Patents

Literature

2042 results about "Manganate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In inorganic nomenclature, a manganate is any negatively charged molecular entity with manganese as the central atom. However, the name is usually used to refer to the tetraoxidomanganate(2−) anion, MnO²⁻₄, also known as manganate(VI) because it contains manganese in the +6 oxidation state. Manganates are the only known manganese(VI) compounds.

Lithium-ion secondary battery

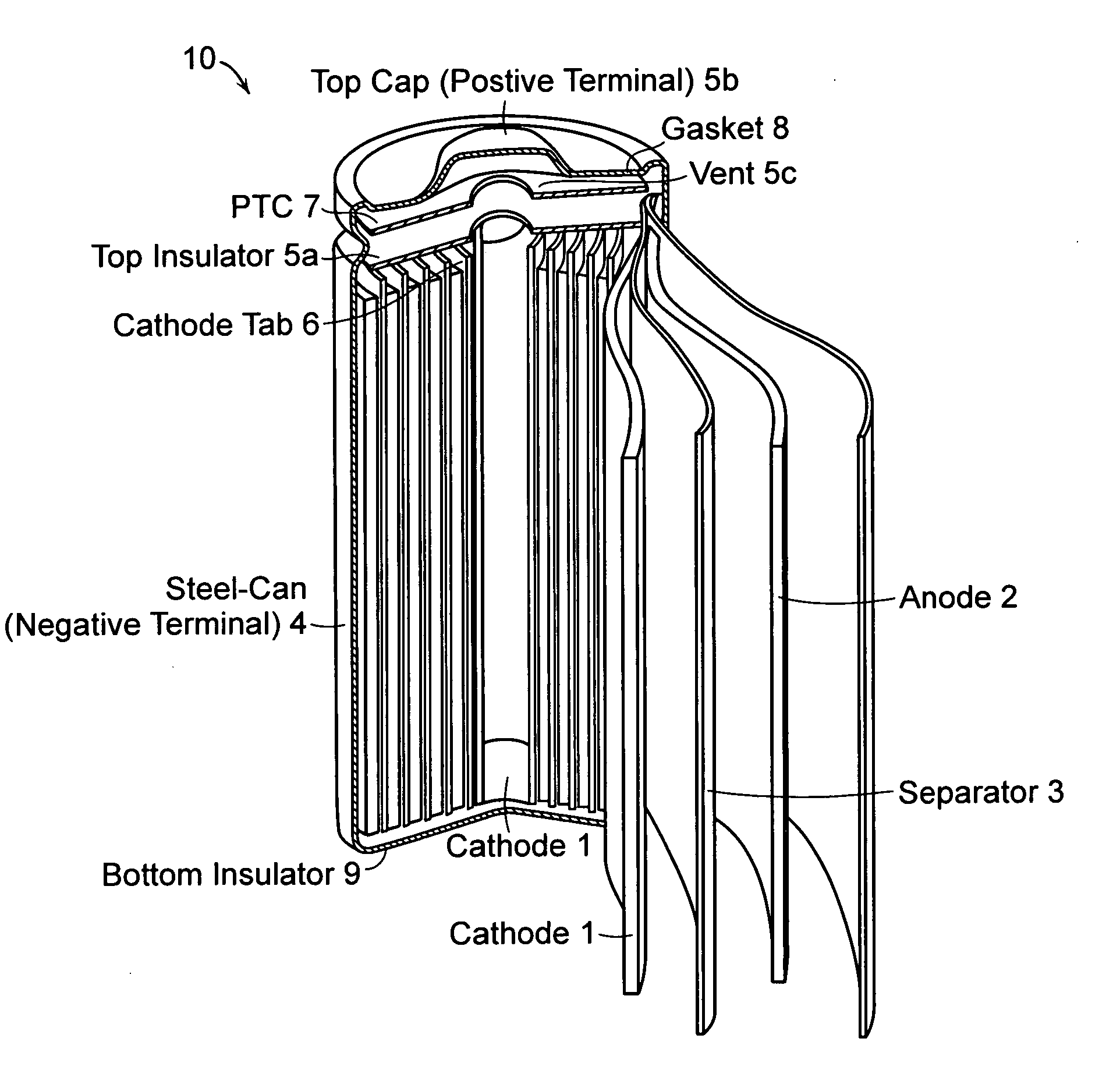

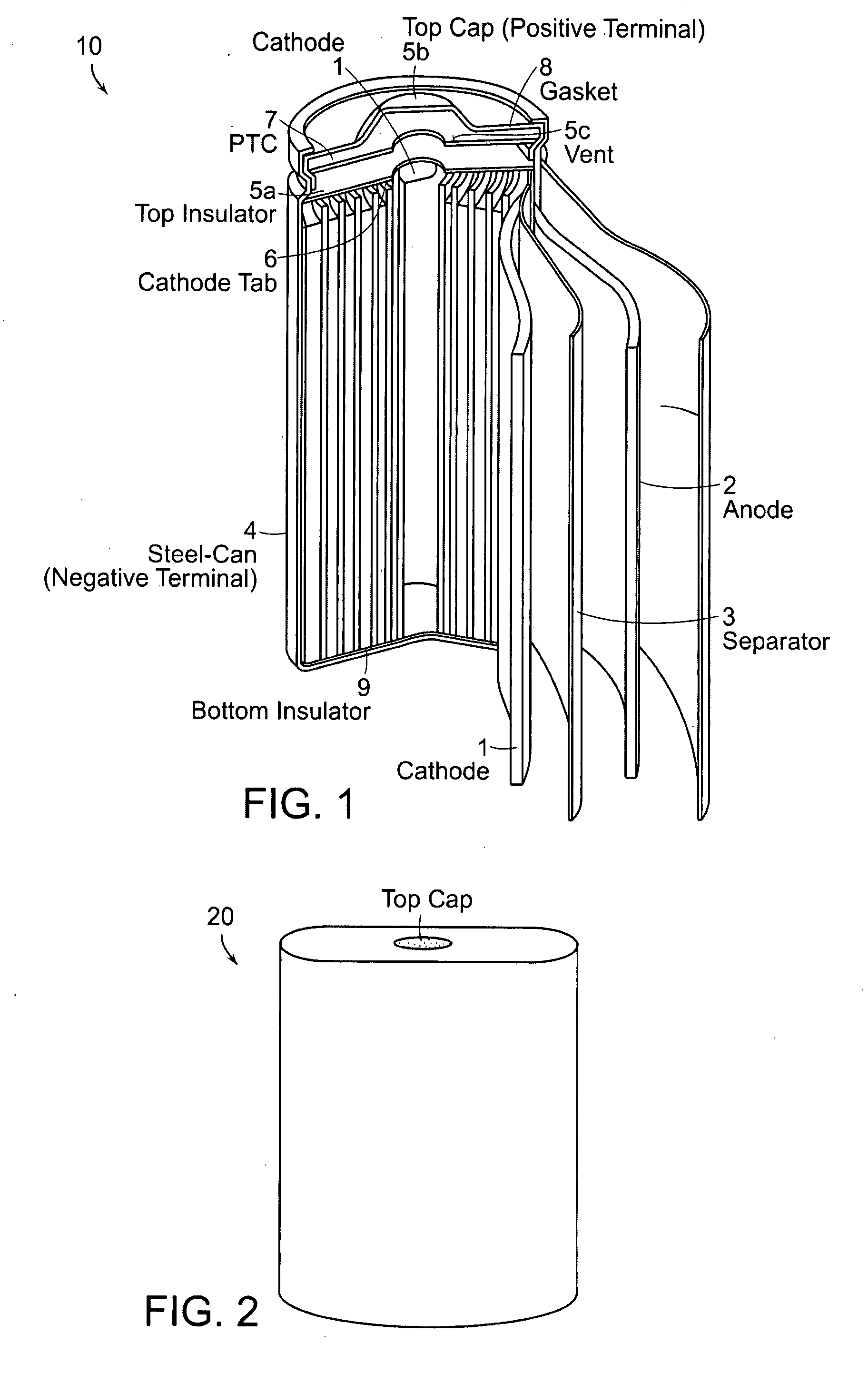

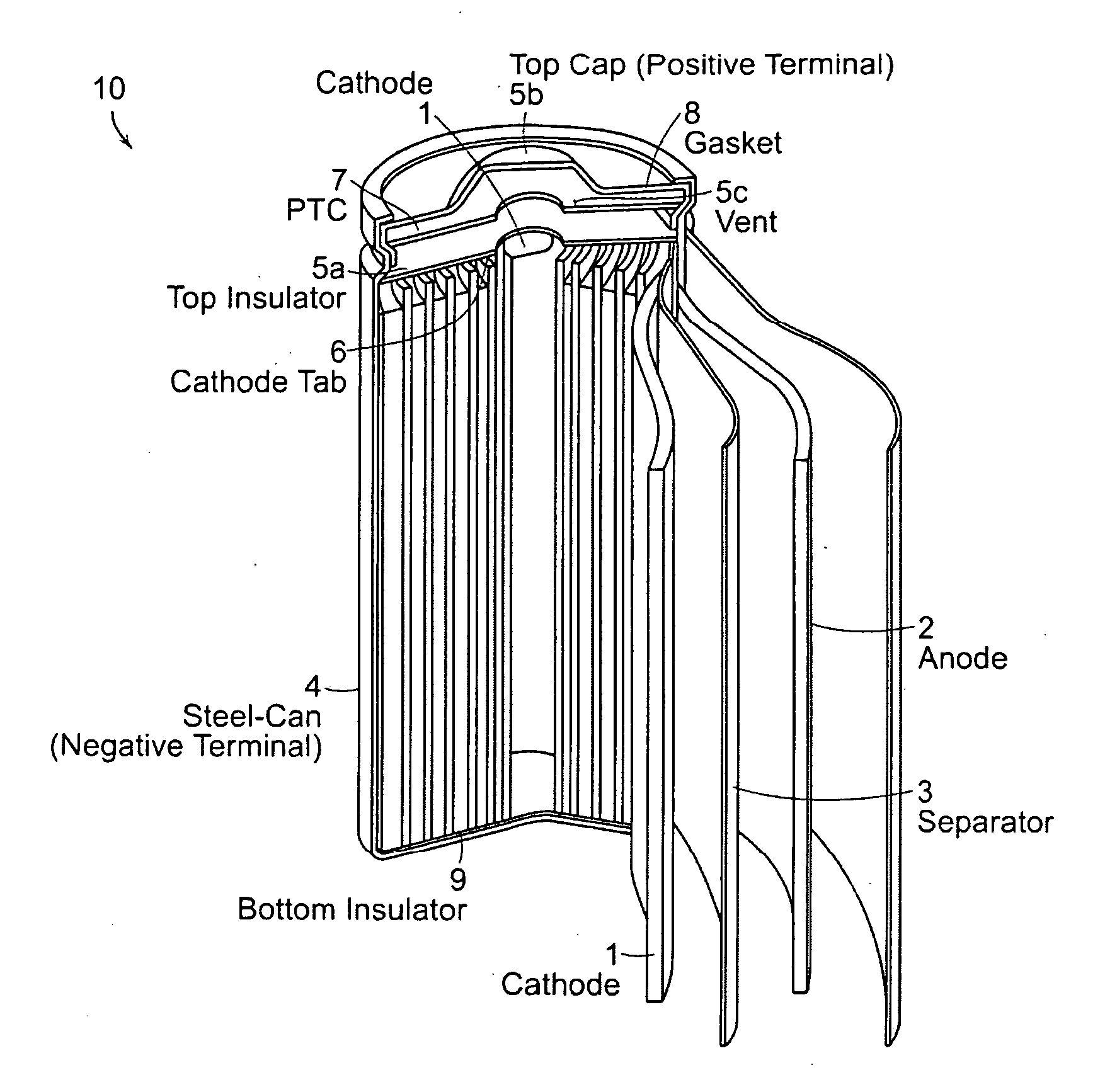

InactiveUS20070026315A1Safer chemistry characteristicLow cathode costPrimary cell to battery groupingFinal product manufactureManganateSpinel

A lithium-ion battery includes a cathode that includes an active cathode material. The active cathode material includes a cathode mixture that includes a lithium cobaltate and a manganate spinel a manganate spinel represented by an empirical formula of Li(1+x1)(Mn1−y1A′y2)2−x2Oz1. The lithium cobaltate and the manganate spinel are in a weight ratio of lithium cobaltate: manganate spinel between about 0.95:0.05 to about 0.55:0.45. A lithium-ion battery pack employs a cathode that includes an active cathode material as described above. A method of forming a lithium-ion battery includes the steps of forming an active cathode material as described above; forming a cathode electrode with the active cathode material; and forming an anode electrode in electrical contact with the cathode via an electrolyte.

Owner:BOSTON POWER INC

Lithium-ion secondary battery

InactiveUS20080008933A1Safer chemistry characteristicLow cathode costPrimary cell to battery groupingElectrode carriers/collectorsManganateManganese

In one embodiment, an active cathode material comprises a mixture that includes: at least one of a lithium cobaltate and a lithium nickelate; and at least one of a manganate spinel represented by an empirical formula of Li(1+x1)(Mn1−y1A′y1)2−x1Oz1 and an olivine compound represented by an empirical formula of Li(1−x2)A″x2MPO4. In another embodiment, an active cathode material comprises a mixture that includes: a lithium nickelate selected from the group consisting of LiCoO2-coated LiNi0.8Co0.15Al0.05O2, and Li(Ni1 / 3Co1 / 3Mn1 / 3)O2; and a manganate spinel represented by an empirical formula of Li(1+x7)Mn2−y7Oz7. A lithium-ion battery and a battery pack each independently employ a cathode that includes an active cathode material as described above. A method of forming a lithium-ion battery includes the steps of forming an active cathode material as described above; forming a cathode electrode with the active cathode material; and forming an anode electrode in electrical contact with the cathode via an electrolyte. A system comprises a portable electronic device and a battery pack or lithium-ion battery as described above.

Owner:BOSTON POWER INC

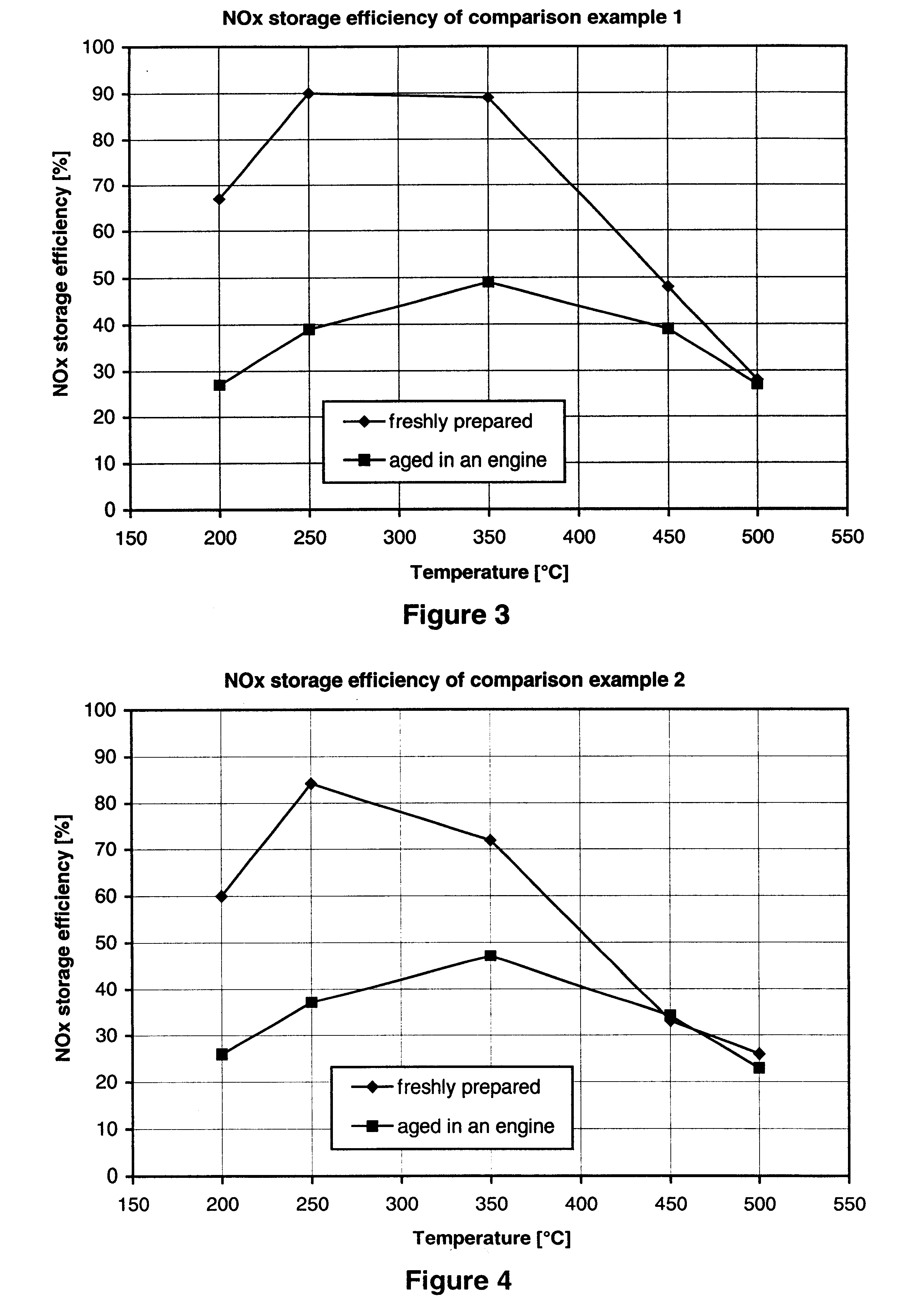

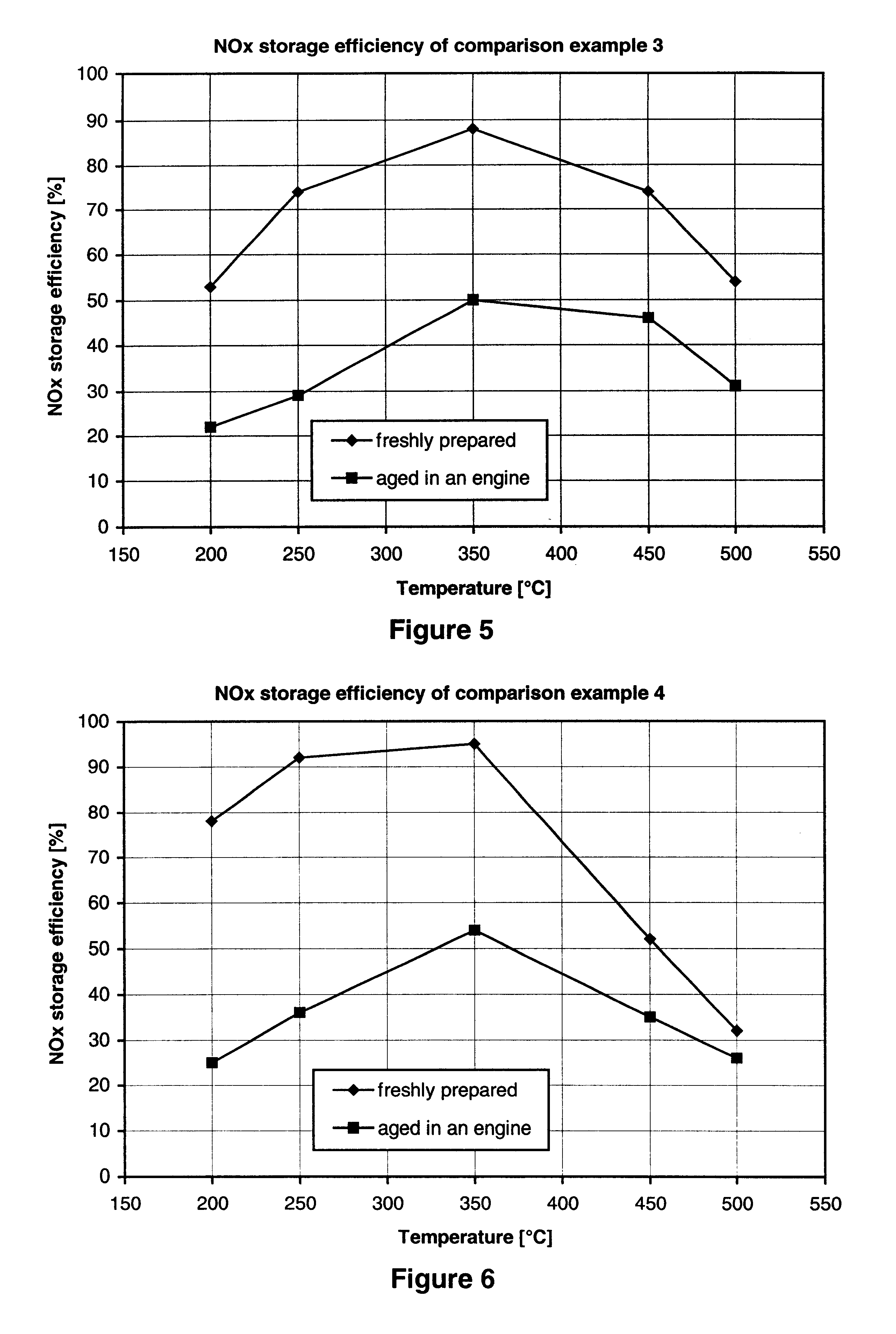

Nitrogen oxide storage material and nitrogen oxide storing catalyst prepared therefrom

InactiveUS6350421B1Determine efficiencyNitrogen compoundsExhaust apparatusAlkaline earth metalCuprate

A nitrogen oxide storage material is disclosed which contains at least one storage component for nitrogen oxides in the form of an oxide, mixed oxide, carbonate or hydroxide of the alkaline earth metals magnesium, calcium, strontium and barium and the alkali metals potassium and caesium on a high surface area support material. The support material can be doped cerium oxide, cerium / zirconium mixed oxide, calcium titanate, strontium titanate, barium titanate, barium stannate, barium zirconate, magnesium oxide, lanthanum oxide, praseodymium oxide, samarium oxide, neodymium oxide, yttrium oxide, zirconium silicate, yttrium barium cuprate, lead titanate, tin titanate, bismuth titanate, lanthanum cobaltate, lanthanum manganate and barium cuprate or mixtures thereof.

Owner:DMC2 DEGUSSA METALS +1

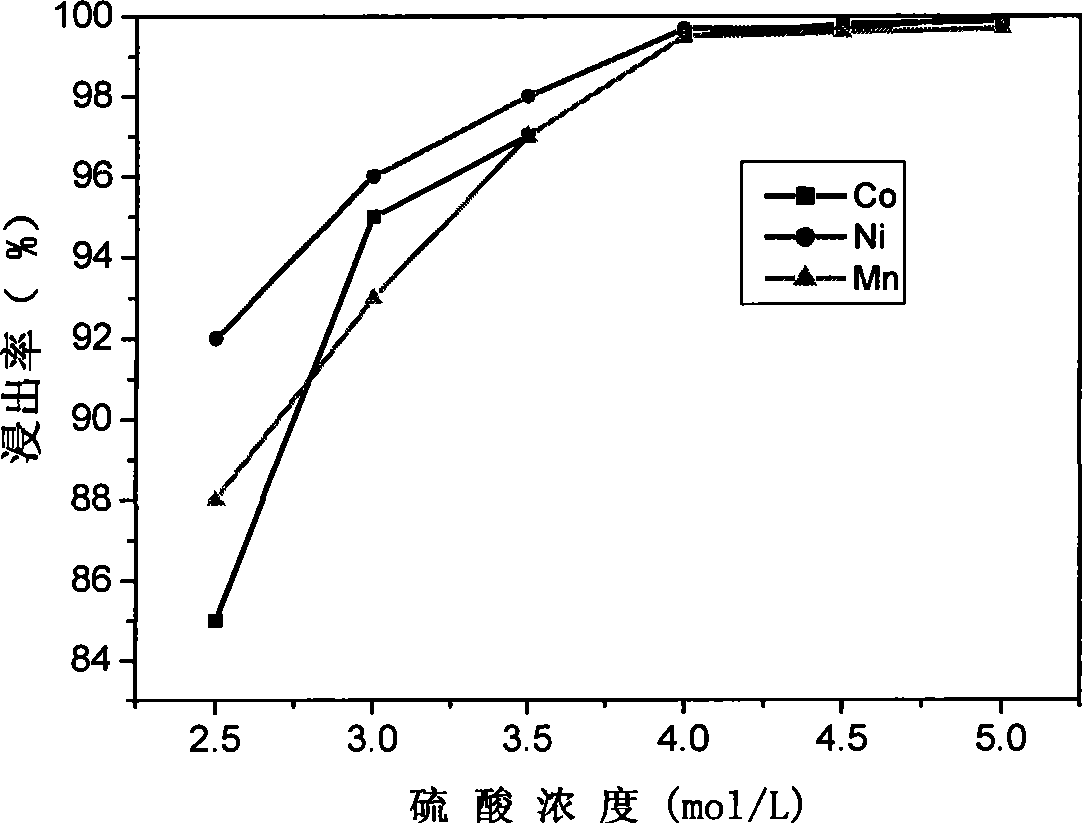

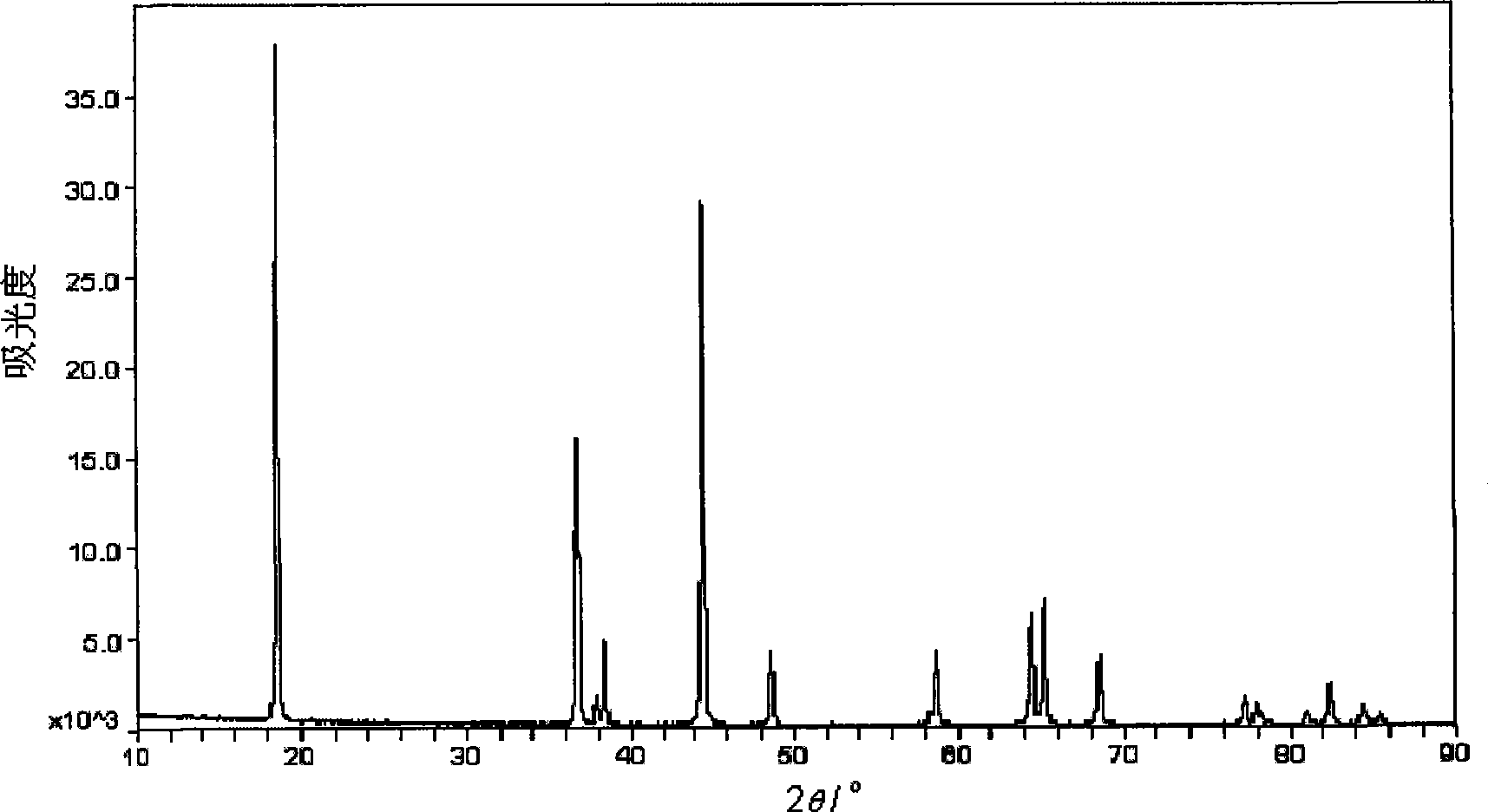

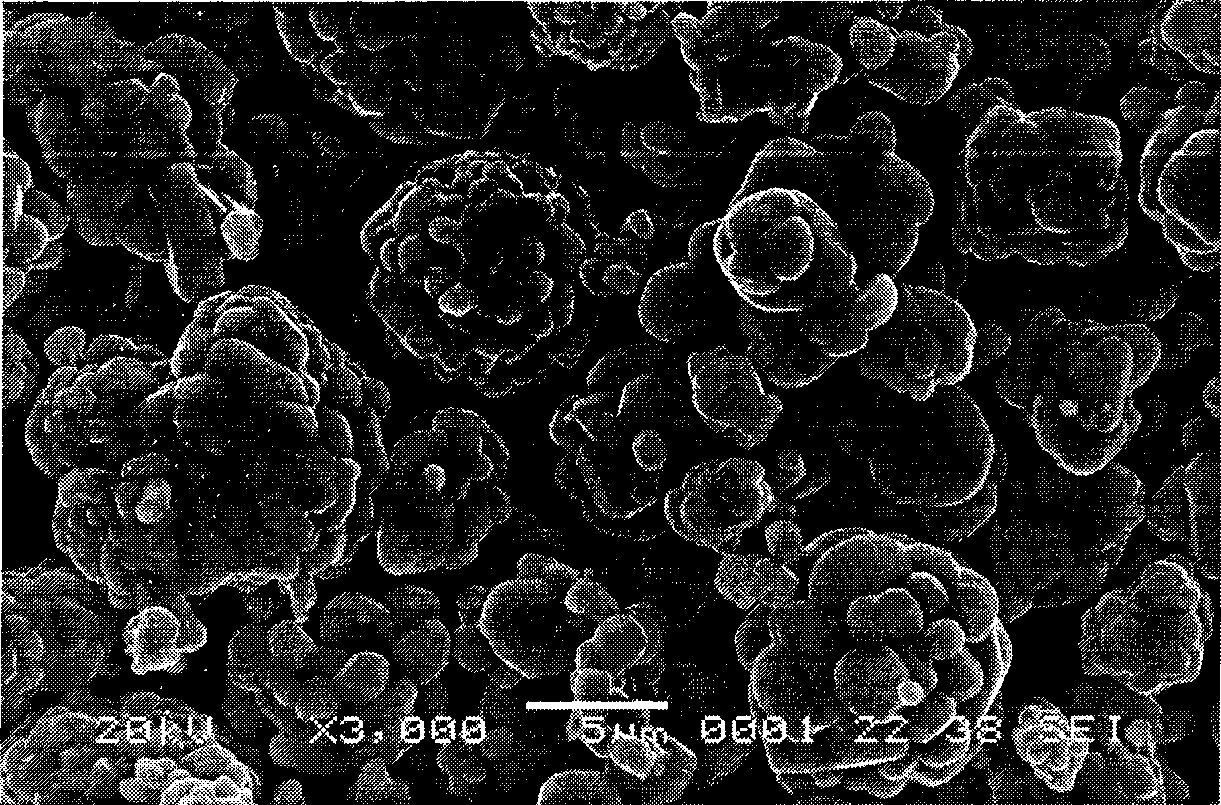

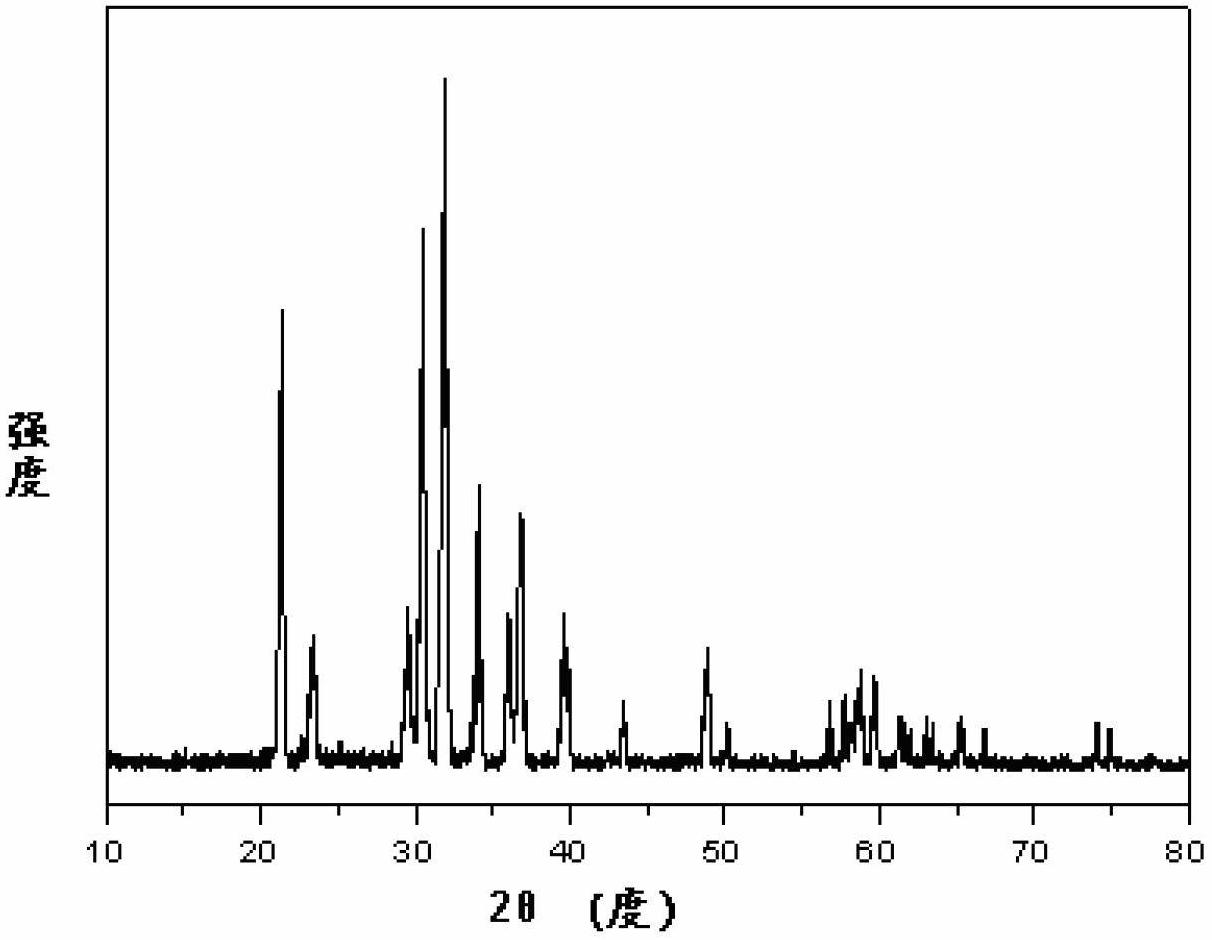

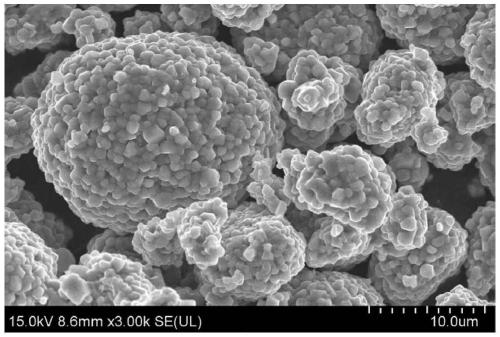

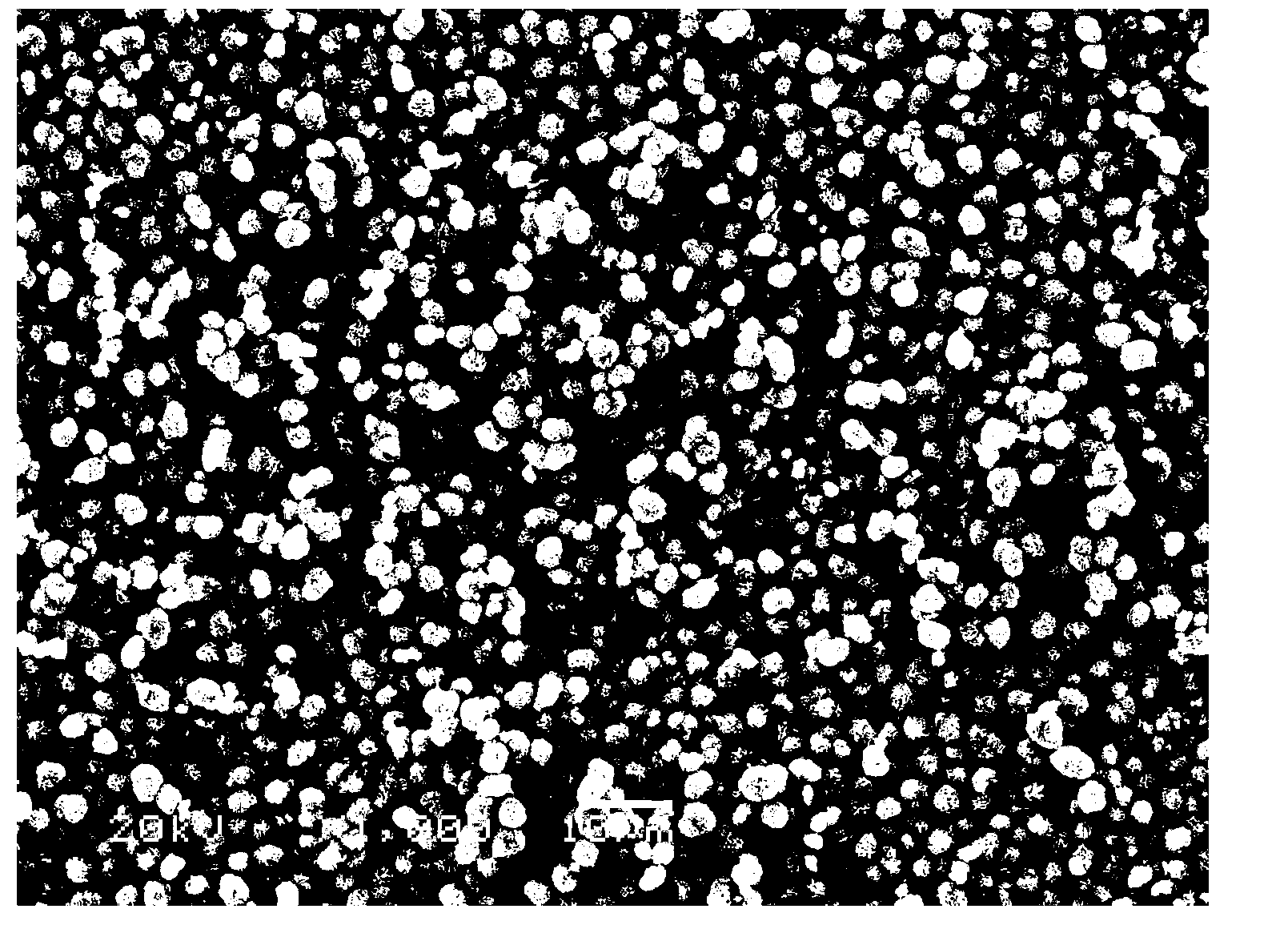

Process for preparing high density spherical nickel-cobalt lithium manganate as anode material of lithium ion cell

InactiveCN1622371AWell mixedImprove performanceElectrode manufacturing processesLithium compoundsNickel saltManganate

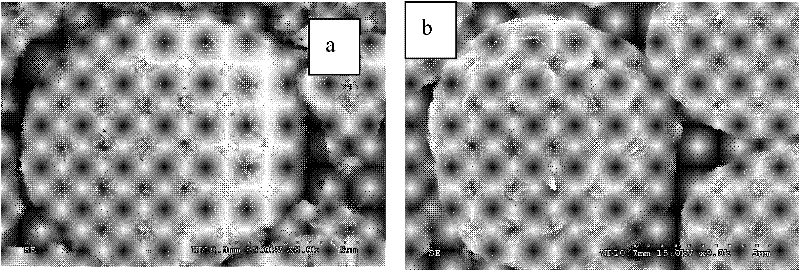

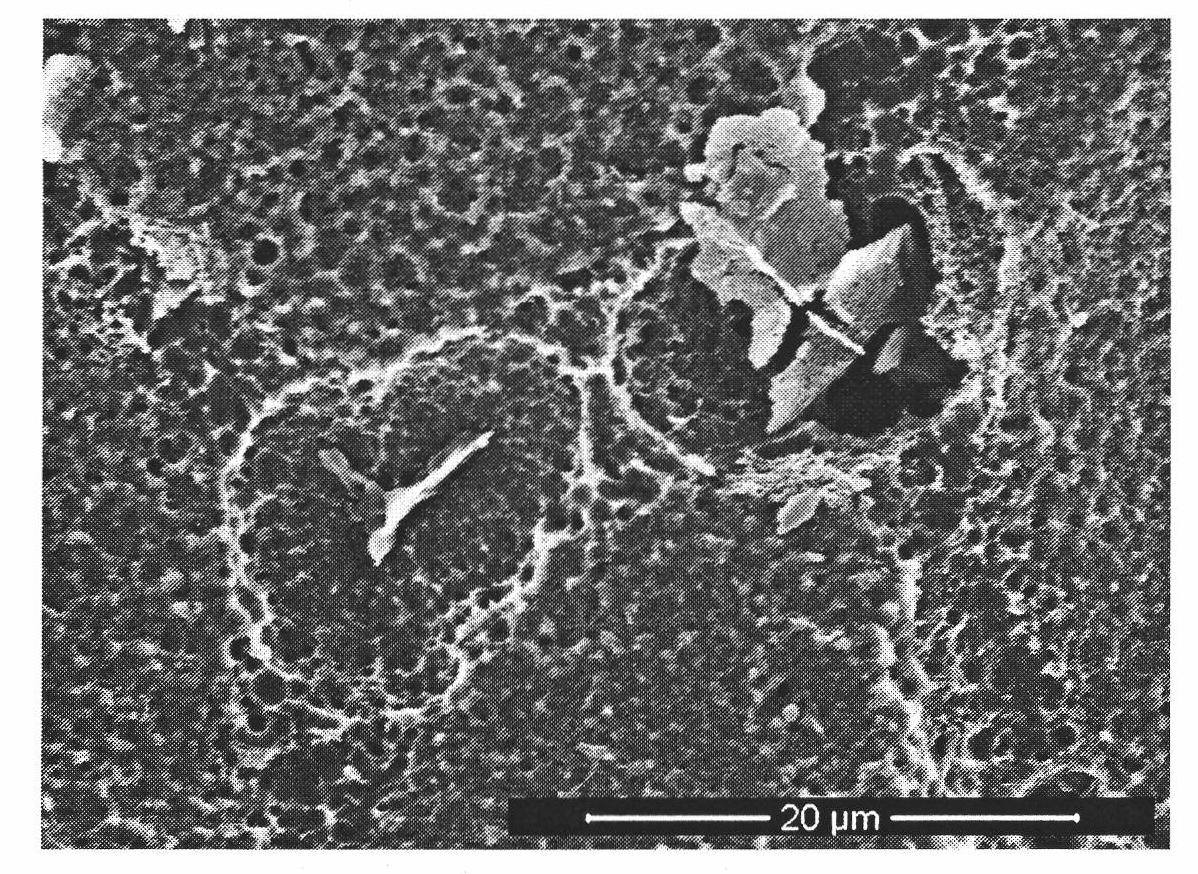

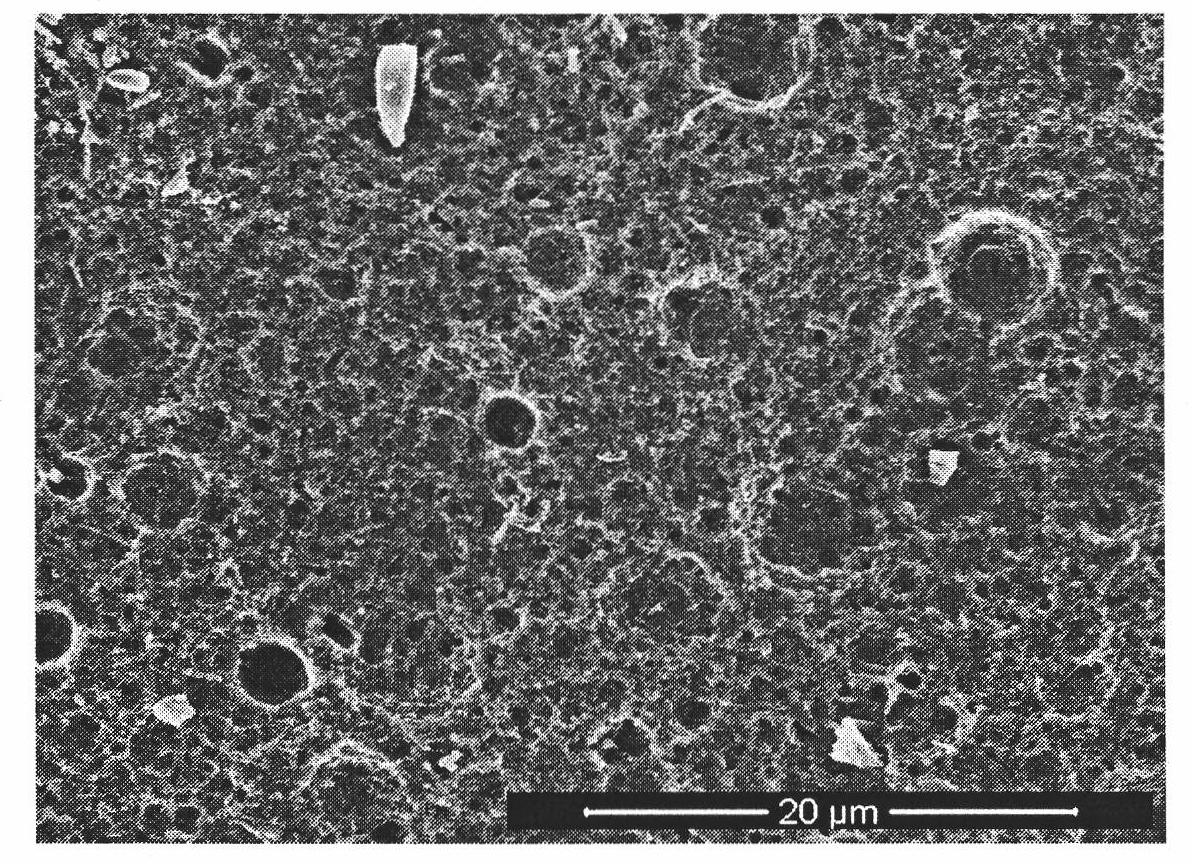

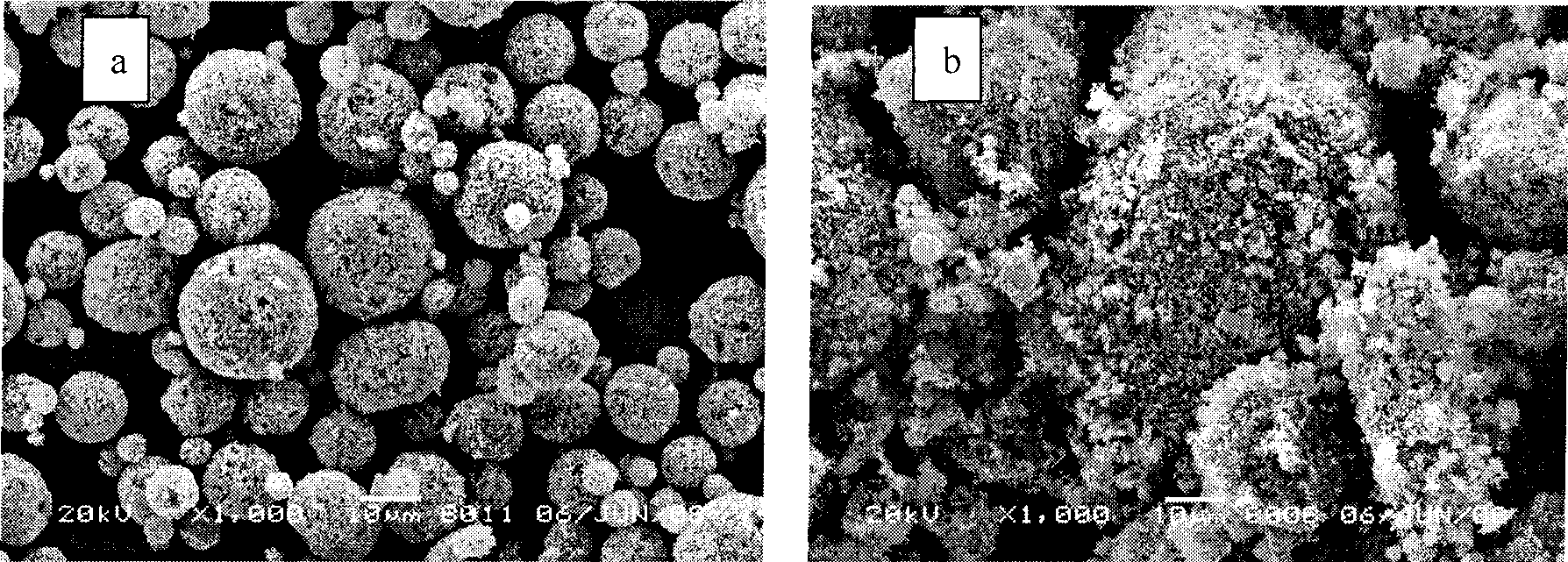

The present invention relates to energy source material technology, and is preparation process of high density spherical lithium nickel-cobalt-manganate as positive electrode material for lithium ion cell. The preparation process includes the reaction of nickel salt, cobalt salt, manganese salt, ammonium hydroxide and ammonian in water solution to synthesize spherical or spheroid precursor Ni1 / 3Co1 / 3Mn1 / 3 (OTHER)2, washing, drying and mixing with lithium carbonate; and high temperature treatment in the air at 750-950 deg.c for 8-48 hr to obtain spherical lithium nickel-cobalt-manganate. The spherical lithium nickel-cobalt-manganate has great bulk density reaching 2.25-2.50 g / cu cm after vibration densifying, average grain size of 3-7 microns, and reversible specific capacity up to 172-185 mA.hr / g.

Owner:TSINGHUA UNIV

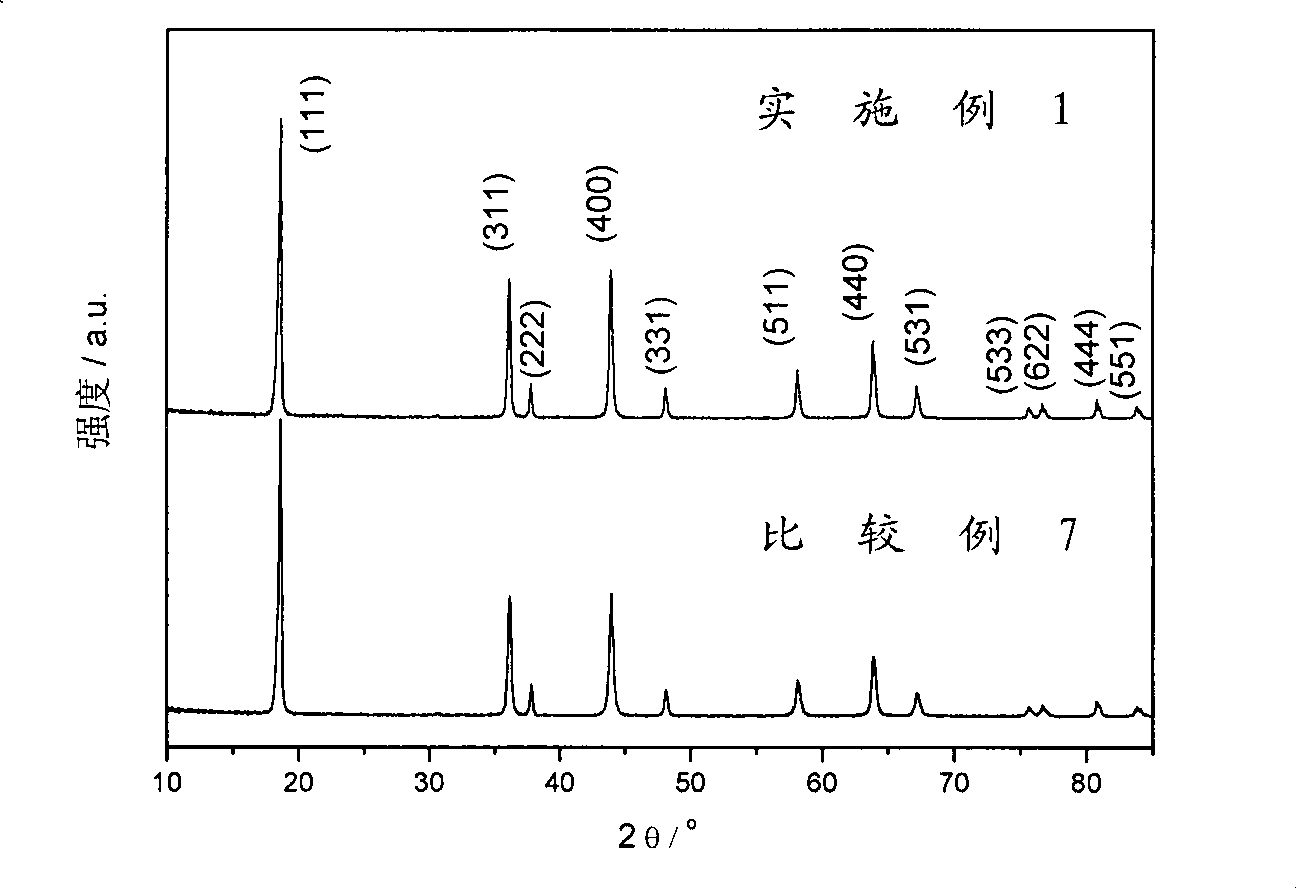

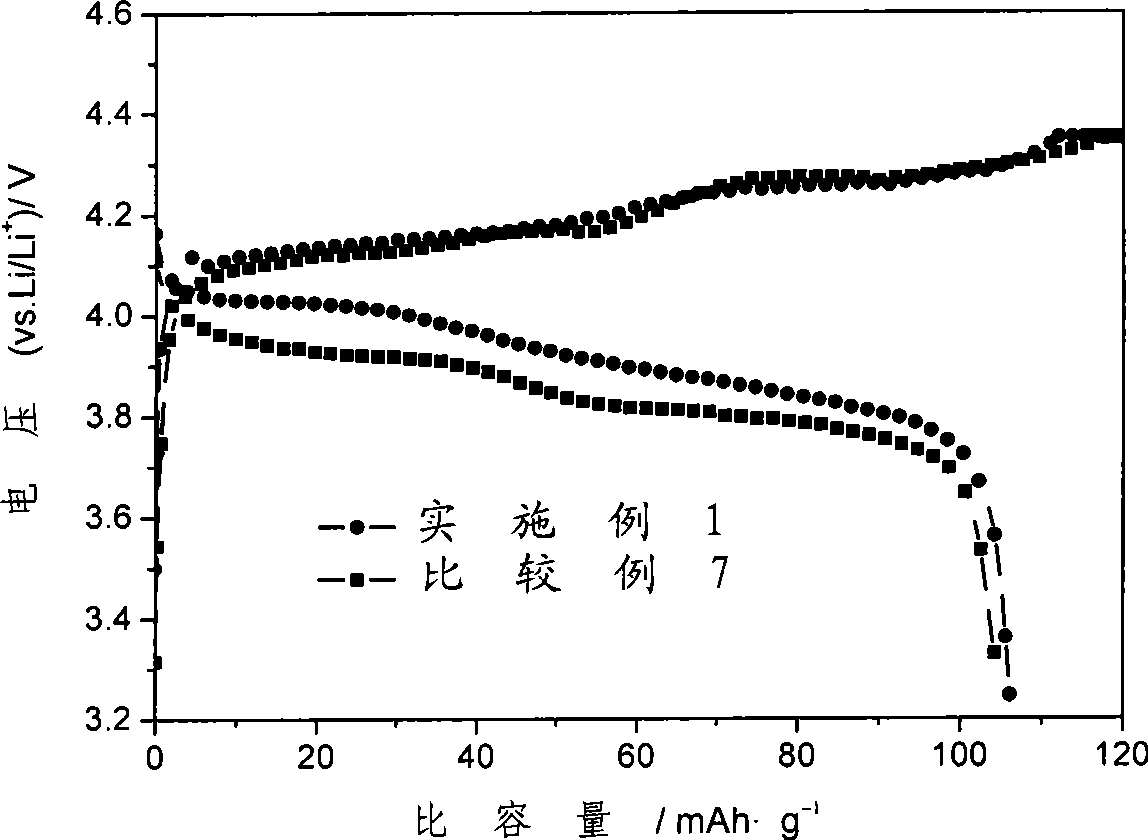

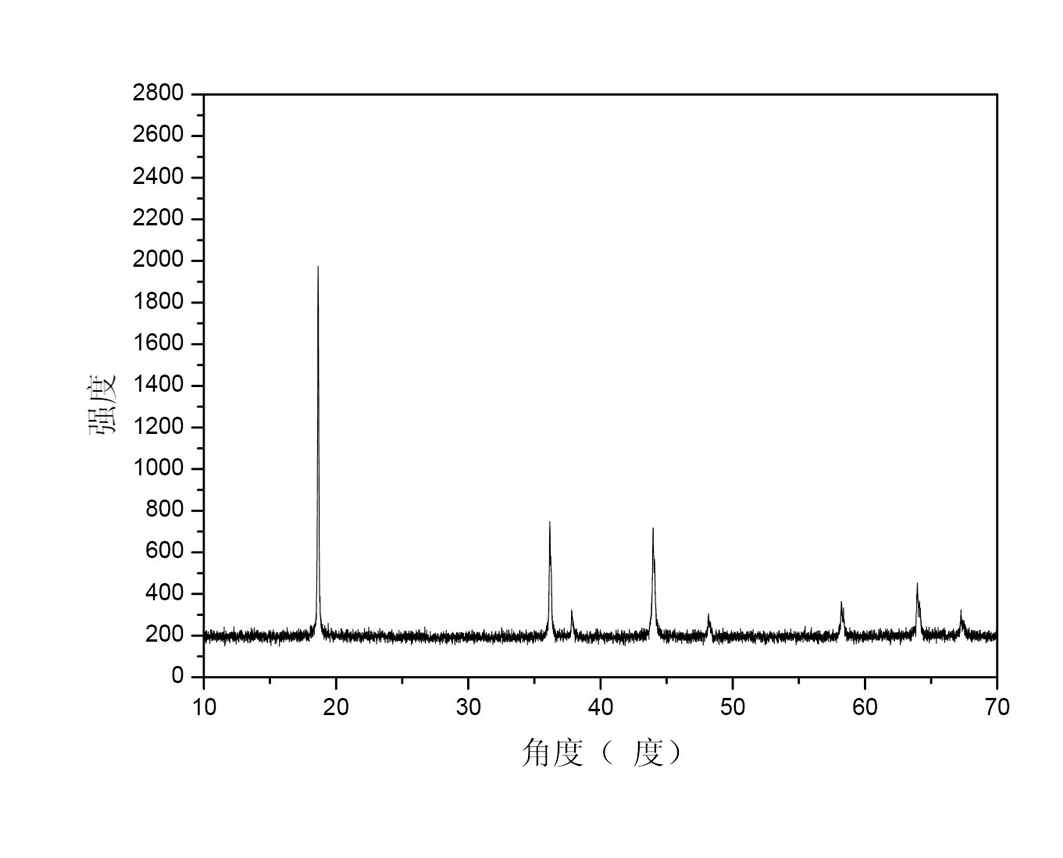

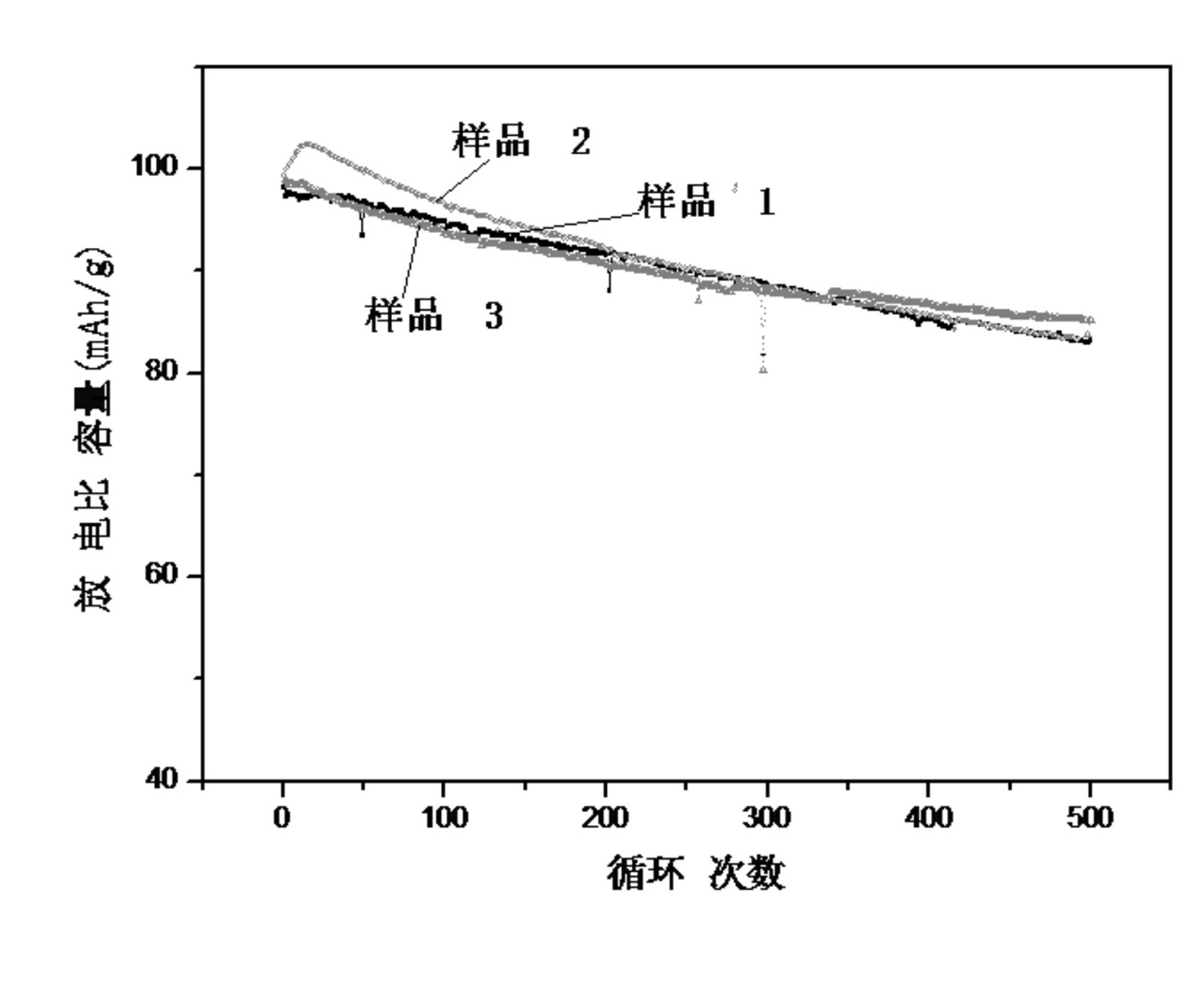

High performance lithium ion battery anode material lithium manganate and preparation method thereof

The invention provides a high performance lithium ion battery anode material lithium manganate and a preparation method of the material. The lithium manganate is a doped lithium manganate LiMn2-yXy04 which is doped with one kind or a plurality of other metal elements X, wherein X element is at least one kind selected form the group of aluminium, lithium, fluorine, silver, copper, chromium, zinc, titanium, bismuth, germanium, gallium, zirconium, stannum, silicon, cobalt, nickel, vanadium, magnesium, calcium, strontium, barium and rare earth elements lanthanum, cerium, praseodymium, neodymium, promethium, samarium, europium, gadolinium, terbium, dysprosium, holmium, erbium, thulium, ytterbium and lutetium, and y is larger than 0 but less than or equal to 0.11. The lithium ion battery anode material lithium manganate provided in the invention has extraordinary charge and discharge cycle performance both in the environments of normal temperature and high temperature. According to the invention, the preparation method of the material is a solid phase method, the operation is simple and controllable and the cost is low so that it is easy to realize large-scale productions.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

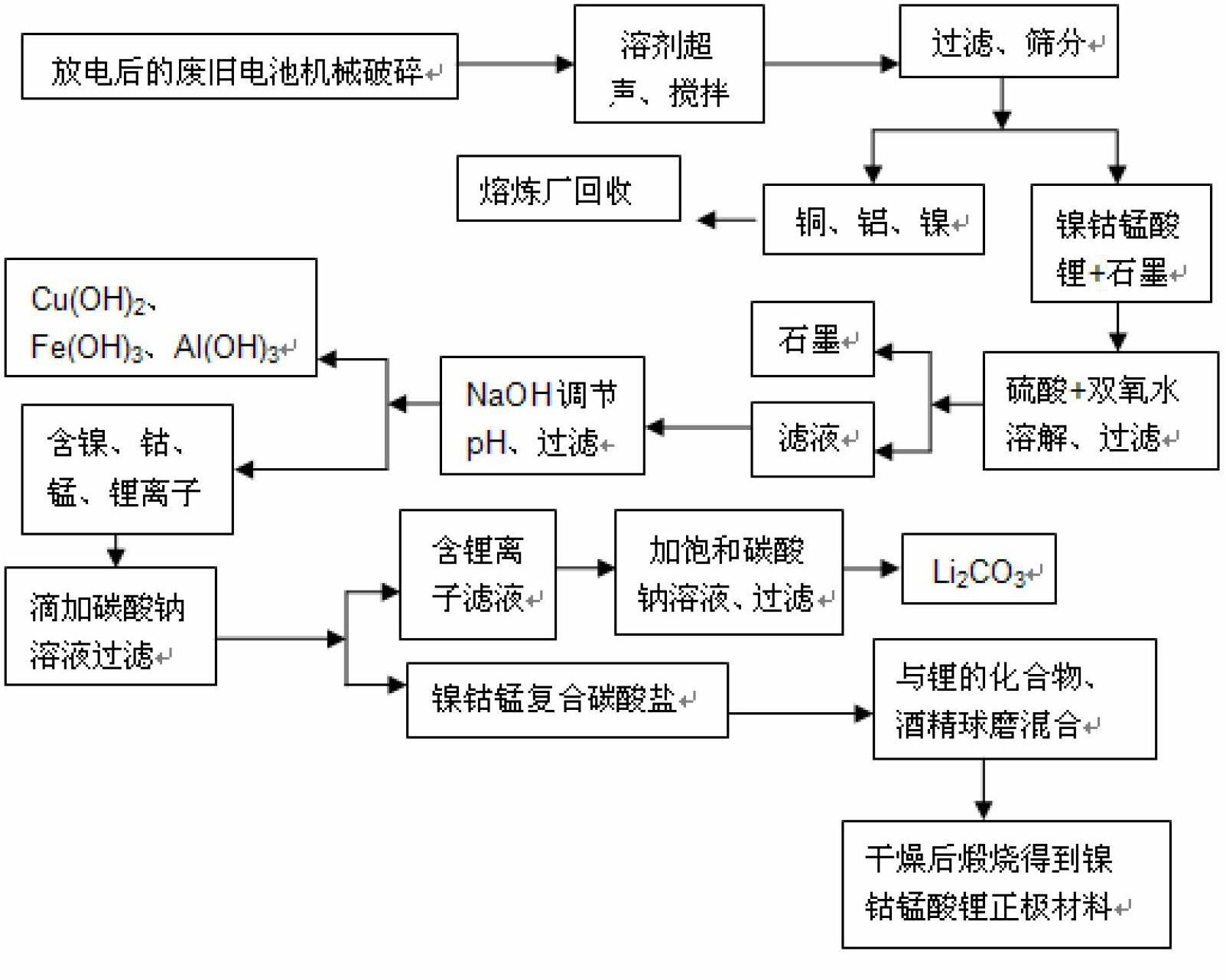

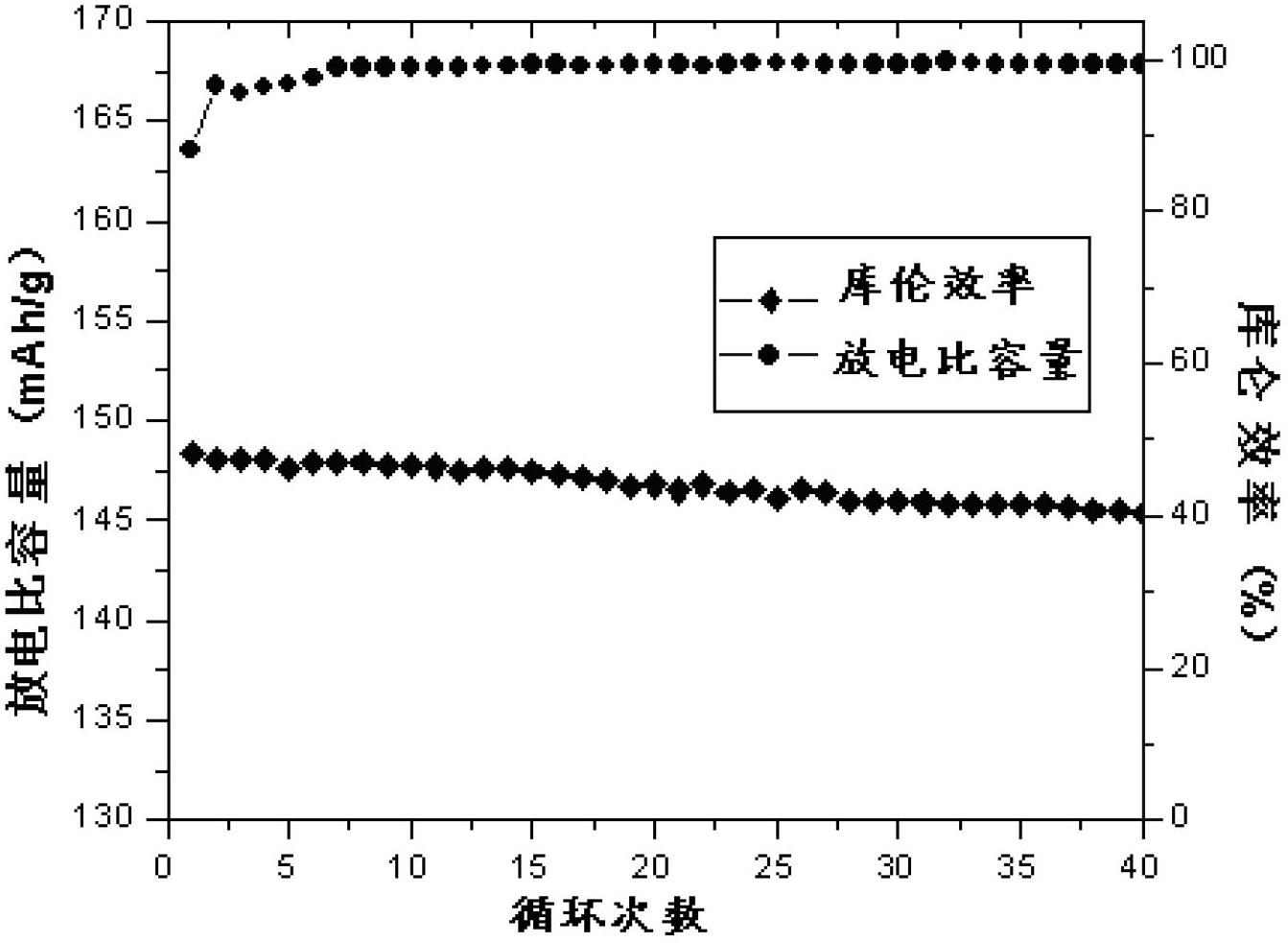

Method for preparing nickel and cobalt doped lithium manganate by using waste and old lithium ionic cell as raw material

InactiveCN101450815ASimultaneous recyclingShort processManganates/permanganatesManganateManganese oxide

The invention discloses a method for preparing lithium nickel cobalt manganese oxide by taking a waste lithium ion battery as a raw material. The method is mainly characterized in that a waste lithium ion battery taking the lithium nickel cobalt manganese oxide, lithium nickel cobalt oxide and so on as a battery positive material is selected as the raw material and is pretreated through disassembly, separation, crushing, screening and so on, and then processes such as adhesive removal at high temperature and aluminum removal by sodium hydroxide are adopted to obtain an inactivated positive material containing nickel, cobalt and manganese; then a sulfuric acid and hydrogen peroxide system is adopted to leach, and P204 is adopted to remove impurities by extraction to obtain pure nickel, cobalt and manganese solution, and proper manganese sulfate, nickel sulfate or cobalt sulfate is blended to ensure that the mol ratio of nickel, cobalt and manganese elements in the solution is 1: 1: 1; and then ammonium carbonate is adopted to adjust the pH value to form a nickel cobalt manganese carbonate precursor, and then a proper amount of lithium carbonate is blended for high temperature sintering to synthesize a lithium nickel cobalt manganese oxide battery material. The first discharge capacity of the material is 150 mAh / g, the discharge capacity is still kept more than 130mAh / g after the circulation for 30 times, and the material has good electrochemical performance.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

Method for recovering valuable metal from nickel cobalt lithium manganate batteries and positive pole materials

ActiveCN102676827ASimple processHigh recovery rateCell electrodesWaste accumulators reclaimingRecovery methodPower battery

The invention provides a method for recovering valuable metal from waste nickel cobalt lithium manganate batteries and positive pole materials made of the valuable metal and belongs to the technical field of waste power battery recovery. The method can solve the problems in the existing recovery method that proportions of nickel, cobalt and manganese in the waste nickel cobalt lithium manganate batteries are different and corresponding metal is required to be added in recovery steps so as to adjust content of nickel, cobalt and manganese to reach required proportions. In the recovering method, by screening the positive pole materials of all nickel cobalt lithium manganate batteries from the waste nickel cobalt lithium manganate batteries and using the positive pole materials as recovery raw materials of the waste nickel cobalt lithium manganate batteries with the same positive pole materials, nickel cobalt manganate composite carbonate capable of being applied to preparation of the positive pole materials of lithium ion batteries directly without adjusting the proportion of nickel, cobalt and manganese is obtain.

Owner:CHERY AUTOMOBILE CO LTD

Positive electrode active material for secondary battery, positive electrode for secondary battery, secondary battery and method for producing positive electrode active material for secondary battery

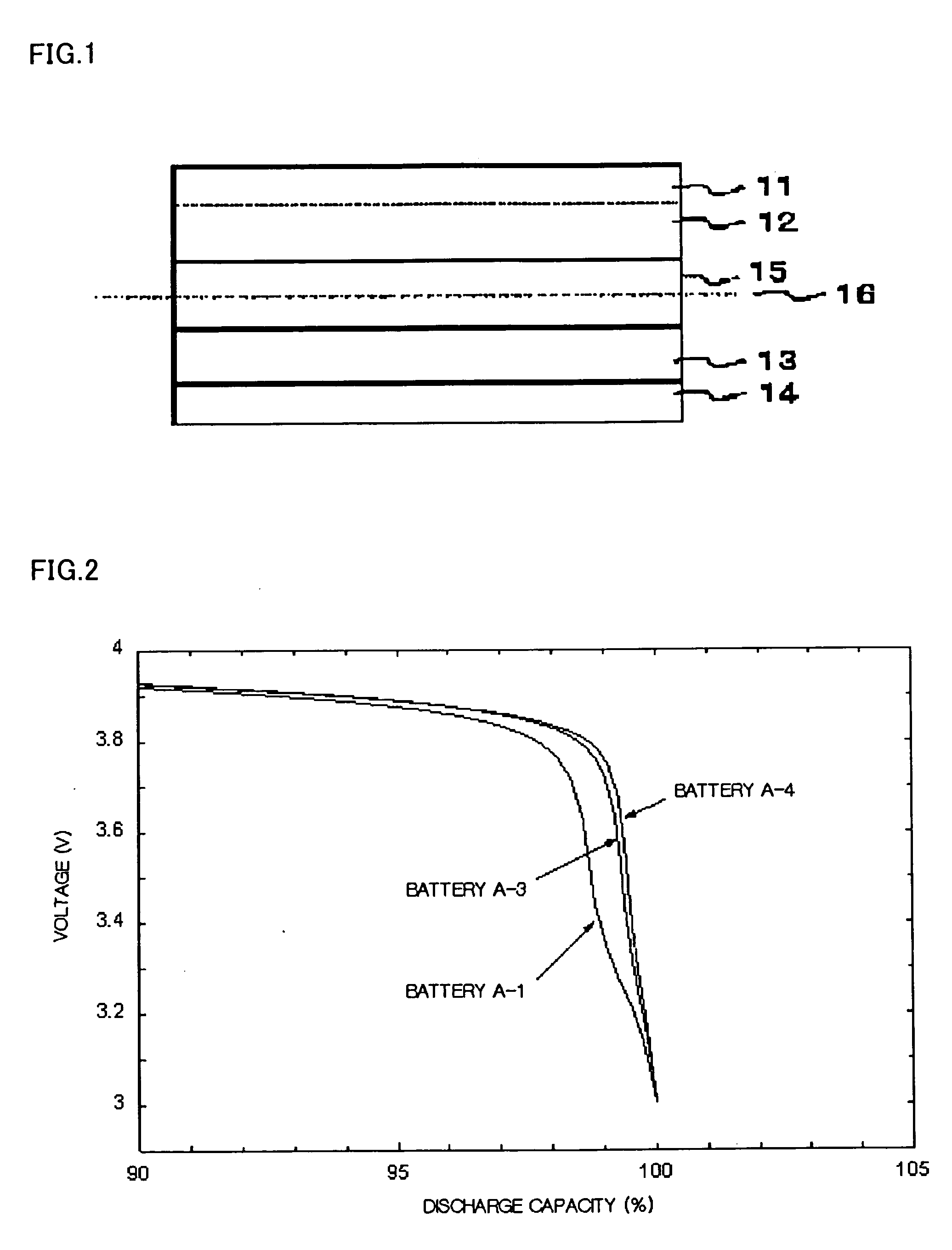

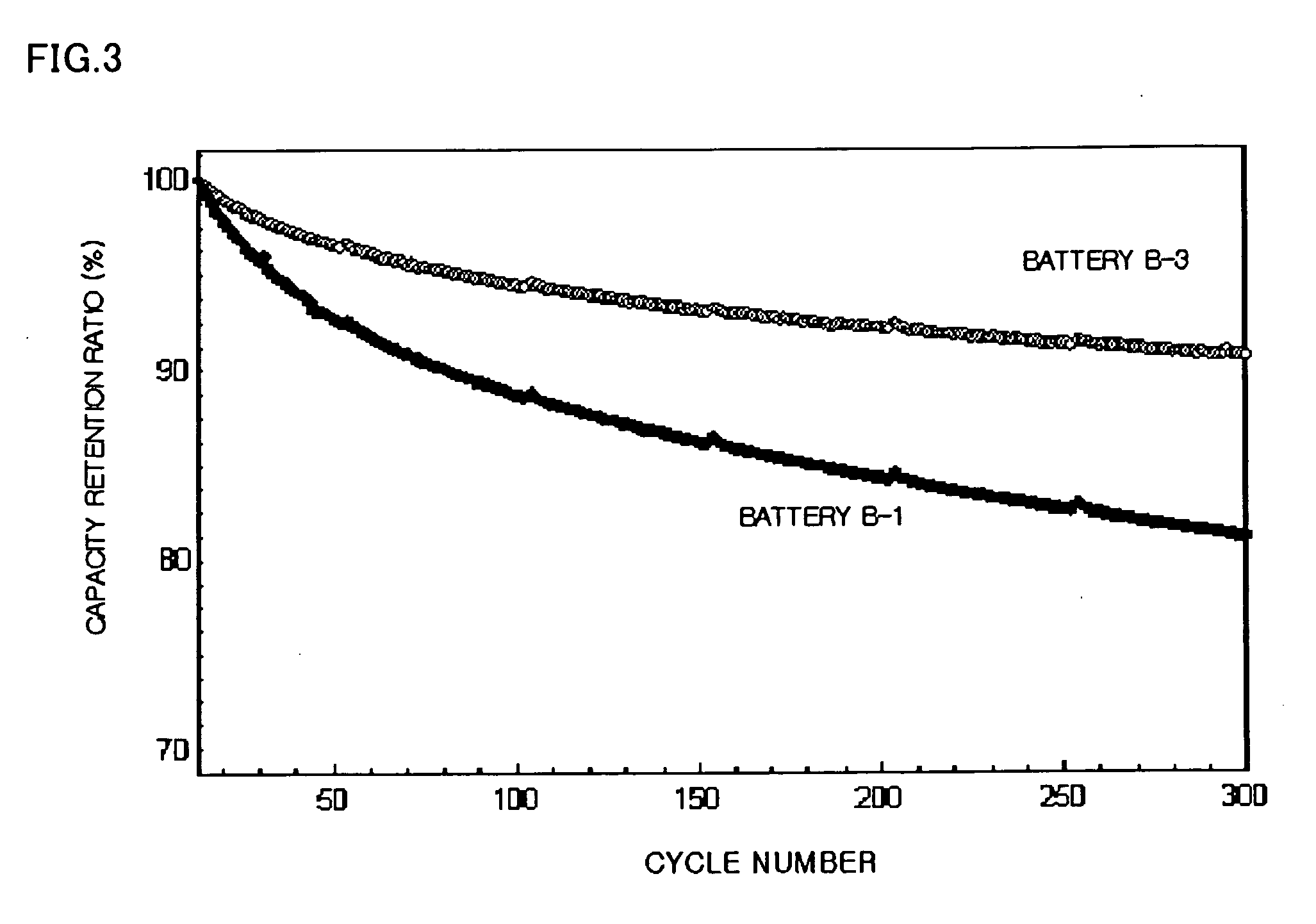

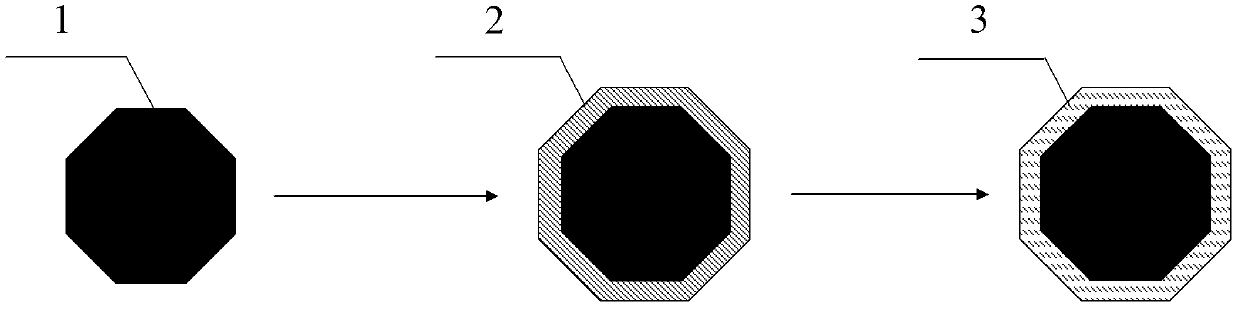

ActiveUS20060035151A1Minimization of increase in resistanceMinimization of in reduction in capacityNon-aqueous electrolyte accumulatorsOrganic electrolyte cellsManganateManganese

A life of a secondary battery is extended, increase in a resistance when storing a secondary battery at an elevated temperature is prevented, and increase in a resistance during a charge-discharge cycle is prevented. A positive electrode active material comprising a lithium manganate and a lithium nickelate are used. The lithium manganate is a compound represented by the following formula (1) or the compound in which some of Mn or O sites are replaced with another element: Li1+xMn2−xO4 (1) (in the above-shown formula (1), 0.15≦x≦0.24).

Owner:NEC CORP

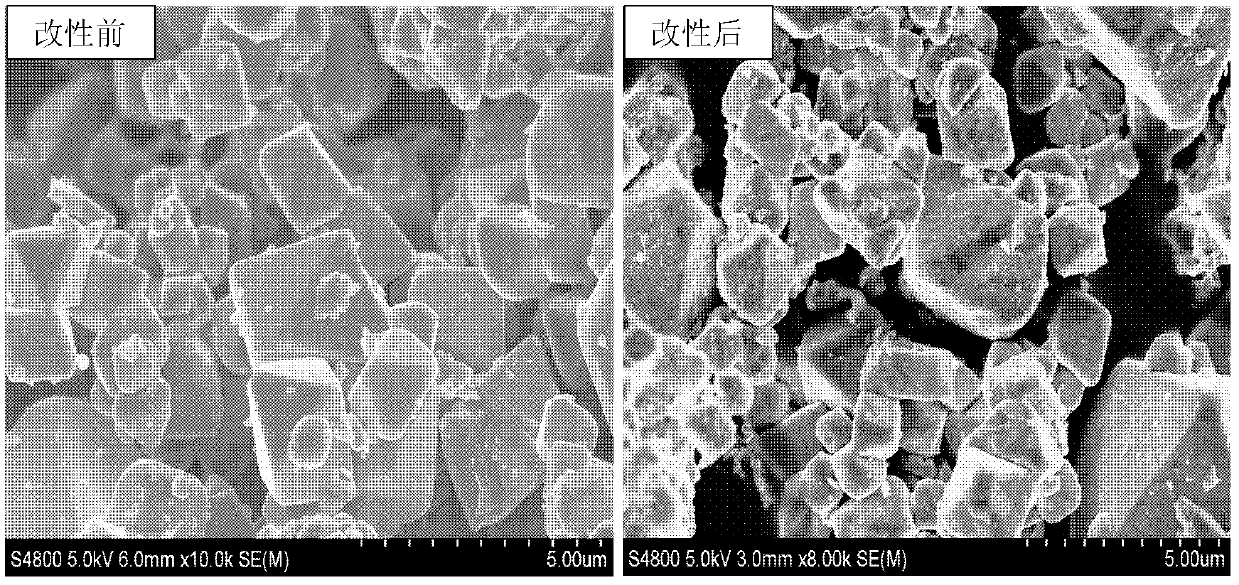

Method for improving cycling stability of lithium ion battery anode material

InactiveCN103107337AImprove cycle stabilityAvoid contactCell electrodesSecondary cells servicing/maintenanceManganateCobalt

The invention discloses a method for improving the cycling stability of a lithium ion battery anode material, belonging to the field of lithium ion battery anode materials. The lithium ion battery anode material comprises an anode material and metal oxides uniformly and compactly coated on the surface of the anode material, wherein the anode material comprises lithium manganate, lithium manganous silicate, lithium-nickel-cobalt-manganate and the like, and the metal oxides mainly comprise Al2O3, ZnO, TiO2, Nb2O5, ZrO2, Ta2O5 and the like. Due to the adoption of the metal oxide coating layer, lithium ions can be rapidly and better transmitted, and an electrolyte can be prevented from being in contact with the anode material in a cycling process and further the anode material is prevented from dissolving in the electrolyte, and thus the cycling stability of the anode material is improved. The method has the advantages of simplicity in operation, low cost, high efficiency, and the like; and massive and industrialized production can be easily realized.

Owner:HUNAN UNIV

Method for preparing anode material lithium nickle cobalt manganic acid of lithium ion battery

InactiveCN101510603AConducive to neutralizing the balanceGood effectElectrode manufacturing processesNickel compoundsLithium hydroxideNew energy

The invention relates to a preparation method of Ni-Co lithium manganate which is a cathode material for a lithium ion battery, which pertains to the field of new energy material and preparative technique. The preparation method comprises the following steps: 1. a sulfate mixture solution of nickel, cobalt and manganese is prepared in accordance with a certain concentration; 2. the mixture solution, NH3 water and a sodium hydroxide solution are continuously injected into a reactor and stirred, and a spherical or quasi-spherical multiple hydroxide A of Ni, Co and Mn is obtained after the filtration, washing and drying are conducted over the mixture; 3. the dry multiple hydroxide A of Ni, Co and Mn is presintered to obtain a spherical multiple oxide B of Ni, Co and Mn; and 4. after being added with a right quantity of alcohol, the product B is evenly mixed with lithium hydroxide and the mixture is sintered, smashed and screened to obtain a spherical LizNixCoyMnxO2 cathode material C for the lithium ion battery. With the preparation method, the particle size and distribution of the product A and product B are easy to control and the spherical Ni-Co lithium manganate C with stable quality, high density, high capacity and high discharge plateau is obtained; therefore, the preparation method is applicable to stabilizing industrial production.

Owner:JILIN JIEN NICKEL IND

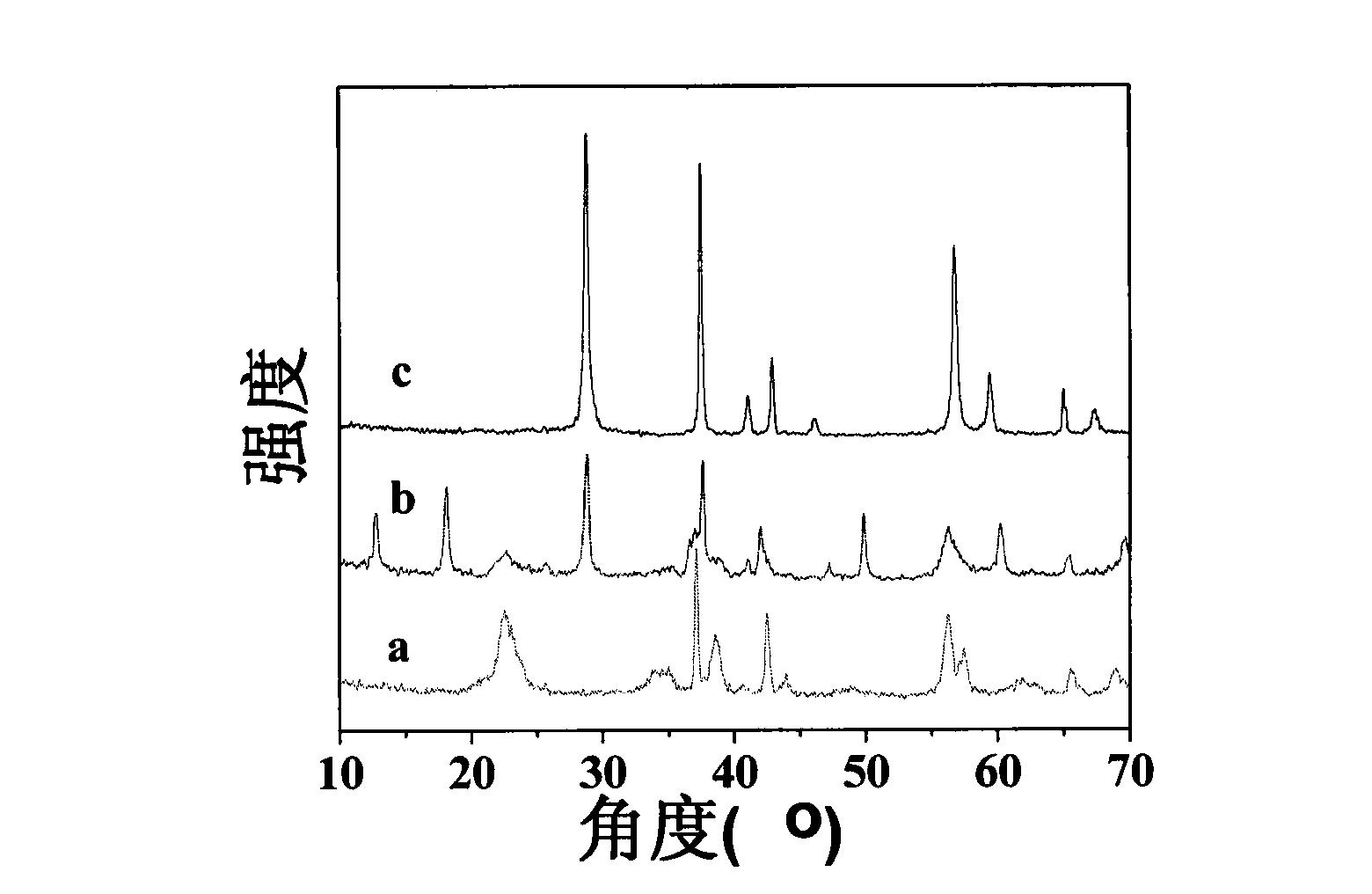

Method and applications thereof for recovering MnO* from anode material of wasted lithium manganate battery

InactiveCN101538655AGood effectAvoid high temperature calcination processProcess efficiency improvementBattery recyclingElectrical batteryManganate

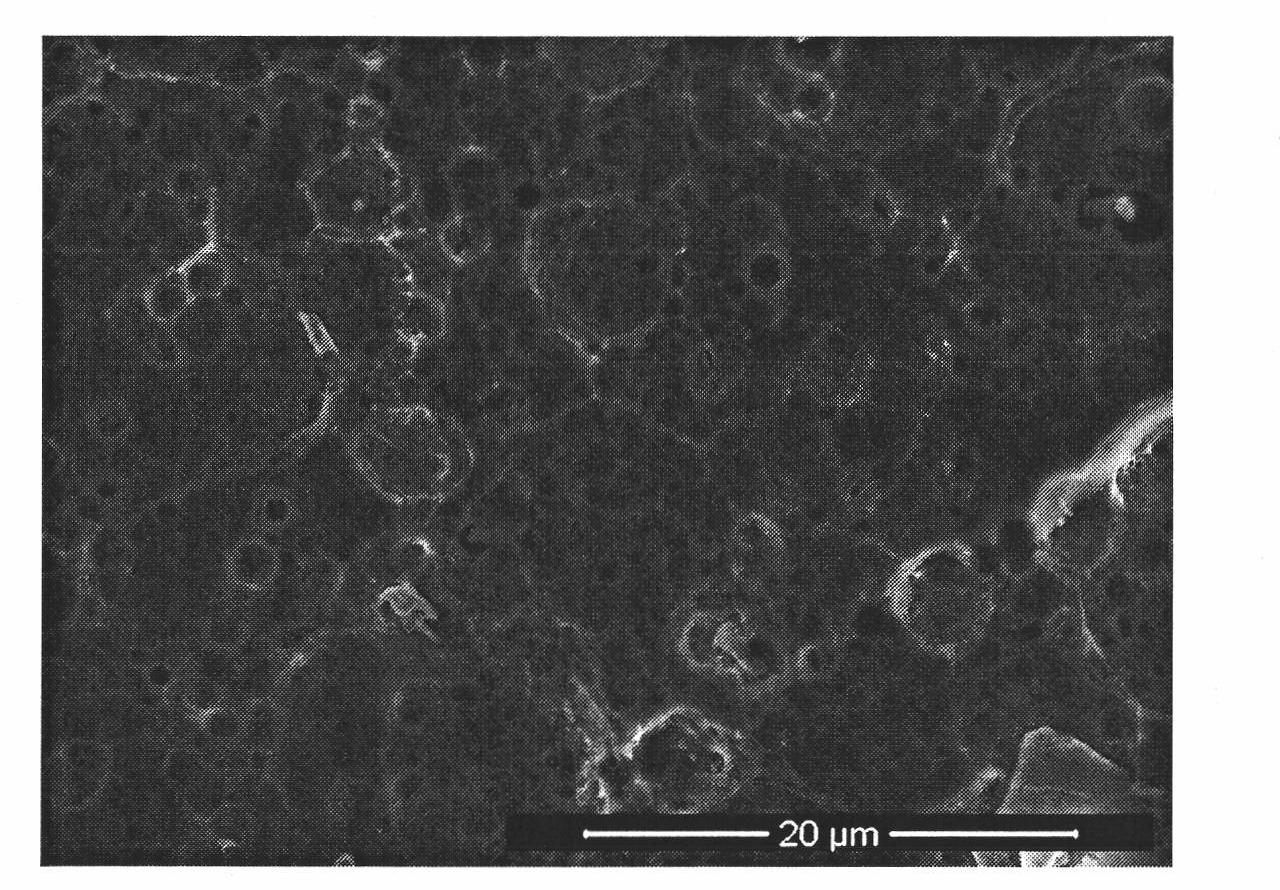

A method for recovering MnO2 from the anode material of a wasted lithium manganate oxide battery comprises the following steps of firstly obtaining an anode active material by pre-disposing assembled anode sheets with alkaline solution, etc., subsequently taking the anode active material as a raw material and obtaining a Lambda-MnO2 by soaking the raw material in an inorganic acid or a normal-pressure acid, or obtaining an Alpha- / Beta- / Gama-MnO2 by soaking the raw material in a hydrothermal acid. The method has simple process, little used acid and convenient separation and purification; the obtained various crystal-type MnO2 with large specific surface area and porous structure can be applied directly to be as a catalyst for synthesizing ester compound or disposable battery anode material of Li / MnO2 or electrode material of a super-capacitor.

Owner:HEFEI UNIV OF TECH

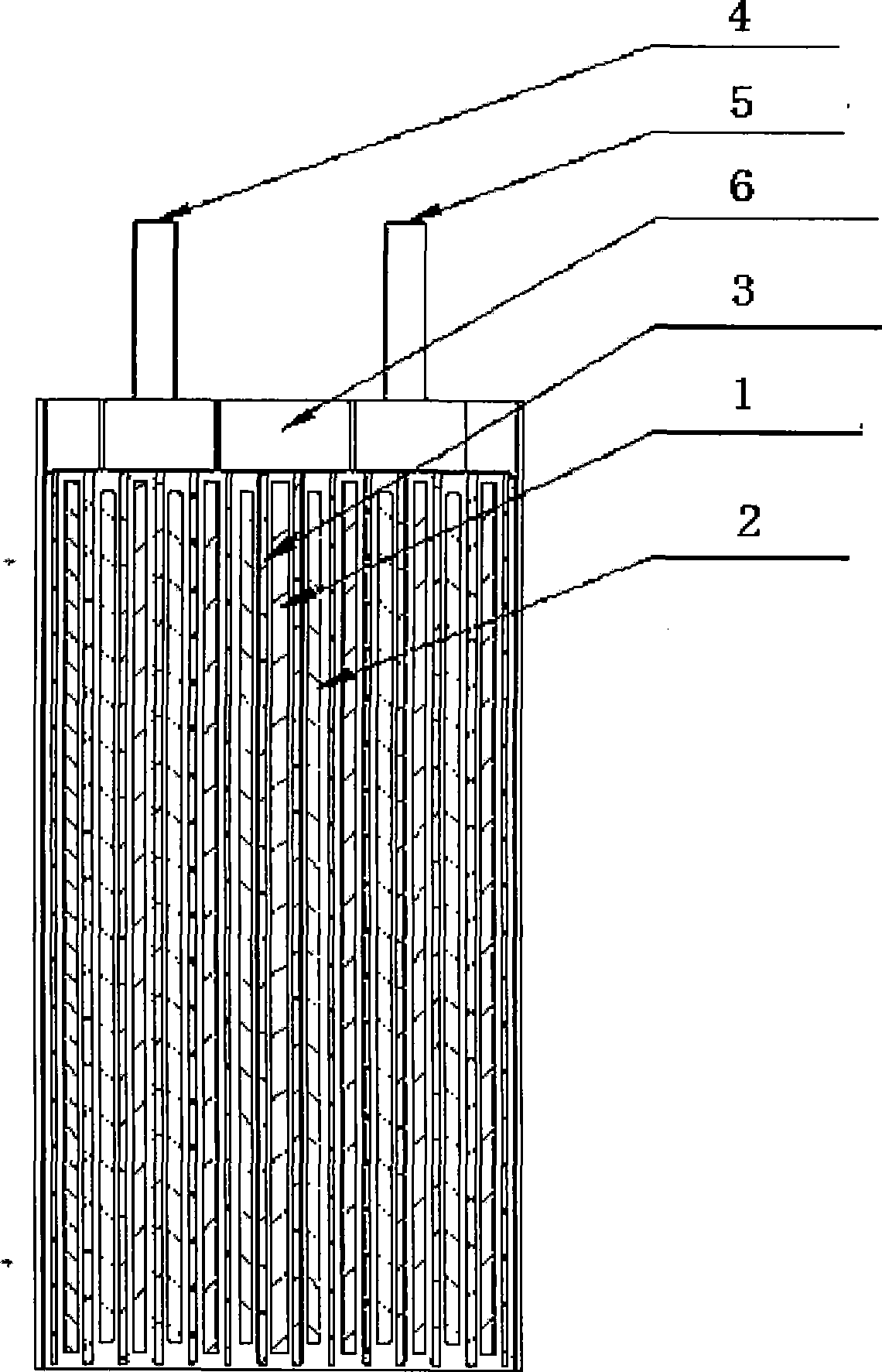

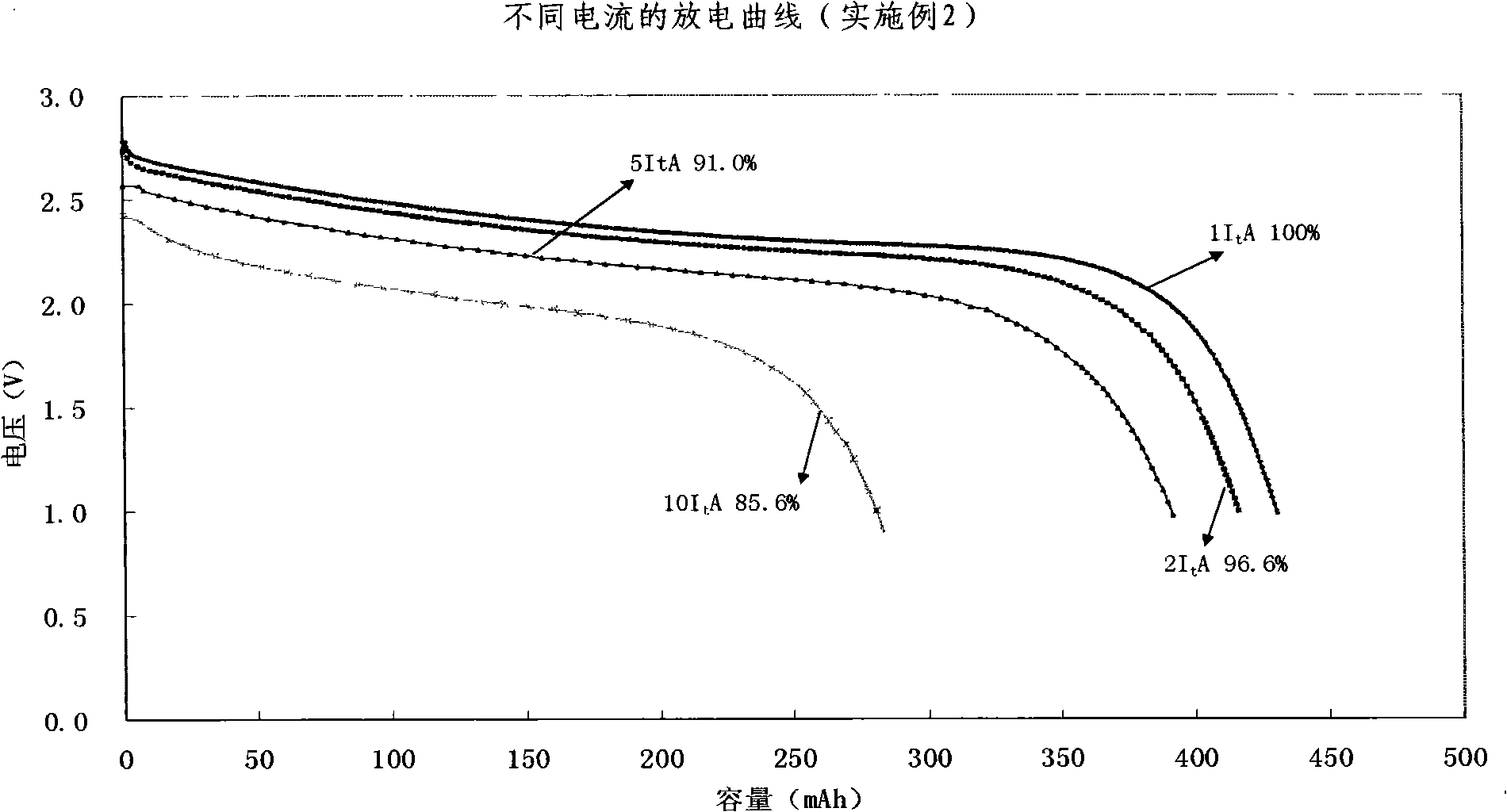

Multi-multiplying power charging-discharging lithium ion battery and method for producing the same

InactiveCN101499530AImprove high rate charge and discharge performanceImprove performanceElectrode manufacturing processesFinal product manufactureHigh rateMicrosphere

The invention provides a high-rate charge-discharge lithium-ion battery and a preparation method thereof. The anode active material of the lithium-ion battery is lithium manganate; the cathode active material is selected from one or more of mesocarbon microbeads, artificial graphite or natural graphite coated by mesophase pitch; a conductive agent is selected from one or more of conductive graphite, conductive carbon black, nano Ag, nano SiO2 or nano Al2O3. The preparation method of the lithium-ion battery comprises the preparation of the anode plate, the parathion of the cathode plate and the assembly of the battery. The lithium-ion battery has the advantages of high-rate charge-discharge performance, long cycle life, high capacity, safe use, environmental protection, low cost and the like. The preparation method has the advantage of simple and easy process operation, and is applicable to the mass production.

Owner:深圳市崧鼎实业有限公司

Electrolyte for lithium manganate power battery

InactiveCN101540419AImprove stabilityExtended storage timeSecondary cellsOrganic solventBoiling point

The invention discloses an electrolyte for a lithium manganate power battery. The electrolyte comprises lithium salt and nonaqueous organic solvent and also comprises 0.5-5 of filming additive, 2-10 of anti-overcharge additive, 0.01-0.5 of additive capable of controlling acidity and water content and 0.1-5 of lithium salt stabilizer according to the weight percentage. The electrolyte selects the nonaqueous organic solvent with a high boiling point and adds functional additives such as the filming additive, the anti-overcharge additive, the additive capable of controlling the acidity and the water content, the lithium salt stabilizer, and the like so that the lithium manganate power battery adopting the electrolyte has excellent safety performance, high-temperature performance and recycle service life.

Owner:GUANGZHOU TINCI MATERIALS TECH

Rich-lithium positive electrode material of lithium ion battery having coreshell structure and preparation method of rich-lithium positive electrode material

The invention discloses a rich-lithium positive electrode material of a lithium ion battery having a coreshell structure and a preparation method of the rich-lithium positive electrode material, and belongs to the field of electrochemistry. The preparation method comprises the following steps of: calcining [NixCoyMn1-x-y](OH)2 and inorganic lithium salt in air to prepare [LiNixCoyMn1-x-y]O2, and adding the [LiNixCoyMn1-x-y]O2 into an organic acid solution to prepare a solution A; dissolving soluble manganate and soluble lithium salt into deionized water to prepare a solution B, adding the solution B into the solution A, keeping stirring to obtain gel C; and drying and pre-calcining the C, calcining the C at high temperature, taking a product out, grinding the product to obtain a ternary layered positive electrode material having the coreshell structure, wherein x is more than 0 and less than 0.5, and y is more than 0 and less than 0.5. Besides the characteristic of the ternary layered material, the material has perfect charging and discharging recycle capability under high capacitance and high potential of a rich-lithium compound; moreover, by surface cladding, the multiplying power performance of the material compared with the multiplying power performance of the non-cladded material is enhanced obviously.

Owner:BEIJING UNIV OF TECH

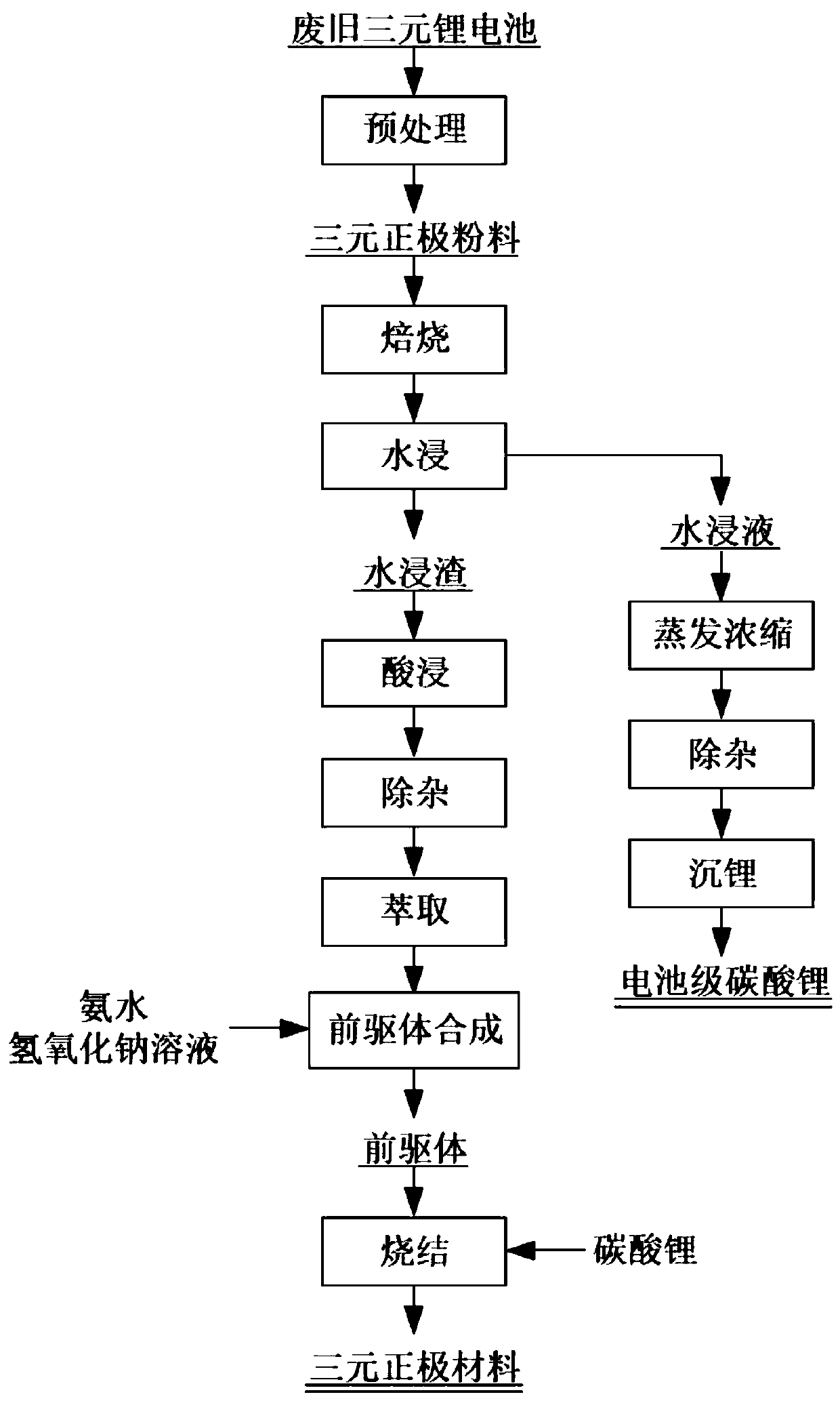

Method for preparing ternary positive electrode material through recovering waste ternary lithium battery

ActiveCN111206148AHigh recovery rateReduce recycling costsCell electrodesWaste accumulators reclaimingManganese sulphatePregnant leach solution

The invention provides a method for preparing a ternary positive electrode material through recovering a waste ternary lithium battery. The method comprises the following steps of 1) mixing pretreatednickel cobalt lithium manganate waste positive electrode powder with sulfate, and roasting to obtain a roasted product; 2) immersing the roasted product in water to obtain water immersion liquid andwater immersion slag; wherein the water immersion liquid contains lithium salt; 3) reacting the water immersion slag with an acid solution and hydrogen peroxide to obtain a nickel-cobalt-manganese leaching solution; 4) removing impurities from the nickel-cobalt-manganese leaching solution, then extracting cobalt, manganese and nickel, and saponifying and reversely extracting obtained organic phaseto obtain a nickel sulfate solution, a cobalt sulfate solution and a manganese sulfate solution; and 5) co-precipitating the nickel sulfate solution, the cobalt sulfate solution and the manganese sulfate solution with a sodium hydroxide solution and ammonia water, mixing obtained precursor with lithium carbonate, sintering, and screening iron to obtain the ternary positive electrode material. According to the method, lithium is extracted firstly, so that the influence of a lithium element on subsequent nickel-cobalt-manganese extraction is reduced, the impurity content in the ternary positiveelectrode material is reduced, and the recovery rate of nickel-cobalt-manganese is greatly improved; and meanwhile the recovery rate of the lithium can be improved.

Owner:NINGBO RONBAY LITHIUM BATTERY MATERIAL CO LTD

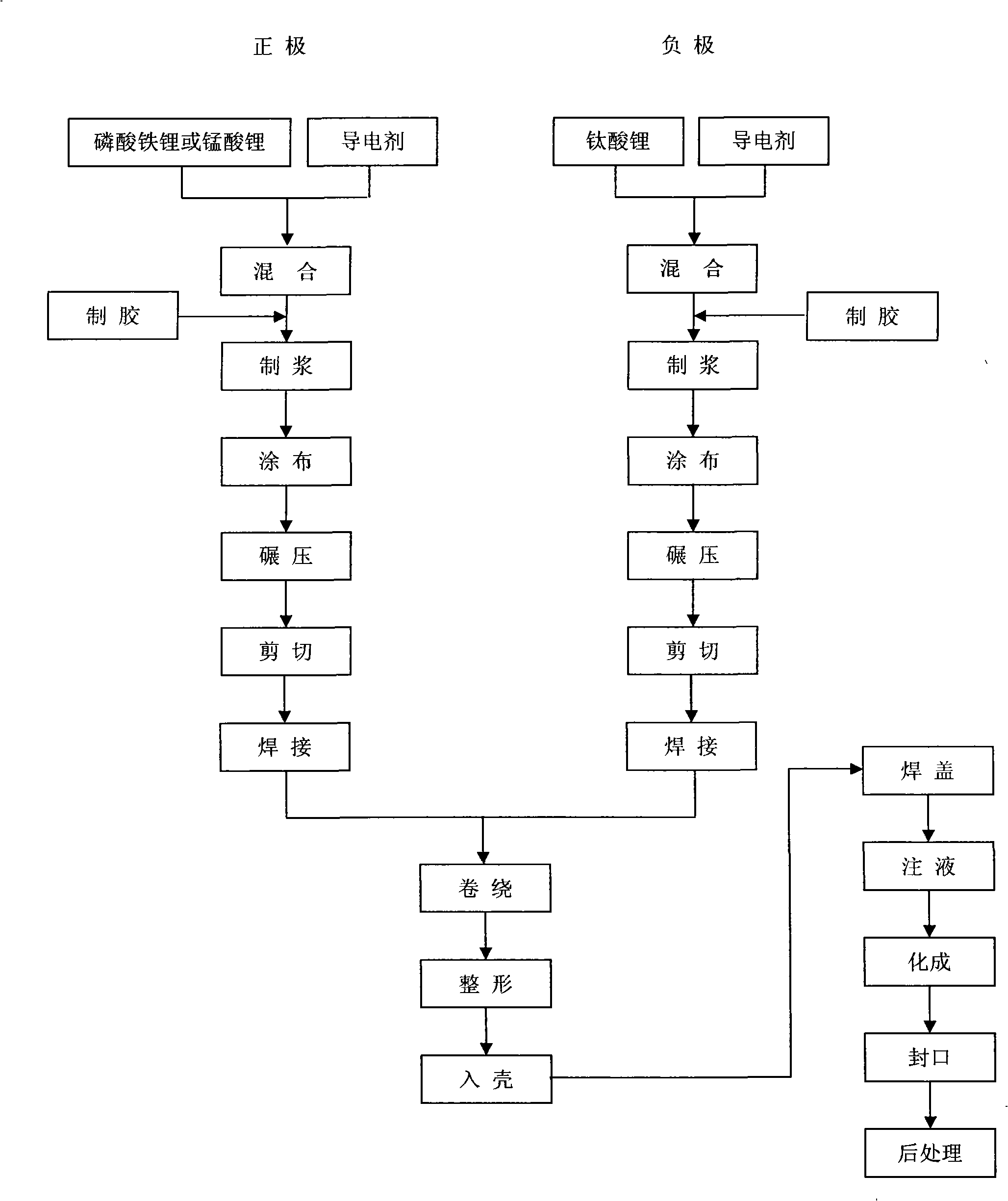

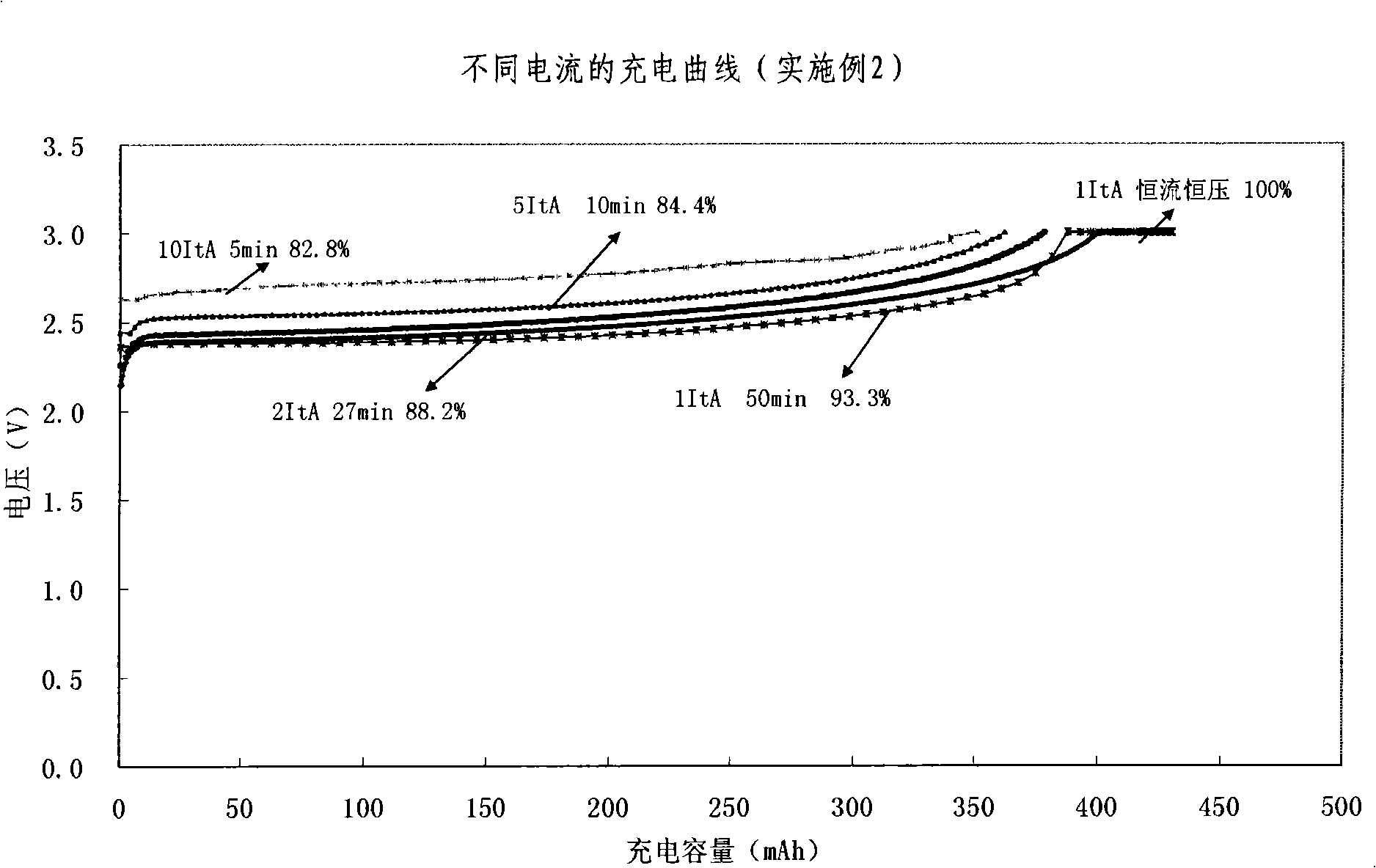

Quickly chargeable lithium ion battery and its making method

InactiveCN101262078AExcellent fast charge and discharge performanceCell electrodesFinal product manufactureMethyl carbonateManganate

The invention discloses a lithium-ion battery with fast charge property, which comprises an anode, a cathode, a diaphragm sandwiched between the anode and the cathode and an organic electrolyte, wherein, sub micrometer lithium titanate is used as the active substance of the cathode; one or several materials of lithium manganate (LiMn2O4), lithium iron phosphate (LiFePO4), lithium nickel cobalt oxide (LiNixCoyMzO2), ternary substance(LiNixMnxCo1-2xO2) are used as active materials of the anode, or a mixture of lithium cobalt (LiCoO2) and one of lithium manganate (LiMn2O4), lithium iron phosphate (LiFePO4), lithium nickel cobalt oxide (LiNixCoyMzO2), ternary substance(LiNixMnxCo1-2xO2) is adopted as the active materials of the anode; lithium hexafluorophosphate (LiPF6) is adopted as the electrolyte, and a multicomponent mixture of ethylene carbonate (EC), dimethylcarbonate(DMC), Ethyl Methyl Carbonate (EMC) is used as a solution. The invention also discloses a preparation method of the lithium-ion battery with fast charged property. The lithium-ion battery of the invention has excellent fast charging and discharging performance.

Owner:TIANJIN B&M SCI & TECH

Method for preparing lithium ion battery anode material doped with nanometer oxide

InactiveCN101719546AInitial reversible capacity improvement and enhancementIncreased initial reversible capacityCell electrodesCapacitanceLithium iron phosphate

The invention relates to a method for preparing a lithium ion battery anode material doped with a nanometer oxide, belonging to the technical field of manufacturing processes of lithium ion battery batteries. The method is characterized in that trace amount of nanometer oxide power is doped in the preparation process of lithium manganate, lithium cobaltoxide and lithium iron phosphate; the doping amount is 0.5-1.0 mol percent of lithium salts; and the nanometer oxide is selected from one or two of alumina, magnesia, titanium oxide, chromic oxide, nickel oxide, monox and zirconia and the nanometer oxide is subject to ball milling, drying, sieving, calcinating, crushing, grading and other processes to obtain the nanometer oxide doped or coated lithium ion battery anode material. The lithium ion battery anode material has reversible initial capacitance, and remarkably-improved attenuation property, charging-discharging properties, high-temperature circulating property and electrochemistry stability.

Owner:SHANGHAI UNIV

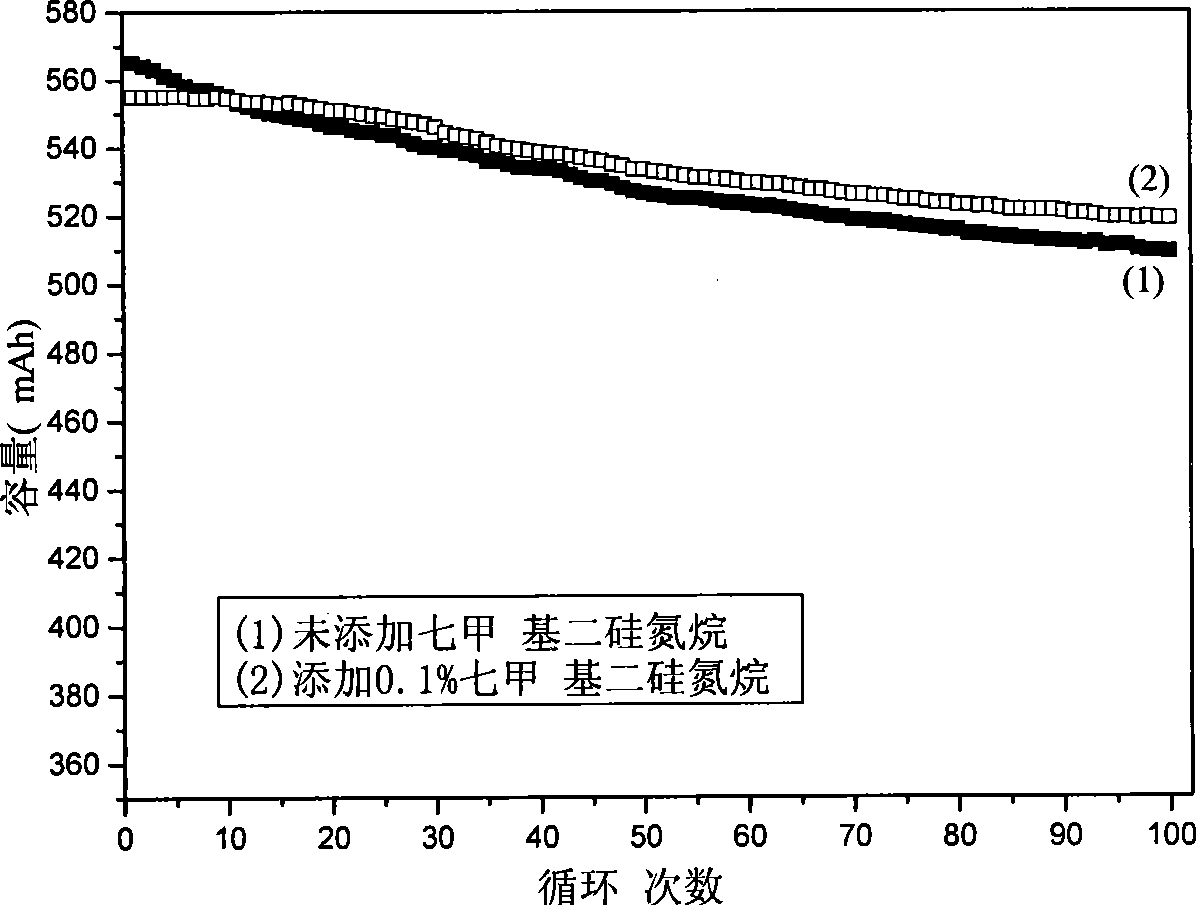

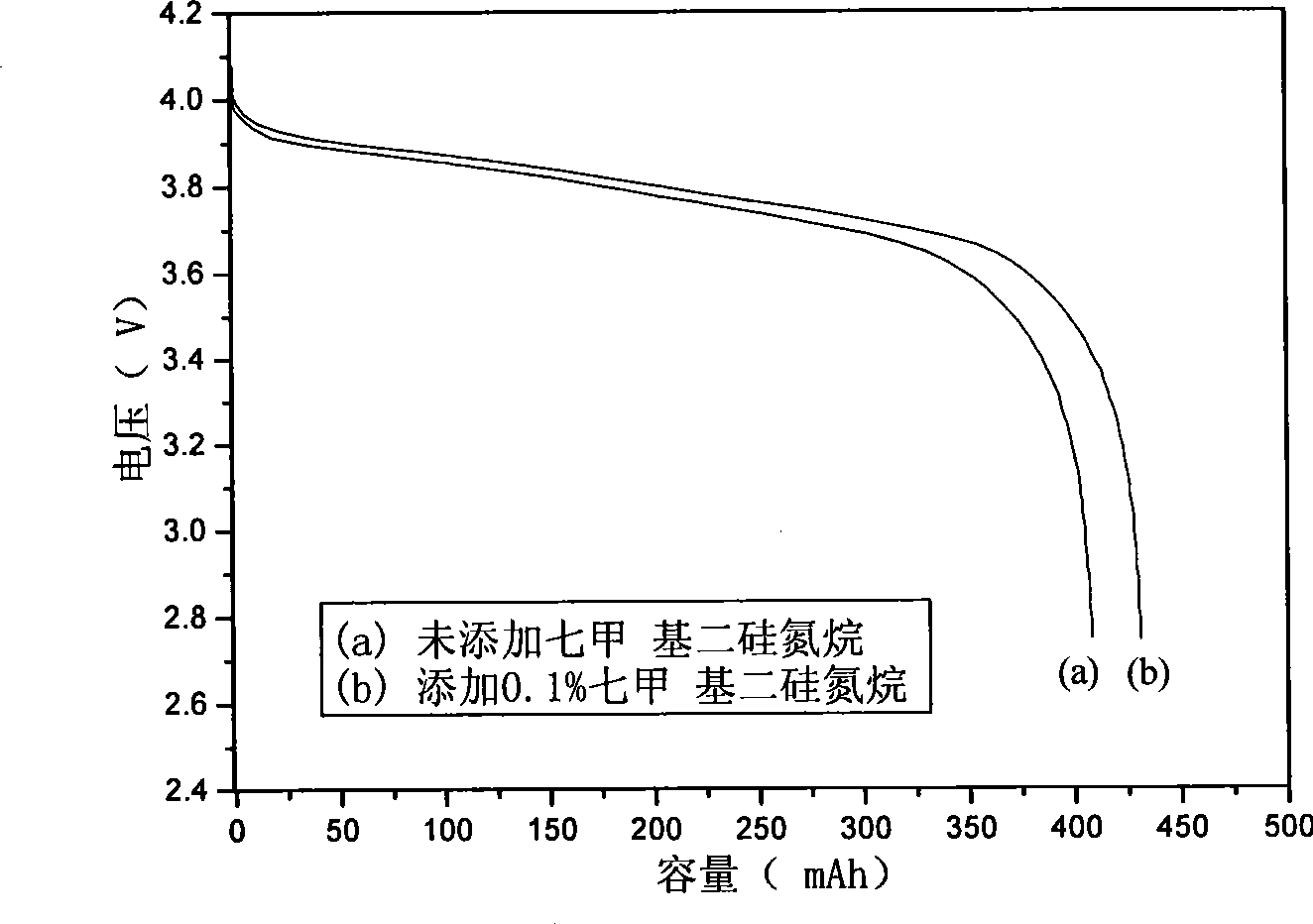

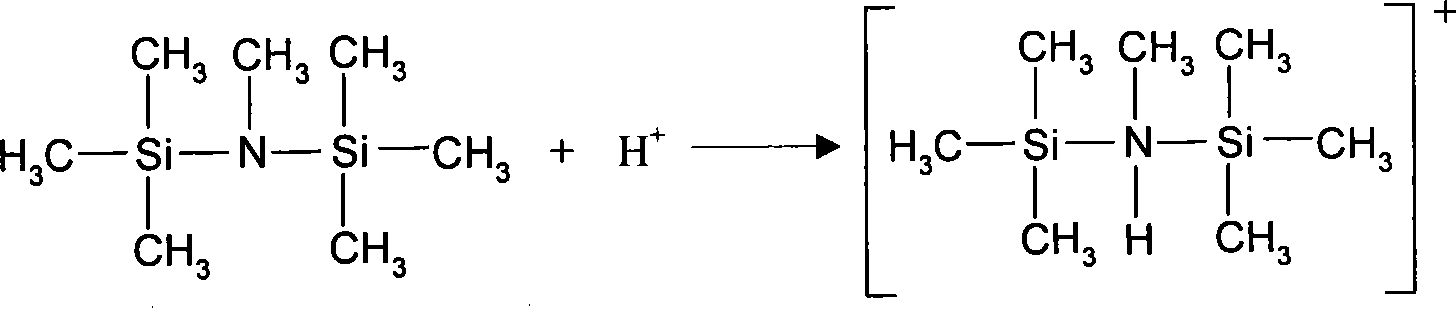

Electrolysis liquid for lithium manganate battery

The invention discloses electrolyte solution of a manganic acid lithium battery. The electrolyte solution comprises lithium salt, non-aqueous organic solvent, film-forming additive and stabilizing additive, namely seven-methyl two-silazane. Because the stabilizing additive, seven-methyl two-silazane is added into the electrolyte solution, the acidity of the electrolyte solution can be controlled. The cycle life and the high temperature storage performance of a lithium ion battery can be improved by using the electrolyte solution to prepare a battery.

Owner:GUANGZHOU TINCI MATERIALS TECH

Treatment liquid and method or preparing Ti/Zr-containing yellow passive film on surface of aluminum alloy

InactiveCN101967633AHigh bonding strengthImprove the protective effectMetallic material coating processesOrganic acidRoom temperature

The invention discloses treatment liquid and a method for preparing a Ti / Zr-containing yellow passive film on the surface of an aluminum alloy. Each liter of treatment liquid comprises the following components by weight: 0.5 to 2.0g of fluorotitanic acid, 0.4 to 2.0g of fluorozirconic acid, 2.0 to 5.0g of manganate and 0.5 to 2.0g of organic acid; and the pH value of the treatment liquid is between 2.0 and 3.0. The treatment liquid of the invention does not contain chromium or other toxic substances, conversion treatment is realized without heating, the treatment time is between 5 and 30 minutes, and a yellow Ti / Zr-containing chemical conversion film can be prepared on the surface of the aluminum alloy. The chemical conversion film prepared by the method has high decay resistance and high bonding strength with a substrate, and is treated at room temperature by a simple process; and the coating does not contain hexavalent or trivalent chromium which is harmful to environment and human bodies.

Owner:SOUTH CHINA UNIV OF TECH

Spray drying preparation of spherical lithium manganate doped slurry

InactiveCN101462773AEvenly dopedUniform particle sizeManganates/permanganatesGranularityLithium carbonate

The invention relates to a method for the spray drying of spherical doped lithium maganate slurry. The method comprises: mixing manganese dioxide, lithium carbonate, doped metal salt and a solution containing a dispersant according to a certain proportion; subjecting the mixture to mechanical mixing to obtain a uniformly mixed slurry; subjecting the uniformly mixed slurry to spray drying to obtain a spherical precursor; and roasting the precursor sectionally to obtain a spherical doped lithium manganate slurry cathode material product. The lithium manganate cathode material for lithium ion batteries has uniform granularity which averagely is 15mu m, uniform spherical shape and good cycle performance. The invention is simple in process, convenient in operation, environmentally friendly and applicable to industrial production.

Owner:CENT SOUTH UNIV

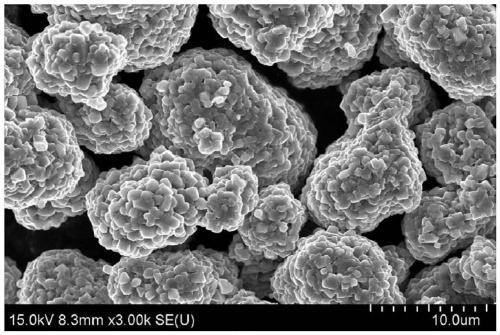

Method for preparing small-size nickel-cobalt lithium manganate precursor

ActiveCN103253717ARealize industrial productionConcentrated particle size distributionManganese oxides/hydroxidesNickel oxides/hydroxidesManganateManganese

The invention relates to a method for preparing a small-size nickel-cobalt lithium manganate precursor. The method is characterized by comprising the following steps of: (1) preparing a solution from soluble salts of nickel, cobalt and manganese as materials, adopting a sodium hydroxide water solution as a precipitator, and adopting ammonia water or ammonium salt as a complexing agent; (2) merging and adding the obtained three solutions into a reaction kettle which contains bottom water and includes stirring and temperature control devices; leading in nitrogen to protect in a reaction process, and continuously carrying out reaction; and (3) stirring and aging for 4-6 hours after a temporary kettle is full, putting the aged material into washing and press filtering equipment to wash; removing moisture in a filter pressing manner; and then mixing and sieving by a 200mesh screen after baking and crushing. By adopting the method disclosed by the invention, industrialized production of the small-size nickel-cobalt lithium manganate precursor can be conveniently achieved; and the method is stable to control the particle size, and convenient to achieve requirements of the materials and equipment.

Owner:宁夏中色金辉新能源有限公司

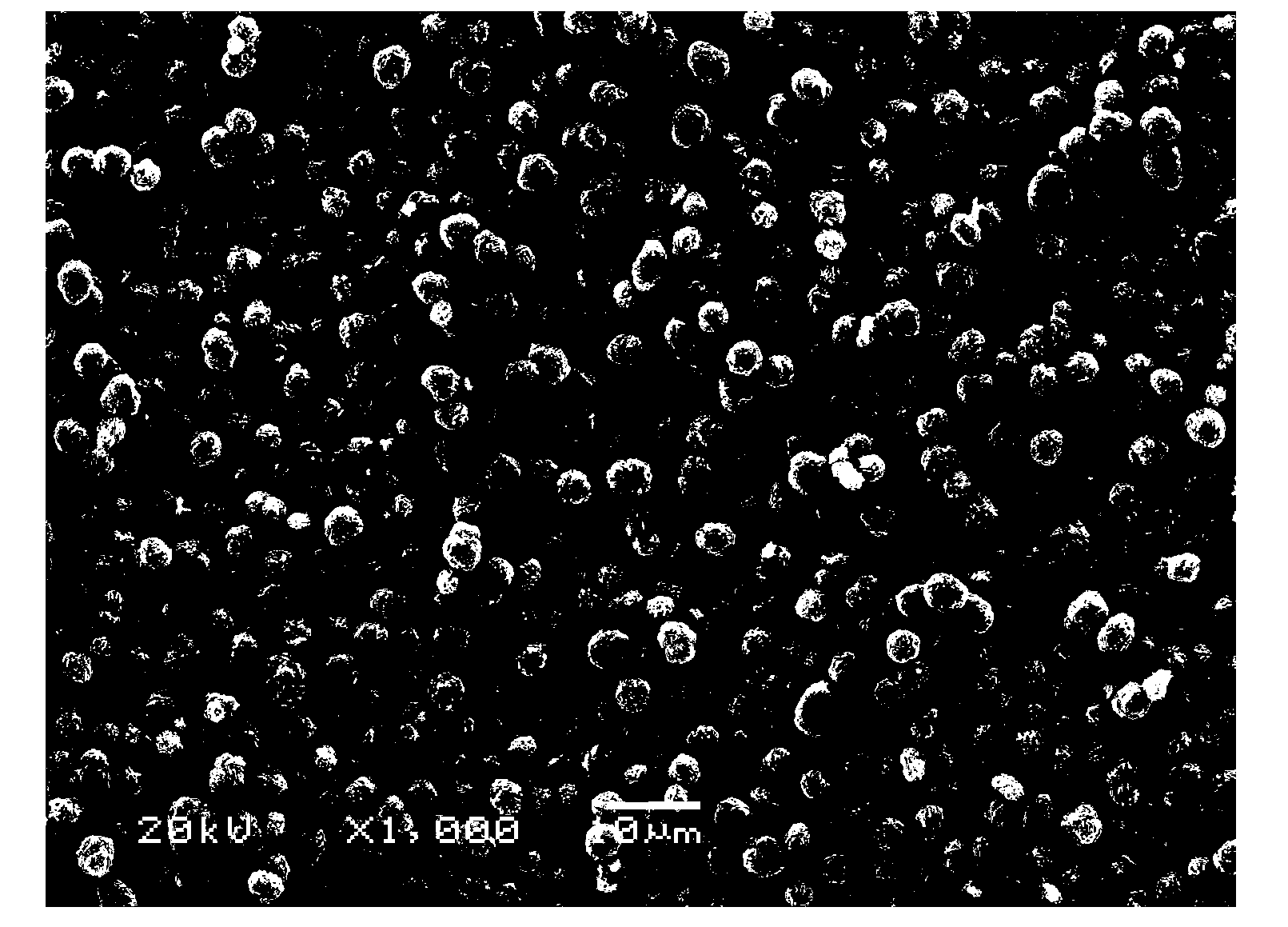

Small-granule monocrystal lithium nickel cobalt manganate positive electrode material and preparation method therefor

The invention belongs to the technical field of a lithium ion battery, and discloses a small-granule monocrystal lithium nickel cobalt manganate positive electrode material and a preparation method therefor. The preparation method comprises the following steps of grinding a big-granule spherical nickel cobalt manganese precursor into fragments, and adding the fragments and a metal additive into a mixed solution of water and ethyl alcohol, stirring uniformly, and spraying and drying to obtain a mixture A; and mixing the mixture A with a lithium source and grinding the mixture, sintering at a temperature of 600-1,200 DEG C for 8-30h, and performing cooling, air flow smashing and sieving to obtain the small-granule monocrystal lithium nickel cobalt manganate positive electrode material, wherein the granule dimensions are small and uniform, the average dimensions are 2-4.5[mu]m, and the specific surface area is 0.5-1.5m<2> / g, so that the structural stability of the positive electrode material is effectively improved. The lithium nickel cobalt manganate positive electrode material adopts monocrystal appearance, so that the problem of high temperature gas production of a ternary material can be effectively relieved; and meanwhile, the compaction density of a battery electrode plate is improved, the energy density of the material can be highly improved consequently, and excellent electrochemical property is achieved.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

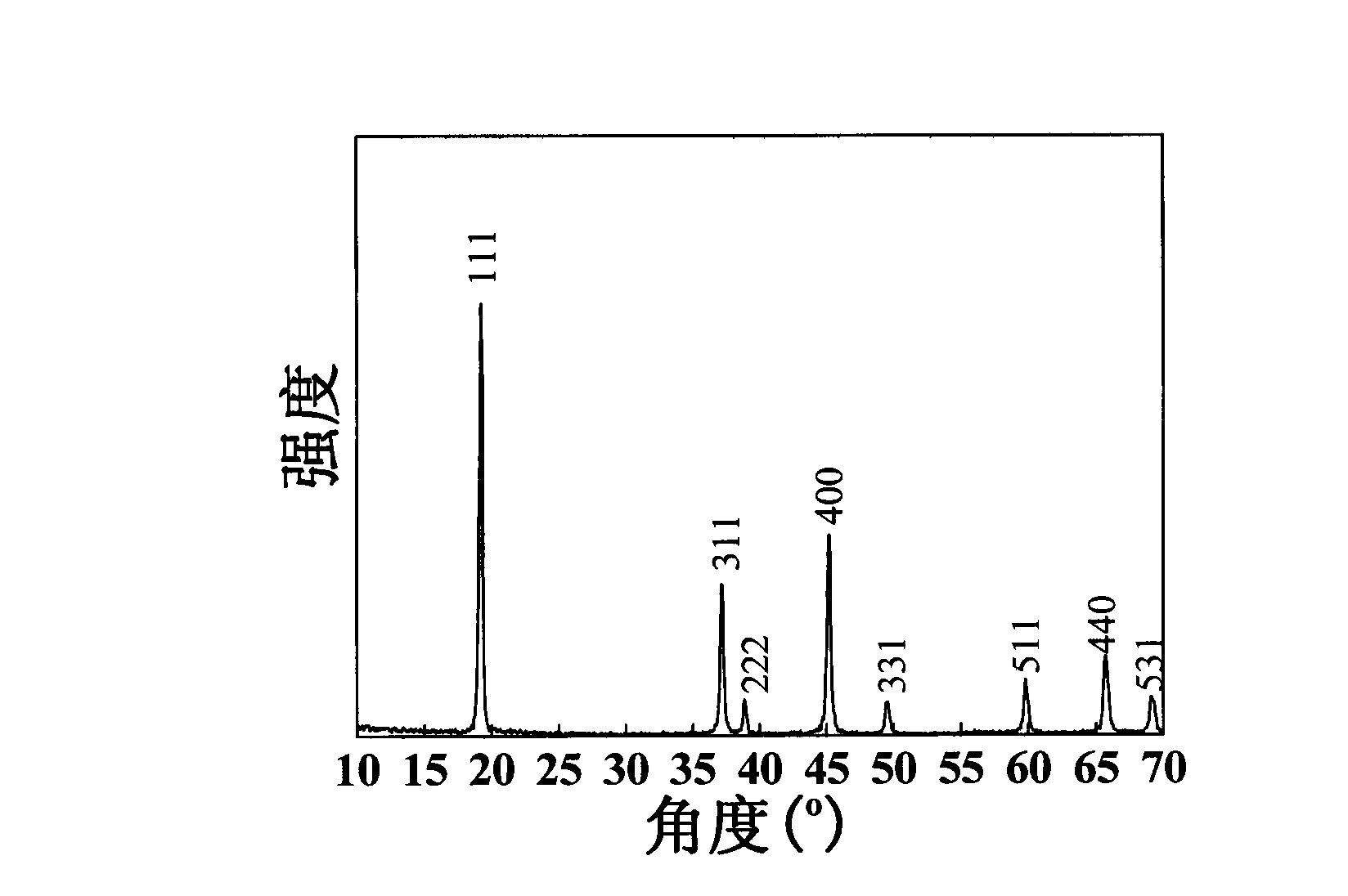

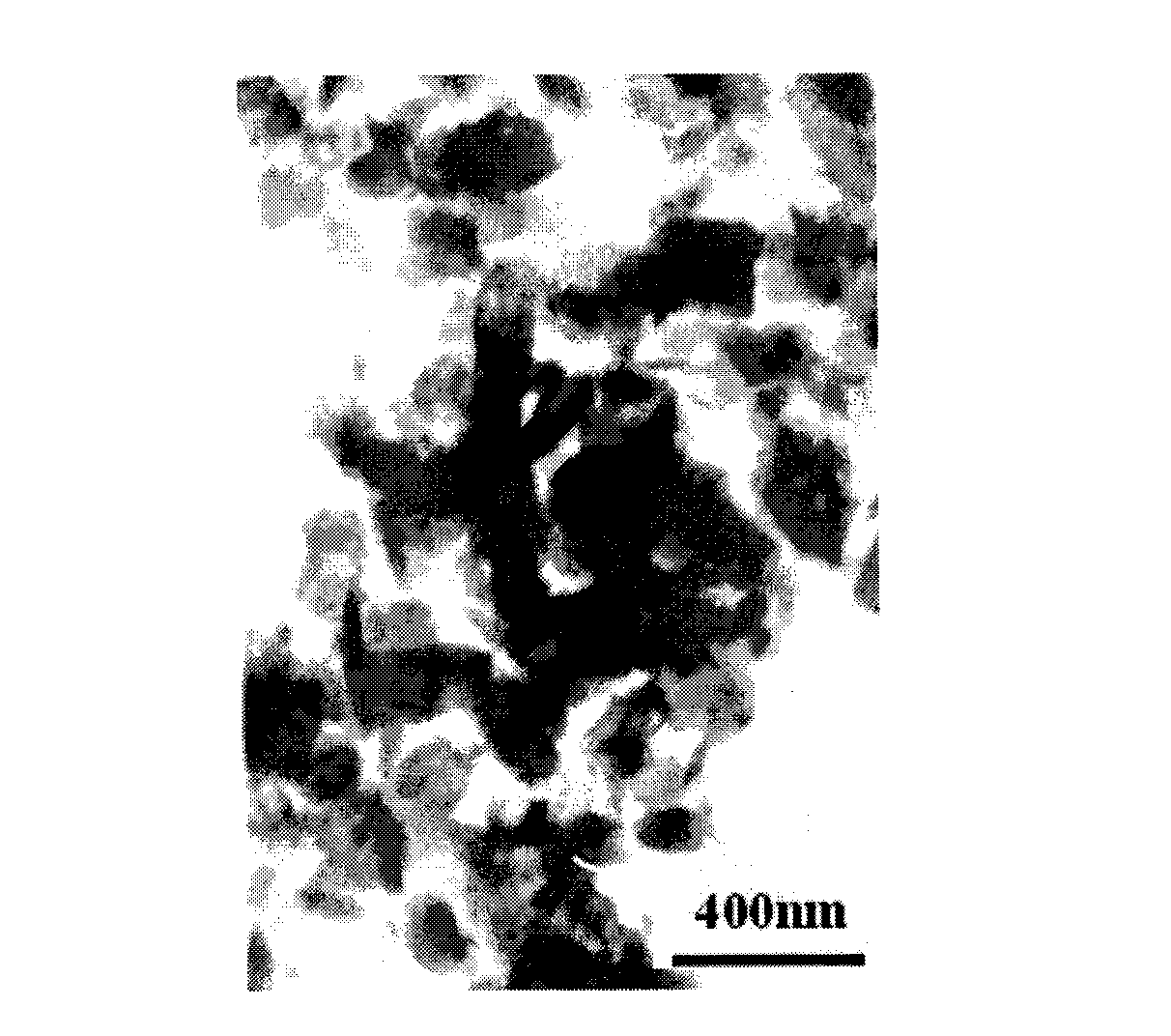

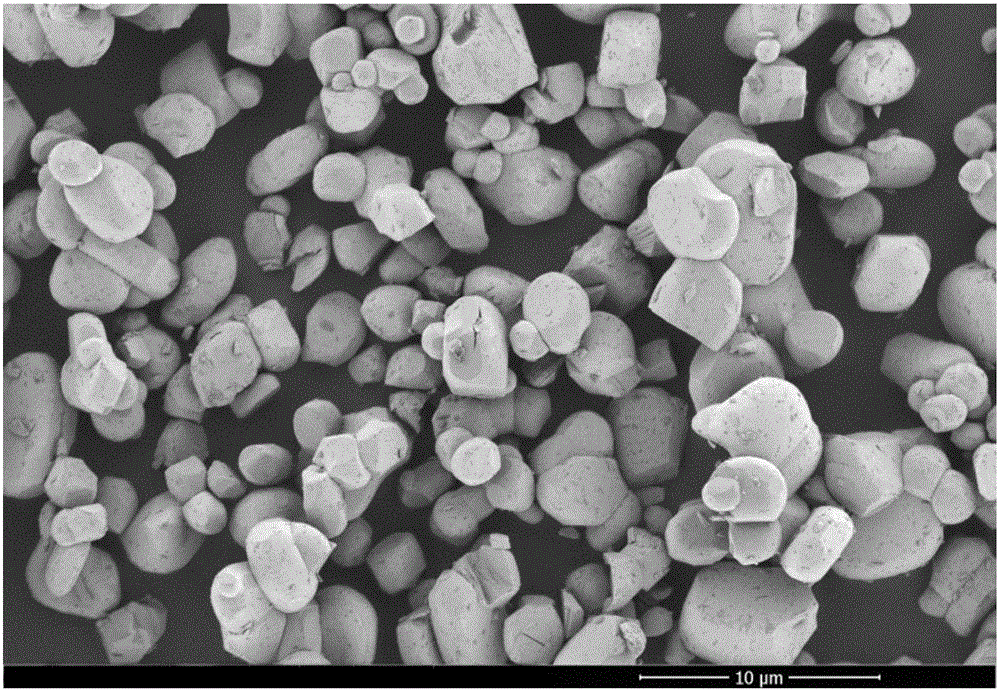

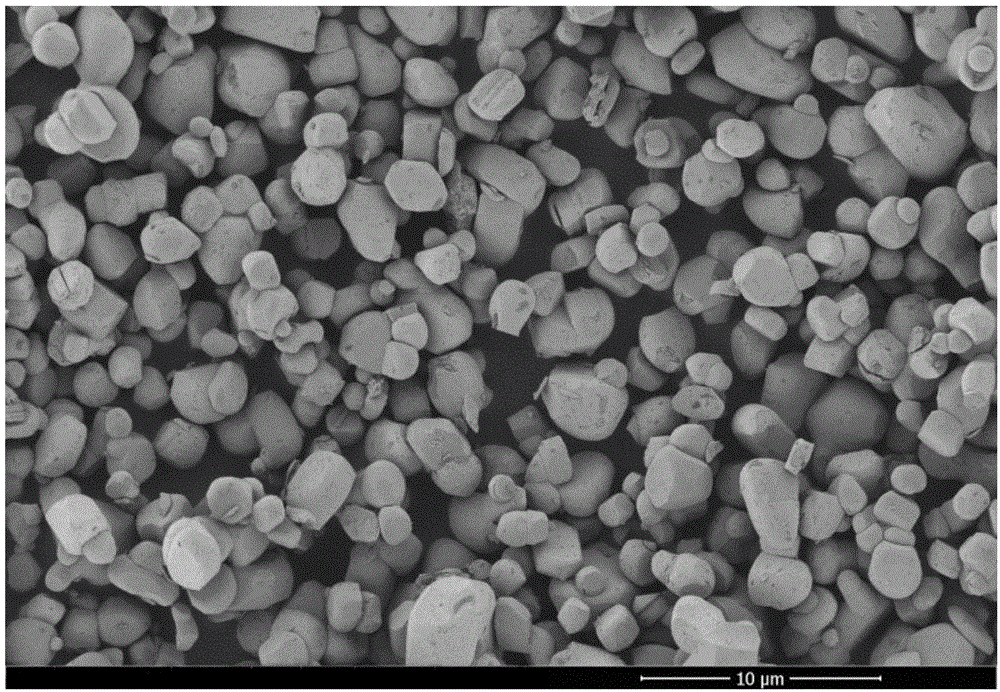

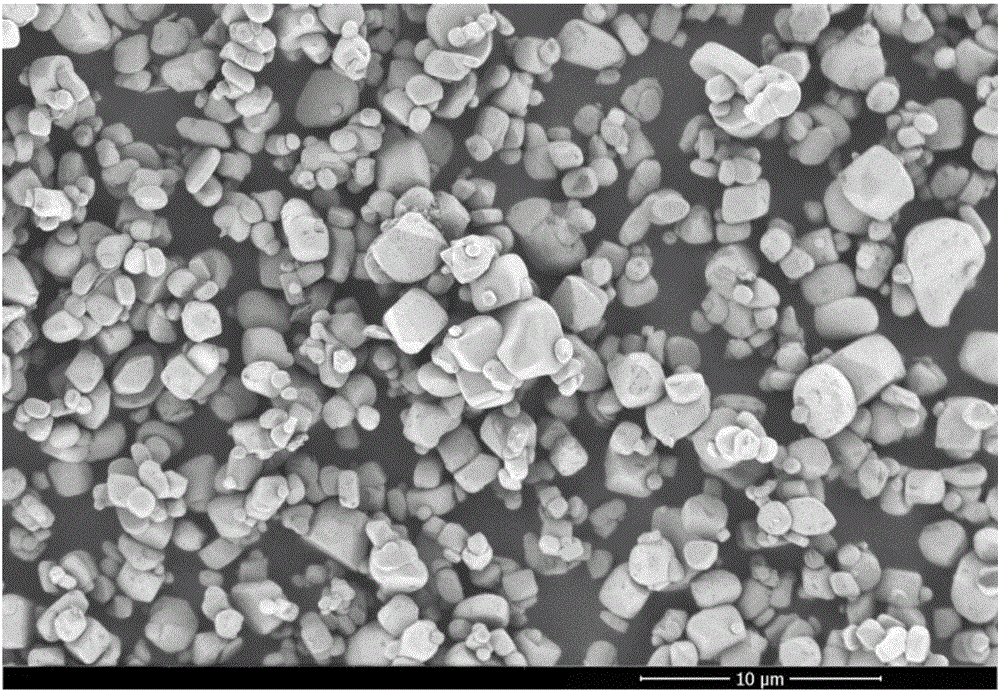

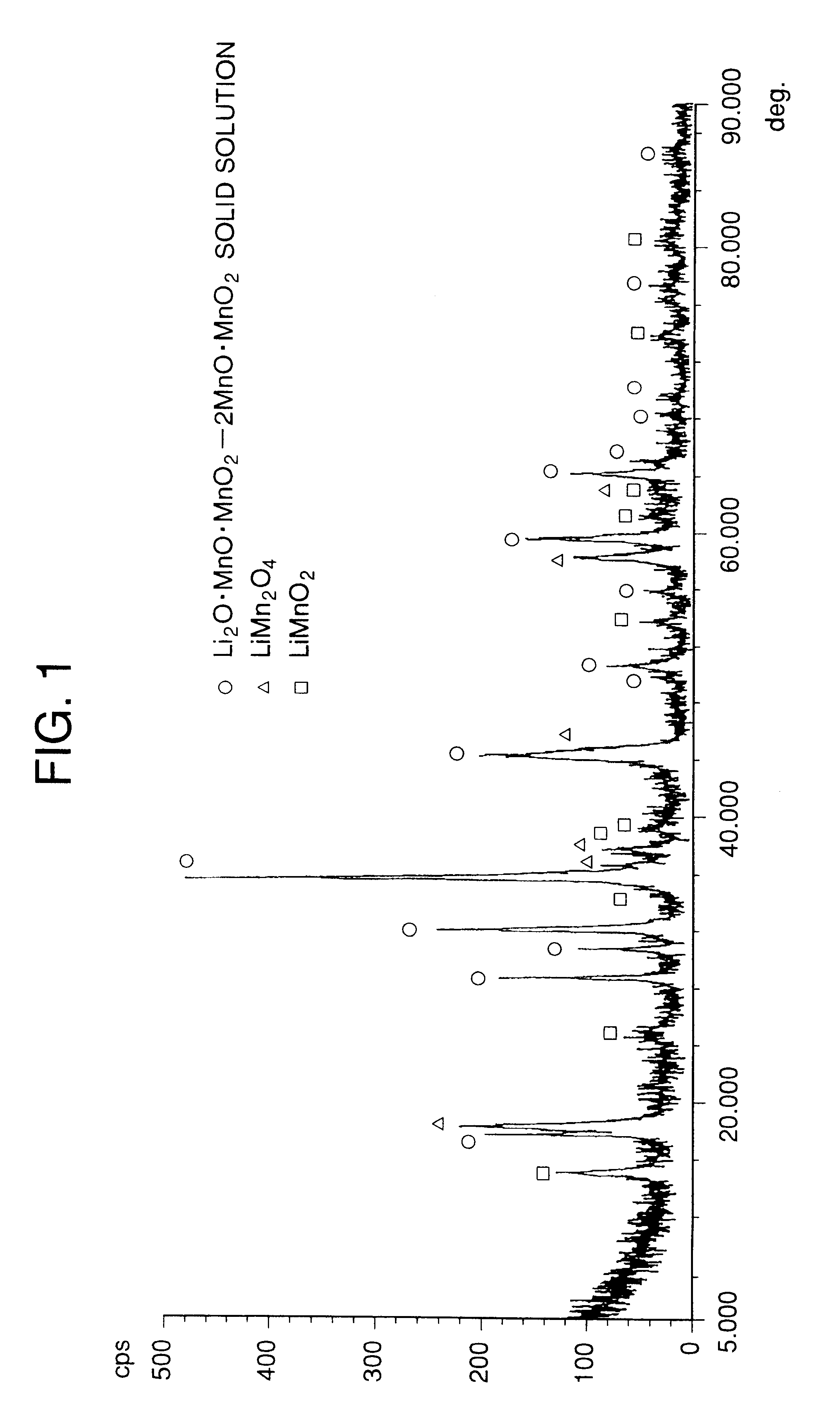

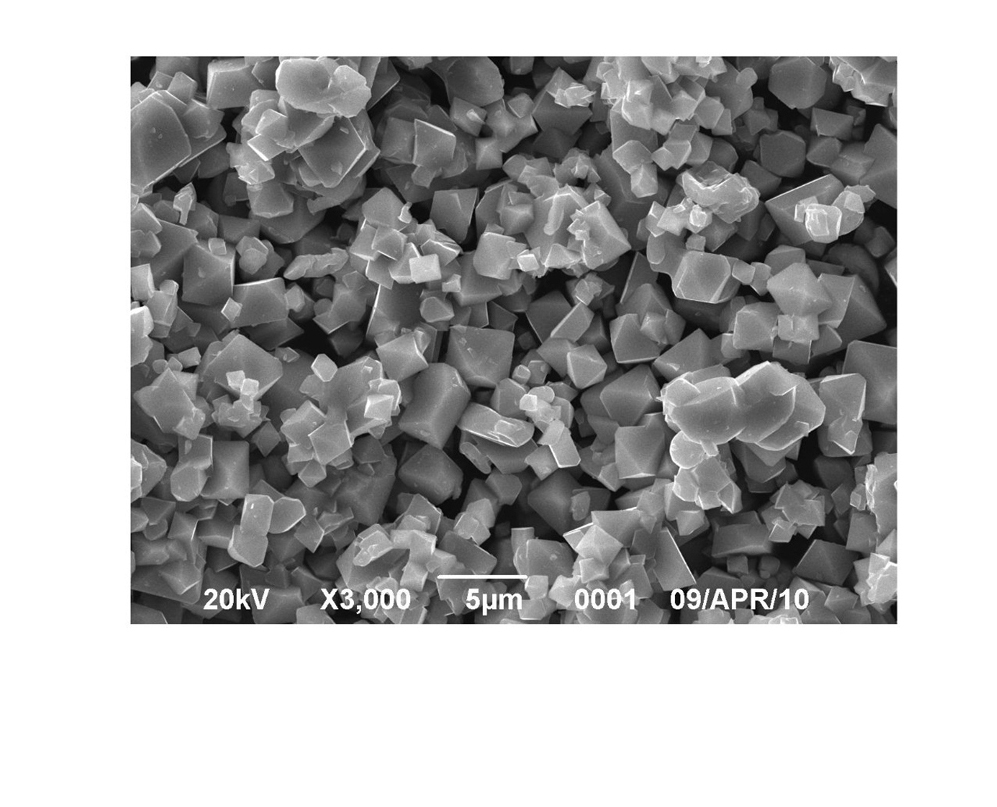

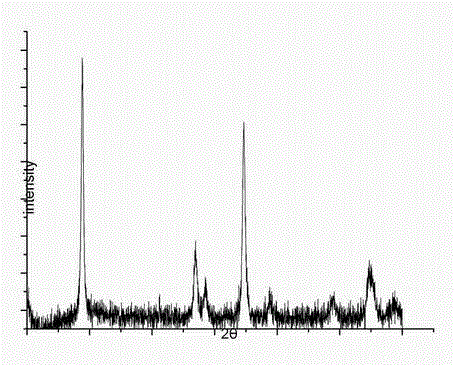

Lithium manganate, method of producing the same, and lithium cell produced by the method

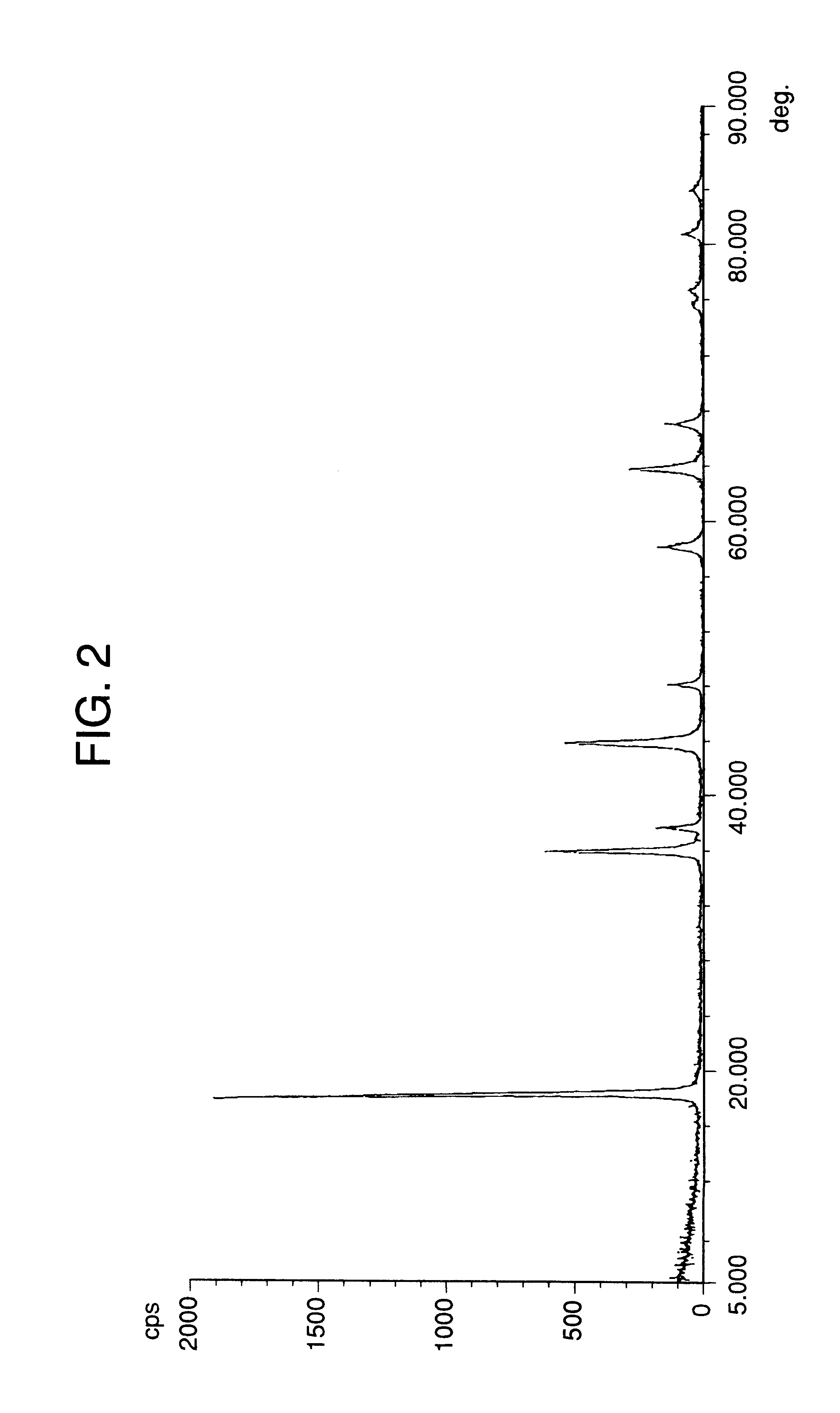

InactiveUS6334993B1Easy to confirmHigh in initial chargeElectrode thermal treatmentLithium compoundsManganateLithium battery

The present invention relates to a lithium manganate useful as an active material of positive electrodes for lithium batteries, and a process for producing the same, a positive electrode which uses the same as an active material of positive electrode, and a lithium battery. The lithium manganate of the present invention has a cubic particle form and contains voids in the particles, and therefore lithium batteries using it as an active material of positive electrodes provides a high initial discharge capacity of at least 95 mAh / g and, besides, are excellent in cycle characteristics.

Owner:ISHIHARA SANGYO KAISHA LTD

Preparation method of lithium ion battery anode material lithium manganate and automobile lithium ion battery

InactiveCN101964416AUniform bulkGood crystallizationCell electrodesSecondary cellsElectrical batteryManganate

The invention relates to a preparation technology of a battery anode material and a related automobile battery and particularly discloses a preparation method of lithium ion battery anode material lithium manganate. The method comprises the following steps: using lithium source, Mn3O4 and nanoscale doping metal additive as raw materials for proportioning, then presintering Mn3O4 or the Mn3O4 processed by ball milling, mixing the presintered Mn3O4 with the mixture of lithium source and metal additive; performing the first sintering and second sintering to the mixed raw material; and finally classifying and screening the sintering product to obtain the spinel lithium manganate product with the required grain size. The invention also discloses an automobile lithium ion battery which is assembled by using the spinel lithium manganate prepared by the method of the invention as anode and using graphite as cathode. The preparation method of the invention has simple operation and environmental friend; and the prepared lithium manganate product has excellent product performance.

Owner:HUNAN CHANGYUAN LICO CO LTD

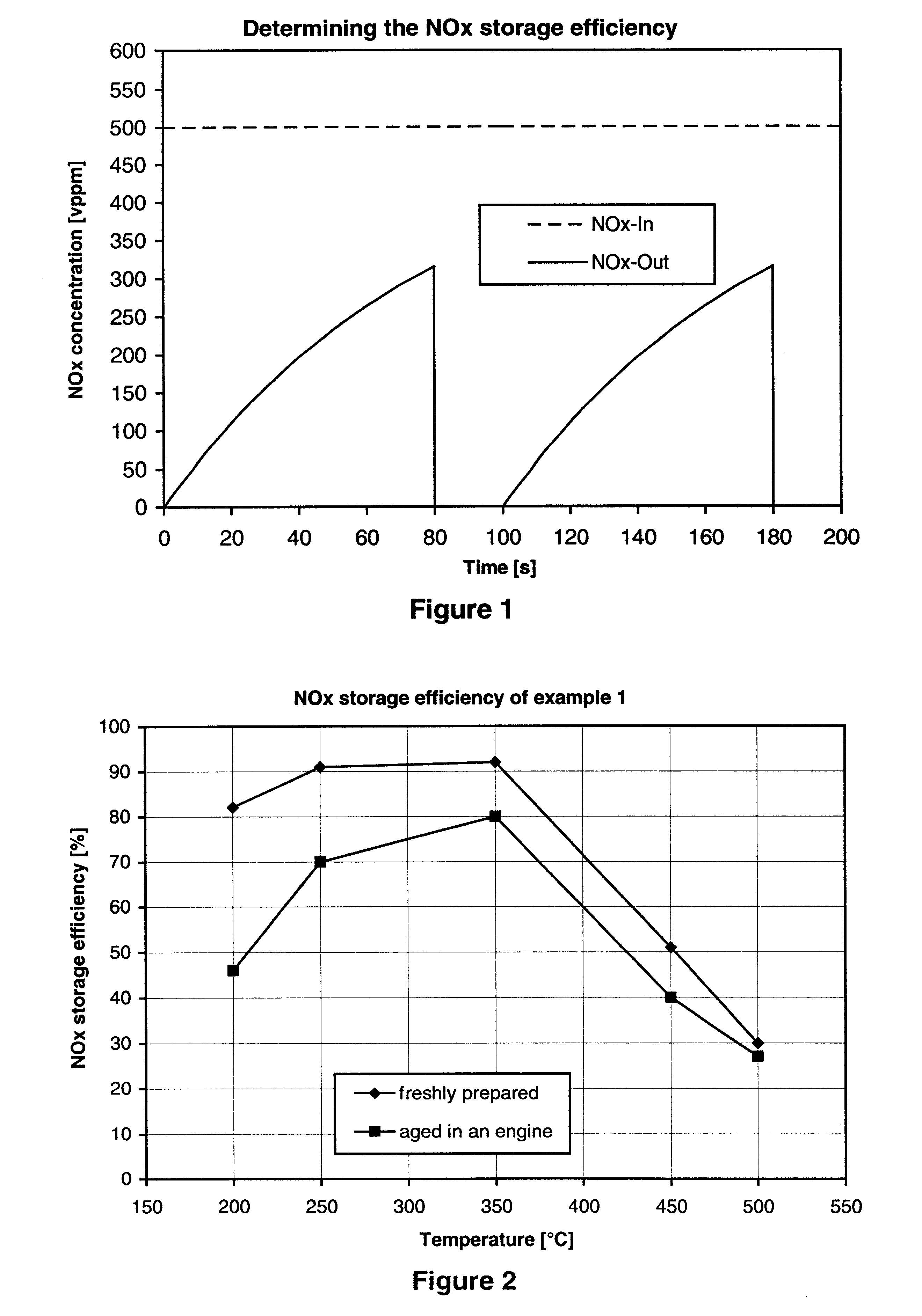

Lithium-Ion secondary battery

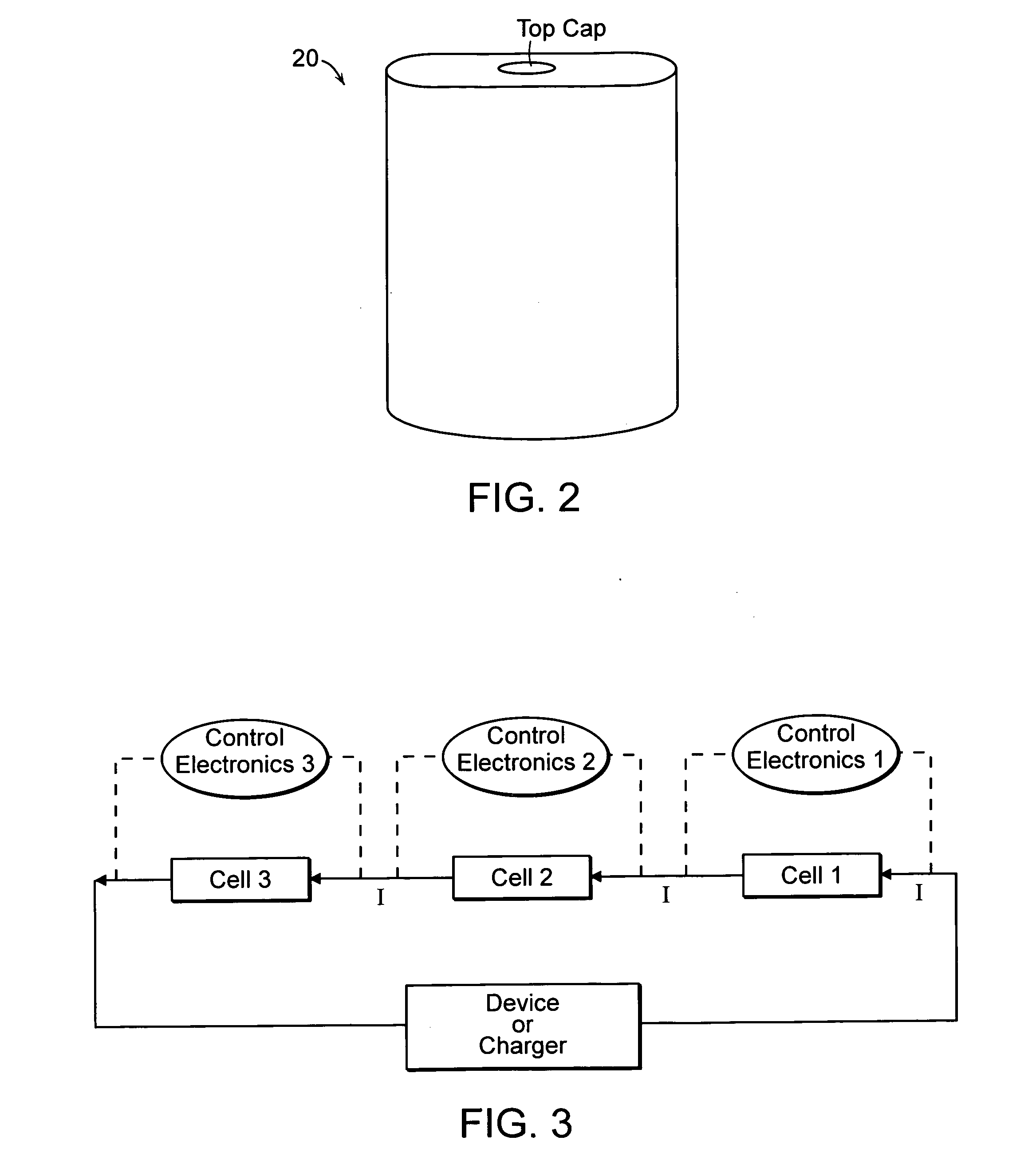

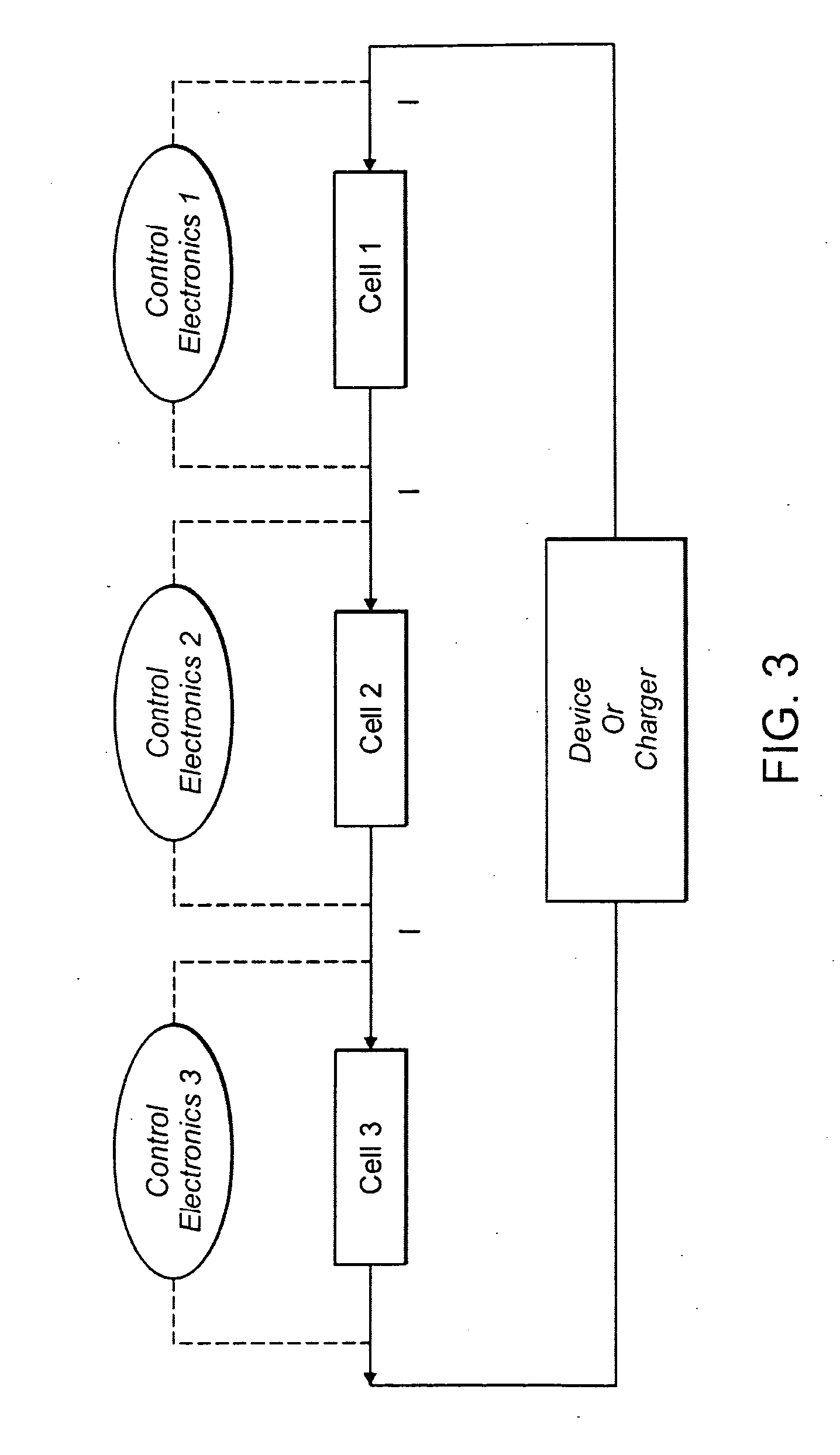

InactiveUS20090181296A1Safer chemistry characteristicMinimize the numberPrimary cell to battery groupingFinal product manufactureManganateSpinel

A lithium-ion battery includes a cathode that includes an active cathode material. The active cathode material includes a cathode mixture that includes a lithium cobaltate and a manganate spinel a manganate spinel represented by an empirical formula of Li(1+x1)(Mn1−y1A′y2)2−x2Oz1 or Li(1+x1)Mn2Oz1. The lithium cobaltate and the manganate spinel are in a weight ratio of lithium cobaltate:manganate spinel between about 0.9:0.1 to about 0.6:0.4. A lithium-ion battery pack employs a cathode that includes an active cathode material as described above. A method of forming a lithium-ion battery includes the steps of forming an active cathode material as described above; forming a cathode electrode with the active cathode material; and forming an anode electrode in electrical contact with the cathode via an electrolyte.

Owner:BOSTON POWER INC

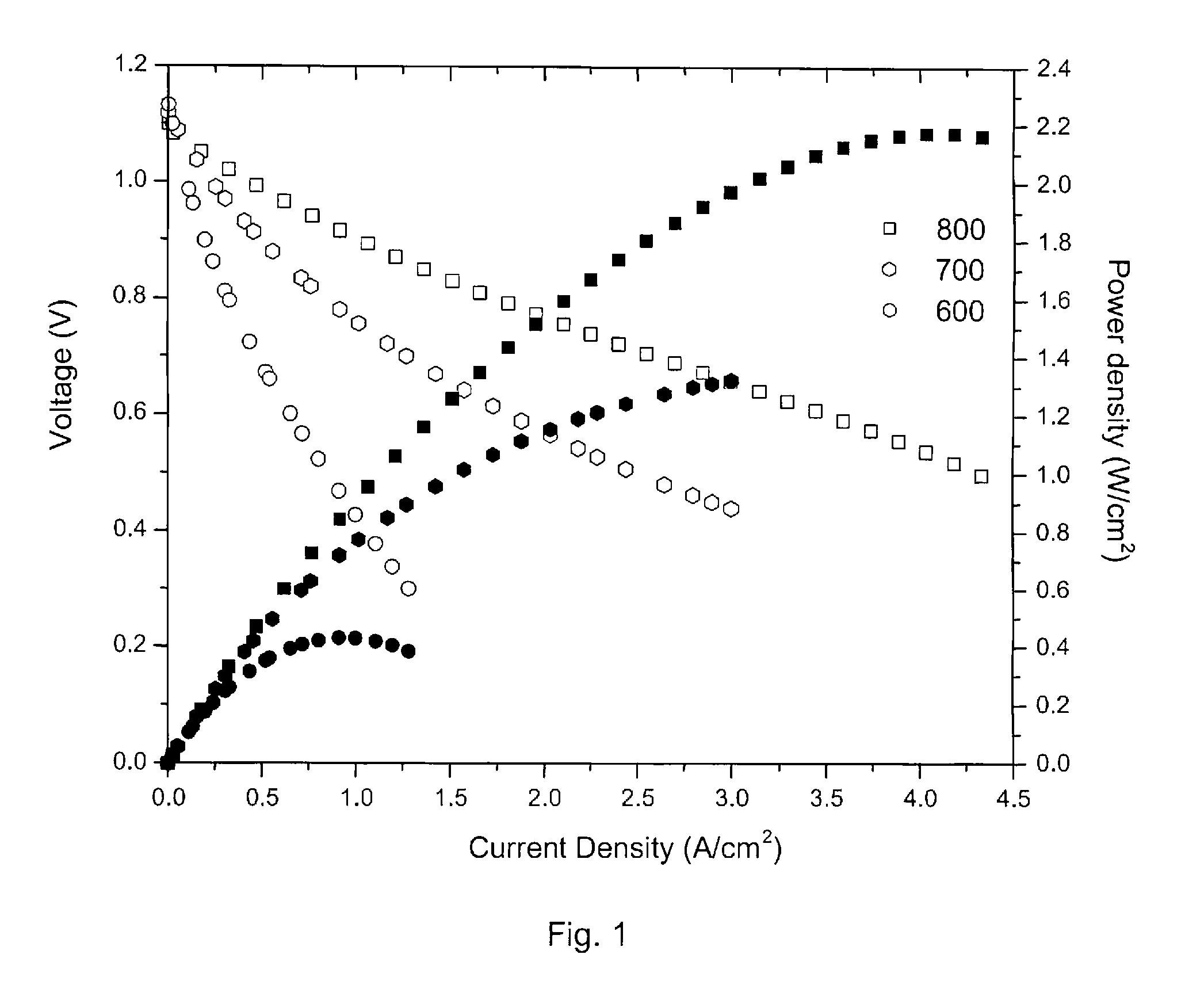

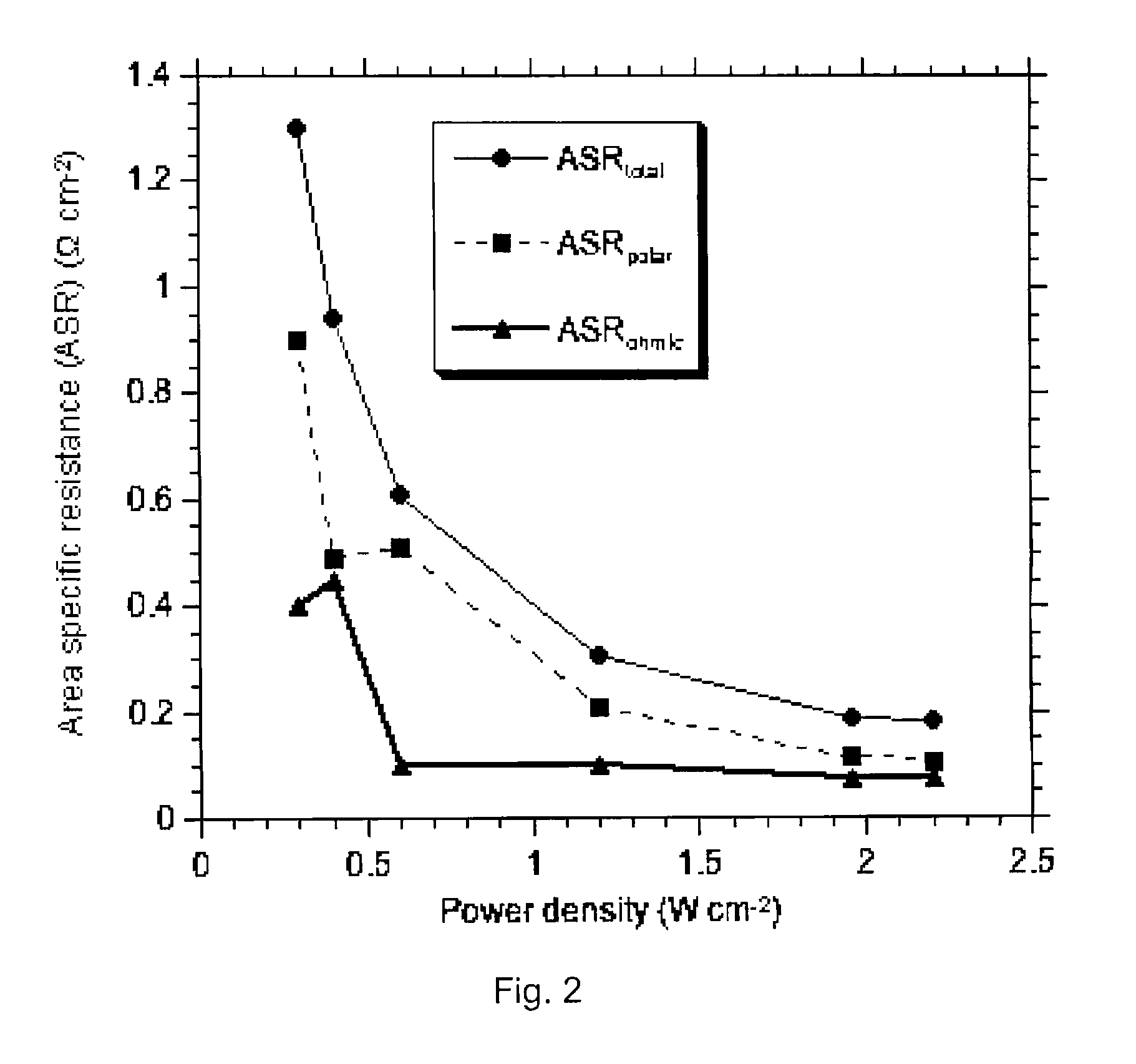

Solid oxide fuel cell cathode comprising lanthanum nickelate

A solid mixture of La2NiO4+δ and an ionic conductive material. A solid oxide fuel cell having a cathode interlayer having a La2NiO4+δ layer and a doped ceria layer, a lanthanum strontium cobaltite or lanthanum strontium manganate cathode current collector, an anode; and an ionic conductive electrolyte between and in contact with the cathode interlayer and the anode.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Method for preparing lithium ion battery anode material nickle cobalt lithium manganate

ActiveCN101355159AWell mixedImprove performanceCell electrodesManganates/permanganatesLithium hydroxideManganate

The invention relates to a method for preparing a LiCoxNiyMnzO2 anode material for a lithium ion battery. The method comprises the following steps that soluble salts of nickel, cobalt and manganese undergo coprecipitation to prepare composite carbonate of nickel, manganese and cobalt; then, the carbonate is reacted with lithium hydroxide; moreover, when the carbonate is converted into hydroxide, lithium is deposited on the surface of the prior particles containing nickel, cobalt and manganese in the form of lithium carbonate. In this way, even mixing of lithium and elements such as nickel, cobalt and manganese is realized to obtain a top-quality precursor for preparing the LiCoxNiyMnzO2 material; moreover, the precursor can be made into a LiCoxNiyMnzO2 product with excellent properties after twice sintering. The method has the advantages of simple and easily controlled technological process, low production cost of prepared product and stable and controllable product performance, and can be used in industrial production.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

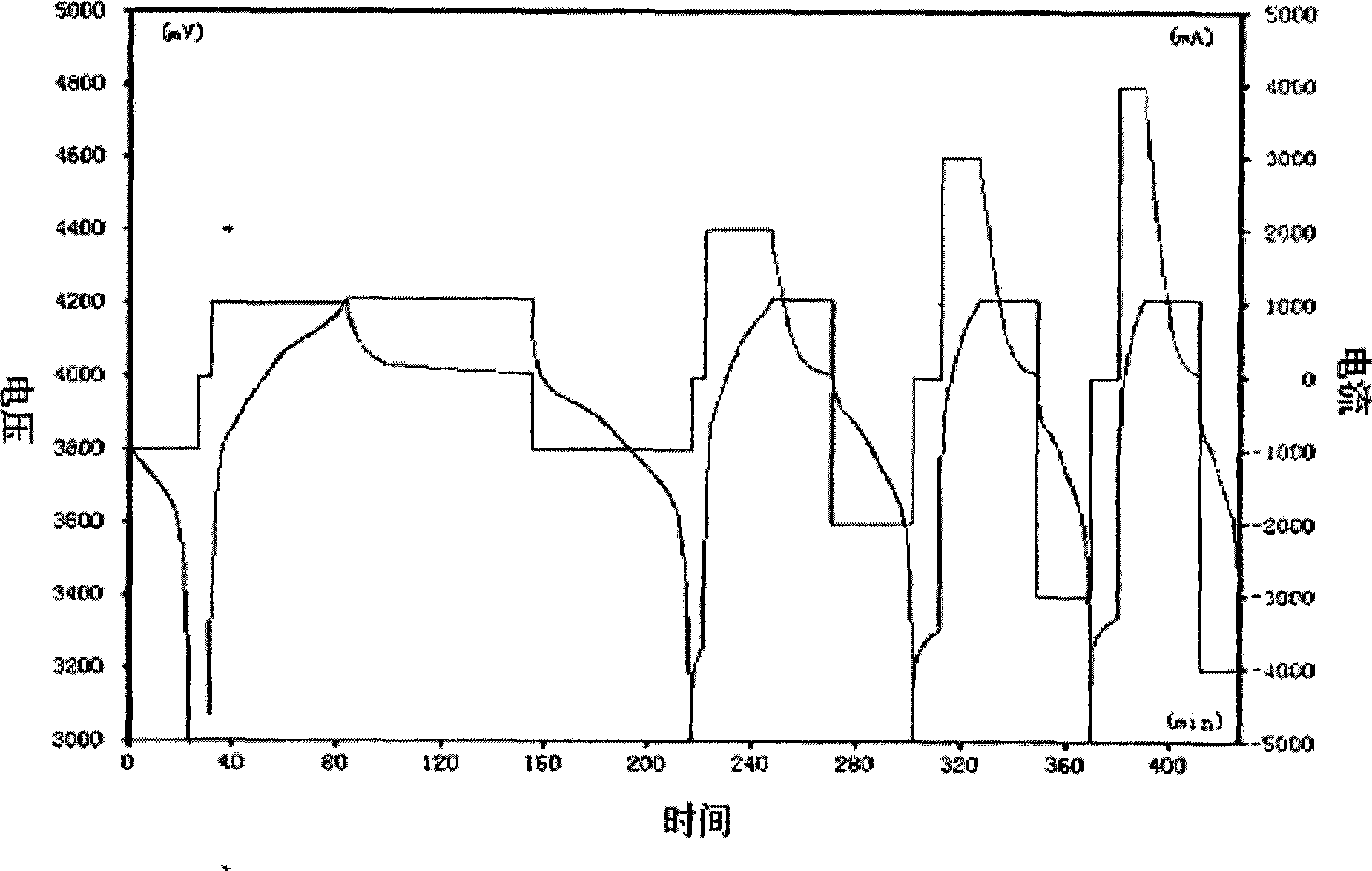

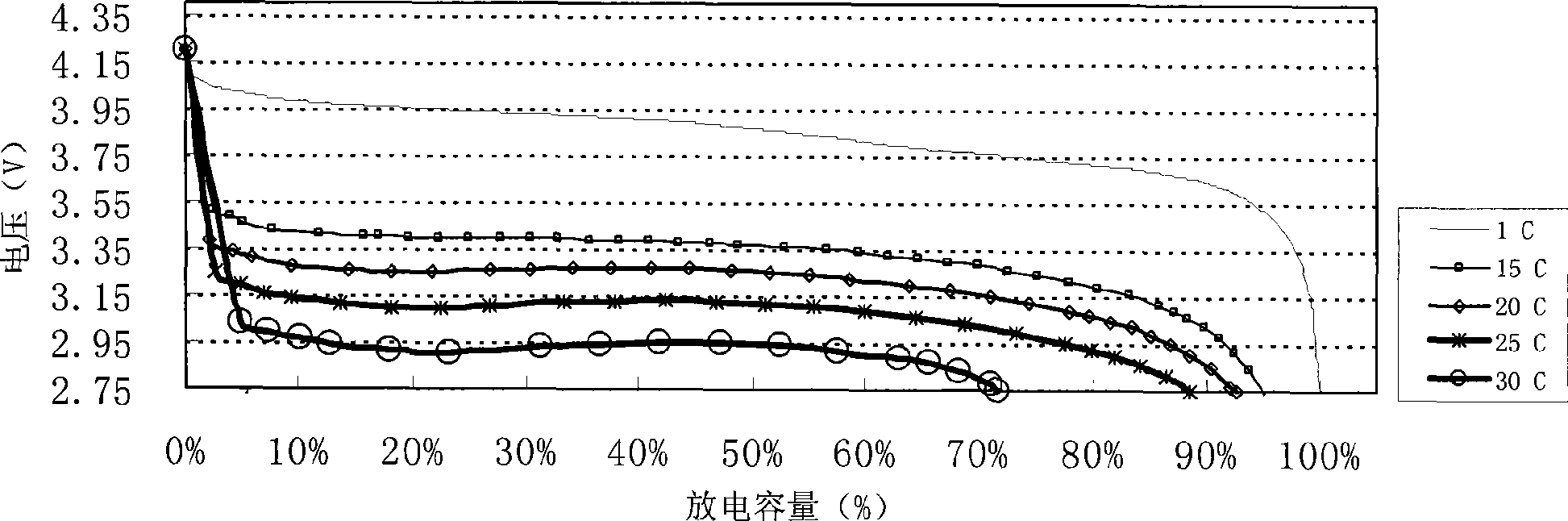

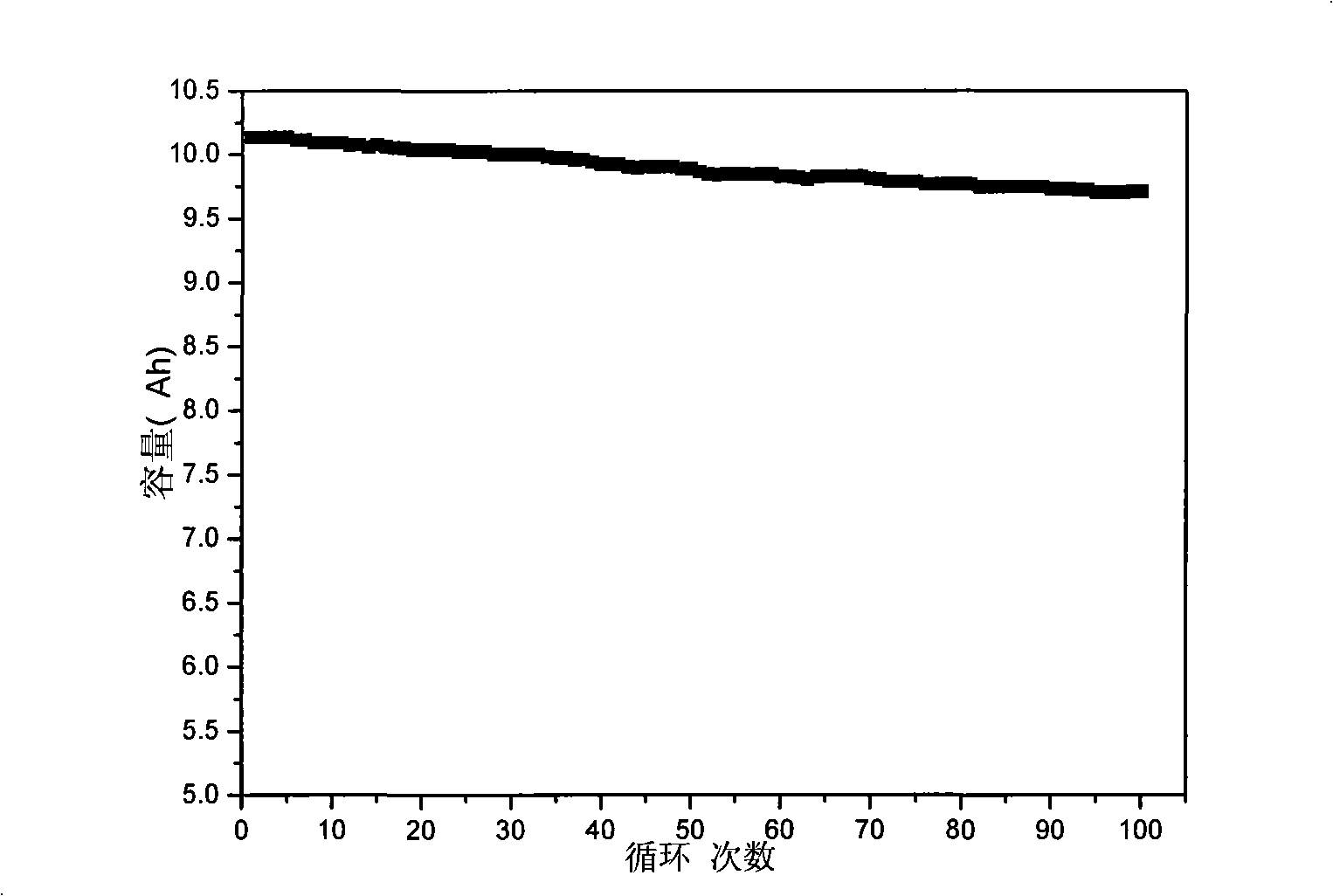

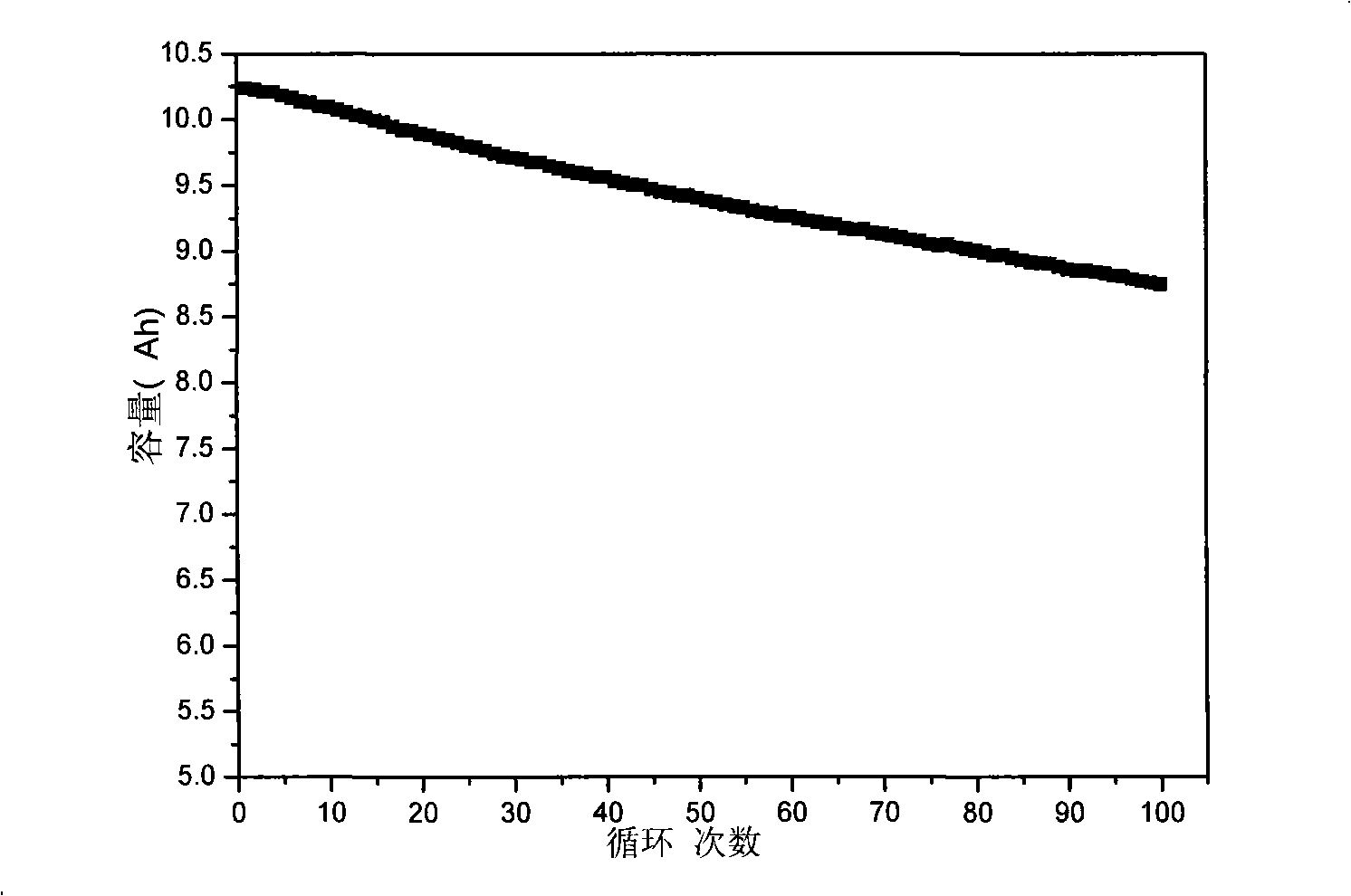

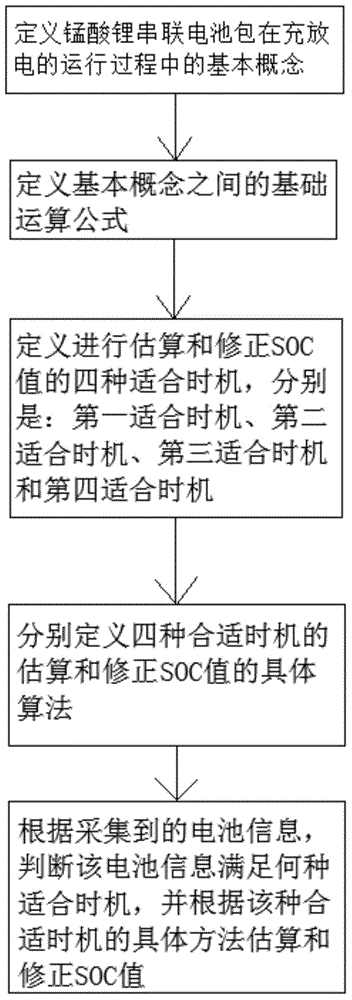

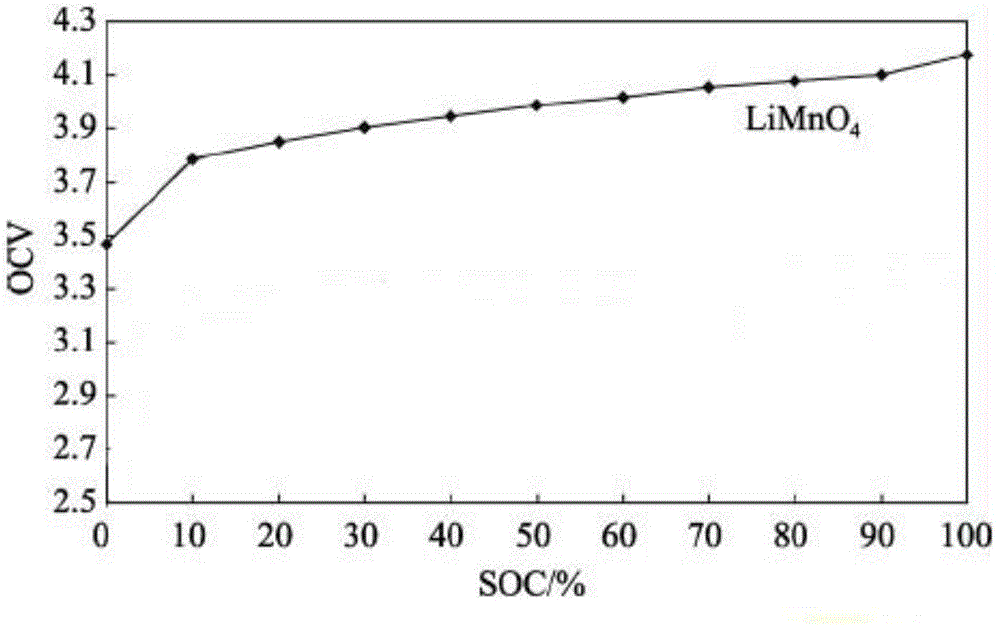

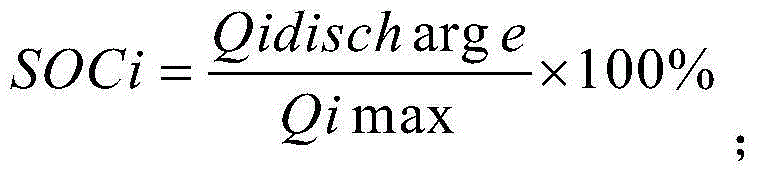

Method for estimating and correcting lithium manganate series battery pack SOC value

ActiveCN105068011AAccurate maximum available capacity parametersImplement single value correctionElectrical testingCapacity valueManganate

The present invention provides a method for estimating and correcting lithium manganate series battery pack SOC value. The SOC calculation method of a single cell and a battery pack is redefined, four different suitable opportunities are selected, different algorithms are used, a single battery remaining capacity affected by an ampere-hour integral accumulation error and a single battery maximum available capacity affected by temperature change and aging are corrected respectively, thus the maximum available capacity and the remaining capacity of a battery pack are corrected, and the correction of an SOC single value at a particular time point is realized. In addition, for a battery pack SOC real-time calculation formula, the invention provides a more accurate initial value and a battery pack maximum available capacity value, and thus the battery pack SOC calculated in an online way is more accurate.

Owner:CHINA AUTOMOTIVE TECH & RES CENT

Composite positive electrode material with core-shell structure for lithium ion batteries and preparing method thereof

InactiveUS20120264018A1Promote circulationImprove conductivityMaterial nanotechnologySecondary cellsHigh rateLithium iron phosphate

A composite positive electrode material with a core-shell structure for a lithium ion battery consists of a core active material and a shell active material. The core active material is a lithium iron phosphate or a lithium manganate, and the shell active material is a composite lithium iron phosphate with carbon. The carbon is one or more of carbon nanotube, superfine conductive carbon black and amorphous carbon material. The composite positive electrode material includes from 65% to 99% core active material and from 1% to 35% shell active material, based on the total weight of the composite positive electrode material. The composite positive electrode material has stable property and excellent electrochemistry performance. The lithium ion battery made with the material has higher charge-discharge capacity, excellent cycle performance. It can be charged quickly and discharged at high rate. A preparing method for the composite positive electrode material is also provided.

Owner:SHENZHEN DYNANONIC

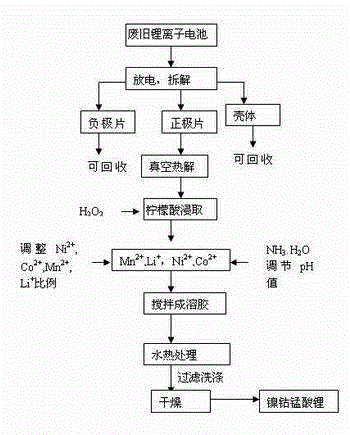

Method for preparing lithium nickelate cobaltate manganate cathode material by taking waste lithium ion batteries as raw material

InactiveCN103606651AAvoid it happening againAvoid high temperature calcinationCell electrodesWaste accumulators reclaimingManganateHYDROSOL

The invention discloses a method for preparing a lithium nickelate cobaltate manganate cathode material by taking waste lithium ion batteries as a raw material. The main points of the technical scheme comprise that an organic acid citric acid is mainly taken as a leaching agent and a gelata, a sol-gel process is employed for preparation of the lithium nickelate cobaltate manganate cathode material, and the specific preparation steps are disclosed. The method helps to avoid pollutions of S, N, chlorine and the like caused by inorganic acid leaching agents employed in conventional methods, helps to avoid by-product generation in metal ion separation process, the whole preparation process helps to avoid a high-temperature calcining link, and the method is low in energy consumption, green, environment-friendly and low in cost; and the prepared product can be returned to factories for sequential use.

Owner:HENAN NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com