Small-granule monocrystal lithium nickel cobalt manganate positive electrode material and preparation method therefor

A technology of nickel-cobalt-lithium-manganese-manganate and positive-electrode materials, applied in chemical instruments and methods, battery electrodes, nickel compounds, etc., can solve the problem of reduced output of small-particle single-crystal nickel-cobalt-lithium-manganese-manganese ternary materials and large-particle spherical precursors Reduced market utilization rate, low output of small particle precursors, etc., to achieve the effect of improving high temperature gas production, excellent electrochemical performance, and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

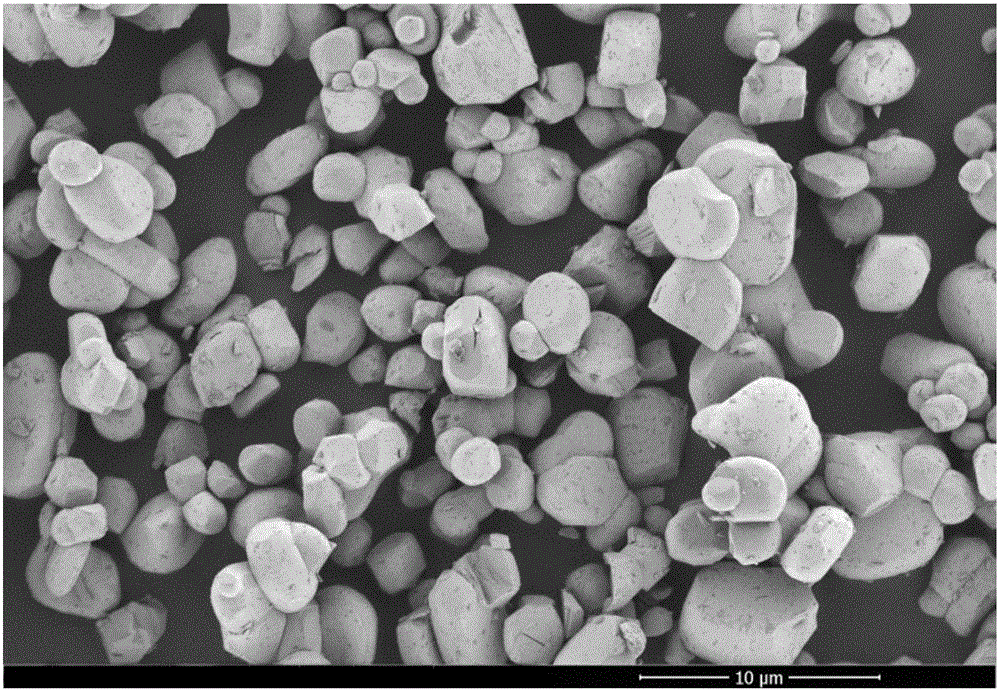

[0034] The large-particle spherical nickel-cobalt-manganese precursor (Ni 0.5 co 0.2 mn 0.3 (OH) 2 , the average particle size is 12 μm) is mechanically finely ground into pieces, and then it and alumina (alumina content is 0.6%) are added to water and ethanol mixed solvent (ethanol volume content 30%) to carry out uniform stirring, and then passed The spray-drying method makes the precursor fragments assemble into a spherical shape to achieve the purpose of embedding the metal additive into the spherical interior to obtain a mixture A, and then the mixture A and lithium carbonate (mass content of lithium carbonate is 43%) are mixed by ball milling, and the resulting mixture is heated at 960 ° C After sintering for 14 hours, after cooling to room temperature, jet milling and passing through a 400-mesh sieve to obtain the nickel-cobalt-lithium-manganese-oxide positive electrode material, the scanning electron microscope shows figure 1 As shown, the positive electrode materia...

Embodiment 2

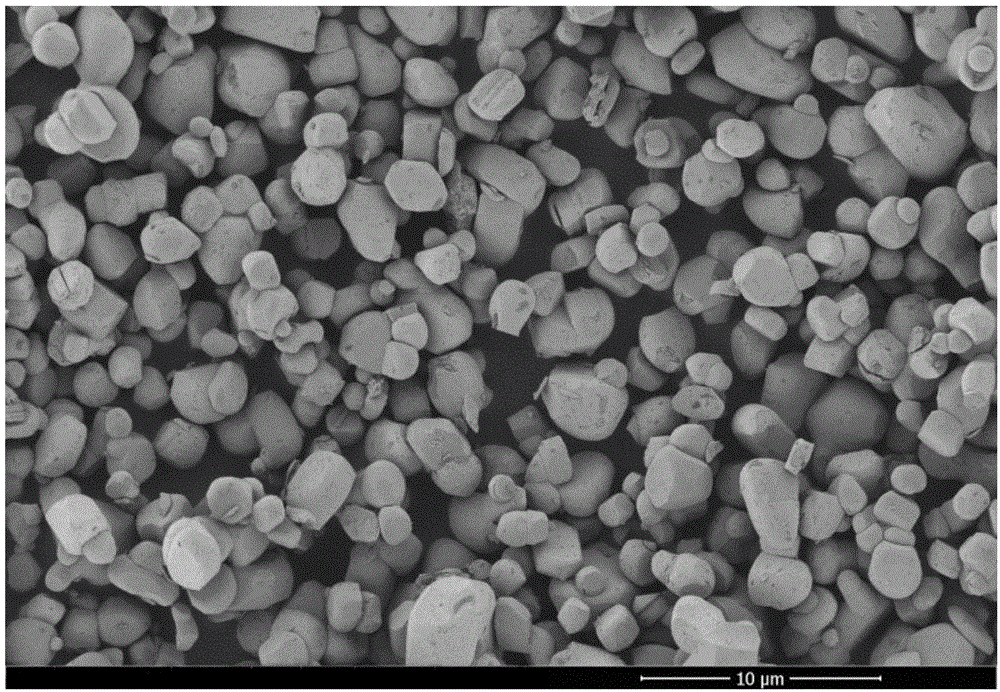

[0036] The large-particle spherical nickel-cobalt-manganese precursor (Ni 0.5 co 0.25 mn 0.25 (OH) 2 , the average particle size is 15 μm) is mechanically ground into fragments, and then it and antimony trioxide (antimony trioxide mass content is 1%) are added in water and ethanol mixed solvent (ethanol volume content is 40%) Stir evenly, then make the precursor fragments assemble into a spherical shape by spray drying to achieve the purpose of metal additives embedded in the spherical interior, to obtain mixture A, and then mix A with lithium carbonate (mass content of lithium carbonate is 45%) by ball milling , the resulting mixture was sintered at 910°C for 15h, cooled to room temperature, airflow pulverized, and passed through a 400-mesh sieve to obtain the nickel-cobalt-lithium-manganese-oxide positive electrode material, as shown in the scanning electron microscope figure 2 As shown, the positive electrode material is a single crystal particle and the particle is uni...

Embodiment 3

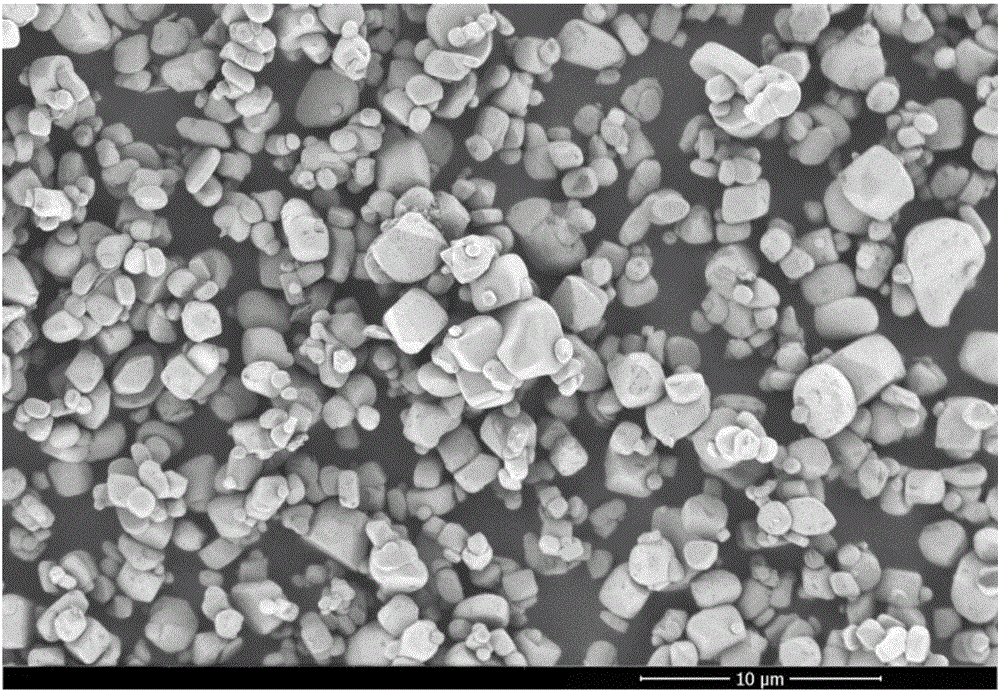

[0038] The large-particle spherical nickel-cobalt-manganese precursor (Ni 1 / 3 co 1 / 3 mn 1 / 3 (OH) 2 , the average particle size is 18 μm) is mechanically finely ground into fragments, and then it and zirconium dioxide (zirconium dioxide mass content is 1.5%) are added in water and ethanol mixed solvent (ethanol volume content is 50%) for uniform Stirring, followed by spray drying to make the precursor fragments assembled into a spherical shape to achieve the purpose of metal additives embedded in the spherical interior, to obtain a mixture A, and then mix the mixture A and lithium acetate (mass content of lithium acetate is 48%) by ball milling, the obtained The mixture was sintered at 990°C for 18 hours, cooled to room temperature, airflow pulverized, and passed through a 400-mesh sieve to obtain the nickel-cobalt-lithium-manganese-oxide positive electrode material, as shown in the scanning electron microscope. image 3 As shown, the positive electrode material is a single ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com