Patents

Literature

862 results about "Film blowing machine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A Film Blowing Machine is used to make polyethylene into plastic film. This may be laminating film, packing film, agricultural covering film, bags or film for textiles and clothing, and other packing material.

Bamboo powder filling biodegradable compound material and preparation method thereof

The invention relates to a bamboo powder filling biodegradable compound material and a preparation method thereof. The bamboo powder filling biodegradable compound material comprises the following raw materials in part by mass: 30 to 80 parts of biodegradable resin, 20 to 70 parts of bamboo powder, 1 to 19 parts of plasticizer, 0.6 to 6 parts of interface modifier and 4 to 12 parts of aids. The preparation method comprises the following steps of: uniformly mixing the biodegradable resin, bamboo powder, plasticizer, interface modifier and auxiliary agent by using a mixer according to formula proportion; performing melt blending and granulation of the obtained mixture by using a screw extruder to obtain particles; and processing the particles by using an injection molding machine, a sheet extrusion forming machine, a blow molding machine or a film blowing machine, and molding in molds of different shapes to obtain the bamboo powder filling biodegradable compound materials of different shapes. The method has the advantages of high production efficiency and low cost; and the powder filling biodegradable compound material prepared by the method has the advantages of high environmentally-friendly property and economy and excellent usability.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Polyester full-biodegradable mulch film

ActiveCN103627151AHigh transparencyGood flexibilityPlant protective coveringsLow-density polyethylenePolyester

The invention relates to a mulch film, in particular to a polyester full-biodegradable mulch film. The polyester full-biodegradable mulch film is prepared from the following raw materials in percentage by mass: 40%-80% of flexible degradable polyester, 10%-55% of rigid degradable polyester, 0.5%-1.5% of a reactive compatibilizing agent, 1%-2% of a heat preservation agent, 1%-2% of a moisturizing agent, 0.5%-1.5% of an ageing-resistant agent, 0.5%-1% of a smooth agent and 0.5%-3% of an anti-block agent. The polyester full-biodegradable mulch film does not contain any non-biodegradable general plastic and starch; the film blowing operation can be performed on a general LDPE (low-density polyethylene) film blowing machine; equipment does not need to be modified; the polyester full-biodegradable mulch film is good in transparency, flexibility and heat preservation property, high in strength, low in water vapor penetration rate and favorable for preserving moisture.

Owner:新疆纳爱斯环保科技有限公司

Preparation method of full biodegradation film

The invention discloses a preparation method of a full biodegradation film, which takes poly adipic acid / polybutylene terephthalate (PBAT) and starch as base materials, poly-epsilon carpolaction (PCL), epoxidized soybean oil (ESO), and phosphorous acid dialkyl ester as plasticizers, and montmorillonoid or calcium carbonate, talcum powder and the like as inorganic fillers. The method comprises the steps that modification and pelleting are performed in a twin screw; modified resin is added to a film blowing machine for film blowing; and the full biodegradation film can be obtained finally. The full biodegradation film produced by the method is better in physical characteristic, can be directly prepared into a film bag, and can serve as a daily-used packaging film, a waistcoat bag, a food packaging bag and the like; the preparation method of the full biodegradation film is simple in technology, and easy to control, and is suitable for industrial mass production; the film bag produced by the method is high in strength, can be biodegraded fully after use, and is easy to dispose; and environmental pollution is reduced.

Owner:DONGGUAN XINHAI ENVIRONMENT PROTECTION MATERIAL

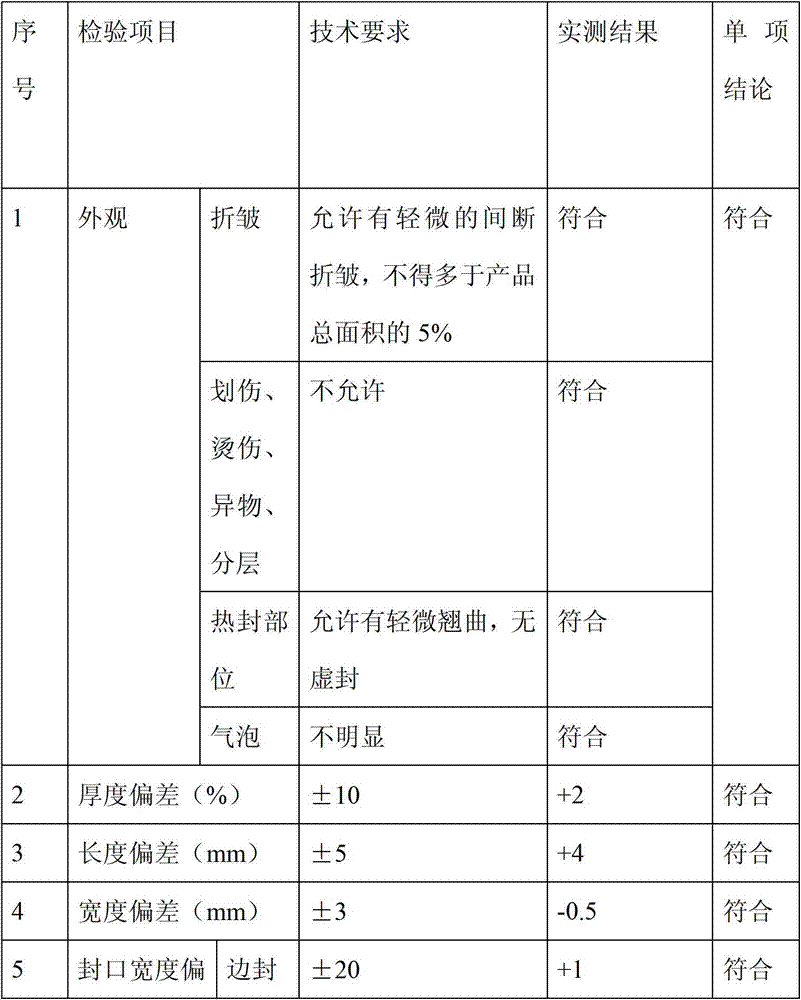

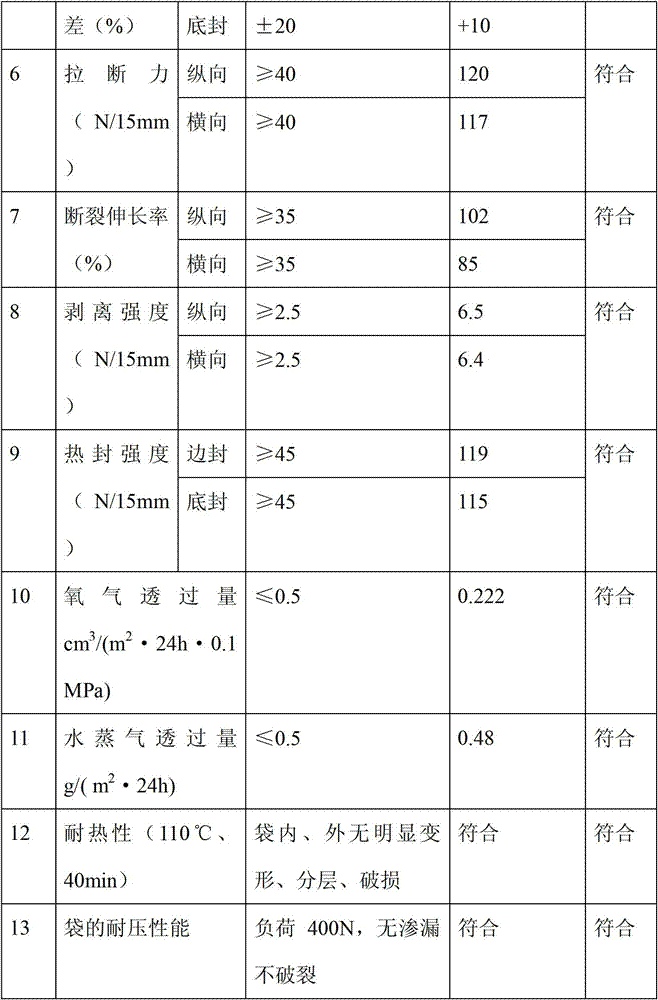

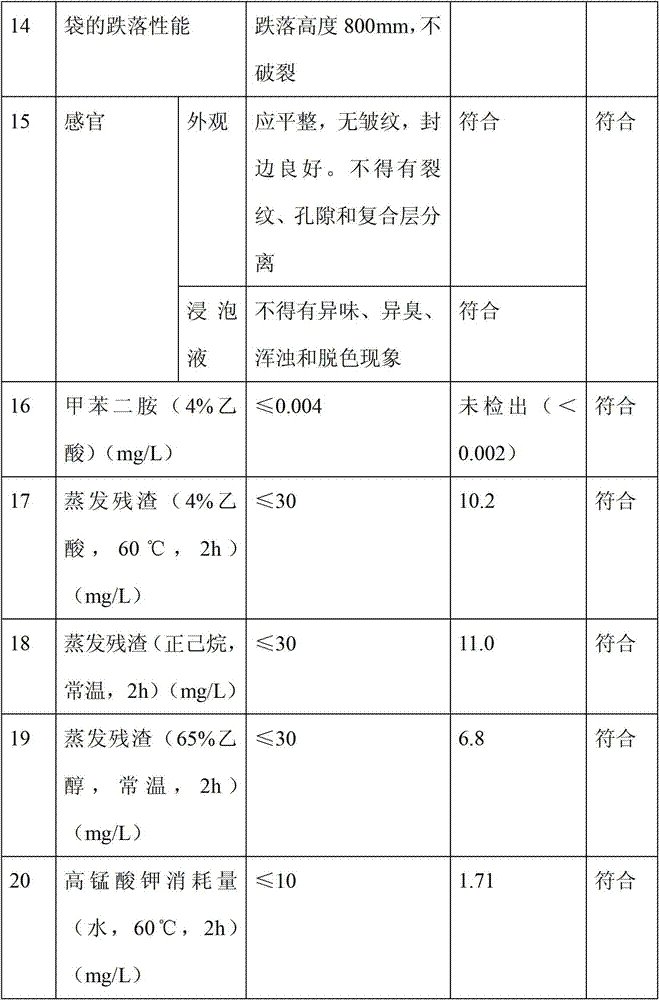

High-barrier semi-high temperature cooking liquid packaging material and packaging bag made of the same

The invention relates to a high-barrier semi-high temperature cooking liquid packaging material and a packaging bag made of the same. The high-barrier semi-high temperature cooking liquid packaging material is a composite membrane prepared by stacking a polyester film (PET) layer, an aluminum foil (Al) layer, a nylon (PA) layer and a polyethylene film (PE) layer from top to bottom by a dry compound machine. The PE layer is prepared by coextrusion blow molding on a surface layer, a middle layer and a heat seal layer; the surface layer is prepared by blending metallocene PE and LDPE in a weight ratio of 2-4:1; the middle layer is prepared by blending metallocene PE and LDPE in a weight ratio of 3-5:1, and adding ethylene propylene copolymer elastomer accounting for 10%-15% of the total weight of the middle layer; and the heat seal layer is prepared by blending metallocene PE and zinc neutralized ethylene copolymer in a weight ratio of 3-5:1. The invention employs a high quality material containing metallocene PE, which is added with a proper amount of an ethylene propylene copolymer elastomer, and especially the heat seal layer is added with the zinc neutralized ethylene copolymer; and the PE layer prepared through blow molding by a three-layer co-extrusion film blowing machine.

Owner:浙江诚信包装有限公司

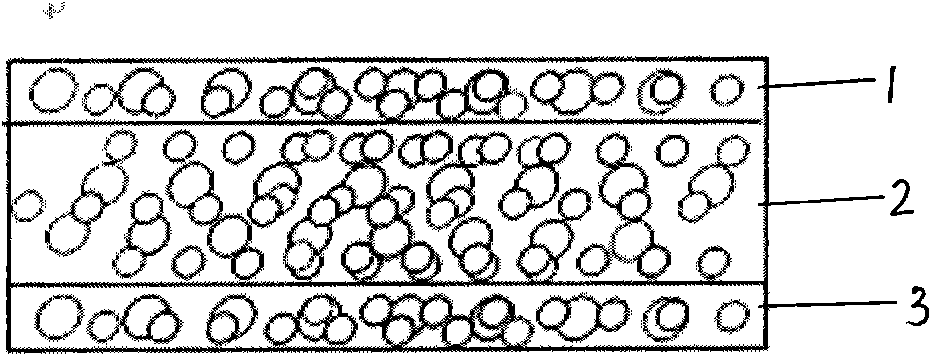

Inorganic powder highly filled polyolefin decorative paper and manufacturing method thereof

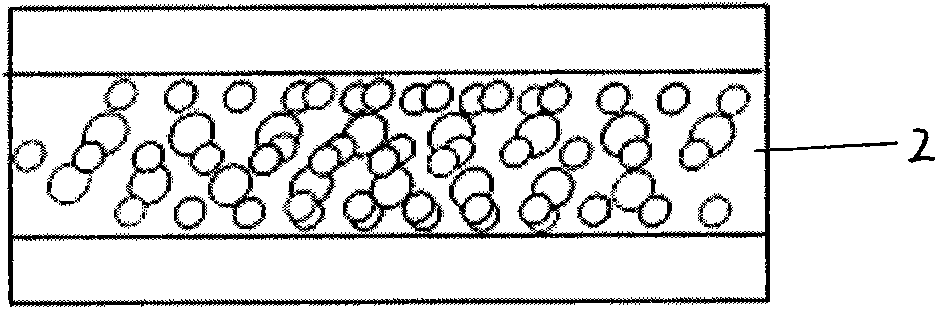

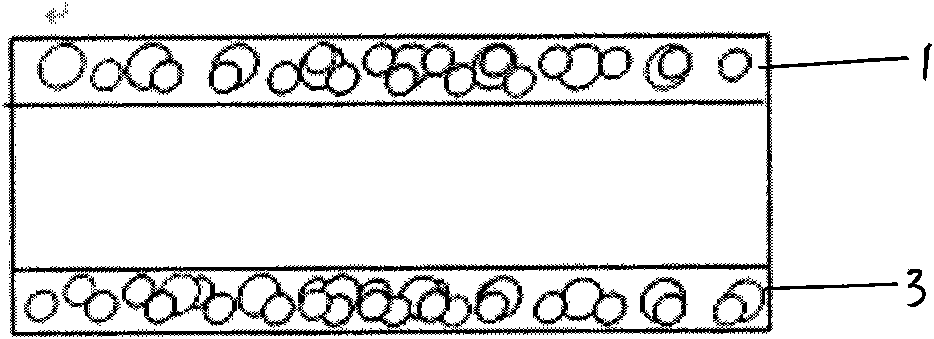

The invention relates to inorganic powder highly filled polyolefin decorative paper. The invention is characterized in that the decorative paper is composed of three-layer sheets or films which are formed by carrying out co-extrusion on raw materials containing 2-15% of HDPE (high density polyethylene), 4-15% of LLDPE (linear low density polyethylene), 3-12.7% of LDPE (low density polyethylene), 45-90% of inorganic powder, 0.1-5% of foaming microspheres, 0.1-0.3% of antioxidant and 0.2-13% of inorganic powder activator by virtue of a T-shaped mould of a three-layer co-extrusion film blowing machine, wherein at least one layer is a foaming body; the upper layer and the lower layer of the decorative paper respectively account for 15-20wt% of the decorative paper, the middle layer accounts for 60-70wt% of the decorative paper; and the grain size of the inorganic powder is 2-15 microns, and the density of the inorganic powder is 0.4-0.95g / cm<3>. The surfaces of the films and sheets prepared by the invention are soft and have elasticity, the paper texture is good, the mechanical strength is high, and the relative density is 0.5-0.95g / cm<3>; and the invention has the advantages that thedensity of the inorganic powder highly filled non-polyvinyl chloride (PVC) polymer decorative paper is greatly reduced, the problem of poor mechanical strength of the foaming sheets and films is solved by virtue of a multilayer co-extrusion process, and an obvious technical effect is achieved.

Owner:宋旭

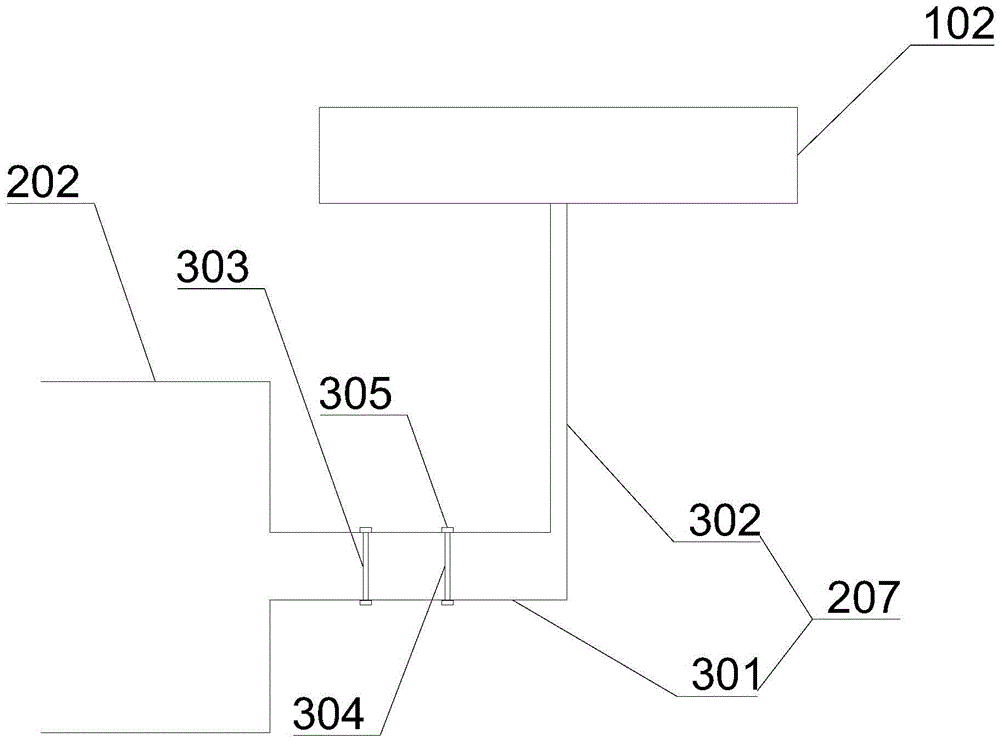

Film blowing machine

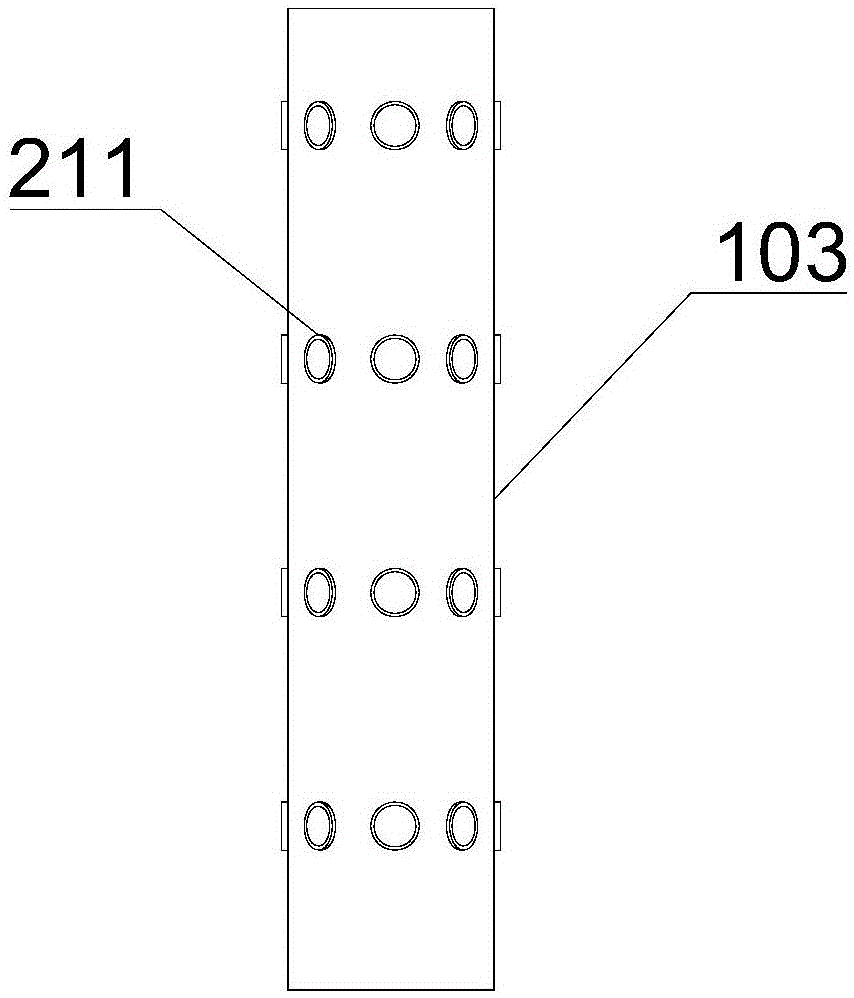

The embodiment of the invention provides a film blowing machine, and relates to the technical field of plastic manufacturing. The film blowing machine comprises an extruder, a mould head, a fixed core rod, a wind ring, a traction roller and an inverted-V-shaped rack, wherein a joint of the mould head and the fixed core rod is provided with a first air outlet; the first air outlet is arranged at the inner side of a discharge hole of the mould head; the fixed core rod is provided with a second air outlet; and the second air outlet is arranged on the rod body of the fixed core rod. According to the film blowing machine provided by the embodiment, the rod body of the fixed core rod is provided with the second air outlet, so that air-out is carried out through the second air outlet when the film blowing machine needs carrying out film blowing in a relatively large blow-up ratio, and therefore, uneven film thickness caused by too strong wind provided by the first air outlet at the joint of the mould head and the fixed core rod is avoided; and meanwhile, the first air outlet is mutually matched with the second air outlet, sot that the blow-up ratio of the film blowing machine can be regulated more flexibly.

Owner:CHONGQING KEXIN PLASTIC

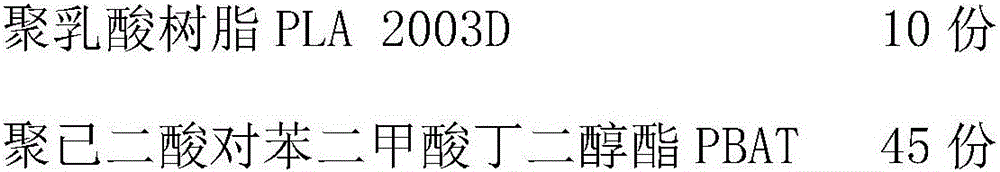

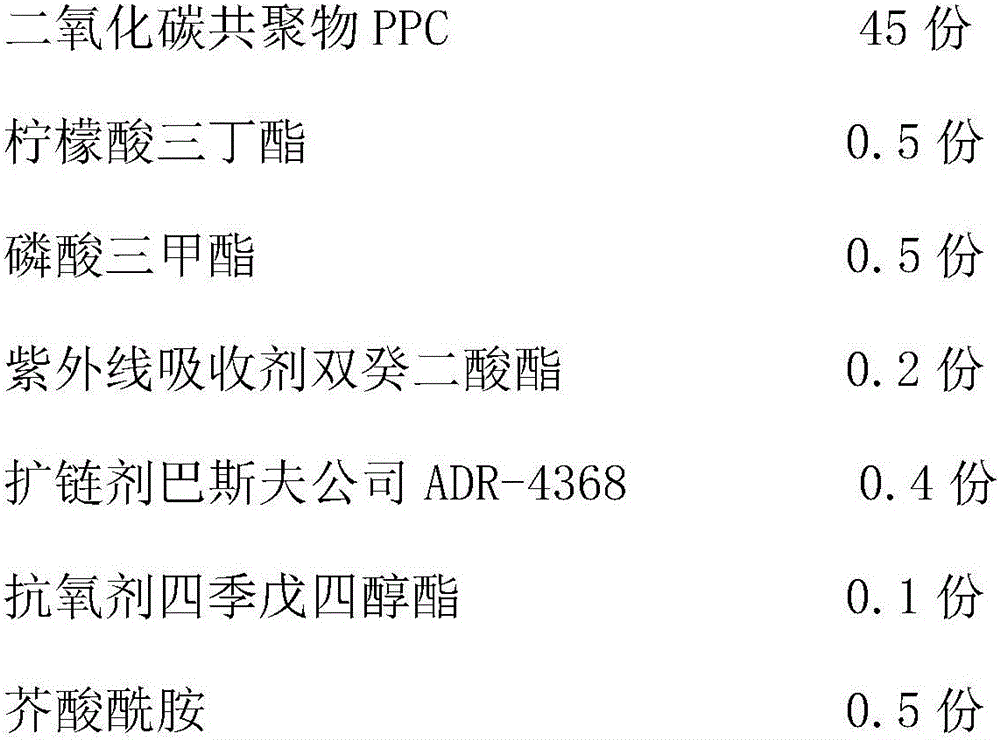

High-barrier-property biodegradable mulching film and preparation method thereof

InactiveCN106046725AFully biodegradableGood mechanical propertiesLow-density polyethyleneAntioxidant

The invention relates to a high-barrier-property biodegradable mulching film and a preparation method thereof, belonging to the field of high-polymer materials. The high-barrier-property biodegradable mulching film is prepared from a polylactic acid resin, a toughener, a heat stabilizer, an ultraviolet absorbent, a chain extender, an antioxidant, an opening agent and the like by using a film blowing machine set. The high-barrier-property biodegradable mulching film can be automatically degraded under the actions of rich oxygen and microbes, does not pollute the environment, has higher barrier property than the LDPE (low-density polyethylene) film with the same thickness by 1.5-2.0 times, and satisfies the functions of moisture retention, water preservation and yield increase for crops. The method has the advantages of simple production technique and high production efficiency, and can easily implement industrial production.

Owner:JILIN COFCO BIOCHEM

Water-foamed, antibacterial and air-permeable microporous film masterbatch, film and preparation method thereof

The invention relates to air-permeable microporous film masterbatch and further relates to a masterbatch containing plastic film and a preparation method thereof. The water-foamed, antibacterial and air-permeable microporous film masterbatch contains a polyolefin polymer, a modifier, a microporous water-absorbing inorganic expanded material, an initiator, a surfactant and a plastic antioxidant. The water-foamed, antibacterial and air-permeable microporous film contains the water-foamed, antibacterial and air-permeable microporous film masterbatch and blow-molded film plastics. The preparation method comprises the steps of granulating the masterbatch, then, carrying out water absorbing aging, adding the blow-molded film plastics, carrying out mixing, and adding the mixture into a foaming and extruding film blowing machine for extrusion, thereby preparing the film. The water-foamed, antibacterial and air-permeable microporous film provided by the invention has the characteristics of simple and stable preparation process, good processability and the like; a water foamer is adopted, is environment-friendly and safe and has an antibacterial function, and the extruded antibacterial and air-permeable film is controllable in micropore density, has the characteristics of fine and uniform open porous texture and cell size, and the like and has the characteristics of excellent comprehensive mechanical properties, environment-friendliness, easiness in recovery, and the like.

Owner:深圳市环美盛科技有限公司

Full-degradable cushion packaging bag and preparation method thereof

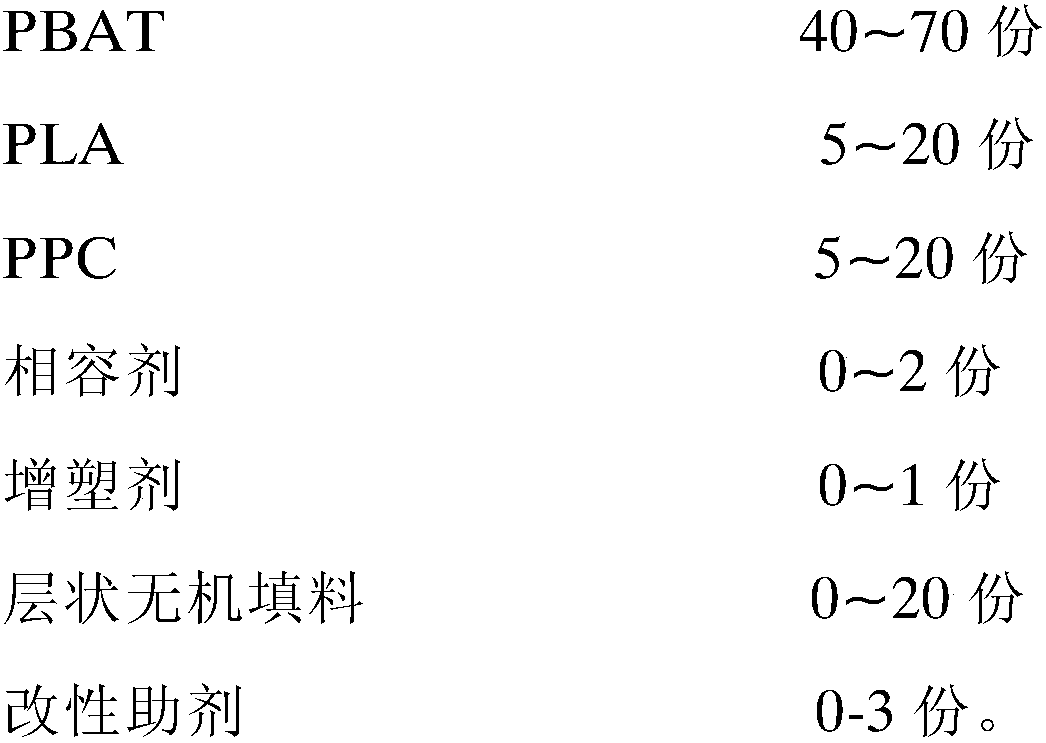

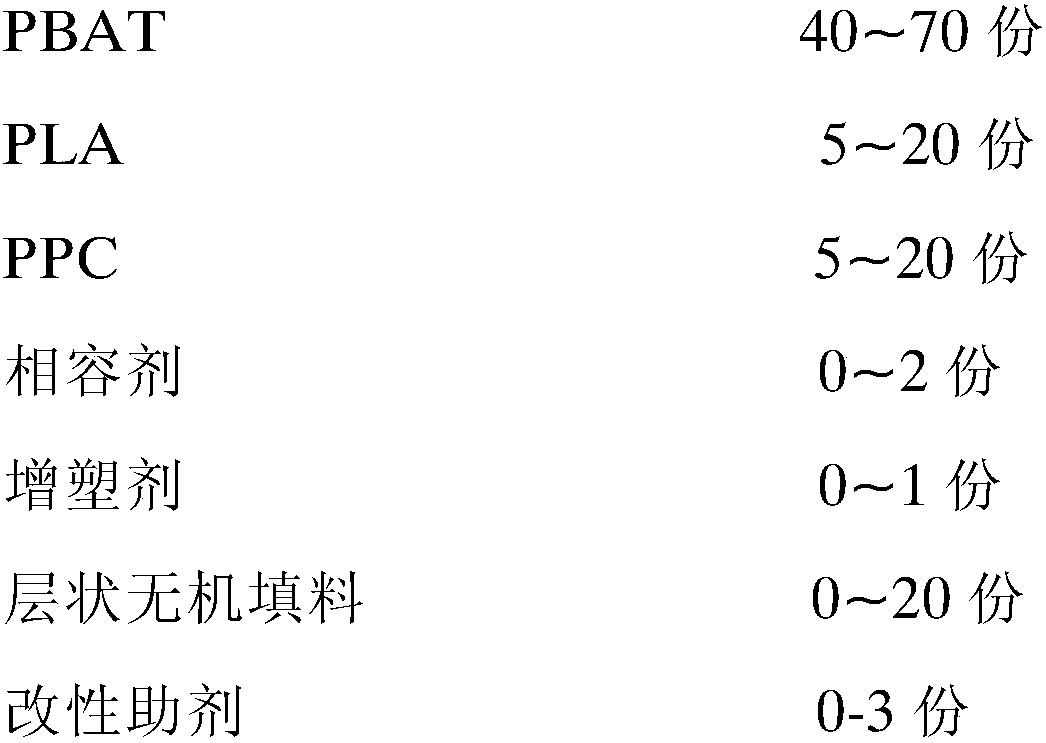

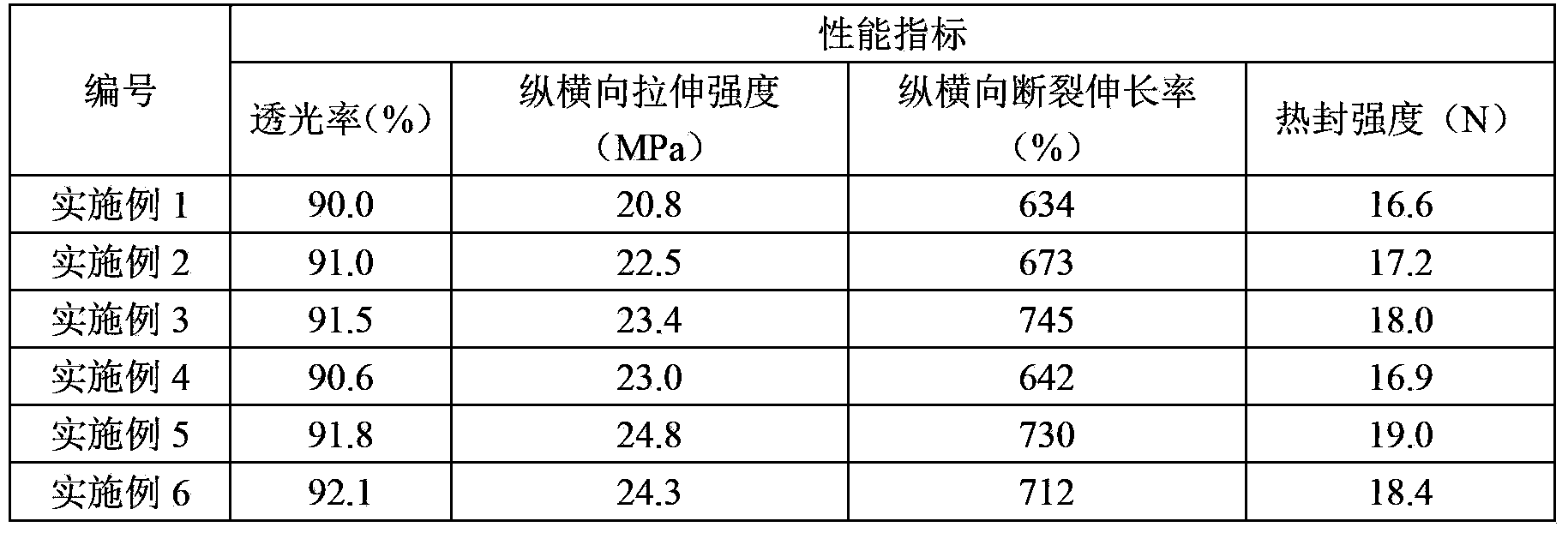

The invention discloses a full-degradable cushion packaging bag and a preparation method thereof. The packaging bag comprises the following raw material components in parts by mass: 40-70 parts of PBAT (Poly(butyleneadipate-co-terephthalate)), 5-20 parts of PLA (Polylactic Acid), 5-20 parts of PPC (Chlorinated Polypropylene), 0-2 parts of a compatilizer, 0-1 part of a plasticizer, 0-20 parts of alayered inorganic filler and 0-3 parts of a performance additive. The preparation method comprises the following steps: drying raw materials; modifying the layered inorganic filler; fully and uniformly mixing the PBAT, PLA, PPC, the compatilizer and the modified layered inorganic filler; adding the mixed materials into a twin-screw extruder for performing melt blending extrusion and drawing, dicing to obtain a granular blended material; and performing blow molding through a three-layer co-extrusion film blowing machine, thereby obtaining the thin film product. The full-degradable cushion packaging bag disclosed by the invention has excellent mechanical property and barrier property, and is high in oxygen permeability and fully degradable. The full-degradable cushion packaging bag is a goodsubstitute of an existing non-degradable cushion packaging bag and is worthy of popularization and application.

Owner:WUHAN HUALI BIOLOGY CO LTD

Thin film and production method thereof

InactiveCN102991074AHigh surface flatnessEasy to coronaSynthetic resin layered productsFilm blowing machineSurface flatness

The invention relates to a thin film. The thin film comprises, by weight, 30% of an outer layer, 40% of a middle layer and 30% of an inner layer. The invention further provides a production method of the thin film. The production method includes the following steps of material mixing, batching and film blowing. The thin film has the advantages that the surface evenness is high, electric corona and composition are easy, and the continuous production can be achieved through a film blowing machine by combining batching equipment.

Owner:KUNSHAN JINMENG PLASTIC FILM

High-transparency polyolefin heat shrinkage film and production method thereof

ActiveCN103360664AGood heat sealing performanceHigh transparencyLow-density polyethyleneLinear low-density polyethylene

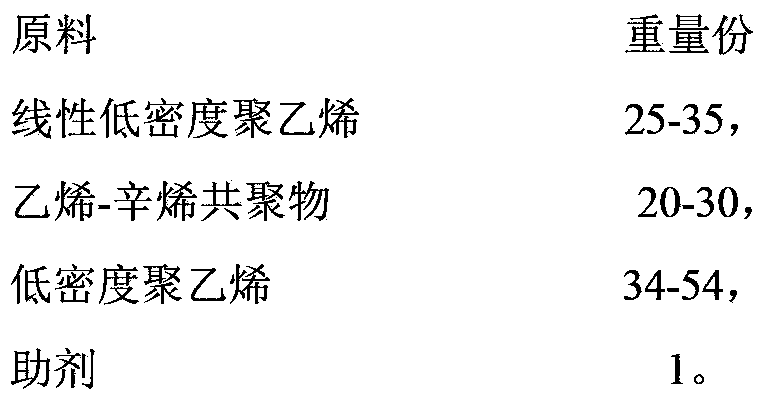

The invention belongs to the technical field of a production method of a polymer film material for packaging and in particular discloses a high-transparency polyolefin heat shrinkage film and a production method thereof. The production method of the high-transparency polyolefin heat shrinkage film comprises the following steps of: extruding 25-35 parts by weight of linear low-density polyethylene, 20-30 parts by weight of ethylene-octylene copolymer, 34-54 parts by weight of low-density polyethylene and 1 part by weight of auxiliaries by a single-screw extruder; extruding the materials into a tube blank by an extruding mould head of a single-layer film blowing machine; cooling and pulling the tube blank into a stretching oven for carrying out transverse and longitudinal stretching of a certain times. According to the high-transparency polyolefin heat shrinkage film provided by the invention, the transparency of the film is improved for enabling the packaging of the printed goods to be more attractive; the strength of the film is improved to broaden the application field; the heat sealing performance of the film is improved for adapting to the mechanical production and improving the packaging resilience; and the product has a constant longitudinal-transverse shrinkage rate, so that the packaging stability can be ensured.

Owner:HUBEI ENG UNIV

Agricultural greenhouse film with high light conversion rate, and making method thereof

InactiveCN104108215AIncrease the intensity of photosynthesisGrow fastSynthetic resin layered productsLaminationRare-earth elementAgricultural engineering

The invention discloses an agricultural greenhouse film with a high light conversion rate, and a making method thereof, and relates to the technical field of greenhouse film production. The agricultural greenhouse film is composed of an external layer film, a middle layer film and an internal layer film. The making method of the agricultural greenhouse film comprises the following steps: respectively weighing raw materials of the external layer film, the middle layer film and the internal layer film, fully and uniformly mixing the raw materials, adding the obtained mixture to a three-layer co-extrusion film blowing machine, heating, extruding, blow-molding, carrying out upper traction, carrying out lower traction, and reeling to form the agricultural greenhouse film. Organic rare earth elements are added to the greenhouse film made in the invention, so the photosynthesis intensity of crops is obviously improved, the crops have the characteristics of fast growth, good fructification, many products, precocity, yield increase and good quality, and the problems of likely mist droplets, low light transmittance, poor oxidation resistance and short service life of general greenhouse films are solved.

Owner:ANHUI CHAOHU SOUTH MEMBRANE IND

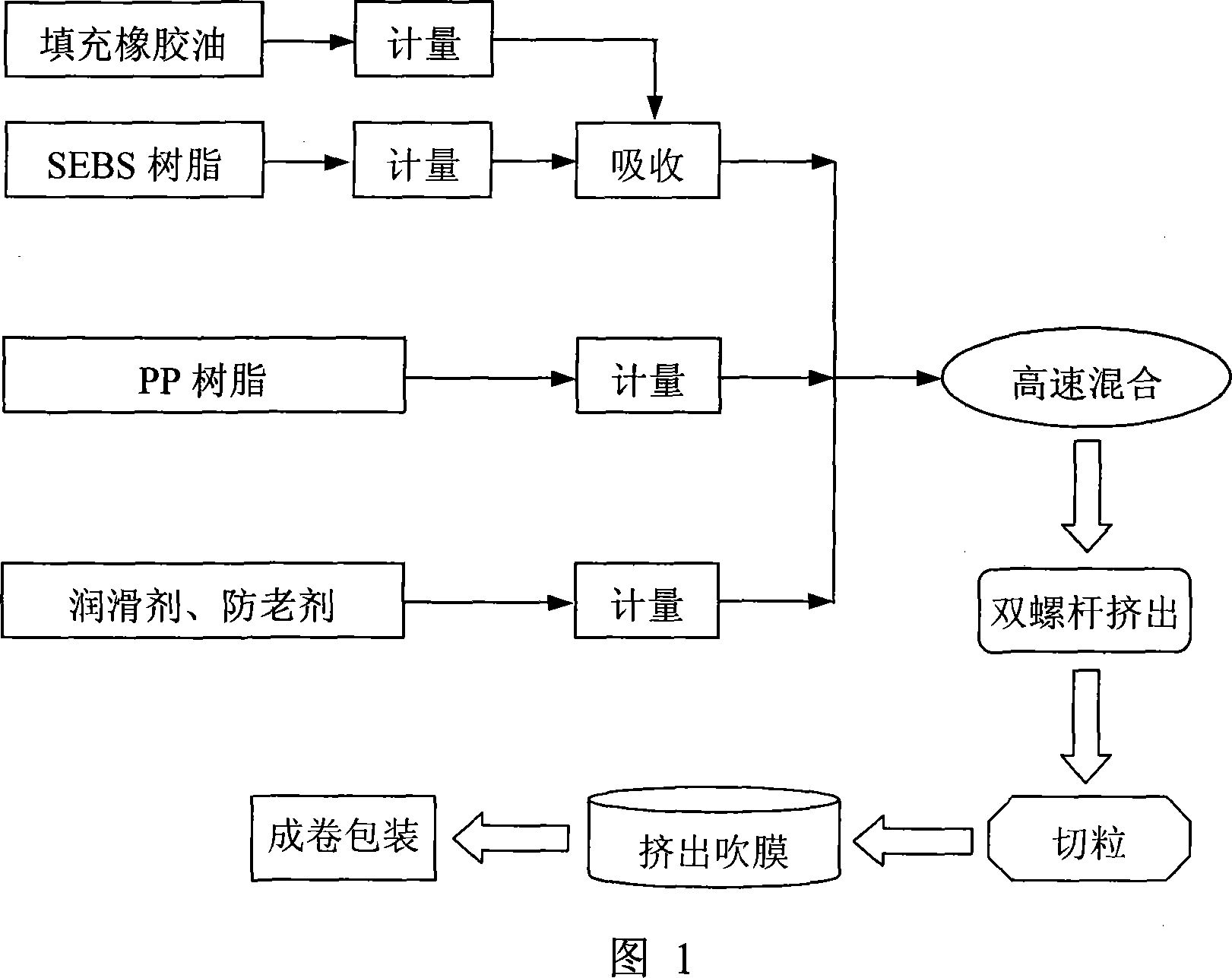

Environment-protective SEBS fresh-preservation film and producing method thereof

The present invention discloses a kind of environmental friendly SEBS fresh-keeping film, and includes the following components with contents of unit mass: SEBS resin 100 units, rubber filling oil 75-125 units, polypropylene 40-115 units, lubricant 0.6-0.8 units, and anti-aging agent 0.4-0.6 units. The present invention also offers a production method of environmental friendly SEBS fresh-keeping film, which includes the following steps: weighting and taking the various components according to their dosages: SEBS resin 100 units, rubber filling oil 75-125 units, polypropylene 40-115 units, lubricant 0.6-0.8 units, and anti-aging agent 0.4-0.6 units; letting SEBS resin to fully absorb rubber filling oil; being even mixed with polypropylene, lubricant, and anti-aging agent, using twin screw extruder to produce particles; finally, using plastic-extruded blower to extrude the shaped fresh-keeping film. The environmental friendly SEBS fresh-keeping film of the present invention has excellent transparence, tackiness, and good mechanical properties, and is health, safe and environmental friendly, which can replace soft PVC fresh-keeping film for foods and packings of other daily-used goods and industrial products.

Owner:SHENZHEN POLYTECHNIC +1

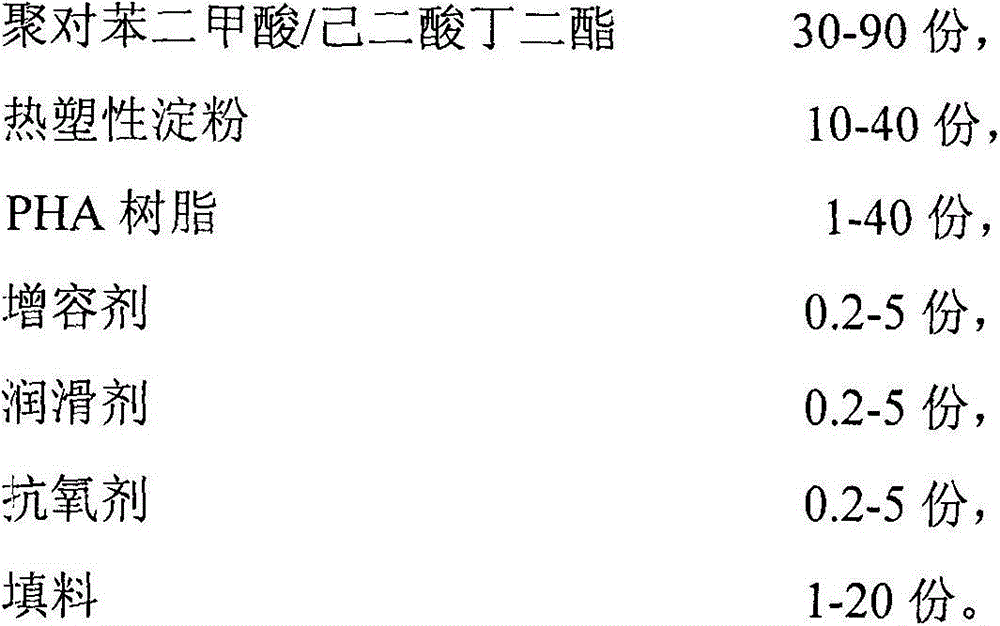

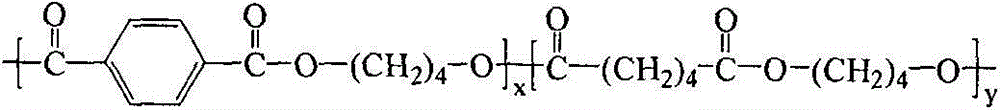

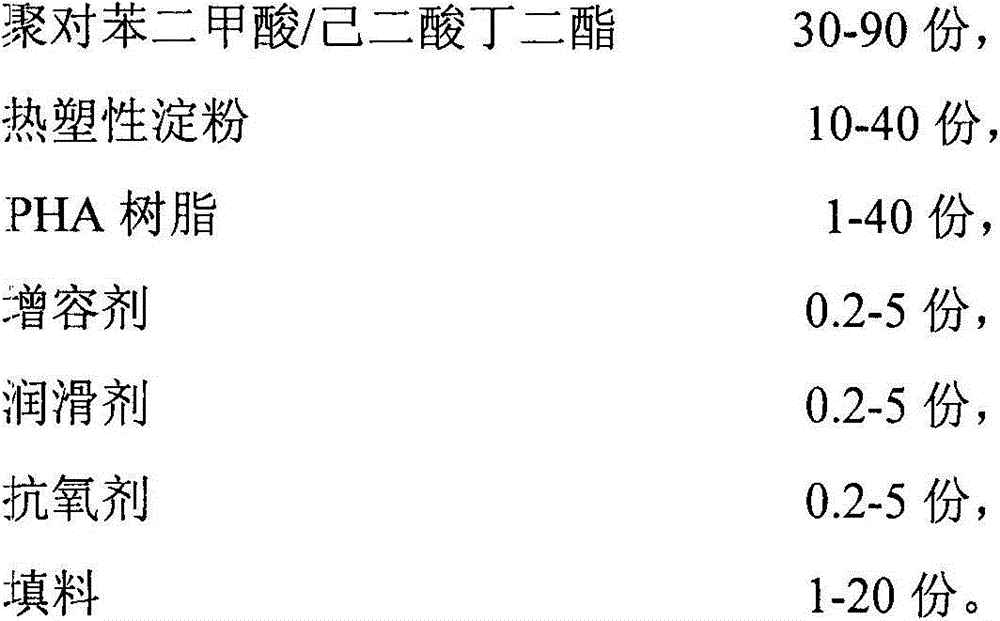

Degradable film and preparation method thereof

The invention relates to a degradable film and a preparation method thereof. The method comprises the following steps: 1) drying PBT / adipate terephthalate, thermoplastic starch, PHA resin and a filling material; 2) weighing PBT / adipate terephthalate, the thermoplastic starch, the PHA resin, a compatibilizer, an and the filling material in proportion, uniformly mixing the components in a high mixing machine for 3-10 minutes; 3) adding a mixture in a double screw extruder for melt blending, bracing the mixture, and pelletizing the mixture to obtain blending particles, wherein the extrusion temperature is 100-170 DEG C; and 4) extruding the blending particles in the step 3) and a lubricant through a single screw extruder, then performing blow molding by a film blowing machine to obtain the degradable film. Compared with the prior art, the prepared degradable film is adapted to different climate condition at different places, is degraded after a certain time, cannot generate secondary pollution, and has important practical meaning for environment treatment.

Owner:六安载丰新材料有限公司

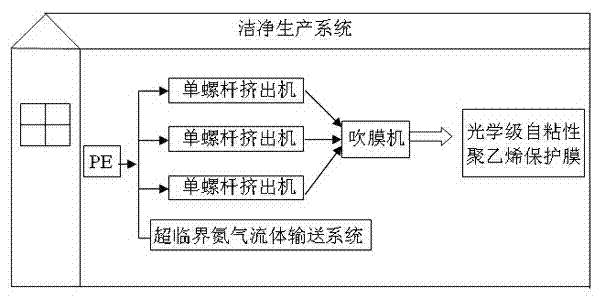

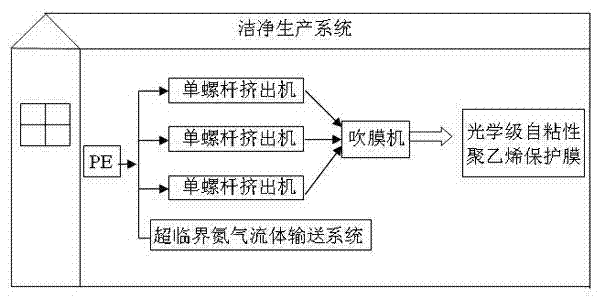

A kind of optical grade self-adhesive polyethylene protective film and preparation method thereof

ActiveCN102294867AHigh transparencyGood self-adhesiveSynthetic resin layered productsPolymer scienceComposite film

The invention belongs to a preparation method of a self-adhesive polyethylene protective film with optical-grade transparency. The protective film of the invention comprises three layers of a self-adhesive layer, an interlayer, and a back-material layer, and is a composite film obtained by coextrusion film blowing. Thereinto, the self-adhesive layer accounts for 10%-20% of the composite film in thickness; the interlayer accounts for 60%-80% of the composite film in thickness; and the back-material layer accounts for 10%-20% of the composite film in thickness. The self-adhesive layer is compounded by low density polyethylene and metallocene low density polyethylene with a ratio of 20 / 80-40 / 60 wt%; the interlayer is compounded by low density polyethylene and medium density polyethylene witha ratio of 20 / 80-40 / 60 wt%; and the back-material layer is composed of low density polyethylene. Three coextrusion film blowing units are all single screw machines with a length-diameter ratio of 28;the plastification extrusion process adopts a supercritical nitrogen fluid conveying system; and the extrusion film blowing process is performed in a dust-free and clean workshop. With the method of the invention, a self-adhesive polyethylene protective film with optical-grade transparency can be prepared.

Owner:佛山新长盛塑料薄膜有限公司

High-toughness transparent polylactic acid film and preparing method thereof

The invention relates to the field of high polymer materials, in particular to a high-toughness transparent polylactic acid film and a preparing method thereof. The high-toughness transparent polylactic acid film comprises, by weight, 97-85 parts of polylactic acid, 3-15 parts of flexibilizer and 0.1-0.6 part of heat stabilizer. The polylactic acid is dried, and the materials, by weight, of 97-85 parts of polylactic acid, 3-15 parts of flexibilizer and 0.1-0.6 part of heat stabilizer are weighed according to the ratio and are added to a highly-mixing machine to be mixed at the normal temperature and at a high speed for 5-10 min; the materials which are evenly mixed in the second step are added to a double-screw extruder to be melted and blended, and modified particles are extruded; the modified particles obtained in the third step are extruded out through a single screw and are blown to form a film through a film blowing machine, and the high-toughness transparent polylactic acid film is obtained.

Owner:WEIHAI GONGDA PLASTIC CEMENT CHEM CO LTD

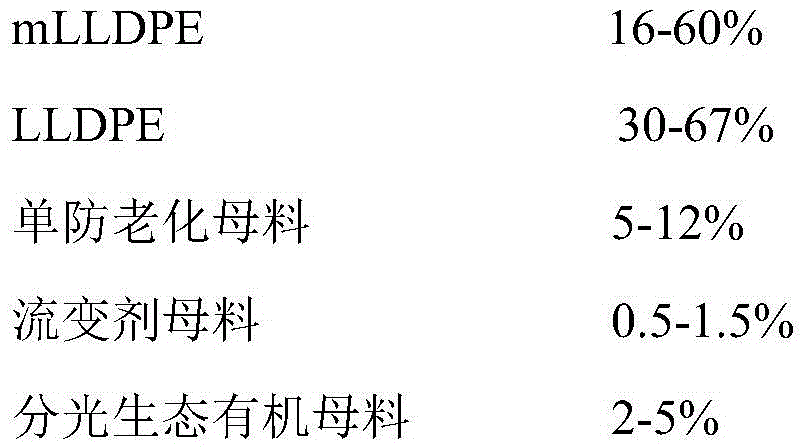

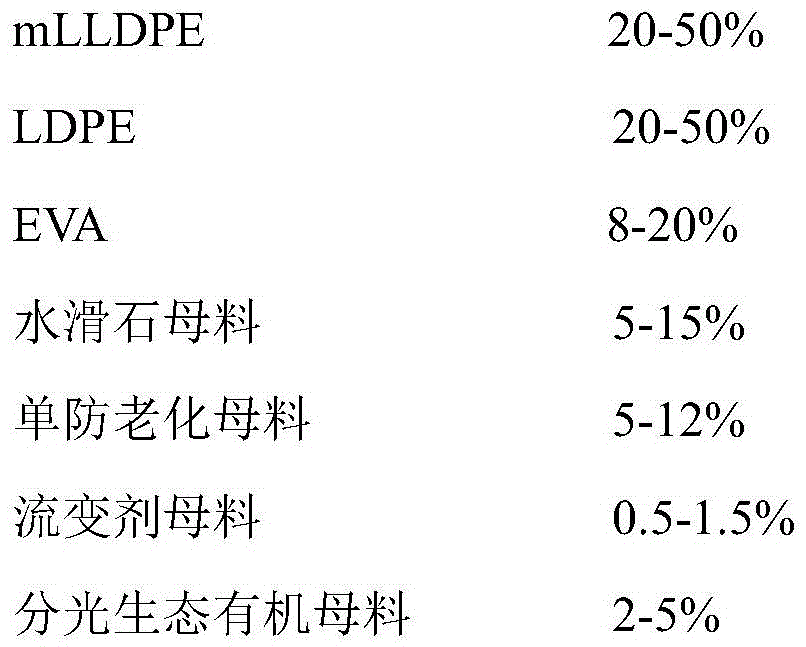

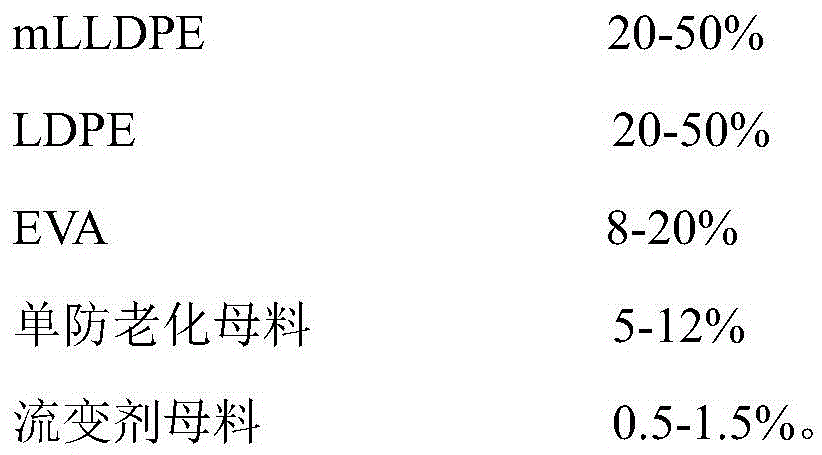

Spectral ecological agricultural greenhouse energy gathering film and preparation method thereof

ActiveCN105623069ATake advantage ofBiomimeticAgricultural articlesClimate change adaptationHalf-lifeAgricultural engineering

The invention relates to a spectral ecological agricultural greenhouse energy gathering film and a preparation method thereof, and belongs to the technical field of agricultural plastic films. The agricultural greenhouse energy gathering film comprises a three-layer structure of an inner layer, a middle layer and an outer layer and is mainly prepared from mLLDPE, LLDPE, LDPE, EVA, single anti-aging masterbatch, rheological agent masterbatch and spectral ecological organic masterbatch; the preparation method comprises the steps that all components are mixed uniformly according to the formula amount, then a three-layer film blowing machine is used for film blowing, and the spectral ecological agricultural greenhouse energy gathering film is obtained after extrusion, plastic film forming, blowing, corona treatment, coating, drying and folding. According to the spectral ecological agricultural greenhouse energy gathering film and the preparation method thereof, all disadvantages caused by the fact that a light conversion agent is merely used for changing light in the greenhouse are changed, collineation of the light is changed into scattering and refraction by adding a double peak material and a reddish orange auxiliary, the spectrum peak of the light transmitted into the greenhouse can be adjusted into the red orange light band suitable for plant growth, the light intensity can be kept continuously, no half-life period exists, and the own energy of the light power is fully used.

Owner:山东宽力新材料有限公司

Degradable plastic bag product

The invention discloses a degradable plastic bag product, which is made from high-density / medium-density / low-density polyethylene particles, fillers, and a certain amount of composite additive and recovered congenerous waste regenerated plastic particles. The degradable plastic bag product comprises the following raw materials in percentage by weight: 50-70% of polyethylene particles, 4-20% of composite additives, 4-20% of fillers and 4-25% of waste regenerated plastic particles. Colored products can be prepared by adding 1-8% of colored polyethylene particles to the raw materials. The degradable plastic bag product has the advantages of simple process, short process flow and small investment of devices mainly comprising a film blowing machine, a printer and a bag machine. According to the process of the degradable plastic bag product disclosed by the invention, a thin film with the thickness of 0.02 can be produced, wherein a thin film with the thickness of 0.025 has the characteristics of mechanical property of 33MPa in longitudinal direction and 25MPa in transverse direction, elongation of 260% in longitudinal direction and 620% in transverse direction and degradation time from three months to two years.

Owner:河南省南街村(集团)有限公司

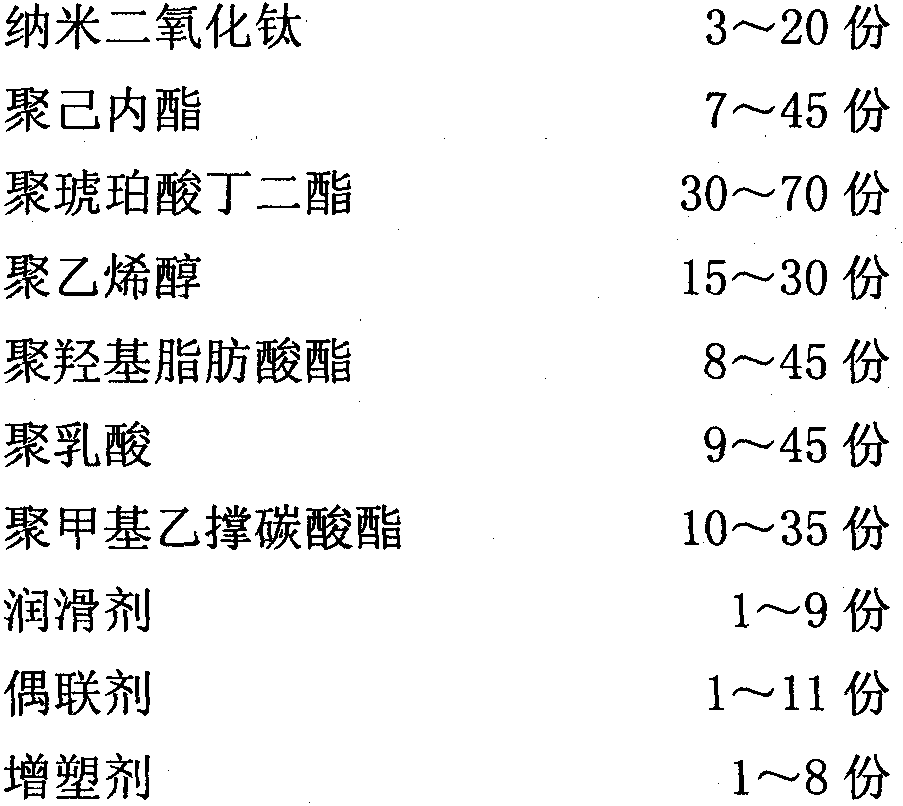

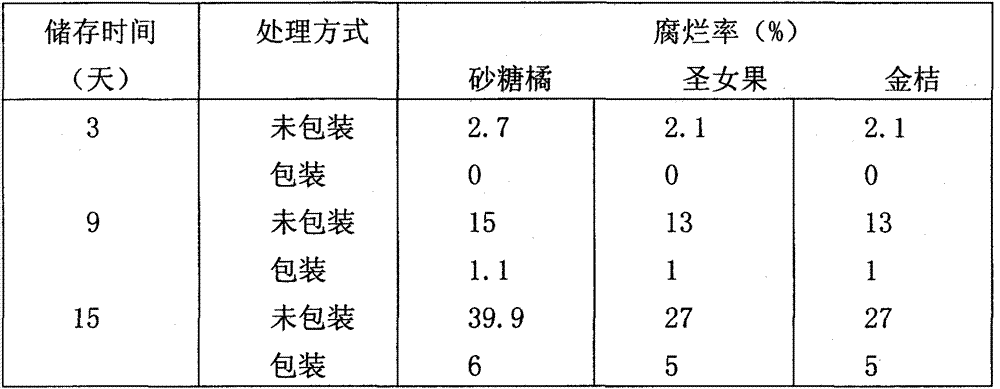

Antibacterial degradable fresh-keeping food packaging material and preparation thereof

InactiveCN106883578AEasy to operateSimple processFlexible coversWrappersAntibacterial activityMixed materials

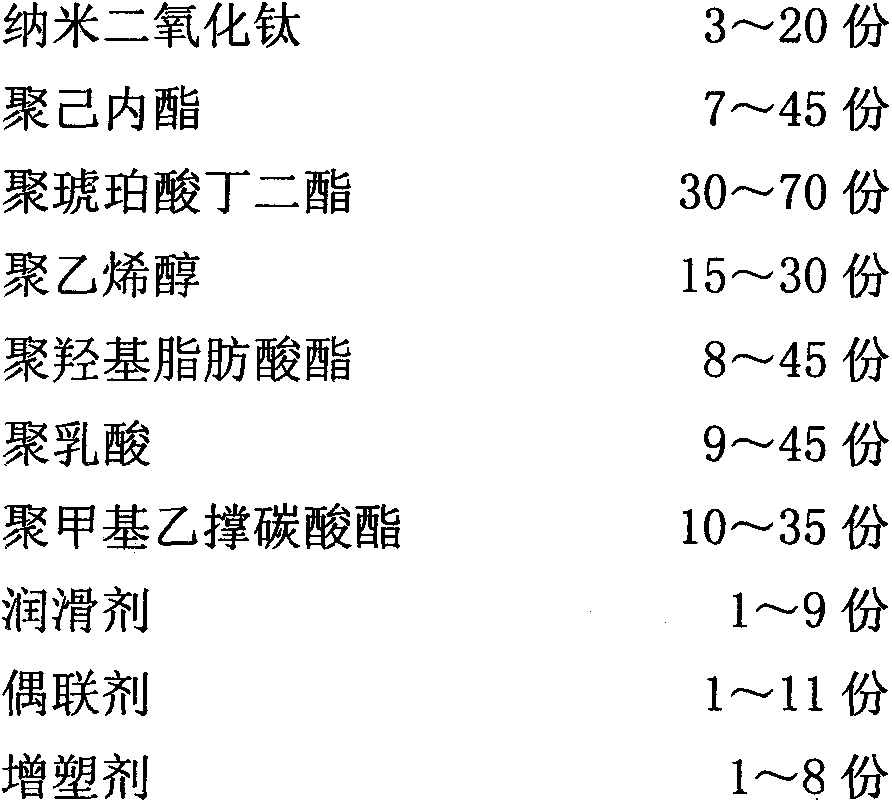

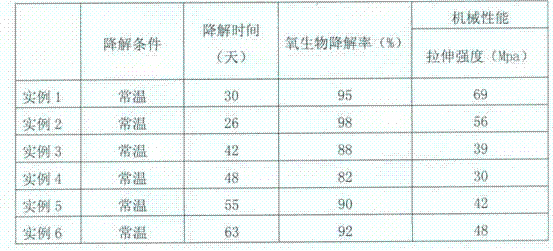

The invention discloses an antibacterial degradable fresh-keeping food packaging material and preparation thereof. The preparation method comprises the steps of adding mixed materials of nanometer titania, polycaprolactone, biodegradable poly butylene succinate, polyvinyl alcohol, polyhydroxyalkanoate, polylactic acid, polymethyl ethylene carbonate and the like to an extruder, carrying out extruding, bracing and pelletizing; and adding prepared aggregates to a film blowing machine to prepare a thin film to obtain the antibacterial degradable food packaging material. The nanometer titania is adopted as an antibacterial raw material, so that the nanometer titania has good antibacterial activity, is capable of killing bacteria, and is free of toxic or side effect and low in dosage; the polycaprolactone, the biodegradable poly butylene succinate, the polyvinyl alcohol, the polyhydroxyalkanoate, the polylactic acid and the polymethyl ethylene carbonate can be completely degraded; the film-forming property is good; the antibacterial degradable fresh-keeping food packaging material has good processability; the thin film material prepared by mixing is taken as an antibacterial fresh-keeping material; and compared with an ordinary packaging material, a lot of cleaning labor can be omitted by the antibacterial packaging material, and the antibacterial timeliness of an antibacterial plastic can be the same as the service life of articles.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Degradable plastic film and production method thereof

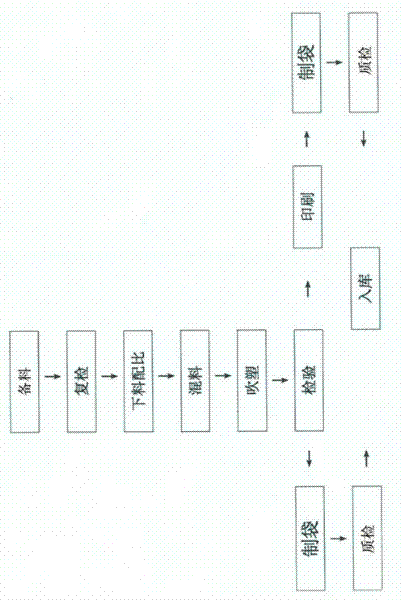

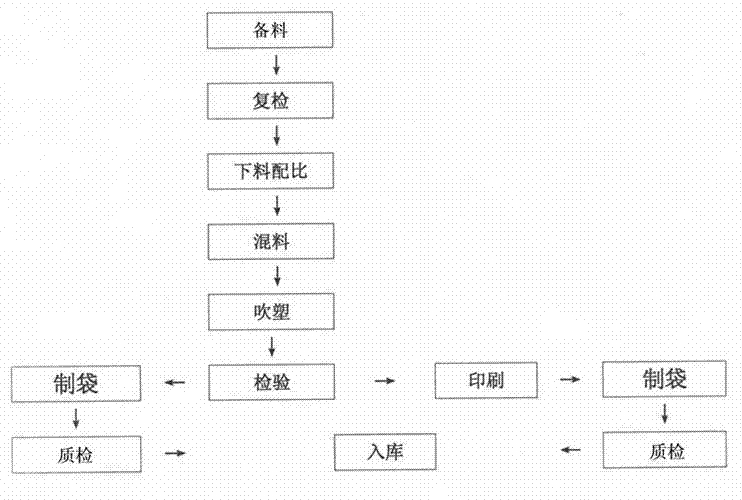

The invention relates to a degradable plastic film, which is characterized by comprising the following components in part by weight: 50 to 80 parts of film-grade polyethylene, 20 to 50 parts of film-grade polyactic acid, 2 to 10 parts of plasticizer and 1 part of heat stabilizer. A preparation method comprises the following steps of: preparing, rechecking, blanking, mixing, performing blow molding, inspecting, making a bag, performing quality inspection and warehousing. The degradable plastic film can be automatically decomposed at the environment temperature of higher than 55 DEG C or under the action of oxygen enrichment or microorganisms; the discarded film can be completely degraded and digested by the microorganisms in the natural world to generate carbon dioxide and water, and the polyactic acid is ideal completely degradable plastic; and degradable plastic with different degradation speeds can be prepared by blending the film-grade polyactic acid with film-grade polyethylene plastic. The degradable plastic film can be produced by the ordinary plastic film blowing machine, film-grade polyethylene particles and the film-grade polyactic acid can be uniformly mixed during production, and the degradable plastic film can be blown by the plastic film blowing machine.

Owner:开原市升达塑料彩印厂

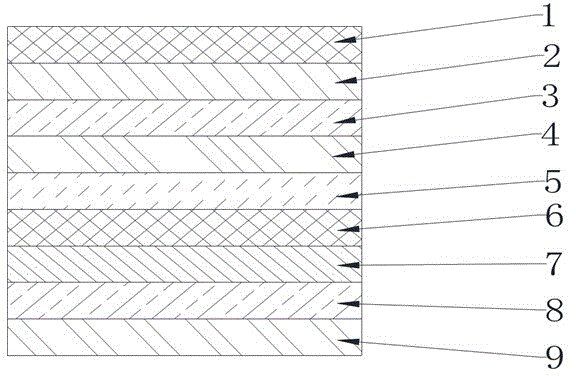

Seven-layer coextrusion composite high-separation packaging film

InactiveCN101525071AHigh barrier and airtight performanceImprove performanceFlexible coversWrappersEnvironmental resistancePolyamide

The invention relates to a seven-layer coextrusion composite high-separation packaging film which comprises polyethylene (PE) resin, ethane and vinyl alcohol copolymer (EVOH) resin, a connecting material (TIE) and polyamide (PA), each layer of the packaging film comprises one of the four kinds of resin, the thickness of the packaging film is -20-15 mu m, and the packaging film is processed by a coextrusion film blowing machine by adopting multilayer coextrusion composite technology. The seven-layer coextrusion composite high-separation packaging film has the advantages of high-separation gas tightness, environmental protection, high mechanical property, high explosion resistance, strong puncture resistance, strong tear resistance, oil resistance, moisture resistance, high-temperature cooking resistance, low-temperature refrigeration resistance, quality assurance, fresh preservation, odor preservation, low cost, good heat sealability, high flexibility and good transparency.

Owner:高永明

Production method of inflaming retarding stone paper

A production method of an inflaming retarding stone paper. The inflaming retarding stone paper comprises raw materials by weight of 55-65% of inorganic mineral, 15-30% of polyolefin, 8-18% of flame retardant and 1-5% of film-forming additive. The materials are sent to a high speed mixer to be uniformly mixed; and a mixed material is sent to an extruder and treated with milling and retrogradation to be prepared into particles; the particles are prepared into the inflaming retarding stone paper with a proper thickness by a paper film blowing machine. Because of addition of a special-purpose flame retardant, a defect of inflammability of existing stone paper is solved; the stone paper of the invention can be used for manufacture of a flame retardant wallpaper, is an ideal option for substituting an existing PVC wallpaper, and has wide market prospect.

Owner:上海石美实业有限公司

Film and production method thereof

InactiveCN103029397AHigh surface frictionInner friction is lowFlexible coversWrappersSurface layerEngineering

The invention relates to a film which comprises the following three parts by weight percentage: 23% of an outer layer, 52% of a middle layer and 25% of an inner layer. The invention further provides a production method of the film, which comprises the following steps of Step (1) mixing, Step (2) batching, and Step (3) blowing the film. The film has the characteristics of great surface layer friction force, small inner layer friction force and higher strength, and can be produced continuously by batching equipment via a film blowing machine.

Owner:KUNSHAN JINMENG PLASTIC FILM

Multilayer co-extrusion high-barrier film and preparation method thereof

ActiveCN104476753AGood oxygen barrier performanceGood stretchabilitySynthetic resin layered productsMolten stateSolvent free

The invention discloses a multilayer co-extrusion high-barrier film, a preparation method of the film and production equipment used by the preparation method. The multilayer co-extrusion high-barrier film has excellent oxygen barrier properties, tensile strength and high strength, the gradation is distinct, solvent residues are avoided, and the requirements on industrial products and food package can be met. According to the preparation method, a co-extrusion form is adopted, different materials are co-extruded in a molten state by virtue of a die head of a film blowing machine, the barrier film with distinct gradation is prepared, a composite processing technology is reduced, the problems such as solvent residues caused by compounding are solved, and the barrier film has the advantages of high efficiency and high yield. Moreover, the production equipment can be matched with the production method so as to perform high-efficiency production process, so that the barrier film has uniform film thickness, and high production efficiency and product quality are guaranteed.

Owner:朝阳佛瑞达科技有限公司

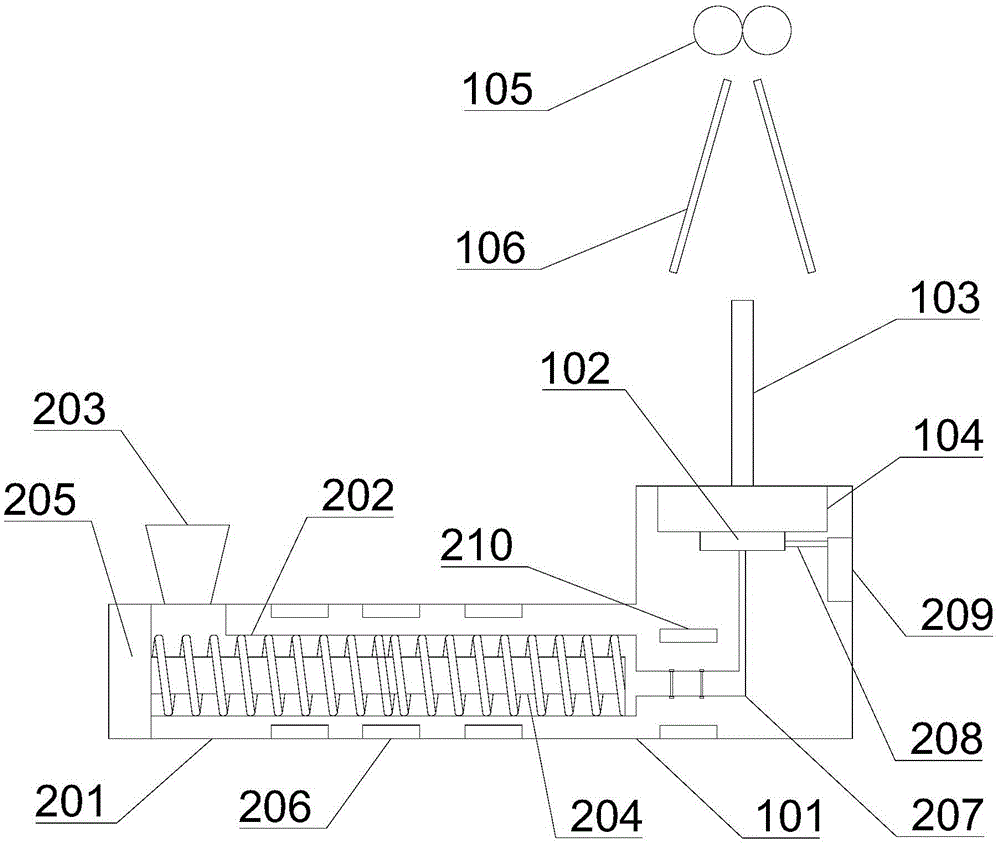

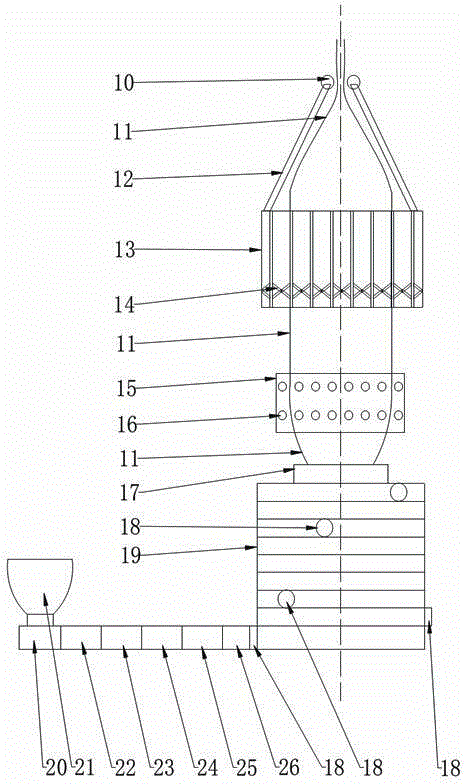

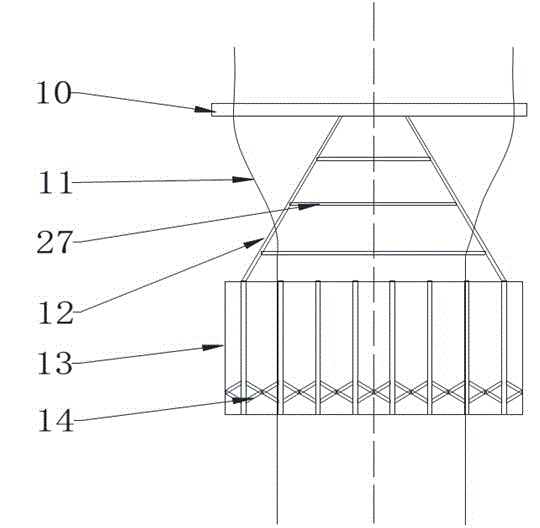

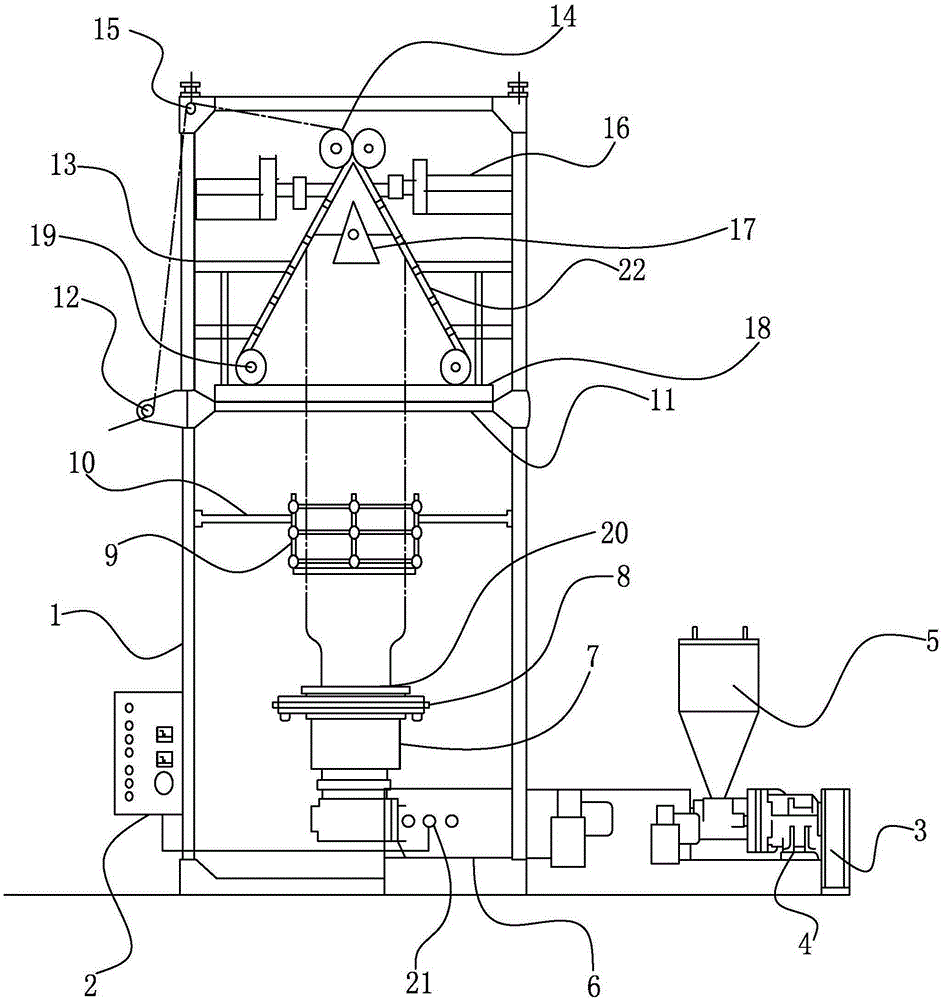

Novel film blowing machine

The invention relates to a novel film blowing machine which comprises a rack, a conveying device and a control panel. The control panel is installed on the rack, and the conveying device is connected with a mould head at the center of the rack. The conveying device comprises a main machine triangular wheel, a gearbox, a feed hopper and a main machine linkage shaft which are sequentially arranged from right to left. The main machine linkage shaft is in transmission connection with the mould head. A high-speed air ring is arranged at the upper end of the mould head. A blow molding core is arranged at the center of the high-speed air ring. By means of the novel film blowing machine, a limiting plate is installed on the rack in a sliding mode and can be pushed up and down, occupied area is saved, and maintenance is convenient. The control panel is adopted so that a full-automatic production mode can be achieved, and the quality of products is guaranteed. Besides, an adjusting handle and an edge folding device are arranged so that the situation that a film face rubs with a herringbone-shaped clamping plate face, wrinkles are generated, and accordingly product quality is influenced can be prevented.

Owner:嘉兴高正新材料科技股份有限公司

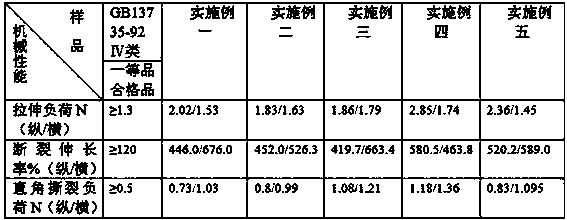

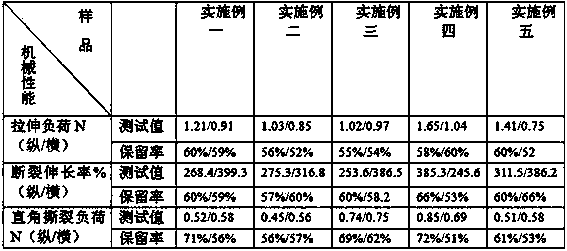

Production method of agricultural land surface covered weeding degradable mulching film

The invention provides a production method of an agricultural land surface covered weeding degradable mulching film. The film is prepared from the raw materials including 95-99% of linear low-density polyethylene LLDPE7042, a compound degradable catalyst, 0.01-1% of an ultraviolet ray adsorbent, 0.45-2% of a powdery herbicide and 0.45-1.5% of emulsified oil herbicide. The production method comprises the following steps of: sufficiently mixing the emulsified oil herbicide into the linear low-density polyethylene LLDPE7042; then adding the compound degradable catalyst, the ultraviolet ray adsorbent and the powdery herbicide; and blowing a sufficiently-mixed mixture by a film blowing machine into the film, wherein the physical performance and the use function of the film accord with the national standard GB13735-92. The degrading time of the mulching film is 90-120 days and the effective weeding time is about 90 days; a weeding range comprises annual dicotyledonous plants and monocotyledon plants; and the film is tightly stuck on the ground to cover and does not have positive and negative faces, and the film is recommended to be used on crops such as corns, tobaccos, cottons, sugarcanes and vegetables.

Owner:云南中蔗农业科技有限责任公司 +1

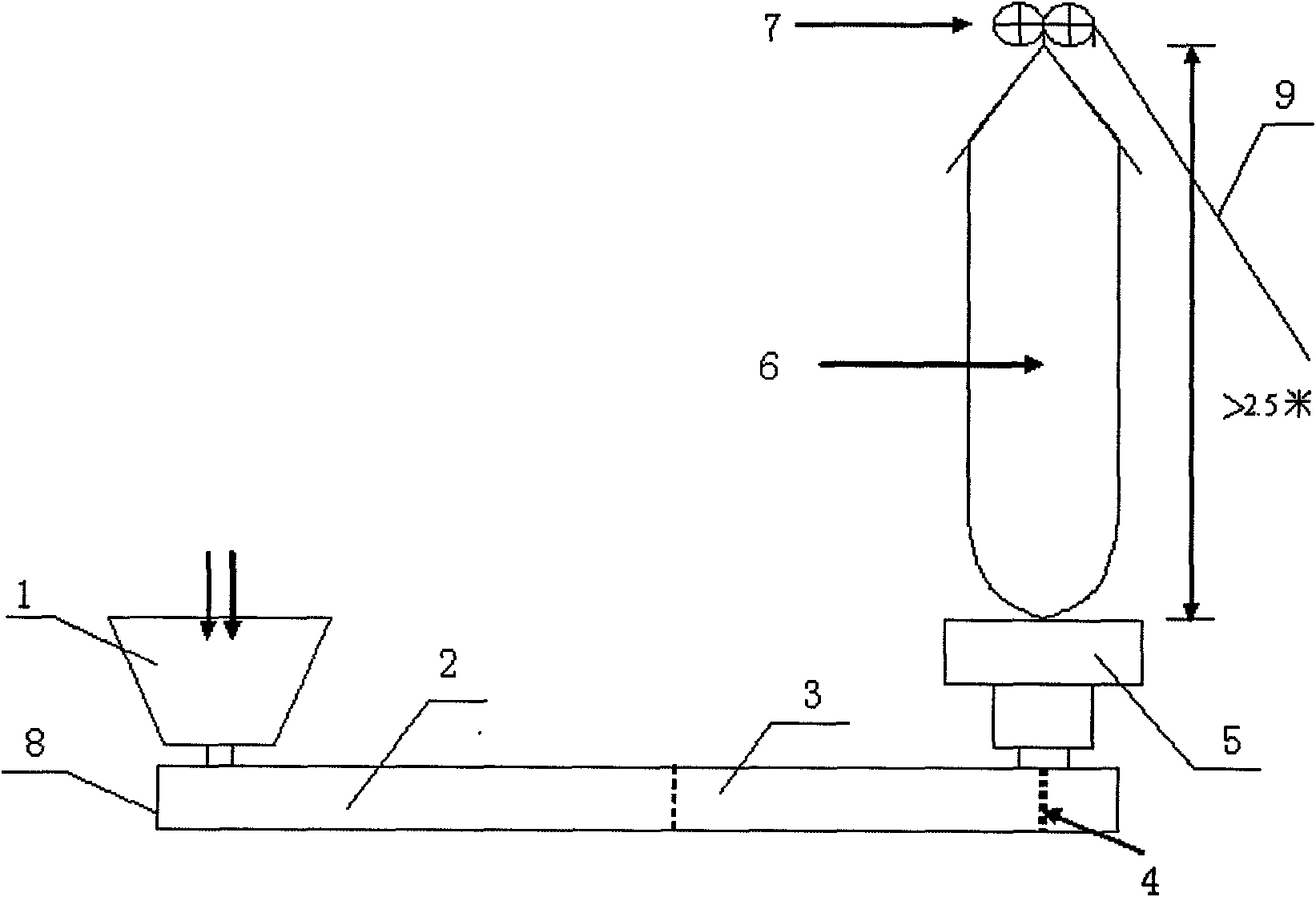

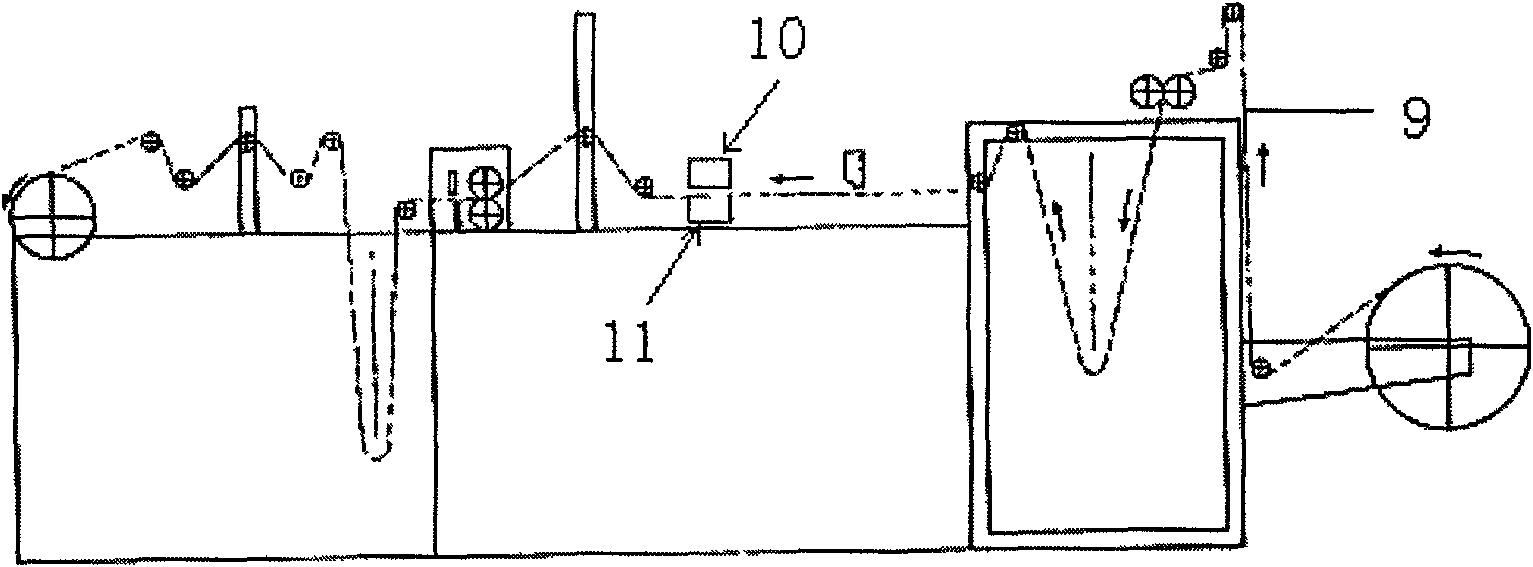

Method for blowing film and making bag by using full biodegradable material as base material

The invention relates to a method for blowing a film and making a bag by using a full biodegradable material as a base material. The method comprises the following steps: (1) work preparation; (2) film blowing: adding a color parent stock, then blowing a film and finally obtaining the film; and (3) bag making: heat-sealing the film, sealing an opening and making a bag so as to obtain a finished bag, wherein the film blowing step has the following parameters: (a) controlling the temperature of a plasticization section of a film blowing machine to be 125-140 DEG C, the temperature of a homogenization section to be 140-150 DEG C and the temperature of an extrusion section to be 140-145 DEG C; (b) ensuring a length-diameter ratio L / D of a screw rod of the film blowing machine to be larger than 28:1, a blow ratio to be 1:2.5-1:3 and a height from a die orifice to a pull roll to be larger than 2.5m; and (c) maintaining the rotating speed of the screw rod to be 17-35 turns / minutes at the beginning and then gradually speeding up until catching up the take-up speed of the film. The method has the process requirement that the temperature of heat sealing and edge sealing is 140-180 DEG C. The existing equipment can be used for blowing the film and making the bag by using the full biodegradable material as the base material by the method to obtain a qualified product.

Owner:盖勇

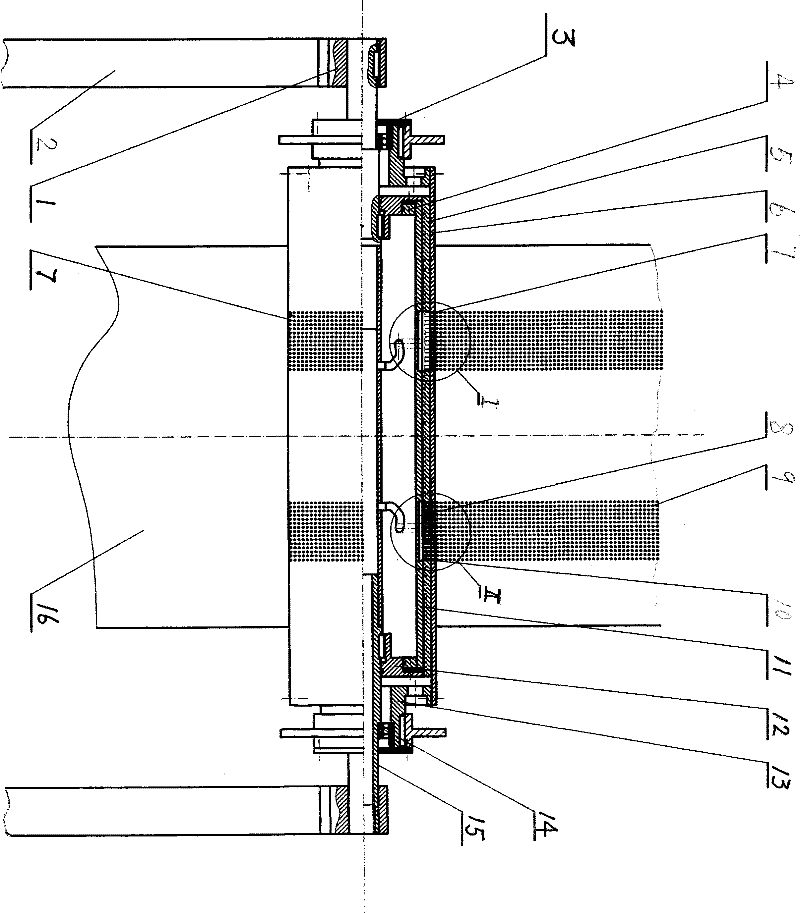

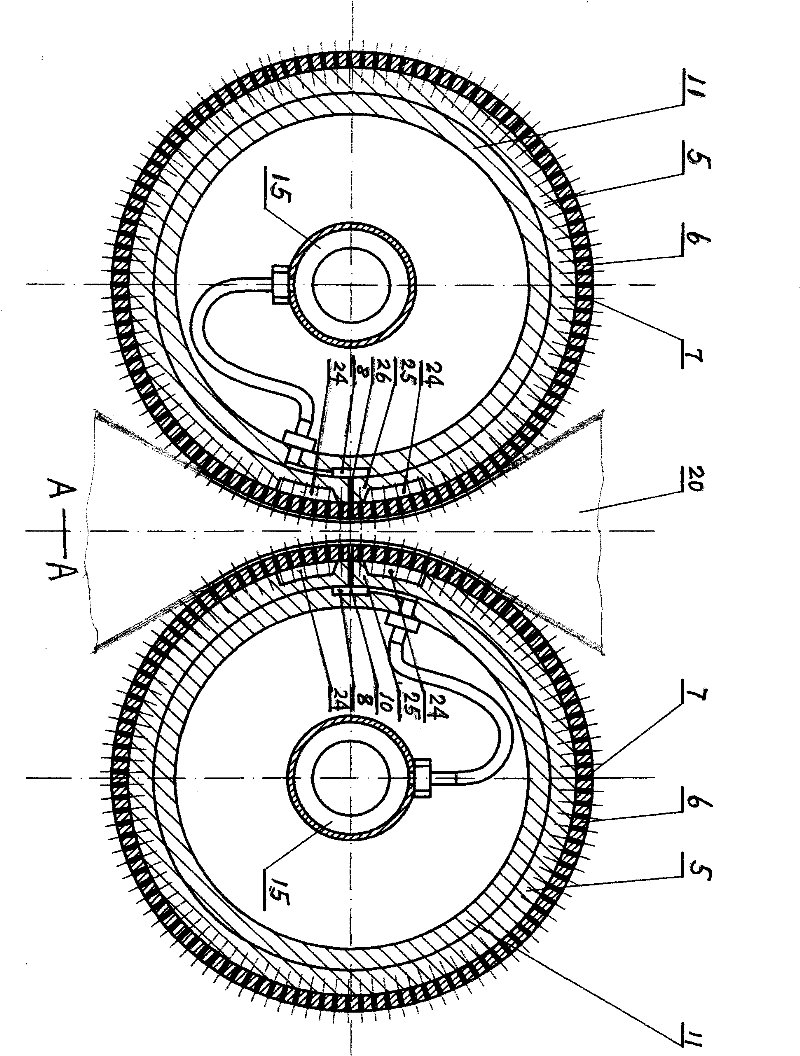

Vacuum plastic suction embossing roll

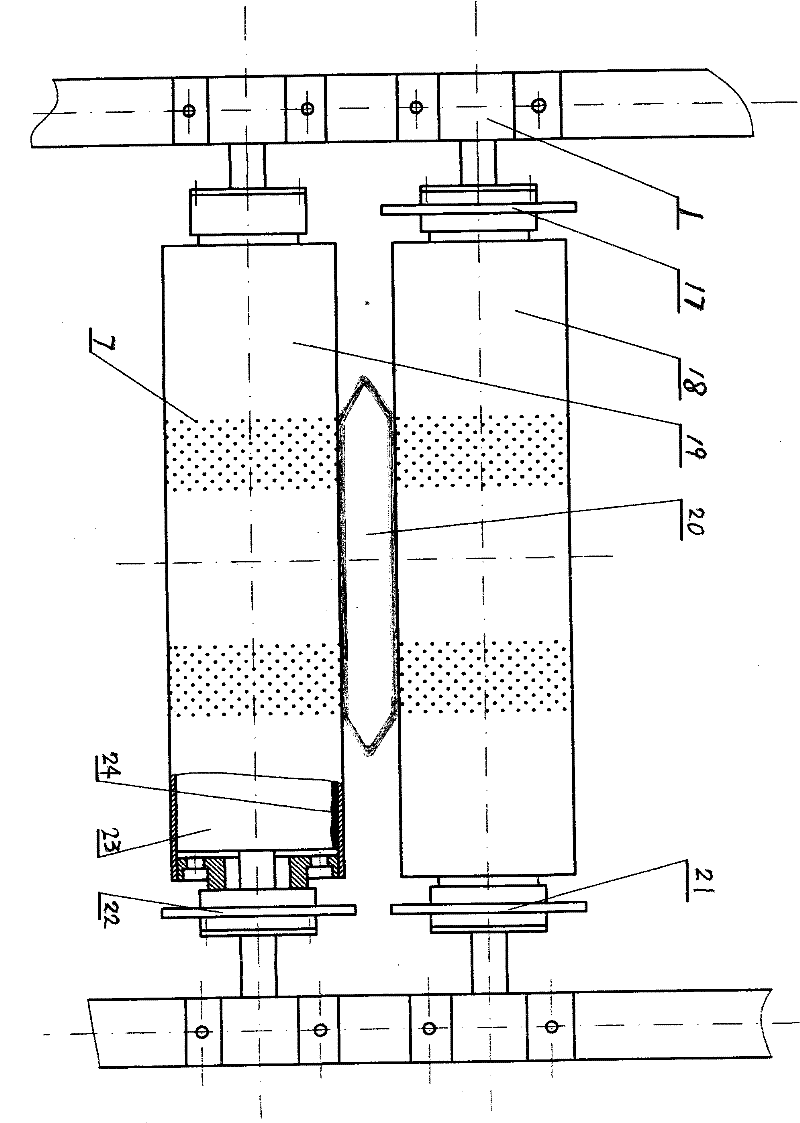

InactiveCN102343671ASolve the problem of direct production of blown embossed filmIncrease productivityFlat articlesDrive wheelSuction stress

The invention relates to a vacuum plastic suction embossing roll. The vacuum plastic suction embossing roll comprises outer mold rollers 6, gas suction rollers 23, hollow shafts 15, sealing covers 12, rolling bearings 14, disc end caps 13, bearing caps 3, driving wheels 18, fixation hinges 1, frames 2 and other components. According to the present invention, the vacuum plastic suction embossing roll adopts a vacuum plastic suction technology and a controllable vacuum release mechanism; during a film blowing process of a blown film, various identification patterns or anti-skid regions are prepared on the film, wherein the identification patterns or the anti-skid regions comprise a plurality of small round convex points 9; during film blowing by a film blowing machine, a blown film tube 20 is introduced in a crack between the two vacuum plastic suction rolls, such that the blown film respectively contacts tangent line positions of the two vacuum plastic suction rolls; a plurality of plastic suction holes 7 are drilled on cylindrical surfaces of the outer mold rollers 6 positioned on the two vacuum plastic suction rolls, when the blown film 16 contacts the plastic suction holes 7, the film is sucked in the plastic suction holes 7 under the vacuum suction effect of the plastic suction holes 7, and is separated from the plastic suction holes 7 after cooling, the small round convex points 9 are formed on the film surface, such that a purpose of embossing on the film is realized.

Owner:张志学

Preparation method of calcium carbonate-filled high-performance degradable polyethylene film

A preparation method of a calcium carbonate-filled high-performance degradable polyethylene film comprises the following steps: 1, drying calcium carbonate; 2, fully mixing dried calcium carbonate with a coupling agent according to a mass ratio of 100:0.5-3; 3, fully mixing high density polyethylene, EVA and calcium carbonate obtained in step 2; 4, adding a photodegradation agent to a mixture obtained in step 3, and uniformly mixing; 5, adding a mixture obtained in step 4 to an extruder, and carrying out fusing extrusion and granulation; and 6, adding granules obtained in step 5 to a film blowing machine, and carrying out blow molding to form the film. The polyethylene film prepared in the invention has the advantages of low cost, good mechanical performances, high tensile strength and elongation at break, degradability and environmental protection.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Ecological environment-friendly light-conversion mulching film

InactiveCN104045905AGood quality indexExtended service lifePlant protective coveringsLinear low-density polyethyleneLow-density polyethylene

The invention provides an ecological environment-friendly light-conversion mulching film which is prepared from the following raw materials in percentage by weight: 35-45% of linear low density polyethylene, 10-15% of low density polyethylene, 10-20% of metallocene linear polyethylene, 10-15% of polyolefin elastomer and 10-15% of nano degradable light-conversion master batch. The preparation technique comprises the following steps: mixing the raw materials, sending into a film blowing machine, carrying out plastification, extrusion, blowing, traction and cooling, cutting, and rolling to obtain the finished mulching film product. The mulching film has the advantage of long service life, increases light required by photosynthesis of crops, and has favorable undercover culture effect on corn, wheat, strawberry, chili, onion, potato and other fruit / vegetable crops.

Owner:GANSU TIANBAO PLASTIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com