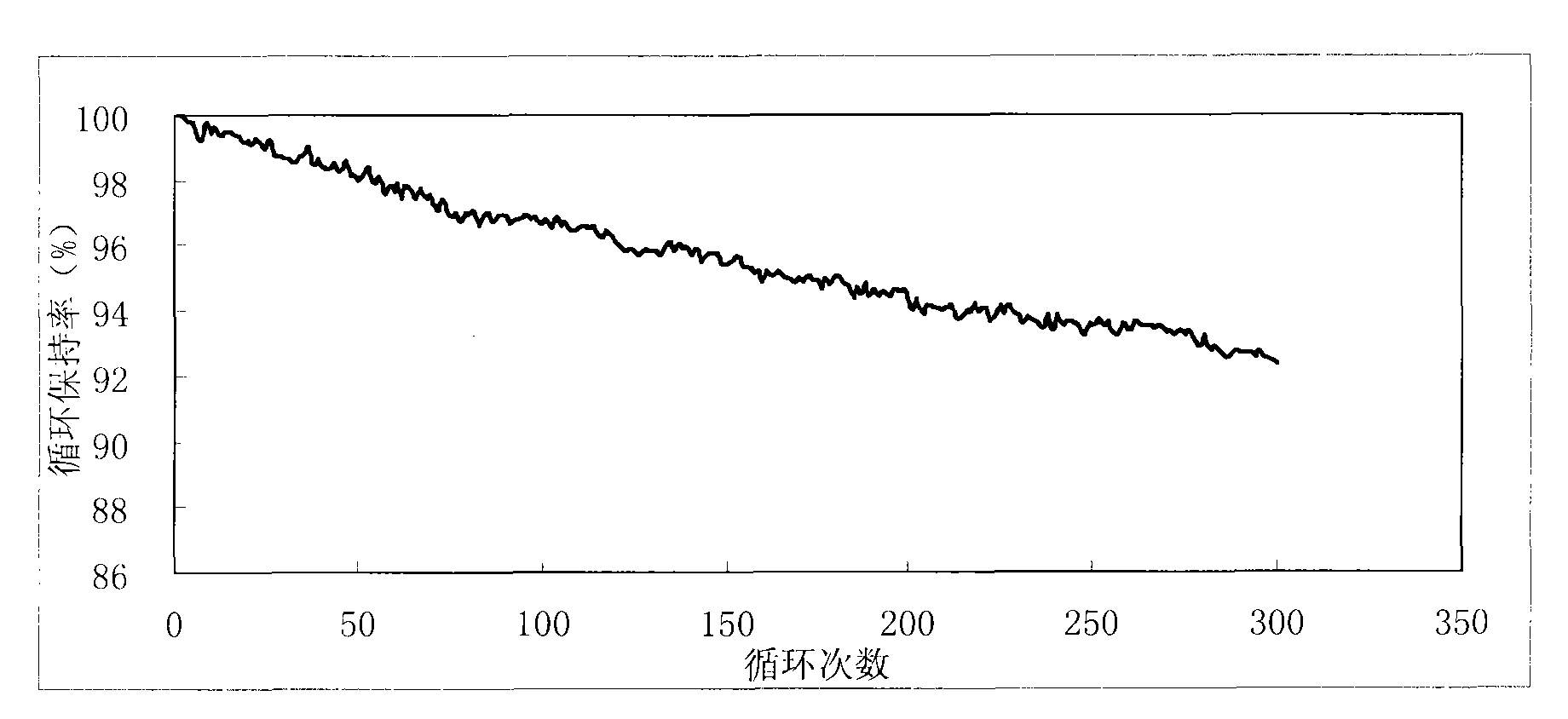

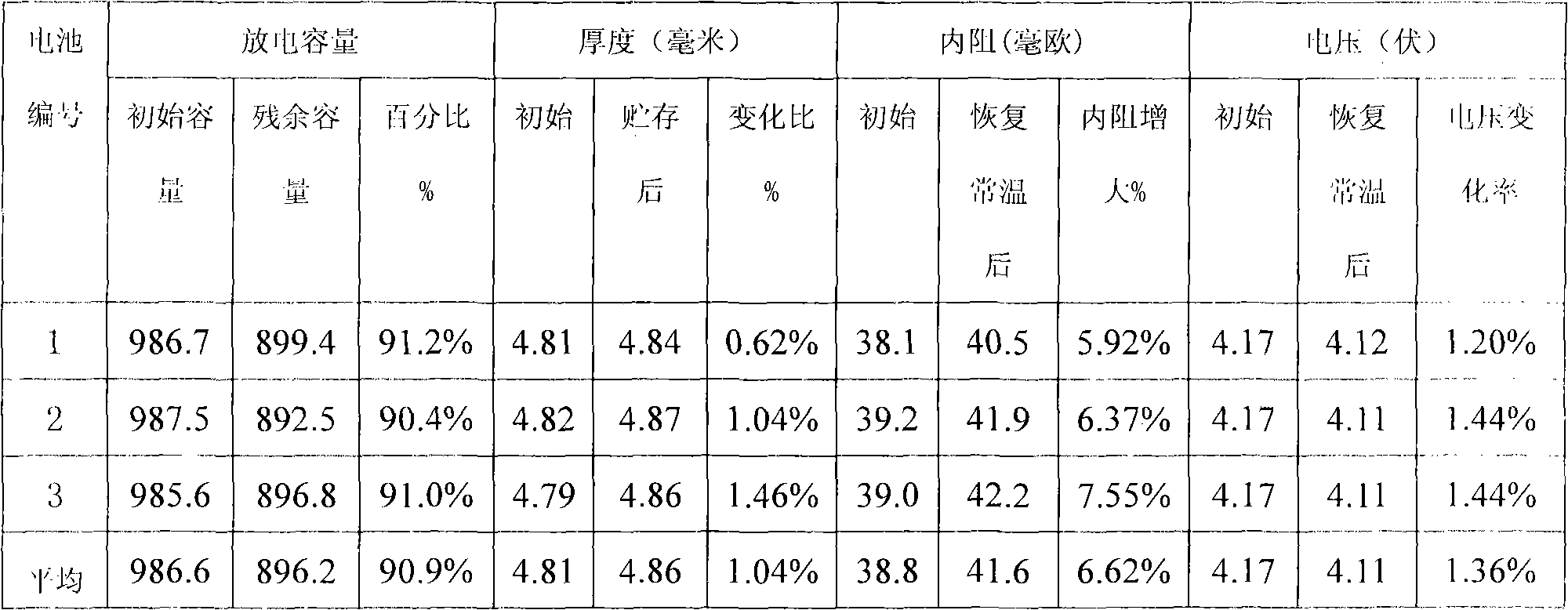

Embodiment 1

[0017] The preparation method of the polymer lithium ion battery of this example is characterized in that the polymer lithium ion battery is composed of a positive electrode system, a negative electrode system and a gel polymer electrolyte, wherein the positive electrode system is: lithium manganate and nickel cobalt manganic acid Lithium (LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 ), the weight ratio range of the two is 1:1; the negative electrode system: natural graphite and artificial graphite, the weight ratio range of the two is 1:1; the gel polymer electrolyte: it is composed of a monomer, an initiator, an organic electrolyte, The mass ratio of each component is: monomer: initiator: organic electrolyte = 1:0.03:18.6, the monomer is methyl acrylate (CH 2 =CH-COOCH 3 ) and tetraethylene alcohol diacrylate (mass ratio: 1:0.85), the initiator is dibenzoyl peroxide, the organic electrolyte is: EC / EMC / DEC (volume ratio: 1:0.2:1.4), lithium salt Concentration (LiPF 6 ): 1mol / L. Battery ...

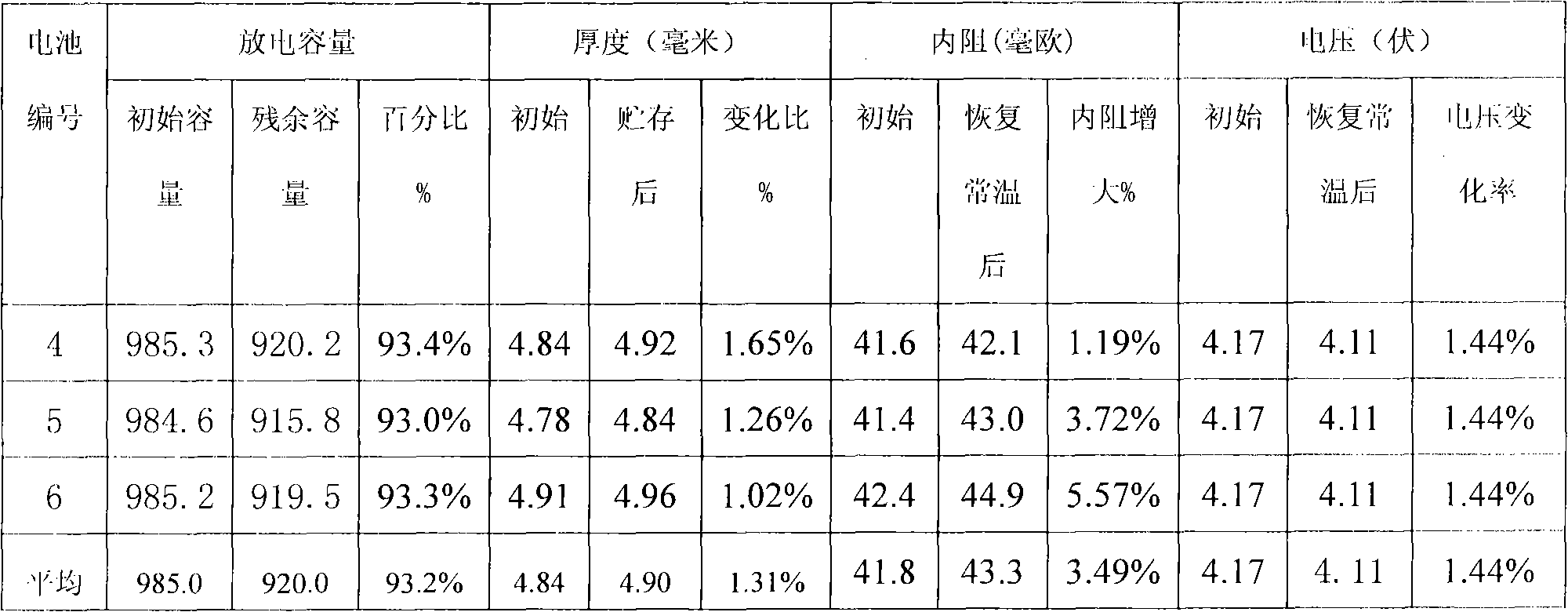

Embodiment 2

[0045] The preparation method of the polymer lithium ion battery of this example is characterized in that the polymer lithium ion battery is composed of a positive electrode system, a negative electrode system and a gel polymer electrolyte, wherein the positive electrode system is: lithium manganate and nickel cobalt manganic acid Lithium (LiNi 1 / 5 co 2 / 5 mn 2 / 5 o 2 ), the weight ratio range of the two is 1:2; the negative electrode system: natural graphite and artificial graphite, the weight ratio range of the two is 1:2.5; gel polymer electrolyte: it is composed of a monomer, an initiator, an organic electrolyte, The mass ratio of each component is: monomer: initiator: organic electrolyte = 1: 0.041: 19.6, the monomer is methyl acrylate (CH 2 =CH-COOCH 3 ) and tetraethylene alcohol diacrylate (mass ratio: 1:0.98), the initiator is dibenzoyl peroxide, the organic electrolyte is: EC / EMC / DEC (volume ratio: 1:0.8:2.1), lithium salt Concentration (LiPF 6 ): 1.18mol / L. Batt...

Embodiment 3

[0053] The preparation method of the polymer lithium ion battery of this example is characterized in that the polymer lithium ion battery is composed of a positive electrode system, a negative electrode system and a gel polymer electrolyte, wherein the positive electrode system is: lithium manganate and nickel cobalt manganic acid Lithium (LiNi 2 / 5 co 1 / 5 mn 2 / 5 o 2 ), the weight ratio range of the two is 1:4; the negative electrode system: natural graphite and artificial graphite, the weight ratio range of the two is 1:3.76; the gel polymer electrolyte: it is composed of a monomer, an initiator, an organic electrolyte, The mass ratio of each component is: monomer: initiator: organic electrolyte = 1:0.05:20.6, the monomer is methyl acrylate (CH 2 =CH-COOCH 3 ) and tetraethylene alcohol diacrylate (mass ratio: 1:1.22), the initiator is dibenzoyl peroxide, the organic electrolyte is: EC / EMC / DEC (volume ratio: 1:1:3), lithium salt Concentration (LiPF 6 ): 1.25mol / L. Batter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com