Patents

Literature

383 results about "Lithium acetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium acetate (CH₃COOLi) is a salt of lithium and acetic acid.

Preparation of lithium iron phosphate positive electrode material for lithium ion power cell

InactiveCN101339995ANo danger of flammabilityImprove securityElectrode manufacturing processesPhosphorus compoundsWater wetPhosphate

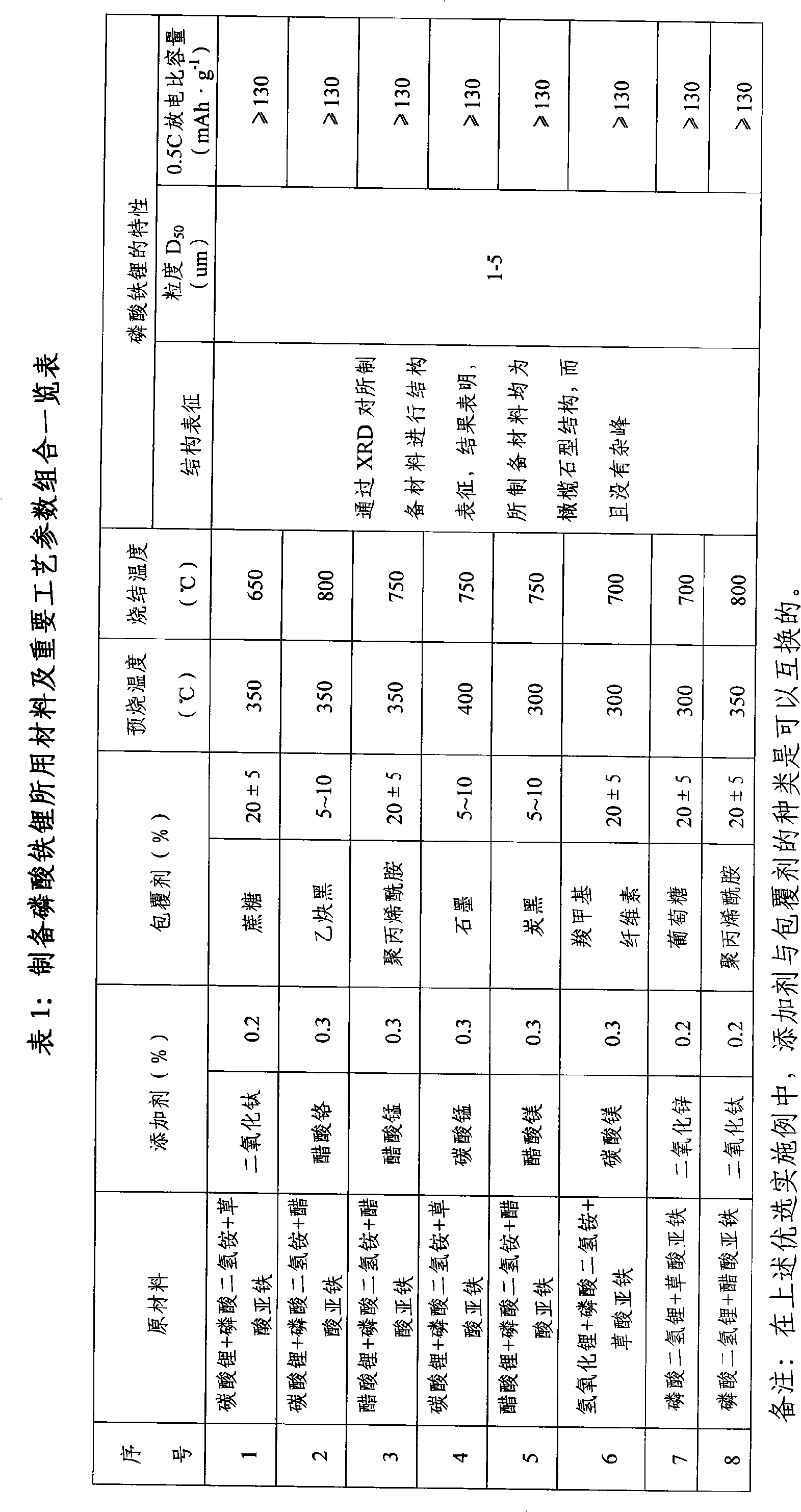

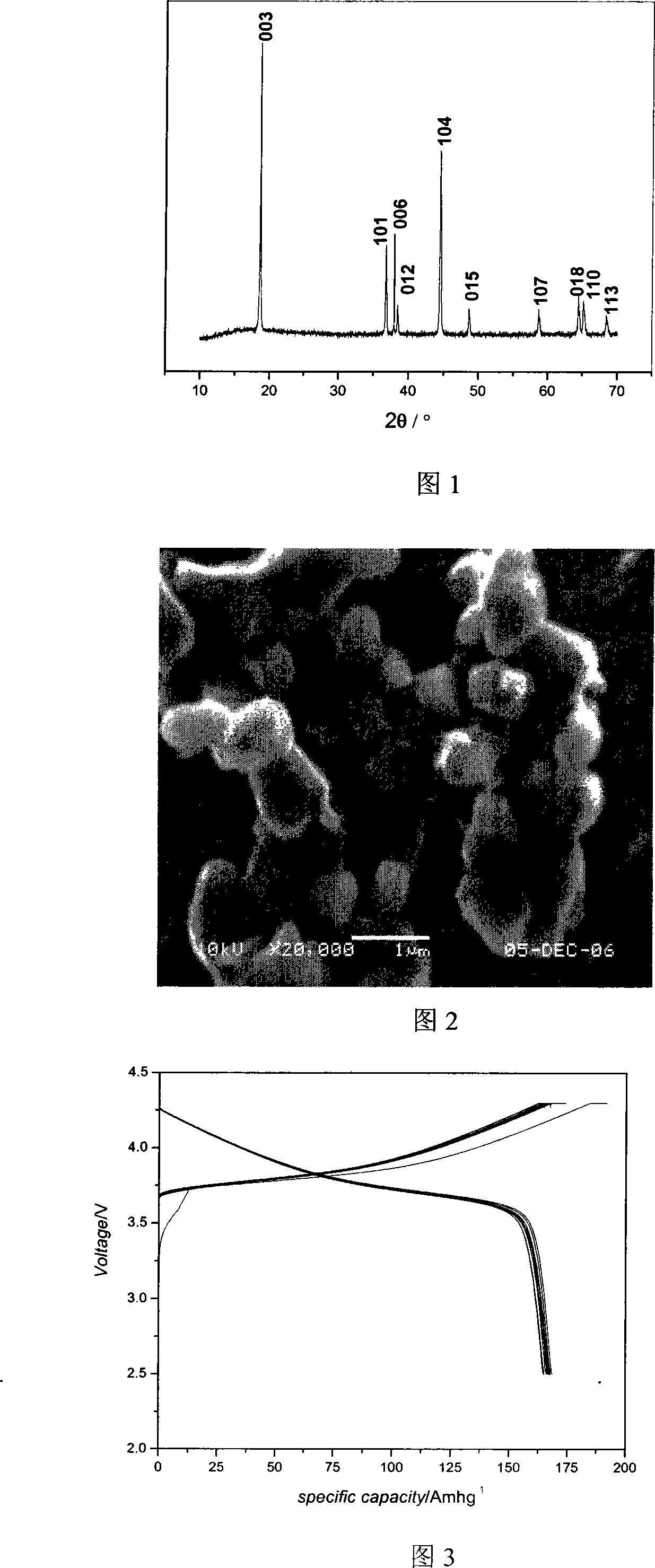

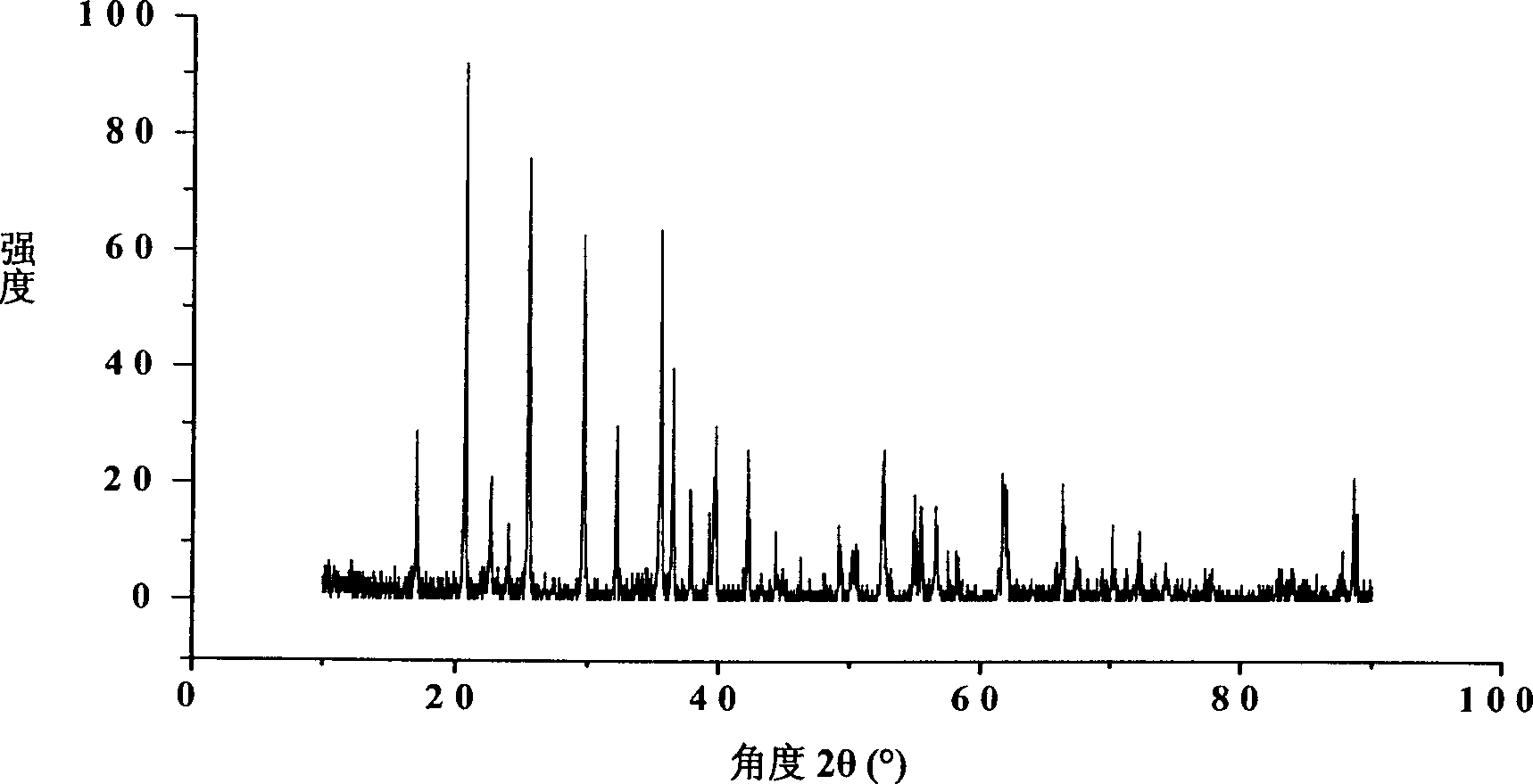

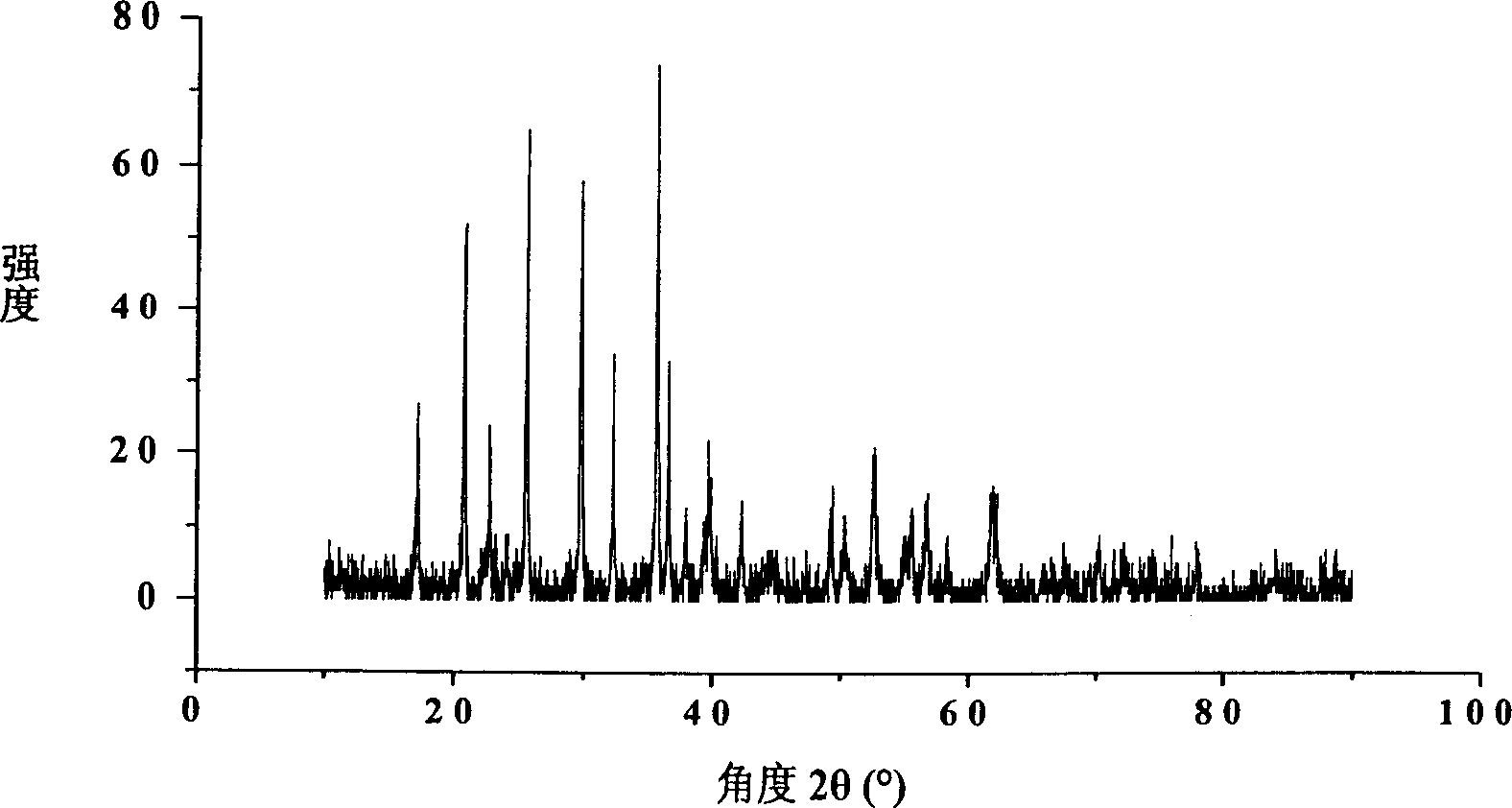

The invention discloses a preparation method of a lithium iron phosphate anode material used in a lithium-ion power battery. The preparation method takes ammonium dihydrogen phosphate and lithium carbonate or lithium hydroxide or lithium acetate and ferrous oxalate or ferrous acetate or takes the lithium dihydrogen phosphate and the ferrous oxalate or ferrous acetate as raw materials, the raw materials are prepared according to the ratio of Li, P and Fe of 1:1:1 or the ratio of LiH2PO4 to Fe of 1:1, and is added with micro amount of nano-metallic oxide or metal salt. After the process of mixing by a water wet method, spraying, drying, rolling and prilling, the mixture is pre-sintered for 10 minus or plus 2 hours at the constant temperature of 300-400 DEG C and is clad with carbon for prilling after being cooled; and then after the process of mixing by the water wet method, spraying, drying, rolling and prilling, the mixture is sintered for 10 minus or plus 2 hours at the temperature of 650-800 DEG C and then is cooled to obtain the lithium iron phosphate which is made after being crashed by gas stream and being compacted. The preparation method has the prominent advantages of safe preparation process, simple operation procedure, easy realization of industrialization and stable material performance of the product.

Owner:中国兵器工业第二一三研究所

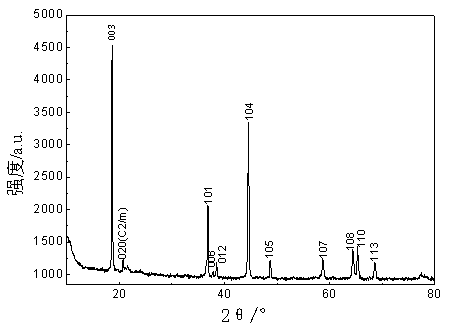

Coprecipitation-combustion synthesis method for lithium nickel cobalt manganate

InactiveCN101215011AGood chemical stabilityEliminate ingredient lossCell electrodesNickel compoundsSynthesis methodsManganate

The invention discloses a process of coprecipitation-combustion synthesis of nickel cobalt manganese lithium carbonate. (1) Utilizing acetate or nitrate of nickel, cobalt, and manganese as transition metal source and ammonia as complexing agent and utilizing H2C2O4, (NH4)3C2O4, (NH4)2CO3 or NH4HCO3 as precipitator, compound carbonate contained Ni-Co-Mn or oxalate precursors is synthesized by coprecipitation method. (2) Directly drying the compound carbonate containing Ni-Co-Mn or the suspension liquid of the oxalate and adding lithium nitrate or lithium acetate or a small quantity of water or ethanol to adjust into rheological phase. (3) Laying the materials in rheological phase in an electric stove to perform burning synthesis reaction, wherein the electric stove heats the materials in rheological phase at temperature of 400-600DEG C and then keeps constant temperature. (4) Temper drawing the reaction product with temperature of 600-1200DEG C, and anode active materials of lithium ion battery LiNixCoyMn1-x-yO2 is obtained. The invention has the advantages of simple technique, easy operation, saving water and energy and environment-friendliness, further, the synthetic material is provided with the shape of sphere or near-sphere, high specific capacity and fine cycle performance.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Process for preparing high density spherical lithium ferric phosphate

InactiveCN1821065AHigh yieldWide variety of sourcesCell electrodesPhosphorus compoundsFerrous ammonium phosphateEnergy source

The present invention is microwave synthesis process of high density spherical lithium ferric phosphate as the positive electrode material of lithium ion cell, and belongs to the field of energy source material preparing technology. Spherical lithium ferric phosphate is prepared through mixing ferrous sulfate and solid phosphorus in the required Fe / P ratio; adding in certain speed into deionized water; adding alkali matter to regulate pH value to form the precursor ammonium ferrous phosphate; drying the precursor, mixing with lithium acetate in the same ratio, adding proper amount of conducting agent, and high temperature treatment at 600-800 deg.c for 3-30 hr in the protecting atmosphere. Thus prepared spherical lithium ferric phosphate has average grain size of 5-10 microns, tap density 2.0-2.3 g / cu cm, and room temperature initial specific discharge capacity of 140-160 mA / g. The process is simple, low in cost, high in yield and suitable for industrial production.

Owner:TSINGHUA UNIV

Microwave synthesis method for carbon coated iron phosphate of ion battery composite anode material

InactiveCN1911792AImprove conductivityReduce polarizationCell electrodesPhosphorus compoundsPhosphateSynthesis methods

The microwave synthesis process of carbon coated lithium iron phosphate as the composite positive electrode material for lithium ion cell includes the following steps: mixing material of lithium salt, organic ferrite, phosphate radical containing material and organic carbon source as coating material in the stoichiometric ratio of Li, Fe, P and C of 1 to 1 to 1 to 0.2-2 via ball milling with ethanol or acetone as dispersant for 3-6 hr; drying the mixture; tabletting; setting into alumina crucible together with active carbon and heating in microwave oven for 5-12 min. The lithium salt material may be inorganic Li2CO3 or LiOH, or organic lithium acetate, lithium lactate, lithium oxalate, lithium citrate or lithium formate; and the phosphate radical containing material may be (NH4)2HPO4 or (NH4)H2PO4.

Owner:NANJING UNIV

Positive pole material of lithium ion battery with nanometer structure and preparation method thereof

The invention discloses a positive pole material of a lithium ion battery with a nanometer structure and a preparation method thereof. The positive pole material is in a particle type core-shell structure, a core material consists of nanometer lithium iron phosphate, lithium vanadium phosphate or cobalt lithium oxide and graphene, and a shell material is porous carbon. The preparation method comprises the following steps of: taking lithium acetate, lithium oxalate, ammonium dihydrogen phosphate, ammonia metavanadate, phosphoric acid, lithium nitrate, cobalt nitrate and graphite oxide as raw materials, adopting a sol-gel method or a ball milling method to prepare a mixture, presintering the mixture in vacuum to obtain the core material, and mixing, grinding and calcining the core material with an organic carbon source to obtain the positive pole material with the particle type core-shell structure. The positive pole material has the advantages of good conductivity, good circulating performance, high capacity, small and uniform particle size, and simple preparation process and is easy for industrialized production.

Owner:深圳清研紫光科技有限公司

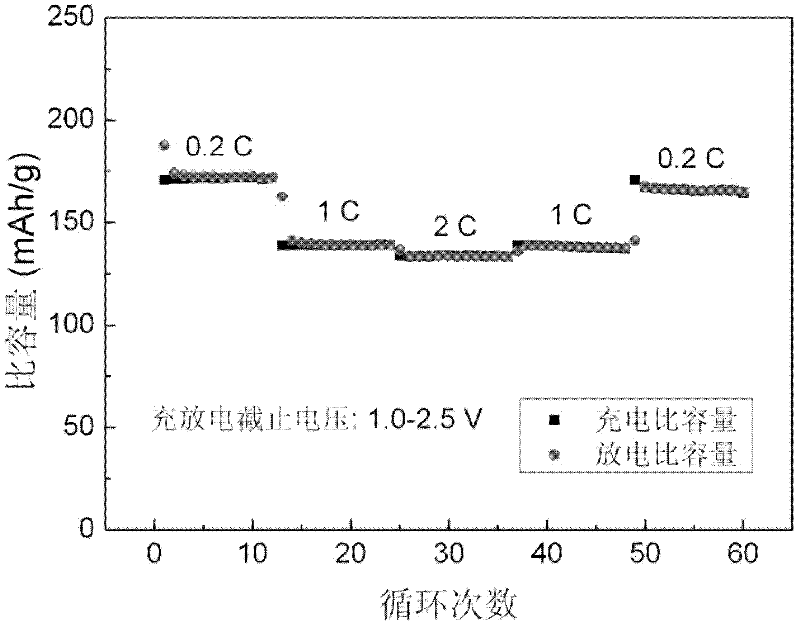

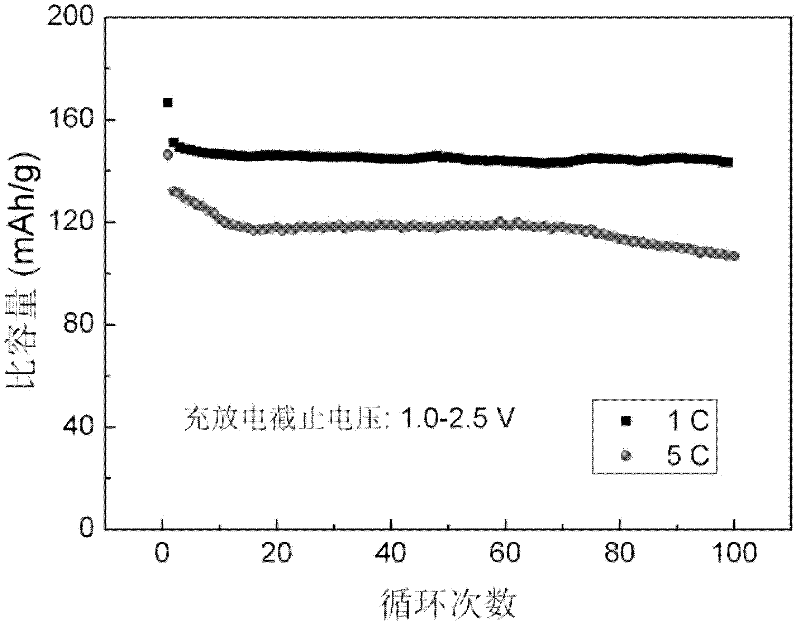

Lithium-enriched ternary anode material of power lithium-ion battery and preparation method of lithium-enriched ternary anode material

InactiveCN103280574AIncrease capacityPromote circulationCell electrodesMANGANESE ACETATEPhysical chemistry

The invention discloses a lithium-enriched ternary anode material of a power lithium-ion battery and a preparation method of the lithium-enriched ternary anode material. The molecule formula of the lithium-enriched ternary anode material of the power lithium-ion battery is Li1.2Ni0.13Co0.13Mn0.54O2. The preparation method comprises the following steps of: dissolving lithium acetate, cobaltous acetate, nickel acetate and manganese acetate in deionized water according to the molar ratio of Li: Co: Ni: Mn: O being 1.2: 0.13: 0.13: 0.54: 2 to obtain a solution 1; adding citric acid according to the ratio of the molar weight of the citric acid to the total molar weight of Ni, Co and Mn being 1:1 to obtain a solution 2; dropwise adding the solution 2 into the solution 1, and then adjusting the pH value to 9, continuously stirring the solution at the temperature of 80 DEG C until purple gel is formed, and then sequentially drying, ball milling, calcining segment by segment and grinding to obtain the lithium-enriched ternary anode material of the power lithium-ion battery with large discharging specific capacity and good cycling performance.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Titanium composite, preparation method thereof and application thereof

ActiveCN101901905AImprove performanceEasy to preparePigmenting treatmentAlkali titanatesLithium chlorideHigh rate

Owner:BYD CO LTD

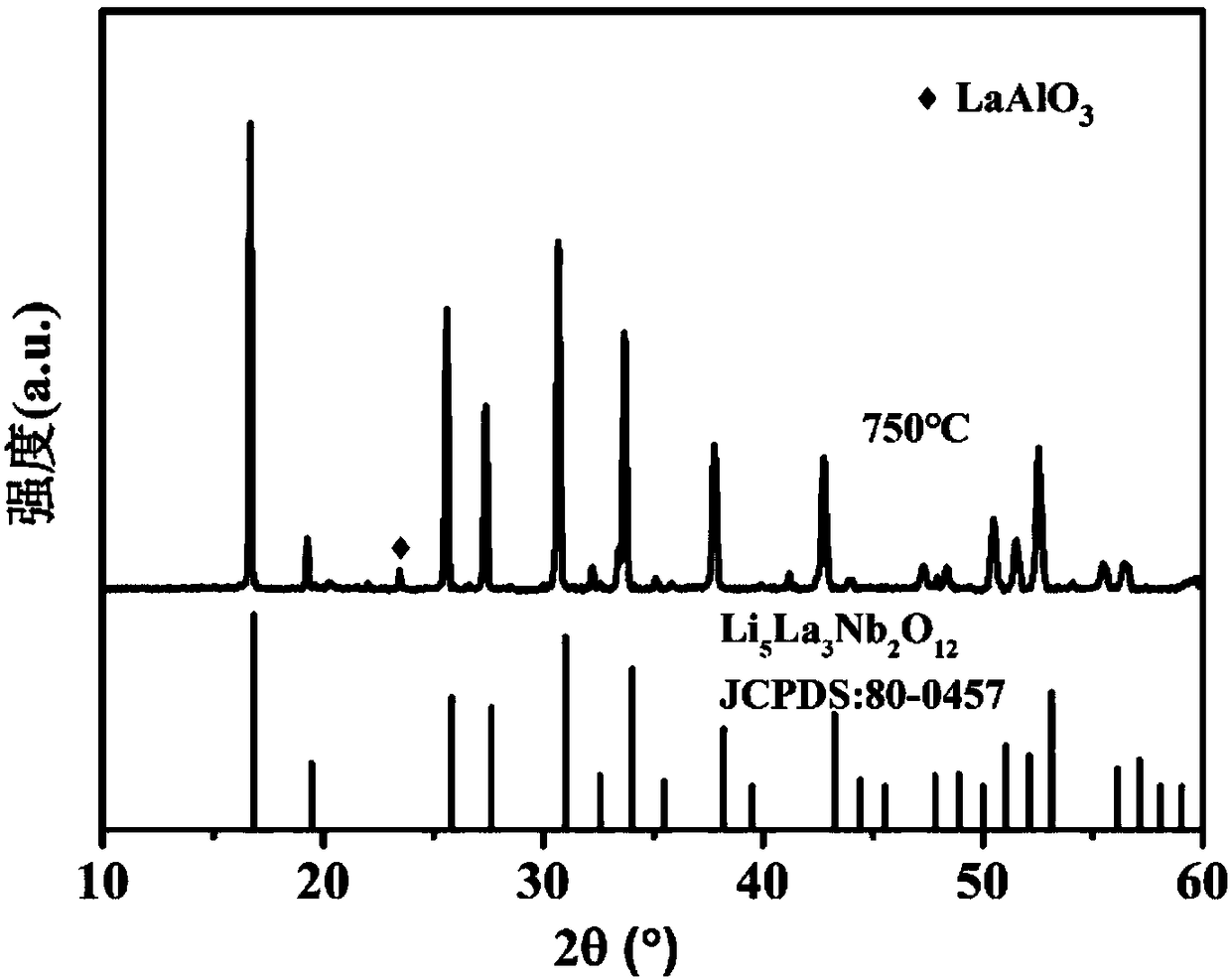

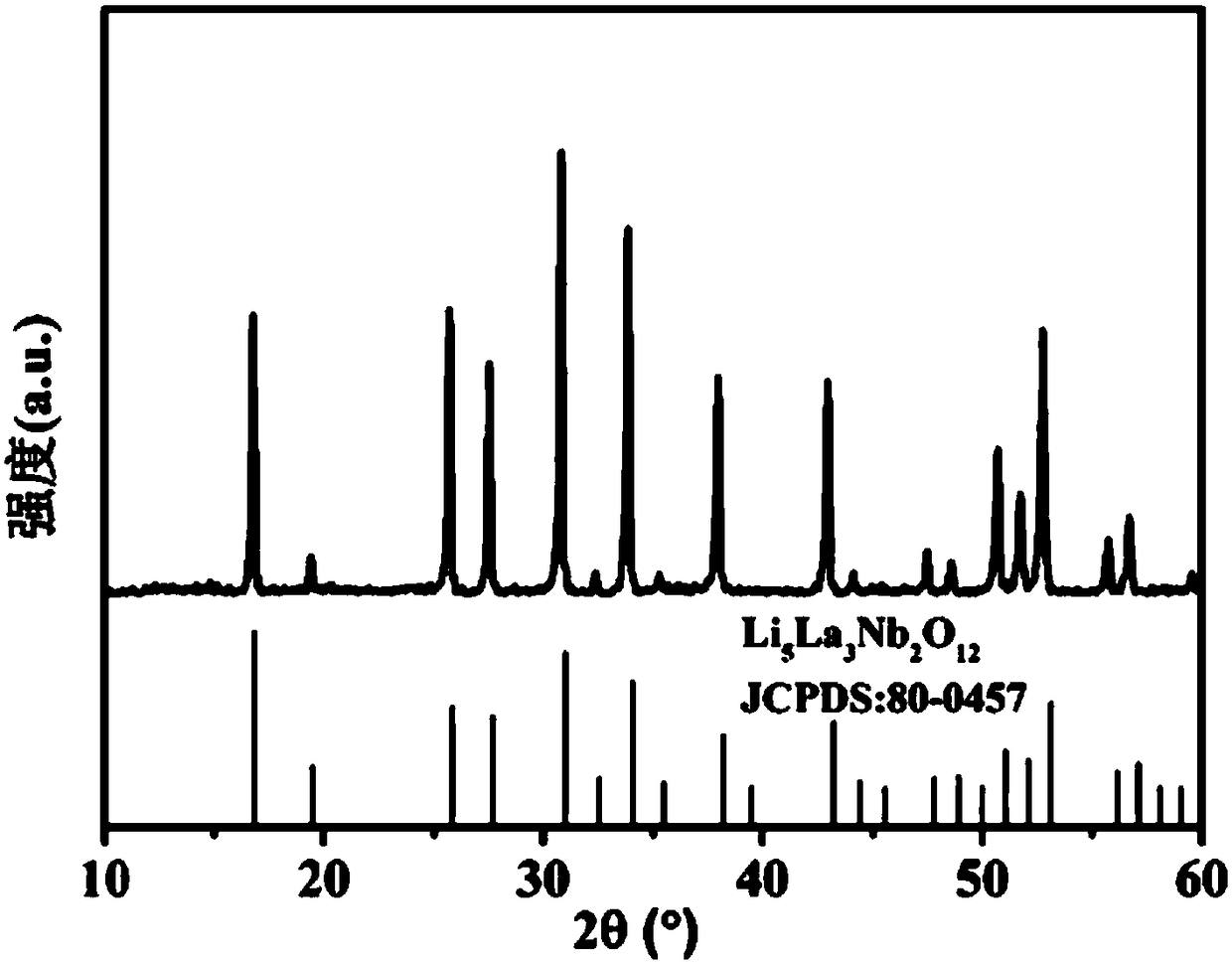

Preparation method of LLZO powder

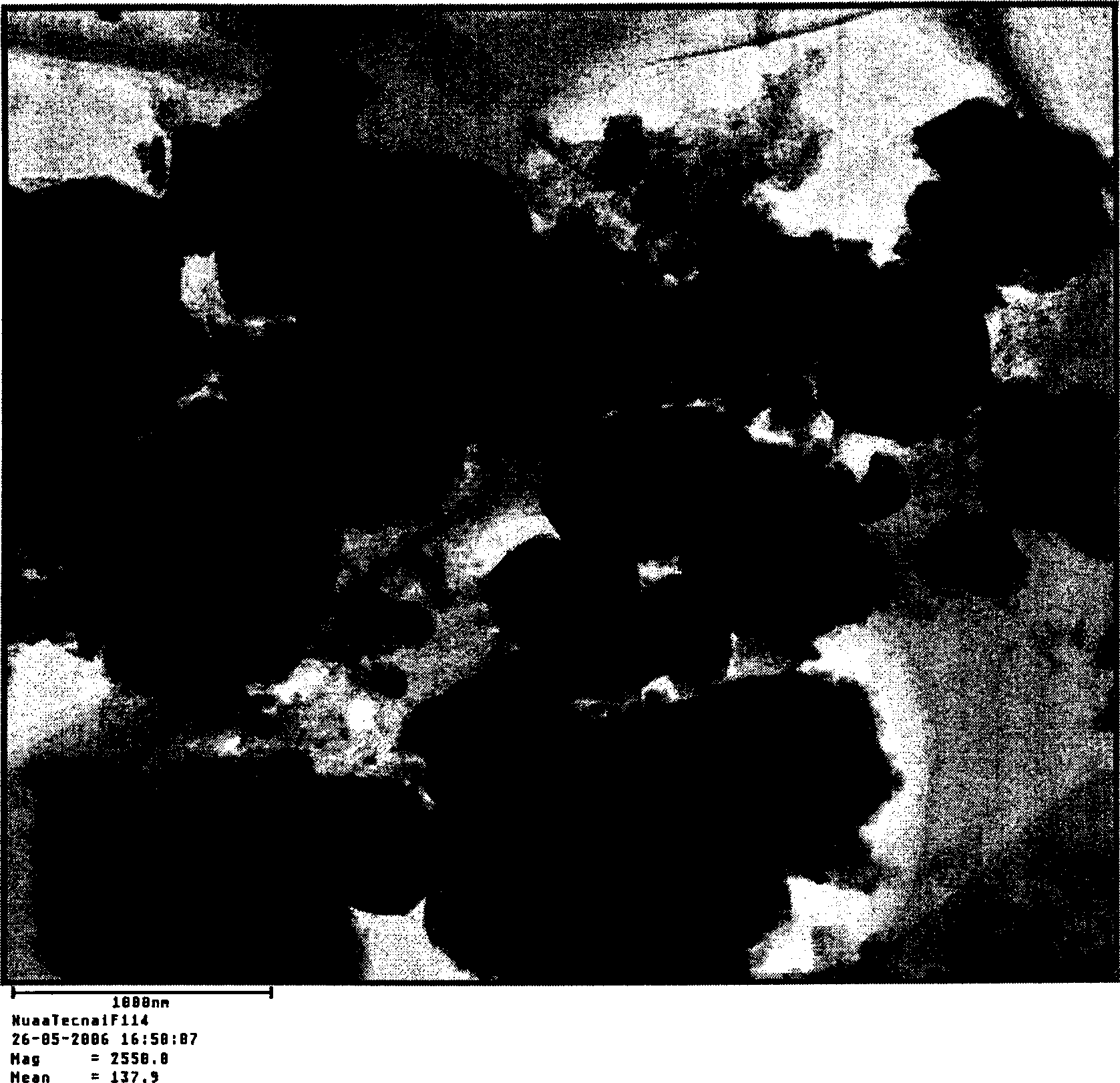

The invention provides a preparation method of LLZO powder. The LLZO powder is prepared by adopting soluble lithium acetate as a lithium source, water as a solvent medium and ZrO2 with high specific surface area as a coating template of a lithium salt through simple mechanical ball-milling and drying and calcining methods. According to the method, reduction of the grain size is facilitated, reduction of the calcination temperature is facilitated, the grain size of the prepared LLZO powder is in nanoscale, the phase is single and the energy consumption is low. The problem that the excessive lithium source needs to be added to compensate the loss of a lithium element due to high temperature in synthesis and sintering when the powder is synthesized is solved; and a compact sheet body with good lithium ion conductivity can be further obtained through granulation, compaction and sintering.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

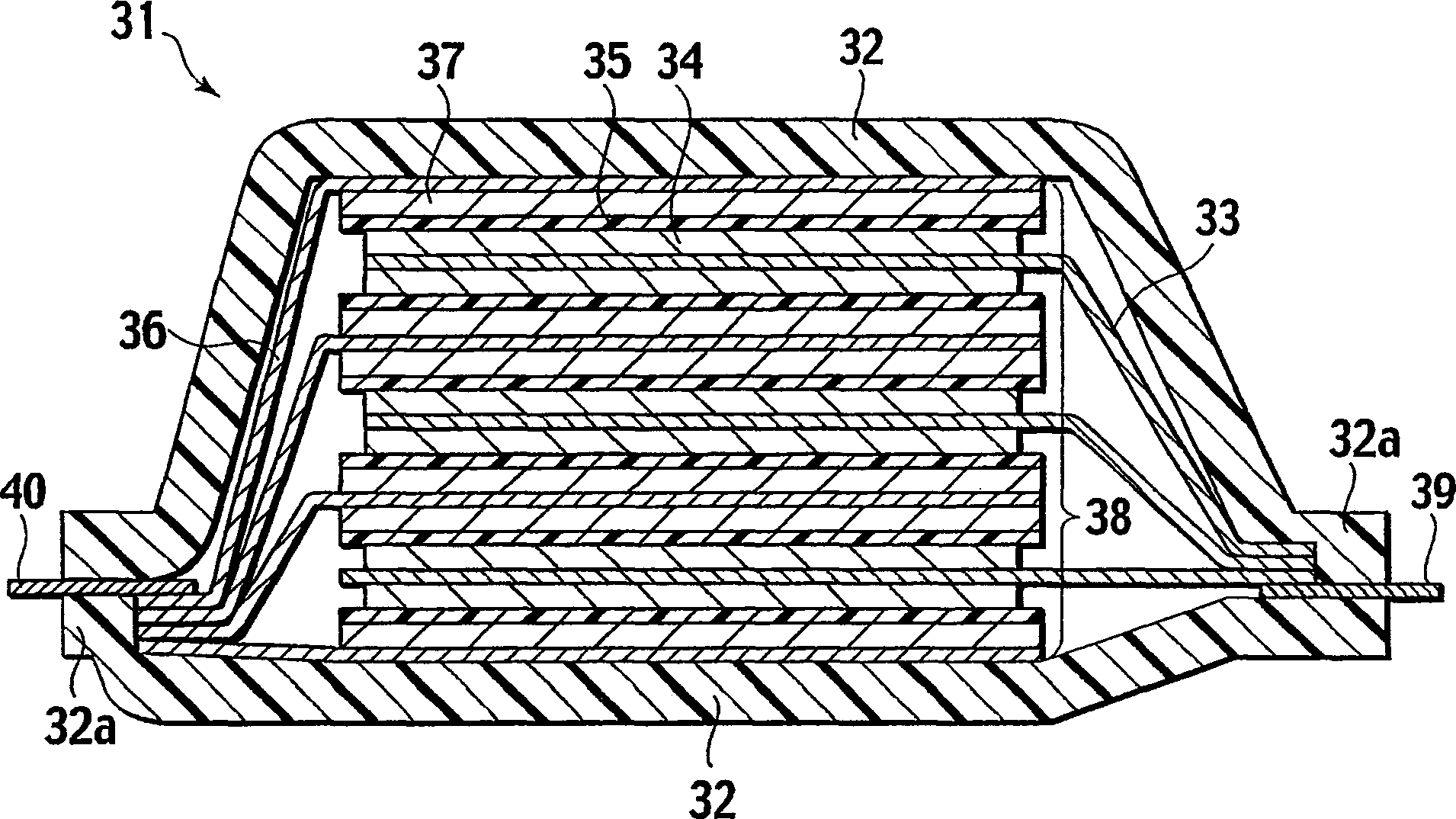

Positive electrode material for non-aqueous electrolyte lithium ion battery and battery using the same

PROBLEM TO BE SOLVED: To provide a positive electrode material for a nonaqueous electrolyte lithium ion battery, which can suppress a decomposition of an electrolyte even when moisture does not enter a cell and a battery is charged or discharged at high temperature.SOLUTION: The positive electrode material for a nonaqueous electrolyte lithium ion battery includes lithium-nickel oxide having a surface covered with an Li compound to be attached. The Li compound is at least one selected from the group consisting of lithium phosphate, an LiPON compound, an Li<SB POS="POST">2< / SB>O-B<SB POS="POST">2< / SB>O<SB POS="POST">3< / SB>compound, an Li<SB POS="POST">2< / SB>O-B<SB POS="POST">2< / SB>O<SB POS="POST">3< / SB>-LiI compound, an Li<SB POS="POST">2< / SB>S-SiS<SB POS="POST">2< / SB>compound, an Li<SB POS="POST">2< / SB>S-SiS<SB POS="POST">2< / SB>-Li<SB POS="POST">3< / SB>PO<SB POS="POST">4< / SB>compound, lithium hydroxide, lithium fluoride, lithium acetate, lithium acetylide ethylenediamine, lithium benzoate, lithium bromide, lithium carbonate, lithium nitrate, lithium oxalate, lithium pyruvate, lithium stearate, lithium tartrate and lithium sulfate.

Owner:ENVISION AESC JAPAN LTD

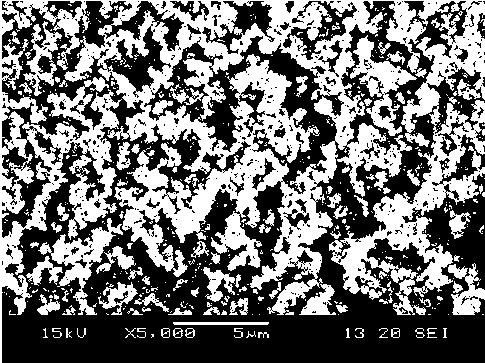

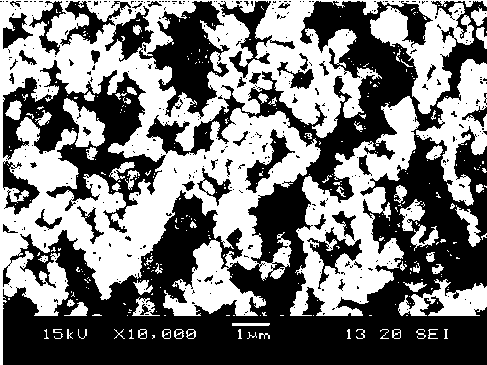

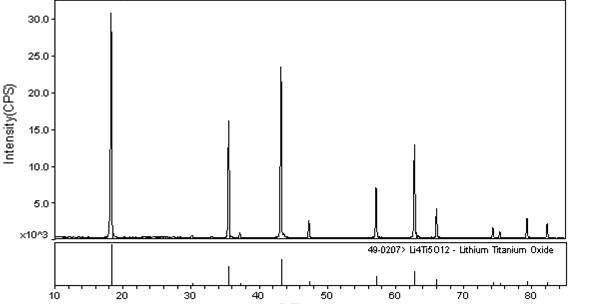

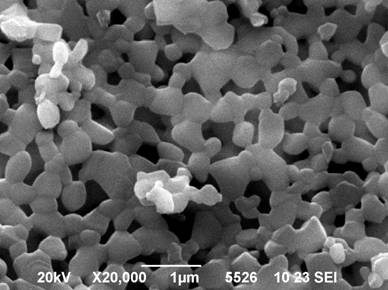

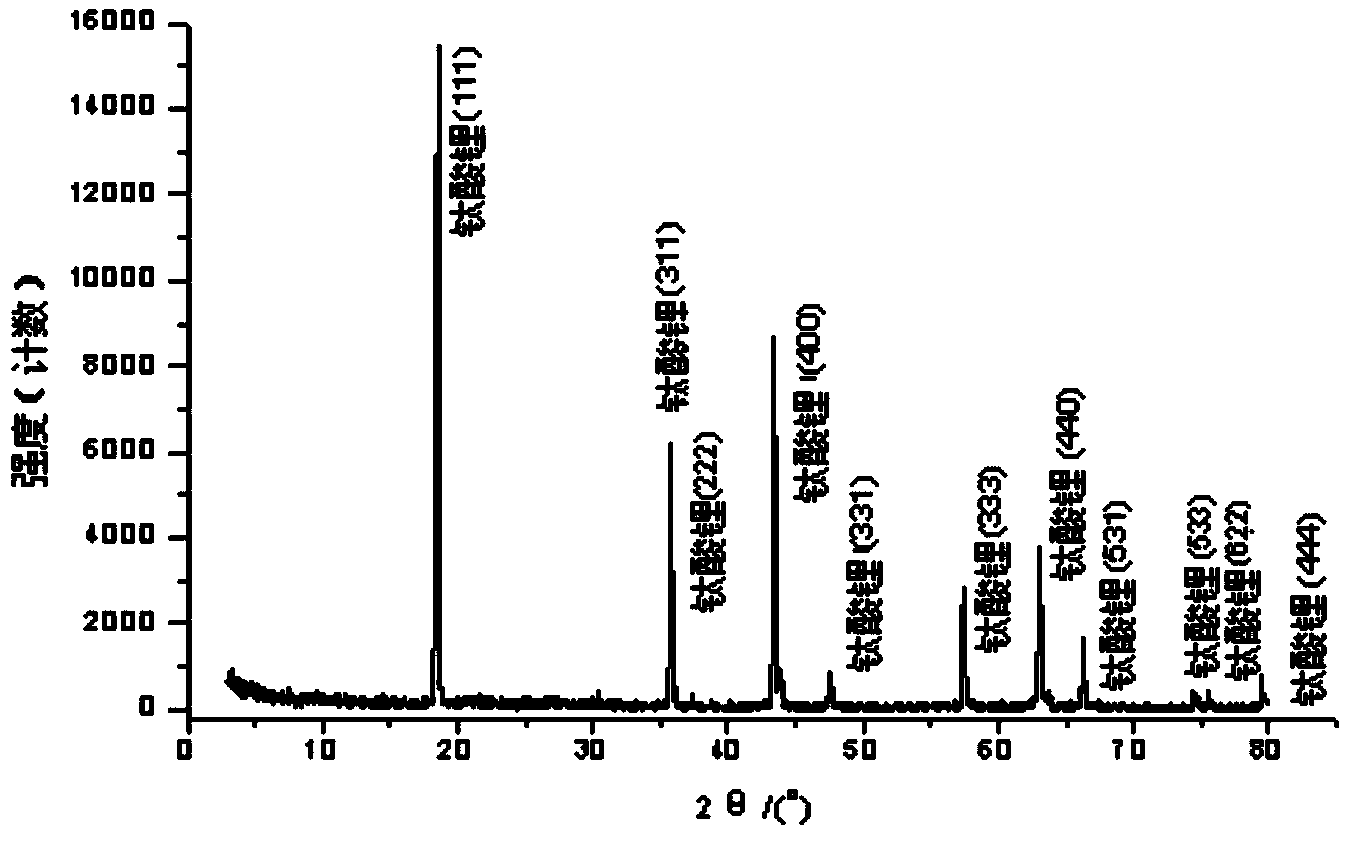

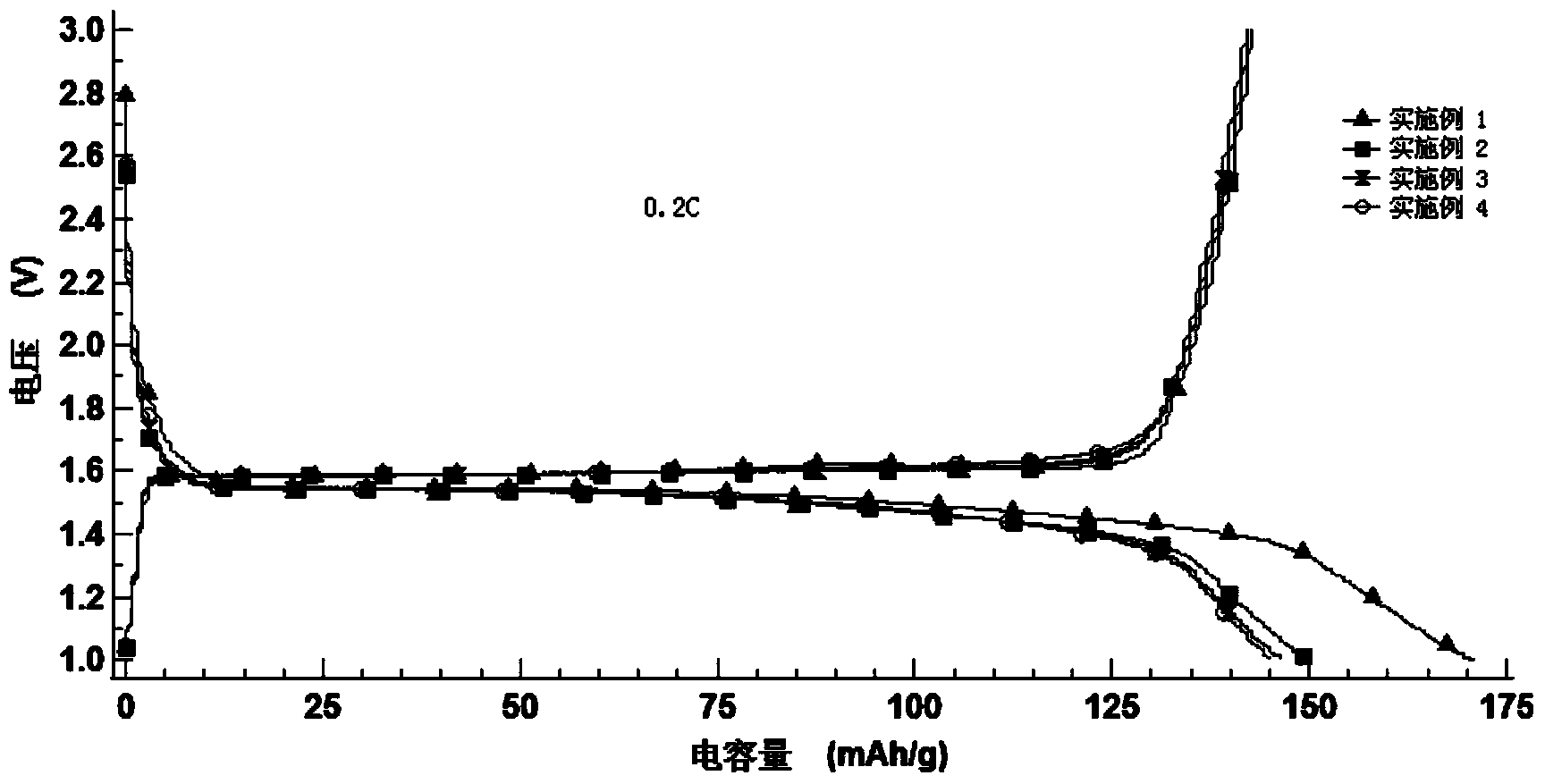

Preparation method of Li4Ti5O12-TiO2 composite electrode material

ActiveCN102386385AGood dispersionUniform particle size distributionCell electrodesElectrical batteryNew energy

The present invention belongs to the technical field of new energy and material, and particularly relates to a preparation method of a Li4Ti5O12-TiO2 composite electrode material. The utility model aims to settle a technical problem of providing a cathode material which has the following advantages: simple preparation method and capability of charging / discharging at a high magnification. Lithium acetate and tetrabutyl titanate are respectively used as a lithium source and a titanium source. Ammonia water is used as a pH value conditioning agent. Amorphous Li4Ti5O12-TiO2 precursor is prepared through the heat of solvent, and Li4Ti5O12-TiO2 composite powder with good crystal form is prepared after heat treatment. The sample which is synthesized according to the invention has the following advantages: small particle, uniform dispersion, regular shape, stable structure. good high-magnification charging / discharging characteristic, high cycling performance, and wide development prospect as cathode material of lithium ion battery. The preparation method of the Li4Ti5O12-TiO2 composite electrode material has the following main advantages: simple synthesis equipment and technique; easy control for phase composition, particle size and particle shape; flexible operation; reduced synthesis temperature; shortened heat treatment time; and reduced energy consumption.

Owner:UNIV OF SCI & TECH BEIJING

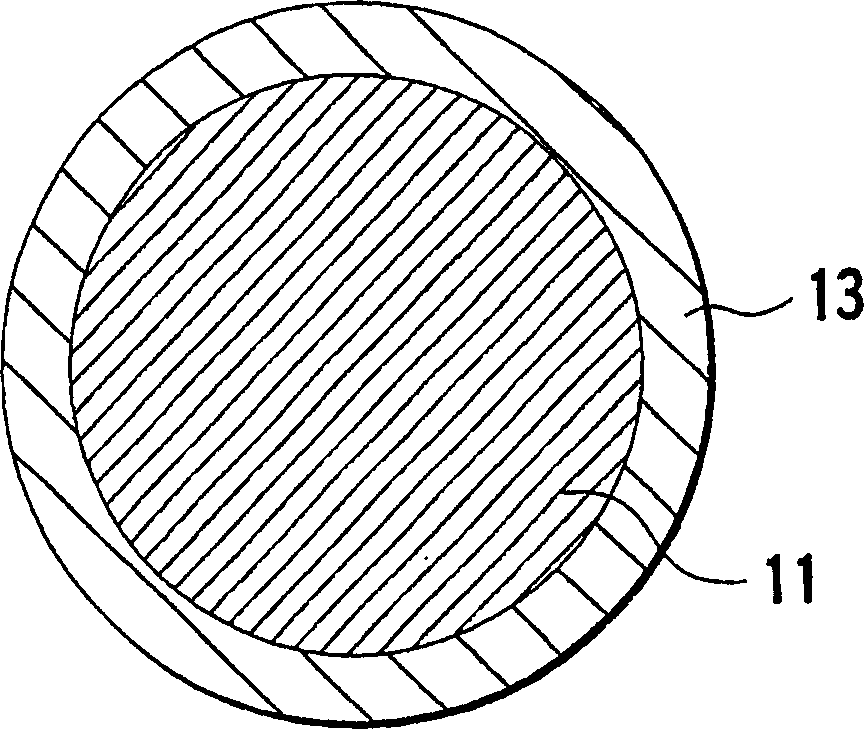

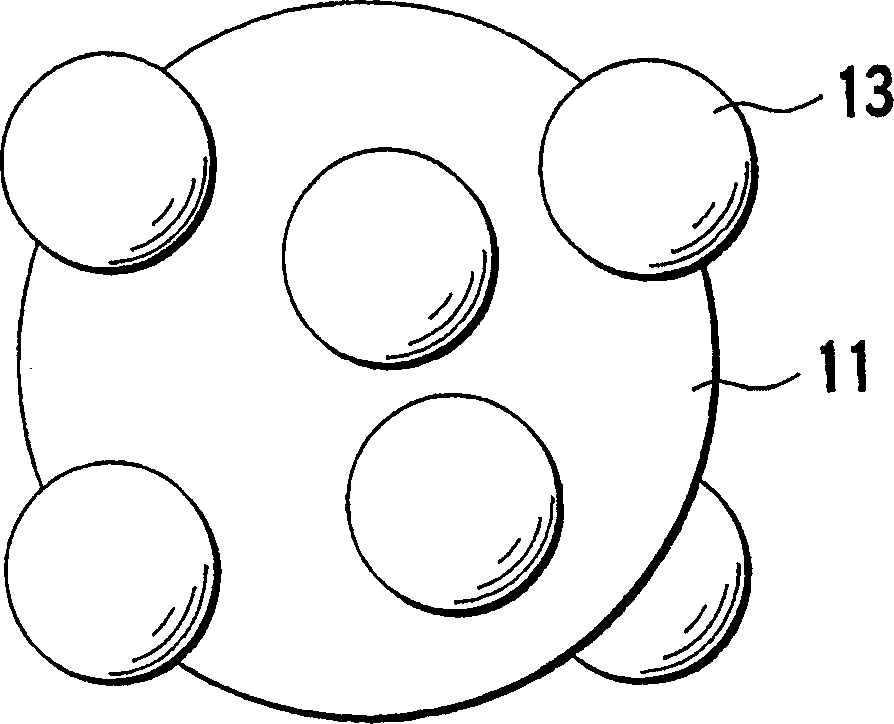

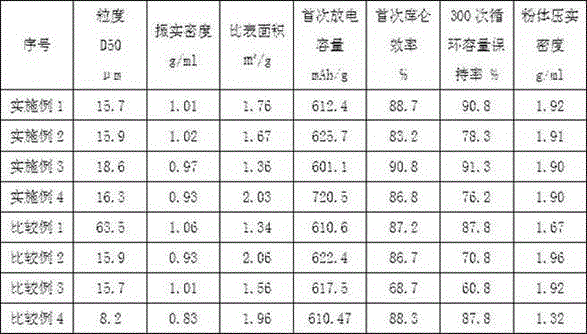

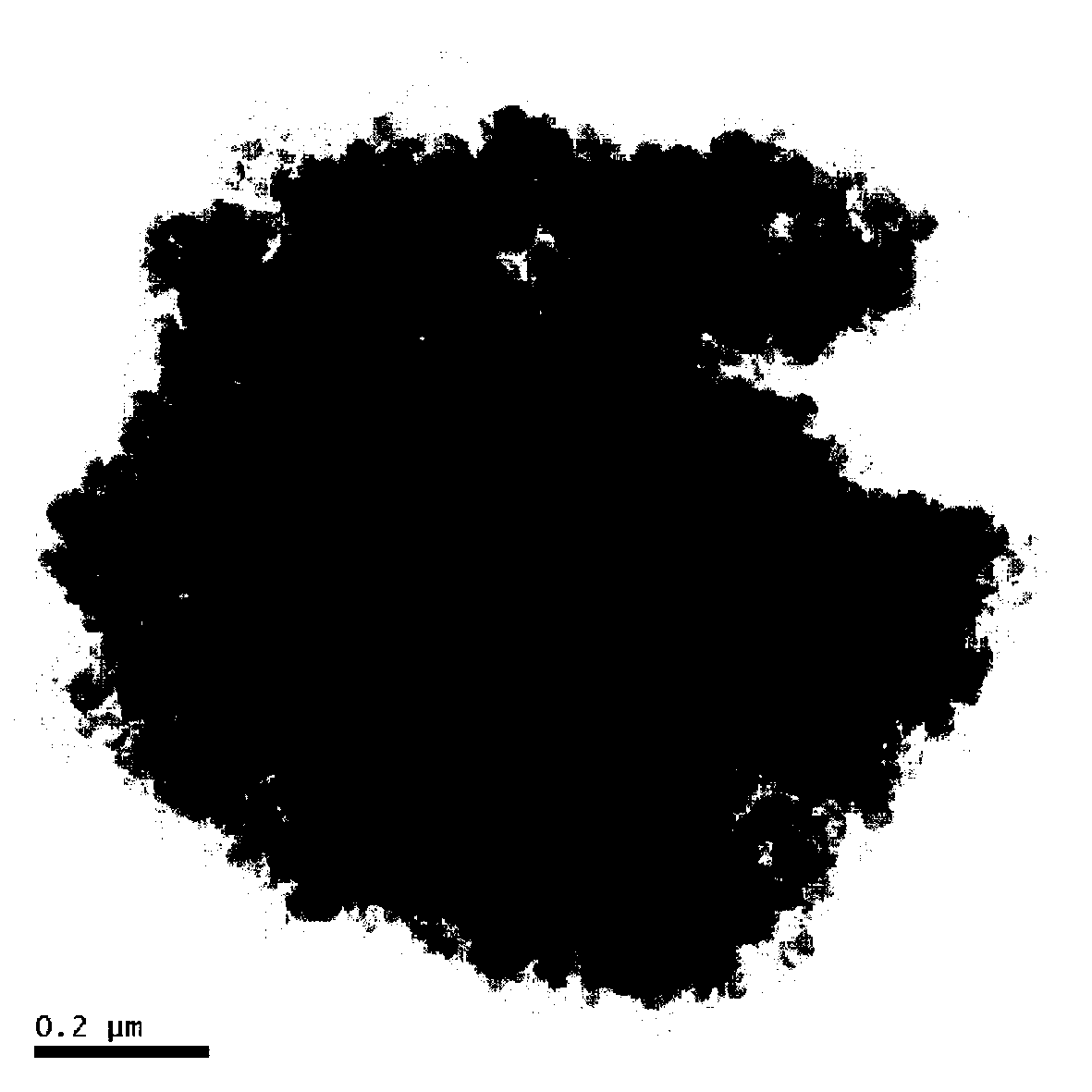

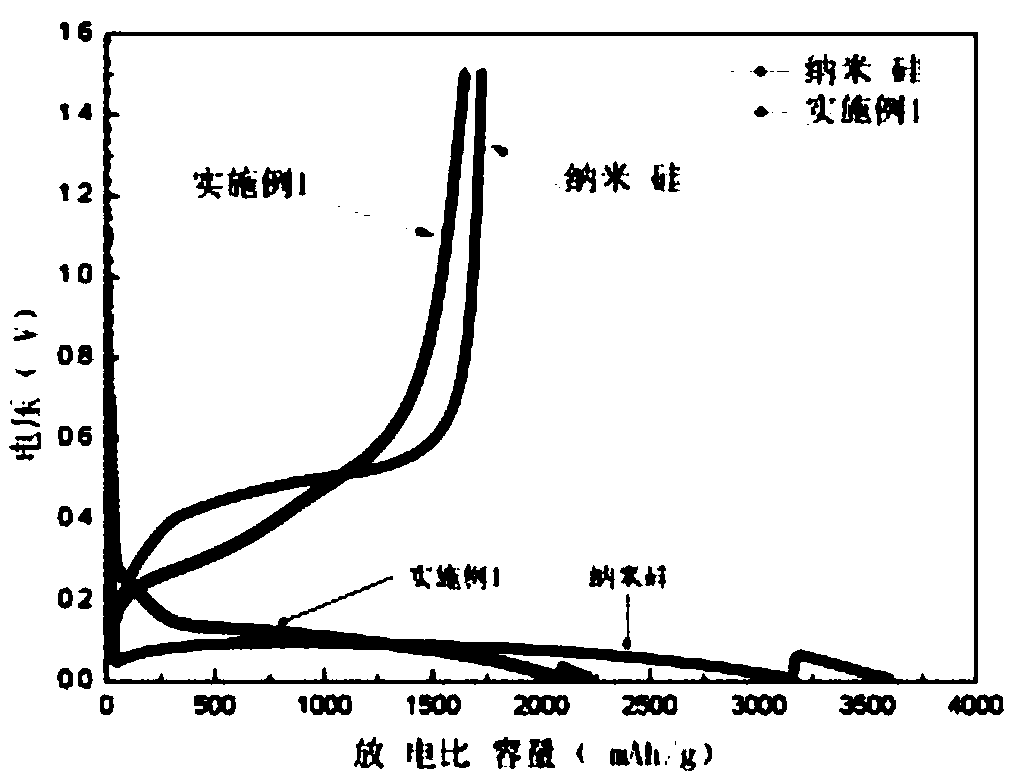

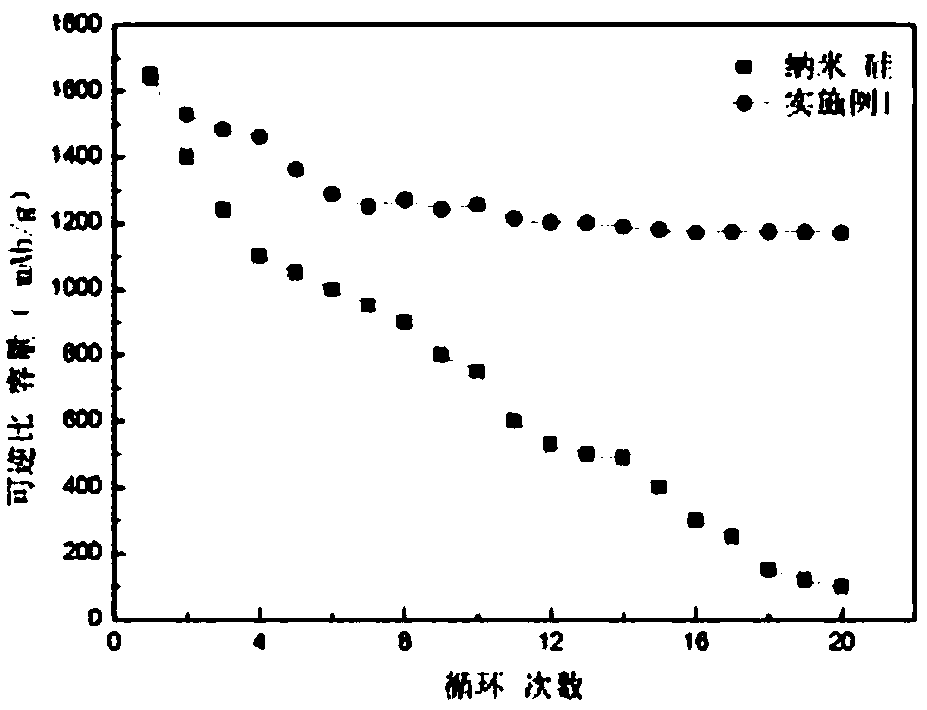

Silicon-carbon cathode material with artificial SEI layers, high specific volumetric capacity and cycle performance

ActiveCN106207177AImprove cycle performanceIncrease capacityMaterial nanotechnologyCell electrodesCarbon compositesLithium-ion battery

The invention relates to a silicon-carbon cathode material with artificial SEI layers, high specific volumetric capacity and cycle performance and application of the silicon-carbon cathode material. The silicon-carbon cathode material is of an intermediate-phase graphite structure which is secondarily granulated, outer shell layers of the intermediate-phase graphite structure are amorphous carbon coating layers, inner shell layers of the intermediate-phase graphite structure are dense LiF membranes, and nanometer silicon is uniformly dispersed to form cores of the intermediate-phase graphite structure. A method for preparing the silicon-carbon cathode material includes steps of 1, crushing and shaping intermediate-phase graphite balls with large particle diameters to obtain intermediate-phase graphite micro-powder with median particle diameters of approximately 7 micrometers; 2, carrying out ball-milling dispersion on the nanometer silicon and the micro-powder obtained at the step 1; 3, uniformly mixing lithium acetate solution and materials obtained at the step 2 with one another; 4, carrying out dropwise addition reaction on NH4F solution and materials obtained at the step 3; 5, carrying out spray-drying on materials obtained at the step 4; 6, mixing PVDF (polyvinylidene fluoride) and materials obtained at the step 5 with one another to obtain mixtures and granulating and coating the mixtures; 7, immobilizing and carbonizing materials obtained at the step 6; 8, sieving materials obtained at the step 7. The silicon-carbon cathode material and the application have the advantages that the silicon-carbon composite cathode material is stable in cycle performance, high in specific volumetric capacity and easy to industrially produce; a lithium ion battery with a cathode which is processed from the silicon-carbon cathode material is high in specific volumetric capacity and excellent in cycle performance.

Owner:天津爱敏特电池材料有限公司

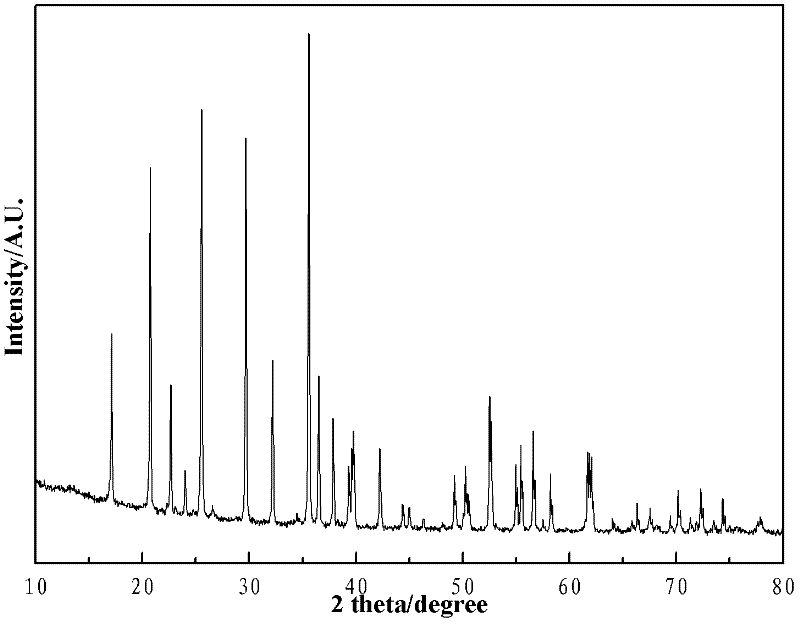

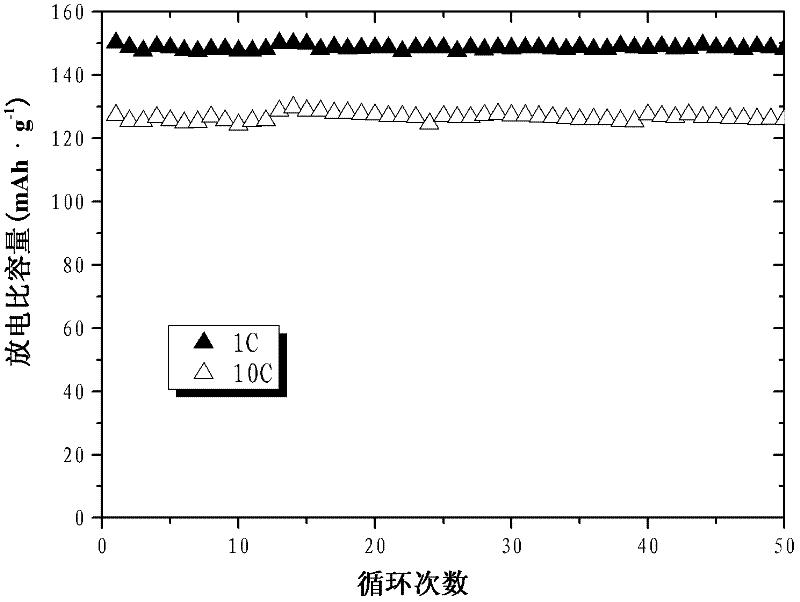

Method for preparing carbon nano tube doped lithium titanate composite electrode material

The invention discloses a method for preparing a carbon nano tube doped lithium titanate composite electrode material. The composite material is prepared from lithium titanate and carbon nano tubes, wherein the mass ratio of lithium titanate to carbon nano tubes is 88-95:5-12. The method is characterized by taking lithium acetate or lithium carbonate, titanium dioxide and carbon nano tubes as rawmaterials and preparing the lithium titanate / carbon nano tube composite electrode material through ball mill and a microwave method. The lithium titanate composite electrode material has the characteristics of simple process, uniform material, small grain size, high specific capacity, high rate and the like.

Owner:GUANGDONG UNIV OF TECH

Method for preparing high purity lithium fluoride

The invention in particular relates to a method for preparing lithium fluoride. The method for preparing the high-purity lithium fluoride is mainly characterized by comprising the following steps: (1) putting a mixture of the lithium fluoride and lithium chloride or the lithium chloride or lithium acetate in deionized water and stirring the solution so as to make the mixture sufficiently dissolve and prepare a meta acid aqueous solution of which the pH value is between 0.1 and 7; (2) under a stirring state, quickly dropping a solution of two simple substances of saturated ammonium fluoride or ammonium hydrogen fluoride or ammonia and fluorine hydride in the aqueous solution of the step (1) so as to obtain lithium fluoride precipitates, and continuing to stir for 0.5 to 1 hour and standing for 1 to 2 hours; and (3) through the step (1) and the step (2), finishing forming the lithium fluoride into the precipitates which are not dissolved in the water, filtering and drying the lithium fluoride precipitates and washing the precipitates for 3 to 5 times, and drying the obtained lithium fluoride in vacuum for 1 to 2 hours at a temperature of between 100 and 200 DEG C. The method has the advantages that the purities of the prepared lithium fluoride meet the following requirements: the purity of lithium fluoride (LiF) is more than or equal to 99.99 percent; the purity of silicon dioxide (SiO2) is less than or equal to 4ppm; the purity of heavy metal is less than or equal to that of iron of which the purity is less than or equal to 1 ppm; and the purity of the total weight of other metals (metered by Ca, Mg and Al) is less than or equal to 1 ppm.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Method for preparing lithium titanate powder

InactiveCN102249297ASimple processReduce manufacturing costTitanium compoundsElectrochemistryMuffle furnace

The invention discloses a method for preparing lithium titanate powder. The method comprises the following steps of: weighing an excessive amount of lithium salt (lithium nitrate or lithium acetate and the like) with the concentration 0-5 percent according to the metering ratio of a chemical formula Li4Ti5O12, preparing the lithium salt into a solution, and adding an appropriate amount of coordination agent and incendiary agent (such as citric acid or EDTA (Ethylene Diamine Tetraacetic Acid) or oxalic acid ) into the Li<+> solution to obtain a uniform mixed solution A; weighing metatitanic acid (H2TiO3) according to the metering ratio of a chemical formula Li4Ti5O12, adding an appropriate amount of hydrogen peroxide (oxyful, H2O2) and an excessive amount of ammonia water (NH3*H2O), and adding a certain amount of coordination agent and incendiary agent (such as citric acid or oxalic acid or EDTA and the like) after the metatitanic acid is fully dissolved to obtain a uniform mixed solution B; mixing the prepared solution A with the solution B, heating and concentrating into jelly (or drying into powder at a temperature between 50 DEG C and 200 DEG C); and putting the powder obtained by drying (or the directly prepared jelly) into a muffle furnace for calcining at a temperature between 500 DEG C and 900 DEG C for 1-10 hours to obtain Li4Ti5O12 powder. The method has the advantages of simple technical process, low cost of raw materials, easiness for control of stoichiometric ratio and excellent electrochemical performance of a product, and is suitable for mass production; and the particle diameter of the powder is between 50 nanometers and 500 nanometers.

Owner:HUNAN UNIV OF HUMANITIES SCI & TECH

Method for preparing positive electrode material of LiFePO4 by phosphorous acid or salt thereof

InactiveCN101332987ALow costWide variety of sourcesCell electrodesPhosphorus compoundsPhosphorous acidPhosphate

The invention relates to a method for preparing lithium iron phosphate by phosphorous acid or phosphite; the preparation method is as follows: lithium salt, ferrous salt, phosphate and phosphorous acid or phosphite are blended, added with carbon-containing compound, and further added with wet milling liquid, processed by ball milling and mixing, and dried at normal atmosphere or vacuum; the dried powder is sintered to prepare lithium iron phosphate cathode material. The lithium is one of or the mixture of lithium carbonate, lithium hydroxide, lithium oxalate, lithium acetate, lithium nitrate, lithium fluoride and lithium phosphate; the ferrous salt is one of or the mixture of iron oxalate, iron acetate, iron dichloride, ferrous sulfate or ferrous carbonate; the phosphate is one of or the mixture of ammonium phosphate, diammonium phosphate of monoammonium phosphate; the molecular formula of phosphite is AH2PO3, A2HPO3, EHPO3, E(H2PO3)2 or G(H2PO3)3; the carbon-containing compound is one of or the mixture of polypropylene, polyacrylamide, polyvinyl alcohol, glucose, cane sugar or starch. The method of the invention has simple preparing process and short time consumed, and the materials have good cycling performance under the heavy current discharging condition.

Owner:FUJIAN NORMAL UNIV

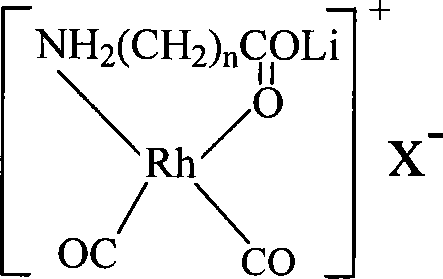

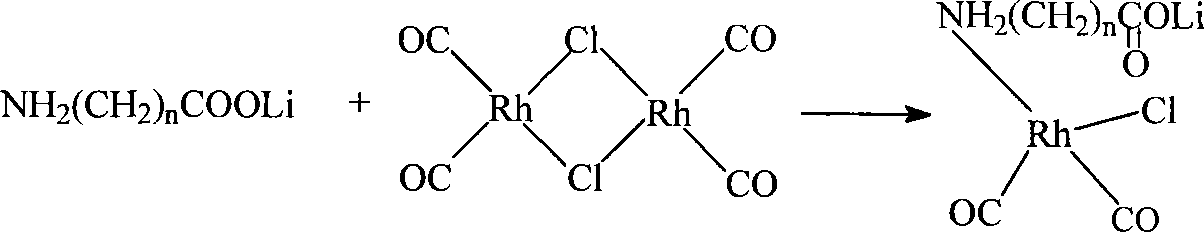

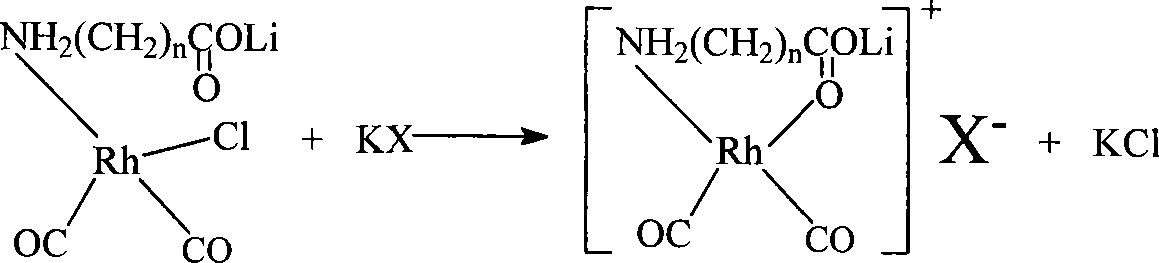

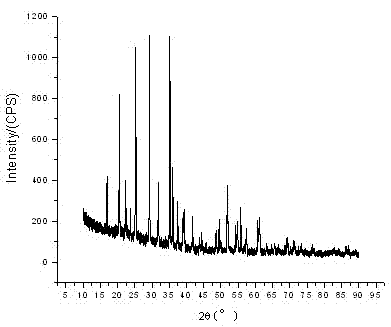

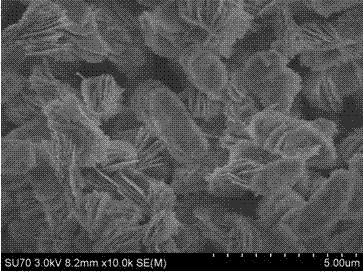

Method for producing acetic acid by carbonylation of methanol as well as special catalyst and preparation method thereof

ActiveCN101182340AHigh selectivityImprove adaptabilityOrganic-compounds/hydrides/coordination-complexes catalystsGroup 8/9/10/18 element organic compoundsPhosphateCarboxylic acid

The invention discloses a method for producing acetic acid by carbonylation of methanol, a special catalyst and a preparation method thereof. The aminocarboxylate lithium rhodium complex of the present invention has a structure as shown in formula I, wherein, X=BPh4 or I; n=1, 2 or 3. In the present invention, lithium aminocarboxylate is used as a ligand and a rhodium complex to form a positive ion active center structure of a strong and weak coordination bond chelation type, and the positive ion part contains a strongly coordinated N→Rh bond and a weakly coordinated O→Rh bond, The stability and activity of the active center are guaranteed. Lithium metal and rhodium metal are co-located in the structure of the active center, which can form a synergistic catalytic effect; moreover, it can also be used in combination with other catalysts to improve its catalytic activity; The strong catalytic effect of the reaction provides a basis for the excellent performance of the catalyst; at the same time, the combination of lithium iodide, lithium acetate and phosphate is used as a promoter, so that the catalyst of the present invention can catalyze the carbonylation of methanol to produce acetic acid. Excellent overall performance.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Preparation method for manganese phosphate lithium nanosheet

InactiveCN102903918AGood dispersionFacilitated DiffusionCell electrodesMANGANESE ACETATEPolyethylene glycol

The invention relates to a preparation method for a manganese phosphate lithium nanosheet. According to the preparation method, glycol and water are used as a solvent, and polyethylene glycol is introduced, so that the formation of crystal nucleus and the growth of crystal are influenced, and as a result, the thermosynthesis of the solvent of the manganese phosphate lithium nanosheet can be achieved. The preparation method comprises the following steps of: dissolving ascorbic acid in the water / glycol solvent; then dissolving into phosphoric acid and manganese acetate in sequence; dropwise adding the water / glycol solution of manganese acetate to the previous solution containing phosphoric acid, lithium acetate and ascorbic acid; then introducing proper polyethylene glycol; fully mixing to obtain a precursor for water / solvent thermal reaction; transferring the precursor into a reaction kettle system to be sealed; thermally processing at 160 to 240 DEC G; and carrying out thermal reaction to the solvent to obtain the manganese phosphate lithium nanosheet. By adopting the preparation method, products are stable in quality, high in purity and high in dispersion of particles; the lithium ions can be dispersed well; the electrochemical performance of a lithium ion battery can be improved; and the preparation method is simple in technical process, easy to control, free of pollution, low in cost, and easy for mass production.

Owner:ZHEJIANG UNIV

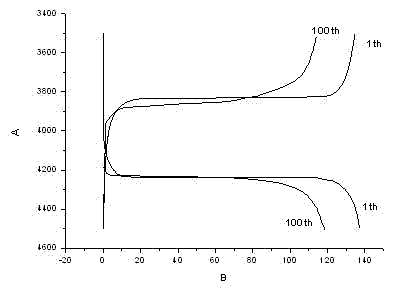

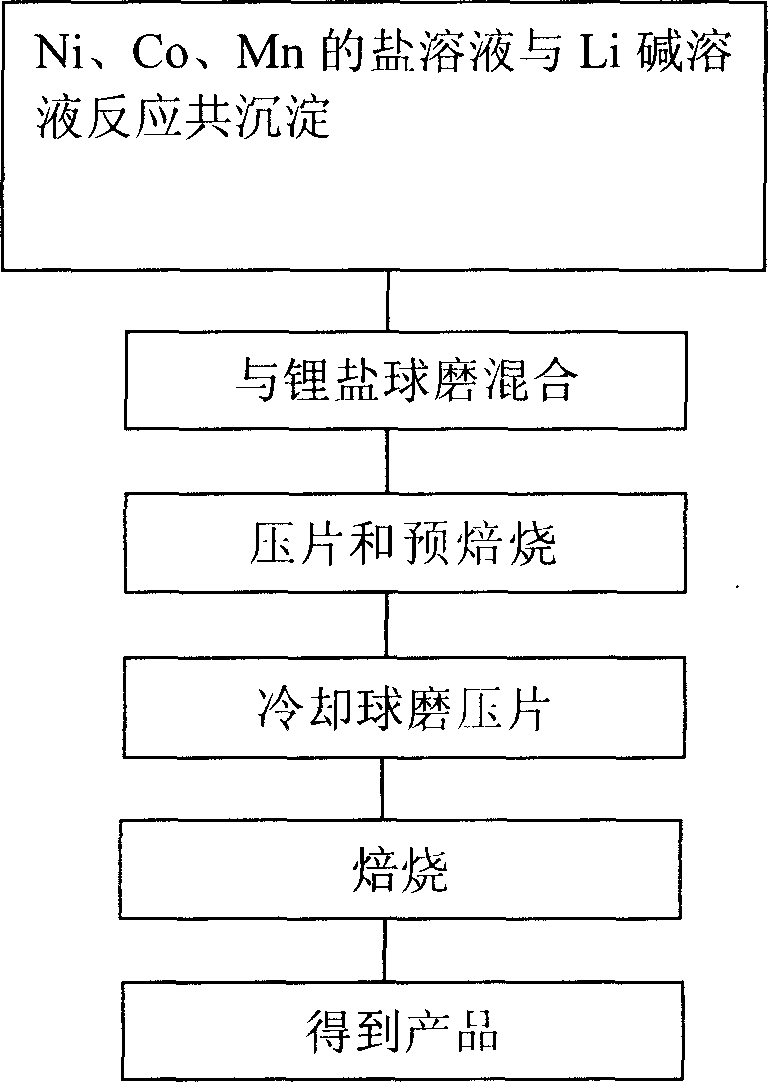

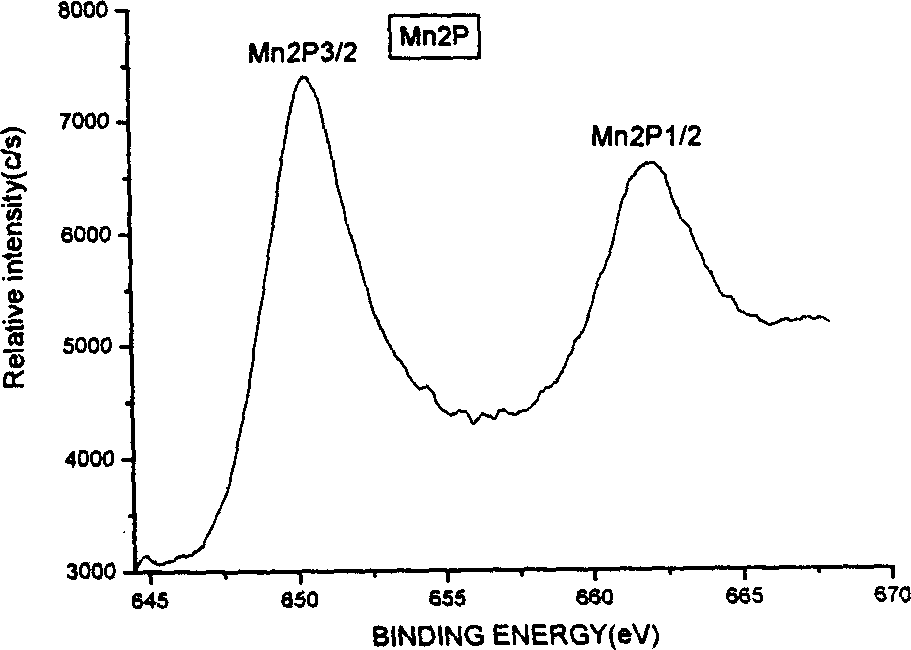

Method for producing anode active material containing lithium, magnesium compound oxide

InactiveCN1741302AStructural Precise TailoringSimple structureElectrode manufacturing processesLithium compoundsMANGANESE ACETATENickel salt

A method for preparing positive electrode multielement active material containing lithium / manganese composite oxide includes directly using lithium hydroxide coprecipitation to prepare M ( OH )2 , mixing it with lithium salt in grinding , forming plate by pressing , prebaking , cooled ball grinding , forming plate by pressing and backing . In the method , applied nickel salt is nickel acetate or nickel nitrate , applied cobalt salt is cobalt acetate or cobalt nitrate, applied manganese salt is manganese nitrate or manganese acetate and applied lithium salt is lithium carbonate or lithium acetate .

Owner:HEBEI UNIV OF TECH

Method for preparing spinel type lithium titanate nanowire array

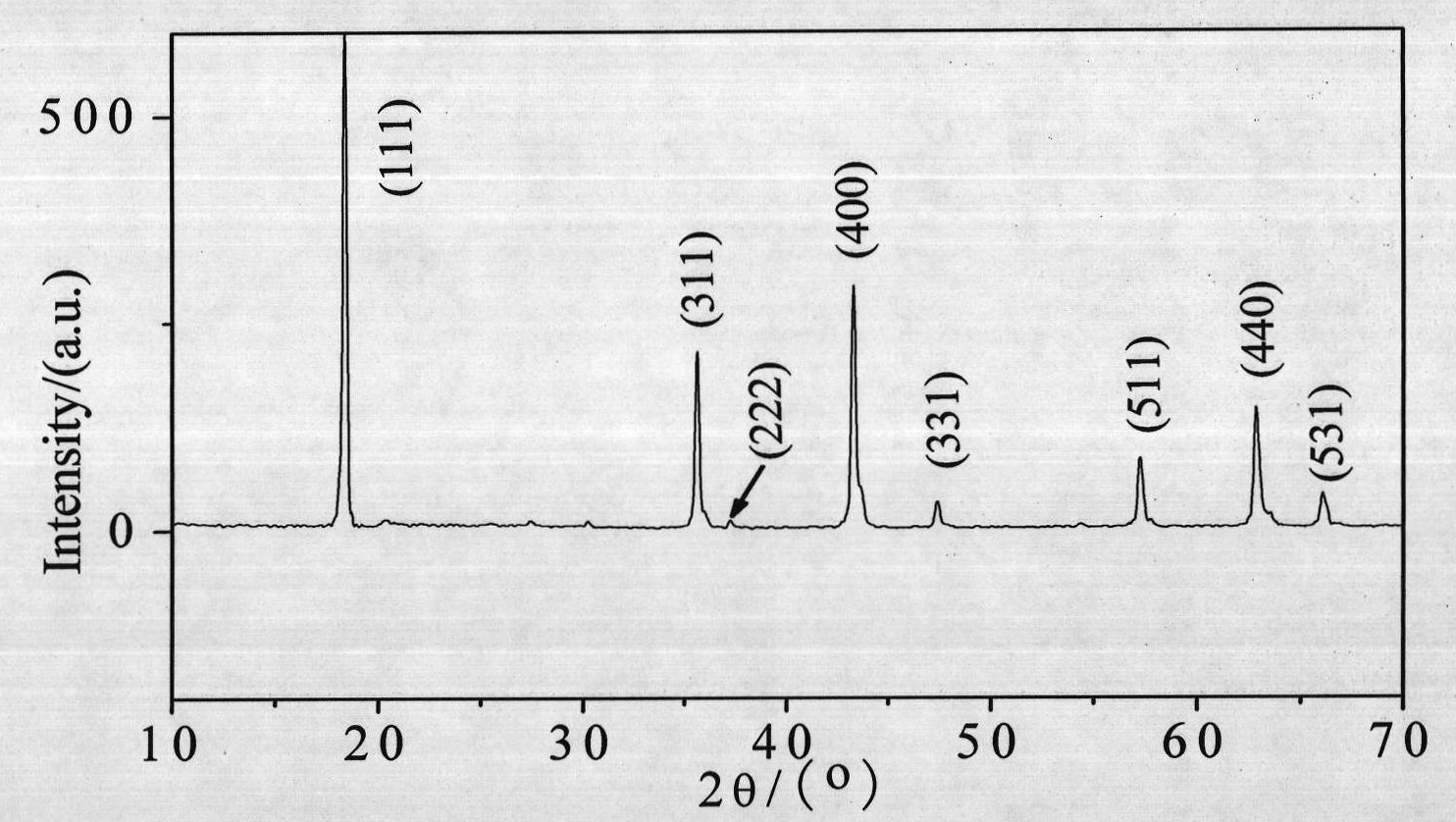

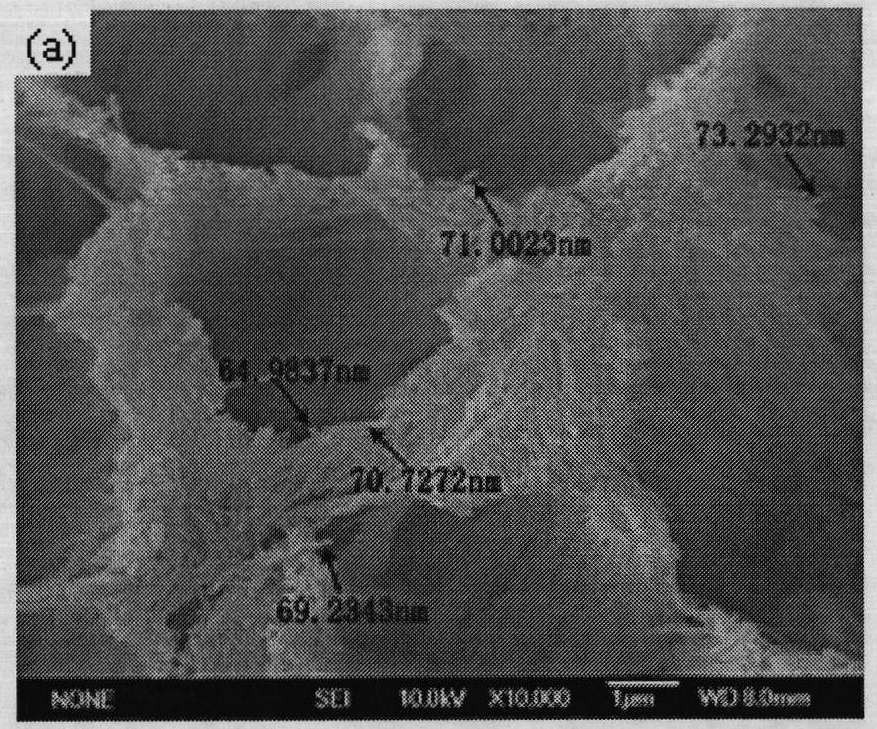

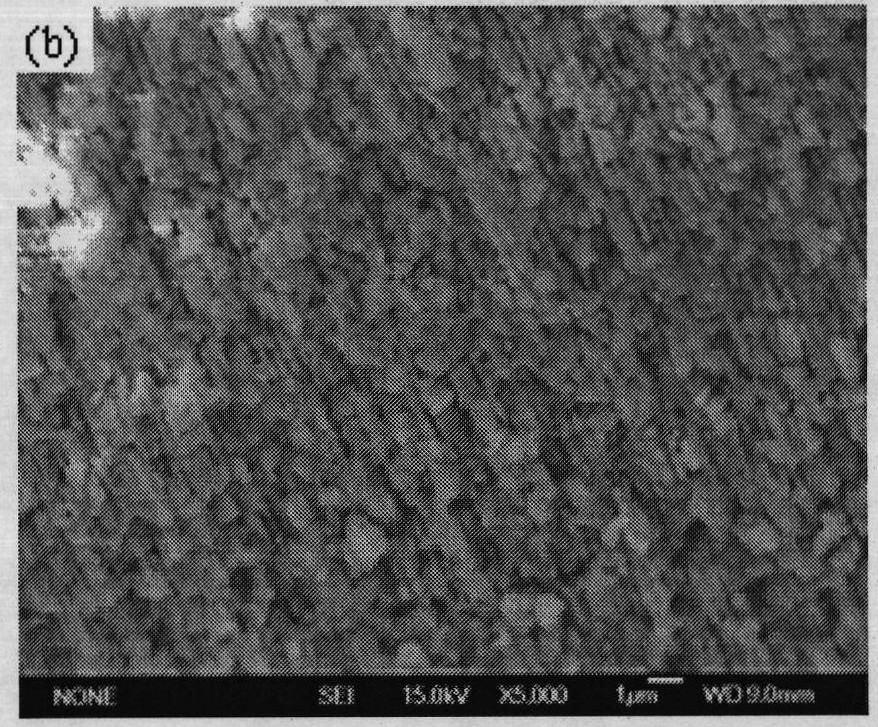

InactiveCN102044662AUniform pore sizeLarge specific surface areaCell electrodesSurface reaction electrolytic coatingRegular distributionSpinel

The invention discloses a method for preparing a spinel type lithium titanate nanowire array, in particular a method for preparing the spinel type lithium titanate nanowire array by using an aluminum oxide template. The method comprises the following steps of: preparing a porous aluminum oxide template; deoiling and annealing an aluminum plate, and performing electrochemical polishing, secondary anodic oxidation and hole expansion; synthesizing a lithium titanate sol precursor; adding butyl titanate, a complexing agent, ethylene glycol and lithium acetate dihydrate into absolute ethanol according to a proportion in turn and continuously stirring; preparing the lithium titanate nanowire array; dipping the porous aluminum oxide template into the lithium titanate sol precursor under vacuum; performing high-temperature roasting; and finally dissolving the template off with NaOH solution. Spinel type lithium titanate nanowires prepared by the method have the diameters of between 50 and 100nm; and the array has the advantages of uniform aperture size, large specific surface area, high degree of order, regular distribution, adjustable composition, controllable structure and the like.

Owner:TAIYUAN UNIV OF TECH

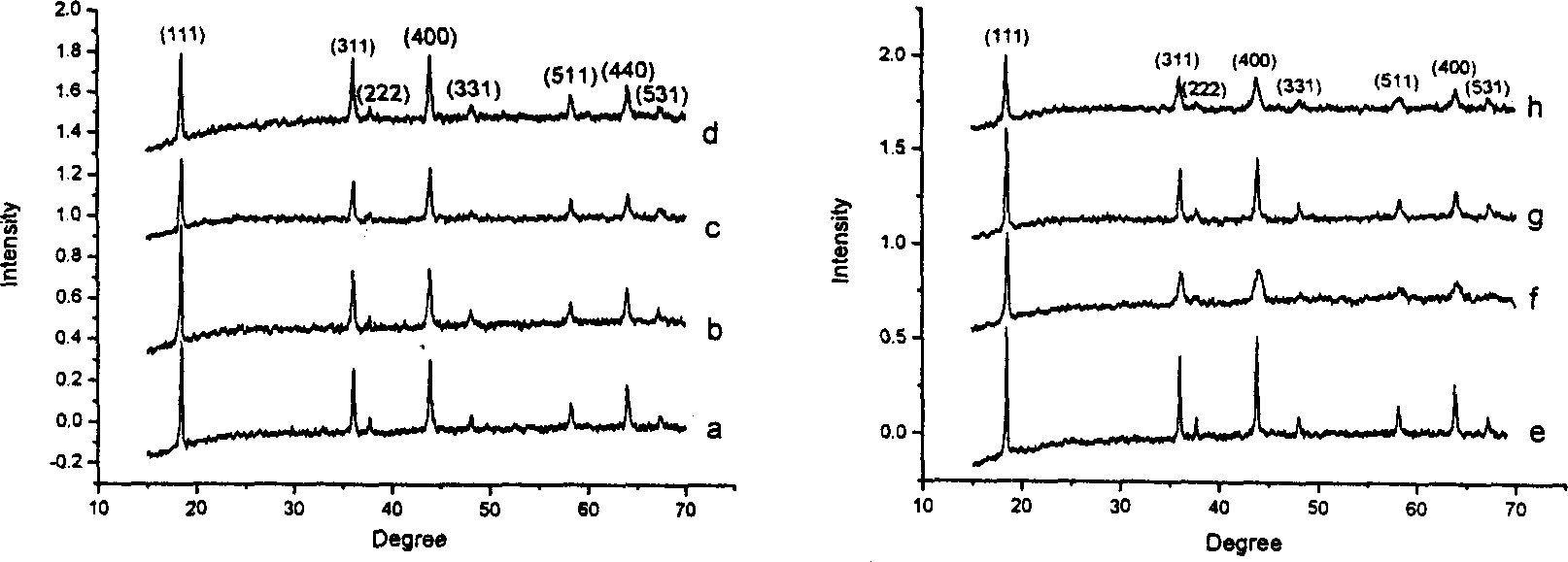

Modified nickel cobalt manganese ternary composite electrode material coated on oxide surface and preparation method thereof

ActiveCN107331852AAvoid corrosionReduce surface resistanceSecondary cellsPositive electrodesMANGANESE ACETATENiobium

The invention provides a modified nickel cobalt manganese ternary composite electrode material coated on an oxide surface and a preparation method thereof. A coating layer of the composite electrode material is prepared from two or three metal oxides MxOy, wherein M is niobium, zirconium or yttrium; the thickness of the coating layer is 0.5-50nm and the weight percent in the composite electrode material is 1%-10%; the prepared nickel cobalt manganese composite electrode material has an alpha-NaFeO2 layered structure. Nickel acetate, cobalt acetate, manganese acetate and lithium acetate are taken as raw materials, the metal oxides are served as surface coating matters and the high-temperature sintering and in-situ coating combined technology is adopted for preparing the high-performance composite electrode material. The coating layer of the composite electrode material can prevent the metal ions in active materials from dissolving, can resist against the corrosion of HF to active materials and can reduce the surface impedance and promote the cycling stability. The preparation process is simple, the operation is easy, the production period is short, the equipment requirement is low and industrial development and popularization and application are benefited.

Owner:ENERGY RESOURCES INST HEBEI ACADEMY OF SCI

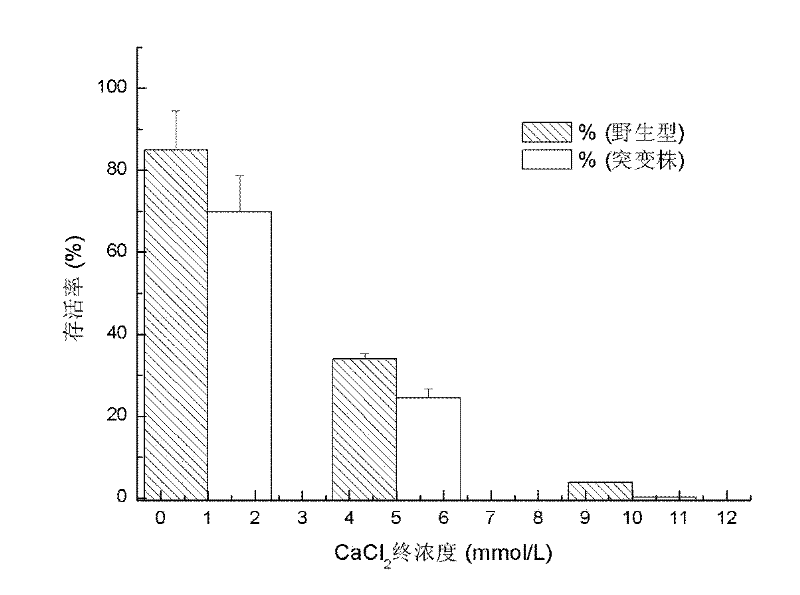

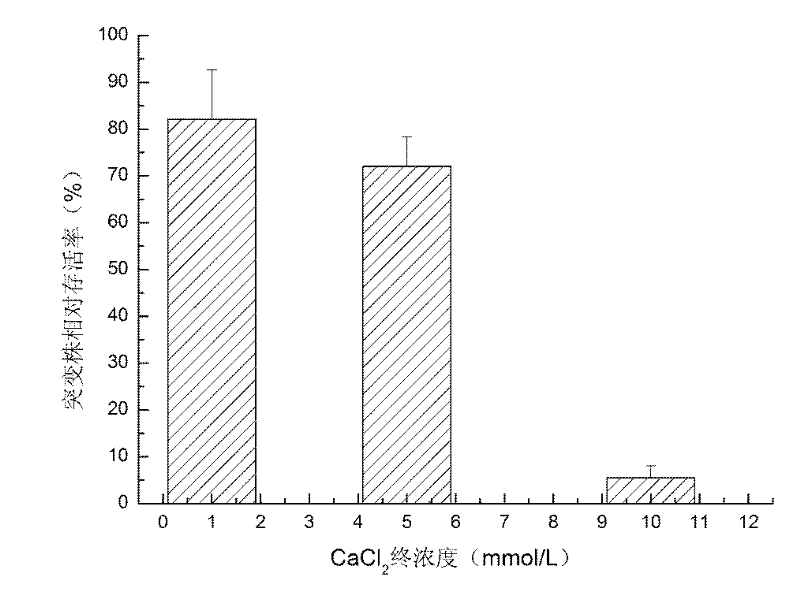

Construction method and application of a kind of Saccharomyces cerevisiae gsh1 deletion mutant strain

InactiveCN102296033AHigh detection sensitivityLower resistanceFungiMicrobiological testing/measurementBiotechnologyForward primer

The invention discloses a construction method and application of a Saccharomyces cerevisiae gsh1 deleted mutant strain. The method is performed according to the description in the document (Yeast, 1998, 14:953-962), including designing of primers and transformation of knockout segment according to the principle of homologous recombination and gene knockout of Saccharomyces cerevisiae gene. The method is a conventional method for gene knockout in the Saccharomyces cerevisiae at present. The method specifically comprises the following steps: designing primers (forward primer P1 and reverse primer P2) according to the gene sequence of Saccharomyces cerevisiae gsh1; carrying out PCR (polymerase chain reaction) amplification on the plasmid pFA6a-Kan MX6 by using the forward primer P1 and the reverse primer P2 to obtain a knockout segment containing forward and reverse sequences of the Saccharomyces cerevisiae gsh1 gene; and introducing the knockout segment into a Saccharomyces cerevisiae BY47421 strain cell by a lithium acetate / PEG (polyethylene glycol) transformation method, and screening to obtain the Saccharomyces cerevisiae DELTAgsh1 mutant strain YJL101C. The Saccharomyces cerevisiae cell DELTAgsh1 mutant strain is constructed by a microbial genetic method, and the cytotoxicity of cadmium chloride or any other heavy metal is detected by using the mutant strain, thereby enhancing the cytotoxicity detection sensitivity. The method is easy to implement and simple to operate.

Owner:WUHAN UNIV

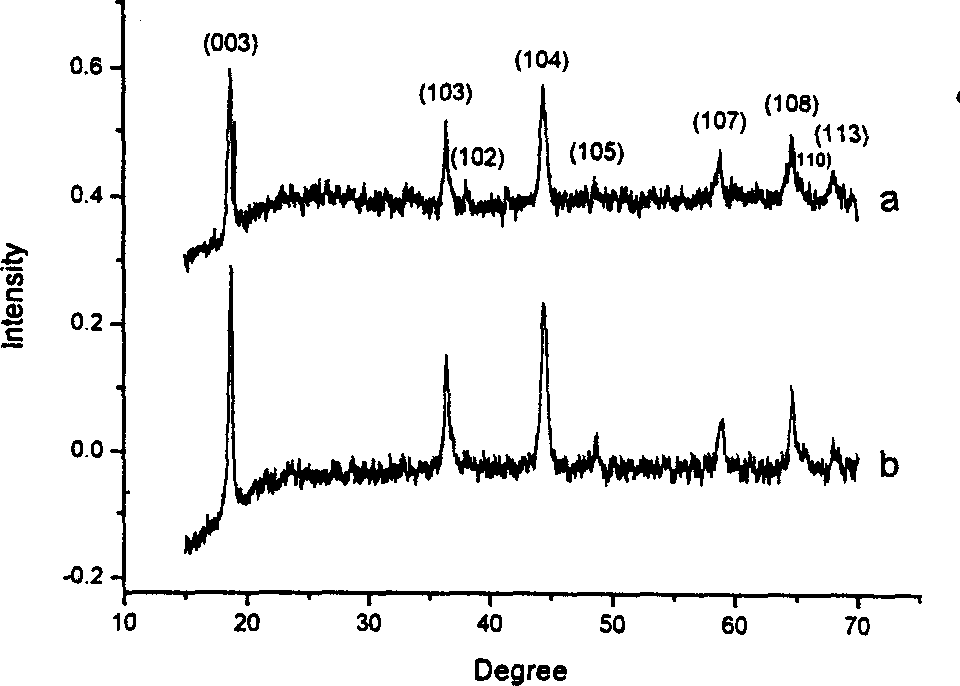

Method for preparing lithium manganese oxide by using low-heat solid phase reaction

InactiveCN1461064ALow priceSimple reaction conditionsElectrode manufacturing processesManganese oxides/hydroxidesMANGANESE ACETATESolvent

The method for preparing lithium-manganese oxide by using low-beat solid phase reaction includes the following steps: according to stoichiometric ratio mixing lithium acetate, manganese acetate and solid phase organic acid or alcohol or sugar or amino acid; grinding at room temp., drying the obtained mixture at 75-85 deg.C and calcining at 350-850 deg.c for 12-18 hr. so as to obtain the invented final product Li1+xMn2O4 or Li1+xMnO2, in which x=-0.1í½+0.2. According to different stoichiometric ratio the spinelle type LiMn2O4 or laminate LiMnO2 can be obtained.

Owner:NANJING UNIV

Sol-gel method for preparing lithium titanate

The invention belongs to the technology field of lithium battery, and especially relates to a sol-gel method for preparing lithium titanate. The invention aims to solve the technology problem of uneasy operation control, which causes the instability of gel, in the conventional sol-gel method. In order to solve the technology problem mentioned above, the invention provides a sol-gel method for preparing lithium titanate. The method comprises following steps: step a, dissolving butyl titanate in glycol to prepare a solution; step b, mixing dihydrate lithium acetate, citric acid, absolute ethanol and deionized water together to prepared a solution; step c, dropwise adding the solution obtained in the step b into the solution obtained in the step a, adding ammonia liquor at the same time, then stirring to obtain transparent sol, then ageing to obtain the gel; step d, drying the gel under constant temperature to obtain dry gel, then fully grinding the dry gel to obtain precursors; step e, and finally sintering the precursors in sections to obtain lithium titanate. The preparation method has the advantages of convenient operation, excellent product properties and preferably good application prospect.

Owner:PANZHIHUA UNIV

Synthesis method for lithium iron phosphate/carbon composite material

ActiveCN102332565AHigh crystallinityImprove electrochemical performanceCell electrodesCarbon compositesSucrose

The invention discloses a synthesis method for a lithium iron phosphate / carbon composite material. The synthesis method is characterized by comprising the following steps of: (1) uniformly mixing lithium phosphate, iron powder, iron phosphate, another lithium source and a carbonous conductive agent precursor, wherein the another lithium source is one or the combination of any of the following components: lithium carbonate, lithium oxalate, lithium acetate, lithium hydroxide and lithium nitrate, and the carbonous conductive agent precursor is one or the combination of any of the following components: glucose, sucrose, citric acid, starch, polyvinyl alcohol, stearic acid and lauric acid; (2) putting the raw material mixture obtained in the step (1) into a ball-milling container and performing full ball milling; and (3) putting the mixture subjected to the ball milling into nitrogen gas and baking the mixture at 600-800 DEG C to prepare the lithium iron phosphate / carbon composite material. The synthesis method is simple in process, and the synthesized lithium iron phosphate / carbon composite material is high in specific capacity and excellent in high-current and cycle performance.

Owner:ZHEJIANG UNIV OF TECH

Method for coating through all-solid-state lithium-ion electrolyte material Li<7>La<3>Zr<2>O<12>

InactiveCN105489929APrevent burnoutCalcination temperature is lowSecondary cellsElectrolytesAll solid stateLithium acetate

The invention discloses a method for coating through an all-solid-state lithium-ion electrolyte material Li<7>La<3>Zr<2>O<12>. The method comprises the following steps: (1) dissolving lithium acetate and lanthanum acetate into water; (2) dissolving zirconium n-butoxide into an ethanol-acetate solution; and (3) adding the solution obtained in the step (1) to the solution obtained in the step (2) under a stirring condition, adding a positive active material, carrying out ultrasonic treatment for 30-60 minutes, ageing for 10-12 hours, drying the obtained gel at 80-100 DEG C for 1-2 hours, heating the gel to 600-650 DEG C for burning for 3-5 hours, and naturally cooling the product to obtain the Li<7>La<3>Zr<2>O<12>-coated positive active material. Compared with an existing method, the method provided in the invention can make the burning temperature obviously lowered; and burning loss of a lithium element at a high temperature is avoided.

Owner:QINGDAO NENGXUN NEW ENERGY TECH CO LTD +1

Normal-temperature stable high-efficiency environment-friendly sealing agent for aluminum and aluminum alloy

ActiveCN107740167AReduce consumptionExtended service lifeSurface reaction electrolytic coatingSodium acetateRoom temperature

The invention discloses a normal-temperature stable high-efficiency environment-friendly sealing agent for aluminum and an aluminum alloy. The formula of the sealing agent comprises, by weight, 3%-15%of sodium acetate, 0%-2% of lithium acetate, 0.2%-5% of sodium benzoate, 0%-2% of urea, 5%-30% of a stabilizer, 0.5%-10% of a dispersing agent, 0%-15% of a complexing agent, 0.5%-10% of a pH buffer agent, 0%-10% of a corrosion inhibitor and the balance deionized water. According to the normal-temperature sealing agent, the solution system is stable; a hole sealing film is compact; the hole sealing agent is small in consumption and long in service life; the surface of a workpiece subjected to hole sealing is smooth and bright, is free of color change, does not generate powder, is capable of effectively preventing fingerprints and can achieve oil stain resistance; the problems that the surface of an aluminum product subjected to hole sealing by a hole sealing agent used in the existing industrial production is not enough in brightness, is relatively dark in color, and is high in hydrophilic performance and prone to generate water stains after being cleaned and dried are solved, and theproblem that a lot of products generate white ash is also solved; and the strength, the hardness and the corrosion resistance of the workpiece are improved.

Owner:JIANGSU FEITUO INTERFACE ENG TECH CO LTD

Electrolyte for inhibiting growth of lithium dendrites and lithium battery

PendingCN110416615AImprove deposition and dissolution efficiencyInhibition formationSecondary cells servicing/maintenanceSolid state electrolyteLithium chloride

The invention discloses an electrolyte for inhibiting the growth of lithium dendrites and a lithium battery. The electrolyte comprises an additive, a lithium salt and an organic solvent. The additiveincludes at least one in the group consisting of lithium hexafluorophosphate, lithium perchlorate, lithium bis(trifluoromethane) sulfonate, lithium trifluoromethanesulfonate, lithium fluoroborate, trilithium hexafluoroaluminate, lithium hexafluoroarsenate, lithium fluoride, lithium chloride, lithium bromide, lithium nitrate, lithium polysulfide, lithium nitride, lithium phosphide, lithium oxalateborate, lithium oxide, lithium sulfite, lithium sulfate, lithium acetate, lithium hydroxide and lithium oxalate, and the lithium salt is different from the additive. According to the lithium battery containing an additive, a layer of solid electrolyte membrane can be formed on a surface of the lithium metal negative electrode during charge and discharge, and the polymerization of the electrolyte can be induced to form an oligomer which covers a surface of a lithium negative electrode and a surface of a positive electrode material matched with the lithium negative electrode. The protective layer can effectively inhibit the growth of the lithium dendrites, and therefore, the safety performance of the battery is improved.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of carbon-coated lithium iron phosphate material with polystyrene microspheres and polyethylene glycol as carbon sources

The invention provides a preparation method of a carbon-coated lithium iron phosphate material with polystyrene microspheres and polyethylene glycol as carbon sources. The preparation method comprises the steps of firstly synthesizing the polystyrene microspheres, dissolving the synthesized polystyrene microspheres and polyethylene glycol in deionized water, then mixing lithium acetate, iron nitrate and ammonium dihydrogen phosphate in a certain ratio to form a mixture, stirring the mixture at a certain temperature to obtain a gel, drying the obtained gel in an oven at a constant temperature, grinding the gel and calcining the powder, thus obtaining the carbon-coated lithium iron phosphate powder material. The carbon-coated lithium iron phosphate material prepared by the preparation method has a grain size of 200-400nm, fine and uniform grains and high purity, thus increasing the electron conductivity and the ion diffusion rate. The preparation method is simple and practicable and fast, can be completed in ordinary chemical laboratories, and can be used for large-scale industrial production. The carbon-coated lithium iron phosphate material prepared by the preparation method can serve as an anode material for lithium ion cells.

Owner:HUBEI UNIV

Method for preparing lithium titanate carbon composite material

InactiveCN103022460AHigh magnificationSuper stable cycle performanceCell electrodesTitanium compoundsPorous grapheneCarbon composites

The invention discloses a method for preparing a lithium titanate carbon composite material, and the method comprises the following steps of: dispersing graphite powder in concentrated sulfuric acid, adding KMnO4 and H2O2 while stirring to obtain a nano graphite oxide material, and preparing an aqueous solution of graphene oxide, thereby obtaining porous graphene material; preparing the porous graphene material into porous graphene solution, and evenly mixing a lithium carbonate / lithium acetate mixture, titanium dioxide and deionized water together through ball milling to obtain slurry; next, mixing the slurry with the porous graphene solution under the stirring condition, thereby obtaining porous graphene and lithium titanate precursor powder; and sintering the precursor powder, thereby obtaining the lithium titanate carbon composite material. The lithium titanate carbon composite cathode material prepared by the method provided by the invention employs the composite material of lithium titanate and porous graphene, and has high multiplying power and ultra-stable cycle performance, and further has high energy density; and therefore, the cathode material is high in specific capacity, good in cycle performance and long in service life if being applied to the lithium ion battery.

Owner:SHANGHAI JINZHONG INFORMATION TECH

Silicon-based negative electrode material for lithium ion battery and preparation method thereof

InactiveCN108110228AImprove the first Coulombic efficiencyImprove electronic conductivitySecondary cellsNegative electrodesCarbon coatingInternal resistance

The invention discloses a silicon-based negative electrode material for a lithium ion battery. The silicon-based negative electrode material comprises an amorphous silica matrix, a plurality of nanometer silicon nucleuses, a carbon coating and a LiF coating, wherein the plurality of nanometer silicon nucleuses are embedded into the amorphous silica matrix; the carbon coating coats the amorphous silica matrix; and the LiF coating coats the carbon coating. The invention also provides a preparation method for the silicon-based negative electrode material. The preparation method comprises the following steps: adding nanometer silicon powder into an alkaline solution, adding a carbon source, evaporating the solution to dryness and then carrying out drying so as to obtain an intermediate material; and sintering the intermediate material under the protection of inert gas, then uniformly dispersing the intermediate material in a lithium acetate solution, adding an ammonium fluoride solution, carrying out a hydrothermal reaction and then carrying out washing, filtering and drying. The preparation method provided by the invention is simple in process and easy for large-scale production; andthe prepared negative electrode material is small in volume expansion, high in electron conductivity, low in internal resistance and good in electrochemical performance.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com