Polyimidazole ionic liquid modified cellulose-based adsorbent as well as preparation method and application of cellulose-based adsorbent

An ionic liquid and cellulose-based technology, which is applied in the field of preparation and development of high-efficiency adsorbents, can solve the problems of low adsorption capacity of cellulose, few adsorption sites, weak adsorption, etc., achieve low toxicity of reactants and improve adsorption performance , Strong adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also discloses a preparation method of the cellulose-based adsorbent modified by the polyimidazole ionic liquid, comprising the following steps:

[0037] S1. Immerse 2g of cellulose in 25mL of a certain concentration of sodium periodate aqueous solution, place it in a water bath at 30-80°C, and react in the dark for 3-7 hours, then add 3mL of ethylene glycol and react for 1 hour to prepare dialdehyde base cellulose crude product;

[0038] S2. Repeatedly washing the dialdehyde-based cellulose crude product in S1 with deionized water and ethanol, washing away the unreacted sodium periodate and ethylene glycol solution on the surface of the dialdehyde-based cellulose, and washing until the supernatant is medium Until the property is obtained, dialdehyde-based cellulose is obtained;

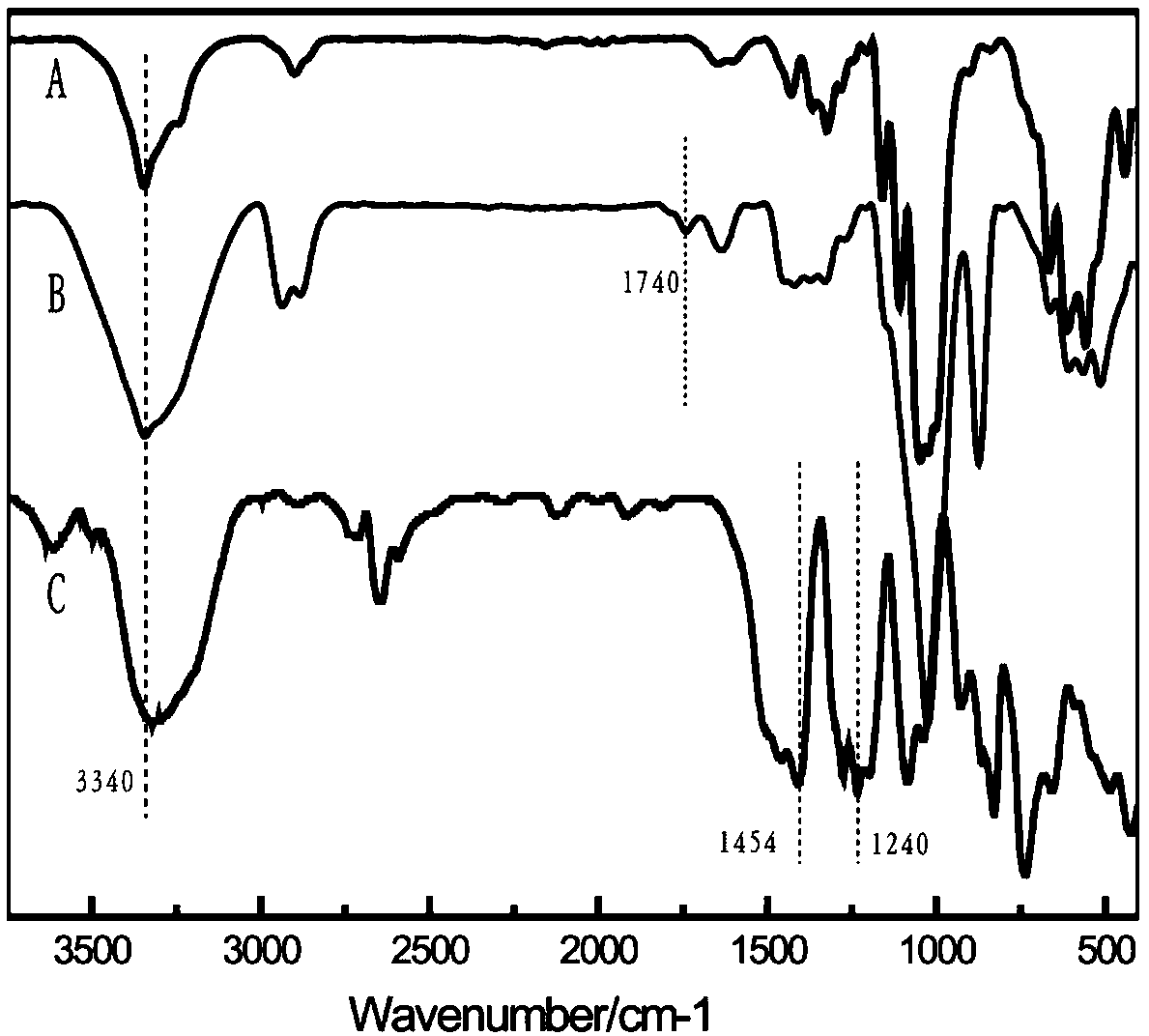

[0039] S3. Dissolve 1-vinylimidazole and 3-bromopropylamine hydrobromide in 20 mL of absolute ethanol, stir the mixture under a nitrogen atmosphere, and reflux at 60-80°...

Embodiment 1

[0052] The process of the preparation method of a kind of polyimidazole ionic liquid modified cellulose-based adsorbent in the present embodiment comprises the following steps:

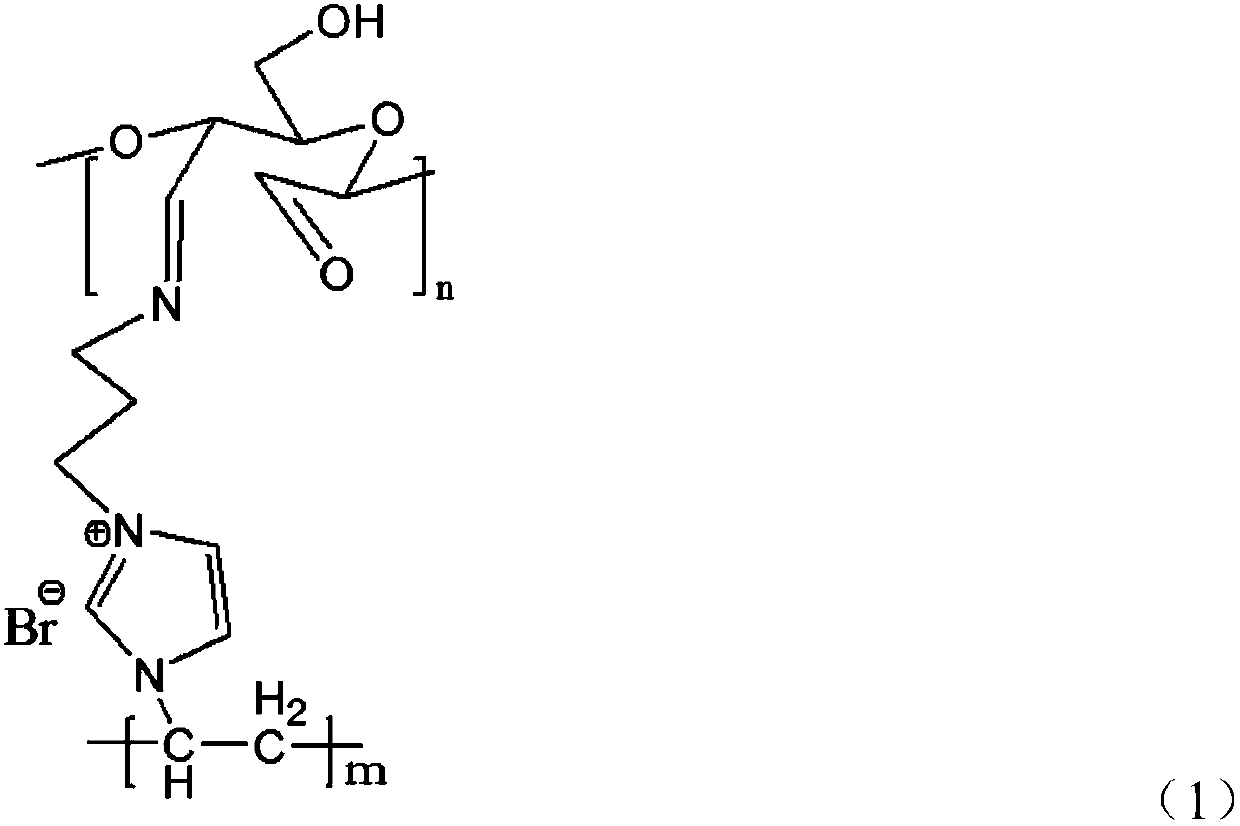

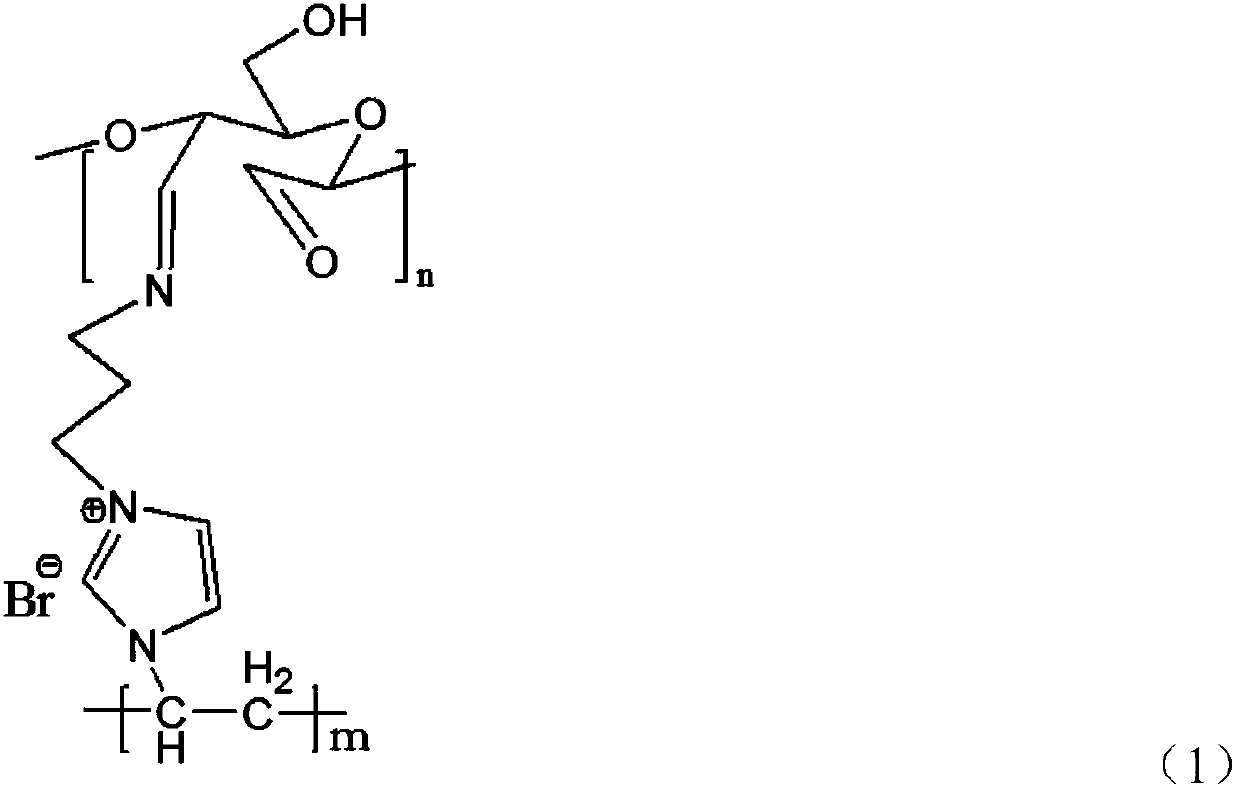

[0053] 1) Submerge 2g of nanocellulose membrane (structure shown in formula (2)) in 25mL of 32g·L -1 Sodium periodate aqueous solution, placed in a water bath at 50°C, and reacted in the dark for 4 hours, and then added 3 mL of ethylene glycol to react for 1 hour to prepare a crude dialdehyde-based cellulose.

[0054]

[0055] 2) After the reaction is finished, wash repeatedly with deionized water and ethanol to remove unreacted sodium periodate and ethylene glycol solution on the surface of the dialdehyde-based cellulose, and wash until the supernatant is neutral to obtain the dialdehyde-based fiber The structure is shown in formula (3).

[0056]

[0057] 3) Add 1-vinylimidazole and 3-bromopropylamine hydrobromide at a mass ratio of 2:1 to a container (such as a 25mL round-bottomed flask), dis...

Embodiment 2

[0065] The process of the preparation method of a kind of polyimidazole ionic liquid modified cellulose-based adsorbent in the present embodiment comprises the following steps:

[0066] 1) Submerge 2g bacterial cellulose membrane (structure shown in formula (2)) in 25mL 16g L -1 The sodium periodate aqueous solution was placed in a water bath at 50°C, and reacted in the dark for 5 hours, and then 3 mL of ethylene glycol was added to react for 1 hour to prepare a crude dialdehyde-based cellulose.

[0067] 2) After the reaction is finished, wash repeatedly with deionized water and ethanol to remove unreacted sodium periodate and ethylene glycol solution on the surface of the dialdehyde-based cellulose, and wash until the supernatant is neutral to obtain the dialdehyde-based fiber The structure is shown in formula (3).

[0068] 3) Add 1-vinylimidazole and 3-bromopropylamine hydrobromide at a mass ratio of 2.1:1 to a container (such as a 25mL round bottom flask), dissolve the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com