Patents

Literature

3148 results about "Nanocellulose" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

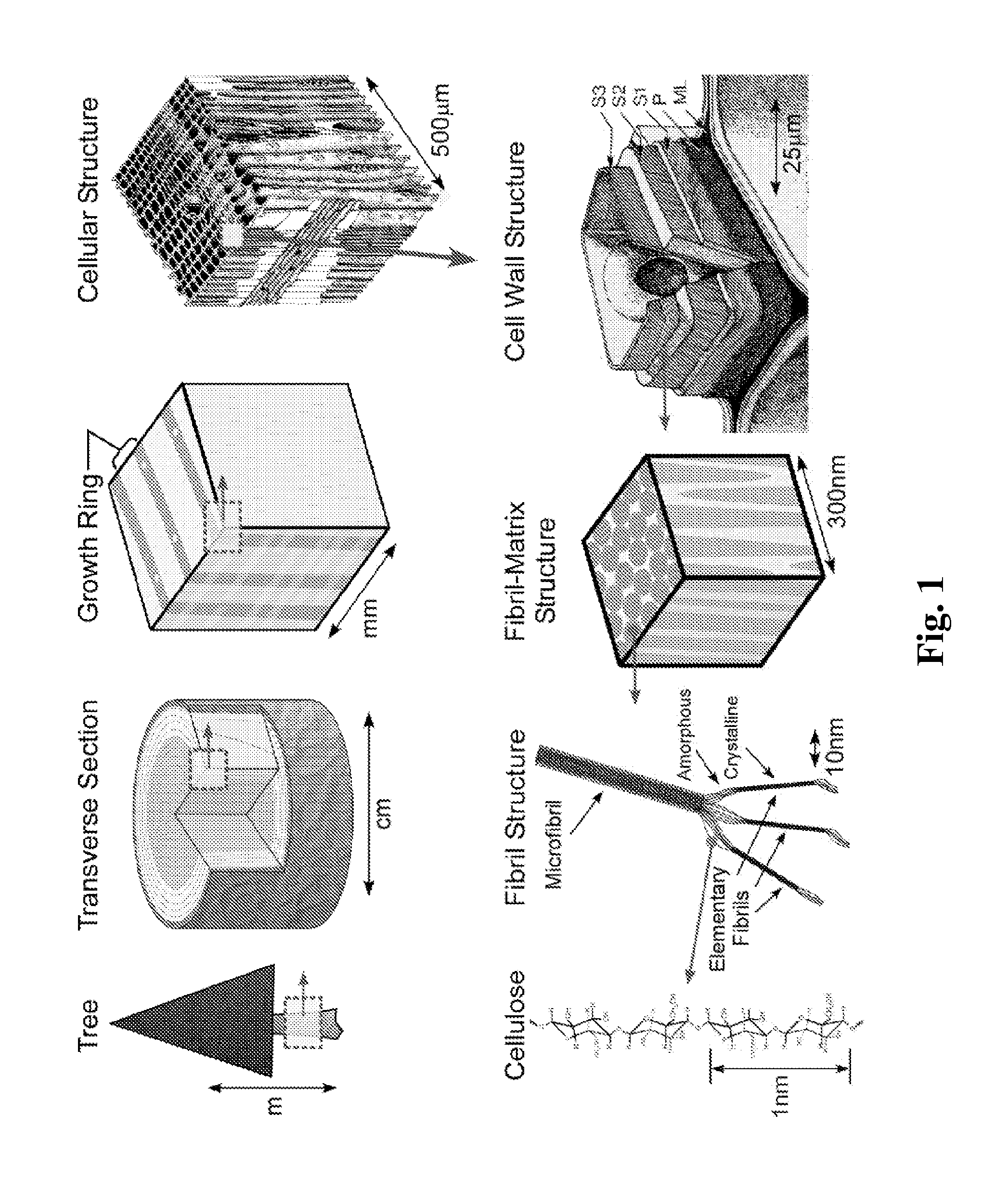

Nanocellulose is a term referring to nano-structured cellulose. This may be either cellulose nanocrystal (CNC or NCC), cellulose nanofibers (CNF) also called nanofibrillated cellulose (MFC), or bacterial nanocellulose, which refers to nano-structured cellulose produced by bacteria.

Method for preparing fibrilia carboxylation cellulose nanowhiskers

The invention provides a method for preparing fibrilia carboxylation cellulose nanowhiskers, which is characterized by comprising the following steps: soaking fibrilia powder in sodium hydroxide for processing, then processing the fibrilia powder by a former treating agent and taking out the fibrilia powder to be dried in a vacuum oven to obtain preprocessed fibrilia powder; and placing the preprocessed fibrilia powder in a TEMPO oxidation system for catalytic oxidation to obtain a stable cellulose nanowhiskers suspending liquid after mechanical processing and freeze drying the suspending liquid to obtain the fibrilia carboxylation cellulose nanowhiskers having grain diameters of 3-10 nm. According to the invention, fibrilia carboxylation and nano fibrillation are realized and surfaces of prepared nanocrystalline celluloses have carboxyl functional groups, thus the surfaces generate negative charges, electrostatic repulsion among the negative charges can avoid the reunion of nanoparticles, so that the nanocrystalline celluloses can be well dispersed in water and the obtained nanocrystalline celluloses have excellent uniformity of grain sizes.

Owner:DONGHUA UNIV

Method for preparing nano cellulose microfibril reinforced polymer composite material

ActiveCN102344685AUniform structureTransparent structureConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsSolubilityFiber

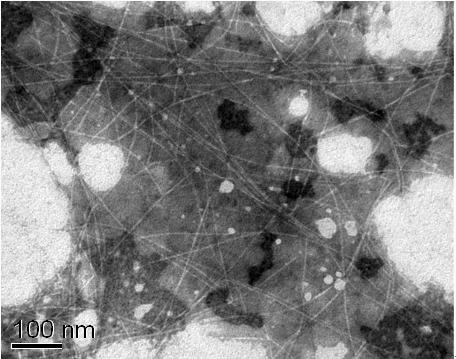

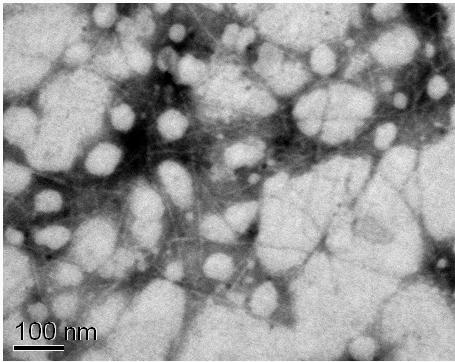

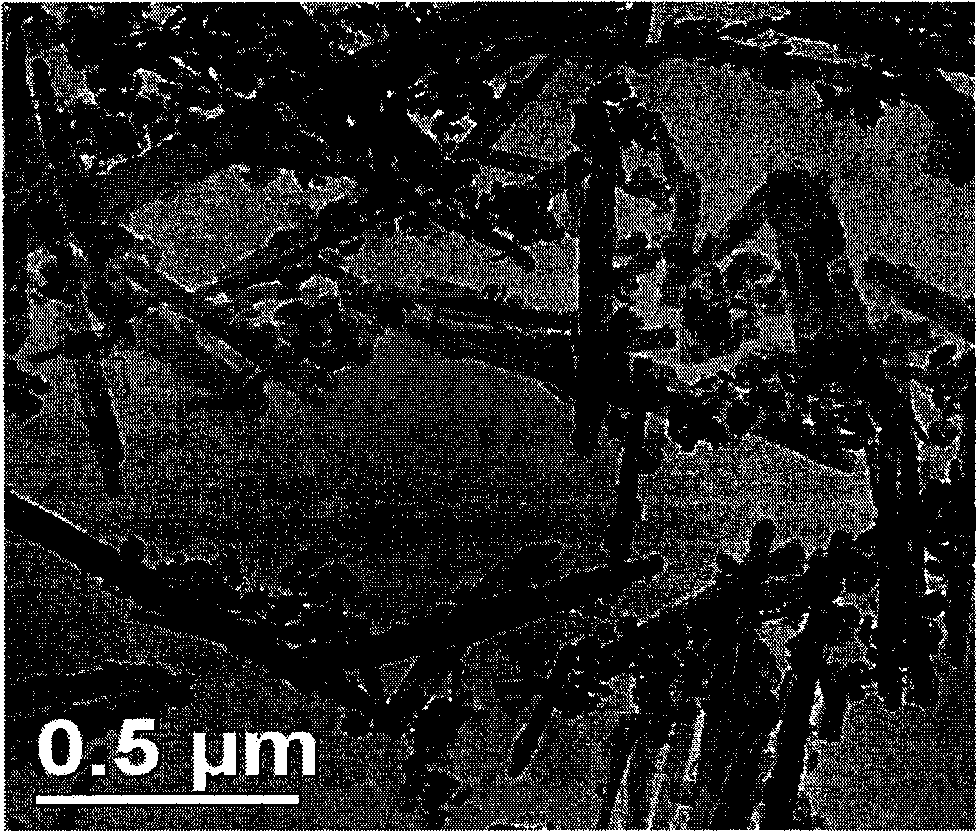

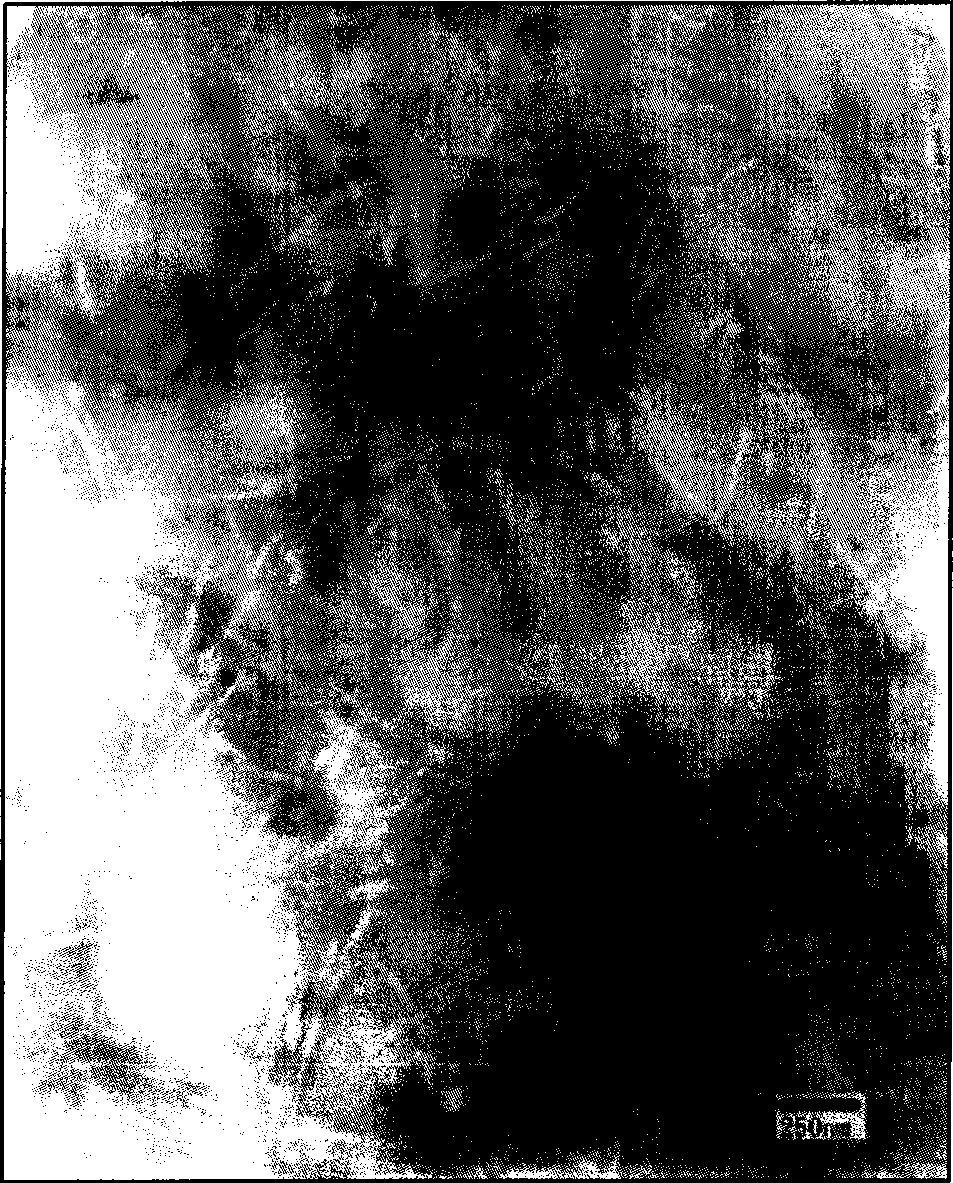

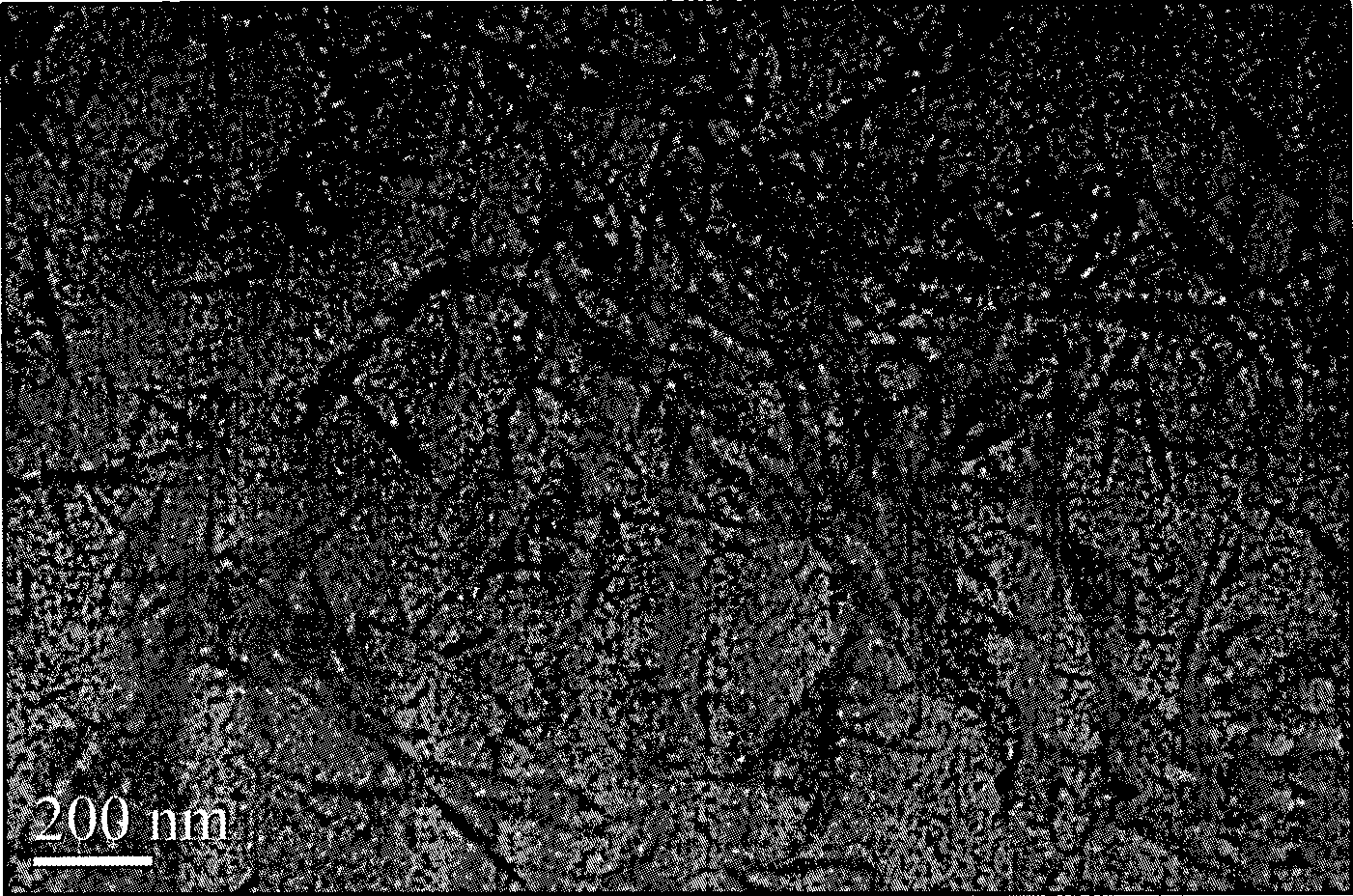

The invention discloses a method for in situ generating a nano cellulose microfibril reinforced polymer composite material, comprising the following steps: using ionic liquid as a primary solvent, dissolving cellulose, or mixing cellulose with other polymers via solution mixing, and controlling the solubility of the cellulosic material in the solvent to maintain naturally occurring nano cellulose microfibril in the cellulosic material, so as to in situ obtain the nano cellulose microfibril reinforced polymer composite material. The nano microfibril can be observed under a transmission microscope obviously, which is different from the completely dissolved cellulose solution. In the preparing process, the dissolving temperature is controlled within 30-150 DEG C, and stirring and vacuum deaeration are used as auxiliary. By controlling the dissolving time, solution concentration and ratio of mixing, a polymer solution containing cellulose microfibril with dimension of 5-300 nanometers can be obtained. The polymer solution can be used for preparing composite material fiber, hollow fibrous membrane, diaphragm, film, gel, porous material and other known applications of enhanced material.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Nano cellulose solid-solid phase transition material and its preparing method

InactiveCN1710012ASimple manufacturing processNo phase separationHeat-exchange elementsPolyethylene glycolFunction group

The invention relates to a kind of nano cellulose solid - solid phrase change material and its producing method. Its characteristics are: in non-homogeneous phase system, according to the reactants proportions as polyethylene glycol containing active group at one end or both ends 19.8% - 82.0%, crosslinking agent 0% - 55.1% and nanometer cellulose or its ramification 4.0% - 69.5%, ingraft the polyethylene glycol containing active group at one end or both ends as energy storing function group onto nanometer cellulose or its ramification framework material. The biggest enthalpy of phase change of the nanometer cellulose solid - solid phrase change material of the invention can get to over 110 J / g, the phrase change temperature is 0 - 60 Deg. C, and can keep good solid state before and after the phrase change. It won't occur phrase separation, besides it is non-toxic and harmless, low cost, simple producing technics.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Preparation method of homogenized fine nano-cellulose fiber

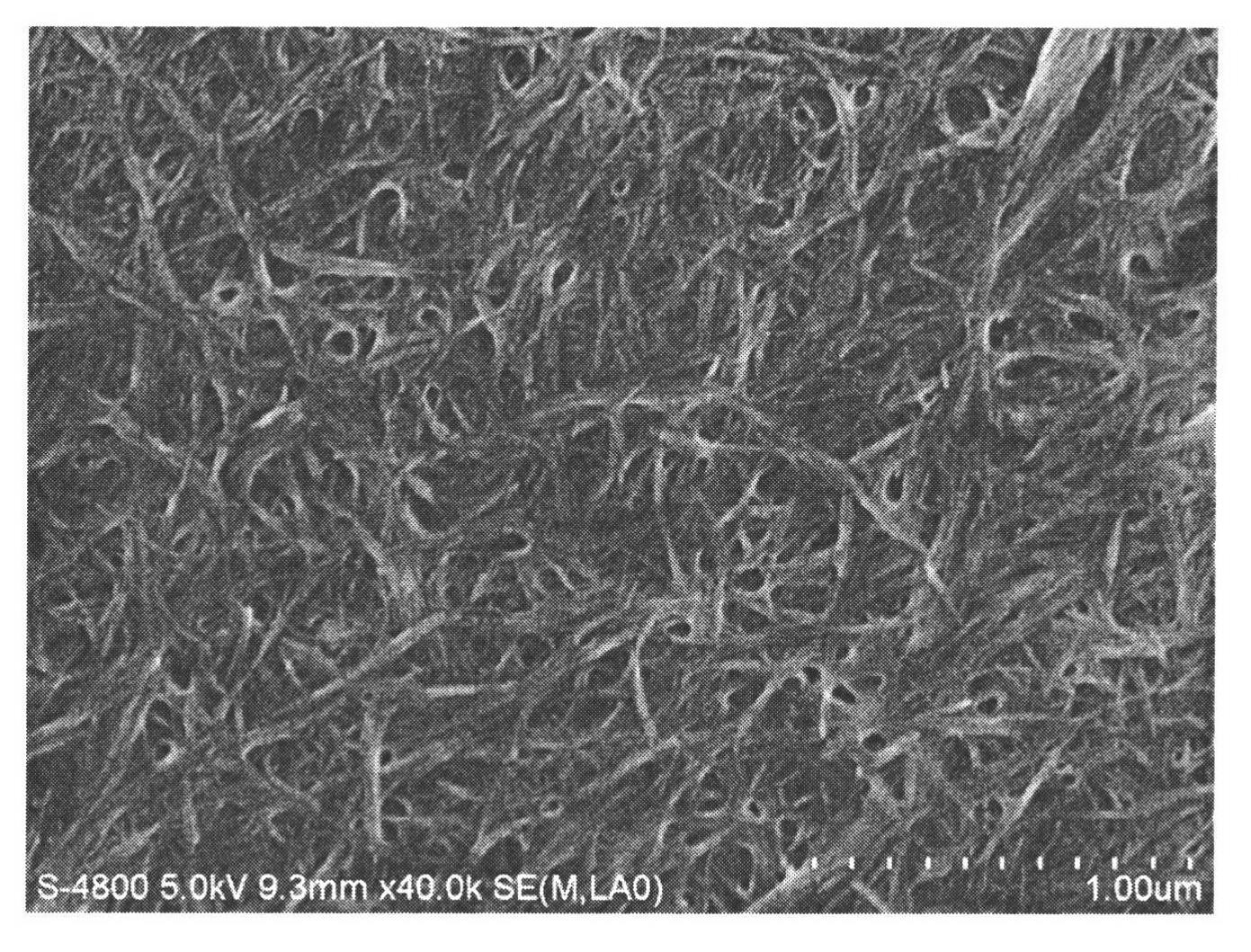

InactiveCN101851295ALow degree of mutual aggregationEvenly dispersedArtificial filaments from cellulose solutionsStrong acidsCatalytic oxidation

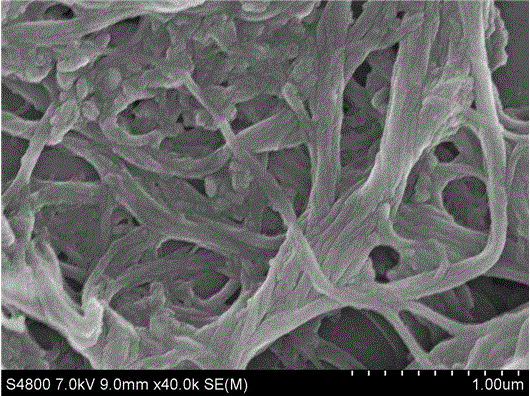

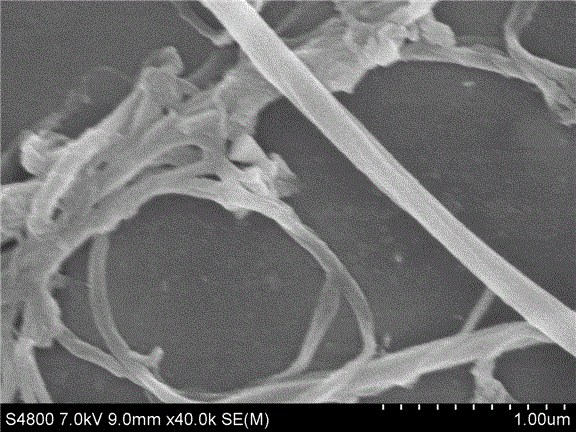

The invention relates to a preparation method of a homogenized fine nano-cellulose fiber. The preparation method can solve the problems of uniform diameter distributor of biomass nano-cellulose prepared by the existing strong acid hydrolysis method and the high-strength mechanical shearing method, easy gathering among the nano-fiber and a narrow range of applications of the TEMPO catalytic oxidation method. The preparation method comprises the following steps: 1) extracting biomass fiber with benzyl alcohol solution; 2) carrying out treatment by using acidified sodium chlorite; 3) carrying out gradient treatment with alkaline liquor; 4) using TEMPO, sodium bromide and sodium hypochlorite for catalytic oxidation treatment; 5) using sodium chlorite for treatment; and 6) carrying out nano-scale processing by using the long-term stirring method, the ultrasonic method or the high-pressure homogenization method, drying, and then obtaining the homogenized fine nano-cellulose fiber. The fiber has the uniform diameter distribution, the diameter is 3-5nm, the length-diameter ratio is not less than 500, the fiber is mutually interwoven into a mesh snarling structure, and the method is applicable to preparing the nano-cellulose fiber by using wood pulp, paper-making pulp, wood, bamboo and crop straw.

Owner:NORTHEAST FORESTRY UNIVERSITY

Multiribbon nanocellulose as a matrix for wound healing

InactiveUS20070053960A1Improve adaptabilityControl thicknessOrganic active ingredientsBiocideFiberWound healing

The present invention includes compositions and methods for the integration of a non-allergenic nanocellulose into a wound bed. The composition may be formed into a wide variety of implants, e.g., a suture, a sheet, a compress, a bandage, a band, a prosthesis, a fiber, a woven fiber, a bead, a strip, a clasp, a prosthesis, a catheter, a screw, a bone plate, a pin, a bandage or combinations thereof.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

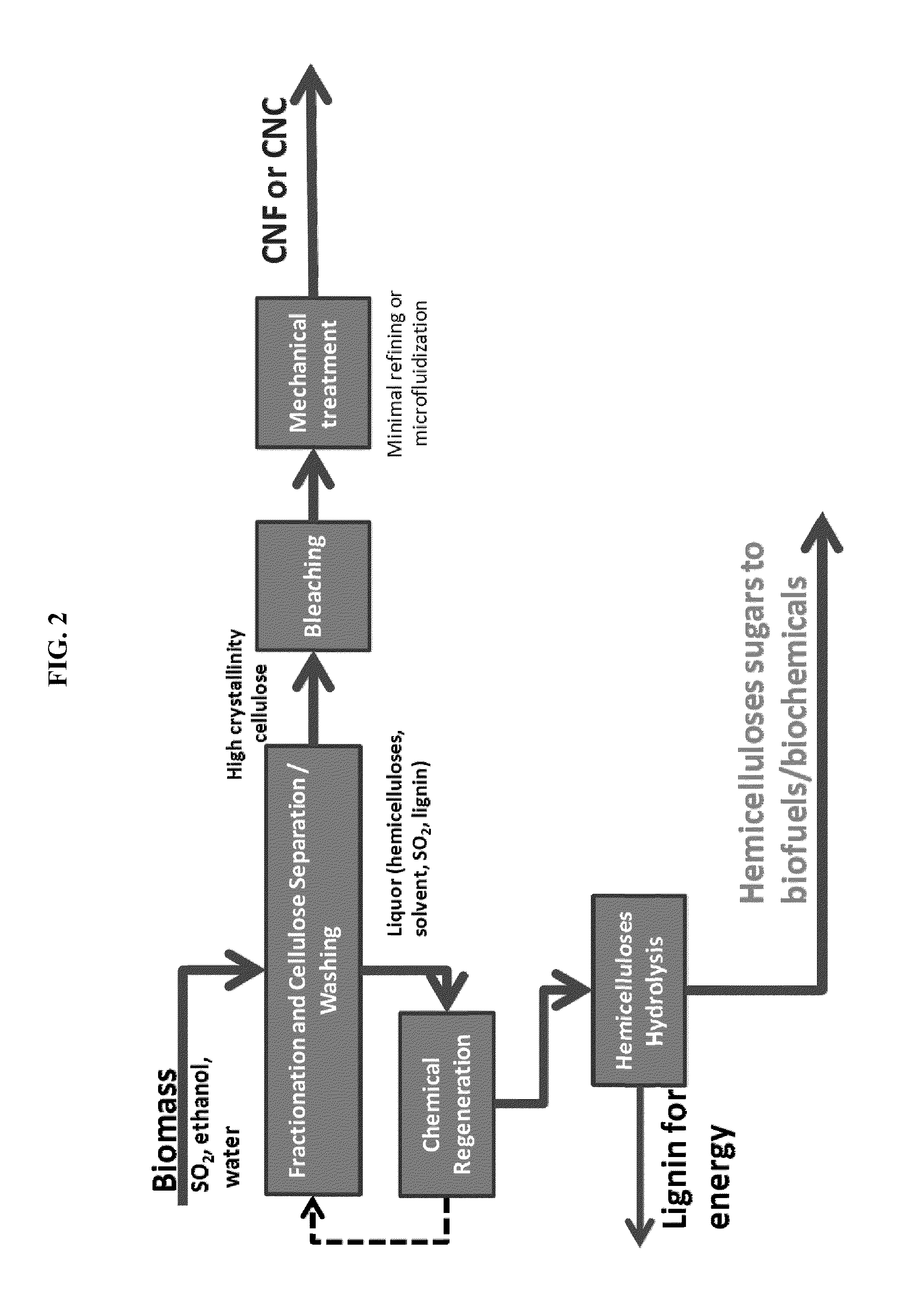

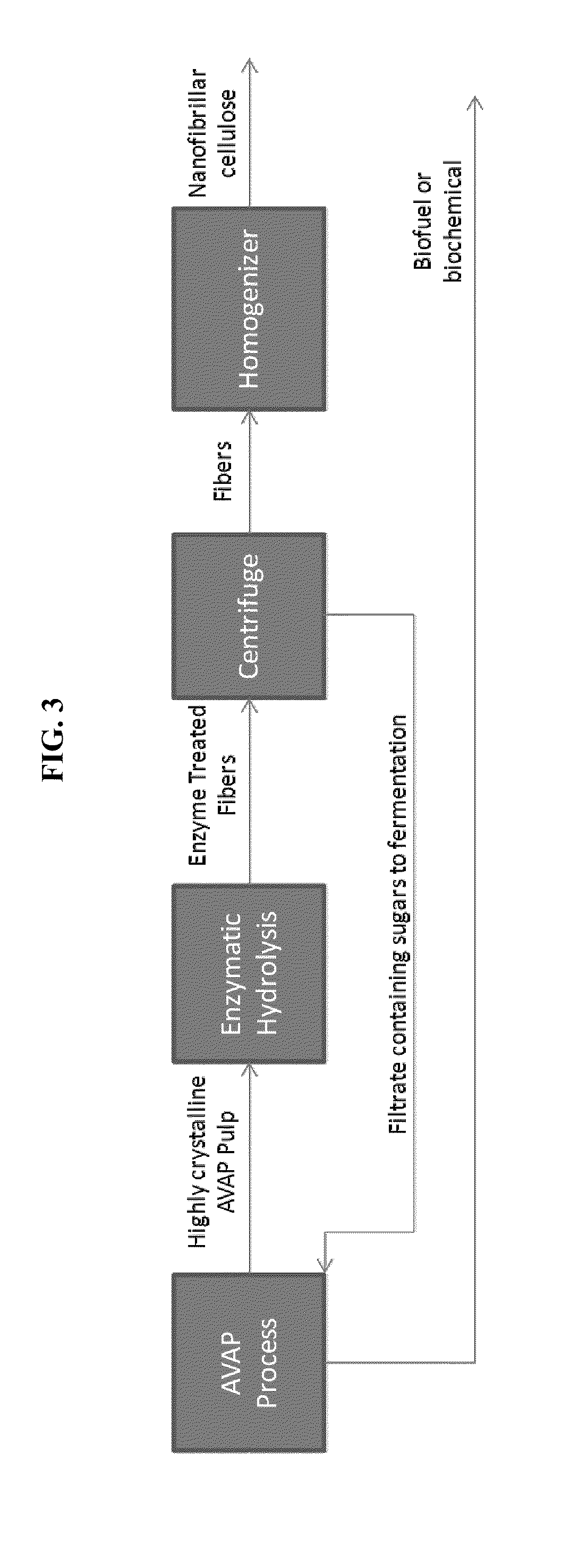

Processes and apparatus for producing nanocellulose, and compositions and products produced therefrom

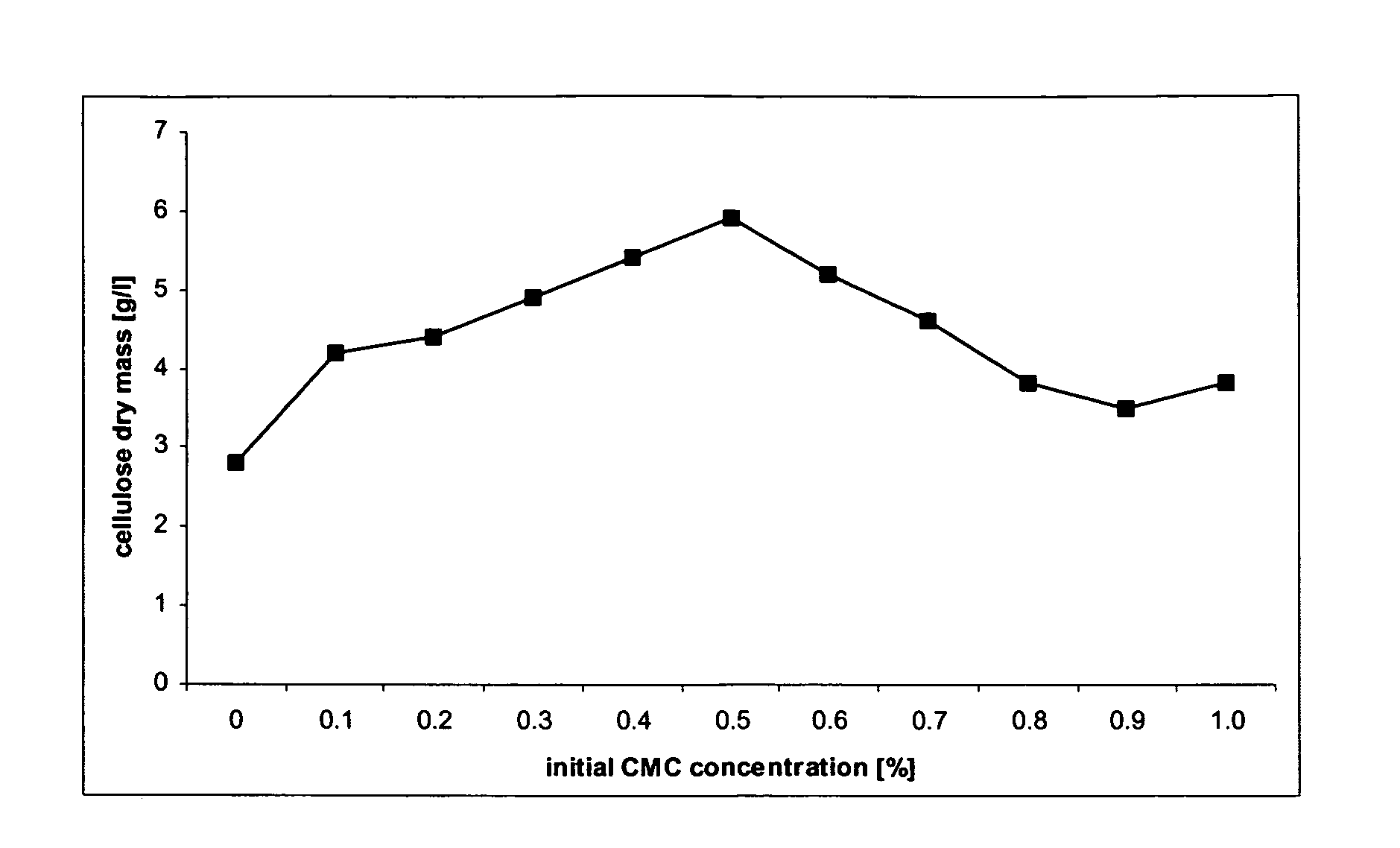

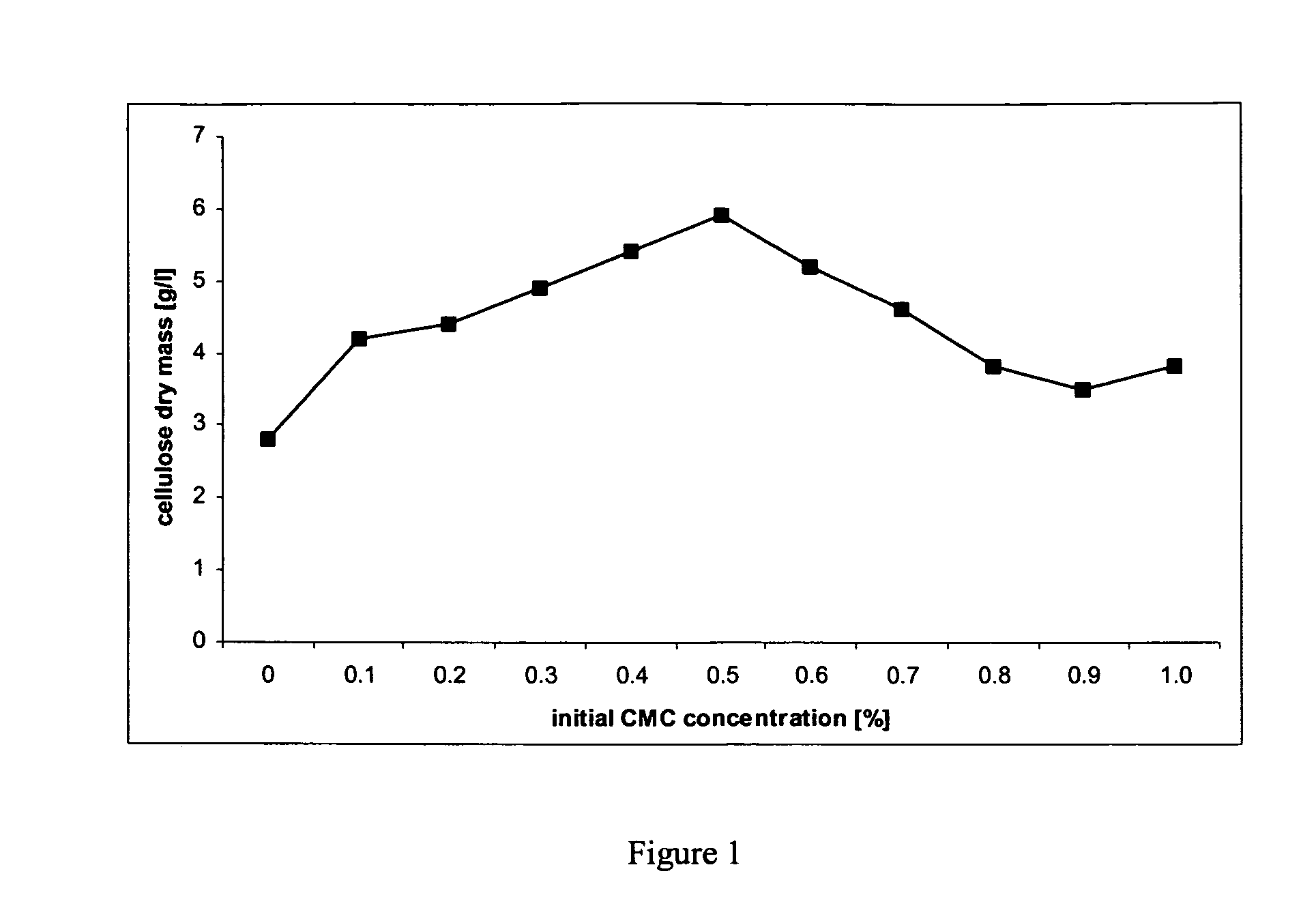

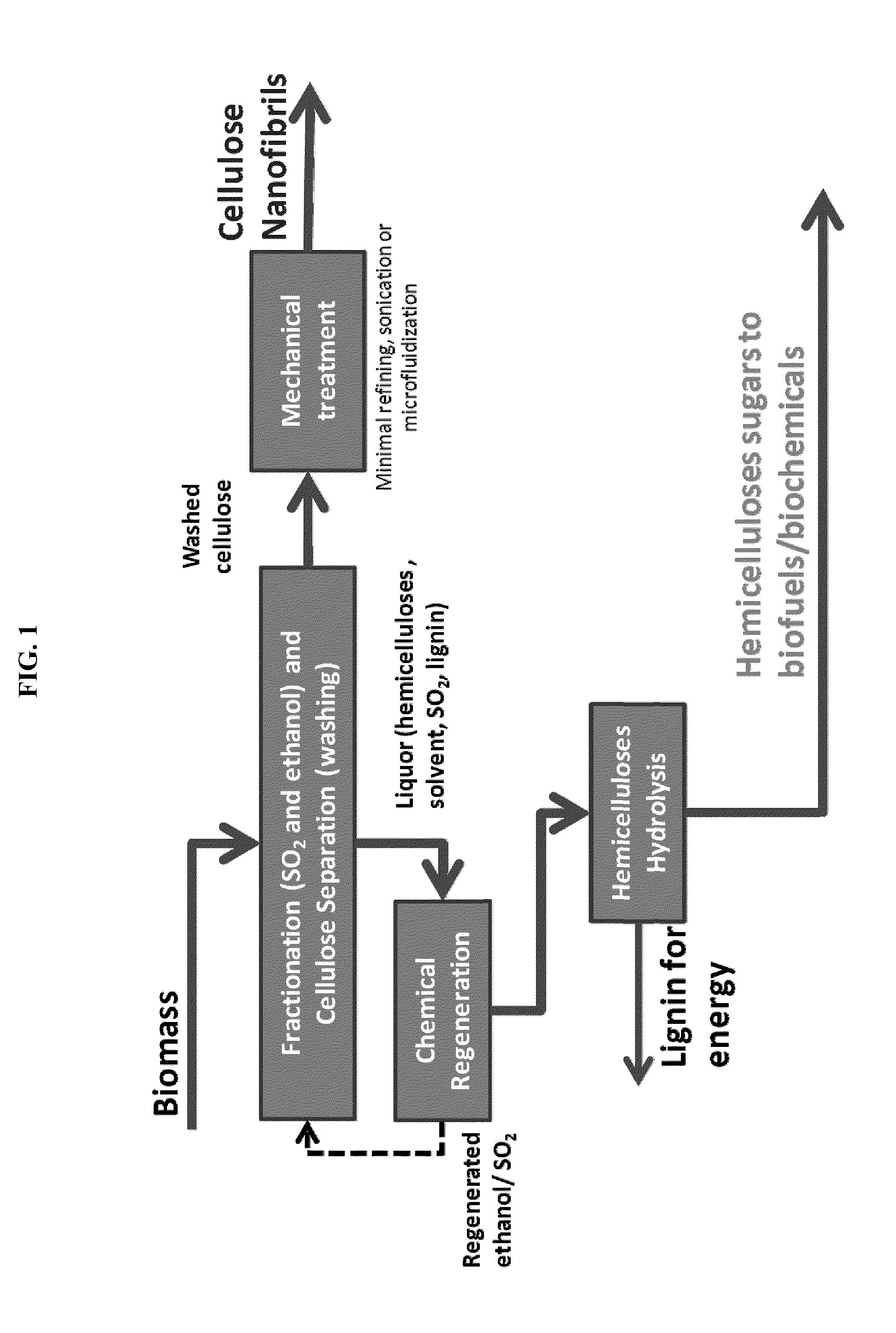

Processes disclosed are capable of converting biomass into high-crystallinity nanocellulose with surprisingly low mechanical energy input. In some variations, the process includes fractionating biomass with an acid (such as sulfur dioxide), a solvent (such as ethanol), and water, to generate cellulose-rich solids and a liquid containing hemicellulose and lignin; and mechanically treating the cellulose-rich solids to form nanofibrils and / or nanocrystals. The total mechanical energy may be less than 500 kilowatt-hours per ton. The crystallinity of the nanocellulose material may be 80% or higher, translating into good reinforcing properties for composites. The nanocellulose material may include nanofibrillated cellulose, nanocrystalline cellulose, or both. In some embodiments, the nanocellulose material is hydrophobic via deposition of some lignin onto the cellulose surface. Optionally, sugars derived from amorphous cellulose and hemicellulose may be separately fermented, such as to monomers for various polymers. These polymers may be combined with the nanocellulose to form completely renewable composites.

Owner:GRANBIO INTELLECTUAL PROPERTY HOLDINGS LLC

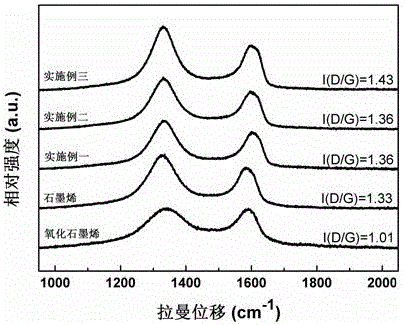

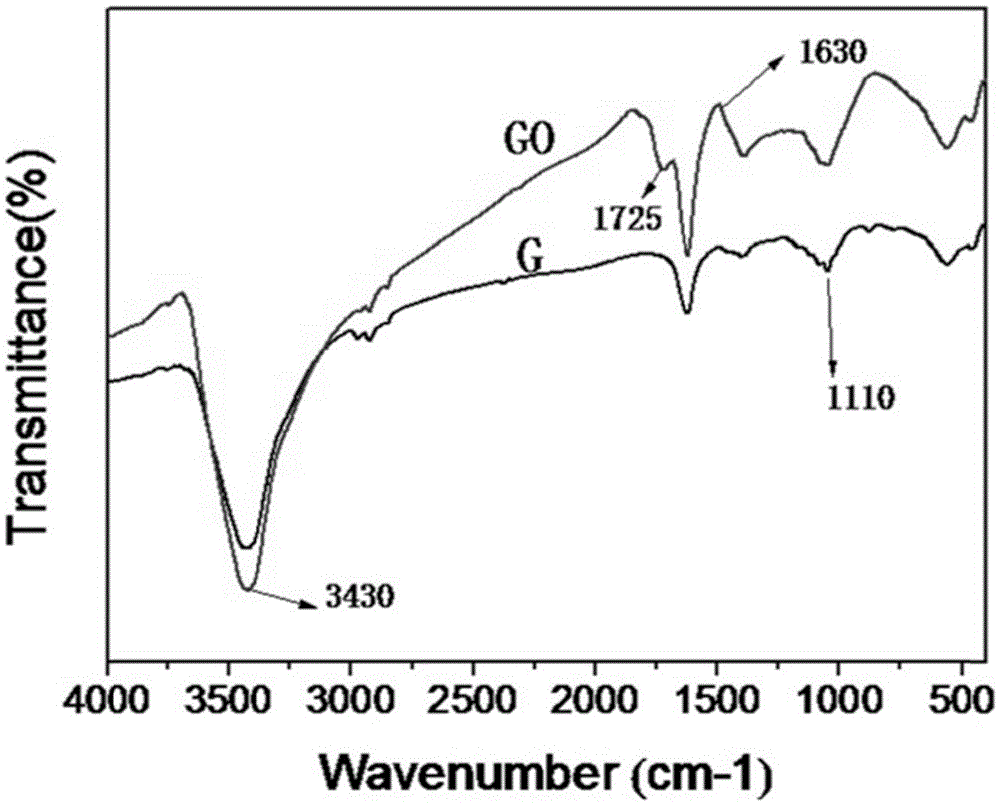

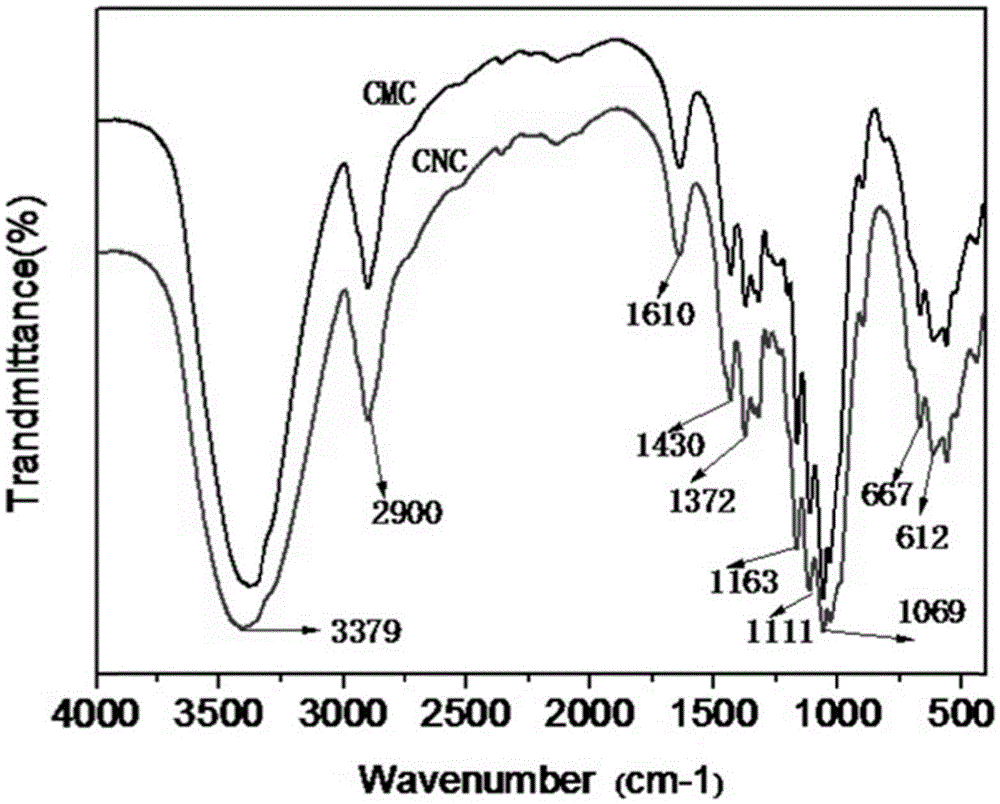

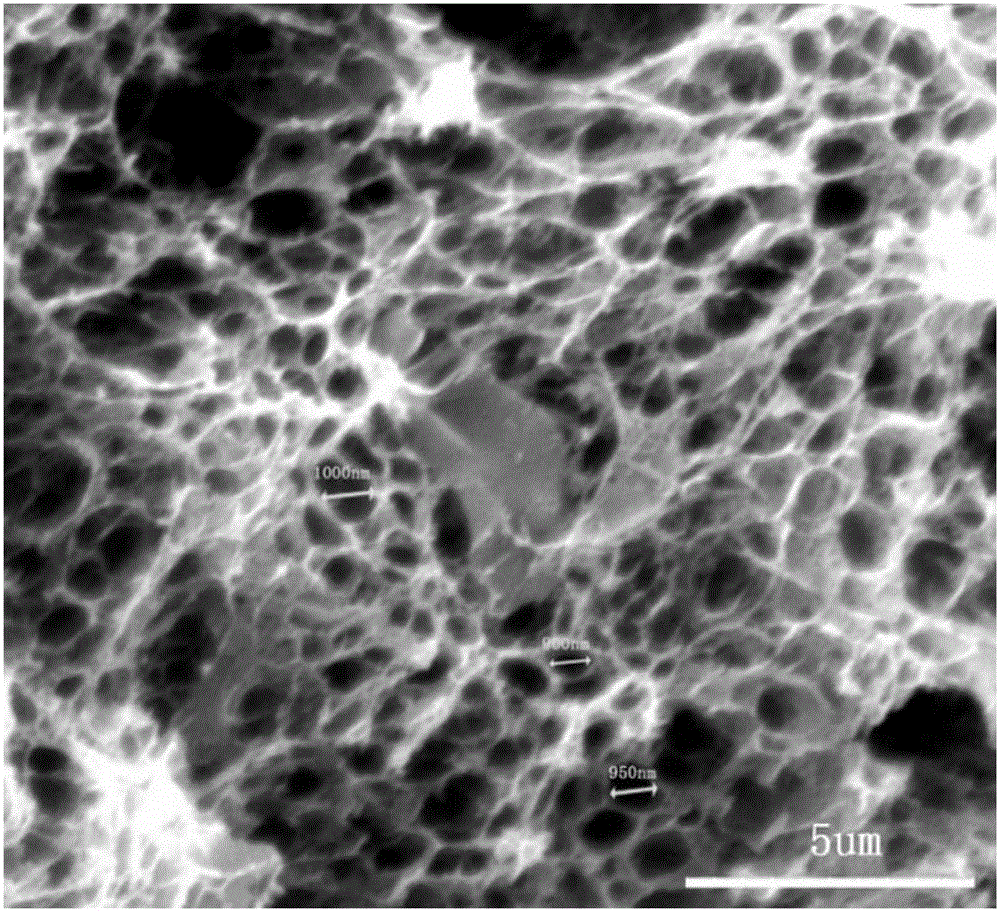

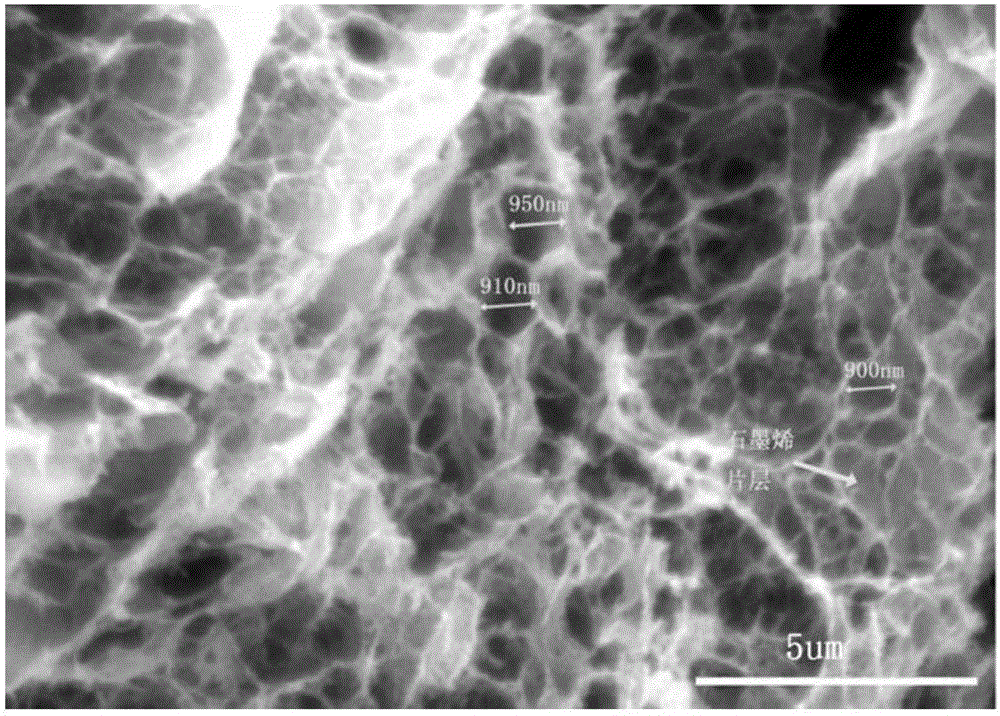

Flexible nanocellulose-graphene composite membrane and preparation method thereof

InactiveCN105860143ANo pollution in the processSimple processHeat-exchange elementsNanofiberCvd graphene

The invention discloses a flexible nano-cellulose-graphene composite film and a preparation method thereof. The mass fraction of the composite film is composed of: graphene 0.1%-90%, nano-cellulose 10%-99.9%, and the preparation steps are as follows: : (1) Prepare a graphene oxide dispersion with a concentration of 0.05-5 mg / ml and a nano-cellulose dispersion with a concentration of 0.05-5 mg / ml, ultrasonically disperse for 1-2 hours, and mix to obtain a concentration of 0.05-5 mg / ml The first dispersion liquid of nanocellulose-graphene oxide; (2) add reducing agent in the first dispersion liquid, heat up, stir, stir evenly, obtain the second dispersion liquid of nanocellulose-graphene; (3) The above-mentioned second dispersion liquid is subjected to centrifugal degassing, and then vacuum-filtered to form a composite film, and the composite film is transferred to an oven, and vacuum-dried to obtain a flexible nanocellulose-graphene composite film. There will be no agglomeration between the graphene sheets in the composite film, and its thermal conductivity in the parallel direction is ≥2W·m ‑1 ·K ‑1 , vertical thermal conductivity ≤0.3W·m ‑1 ·K ‑1 , Thermal conductivity anisotropy ratio ≥ 5.

Owner:SHANGHAI UNIV

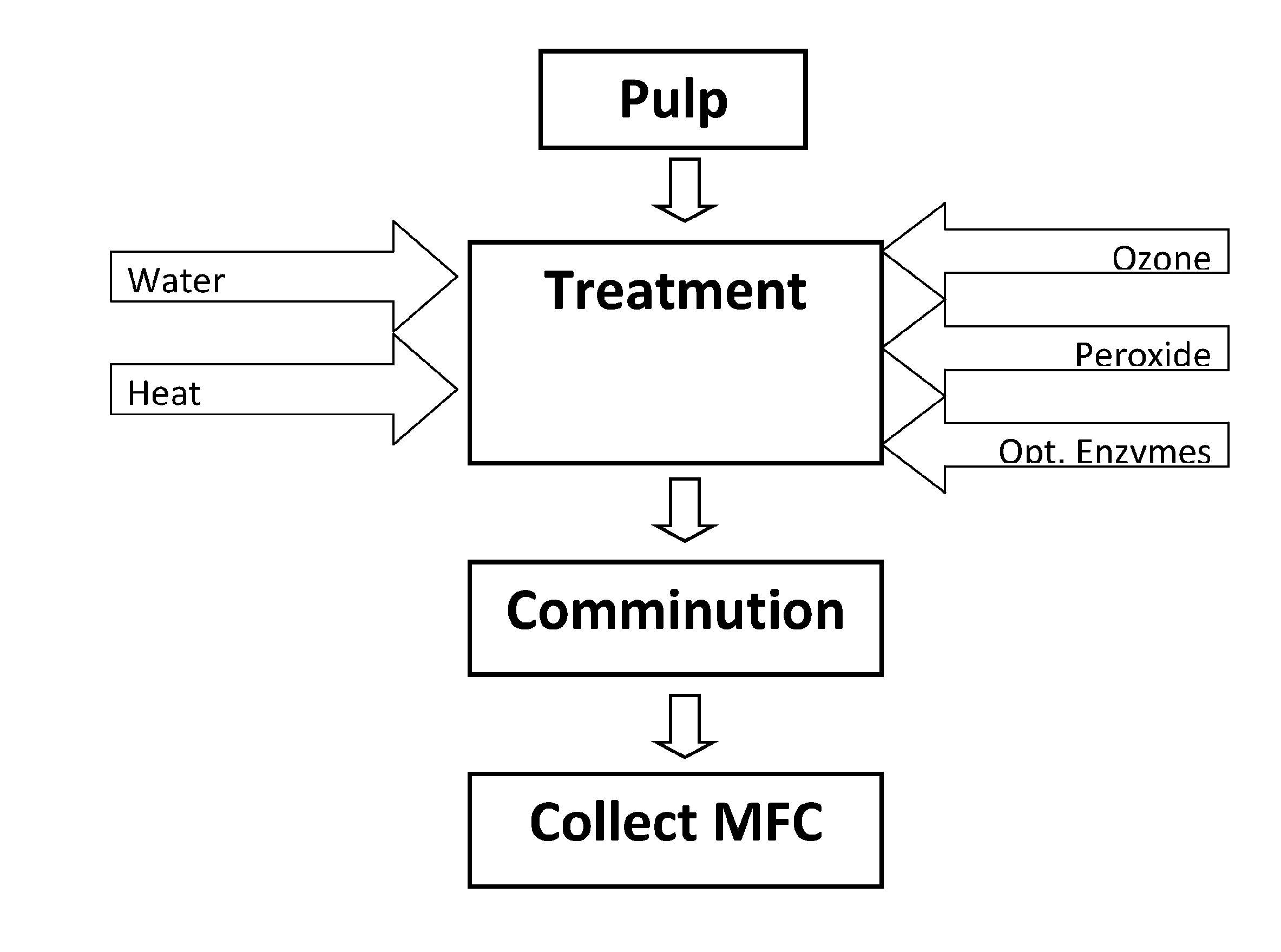

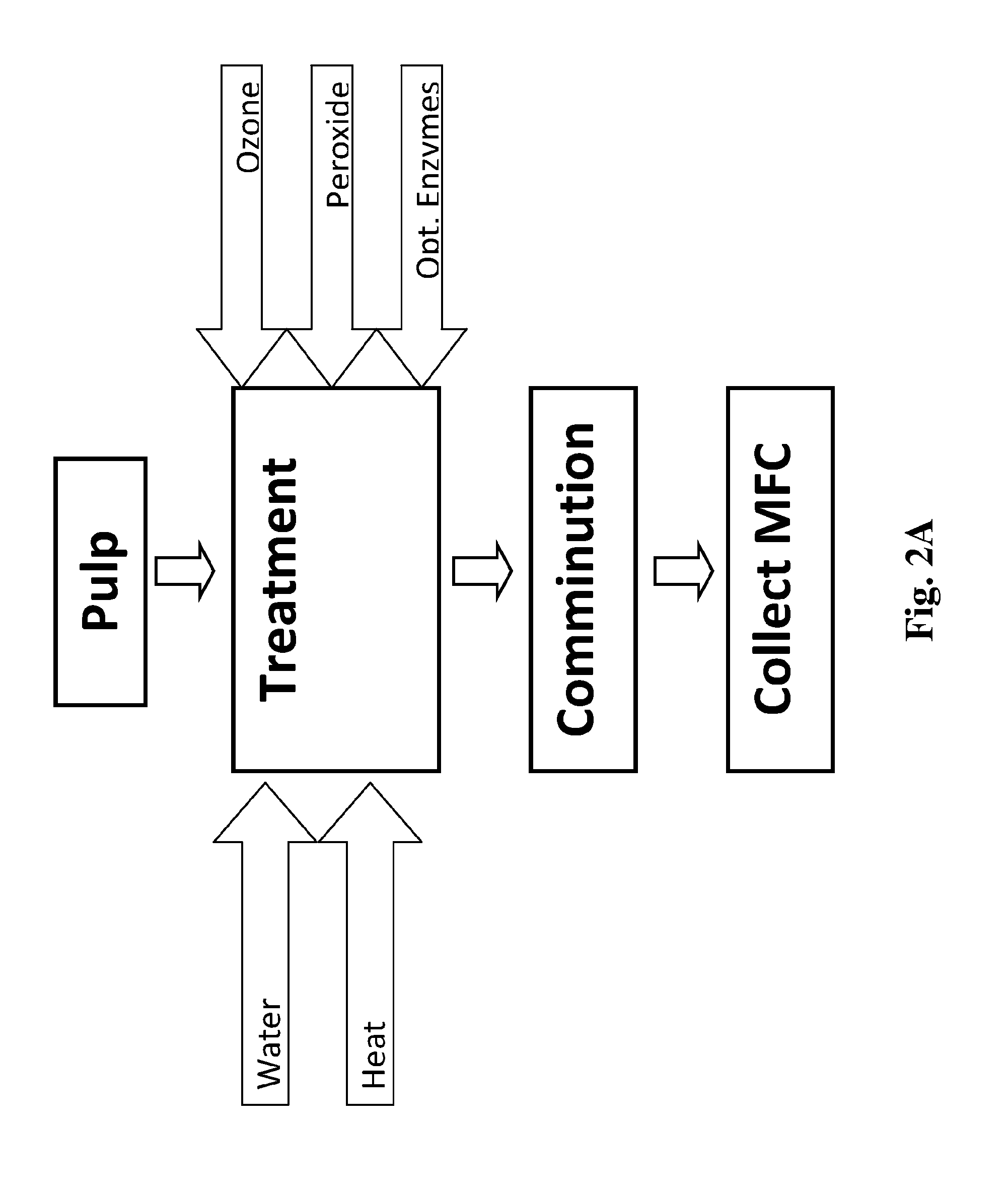

Energy Efficient Process for Preparing Nanocellulose Fibers

ActiveUS20150167243A1Improve efficiencyWeaken energySpecial paperPaper after-treatmentDepolymerizationNanofiber

A scalable, energy efficient process for preparing cellulose nanofibers is disclosed. The process employs a depolymerizing treatment with one or both of: (a) a relatively high charge of ozone under conditions that promote the formation of free radicals to chemically depolymerize the cellulose fiber cell wall and interfiber bonds; or (b) a cellulase enzyme. Depolymerization may be estimated by pulp viscosity changes. The depolymerizing treatment is followed by or concurrent with mechanical comminution of the treated fibers, the comminution being done in any of several mechanical comminuting devices, the amount of energy savings varying depending on the type of comminuting system and the treatment conditions. Comminution may be carried out to any of several endpoint measures such as fiber length, % fines or slurry viscosity.

Owner:UNIVERSITY OF MAINE

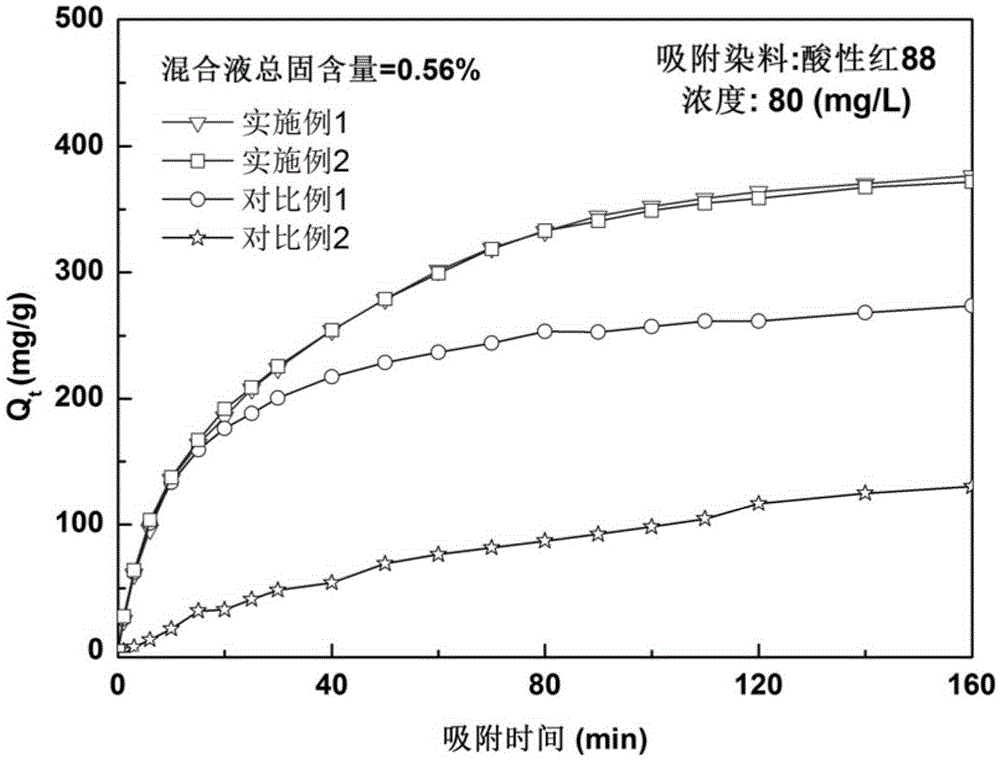

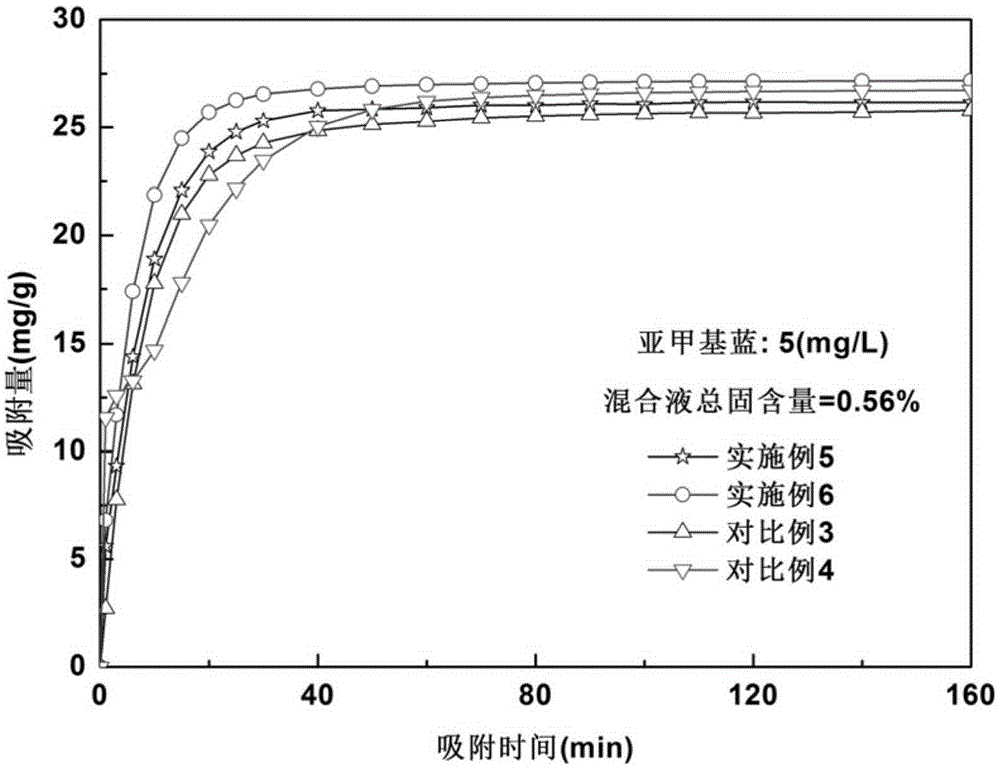

Preparation method of nano-crystalline cellulose-based composite aerogel type organic dye absorption material

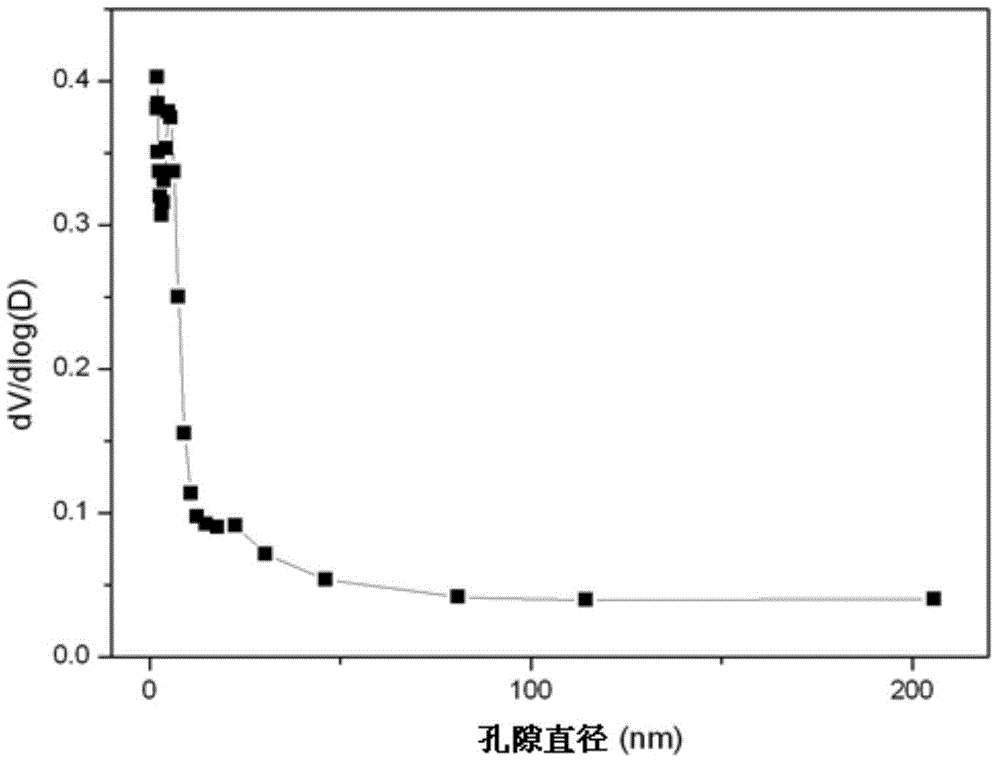

ActiveCN105148868AAdsorption is widely applicableOther chemical processesColloidal chemistry detailsPorosityPretreatment method

The invention discloses a preparation method of a nano-crystalline cellulose-based composite aerogel type organic dye absorption material. The method comprises the following steps: preparing nanofibers having functional surfaces by combining a chemical pretreatment method and a mechanical treatment method; and mixing the nanofibers and a natural absorption material to prepare composite aerogel which is used as the organic dye absorption material, wherein the porosity of the prepared composite aerogel is up to 99% or more, the decolourization ratio of the prepared material on organic dyes can exceed 90%, and the prepared material can be widely applied to absorbing the various water-soluble organic dyes.

Owner:ZHEJIANG FORESTRY UNIVERSITY

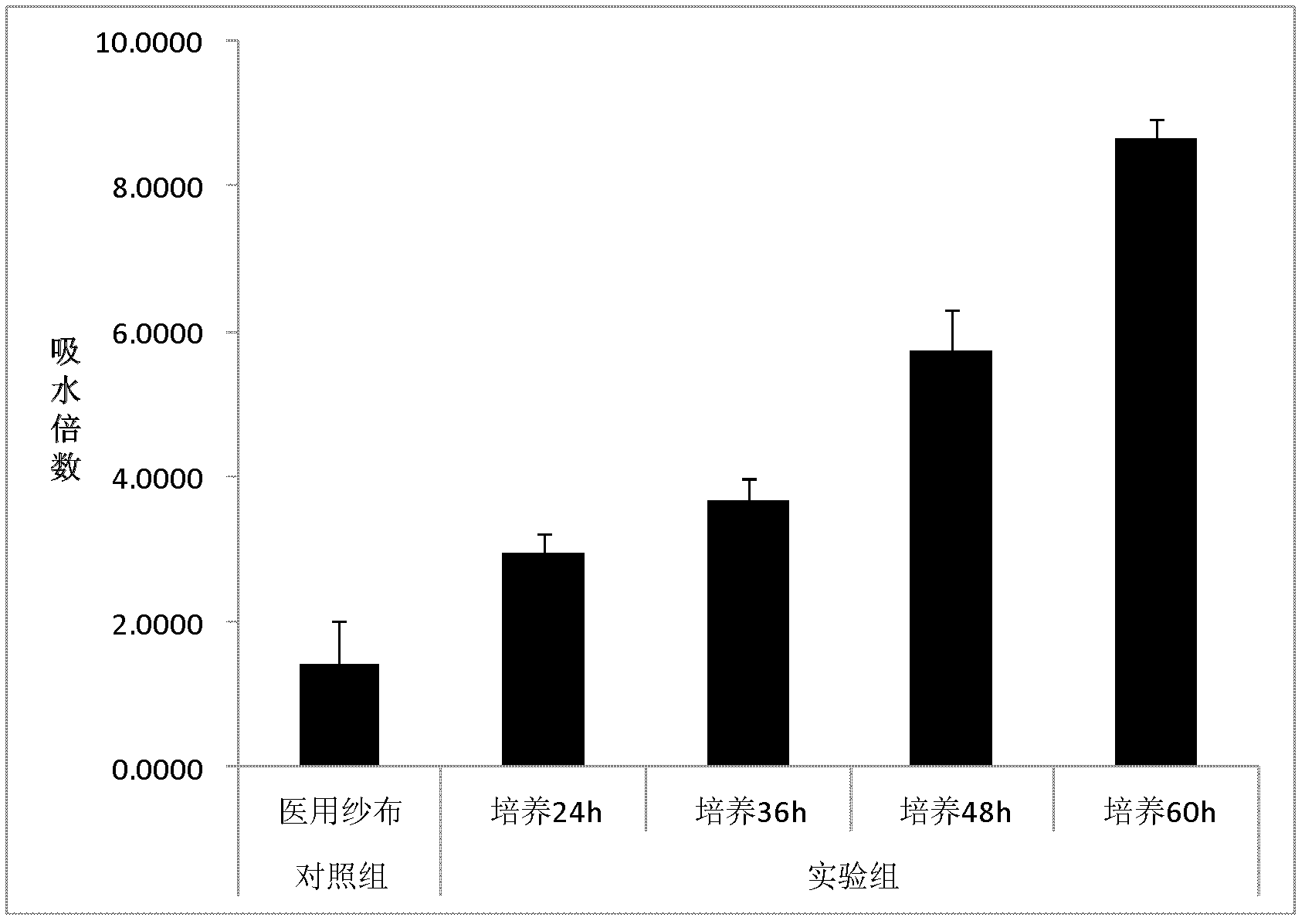

Method for preparing nano-cellulose antibacterial composite material through on-line culture

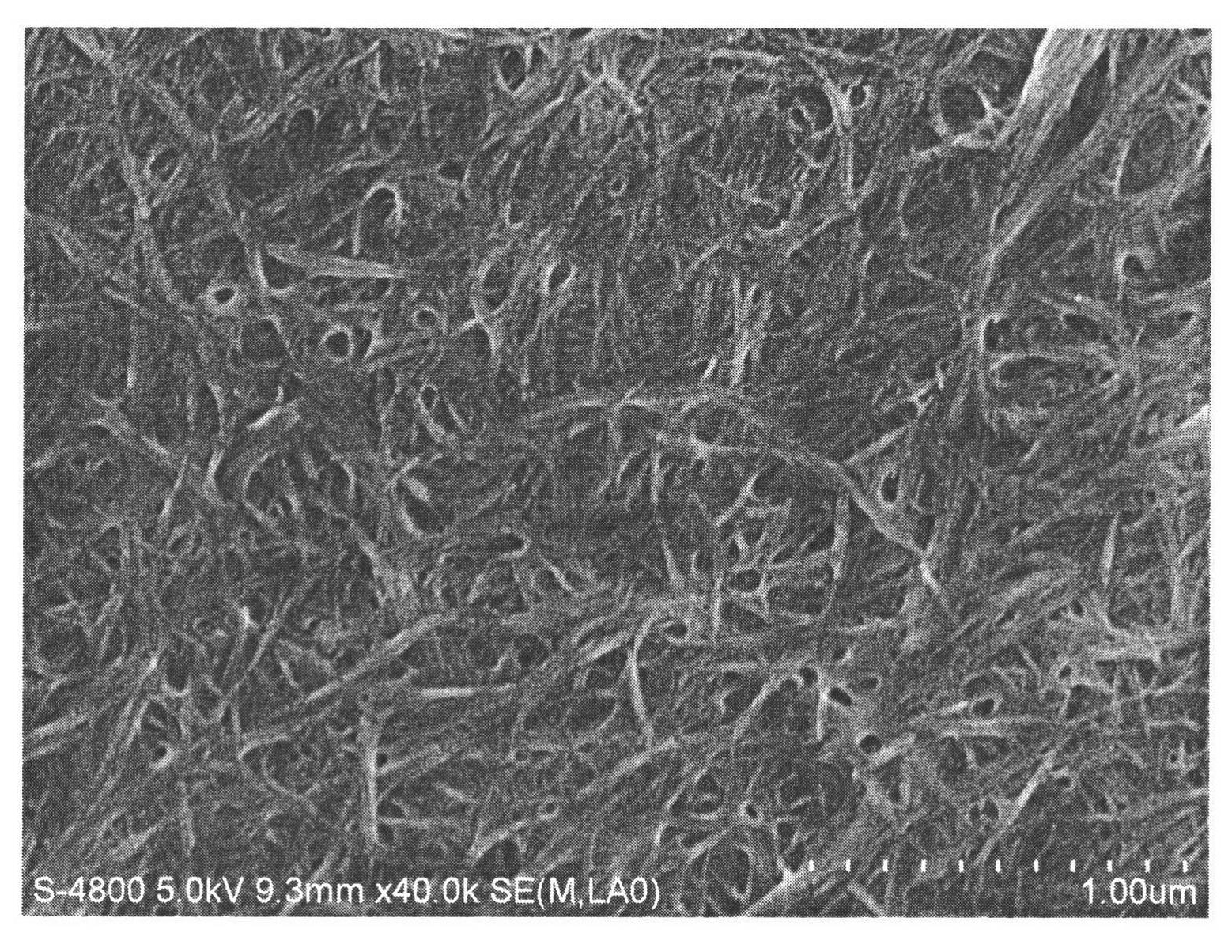

ActiveCN102552965ARealize fermentation productionImprove continuityCosmetic preparationsBacteriaWater bathsFiber

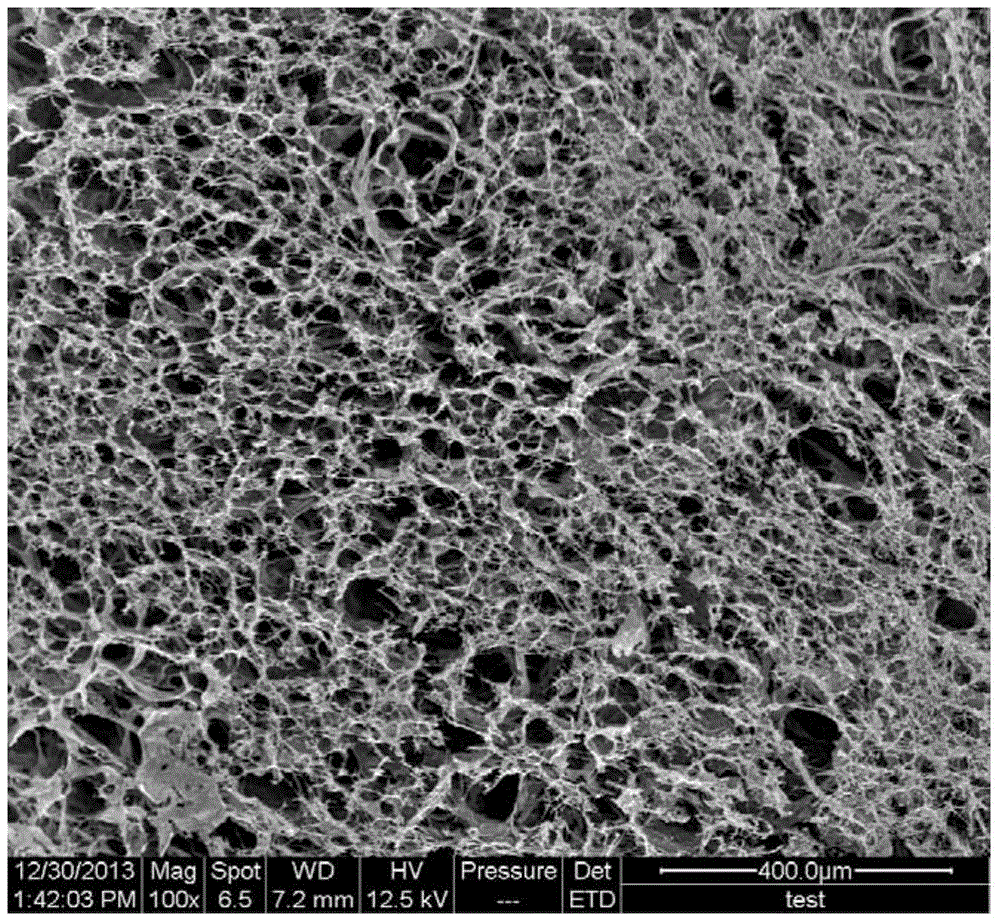

The invention relates to a method for preparing a nano-cellulose antibacterial composite material through on-line culture. The method comprises the following steps of: (1) inoculating an activated bacterial cellulose producing strain into a liquid culture medium, performing amplification culture, transferring the liquid culture medium into a bioreactor, culturing, adding an antibacterial material into the liquid culture medium, and continuing to culture to obtain an unpurified antibacterial bacterial cellulose composite material; and (2) peeling a bacterial cellulose membrane from a framework or directly soaking the composite material in a NaOH solution, treating in water bath, and washing until an obtained product is neutral to obtain the nano-cellulose antibacterial composite material. The preparation efficiency is high, and the method is simple, convenient, feasible and low in cost; and the surface of the bacterial cellulose composite material has a nanoscale three-dimensional fibrous mesh-shaped structure, the tensile strength of the material is greatly improved compared with that of a pure bacterial cellulose membrane, and the material can be widely applied to products such as facial masks, wound dressings, plasters, artificial skins and the like.

Owner:DONGHUA UNIV

Edible film material containing nanocellulose, edible film and preparation method of edible film

ActiveCN103254469AImprove mechanical propertiesImprove barrier propertiesFlexible coversWrappersMechanical propertyFilm material

The invention discloses an edible film material, an edible film made of the edible film material and a preparation method of the edible film. The edible film material comprises nanocellulose, modified starch and other edible auxiliary materials. With the adoption of the nanocellulose, the mechanical performance and the barrier property of the edible film are improved. The edible film can be widely applied to the inner packing of food such as high-class candies and chocolate.

Owner:珠海市红旌发展有限公司

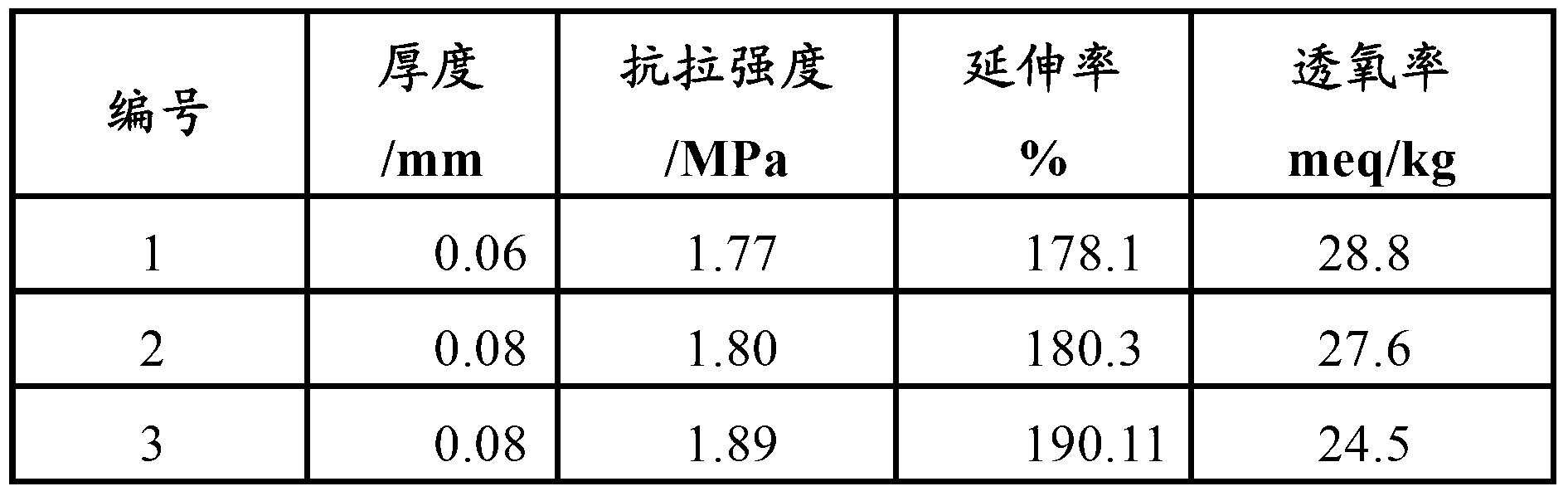

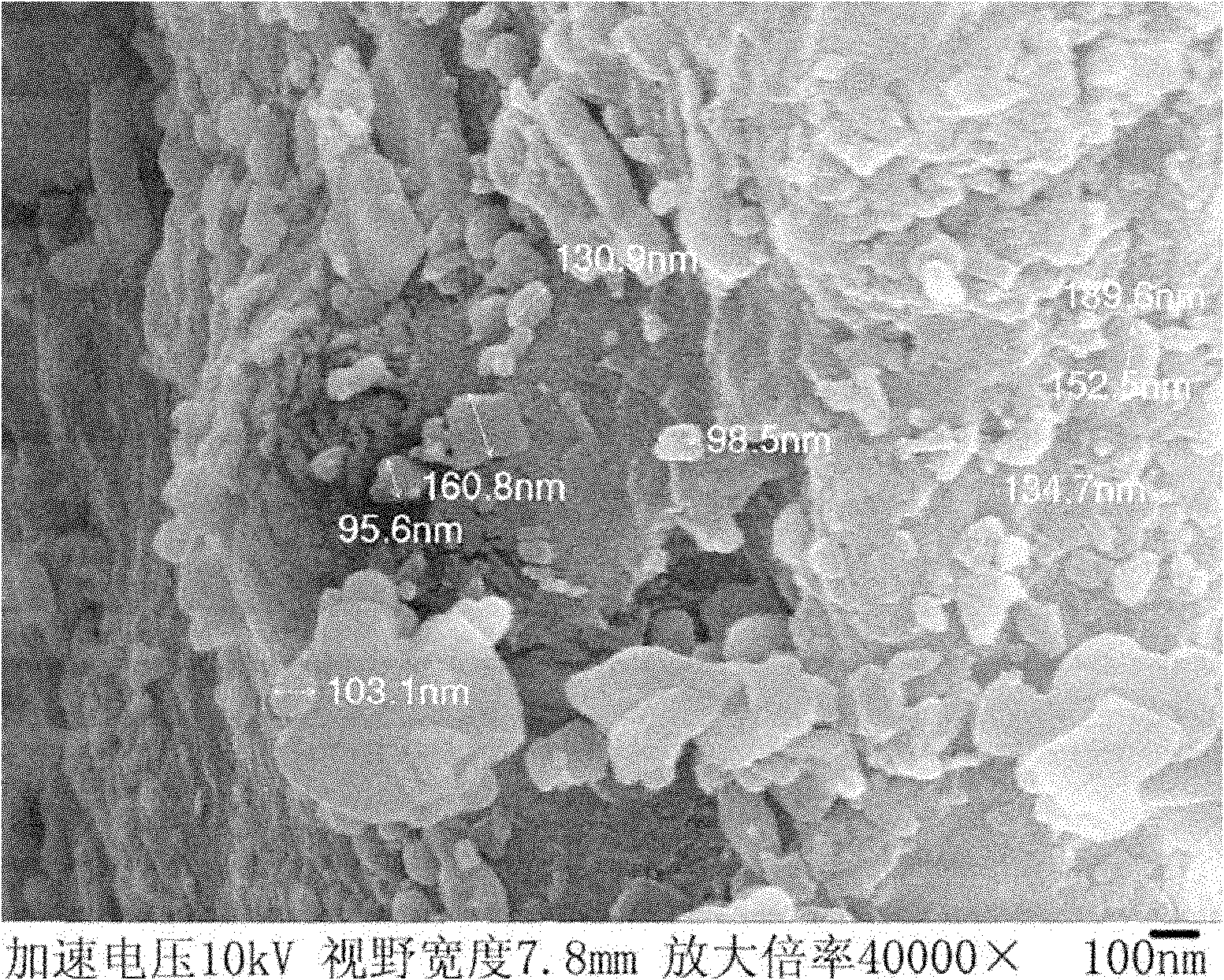

Preparation method of cellulose nano-fiber/polylactic acid composite membrane

InactiveCN103387688AUniform diameter distributionReduce hydrogen bondingPaper material treatmentFiberChemical treatment

The invention provides a preparation method of a cellulose nano-fiber / polylactic acid composite membrane. The preparation method comprises the following steps of: (1) treating raw materials; (2) performing chemical treatment; (3) performing mechanical treatment; (4) preparing a nano cellulose membrane; (5) preparing a nano cellulose / polylactic acid composite membrane material by using a mixing and dissolving method or an immersion method. The preparation method has the advantages that lignin and most of hemicellulose are removed by using a chemical method, and under a water wet swelling condition, water fills the positions in which most of the hemicellulose and the lignin are removed, so that the hydrogen bond acting force among fibrillae is reduced; then lignocellulose nano fibrillae with uniform morphological sizes and mesh gangles are prepared by adopting mechanical treatment. The nano celluloses prepared by grinding for 30 minutes and homogenizing are small in diameter size and are uniformly distributed, the diameters of the nano fibrillae is 15-50nm, and the length-diameter ratio is high and reaches 1200. The cellulose nano-fiber / polylactic acid composite membrane can be used as a substitute and the like for a flexible display, electronic paper, a solar battery, a flexible circuit and a glass substrate.

Owner:NANJING FORESTRY UNIV

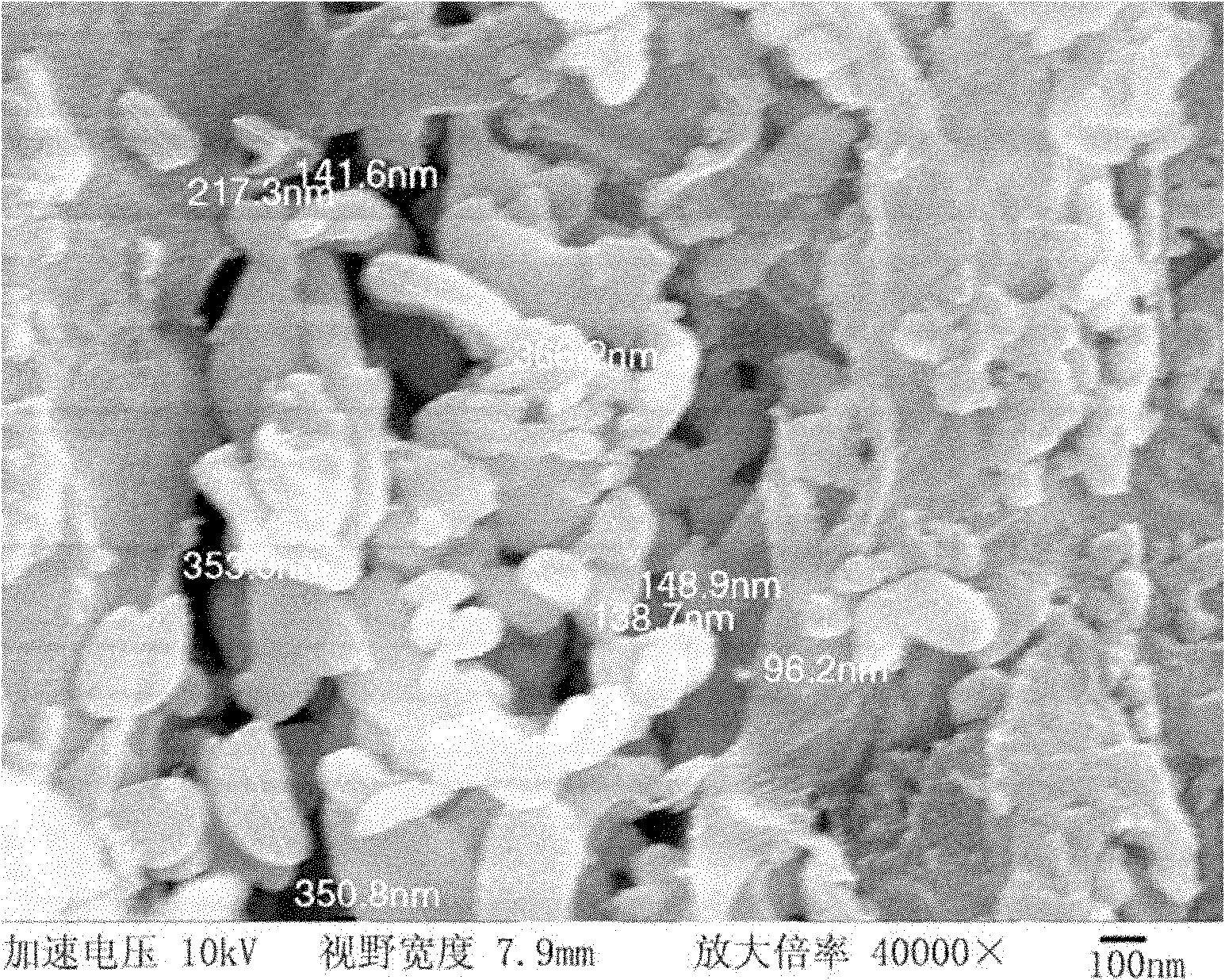

Preparation method of straw micro-nano cellulose

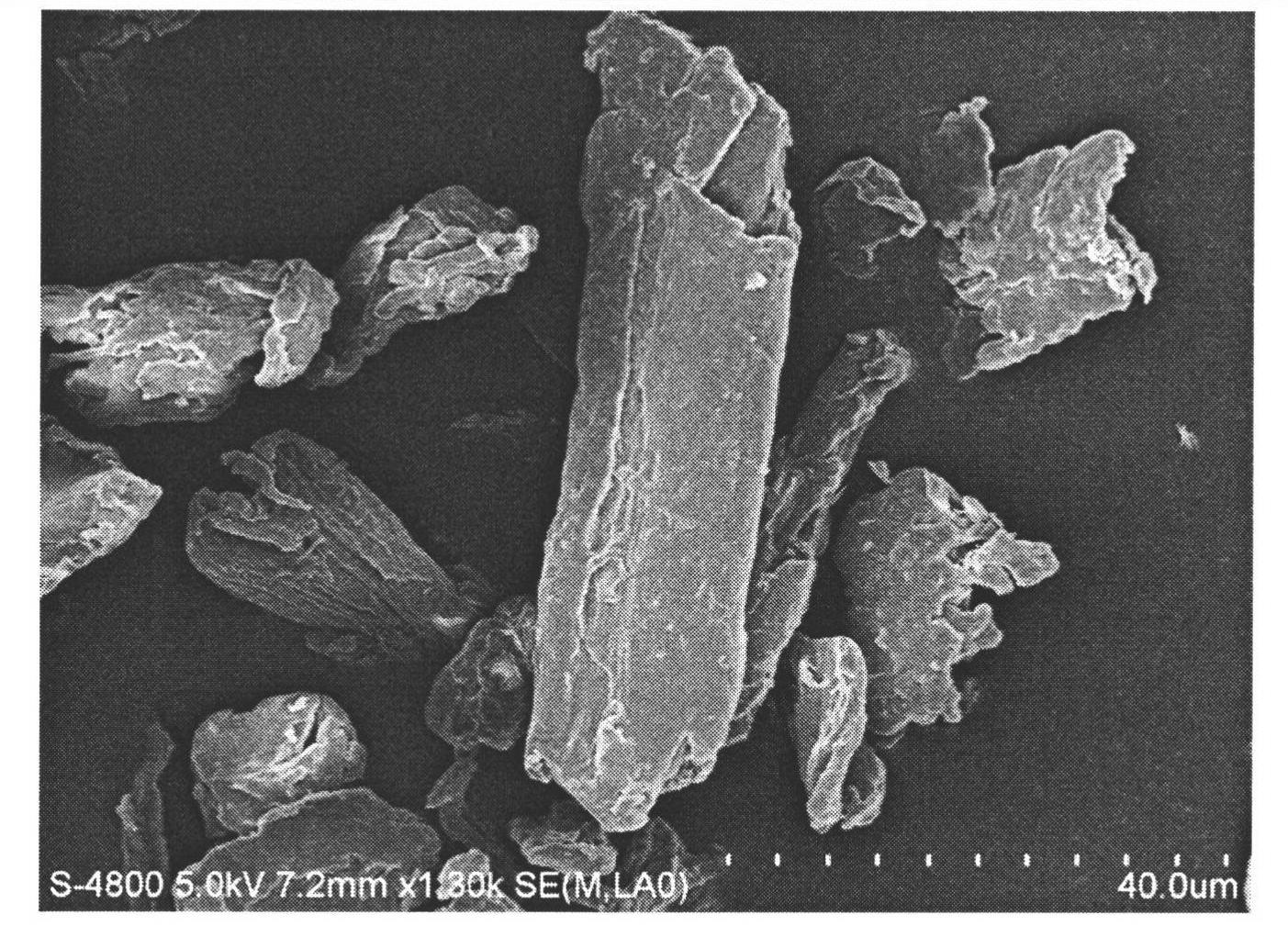

ActiveCN101949103AHigh aspect ratioLarge specific surface areaPaper material treatmentMicro nanoHydrolysis

The invention discloses a preparation method of straw micro-nano cellulose, relating to a preparation method of micro-nano cellulose. The invention solves the problems that the prior art for preparing nano cellulose comprises more steps, and rodlike nano cellulose has low draw ratio. The preparation method is as follows: 1, stewing; 2, dipping and washing; 3, screening; 4, bleaching; 5, carrying out hydrolysis and supersonic treatment; and 6, neutralizing, rinsing, breaking, decentralizing and drying to obtain the straw micro-nano cellulose. The micro-nano cellulose prepared by the preparation method of the invention has fibroid appearance, has the diameter of 10-200 nm and the length of 200-10 mu m, and has high draw ratio and large specific surface area. The invention is applied to the field of composite materials.

Owner:NORTHEAST FORESTRY UNIVERSITY

Preparation method of polylactic acid/nano-cellulose composite material

The invention provides a preparation method of a polylactic acid / nano cellulose composite material. The composite material comprises the following components in percentage by weight: 55 to 99.8% of polylactic acid, 0.1 to 15% of nano cellulose, and 0.1 to 30% of polyethylene glycol. The method comprises the following steps of: preparing a 5 to 15% an aqueous solution of microcrystalline cellulose, dripping concentrated sulfuric acid until the concentration of sulfuric acid reaches 40 to 60%, stirring and reacting for 1 to 2hours, carrying out centrifugation, ultrasound treatment and adjusting pH value to be neutral to obtain a nano cellulose suspension; dissolving polyethylene glycol, mixing with the nano cellulose suspension, stirring for 1 to 3hours at the temperature of 90 DEG C and carrying out vacuum drying to obtain a polyethylene glycol / nano cellulose comixture; and carrying out melt blending on the polyethylene glycol / nano cellulose comixture and polylactic acid for 5 to 8minutes at the temperature of 120 to 170 DEG C to obtain the composite material. The method is convenient and simple to operate, short in the time of the preparation process and solves the problem of uniform dispersion of nano-cellulose in the polylactic acid.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

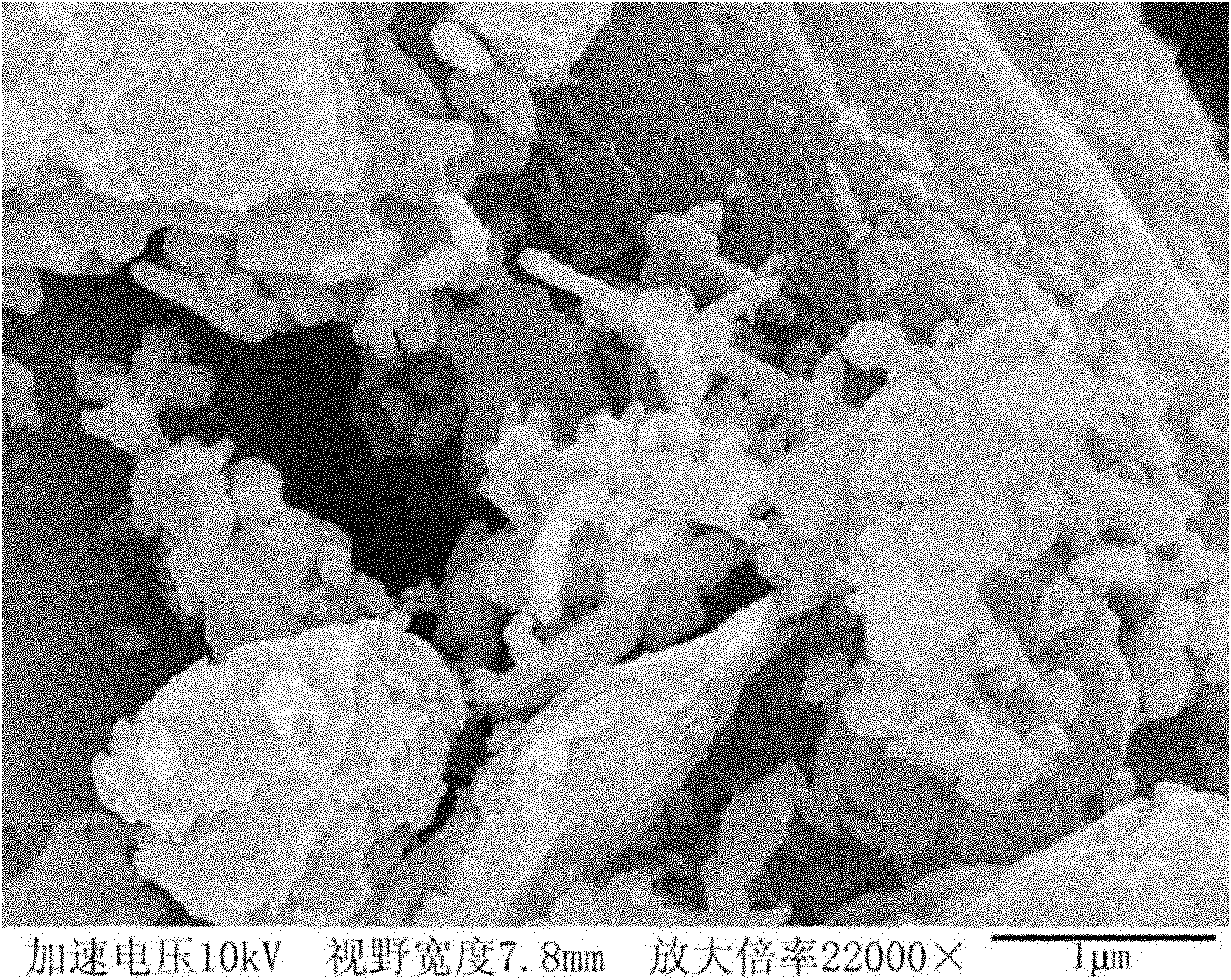

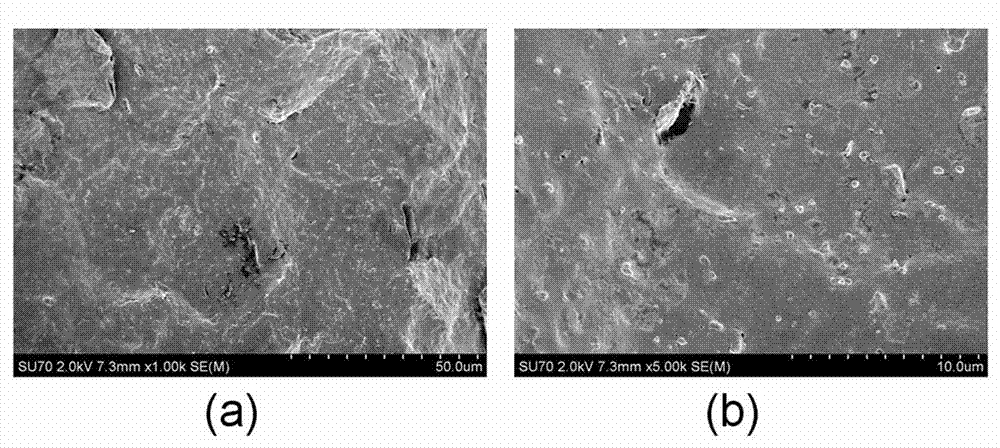

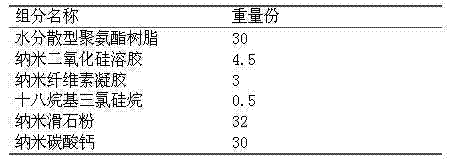

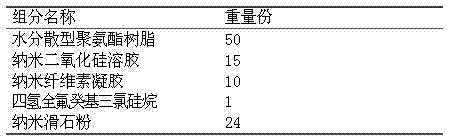

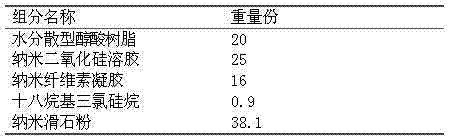

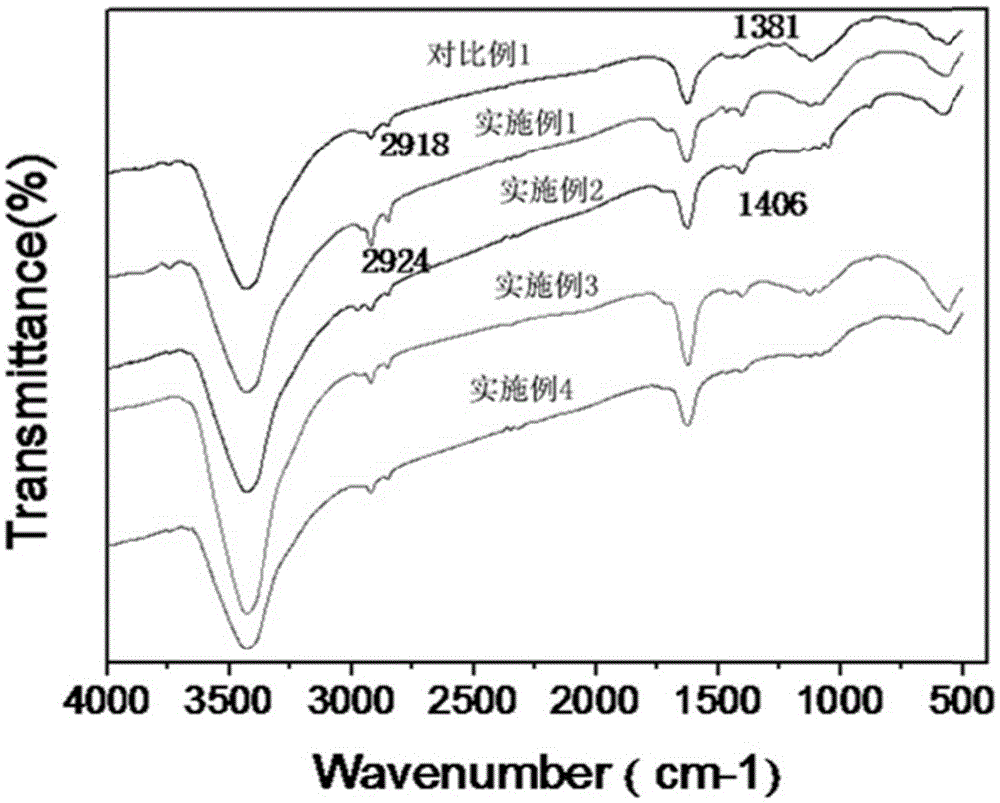

Transparent super-hydrophobicity wood coating and preparation method thereof

InactiveCN103756541AParticle size controllableHydrophobic hasPolyurea/polyurethane coatingsPolyester coatingsOctadecyltrichlorosilanePolymer science

The invention discloses a transparent super-hydrophobicity wood coating which comprises the following components in parts by weight: 20-50 parts of water dispersive polyurethane resin or water dispersive alkyd resin, 4.5-25 parts of nano silica sol, 3-16 parts of nano cellulose gel, 0.1-1 part of octadecyl trichlorosilane or tetrahydroperfluorodecyltrichlorosilane or stearic acid and 0-45 parts of nano talc powder or nano calcium carbonate. A preparation method of the transparent super-hydrophobicity wood coating comprises the following steps: adding matrix resin and filler into a stirring kettle, and stirring uniformly to obtain slurry; grinding the slurry with a sand mill; adding a low-surface energy substance and supported nano silica sol; performing ultrasonic sufficient mixing for 30 minutes to obtain the transparent super-hydrophobicity coating. The transparent super-hydrophobicity wood coating disclosed by the invention has the advantages of low cost, controllable process, adjustable size and good applicability and is suitable for a preparation method of large-area preparation of transparent super-hydrophobicity surface; the prepared super-hydrophobicity film has good self-cleaning property, antifouling property, hydrophobic property, oleophobic property and the like.

Owner:GUANGDONG YIHUA TIMBER IND +1

Graphene oxide/nano cellulose aerogel and preparation method and application thereof

ActiveCN105566659AGood removal effectEfficient purificationWater/sewage treatment by sorptionOrganic dyePhenol

The invention discloses a graphene oxide / nano cellulose aerogel and a preparation method and an application thereof, and belongs to the technical field of aerogel material. The aerogel is prepared by the method including the following steps: 1) dispersing nano cellulose in hydrochloric acid to prepare a nano cellulose dispersion liquid; 2) mixing a graphene oxide dispersion liquid with the nano cellulose dispersion liquid obtained in the step 1) evenly, and carrying out a hydrothermal reaction at the temperature of 170-190 DEG C to obtain a hydrogel; and 3) carrying out freeze drying of the hydrogel obtained in the step 2) to obtain the aerogel. According to the graphene oxide / nano cellulose aerogel provided by the invention, nano cellulose and graphene oxide as raw materials are subjected to hydrothermal reaction to prepare the hydrogel, the hydrogel is further subjected to freeze drying to obtain the final product. Compared with a graphene oxide aerogel, the aerogel has better removal effect on phenol in a phenol aqueous solution, can be used for removal of organic dye molecules or other impurities in sewage, and efficiently purifies the sewage.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Method For Preparing Functional Engineered Wood

ActiveUS20170239836A1Improve permeabilityWell mixedLiquid surface applicatorsPressure wood treatmentFire retardantEngineered wood

The present invention relates to furniture panels, and more particularly, to a method for preparing functional engineered wood. It includes the following steps: make veneer blanks by rotary cutting or splicing, and cut the veneer blanks into desired dimensions to obtain veneers A. Soak the veneers A in a ternary mixed solution of a biomass nanocellulose solubilizer, a fire retardant and an acid dye for toughening, fire retardation and dyeing to obtain veneers B. Add a formaldehyde decomposing powder into a modified MUF adhesive, mix them up, coat the veneers B with the mixture to obtain veneers C. Assemble and cold-press the veneers C to obtain flitches D, and saw the flitches D into desired patterns and dimensions to obtain finished products.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Preparation method of powder nano cellulose

The invention discloses a preparation method of powder nano cellulose, comprising the following steps: hydrolyzing the cellulose with sulfuric acid; filtering the obtained mixture, and then introducing a buffer solution for neutralization until pH is equal to 7; and centrifugally filtering, rinsing and drying the neutralized mixture to obtain the powder nano cellulose. In the preparation method, acid liquor adsorbed by the nano cellulose is effectively neutralized and surface hydrogen bonds are damaged, thus the obtained powder nano cellulose is not agglomerate while being dried and can conveniently form stable colloid in water. The preparation method has the advantages of cheap and available buffer solution adopted in reaction and mild reaction condition, thus being applicable to industrial production.

Owner:SOUTHEAST UNIV

Preparation method of biomass nano cellulose carbon aerogel

The invention relates to a preparation method of a carbon aerogel, particularly a preparation method of a biomass nano cellulose carbon aerogel, and aims to solve the problems of complex preparation process and lack of raw materials in the traditional carbon aerogel. The method comprises the following steps: 1. treatment of biomass material: treating the biomass material with acidified sodium chlorite, and treating with a 1-10 wt% potassium hydroxide solution to obtain purified cellulose; 2. preparing purified cellulose water solutions with different concentrations; 3. mechanical treatment: carrying out ultrasonic treatment on the purified cellulose water solution, carrying out high-pressure homogenization treatment to obtain a nano cellulose water suspension, and standing the nano cellulose water suspension to obtain the nano cellulose aquagel by self-assembly; 4. drying the nano cellulose aquagel to prepare the nano cellulose aerogel; and 5. carrying out carbonizing treatment on the nano cellulose aerogel in a pipe furnace in an inert gas protective atmosphere to prepare the nano cellulose carbon aerogel. The method is applicable to the field of aerogel materials.

Owner:NORTHEAST FORESTRY UNIVERSITY

Cellulose/titanium dioxide/silica aerogel and preparation method thereof

ActiveCN103203206AGood biocompatibilityGood flexibilityColloidal chemistry detailsThermal insulationSilica gel

The invention relates to a cellulose / titanium dioxide / silica aerogel and a preparation method thereof. The method comprises the steps such as cellulose sol preparation, nano-grade titanium dioxide surface loading, silica surface coating, curing, aging, hydrophobizing, bonding forming, drying treatment, and the like. According to the invention, nano-grade cellulose is adopted as a core, and is loaded with nano-grade titanium dioxide; a silica layer is coated; and the steps such as curing, aging, hydrophobizing, bonding forming, drying treatment, and the like are carried out, such that the cellulose / titanium dioxide / silica aerogel is obtained. The aerogel has the performances such as flexibility, high strength, bacterium resistance, ultraviolet resistance, odor-removing function, warm-keeping function, thermal insulation, and sound insulation. The aerogel can be widely applied in the fields such as thermal underwear, body armor, insulation materials, pressure-resistant materials, special coatings, aerospace materials, and the like.

Owner:SHANDONG CAYON TESTING TECH

Method of preparing clubbed nano-cellulose

The invention discloses a method for preparing nano-rod cellulose, which comprises the following steps: dispersing fiber raw material into sulphuric acid water solution of which mass concentration is 50 to 65 percent, hydrolyzing the fiber raw material by single-mode microwave radiation for 5 to 60 minutes at a temperature of between 20 and 50 DEG C and at the microwave radiation power of 10 to 100 watts, then adding distilled water into hydrolysis solution and diluting the hydrolysis solution to have 10 times of volume, and obtaining stable nano-rod cellulose suspension through post treatment processes such as centrifugal separation, dialysis, filter, ultrasonic dispersion and the like of the diluent, so as to obtain the nano-rod cellulose of which width is about 10 nanometers and length is about 200 to 300 nanometers.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

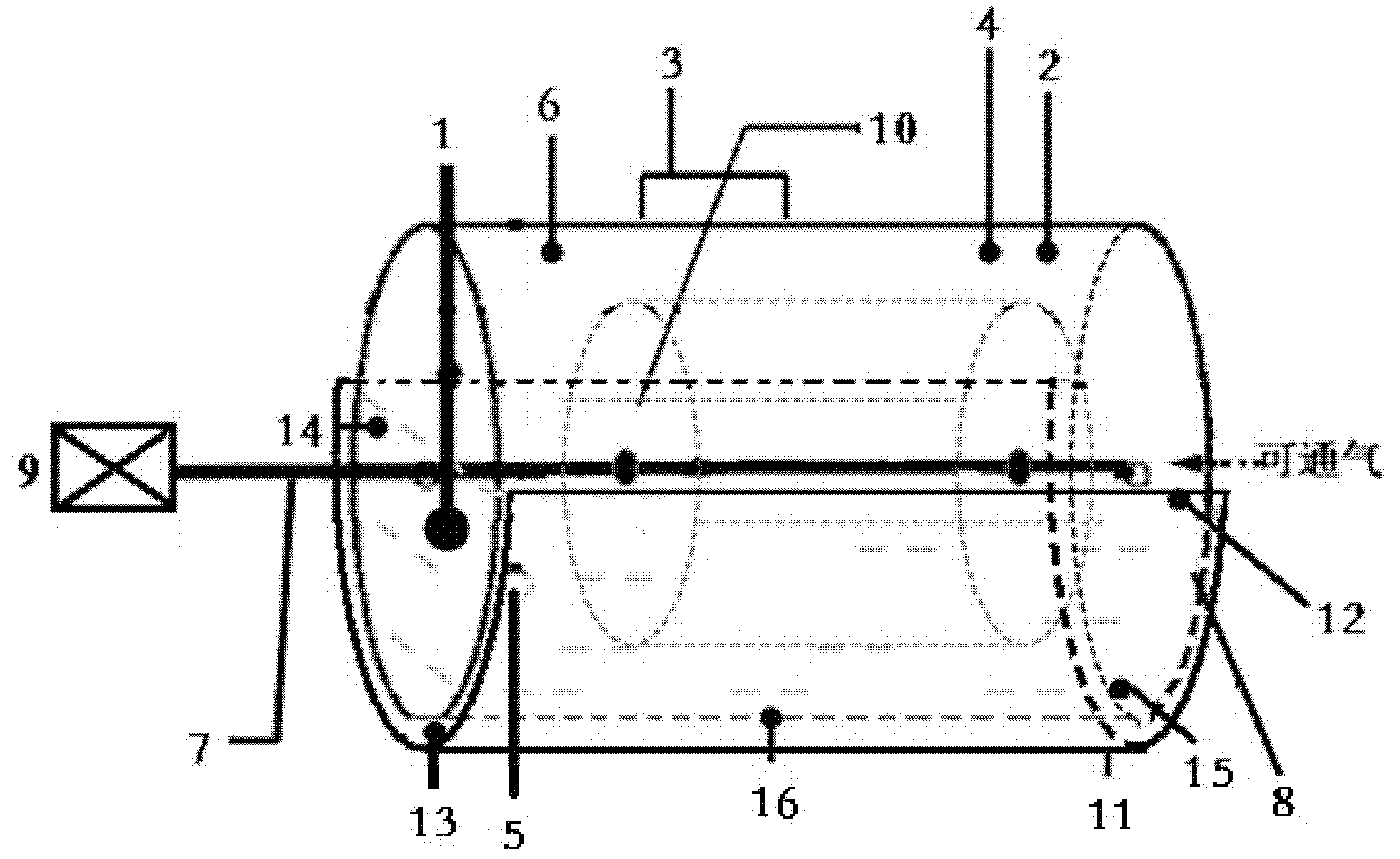

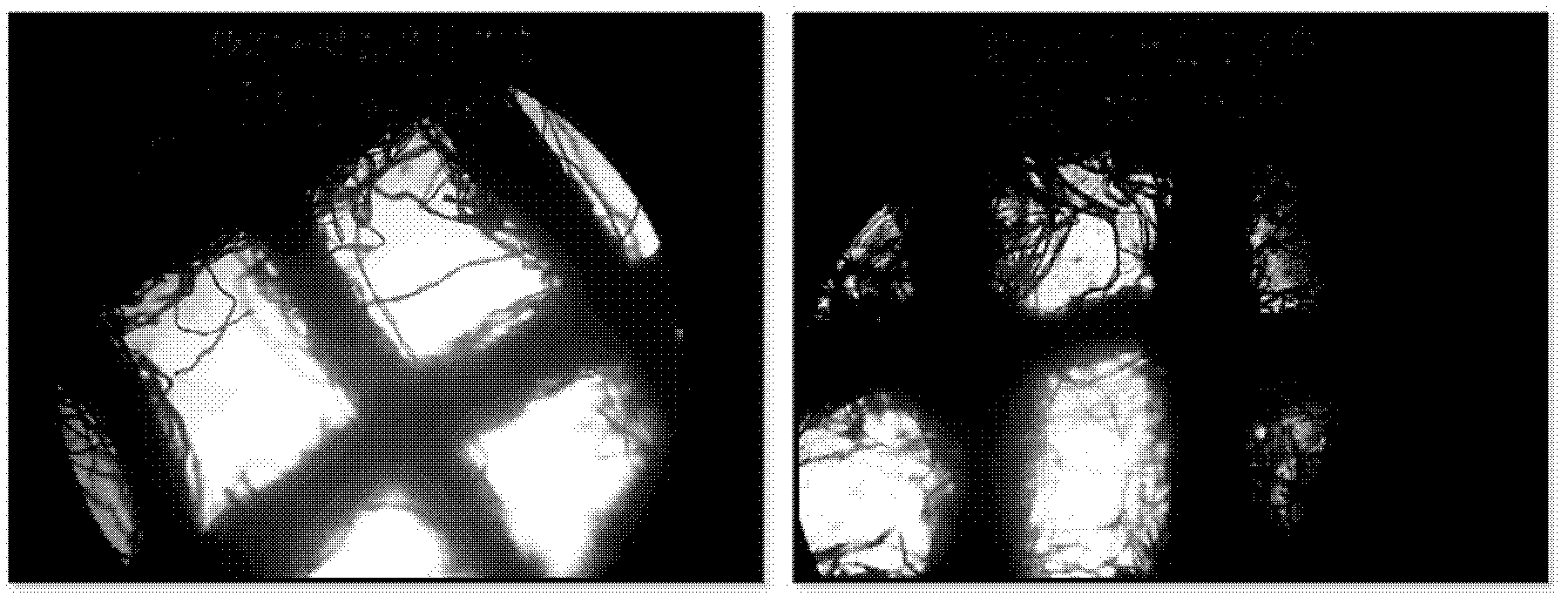

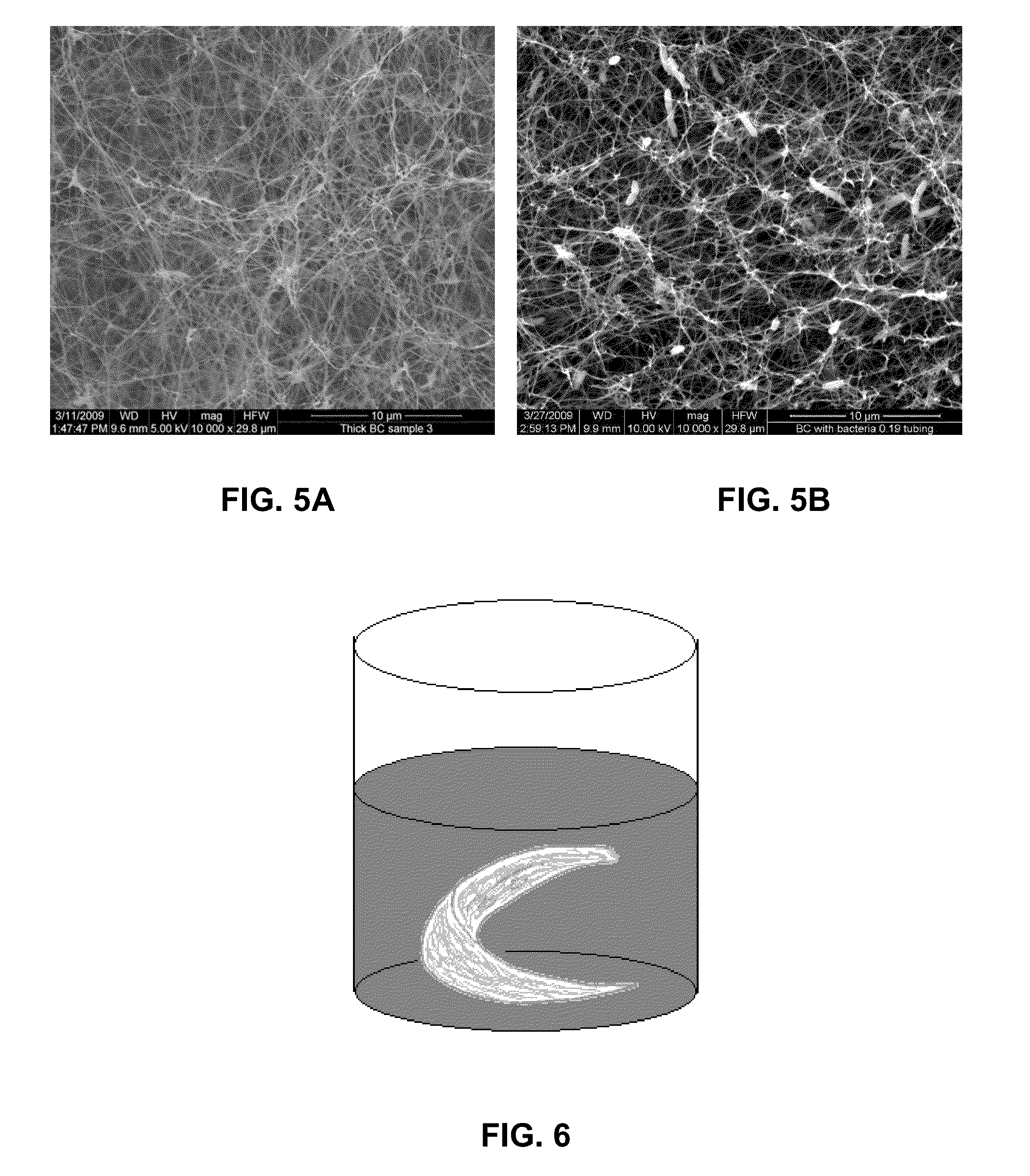

Three-dimensional bioprinting of biosynthetic cellulose (BC) implants and scaffolds for tissue engineering

InactiveUS8691974B2Optimize thicknessStrength optimizationOrganic active ingredientsSugar derivativesInterconnectivityPorosity

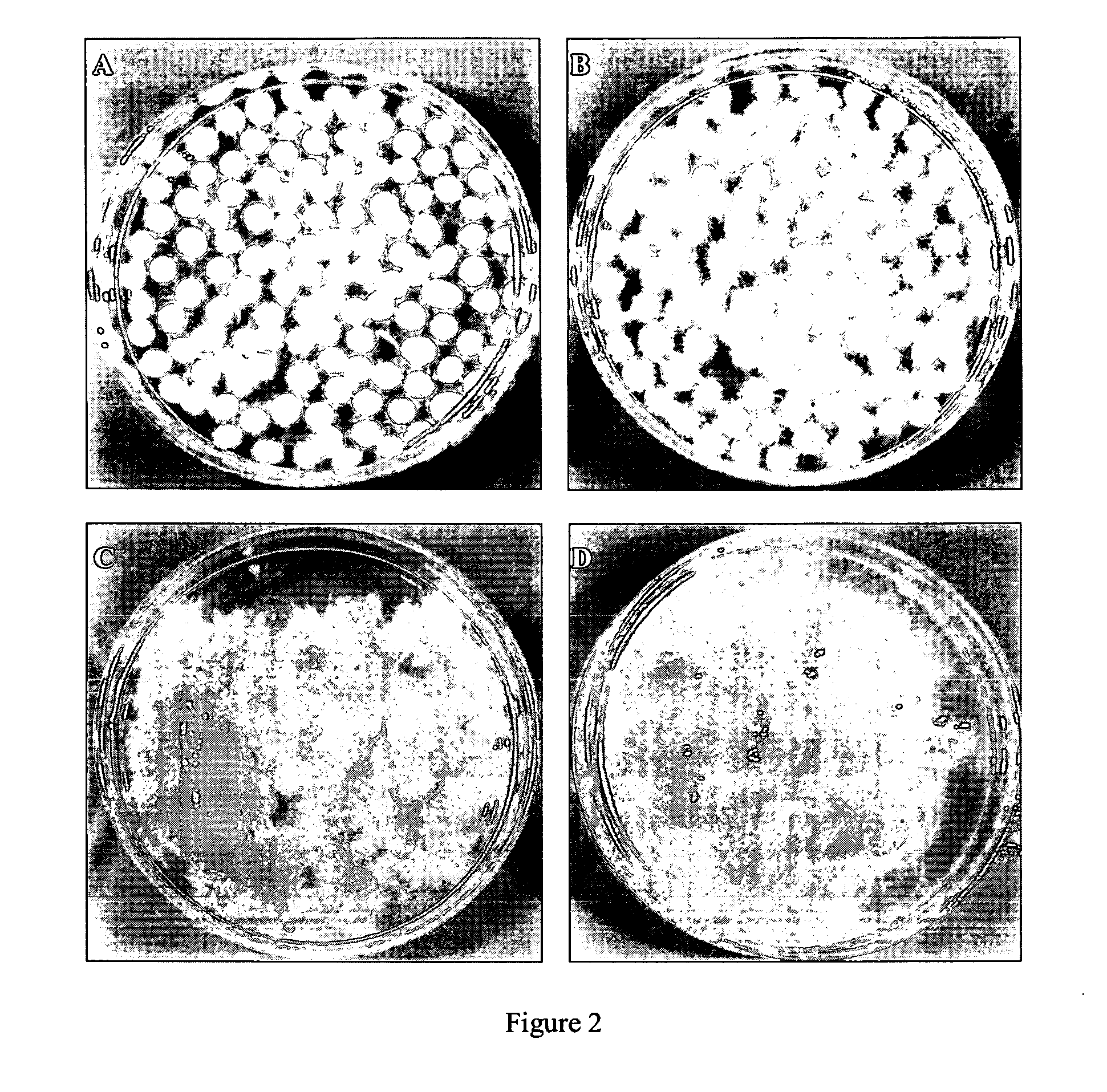

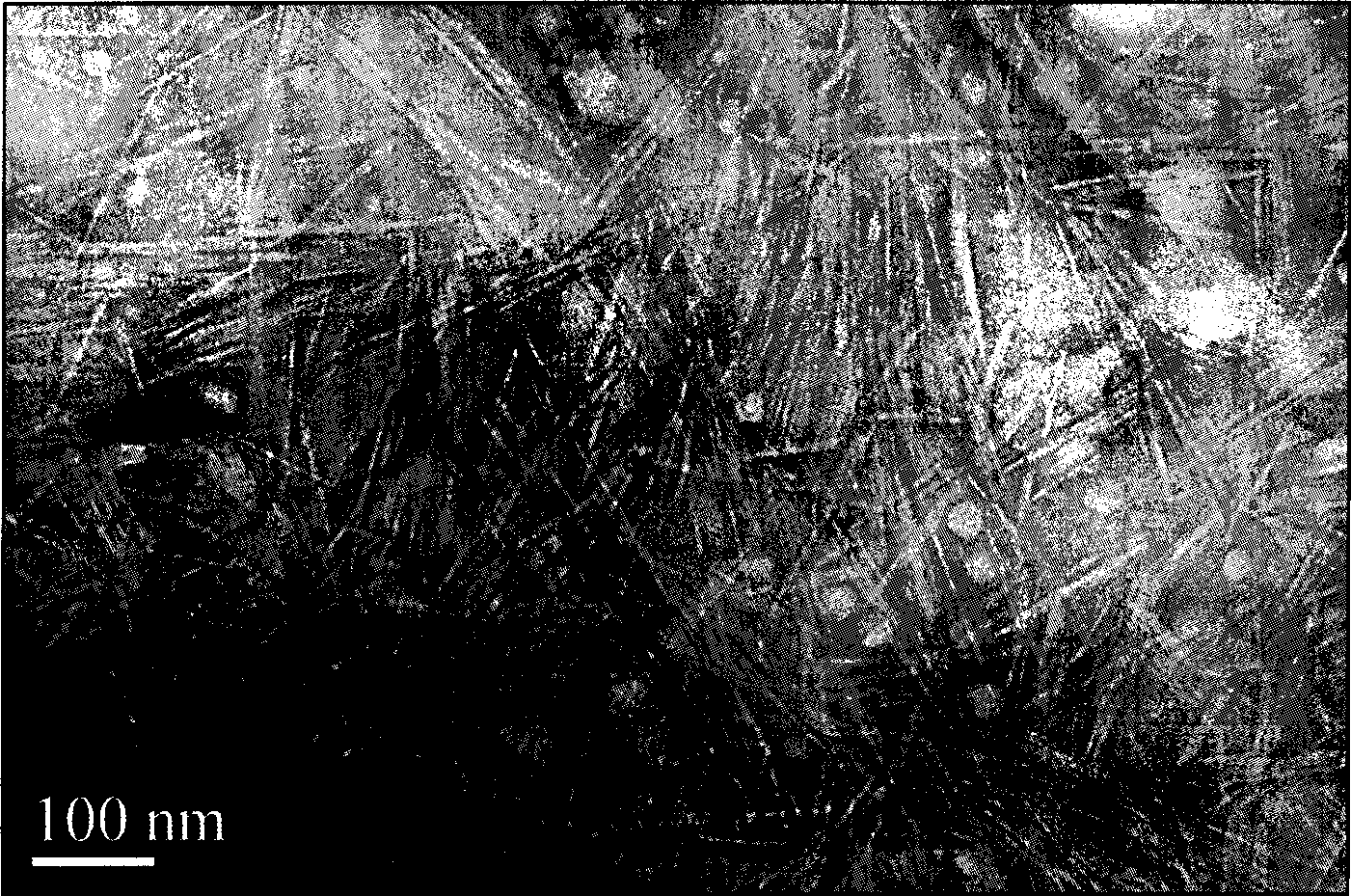

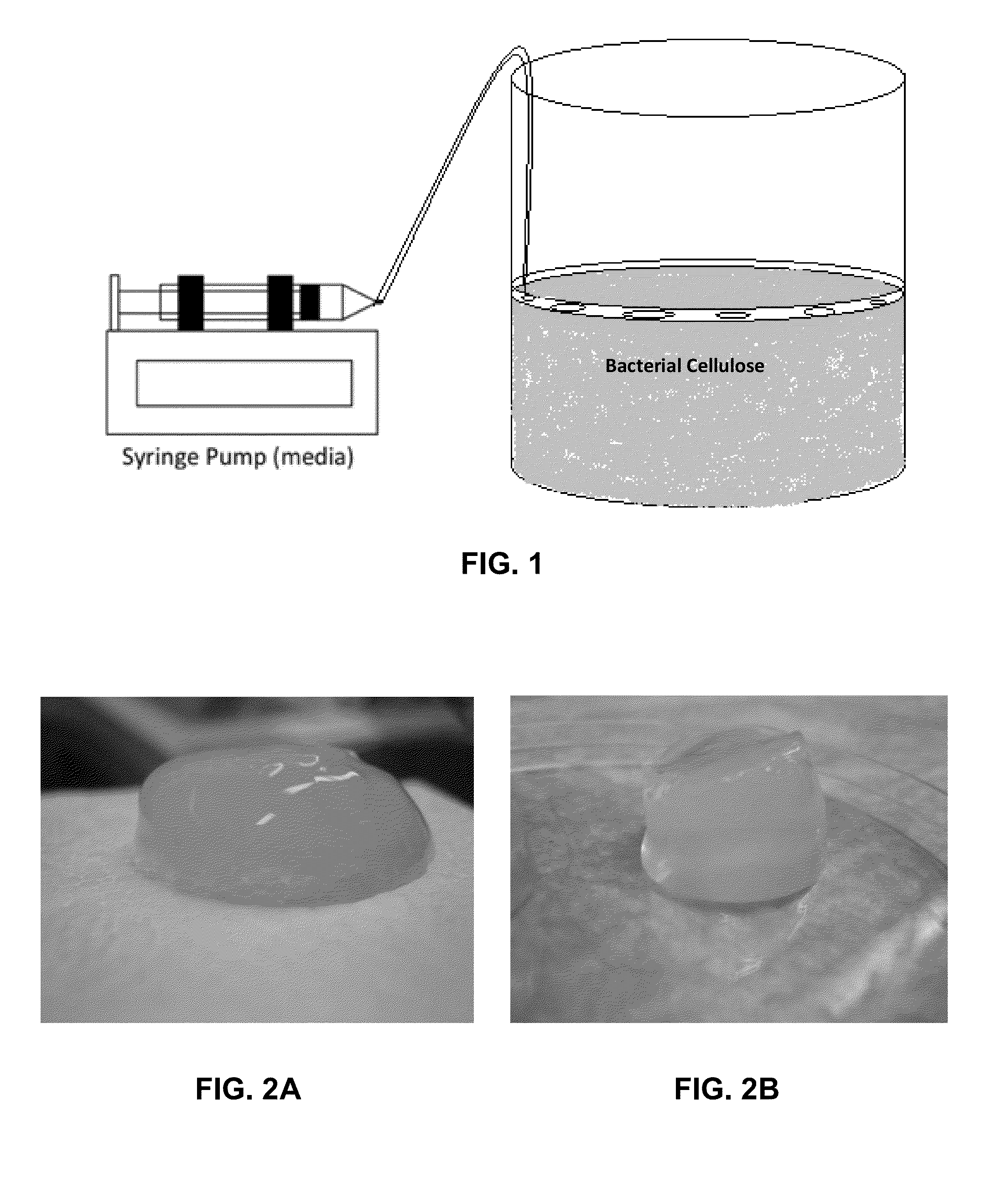

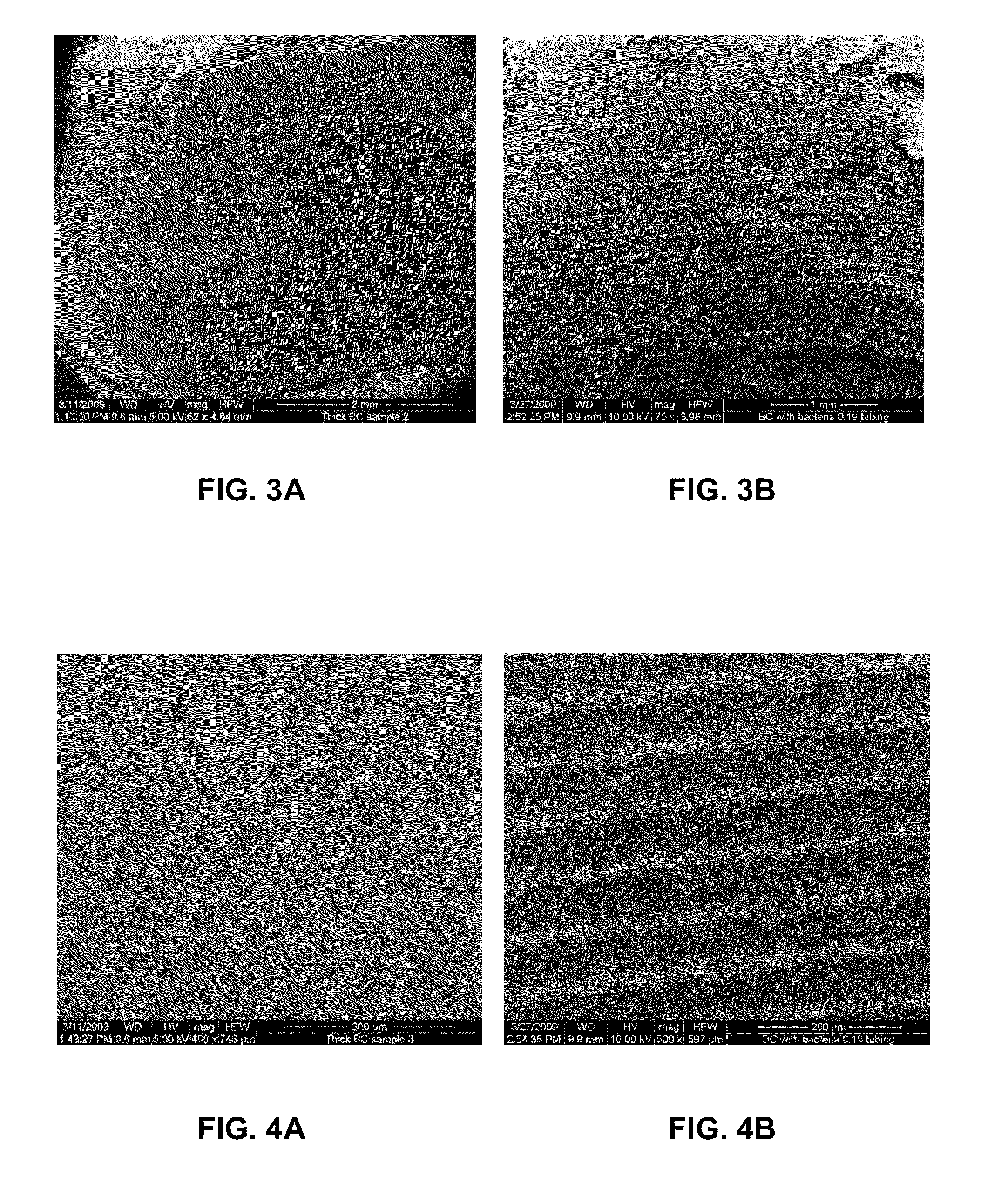

A novel BC fermentation technique for controlling 3D shape, thickness and architecture of the entangled cellulose nano-fibril network is presented. The resultant nano-cellulose based structures are useful as biomedical implants and devices, are useful for tissue engineering and regenerative medicine, and for health care products. More particularly, embodiments of the present invention relate to systems and methods for the production and control of 3-D architecture and morphology of nano-cellulose biomaterials produced by bacteria using any biofabrication process, including the novel 3-D Bioprinting processes disclosed. Representative processes according to the invention involve control of the rate of production of biomaterial by bacteria achieved by meticulous control of the addition of fermentation media using a microfluidic system. In exemplary embodiments, the bacteria gradually grew up along the printed alginate structure that had been placed into the culture, incorporating it. After culture, the printed alginate structure was successfully removed revealing porosity where the alginate had been placed. Porosity and interconnectivity of pores in the resultant 3-D architecture can be achieved by porogen introduction using, e.g., ink-jet printer technology.

Owner:VIRGINIA TECH INTPROP INC

Biomimetic preparation method of high-strength regenerated silk protein fiber

ActiveCN103498210AHigh crystallinityHigh strengthConjugated cellulose/protein artificial filamentsWet spinning methodsMechanical propertyProtein fiber

The invention discloses a biomimetic preparation method of a high-strength regenerated silk protein fiber. The method takes high crystallization degree, high strength, high modulus nano cellulose whiskers with a large length-diameter ratio to simulate the beta-fold microcrystal in the natural silk fiber, then mixes the nano cellulose whiskers with a regenerated silk fibroin solution, and finally prepares the high-strength regenerated silk protein fiber through a wet spinning method. The characteristic that a large amount of hydroxyl groups in the molecular chains of the rigid nano cellulose whiskers can form intermolecular hydrogen bonds with polar groups such as carboxyl groups, amino groups, and the like, in the molecular chains of silk protein is utilized to achieve the structural bionics of the regenerated silk protein fiber, and thus improves the mechanical properties of the regenerated silk protein fiber. The preparation method is simple, and does not pollute the environment. The mechanical properties of the obtained regenerated silk fiber are equal to or even better than those of natural silk, and the regenerated silk fiber has the similar micro-structure and configuration as the natural silk.

Owner:浙江枫翎新材料科技有限公司

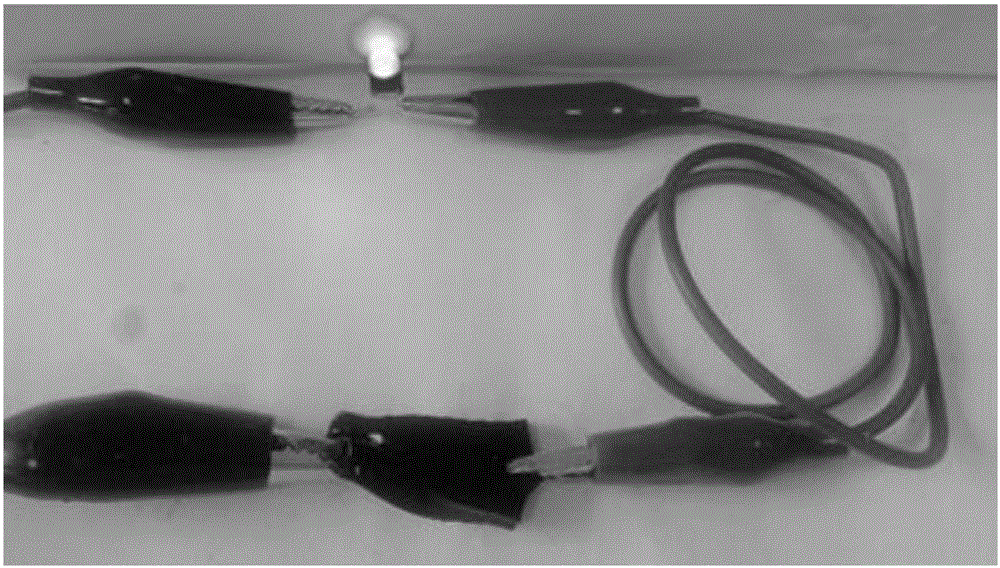

Graphite-nanocellulose-polyvinyl alcohol composite conductive hydrogel and preparation method and application thereof

InactiveCN106750396ASimple processReduce energy consumptionNon-conductive material with dispersed conductive materialConductive materialsGraphite

The invention belongs to the field of macromolecule composite conductive materials, and discloses a graphite-nanocellulose-polyvinyl alcohol composite conductive hydrogel and a preparation method and an application thereof. The graphite-nanocellulose-polyvinyl alcohol composite conductive hydrogel is prepared by the following steps of a, preparing a graphite dispersing liquid; b, preparing a nanocellulose suspension liquid; c, mixing the graphite dispersing liquid and the nanocellulose suspension liquid, adding a polyvinyl alcohol water solution and a crosslinking agent, stirring, and forming a gel, so as to obtain the hydrogel. The graphite-nanocellulose-polyvinyl alcohol composite conductive hydrogel can be used for preparing flexible conductive materials, and has better application prospect.

Owner:NANJING FORESTRY UNIV

Method for preparing nano celluloses through high-pressure homogenizing and low-temperature cooling

The invention relates to a method for preparing nano celluloses through high-pressure homogenizing and low-temperature cooling. The method comprises the following steps: dispersing the raw fibers in a sulfuric acid aqueous solution with the mass fraction of 10-20%, maintaining the raw fibers in the aqueous solution for 2-6 hours at 20-60 DEG C, adding a dispersing agent after dilution, centrifugal separation and cyclic dialysis, utilizing a high-pressure homogenizer for high-pressure homogenizing, simultaneously carrying out low-temperature cooling in the process of high-pressure homogenizingto obtain nano cellulose colloids and obtaining the nano celluloses through centrifugal separation and freeze drying, wherein the pressure is 1000-1200bar; and the cycle index is 4-16. The diameter and length of the obtained nano celluloses are respectively about 10-30nm and 300nm. The method has the beneficial effect of solving the following problems: the existing nano celluloses prepared by utilizing the homogenizers have wide and nonuniform diameter distribution; the fibers are interwoven in micron size; and the pressure and the temperature are raised in the process of high-pressure homogenizing.

Owner:NANJING FORESTRY UNIV

Oxidation nanocellulose adsorbing material and preparation method thereof

ActiveCN105498733AMicroscale reductionImprove accessibilityOther chemical processesSorbentCatalytic effect

The invention provides a preparation method of an oxidation nanocellulose adsorbing material. The preparation method comprises the following steps of conducting pretreatment and then cleaning cellulose; and under the catalytic action of 2, 2, 6, 6-tetramethyl piperidine-nitrogen-oxide and sodium bromide, conducting an oxidation reaction on obtain cellulose under the action of an oxidizing agent, so that oxidation nanocellulose is obtained, wherein sodium hypochlorite serves as the oxidizing agent; mixing the nanocellulose with an organic solution containing amino high molecules, then conducting centrifugation, then mixing the mixture with a cross-linking agent, and conducting a reaction, so that the oxidation nanocellulose adsorbing material is obtained. By means of the preparation method, the specific surface area of the cellulose is increased, the contactable performance of heavy metal pollutants and adsorbent is improved, the surface of the material can have a large number of adsorption functional groups, and heavy metal ions can be aggregated to the surface of the adsorbent from a sewage system through the complexation effect and the electrostatic effect. The invention further provides the oxidation nanocellulose adsorbing material.

Owner:UNIV OF SCI & TECH OF CHINA

Cationization modification method for nano-crystalline cellulose and preparation method of high-strength cigarette paper

ActiveCN102180979ALess investmentHigh strengthReinforcing agents additionPaper/cardboardFiberReaction temperature

The invention belongs to the field of production of special paper, and in particular relates to a cationization modification method of nano-crystalline cellulose and a method for preparing high-strength cigarette paper from the modified nano-crystalline cellulose. Specific to the characteristic of high specific surface area of nano-crystalline cellulose, KOH and a method for adding an etherification reaction accelerant are adopted, the reaction temperature is lowered below 50 DEG C, cationization modification is performed on the nano-crystalline cellulose, and the modified nano-crystalline cellulose has the characteristics of retention and enhancement, so that the modified nano-crystalline cellulose has a wider application prospect; in the method for preparing cigarette paper, softwood pulp is not used, and higher natural air permeability and higher bonding strength of a product are ensured under the condition of reducing broadleaf wood fiber devillicate and fibrillation, so that energy consumption in the production process of paper, in particular in the pulping process, is remarkably lowered, equipment investment of a paper mill is reduced, high-strength cigarette paper is manufactured, the page quality is improved, higher strength and air permeability of the product are achieved, and the requirements on energy conservation and emission reduction are met.

Owner:MUDANJIANG HENGFENG PAPER CO LTD

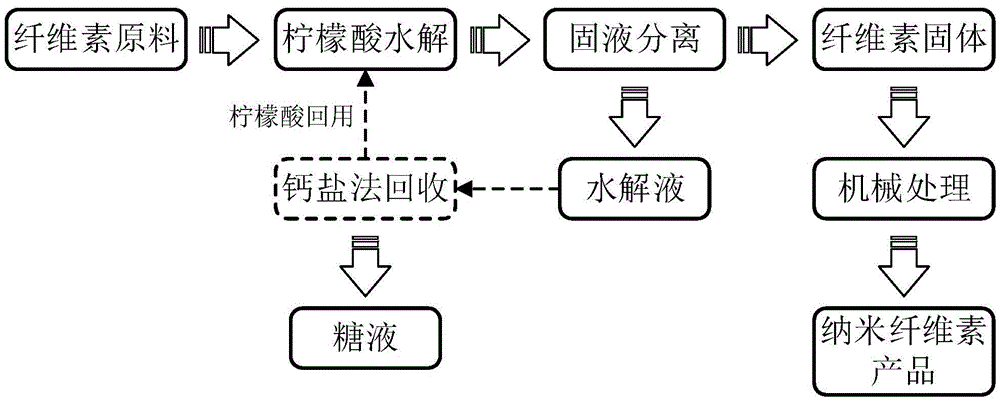

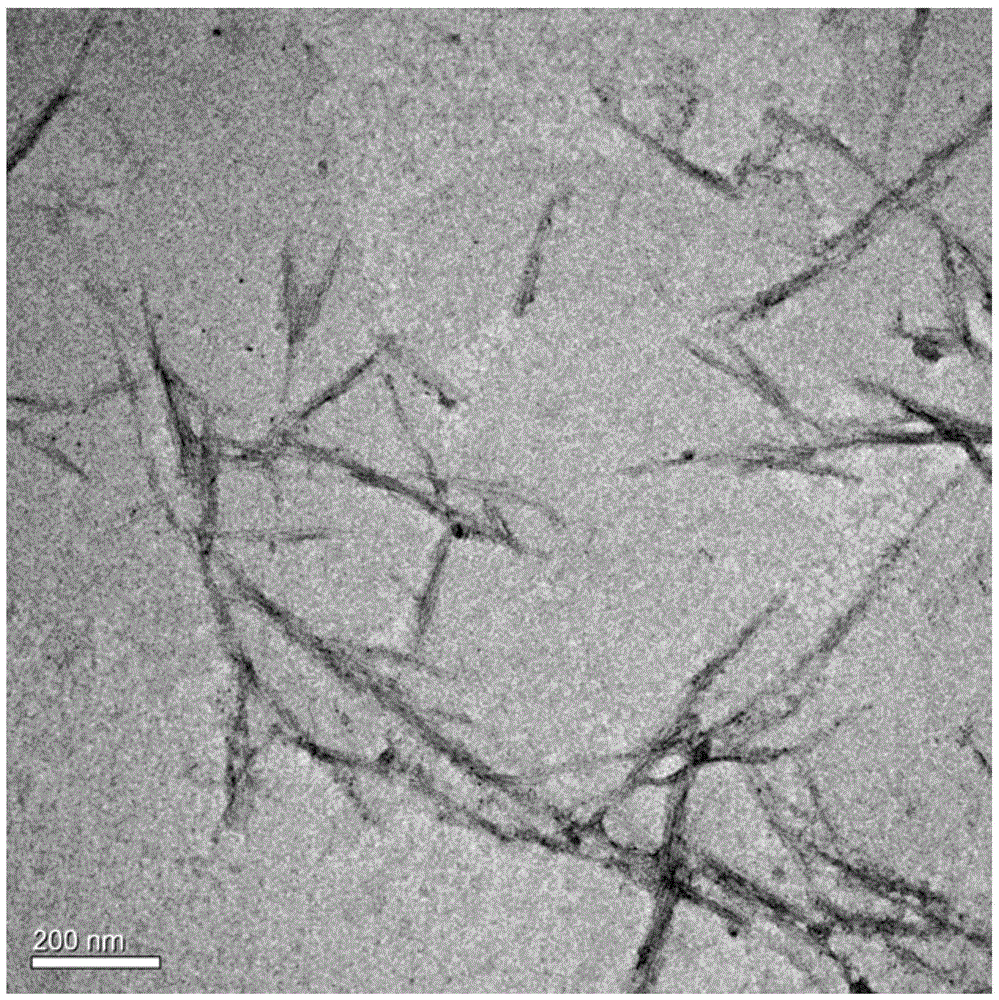

Preparation method of nanocellulose fibrils

The invention relates to a green, economical and sustainable method for preparing nanocellulose fibrils. The preparation method comprises the following steps that 1, a cellulose raw material is added to a citric acid solution to be heated, stirred and hydrolyzed; 2, treated cellulose and hydrolysate are separated through methods of centrifugal sedimentation and the like, and precipitated cellulose is centrifugally washed with water multiple times and diluted into a cellulose suspension; 3, the separated hydrolysate can be directly recycled at least once, citric acid is recovered from the recycled hydrolysate, and the citric acid obtained through recovery can be recycled continuously; 4, the natural structure of the cellulose suspension obtained in the second step is further destroyed through a high pressure homogenizer or ultrasonication or physical mechanical treatment of a disc mill, and the colloidal nanocellulose fibrils are obtained. According to the method for preparing the nanocellulose fibrils, a catalyst is not adopted, the reaction condition is relatively mild, the reaction is easy to control, operation is easy, and the method is friendly to environment.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

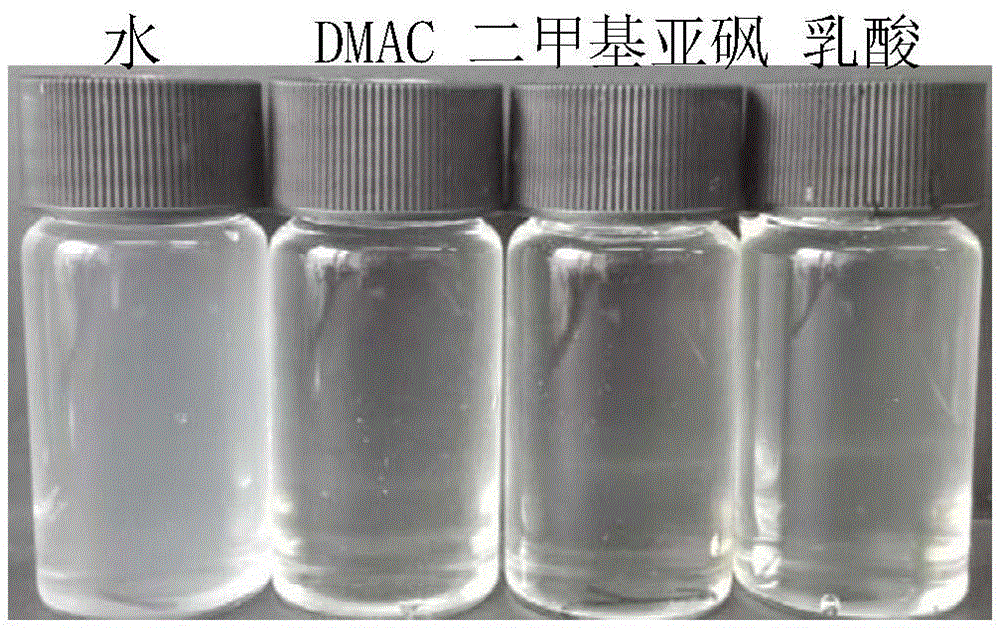

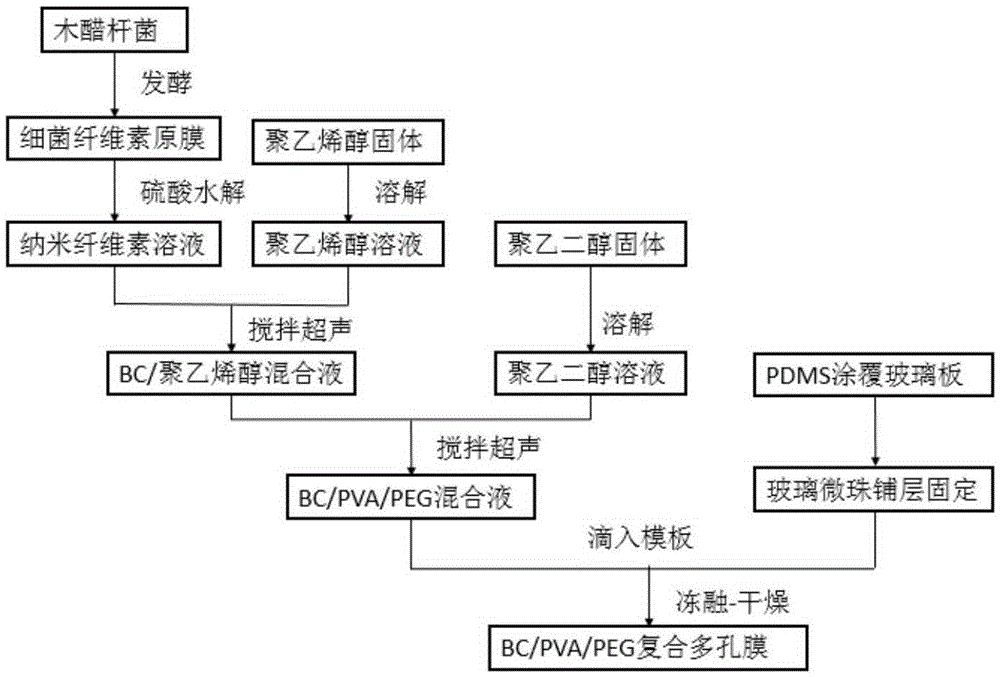

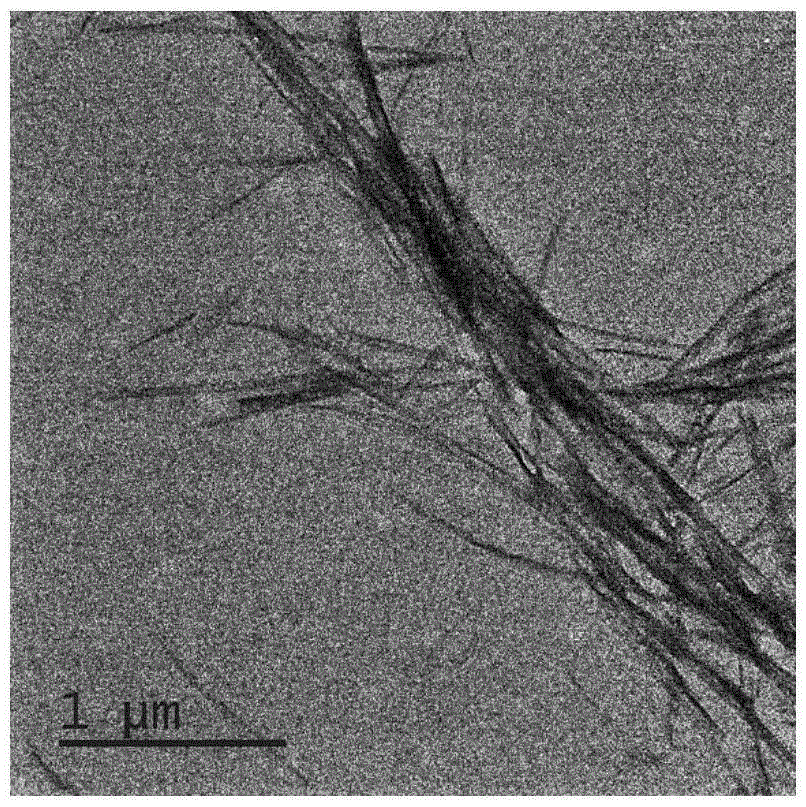

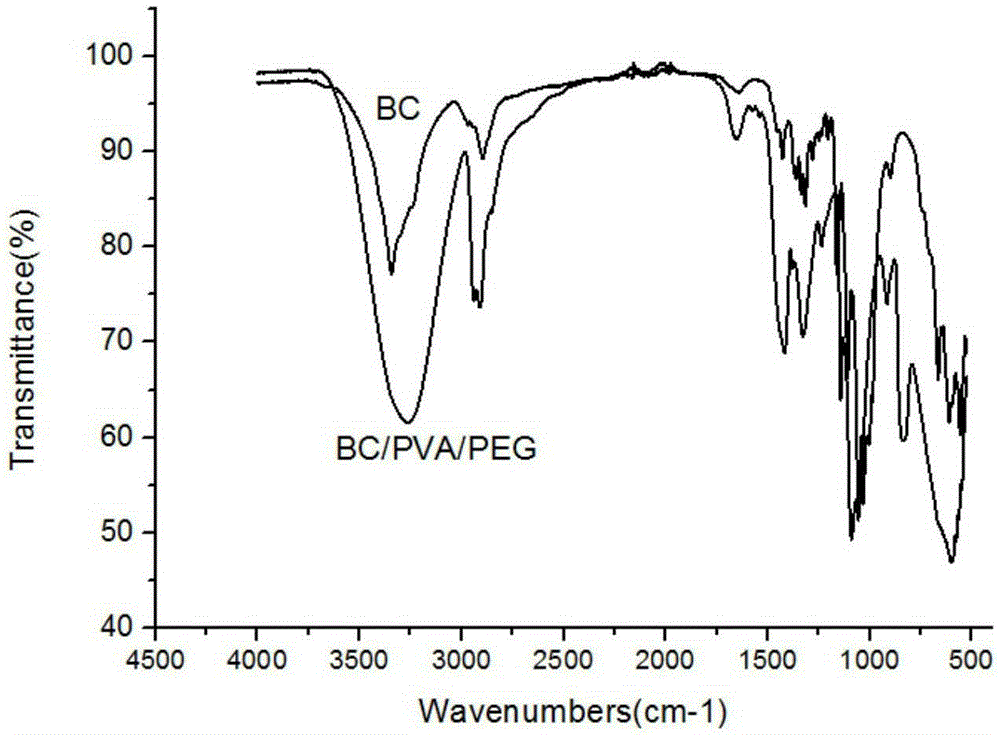

Nanometer bacterial cellulose\polyvinyl alcohol\polyethylene glycol porous composite hydrogel

The invention discloses a nanometer bacterial cellulose\polyvinyl alcohol\polyethylene glycol porous composite hydrogel. The porous composite hydrogel comprises nanometer bacterial cellulose, polyvinyl alcohol and polyethylene glycol. The invention also discloses a preparation method of the porous composite hydrogel. The method comprises the following steps: hydrolyzing clean bacterial cellulose by sulfuric acid to obtain a nanometer cellulose solution, carrying out neutral treatment, mixing the treated solution in a polyvinyl alcohol solution, carrying out ultrasonic dispersion until uniformity, adding a small amount of a polyethylene glycol solution, carrying out ultrasonic stirring mixing, adding the above obtained mixed solution into a glass bead template in a dropwise manner, repeatedly freeze-thawing to cross-link the obtained mixture, and drying to obtain the porous composite hydrogel. The porous composite hydrogel prepared in the invention has the advantages of low cost, mild reaction, fast speed, good biocompatibility, high mechanical strength, uniform porous structure, and wide application prospect in the fields of biomedical science and tissue engineering.

Owner:NANJING UNIV OF SCI & TECH

Preparation method of surface-modified ball-milling refined plant fibers

InactiveCN102978984ABall milling method is simpleBall milling method is convenientPulping with inorganic basesGrain treatmentsChemical industryCrude fibre

The invention relates to a preparation method of surface-modified ball-milling refined plant fibers. According to the preparation method, natural plant fibers are subjected to wet method ball milling after pretreatment, and the original micro-fibers can be scattered along the long-axis direction and broken along the diameter direction, so that the refined plant fibers are obtained. Compared with nano-celluloses prepared by a hydrolysis method, the refined long fibers obtained by the preparation method have the characteristics that the length is long, the length-diameter ratio is greater, and by controlling the ball milling condition, fine fibers and coarse fibers in the product are interconnected to from a net-like structure, and separated single fibers can be obtained. The fiber product does not contain acidic groups remained during preparation by the hydrolysis method. The plant fibers are subjected to appropriate surface modification, and then the surface-modified ball-milling refined plant fibers are prepared. The surface-modified ball-milling refined plant fibers have good application prospects in construction foods, medicaments, chemical industry, papermaking, spinning, new material preparation and the like.

Owner:SUN YAT SEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com