High-transparency polyolefin heat shrinkage film and production method thereof

A polyolefin heat and high transparency technology, which is applied in the high transparency polyolefin heat shrinkable film and its production field, can solve the problems of not meeting higher requirements, insufficient heat sealing strength, and low film transparency, etc., to ensure stability, The effect of improving transparency and increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

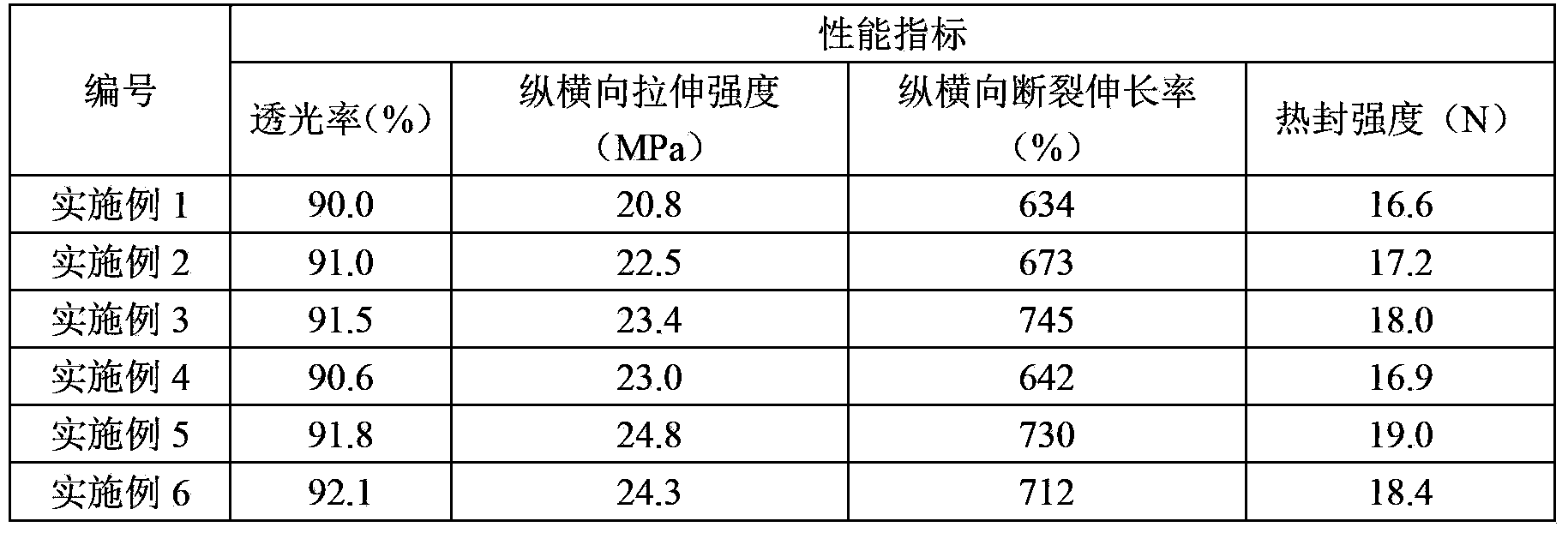

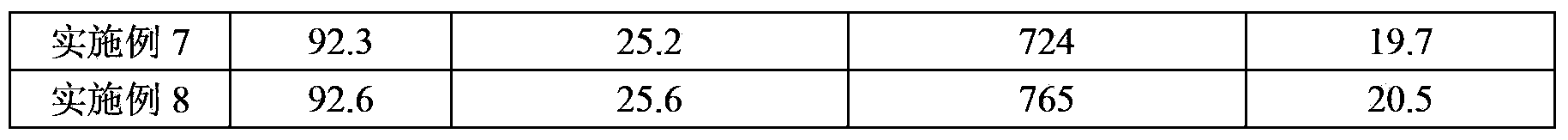

Embodiment 1

[0033] A kind of production method of high-transparency polyolefin heat-shrinkable film, its step is as follows:

[0034] 25kg LLDPE, 20kg ethylene-octene copolymer, 54kg LDPE, 0.5kg calcium stearate and 0.5kg glycerol are mixed evenly, then transported to the storage tank, extruded through a single-screw extruder, and the extrusion temperature is 160°C, the extruded material is extruded into a tube blank through the extrusion die of the single-layer blown film machine. The temperature of the extrusion die is 170°C. The temperatures in Zones 1-4 are: 170°C, 210°C, 240°C, 280°C; the temperatures in Zones 5-8 in the stretching oven are: 370°C, 320°C, 230°C, 150°C. Stretch in an oven with air (the inflated gas is compressed air, the same as in the following examples), the stretching temperature is 90°C, the transverse stretching ratio is 5.0-5.2, the longitudinal stretching ratio is 5.0-5.2, and the stretching is 15-18μm thickness of the film, that is.

Embodiment 2

[0036] A kind of production method of high-transparency polyolefin heat-shrinkable film, its step is as follows:

[0037] 25kg LLDPE, 25kg ethylene-octene copolymer, 49kg LDPE, 0.5kg magnesium stearate and 0.5kg glycerol are mixed evenly, then transported to the storage tank, extruded through a single-screw extruder, and the extrusion temperature is 165°C, the extruded material is then extruded into a tube blank through the extrusion die of a single-layer blown film machine. The temperature of the extrusion die is 175°C. The temperatures in zones 1-4 are: 180°C, 210°C, 250°C, 280°C; the temperatures in zones 5-8 in the stretching oven are: 370°C, 340°C, 260°C, 150°C. Inflatable stretching in an oven, the stretching temperature is 90°C, the transverse stretching ratio is 5.0-5.2, the longitudinal stretching ratio is 5.0-5.2, and stretched into a film with a thickness of 15-18 μm.

Embodiment 3

[0039] A kind of production method of high-transparency polyolefin heat-shrinkable film, its step is as follows:

[0040] 25kg LLDPE, 30kg ethylene-octene copolymer, 44kg LDPE, 0.5kg stearic acid and 0.5kg pentaerythritol were mixed evenly, then transported to the storage tank, extruded through a single-screw extruder, the extrusion temperature was 165 ° C, The extruded material is then extruded into a tube blank through the extrusion die of the single-layer blown film machine. The temperature of the extrusion die is 180°C. The temperatures in zone 4 are: 180°C, 210°C, 240°C, and 280°C; the temperatures in zone 5-8 in the stretching oven are: 370°C, 340°C, 260°C, and 150°C, and the tube blank is inflated in the stretching oven Stretching, the stretching temperature is 92°C, the transverse stretching ratio is 4.8-5.0, the longitudinal stretching ratio is 4.8-5.0, and stretched into a film with a thickness of 18-20 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com