Film for flexible bags

a flexible bag and film technology, applied in the field of films, can solve the problems of reducing efficiency, reducing operational speed, reducing efficiency, and reducing the efficiency of retrieving the opener, so as to prevent product weeping and relieve any residual pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

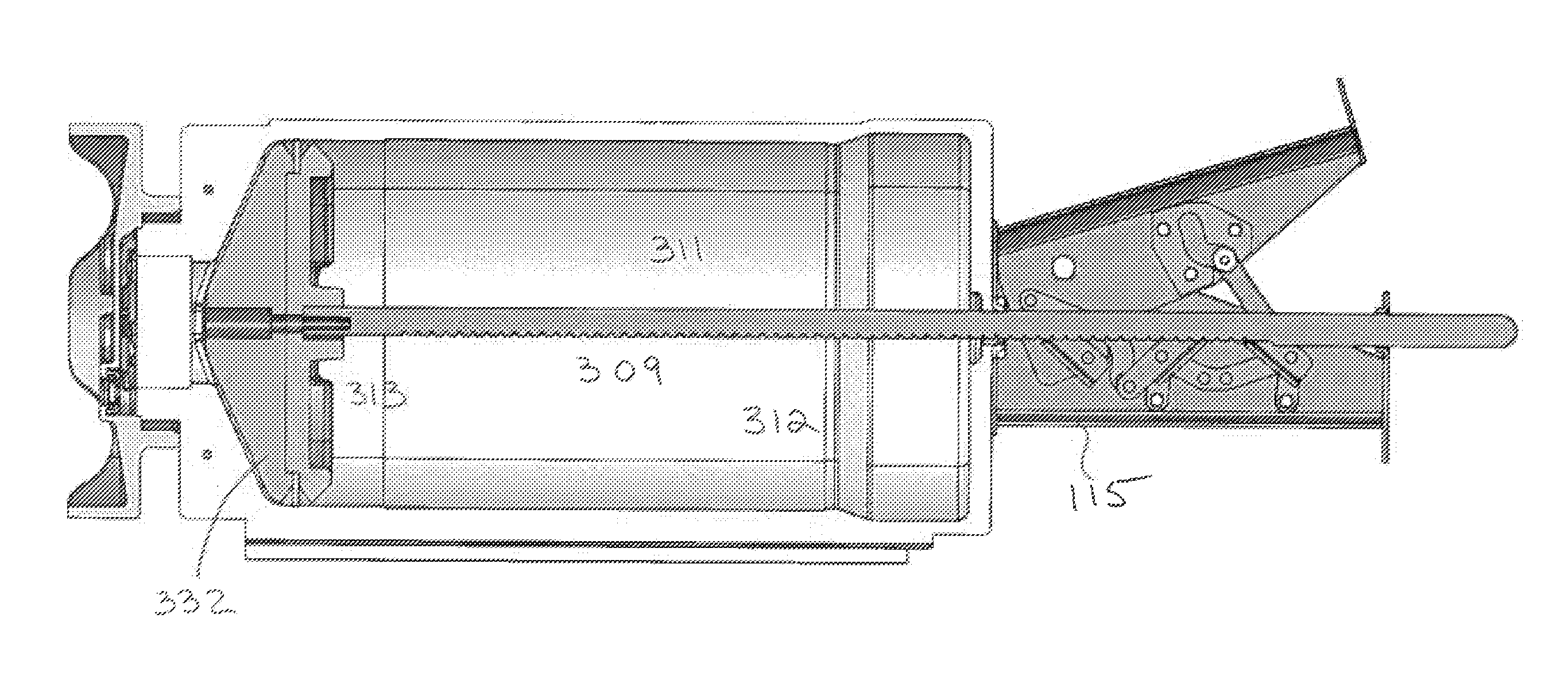

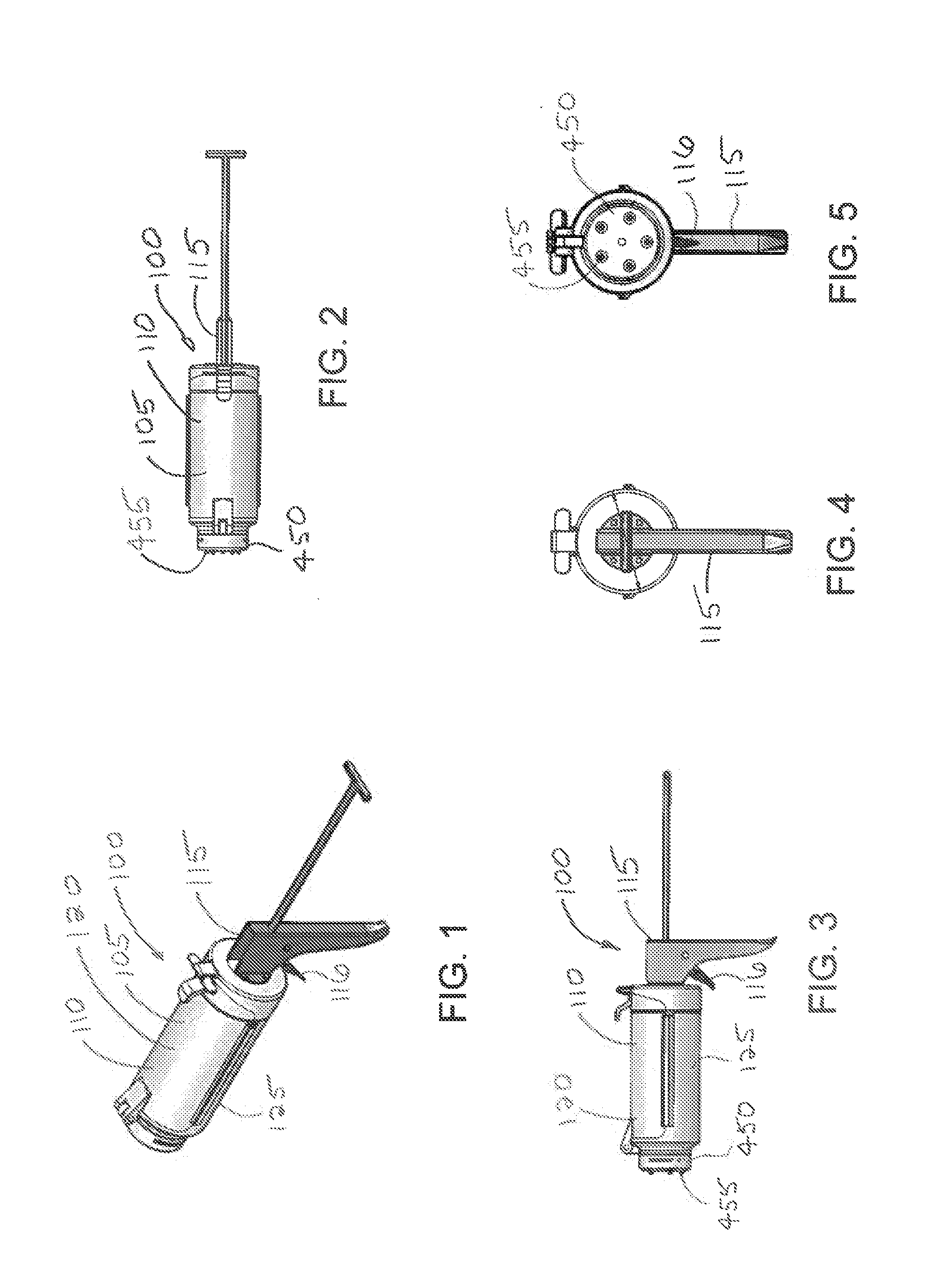

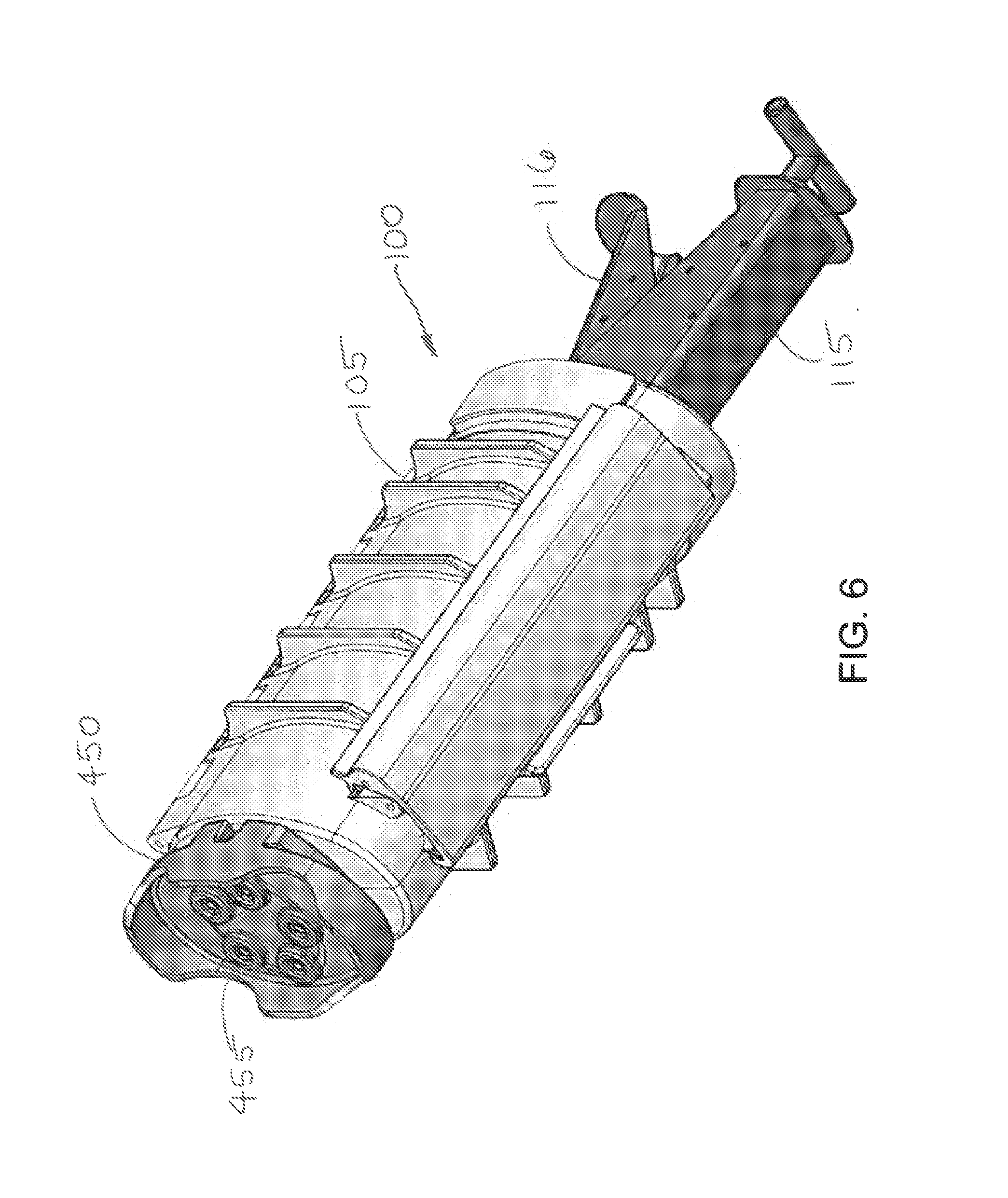

[0172]FIGS. 1-6 depict one embodiment of a dispenser in accordance with the present invention; while FIGS. 7-14 depict another embodiment of a dispenser in accordance with another embodiment of the present invention.

[0173]FIGS. 1-14 illustrate a dispenser 100 that may include a container 110 including a containment portion 105 and a handle portion 115. Handle portion 115 may include a trigger or actuating device 116 to selectively actuate a pump. Alternative embodiments of dispensers in accordance with the invention are illustrated in FIGS. 6-13, and other arrangements and shapes are possible. As illustrated in FIGS. 1 and 6, dispenser 100 may include a first wall 120 and a second wall 125 that are hingedly connected. In one embodiment, dispenser 100 further comprising a valve 450 separate from the pump, as seen in FIGS. 5-7 and 14. Although FIGS. 5-7 and 14 illustrate valve 450 as including a plurality of outlets 455 arranged substantially circularly, any number of outlets 455, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com