Patents

Literature

21265 results about "Gas supply" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

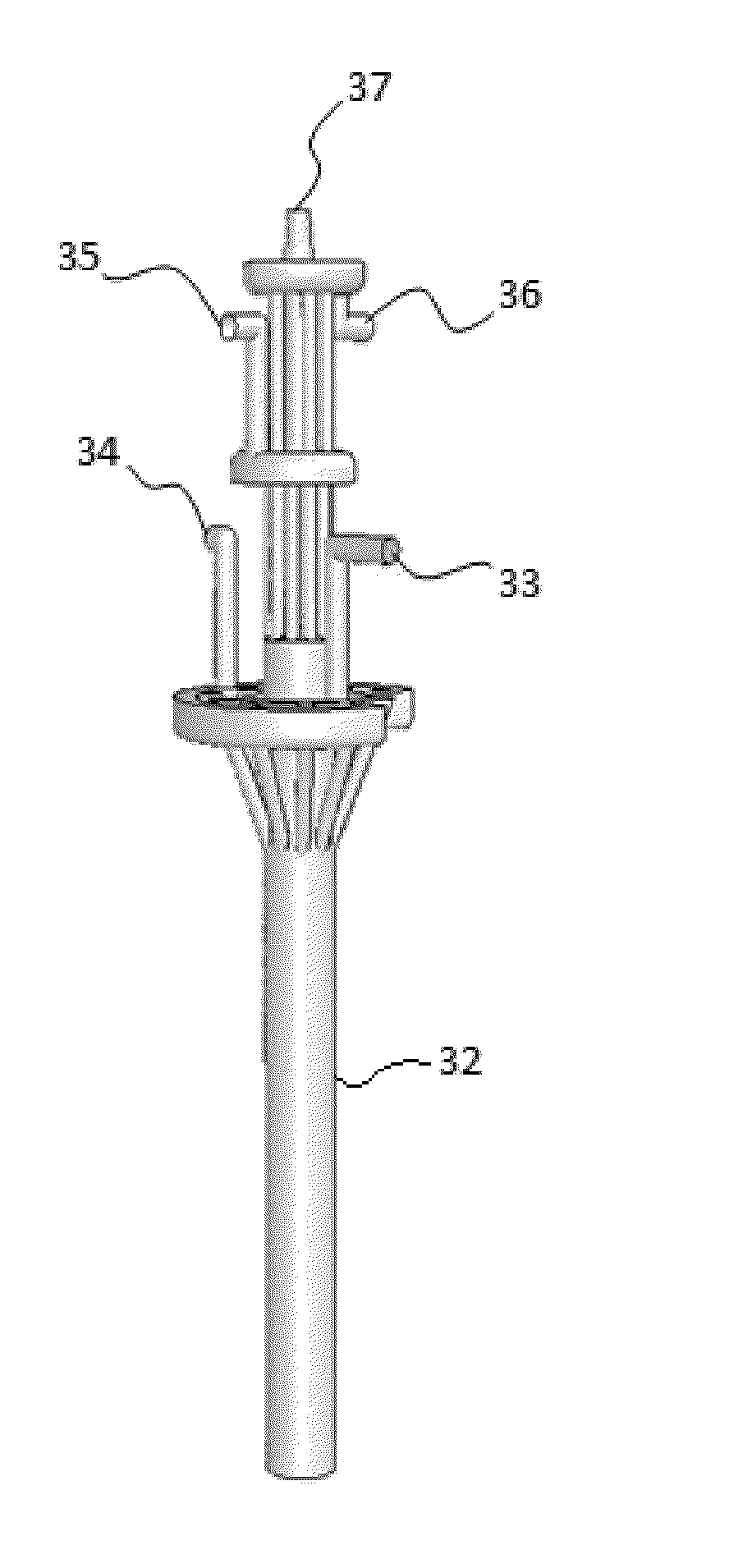

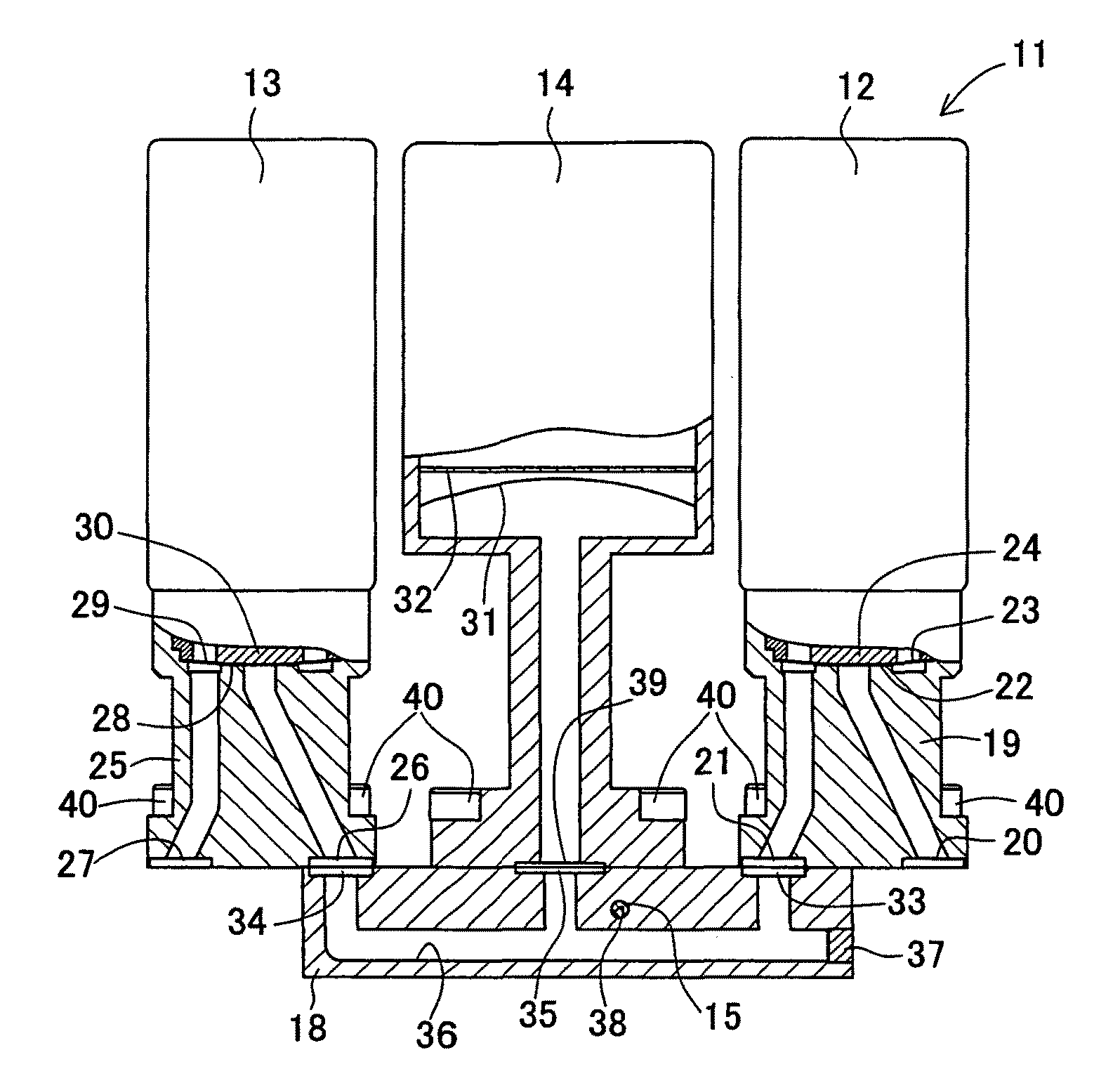

Gas separation type showerhead

InactiveUS20070163440A1Minimize hydrogen contentIncrease diversityElectric discharge tubesExternal electric electrostatic seperatorEngineeringProcess engineering

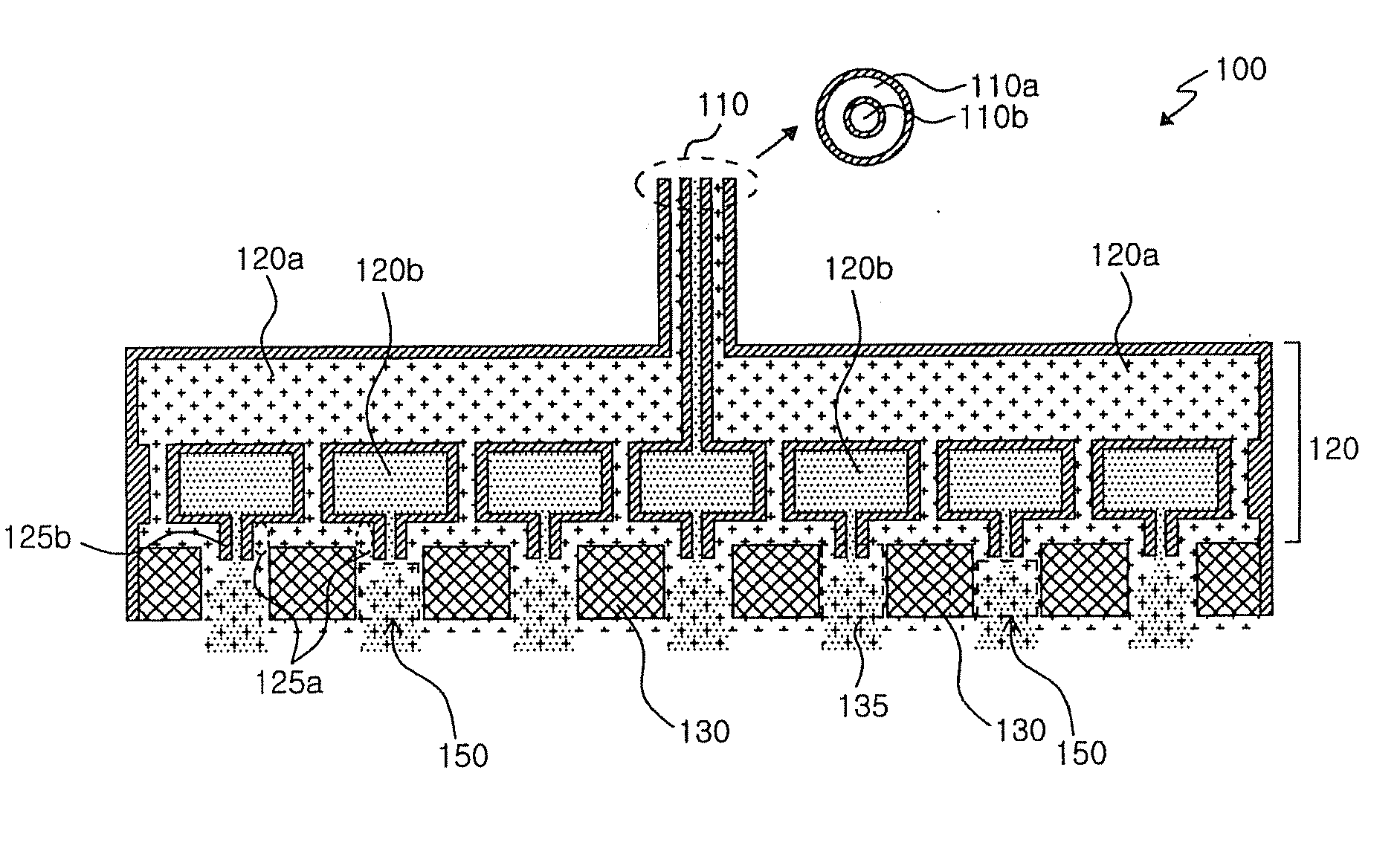

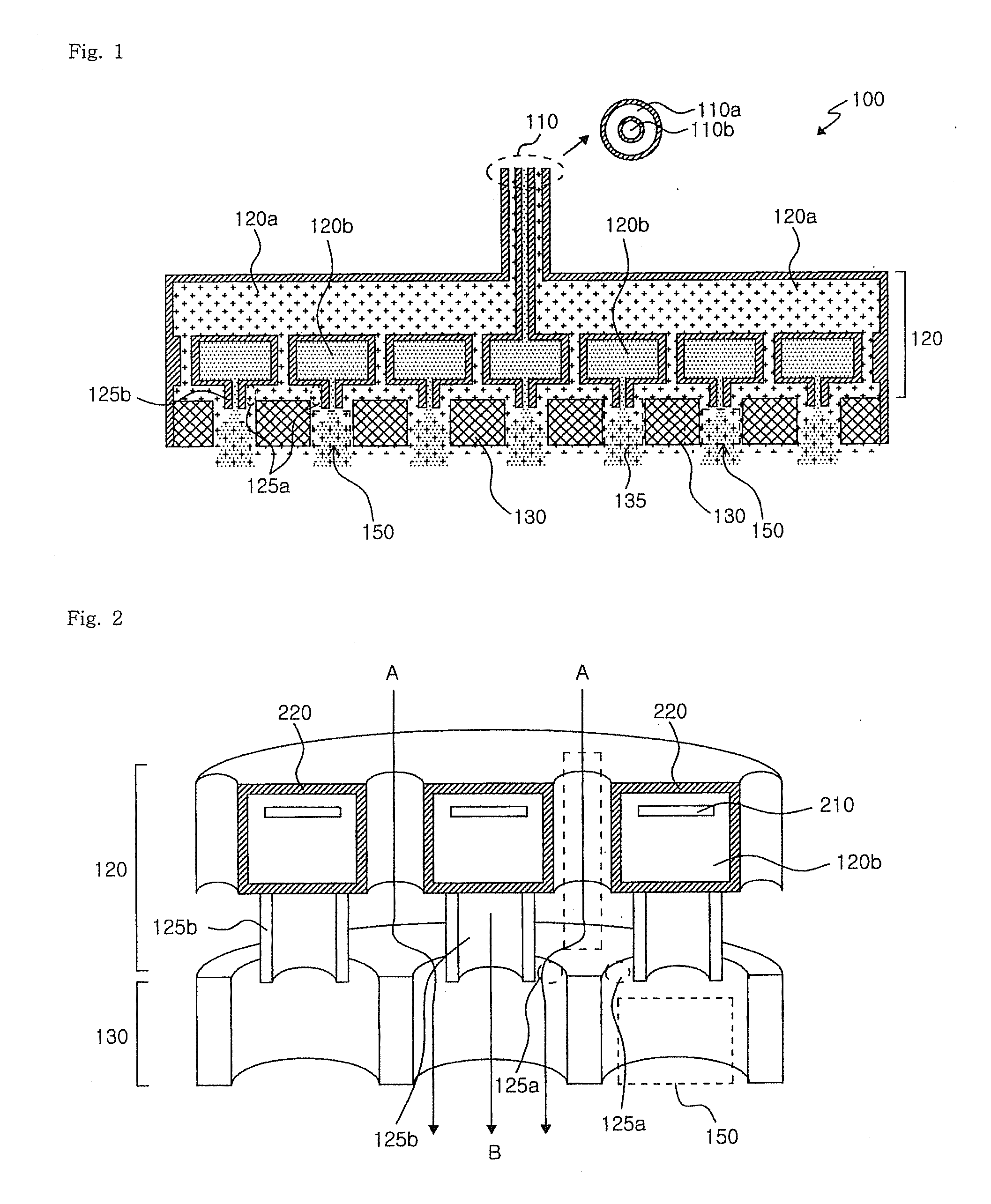

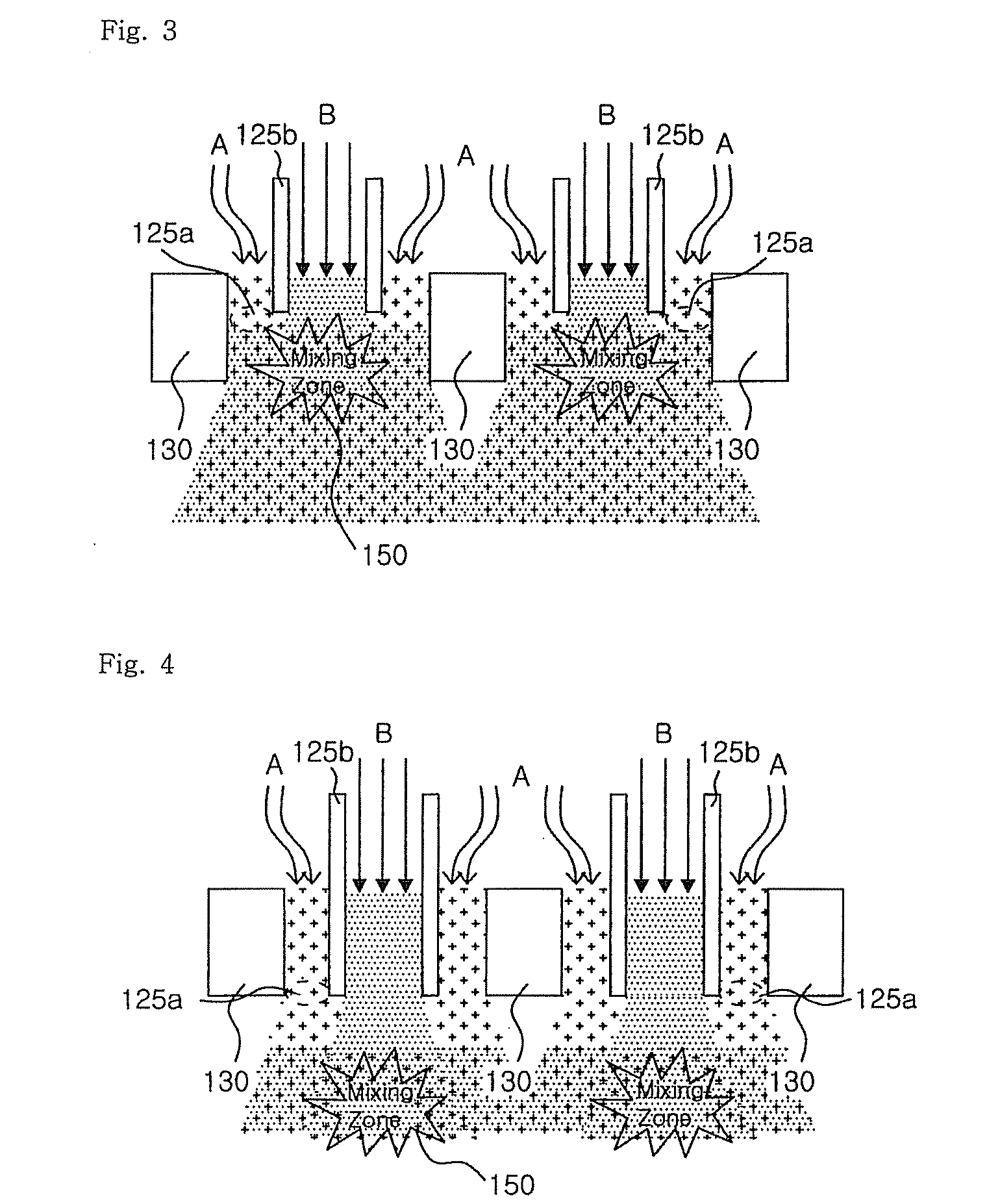

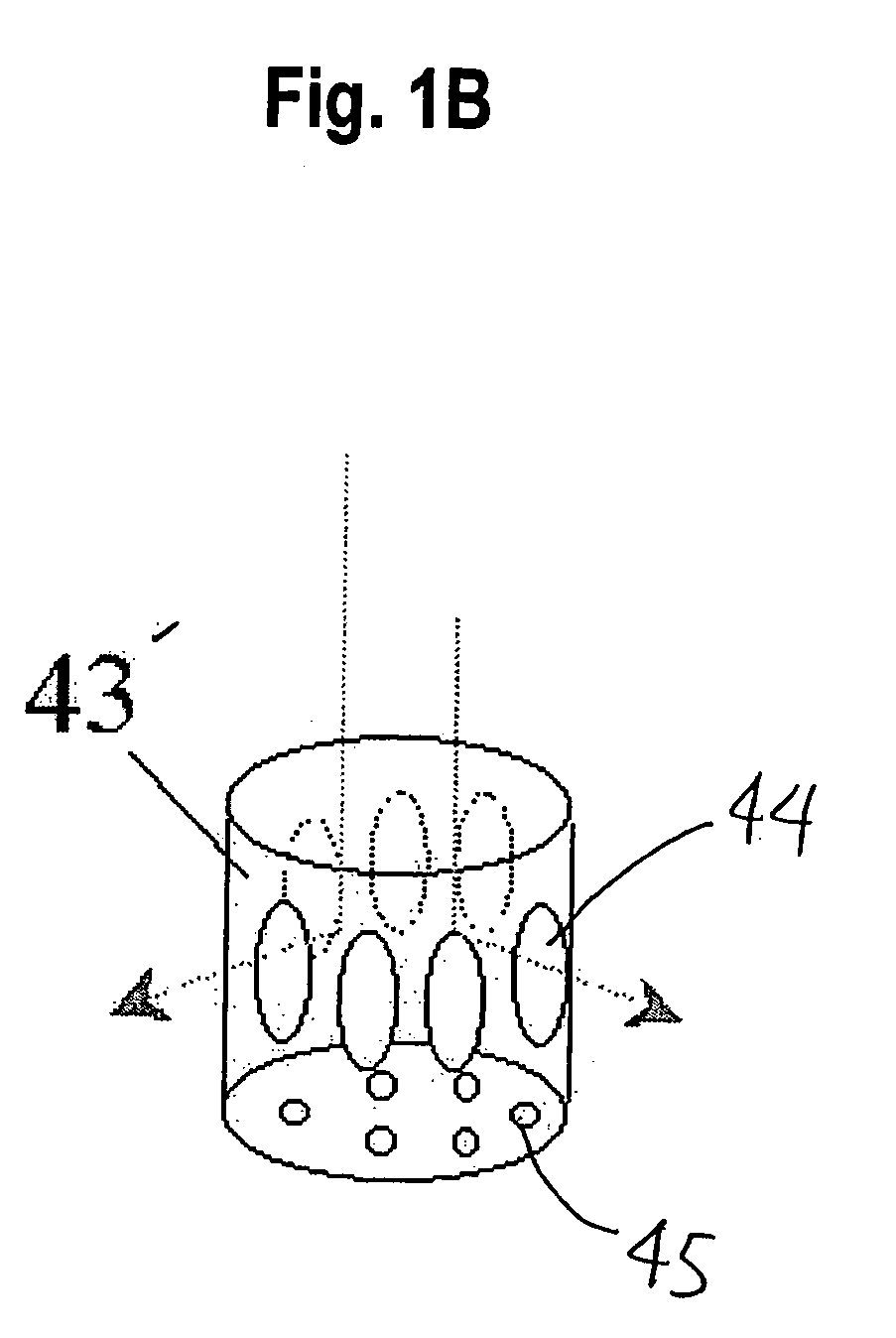

Provided is a gas separation type showerhead for effective energy supply. The gas separation type showerhead includes: a gas supply module to which a first gas and a second gas are separately supplied; a gas separation module in which the supplied first and second gases are separately dispersed; and a gas injection module which is a multi-hollow cathode having a plurality of holes and in which the first and second gases separately dispersed are ionized in the holes to be commonly dispersed.

Owner:ATO

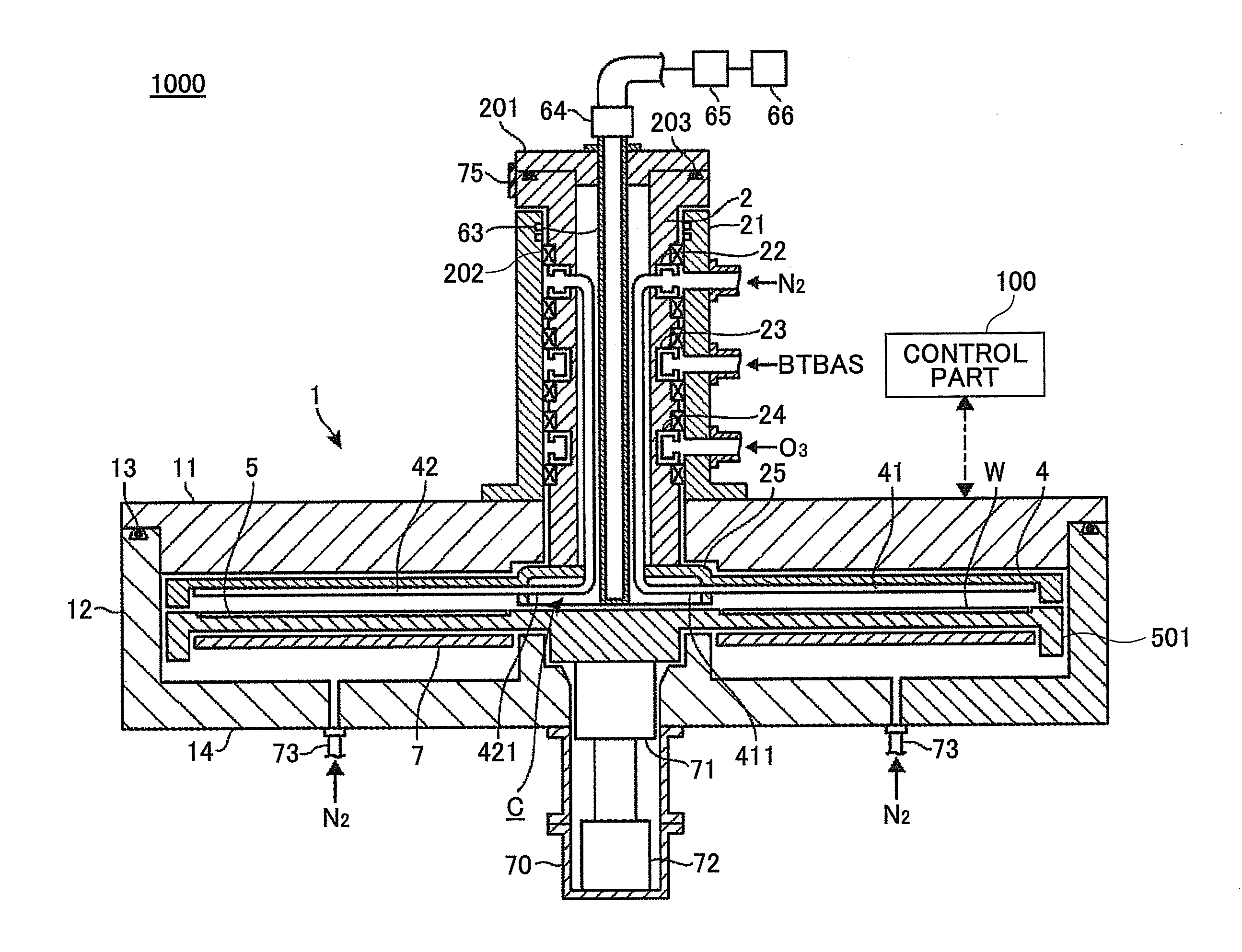

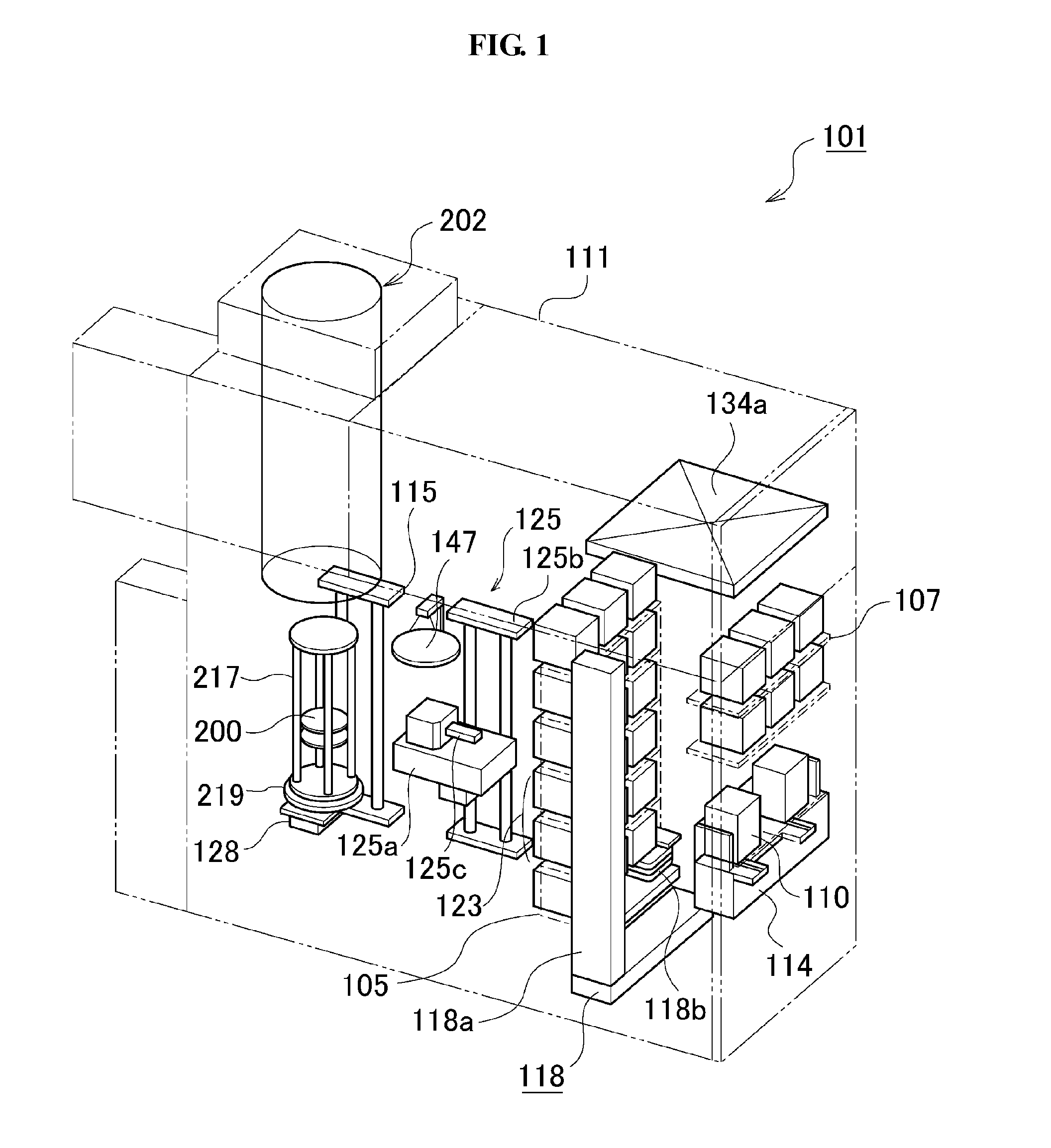

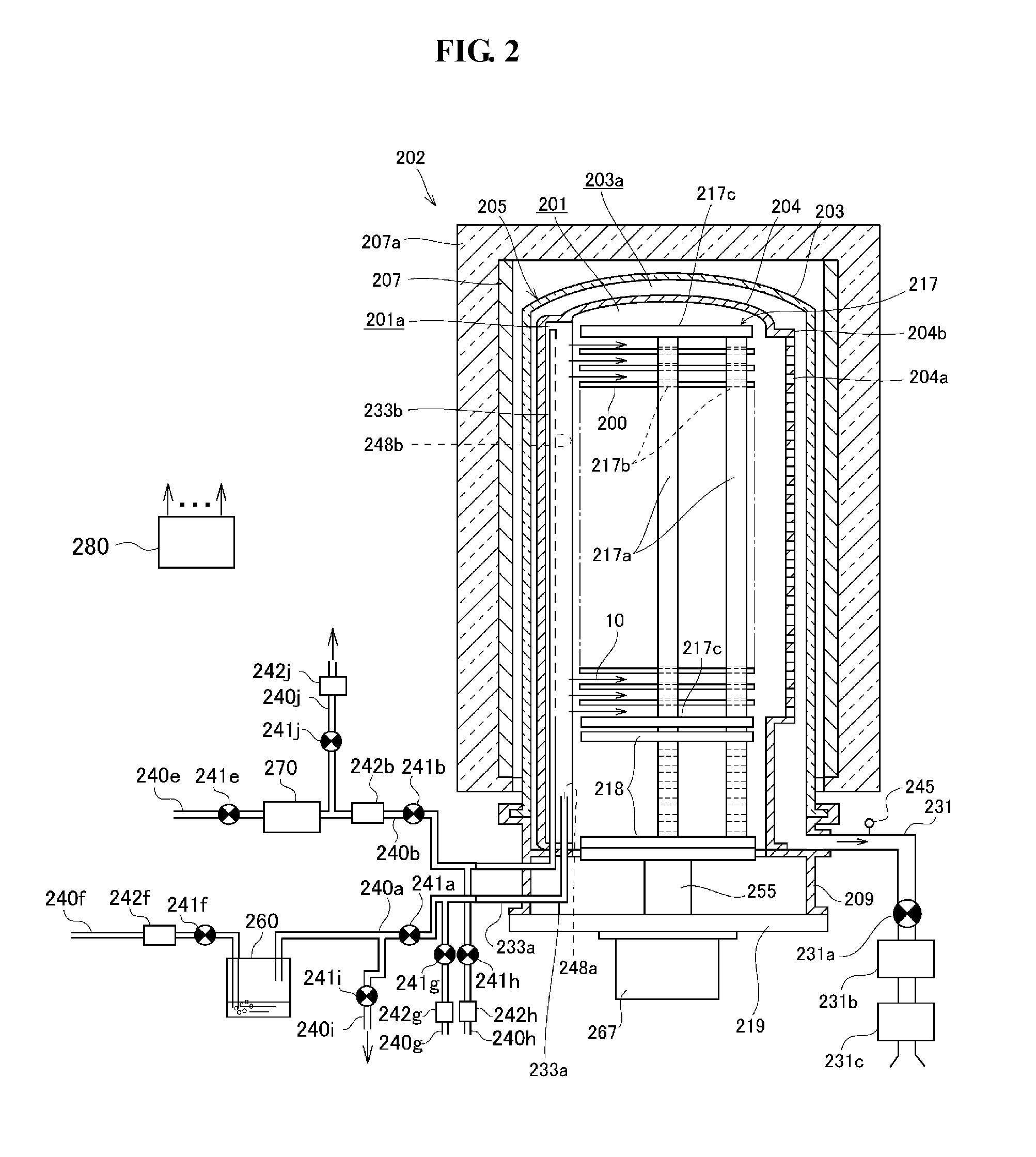

Film deposition apparatus and film deposition method

ActiveUS8506713B2Efficient solutionImprove uniformitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringDeposition process

Owner:TOKYO ELECTRON LTD

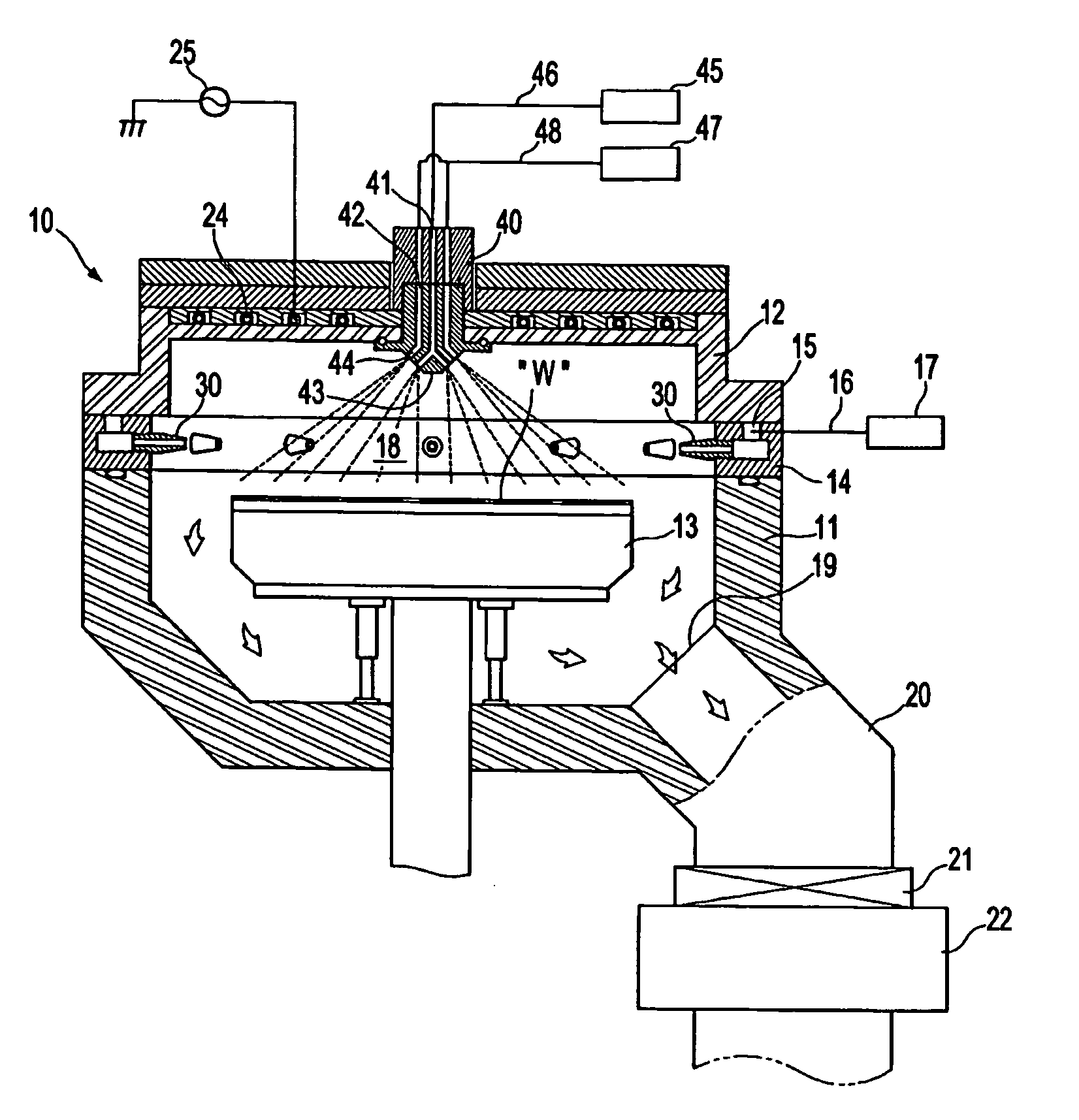

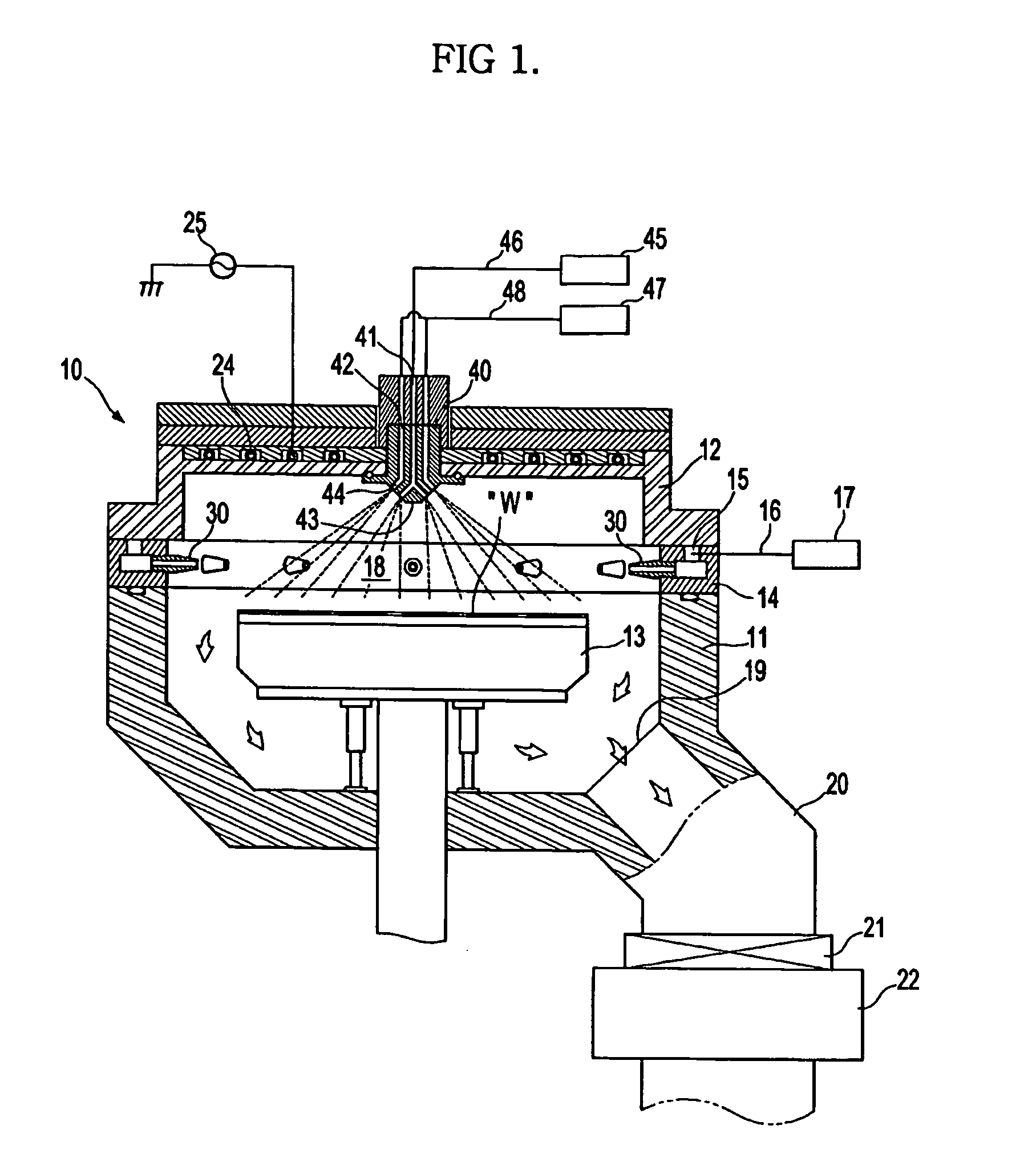

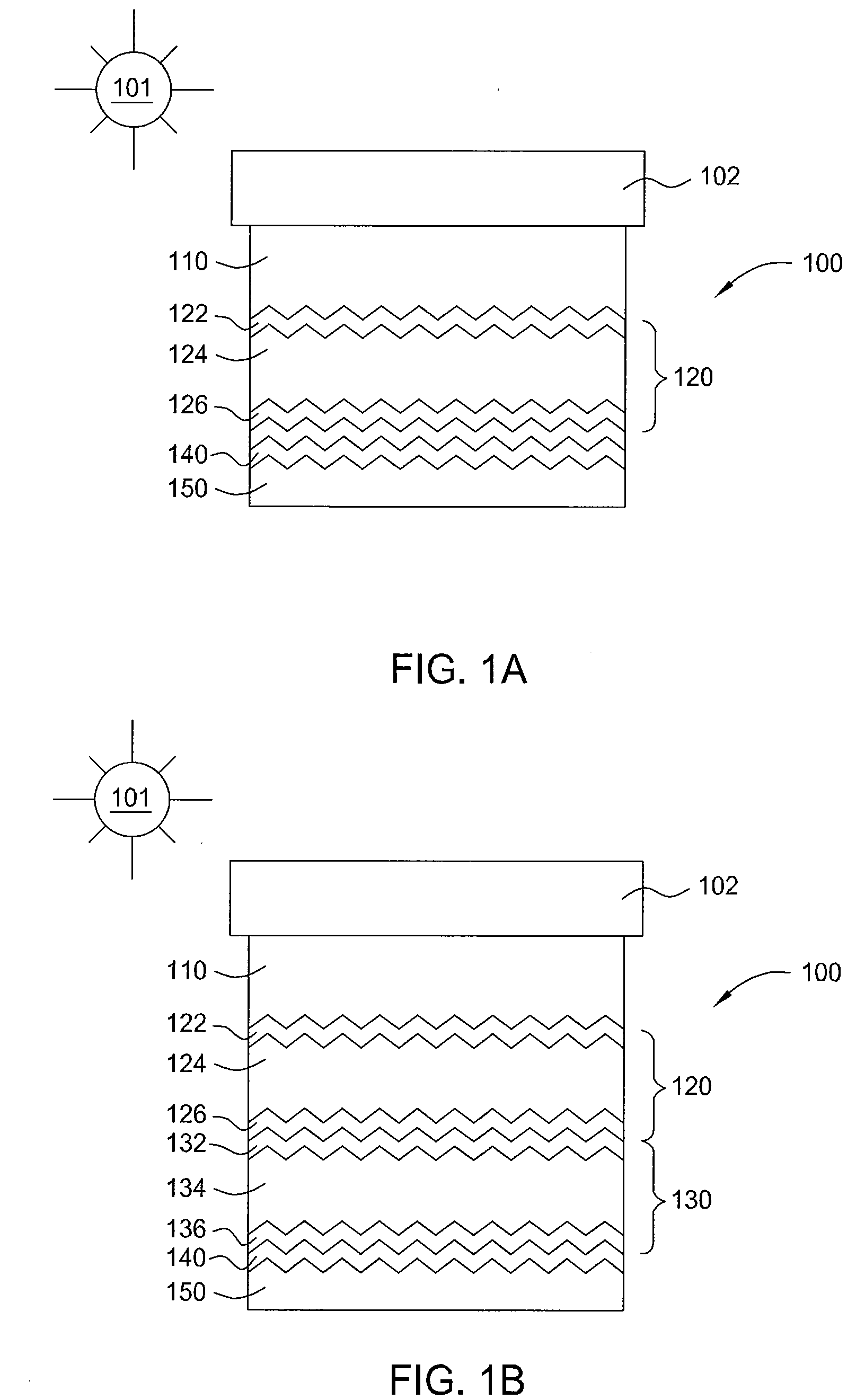

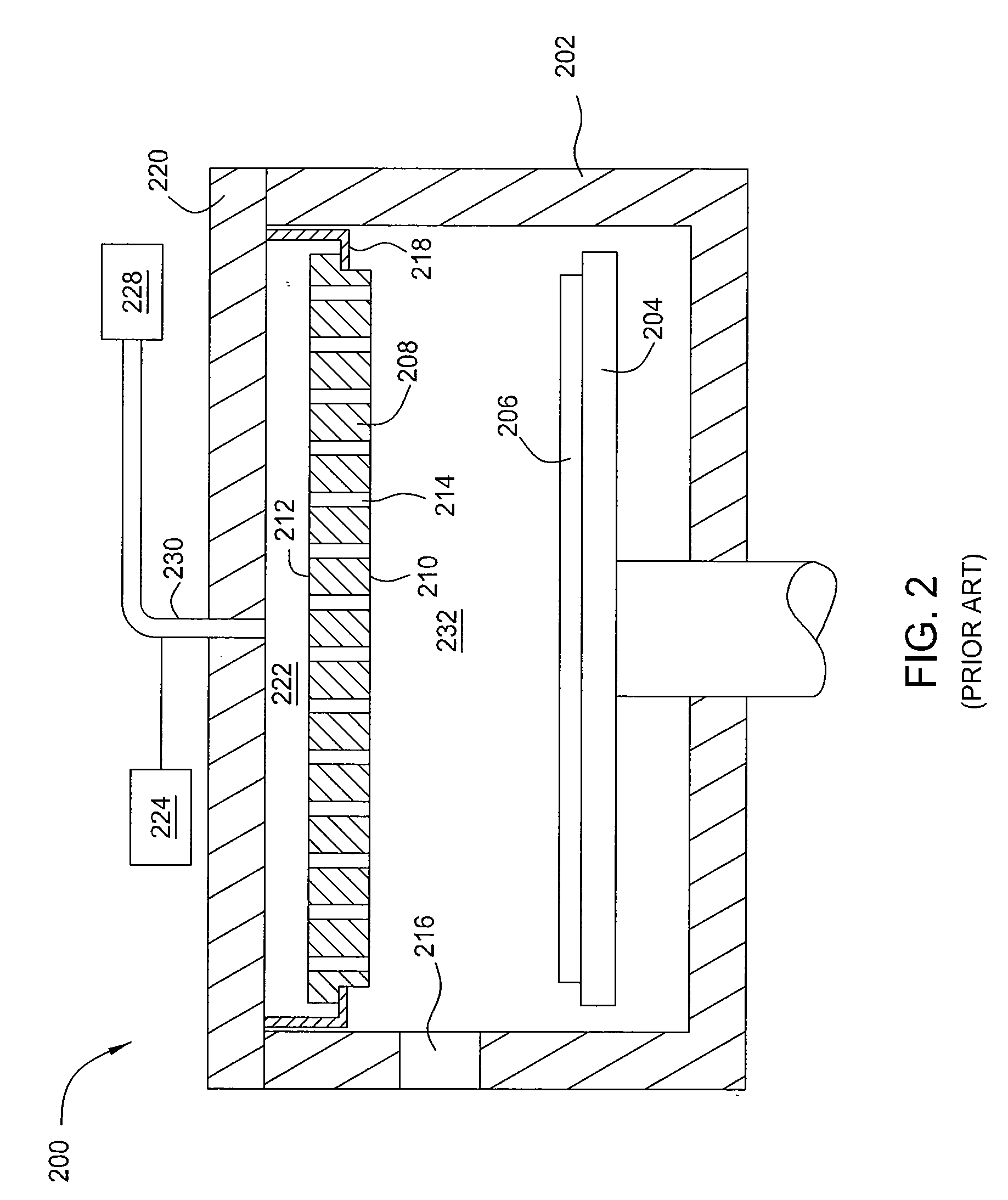

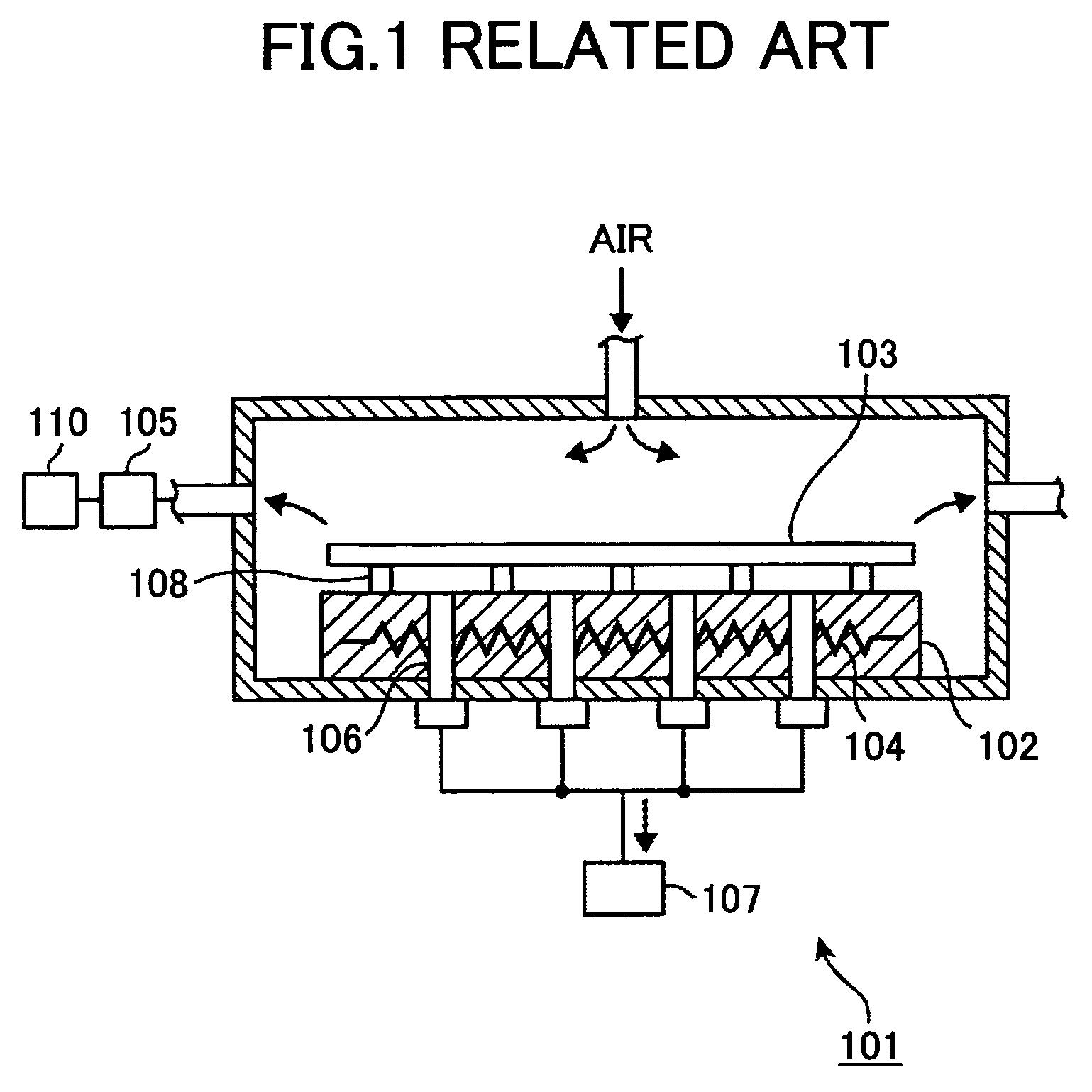

Apparatus and method for forming thin film using upstream and downstream exhaust mechanisms

ActiveUS20050208217A1Improve throughputUniform supplyElectric discharge tubesSemiconductor/solid-state device detailsGas supplySubstrate surface

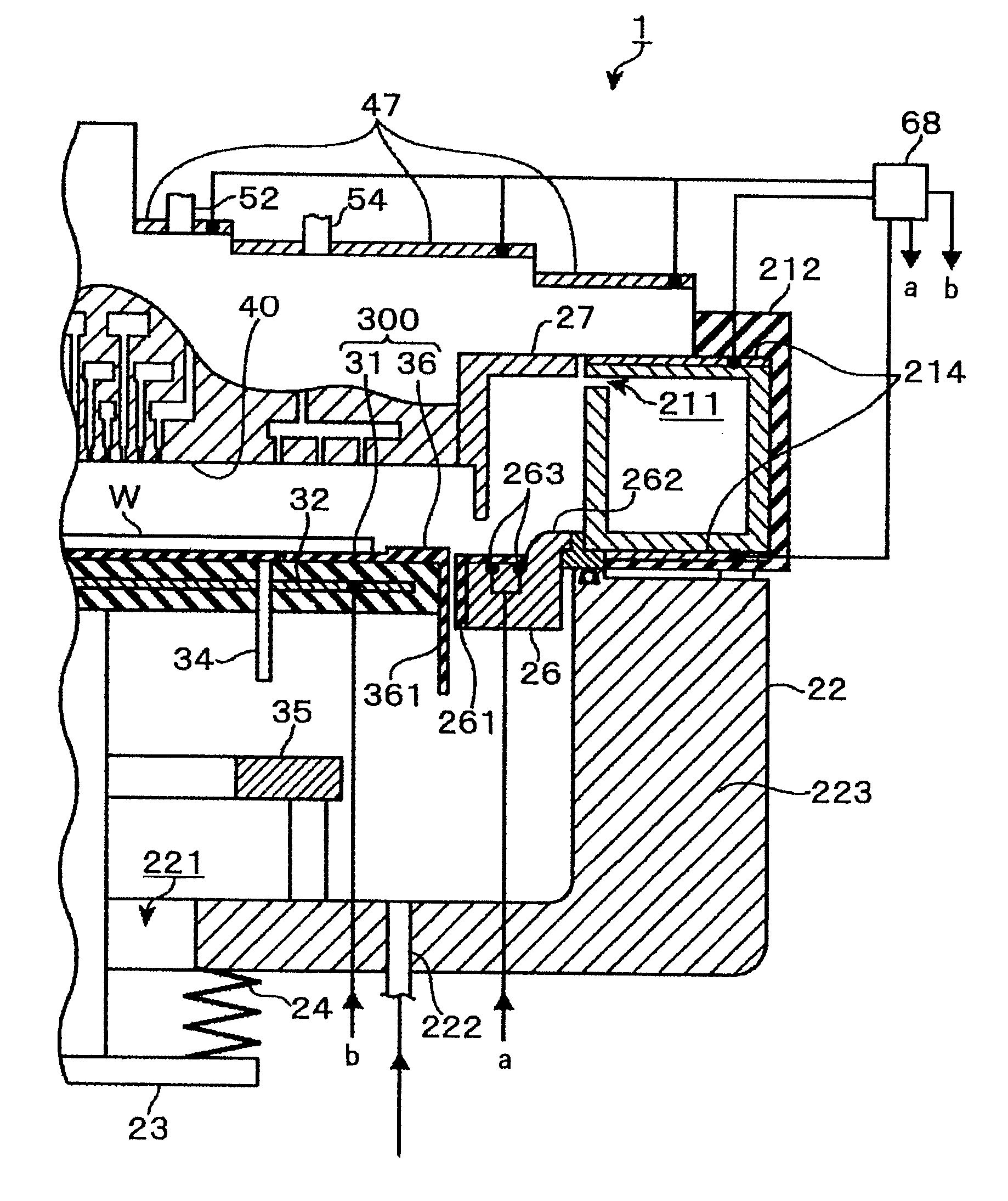

A thin-film formation apparatus possesses a reaction chamber to be evacuated, a placing portion on which a substrate is placed inside the reaction chamber, a gas-dispersion guide installed over the placing portion for supplying a gas onto a substrate surface, a gas-supply port for introducing the gas into the gas-dispersion guide, a gas-dispersion plate disposed on the side of the substrate of the gas-dispersion guide and having multiple gas-discharge pores, a first exhaust port for exhausting, downstream of the gas-dispersion plate, the gas supplied onto the substrate surface from the gas-dispersion plate, and a second exhaust port for exhausting, upstream of the gas-dispersion plate, a gas inside the gas-dispersion guide via a space between the gas-dispersion guide and the gas-dispersion plate.

Owner:ASM JAPAN

Plasma treatment apparatus

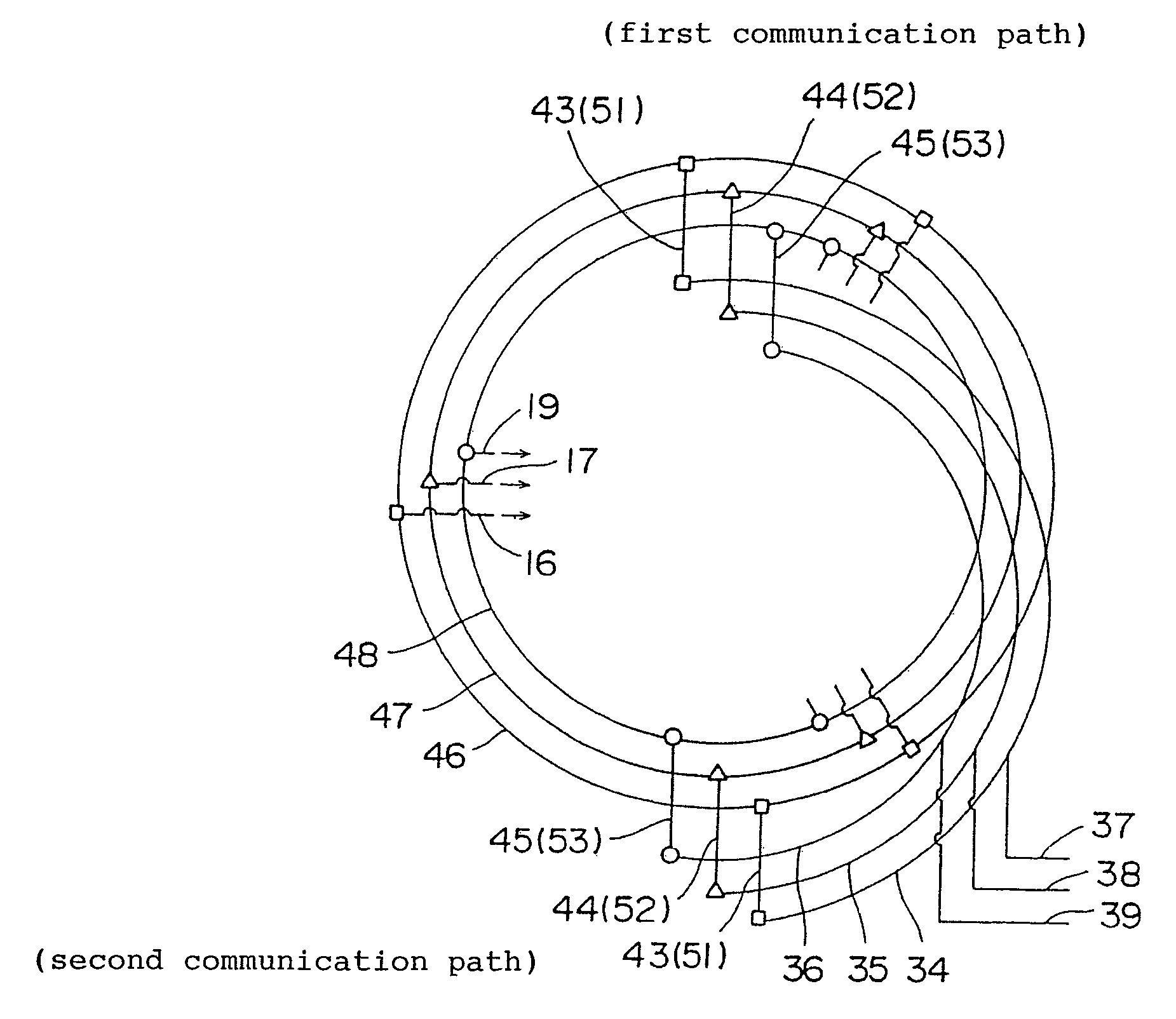

InactiveUS7806078B2Simply the configuration of the containerContainer can be simplifiedElectric discharge tubesSemiconductor/solid-state device manufacturingProduct gasEngineering

A plasma CVD apparatus has a container, and channels composed of introduction grooves and circumferential grooves for different types of gases are formed within the container. The gases introduced through source gas piping, auxiliary gas piping, and cleaning gas piping are equally supplied to a plurality of supply nozzles, a plurality of auxiliary gas supply nozzles, and a plurality of cleaning gas nozzles. The configuration of the container can be simplified without complicating pipings for the gases.

Owner:MITSUBISHI HEAVY IND LTD

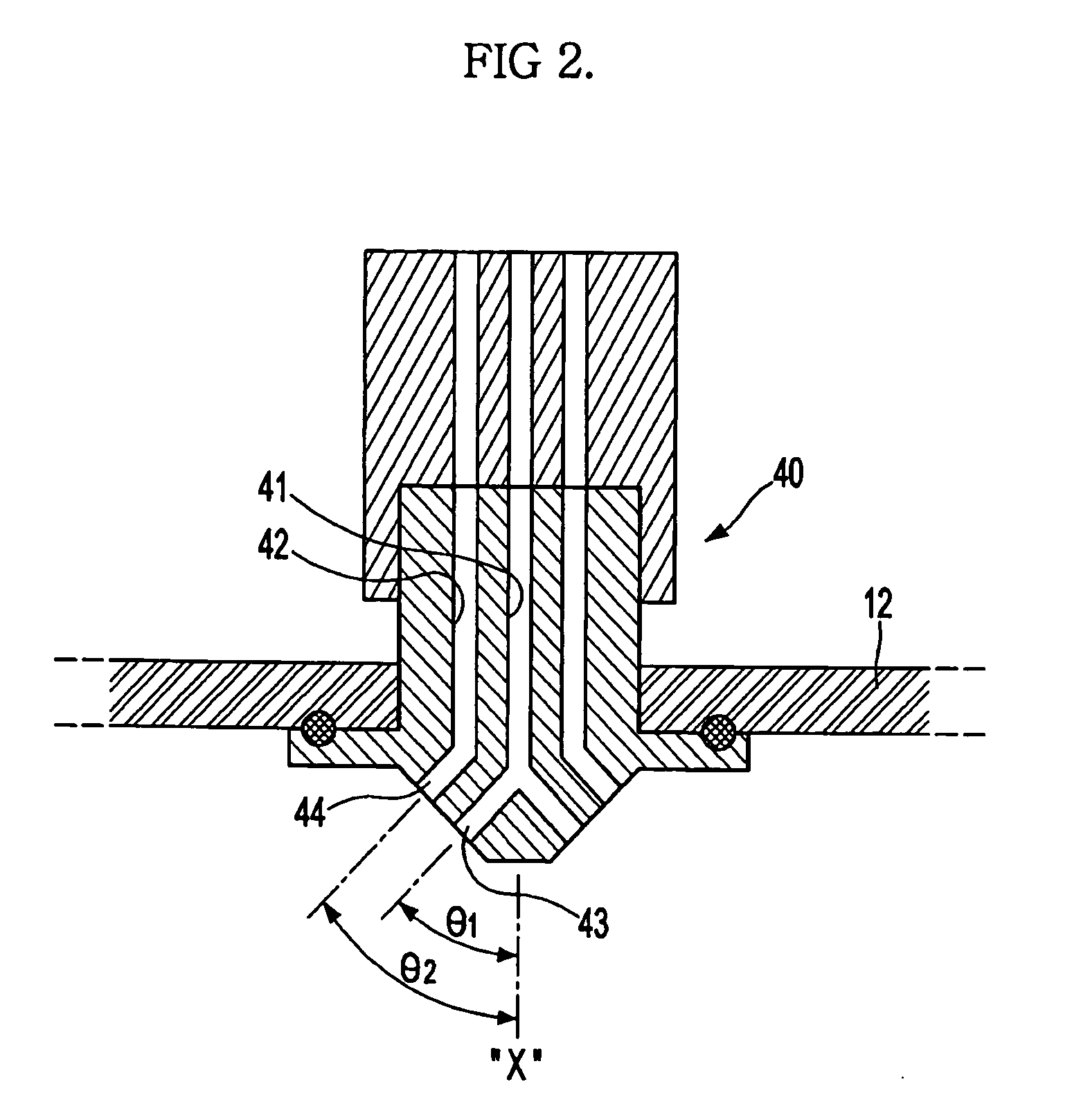

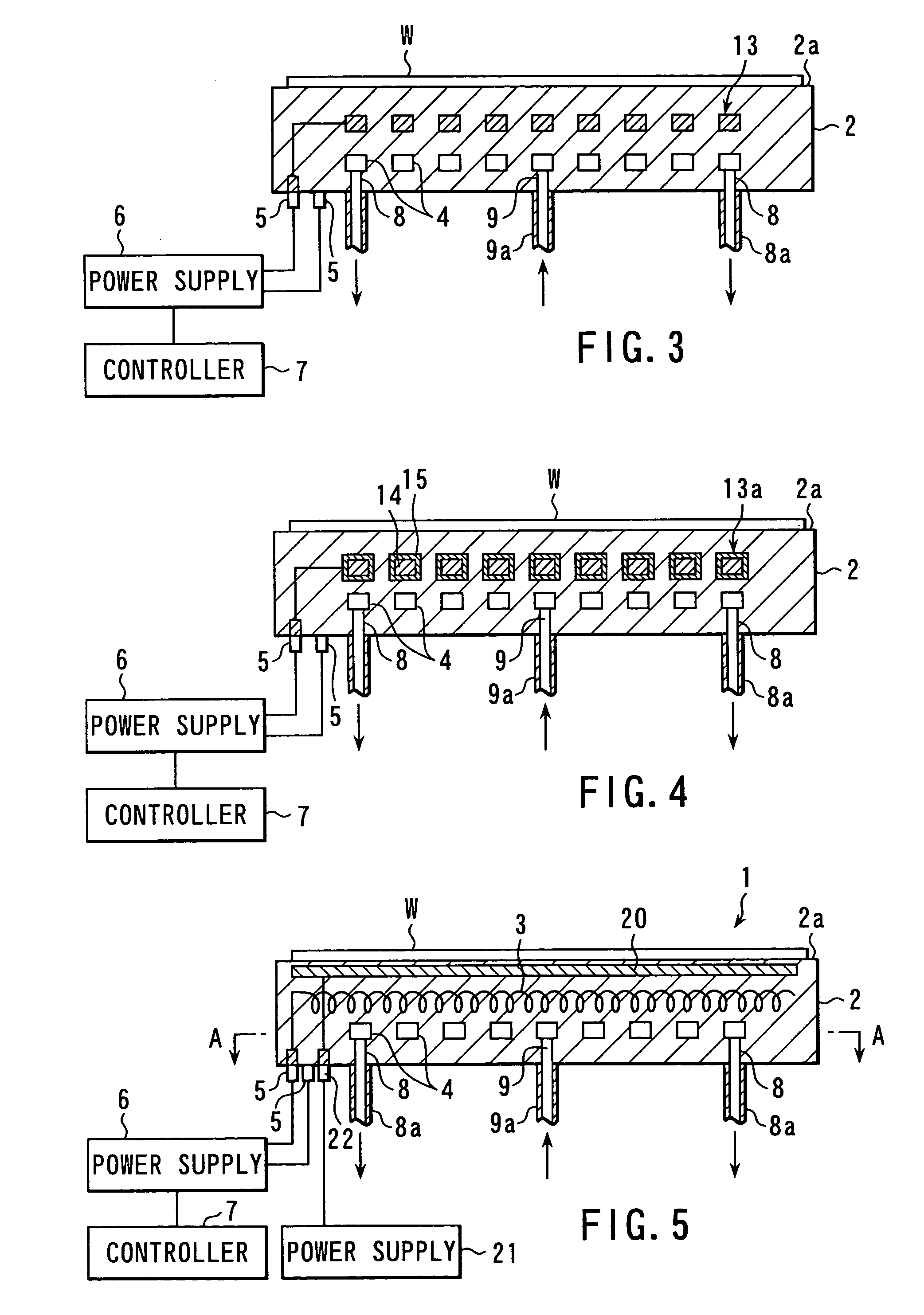

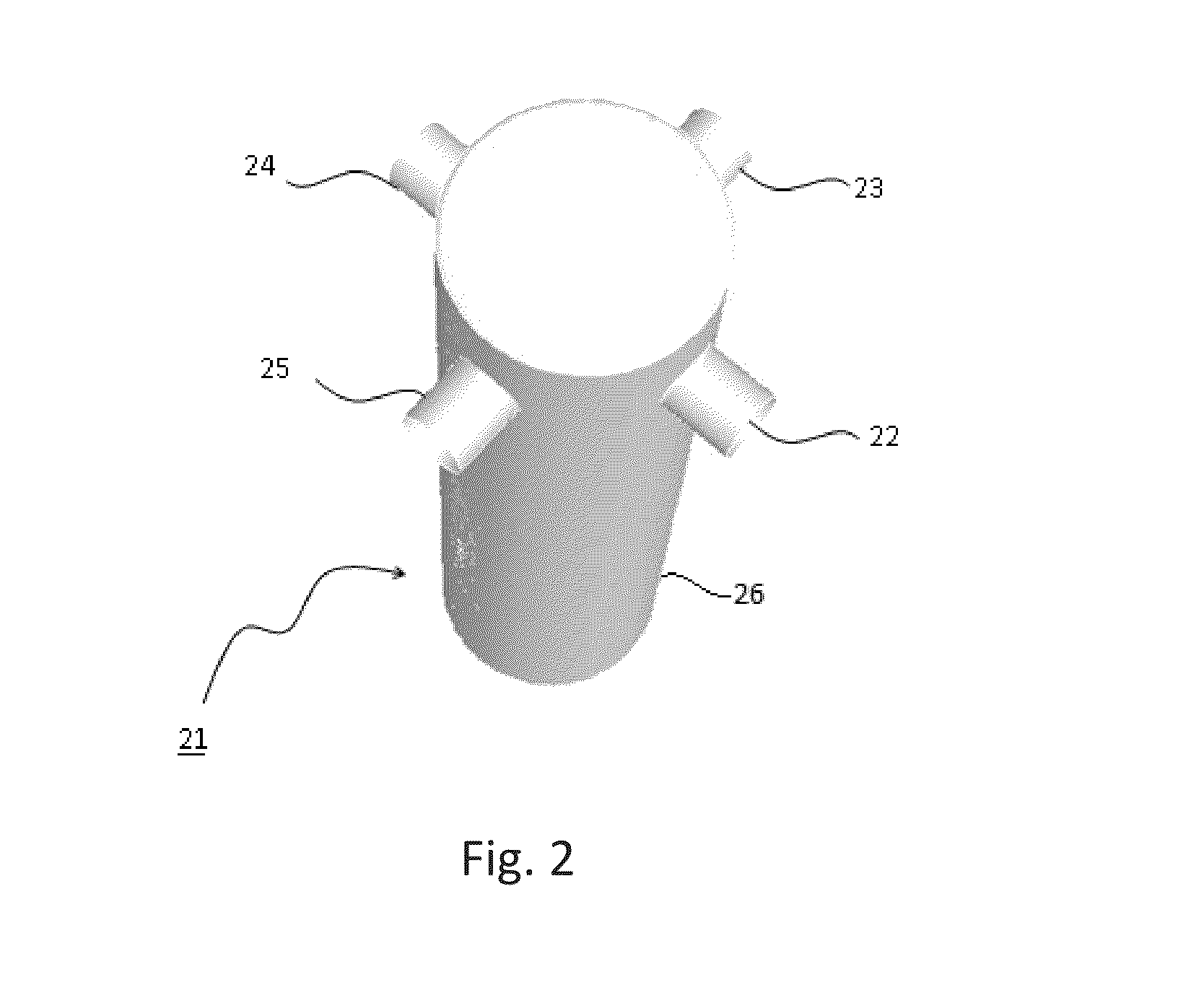

Apparatus to manufacture semiconductor

InactiveUS20060096540A1Expand the scope of diffusionUniformlySemiconductor/solid-state device manufacturingChemical vapor deposition coatingProcess engineeringGas supply

An apparatus to manufacture a semiconductor, in which distribution of process gases supplied to a reaction region in a reaction chamber is uniform, includes a gas supply nozzle to supply process gases to a semiconductor substrate in the reaction chamber, wherein the gas supply nozzle includes a first supply channel formed in a longitudinal direction, and first outlet channels formed at an outlet of the first supply channel such that the first outlet channels are inclined with respect to the direction of the first supply channel at a designated angle to diffuse the process gas supplied through the first supply channel.

Owner:SAMSUNG ELECTRONICS CO LTD

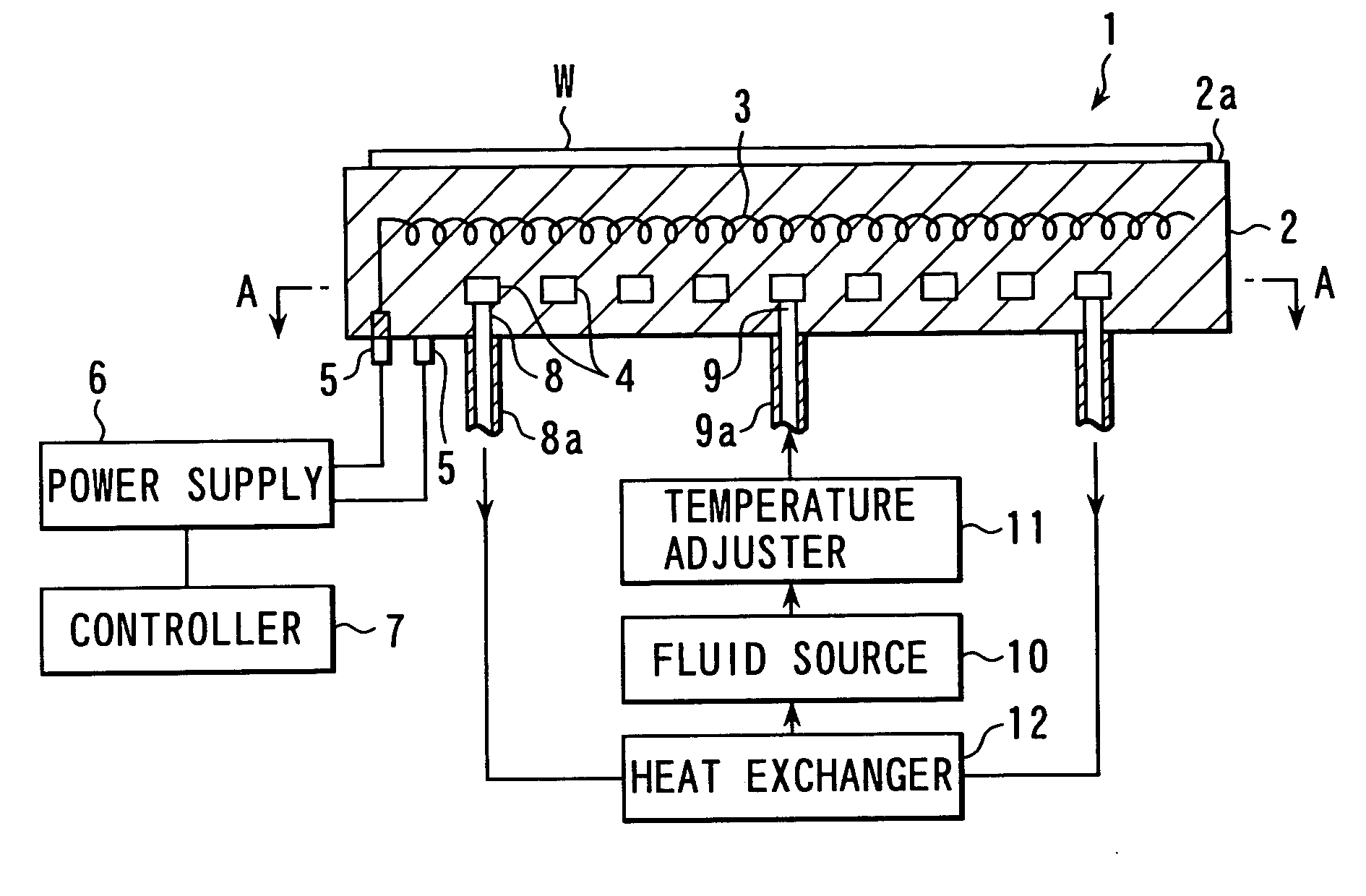

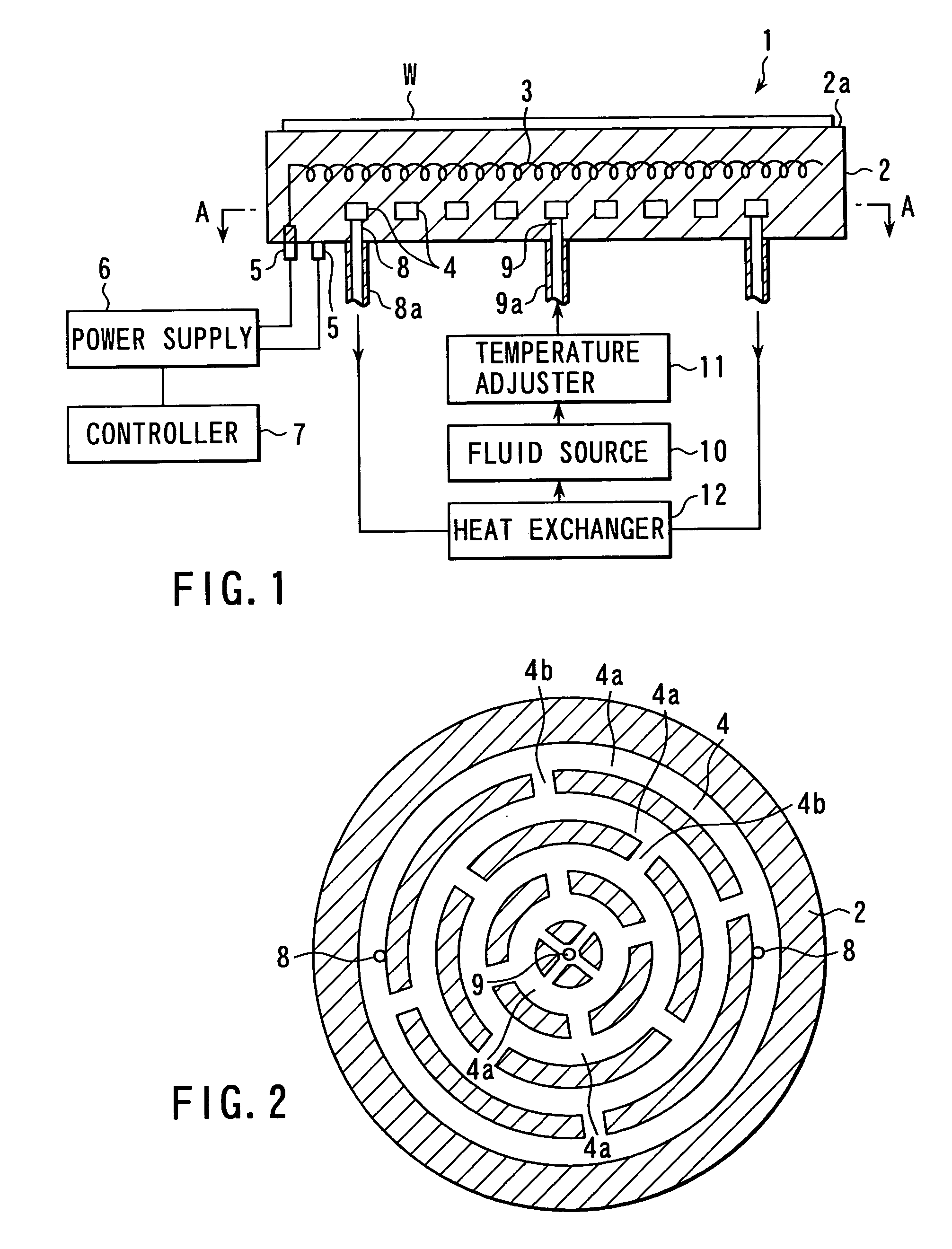

Ceramic heater system and substrate processing apparatus having the same installed therein

InactiveUS6951587B1Improve cooling efficiencyUniform heating effectSemiconductor/solid-state device manufacturingOhmic-resistance heatingMetallurgyGas supply

A ceramic heater system has a ceramic heater base having a substrate-mounting surface formed on the top surface thereof and a heater, buried in the heater base, for heating a substrate. A fluid passage is formed buried in the heater base below where the heater is buried. The heater base is cooled as a fluid whose temperature is lower than the temperature of the heater base is let flow in the fluid passage. A substrate processing apparatus has the ceramic heater system installed in a process chamber whose vacuum state can be maintained, a gas supply mechanism for feeding a gas into the process chamber, and a power supply. The substrate processing apparatus performs a heat treatment, etching and film deposition on a substrate placed in the process chamber.

Owner:TOKYO ELECTRON LTD

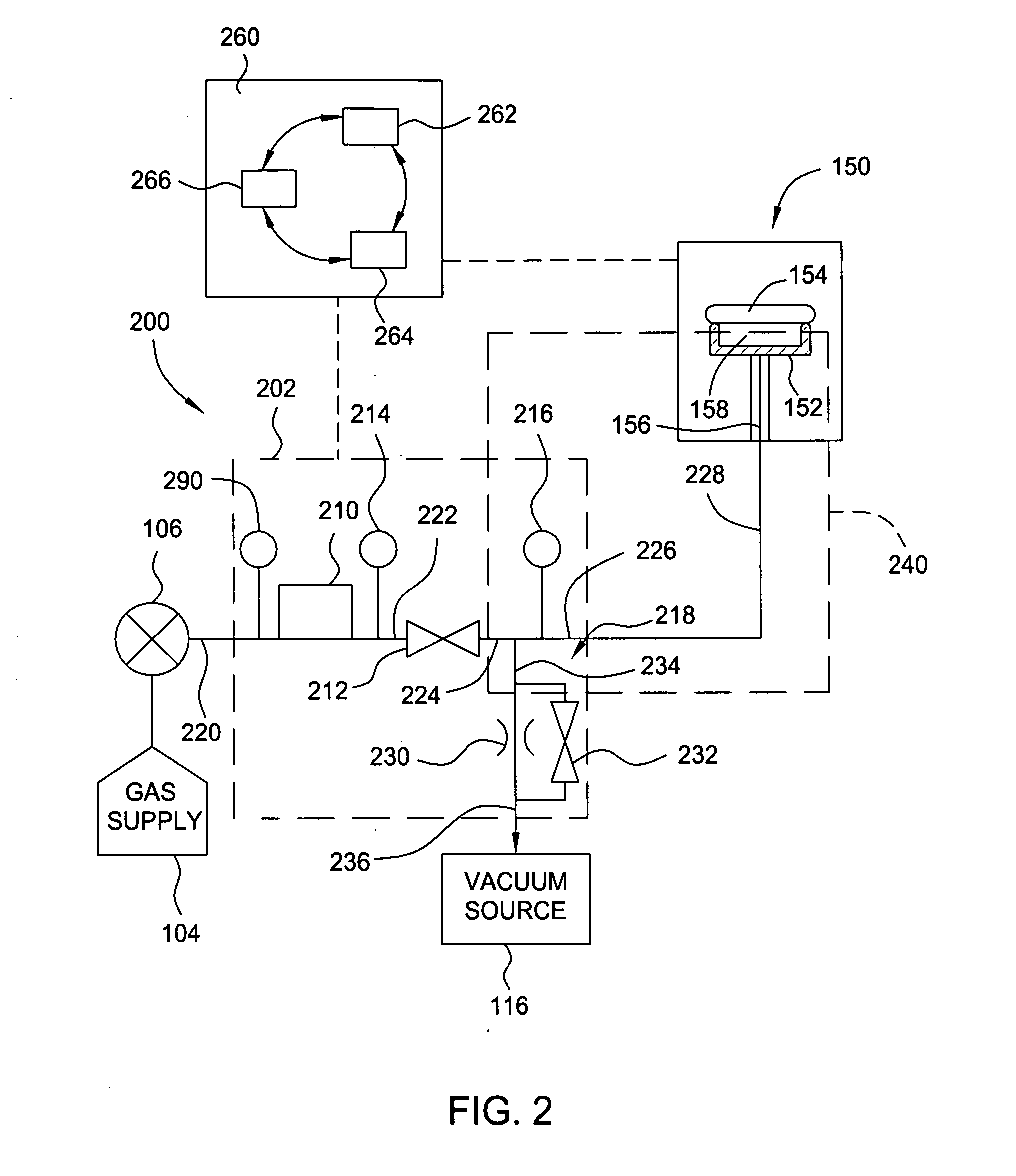

Gas Supply Manifold And Method Of Supplying Gases To Chamber Using Same

ActiveUS20150240359A1Well mixedReduce time scaleElectric discharge tubesSemiconductor/solid-state device manufacturingInjection portProcess engineering

A gas inlet system for a wafer processing reactor includes a tubular gas manifold conduit adapted to be connected to a gas inlet port of the wafer processing reactor; and gas feeds including a first feed for feeding a first gas into the tubular gas manifold conduit and a second feed for feeding a second gas into the tubular gas manifold conduit. Each feed has two or more injection ports connected to the tubular gas manifold conduit at a first axial position of the tubular gas manifold conduit, and the injection ports of each of the gas feeds are evenly distributed along a circumference of the tubular gas manifold conduit at the first axial position.

Owner:ASM IP HLDG BV

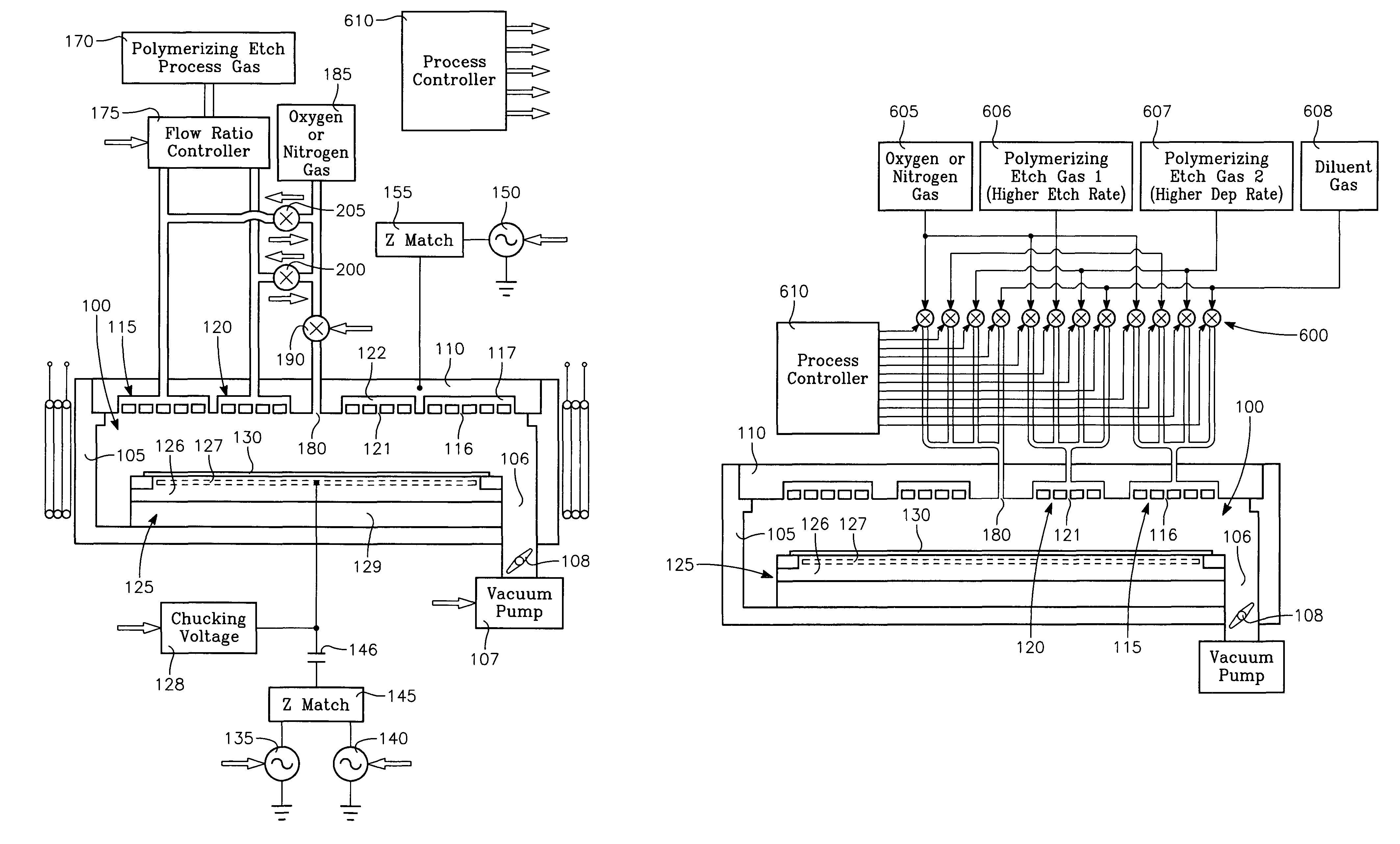

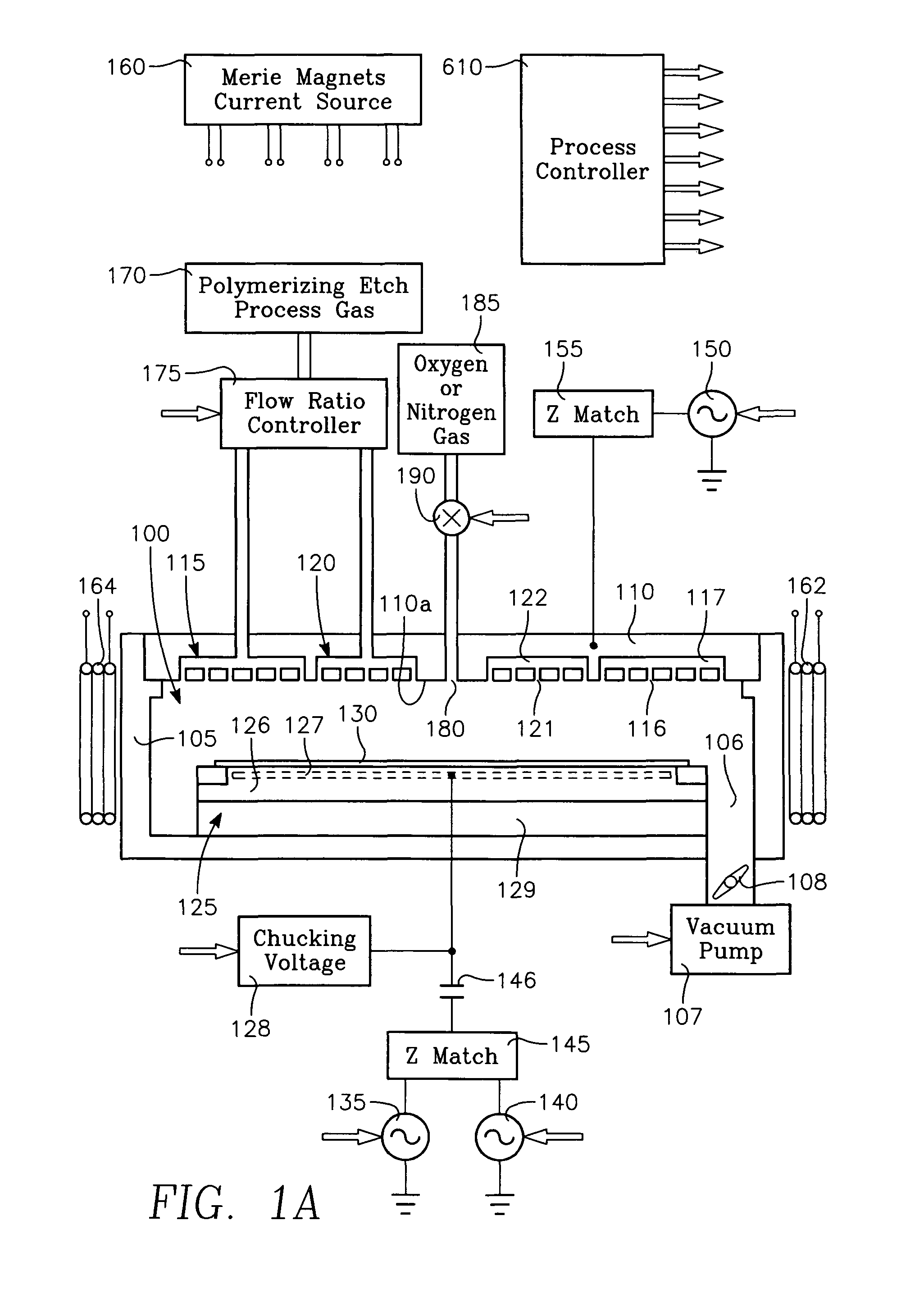

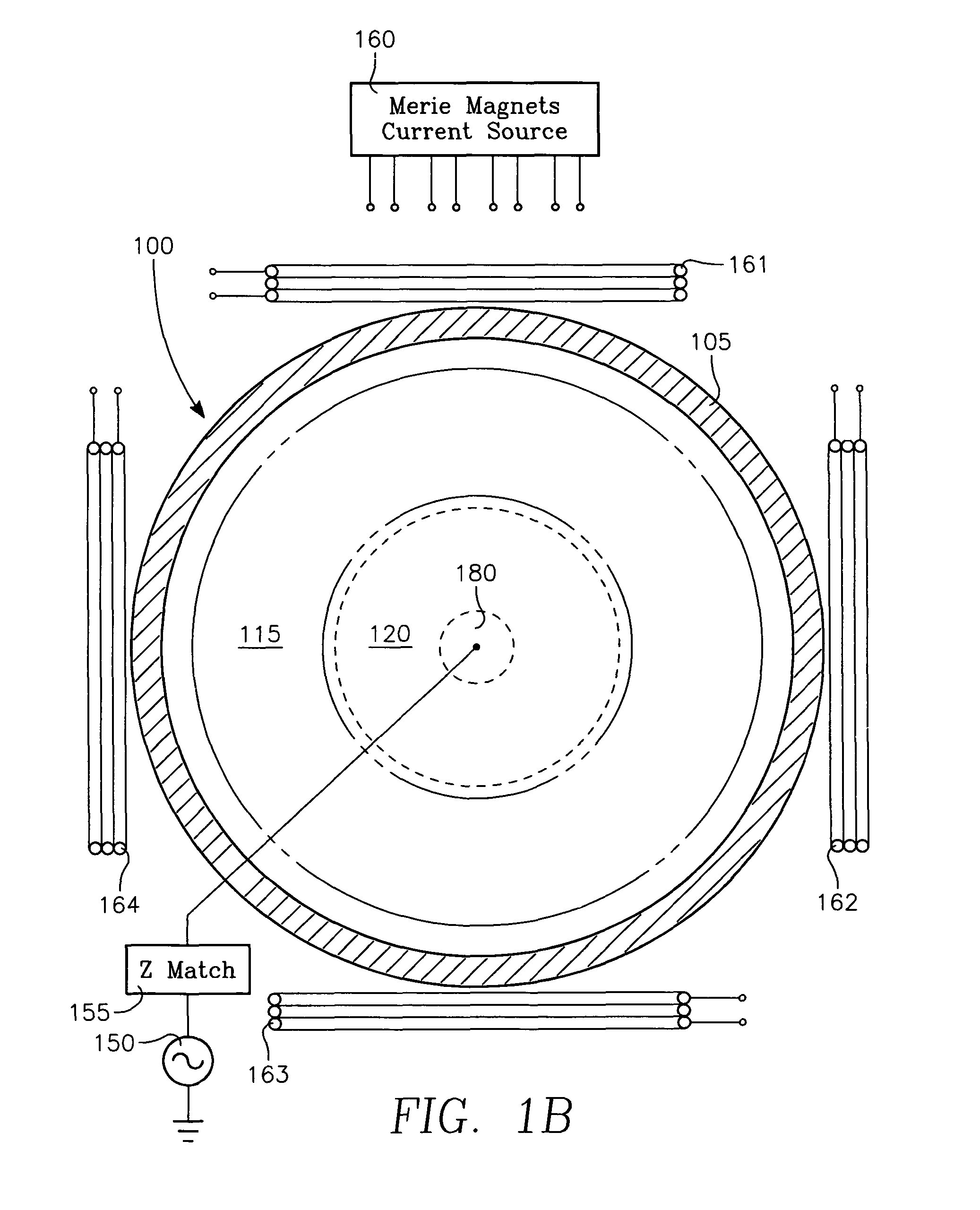

Plasma reactor apparatus with multiple gas injection zones having time-changing separate configurable gas compositions for each zone

ActiveUS8231799B2Electric discharge tubesVacuum gauge using ionisation effectsGas compositionEngineering

Owner:APPLIED MATERIALS INC

Gas distribution blocker apparatus

ActiveUS20100136216A1Final product manufactureVacuum evaporation coatingEngineeringPressure difference

Embodiments of the present invention generally provide apparatus and methods for altering the flow and pressure differential of process gases supplied across a showerhead of a processing chamber to provide improved deposition uniformity across the surface of a substrate disposed therein. In one embodiment, a blocker plate is disposed between a backing plate and a showerhead. In one embodiment, the distance between the blocker plate and the showerhead is adjustable. In another embodiment, the blocker plate has a non-planar surface contour. In another embodiment, a regional blocker plate is disposed between a backing plate and a showerhead. In another embodiment, a central blocker plate and a peripheral blocker plate are disposed between a backing plate and a showerhead.

Owner:APPLIED MATERIALS INC

Heating apparatus, heating method, and computer readable storage medium

ActiveUS7992318B2Improve temperature uniformityDryer sectionDrying gas arrangementsProcess engineeringGas supply

A disclosed heating apparatus for heating a substrate on which a film is coated includes a process chamber having a gas supply opening for supplying a first gas to the process chamber and a gas evacuation opening for evacuating the first gas from the process chamber; a heating plate that is arranged in the process chamber and includes a heating element for heating the substrate; plural protrusions arranged on the heating plate so as to support the substrate; plural suction holes formed in the heating plate so as to attract by suction the substrate toward the heating plate; and a gas inlet adapted to supply a second gas to a gap between the heating plate and the substrate supported by the plural protrusions.

Owner:TOKYO ELECTRON LTD

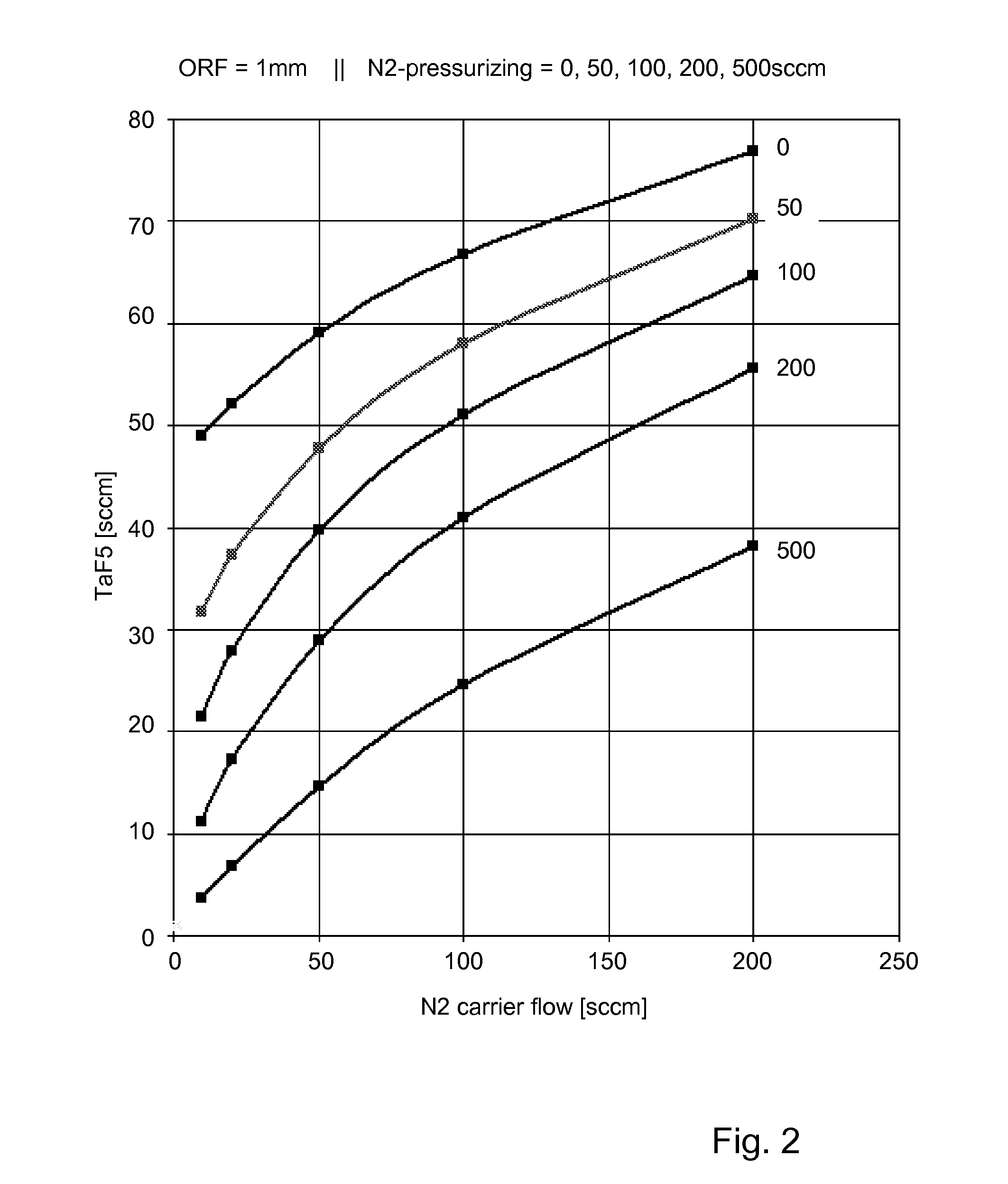

Bubbler assembly and method for vapor flow control

InactiveUS20120304935A1Mitigate and overcomeLess expensiveUsing liquid separation agentMixing methodsSource materialEngineering

Disclosed is a bubbler assembly. The bubbler assembly includes a vessel configured to contain a liquid source material and its vapor. It also includes a carrier gas supply line, a downstream end of which discharges in a lower portion of the vessel, and a gas outlet line, an upstream end of which is in fluid communication with an upper portion of the vessel. The gas outlet line includes a constriction. The bubbler assembly further includes a pressurizing gas supply line, a downstream end of which discharges in either the upper portion of the vessel or in the gas outlet line at a point upstream of the constriction.

Owner:ASM INTERNATIONAL

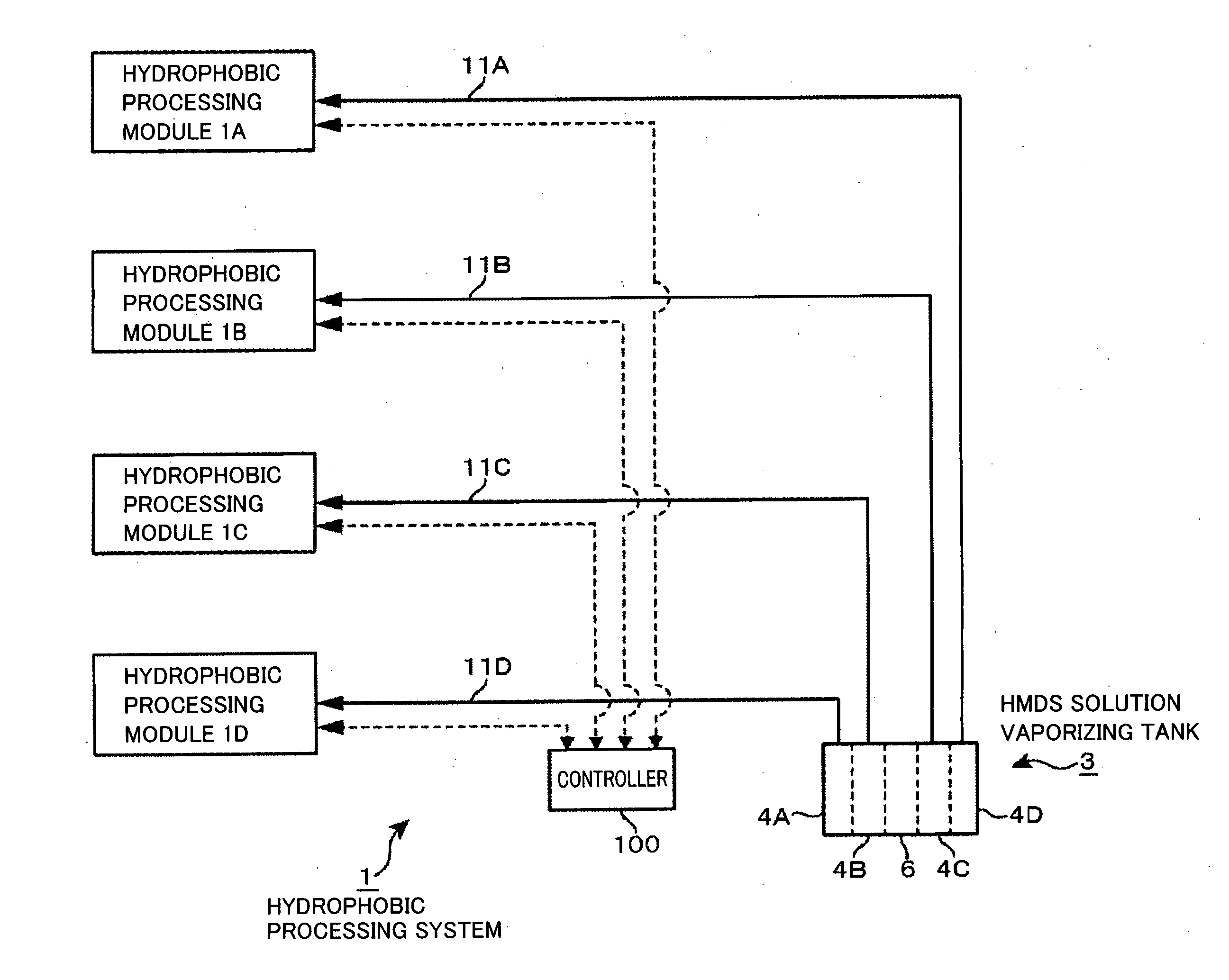

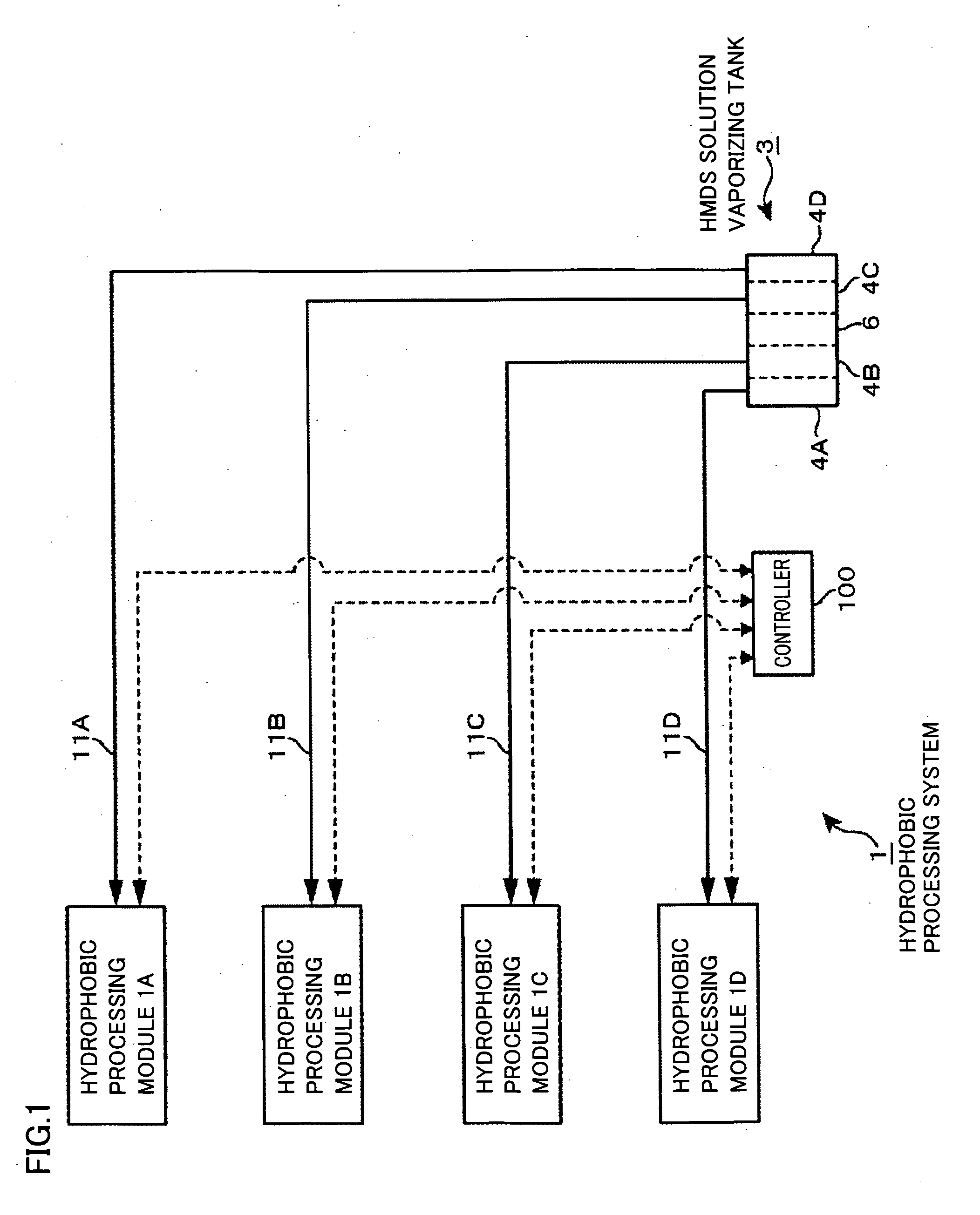

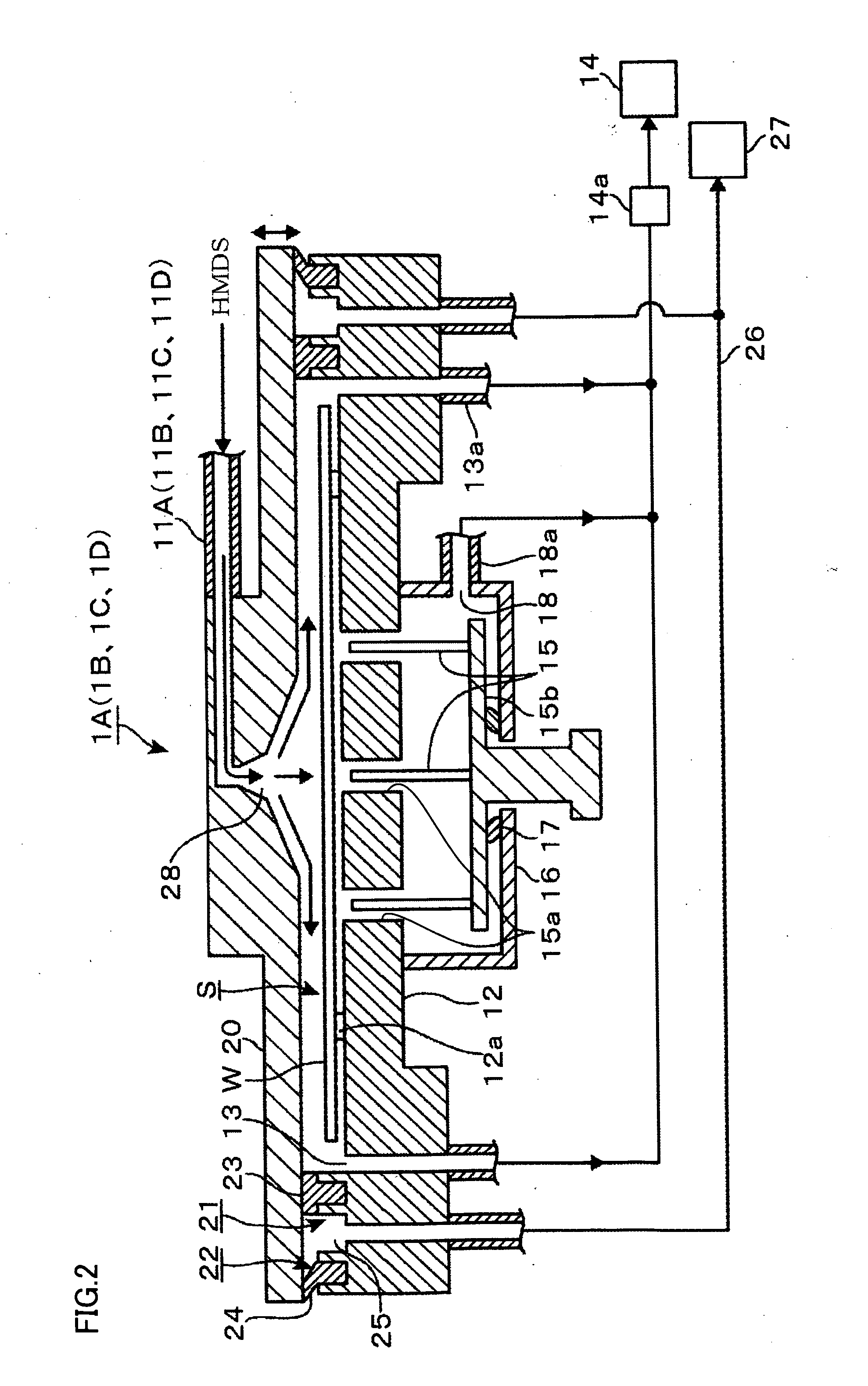

Chemical solution vaporizing tank and chemical solution treating system

ActiveUS20090020072A1Concentration differenceVariations in concentration of the chemical solutions can be suppressedLiquid surface applicatorsSemiconductor/solid-state device manufacturingChemical solutionProduct gas

An object is to suppress differences in concentration between processing gases supplied to a plurality of works in a chemical solution vaporizing tank. The chemical solution vaporizing tank includes a tank body having a plurality of vaporizing chambers formed by laterally and airtightly partitioning an internal space of the tank body, a chemical solution passage located under a liquid level in each vaporizing chamber and formed at each partition member for passing the chemical solution between the vaporizing chambers, and a gas passage located above the liquid level in each vaporizing chamber and formed at the partition member to communicate the vaporizing chambers with each other for uniformizing pressures in the respective vaporizing chambers. A quantity of the channel layer in each vaporizing chamber is controlled by managing, e.g., the liquid level.

Owner:TOKYO ELECTRON LTD

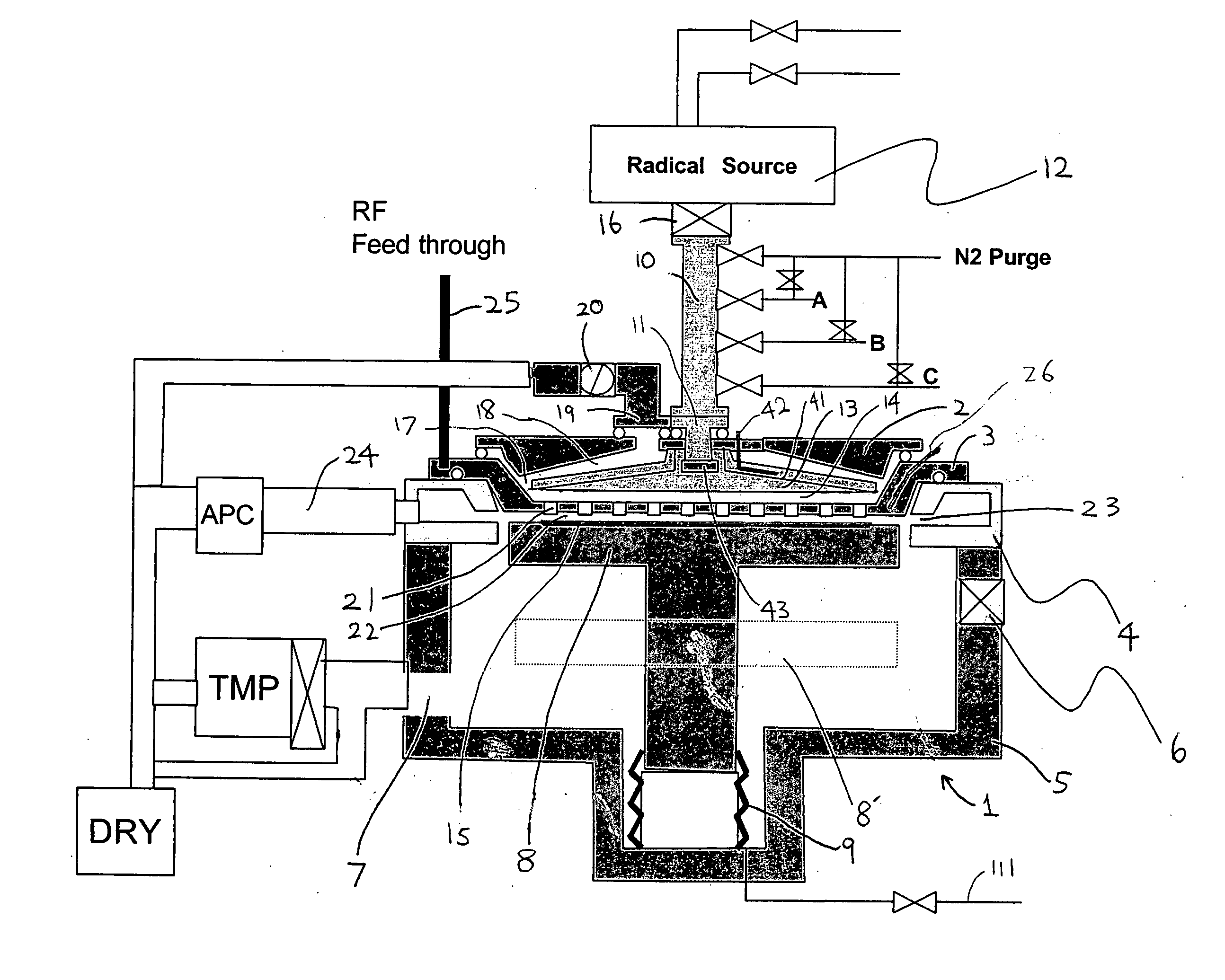

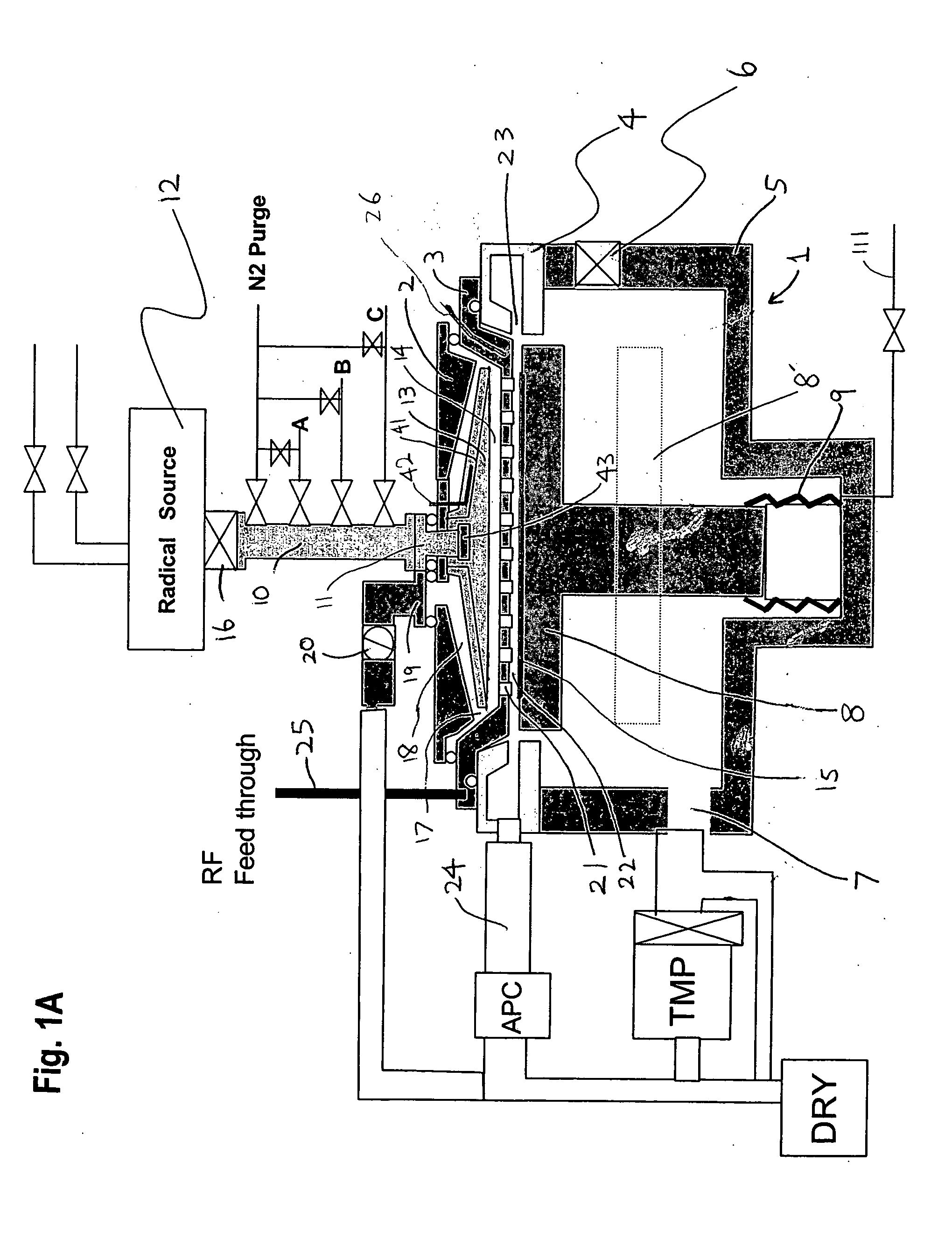

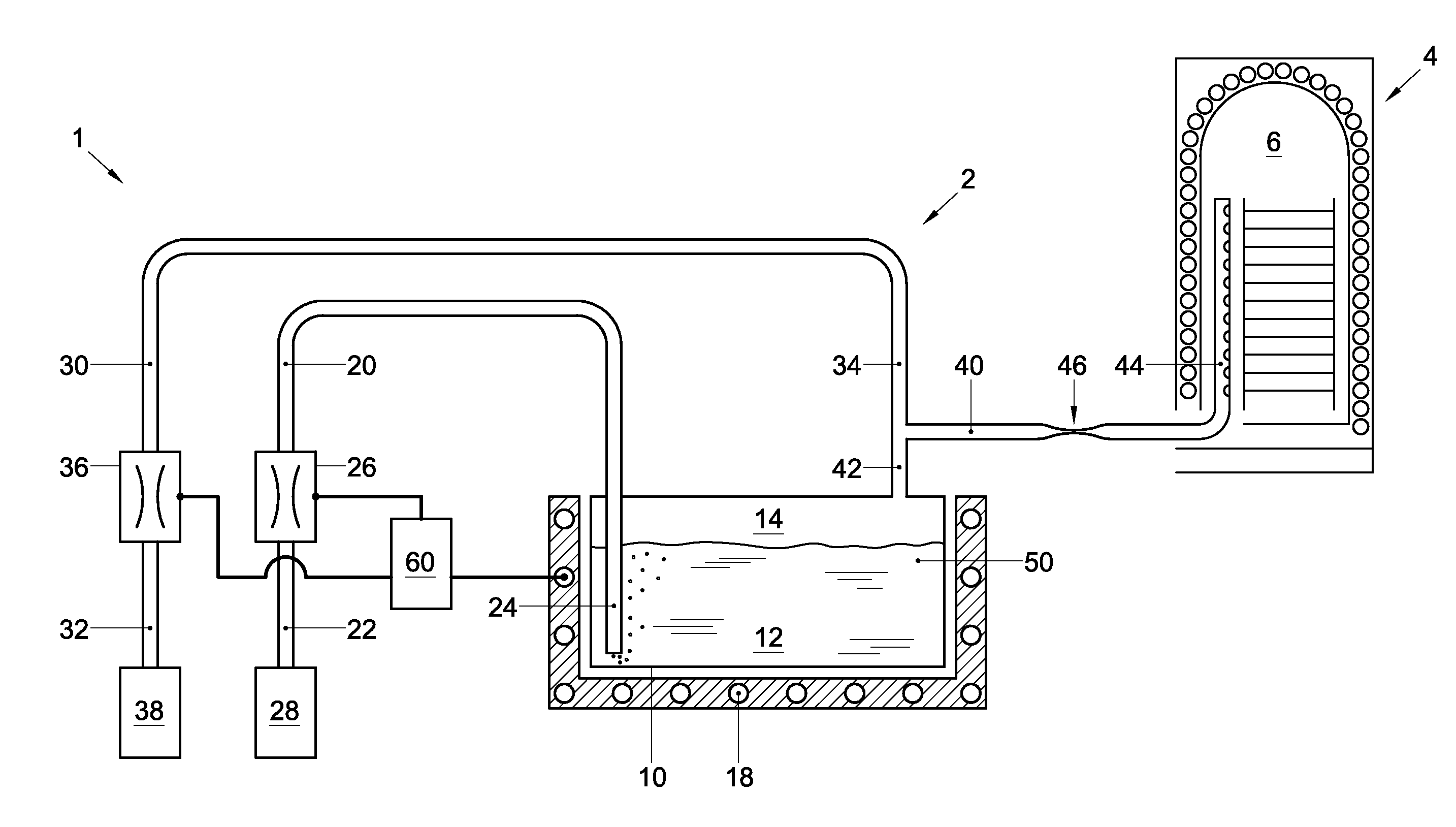

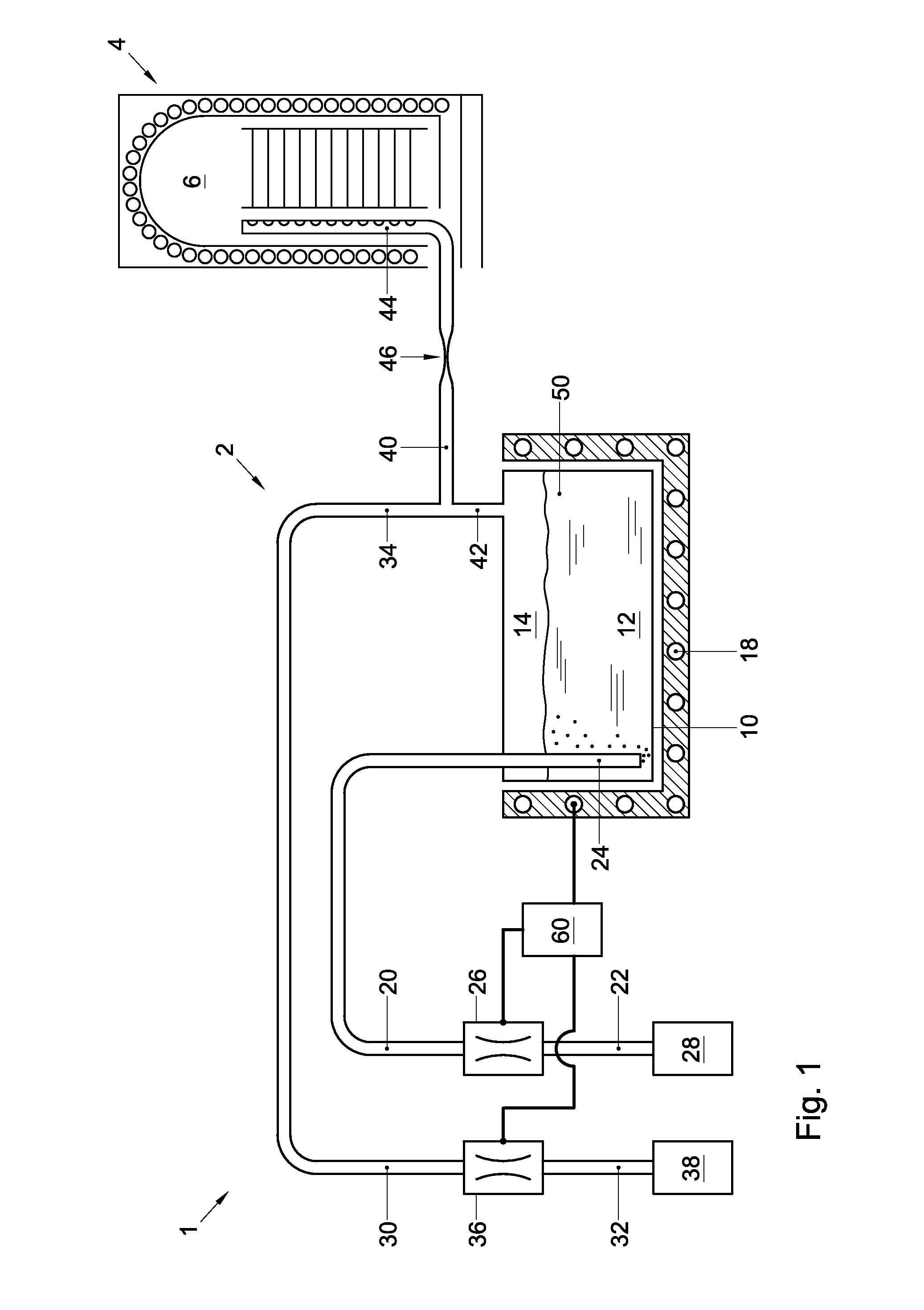

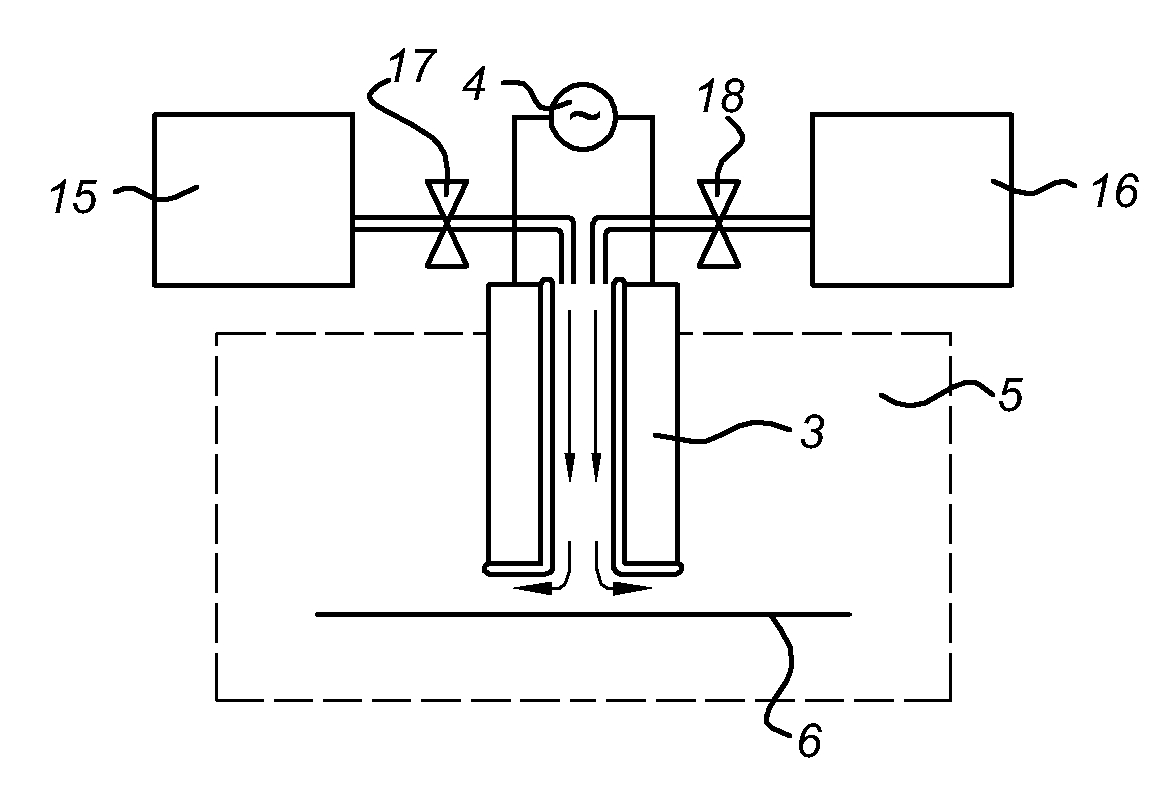

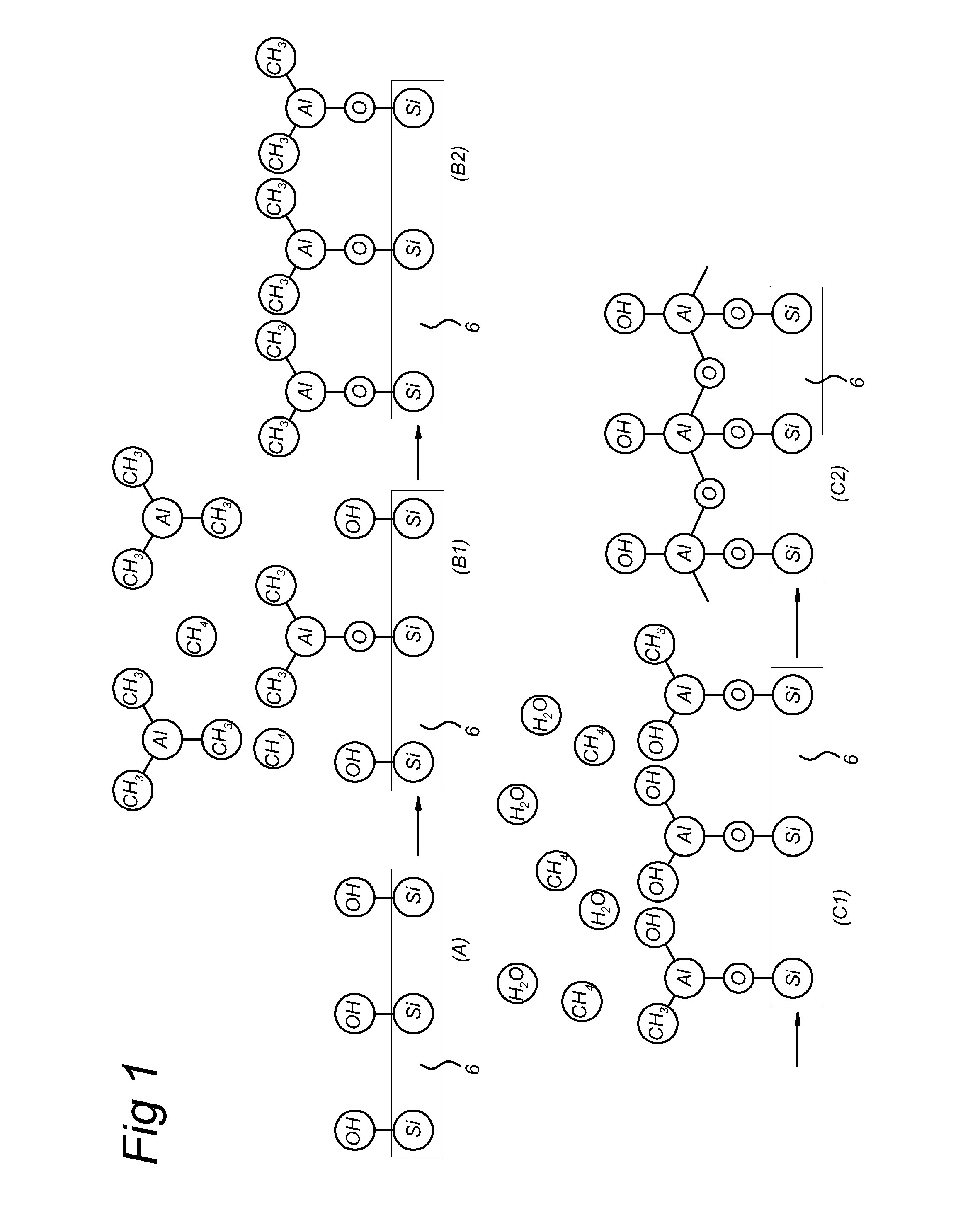

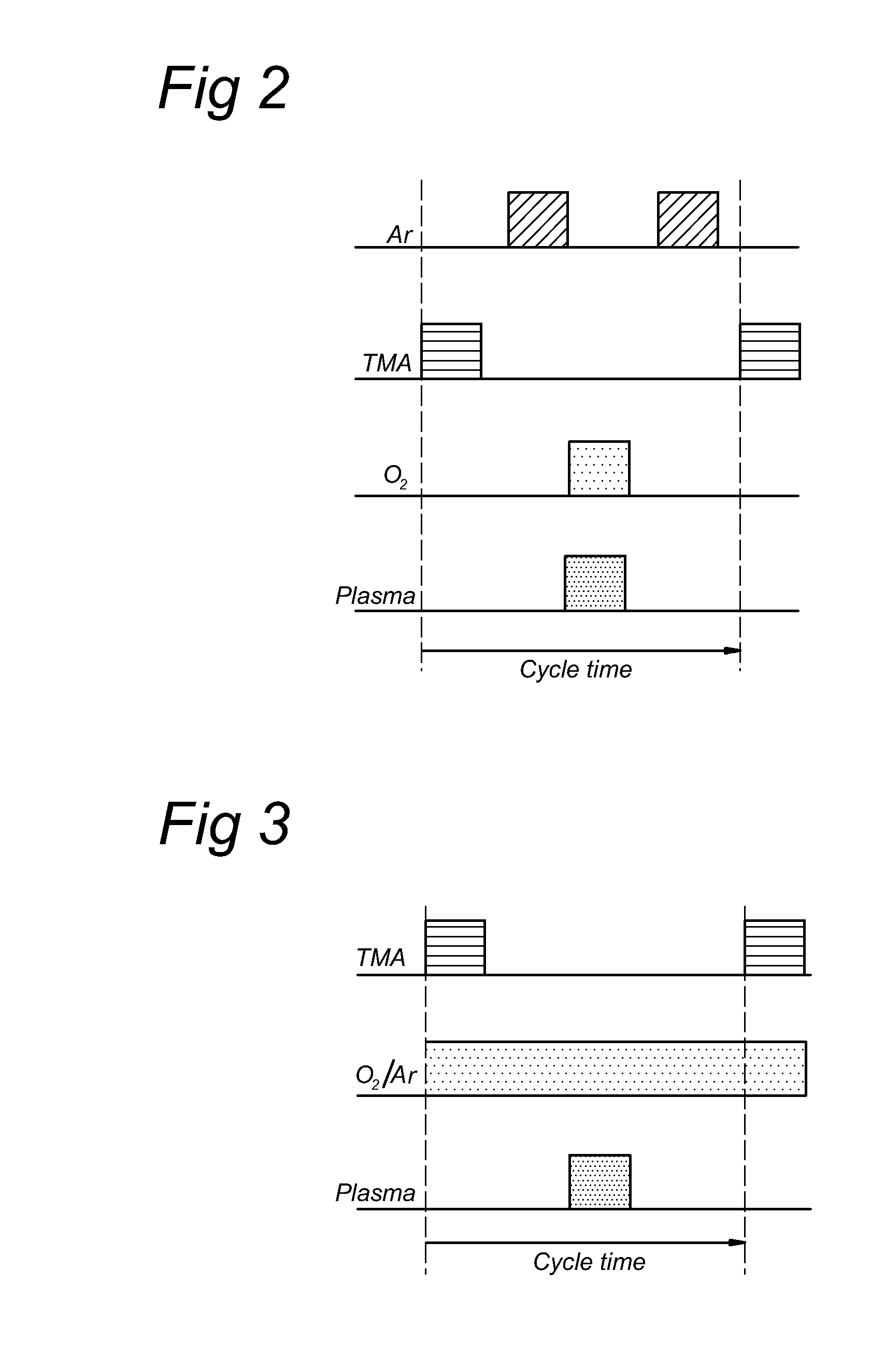

Method and apparatus for atomic layer deposition using an atmospheric pressure glow discharge plasma

InactiveUS20100255625A1Comparable and good performanceSemiconductor/solid-state device manufacturingChemical vapor deposition coatingPlasma generatorProduct gas

Apparatus and method for atomic layer deposition on a surface of a substrate (6) in a treatment space. A gas supply device (15, 16) is present for providing various gas mixtures to the treatment space (1, 2). The gas supply device (15, 16) is arranged to provide a gas mixture with a precursor material to the treatment space for allowing reactive surface sites to react with precursor material molecules to give a surface covered by a monolayer of precursor molecules attached via the reactive sites to the surface of the substrate. Subsequently, a gas mixture comprising a reactive agent capable to convert the attached precursor molecules to active precursor sites is provided. A plasma generator (10) is present for generating an atmospheric pressure plasma in the gas mixture comprising the reactive agent, the plasma generator being arranged remote from the treatment space (1, 2).

Owner:FUJIFILM MFG EURO

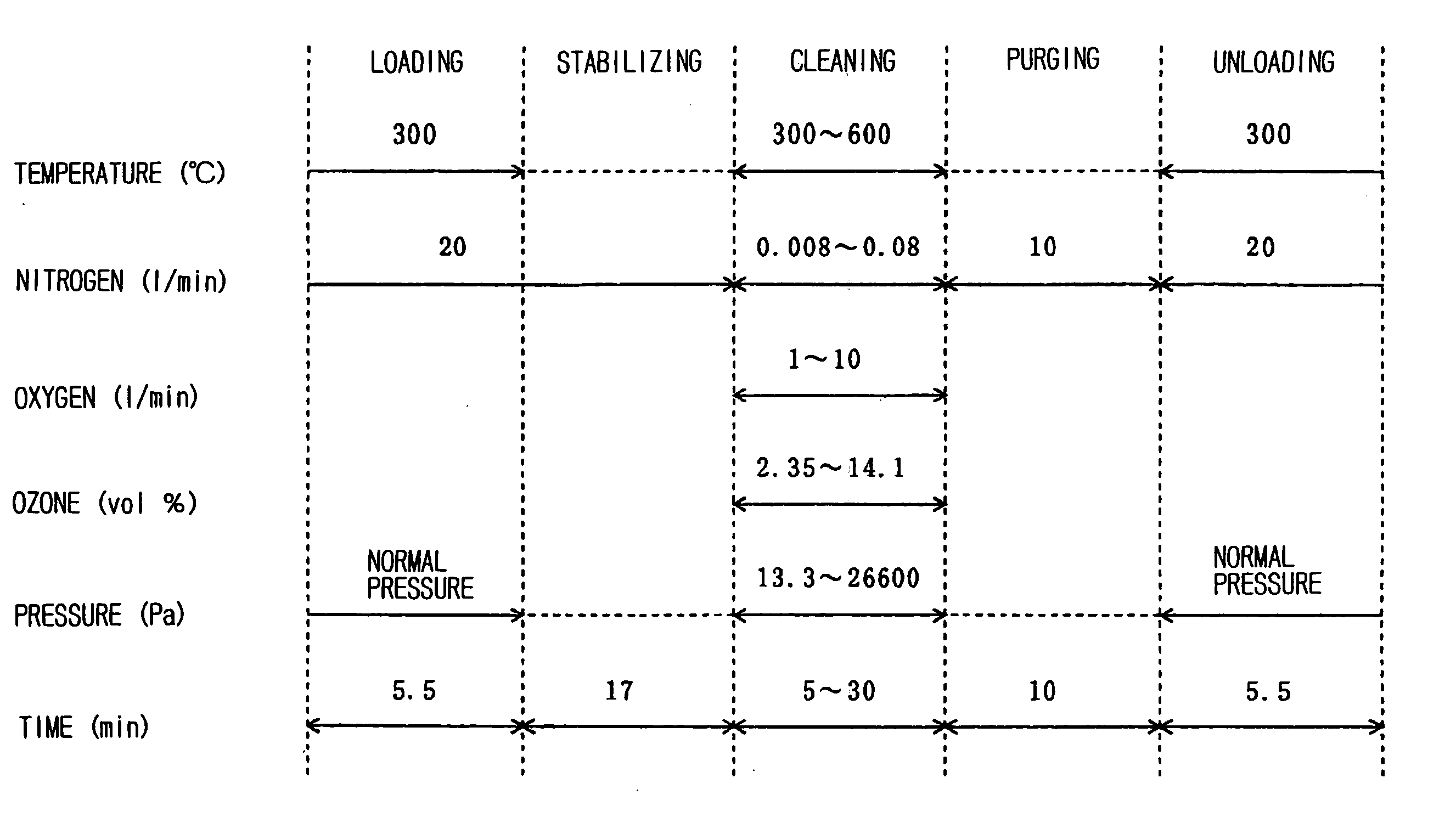

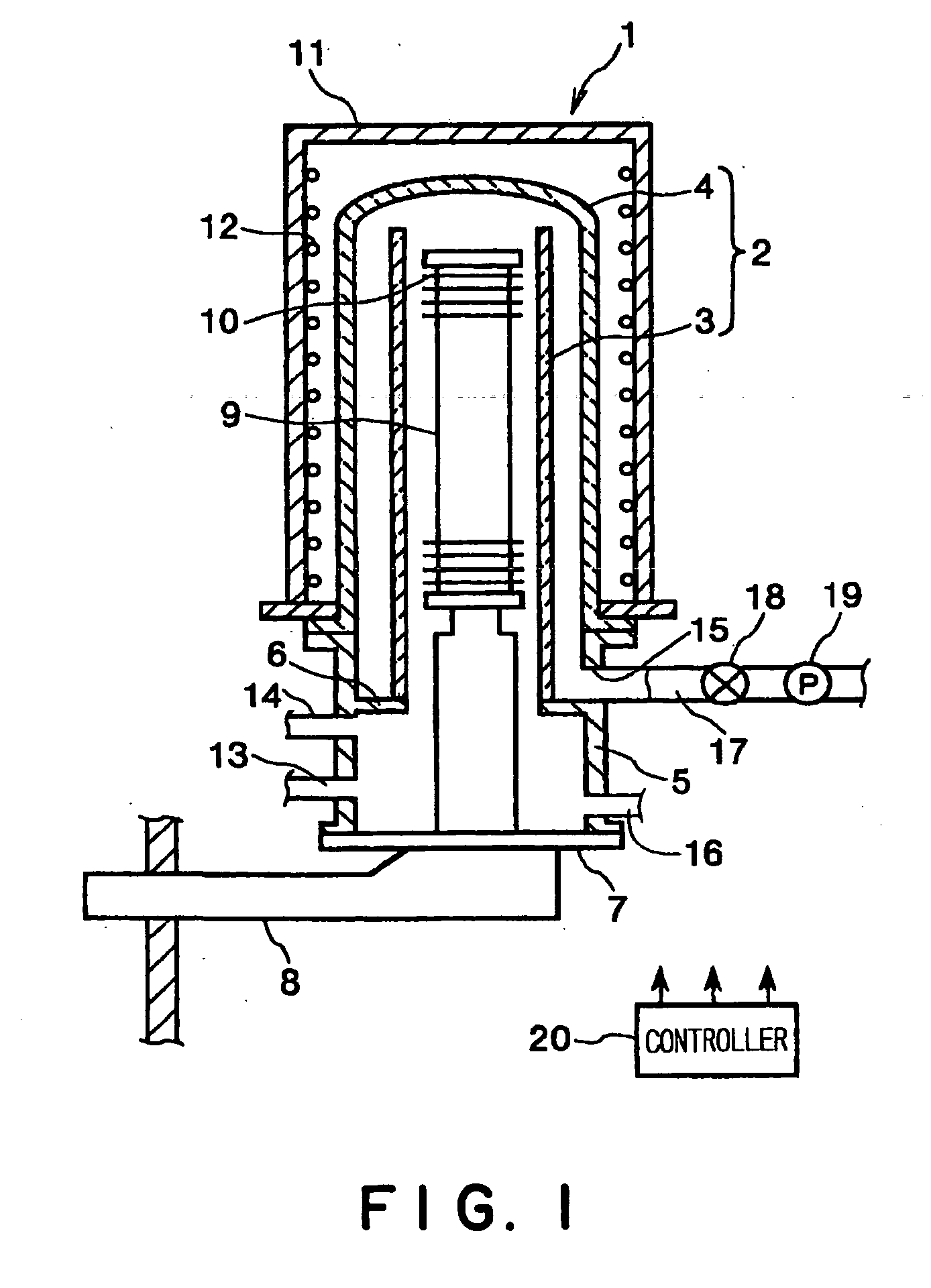

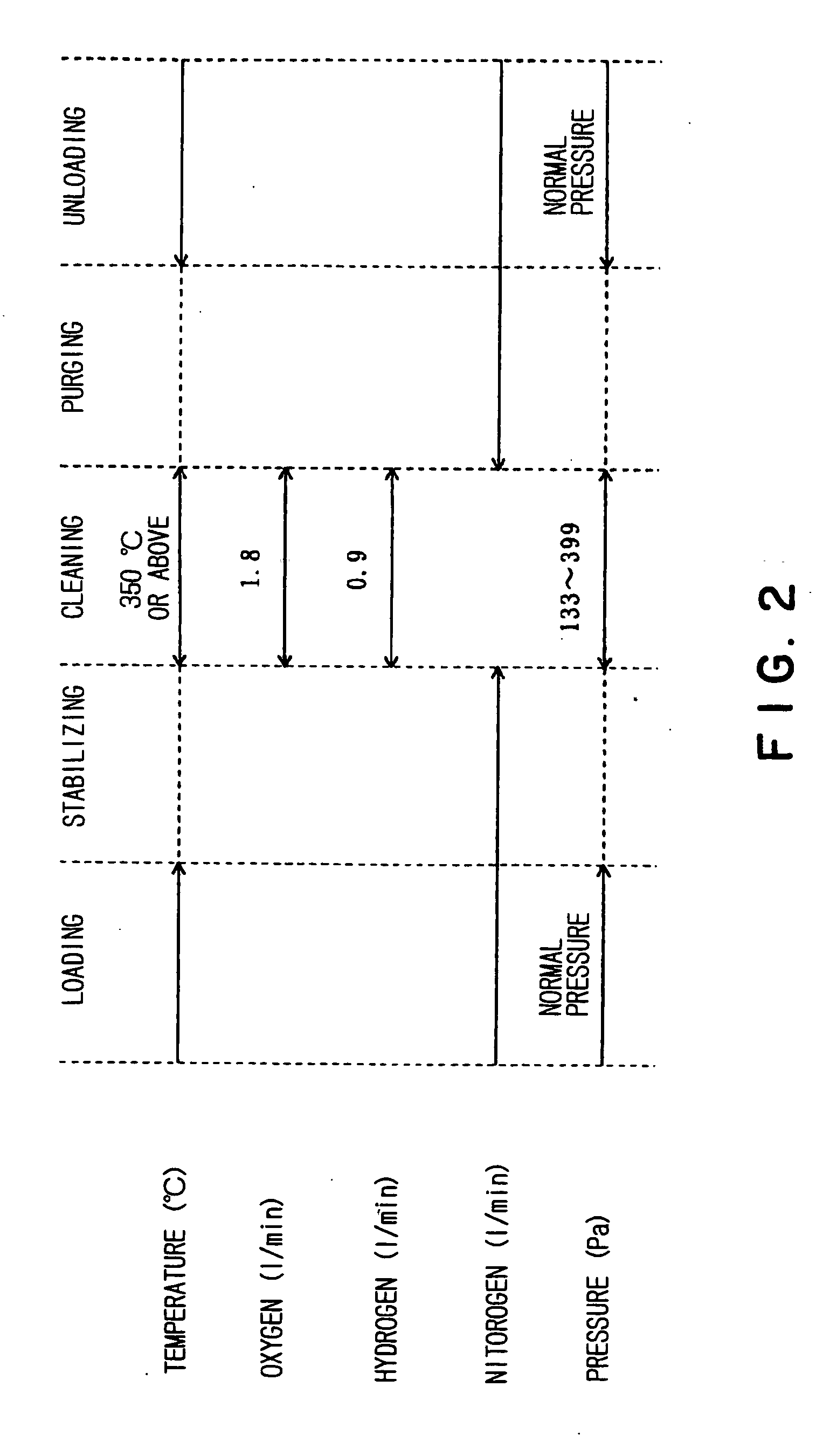

Method and apparatus for treating article to be treated

InactiveUS20040219793A1Efficient removalShort timeAfter-treatment detailsSemiconductor/solid-state device manufacturingCombustionHydrogen

A thermal treatment apparatus 1 includes a reaction tube 2 for containing wafers 10 contaminated with organic substances having a heater 12 capable of heating the reaction tube; a first gas supply pipe 13 for carrying oxygen gas into the reaction tube 2; and a second gas supply pipe 14 for carrying hydrogen gas into the reaction tube 2. Oxygen gas and hydrogen gas are supplied through the first gas supply pipe 13 and the second gas supply pipe 14, respectively, into the reaction tube 2, and the heater 12 heats the reaction tube 2 at a temperature capable of activating oxygen gas and hydrogen gas. A combustion reaction occurs in the reaction tube 2 and thereby the organic substances adhering to the wafers 10 are oxidized, decomposed and removed.

Owner:TOKYO ELECTRON LTD

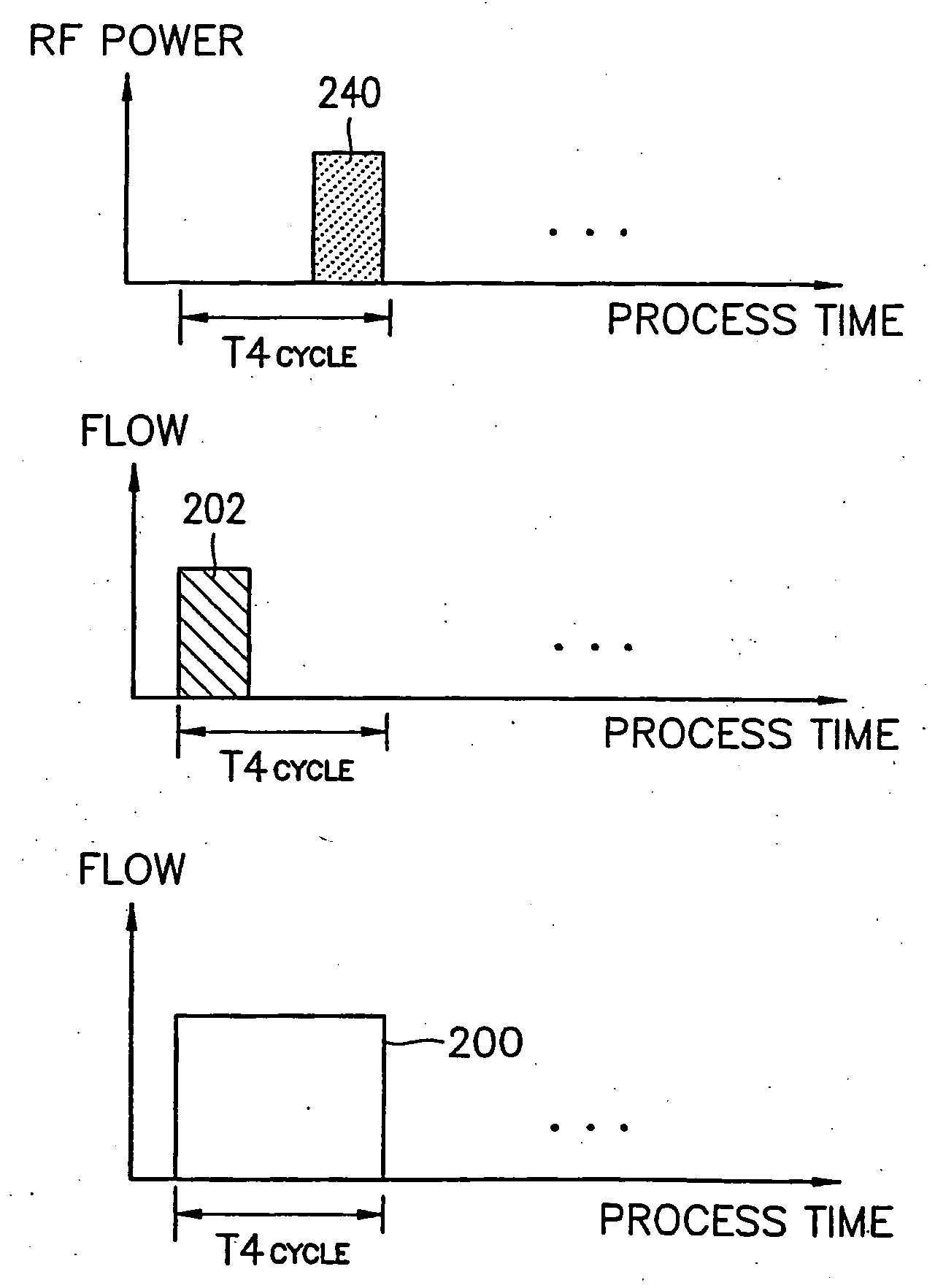

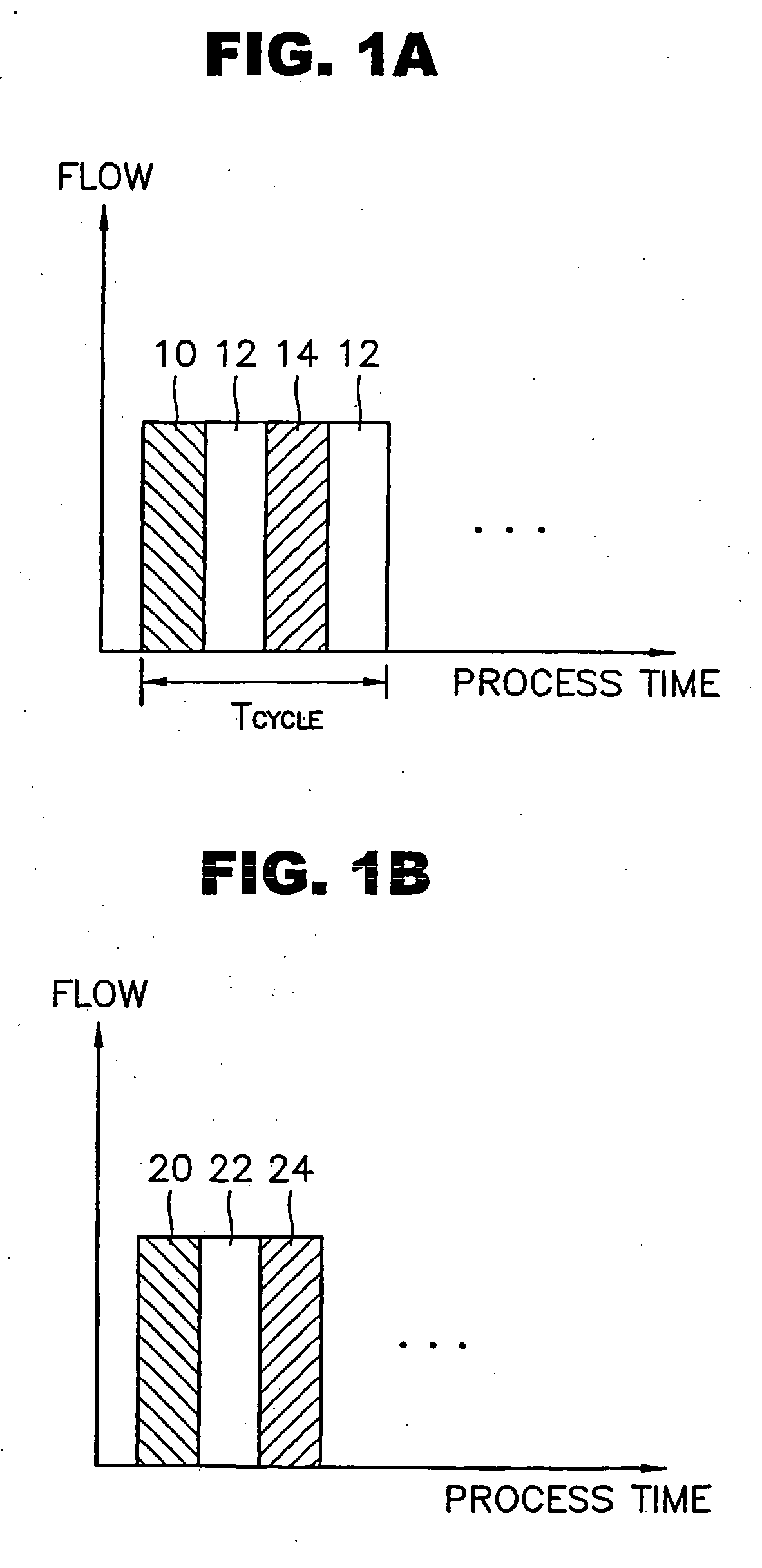

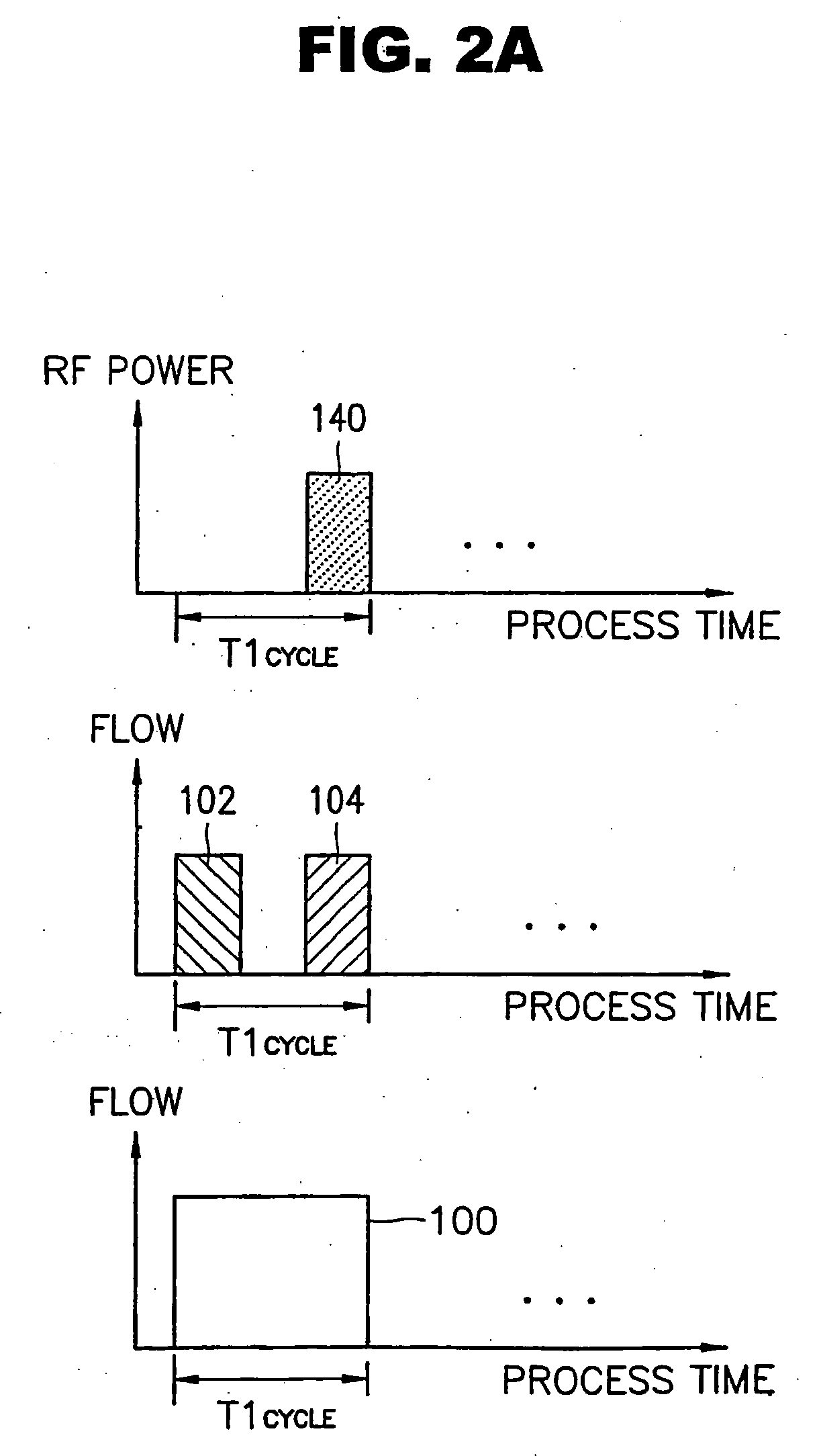

Method for forming thin film

InactiveUS20050037154A1Prolonged durationIncrease ratingsSemiconductor/solid-state device manufacturingChemical vapor deposition coatingThin layerProduct gas

Method for forming a thin film at low temperature by using plasma pulses is disclosed. While a purge gas or a reactant purge gas activated by plasma is continuously supplied into a reactor, a source gas is supplied intermittently into the reactor during which period plasma is generated in the reactor so that the source gas and the purge gas activated by plasma reacts, so that a thin film is formed according to the method. Also, a method for forming a thin layer of film containing a plural of metallic elements, a method for forming a thin metallic film containing varied contents by amount of the metallic elements by using a supercycle Tsupercycle comprising a combination of simple gas supply cycles Tcycle, . . . , and a method for forming a thin film containing continuously varying compositions of the constituent elements by using a supercycle Tsupercycle comprising a combination of simple gas supply cycles Tcycle, . . . , are disclosed. The methods for forming thin films disclosed here allows to shorten the purge cycle duration even if the reactivity between the source gases is high, to reduce the contaminants caused by the gas remaining in the reactor, to form a thin film at low temperature even if the reactivity between the source gases is low, and also to increase the rate of thin film formation.

Owner:ASM GENITECH KOREA

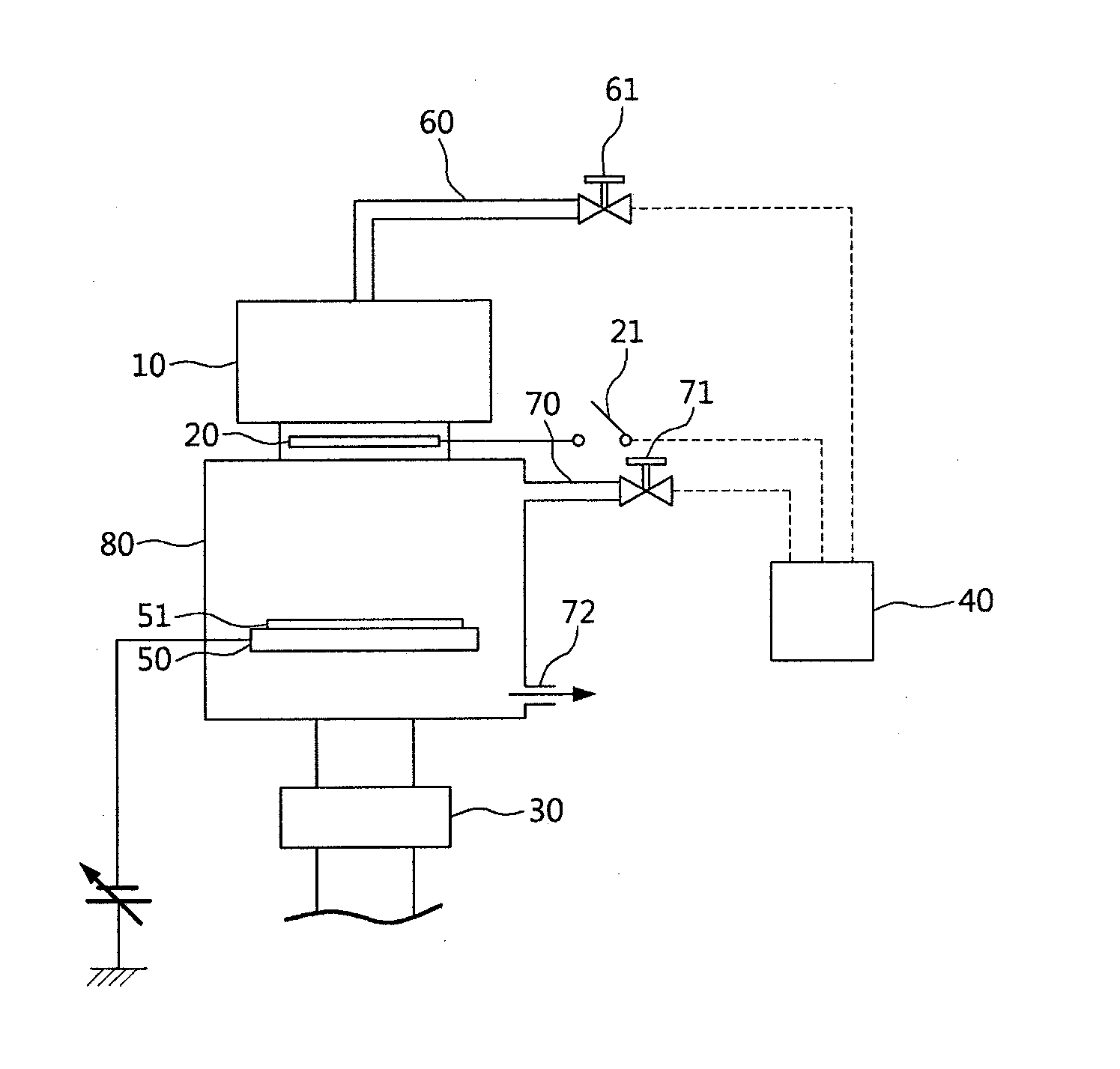

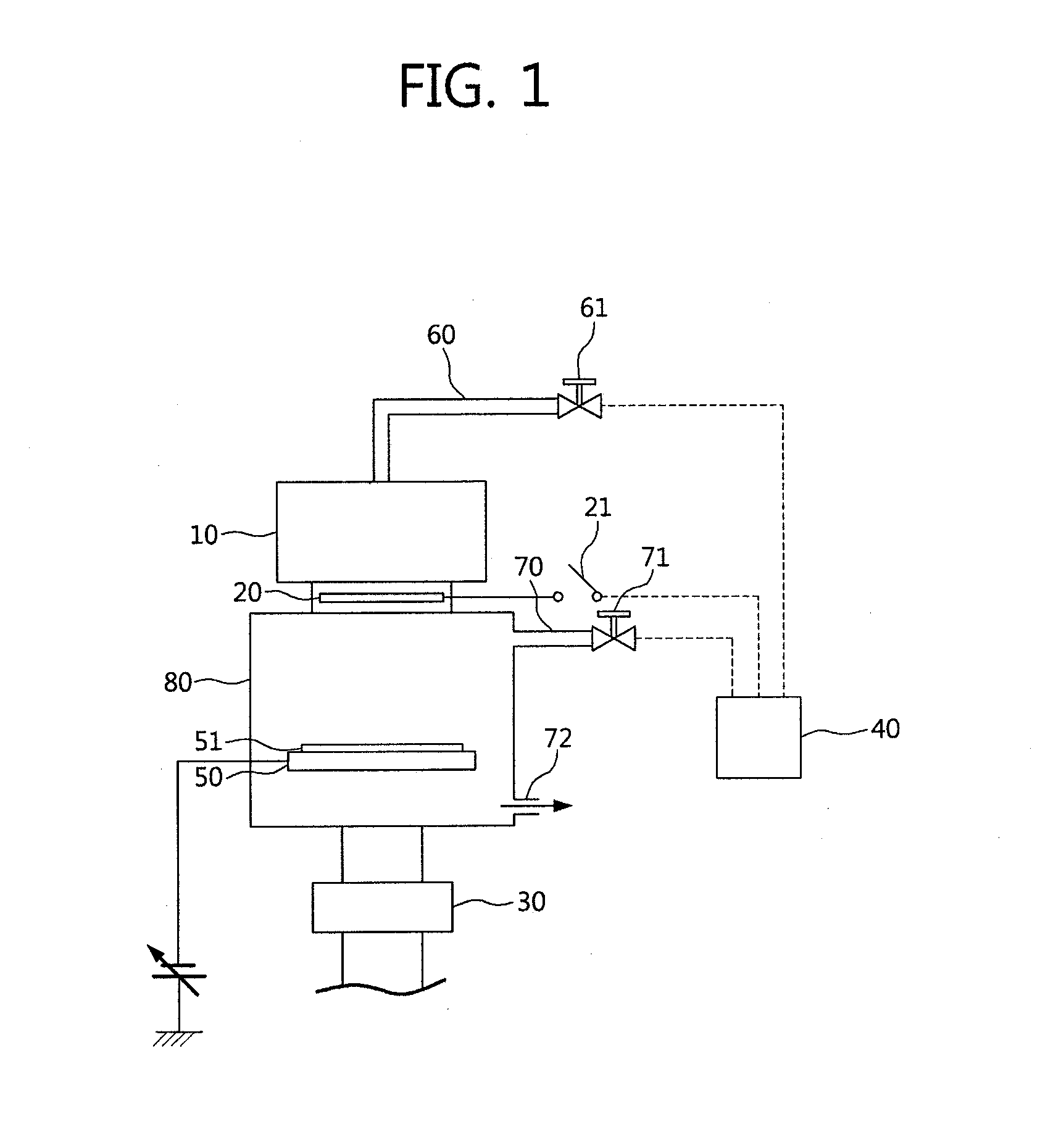

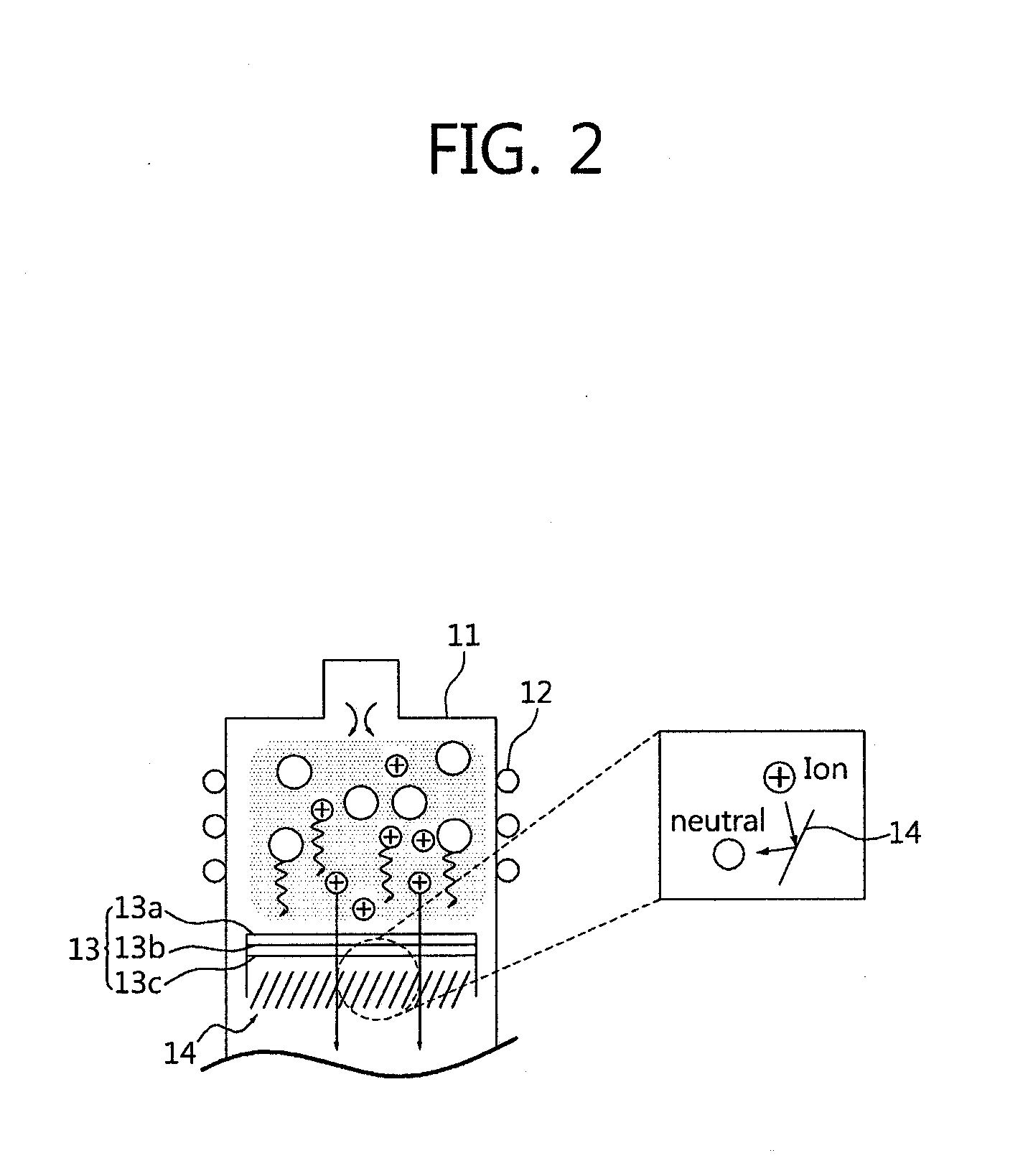

Atomic layer etching apparatus and etching method using the same

An atomic layer etching apparatus using reactive radicals and neutral beams and an etching method using the same are provided. The atomic layer etching apparatus includes a reaction chamber including a stage on which a substrate to be etched is seated, a plasma generator including a plasma chamber configured to supply reactive radicals and neutral beams into the reaction chamber and receive a source gas to generate plasma, an inductive coil configured to surround the exterior of the plasma chamber to generate an electric field, a grid assembly disposed at a lower part of the plasma chamber and including first, second and third grids for extracting ion beams, and a reflective body disposed under the grid assembly and configured to supply electrons to the ion beams to convert the ion beams into neutral beams, a shutter installed between the plasma generator and the reactive chamber and configured to adjust supply of the neutral beams into the reaction chamber, a purge gas supply part configured to supply a purge gas into the reaction chamber, and a controller configured to control supply of the source gas, an etching gas and the purge gas, and opening / closing of the shutter.

Owner:RES & BUSINESS FOUND SUNGKYUNKWAN UNIV

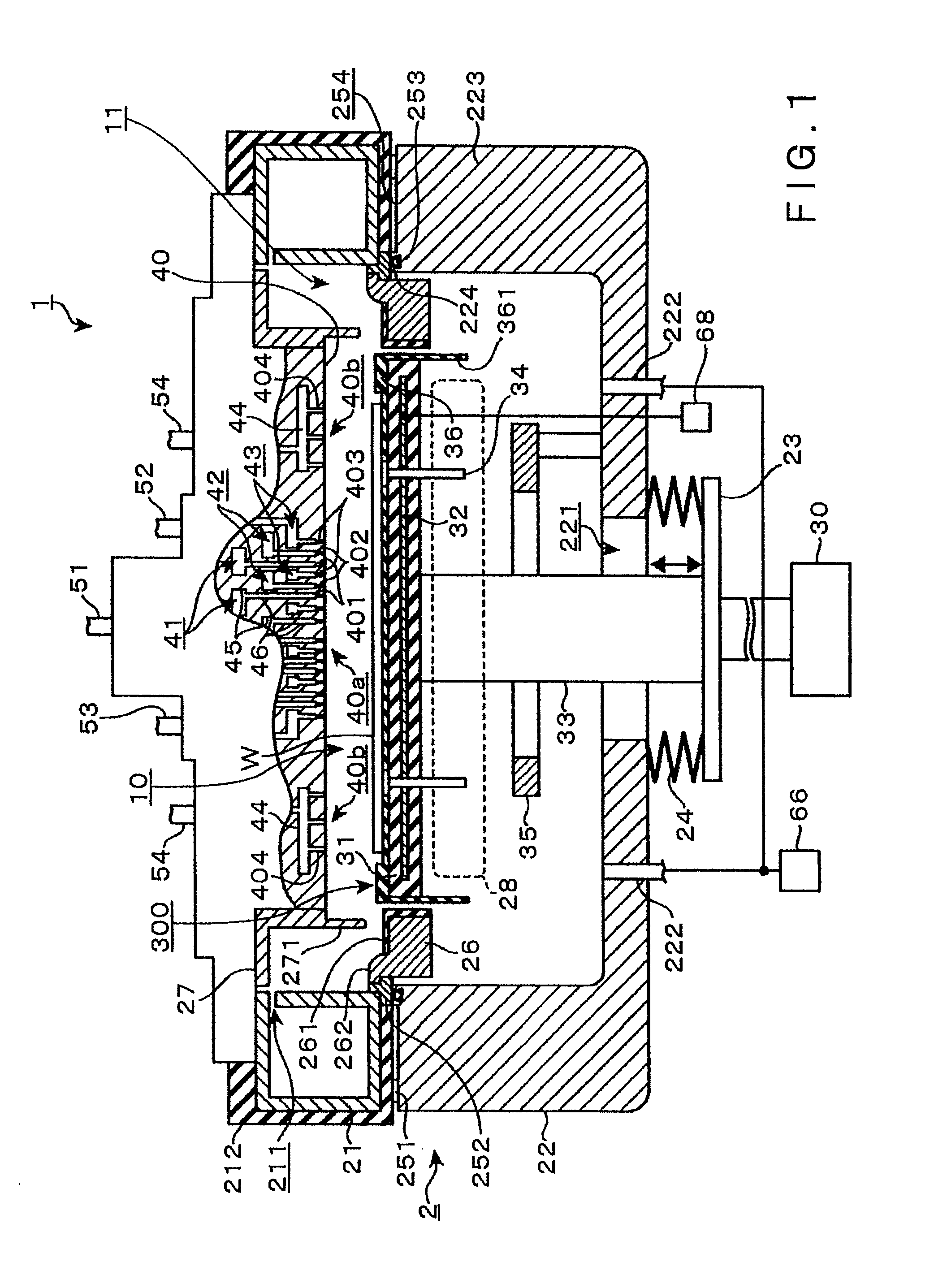

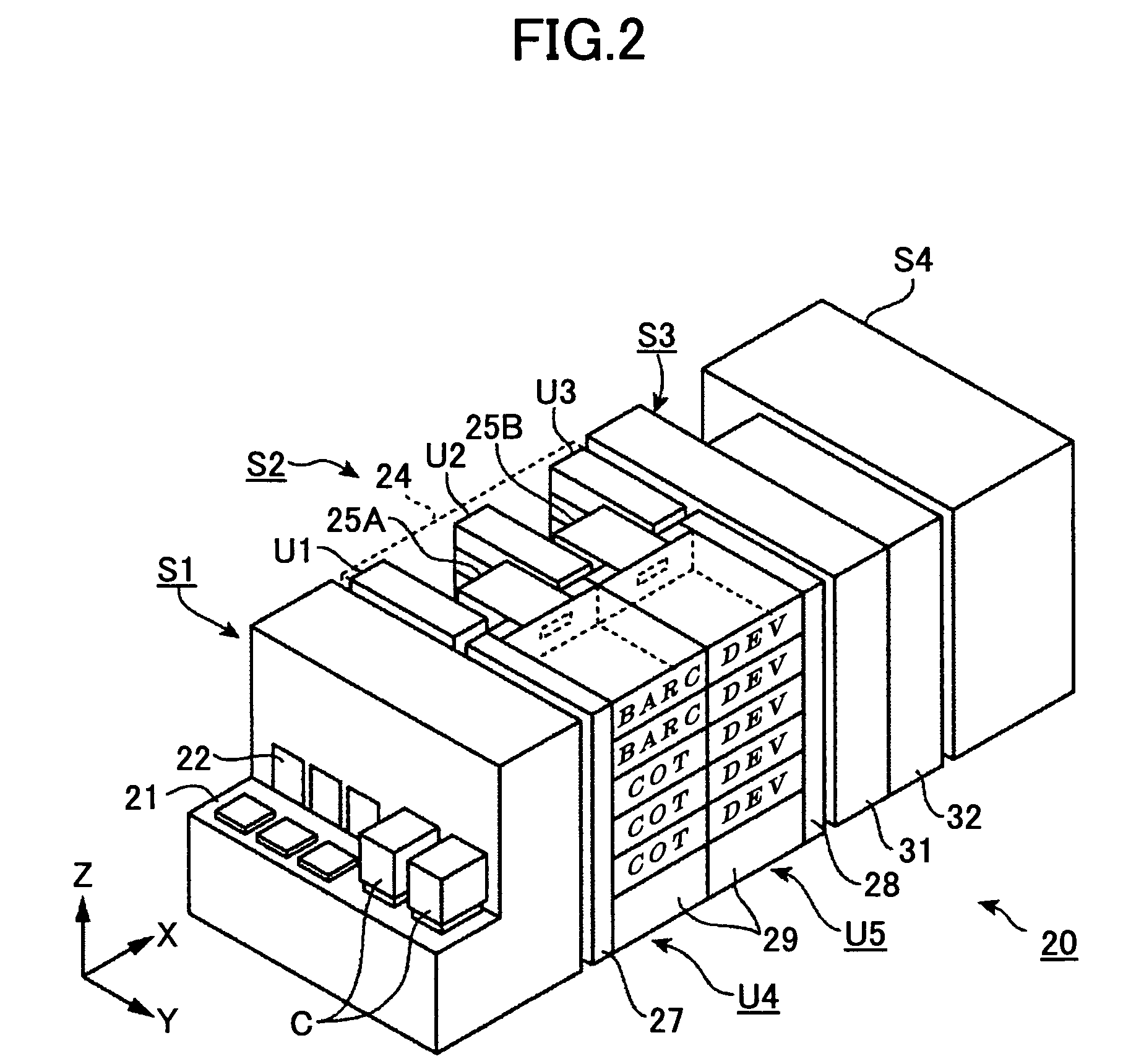

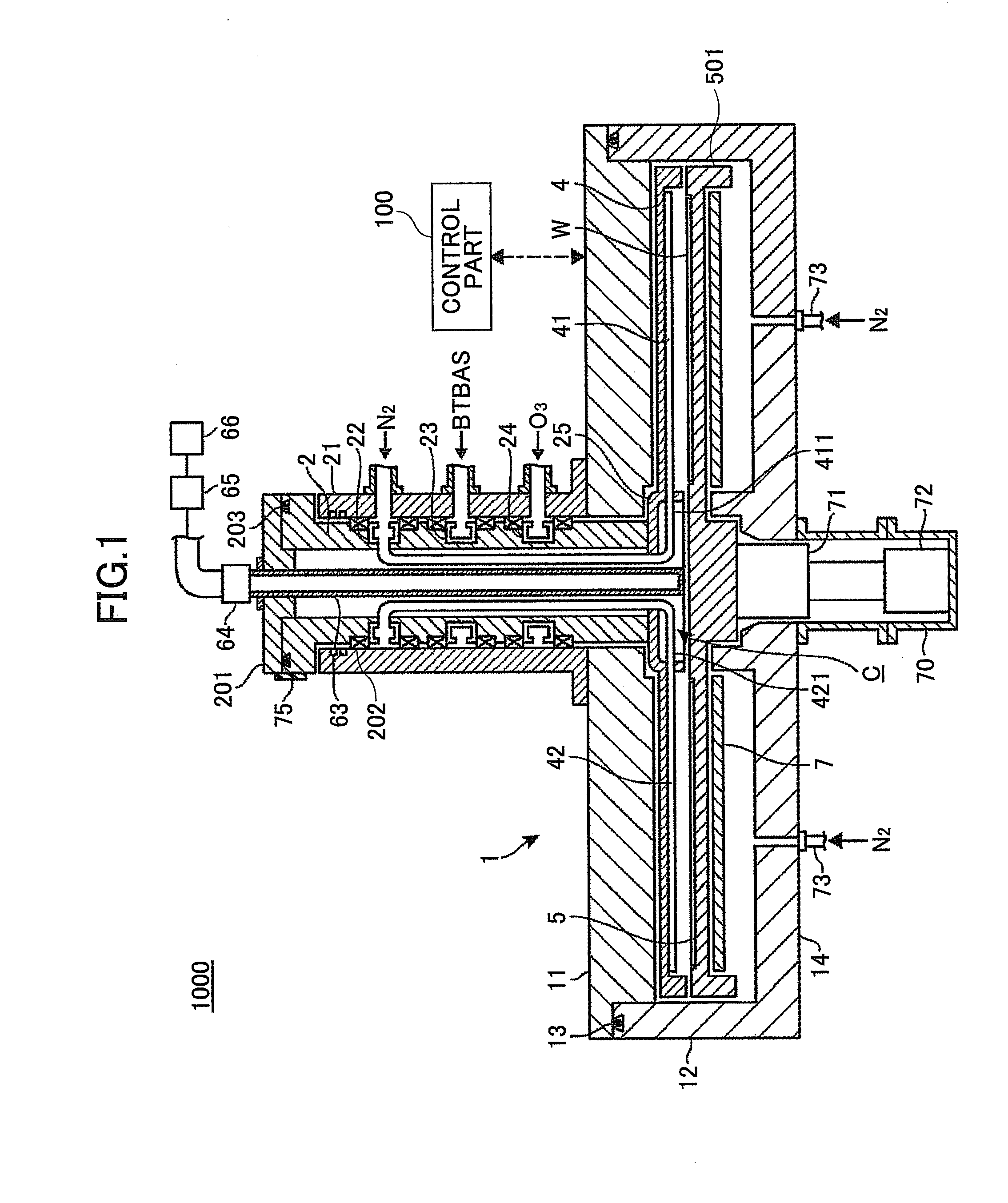

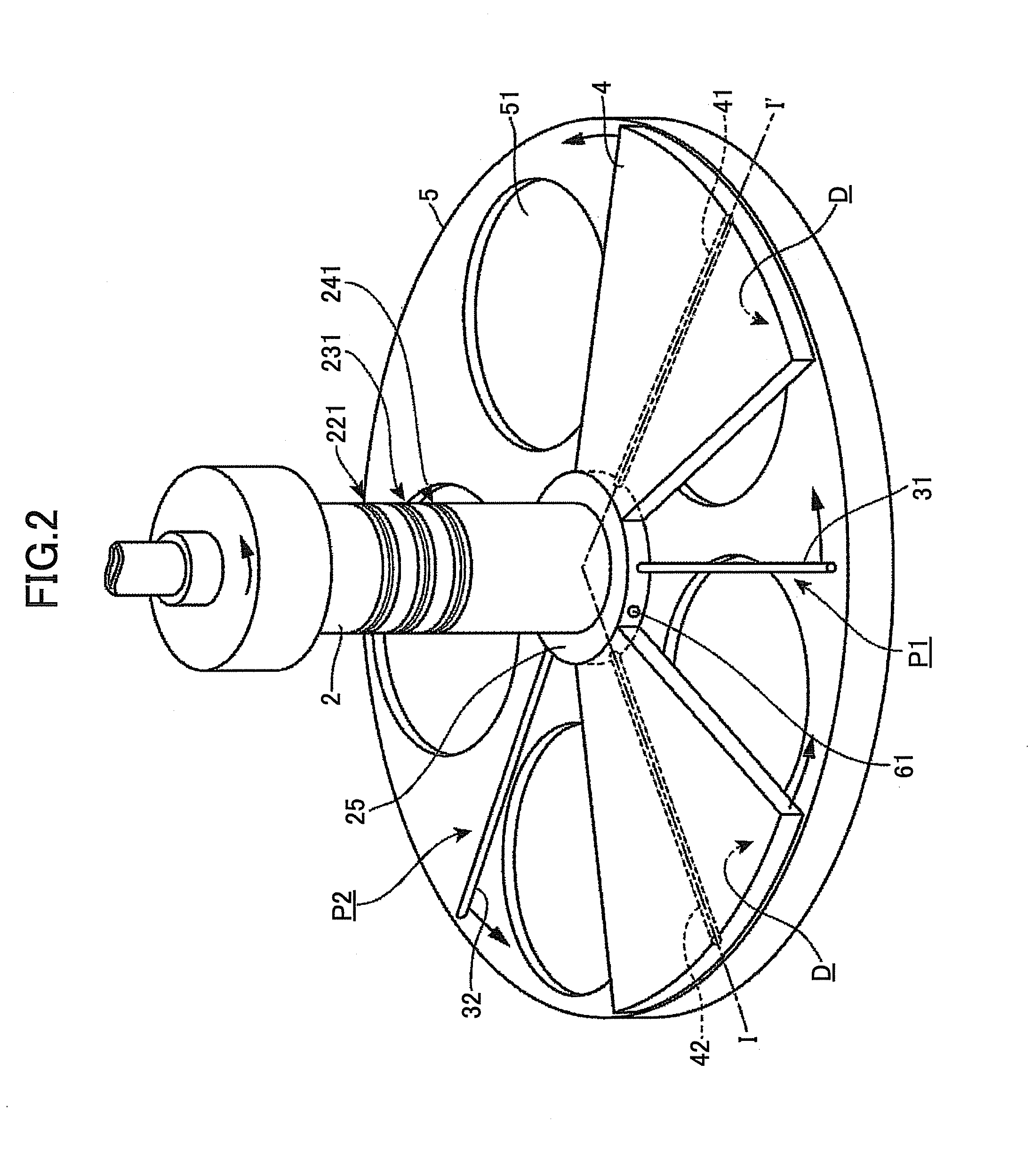

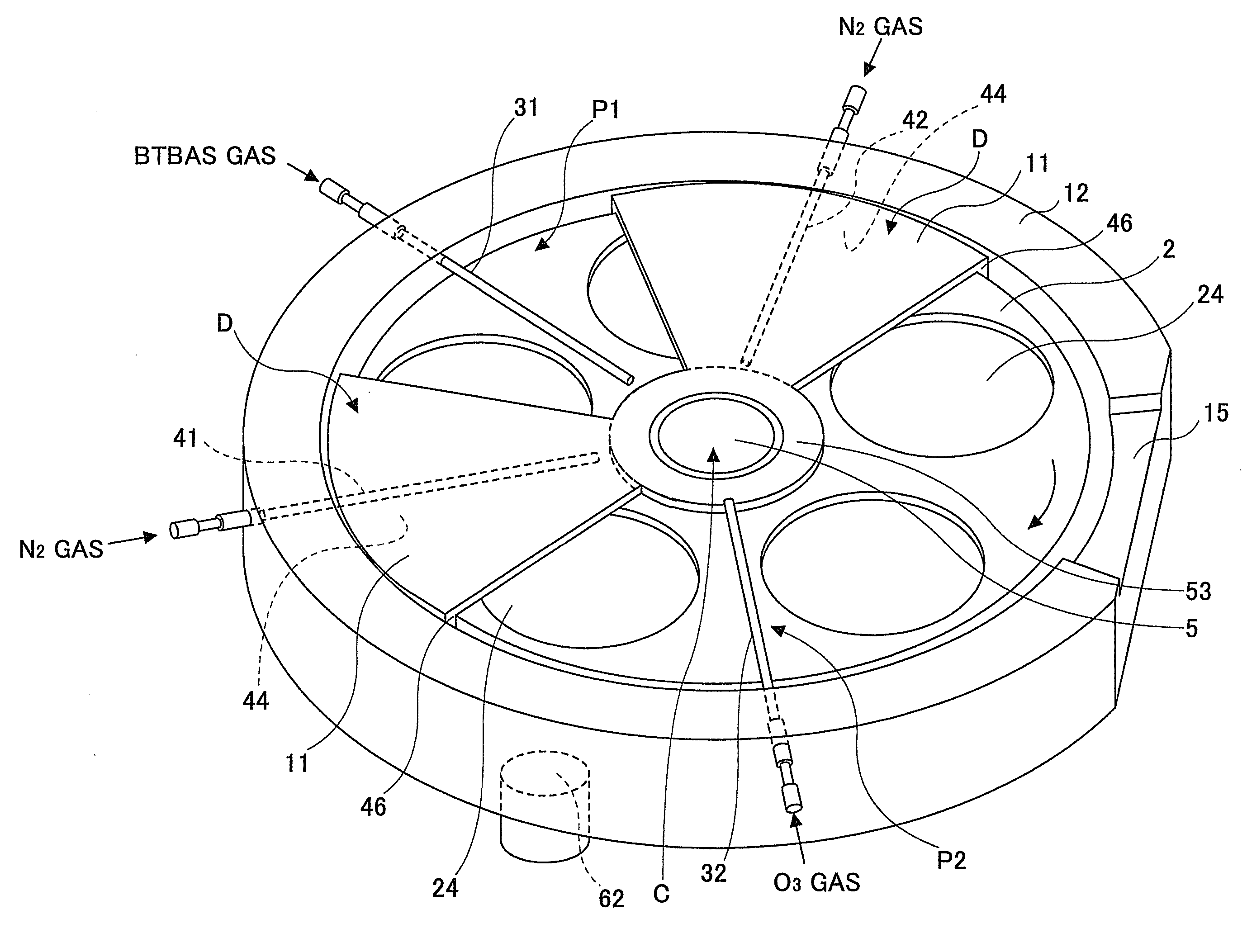

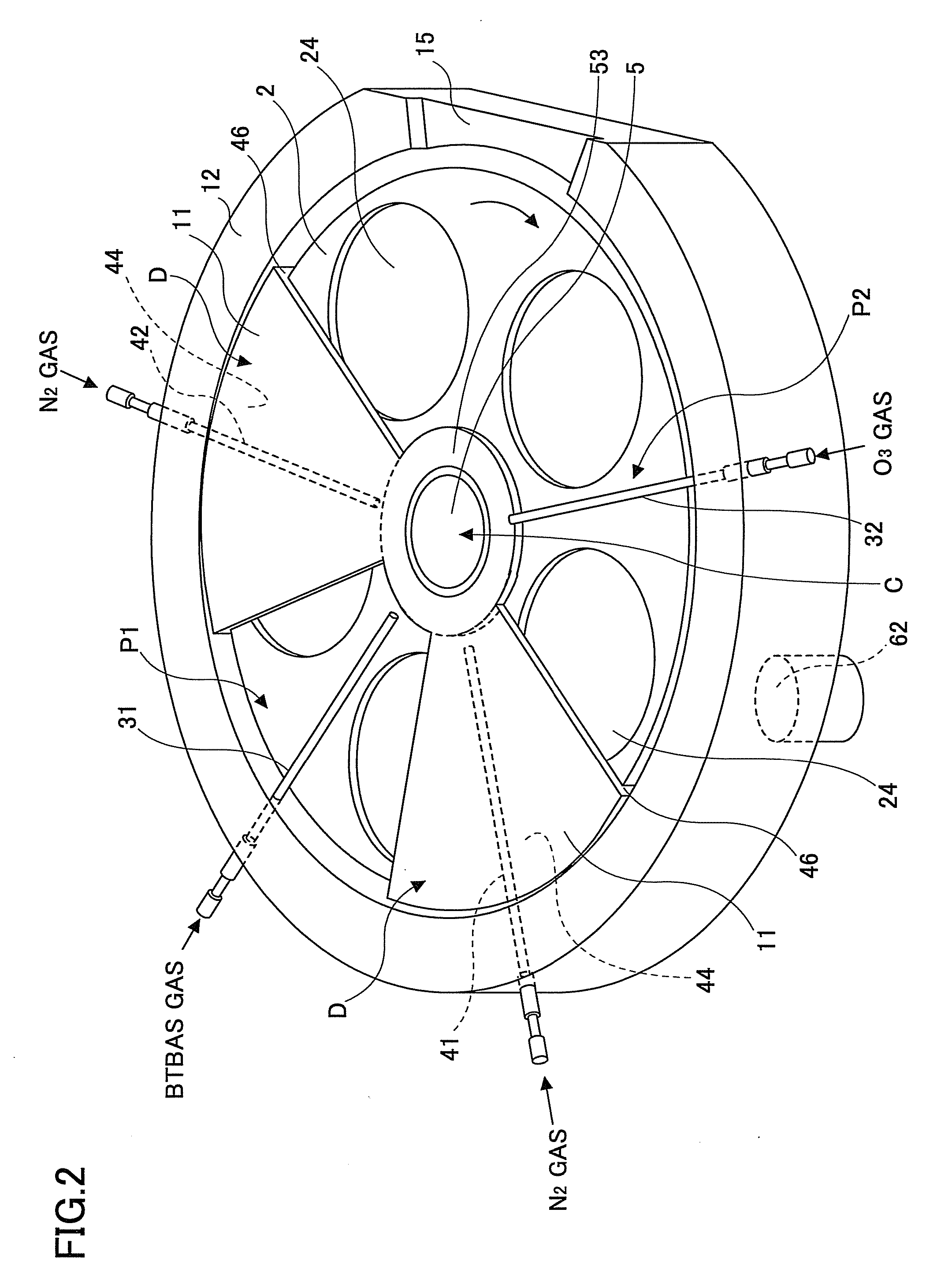

Film deposition apparatus

InactiveUS20100116209A1Eliminate the problemSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringGas supply

A film deposition apparatus including a rotational member is rotated by a rotation mechanism around a vertical axis inside a chamber, a pedestal in the chamber and including substrate receiving areas formed along a circle having the vertical axis as a center, and first and second reaction gas supplying parts provided separately along a circumferential direction of the circle and supplying first and second reaction gases to the pedestal, a separating area in the rotational member and between first and second process areas to which first and second reaction gases are supplied, an evacuation port to evacuate an atmosphere inside the chamber, a separation gas supplying part in the separating area for supplying a separation gas, and an opposing surface part in the separating area on both sides of the separation gas supplying part and at a position forming a thin space between the opposing surface part and the pedestal.

Owner:TOKYO ELECTRON LTD

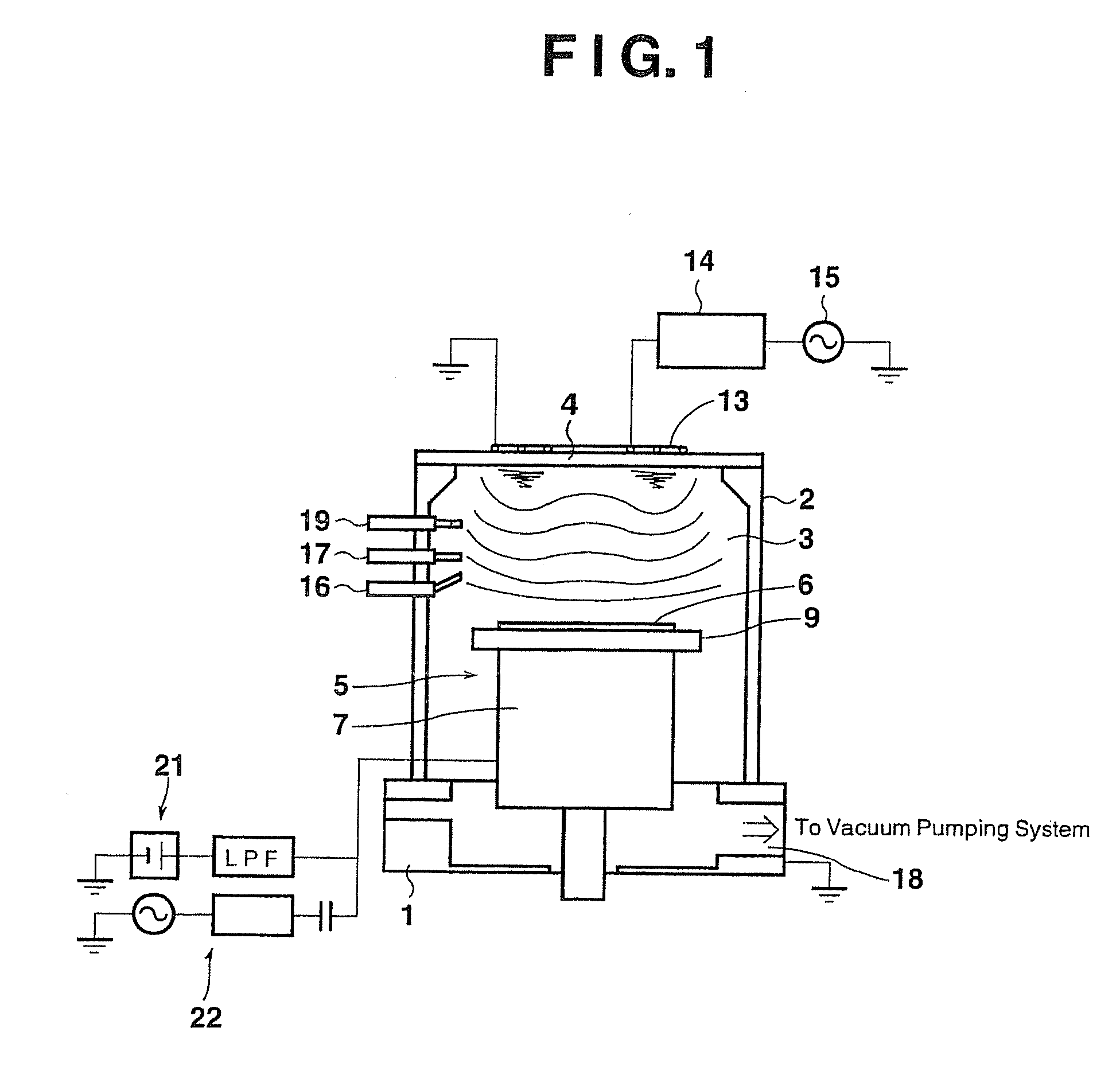

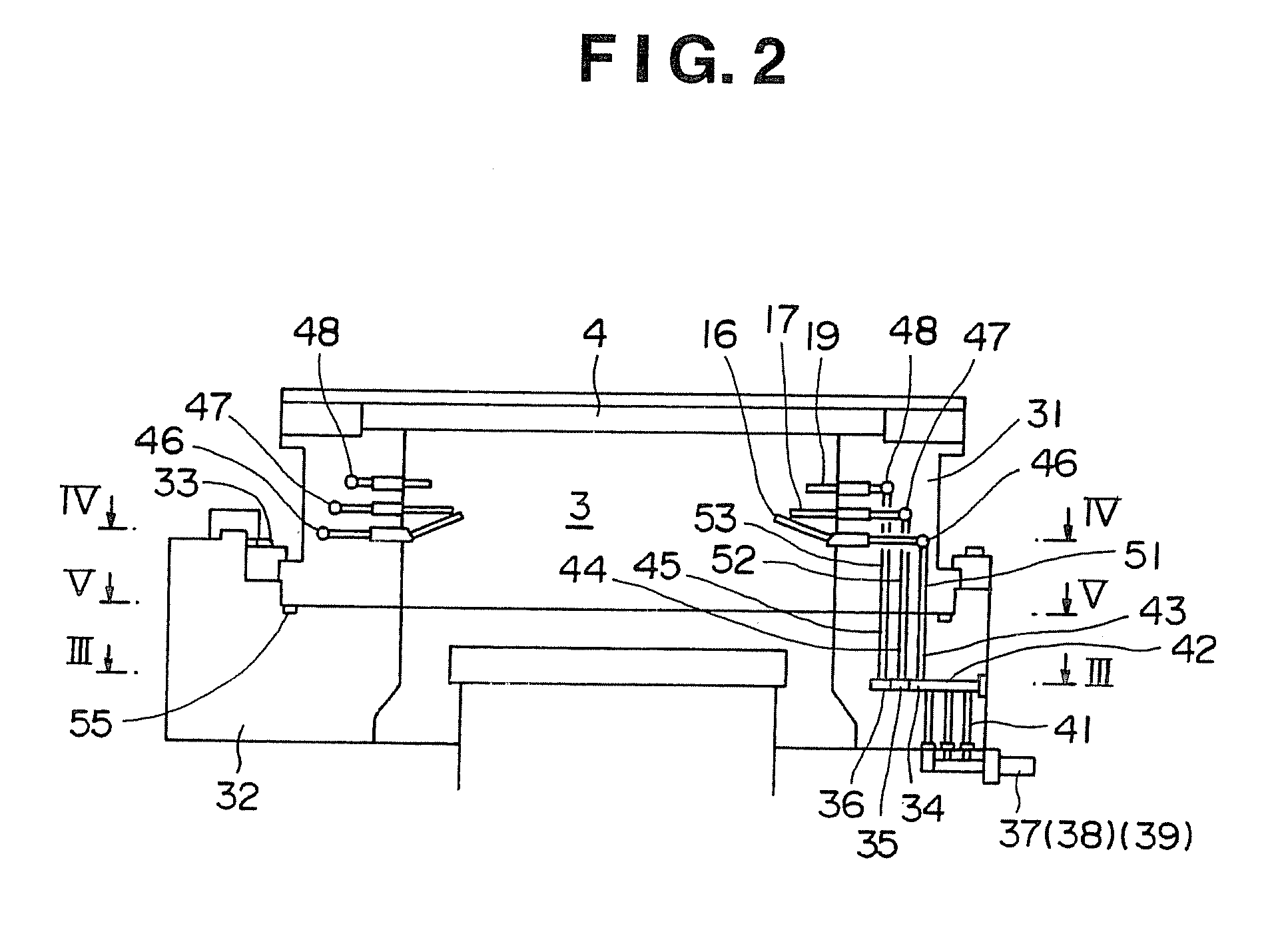

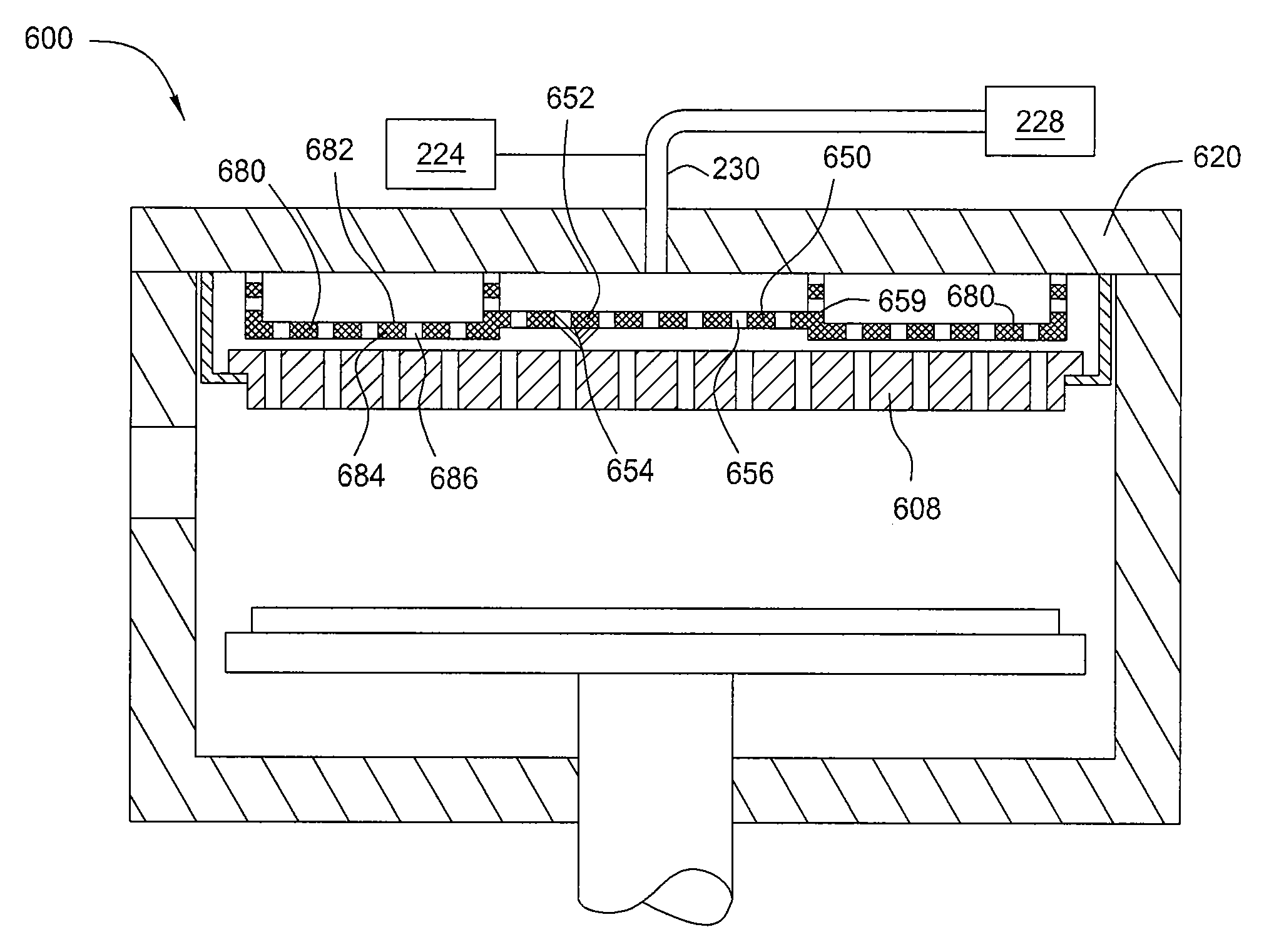

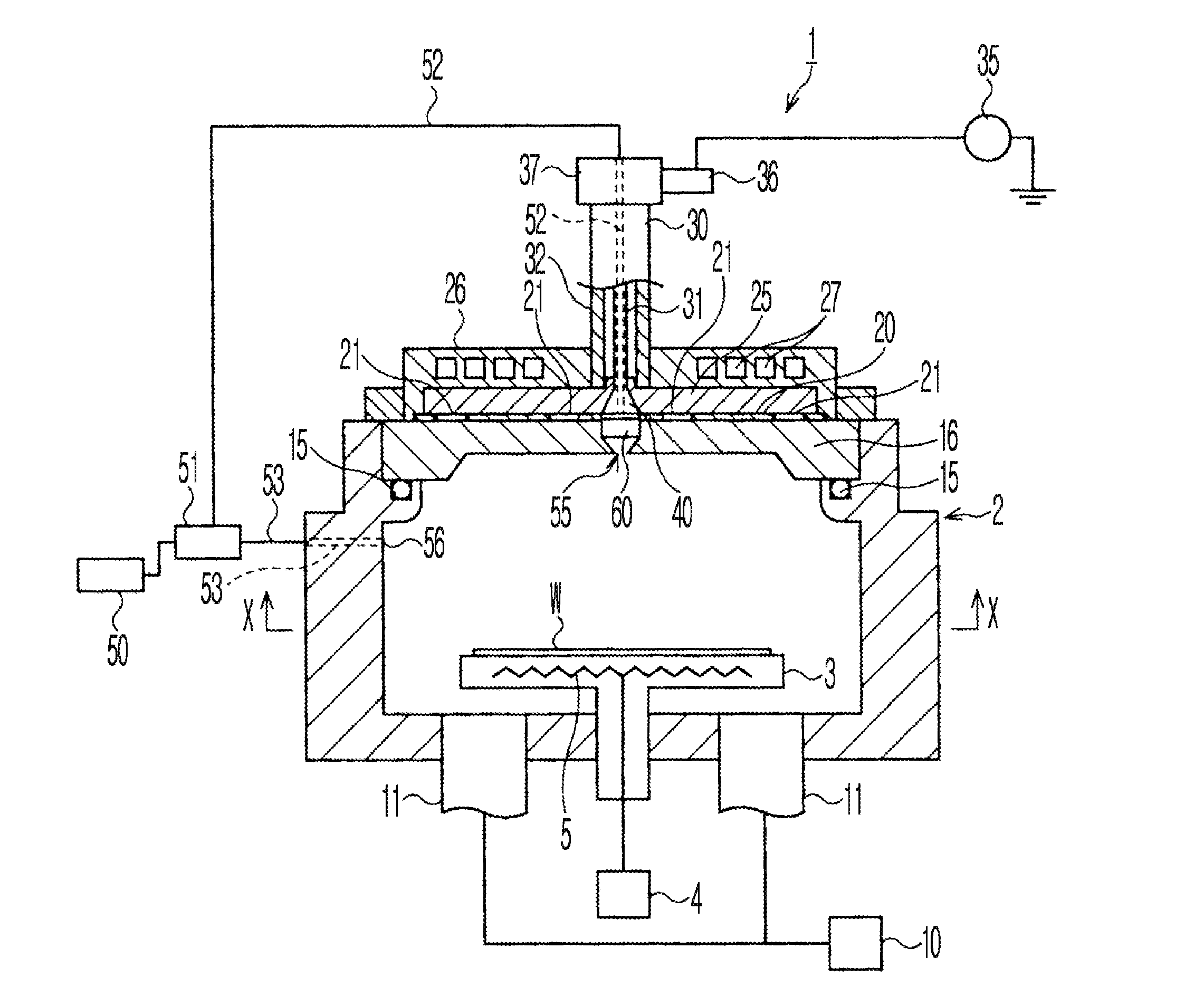

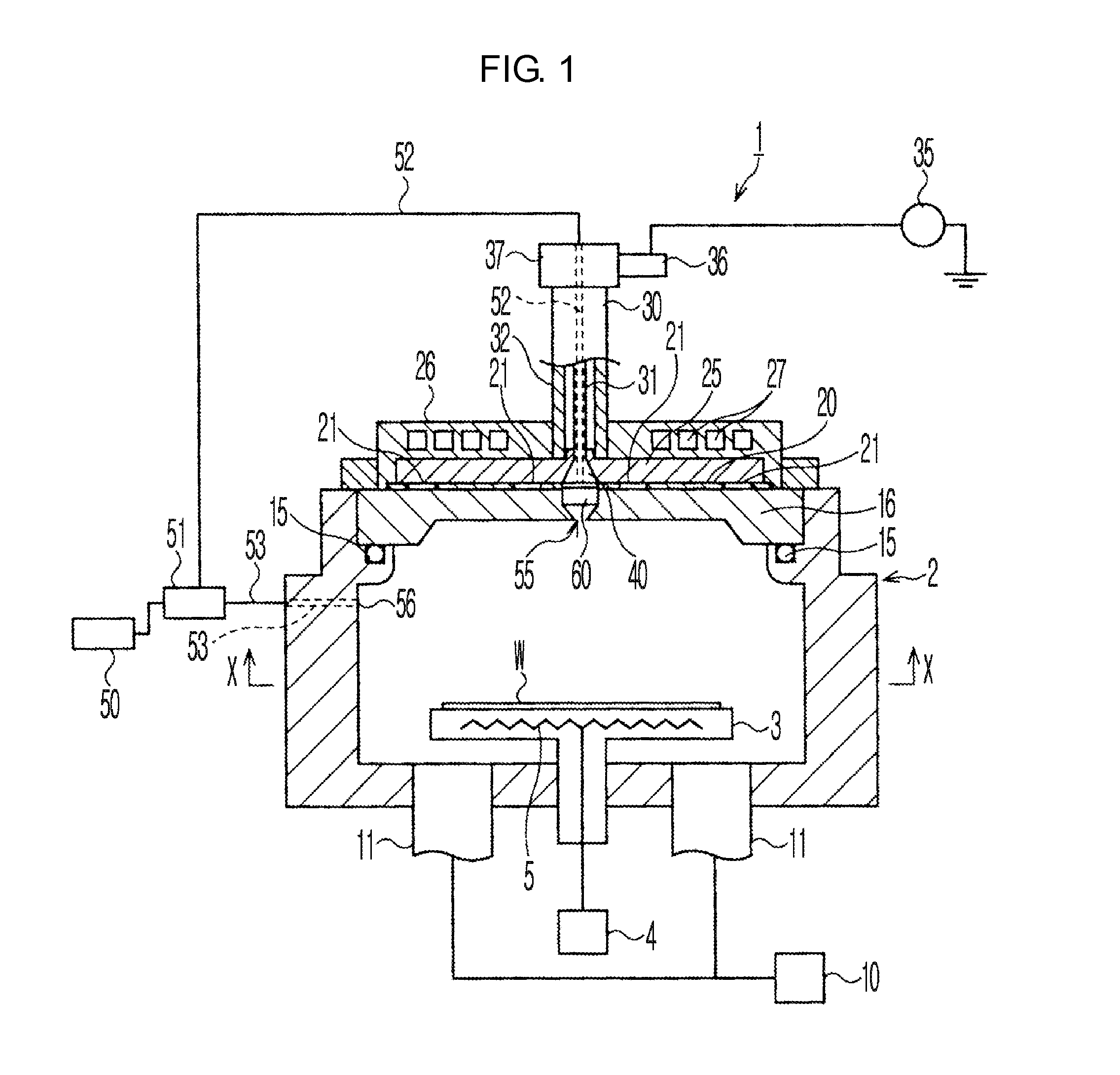

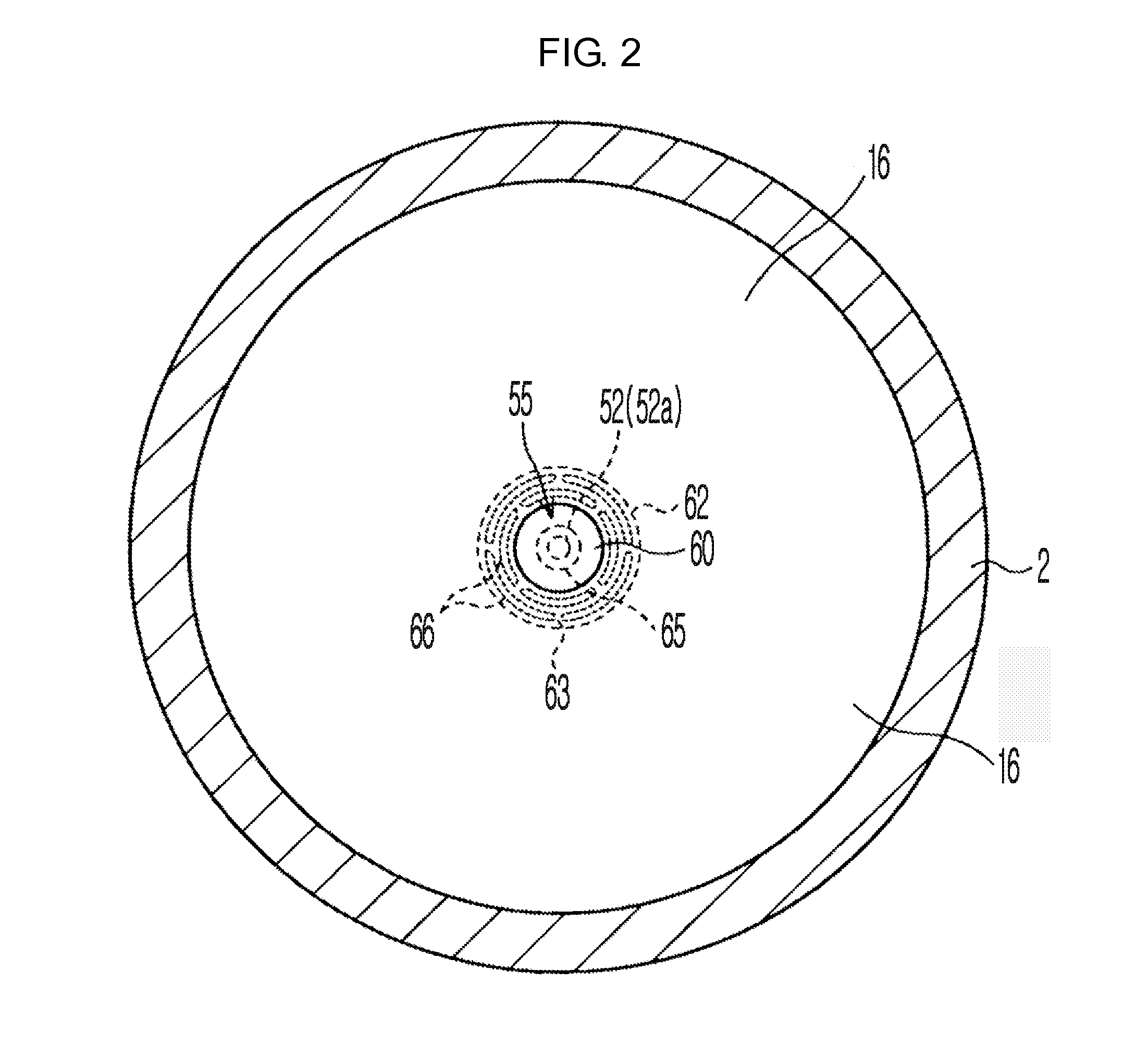

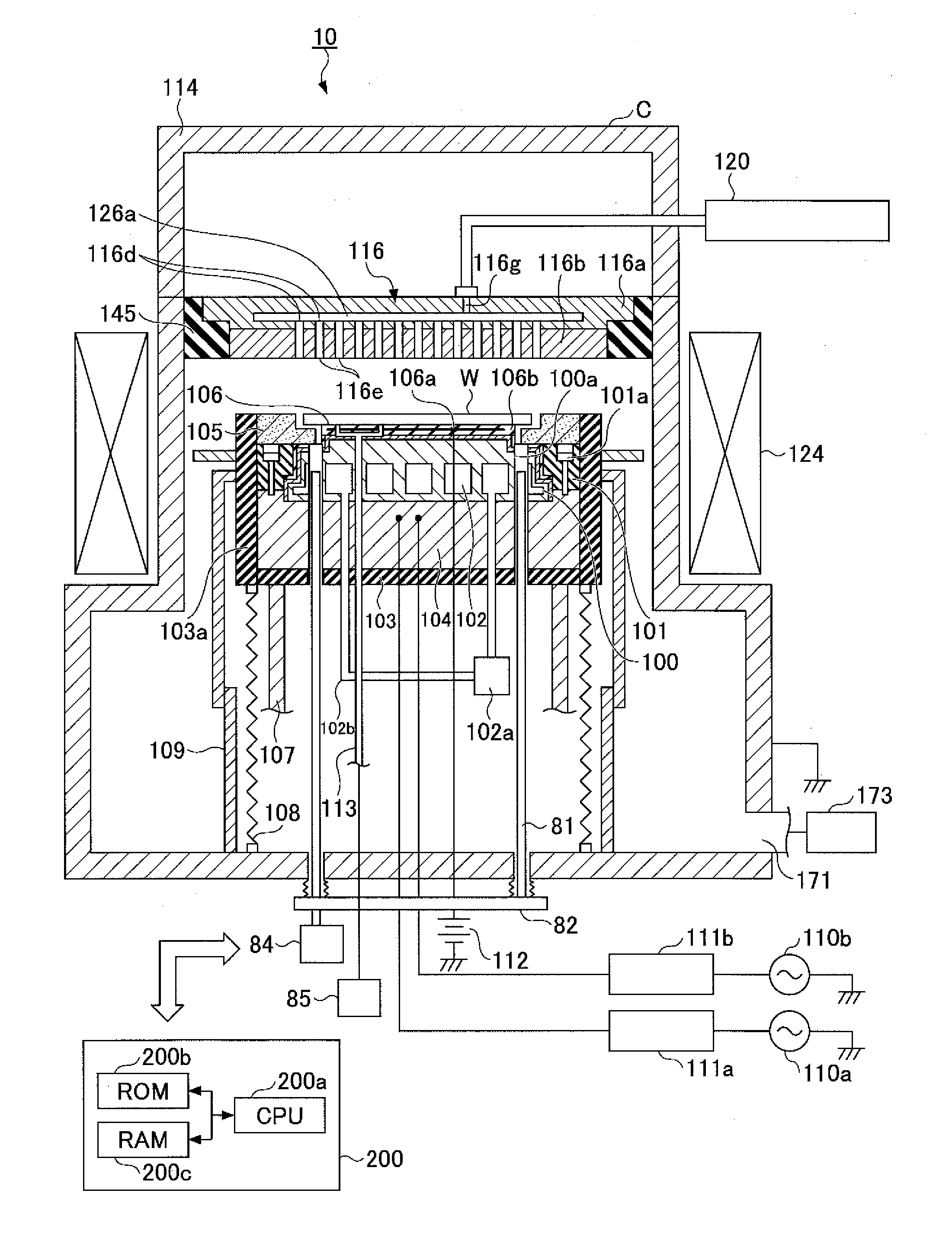

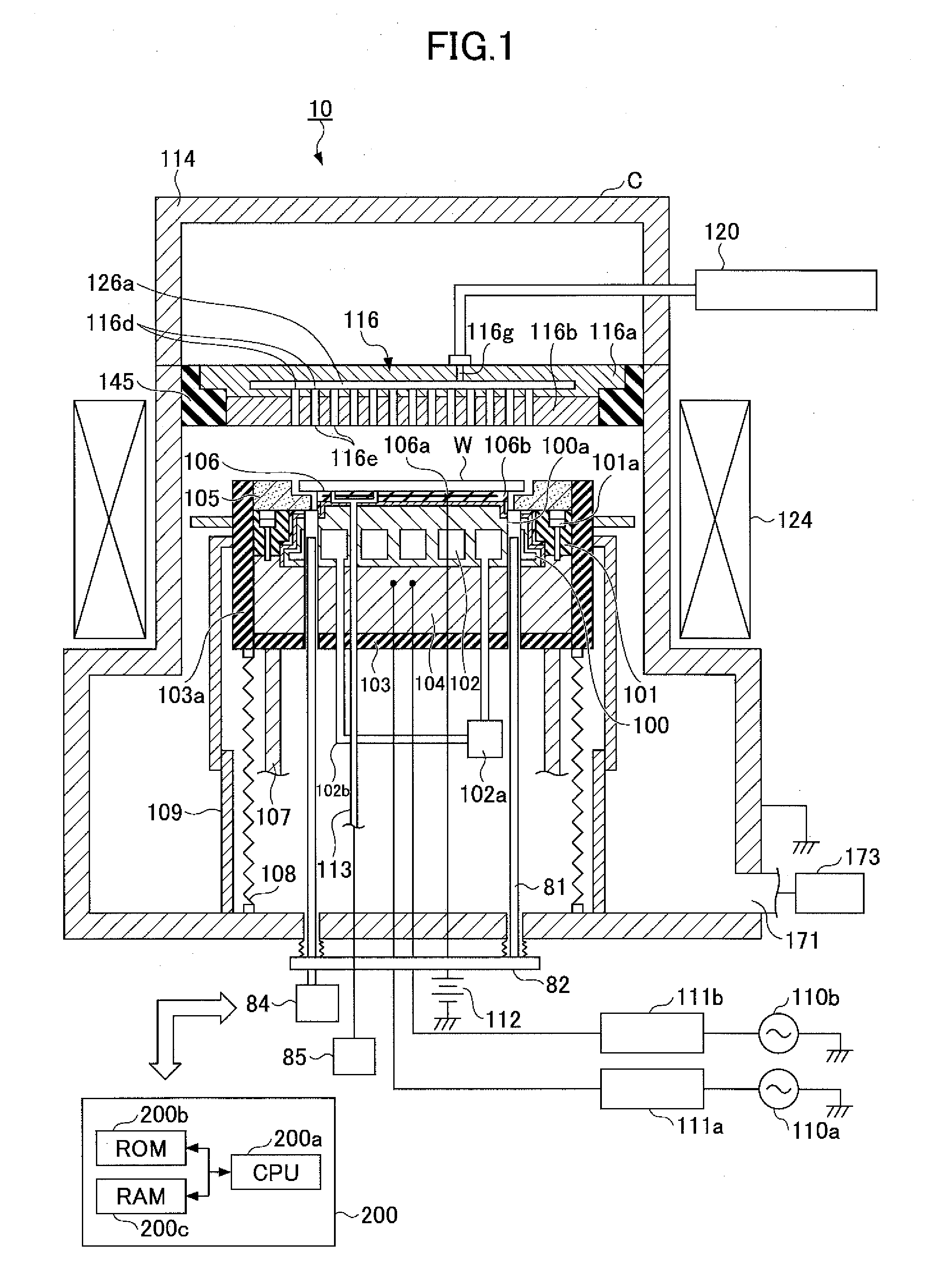

Plasma processing apparatus

ActiveUS20110048642A1Improve removabilityElectric discharge tubesSemiconductor/solid-state device manufacturingProcess engineeringGas retention

In a plasma processing apparatus for processing a substrate by plasmatizing a process gas introduced into a processing container, an introducing unit which introduces the process gas is formed on a ceiling surface of the processing container; a gas retention portion which gathers the process gas supplied from the outside of the processing container through a supply passage, and a plurality of gas ejection holes which allow communication between the gas retention portion and the inside of the processing container are formed in the introducing unit; a gas ejection hole is not formed in a location of the gas retention portion that faces an opening of the supply passage; and a cross section of each of the gas ejection holes has a flat shape.

Owner:TOKYO ELECTRON LTD

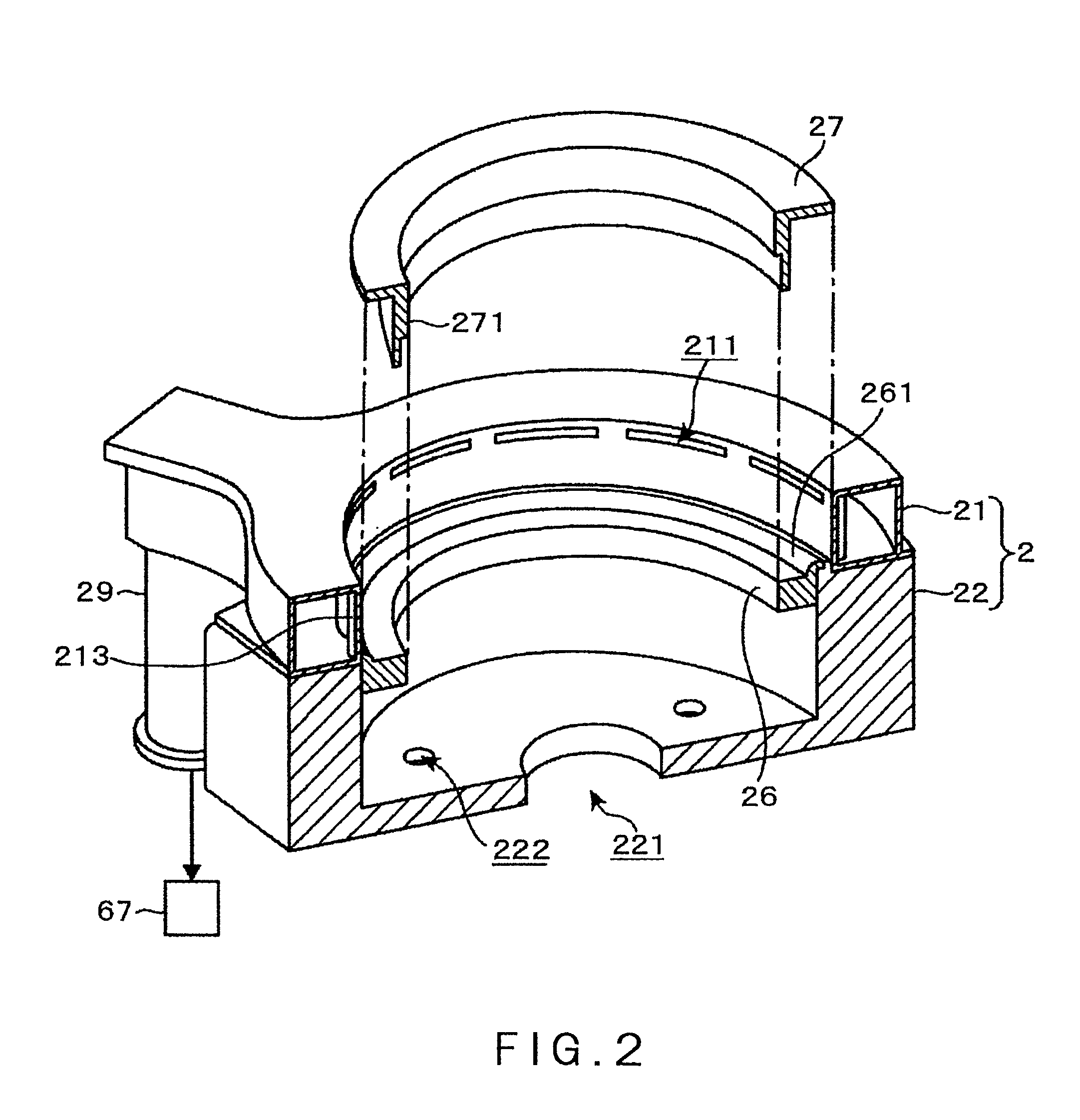

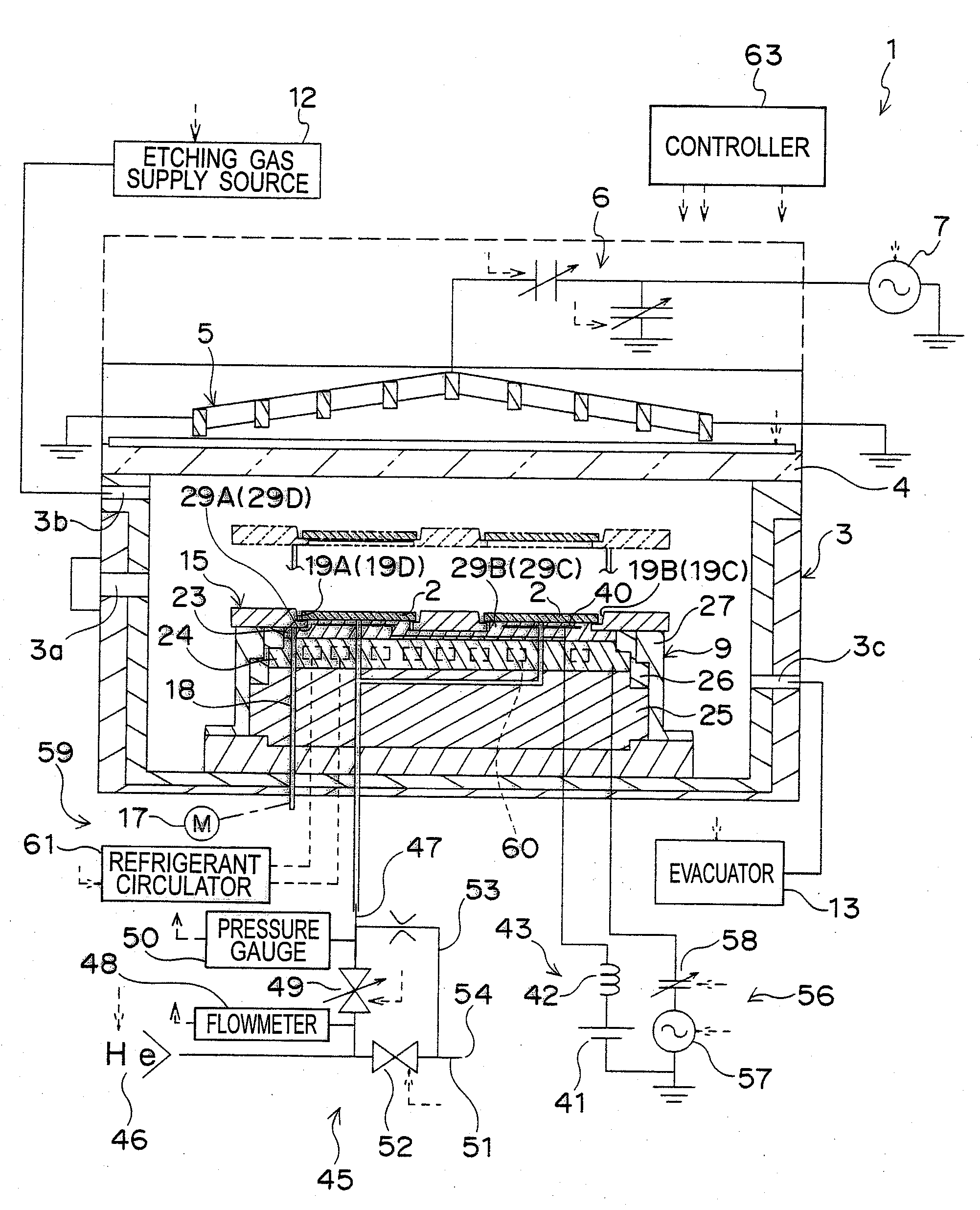

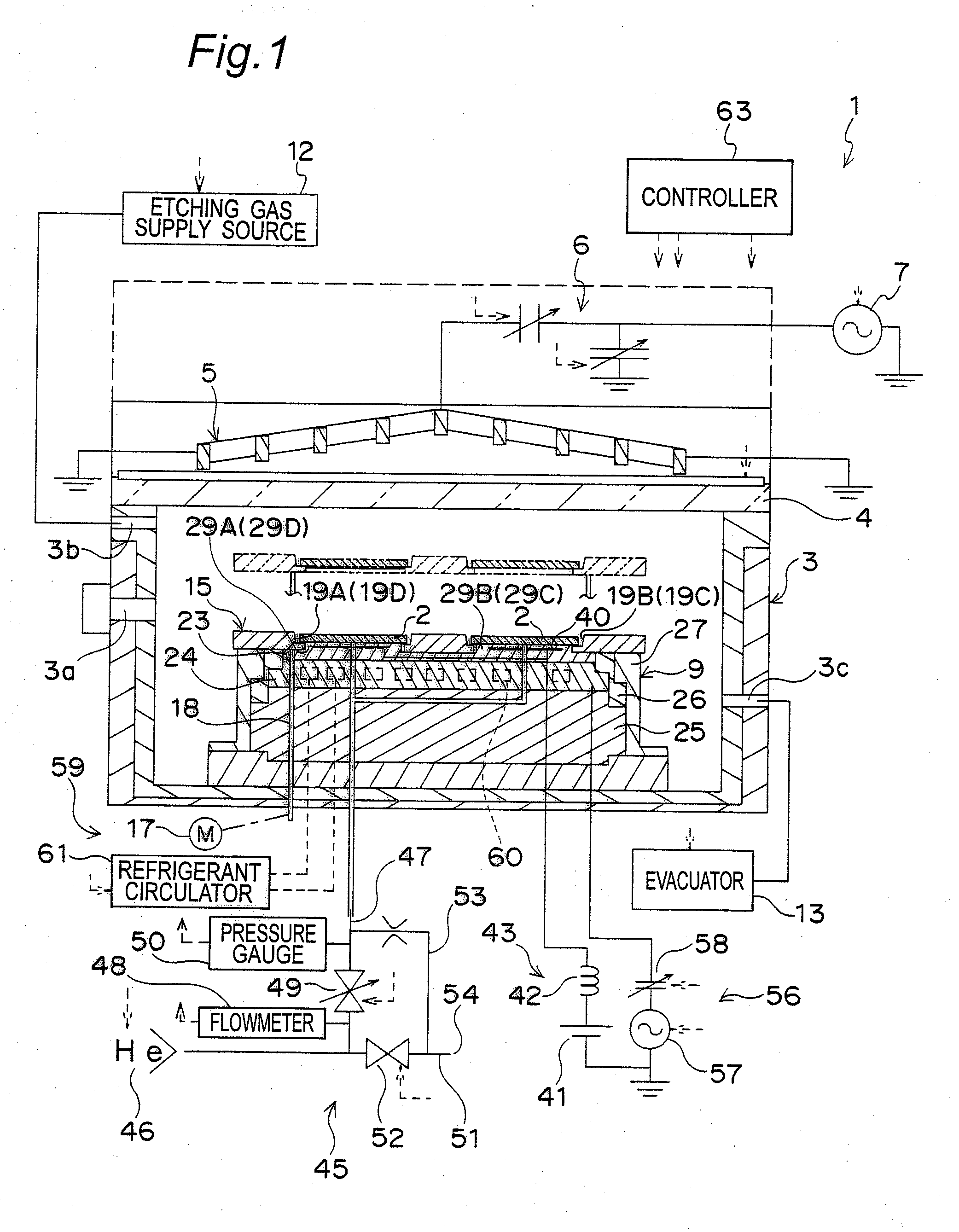

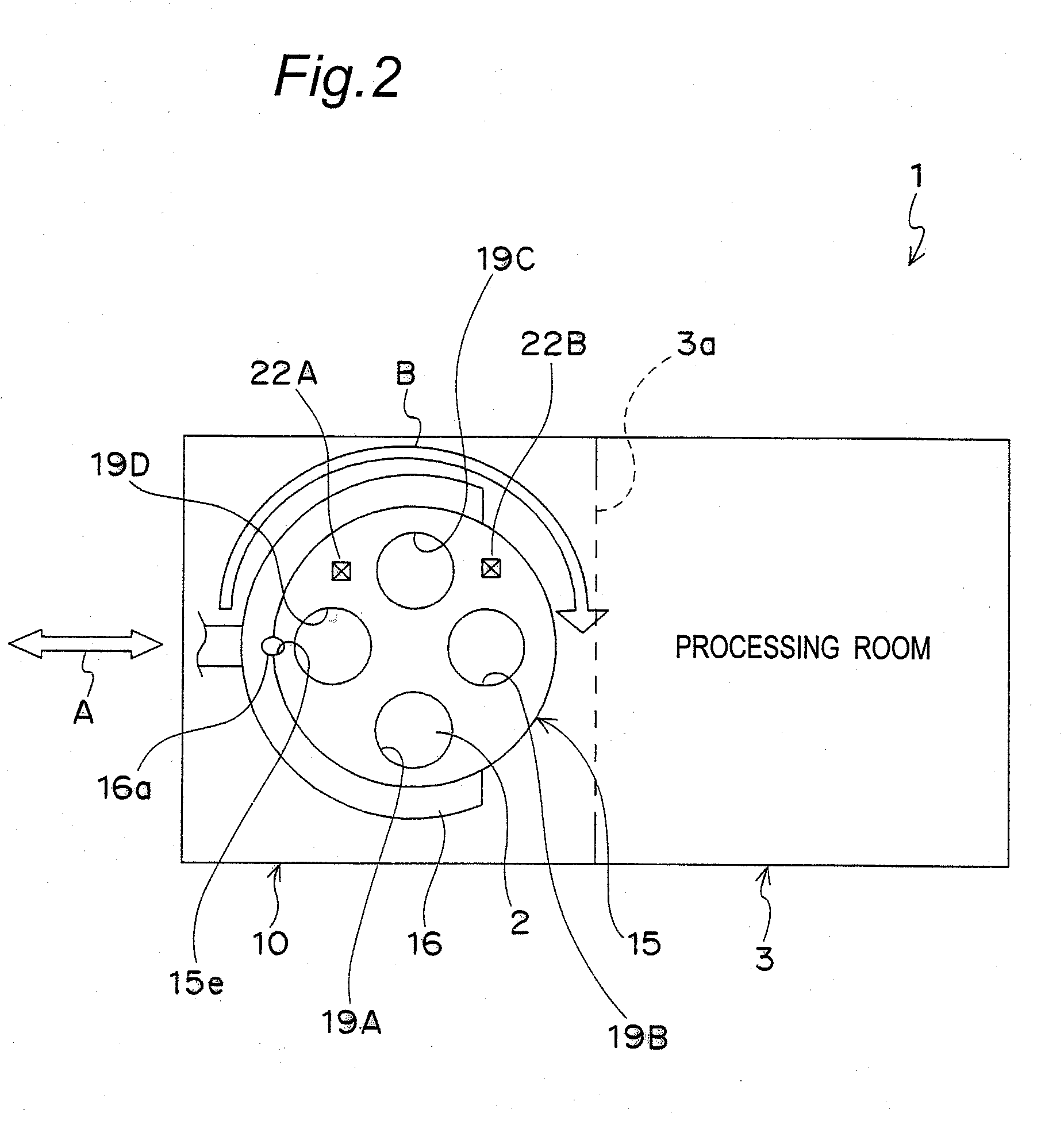

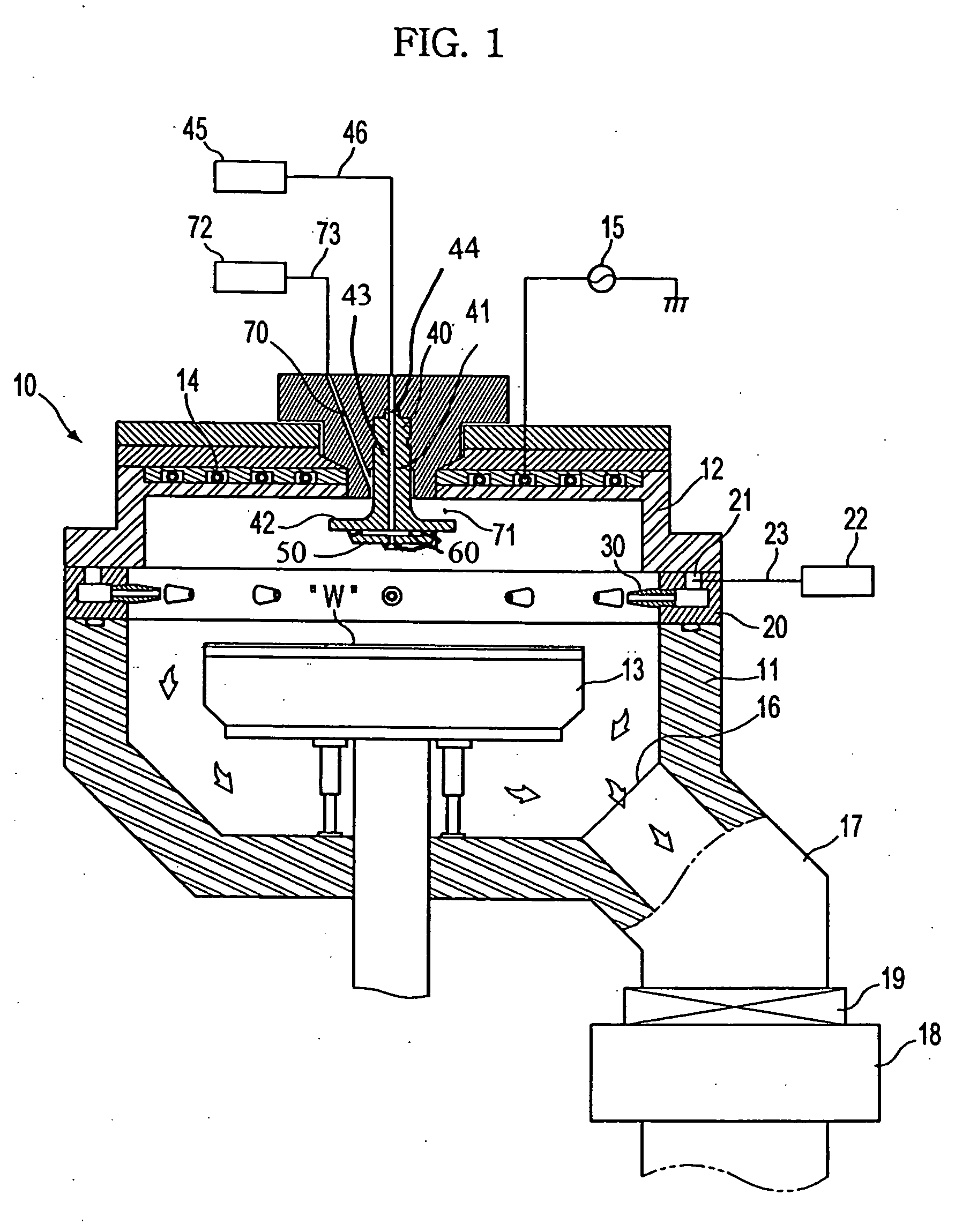

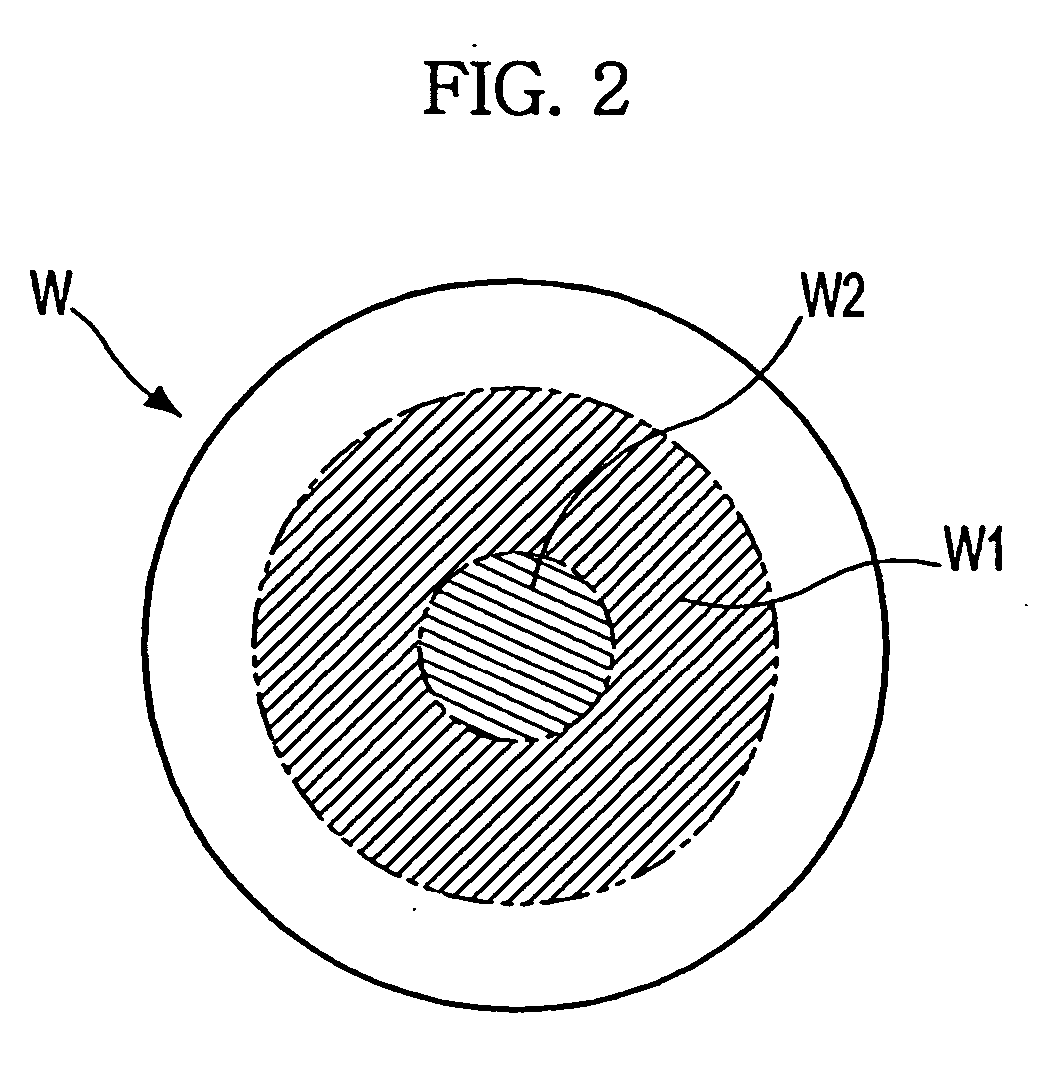

Plasma processing apparatus, plasma processing method, and tray

ActiveUS20090255901A1Uniform plasma treatmentImprove adhesionElectric discharge tubesDecorative surface effectsDielectric plateEngineering

A tray 15 for a dry etching apparatus 1 has substrate accommodation holes 19A to 19D penetrating thickness direction and a substrate support portion 21 supporting an outer peripheral edge portion of a lower surface 2a of a substrate 2. A dielectric plate 23 has a tray support surface 28 supporting a lower surface of the tray 15, substrate placement portions 29A through 29D inserted from a lower surface side of the tray 15 into the substrate accommodation holes 19A through 19D and having a substrate placement surface 31 at its upper end surface for placing the substrate 2. A dc voltage applying mechanism 43 applies a dc voltage to an electrostatic attraction electrode 40. A heat conduction gas supply mechanism 45 supplies a heat conduction gas between the substrate 2 and substrate placement surface 31. The substrate 2 can be retained on the substrate placement surface 31 with high degree of adhesion. This results in that the cooling efficiency of the substrate 2 is improved and processing is uniformed at the entire region of the substrate surface including the vicinity of the outer peripheral edge.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

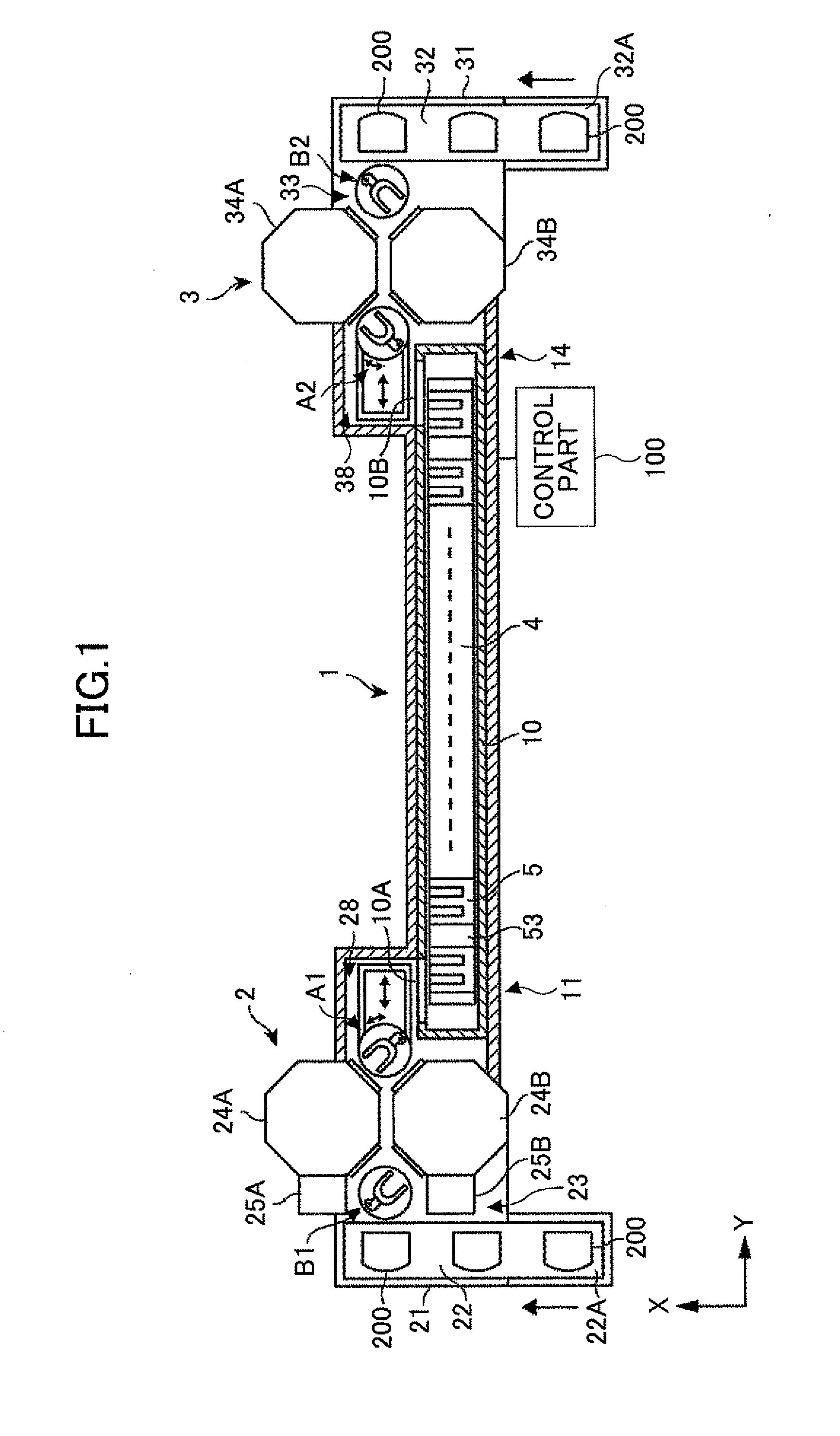

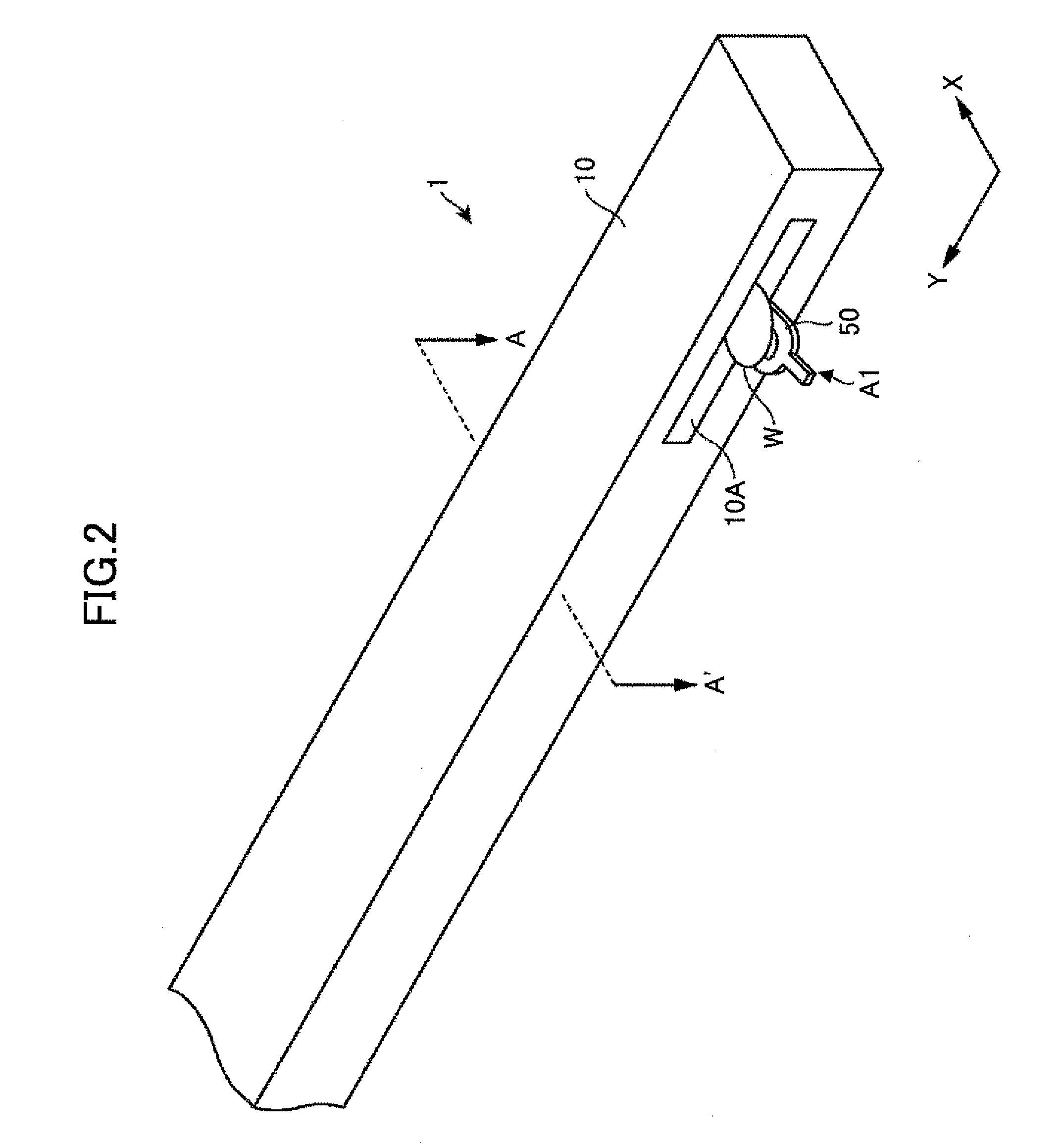

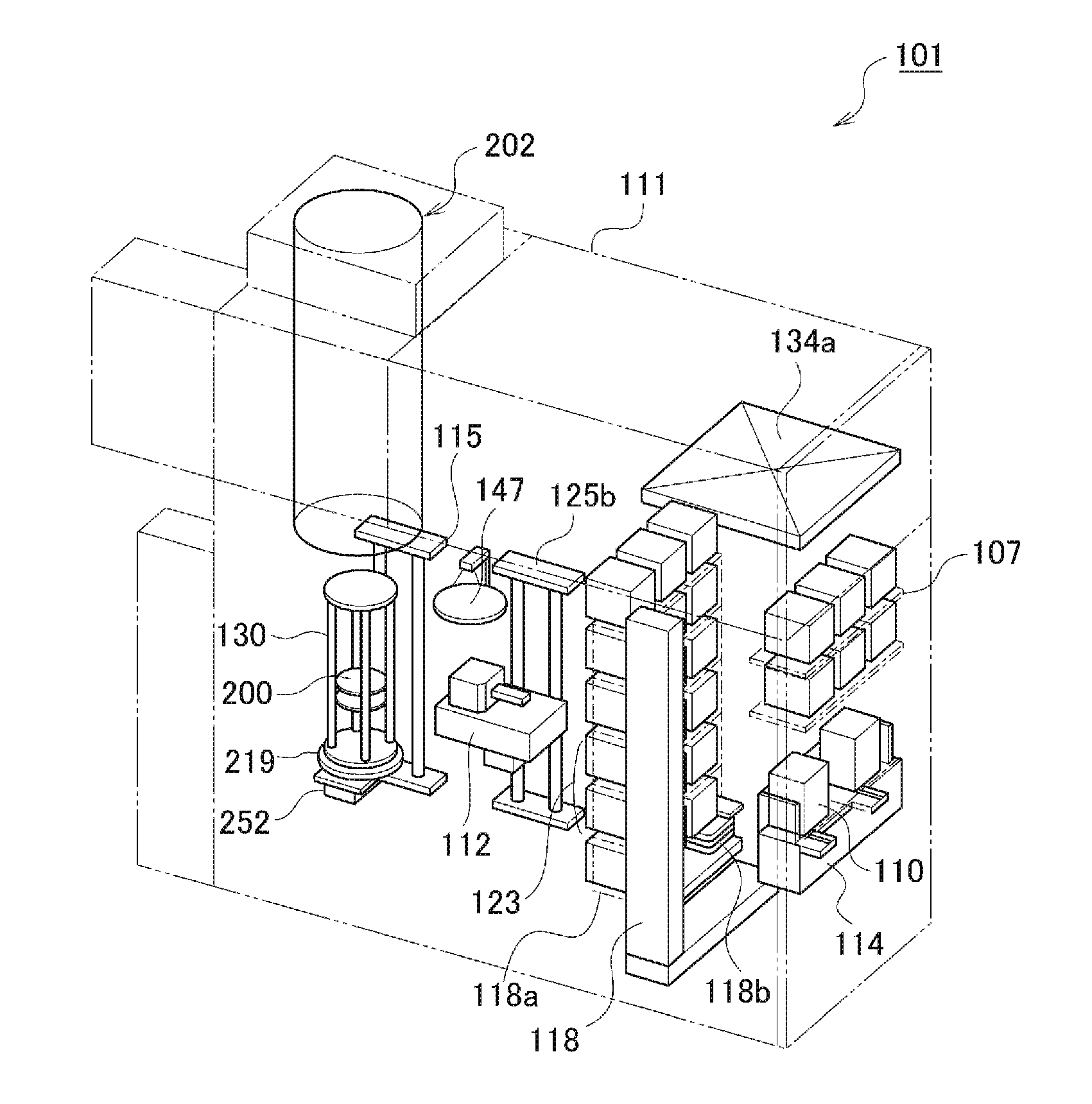

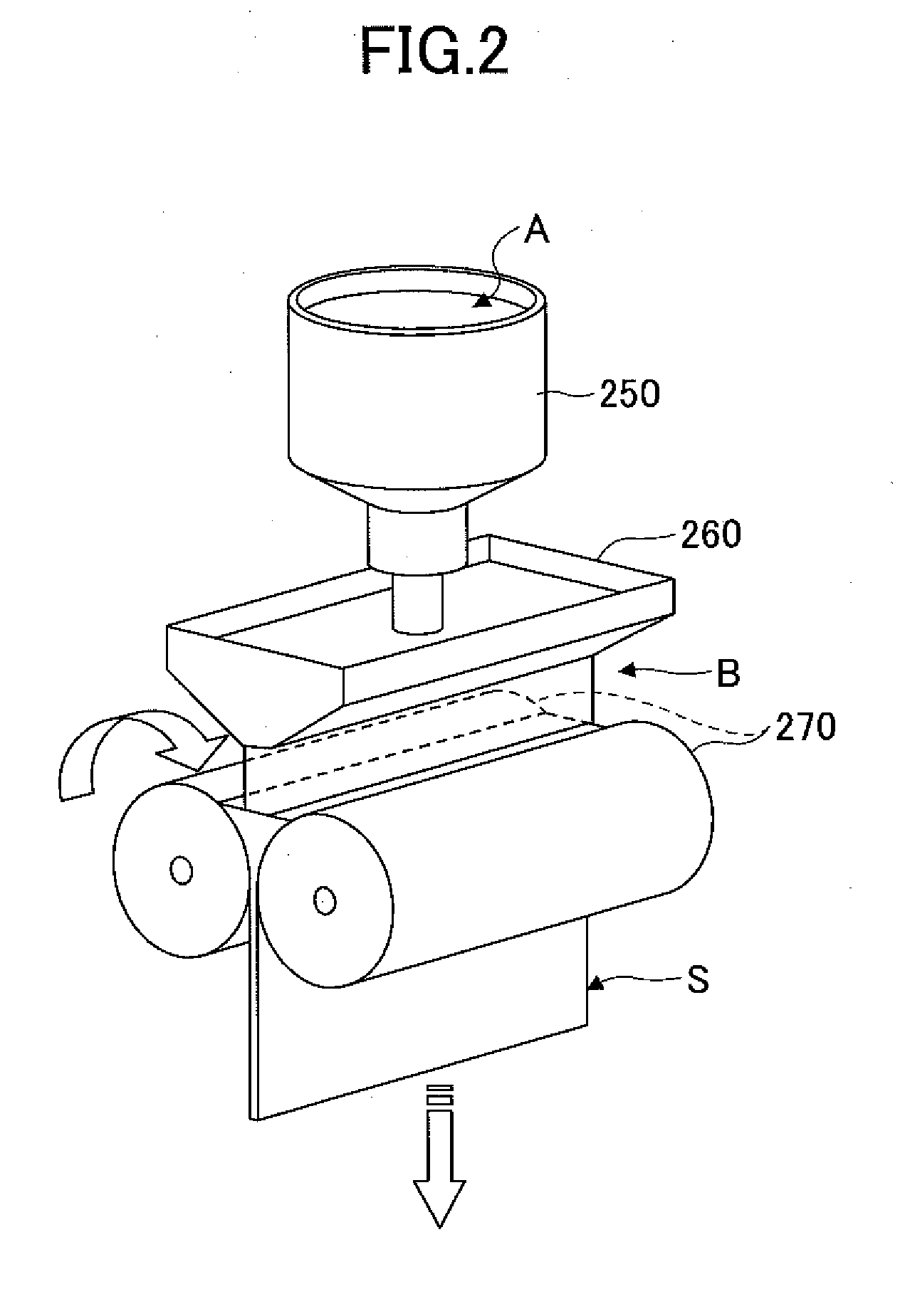

Film deposition device and substrate processing device

InactiveUS20110265725A1Improve throughputLow gas consumptionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingReactive gasGas supply

A film deposition device includes a substrate transporting device arranged in a vacuum chamber to include a circulatory transport path in which substrate mounting parts arranged in a row are transported in a circulatory manner, the circulatory transport path including a linear transport path in which the substrate mounting parts are transported linearly. A first reactive gas supplying part is arranged along a transporting direction in which the substrate mounting parts are transported in the linear transport path, to supply a first reactive gas to the substrate mounting parts. A second reactive gas supplying part is arranged alternately with the first reactive gas supplying part along the transporting direction, to supply a second reactive gas to the substrate mounting parts. A separation gas supplying part is arranged to supply a separation gas to a space between the first reactive gas supplying part and the second reactive gas supplying part.

Owner:TOKYO ELECTRON LTD

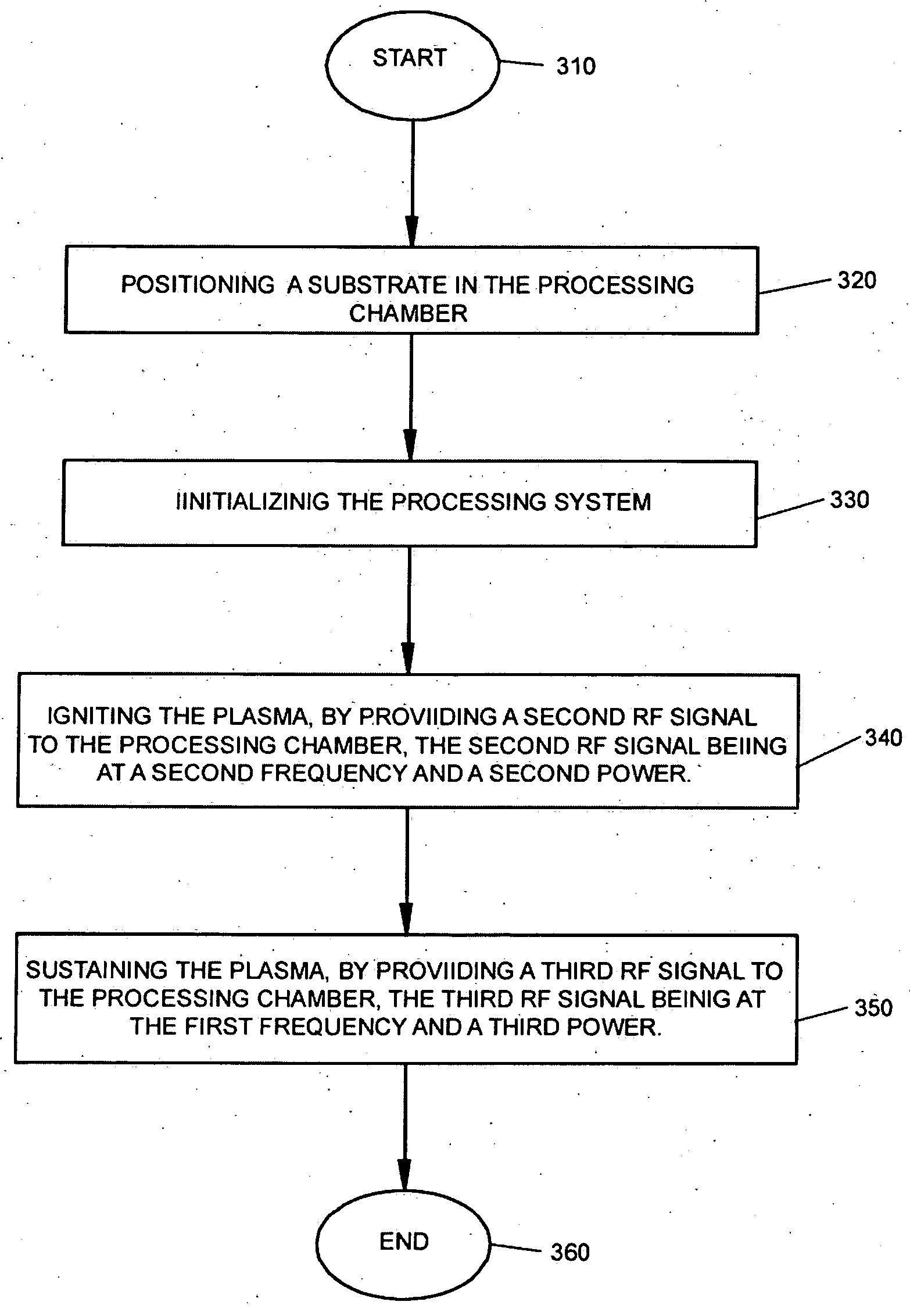

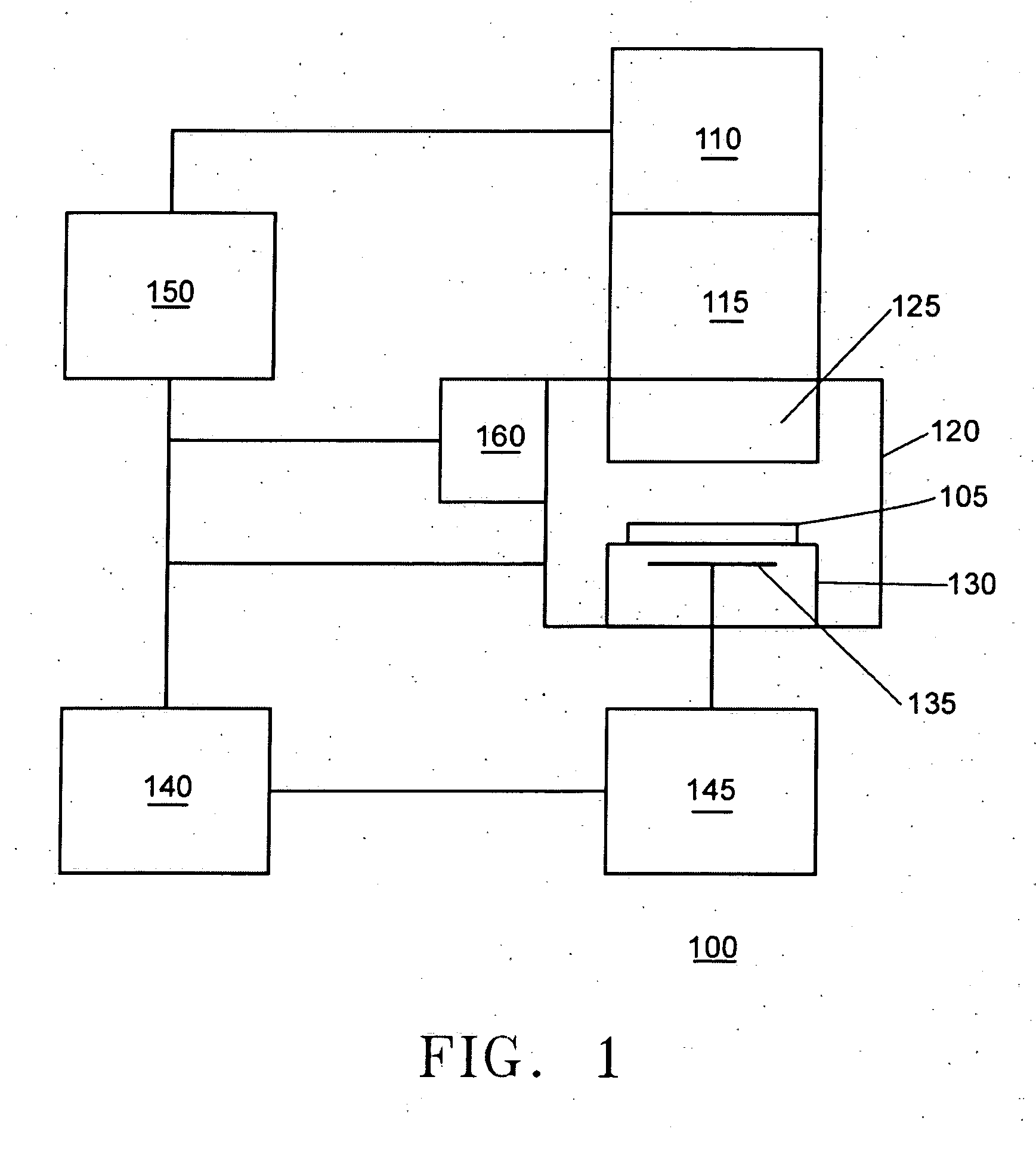

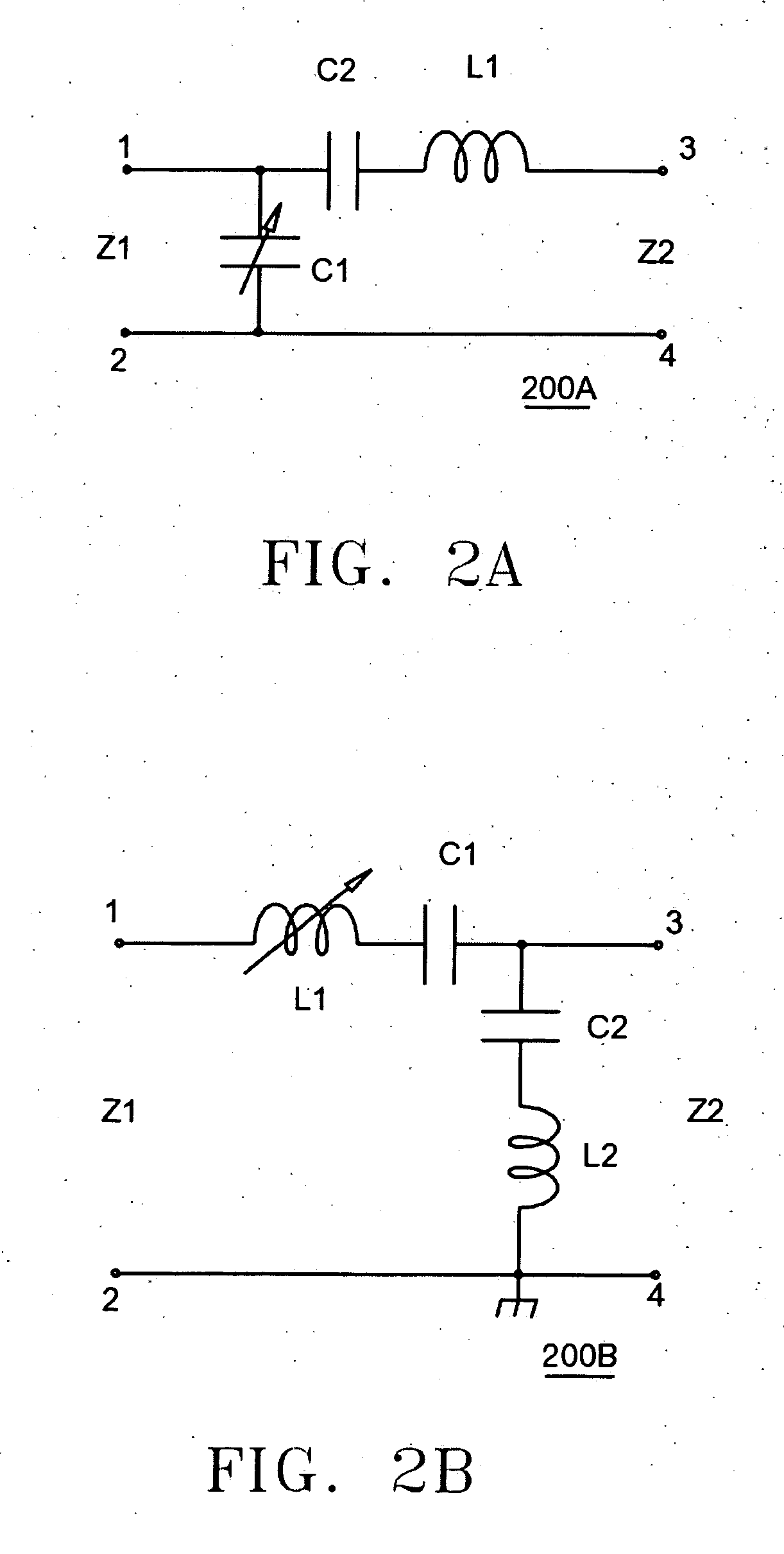

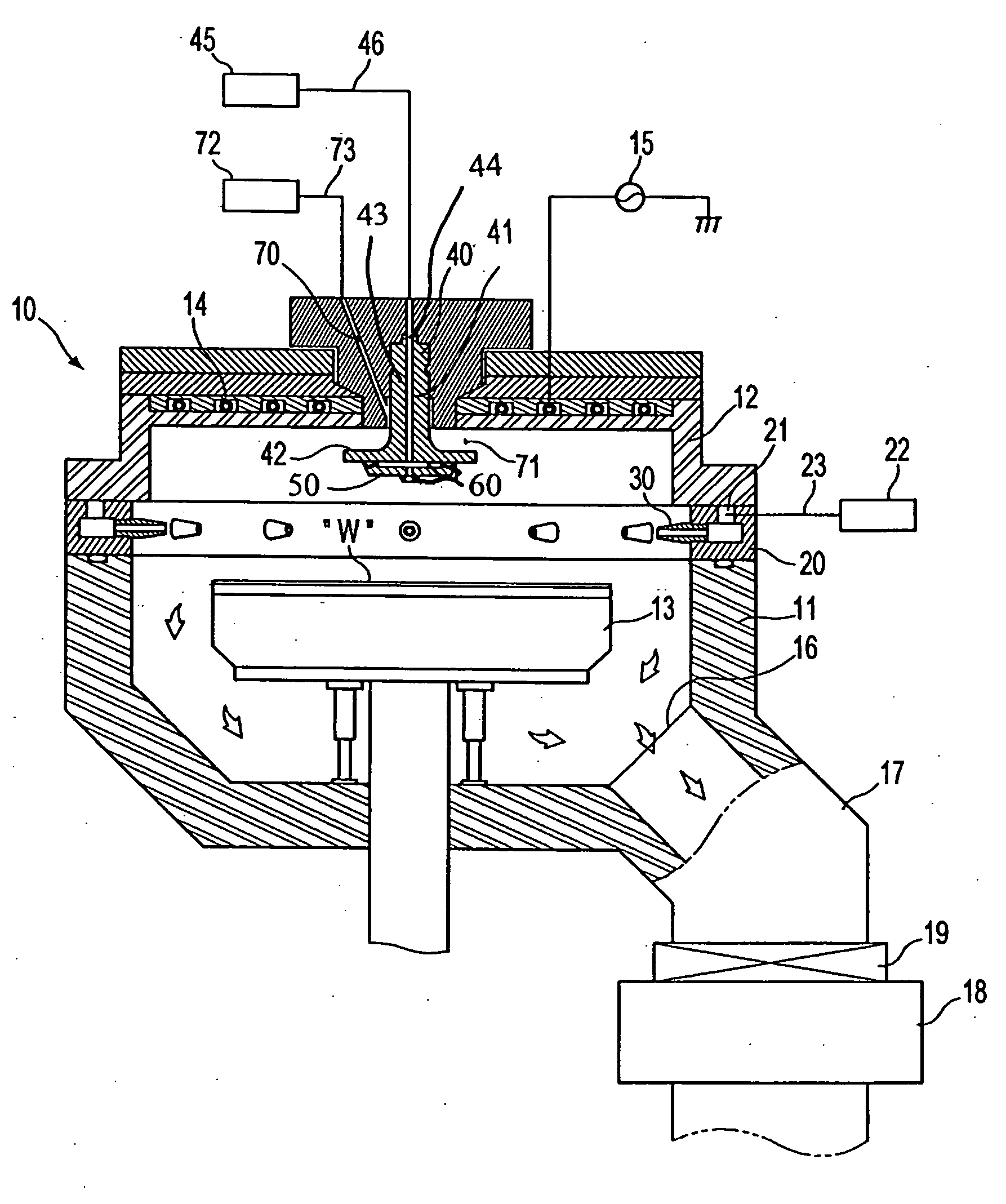

Plasma processing system

A processing system having a processing chamber that includes a substrate holder and an electrode. The processing system can include a pressure control system, gas supply system, and monitoring system. A multi-frequency RF source is coupled to the electrode using a reduced-element matching network having a single variable element. The multi-frequency RF source is set to a first frequency to ignite a plasma and to a second frequency to maintain the plasma.

Owner:TOKYO ELECTRON LTD +1

High density plasma chemical vapor deposition apparatus

InactiveUS20060196420A1Unified performanceEasy to handleElectric discharge tubesVacuum evaporation coatingHigh densityEngineering

A high density plasma chemical vapor deposition apparatus includes an upper gas supply nozzle which includes a nozzle body, a gas supply passage formed vertically in the nozzle body, a nozzle cover attached to a lower surface of the horizontal portion of the nozzle body, and a plurality of gas inlets formed through the nozzle cover to uniformly supply the processing gas towards a semiconductor wafer within the processing chamber.

Owner:SAMSUNG ELECTRONICS CO LTD

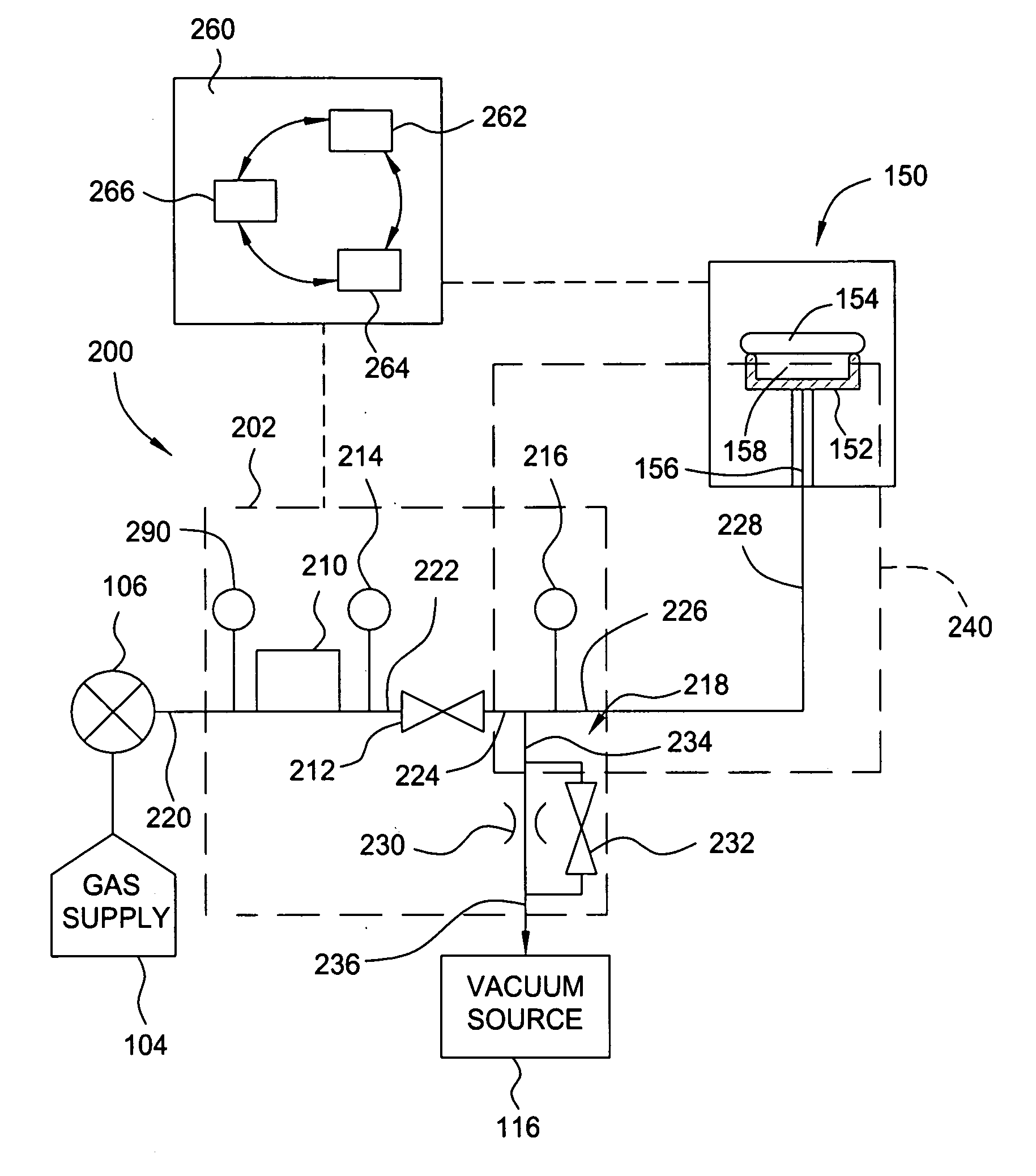

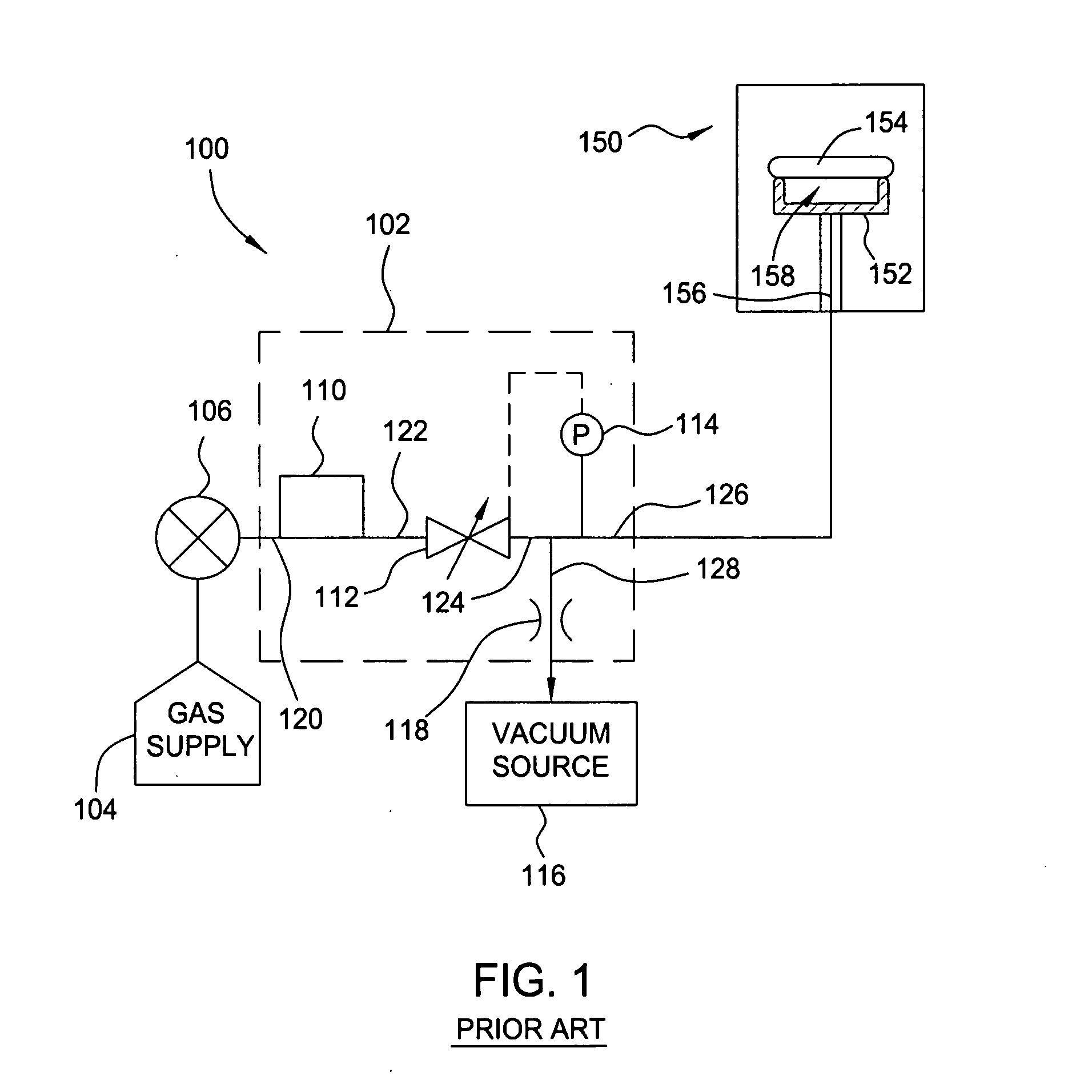

Method and apparatus for substrate temperature control

InactiveUS20050120805A1Electric discharge tubesAerodynamic testingTemperature controlFlow transducer

A method and apparatus for gas control is provided. The apparatus may be used for controlling gases delivered to a chamber, controlling the chamber pressure, controlling the delivery of backside gas between a substrate and substrate support and the like. In one embodiment, an apparatus for controlling gas control includes at least a first flow sensor having a control valve, a first pressure sensor and at least a second pressure sensor. An inlet of the first flow sensor is adapted for coupling to a gas supply. A control valve is coupled to an outlet of the flow sensor. The first pressure sensor is adapted to sense a metric indicative of the pressure upstream of the first flow sensor. The second pressure sensor is adapted to sense a metric indicative of the pressure downstream of the control valve.

Owner:APPLIED MATERIALS INC

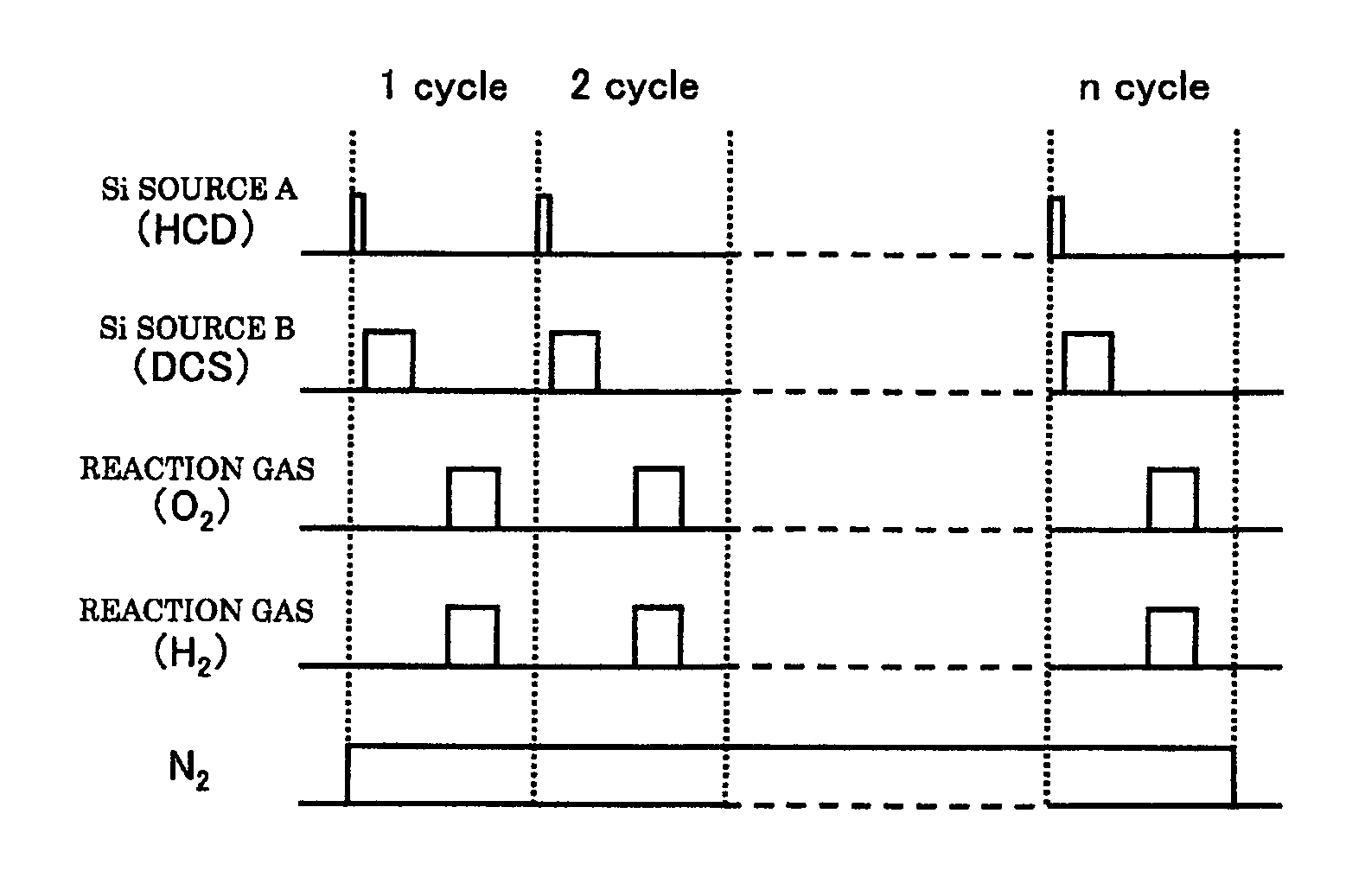

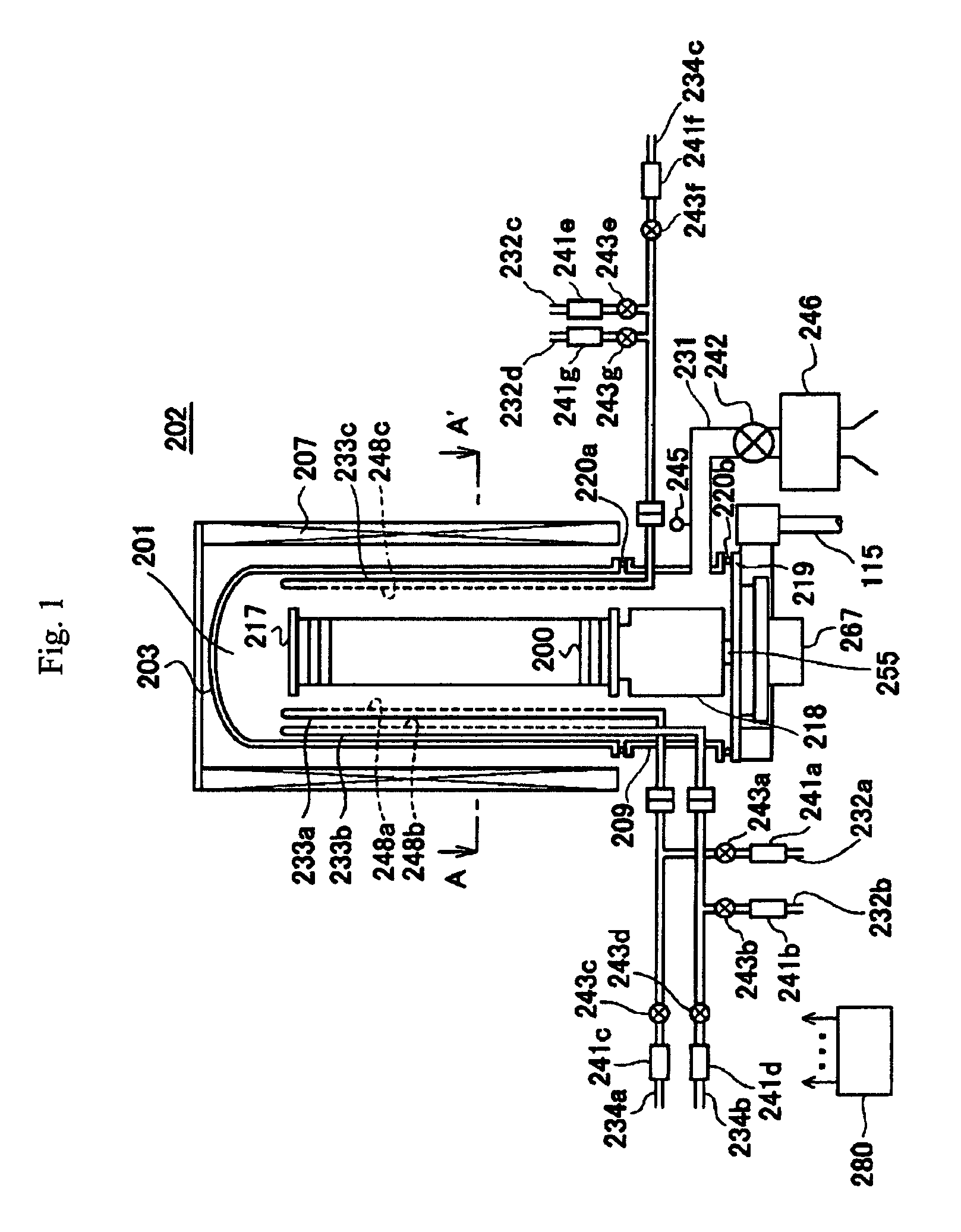

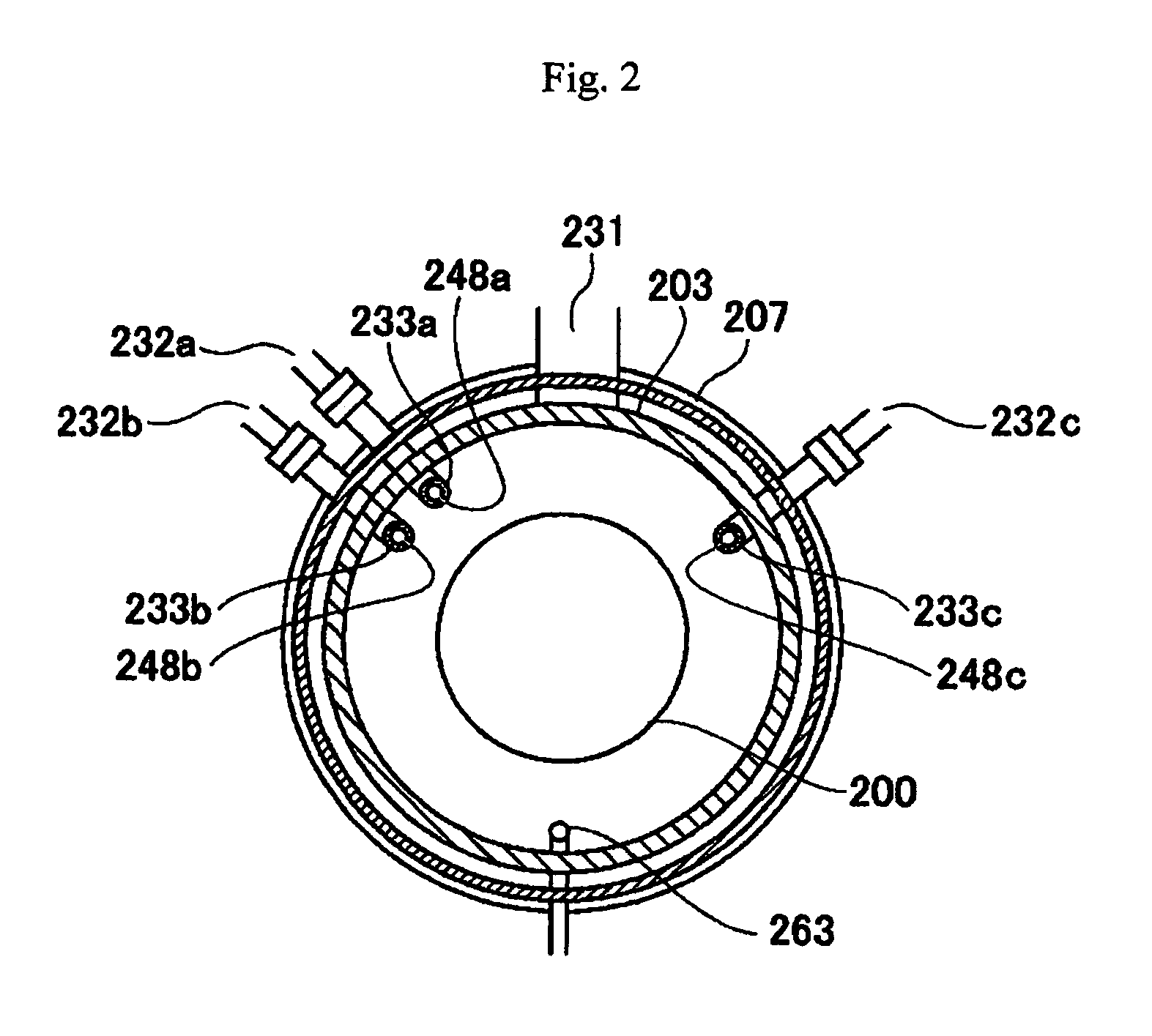

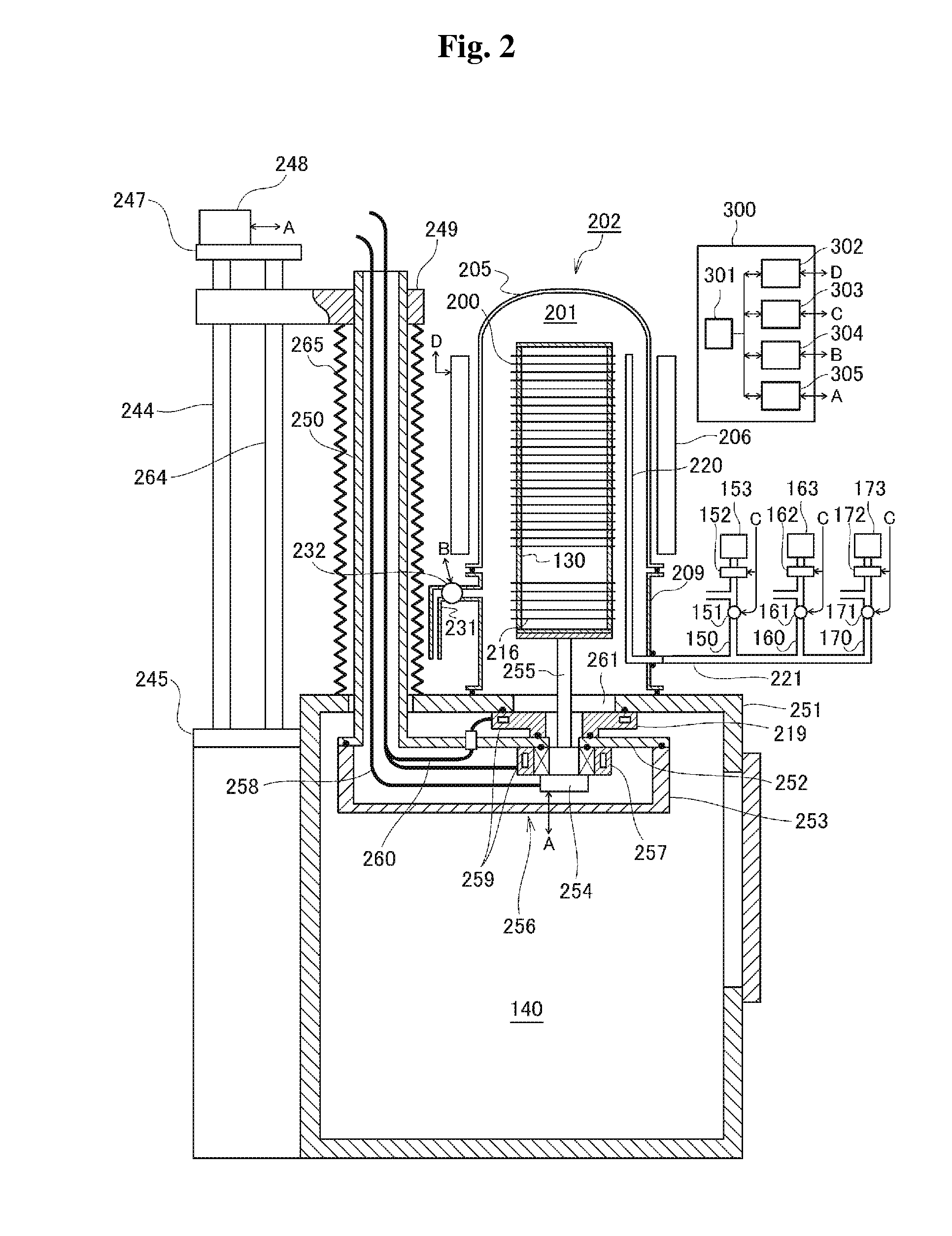

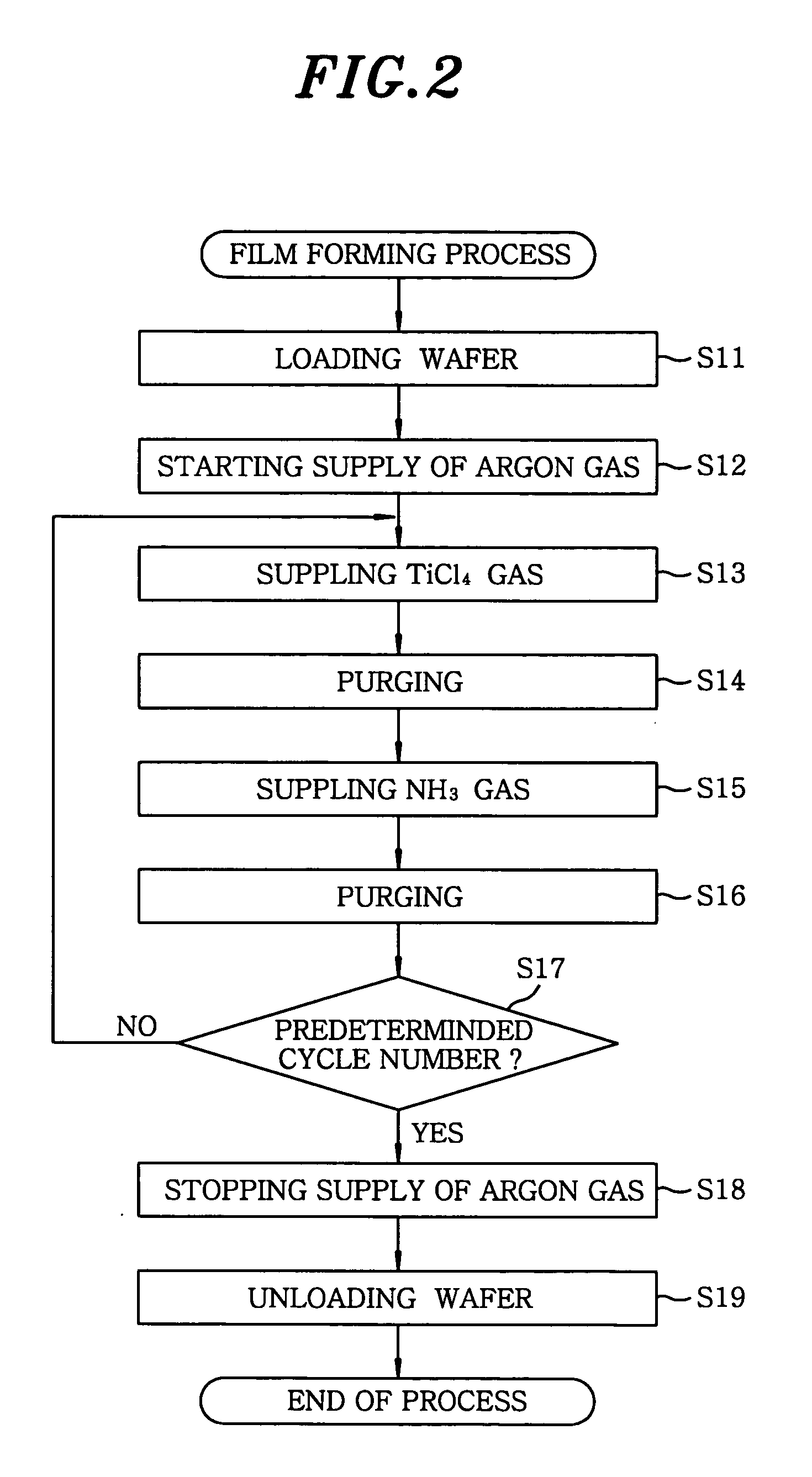

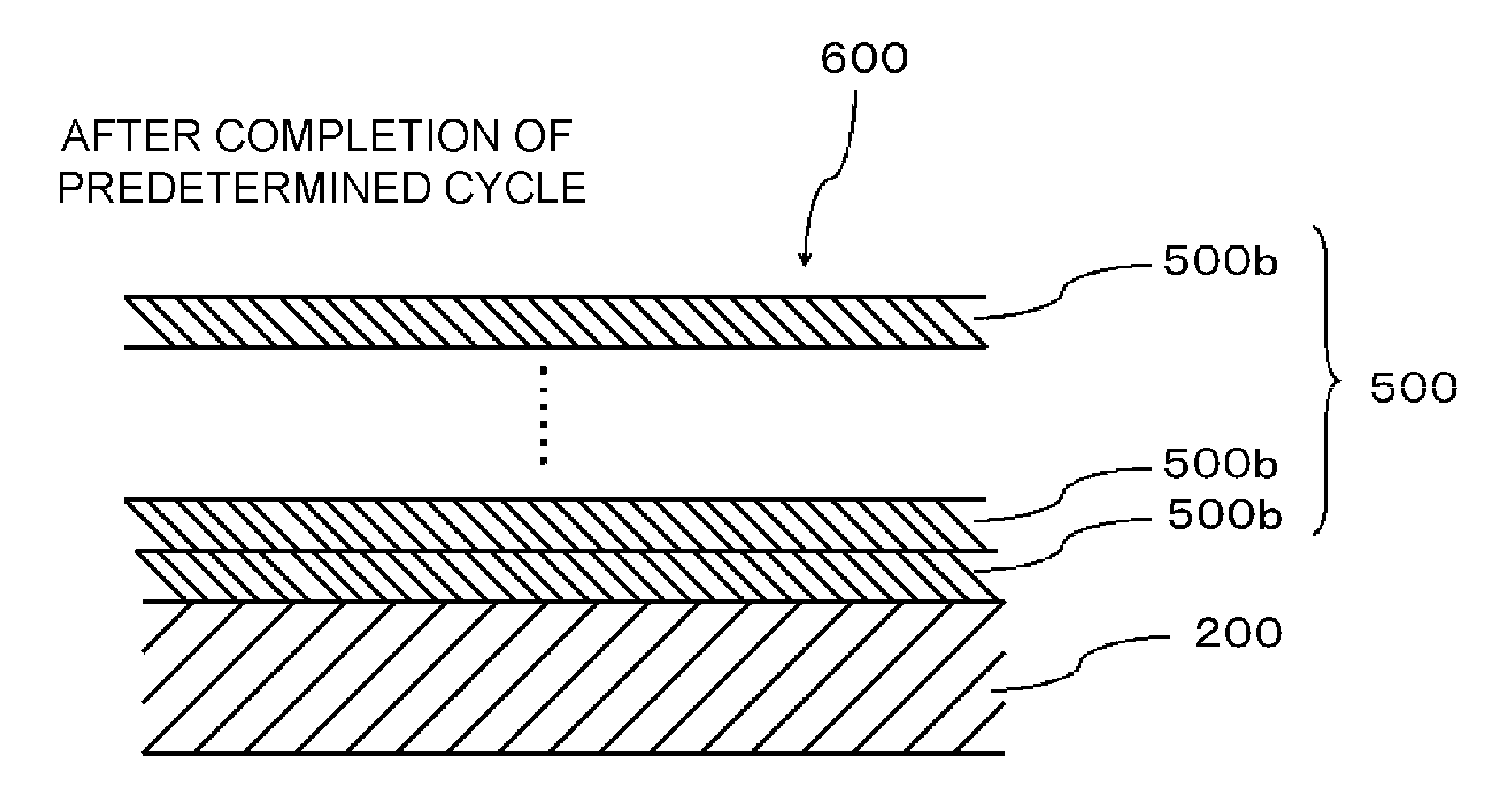

Method of manufacturing semiconductor device, method of processing substrate and substrate processing apparatus

ActiveUS8076251B2Increase probabilityLow costSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDevice materialPhysical chemistry

Provided is a method of manufacturing a semiconductor device. The method includes: loading a substrate into a process vessel; performing a process to form an oxide, nitride, or oxynitride film on the substrate by alternately repeating: (a) forming a layer containing an element on the substrate by supplying and exhausting first and second source gases containing the element into and from the process vessel; and (b) changing the layer containing the element into an oxide, nitride, or oxynitride layer by supplying and exhausting reaction gas different from the first and second source gases into and from the process vessel; and unloading the substrate from the process vessel. The first source gas is more reactive than the second source gas, and an amount of the first source gas supplied into the process vessel is set to be less than that of the second source gas supplied into the process vessel.

Owner:KOKUSA ELECTRIC CO LTD

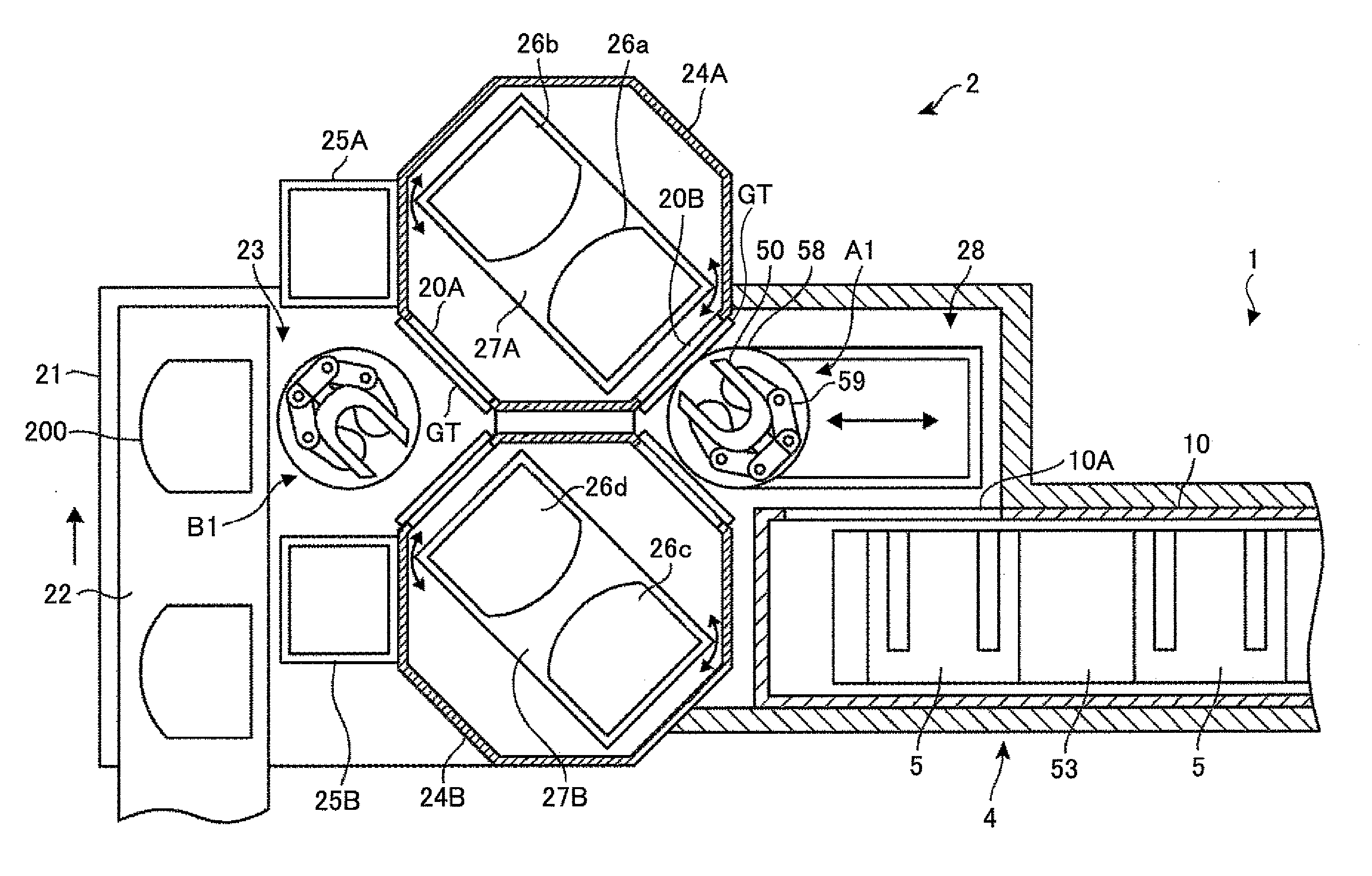

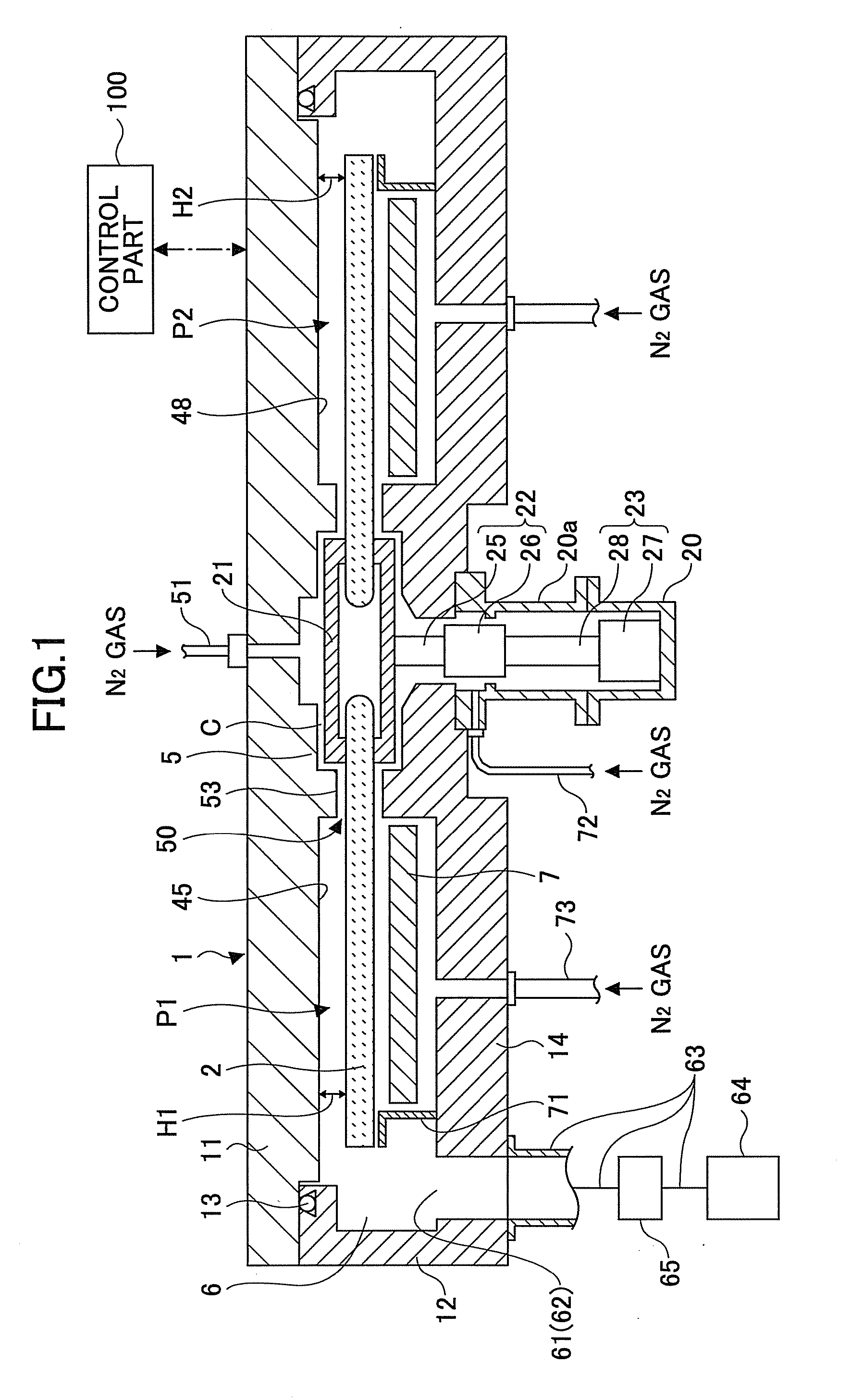

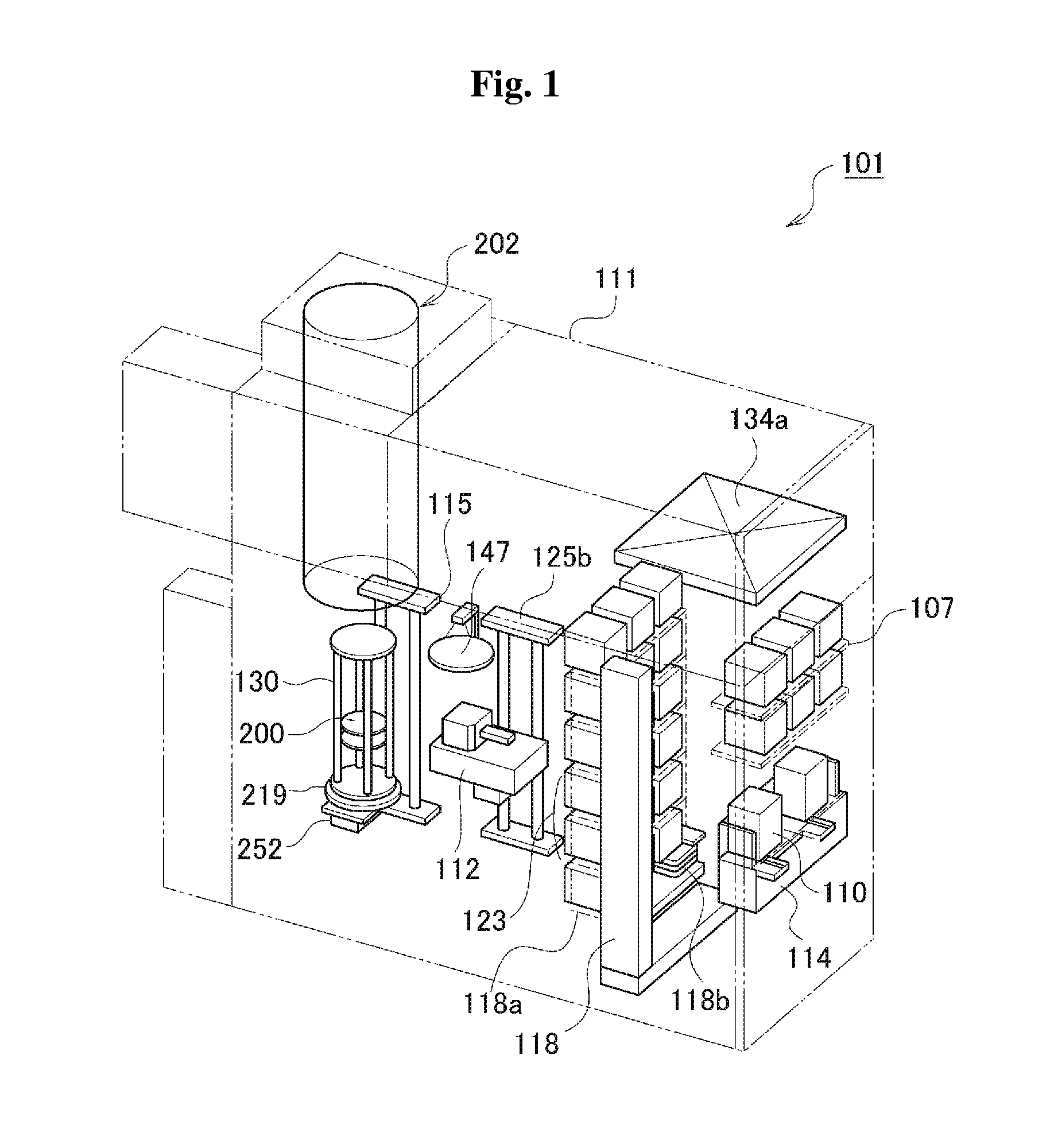

Film deposition apparatus and substrate processing apparatus

ActiveUS20100050943A1Eliminate the problemImprove throughputSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDrive shaftProcess engineering

A film deposition apparatus includes: a turntable; a first reaction gas supply part and a second reaction gas supply part extending from a circumferential edge toward a rotation center of the turntable; and a first separation gas supply part provided between the first and second reaction gas supply parts. A first space contains the first reaction gas supply part and has a first height. A second space contains the second reaction gas supply part and has a second height. A third space contains a first separation gas supply part and has a height lower than the first and second heights. A motor provided under the rotation center of the turntable rotates the turntable. A rotation shaft of the turntable and a drive shaft of the motor are coupled without generation of slip.

Owner:TOKYO ELECTRON LTD

Substrate Processing Apparatus

InactiveUS20100058984A1Inhibited DiffusionPolycrystalline material growthSemiconductor/solid-state device manufacturingProcess engineeringVacuum pump

Process gas discharged from a bypass pipe to a gas exhaust system can be prevented from diffusing back to the inside of a process chamber without having to install a dedicated vacuum pump at the downstream side of the bypass pipe. The substrate processing apparatus includes a process chamber accommodating a substrate, a gas supply system supplying process gas from a process gas source to the process chamber for processing the substrate, a gas exhaust system configured to exhaust the process chamber, two or more vacuum pumps installed in series at the gas exhaust system, and a bypass pipe connected between the gas supply system and the gas exhaust system. The most upstream one of the vacuum pumps is a mechanical booster pump, and the bypass pipe is connected between the mechanical booster pump and the rest vacuum pumps located at a downstream side of the mechanical booster pump.

Owner:KOKUSA ELECTRIC CO LTD

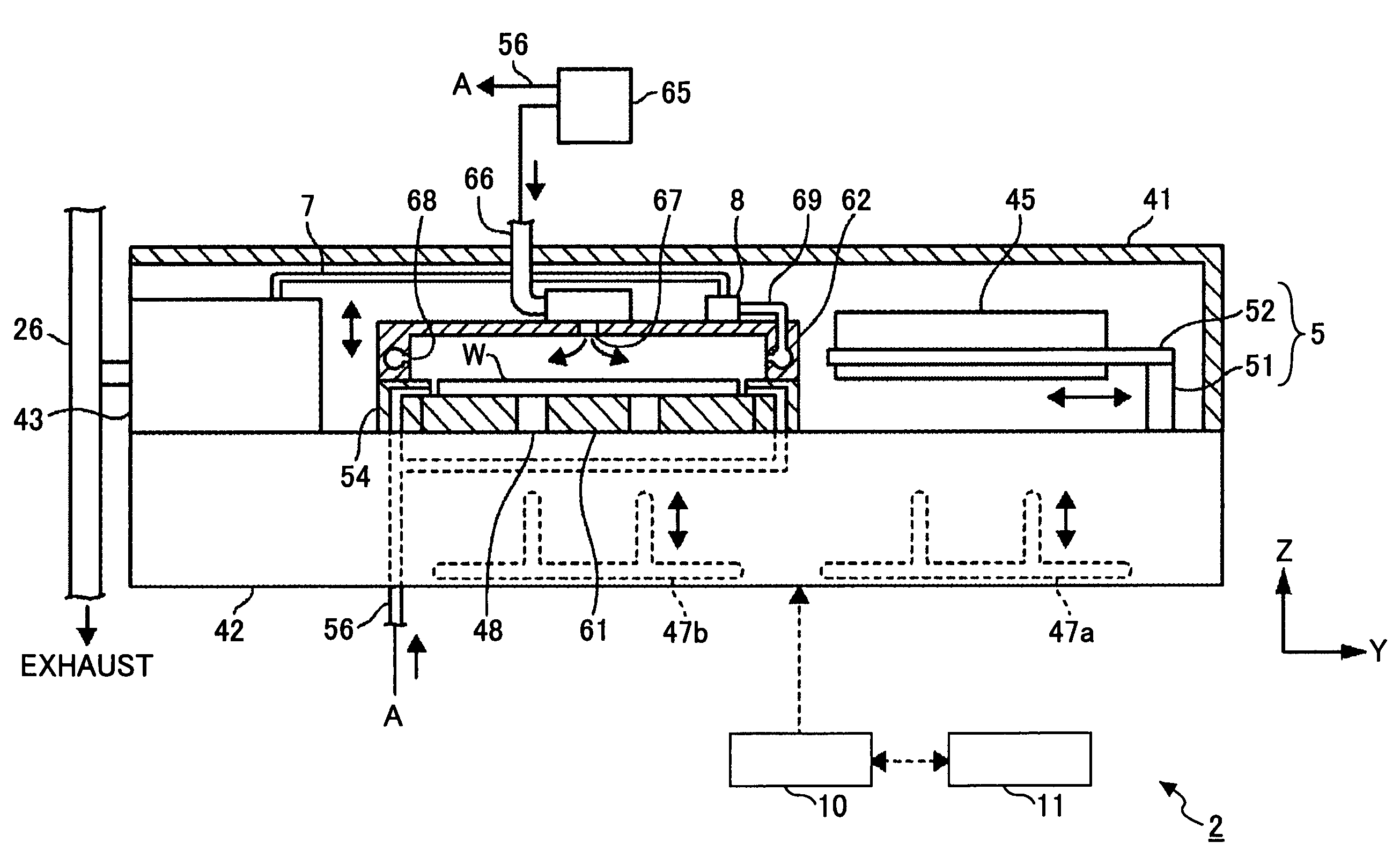

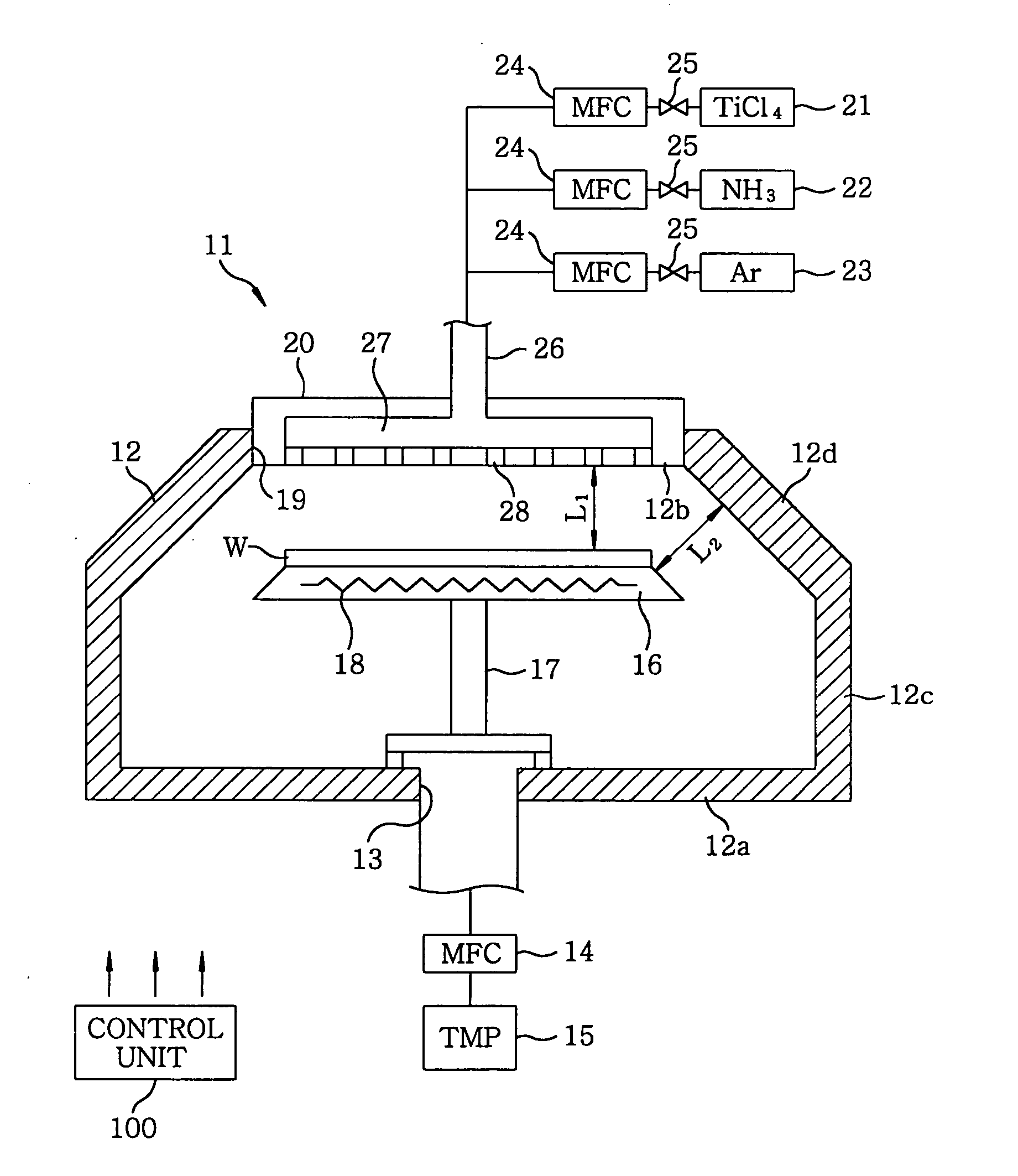

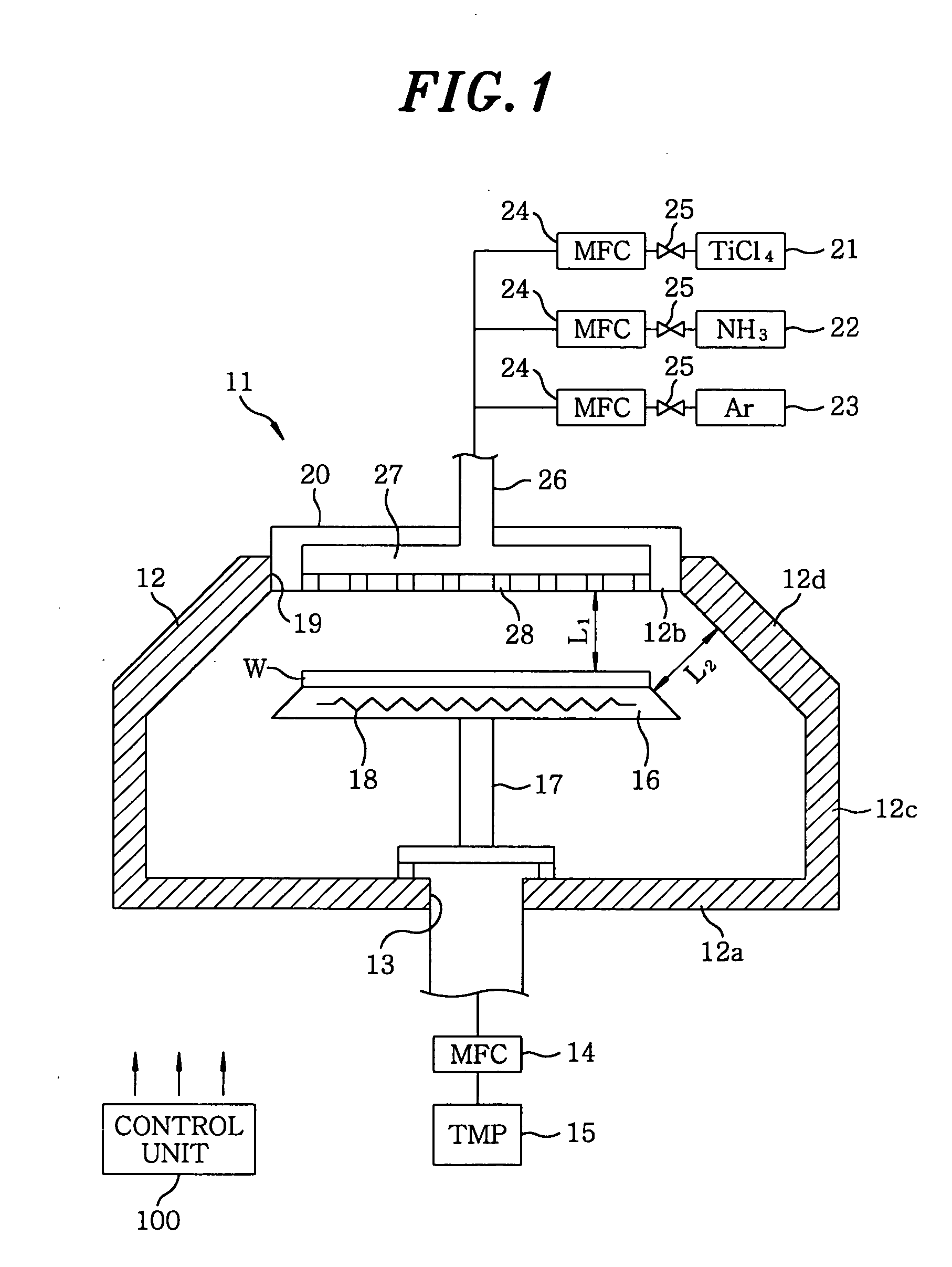

Processing device and processing method

InactiveUS20050211167A1Increase speedHigh productSemiconductor/solid-state device manufacturingFrom chemically reactive gasesSusceptorEngineering

The ceiling surface (12b) of a chamber (12) is substantially entirely formed with a gas supply port (19). Further, the gas supply port (19) has shower head (20) fitted therein. The peripheral edge of the ceiling surface (12b) has connected thereto a second side wall (12d) forming an angle greater than 90 degrees with ceiling surface (12b). Further, the side surface of a susceptor (16) is formed such that it forms an angle greater than 90 degrees with a mounting surface for a wafer (W) and is substantially parallel with the second side wall (12d) of the chamber (12). Further, the susceptor (16) is disposed such that the distance (L2) between its side surface and the second side wall (12d) is greater than the distance (L1) between the shower head (20) and the wafer (W).

Owner:TOKYO ELECTRON LTD

Substrate processing apparatus, method of manufacturing semiconductor device and semiconductor device

ActiveUS20120119337A1Avoid processing qualitySuppress scatterLiquid surface applicatorsSemiconductor/solid-state device detailsForeign matterThermodynamics

Provided is a substrate processing apparatus capable of suppressing accumulation of reaction products or decomposed matters on an inner wall of a nozzle and suppressing scattering of foreign substances in a process chamber. The substrate processing apparatus includes a process chamber, a heating unit, a source gas supply unit, a source gas nozzle, an exhaust unit, and a control unit configured to control at least the heating unit, the source gas supply unit and the exhaust unit. The source gas nozzle is disposed at a region in the process chamber, in which a first process gas is not decomposed even under a temperature in the process chamber higher than a pyrolysis temperature of the first process gas, and the control unit supplies the first process gas into the process chamber two or more times at different flow velocities to prevent the first process gas from being mixed.

Owner:KOKUSA ELECTRIC CO LTD

Substrate processing apparatus and susceptor

ActiveUS20140202386A1Increase temperatureLiquid surface applicatorsMolten spray coatingHigh frequency powerSusceptor

A substrate processing apparatus includes a chamber, a susceptor to receive a substrate and provided in the chamber, a gas supply source to supply a predetermined gas into the chamber, and a high frequency power source to treat the substrate by plasma. The susceptor includes a first ceramics base member including a flow passage to let a coolant pass through, a first conductive layer formed on a principal surface and a side surface on a substrate receiving side of the first ceramics base member, and an electrostatic chuck stacked on the first conductive layer and configured to electrostatically attract the wafer received thereon. A volume of the flow passage is equal to or more than a volume of the first ceramics base member. The high frequency power source is configured to supply high frequency power to the first conductive layer.

Owner:TOKYO ELECTRON LTD

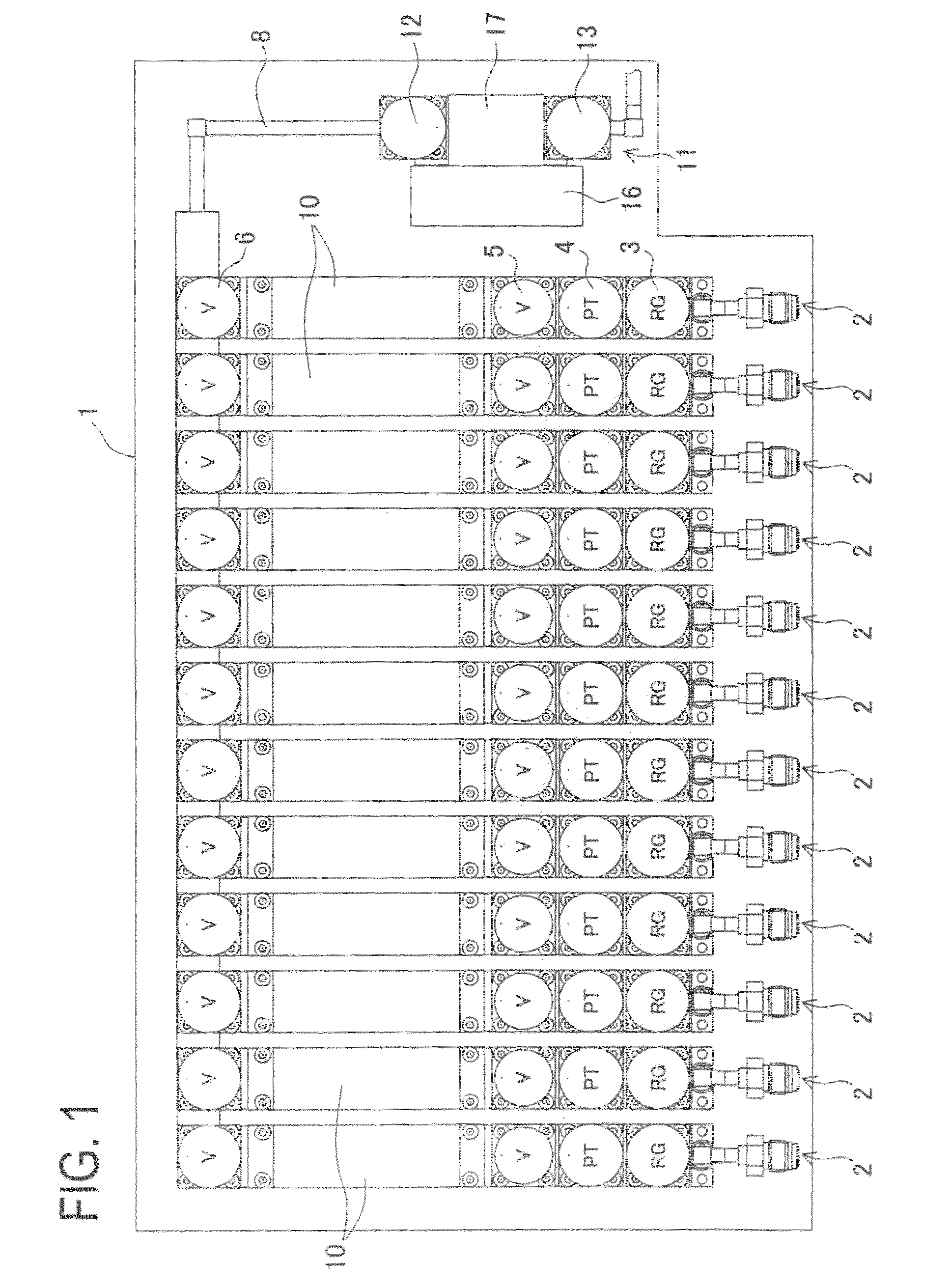

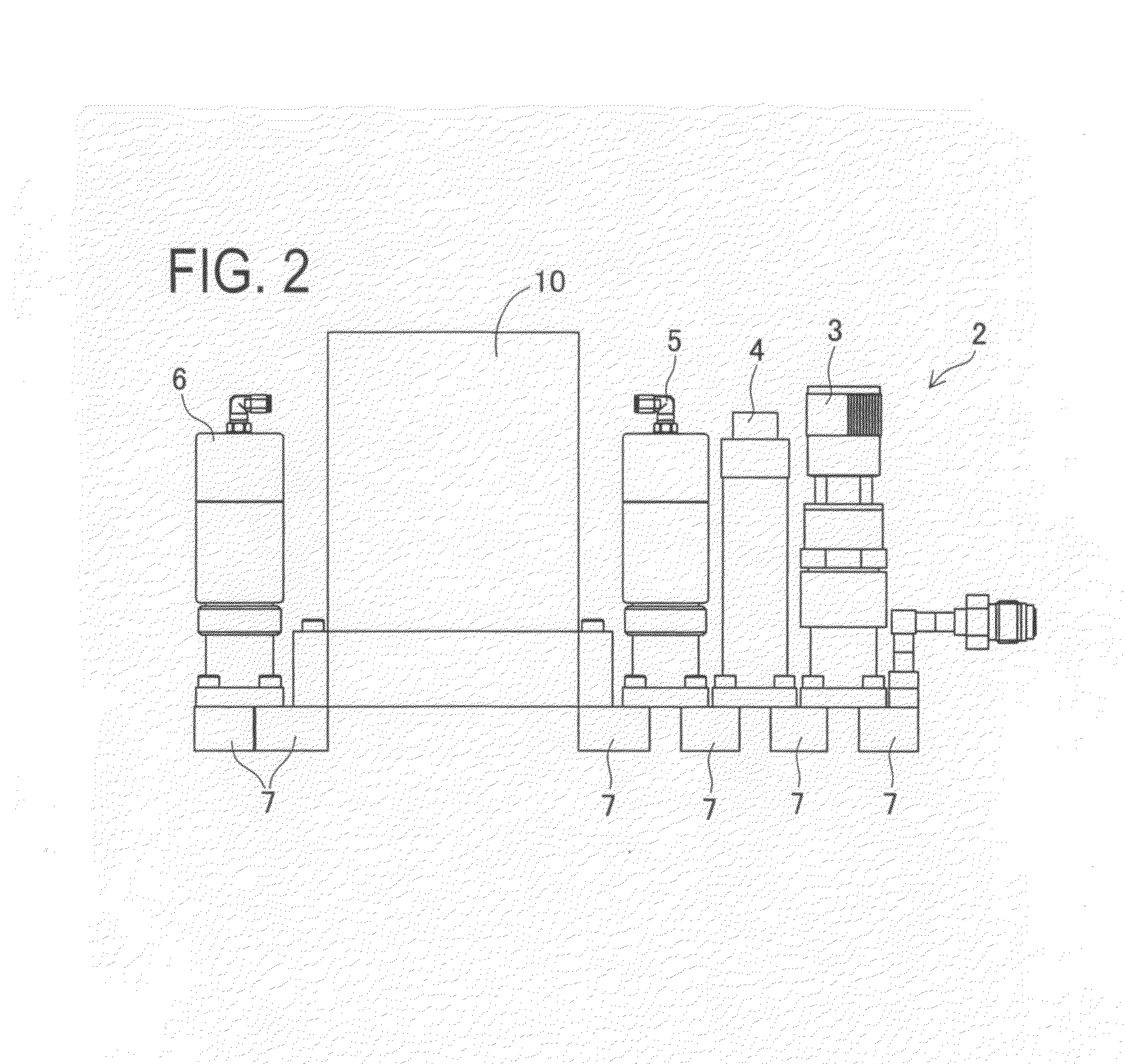

Gas flow rate verification unit

ActiveUS7716993B2Increase flow rateUniform pressureMultiple way valvesPipeline systemsEngineeringGas supply

A gas flow rate verification unit capable of enhancing reliability of gas flow rate verification. The gas flow rate verification unit has a first cutoff valve that is connected to a flow rate control device and to which gas is inputted, a second cutoff valve for discharging the gas, a communication member for allowing the first cutoff valve and the second cutoff valve to communicate with each other, a pressure sensor for detecting the pressure of the gas supplied between the first cutoff valve and the second cutoff valve, a temperature detector for detecting the temperature of the gas supplied between the first cutoff valve and the second cutoff valve, and a control means for verifying the flow of the gas flowing in the flow control device, the verification being performed by using both the result of the pressure detected by the pressure sensor and the result of the temperatures detected by the temperature detector. The volume (Vk) between the valve seat of the first cutoff valve and the valve seat of the second cutoff valve is equal to or less than the volume (Ve) between the outlet of the flow control device and the valve seat of the first cutoff valve.

Owner:CKD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com