Patents

Literature

3156results about How to "Uniform structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for quick-speed preparing aerogel by hydro-thermal synthesis at low cost

InactiveCN101456569AReduce surface tensionIntegrity guaranteedSilicaAlkali metal silicatesReaction temperatureHydrothermal synthesis

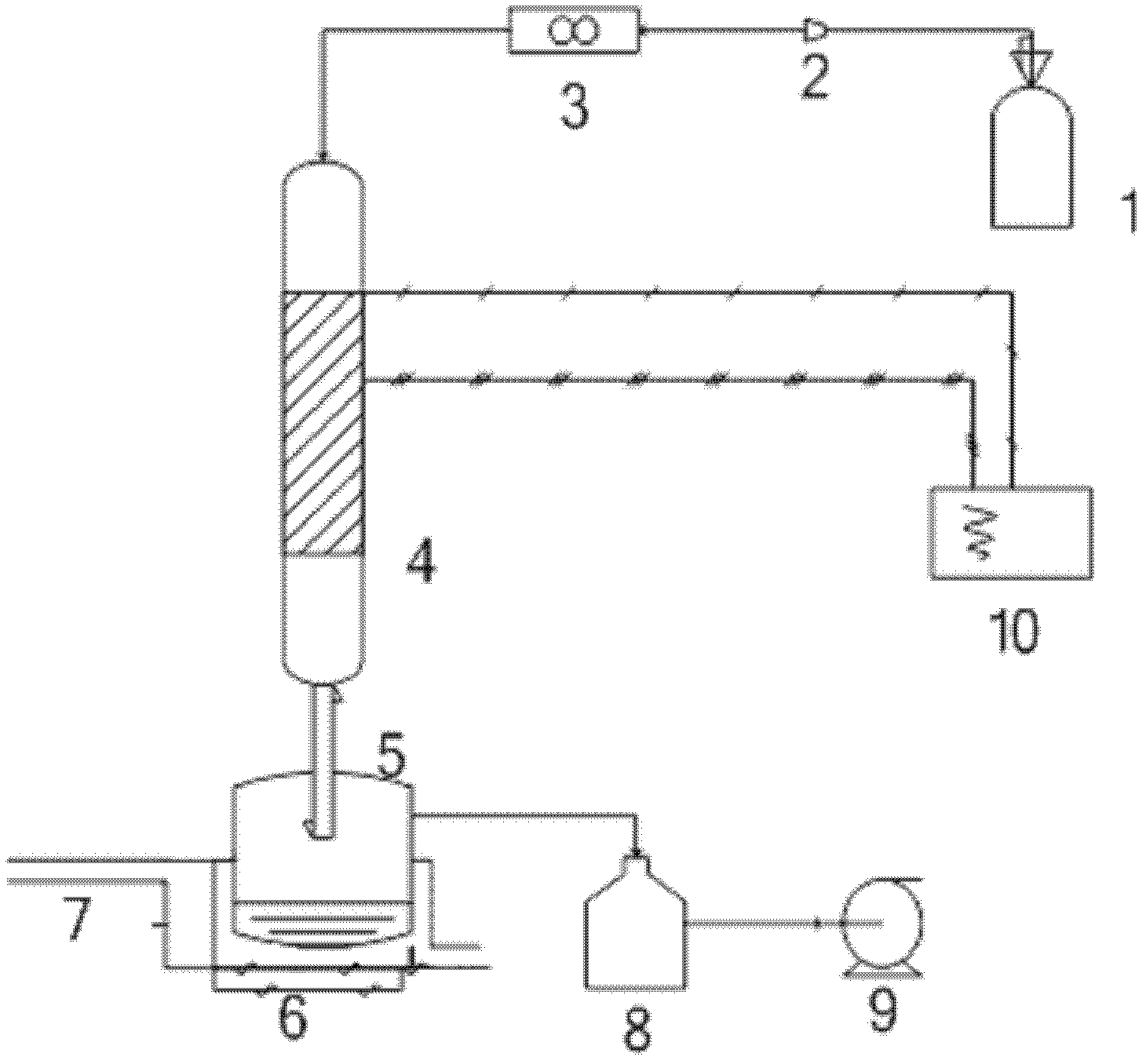

The invention discloses a method for preparing aerogel materials by combining hydrothermal synthesis technology and sol-gel technology. The prepared aerogel comprises one or more of alumina aerogel, silica aerogel, zirconia aerogel and titania aerogel. The method comprises the following steps: mixing a reactant and a structure-directing agent according to certain proportion, and adding a pH value control agent to adjust the pH value; sealing hydrothermal reaction equipment, heating the mixture to be between 50 and 280 DEG C, making the mixture stand for 0 to 72 hours, raising the temperature to be between 60 and 300 DEG C, and continuously reacting for 0.1 to 72 hours; and cooling gel, taking out the gel, drying the gel and obtaining the aerogel. Compared with the prior art, the method has low reaction temperature and pressure, small equipment investment and simple and controllable technology, reduces potential safety hazards, greatly improves the preparation speed of the aerogel, saves the production cost, and is favorable to realize commercial mass production.

Owner:纳诺科技有限公司 +1

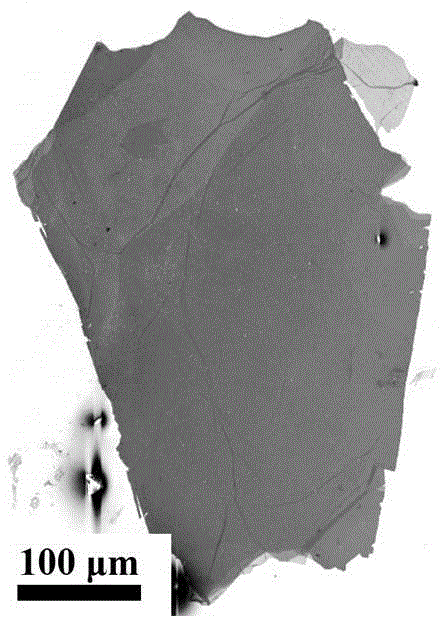

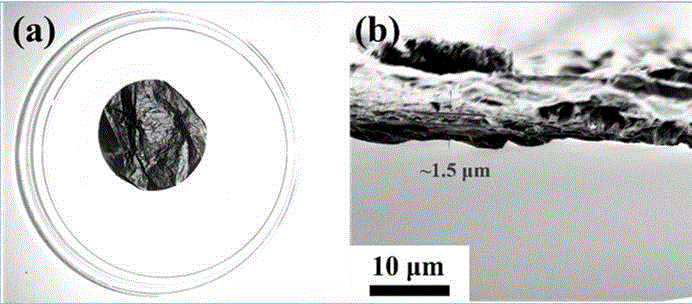

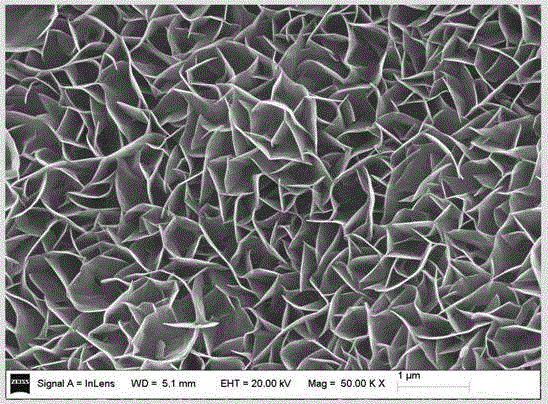

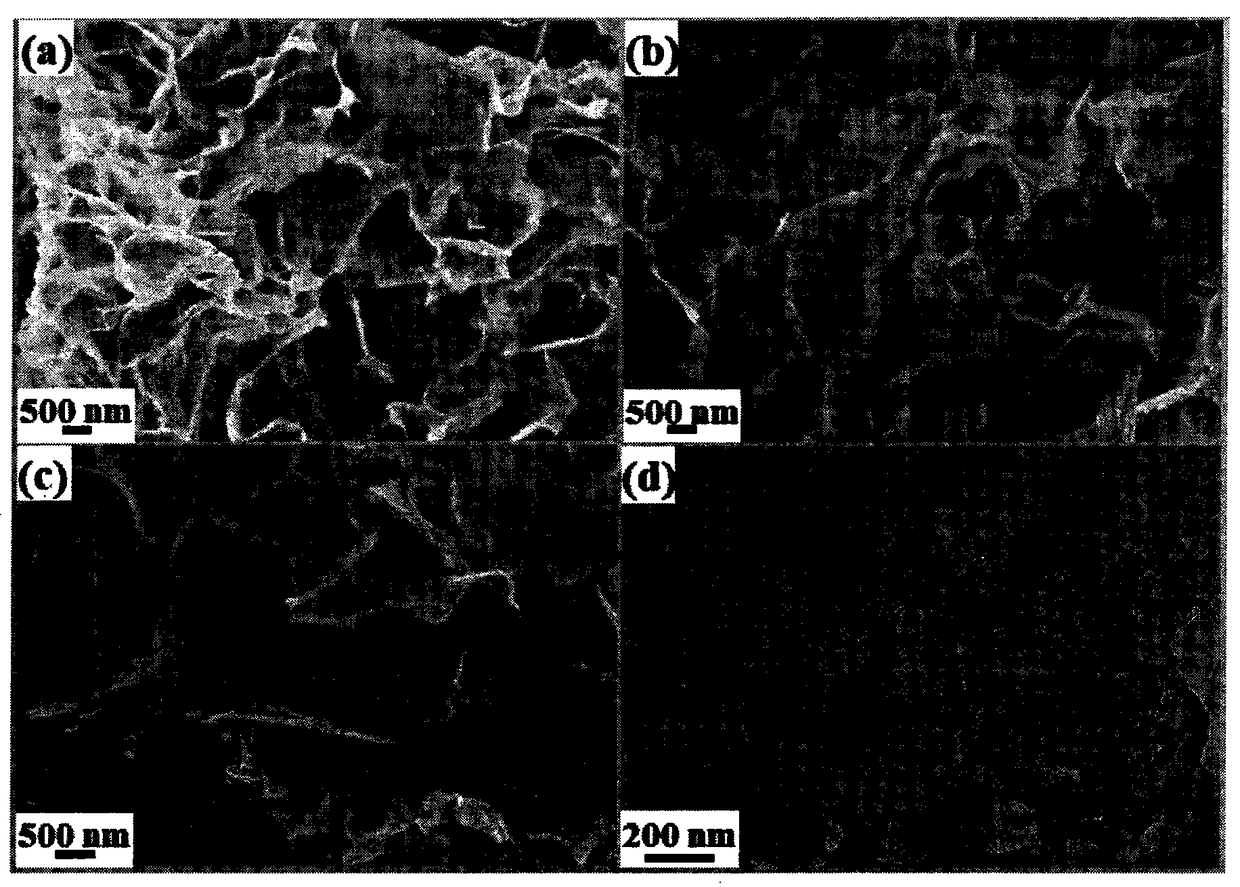

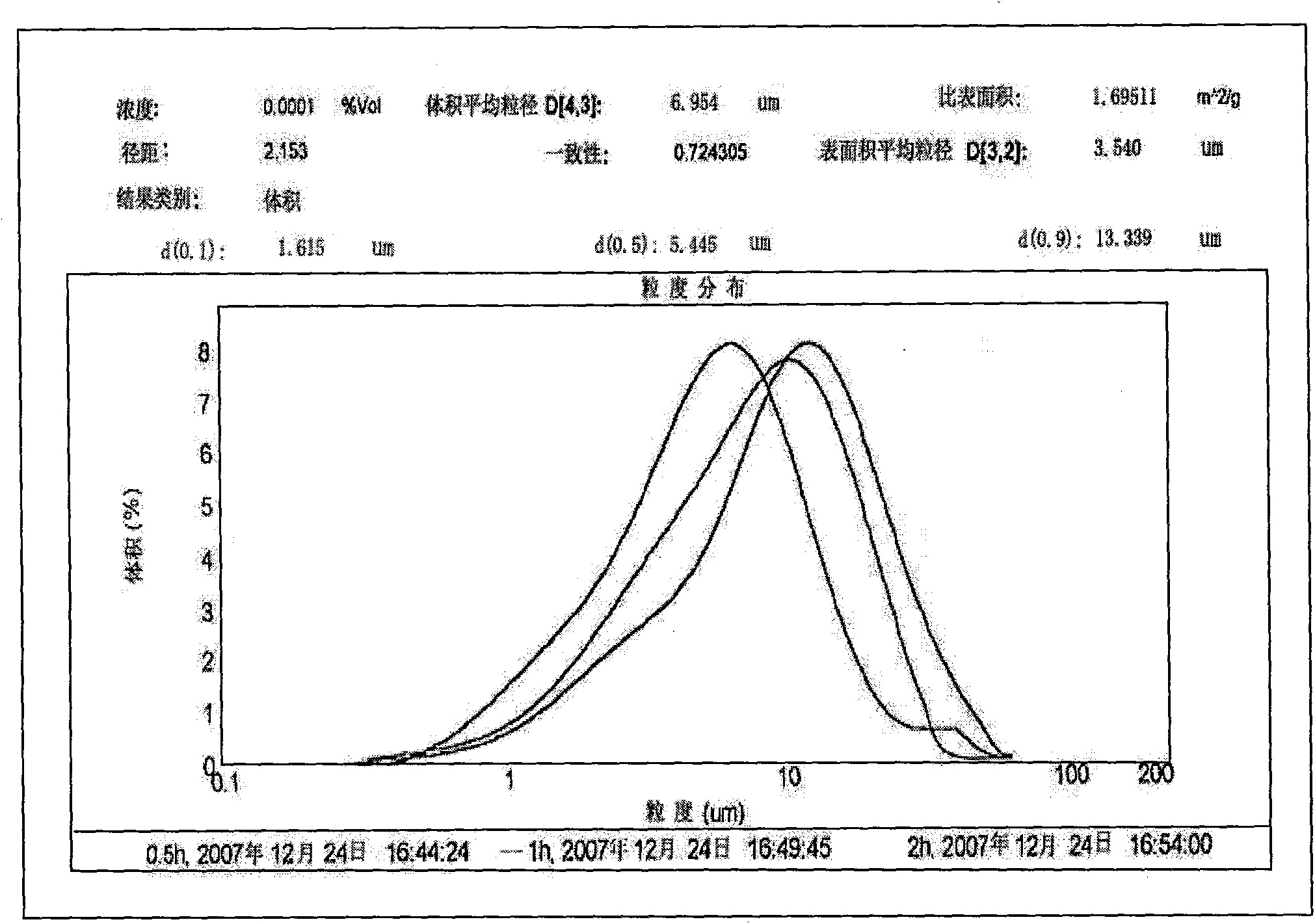

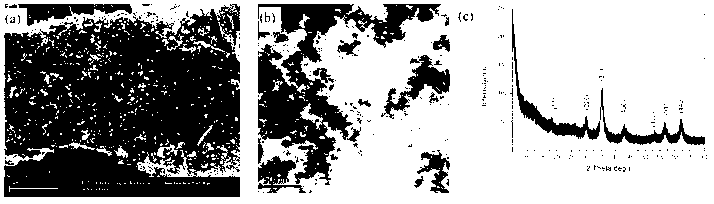

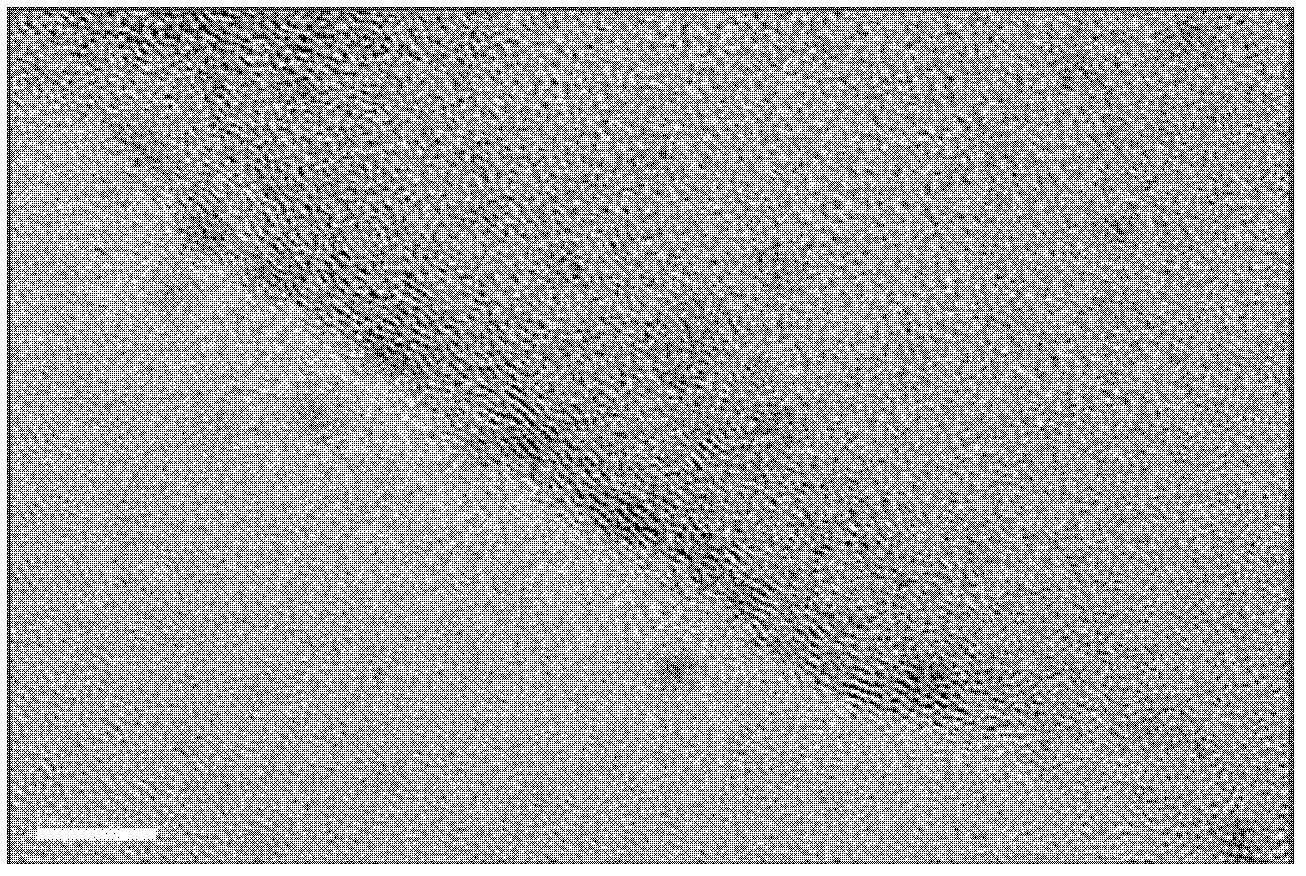

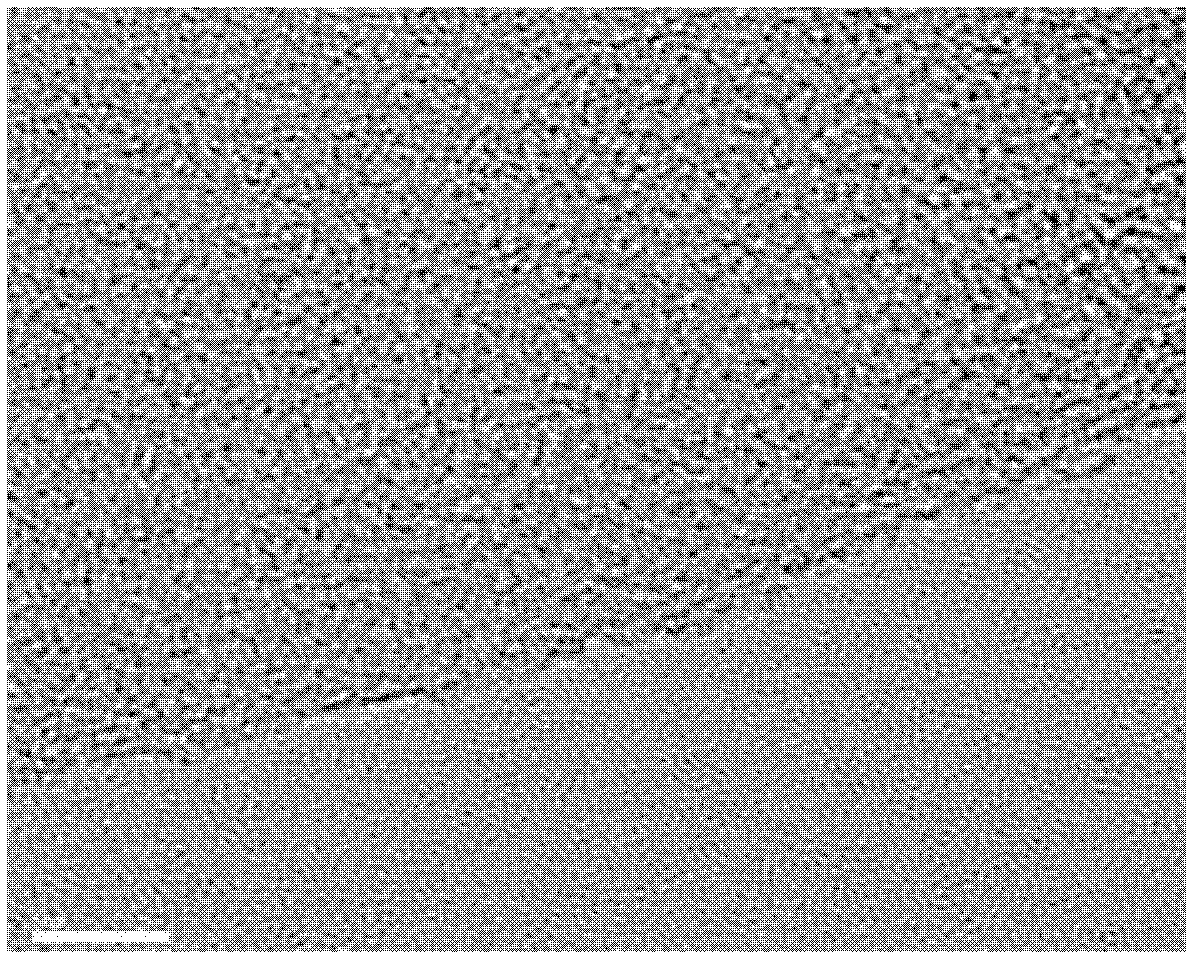

Preparation method of large-size graphene oxide or graphene

ActiveCN105293476ASmall sizeQuality improvementMaterial nanotechnologySingle layer grapheneHigh energyReducing agent

The invention discloses a preparation method of large-size graphene oxide or graphene. The preparation method mainly utilizes graphite as a raw material and comprises that 1, under the action of an intercalator and an expanding agent, graphite fully releases interlayer spaces so that interlayer interaction is reduced and a graphene aggregate is obtained, 2, the graphene aggregate is oxidized by an oxidizing agent, and then the oxidized graphene aggregate is peeled in water under gentle mechanical action so that a large area of a dispersion liquid of graphene oxide is obtained, and 3, the peeled graphene oxide is reduced by a reducer or heat treatment so that high conductivity graphene is obtained. The preparation method utilizes cheap raw materials, has a simple process, can be controlled easily, realizes fast and high efficiency solid-liquid separation, is convenient for industrial large scale production, prevents graphene crystal structure destroy caused by high energy supersonic wave, high speed shearing or fluid crushing. The obtained graphene has a large size and high conductivity and can be popularized and used in fields of high efficiency heat management, flexible display, energy conversion and storage.

Owner:FUDAN UNIV

Bamboo powder filling biodegradable compound material and preparation method thereof

The invention relates to a bamboo powder filling biodegradable compound material and a preparation method thereof. The bamboo powder filling biodegradable compound material comprises the following raw materials in part by mass: 30 to 80 parts of biodegradable resin, 20 to 70 parts of bamboo powder, 1 to 19 parts of plasticizer, 0.6 to 6 parts of interface modifier and 4 to 12 parts of aids. The preparation method comprises the following steps of: uniformly mixing the biodegradable resin, bamboo powder, plasticizer, interface modifier and auxiliary agent by using a mixer according to formula proportion; performing melt blending and granulation of the obtained mixture by using a screw extruder to obtain particles; and processing the particles by using an injection molding machine, a sheet extrusion forming machine, a blow molding machine or a film blowing machine, and molding in molds of different shapes to obtain the bamboo powder filling biodegradable compound materials of different shapes. The method has the advantages of high production efficiency and low cost; and the powder filling biodegradable compound material prepared by the method has the advantages of high environmentally-friendly property and economy and excellent usability.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

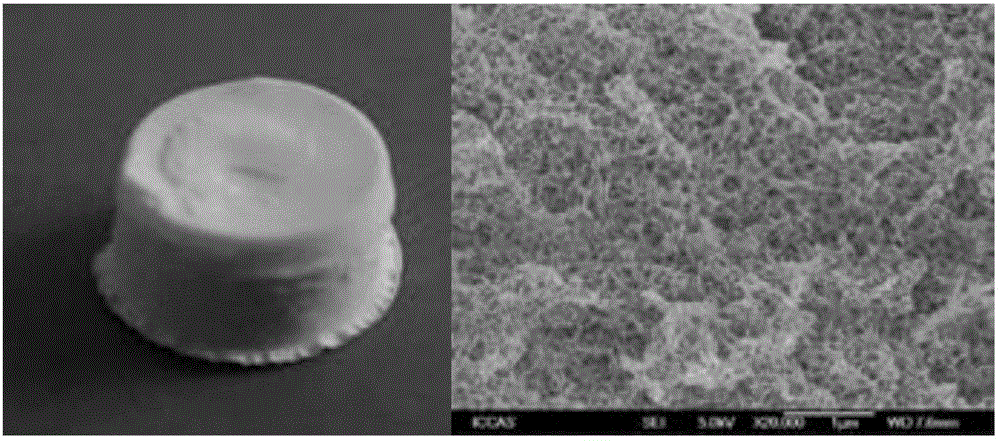

Method for preparing spongy graphene oxide by using freeze-drying method

ActiveCN103058179ASimple processEasy to operateMaterial nanotechnologyCarbon compoundsCvd graphenePore distribution

The invention relates to a method for preparing spongy graphene oxide by using a freeze-drying method, which is in a loose and porous type and is in a spongy type in a macro-morphology. The method comprises the steps of: after an improved Hummers process is utilized to prepare graphite oxide, preparing graphite oxide into a solution with water or ethanol, and then carrying out quick-freezing and vacuumizing on the solution, and sublimating a solvent to obtain the graphene oxide. The graphene oxide is different from general blocky, film type or powdery graphene oxide. The obtained loose and porous graphene oxide provided by the invention is in a spongy type, is an excellent precursor for preparing graphene, and has a great application foreground in the field of an anti-flaming composite material, an adsorbent and the like. The method for preparing spongy graphene oxide by using a freeze-drying method is free from environmental pollution, convenient in technology and small damage to graphite oxide sheets, and completely strips graphite oxide; and the porosity of the graphene oxide is 20-90% and the pore distribution is uniform.

Owner:无锡烯创科技有限公司

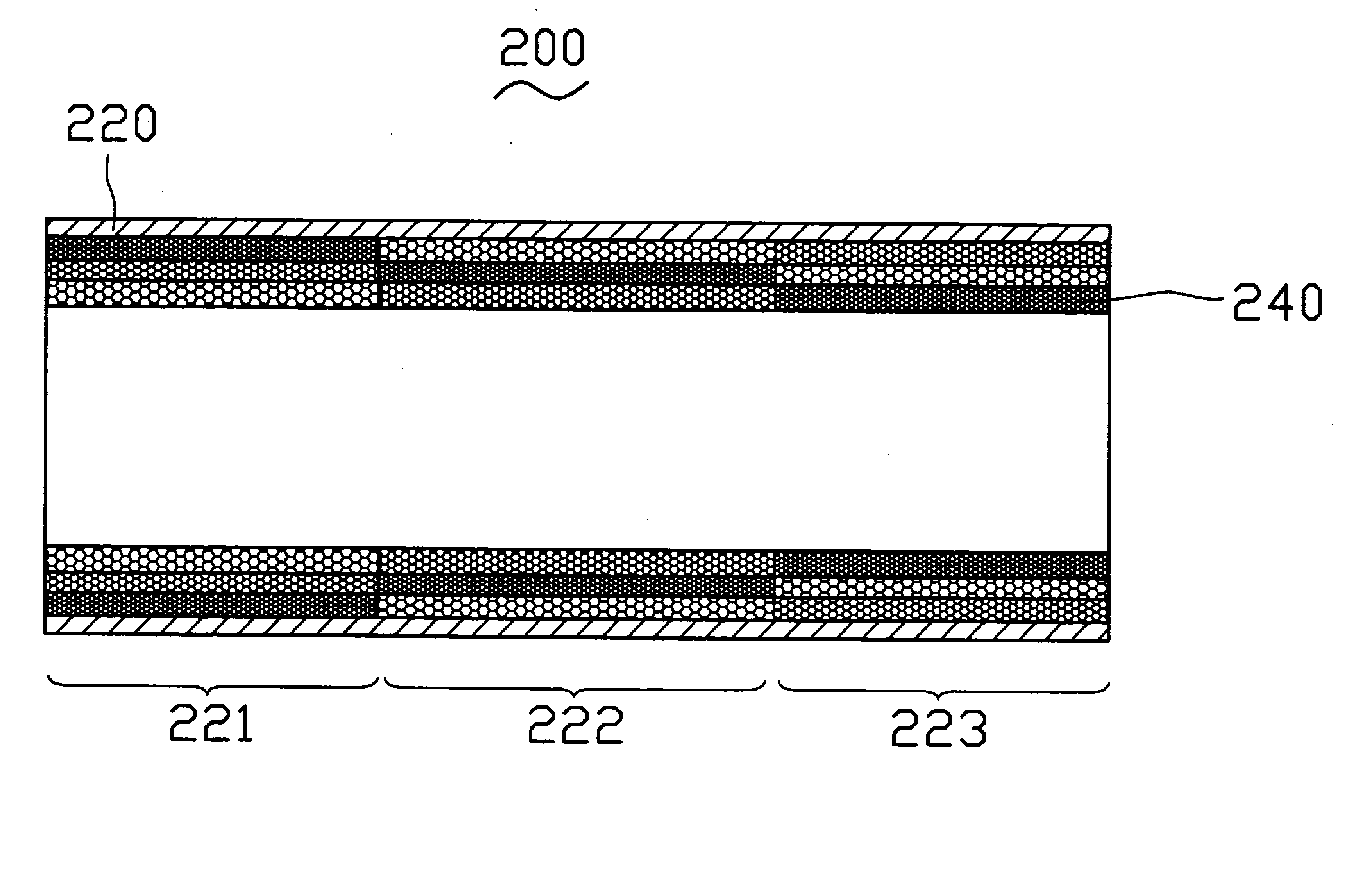

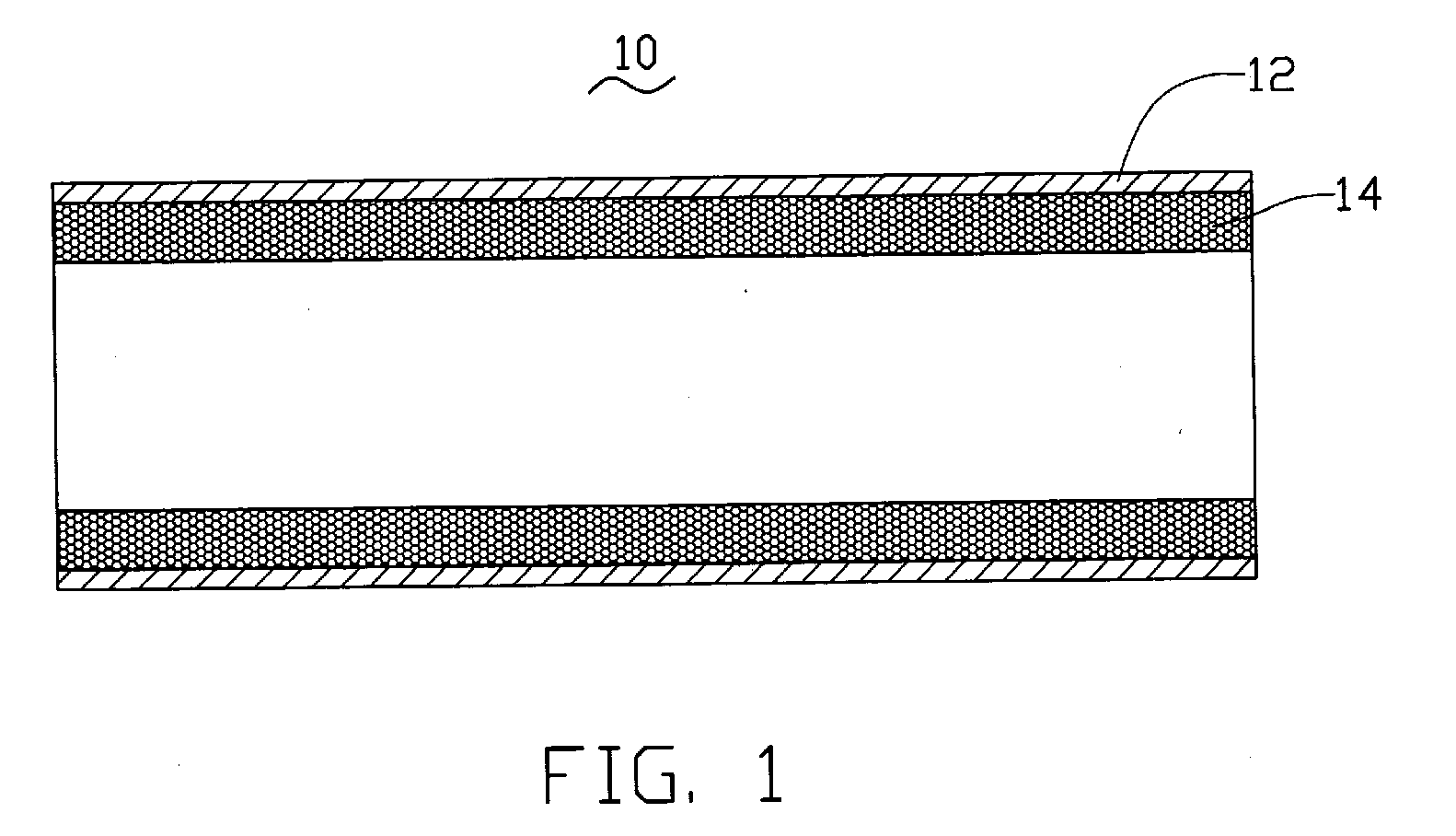

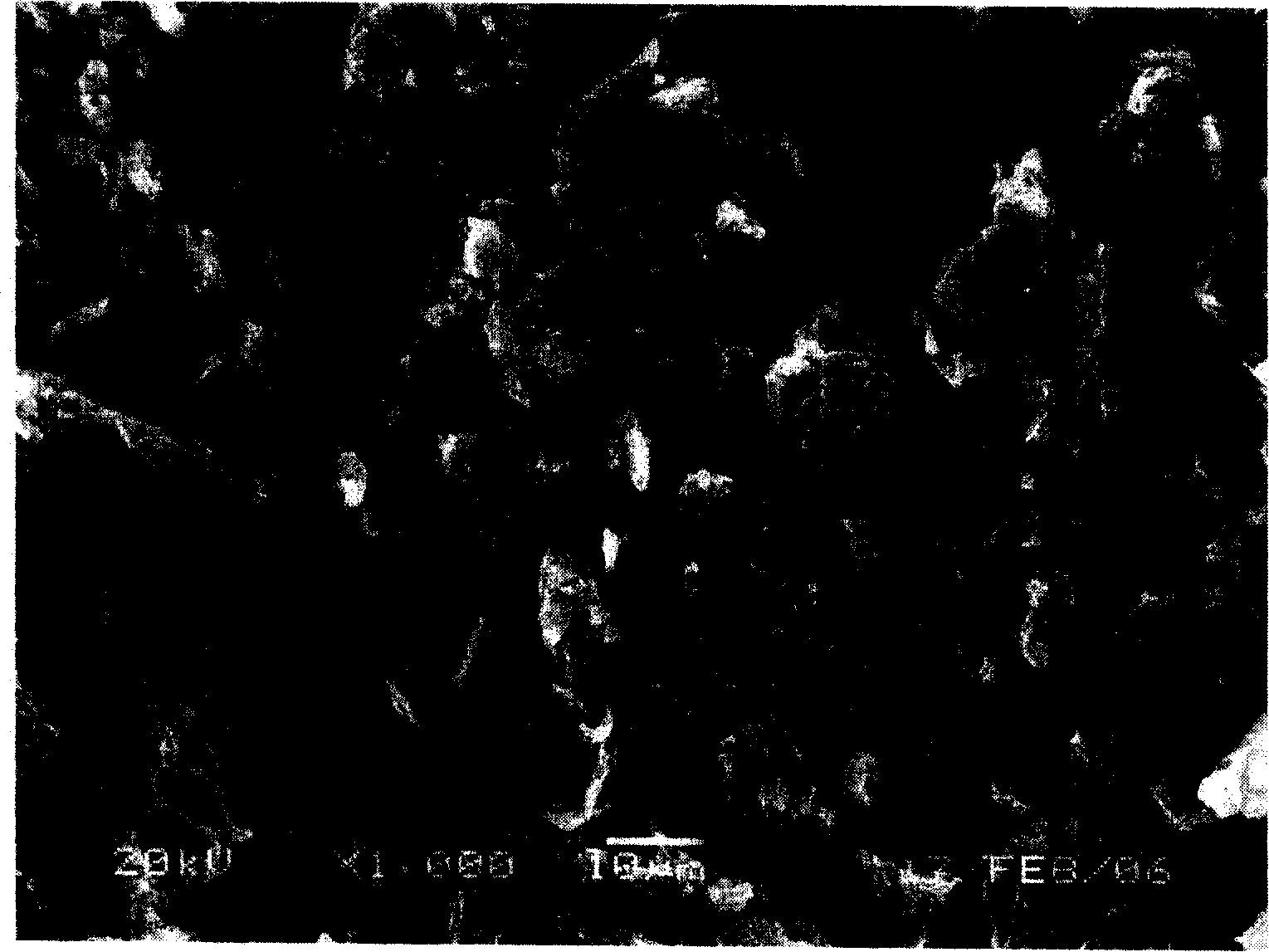

Method of manufacturing heat pipe having sintered powder wick

InactiveUS20060197245A1Improve heat transfer performanceImprove the preparation effectLinings repairLaminationGreen tapeMetallurgy

A method is disclosed to produce a heat pipe with a sintered powder wick formed inside the heat pipe. The method employs tape-casting technology to firstly produce thin sheets of powder and then these sheets are sintered to form the wick. In the tape casting procedure, a slurry of the powders necessary to construct said wick is cast onto a moving surface to form a slurry layer and then the slurry layer is dried to form a green tape. The green tape is rolled onto a mandrel and then is inserted into a hollow casing and sintered to cause the powders in the green tape to diffusion-bond together. Thus, the sintered powder wick is constructed.

Owner:HON HAI PRECISION IND CO LTD

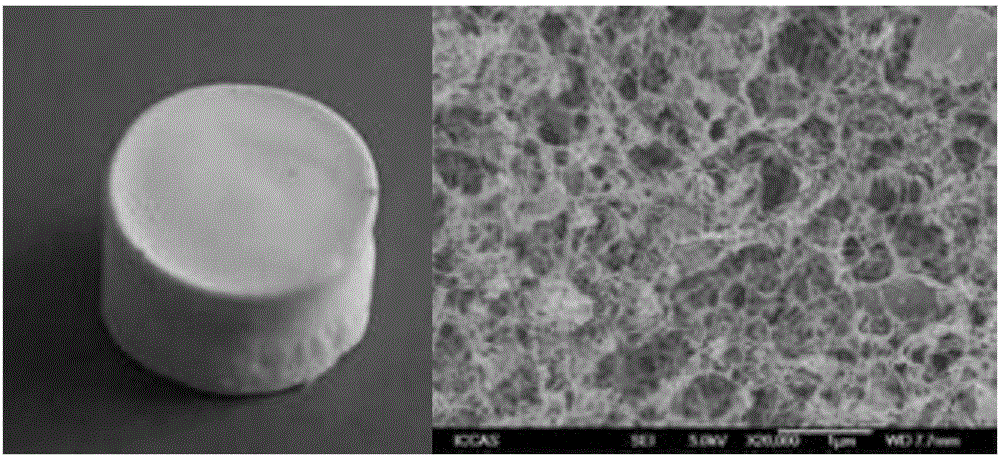

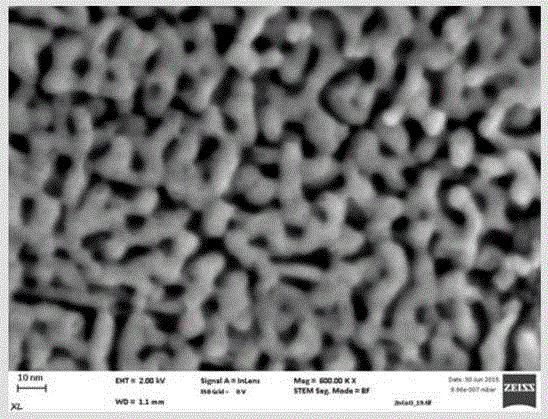

Cellulose aerogel and preparation method for hybrid aerogel thereof

The invention discloses low-cost green cellulose aerogel and a preparation method for hybrid aerogel thereof. The preparation method for the hybrid aerogel of the cellulose aerogel comprises the following steps that cellulose is dissolved into a zinc chloride aqueous solution, centrifugal deaeration is performed, and a uniform and transparent cellulose solution is obtained; the cellulose solution is formed, then the formed cellulose solution is placed into a coagulating bath to be regenerated, in addition, the regenerated cellulose solution is fully washed by use of a solvent, and cellulose solvent gel is obtained; the solvent in the cellulose solvent gel is removed by use of supercritical carbon dioxide drying or freeze drying, and the cellulose aerogel is obtained. Functional filler can be added into the cellulose solution to obtain the hybrid aerogel. By the adoption of different solution forming methods, the cellulose aerogel and the hybrid aerogel thereof in the shapes of sheets, fibers, particles and the like can be prepared. The preparation method is low in cost and is environmentally friendly, and the prepared aerogel is provided with a uniform nano-grade net porous structure.

Owner:INST OF CHEM CHINESE ACAD OF SCI

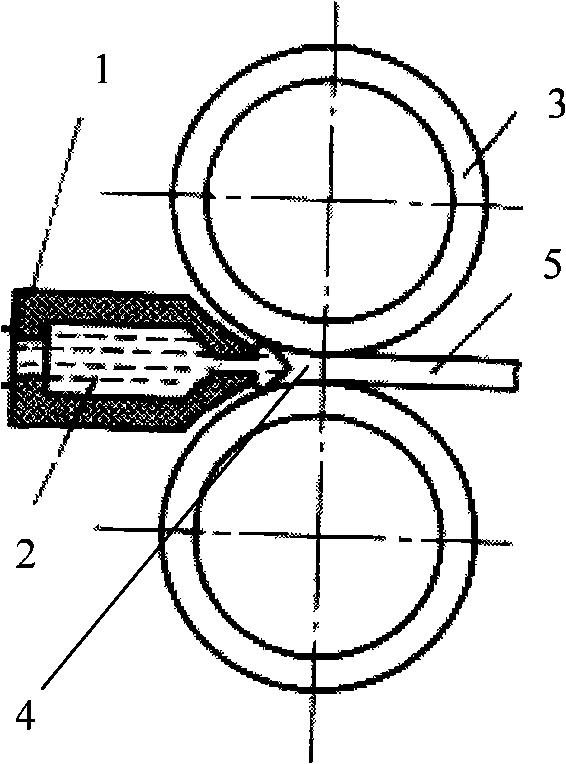

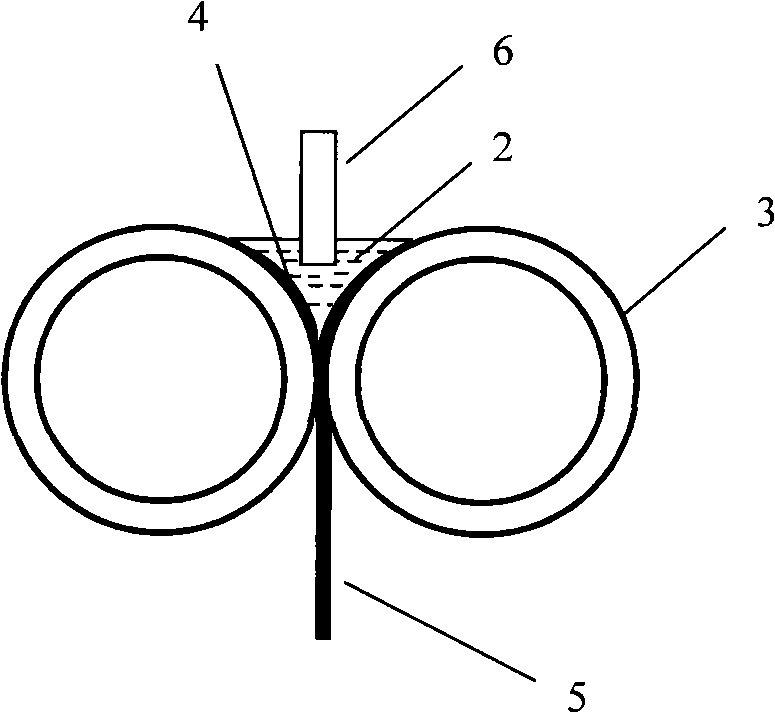

Continuous casting technique for aluminum alloy thin belt blank

InactiveCN101269406AImprove organizationComprehensive mechanical properties of high thin stripIngotMaterials science

The invention discloses a continuous casting process of an aluminum thin billet, which is characterized in that the following steps are included: aluminum alloy ingots are preheated and are melted in a melting furnace in the role of a flux; before casting, a side closure system is preheated to 400-450 DEG C, when the temperature of a melting body ranges from 650 DEG C to 680 DEG C, the aluminum alloy ingots are arranged into a tundish for 15 to 30 minutes in the role of the flux, then through a flux distributing device, the aluminum alloy ingots flow into an equant vertical twin-roll thin strip billet continuous caster, with a left forging seam gap being 0 mm and maintaining the height of a melting pool between 90 mm and 340 mm, the casting is carried out in a sinking way; when in casting, the casting speed of the casting machine ranges from 20 to 120m / min, the thin strip blank is sent into a pinch roll after leaving a casting roller, and the forged aluminum alloy thin strip has a thickness between 1.0 mm and 3.5 mm. The continuous casting process can directly make aluminum alloy thin strip blank from the liquid aluminum alloy, the forged thin strip blank has good quality on the surface, and the internal organizational structure is uniform, thereby being conducive to succeeding rolling processes. The continuous casting process for an aluminum thin blank has short process and low cost.

Owner:CHONGQING UNIV

Open-cell expanded ceramic with a high level of strength, and process for the production thereof

InactiveUS6635339B1High strengthSimple and economical processLayered productsPretreated surfacesPorosityHigh intensity

The disclosed invention relates to the field of ceramics and concerns an open-cell expanded ceramic which may be used in the form of a deep-bed filter, and a process for the production thereof. The primary object is to produce an open-cell expanded ceramic by a simple and economical process. This object is attained by an open-cell expanded ceramic in which the inner cavities, cracks and the porosity of the ceramic members are filled partially or completely by one or a plurality of metal and / or ceramic phases and / or glass phases. The open-cell expanded ceramic is also produced in that during or after sintering the cavities, cracks and the porosity of the ceramic members are partially or completely filled with a melt or a suspension which melt below the melting temperature of the expanded ceramic, have a coefficient of expansion similar to the coefficient of expansion of the expanded ceramic, and a very good wetting capacity, and only react partially or not at all with constituents of the expanded ceramic.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

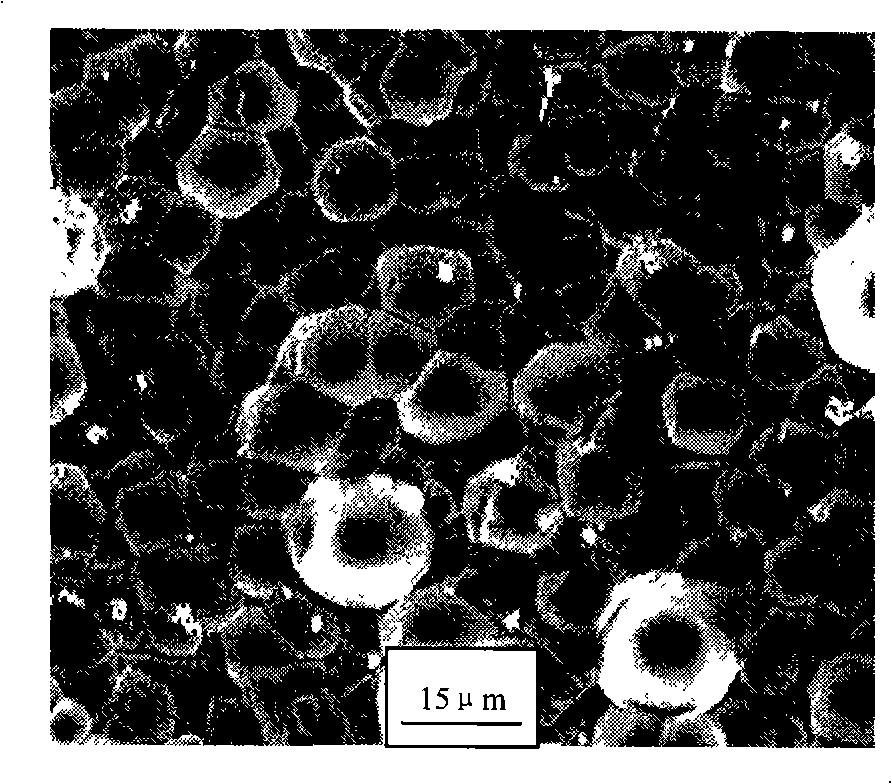

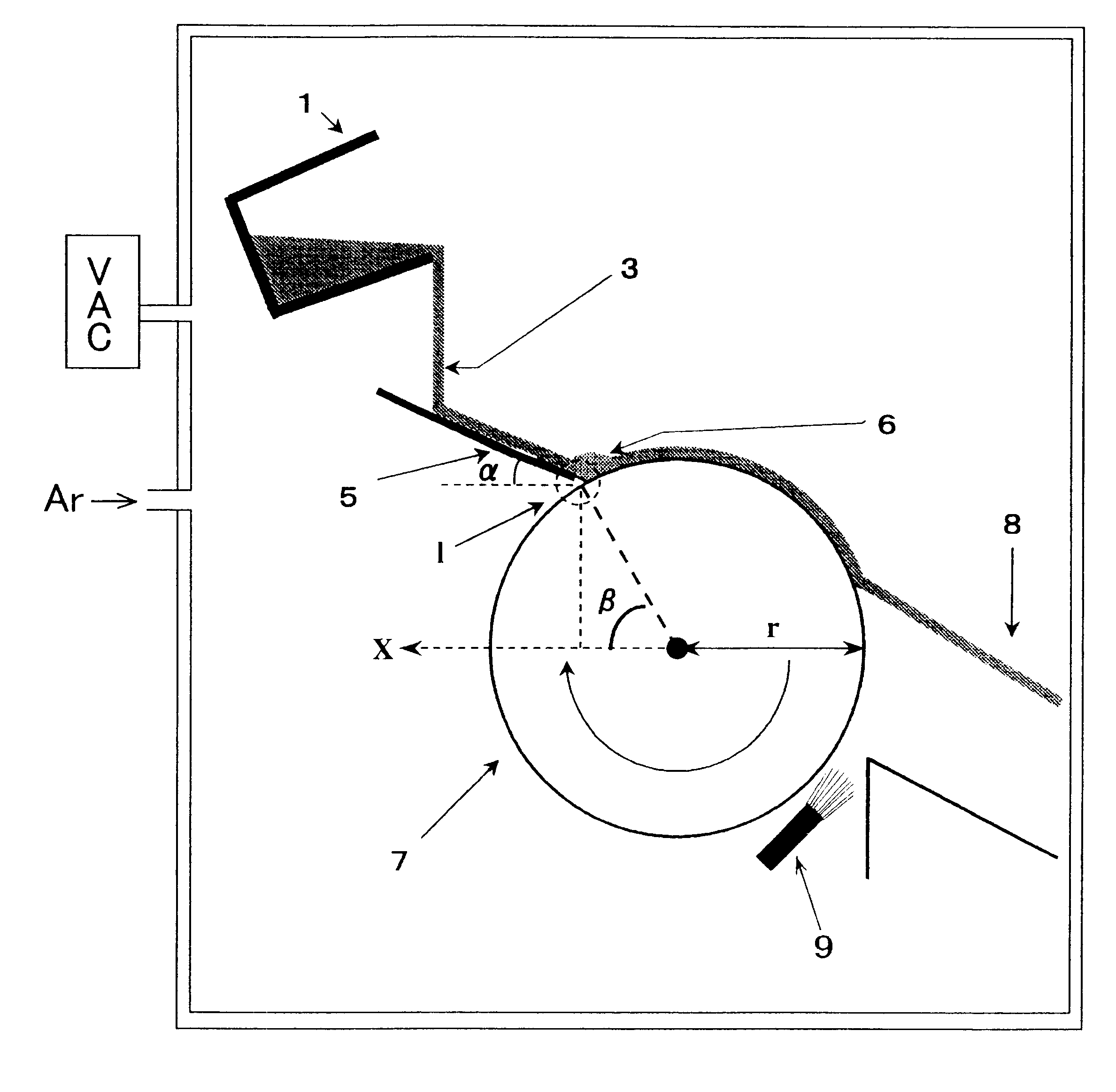

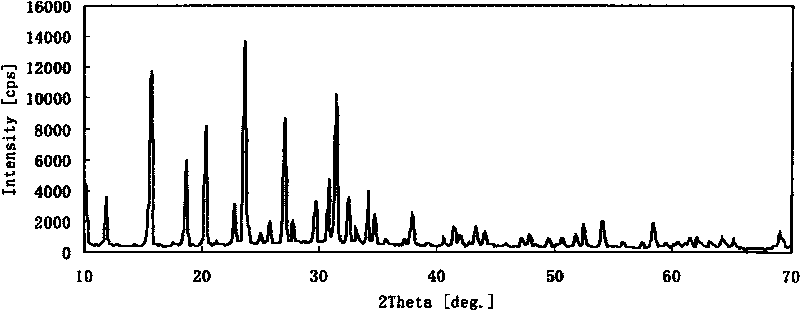

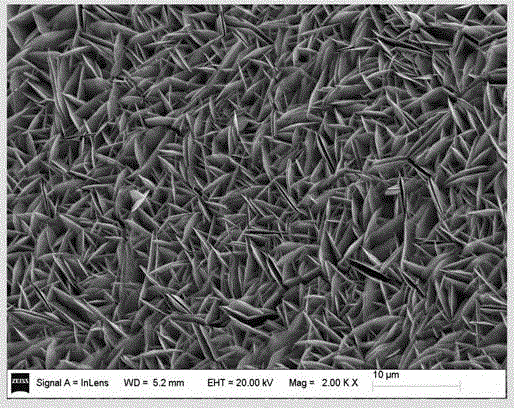

Method of making material alloy for iron-based rare earth magnet

InactiveUS6695929B2Good reproducibilityUniform structureNanomagnetismInorganic material magnetismRare-earth elementRare-earth magnet

A melt of an iron-based rare earth material alloy, represented by (Fe1-mTm)100-x-y-zQxRyMz, is prepared, wherein T is Co and / or Ni; Q is B and / or C; R is selected from Y (yttrium) and the rare earth elements; M is selected from Al, Si, Ti, V, Cr, Mn, Cu, Zn, Ga, Zr, Nb, Mo, Ag, Hf, Ta, W, Pt, Au and Pb; 10<=x<=30 at %; 2%<=y<10 at %; 0<=z<=10 at % and 0<=m<=0.5. The melt is fed onto a guide to form a flow of the melt thereon and move the melt onto a melt / chill roller contact region, where the melt is rapidly cooled by the chill roller to make a rapidly solidified alloy. An oxygen concentration of the melt yet to be fed onto the guide is controlled at about 3,000 ppm or less in mass percentage.

Owner:SUMITOMO SPECIAL METAL CO LTD

Silicon-containing composite material and its preparation method and application

ActiveCN101210119ASimple processReduce energy consumptionPigment treatment with macromolecular organic compoundsState of artLithium

The invention provides a siliceous composite material, comprising silicon particles and a clad wrapped on the surface of silicon particles, wherein, the clad is conducting polymer. The siliceous composite material provided by the invention takes the conducting polymer as the clad; the polymer does not need to be transformed further into 'hard carbon', and the siliceous composite material is guaranteed to have excellent conductivity; meanwhile, the aggregation between silicon particles can be avoided. When the composite material is taken as negative active material of a lithium iron battery, the lithium iron battery is ensured to have high reversible capacity and good cycle performance. Therefore, the invention can be taken as the negative active material of the lithium iron battery. As the polymer does not need to be transformed further into the 'hard carbon' and the siliceous composite material has good conductivity in the preparation of the siliceous composite material provided by the invention, the manufacturing technique is simplified and the problem of huge energy consumption caused by the high temperature carbonization process in the prior art is solved.

Owner:BYD CO LTD

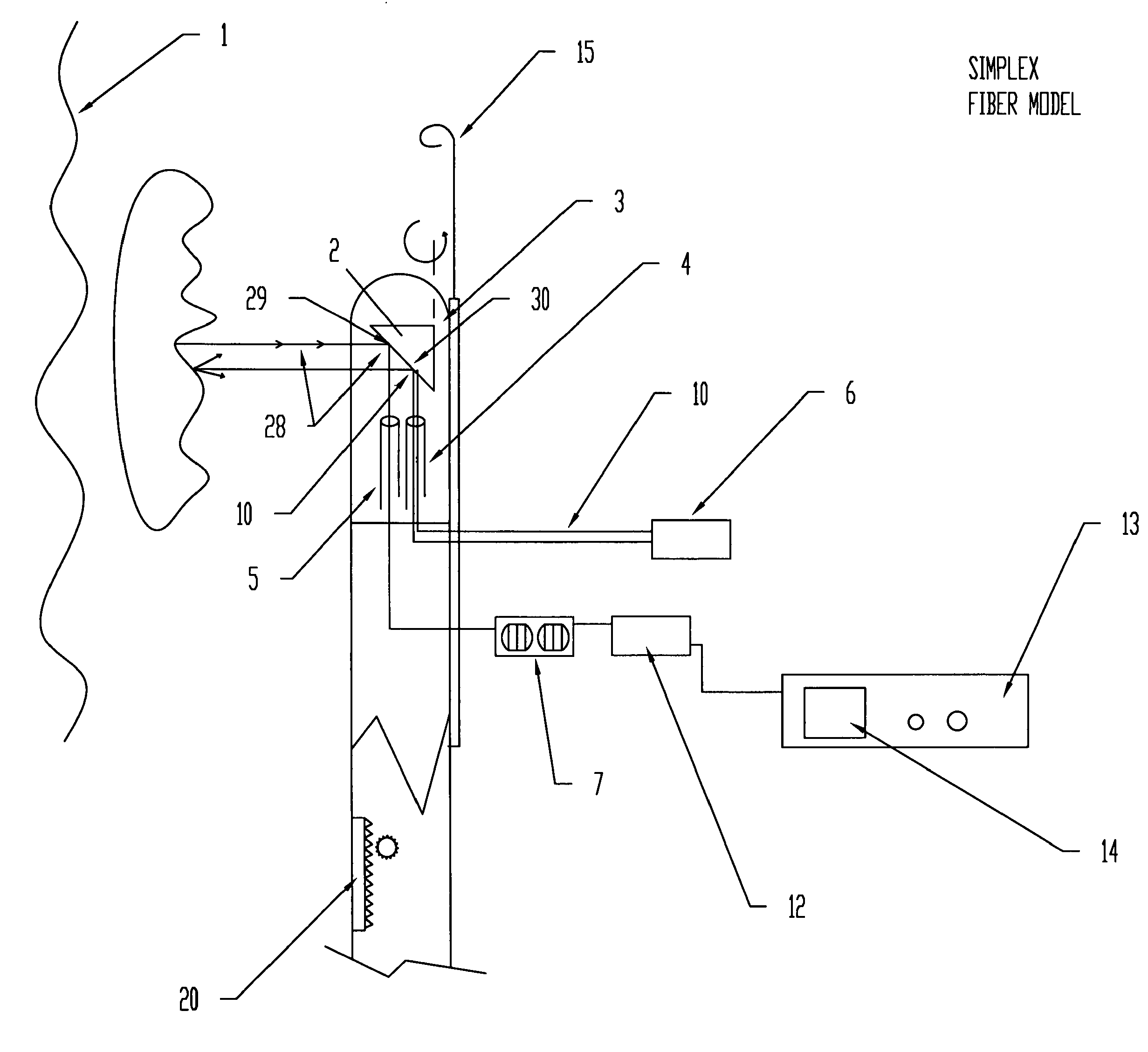

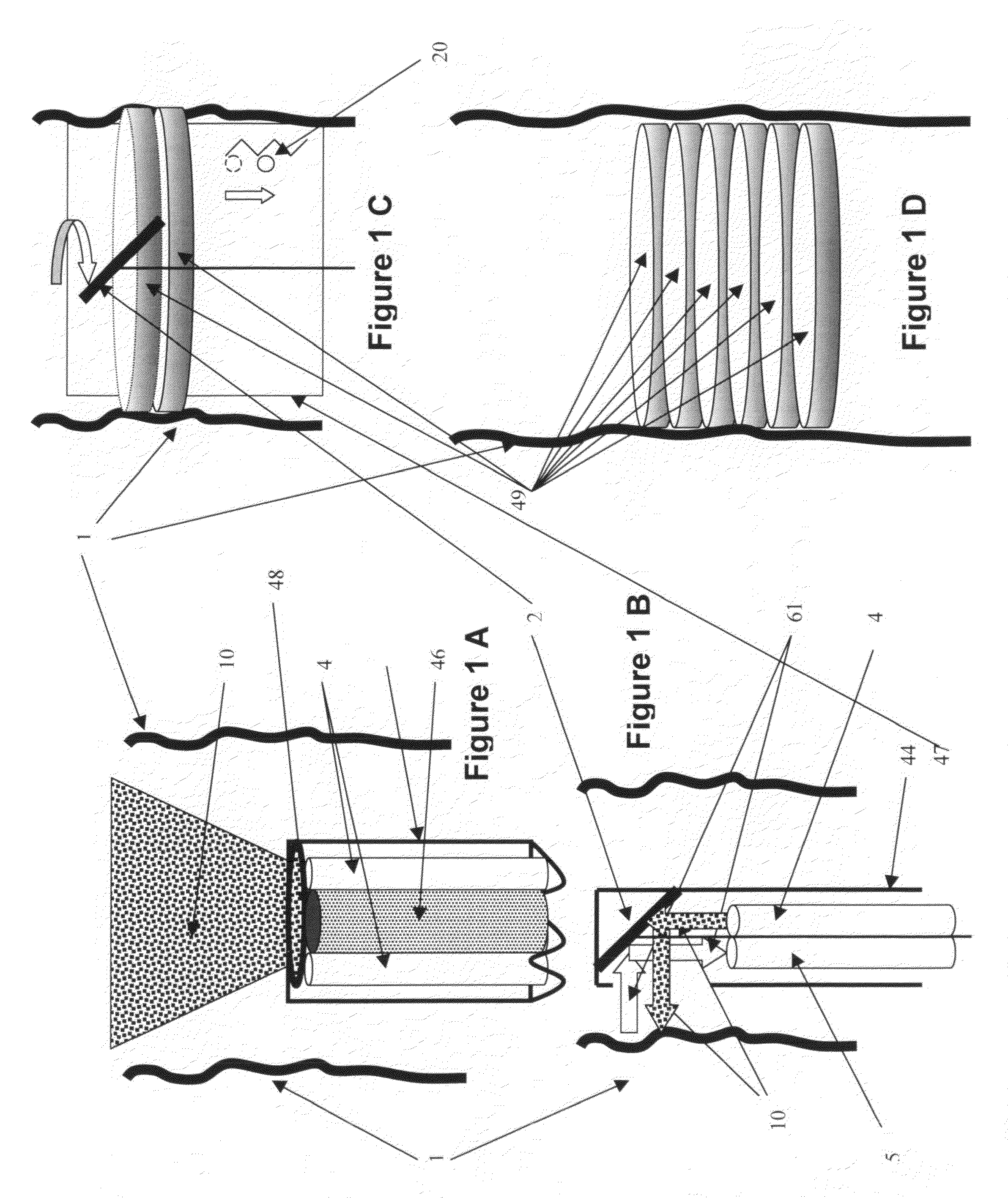

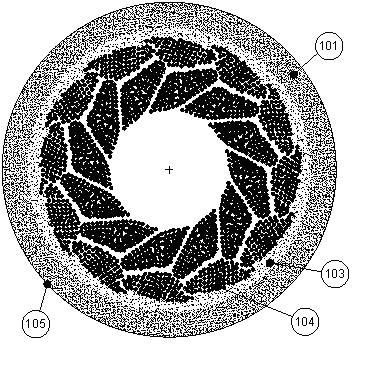

Scanning light imager

InactiveUS20100198081A1Reduce chanceUniform structureDiagnostics using spectroscopyDiagnostics using fluorescence emissionFiberCancer cell

This invention describes the detection of atherosclerotic plaque or cancer cells by a light probe inside a blood vessel or internal to an elongate organ. In one embodiment, vessel wall is imaged by employing a scanning mechanism using one emitting and one receiving fiber, whereby light is directed at a spinning mirror, approximately normal to the vessel or elongate organ surface. The light is reflected circumferentially around the vessel or elongate organ surface as the mirror rotates and received by a low-numerical aperture (NA) fiber, which transmits it to a light detector, thereby generating a set of light amplitudes circumferentially around the vessel / elongate organ surface. Multiple rings are acquired by translating the probe within the vessel / elongate organ. In another embodiment, adding a piezoelectric transducer in proximity to the distal ends of the fibers permits simultaneous ultrasound and light images to be created.

Owner:HANLIN JOHN HAROLD +1

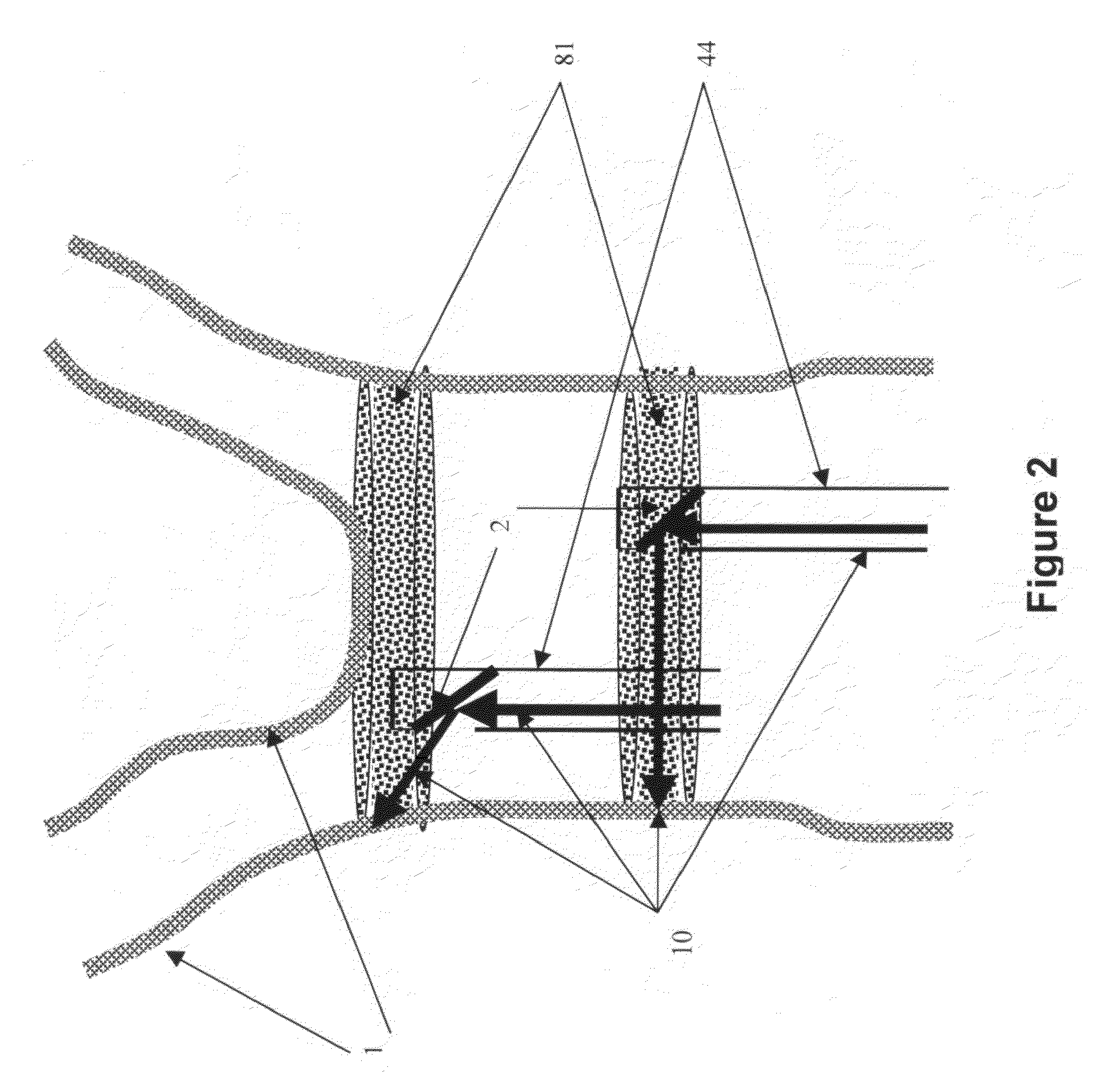

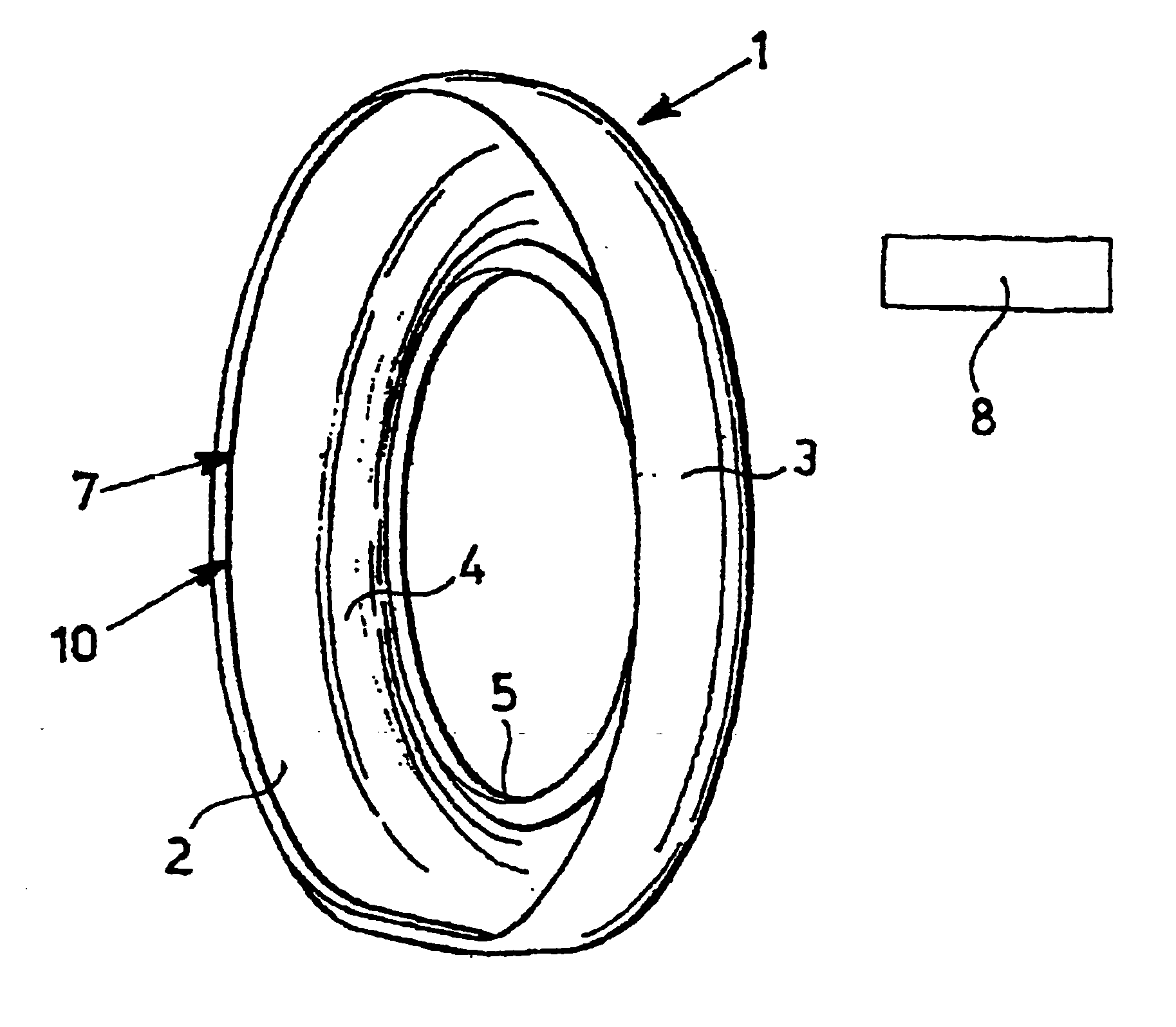

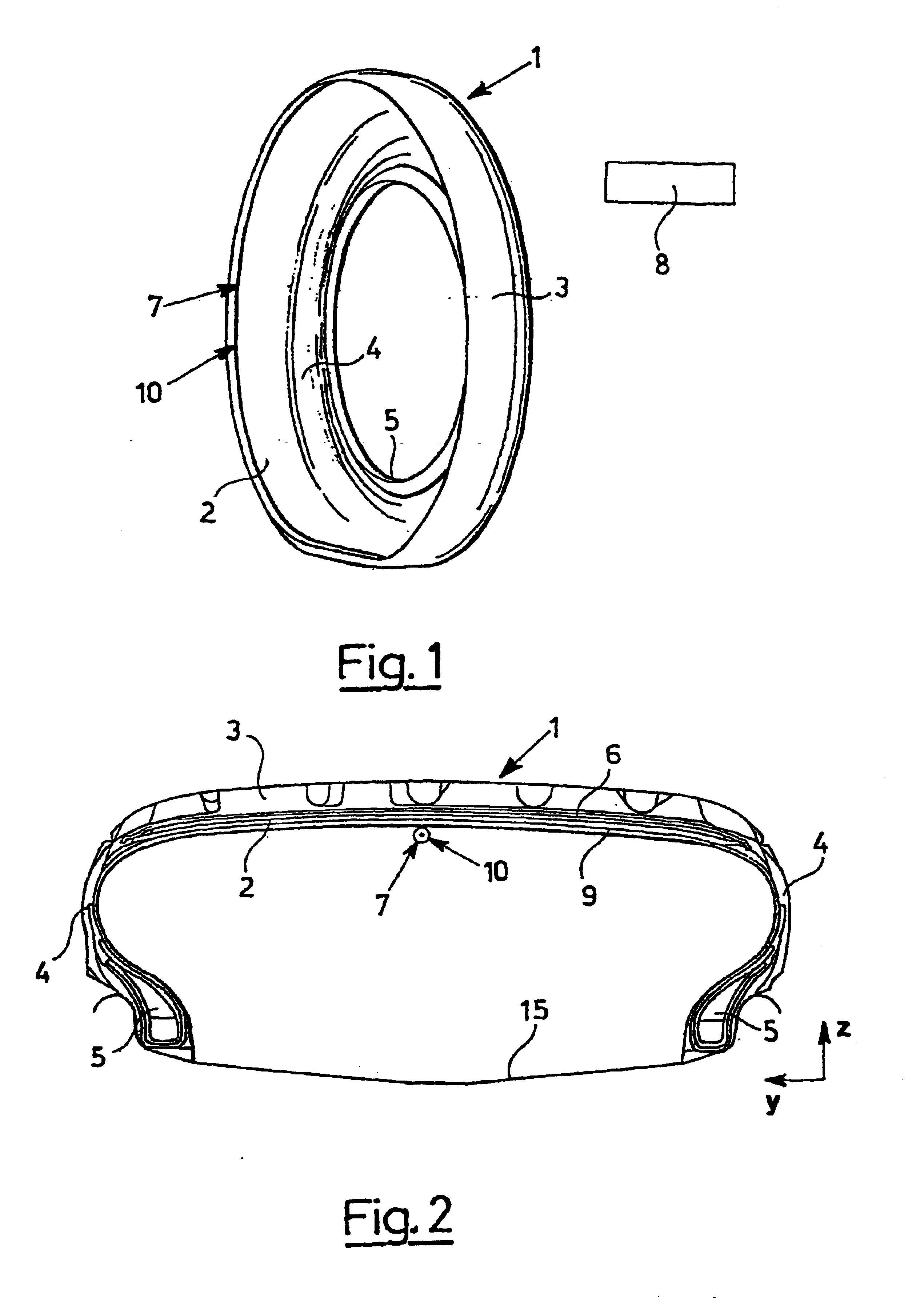

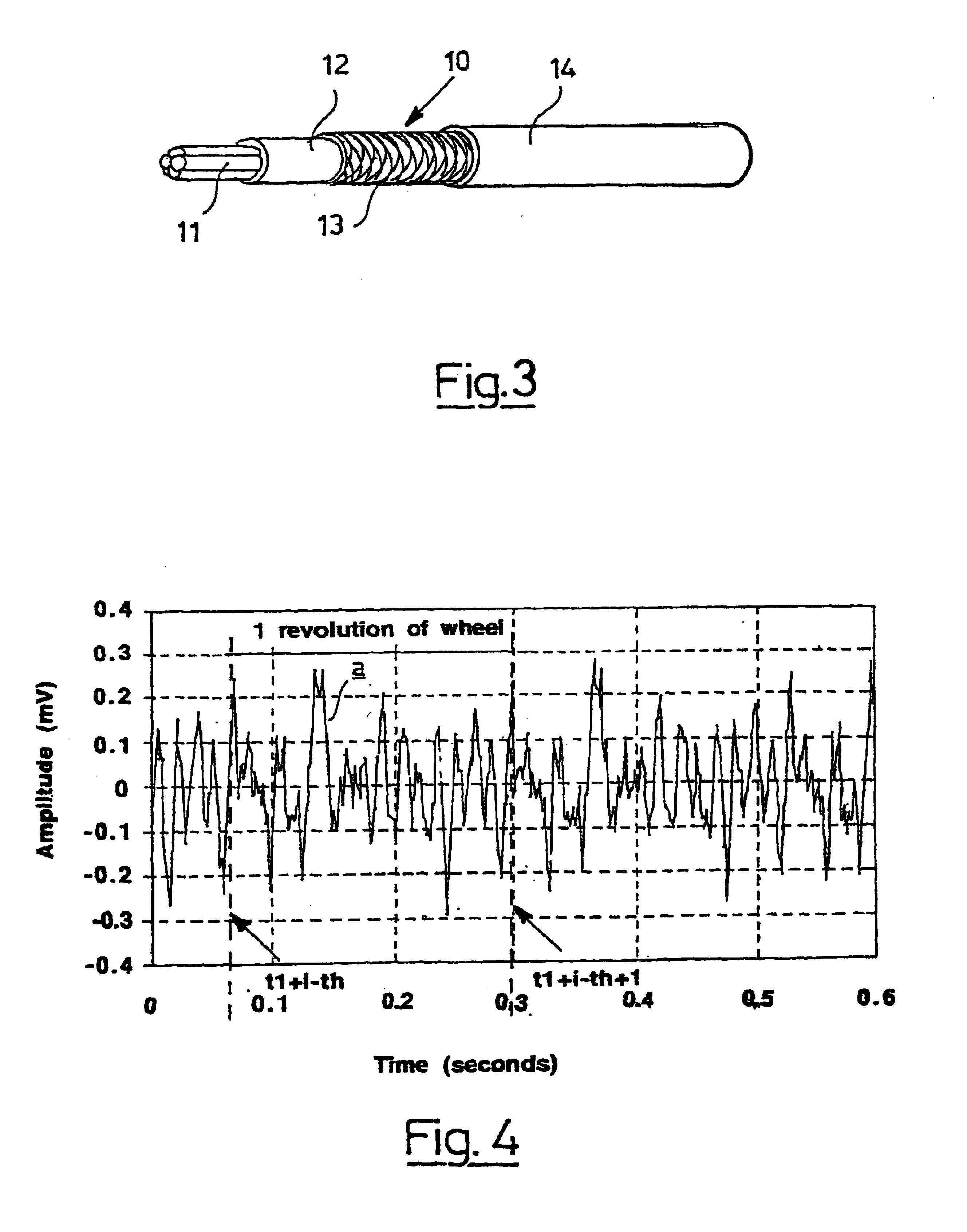

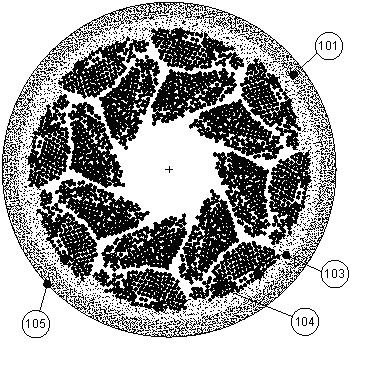

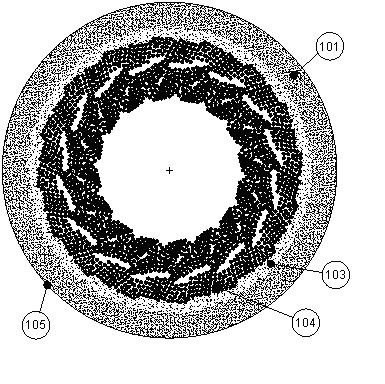

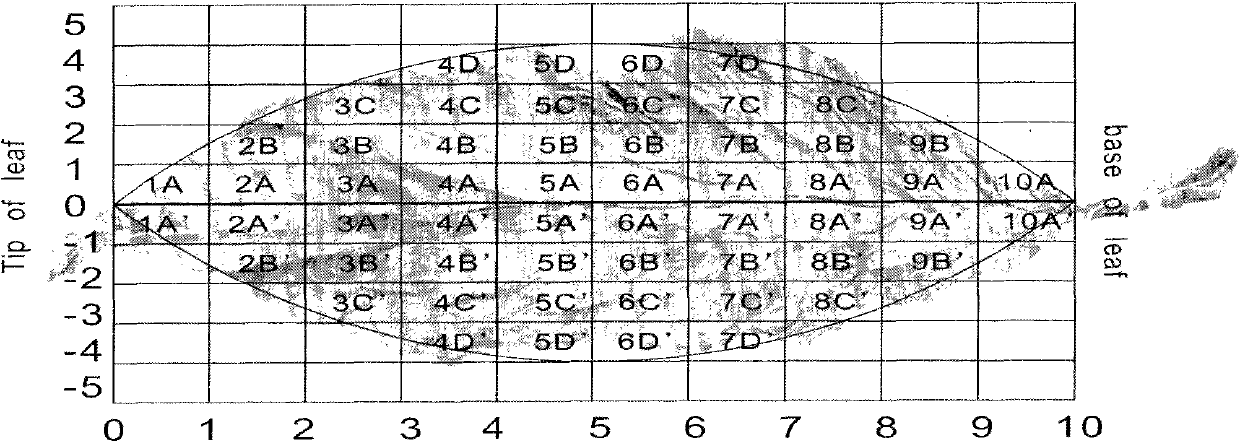

System, tire, wheel, vehicle, and method for determining the behavior of a tire in motion

InactiveUS6959593B2Uniform structureAvoid physical contactSuspensionsSubsonic/sonic/ultrasonic wave measurementElectricityMobile vehicle

A system for determining interaction between a tire and a contact surface during movement of a motor vehicle includes at least one first sensor and processing means. The at least one first sensor includes one or more first elongated piezoelectric elements which extend along at least a first portion of the tire. The at least one first sensor supplies a first signal to the processing means. The first signal is generated by rotation of the tire and is generated cyclically with each revolution of the tire. The processing means detects variations in time intervals between distinctive elements of the first signal. A tire including the system, a kit for detecting behavior of a tire moving with respect to a contact surface, a method for monitoring events correlated with interactions between tires of a moving vehicle and a contact surface, and related systems, tires, methods, and vehicles are also disclosed.

Owner:PIRELLI TYRE SPA

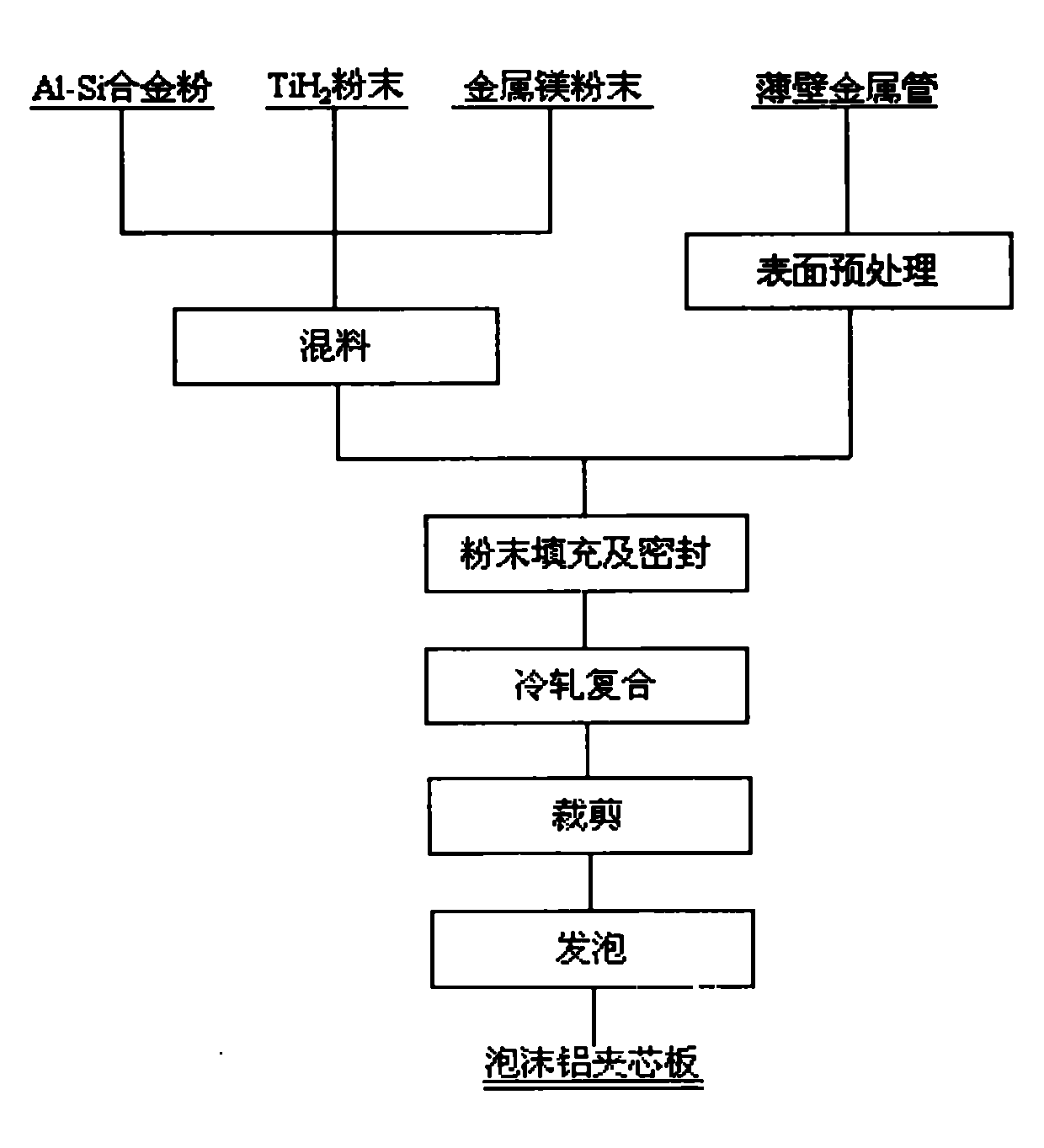

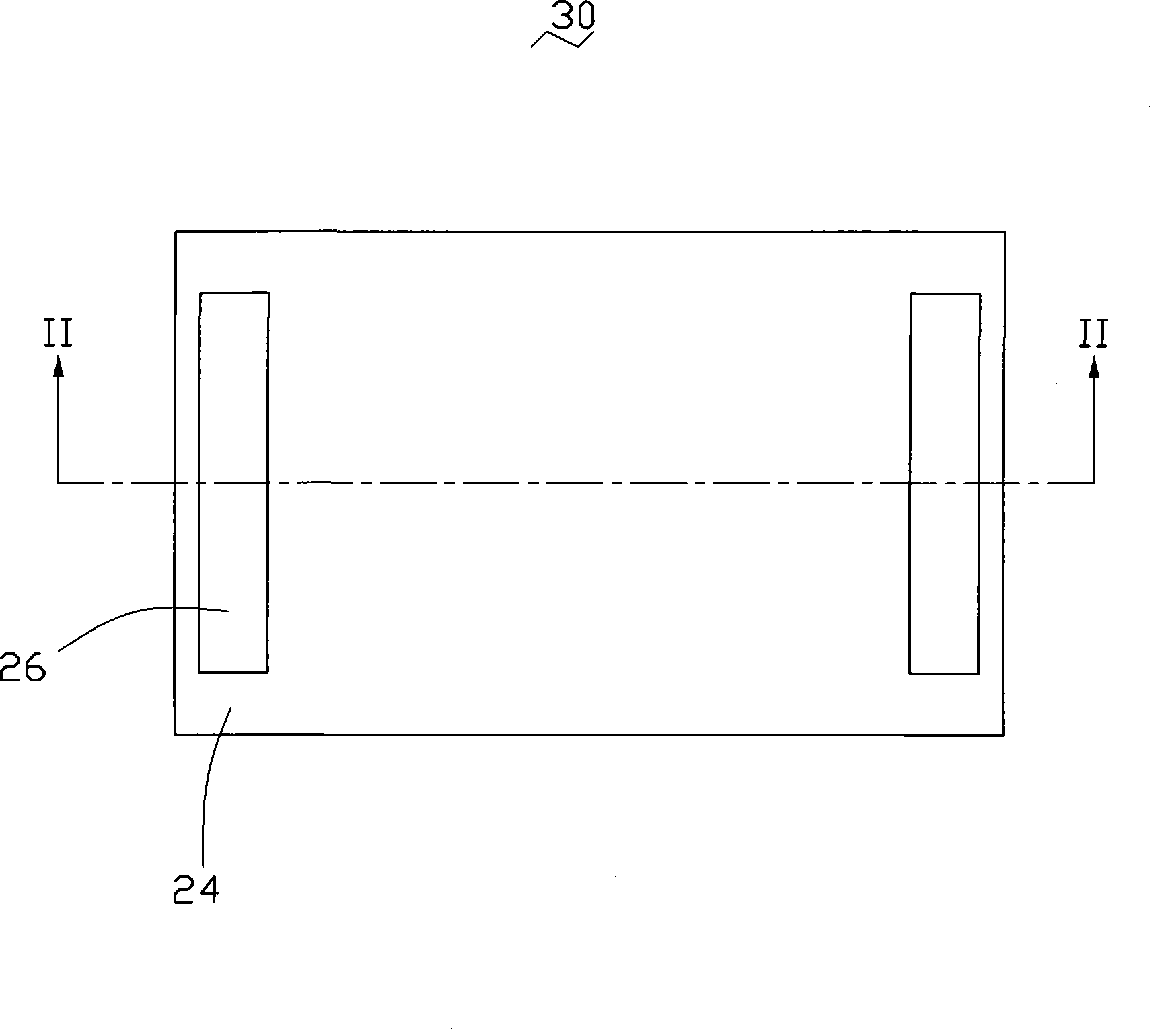

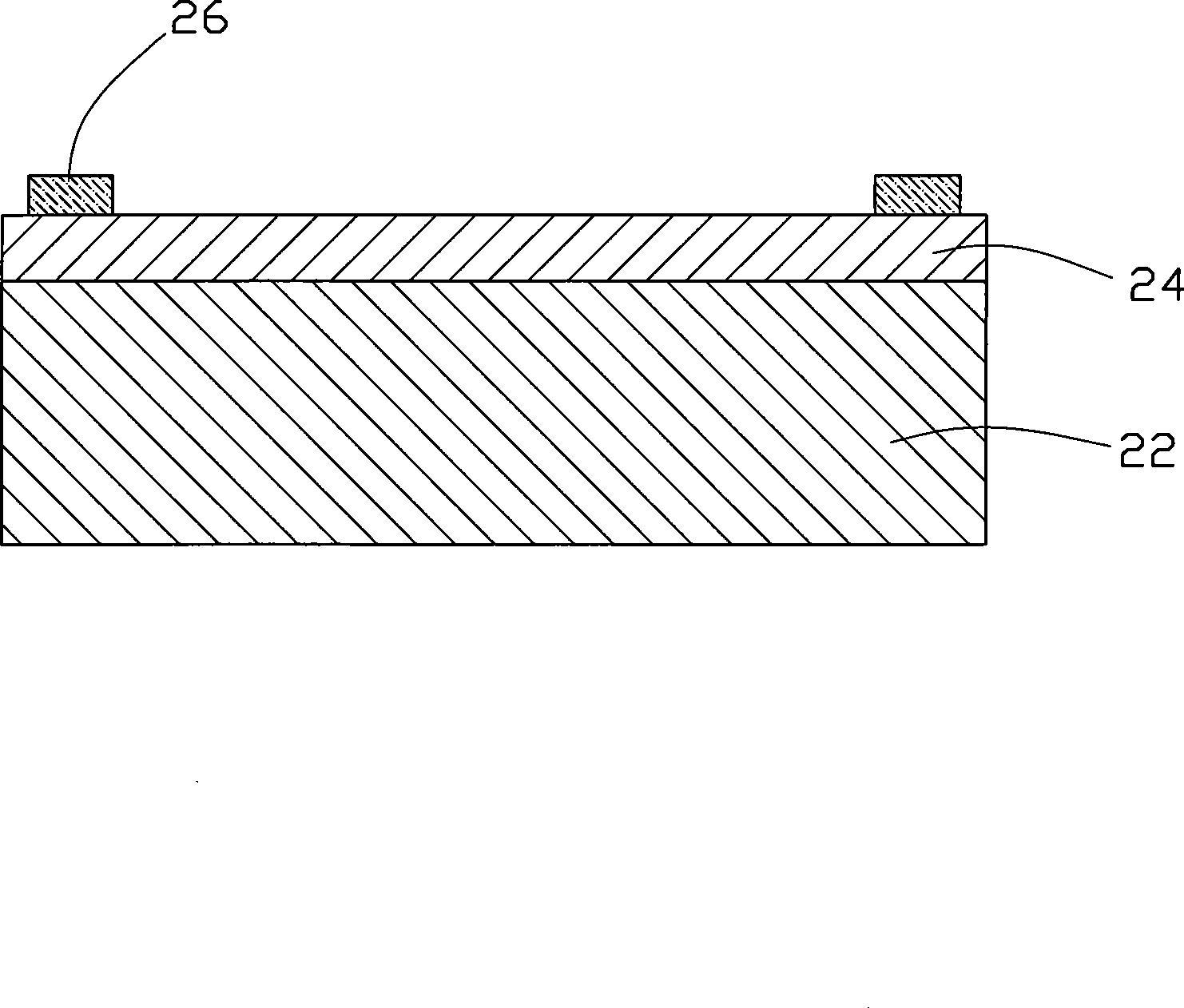

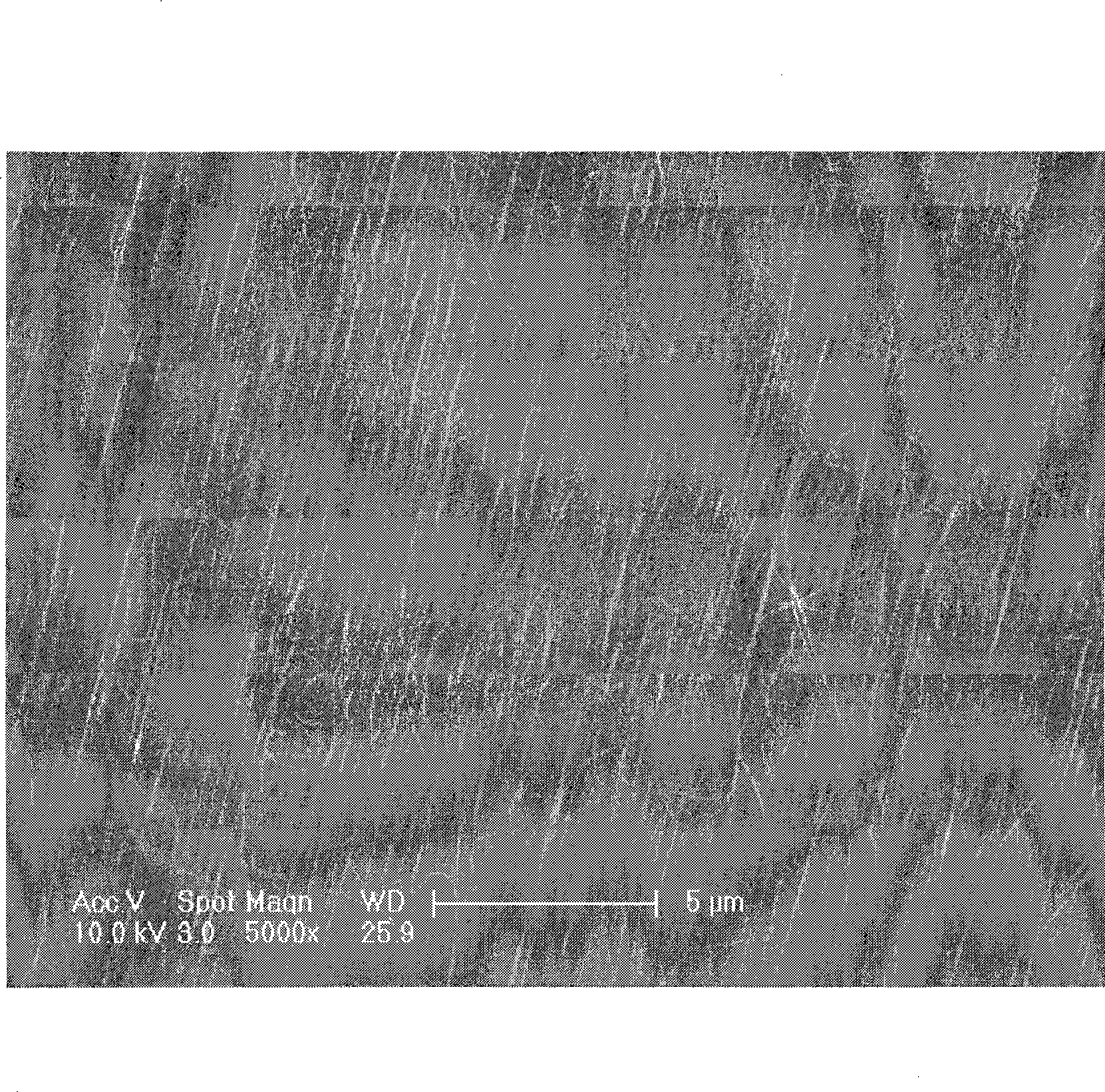

Method for manufacturing foamed aluminum sandwich plate

The invention relates to a method for manufacturing a foamed aluminum sandwich plate, which belongs to the field of porous foam metal and laminar composite materials. The method comprises the following steps of: uniformly mixing aluminum-silicon alloy powder prepared by an atomization method, and foaming agent titanium hydride powder and metal magnesium powder in a certain ratio; filling the powder into a thin-wall steel (or aluminum alloy) tube with one sealed end; sealing the other end of the tube after powder filling and preparing a rolled blank; rolling and compounding at a slow speed on a cold rolling mill; trimming an obtained composite plate and cutting a foamed preformed blank according to the size of a foaming mold; foaming the preformed blank in a steel mold in a limited way; adjusting foaming temperature and foaming time as required; and foaming at a high temperature for a short period of time to obtain a high-quality foamed aluminum sandwich plate with a uniform foam structure in a core layer, good interface bonding, high thickness accuracy and excellent plate profile. The method has the outstanding characteristics of low equipment requirement, high plate profile accuracy of a product, high three-point bending strength and the like and is advantaged technology suitable for mass industrial production of foamed aluminum sandwich structural materials.

Owner:NORTHEASTERN UNIV

Electronic element

ActiveCN101458975AIncreased durabilityImprove performanceMaterial nanotechnologyNanomagnetismCarbon nanotubeOptoelectronics

Owner:TSINGHUA UNIV +1

Method for coating micro/nano-metal powder by chemical vapor deposition

ActiveCN102581274ALow ignition temperatureShorter ignition delay timeChemical vapor deposition coatingThermal chemical vapor depositionIgnition delay

The invention discloses a method for coating micro / nano-metal powder by chemical vapor deposition, including: decomposing difluorocarbene precursor gas via a cracking pipe to generate difluorocarbene free radicals; contacting the generated difluorocarbene free radicals with micro / nano-metal powder, and due to polymerization between difluorocarbene free radicals, a compact polytetrafluoroethylene coating film is generated on the surface of micro / nano-metal powder. In allusion to disadvantages and defects of the application of micro / nano-metal powder in energy-containing materials, polytetrafluoroethylene is polymerized on the surface of metal powder by chemical vapor deposition in order to coat micro / nano-metal powder. In the invention, the ignition temperature of metal powder is effectively decreased, the ignition delay time is shortened, and the combustion speed of metal powder is improved; the surface of metal powder coated with polytetrafluoroethylene is highly hydrophobic, so that reactive metal powder can be effectively prevented from absorption of moisture and oxidation.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

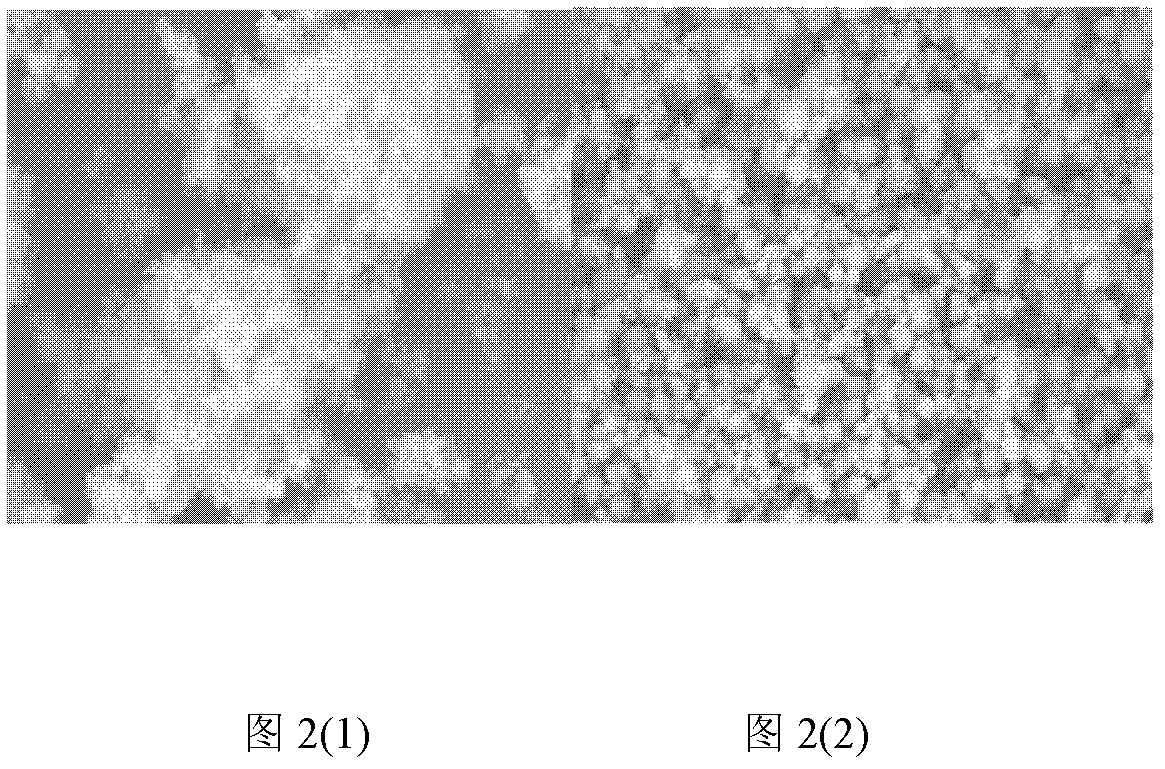

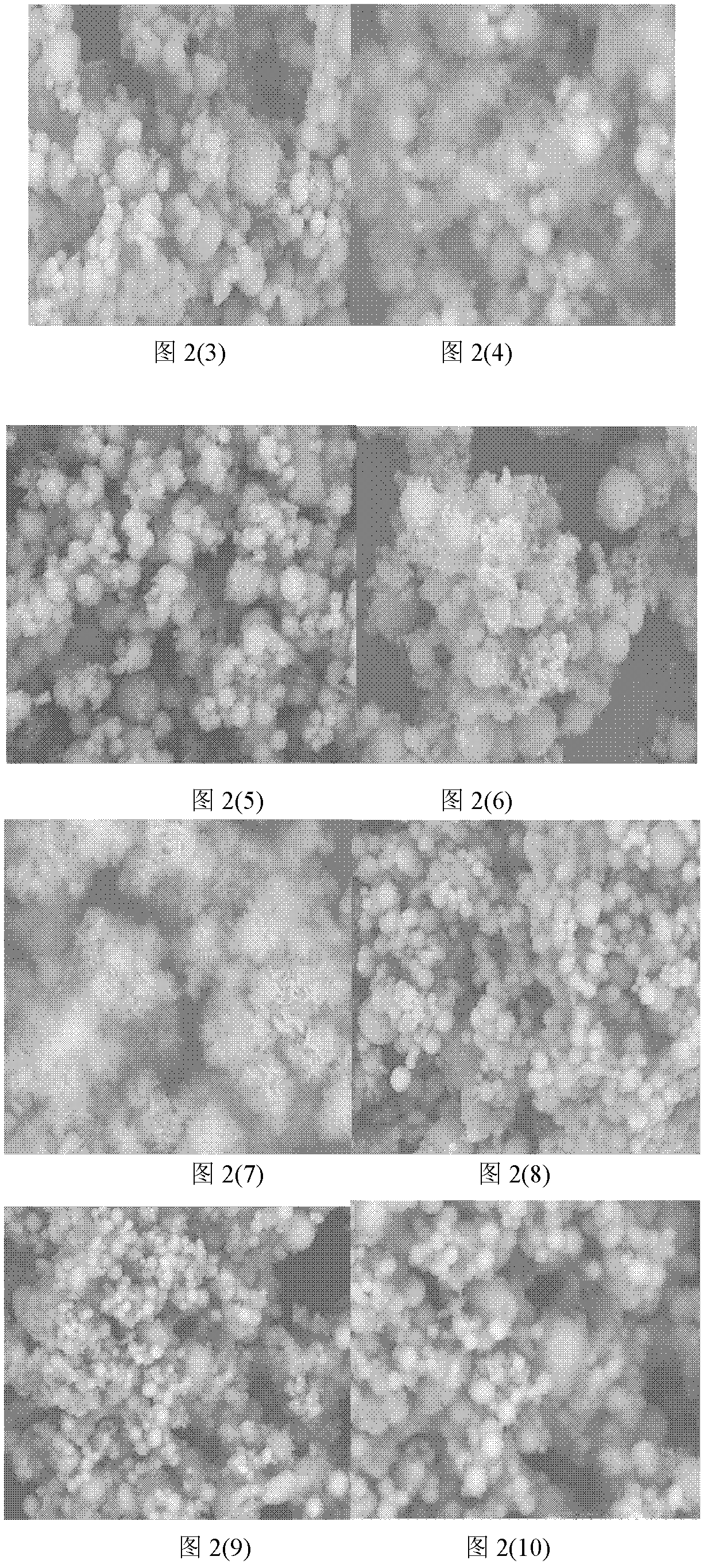

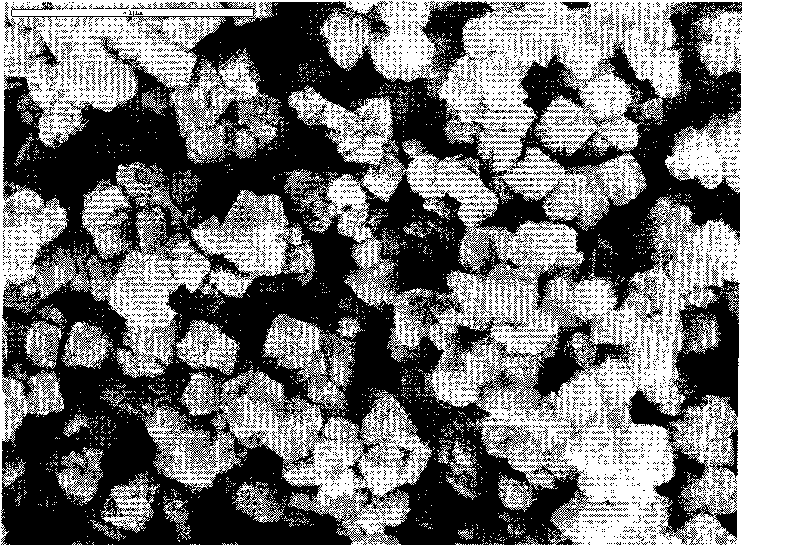

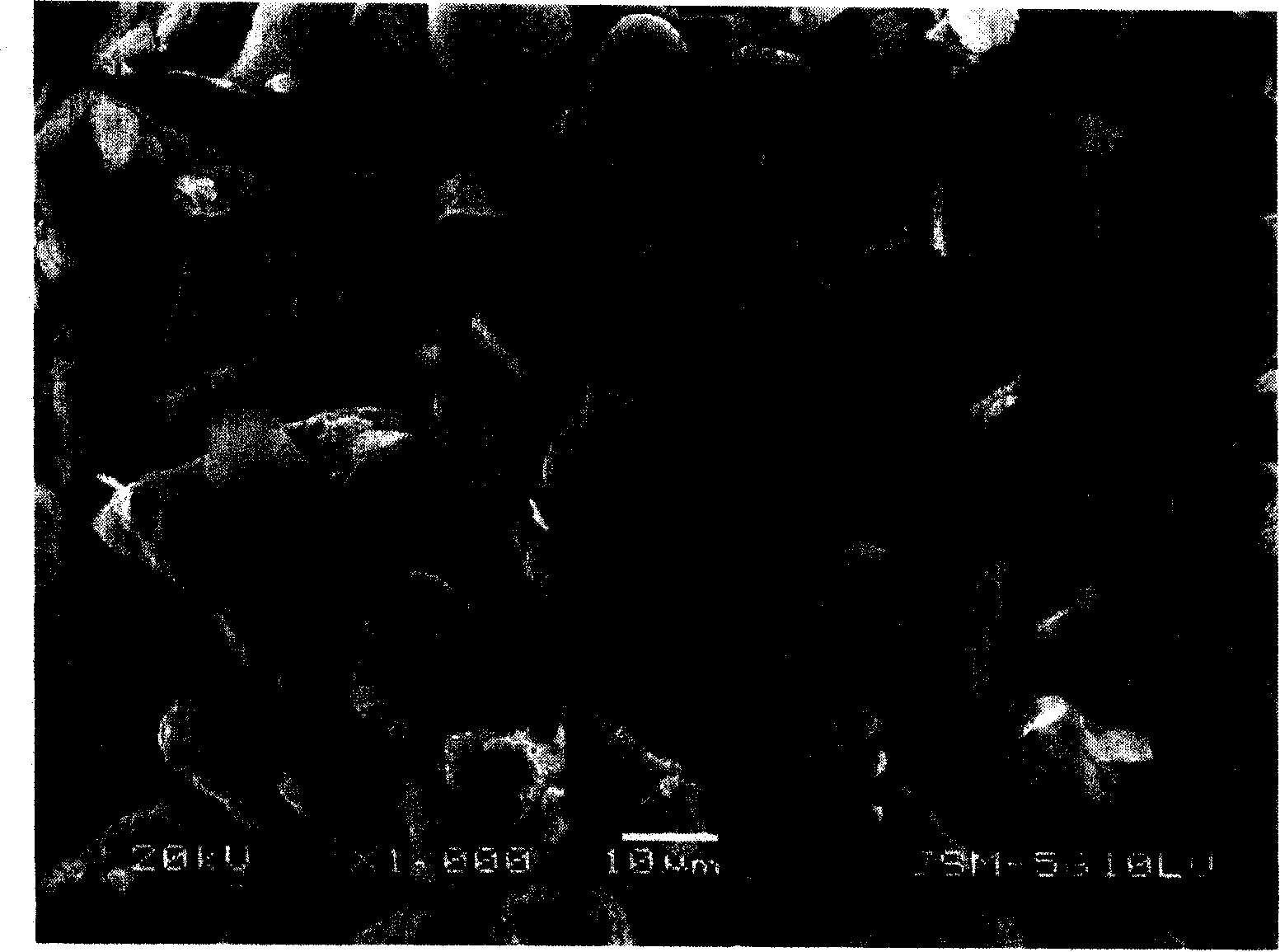

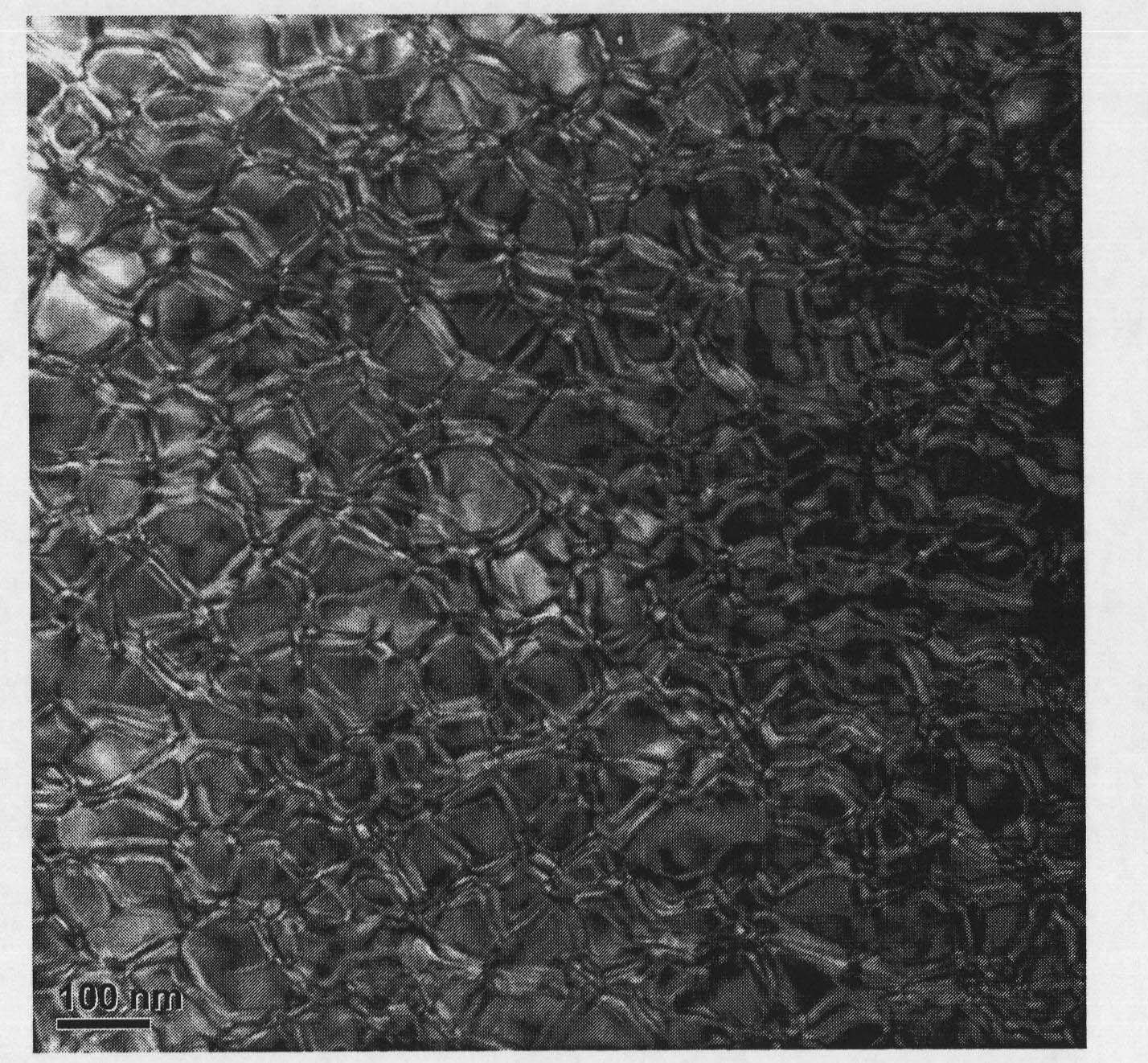

Small crystal grain Y-shaped molecular sieve and preparation method thereof

ActiveCN101723400AGuaranteed skeleton continuityReduce collapseFaujasite aluminosilicate zeoliteOxygenFluosilicates

The invention discloses a small crystal grain Y-shaped molecular sieve and a preparation method thereof. The small crystal grain Y-shaped molecular sieve has the following properties that: the molar ratio of SiO2 / Al2O3 is 5.0-20.0; the average diameter of crystal grains is 100 to 700nm; the crystallization reservation degree is over 95 percent; and the weight percentage of sodium oxide is less than or equal to 0.1 percent. The small crystal grain Y-shaped molecular sieve takes a small crystal grain NaY molecular sieve with good thermal stability and hydrothermal stability as a raw material, has a high silicon-aluminum ratio, good stability and a uniform framework, namely a silicon-aluminum structure, can uniformly remove aluminum and supplement silica in an ammonium exchanging and ammonium fluosilicate dealuminizing and silica-supplementing process, guarantees the framework continuity of the molecular sieve product, decreases the probability of framework structure collapse, and furthest reserves the integrity of the product, namely the silicon-aluminum-oxygen structure so that the product has very high crystallization reservation degree.

Owner:CHINA PETROLEUM & CHEM CORP +1

Silicon-containing composite material and its preparation method and application

ActiveCN101210112ASimple processReduce energy consumptionCell electrodesPigment treatment with macromolecular organic compoundsLithiumConductive polymer

The invention provides a siliceous composite material, comprising silicon particles, graphite particles and conducting polymer, wherein, the conducting polymer is wrapped on the surface of the graphite particles; at least part of the silicon particles is adhered to the surface of the conducting polymer. The siliceous composite material provided by the invention takes the conducting polymer as a clad material; the polymer does not need to be transformed further into 'hard carbon' and the siliceous composite material is guaranteed to have excellent conductivity; meanwhile, the aggregation between silicon particles can be avoided. When the composite material is taken as negative active material of a lithium iron battery, the lithium iron battery is guaranteed to have high reversible capacity and good cycle performance. Therefore, the invention can be used as the negative active material of the lithium iron battery. As the polymer does not need to be transformed further into the 'hard carbon' and the siliceous composite material has good conductivity in the preparation of the siliceous composite material provided by the invention, the manufacturing technique is simplified and the problem of huge energy consumption caused by the high temperature carbonization process in the prior art is solved.

Owner:BYD CO LTD

Ultrathin nanosheet array electro-catalytic material with nano-porous structure and oxygen vacancies

The invention relates to an ultrathin nanosheet array electro-catalytic material with a nano-porous structure and oxygen vacancies. The material is a cobaltosic oxide primary nanosheet array which grows vertically on a conductive substrate and is doped with a metal; an ultrathin nanosheet with oxygen vacancies and nanopores is obtained on each primary nanosheet; the conductive substrate is a titanium sheet or a foamed nickel sheet, and the doped metal is zinc, nickel or manganese; and the thickness of each cobaltosic oxide ultrathin nanosheet doped with the metal is 1.22 nm, nanosheets are in a three-dimensional porous structure, and the nano-pore diameter is 3-6 nm. The ultrathin nanosheet array electro-catalytic material with the nano-porous structure and oxygen vacancies has the following advantages: the material can effectively reduce the overpotential and the spike potential of an oxygen evolution reaction, increase the conversion rate of a single cobalt atom and work continuously and stably in an alkali environment; the steps of a preparation method of the material are simple, the operation is convenient, the cost is low, and the material is environmental-friendly; and new ideas and strategies are provided for the function-oriented design and the performance optimization of an oxygen evolution catalyst of a water electrolysis system.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

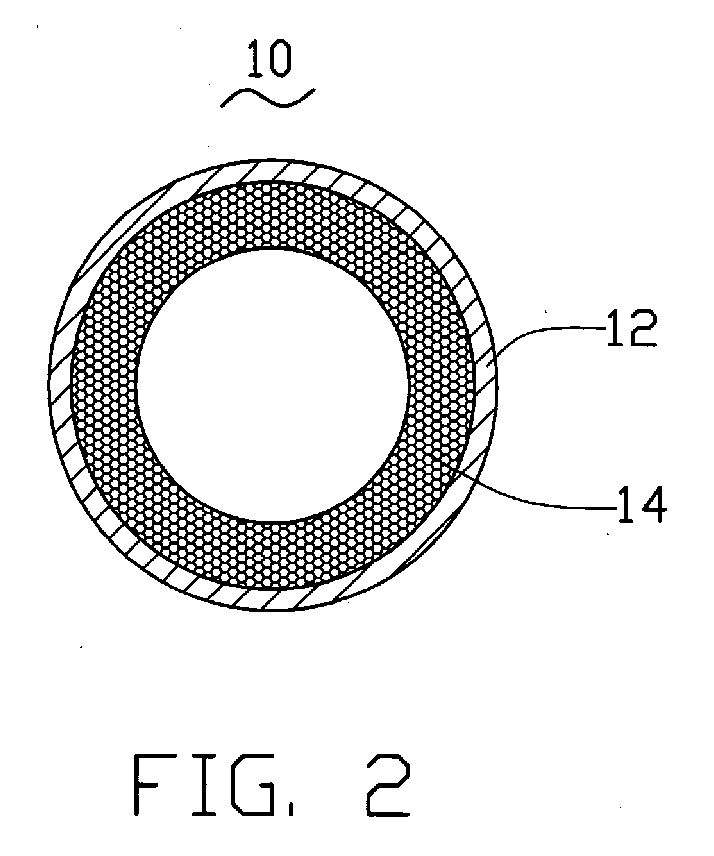

Lining-reinforced hollow fiber membrane tube as well as preparation device and preparation method thereof

ActiveCN102160967AIncrease asymmetryLow elongationSemi-permeable membranesHollow fibrePolymer science

The invention relates to a lining-reinforced hollow fiber membrane tube as well as a preparation device and preparation method thereof, belonging to the field of preparation of polymer hollow fiber microporous membranes. In the membrane tube, a film forming chimney is designed reasonably, a coating layer on a braided tube led from a coating machine is subjected to controllable steam diffusion-induced phase inversion firstly, and then enters a coagulating bath, so that an open-pore surface skin layer with high porosity is formed on a film separation layer, and the radial direction of the membrane layer is in an integral asymmetric and interpenetrating cell-shaped structure; a composite material is selected to prepare a transition layer, so that the transition layer has excellent adhesive force and hardness, excellent compatibility with a surface separation layer and tiny cubical contraction in a phase conversion process at the same time; optimized braided tube size and braiding densityare selected to ensure that the braided tube has lower flexibility; and a method capable of maintaining reasonable roundness and the like in the production process ensures that the lining polyvinylidene fluoride (PVDF) hollow ultrafiltration membrane tube has the advantages of integral asymmetric structure with high integrity, high-porosity surface separation layer, higher back pressure enduring capability and the like.

Owner:南京久盈膜科技有限公司

Method for preparing flame-proof viscose fiber

InactiveCN101215726ASimple and convenient filteringFilter is not easy to clogFlame-proof filament manufactureMonocomponent cellulose artificial filamentPolymer scienceEmulsion

The invention discloses a process for preparing flame retarding cellulose viscose, which adopts pyrophosphate exchange reaction flame retardant particle whose mean particle diameter is <= 1.0um, non-ionic surface active agent, dispersing agent and solvent water to mix and obtain flame retardant emulsion, each percentage by weight is pyrophosphate exchange reaction flame retardant 20-45 wt%, non-ionic surface active agent 5-10 wt% and dispersing agent 0.5-1.0 wt%, and residue is solvent water. The process for preparation comprises adding pyrophosphate exchange reaction flame retardant of flame retardant emulsion which is corresponded to alpha cellulose 15-30 % into spinning original liquid which is filtered to mix, shaping spinning by adopting spinning bath which is low acid, low salt, low temperature and high zinc. The spinning original liquid of the invention has simple and convenient preparation, fiber does not contain halogen elements, which avoids environmental pollution, when in burning, the invention is not melted, while charring only happens to keep the original shape of fiber, the invention prevents dripping which is melted in high temperature from scalding human body, and flame retardant is distributed evenly in adhesive, which can not smolder after leaving fire and easy to be self-extinguished.

Owner:CHTC HELON

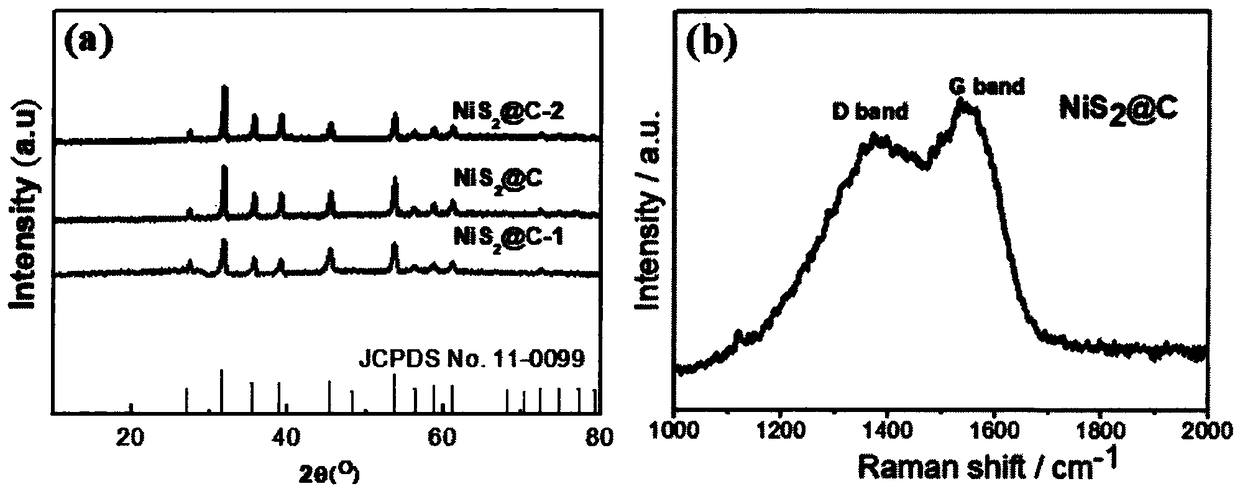

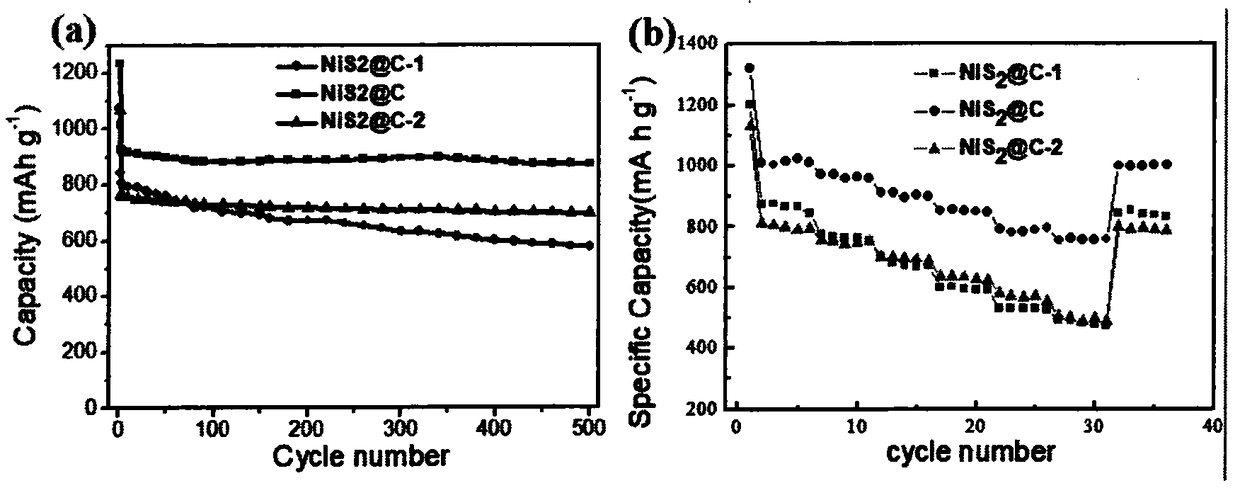

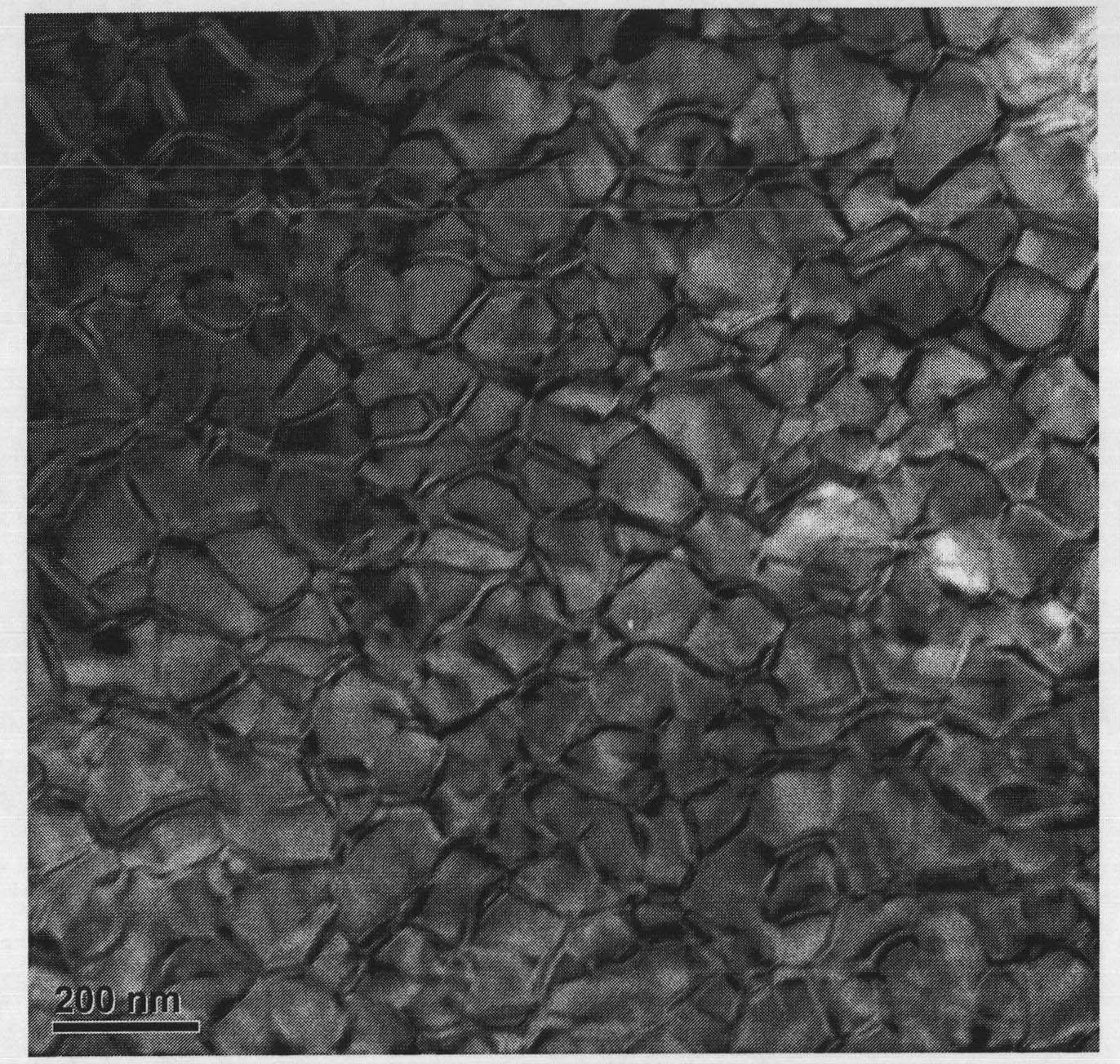

Nickel disulfide carbon nano composite material and preparation method and application thereof

InactiveCN108832097AGood biocompatibilityStrong adhesionMaterial nanotechnologyHybrid capacitor electrodesCarbon compositesCarbon layer

The invention relates to a nickel disulfide carbon nano composite material and a preparation method and an application thereof, wherein the composite material is formed by coating a nickel disulfide nanosheet with a carbon layer. The preparation method comprises the following steps of preparing a nickel hydroxide nanosheet precursor by a hydrothermal method, performing magnetic stirring and dispersing in deionized water to obtain a uniform dispersion liquid of the nickel hydroxide nanosheet precursor, adding a buffering agent tris(hydroxymethyl) aminomethane hydrochloride, and adjusting the pHvalue to be 8.5 by adopting an alkali solution with the pH value of 13, adding dopamine hydrochloride, and magnetically stirring at room temperature for in-situ polymerization, and carrying out washing and centrifugally drying to obtain a nickel hydroxide nanosheet precursor / polydopamine composite material, and carrying out heat treatment and vulcanization with sublimed sulfur powder in a tubularfurnace in nitrogen atmosphere at a certain temperature to obtain the composite material. The preparation process is simple, easy to operate, green and non-toxic and friendly in material preparationprocess; and the prepared nickel disulfide carbon nano composite material is stable in structure, uniform in morphology and high in dispersion. The obtained nickel disulfide carbon nano composite material can be an ideal electrode material of a high-performance lithium ion battery, a supercapacitor and other new energy devices.

Owner:DONGHUA UNIV

Samarium-cobalt sintered magnet material and preparation method thereof

InactiveCN101882494ALower temperature coefficient of remanenceLower flux temperature coefficientMagnetic materialsRare earthCobalt

The invention discloses a 2:17 type samarium-cobalt sintered magnet material and a preparation method thereof. The 2:17 type samarium-cobalt sintered magnet material comprises the following raw materials in percentage by mass: 10 to 25 percent of samarium, 45 to 55 percent of cobalt, 10 to 20 percent of iron, 3 to 9 percent of copper, 1 to 3 percent of zirconium and 5 to 15 percent of at least one heavy rear earth element. Due to the selection and the proportion of the raw materials and the innovation of the sintering process, a microstructure of the magnet material is optimized, and the aims of reducing the temperature coefficient of a magnet and simultaneously maintaining higher magnetic energy product of the magnet are fulfilled, wherein the magnetic energy product of the prepared magnet is 14 to 25 MGsOe, the residual magnetism temperature coefficient is about -0.005 to -0.03 percent per DEG C, and a lower magnetic flux temperature coefficient is maintained in an environment at the temperature of between -35 and 300 DEG C.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

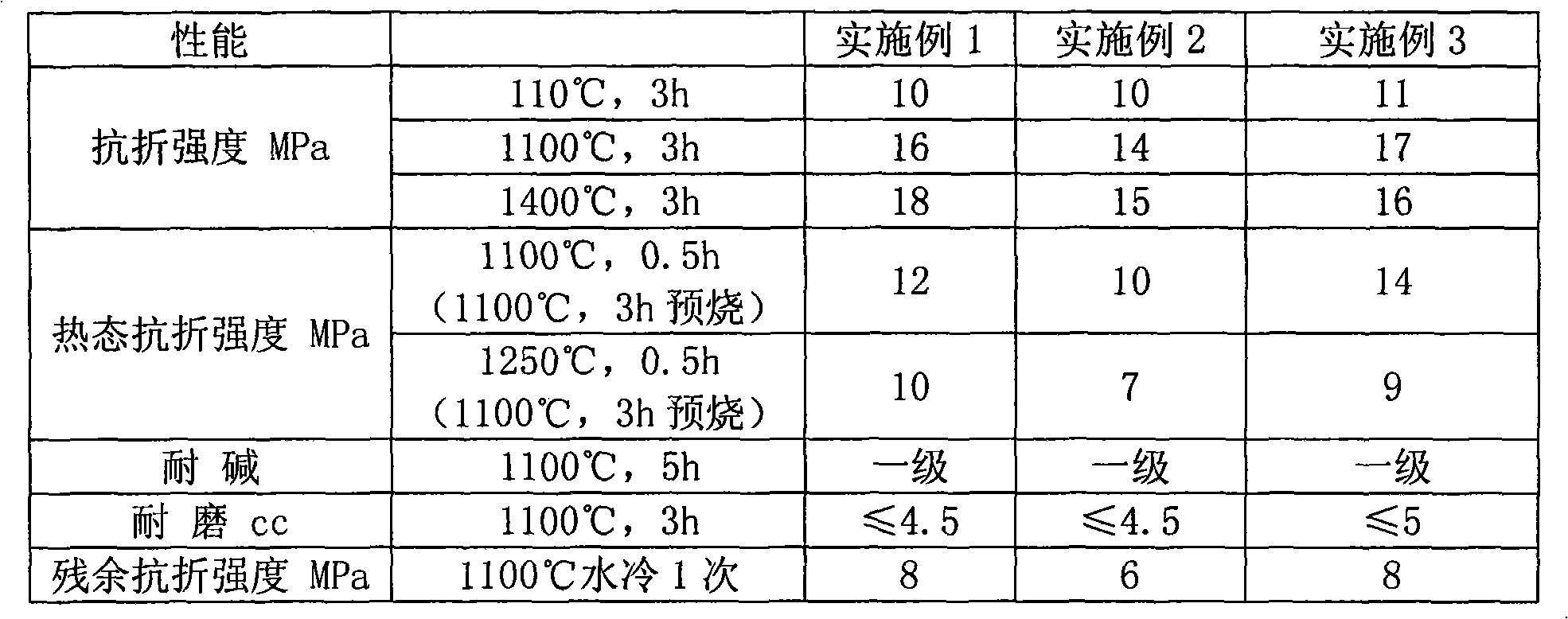

Wear and corrosion resistant castable prepared from bauxite-based homogenous material and preparation method thereof

ActiveCN101885617AUniform structureSmall fluctuations in water addition during constructionPliabilityCement kiln

The invention discloses wear corrosion resistant castable prepared from a bauxite-based homogenous material and a preparation method thereof, which belong to the technical field of castable refractory. In the invention, by using the characteristics of the bauxite-based homogenous material, such as homogeneous chemical components and structure, stable performance, mulite main crystal phase, small linear change, high high-temperature strength and certain flexibility due to mutual insertion of micro crystals and the like, the shortcomings of low middle-temperature strength and poor wear resistance and alkali corrosion resistance of the conventional high-aluminum bauxite castable are overcome, and the problems of low middle-temperature strength, poor wear resistance and poor alkali, chloride and sulphur corrosion resistance of the conventional high-aluminum and corundum castable are effectively solved. The wear and corrosion resistant castable with high middle-temperature performance is prepared. The wear corrosion resistant castable and the preparation method thereof have the advantages of small fluctuation of water adding amount in construction, stable usability, reduction rate of partial corrosion, prolonged service life and wide application to a kiln hood, a grate cooler, a tertiary air duct and a decomposing furnace of a dry process cement kiln and relative parts of other ceramic and petrified thermo-technical kilns and the like.

Owner:YANGQUAN JINYU TONGDA HIGH TEMPERATURE MATERIALS +1

Permanent ferrite magnetic tile and preparation method thereof

InactiveCN101202138AIncrease solid solutionImprove performancePermanent magnetsInorganic material magnetismFiberSilicon oxide

The invention relates to a permanent ferrite magnetic arc and the manufacturing method thereof, belonging to a manufacturing field of a motor permanent ferrite. Weight proportions of main material components and additive components are as the following: main materials: 8.7 to 9.0 percent of strontium oxide; 86 to 87 percent of iron oxide red; additives: 0.6 to 1.0 percent of calcium carbonate; 0.6 to 1.0 percent of aluminum oxide; 0.4 to 0.8 percent of chrome oxide; 0.3 to 0.6 percent of boric acid; 0.3 to 0.5 percent of silicon oxide; 0.2 to 0.4 percent of cobalt oxide; 0.2 to 0.4 percent of lanthanum oxide and 0.1 to 0.3 percent of silicate fiber. The invention is provided with high surplus magnetic induction strength and high intrinsic coercivity so as to enhance a mechanical strength of the magnetic arc.

Owner:CHANGZHOU DIER MAGIC MATERIALS

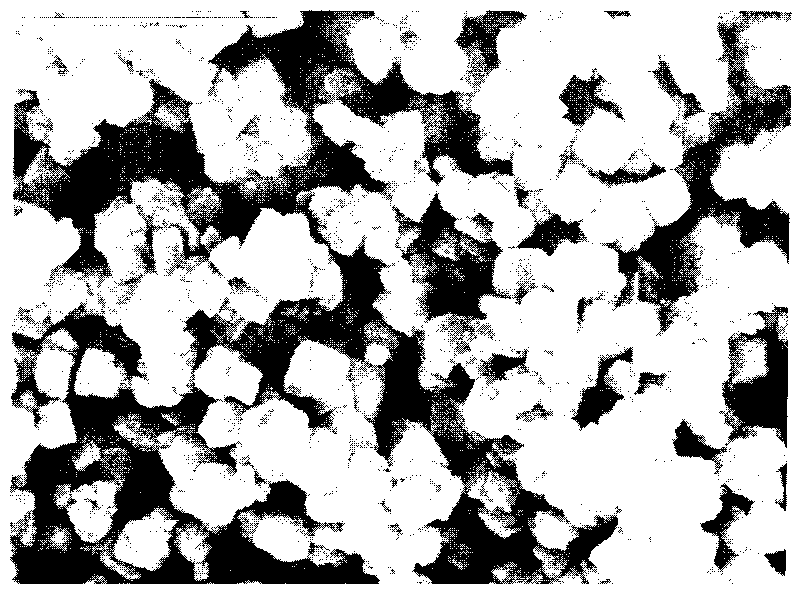

Non-transparent quartz crucible for polysilicon crystallization and manufacturing method thereof

InactiveCN101348324AHighlight substantive featuresSignificant progressGlass shaping apparatusSilicon compoundsCrack resistanceSlurry

The invention provides an opaque quartz crucible used in multicrystal silicon crystallization and a method for manufacturing the same. The crucible is of a regular square structure, and the compositions in mass ratio of the crucible are more than 99.7 Wt percent of silicon dioxide, less than 600ppm of aluminum oxide and less than 30ppm of ferric oxide. The method comprises the following steps: firstly, a raw material, i.e. high purity quartz is put into granulation equipment for wet method granulation, the grain size is controlled between 70 and 100mu m; then, slurry is fully stirred and then is fed into a gypsum mould under a pressure of between 2 and 3bar after being deposited for 24 to 48 hours; moreover, early grouting is assisted by slight vibration; the slurry is further settled for 5 to 8 hours, and is demoulded after fully dewatered; the slurry is dried inside a drier; and finally, a blank is put in a kiln for sintering so as to obtain the opaque quartz crucible. The proposal adopts grouting forming by a high-purity quartz material, and the sintered crucible has uniform inner structure; moreover, the crucible has excellent thermal shock stability and cracking resistance, and can meet the technological requirements for manufacturing multicrystal silicon cast ingots.

Owner:常熟华融太阳能新型材料有限公司

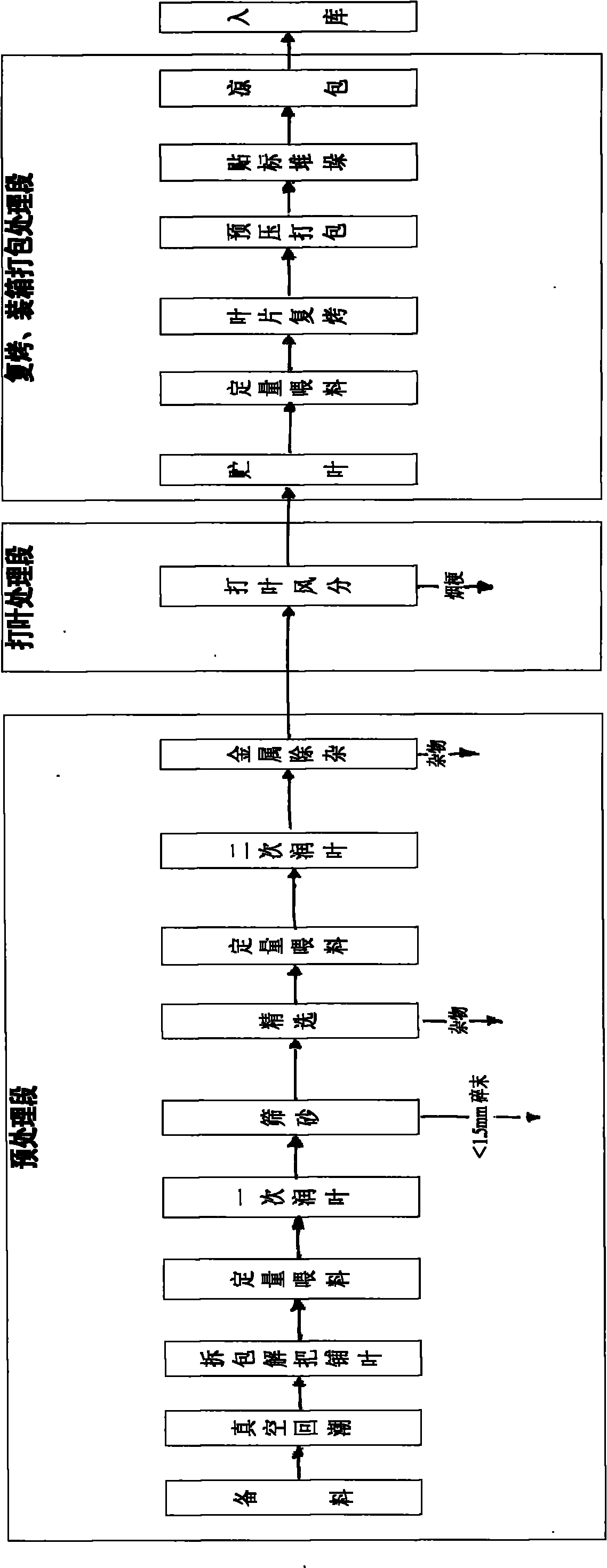

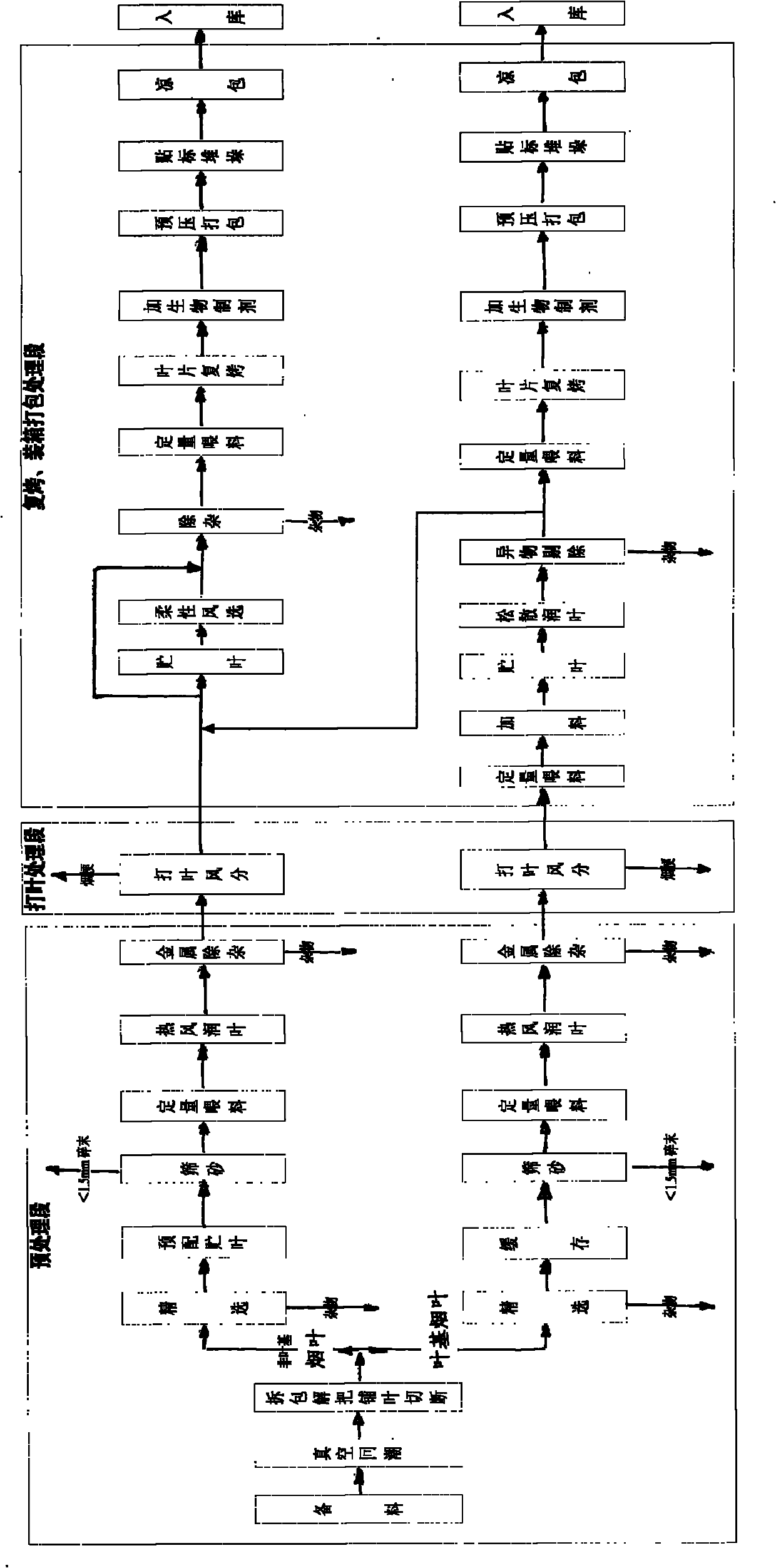

Method for slitting, striking and redrying tobacco

The invention relates to a method for slitting, striking and redrying tobacco, which is technically characterized by comprising the following step of: cutting tobacco lead bases with minimum tensile strength, poorest physical processing resistance and poorer perception smoke panel test quality and appearance quality in the tobacco for singly cutting, striking and redrying. The method has the mainadvantages that remained non leaf base tobacco leaves are crushed to be smaller when leaves and stems are separated singly after the tobacco leaf bases are cut for being singly processed, the leaf structures are more uniform after the leaves are separated from the stems, the green and impurity content in the tobacco is reduced, thus the large-medium leaf ratio after the striking is improved, the crushing generated when the leaves are separated from the stems is reduced, the leaf yield is improved, and the purity of the tobacco is increased. After the tobacco is processed by using a slitting, striking and redrying method of the invention, the leaf base smoking quality is better, the fragrance quantity is improved, the smoke explosive force is increased, the smoking comfort is enhanced, andthe impurity gases are reduced, thus the use value of the tobacco can be improved.

Owner:HONGTA TOBACCO GRP

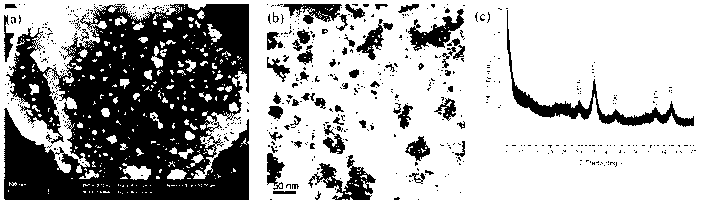

Preparation method of spinel-type magnetic MFe2O4/graphene composite material

InactiveCN102745675AHigh purityImprove bindingIron oxides/hydroxidesZinc oxides/hydroxidesNitrogen gasSolvent

The invention discloses a preparation method of a spinel-type magnetic MFe2O4 / graphene composite material. The preparation method utilizes a water-soluble metal M<2+> salt and a Fe<3+> salt as precursors and graphite oxide as a matrix and comprises the following steps of carrying out ultrasonic dispersion of graphite oxide in ethanol or water as a solvent to obtain a graphene oxide dispersion, adding a M<2+> salt and Fe<3+> salt-containing aqueous solution having a M<2+> / Fe<3+> mole ratio of 1: 2 into the graphene oxide dispersion, fully stirring to obtain a mixed solution, adjusting a pH value of the mixed solution to a value more than 10 by an alkali liquor, adding a reducing agent into the mixed solution, stirring at a temperature of 80 to 150 DEG C for a reaction lasting for 4 to 10 hours, after the reaction is finished, carrying out separation, washing, drying and grinding, and carrying out calcination of the grinded powder at a temperature of 300 DEG C in a nitrogen or argon atmosphere for 2 to 10 hours. Magnetic MFe2O4 nano particles of the spinel-type magnetic MFe2O4 / graphene composite material have high loading capacity, stable structures, good uniformity, good dispersibility and strong adhesion with graphene. The spinel-type magnetic MFe2O4 / graphene composite material can be widely used in the fields of magnetic targeting materials and other related function materials.

Owner:HEFEI UNIV OF TECH

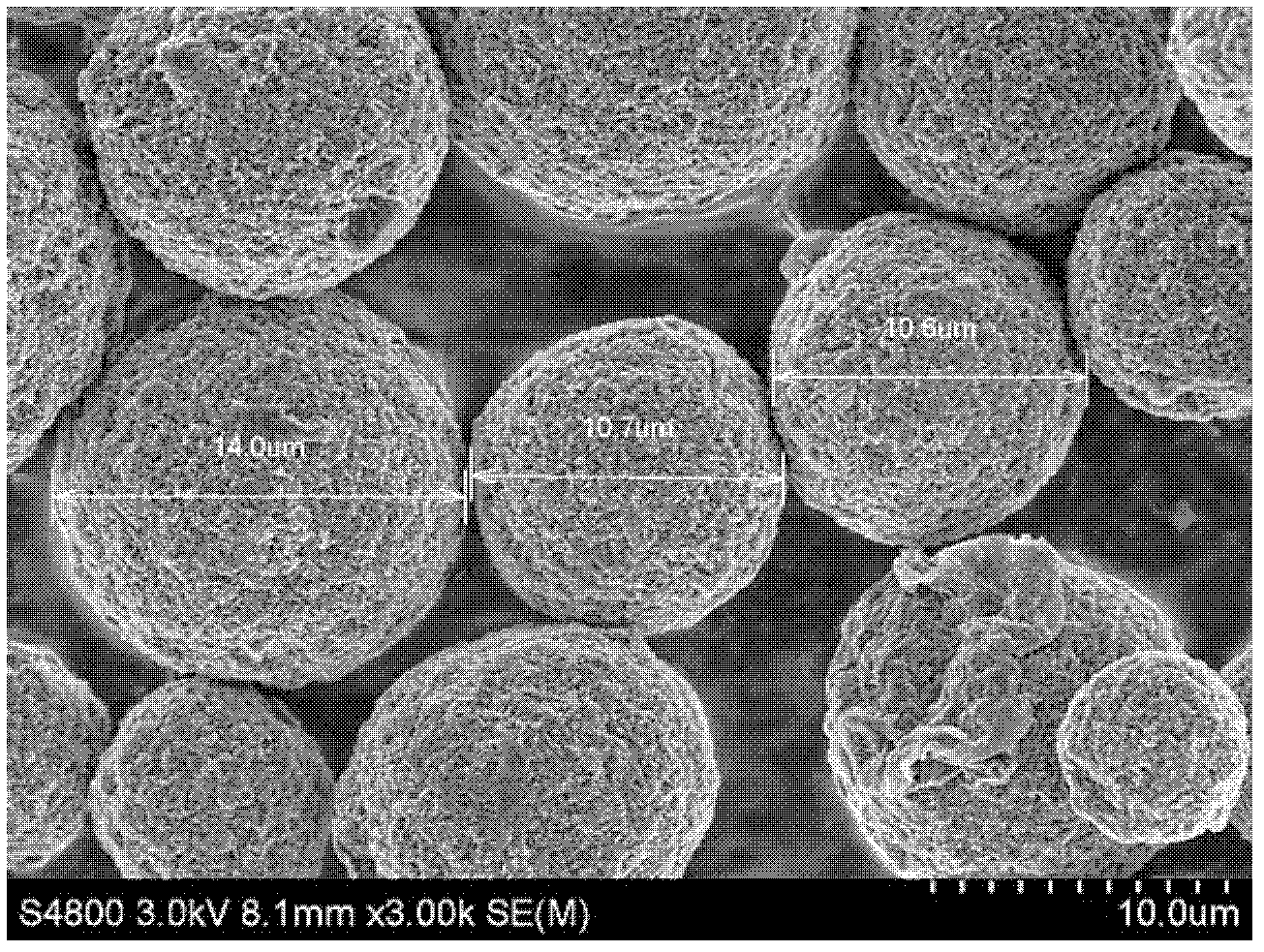

Method for preparing spheroidal graphene

The invention discloses a method for preparing spheroidal graphene, and a technical problem to be solved is to increase the density of graphene and make the transportation and storage convenient. The method comprises the following steps: dispersing graphene in water or alcohol, carrying out ultrasonic processing or ball milling, and carrying out granulation and drying to obtain the spheroidal graphene; or dispersing graphene in water with stirring, carrying out decentralized processing, and carrying out granulation and drying to obtain the spheroidal graphene. Compared with the prior art, by high temperature granulation or low temperature refrigeration granulation processing, the obtained graphene has uniform structure, small volume, large density, good electrical conductivity, and convenience in transportation, and can be applied in catalyst carrier, drug delivery, lithium ion battery and super capacitor as a carbosphere; by ultrasonic processing, the spheroidal graphene is dispersedinto graphene monomers with less than 10 layers, and the excellent properties of the graphene are kept, the obtained spheroidal graphene can be convenient for being applied in various fields, the safety performance is high, the continuous preparation production can be realized, the processing capacity can be controllable and adjustable, and the invention is suitable for large scale production.

Owner:BTR NEW MATERIAL GRP CO LTD

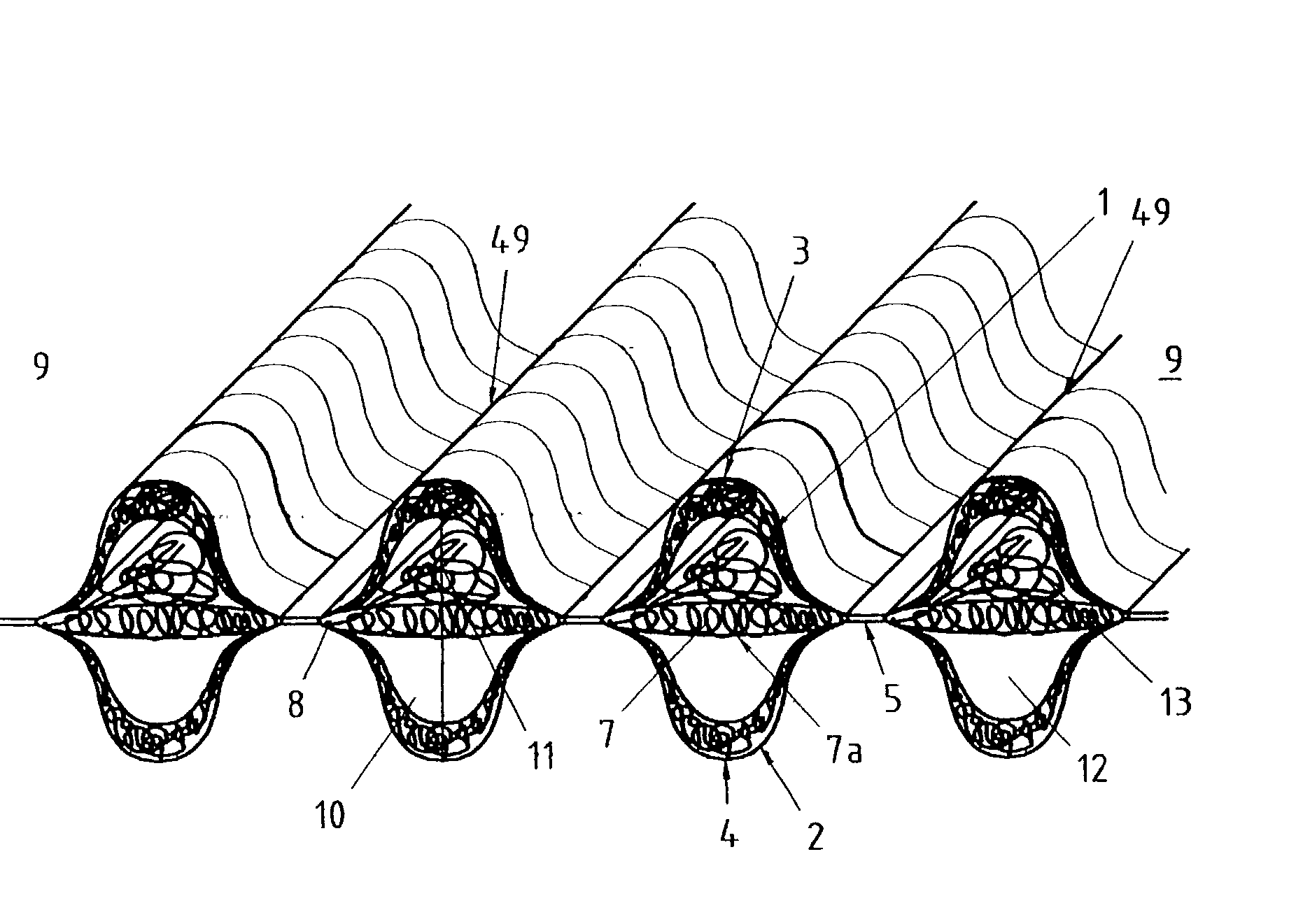

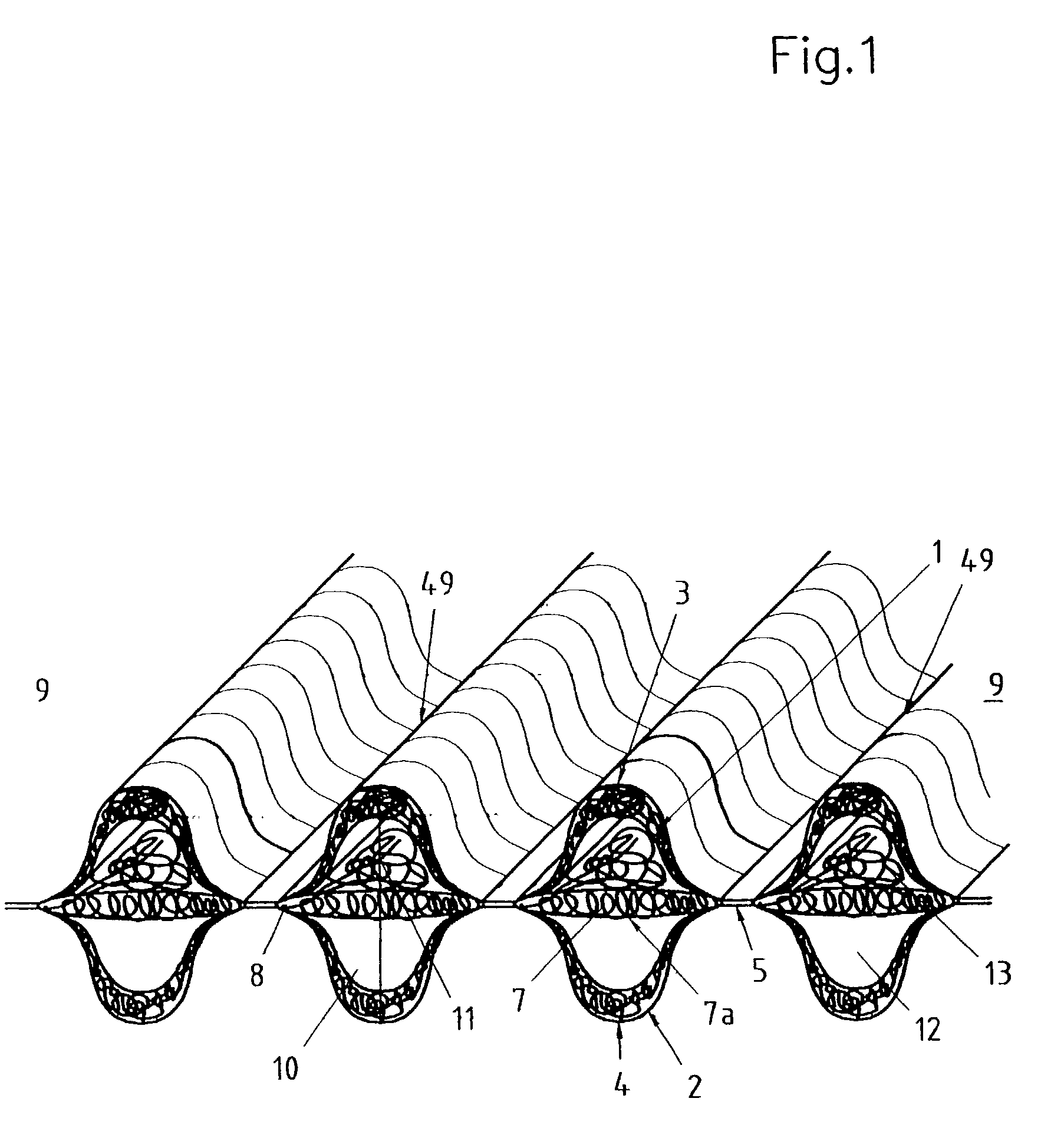

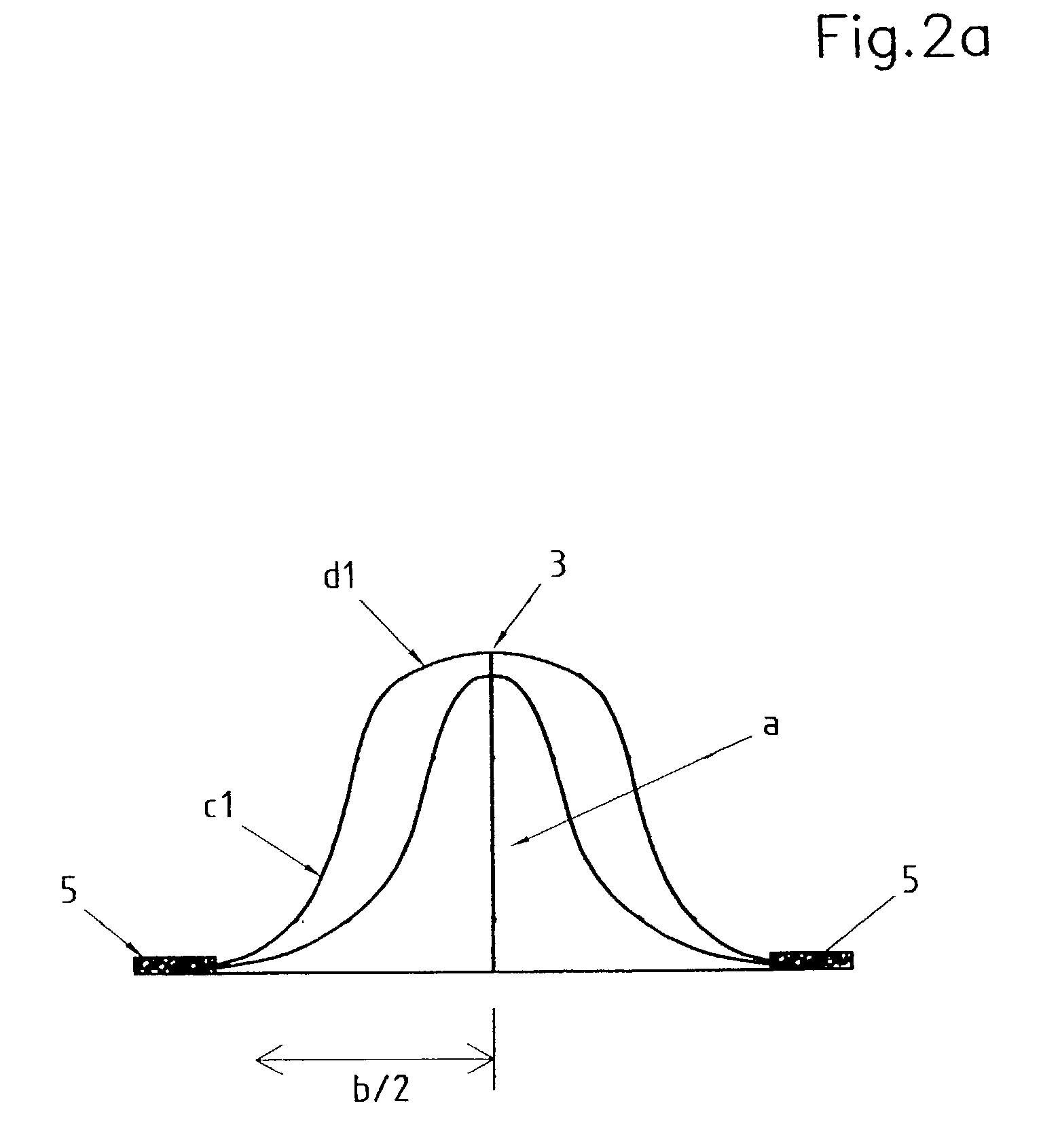

Regularly structured nonwoven fabrics, method for their manufacture, and their use

InactiveUS20030096548A1Prevent randomness and irregularityUniform structureSynthetic resin layered productsRecord information storageEngineeringNonwoven fabric

A three-dimensionally structured fibrous fabric having elevations and depressions occurring regularly in alternation in relation to the surface plane, includes at least one nonwoven fabric layer and a shrunk fabric bonded thereto. In this context, the nonwoven fabric layer and the shrunk fabric were bonded by heat sealing performed at least perpendicular to the direction of the greatest shrinkage of the shrunk fabric in the form of lines. The fabric may be used as filter materials, in hygiene articles or as the mechanically sticking part of Velcro fasteners.

Owner:CARL FREUDENBERG KG

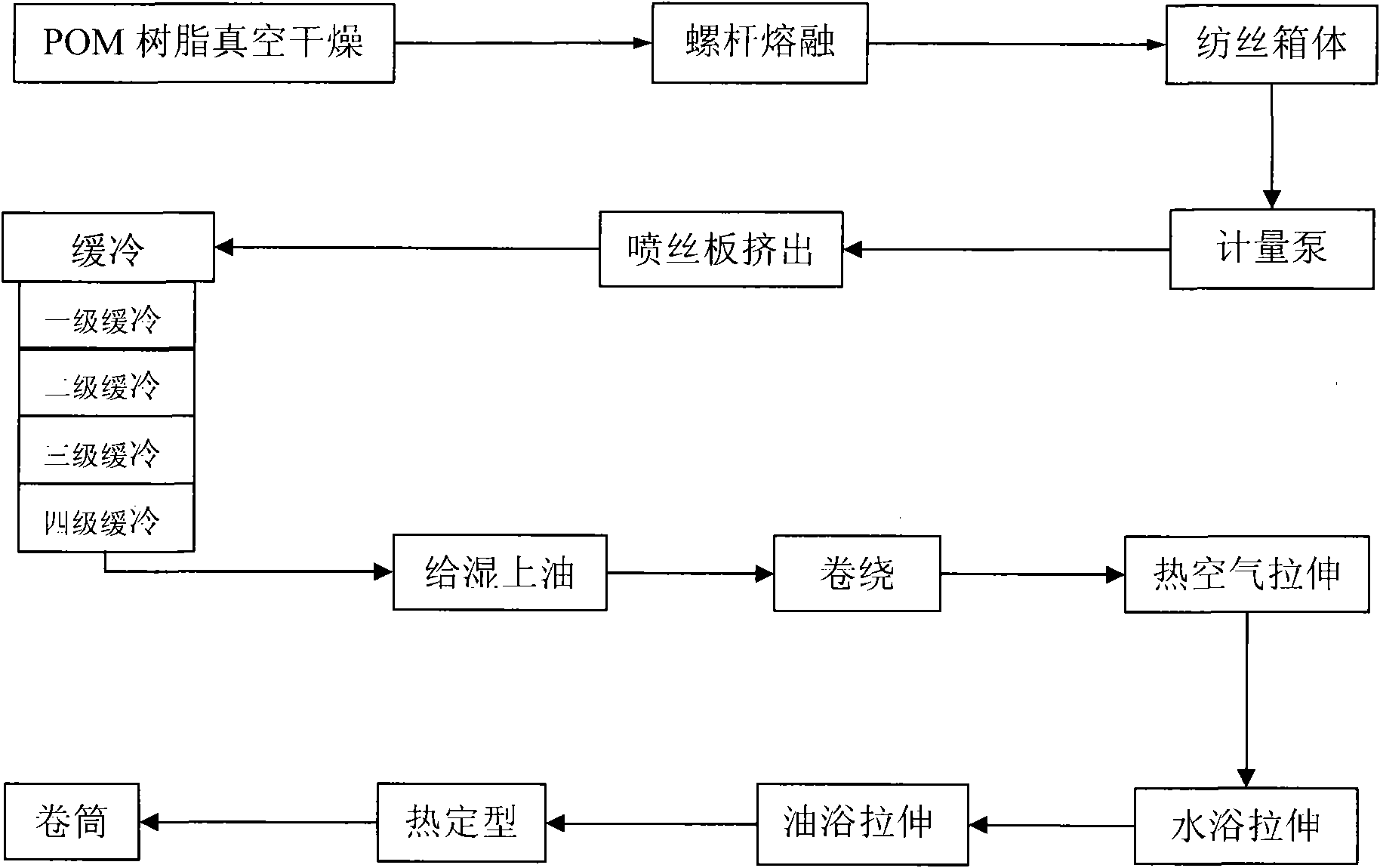

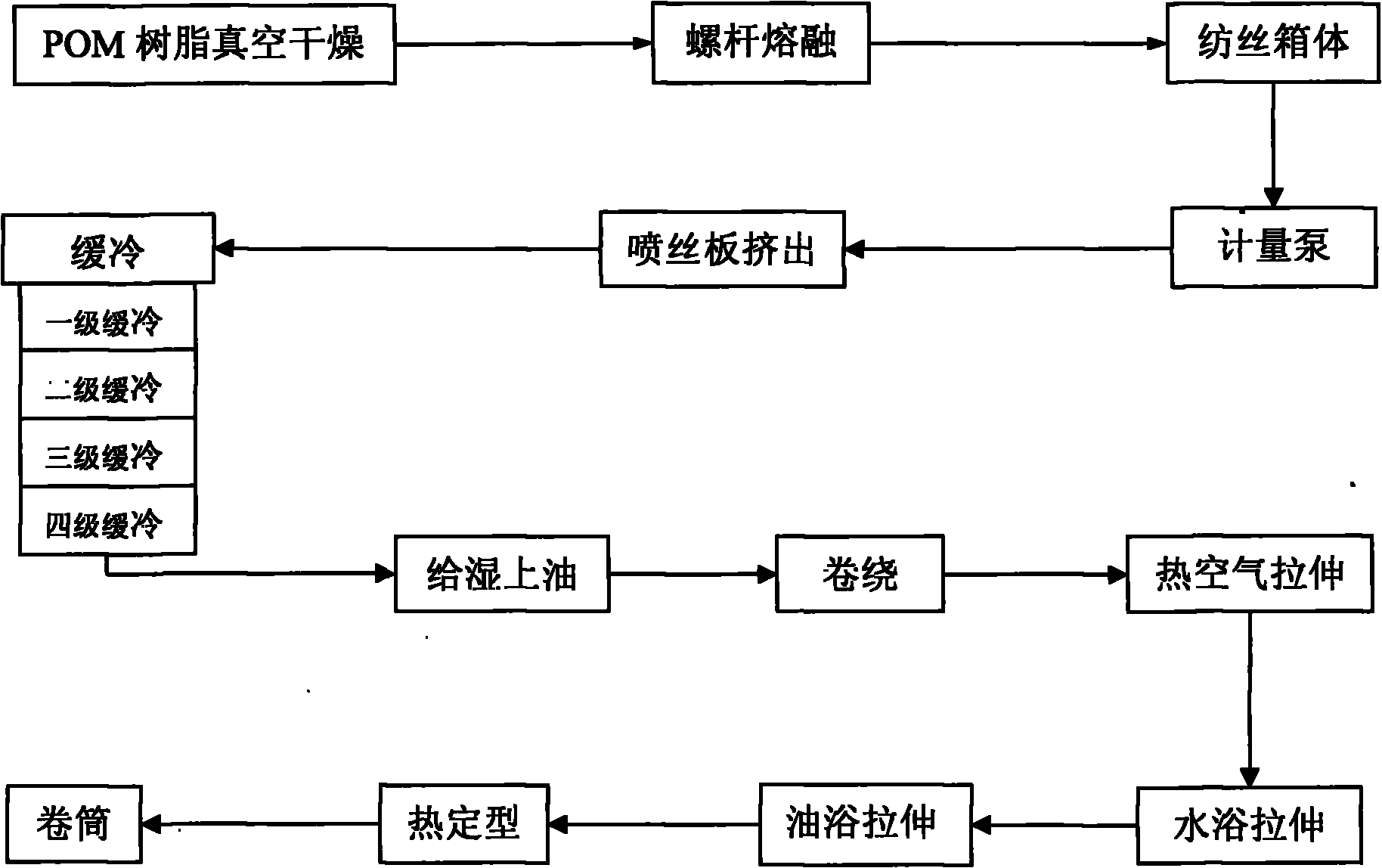

Novel preparation technology of polyoxymethylene fiber

InactiveCN101792938AStable structureReduce swellingArtificial filament heat treatmentStretch-spinning methodsFiberSolvent

The invention relates to a novel preparation technology of polyoxymethylene fiber, in particular to the novel preparation technology of the polyoxymethylene fiber via multi-stage slow cooling and three-stage drawing with different media, which comprises the following steps: vacuum-drying polyoxymethylene granular materials, heating and melting via a screw extruder, melting and extruding by a spinneret, leading small melt flow to pass through the multi-stage slow cooling, carrying out high-speed traction, passing through a moistening and oiling cluster, winding, then obtaining as-spun fiber, carrying out hot air drawing and two times of drawing with different types of solvent, then carrying out hot molding and finally preparing the polyoxymethylene fiber. The novel prepration technology can solve the problems of matching between the multiple sections of atmosphere and temperature and the spinning process control and the control of the drawing with multiple media and make up for the deficiencies that the single atmosphere and temperature and the single medium drawing of the prior art lead the structure to be difficult to stable and uniform.

Owner:DONGHUA UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com