Patents

Literature

736 results about "Cobalt acetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

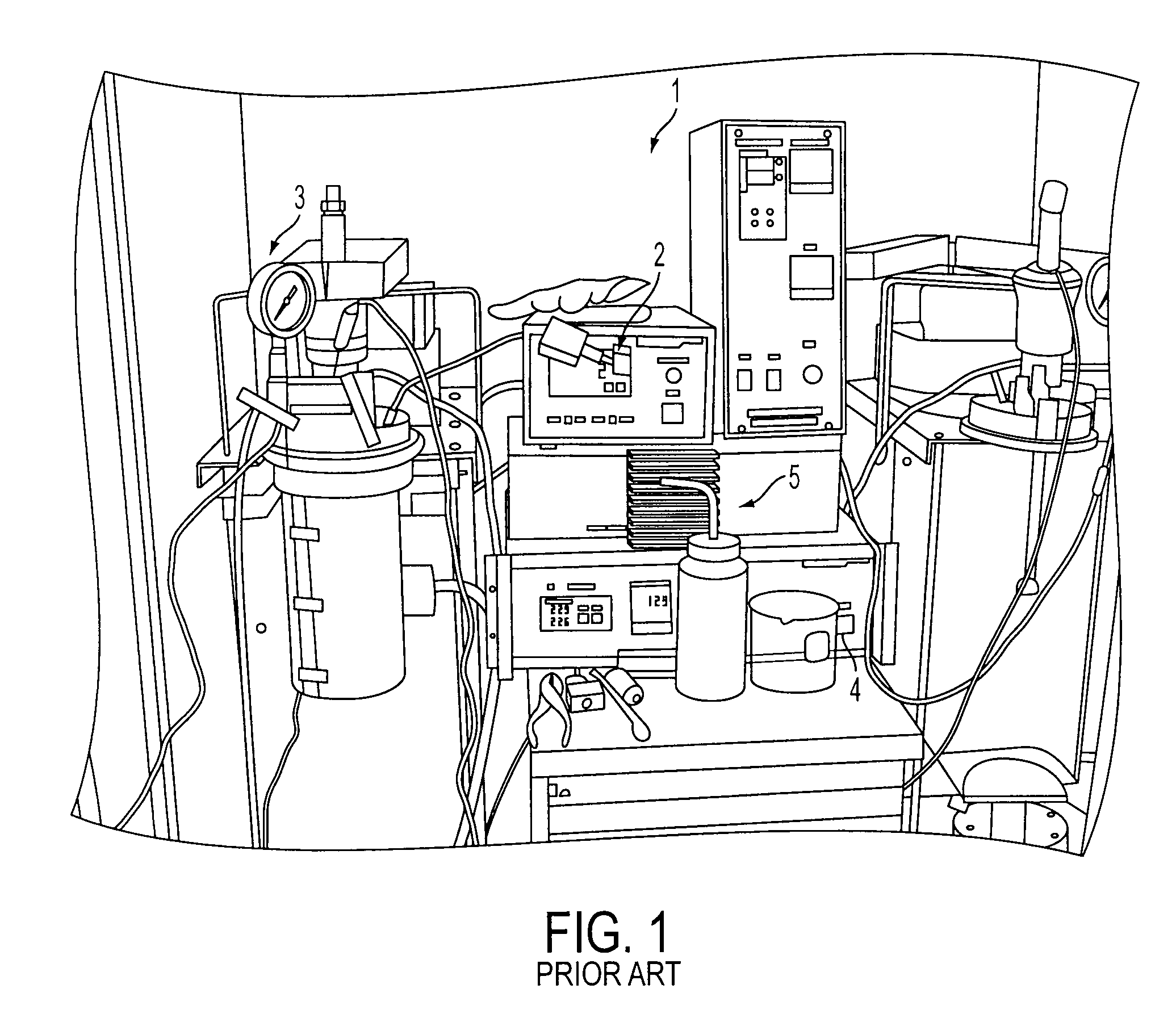

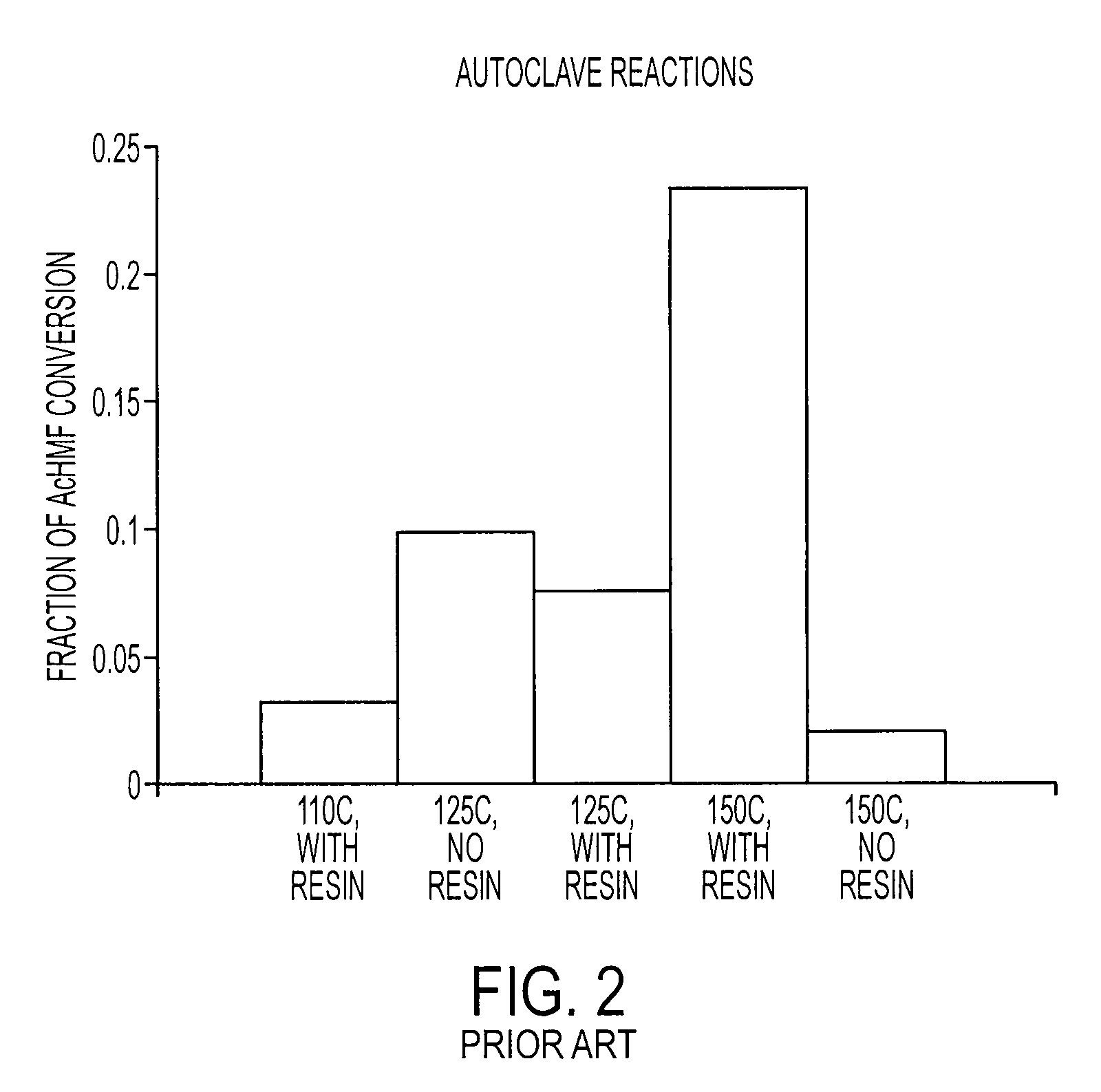

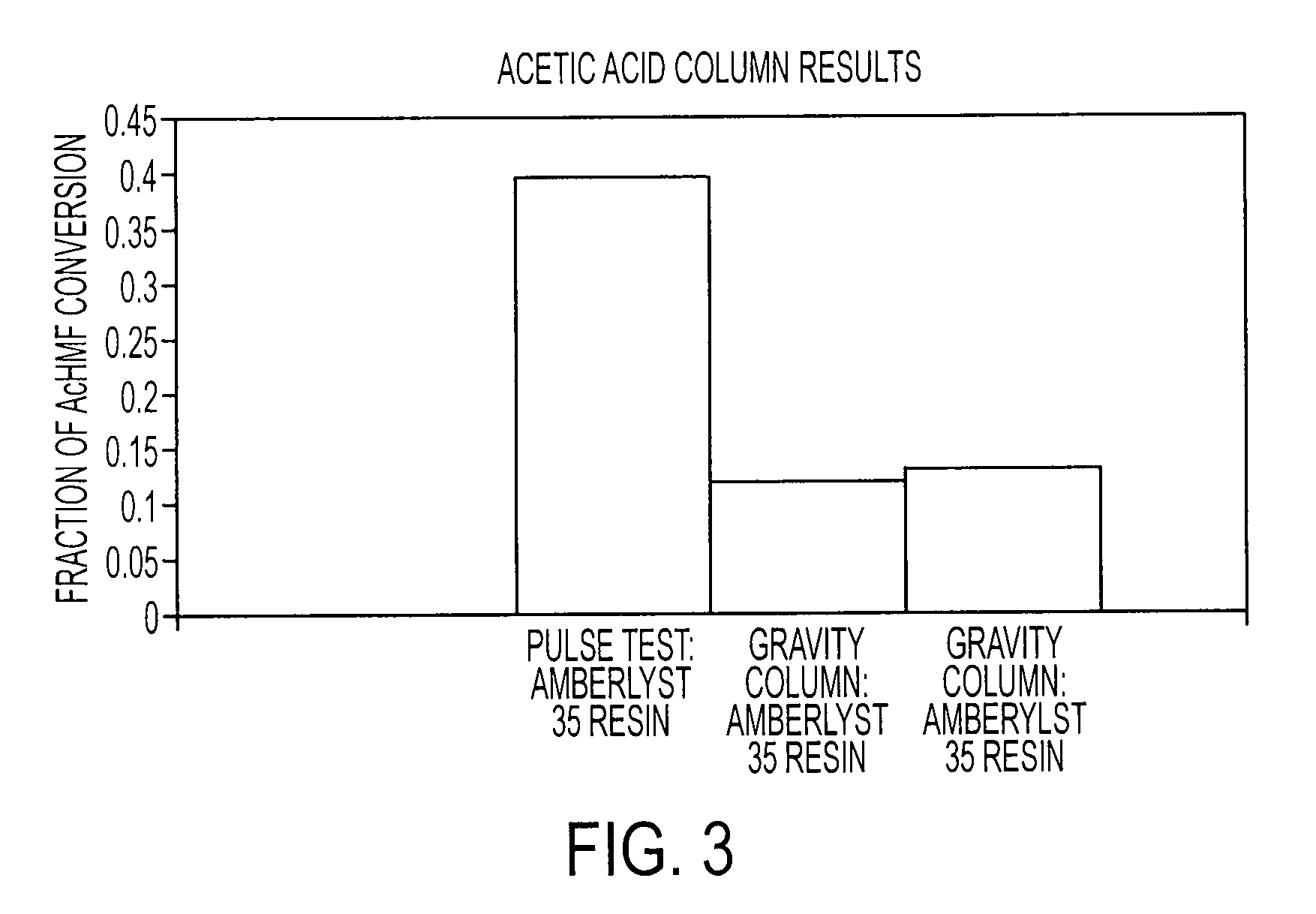

Conversion of carbohydrates to hydroxymethylfurfural (HMF) and derivatives

InactiveUS20090156841A1Increase conversion rateStable formOrganic compound preparationCarboxylic compound preparationMANGANESE ACETATEFuran

A method of producing substantially pure HMF, HMF esters and other derivatives from a carbohydrate source by contacting the carbohydrate source with a solid phase catalyst. A carbohydrate starting material is heated in a solvent in a column and continuously flowed through a solid phase catalyst in the presence of an organic acid, or heated with the organic acid and a solid catalyst in solution to form a HMF ester. Heating without organic acid forms HMF. The resulting product is purified by filtration to remove the unreacted starting materials and catalyst. The HMF ester or a mixture of HMF and HMF ester may then be oxidized to 2,5-furandicarboxylic acid (FDCA) by combining the HMF ester with an organic acid, cobalt acetate, manganese acetate and sodium bromide under pressure. Alternatively, the HMF ester may be reduced to form a furan or tetrahydrofuran diol.

Owner:ARCHER DANIELS MIDLAND CO

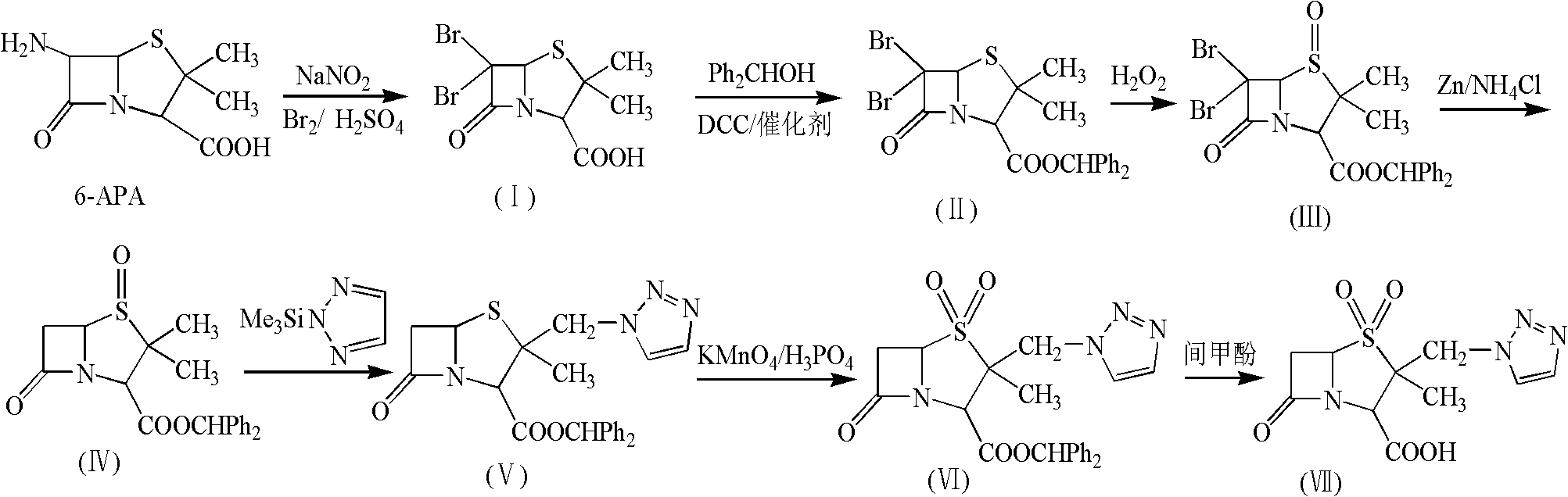

Tazobactam synthesis method

ActiveCN102020663AReduce usageWill not polluteOrganic chemistryChemical recyclingMetacresolSynthesis methods

The invention relates to a tazobactam synthesis method which comprises the steps of: with 6-APA(Amino Penicillanic Acid) as raw material, preparing a key intermediate 6,6-dihydro penam sulphoxide acid diphenylcarbinol ester through successive reactions of esterification, oxidation, reduetive debromination and the like without separation; then, reacting with 2-triphenyl silicon-1,2,3-triazole; introducing a triazole ring; and finally obtaining the final product of tazobactam through potassium permanganate oxidation and metacresol deprotection. The tazobactam synthesis method is mainly characterized in that a phase transfer catalyst is introduced in the first step, therefore, the reaction rate and the product purity are improved; since an environment-friendly hydrogen peroxide-cobalt acetate catalytic oxidation system is adopted in the third step, the characteristics of good reaction selectivity, high yield, catalyst recyclability and the like are achieved; a method for synthesizing 2 alpha-methyl-2 beta-(1,2,3- triazole-1- radical) methyl penam-3 alpha-carboxylic acid diphenylcarbinol ester by using 2-triphenyl silicon-1,2,3-triazole is adopted in the fifth step, and the tazobactamsynthesis method is simple and convenient to operate, is safe and reliable, shortens the reaction route and improves the total yield. Compared with the traditional process, the tazobactam synthesis method greatly reduces the production cost and the environment pollution and has greater implementation value and economic benefits.

Owner:YIYUAN XINQUAN CHEM

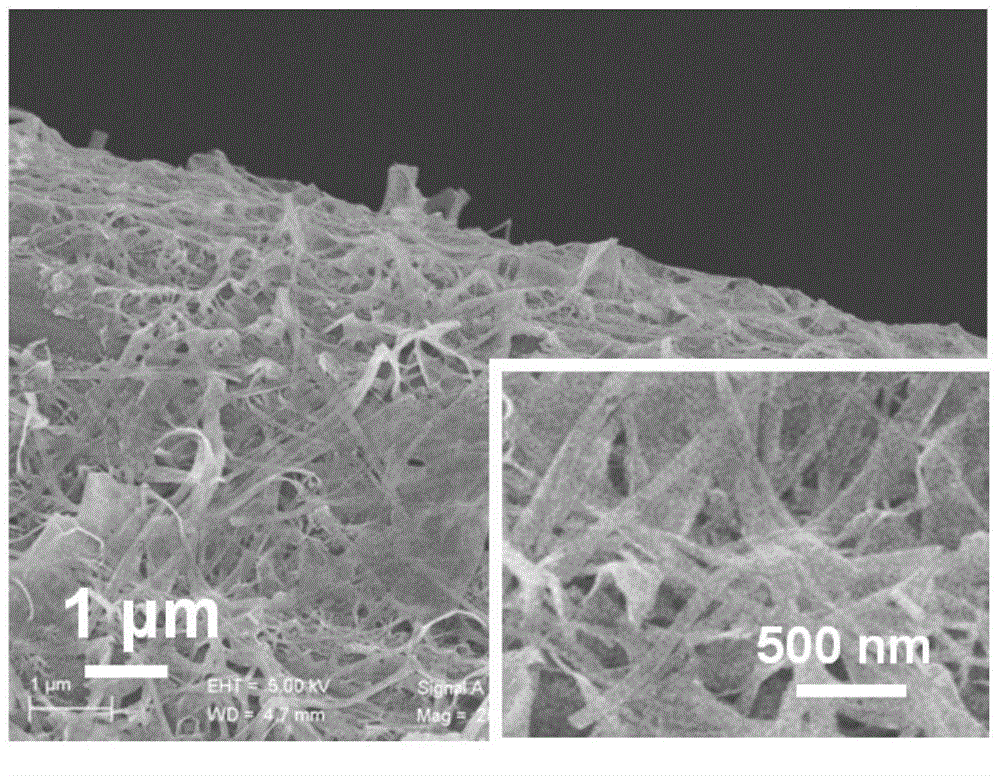

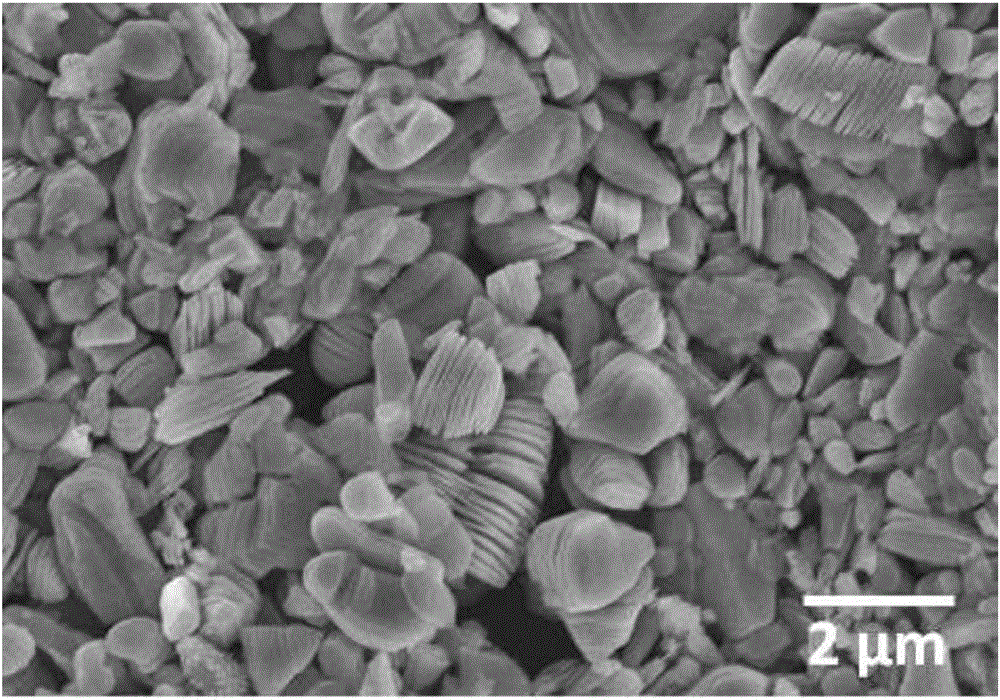

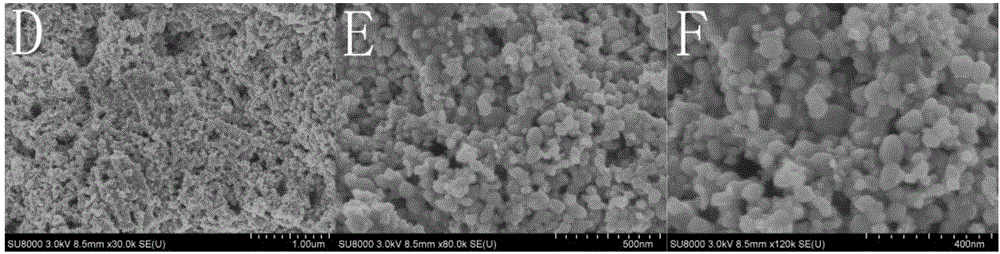

Graphene oxide/metal organic framework composite material and preparation method and application thereof

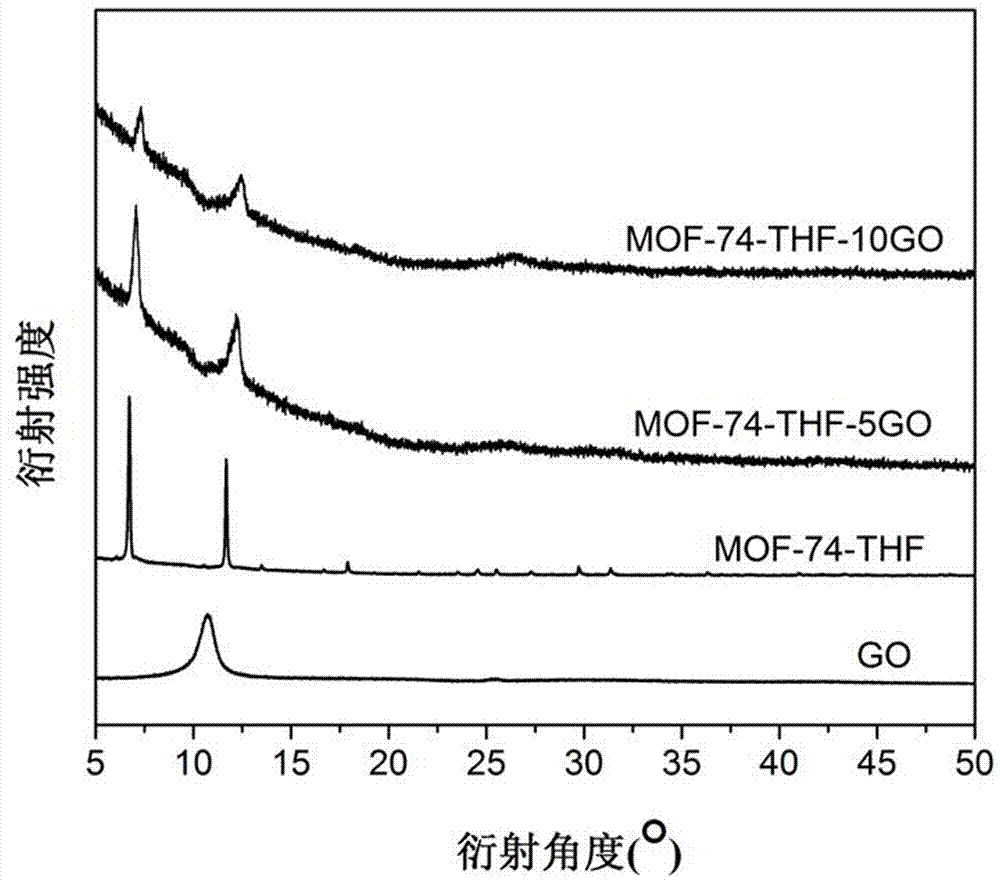

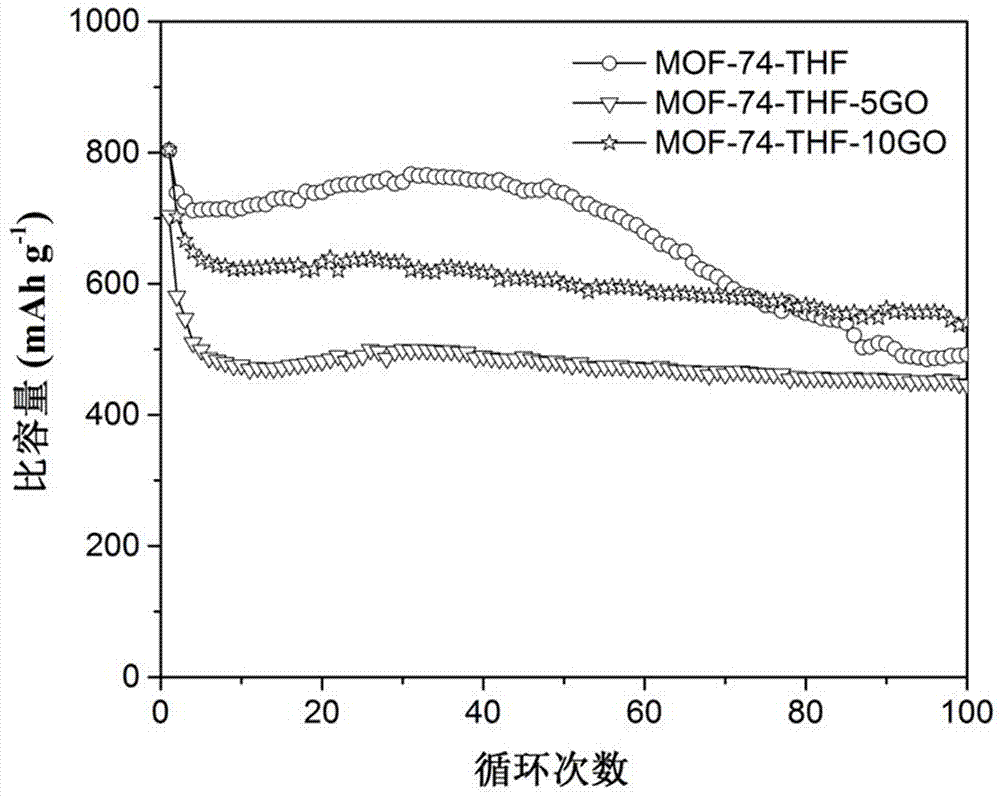

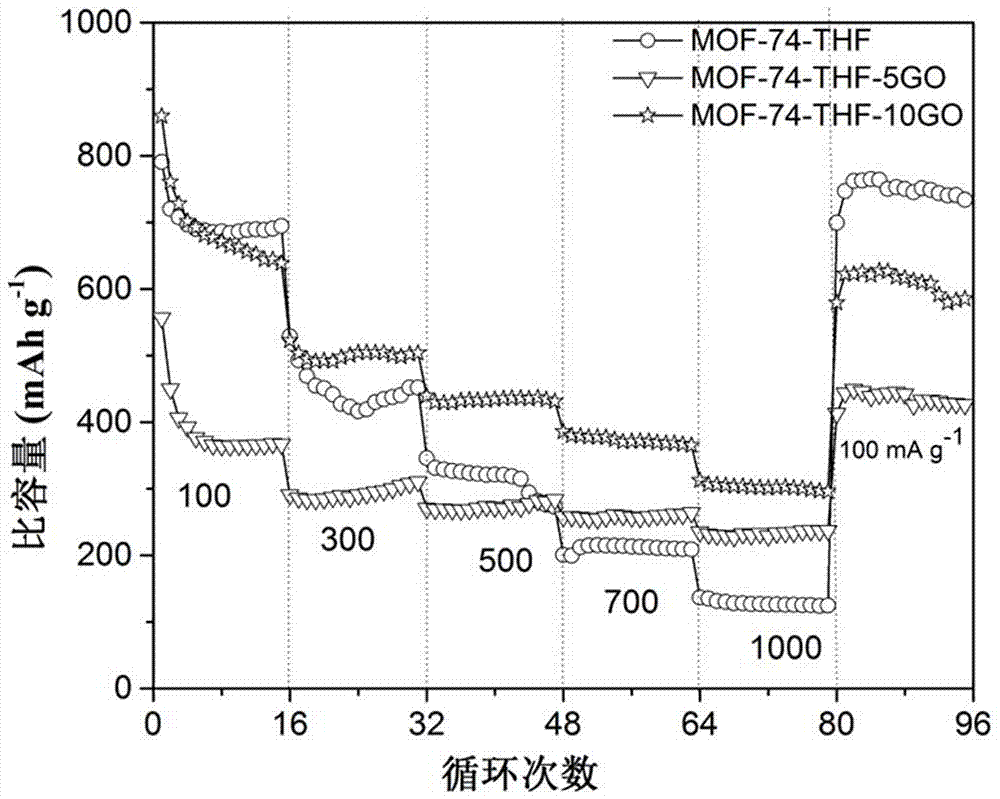

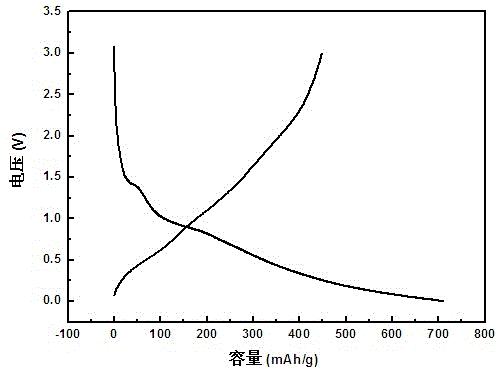

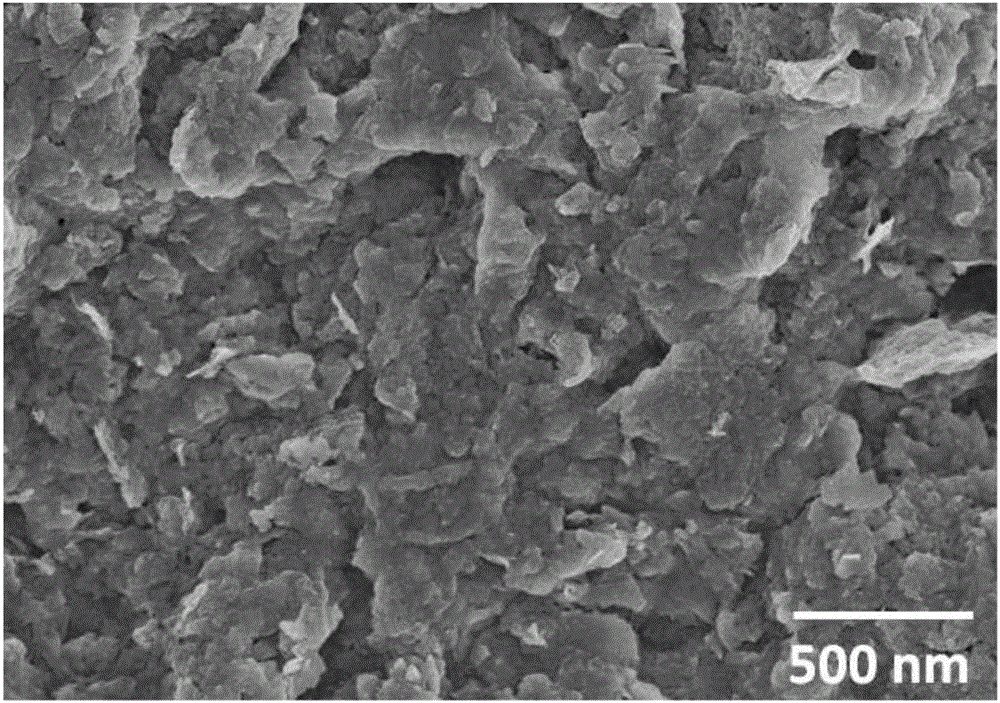

InactiveCN106935825AImprove electrochemical performanceImprove charge and discharge cycle lifeCell electrodesMetal-organic frameworkCharge discharge

The invention provides a graphene oxide / metal organic framework composite material. The composite material is prepared from graphene oxide, cobalt acetate tetrahydrate and 2, 5-dihydroxyterephthalic acid which are mixed based on a certain proportion through a solvothermal method. The preparation method comprises the steps of (1) dispersing graphene oxide into a solvent to obtain a graphene oxide solution; (2) adding the cobalt acetate tetrahydrate and 2, 5-dihydroxyterephthalic acid into deionized water to form a mixed solution; (3) enabling the obtained mixed solution to be mixed with the obtained graphene oxide solution, and then putting the mixture into a reaction kettle; and (4) performing constant-temperature heating in a drying oven, taking out the product, washing and drying. According to the application of the composite material as a negative electrode material of a lithium ion battery, the specific capacity value can reach 520-600mAh g<-1> at current density of 100mAg<-1> in an electrochemical performance test. The composite material is high in cycling stability, long in charging-discharging service life, and has wide application prospect in the field of the lithium ion battery.

Owner:GUILIN UNIV OF ELECTRONIC TECH

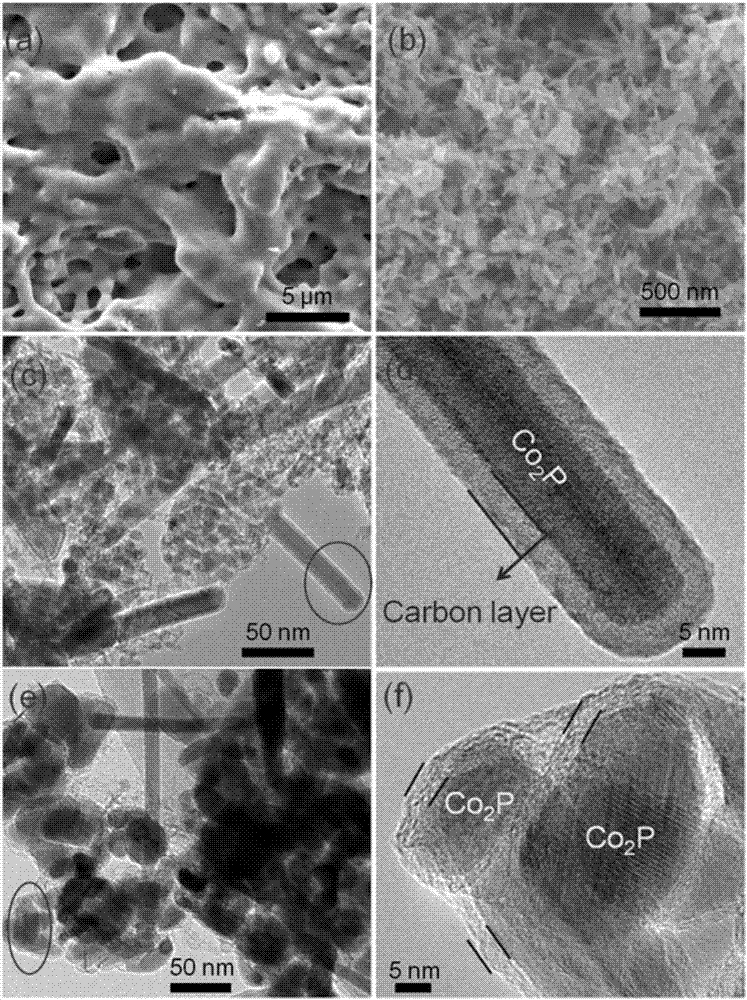

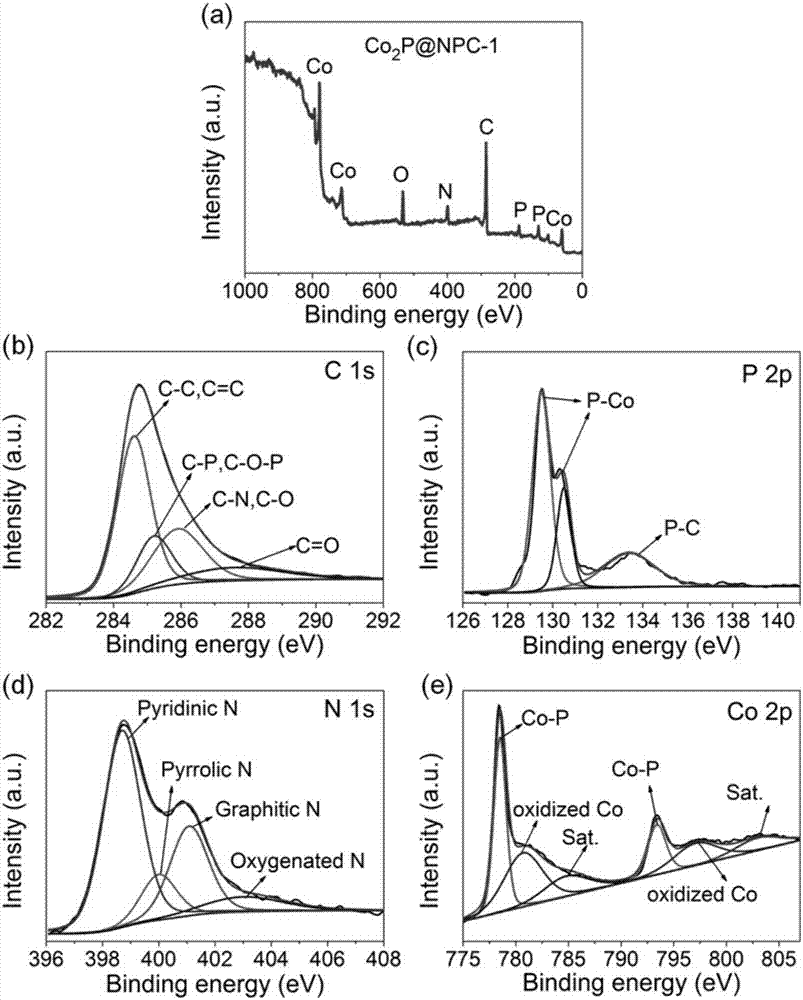

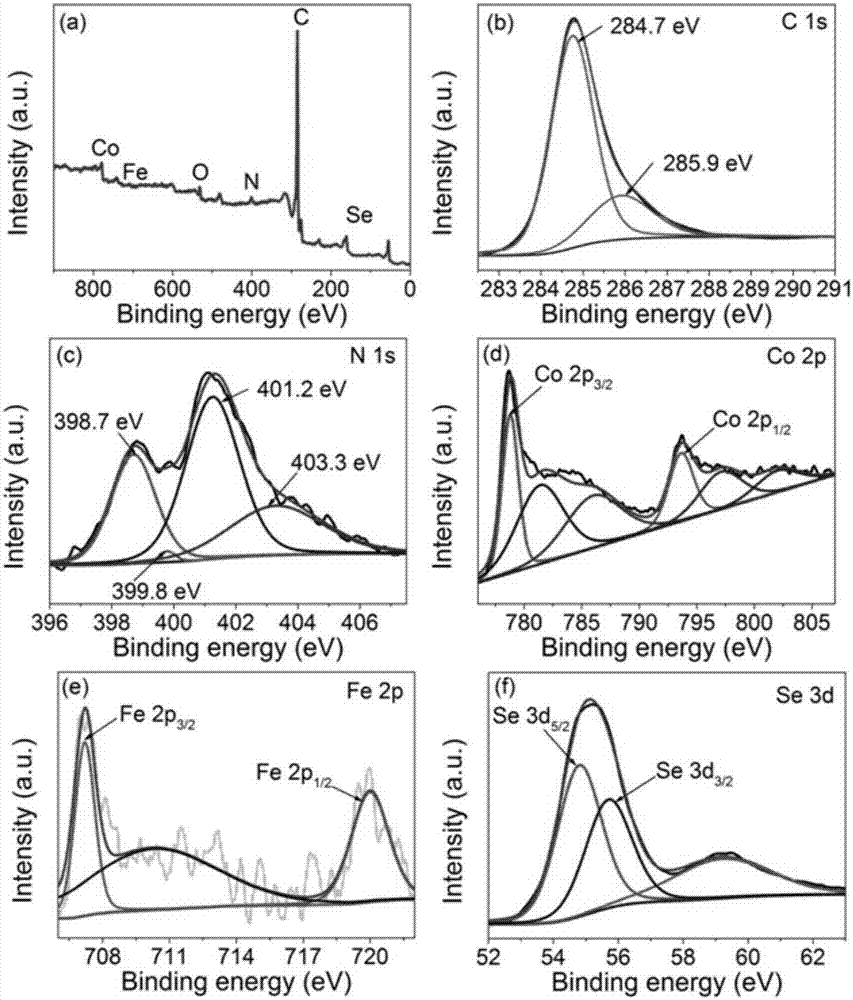

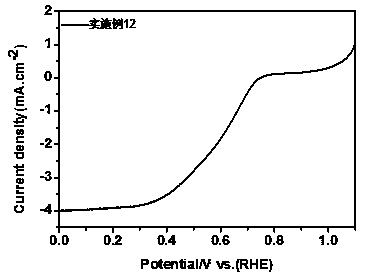

Oxygen reduction and oxygen evolution cobalt phosphide@NPC double-function compound catalyst and preparation method and application thereof

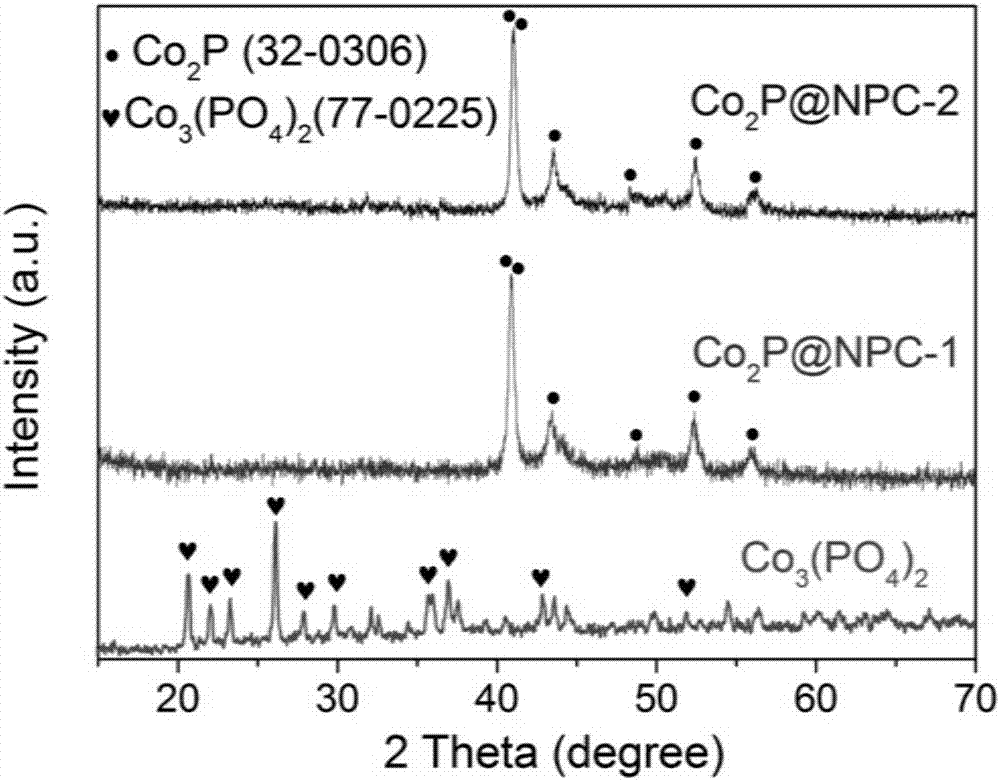

ActiveCN107051559AHigh catalytic activityImprove electrocatalytic performancePhysical/chemical process catalystsCell electrodesCarbon layerDecomposition

The invention discloses an oxygen reduction and oxygen evolution Co2P@NPC double-function compound catalyst and a preparation method and application thereof. The compound catalyst comprises N-P-codoped carbon layer coated Co2P nano rods and / or nano particles. The preparation method includes: evaporating and drying the solution of cobalt acetate, concentrated phosphoric acid and urea, and performing high-temperature treatment under protective atmosphere to obtain the compound catalyst. The preparation method has the advantages that the method is simple, low in cost and beneficial to industrial production; the prepared oxygen reduction and oxygen evolution Co2P@NPC double-function compound catalyst is applicable to fuel cell and water decomposition, high in activity and good in stability, the catalytic performance of the compound catalyst is close to that of a commercial precious metal 20wt% Pt / C and RuO2 catalyst, and the compound catalyst is promising in application prospect.

Owner:CENT SOUTH UNIV

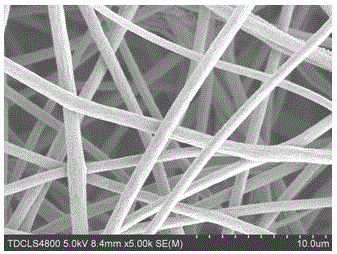

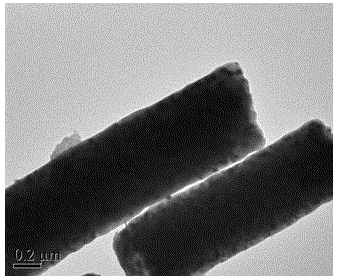

Preparation for anode material of tin-cobalt alloy/carbon nanofiber film lithium ion battery

InactiveCN102751475AImprove conductivitySmall volume changeMaterial nanotechnologyCell electrodesFiberComposite film

The invention discloses a preparation method for anode material of tin-cobalt alloy / carbon nanofiber film lithium ion battery. The method process comprises a first step of preparing a polymer nanofiber film via electrostatic spinning with proper electrostatic spinning parameters by a uniform electrostatic spinning solution which is formed by employing stannous octoate as a tin precursor, cobalt acetate as a cobalt precursor, polyacrylonitrile as a carbon nanofiber precursor and an organic solvent; and a second step of preparing the tin-cobalt alloy / carbon nanofiber film by using a pre-oxidation treatment and a carbonization treatment. The tin-cobalt alloy / carbon nanofiber composite film prepared by the method effectively improves specific capacity and cycle performance of the anode material of the lithium ion battery, because tin-cobalt alloy particles are uniformly dispersed in the carbon nanofibers with uniform diameters; cobalt metal component increases conductivity of the material and can buffer volume change to a certain degree when the tin metal is charged and discharged; and simultaneously the carbon fibers can further play a role for buffering the volume change of the materials.

Owner:TIANJIN UNIV

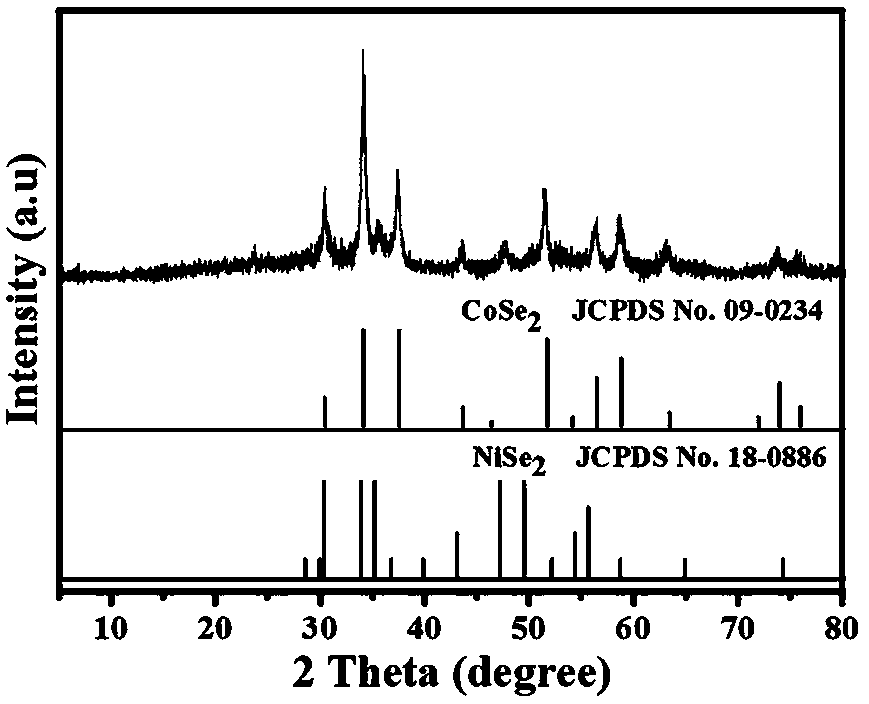

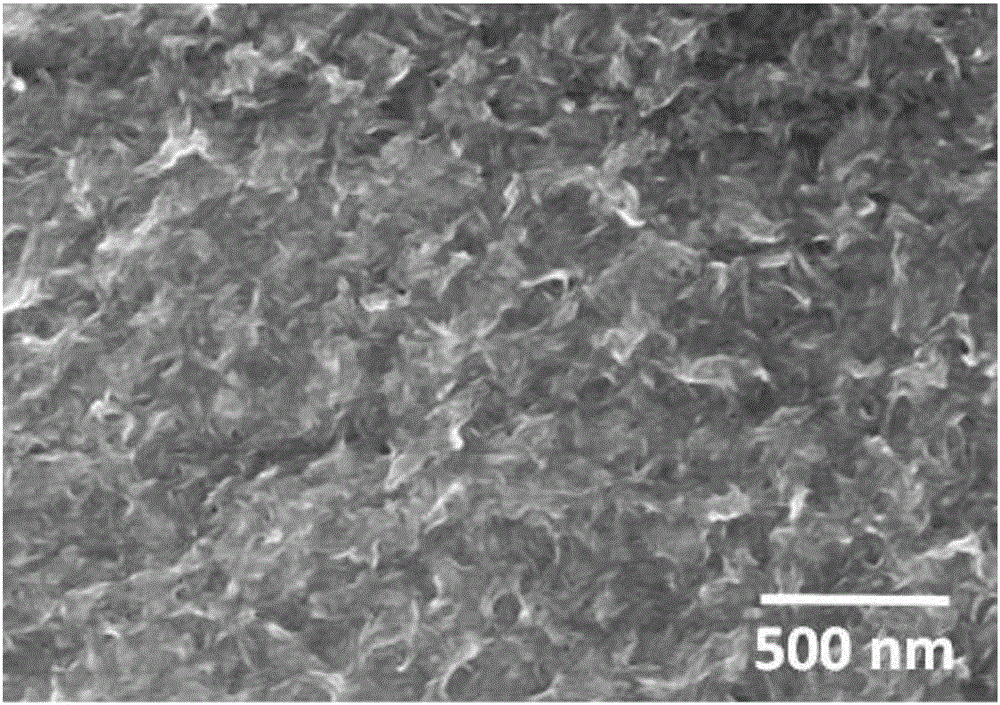

Co-Ni bimetallic selenide/graphene composite electrode material

InactiveCN109243852AAvoid residueHigh purityHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceNickel acetate tetrahydrate

The invention discloses a cobalt-nickel bimetallic selenide / graphene composite electrode material, and belongs to the preparation field of electrode material for supercapacitors. A manufacture methodcomprises that follow steps: adding graphene oxide (GO) into ethylene glycol solution, ultrasonic dispersing, and uniformly dispersing GO in the ethylene glycol solution; Adding polyvinylpyrrolidone(PVP), cobalt acetate tetrahydrate and nickel acetate tetrahydrate into the GO dispersion, ultrasonic dispersing and dissolving, transferring it to a round bottom flask for oil bath reaction and centrifugal washing and drying; After centrifugal washing and drying after oil bath, the product was hydrothermally selenized with sodium selenite and hydrazine hydrate to obtain Co-Ni bimetallic selenide / graphene composite electrode material. A large number of uniform size Co-Ni-Se nanosheets were uniformly loaded on graphene substrate, and the prepared electrode materials had high specific capacitance and excellent rate performance.

Owner:FUZHOU UNIV

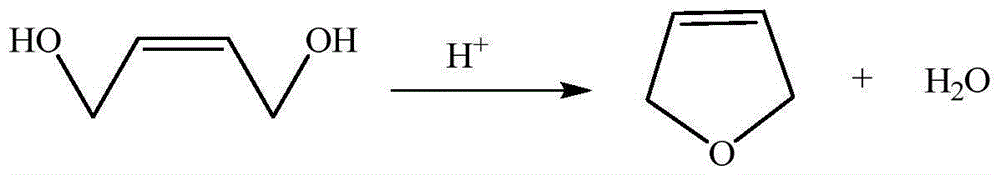

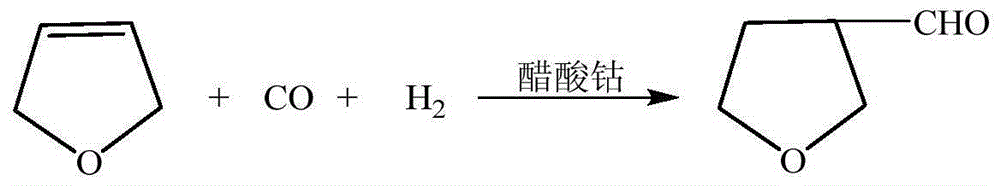

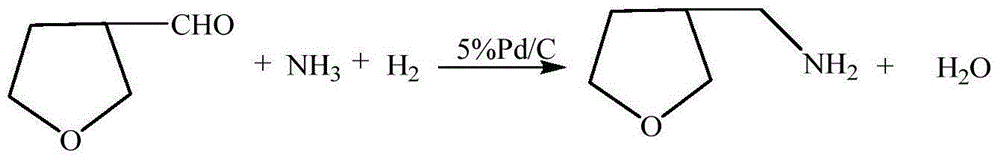

3-methylamine tetrahydrofuran preparation method

ActiveCN106397372ARaw materials are cheap and easy to getThe synthesis process is simpleOrganic chemistryCobalt acetateHydrogenation reaction

The invention provides a 3-methylamine tetrahydrofuran preparation method, wherein 1,4-butenediol is adopted as a raw material and is subjected to cyclization dehydration under the catalysis effect of a solid acid to produce 2,5-dihydrofuran, the 2,5-dihydrofuran reacts with water gas under the catalysis effect of cobalt acetate to produce 3-tetrahydrofuran formaldehyde, and the 3-tetrahydrofuran formaldehyde, ammonia gas and hydrogen gas are subjected to a hydrogenation reaction under the catalysis effect of 5% Pd / C to prepare the target product3-methylamine tetrahydrofuran, wherein the purity is 98.12%, and the total yield is 74.16%. According to the present invention, the preparation method has advantages of cheap and easily available raw materials, less steps, simple operation, high product purity, high yield, less three-waste pollution and production cost reducing, and is suitable for industrial production.

Owner:浙江捷达科技有限公司

Method for preparing three-dimensional nitrogen-doped graphene/CoOx composite material

InactiveCN104319395AEasy to prepareEvenly dispersedMaterial nanotechnologyCell electrodesDoped grapheneActive agent

The invention relates to a method for preparing a three-dimensional nitrogen-doped graphene / CoOx composite material, and belongs to the technical field of functional materials. The method comprises the main processes of: by taking phthalonitrile as a nitrogen-containing precursor, cobalt acetate as a transition metal precursor, and graphene oxide prepared by the Hummers method as a carbon carrier, adding a surface active agent and carrying out solvent-thermal-technology one-step in-situ coordination, assembling, freeze drying and calcination treatment to obtain the three-dimensional structured nitrogen-doped graphene / CoOx composite nano material. In comparison with the prior art, the three-dimensional nitrogen-doped graphene / CoOx composite material prepared by the invention has the advantages that particles are homogeneous and do not agglomerate; in addition, more electron transmission channels exit because of mesopores left after the surface active agent is removed, the impedance is reduced, and the electrochemical property of the material is improved.

Owner:SHANGHAI UNIV

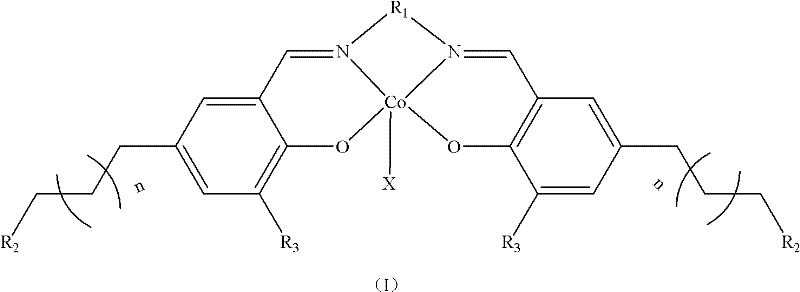

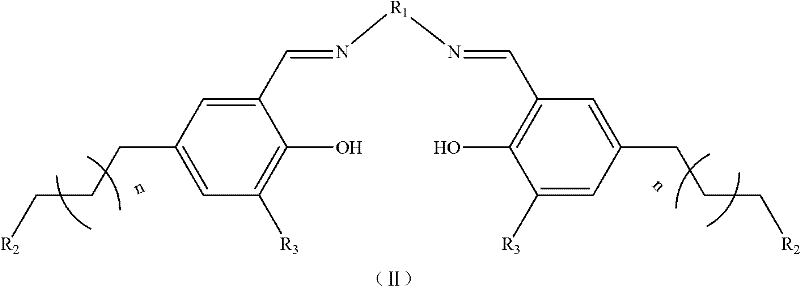

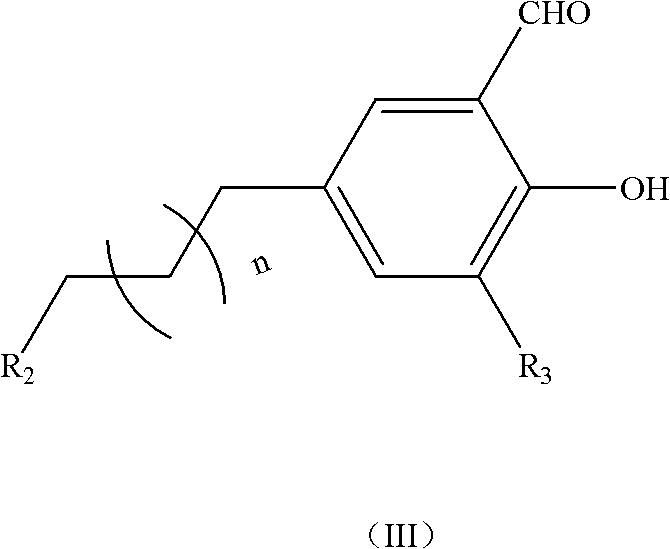

Method for preparing Salen-metal complex

InactiveCN102212085ALow costHigh catalytic efficiencyOrganic-compounds/hydrides/coordination-complexes catalystsCobalt organic compoundsSodium methoxideFiltration

The invention provides a method for preparing a Salen-metal complex. The method comprises the following steps of: under the argon atmosphere, adding ligands(II), sodium methoxide, absolute methanol soluble ligands(II) and sodium methoxide into a reactor in sequence; stirring the mixture for 2 minutes, and adding 1mol / L cobalt acetate anhydrous / methanol solution dropwise, wherein the molar ratio of the ligands(II) to sodium methoxide to cobalt acetate is 1:1:1; and making the mixture reacted at the room temperature for 24 hours, adding anionic salt which has the same molar weight as the cobalt acetate, stirring the mixture for three days in the air, stopping the reaction, concentrating the mixture, performing dissolution and filtration by adding methylene chloride, drying the filtrate by anhydrous sodium sulfate overnight, filtering the mixture, concentrating under reduced pressure, and drying the mixture under the vacuum condition to obtain the Salen-metal complex. The Salen-metal complex prepared by the method has the advantages of simple method, low cost and high catalytic efficiency.

Owner:HEBEI UNIV OF TECH

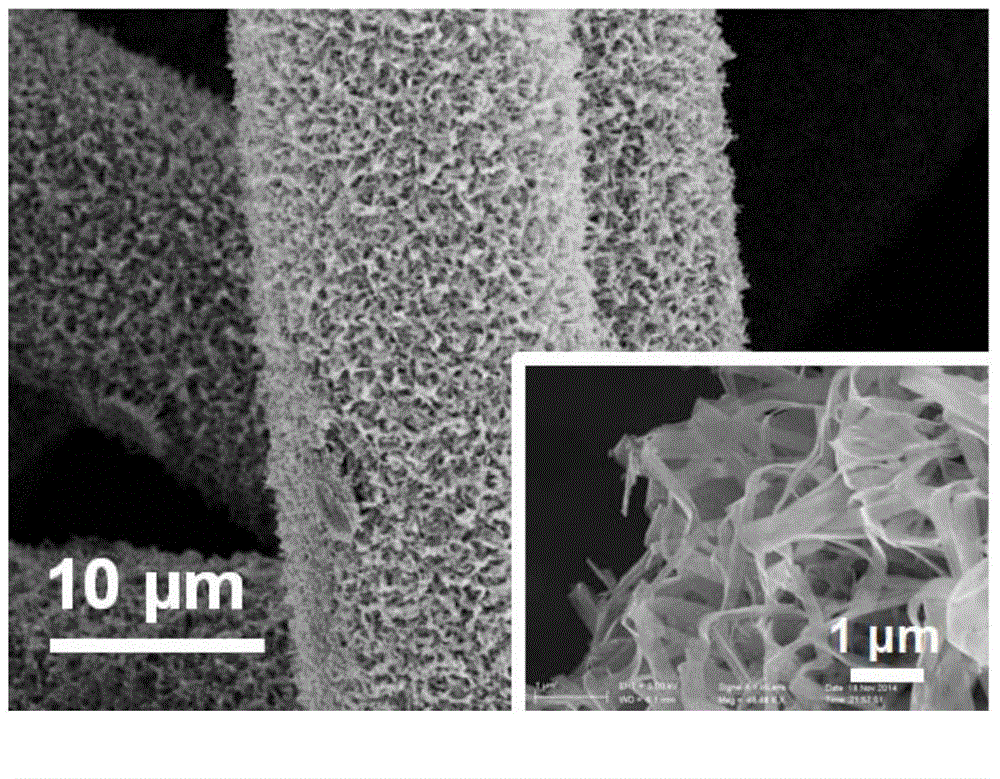

Cobalt diselenide modified carbon fiber composite material and preparation method and application thereof

ActiveCN104399496AThe load is easy to controlThe synthesis method is simplePhysical/chemical process catalystsElectrodesFiberCobalt acetate

The invention discloses a cobalt diselenide modified carbon fiber composite material and a preparation method and application thereof. The invention is characterized in that the cobalt diselenide modified carbon fiber composite material is formed by loading a cobalt diselenide nanobelt on the surface of a carbon fiber felt and is prepared by the following steps: dissolving cobalt acetate and sodium selenite in a mixed solvent consisting of diethylenetriamine and water, then adding the carbon fiber felt, conducting reaction for 12-18 hours at 150-200 DEG C, and washing and drying the product to obtain the cobalt diselenide modified carbon fiber composite material. The cobalt diselenide modified carbon fiber composite material can be used as a catalyst in a water electro-catalysis hydrogen evolution reaction. The cobalt diselenide modified carbon fiber composite material has a simple synthetic method, is lower in production cost and can be produced in a large scale. The prepared cobalt diselenide modified carbon fiber composite material can be used as a catalyst in the water electro-catalysis hydrogen evolution reaction and has high activity and favorable stability.

Owner:UNIV OF SCI & TECH OF CHINA

Method for recovering organic acid and cobalt-manganese metal in terephthalic acid oxidized residues

ActiveCN102503813AOrganic-compounds/hydrides/coordination-complexes catalystsChemical recyclingMANGANESE ACETATEBenzoic acid

The invention belongs to the technology for recovering organic acid and catalyst from terephthalic acid oxidized residues, which includes the steps of firstly, discharging high-temperature oxidized residues from a pure terephthalic acid (PTA for short) production device, controlling the solid content within the range from 20% to 45% and implementing primary filtering separation within the temperature range from 55 DEG C to 90 DEG C, and directly vending separated solid for manufacturing resin or paint or returning the separated solid to an oxidation reactor for use, wherein primary filtrate is treated according to the process: (I) adding oxalic acid to obtain cobalt-manganese oxalate precipitation, obtaining cobalt-manganese oxalate by means of filtering separation, further cooling the filtrate by means of filtering separation, utilizing the separated solid for extracting benzoic acid and delivering the filtrate to a waste water treating device; or (II) directly cooling the primary filtrate for secondary filtering separation, utilizing the separated solid for extracting benzoic acid, adding oxalic acid into secondary filtrate to obtain cobalt-manganese oxalate precipitation, obtaining cobalt-manganese oxalate by means of filtering separation and delivering the filtrate to a waste water treating device; and secondly, carrying out reaction of the cobalt-manganese oxalate obtained from (I) or (II) with oxidant such as hydrogen peroxide, peroxyacetic acid, bromine, manganate, permanganic acid, manganese dioxide or / and hydrobromic acid, utilizing cobalt acetate aqueous liquor, cobalt bromide aqueous liquor, manganese acetate aqueous liquor, manganese bromide aqueous liquor, acetic acid or / and pure water as dissolvent, then carrying out reaction of the cobalt-manganese oxalate with metallic cobalt, metallic manganese or / and hydrobromic acid after the cobalt-manganese oxalate is completely dissolved, and obtaining homogeneous phase liquor containing cobalt-manganese bromide ions by means of purification and filtration, wherein the mixed liquor can be directly mixed with cobalt acetate, manganese acetate, cobalt bromide, manganese bromide, acetic acid or water to serve as oxidation catalyst for the terephthalic acid.

Owner:浙江上虞利星化工有限公司

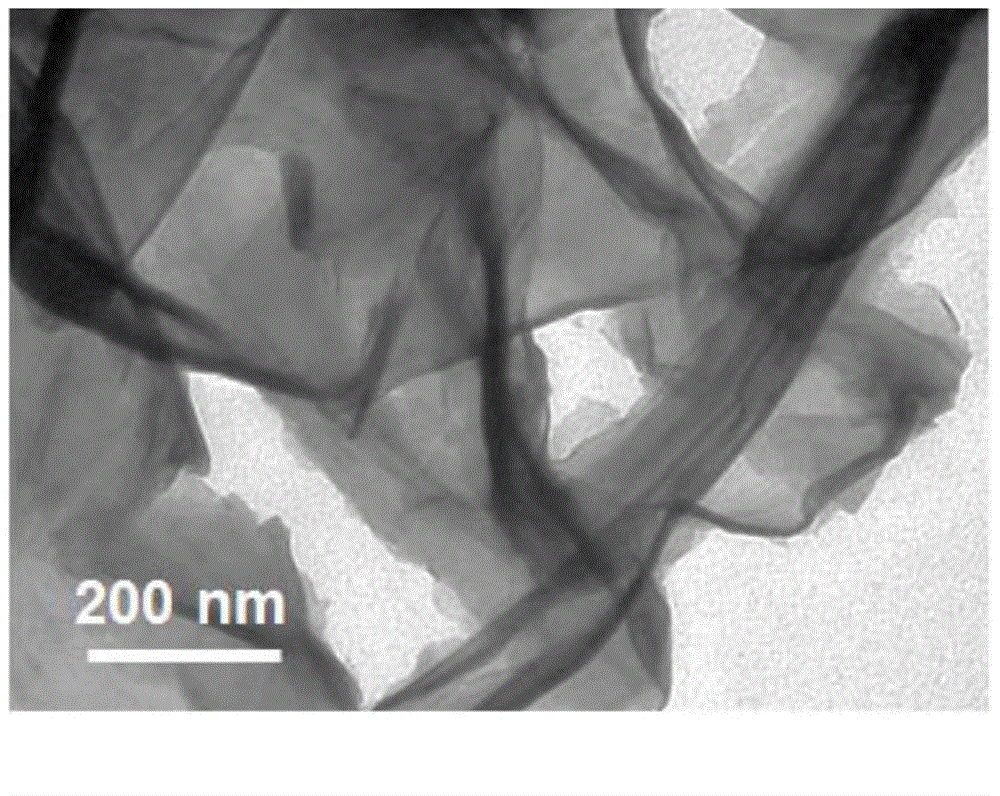

Nano crystalline CoO-graphene composite material as well as preparation and application thereof

ActiveCN104393283AAvoid pollutionThe preparation process is simple and cheapMaterial nanotechnologyCell electrodesCapacitanceSingle layer graphene

The invention discloses a graphene composite material, in particular a CoO and graphene composite material. The invention also relates to a preparation method of the graphene composite material and application of the graphene composite material in a lithium-ion battery. The preparation method comprises the steps of performing low-temperature recrystallization on cobalt acetate tetrahydrate, compositing the recrystallized cobalt acetate tetrahydrate and graphene oxide to obtain a precursor, and performing low-temperature annealing on the precursor under a high vacuum environment to obtain two-dimensional nano crystalline CoO-graphene composite material, wherein single-layer graphene with the thickness of 1-50 micrometers is taken as a carrier frame, and CoO nanocrystals with the average particle diameter of 2-20 nm are uniformly embedded in the upper and lower surfaces of the single-layer graphene. The prepared nano crystalline CoO-graphene composite material can be used as the negative electrode of a lithium-ion battery to effectively improve the capacitance of the lithium-ion battery; the preparation method is simple, the preparation period is short, the preparation efficiency is high, no toxic effect exists, the environment pollution is avoided, and the potential safety hazard is reduced.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

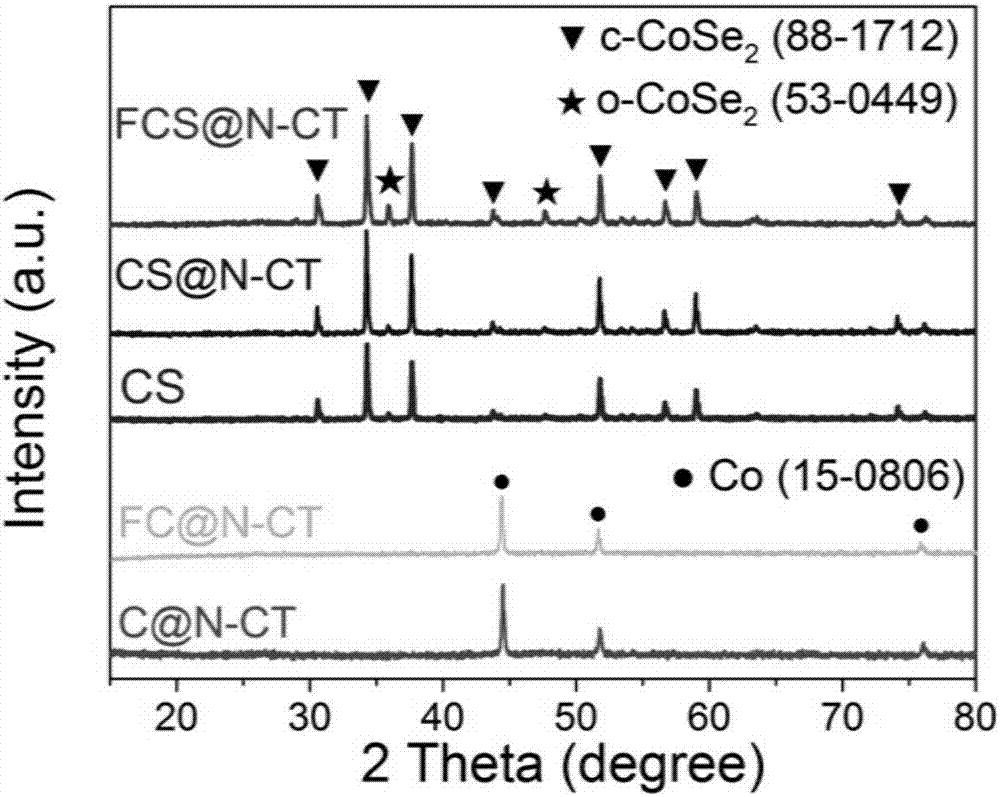

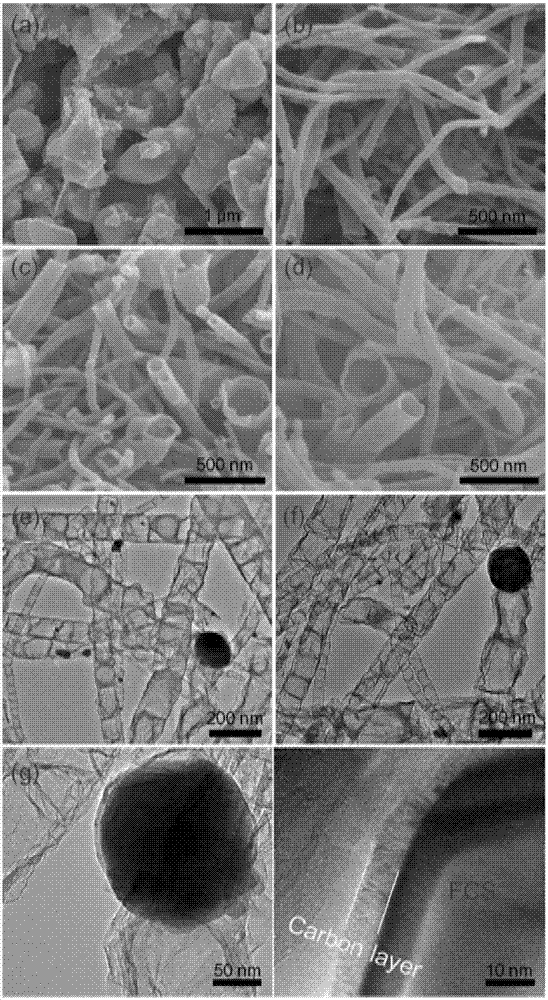

Oxygen evolution Fe-doped cobalt diselenide@N-CT compound catalyst and preparation method and application thereof

ActiveCN107051568AHigh catalytic activityHigh OER catalytic performanceOrganic-compounds/hydrides/coordination-complexes catalystsElectrodesDecompositionOxygen evolution

The invention discloses an oxygen evolution Fe-doped cobalt diselenide@N-CT compound catalyst and a preparation method and application thereof. The compound catalyst comprises Fe-doped CoSe2 nano particles coated by an N-doped carbon nanotube. The preparation method includes: evaporating and drying the solution of cobalt acetate, iron nitrate and urea, and performing high-temperature treatment to obtain the Fe-doped CoSe2 nano particles coated by the N-doped carbon nanotube; mixing the Fe-doped CoSe2 nano particles coated by the N-doped carbon nanotube with Se powder to obtain a mixture, and performing selenylation on the mixture under protective atmosphere to obtain the compound catalyst. The preparation method has the advantages that the method is simple, low in cost and beneficial to industrial production; the prepared Fe-doped CoSe2@N-CT (recorded as FCS@N-CT) compound catalyst is applicable to electrocatalytic water decomposition, and the compound catalyst is good in comprehensive performance as compared with a commercial RuO2 catalyst and is promising in application prospect.

Owner:CENT SOUTH UNIV

Easy-to-alkaline-hydrolysis poly ester and preparation method

The invention refers to a method of preparing easy-alkaline hydrolysis polyester. The main repeated unit is diglycol terephthalate, the acid containing 5-sodium sulfonate-diglycol isophthalate (SIPE), 5-10 mol% and isophthalic acid (IPA), 4-8 mol%, the polymer containing polyethylene glycol (PEG), molecular weight 1000-8000, weight %: 6-12, and compound heat stabilizing agent composed of antioxygen, cobalt acetate, phosphoric acid and phosphorous acid or its esters.

Owner:济南正昊化纤新材料有限公司

Ceramic wine bottle colored glaze and glaze spraying method

The invention discloses a glaze spraying method for water-repellent ceramic wine bottle colored glaze. The ceramic wine bottle colored glaze is characterized in that the glaze material is prepared from the following materials in parts by weight: 10-12 parts of bauxite, 3-4 parts of dolomite, 5-6 parts of zinc sulfate, 2-3 parts of magnesium sulfate, 3-4 parts of cobalt acetate, 9-12 parts of CaO, 2-3 parts of MgO, 3-4 parts of BaO, 2-3 parts of silicon carbide, 1-2 parts of graphite, 3-4 parts of SnO2, 1-2 parts of Sc2O3, 13-14 parts of binder and a proper amount of water. The ceramic wine bottle glaze disclosed by the invention is smooth and fine in glaze, extremely good in hand feeling, has very good hydrophobicity, can prevent water from gathering on the glaze, can keep the glaze dry, and therefore, the ceramic wine bottle colored glaze has very good waterproof and moisture-resistant performances.

Owner:ANHUI YICAI GLASSWARE

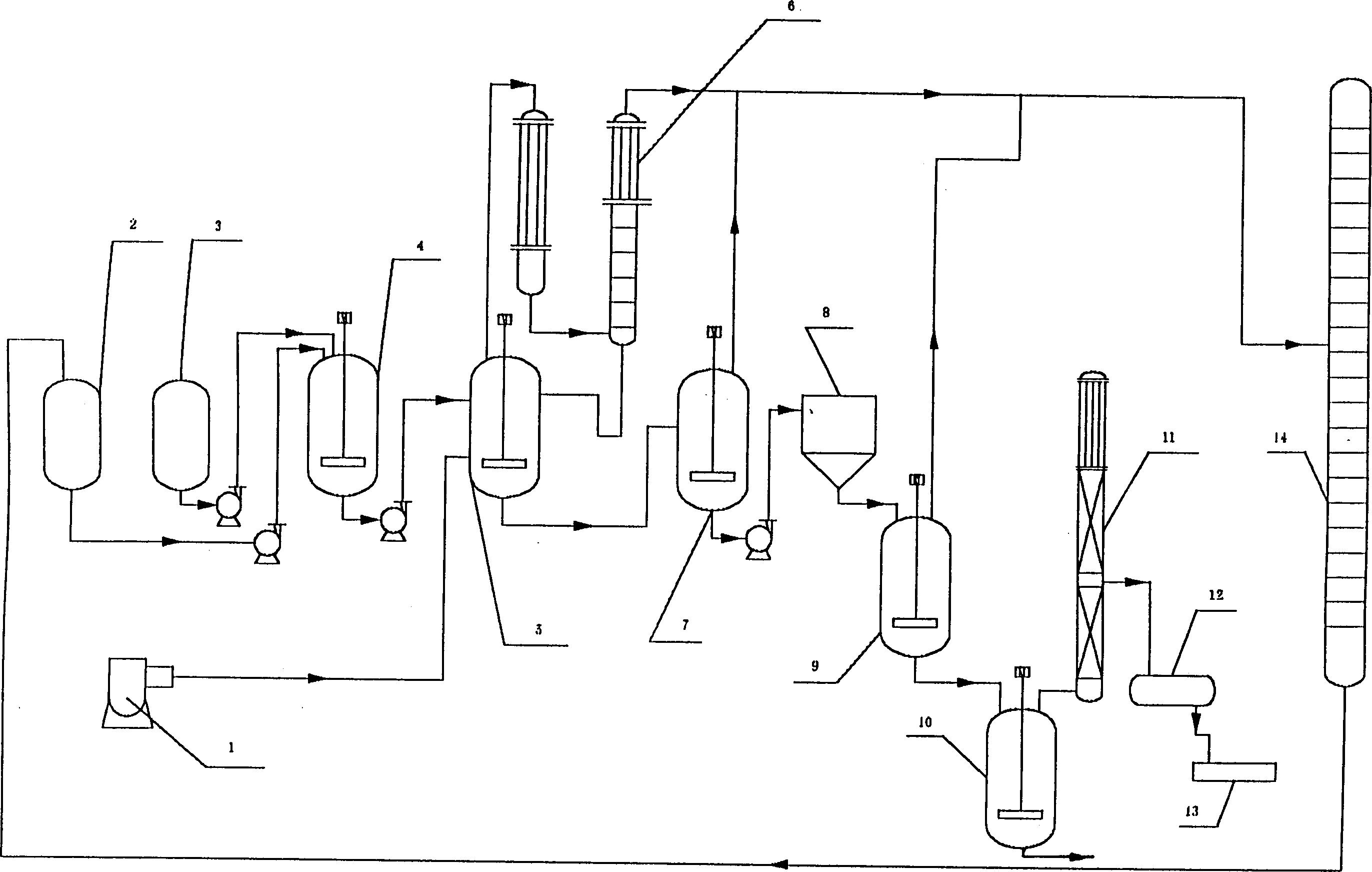

Process for production of trimellitic anhydride by continuous oxidizing process

A process for preparing trimellitic anhydride from metatritoluene, acetic acid as solvent, and catalyst (cobalt acetate, manganess acetate, tetrebromoethane, or hydrogen bromide) by continuous oxidization method includes continuous oxidizing reaction, anhydridization, refining, slicing or granulating and recovering solvent. Its advantages are high yield (up to 120%), high safety, high quality of product, and long service life of equipment.

Owner:JIANGSU ZHENGDAN CHEM IND CO LTD

Preparation technology of p-tert-butyl benzoic acid

ActiveCN101648866ASimple preparation processReduce manufacturing costOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsBenzoic acidOrganic synthesis

The invention discloses a preparation technology of p-tert-butyl benzoic acid, comprising the following steps: firstly, adding toluene, isobutene and concentrated sulfuric acid into a reaction kettle, carrying out alkylation reaction to obtain coarse p-tert-butyl toluene, and rectifying to obtain fine p-tert-butyl toluene; secondly, adding a composite catalyst containing the p-tert-butyl toluene,cobalt acetate and bromide into the reaction kettle, heating and introducing oxygen to obtain coarse p-tert-butyl benzoic acid, decoloring by activated carbon and diatomite , crystallizing and dryingto obtain fine p-tert-butyl benzoic acid. The prepared p-tert-butyl benzoic acid is an organic synthesis intermediate, can be used for the fields of additives, antioxidants, alkyd resin modifying agents, soldering fluid, dye, and the like of polypropylene nucleating agents, polyvinyl chloride heat stabilizers, metal machining and lubricating oil and has excellent performance. The p-tert-butyl benzoic acid has low energy consumption, high yield, simple separation, and the like and can satisfy ever-increasing market demands of the p-tert-butyl benzoic acid.

Owner:JIANGXI YONGTONG TECH

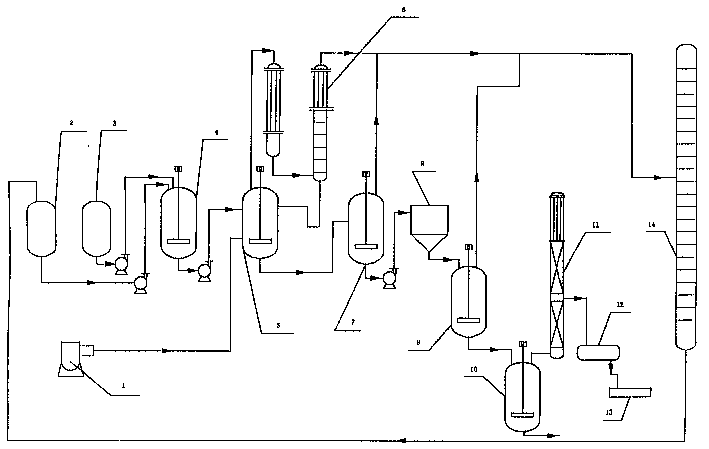

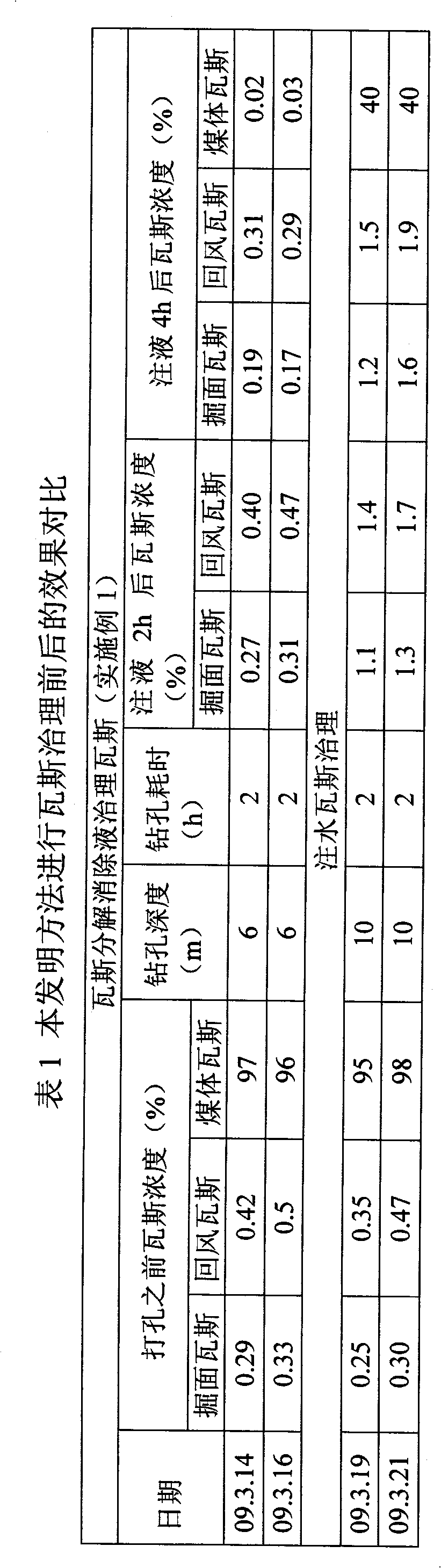

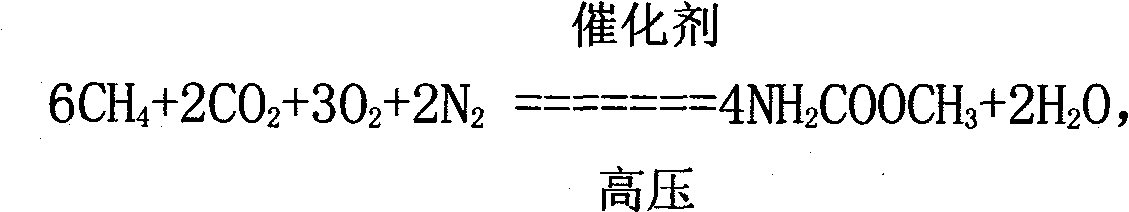

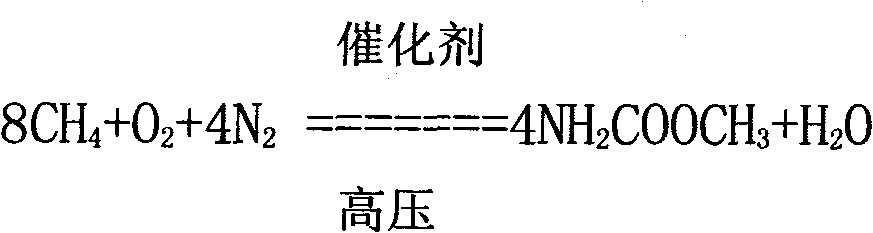

Gas decomposition eliminating liquid and coal mine gas control method

InactiveCN101906989AReduce governance costsCompliance with security governance regulationsGas removalAcetic acidCobalt acetate

The invention relates to a gas decomposition eliminating liquid and a coal mine gas control method. The gas decomposition eliminating liquid is mainly prepared by uniformly mixing beer, acetic acid, cobalt acetate and the like, the gas control method by the gas decomposition eliminating liquid comprises the steps of: drilling liquid injection drill holes on a coal mining face at an interval between 0.6m and 1.5m in the direction same as an inclined direction of a coal layer or at an inclined angle between 0 degree and 20 degrees with the inclined direction of the coal layer, and then injecting the gas decomposition eliminating liquid in the drill holes under a certain pressure to react for 3.5-5 hours. The gas decomposition eliminating liquid is green, satisfies the environmental protection requirement, and is prepared from nontoxic and harmless raw materials, and reaction products of the gas composition eliminating liquid with components of gas are also nontoxic and harmless, and have not harmful affects to the quality and use of coal. The gas control method has simple operation and low cost, and can effectively eliminate gas in coal by over 96%, and gas in coal lanes obviously reduces under a safety limit in the process of injecting the gas decomposition eliminating liquid in the coal.

Owner:吴星剑

Novel catalyst based on metal organic framework material and preparation method and application of novel catalyst

InactiveCN106582887AReact SafeShort reaction timeOrganic-compounds/hydrides/coordination-complexes catalystsCobalt acetateMetal-organic framework

The invention relates to a novel catalyst based on metal organic framework material and a preparation method and application of the novel catalyst, and belongs to the technical fieldo f functional nanomaterial preparation. Ti3AlC2 is taken as a raw material, Ti3AlC2 obtained after ball-milling and screening is corroded with an acid solution, an Al atom layer is removed, and a two-dimensional Ti3C2 nanosheet is generated; the Ti3C2 nanosheet, cobalt acetate tetrahydrate and 1,4-terephthalic acid are taken as precursors, cobalt acetate tetrahydrate and 1,4-terephthalic acid generate a metal organic framework complex (MOF)-cobalt terephthalic acid complex (CoBDC) on the surface of Ti3C2 through an in-situ growth method respectively, the two complexes are compounded, the metal organic framework complex (MOF)-cobalt terephthalic acid complex (CoBDC) and Ti3C2 are compounded, and then a compound Ti3C2-CoBDC of the product titanium carbide-cobalt terephthalic acid complex is obtained. The method is easy and convenient to operate in preparation, safe in preparation operation, short in production cycle, low in production cost, high in yield, basically free of by-products and beneficial for a achieving expanded production and has a very good application prospect.

Owner:NANJING UNIV OF TECH

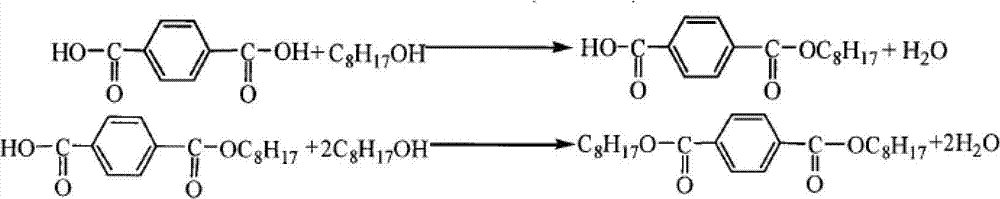

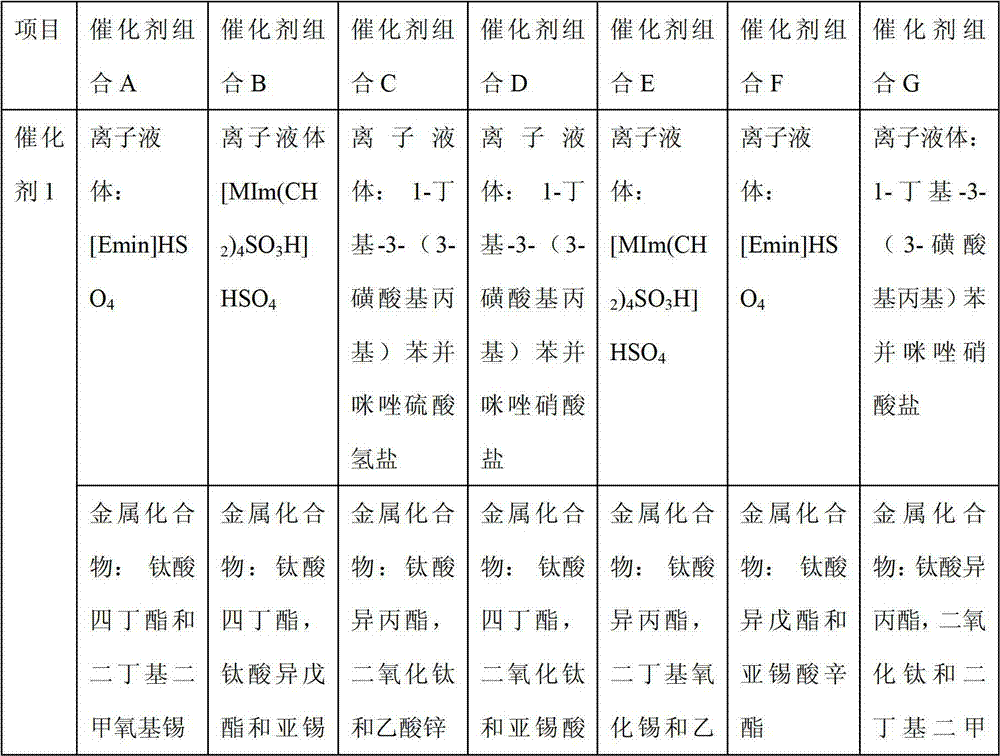

Preparation method of dioctyl terephthalate and used catalyst

InactiveCN102824929AIncrease contact areaShrink wellOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsDibutyltin oxideTitanium metal

The invention provides a catalyst for use in synthesis of dioctyl terephthalate and a method for preparing dioctyl terephthalate by applying the catalyst. The catalyst consists of a catalyst 1 and a catalyst 2, wherein the catalyst 1 consists of an ionic liquid and a metal compound; the catalyst 2 consists of a titanium metal compound and other metal compound; the positive ion of the ionic liquid are an imidazole ion or a benzimidazole ion; the negative ion of the ionic liquid is a bisulfate ion; or the positive ion of the ionic liquid is a benzimidazole ion or an imidazole ion with one or two sulfonic acid radicals; the titanium metal compound is selected from at least one compound of tetrabutyl titanate, isopentyl ester titanate, isopropyl titanate or titanium dioxide; and the other compound is selected from at least one compound of dibutyldimethoxytin, dibutyltin oxide, monooctyl ester stannite, zinc acetate and cobalt acetate. Due to the adoption of the technical scheme provided by the invention, the cost can be reduced, the reaction speed is increased, energy consumption is lowered, and the quality of an obtained product is high.

Owner:FOSHAN GAOMING XIONGYE CHEM

Manganese cobalt composite oxide (MnCo2O4) magnetic nanocrystal and preparation method thereof

ActiveCN103073072AReduce the introductionEasy to separateNanotechnologyCobalt compoundsMANGANESE ACETATEHigh pressure

The invention belongs to the technical field of active substances of inorganic oxide of nickel, cobalt or ferrum, and particularly relates to a manganese cobalt composite oxide (MnCo2O4) magnetic nanocrystal and a preparation method thereof. The preparation method adopts a hydrothermal synthesis method and comprises the following steps of (1) weighing a certain amount of potassium permanganate, manganese acetate and cobalt acetate on the condition that a molar ratio of nKMnO4 to nMn(Ac)2 to nCo(Ac)2 is 2:3:10, adding pure water, uniformly stirring, obtaining a reaction mixture, (2) shifting the reaction mixture into a polytetrafluoroethylene-stainless steel high-pressure reaction kettle, sealing the high-pressure reaction kettle, placing in an oven, keeping warm at 150-200 DEG C for a certain time, conducting hydrothermal reaction for 10-24h, taking out the high-pressure reaction kettle, and (3) opening the high-pressure reaction kettle after cooling, conducting centrifugal separation on a reactant, using the pure water to wash a sample, obtaining a black precipitate, conducting vacuum drying, and obtaining the MnCo2O4 magnetic nanocrystal. The method is simple and easy, and the obtained MnCo2O4 magnetic nanocrystal is uniform in particle size, regular in shape, good in crystallinity, and controllable in atom proportioning and has a good magnetic property.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

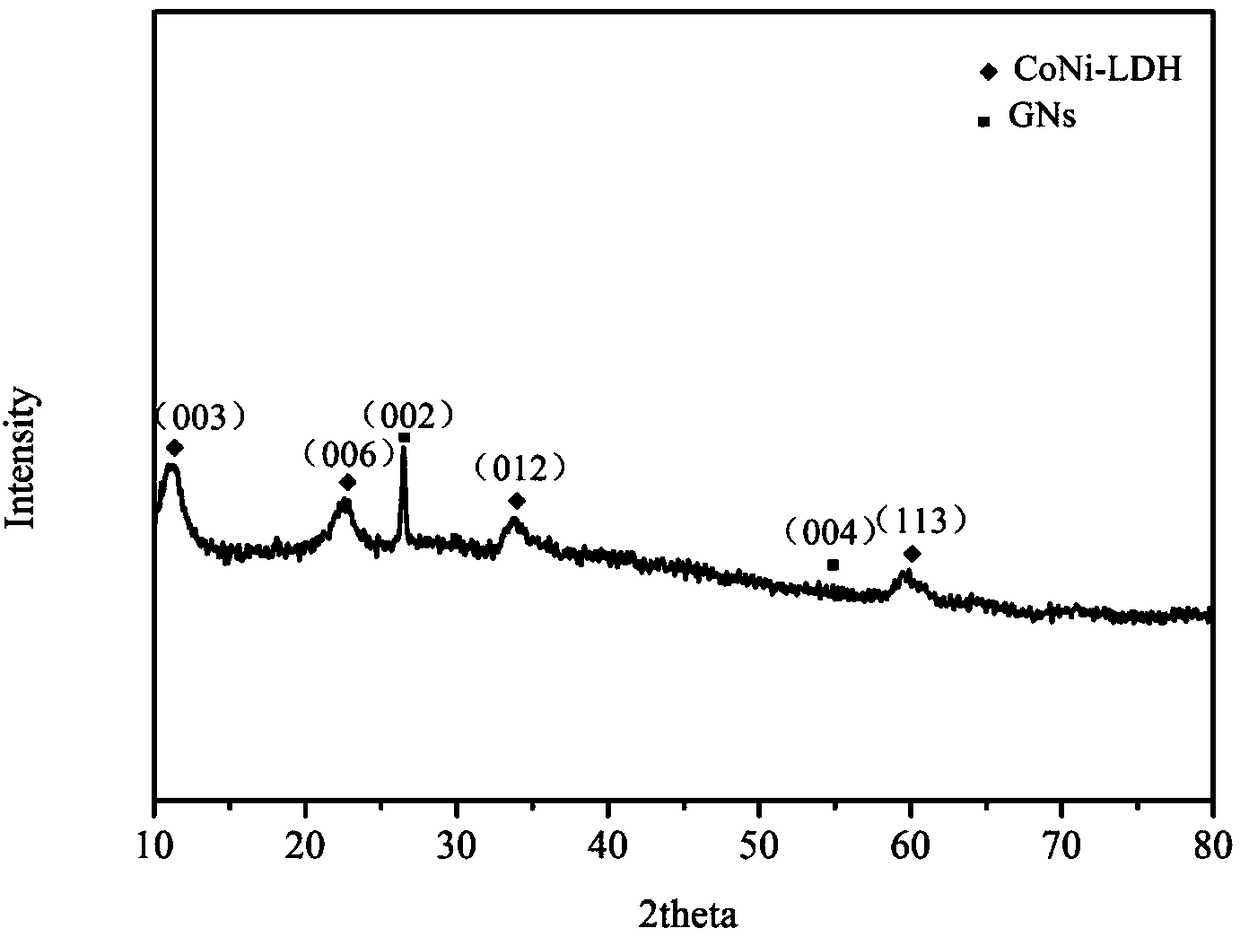

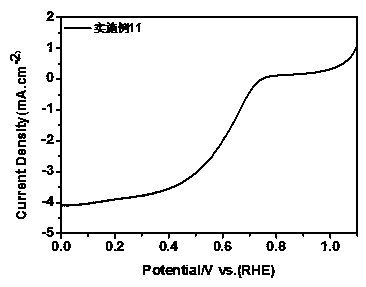

CoNiFe-LDH/multilayer graphene high-performance composite energy storage material and preparation method thereof

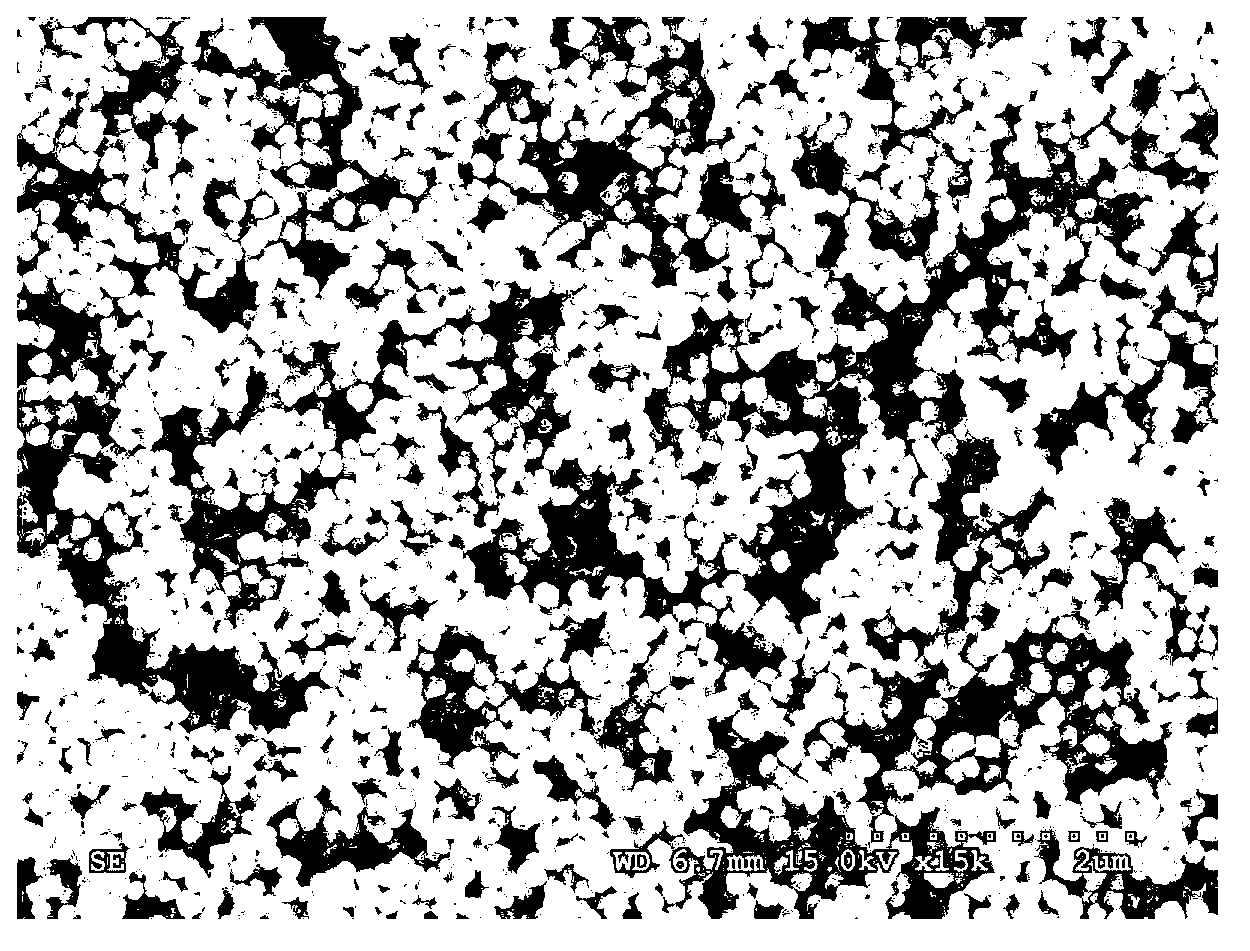

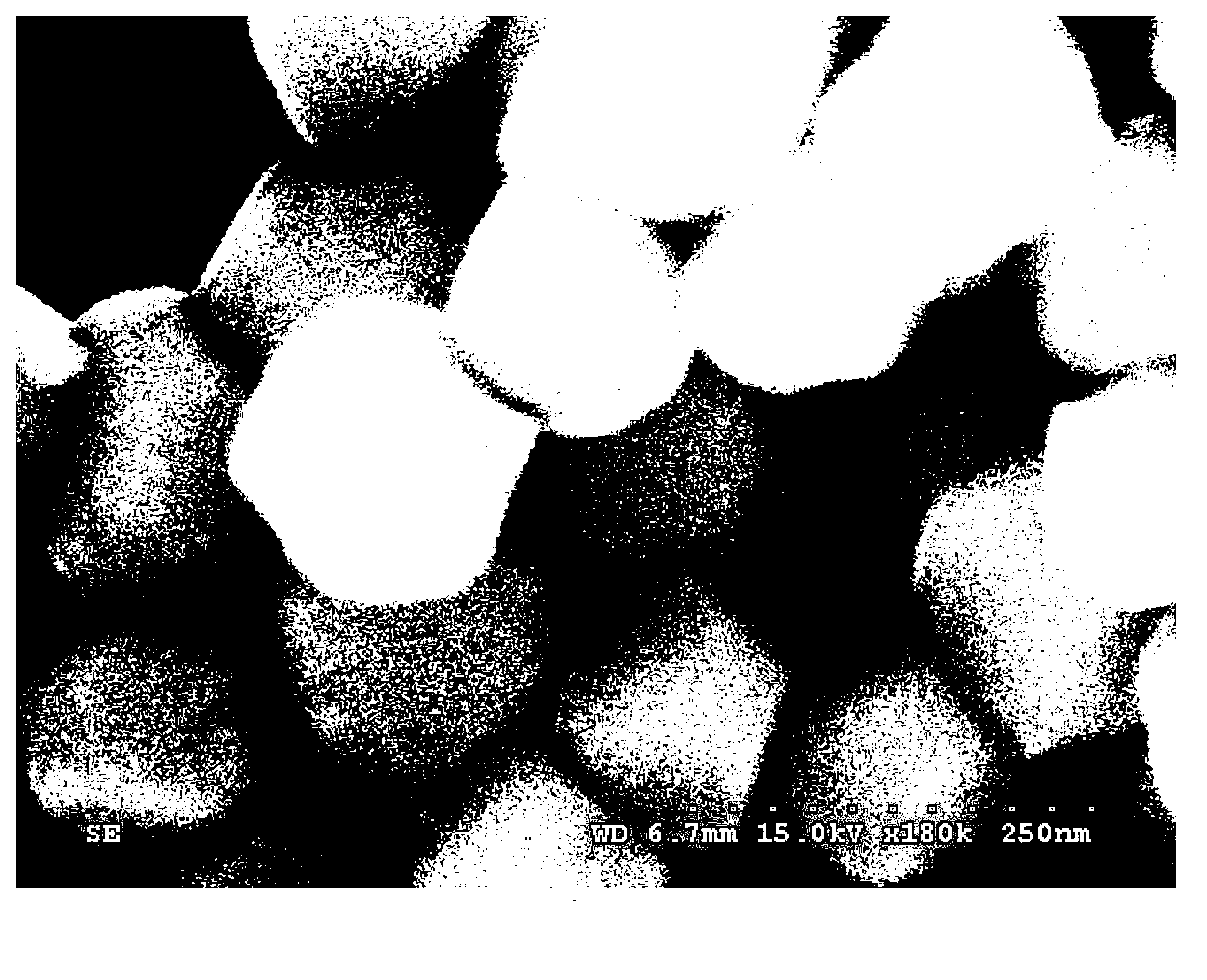

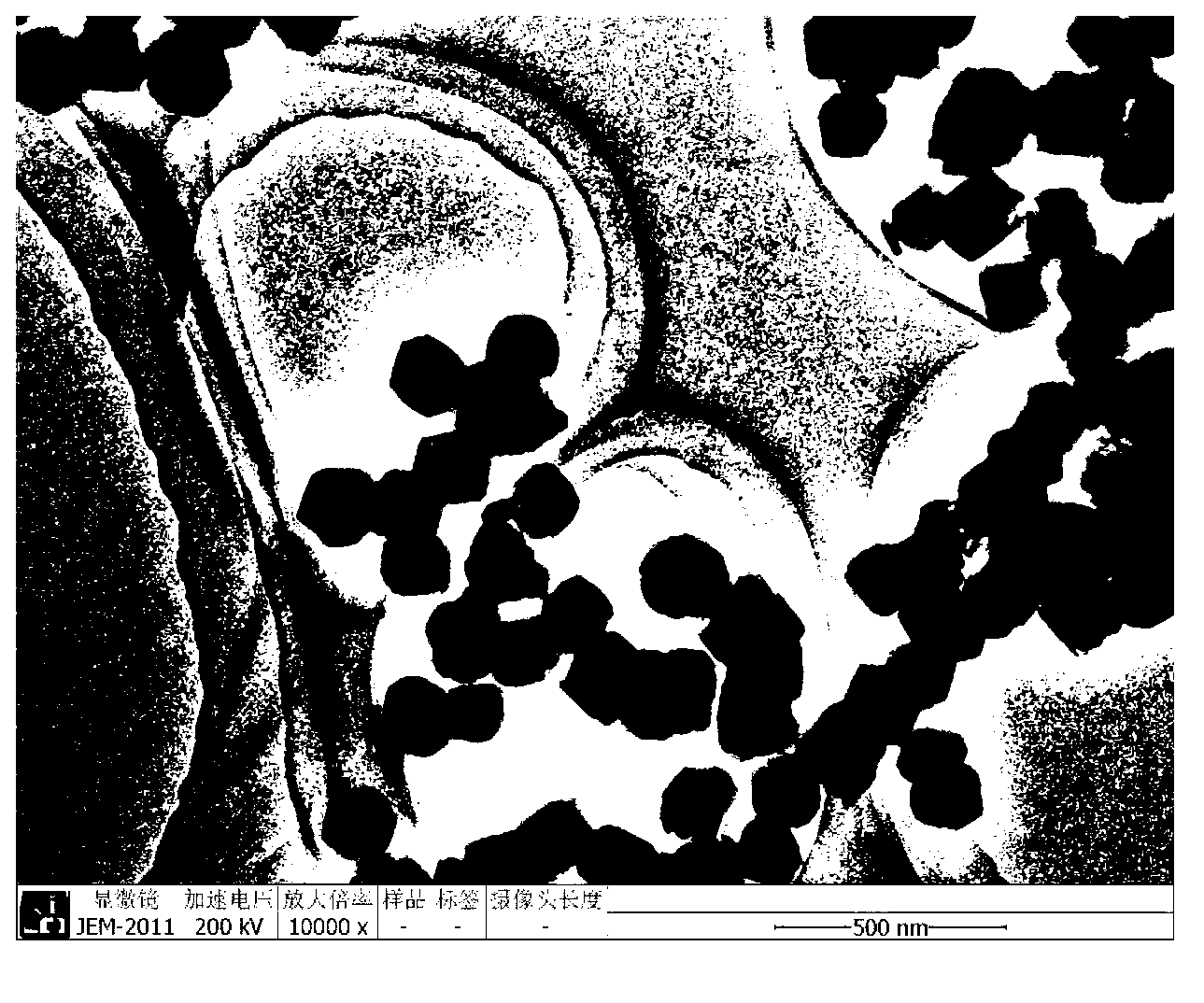

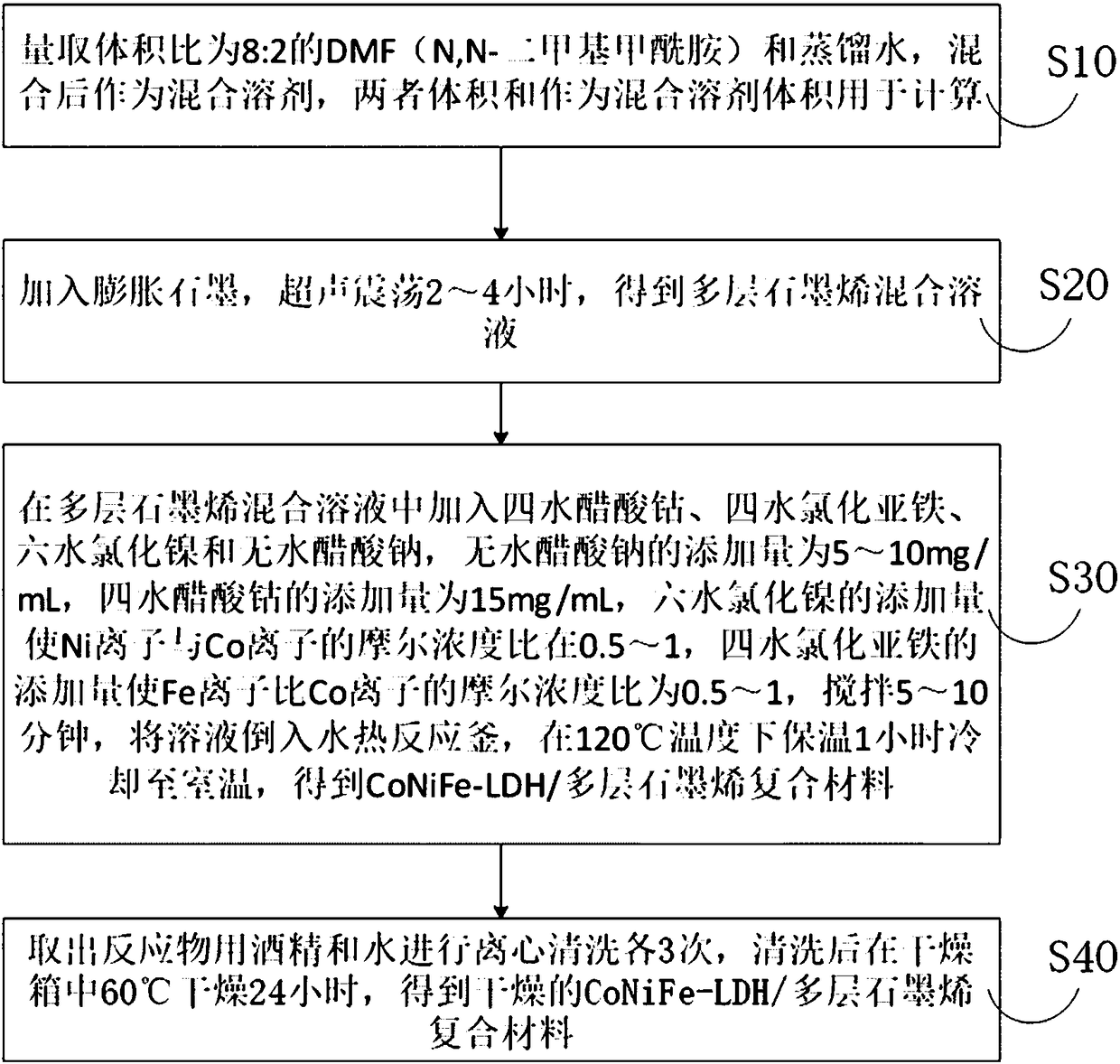

ActiveCN108364793AStrong ion capacityEasy to makeMaterial nanotechnologyHybrid capacitor electrodesSolventOxygen

The invention discloses a CoNiFe-LDH / multilayer graphene high-performance composite energy storage material and a preparation method thereof. the preparation method comprises the steps of: measuring DMF and distilled water with a volume ratio of 8:2, and mixing the DMF and the distilled water to serve as a mixed solvent; adding expanded graphite into the mixed solvent, carrying out ultrasonic processing on the solution for 2 to 4 hours to obtain a multi-layer graphene mixed solution; adding cobalt acetate tetrahydrate, ferrous chloride tetrahydrate, nickel chloride hexahydrate and anhydrous sodium acetate into the mixed solution, stirring the solution for 5 to 10 minutes, pouring the solution into a hydrothermal reaction kettle, maintaining the temperature of the solution at 120 DEG C for1 hour, and then cooling the solution to room temperature; taking out a reactant and centrifugally washing the reactant with alcohol and water for three times, and drying the reactant in a 60 DEG C oven for 24 hours to obtain a dry CoNiFe-LDH / multilayer graphene composite material. According to the CoNiFe-LDH / multilayer graphene high-performance composite energy storage material and the preparation method thereof, a method of complexing metal by means of organic molecules is adopted for preparing laminar multi-element metal hydroxide ont eh surface of multilayer graphene which does not containoxygen functional groups, and the process is simple and suitable for production.

Owner:嘉善县国创新能源研究院

Preparation method and application of carbon-loaded platinum cobalt nanometer alloy catalyst

InactiveCN108258251AGood dispersionSmall particle sizeMaterial nanotechnologyCell electrodesNano catalystAlloy

The invention discloses preparation method and application of a carbon-loaded platinum cobalt nanometer alloy catalyst, and belongs to the technical field of synthesis of a fuel cell nanometer catalyst. The preparation method comprises the steps of taking platinum acetylacetonate and cobalt acetate as a precursor and carbon powder as a carrier, synthesizing the carbon-loaded platinum cobalt nanometer alloy catalyst by a chemical thermal reduction method, drying the carbon-loaded platinum cobalt nanometer alloy catalyst, performing thermal processing to control surface constituent of Pt-Co nanometer alloy under reduction atmosphere so that Pt is segregated onto a surface of nanoparticle, and finally obtaining the high-activity carbon-loaded platinum cobalt nanometer alloy catalyst with richPt on the surface of the Pt-Co nanoparticle. The carbon-loaded platinum cobalt nanometer alloy catalyst has relatively high oxidization-reduction reaction activity and chemical stability when appliedto a negative electrode catalyst of a low-temperature hydrogen-oxygen fuel cell; by the method, the detect that precious metal particle is easy to agglomerate and is poor in dispersion performance issolved; and moreover, the preparation method is simple and convenient to operate, is low in cost and is suitable for industrial production on a large scale, and the problem of high cost of a fuel cell is solved.

Owner:KUNMING UNIV OF SCI & TECH

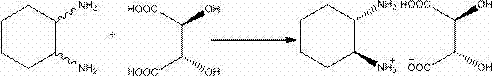

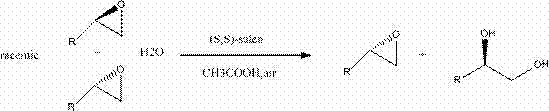

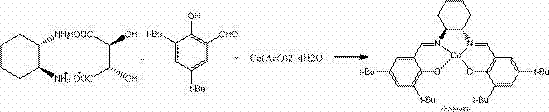

Synthetic method of (S,S)-salenCo(II) catalyst and application thereof in split of end epoxide compound

ActiveCN102728407ASimple processHigh yieldOrganic-compounds/hydrides/coordination-complexes catalystsCobalt organic compoundsCobalt acetateSalicylaldehyde

The invention relates to a synthetic method of a (S,S)-salenCo(II) catalyst and application of the (S,S)-salenCo(II) catalyst in split of an end epoxide compound. The filtrate of the intermediate (R,R)-cyclohexanediamine single salt of a (R,R)-salenCo(II) catalyst is used for synthesizing the (S,S)-cyclohexanediamine single salt; and the (S,S)-cyclohexanediamine single salt is further reacted with 3,5-di-tert-butyl salicylaldehyde and cobalt acetate in a single solvent so as to obtain the (S,S)-salenCo(II) catalyst. With the adoption of the method, the waste, i.e. the intermediate (R,R)-single salt of the (R,R)-salenCo(II) catalyst, is changed into wealth; the single solvent is used; the process is simple; the reaction step is short; the yield is high, the industrialization is easy to achieve; the synthesized (S,S)-salenCo(II) catalyst is activated into a (S,S)-salenCo(III) catalyst with catalytic activation by using air directly in the end epoxide compound; the mode of the (S,S)-salenCo(III) catalyst is synthesized by using the (S,S)-salenCo(II) catalyst is avoided; the splitting effect is the same as that of the method in which the (S,S)-salenCo(III) catalyst is used directly; and the obtained chirality end epoxide compound of which the e value is 99%e is obtained.

Owner:YUEYANG YETOP FINE CHEM

Processing method based on chemical vapor flow spinning method for preparing carbon nanotube fiber in inert atmosphere

The invention relates to a processing method based on chemical vapor flow spinning method for preparing carbon nanotube fiber in inert atmosphere. The method comprises the following steps: using ethanol, acetone, ethylene glycol, xylol or n-hexane as carbon source, using ferrocene, ferric chloride, nickel oxalate or cobalt acetate as catalyst, using thiophene as promoter, and using argon, nitrogen and helium as carrier gas to prepare continuous carbon nanotube fiber within the temperature range of 1100-1300 DEG C and with the flow rate of carrier gas being 50-500sccm. The invention has the advantage that inert gas is used as carrier gas in the preparation technology, thus being beneficial for large-scale preparation of carbon nanotube fiber.

Owner:TIANJIN UNIV

Preparation method of corn stalk modified cellulose gel

InactiveCN104387617ALow toxicityImprove adsorption capacityOther chemical processesPaper material treatmentCobalt acetateThiourea

The invention discloses a preparation method of corn stalk modified cellulose gel capable of adsorbing heavy metal ions. The preparation method comprises the steps of stripping and shearing air-dried corn stalks to obtain two raw materials including basts and piths, respectively carrying out glacial acetic acid / hydrogen peroxide / cobalt acetate treatment, and then, further reacting after dropwise adding a potassium hydroxide solution to obtain two parts of cellulose; dissolving bastuse by using a low-temperature lithium hydroxide / thiourea method; oxidizing pith cellulose by using a piperidine-N-oxide radical / cooxidation system method to obtain a product, carrying out solid-liquid separation on the product, carrying out alcohol precipitation and freeze drying on filtrate to obtain pith oxidized cellulose, dispersing the product into a chitosan / acetic acid solution, and heating to obtain an oxidized cellulose / chitosan cross-linked product; and mixing the cross-linked product and a bastuse solution, molding by using a mold, carrying out alcohol bath dehydration, washing and drying to obtain the corn stalk modified cellulose gel. The gel prepared by using the method is microporous and flaky and has relatively high adsorption capacity for heavy metal ions such as Zn<2+>, Fe<3+>, Cd<3+> and Cu<2+>.

Owner:KUNMING UNIV OF SCI & TECH

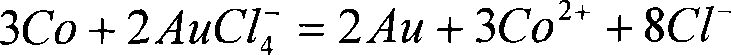

Method for preparing hollow nano gold powder material

The invention belongs to a method for preparing a hollow nano gold powder material. The method uses sodium borohydride, sodium citrate and sodium citrate as raw materials and selects cheap cobalt as a sacrificial template to prepare hollow nano gold powder material in scale. The method comprises the following steps: making the concentration of sodium citrate in de-ionized water between 0.0004 and 0.0006M and the concentration of sodium borohydride in the de-ionized water between 0.03 and 0.09M; adding cobalt acetate into the de-ionized water to make the concentration of cobalt acetate in the de-ionized between 0.003 and 0.009M; continuing stirring till the sodium borohydride in the reaction system are used up; adding the sodium citrate into the de-ionized water to make the concentration of the sodium citrate in the de-ionized water between 0.002 and 0.006M; stirring the de-ionized water with magnetic force at room temperature for 6 to 12h; centrifuging and washing products and performing vacuum drying on the products for 4 to 10h; and obtaining the hollow nano gold powder material which has an average grain diameter of between 20 and 50nm and a shell which is formed by piling gold particles with a diameter of between 2 and 4nm and is formed with a 5 to 8 nm of thick surrounding wall. The method is simple in process and low in cost and allows for batch production.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

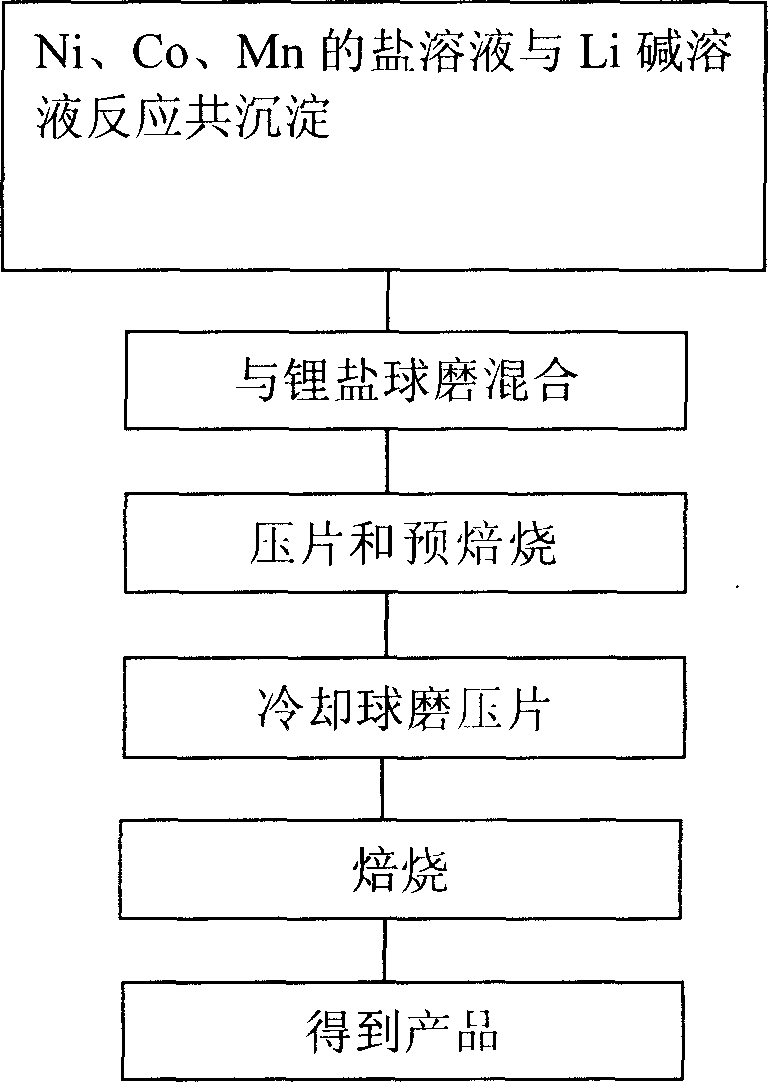

Method for producing anode active material containing lithium, magnesium compound oxide

InactiveCN1741302AStructural Precise TailoringSimple structureElectrode manufacturing processesLithium compoundsMANGANESE ACETATENickel salt

A method for preparing positive electrode multielement active material containing lithium / manganese composite oxide includes directly using lithium hydroxide coprecipitation to prepare M ( OH )2 , mixing it with lithium salt in grinding , forming plate by pressing , prebaking , cooled ball grinding , forming plate by pressing and backing . In the method , applied nickel salt is nickel acetate or nickel nitrate , applied cobalt salt is cobalt acetate or cobalt nitrate, applied manganese salt is manganese nitrate or manganese acetate and applied lithium salt is lithium carbonate or lithium acetate .

Owner:HEBEI UNIV OF TECH

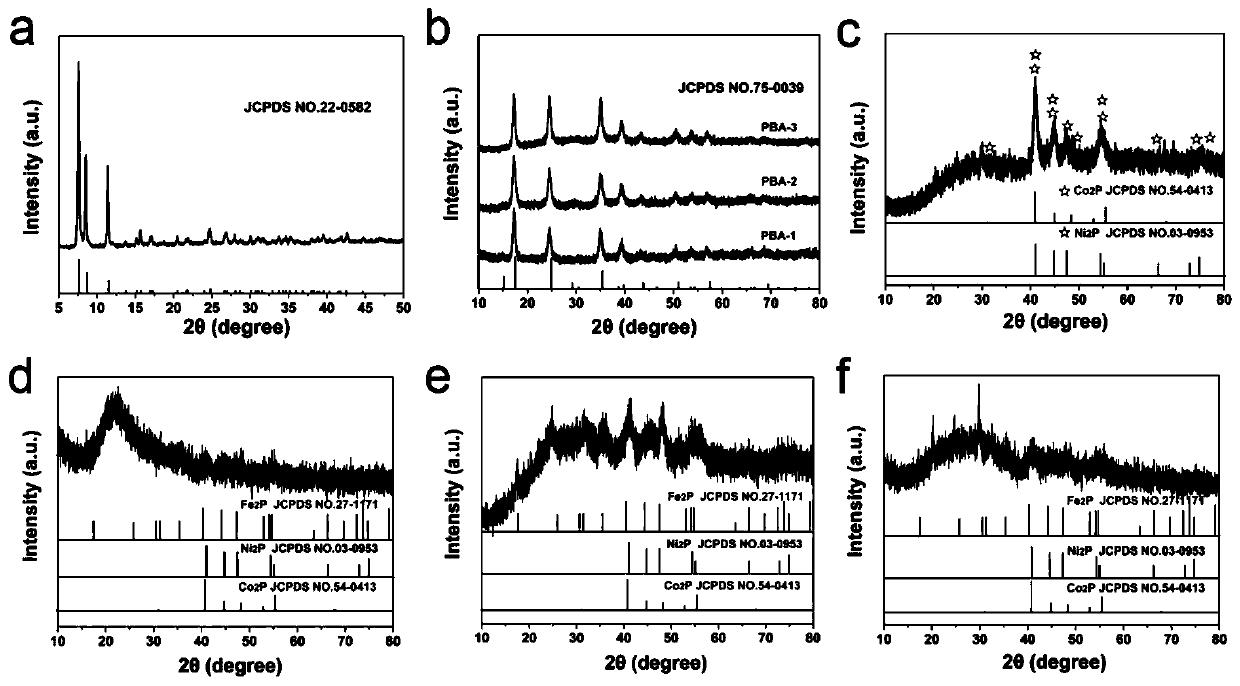

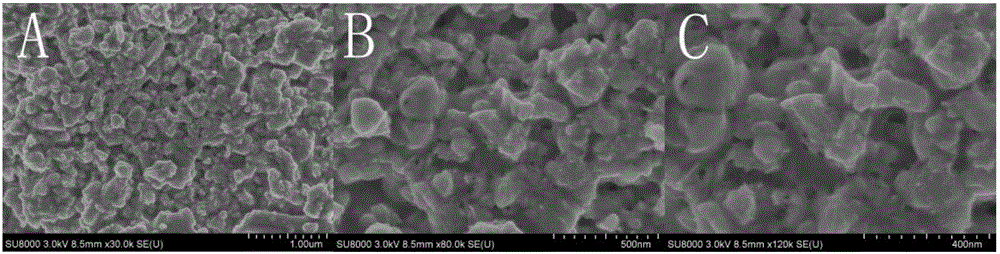

Preparation method of hollow Ni2P/Co2P/Fe2P nano-composite electrocatalyst

ActiveCN110354876AGood repeatabilityImprove electrocatalytic performancePhysical/chemical process catalystsElectrodesPotassium ferricyanideOxygen

The invention discloses a preparation method of a hollow Ni2P / Co2P / Fe2P nano-composite electrocatalyst. The method comprises the following steps: preparing a nickel-cobalt precursor, used as a template, by using nickel acetate, cobalt acetate and polyvinylpyrrolidone as reaction materials and ethanol as a reaction solvent, adding potassium ferricyanide, and preparing a hollow Prussian blue analogthrough room temperature stirring by using ethanol and water as reaction solvents; and phosphating PBA in a tubular furnace at a low temperature with sodium hypophosphite as a phosphorus source to prepare the hollow Ni2P / Co2P / Fe2P nano-composite material. The hollow Ni2P / Co2P / Fe2P nano-composite electrocatalyst prepared in the invention has the advantages of high repeatability, simple and high preparation process, and superior catalytic activity and stability in electrocatalytic oxygen evolution reactions.

Owner:NANJING UNIV OF SCI & TECH

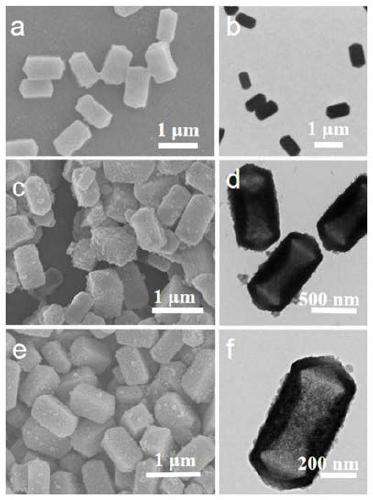

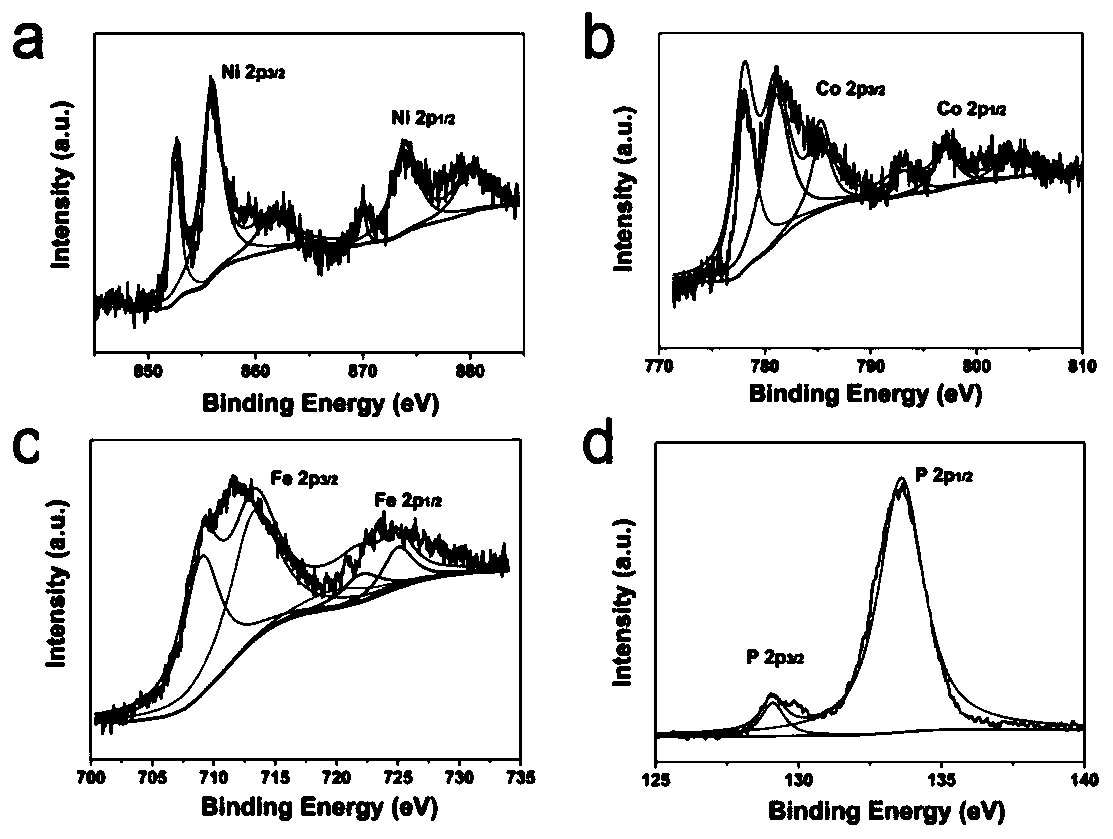

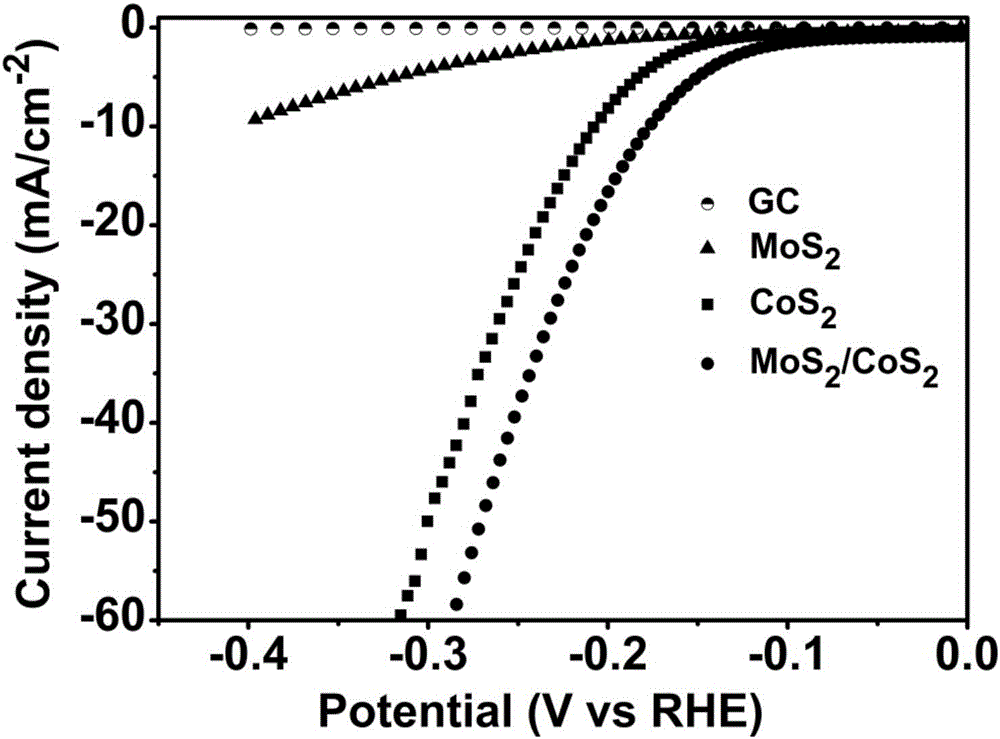

MoS2/CoS2 composite water-splitting hydrogen-production low-overpotential electrocatalyst and sulfidation preparation method thereof

ActiveCN106622296AReduced energy consumption for hydrogen productionMeet the requirements of industrialization promotionPhysical/chemical process catalystsElectrodesNitrogen gasAlternating current

The invention relates to a MoS2 / CoS2 composite water-splitting hydrogen-production low-overpotential electrocatalyst and a sulfidation preparation method thereof, belonging to the technical field of catalyst preparation. The electrocatalyst provided by the invention is prepared through the following concrete steps: subjecting one selected from the group consisting of cobalt nitrate, cobalt chloride, cobalt acetate and cobalt sulfate and one selected from the group from sodium molybdate and ammonium molybdate to a hydrothermal process so as to prepare a precursor, washing the precursor so as to remove unreacted impurities like sodium ions and cobalt ions, then carrying out drying, respectively placing a proper amount of the dried precursor and a proper amount of sublimed sulfur in two quartz boats, controlling a certain heating rate and a certain calcination temperature in a nitrogen protection environment, and carrying out calcination for a certain period of time so as to obtain the MoS2 / CoS2 composite water-splitting hydrogen-production low-overpotential electrocatalyst. The electrocatalyst provided by the invention has an overpotential of only minus 287 mV when the alternating current density is minus 60 mA / cm2, and is an electrocatalyst with a low overpotential in non-noble metal electrocatalysts.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com