Novel catalyst based on metal organic framework material and preparation method and application of novel catalyst

A metal-organic framework and catalyst technology, applied in organic compound/hydride/coordination complex catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of poor conductivity of MOF, limited applications, and no MXene- The application of MOF composite materials and other issues to achieve good oxygen evolution performance, short reaction time, and good oxygen reduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1. Add 5g Ti 3 AlC 2 Dissolve in 30ml of ethanol, ball mill at 450r / min for 4h, filter the suspension with suction, and dry the product on the filter cake at 50°C for 12h. The dried product was sieved (160 mesh sieve).

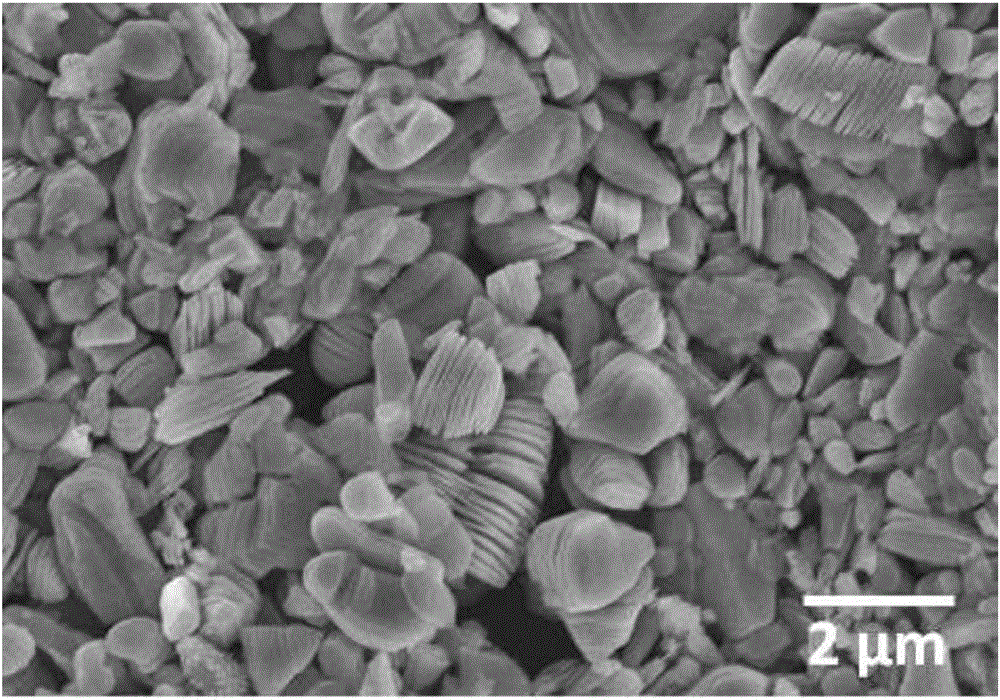

[0041] 2. Take 180mg of Ti after ball milling and sieving 3 AlC 2 , 600mg of 1,4-naphthalene dicarboxylic acid, 3mL of hydrofluoric acid and 60mL of water are added to a hydrothermal kettle with 150mL of polytetrafluoroethylene as the liner at the same time. Under heating for 6h. After the reaction was completed, it was left to cool naturally at room temperature. The black solid obtained by the reaction was separated by centrifugation (washed three times with DMF) to obtain accordion-shaped Ti 3 C 2 Nanosheets.

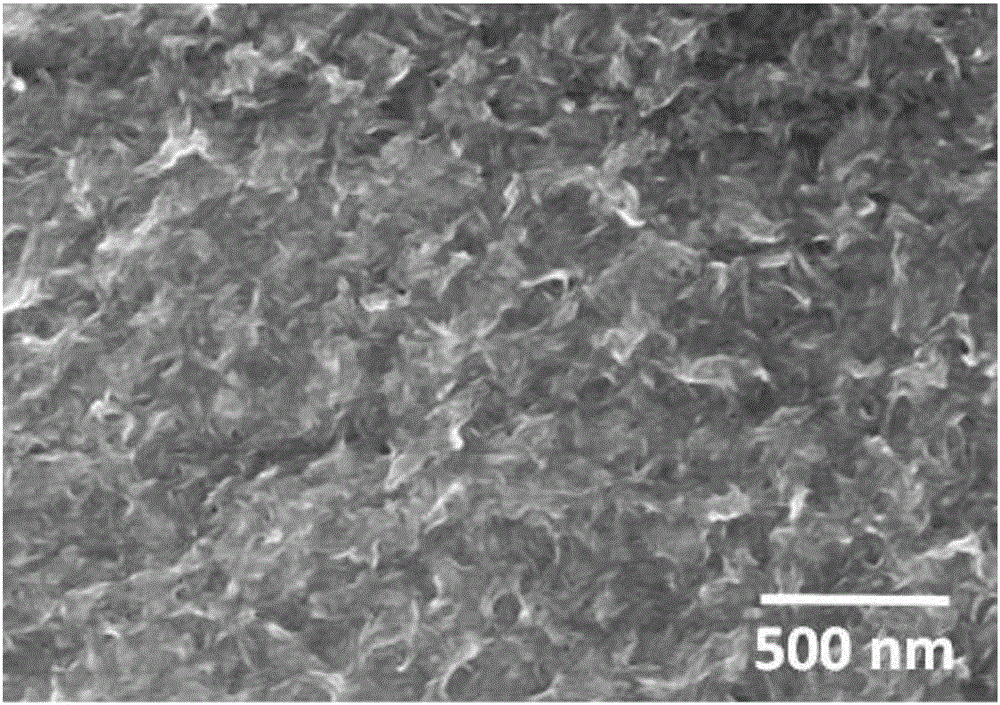

[0042] 3. the above-mentioned obtained Ti 3 C 2 Ultrasound for 8h to further open Ti 3 C 2 lamellae, resulting in few-layered Ti 3 C 2 Nanosheets.

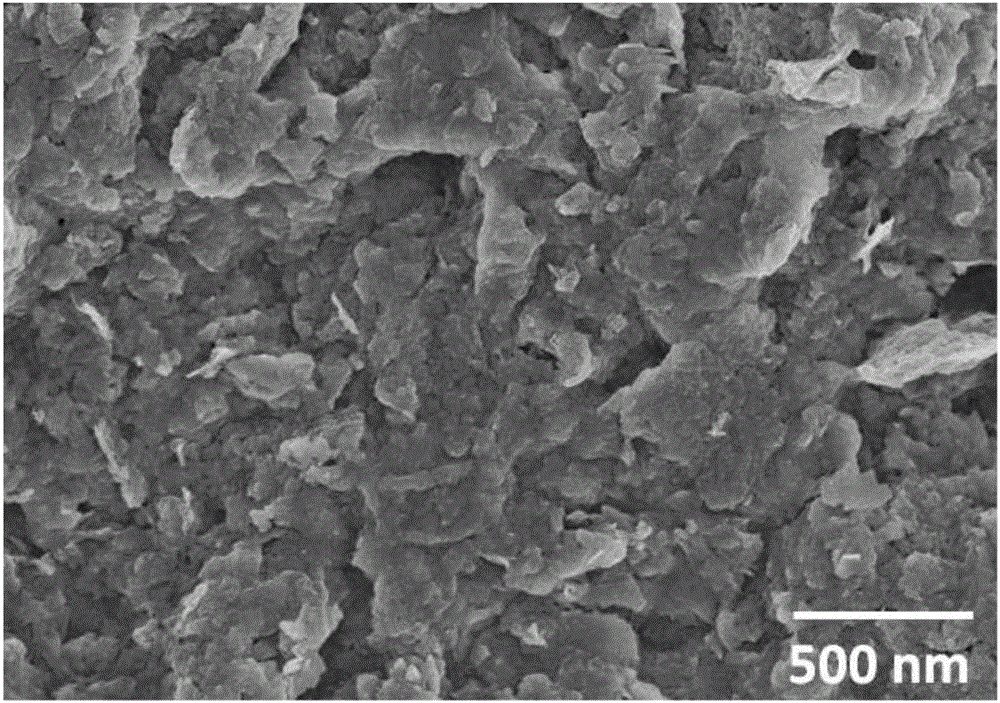

[0043] 4. Add 10mg Ti 3 C 2 Nanosheets were dissolved with 50 mg cobalt acetat...

Embodiment 2

[0054] 1. Add 5g Ti 3 AlC 2 Dissolve in 30ml of ethanol, ball mill at 450r / min for 4h, filter the suspension with suction, and dry the product on the filter cake at 50°C for 12h. The dried product was sieved (160 mesh sieve).

[0055] 2. Take 180mg of Ti after ball milling and sieving 3 AlC 2 , 600mg of 1,4-terephthalic acid, 3mL of hydrofluoric acid and 60mL of water are added to a hydrothermal kettle with 150mL of polytetrafluoroethylene as the liner at the same time. Heating at ℃ for 8h. After the reaction was completed, it was left to cool naturally at room temperature. The black solid obtained by the reaction was separated by centrifugation (washed three times with DMF) to obtain accordion-shaped Ti 3 C 2 Nanosheets.

[0056] 3. the above-mentioned obtained Ti 3 C 2 Ultrasonic 2h, further will open Ti 3 C 2 lamellae, resulting in few-layered Ti 3 C 2 Nanosheets.

[0057] 4. Add 2mg Ti 3 C 2 Nanosheets were dissolved with 50 mg cobalt acetate tetrahydrate ...

Embodiment 3

[0060] 1. Add 5g Ti 3 AlC 2 Dissolve in 30ml of ethanol, ball mill at 450r / min for 4h, filter the suspension with suction, and dry the product on the filter cake at 50°C for 12h. The dried product was sieved (160 mesh sieve).

[0061] 2. Take 180mg of Ti after ball milling and sieving 3 AlC 2 , 600mg of 1,4-naphthalene dicarboxylic acid, 3mL of hydrofluoric acid and 60mL of water are added to a hydrothermal kettle with 150mL of polytetrafluoroethylene as the liner at the same time. Under heating for 12 hours. After the reaction was completed, it was left to cool naturally at room temperature. The black solid obtained by the reaction was separated by centrifugation (washed three times with DMF) to obtain accordion-shaped Ti 3 C 2 Nanosheets.

[0062] 3. the above-mentioned obtained Ti 3 C 2 Ultrasonic 4h, further will open Ti 3 C 2 lamellae, resulting in few-layered Ti 3 C 2 Nanosheets.

[0063] 4. Add 5mg Ti 3 C 2 Nanosheets were dissolved with 50 mg cobalt acet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com