Method for producing anode active material containing lithium, magnesium compound oxide

A technology of composite oxides and active materials, which is applied in the field of preparation of positive multi-component active materials, can solve the problems of low capacity of lithium manganese oxide positive electrode materials, complex synthesis process, and limited application range, so as to improve electrochemical performance and synthesis process. Simple and shortened heat treatment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

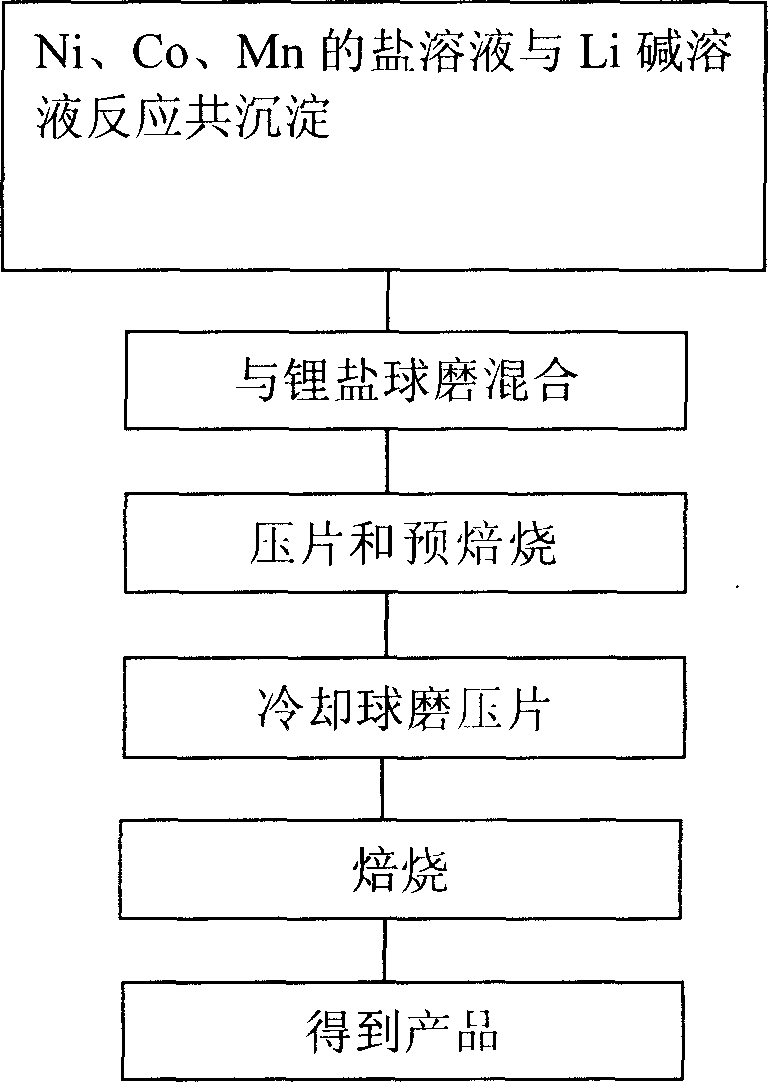

Method used

Image

Examples

Embodiment 1

[0037] Under normal temperature and pressure, a 0.1M mixed solution of nickel acetate, cobalt acetate and manganese nitrate was prepared stoichiometrically, and was added dropwise to a lithium hydroxide solution with a concentration of 2mol / l at a flow rate of 0.3ml / min to react and control The pH value of the reaction is at 8, and the precipitate obtained by the reaction is filtered out, and washed repeatedly with deionized water until the pH value reaches neutrality, and then the precipitate is vacuum-dried to obtain a coprecipitate M(OH) 2 , where M includes Ni, Co and Mn; the prepared coprecipitate M(OH) 2 According to M(OH) 2 : Lithium carbonate=1: 1 mol ratio adds lithium carbonate and carries out ball milling and mixes, and makes the mixed powder that contains Li and M; The mixed powder technique that contains Li and M that is made is compressed under the hydraulic press of 50MPa pressure, then Place the pressed tablet in a muffle furnace for pre-calcination at 480°C f...

Embodiment 2

[0039] Under normal temperature and pressure, prepare 0.5M mixed solution of soluble nickel nitrate, cobalt nitrate and manganese acetate according to stoichiometry, and add it dropwise at a flow rate of 0.3ml / min to a lithium hydroxide solution with a concentration of 2mol / l for reaction. Control the pH value of the reaction at 10, filter the precipitate obtained from the reaction, and use deionized water to wash repeatedly until the pH value reaches neutrality, and then vacuum dry the precipitate to obtain a coprecipitate M(OH) 2 , where M includes Ni, Co and Mn; the prepared coprecipitate M(OH) 2 According to M(OH) 2 : The mol ratio of Lithium Hydroxide=1:1 adds Lithium Hydroxide and carries out ball milling mixing, makes the mixed powder that contains Li and M; The mixed powder that makes Li and M is compressed under the hydraulic press of 50MPa pressure, Then place the pressed tablet in a muffle furnace for pre-calcination at 480°C for 3 hours; cool the pre-calcined prod...

Embodiment 3

[0041] Except that the prepared pellets were baked in a muffle furnace at 800°C for 6 hours, the others were the same as in Example 2, and the obtained LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 The scanning electron microscope image is shown in image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com